Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

604results about "Monocomponent polyurethanes artificial filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vascular prosthesis and method for production thereof

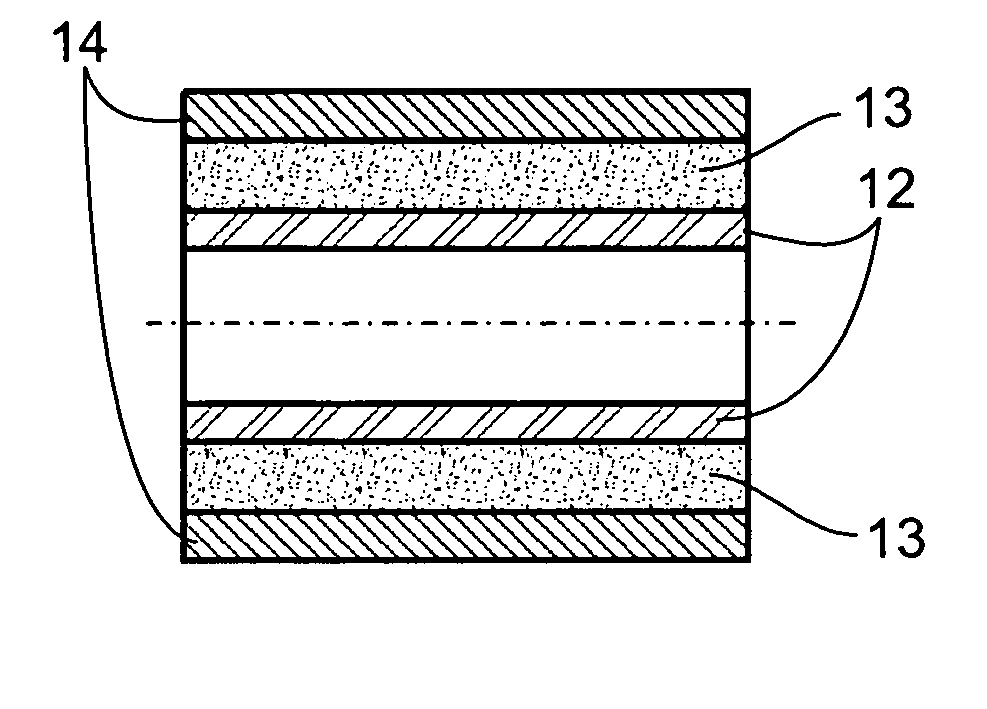

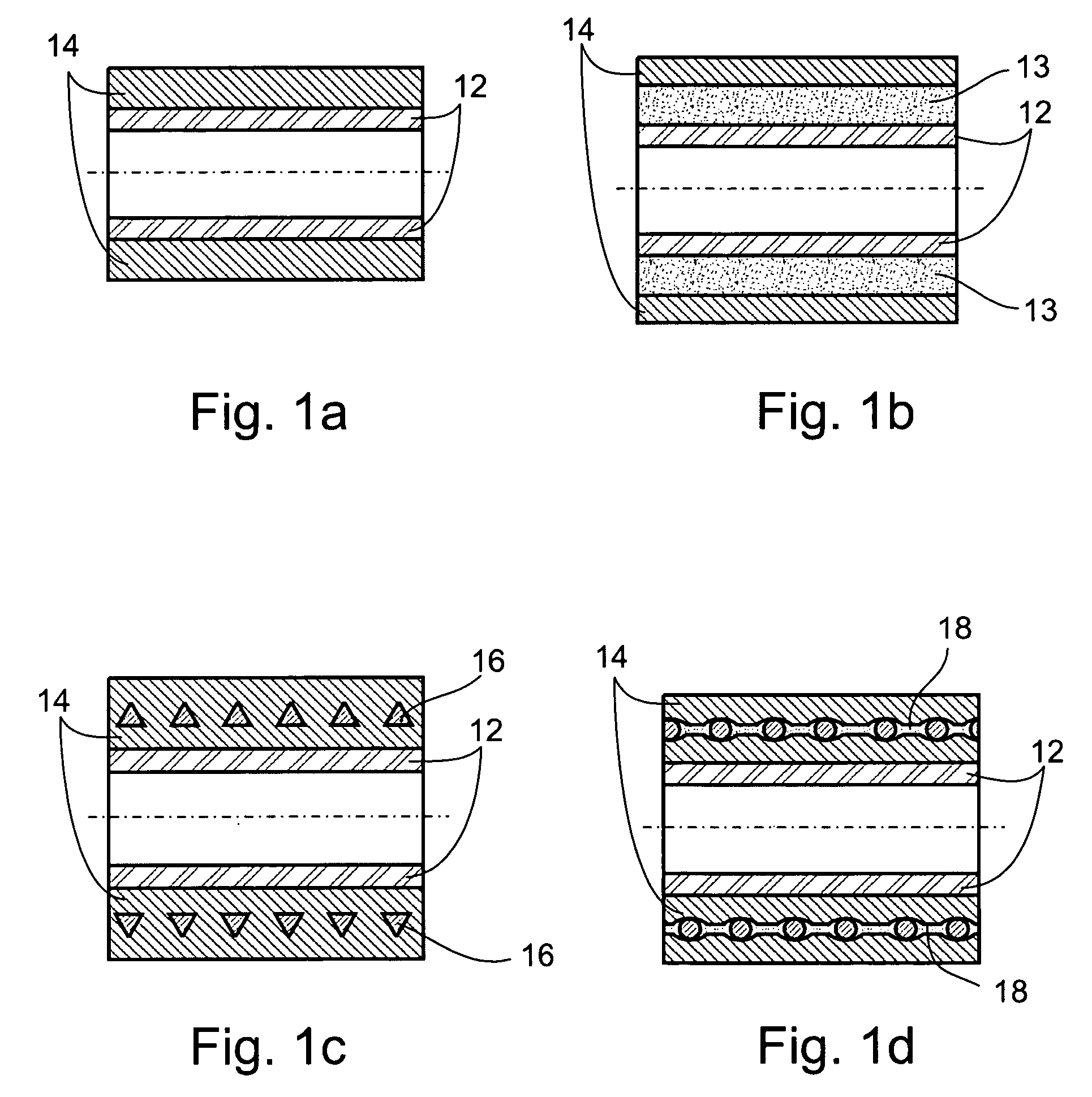

A vascular prosthesis comprising a first layer having a predetermined first porosity and a second layer having a predetermined second porosity, wherein the first layer and the second layer are each made of first and second electrospun polymer fibers.

Owner:NICAST LTD

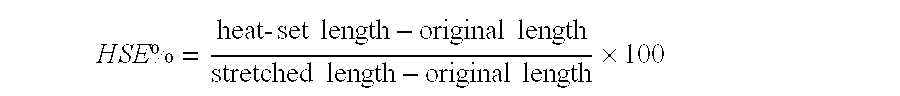

Spandex with high heat-set efficiency

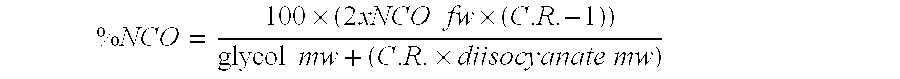

A high heat-set efficiency, high unload power spandex, based on a polyurethaneurea prepared from a polyether glycol, mixtures of 2,4'-MDI and 4,4'-MDI, and chain extenders, is provided.

