Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Improve malleability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Malleable paste for filling bone defects

InactiveUSRE38522E1Easy to packFast absorptionSurgical adhesivesPeptide/protein ingredientsBone defectBiomedical engineering

The invention is directed toward a malleable bone putty and a flowable gel composition for application to a bone defect site to promote new bone growth at the site which comprises a new bone growth inducing compound of demineralized lyophilized allograft bone powder. The bone powder has a particle size ranging from about 100 to about 850 microns and is mixed in a high molecular weight hydrogel carrier, the hydrogel component of the carrier ranging from about 0.3 to 3.0% of the composition and having a molecular weight of about at least 10,000 Daltons. The composition contains about 25% to about 40% bone powder and can be additionally provided with BMP's and a sodium phosphate buffer.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

Welding wire prepared from aluminum alloy in use for welding

InactiveCN101092007AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaUltimate tensile strengthImpurity

The invention relates to welding using aluminum alloy welding wire that includes Mg 4.0-6.0wt%, Mn 0.03-0.20wt%, Cr 0.05-0.10wt%, Si less than or equal to 0.25wt%, Fe is less than or equal to 0.40wt%, Cu is less than or equal to 0.20wt%, Zn is less than or equal to 0.20wt%, Be is less than or equal to 0.0003wt%, Ti 0.10-0.15wt%, and the rest is Al and other impurities. The advantages of the invention are stable technology, good extending capacity of welding wire, good welding technology, high intension, and good corrosion resistance.

Owner:哈焊所华通(常州)焊业股份有限公司

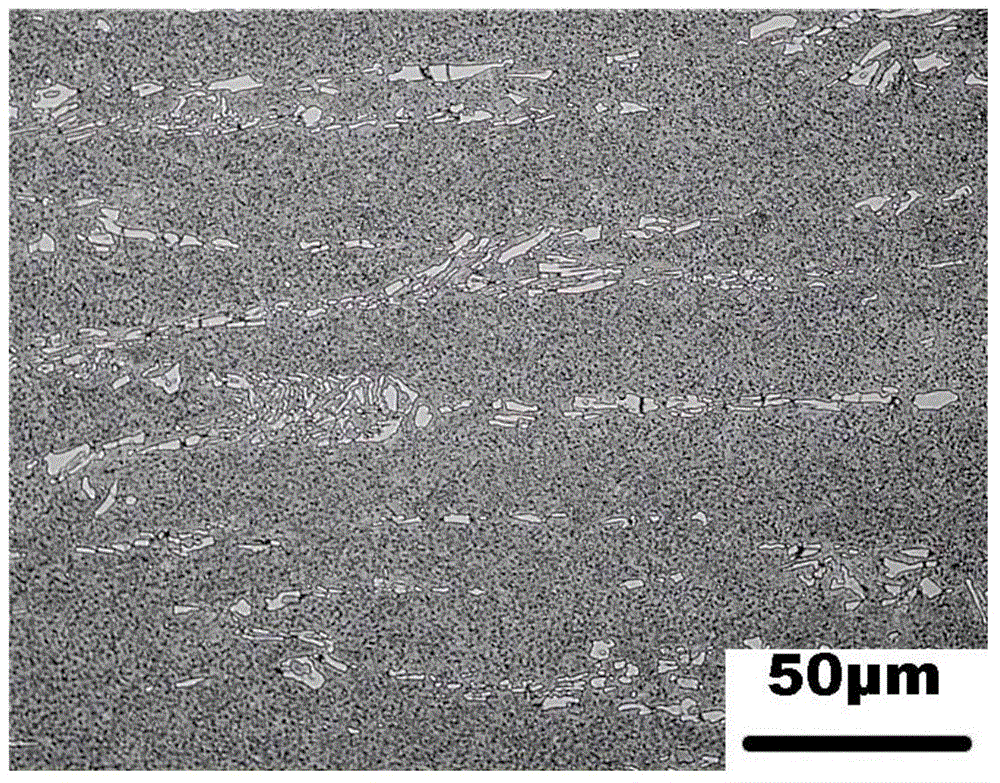

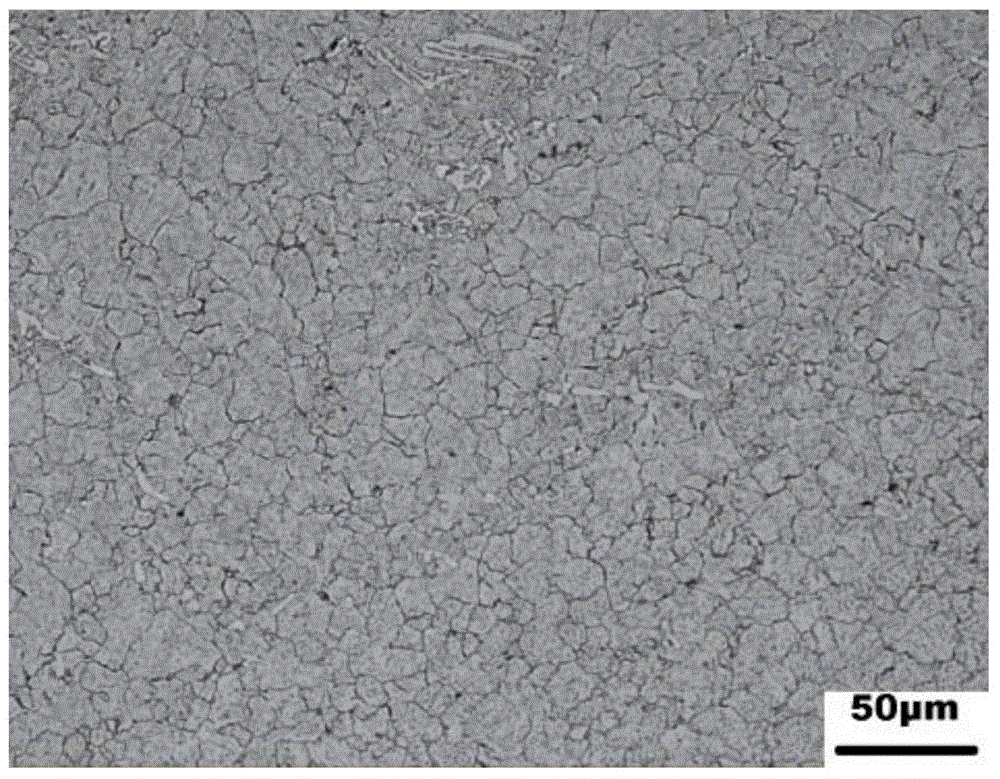

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

Steel for carburizing, carburized steel component, and method of producing the same

InactiveUS20130146181A1Little resistanceLarge critical working ratioSolid state diffusion coatingFurnace typesChemical compositionHardness

A steel for a carburizing and a carburized steel component having a steel portion and a carburized layer with a thickness of more than 0.4 mm to less than 2 mm which is formed on an outside of the steel portion. A chemical composition of the steel for the carburizing and the steel portion of the carburized steel component satisfies simultaneously equations of a hardness parameter, a hardenability parameter, and an AlN precipitation parameter.

Owner:NIPPON STEEL CORP

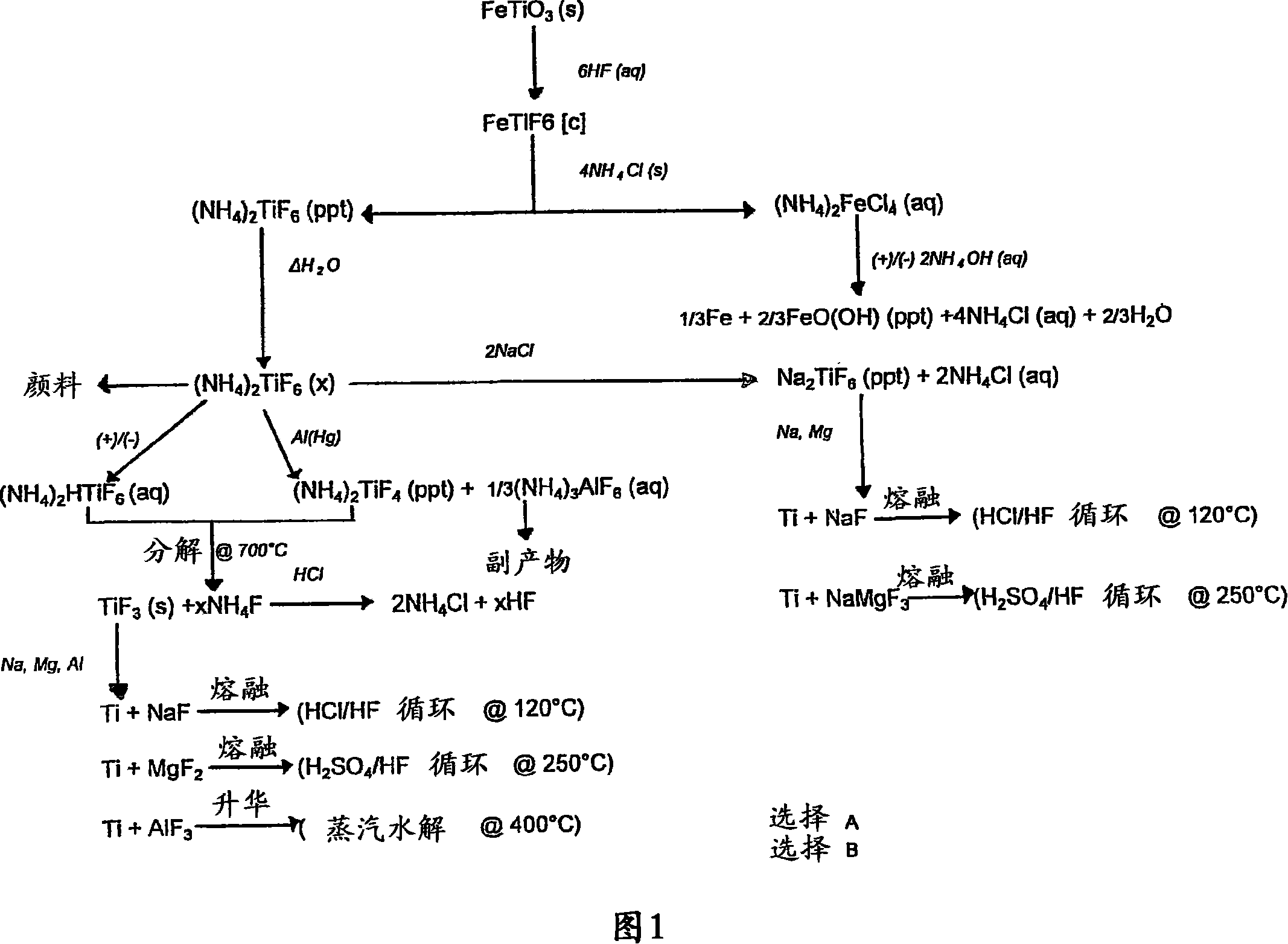

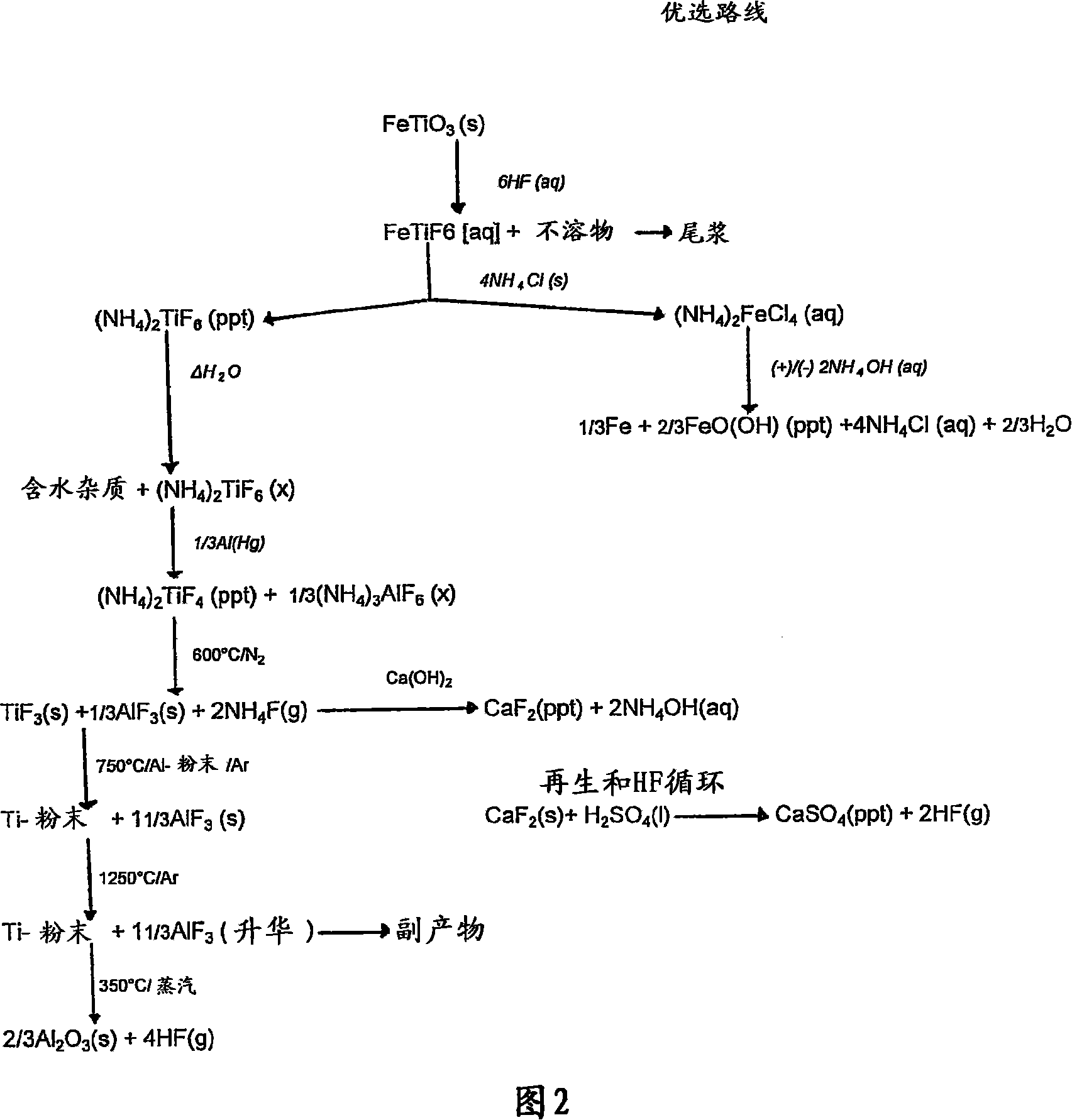

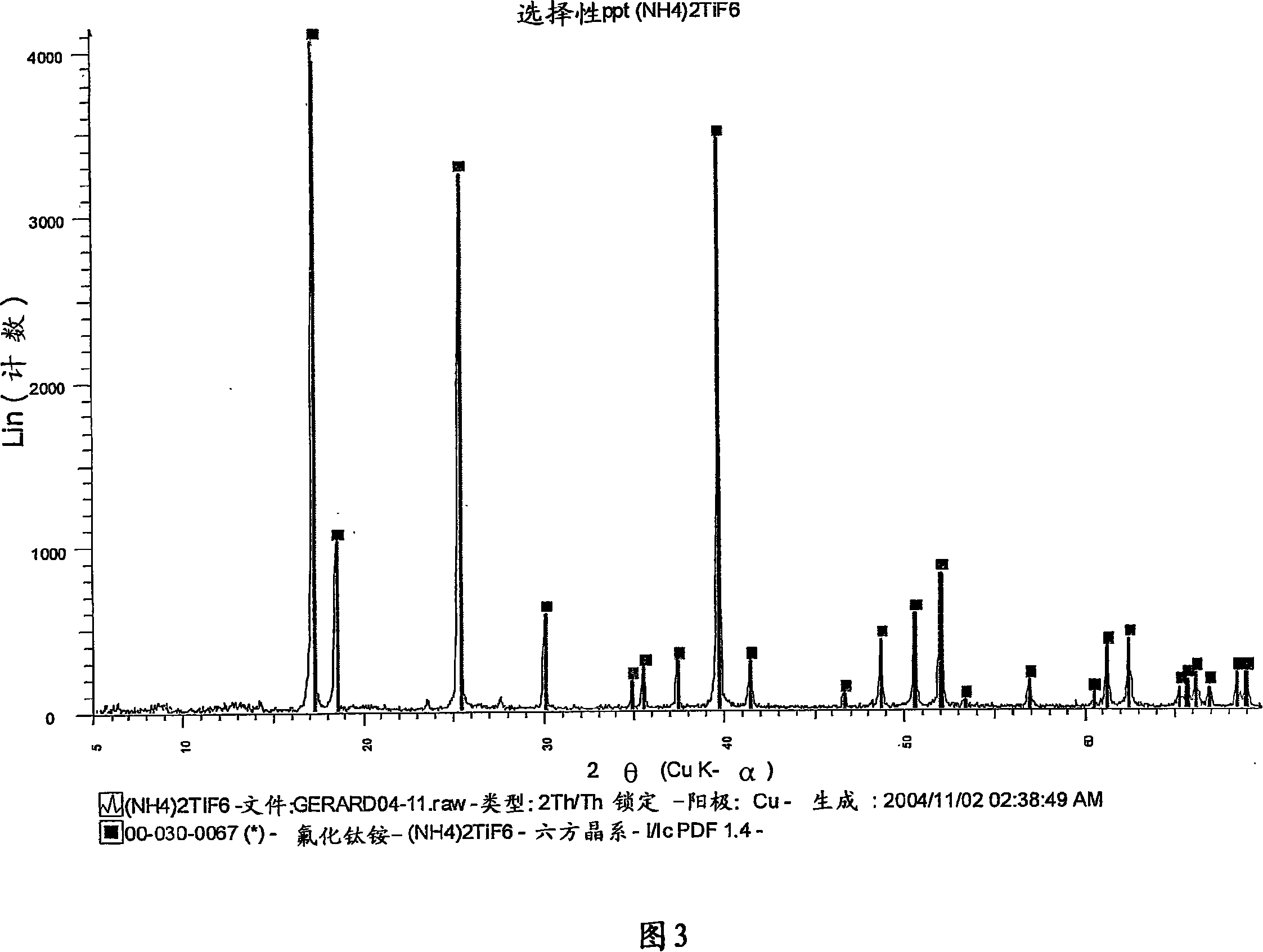

A method of producing titanium

InactiveCN101111616AIncrease global marketImprove malleabilityTitanium compoundsThin material handlingNitriteTitanium metal

A method for preparing titanium metal from a titanium-containing material, comprising the steps of: preparing a M"TiF6 solution from a titanium-containing material, selectively precipitating M'2TiF6 from the solution by adding (M')aXb, utilizing the selectivity Precipitated M'2TiF6 prepares titanium. M" is a cation forming hexafluorotitanate, M' is selected from ammonium and alkali metal cations, X is selected from halides, sulfates, nitrites, acetates and nitrates Anion of , and a and b are 1 or 2.

