Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3151results about How to "Uniform tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Martensite series wear-resistant steel and preparation method thereof

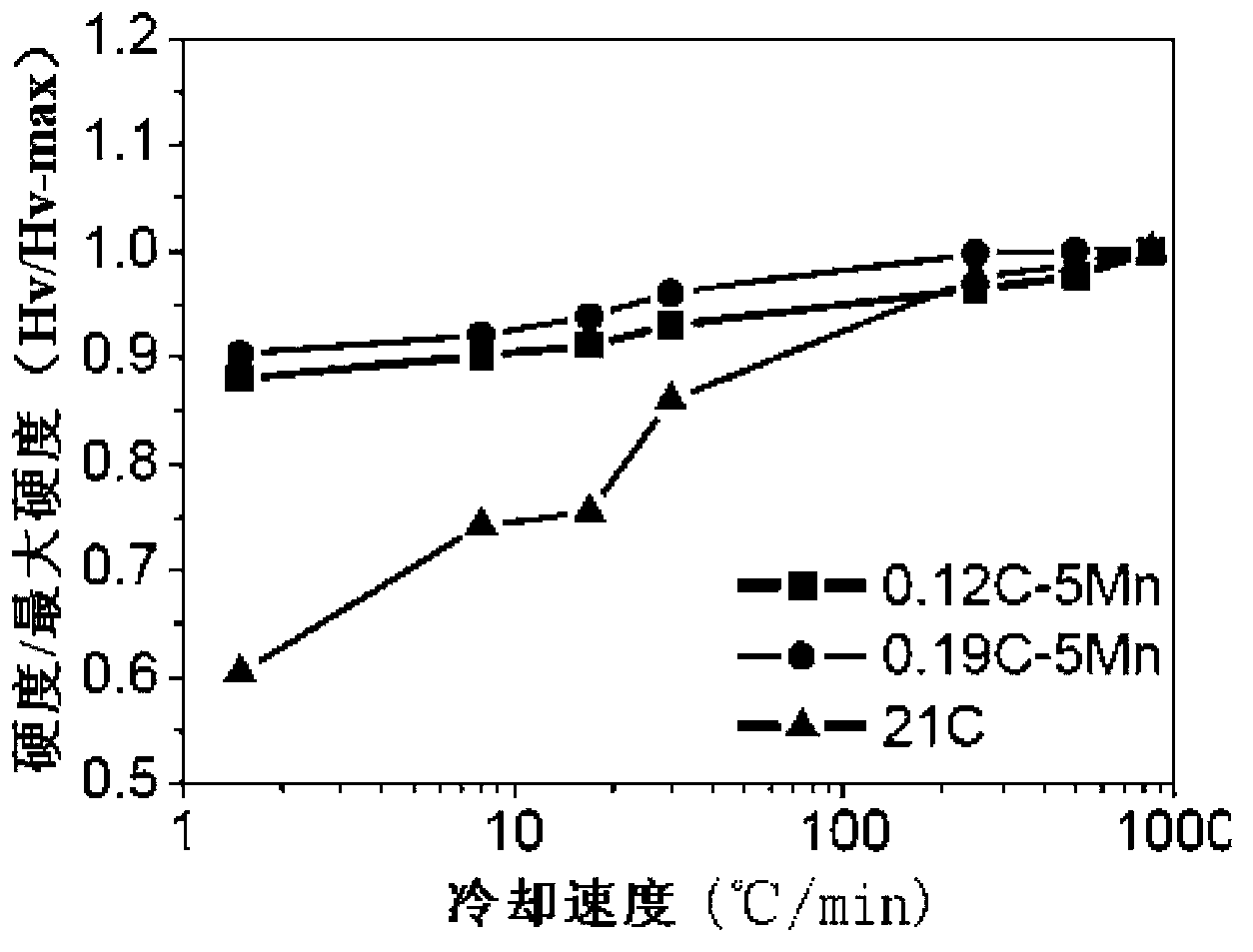

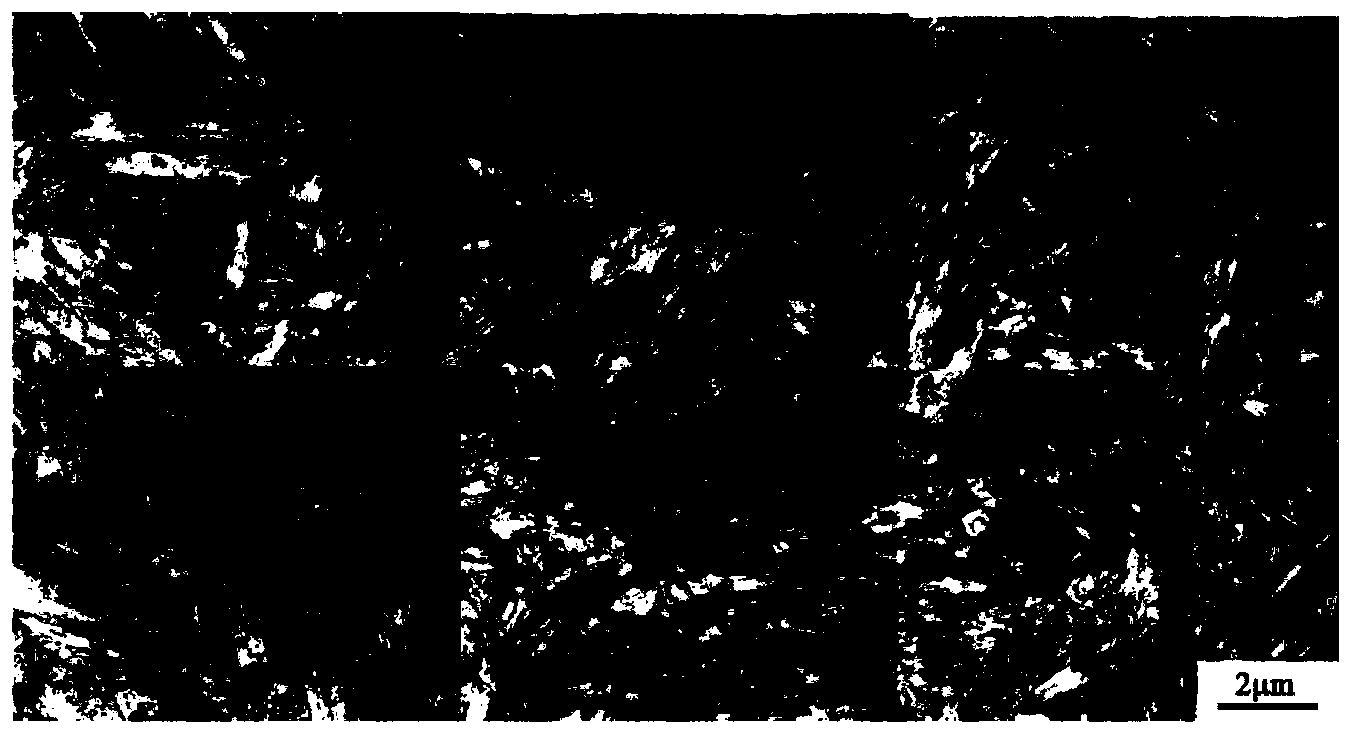

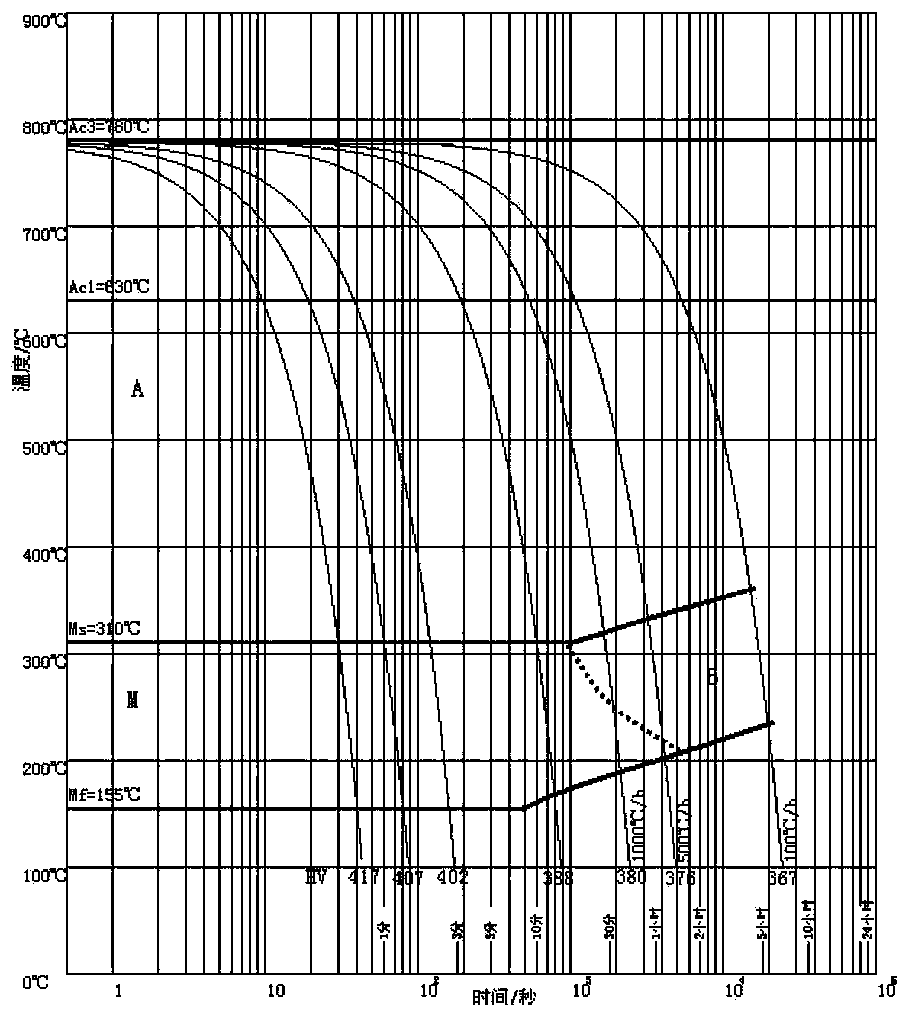

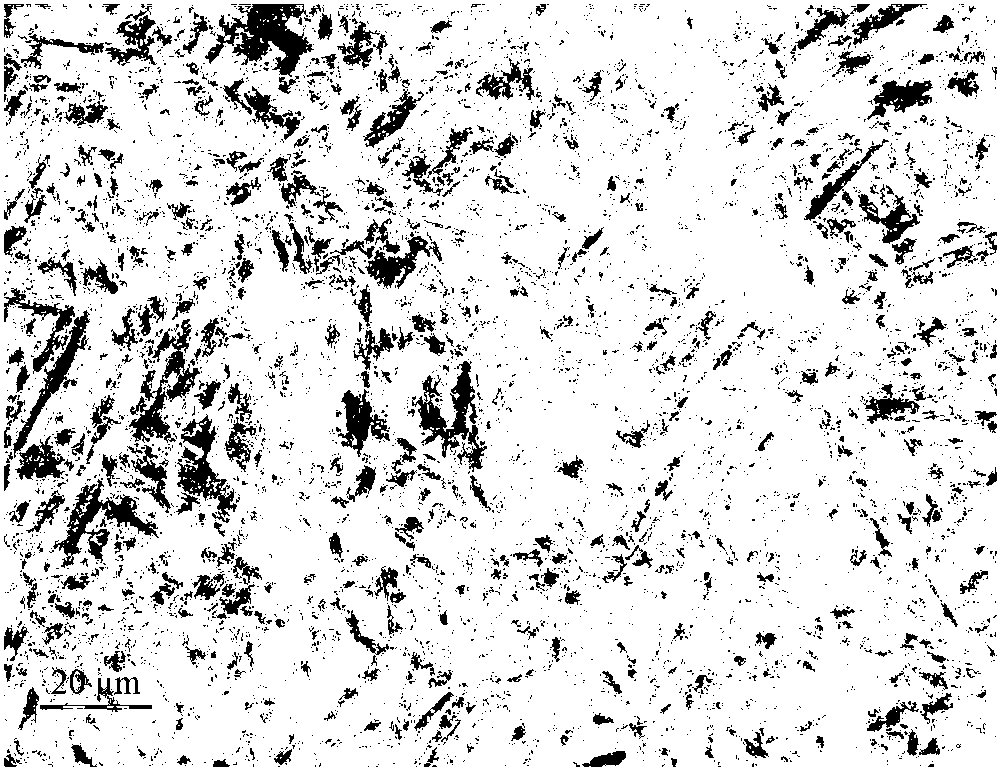

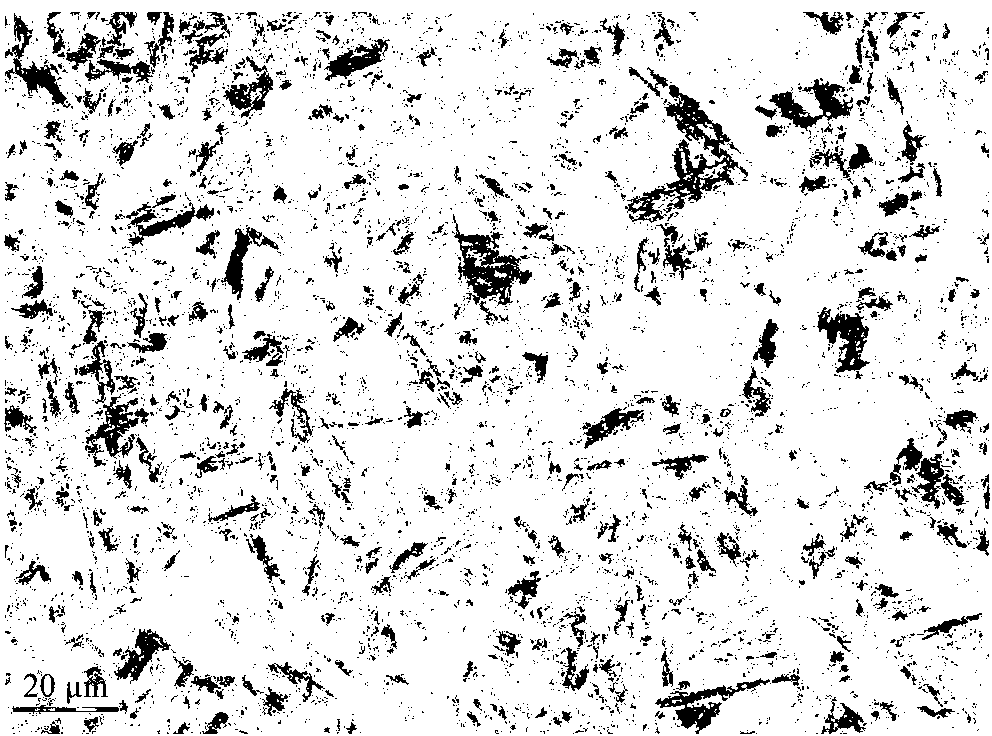

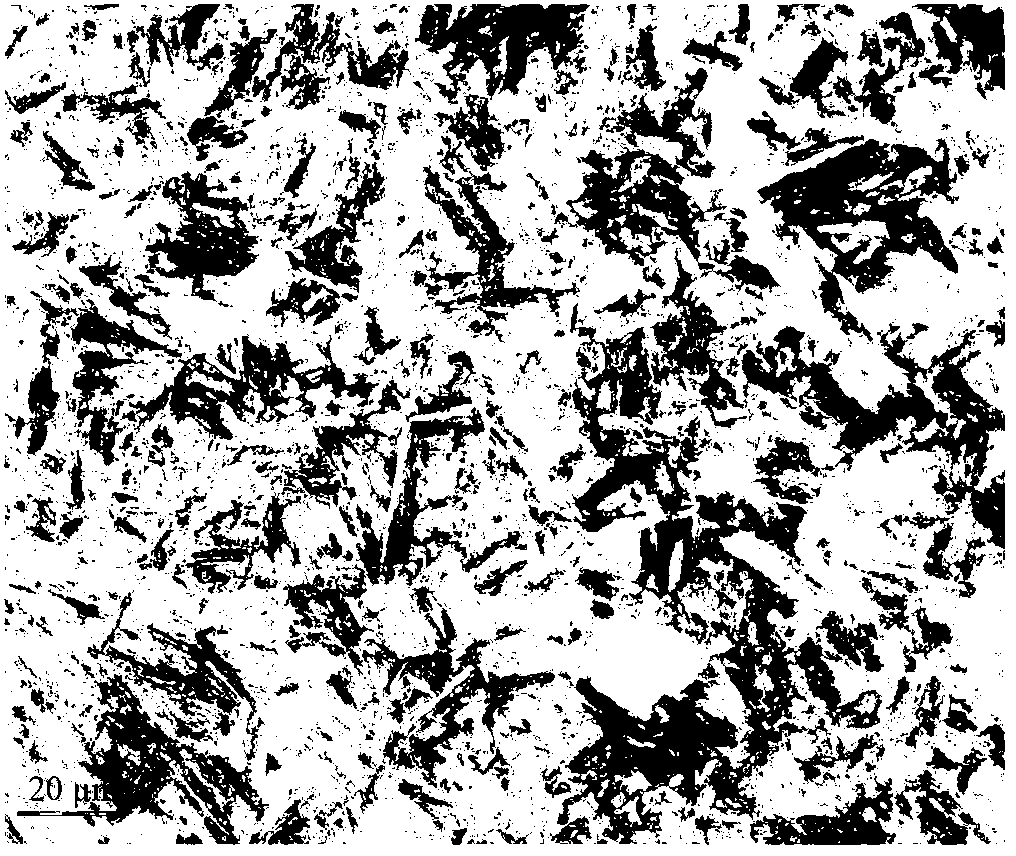

The invention relates to martensite series wear-resistant steel and a preparation method thereof, belonging to the technical field of wear-resistant steel. The steel comprises the following chemical components: 0.05-0.51wt% of C, 2.0-10wt% of Mn, 0-1.5wt% of Al, 0-1.5wt% of Si, 0-1.5wt% of Cr, 0-1.5wt% of Cu, 0-1.5wt% of Ni and the balance of Fe and inevitable impurities, wherein the Mn / C ratio is not less than 9. Based on this, the following one or more composite elements can be optionally added: 0.02-0.50wt% of Mo, 0.02-0.50wt% of V, 0.02-0.50wt% of Nb, 0.01-0.5wt% of Ti, 0.02-0.50wt% of B and 0.02-0.50wt% of RE. The wear-resistant steel provided by the invention is easy to produce, low in cost and high in performance. The invention is applicable to the technical field of wear-resistant materials for mines, energy, transportation, agricultural machinery, engineering machinery and other industries.