Owner:THE LYCRA CO LLC

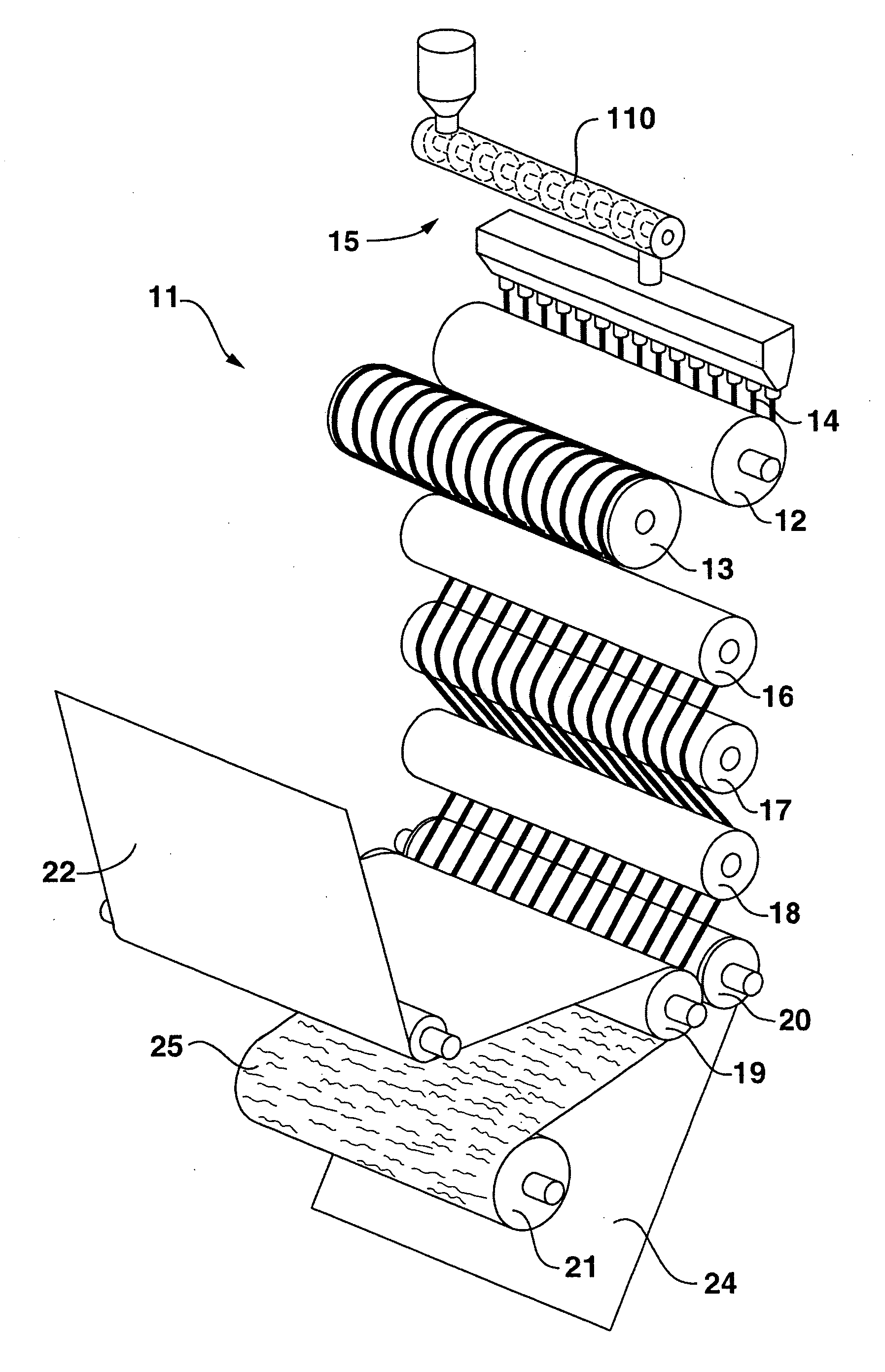

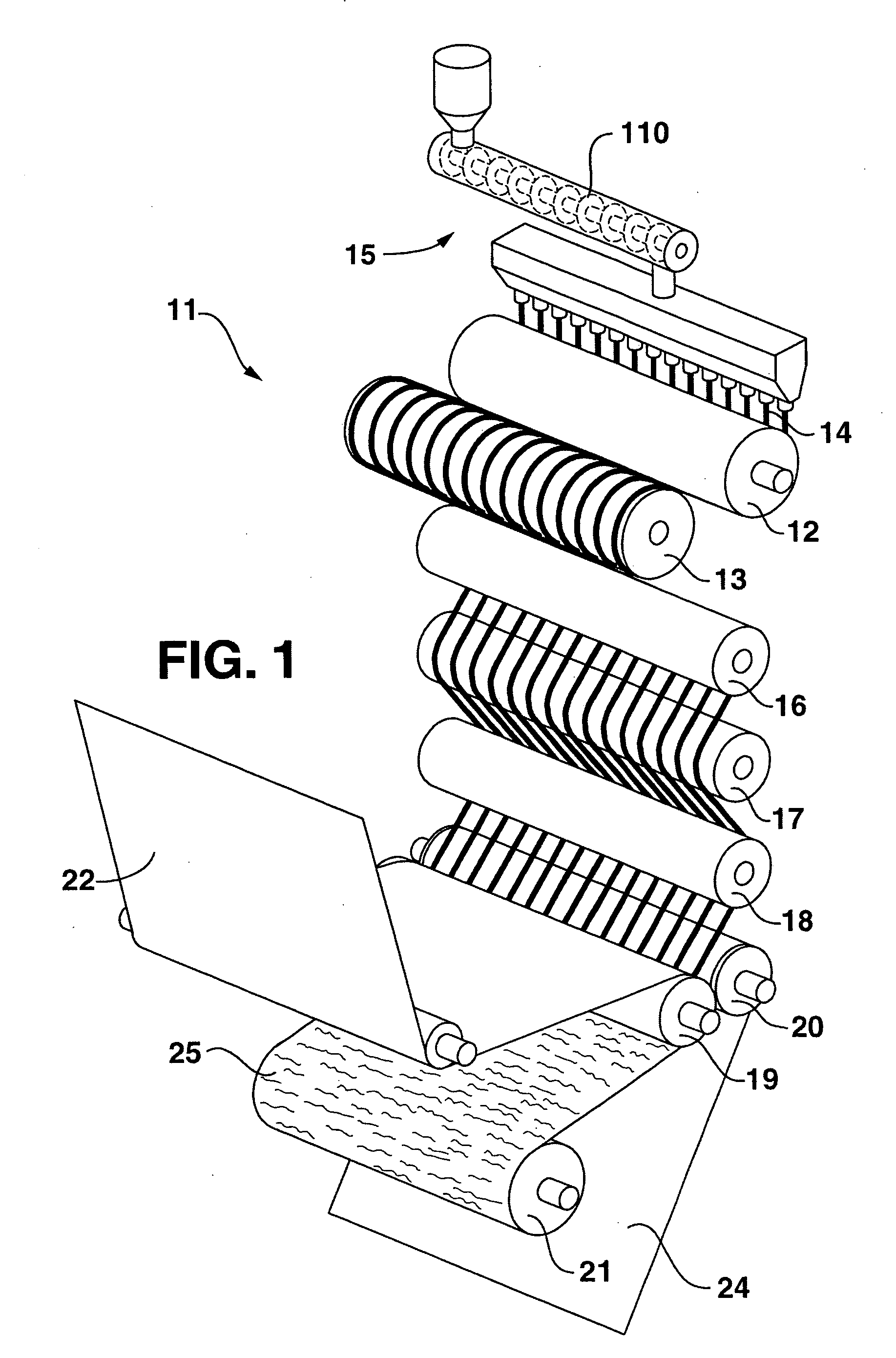

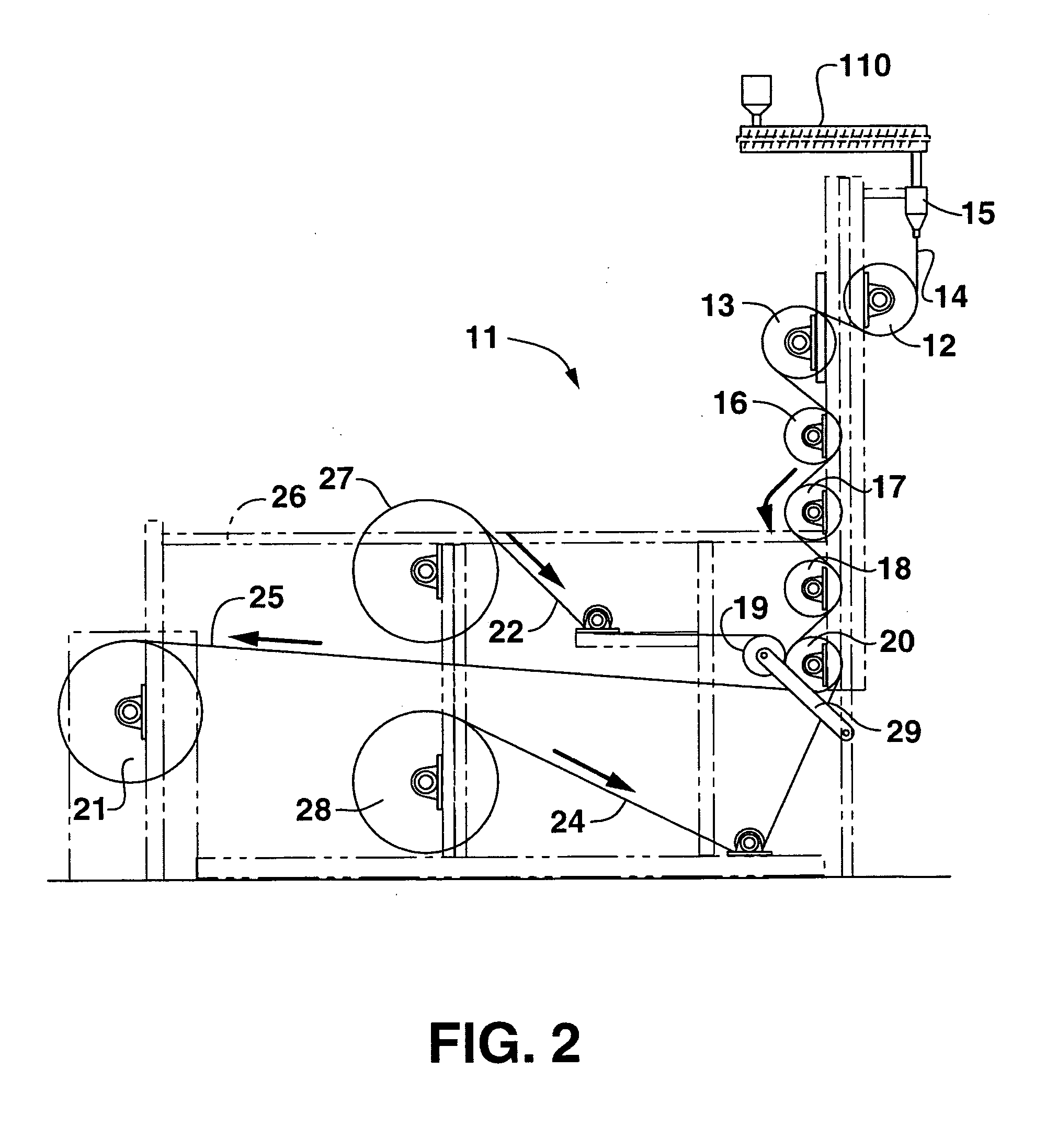

Stretch bonded laminate including an elastic member containing an adhesive composition

InactiveUS20070135008A1Monocomponent polyurethanes artificial filamentDecorative surface effectsComposite laminatesEngineering

Elastic composite laminates are disclosed. The laminates include an elastic member bonded to at least one facing material. In accordance with the present disclosure, an adhesive composition is coextruded with an elastomeric material to form the elastic member. In this manner, the elastic member can be bonded to the facing material in a stretched state without having to apply a separate adhesive layer between the two materials. In one embodiment, the elastic member can be bonded to the facing material according to a pattern that includes bonded areas and non-bonded areas.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Anti-tack spandex fibers containing antimicrobial agents therein and fabrics made therefrom

InactiveUS6479144B2Easy to processImprove cohesionMonocomponent polyurethanes artificial filamentBiocideYarnFiber

Polyurethane elastomer yams (particularly spandex) containing certain silver-based antimicrobial formulations therein are provided. This invention relates to polyurethane elastomer yams (particularly spandex) containing certain silver-based antimicrobial formulations therein. Such formulations comprise antimicrobial compounds, such as, preferably, triclosan and / or silver-containing ion-exchange resins, such as zirconium phosphate, glass, and / or zeolite compounds. The inventive spandex yarns exhibit excellent antimicrobial qualities as well as surprisingly good anti-tack / frictional characteristics. As a result, antimicrobial spandex yams are provided which exhibit ease in processing, particularly in further knitting, weaving, etc., to produce fabrics therefrom. Such fabrics are also encompassed within this invention.