Owner:PERUKE

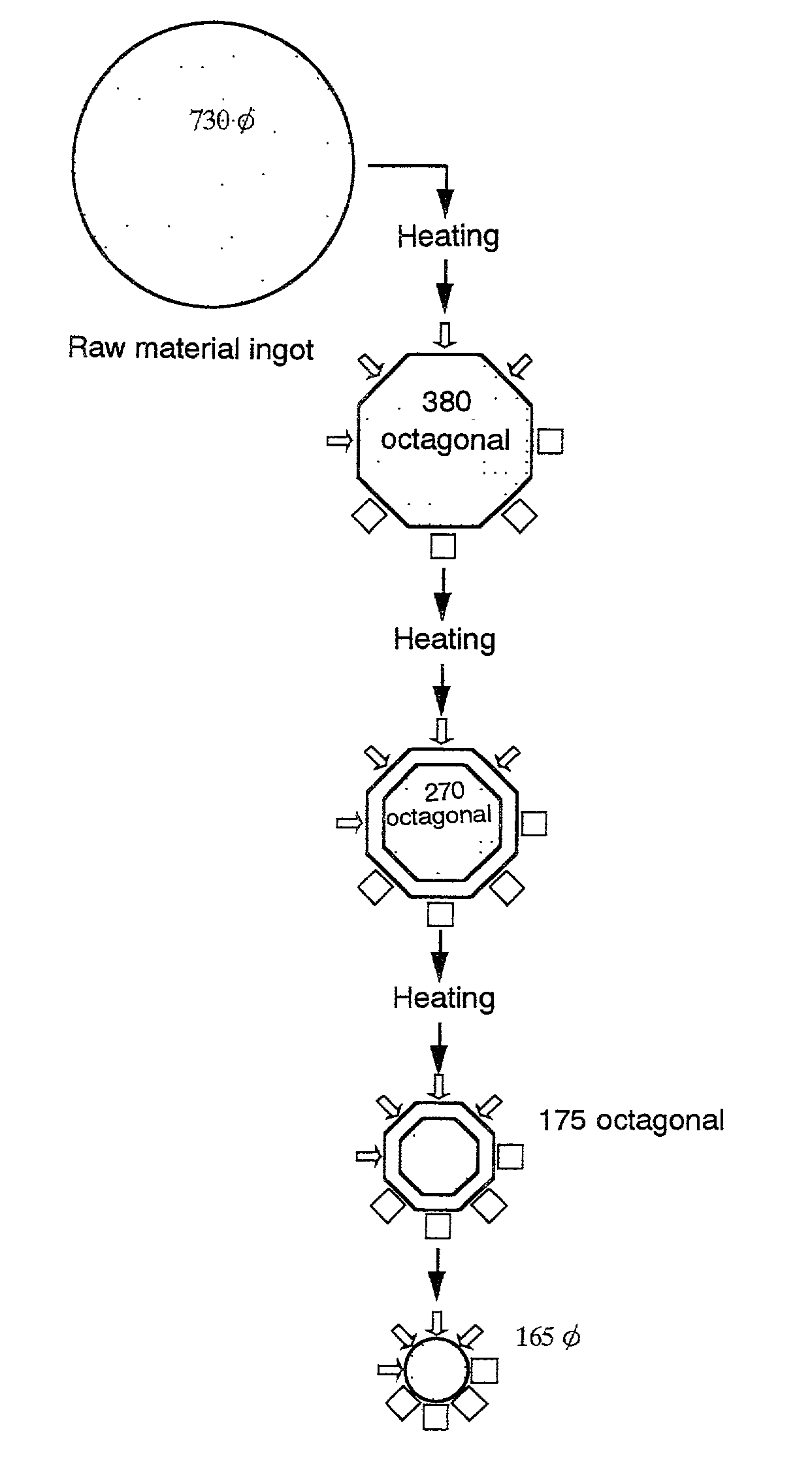

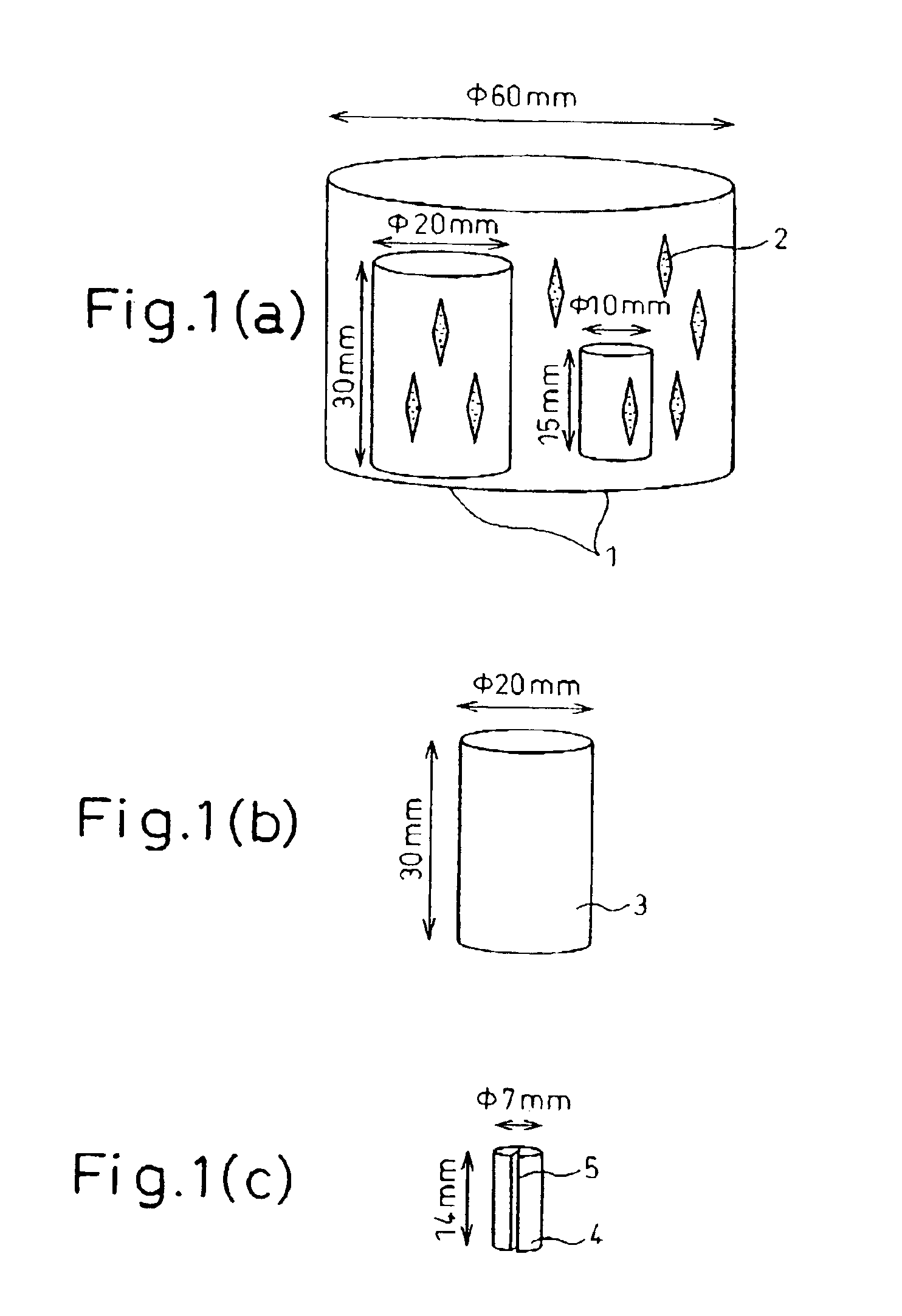

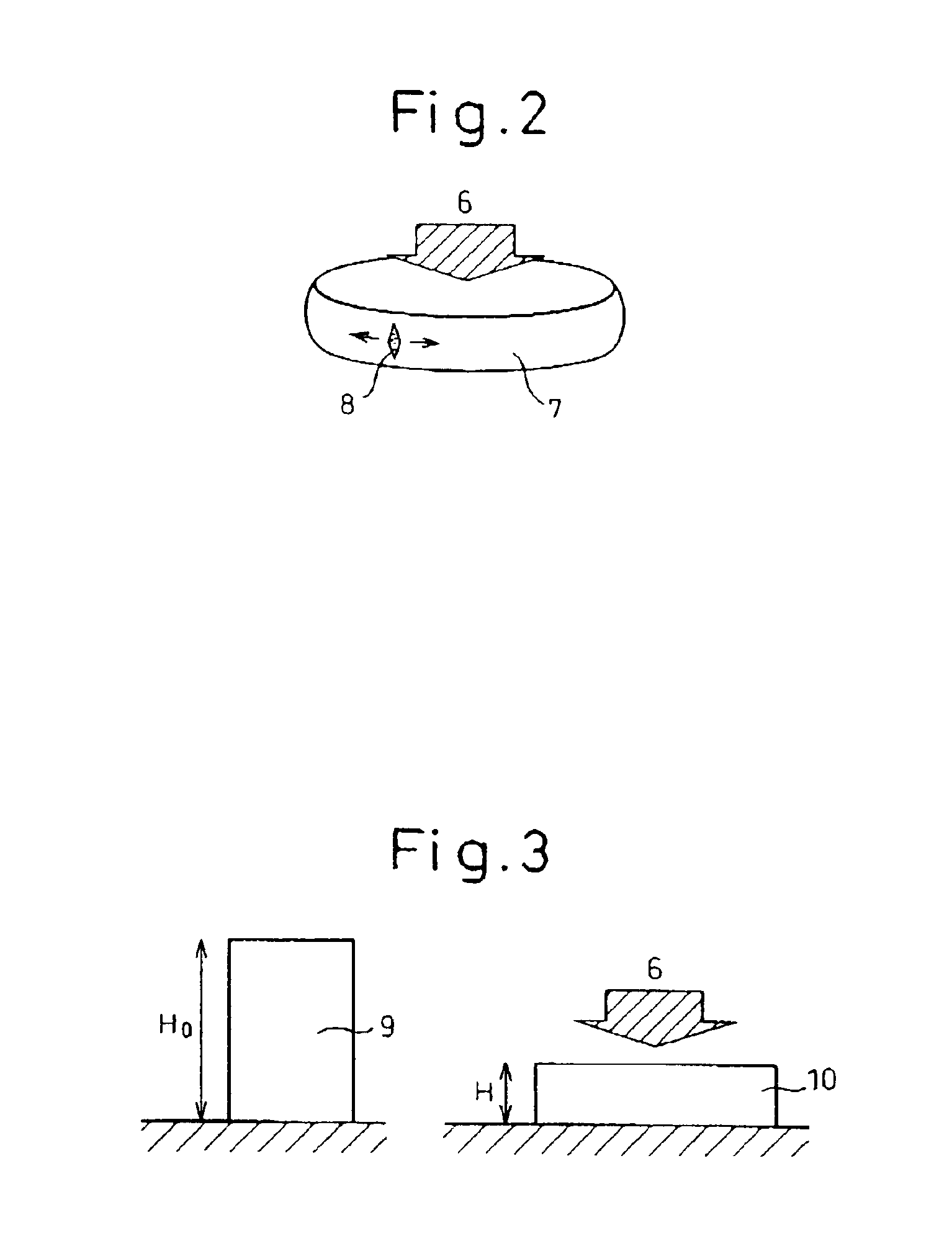

Titanium material superior in upset-forgeability and method of producing the same

InactiveUS7014722B1Good upset forgeabilityImprove malleabilityVacuum evaporation coatingMetal-working apparatusSemiconductor materialsDiameter ratio

In finifsh-cogging a high-purity titanium material into a cylindrical form as the final shape, if cylindrical cogging is performed in all stages of warm forging or if cylindrical cogging is performed in the initial stage of the warm forging, there is no need of peripherally restricting the cylindrical cogging material, so that even if longitudinal upset-forging is effected with an upsetting ratio of 2, the condition that the major diameter / minor diameter ratio of the section after forging is not more than 1.01 can be satisfied, developing superior upset-forgeability. This makes it possible, in producing disk-like targets for sputtering, to minimize cutting loss produced during the rolling and machining and to maximize the yield of products; therefore, the material can be widely used as a semiconductor material for electrodes and the like using a high-purity titanium material.

Owner:OSAKA TITANIUM TECHNOLOGIES

Super high-strength, high-toughness and wear-resistant steel and preparation method thereof

The invention discloses super high-strength, high-toughness and wear-resistant steel and a preparation method thereof. The steel comprises the chemical composition by the weight percentage: 0.25 to 0.55 wt% of C, 1.50 to 2.50 wt% of Si, 1.50 to 2.20 wt% of Mn, 0.3 to 1.0 wt% of Cr, 0.2 to 0.8 wt% of Mo, 0.01 to 0.1 wt% of Re, less than 0.01 wt% of S, less than 0.01 wt% of P, and the balance Fe. Steel scrap or molten iron is smelted with an alloying material through an electric arc furnace or medium frequency induction furnace and then refined by VOD or LF, and molding is carried out by continuous casting or mold casting. The continuous casting billet or casting ingot is molded through rolling or forging and is subjected to special heat treatment, then the tensile strength of a part is 1800to 2000 MPa, the elongation percentage is 16 to 18%, the impact toughness aku is 60 to 80 J / cm<2>, and the hardness HRC is 55 to 62. The super strong wear-resistant steel not only has welding performance, but also has prominent plasticity, and is 2000 MPa-graded super high-strength steel having the elongation percentage at break reaching 18%.

Owner:高博扬

Use of martensitic precipitation hardening stainless steel

InactiveCN1758928AGood biocompatibilityImprove corrosion resistanceSurgeryProsthesisNiobiumManganese

The invention relates to the use of a chrome-nickel martensitic precipitation hardening stainless steel having the following composition: 10-14 mass % chromium, 7-11 mass % nickel, 0.5-6 mass % molybdenum, 0.5-4 mass % copper, 0.05-0.55 mass % aluminium, 0.4-1.4 mass % titanium, up to 0.3 mass % carbon + nitrogen, less than 0.05 mass % sulfur, less than 0.05 mass % phosphorus, up to 0.5 mass % manganese, up to 0.5 mass % silicium, up to 0.2 mass % tantalum, niobium, vanadium and tungsten, respectively, possibly 0.9 mass % cobalt, possibly 0.0001-0.1 mass % boron, the rest being iron and ordinary impurities. Said steel is used for producing surgery implants and osteosynthesis products which are pointwisely or long-lastingly used outside and inside a body.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

High-hardness high-toughness cold work die steel as well as preparation method thereof

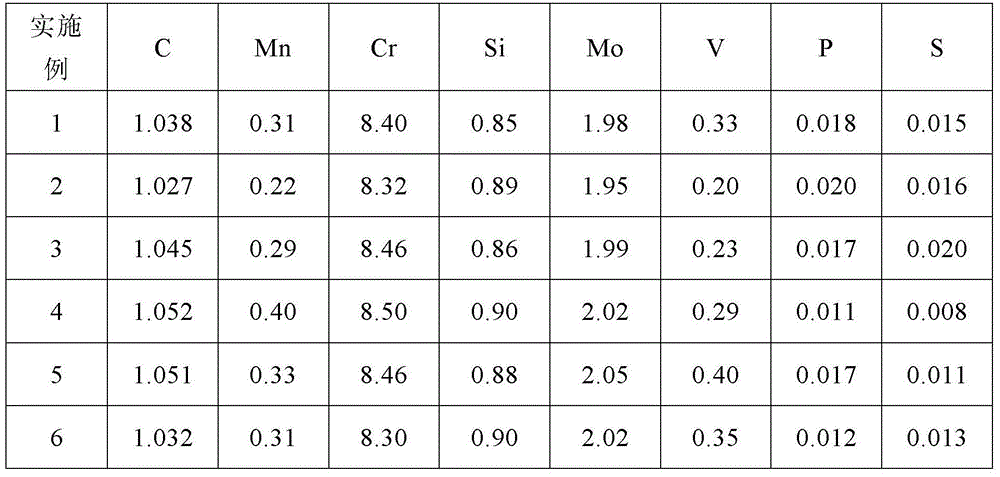

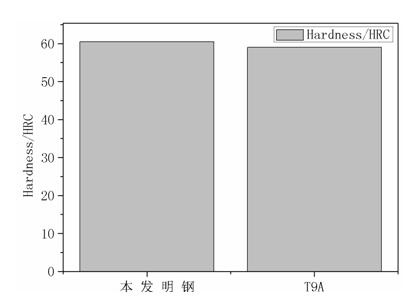

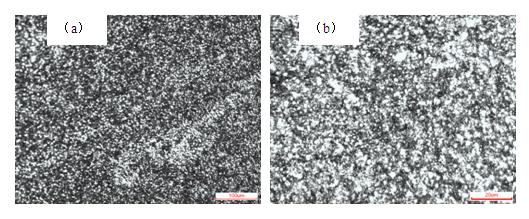

The invention relates to high-hardness high-toughness cold work die steel as well as a preparation method thereof. The high-hardness high-toughness cold work die steel comprises the following chemical components in percentage by weight: 1.025-1.055% of C, 0.85-0.90% of Si, 0.20-0.40% of Mn, less than 0.02% of P, less than 0.02% of S, 8.30-8.50% of Cr, 1.95-2.05% of Mo, 0.20-0.40% of V and the balance of Fe and inevitable impurities, wherein the elements satisfy the following relationship: C=0.1(Cr+Mo). The preparation method comprises the following steps: smelting and pouring to obtain a steel ingot which serves as a consumable electrode and is placed in an electroslag remelting device for electroslag remelting and then re-solidifying to form the steel ingot; and heating the re-solidified steel ingot to 1200-1220 DEG C and then forging, quenching and tempering to obtain the cold work die steel. The impact energy of the steel is greater than or equal to 76J and the hardness of the steel is greater than or equal to 63HRC, and the steel has relatively good hardness and toughness match.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Steel, and processing method for the production of higher-strength fracture-splittable machine components

The invention relates to a steel and a processing method for higher-strength fracture-splittable machine components that are composed of at least two fracture-splittable parts. Said steel and method are characterized in that the chemical composition of the steel (expressed in percent by weight) is as follows: C is between 0.40% and 0.60%; Si is between 0.20% and 1.00%; Mn is between 0.540% and 1.50%; Cr is between 0% and 1.00%; Ni is between 0% and 0.50%; Mo is between 0% and 0.20%; Nb is between 0% and 0.050%; V is between 0% and 0.30%; Al is between 0% and 0.05%; N is between 0.005% and 0.020%; the rest is composed of iron and smelting-related impurities and residual matter.

