Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

595results about How to "Meet the mechanical performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-strength structural steel board for ocean engineering and production method thereof

The invention relates to an ultrahigh-strength structural steel board for ocean engineering and a production method thereof, belonging to the technical field of ultrahigh-strength steel. A board blank comprises the following components: 0.05-0.13% of C, 0.1-0.4% of Si, 0.7-1.7% of Mn, 0.01-0.04% of Alt, 0.02-0.05% of Nb, 0-0.05% of V, 0.008-0.02% of Ti, 0-0.6% of Cr, 0.2-0.4% of Mo, 0.15-0.8% of Ni, 0-0.5% of Cu, 0-0.0011% of B, less than 0.01% of P, less than 0.005% of S, less than 0.0010% of O, less than 0.005% of N, less than 0.00015% of H, and the balance of Fe and inevitable impurities, wherein Nb+V+Ti is not more than 0.12%. Aiming at different thickness standards, different chemical component as well as rolling and heat treatment process parameters are adopted. The production process comprises the steps of molten iron desulfurization, converter top and bottom blowing, vacuum treatment, continuous casting, controlled rolling and controlled cooling, quenching and tempering. The steel board has the advantages that: the production cost is lower, and the comprehensive mechanical properties can meet the requirements of the steel for the ocean engineering for various mechanical properties.