Owner:MILLIKEN & CO

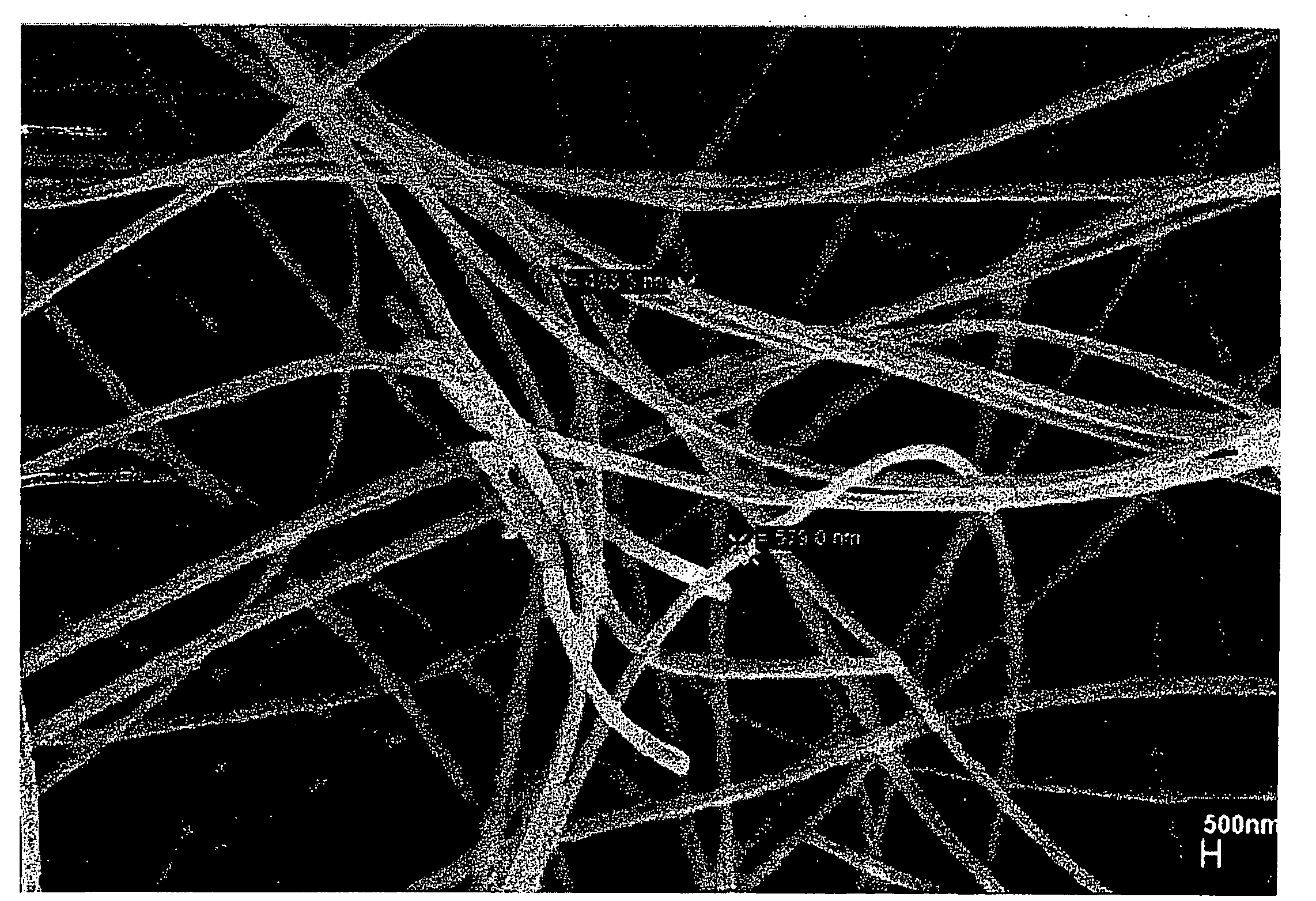

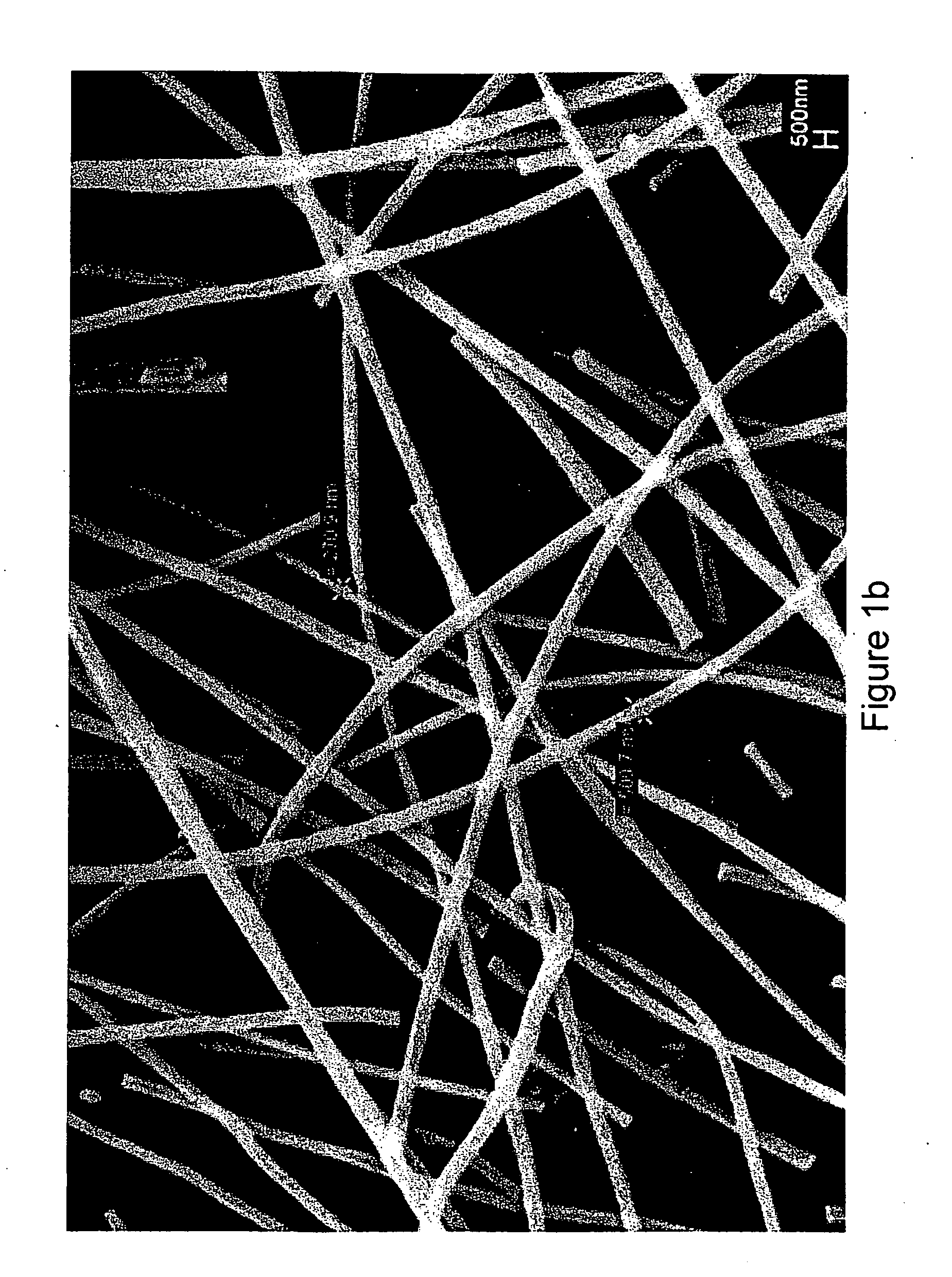

Fibers and methods relating thereto

InactiveUS20090326128A1Monocomponent polyurethanes artificial filamentMaterial nanotechnologyFiberNanofiber

The present invention provides micro- and nanofibers made from polymers that comprise nanoparticles, such as carbon nanoparticles and inorganic nanoparticles, and methods of making such fibers.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

