Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

347 results about "Desiccation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desiccation (from Latin de- "thorougly" + siccare "to dry") is the state of extreme dryness, or the process of extreme drying. A desiccant is a hygroscopic (attracts and holds water) substance that induces or sustains such a state in its local vicinity in a moderately sealed container.

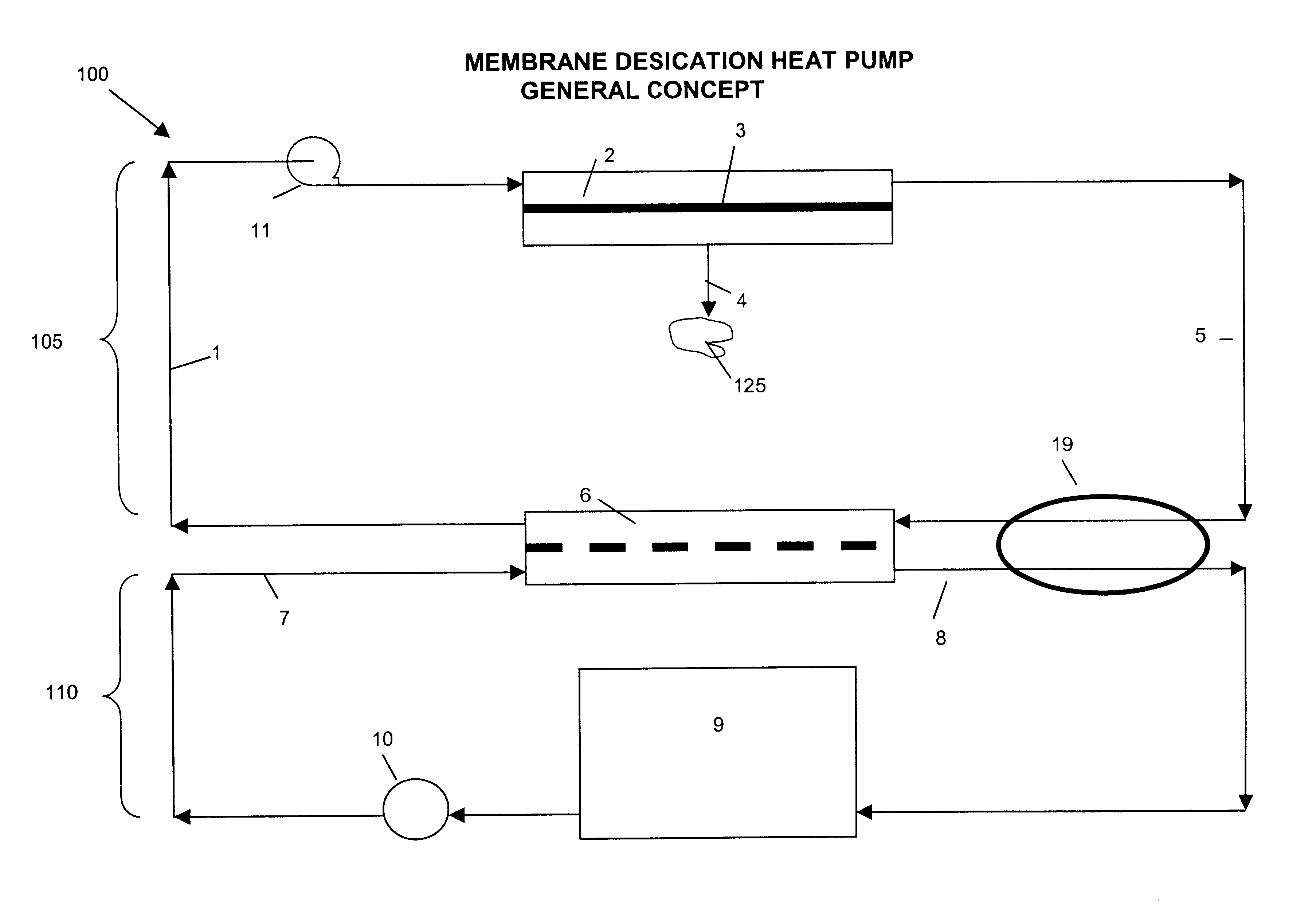

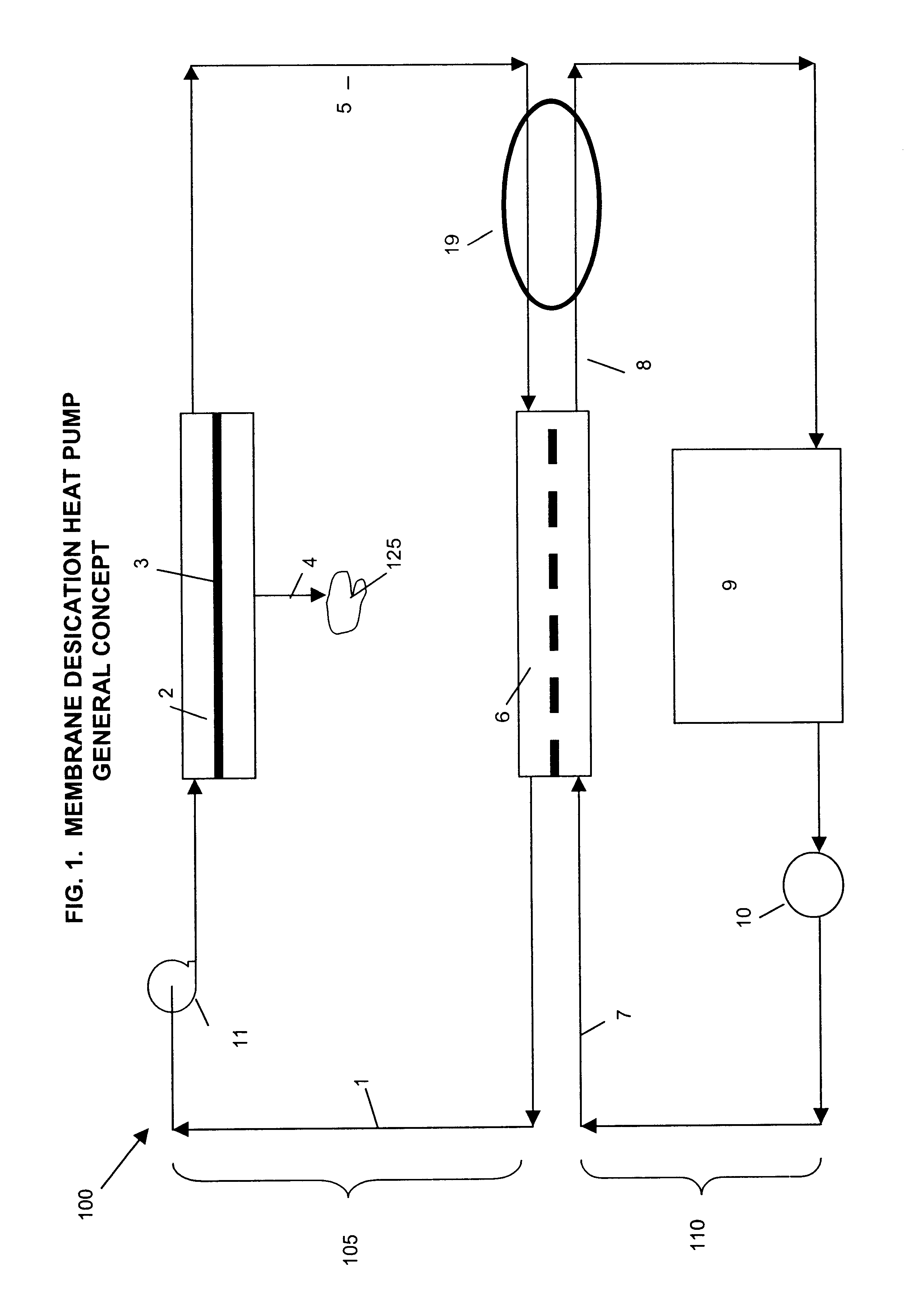

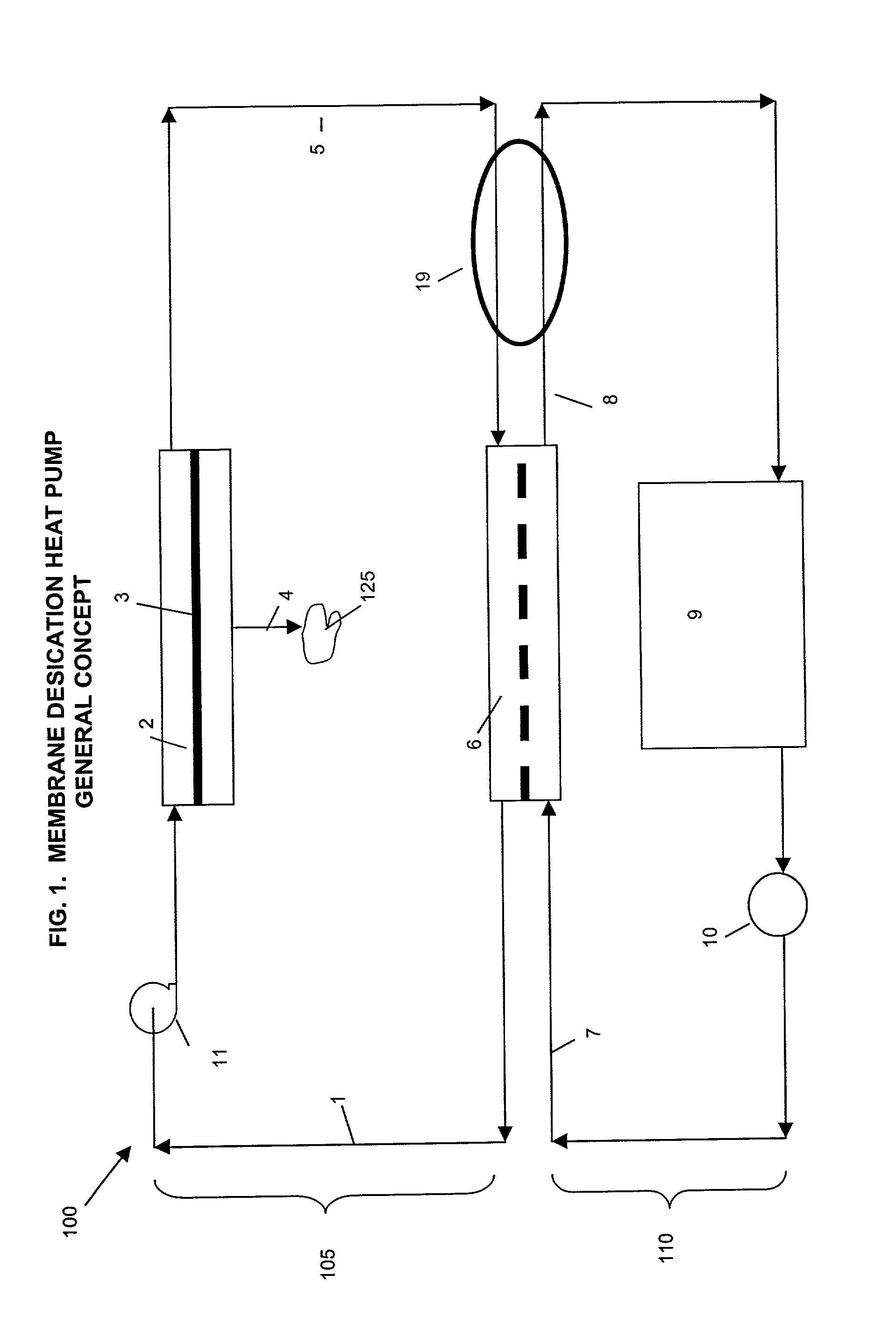

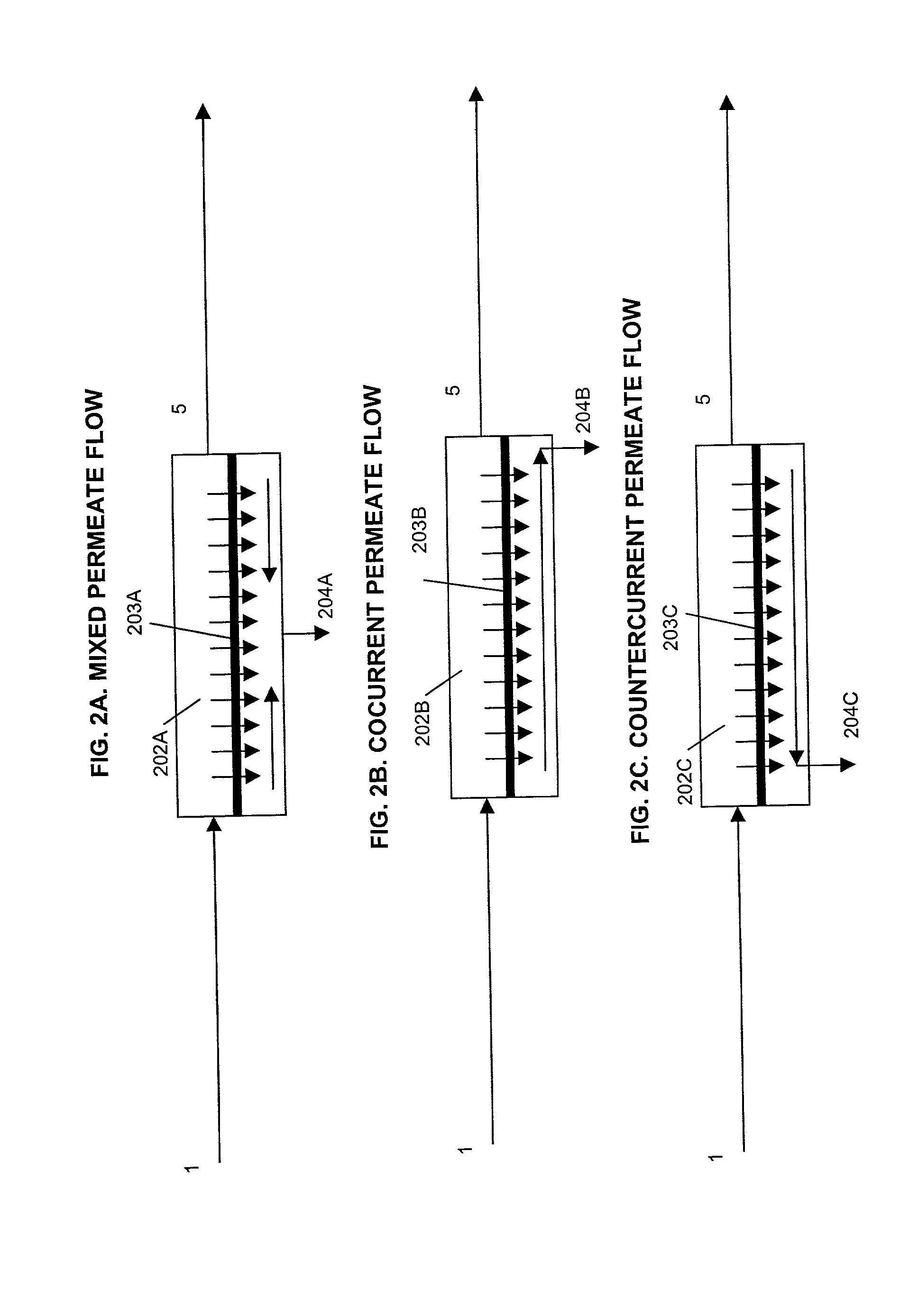

Membrane desiccation heat pump

InactiveUS6739142B2Great flexibility and controlReduce in quantityAir-treating devicesHeat pumpsThermal energyProcess engineering