Owner:SHOUGANG CORPORATION +1

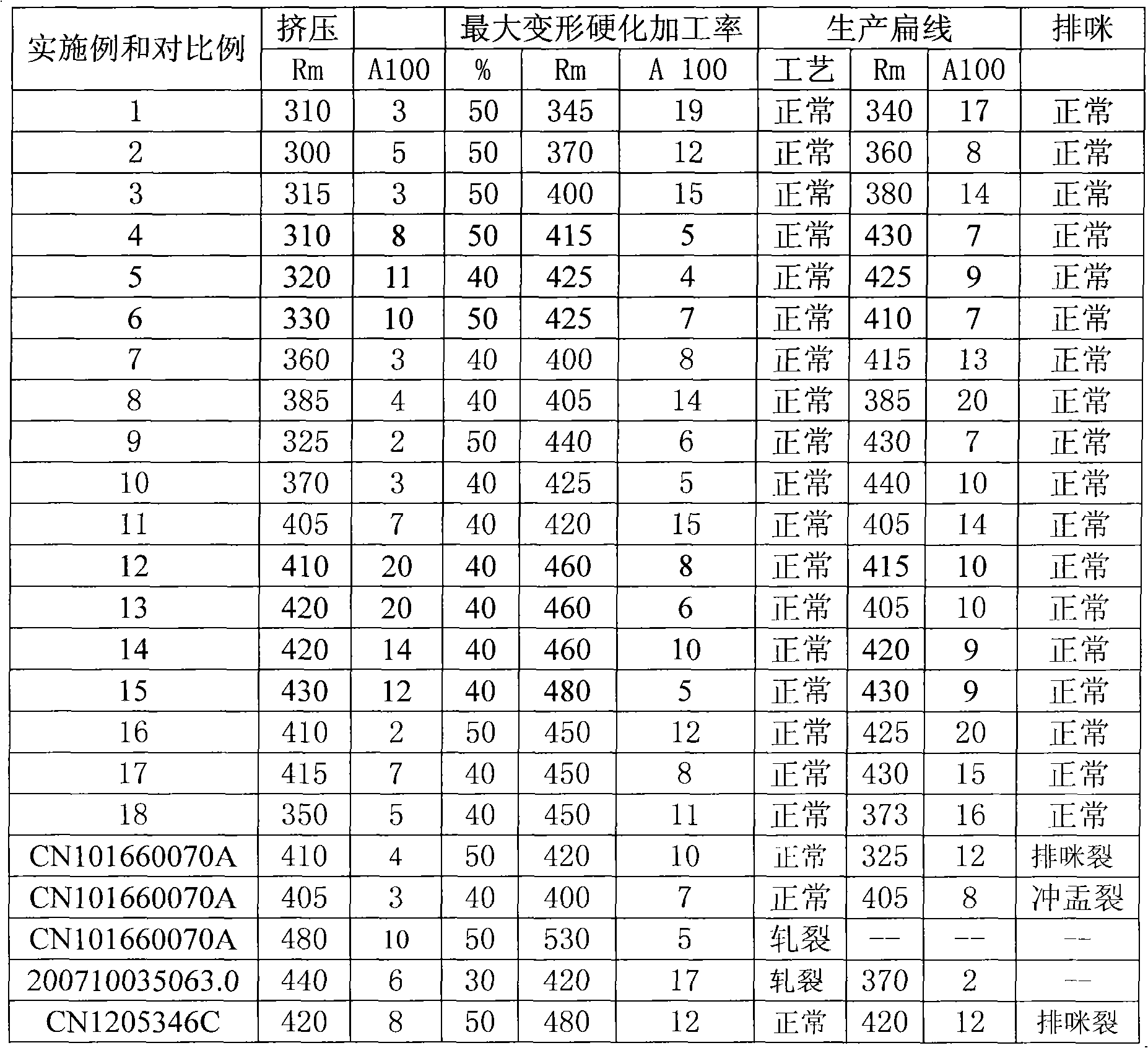

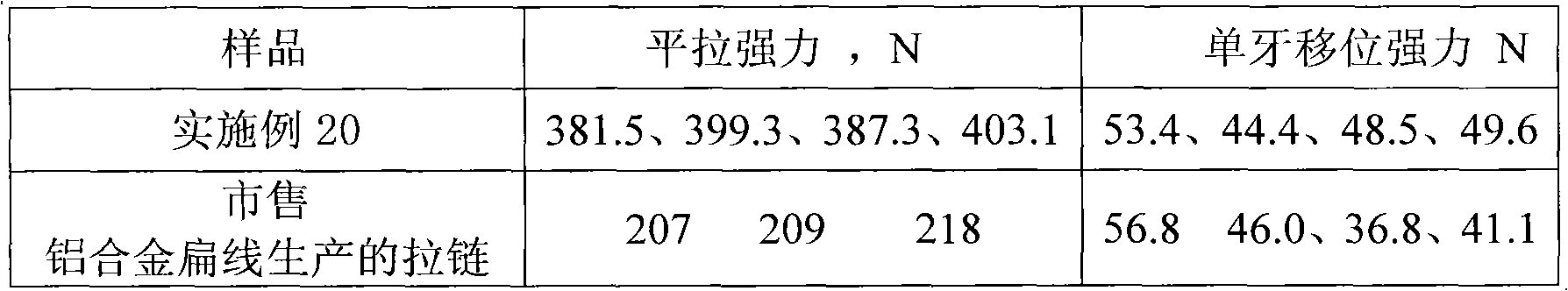

Zinc alloy for zipper tooth belt and preparation method of zipper tooth belt

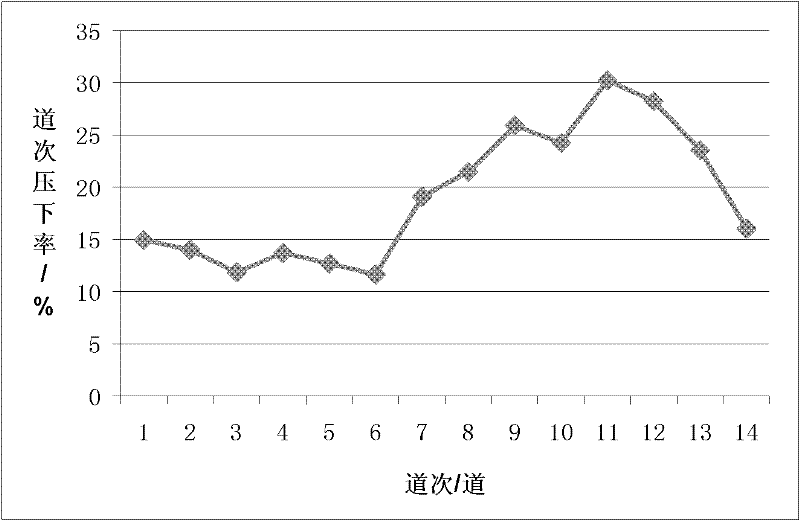

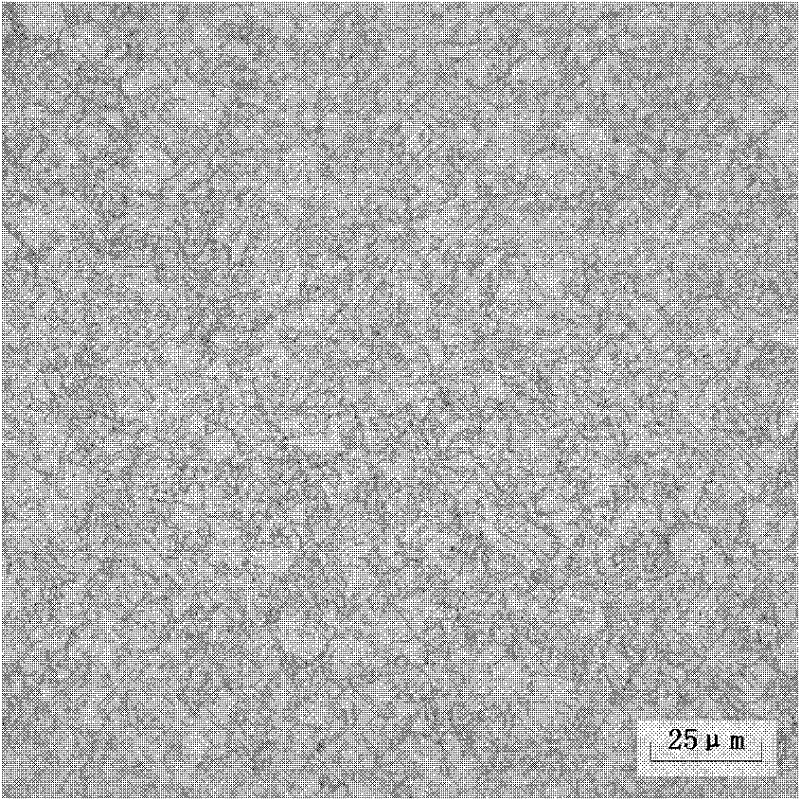

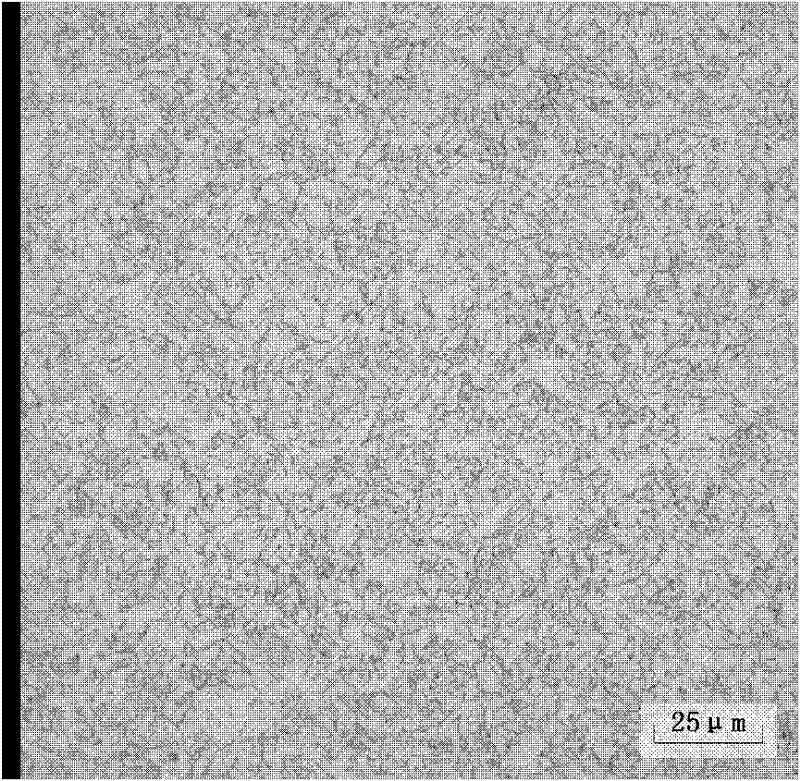

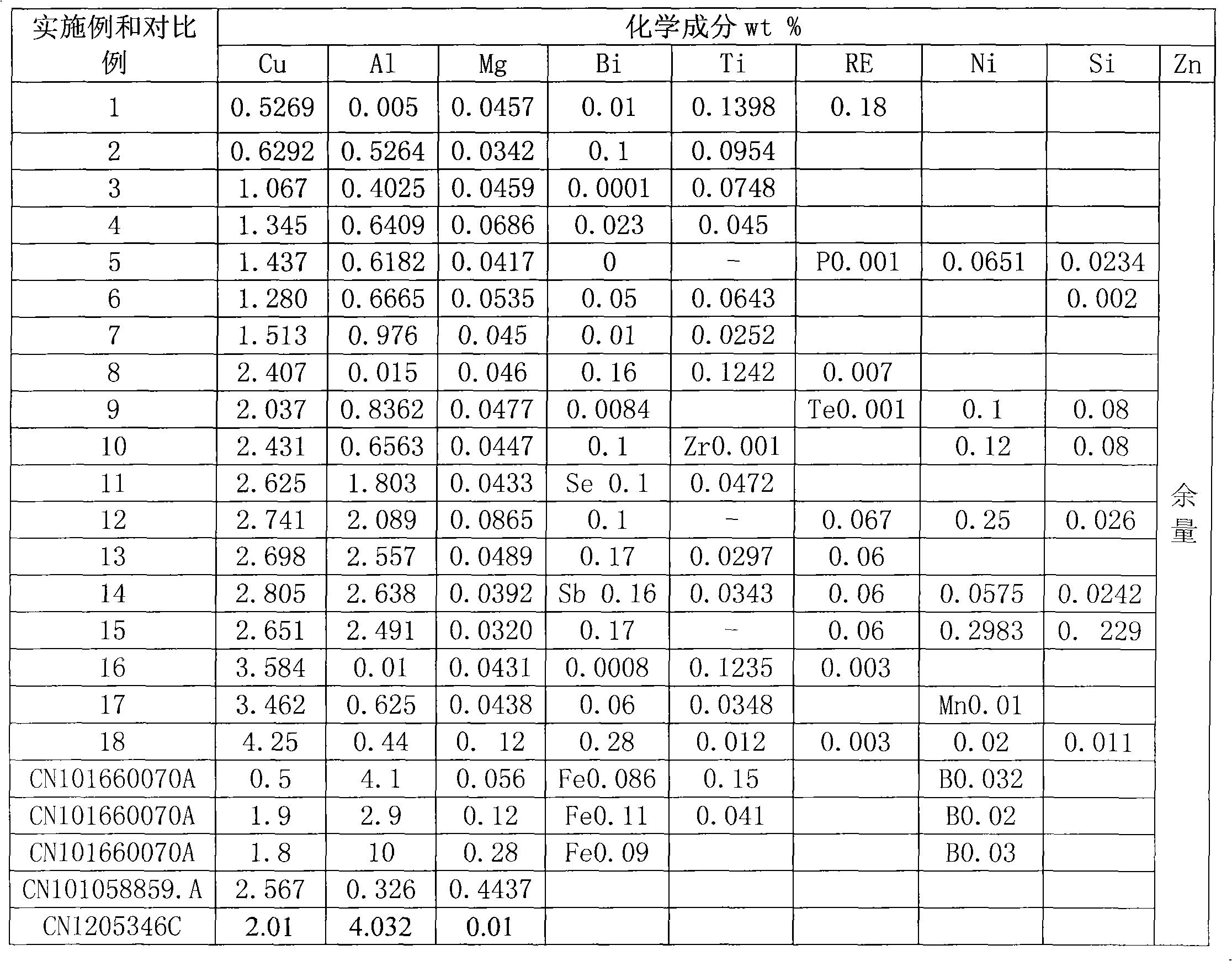

ActiveCN102011029AOvercoming difficult deformationMeet the mechanical performance requirementsSlide fastenersZinc alloysImpurity

The invention discloses a zinc-alloy zipper tooth belt produced by a row microphone method, in particular to zinc alloy for a zipper tooth belt and a preparation method of the zipper tooth belt. The alloy comprises the following components by weight percent: 0.5-5% of Cu, 10-4.5% of Al, 0.01-0.2% of Mg and the balance of X, Y, Zn and unavoidable impurities, wherein the sum of the percentages of the components is 100%; the X is selected from at least one of 0.0001-0.5% of Bi, 0.01-0.19% of Ti, 0.001-0.3% of RE, 0.001-1% of Ni and 0.001-1% of Si; and Y is selected from at least one of Mn, Co, Nb, Zr, Cr, Ca, P, Sb, Te and Se. By adopting the deformed zinc alloy and the alloy producing method disclosed in the invention, the production of the zipper line can be met, and the zipper tooth belt can be produced smoothly by the row microphone method; and the produced zipper can be processed into different colors.

Owner:NINGBO POWERWAY ALLOY MATERIAL

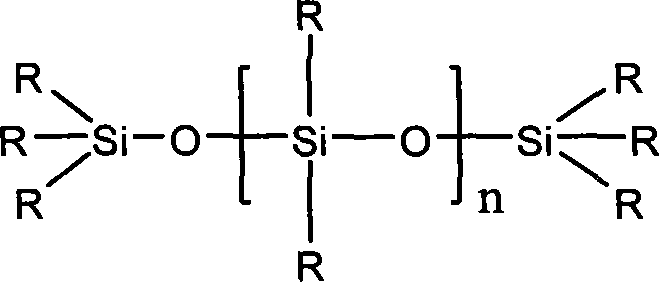

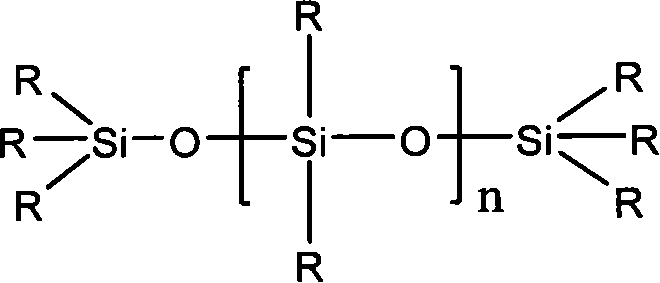

High heat conduction organosilicon filling and sealing gum

InactiveCN101054507AImprove mechanical propertiesGood electrical propertiesOther chemical processesAdhesivesHeat conductingCohesive strength

The invention discloses an organic silicon potting adhesive with a high heat conduction capacity. The curing time of the additive type organic silicon potting adhesive with a high heat conduction capacity can be controlled by the temperature and the amount of the catalyst. The condensate has good mechanical and electrical properties, especially outstanding cohesive strength, high and low temperature resistance and radiation resistance. The inventive heat-conducting organic silicon potting adhesive includes component A and B: said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, 3-20 shares of reinforced-filling, 1-10 shares of catalyst; said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, and 1-10 shares curing agent.

Owner:NANJING UNIV OF TECH

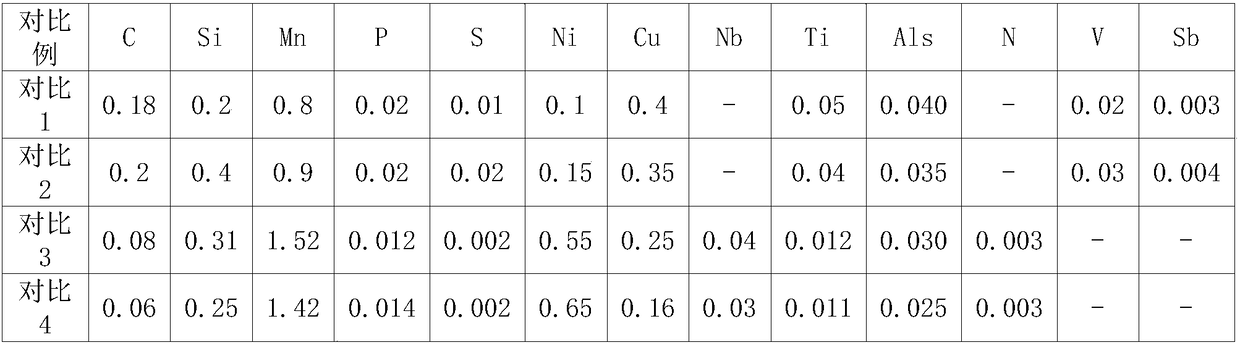

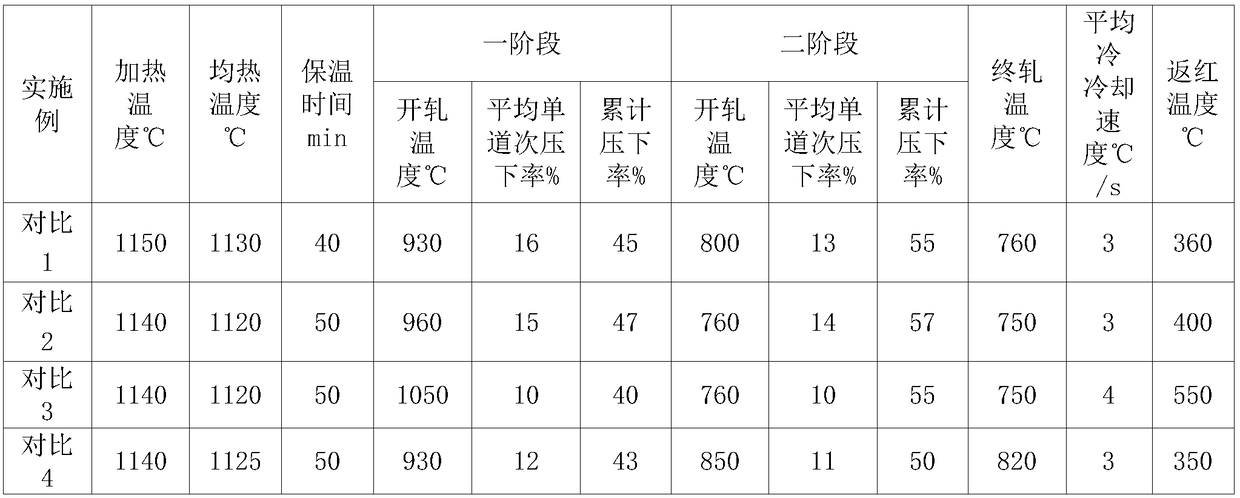

690MPa-yield-strength low-yield-tensile-ratio antiseismic steel and manufacturing method thereof

InactiveCN103710622AMeet the mechanical performance requirementsChemical compositionMechanical property

The invention relates to a 690MPa-yield-strength low-yield-tensile-ratio antiseismic steel and a manufacturing method thereof, belonging to the technical field of architectural structural steel. The antiseismic steel comprises the following chemical components: 0.05-0.13wt.% of C, 0.00-0.50wt.% of Si, 1.50-2.50wt.% of Mn, less than 0.012wt.% of P, less than 0.006wt.% of S, 0.15-0.50wt.% of Mo, 0.02-0.12wt.% of Nb, 0.00-0.15wt% of V, 0.01-0.025wt.% of Ti, 0.0010-0.0030wt.% of B, 0.01-0.06wt.% of Al and the balance of Fe and inevitable impurities. On such basis, one or more of the following alloy elements are added: 0.00-0.80wt% of Cu, 0.00-0.50wt% of Cr and 0.00-1.00wt% of Ni. The total addition amount of the alloy elements in the steel is not greater than 5%. A heavy and medium plate mill is utilized to perform controlled rolling and controlled cooling to obtain the fine-grain bainite-martensite structure; and two-phase region secondary isothermal heat treatment is combined to obtain a certain amount of metastable austenite / microalloy precipitate enhanced substrate; the antiseismic steel satisfies the requirements for mechanical properties of 690MPa-yield-strength architectural antiseismic design code, can be used in an antiseismic structure, and can also be used in the field of engineering machinery.

Owner:CENT IRON & STEEL RES INST

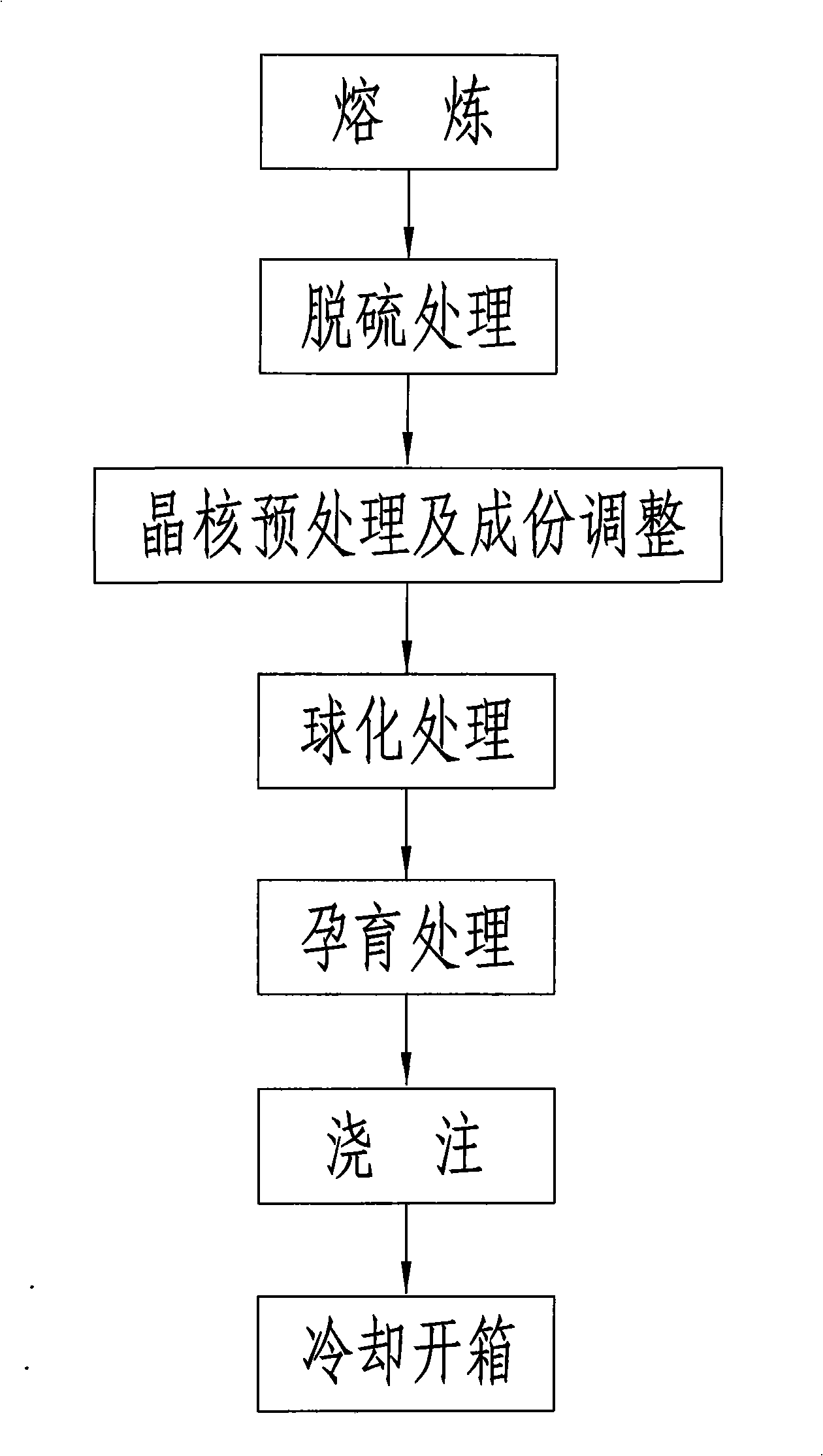

Smelting technique for cast of wind energy apparatus

InactiveCN101407884AHigh nodularityMeet mechanical performance requirementsSmelting processLiquid iron

The invention discloses a smelting process of castings of wind energy equipment, which is suitable for the smelting production of castings of wind energy equipment with the wall thickness of 60 to 200mm and includes the following steps: a. new pig iron, scrap steel and carburants with special requirements are sent into a melting electric furnace for smelting; b. high temperature liquid iron is subjected to desulfurization treatment by a desulfurization agent; c. the desulfurized liquid iron is returned into a heat insulation electric furnace for component adjustment, and the carburant is added for carrying out pre-treatment of crystal nucleus to graphite in the liquid iron; d. spheroidization treatment is carried out to the liquid iron; e. an inoculant is added into the liquid iron for inoculation; f. the liquid iron is poured to casting sand mold; and g. the castings are naturally cooled to 500 to 550 DEG C for unpacking after finishing pouring. The smelting process of castings of wind energy equipment can increase the spheroidization efficiency of ductile iron castings used by the wind energy equipment, which causes the castings to have good intensity of tension, extensibility and high impact ductility in low temperature environments, thus meeting the requirements on the castings used by the wind energy equipment.

