Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

808results about How to "Avoid arcing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

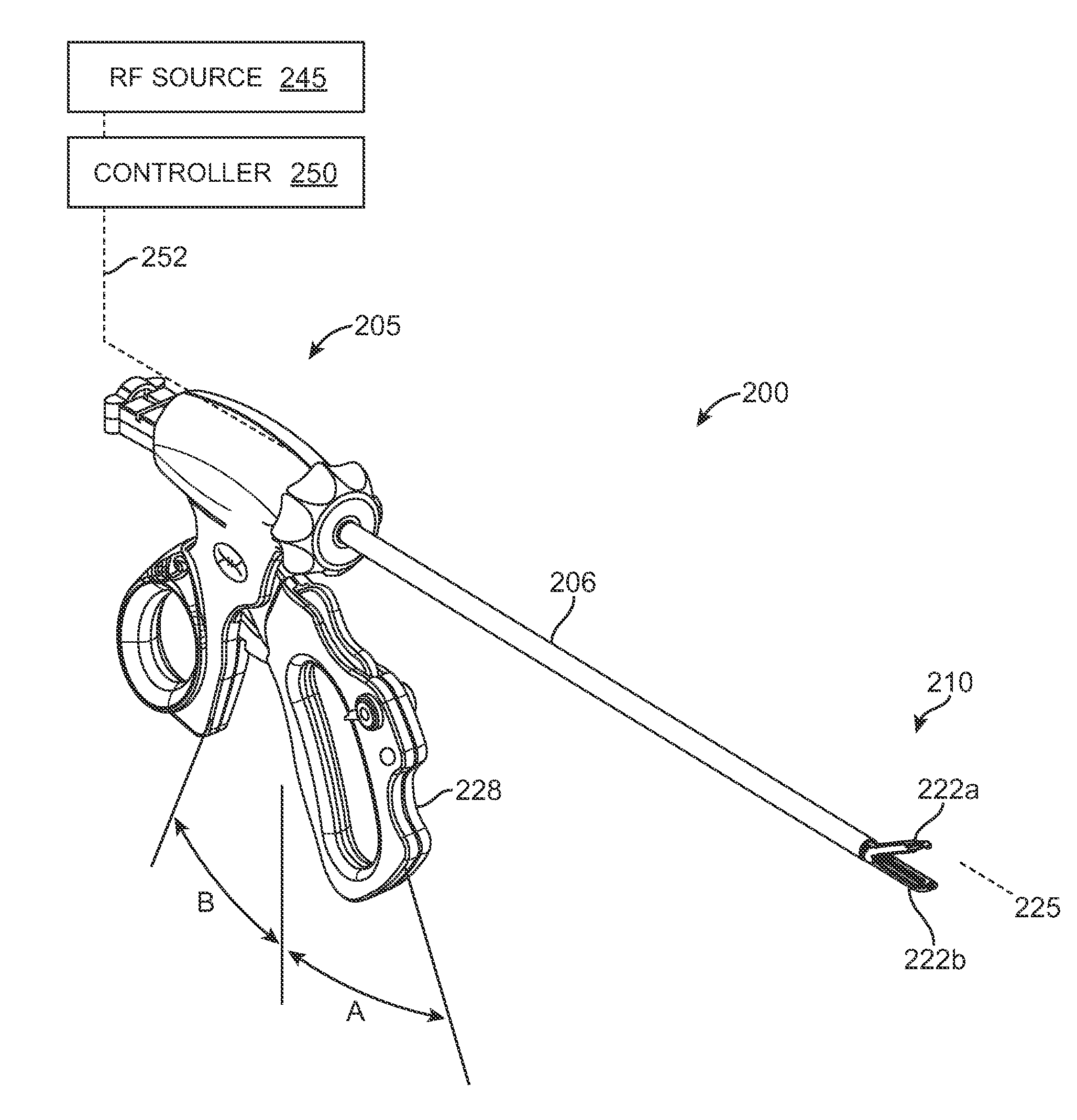

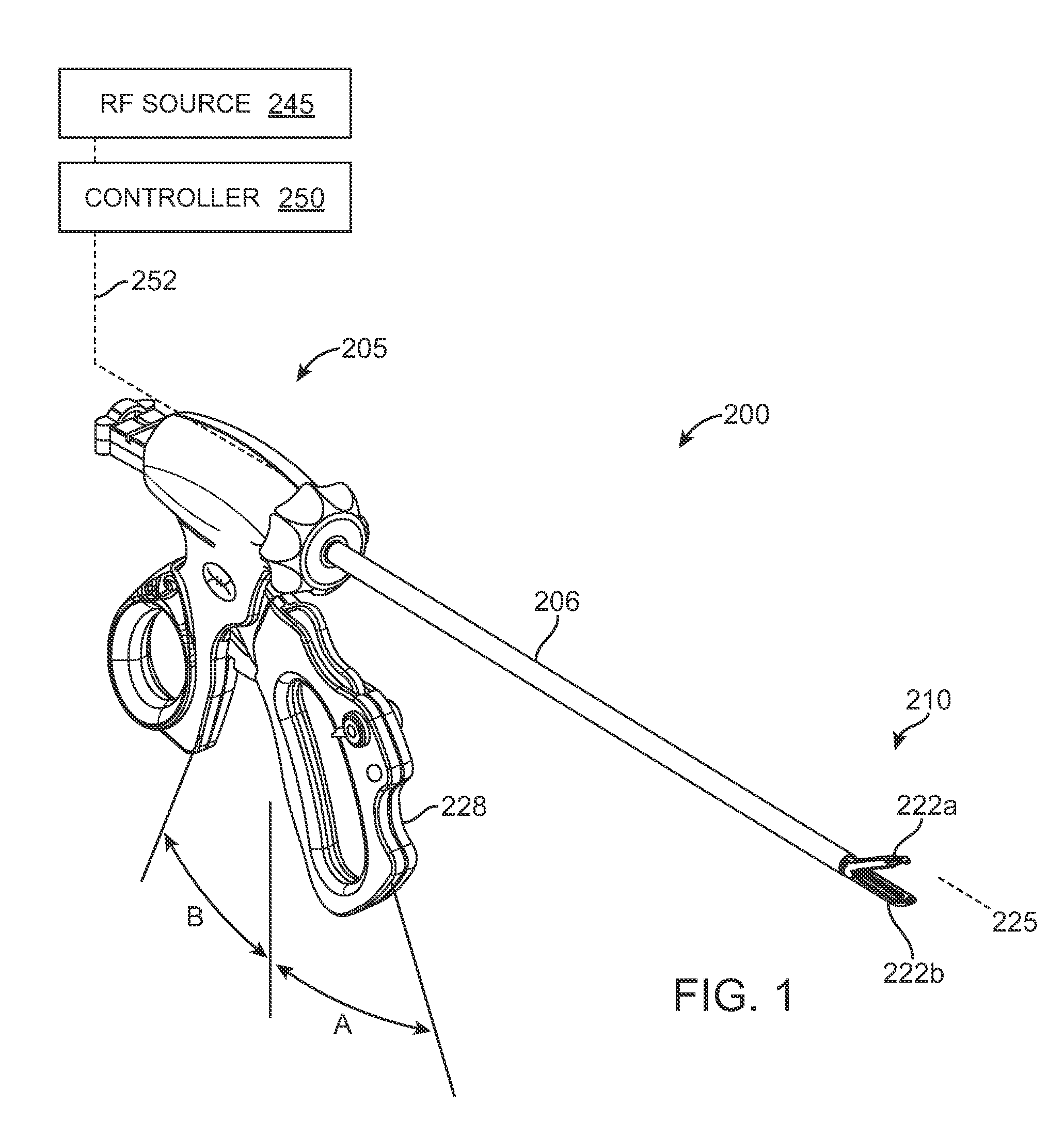

Electrosurgical instrument and method

InactiveUS20090076506A1Controllably seal the tissueImprove the immunitySurgical instruments for heatingSurgical forcepsTissue volume

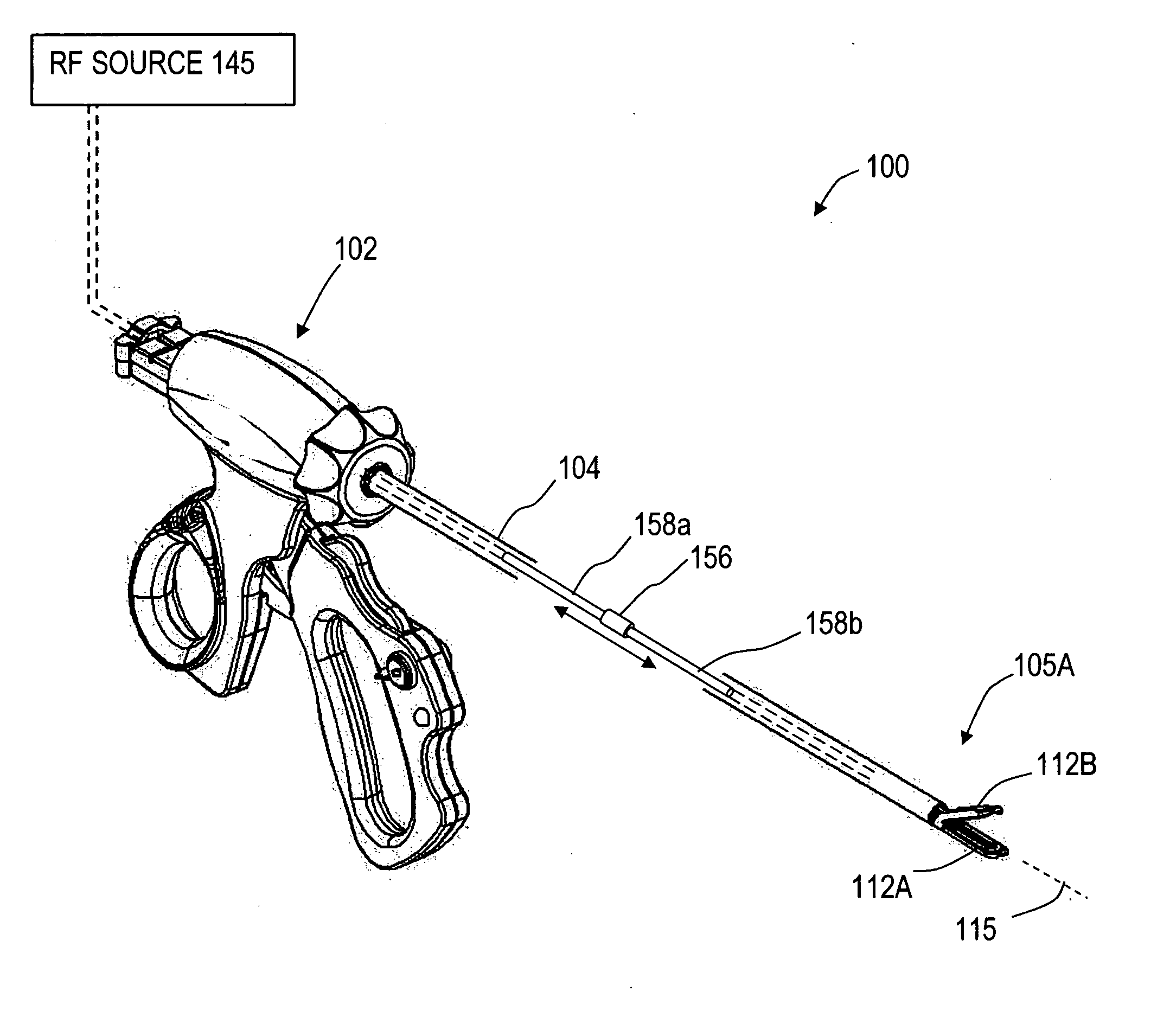

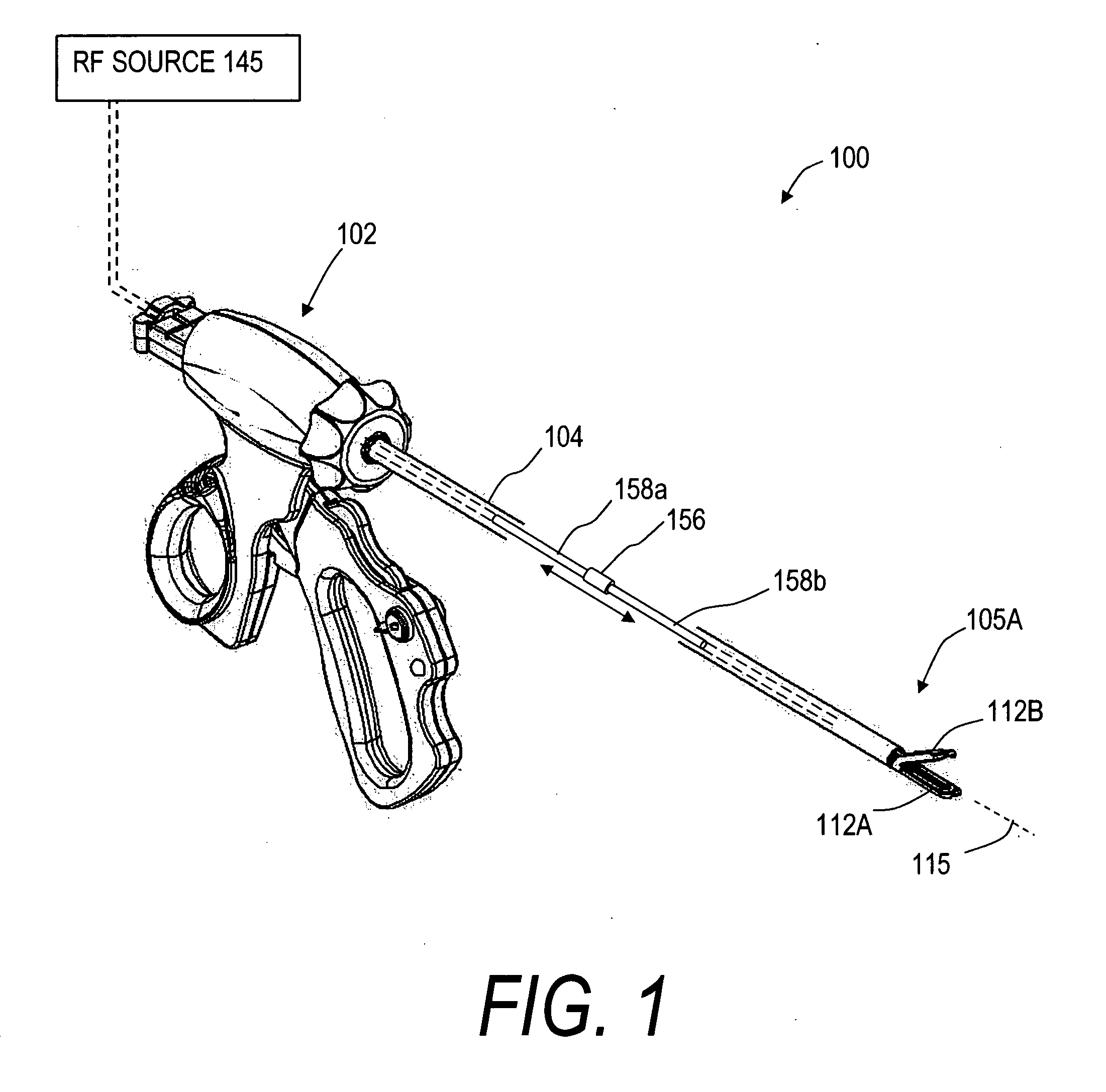

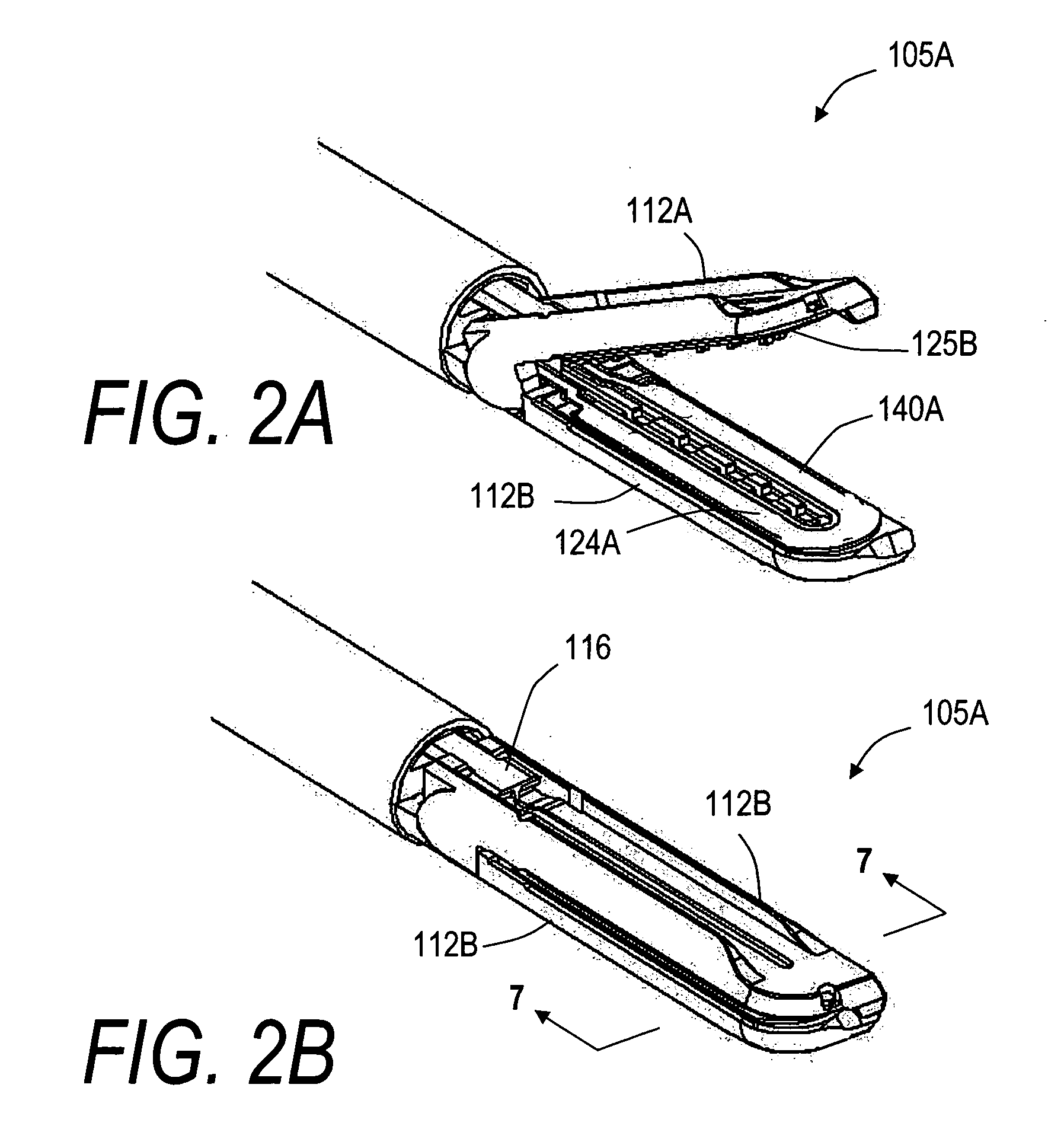

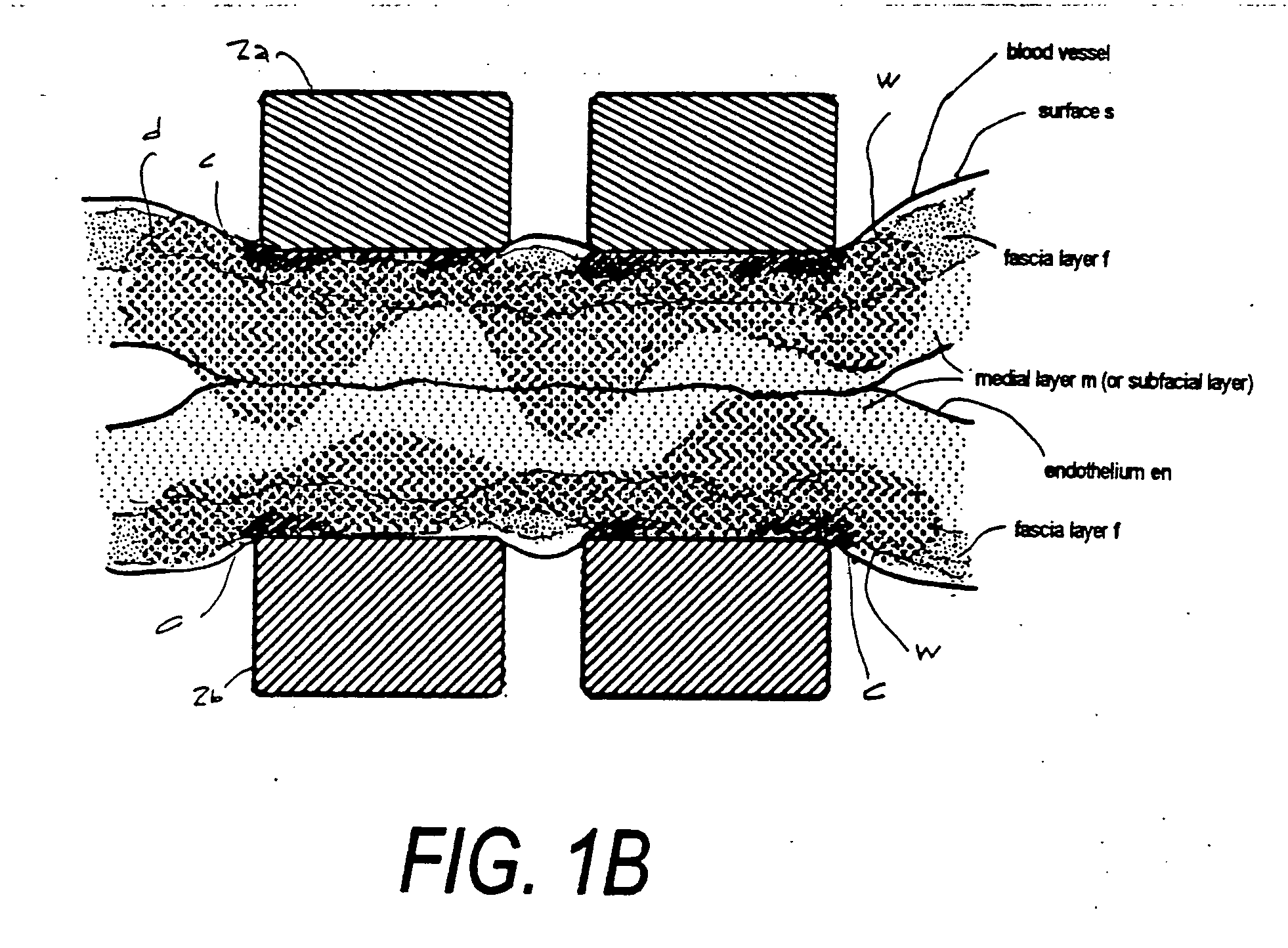

An electrosurgical working end and method for sealing and transecting tissue are provided. An exemplary electrosurgical working end has openable-closeable first and second jaws for progressively clamping a selected tissue volume. A method of the invention comprises applying electrosurgical energy to the tissue in either a first mode or a second mode based on the degree of jaw closure.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method

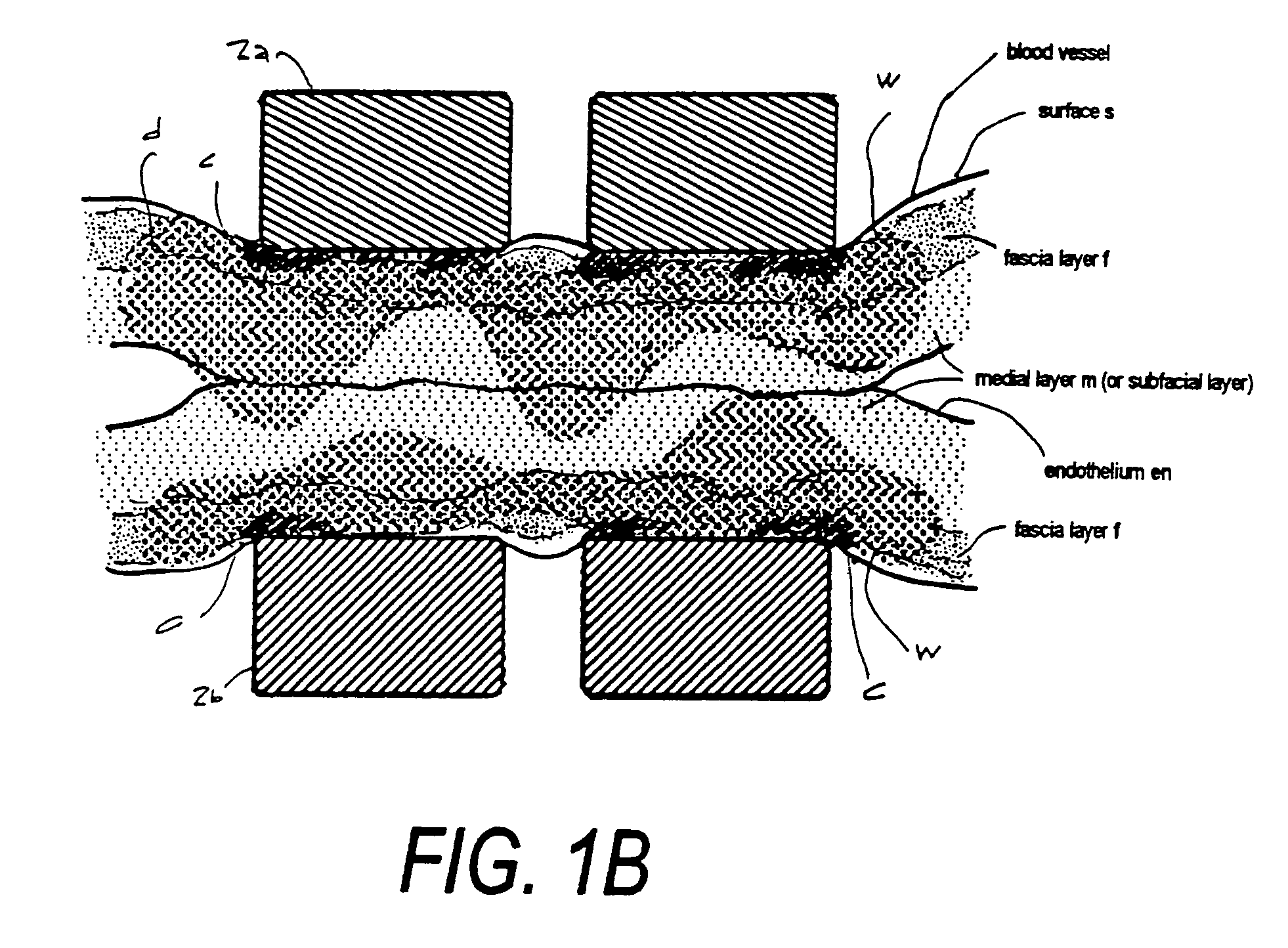

InactiveUS7517349B2Lower base resistanceRule out the possibilityDiagnosticsSurgical instruments for heatingElectrical resistance and conductanceVaricose veins