Owner:GEORGSMARIENHUTTE

Preparation method of large-sized magnesium alloy forged disc

ActiveCN103447433AReduce cumbersomeImprove plastic deformation abilityMetal-working apparatusIngotUltimate tensile strength

The invention relates to a preparation method of a large-sized magnesium alloy forged disc and belongs to the technical field of magnesium alloy materialmachining. The preparation method of the large-sized magnesium alloy forged disc comprises the following steps of heating a casting magnesium alloy ingot to 400-430 DEG C and preserving the heat, wherein the casting magnesium alloy ingot after homogenizing thermal treatment is 300-350mm in diameter and 1.5-1.85 in height-diameter ratio; upsetting and drawing out the heated casting magnesium alloy ingot at 400-430 DEG C to obtain a magnesium alloy forged disc; repeating processes of heating, preserving the heat, upsetting and drawing out till the diameter of the magnesium alloy forged disc is larger than or equal to 670mm to obtain the large-sized magnesium alloy forged disc, wherein the temperature when repeating the procedures of preserving the heat and upsetting every time is 10-20 DEG C lower than the temperature when previously repeating the procedures of preserving the heat and upsetting, the forging ratio in each upsetting procedure is 1.5-2, the forging ratio in each drawing-out procedure is 1.02-1.05, and the deformation speeds in the upsetting and drawing-out procedures both are 12-16mm / s. According to the preparation method of the large-sized magnesium alloy forged disc, which is disclosed by the invention, the large-sized magnesium alloy forged disc with the diameter of 670-720mm, the thickness of 80-120mm, the tensile strength of larger than or equal to 300MPa, the yield strength of larger than or equal to 180Mpa and the elongation percentage of larger than or equal to 10% can be manufactured, and the manufactured large-sized magnesium alloy forged disc can completely meet the requirements on the preparation of a large-sized magnesium alloy die forged piece.

Owner:CENT SOUTH UNIV

Forging method of nickel-based high-temperature alloy annular part

ActiveCN108672624AGuaranteed temperatureImprove malleabilityMetal rollingSuperalloyMechanical property

The invention discloses a forging method of a nickel-based high-temperature alloy annular part. The method comprises following steps of discharging, punching, high-temperature ring forging rolling, relative low-temperature ring forging rolling, temperature rising high-temperature ring forging rolling, and low-temperature circle checking shaping. Through the above manner, the surface of the annularpart is coated with a heat preservation coating, in the rolling process, the temperature of the annular part is ensured, meanwhile, rolling deformation resistance can be reduced, forging of the annular part is improved, and the roundness error, the cracking and the like appearing in the forging process can be effectively reduced. The technology processes of high-temperature ring forging-process relative low-temperature rolling-temperature rising high-temperature ring forging-final relative low-temperature circle checking shaping are adopted, the product structure can be effectively convertedand controlled to be optimal, the cross section room temperature stretching property of the forging part meets the design need, the full cross section mechanical property of the part is evenly distributed, the product mechanical property is improved, and the part size precision is ensured.

Owner:豪梅特航空机件(苏州)有限公司

A kind of nearly beta type high-strength high-toughness titanium alloy and its preparation method

InactiveCN106507832BAdapt to the requirements of high strength and high impact toughness titanium alloyHigh strengthThermal deformationHigh intensity

A near-beta high-strength and high-toughness titanium alloy relates to a near-beta titanium alloy, which is suitable for aerospace armor-piercing projectile body materials. The weight percent composition of its alloy is: Al: 3.0%-7%, Zr: 1%-4%, Mo: 2%-6%, Fe: 0.5%-2.5%, Cr: 0.5%-4%, Sn: 1%-6%, the balance is Ti and unavoidable impurity elements. The alloy is blank-forged at a temperature of 1050°C-1150°C, and the heat deformation is 60%-75%. The forging temperature of the finished forging is controlled at a temperature of 930°C-980°C, and the final forging temperature is 800°C-850°C. Alloy finished products are used after air-cooling treatment. Under the optimal heat treatment system, the alloy can obtain comprehensive performance matching such as excellent strength, plasticity, impact toughness and hardness.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

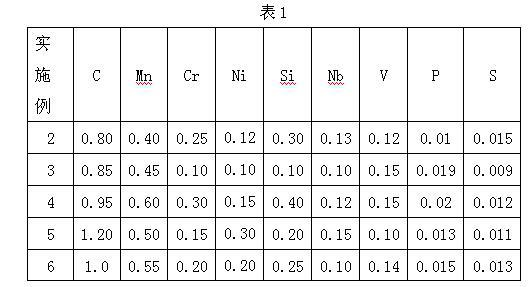

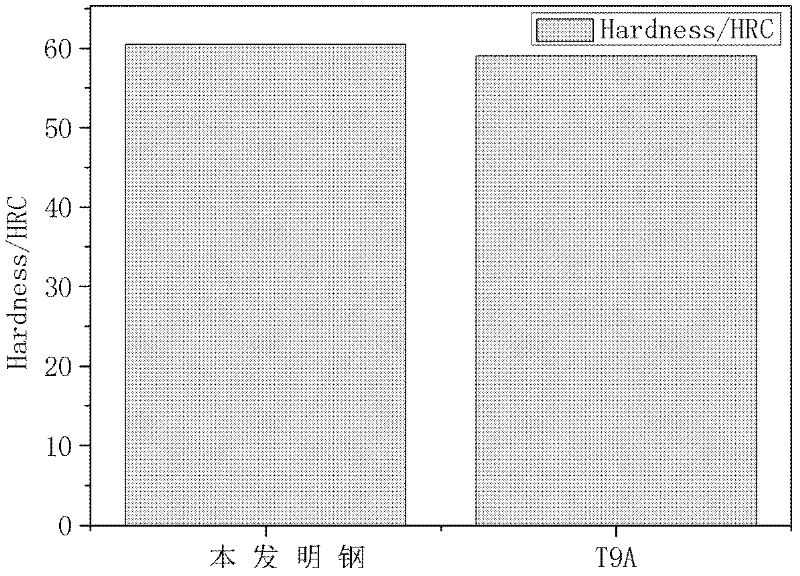

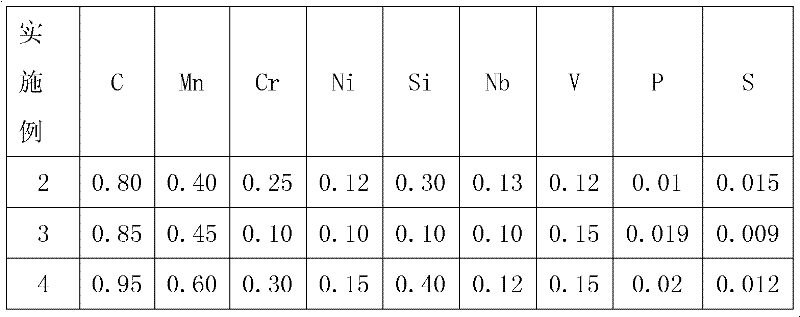

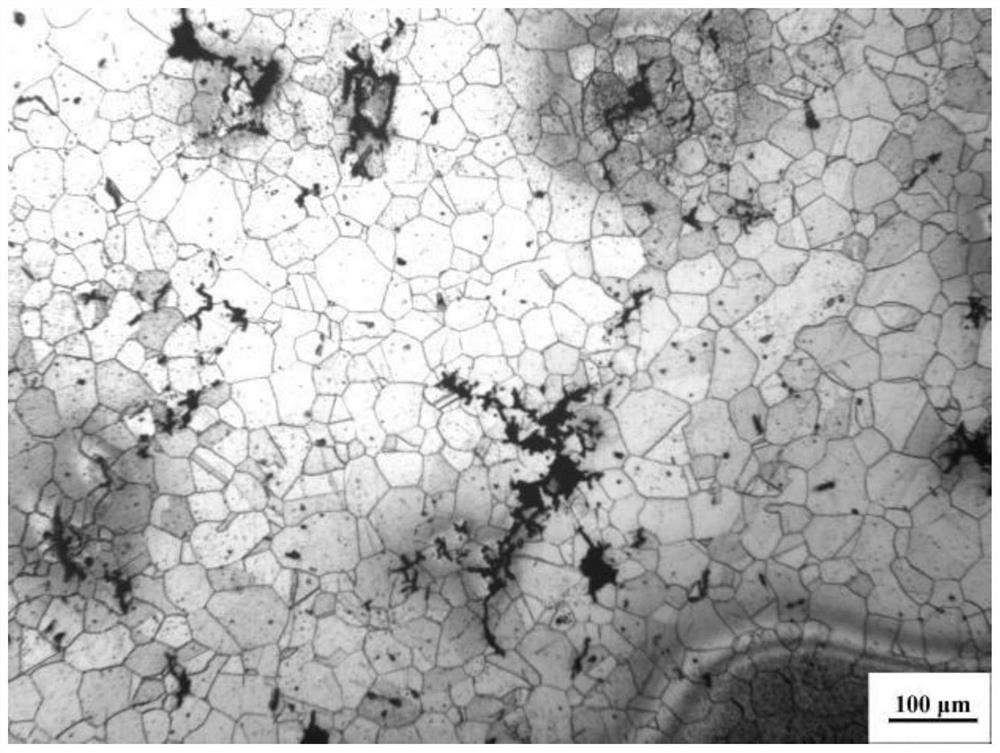

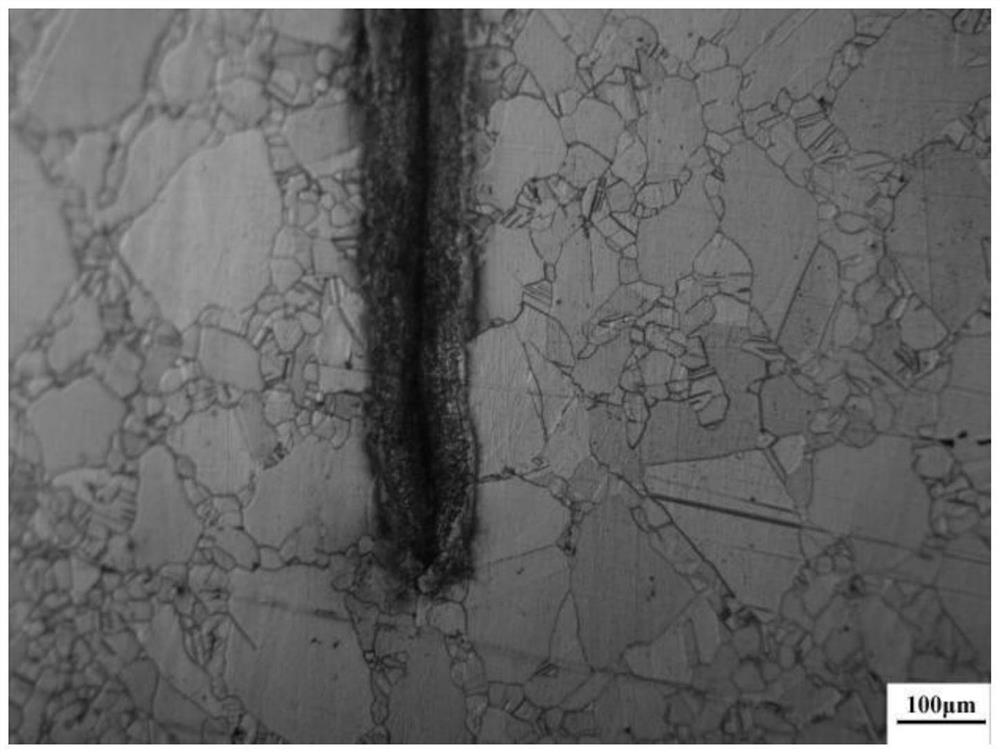

High-wear-resistant steel for knitting needle and manufacturing method thereof

The invention relates to the field of steel for knitting machinery, in particular to high-wear-resistant steel for a knitting needle and a manufacturing method of the high-wear-resistant steel for the knitting needle. The high-wear-resistant steel comprises the following ingredients (weight percentage): C 0.8-1.2%, Si 0.1-0.4%, Mn 0.4-0.6%, Nb 0.1-0.15%, V 0.1-0.15%, Ni 0.1-0.3%, Cr 0.1-0.3%, and Fe and other unavoidable impurities in balance. A steel ingot casted after being subjected to smelting in an induction furnace is arranged in an electroslag remelting device as a consumable electrode for electroslag remelting, and then liquid metal drops in a water-cooling crystallizer at the bottom through a slag layer of a slag pool so as to be re-solidified to a steel ingot. After being heated a temperature range of 1000-1030 DEG C and kept for 3-5 hours, the re-solidified steel ingot is sequentially forged, bent, flattened, milled and subjected to thermal treatment to obtain cold working die steel with high combination of strength and toughness , high hardness, high wear resistance and the like.

Owner:LANGSHA KNITTING

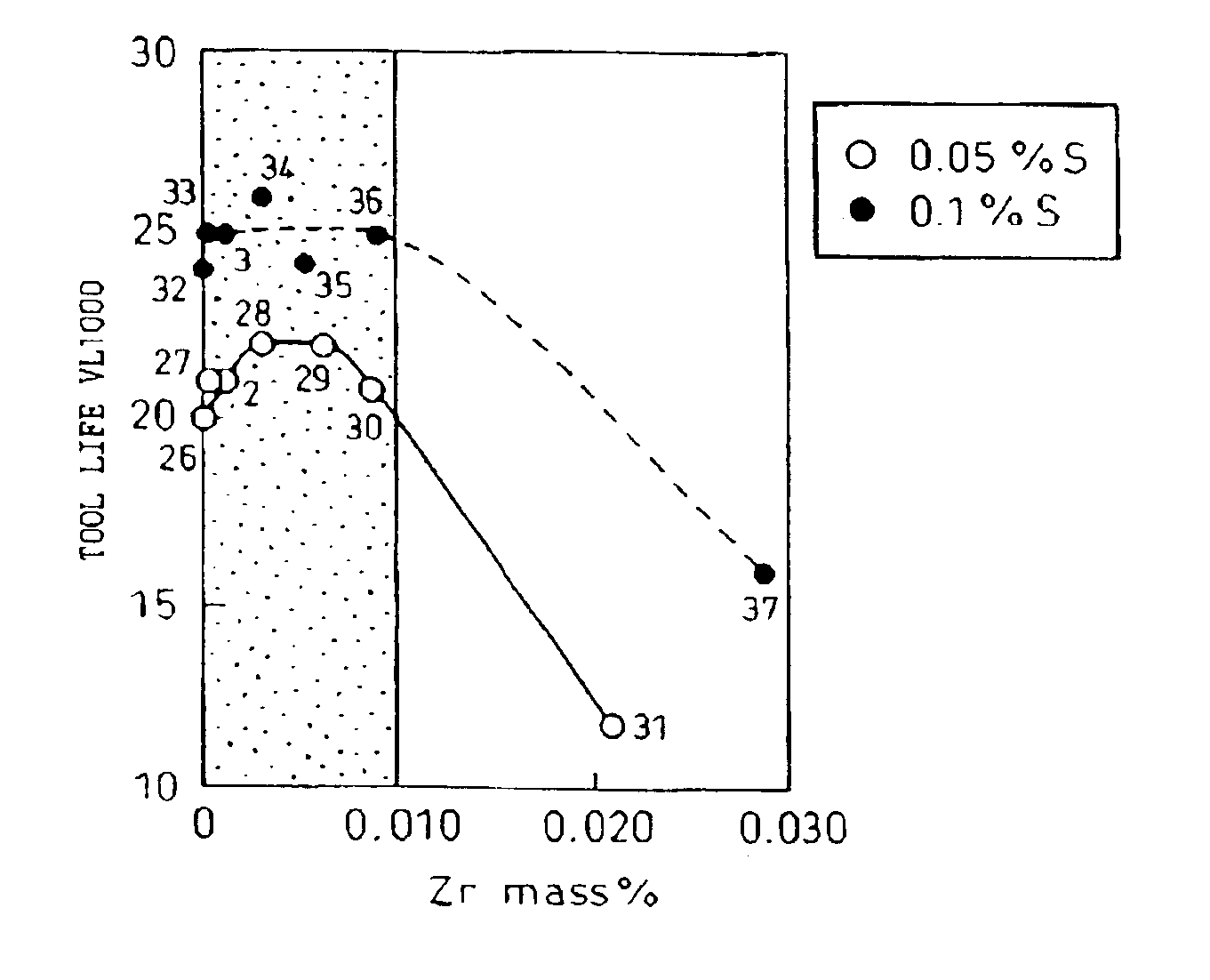

Steel excellent in forgeability and machinability

The present invention is a steel, excellent in machinability, wherein forging workability is improved by suppressing the deterioration of mechanical properties in the direction in which the mechanical properties are the lowest, and more specifically, is a steel excellent in forgeability and machinability, characterized in that: the steel contains, in mass, C: 0.1 to 0.85%, Si: 0.01 to 1.5%, Mn: 0.05 to 2.0%, P: 0.003 to 0.2%, S: 0.003 to 0.5%, and Zr: 0.0003 to 0.01%; the following steel components are controlled in the following ranges respectively, in mass, Al: 0.01% or less, total O: 0.02% or less, and total N: 0.02% or less; the average aspect ratio of MnS grains is 10 or less and the maximum aspect ratio of those is 30 or less; and the balance of the steel components consists of Fe and unavoidable impurities.