Owner:CHANGZHOU ZHUORUN WIND POWER EQUIP

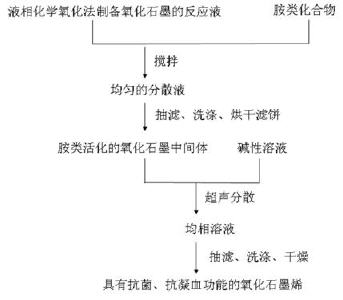

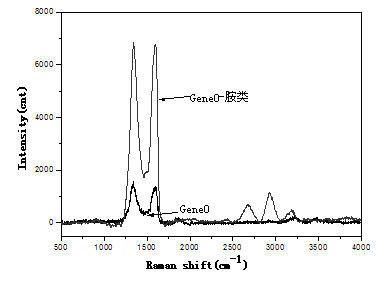

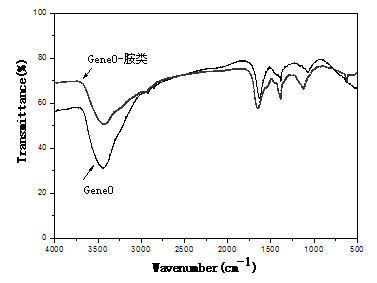

Graphene oxide with antibacterial and anticoagulant functions and preparation method thereof

The invention discloses a method for modifying graphene oxide by controllable synthetic amination with amine based compounds and prepared graphene oxide nano material with antibacterial and anticoagulant functions. The method utilizes Brodie method, Hummers method, or Staudenmaier method to prepare graphene oxide, does not conduct post-treatment to reaction liquid, adds amine based compounds intothe reaction liquid for reaction, prepares amine activated graphene oxide intermediate product, and disperses by ultrasonic the intermediate product in alkaline solution to obtain graphene oxide withantibacterial and anticoagulant functions. The invention introduces amine based compounds into graphite oxide laminate. The amine based compounds can be acid-capturer in the reaction liquid of the synthesis process and promoter in controllable decomposition of graphite oxide laminate, and can make the prepared graphene oxide have antibacterial and anticoagulant functions.

Owner:NANJING NORMAL UNIVERSITY

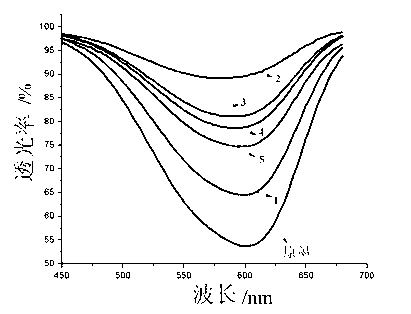

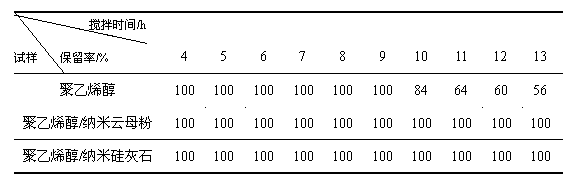

Polyvinyl alcohol/ inorganic nanocomposite hydrogel and preparation method thereof

The invention discloses polyvinyl alcohol / inorganic nanocomposite hydrogel, which is characterized by being formed by the following components: 30-90 parts by weight of polyvinyl alcohol and 0.1-20 parts by weight of inorganic nanocomposite particles through a chemical crosslinking gel method, wherein the inorganic nanocomposite particles comprise nano clay, nano mica powder, a nano molecular sieve, nano wollastonite, nano graphite, nanosilicon dioxide or a carbon nano tube. With the adoption of the polyvinyl alcohol / inorganic nanocomposite hydrogel, the mechanical strength of polyvinyl alcohol hydrogel is enhanced on the basis of not influencing the moisture of the hydrogel, the service life is prolonged, the permeability of the polyvinyl alcohol hydrogel is improved, and a channel is reserved for transmission of matters. As the selection of the materials, the production cost is controlled, and the better economic benefit is brought. The invention also discloses a preparation method of the polyvinyl alcohol / inorganic nanocomposite hydrogel. The preparation method is simple and feasible to operate and good in mechanical strength, and can be produced industrially.

Owner:CHINA PETROCHEMICAL CORP +2

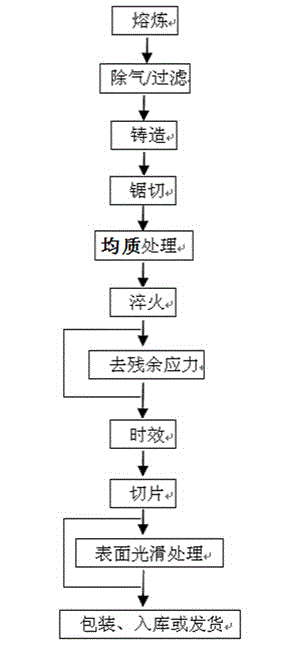

Processing method for aluminium alloy middle thick plate

The invention discloses a processing method for an aluminium alloy middle thick plate. The processing method comprises the following steps of smelting, degassing and filtering, casting, sawing, homogenizing, quenching, removing residual stress, carrying out aging treatment, cutting into slices and performing surface treatment to obtain the aluminium alloy middle thick plate. The aluminium alloy middle thick plate is uniform in structure, low in internal stress, high in size precision, high in strength and low in production cost, and has relatively good economic benefits and social benefits.

Owner:广西南南铝加工有限公司

Aluminum alloy material and production method of cast-rolling stock of decorative strip of same

The invention relates to a 3004 aluminum alloy material and a production method of a cast-rolling stock of a decorative strip of the 3004 aluminum alloy material. The compositions of the aluminum alloy material comprise smaller than or equal to 0.25 percent of Si, 0.20 to 0.60 percent of Fe, 0.10 to 0.15 percent of Cu, 1.0 to 1.20 percent of Mn, 0.85 to 1.25 percent of Mg, smaller than or equal to 0.05 percent of Ti, and the remaining amount of Al. The production method comprises the steps of smelting, refining, on-line degassing, grain refinement, filtration, cast rolling, and the like; during the smelting, 50 percent to 60 percent of electrolytic aluminum liquid and the rest of aluminum alloy waste materials are mixed and smelted; the compositions except Mg are added to the mixture; and after the steps of powder injection refining, slag skimming, magnesium ingot adding, furnace turning-down and refining are conducted, the stock of the strip is cast-rolled. A product of the production method has even and steady chemical compositions and can satisfy the mechanical property requirements of subsequent rolling, so that the yield of subsequent rolling is increased; by using the aluminum alloy waste materials as raw materials, the raw materials are saved; by directly adding the electrolytic aluminum liquid, gas loss in the melting process is reduced, and burning loss in the waste material melting process can also be decreased; and by using a cast-rolling manner to replace a hot-rolling manner, the process is simplified and the production cost is greatly reduced.

Owner:沁阳市鼎建建设发展有限公司

High-strength hydrogel based on three-dimensional network support and preparation method of high-strength hydrogel

ActiveCN108525018AHigh mechanical strengthImprove mechanical propertiesTissue regenerationProsthesisBiomechanicsIn situ polymerization

The invention provides high-strength hydrogel based on a three-dimensional network support and a preparation method of the high-strength hydrogel. The high-strength hydrogel is formed by interfingering and in-situ polymerization of hydrogel and the three-dimensional network support. The method comprises the following steps: immersing the three-dimensional network support in a hydrogel prepolymer solution; enabling the hydrogel to penetrate in the three-dimensional network support after in-situ polymerization forming, and enabling an interpenetrating polymer network to be formed between the hydrogel and the support by polymerizing and winding of macromolecule long chains through support meshes. The high-strength hydrogel based on the three-dimensional network support has the advantages thatthe prepared high-strength hydrogel has excellent wear resistance and mechanical strength resisting various direction forces such as stretching, compression and shearing, and a severe biomechanical property requirement to a replaced body in a physiological environment of a using portion can be met; and the tribological property of the surface of a complex is regulated and controlled effectively,the interfacial friction coefficient is reduced, and simulation to a self-lubricating function of a hyaline cartilage of a joint is realized. The method has simple operation steps, and is low in energy consumption, the materials have good biological compatibility, and the high-strength hydrogel can be produced on the large scale.

Owner:SICHUAN UNIV

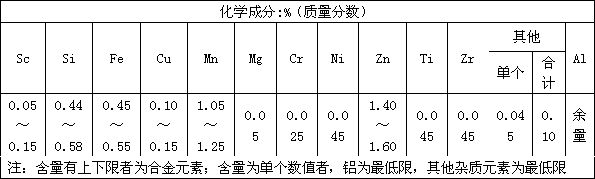

Method for producing Al-Mn-Zn-Sc aluminum alloy foil for automobile radiating fin by continuous roll casting

The invention relates to a method for producing Al-Mn-Zn-Sc aluminum alloy foil for an automobile radiating fin by continuous roll casting. The method is characterized by comprising 0.05 to 0.15% by mass of Sc, 0.44 to 0.58% by mass of Si, 0.45 to 0.55% by mass of Fe, 0.10 to 0.15% by mass of Cu, 1.05 to 1.25% by mass of Mn, less than or equal to 0.05% by mass of Mg, 1.40 to 1.60% by mass of Zn, less than or equal to 0.025% by mass of Cr, less than or equal to 0.045% by mass of Ni, less than or equal to 0.045% by mass of Ti, less than or equal to 0.045% by mass of Zr, and the balance Al. The method has the advantages of short production technological process, simple production processes, high production efficiency, high yield, low cost, good plate shape, high Al-Mn-Zn-Sc aluminum alloy foil strength, good toughness, good weldability, good thermostability, high heat resistance and stable and reliable product quality.

Owner:靖西天桂铝业有限公司

Silk fibroin/ cellulose 3D printing ink

ActiveCN106267370AGood biocompatibilityHigh viscosityPharmaceutical delivery mechanismTissue regenerationCelluloseHuman body

The invention relates to silk fibroin / cellulose 3D printing ink, which comprises the following main ingredients: water-soluble silk fibroin with good biocompatibility, non-water soluble cellulose micron / nanometer materials with good biocompatibility, non-toxic polyhydric alcohols capable of inducing the silk fibroin to carry out physical crosslinking, bioactive substance capable of accelerating tissues to regenerate, and water. The silk fibroin / cellulose 3D printing ink disclosed by the invention has high viscosity, dynamic viscosity is 1000-5000cP, curing molding speed is high, self-gelation time is 0.5-3min, printing conditions are moderate, and printing temperature is 25-37DEG C; an obtained printing bracket has high precision and good mechanical property, a resolution ratio is 50-300mum, and a modulus of compression is 10-50MPa. The bracket formed by the silk fibroin / cellulose 3D printing ink can be used for the field of the repairing and the reconstruction of various damaged tissues or organs of a human body.

