Growth equipment and growth method for large-size gallium oxide monocrystalline

A gallium oxide, large-scale technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of exacerbating melt decomposition and volatilization, affecting crystal quality, and covering volatiles, so as to reduce volatilization and decomposition , Stable growth interface, small buoyancy and convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

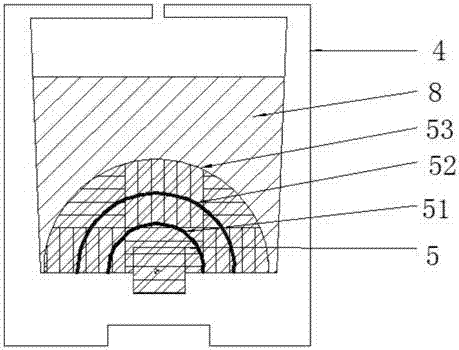

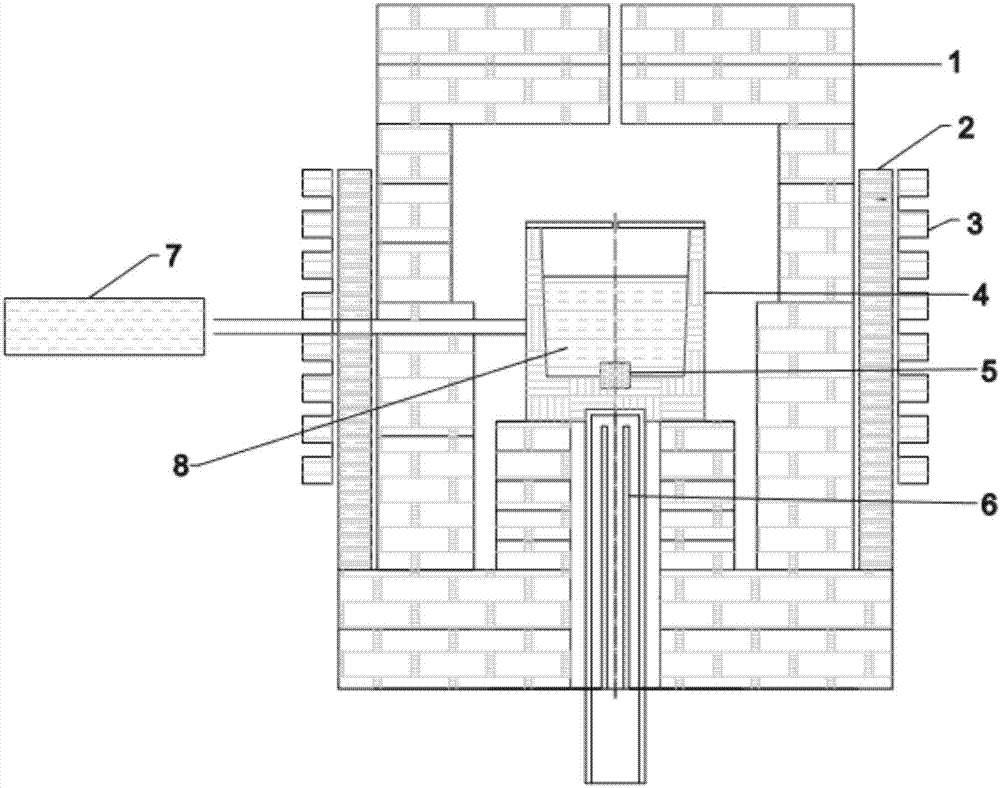

[0031] like figure 1 As shown, a large-size gallium oxide single crystal growth equipment, including zirconia insulation brick 1, quartz cylinder 2, water-cooled copper electrode 3, iridium gold crucible 4, heat exchanger 6, infrared thermometer 7, the described The iridium crucible 4 is placed in the crystal growth furnace chamber formed by the zirconia insulating brick 1, and the outer side of the zirconia insulating brick 1 is provided with a quartz cylinder 2 and a water-cooled copper electrode 3 in turn, and the heat exchanger 6 is placed in the iridium crucible 4. At the bottom, the infrared thermometer 7 is connected to the iridium crucible 4, and the iridium crucible 4 is filled with a gallium oxide solution 8 and a seed crystal 5. The side wall of the iridium crucible 4 is provided with an infrared temperature measuring point, which is connected to an infrared thermometer 7 for monitoring the temperature of the crucible material and crystal growth. The heat exchanger...

Embodiment 2

[0044] The angle a between the inner wall of the iridium crucible and the horizontal plane is: 30 degrees

[0045] The heating method of the equipment is induction heating; the power frequency is 20khz.

[0046] Wherein, the annealing treatment of the crystal is performed, and the annealing time can be selected according to the actual situation, such as 50h, 200h, and the like.

[0047] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com