Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

254results about How to "High nodularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smelting method for medium-thin wall cast-state nickel-free low-temperature ductile cast iron

ActiveCN102690986AImprove densification performanceImprove roundnessIntermediate frequencyStress relief

The invention relates to a smelting method for medium-thin wall cast-state nickel-free low-temperature ductile cast iron. The medium-thin wall cast-state nickel-free low-temperature ductile cast iron comprises the following chemical components in percentage by mass: 3.5-4.1 percent of C, 1.7-2.2 percent of Si, 0.10-0.25 percent of Mn, not more than 0.035 percent of P, not more than 0.020 percent of S, 0.015-0.030 percent of Re, 0.025-0.045 percent of Mg, 0-0.20percent of Cu, less than 0.1 percent of residual element, and Fe in balancing amount. The medium-thin wall cast-state nickel-free low-temperature ductile cast iron is obtained by mixing furnace materials and carrying out high-temperature smelting in an intermediate-frequency furnace, modularization and inoculation treatment and casting and heat-insulating treatment on the mixed furnace materials. Cast iron products obtained by adopting the smelting method disclosed by the invention obtain normal-temperature mechanical property and low-temperature mechanical property under the cast state conditions; complex medium-thin wall parts are required to be subjected to low-temperature stress relief annealing; and simple medium-thin wall parts are free from being annealed, so that the production cost is greatly reduced, the production period is greatly shortened and the production efficiency is increased.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

