Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Uniform temperature gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

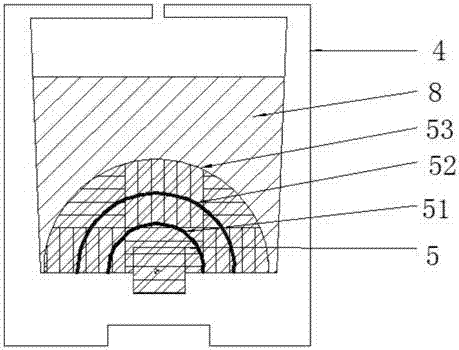

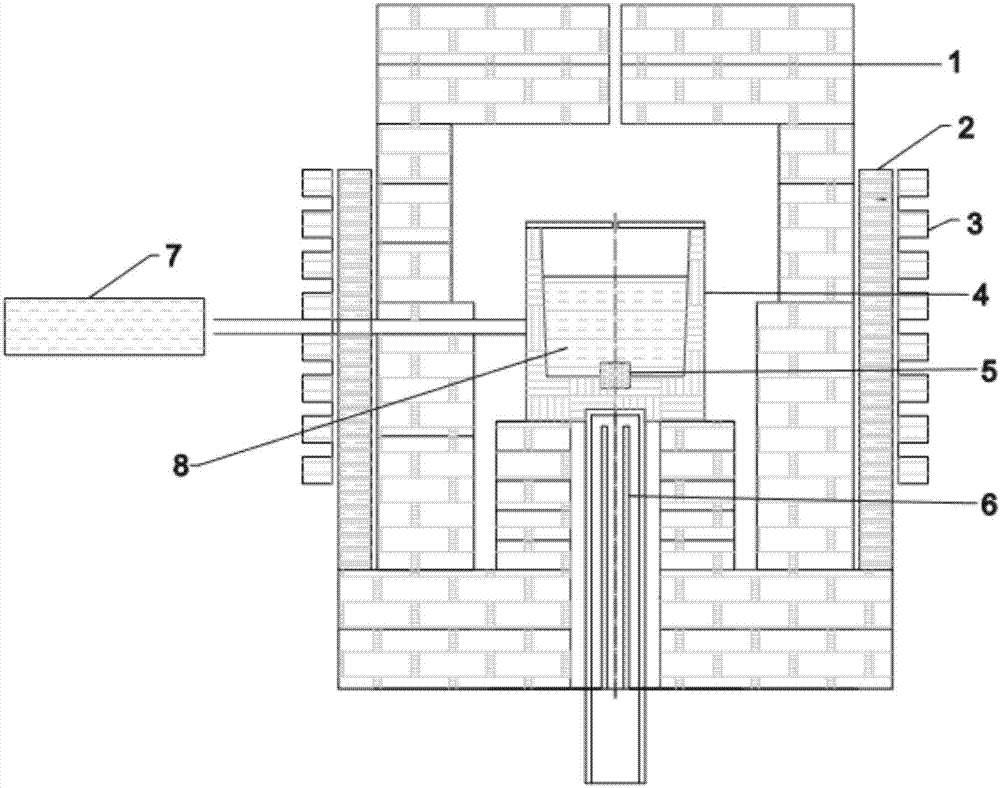

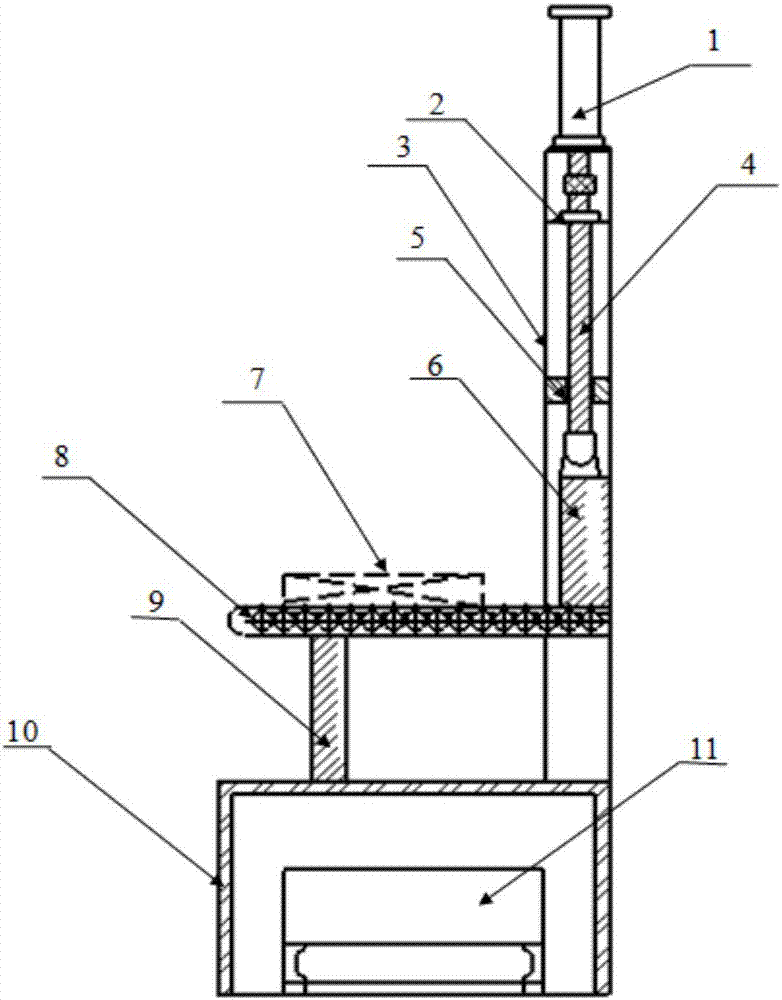

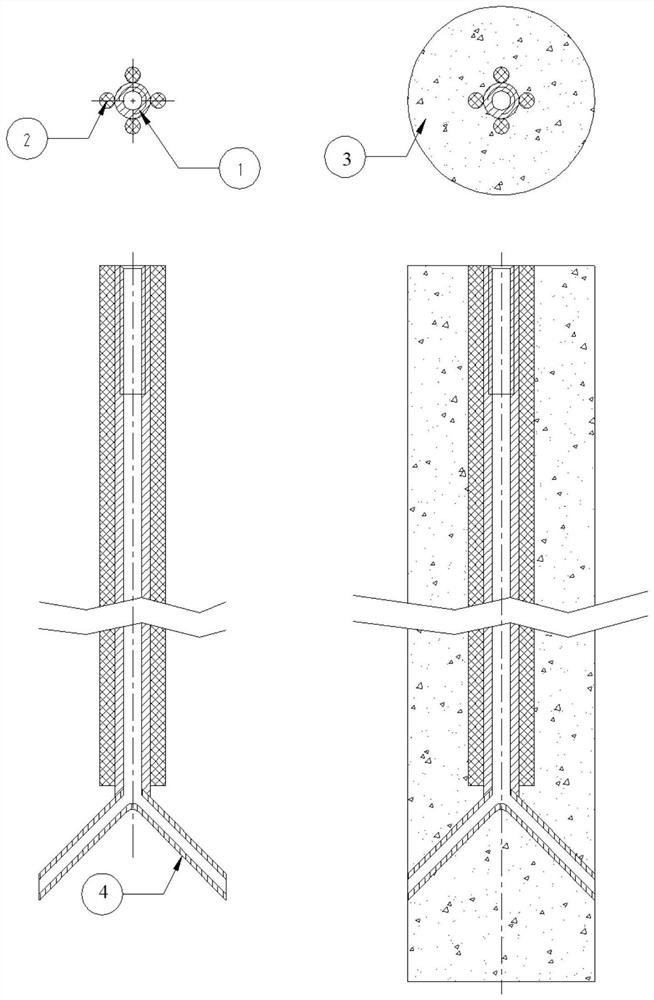

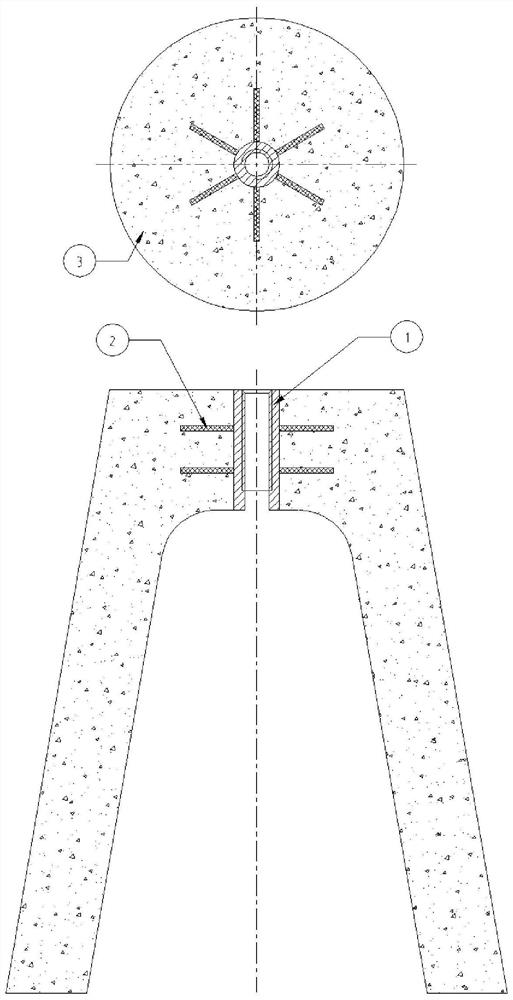

Growth equipment and growth method for large-size gallium oxide monocrystalline

InactiveCN107541776AReduce volatilityReduce decompositionPolycrystalline material growthUnder a protective fluidBrickCopper electrode

The invention relates to a piece of growth equipment and a growth method for large-size gallium oxide monocrystalline. The equipment comprises the following components: a zirconia insulating brick (1), a quartz cylinder (2), a water cooling copper electrode (3), an iraurita crucible (4), a heat exchanger (6), and an infrared thermometer (7). The method comprises the following steps: the iraurita crucible (4) is placed in the crystal growth furnace cavity formed by the zirconia insulating brick (1), the outside of the zirconia insulating brick (1) is provided with the quartz cylinder (2) and the water cooling copper electrode (3) in order, the heat exchanger (6) is placed at the bottom of the iraurita crucible (4), the infrared thermometer (7) is connected to the iraurita crucible (4), andthe iraurita crucible (4) contains a gallium oxide solution (8) and seed crystal (5). Compared with the prior art, heat exchange method is used for growing crystal, the efficiency is improved, and production cost is reduced; at the same time, grown crystal has the advantages of excellent quality, little stress, low dislocation density, good crystal perfection and optical homogeneity, improved utilization rate of the gallium oxide material, and simplified processing operation.

Owner:TONGJI UNIV

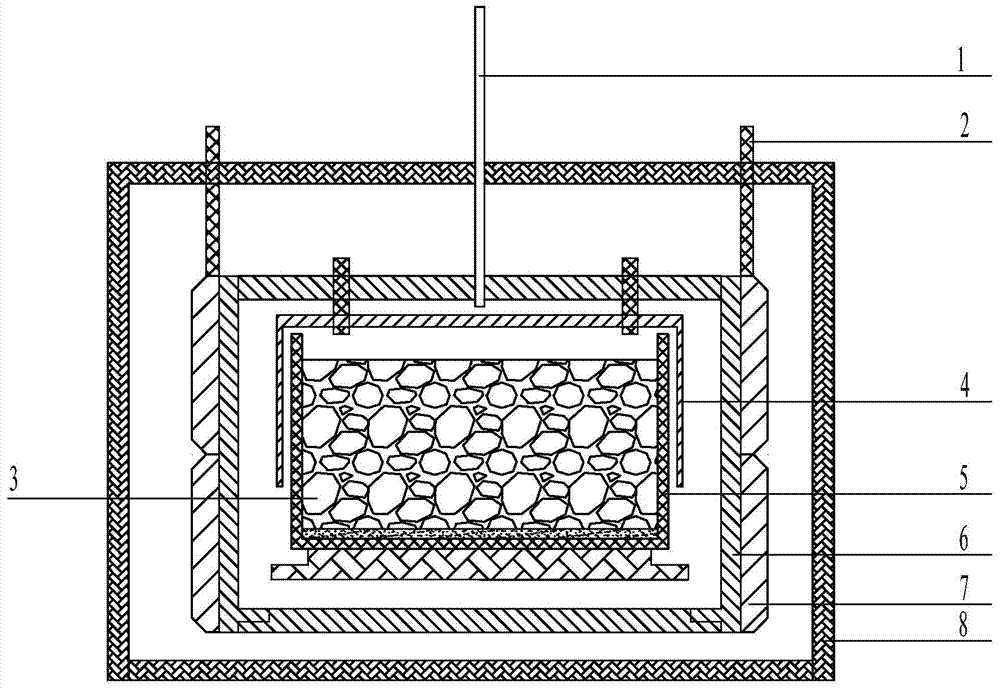

Efficient ingot casting semi-melting technology capable of achieving low dislocation density

InactiveCN104726934AImprove photoelectric conversion efficiencyReduce dislocation densityPolycrystalline material growthSingle crystal growth detailsPressure riseIngot casting

The invention belongs to the field of polycrystalline silicon ingot casting, and particularly relates to an efficient ingot casting semi-melting technology capable of achieving low dislocation density. The technology comprises loading vacuumizing, argon adding to achieve pressure rising, heating to achieve silicon mixture melting, crystal growing, annealing heat preservation and cooling. In the loading stage, firstly, a layer of broken single crystals or broken polycrystal is laid on the bottom inside a quartz crucible; in the melting stage, a heat insulation cage is improved at the speed of 0.5 cm / h to 1 cm / h, thus ensuring that the broken single crystals or broken polycrystal is not melted. The technological process can ensure that the silicon mixture can be sequentially and slowly melted from top to bottom, and a flat solid liquid interface is obtained; the temperature in the horizontal direction is coincident, the temperature gradient in the vertical direction is uniform, and some impurities and hard particles difficult to melt are ensured to be melted, and dislocation caused by the impurities and hard particles is reduced. The ingot casting dislocation density obtained through the technology is obviously reduced, the size of grains ranges from 6 mm to 8 mm, meanwhile, the photoelectric conversion efficiency of a solar cell piece is improved to 17.5 percent from 17.2 percent.

