Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

209 results about "Upset forging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Upset forging, also known as heading, is a manufacturing process which decreases the length of a workpiece in order to increase the diameter of the material in this area.

Method for producing wind-electricity principal axis with gathering stock full fibre upset forging

InactiveCN101314202ASolve the strength problemSolve process problemsShaftsFurnace typesElectricityIngot

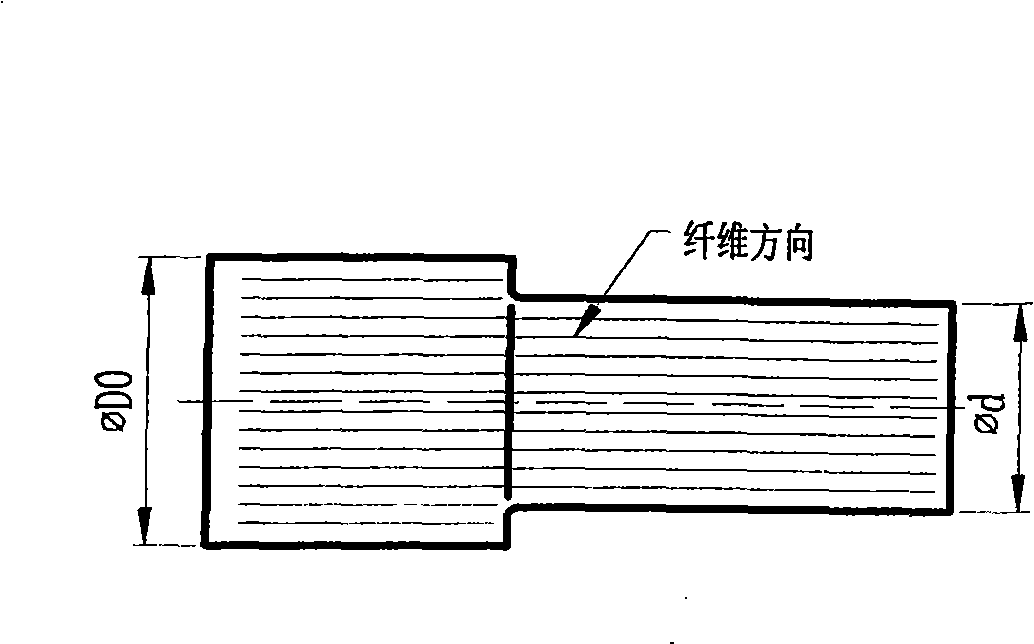

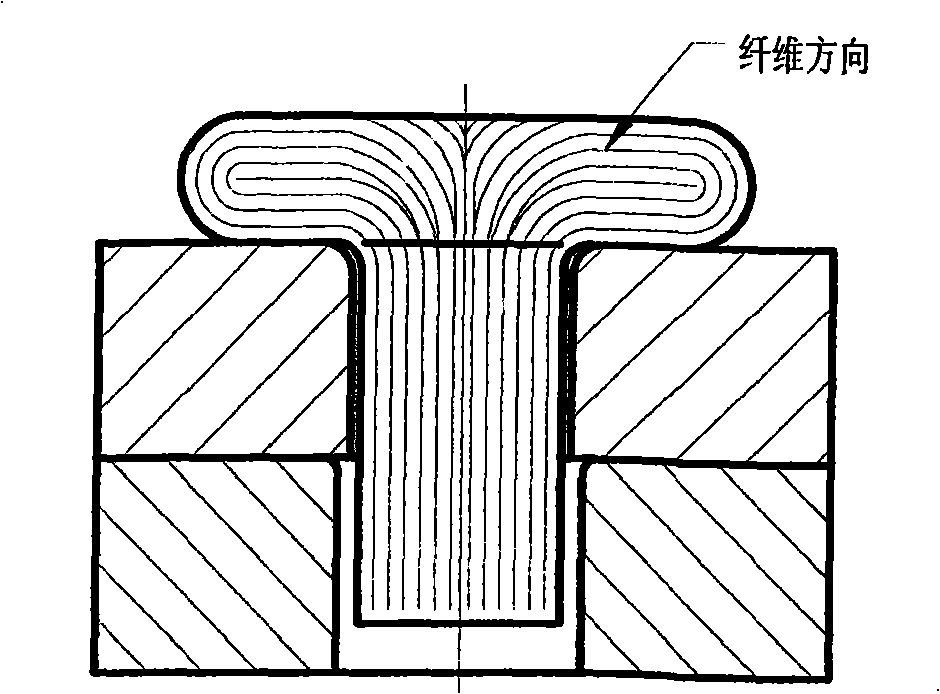

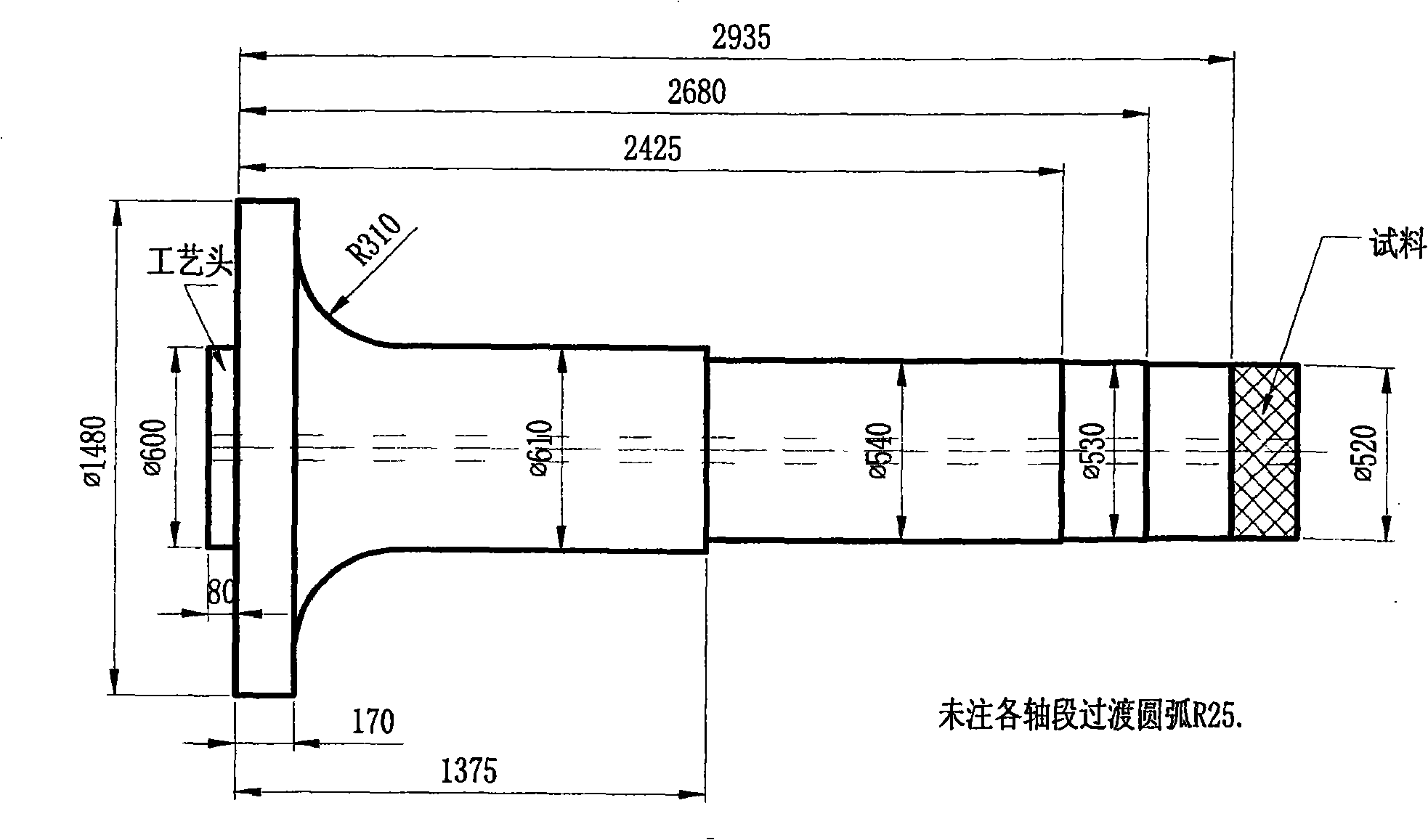

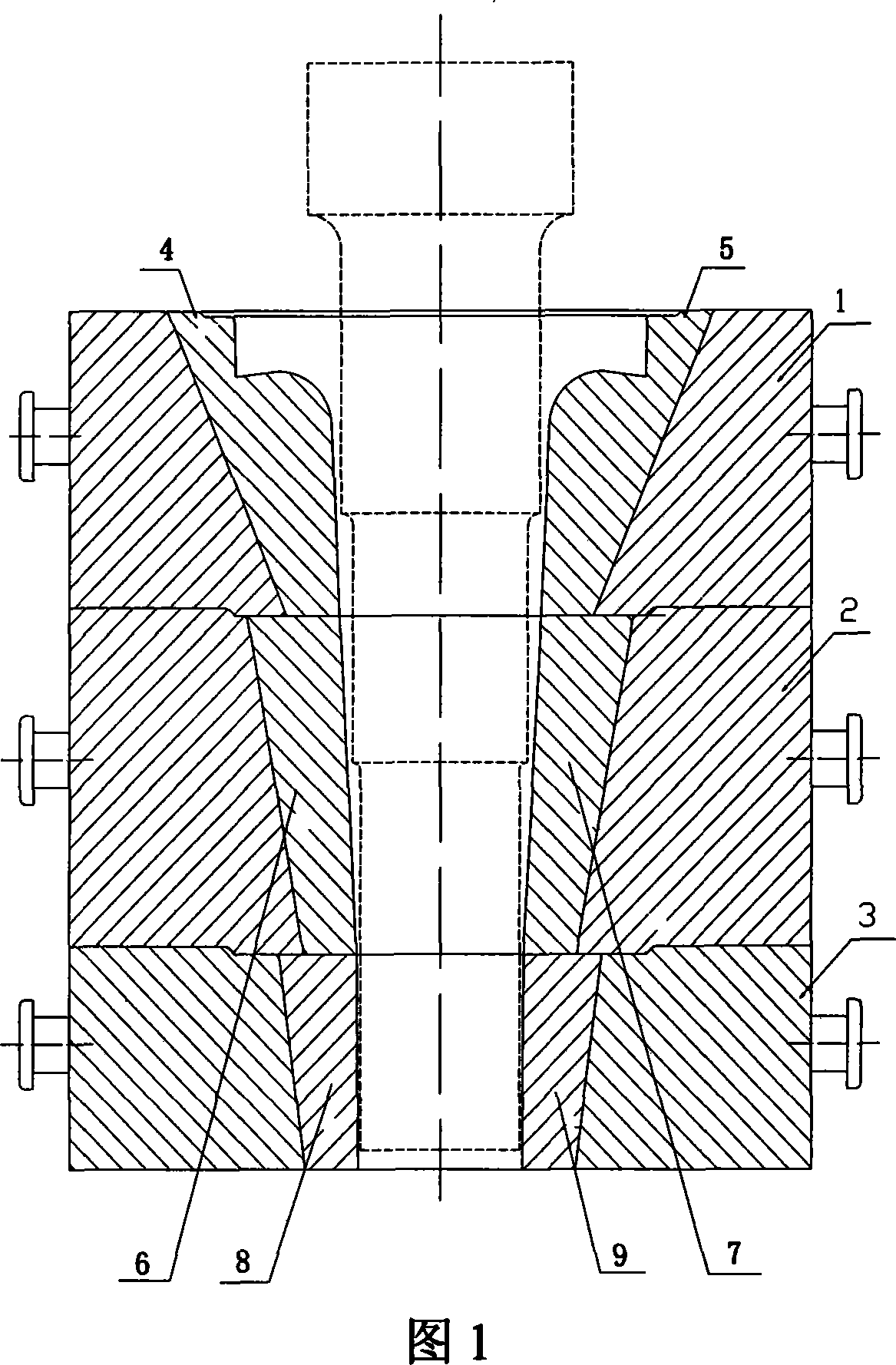

The invention relates to a method for producing a wind-power mainshaft by local continuous upsetting and all-fibre upset forging. The method comprises the following: step one, the heating of steel ingot; step two, forging; step three, first heat processing; step four, rough machining and ultrasonic inspection; step five, quenching and tempering and heat processing; step six, fine machining, wherein, during the step two, the forging comprises that: (1) a first fire, during which, a steel ingot is subject to upset forging at a forging temperature of between 1250 and 900 DEG C; firstly, the bottom of the steel ingot is sawed off, and the steel ingot is subject to capping and upset forging; (2) a second fire, during which, the steel ingot is stretched towards various directions, marked and subject to intermediate billet cogging; after a pole part is molded, scrap on a T end is chopped and removed; after the forging is finished, the steel ingot returns to a heating furnace for being reheated; (3) a third fire, during which, the steel ingot is subject to local continuous upsetting and all-fibre upset forging; (4) a fourth fire, during which, the steel ingot is subject to rolling and leveling; the pole part is stretched; the disc edge of a hub end on the head part of an intermediate billet material after the local continuous upsetting and all-fibre upset forging is subject to rolling operation; after the rolling, the intermediate billet material is inserted into a leaking disc component again; the end face of the disc is pressed and leveled; after the shaping of the disc end is completed, a manipulator clamps the disc and stretches the pole part of the intermediate billet material to a dimension of a forgeable piece; thus, the mainshaft forging is completed. The method can improve the fatigue resisting strength of a wind-power mainshaft forging piece.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

Fabrication technology of big flange stub axle type components

InactiveCN101116891AImprove forgeabilitySave raw materialsForging/hammering/pressing machinesEngine componentsStub axleLarge size

The invention relates to a processing technique for large flange short-axle type parts. The invention is characterized in that: the processing technique comprises the processing procedures of refining, forging, heat treating, detecting, and machining. The forging processing procedure is that: firstly a preformed stock is forged by free forging on a large-size hydraulic machine, and secondly, the preformed stock is placed in the die to be vertically upset forged into a die-forging part the dimension of which is approximate to that of a finish product. The invention overcomes the drawbacks that the large water press can only freely form by large-size forging piece, and can save raw materials and shorten cold processing time. The invention has the most advantage that the processing technique improves forging ability of the large flange arranged at the end of large flange short-axle parts.

