Fluid-bed drying system

A boiling drying and drying technology, which is used in drying solid materials, drying gas arrangement, heating to dry solid materials, etc. It can solve the requirements that the heat retention temperature should not be higher than 10° of room temperature, anti-moisture, drying and cooling of heat-sensitive materials. High and other problems, to achieve the effect of satisfying mass industrial production, simplifying process links, and improving drying and cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

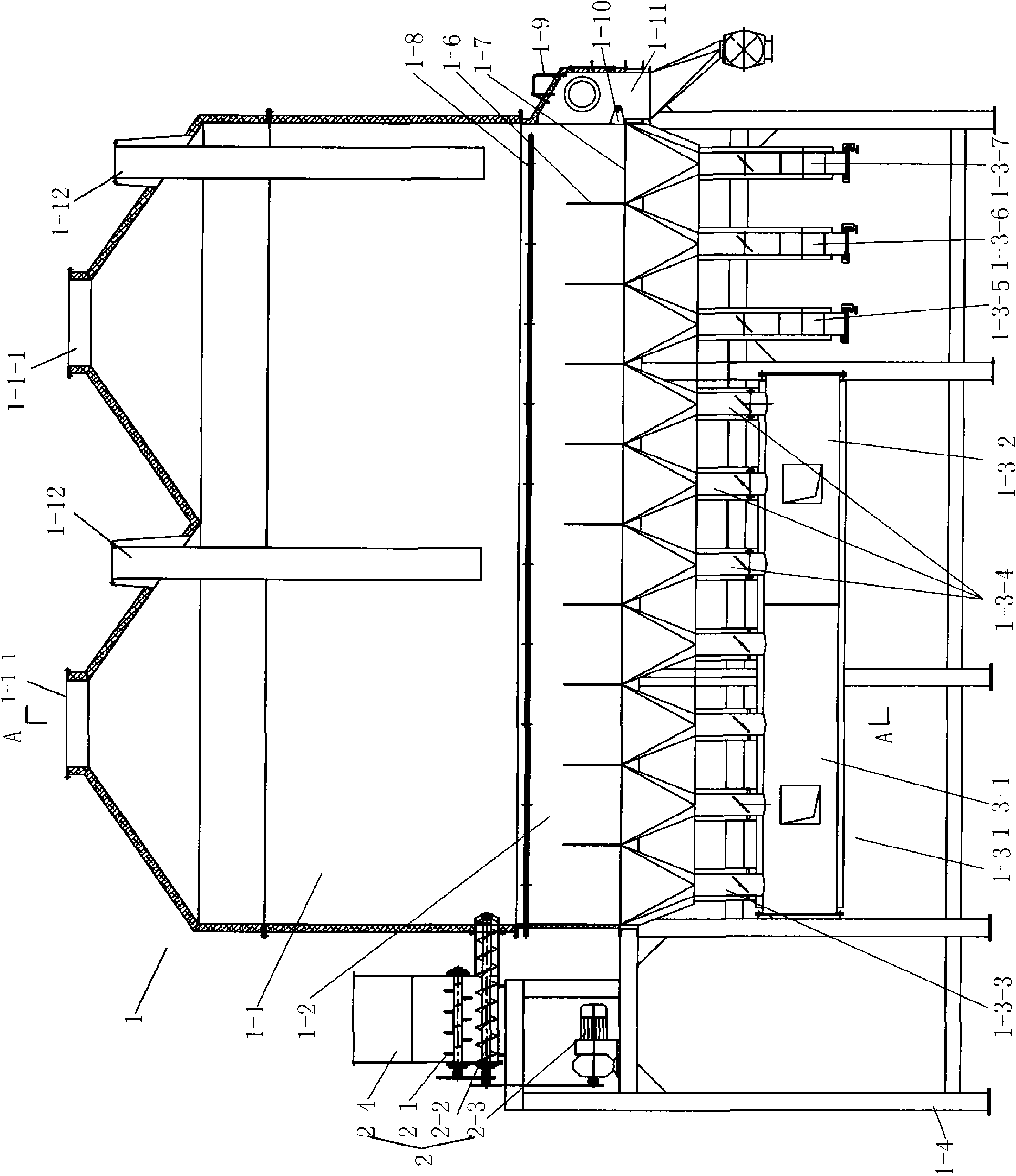

[0033] See Figure 1 to Figure 3 , the present embodiment includes drying host 1, feeding device 2, 1 # Blower 3-1, 2 # Blower 3-2, 1 # Heat exchanger 4-1, 2 # Heat exchanger 4-2, 3 # Heat exchanger 4-3, 4 # Heat exchanger 4-4, 1 # Cooling water tank 5-1, 2 # Cooling water tank 5-2, 1 # Cooling pump 6-1, 2 # Cooling pump 6-2, 1 # Demister 7-1, 2 # Demister 7-2, vibrating screen 8, vibrating fluidized bed cooling device 11, 1 # Cyclone separator 12-1, 2 # Cyclone separator 12-2, 1 # Bag filter 15-1, 2 # Bag filter 15-2, 1 # Water film dust collector 18-1, 2 # Water film dust collector 18-2, 1 # Gas-liquid separator 20-1, 2 # Gas-liquid separator 20-2.

[0034] A screw conveyor 9 is provided between the discharge port of the drying host 1 and the feed port of the vibrating screen 8 . A receiving hopper 10 is provided between the screw conveyor 9 and the fluidized bed cooling device 11 . Below the outlet of fluidized bed cooling device 11 is provided with 1 #...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com