Owner:青岛隆盛晶硅科技有限公司

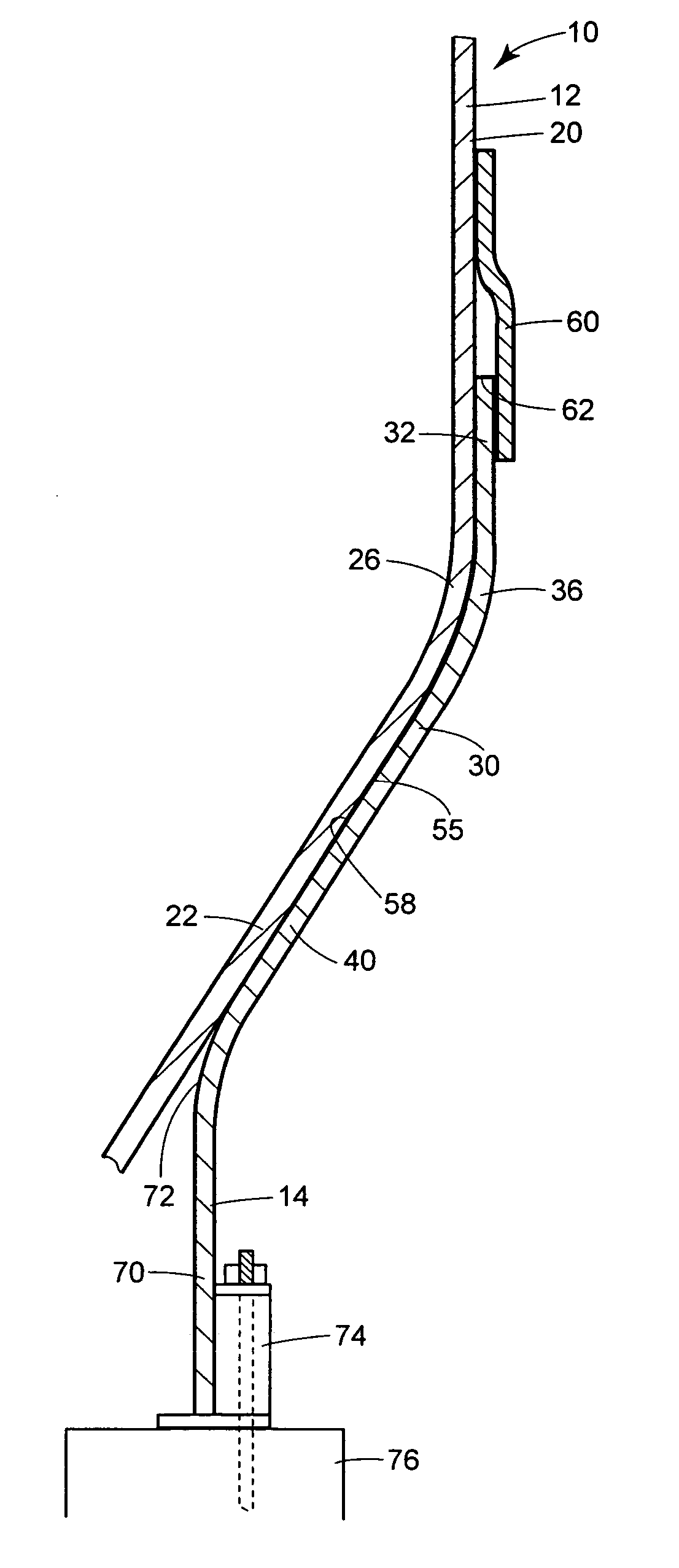

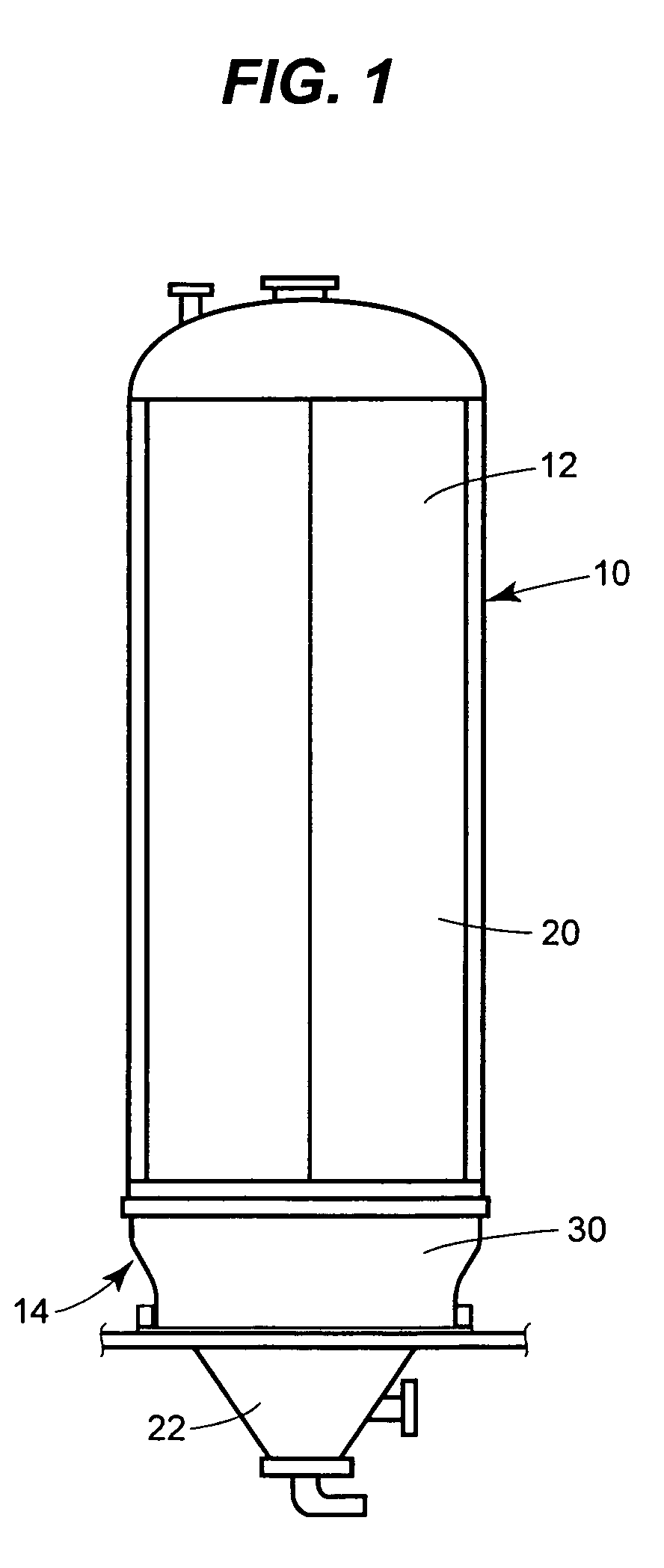

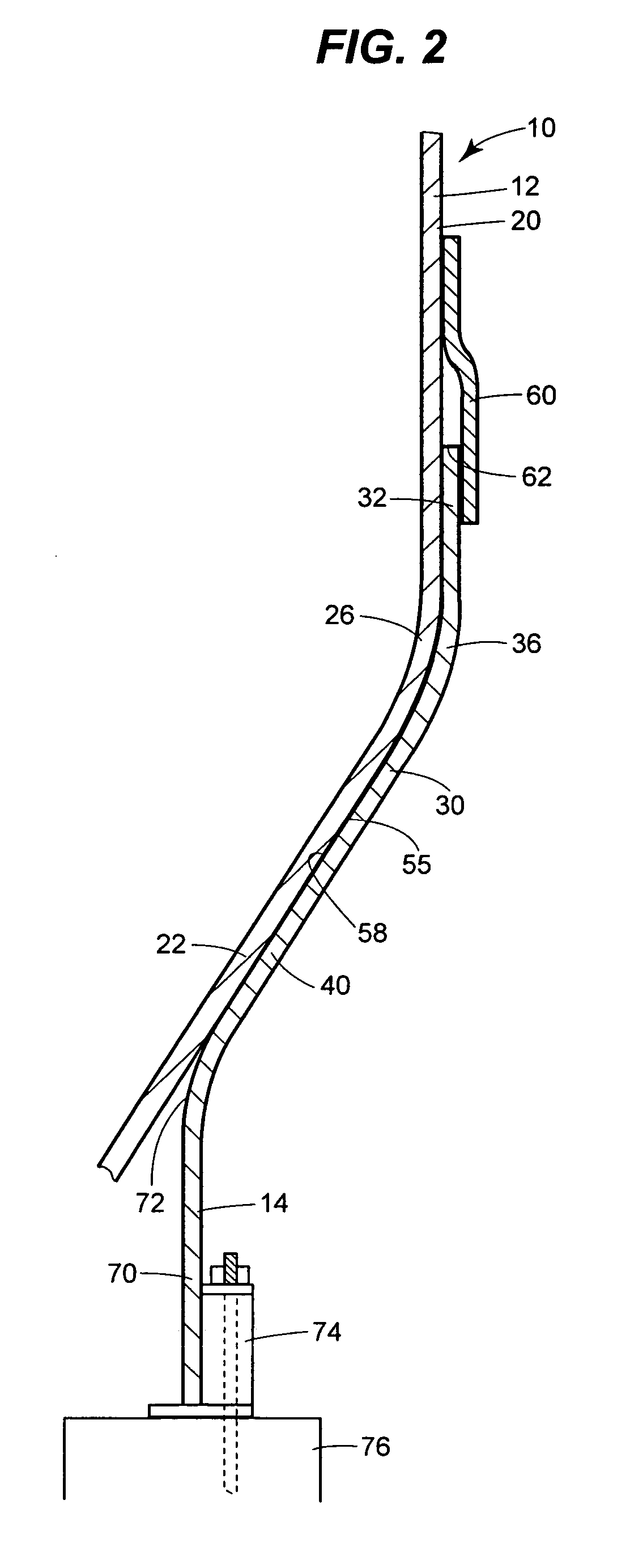

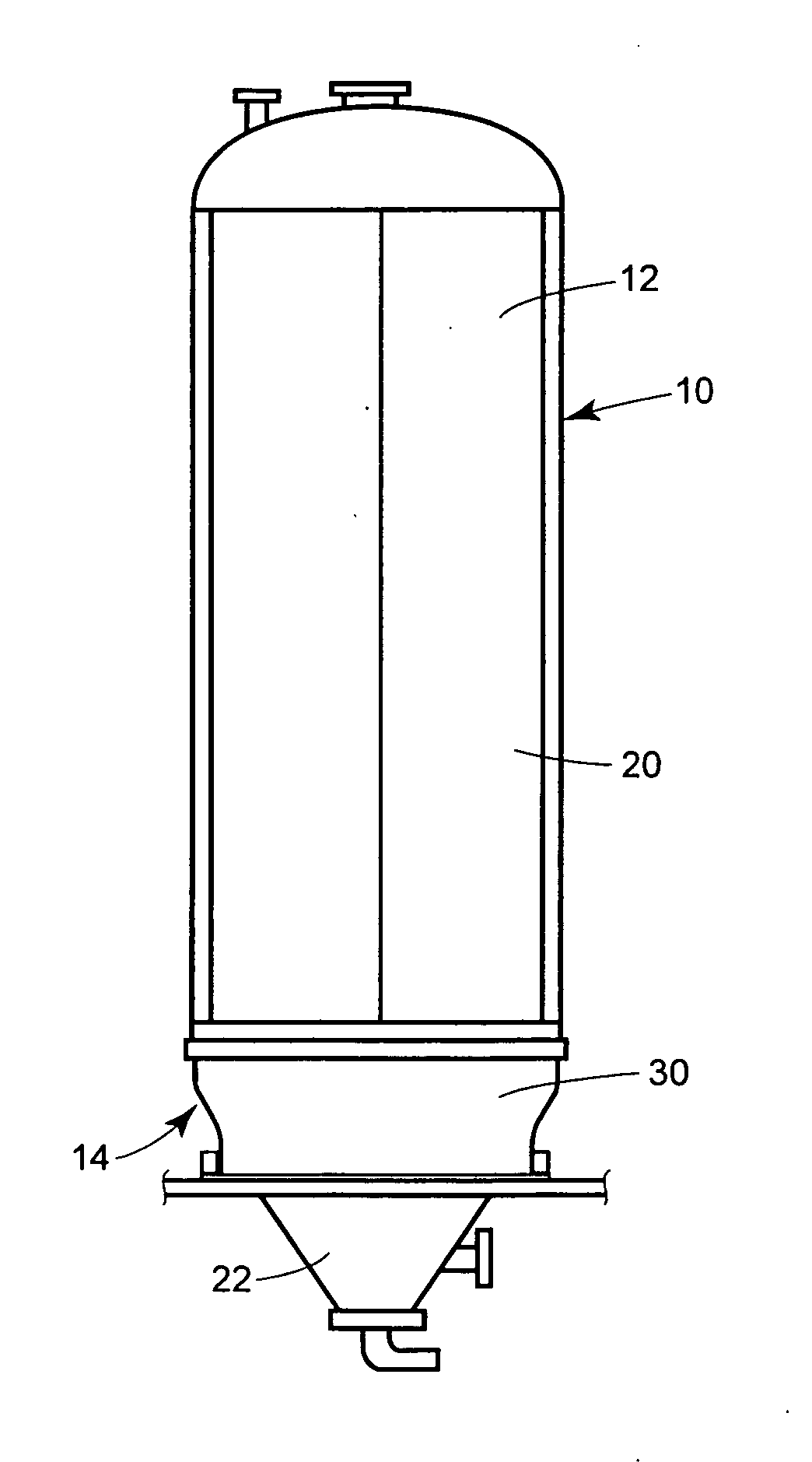

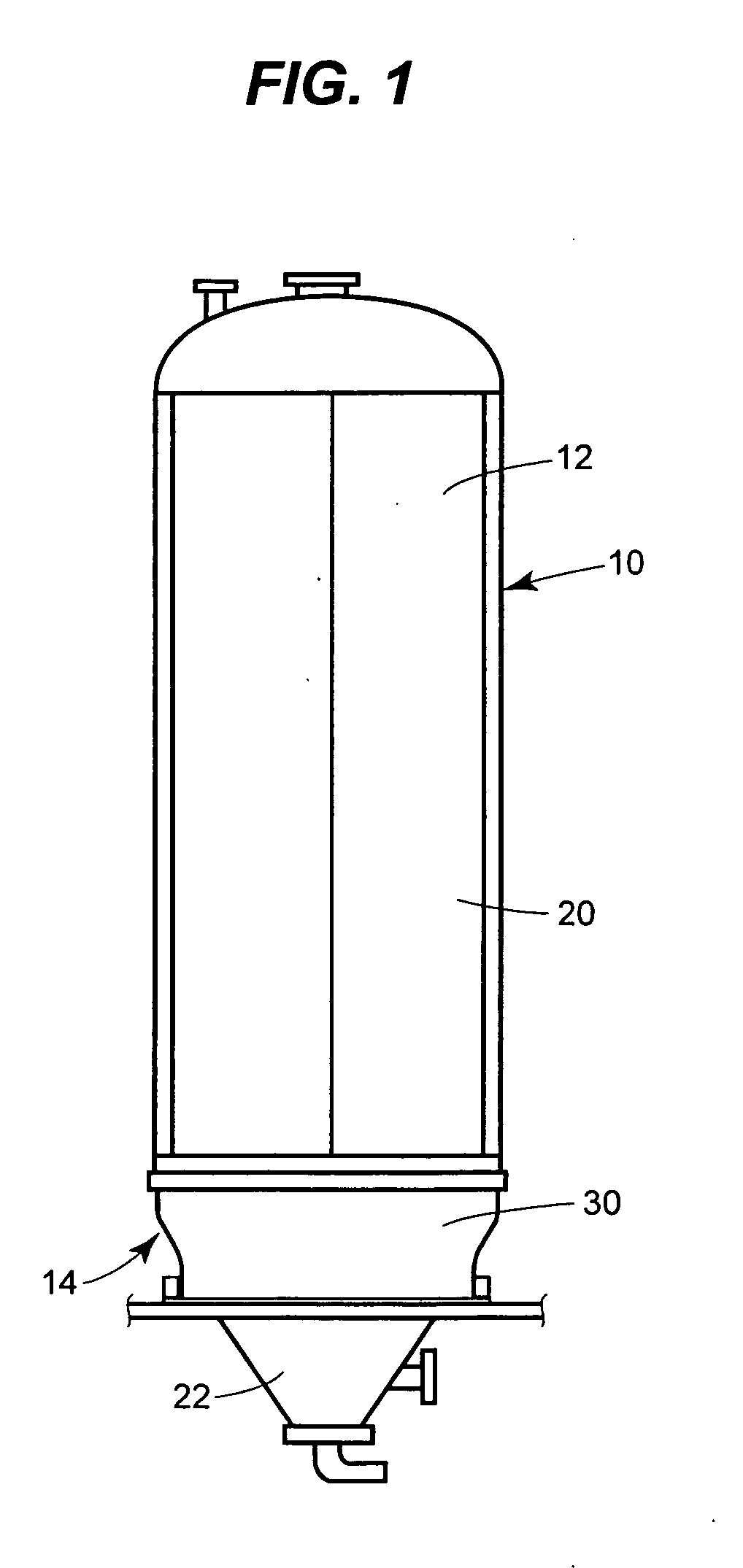

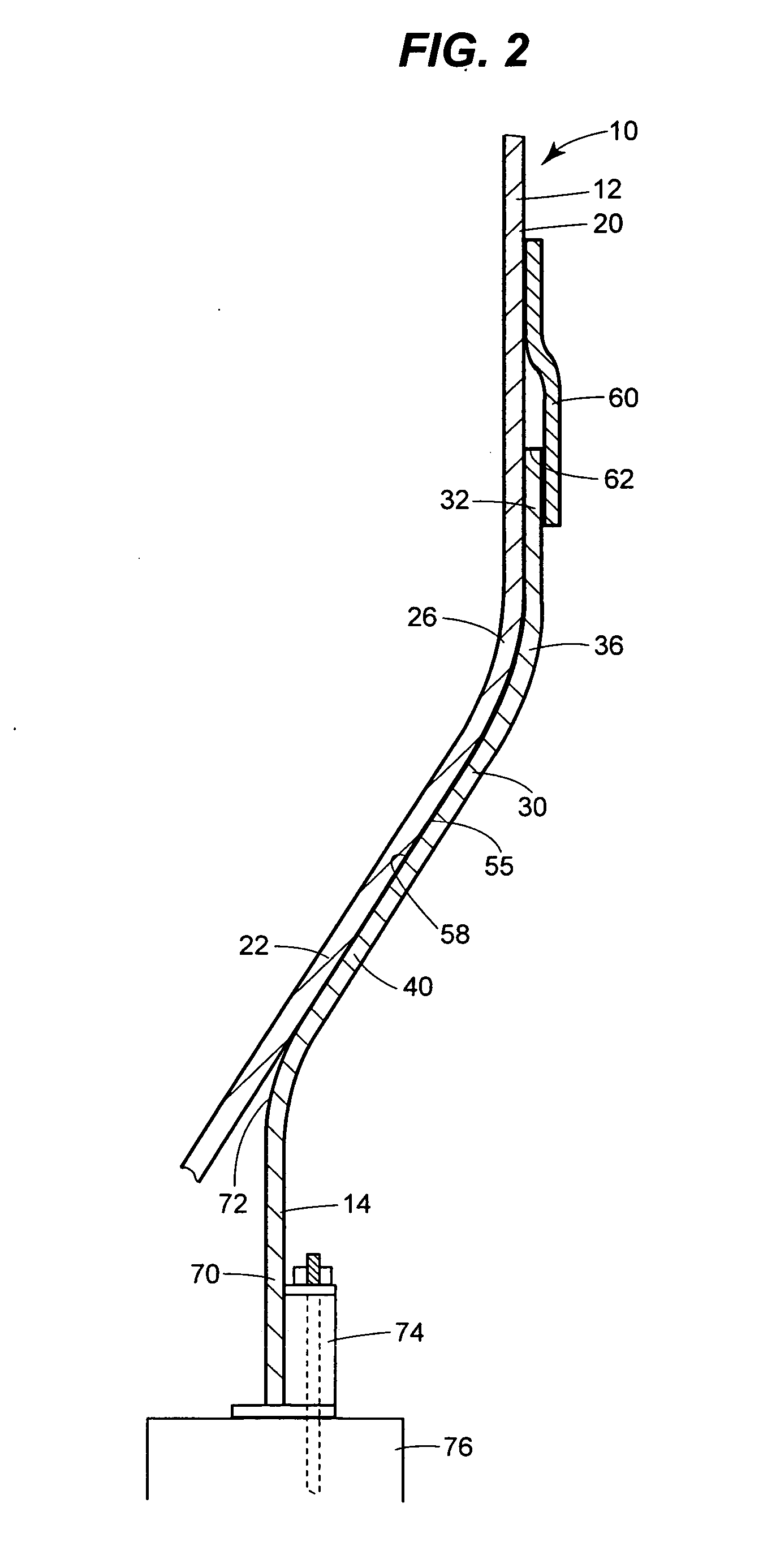

Structure for extreme thermal cycling

ActiveUS7666279B2Reduce the amount of weldingFlexible connectionMechanical conveying coke ovensCharging-discharging device combinationsPre stressPre stressing

A structure for extreme thermal cycling has a support element that supports a vessel primarily by bearing and frictional forces rather than by welds. The support element has a bearing portion that tapers inwardly beneath a knuckle that separates a cylindrical section of the vessel from a sloped lower section. The bearing portion of the support element follows that slope, providing an extended area of contact between the support element and the vessel. An annular section of the support element can be heated and expanded before placing it around the cylindrical section of the vessel to provide pre-stressing. If required, a strap may extend downwardly from the vessel over an upper edge of the support element.

Owner:CB&I STS DELAWARE LLC

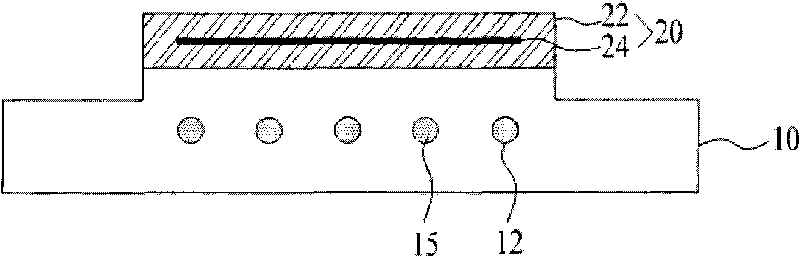

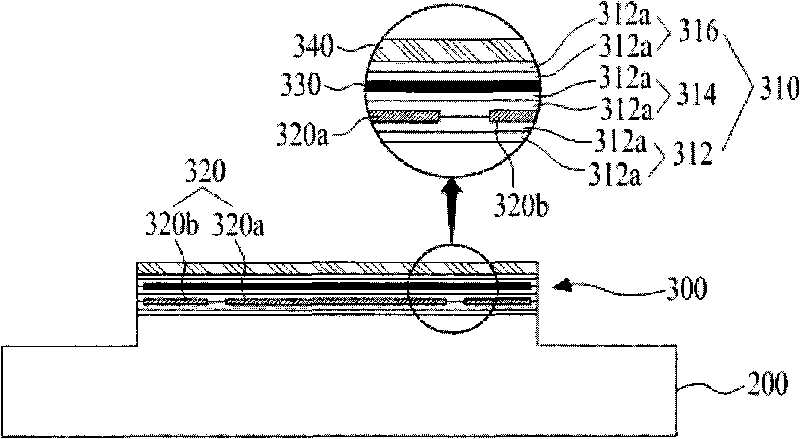

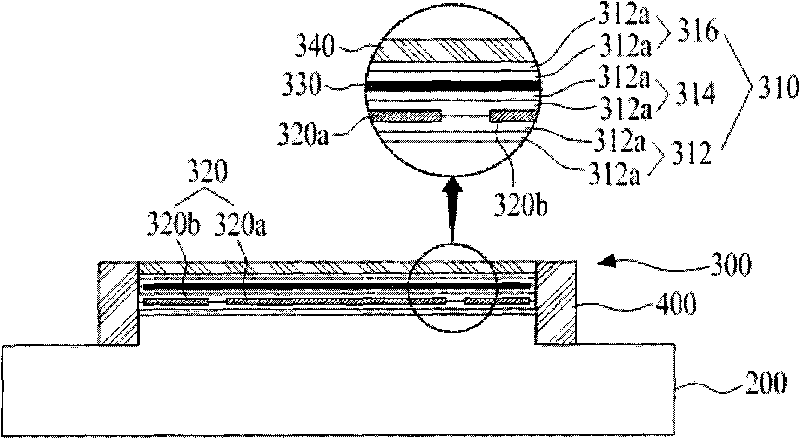

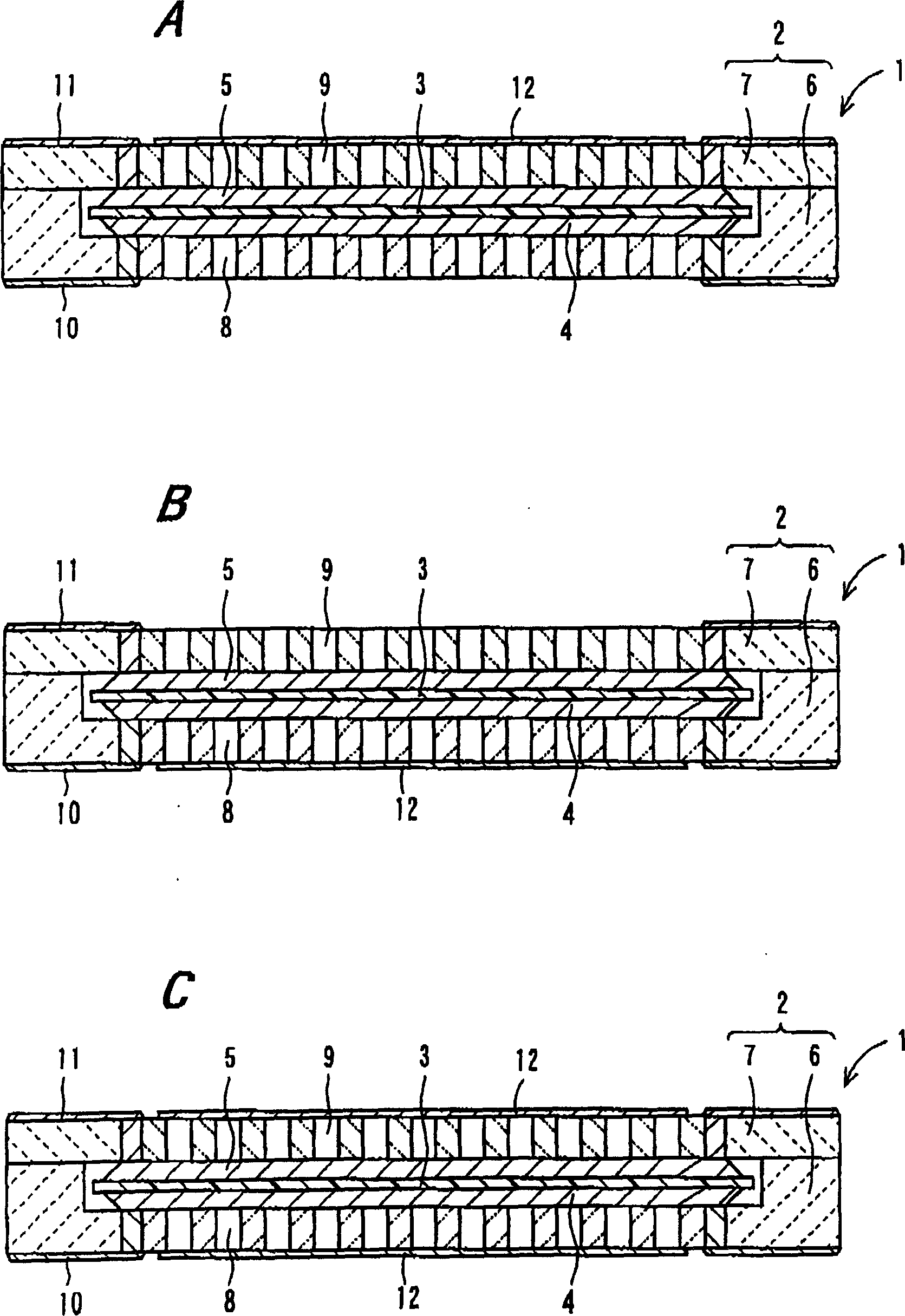

Electrostatic chucking apparatus and method for manufacturing the same

InactiveCN101728297AExtended service lifeUniform temperature gradientSemiconductor/solid-state device manufacturingAdhesivesTemperature gradientDirect current

An electrostatic chucking apparatus and a method for manufacturing the same is disclosed, which is capable of enabling the increase of lifetime of an electrostatic chuck and realizing a uniform temperature gradient in an entire substrate by preventing an insulating material from being etched, the electrostatic chucking apparatus comprising a base member; and an electrostatic chuck, loaded onto the base member, for chucking a substrate by an electrostatic force, wherein the electrostatic chuck comprises an insulating member formed on the base member and provided with a plurality of first insulating sheets of aluminum nitride; a heater for heating the substrate, the heater positioned among the plurality of first insulating sheets; a direct current electrode formed on at least one first insulating sheet provided above the heater among the plurality of first insulating sheets, the DC electrode electrically connected with a direct current power source; and an insulator etch stopping layer, formed of aluminum oxide on an entire surface of the insulating member, for preventing the insulating member from being etched.

