Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

318results about How to "Shorten heat treatment time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of polyacrylonitrile pre-oxidation fiber and carbon fiber

ActiveCN102704043AIncrease productivityShorten heat treatment timeFibre chemical featuresNitrogen gasCarbonization

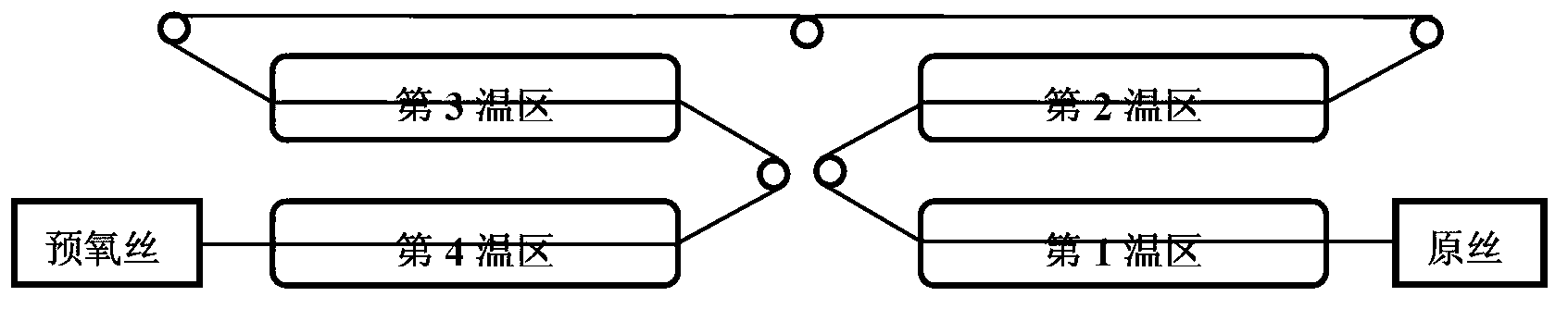

The invention discloses a preparation method of a polyacrylonitrile pre-oxidation fiber and a carbon fiber, belonging to the technical field of fiber preparation. The preparation method comprises the steps of: enabling polyacrylonitrile protofilament to pass through a continuous pre-oxidization device at a constant speed in a normal pressure and an air medium and carrying out pre-oxidization treatment, wherein the temperature rises by adopting 2-4 temperature zone gradients, and the total time is controlled within 30-45 min; in the low temperature stage of the pre-oxidization process, the reaction temperature is 200-240 DEG C, positive drafting accounting for 0%-8% of the total drafting is added, and the total time is 15-25 min; and in the high temperature stage, the reaction temperature is 240-275 DEG C, negative drafting accounting for 0%-3% of the drafting is added, the total time is 15-20min, the low temperature stage is divided into one or two temperature zones, and the high temperature stage is divided into one or two temperature zones, and the temperature of the 2-4 temperature zones rises in sequence, therefore the pre-oxidization fiber is obtained; furthermore, performing a regular carbonization treatment in the atmosphere of nitrogen for 5-8 min to obtain the carbon fiber. The preparation method of the polyacrylonitrile pre-oxidation fiber and the carbon fiber, disclosed by the invention, has the advantages of improving production efficiency of the pre-oxidization and shortening the pre-oxidization heat treatment time.

Owner:BEIJING UNIV OF CHEM TECH

High-accuracy zinc base alloy electrode wire and preparing method thereof

ActiveCN104191056AGood for taking awayCutting discharge mitigationElectrical-based machining electrodesSurface finishImpurity

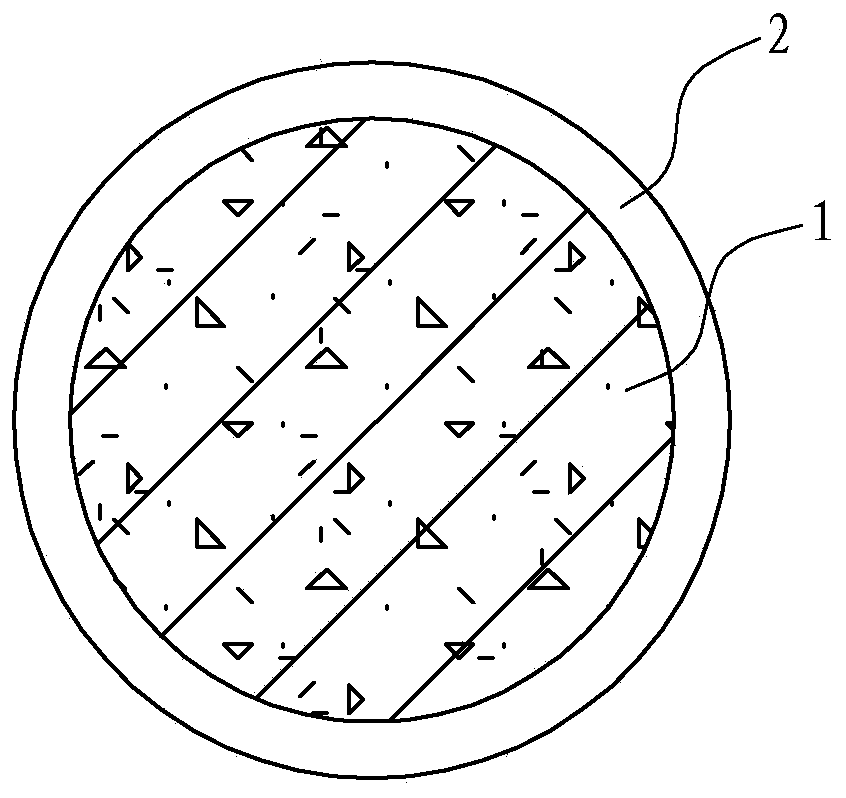

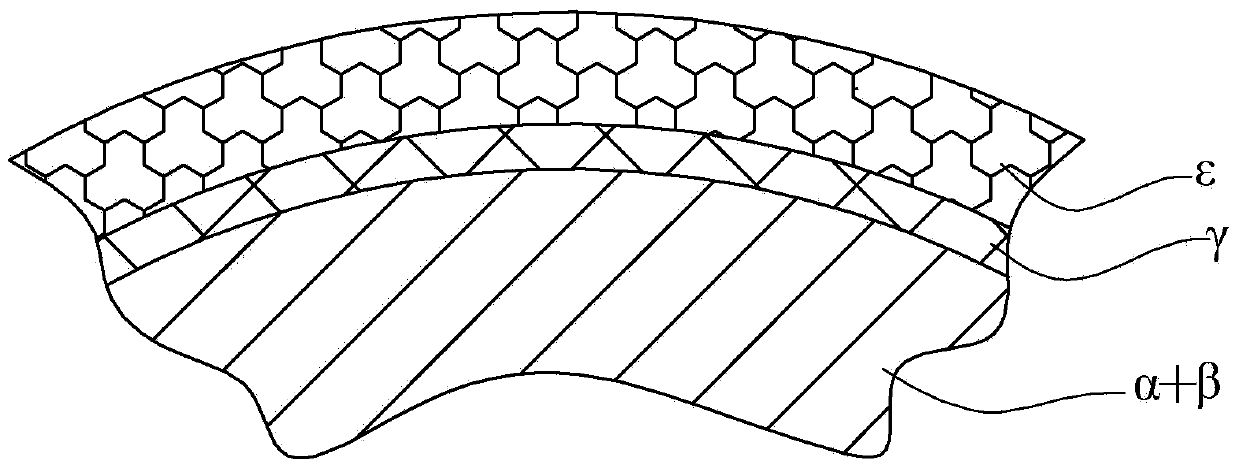

The invention relates to a high-accuracy zinc base alloy electrode wire. Components in a shell layer comprise, by weight, 70.5%-95% of Zn, 2.5%-27% of Cu, 0.02%-4.0% of X, 0.002%-0.4% of Y and inevitable impurities brought in by raw materials. X is any two kinds of metal from Ni, Ag, Cr, Si and Zr, the content ranges of the two kinds of metal are both 0.01%-2.0%, Y is any two kinds of elements of Ti, Al, Co, B and P, and the content range of the two elements are both 0.001%-0.2%. The epsilon phase content in the shell layer structure is over 80% by weight, the balance is a gamma phase or an eta phase, and epsilon phases are evenly distributed on the surface of core materials. Meanwhile, the invention relates to a preparing method of the electrode wire. Compared with the prior art, a metal workpiece subjected to cutting processing by the electrode wire is high in surface smoothness and good in surface quality, accordingly, cutting accuracy is high, meanwhile, the electrode wire preparing technology is simple, operability is high, the number of manufacturing steps is small, and large-scale and automatic production can be achieved easily.

Owner:NINGBO BODE HIGHTECH CO LTD

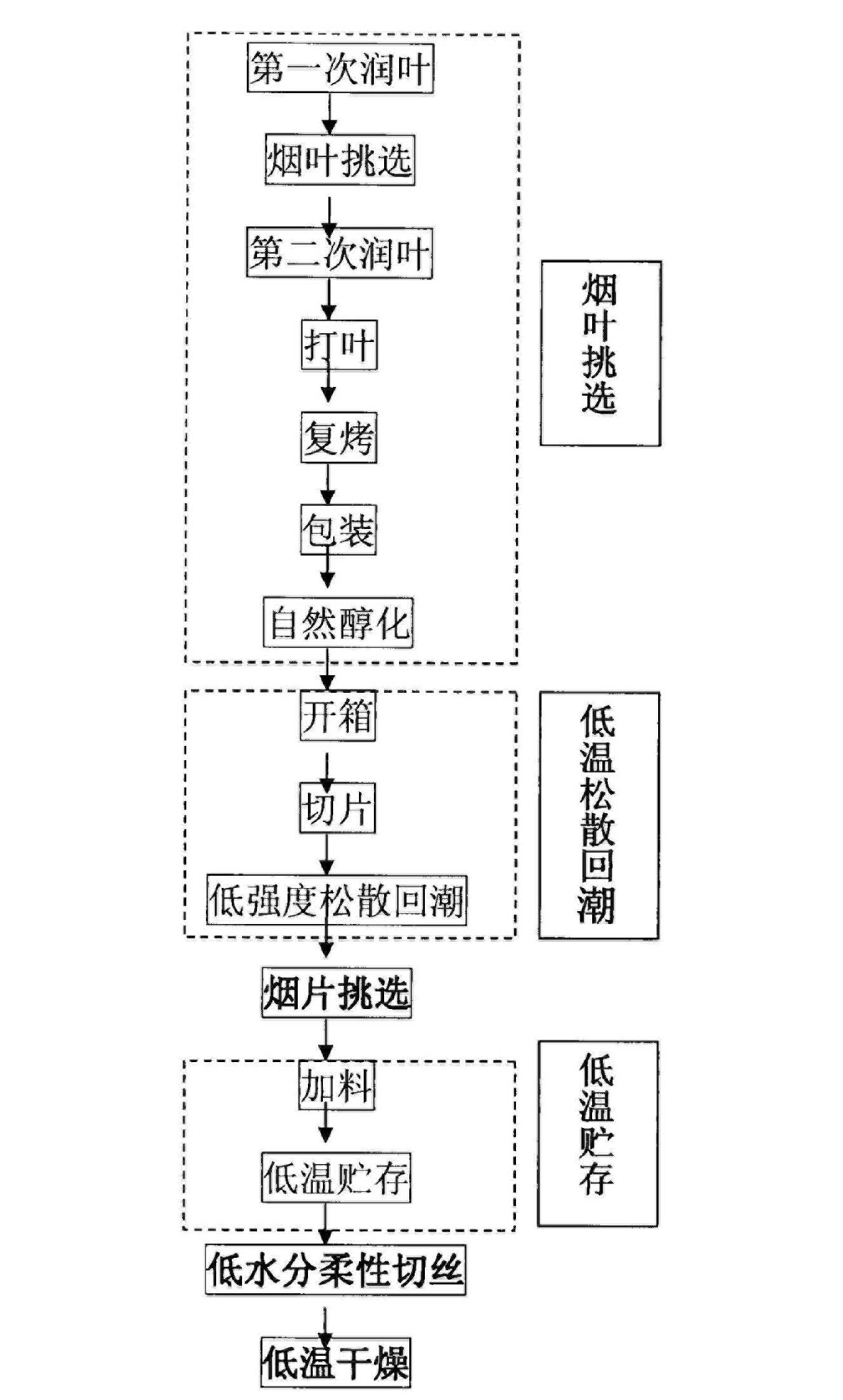

Processing technique for manufacturing golden tobacco shreds

ActiveCN101946975AHigh purityReduced color browningTobacco preparationTobacco treatmentHorticultureAgricultural engineering

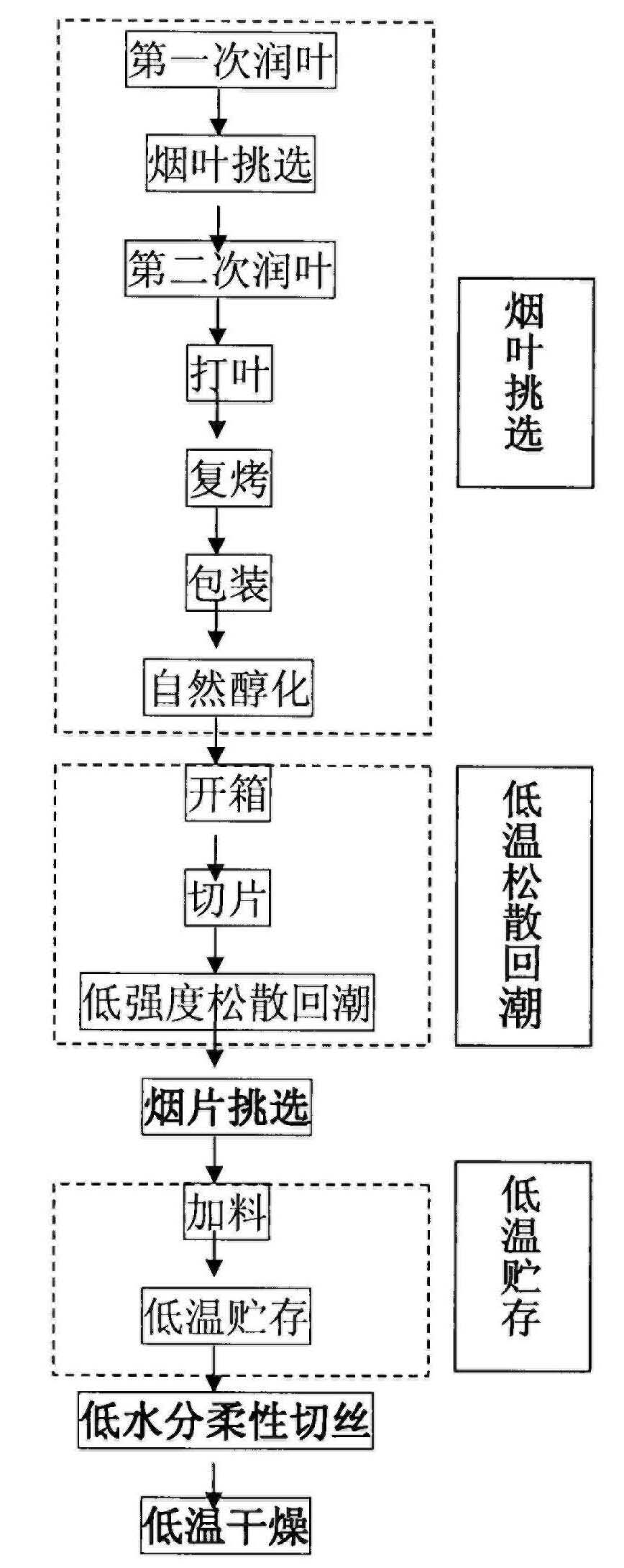

The invention discloses a processing technique for manufacturing golden tobacco shreds. The technique is characterized by comprising the processes of tobacco leaf selection, low-strength loose moistening, tobacco sheet selection, low-temperature storage, low-moisture flexible shredding and low-temperature leaf shred drying. The technique has the advantages that: (1) the prepared tobacco shreds are golden and have good appearance quality; on the one hand, the tobacco leaves with poor appearance quality in the tobacco leaf raw material are removed by adopting the tobacco leaf and tobacco sheet selection processes so as to improve the purity of the golden tobacco leaves in the tobacco leaf raw material; on the other hand, the tobacco sheet moisture content during shredding and the knife door pressure of a shredder are reduced by adopting the low-moisture flexible shredding process so that the tobacco shreds producing brown stains after shredding are reduced; and (2) the prepared tobacco shreds have predominant fragrance and good sense quality. The tobacco sheets are treated by adopting the low-strength loose moistening, low-temperature storage and low-temperature drying processes so as to reduce the return air temperature of a tobacco sheet loose moistening device, the storage environment temperature, the leaf shred drying temperature and the tobacco sheet heating time and reduce the fragrance loss of the tobacco sheets during preparing the shreds.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

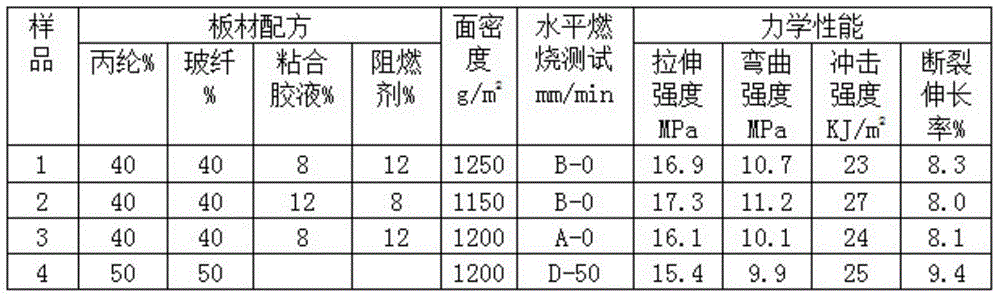

Formula and preparation technology of light fiber-reinforced thermoplastic resin composite sheet material with high flame resistance

ActiveCN103950251AImprove mechanical propertiesImprove flame retardant performanceSynthetic resin layered productsLaminationHigh resistanceFree falling

The invention discloses a formula and a preparation technology of a light fiber-reinforced thermoplastic resin composite sheet material with high flame resistance. The sheet material is composed of, 30-50% of reinforced fiber, 30-50% of thermoplastic resin fiber, 5-15% of halogen-free fire retardant powder and 5-15% of a bonding glue solution. The preparation technology comprises: weighing reinforced fiber and thermoplastic resin fiber according to the ratio, and performing preliminary mixing; utilizing a blower fan to convey reinforced fiber and thermoplastic fiber to a cotton storage bin; and utilizing the effect of free fall to enable fiber to be mixed fully, dispersed uniformly and the like. The light fiber-reinforced thermoplastic resin composite sheet material with high flame resistance has the advantages of simple production technology, low cost, excellent flame resistance and no obvious reduction on mechanical properties, is extremely applicable to fields of automotive trims, building decoration and the like, and has great practical value.