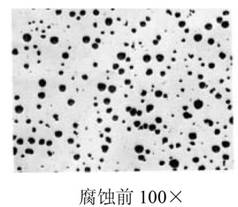

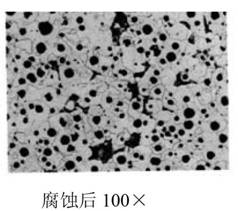

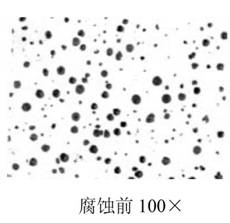

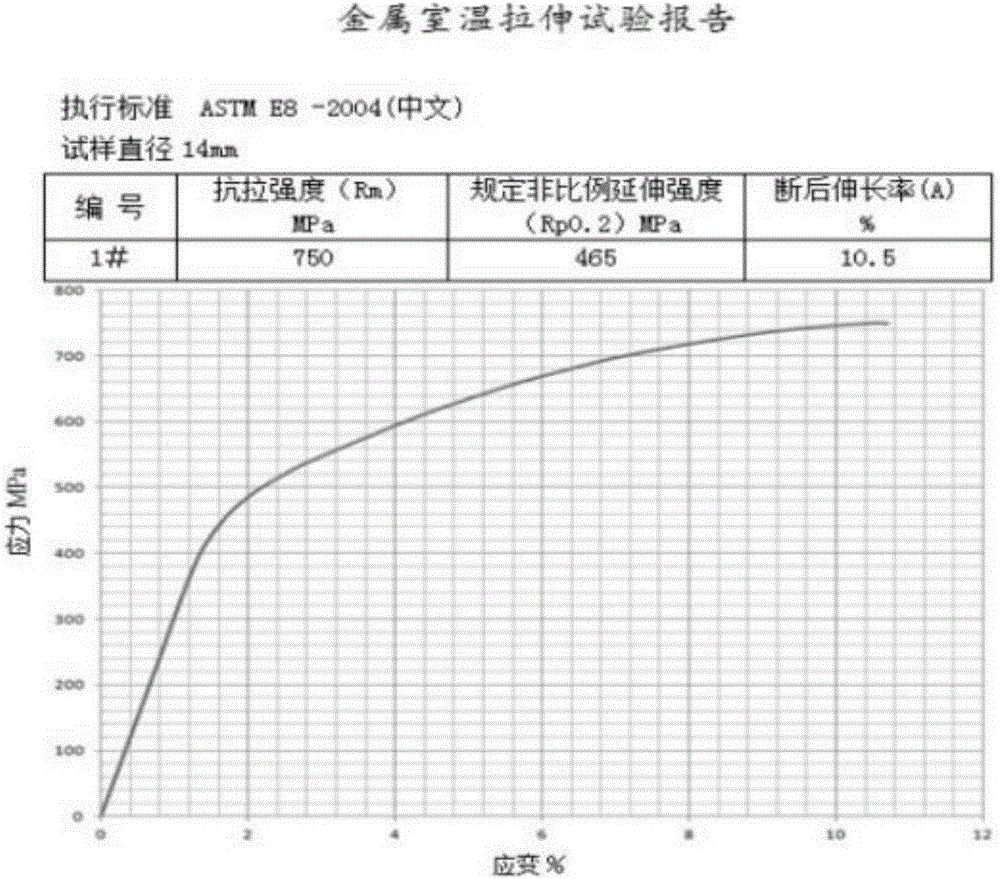

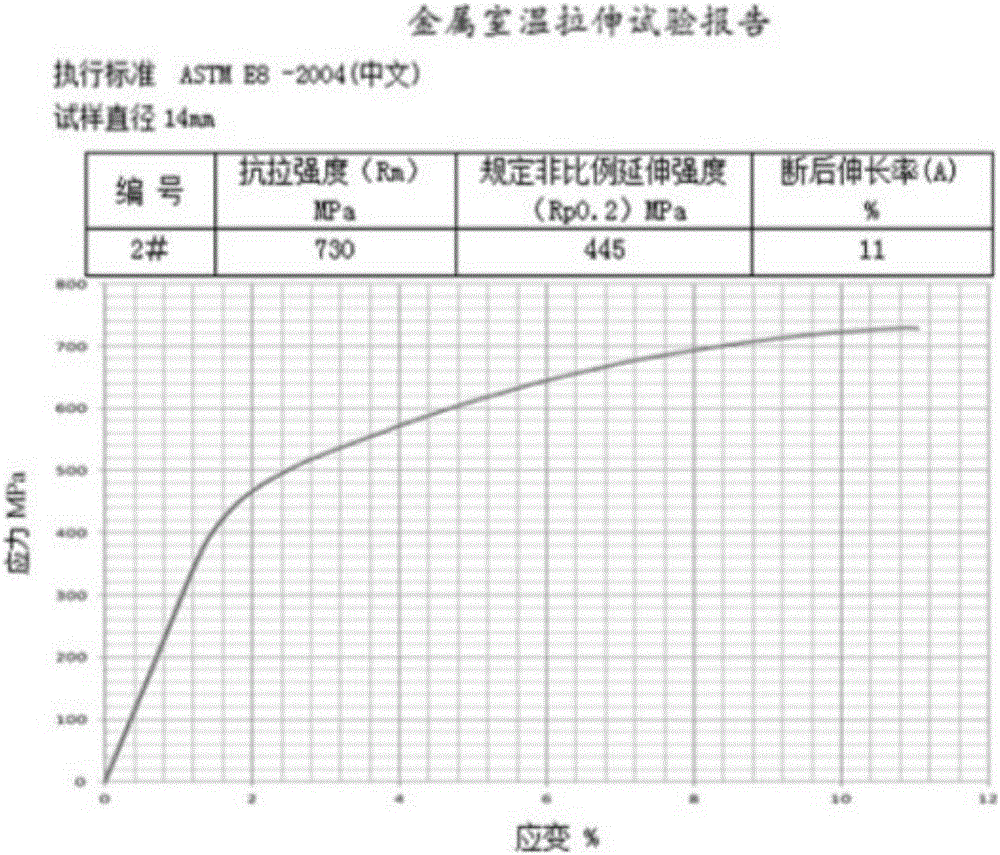

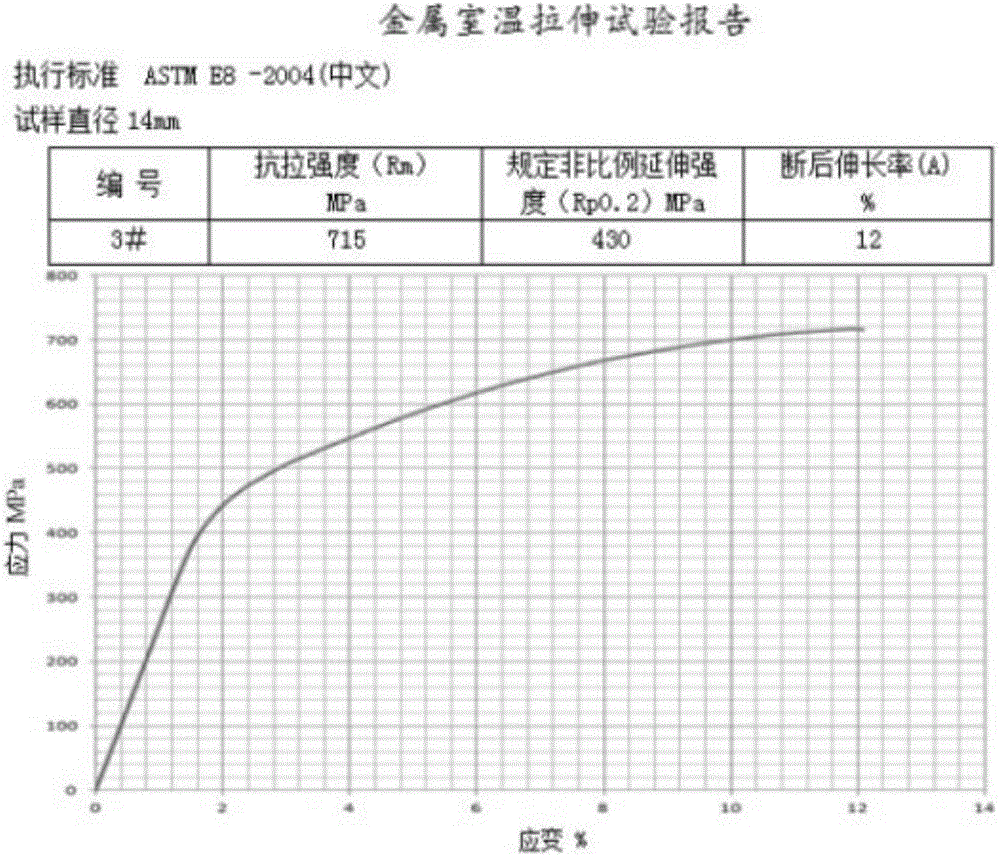

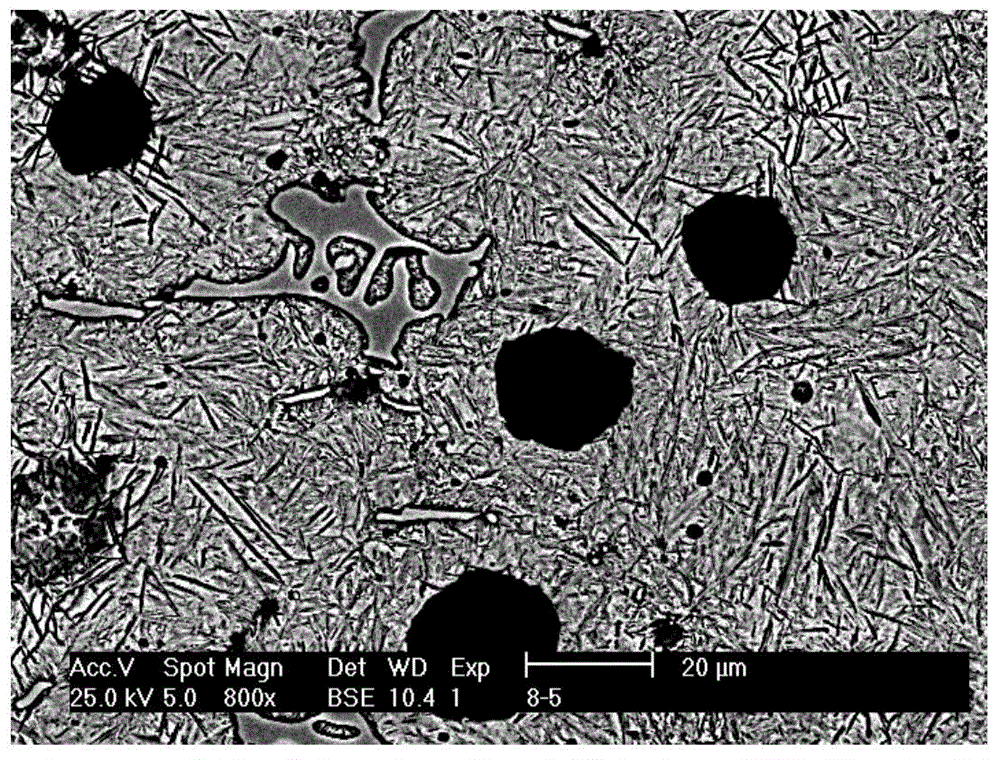

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

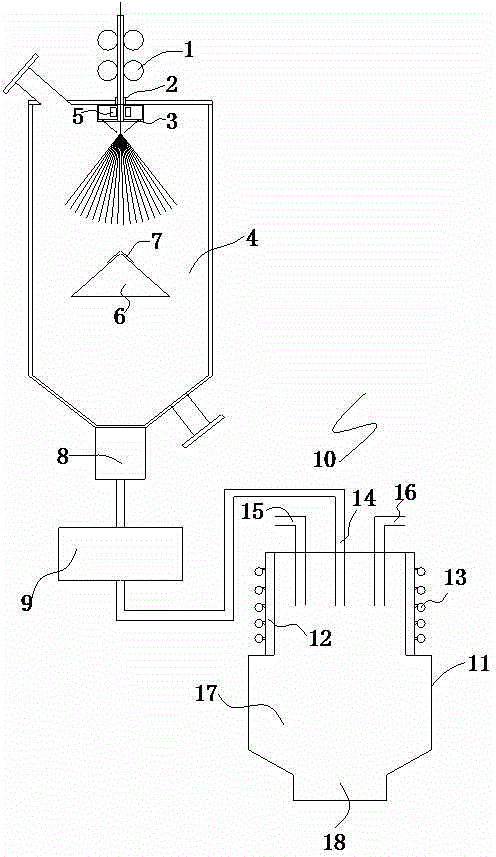

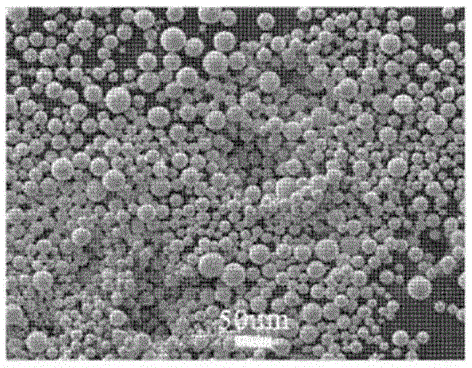

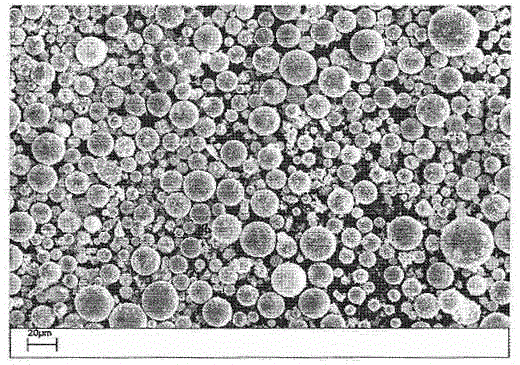

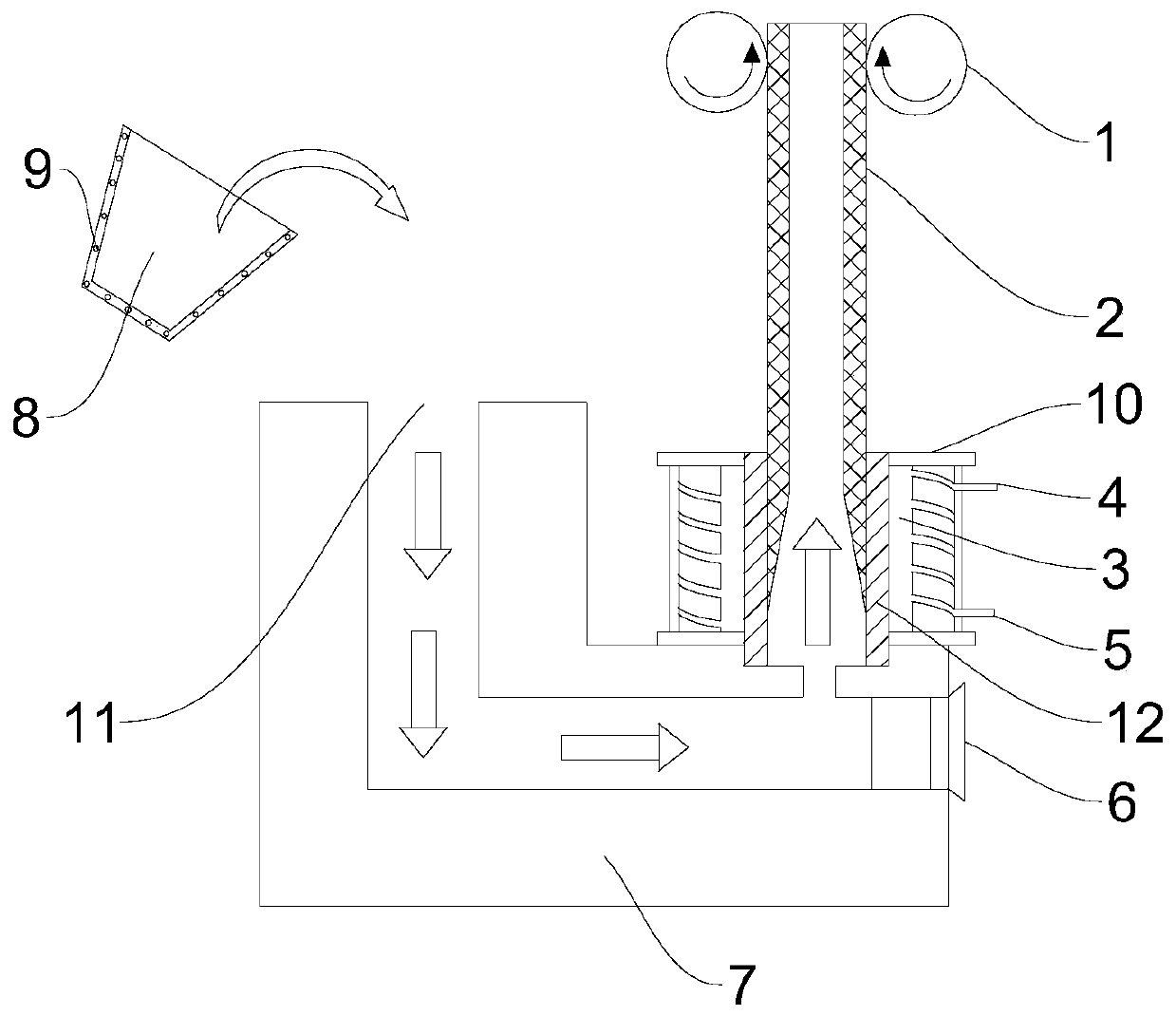

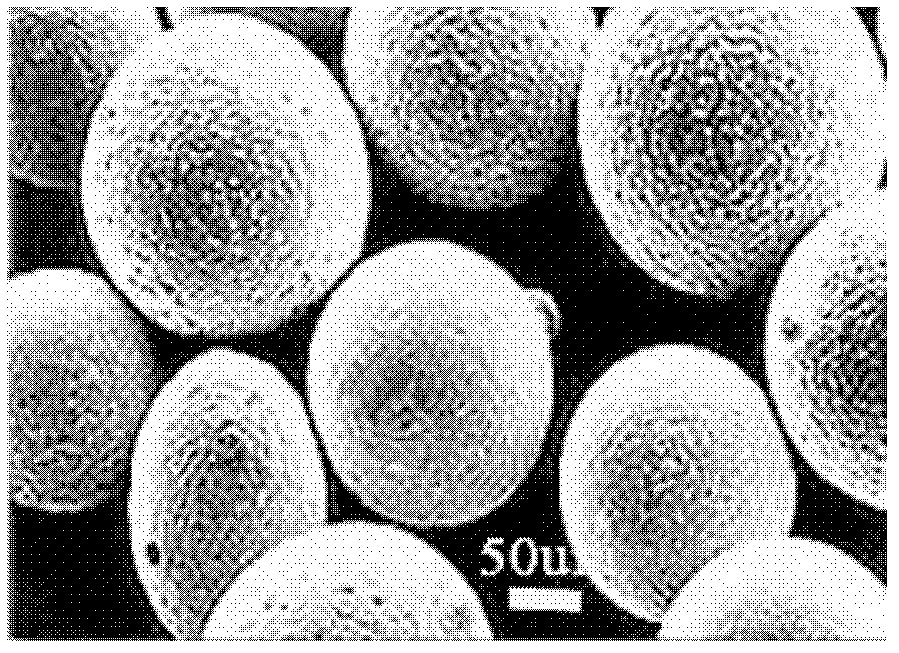

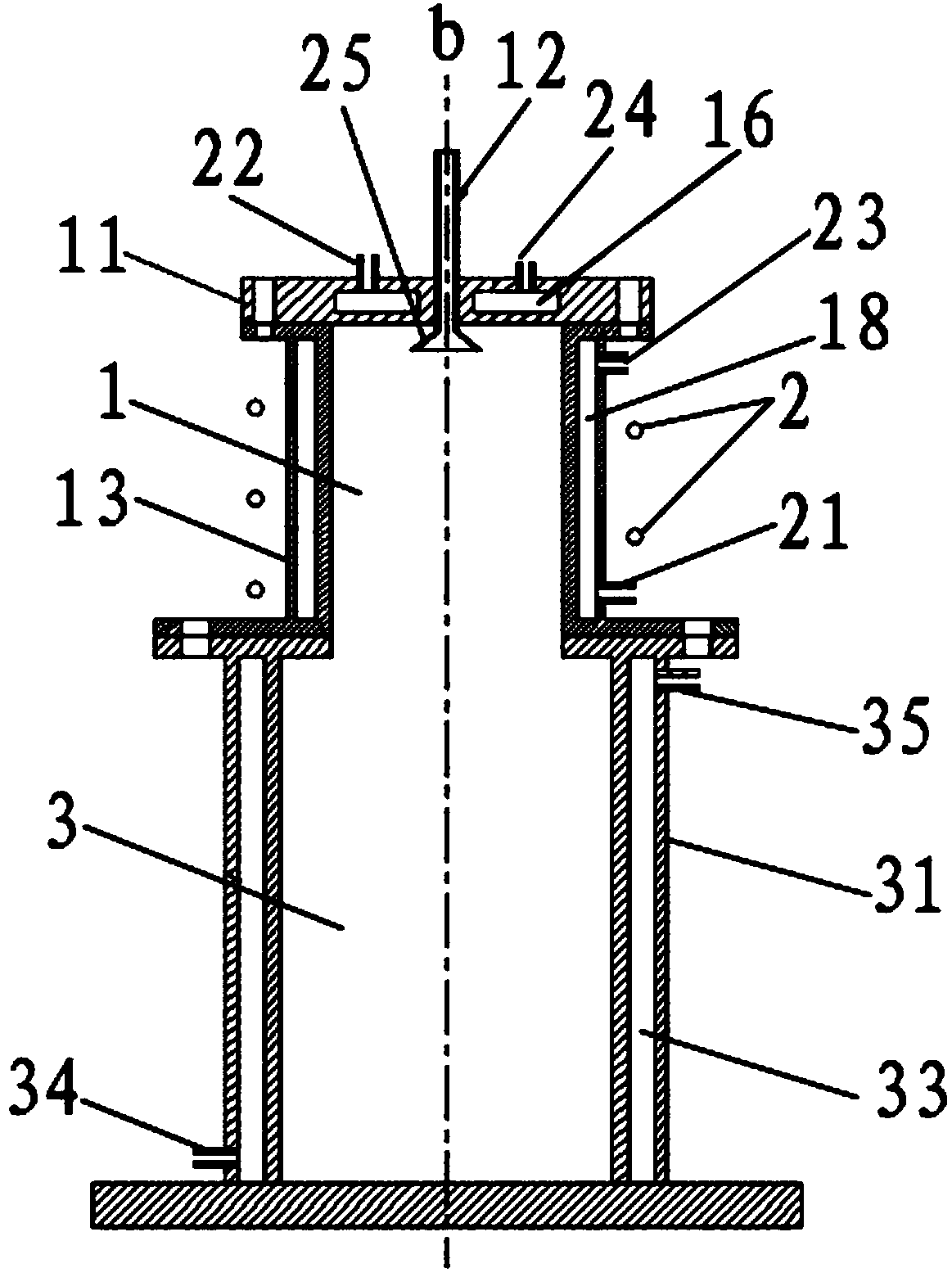

Device and method for preparing superfine micro-spherical titanium powder for 3D printing

InactiveCN105057689AGood sphericityHigh purityAdditive manufacturing apparatusPlasma torchRadio frequency plasma

The invention relates to a device for preparing superfine micro-spherical titanium powder for 3D printing. The device for preparing the superfine micro-spherical titanium powder for 3D printing comprises an automatic feeding system, an insulation dynamic seal unit, an annular gas atomization nozzle, an atomization chamber, an arc cathode smelting well, a radiating cover, a protection cover, a powder collection tank, a supersonic gas crushing mill and a radio frequency plasma reactor. The invention further relates to a method for preparing the superfine micro-spherical titanium powder for 3D printing. The method comprises the steps that firstly a gas atomization unit is used for performing initial powder production on raw titanium powder; then crushing is used for further reducing the granularity of the titanium powder; a