Owner:JUSUNG ENG

Structure for extreme thermal cycling

ActiveUS20070215452A1Reduce fatigueImprove fatigue resistanceMechanical conveying coke ovensCharging-discharging device combinationsPre stressPre stressing

A structure for extreme thermal cycling has a support element that supports a vessel primarily by bearing and frictional forces rather than by welds. The support element has a bearing portion that tapers inwardly beneath a knuckle that separates a cylindrical section of the vessel from a sloped lower section. The bearing portion of the support element follows that slope, providing an extended area of contact between the support element and the vessel. An annular section of the support element can be heated and expanded before placing it around the cylindrical section of the vessel to provide pre-stressing. If required, a strap may extend downwardly from the vessel over an upper edge of the support element.

Owner:CHICAGO BRIDGE & IRON CO

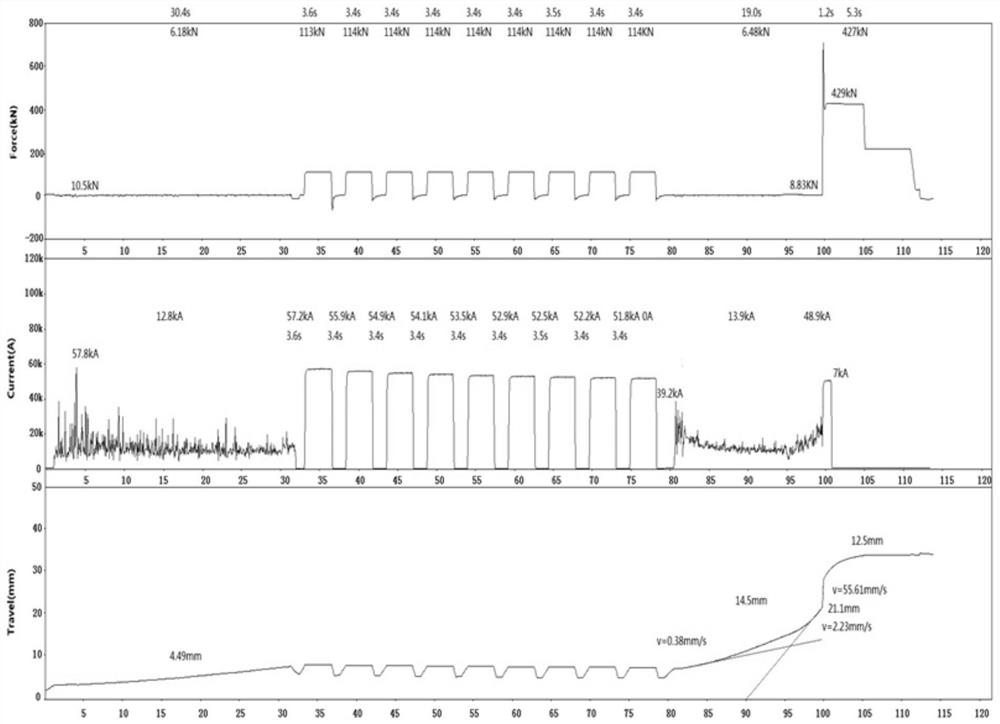

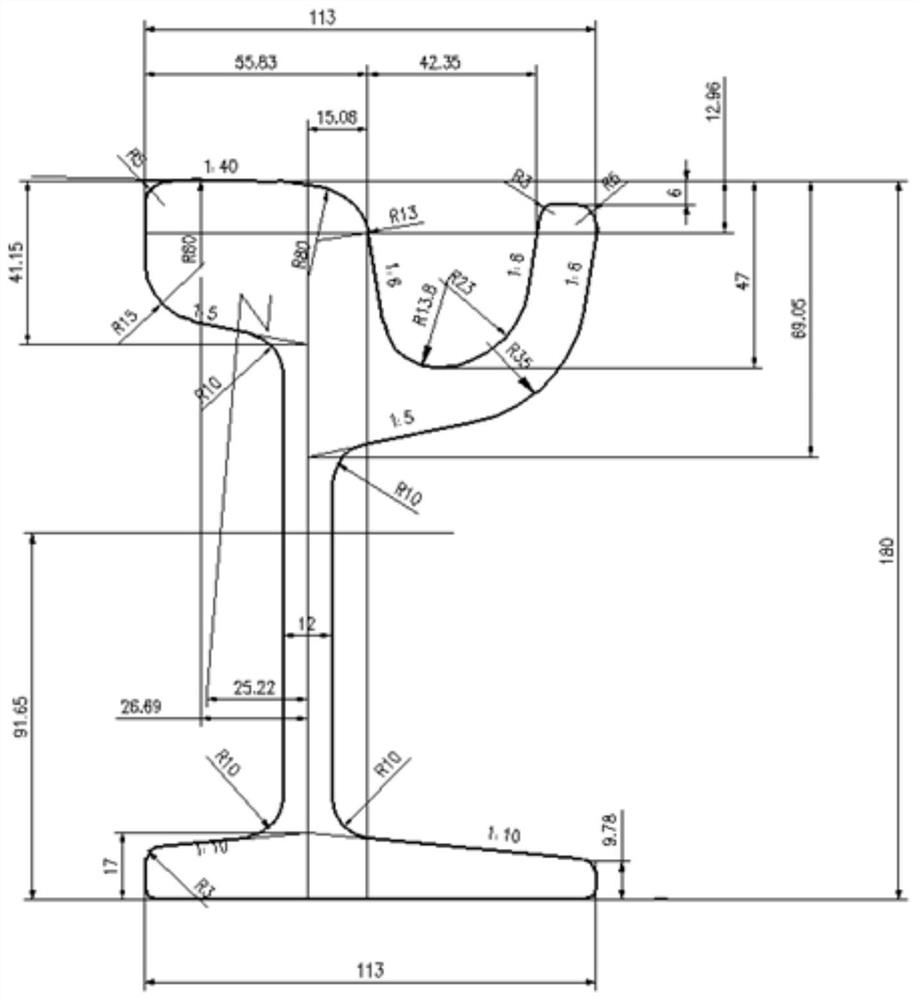

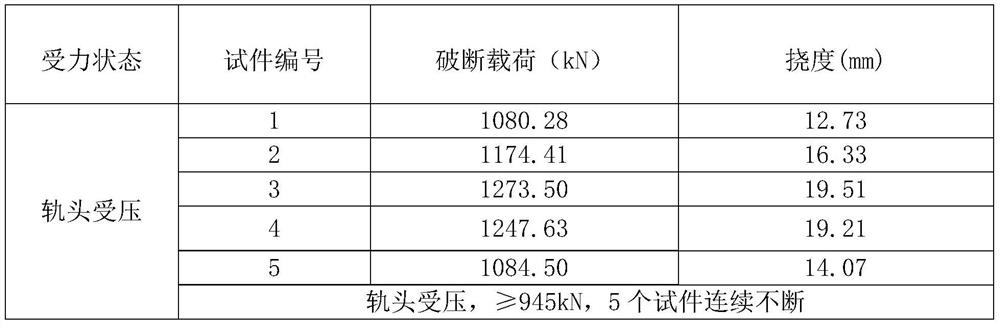

Welding process of alloy steel and trough type steel rail

ActiveCN110102864AStress reliefEnhanced breaking loadResistance welding apparatusUpset forgingAlloy steel

The invention relates to the technical field of tracked trolley bus frog welding, in particular to a welding process of alloy steel and a trough type steel rail. According to the welding process of the alloy steel and the trough type steel rail, the alloy steel and the trough type steel rail are welded together through a flash welding method; the welding process comprises a flash levelling stage,a preheating stage, a burning stage, an upset forging stage and a postheating stage; the total duration time of the welding process is 114s to 115s; the upset forging amount of the welding process is12mm to 12.8mm; and the total consumption amount of the steel rail of the welding process is 30 to 31.8mm. According to the welding process of the alloy steel and the trough type steel rail provided by the invention, the flash welding of the alloy steel and the trough type steel rail is realized successfully, the mechanical property of a formed welding joint is good, and the welding quality is stable.

Owner:CNR BEIJING RAIL EQUIP +1

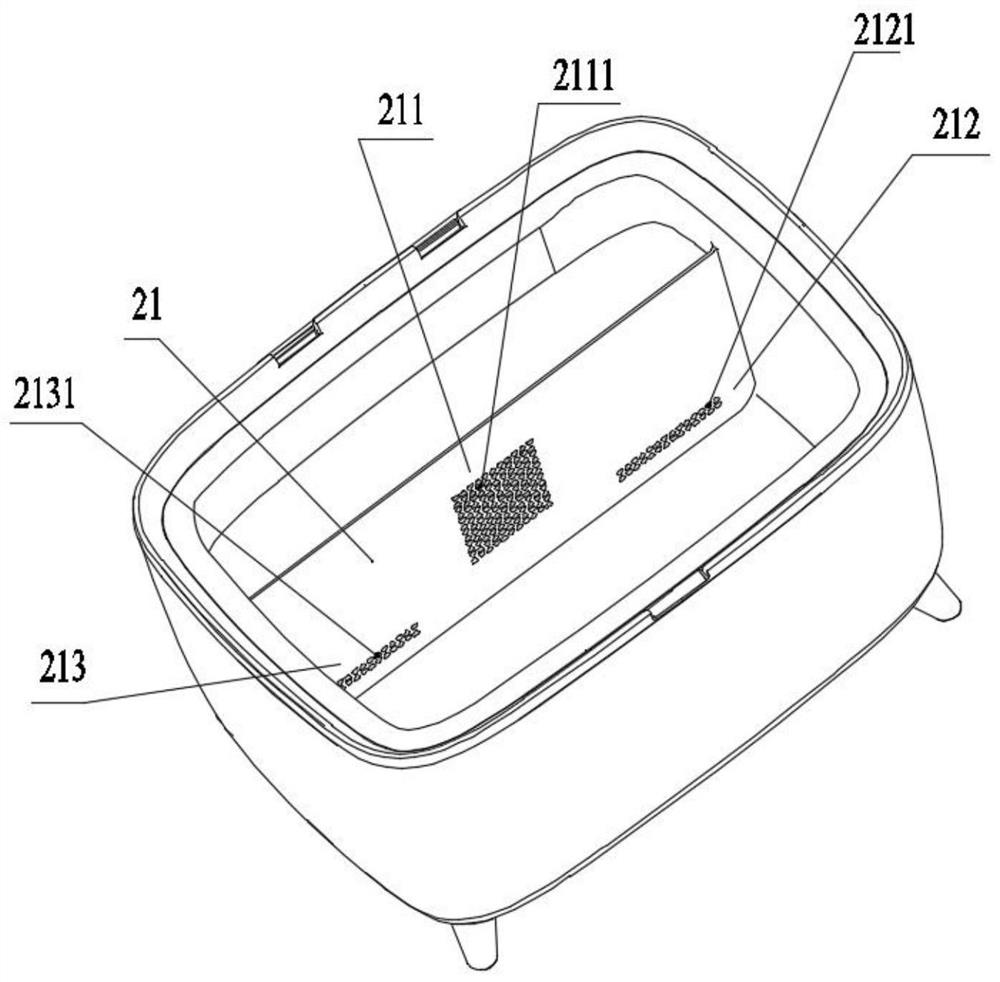

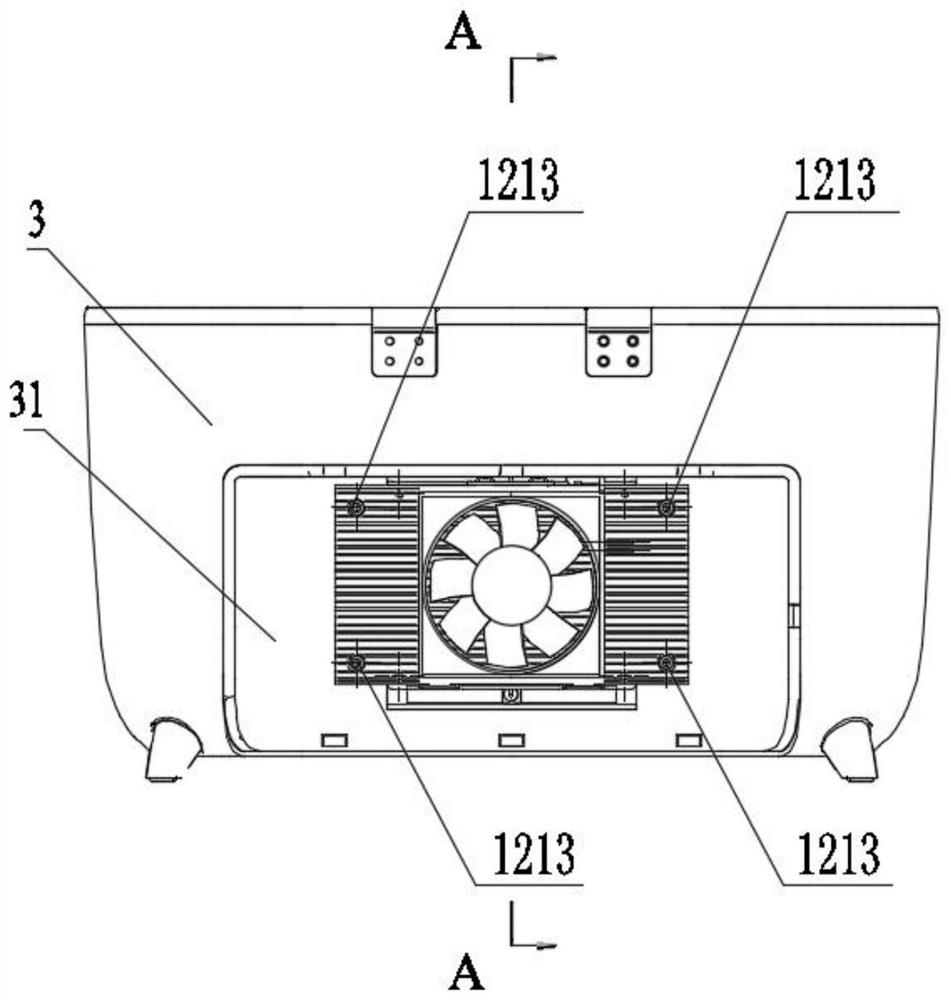

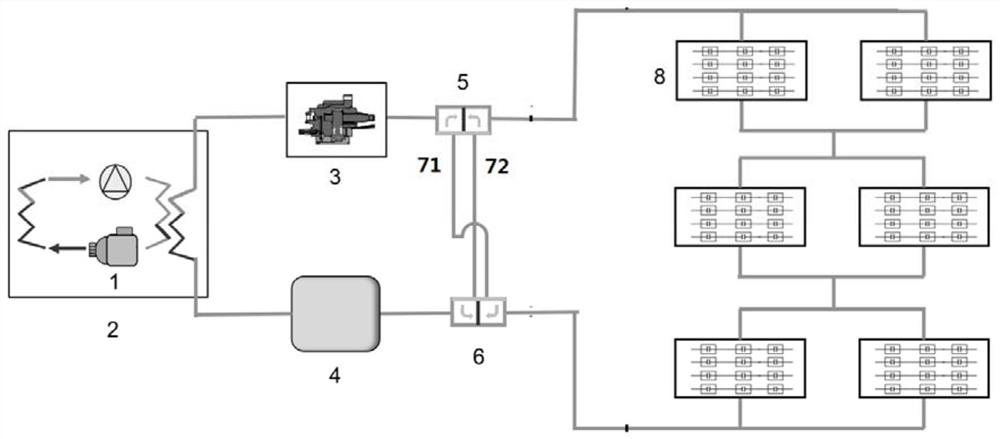

Air-cooled refrigeration system and semiconductor refrigerator

InactiveCN111765704AImprove heat transfer efficiencyFast coolingDomestic refrigeratorsMachines using electric/magnetic effectsThermal insulationIcebox

The invention discloses an air-cooled refrigeration system and a semiconductor refrigerator, and relates to the technical field of refrigerators. The air-cooled refrigeration system comprises a heat exchange system, an air duct system and a box outer barrel; the box outer barrel comprises a box outer barrel back; the heat exchange system comprises a refrigeration module and a heat dissipation module; a semiconductor module is arranged between the refrigeration module and the heat dissipation module; the air duct system comprises a box inner barrel and a box middle frame; the box outer barrel and the box inner barrel are connected by the box middle frame; thermal insulation materials are filled in the box middle frame; the refrigeration module and the semiconductor module are arranged inside the box middle frame; the heat dissipation module is arranged at the outer side of the box outer barrel back; the refrigeration module comprises a refrigeration block and a refrigeration fan; and the refrigeration module is arranged in the box middle frame. According to the air-cooled refrigeration system provided by the invention, an air return channel structure is added in the refrigerator, forced convection is achieved through the air duct system in the box, and the problem that an existing semiconductor refrigerator is not ideal in refrigeration effect, low in overall efficiency, especially slow in refrigeration speed is solved.

Owner:CHANGHONG MEILING CO LTD

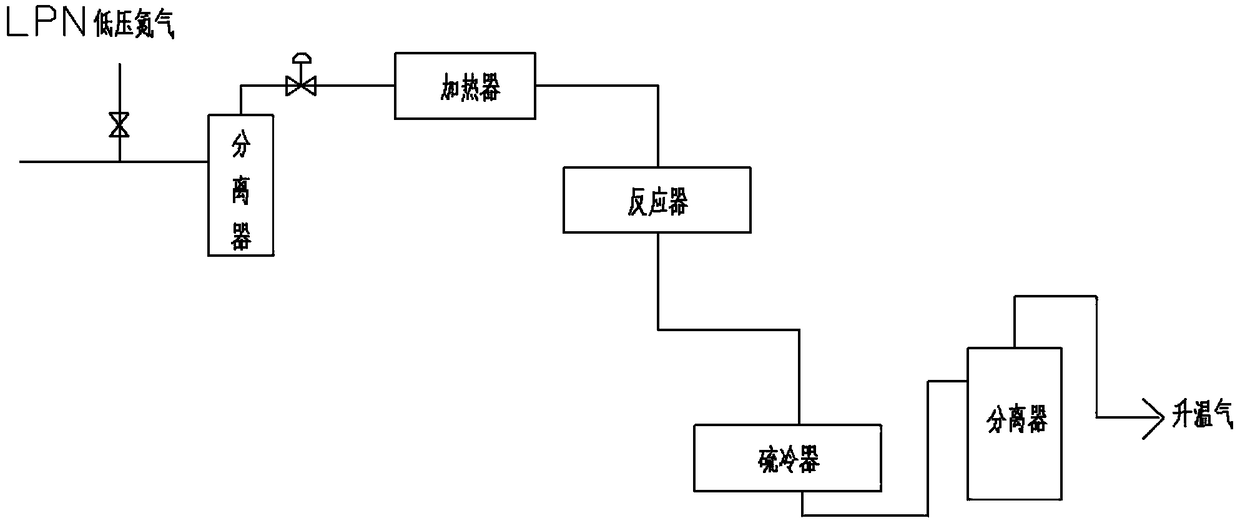

Recovery process for purifying sulfur with coal-to-methanol synthesis gas

ActiveCN109485018AAvoid overheating inactivationSmooth temperature changeSulfur compoundsEnergy inputWater vaporCarbon deposit

The invention provides a recovery process for purifying sulfur with coal-to-methanol synthesis gas. The process comprises the following steps: performing replacement on a reactor and a system nitrogentemperature rise system, and heating a sulfur recovery catalyst bed by adopting nitrogen; clearing sulfur after stopping sulfur recovery, controlling the temperature of a heater at the inlet of the reactor, heating by medium pressure steam, ensuring the temperature of the inlet of the bed to be 120-260 DEG C, and clearing sulfur while controlling the bed temperature to 120-260 DEG C. The volume content of H2S and S at the outlet of the bed is less than 0.01%, and when no liquid sulfur is discharged during drain recovery of a system condenser, the operation of clearing sulfur with nitrogen isended. According to the process disclosed by the invention, catalyst starting can be completed, the activity temperature is met, and in the processes of raising the temperature of the sulfur recoverycatalyst and stopping sulfur clearing, incineration side-reactions are fundamentally avoided, so that the influences of carbon deposit and water vapor on the catalyst activity can be eliminated. In addition, the inert gas nitrogen is taken as the sulfur-clearing carrier, so that unsafe factors brought by leakage are fundamentally eliminated, and intrinsic safety is realized.

