Plasma jet-stream protective cover

A technology of plasma and protective cover, which is applied in the direction of metal material coating process, fusion spraying, coating, etc., can solve the problems of complex structure, increased equipment operation cost, and ineffective oxidation and nitriding effect, so as to avoid oxidation and Nitriding, the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

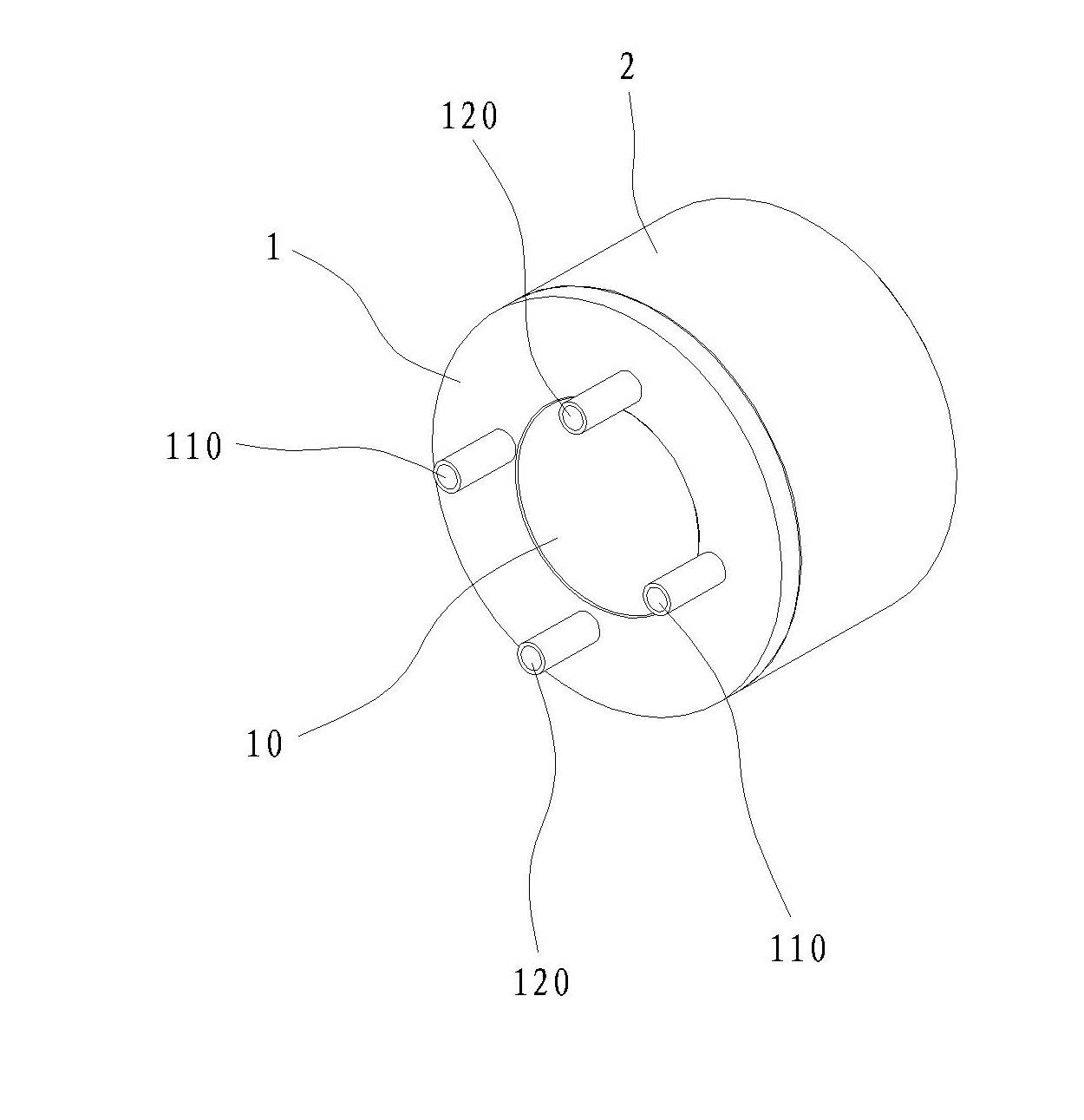

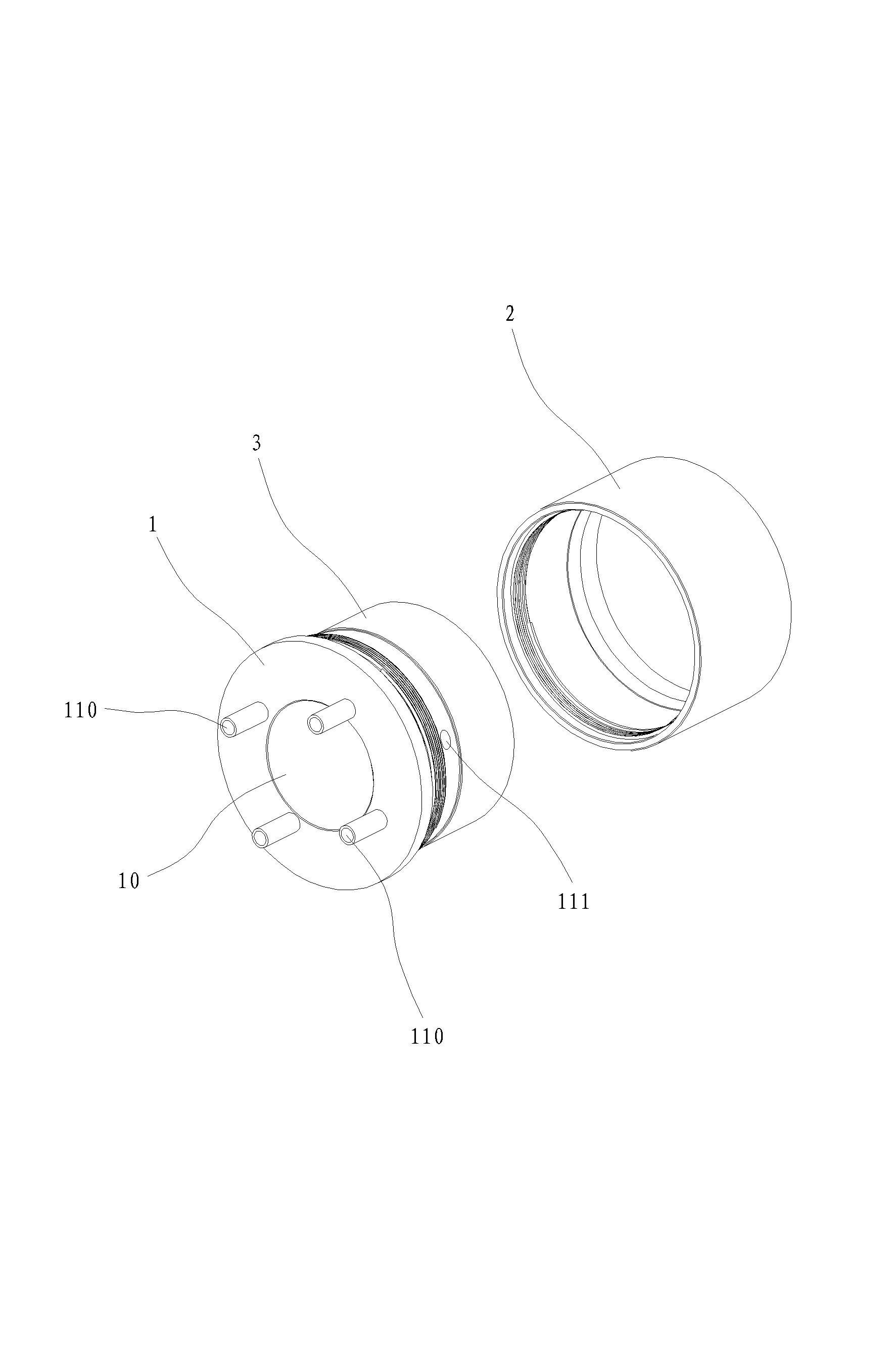

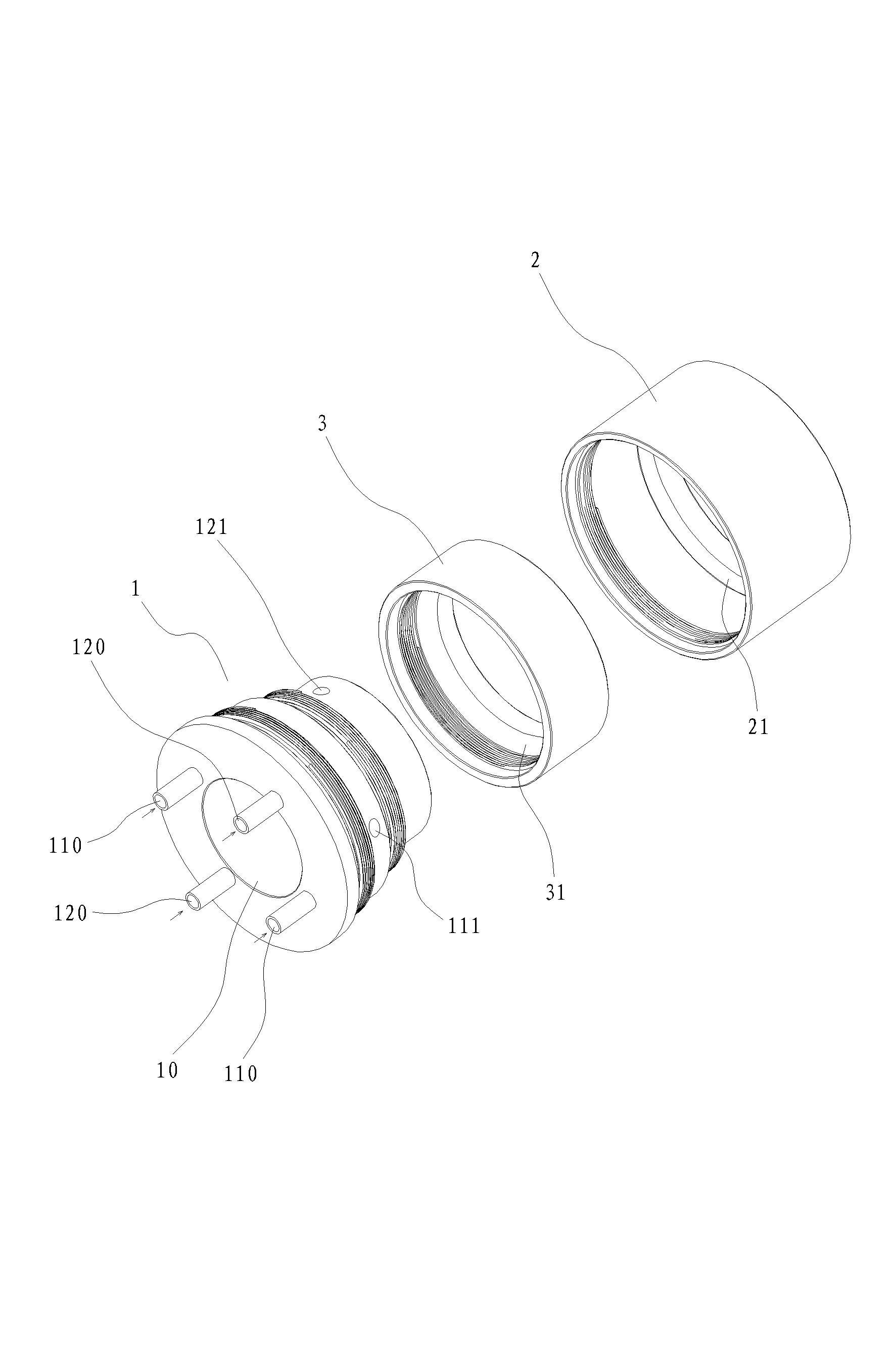

[0028] Example: see Figure 1 to Figure 5 , a plasma jet shield, comprising a jet core 1, an outer ring 2 and an inner ring 3, wherein:

[0029] The jet core 1 has a central axial through hole 10, and one end surface of the core is provided with two groups of air inlet holes 110, 120. Two groups of air outlet holes 111, 121, each group of air outlet holes are symmetrically distributed, and the two groups of air outlet holes communicate with the matching air inlet holes to form inner and outer layers of protective gas 11, 12;

[0030] The inner ring 3 is connected to the jet core 1 and cooperates with a group of air outlet holes at the front end of the peripheral wall of the core. The inner peripheral wall of the inner ring and the front end of the peripheral wall of the jet core form an annular flow channel to form an inner protective gas channel;

[0031] The outer ring 2 is connected to the jet core 1 and cooperates with another group of air outlet holes on the peripheral w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com