Owner:常州增材制造研究院有限公司

Geopolymer composite material for 3D printing and preparation method and application thereof

ActiveCN106082898ASave energyEnvironmentally friendlyAdditive manufacturing apparatusSolid waste managementAdditive ingredientSlag

A geopolymer composite material for 3D printing and a preparation method and application thereof are disclosed. The geopolymer composite material comprises the following ingredients (by weight): 20-25% of water-quenched granulated blast furnace slag powder, 10-15% of ground steel slag, 0-5% of fly ash, 33-45% of tailings machine-made sand, 3-5% of a composite activator, 2.5-3% of a high-molecular polymer, 1-3% of a volume stabilizer, 1-2% of a thixotropic agent, 0.05-0.1% of an antifoaming agent and 13.9-12.45% of mixing water. The above ingredients are fully and uniformly stirred and then the mixture is subsequently pumped into a 3D printer for construction. The geopolymer composite material has good caking property, strong stability and has good pump-out morphology maintaining capability and bond property. Printed buildings have good morphology and volume stability, and houses and buildings have good overall stability and use security.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

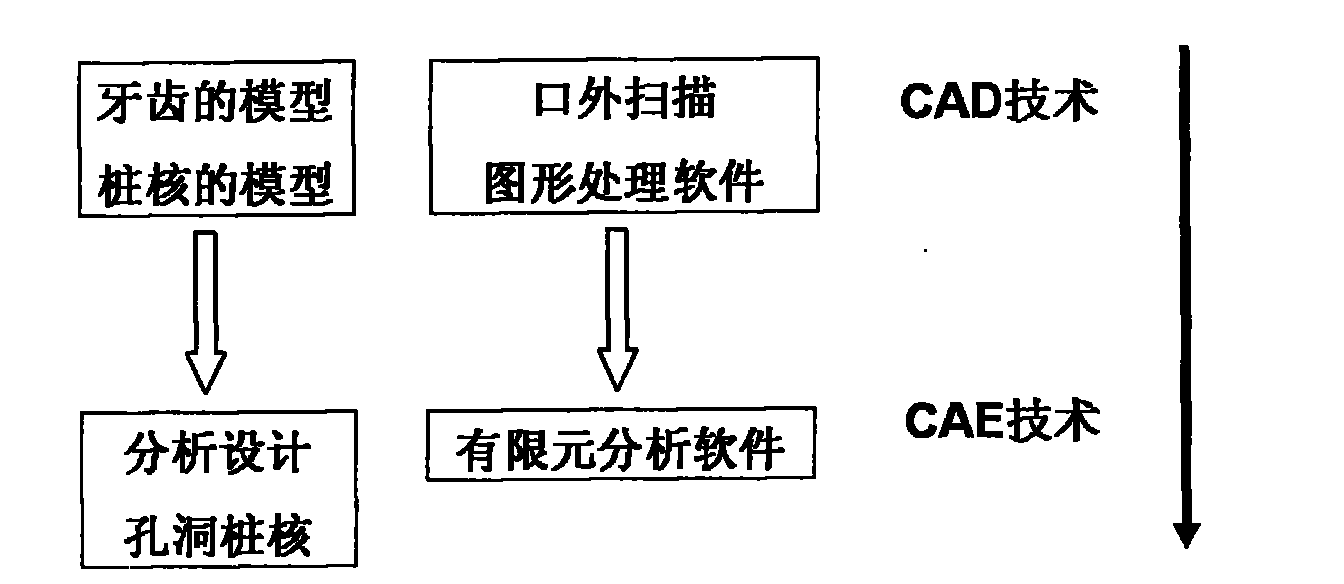

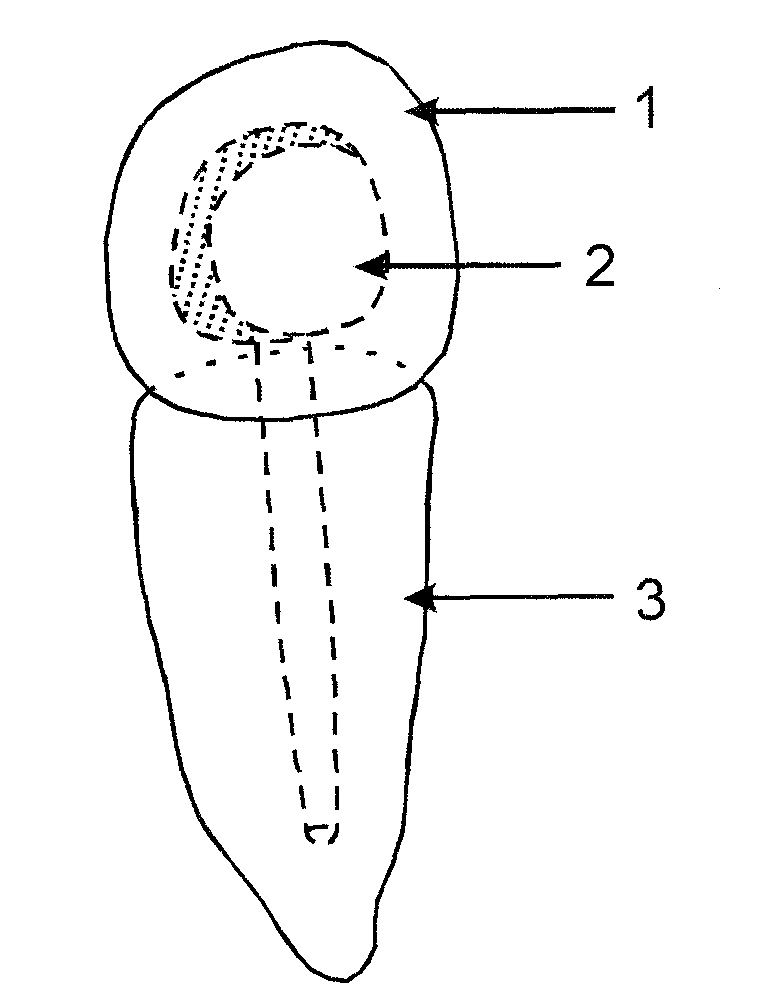

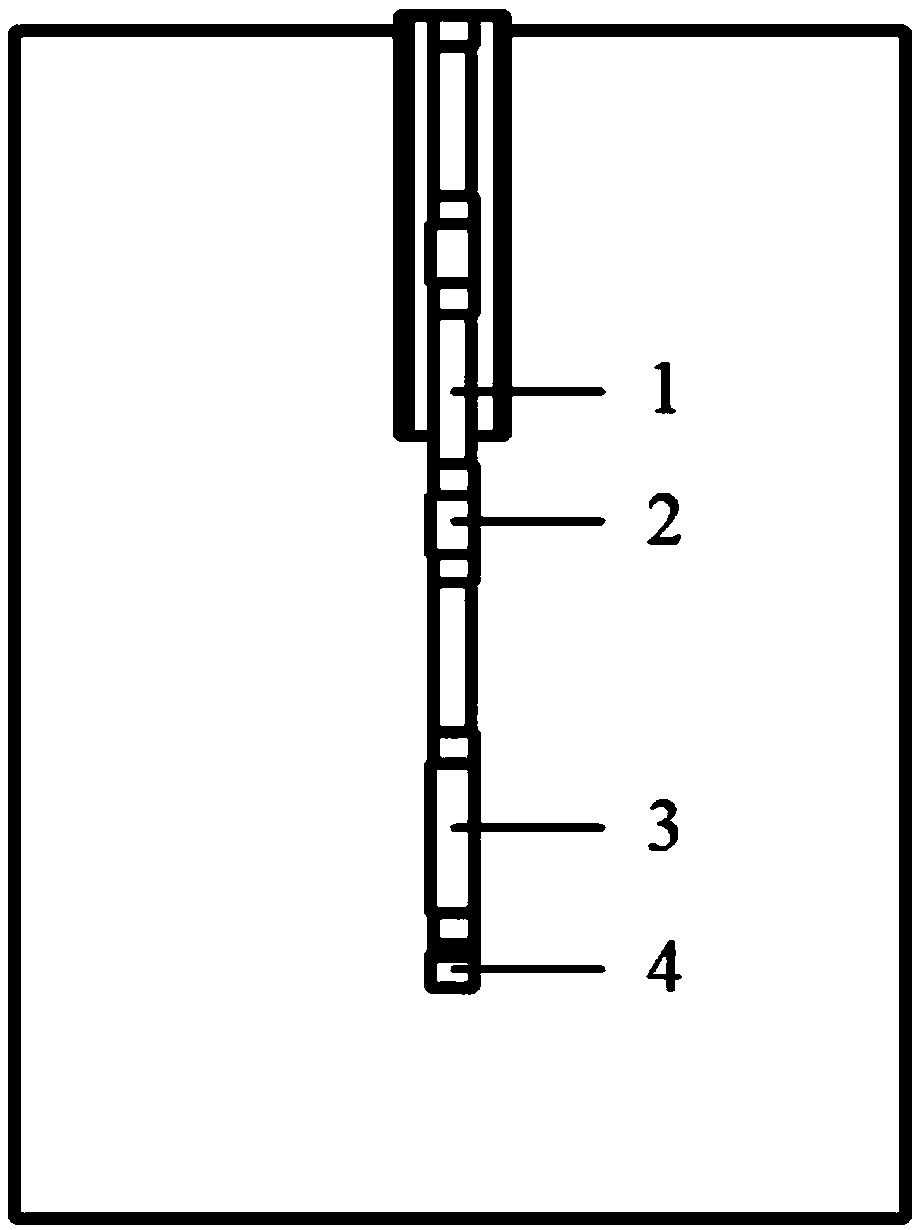

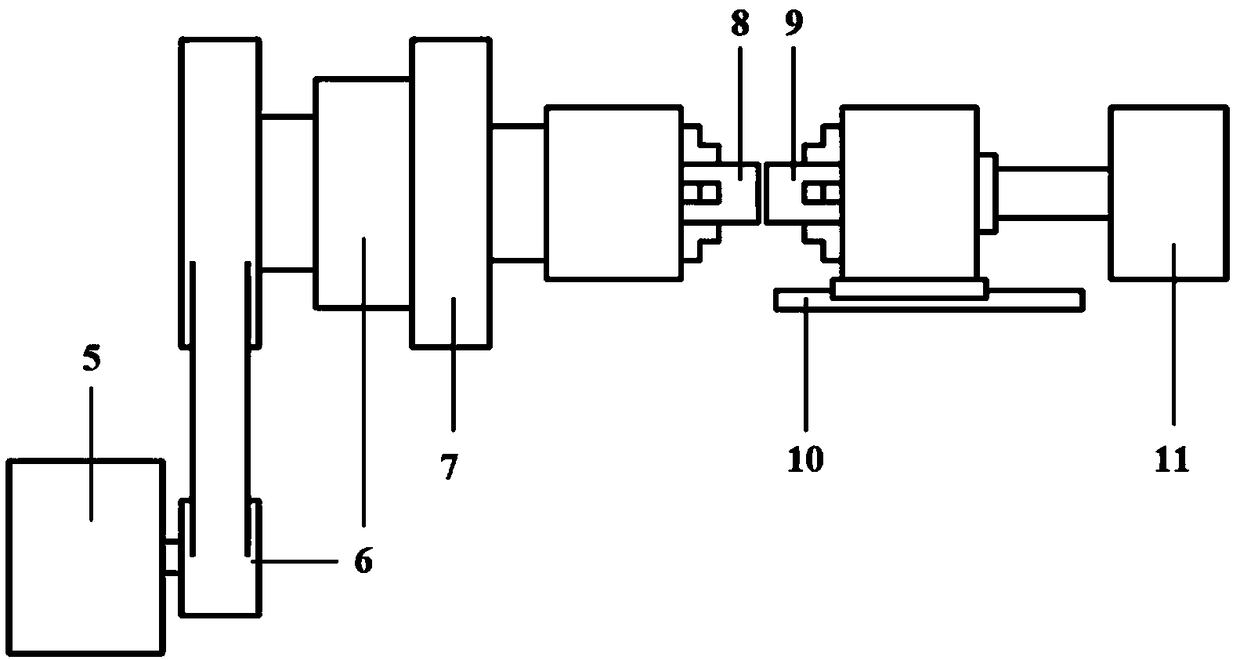

Integrated fiber post for dental restoration and preparation method thereof

ActiveCN101803958AHigh strengthImprove stress distributionImpression capsFastening prosthesisNumerical controlStress concentration

The invention discloses an integrated fiber post for dental restoration and a preparation method thereof. The integrated fiber post for dental restoration is characterized by integrating a post and a core and comprising a post and core tail part and a head core part; the conical structure of the post and core tail part is consistent with the conical structure of a dental drilling head; the head core part is in an umbrella cap structure; the lower edge of the umbrella cap structure is fully matched with the residual part of a defected tooth; the outline part of the umbrella cap structure is fully matched with a crown part; and a porcelain crown is directly sleeved on the head core part. The method for forming and machining the integrated fiber post comprises the following steps of: (1) acquiring CT (computed tomography) data of the defected tooth; (2) reconstructing the three-dimensional model of the tooth and a post and core crown through a computer; (3) building a CAD (computer-aideddesign) model of the integrated post and core; (4) transferring the information of the CAD model of the integrated fiber post and core into a CAM (computer-aided manufacturing) numerical control center; and (5) cutting and machining the integrated fiber post and core by a machining center of a numerical control machine. The fiber post of the invention has improved strength, reduced post and core abhesion in application, and avoidances of breakage of tooth posts and failure of restoration caused by stress concentration.

Owner:北京欧亚瑞康新材料科技有限公司

Polyving alcohol composite hydrogel and preparation method thereof

The invention relates to polyving alcohol composite hydrogel and a preparation method thereof. The polyving alcohol composite hydrogel is prepared from the following raw materials in parts by weight through cross-linking solidifying compounding of boric acid solution containing solidifier: 30 to 90 parts of polyving alcohol, 0.1 to 50 parts of sodium alginate, 0.1 to 20 parts of inorganic nanoparticles, 1 to 20 parts of elastomer material, 0.5 to 5 parts of coupling agent and 200 to 2000 parts of water, wherein the degree of polymerization of polyving alcohol is 400 to 3000, and the alcoholysis degree is 75 to 99 percent. The polarity elastomer material and the inorganic nanoparitcles which are processed through the coupling agent are compounded with the polyving alcohol, the mechanical strength and flexibility of the polyving alcohol hydrogel can be improved through the toughening effect of the elastomer material and the synergistic effect of the inorganic nanoparticles, so that the service life is prolonged, and the requirement of the real application on the mechanical performance can be met; the preparation method of the polyving alcohol composite hydrogel is simple in process, easy to operate and applicable to the mass production.