Owner:TYCO HEALTHCARE GRP LP

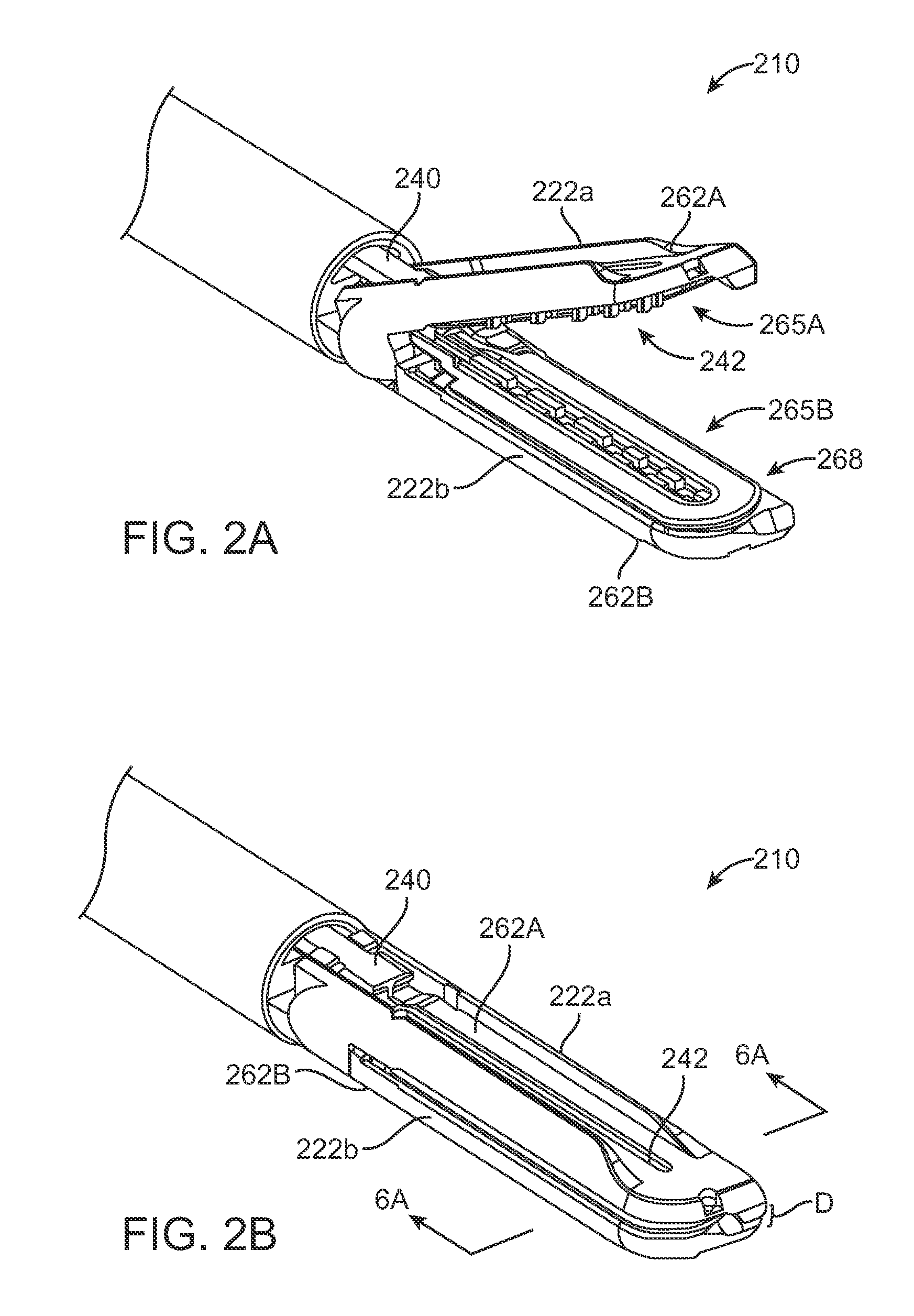

Electrosurgical instrument and method

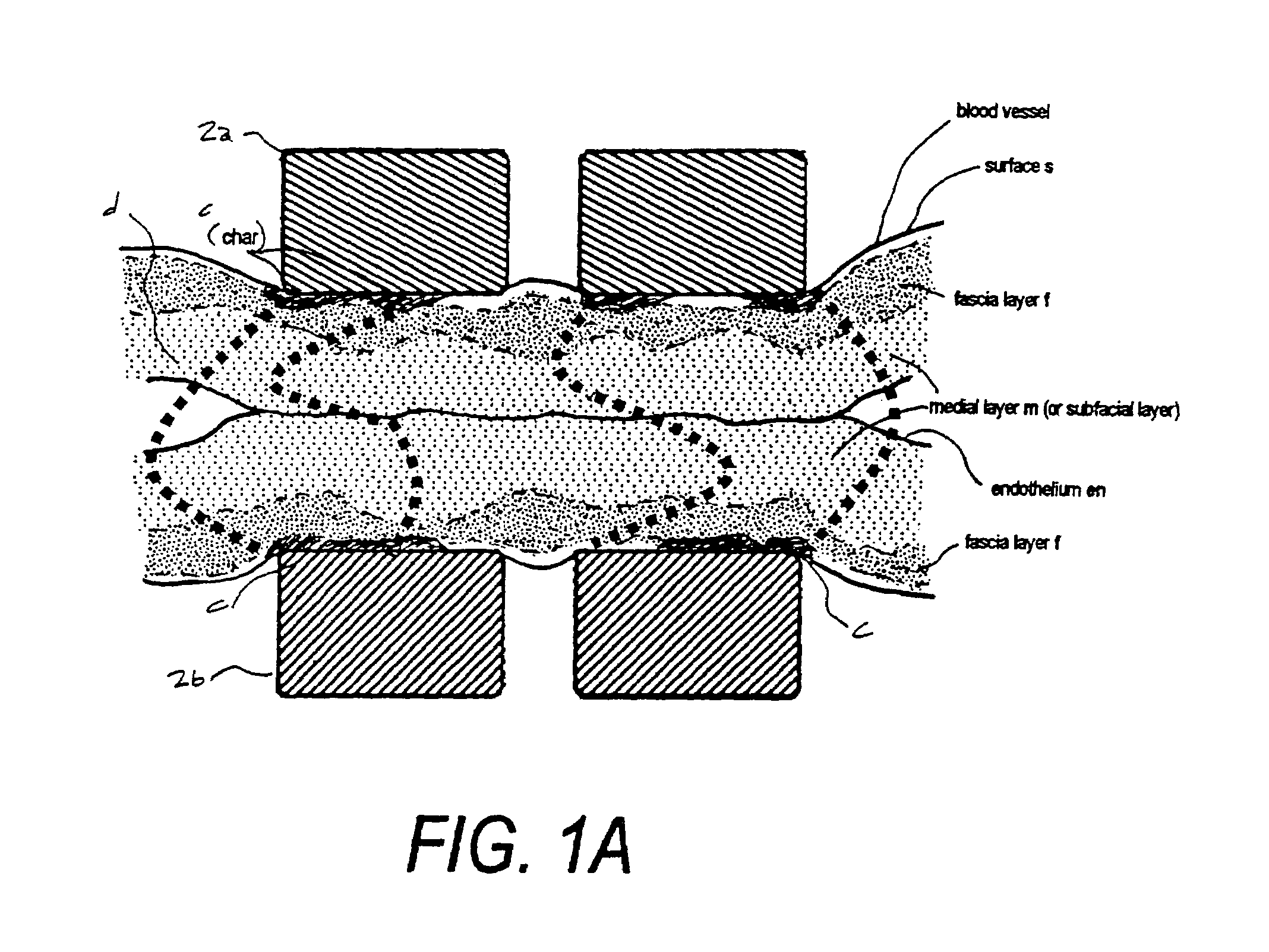

ActiveUS8075558B2Speed up the flowHeating evenlySurgical scissorsSurgical instruments for heatingElectrical resistance and conductanceHigh intensity

An electrosurgical working end and method for sealing and transecting tissue. An exemplary working end provides curved jaw members that are positioned on opposing sides of the targeted anatomic structure. The working end carries a slidable extension member having flange portions with inner surfaces that slide over the jaw members to clamp tissue therebetween. The working end carries an independent slidable cutting member that is flexible to follow the curved axis of the jaws. The electrosurgical surfaces of the jaws include partially-resistive bodies for carrying a current or load which modulates ohmic heating in the engaged tissue to prevent charring and desiccation of tissue to create a high strength thermal seal.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method of use

InactiveUS20060293656A1High energyLimit electrosurgical energy deliveryDiagnosticsSurgical instruments for heatingElectrical resistance and conductanceBiomedical engineering

Electrosurgical jaw structures are disclosed that include pressure sensitive variable resistive materials in electrosurgical energy delivery surfaces for welding tissue. The pressure sensitive materials are configured to have megaohm impedance when not engaging tissue and can transform into highly conductive electrodes when compressed under a selected pressure. In a method of the invention, the pressure sensitive variable resistive materials prevent arcing and tissue desiccation when applying bi-polar Rf current to tissue engaged under high compression in an electrosurgical jaw structure.

Owner:SURGRX

Electrosurgical instrument and method

ActiveUS20060069388A1Speed up the flowHeating evenlySurgical scissorsSurgical instruments for heatingElectrical resistance and conductanceHigh intensity

An electrosurgical working end and method for sealing and transecting tissue. An exemplary working end provides curved jaw members that are positioned on opposing sides of the targeted anatomic structure. The working end carries a slidable extension member having flange portions with inner surfaces that slide over the jaw members to clamp tissue therebetween. The working end carries an independent slidable cutting member that is flexible to follow the curved axis of the jaws. The electrosurgical surfaces of the jaws include partially-resistive bodies for carrying a current or load which modulates ohmic heating in the engaged tissue to prevent charring and desiccation of tissue to create a high strength thermal seal.

Owner:ETHICON ENDO SURGERY INC

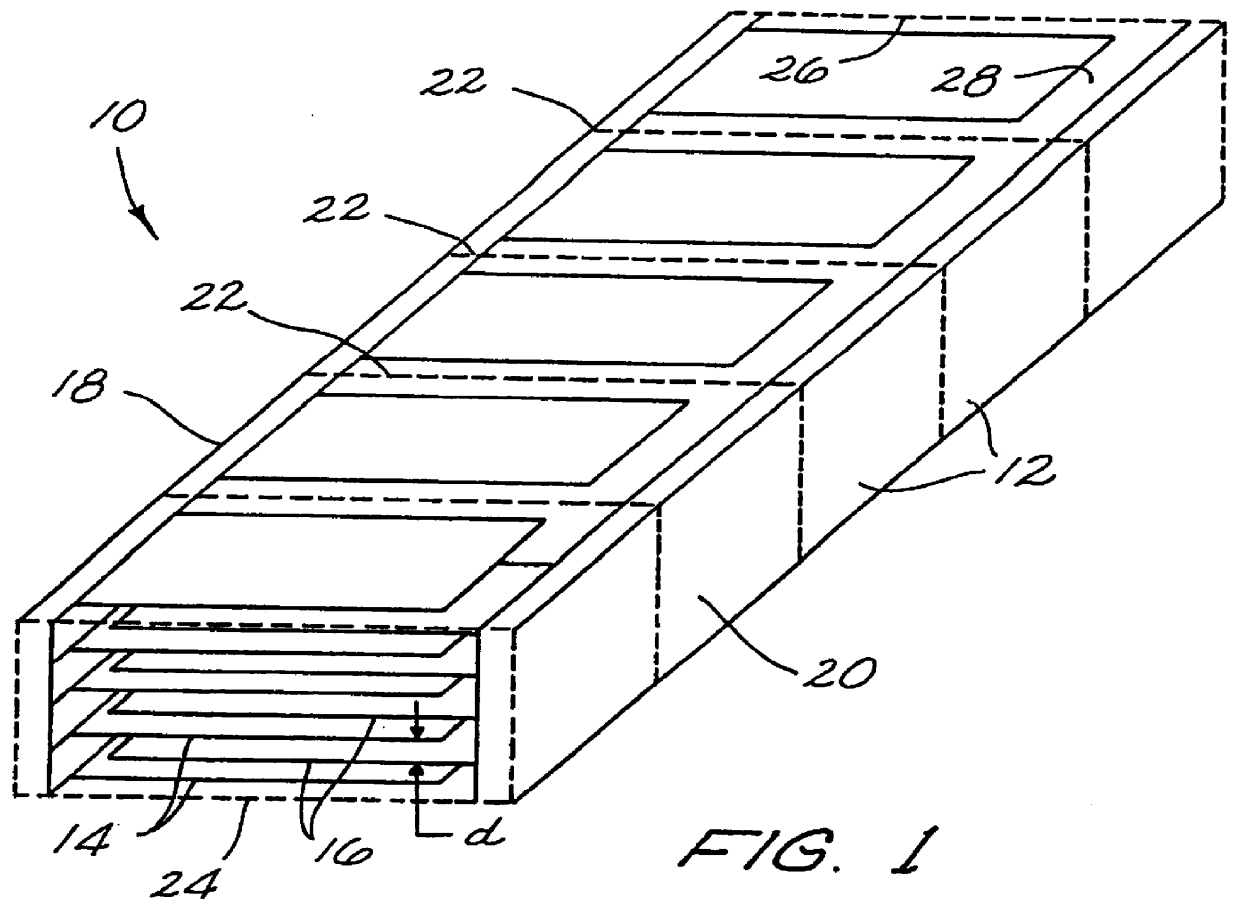

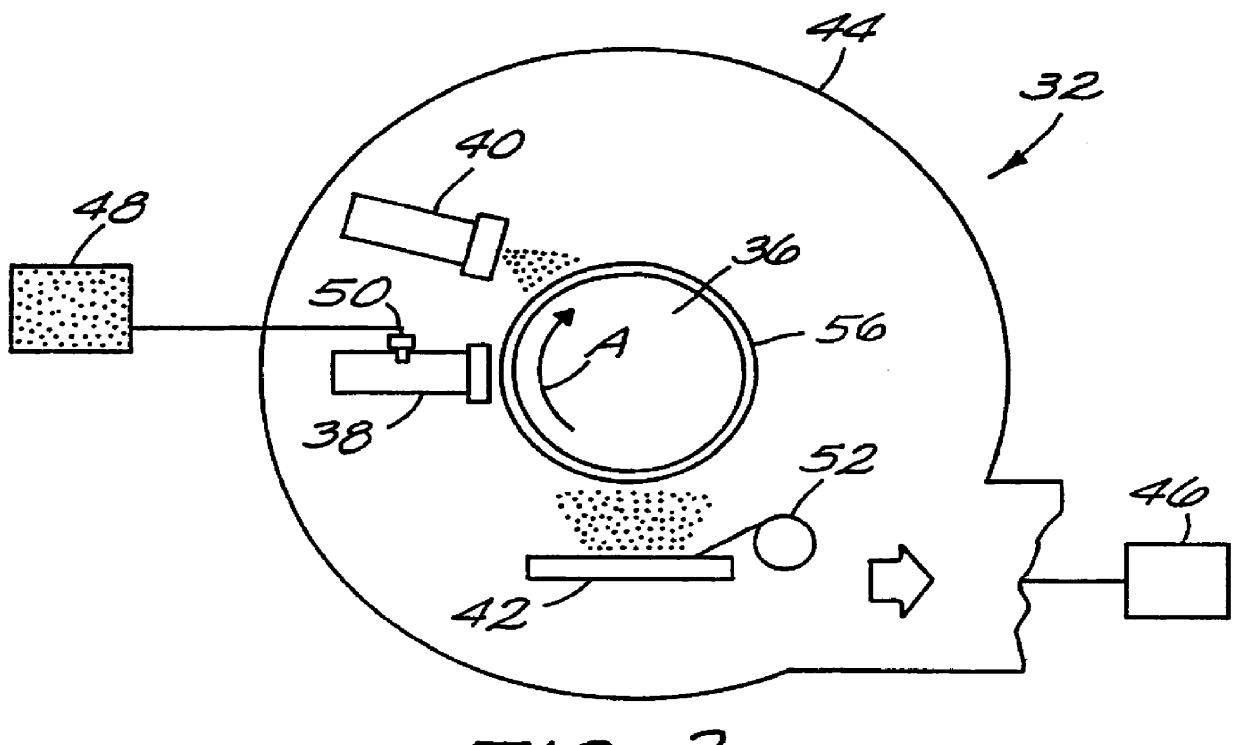

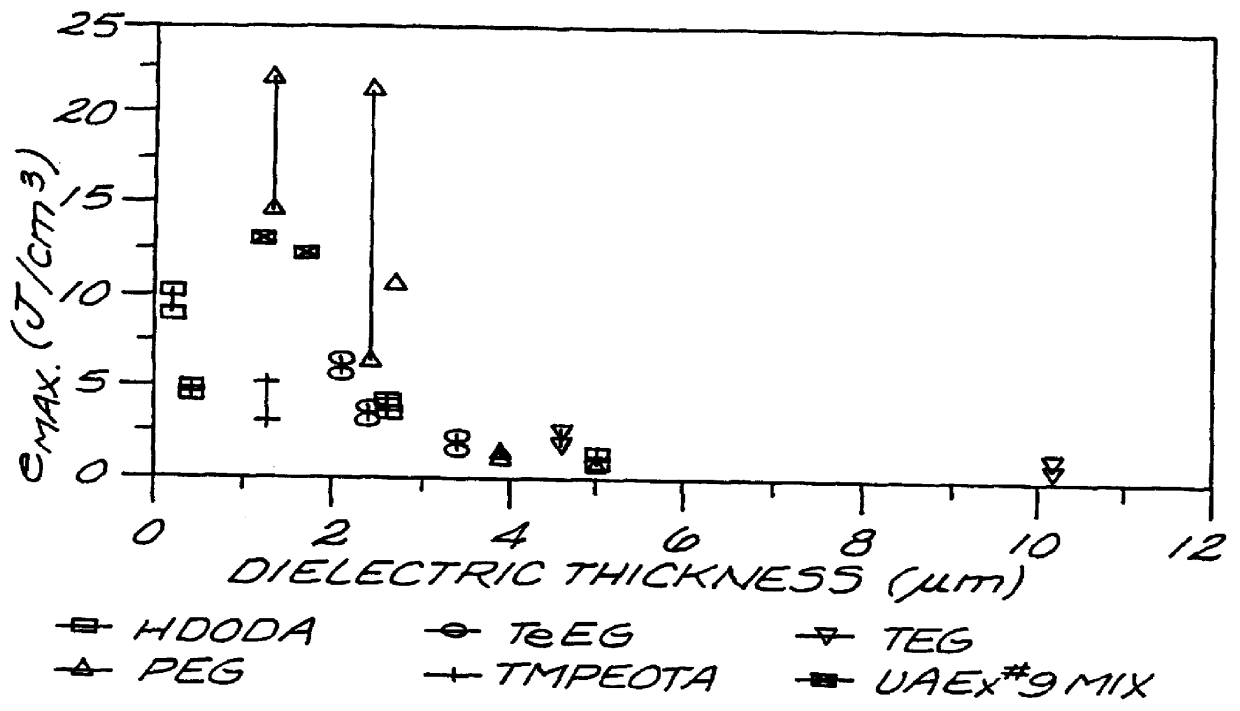

High energy density capacitor

A high energy density, high power density capacitor having an energy density of at least about 0.5 J / cm3 is provided. The capacitor comprises a plurality of interleaved metal electrode layers separated by a polymer layer. The interleaved metal electrode layers terminate at opposite ends in a solder termination strip. The high energy density aspect of the capacitors of the invention is achieved by at least one of the following features: (a) the dielectric thickness between the interleaved metal electrode layers is a maximum of about 5 mu m; (b) the polymer is designed with a high dielectric constant kappa of at least about 3.5; (c) the metal electrode layers within the polymer layer are recessed along edges orthogonal to the solder termination strips to prevent arcing between the metal electrode layers at the edges; and (d) the resistivity of the metal electrode layers is within the range of about 10 to 500 ohms per square, or a corresponding thickness of about 200 to 30 ANGSTROM .

Owner:SIGMA LAB OF ARIZONA

Electrocautery method and apparatus

ActiveUS20080221565A1Avoid arcingSurgical instruments for heatingCoatingsBiomedical engineeringElectrode

An electrode structure and a mechanism for automated or user-selected operation or compensation of the electrodes, for example to determine tissue coverage and / or prevent arcing between bottom electrodes during electrocautery is disclosed.

