Plasma jet apparatus

A plasma and jet technology, applied in the direction of plasma, discharge tube, electrical components, etc., can solve the problems of short plasma jet length, high temperature, unsafe, etc., to widen the application range, improve the application effect, portable good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

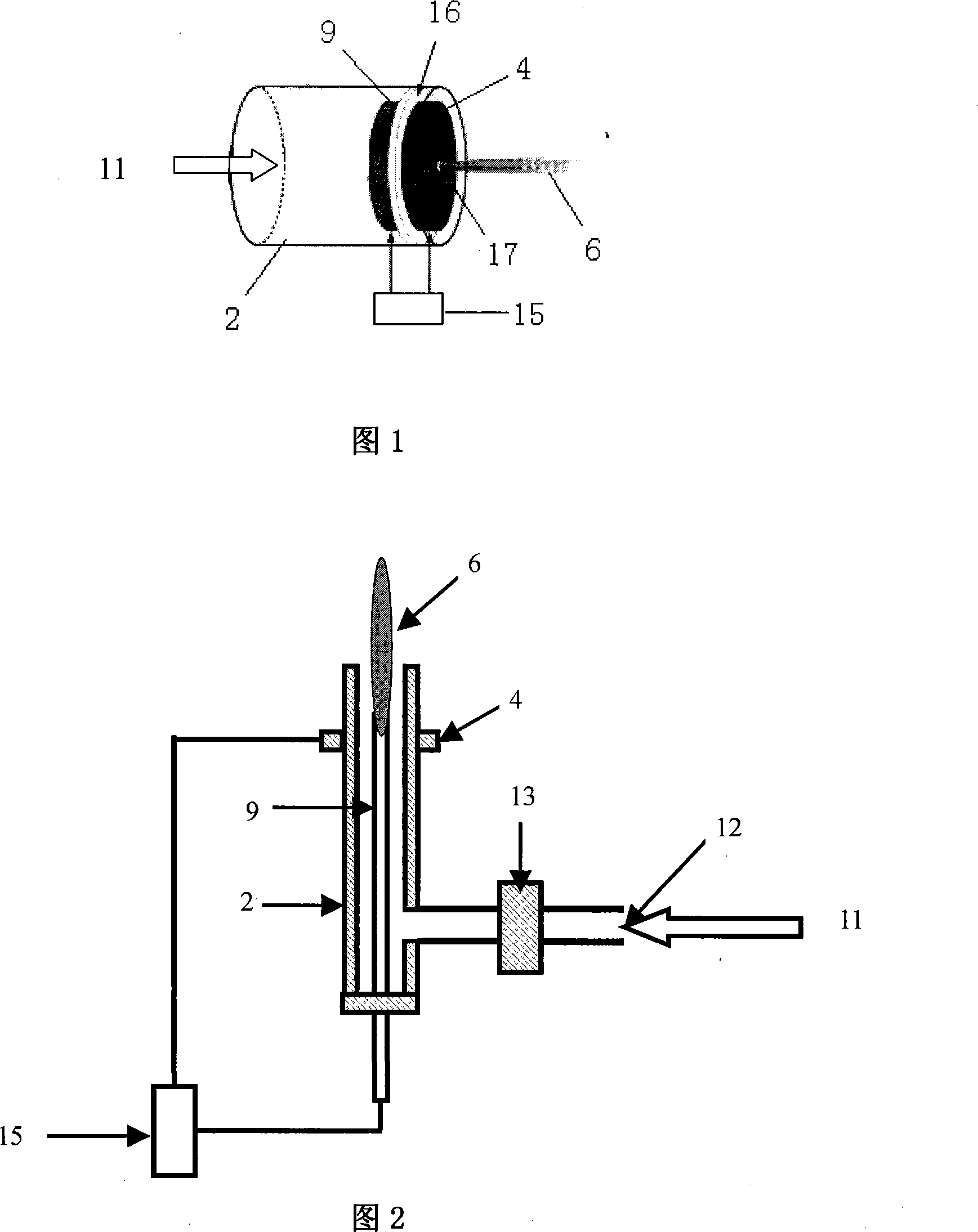

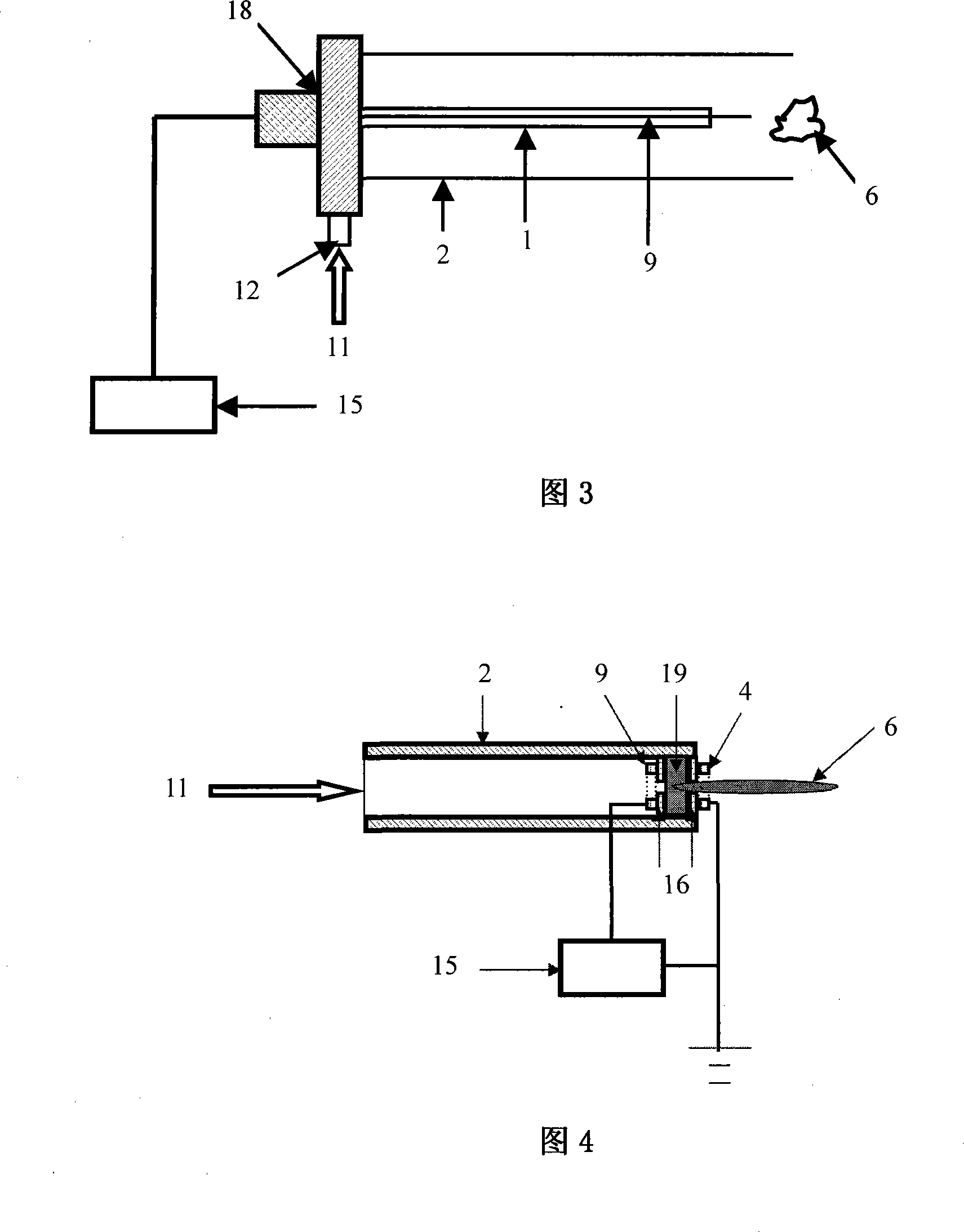

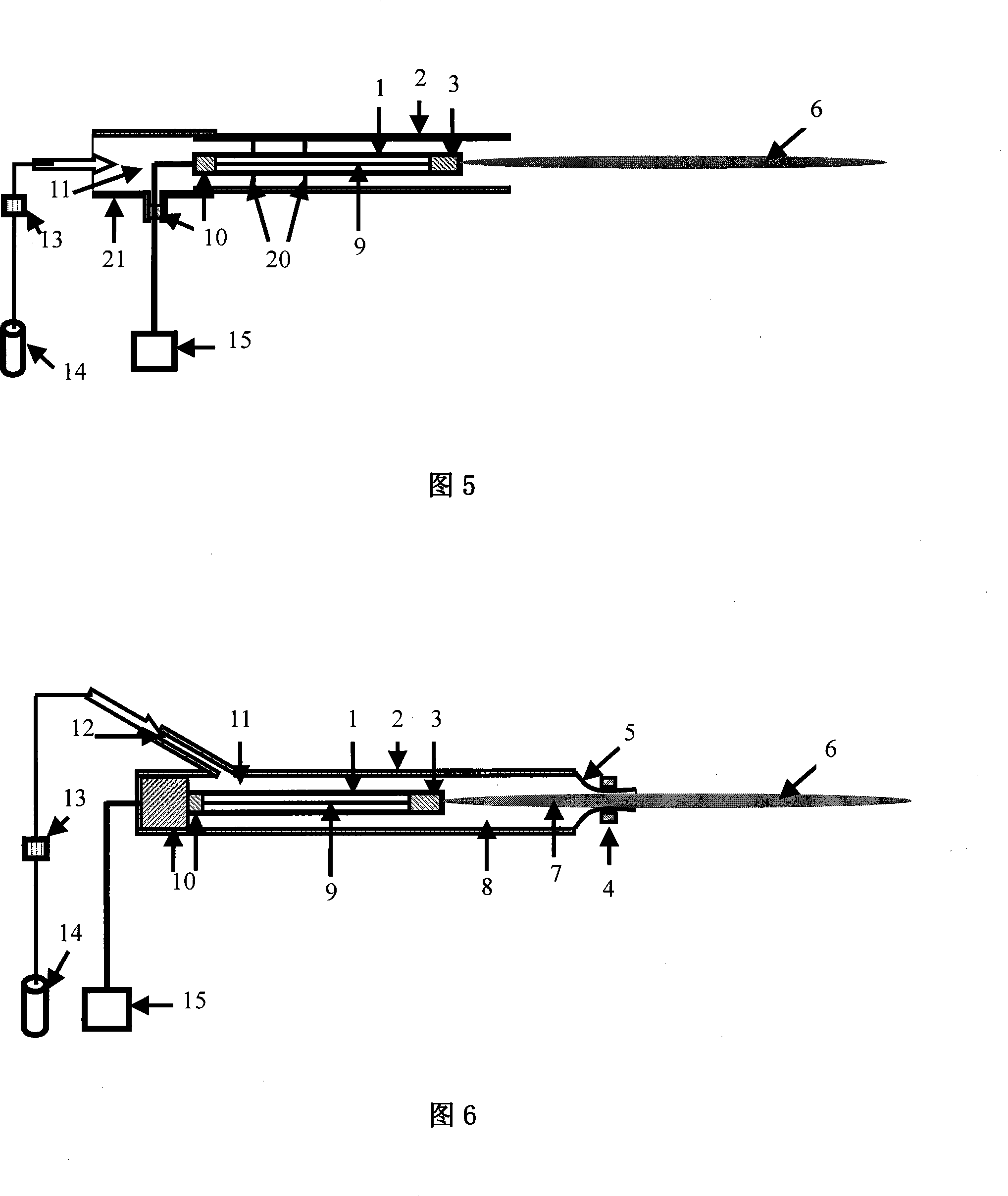

[0045] The present invention will be described in detail below with reference to the accompanying drawings.

[0046] As shown in Figure 5, the first embodiment of the present invention includes a working gas source 14, a power supply 15, a high-voltage electrode 9, an inner medium pipe 1, and an outer medium container 2, and the high-voltage electrode 9 is placed in the inner medium pipe 1, and Commonly located in the outer medium container 2, the power supply 15 is connected to the high-voltage electrode 9, and the inner medium tube 1 is in the shape of a hollow tube sealed at one end, with a conductive material 3 connected to the high-voltage electrode 9 inside the sealed end, and an insulating plug 10 at the other end , the high-voltage electrode 9 is fixed by the insulating plug 10 and the conductive material 3 , and the inner medium pipe 1 is fixed in the outer medium container 2 by the fixing frame 20 . The high-voltage electrode 9 is connected to the power supply 15 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com