Owner:KORIN AMOS

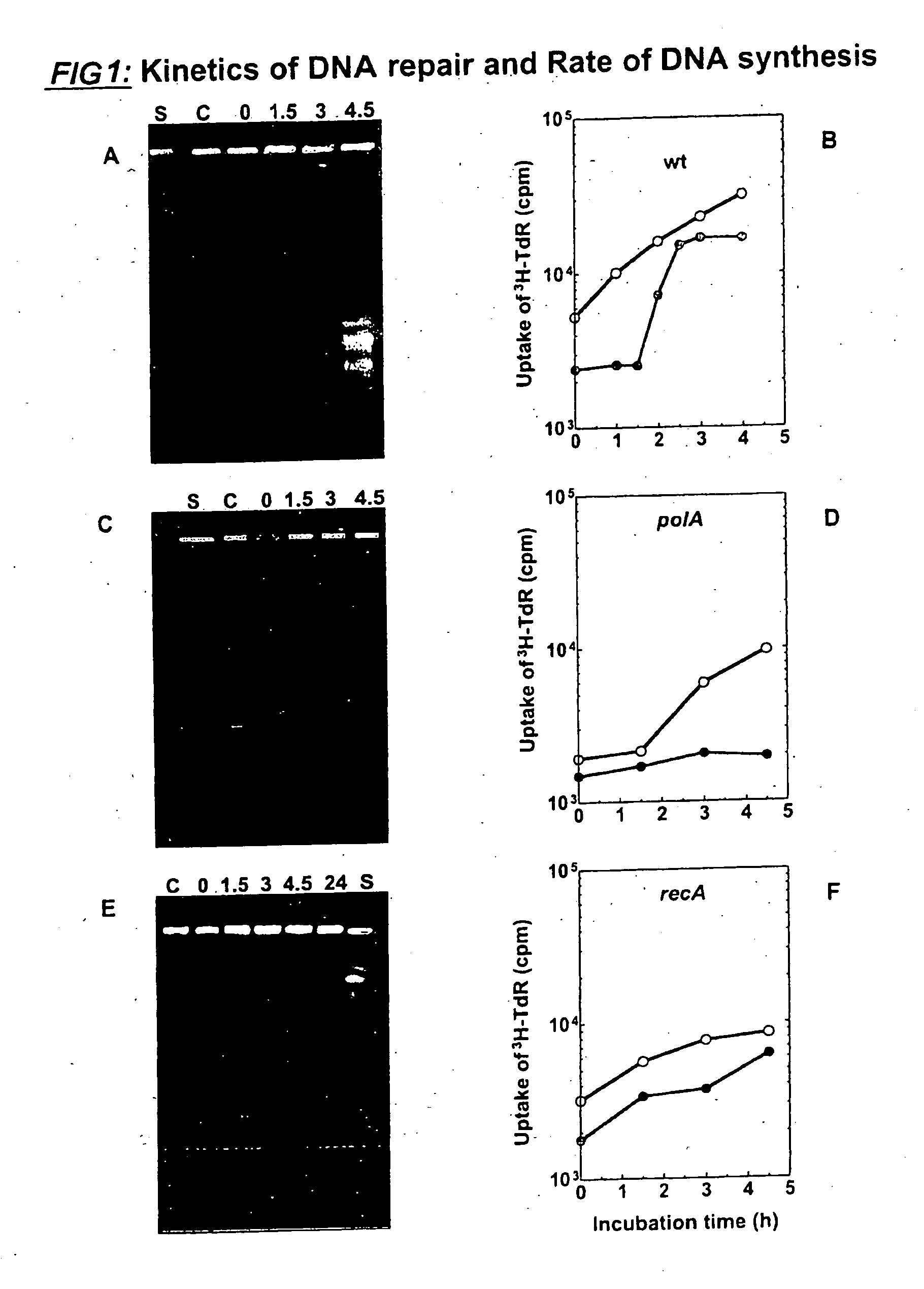

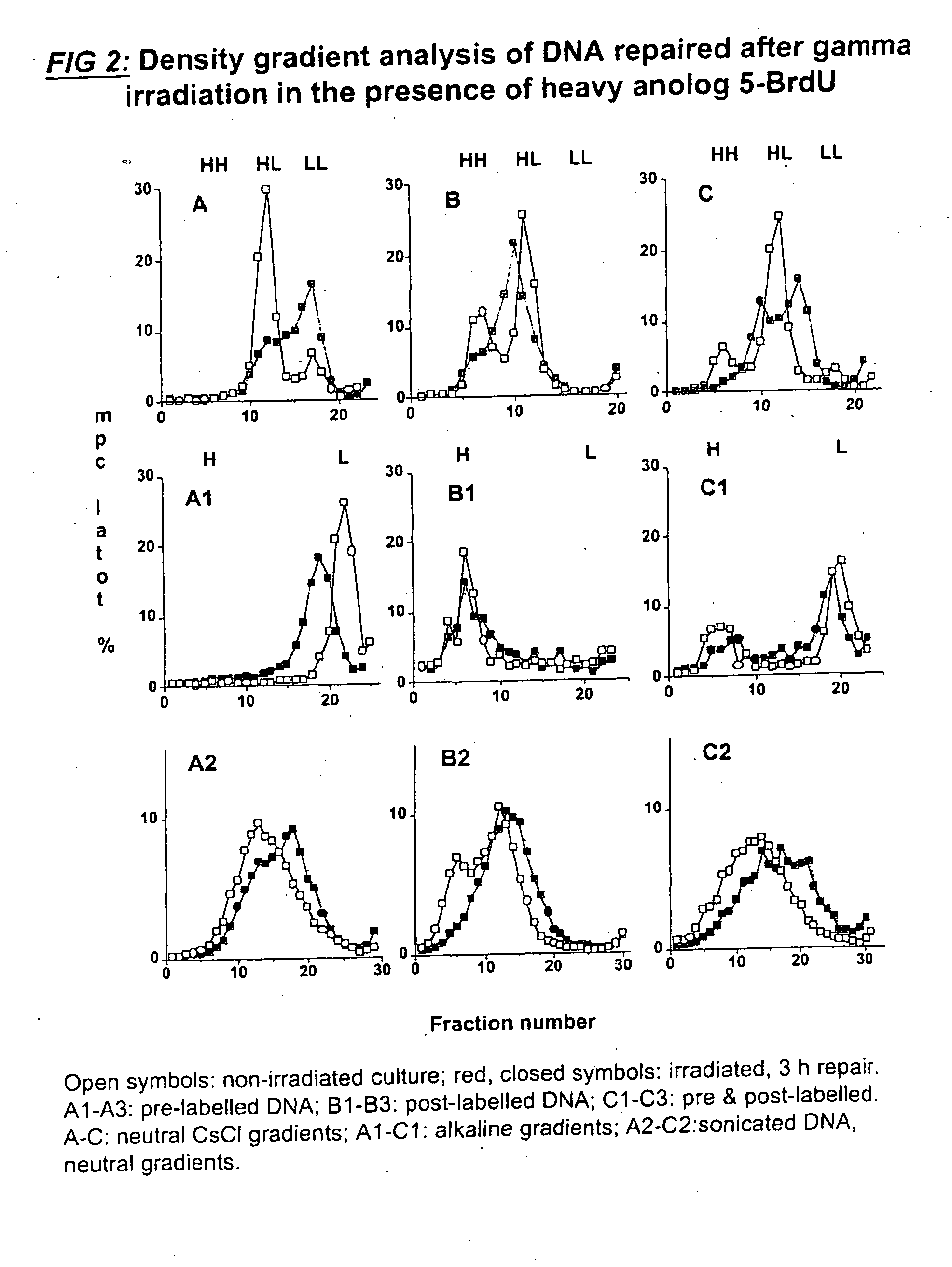

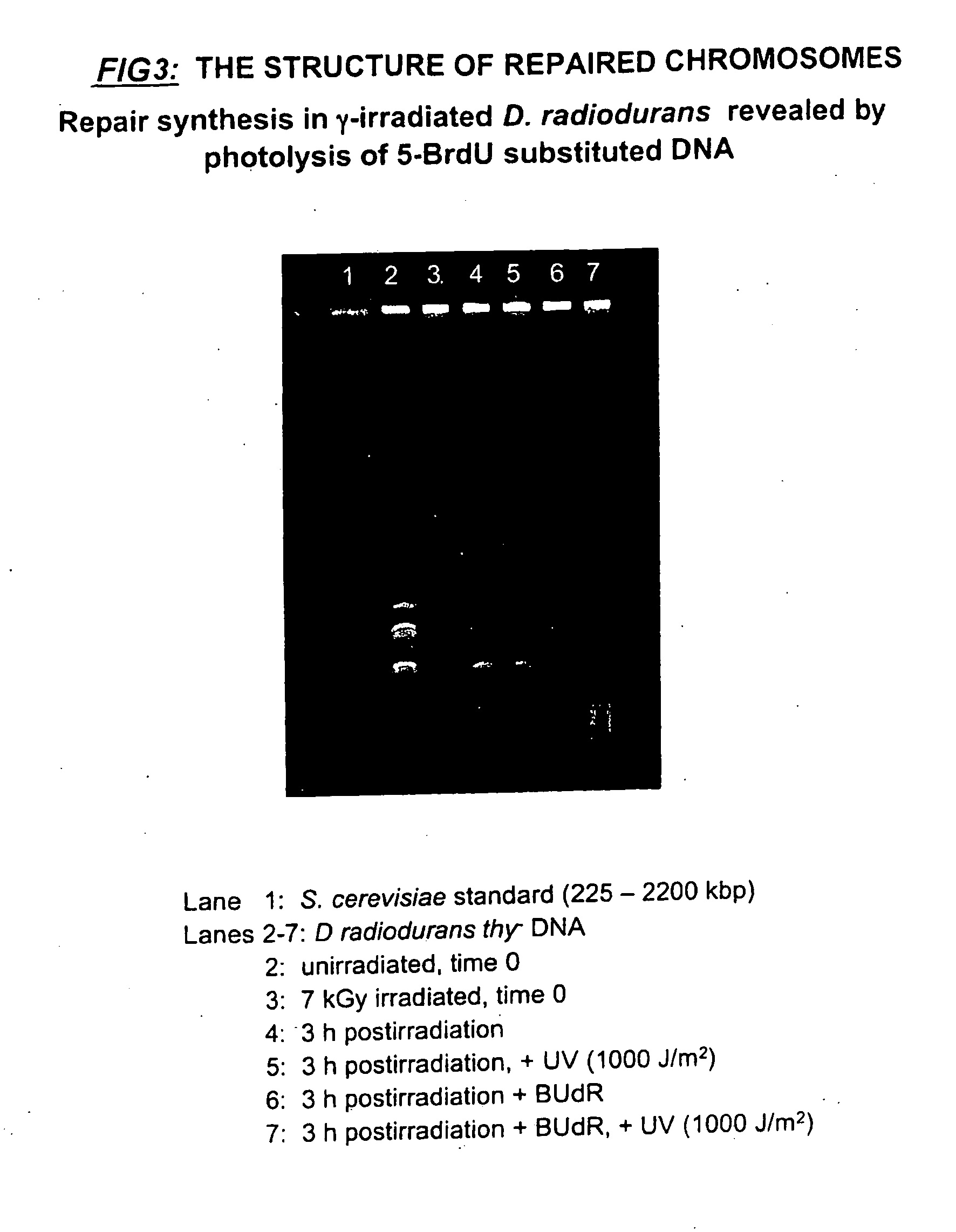

Process for Chromosomal Engineering Using a Novel Dna Repair System

This invention relates to chromosomal engineering via DNA repair process. The process of the invention comprises the steps of: 1) submitting at least one source of biological activity, e.g. Deinococcus radiodurans, to radiation, desiccation and / or chemical treatment liable to damage the DNA, so as to substantially shatter its chromosomes into short fragments; 2) annealing complementary single strand tails extended by the synthesis templated on partially overlapping DNA fragments of said shattered chromosomes; 4) converting the resulting long linear DNA intermediates into intact circular chromosomes, by means of a RecA dependent homologous recombination; whereas at least one foreign source of genetic material, e.g. DNA, can be introduced during steps 2 and / or 3; and 4) optionally separating and collecting the recombined chromosomes thus obtained.

