Boiling fluidization drying apparatus

A fluidized drying and equipment technology, applied in the field of drying heat-sensitive materials, can solve the problems of heat holding temperature not higher than 10° above room temperature, high drying requirements for heat-sensitive materials, and anti-moisture, so as to prolong the drying residence time and achieve good drying effect. , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

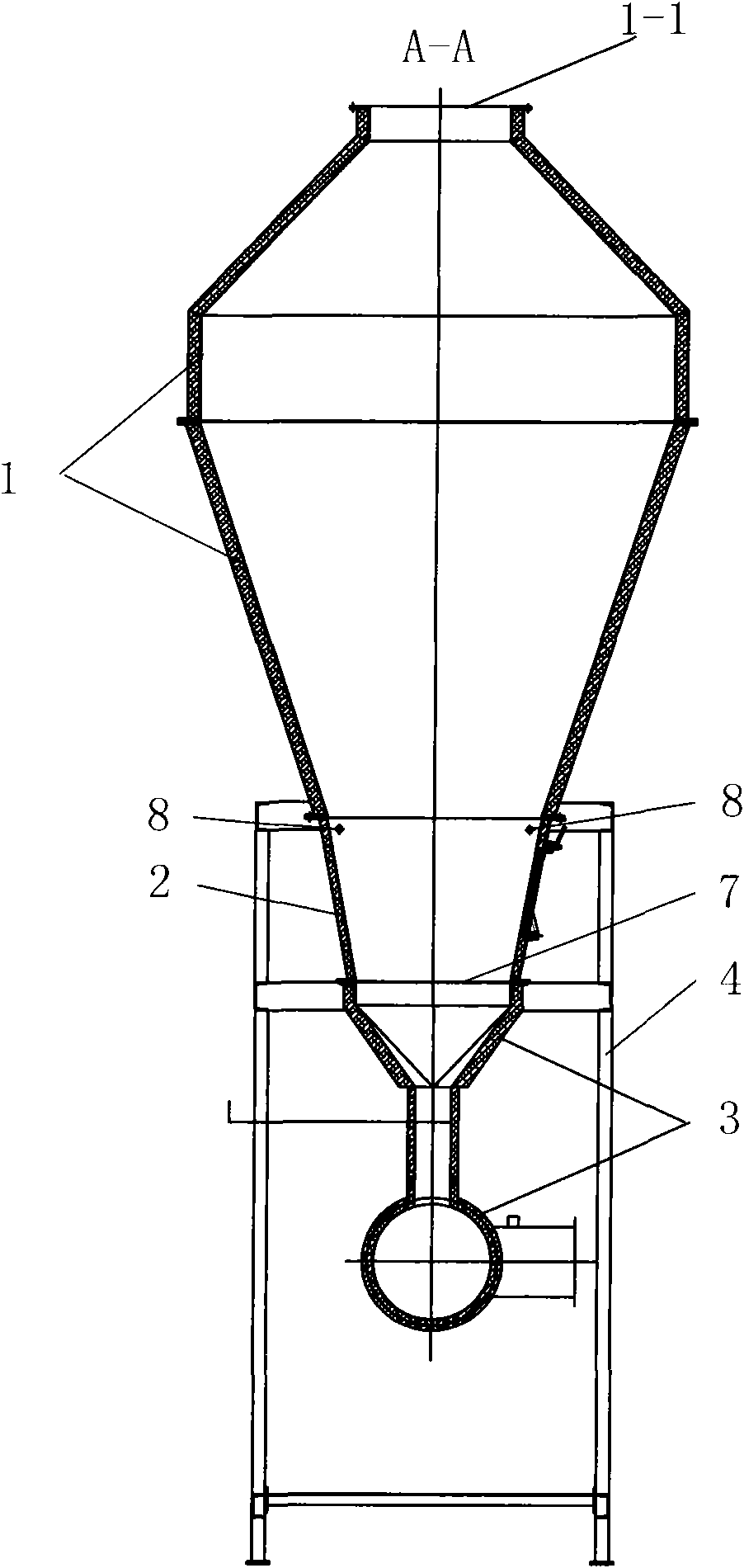

[0025] See figure 1 and figure 2 , the present embodiment has an upper bed body 1, a middle bed body 2, a lower bed body 3 and a frame 4. The upper bed body 1 is formed by flange connection between the upper upper bed body and the upper and lower bed bodies, and the top surface of the upper bed body 1 is in the shape of two parallel truncated cones. The upper bed body 1 and the middle bed body 2 are connected by a flange. The top surface of the upper bed body 1 is provided with two air outlets 1-1, and the two air outlets 1-1 are respectively located in the center of the two cones; Insert the rear end of the table. The front and back of the lower part of the middle bed body 2 are respectively provided with a feed port 1-2 and a discharge chamber 11. The lower bed body 3 is the air distribution device 3 . An orifice plate 7 is provided at the junction of the middle bed body 2 and the lower bed body 3 , that is, the air distribution device 3 .

[0026] See Figures 3 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com