Owner:浙江华江科技股份有限公司

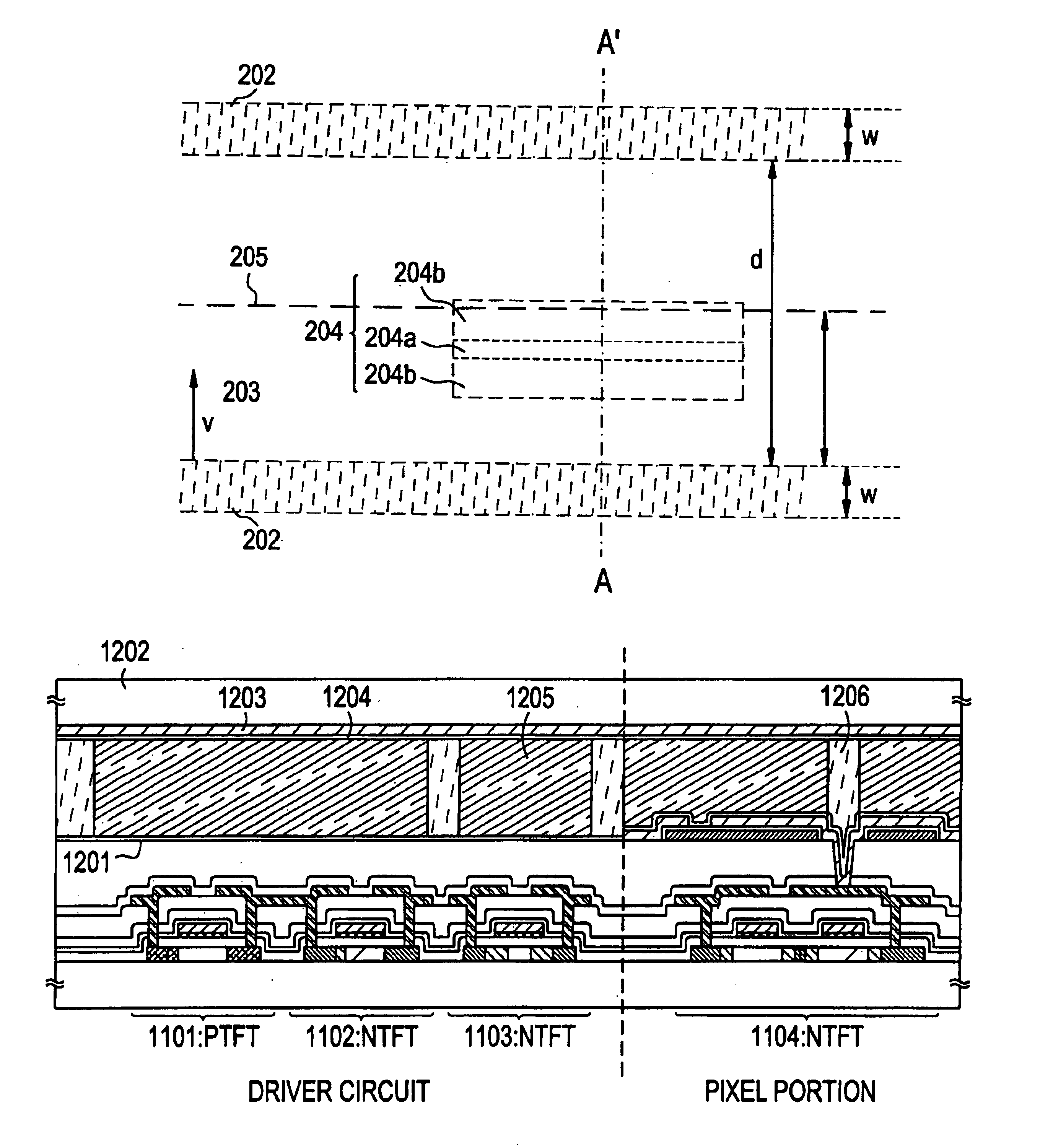

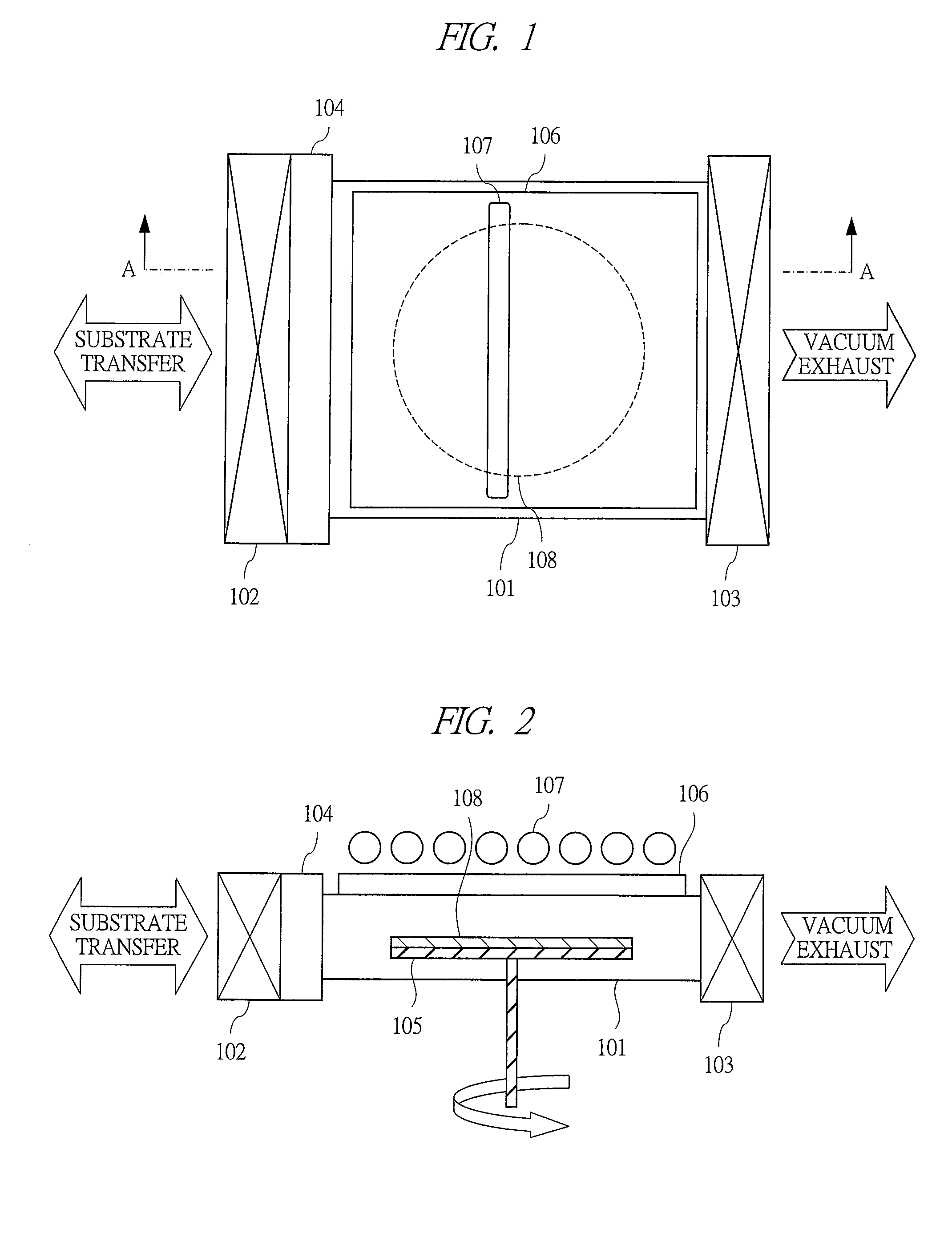

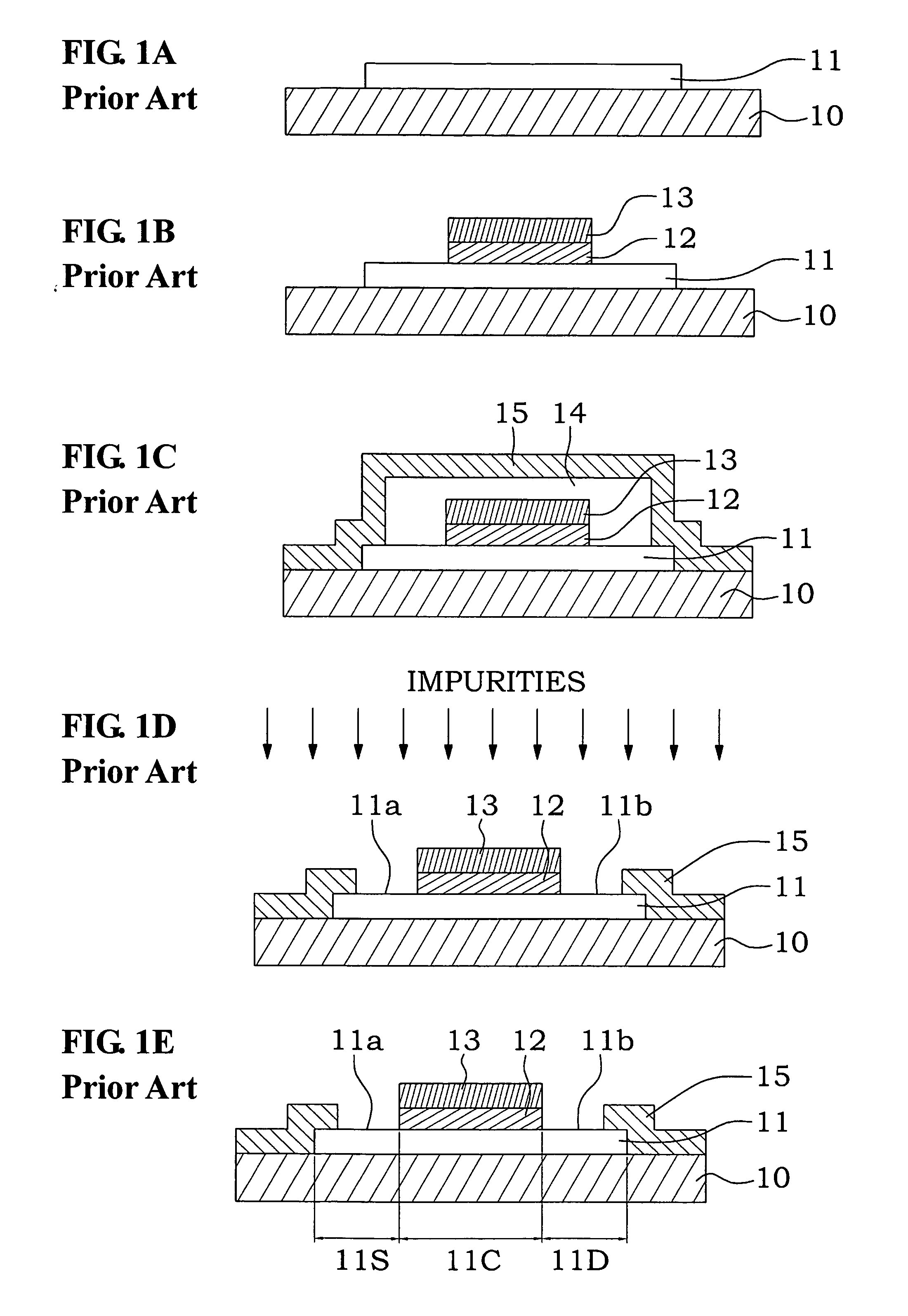

Semiconductor device applying to the crystalline semiconductor film

InactiveUS6909115B2Efficient executionTimely treatmentTransistorStatic indicating devicesActive layerCrystal growth

There is disclosed a semiconductor device and a method of fabricating the semiconductor device in which a heat treatment time required for crystal growth is shortened and a process is simplified. Two catalytic element introduction regions are arranged at both sides of one active layer and crystallization is made. A boundary portion where crystal growth from one catalytic element introduction region meets crystal growth from the other catalytic element introduction region is formed in a region which becomes a source region or drain region.

Owner:SEMICON ENERGY LAB CO LTD

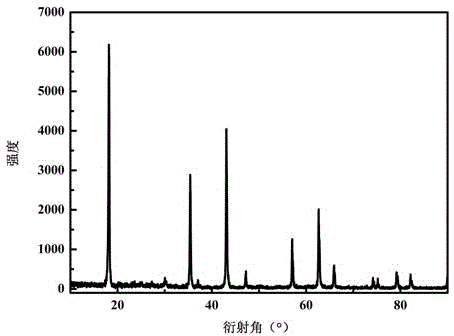

Collosol of yttrium barium cupper oxygen superconducting film and process for preparing high temp. superconducting film thereof

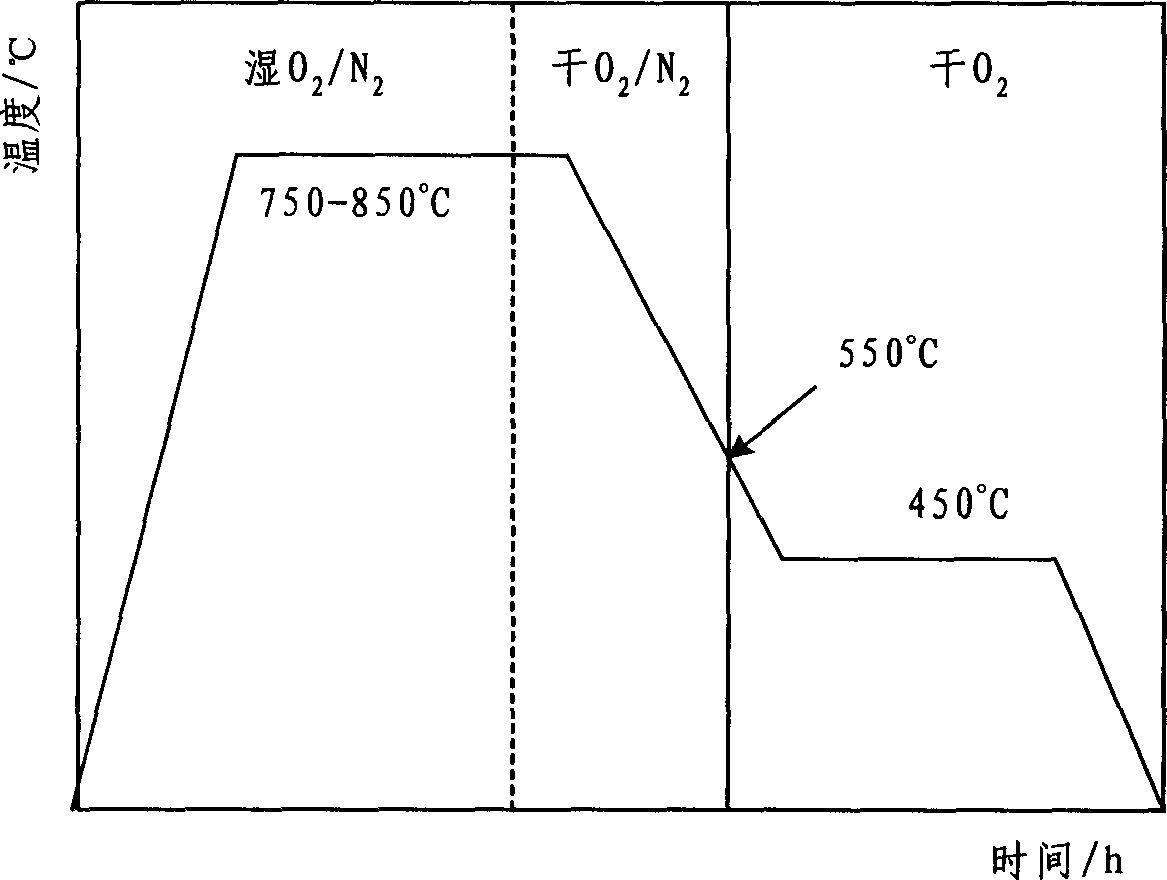

InactiveCN1792806AShorten heat treatment timeEasy to makeSuperconductors/hyperconductorsSuperconductor devicesPolymer scienceOxygen

A sol of the Y-Ba-Cu-O (YBCO) superconductor film is proportionally prepared from yttrium acetate, barium acetate, copper acetate, trifluoroacetic acid, water, alpha-methylacrylic acid, divinyltriamine and methanol. A process for preparing the high-temp superconductor film from said sol is also disclosed.

Owner:XIAN UNIV OF TECH

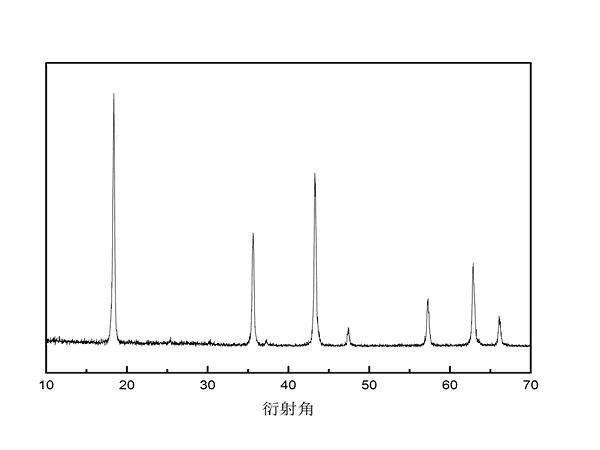

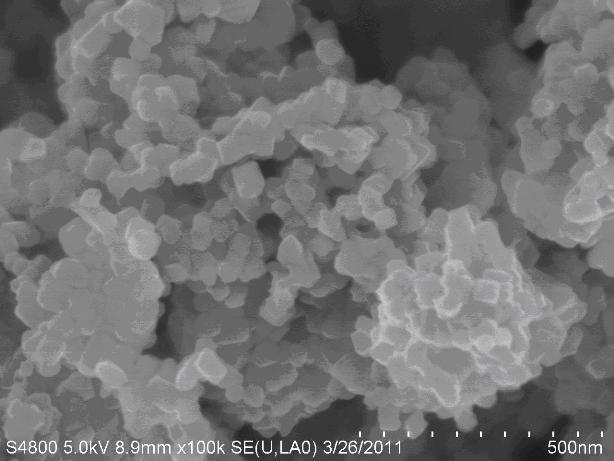

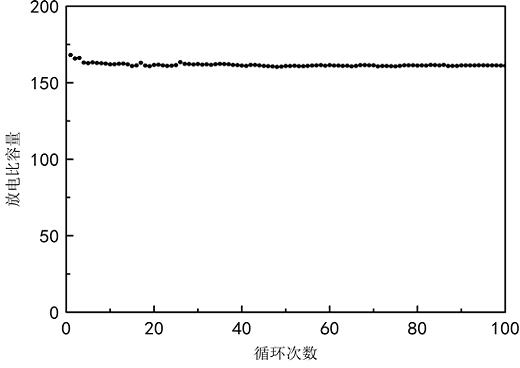

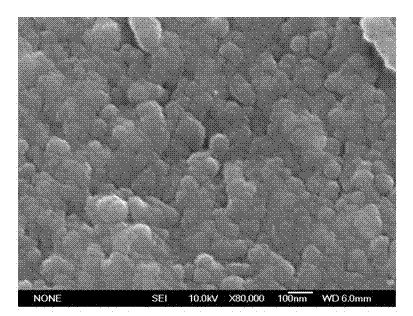

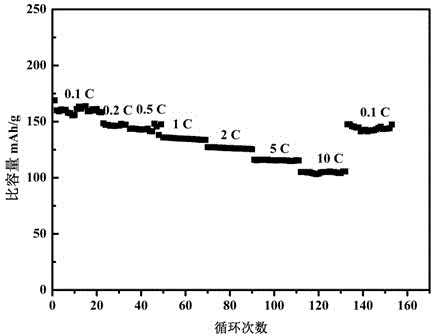

Preparation method of lithium titanate (Li4Ti5O12)/Ag composite lithium-ion negative electrode materials

InactiveCN102610824AEvenly distributedReduce consumptionCell electrodesElectric carsElectric vehicle

The invention discloses a preparation method of nanometer lithium titanate (Li4Ti5O12) / Ag composite lithium-ion negative electrode materials. The Ag doping modification is simultaneously carried out on the nanometer Li4Ti5O12. The chemical ingredients and the grain diameters of the Li4Ti5O12 are effectively controlled through hydrothermal treatment, the temperature during the subsequent treatment is greatly shortened, the grain agglomeration is prevented, and the industrial implementation is easier. In the preparation process, the Ag is doped, the conductivity of the materials is greatly improved, and meanwhile, the high-power charging and discharging performance and the cyclic times of the materials are effectively improved. The high-power specific capacity of the prepared materials is high, and the materials can be used for batteries required by various kinds of portable electronic equipment and various electric vehicles.

