Method for preparing DLC film on surface of super martensitic stainless steel

A martensitic stainless steel, super technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of changing structure performance, matrix phase transformation, low phase transformation temperature, etc., to prevent phase transformation , dense structure, and the effect of improving weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

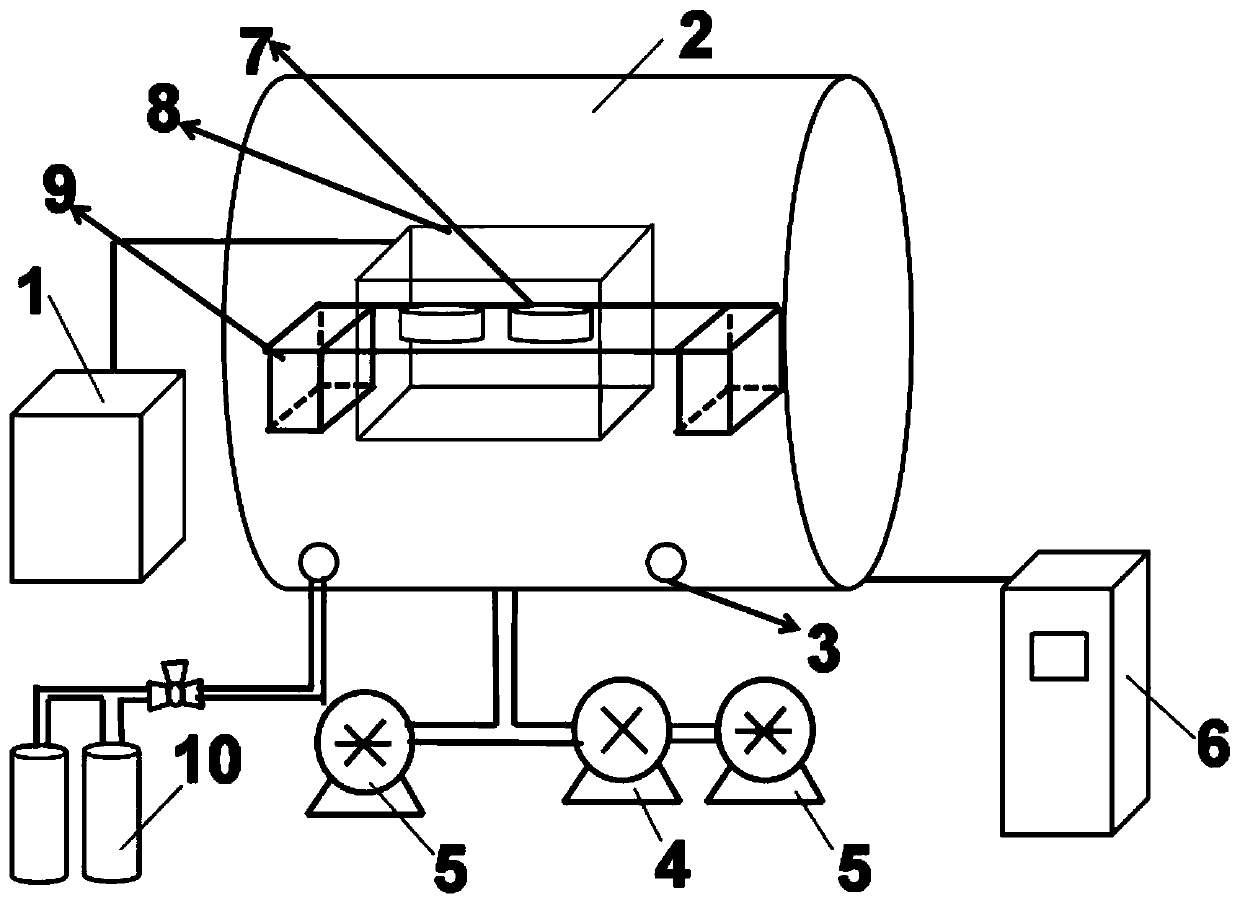

[0033] The method for preparing DLC thin film on super martensitic stainless steel surface, comprises the following steps:

[0034] 1) Substrate preparation: 13Cr super martensitic stainless steel is selected as the substrate 7 for coating, and the chemical composition of 13Cr super martensitic stainless steel is calculated by weight percentage:

[0035] C: 0.01%~0.03%, Si: 0.15%~0.5%, Mn: 0.2%~2%, Cr: 12%~13%, Mo: 0.5~3.5%, Ni: 5.0%~8.0%, S≤0.035 %, P≤0.015%, Cu≥0.047%, and the rest are iron and unavoidable impurities.

[0036] The substrate 7 was cut into a sample with a specification of 15×15×8 mm, and was polished to a mirror surface with metallographic sandpaper, and then polished until there were no scratches visible to the naked eye on the surface.

[0037] The prepared samples were immersed in absolute ethanol for ultrasonic cleaning, the heating temperature was 50°C, the ultrasonic frequency was 50 Hz, and the cleaning was performed for 20-30 minutes. Take it out ...

Embodiment 2

[0048] In this example, a DLC film is prepared on the surface of 13Cr super martensitic stainless steel by plasma enhanced chemical vapor deposition technology, and the working gas is acetylene and argon with a purity of 99.99%; high-pressure cleaning is carried out with a pulse bias voltage of 3000V for 1 hour; the chamber pressure is 2Pa. By adjusting the pulse bias voltage and comparing the quality of DLC films prepared under different parameter conditions, the optimal process parameters for film preparation are given.

[0049] The specific operation steps of the present embodiment are the same as in Example 1, and the specific preparation process parameters are respectively:

[0050] The pulse bias voltage is: 1800V;

[0051] The deposition temperature is: 100°C;

[0052] Deposition time: 2h

[0053] The morphology, mechanical properties and corrosion resistance of the prepared films were tested.

[0054] The thickness of the DLC film prepared by this method is 1.2052μ...

Embodiment 3

[0056] In this embodiment, a DLC film is prepared on the surface of 13Cr super martensitic stainless steel by plasma enhanced chemical vapor deposition technology, and the working gas is acetylene and argon with a purity of 99.99%; the chamber pressure is 2Pa. By adjusting the pulse bias voltage and comparing the quality of DLC films prepared under different parameter conditions, the optimal process parameters for film preparation are given.

[0057] The specific operation steps of this embodiment are the same as those of Embodiment 1.

[0058] The specific preparation process parameters are respectively:

[0059] The pulse bias voltage is: 2400V;

[0060] The deposition temperature is: 100°C;

[0061] Deposition time: 2h

[0062] The morphology, mechanical properties and corrosion resistance of the prepared films were tested.

[0063] The thickness of the DLC film prepared by this method is 1.7132μm. The thin film has a dense structure with a roughness of 3.04nm, complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com