Owner:CENT IRON & STEEL RES INST

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

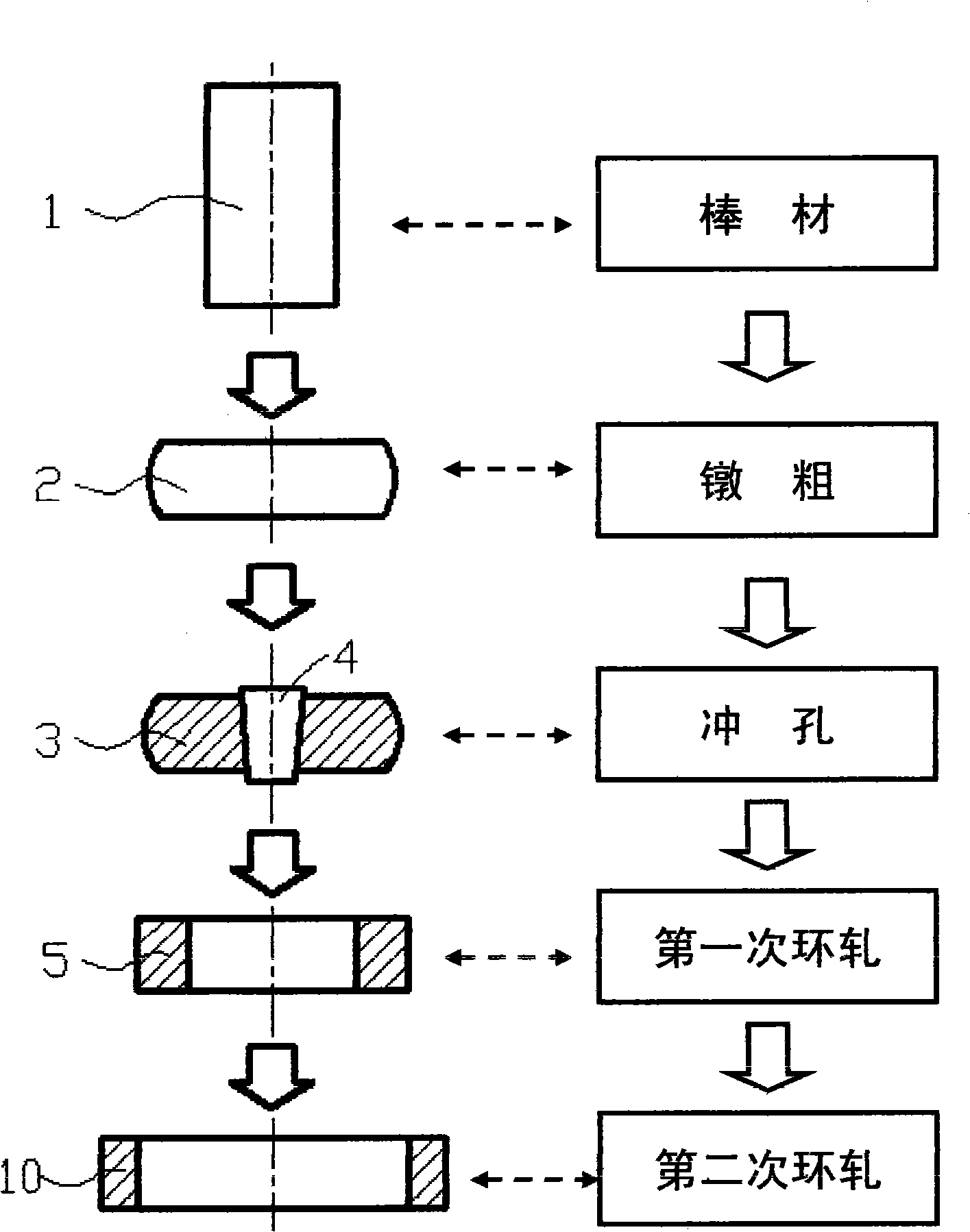

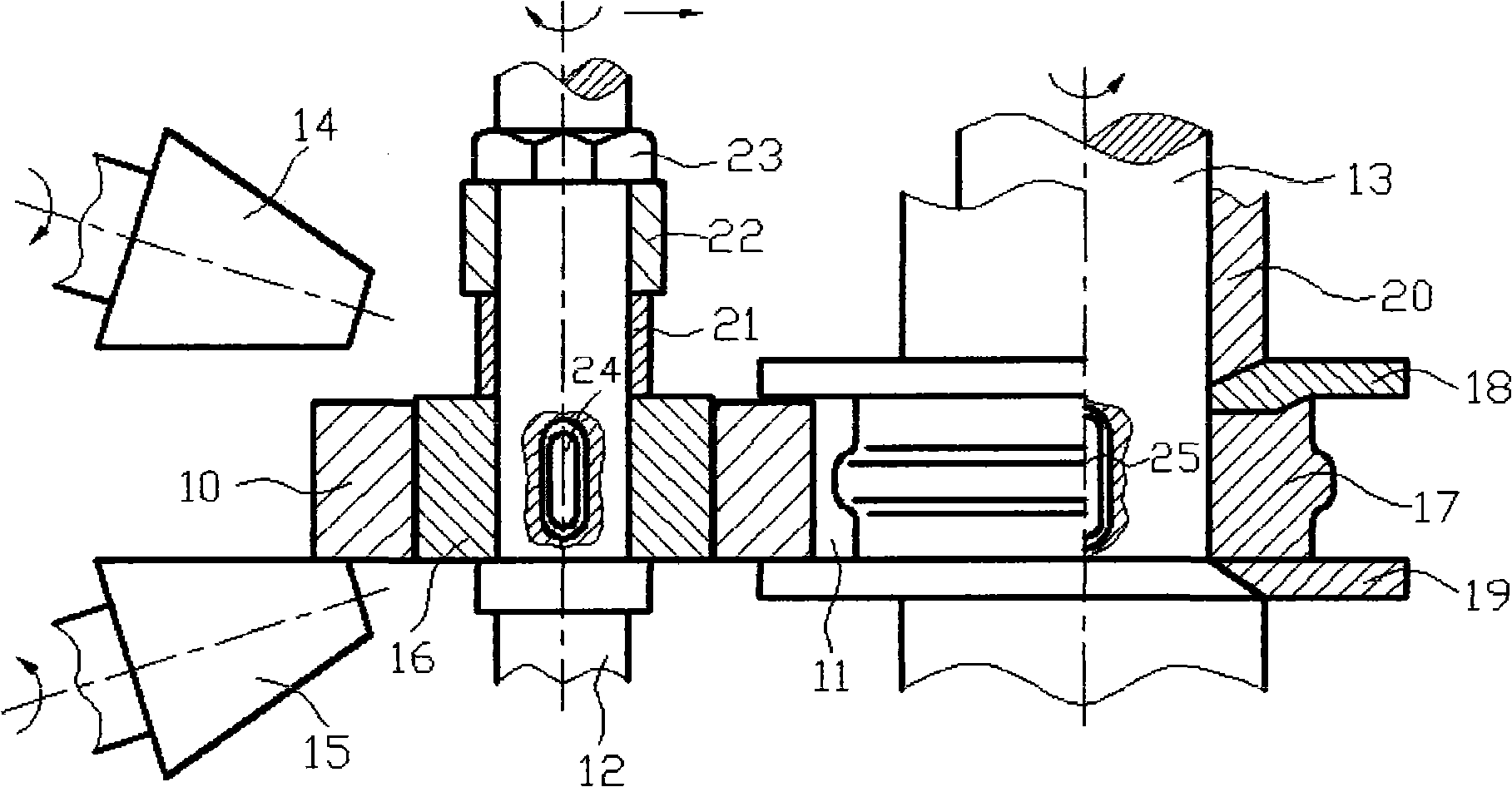

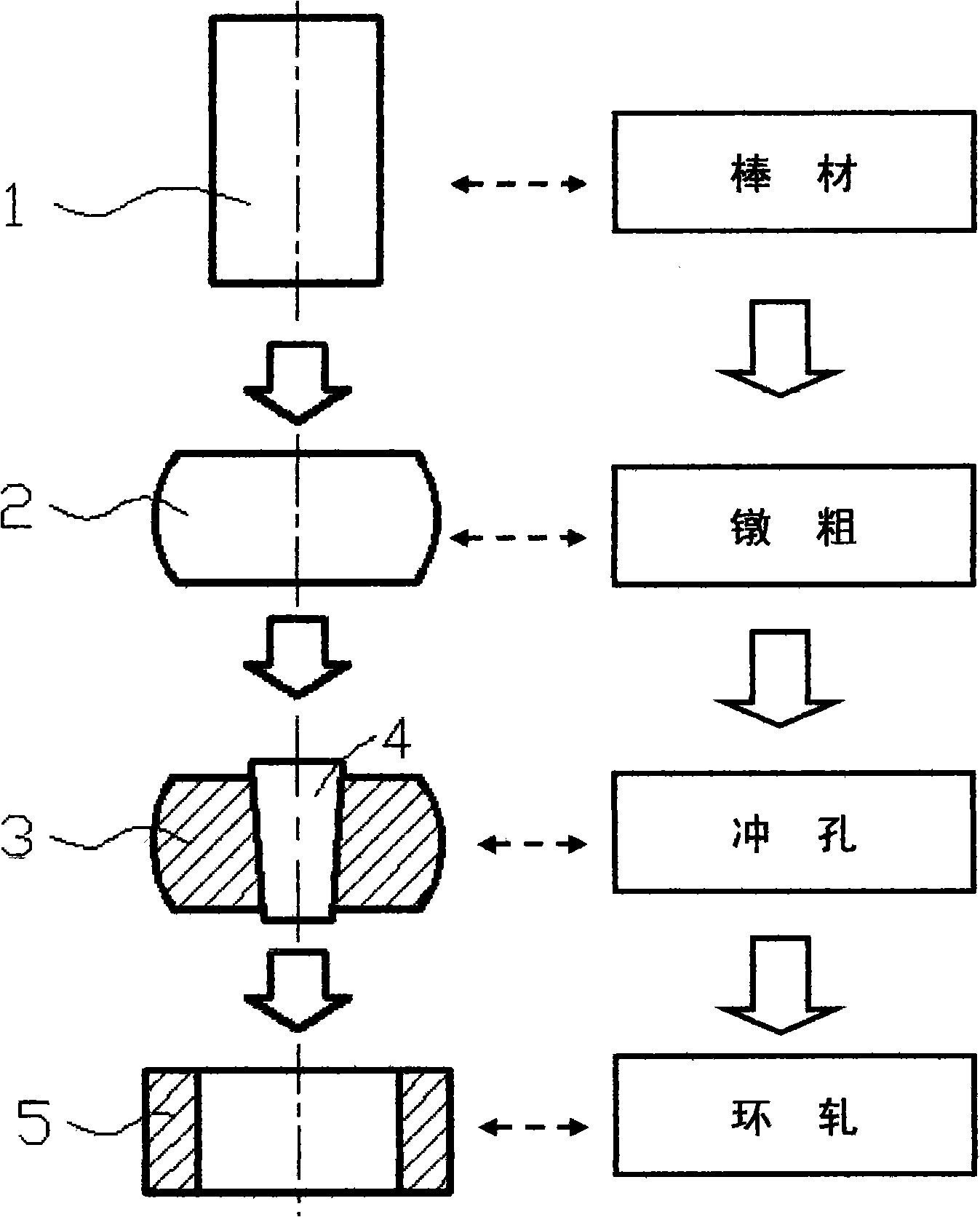

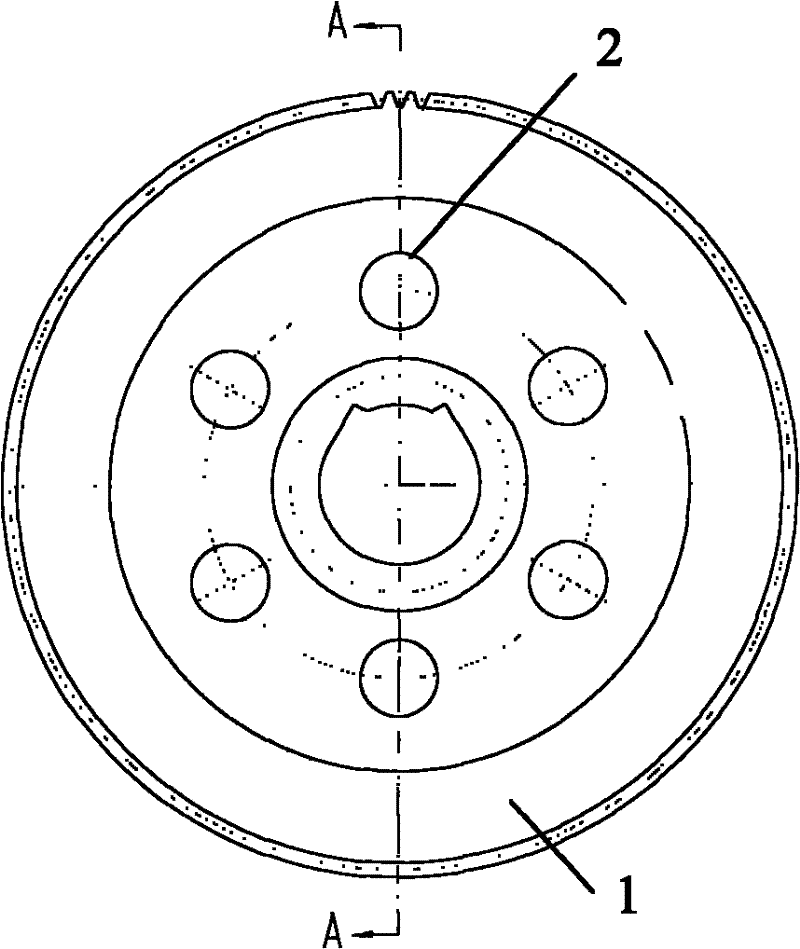

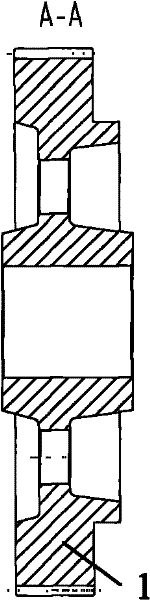

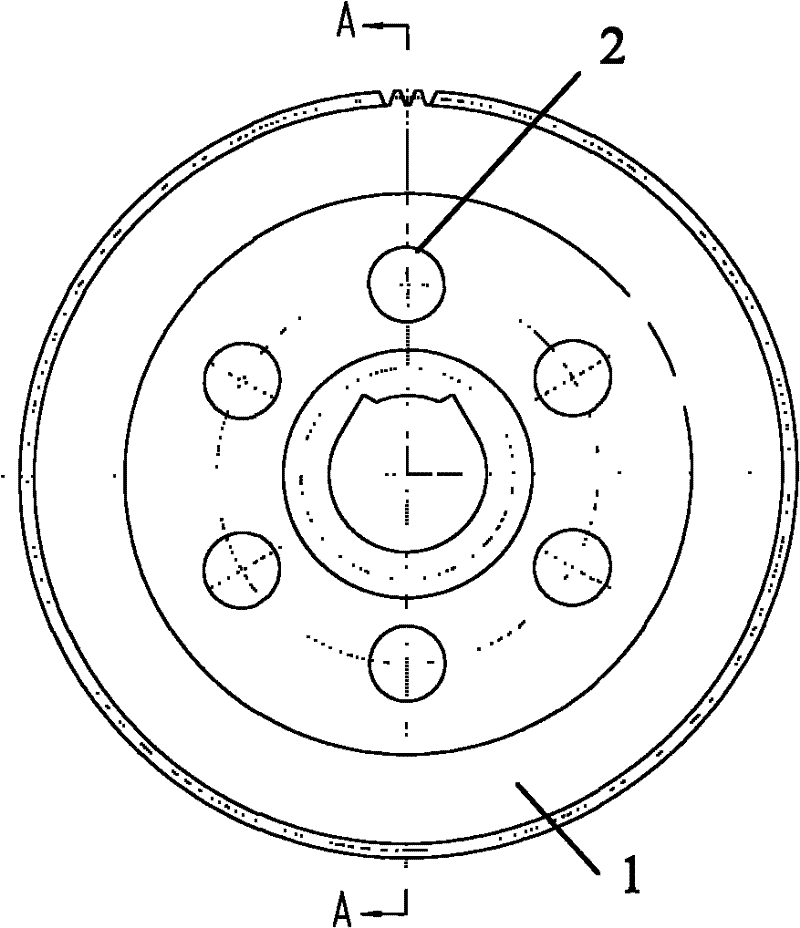

Method for rolling and shaping titanium alloy special-shaped ring forging

ActiveCN101279345AReduce manufacturing costHigh dimensional accuracyMetal rollingTitanium alloyAbnormal shaped

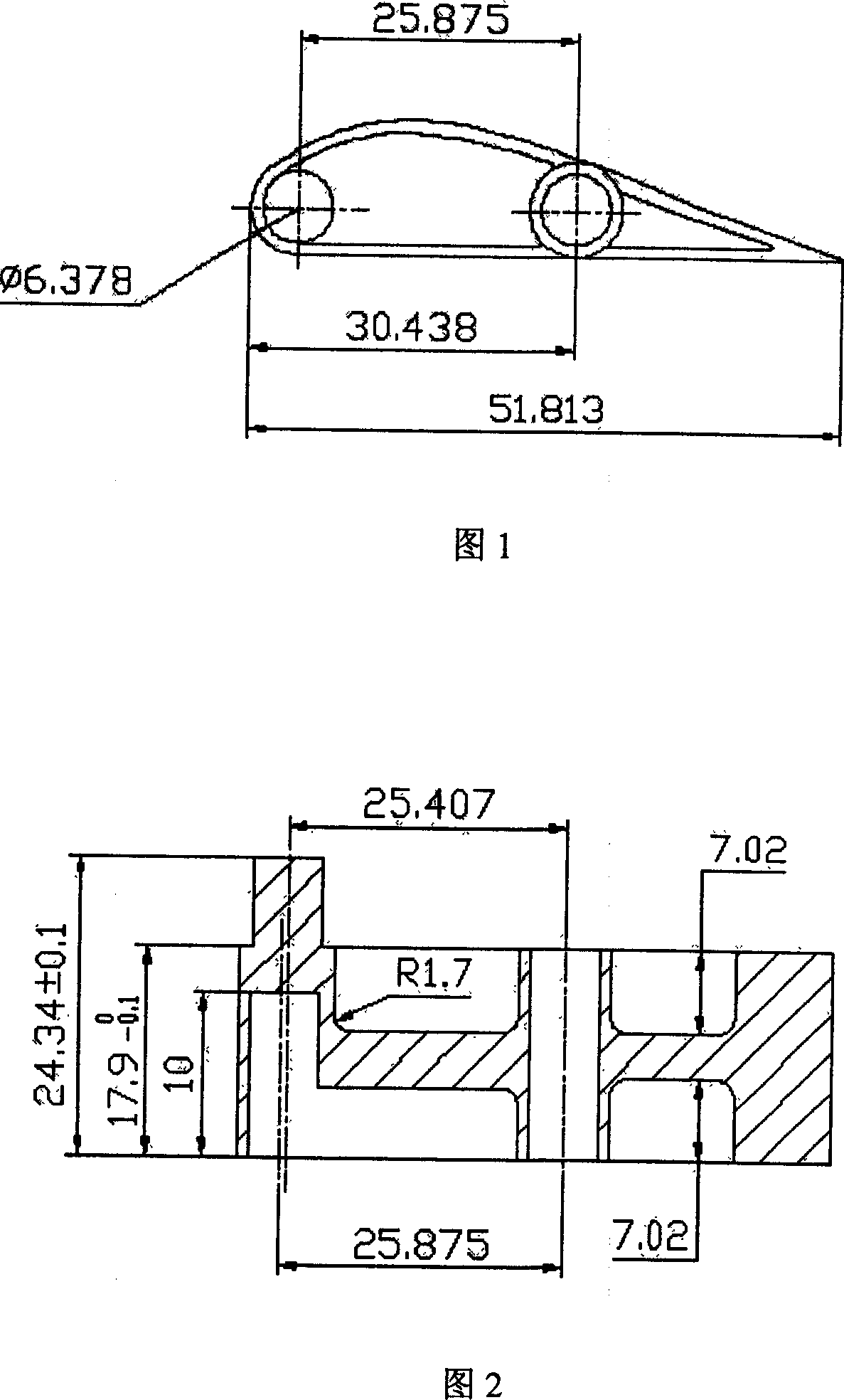

The invention discloses a rolling and shaping method for a titanium alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 65 to 70 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 25 to 30 percent; a rectangle pre-rolling blank is obtained after the rectangle ring blank is heated, rolled circularly and deformed by 25 to 30 percent again; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and becomes a heterotypic ring forging after being rolled and deformed by 40 to 45 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine or a gas turbine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