Owner:DEINOVE SA

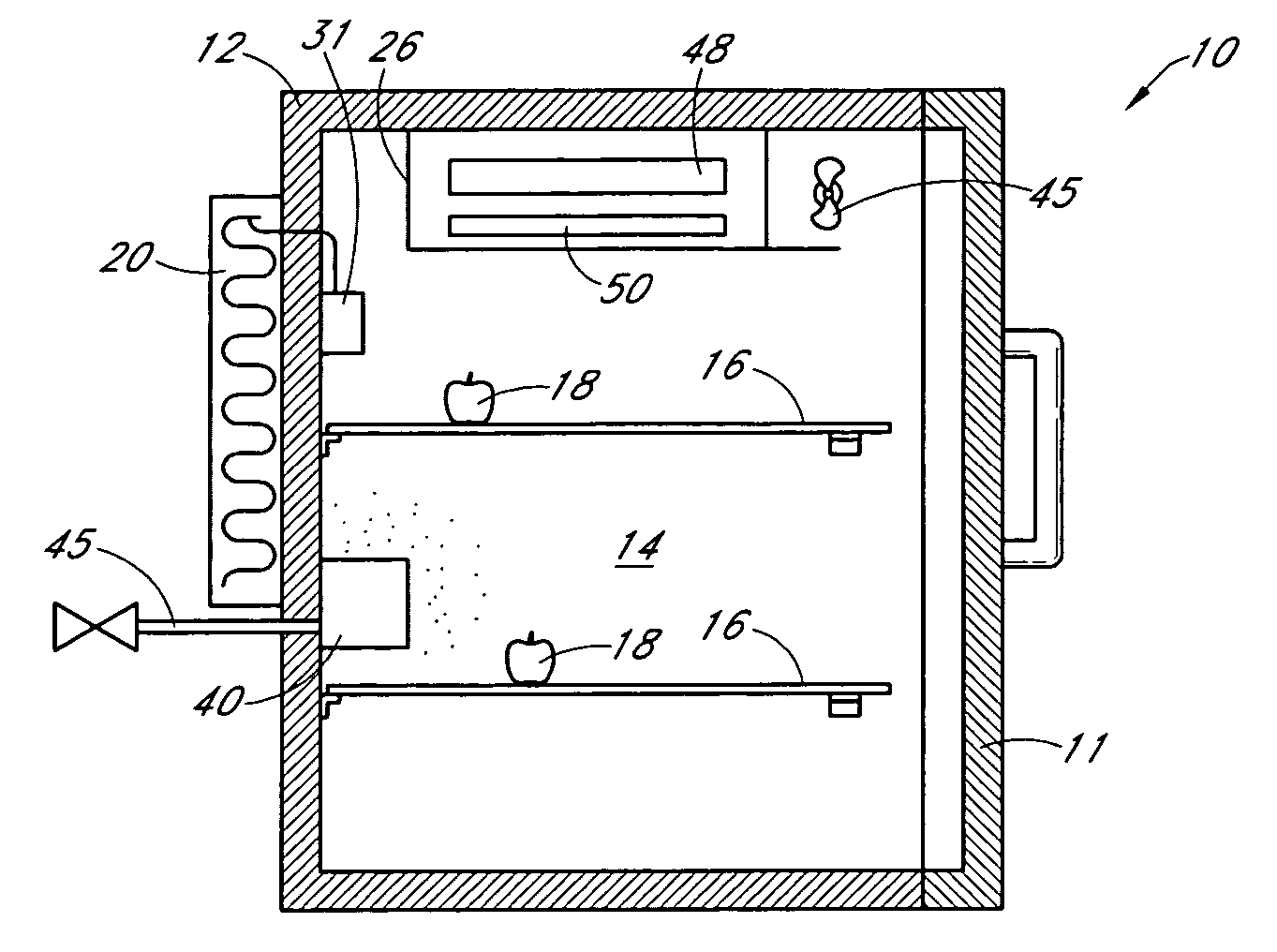

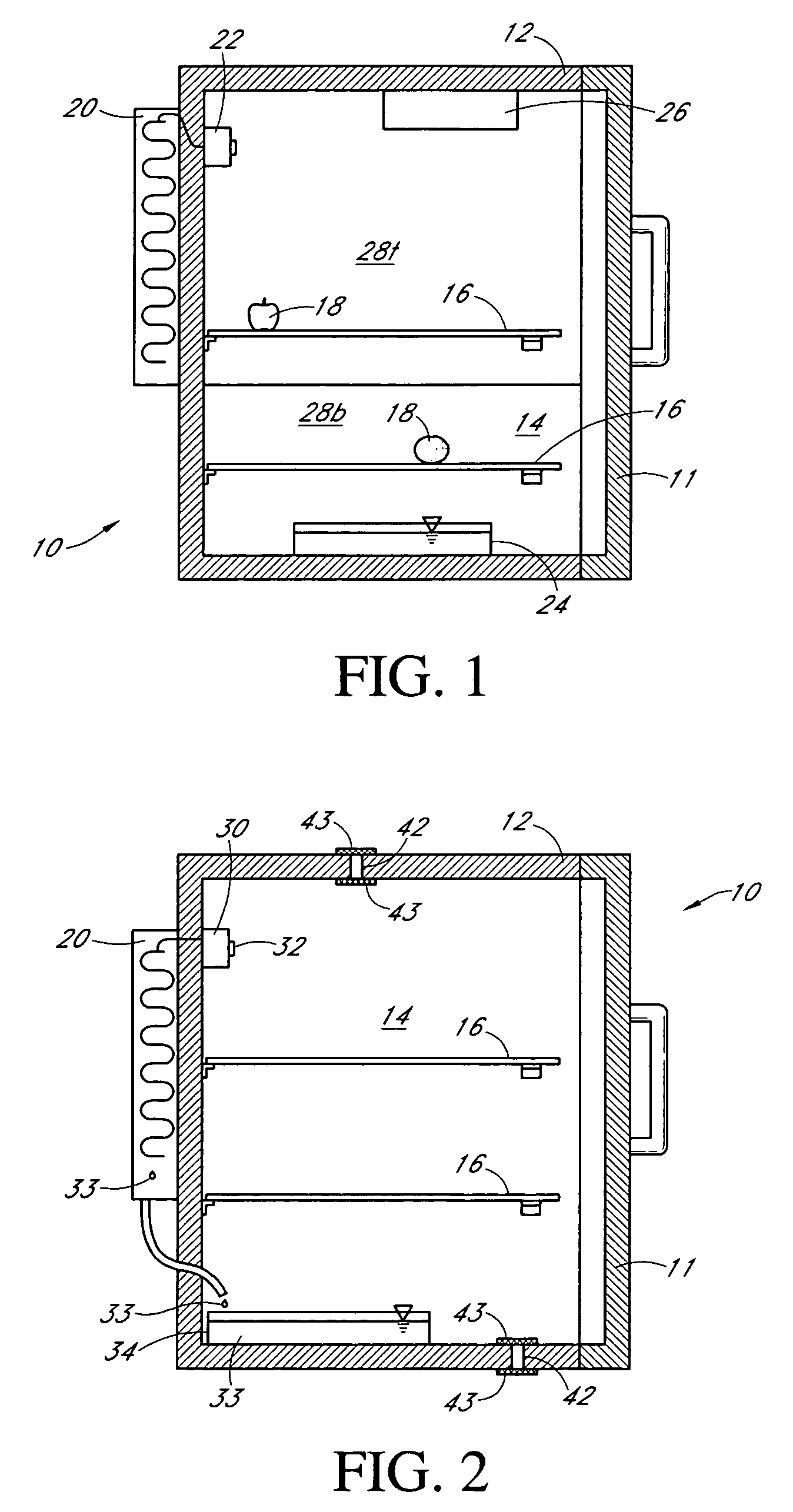

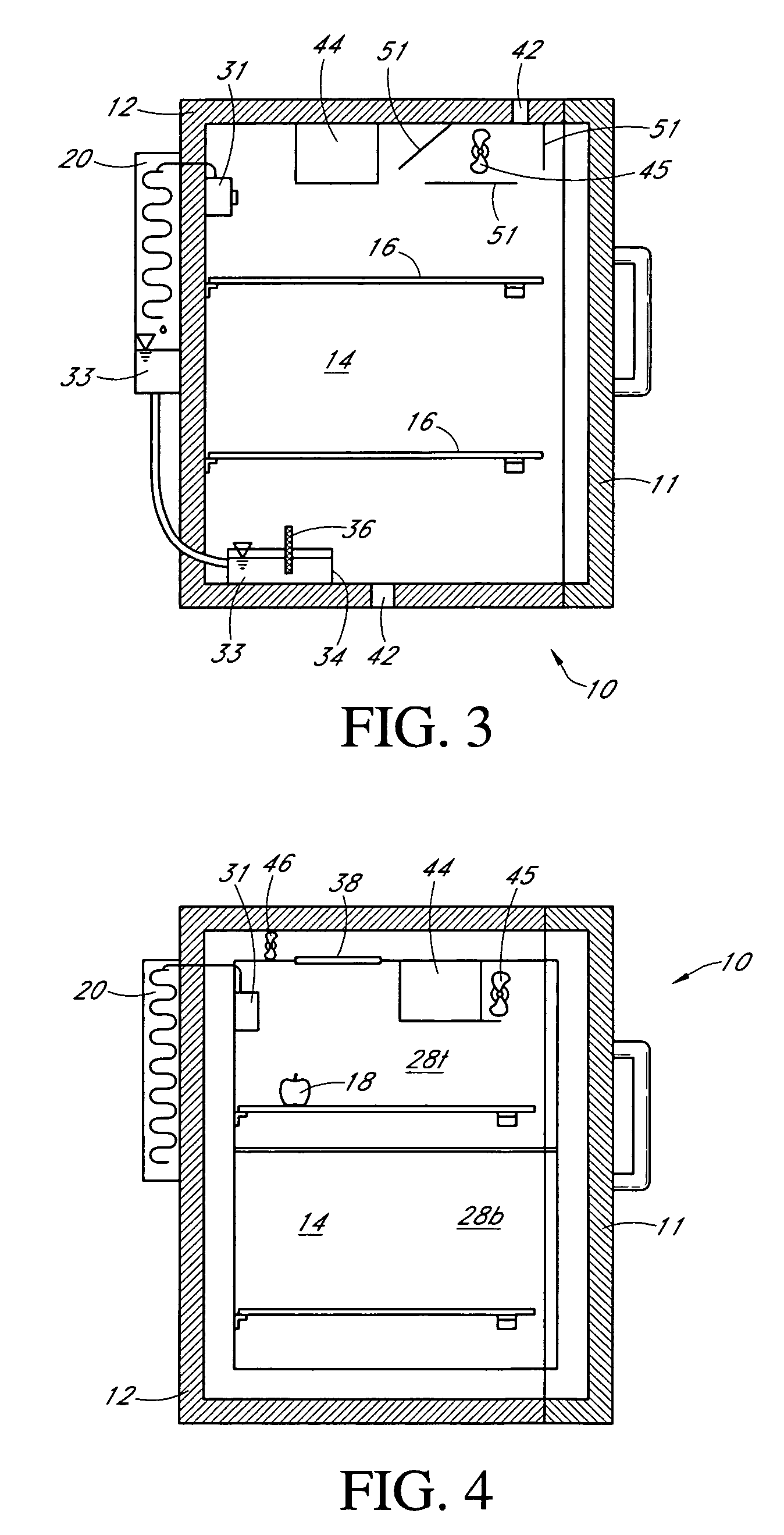

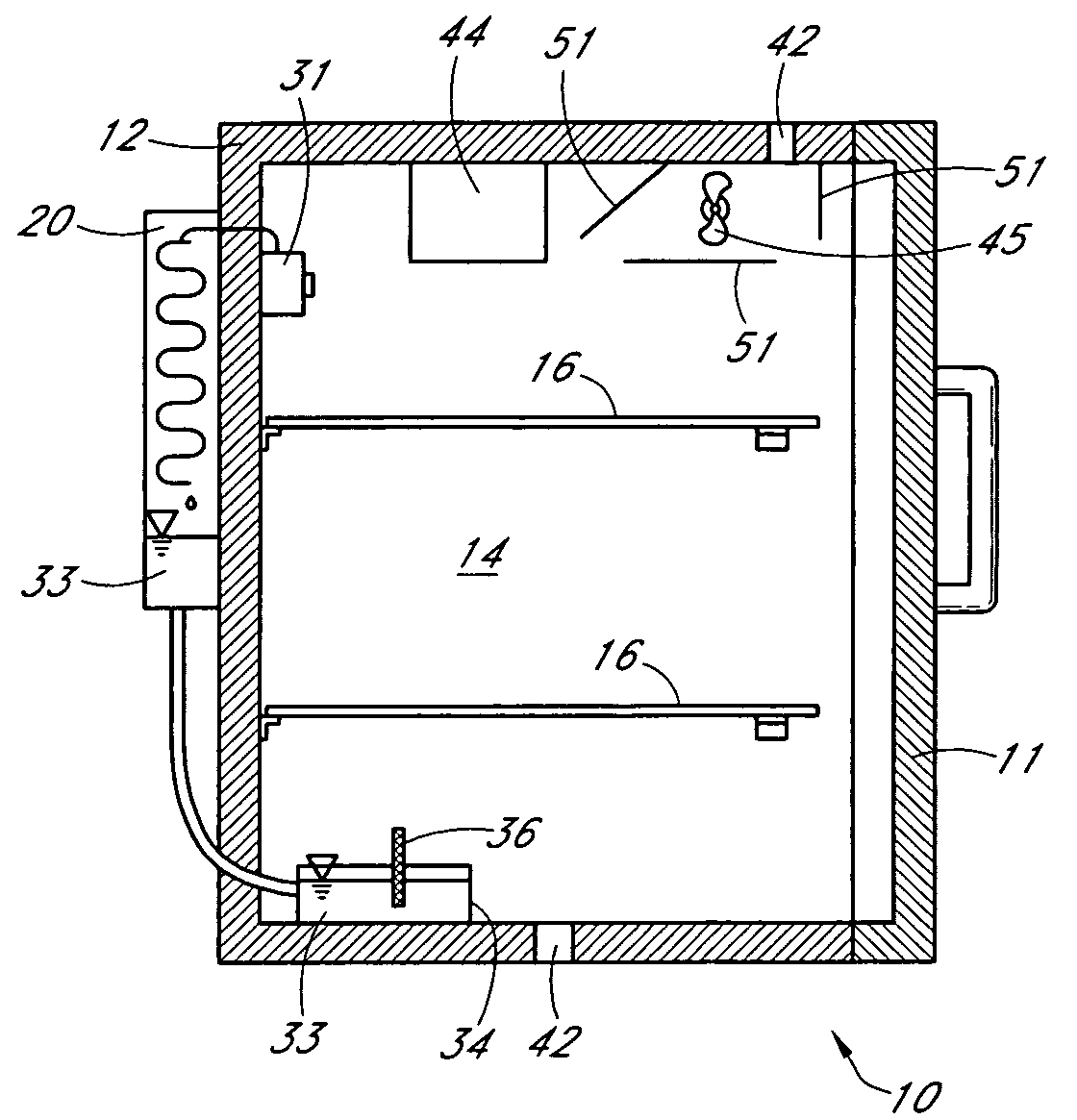

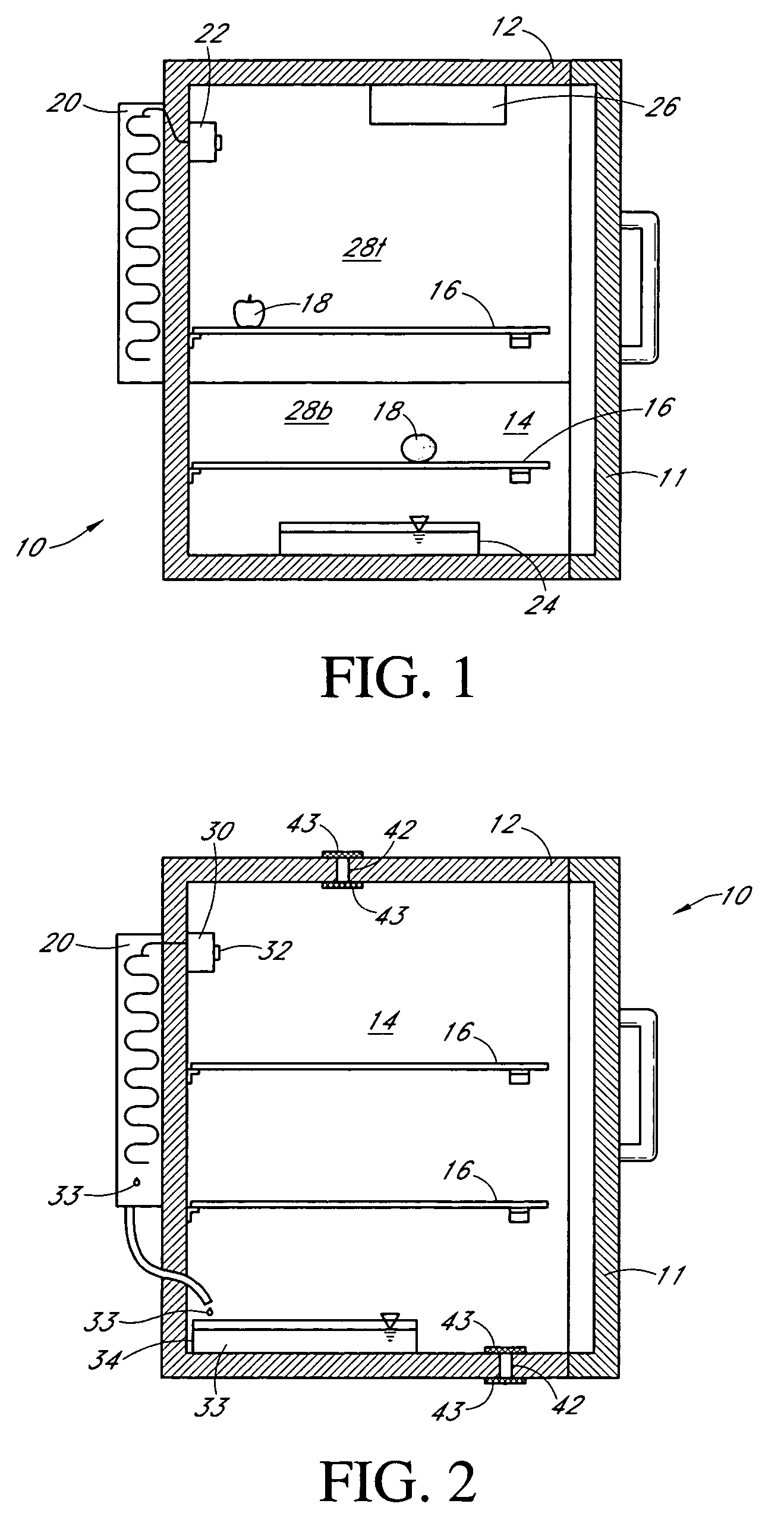

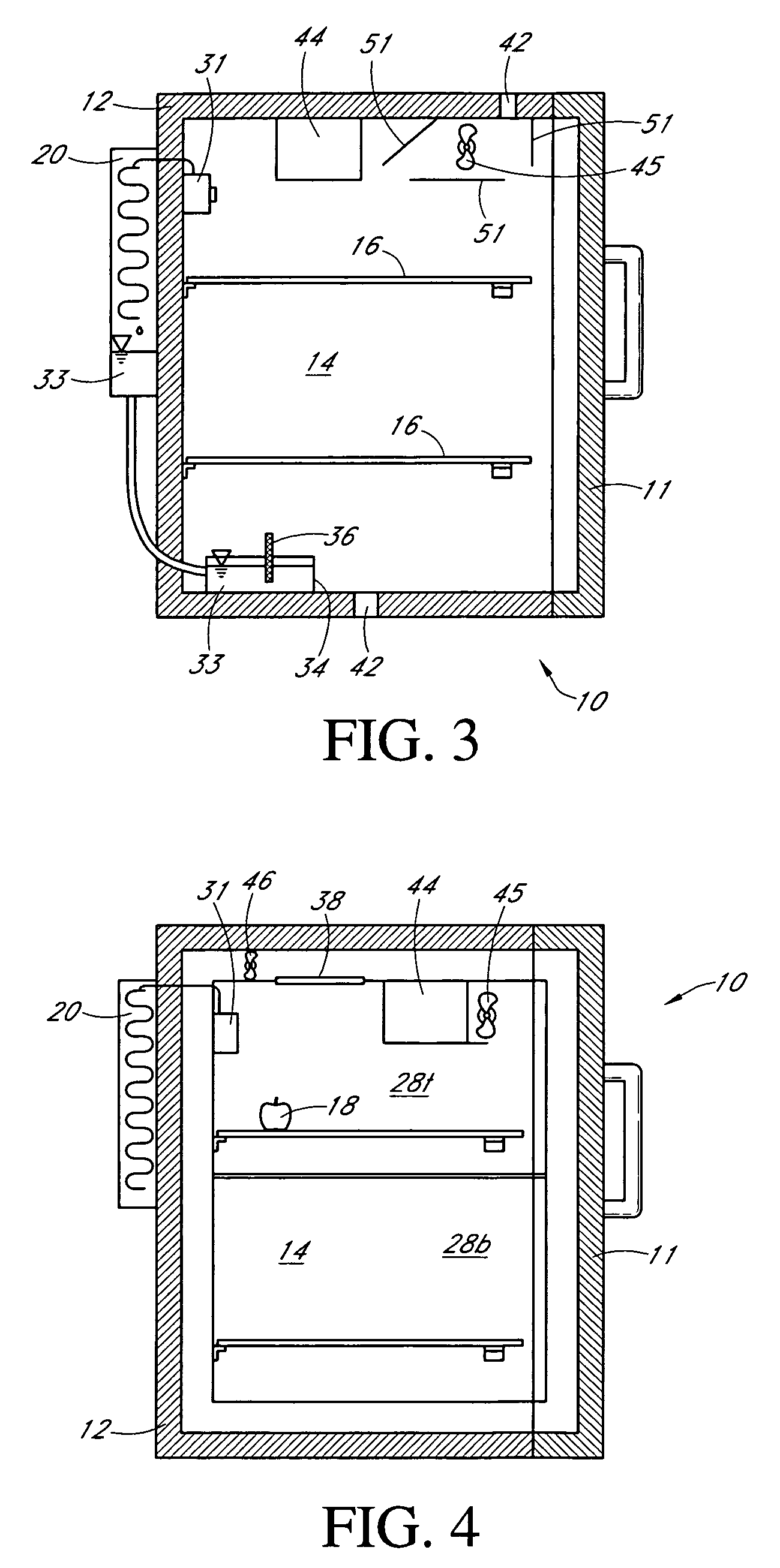

Produce preservation system

ActiveUS20050217282A1Prevent excessive dryingAccelerated ripeningFruit and vegetables preservationDomestic refrigeratorsRipeningEngineering

A refrigerated unit is well suited for storing fruits and vegetables. A household-sized refrigerated unit includes a storage space for retaining fruits and vegetables. The temperature within the storage space is controllable within a range of approximately 40-65 degrees Fahrenheit. The humidity level within the storage space is regulated to prevent unnecessary desiccation of the fruit and vegetables, and to prevent excessive condensation. The unit is provided with a mechanism for regulating the level of ethylene gas within the storage space to either retard or accelerate ripening, as desired.