Owner:NIPPON STEEL CORP

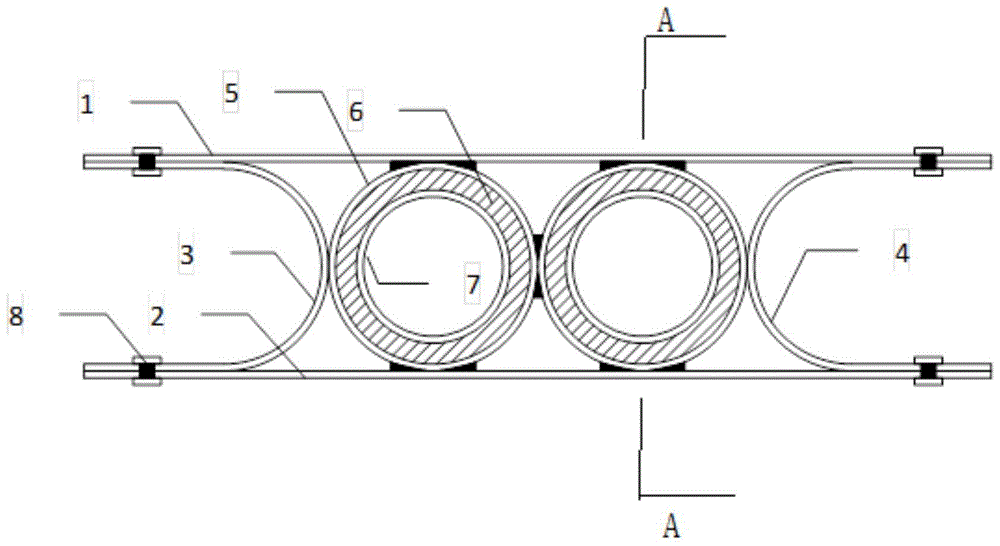

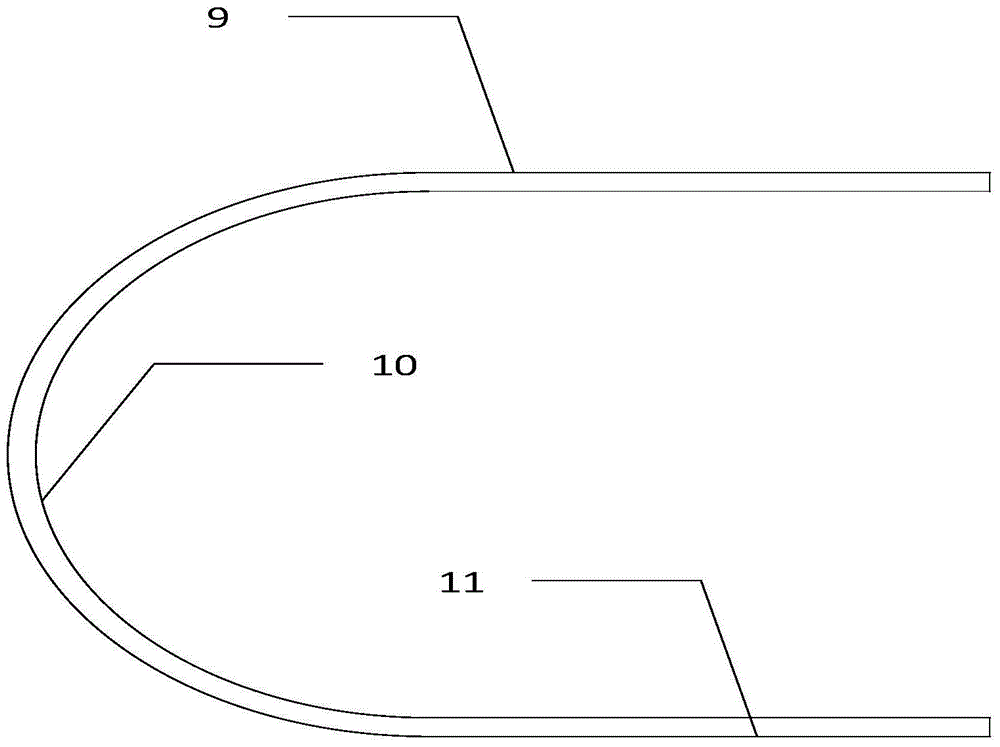

Novel lead core steel pipe U-shaped damper

ActiveCN105696454AImprove plastic deformation abilityImprove flexibilityBridge structural detailsSheet steelEngineering structures

The invention provides a novel lead core steel pipe U-shaped damper and belongs to the technical field of civil engineering structure damping. The novel lead core steel pipe U-shaped damper is mainly composed of an upper cover board, a lower cover board, U-shaped metal boards, lead core filling steel pipes and connecting bolts. Each lead core filling steel pipe is composed of an outer-layer steel pipe, a lead core filling layer and an inner-layer steel pipe. Each U-shaped metal board is composed of an upper straight section, a middle arc section and a lower straight section. Each middle arc section is semicircular, and the outer diameter of each middle arc section is the same as that of the corresponding outer-layer steel pipe. Each lead core filling steel pipe comprises the outer-layer steel pipe, the lead core filling layer and the inner-layer steel pipe from outside to inside. The placing direction of energy consumption components between the upper cover board and the lower cover board is set in the manner that the axis direction of the arc section of each U-shaped metal board is parallel to the width direction of the upper cover board and the lower cover board; the lead core filling steel pipes are located between the left U-shaped metal board and the right U-shaped metal board and are tangent to the arc sections of the two U-shaped metal boards; and the axis direction of each lead core filling steel pipe is parallel to the width direction of the upper cover board and the lower cover board. By the adoption of the damper, the double energy consumption effects of the U-shaped steel boards and the lead core steel pipes are used so that the earthquake action of a bridge and a structure can be effectively reduced.

Owner:BEIJING UNIV OF TECH

Isothermal die forging technology for large-size high-strength aluminum alloy parts

InactiveCN105964849AImprove plasticityImprove malleabilityMetal-working apparatusLarge deformationLarge size

The invention relates to an isothermal die forging technology for large-size high-strength aluminum alloy parts, and belongs to the technical field of aluminum alloy machining. According to the isothermal die forging technology, large-size aluminum alloy forging cake blanks undergo isothermal die forging formation in one step after being heated and thermally insulated for obtaining forge pieces, the forge pieces are taken out and cooled, and finally finished products are obtained; in the isothermal die forging process, the descending speed of upper dies is 0.1-0.2 mm / s. By selecting raw materials and strictly controlling forging parameters, continuous large deformation is realized on the condition that alloy crystal grains do not grow, and the large-size and high-performance aluminum alloy parts can be prepared with high efficiency and low cost. The isothermal die forging technology has the advantages that the operation is easy, the production efficiency is high, the product quality is high and the practicability is high, thereby being suitable for industrialized use and popularization.