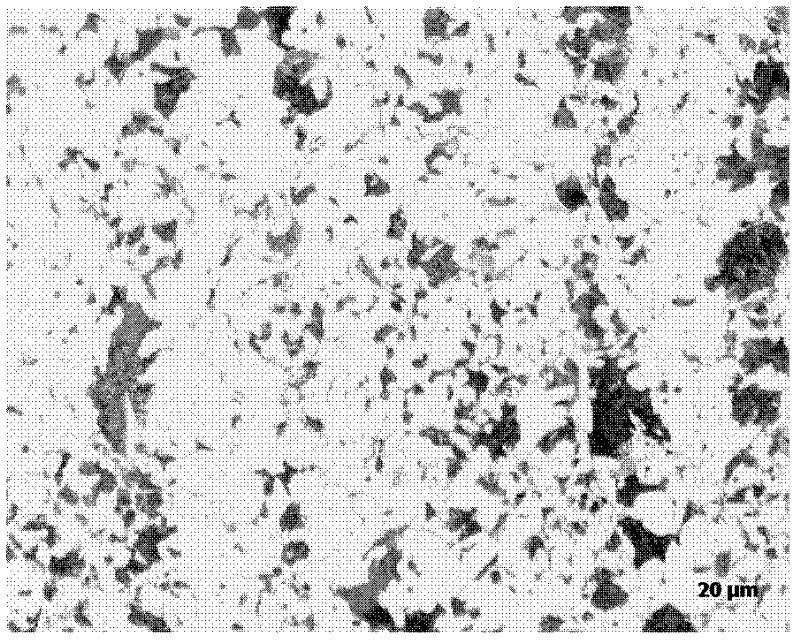

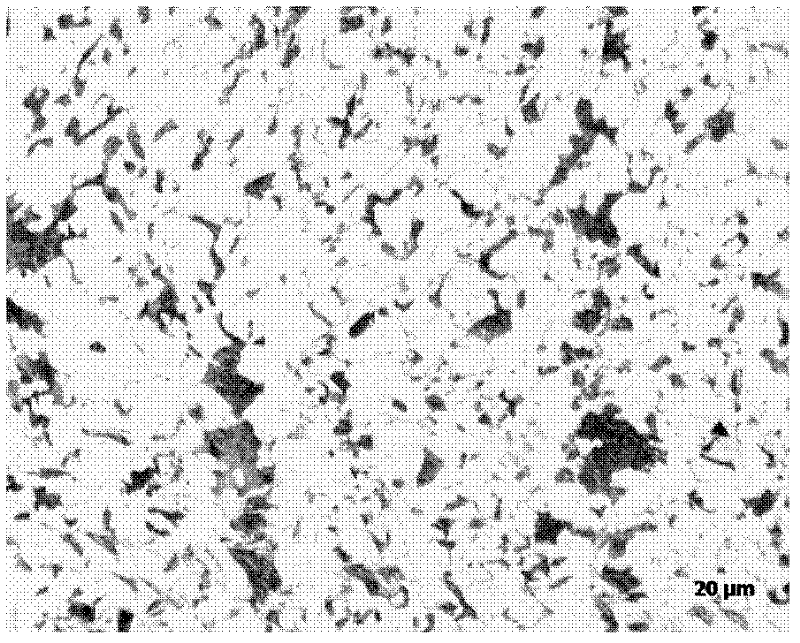

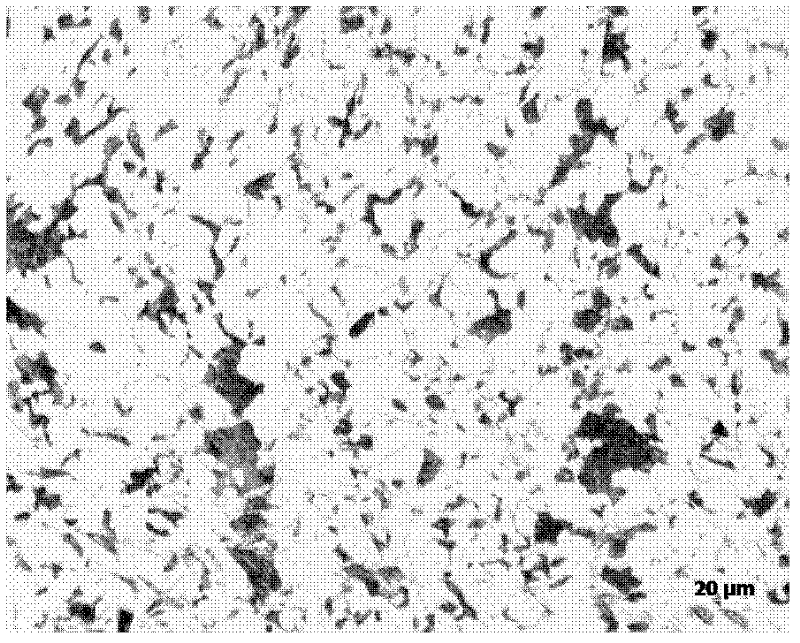

High boron wear-resisting casting steel and preparation process thereof

InactiveCN100999803ASufficient sourceReduce manufacturing costFurnace typesHeat treatment process controlFerromanganeseAluminium

The present invention discloses one kind of antiwear high-boron cast steel and its preparation process. The antiwear high-boron cast steel has the chemical components including C 0.10-0.50 wt%, B 0.8-5.0 wt%, Cu 0.3-0.6 wt%, Mn 0.8-2.0 wt%, Cr 1.0-2.5 wt%, Si less than 1.5 wt%, Ti 0.08-0.20 wt%, Ce 0.04-0.12 wt%, Mg 0.02-0.18 wt%, N 0.06-0.18 wt%, S less than 0.05 wt%, P less than 0.05 wt%, and Fe and inevitable impurity for the rest. Its preparation process includes smelting in an electric furnace while adding ferromanganese, frrroboron and Al to deoxidize, composite modification of molten steel, fast cooling, and low temperature tempering to eliminate stress. The present invention has simple production process, low production cost and other advantages.