plasma unit is used for further processing the titanium powder; the high-energy characteristic of radio frequency plasma is used for injecting carrying gas for irregular-shaped titanium powder particles into a plasma torch, the irregular titanium powder is heated rapidly and melted, the melted particles form drops with high sphericity degree under the action of surface tension, and the drops are solidified rapidly under an ultra-high temperature gradient to form the superfine micro-spherical titanium powder good in sphericity degree, high in purity and low in oxygen content.

Owner:SHANXI ZHUOFENG TITANIUM IND

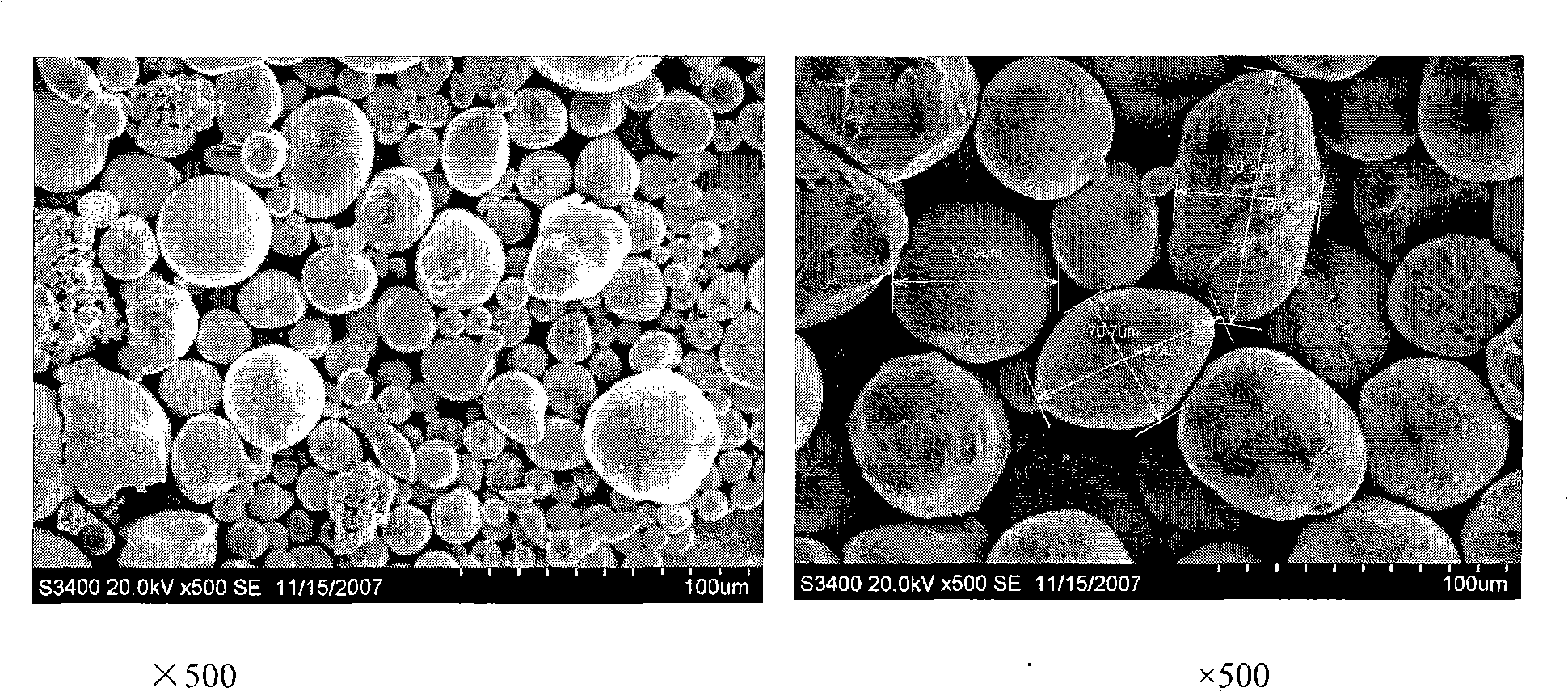

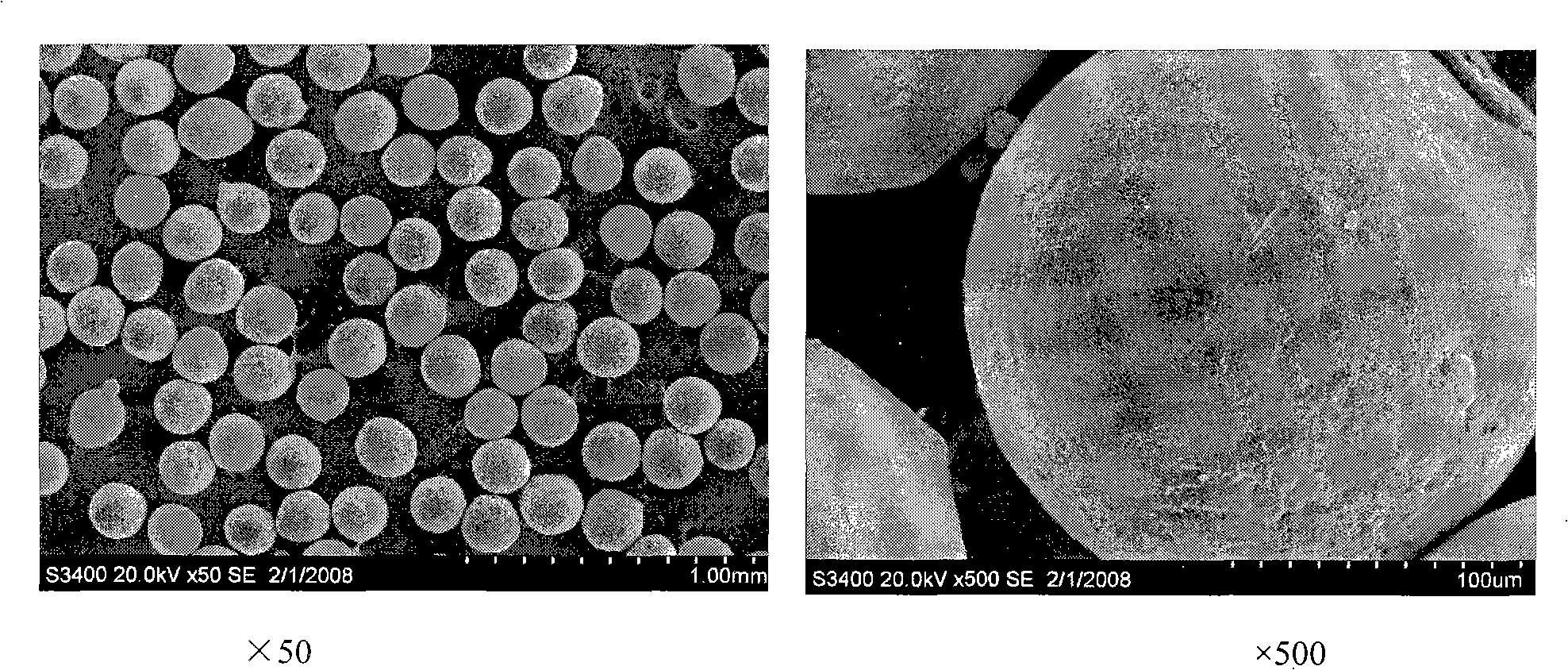

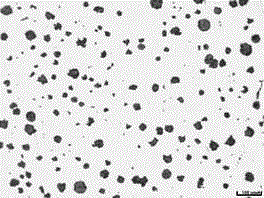

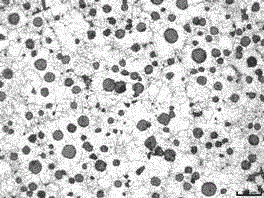

Preparation method of fine globular tungsten powder

The invention relates to a powder material preparation method, in particular to a method for preparing fine spherical tungsten powder. Plasma parameters are adjusted by building a stable argon plasma, thereby heating tungsten powder material and acquiring the fine spherical tungsten powder through the separation after cooling and solidification, and the obtained tungsten powder has better fluidity, higher density, purity and particle cleanliness of surface, and lower powder particle porosity compared with the tungsten original powder; and the method has advantages of changing shapes of tungsten powder particles, high sphericity, increasing the apparent density of powder, improving the tungsten powder fluidity and physical characteristics of the tungsten powder, and reducing costs.