Owner:SHANDONG NANSHAN ALUMINUM

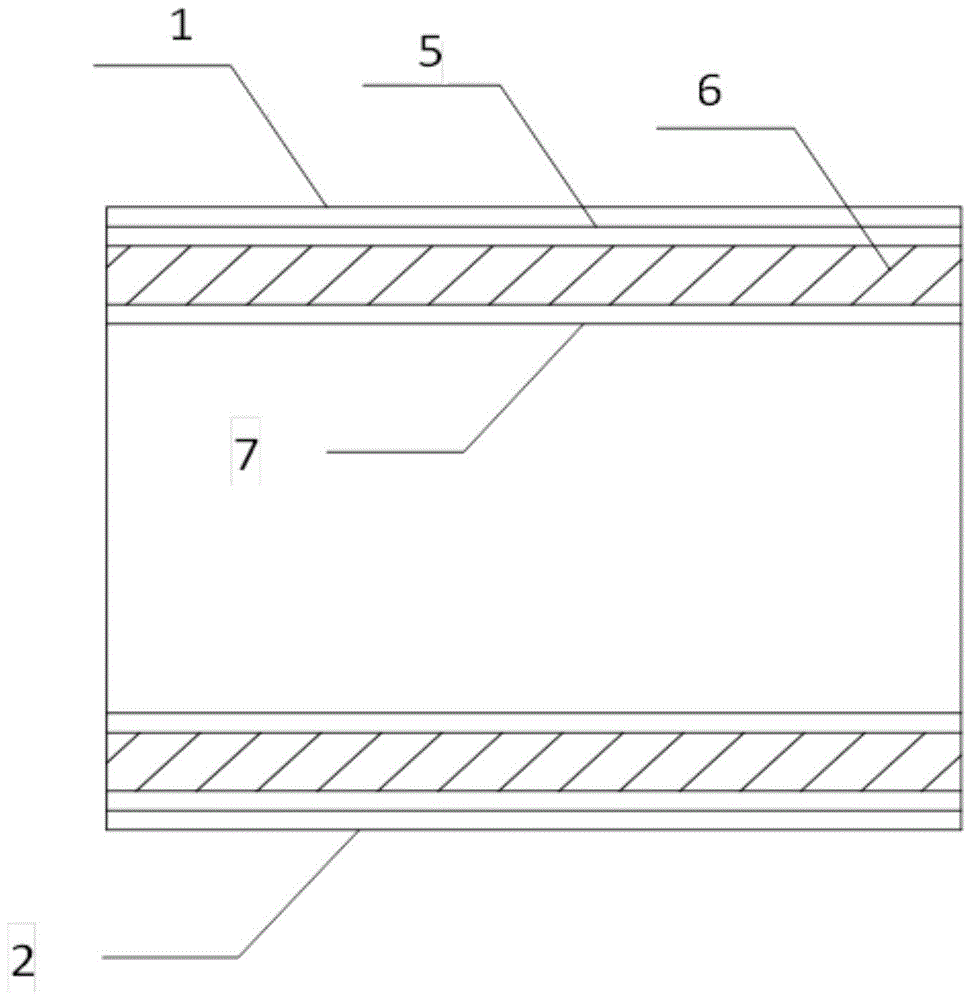

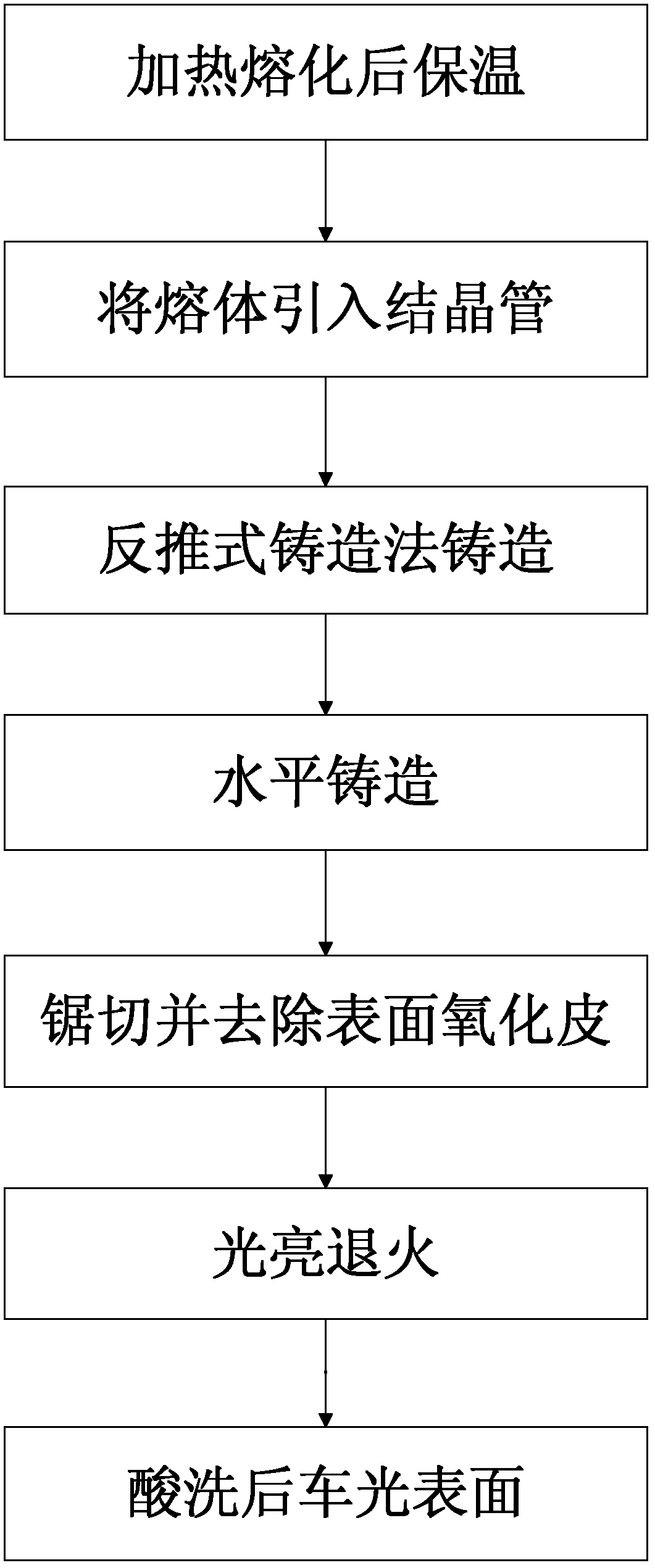

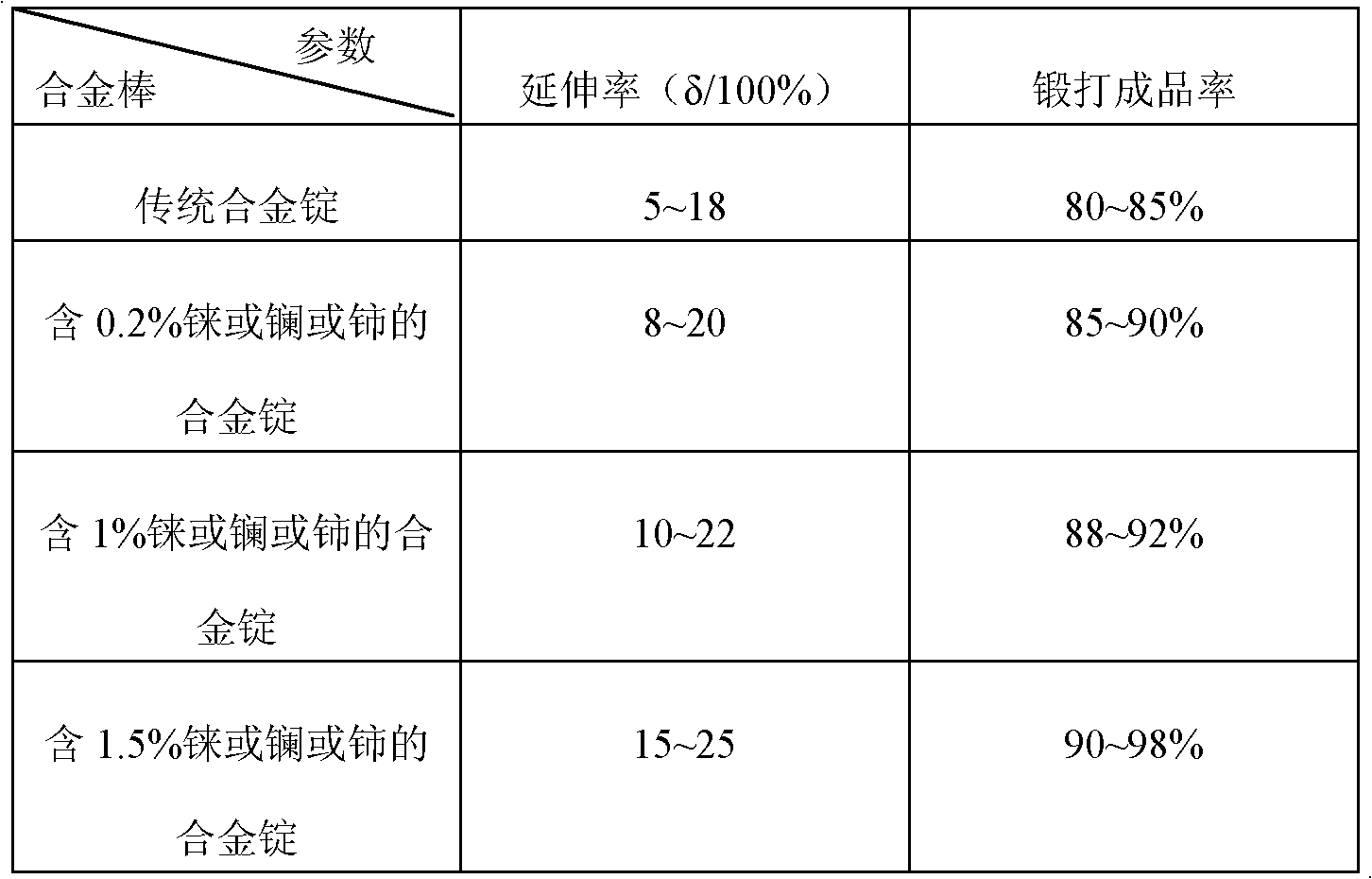

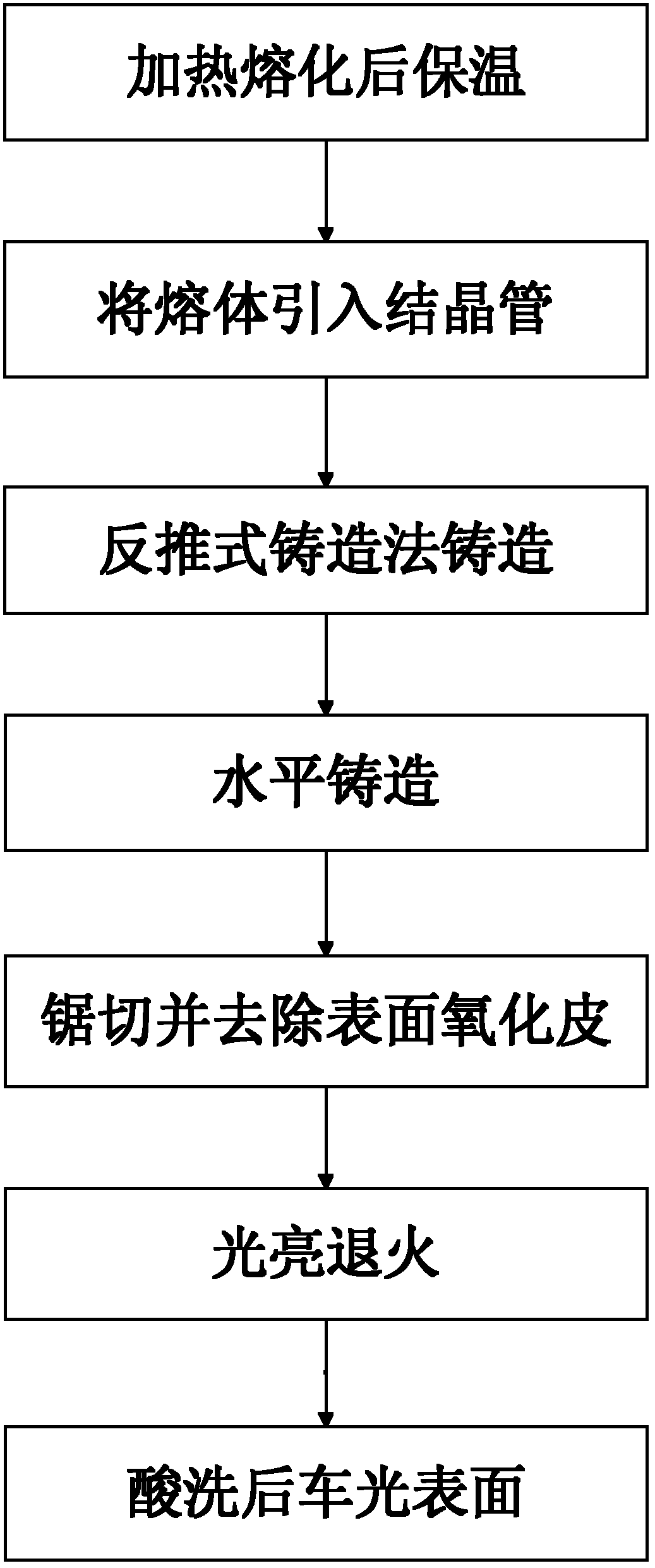

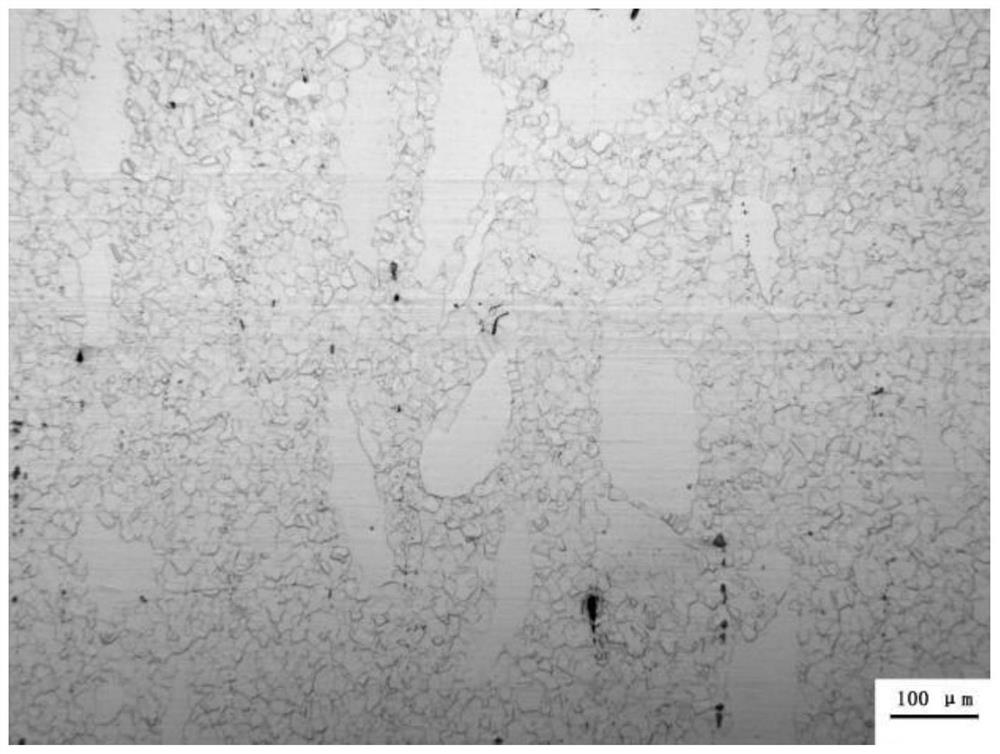

Wrought alloy pig for nuclear steam turbine and manufacturing method thereof

The invention provides a wrought alloy pig for a nuclear steam turbine. The alloy pig comprises the components of aluminum, iron, manganese, rhenium or lanthanum or cerium and copper, wherein the components of the alloy pig are as follows by weight percentage: 13-16% of the aluminum, 1-3% of the iron, 5-9% of the manganese, 0.2-1.5% of the rhenium or the lanthanum or the cerium and 70.5-80.8% of the copper. According to the invention, the rare-earth element of rhenium or lanthanum or cerium which is added into the traditional bronze pig is easily combined and molded with alloys including the copper and the like, so that the forgeability and the ductility of the alloys are greatly enhanced and the loss caused by forge crack of a product in a nuclear pump valve type sectional material. Furthermore, the invention provides the manufacturing method of the wrought alloy pig for the nuclear steam turbine; a traditional sand casting method is changed into a continuous casting method; and inner and outer air pores of the product are reduced so that the crystallization of the product is more fine and smooth.

Owner:SUZHOU JINCANG ALLOY NEW MATERIAL

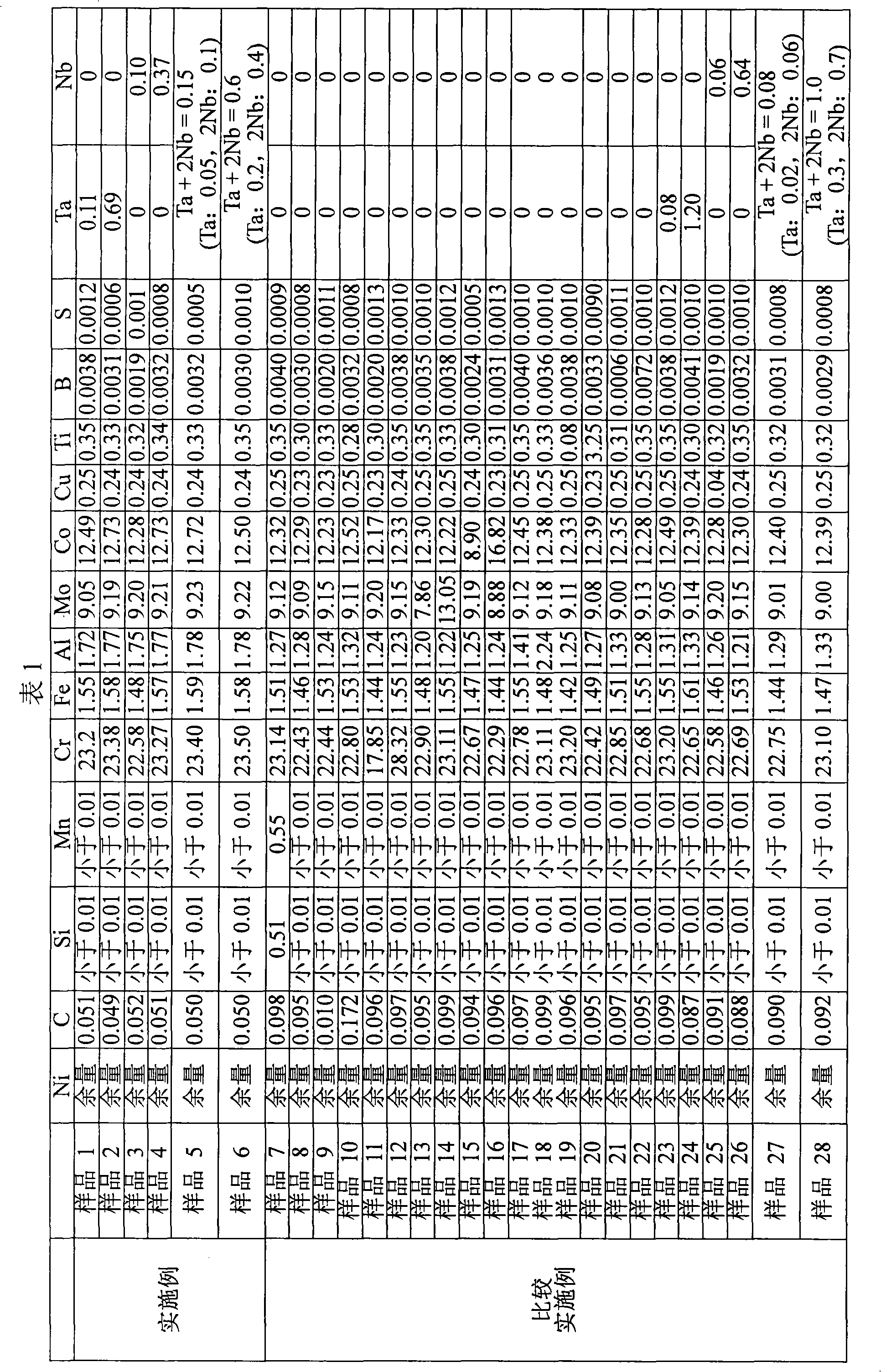

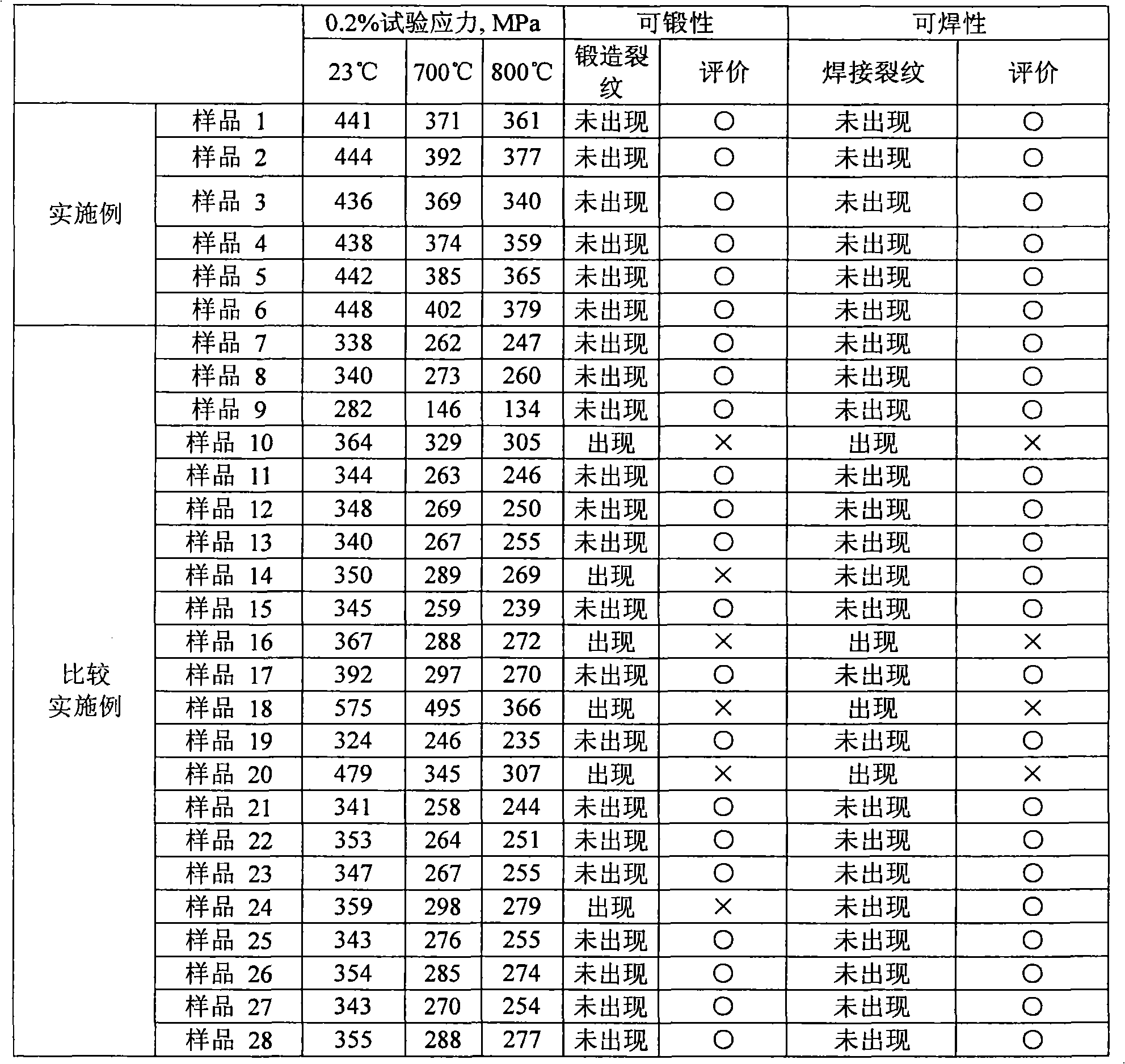

Ni-based alloy for a forged part of a steam turbine, rotor blade of a steam turbine, stator blade of a steam turbine, screw member for a steam turbine, and pipe for a steam turbine

InactiveCN101818286AImprove high temperature strengthImprove malleabilityBlade accessoriesMachines/enginesMetallurgyRazor Blade

A Ni-based alloy for a forged part of a steam turbine having excellent high temperature strength, forgedability and weldability includes, in percentage by mass, 0.01 to 0.15 of C, 18 to 28 of Cr, 10 to 15 of Co, 8 to 12 of Mo, 1.5 to 2 of Al, 0.1 to 3 of Ti, 0.001 to 0.006 of B, 0.1 to 0.7 of Ta, and the balance of Ni plus unavoidable impurities.

Owner:KK TOSHIBA

High wear resistance steel for knitting needle and manufacture method thereof

ActiveCN102383052AGood effectPrevent thermal stress cracksIncreasing energy efficiencySlagLiquid metal

The invention relates to the field of steel for knitting machinery and specifically relates to a high wear resistance steel for knitting needle and a manufacture method thereof. The high wear resistance steel for knitting needle comprises, by weight, 0.8-1.2% of C, 0.1-0.4% of Si, 0.4-0.6% of Mn, 0.1-0.15% of Nb, 0.1-0.15% of V, 0.1-0.3% of Ni, 0.1-0.3% of Cr and the balance of Fe and inevitable impurities. A steel ingot casted after melting in an induction furnace is employed as a consumable electrode and placed in an electroslag remelting apparatus for electroslag remelting; liquid metal passes through a slag layer of a slag bath, falls to a water cooling crystallizer below and solidifies into a steel ingot again; the steel ingot is heated to 1000-1030 DEG C, insulated for 3-5 h and treated with forging, turning, flattening and milling and heat treatment, so as to obtain a cold working die steel with characteristics of high strength and toughness cooperation, high hardness and high wear resistance, etc.

Owner:LANGSHA KNITTING

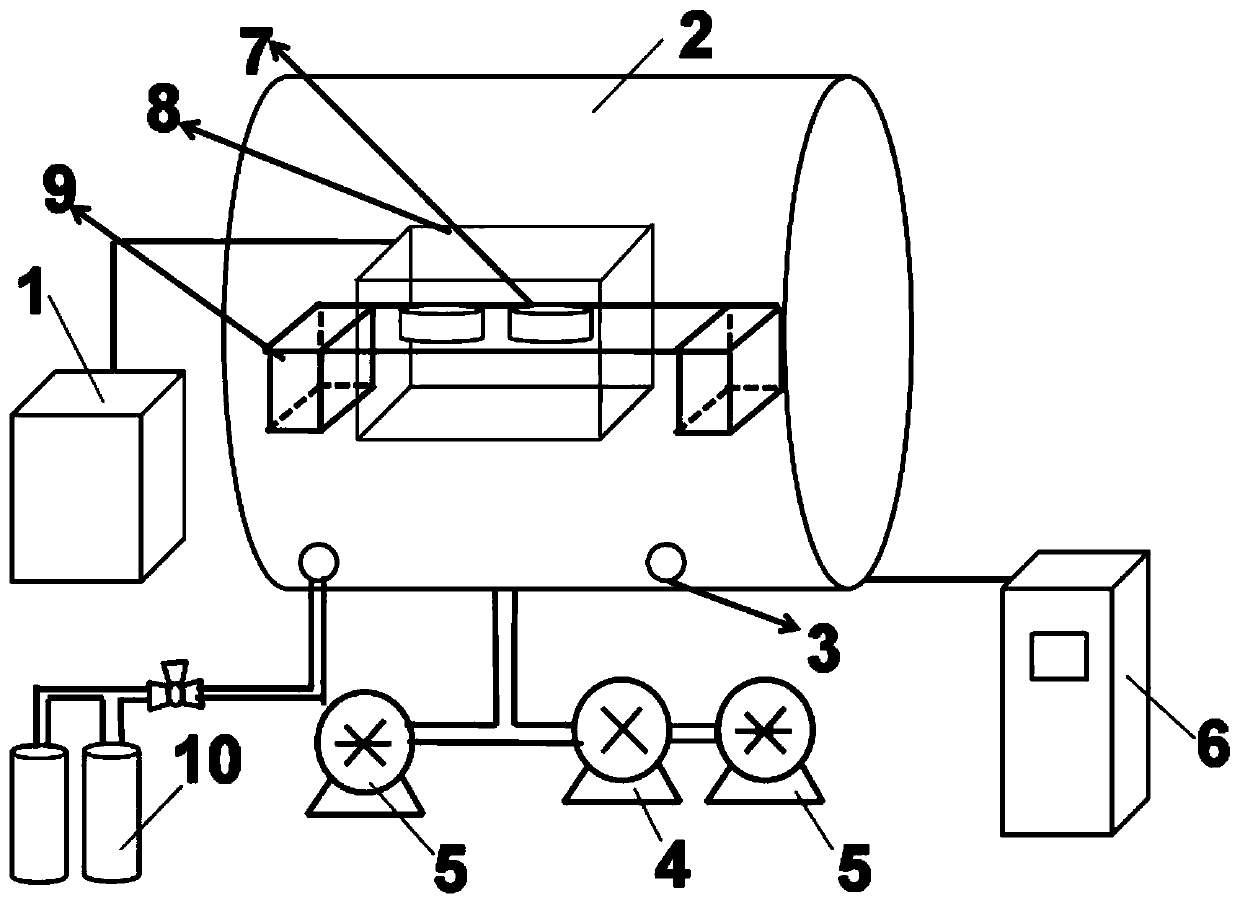

Method for producing nickel-based high-temperature alloy difficult to deform through compensation heating assisted free forging

ActiveCN112139415AImprove hot working plasticityBore size is smallMetal-working apparatusIngotSuperalloy

The invention belongs to the technical field of high-temperature alloy manufacturing, and particularly relates to a method for producing a nickel-based high-temperature alloy difficult to deform through compensation heating assisted free forging. The method for producing the nickel-based high-temperature alloy difficult to deform through compensation heating assisted free forging comprises the following technological processes: vacuum induction furnace smelting, vacuum self-consuming remelting, turning treatment, alloy ingot forging heating, compensation heating and multiple times of heating forging for forming a material during free forging. Through the mode of supplementing compensation heating in a free forging process, the temperature loss in a material transfer process is reduced, sothat the deformation temperature is increased, and on the premise that the deformation amount is not reduced, high-temperature alloy bars difficult to deform and provided with better comprehensive performance are obtained.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

Method for preparing DLC film on surface of super martensitic stainless steel

The invention relates to a method for preparing a DLC film on a surface of super martensitic stainless steel; 13Cr super martensitic stainless steel is used as a substrate for coating the film; a metal mesh cage is arranged in a vacuum cavity, a hollow glass brick with an explosion-proof port is placed in the vacuum cavity, a metal mesh cage is placed on an insulation glass brick, the front, rear,left and right faces of the metal mesh cage are opened, so that electronic escape forms a loop; the substrate is subjected to ultrasonic cleaning after polishing, and then the substrate is placed inthe metal mesh cage of the vacuum cavity for high pressure cleaning, the film to be coated of the substrate is upwards; a Si / Si-C transition layer is prepared before coating the film, so that the film-based bonding force is improved; and the DLC film is prepared through a plasma-enhanced chemical vapor deposition technology. The method has the following advantage that the high modulus of the substrate solves the problem of excessive stress during the preparation process of the DLC film. The DLC film prepared on the surface of the super martensitic stainless steel has a dense structure, obviously improves the substrate hardness and reduces friction and corrosion resistance.