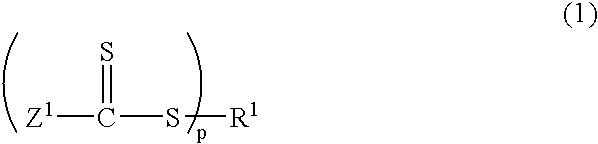

Polyurethane polymer

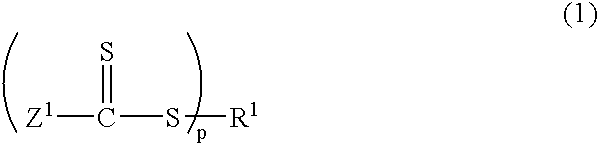

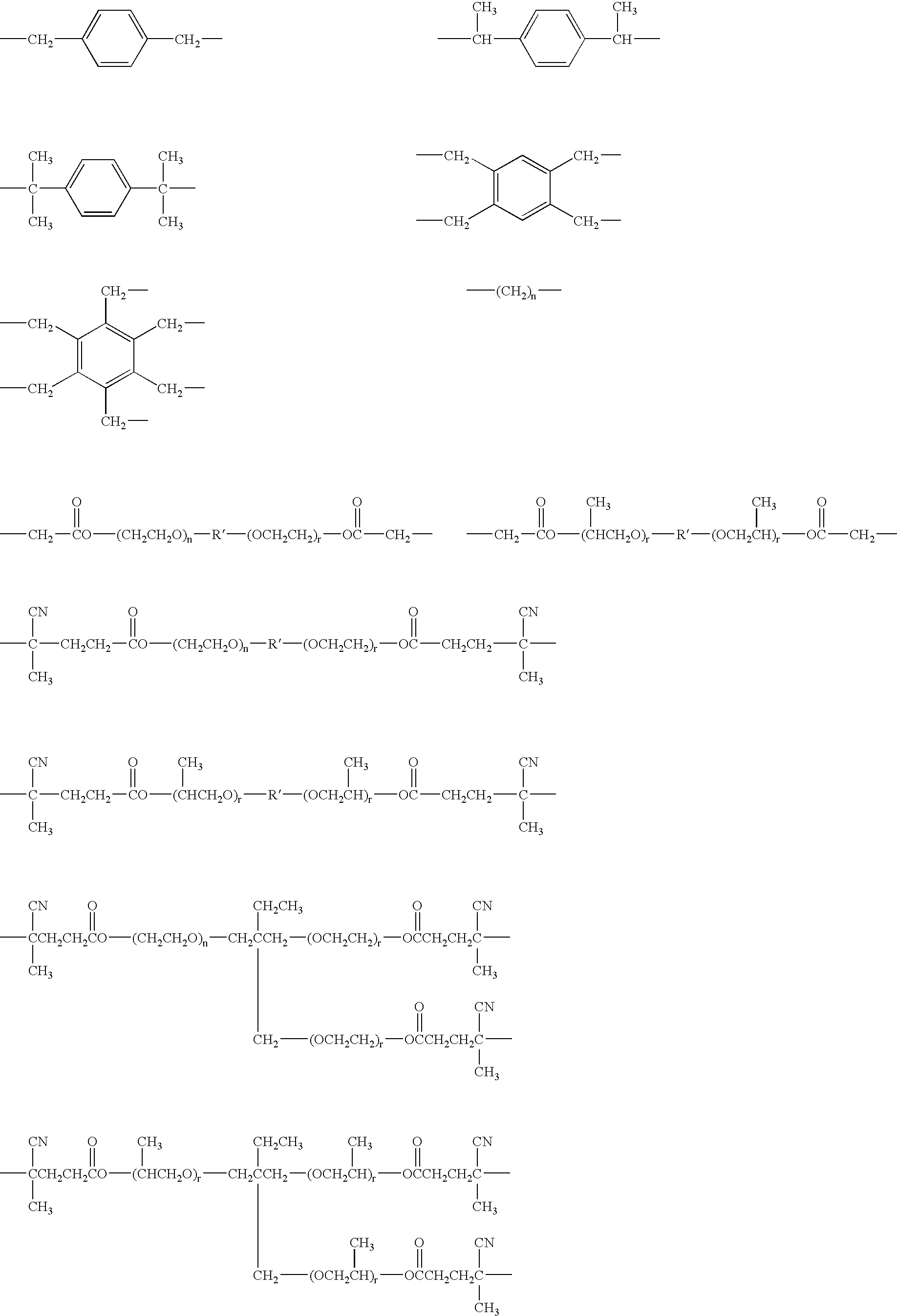

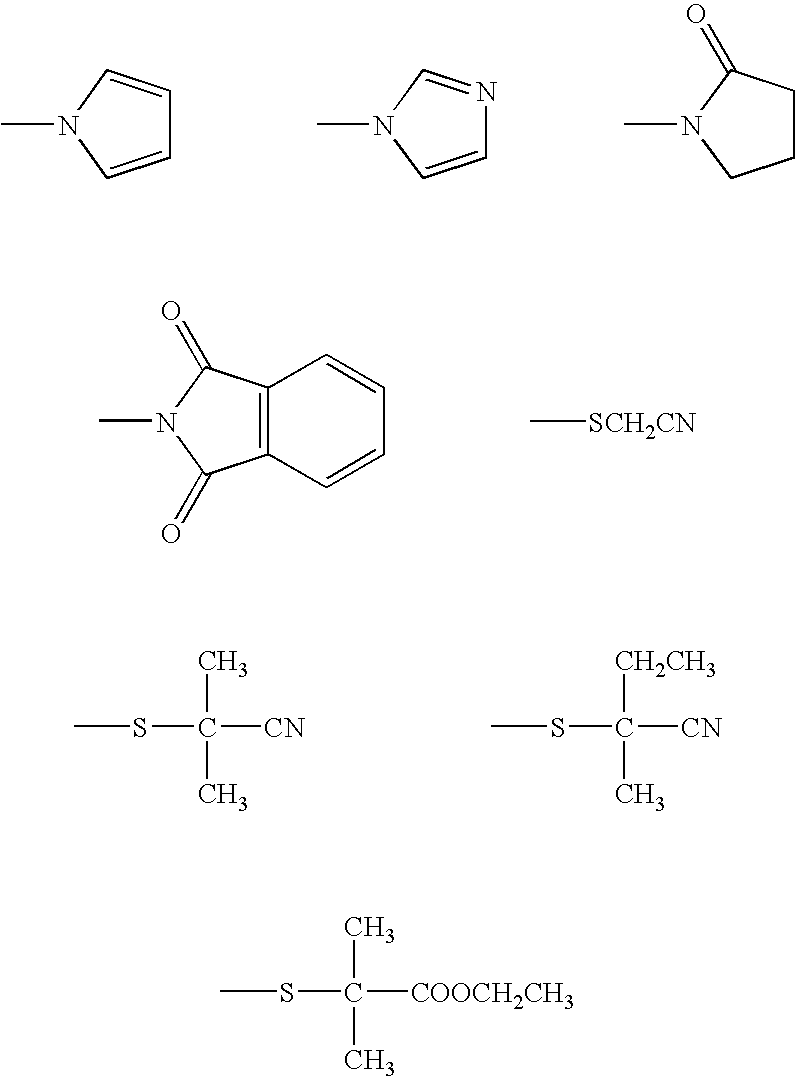

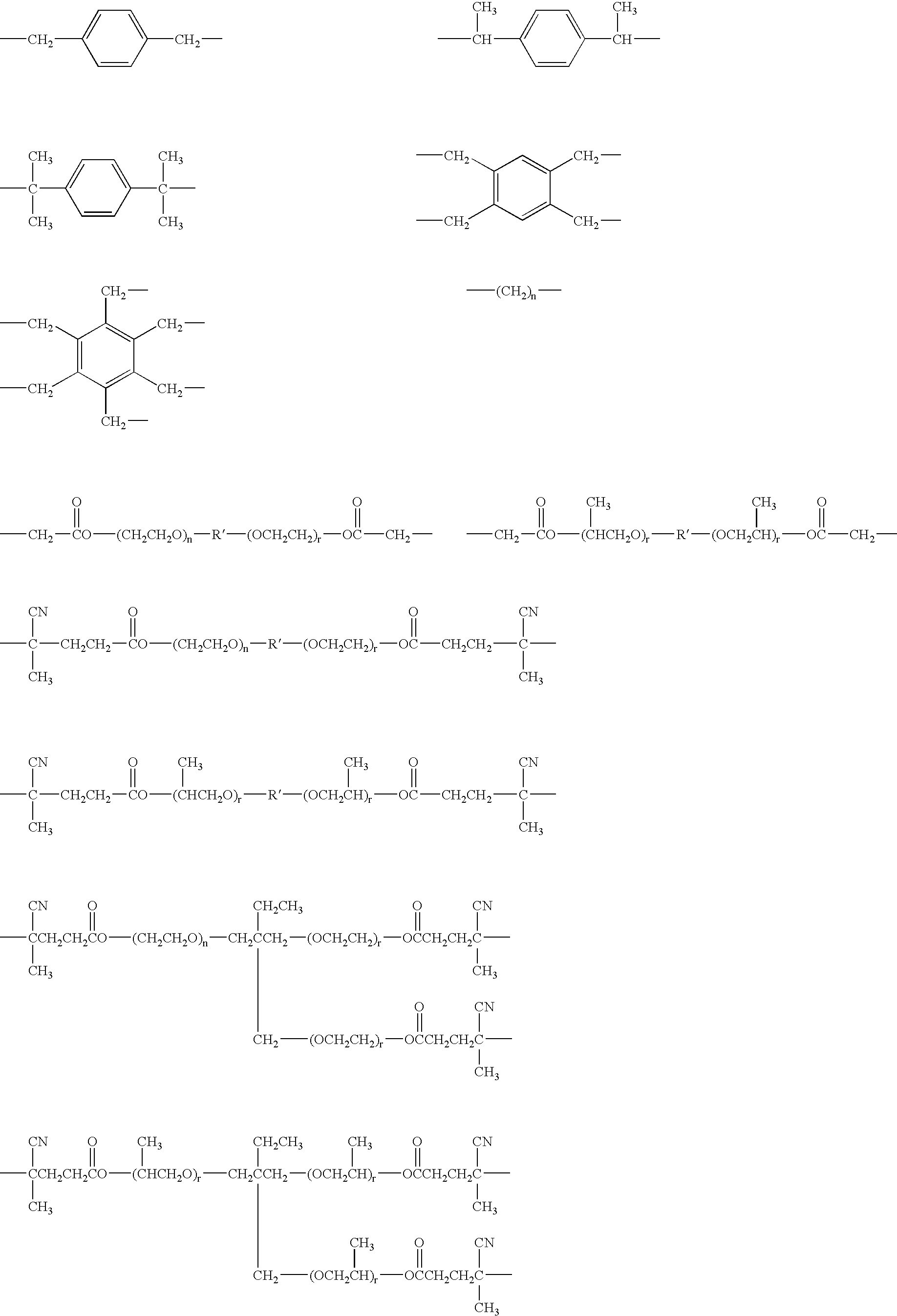

InactiveUS20040171765A1Good chemical resistanceImprove chlorine resistanceMonocomponent polyurethanes artificial filamentHeat resistanceReversible addition−fragmentation chain-transfer polymerization

Provided is a polyurethane polymer which is excellent in oil resistance, weatherability, light resistance, heat resistance, hot water resistance, hydrolysis resistance, strength, chlorine resistance, and chemical resistance, and which can be produced simply and economically. The polyurethane polymer is produced by polymerizing at least two components: a vinyl polymer (A) having a mercapto group at each end of the molecular chain produced by a reversible addition-fragmentation chain transfer polymerization method, and an organic polyisocyanate (B). Also provided are polyurethane-based materials containing the polyurethane polymer, and polyurethane elastic fiber.