Owner:SOUTHWESTERN INST OF PHYSICS

Ausferrite ductile cast iron grinding ball

ActiveCN104152792AHighlight substantive featuresImprove absorption rateGrain treatmentsAlloyDuctile iron

The invention discloses an Ausferrite ductile cast iron grinding ball, and relates to a spherulitic graphite-contained cast iron alloy. The Ausferrite ductile cast iron grinding ball comprises the following chemical elements in percentage by mass: 3.3-3.7% of C, 2.0-3.0% of Si, 1.0-2.5% of Mn, 0.7-3.0% of Cr, 0.1-1.0% of Mo, 0.1-1.0% of Cu, 0.04-0.08% of P, 0.01-0.020% of S, 0.03-0.05% of Mg, 0.02-0.04% of Ce, 0.03-0.07% of B, 0.06-0.12% of Ti, 0.03-0.2% of V, and the balance of Fe. The Ausferrite ductile cast iron grinding ball is prepared by the steps of preparation and smelting of raw materials, spheroidizing treatment, inoculation treatment and microalloying treatment, and isothermal quenching heat treatment. The Ausferrite ductile cast iron grinding ball overcomes the defects of low production efficiency and high consumption of electric energy of a ball mill due to easy surface stripping and crushing and shorter fatigue life of an existing grinding ball product in the service process.

Owner:HEBEI UNIV OF TECH

Plasma preparation method of spherical titanium powder for 3D printing

InactiveCN105562700AHigh sphericityUniform particle size distributionAdditive manufacturing apparatusTransportation and packagingPrillSpherical shaped

The invention discloses a plasma preparation method of spherical titanium powder for 3D printing. Titanium powder in an irregular shape is selected as the raw material; argon carries titanium powder particles to be sprayed into a plasma torch through a feeding gun; the titanium powder particles are rapidly heated and fused, and the fused particles form liquid drops with a high degree of sphericity under the action of surface tension; and crushing gas is introduced to crush the fused liquid drops again, the fused liquid drops are rapidly cooled and solidified to form spherical titanium powder particles under the two different progressively increasing temperature gradients, powder is separated from plasma gas due to the efficient filtering gas, and the spherical powder is collected through a powder collection device. The titanium powder prepared by the method is controllable in component, particle size and degree of sphericity; the prepared spherical titanium powder is high in degree of sphericity, good in mobility, uniform in size distribution, little in impurity, high in compactness, high in quality and used for 3D printing; the preparation process is rapid and easy, and one-time molding is achieved.

Owner:LONGYAN ZIJIN INNOVATION RES INST

Preparation method for high-purity spherical silica micropowder

The invention discloses a preparation method for high-purity spherical silica micropowder. The preparation method comprises the following steps: subjecting purified organosilicon to hydrolysis and condensation so as to obtain an organosilicon polymer; then reacting the organosilicon polymer with an alkaline aqueous solution and carrying out in-situ curing so as to form spherical silicon oxide particles; subjecting the spherical silicon oxide particles to ageing and then carrying out separation so as to obtain spherical silica micropowder; and carrying out high-temperature calcining so as to obtain high-purity spherical silica micropowder. According to the invention, high-purity organosilicon is used as a silicon source and no other additive or adjuvant is needed, so secondary pollution of silica micropowder is reduced; and the prepared high-purity spherical silica micropowder is high in purity and almost free of alpha ray pollution of radioactive elements, and the content of each metal impurity in the silica micropowder is 1 ppm or below.

Owner:SUZHOU NANODISPERSIONS

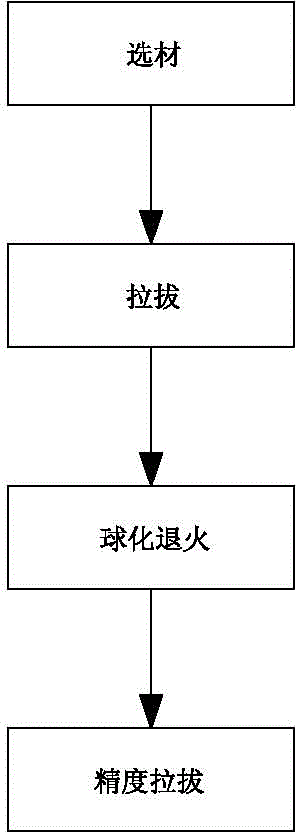

Process for producing high-nodularity fastener wire rod

The invention discloses a process for producing a high-nodularity fastener wire rod. The process comprises the following steps: (1) selecting materials, namely selecting a steel wire with the model of SWRCH22A; (2) drawing, namely drawing the steel wire by adopting a drawing machine, wherein the compression rate is more than or equal to 50 percent; (3) performing spheroidizing annealing, namely lifting the steel wire into an atmosphere protection furnace, adding a protective atmosphere into the atmosphere protection furnace, heating the steel wire to a temperature which is 20-30 DEG C higher than the austenite transformation temperature, preserving the heat for 4-6 hours, slowly cooling to a temperature which is 20-30 DEG C lower than the austenite transformation temperature at a rate of 10 DEG C per hour, preserving the heat for 3-4 hours, and performing furnace cooling until the product is discharged out of the furnace; and (4) performing precision drawing, namely drawing the steel wire again by adopting the drawing machine, wherein the compression rate is less than or equal to 10 percent. The treated steel wire has the grain size of more than or equal to 10 grades, the grains are uniform, the nodulizing grade is more than or equal to 5, the nodulizing rate is high, the pearlite is uniform in distribution, and the wire rod does not have abnormal tissues, has high plastic deformation capacity and is suitable for subsequent plastic forming, and the wire rod with excellent size and surface is obtained.

Owner:DONGGUAN KELEE STEEL WIRE

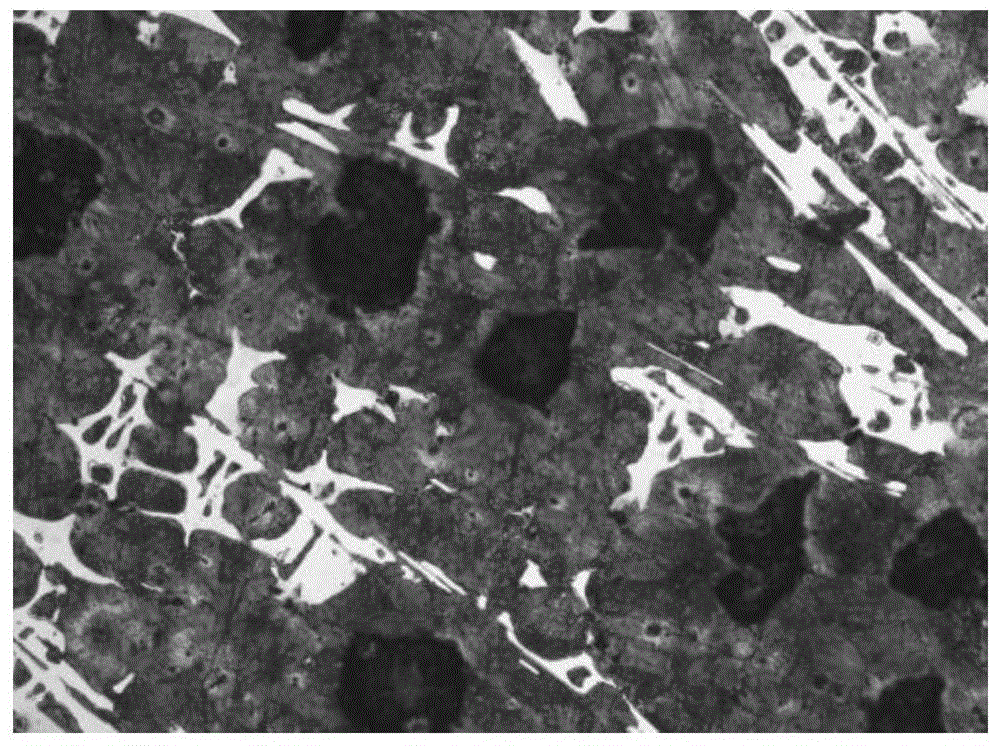

Self-lubricating wear-resistant eutectic graphitic steel and preparation method thereof

The invention discloses self-lubricating wear-resistant eutectic graphitic steel and a preparation method thereof, and relates to the field of ferrous materials. The eutectic graphitic steel is different from ordinary isothermal quenching nodular cast iron in the preparation method, graphite shape and engineering service response behavior. Sectionoal materials are drawn through a continuous casting method with the rapid cooling ability, the composition of molten iron is strictly controlled at the eutectic point, and thus eutectic graphite nodules with the spheroidization rate of 100% are obtained; in addition, the fine graphite nodules are in dispersed distribution, the peripheries of the graphite nodules are coated with layers of amorphous mechanical impurities, impurity elements in the molten iron are collected, and the grain boundary of a matrix is purified; and tiny high-frequency elastic deformation of the materials in service can appear rings of 'strain aging and heat aging' softening structures around the graphite nodules, initiation of fatigue cracks is effectively inhibited, and the fatigue life is prolonged. In summary, the eutectic graphite steel has excellent mechanicalperformance of quenched steel and physical properties of self-lubrication, sound absorption and noise reduction, shock absorption and friction reduction of cast iron materials.