Owner:UNIV OF SCI & TECH LIAONING

High strength aluminum-magnesium-silicon alloy with excellent forgeability and producing method thereof

An high strength forgeable Al-Mg-Si alloy and its production are both disclosed herewith. It contains Al, Si, Mg, Fe additive,Mn additive, Cr additive, Ti-B fining agent and Al-rare-earth alloy at certain ratio, prepared by: smelting, modifying in furnace, purifying, casting into bars, intimate treating, and water cooling. It has excellent tension resistance to meet demands of automotive control arm.

Owner:JIANGSU ASIA PACIFIC LIGHT ALLOY TECH CO LTD

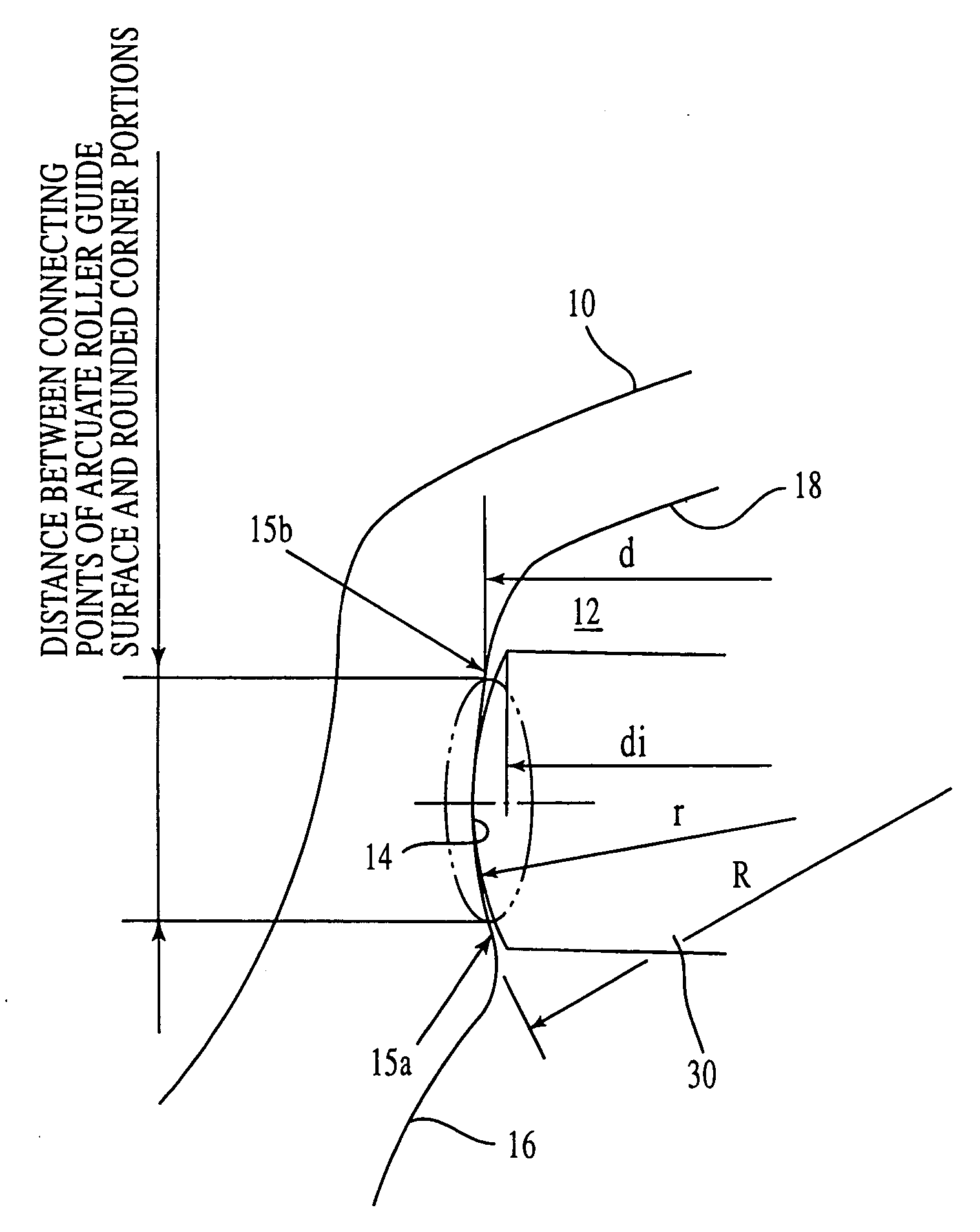

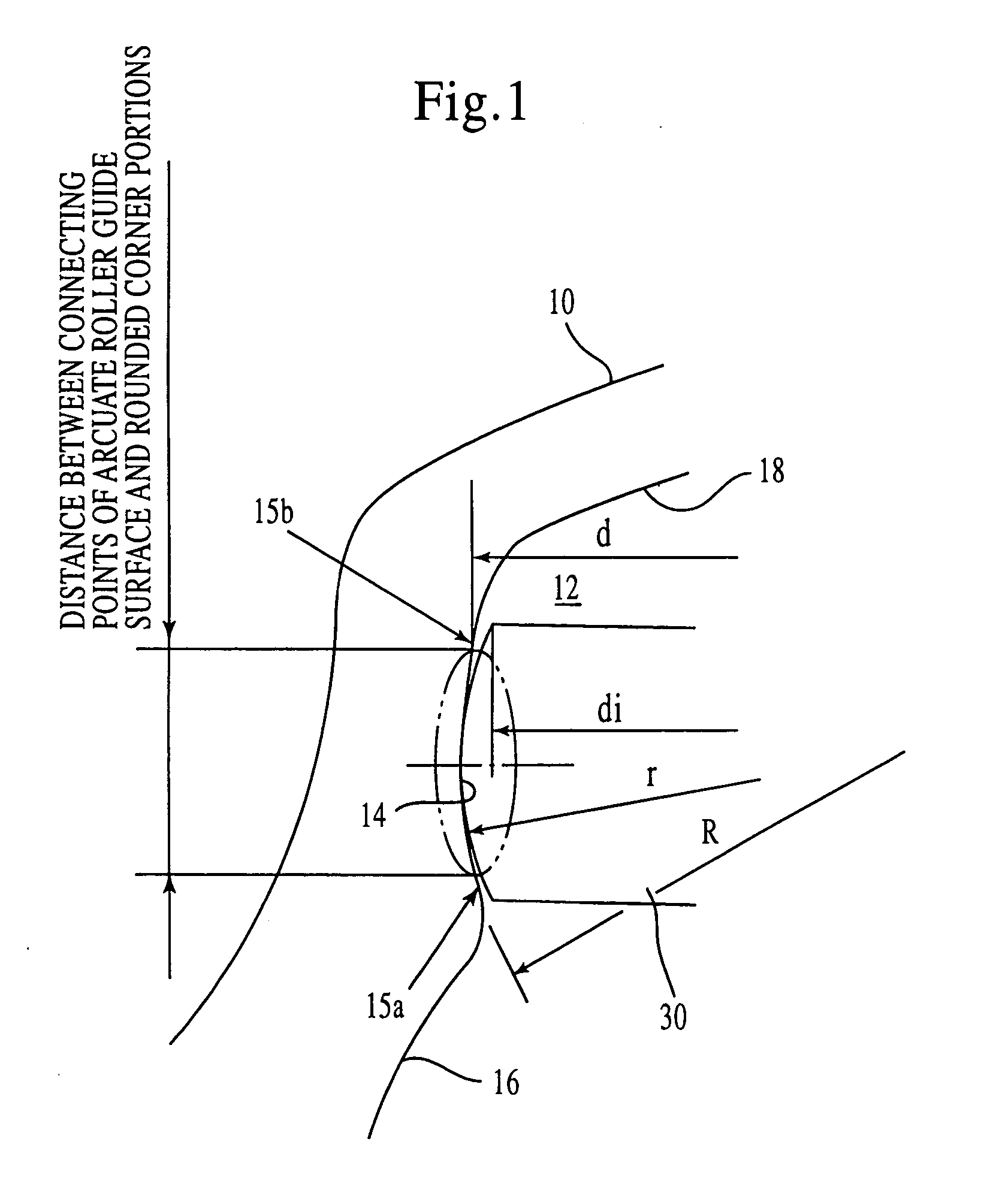

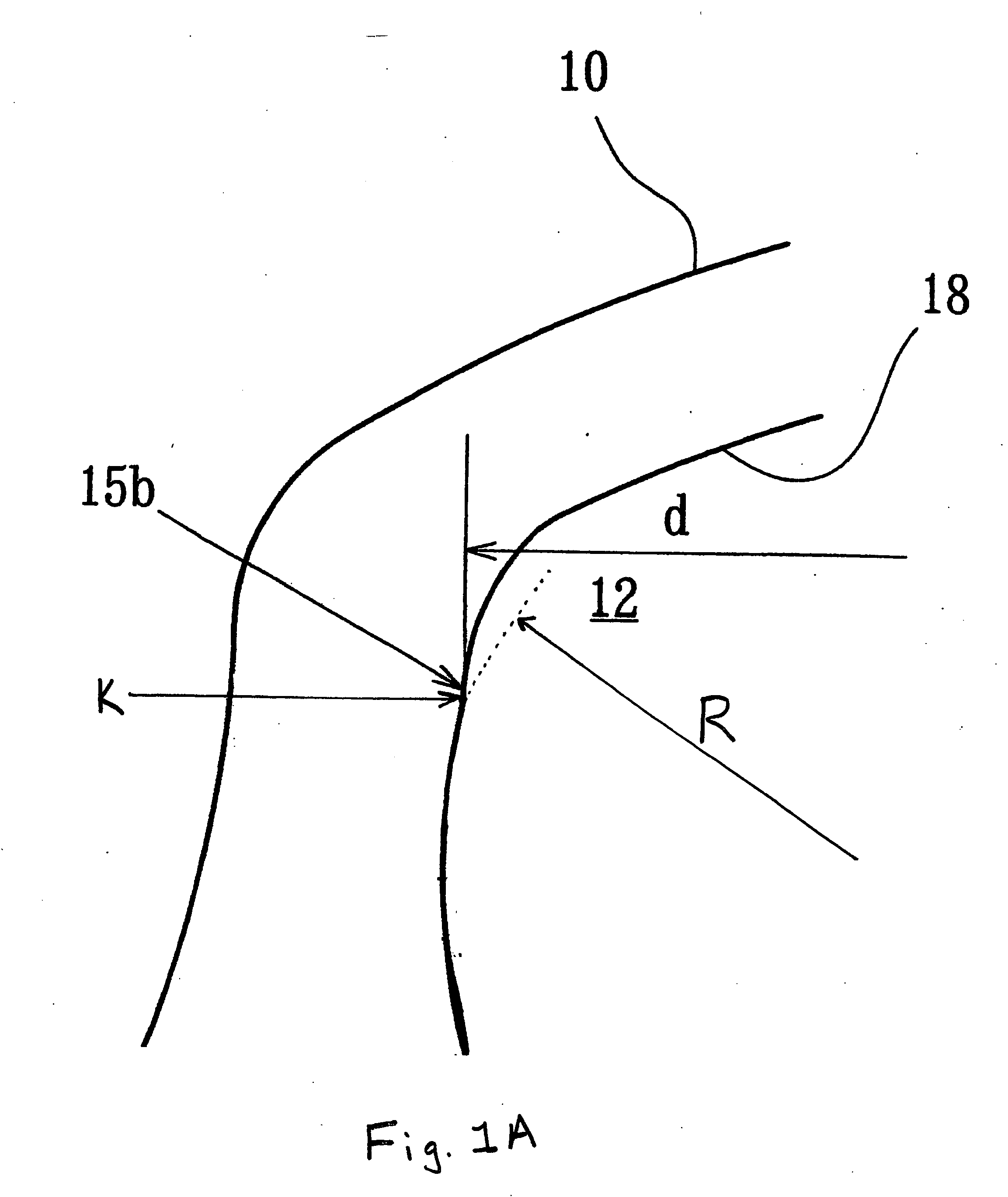

Tripod constant velocity universal joint

InactiveUS20050026705A1Reduce vibrationWithout aggravating vibration characteristicYielding couplingUniversal jointEngineering