Owner:AESCULAP AG

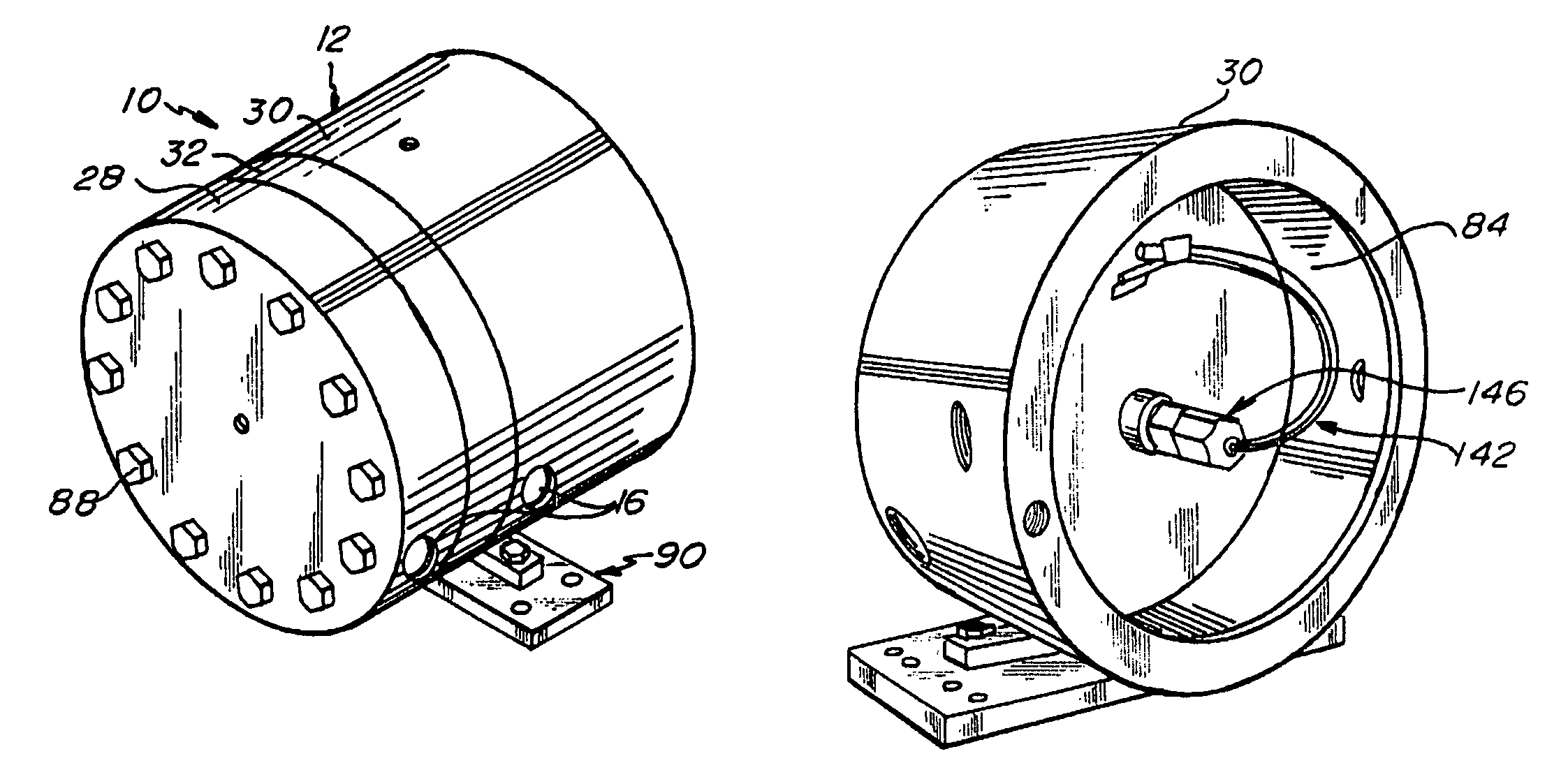

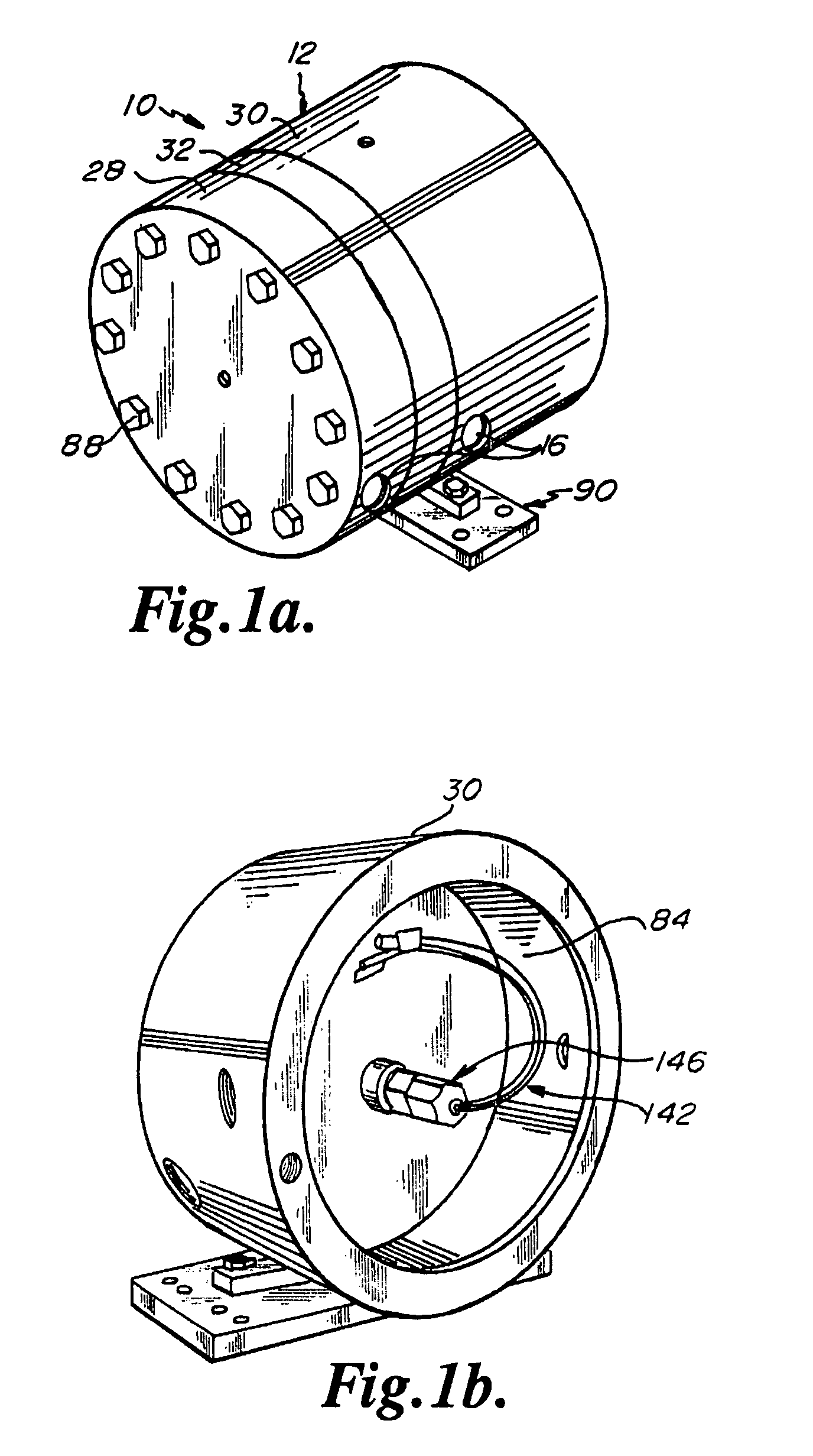

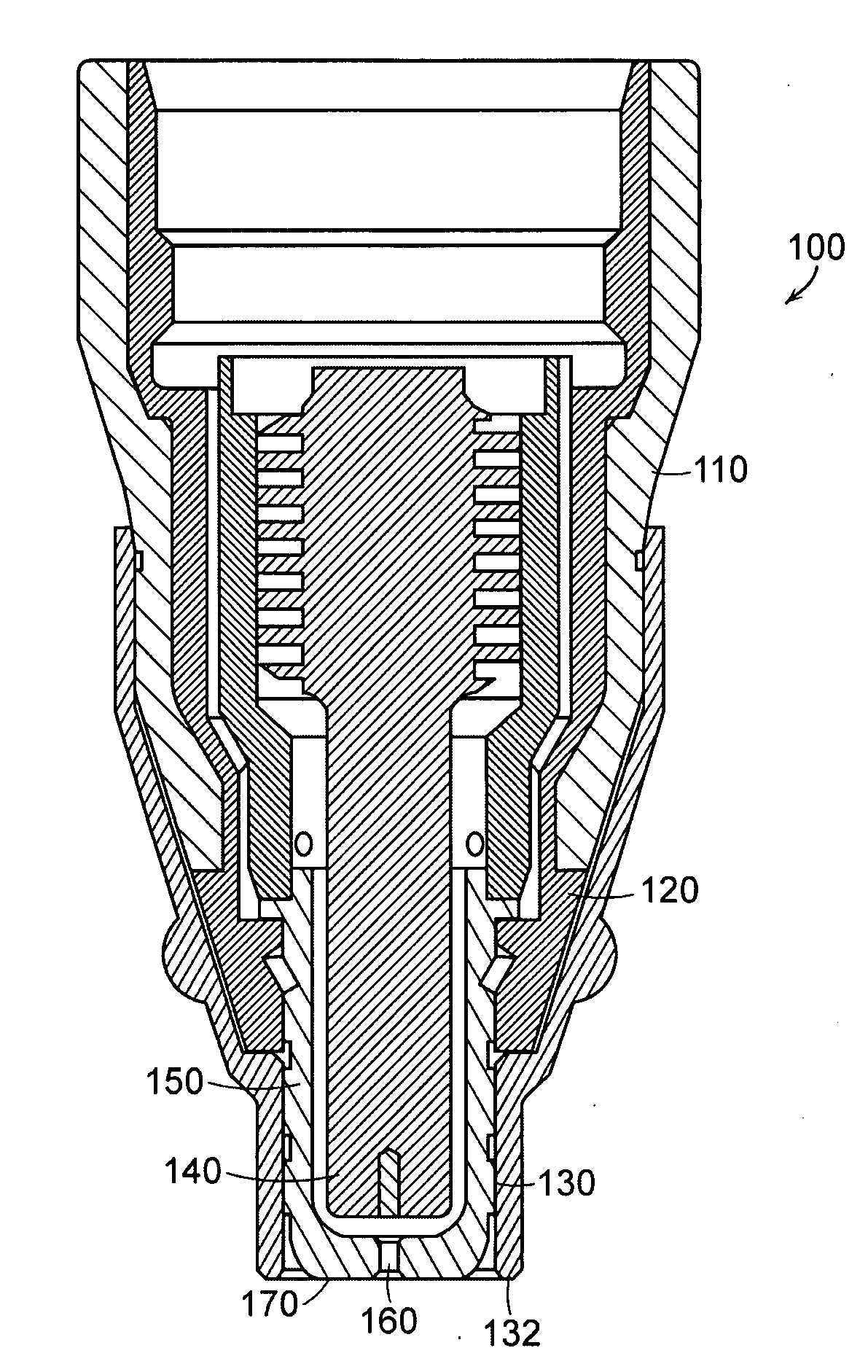

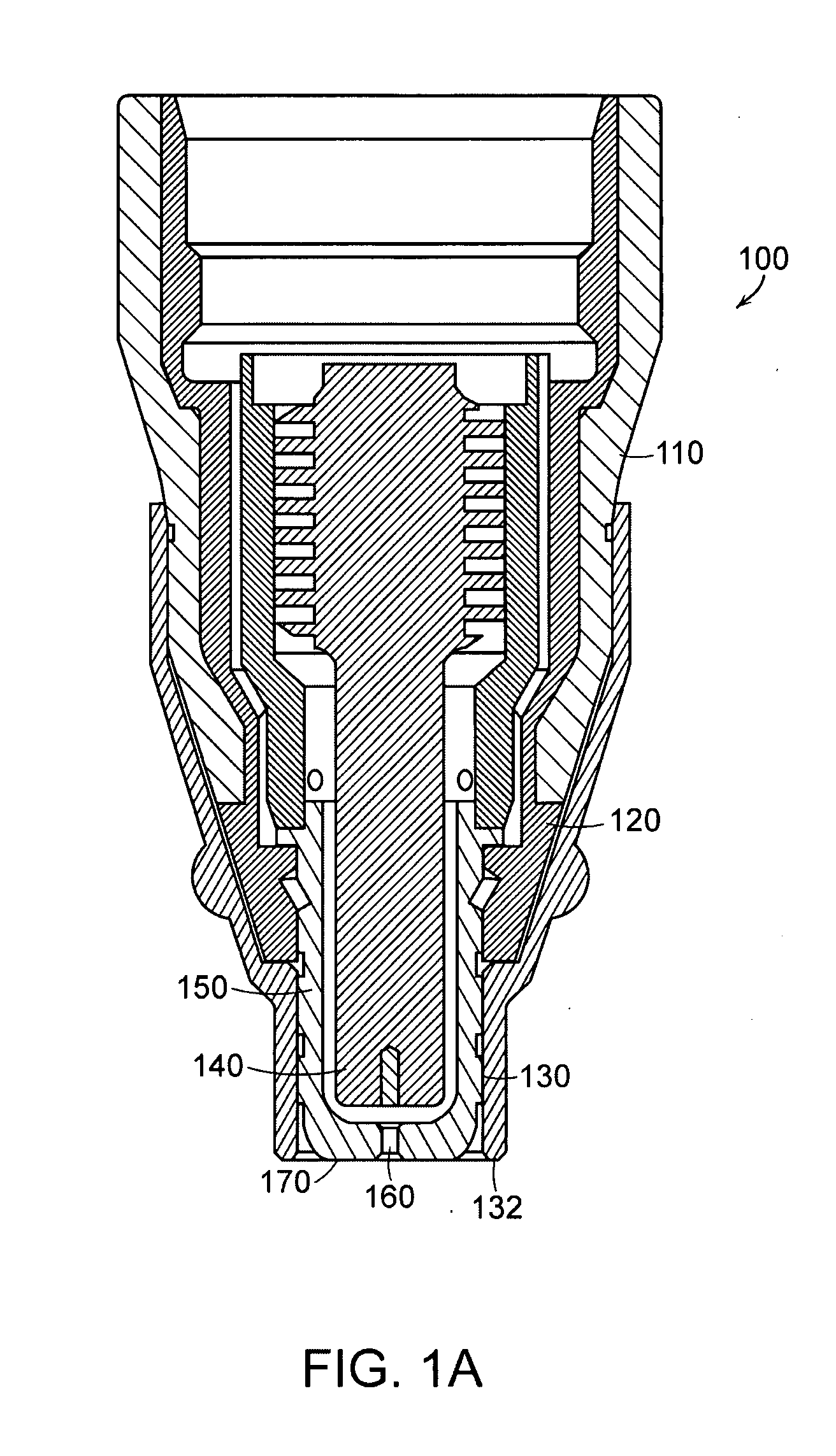

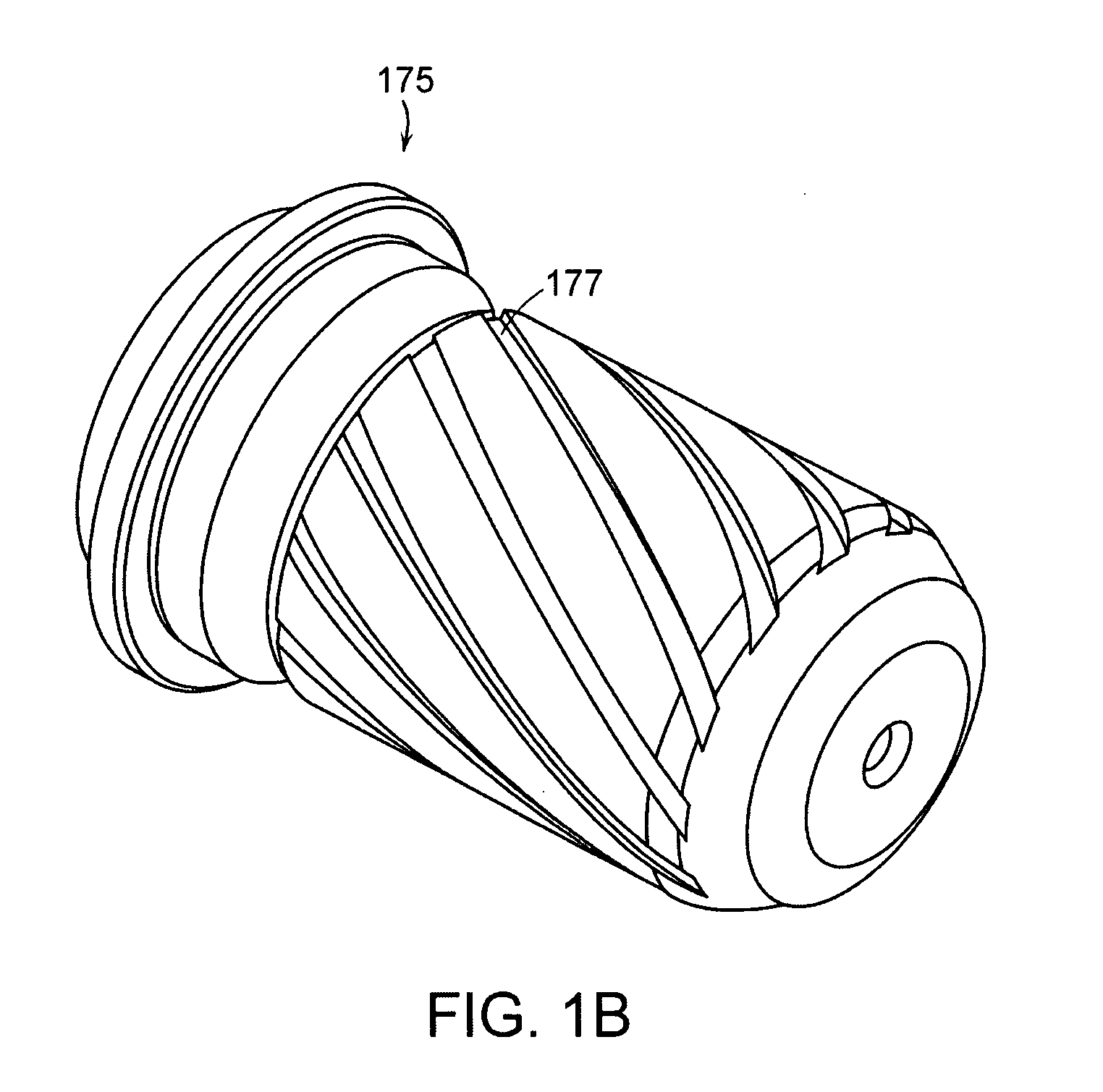

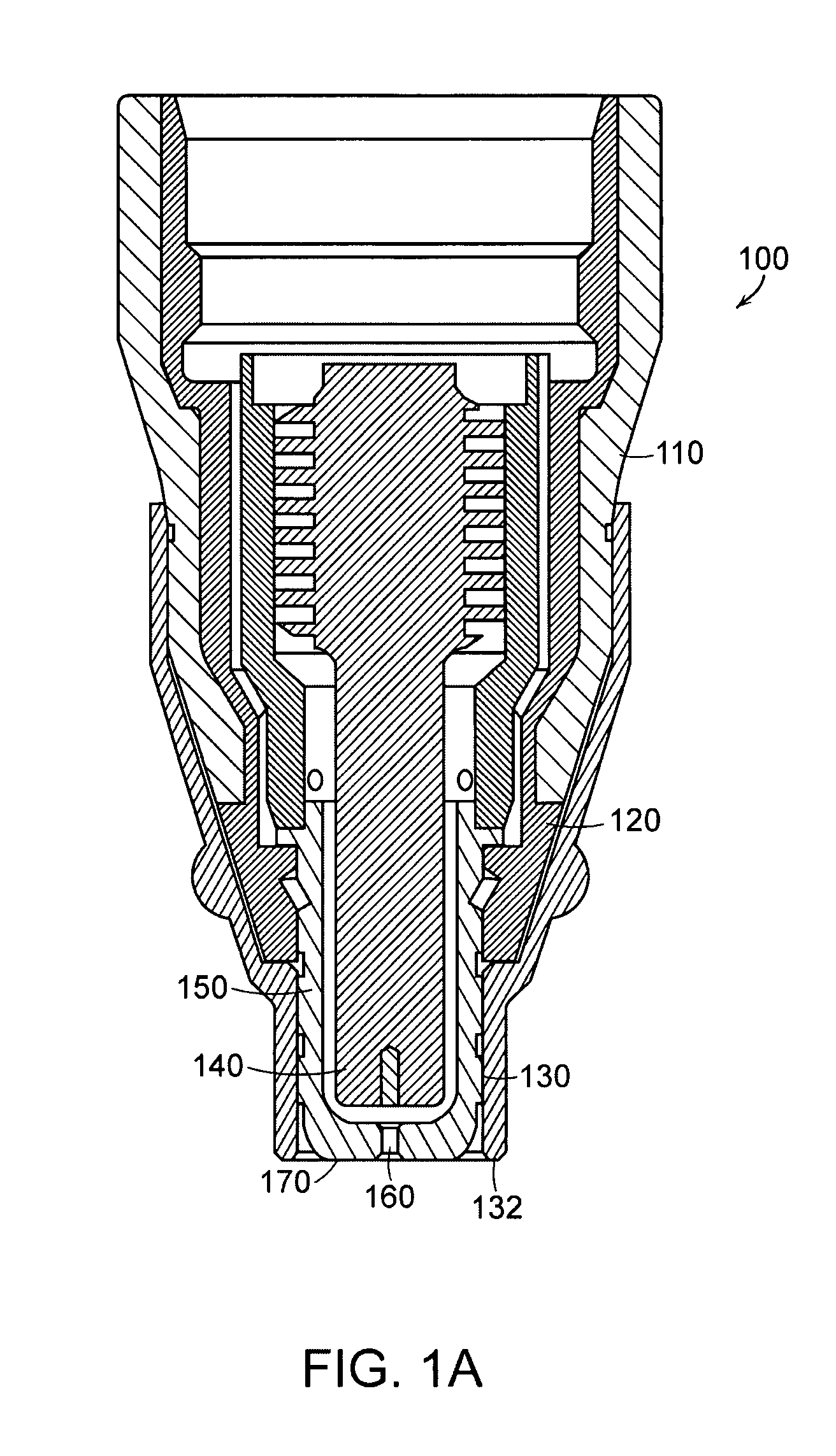

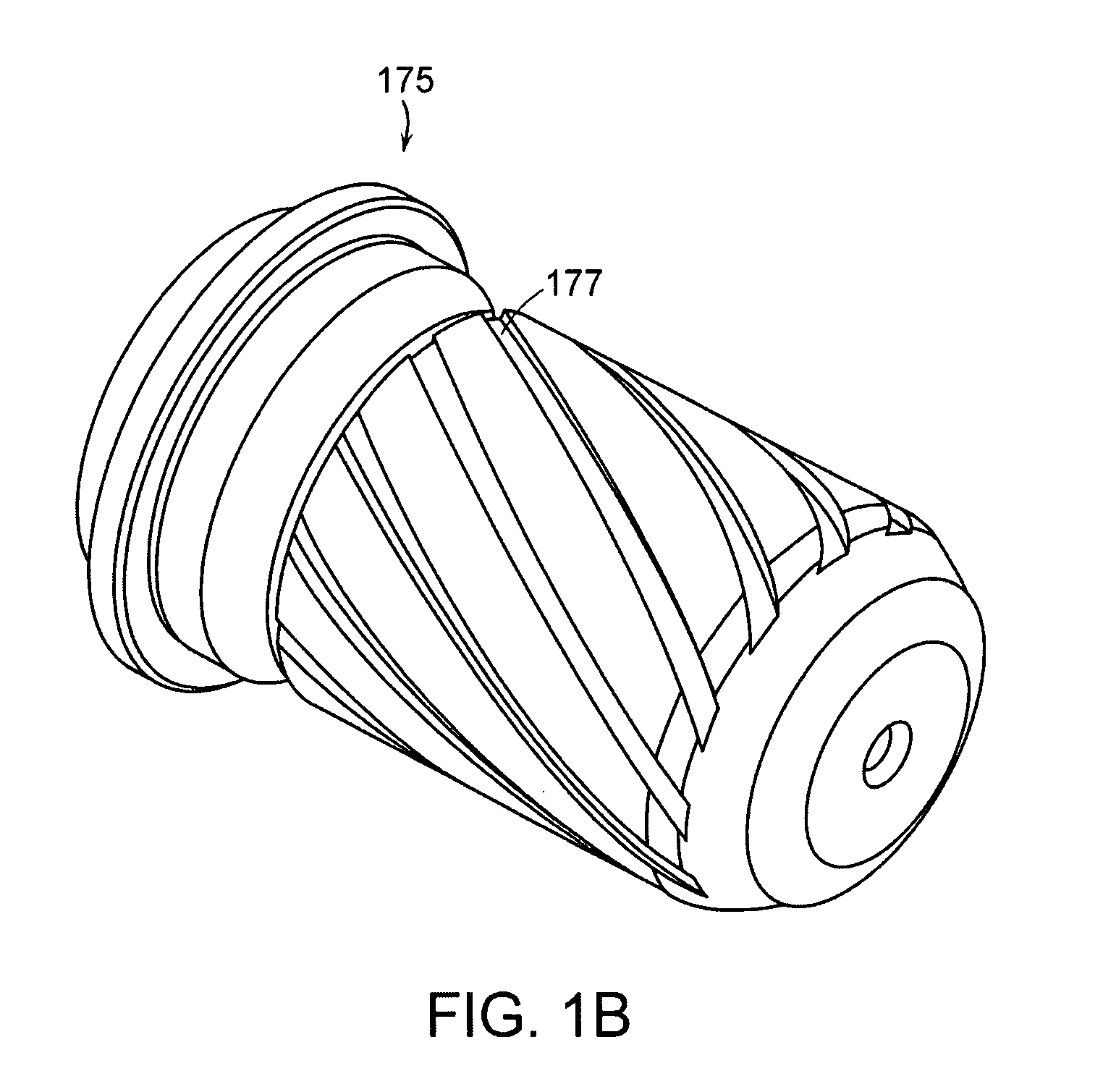

Natural gas turbine generator

ActiveUS7683499B2Minimize explosion hazardEliminating carbon bridging between connectionsMotor/generator/converter stoppersWindingsElectricityMomentum

A turbine generator utilizing a passive high pressure fluid source such as a natural gas well head. The generator includes a core and lead wires encapsulated in a dielectric medium to isolate current-bearing components from the motivating fluid, thereby preventing carbon bridging and reducing the explosion hazard when the motivating fluid is a hydrocarbon. The turbine generator includes a rotor that utilizes the full length as an impingement surface for imparting momentum to the rotor, thereby maintaining a compact design that reduces the overall footprint of the turbine generator. Fluid exits the generator via horizontal passages that penetrate the lower extremities of the turbine generator, preventing the buildup of condensation in the unit.