Owner:天津市天重江天重工有限公司

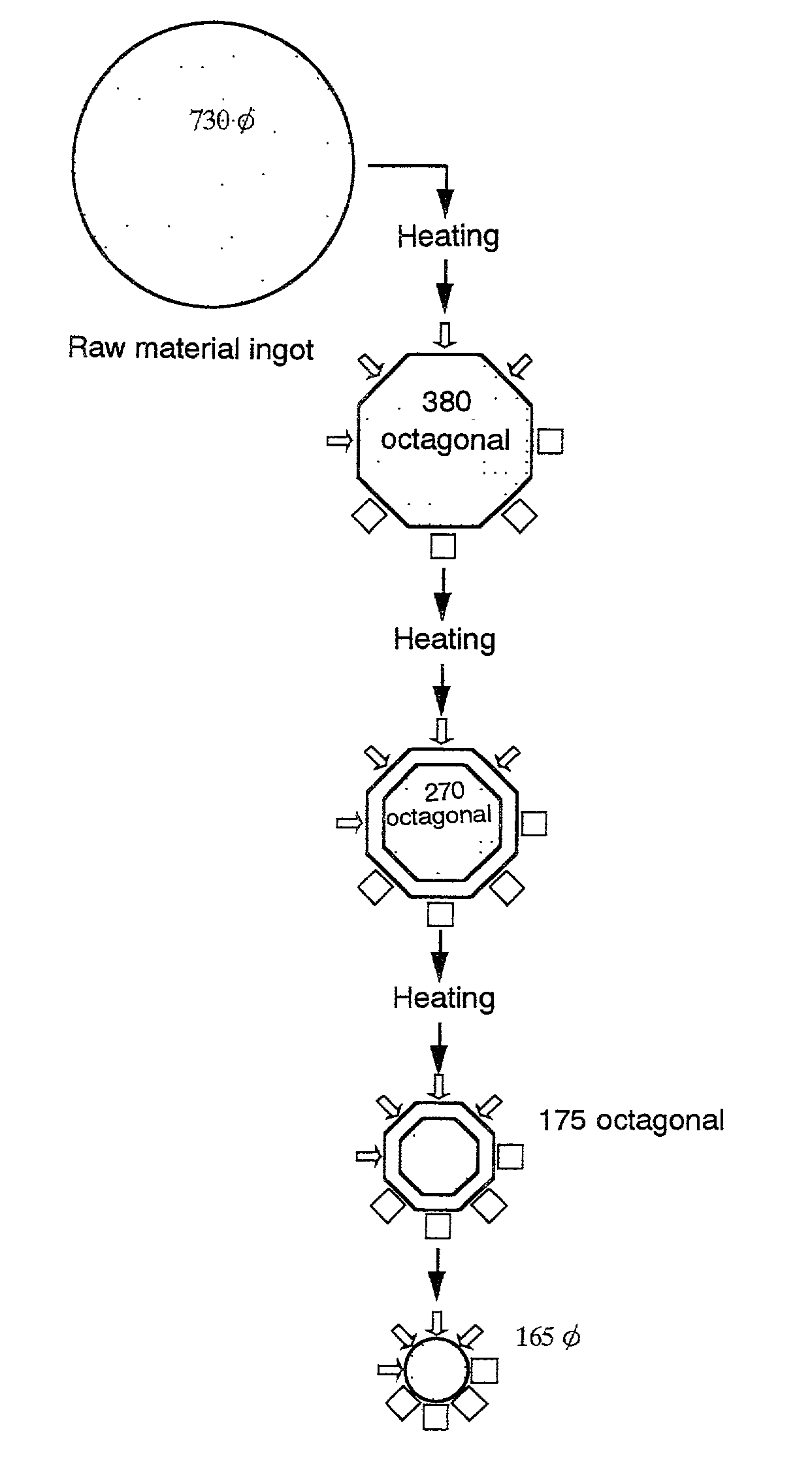

Method for producing TC25 two-phase titanium alloy rod material with large specification

The invention discloses a method for producing a TC25 two-phase titanium alloy rod material with large specification. The method comprises the following steps of: firstly, cutting off a riser and an ingot bottom of a TC25 two-phase titanium alloy cast ingot to remove cast ingot skin gas holes; and then breaking down and forging the cast ingot subjected to skin gas hole removal by using an oil press or a water press two times so as to obtain a forged blank; next, upsetting the forged blank again and again and carrying out extension forging on the upset forged blank so as to obtain a blank; and finally, chamfering, rounding and forging the blank again and again, and cooling the blank with air to the room temperature so as to obtain the large-specification TC25 two-phase titanium alloy rod material with diameter phi of not less than 200 mm. The method for producing the TC25 two-phase titanium alloy rod material with large specification, disclosed by the invention, has the advantages of simple process, no need of special equipment, low machining cost, no cracking in the production process and easiness for realizing industrial production. The TC25 two-phase titanium alloy rod material product with large specification, manufactured by using the method disclosed by the invention, has the advantages of fewer interior defects, high safety and good product stability; compared with the prior art, the method disclosed by the invention has the advantage of increasing the product yield by at least 15 percents; and the manufactured rod material can be used as gas compressors of aircraft engines and other parts.

Owner:WESTERN TITANIUM TECH

Ta sputtering target and method for producing the same

InactiveUS20070240795A1Reduce uniformityFine and uniform microstructureVacuum evaporation coatingSputtering coatingIngotMaterials science

A method for producing a Ta sputtering target including the following steps: (a) a step of forging a Ta ingot, comprising subjecting the Ta ingot to a forging pattern over at least 3 times, wherein each forging pattern is “a cold forging step comprising stamp-forging and upset-forging operations alternatively repeated over at least 3 times; (b) an in-process vacuum heat-treating step carried out between every successive two forging patterns to thus prepare a Ta billet; (c) a step of rolling the Ta billet to obtain a rolled plate; and (d) a step of vacuum heat-treating the rolled plate to obtain a Ta sputtering target. A sputtering target produced by the above method.

Owner:ULVAC INC

Preparation method of TC21 titanium alloy large-specification bar

The invention provides a preparation method of a TC21 titanium alloy large-specification bar, which comprises the following steps: 1, carrying out cogging forging on a TC21 titanium alloy ingot to obtain a primary forging stock; 2, carrying out upsetting forging on the primary forging stock to obtain an intermediate forging stock; 3, carrying out homogenization treatment; 4, carrying out forming forging on the intermediate forging stock to obtain the cylindrical TC21 titanium alloy large-specification bar with a section diameter of 160 mm to 400 mm. According to the invention, by carrying out homogenization treatment and optimizing a forging process, control of an alloy from an equiaxed structure to a tristate structure can be implemented, so that comprehensive regulation and control on intensity, plasticity, toughness and fatigue property are implemented. The preparation method adopts a simple and feasible process; the prepared TC21 alloy large-specification bar has uniform and fine tissues and high mechanical property, is suitable for large-scale industrial production and meets the development requirements of the aerospace industry on the high-quality large-specification TC21 titanium alloy bar.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

60kg/m R260 hot-rolled rail moving flash welding method

ActiveCN108890106AImprove welding qualityReduce internal defectsResistance welding apparatusHeat-affected zoneEngineering

The invention discloses a 60 kg / m R260 hot-rolled rail moving flash welding method, which comprises five stages of flash, flash, accelerated firing, upset and holding pressure. The total heat input during welding is 3.0-4.8 MJ, the total welding duration is 110-135s, and the welding upset is 12.4-16.7 mm. The invention improves the welding quality of the rail by controlling the total welding heatinput, the total welding time and the upset forging amount in the moving flash welding process, and controlling the welding heat input and the duration time of each of the five stages of flash, flash,accelerated firing, upset forging and holding pressure; 60 kg / m R260 hot-rolled rail can be successfully move for flash welding by that invention, The total width of HAZ of the whole 60kg / m R260 hot-rolled rail moving flash welding joint is controlled within 32mm, and the difference between the maximum and minimum of the total width is less than 8.2 mm. The internal defects of the rail joint areless, and the welding quality is stable.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Agitation friction point braze welding method for metal plate overlap joint combination

ActiveCN104227225AEliminate wear and tearSimple design and manufactureSoldering apparatusNon-electric welding apparatusNeedle freeElectric vehicle

The invention discloses an agitation friction point braze method for a metal plate overlap joint combination. The method comprises the following steps: placing a brazing filler metal at a to-be-welded position in advance, starting a needle-free tool to rotate, and melting the brazing filler metal by virtue of frictional heat between a shoulder and the surface of an upper plate; after in-situ friction is performed for few seconds, shutting down, and applying upset forging, thereby finishing a large-area spot welding process under the condition of no abrasion and no key holes. By virtue of the twisting effect of a tool on an interface in a friction stage, the dissolution effect of the brazing filler metal on a mother metal in an in-situ friction stage and the upset forging effect of the tool on the interface in a shutdown stage, an oxidation film is easily broken, and oxidation film fragments are easily extruded along with the molten brazing filler metal which is alloyed; meanwhile, the interface wetting property and final compactness are improved, crystal structures containing brittle phases are eliminated, the soldering seam tenacity is improved, and the method can be used in occasions such as electric power fittings, electric contacts, cookers, hybrid electric vehicle series welding and overlap joint welding of thin aluminum plates in automobile and aircraft manufacturing.

Owner:咸阳瞪羚谷新材料科技有限公司

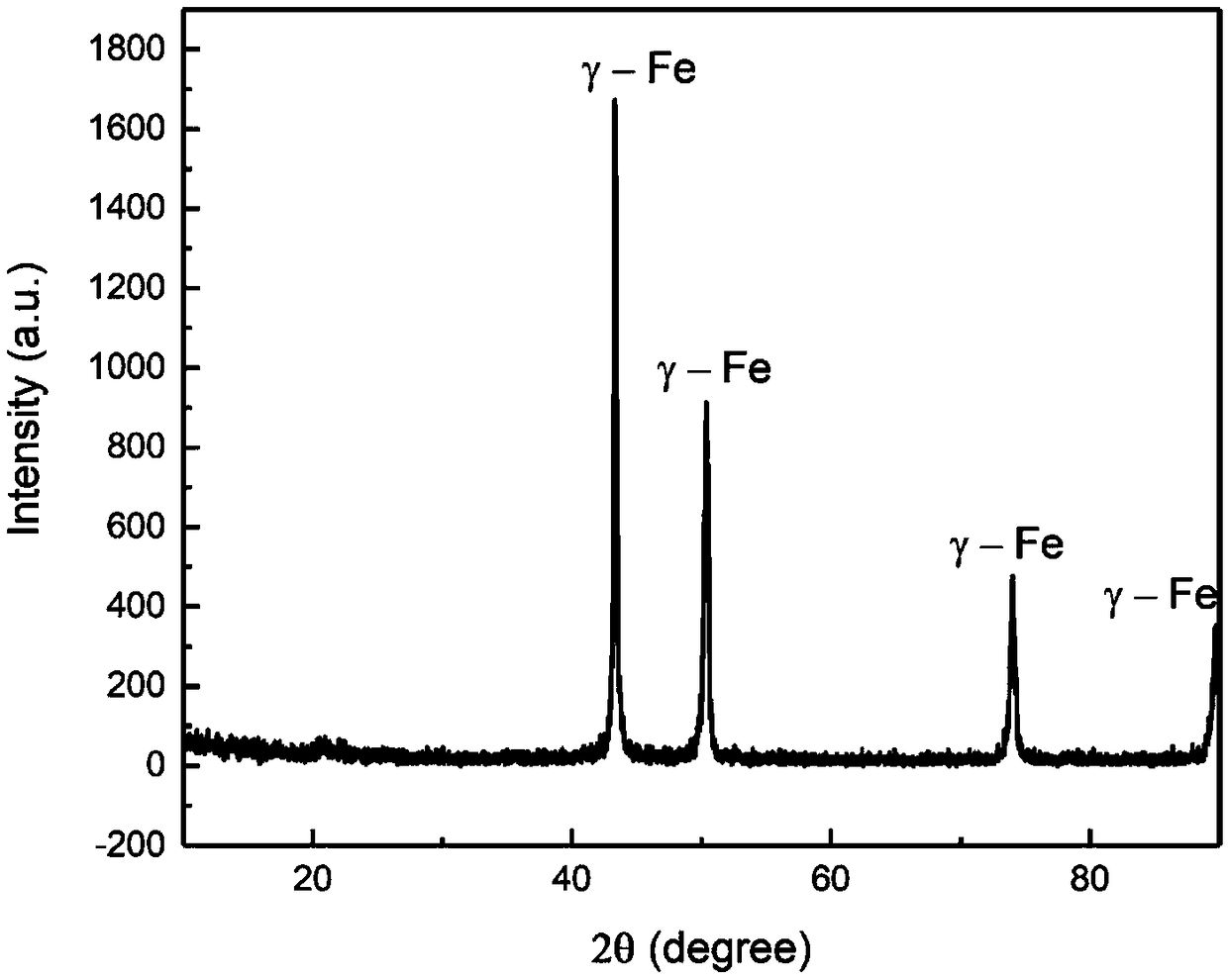

Axial friction welding process method of high-nitrogen austenitic stainless steel and non-magnetic drill collar

InactiveCN108907447AAchieve weldingGuaranteed normal work requirementsTubular articlesHollow articlesFriction weldingNon magnetic

The invention relates to an axial friction welding process method of a high-nitrogen austenitic stainless steel and non-magnetic drill collar and belongs to the field of preparation of oil-gas drilling tools. The method comprises the application steps: workpieces made from high-nitrogen austenitic stainless steel are clamped into a friction welding machine, then, workpieces in a clamp of a rotating end and a clamp of a moving end are welded, the workpiece of the moving end moves towards the workpiece of the rotating end when welding is started, at this time, the workpiece of the rotating end starts to rotate, the workpiece of the rotating end and the workpiece of the moving end start to produce heat due to friction under the action of frictional pressure after contact, rotation is stoppedwhen a friction amount of deformation reaches a set value, upset forging is started, upset forging pressure is applied to the workpieces along the axial direction of the workpieces and is maintained,and a workpiece is taken out after the upset forging pressure is unloaded, thereby obtaining the non-magnetic drill collar. According to the method, the non-magnetic drill collar is processed and repaired by an axial friction welding method, so that the problems, i.e., material waste, relatively high cost and relatively low production efficiency of the existing processing methods are improved, andthe problem that a failed drill collar is difficult to repair is solved.