Owner:XIAN UNIV OF TECH

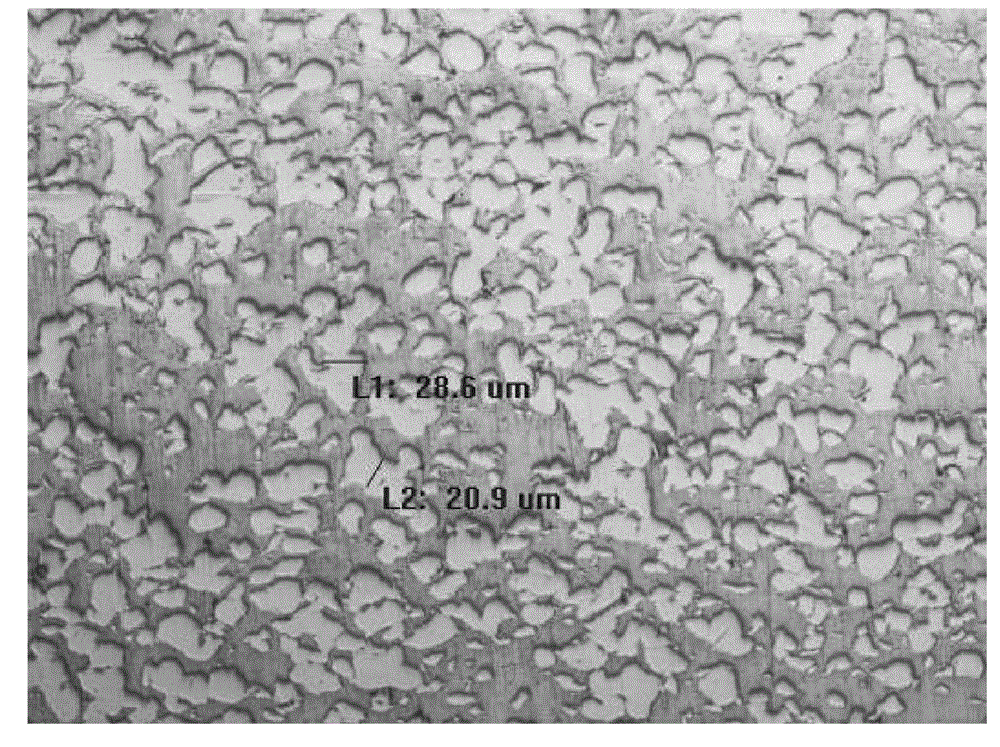

Method for preparing semisolid blank

The invention relates to a method for preparing a semisolid blank, utilizes an improved SIMA (strain induced melt activation) method to prepare the semisolid blank, and belongs to the technical field of metal semisolid blank. The method comprises the following steps of: firstly, measuring a liquid solid phase line point of the semisolid alloy to be prepared, then, heating an alloy blank so as to carry out asynchronization multitrack rolling or pillar squeezing transformation, finally, remelting, and carrying out heat preservation for a long time so as to obtain the required semisolid blank. The asynchronization rolling or pillar squeezing transformation is capable of generating large deformation amount, group bough crystal formed in the blank is destroyed, the asynchronization rolling is utilized to replace pre-deformation processes such as the existing upset, compression, equal diameter angle compression, and the semisolid blank is prepared and has the advantages of uniform formation, high nodularity, and accurate control solid phase rate.