Owner:REVOLUTION TURBINE TECH LLC

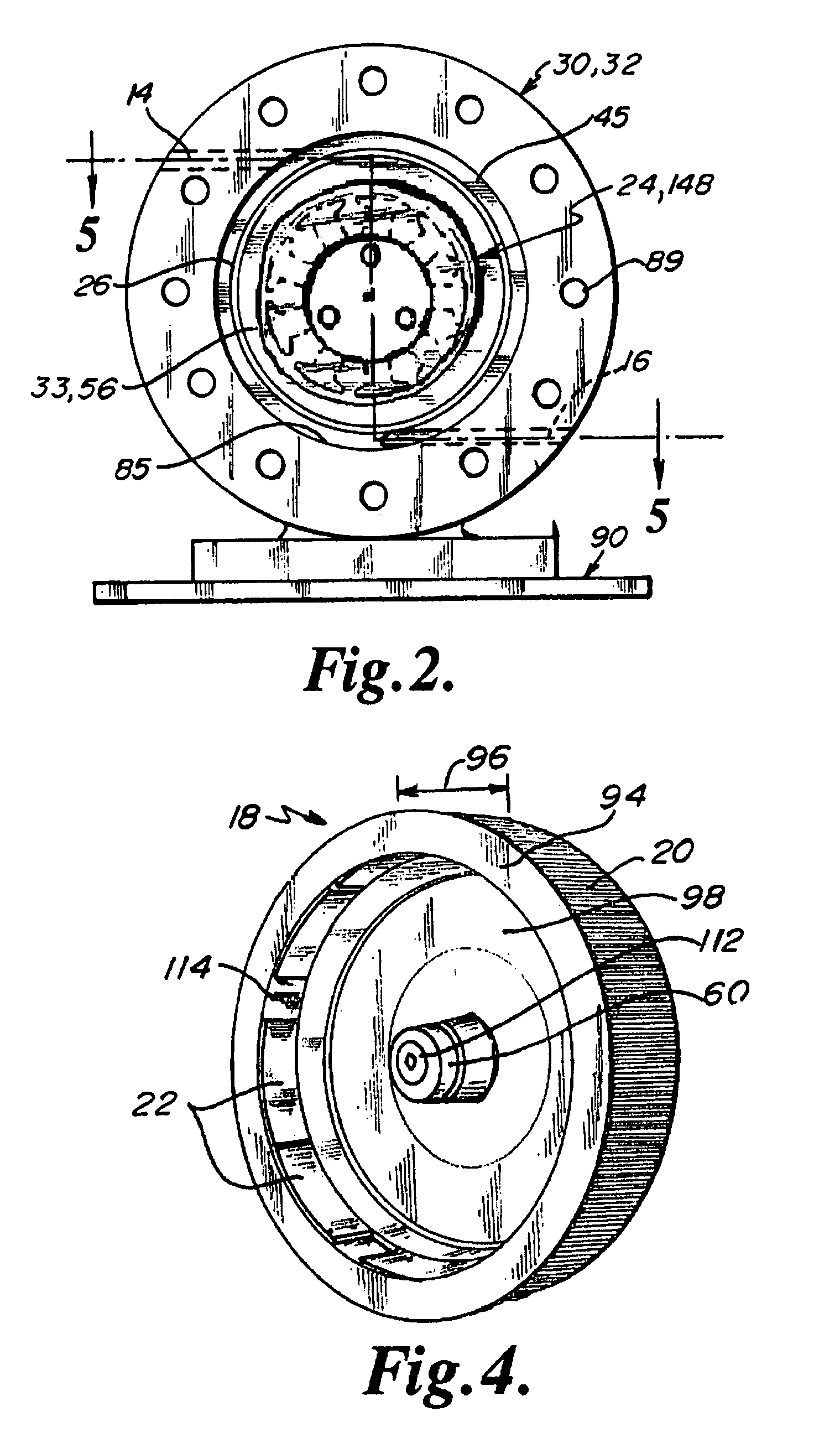

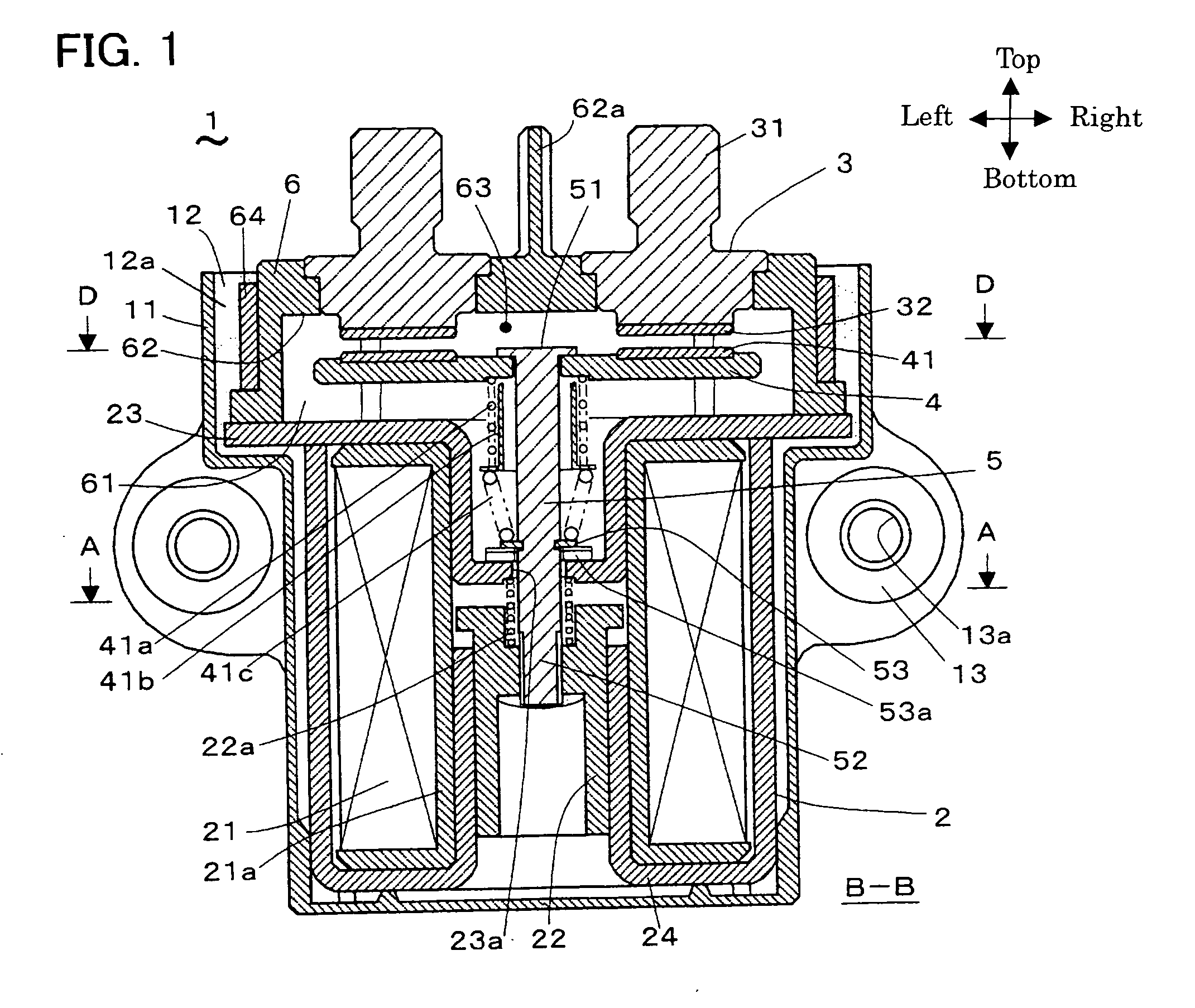

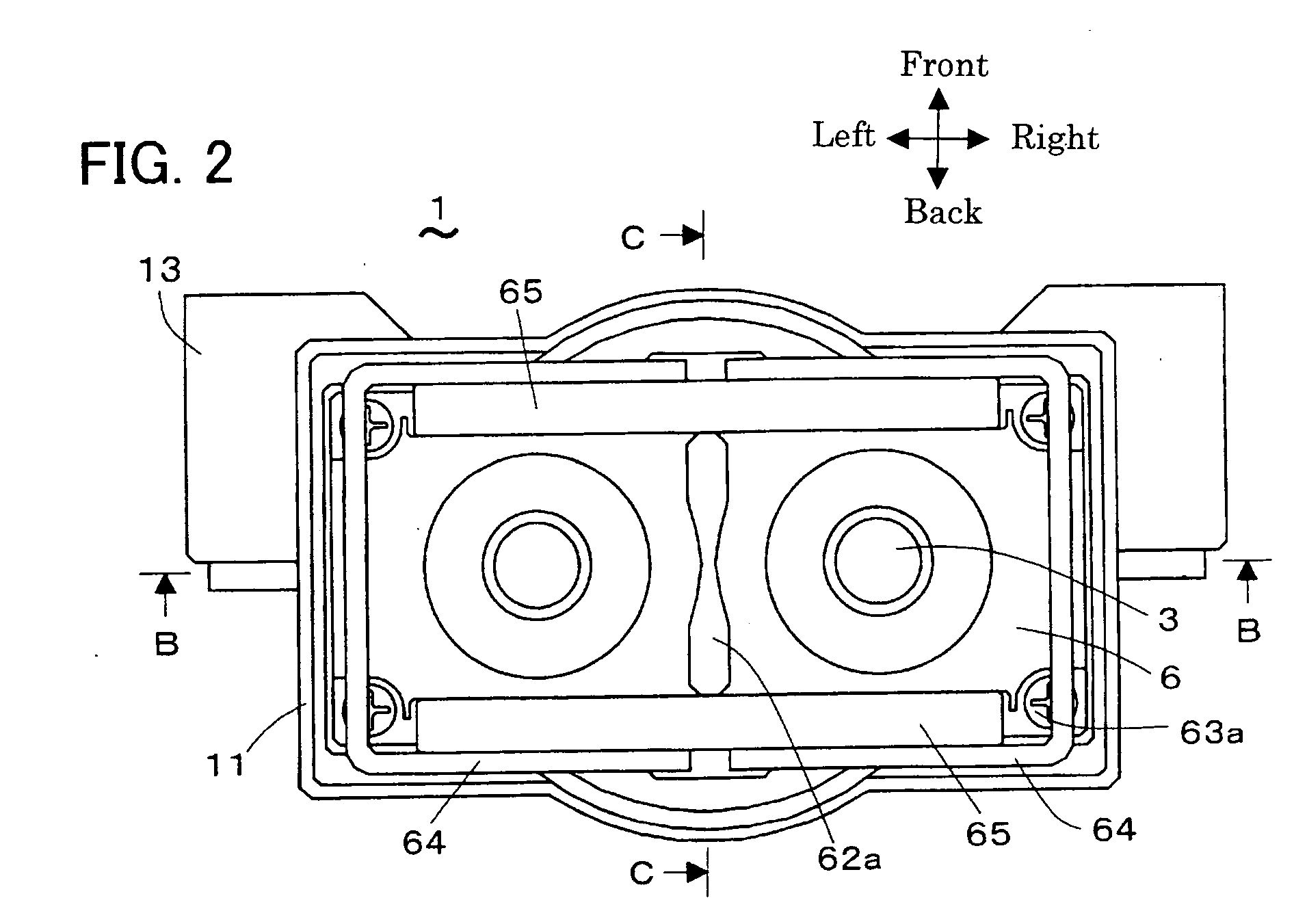

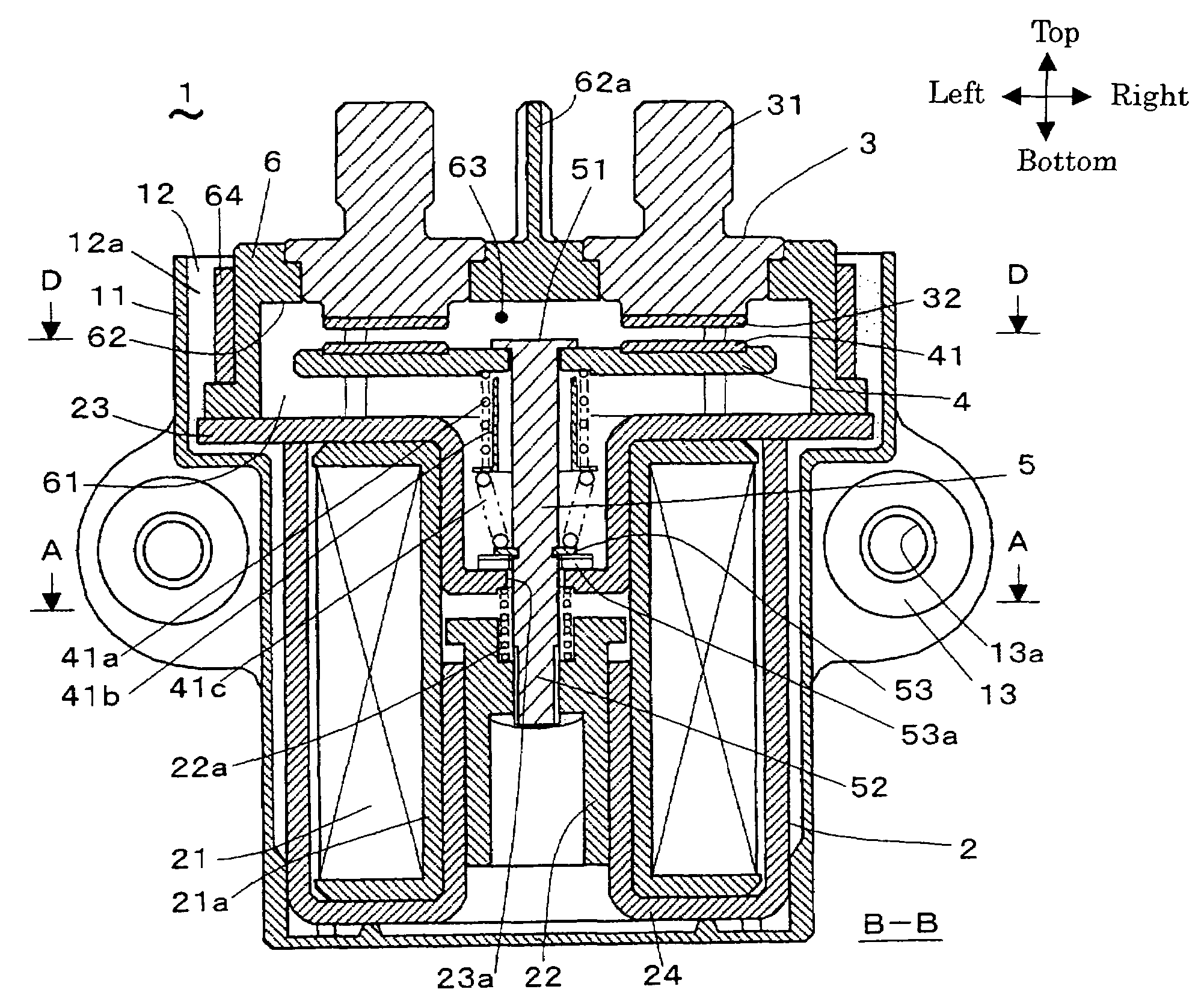

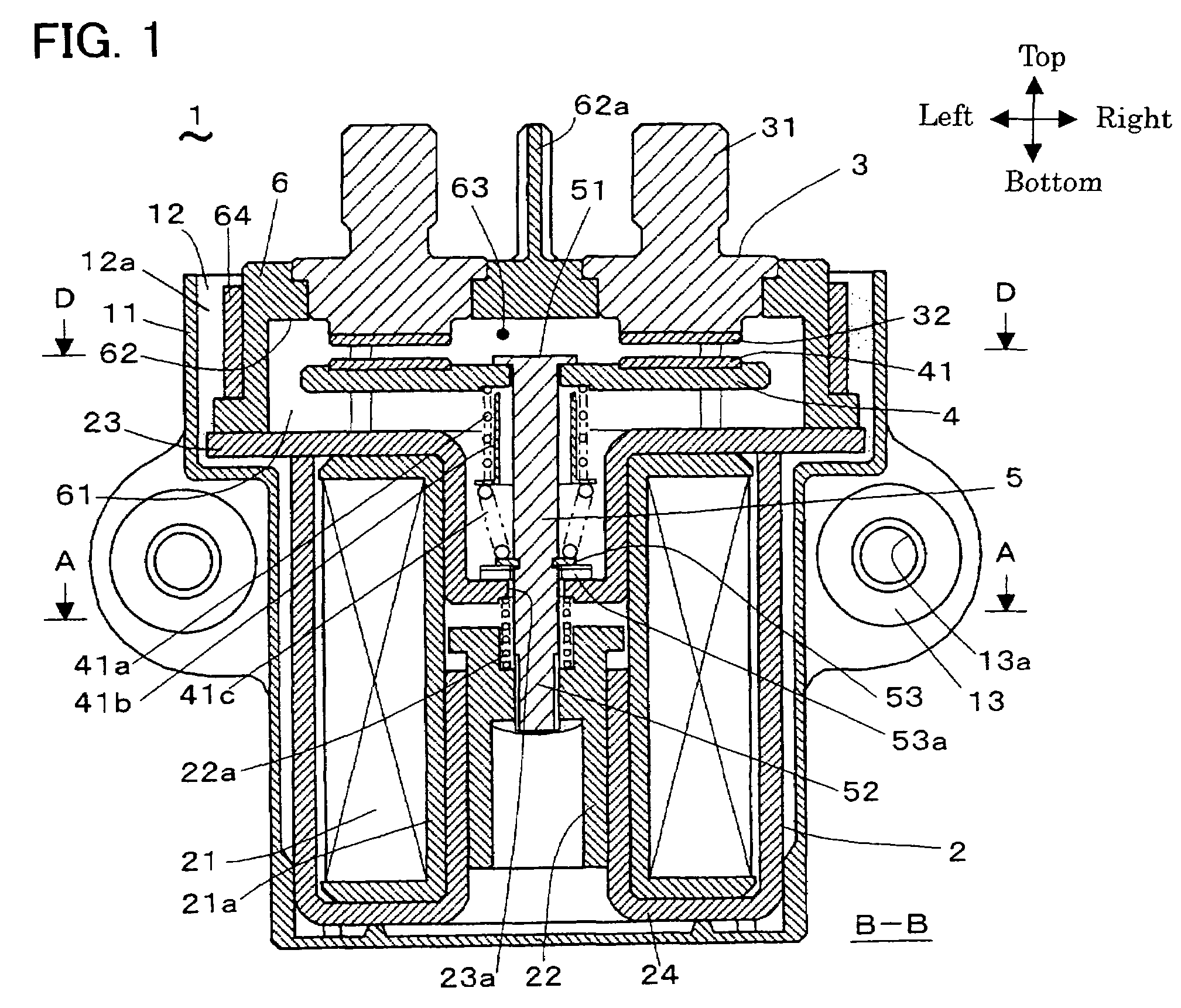

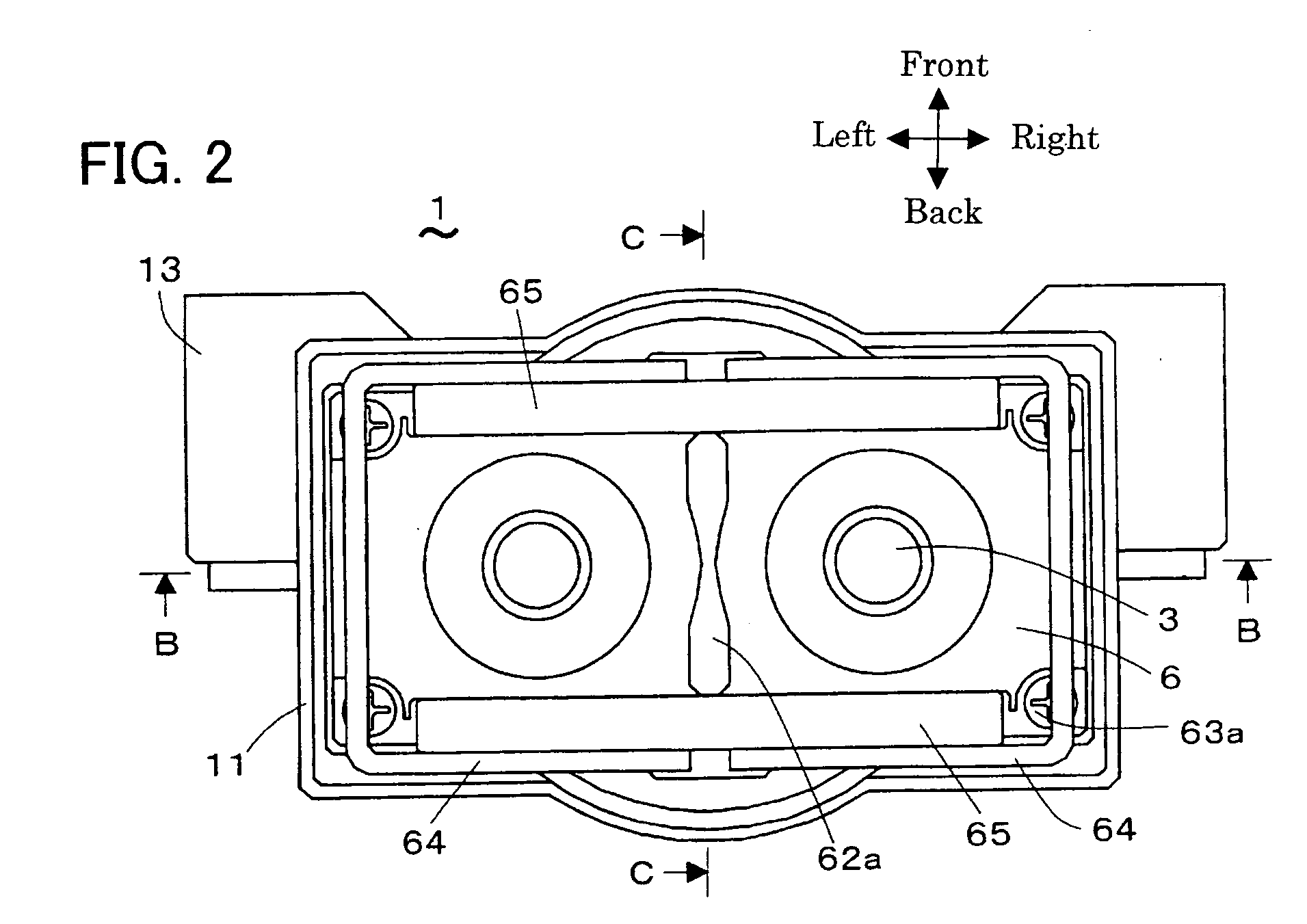

Electromagnetic switching device

InactiveUS20060050466A1Avoid vibrationImprove abilitiesElectric switchesElectromagnetic relay detailsMiniaturizationEngineering

In the electromagnetic switching device, it is possible to miniaturize and have low costs, have quiet operation noise, and also quickly extinguish the arc. The electromagnetic switching device has an electromagnetic actuator with a movable iron core, a pair of fixed terminals that respectively have a fixed contact point, a movable contact that has movable contact points on the right and left ends, a shaft, and an enclosing component that holds the movable contact points and the fixed contact points. The pair of movable contact points respectively contact with and detach from the pair of fixed contact points, and the pair of fixed contact points respectively conduct each other and are insulated again through the shaft by moving the movable iron core along the axis using the electric magnetic actuator. A quasi-hermetically sealed space, which is the extinguishing space, is formed by the enclosing component and a first yoke. A potting compound is charged, into the space between a body and the quasi hermitically sealed space.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Lightning protection system for a wind turbine

In a wind turbine (104, 500, 704) having a plurality of blades (132, 404, 516, 744) and a blade rotor hub (120, 712), a lightning protection system (100, 504, 700) for conducting lightning strikes to any one of the blades and the region surrounding the blade hub along a path around the blade hub and critical components of the wind turbine, such as the generator (112, 716), gearbox (708) and main turbine bearings (176, 724).

Owner:WEG ELECTRIC CORP

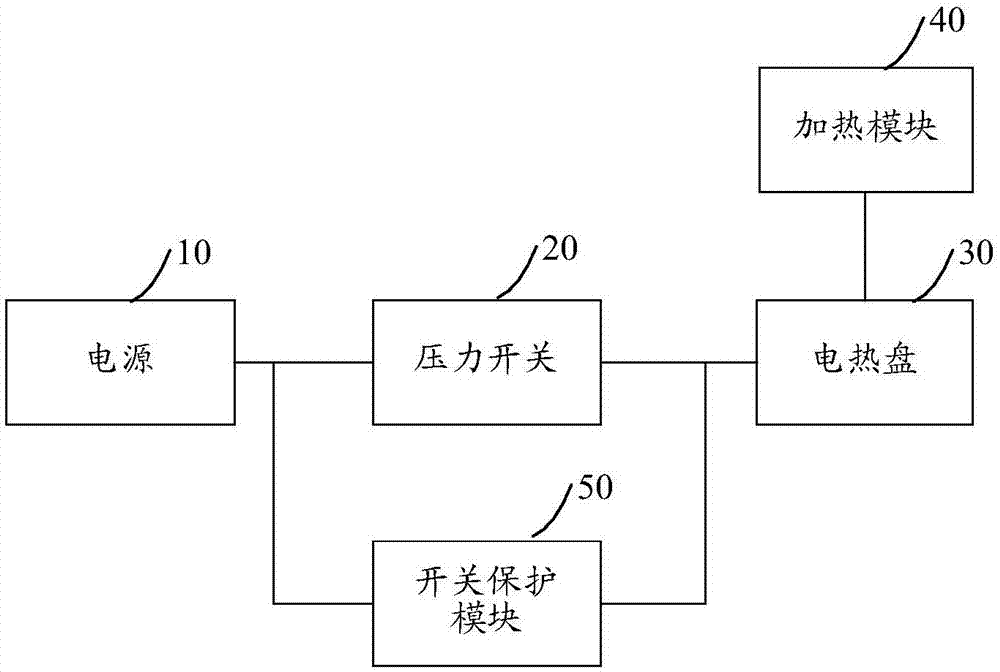

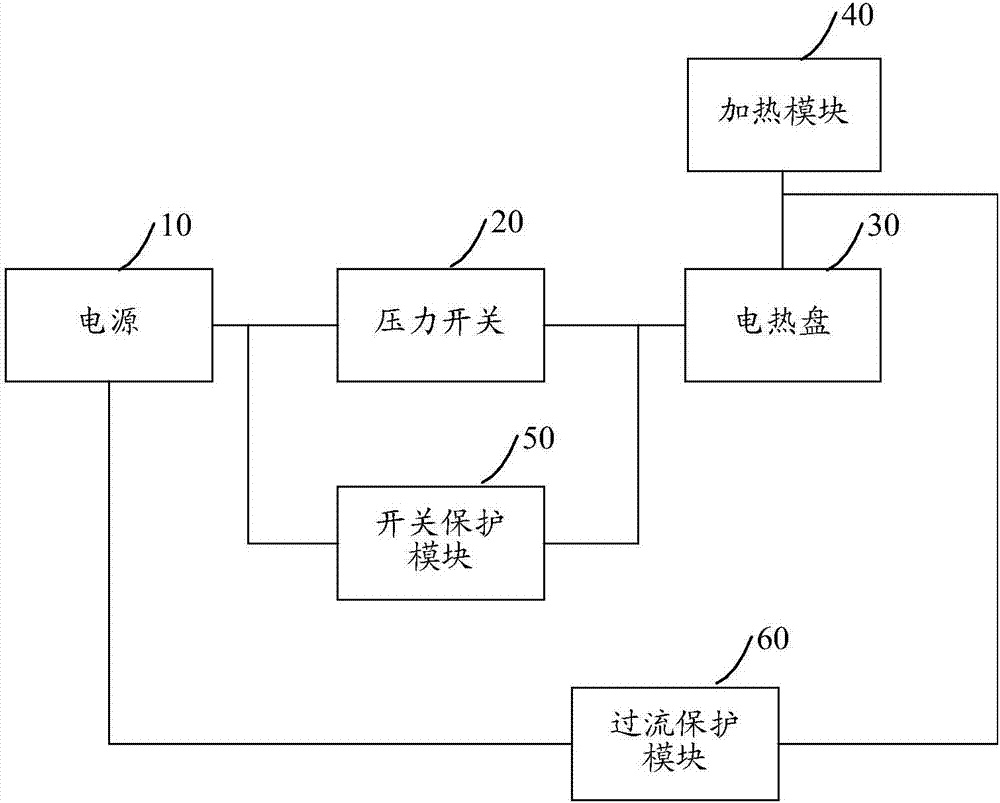

Method of protection circuit and electric pressure cooker and protection pressure switch

PendingCN107997571AExtended service lifeReduce voltagePressure-cookersWarming devicesComputer moduleEngineering

The embodiment of the invention discloses a method of a protection circuit and an electric pressure cooker and a protection pressure switch; wherein the protection circuit comprises a pressure switchconnected with a power supply, an electric hot tray connected with the pressure switch and a heating module connected with the electric hot tray and used for heating the electric hot tray; the protection circuit further comprises a switch protection module, the switch protection module is connected in parallel with the pressure switch, and used for absorbing the energy flowing through the pressureswitch when the connected state of the pressure switch is changed to the off-state. According to the method, the arcing phenomenon generated by the oversize pressure between the two contactors of thepressure switch can be avoided, and the service life of the pressure switch is prolonged.

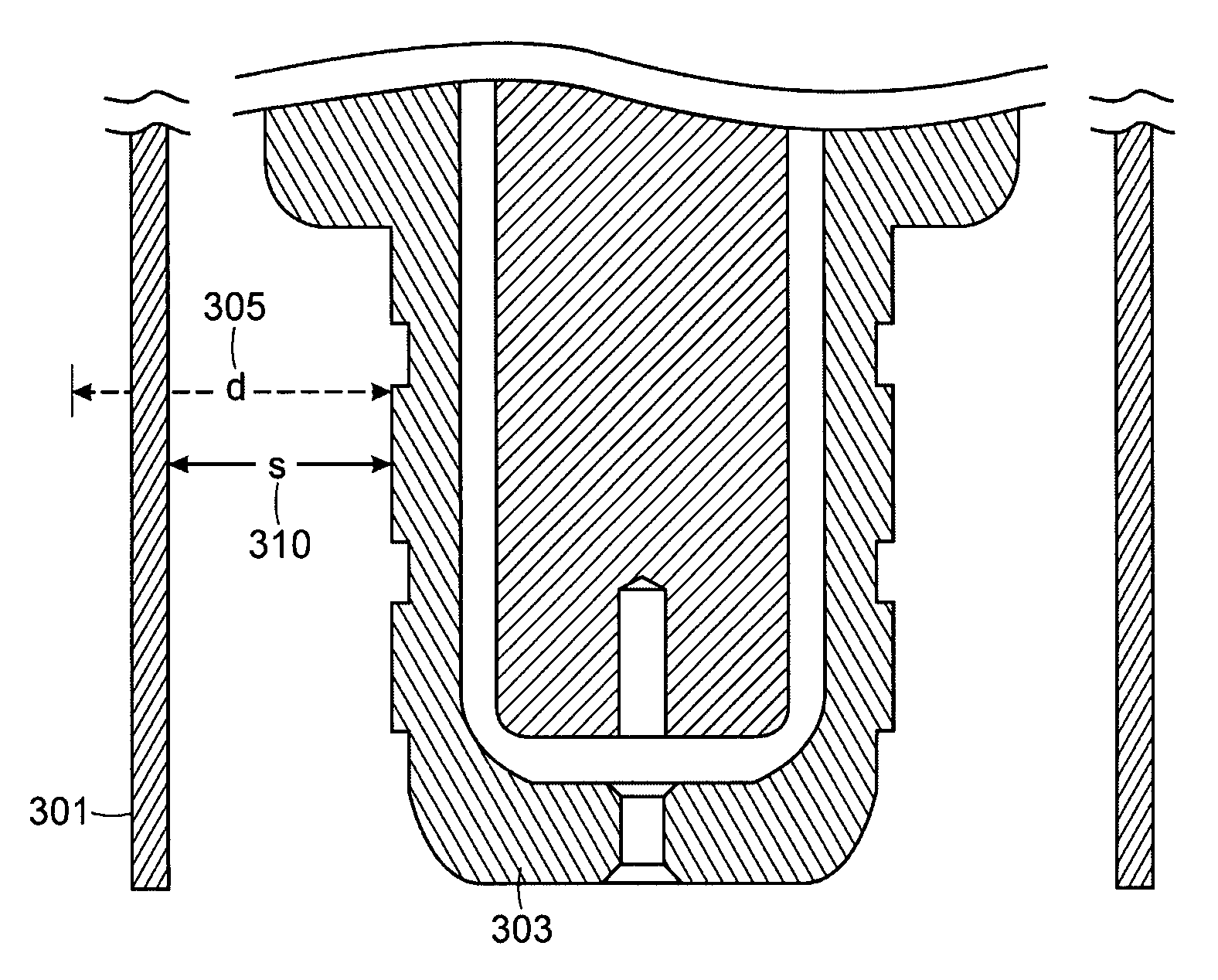

Polyceramic e-chuck

ActiveUS20090002913A1Reduce thermal stressEasy to controlSleeve/socket jointsElectric discharge tubesCapacitanceDielectric layer

The present invention discloses an electrostatic chuck for clamping work substrates, said chuck comprising three layers, where the dielectric constant of included non-conductive layers is selected to provide overall lower capacitance to the chuck. In the chuck assembly of the present invention, the top dielectric layer that is in contact with a substrate, such as, for example, a wafer, has a dielectric constant that is preferably greater than about 5, with a resistivity that is preferably greater than about 1E6 ohm.m, whereas the bottom dielectric layer has a dielectric constant that is preferably less than about 5 and a resistivity that is preferably greater than about 1E10 ohm.m. The intermediate layer preferably has a conductive layer where the resistivity is less than about 1 ohm.m. The electrostatic chuck may be bonded to heat sinks coated with anti-arc dielectrics. The heat sink can also be used as an RF electrode. The heat sink may have provisions for coolants and gas channels to feed a cooling gas to the backside of a wafer. The heat sink may have feed thrus to power the segmented electrodes in the electrostatic chuck. The passages for the feed thrus, gas feed holes and lift pins may be lined with ceramics or polymers to prevent any discharge to the heat sink. The electrostatic chuck is for clamping work substrates like Si, GaAs, SiO2, etc. used in semiconductor tools.