Owner:SHANDONG UNIV

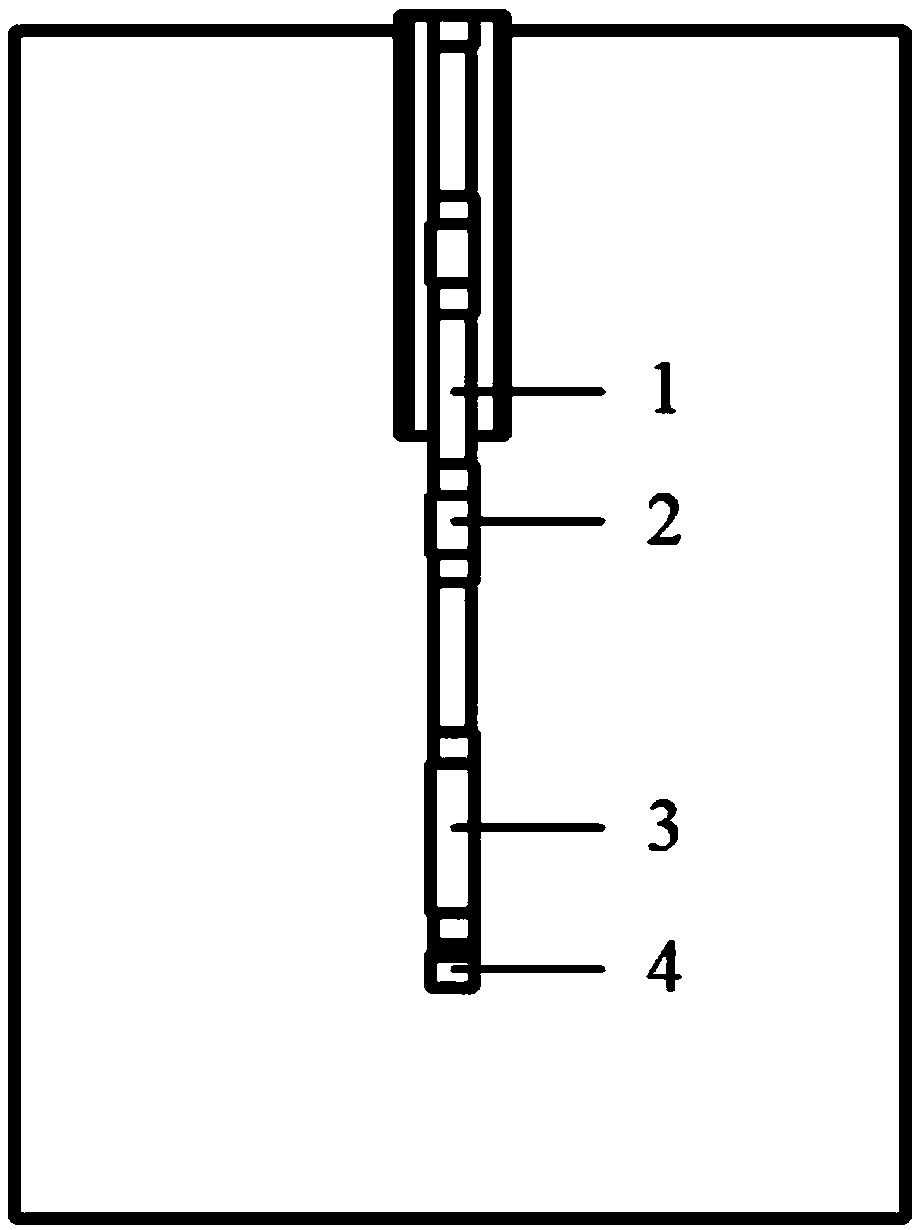

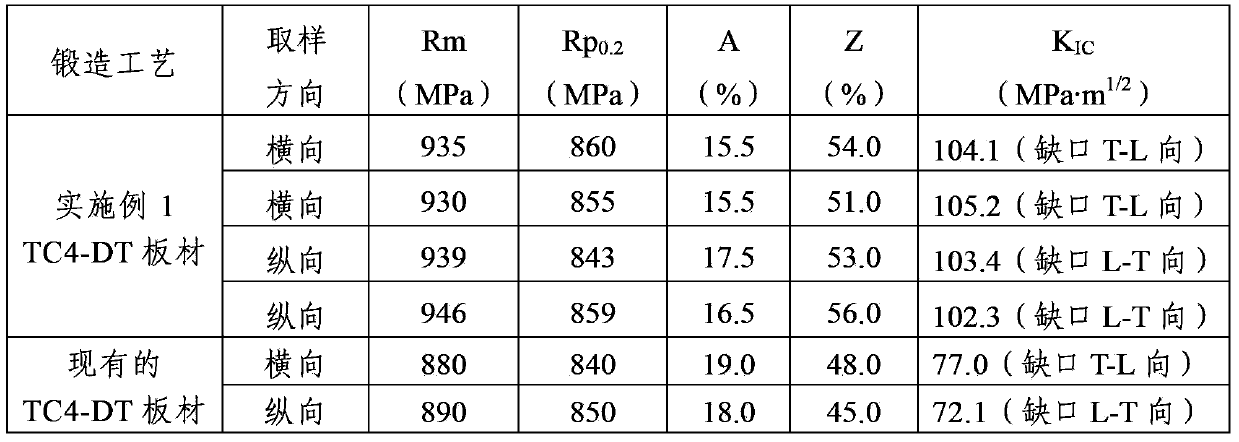

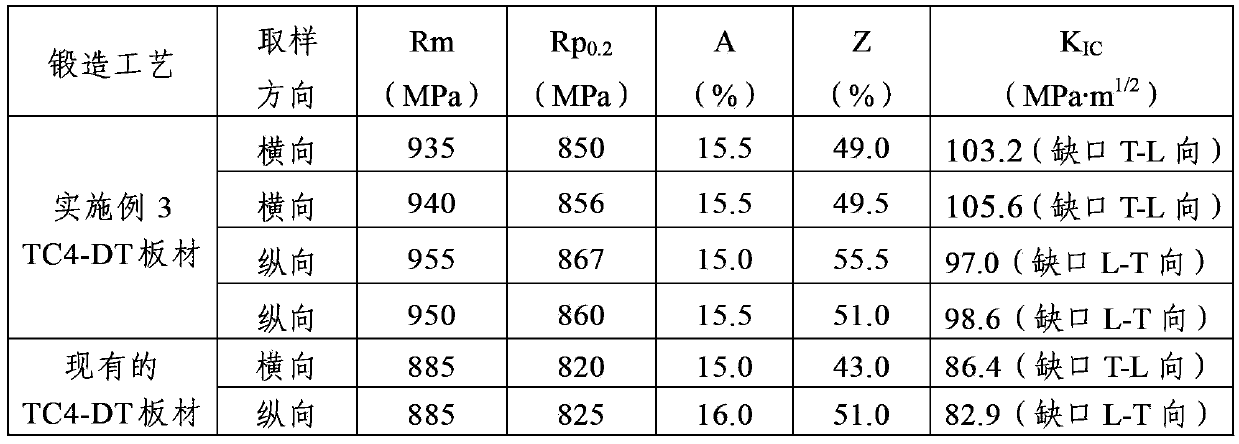

Processing method for raising strength and toughness of TC4-DT titanium alloy sheet materials

The invention provides a processing method for raising strength and toughness of TC4-DT titanium alloy sheet materials. The method comprises the following steps: first, TC4-DT titanium alloy ingot castings are subjected to cogging forging to obtain first forging stocks; second, the first forging stocks are subjected to first upsetting forging to obtain second forging stocks; third, the second forging stocks are subjected to second upsetting forging to obtain third forging stocks; fourth, the third forging stocks are subjected to drawing forging to obtain fourth forging stocks; fifth, the fourth forging stocks are subjected to saw cutting blanking, heated, and subjected to plate slab pressing forging to obtain semi-finished product sheet materials with a thickness of 31mm-56mm; sixth, the semi-finished product sheet materials are subjected to heat treatment and machine processing treatment to obtain TC4-DT titanium alloy sheet materials with a thickness of 25mm-50mm. The processed TC4-DT titanium alloy sheet materials have advantages of uniform structure properties, good match of strength, plasticity and toughness, good batch stability and good comprehensive properties.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Welding method of bainitic steel frog and carbon steel rail

InactiveCN101337303AHigh degree of automationIncrease productivityRailsResistance welding apparatusSolution treatmentMetallurgy

A method for welding a bainite steel frog and a carbon steel rail is characterized in that CrNi series austenite-ferrite dual phase steel is adopted as a connecting material; the technological process is as follows: (1) the carbon steel rail is preheated to 300-500 DEG C; (2) the carbon steel rail and the connecting material are butt-welded together; (3) the connecting material is cut and retained at the length of 20-30mm; (4) the bainite steel frog is preheated to 300-500 DEG C; (5) the retained connecting material and the bainite steel frog are flash welded; and (6) the temperature of a welding joint is preserved between 900-1,000 DEG C for 10-20 minutes, and then the welding joint is air cooled. The connecting material has the following composition (weight %): C is equal to or less than 0.2; Cr is 15-17; Ni is 7-9; Si is equal to or less than 0.3; S+P is equal to or less than 0.04; and iron is in balancing amount. The connecting material is heated to 1,050 DEG C, and then solution treatment is performed to obtain austenite-ferrite dual phase tissue, wherein the content of ferrite is 10-20%; the flash speed of flash welding is 2-3mm / s; the upset forging speed is 80-100mm / s; the upset forging pressure intensity is 40-50MPa; and the extension elongations of the material are equal during the welding process.

Owner:YANSHAN UNIV

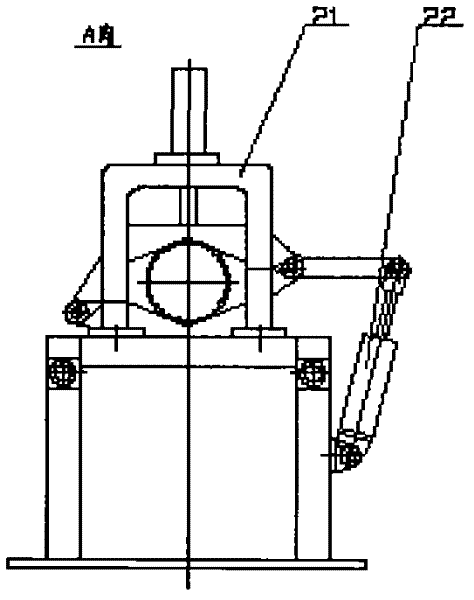

Steel pipeline friction-welding device

ActiveCN102500913AQuality improvementImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingProgrammable logic controller

The invention relates to a steel pipeline friction-welding device. A programmable logic controller (PLC) device is respectively connected with an oil cylinder 1, an oil cylinder 4, an oil cylinder 6, an oil cylinder 8, an oil cylinder 13, an oil cylinder 22 and an oil cylinder 15 through a magnetic valve. The oil cylinder 1 is connected with a trolley, a rail is arranged under the trolley, the oil cylinder 4 is connected with an engine base plate, the oil cylinder 6 is connected with a clamp 7, and the clamp 7 is connected with a clamp base. The oil cylinder 8, a friction wheel and the oil cylinder 13 are connected with a movable clamping frame, the movable clamping frame is connected with the oil cylinder 15, and the oil cylinder 22 is connected with a fixed clamping frame. The fixed clamping frame 20 is connected with a clamp 21, the trolley 3 is installed on the engine base plate, and the movable clamping frame is connected with an upset forging vertical seat through the oil cylinder 13. The PLC device is connected with a pressure sensor, a temperature sensor and a power device. The power device is connected with the clamp 7. By means of the steel pipeline friction-welding device, the fact that weld joint strength is equal to strength of a matrix material in respect of welding quality can be achieve, welding efficiency is high, the quality is stable, and consistency is good.

Owner:QINGDAO DACANG CORROSION PREVENTION CO LTD

Method for forming hollow front shaft

The invention relates to a method for forming a hollow front shaft, which is characterized in that the specific process is as follows: (1) firstly blanking a pipe section, adopting a band sawing machine and the like to cut a circular pipe material into a fixed-scale pipe blank in a required size, (2) utilizing a medium frequency induction heating furnace to heat pipe ends and a transition region of the cut pipe blank; (3) utilizing a special diameter-reducing machine to perform extrusion and diameter reduction or utilizing a rotary forging device to perform diameter reduction forming on the pipe ends and the transition region through a rotary extrusion and diameter reduction process; (4) carrying out upset forging and forming on the pipe ends; (5) heating the whole; (5) forming the whole; and (7) machining main pin holes at two ends of a pipe. The method for manufacturing a hollow front shaft through the forming process of a pipe blank is simple in manufacturing process, easy to realize the standardization of a mold, fast to remodel, few in production steps, light in weight of a front beam, low in remodeling cost, short in production preparation time and low in cost.

Owner:FAW GROUP

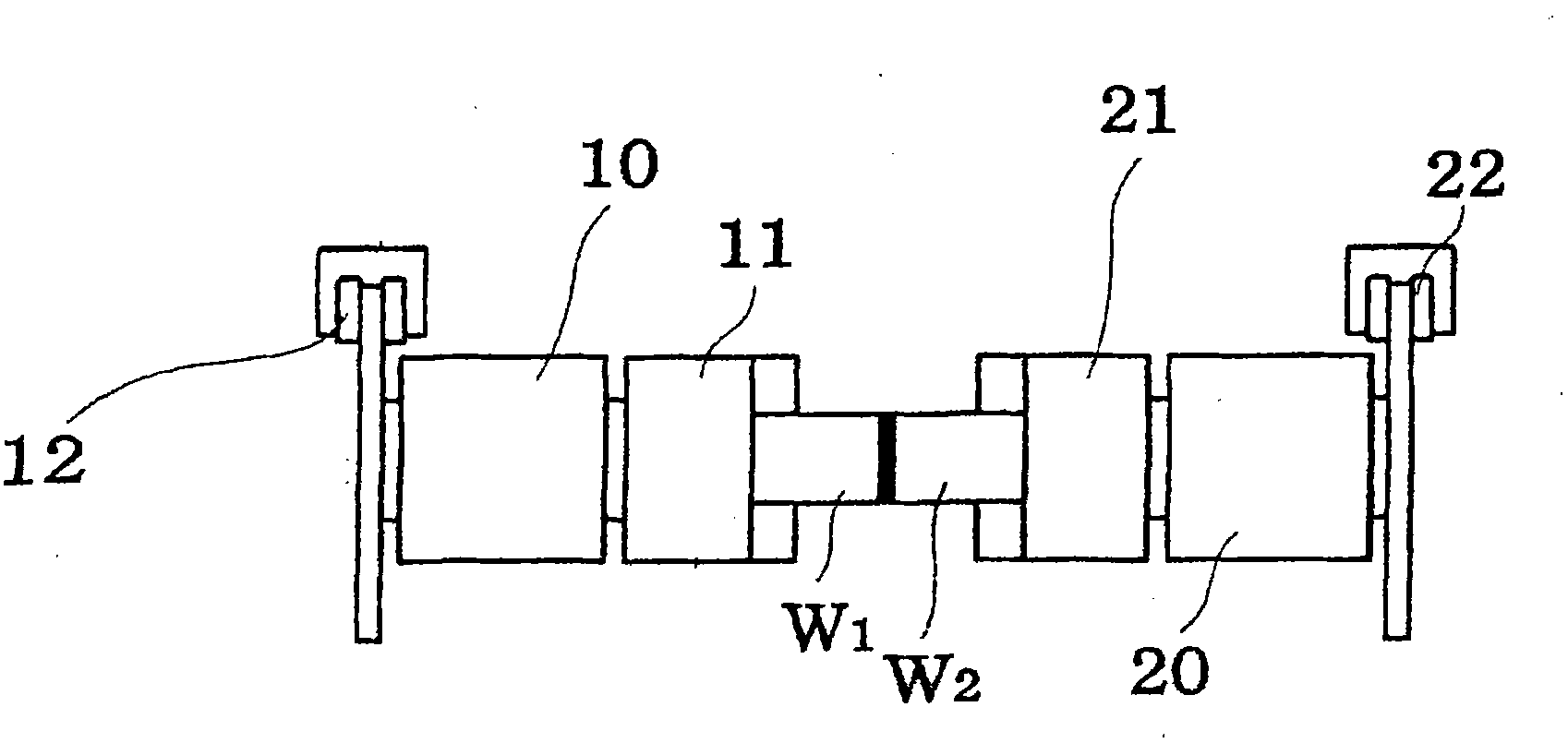

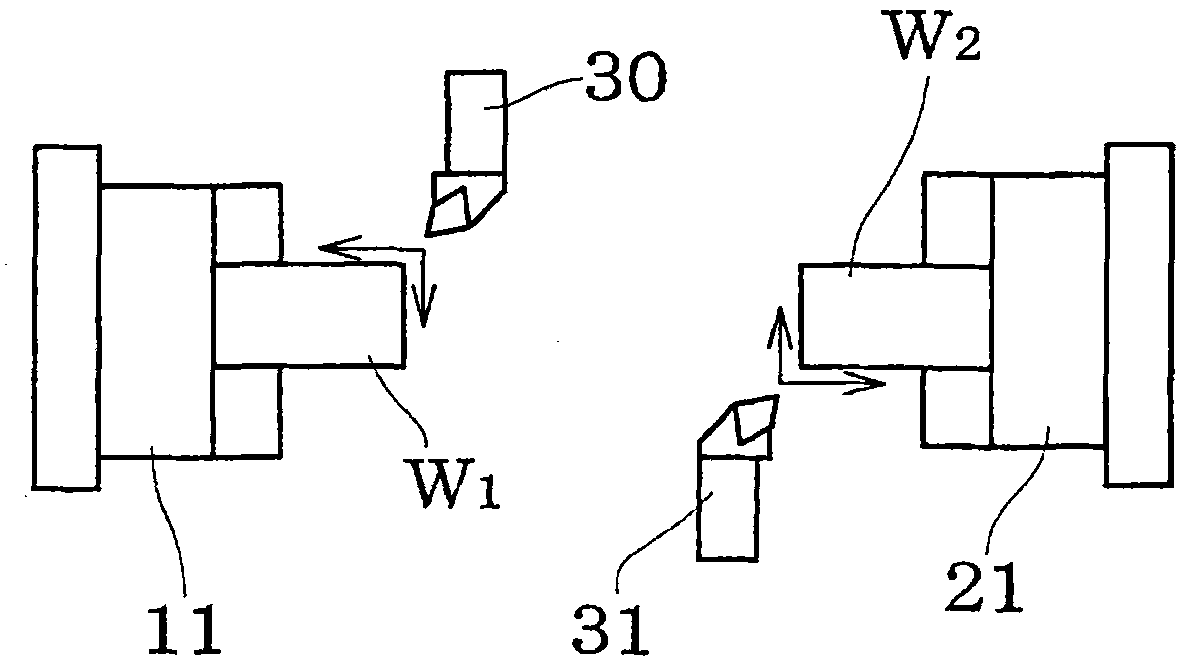

Friction compression joint method

The invention provides a friction compression joint method capable of performing stable declining compression and upset-forging compression and easily performing the phase alignment between the workpieces. The method for friction compression joint of two workpieces (W1,W2) is characterized in that: the workpiece (W1) at one side is mounted and clamped on a main axle (L) rotation and driving under control and the workpiece (W2) at another side is mounted and clamped on another opposite main axle (R) or a clamping device (R) to make joint surfaces opposite with each other. The main axle (L) rotates, thus the joint surface of the workpiece (W1) and the joint surface of the workpiece (W2) heat by friction and contact with each other to rotate. In order to arrive at the object coordination of the inclined side pressure along the Z axle direction, the opposite main axle (R) or the clamping device (R) is subject to movement control and secondly in order to arrive at the object coordination of the upset forging pressure, the main axle (R) or the clamping device (R) is subject to movement control.