Owner:CHINA PETROCHEMICAL CORP +2

Nitrogen contained austenitic cast iron in use for beset ring of piston

InactiveCN101092674AReduce manufacturing costMeet the mechanical performance requirementsPiston ringsMachines/enginesManganeseTitanium

This invention discloses a cast iron material for piston inlay ring, which comprises: N 0.0005-0.2 wt.%, C 2.0-3.6 wt.%, Si 1.1-3.5 wt.%, Mn 2.8-9.0 wt.%, Ni 1.2-13.5 wt.%, Cu 1.1-8 wt.%, Cr 0-2.3 wt.%, Ti 0-2 wt.%, Mo, 0-2 wt.%, V 0-2 wt.%, Zr 0-2 wt.%, Al 0-2 wt.%, P less than or equal to 0.2 wt.%, S less than or equal to 0.2 wt.%, and Fe as balance. The cast iron material is prepared by: mixing the above components, smelting in an electric furnace, incubating, and pouring into a mold to obtain roughcast for casting inlay ring. The tensile strength (deltab), bending strength (deltabb) and Brinell hardness of the cast iron material are greater than or equal to 130 MPa, greater than or equal to 300 MPa and HB 120-170, respectively. The cast iron material has such advantages as low Ni content; lwo cost and high wear resistance, and can satisfy the mechanical property requirements of piston inlay ring of high-performance engine.

Owner:SHANDONG BINZHOU BOHAI PISTON

Method for producing plants basin by using compost decomposed stalk

InactiveCN1922970AImprove plasticityStrong toughnessBio-organic fraction processingOrganic fertiliser preparationEmulsionNitrogen

The invention relates to a method for using compost to decay straw to make plant pot. Wherein, it comprises breaking straw into sections; emerging with water; adding nitrogen and phosphor fertilizers; grafting compost product to decay, breaking, screening and adding additive to obtain pot material; compressing and shaping the material, then removing the mould. The inventive pot has strong flexibility. And its surface can be emerged by acrylate emulsion, to be used in plant cultivation. And the invention uses temperature-different demould technique or lift demould technique, to reduce the cost.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

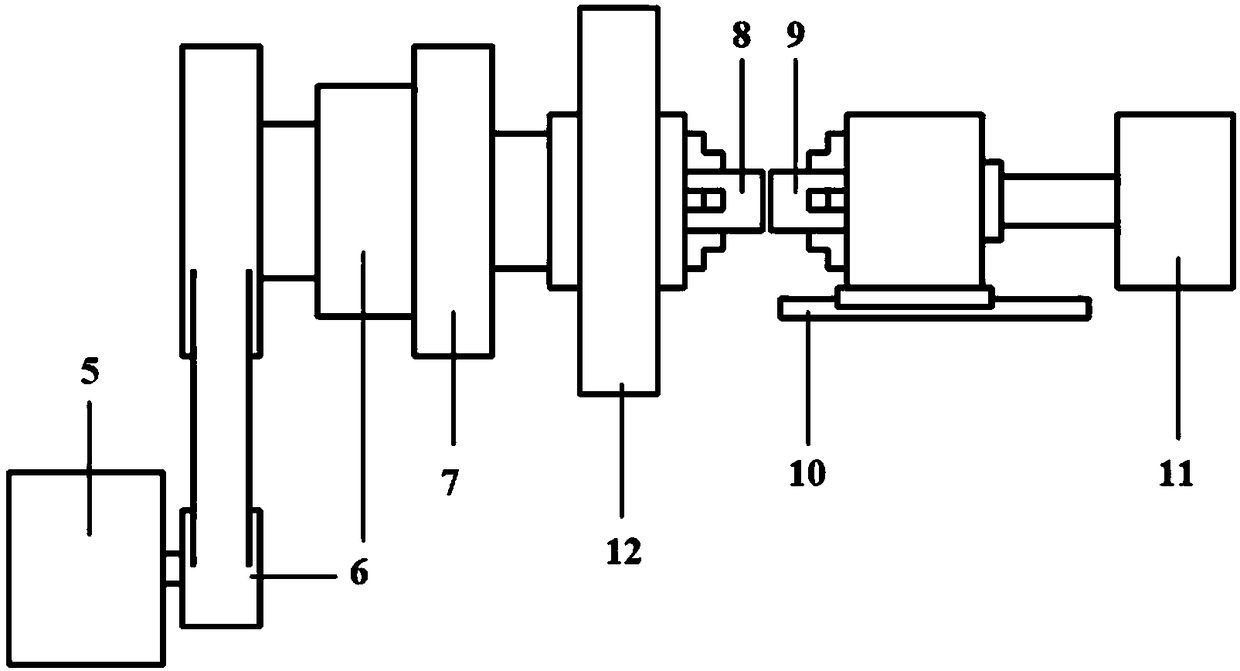

Axial friction welding process method of high-nitrogen austenitic stainless steel and non-magnetic drill collar

InactiveCN108907447AAchieve weldingGuaranteed normal work requirementsTubular articlesHollow articlesFriction weldingNon magnetic

The invention relates to an axial friction welding process method of a high-nitrogen austenitic stainless steel and non-magnetic drill collar and belongs to the field of preparation of oil-gas drilling tools. The method comprises the application steps: workpieces made from high-nitrogen austenitic stainless steel are clamped into a friction welding machine, then, workpieces in a clamp of a rotating end and a clamp of a moving end are welded, the workpiece of the moving end moves towards the workpiece of the rotating end when welding is started, at this time, the workpiece of the rotating end starts to rotate, the workpiece of the rotating end and the workpiece of the moving end start to produce heat due to friction under the action of frictional pressure after contact, rotation is stoppedwhen a friction amount of deformation reaches a set value, upset forging is started, upset forging pressure is applied to the workpieces along the axial direction of the workpieces and is maintained,and a workpiece is taken out after the upset forging pressure is unloaded, thereby obtaining the non-magnetic drill collar. According to the method, the non-magnetic drill collar is processed and repaired by an axial friction welding method, so that the problems, i.e., material waste, relatively high cost and relatively low production efficiency of the existing processing methods are improved, andthe problem that a failed drill collar is difficult to repair is solved.