Owner:MAYTAG

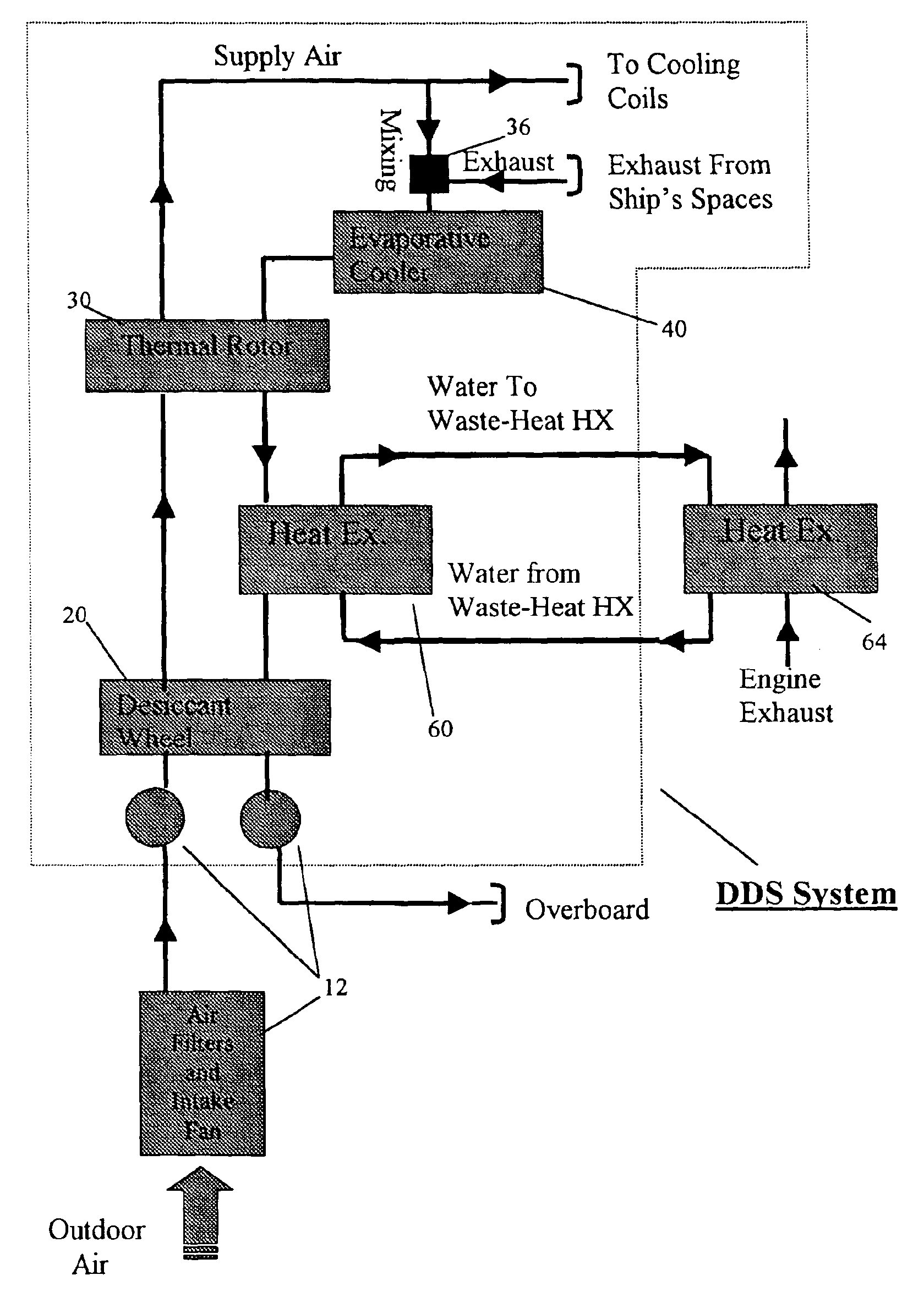

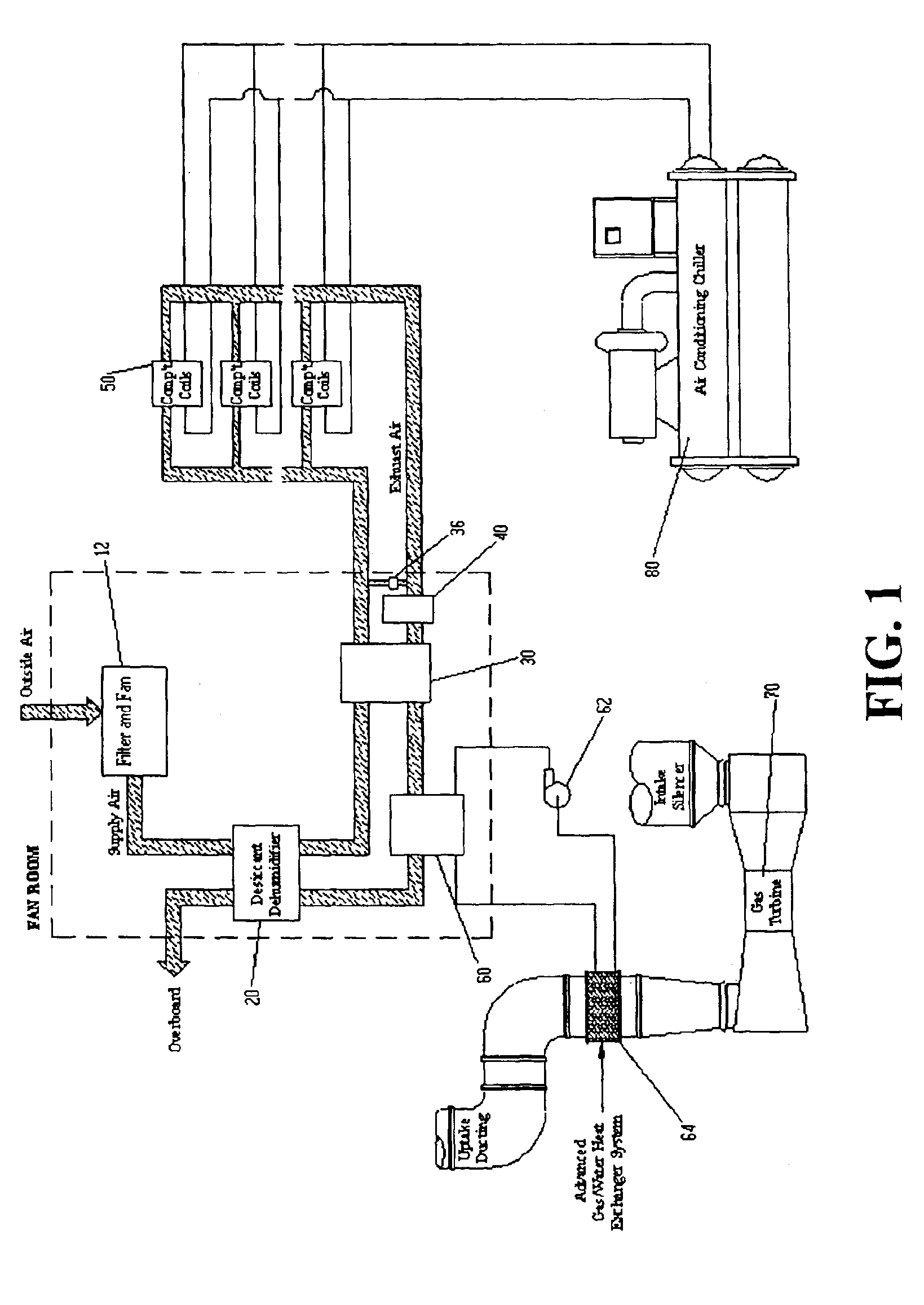

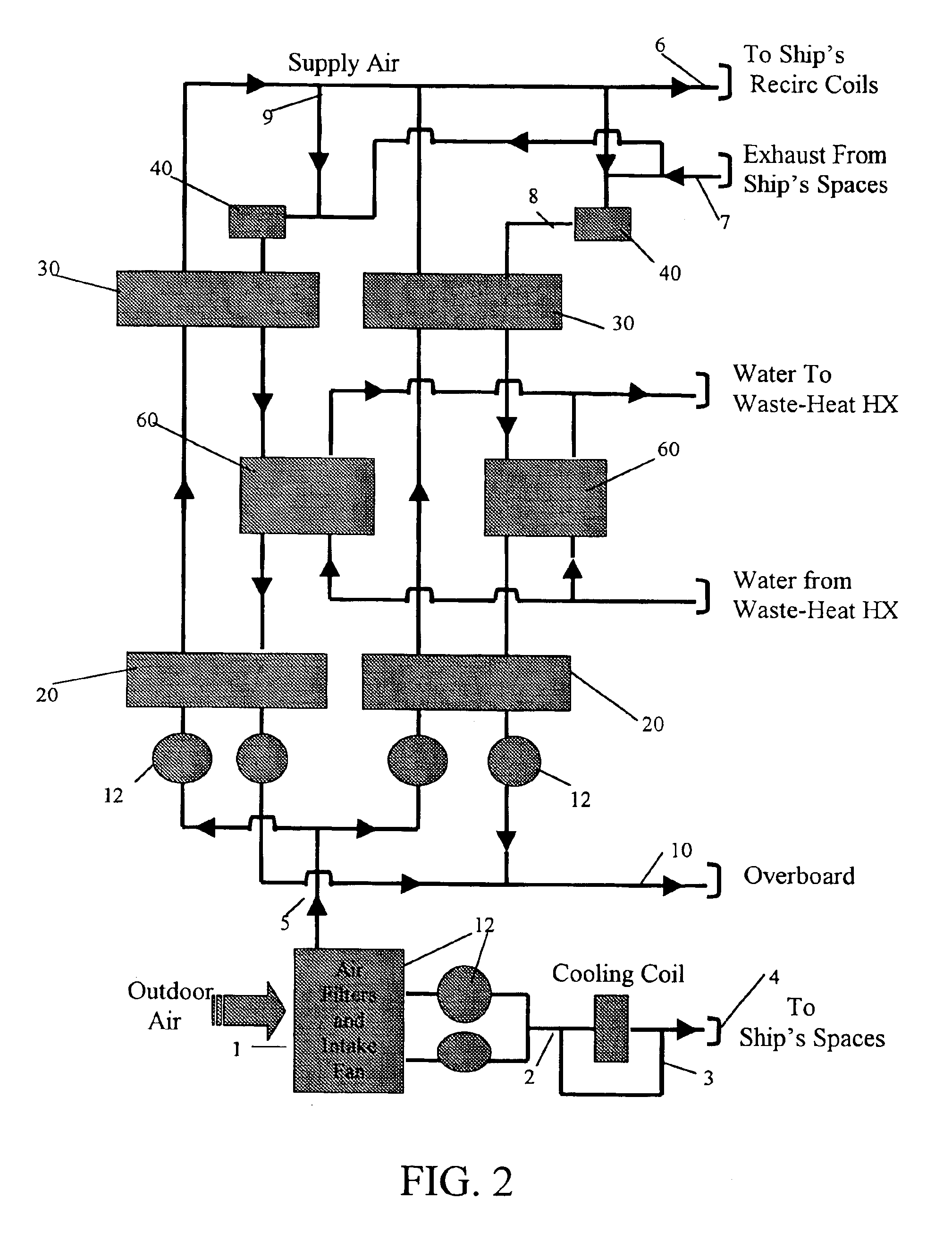

Dynamic desiccation cooling system for ships

InactiveUS6854279B1Air treatment detailsLighting and heating apparatusAir preheaterEvaporative cooler

The present invention describes methods and apparatus for controlling the humidity of air supplied to cooling coils on a gas turbine powered ship through a dynamic desiccation system. The system passes supply air through a desiccant wheel, which dries and concomitantly heats the supply air. This supply air stream is then passed through a rotatable thermal wheel, wherein heat is transferred from the dry supply air to an exhaust-air mixture, thereby conditioning the supply air for delivery and circulation to a plurality of cooling-coil units in a plurality of compartments. The exhaust air from the compartments is first mixed with some of the treated supply air to lower the absolute humidity to a value needed for effective regeneration of the desiccant wheel. An evaporative cooler then conditions the exhaust-air mixture for effective cooling of the supply air in the thermal rotor, which also serves as an air preheater for desiccant regeneration. The exhaust-air mixture is then heated to the desiccant regeneration temperature by passing the preheated exhaust air through a heat exchanger supplied with gas-turbine waste heat. After this heated exhaust-air mixture regenerates the desiccant wheel by fully drying out the desiccant on the wheel, it is expelled from the fan room.

Owner:CHIEF OF NAVAL RES OFFICE OF COUNSEL DEPT OF COUNSEL

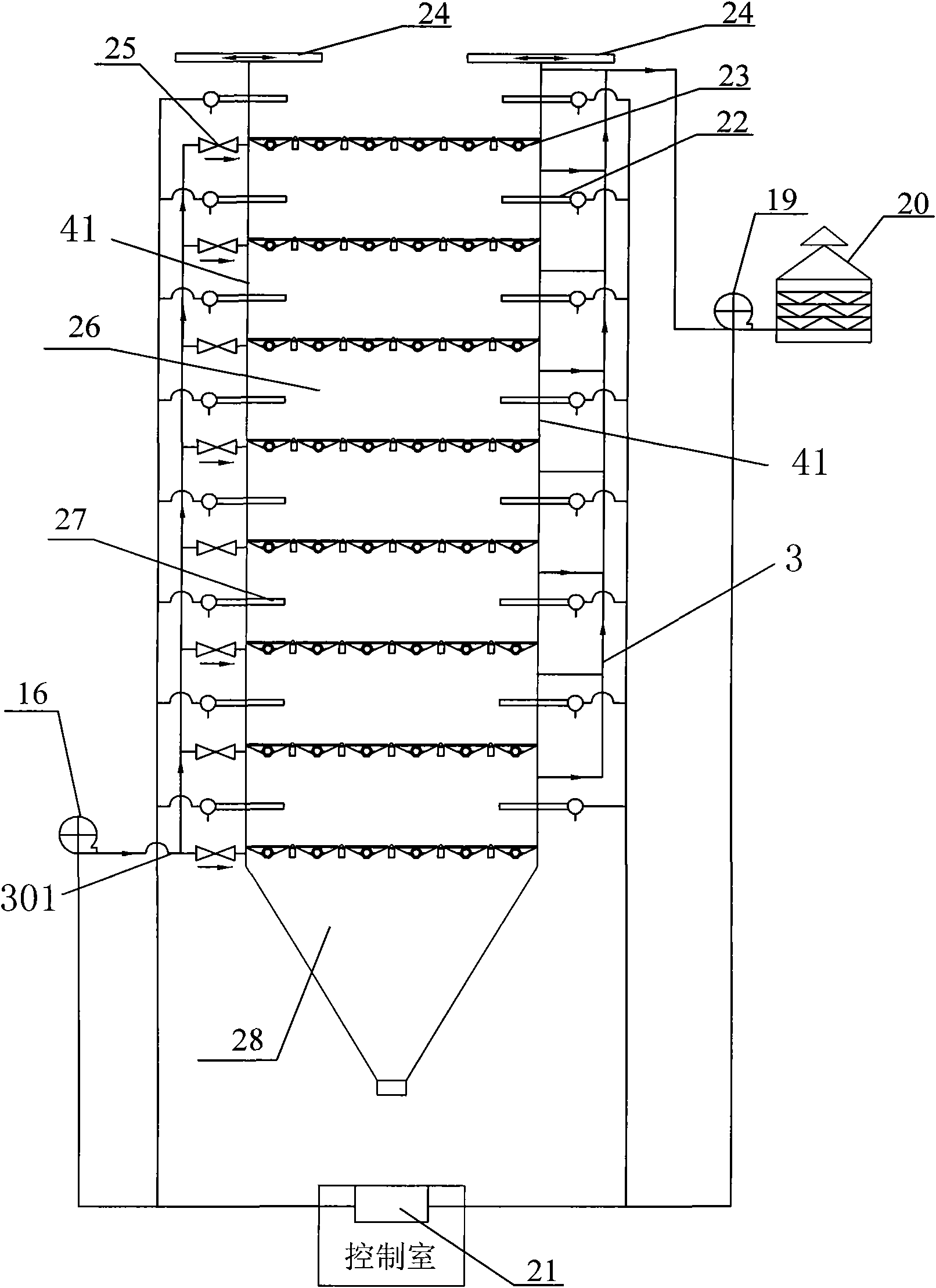

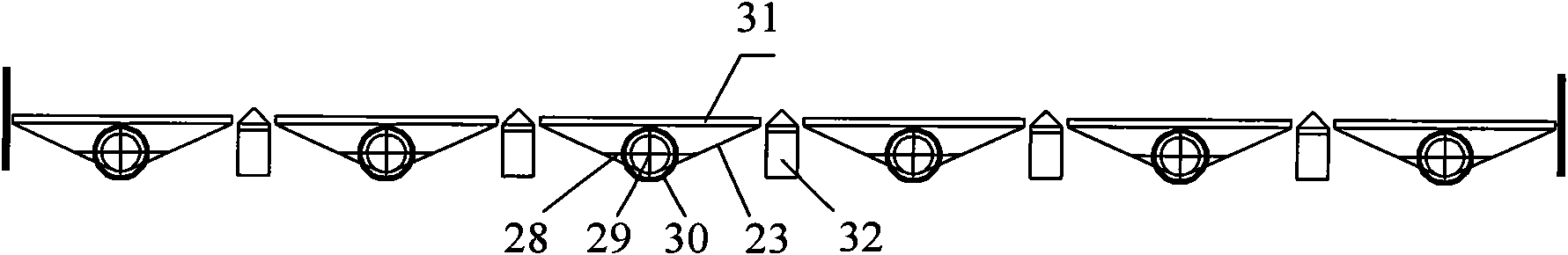

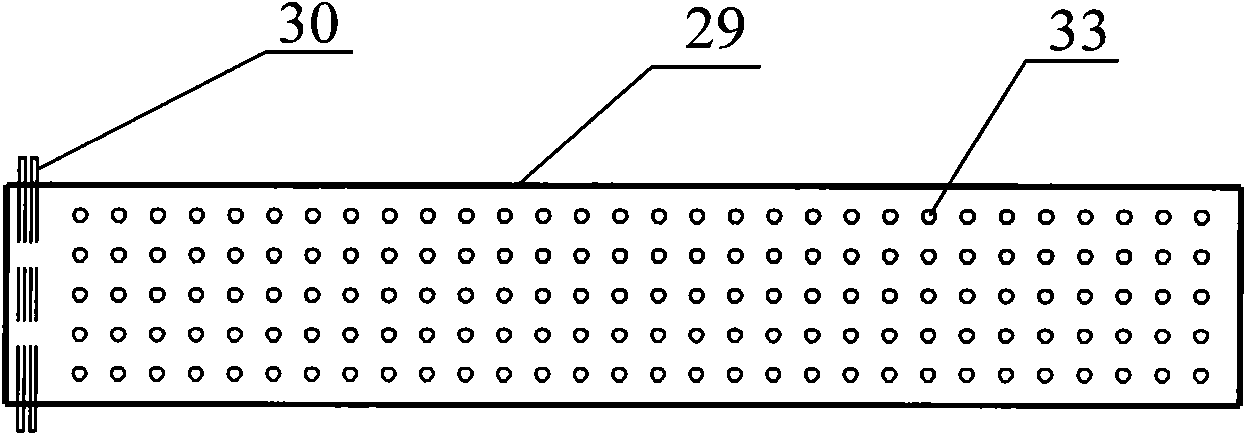

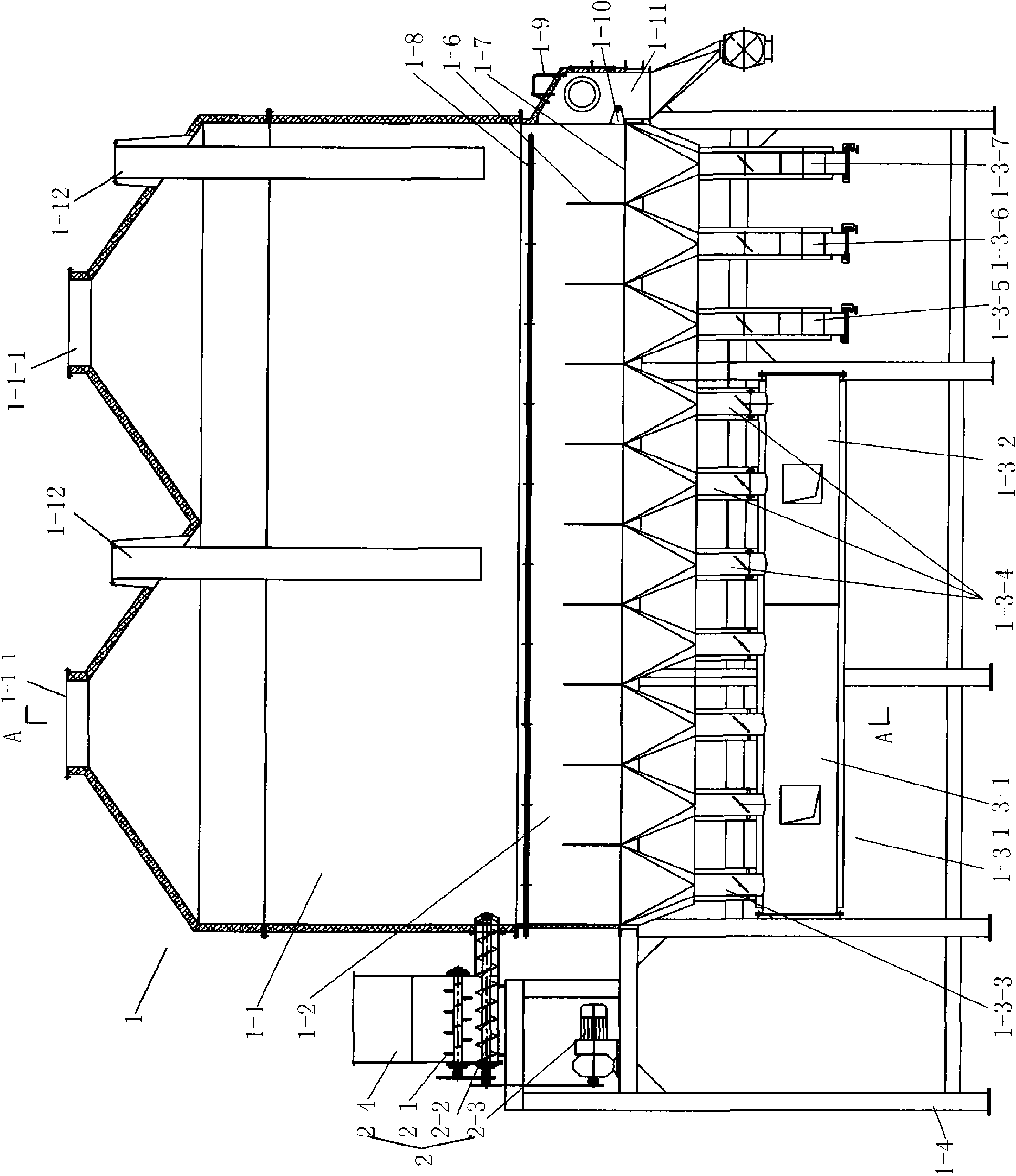

Circulating sludge biological fermentation tank, processing system and processing method

ActiveCN102153388AReduce wind pressureReduce air volumeBio-organic fraction processingSludge treatment by de-watering/drying/thickeningSludgeControl room

The invention discloses a circulating sludge biological fermentation tower which comprises a tower body, an openable tower cover, a storage tank and a plurality of rotatable fermentation devices, wherein the openable tower cover is arranged on the top of the tower body; the storage tank is arranged at the bottom of the tower body; the rotatable fermentation devices are arranged in the tower body in parallel; the fermentation devices divide an inner cavity of the tower body into a plurality of layers of fermentation bins along the axial direction; the lower part of each layer of fermentation device is provided with a ventilating oxygen supply pipeline communicated with a blower; the upper part of each layer of fermentation device is provided with an air outlet pipeline communicated with aninduced draft fan and a monitoring device; the monitoring device is controlled by a control room; and a mechanism for driving the fermentation devices and the tower cover to move, the blower and the induced draft fan are all controlled by the control room. The invention also discloses a circulating sludge biological processing system and a processing method. By the circulating sludge biological fermentation tower, the circulating sludge biological processing system and the processing method, industrial biological fermentation desiccation treatment can be continuously and stably carried out onsludge under the conditions of high efficiency and low energy consumption.