Owner:NAKAMURATOME SEIMITSU IND

Dissimilar steel welding method for martensite heat-resisting steel and austenitic heat-resisting steel

InactiveCN104014928AImprove joint qualityQuality improvementFurnace typesWelding/soldering/cutting articlesFriction weldingAustenite

A dissimilar steel welding method for martensite heat-resisting steel and austenitic heat-resisting steel includes the following steps that (1) according to technical requirements of a friction welding machine, a martensite heat-resisting steel tube and an austenitic heat-resisting steel tube are respectively installed and clamped through a fixture of the friction welding machine and cannot shake, and the center line of the martensite heat-resisting steel tube and the center line of the austenitic heat-resisting steel tube are kept in the same horizontal line; (2) at a first-level pressurization stage, the rotation speed is 1200-1800 revolutions per minute, friction pressure is 25-75 MPa, and friction time is 4-6 seconds; (3) at a second-level pressurization stage, the rotation speed is 1200-1800 revolutions per minute, friction pressure is 100-200 MPa, and friction deformation is 4-8 mm; (4) at an upset forging stage, upset forging pressure is 150-250 MPa, and upset forging time is 4-6 seconds; (5) partial heat treatment needs to be carried out on a welded joint between the martensite heat-resisting steel tube and the austenitic heat-resisting steel tube after welding, so that residual stress is eliminated. The method has the advantages that quality of the joints is high, the method is suitable for welding of heterogeneous materials, production efficiency is high, production cost is low, energy is saved, and environment is protected.

Owner:XIAN SPECIAL EQUIP INSPECTION INST

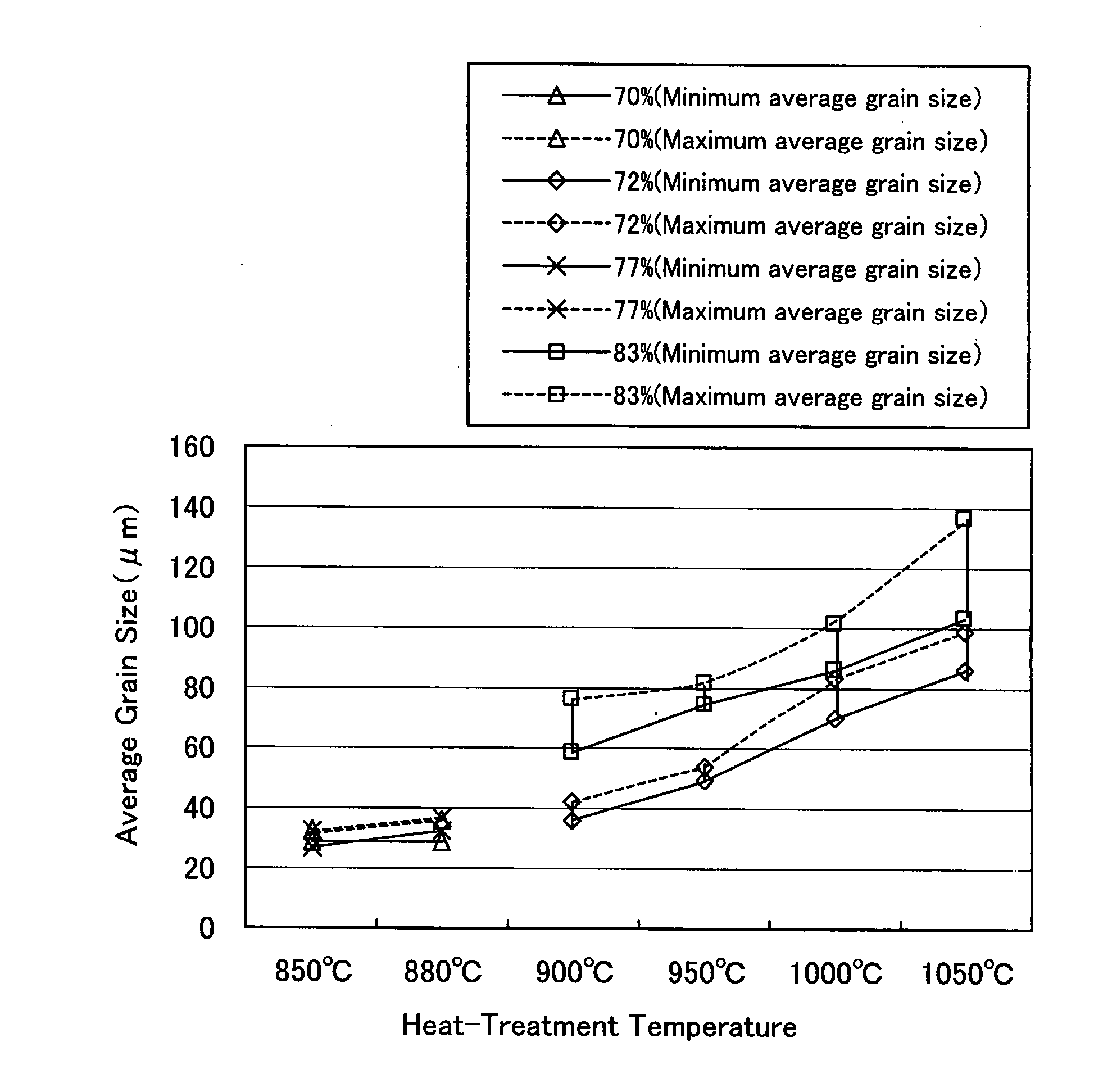

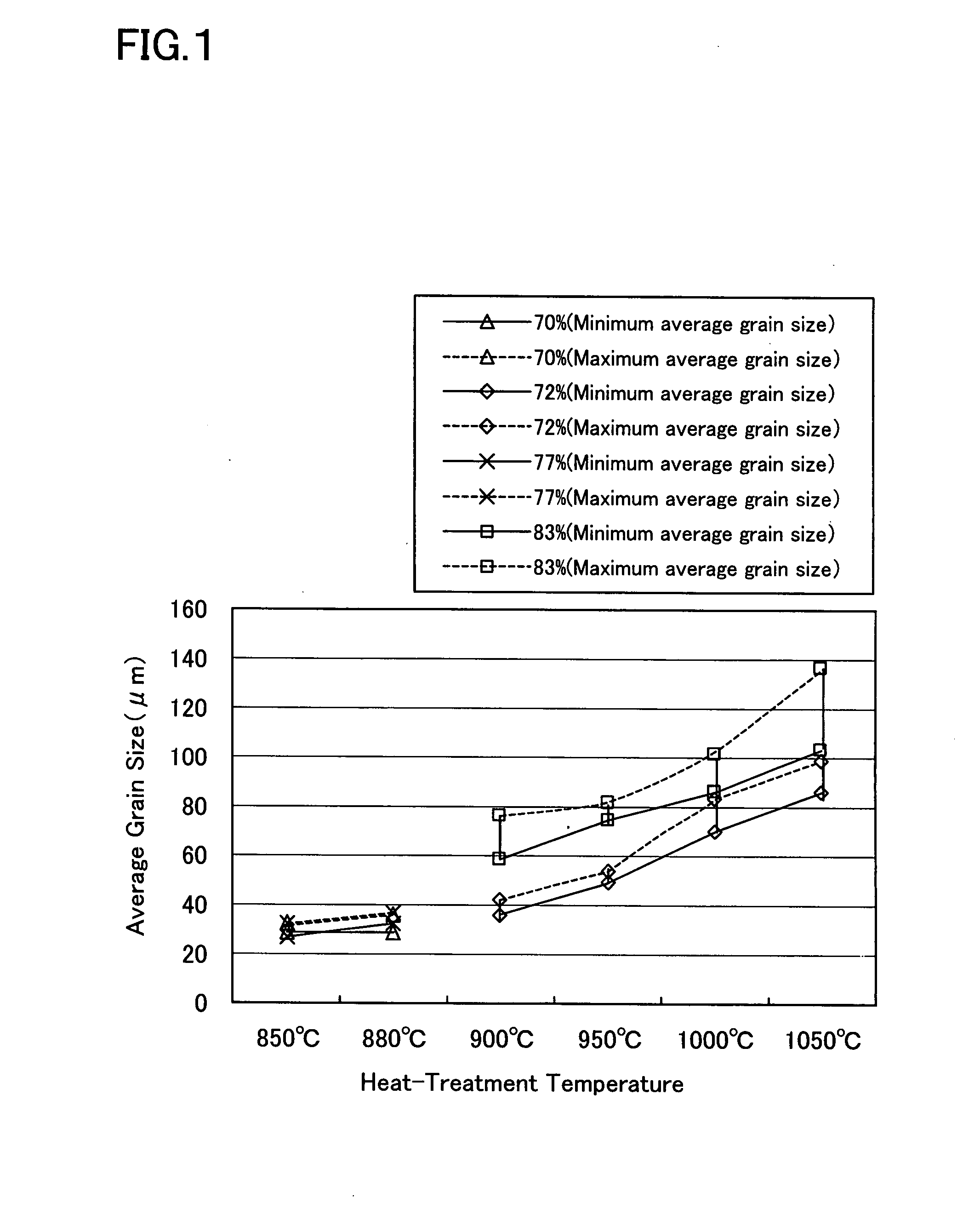

Titanium material superior in upset-forgeability and method of producing the same

InactiveUS7014722B1Good upset forgeabilityImprove malleabilityVacuum evaporation coatingMetal-working apparatusSemiconductor materialsDiameter ratio

In finifsh-cogging a high-purity titanium material into a cylindrical form as the final shape, if cylindrical cogging is performed in all stages of warm forging or if cylindrical cogging is performed in the initial stage of the warm forging, there is no need of peripherally restricting the cylindrical cogging material, so that even if longitudinal upset-forging is effected with an upsetting ratio of 2, the condition that the major diameter / minor diameter ratio of the section after forging is not more than 1.01 can be satisfied, developing superior upset-forgeability. This makes it possible, in producing disk-like targets for sputtering, to minimize cutting loss produced during the rolling and machining and to maximize the yield of products; therefore, the material can be widely used as a semiconductor material for electrodes and the like using a high-purity titanium material.

Owner:OSAKA TITANIUM TECHNOLOGIES

Method for controlling microstructure and texture of tantalum

A method for controlling the microstructure and texture of tantalum, proposed in the present invention, comprises: a step for performing cold working on a tantalum billet having the shape of a rectangular prism; and a step for performing cold rolling multiple times, wherein the step for performing the cold working includes: a first forging step for performing upset forging and come-back forging on the tantalum billet multiple times in different directions, the upset forging being performed to press two surfaces of the tantalum billet in order to make the two surfaces close to each other and the come-back forging being performed to restore the tantalum billet to the original shape; and a second forging step for performing wedge forging and come-back forging on the tantalum billet multiple times in different directions, the wedge forging being performed to press two edges located in a diagonal direction of the tantalum billet and parallel to each other in order to make the two edges close to each other and the come-back forging being performed to restore the tantalum billet to the original shape.

Owner:AGENCY FOR DEFENSE DEV

Methods for welding austenitic alloy steel and preparing non-magnetic drill collar by utilizing linear friction welding technology

InactiveCN108817646AReduce permeabilityGuarantee the requirements for working in a low magnetic environmentWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingNon magnetic

The invention relates to methods for welding austenitic alloy steel and preparing a non-magnetic drill collar by utilizing a linear friction welding technology. The methods comprise the steps that workpieces made of the austenitic alloy steel are clamped into a friction welding machine, then the workpieces in clamps at the vibration end and the moving end are welded, when welding is started, the workpiece at the moving end moves towards the workpiece at the vibration end, at the moment, the workpiece at the vibration end begins to vibrate, after the workpiece at the vibration end makes contactwith the workpiece at the moving end, friction heat generation begins under action of the friction pressure, when the friction time reaches the set value, vibration stops, upset forging begins to beconducted, upset forging pressure is applied to the workpieces in the axial direction of the workpieces and maintained, after the upset forging pressure is released, the workpieces are taken out, andthus the non-magnetic drill collar is obtained. According to the methods for welding the austenitic alloy steel and preparing the non-magnetic drill collar by utilizing the linear friction welding technology, the mode that the non-magnetic drill collar is machined and repaired through the linear friction welding technology is proposed so as to solve the problems that as for an existing machining method, materials are wasted, the cost is high and the production efficiency is low, and overcome the defect that the invalid drill collar is difficult to repair.