Owner:HENAN LONGYU COAL CHEM

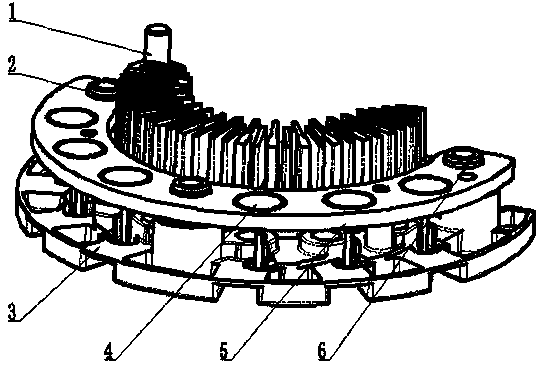

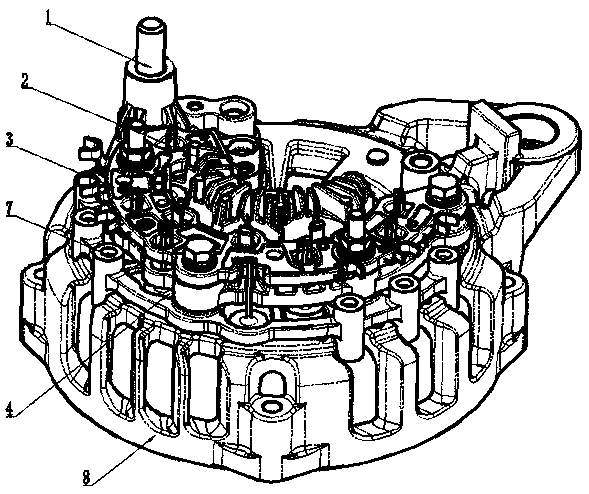

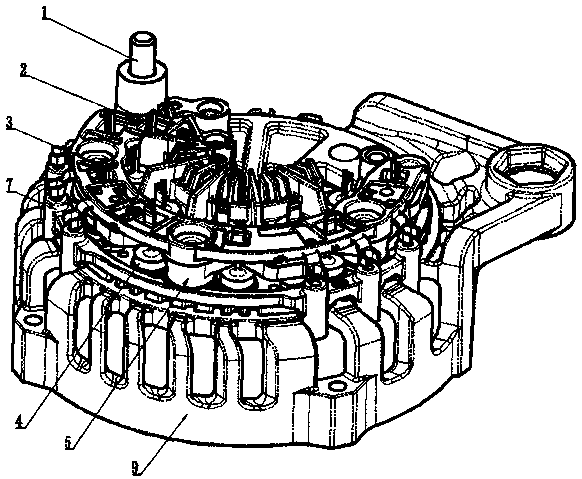

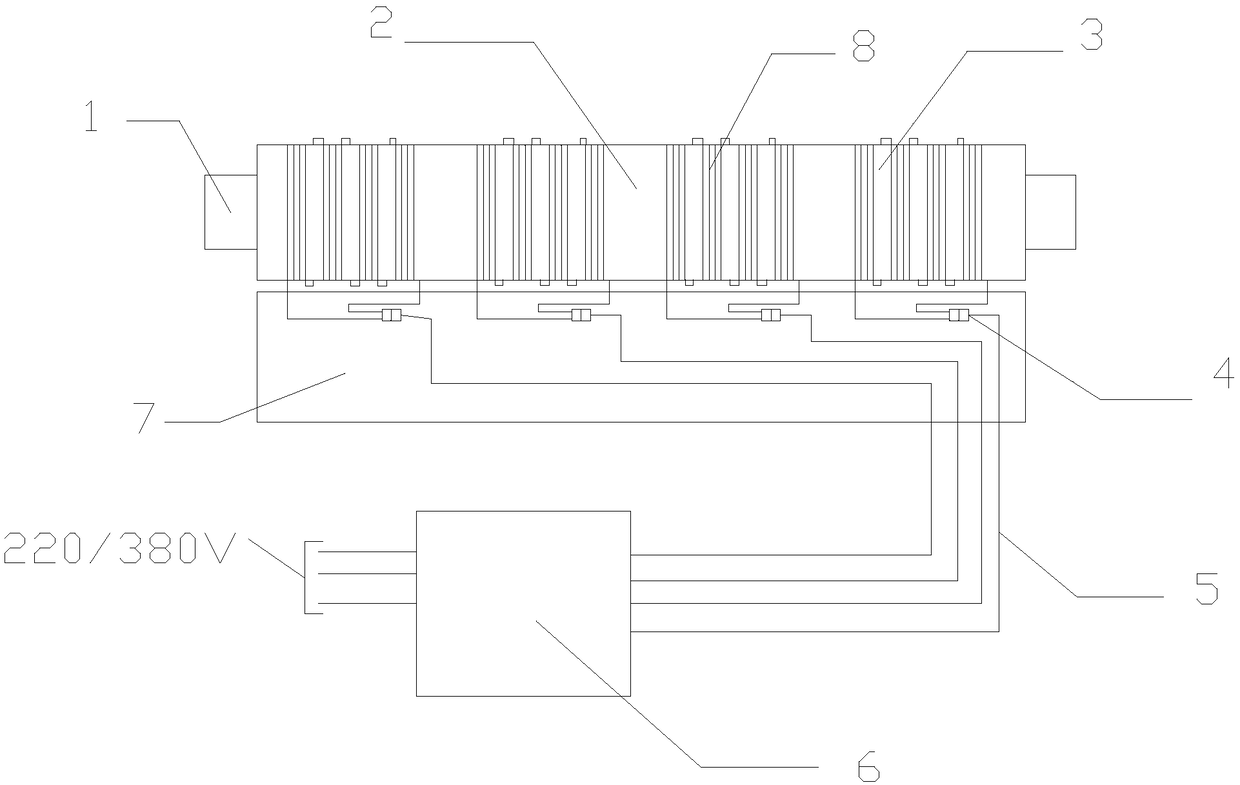

High-efficiency flat wire generator rectifier structure and assembling method thereof

PendingCN107666216AReliable insulationUniform temperature gradientConversion constructional detailsModifications for power electronicsRectifier diodesStator

The invention discloses a high-efficiency flat wire generator rectifier structure which comprises a conductive negative plate, an intermediate supporting insulating bracket, a conductive positive plate, a junction bridge bracket, positive output screw rods, rectifier diodes, tubular rivets, a rear generator fixed cover, a rear generator fixed cover supporting boss and a plastic protective cover. The rectifier structure is characterized in that the intermediate supporting insulating bracket that is used for replacing an insulating bush is installed between the conductive negative plate and theconductive positive plate; the conductive negative plate is installed below a rectifier and is connected and fixed with the rear generator fixed cover supporting boss; the lower edge of the plastic protective cover is flush with the upper edge of the conductive negative plate; the junction bridge bracket is installed above the conductive positive plate and is connected and fixed with motor statorline connection threads. The rectifier structure has the following advantages: with a bidirectional air-intake mode, the temperature gradients on the positive and negative plates become uniform to guarantee spot welding reliability; different output direction requirements of clients are met; the generator power and product reliability are improved; and the service life of the high-efficiency generator is prolonged.

Owner:JIANGSU YUNYI ELECTRIC

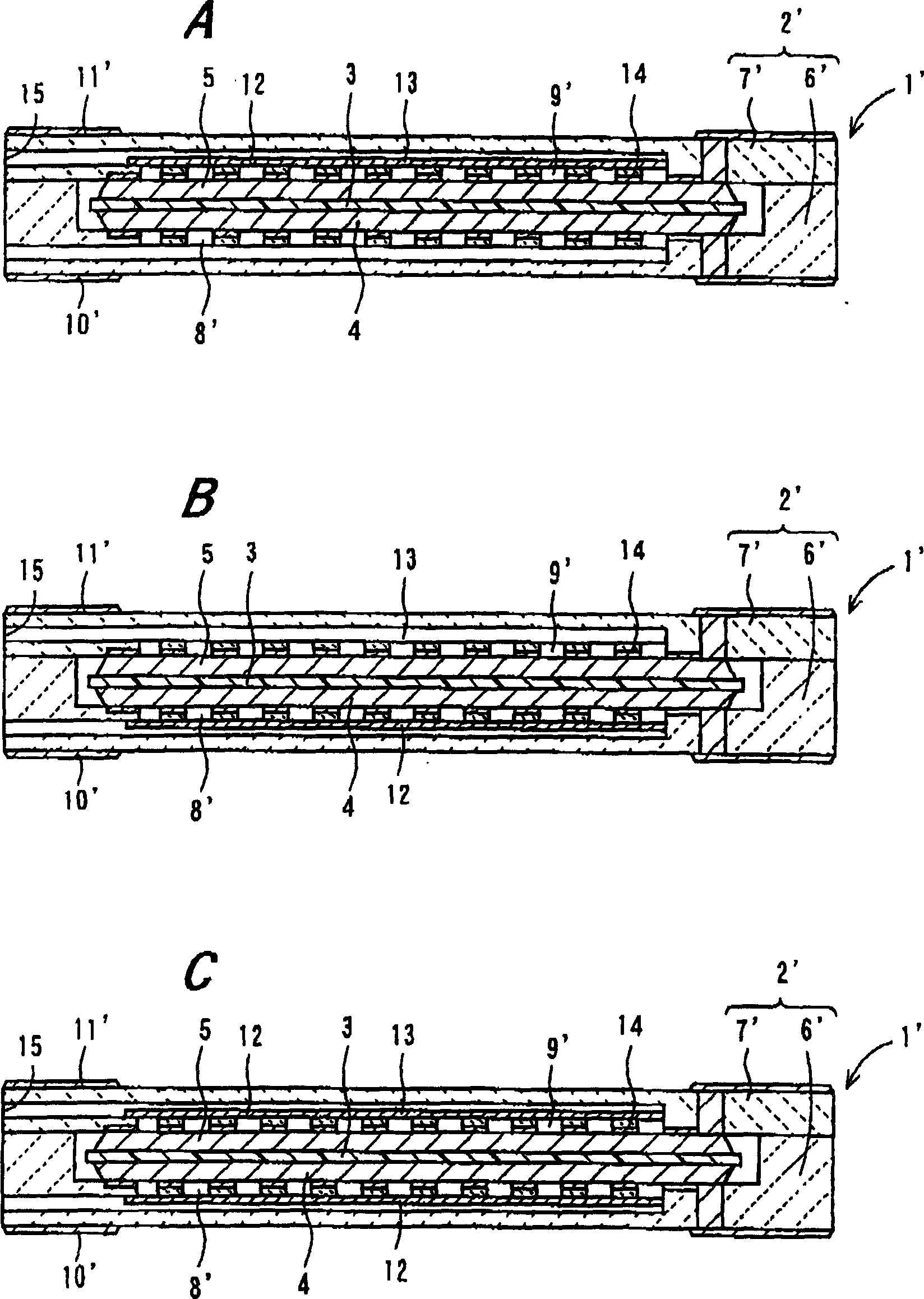

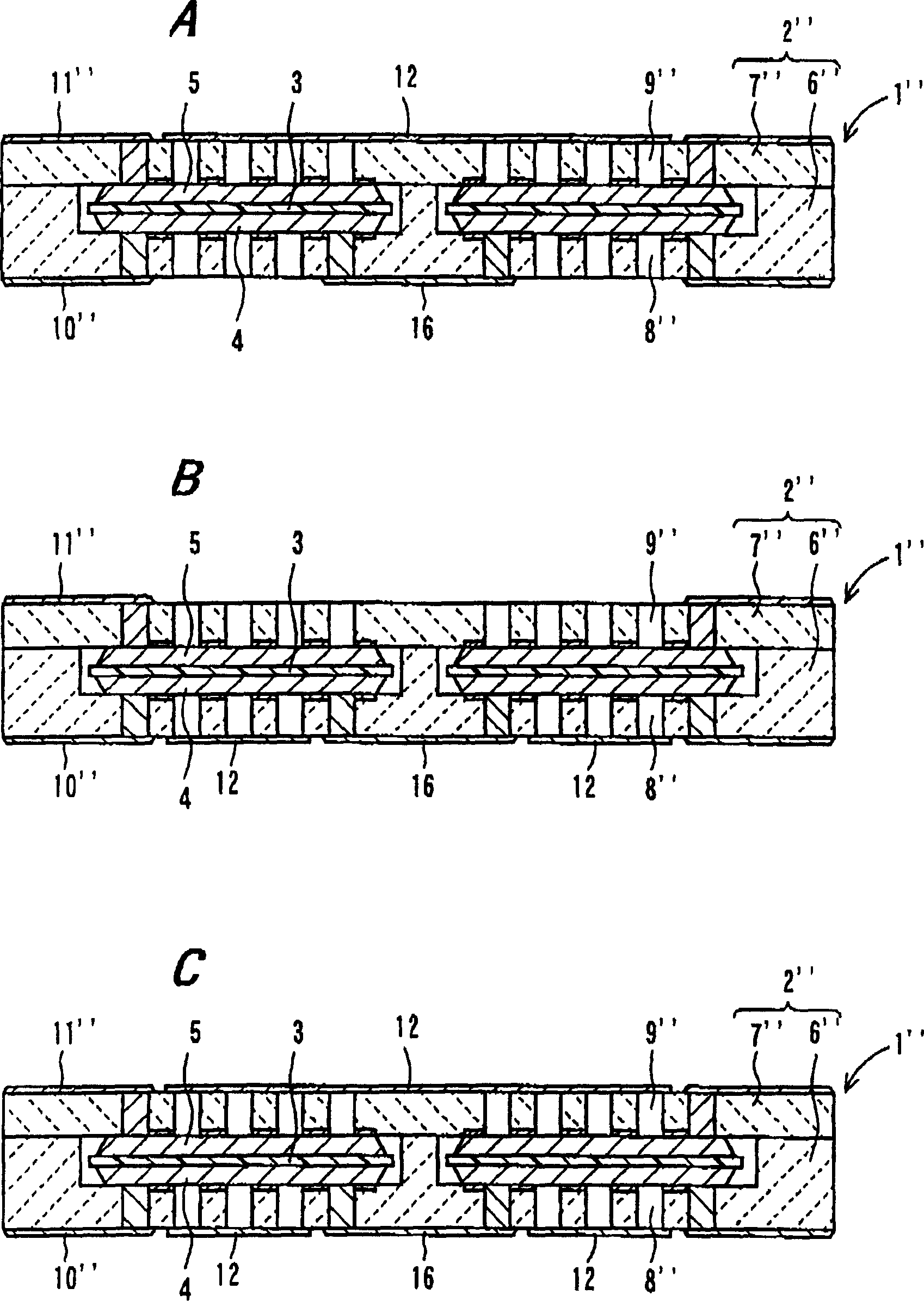

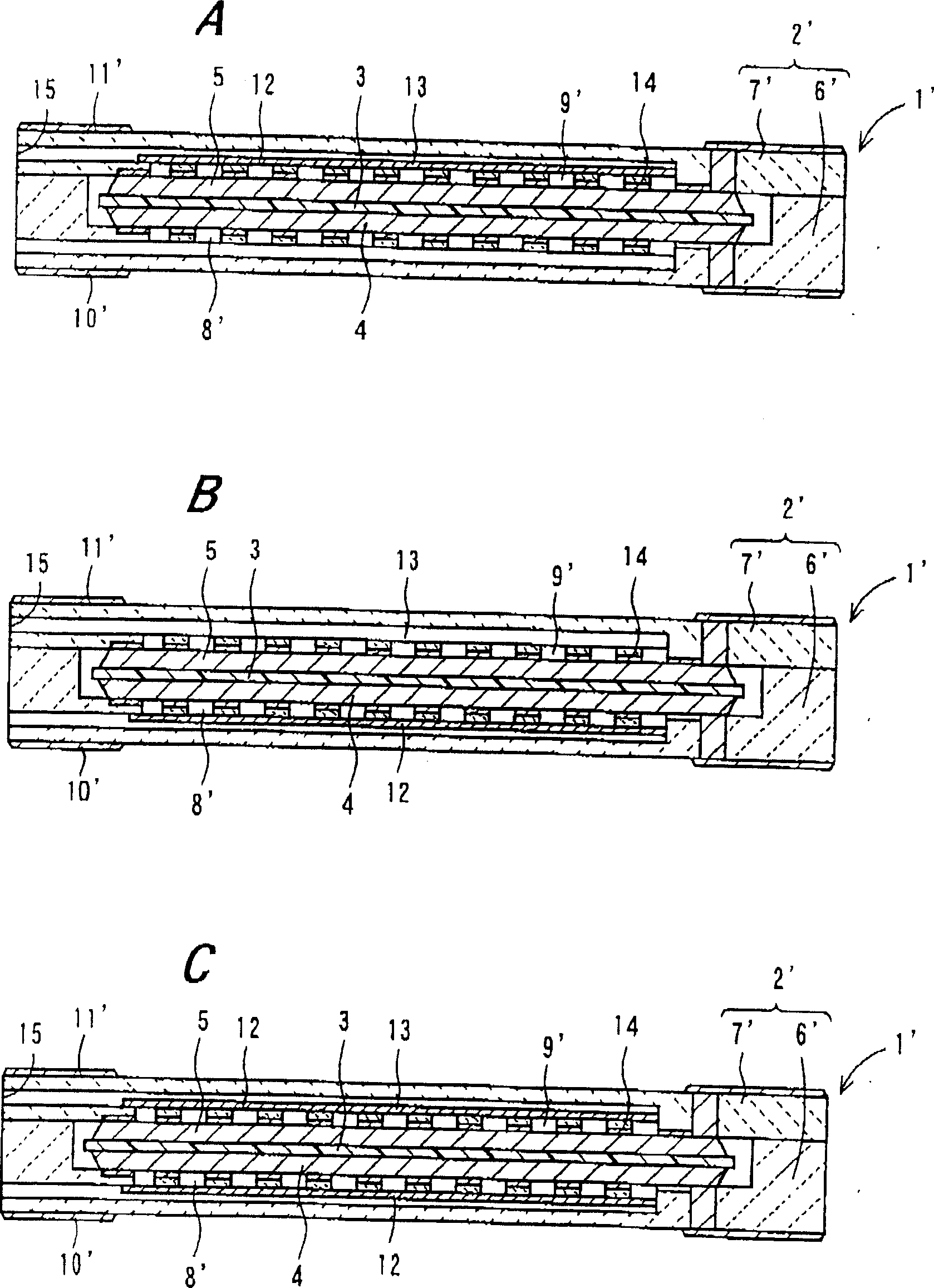

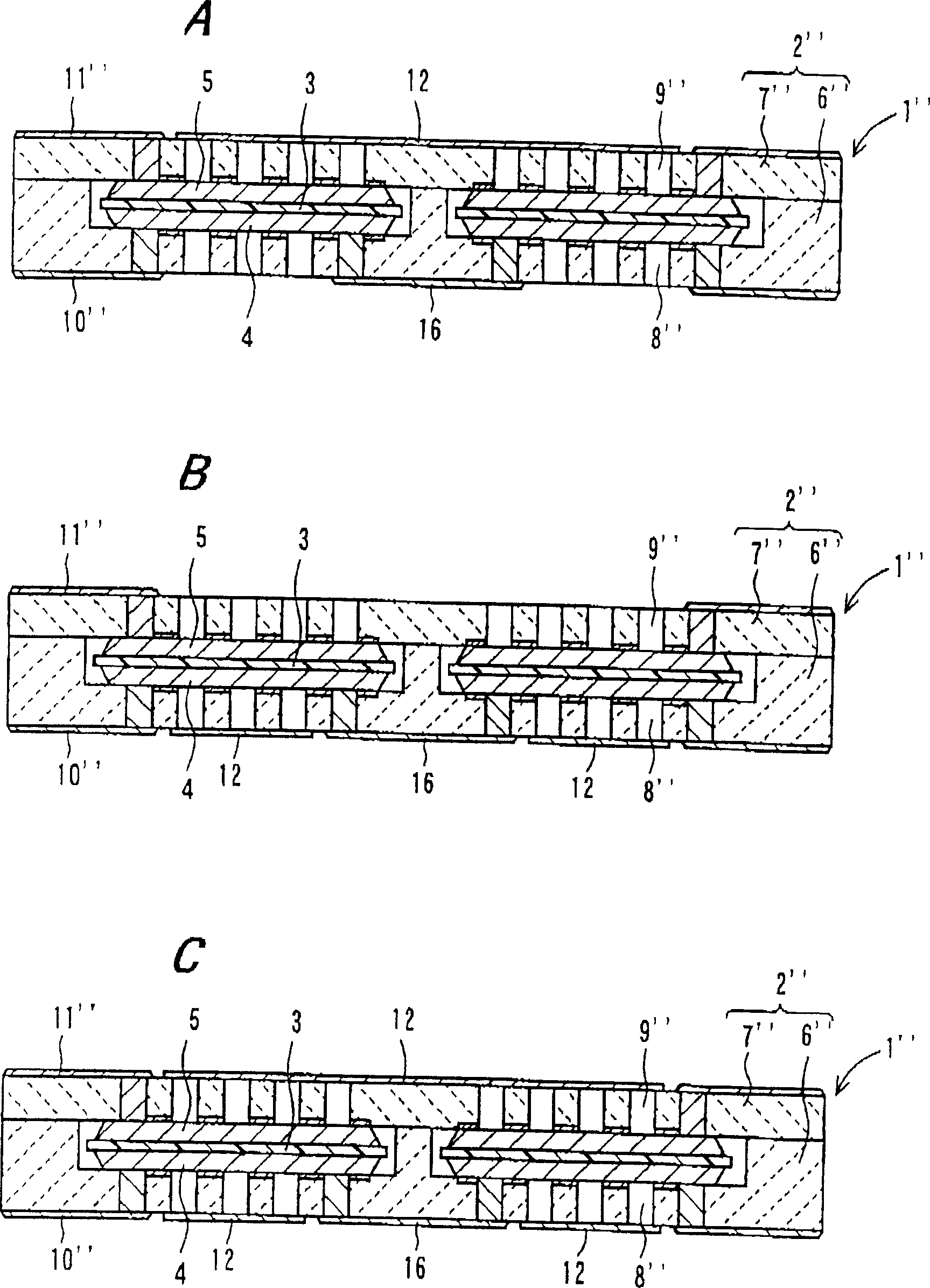

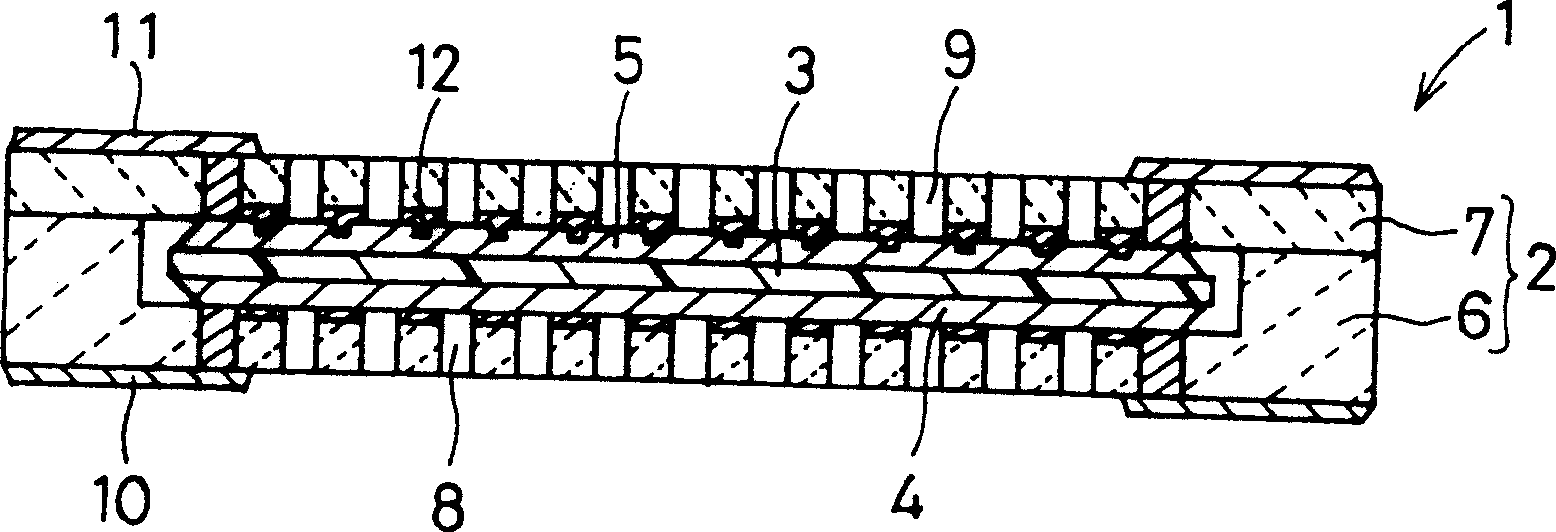

Container for fael cell, fuel cell and electronic apparatus

InactiveCN1591952AHigh mechanical reliabilityImprove reliabilityFuel cells groupingCell component detailsFuel cellsElectrical conductor

PURPOSE: Provided are a container for a fuel cell which can accommodate an electrolyte member, is compact and strong, and can allow gas to be distributed uniformly and temperature to be gradient uniformly, a fuel cell containing the container for portable electronic device, and an electronic tool containing the fuel cell. CONSTITUTION: The container comprises a base body which comprises a ceramic a concave part accommodating an electrolyte member having first and second electrodes at one and the other main faces, at the one side; a first fluid channel which is formed from the bottom face of the concave part facing the one main face of the electrolyte member to the outer face of the base body; a first wire conductor whose one end is located at the bottom face of the concave part facing the first electrode of the electrolyte member and whose the other end is drawn to the outside of the base body; a cover body which is installed by covering the one side of the environment of the concave part of the base body with the concave part and seals tightly the concave part; a second fluid channel which is formed from the one side of the cover body facing the other main face of the electrolyte member to the outer face of the cover body; a second wire conductor whose one end is located at the one face of the cover body facing the second electrode of the electrolyte member and whose the other end is drawn to the outside of the cover body; and a porous body which is located at the base body or the cover body so as to cover one of the first and second fluid channels where an oxidizing gas is supplied.