Owner:深圳市如茵生态环境建设有限公司

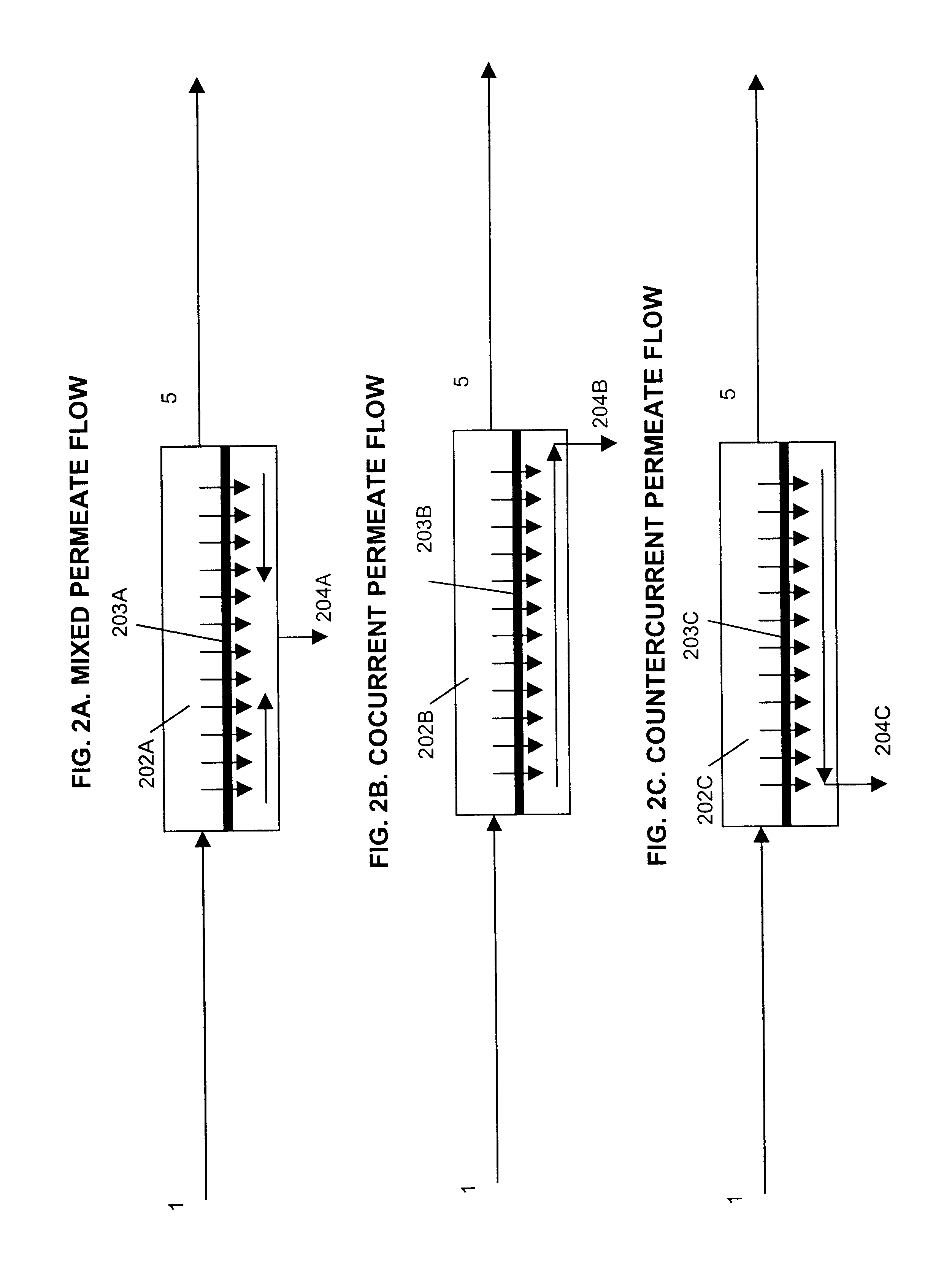

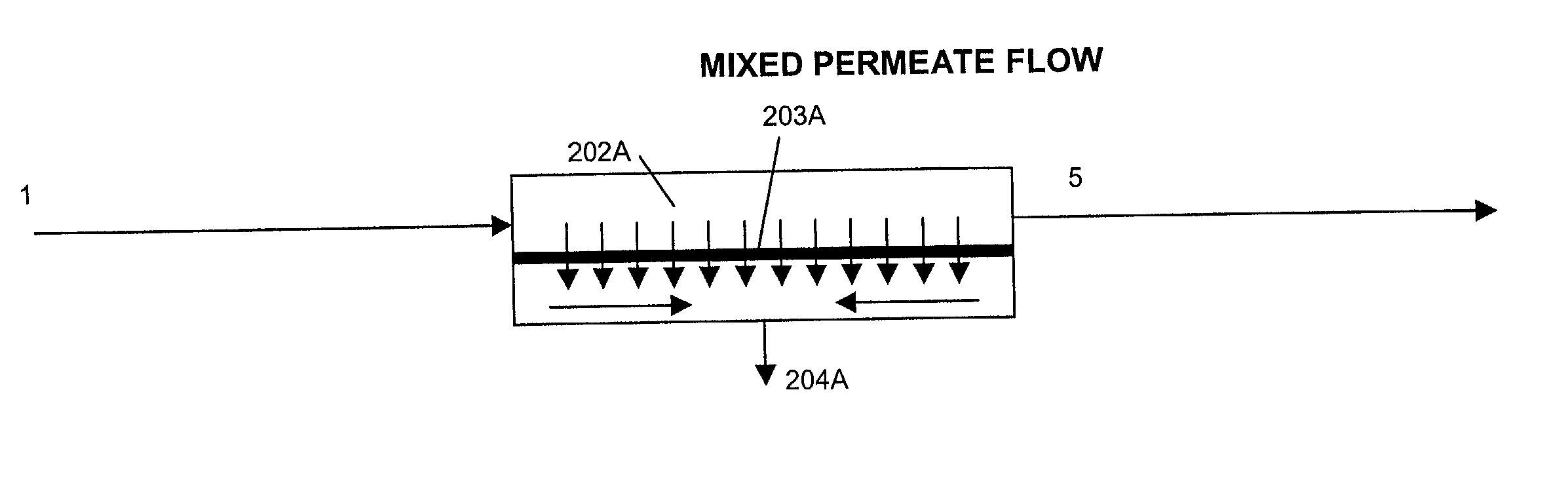

Membrane desiccation heat pump

InactiveUS20020096312A1Great flexibility and controlReduce in quantityAir-treating devicesHeat pumpsThermal energyProduct gas

There is provided a system for pumping thermal energy. The system includes (a) a membrane permeator for removing vapor from a process gas and for providing a vapor-depleted process gas, and (b) a gas-liquid contactor for adding vapor from a liquid to a vapor-depleted gas to produce a vapor-added process gas. The system transfers a quantity of thermal energy from the liquid to the vapor-added process gas, and is also capable of upgrading the thermal energy to a higher temperature. The system may be used for various heat pump applications including chilling and waste heat or low level heat recovery.

Owner:KORIN AMOS

Produce preservation system

ActiveUS7296422B2Prevent excessive dryingPrevent water condensationFruit and vegetables preservationDomestic refrigeratorsRipeningEngineering

A refrigerated unit is well suited for storing fruits and vegetables. A household-sized refrigerated unit includes a storage space for retaining fruits and vegetables. The temperature within the storage space is controllable within a range of approximately 40-65 degrees Fahrenheit. The humidity level within the storage space is regulated to prevent unnecessary desiccation of the fruit and vegetables, and to prevent excessive condensation. The unit is provided with a mechanism for regulating the level of ethylene gas within the storage space to either retard or accelerate ripening, as desired.