Owner:SHANDONG UNIV

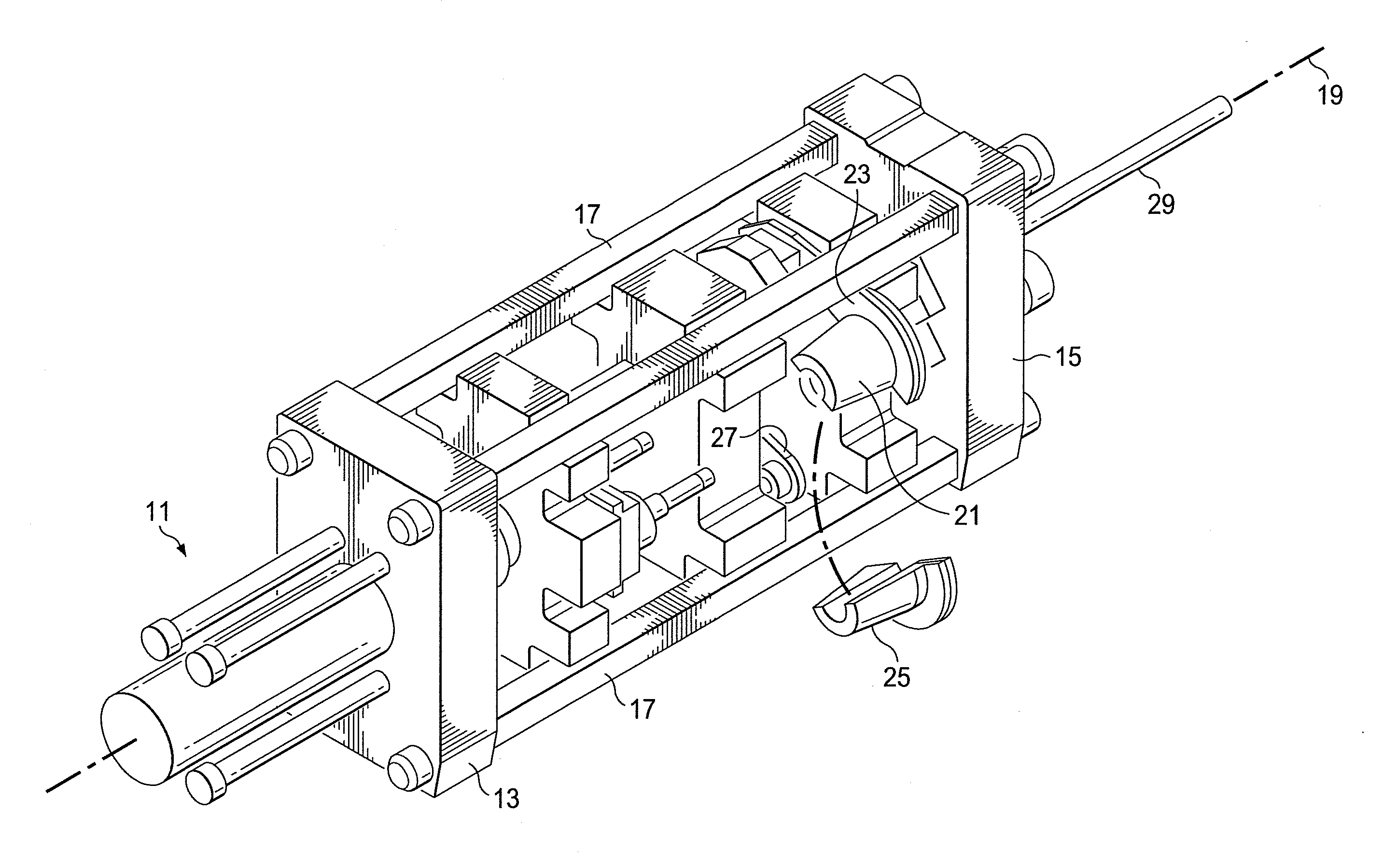

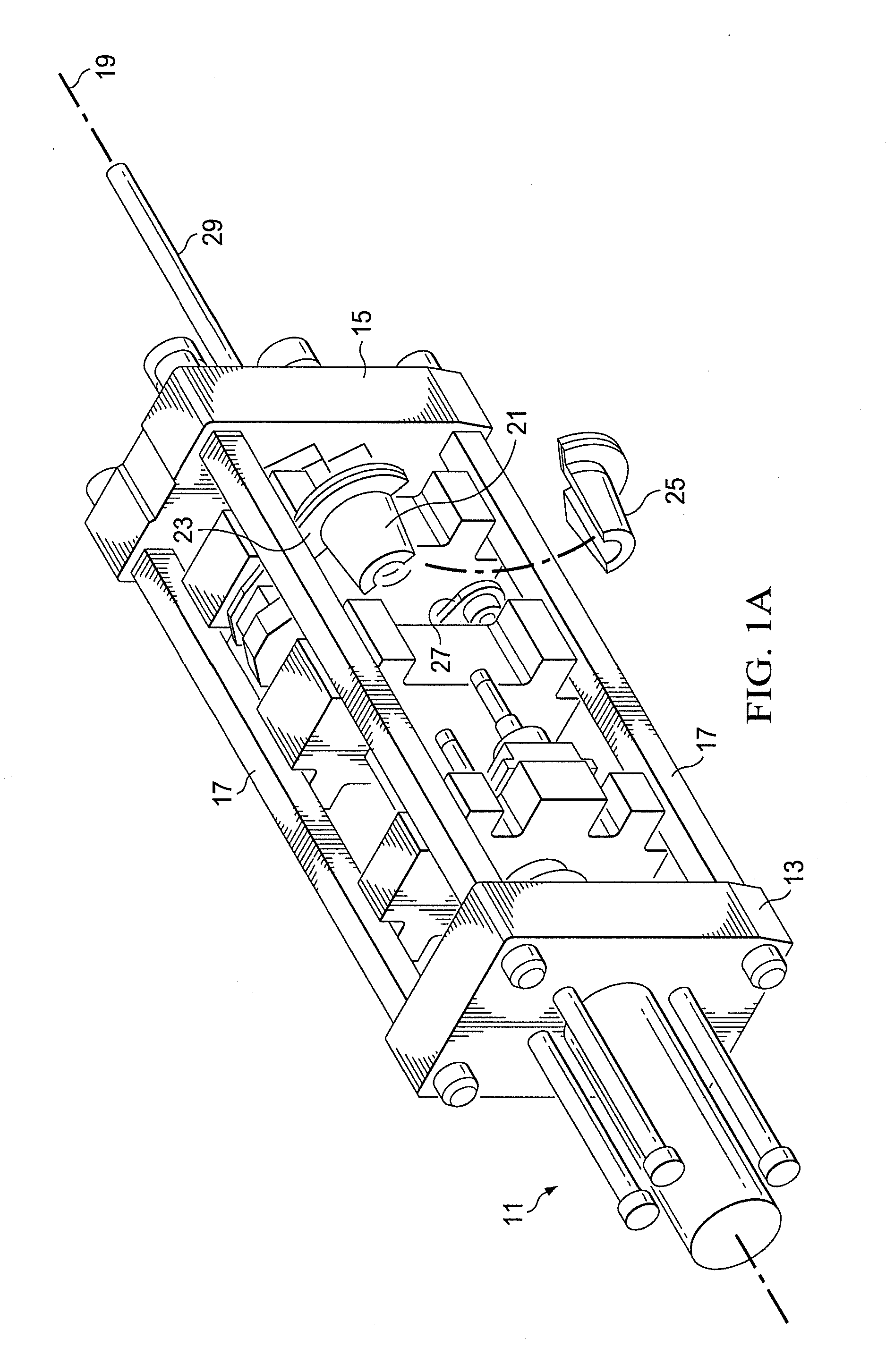

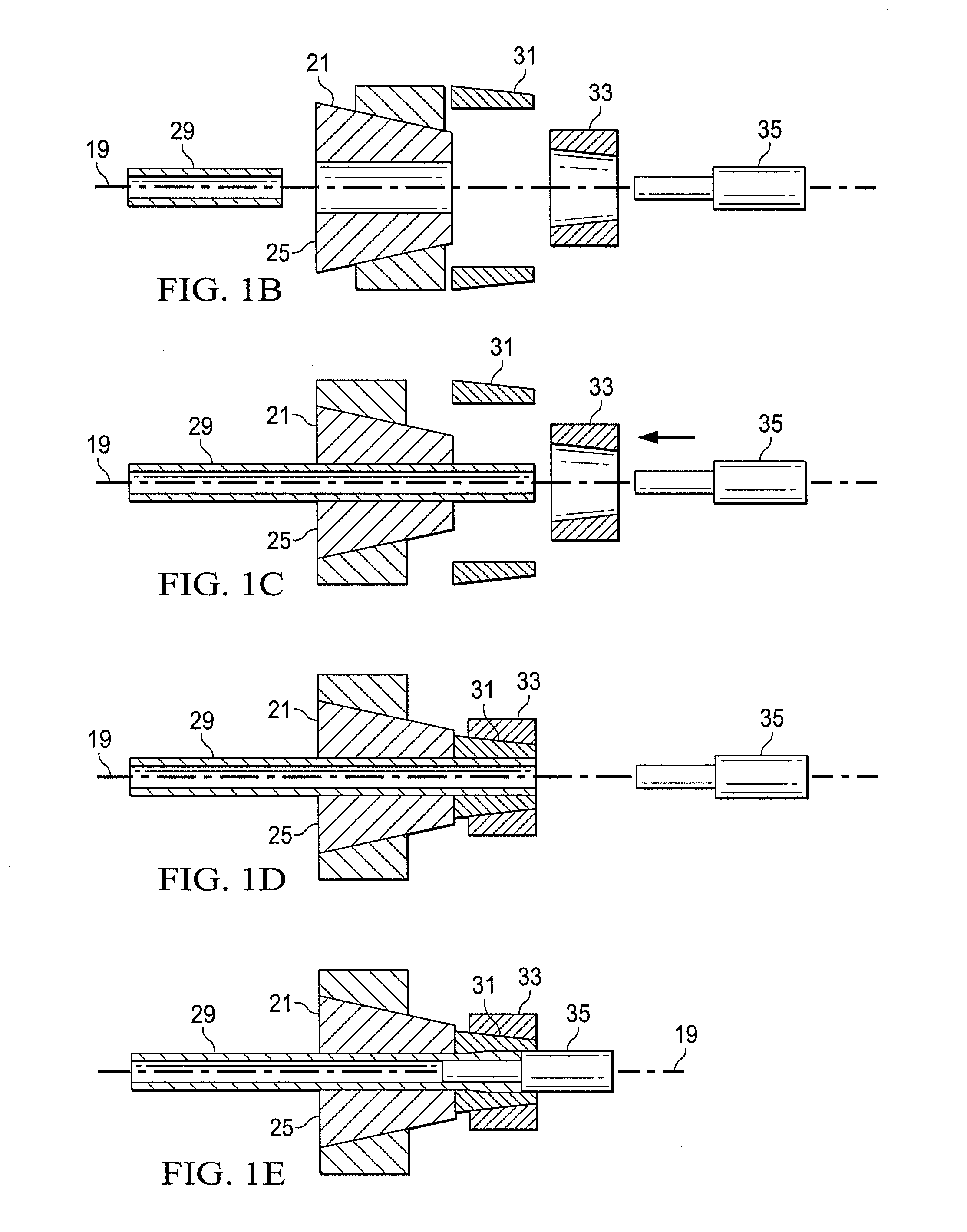

Process for Upset Forging of Drill Pipe and Articles Produced Thereby

ActiveUS20150096346A1Thicker upsetSmall inner diameterShaping toolsDrilling rodsEngineeringUpset forging

Shown is a method for manufacturing horizontal directional drilling pipe having internally and externally upset pipe ends. The forging is done by heating the green tube ends and applying pressure using a closed die hydraulic forging press to form the upsets. One end of a steel tube is worked by upsetting and pressing to form an external upset portion having an outer taper being shaped by upset forging. That portion is then pressed by an internal upset die so as to displace the outer taper to an internal upset portion having an inner taper. Internal upset forging is then carried out by an internal upset die to produce the finished part. The process allows the manufacturer to produce a thicker upset horizontal directional drilling pipe, where the ratio of the outside diameter to the inside diameter of the upset can be on the order of 3.5, or even greater.

Owner:HUNTING ENERGY SERVICES LLC

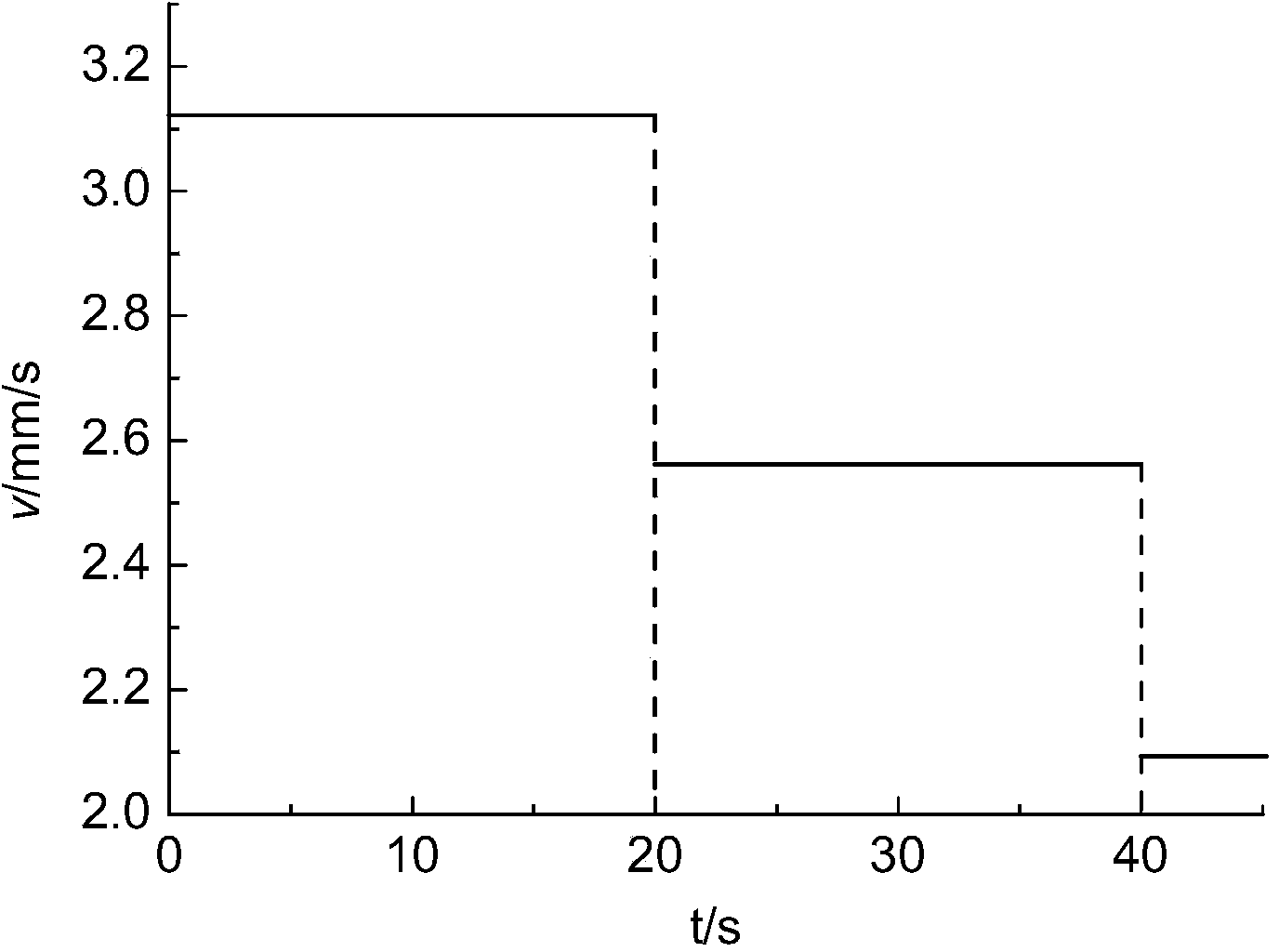

Flash welding process of high-strength low-magnetic anchor chain

InactiveCN107891219ASolve the cooling problemSolve heatingWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneSystem pressure

The invention provides a flash welding process of a high-strength low-magnetic anchor chain. The flash welding process is characterized in that the burn-off degree reaches 7-9 mm, the upset forging length reaches 6-8 mm, the burn-off speed reaches 1.8-2.0 mm / s, the secondary no-load voltage reaches 4.7 V, and the system pressure reaches 14-16 MPa. Compared with a conventional technological process, the flash welding process has the advantages that a pre-flash process is added, so that the problems about the rapid heat dissipation of a material and the heating of welds during low-temperature welding can be solved, the heat-affected area can be effectively enlarged, the upset forging effect can be guaranteed, and the relatively consistent shapes of welding joints can be guaranteed; sufficient upset forging pressure is exerted on welding end surfaces, gaps among the joints are rapidly reduced, the lintel blasting is stopped, liquid metal and oxide inclusion on the end surfaces are extruded, and joint areas are subjected to certain plastic deformation, so that the progress of recrystallization can be promoted, common crystal grains can be formed, and firm butt joints can be acquired; and after the upset forging is finished, the pressure of electrodes and the pressure of an upset forging oil cylinder are maintained for a certain time, and then the electrodes and the upset forging oil cylinder are cooled, so that the deformation resistance of the joints can be sufficient and welding end ports can be protected against cracking caused by ring-shaped springback.