Owner:SHANGHAI UNIV

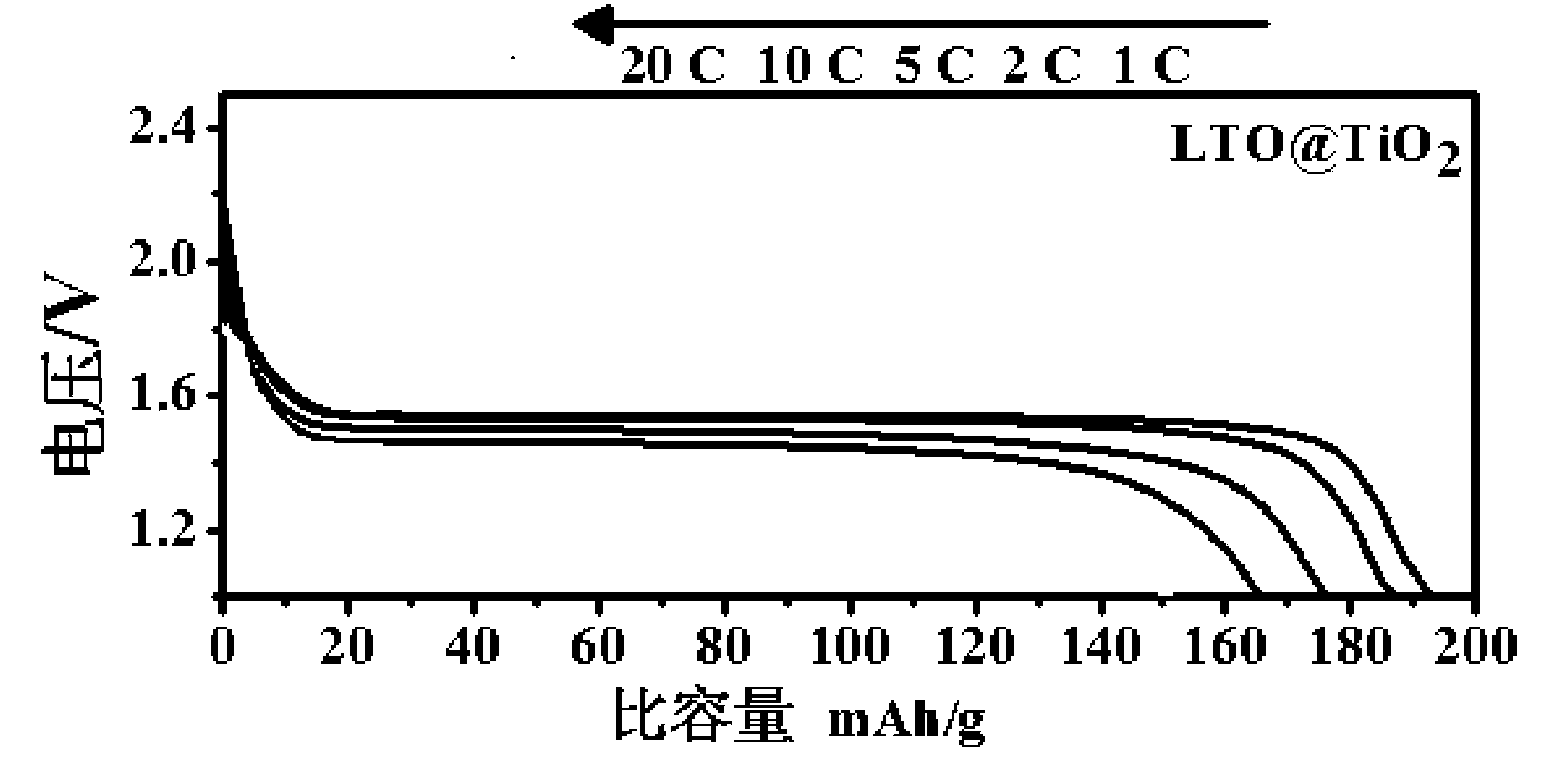

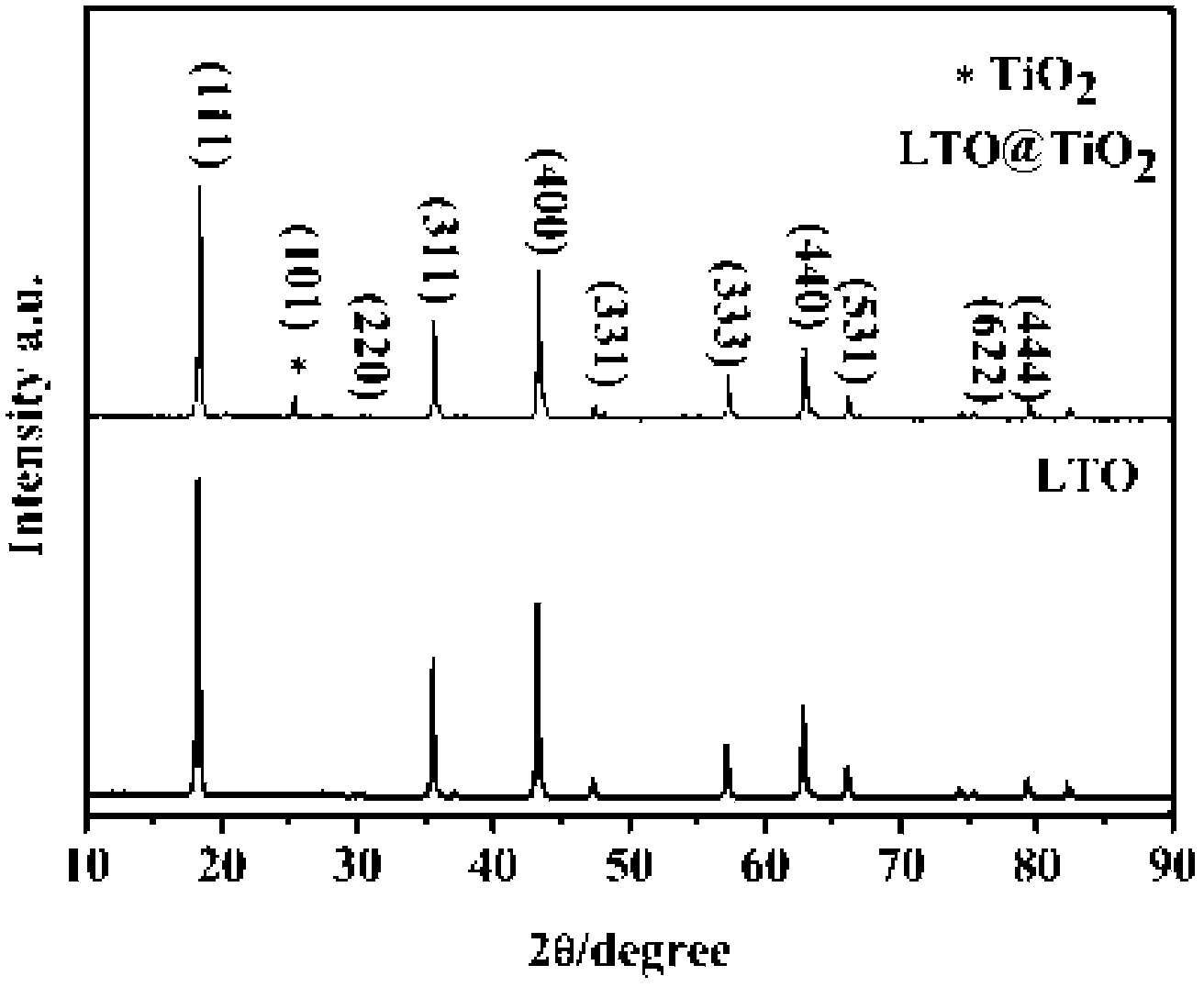

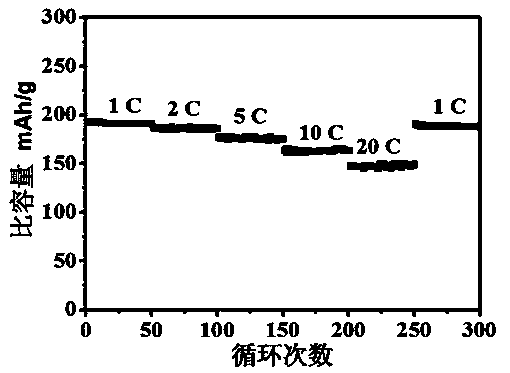

Preparation method for nanoscale lithium titanate material with high specific capacity

ActiveCN103682296AEvenly distributedReduce consumptionMaterial nanotechnologyAlkali titanatesAlcoholRoom temperature

The invention discloses a preparation method for a nanoscale lithium titanate material with high specific capacity. The preparation method comprises the following steps: (1) preparing a liquid A; (2) preparing a liquid B; (3) under a condition of magnetic stirring, slowly adding the liquid B into the liquid A, so as to obtain a mixed dispersion liquid; (4) putting the mixed dispersion liquid into a high-temperature reaction still, then placing the high-temperature reaction still in a drying oven for reaction, after the reaction, naturally cooling to room temperature, leaching, washing with deionized water and absolute ethyl alcohol, and then drying under a condition that the temperature is 60-120 DEG C so as to obtain a precursor; (5) sintering the precursor for 1-5 hours in anitrogen atmosphere under a condition that the temperature is between 400-1000 DEG C, so as to obtain the nanoscale lithium titanate material; (6) immersing the nanoscale lithium titanate material in an acid solution with the hydrogen ion concentration of 0.01-14mol / L under a condition that the temperature is 20-200 DEG C, then leaching, washing with deionized water and absolute ethyl alcohol, and then drying, so as to obtain the nanoscale lithium titanate material with high specific capacity.

Owner:上海大学浙江嘉兴新兴产业研究院

Heat treatment process for ZL101A aluminium alloy for automobile wheel hub

InactiveCN101880844AReduce energy consumptionShorten heat treatment timeSolution treatmentEnergy consumption

The invention discloses a heat treatment process for a ZL101A aluminium alloy for an automobile wheel hub. The process comprises the following steps of: putting an as-cast blank into a solution treatment furnace for raising temperature, performing solution treatment at a solution temperature, taking the blank out of the solution treatment furnace, quenching the blank, putting the as-cast blank into an ageing treatment furnace for raising the temperature, performing ageing treatment on the blank at an aging treatment temperature; and after taking the blank out of the ageing treatment furnace, cooling the blank in the air medium. The heat treatment process is characterized in that: the solution treatment temperature is 525 to 550 DEG C; the heat maintaining time during the solution treatment is 60 to 120 minutes; the ageing treatment temperature is 165 to 180 DEG C; and the heat maintaining time during the ageing treatment is 90 to 180 minutes. The heat treatment process organically combines the short-time solution treatment and the short-time ageing treatment and fulfils the aim of low energy consumption and high work efficiency. At the same time, compared with the standard T6 heat treatment process, the heat treatment process can shorten the heat treatment time by over one time and guarantee that an alloy microstructure obtained through the solution treatment and the ageing treatment reaches an ideal state of the standard T6 treatment.

Owner:GUANGZHOU KINBON NON FERROUS ALLOY METALS CO LTD +1

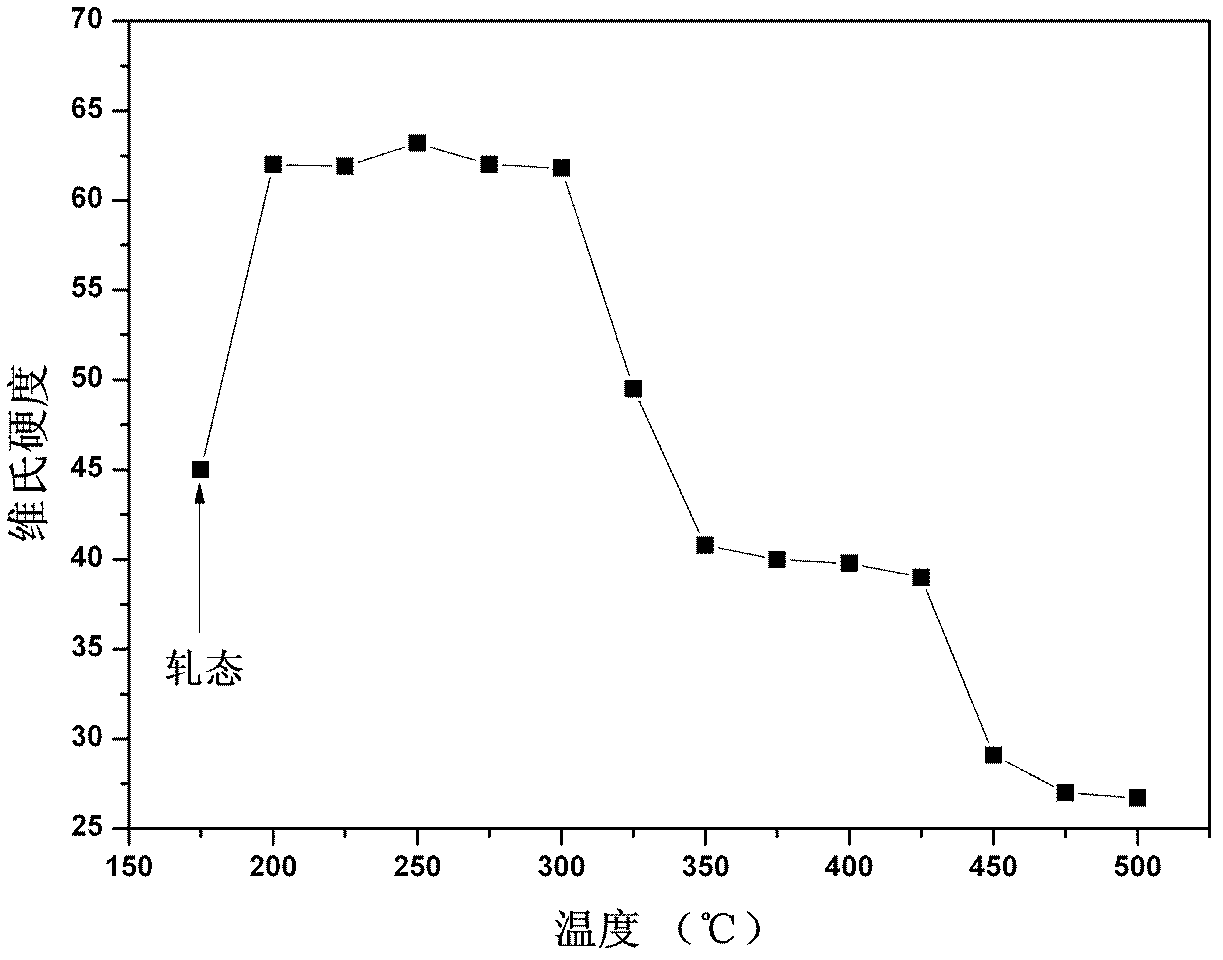

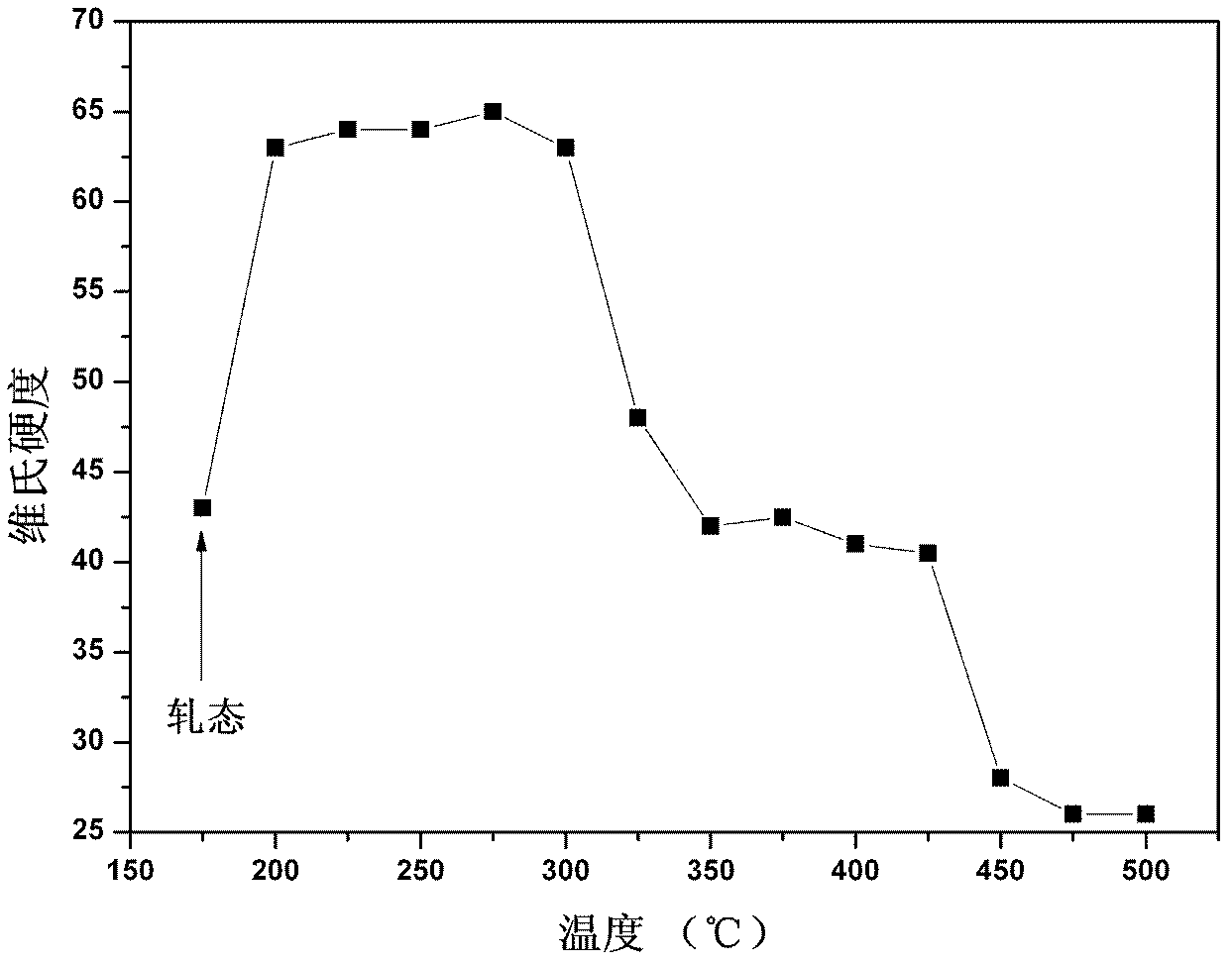

High-strength, high-conductivity and heat-resistant aluminum alloy conductor material and preparation method thereof

InactiveCN102534318AImprove conductivitySufficient precipitationMetal/alloy conductorsHeat resistanceIngot

The invention relates to a high-strength, high-conductivity and heat-resistant aluminum alloy conductor material and a preparation method thereof, and belongs to the technical field of alloy materials. The conductor material comprises the following components in percentage by weight: 0.2 to 0.3 percent of Zr, 0.15 to 0.25 percent of Er, less than 0.3 percent of impurities and the balance of aluminum. The preparation method comprises the following steps of: adding an AlEr intermediate alloy and an AlZr intermediate alloy in the process of smelting the aluminum, smelting at the temperature of 780+ / -10 DEG C, preserving heat for 30 minutes, and casting; and performing homogenization treatment, rolling and heat treatment on an ingot in turn. Er and Zr in the component ratio are compositely microalloyed, a large number of precipitated phases which are distributed in a dispersed mode can be precipitated by the process, a large number of deformation structures can be stored, and the high conductivity (59.6 to 60 percent international annealed copper standard IACS), high strength (Vickers hardness 62.5 to 66.5) and heat resistance (capability of resisting the temperature of 375 DEG C in a short term and resisting the temperature of 225 DEG C in a long term) of the alloy are kept simultaneously.

Owner:BEIJING UNIV OF TECH

Method for manufacturing soft-magnetic alloy powder

The production method of soft magnetic alloy powder includes the following steps: smelting soft magnetic mother alloy, making molten metal be quickly coagulated into crystalline sheet alloy, breaking the sheet alloy to obtain alloy powder, and making the alloy powder undergo the processes of activation, annealing treatment and passivation treatment. Said soft magnetic alloy powder is low in oxygen content, stable in property and good in magnetic powder core performance.

Owner:CENT IRON & STEEL RES INST

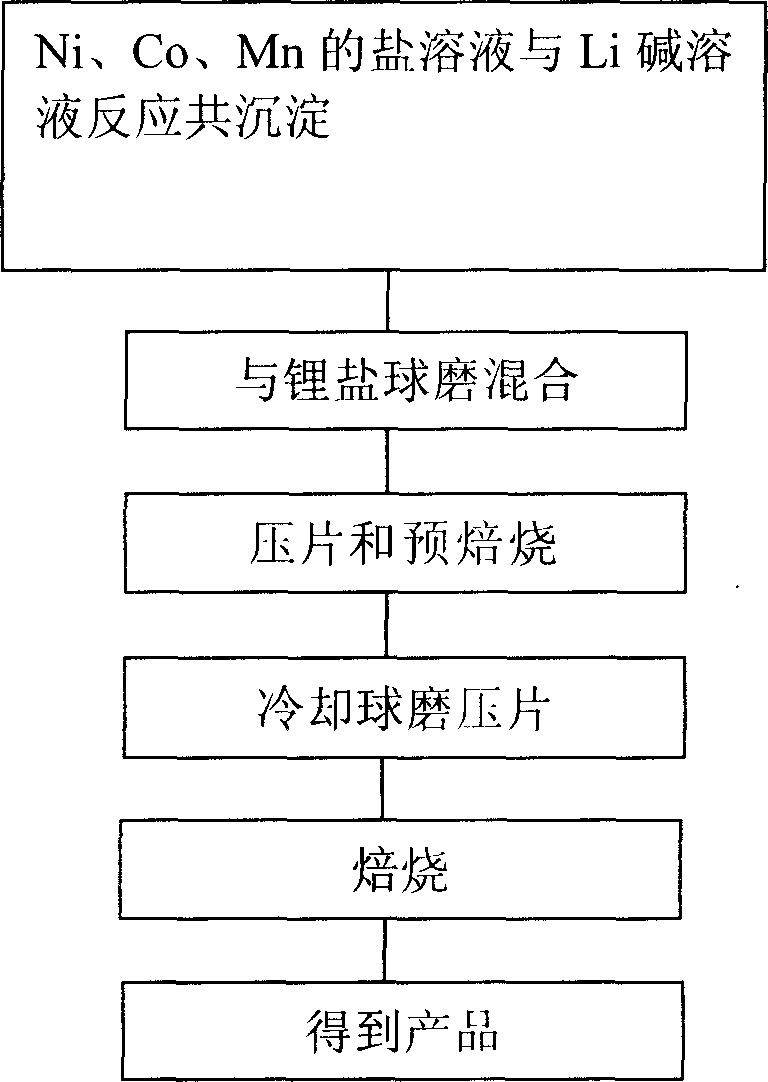

Method for producing anode active material containing lithium, magnesium compound oxide

InactiveCN1741302AStructural Precise TailoringSimple structureElectrode manufacturing processesLithium compoundsMANGANESE ACETATENickel salt

A method for preparing positive electrode multielement active material containing lithium / manganese composite oxide includes directly using lithium hydroxide coprecipitation to prepare M ( OH )2 , mixing it with lithium salt in grinding , forming plate by pressing , prebaking , cooled ball grinding , forming plate by pressing and backing . In the method , applied nickel salt is nickel acetate or nickel nitrate , applied cobalt salt is cobalt acetate or cobalt nitrate, applied manganese salt is manganese nitrate or manganese acetate and applied lithium salt is lithium carbonate or lithium acetate .