Owner:KYOCERA CORP

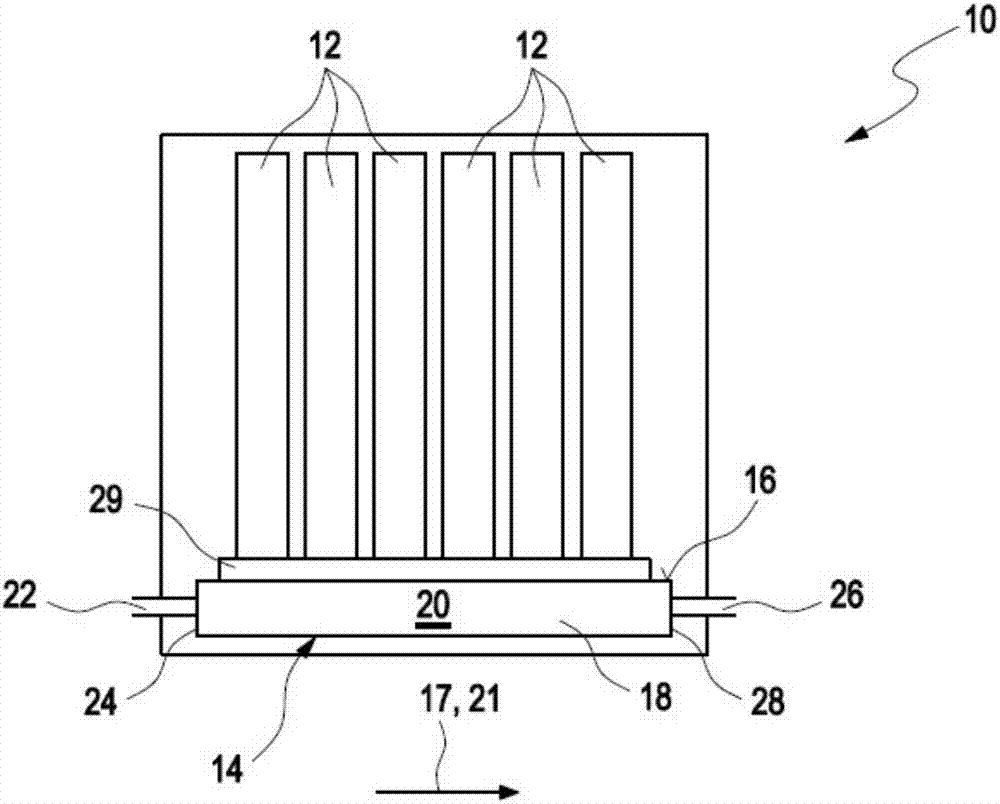

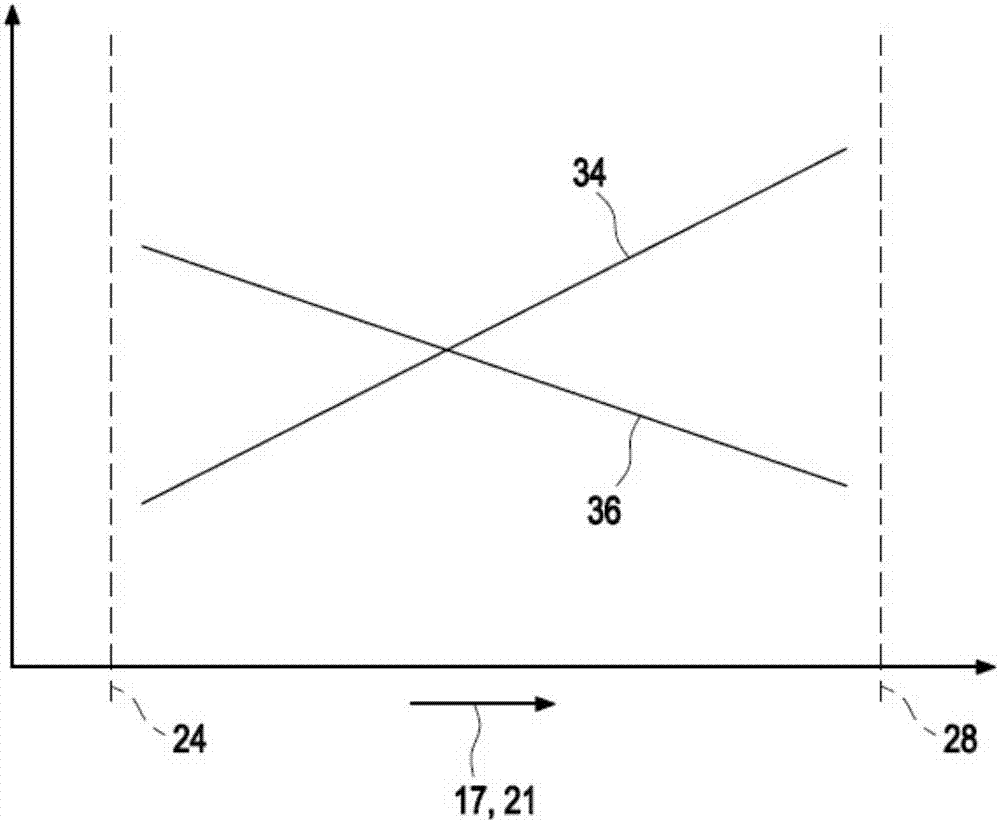

Heat exchanger for controlling the temperature of energy storage elements of an energy store

InactiveCN107078313AImpact ratioUniform temperature changeProtecting/adjusting hybrid/EDL capacitorCells cooling/heatingHeat conductingEngineering

The invention relates to a heat exchanger for controlling the temperature of energy storage elements (12) of an energy store (10) and / or of power electronics, for example of battery cells, having a heat exchange surface (16) which is placed on the energy store (10). Essential to the invention is the fact that the heat exchanger surface (16) is partially coated with a layer (29) comprising a heat-conducting material, and that the heat exchange surface (16) has contact regions (30) which are provided with the heat-conducting layer (29), and insulating regions (32) which are not provided with the heat-conducting layer (29). The invention further relates to an energy store and to the production thereof having energy storage elements (12) and at least one such heat exchanger (14), which rests on the energy storage elements (12) in order to control the temperature of the energy storage elements (12). Essential to the invention is the fact that a contact area between the energy storage elements (12) and the heat exchanger (14) is formed by the heat-conducting layer (29) applied to the heat exchanger (14).

Owner:MAHLE INT GMBH

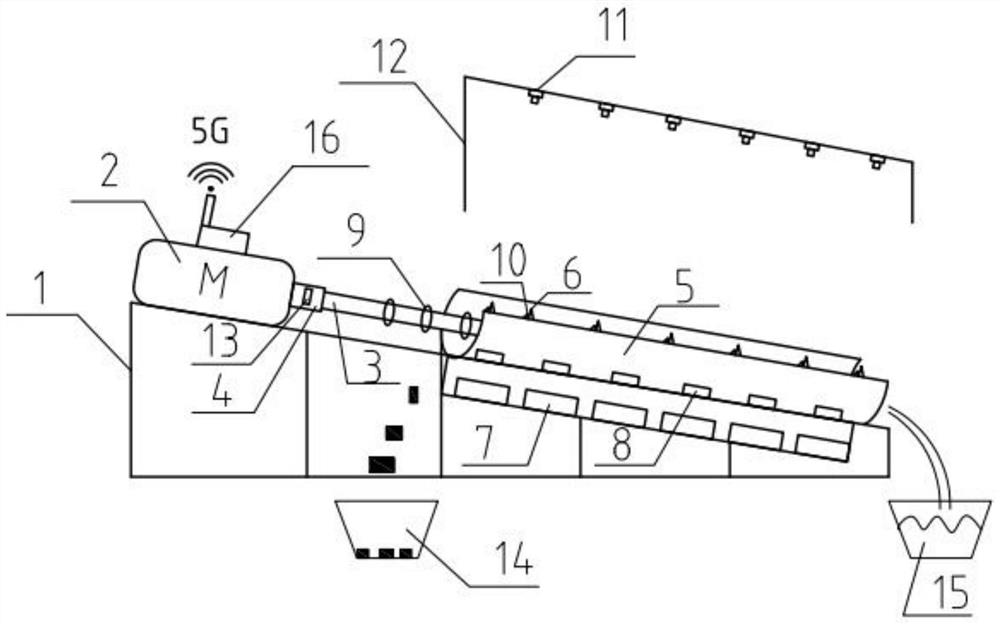

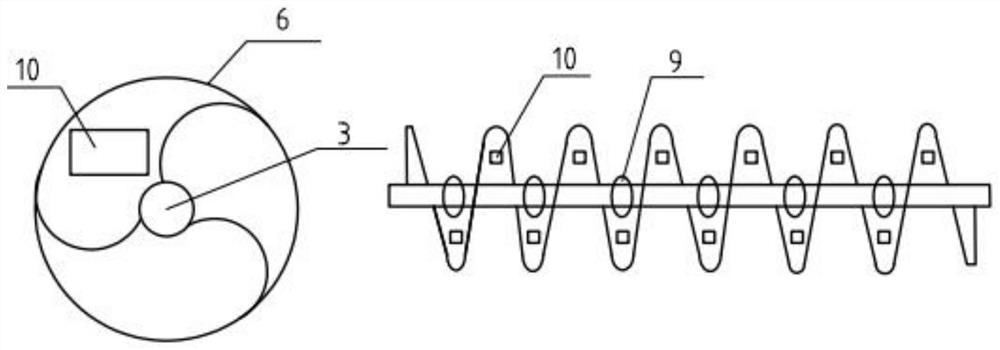

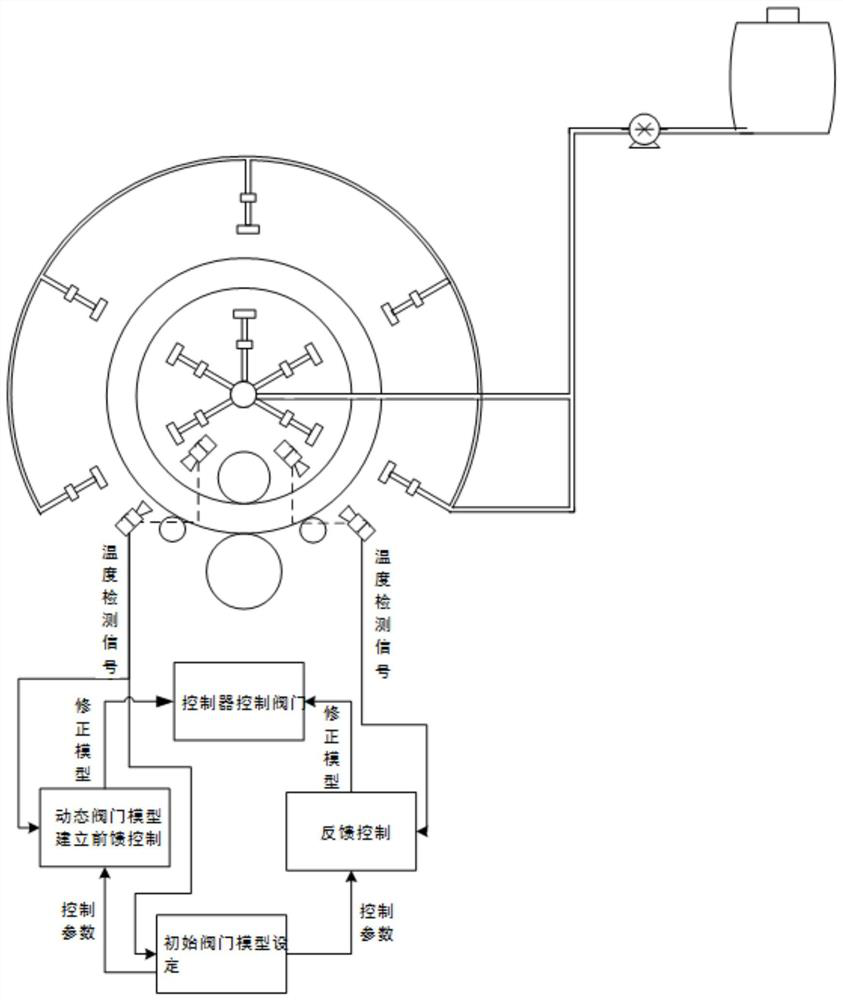

Intelligent continuous solidification separator for crude tin purification and crystallization method

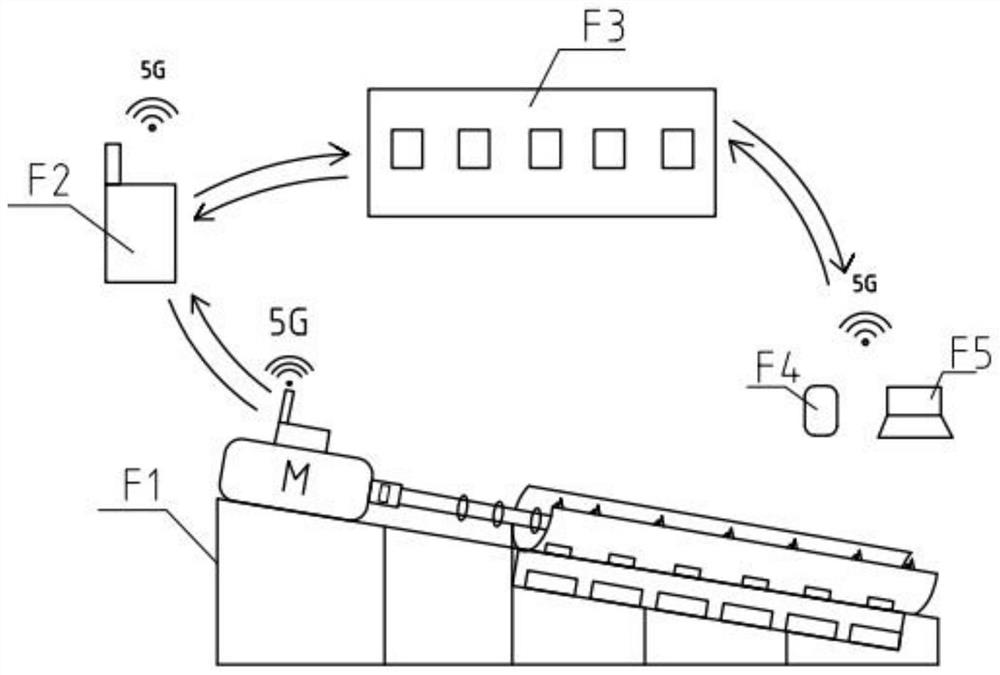

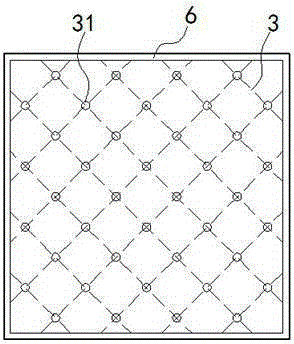

PendingCN113999992AEasy to operatePrecise controlSolution crystallizationHeat exchange cooling cystallizationChemistryMobile end

The invention discloses an intelligent continuous solidification separator for crude tin purification and a crystallization method. The separator comprises a separator support, a motor, a rotating shaft, a U-shaped crystallization tank, a spiral blade, a modular heating body, a bottom patch type temperature sensor, a shaft sleeve type temperature sensor, a blade patch type temperature sensor, a high-definition infrared temperature sensor, an infrared temperature measurement system support, a speed sensor, a material melting pot, a crystal pot, a melt pot and a 5G wireless transceiver. The temperature of the solidification separator is monitored and controlled in real time through a multi-dimensional temperature measurement system and a modular heating system, the rotating speed of a solidification separator is controlled in real time through an intelligent speed regulation system, meanwhile, the high-temperature-resistant 5G wireless transceiver is adopted for real-time online transmission of data, the data is fed back to a mobile terminal after being processed by the server, and the mobile terminal can also directly regulate and control the separator in real time.

Owner:KUNMING UNIV OF SCI & TECH

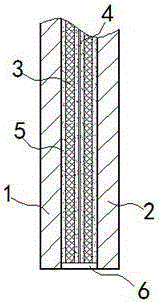

Explosion-proof curtain wall plate

The invention relates to an explosion-proof curtain wall plate which comprises an outer-layer plate and a back plate. A screen is clamped between the outer-layer plate and the back plate, and hard isolation beads are adhered onto the screen; the peripheral edge of the outer-layer plate and the peripheral edge of the back plate are adhered to each other by adhesive to form a liquid-seal cavity, and the cavity is filled with heat-insulation liquid. The explosion-proof curtain wall plate has the advantages that the explosion-proof curtain wall plate is simple in structure and is explosion-proof; the curtain wall plate has low sealing requirements, is stable in structure and has excellent explosion-proof and heat-insulation functions.

Owner:中科深美环境科技股份有限公司

Crystal growth furnace and crystal production process

The invention discloses a crystal growth furnace and a crystal production process. The crystal growth furnace comprises a furnace body, a crucible assembly, a heating assembly and a heat insulation assembly, the crucible assembly comprises a first crucible, a second crucible and a third crucible, a first cavity is suitable for being constructed into a raw material discharging area, and a third cavity is suitable for being constructed into a crystal growth area; the heating assembly comprises a first heater and a second heater, the first heater is arranged around the crucible assembly, and thesecond heater is arranged under the crucible assembly; the heat insulation assembly comprises a first heat insulation part, a second heat insulation part and a third heat insulation part, the first heat insulation part is arranged around the first heater, the second heat insulation part is arranged at the upper end of the first heat insulation part and extends inwards to exceed the first heater soas to surround the crucible assembly, the third heat insulation part is arranged at the upper end of the second heat insulation part and located above the crucible assembly, and the third heat insulation part at least extends inwards to the radial inner side of the first crucible. According to the crystal growth furnace, production of defect-free crystals is facilitated.

Owner:XUZHOU XINJING SEMICON TECH CO LTD +1

Method for preparing foam glass by utilizing waste glass and porous ceramsite

The invention discloses a method for preparing foam glass by utilizing waste glass and porous ceramsite. The method particularly comprises the following steps: preparing a hydrotalcite-like material by taking manganese nitrate, aluminum nitrate and urea as raw materials, and mixing the hydrotalcite-like material and silicon carbide to prepare a foaming agent; preparing porous ceramic by taking plant powder, zeolite powder, polyvinyl alcohol, deionized water, montmorillonite, aluminum nitride fiber and urea as raw materials; and preparing a green body by taking waste glass powder, modified porous ceramsite, a cosolvent, the foaming agent and a foaming accelerant as raw materials through the steps of grinding, mixing and performing compression molding, placing the green body into a muffle furnace and performing sintering treatment to prepare the foam glass. The foam glass prepared with the method has high mechanical property and excellent sound-absorbing and heat-insulating properties.

