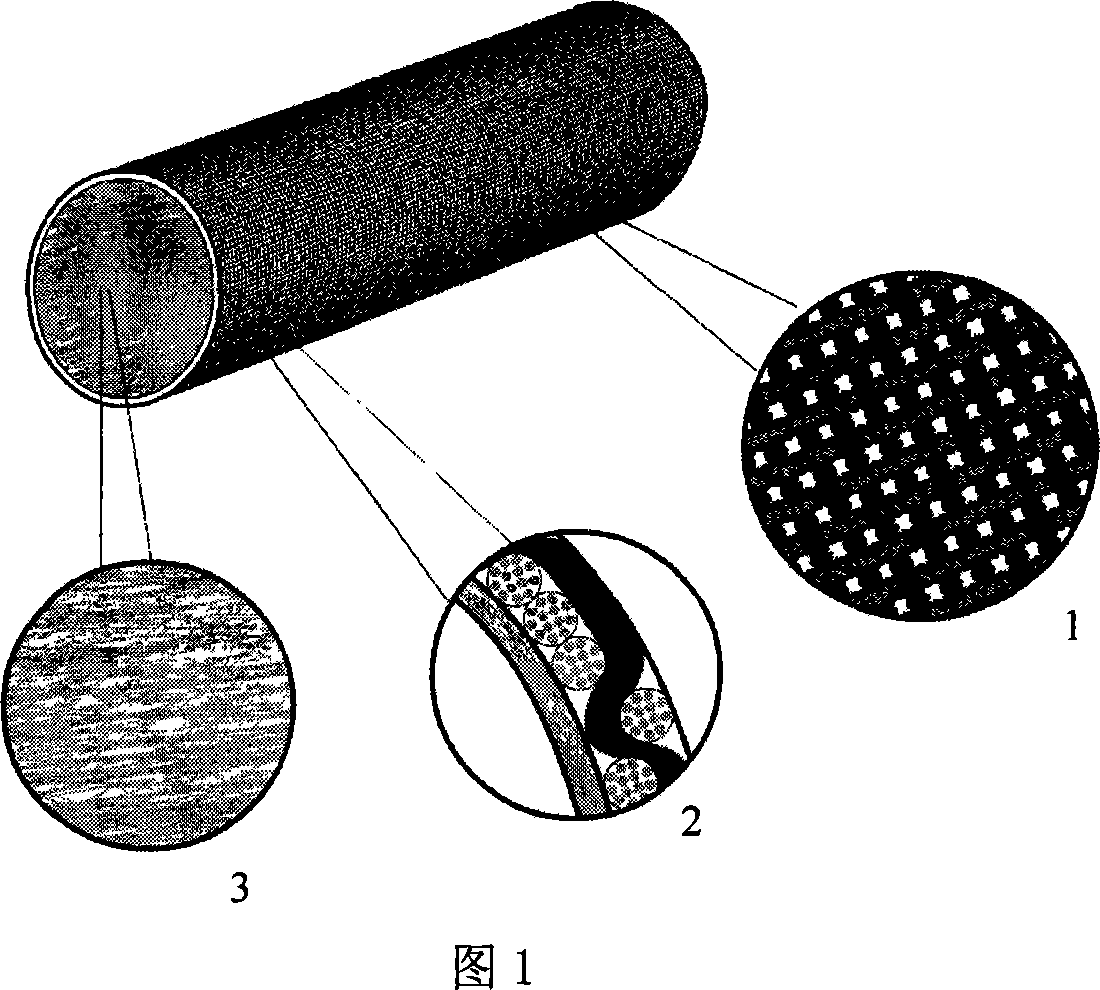

Woven artificial blood vessel in double layer structure

A technology of artificial blood vessels with a double-layer structure, applied in the direction of catheters, etc., can solve the problems that the smooth growth of cells and tissues cannot be achieved at the same time, and blood seepage from the vessel wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Use 300dtex / 250f polyester fiber filaments as warp yarns, 300dtex / 250f polyester fiber filaments as weft yarns, and the twist of warp yarns and weft yarns is 100 twists / m. The weave of the fabric is 3 / 1 twill, the warp density of the fabric is 400 threads / 10cm, and the weft density is 350 threads / 10cm. Woven tubular fabrics are manufactured on shuttle looms. The water permeability of the tubular fabric after getting off the machine is 1100ml / cm 2 · min · 16kPa.

[0020] The PEO resin (Mw=900,000) was dissolved in a solvent (water) to prepare a spinning solution with a resin ratio of 3 wt%.

[0021] Put the tubular fabric on the collection roller, apply an electrostatic voltage of 11kV between the spinning head and the collection roller, spin the spinning solution on the electrostatic spinning device to spin nanofibers, and rotate the collection roller at a constant speed to make the nanofibers evenly Lay on the surface of the tubular fabric. After the spinning is fi...

Embodiment 2

[0024] Use 110dtex polyester fiber filaments with a twist of 120 twists / m to weave tubular fabrics on a double needle bed warp knitting machine. . The water seepage of the tubular fabric after getting off the machine is 2000ml / cm 2 · min · 16kPa.

[0025] The PVA resin is melted with a solvent (water) to prepare a spinning solution with a resin ratio of 3 wt%.

[0026] Put the tubular fabric on the collection roller, apply an electrostatic voltage of 11kV between the spinning head and the collection roller, spin the spinning solution on the electrostatic spinning device to spin nanofibers, and rotate the collection roller at a constant speed to lay the nanofibers evenly on the surface of the tube fabric. After the spinning is finished, turn the inside and outside of the tube, so that the nanofiber layer condensed on the outer layer is turned over to the inner layer of the tube fabric, and a tubular fabric with a double-layer structure tube wall is made.

[0027] The artifi...

Embodiment 3

[0029] Use 110dtex polyester fiber filaments with a twist of 120 twists / m to weave tubular fabrics on a double needle bed warp knitting machine. . The water seepage of the tubular fabric after getting off the machine is 3000ml / cm 2 · min · 16kPa.

[0030] The PVA resin is melted with a solvent (water) to prepare a spinning solution with a resin ratio of 3 wt%.

[0031] Put the tubular fabric on the collection roller, apply an electrostatic voltage of 11kV between the spinning head and the collection roller, spin the spinning solution on the electrostatic spinning device to spin nanofibers, and rotate the collection roller at a constant speed to lay the nanofibers evenly on the surface of the tube fabric. After the spinning is finished, turn the inside and outside of the tube, so that the nanofiber layer condensed on the outer layer is turned over to the inner layer of the tube fabric, and a tubular fabric with a double-layer structure tube wall is made.

[0032] The artifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com