Owner:HEBEI UNIV OF TECH

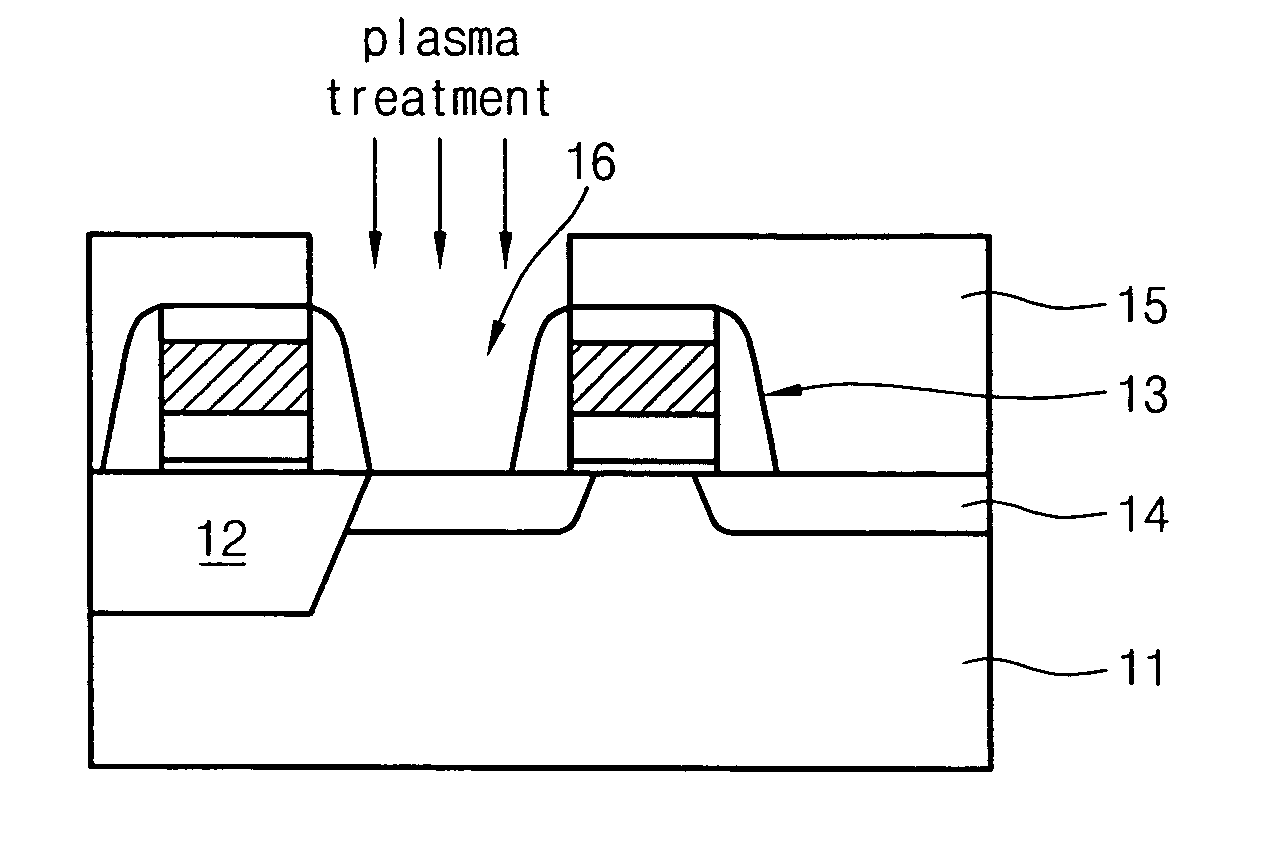

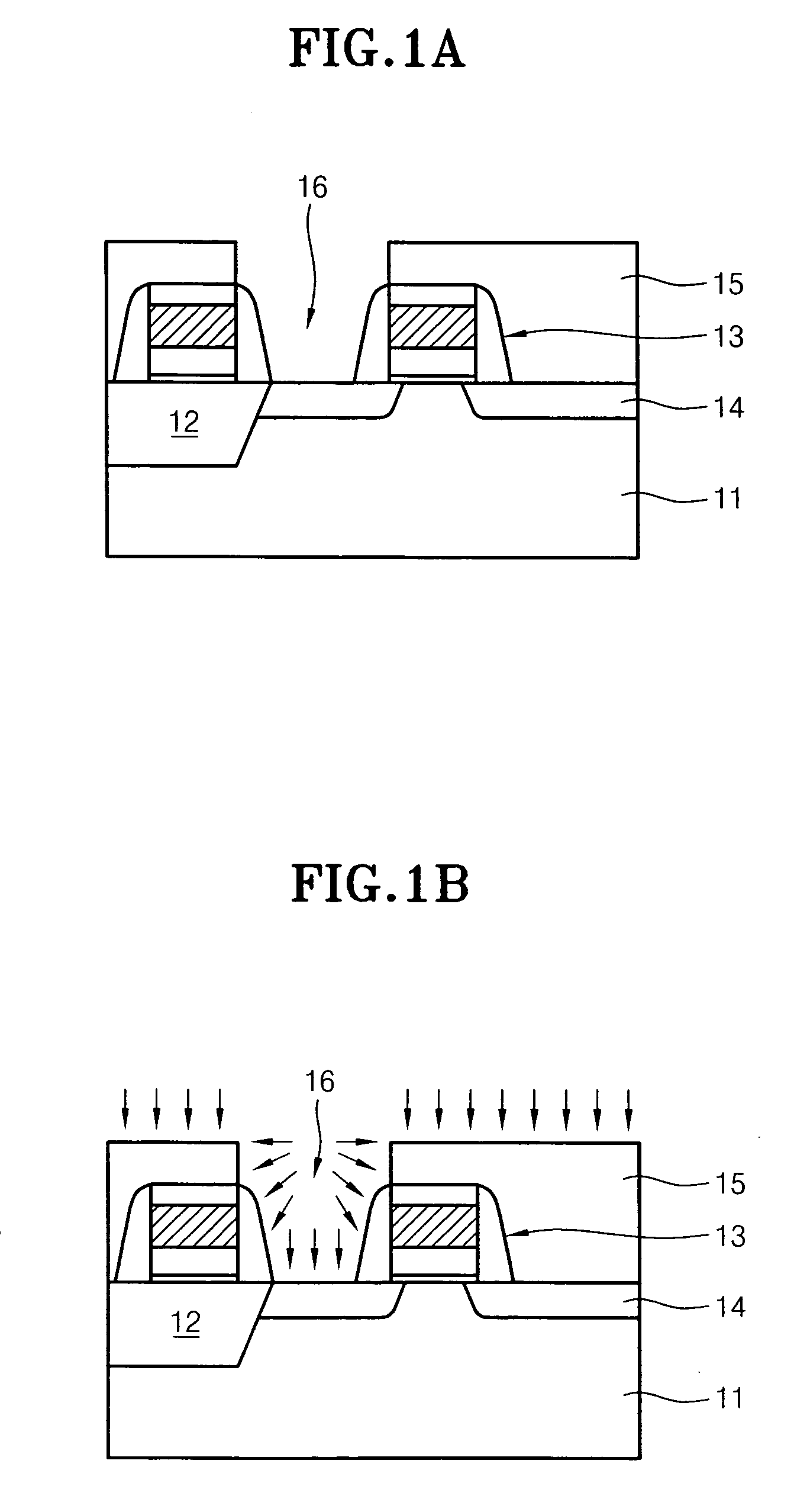

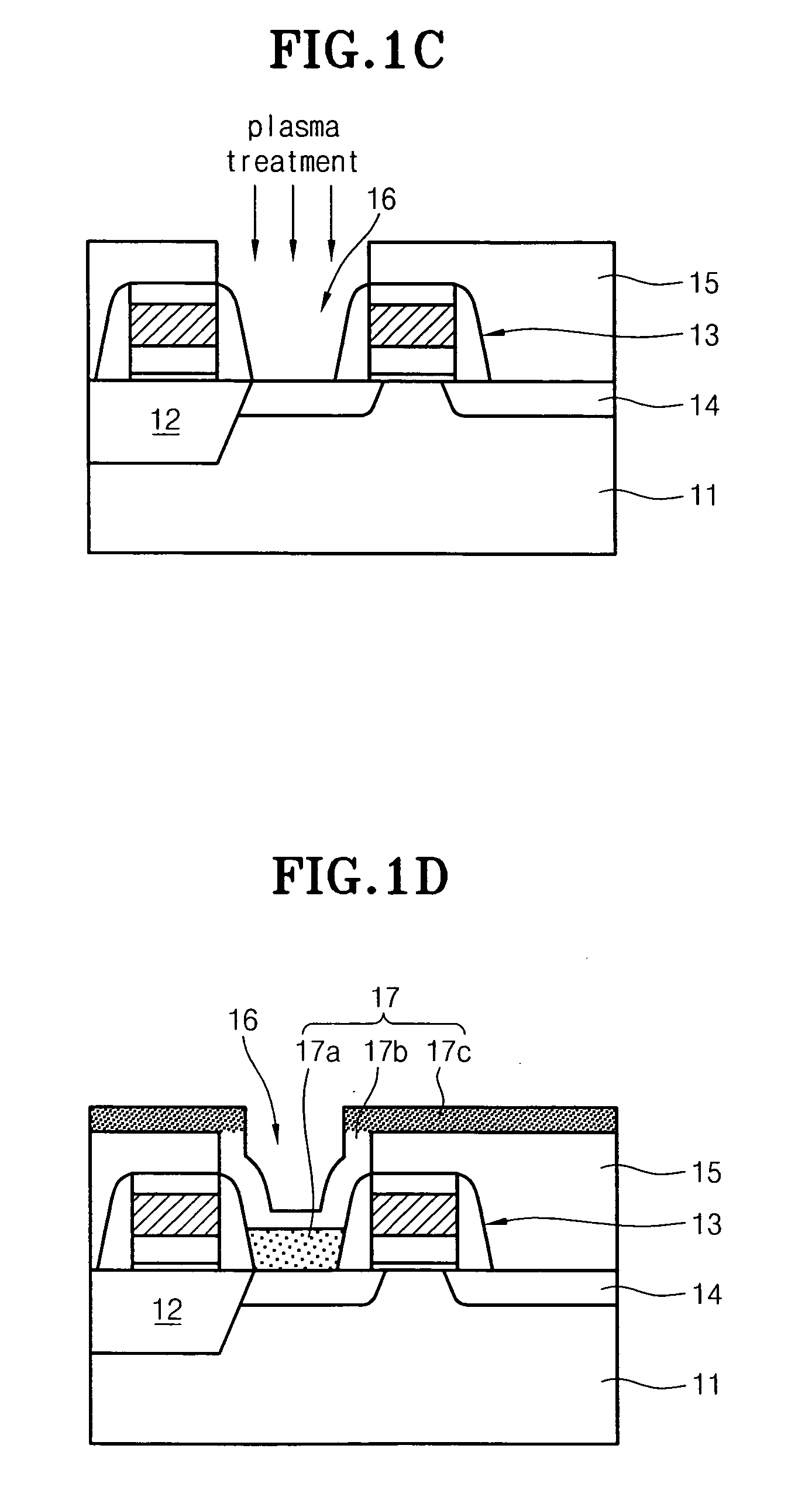

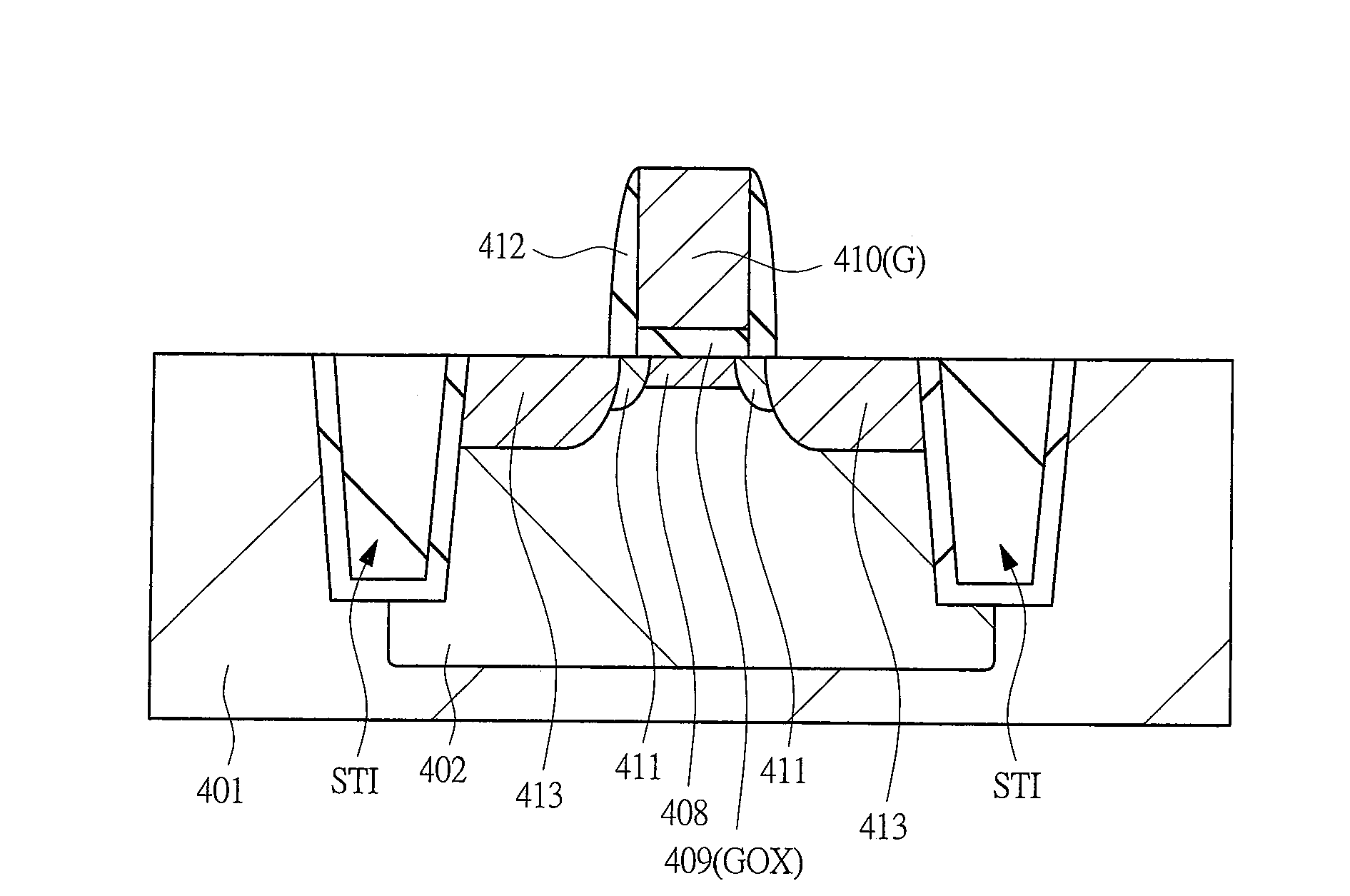

Method of forming a contact plug in a semiconductor device

InactiveUS20050112870A1Shorten heat treatment timeMinimize degradationSolid-state devicesSemiconductor/solid-state device manufacturingOxideSemiconductor

A contact plug is formed in a semiconductor device having a silicon substrate having a gate electrode, a junction area and an insulating interlayer. A contact hole is formed to expose the junction area. A plasma process is carried out with respect to a resultant substrate, thereby removing natural oxides created on an exposed surface of the junction area. A first silicon layer is deposited on the contact hole and on the insulating interlayer. A heat-treatment process is carried out with respect to the first silicon layer so as to grow the amorphous silicon into the epitaxial silicon. A second silicon layer is deposited on the first silicon layer.

Owner:SK HYNIX INC

Method for preparing yttrium-barium-copper-oxygen super conductive-film sol-gel

InactiveCN1850723AShorten heat treatment timeEasy to makeSuperconductors/hyperconductorsSuperconductor devicesPorosityOxygen

This invention discloses sol-gel preparation method of yttrium barium copper oxygen superconducting film. The materials are acetic yttrium, acetic barium, acetic copper, their mol ratio is that acetic yttrium 1 part, acetic barium 2 parts, acetic copper 3-4 parts, trifluoroacetic acid 4-10 parts, water 20-160 parts, acrylic acid 6-40, diethylene triamine 1-5, methanol 60-240, benzoyl acetone 1-10. Fluorine content of the sol is low, components are easy to adjust, chemical stability is good, and preparation process is simple. High temperature superconductive film made by this sol is easy to get superconductive thickness film, its technique repeatability is high, this method can be used to make large area yttrium barium copper oxygen film, the film porosity is low, surface purify is good, and good superconducting characteristic.

