Heat treatment process for ZL101A aluminium alloy for automobile wheel hub

A technology for automobile wheels and aluminum alloys, which is applied in the field of heat treatment of cast Al-Si alloys, can solve the problems of insufficient precipitation phase strengthening and insufficient aging treatment, and achieve the effects of shortening heat treatment time, high work efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

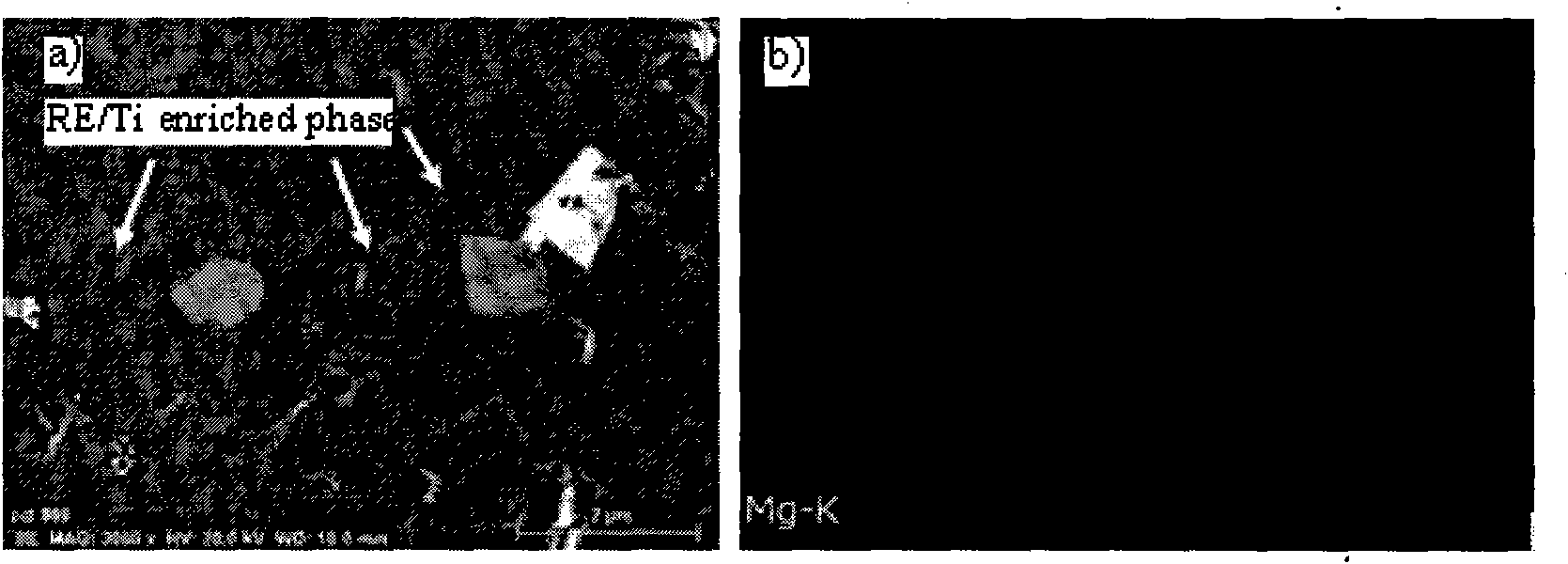

Image

Examples

Embodiment 1

[0020] Cut 50×70×120mm from cast ZL101AA cast aluminum alloy billet 3 blanks. The BSK-L40 resistance heat treatment furnace (rated power 4KW) produced by Luoyang Best Electronic Materials Co., Ltd. is used. The temperature of the two resistance furnaces 1# and 2# was raised to 535°C and 170°C respectively in advance, and the fluctuation range of the furnace temperature was controlled within ±5°C. Put the intercepted alloy blank into heat treatment 1# furnace for solid solution treatment, and set the time for heating up to 535°C for 30 minutes, and the holding time for 120 minutes. After the solid solution heat preservation is over, the blank is moved to a hot water bath at 80°C. It takes 15 seconds to move from the oven to the hot water bath, and quench in the hot water bath for 3 minutes. Take the sample out of the hot water bath and wipe off the water on the surface of the sample with a dry cloth. Put the alloy billet into 2# resistance furnace for aging treatment, set t...

Embodiment 2

[0022] Prepare five φ12 test rods of ZL101AA alloy according to the national standard GB / T 1173-1995 "standard sample of casting aluminum alloy metal mold and pouring riser system". The BSK-L40 resistance heat treatment furnace (rated power 4KW) produced by Luoyang Best Electronic Materials Co., Ltd. is used. The temperature of the two resistance furnaces 1# and 2# was raised to 550°C and 165°C respectively in advance, and the fluctuation range of the furnace temperature was controlled within ±5°C. Put the test rod into heat treatment 1# furnace for solid solution treatment, and set the time for heating up to 550°C for 30 minutes, and the holding time for 90 minutes. After the solid solution heat preservation is over, move the test rods into a hot water bath at 60°C. It takes 30 seconds for all the test rods to move from the furnace to the hot water bath, and quench in the hot water bath for 1 minute. Take the sample out of the hot water bath and wipe off the water on the sur...

Embodiment 3

[0025] Cut 50×70×120mm from cast ZL101AA cast aluminum alloy billet 3 blanks. The BSK-L40 resistance heat treatment furnace (rated power 4KW) produced by Luoyang Best Electronic Materials Co., Ltd. is used. The temperature of the two resistance furnaces 1# and 2# was raised to 550°C and 180°C respectively in advance, and the fluctuation range of the furnace temperature was controlled within ±5°C. Put the intercepted alloy blank into heat treatment 1# furnace for solid solution treatment, and set the time for heating up to 550°C to be 40 minutes, and the holding time to be 120 minutes. After the solid solution heat preservation is over, the blank is moved into a hot water bath at 80°C, the time from being out of the furnace to being moved into the hot water bath is 18 seconds, and quenched in the hot water bath for 3 minutes. Take the sample out of the hot water bath and wipe off the water on the surface of the sample with a dry cloth. Put the alloy billet into 2# resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com