Owner:MAYTAG

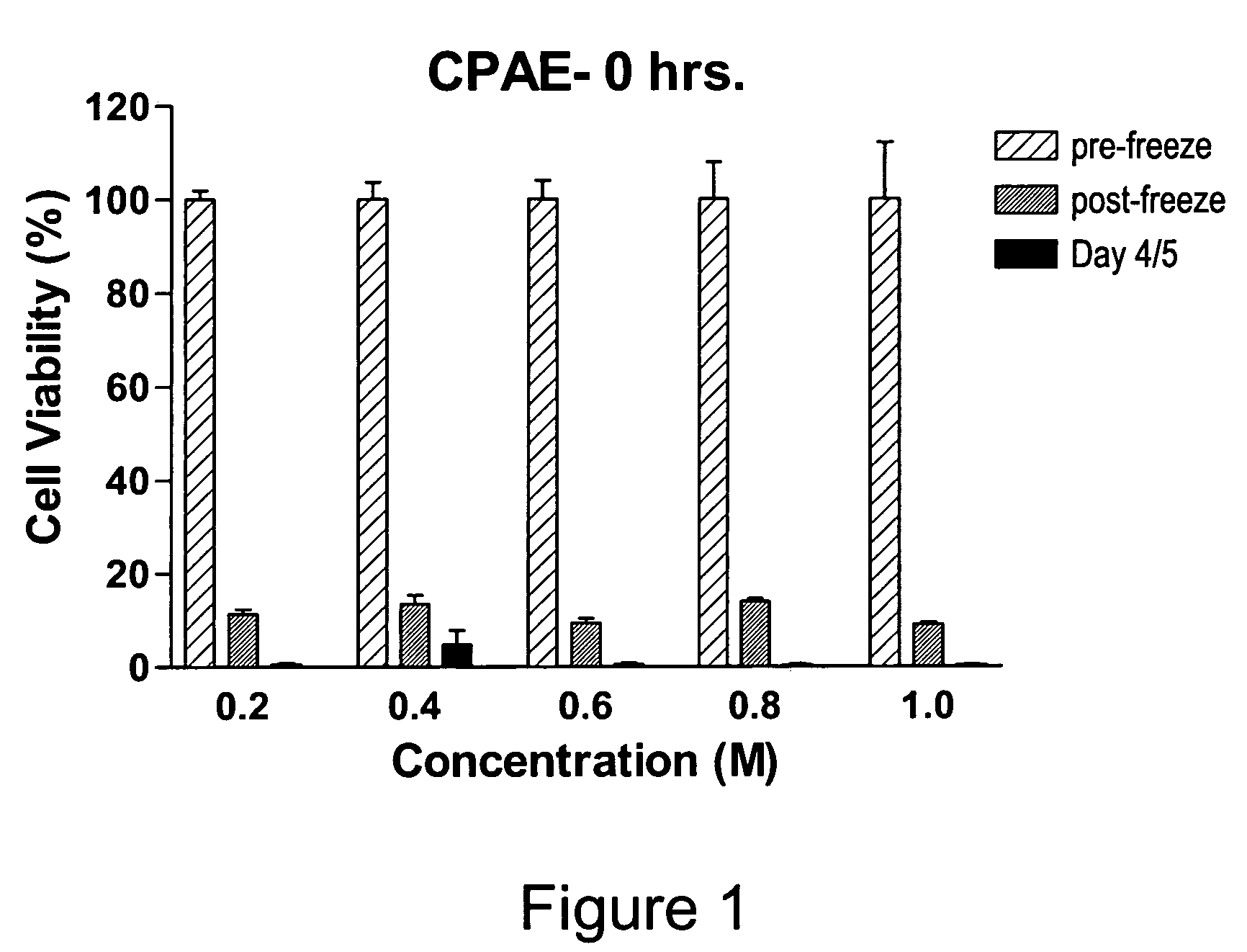

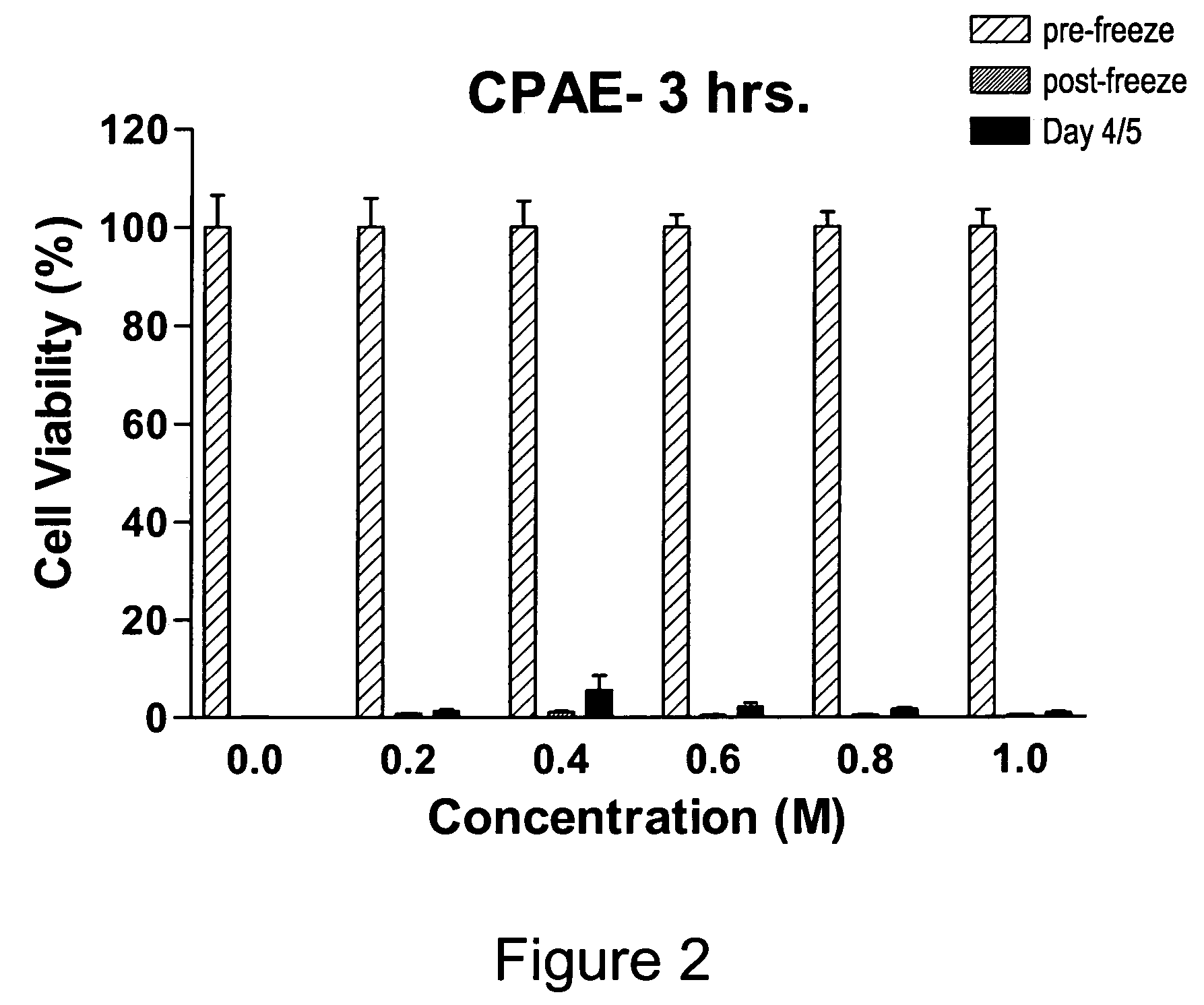

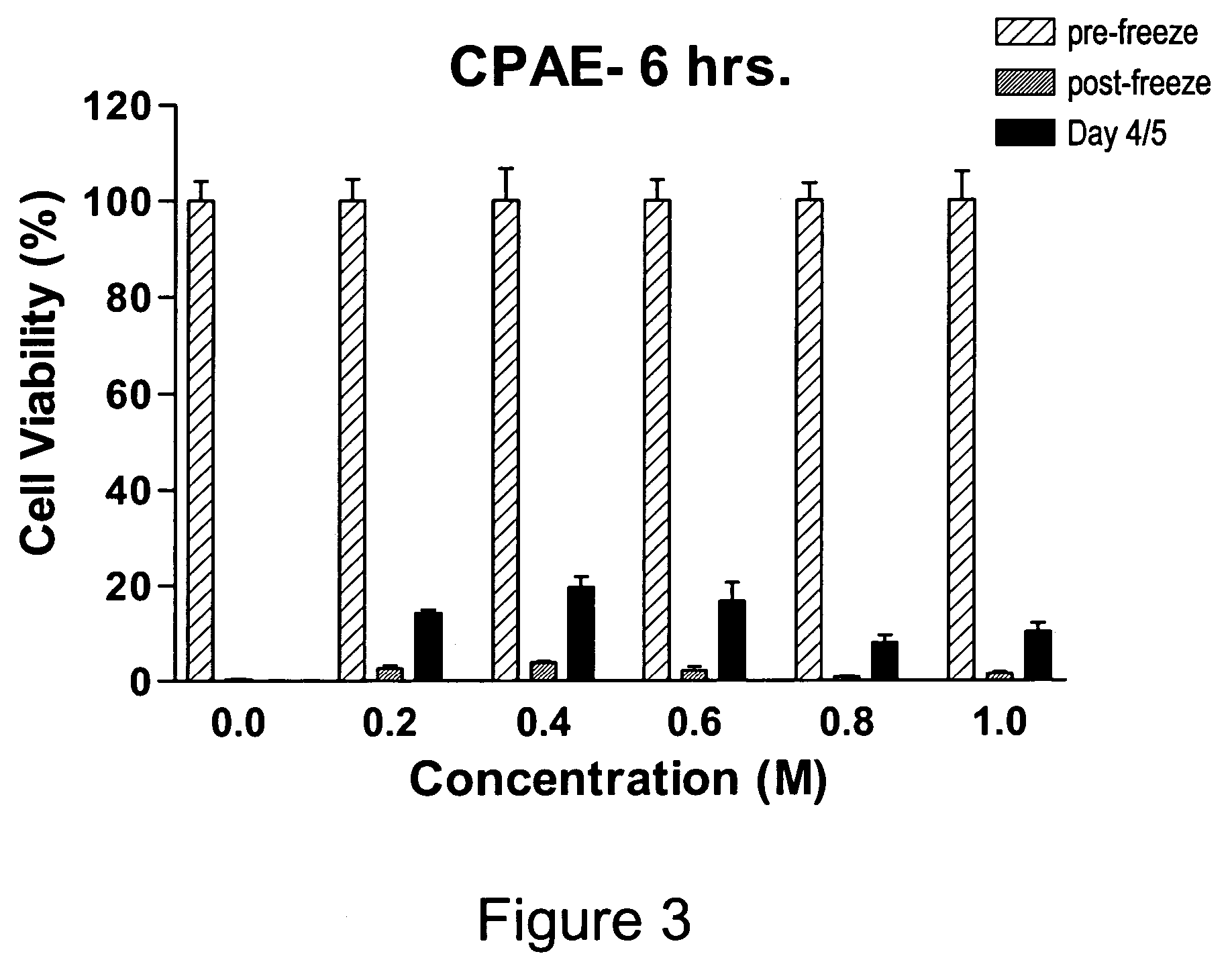

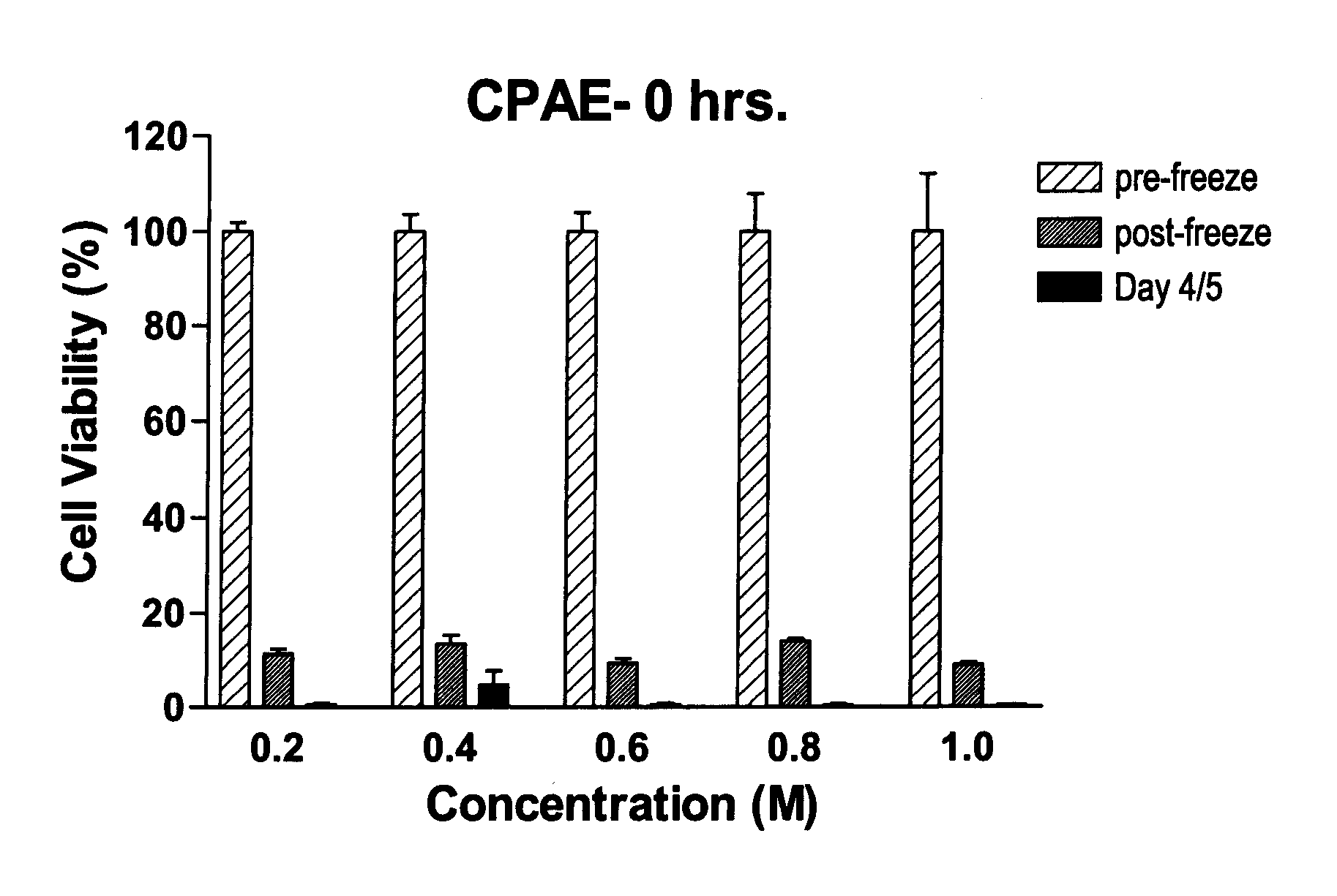

Method for treatment of cellular materials with sugars prior to preservation

ActiveUS7270946B2Enhance cell viabilityImprove abilitiesBiocideOrganic active ingredientsBiotechnologyVitrification

Living cellular material may be preserved by incubating the cellular material in a culture medium containing at least one sugar, particularly for at least three hours, and then subjecting the cellular material to a preservation protocol, such as freezing, vitrification, freeze-drying and desiccation.

Owner:LIFELINE SCI

Novel strain of lactobacillus crispatus

The invention provides a naturally occurring strain of Lactobacillus crispatus with advantageous characteristics. The strain colonizes mucosal surfaces, particularly vaginal surfaces. The strain is also capable of rapid growth in a number of conditions and is highly viable after desiccation. Moreover, the strain is capable of preventing and reducing pathogenic infection of vaginal mucosa.

Owner:OSEL

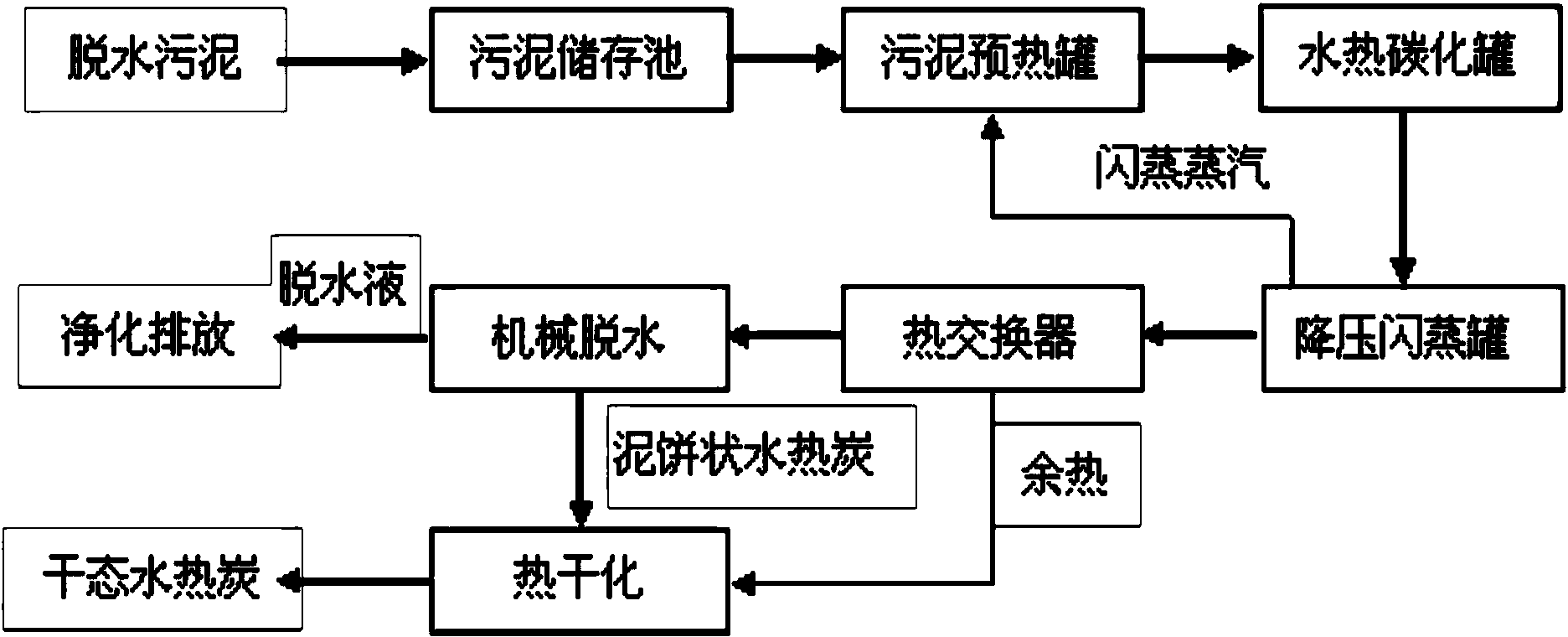

Sludge treatment method based on hydrothermal carbonization

InactiveCN103755124AEmission reductionIncrease organic carbon contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeToxic material

The invention relates to a treatment method of sludge generated by urban sewage treatment plant and industrial sludge and discloses a sludge treatment method based on hydrothermal carbonization. The sludge treatment method comprises four steps: sludge preheating treatment, hydrothermal carbonization, waste heat recovery and dehydration desiccation. By adopting the sludge treatment method, as the sludge is converted to hydrothermal carbon by adopting a hydrothermal carbonization technology, pathogenic microorganisms in the sludge are completely killed, most heavy metal pollutants in the sludge are dissolved out, and organic toxic substances in the sludge are effectively decomposed, so that the energy recovery utilization rate is high, and the sludge treatment method is clean, environment-friendly, rapid and effective and has high product additional values.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

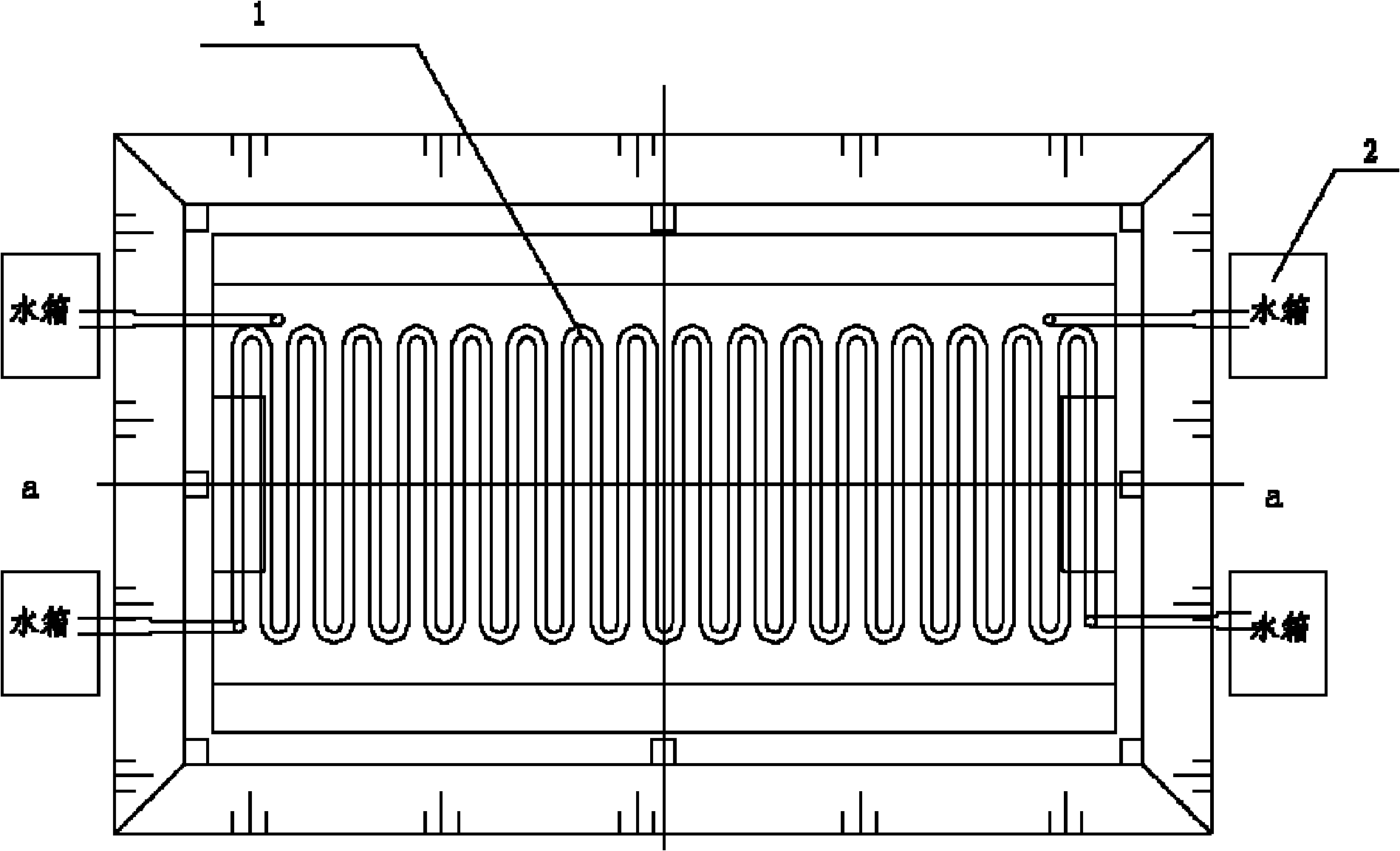

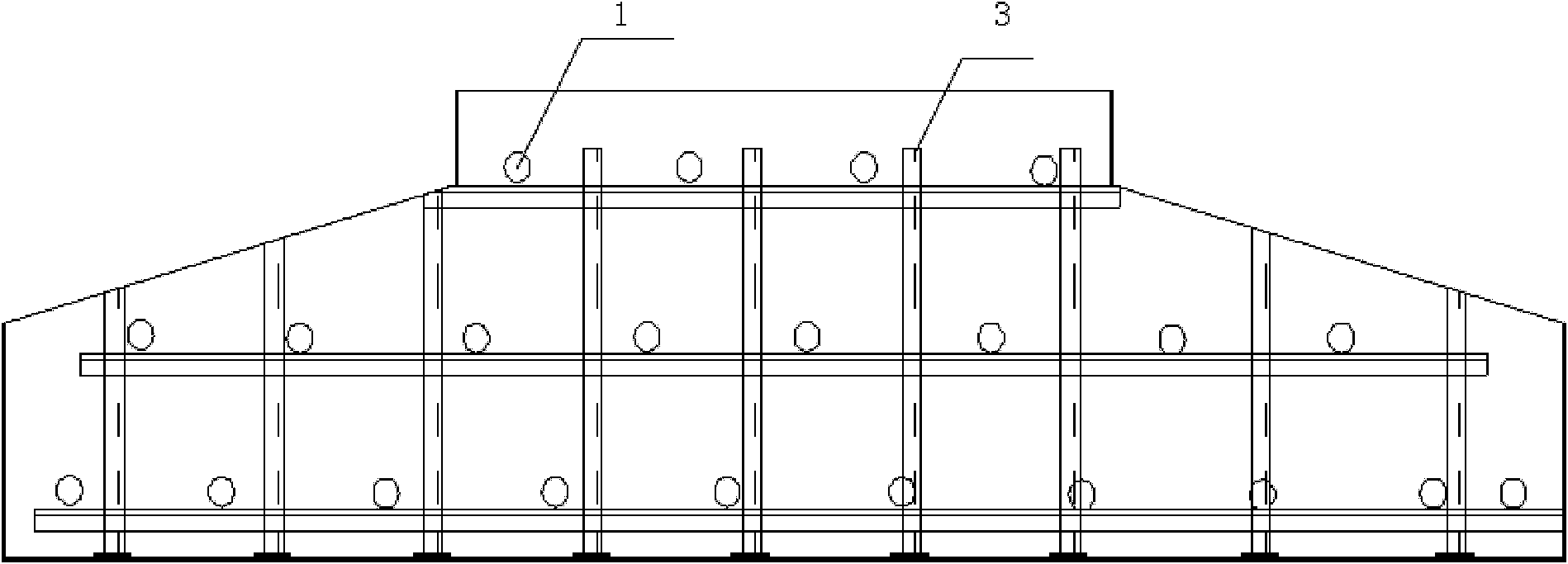

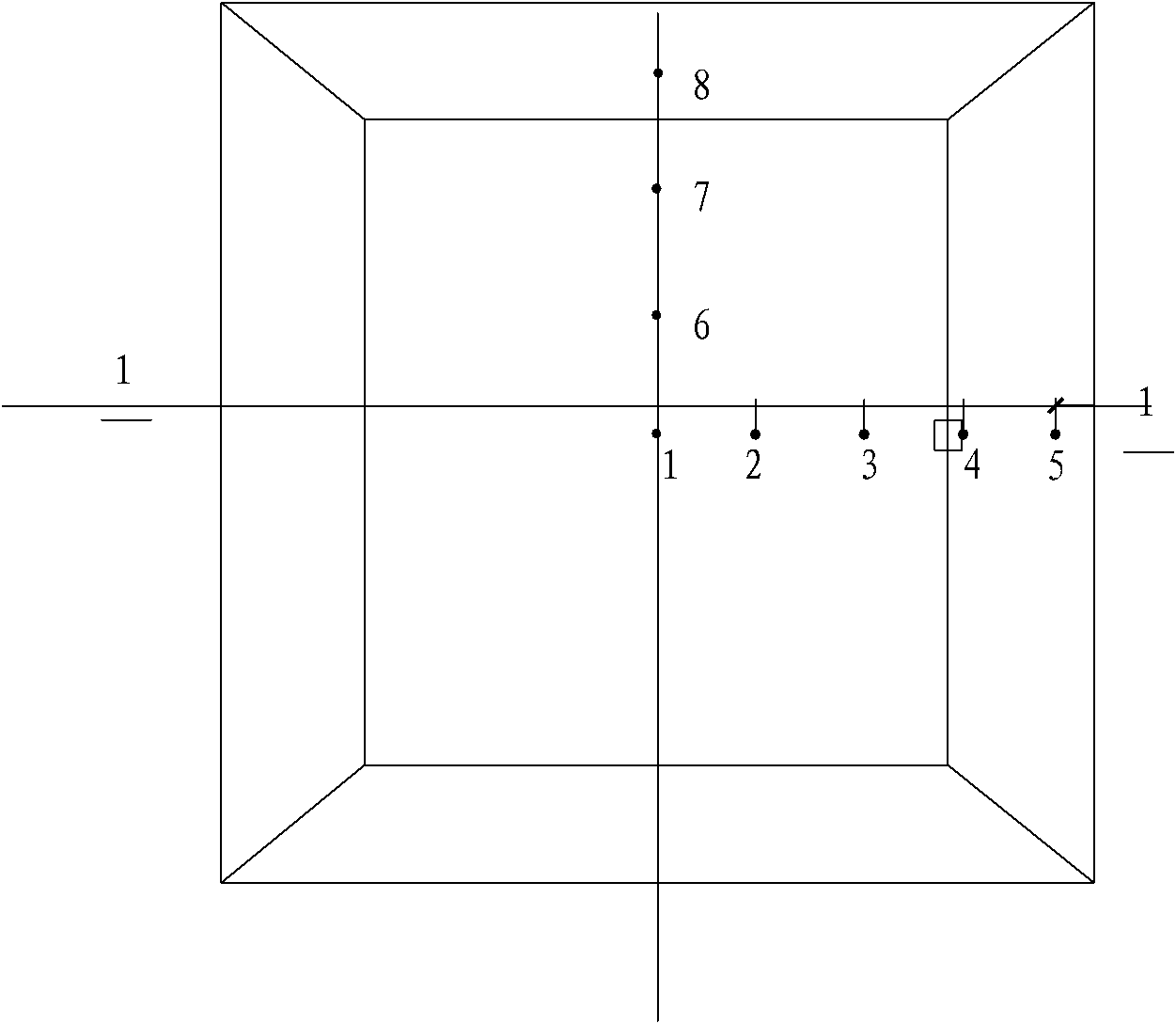

Mass concrete construction method of super-thick foundation

InactiveCN101962997AQuality improvementReduce dosageFoundation engineeringBuilding material handlingDesiccationRebar

The invention discloses a mass concrete construction method of a super-thick foundation, comprising the following steps of: (1) binding the steel bars on a base plate of the foundation, and fixing cooling water pipes on a steel bar fixing frame, wherein the cooling water pipes are evenly distributed at the inside layers of the foundation; (2) blending the concrete; (3) pouring the concrete; (4) carrying out press polishing to the concrete on the surface of the foundation before the final setting of the concrete of the foundation; and (5) maintaining the foundation. The invention adopts the anti-cracking concrete so as to reduce the cement content and decrease the generation of the heat of hydration; the embedding of the cooling water pipes can shorten the emission time of the heat in the concrete and decrease the maintenance time of the concrete structure; the press polishing is carried out to the surface of the concrete structure to ensure that the desiccation fissures are prevented; and maintaining the concrete with preserved temperature and humidity can improve the quality of the concrete. The invention has the effects of at least improving the work efficiency by 4 times, greatly saving the cost, improving the work efficiency and paving the way for the advanced construction of the next process.