Owner:XI AN JIAOTONG UNIV

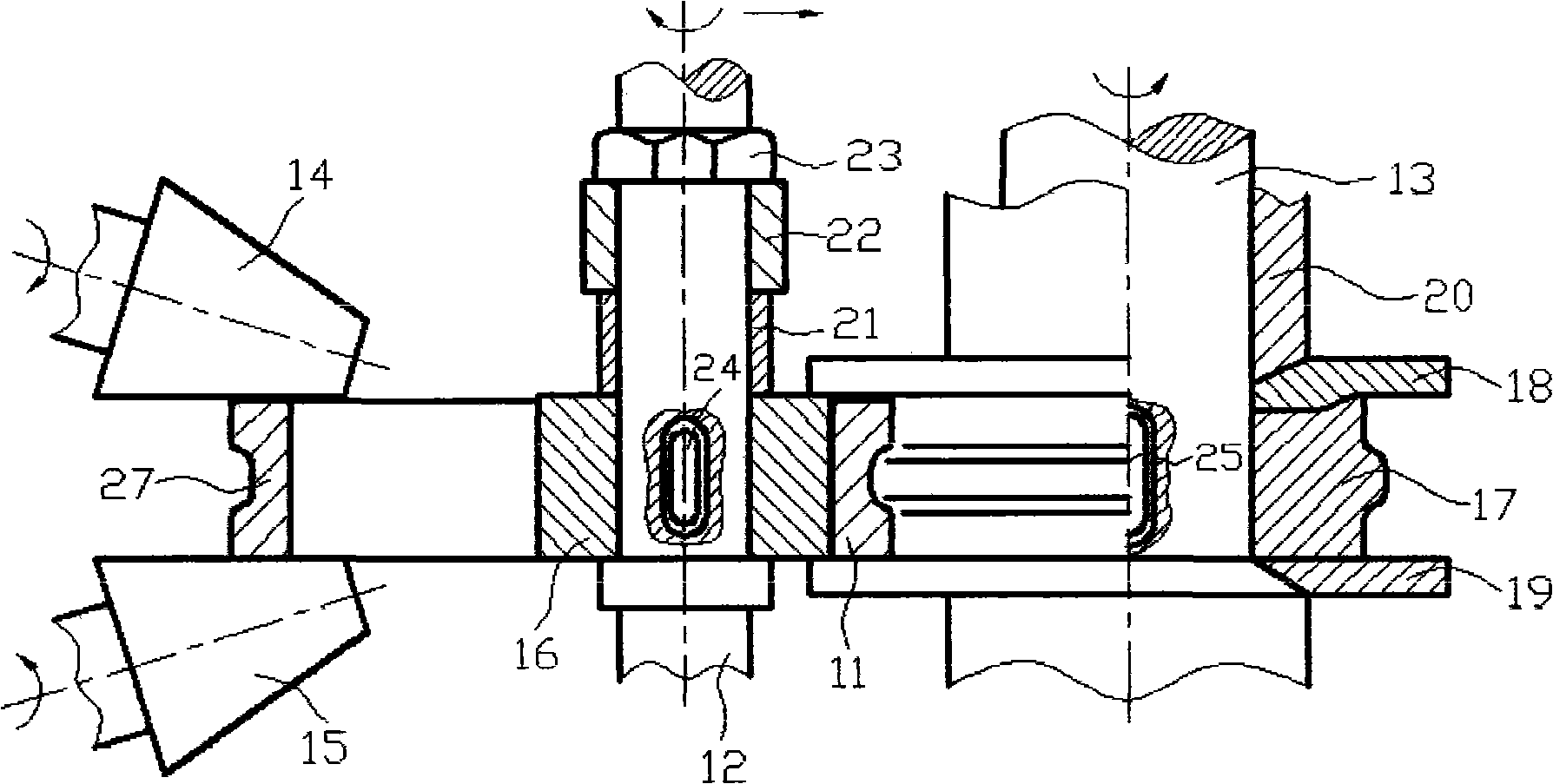

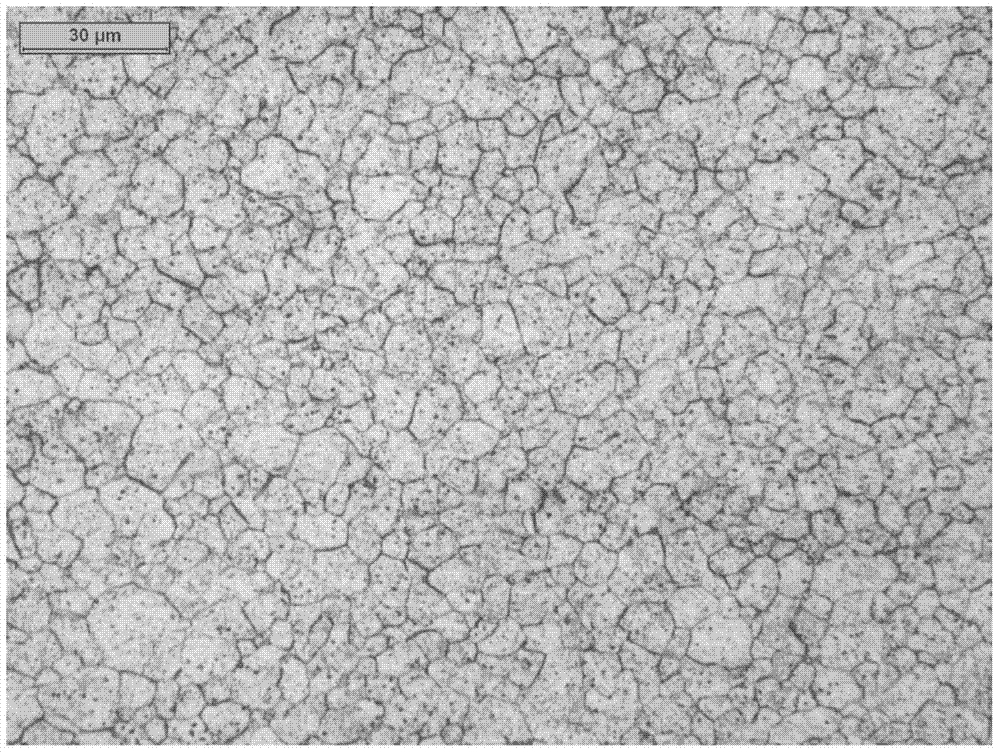

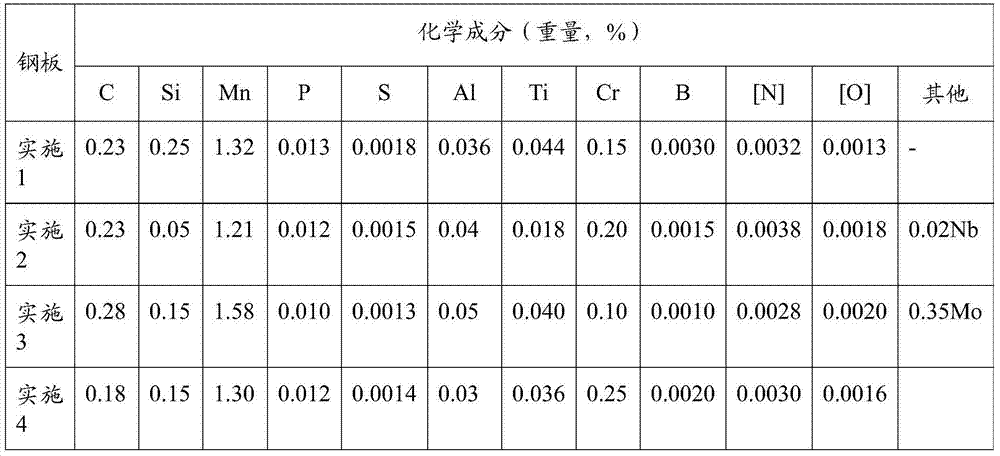

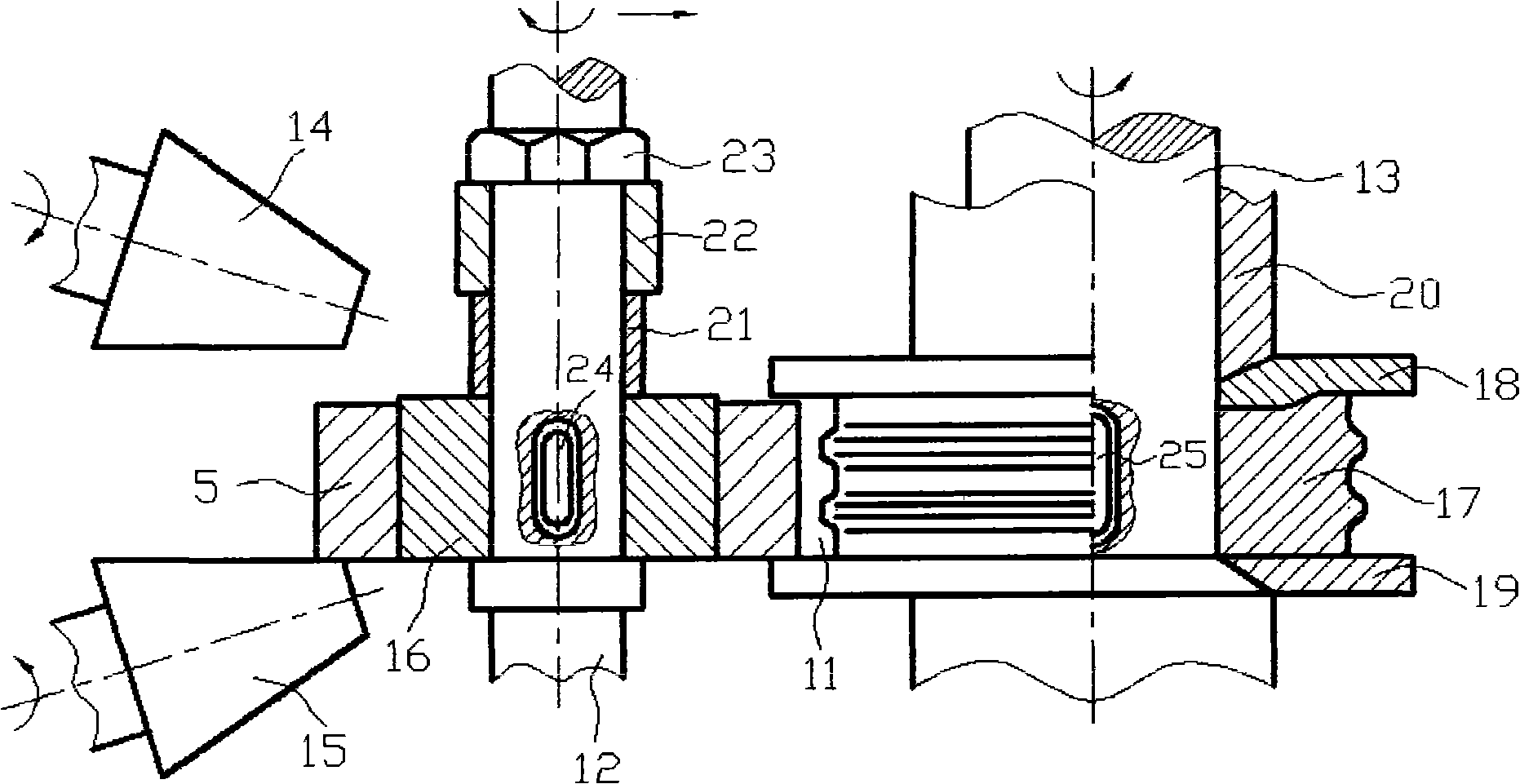

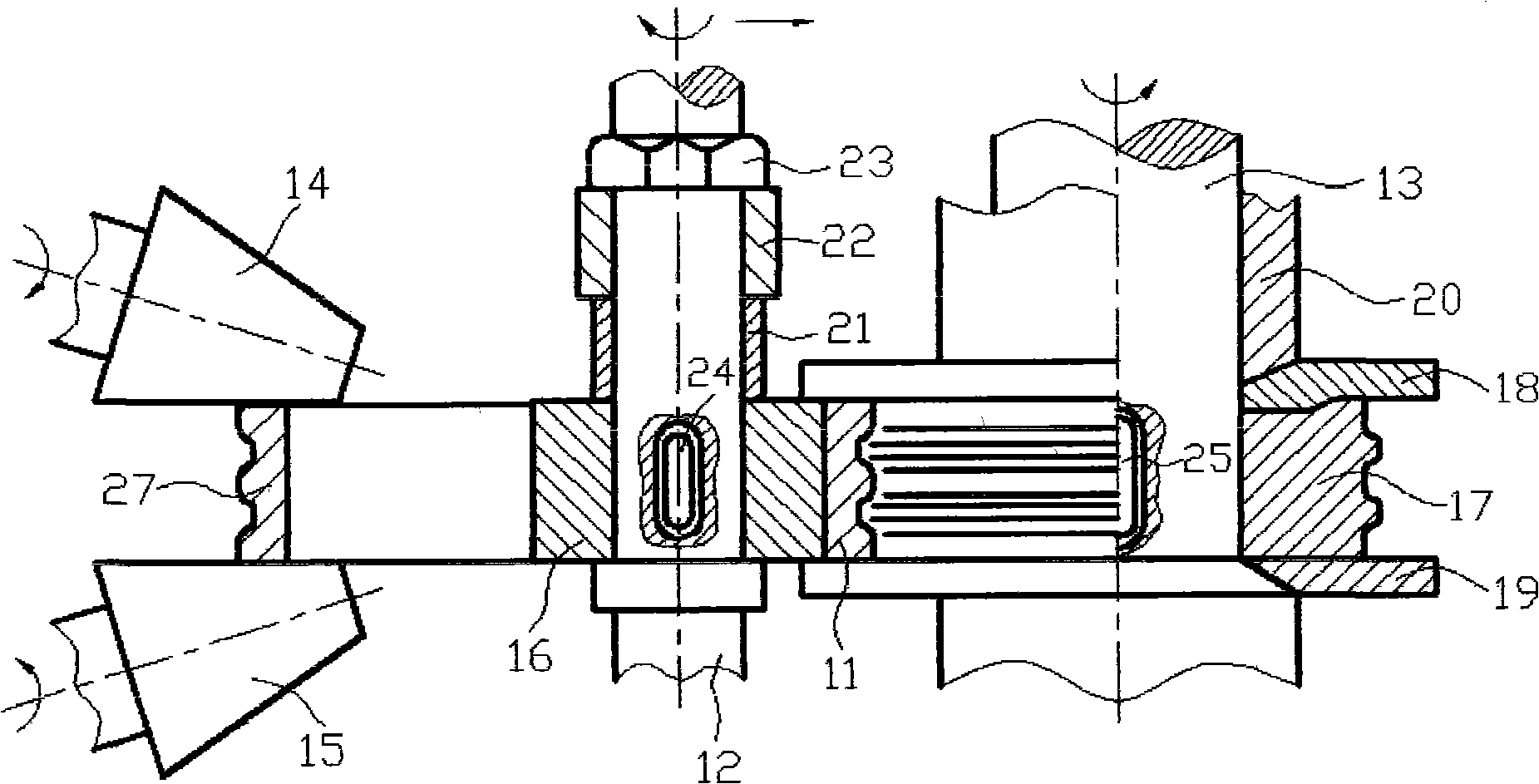

High-flexural-behavior hot-formed steel used for automobiles and manufacturing method thereof

The invention belongs to the technical field of steel rolling, and particularly relates to high-flexural-behavior hot-formed steel used for automobiles and a manufacturing method thereof. The steel comprises following trace elements by mass: 0.18-0.3% of C, not more than 0.3% of Si, 1-1.6% of Mn, not more than 0.015% of P, not more than 0.002% of S, 0.1-0.3% of Cr, 0.02-0.06% of Ti, 0.02-0.06% of Al, 0.0005-0.004% of B, not more than 0.004% of [N] and not more than 0.003% of [O]. The manufacturing method includes: heating a casting blank at a low temperature, performing controlled rolling in two stages, rapidly cooling, reeling up at a low temperature, preparing a steel coil by cold rolling and low-temperature critical annealing, shearing to prepare component tablets and performing hot press molding. By the manufacturing method, steel crystal grains are refined and ductility and toughness of the steel are enhanced, so that more energy is absorbed during deformation of the steel and automobile safety performance is enhanced.

Owner:SHOUGANG CORPORATION

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

Method for rolling and shaping aluminum alloy special-shaped ring forging

InactiveCN101279344AReduce manufacturing costHigh dimensional accuracyMetal rollingAbnormal shapedAero engine

The invention discloses a rolling and shaping method for an aluminum alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 50 to 55 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle pre-rolling blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 40 to 45 percent; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and forms a heterotypic ring forging after being rolled and deformed by 50 to 55 percent in a section groove. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 20000kg to 120000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

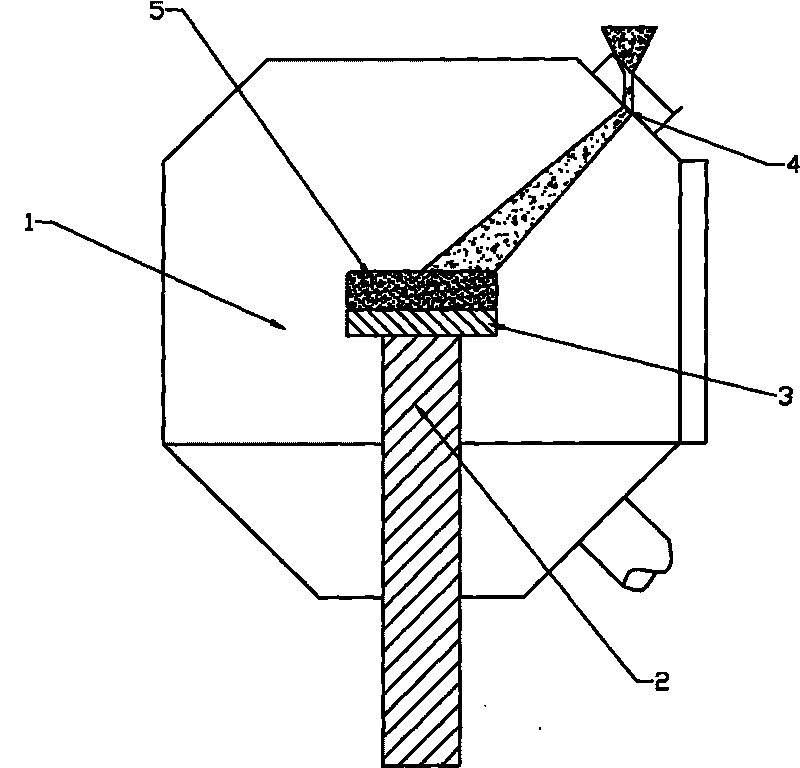

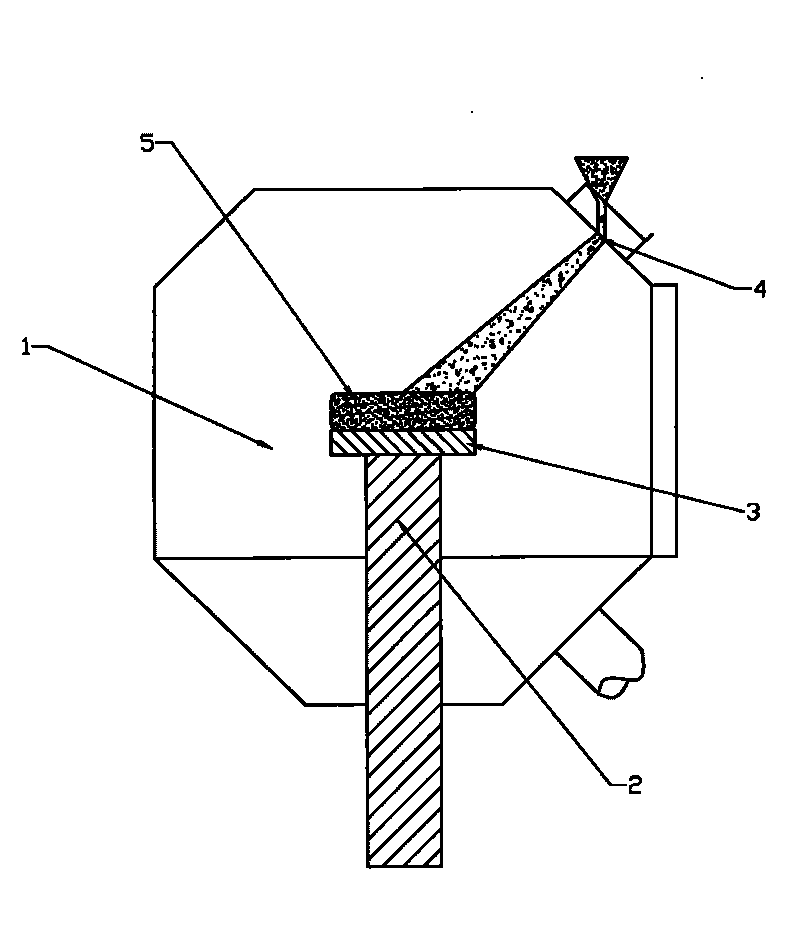

Method for manufacturing high-strength 7055 aluminum alloy forge piece formed by spraying

The invention belongs to a manufacturing technology of aluminum alloy and relates to a method for manufacturing a high-strength 7055 aluminum alloy forge piece formed by spraying. The method sequentially comprises the following steps: (a) melting components of 7055 alloy in an intermediate frequency furnace; (b) degassing, deslagging, refining and filtering an aluminum alloy fusant; (c) forming the filtered fusant by spraying to obtain a columnar aluminum alloy ingot blank; (e) carrying out hot extrusion on the aluminum alloy ingot blank formed by spraying; (f) constantly cutting the extrusion ingot as required and then carrying out free forging; (g) carrying out blocker-type forging and / or stamp forging on the blank after the free forging to obtain a stamp forging piece; and (h) carrying out T6 heat treatment on the stamp forging piece. A large-specification and high-property 7055 product can be obtained by using the method which is suitable for industrial production.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

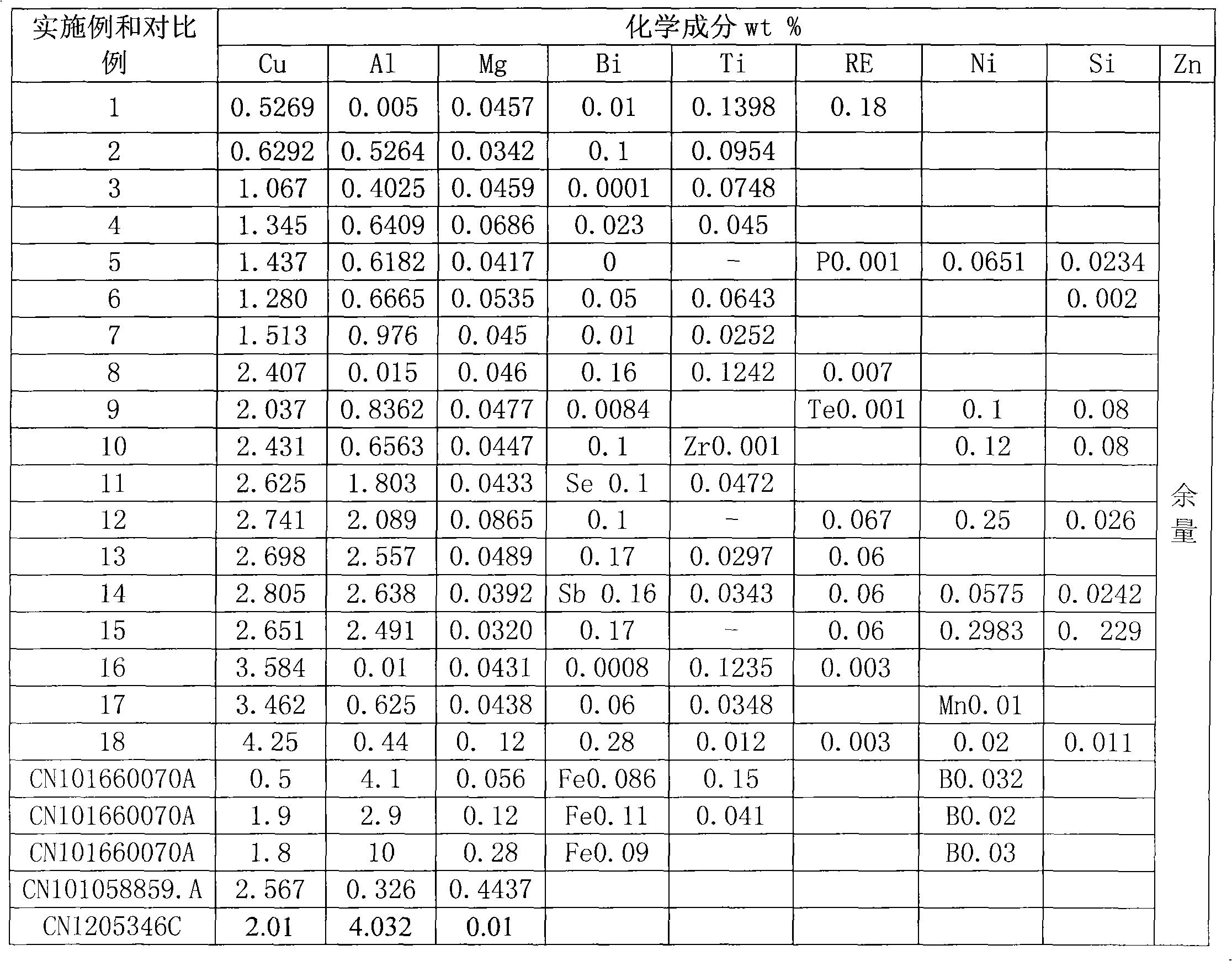

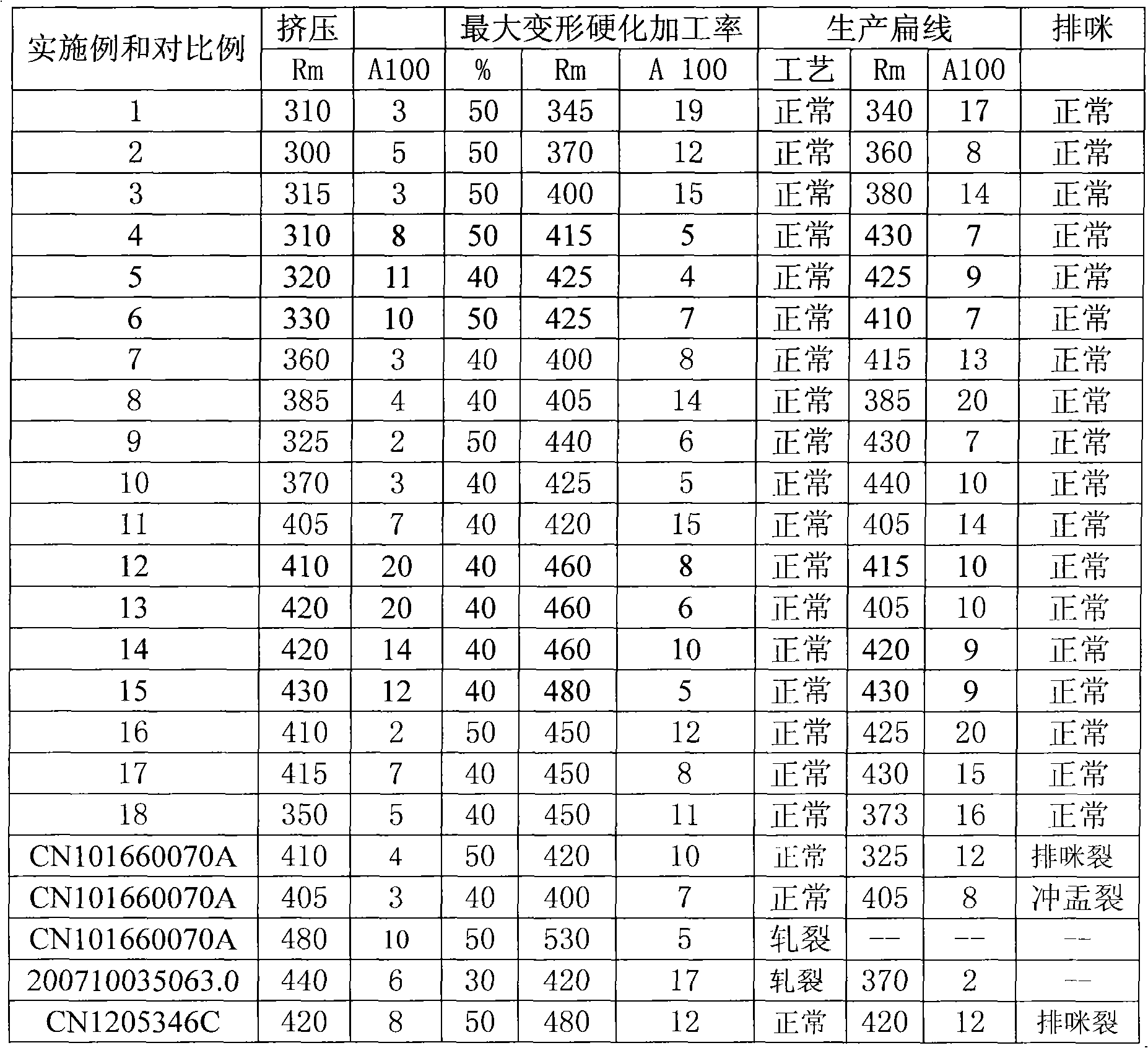

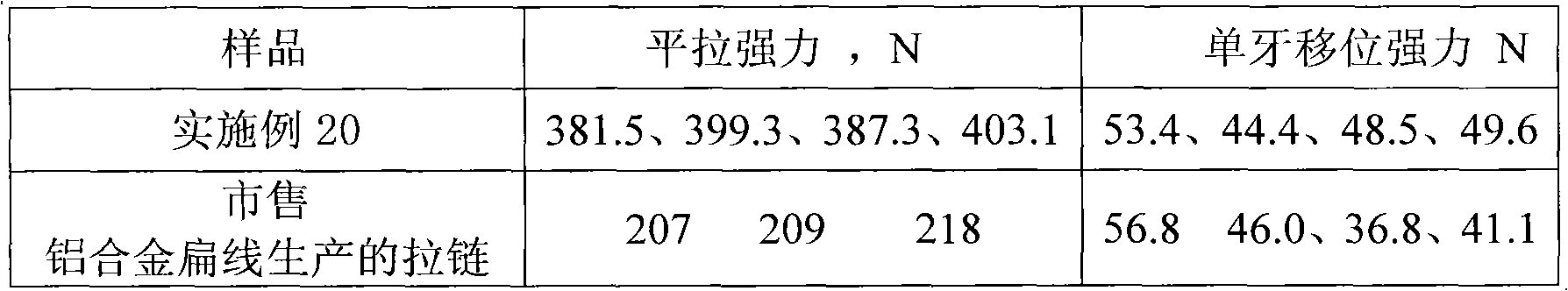

Zinc alloy for zipper tooth belt and preparation method of zipper tooth belt

ActiveCN102011029AOvercoming difficult deformationMeet the mechanical performance requirementsSlide fastenersZinc alloysImpurity

The invention discloses a zinc-alloy zipper tooth belt produced by a row microphone method, in particular to zinc alloy for a zipper tooth belt and a preparation method of the zipper tooth belt. The alloy comprises the following components by weight percent: 0.5-5% of Cu, 10-4.5% of Al, 0.01-0.2% of Mg and the balance of X, Y, Zn and unavoidable impurities, wherein the sum of the percentages of the components is 100%; the X is selected from at least one of 0.0001-0.5% of Bi, 0.01-0.19% of Ti, 0.001-0.3% of RE, 0.001-1% of Ni and 0.001-1% of Si; and Y is selected from at least one of Mn, Co, Nb, Zr, Cr, Ca, P, Sb, Te and Se. By adopting the deformed zinc alloy and the alloy producing method disclosed in the invention, the production of the zipper line can be met, and the zipper tooth belt can be produced smoothly by the row microphone method; and the produced zipper can be processed into different colors.