Owner:NTN CORP

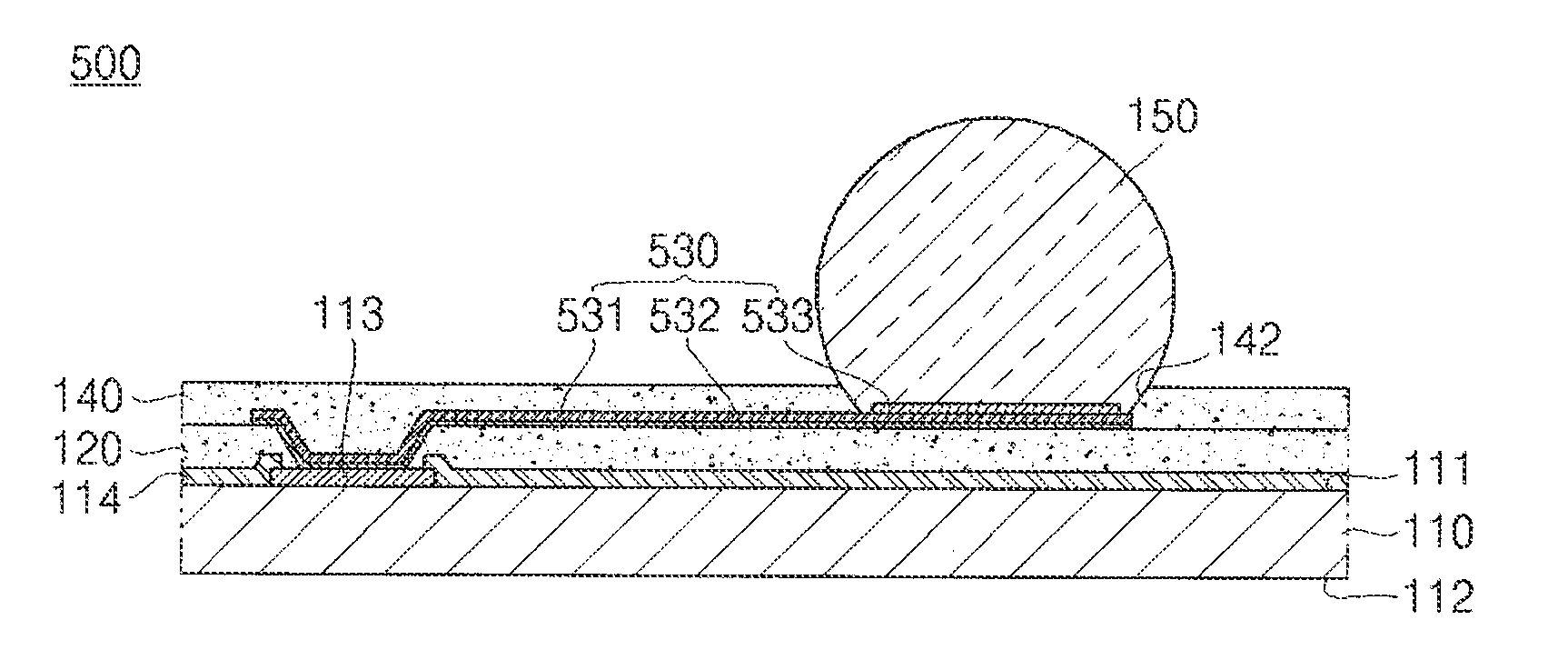

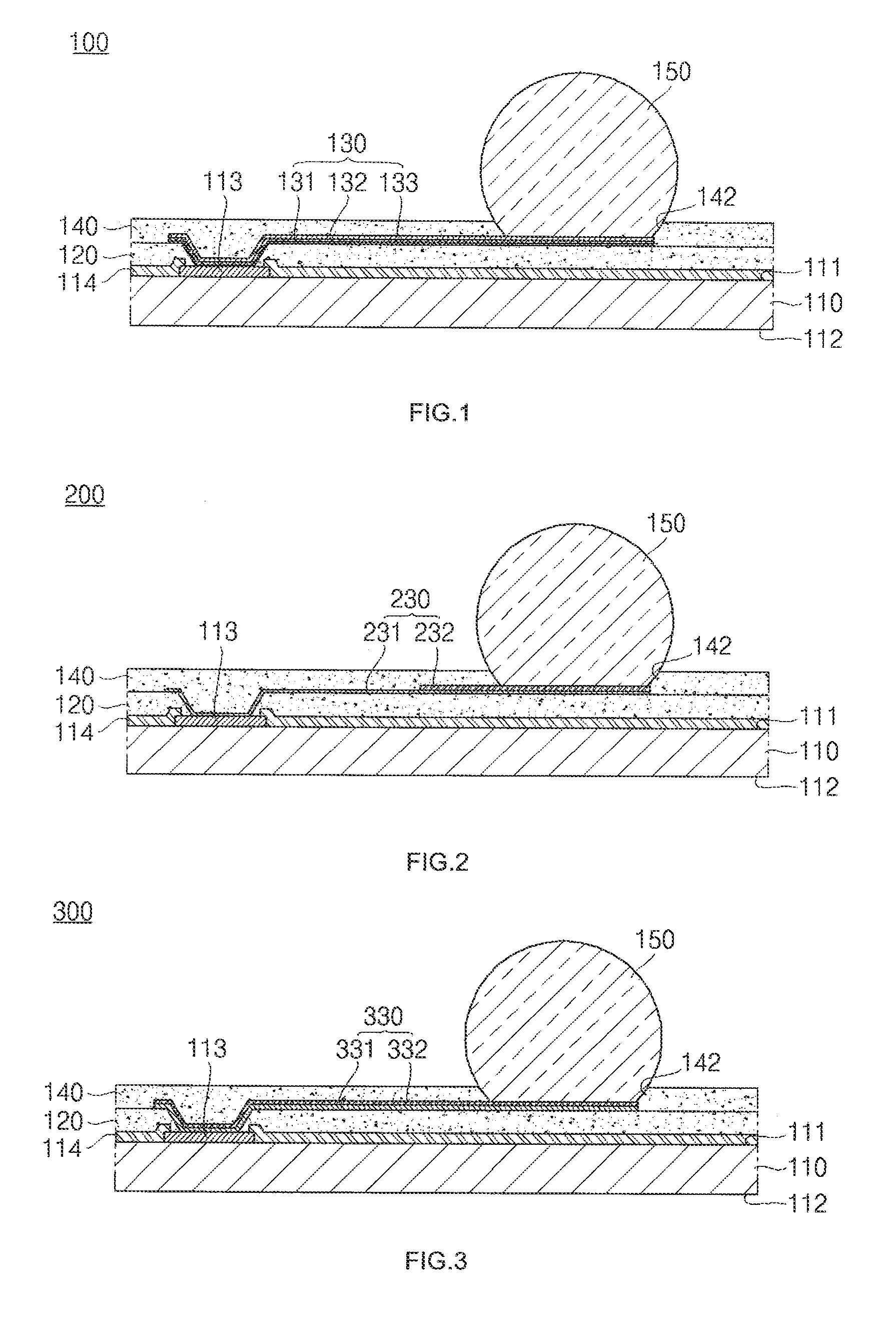

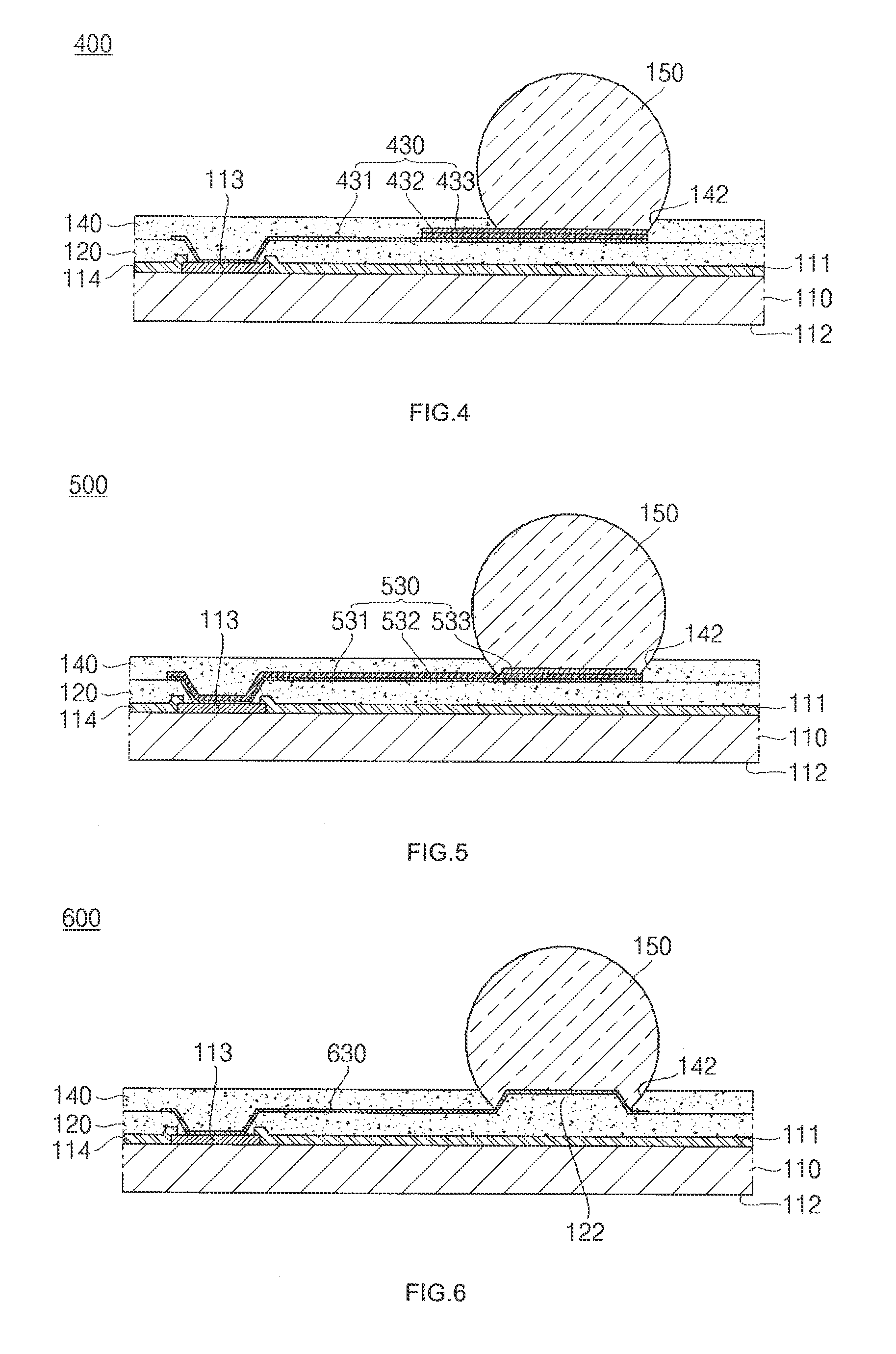

Semiconductor device and manufacturing method thereof

ActiveUS9123543B1Improve malleabilityImprove ductilitySemiconductor/solid-state device detailsSolid-state devicesRedistribution layerSolder ball

A semiconductor device and method of manufacturing the same are provided. The semiconductor device comprises a semiconductor die including a bond pad, a redistribution layer, and a solder ball. The redistribution layer is formed by sequentially plating copper and nickel, sequentially plating nickel and copper, or sequentially plating copper, nickel, and copper. The redistribution layer includes a nickel layer in order to prevent a crack from occurring in a copper layer. Further, a projection is formed in an area of the redistribution layer or a dielectric layer to which the solder ball is welded and corresponds, so that an area of the redistribution layer to which the solder ball is welded increases, thereby increasing bonding power between the solder ball and the redistribution layer.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Sustained release biological medicinal fertilizer

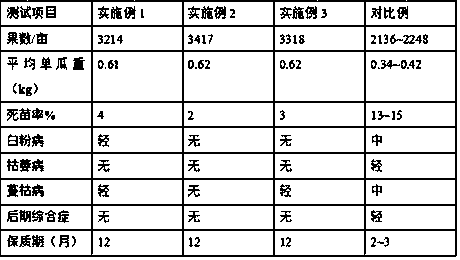

InactiveCN108503486AEfficient use ofIncrease productionBiocidePlant growth regulatorsPotassiumPolyacrylamide

The invention discloses a sustained release biological medicinal fertilizer, and belongs to the field of fertilizers. The sustained release biological medicinal fertilizer is prepared by taking 5-10 parts of borax, 6-13 parts of triadimenol and 7-15 parts of organosilicone polyoxyethylene ether compound, mixing, pulverizing, screening by a 100-mesh sieve, collecting a sieved particle, extruding, and pelletizing to obtain a medicine particle; taking 25-40 parts of urea, 10-20 parts of potassium chloride, 15-20 parts of zinc chloride, 30-45 parts of polyaspartic acid, mixing, pulverizing, screening by the 100-mesh sieve, collecting a sieved particle, extruding, and pelletizing to obtain a fertilizer particle; taking 5-12 parts of hyaluronic acid, 6-10 parts of polyacrylamide, and 5-12 partsof ethylene-vinyl acetate copolymer, stirring and mixing evenly for 20-30 minutes, adding 12-18 parts of sodium secondary alkyl sulfonate, 6-12 parts of sodium dodecylbenzene sulfonate and 20-30 partsof water, stirring for 15-20 minutes to obtain a compound coating emulsion; taking 5-10 parts of white gourd extract, 5-10 parts of medicine particle and 30-40 parts of fertilizer particle, mixing evenly, spraying the compound coating emulsion, drying to obtain the sustained release biological medicinal fertilizer. The sustained release biological medicinal fertilizer solves the problems that theexpiration date of the medicinal fertilizer is short at present and the too long expiration date causes reduced medicinal effect or failure.