Owner:KANEKA CORP

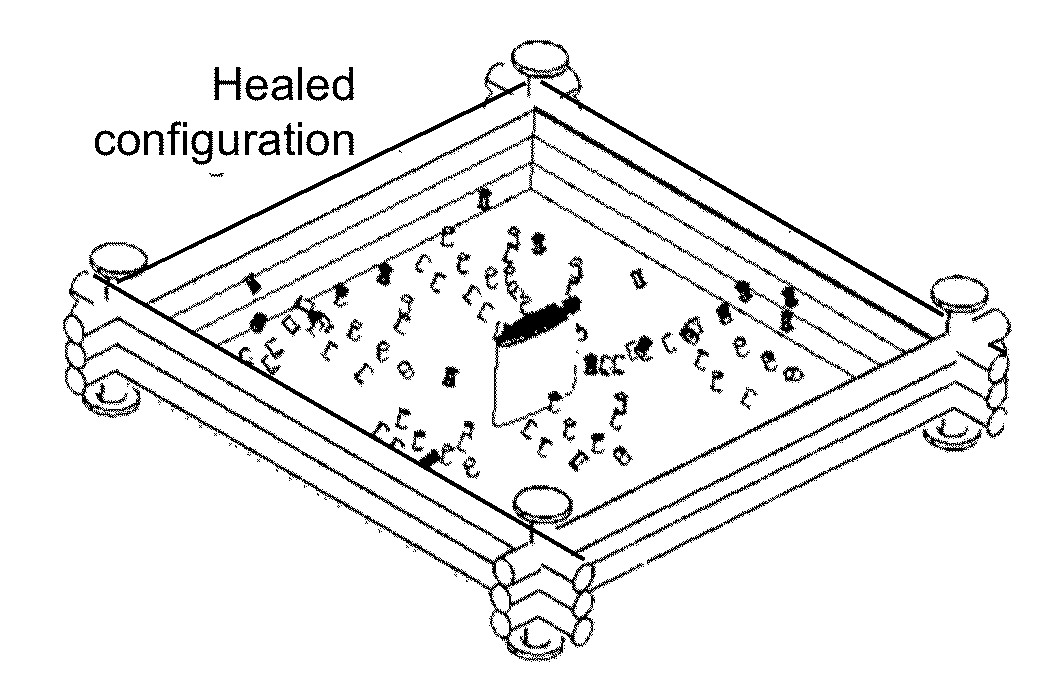

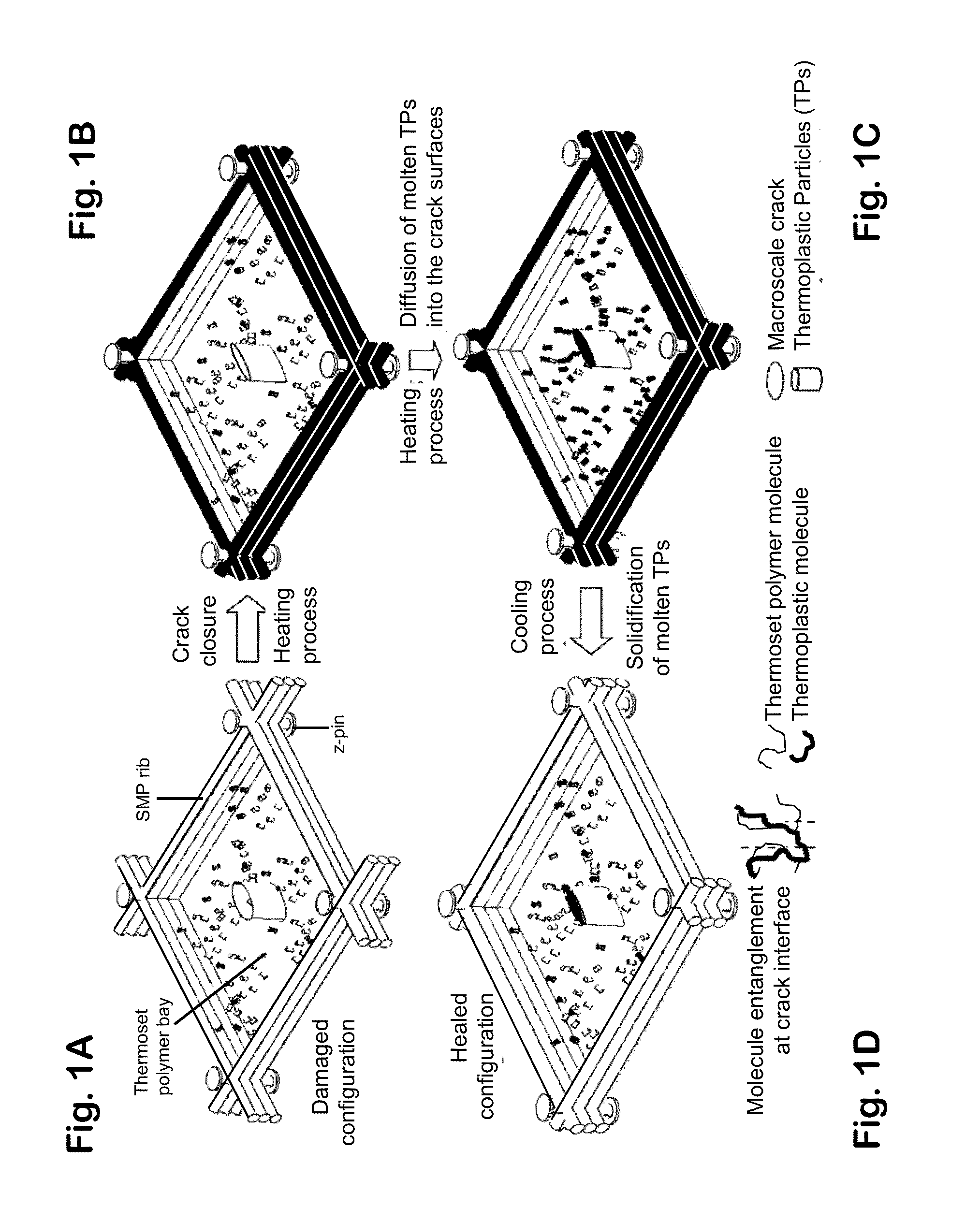

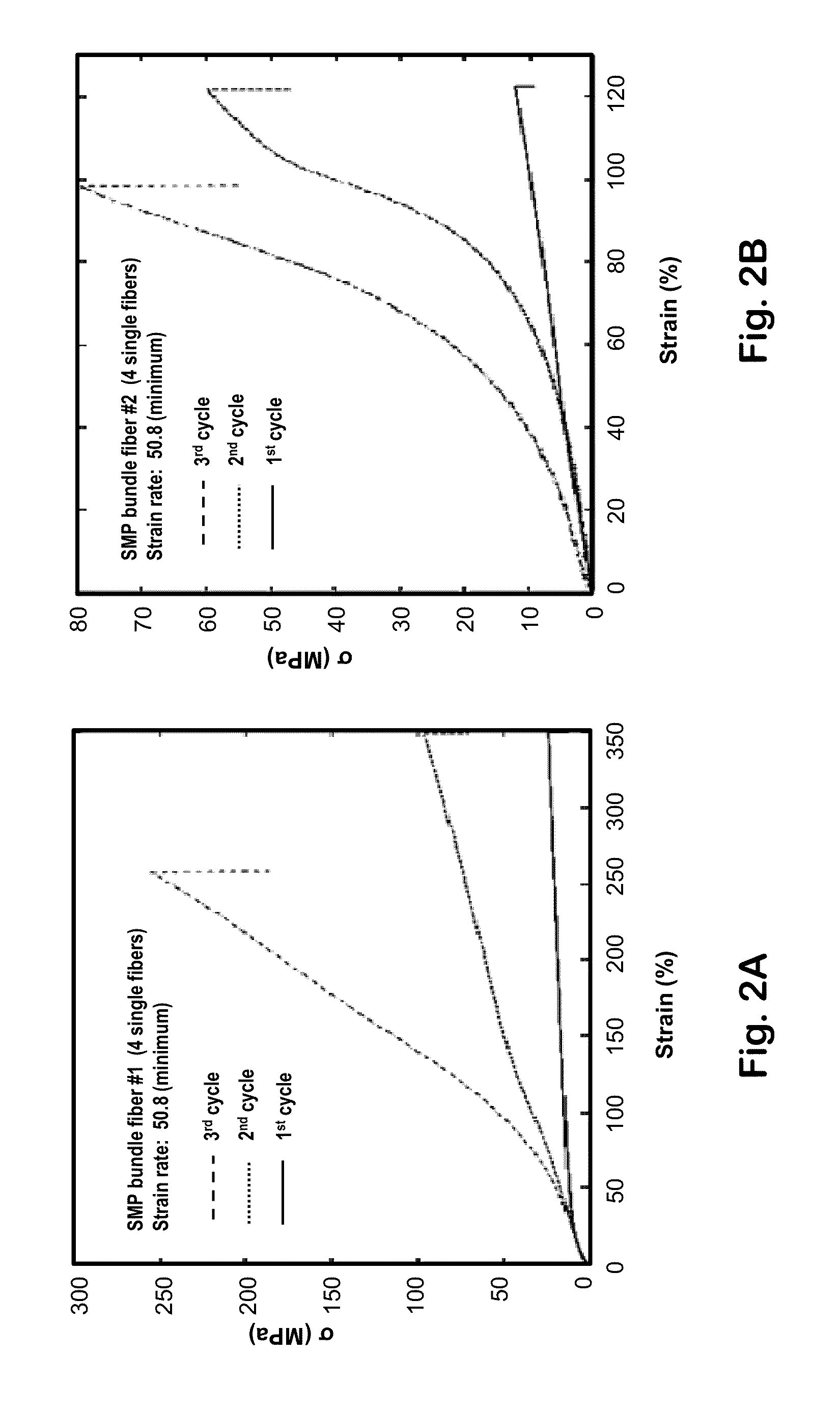

Self-Healing Composite of Thermoset Polymer and Programmed Super Contraction Fibers

ActiveUS20140303287A1Light weightReduce vibrationMonocomponent polyurethanes artificial filamentPretreated surfacesFiberThermoplastic

A composition comprising thermoset polymer, shape memory polymer to facilitate macro scale damage closure, and a means for molecular scale healing is disclosed; the composition has the ability to resolve structural defects by a bio-mimetic close-then heal process. In use, the shape memory polymer serves to bring surfaces of a structural defect into approximation, whereafter use of the means for molecular scale healing allowed for movement of the healing means into the defect and thus obtain molecular scale healing. The means for molecular scale healing can be a thermoplastic such as fibers, particles or spheres which are used by heating to a level at or above the thermoplastic's melting point, then cooling of the composition below the melting temperature of the thermoplastic. Compositions of the invention have the ability to not only close macroscopic defects, but also to do so repeatedly even if another wound / damage occurs in a previously healed / repaired area.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Dyeable spandex

InactiveUS20050165200A1Increase brightnessMonocomponent polyurethanes artificial filamentWeft knittingFiberPolymer solution

Commercial spandex can be prepared with greater efficiency, improved consistency and at lower costs from a high-solids content polyurethaneurea polymer solution. The polyurethaneurea is prepared using a combination of 4,4′-MDI and 2,4′-MDI, and an amount of chain extenders and chain terminators such that the polymer solution, prior to spinning, is highly soluble and has an appropriate pre-spun IV and primary amine content. Such spandex fibers, and the fabrics and garments comprising them, have good dyeability and colorfastness, as well as other desirable characteristics.

Owner:THE LYCRA CO LLC

Polyurethane fibers and films

InactiveUS6203901B1Monocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberPolyurethane

Owner:INVISTA NORTH AMERICA R L

Method for producing urethane elastomer and application

ActiveCN101148494AGood spinning stabilityIncrease elasticityMonocomponent polyurethanes artificial filamentPolyesterPolyurethane elastomer

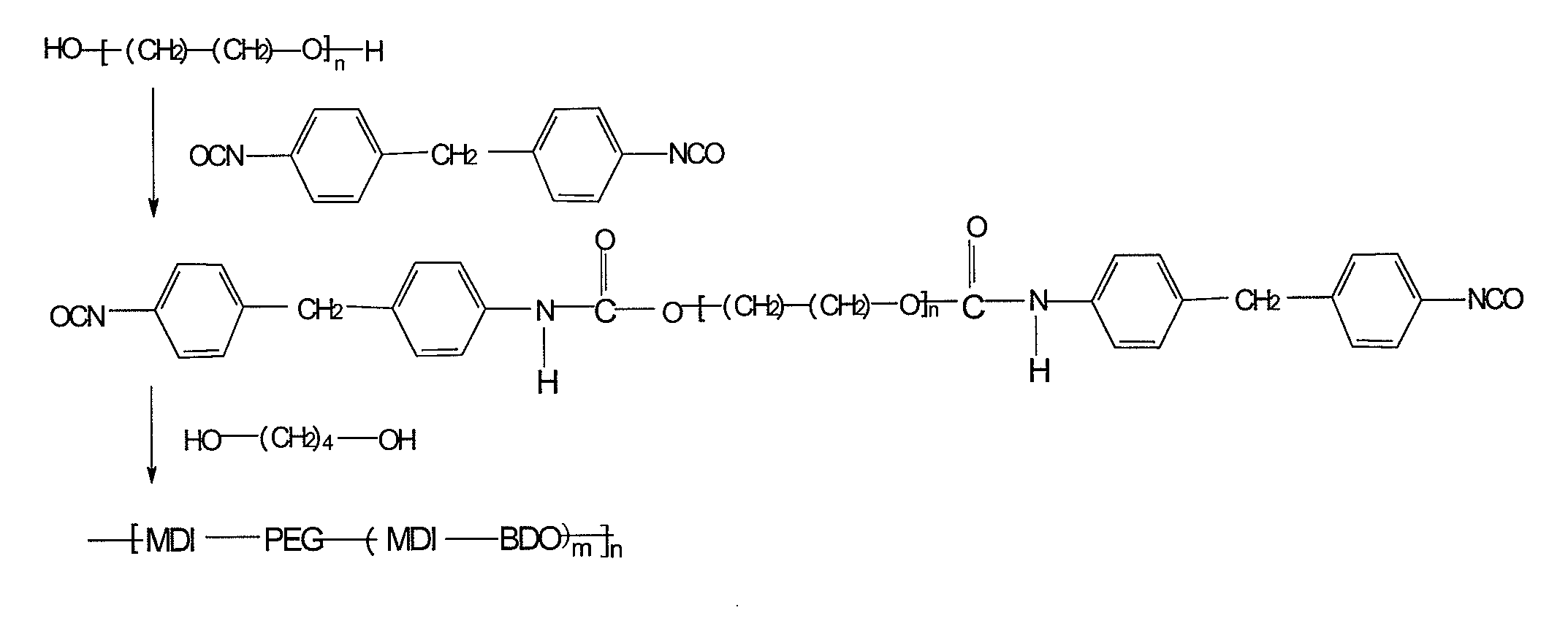

The process of producing polyurethane elastomer with the material including one component A of polyether glycol and / or polyester polyol, one component B of organic diisocyanate and one component C of small molecular diol as the chain expanding agent, includes the following steps: melting the components while adding organic tin catalyst in 0.001-0.05 wt% to the component A, metering precisely with one metering system, and mixing and bulk polymerizing in a double screw extruder with precise temperature control system at 180-260 deg.c for 3-15 min to obtain the polyurethane elastomer. The polyurethane elastomer is applied in melt spinning to produce elastic polyurethane fiber. The production process is simple, easy in control and low in cost, and elastic polyurethane fiber produced with the polyurethane elastomer has high quality.

Owner:SHANGHAI YITAN NEW MATERIAL CO LTD

Thermoplastic polymers with thermally reversible and non-reversible linkages, and articles using same

InactiveUS20050037194A1Color stableHigh strengthMonocomponent polyurethanes artificial filamentMonocomponent polyethers artificial filamentPolymer chemistryChemistry

The invention provides a polymer adapted for use in melt processes, the polymer having thermally reversible and non-thermally reversible bonds which polymer is adapted to evanesce at an elevated temperature and revert to a thermally reversible bond upon cooling to ambient temperature so that the polymer is adapted, upon being heated to the elevated temperature, to dissociate into melt processable polymeric fragments and, upon being cooled to ambient temperature, to re-associate.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Process for producing polyurethane and use of polyurethane obtained by the same

InactiveUS20090247658A1Function increaseHigh elongation at breakMonocomponent polyurethanes artificial filamentFiberPolyurethane elastomer

A polyurethane and a polyurethane-urea are provided which are extremely useful in high-performance polyurethane elastomer applications such as elastic polyurethane fibers, synthetic / artificial leathers, and TPUs. Disclosed are: a process for producing a polyurethane from (a) a polyether polyol obtained by a dehydration condensation reaction of a polyol and containing a 1,3-propanediol unit, (b) a polyisocyanate compound, and (c) a chain extender, wherein the polyurethane is produced in the co-presence of an aprotic polar solvent; a polyurethane produced by the process for polyurethane production; and a film and a fiber each comprising the polyurethane.