Owner:FM INDS

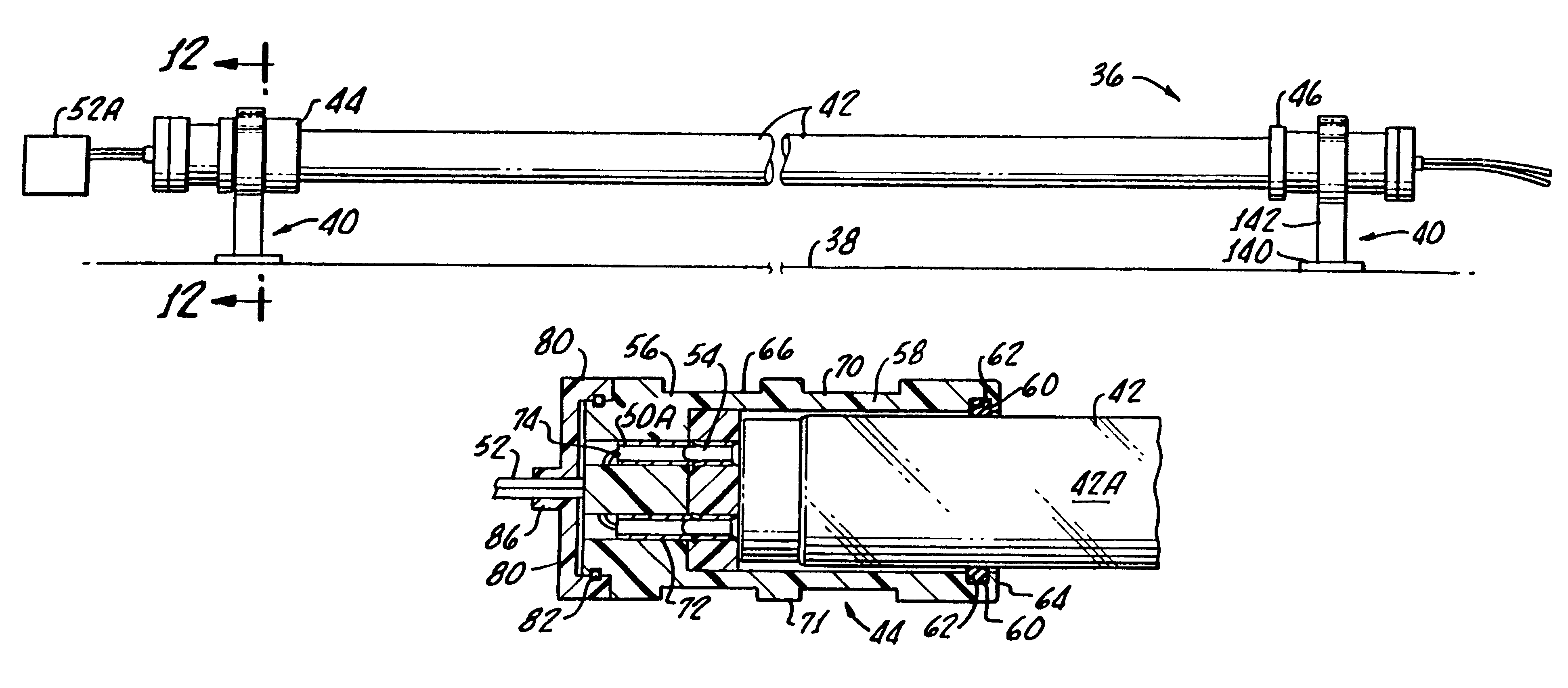

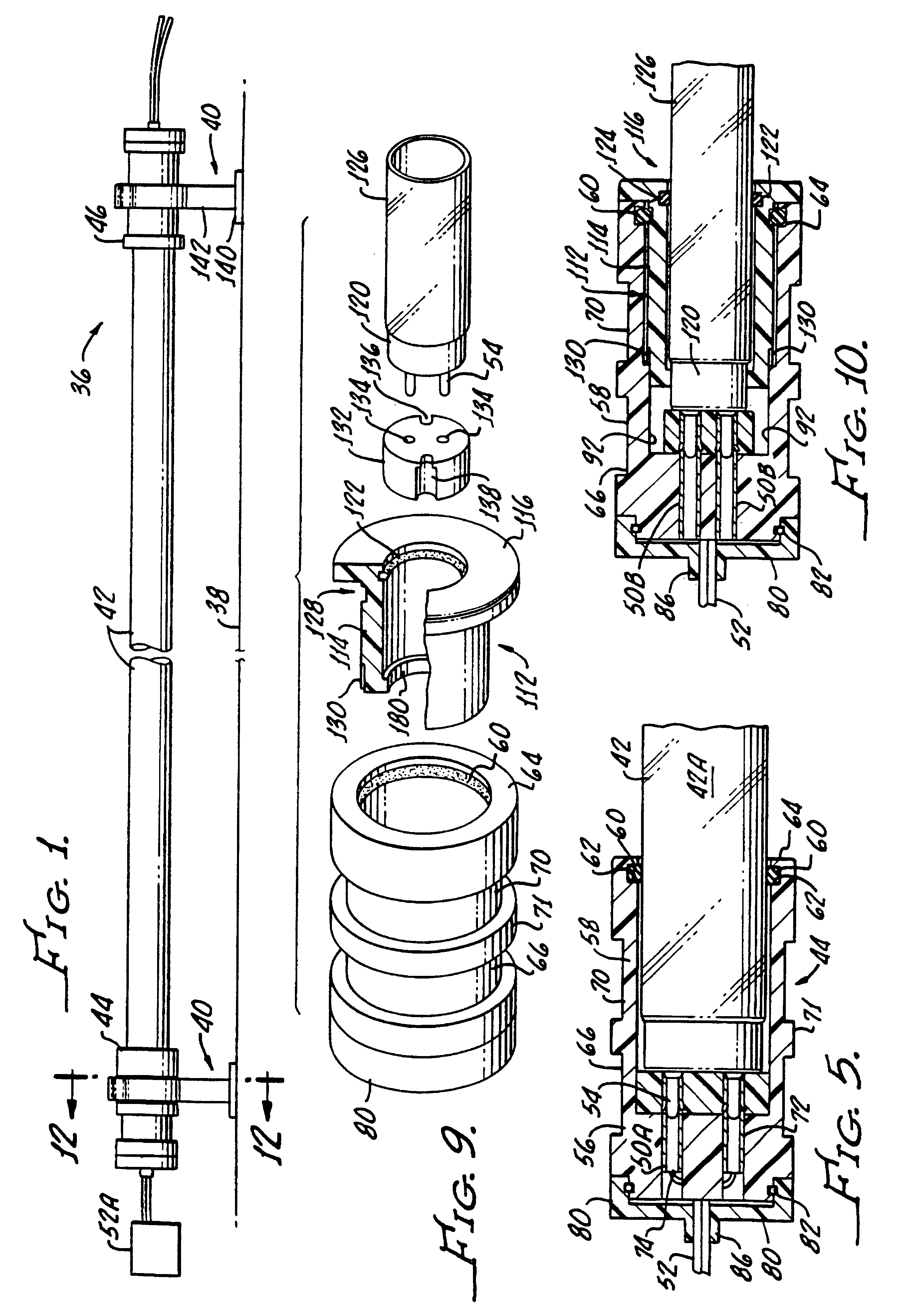

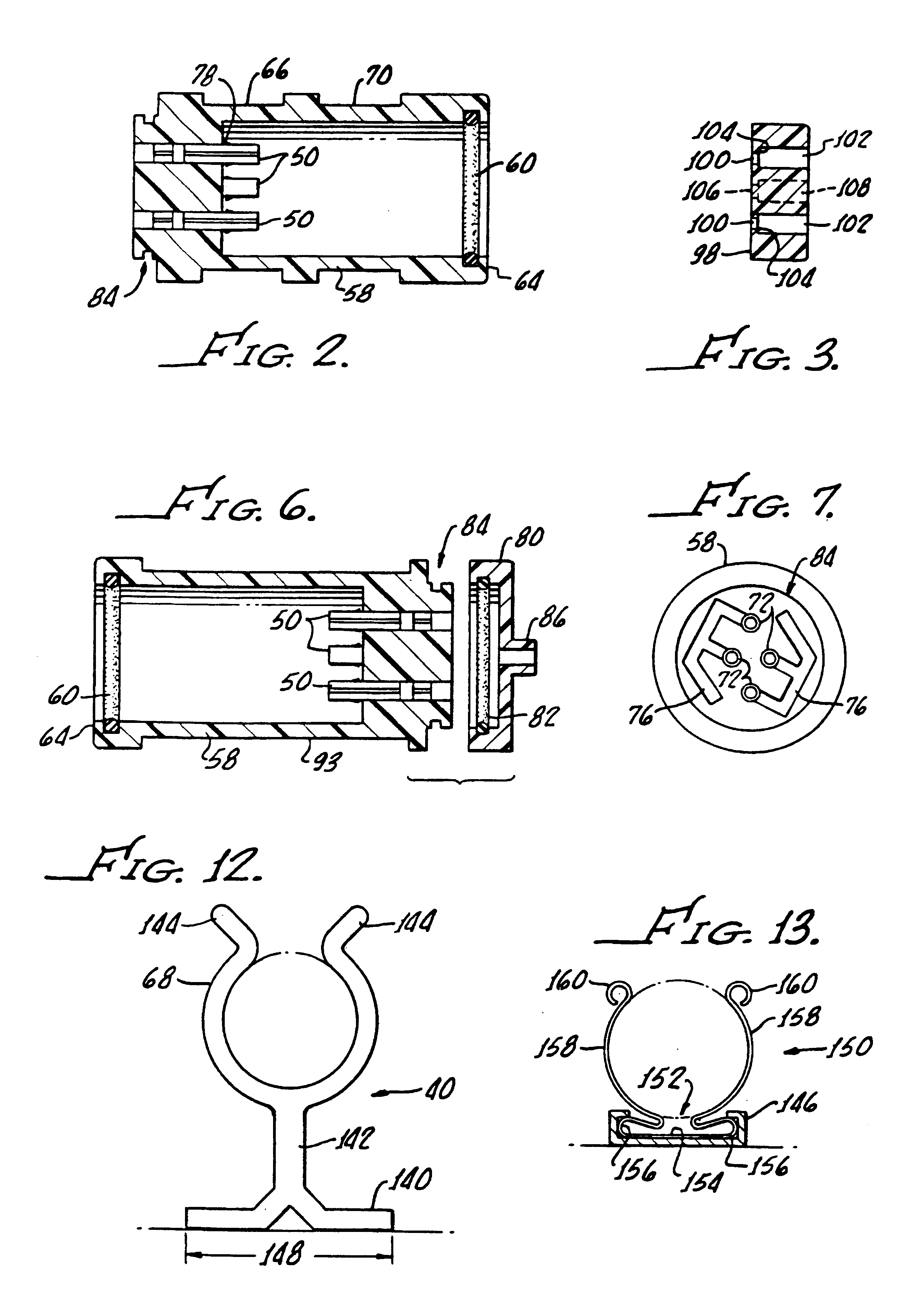

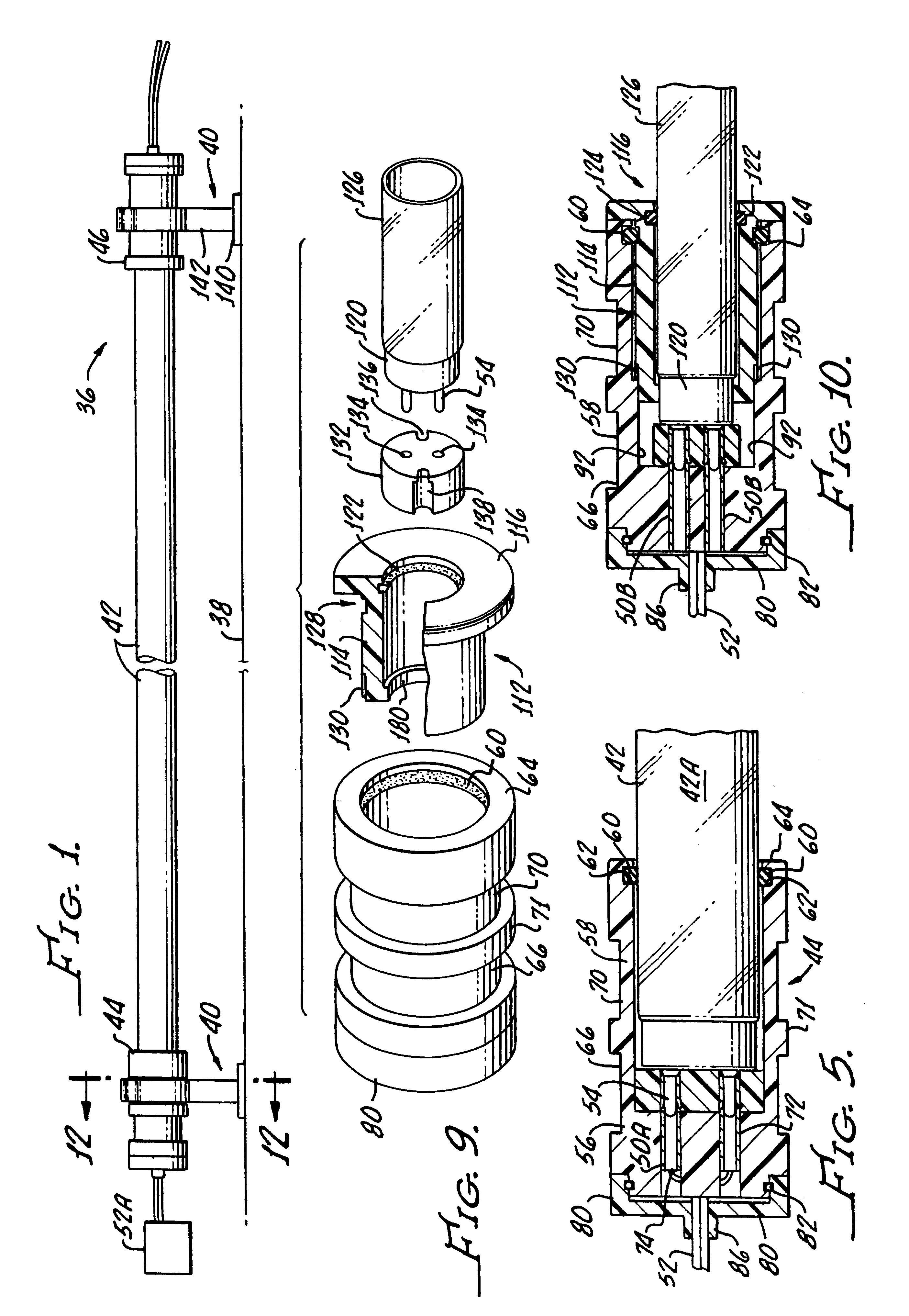

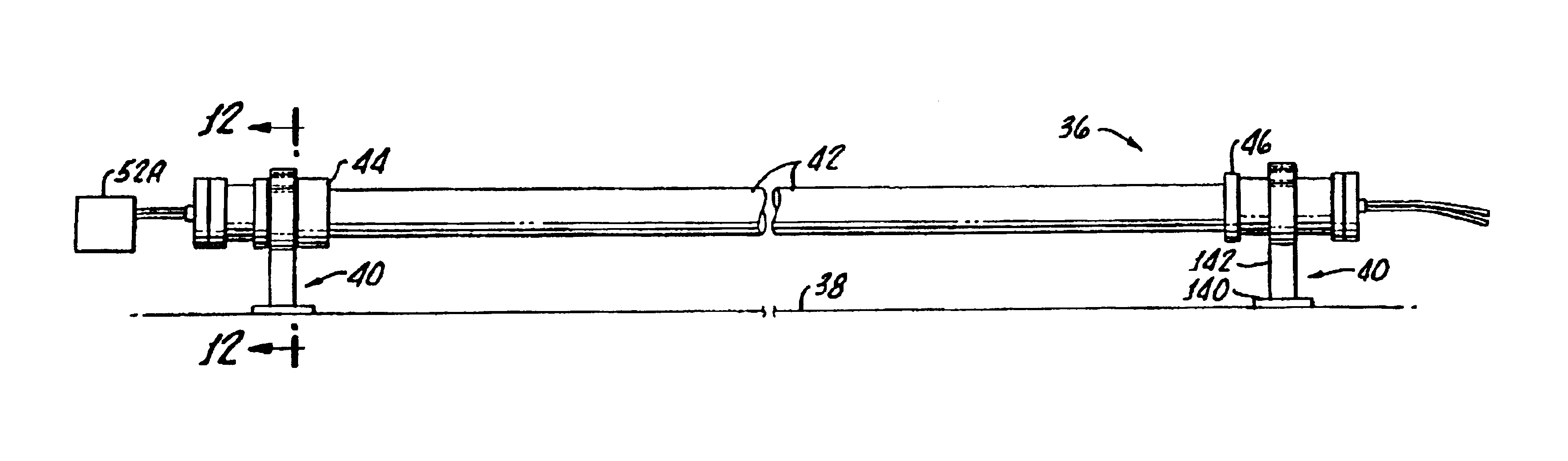

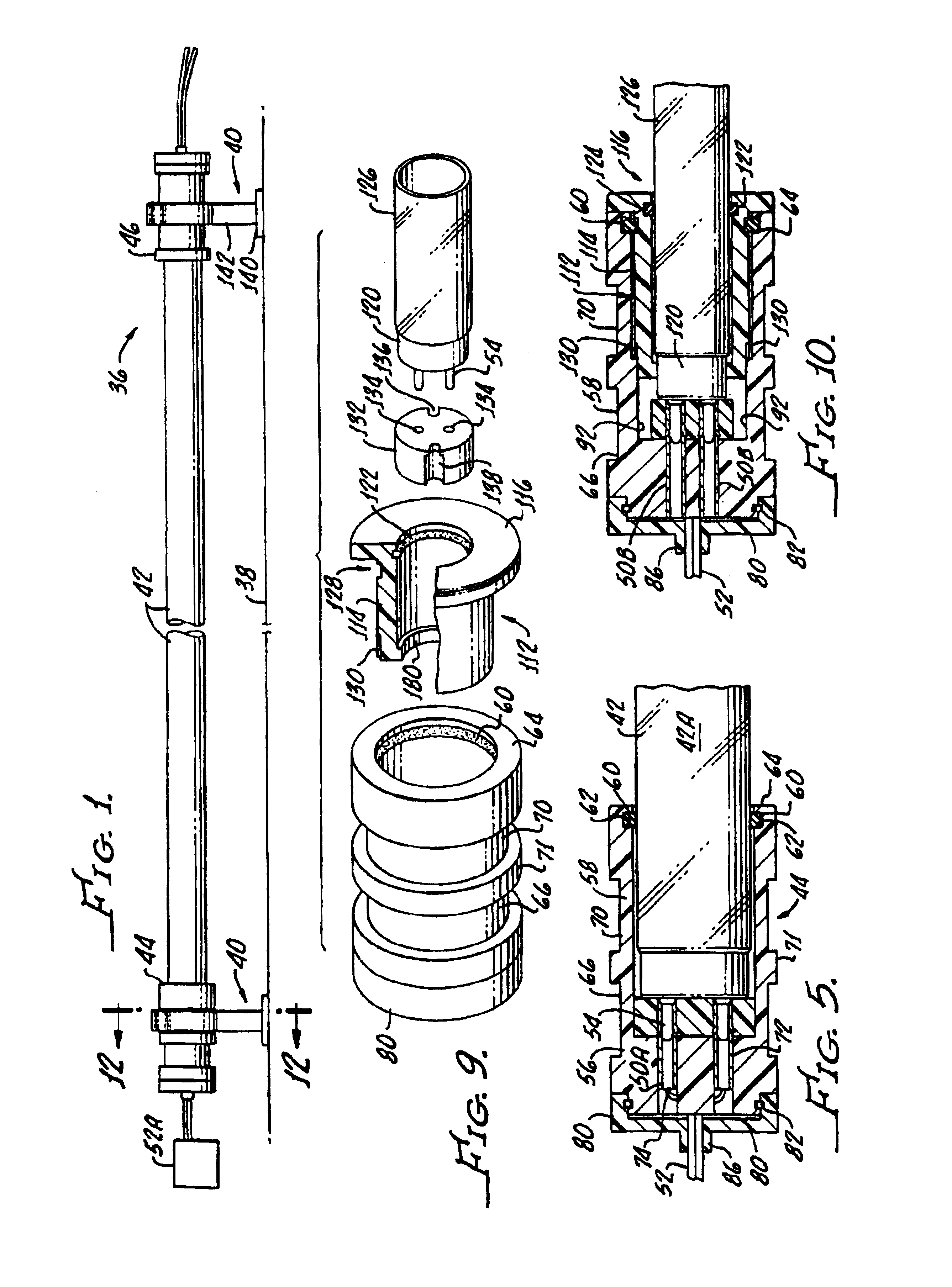

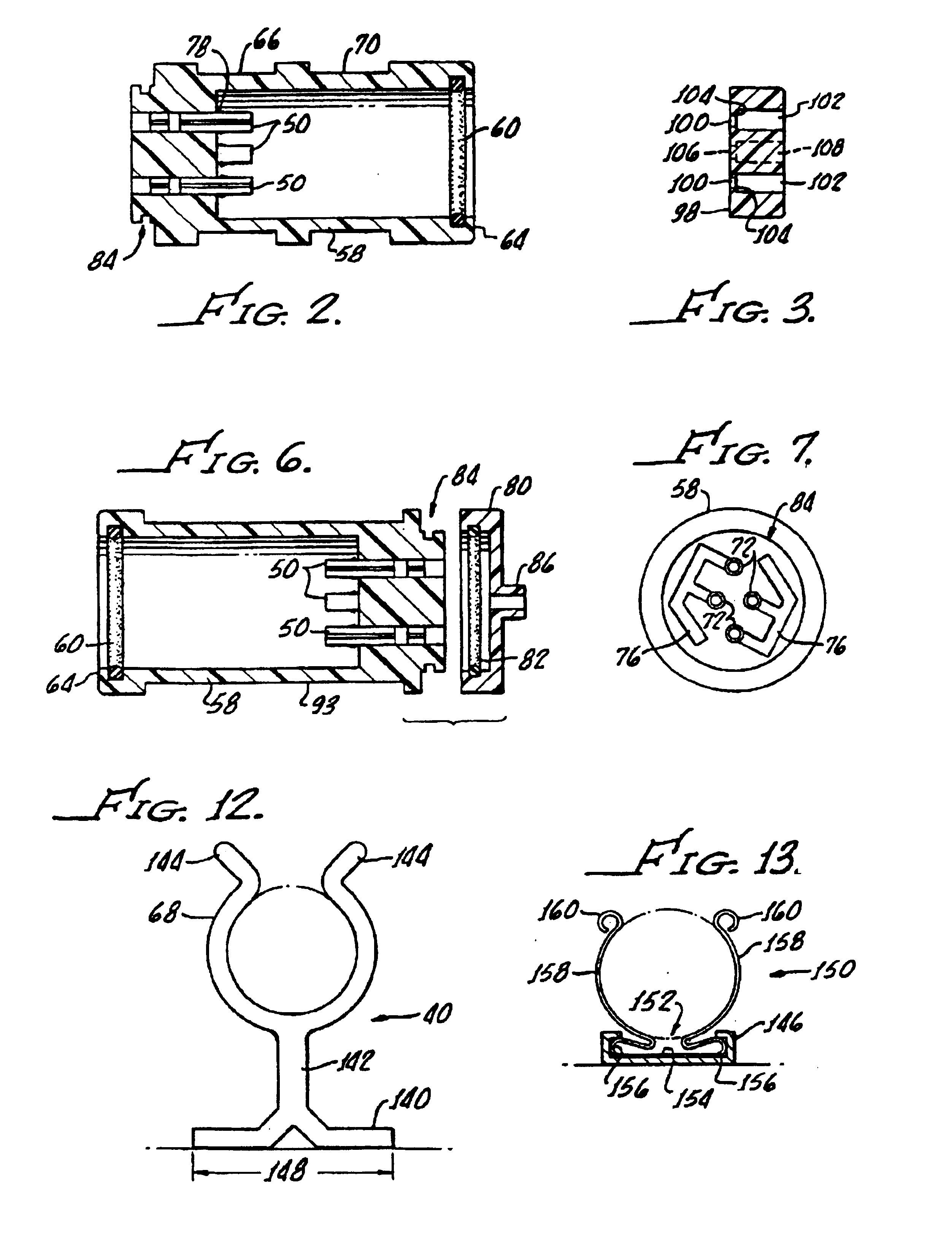

Lighting circuit, lighting system method and apparatus, socket assembly, lamp insulator assembly and components thereof

InactiveUS6641419B1Minimize the possibilityConvenient thermal protectionCoupling device connectionsMechanical apparatusElectrical conductorEffect light

A socket for a lighting assembly includes a socket body defining an enclosure such that a lamp with a pin contact can extend into the enclosure. Electrical connectors extend away from the enclosure in a second direction. The body includes a wall extending away from the enclosure past the electrical connectors and is spaced from the connectors to allow access to the connectors, and a further wall between the electrical connectors. The further wall can provide an insulating barrier between the connectors. The connectors may be cylindrical. The wall extending away from the enclosure may include a cap covering the wall, and one or more conductors can pass underneath the cap to connect to the electrical connectors for powering the lamp.

Owner:ANTHONY INC

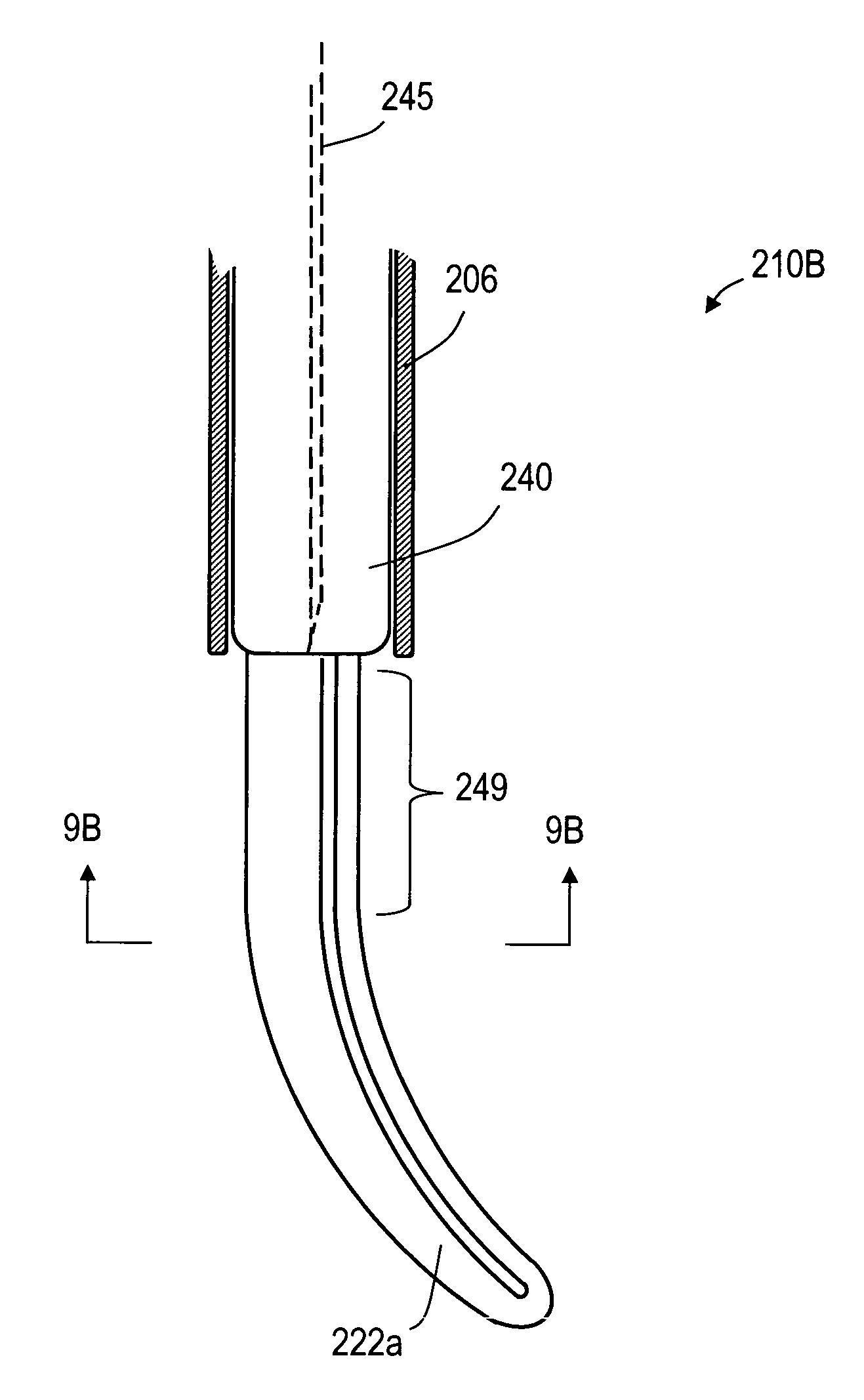

Electrocautery method and apparatus

InactiveUS20080228179A1Avoid arcingSurgical instruments for heatingSurgical forcepsBiomedical engineeringElectrode

An electrode structure and a mechanism for automated or user-selected operation or compensation of the electrodes, for example to determine tissue coverage and / or prevent arcing between bottom electrodes during electrocautery is disclosed.

Owner:AESCULAP AG

X-ray tube cathode with reduced unintended electrical field emission

ActiveUS7382862B2Easy to controlFocusX-ray tube electrodesCathode ray concentrating/focusing/directingSoft x rayX-ray

An x-ray source has an evacuated tube. An anode is disposed in the tube and includes a material configured to produce x-rays in response to impact of electrons. A cathode is disposed in the tube opposing the anode configured to produce electrons accelerated towards the anode in response to an electric field between the anode and the cathode. A flange extends from the cathode toward the anode, and has a smaller diameter than the evacuated tube. The flange extends closer to the anode than an interface between the cathode and the tube thus forming a reduced-field region between the evacuated tube and the flange.

Owner:MOXTEK INC

Electrocautery method and apparatus

ActiveUS20090182323A1Avoid arcingSurgical instruments for heatingSurgical forcepsBiomedical engineeringElectrode

An electrode structure and a mechanism for automated or user-selected operation or compensation of the electrodes, for example to determine tissue coverage and / or prevent arcing between bottom electrodes during electrocautery is disclosed.

Owner:AESCULAP AG

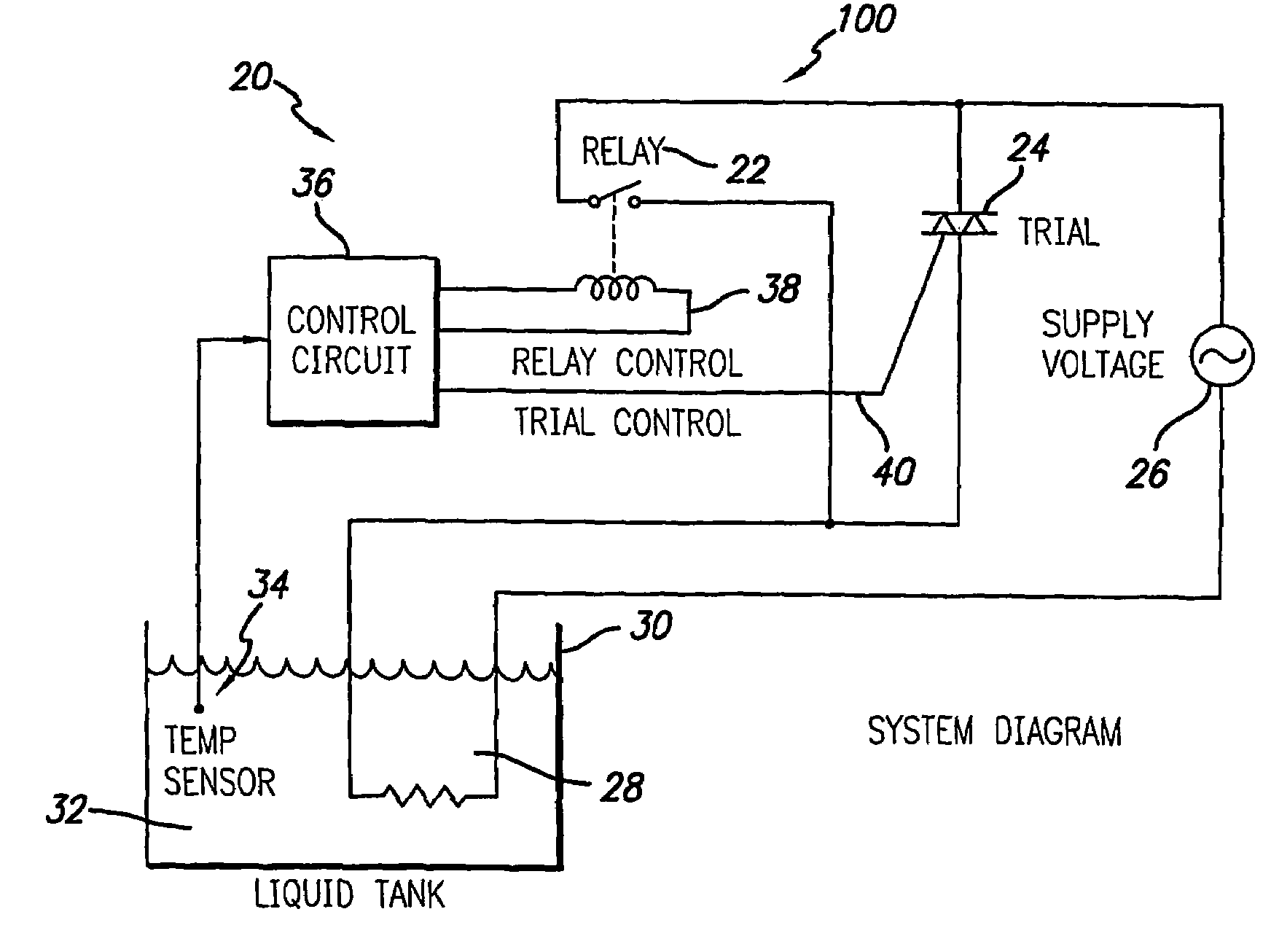

Electronic thermostat for liquid heating apparatus

InactiveUS7263283B2Avoid arcingTemperature control using analogue comparing deviceImmersion heating arrangementsSolid-stateEngineering

An electronic thermostat (20) has a mechanical switch (22) and a solid-state switch (24). The electronic thermostat (20) is suitable for use in a liquid heating apparatus, such as a coffee maker or any other apparatus that dispenses heated beverages. In an illustrative embodiment, the electronic thermostat (20) has a controller (36) and a temperature sensor (34).

Owner:BUNN O MATIC

Electromagnetic switching device

InactiveUS7157996B2Improve abilitiesFast blockingElectric switchesElectromagnetic relay detailsMiniaturizationElectromagnetic actuator

In the electromagnetic switching device, it is possible to miniaturize and have low costs, have quiet operation noise, and also quickly extinguish the arc. The electromagnetic switching device has an electromagnetic actuator with a movable iron core, a pair of fixed terminals that respectively have a fixed contact point, a movable contact that has movable contact points on the right and left ends, a shaft, and an enclosing component that holds the movable contact points and the fixed contact points. The pair of movable contact points respectively contact with and detach from the pair of fixed contact points, and the pair of fixed contact points respectively conduct each other and are insulated again through the shaft by moving the movable iron core along the axis using the electric magnetic actuator. A quasi-hermetically sealed space, which is the extinguishing space, is formed by the enclosing component and a first yoke. A potting compound is charged, into the space between a body and the quasi hermitically sealed space.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Lighting circuit, lighting system method and apparatus, socket assembly, lamp insulator assembly and components thereof

InactiveUS6638088B1Convenient thermal protectionGuaranteed uptimeCoupling device connectionsMechanical apparatusElectricityEnvironmental effect

A lighting system and components are described for a lighting assembly, including a socket having a socket body and an electrical connector with a seat in the socket to seal around a light source. The socket is preferably configured to be independent of the mounting arrangement for the lighting assembly. An insulator is also disclosed for a lamp such as a fluorescent lamp having a body which protects the contact on the lamp so as to form a recessed lamp conductor. The combination of a socket and lamp insulator is also disclosed for providing a socket and insulator assembly for reducing the possibility of injury or damage due to high open circuit voltage, environmental effects and the like. Additionally, a lighting assembly is disclosed incorporating the insulator, socket and mounting arrangements.