Owner:常州市蒽盗钟情生物科技有限公司

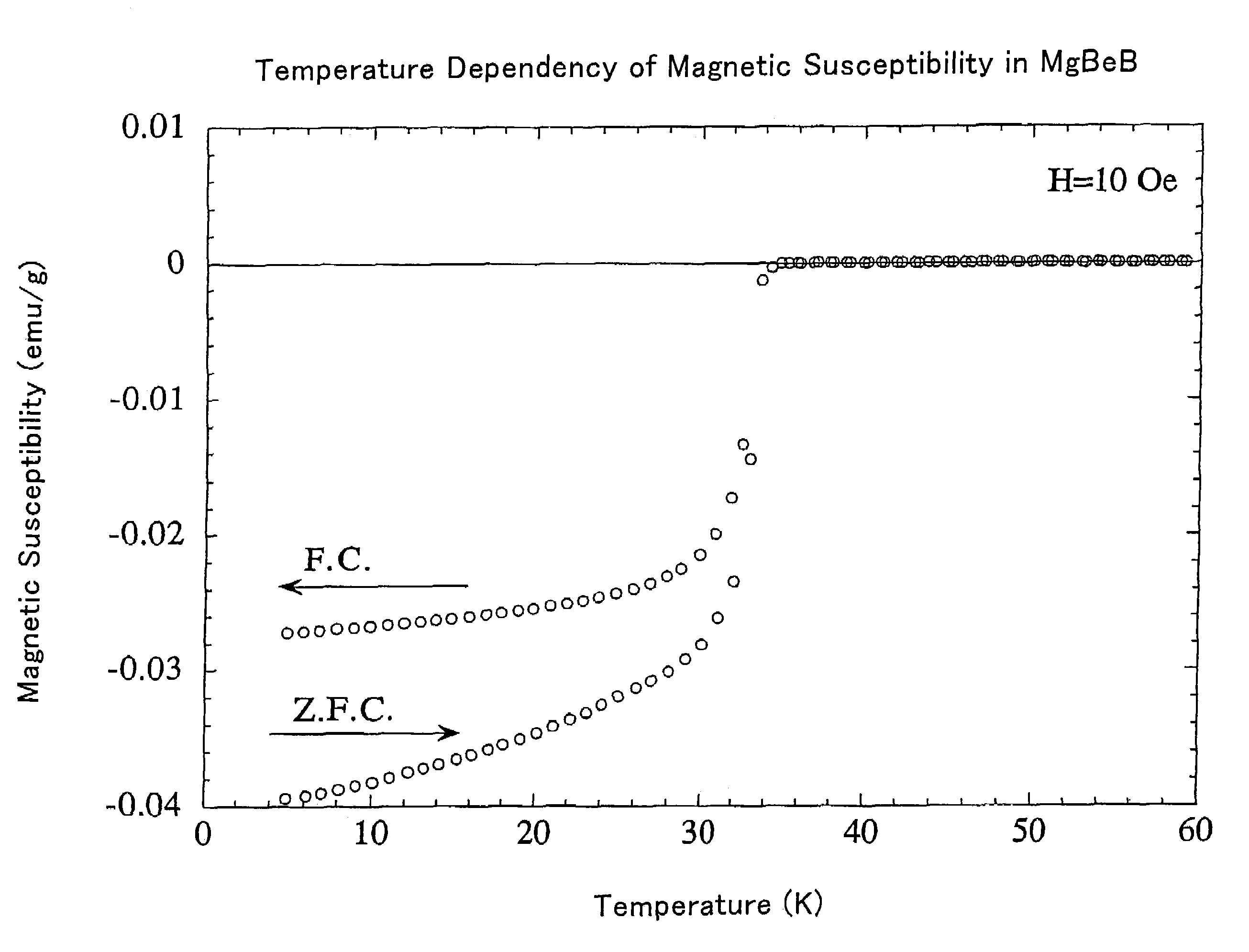

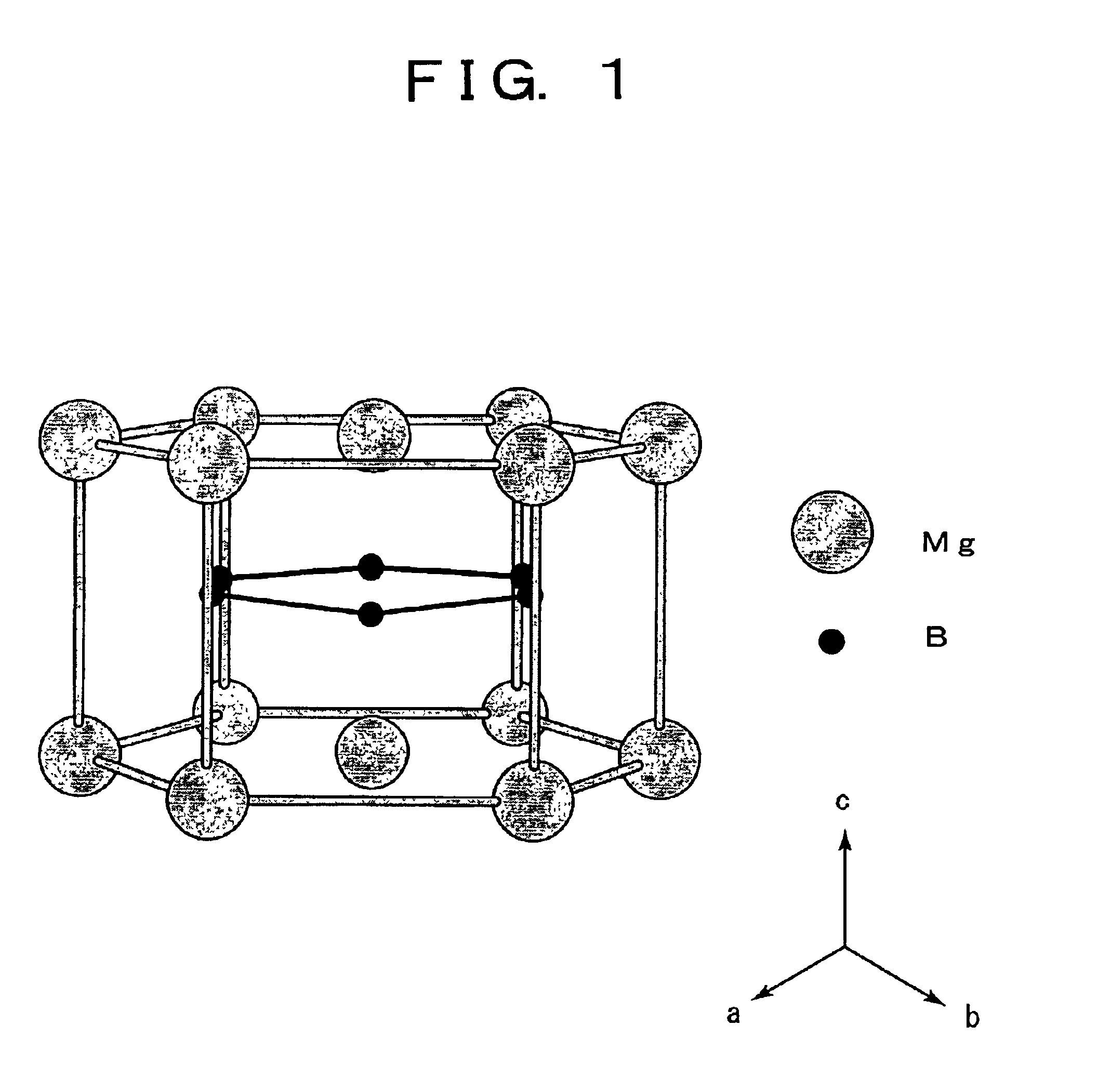

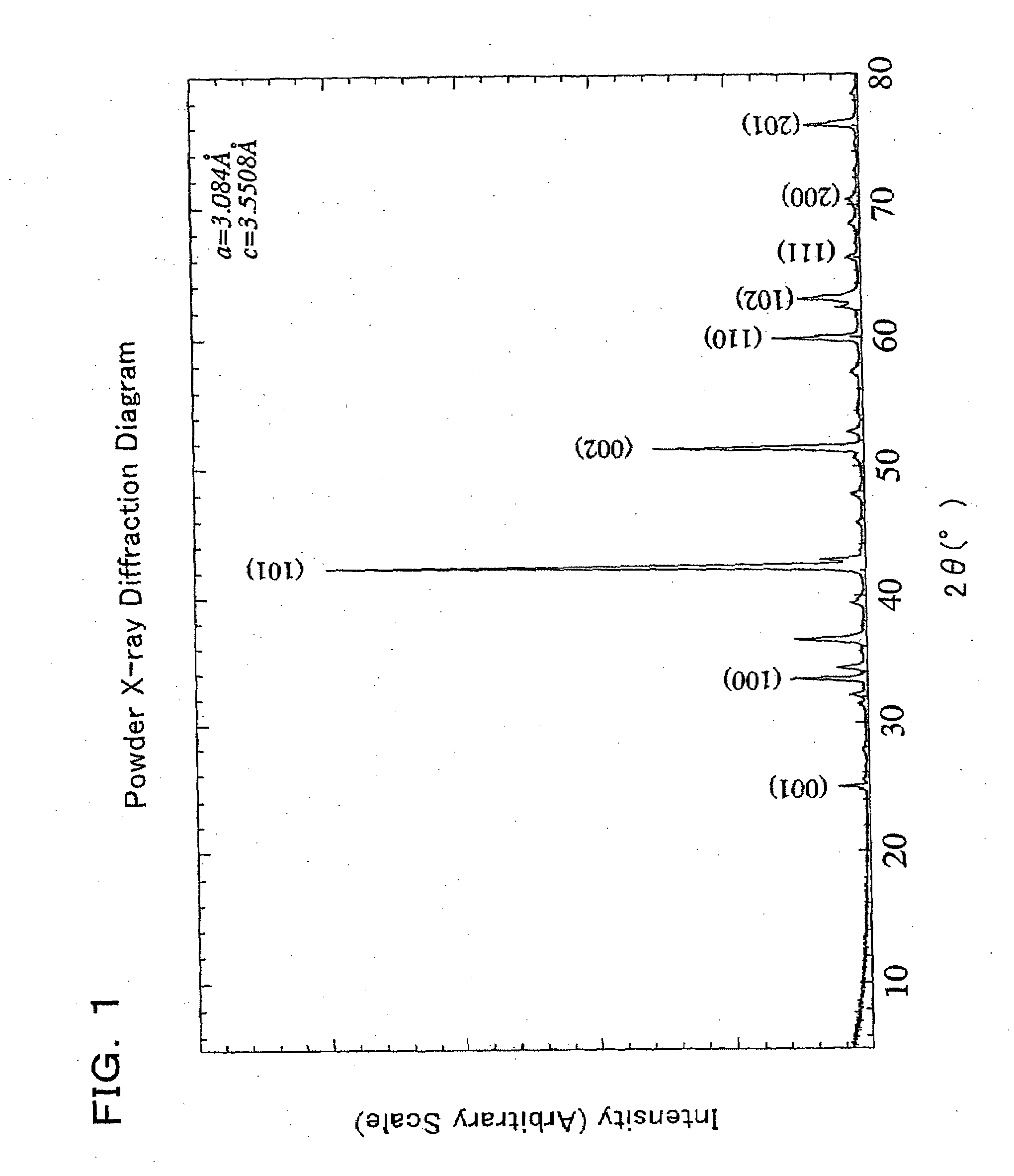

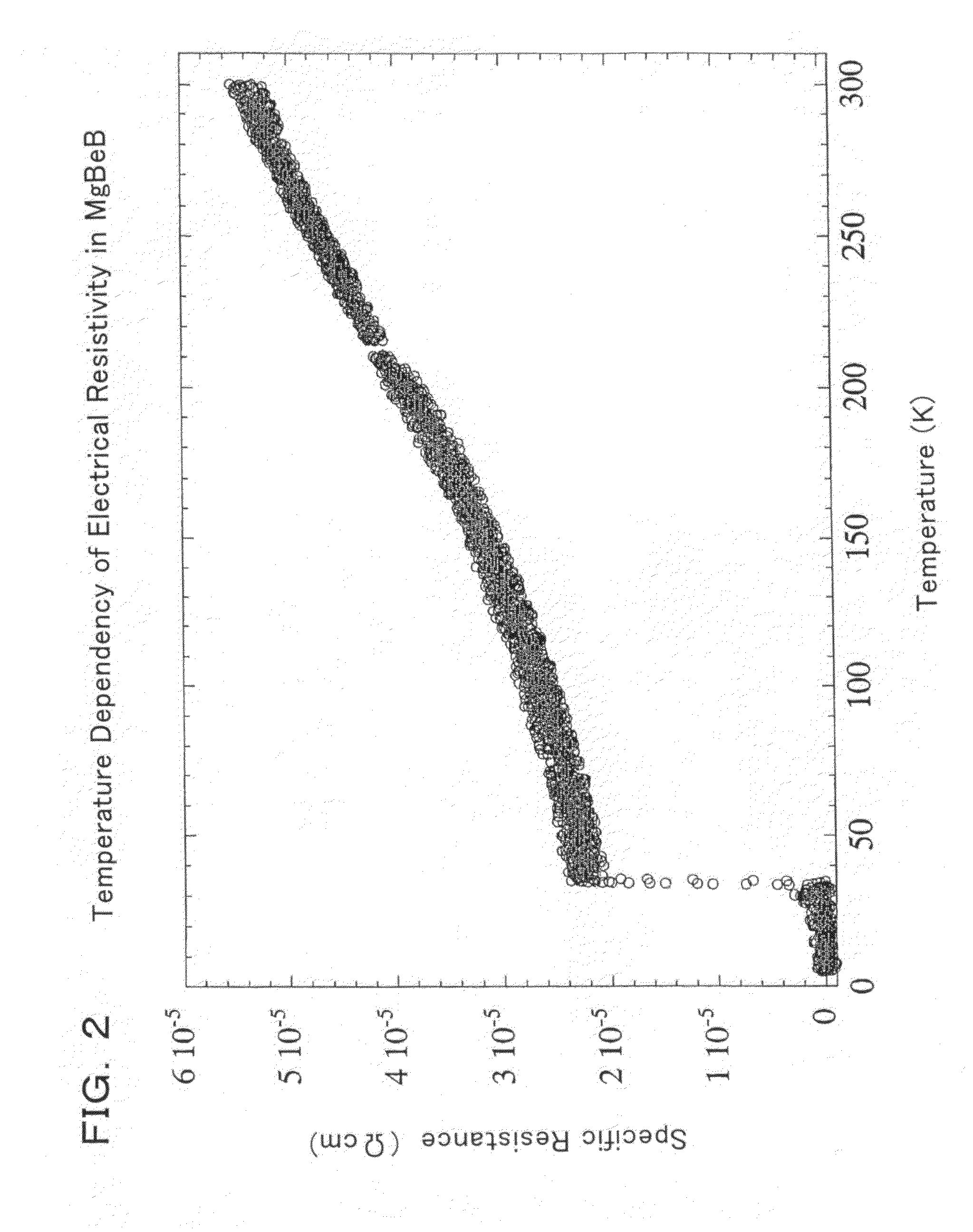

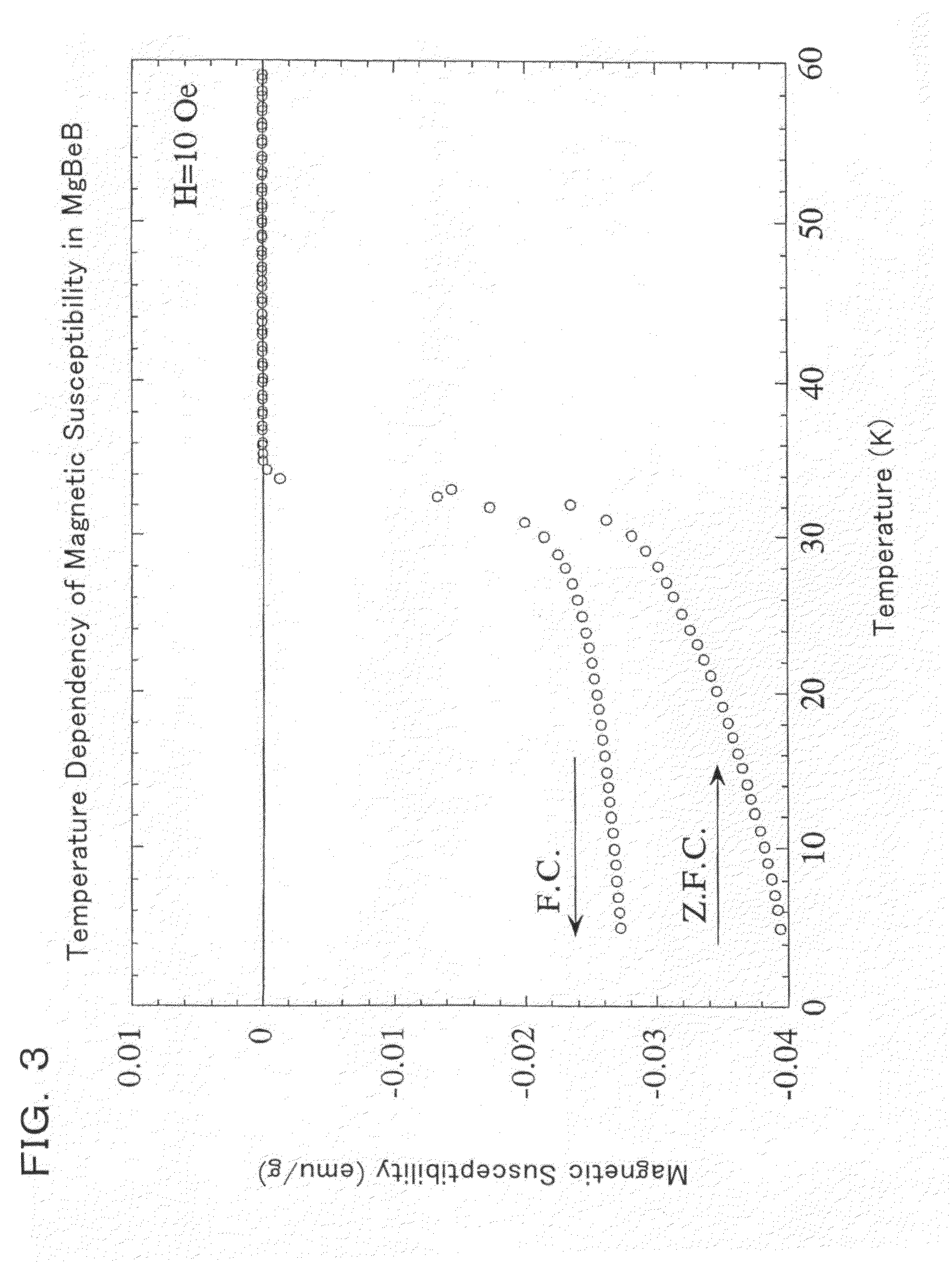

Intermetallic compound superconducting material comprising magnesium and beryllium and alloy superconducting material containing the intermetallic compound

InactiveUS7445681B2Easy to makeRaise the transition temperaturePolycrystalline material growthSuperconductors/hyperconductorsSuperconducting transition temperatureDuctility

There are provided an intermetallic-compound superconductor that is high in superconducting transition temperature, and an alloy superconductor that is high in superconducting transition temperature and excels in malleability and ductility, as well as a method of making such a superconductor with good reproducibility and at a low cost of manufacture. This entirely new intermetallic compound superconductor is made of magnesium (Mg) and beryllium (Be) and has a chemical composition expressed by formula: Mg1Be2, has a hexagonal AlB2 type crystallographic structure and has a superconducting transition temperature (Tc) of 35 K. An alloy containing this intermetallic compound excels in malleability and ductility and constitutes the alloy superconductor having a superconducting transition temperature (Tc) of 35 K and being low in specific resistance for normal conduction at a temperature ranging from the superconducting transition temperature to a room temperature. In the method of manufacture, a Mg containing feedstock powder and a Be containing feedstock powder are mixed together to form a mixture thereof which is, e.g., hot pressed to produce a semiconductor product.

Owner:JAPAN SCI & TECH CORP

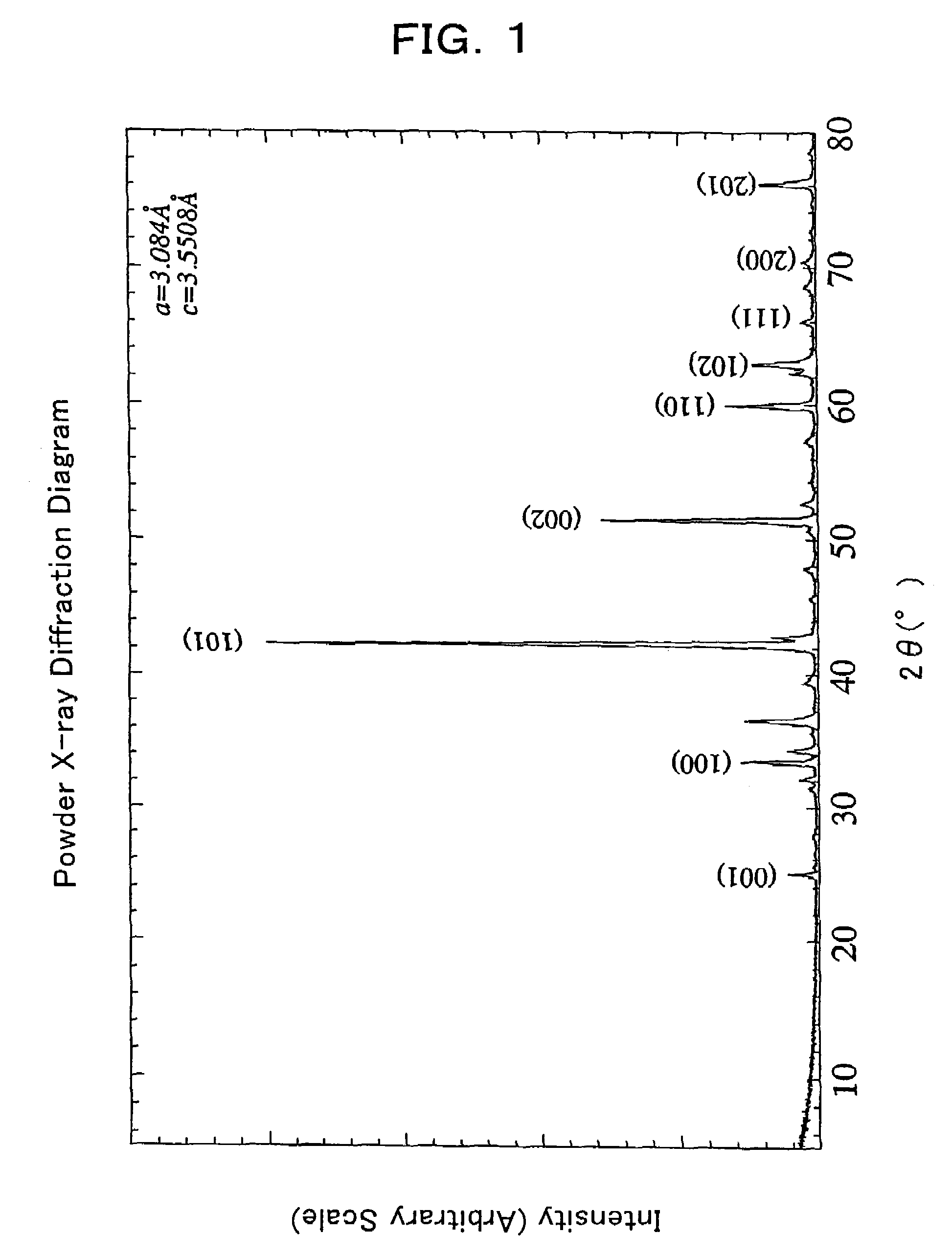

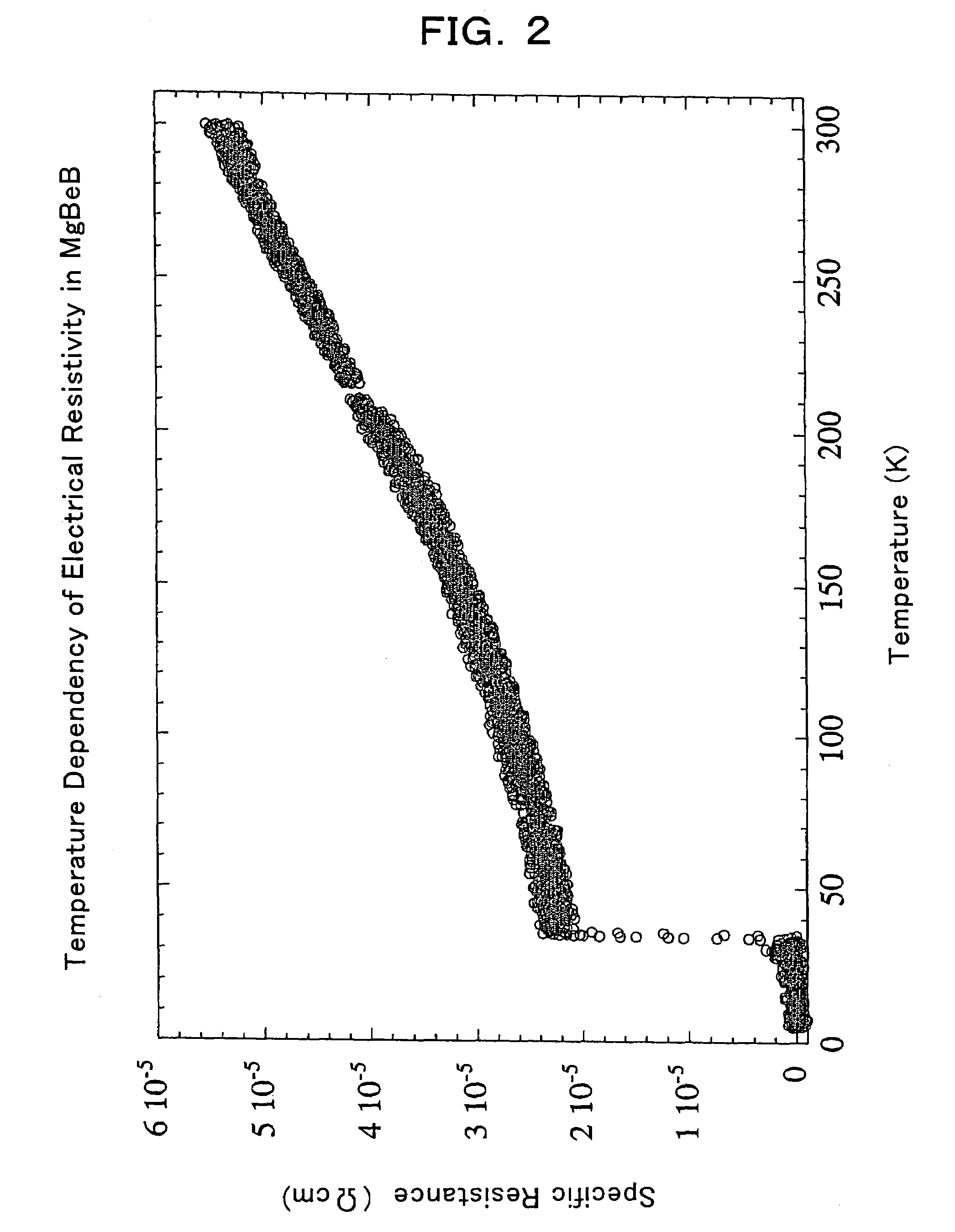

Intermetallic compound superconductors and alloy superconductors, and method for their preparation

InactiveUS6956011B2Easy to makeRaise the transition temperatureSuperconductors/hyperconductorsSuperconductor detailsChemical compositionCrystal structure

There are provided an intermetallic compound superconductor that is high in superconducting transition temperature, and an alloy superconductor that is high in superconducting transition temperature and excels in malleability and ductility, as well as a method of making such a superconductor with good reproducibility and at a low cost of manufacture. This entirely new intermetallic compound superconductor is made of magnesium (Mg) and boron (B) and has a chemical composition expressed by formula: Mg1B2, has a hexagonal AlB2 type crystallographic structure and has a superconducting transition temperature (Tc) of 39 K. An alloy containing this intermetallic compound excels in malleability and ductility and constitutes the alloy superconductor having a superconducting transition temperature (Tc) of 39 K. In the method of manufacture, a Mg containing feedstock powder and a B containing feedstock powder are mixed together to form a mixture thereof which is, e.g., hot pressed to produce a semiconductor product.

Owner:AKIMITSU JUN +1

Low S low Pb forgeable free cutting steel and its producing process

ActiveCN1858282AReasonable smelting process designImprove rolling yieldMetal rolling arrangementsChemical compositionContinuous rolling

The present invention belongs to the field of metal material, and is especially one kind of forgeable free cutting steel with low S and Pb content and its production process. The forgeable free cutting steel contains (in wt%): C 0.36-0.44, Si 0.17-0.37, Mn 0.80-1.20, As 0.20-0.30, Sn+Pb 0.05-0.20, P not more than 0.040, S not more than 0.060, Cu not more than 0.25 and Fe and impurity for the rest. The production process includes the steps of: smelting in a converter, ladle refining, continuous casting and continuous rolling. The present invention has low production cost, less environmental pollution, high production efficiency and high product quality.

Owner:HANGZHOU IRON & STEEL GRP

Alloy superconductor and methods of making the same

InactiveUS20090048114A1Raise the transition temperatureExcels in ductilityPolycrystalline material growthSuperconductors/hyperconductorsAlloySuperconducting transition temperature

There are provided an intermetallic-compound superconductor that is high in superconducting transition temperature, and an alloy superconductor that is high in superconducting transition temperature and excels in malleability and ductility, as well as a method of making such a superconductor with good reproducibility and at a low cost of manufacture. This entirely new intermetallic compound superconductor is made of magnesium (Mg) and beryllium (Be) and has a chemical composition expressed by formula: Mg1Be2, has a hexagonal AlB2 type crystallographic structure and has a superconducting transition temperature (Tc) of 35 K. An alloy containing this intermetallic compound excels in malleability and ductility and constitutes the alloy superconductor having a superconducting transition temperature (Tc) of 35 K and being low in specific resistance for normal conduction at a temperature ranging from the superconducting transition temperature to a room temperature. In the method of manufacture, a Mg containing feedstock powder and a Be containing feedstock powder are mixed together to form a mixture thereof which is, e.g., hot pressed to produce a semiconductor product.

Owner:JAPAN SCI & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com