Owner:NINGBO POWERWAY ALLOY MATERIAL

High-speed steel roll ring and its production

A high-speed steel roller ring for rolling wire or rod material contains C, W, Mo, V, Cr, Al, Ni, Co, Nb, Ti, Ce, Na, Mg, Si, Mn, S, P and Fe proportionally. It is prepared through smelting in electric furnace, centrifugal casting, and annealing, high-temp quenching and tempering twice. Its advantages are high hardness, tension strength and toughness for breaking, smooth surface and high size stability.

Owner:XI AN JIAOTONG UNIV

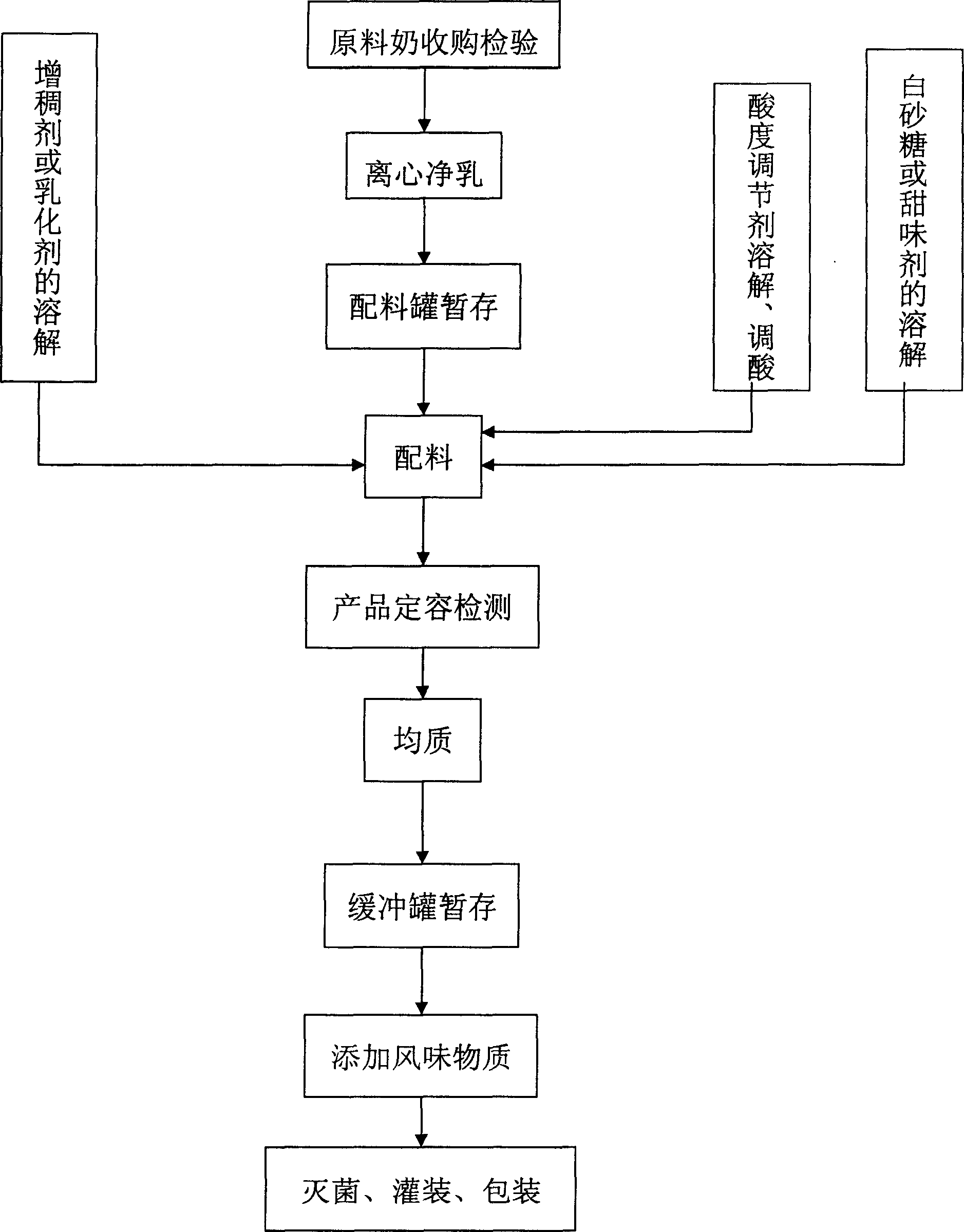

Milk containing jelly and method for its manufacture

InactiveCN1907094AReduce intensityHas a comprehensive nutritional effectMilk preparationFood preparationFlavoring essencesAdditive ingredient

The invention discloses a jelly and its preparing method, wherein each 100g of the jelly comprises the following constituents: milk 30-60g, sugar 6.0-12.0g, stabilizing agent 0.06-0.15g, acidness modifier 0.2-0.5g, edible flavoring essence 0.04-0.2g, and balancing water.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

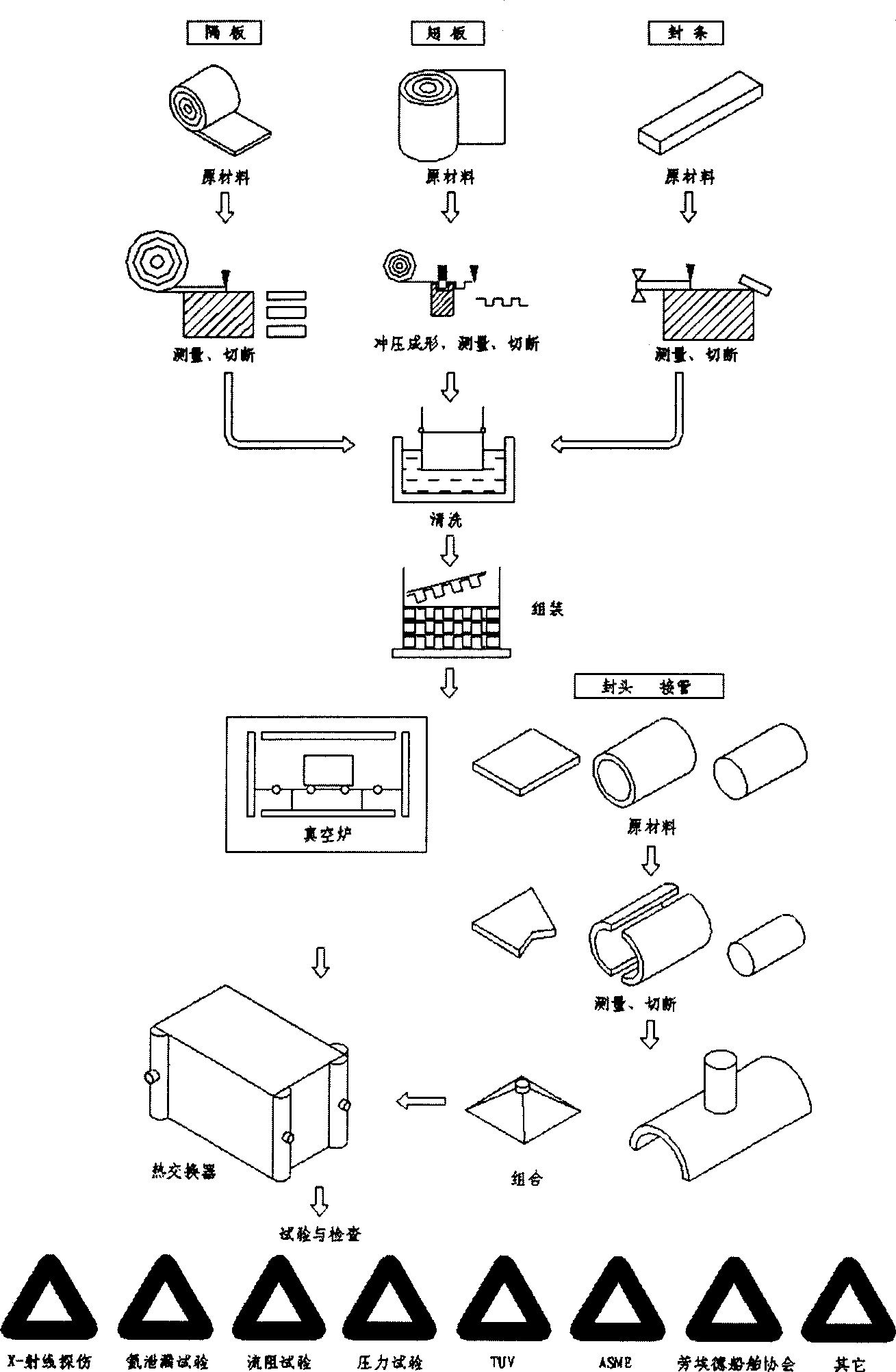

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1375374AImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weldscaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING UNIV OF TECH

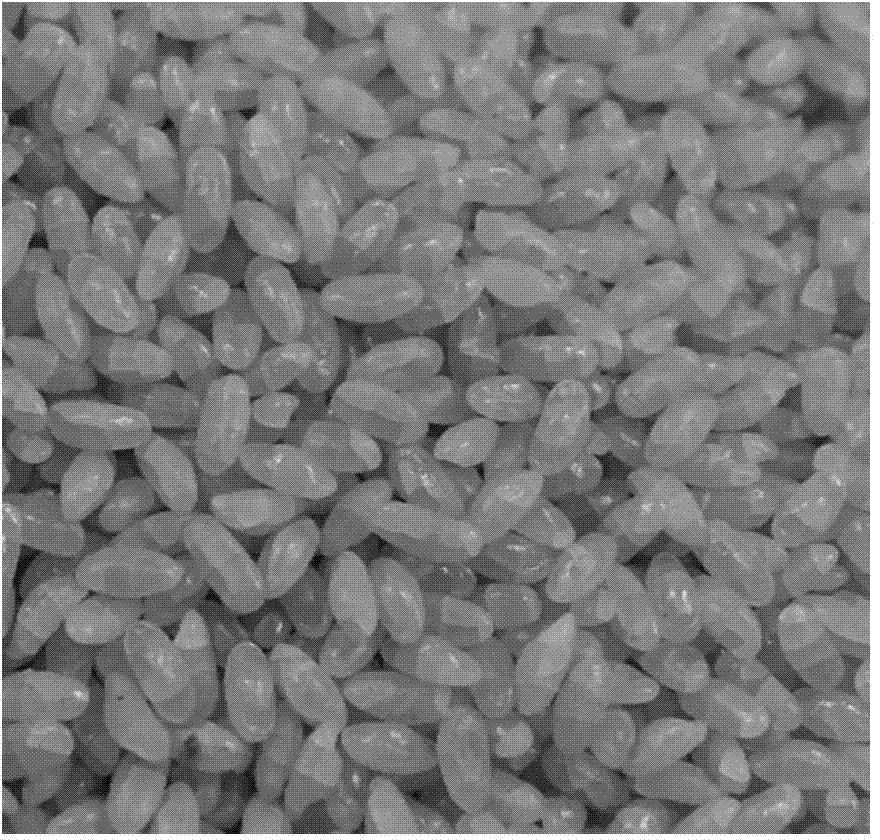

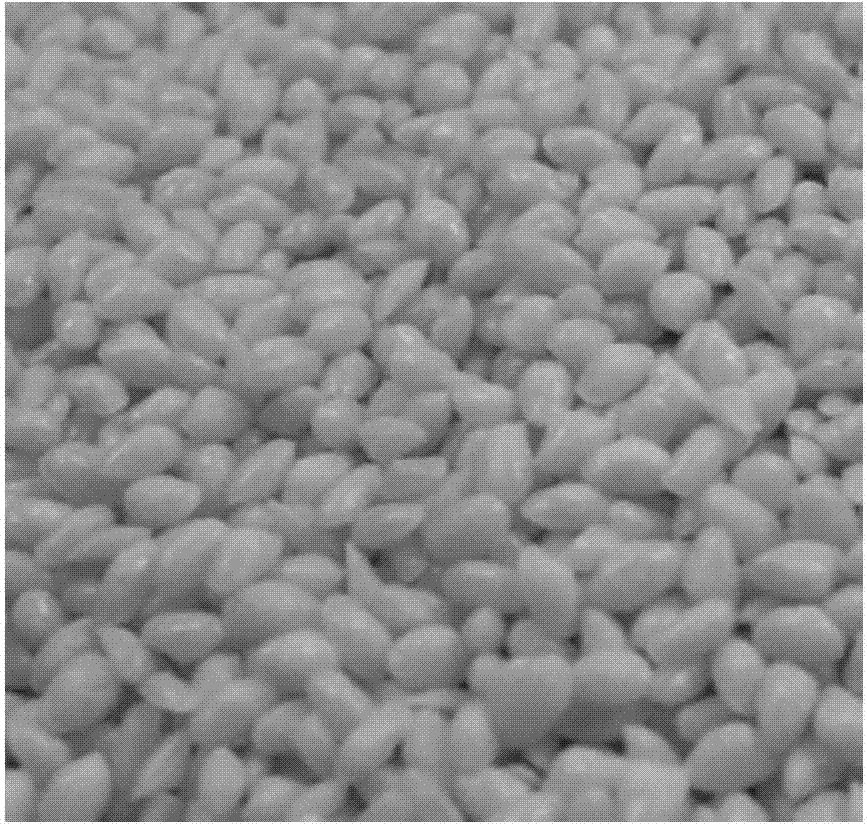

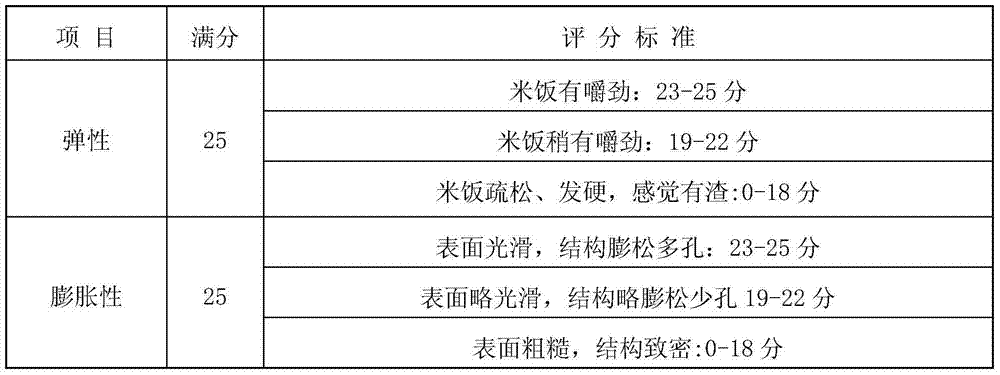

Coarse cereal instant rice and preparation method thereof

ActiveCN103564344ABlocking stickingPrevent too softFood ingredient functionsFood preparationPearl barleyGram

The invention discloses a coarse cereal instant rice and a preparation method of the coarse cereal instant rice. The coarse cereal instant rice is mainly prepared by conducting extrusion curing, cutting, pelletizing, drying, then baking and puffing on coarse cereal powder, starch and solid vegetable oil, wherein the coarse cereal is selected from one or combination of corn flour, rice flour, sorghum flour, buckwheat, pearl barley flour, black rice four, sweet potato flour, millet flour, coarse rice powder, glutinous rice flour, red rice flour, soybean flour, red bean flour, green gram starch, black bean flour, oat powder and wheat flour. The coarse cereal instant rice provided by the invention adopts a loose porous structure inside, so that the coarse cereal instant rice is good for digesting and absorbing and is excellent in rehydration property, the rehydration time is relatively short, the rehydrated rice is in full grain, and the coarse cereal instant rice is chewy and not hard or sticky when being eaten.

Owner:王金玺

Flying-shear main-transmission gearwheel steel and preparation method thereof

ActiveCN102162069AReduce the effect of heat treatment distortionOvercoming brittlenessGear grindingHobbing

The invention discloses a flying-shear main-transmission gearwheel steel and a preparation method thereof. The flying-shear main-transmission gearwheel steel comprises the following elements in percentage by mass: 0.10-0.20% of C, 2.00-3.00% of Cr, 2.50-3.50% of Ni, 0.4-1.00% of Mo, 0.10-0.40% of Si, 0.40-1.00% of Mn, at most 0.25% of Cu, at most 0.1% of Al, at most 0.020% of P, at most 0.015% ofS, at most 30ppm of O, at most 100ppm of N and at most 2ppm of H. The preparation method comprises the following steps: (1) smelting according to the percentage by mass to obtain a forging stock; (2)forging; (3) carrying out normalizing heat treatment; (4) carrying out gear hobbing; (5) carrying out surface carburization quenching heat treatment; and (6) carrying out gear grinding. The inventionenhances the bearing capacity and reliability of the gearwheel, and satisfies the production demands of high-carbon high-alloy steel and enhanced specifications, thereby having wide popularization and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

Composite roller for high vanadium high speed steel and its production process

The invention offers the high V super-speed steel complex roller and its producing craft. The roller includes roller heart and roller shell, the roller heart uses low metal alloy steel or middle carbon steel to produce, the shell uses high V super-speed steel, whose main element is : C: 1.8--3.5A%, V: 7--12%, Cr: 4--5%, Mo: 2--4%, Ni: 0.5--1.5%, other is Fe. The producing craft is: melt and cast the heart and shell by responding heat way. The roller in the invention has good whet feature, high rate of feature and price, using safely. Fine roller, high strength of combination, no crush in use; it can reduce the stop times. It efficiently increase the roller tenacity and whet feature, solve the problems in the heart leaving foundry, and solve the problems of complicated craft and high cost.