Owner:ANTHONY INC

Dielectric devices for a plasma arc torch

ActiveUS20070262060A1Decreasing damaging interactionGood operating visionPlasma welding apparatusWelding/cutting media/materialsDielectricVisibility

Apparatus and methods for thermally processing a workpiece include directing a plasma arc to the workpiece and using a dielectric shield or dielectric coating to protect a forward portion (e.g., a torch head) of a plasma arc torch. The dielectric shield or dielectric coating covers a nozzle disposed within the torch head and protects the nozzle from the effects of slag and double arcing. The shield also improves operator visibility due to the spatial relationship between the dielectric shield and the nozzle.

Owner:HYPERTHERM INC

Dielectric devices for a plasma arc torch

ActiveUS8097828B2Decreasing damaging interactionGood operating visionPlasma welding apparatusWelding/cutting media/materialsVisibilityDielectric

Apparatus and methods for thermally processing a workpiece include directing a plasma arc to the workpiece and using a dielectric shield or dielectric coating to protect a forward portion (e.g., a torch head) of a plasma arc torch. The dielectric shield or dielectric coating covers a nozzle disposed within the torch head and protects the nozzle from the effects of slag and double arcing. The shield also improves operator visibility due to the spatial relationship between the dielectric shield and the nozzle.

Owner:HYPERTHERM INC

Power transmission safety system

ActiveUS7462792B1Avoid arcingElectric switchesEmergency protective devicesEngineeringCircuit breaker

A power transmission safety system is disclosed having a pair of power transmission members, each of the power transmission members having a switch arm. Each of a pair of switch arm engaging members reversibly engage a switch arm of its respective power transmission member. Each of a pair of pivoting shaft members are coupled to a respective one of the pair of switch arm engaging members on one end, and a rotatable handle on an opposing end. An interlocking power activation bar has a pair of openings located thereon, whereby rotation of one of the pivoting shaft members engages a switch arm of a respective circuit breaker into an “on” position and displaces the interlocking power activation bar to lock the other of the shafts from rotating, thereby preventing both of said power transmission members from being “on” concurrently.

Owner:ESL POWER SYST

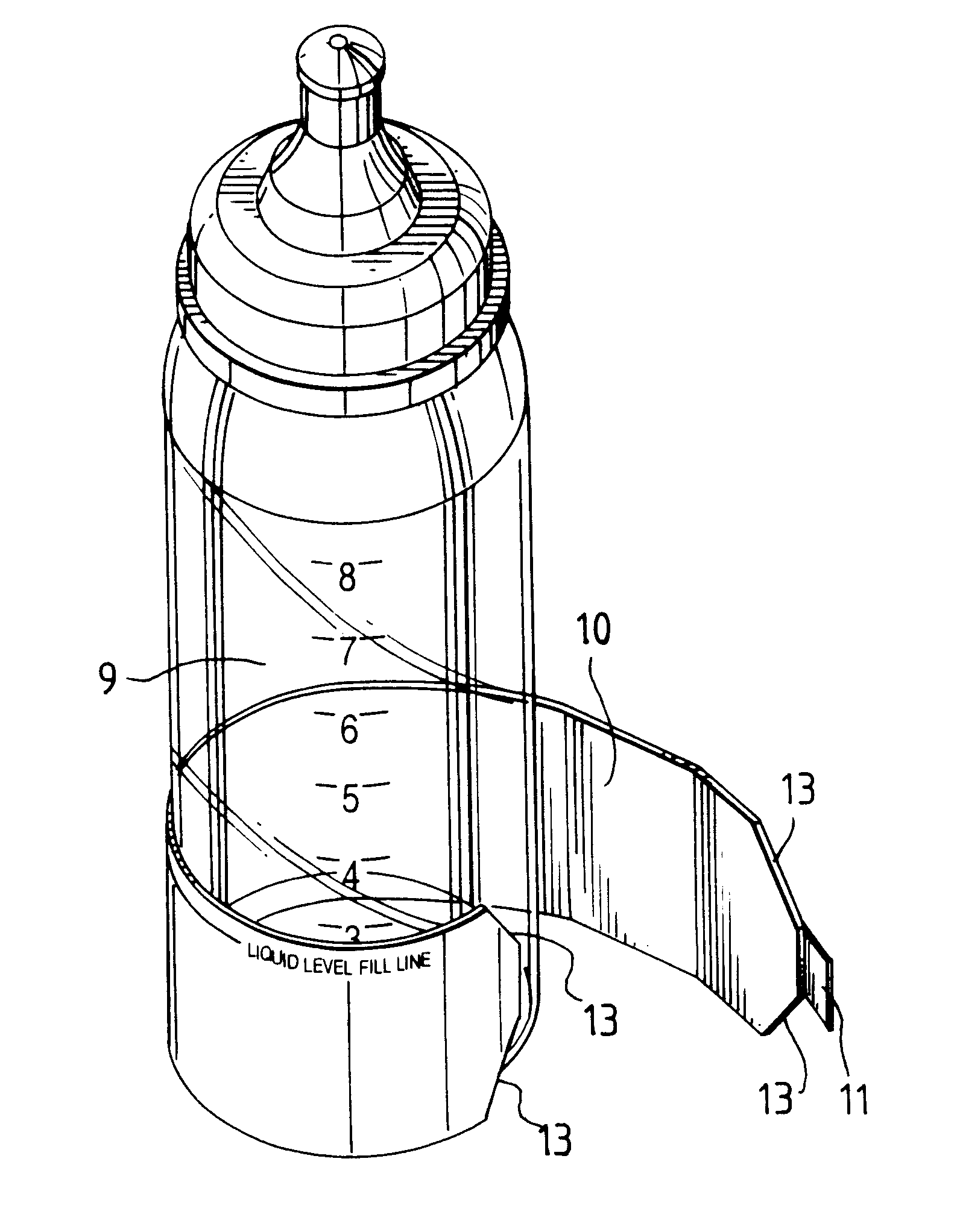

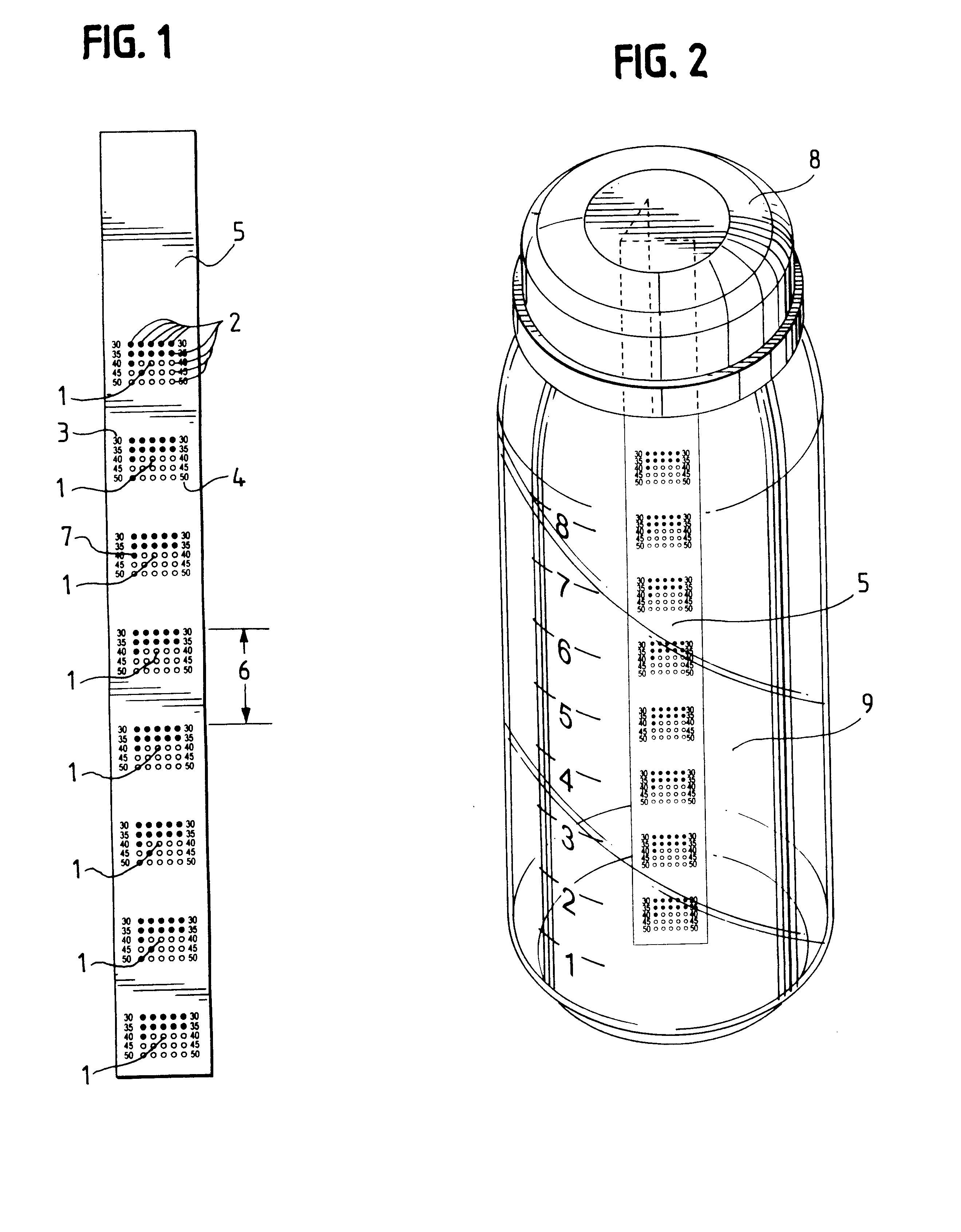

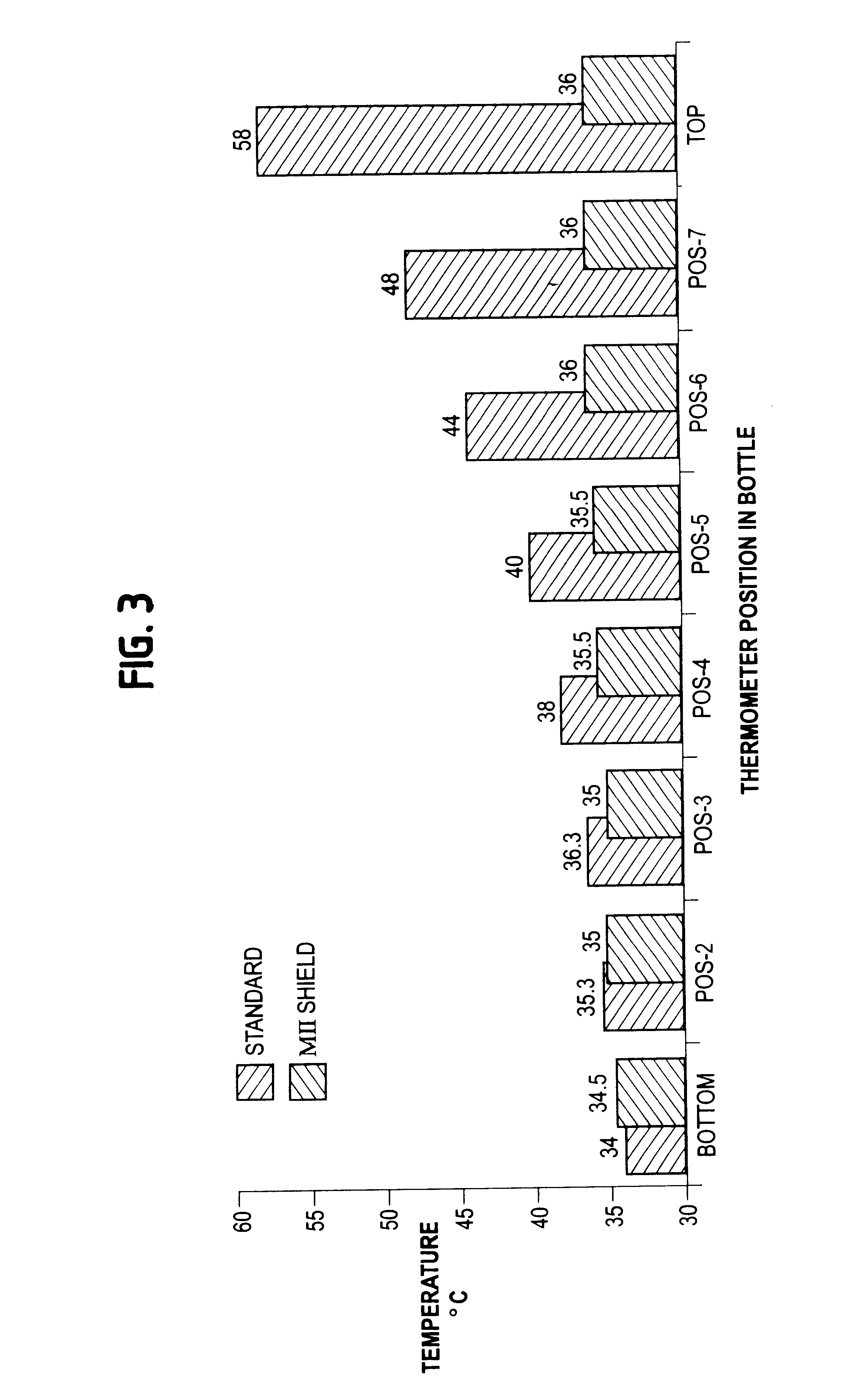

Shielding method for microwave heating of infant formula to a safe and uniform temperature

InactiveUS6410896B2Minimal reflectionMinimize electric field intensityThermometer detailsDough treatmentVertical mixingEngineering

Owner:MEDICAL INDICATORS INC

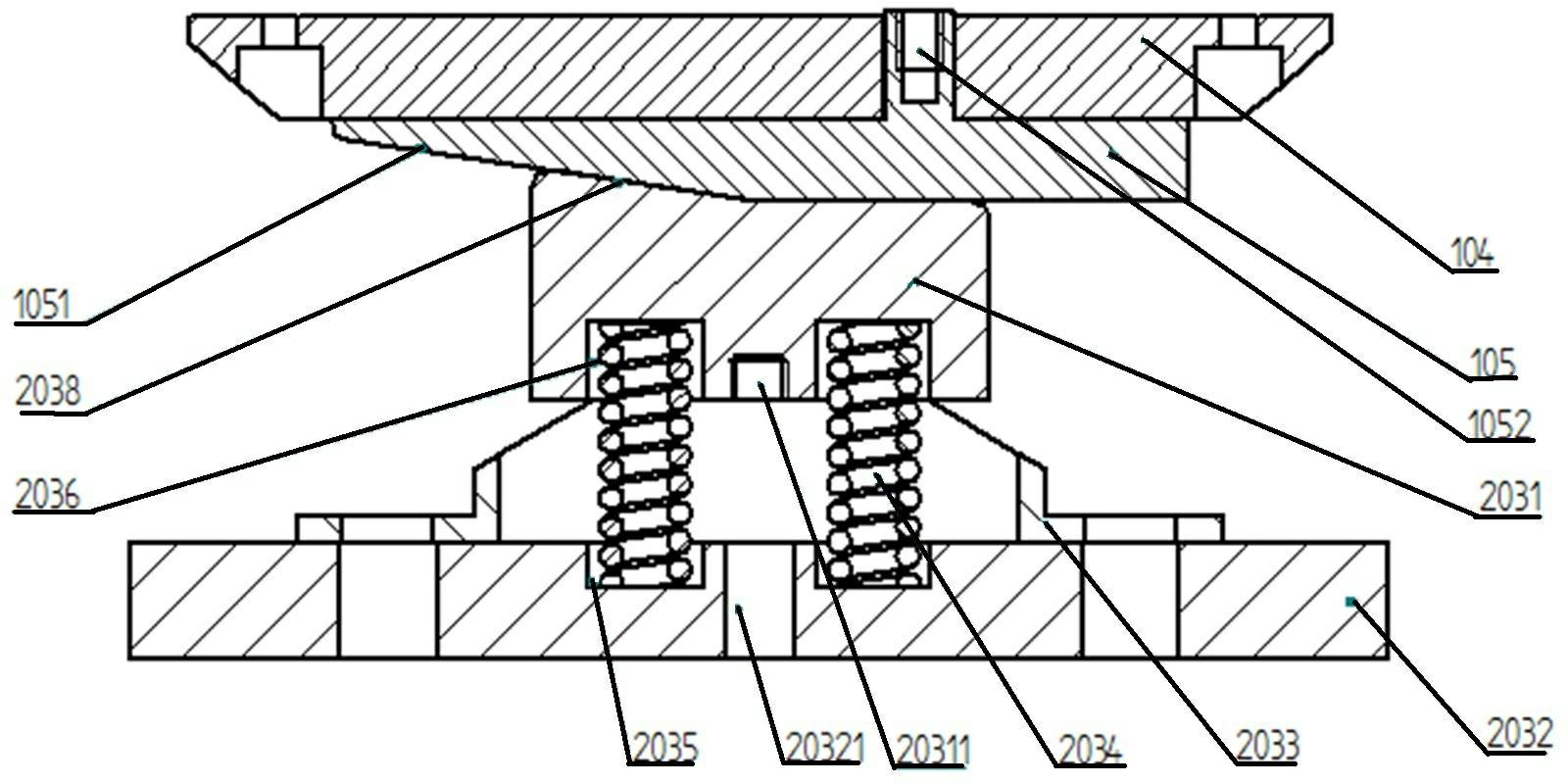

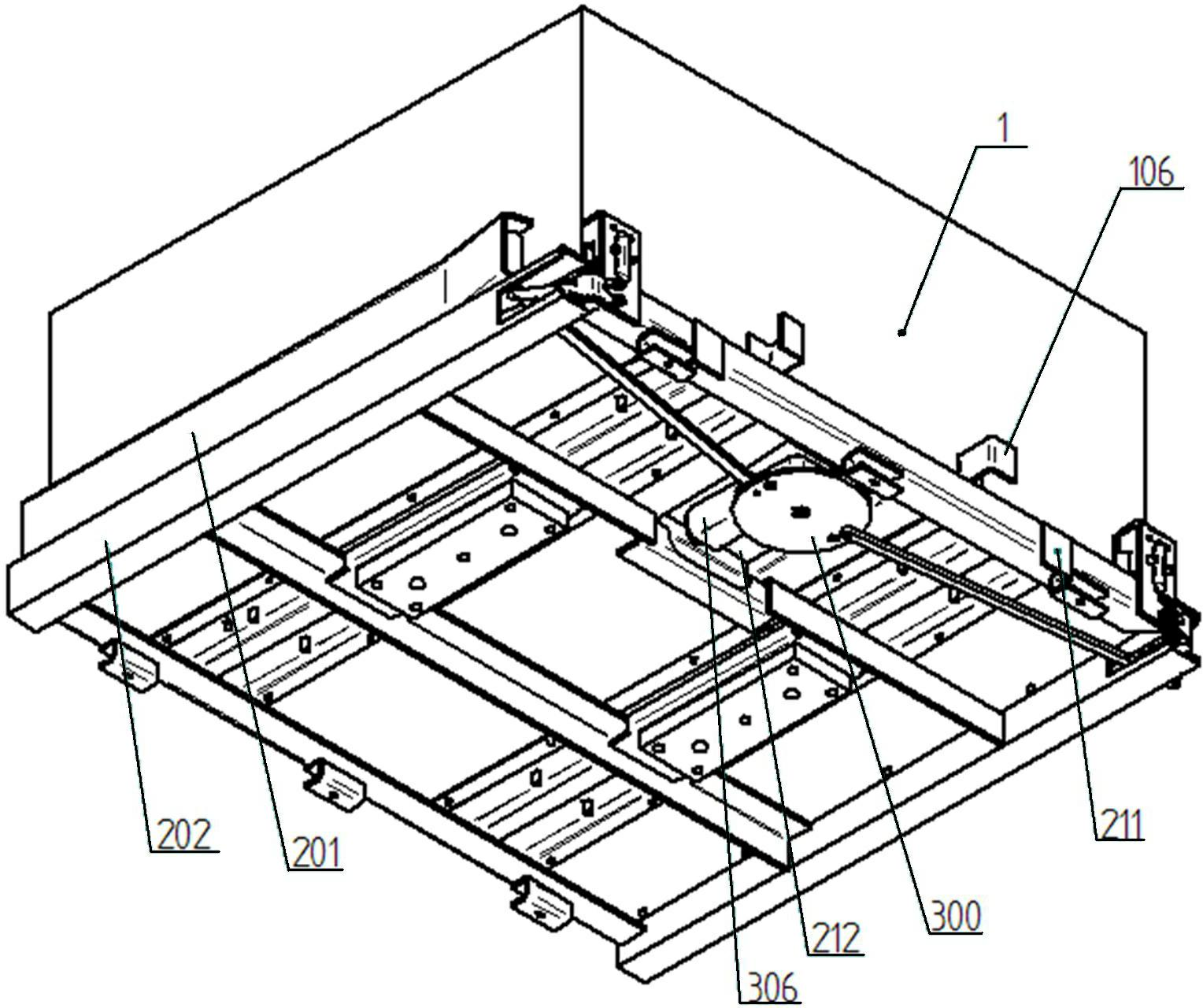

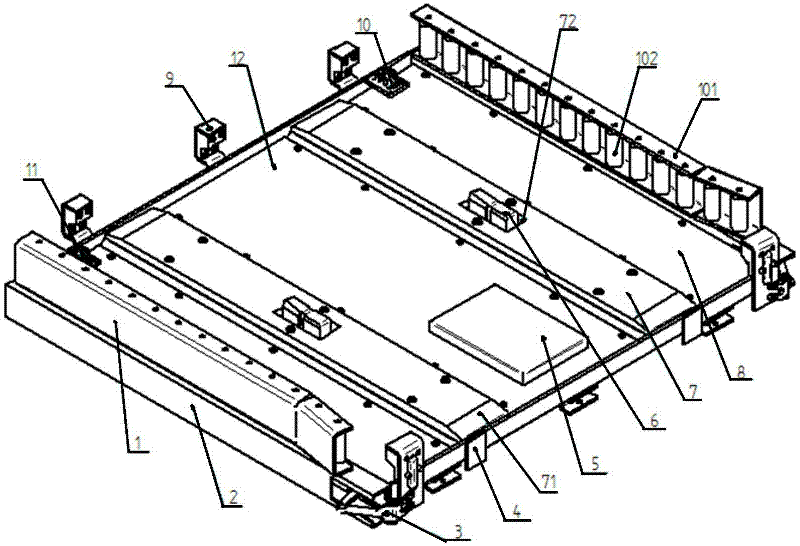

Bottom power taking self-locking electric bus battery box system capable of quickly changing battery

ActiveCN102303589AEasy to installPositioning constraints resolvedElectric propulsion mountingElectric vehicle charging technologyElectricityPower battery

The invention discloses a bottom power taking self-locking electric bus battery box system capable of quickly changing a battery. The system comprises a battery box (1), a tray (2) used for bearing the battery box and arranged on an electric bus, mobile equipment (4) for conveying the battery box, and a grabbing device (5) arranged on the mobile equipment; and a battery box locking and unlocking device (3) is arranged on the tray. Through the system, automatic assembly of the battery box in the electric bus battery box system is realized, and the problems of over positioning, deformation of power wire connection pegs, breakage, arc discharge, welding, difficulty in automatically realizing unlocking due to impact of the battery box to a bolt of a locking mechanism in jolt and deformation of the battery box due to impact in jolt. The system is reasonable, reliable, simple and compact in structure, and can full-automatically, quickly and conveniently realize quick change of the power battery.

Owner:KUNMING SHIPBUILDING EQUIP

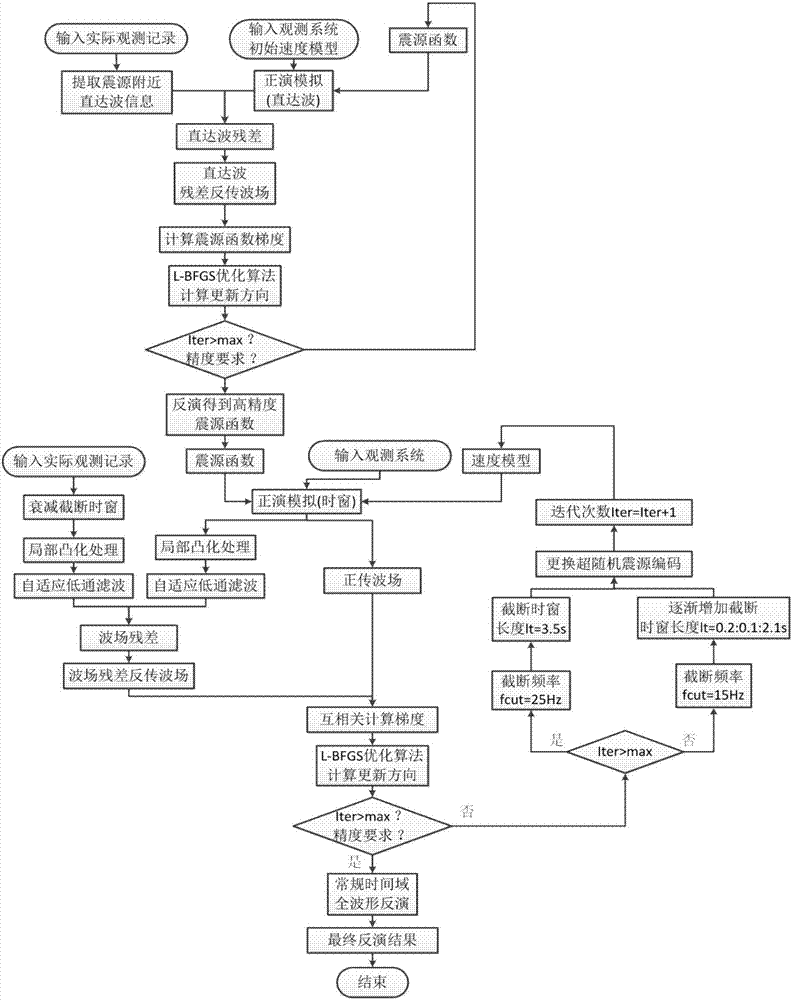

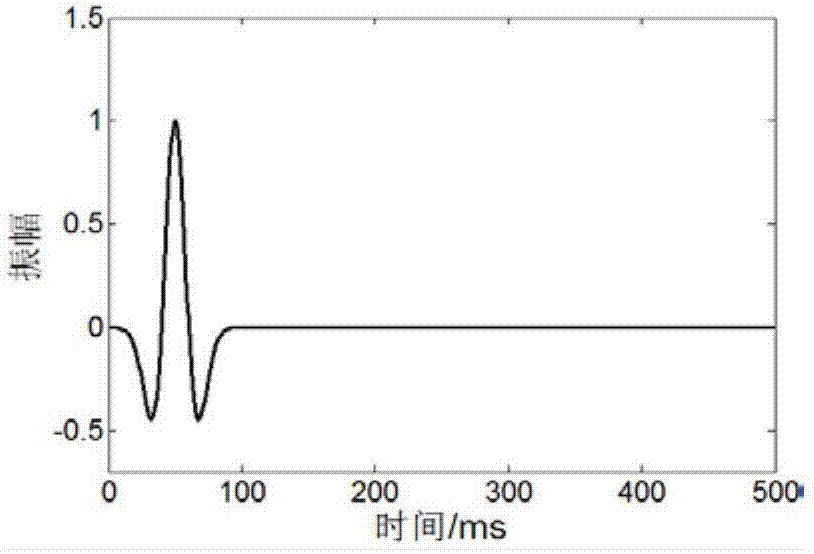

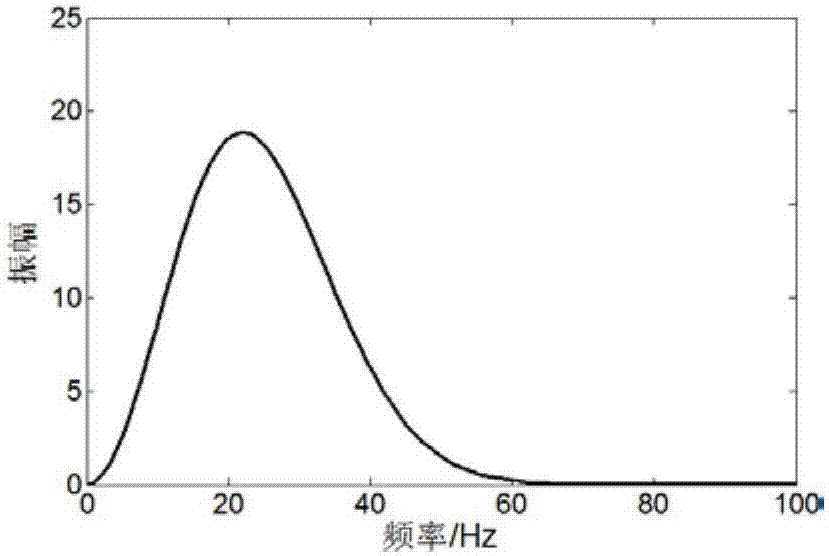

Multi-scale seismic full-waveform inversion method based on local adaptive convexification method

ActiveCN107422379AAvoid skippingSolve the problem of inaccurate estimatesSeismic signal processingWave fieldSource function