Owner:深圳市辉翰科技发展有限公司

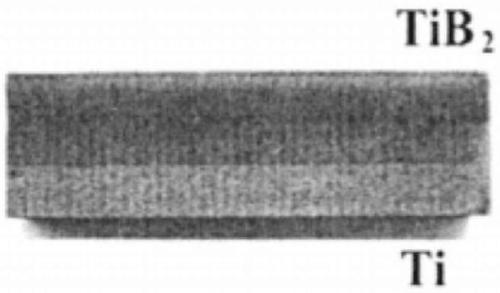

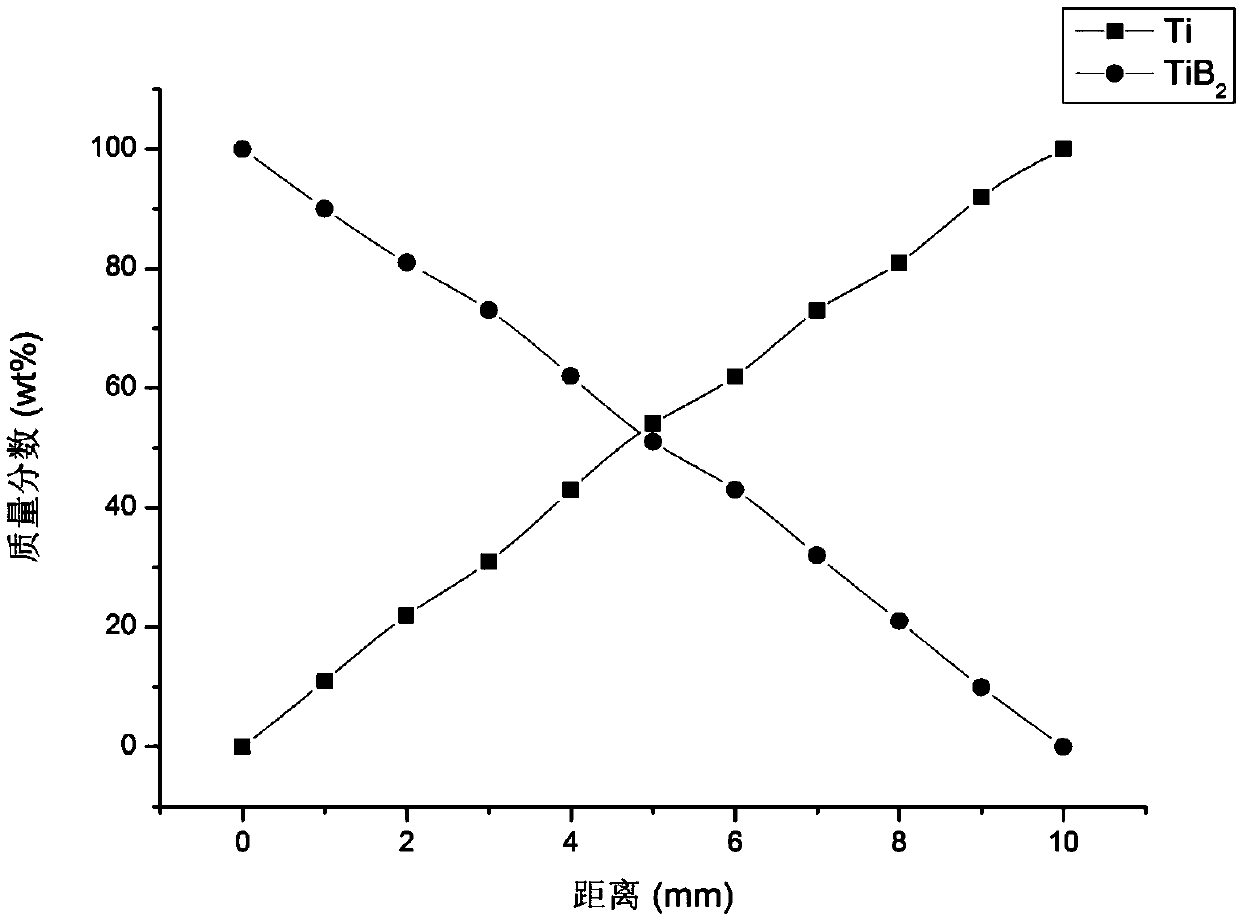

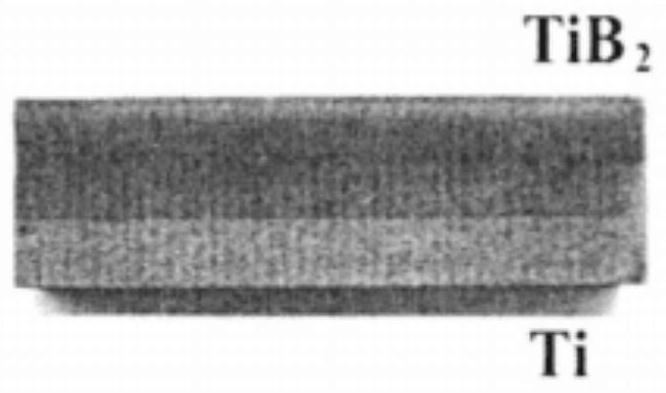

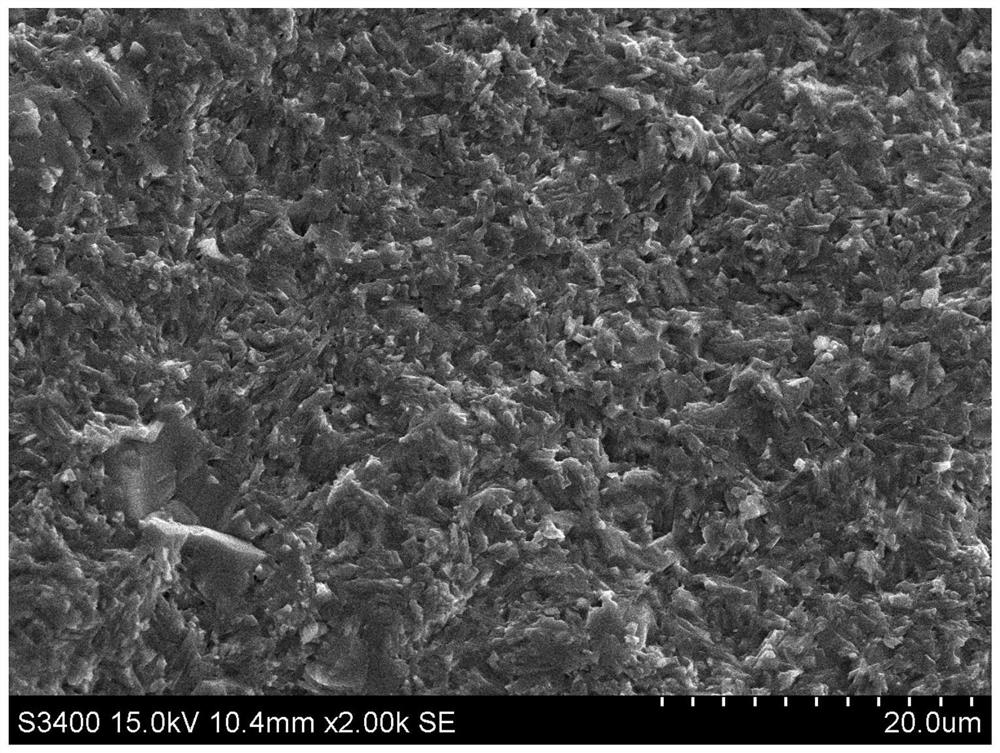

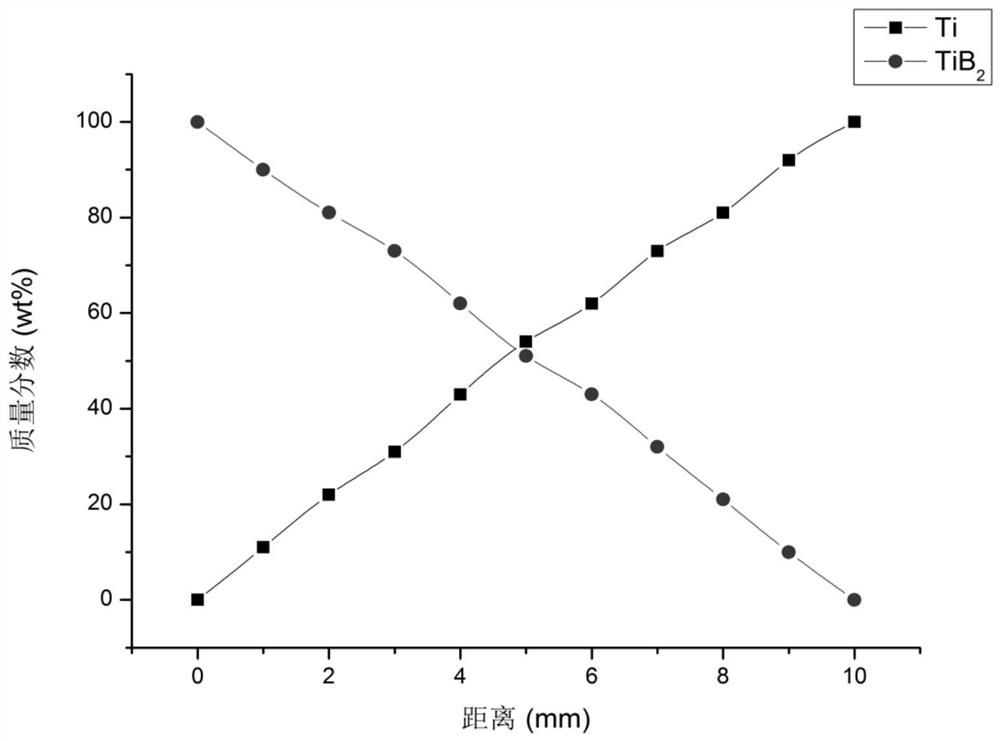

Centrifugal sintering method for functionally graded material of thin-wall pipe fitting

The invention discloses a centrifugal sintering method for a functionally graded material of a thin-wall pipe fitting. The centrifugal sintering method for the functionally graded material of the thin-wall pipe fitting comprises the following steps of mixing two evenly distributed powder, a solvent and a dispersing agent, stirring in air, and vacuum degassing to form an even slurry; loading the slurry into a pulp spraying machine, then stretching a spraying head into a base plate in a centrifugal machine, and evenly spraying the slurry onto the inner wall of the base plate; changing the relative volume percentage of the two powder, and forming a second layer of composite material layer; repeating the steps, and forming multilayer spraying; stretching a graphite radiation heating element into an inner cavity of the base plate, electrifying, moving up and down, installing a layer of heat insulation layer on the outer wall of the base plate, and electrifying the heat insulation layer; andturning off the centrifugal machine, sintering a green body, taking the green body out from the base plate, and obtaining a hollow pipe fitting. According to the centrifugal sintering method for thefunctionally graded material of the thin-wall pipe fitting provided by the invention, through adding the graphite radiation heating element, and installing the heat insulation layer on the outer layerof the base plate, the even temperature gradient is realized internally, so that an effective guarantee is provided for preparing the uniform and compact thin-wall pipe fitting.

Owner:WUHAN UNIV OF TECH

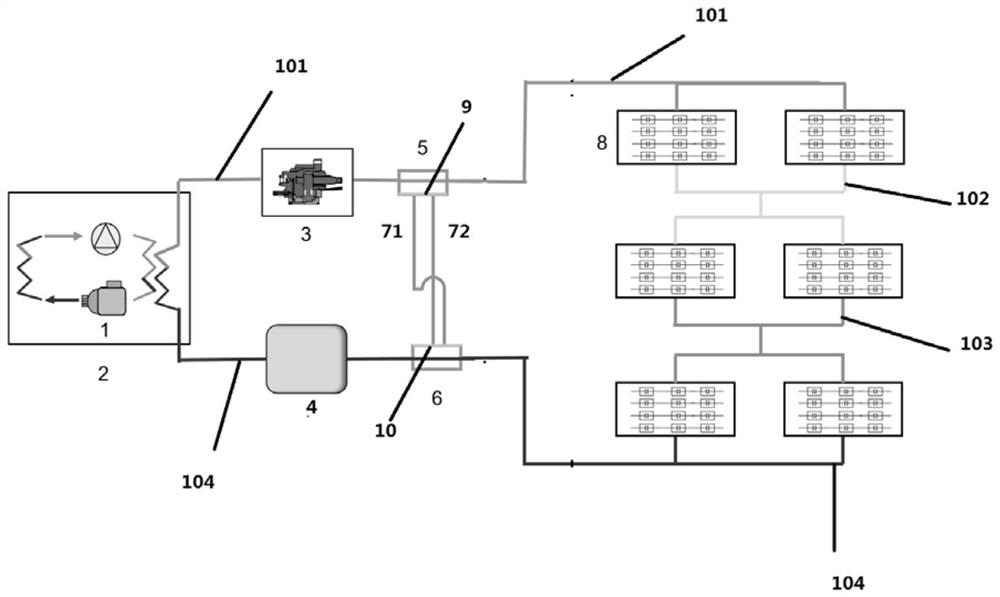

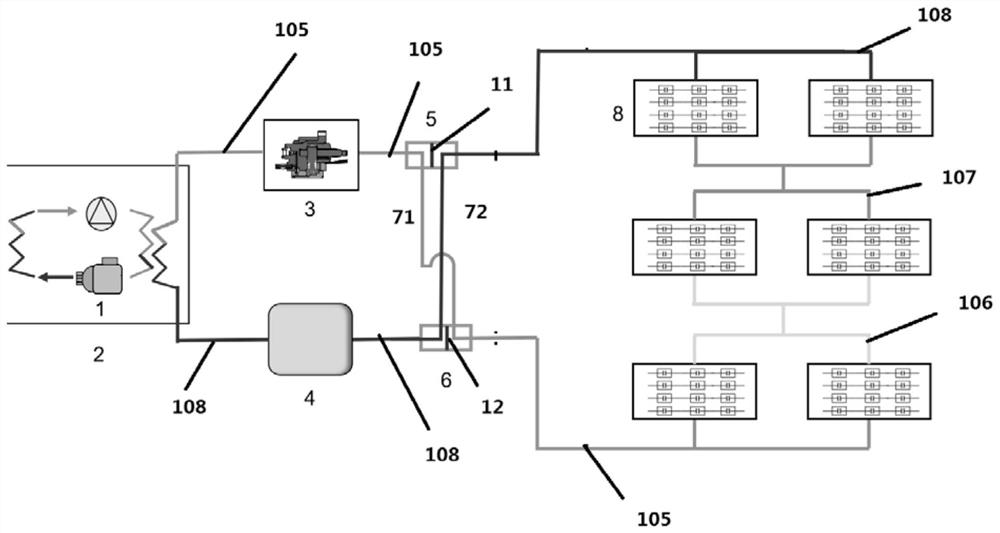

Capacitor pack or battery pack cooling system and control method thereof

PendingCN113904032AUniform temperatureUniform temperature gradientProtecting/adjusting hybrid/EDL capacitorSecondary cellsCapacitanceProcess engineering

The present invention aims to provide a capacitor pack or battery pack cooling system and a control method thereof. According to the present invention, the temperature gradient between the capacitor packs or the battery packs is effectively balanced through the forward circulation or reverse circulation of cooling water in a forward circulation and reverse circulation switching pipeline, the capacitor packs or the battery packs can be in a temperature balance state, the problem of large monomer temperature difference in the capacitor packs or the battery packs of a series cooling structure is solved, the performance and the service life of a super capacitor can be improved, the monomer circuit temperature is effectively balanced, and higher safety and economical efficiency are achieved.

Owner:SHANGHAI AOWEI TECH DEV

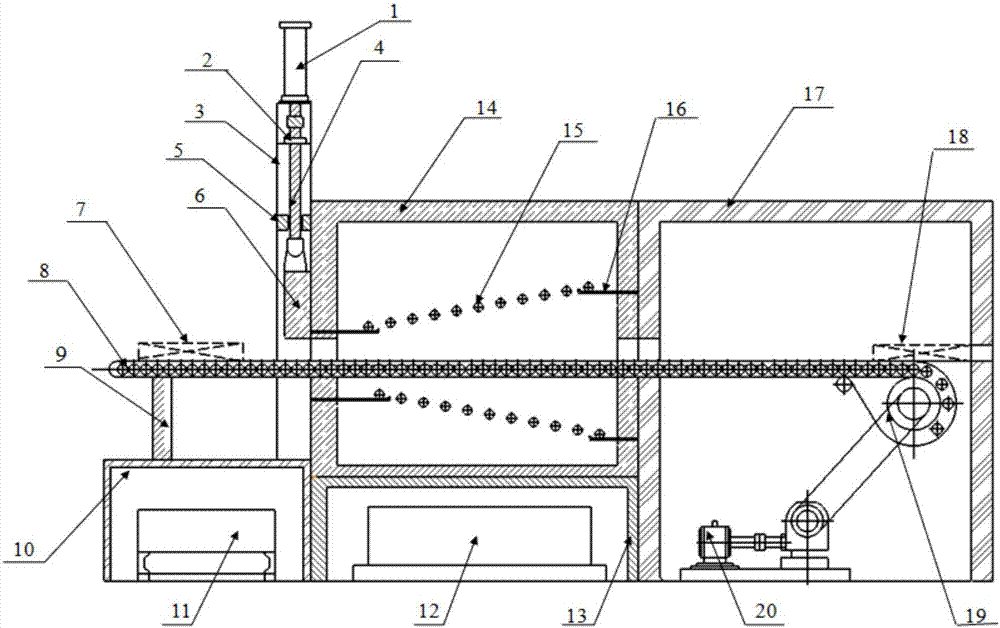

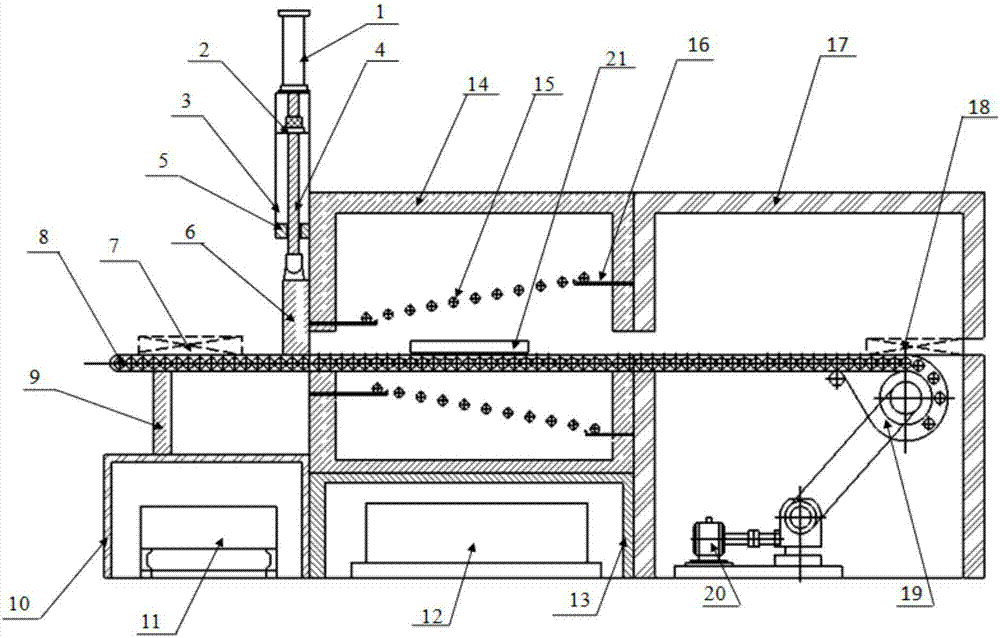

High-strength steel gradient induction heating device

InactiveCN105821185BNo pollution in the processHigh heating temperatureIncreasing energy efficiencyFrequency conversionConveyor belt

The invention discloses a gradient induction heating device for high-strength steel. The gradient induction heating device for high-strength steel comprises a heating chamber, a conveyor belt, an induction heating coil, a frequency conversion device and a control device, wherein the heating chamber is provided with a feed inlet for conveying parts; the conveyor belt penetrates through the heating chamber via the feed inlet to reach the outside, and used for conveying the parts to be heated in the heating chamber; the induction heating coil is of a taper structure with the inner diameter gradually increasing; the conveyor belt can pass through in the center axis direction of the induction heating coil; the frequency conversion device is electrically connected with the induction heating coil and used for changing the power-on frequency of the induction heating coil; and the control device is electrically connected with the conveyor belt and used for controlling the stop locations of the parts. The gradient induction heating device for high-strength steel has the characteristics that errors are small, temperature can be controlled, and the heating temperature gradient is uniform.

Owner:JILIN UNIV

Long-life desulfurization spray gun refractory piece and preparation process thereof

The invention discloses a long-life desulfurization spray gun refractory piece and a preparation process thereof, and relates to the technical field of refractory materials. The refractory piece is a carbon-bonded metal plasticity reinforced refractory material, and comprises the following raw materials by weight: 15-45% of alumina or flint clay, 30-65% of corundum, 5-15% of silicon carbide, 3-5% of crystalline flake graphite, 5-8% of simple substance or composite metal powder, 6-8% of a composite carbon binder, and 0.5-2% of a burning promoting agent. According to the invention, the long-life desulfurization spray gun refractory piece is a carbon-bonded metal plasticity reinforced refractory material, and has high mechanical property and excellent thermal shock resistance, and a carbon-bonded metal plasticity reinforced spray gun refractory piece which is good in thermal shock stability, good in toughness, resistant to erosion, efficient in production and long in service life is obtained.

