Injection molding machine electromagnetic induction heating soaking device

An electromagnetic induction heating and heating device technology, which is applied in the heating field, can solve the problems of large heat loss, shortened screw life, and rising ambient temperature, and achieve the effects of uniform temperature steps, extended service life, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

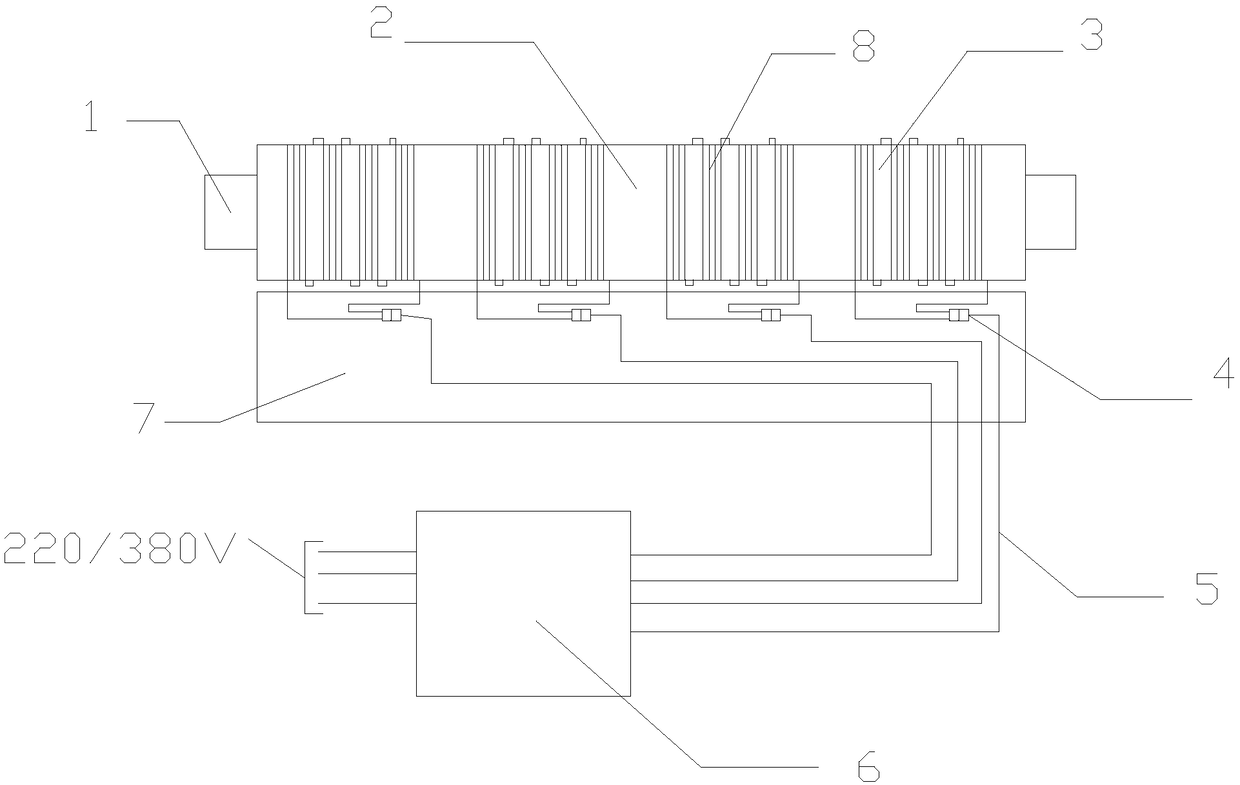

[0021] Such as figure 1 As shown, it is an electromagnetic induction heating equalizing device for an injection molding machine according to the present invention, which includes an electromagnetic heating cylinder and an electromagnetic heating controller 6, and also includes a wire joint 4, a wire groove 7 and a connecting wire 5. The electromagnetic heating cylinder includes an inner layer The barrel 1, the insulation cotton 2 of the middle layer and the high-temperature wire electromagnetic coil 3 wound on the outer layer, the lead wires at both ends of the high-temperature wire electromagnetic coil 3 are connected to one end of the connecting wire 5 through the wire joint 4, and the other end of the connecting wire 5 is connected to the connecting wire 5. The electromagnetic heating controller 6 is connected, the lead wires at both ends of the high-temperature wire electromagnetic coil 3, the wire joint 4 and part of the connecting wire 5 are fixed in the wire groove 7, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com