Owner:XIAN UNIV OF TECH

Method for surface crosslinking water-absorbing resin and method for manufacturing water-absorbing resin

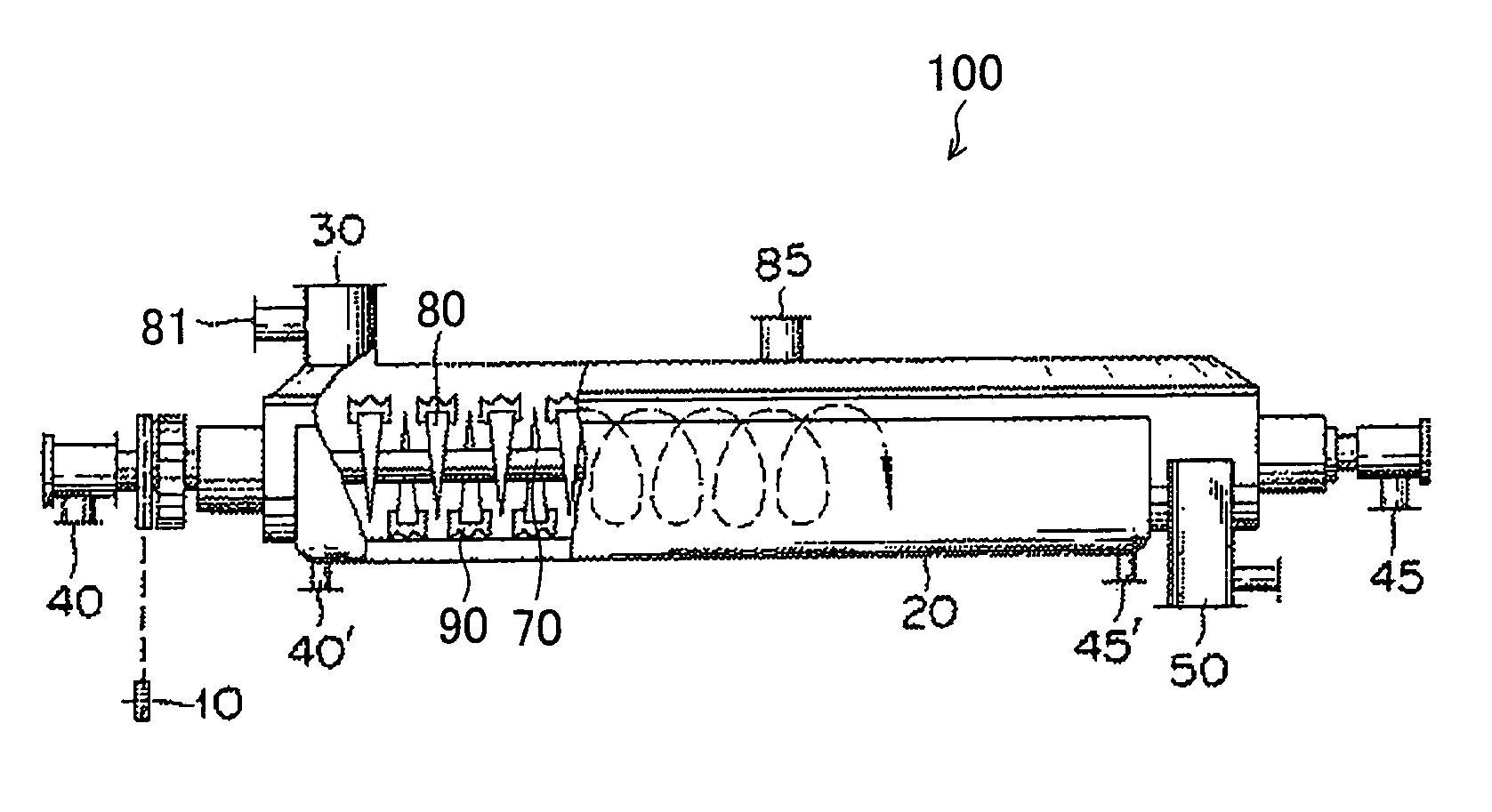

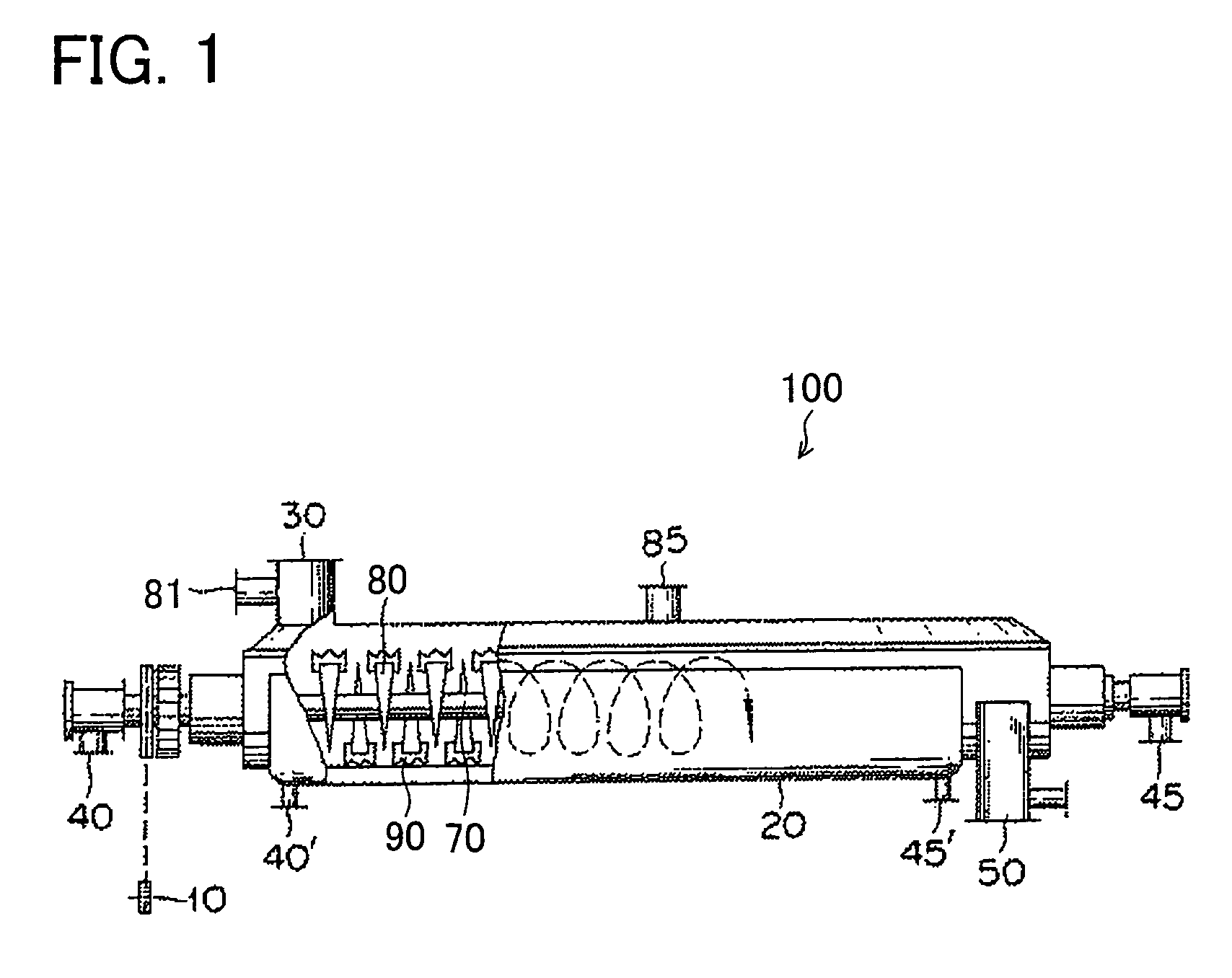

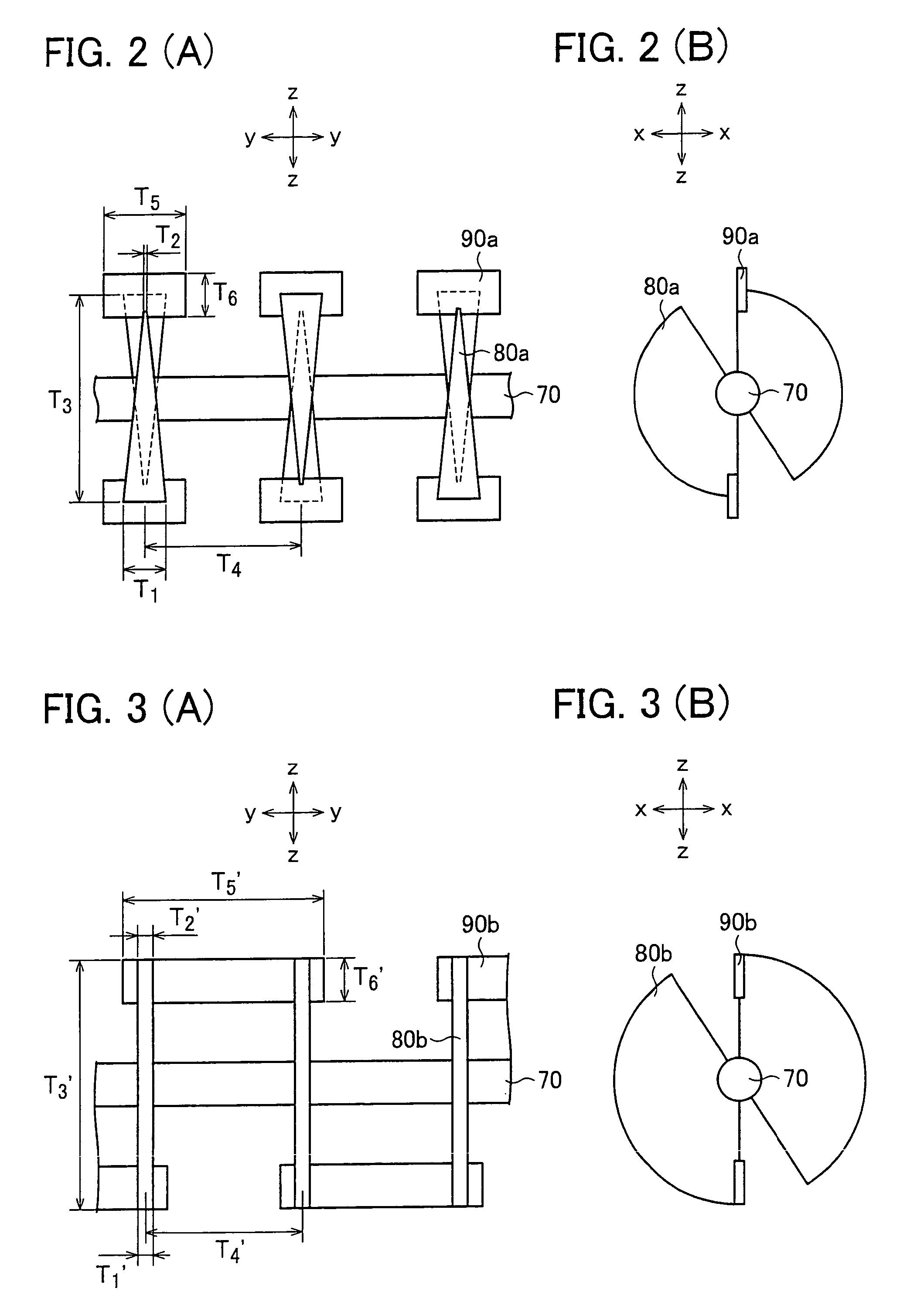

ActiveUS7851550B2Good physical propertiesShorten heat treatment timeTransportation and packagingRotary stirring mixersRotational axisPolymer science

A method for surface crosslinking water-absorbing resin of the present invention includes a step (1) of obtaining a wet mixture, a step (2) of obtaining a dried particulate composition, and a step (3) of carrying out a surface crosslinking reaction. With this, since a processing time of each step becomes short, it is possible to mass produce the water-absorbing resin having excellent physical properties. Moreover, a method for manufacturing the water-absorbing resin of the present invention includes a modifying step and a cooling step. The modifying step and / or the cooling step are / is carried out by using stirring means including a rotation axis having a plurality of stirring boards, and the stirring means includes the stirring board having a specific thickness and / or a scraping blade having a specific shape. With this, it is possible to suppress the generation of the fine powder in the modifying step and / or the cooling step.

Owner:NIPPON SHOKUBAI CO LTD

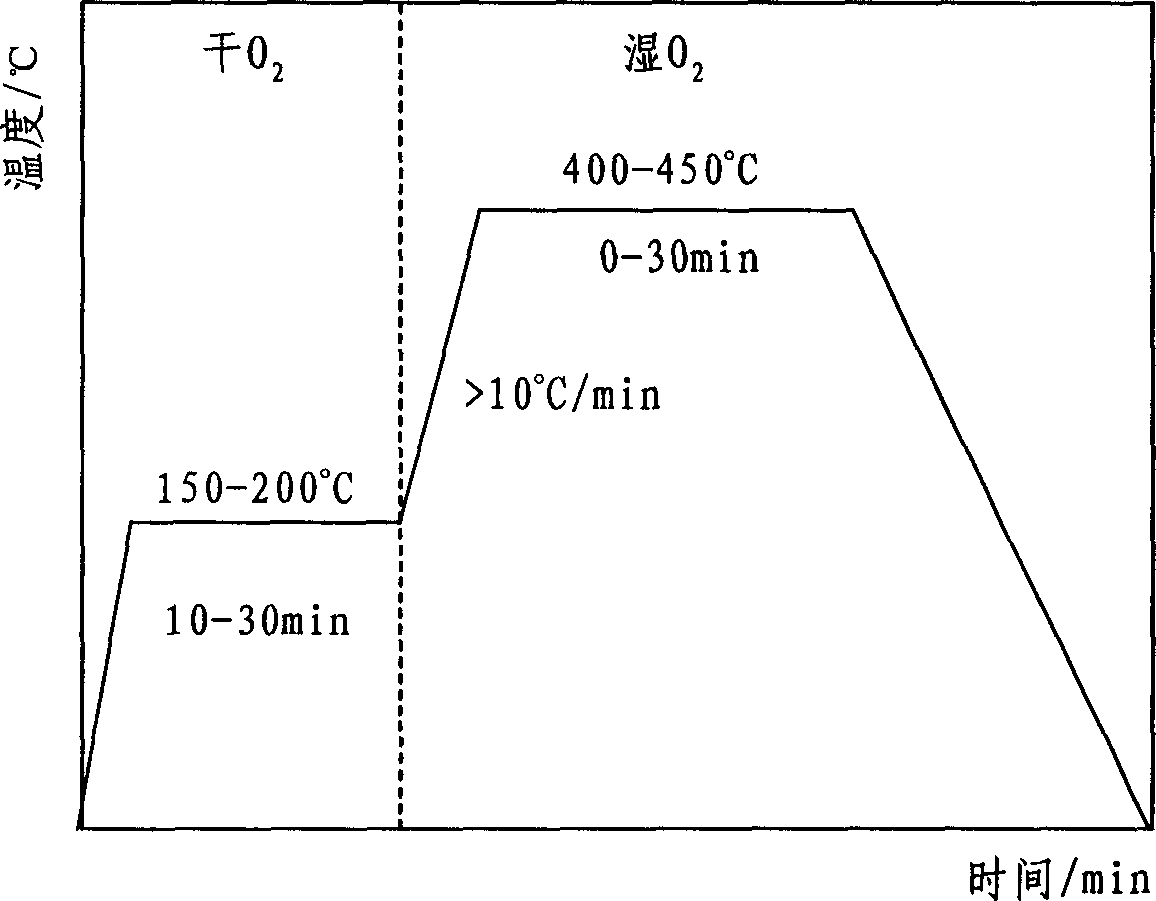

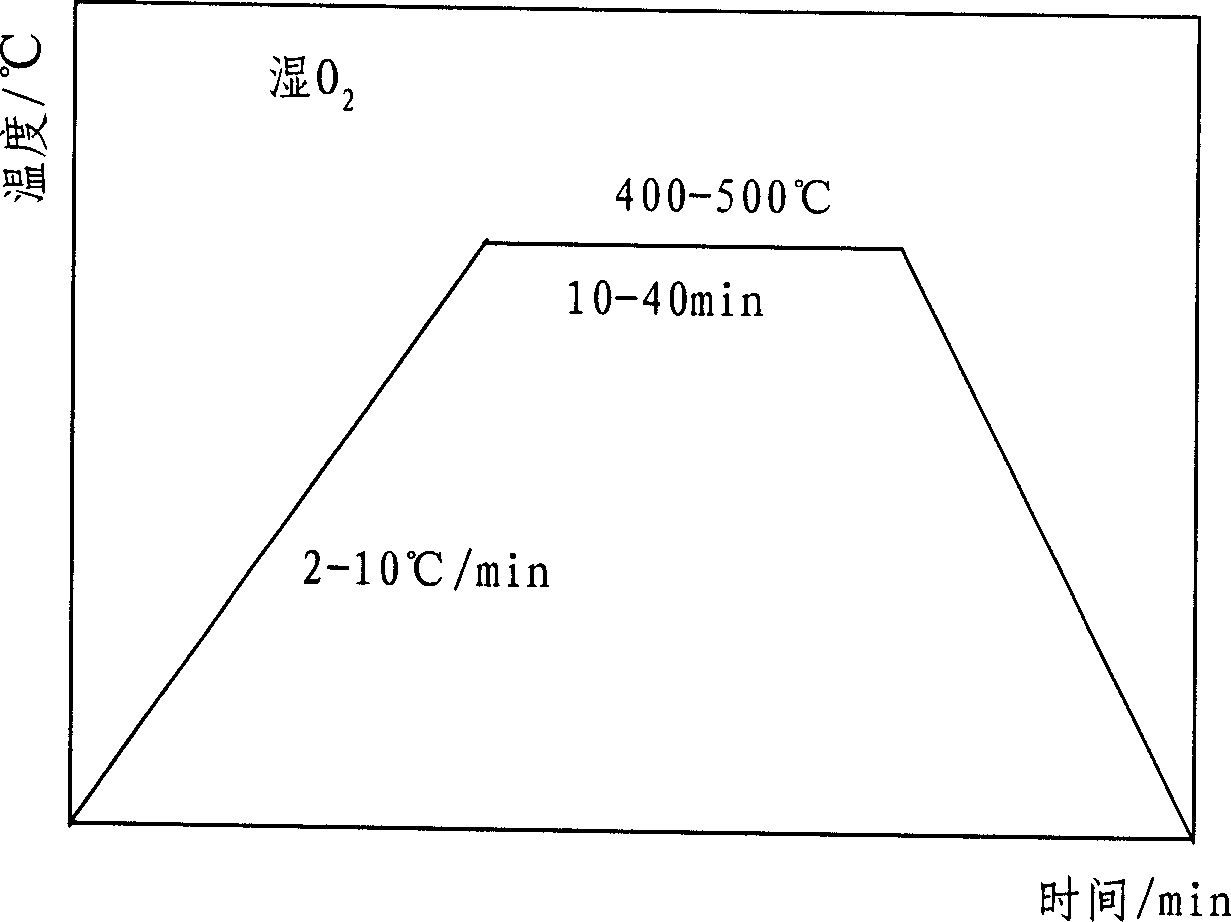

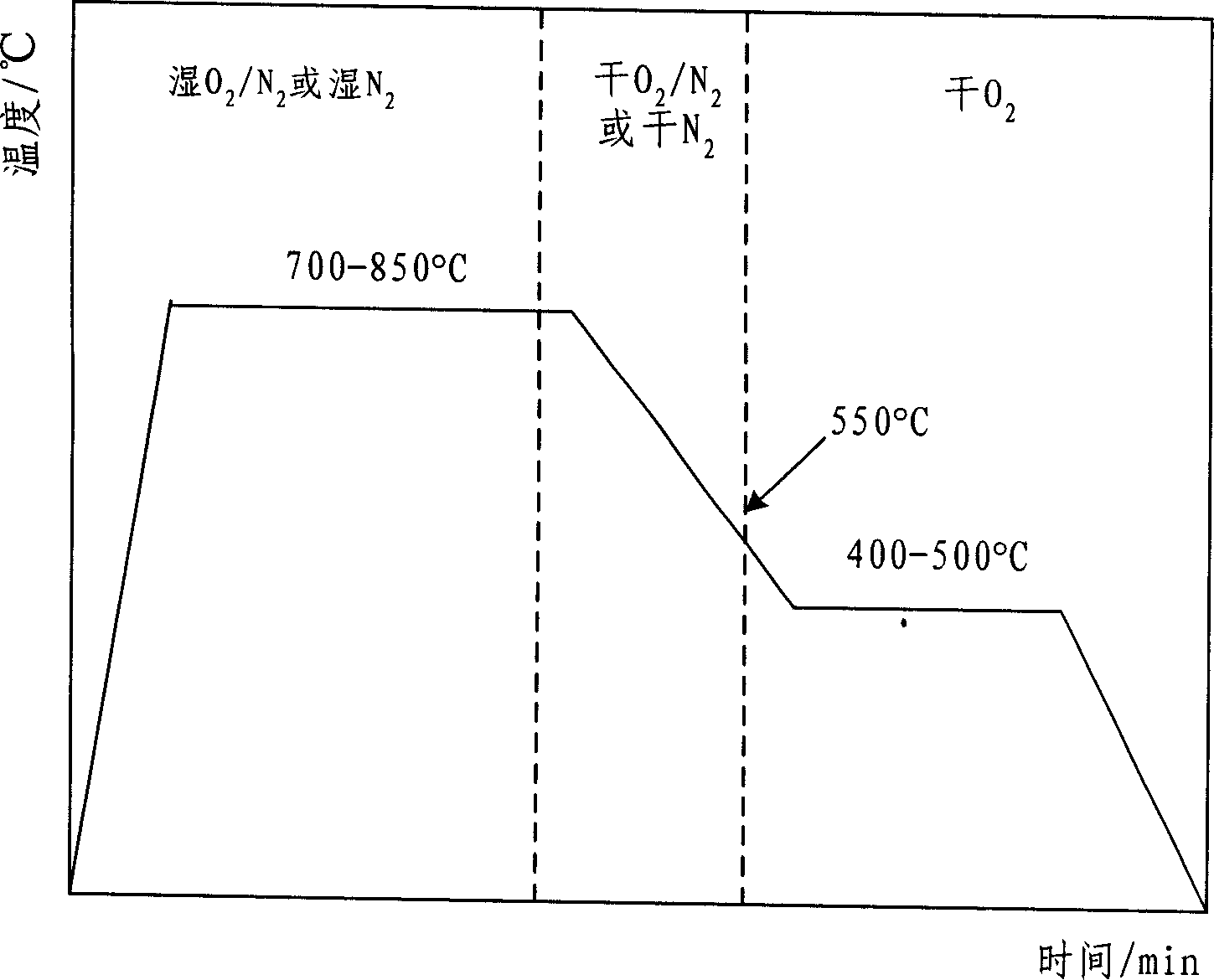

Method of manufacturing semiconductor device

InactiveUS20090275183A1Suppress DiffuseLower heat treatment temperatureTransistorSemiconductor/solid-state device manufacturingSilicon oxideOxygen

A thermal oxidation method capable of obtaining a high oxidation rate by generating a sufficient enhanced-rate oxidation phenomenon even in a low temperature region is provided. In addition, a thermal oxidation method capable of forming a silicon oxide film having a high reliability even when formed at a low temperature region. A basic concept herein is to form a silicon oxide film by thermal reaction by generating a large amount of oxygen radicals (O*) having a large reactivity without using plasma. More specifically, ozone (O3) and other active gas are reacted, so that ozone (O3) is decomposed highly efficiently even in a low temperature region, thereby generating a large amount of oxygen radicals (O*). For example, a compound gas containing a halogen element can be used as the active gas.