Owner:MITSUBISHI CHEM CORP

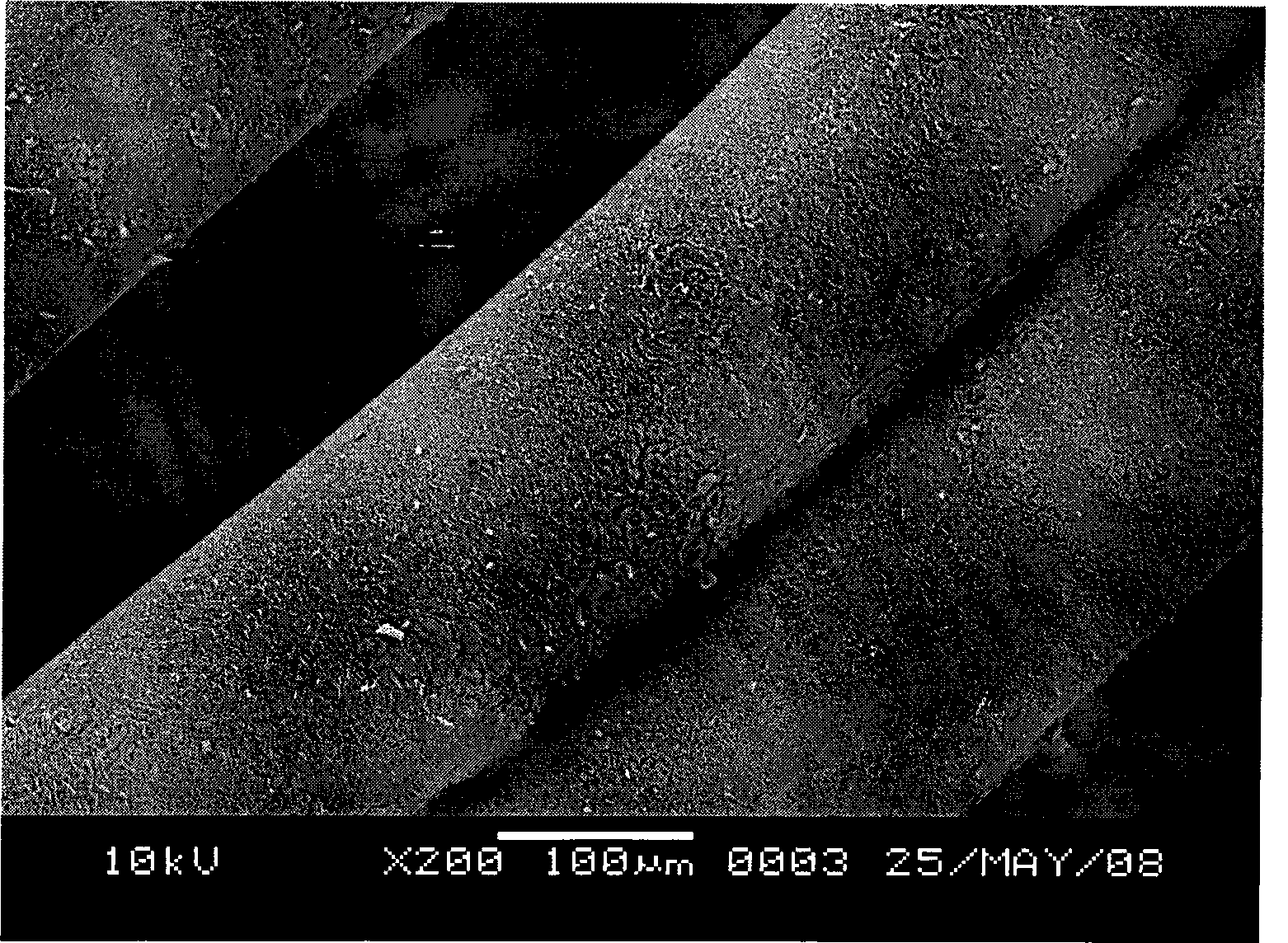

Antistatic polyurethane elastic fiber and material for producing the same

InactiveUS6849676B1Monocomponent polyurethanes artificial filamentElectroconductive/antistatic filament manufacturePolymer sciencePhosphate

Inorganic salts are generated in the production process of metal salts, such as sulfonates, sulfates and phosphates. When such metal salts containing inorganic salts are added as an antistatic agent to a polymer for producing polyurethane fiber, the inorganic salts cause fiber breakage or pack choking in fiber extrusion process. In addition, such antistatic agents are highly hygroscopic and contain trace of water. When such an antistatic agent is added to the material for polymerizing polyurethane, the alcohol and water in the agent react with isocyanate to result in lowered degree of polymerization and generation of oligomer. Such polyurethane polymer is spun into fiber of low elongation and tenacity. The material for polyurethane elastic fibers of the present invention comprises a mixture of 5 to 95 weight percent of at least one of the above-mentioned antistatic agents and 95 to 5 weight percent of a isocyanate-free starting material for elastic fibers, and eliminates the above troubles.