Owner:HENAN UNIV OF SCI & TECH +1

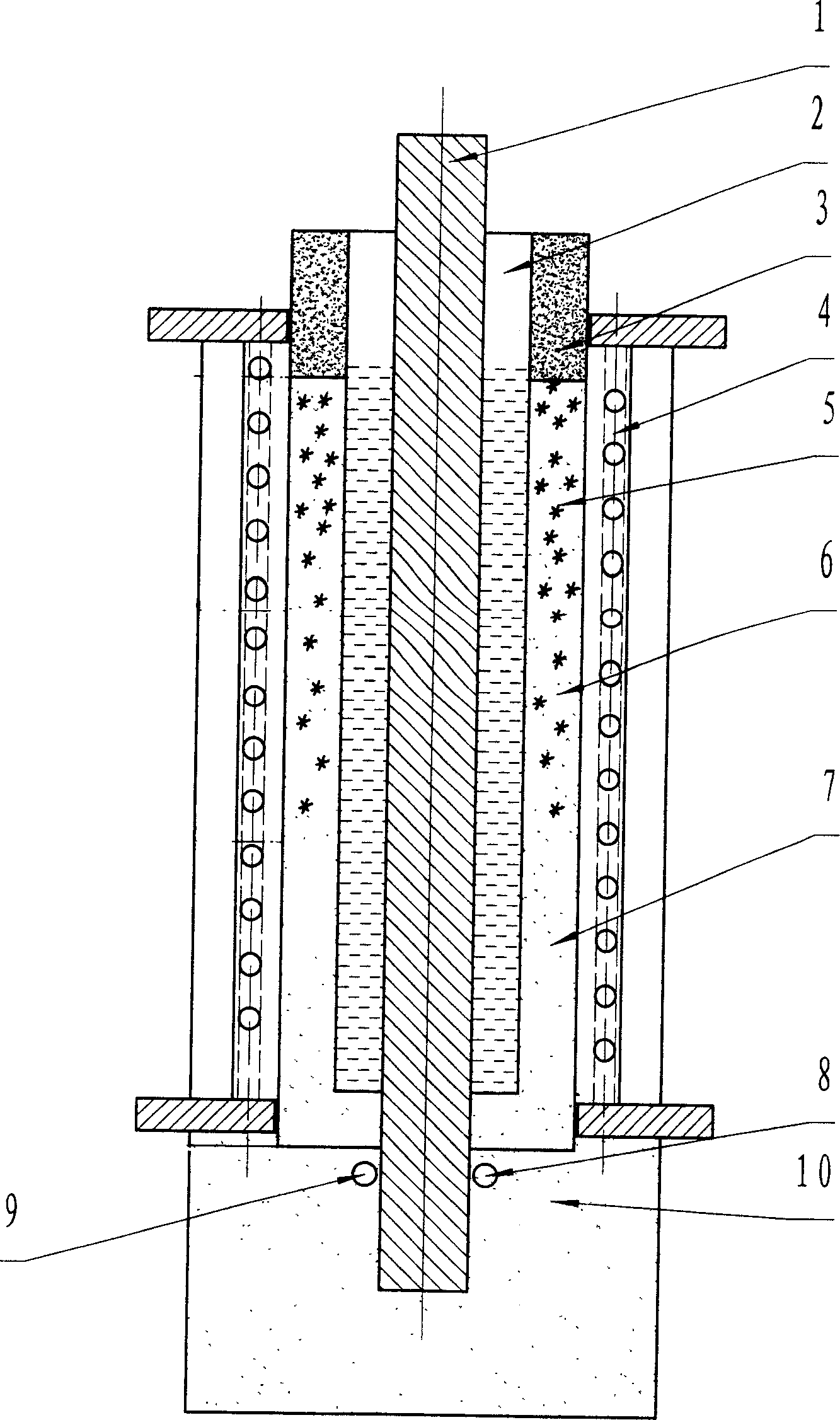

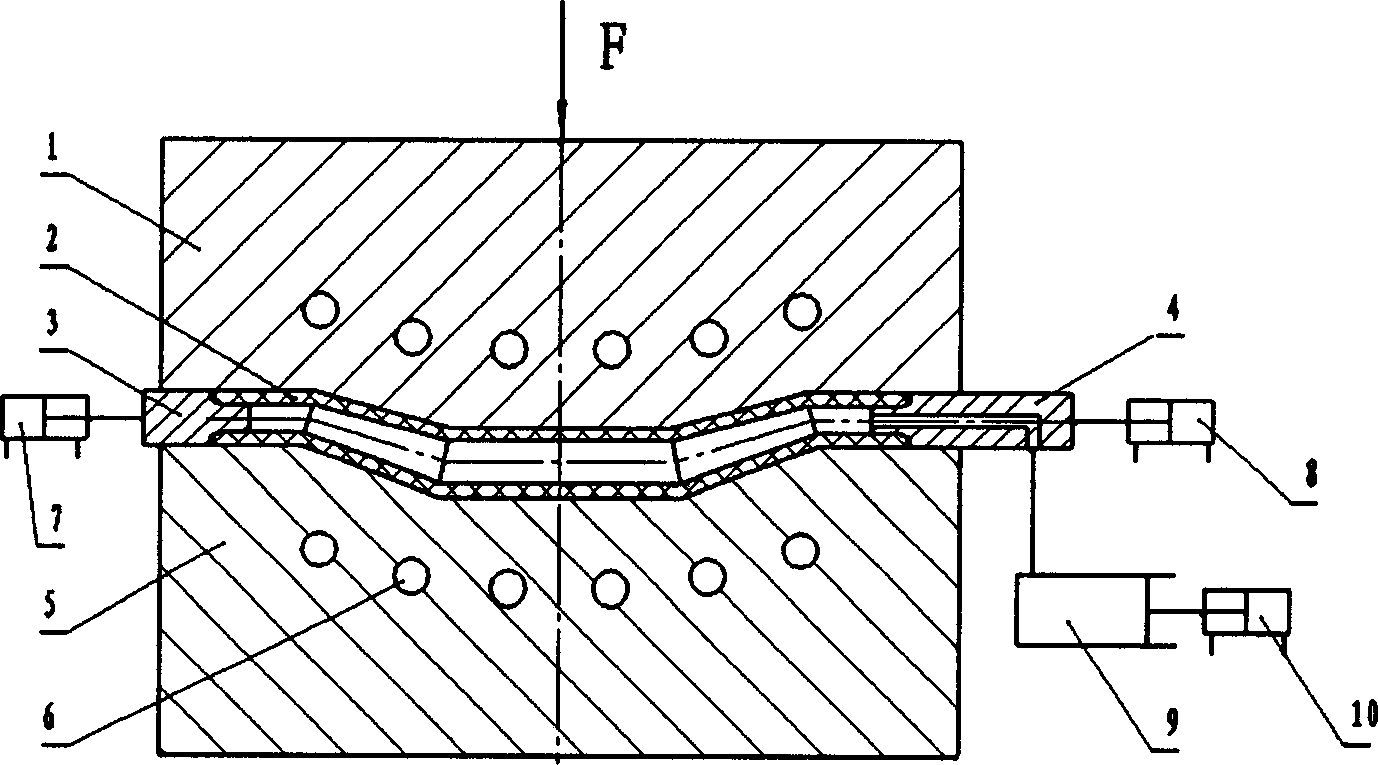

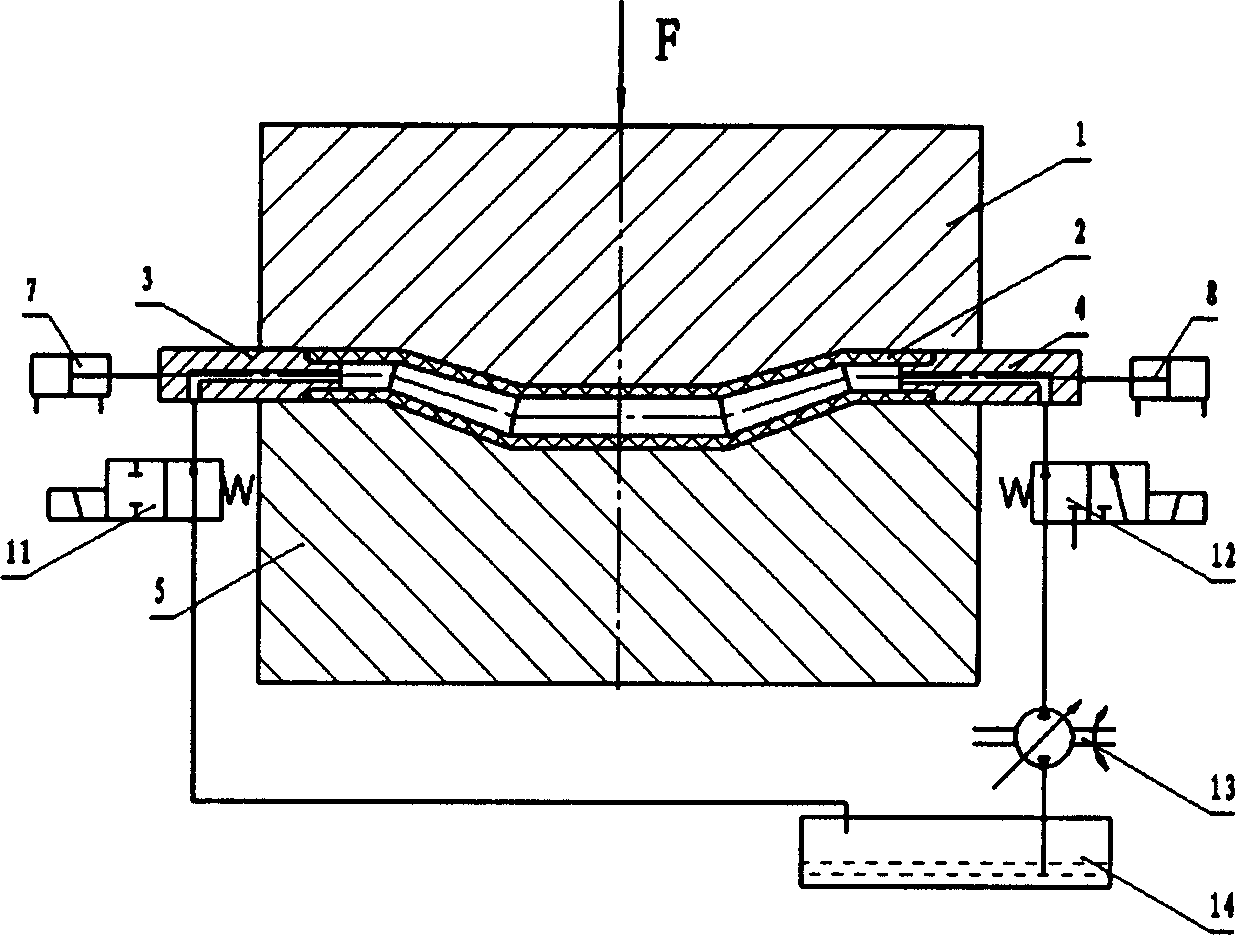

Method for forming magnesium alloy pipe fitting

InactiveCN1792493AMeet the requirements of superplastic formingHigh dimensional accuracyShaping toolsHydraulic cylinderPipe fitting

A method for shaping a Mg-alloy pipe includes such steps as putting a Mg-alloy pipe blank in a mould for generating superplastic bending, and introducing a pressure medium to the inside of said pipe blank for generating superplastic expansion to form a Mg-alloy pipe. Its apparatus is composed of mould consisting upper and lower moulds, sealing unit consisting of sealing block and two hydraulic cylinders, pressure medium source, and heating unit.

Owner:HENAN UNIV OF SCI & TECH

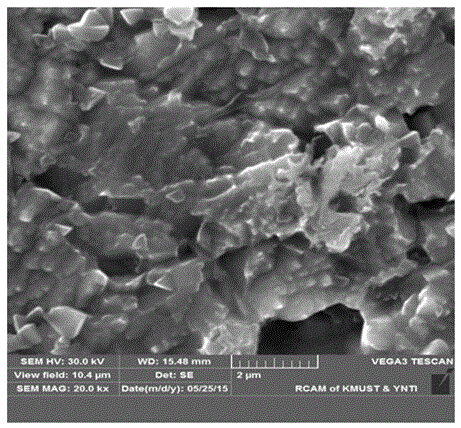

Method for preparing rare-earth oxide dispersion strengthened fine-grained tungsten material

ActiveCN105518169AGood compatibilityEvenly distributedTransportation and packagingMetal-working apparatusRare-earth elementTungstate

A method for preparing a rare-earth oxide dispersion strengthened fine-grained tungsten material, comprising: according to a condition that a mass percentage of rare-earth oxide is 0.1-2%, and the remaining composition is W, weighing soluble rare-earth salt and tungstic acid salt, and respectively preparing 50-100 g / L of rare-earth saline solution and 150-300 g / L of tungstic acid saline solution; adding a minor amount of alkali into the rare-earth salt to control the pH to be 7-8, adding an organic dispersing agent, and stirring to enable the rare-earth salt to form uniformly suspending R(OH)3 colloidal particles (R represents a rare-earth element); adding the tungstic acid saline solution into the R(OH)3 colloidal particles, adding a minor amount of acid to control the pH to be 6-7, adding the organic dispersing agent, stirring to enable the tungstic acid salt to form tungstic acid micro-particles, precipitating and coating the R(OH)3 colloidal particles with the R(OH)3 colloidal particles as a core, and forming coprecipitated coated colloidal particles; conducting spray drying on the coprecipitated coated colloidal particles to obtain a composite precursor powder of tungsten and rare-earth oxide; calcining, conducting thermal reduction via hydrogen, and preparing superfine nanometer tungsten powder having a particle size of 50-500 nm; and conducting normal high-temperature sintering after a general pressing forming. The high-performance fine-grained tungsten material dispersed and strengthened by a minor amount of rare-earth oxide prepared by the above method has a density approximate to full density (>=98.5%), and uniform and small tungsten grains having an average size of 5-10 [mu]m; in addition, rare-earth oxide particles having a particle size of 100 nm - 500 nm are uniformly distributed in a tungsten crystal or a crystal boundary.

Owner:长沙微纳坤宸新材料有限公司

Steel plate with thickness of 80mm and low compression ratio for ocean engineering and manufacturing method thereof

ActiveCN102392192ASuitable for productionWide applicabilityTemperature control deviceFurnace typesLaminar coolingCooling temperature

The invention relates to steel for ocean engineering and a manufacturing method thereof, in particular to a steel plate with a thickness of 80mm and a low compression ratio for ocean engineering and a manufacturing method thereof. The steel plate comprises the chemical components with the weight percentages as follows: 0.12 to 0.16 percent of C, 0.20 to 0.40 percent of Si, 1.20 to 1.60 percent ofMn, smaller than or equal to 0.010 percent of P, smaller than or equal to 0.003 percent of S, 0.025 to 0.050 percent of Nb, 0.030 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than or equal to 0.20 percent of Cr, 0.10 to 0.40 percent of Ni, smaller than or equal to 0.20 percent of Cu, smaller than or equal to 0.08 percent of Mo, 0.0250 to 0.050 percent of Al, smaller than or equal to 20ppm of O, smaller than or equal to 40ppm of N, smaller than or equal to 3ppm of H, and the remaining amount of Fe and inevitable impurities. A controlled rolling and cooling technology is adopted, the heating temperature before rolling is 1180 DEG C to 1250 DEG C, the rough rolling temperature is 1000 to 1100 DEG C, and the finish rolling starting temperature is 850 to 880 DEG C; laminar cooling is conducted after the rolling, the final cooling temperature is 640 to 680 DEG C, and the cooling rate is 5 to 15 DEG C / s; and normalizing treatment is conducted, the normalizing temperature is 890 to 910 DEG C, the heating rate is 1.4min / mm, and the heat preservation time is 50 to 90min. The obtained steel has the characteristics of high strength, good Z-direction lamellar tearing resistant performance, high plasticity, and the like.

Owner:NANJING IRON & STEEL CO LTD

Method for processing metastable beta-type titanium alloy plate

The invention relates to a method for processing a metastable beta-type titanium alloy plate and belongs to the technical field of titanium alloy processing. The invention aims to overcome defects in the prior art, provides technology for processing a Ti-15-3 alloy plate and improves the cold working performance of alloy. The method for processing the metastable beta-type titanium alloy plate comprises the following steps of: smelting the titanium alloy plate into an ingot, charging at the temperature of between 800 and 850 DEG C and keeping the temperature for 100 to 150 minutes, raising the temperature to between 1,100 and 1,150 DEG C and keeping the temperature for 240 to 360 minutes, and finishing the first fire by repeatedly upsetting and drawing; drawing unidirectionally until cogging is finished so as to obtain a blank; sawing and rolling the plate blank into a hot-rolled plate blank with the thickness of 4 to 10 mm at the temperature of between 850 and 1,000 DEG C; and cold rolling to obtain a plate with the thickness of 1 to 3 mm after annealing and alkaline and acid washing. By controlling the rolling temperature, the deformation degree and the cooling speed after deformation, the method controls the structure of a forging stock to fully break the forging stock, and effectively suppresses phase precipitation resulting in a brittle alloy. Therefore, the cold working plasticity and cold working performance are improved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Thermal treatment method for super-thick steel plate

The invention provides a thermal treatment method for a super-thick steel plate. The thermal treatment method for the super-thick steel plate provided by the invention comprises the following steps of: performing shot blasting on the steel plate; placing the steel plate after shot blasting in a heating furnace to heat, wherein the heating temperature is controlled at 900-920 DEG C, and insulating for 20-30minutes after the steel plate reaches a predetermined temperature; quenching and cooling the heated steel plate, wherein the steel plate passes through a high pressure section and a low pressure section of a quencher sequentially; then, water-cooling to room temperature, wherein the steel plate out of the heating furnace passes through the high pressure section of the quencher quickly, and the operating speed of the steel plate in the high pressure section is 2.0-3.0m / min. The method provided by the invention has the characteristics of simple process and good quenching effect, and the problem that the super-thick steel plate which is thicker than 100mm is 'incompletely' quenched is solved.