Owner:SHANDONG UNIV

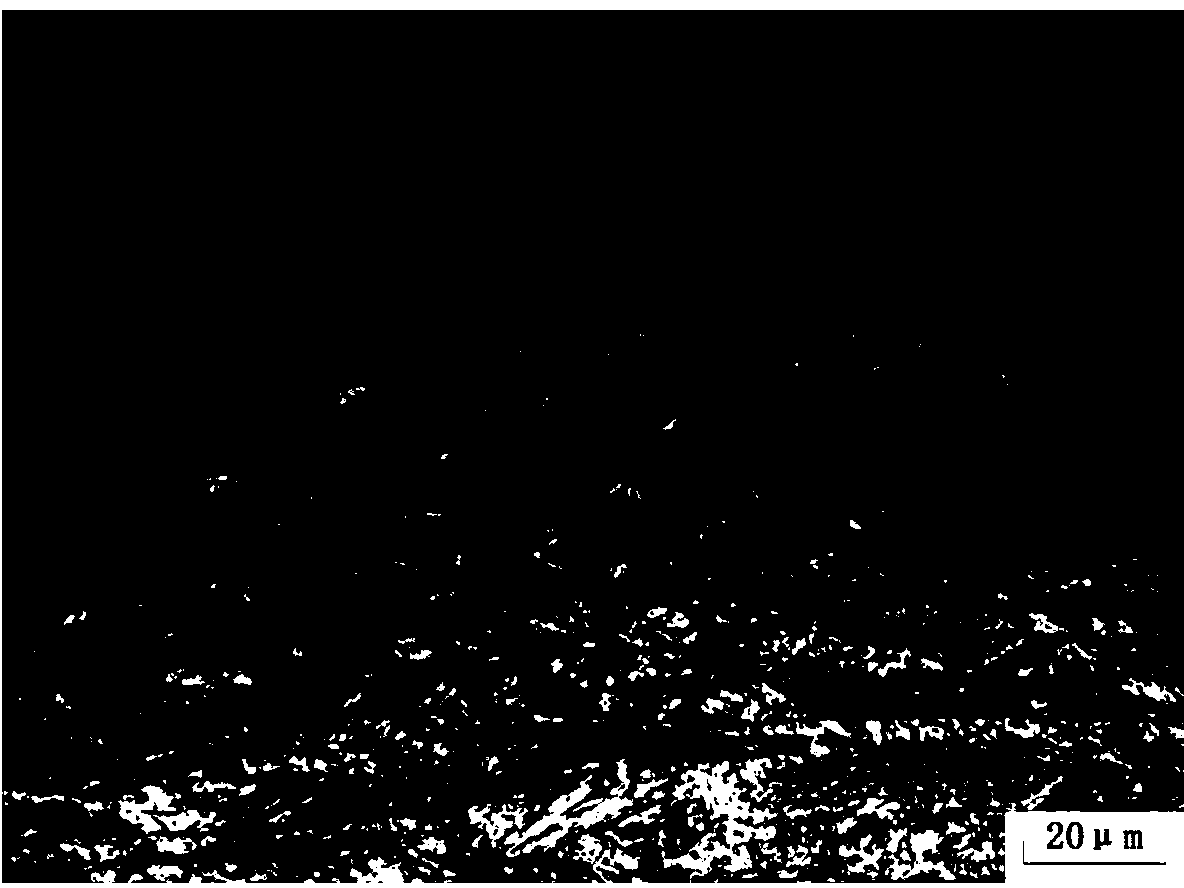

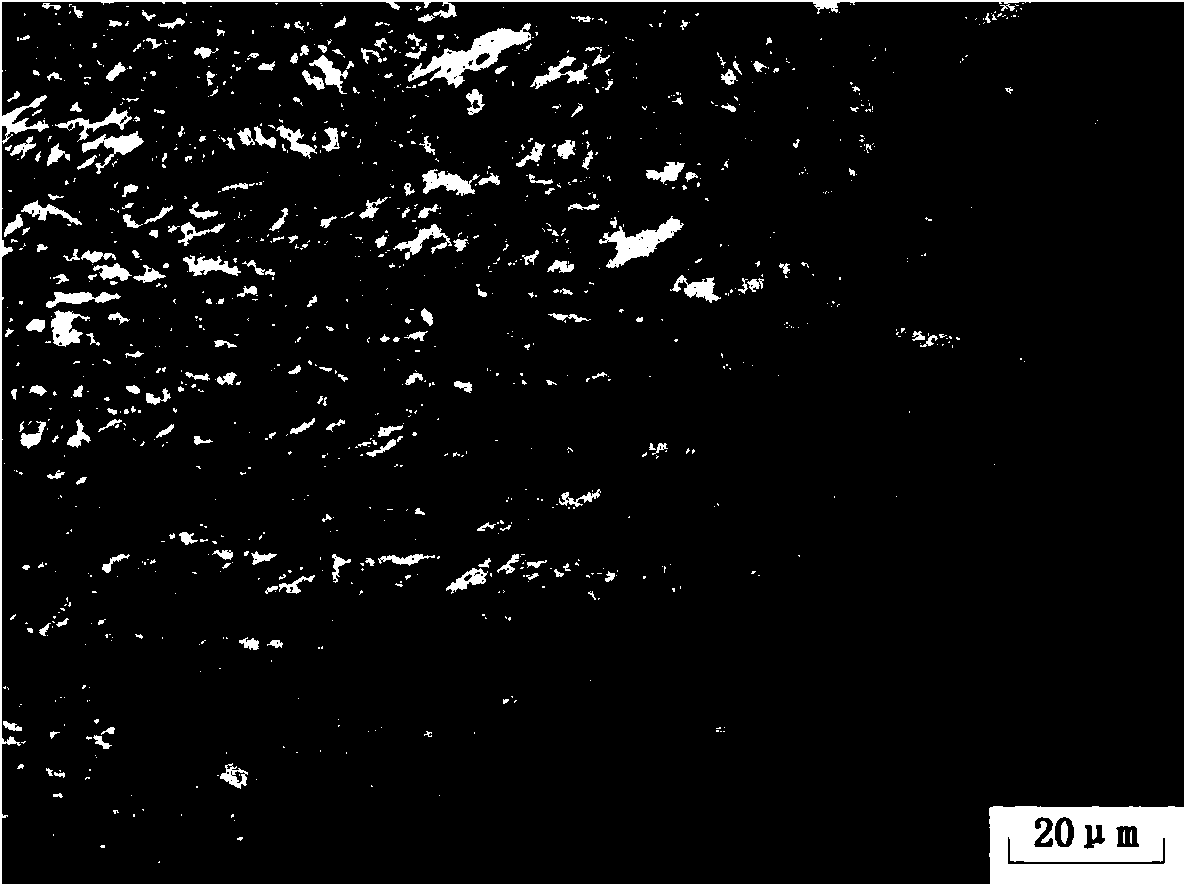

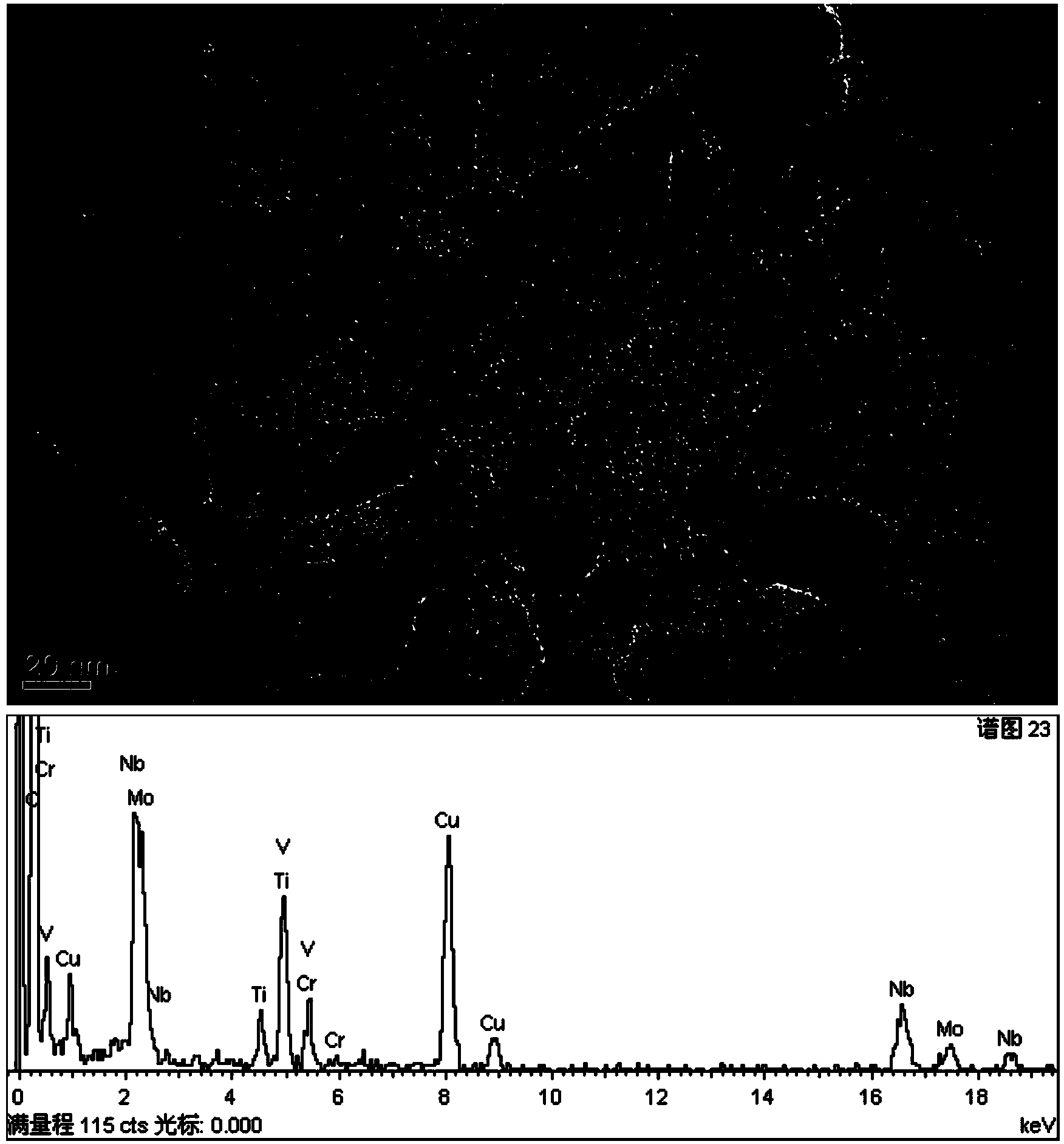

Thermal treatment process for nickel-based superalloy

ActiveCN105385973AImprove mechanical propertiesIncrease the precipitation volume fractionSolution treatmentRoom temperature

The invention relates to a thermal treatment process for nickel-based superalloy. The process includes the following steps that homogenizing treatment is carried out, the temperature ranges from 1160 DEG C to 1195 DEG C, the heat preservation time is 1-36 h, and then the superalloy is cooled to the room temperature; solution treatment is carried out, the temperature ranges from 935 DEG C to 995 DEG C, the heat preservation time is 0.5-15 h, the superalloy is cooled to 650 DEG C at the cooling speed of 50-650 DEG C / h, and then the superalloy is air-cooled to the room temperature; and aging treatment is carried out in two periods, according to the first period, the treatment temperature is 720+ / -10 DEG C, the heat preservation time is 8+ / -0.1 h, and then the superalloy is cooled to 620 DEG C at the cooling speed of 50-56 DEG C / h, and according to the second period, the treatment temperature is 620+ / -10 DEG C, the heat preservation time is 8 h, and then the superalloy is air-cooled to the room temperature. The aging treatment can also be carried out in two periods, according to the first period, the treatment temperature is 760+ / -10 DEG C, the heat preservation time is 5+ / -0.1 h, and then the superalloy is cooled to 650 DEG C at the cooling speed of 50-56 DEG C / h, and according to the second period, the treatment temperature is 650+ / -10 DEG C, the heat preservation time is 1+ / -0.1 h, and then the superalloy is air-cooled to the room temperature. According to the thermal treatment process, the limitation of an existing standard thermal treatment regime and the limitation of an existing modification thermal treatment regime are broken through, and the mechanical property of the nickel-based superalloy is substantially improved.

Owner:CENT IRON & STEEL RES INST

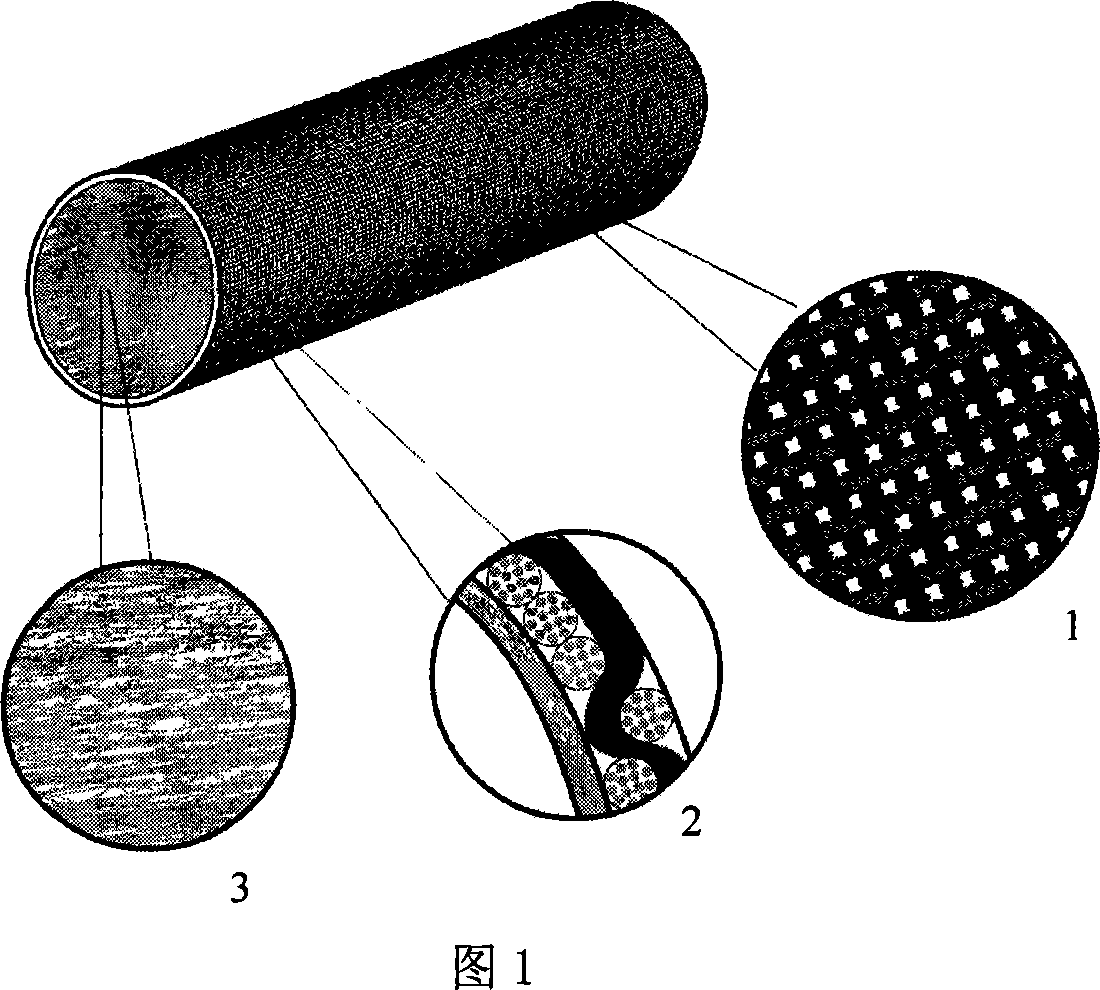

Two-lay machine-knitted structure textile type artificial blood vessel

The present invention relates to a textile type artificial blood vessel with double-layer machine-woven structure. It is characterized by that it includes outer layer machine-woven structure whose water permeability is 1000-3000 ml / sq.cm.min.16kPa and inner layer machine-woven structure whose water permeability is 250-300 ml / sq.cm.min.16kPa, and adopts stitching warp or stitching weft to make the above-mentioned outer layer machine-woven structure and inner layer machine-woven structure be combined together so as to obtain the invented artificial blood vessel.

Owner:DONGHUA UNIV

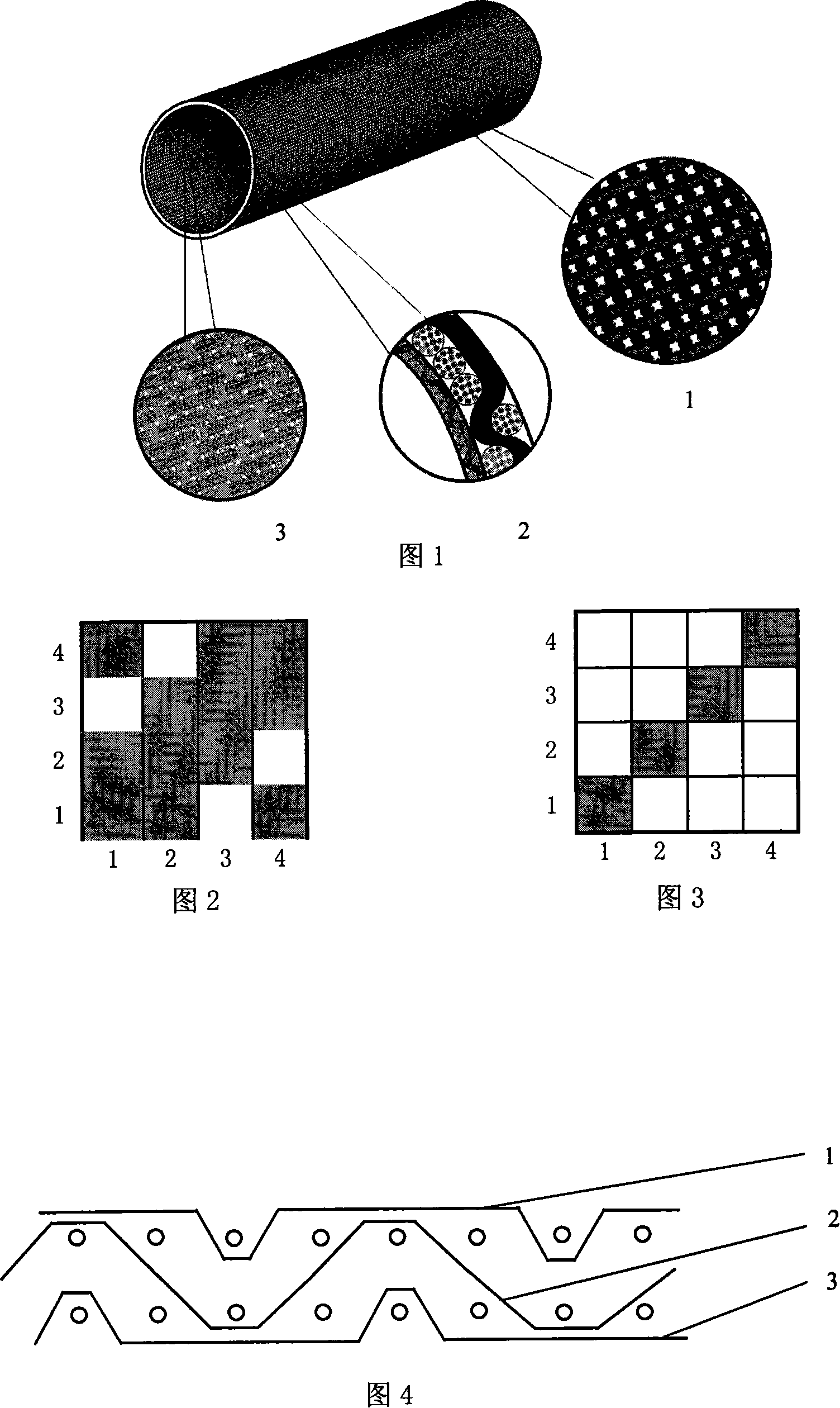

Woven artificial blood vessel in double layer structure

InactiveCN101066476ASufficient mechanical propertiesMeet the mechanical performance requirementsCatheterSurgical operationFiber

The present invention provides one kind of woven artificial blood vessel in double layer structure. The woven artificial blood vessel includes one woven outer layer and one inner layer of nanometer fiber. The woven artificial blood vessel can prevent blood permeation during surgical operation, is favorable to smooth growth of cell tissue to its inside after operation, and has high mechanical strength enough for being crinkled and being handled in operation.