Owner:KUNMING UNIV OF SCI & TECH

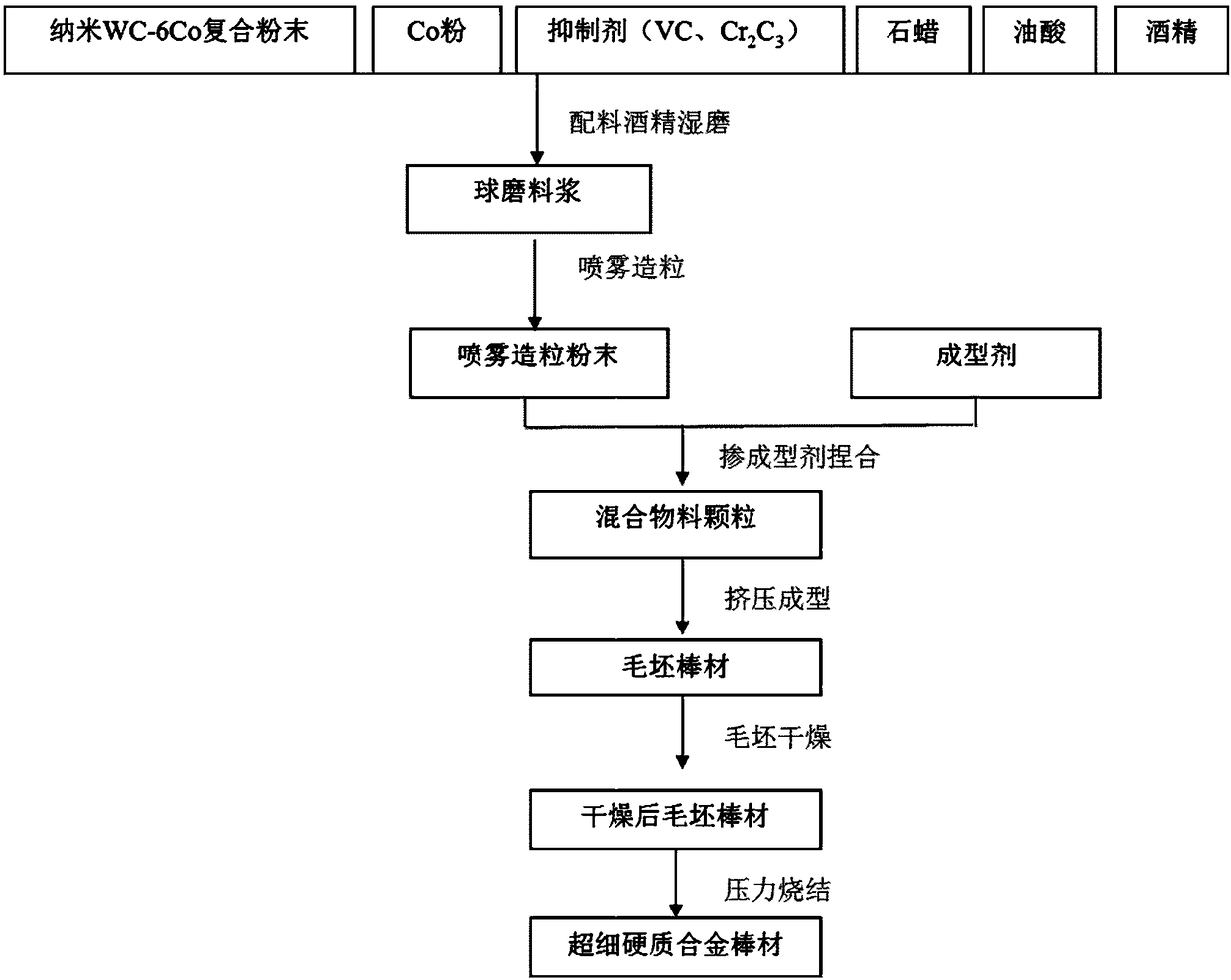

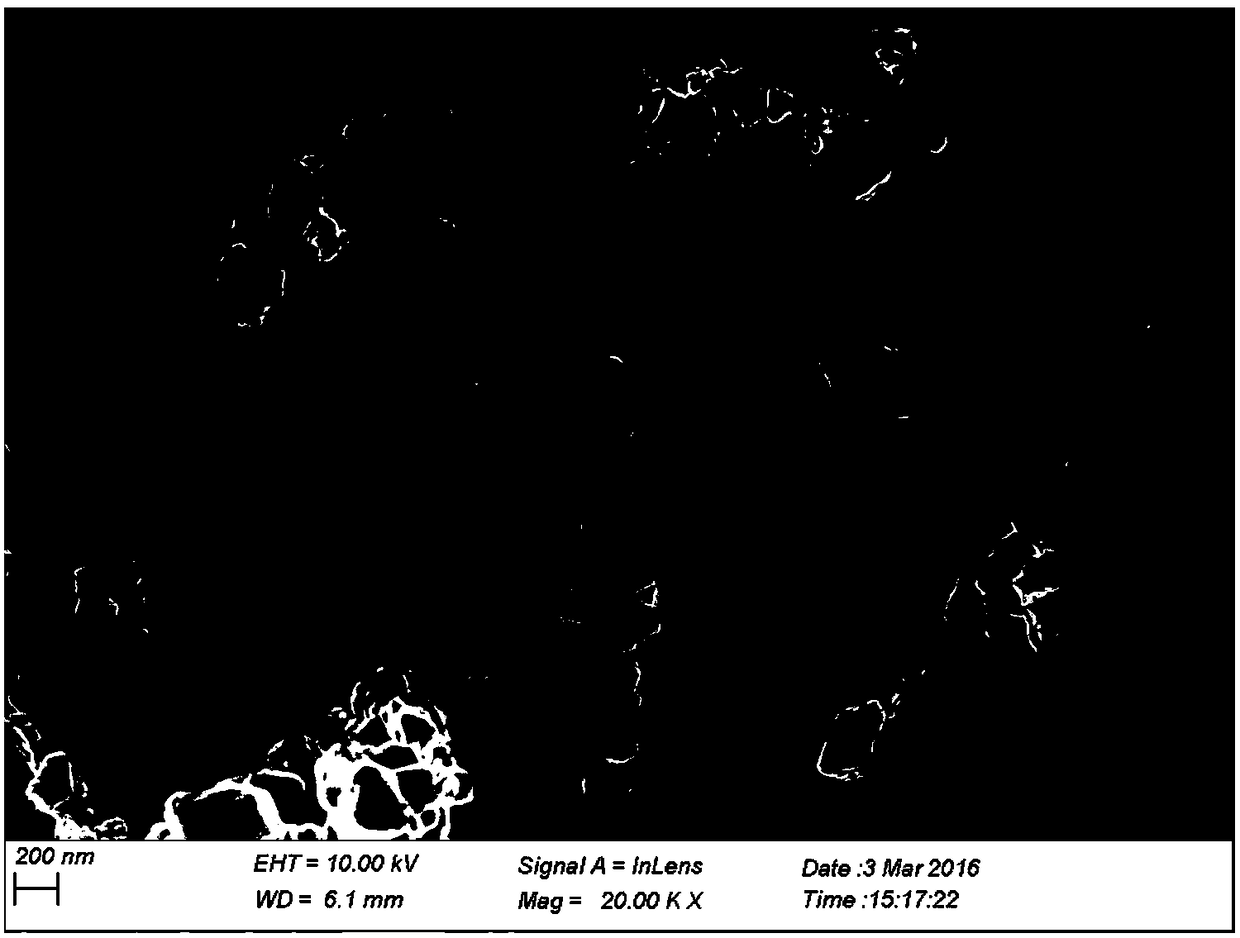

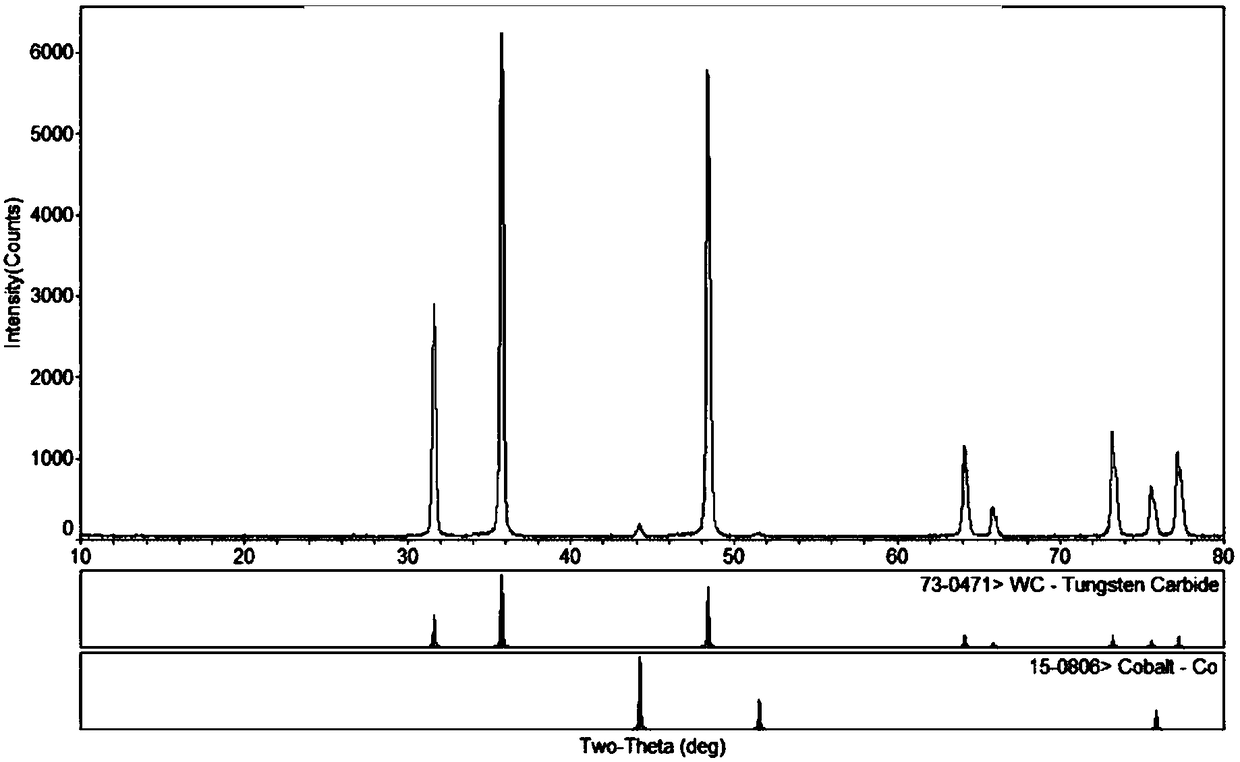

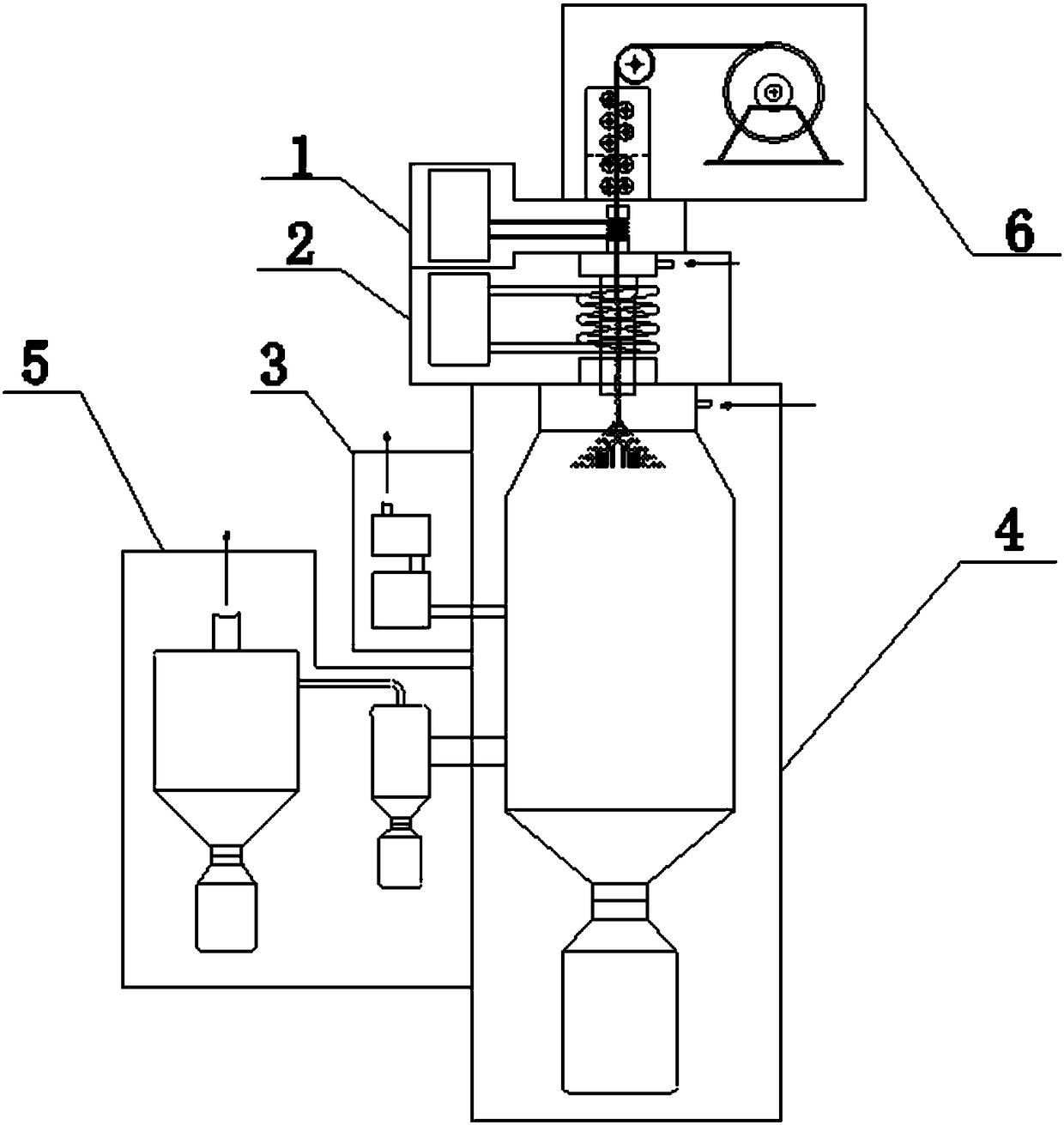

Method for preparing ultrafine cemented carbide by taking nano WC-6Co composite powder added with Co powder as raw materials

The invention discloses a method for preparing ultrafine cemented carbide by taking nano WC-6Co composite powder added with Co powder as raw materials. According to the method, by taking the nano WC-6Co composite powder as the raw materials, the Co powder, inhibitors and paraffin are added to the raw materials; through alcohol wet grinding and spray granulation, cemented carbide mixtures of whichthe Co content is 8%-15% are obtained; and then, by taking the cemented carbide mixtures as raw materials, through the working procedures of kneading by mixing forming agents, extrusion forming, blankdrying and pressure sintering, ultrafine cemented carbide rods are prepared. The ultrafine cemented carbide prepared with the method disclosed by the invention has the advantages of high strength, hardness and density, small WC grains, uniform grain size, and high resistance to plastic deformation.

Owner:HEFEI UNIV OF TECH

Preparation method for porous tungsten bulk material with uniform and controllable pores

The invention discloses a preparation method for a porous tungsten bulk material with uniform and controllable pores. The preparation method is characterized by comprising the following steps of: by taking tungsten powder as a raw material, obtaining spherical tungsten powder through plasma balling treatment and electric vibrating and screening treatment; and then, obtaining the porous tungsten bulk material by discharge plasma sintering. According to the preparation method, the porous tungsten bulk material with uniform and controllable pores is obtained by combining a plasma balling technology, an electric vibrating and screening technology and a discharge plasma sintering technology; the preparation method is simple and liable to realize; the control on pores of the product can be realized by regulating the process parameters, so that the porous tungsten bulk material with porosity of 17%-22.5% and pore size of 2-5 mum; the prepared porous tungsten bulk material can be used for remarkably improving the infiltration performance of the material, so that the launch stability of a barium-tungsten cathode is greatly improved, and the service life of the barium-tungsten cathode is prolonged.

Owner:HEFEI UNIV OF TECH

Semi-solid forming and casting technology of aluminum magnesium alloy pot

The invention discloses a semi-solid forming and casting technology of aluminum magnesium alloy pot. The semi-solid smelting of the casting technology adopts the rheological slurry temperature control smelting technology; metal tree crystal is broken up in rheological slurry temperature control smelting by electromagnetic mixing to form spherical crystal, the metal crystalline state as well as the metallic crystal nodularity of the aluminum magnesium alloy pot are improved, so that the aluminum magnesium alloy pot has high strength and high tenacity and is light in weight and firm compared with the traditional cast aluminum magnesium alloy pot; the smelting temperature of semi-solid slurry is low compared with the traditional casting, therefore, not only the energy consumption is greatly saved, but also the service life of casting dies is prolonged; and the aluminum magnesium alloy pot has no bubbles and needle holes on the surface, and the firm part has compact crystal and no casting defects. The technology realizes the semi-solid rheological extrusion forming of the aluminum magnesium alloy pot, and has high production efficiency, therefore, not only the quality of casts and the utilization ratio of materials are improved, but also the surface quality of the product is improved and the interior quality is equivalent to forging products; and the invention is suitable for scale production and has great popularization and application value.

Owner:李扬德

Powder preparation method for induction heating and radio frequency plasma combined atomizing powder system

ActiveCN108161019AHigh purityPrevent purityAdditive manufacturing apparatusHigh pressureRadio frequency

The invention relates to a powder preparation method for an induction heating and radio frequency plasma combined atomizing powder system. The powder preparation method comprises the following steps that (1), raw materials are prepared and processed; (2), the system is pre-vacuumed and a protective atmosphere is established; (3), wire materials are straightened and conveyed; (4), high-frequency induction preheating is carried out; (5), radio frequency plasma melting is carried out; (6), powders are prepared by atomizing; (7), separation and dust removal are carried out; and (8), the powder size is graded. The powder preparation method for the induction heating and radiofrequency plasma combined atomizing powder system uses high purity metal wire material instead of the powders as the raw materials, so that the carrying of raw materials to adsorb gas and water is reduced; a technology of the high frequency induction heating combined with the radio frequency plasma smelting and gas atomization is adopted, during the whole process of heating, melting, and the gas atomization is free of pollution and impurities in the protective atmosphere, and the degree of superheat of liquid flow ordroplets is increased during the process of radio frequency plasma smelting; and high quality spherical powders can be obtained by adopting high pressure atomizing nozzles atomizing, and the yield ofmetal powders per unit time is increased.