Owner:LAIWU IRON & STEEL GRP

Method for preparing blades of adjustable nozzle in use for turbocharger of engine by using powder as raw material

A process for preparing the blades of adjustable nozzle for the turbine booster of engine from raw powder includes proportionally mixing a chosen alloy pwoder with the adhesive prepared from paraffin wax, high-density polyethene, stearic acid and polypropene, pugging, injection molding at 150-175 deg.C under 75-125 MPa, degreasing and sintering.

Owner:UNIV OF SCI & TECH BEIJING

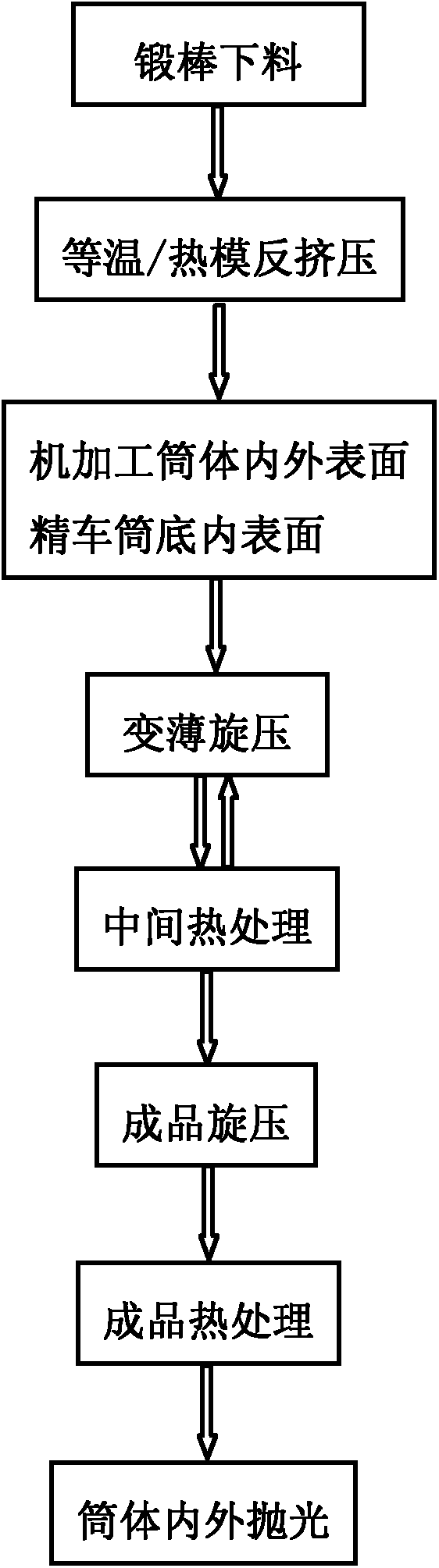

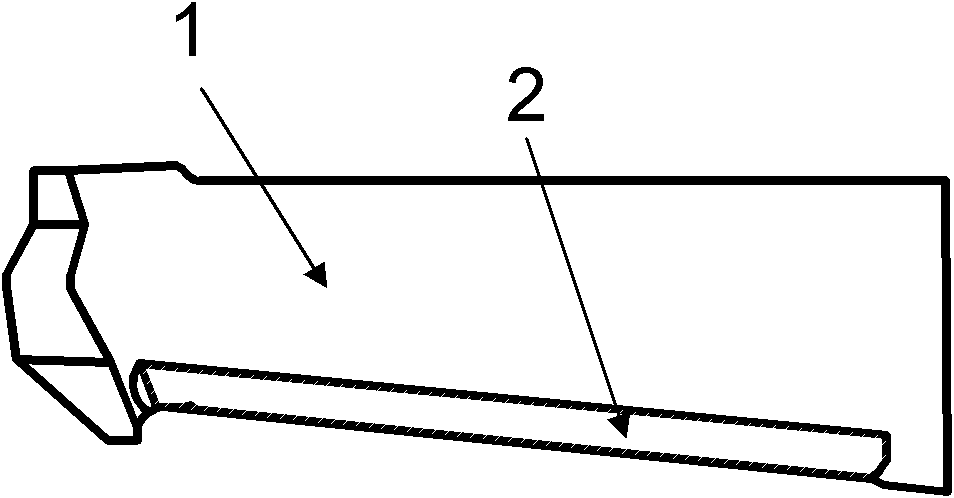

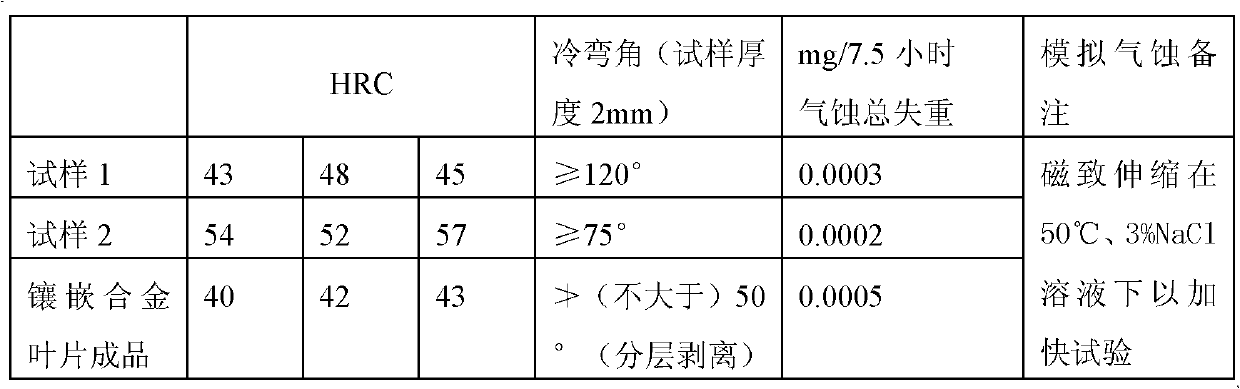

Machining method of high-quality large-diameter thin-wall metal barrel body

The invention relates to a machining method of a high-quality large-diameter thin-wall barrel body. The machining method comprises the following steps. Firstly, isothermy or hot die anti-extrusion technology is utilized, and anti-extrusion is performed on an alloy forging rod. Secondly, machining is performed on the inner and outer surfaces of a spinning barrel billet, and finish turning is performed on the inner surface of the barrel bottom of the barrel billet. Thirdly, multi-pass brute force thinning spinning is performed on the machined spinning barrel billet, and the spinning is hot spinning or cold spinning. Fourthly, intermediate heat treatment is performed on a spinning semi-finished product, and the intermediate heat treatment is annealing or solution treatment. Fifthly, the third step and the fourth step are performed repeatedly and alternatively so that finished product spinning is performed. Sixthly, scouring and cleaning are performed on the barrel body, and finished product heat treatment is performed. Seventhly, polishing of the inner and outer surfaces of the barrel body after heat treatment in the sixth step is performed, and a finished product barrel body is obtained. By adoption of the machining method of the high-quality large-diameter thin-wall barrel body to machine a large-diameter thin-wall metal barrel body without welding lines, organization is even and fine, comprehensive performance is high, the process is short, product additional values are high, and good application and popularizing prospects and certain economic and social benefits are achieved.

Owner:有研金属复材技术有限公司

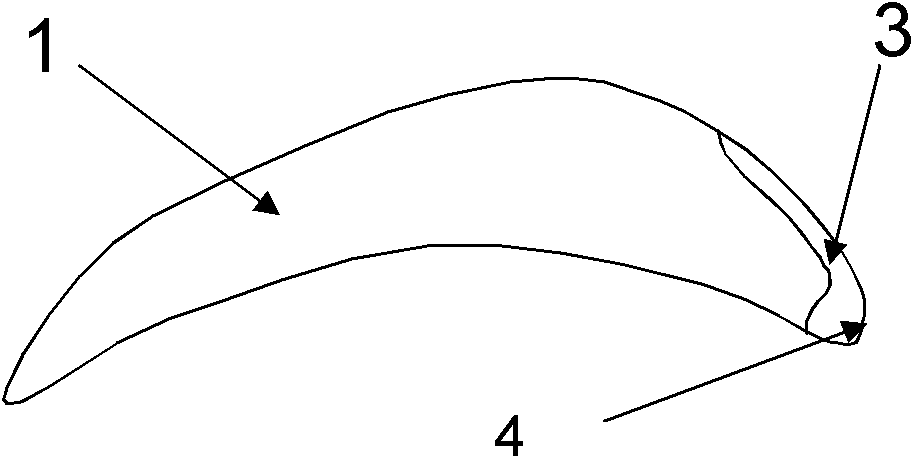

Laser cladding technological method and alloy material for laser cladding

ActiveCN102168210AUniform tissueSmall tissueMetallic material coating processesLaser beam welding apparatusCavitationSlag

The invention discloses an alloy material for laser cladding. The alloy material is alloy powder and contains the following components in percent by weight: C: 0.85-0.98%, Cr: 35-45%, Fe: 3-5%, Si: 0.5-1.0%, W: 3.5-5.5%, Mo: 1 .0-1.5%, Ni: 6-8%, V: 1.5-2.0%, Ti: 1.0-2.0%, B: 0.5-1.5%, Nb: 0.10-0.50%, Re: 0.5-1.5%, and Co: the balance. The invention also discloses a laser cladding technological method adopting the alloy material. In the technical scheme, under the combined action of the added alloy elements, cladding layer tissue is uniform and tiny and has no pore, no inclusion and no included slag; and preheating is not needed when a blade is cladded and crack does not emerge. The alloy material has high rigidity and excellent cavitation resistance; without follow-up heating treatment, a cladded part can be directly fine machined to use; and the laser treatment technology has good adaptivity and is simple and feasible in operation.

Owner:HANGZHOU BOHUA LASER TECH

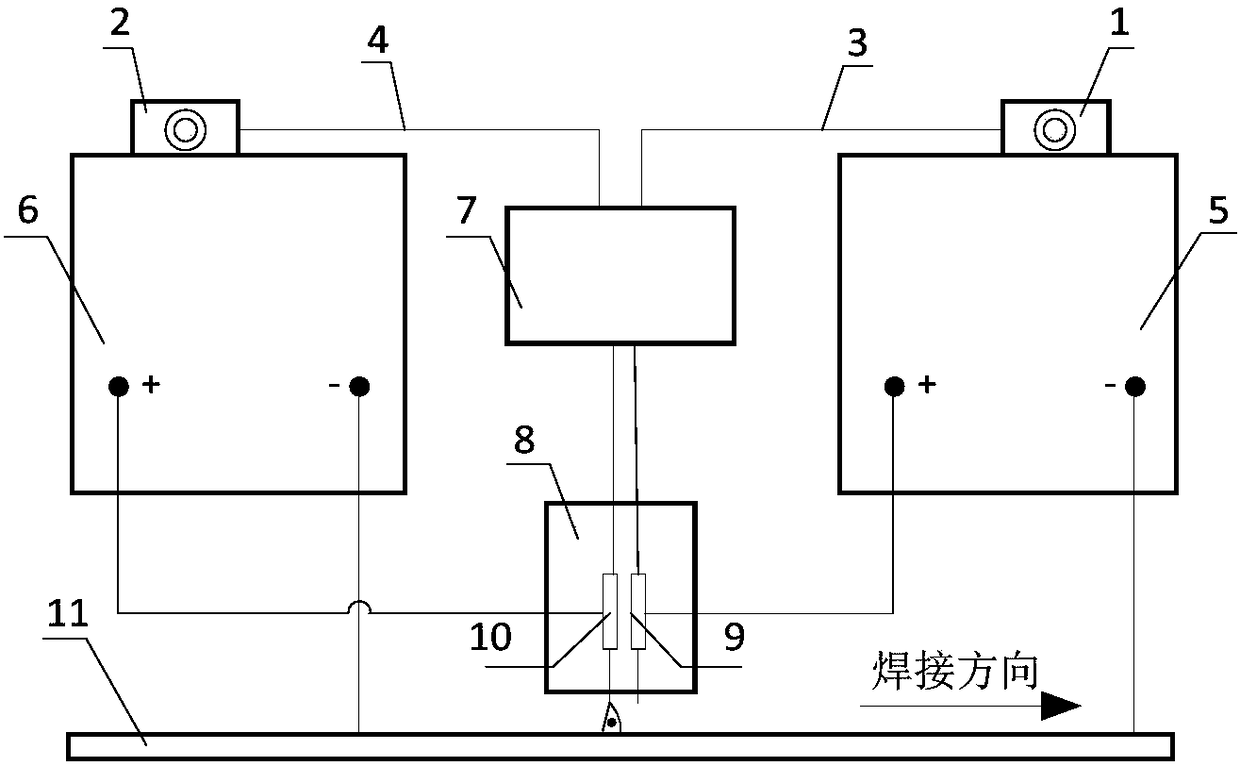

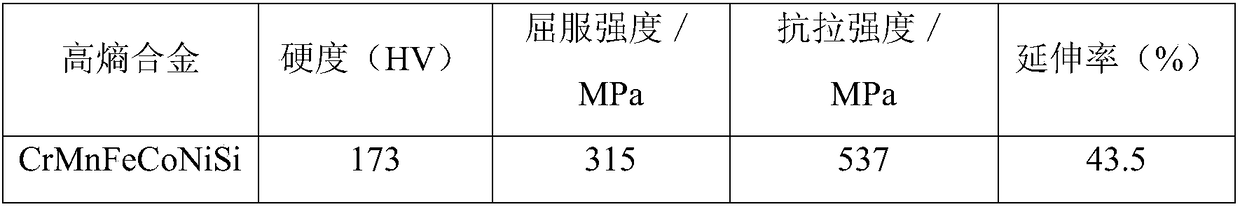

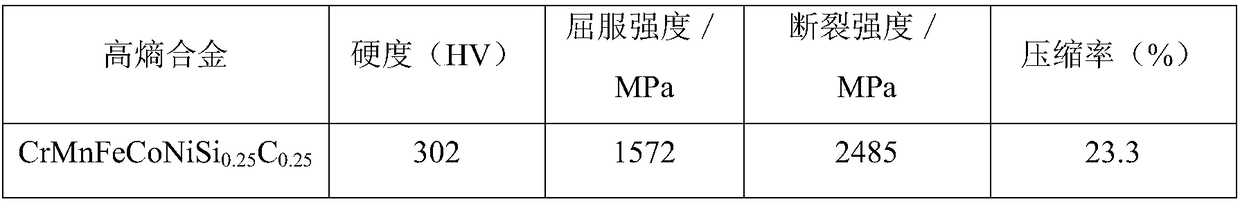

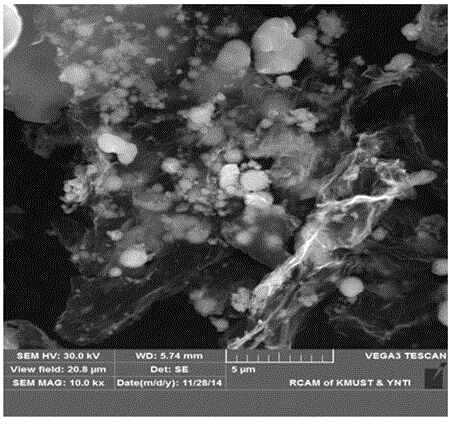

Double-arc fuse collaborative additive manufacturing method of high-entropy alloy

ActiveCN108326427AEasy to adjust ingredientsEasy to adjust grain sizeAdditive manufacturing apparatusLaser beam welding apparatusManufacturing technologyHigh entropy alloys

The invention relates to the technical field of high-entropy alloys, and specifically discloses a double-arc fuse collaborative additive manufacturing method of a high-entropy alloy. The method is characterized in that raw materials are supplied based on a formula of the high-entropy alloy, wherein the raw materials include an alloy strip and flux core powder; the alloy strip and the flux core powder are prepared into a flux cored welding wire; and then a double-arc fuse collaborative additive manufacturing method is carried out to obtain a part or a blocky alloy as requirement. The method isstable in processes, high in cladding efficiency, high in preparation efficiency, wide in heat input adjusting range, low in cost, convenient to adjust the components of the alloy and the size of crystal grains; in addition, the method is applicable to manufacturing of massive high-entropy alloys as well as precise high-entropy alloy parts.

Owner:SHIJIAZHUANG TIEDAO UNIV

Method for preparing aluminum foil for lithium battery

ActiveCN105063429AImprove performanceUniform compositionMetal rolling arrangementsFiltrationAluminum foil

The invention relates to a method for preparing an aluminum foil for a lithium battery and belongs to the technical field of machining of aluminum alloy materials. The method for preparing the aluminum foil for the lithium battery includes the steps of performing smelting and cast rolling processes: heating and smelting raw materials of the aluminum foil for the lithium battery to form an aluminum alloy melt, sequentially carrying out refining slagging-off, grain refining, degassing deslagging and filtration treatment and subjecting the filtered aluminum alloy melt to continuous cast rolling to form a blank; performing a cold rolling process: subjecting the blank to cold rolling firstly and then to primary annealing treatment, rough rolling and secondary annealing treatment; performing foil pressing treatment: carrying out finish rolling on the annealed aluminum foil, and finally slitting the foil to obtain the aluminum foil finished product for a lithium battery finished product. According to the method for preparing the aluminum foil for the lithium battery, composition segregation in the process of alloy cast rolling is improved through added uniform annealing treatment; an original cast rolling structure is improved so that the product with uniform constituents and structure and stable performances can be obtained; moreover, the performances of the aluminum foil for the lithium battery can be improved.

