Telescopic nozzle device for narrow gap welding and adjusting method of telescopic nozzle device

A nozzle device, telescopic adjustment technology, applied in welding equipment, welding accessories, electrode support devices, etc., can solve the problems of nozzle seat and sleeve-shaped nozzle shaking, external air being involved in the nozzle inner cavity, and complex nozzle height adjustment mechanism, etc. , to achieve the effect of simple and compact adjustment mechanism, preventing air from being involved in the inner cavity of the nozzle, and increasing the effective protection range of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

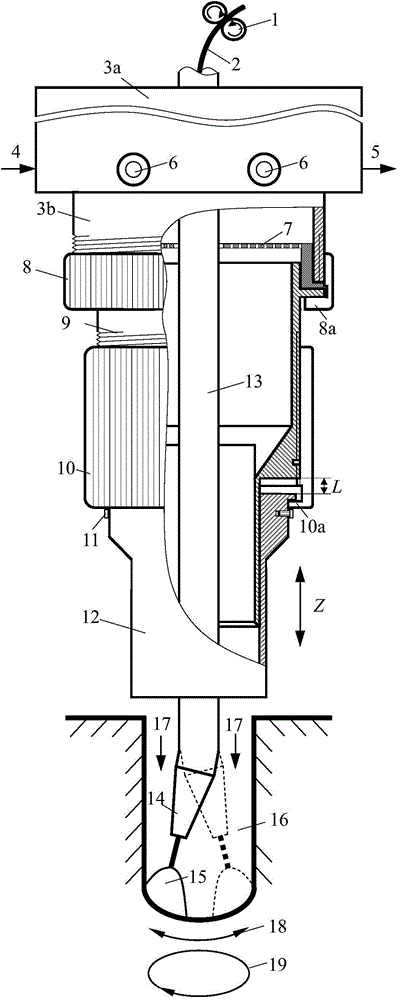

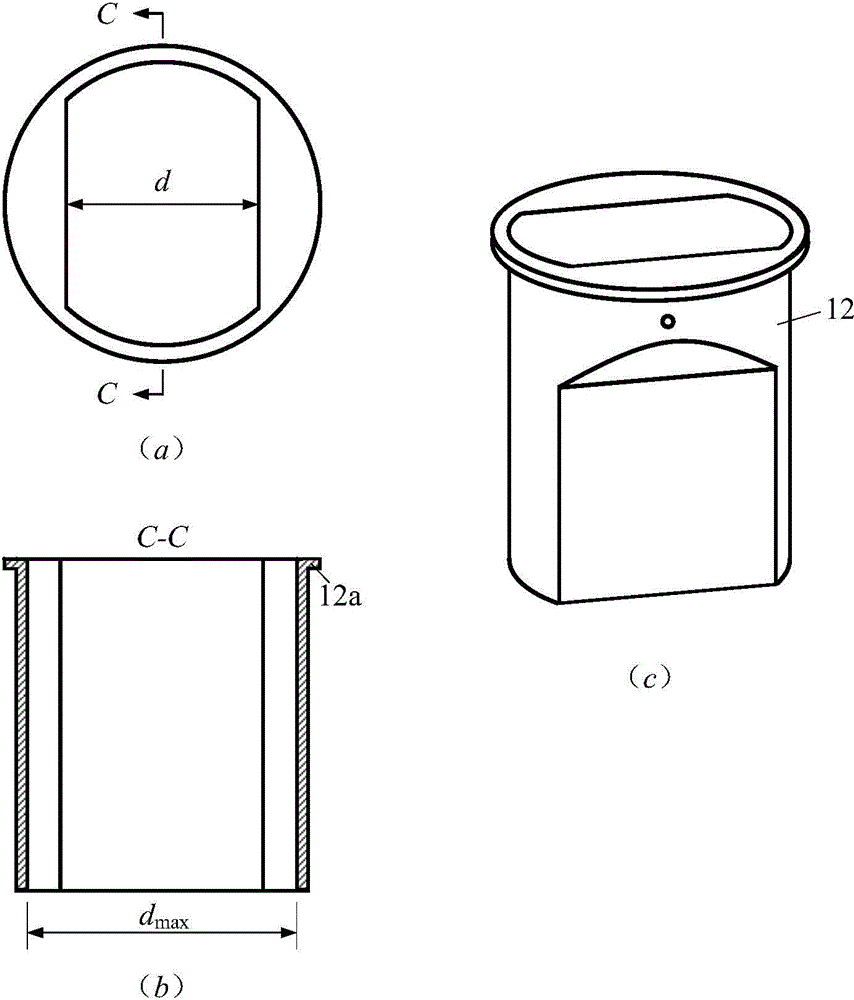

Embodiment 1

[0042] For the case where the extension length L=0 when the movable nozzle sleeve 12 is moved down, it is suitable for the welding of the initial filling weld when using the retractable nozzle device, such as Figure 6 shown. In actual operation, by turning the telescopic adjustment nut 10, the downward extension length L of the movable nozzle sleeve 12 is reduced to the minimum value (that is, L=0), so that the conductive tip 14 connected to the conductive rod 13 is stretched out and moved The length of the end face of the air outlet of the type nozzle sleeve 12 is L 2 ; Then, through the overall adjustment of the height of the welding torch, the distance from the end face of the gas outlet of the movable nozzle sleeve 12 to the upper surface of the narrow gap welding groove side wall 23 is kept as H 1 (It can be 1~5mm); then according to the given distance L from the contact tip 14 to the bottom of the groove (or the surface of the weld) 1 (Generally selected within the ra...

Embodiment 2

[0045] It is aimed at the welding situation of the general filling weld in the narrow gap groove 16. After each filling weld 24 with an interlayer thickness of t is welded in the narrow gap groove 16, the retractable nozzle device and the conductive rod 13 are raised by a distance t as a whole, and then the telescopic adjusting nut 10 is rotated to move The downward extension length L of the type nozzle sleeve 12 increases the distance t, so that the conductive rod 13 and the conductive tip 14 connected to it gradually retract into the inner cavity of the movable nozzle sleeve 12, and the movable nozzle sleeve 12 The distance from the end face of the air outlet to the upper surface of the narrow gap welding groove side wall 23 is kept at a constant value H 1 , so that when the filling welding operation gradually approaches the upper surface of the groove side wall 23, the best gas shielding effect can still be maintained.

[0046] When the telescopic adjustment limit mark lin...

Embodiment 3

[0048] For the welding situation of the cover weld 25, such as Figure 8 shown. When the cover weld 25 is welded, the depth P of the groove to be welded is already smaller than the interlayer thickness t of the filled weld, and the effect of the groove on the storage of the protective airflow and the constraint on the welding pool is already very small. In this way, on the one hand, it makes The protective effect of the flat nozzles used in Examples 1 and 2 is reduced, and on the other hand, the width of the cover weld 25 is significantly increased. Therefore, it is necessary to replace the nozzle telescopic mechanism composed of the gas calming sleeve 9, the telescopic adjusting nut 10 and the movable nozzle sleeve 12 with an integrated cylindrical sleeve-shaped nozzle 26 with a larger air outlet, so as to provide a suitable surface for the cover weld 25 Provides effective gas protection.

[0049] Summarizing the adjustment process involved in the above embodiments, the adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com