Owner:JIANGSU ASIAN STAR ANCHOR CHAIN

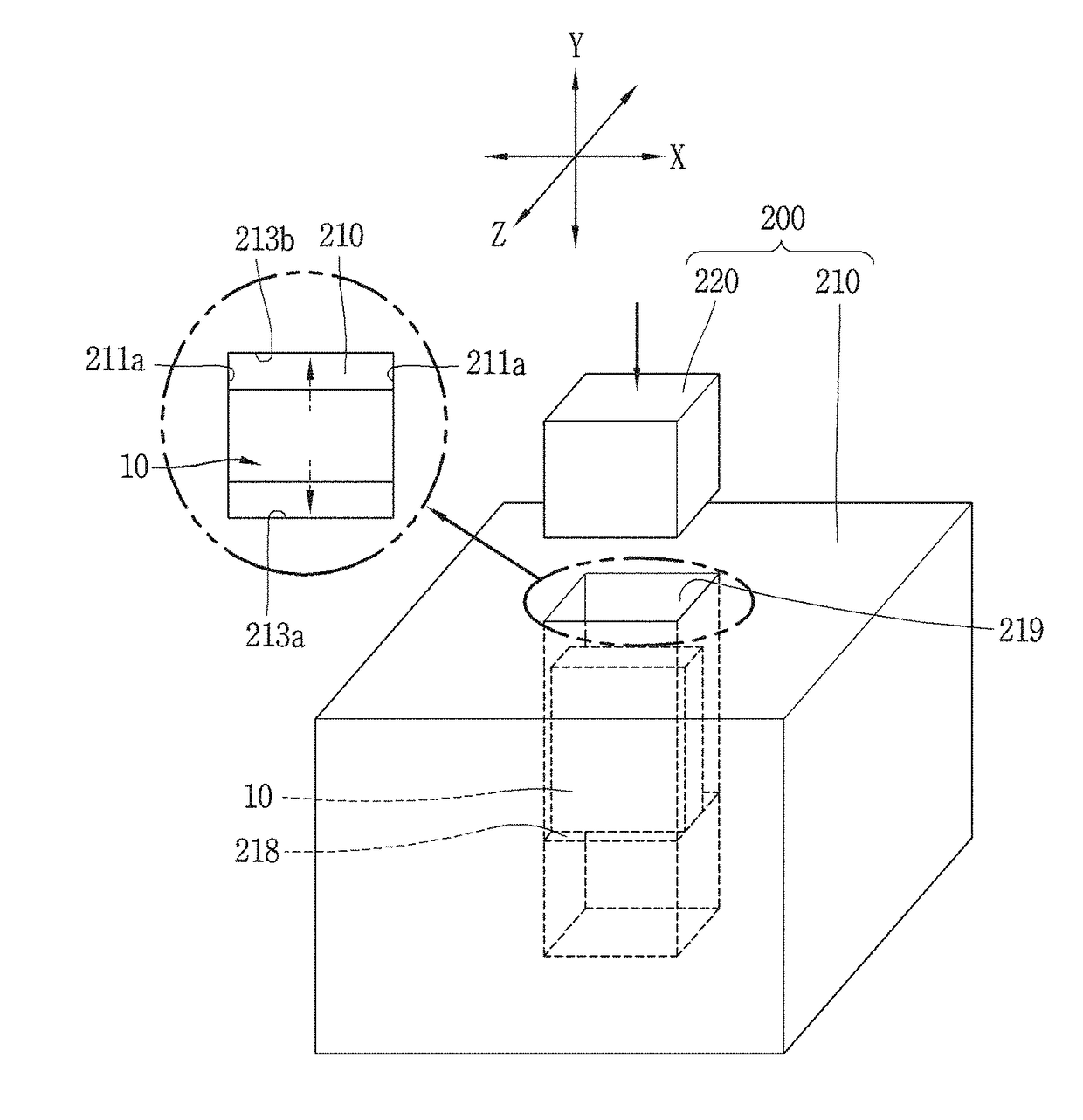

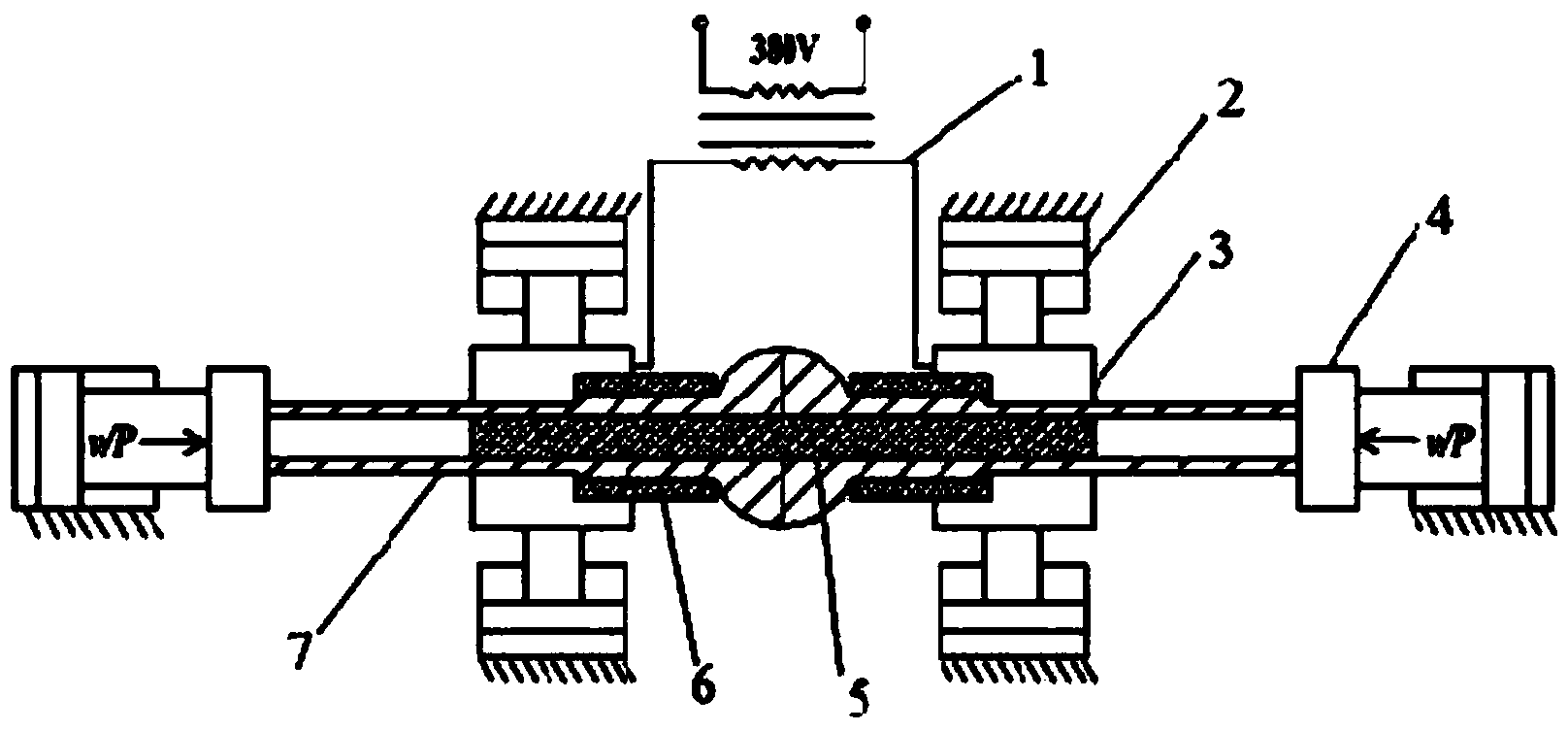

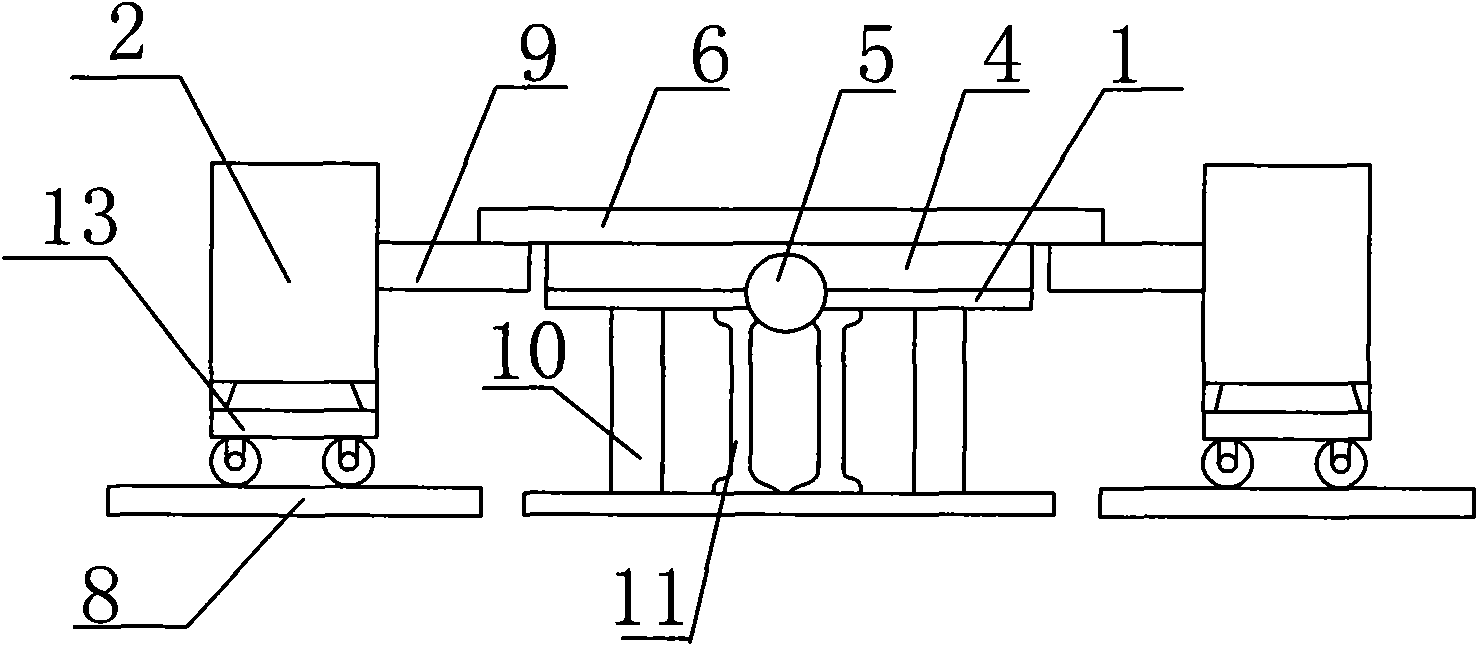

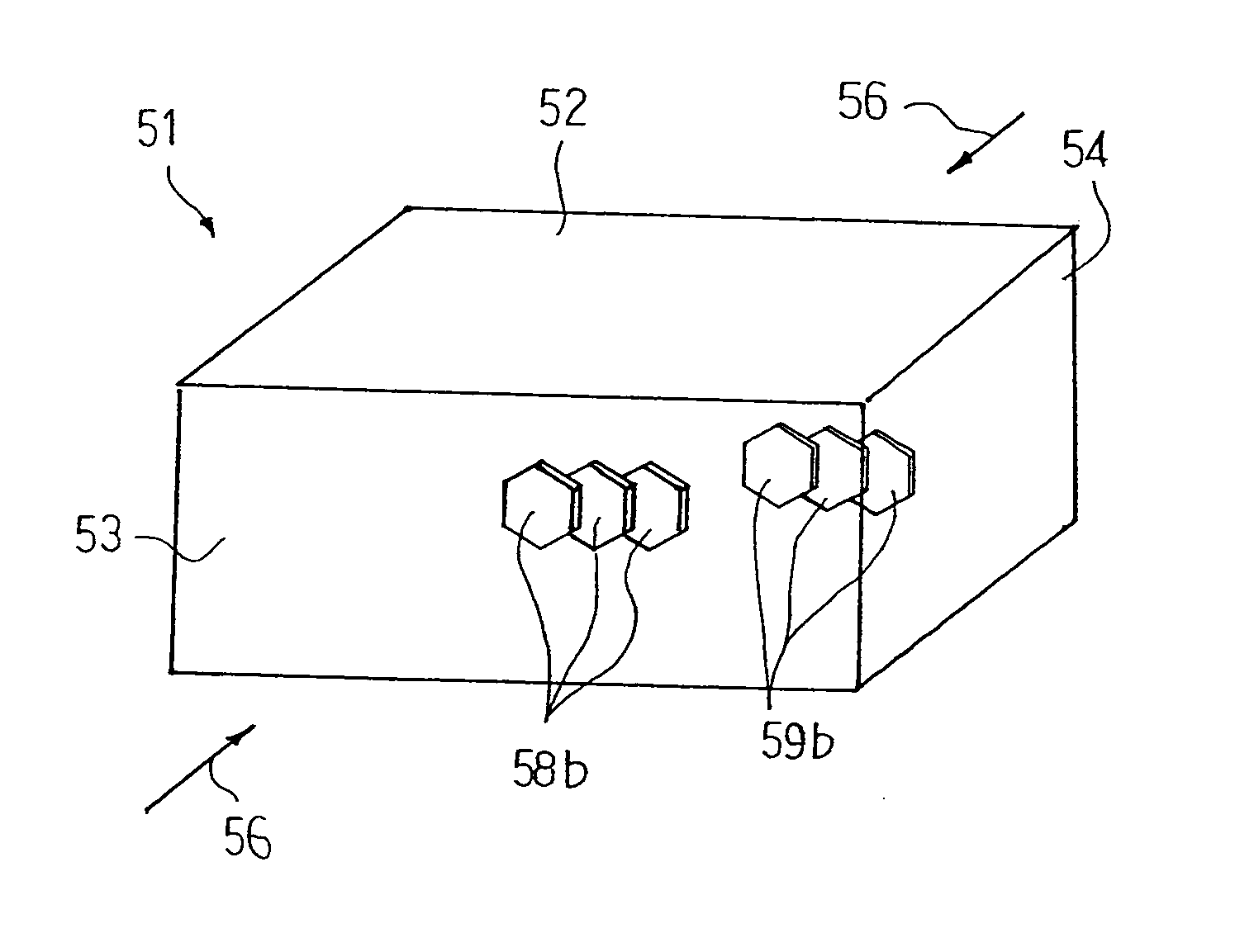

Method and device for manufacturing double axle tube blanks at one time in a local electric upsetting mode

ActiveCN103586382AEasy to processShort production process cycleForging press detailsTransformerEngineering

The invention discloses a device and method for manufacturing double axle tube blanks at one time in a local electric upsetting mode. The device comprises two pairs of clamping cylinders, the front ends of telescopic arms of each pair of clamping cylinders are provided with a pair of clamping components, and the two pairs of clamping components are made of conductive materials and connected with the output end of a heating transformer through wires respectively; the device further comprises the heating transformer, two heading cylinders which are oppositely arranged at the two ends of the direction of the central line of two pairs of clamping rods, two sleeves and a mandrel. The method is implemented through the device, according to the technological process, the end portions of two steel tubes with the same specification are connected in a butted mode. and the two steel tubes are placed on the manufacturing device to undergo local upset forging, and finally the double axle tube blanks are formed at one time. The device and method solve the problem that in the prior art, the end portions are large and a flange is difficult to form, moreover, the double through hollow tube blanks difficult to form can be produced just in one process through the forming technology, and thus the axle tube blanks can be formed fast and conveniently.