Owner:JIANGSU ZHENGDA FURNACE CHARGE

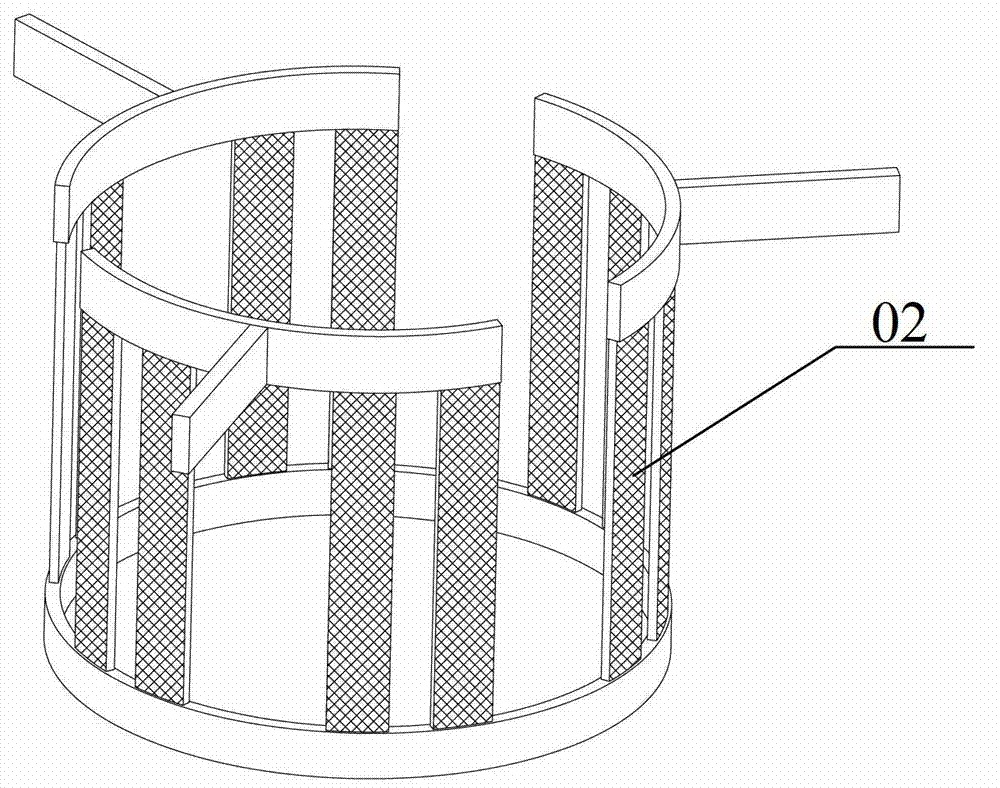

A double-heater structure for a large-scale sapphire furnace

ActiveCN103046135BMore controllable combinationsFavorable thermal field conditionsPolycrystalline material growthUsing seed in meltElectricityField conditions

Owner:苏州恒嘉晶体材料有限公司

A kind of uniform cooling system and method for differential temperature rolling of large cylinder section

ActiveCN113695405BHomogeneous temperature gradientUniform internal organizationTemperature control deviceMeasuring devicesThermodynamicsJet flow

Owner:YANSHAN UNIV

Container for fuel cell,fuel cell and electronic apparatus

InactiveCN1298069CHigh mechanical reliabilityImprove reliabilityFuel cells groupingCell component detailsFuel cellsElectrical conductor

PURPOSE: Provided are a container for a fuel cell which can accommodate an electrolyte member, is compact and strong, and can allow gas to be distributed uniformly and temperature to be gradient uniformly, a fuel cell containing the container for portable electronic device, and an electronic tool containing the fuel cell. CONSTITUTION: The container comprises a base body which comprises a ceramic a concave part accommodating an electrolyte member having first and second electrodes at one and the other main faces, at the one side; a first fluid channel which is formed from the bottom face of the concave part facing the one main face of the electrolyte member to the outer face of the base body; a first wire conductor whose one end is located at the bottom face of the concave part facing the first electrode of the electrolyte member and whose the other end is drawn to the outside of the base body; a cover body which is installed by covering the one side of the environment of the concave part of the base body with the concave part and seals tightly the concave part; a second fluid channel which is formed from the one side of the cover body facing the other main face of the electrolyte member to the outer face of the cover body; a second wire conductor whose one end is located at the one face of the cover body facing the second electrode of the electrolyte member and whose the other end is drawn to the outside of the cover body; and a porous body which is located at the base body or the cover body so as to cover one of the first and second fluid channels where an oxidizing gas is supplied.

Owner:KYOCERA CORP

Injection molding machine electromagnetic induction heating soaking device

InactiveCN108790086AUniform temperature gradientUniform plasticizationCapacitanceElectromagnetic induction

The invention discloses an injection molding machine electromagnetic induction heating soaking device and relates to the technical field of heating. The injection molding machine electromagnetic induction heating soaking device comprises an electromagnetic heating cylinder and an electromagnetic heating controller. The electromagnetic heating cylinder comprises an inner layer material cylinder, middle layer insulation cotton and an outer layer wound high-temperature wire electromagnetic coil. The surface of the insulation cotton is fixedly wrapped with a high-temperature-resistant cloth. Effective gaps are kept between wound wires of the high-temperature wire electromagnetic coil. The electromagnetic heating controller has matched capacitance inductance and current range. The high-temperature wire electromagnetic coil comprises two or more coil sets. All the coil sets are tightly wound on the insulation cotton and are separated from each another. Every two adjacent coil sets adopt a rewinding mode, namely the high-temperature wire electromagnetic coil is opposite in winding direction, and generated electromagnetism directions are opposite. The injection molding machine electromagnetic induction heating soaking device provided by the invention is even in temperature distribution, stable in product quality, long in device service life and good in energy saving effect.

Owner:长沙水星包装有限公司

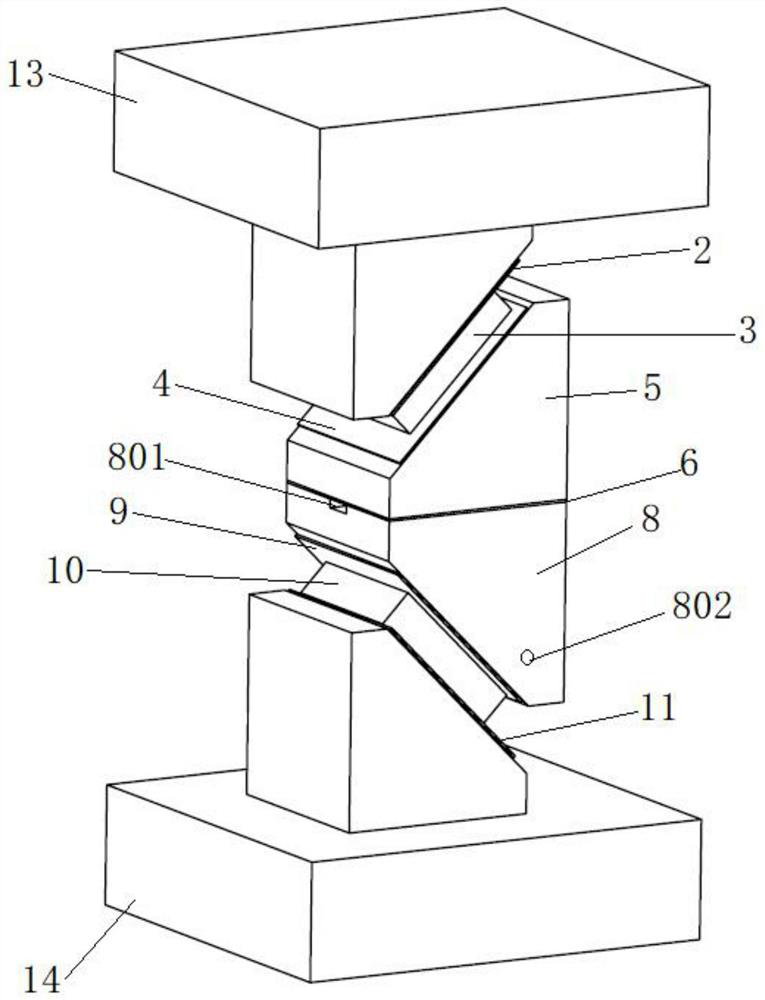

A Crystal Furnace Device Compensating the Gouy Phase Shift to Increase Nonlinear Interactions

ActiveCN111060452BEnhanced interactionImprove thermal conductivityMaterial analysis by optical meansGaussian beamIndium

The invention belongs to the technical field of nonlinear optics, and in particular relates to a crystal furnace device for compensating Gouy phase shift to increase nonlinear interaction. The purpose of the present invention is to overcome the problem that the Gouy phase shift cannot be compensated by the Gaussian beam passing through the nonlinear crystal in the existing nonlinear optics experiments. Indium foil, upper Peltier element, second indium sheet, upper wedge-shaped metal furnace, third indium foil, nonlinear crystal, lower wedge-shaped metal furnace, fourth indium foil, lower Peltier element and fifth indium For the thin sheet, the inclined surfaces on the upper wedge-shaped metal furnace body and the lower wedge-shaped metal furnace body of the present invention are inclined backward and backward respectively, so that the nonlinear crystal is separated from the surface of the upper Peltier element and the lower Peltier element along the axial direction. The distance between them increases sequentially, so that the nonlinear crystal forms a temperature gradient along the axial direction.

Owner:山西斯珂炜瑞光电科技有限公司

A centrifugal sintering method of functionally graded material for thin-walled pipe fittings

The invention discloses a centrifugal sintering method for a functionally graded material of a thin-wall pipe fitting. The centrifugal sintering method for the functionally graded material of the thin-wall pipe fitting comprises the following steps of mixing two evenly distributed powder, a solvent and a dispersing agent, stirring in air, and vacuum degassing to form an even slurry; loading the slurry into a pulp spraying machine, then stretching a spraying head into a base plate in a centrifugal machine, and evenly spraying the slurry onto the inner wall of the base plate; changing the relative volume percentage of the two powder, and forming a second layer of composite material layer; repeating the steps, and forming multilayer spraying; stretching a graphite radiation heating element into an inner cavity of the base plate, electrifying, moving up and down, installing a layer of heat insulation layer on the outer wall of the base plate, and electrifying the heat insulation layer; andturning off the centrifugal machine, sintering a green body, taking the green body out from the base plate, and obtaining a hollow pipe fitting. According to the centrifugal sintering method for thefunctionally graded material of the thin-wall pipe fitting provided by the invention, through adding the graphite radiation heating element, and installing the heat insulation layer on the outer layerof the base plate, the even temperature gradient is realized internally, so that an effective guarantee is provided for preparing the uniform and compact thin-wall pipe fitting.

Owner:WUHAN UNIV OF TECH

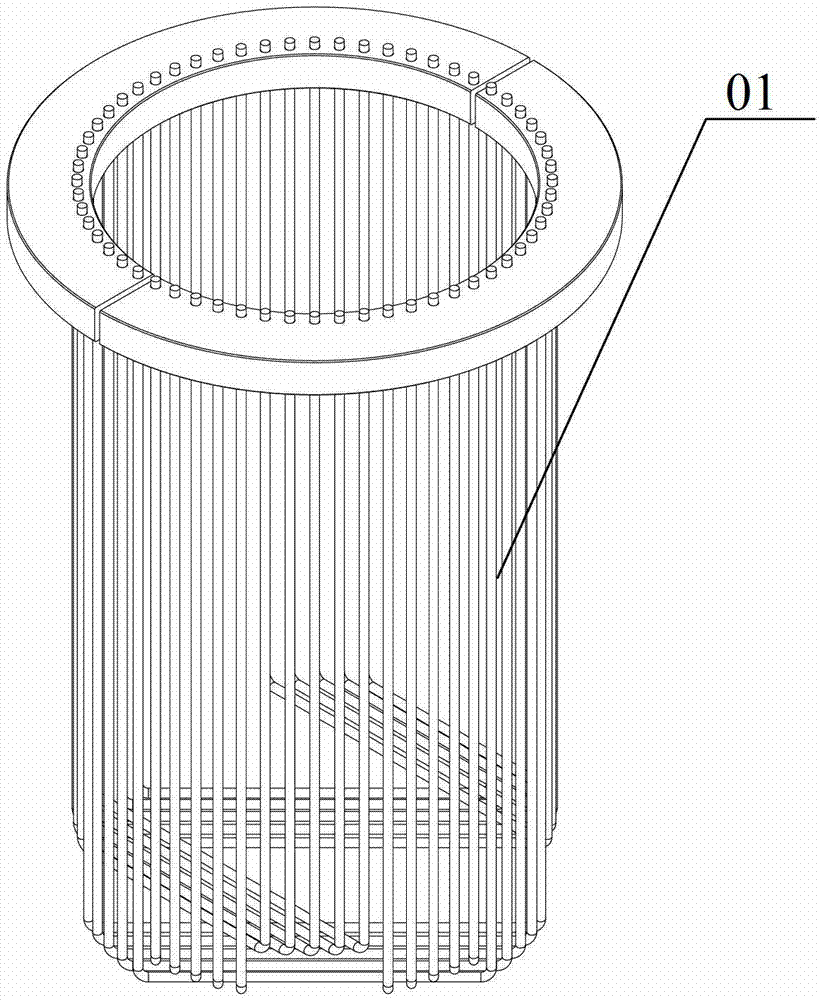

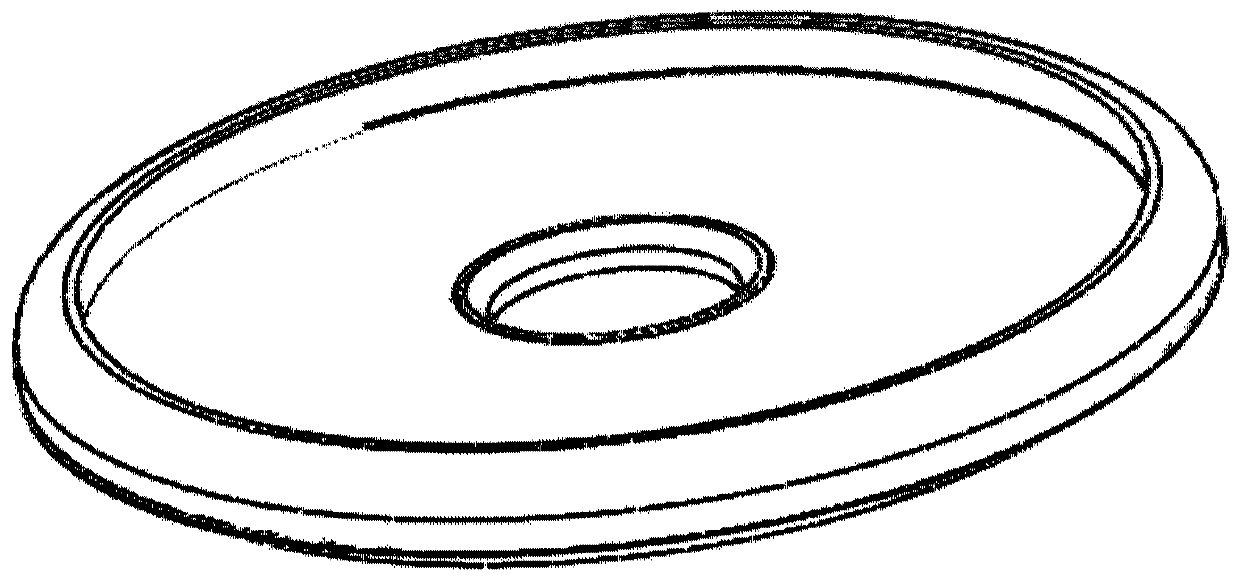

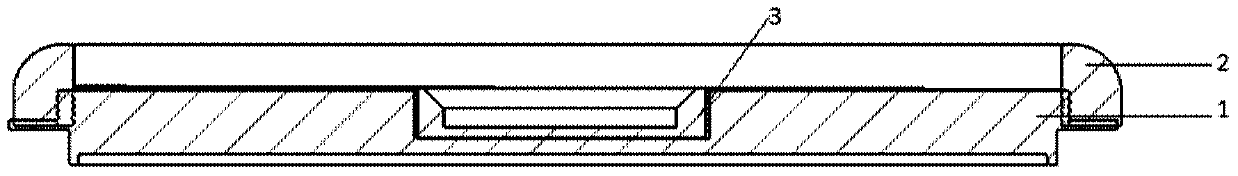

Combined Substrate Holder for Microwave Plasma Chemical Vapor Deposition Equipment

ActiveCN107304475BHigh precisionImprove reliabilityChemical vapor deposition coatingCircular discMicrowave plasma chemical vapor deposition

The invention discloses a combined substrate base for a microwave plasma chemical vapor deposition device. The combined substrate base comprises a tray main body, an outer edge part and an embedded part, wherein the tray main body is of a disc structure; an external thread is arranged on the outer side edge of the disc; a groove is formed in the center of the disc; the outer edge part is of a circular ring structure; an internal thread matched with the external thread is arranged on the inner side edge of the circular ring; an outer ring part is screwed on the tray main body through a matched thread structure; the height position of the outer ring part relative to the tray main body can be changed through controlling the screwing turn number; the embedded part is embedded in the groove; and a pit used for placing a sample is formed in the middle of the embedded part. The combined substrate base adopts a three-section split structure, the structure of a tray can be slightly adjusted, the influence degree of the tray structure on experiments is finely studied, and accuracy and reliability of the experiments are improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

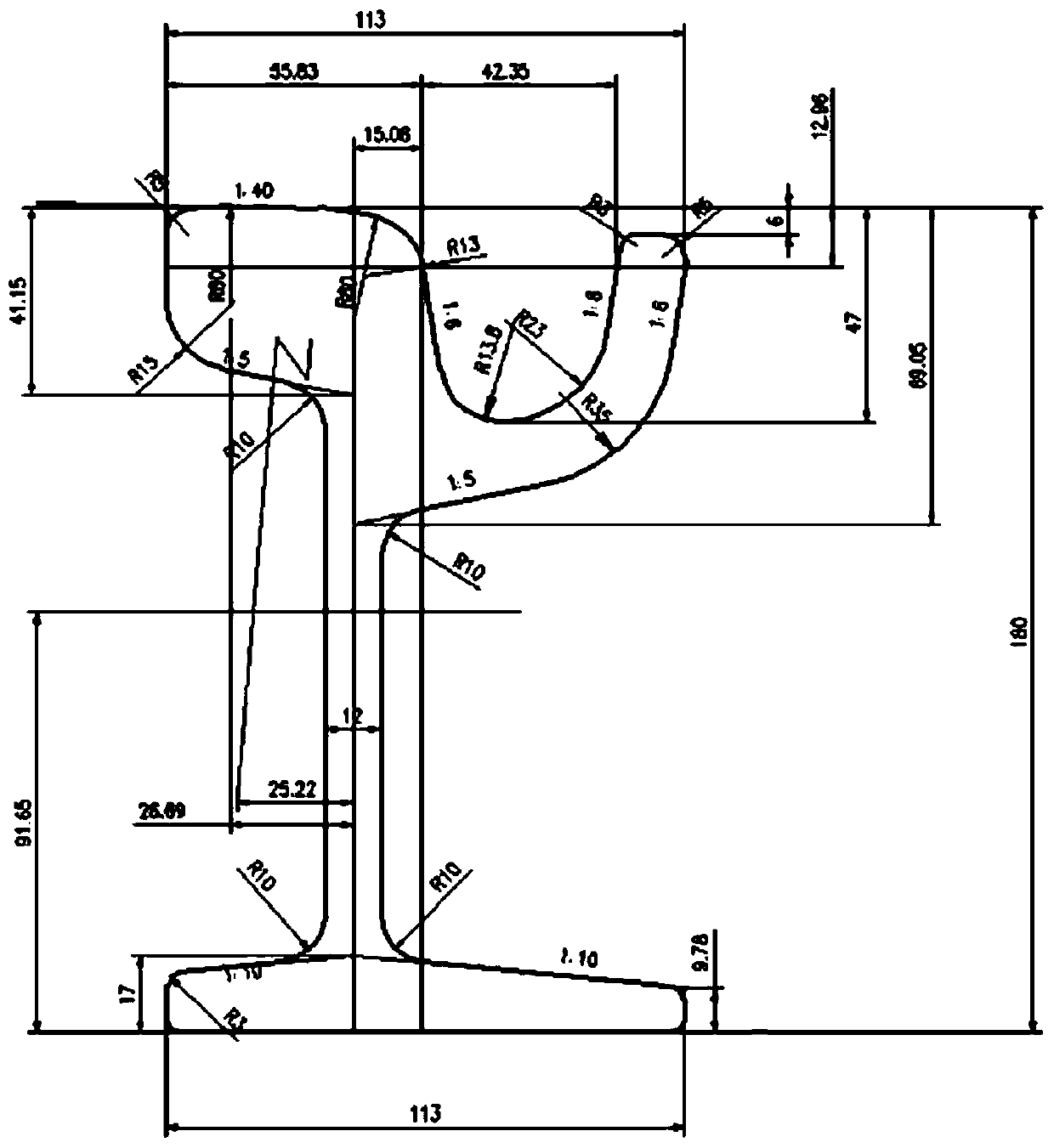

A Welding Process of Alloy Steel and Channel Rail

ActiveCN110102864BStress reliefIncrease breaking loadResistance welding apparatusFlash weldingUpset forging

The invention relates to the field of trolley frog welding technology, in particular to a welding process of alloy steel and grooved steel rail. The welding process of alloy steel and channel rail provided by the present invention is to weld alloy steel and channel rail together by flash welding method, including flash flat stage, preheating stage, burning stage, upsetting stage and post-heating stage. The total duration of the welding process is 114s-115s, the upsetting amount of the welding process is 12mm-12.8mm, and the total rail consumption of the welding process is 30-31.8mm. The welding process of the alloy steel and the grooved rail provided by the invention successfully realizes the flash welding of the alloy steel and the grooved rail, and the formed welded joint has good mechanical properties and stable welding quality.