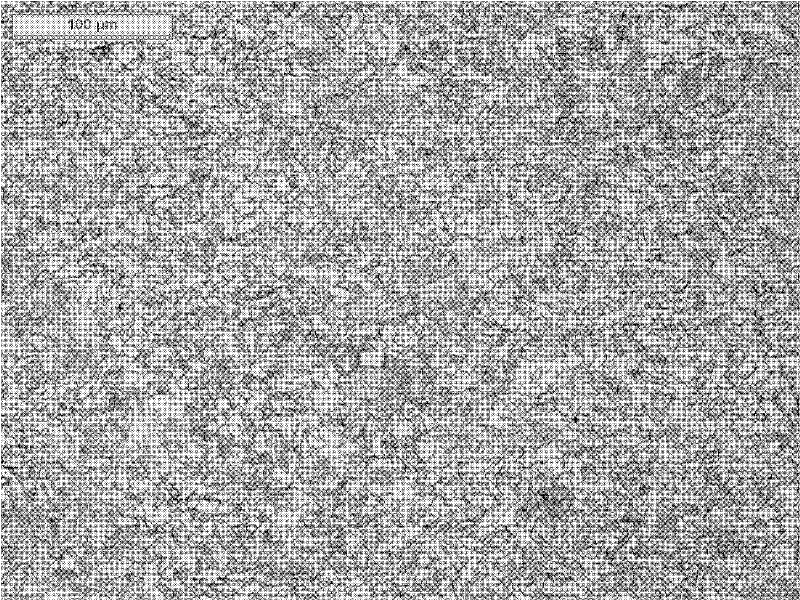

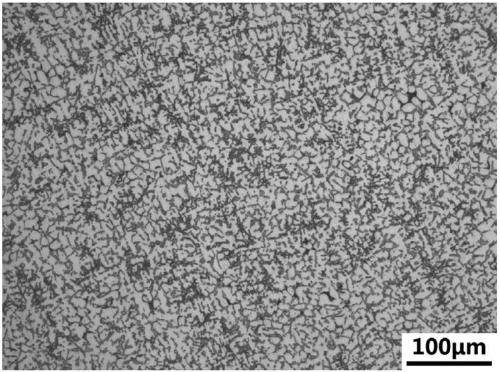

Hot-rolled ferrite-bainite dual-phase steel and production process thereof

InactiveCN102443735AMeet the mechanical performance requirementsHigh strengthTemperature control devicePlasticityMechanical properties of carbon nanotubes

The invention provides hot-rolled ferrite-bainite dual-phase steel and a production process thereof, belonging to the field of high-strength punching steel. The hot-rolled dual-phase steel comprises, in weight percent, 0.09 to 0.10% of C, 0.01 to 0.4% of Si, 1.3 to 1.4% of Mn, no more than 0.012% of P and no more than 0.006% of S, with the balance being Fe and other impurity elements. The production process comprises the following sequential steps: heating, insulation, rough rolling, finish rolling, post-rolling cooling and reeling. The dual-phase steel in the invention has the advantages of a yield strength greater than 340 MPa, a tensile strength greater than 450 MPa, good matching of strength and plasticity, good fracture performance and capacity of meeting requirements for mechanical properties of 450 MPa grade ferrite-bainite hot-rolled dual-phase steel.

Owner:SHOUGANG CORPORATION

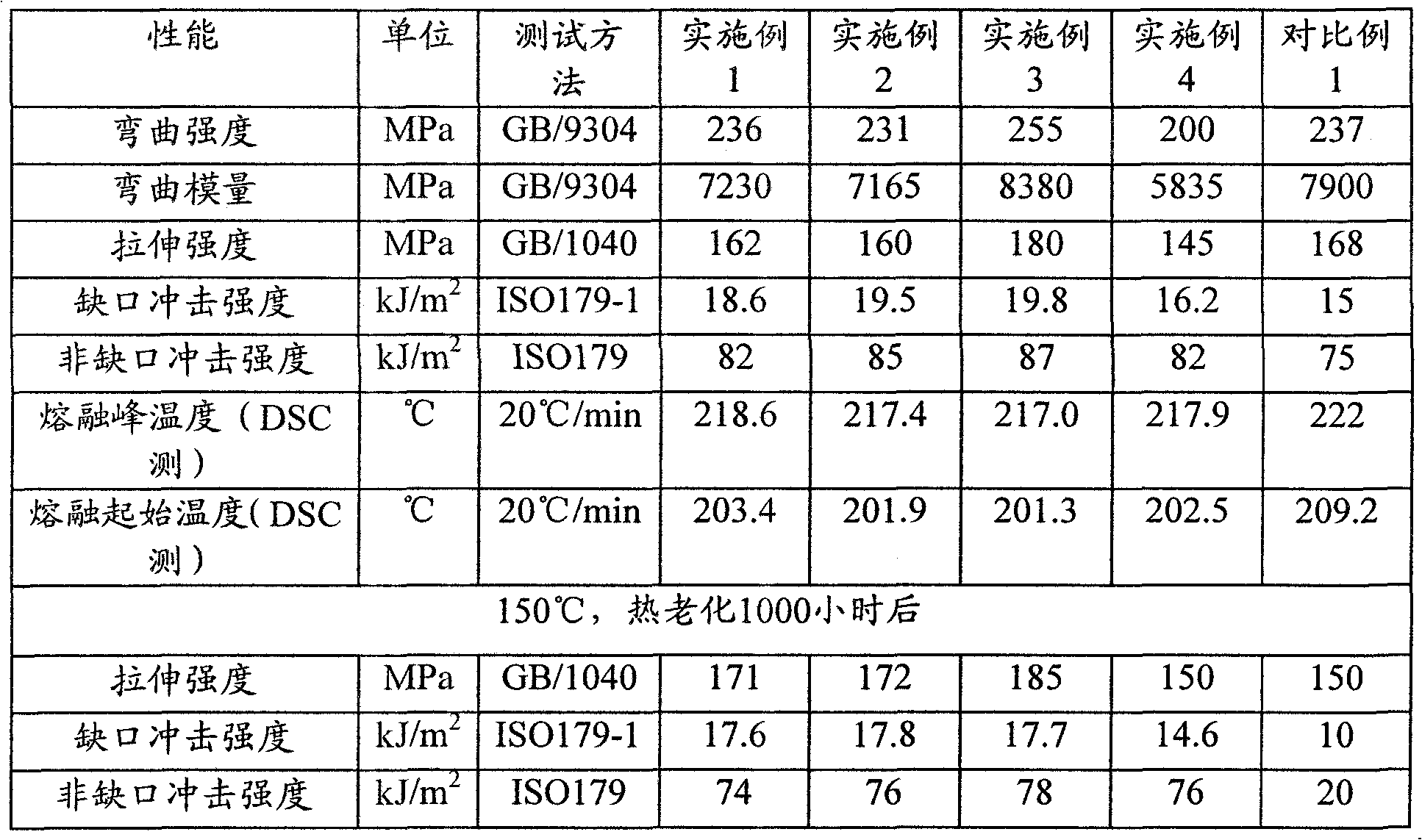

Polyamide composite material for vehicle induction manifold and preparation method thereof

InactiveCN101812230ASolve the problem of high temperature thermal oxygen agingImprove interface strengthCombustion-air/fuel-air treatmentMachines/enginesPolyamideHeat fusion

The invention discloses a polyamide composite material for a vehicle induction manifold. The polyamide composite material comprises the following raw materials in percentage by weight: 40-70 percent of polyamide 6, 1-10 percent of low-fusion point polyamide, 1-5 percent of compatilizer, 0.2-5 percent of composite heat stabilizer, 0.5-5 percent of lubricant and 20-40 percent of reinforcement component. Meanwhile, the invention discloses a preparation method of the polyamide composite material for the vehicle induction manifold. The composite material has good heat-resistant performance and heat fusion performance and is especially suitable for preparing workpieces of vehicle induction manifolds; moreover, the preparation method is simple, adopts traditional equipment, and is suitable for industrial production.

Owner:CGN JUNER NEW MATERIALS +1

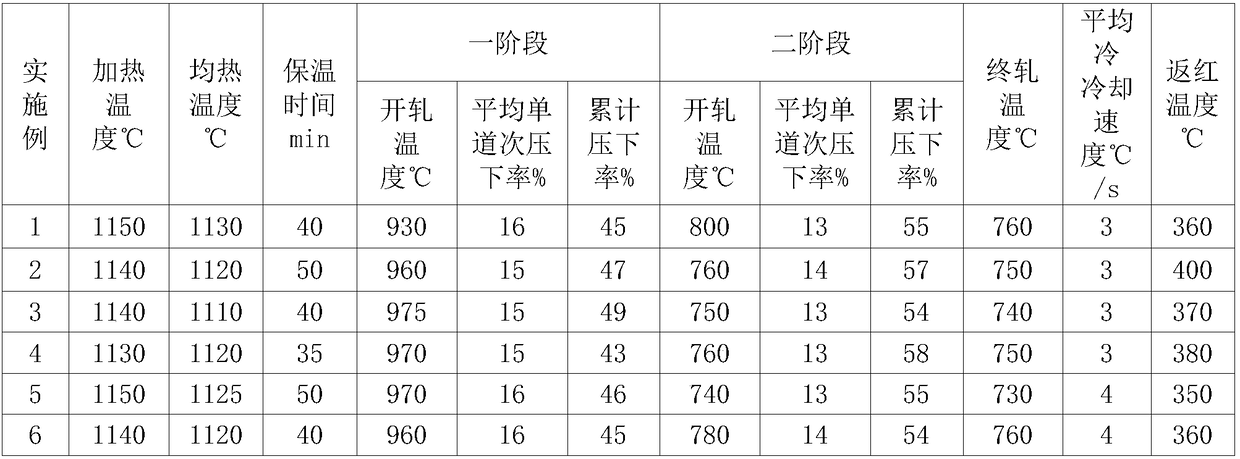

High-strength thick steel plate with excellent crack-arrest property and manufacturing method thereof

The invention relates to a high-strength thick steel plate with an excellent crack-arrest property. The steel plate has the following characteristics: a wide-plate tensile value Kca for determining the crack-arrest property is larger than 6000 N / mm<1.5>; yield strength at the positions, which are respectively 1 / 4 and 1 / 2 the thickness of the steel plate away from the surface of the steel plate, isno less than 460 MPa; tensile strength is 570 to 720 MPa; Charpy impact energy at minus 40 DEG C is no less than 200 J; and a zero-ductility transition temperature is less than minus 60 DEG C. The steel plate provided by the invention comprises the following components by weight: 0.04 to 0.16% of C, 0.1 to 0.5% of Si, 0.9 to 1.6% of Mn, 0.1 to 0.3% of Cu, 0.2 to 0.9% of Ni, no more than 0.02% ofP, no more than 0.02% of S, 0.01% to 0.05% of Als, 0.002 to 0.010% of N, 0.02% to 0.05% of Nb and 0.01 to 0.03% of Ti, with the balance being Fe and unavoidable impurities. According to the invention,through optimization of chemical components of a high-strength steel plate and adoption of controlled rolling and controlled cooling processes for controlling the microscopic structure and grain sizein a plate thickness direction, the crack-arrest steel plate with high yield and stable strength and toughness is obtained. The high-strength thick steel plate provided by the Invention is used as container vessel steel, and has the characteristics of excellent crack-arrest toughness, high yield strength, excellent low-temperature toughness and large thickness.

Owner:ANGANG STEEL CO LTD

Preparing method for battery box cover

InactiveCN109353031AMeet the mechanical performance requirementsImprove mechanical propertiesDomestic articlesFiberVacuum pumping

The invention provides a preparing method for a battery box cover. The preparing method comprises the following steps that firstly, continuous fiber reinforced thermosetting resin prepreg and SMC sheets are provided; secondly, a prepreg layer, an SMC layer and a prepreg layer are sequentially laid on a die core, and a prefabricated body is obtained; thirdly, the die core and the prefabricated bodyare placed in vacuum pumping equipment together, and vacuum pumping pre-compacting is conducted; fourthly, the die core and the pre-compacted prefabricated body are arranged on a preheated male die,and die assembly and curing are conducted; and fifthly, after curing sizing, the die core and a cured and formed product are taken out of the die, a sizing tool is adopted for pressing the product, and cooling is conducted. The battery box cover obtained through the preparing method can meet the high mechanical performance requirement for the box cover, and meanwhile the product appearance and airtightness are optimized. Compared with a traditional box cover, the mechanical performance, impact resistance, burning resistance and other performance of the battery box cover are improved, meanwhile, through the preparing method, the material cost is further reduced, and the production efficiency is improved.

Owner:苏州康本新能源科技有限公司

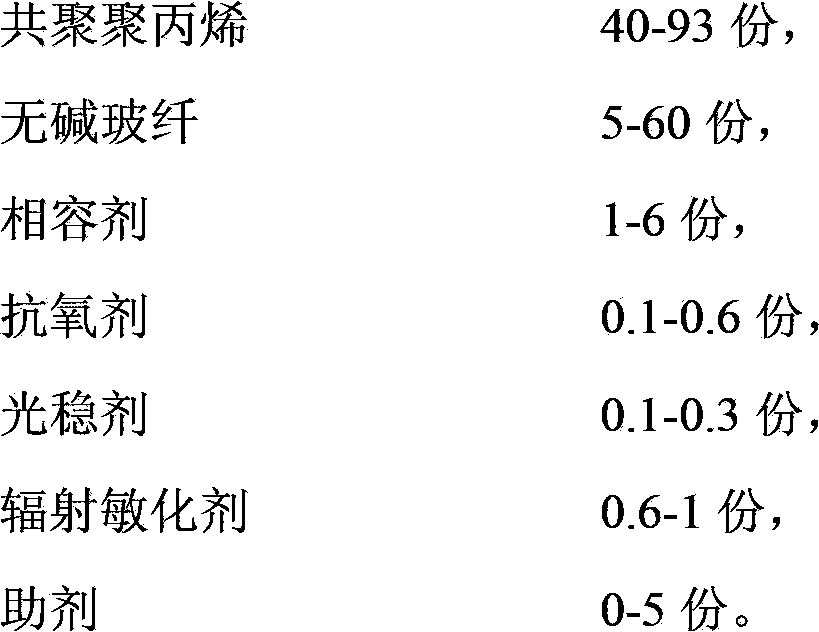

Weather resistant polypropylene composite material and its preparation method and uses

InactiveCN103509247AAvoid damageAvoid breakingForming/stuttering elementsGlass fiberPolypropylene composites

The invention belongs to the technical field of polymer composite materials, and relates to a polypropylene composite material and its preparing method and uses. The polypropylene composite material comprises the following components by weight: 40-93 parts of co-polypropylene, 5-60 parts of alkali free glass fiber, 1-6 parts of a compatible agent, 0.1-0.6 part of an antioxidant, 0.1-0.3 part of a light stabilizer, 0.6-1 part of a radiation sensitizing agent and 0-5 parts of an additive. Through cooperation of the functional additives, the high-strength, high-toughness and weather resistant composite material for building templates can be prepared, and the polypropylene composite material can be used for the preparation of various building templates and other outdoor equipment due to its excellent comprehensive properties.