Owner:RENESAS TECH CORP

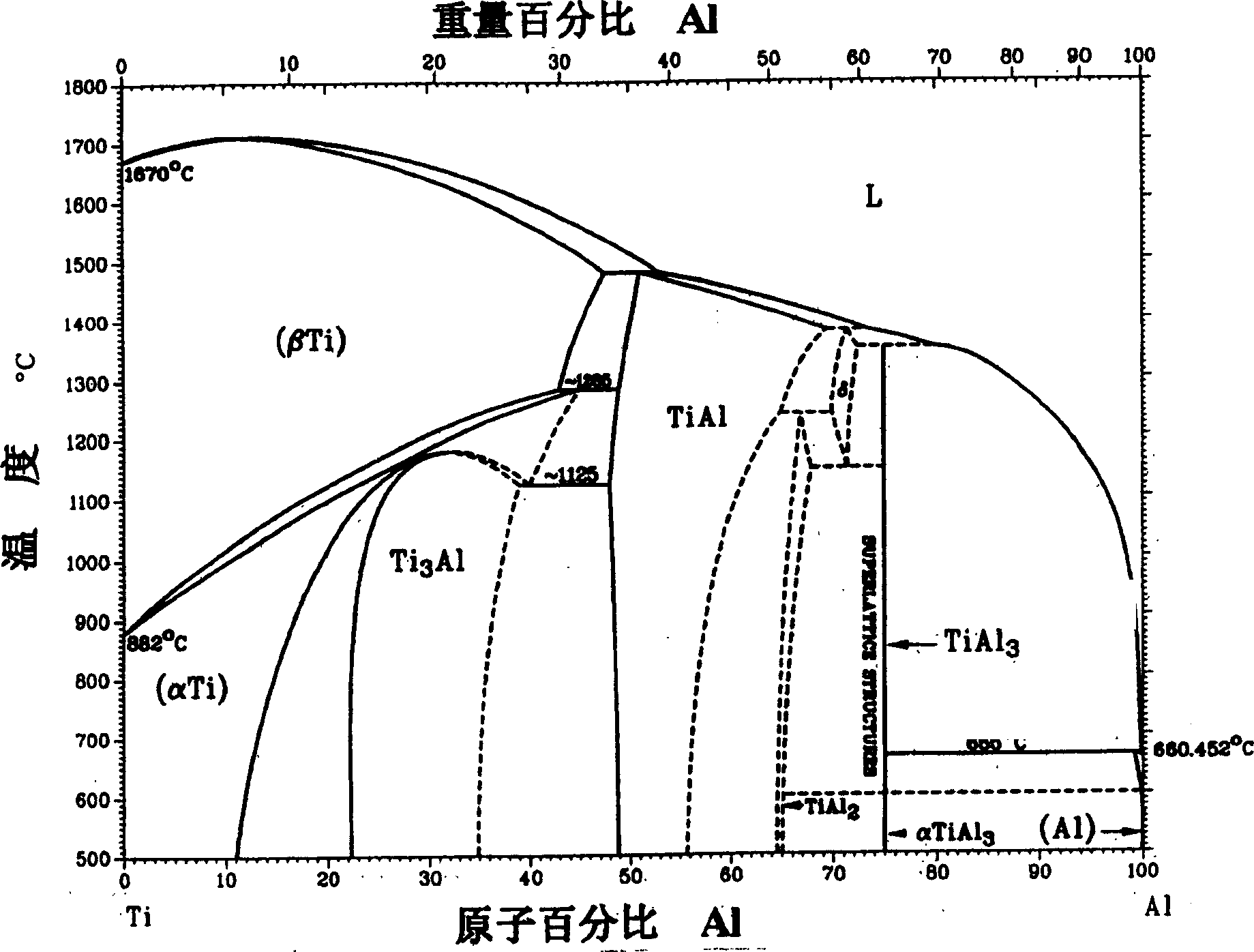

Heating technology for refining TiAl alloy ingot microscopic texture

Owner:UNIV OF SCI & TECH BEIJING

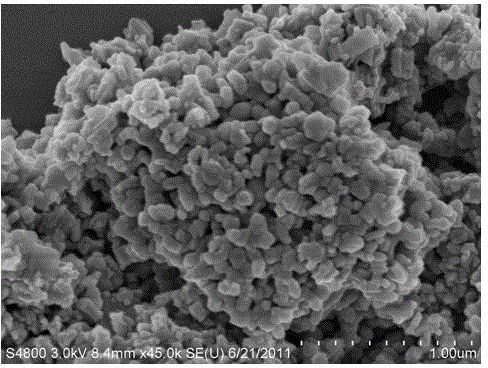

Method for preparing hard carbon negative electrode materials of lithium ion battery

The invention discloses a method for hard carbon negative electrode materials of a lithium ion battery and belongs to the technical field of hard carbon negative electrode materials of the lithium ion battery. By means of the method, one or several kinds with any proportion of sulfuric acid, sulfate, boric acid, borate, phosphoric acid, phosphate, muriatic acid, muriate and ammonia or ammonium salt is / are chosen as a catalyst / catalysts for preparing the hard carbon negative electrode materials of the lithium ion battery in a catalysis method, and compared with the catalysts used in the prior art, the catalysts used in the preparing process of the materials are reduced in low-temperature section stabilized heat treatment temperature, the time is shortened by nearly 10 times, a large number of resources are saved, production cost is reduced, and capacity is improved.

Owner:DONGFANG ELECTRIC CORP LTD

Processing method of high precision steel ball

The invention discloses a processing method of a high precision steel ball. The processing method comprises the following steps: cold heading forming; annealing; ball polishing; primary soft grinding; primary hot pickling for appearance; secondary soft grinding; primary heat treatment; hard grinding; secondary cold pickling for appearance; removal of a corrosion layer; primary stabilizing; strengthening treatment; primary grinding; secondary stabilizing; lapping; appearance selection; super-lapping; secondary heat treatment; oil washing; detection. The processing method of a high precision steel ball provided by the invention shortens the whole quenching and heat treatment time during processing by 50% or more, greatly improves heat treatment efficiency, greatly improves the spheroidization rate, hardness and strength properties of the processed steel ball compared with the steel ball with long quenching and heat treatment time, prolongs service life, satisfies relatively high quality requirements on the steel balls of the roller industry, not only reduces labor intensity, manual input and production cost, but also ensures the quality of products, and increases the added value of the products.

Owner:ANSHUN HONGYI SPECIAL STEEL BALL MFG

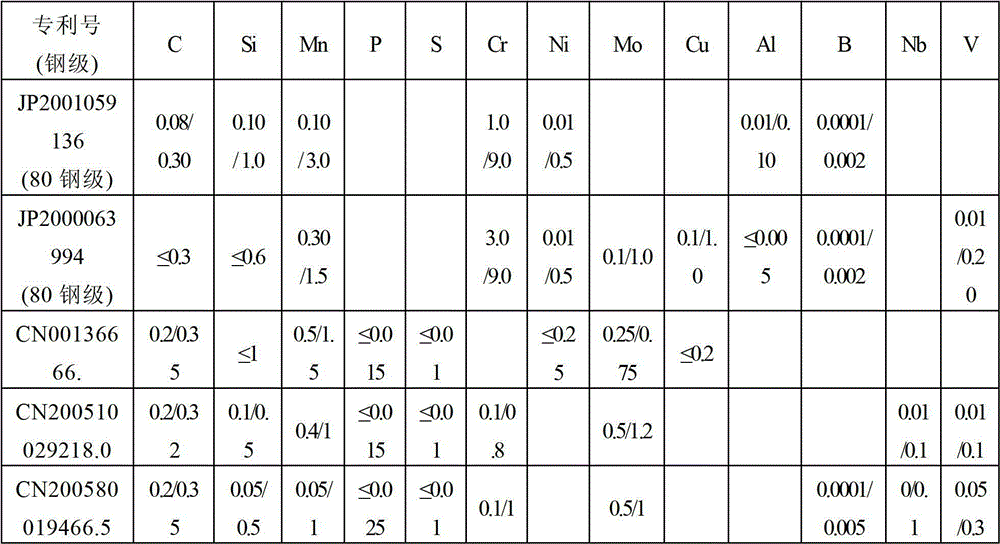

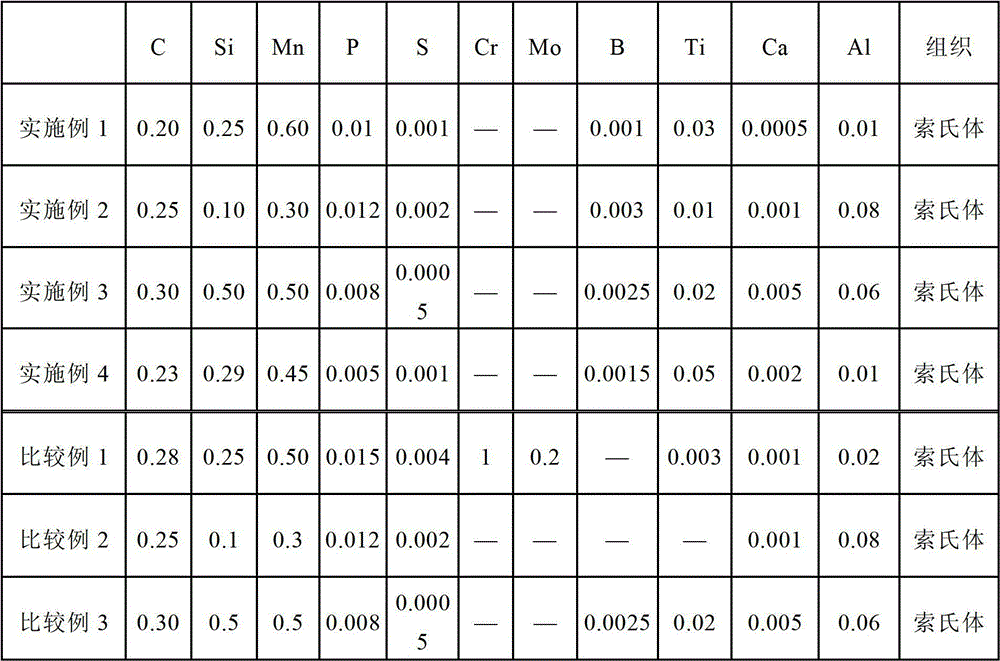

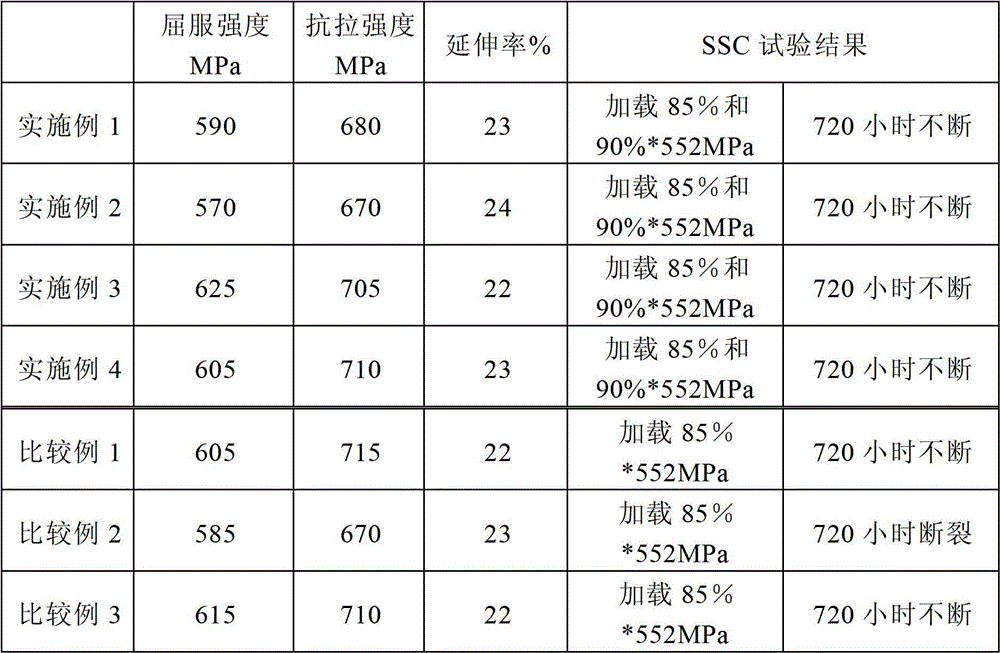

Oil casing capable of resisting hydrogen sulfide stress corrosion cracking and manufacturing method thereof

InactiveCN102747279AShorten heat treatment timeGuaranteed resistance to hydrogen sulfide stress corrosionFurnace typesHeat treatment furnacesCrack resistanceSulfide

An oil casing capable of resisting hydrogen sulfide stress corrosion cracking and a manufacturing method thereof. The oil casing comprises components of, by weight percentage, 0.2-0.3% of C, 0.1-0.5% of Si, 0.3-0.6% of Mn, no more than 0.012% of P, no more than 0.002% of S, 0.01-0.05% of Ti, 0.01-0.08% of Al, 0.0005-0.005% of Ca, 0.001-0.003% of B, and the balance of Fe and unavoidable impurities. The manufacture method comprises steps of: 1) smelting and casting: smelting and casting the above components into a tube billet; 2) rolling: rolling the tube into a steel tube; and 3) heat treatment: heating at 900-950 DEG C, and insulating for 30-60min; and carrying out water quenching and tempering at 710-730 DEG C, and insulating for 40-60min. The oil casing of the invention has low cost and good resistance to sulfide stress corrosion cracking, and can meet requirement of sulfide stress corrosion cracking resistance in gas field exploration and development.

Owner:BAOSHAN IRON & STEEL CO LTD

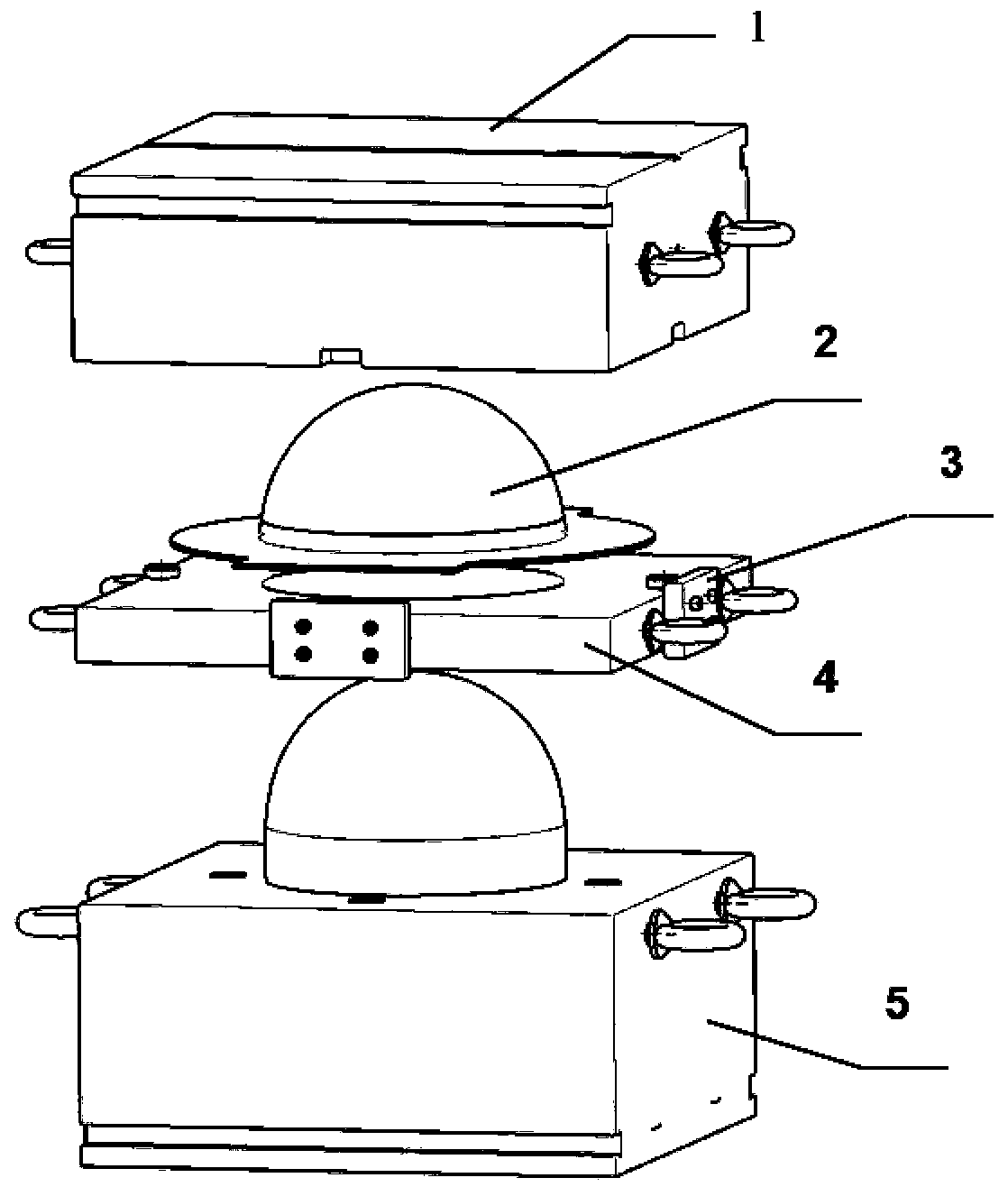

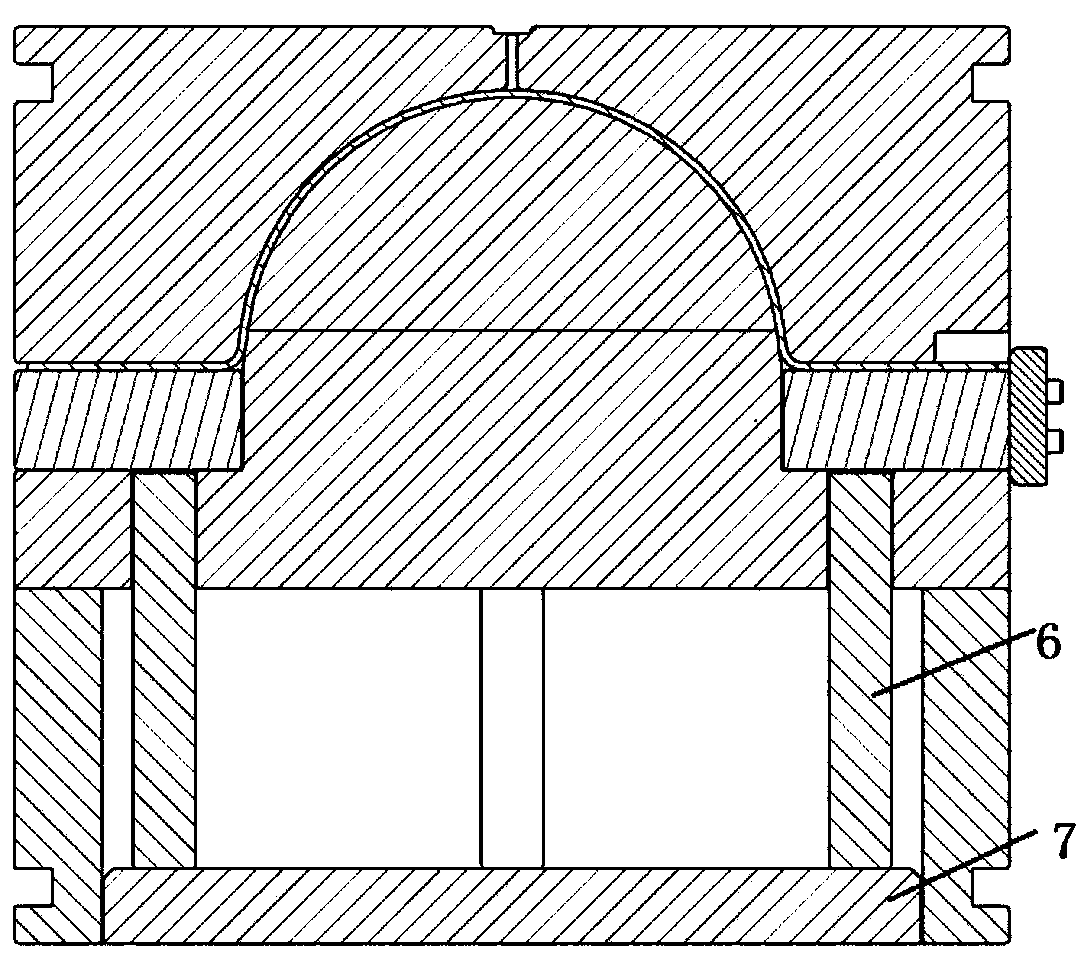

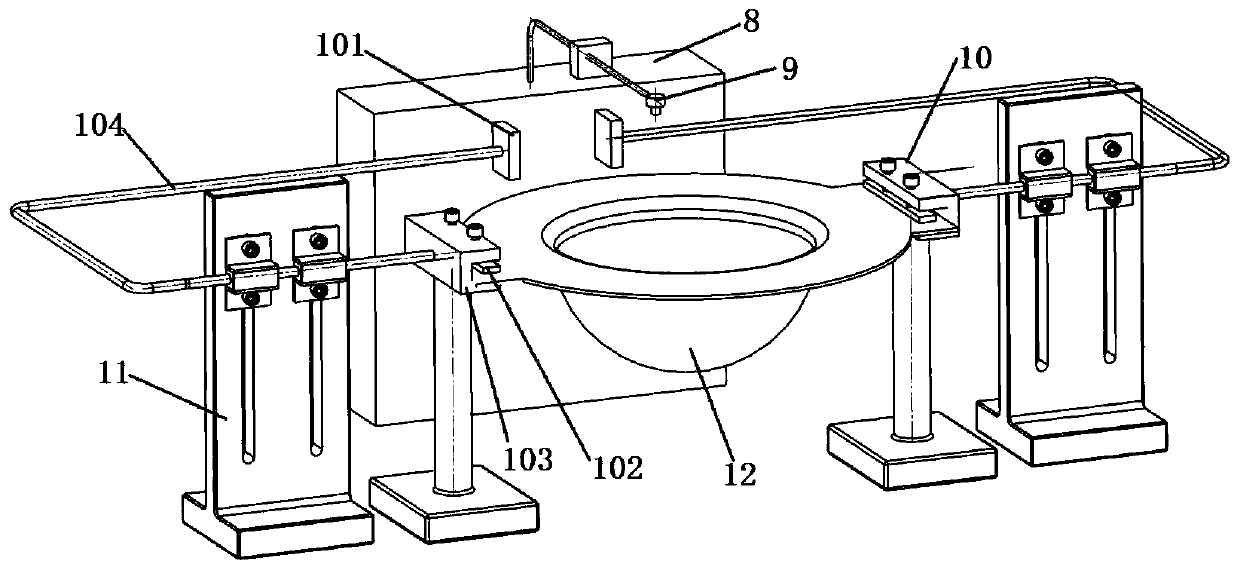

Forming mold for semi-spherical components and multi-pass forming method

ActiveCN110479843AAchieving Precise FormingBreak through the bottleneck of forming technologyShaping toolsDiameter ratioSpherical shaped

