A Welding Process of Alloy Steel and Channel Rail

A grooved rail and welding process technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor mechanical properties of welded joints, easy cracks in the rail waist of welded joints, etc., to achieve stable welding quality and improve unevenness. Uneven conditions, enhanced breaking load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

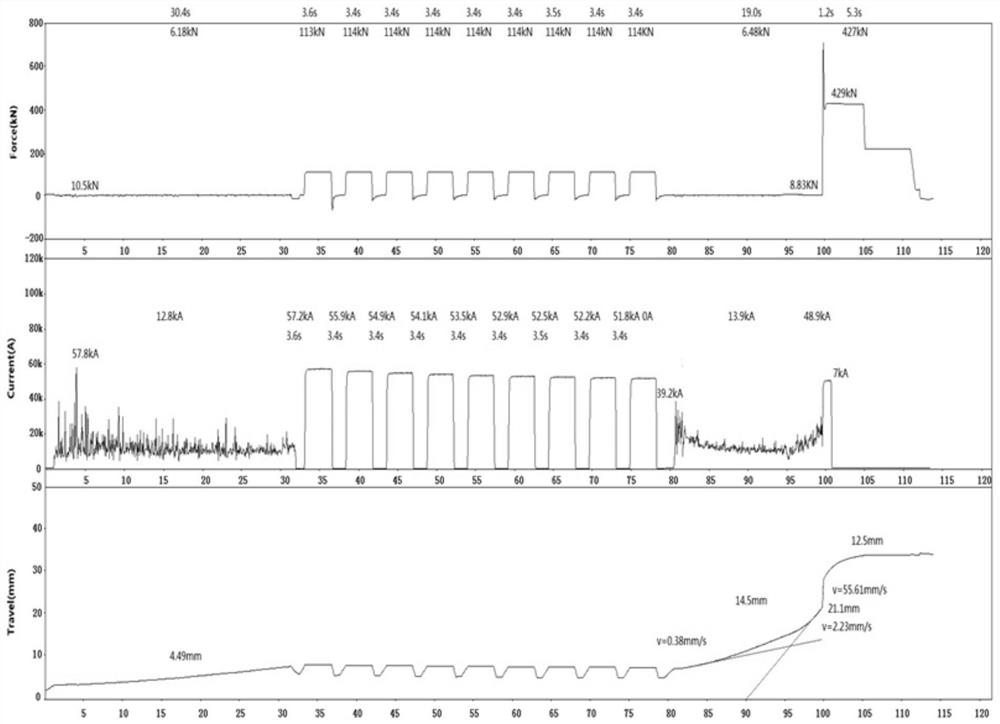

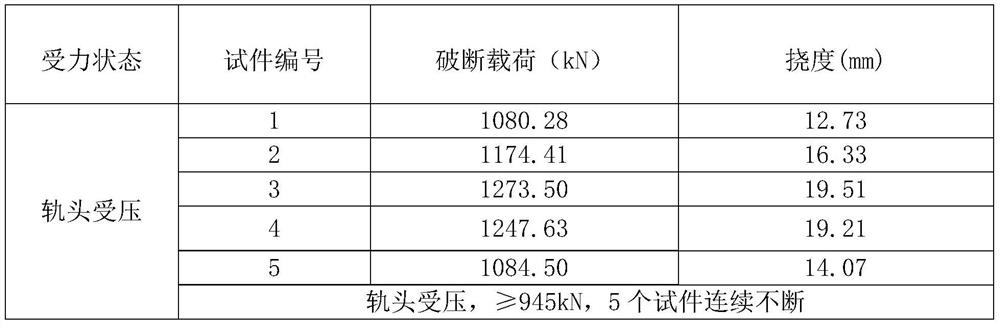

Embodiment 1

[0030] This embodiment provides a welding process for alloy steel (59R2 rail type, bainitic alloy steel) and channel rail (59R2 rail type, U75V rail), using GAA100 / 580 flash welding machine, and the shellfish is welded by flash welding method Butt welded steel alloy steel (length 600mm) and U75V grooved steel rail (length 600mm) together, including flash-flat stage, preheating stage, burning stage, upsetting stage and post-heating stage, the total duration of the welding process The time is 114s, the upsetting amount of the welding process is 12mm, and the total rail consumption of the welding process is 30mm.

[0031] Wherein, the rail consumption in the flashing stage is 4mm, and the duration is 32s.

[0032] The number of times of heating in the preheating stage is 8 times, the duration is 50s, and the preheating temperature is 1250°C.

[0033] The rail consumption in the sintering stage is 14mm, and the duration is 19s.

[0034] The upsetting pressure in the upsetting st...

Embodiment 2

[0041]This embodiment provides a welding process for alloy steel (59R2 rail type, bainitic alloy steel) and channel rail (59R2 rail type, U75V rail), using GAA100 / 580 flash welding machine, and the shell is welded by the flash welding method. Butt welded steel alloy steel (length 600mm) and U75V grooved steel rail (length 600mm) together, including flash-flat stage, preheating stage, burning stage, upsetting stage and post-heating stage, the total duration of the welding process The time is 115s, the upsetting amount of the welding process is 12.8mm, and the total rail consumption of the welding process is 31.8mm.

[0042] Wherein, the rail consumption in the flash-flat stage is 4.5mm, and the duration is 31s.

[0043] The number of times of heating in the preheating stage is 10 times, the duration is 50s, and the preheating temperature is 1350°C.

[0044] The rail consumption in the sintering stage is 14.5mm, and the duration is 18s.

[0045] The upsetting pressure in the u...

Embodiment 3

[0052] This embodiment provides a welding process for alloy steel (59R2 rail type, bainitic alloy steel) and channel rail (59R2 rail type, U75V rail), using GAA100 / 580 flash welding machine, and the shell is welded by the flash welding method. Butt welded steel alloy steel (length 600mm) and U75V grooved steel rail (length 600mm) together, including flash-flat stage, preheating stage, burning stage, upsetting stage and post-heating stage, the total duration of the welding process The time is 114s, the upsetting amount of the welding process is 12mm, and the total rail consumption of the welding process is 31mm.

[0053] Wherein, the rail consumption in the flash-flat stage is 4.5mm, and the duration is 31s.

[0054] The number of times of heating in the preheating stage is 9 times, the duration is 49s, and the preheating temperature is 1300°C.

[0055] The rail consumption in the sintering stage is 14.5mm, and the duration is 18s.

[0056] The upsetting pressure in the upset...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com