Owner:HEFEI GENIUS NEW MATERIALS

Cold rolling method for hard stainless steel band

InactiveCN102029290AEasy to shapeHigh hardnessTension/compression control deviceMetal rolling arrangementsWork in processSubmarine

The invention relates to a cold rolling method for a hard stainless steel band, which comprises the following steps: selecting a stainless steel band blank; using a four-roller finishing rolling mill unit to carry out primary rolling on a 3mm-thick stainless steel band into a 1.6mm-thick semi-finished stainless steel band, carrying out intermediate annealing and finish rolling, rolling the 1.6mm-thick semi-finished stainless steel band into a 0.8mm-thick finished stainless steel band, and cutting the finished stainless steel band to a user-required width; and finally, inspecting, packaging, and warehousing. The stainless steel band has favorable form and extremely high hardness which can be up to 400 degrees or above. By arranging the annealing procedure prior to the finish rolling procedure, the invention eliminates the internal stress generated in the primary rolling process, improves the performance quality of the finished product and meets the requirements for mechanical properties of the finished product, thereby being widely used in the high-technology fields of IT industry, submarines, aircrafts and the like.

Owner:WUXI JIALIAN STAINLESS STEEL

High-heat-conductivity high-corrosion-resistance cast aluminum alloy and preparation method thereof

The invention discloses high-heat-conductivity high-corrosion-resistance cast aluminum alloy and a preparation method thereof. The high-heat-conductivity high-corrosion-resistance cast aluminum alloycomprises the raw material components of, by weight, 7-9% of Si, 0.6-1.0% of Fe, 0.2-0.6% of Zn, 0.1-0.5% of Co, 0.05-0.15% of B, 0.2-0.5% of RE, 0.05-0.2% of Sr and the balance Al. In the preparationprocess, the aluminum alloy containing the elements of Si, Fe and Co is melted at the high temperature at first, and then is subjected to still standing and cooled; pure Zn, Al-RE intermediate alloy,Al-B intermediate alloy and Al-Sr intermediate alloy are added into the melt for further alloying; and the melt is subjected to refining and slag removal, and molding is achieved through casting. According to the alloy preparation process, the technology effect is remarkable, the Co, B, Sr and RE multi-element compound synergistic effect is sufficiently realized, and thus, the alloy casting piecehas the excellent heat conductivity, high mechanical property and good corrosion resistance.

Owner:SOUTH CHINA UNIV OF TECH +1

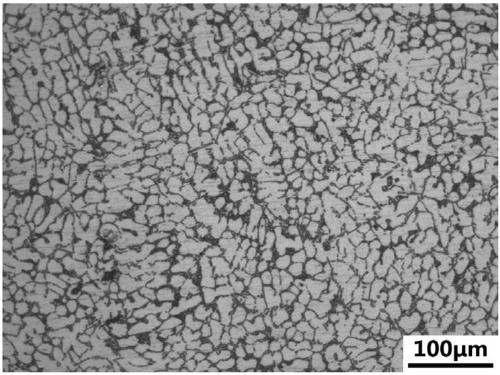

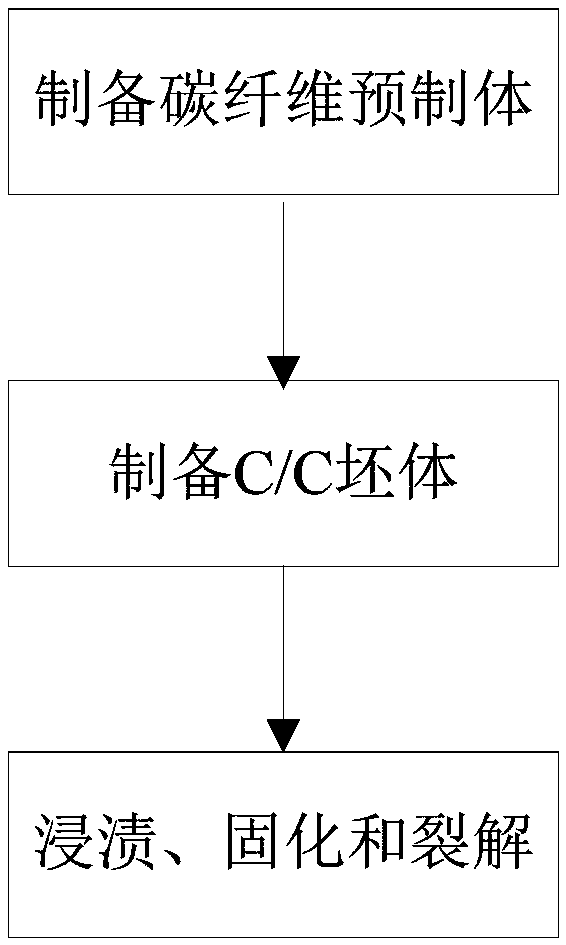

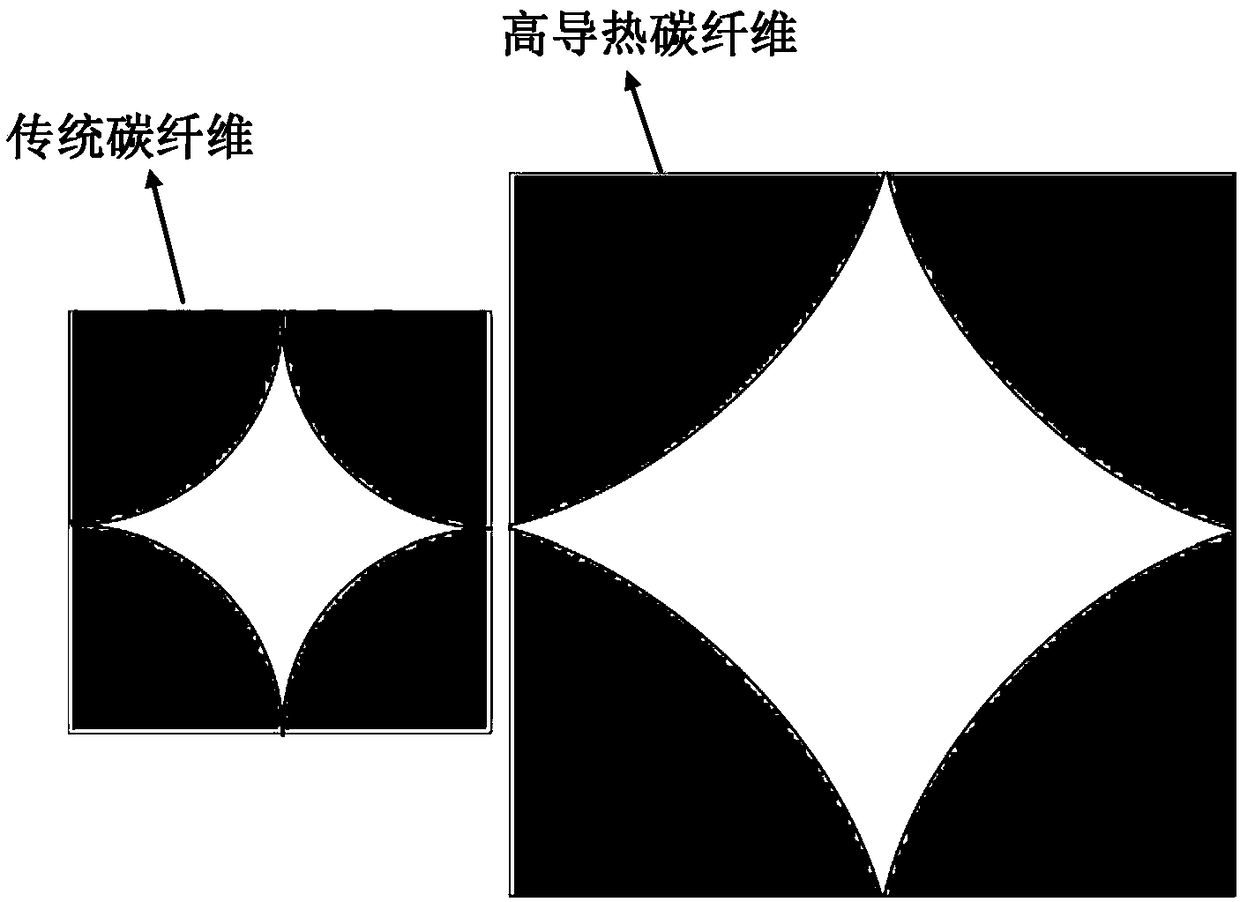

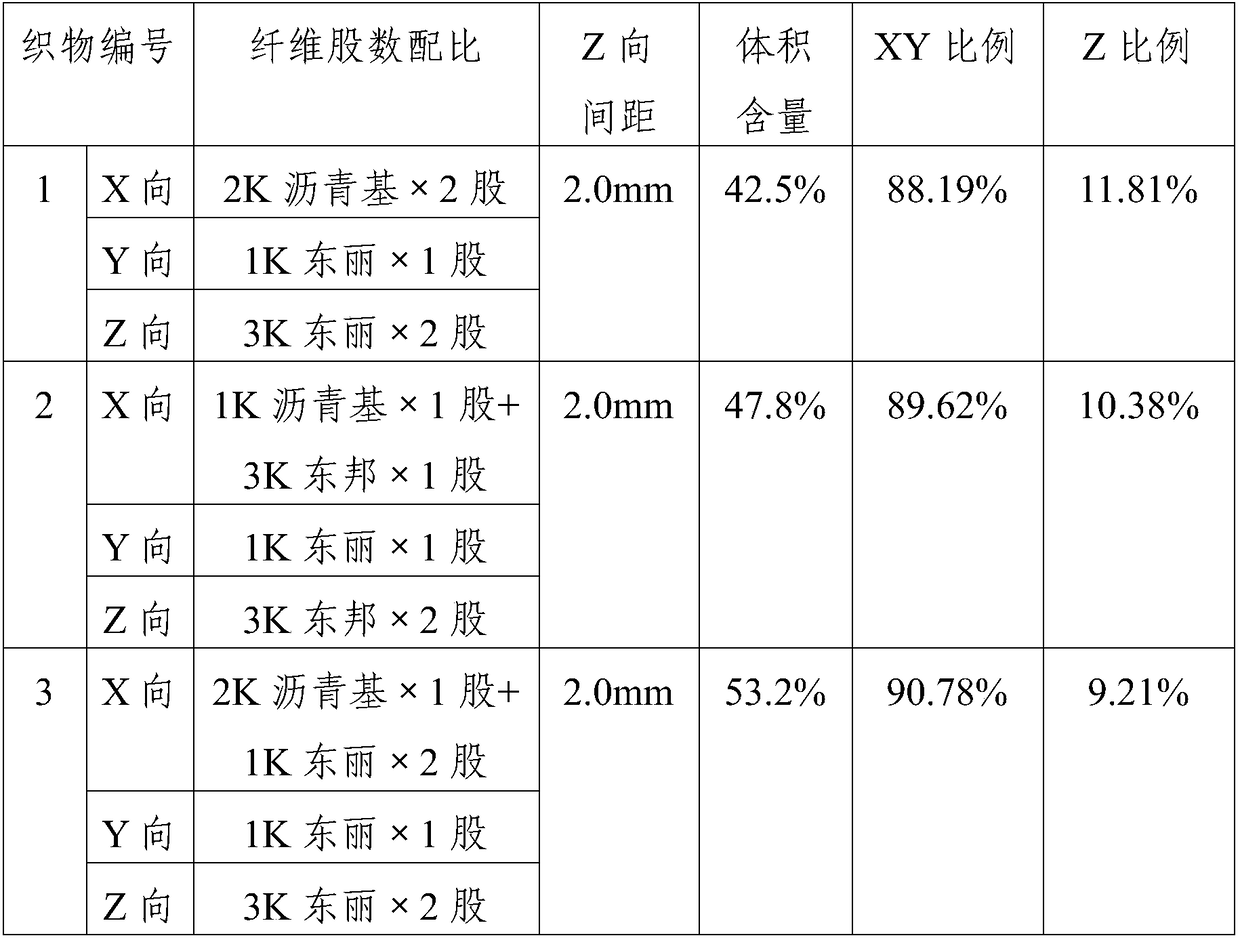

Heat transmission ceramic matrix composite material and preparation method thereof

ActiveCN109320278AImprove mechanical propertiesGood knitting performanceCarbon fibersHeat transmission

The invention relates to a heat transmission ceramic matrix composite material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing carbon fiber prefab: utilizing mesophase pitch-based high thermal conductivity carbon fibers and polyacrylonitrile-based carbon fibers to be mixed and woven into the carbon fiber prefab; (2) preparing a C / C green body:preparing the carbon fiber prefab into the C / C green body with a certain density; (3) dipping, curing and cracking: dipping, curing and cracking the C / C green body in a ceramic precursor solution andrepeating the dipping, curing and cracking step until the weight increment of the composite material meets a design requirement to obtain the heat transmission ceramic matrix composite material. According to the preparation method, the heat conductivity limitation of an existing ceramic matrix composite material is broken through, a technology is controllable and convenient to operate, and a highthermal conductivity carbon fiber application method which is feasible and has excellent technological effects is also provided.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Casting process of nodular cast iron planet carrier

The invention relates to a casting process of a nodular cast iron planet carrier, which comprises the following procedures of modeling, iron melt melting, spheroidizing, modifying, casting and stress relieving and annealing. The design of a casting system adopts a step casting method which takes consideration of both bottom casting and top casting to improve the finished product rate of castings, and also adopts technical schemes of placing chill iron at the position of thick walls, adding Sn element in the iron melt, optimizing, spheroidizing, modifying, casting and the like, so that the produced planet carrier not only meets the high demands on property, but also achieves great improvement in production cost and efficiency.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com