Owner:浙江中金铝业有限公司

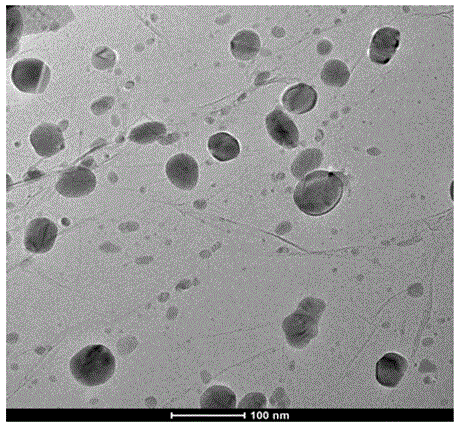

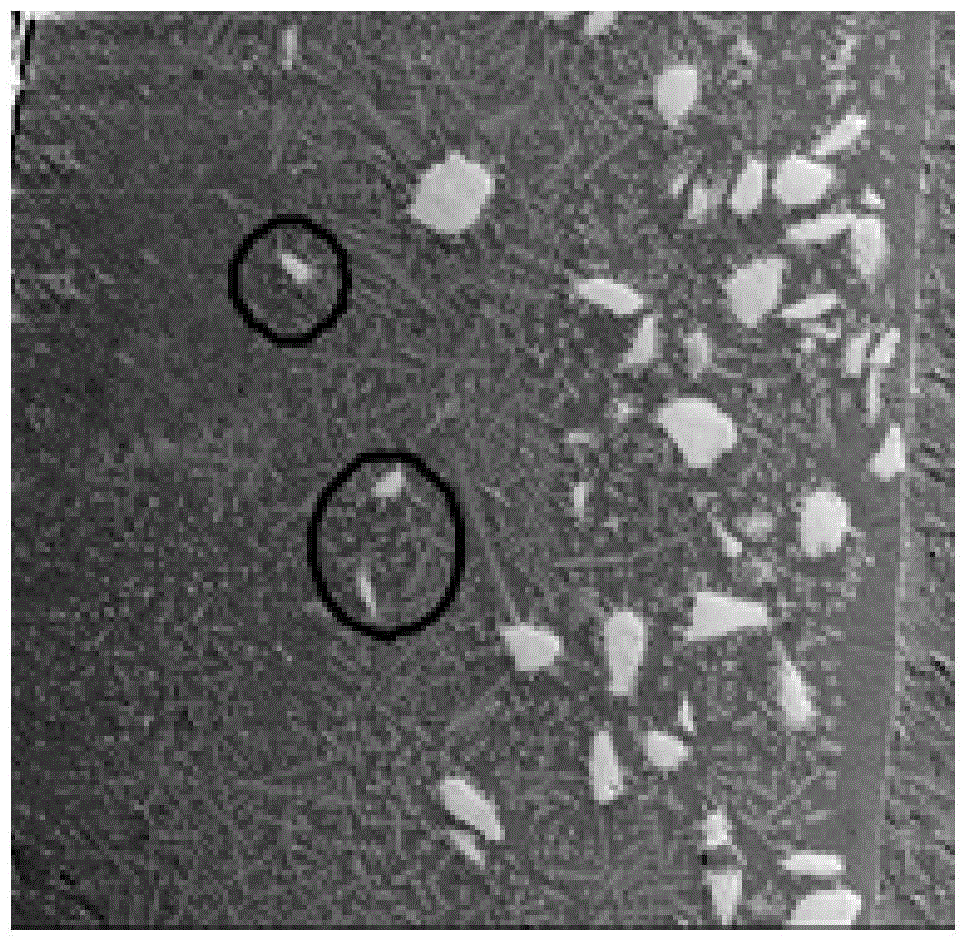

Preparation method of graphene-reinforced copper-based composite

ActiveCN105624445AImprove performanceEasy to organizeTransportation and packagingMetal-working apparatusSlurryCobalt

The invention discloses a preparation method of a graphene-reinforced copper-based composite and belongs to the field of preparation of high-strength and high-conductivity composites. The method comprises steps as follows: graphene, nano copper powder and cobalt powder in the required mass ratio are mixed in absolute ethyl alcohol, the mixture is physically dispersed under electromagnetic stirring, and then physically dispersed mixed slurry is added to a ball milling tank for mechanical ball milling; after evenly mixed slurry is centrifugally dried, obtained mixed powder is annealed and then subjected to hot-pressing SPS (spark plasma sintering) forming; an obtained block blank is annealed and then subjected to hot extrusion, and the graphene-reinforced copper-based composite is obtained. The graphene-reinforced copper-based composite prepared through the method has the good mechanical property, uniform structure and good heat and electricity conductivity.

Owner:KUNMING UNIV OF SCI & TECH

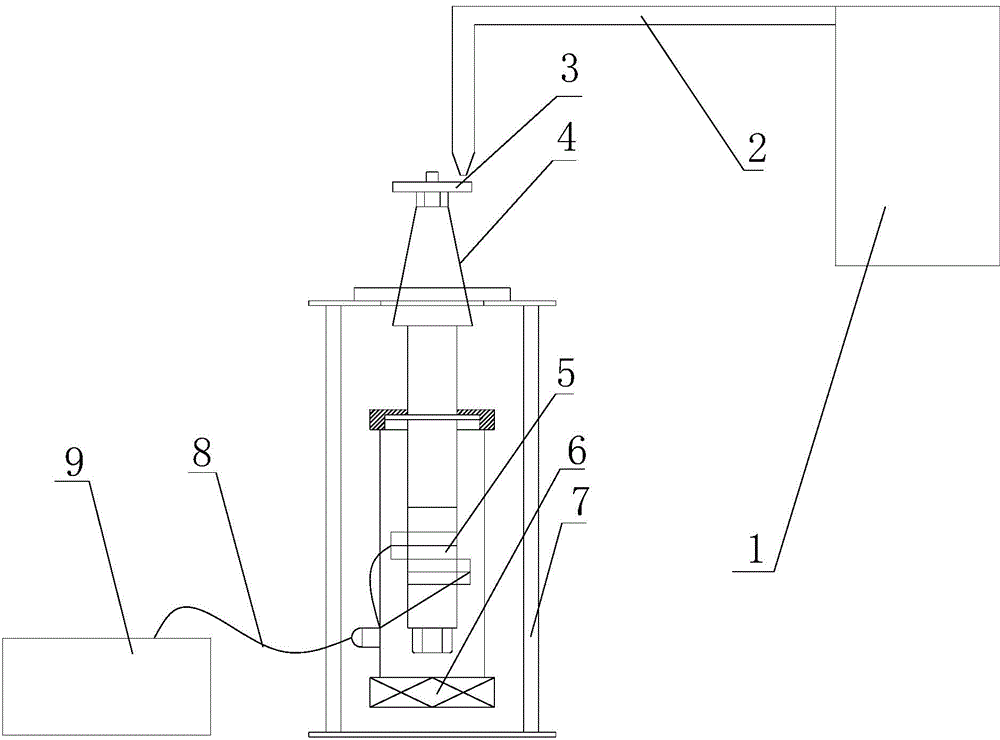

Method for preparing ultra-high hardness cladding layer through synchronous ultrasonic vibration assisting laser technology

InactiveCN104451673AIncreased microhardnessImprove wear resistanceMetallic material coating processesCeramic coatingLiquid metal

The invention provides a method for preparing an ultra-high hardness cladding layer through the synchronous ultrasonic vibration assisting laser technology. According to the specific scheme, the method includes the steps that ultrasonic vibration is synchronously introduced in the Ni-based metal ceramic coating cladding process, mobility of liquid metal can be improved in the mode, tissue distribution is more uniform, in the solidification process, a growing dendrite net can be broken and made to be dispersed to all portions of melt, small crystal nucleuses which are uniformly distributed are formed, segregation of metal ceramic is avoided, and therefore it is guaranteed that the cladding layer is not prone to cracking when ultra-high hardness is acquired; equipment is simple, calibration and installation are facilitated, energy consumption is low, the working environment is good, and acquired coating metal ceramic particles are uniform in distribution, high in hardness and good in abrasion resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

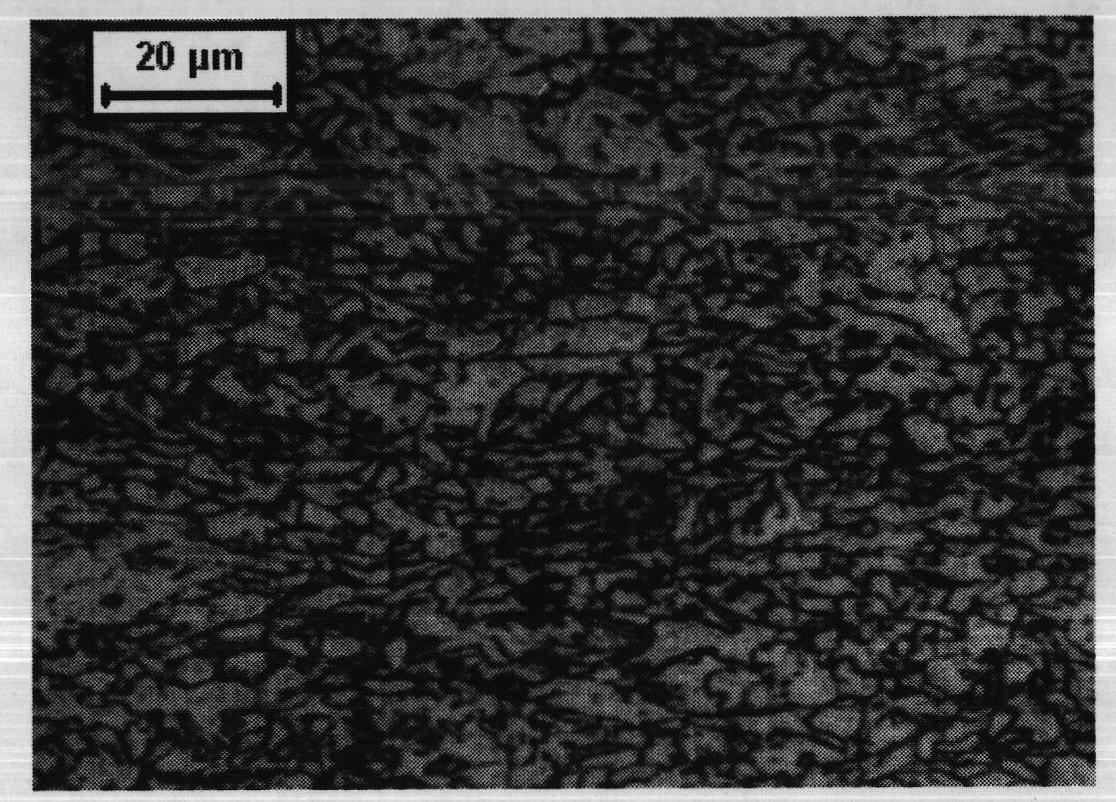

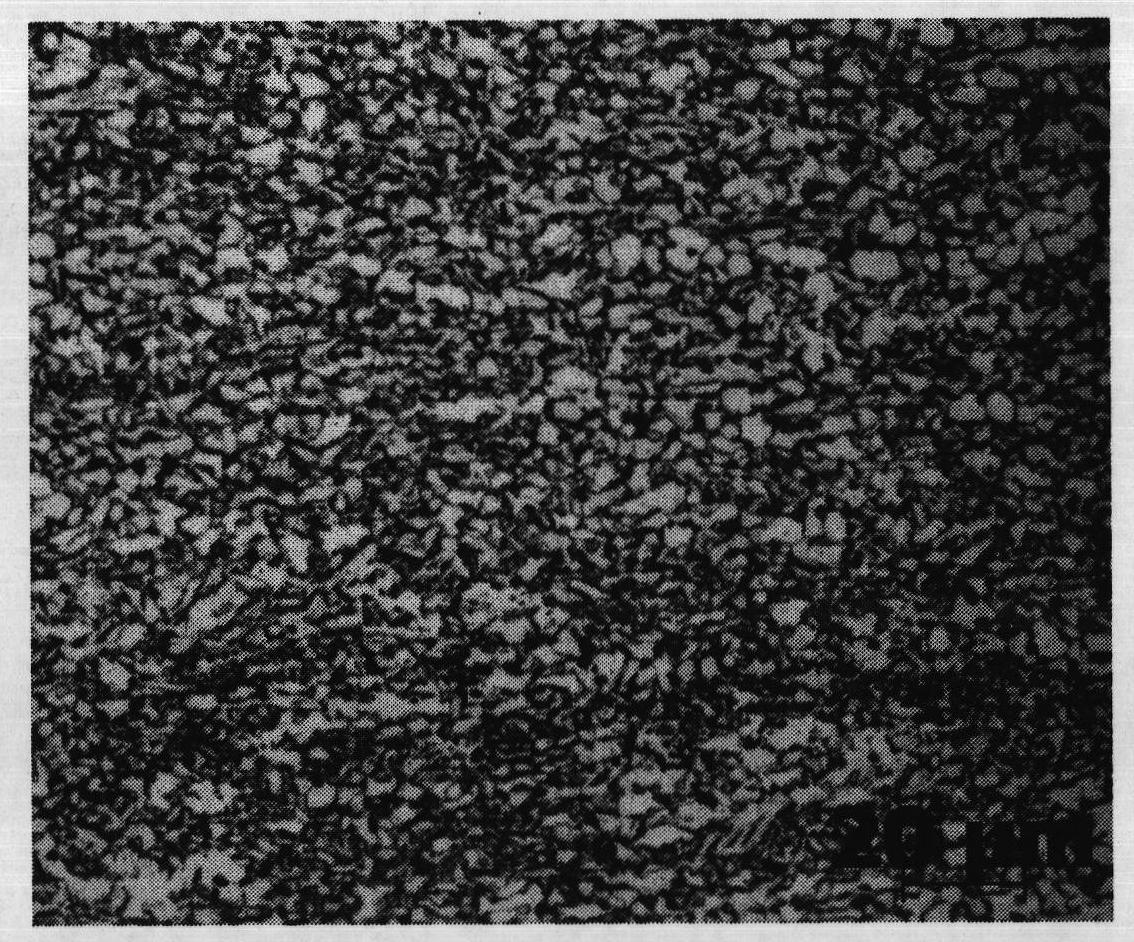

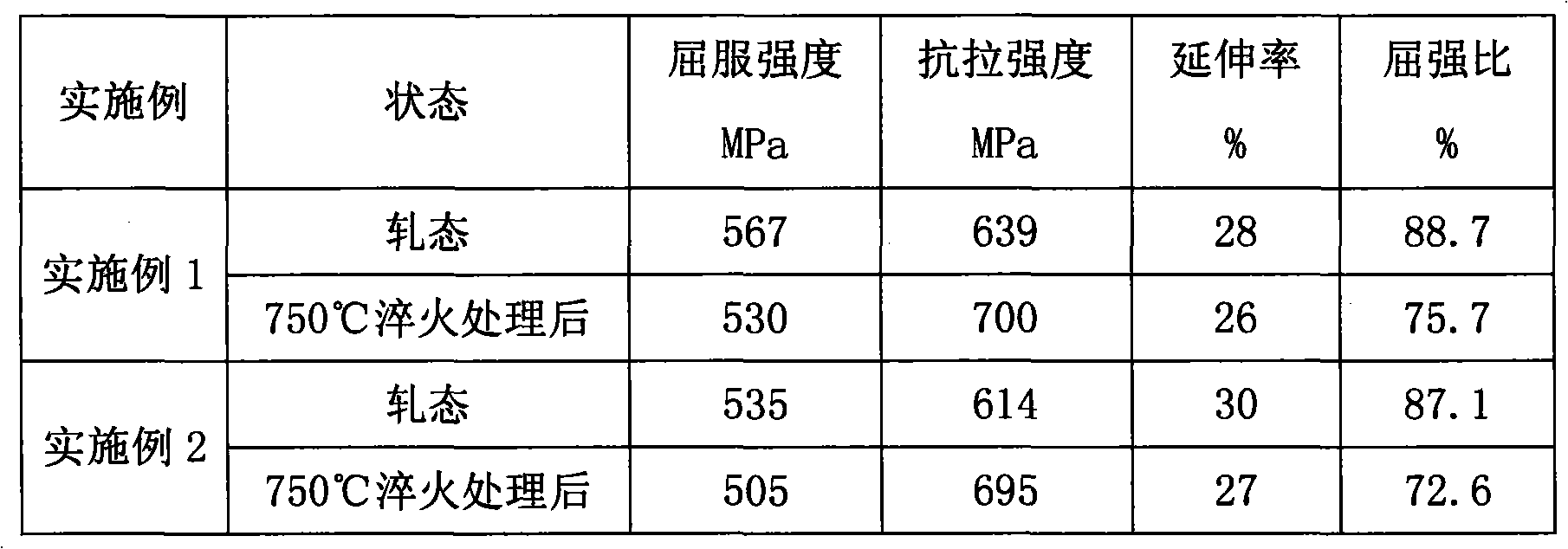

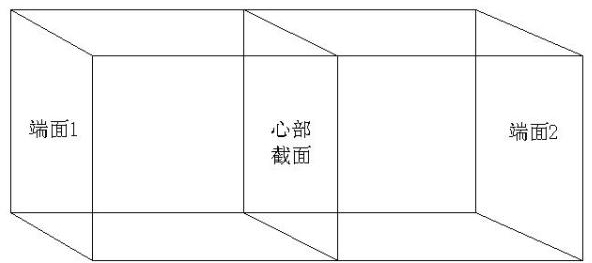

Pipeline steel plate with low yield ratio, fine grains and high strength and production method thereof

The invention discloses a pipeline steel plate with low yield ratio, fine grains and high strength and a manufacturing method thereof, and steel in the pipeline steel plate comprises the following chemical components by weight percent: 0.03-0.10% of C, 0.10-0.30% of Si, 1.20-1.80% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.040-0.060% of Nb, 0.006-0.020% of Ti, 0.10-0.40% of Cr, 0.10-0.30% of Ni, 0.010-0.050% of Al and the balance of Fe and inevitable impurities. The manufacturing method adopts a converter for smelting, adopts the TMCP (thermo mechanical control process) and the two-phase region subthermal quenching treatment at 720-750 DEG C, thereby obtaining the pipeline steel plate with low yield ratio, fine grains and high strength; and the manufacturing method has stable production process, strong operability, low cost and high performances.

Owner:NANJING IRON & STEEL CO LTD

Bainite pre-hardening plastic mold steel and preparation method and heat treatment method thereof

The invention relates to bainite pre-hardening plastic mold steel and a preparation method and a heat treatment method thereof. Chemical components of the steel are optimized on the basis of P20 steel, the content of manganese (Mn) is appropriately increased, the content of the chromium (Cr) and molybdenum (Mo) is reduced, little niobium (Nb) is added, and no nickel (Ni) and vanadium (V) in expensive price are not contained. The preparation method of the plastic mold steel comprises the following steps of: compounding, smelting and casting; carrying out the multi-directional forging heat machining; carrying out the wind cooling and the air cooling; and finally carrying out the tempering heat treatment. The plastic mold steel has characteristics of large cross section, low cost, high hardenability, good hardness uniformity and the like and also has low susceptibility of flake formation, a diffusion hydrogen annealing process is omitted, in addition the post-forging normalizing is adopted to substitute a thermal refining process, so that the production period is greatly shortened, the domestication of the plastic mold steel with large cross section, long service life, top quality and short period can stride forward for a large step, and the existing domestic manufacturing concept of energy conservation, emission reduction, sustainability and economical type can be met.

Owner:SHANGHAI UNIV

Technology for processing high strength large hexagon-headed bolt used for steel structure

InactiveCN101934466AImprove heating uniformityFast heatingBoltsFurnace typesHigh intensityElectrical current

The invention provides a technology for processing high strength large hexagon-headed bolt used for steel structure. The invention relates to a technology for processing high strength connecting piece. High frequency induction current hot forging and cold extruding are adopted, so as to produce a bolt. The invention is on the basis of patent application with patent application number of 200810020090.5, high frequency induction heating is adopted in hot forging, frequency thereof is controlled to be 20000-50000Hz, and the advantages of high frequency induction heating that speed is fast and heating is uniform are utilized, so that work piece surface can obtain uniform tissue and properties from center part to the surface, heating uniformity of work piece is improved, better crystal phase structure can be obtained, and high strength bolt with better property can be obtained.

Owner:扬州狮鹤高强度螺栓有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com