The invention discloses a forming mold for semi-spherical components and a multi-pass forming method, belongs to the technical field of semi-sphere formation, and solves the problems of corrugation and cracking in deep drawing formation of high-height-diameter-ratio semi-spherical components, difficult control of deep drawing process parameters and weaker wall thickness uniformity in the prior art. The forming mold comprises a concave mold, a convex mold, a blank holder and a positioning plate; the concave mold and the convex mold are used for forming the semi-spherical components; the blank holder is arranged between the concave mold and the convex mold, and is matched with the concave mold to tightly press blanks to prevent corrugations of the blanks in the forming process; the blank holder is provided with a positioning plate; and the positioning plate is used for positioning an upper mold and a lower mold. The forming mold and the forming method are suitable for formation of high-height-diameter-ratio semi-spherical components.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Preparation method of rye buckwheat tea

InactiveCN1478406AEfficient killingAvoid churnTea substituesFood preparationBiotechnologyPolygonum fagopyrum

Owner:王永强

Manufacturing method for medium-carbon cold forging steel rods and wires

ActiveCN103966411ASame nodularitySame hardnessTemperature control deviceMetal rolling arrangementsHardnessSteel ball

The invention relates to a manufacturing method for medium-carbon cold forging steel rods and wires. The method comprises the following steps: low temperature rolling with a finish rolling temperature of 700 to 750 DEG C; rapid air cooling after rolling through cooling to 450 to 550 DEG C at a speed of no less than 0.5 DEG C / s; rapid induction heating pretreatment through heating to 730 to 750 DEG C at a speed of 5 to 15 DEG C / s and heat preservation for 2 to 3 min; and spheroidizing annealing heat treatment through heating to 760 to 780 DEG C with a furnace, heat preservation for 60 to 80 min, cooling to 680 to 710 DEG C, heat preservation for 80 to 120 min and air cooling out of the furnace. With the method provided by the invention, spheroidizing annealing heat treatment time for medium-carbon cold forging steel balls is substantially shortened by more than 50%, and heat treatment efficiency is greatly improved; obtained medium-carbon cold forging steel has at least a same balling rate and same hardness and cold forging performance compared with current medium-carbon cold forging steel annealed for a long time, and high requirements on cold forging steel in the fastener industry are satisfied.

Owner:BAOSHAN IRON & STEEL CO LTD

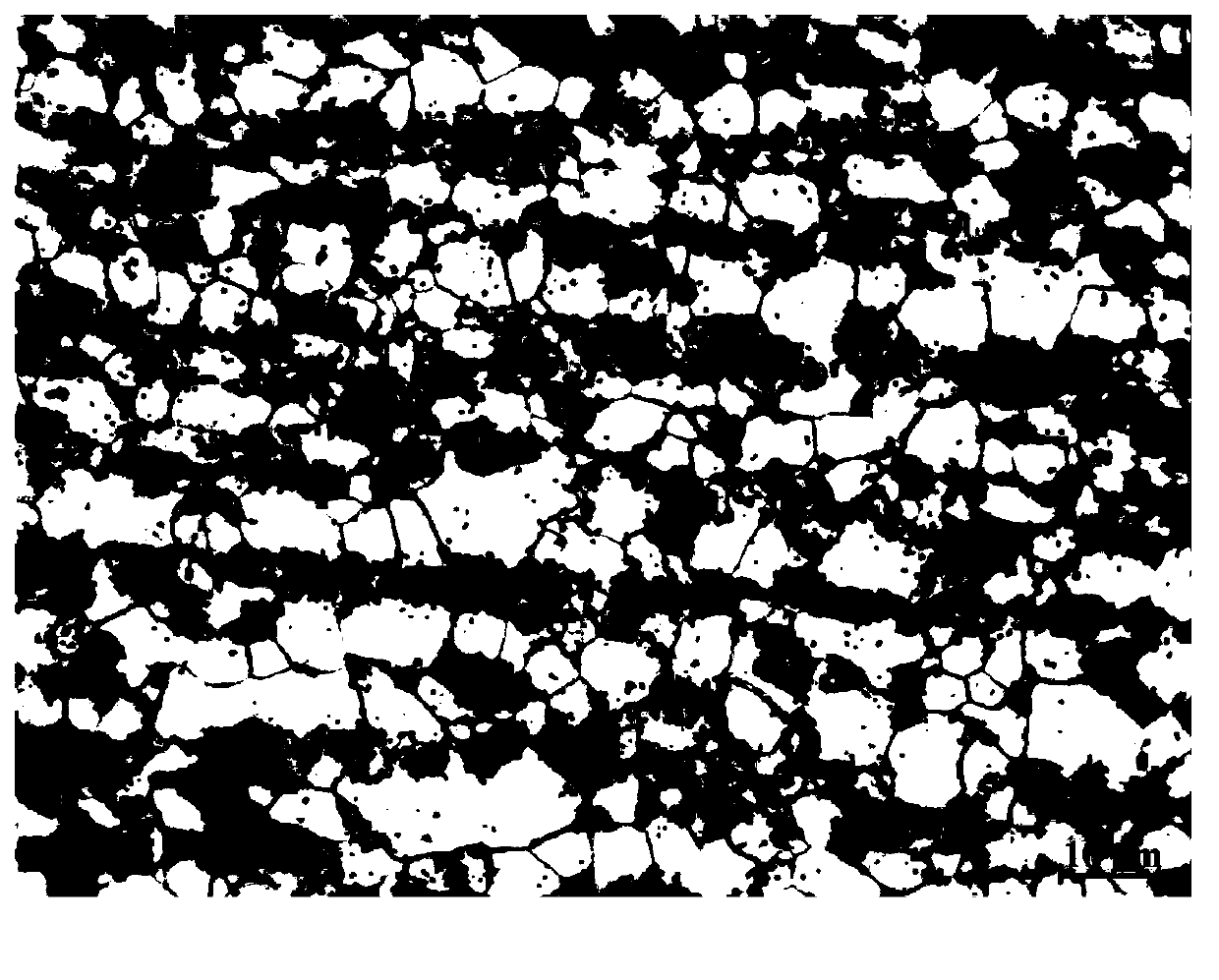

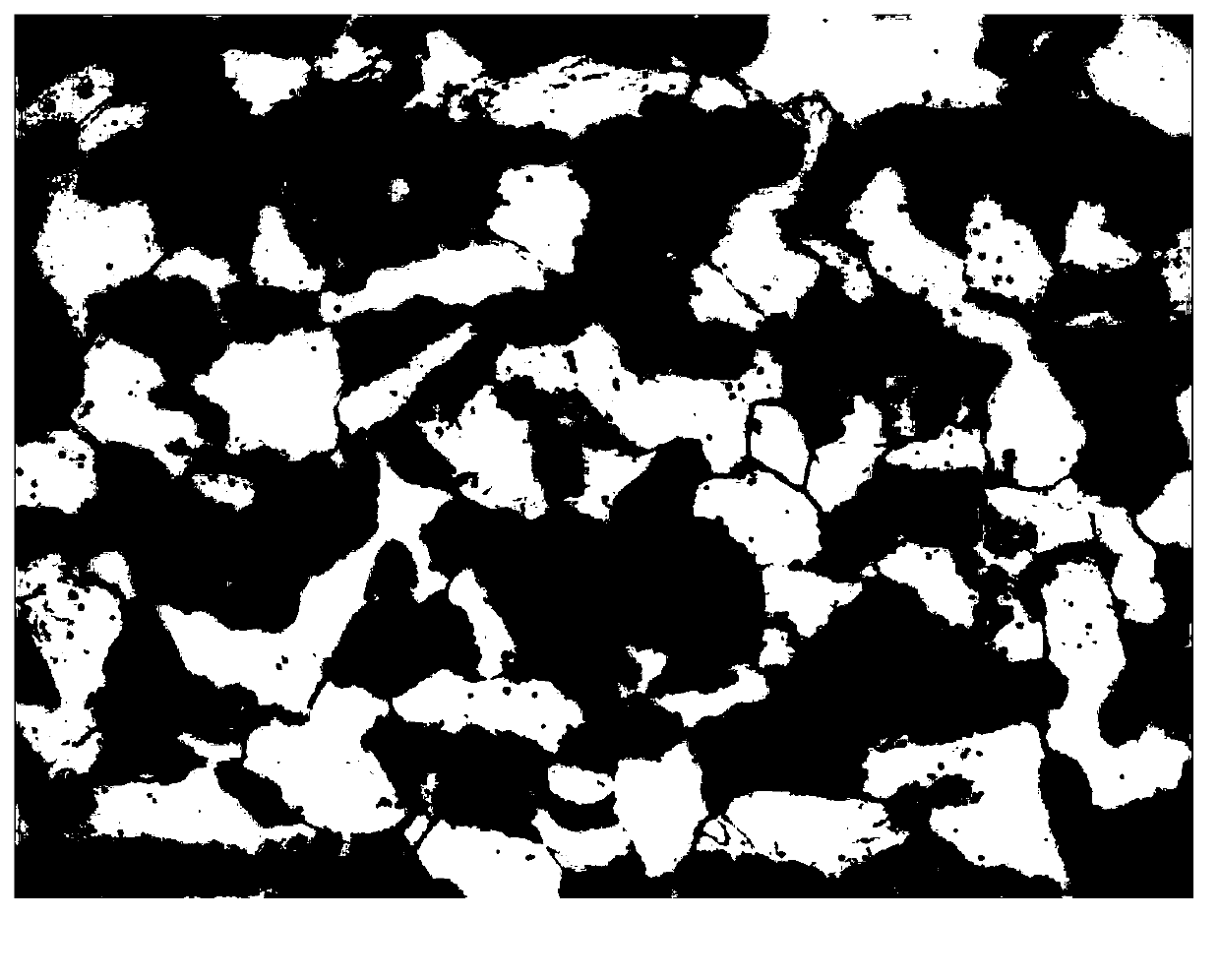

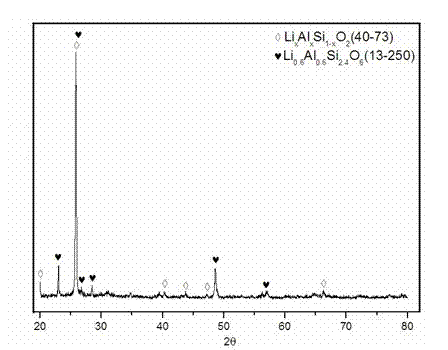

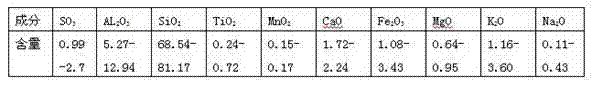

Method for manufacturing low-swelling microcrystalline glass through microwave heat treatment of gold tailings

ActiveCN103086602AIncrease the amount of participationReduce stockpilesThermal dilatationHeat stability

The invention relates to a method for manufacturing low-swelling microcrystalline glass through microwave heat treatment of gold tailings. The low-swelling microcrystalline glass comprises the following raw materials in percentage by weight: 40-50% of gold tailings, 20-25% of quartz, 13-18% of aluminum oxide, 5-13% of lithium carbonate, 2-4% of magnesium oxide, 2-4% of titanium oxide, 0.5-1% of zirconium oxide and 1-3% of borax. The method comprises the following steps: evenly mixing the raw materials, placing into an aluminum oxide crucible, and melting by microwave heating, thus obtaining glass metal; and transferring the molded glass metal into an industrial microwave oven, annealing, and performing crystallization treatment to obtain the product. According to the invention, the mining waste gold tailings are used as the main raw material, and the waste is changed into a valuable substance, thereby realizing the comprehensive utilization of the waste; a one-step heat treatment process is adopted, and the production cycle is shortened; the industrial microwave oven is used for heating in the melting, annealing and crystallization processes, thereby ensuring high heating speed and no pollution; for the obtained sample, grains are refined, the structure is uniform, and energy is saved; and the obtained microcrystalline glass is low in heat expansion coefficient and high in heat stability.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Preparation method of nanoscale zirconium-doped lithium titanate material

InactiveCN103151506AEvenly distributedGrain refinementCell electrodesElectrical batteryElectric cars

The invention discloses a preparation method of a nanoscale zirconium-doped lithium titanate material. Nanoscale lithium titanate is prepared by the method, and simultaneously is modified through doping zirconium. According to the preparation method, chemical components and grain sizes of the lithium titanate are effectively controlled by using hydro-thermal treatment, the temperature during subsequent treatment is greatly reduced, and grains are prevented from being agglomerated; and the preparation method is easy to implement in industry. The lithium titanate is doped with the zirconium in a preparation process, so that the specific discharge capacity of the material is increased at high magnification. Simultaneously, the gas expansion problem existing in the charge-discharge process of lithium titanate batteries is solved to a certain extent. The material prepared by the method has high magnification and high specific capacity and can be applied to the batteries needed for various portable electronic equipment and various electric vehicles.

Owner:SHANGHAI UNIV

Method of crystallizing amorphous semiconductor thin film and method of fabricating poly crystalline thin film transistor using the same

InactiveUS20060121655A1Shorten heat treatment timeSuppress surface roughnessPolycrystalline material growthFrom solid stateLow leakageImpurity

A method of crystallizing an amorphous semiconductor thin film used for a thin film transistor (TFT) is provided. The method includes the steps of: forming first and second crystallization induced metal patterns locally in respective portions of a source region and a drain region of the TFT on an amorphous semiconductor thin film; and crystallizing an amorphous semiconductor via independent two-times heat treatment using the first and second crystallization induced metal patterns. In this case, the independent two-times heat treatment is executed before and after ions of impurities are injected, respectively. In this way, a metal induced lateral crystallization double heat treatment is executed before and after ions of impurities are injected, respectively. As a result, the entire crystallization heat treatment time necessary for crystallizing the amorphous semiconductor thin film can be greatly reduced, and a poly-crystalline TFT having low leakage current can be obtained.

Owner:PAIK WOON SUH

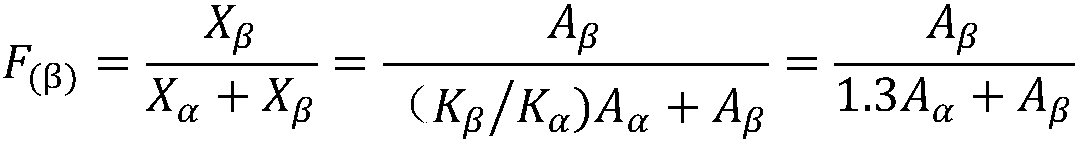

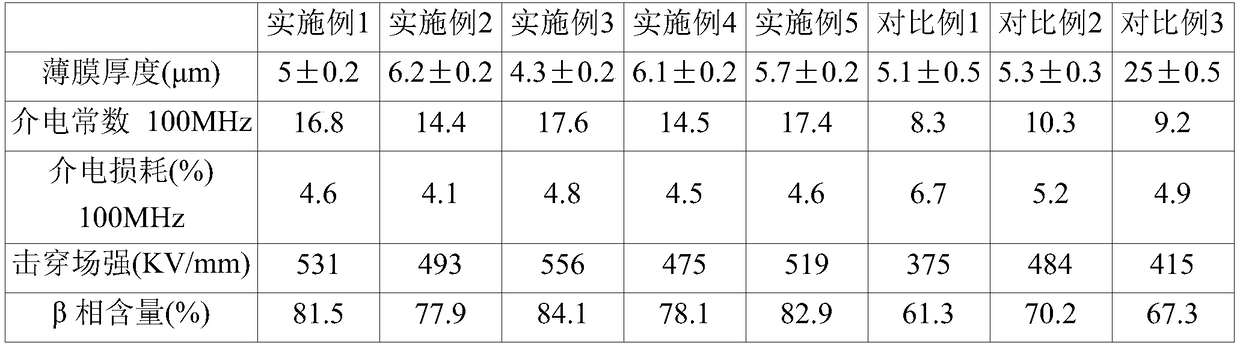

Preparation method for polyvinylidene fluoride dielectric film

The invention discloses a preparation method for a polyvinylidene fluoride dielectric film. The preparation method comprises the following steps: 1) preparation of a film casting solution, adding polyvinylidene fluoride resin into an organic solvent, heating, stirring and dissolving, thereby obtaining the film casting solution; 2) and preparation of the film: coating a base material with the filmcasting solution through a coater, entering a three-section oven to dry, entering a water slot to quench after drying, stripping through stripping stick, annealing after oriented thermal stretching, and rolling, thereby obtaining a film product. The preparation method disclosed by the invention selects flexible high-temperature-resistant materials such as surface-treated aluminum foil and a polyester film as coating base materials, adopts a process treatment method integrating melting-quenching and stretching-annealing, avoids defects caused by a single method, and provides important referencefor industrial production of the polyvinylidene fluoride dielectric film. The obtained polyvinylidene fluoride dielectric film is high in beta-phase content, is thin and uniform in thickness, has excellent properties such as a high dielectric constant and great disruptive strength, and is expected to be applied to manufacturing high-energy-storage electronic apparatuses.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Aluminum oxide particle strengthened niobiumtin superconducting composite wire

ActiveUS20080146451A1Shorten heat treatment timeSave energySuperconductors/hyperconductorsSuperconductor device manufacture/treatmentNiobiumUltimate tensile strength

A composite superconducting wire and a method of manufacturing the wire is disclosed. Nano-particle dispersion strengthened copper is co-drawn with Niobium rod to produce DSC-1Nb wire. n numbers of DSC-1Nb wires are then stacked in a hollow DSC tube and drawn to form a DSC-n.Nb hexagonal wire. In a separate preliminary process, Tin rod is co-deformed with Copper tube to form a Cu-1Sn wire. m DSC-n Nb wires and 1 Cu-1Sn wires are then wrapped by Niobium foil and placed into a Copper tube. This entire assembly is then drawn to a finished size. The drawn composite is then subjected to heat treatment with a final stage at 650-700° C. for about 100 hours or longer. The new wire has higher electric critical current and higher mechanical strength than the controlled conventional ones.