Owner:CHONGQING UNIV

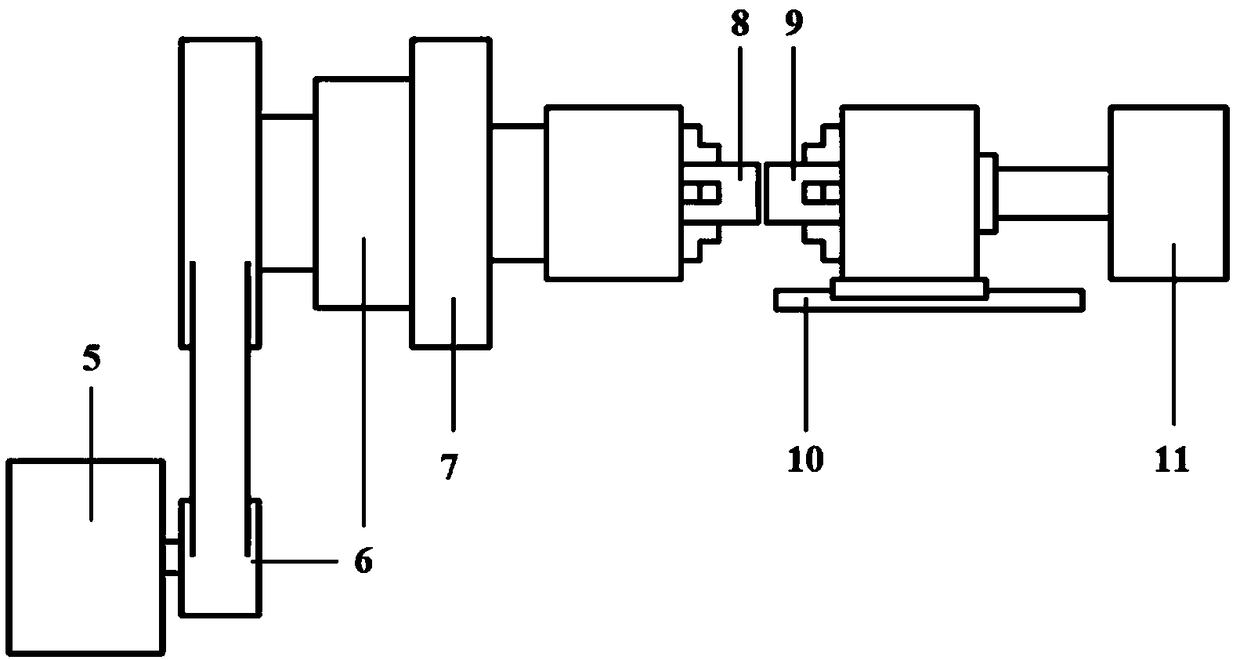

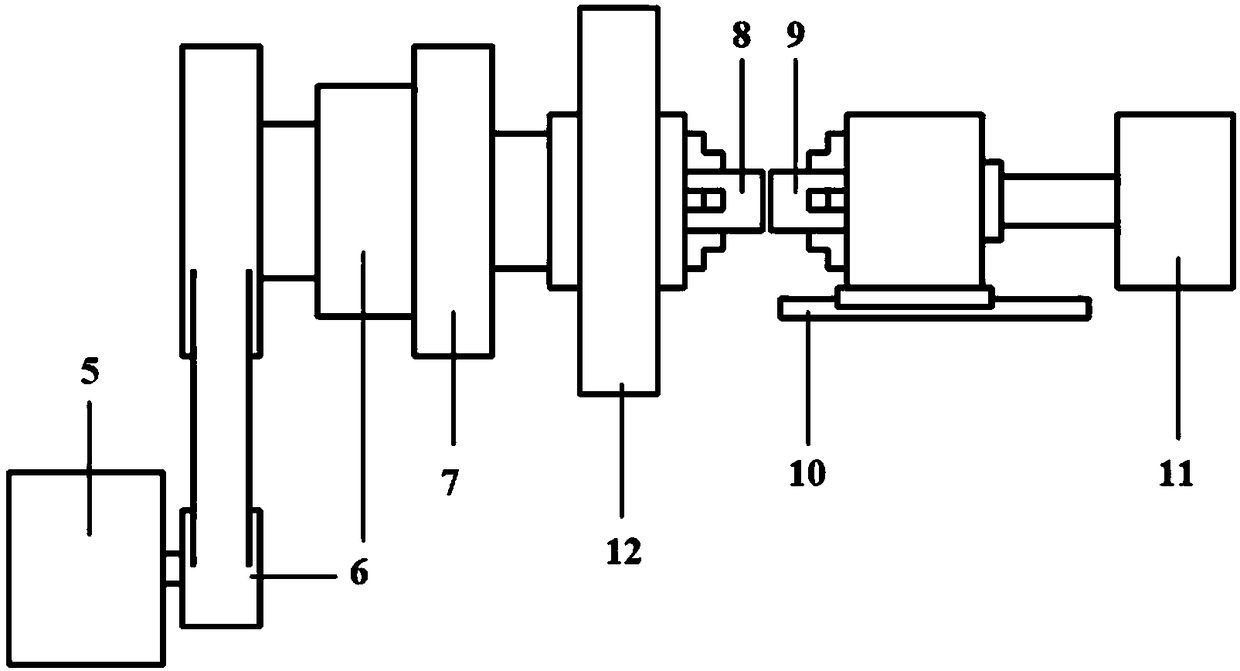

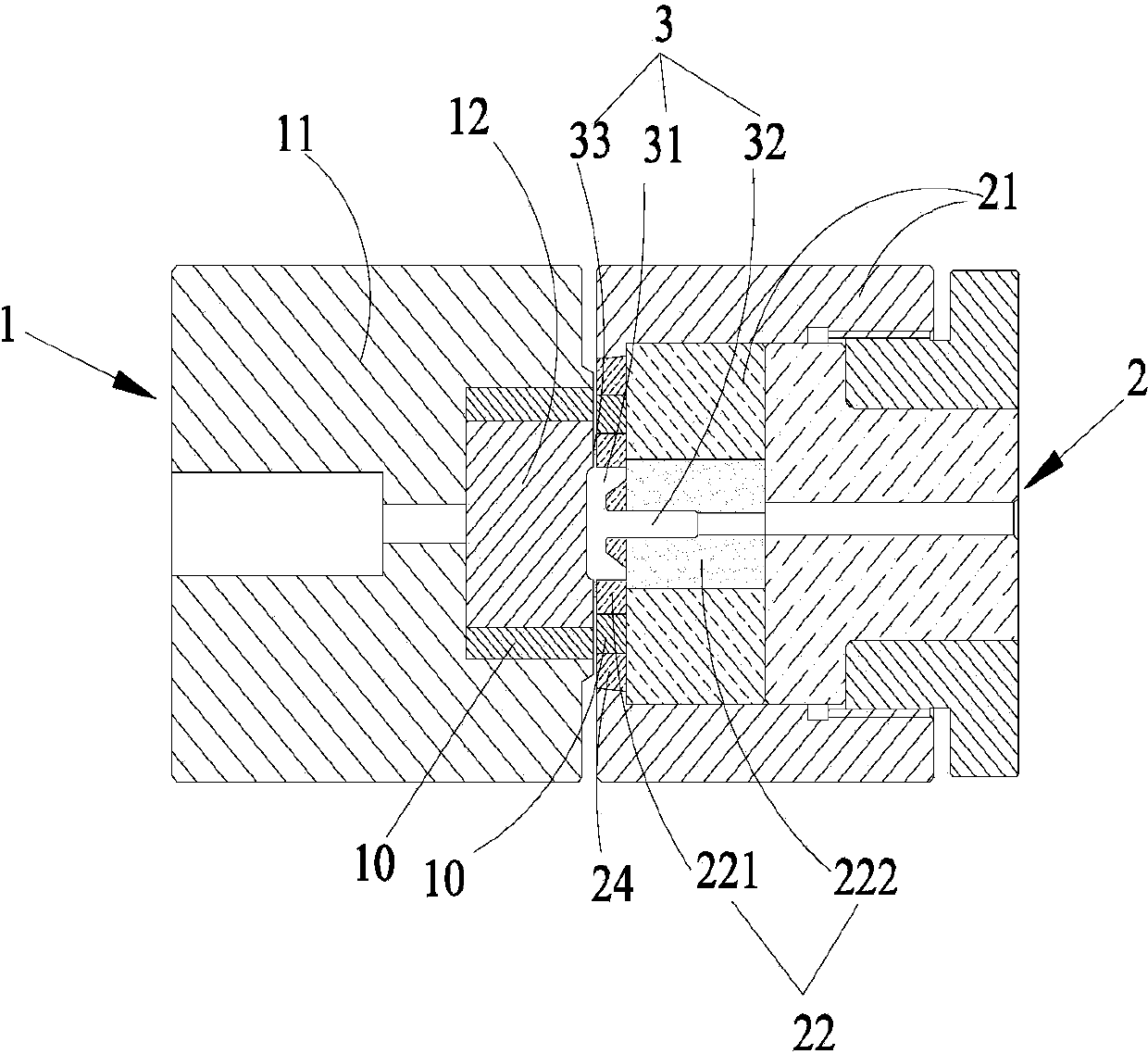

Current-loaded linear friction welding device

InactiveCN102303184AReduce complexityReduce energy consumptionNon-electric welding apparatusCurrent loadElectricity

The invention relates to the technical field of linear friction welding, in particular to a linear friction welding device, and in particular discloses current-loaded linear friction welding equipment which has a simple structure, and is low in energy consumption, high in efficiency and low in welding cost. The linear friction welding equipment comprises a control system, an upset forging end system, a vibrating end system and an auxiliary power supply, wherein the upset forging end system comprises an upset forging end clamp; the vibrating end system comprises a vibrating end clamp; the upset forging end clamp and the vibrating end clamp are arranged oppositely; and two electrodes of the auxiliary power supply are electrically connected with the upset forging end clamp and the vibrating end clamp. When the current-loaded linear friction welding device is used, current is loaded on a test piece during welding, so resistance heat is generated on the contact end face of the test piece, the requirement on friction heat can be reduced, and the complexity and energy consumption of a vibrating assembly can be reduced; and the vibrating assembly can be driven by a linear motor, and the welding efficiency can be improved.

Owner:CHONGQING UNIV

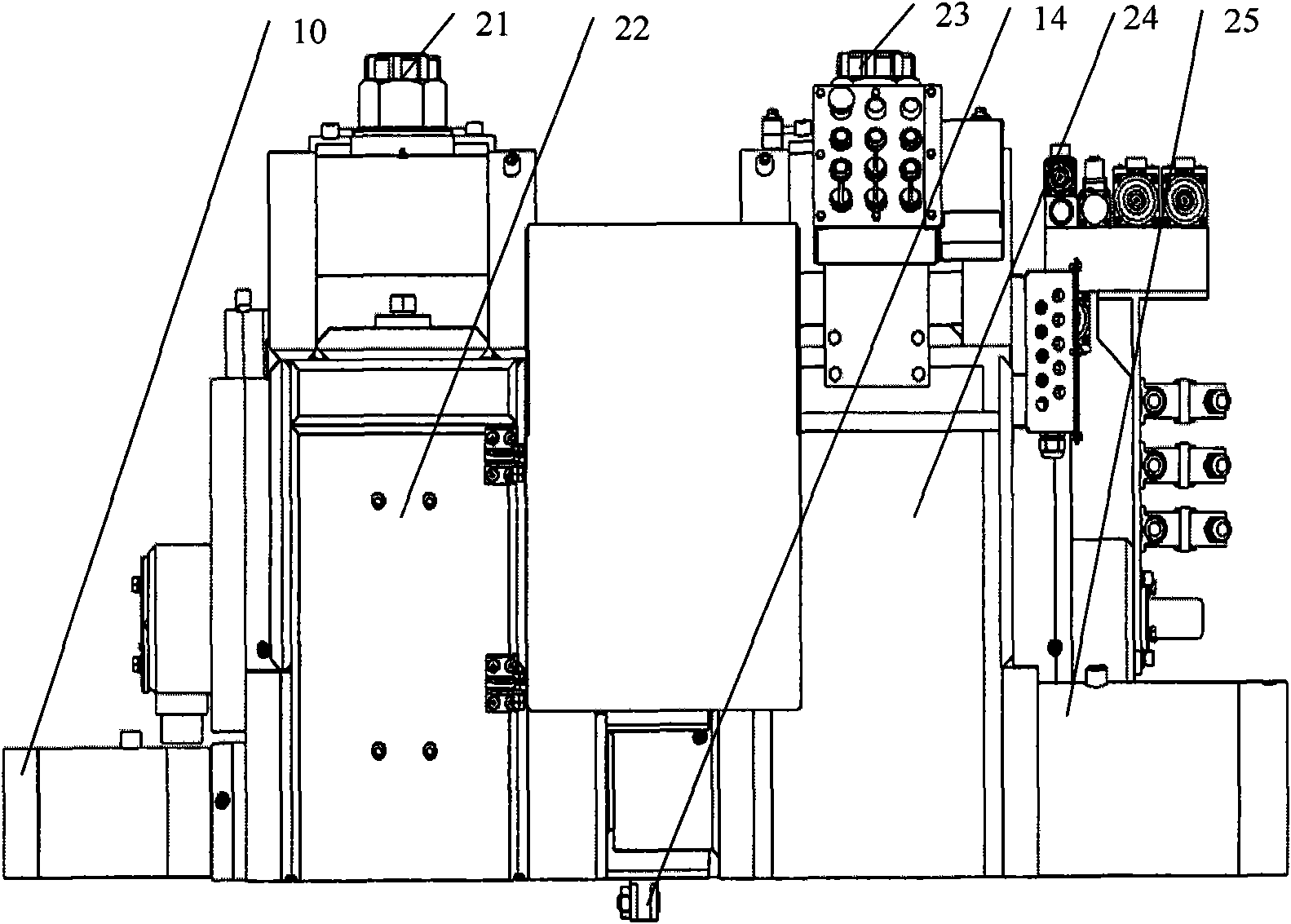

Steel rail flash welding machine and container type steel rail flash welding equipment

ActiveCN102049602AExtended service lifeCompact structureResistance welding apparatusTransformerFlash welding

The invention provides a steel rail flash welding machine which comprises fulcrums arranged thereon, at least two steel rail clamping mechanisms arranged on the corresponding fulcrums, a flash welding transformer and an upset forging actuating mechanism. Each steel rail clamping mechanism comprises an operating mechanism, two lever structures and two connecting rod pieces, wherein the operating mechanism is provided with an operating rod capable of vertically applying force or actuating; the two lever structures can pivot around the fulcrums, and the lower end of each lever structure can loosen or clamp a steel rail; and one end of each connecting rod piece is pivotally connected with a common first pivot point on the operating rod, and the other end of the connecting rod piece is pivotally connected with one of second and third pivot points lower than the first pivot point on the corresponding lever structure, and the operating rod vertically applies the force to or actuates the connecting rod pieces, so that the lower ends of the lever structures loosen or clamp the steel rails. The invention also provides container type steel rail flash welding equipment with the steel rail flash welding machine.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +1

Dissimilar metal welding method for martensite heat-resisting steel and high-temperature nickel base alloy

InactiveCN104014929AImprove joint qualityQuality improvementFurnace typesWelding/soldering/cutting articlesFriction weldingAlloy

A dissimilar metal welding method for martensite heat-resisting steel and high-temperature nickel base alloy includes the following steps that (1) according to technical requirements of a friction welding machine, a martensite heat-resisting steel tube and a high-temperature nickel base alloy tube are respectively installed and clamped through a fixture of the friction welding machine and cannot shake, and the center line of the martensite heat-resisting steel tube and the center line of the high-temperature nickel base alloy tube are kept in the same horizontal line; (2) at a first-level pressurization stage, the rotation speed is 1200-1500 revolutions per minute, friction pressure is 20-50 MPa, and friction time is 1-3 seconds; (3) at a second-level pressurization stage, the rotation speed is 1200-1500 revolutions per minute, friction pressure is 50-100 MPa, friction deformation is 1-4 mm, and friction time is shorter than 10 seconds; (4) at an upset forging stage, upset forging pressure is 100-200 MPa, and upset forging time is 2-4 seconds; (5) partial heat treatment needs to be carried out on a welded joint between the martensite heat-resisting steel tube and the high-temperature nickel base alloy tube after welding, so that residual stress is eliminated. The method has the advantages that quality of the joints is high, the method is suitable for welding of heterogeneous materials, production efficiency is high production cost is low, energy is saved, and environment is protected.