Owner:MATSUMOTO YUSHI SEIYAKU

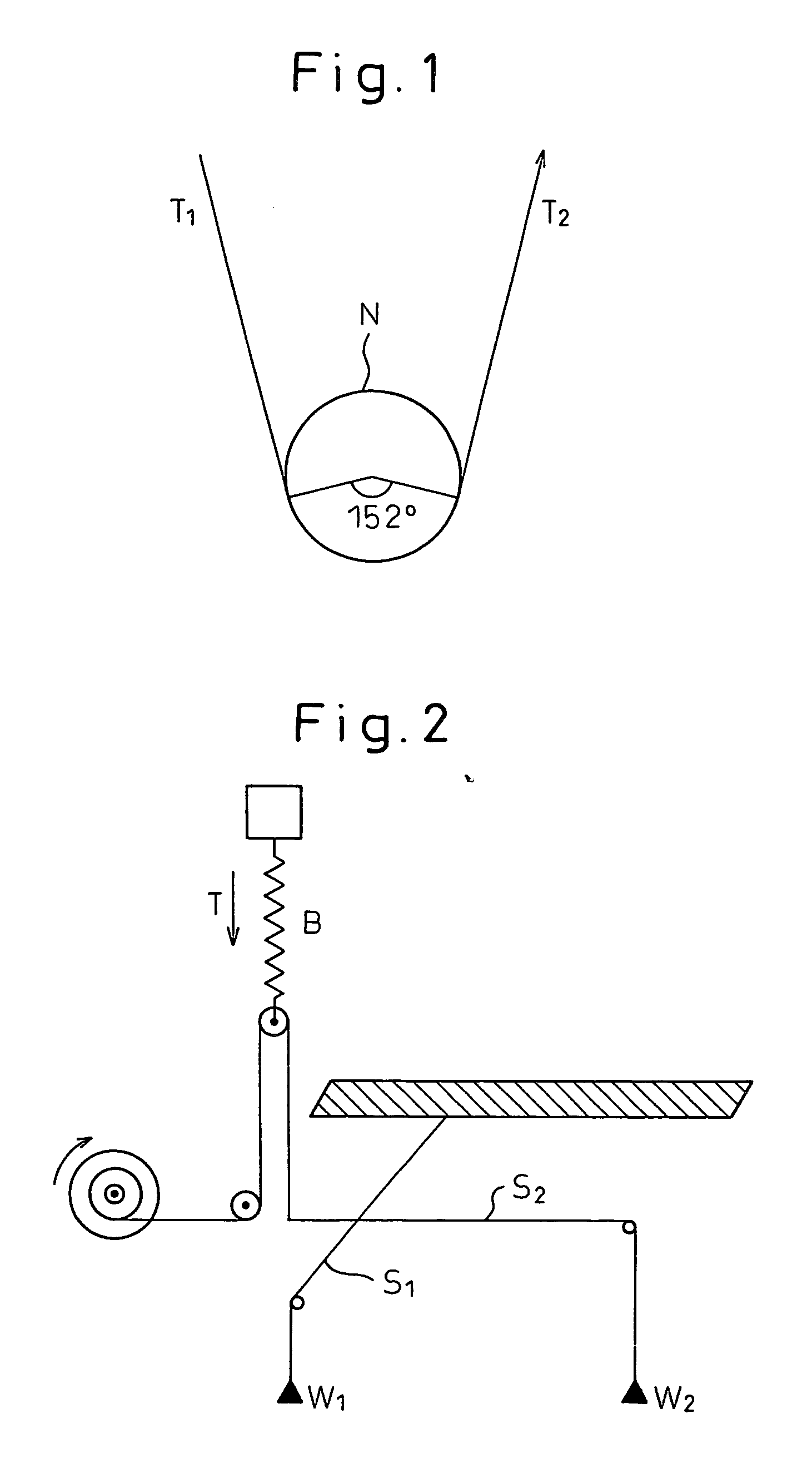

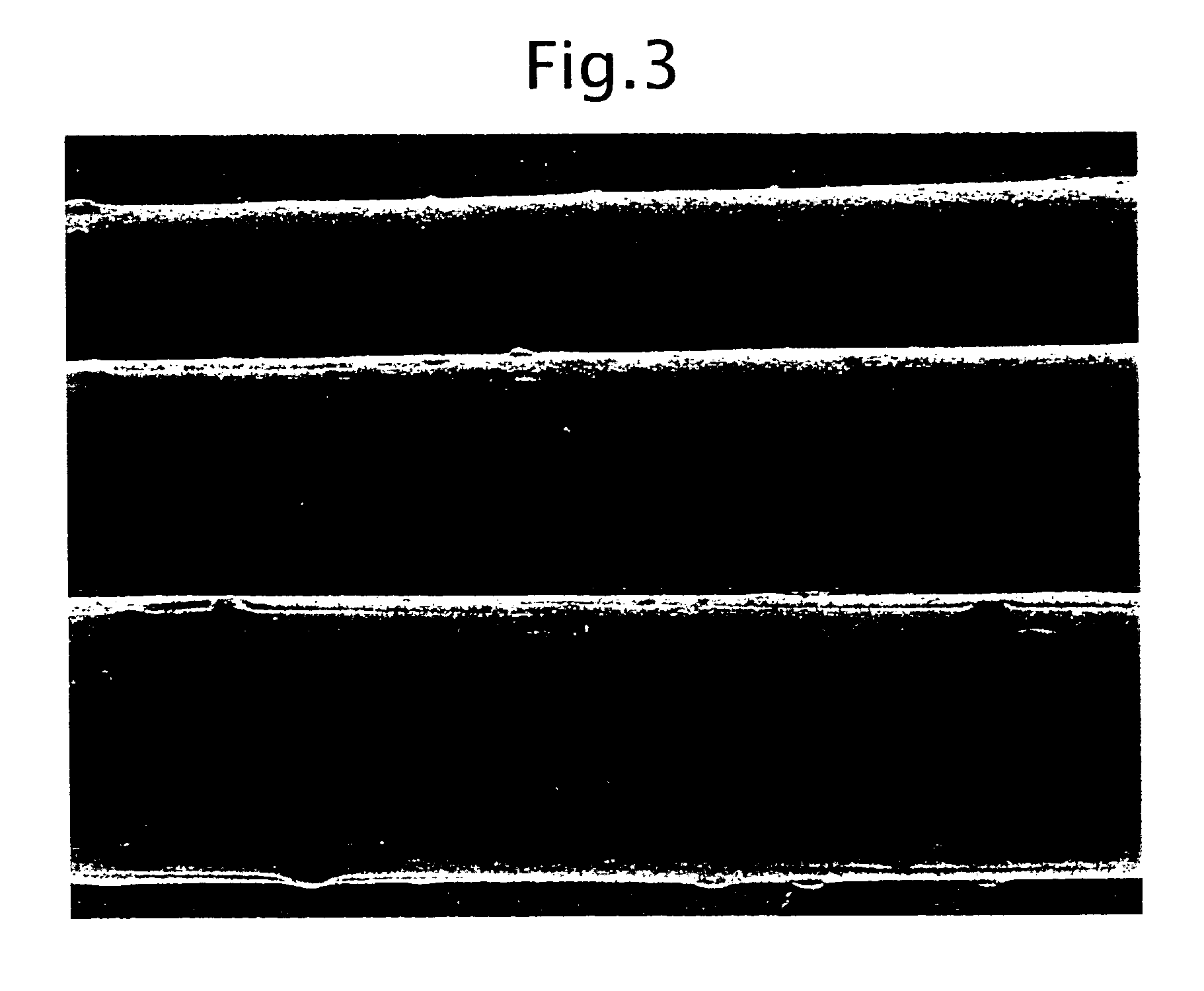

Polyurethane Elastic Fiber And Process For Producing Same

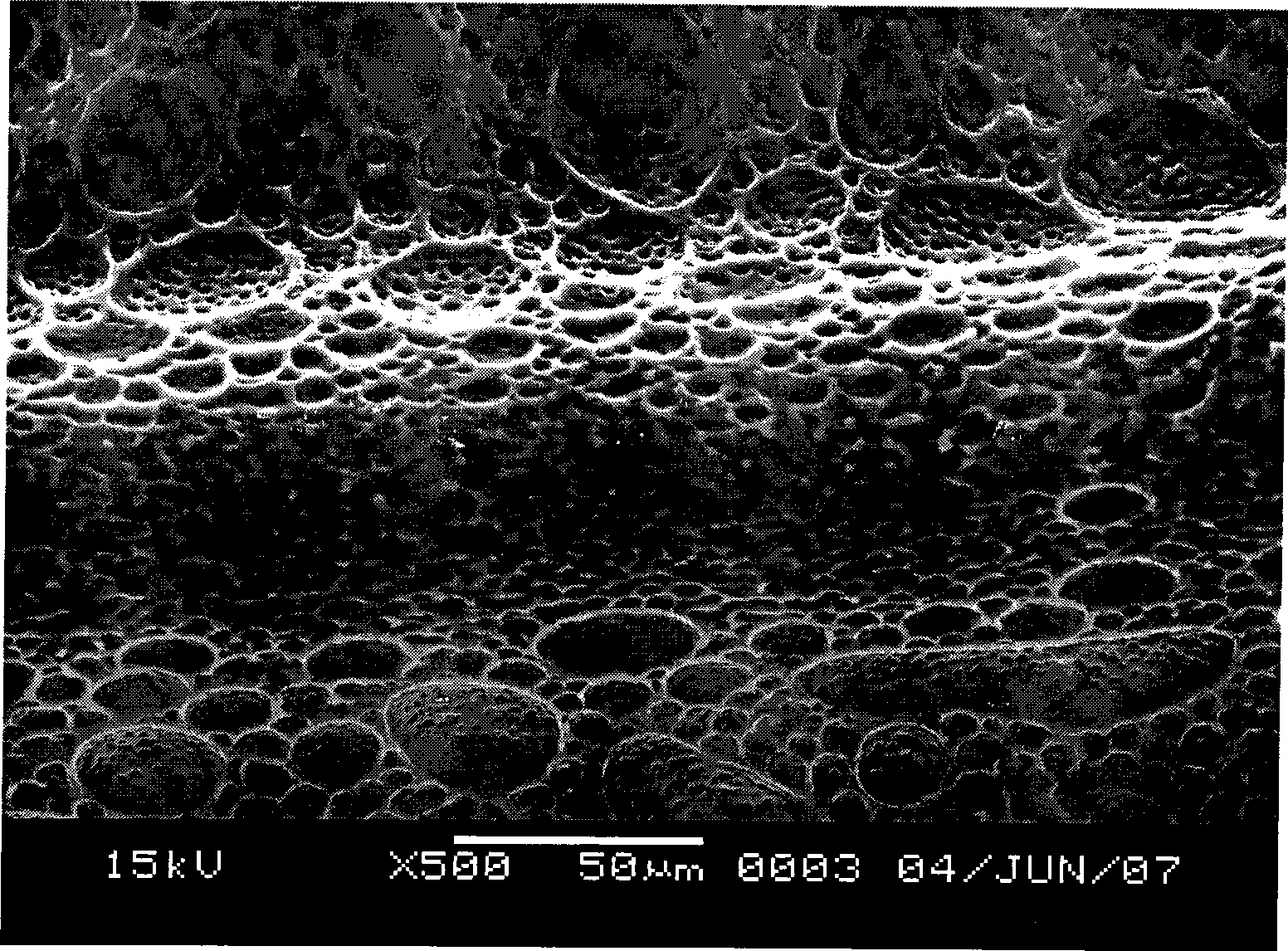

ActiveUS20070196650A1Improve stabilityReduce yarn breakageMonocomponent polyurethanes artificial filamentOther chemical processesFiberInorganic compound

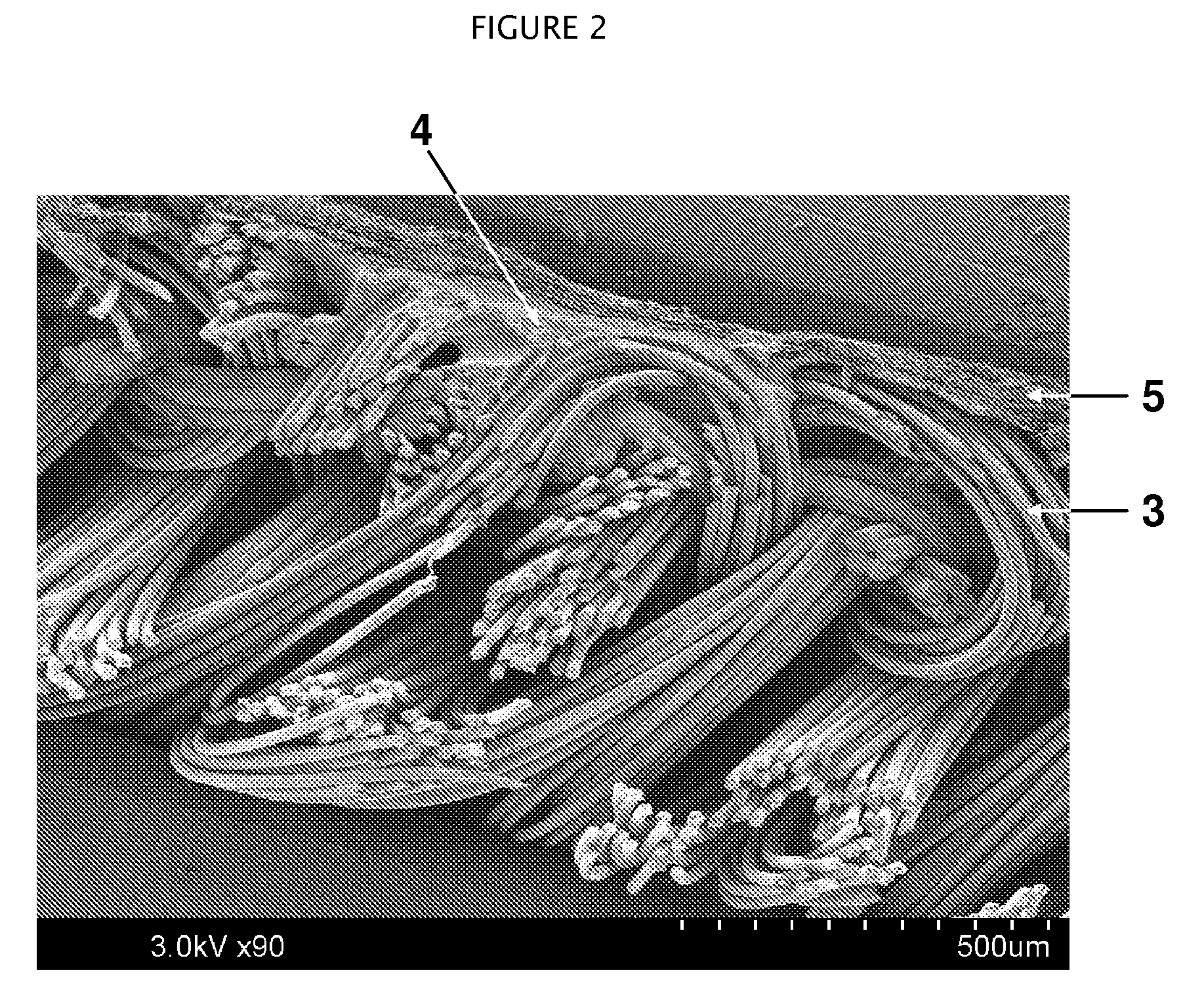

A polyurethane elastic fiber, containing inorganic compound particles that have an average particle size of 0.5 to 5 mm and that show a refractive index of 1.4 to 1.6, having at least one protruded portion that has a maximum width of 0.5 to 5 μm, in the fiber surface, per 120-μm length in the fiber axis direction.

Owner:ASAHI KASEI FIBERS CORPORATION

Polyurethane polymer

Provided is a polyurethane polymer which is excellent in oil resistance, weatherability, light resistance, heat resistance, hot water resistance, hydrolysis resistance, strength, chlorine resistance, and chemical resistance, and which can be produced simply and economically. The polyurethane polymer is produced by polymerizing at least two components: a vinyl polymer (A) having a mercapto group at each end of the molecular chain produced by a reversible addition-fragmentation chain transfer polymerization method, and an organic polyisocyanate (B). Also provided are polyurethane-based materials containing the polyurethane polymer, and polyurethane elastic fiber.