The invention relates to a multi-scale seismic full-waveform inversion method based on a local adaptive convexification method. The method comprises steps: pre-processing is carried out, a zero value sequence serves as an initial value, and an initial speed model serves as a starting value; direct wave information is intercepted; forward modeling direct waves are obtained; an objective function inverted by a seismic source function is built; a direct wave residual and a direct wave residual back propagation wave field are obtained; an updating gradient and an updating direction of the seismic source function are calculated, and a step length is searched; the high-precision seismic source function obtained through inversion is outputted; attenuation time window processing is carried out; seismic data in the time window are simulated; local convexification processing and separation processing are carried out; a high-frequency component in an observation record is removed; a least square objective function is built, and a wave field residual is obtained; a residual back propagation wave field of the model space is obtained; the model updated gradient is obtained; the model updated direction is calculated, and the step length is searched; a multi-scale seismic full-waveform inversion result is outputted; and a final inversion result is outputted. The method is widely applied in the technical field of seismic exploration.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Lighting circuit, lighting system method and apparatus, socket assembly, lamp insulator assembly and components thereof

InactiveUS6773130B1Minimize the possibilityConvenient thermal protectionCoupling device connectionsMechanical apparatusElectrical conductorEnvironmental effect

Owner:ANTHONY INC

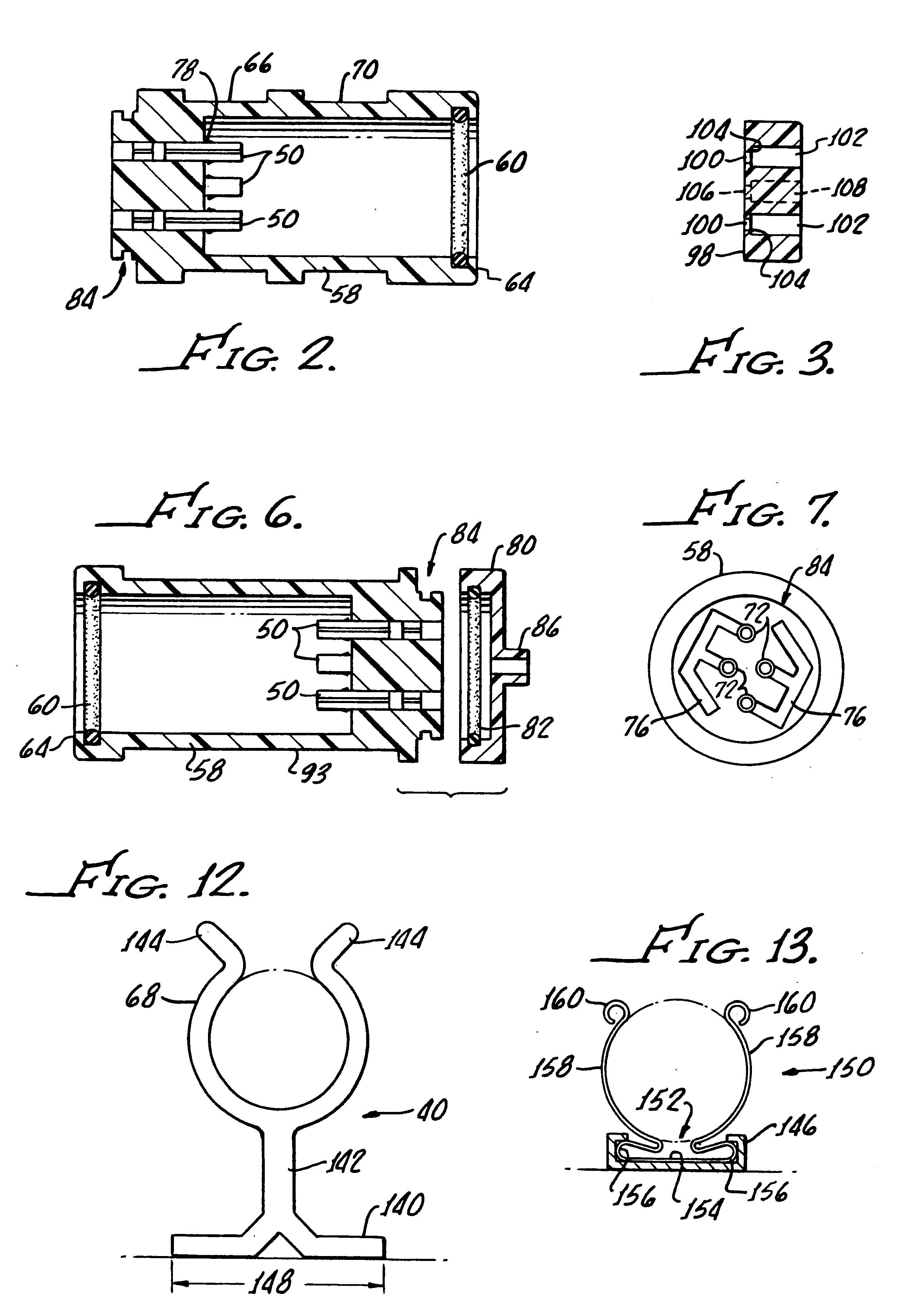

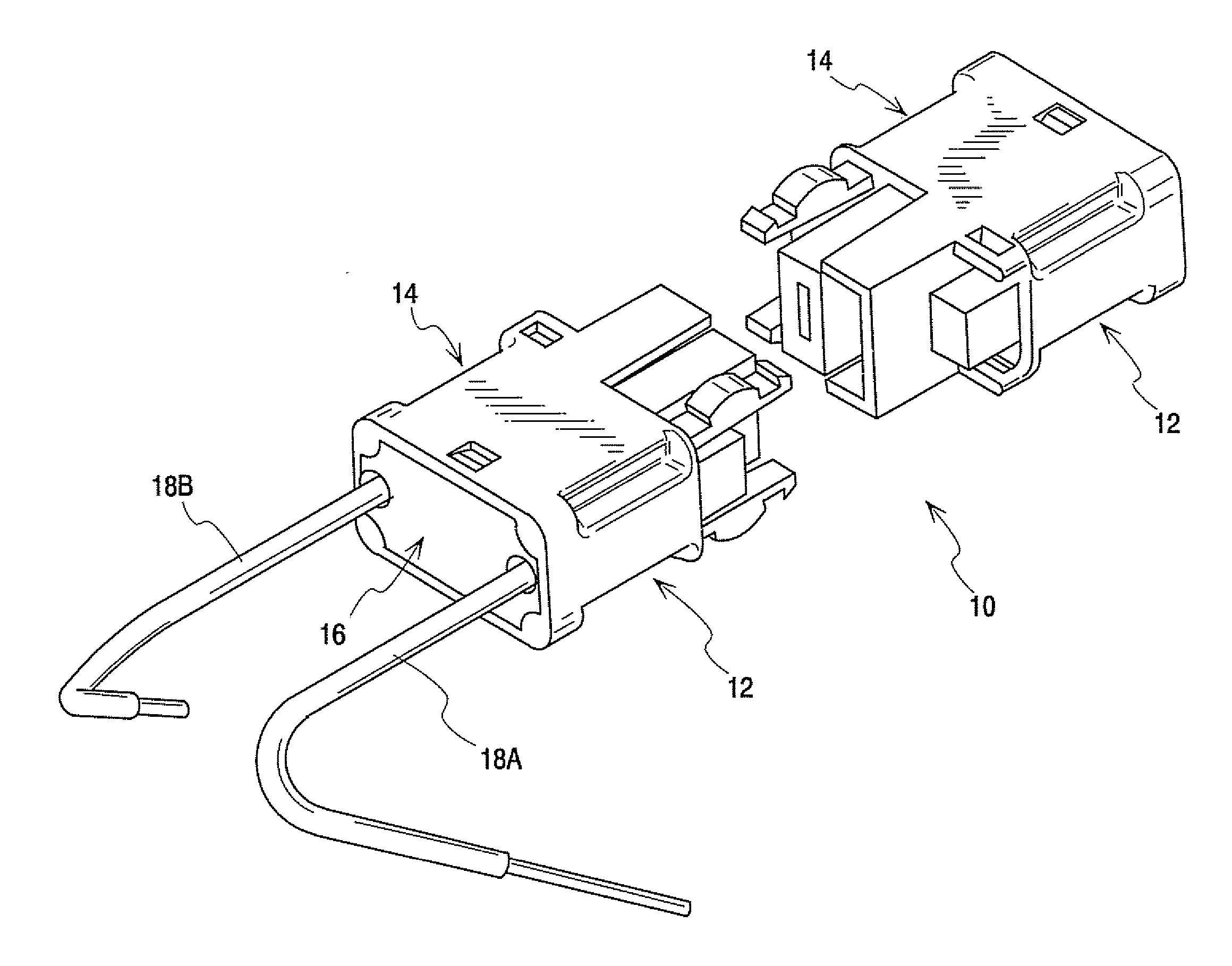

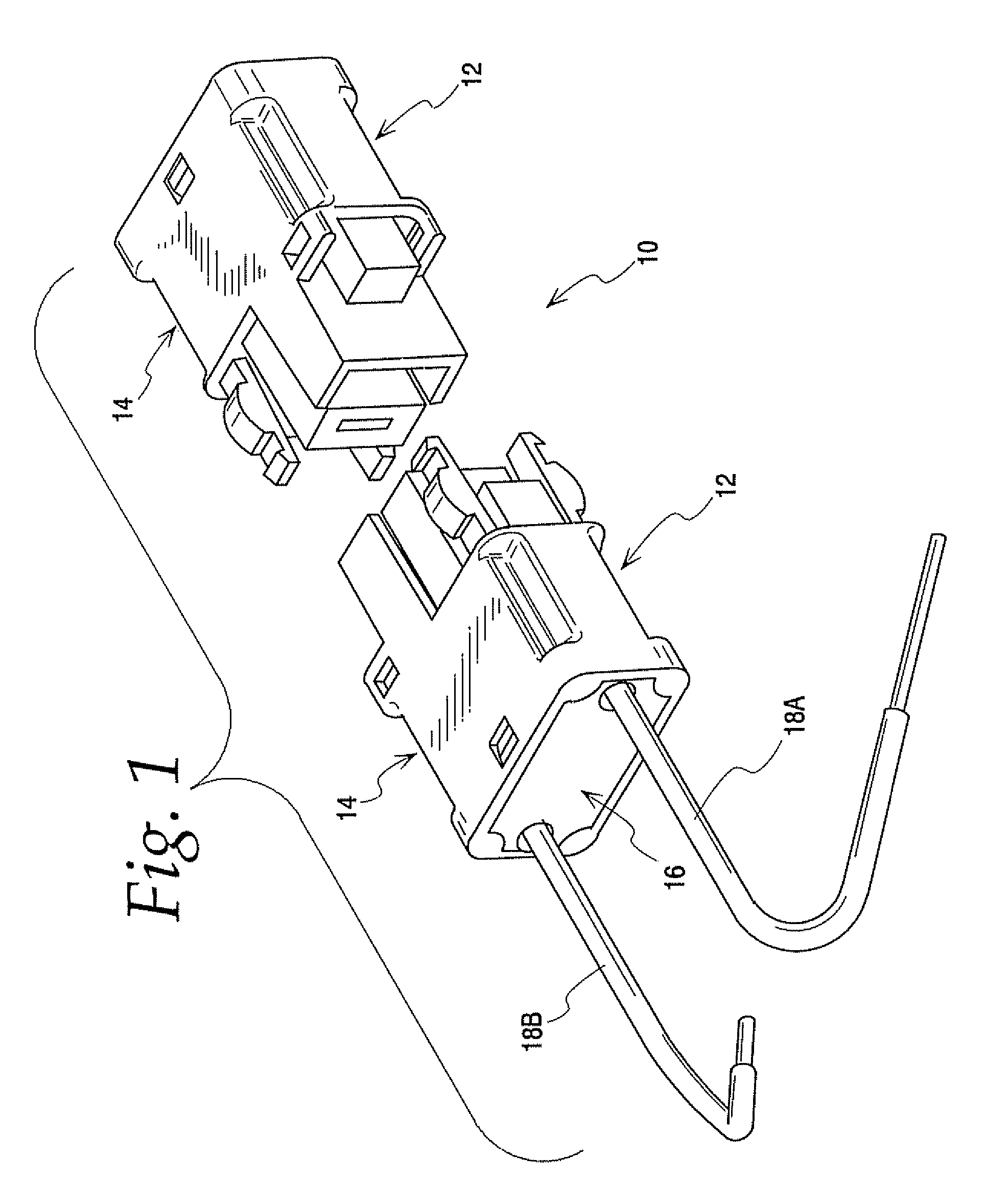

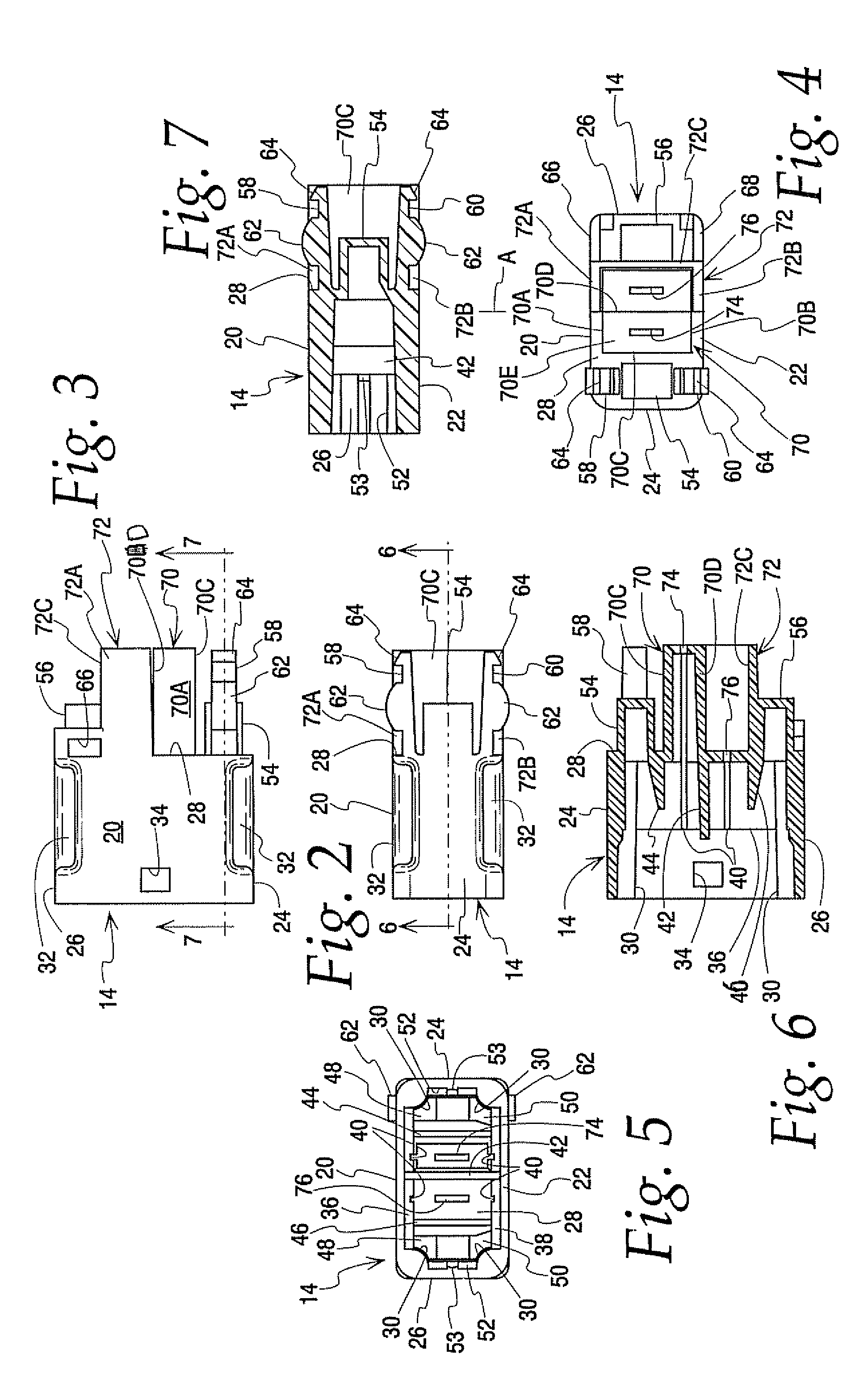

Electrical Disconnect With Push-In Connectors

ActiveUS20060286864A1Improve securityAvoid shortingTwo pole connectionsSecuring/insulating coupling contact membersEngineeringElectric wire

A wire connector has an enclosure including a housing and a cap and one or more contacts supported in the enclosure. The contacts each have outer ends opposite wire ports in the cap to receive a stripped end of a wire in a push-in engagement. One set of contacts has a male blade and the other set of contacts has a female socket at the inner or forward ends thereof. The housings are arranged so that two housings are releasably engagable with one another. When two housings are engaged the male contacts electrically engages the female contacts of the other housing. The female contacts include a sacrificial tine that is always first to make and last to break engagement with the male contact so that any degradation due to arcing always occurs at the sacrificial tine.