Owner:CNR BEIJING RAIL EQUIP +1

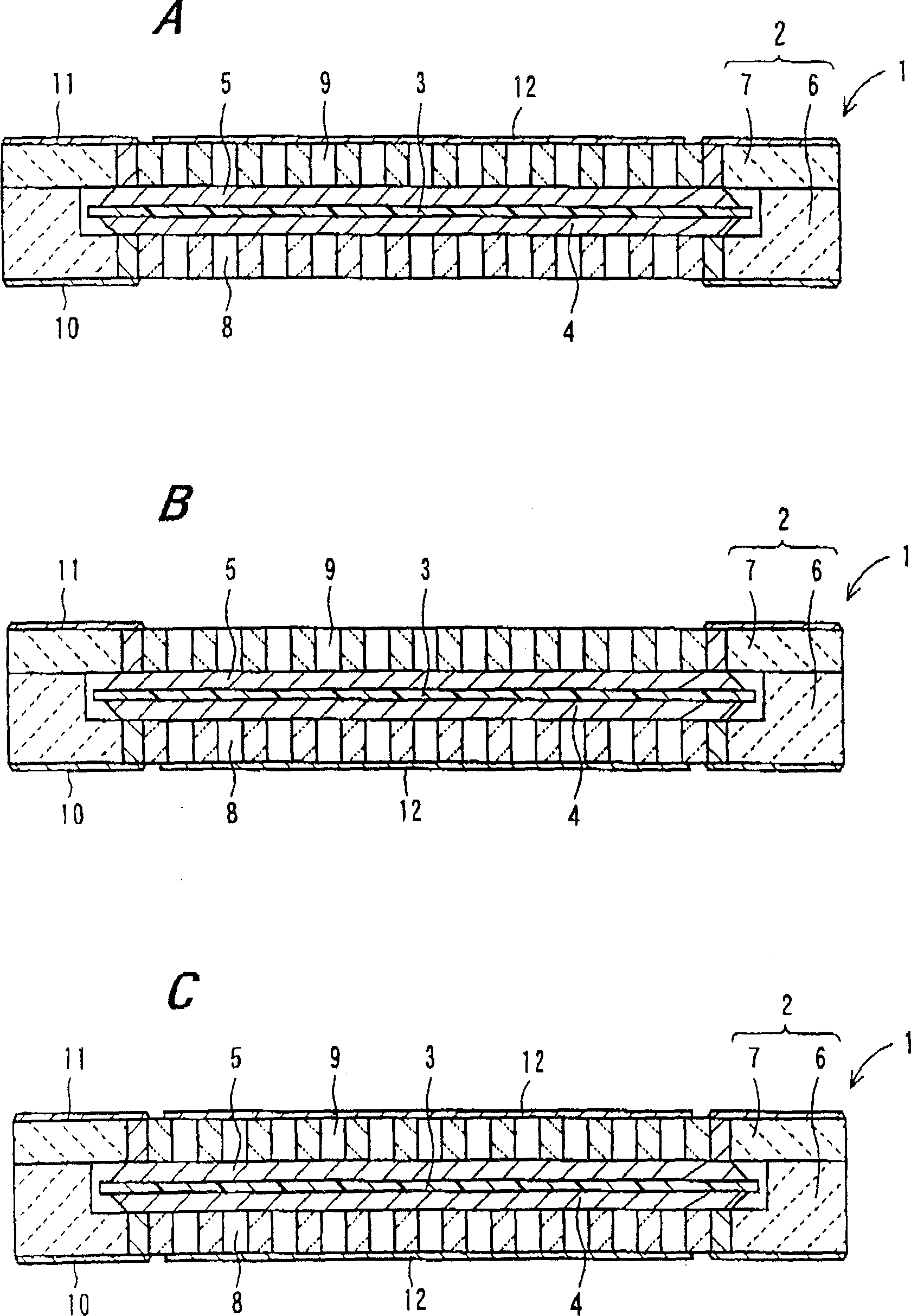

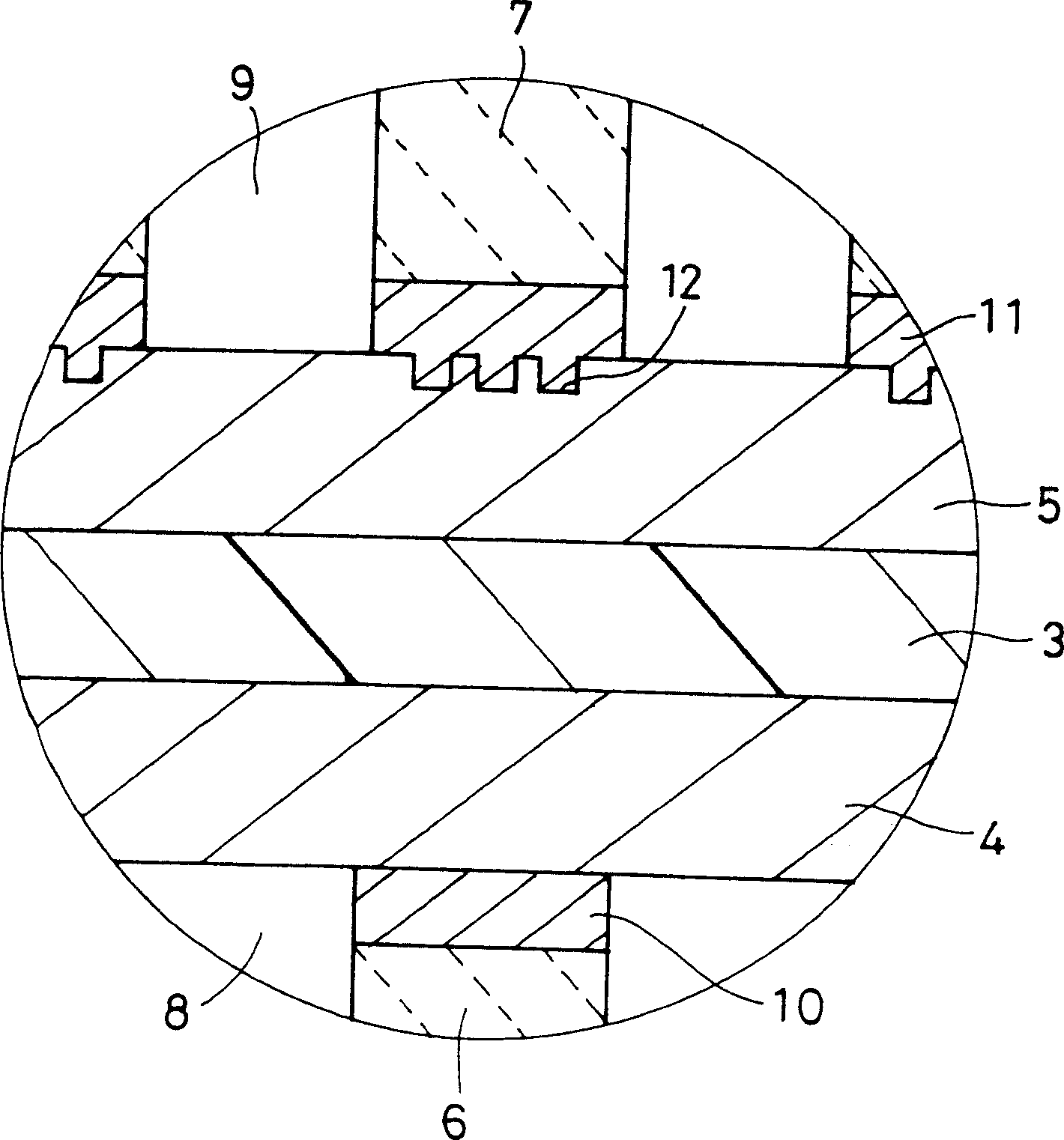

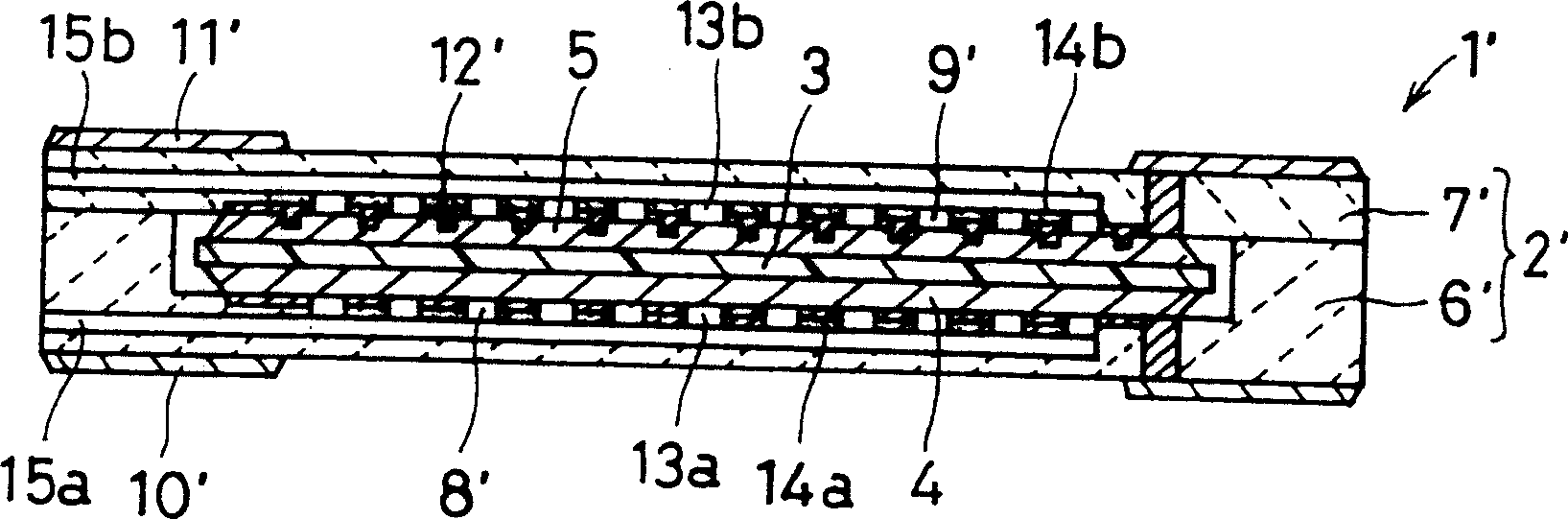

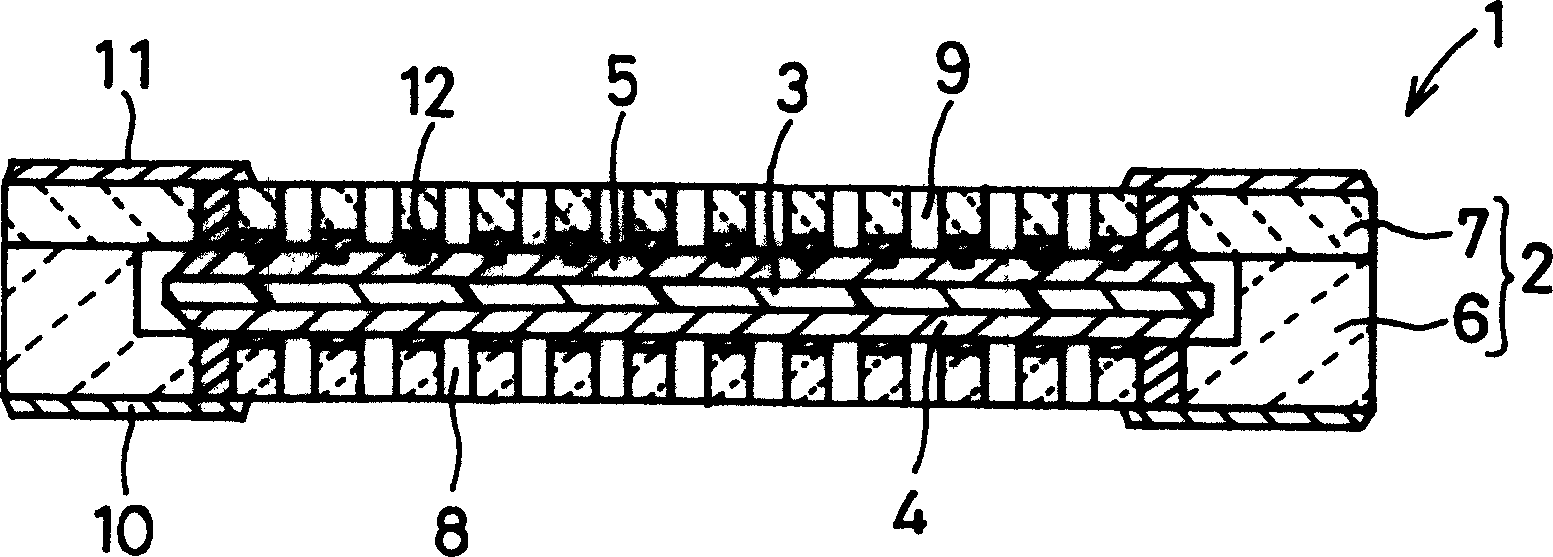

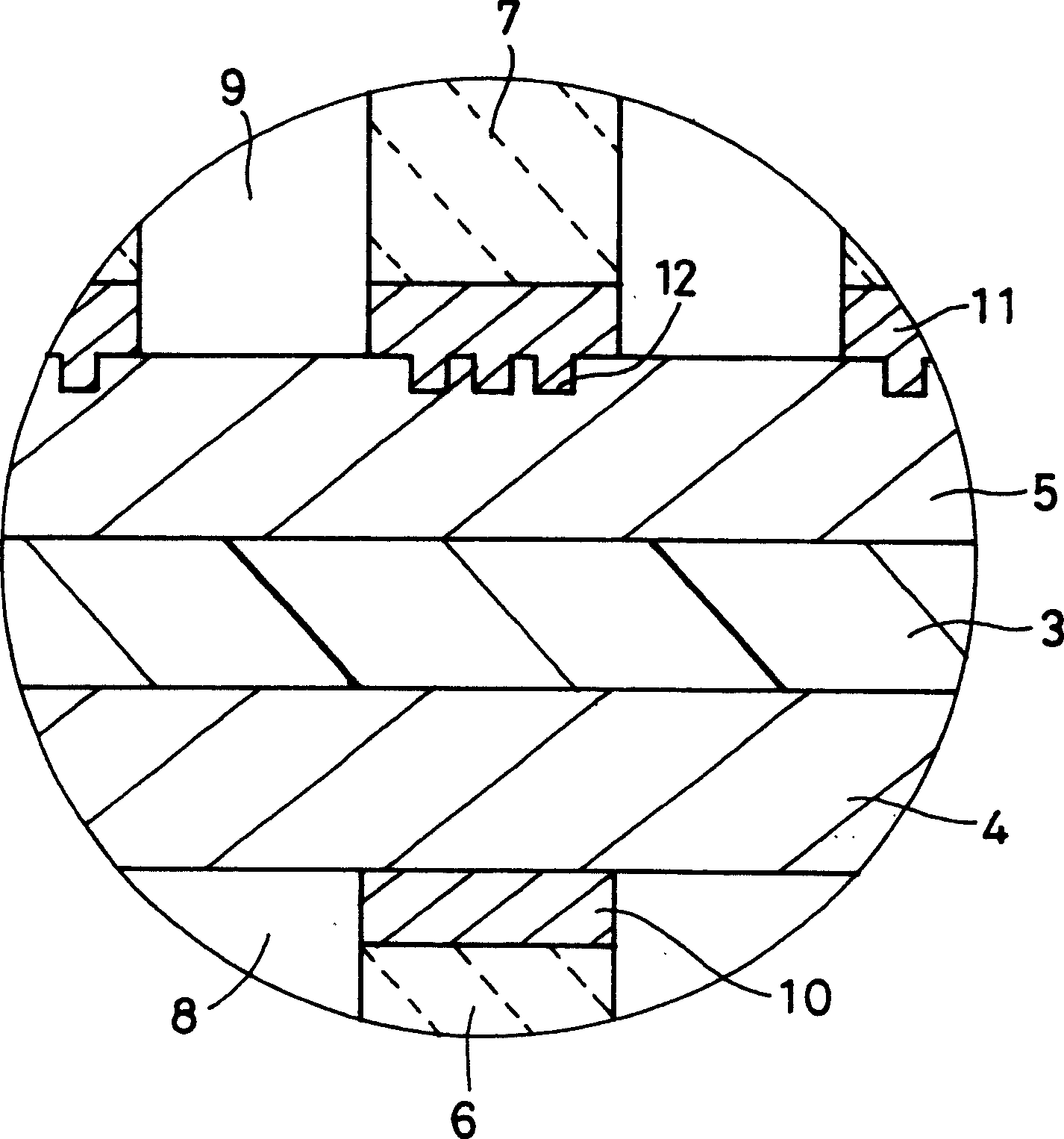

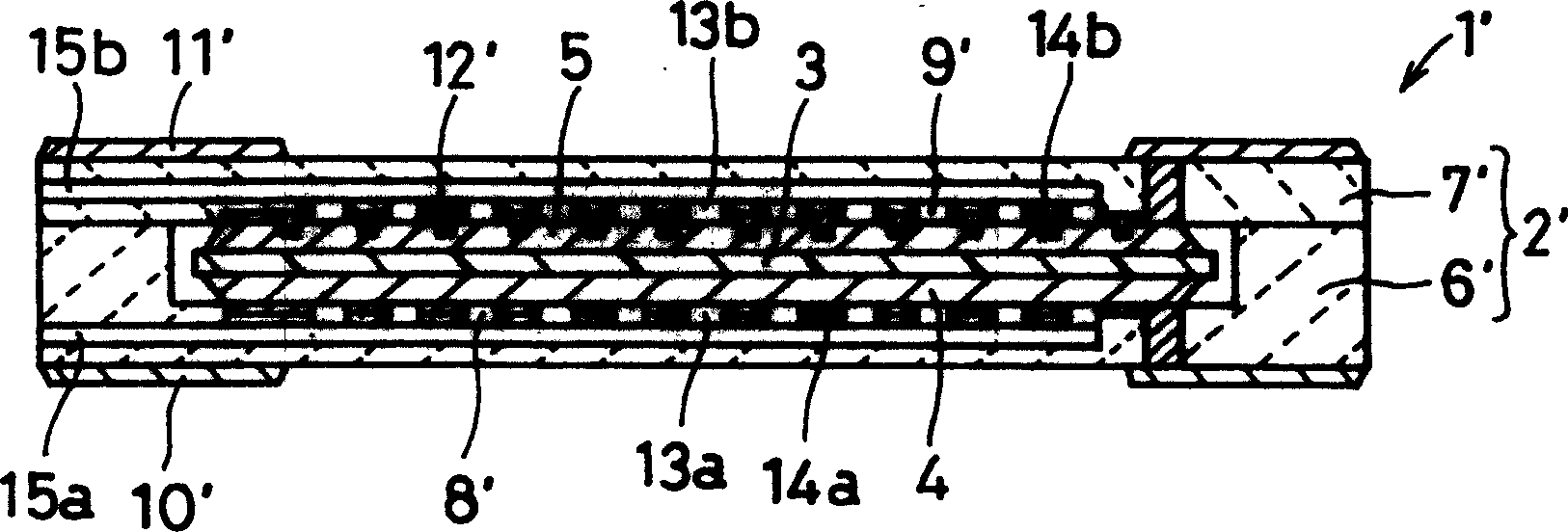

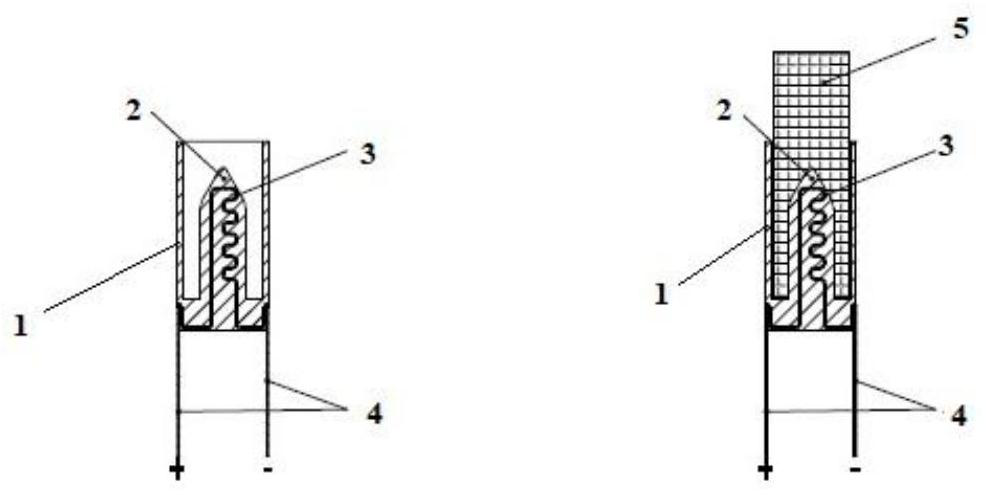

Container for fuel cell, fuel cell and electronic device

InactiveCN1297027CEfficient actionHigh mechanical reliabilityFuel cell shape/formSolid electrolyte fuel cellsFuel cellsElectrical conductor

This fuel cell container is equipped with a substrate 6 having a recessed part to house the electrolyte member 3 having first and second electrodes 4, 5, a first fluid passage 8 formed from the bottom surface of the recessed part on to the external surface of the substrate 6, a first wiring conductor 10 one end of which is disposed on the bottom surface of the recessed part and the other end of which is led out to the external surface of the substrate 6, a lid body 7 attached to the upper surface of the periphery of the recessed part of the substrate 6, a second fluid passage 9 formed from the lower surface of the lid body 7 on to its external surface, and a second wiring conductor 11 one end of which is disposed on the lower surface of the lid part 7 and the other end of which is led out to the external surface of the lid part 7, and a recessed part 12 is formed in either one of the contact part where the first electrode 4 is brought into contact with the substrate 6 or the contact part where the second electrode 5 is brought into contact with the lid part 7.

Owner:KYOCERA CORP

Container for fuel cell, fuel cell and electronic device

InactiveCN1585176AEfficient actionHigh mechanical reliabilityFuel cell shape/formSolid electrolyte fuel cellsFuel cellsElectrical conductor

This fuel cell container is equipped with a substrate 6 having a recessed part to house the electrolyte member 3 having first and second electrodes 4, 5, a first fluid passage 8 formed from the bottom surface of the recessed part on to the external surface of the substrate 6, a first wiring conductor 10 one end of which is disposed on the bottom surface of the recessed part and the other end of which is led out to the external surface of the substrate 6, a lid body 7 attached to the upper surface of the periphery of the recessed part of the substrate 6, a second fluid passage 9 formed from the lower surface of the lid body 7 on to its external surface, and a second wiring conductor 11 one end of which is disposed on the lower surface of the lid part 7 and the other end of which is led out to the external surface of the lid part 7, and a recessed part 12 is formed in either one of the contact part where the first electrode 4 is brought into contact with the substrate 6 or the contact part where the second electrode 5 is brought into contact with the lid part 7.

Owner:KYOCERA CORP

Superlattice heat-resistant ceramic core and preparation method thereof

The invention discloses a superlattice heat-resistant ceramic core and a preparation method thereof, and belongs to the technical field of electronic cigarette atomization cores. The invention relates to a preparation method of a superlattice heat-resistant ceramic core. The superlattice heat-resistant ceramic core comprises a nano superlattice coating layer, a ceramic base body, a nickel-chromium heating wire, a silver electrode and a ceramic core sealing base, the nickel-chromium heating wire serves as an embedded part to be implanted into the ceramic base body, and the nanometer superlattice coating layer is plated on the surface of the ceramic base body. Non-contact heating is achieved through the nanometer superlattice coating technology, contact heating is achieved through the nickel-chromium heating wire, uniform distribution of a temperature field is promoted through combination of the nanometer superlattice coating technology and the nickel-chromium heating wire, the heating rate and the heat efficiency are improved, the product response speed is greatly increased, and the user experience effect is promoted to be improved.

Owner:深圳雾曼科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com