Owner:北京金物科技发展有限公司

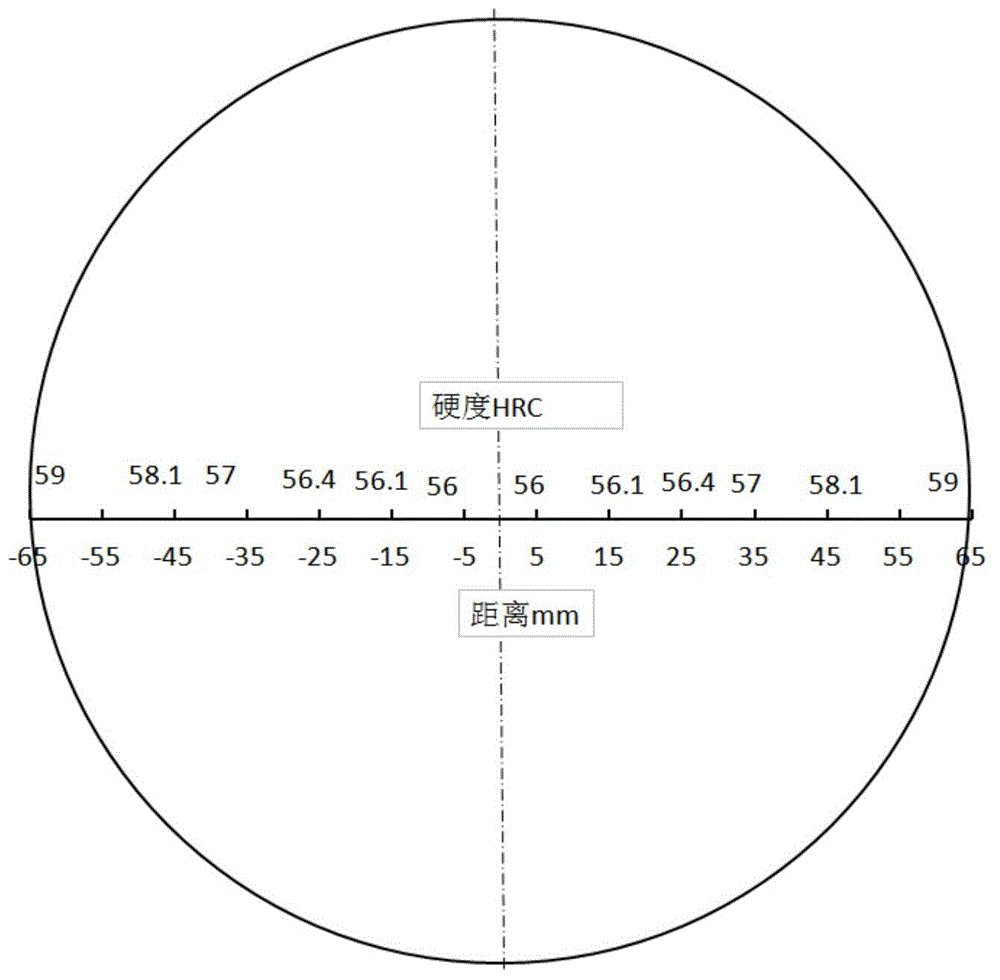

Processing method of high precision steel ball

The invention discloses a processing method of a high precision steel ball. The processing method comprises the following steps: cold heading forming; annealing; ball polishing; primary soft grinding; primary hot pickling for appearance; secondary soft grinding; primary heat treatment; hard grinding; secondary cold pickling for appearance; removal of a corrosion layer; primary stabilizing; strengthening treatment; primary grinding; secondary stabilizing; lapping; appearance selection; super-lapping; secondary heat treatment; oil washing; detection. The processing method of a high precision steel ball provided by the invention shortens the whole quenching and heat treatment time during processing by 50% or more, greatly improves heat treatment efficiency, greatly improves the spheroidization rate, hardness and strength properties of the processed steel ball compared with the steel ball with long quenching and heat treatment time, prolongs service life, satisfies relatively high quality requirements on the steel balls of the roller industry, not only reduces labor intensity, manual input and production cost, but also ensures the quality of products, and increases the added value of the products.

Owner:ANSHUN HONGYI SPECIAL STEEL BALL MFG

Nodular cast iron winding drum high in strength and ductility and preparation method thereof

The invention discloses a nodular cast iron winding drum high in strength and ductility. Nodular cast iron is composed of, by weight, 3.0-3.3% of C, 3.8-4.2% of Si, Mn smaller than 0.3%, 0.03-0.05% of Mg, 0.01-0.025% of RE, S smaller than 0.02%, P smaller than 0.03%, 0.2-0.3% of Mo, 0.12-0.15% of Ni, 0.003-0.010% of Ca, 0.005-0.010% of Ba, Bi smaller than or equal to 0.003% and the balance Fe and inevitable impurities, wherein the total content of Ca and Ba is greater than or equal to 0.010% and smaller than or equal to 0.020%. The nodular cast iron winding drum is high in strength and ductility and can be used for large or ultra-large engineering equipment. The invention further discloses a preparation method for the nodular cast iron winding drum.

Owner:SHANDONG HUIFENG CASTING TECH

Method for preparing special type molybdenum powder

A method for preparing a special molybdenum powder relates to a method for preparing the molybdenum powder specially used for the industries of thermal spraying and machining as well as pressing fine apparatuses. The powder is characterized in that the preparing process includes the steps as follows: (1) sintering normal molybdenum powder for increasing the granularity; (2) grading the molybdenum powder, the granularity of which is increased; carrying out spheroidisation on the molybdenum powder with approximate granularity by a plasma device, then cooling and collecting the molybdenum powder; (3) reducing the molybdenum powder after being spheroidized, screening, grading and then obtaining the special molybdenum powder. The molybdenum powder prepared by the method of the invention has the advantages of good fluidity, simple technique, high finished product rate and relates to a technique for preparing the special molybdenum powder used in the fields of thermal spraying and pressing fine apparatuses.

Owner:JINDUICHENG MOLYBDENUM CO LTD

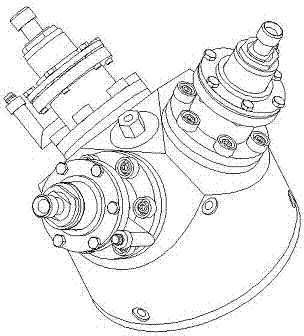

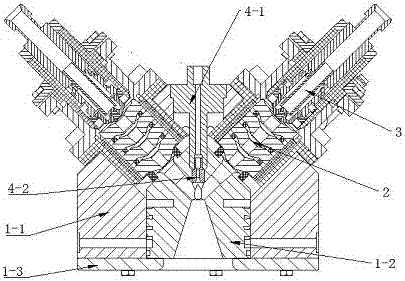

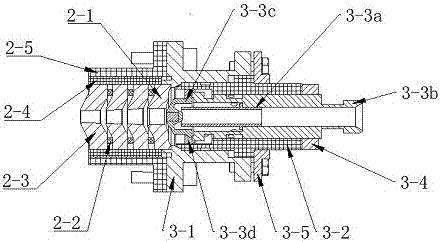

Multi-cathode laminar flow plasma powder spheroidization device

PendingCN107124814AReduce volatilityReduce ablationTransportation and packagingMetal-working apparatusJet flowControllability

The invention provides a multi-cathode laminar flow plasma powder spheroidization device, which consists of an anode part, an interpole part, a cathode part, a power feeding part and an accessory, wherein the anode electrode part consists of an anode casing, an anode, a compression cover and the like. Each part is compressed and connected through screw bolts; the interpole part consists of an arcing ring, an insulation ring, an interpole, an interpole inner sleeve, an interpole outer sleeve and the like; the cathode part and the anode part are simultaneously compressed; the cathode part consists of a cathode case, a cathode sleeve, a cathode and a cathode fastening ring; each part is sequentially connected; the cathode compression ring is in contact with the cathode sleeve and is fixedly connected with the cathode case; the powder feeding part consists of a power feeding pipe and a powder feeding spray nozzle which are sequentially and fixedly connected. The excellent characteristics of good jet flow controllability, high enthalpy value, long jet flow length and the like of the laminar plasma are utilized for realizing the spheroidization on powder; the treated powder has the advantages of high spheroidization rate, high uniformity and the like.

Owner:SICHUAN UNIV

Method for manufacturing micro-fine spherical titanium powder

Owner:WESTERN BAODE TECH CO LTD

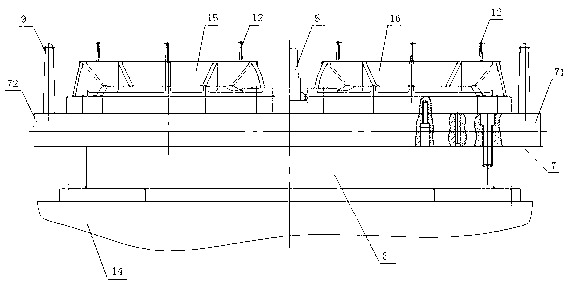

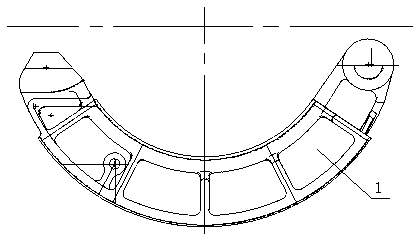

Sand lined metal mould casting brake shoe tool device and production method thereof

ActiveCN103273006AImprove casting yieldUniform materialFoundry mouldsMoulding machinesBrake shoeMetal

The invention relates to a sand lined metal mould casting brake shoe tool device and a production method thereof, and belongs to the field of sand lined metal mould casting. The sand lined metal mould casting brake shoe tool device comprises a lower casting piece and a gating system, wherein the lower casting piece and the gating system are both arranged on a mould board; the sand lined metal mould casting brake shoe tool device further comprises an upper casting piece, a single casting piece, a connection board, a loam core and a flow gate; the lower casting piece and the upper casting piece are both connected with the connection board to form the single casting piece; the loam core is arranged inside an iron mould and used for forming an inner cavity of the single casting piece, a sprue base and the lower part of a cross gate; the inner flow gate is arranged in an inner pouring gate; and one end of the flow gate is connected with the cross gate, and the other end of the flow gate is connected with the single casting piece. According to the invention, the lower casting piece and the upper casting piece are connected into a circle to form the single casting piece, the inner cavity of the single casting piece is formed by the loam core, and the production method of the sand lined metal mould casting brake shoe tool device has simple operation and high efficiency, so that the yield of the casting piece is increased, the production efficiency is improved, and the produced casting piece of the brake shoe is smooth and clean in surface and accurate in size.