Owner:XIAN SPECIAL EQUIP INSPECTION INST

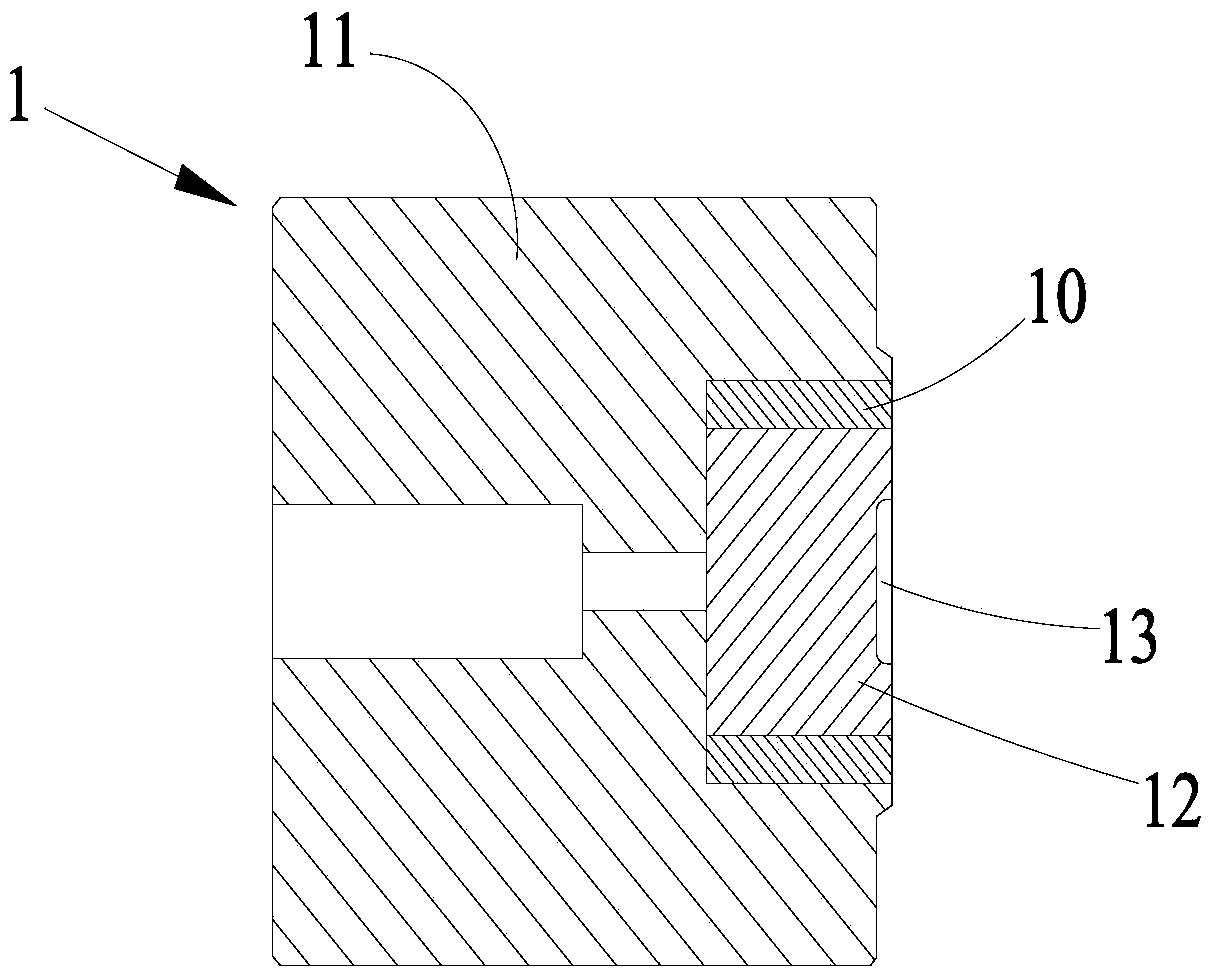

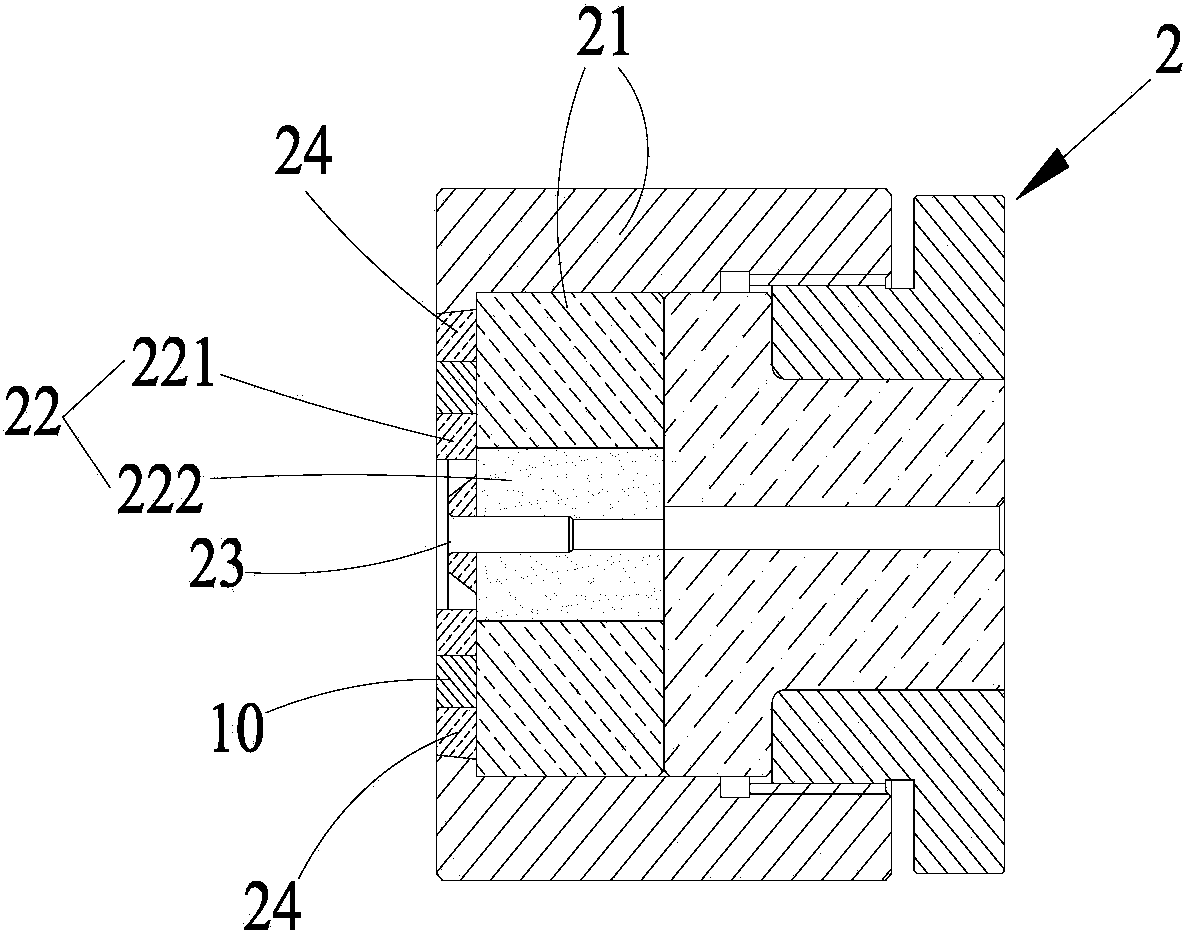

Manufacturing process and equipment for upset forging of flanges

InactiveCN101961765AQuality improvementGuaranteed traceless weldingEngine componentsHeating/cooling devicesUpset forgingManufacturing engineering

The invention relates to manufacturing process and equipment for the upset forging of flanges, relating to manufacturing process and equipment for flanges. The manufacturing process comprises the following steps of: making materials into flange metal semicircles, evenly heating and butting the flange metal semicircles by adopting upset forging equipment, wherein the pressure on an extrusion surface is 40 to 70MP and the heating temperature is 500 to 1300 DEG C; and quickly connecting the two semicircles after the extrusion through the upset forging equipment to obtain a product. The invention has the advantages of capability of producing various annular steel flanges and aluminum flanges with different specifications only by using the upset forging equipment and simple matched moulding beds so that the investment in equipment and the energy consumption only account for a fraction or one of dozens of that of traditional equipment, cost is saved by more than 30% and production efficiency is increased by several times.

Owner:岳炳坤

Upsetting method of cylindrical ingot blank or bar with large height to diameter ratio

InactiveCN106607534ASolve the bendSolve forming defects such as twistingMetal-working apparatusDiameter ratioIngot

The invention discloses an upsetting method of a cylindrical ingot blank or bar with the height to diameter ratio being between 2.5 and 4.2, and relates to the field of cogging of cylindrical ingot blanks or bars and upsetting forging of bars. On the basis of cogging an ingot blank or a bar in a conventional upsetting method, a moulding bed is arranged on the outer side of the ingot blank or the bar, and a defect that the cylindrical ingot blank or bar with the height to diameter ratio being between 2.5 and 4.2 is bent in the cogging and upsetting process is overcome; dedicated guide rings are manufactured, and the condition that the ingot blank or the bar can be positioned in the center of the moulding bed when being placed in the moulding bed and keeps perpendicular to the horizontal plane is ensured; and a dedicated punch is manufactured to ensure smooth completion of the ingot blank or bar cogging operation. The upsetting method has the advantages of being low in tool manufacturing cost and small in processing volume, and provides a new selection method for cogging of small-batch blanks with large height to diameter ratio and upsetting of bars.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Method for manufacturing constituents of a hollow blade by press forging

ActiveUS20070240307A1Material minimizationReduce manufacturing costEngine componentsComponent unification devicesMechanical pressUpset forging

A method for manufacturing a hollow blade for a turbomachine is disclosed in which the blade is manufactured using a preform derived from external primary parts. A primary part comprising a root portion is formed by upset forging a bar in which material has been forced into a large volume area. Finish forging is done in at least two complementary stamping operations using an intermediate blank in order to limit costs and to use mechanical presses even for large and thin primary parts. Dies for forging the primary part are defined so as to double up at least the forging capacity of a press.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

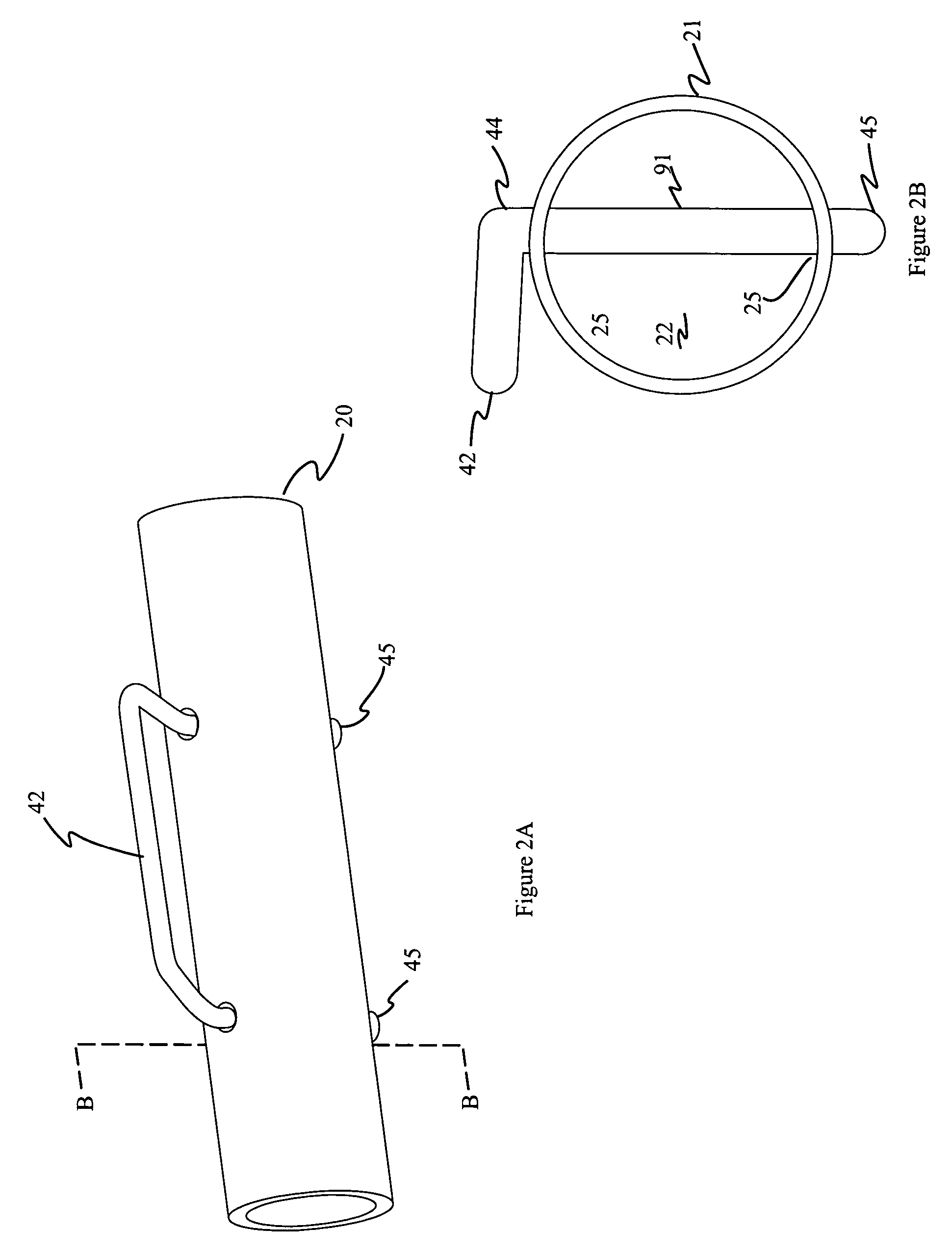

Resistance welded wire to hollow tubing joints and method

InactiveUS7721406B2Little riskReduce consumable costsPipe supportsSeat framesEngineeringMechanical engineering

Upset forging is utilized to join formed wire (40) to metal tubing (20). The ends (41) of formed wires (40) are passed completely across the width of the tube and heating electrodes (74) positioned only on the side of the tubing (20) from which the ends protrude and only the protruding ends (41) are heated to a plastic state. Back plates (30) are employed about the ends (41) to facilitate the upset forging process. An improved ISOFIX support is provided wherein a wire (40) is mounted across the width of a tube (20) and a bracket (30) placed over the wire (40) in contact with the tube (20) and these components are held together by upset forging the wire ends (41).

Owner:L & P PROPERTY MANAGEMENT CO

Thermoelectric material having crystal grains well oriented in certain direction and process for producing the same

InactiveUS20060118161A1Increase consumptionLarge figure of meritThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsFigure of merit

Thermoelectric material is produced through a process sequence including a liquid quenching, a primary solidification such as a hot pressing or extrusion and an upset forging; although the C-planes of the crystal grains are directed in parallel to the direction in which the force is exerted on flakes during the hot pressing / extrusion, the a-axes are randomly directed; the a-axes are oriented in a predetermined direction through the upset forging; this results in improvement of electric resistivity without reduction in the figure of merit.

Owner:YAMAHA CORP

Compressor, manufacturing method and application of compressor

ActiveCN103032295AGood welding performanceSimple structural designPositive displacement pump componentsPositive-displacement liquid enginesButt weldingButt joint

The invention relates to the field of a compressor, in particular to the compressor, a manufacturing method and application of the compressor. The compressor comprises a compressor shell and a liquid reservoir shell, wherein the compressor shell is formed by welding at least two parts, and butt-joint ends of constituent parts of the compressor shell are subjected to flash welding butt welding; and the liquid reservoir shell is formed by welding at least two parts, and butt joint ends of constituent parts of the liquid reservoir shell are subjected to flash welding butt welding. The manufacturing method of the compressor shell and the liquid reservoir shell comprises preheating and upset-forging. The compressor is applied to optional one of an air conditioning compressor, a refrigerator compressor and a scroll compressor. According to the compressor disclosed by the invention, not only is the welding performance of welding parts of the compressor shell and the liquid reservoir shell excellent, but also the structural design is simpler, a flange is not needed to be additionally arranged for assisting the welding, the material is saved, and the cost is reduced.

Owner:DONGGUAN JINRUI HARDWARE PROD

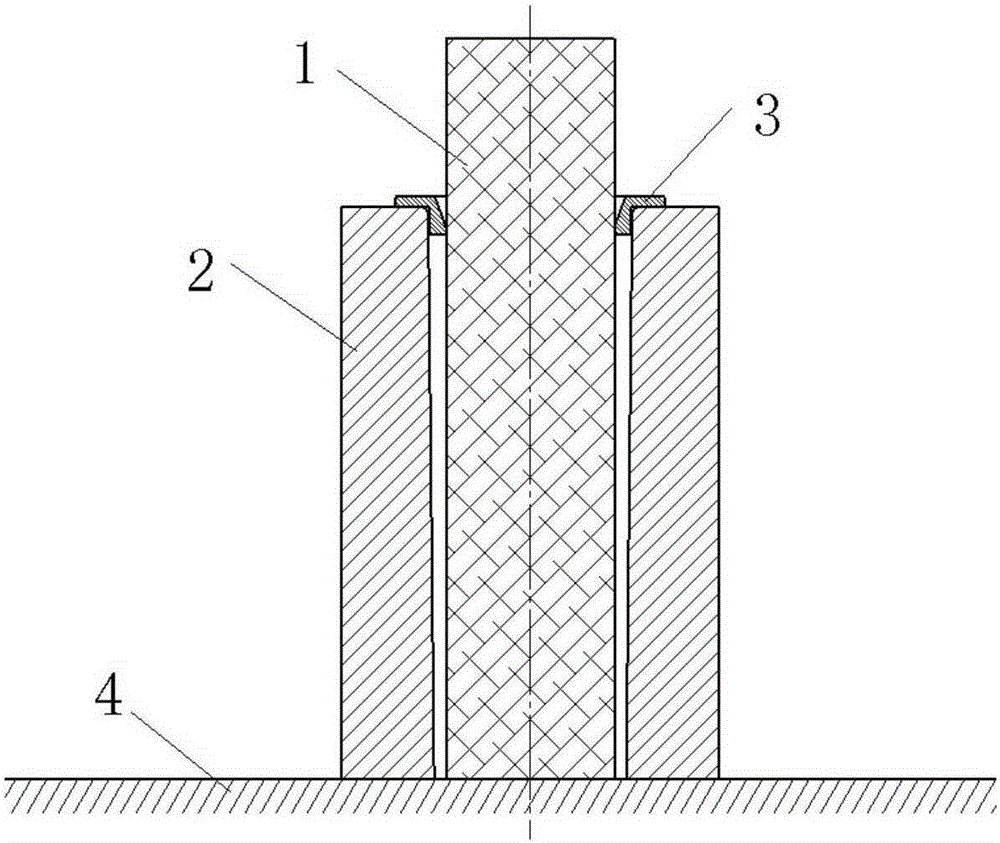

Die structure for hot upset forging of stainless steel bolt

InactiveCN104190840ALow costExtended service lifeBoltsForging/hammering/pressing machinesUpset forgingMaterials science

The invention belongs to the technical field of dies, and particularly relates to a die structure for hot upset forging of a stainless steel bolt. The die structure comprises a female die and a male die, wherein the male die comprises a first die shell, a first die core and a first cavity, the first die core is placed in the first die shell, the first cavity is formed in the first die core, the female die comprises a second die shell, a second die core and a second cavity, the second die core is placed in the second die shell, the second cavity is formed in the second die core, and a containing space for the bolt is jointly formed by the first cavity and the second cavity. According to the die structure, compared with the prior art, the female die and the male die are arranged to be of a split structure with parts replaceable, and thus replacement can be performed more conveniently and fast; if some part in a die is damaged, the die does not need to be scrapped as a whole, only the damaged part needs to be replaced, and therefore die cost is greatly reduced, and the service life of the whole die is prolonged.

Owner:DONGGUAN SHING HING METAL MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com