Cutting device

A cutting machine and workbench technology, applied in the field of cutting machines, can solve the problems of stagnation of sealing sheets, and achieve the effects of reducing the number of parts, simplifying manufacturing and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

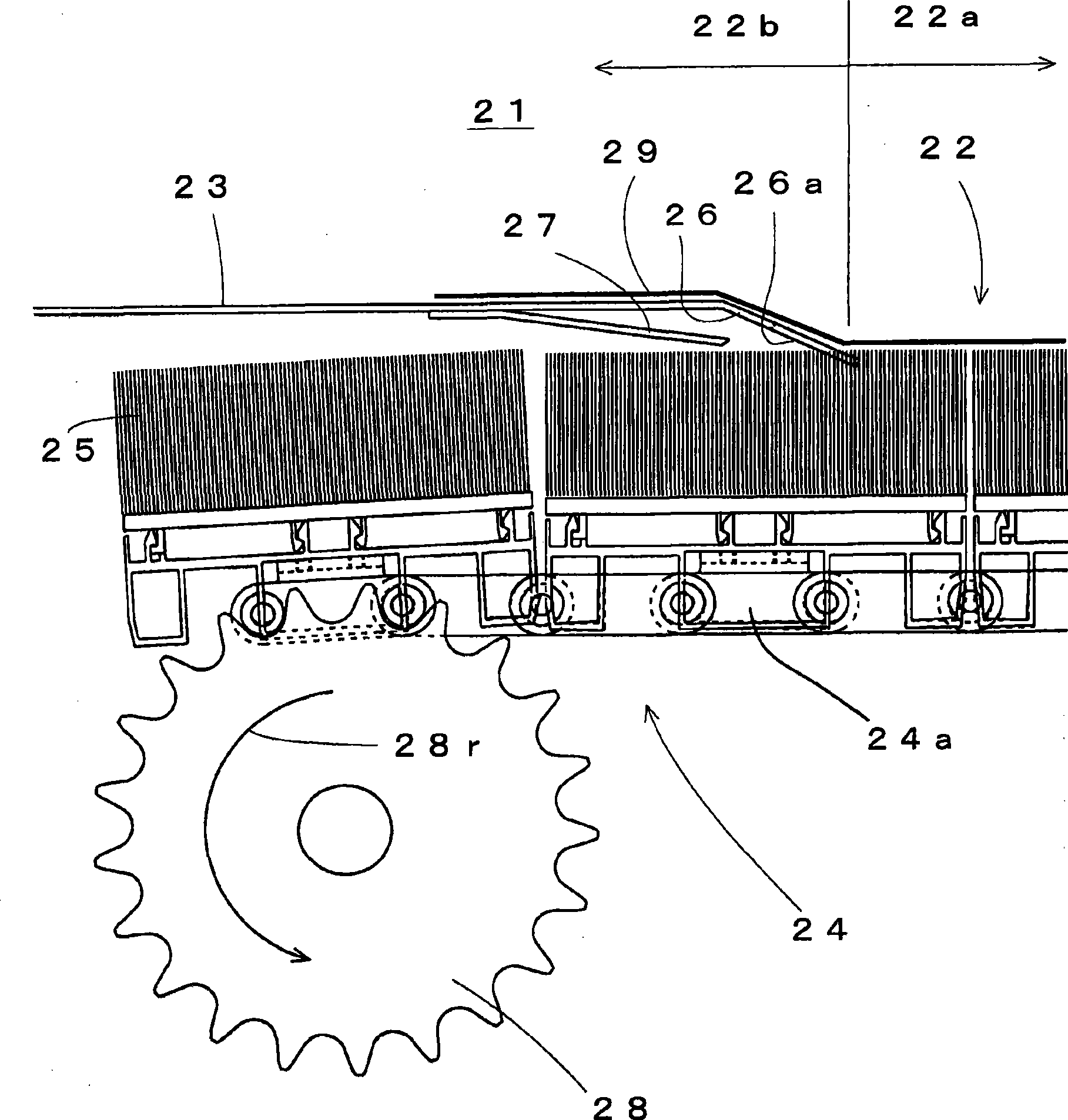

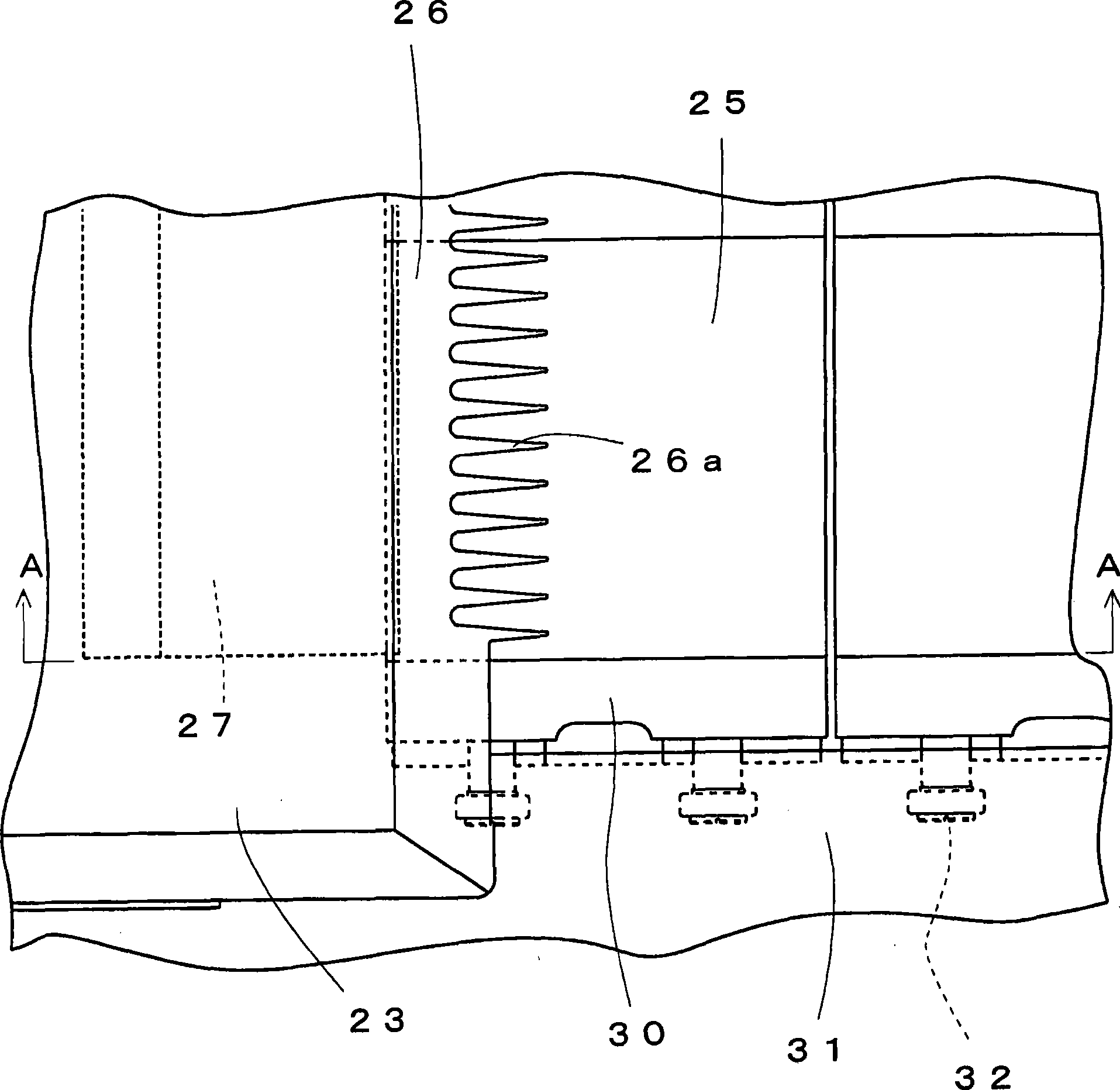

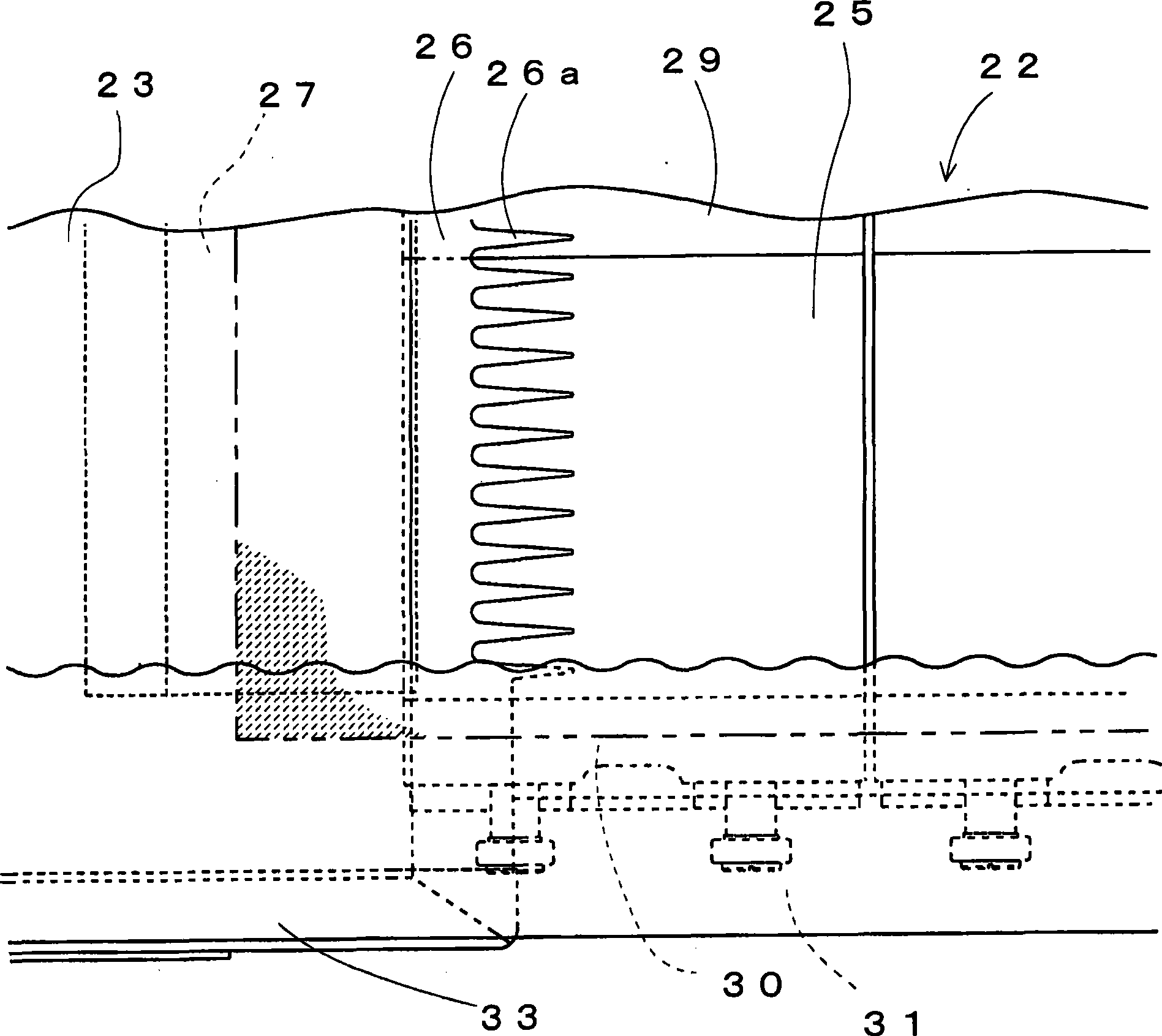

[0032] figure 1 It is the cutting machine 21 which is one embodiment of this invention, and the structure of the vicinity of the transfer part from the cutting table 22 to the carrying-out side wind table 23 is shown briefly. Carry out the side wind power workbench 23 and play the effect of taking out workbench. Regarding the structure of the cutting workbench 22, it is basically the same as the cutting machine of FIG. In the cutting machine 21, the guide plate 26 corresponding to the guide claw 16 of FIG. 5 is integrated with the carrying-out side wind table 23 using plate materials, such as a metal plate. That is, the front end side of the wind power table 23 on the bending delivery side is formed as an inclined part of the guide plate 26, and the further end of the guide plate 26 is formed in a comb-tooth shape as the guide claws 26a. The guide plate 26 can also be formed separately from the wind table 23 on the delivery side and then combined. However, the number of pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com