Owner:FLORIDA STATE UNIV RES FOUND INC

Production method of oyster mushroom puffing chips

The invention relates to a production method of oyster mushroom puffing chips, which belongs to the technical field of further processing of agricultural products. The production method of the oyster mushroom puffing chips comprises the following steps: harvesting oyster mushroom with good quality, removing the stem of the oyster mushroom, washing, carrying out fixation, boiling, pre-drying through hot air, carrying out vacuum microwave puffing and nitrogen packaging. Compared with the traditional process, the method has the advantages that by adopting the vacuum microwave puffing technology, the heat treatment time of the entire production process is short, the color, flavor and nutrients of the oyster mushroom can be maximally maintained, and the defects that the oil content is high, the color is poor, the taste is poor and the like in the traditional frying chips can be avoided. The oyster mushroom puffing chips prepared through the method have the characteristics of good shape, strong flavor, attractive color and crisp taste, and a feasible novel way is provided for the further processing and utilization of the oyster mushroom.

Owner:NANJING FEIMA FOOD

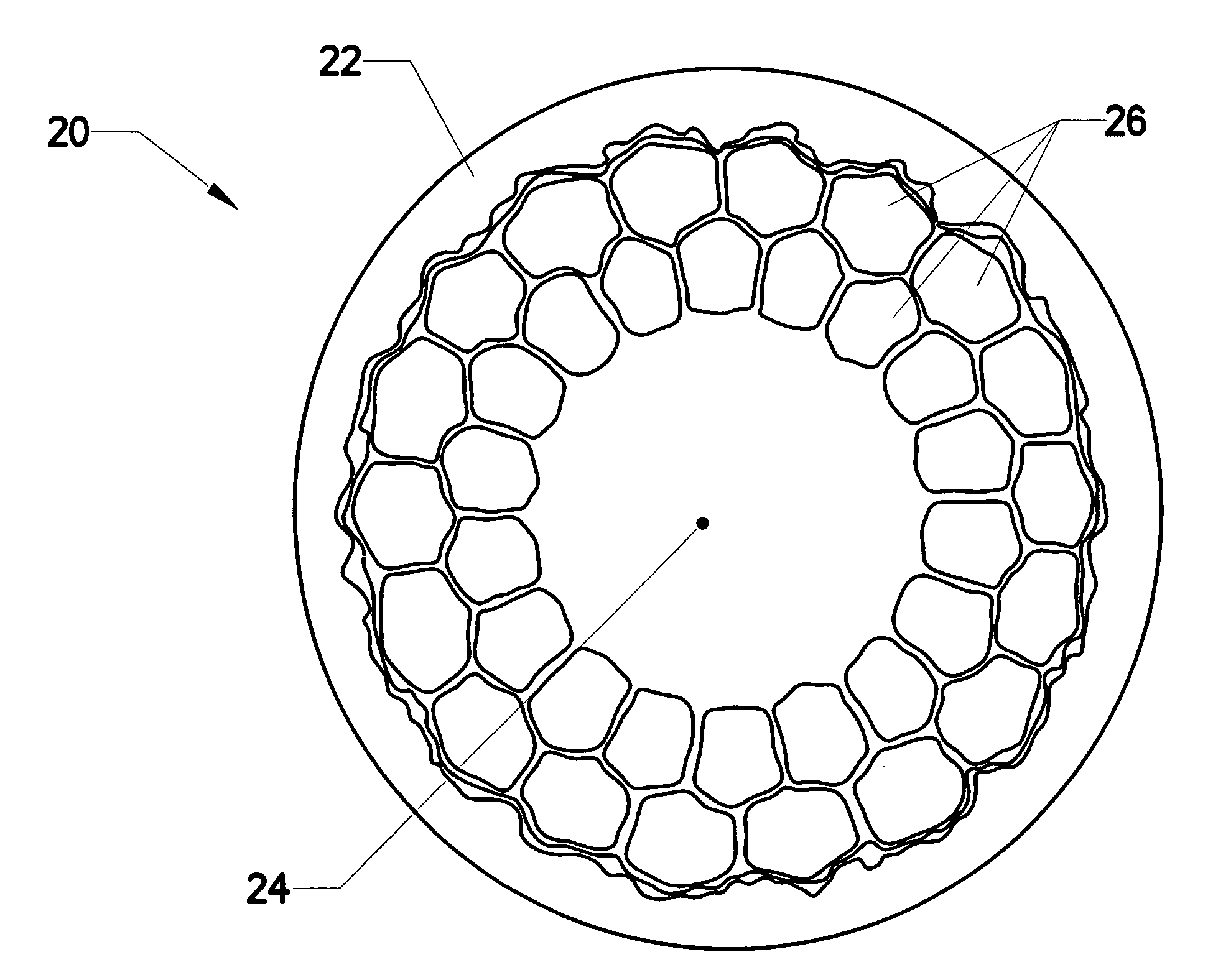

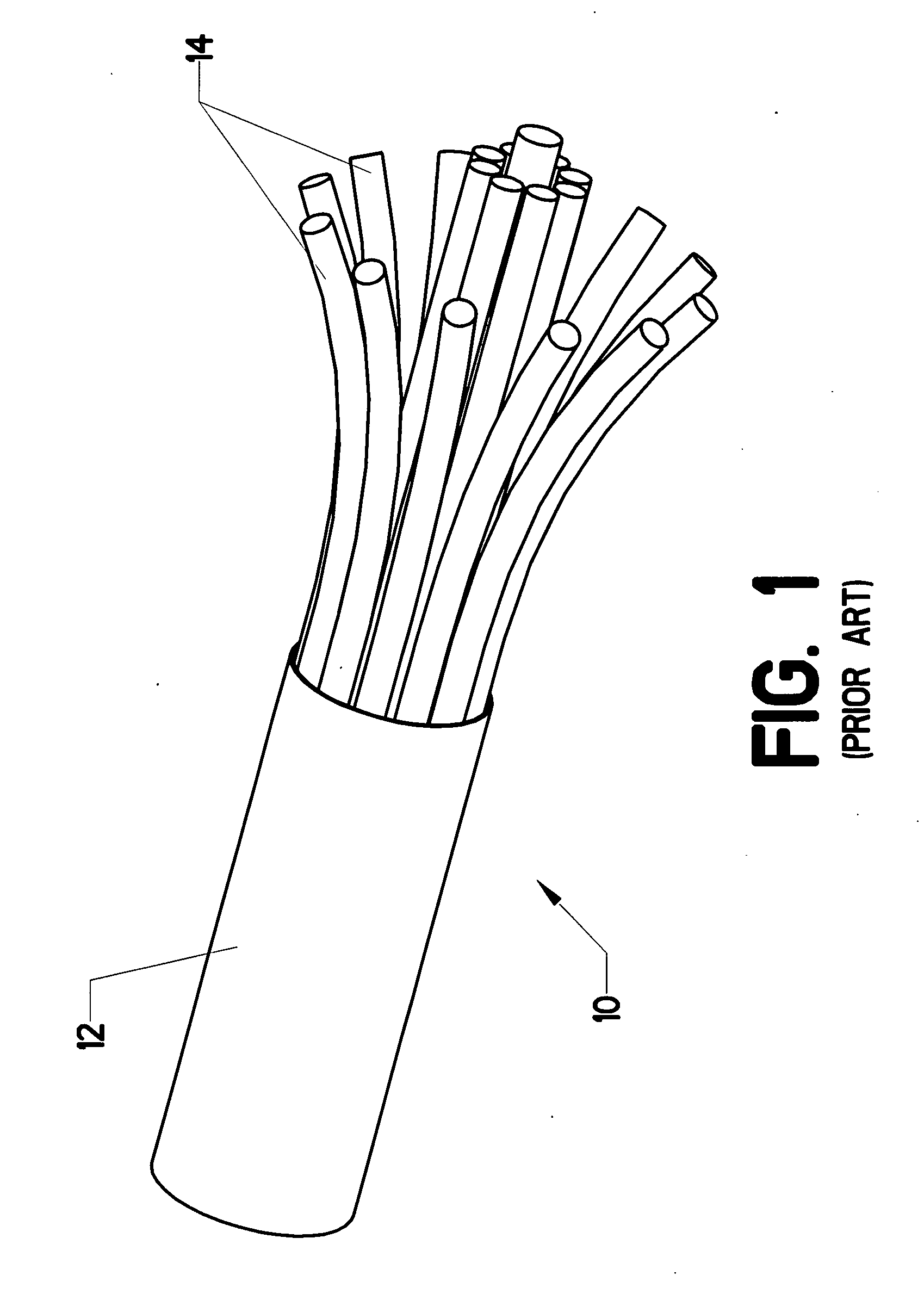

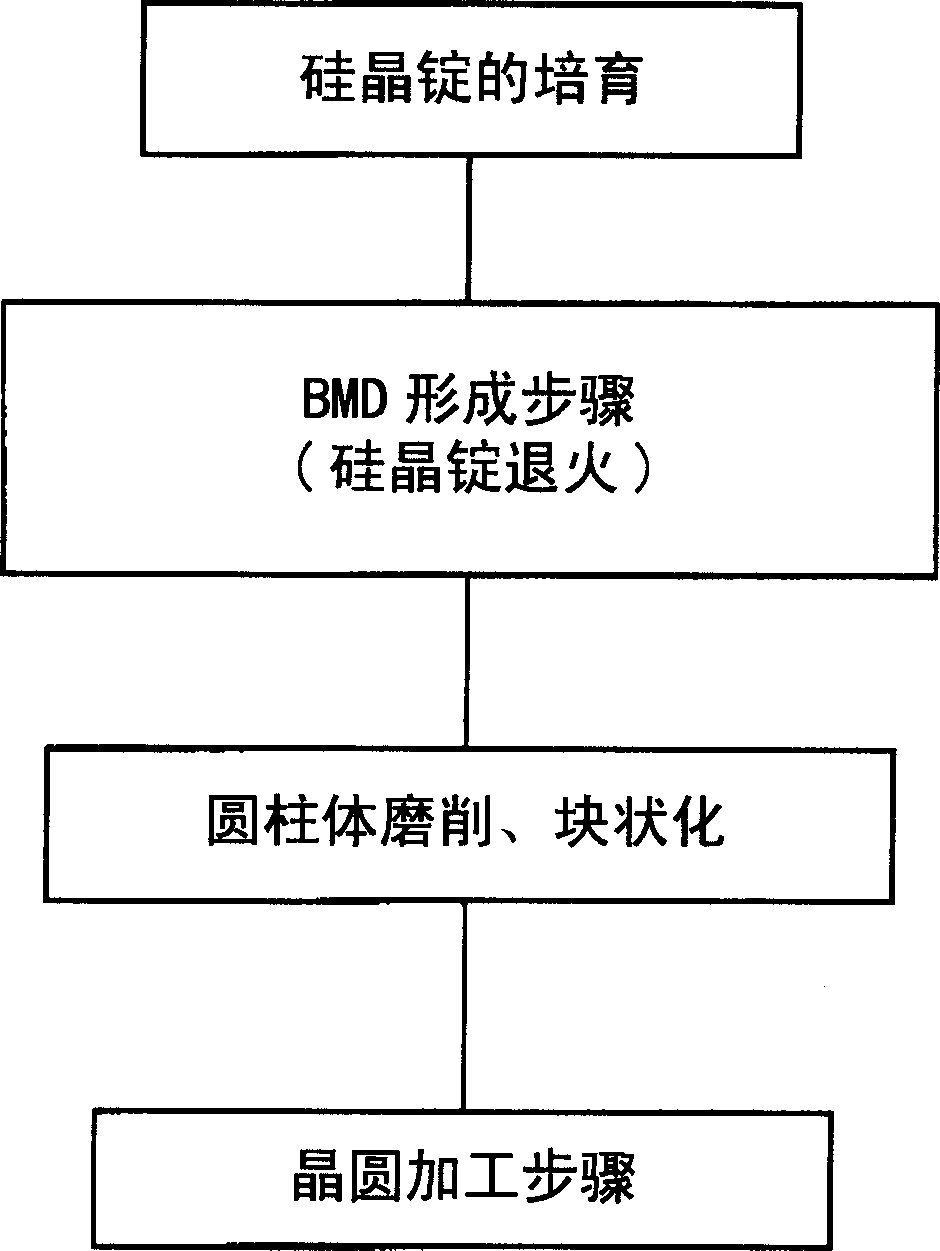

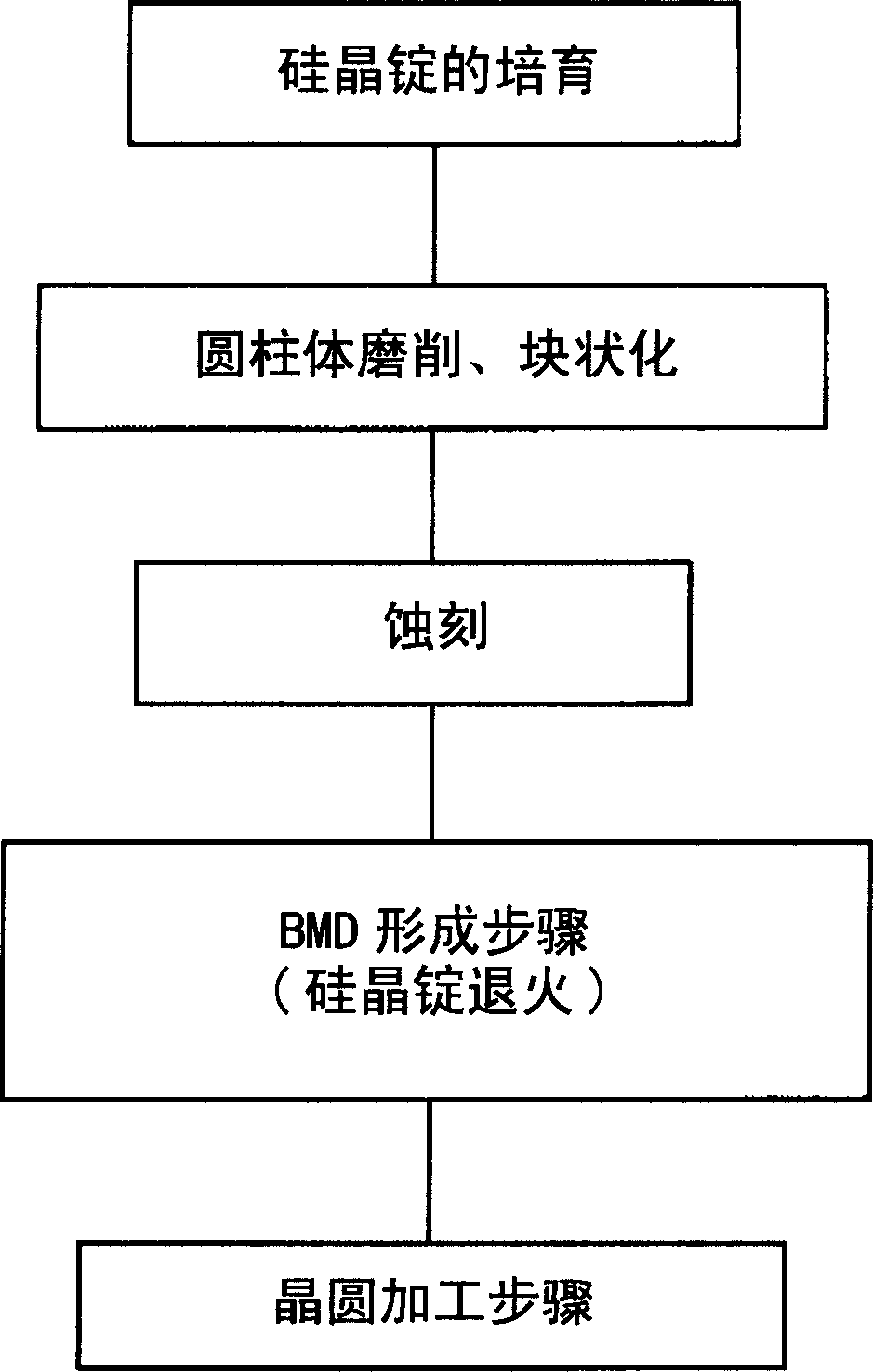

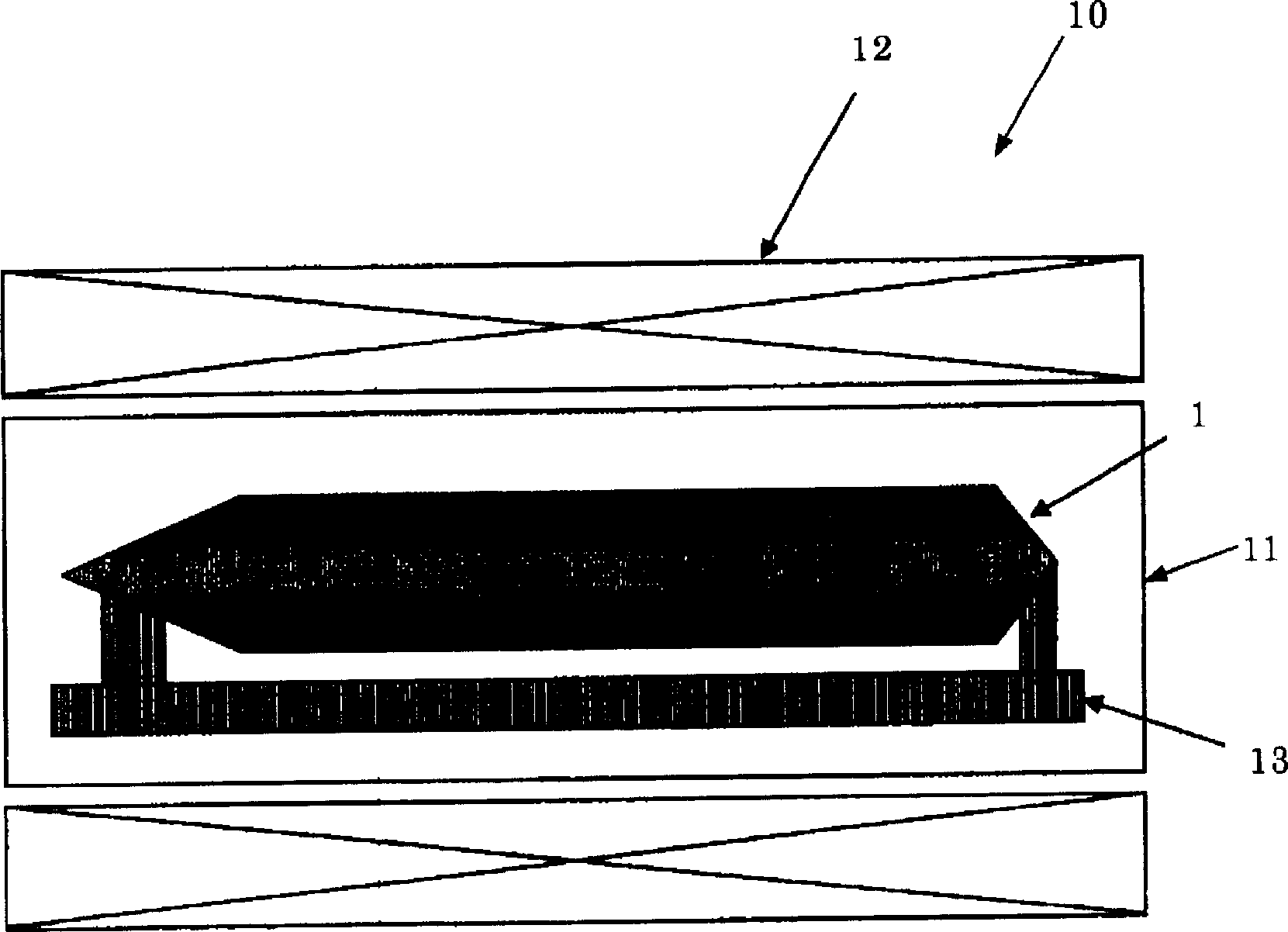

Process for producing wafer

InactiveCN1836062AHigh IG capabilityIncrease production capacityPolycrystalline material growthSemiconductor/solid-state device manufacturingIngotSingle crystal

A process for producing a wafer, comprising at least the BMD formation step of subjecting a silicon single crystal having the form of an ingot to heat treatment to thereby form bulk microdefects (BMD) in the interior thereof, and the wafer machining step of machining the ingot furnished with the bulk microdefects (BMD) into a wafer. In this process for producing a wafer, the heat treatment for imparting IG capability in the wafer production can be shortened to thereby enable mass production of wafers of high IG capability. The process can further comprise the wafer heat treatment step of performing heat treatment of wafers after machining and the epitaxial growth step of forming an epitaxial layer on each of the wafers with the result that the productivity of, excelling in gettering effect, anneal wafers and epitaxial wafers can be enhanced.

Owner:SHIN-ETSU HANDOTAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com