Owner:TIANJIN 20 CONSTR

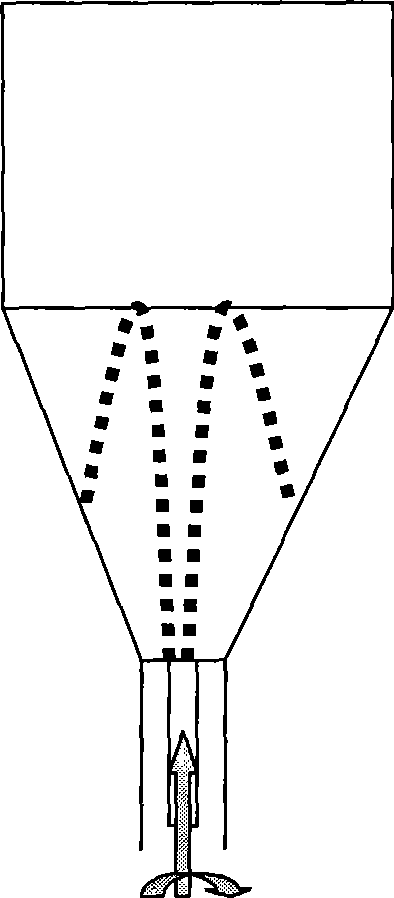

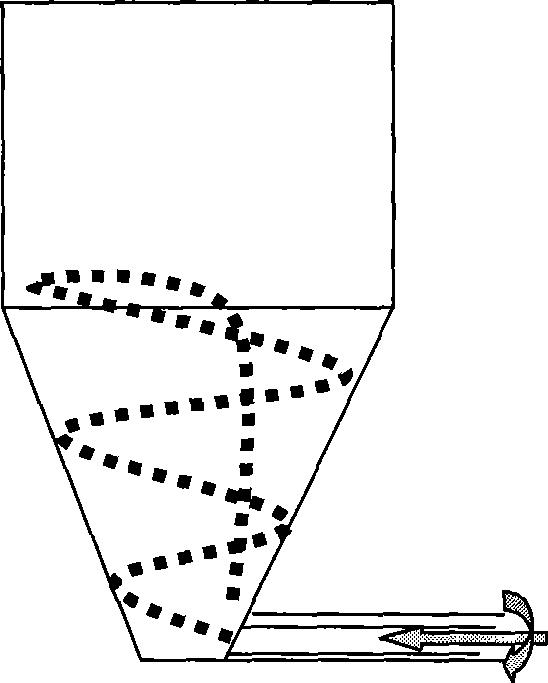

Sprouted auxiliary means for improving microwave desiccation homogeneity of granular garden stuff

InactiveCN101433233ASpray evenlyImprove uniformityFruits/vegetable preservation by dehydrationFood treatmentAir volumeAgricultural engineering

The invention discloses an auxiliary spouting method for improving the uniformity of microwave drying of granular fruits and vegetables, which belongs to the technical field of the processing of fruit and vegetable food. Pretreated fruits and vegetables are placed into a microwave spouting drying bed, the microwave power and the air intake heating temperature are preset, then the central air intake volume and the air intake angle of the spouting bed are adjusted to ensure that a dried material spouts in the spouting bed in different forms, the air intake pressure and the air intake angle are adjusted according to different drying stages of the material at the same time, and the microwave energy received by the material is more uniform than that of the prior fixation or fluidization mode; and the microwave adopts internal heating, so the moisture of the dried fruits and vegetables is effectively and quickly evaporated to achieve the aim of uniform drying. Through the auxiliary spouting method, the material is uniformly heated in a microwave field, the moisture is evaporated quickly, the drying time is greatly shortened, the prior color and luster, shape and nutrient substances of the dried fruits and vegetables can be furthest retained, and the dried fruits and vegetables have porous structures and good rehydration property, thereby obtaining a high-quality dehydrated fruit and vegetable product.

Owner:JIANGNAN UNIV +1

Method for preparing mulberry leaf tea

The invention discloses a method for preparing mulberry leaf tea. The method comprises the following processing steps that: 1, mulberry leaf picking; 2, air-drying and withering; 3, rotating; 4, desiccating at high temperature; 5, spreading for cooling; 6, secondary desiccation at high temperature; 7, rolling; 8, initial drying; 9, winnowing; 10, chopping; and 11, baking. The invention provides the method for preparing mulberry leaf tea without physical and chemical pollution of plant diseases and insect pests, mud, faecal pollution of birds and insects, pesticide pollution, air pollution and the like.

Owner:GUANGDONG XINDA CHRYSALIS SILK

Sludge desiccation system

ActiveCN102358678AAdjustable temperatureImprove stabilitySludge treatment by de-watering/drying/thickeningTemperature controlSludge

The invention mainly aims to provide a sludge desiccation system. A technical scheme is as below: a sludge desiccation system comprises a drying chamber communicating with a hot-air pipeline and an auxiliary heat source pipeline; the drying chamber comprises a wet sludge inlet, a dry sludge outlet, a moisture exhaust and a sludge conveyor belt inside the drying chamber; the hot-air pipeline is communicating with a solar heat collector, which is communicating with a blower fan through an air channel; and the auxiliary heat source pipeline is provided with a temperature control valve. The desiccation system not only utilizes solar energy and heat tail gas or steam discharged by a factory effectively to enhance desiccation efficiency and desiccation effect, but also enhances operating stability of the desiccation system.

Owner:安徽省通源环境节能股份有限公司

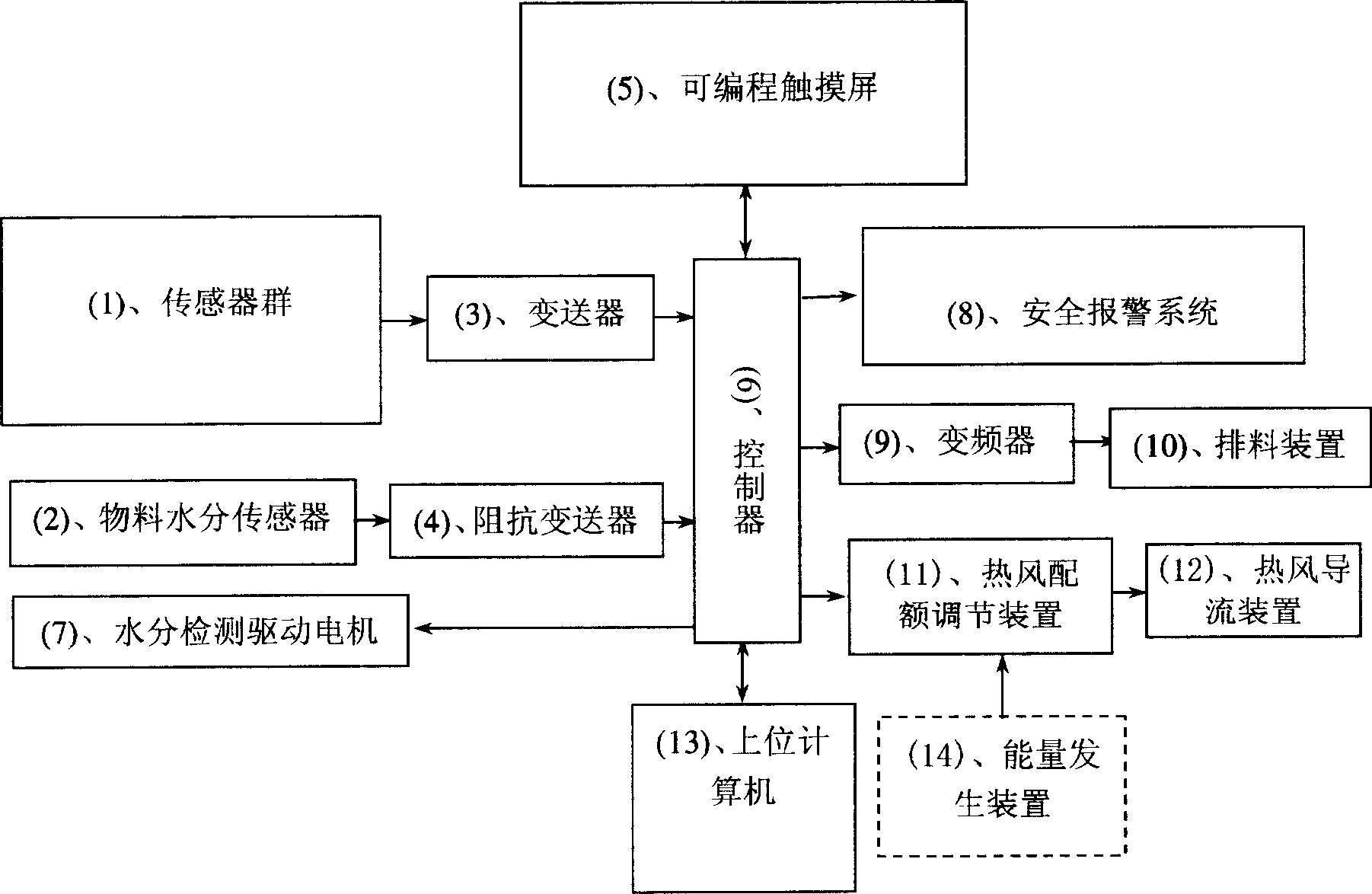

Adaptive control system of hot air drying

InactiveCN1904533AReduce consumptionHigh control precisionDrying solid materialsCommunication interfaceFrequency changer

The invention relates to a kind of hot-wind desiccation controlling system. It includes a sensor group(1), a water sensor of the material(2), a transducer(3), a impedance transducer(4), a controller(6),a converter(9),a blowdown device(10) and a superior computer(13). The output signal of the sensor group(1) and the water sensor of the material(2) connect with the input end of the controller(6) individually through the transducer(3) and the impedance transducer(4). The input and the output interface of the controller (6) and the output and the input interface of the superior computer (13) realize the two-direction communication through the communication interface. The output interface of the controller (6) connects with the blowdown device (10) of the hot-wind desiccation chamber through the converter (9). The input quantity and the change rule of the system is not predefined but determined real time by the superior computer according to the online measuring value. It can save the energy loss, increase the desiccation efficiency and security and improve the hot-wind desiccation quality farthest as the character of the material in desiccation.

Owner:SOUTH CHINA AGRI UNIV

Treatment method and device for riverway and lake heavy metal pollution bottom sludge

ActiveCN102745872AAvoid cloggingReduce disposal costsSludge treatment by de-watering/drying/thickeningSludgeCrushed stone

The invention provides treatment method and device for riverway and lake heavy metal pollution bottom sludge. The treatment method comprises the following steps: removing heavy metal pollution bottom sludge from a riverway or a lake through cutter-suction environmental dredging, transporting the heavy metal pollution bottom sludge to the shoreside, directly sieving and dehydrating the heavy metalpollution bottom sludge, and dividing the removed heavy metal pollution bottom sludge into gravels, coarse sands, fine sands, clay particles and dehydration solution; adding a heavy metal adsorption agent in the dehydration solution, removing heavy metals through settlement, discharging supernate into water, and sending precipitate after dehydration to a dangerous solid waste landfill to be treated; and respectively carrying out subsequent treatment on solid with different particle sizes. The treatment device comprises a sieving cylinder body and a sludge dehydrator, wherein the bottom surface of the sieving cylinder body is communicated with a feeding hole of the sludge dehydrator, and a gravel sieve net, a coarse sand sieve net and a fine sand sieve net are sequentially arranged in the sieving cylinder body from top to bottom. With the adoption of the treatment method and device, the riverway and lake heavy metal pollution bottom sludge collected by cutter-suction dredging is directly classified and treated without desiccation, the treatment period is short, and the cost is low.

Owner:山东瑞密迪环保科技有限公司

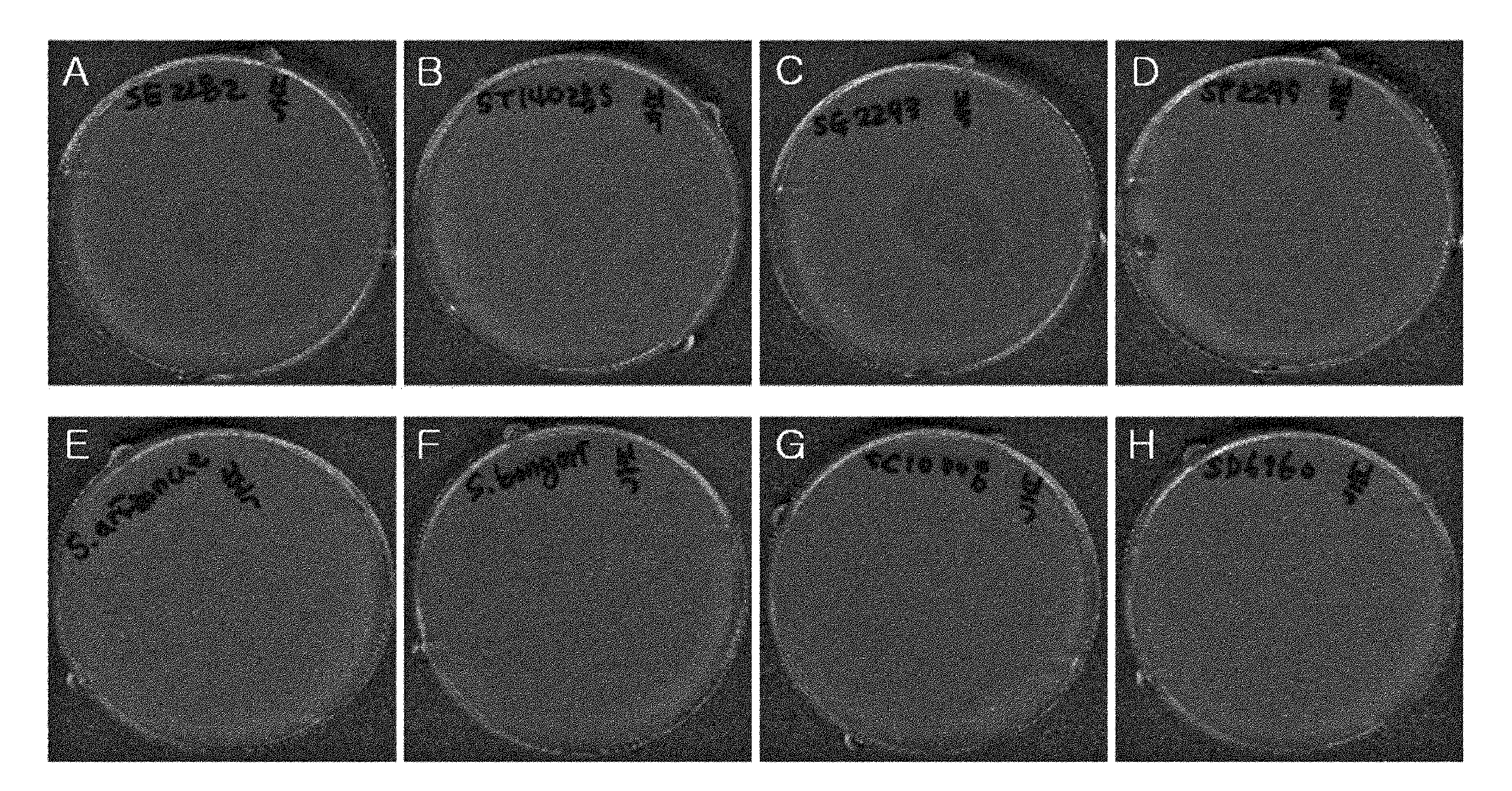

Novel bacteriophage and antibacterial composition comprising the same

ActiveUS20110052542A1Effective preventionEffective treatmentAntibacterial agentsBiocideBacteroidesFood poisoning

Disclosed herein is a novel bacteriophage which has specific bactericidal activity against one or more Salmonella bacteria selected from the group consisting of Salmonella Enteritidis, Salmonella Typhimurium, Salmonella Gallinarum, and Salmonella Pullorum without affecting beneficial bacteria, in addition to showing excellent tolerance to acid, heat and desiccation. The novel bacteriophage can be widely used as an active ingredient for therapeutic agents, animal feeds or drinking water, cleaners and sanitizers for preventing and treating the infectious diseases caused by Salmonella Enteritidis, Salmonella Typhimurium, Salmonella Gallinarum or Salmonella Pullorum including salmonellosis, Salmonella food poisoning, Fowl Typhoid, and Pullorum disease or for controlling the salmonella bacteria.

Owner:CJ CHEILJEDANG CORP

Sludge desiccation burning integral treatment method and device

InactiveCN101210678AAchieve burnoutSave burnoutSludge treatment by thermal conditioningDrying solid materials with heatAir preheaterFluidized bed

A method of integrated treatment of sludge drying and incineration is provided, which comprises the follow steps of: feeding sludge into a rotary-type sludge dryer, introducing a part of moderate-temperature fume inside a fluidized bed incinerator into the rotary-type sludge dryer to heat and evaporate the water in the sludge, feeding the obtained semi-dried sludge into the fluidized bed incinerator; introducing the other part of moderate-temperature fume into an air pre-heater, heating the fist-stage and second-stage air of the fluidized bed incinerator, transferring parts of ash and bed media exhausted from the fluidized bed incinerator to the rotary-type sludge dryer, and mixing with the sludge inside the rotary-type sludge dryer. A device for implementing the method comprises a storage feed device, the rotary-type sludge dryer and the fluidized bed incinerator. The invention realizes the integrated treatment of drying and incineration; omits the intermediate links between the drying and incineration links, such as sludge cooling, sludge storage, sludge transportation and heat medium drying; simplifies the system; reduces the occupied area; and reduces the investment and cost.

Owner:上海环保工程成套有限公司 +1

Deposition chamber desiccation systems and methods of use thereof

InactiveUS20060272174A1Rapidly and inexpensively dryDesiccates the chamber much more rapidlyDrying solid materials with heatVacuum evaporation coatingEngineeringSputter deposition

The present invention provides a system and method for removing contaminating moisture from a deposition chamber prior to use. Dry air, preferably hot dry air, is blown into the deposition chamber where it absorbs and removes moisture. This is done by connecting a desiccation system including a blower and a dryer to the deposition chamber. The deposition chamber is also provided with a vacuum source; this may be connected to the deposition chamber using the same line as that used for the desiccation source, or may be connected through a separate line. The dry air may re-circulate through the chamber during this flushing method, or the dry air may flow through the deposition chamber continuously. A heat exchanger may also be provided to efficiently reuse hot air used to recharge the desiccation system. The desiccation system and method are particularly suited for decontaminating a magnetron sputtering deposition chamber.

