Integrated fiber post for dental restoration and preparation method thereof

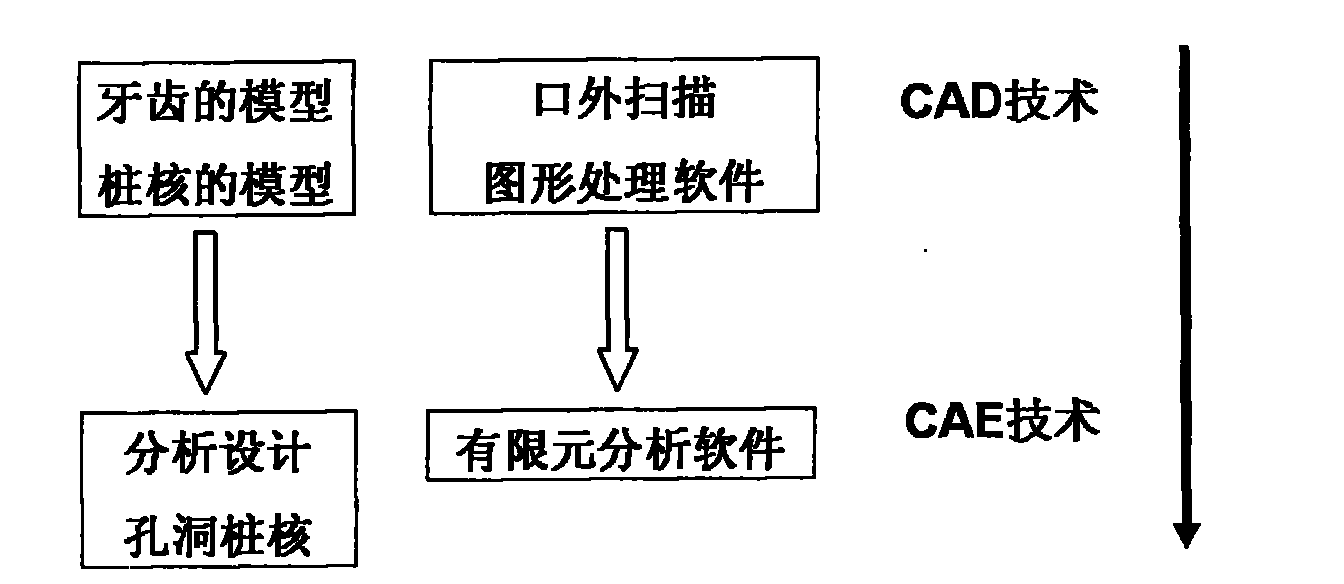

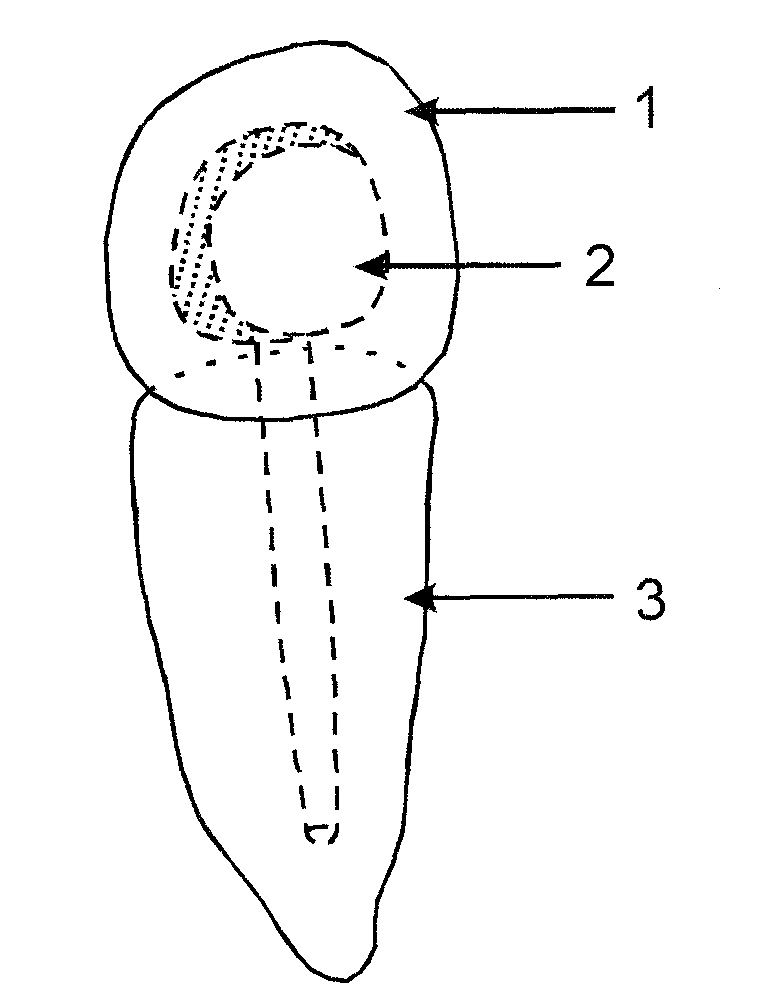

A dental restoration and fiber technology, which is applied in dental prostheses, dental preparations, dentistry, etc., can solve the problem that fiber posts cannot well meet the restoration of tooth defects, and achieves high consistency, simple processing methods, and easy application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Pultrusion preparation of fiber-reinforced resin-based composite body:

[0035] The basic formula of matrix resin is: American Dow Der331 epoxy resin: 100 parts, curing agent: methyltetrahydrophthalic anhydride (80 parts), accelerator: DMP-30 (1 part), mold release agent: 1.5 parts, strengthen The fiber is HS4 continuous long fiber, the fiber tensile strength is 4600MPa, the elastic modulus is 86.4GPa, the density is 2.53g / cm3, and the elongation at break is 5.3%. It is produced by Nanjing Glass Fiber Research and Design Institute; the surface of non-woven glass fiber Felt 30-80g / m 2 , produced by Yixing Fuxing Fiberglass Co., Ltd.

[0036] The green body is prepared by pultrusion process in a circular mold with a diameter of 10mm. The pultrusion process adopts a three-stage heating method, the temperature of the first stage: 140°C, the temperature of the second stage: 165°C, and the temperature of the third stage: 185°C. The stretch-extruded strip was post-cured in ...

Embodiment 2

[0047] In-situ light-curing molding preparation of fiber-reinforced resin-based composite body:

[0048] The basic formula system is: photocurable resin monomer bisphenol A glycidyl methacrylate (Bis-GMA), diluent triethylene glycol dimethacrylate (TEGDMA), catalyst camphorone (CQ) and co-initiator Reagent N,N-dimethylaminoethyl methacrylate (DMAEMA) was purchased from Aldrich Company. High-strength glass fiber, HS4, fiber tensile strength is 4600MPa, elastic modulus is 86.4GPa, density is 2.53g / cm 3 , The elongation at break is 5.3%, produced by Nanjing Glass Fiber Research Institute. Non-woven fiberglass surface mat 30-80g / m 2 , produced by Yixing Fuxing Fiberglass Co., Ltd.

[0049] On-site light-curing molding green body of light-curing prepreg: Weigh 49.5g Bis-GMA and TEGDMA respectively and put them in a 250ml three-neck flask, stir at high speed for 6h to mix evenly, then add 0.5g each of CQ and DMAEMA to the resin system, and then Stir for 1 h to obtain a photocura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com