Preparation method of flexible supercapacitor electrode

A supercapacitor and electrode technology, applied in the field of nanomaterials, can solve the problems of high process, price restrictions, and restrictions on the application of flexible electrode materials, and achieve the effect of good dispersion and improved feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

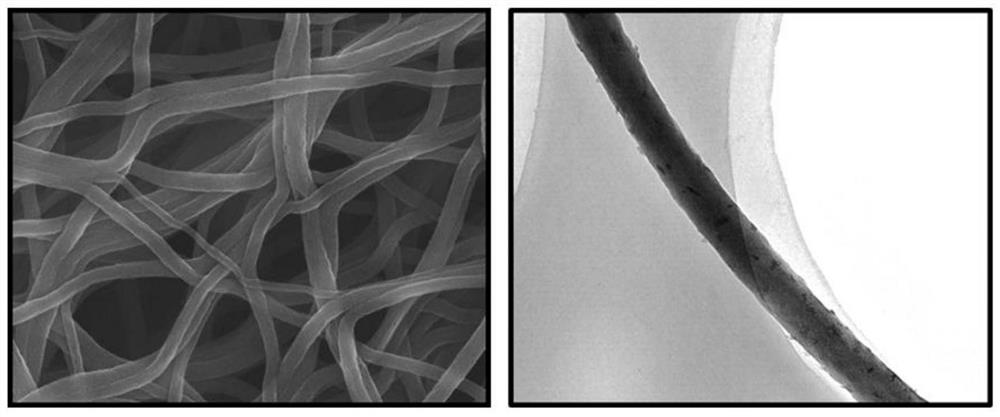

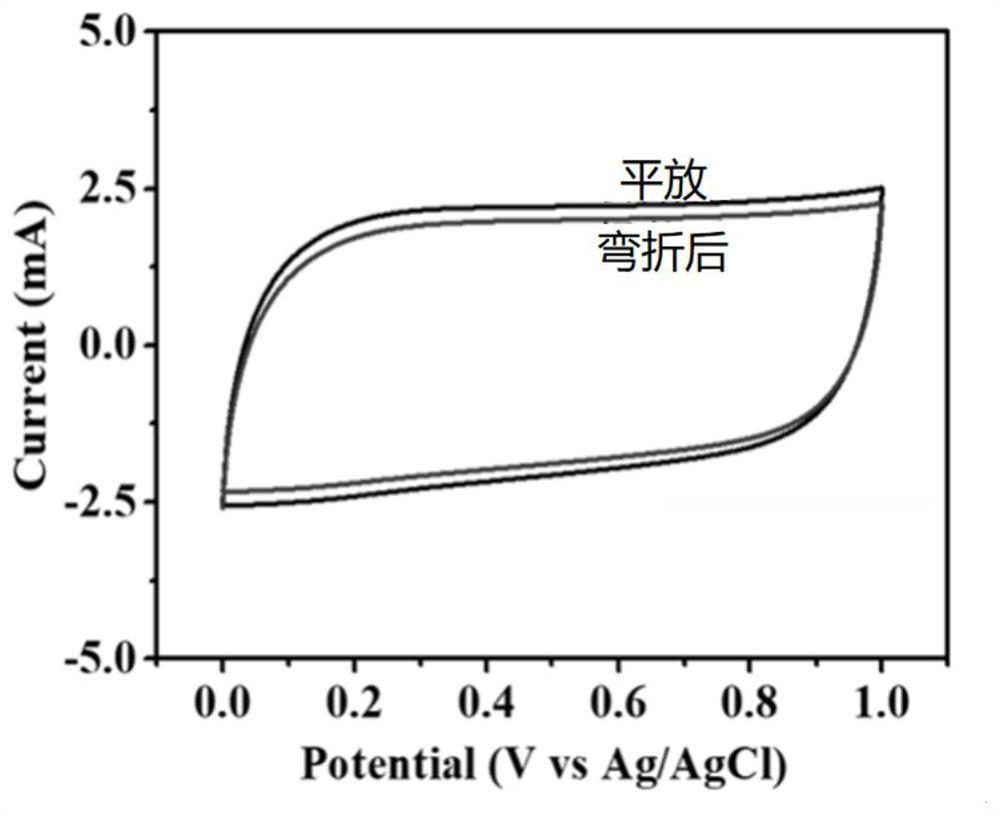

[0019] In this embodiment, electrospinning is used to prepare a nanofiber doped with graphene quantum dots. The specific steps include:

[0020] The first step is to use graphite oxide aqueous solution and hydrogen peroxide as raw materials, add deionized water and place it in a photochemical reactor for reaction. After the reaction is completed, vacuum filter and spin dry to obtain graphene quantum dots. Specifically: take a certain amount of oxidized Graphene is dispersed in deionized water, configured as a 2mg / mL graphene oxide solution, and ultrasonicated for 30min. Then, 5 mL of graphene oxide solution, 0.5 mL of hydrogen peroxide and 70 mL of deionized water were added dropwise to the five quartz tubes, and placed in the photochemical reactor. After reacting for 37 minutes, the product was taken out, rotated at 50°C for 30 minutes, transferred to a dialysis bag, dialyzed for 2-3 days, and then rotated to dryness to collect graphene quantum dots.

[0021] In the second s...

Embodiment 2

[0025] This embodiment specifically includes the following steps:

[0026] Step 1. Take a certain amount of graphene oxide, disperse it in deionized water, prepare a 2 mg / mL graphene oxide solution, and ultrasonicate for 30 minutes. Then, 5 mL of graphene oxide solution, 0.5 mL of hydrogen peroxide and 70 mL of deionized water were added dropwise to the five quartz tubes, and placed in the photochemical reactor. After reacting for 37 minutes, the product was taken out, rotated at 50°C for 30 minutes, transferred to a dialysis bag, dialyzed for 2-3 days, and then rotated to dryness to collect graphene quantum dots.

[0027] Step 2. Take 60 mg of graphene quantum dots obtained in step 1, disperse them in 5 mL of DMF, and add 0.6 g of polyacrylonitrile and 0.6 g of polymethyl methacrylate to it after ultrasonication for 1 h, and heat in an oil bath at 60°C Stir for 8 hours to obtain a uniformly mixed precursor solution.

[0028] Step 3. Transfer the precursor solution to a 20mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com