Owner:CARDINAL CG

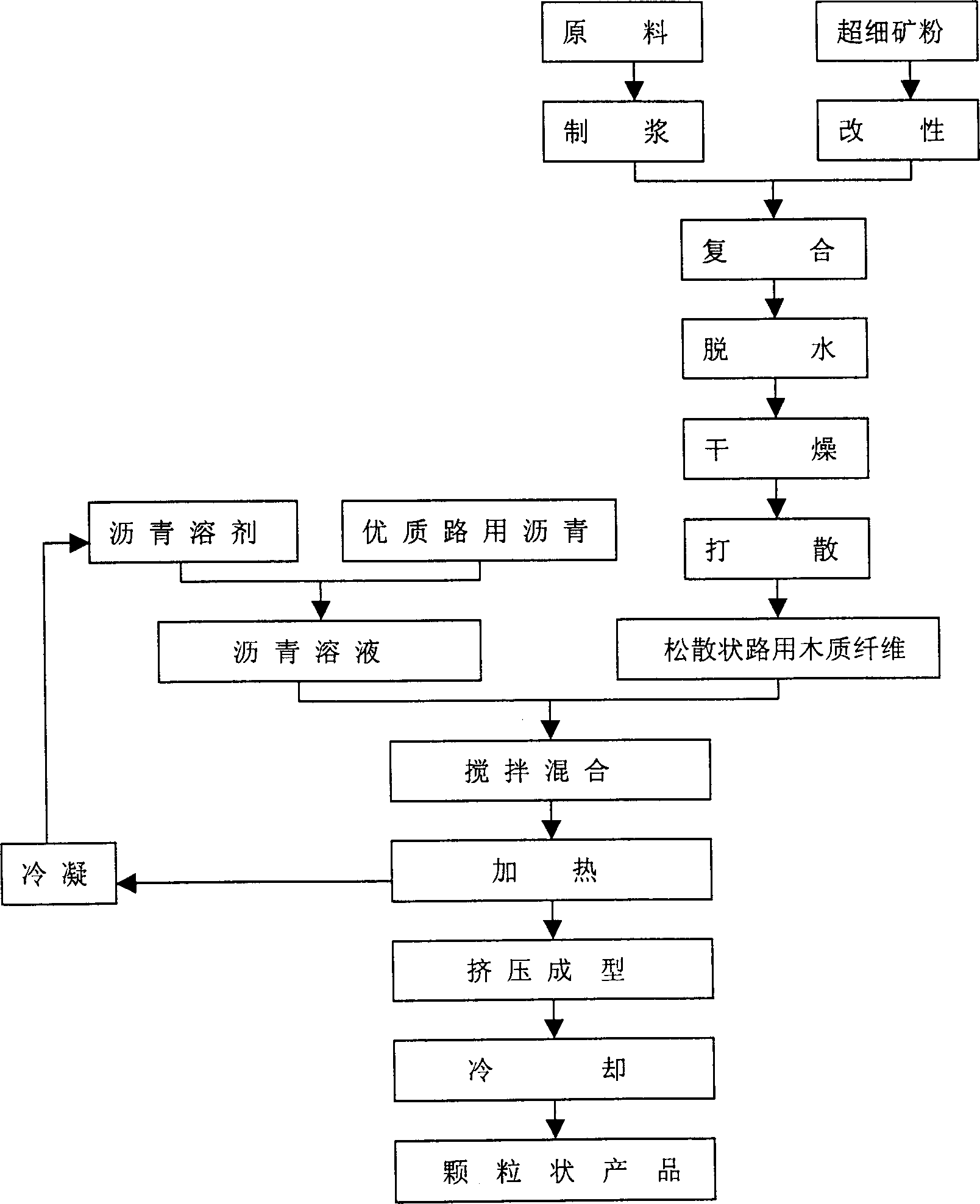

Method for preparing lignocellulose for road

InactiveCN1405372AHigh oil absorption valueLarge specific surface areaTextile disintegration and recoveryFibre disintegrationFiberRoad surface

Owner:NORTHEASTERN UNIV

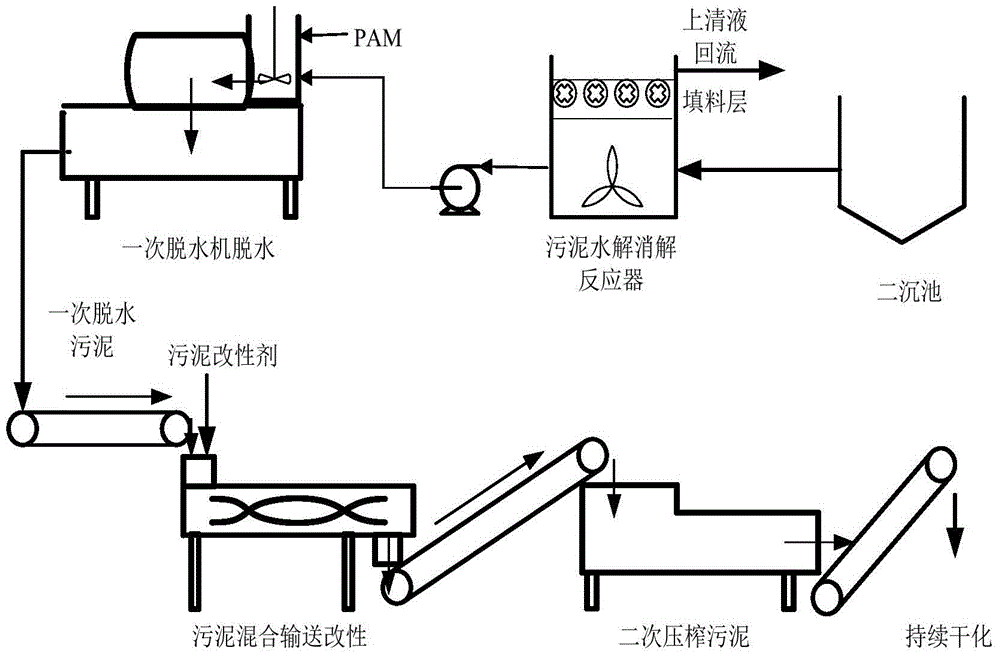

Sludge reduction and desiccation combination method

ActiveCN103951146AAchieve the purpose of separationSolve problemsSludge treatment by de-watering/drying/thickeningSludge processingSludgeResource utilization

The invention relates to a sludge reduction and desiccation combination method. Sludge with a moisture content of 99% in a secondary sedimentation tank is inputted into a sludge hydrolysis digestion reactor internally provided with a filler layer, in the reaction conditions of full stirring, sludge floc cell wall is broken for sludge liquefaction to realize sludge and water separation, an acidizing fluid discharging from the top of the filler layer flows back to flooding water of a sewage plant for carbon source recycling, the sludge reduction rate can reach 20-60%; after first dehydration, the reduced sludge is modified for cell wall disruption, and then is dehydrated by secondary pressing, and finally the moisture content of the sludge is reduced to 20%-30% by continuous desiccation reaction. According to the method, the sludge output can be reduced from the source, the sludge desiccation treatment cost can be saved, the sludge after desiccation treatment is not easy to rot and is good in stabilizing effect, and the method can be widely used in the treatment and disposal of residual sludge in the sewage plant, and finally realizes the reduction and resource utilization of the residual sludge.

Owner:SHANGHAI SHENYAO ENVIRONMENTAL PROTECTION ENG +1

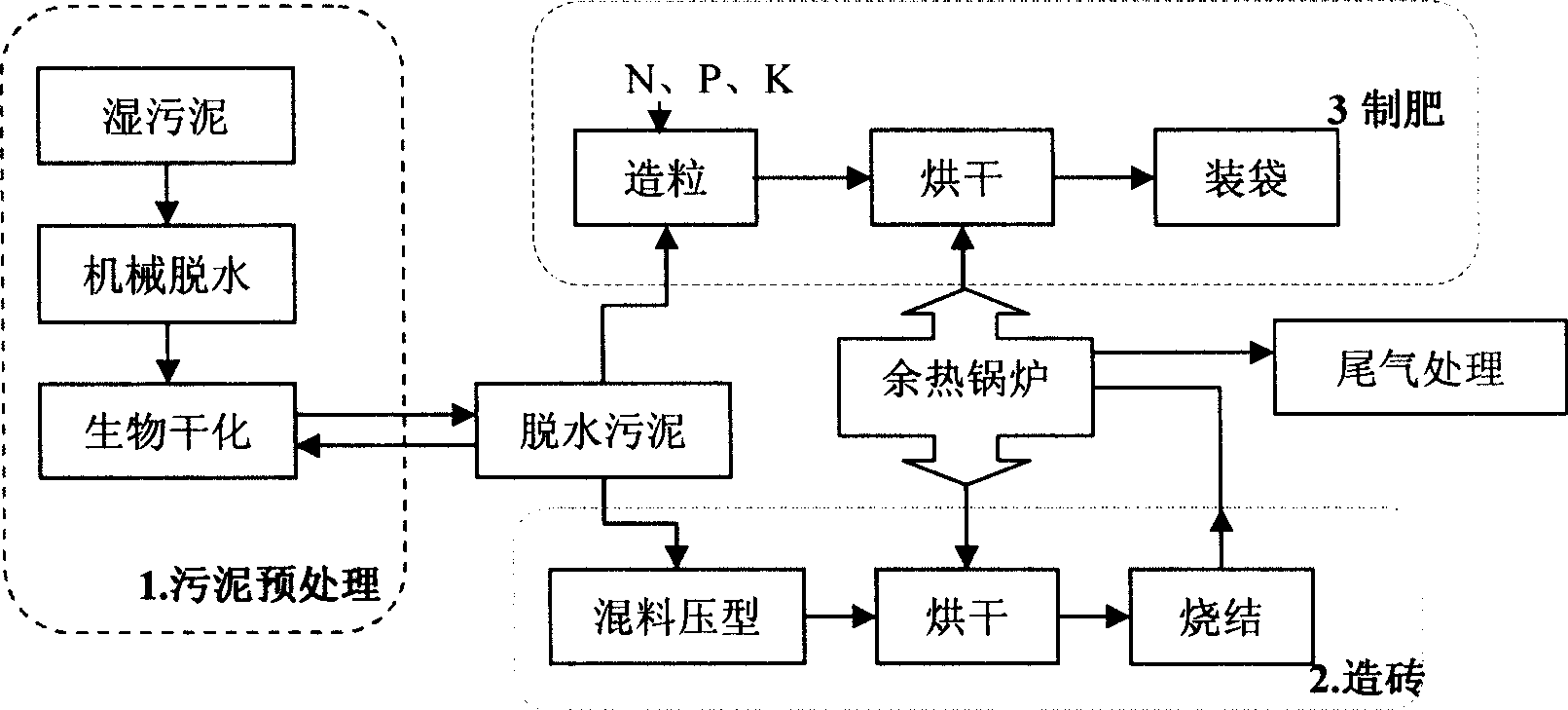

Mechanical deep dehydration, biological desiccation and reclamation combined treatment process for sewage sludge

InactiveCN101428955ASignificant reductionSave storage areaSludge treatment by de-watering/drying/thickeningClimate change adaptationBrickResource utilization

The invention relates to a treatment technology for combination of mechanical deep dehydration of sludge, biological drying and resource utilization, which consists of three parts of mechanical deep dehydration of the sludge, biological drying and resource utilization. The treatment technology comprises the following steps: firstly, dirty and wet sludge is subjected to dehydration by the mechanical method through a diaphragm high-pressure plate and frame filter press, and the water content is reduced to less than 65 percent; secondly, the sludge which is subjected to mechanical dehydration is dried by using biological energy, and the water content of the sludge is reduced to between 30 and 35 percent again; and finally, dried sludge after dehydration is used for producing fertilizer and building materials, wherein the production of the fertilizer adopts the compound fertilizer producing technique, that is, the dried sludge is subjected to nutrition adaptation, granulation, drying and bagging; and the production of the building materials adopts the sintering technique, that is, the dried sludge is subjected to mixture, green brick briquetting, drying and sintering. High-temperature flue gas generated during brick baking is utilized by a waste heat boiler, and tail gas is treated and exhausted after reaching the standards. The three working procedures of the technology are organically combined and conditional mutually, and the technology realizes reduction, innoxiousness and stability of the sludge, and simultaneously creates economic benefit.

Owner:宋乾武 +1

Composition for treaitng contact lens and its application

InactiveCN1390606AImprove the lubrication effectGood moisturizing effectChemicalsIrritationDesiccation

A composition for treating contact lens is a nursing solution containing sodium hyaluronate, and can be used for cleaning, sterilizing and storing contact lens, and wetting eye and lens, preventing eye's desiccation and irritation.

Owner:上海卫康光学眼镜有限公司

Experimental method of oil-containing sludge heat treatment

ActiveCN102849905AImplement resourcesReduce pollutionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisResource utilizationEvaporation

An experimental method of oil-containing sludge heat treatment is applicable to research of oil-containing sludge heat treatment effect and characteristics. The programmed heating process comprises the following steps of: firstly, desiccation treatment, wherein an oil-containing sludge sample is heated from room temperature to 200-250 DEG C to realize complete moisture evaporation, and the composition of non-condensable gas and recovered oil is analyzed; secondly, pyrolysis treatment, wherein the desiccated oil sludge is heated to 600-700 DEG C to realize complete pyrolysis of organic substances such as heavy oil, asphaltene and the like in the oil sludge by high-temperature heating, and the composition of recovered oil and non-condensable gas is analyzed; thirdly, calcination treatment, wherein the oil-containing sludge pyrolytic residues are heated to 800-900 DEG C, and the content of pollutants such as petroleum and the like is analyzed. The method is convenient and rapid for the obtaining of the yield and composition data of heat treatment products of the oil-containing sludge at different heating temperature phases, and for the research and mastering of the heat treatment effect and characteristics of oil-containing sludge, and can realize the purpose of harmless and resource utilization of oil-containing sludge.

Owner:PETROCHINA CO LTD +1

Method for treatment of cellular materials with sugars prior to preservation

ActiveUS20080070302A1Enhance cell viabilityImprove abilitiesDead animal preservationTissue cultureVitrificationBiotechnology

Living cellular material may be preserved by incubating the cellular material in a culture medium containing at least one sugar, particularly for at least three hours, and then subjecting the cellular material to a preservation protocol, such as freezing, vitrification, freeze-drying and desiccation.

Owner:LIFELINE SCI

Semi-conductor dehumidifying clothes-drier and clothes-drying method

InactiveCN1837452AImprove heating efficiencyImprove dehumidification effectEnergy efficient heating/coolingMachines using electric/magnetic effectsDrying timeDesiccation

This invention discloses a semi-conducting and xerantic-type clothes dryer, which is characterized in that the air outlet of heating chamber connected with air inlet pipe, its air inlet connected with air outlet pipe, the air outlet of xerantic chamber connected with air outlet pipe, its air inlet connected with air channel, the orifice of air outlet pipe directly connected with air channel. According to the invention, dividing circulated air from drying barrel into two parts, one part is to heater for heating, and the other is delivered to heat absorber for cooling and is delivered to heater for heating again after delivered to the xerantic chamber for dehumidification. Two parts air are marshaled in the heater and are delivered to drying barrel for circulating use after heated. The dryer can improve heating efficiency and desiccation effect, and shorten the drying time.

Owner:俞宝良

Method for preparing sludge organic fertilizer from high moisture percentage sludge

The invention relates to a method of preparing organic sludge manure, which utilizes hight water-absorption resin to improve the sludge performance and increase the composting of sludge with high water content. High water-absorption resin conditioner accounting for one to two point five percent of the weight of the sludge and carbonaceous conditioner accounting for three to ten percent of the weight of the sludge are added into the sludge with high water content, which is discharged by the sewage treatment plants of a city, and the sludge is dumped into a dedicated fermentor, and after being uniformly mixed, undergoes composting fermentation. In the course of fermentation, the fermentation temperature is controlled in a range of thirty five to sixty five DEG C, the sludge is intervalically stired and ventilated, the composting lasts twenty to thirty two days, and therefore an organic sludge manure product is prepared. The invention introduces the high water-absorption resin as the sludge compost conditioner for the first time, and the added high water-absorption resin realizes the aerobic compost of the sludge with high water content and promotes the process of sludge composting. Meanwhile, the traditional desiccation process of sludge compost is left out, as a result, the process is simplified, the preparation cost is low, and the content of organic matters and nitrogen is high.

Owner:FUJIAN NORMAL UNIV

Fluid-bed drying system

InactiveCN101571341AIncrease or extend drying dwell timeImprove protectionDrying solid materials with heatDrying gas arrangementsCycloneVapor–liquid separator

The invention discloses a fluid-bed drying system. The system comprises a main drying machine, a feeding device, a 1 heat exchanger, a 2 heat exchanger, a 3 heat exchanger, a 4 heat exchanger, a 1 scum skimmer, a 2 scum skimmer, a 1 cyclone separator, a 2 cyclone separator, a 1 bag dust collector, a 2 bag dust collector, a 1 water film deduster, a 2 water film deduster, a 1 gas liquid separator, a 2 gas liquid separator, a vibrating screen and a fluidized bed cooling device. Three air flows with different temperatures are input into different positions of a bed body of the main drying machine, air outlet directions of air ports of a pore plate of the main drying machine are different, a middle bed is equipped with a variable cross-section air passage, thus increasing drying and staying time of materials in the main drying machine, the materials output from the main drying machine are cooled by desiccation and cooling air in the fluidized bed cooling device to further reduce moisture of finished product and discharge temperature of the finished product, thus realizing good drying and cooling effect.

Owner:陆文光

Medicinal lipstick and preparing method thereof

InactiveCN107184502ATo promote metabolismImprove immunityCosmetic preparationsAntipyreticAdhesiveDesiccation

The invention discloses a medicinal lipstick. The medicinal lipstick is prepared from, by mass, 65%-75% of plant emollient, 1%-5% of colorant, 10%-15% of thickener, 10%-15% of adhesive, 0.1%-1% of antioxidant, 1%-5% of plant essence and 0.1%-1% of medicinal plant extracts. In the medicinal lipstick, the medicinal plant extracts have medicinal plant components, can restore the lip, prevent lip desiccation and decrustation, promote metabolism of the tender skin, inhibit the occurrence of lip inflammation and maintain the lip skin, and has remarkable functions to treatment of cheilitis.

Owner:QINZHOU UNIV

Perennial sowthistle health-care tea and its preparation method

InactiveCN102239946AImprove drinking tasteReduce bitternessPre-extraction tea treatmentTea substituesPrickly sow-thistleHazardous substance

The invention discloses perennial sowthistle health-care tea, which is prepared by using the Sonchus L. plant perennial sowthistle as the raw material and carrying out steps of rinsing, high temperature desiccation, airing, slice processing, tea-leaf curing and rolling processing, second tea-leaf curing, rolling, drying and packing. The perennial sowthistle health-care tea can be directly drunk and also can be drunk with other teas such as black tea, scented tea, green tea and oolong tea. The product provided by the invention is convenient to drink, has a good taste and strong incense, is an ideal tea substitute, has a natural Perennial sowthistle medical value, and has an active effect of effectively reducing the harm of hazardous substances in tobaccos to smokers and passive smokers.

Owner:徐州绿之野生物食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com