Owner:IDEAL IND INC

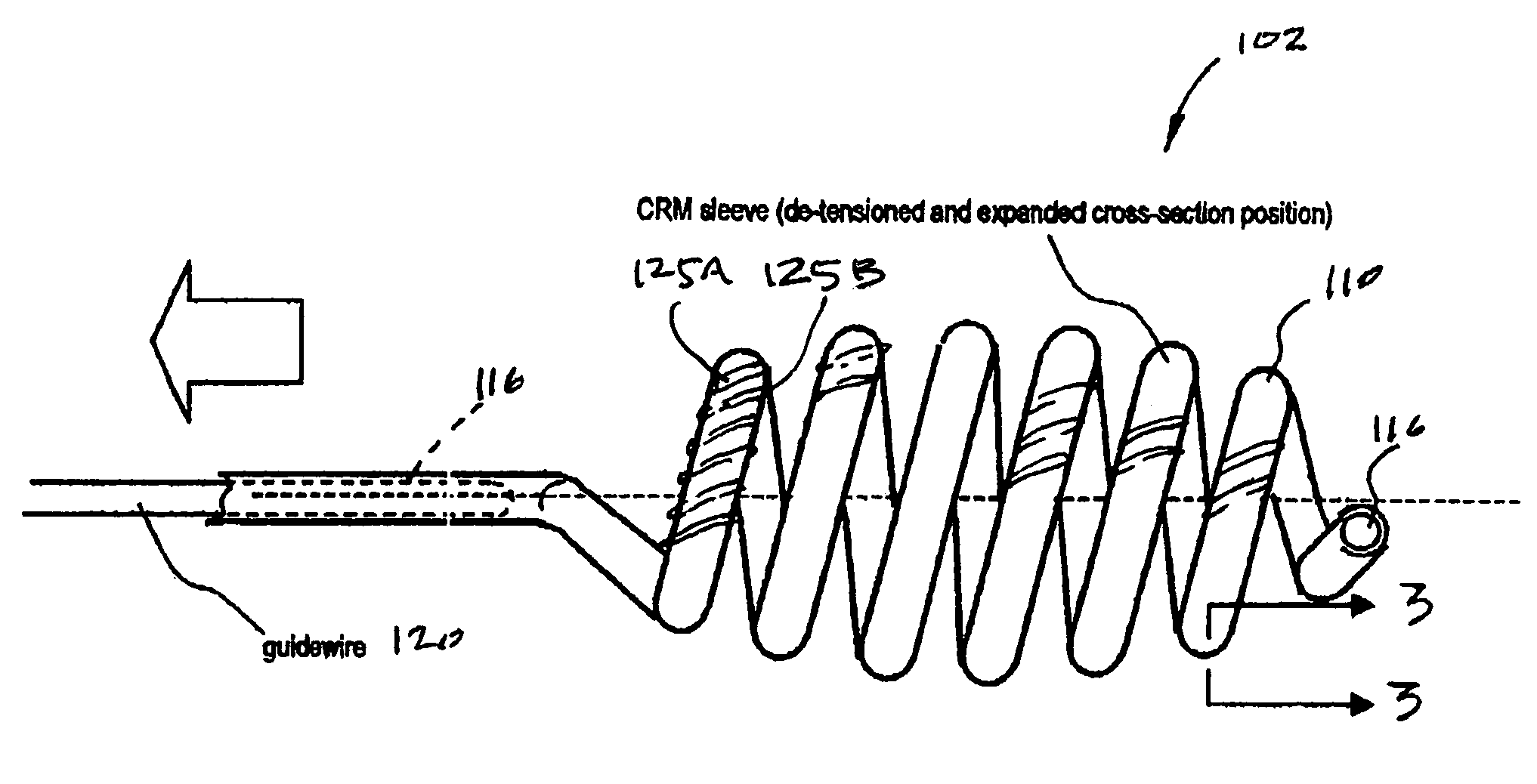

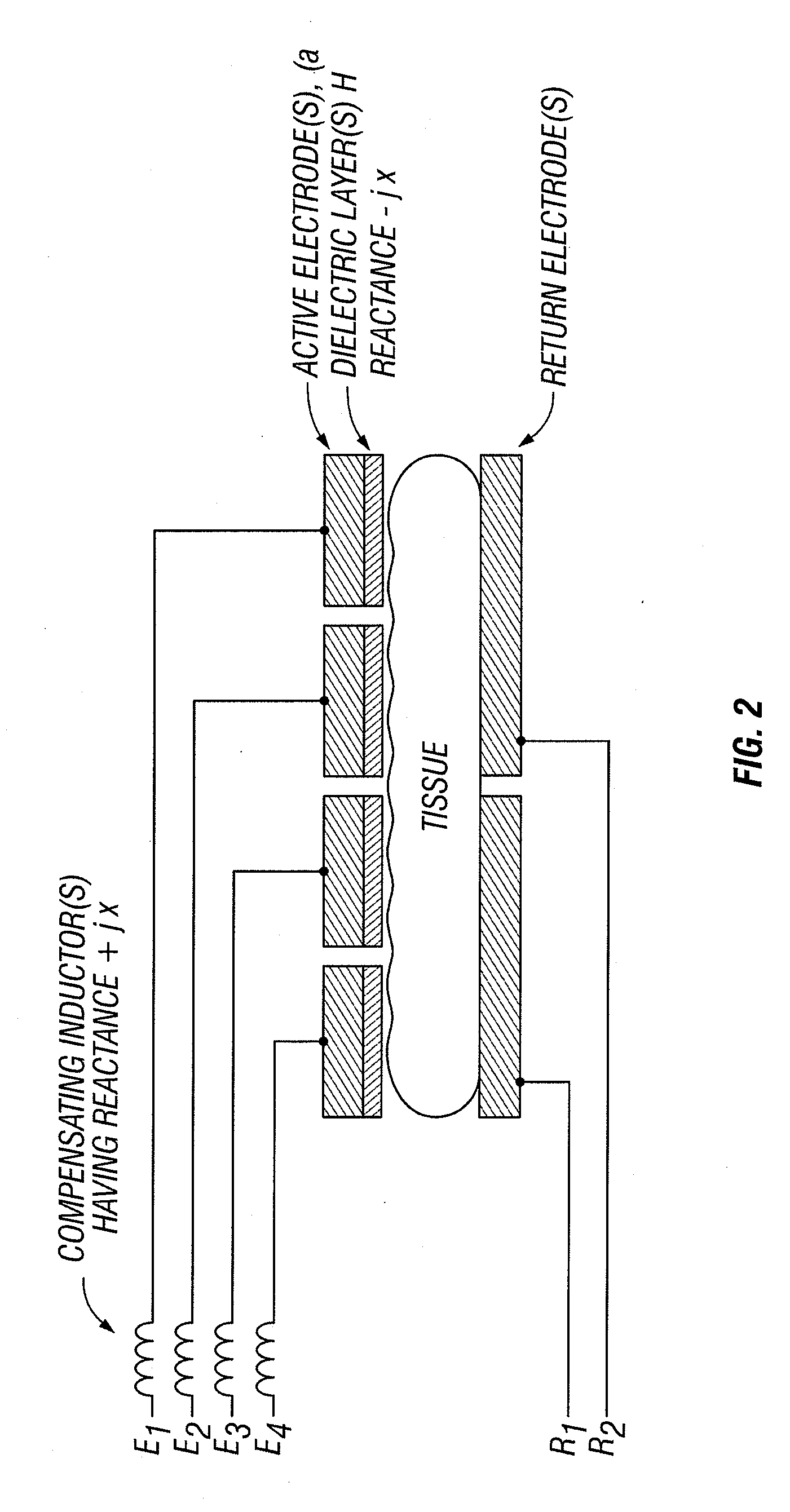

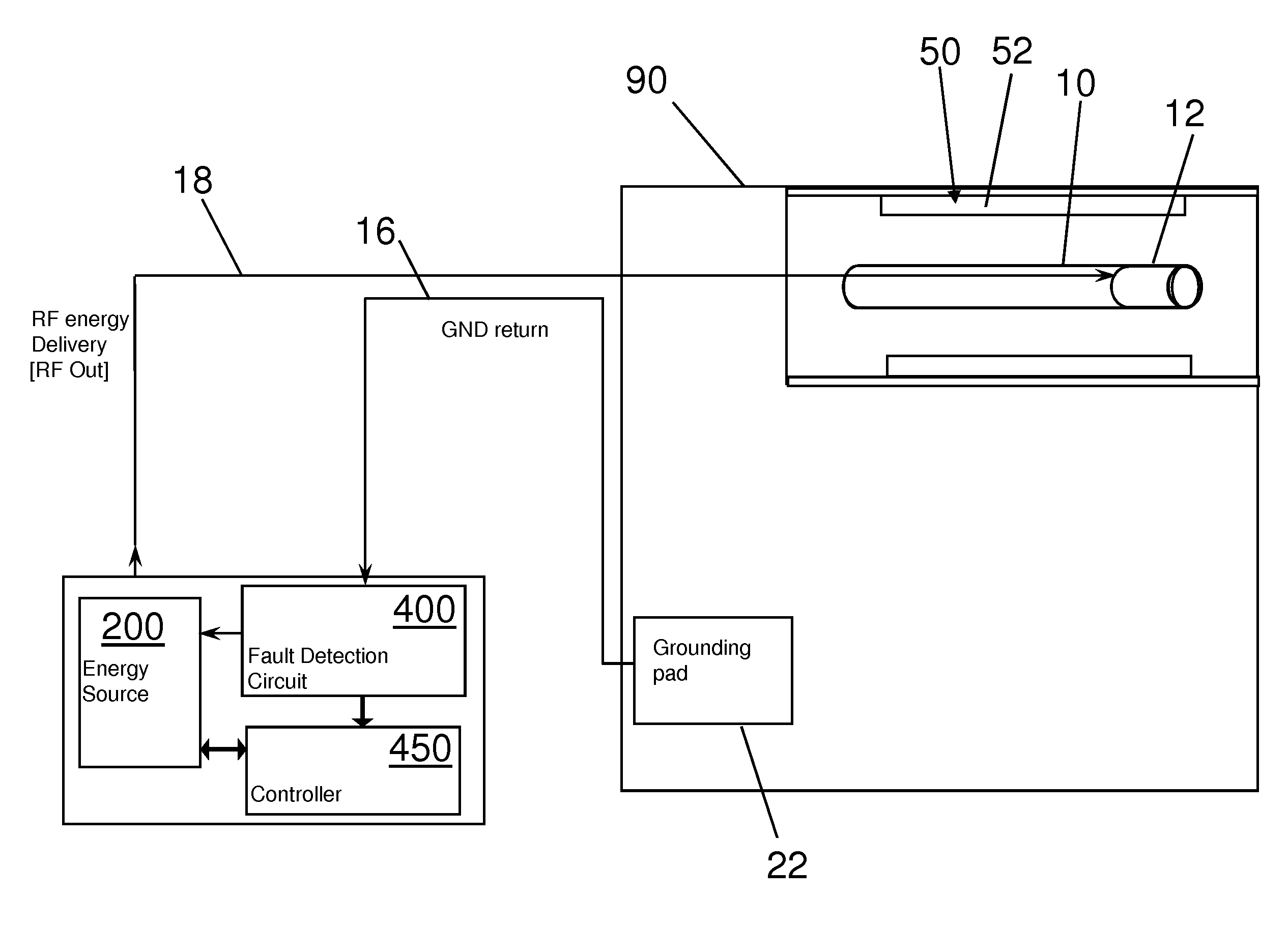

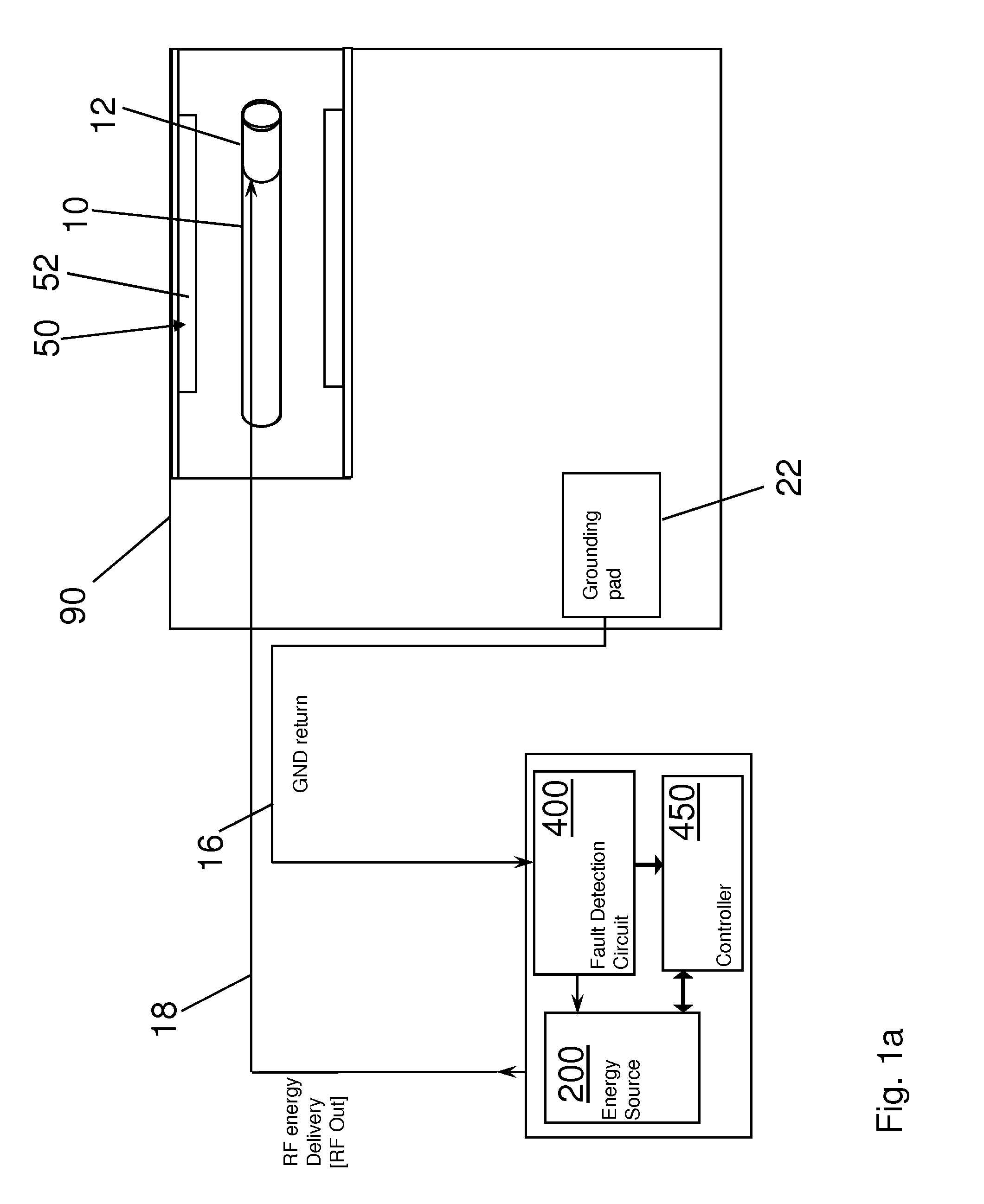

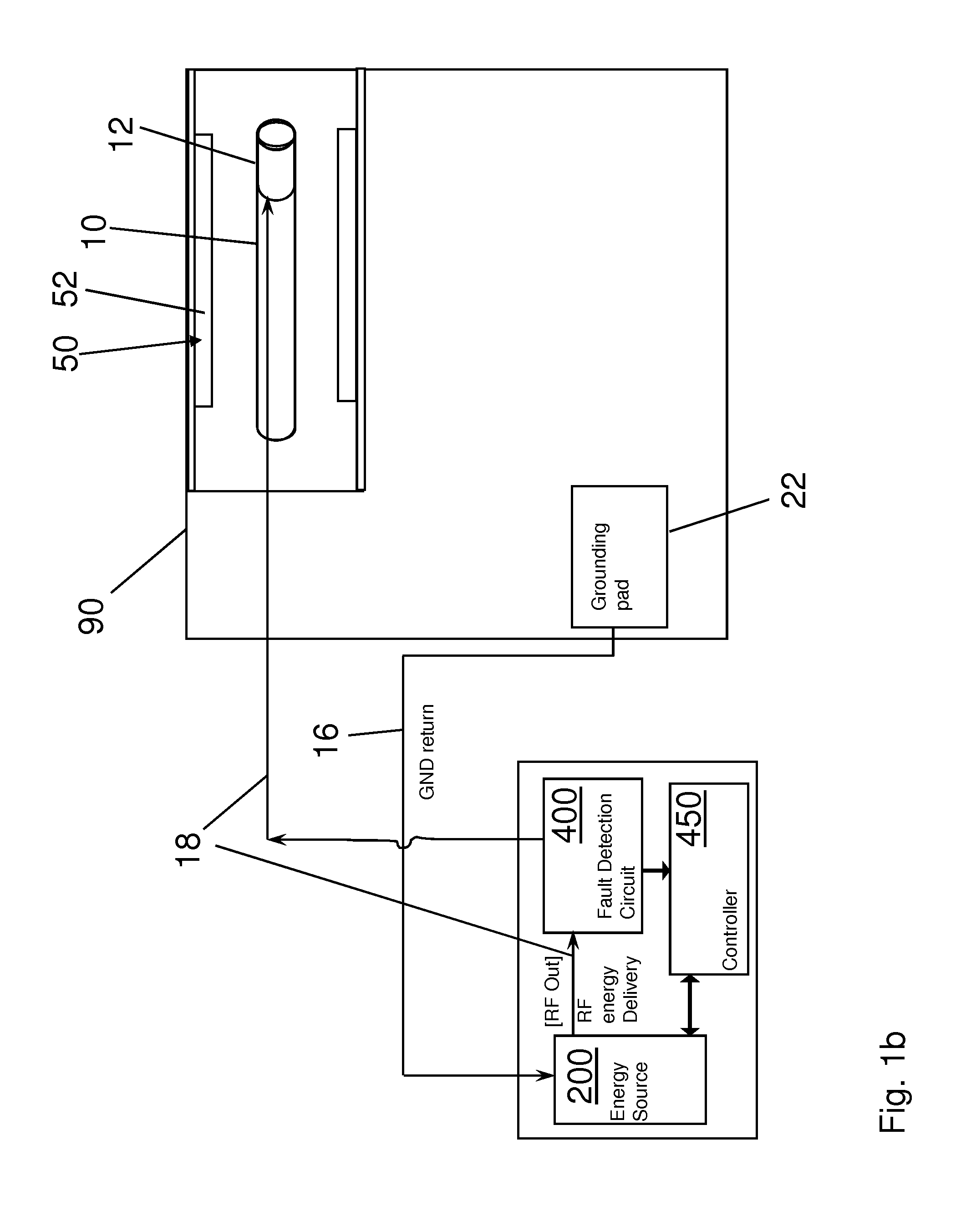

Monitoring and controlling energy delivery of an electrosurgical device

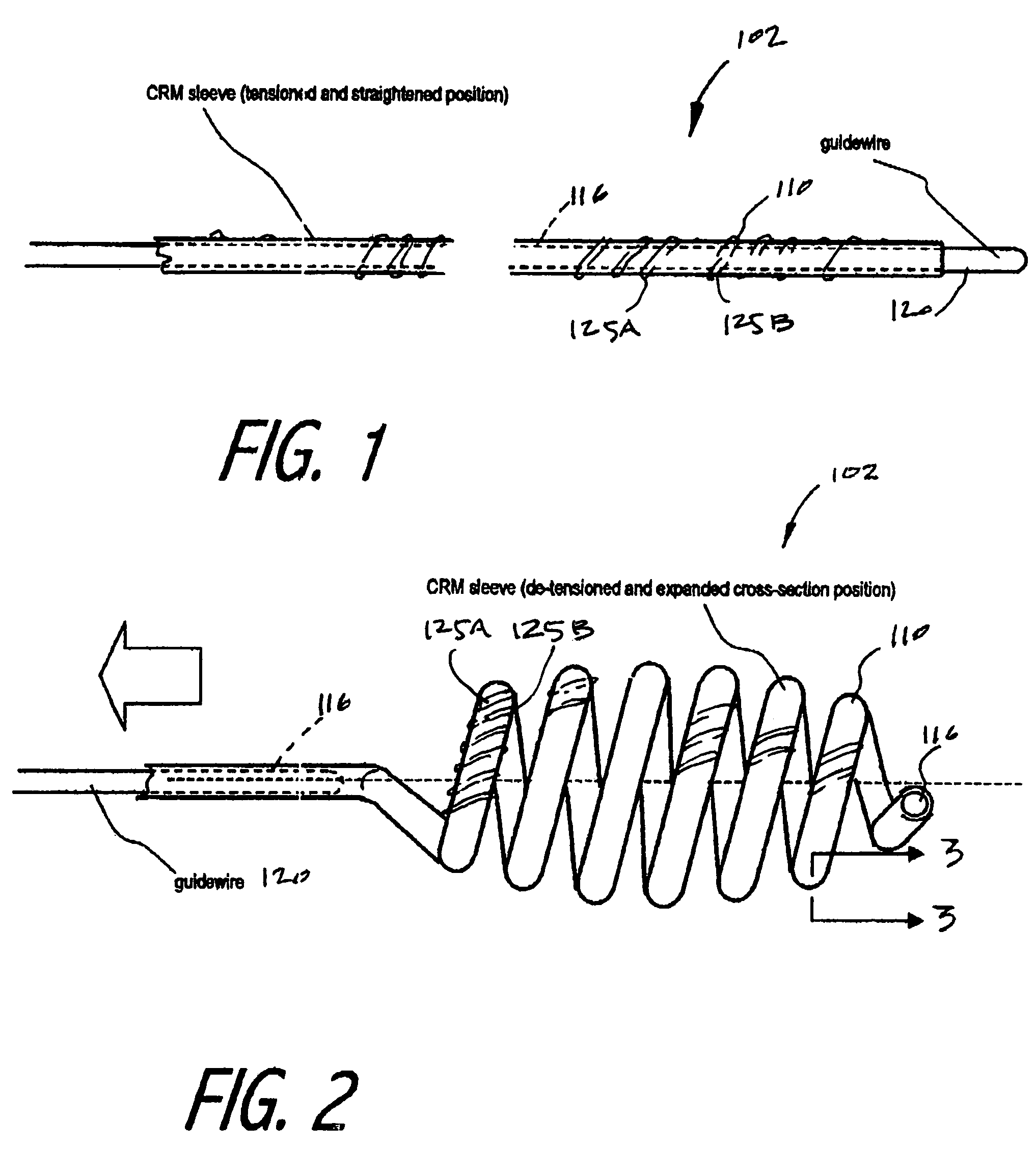

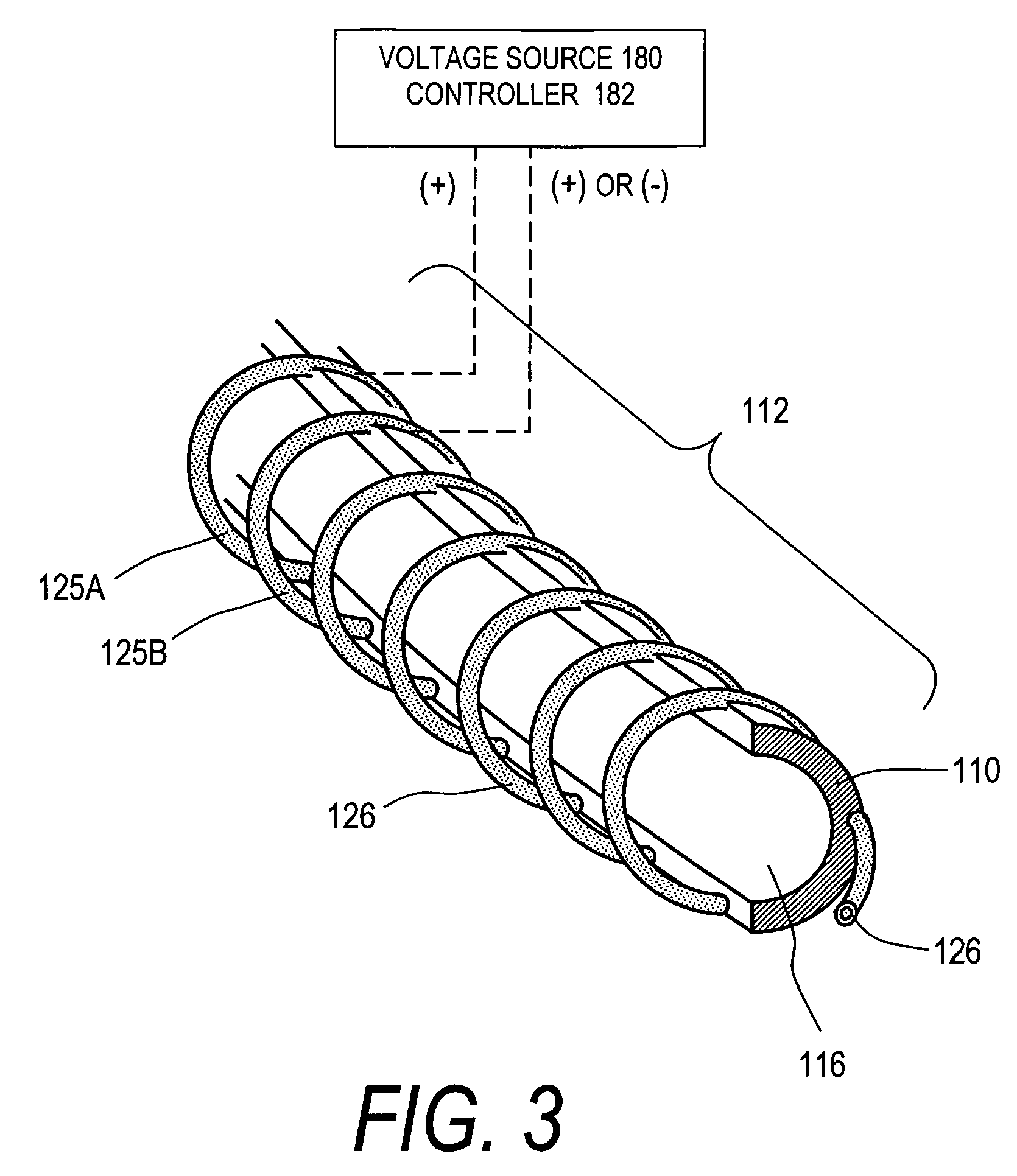

ActiveUS20120215213A1Avoid arcingAllow useCatheterSurgical instruments for heatingMedicineMedical treatment

A method is disclosed for delivering energy to a region of tissue within a patient's body using a medical treatment system. The medical treatment system comprises an energy delivery device coupled to an energy source. Energy is delivered through the energy delivery device positioned within the patient's body. An energy delivery parameter associated with the delivery of energy by the medical treatment system is monitored and if one or more values of the energy delivery parameter exceed a predetermined magnitude threshold, one or more errors are detected. The extent of the detected errors is determined or assessed and the delivery of energy is controlled if the extent of the errors detected exceeds a sensitivity threshold before the expiry of a predetermined time period.

Owner:BOSTON SCI MEDICAL DEVICE LTD

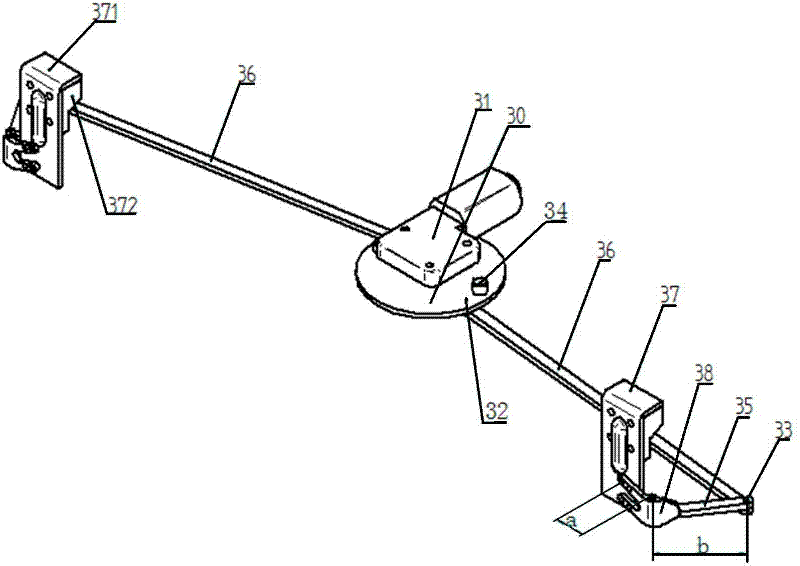

Sliding bottom electricity-taking and self-locking electric bus battery quick-change pellet device

ActiveCN102343894APositioning constraints resolvedAvoid the problem of severe squeezing that cannot be unlockedCharging stationsElectric propulsion mountingElectricityEngineering

The invention provides a sliding bottom electricity-taking and self-locking electric bus battery quick-change pellet device. The electric bus battery quick-change tray device comprises a pellet and a locking and unlocking mechanism (3) mounted on the pellet. According to the invention, the battery box can be correctly positioned and reliably locked reasonably; the force is reasonably applied to the battery box; simple structure and simple and reasonable power wire splicing mode are obtained; and the arc discharge phenomenon can be effectively prevented.

Owner:KUNMING SHIPBUILDING EQUIP

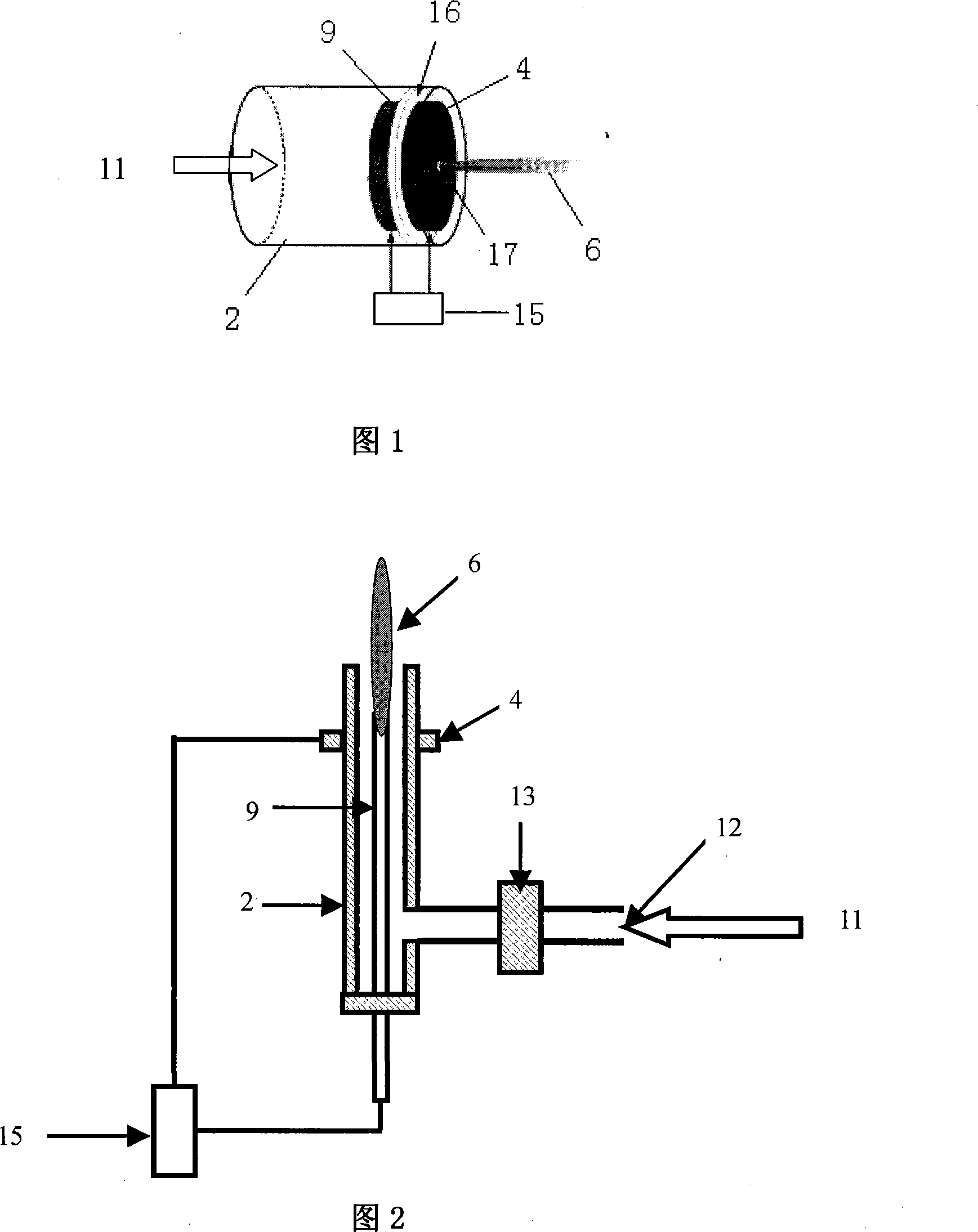

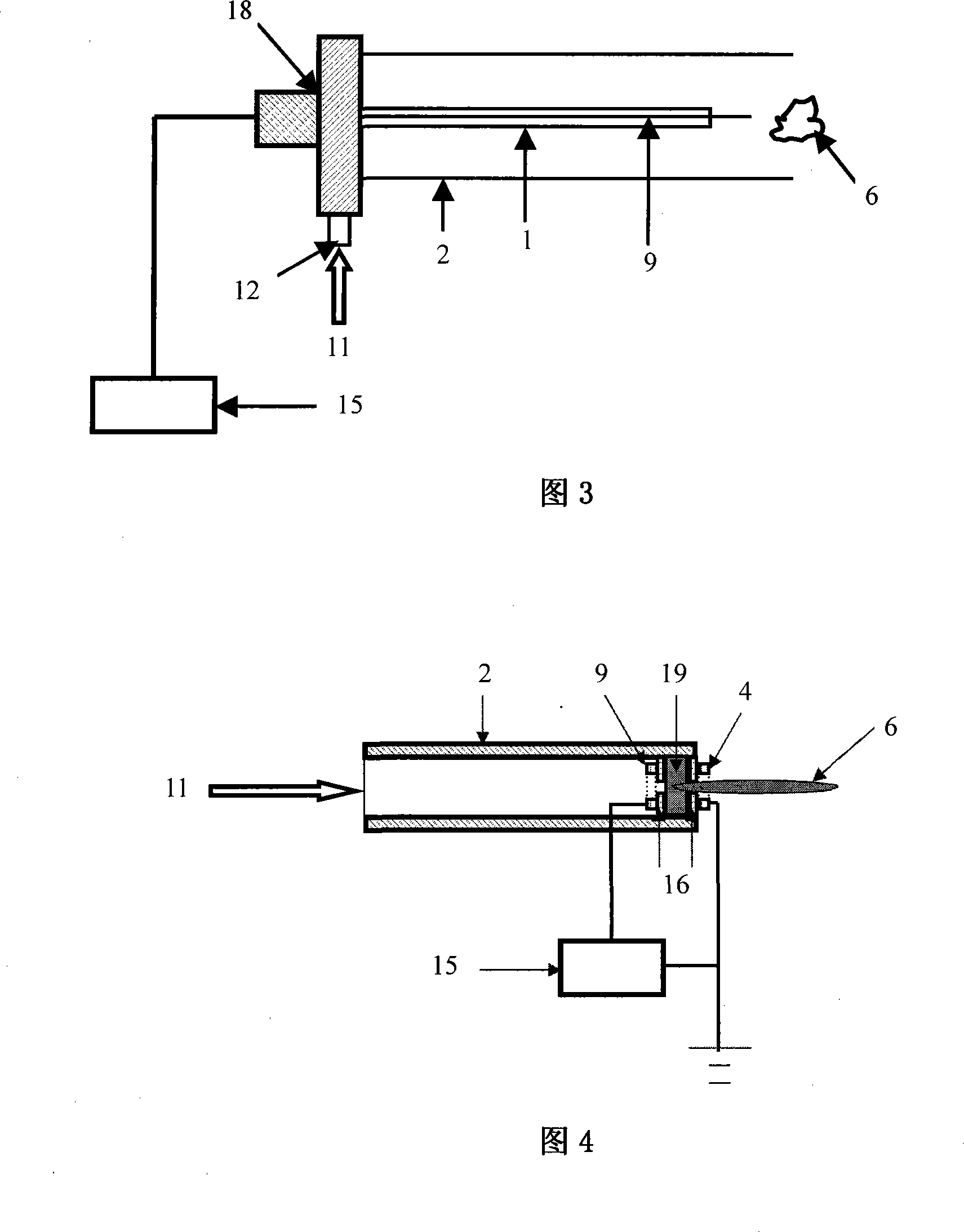

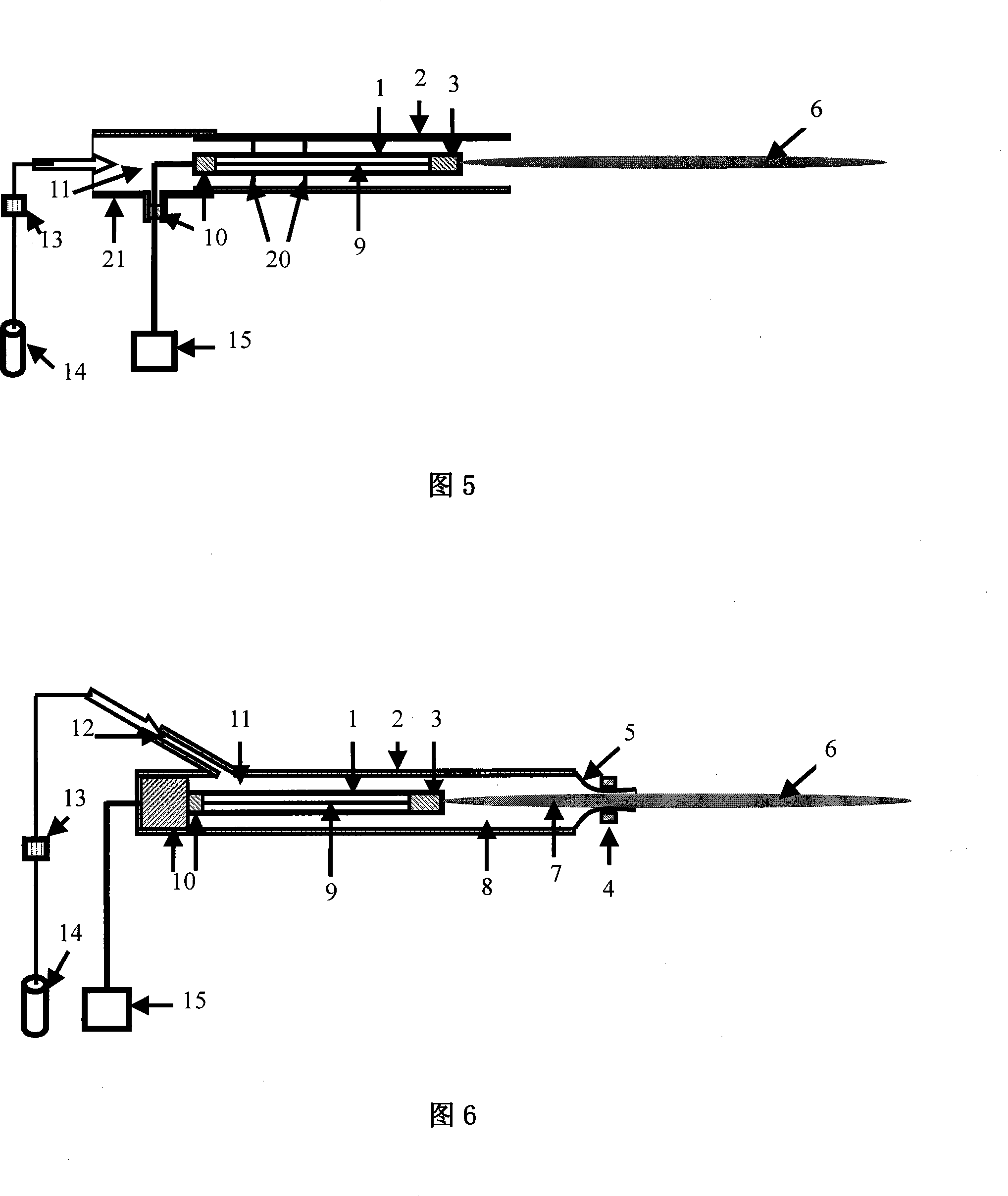

Plasma jet apparatus

ActiveCN101227790AIncrease varietyIncrease the number ofElectric discharge tubesPlasma techniquePlasma jetConductive materials

A plasma body jet flow device belongs to a plasma body generating device and aims at producing plasma body jet flows with long distance, low temperature and rich active compositions, the electrode position is safe, the device is applied in a plurality of discharge. The high voltage electrode of the invention is arranged in an inner dielectric tube and commonly located in an outer dielectric container, power supply is connected with the high voltage electrode, the outer dielectric container is communicated with a working gas source, the inner dielectric tube takes a hollow tubular shape with a sealed single end, the sealed end of the inner dielectric tube is provided with conducting materials which are communicated with one end of the high voltage electrode, the other end of the high voltage electrode in the inner dielectric tube is provided with an insulating plug, and the high voltage electrode is fixed by the insulating block head and the conducting materials. The invention has easy manufacture, good maintenance, safe and convenient use, wide working gas range and changeable temperature, length and thickness of the plasma body jet flows, further develops the range of application of a plasma body technique, and increases the application effects of the plasma body.

Owner:武汉海思普莱生命科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com