Owner:浙江省机电设计研究院有限公司

Method of preparing high-purity ultra-fine sphere silicon micro-powder

InactiveCN101033068AHigh nodularityHigh whitenessPigmenting treatmentSilicaSpherical shapedUltra fine

This invention discloses a method for preparing purified super-fine spherical Si micro-powder, which first of all selects natural quartz breeze roughly, cleans it and adds an aging agent to be aged in an alkali condition and filtered, then dehydrates and dries the filtered matter and processes it to powder or blocks by adding a binder to be burnt under 1280-1680deg.C in a high temperature furnace for 1-10h to be cooled and dispersed to be grinded to powder spheres and graded by magnetic selection and wind selection to get purified super-fine spherical silicon micro-powder.

Owner:袁茂豪

High-strength sulfur-oxygen nucleating agent

The invention provides a high-strength sulfur-oxygen nucleating agent. The high-strength sulfur-oxygen nucleating agent comprises the following elements in percentages by mass: 70-76% of Si, 0.2-1.0%of Ca, 0.3-0.5% of Ba, 1.5-2.0% of La, 0.5-1.5% of Al, 0.3-0.9% of S, 0.3-0.9% of O, 0.5-1.5% of Sb and the balance of iron. The sulfur-oxygen nucleating agent is prepared from the following raw materials in parts by weight: 2-4 parts of steel scrap, 130-140 parts of silicon iron, 1-1.4 parts of silicon barium, 1-1.8 parts of calcium silicon, 2-4 parts of pure lanthanum, 1.5-2.5 parts of stibonium, 1-2 parts of FeS and 1-1.4 parts of FeO. By the prepared high-strength sulfur-oxygen nucleating agent, the number of graphite nodules in nodular cast iron can be increased obviously, the strength and toughness of the nodular cast iron can be improved, the chilling tendency of the nodular cast iron is relieved obviously, the nodularity, the number of graphite nodules and the number of ferrites ofthe nodular cast iron are increased, shrinkage in a casting process is eliminated, and complicated castings with excellent quality can be formed.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Ferritic spheroidal graphite cast iron and preparation method thereof

The invention relates to the field of spheroidal graphite cast iron, in particular to ferritic spheroidal graphite cast iron and a preparation method thereof. The ferritic spheroidal graphite cast iron comprises, by mass, 3.5%-3.8% of carbon, 2.4%-2.7% of silicon, 0.29%-0.35% of manganese, 0.03%-0.04% of cerium, 0.045%-0.06% of magnesium, 0.08%-0.1% of yttrium, 0.01%-0.02% of molybdenum, 0.02%-0.03% of rhenium, not more than 0.04% of phosphorus, not more than 0.018% of sulphur and the balance iron. The preparation method particularly includes the steps of (1), melting raw materials by a medium-frequency induction furnace prior to desulfurization; (2), uniformly mixing silicon carbide powder with rare earth magnesium alloy, then pouring the mixture into a spheroidizing package, covering the spheroidizing package with a first inoculant for spheroidizing and primary inoculation treatment prior to secondary inoculation treatment, and casting so as to obtain a cast; (3), subjecting the cast to heat treatment so as to obtain the ferritic spheroidal graphite cast iron. The ferritic spheroidal graphite cast iron is high in spheroidizing ratio and strength and excellent in toughness and impact plasticity, and the preparation method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

Mo2FeB2-based thermal spraying alloy powder and preparation method thereof

InactiveCN103088281AHigh puritySmall particle size distribution rangeMolten spray coatingAlloyWear resistance

The invention discloses Mo2FeB2-based thermal spraying alloy powder which can be used for improving the performance of components and parts and prolonging the service life of the components and parts. The Mo2FeB2-based thermal spraying alloy powder is prepared from the following raw materials in percentage by weight: 14.64-36.5% of FeB, 21.3-47.5% of Mo, 1.3-4.7% of Ni, 2.4-8.1% of Cr, 0-5% of W and 8.82%-49.66% of carbonyl iron. The invention also discloses a preparation method of the Mo2FeB2-based thermal spraying alloy powder. The thermal spraying alloy powder prepared by the method has high purity, narrow distribution range of powder size, high spheroidization rate and good flowability and is suitable for a thermal spraying technology of a wear resistance anti-corrosion coating.

Owner:KING STRONG MATERIAL ENG LTD

Alloy modificator for preparing metal semi-solid slurry

The invention discloses an alloy modificator for preparing metal semi-solid slurry, an alloy modificator preparation method and an alloy modificator use method. After the alloy modificator is added into the molten semi-solid slurry, the solid-to-liquid ratio of the semi-solid slurry and the content of globular crystals can be greatly increased, the preparation efficiency and the quality of the semi-solid slurry can be improved, and the quality of final die-cast products is ensured. The preparation method is simple and easy to operate, and the alloy modificator can be prepared on a large scale in simple equipment. The alloy modificator has excellent use effect and popularization significance.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

High-strength and high-tenacity nodular cast iron and working roll of wide thick plate

ActiveCN101775533AEnhanced quenching performanceImprove anti-globularization and prevent recessionPearliteSilicon iron

The invention relates to the improvement of nodular cast iron, which is characterized in that 3.0-3.5 wt% of C, 2.0-2.8 wt% of Si, 0.5-0.8 wt% of Mn, not more than 0.08 wt% of P, not more than 0.02 wt% of S, 0.5-1.2 wt% of Cu, 0.2-0.6 wt% of Mo, 0.05-0.1 wt% of Mg, 0.01-0.03 wt% of Ca, 0.01-0.015 wt% of Re, 0.001-0.003 wt% of Sb, 0.01-0.05 wt% of Ba and the balance of Fe and impurity elements are smelted, then added into yttrium-based heavy rare earth magnesium for nodulizing by using a pour-over process; after nodulizing, a long-acting yttrium-based inoculant and silicon iron are utilized to carry out compound inoculation. The obtained nodular cast iron has both high strength and high tenacity, wherein the tensile strength of as-cast nodular cast iron is not less than 500MPa, and the tenacity is not less than 9J / cm2; by metallographic analysis, the as-cast nodular cast iron has a structure with part of fine pearlites and globular graphite, and the graphite globuring ratio can be improved by more than 2 levels. The invention is especially suitable for the high-strength nodular cast iron used for the core of the working roll of a wide thick plate, thereby greatly prolonging the service life of the working roll.

Owner:JIANGSU GONGCHANG ROLL

Preparation method of copper-chromium alloy powder and preparation method of copper-chromium alloy pig

The invention discloses a preparation method of copper-chromium alloy powder and a preparation method of a copper-chromium contact, and relates to a preparation method for metal powder and application of the metal powder. The preparation method of the copper-chromium alloy powder comprises the following steps of: preparing a copper bar and a chromium block at the mass ratio of (25-50):(75-50); heating and smelting raw materials into an alloy stream by vacuum induction; enabling the above alloy liquid to flow into an atomizing chamber to be atomized; when the alloy liquid is atomized, continuously introducing inert gas at the pressure of 0.1-0.5Mpa; and screening powder size obtained after atomization by a sieve of 150 micrometers or below 150 micrometers to obtain the copper-chromium alloy powder. The invention provides a preparation method of the copper-chromium alloy powder, and the prepared copper-chromium alloy powder has the advantages of small particle, high nodulizing degree and low air content. The invention also provides a preparation method for a copper-chromium alloy pig, and the prepared copper-chromium alloy pig has the advantages of high density and small pressure required for pressing.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Device and system for spheroidizing powder by using alternating-current plasmas

ActiveCN103736435AAvoid pollutionAvoid the problem of uneven feedingMaterial granulationEnergy based chemical/physical/physico-chemical processesEvaporationShielding gas

The invention discloses a device for spheroidizing powder by using alternating-current plasmas. The device comprises a discharge chamber, an inductance coil and a heat exchange chamber, wherein the heat exchange chamber is communicated with the bottom of the discharge chamber; the discharge chamber comprises a roof cover, a powder feeding tube and a cylindrical discharge chamber side-wall, the powder feeding tube extends to the inside of the discharge chamber, and the inductance coil is wound on the cylindrical discharge chamber side-wall; the heat exchange chamber comprises a heat exchange chamber side-wall and a spherical powder outlet, and the spherical powder outlet is located at the bottom of the heat exchange chamber; a working gas inlet pipe is arranged in the discharge chamber, the discharge chamber side-wall is provided with a protective gas inlet pipe, and a cooling cavity is arranged in each of the roof cover, the discharge chamber side-wall and the heat exchange chamber side-wall. The invention also discloses a powder spheroidizing system comprising the device. According to the invention, irregularly-shaped powder is spheroidized by using alternating-current plasmas generated by the inductance coil, so that a mode of spheroidizing powder by using plasmas generated by electrode discharge in the prior art is changed, and the pollution of products caused by electrode evaporation is avoided.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Vanadium-titanium ferrite ductile iron automobile hub and production process thereof

The invention relates to the field of cast iron alloys, and particularly relates to a vanadium-titanium ferrite ductile iron automobile hub and a preparation method thereof. The automobile hub is made of vanadium-titanium ferrite ductile iron, and the vanadium-titanium ferrite ductile iron comprises the following chemical compositions in percentage by mass: 3.3-3.6% of C, 3.0-3.4% of Si, 0.0-0.4% of Mn, less than or equal to 0.06% of P, less than or equal to 0.02% of S, 0.12-0.18% of V, 0.05-0.10% of Ti, 0.0-0.08% of Cr, 0.040-0.060% of RE, 0.040-0.060% of Mg, and the balance of Fe and other trace elements and impurities. The vanadium-titanium ferrite ductile iron automobile hub disclosed by the invention is 550-650 MPa in strength and 12-15% in elongation percentage. Comprehensive properties of the vanadium-titanium ferrite ductile iron automobile hub disclosed by the invention are significantly better than those of common ferrite ductile iron automobile hubs.

Owner:陈国

Atomizing pulverization system combined with induction heating and radio frequency plasma

PendingCN108031855AReasonable system designEasy to operateAdditive manufacturing apparatusRadio frequency plasmaHigh frequency

The invention relates to an atomizing pulverization system combined with induction heating and radio frequency plasma. The atomizing pulverization system comprises a high frequency induction heating device, a radio frequency induction plasma device, a vacuum device, an atomizing collection device, a separation and dust removal device and a wire conveyor device. The atomizing pulverization system is rational in design and easy in operation; by adopting the technology that high the frequency induction heating is combined with the radio frequency plasma melting and gas atomization, the whole heating, melting and gas atomization process is subjected to vacuum pumping by the system, and then inert gas is filled for protection; no pollution or inclusions are generated; by combining the high frequency induction heating device used for preheating wires with the radio frequency induction plasma device used for melting the wires, the heat absorption rate in the preheating and melting process isimproved, and the superheat degree of liquid flow or drop is improved, so that high-quality spherical powder, with high sphericity degree and spheroidization rate and small particle size and without hollow spheres, can be obtained after gas atomization; and a high-pressure atomizing nozzle is adopted in the atomization process, and the output rate of metal powder within unit time is improved.

Owner:北京金物科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com