Owner:KANEKA CORP

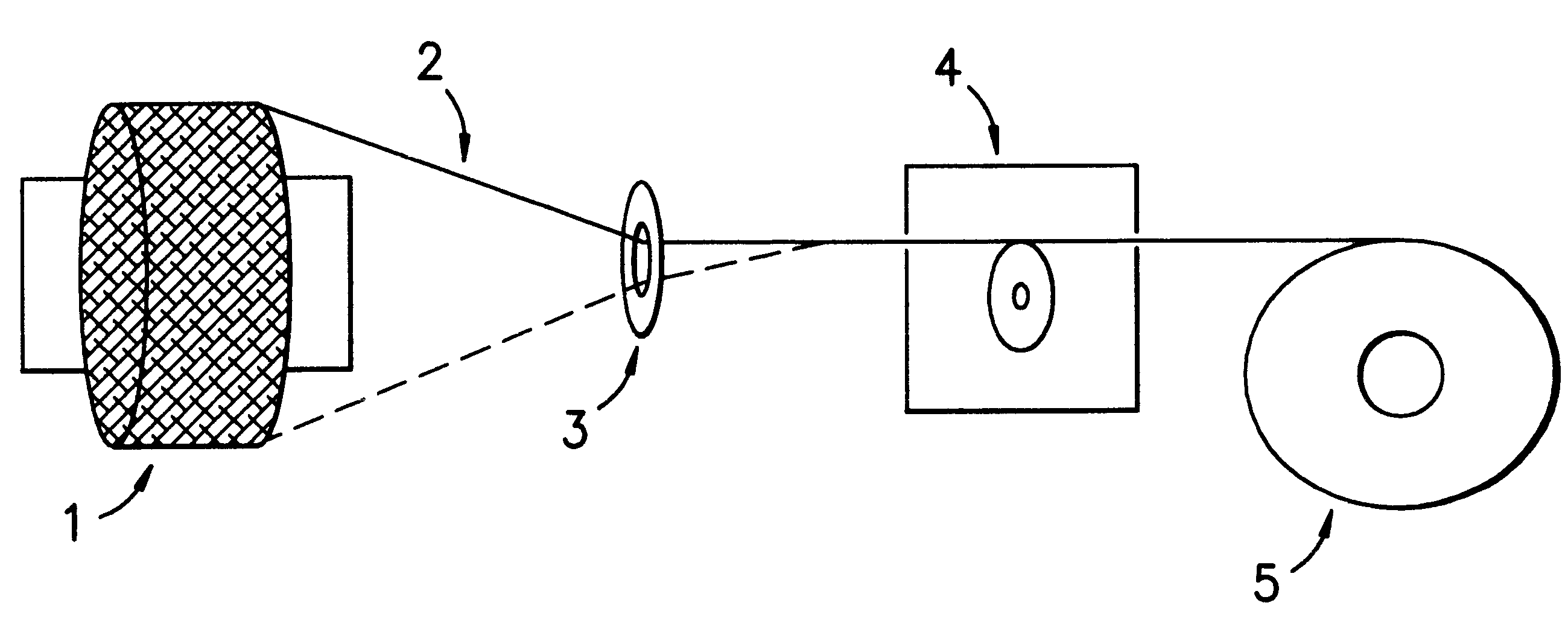

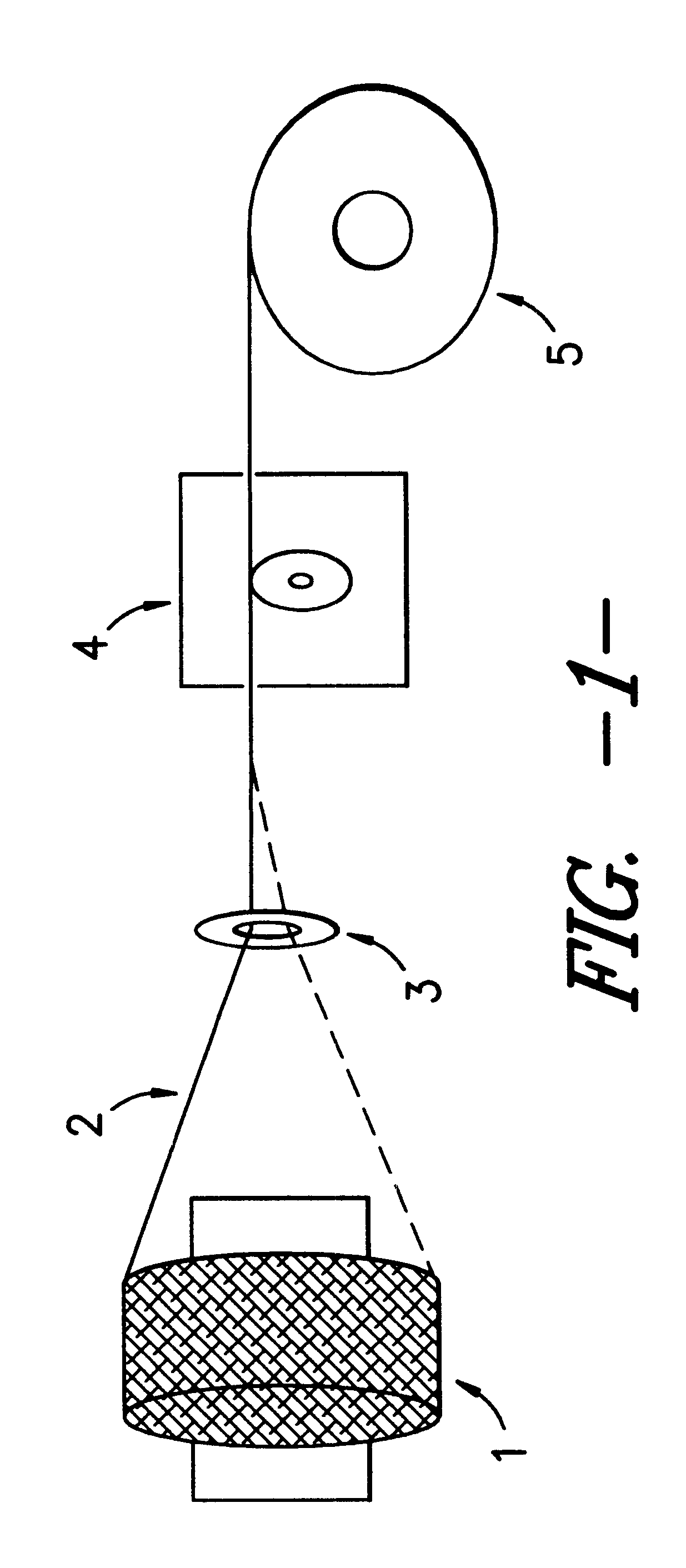

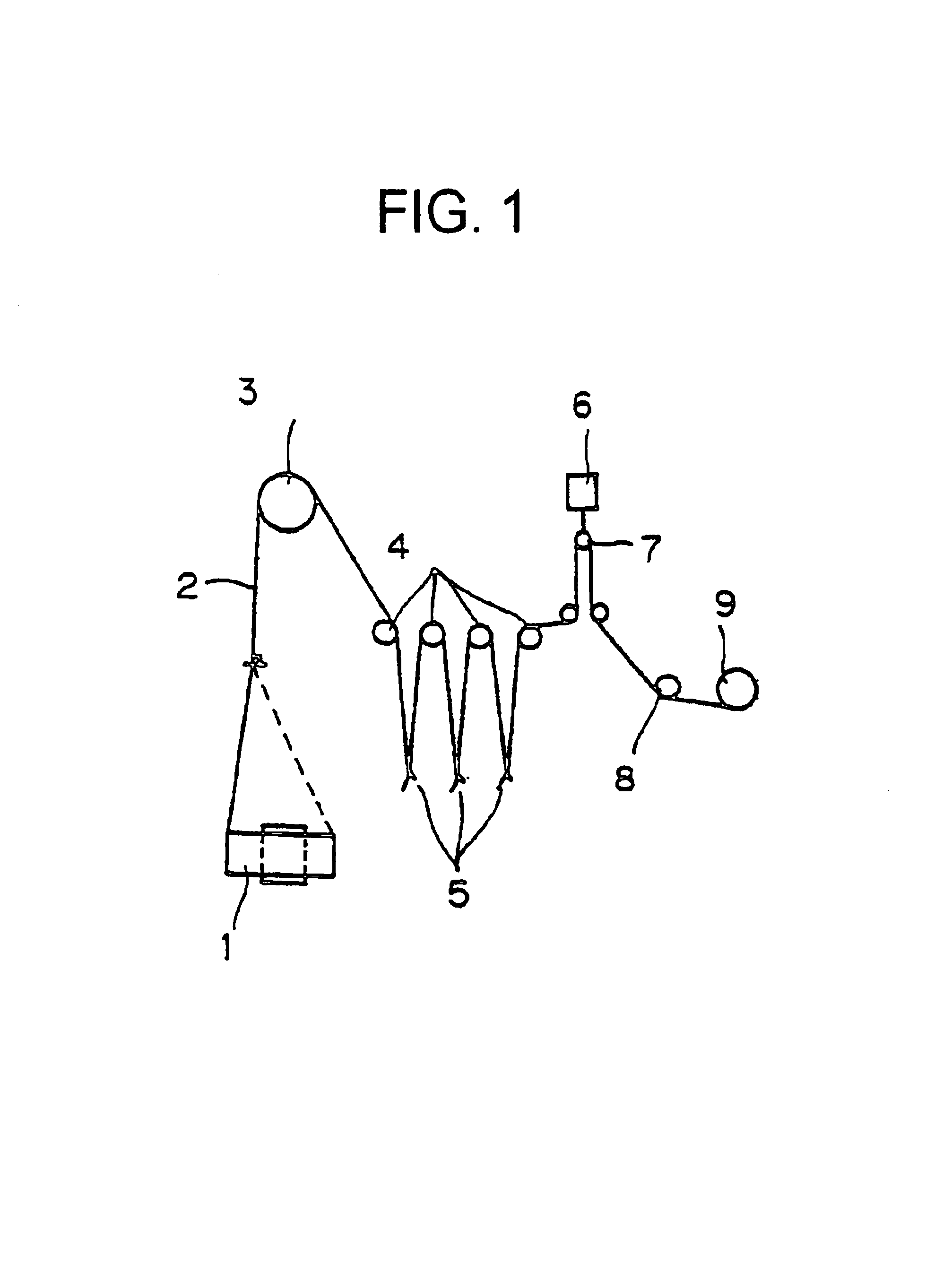

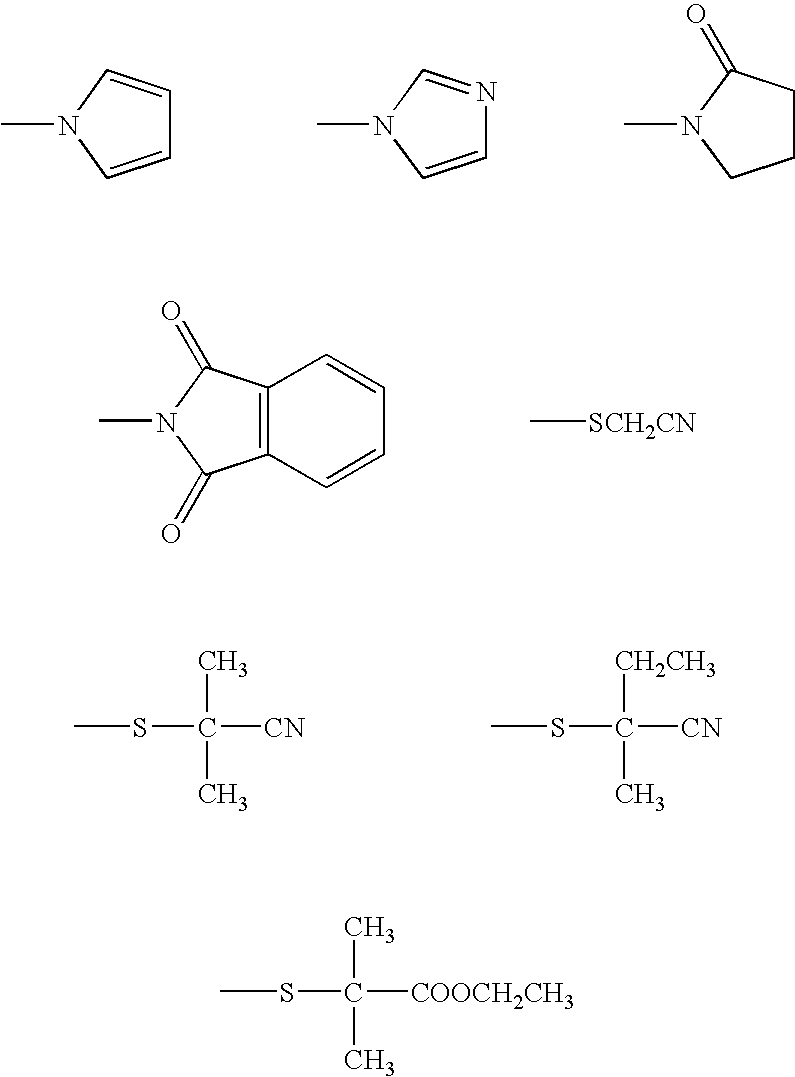

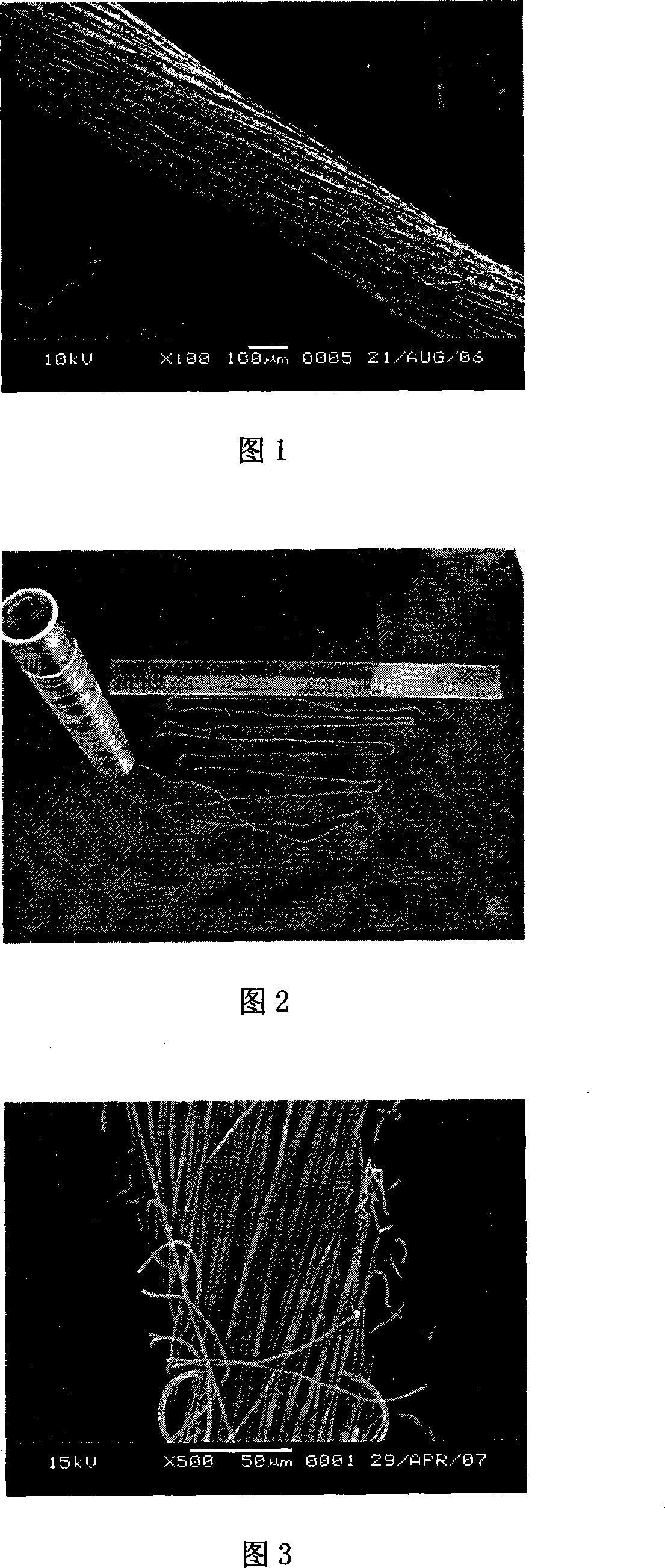

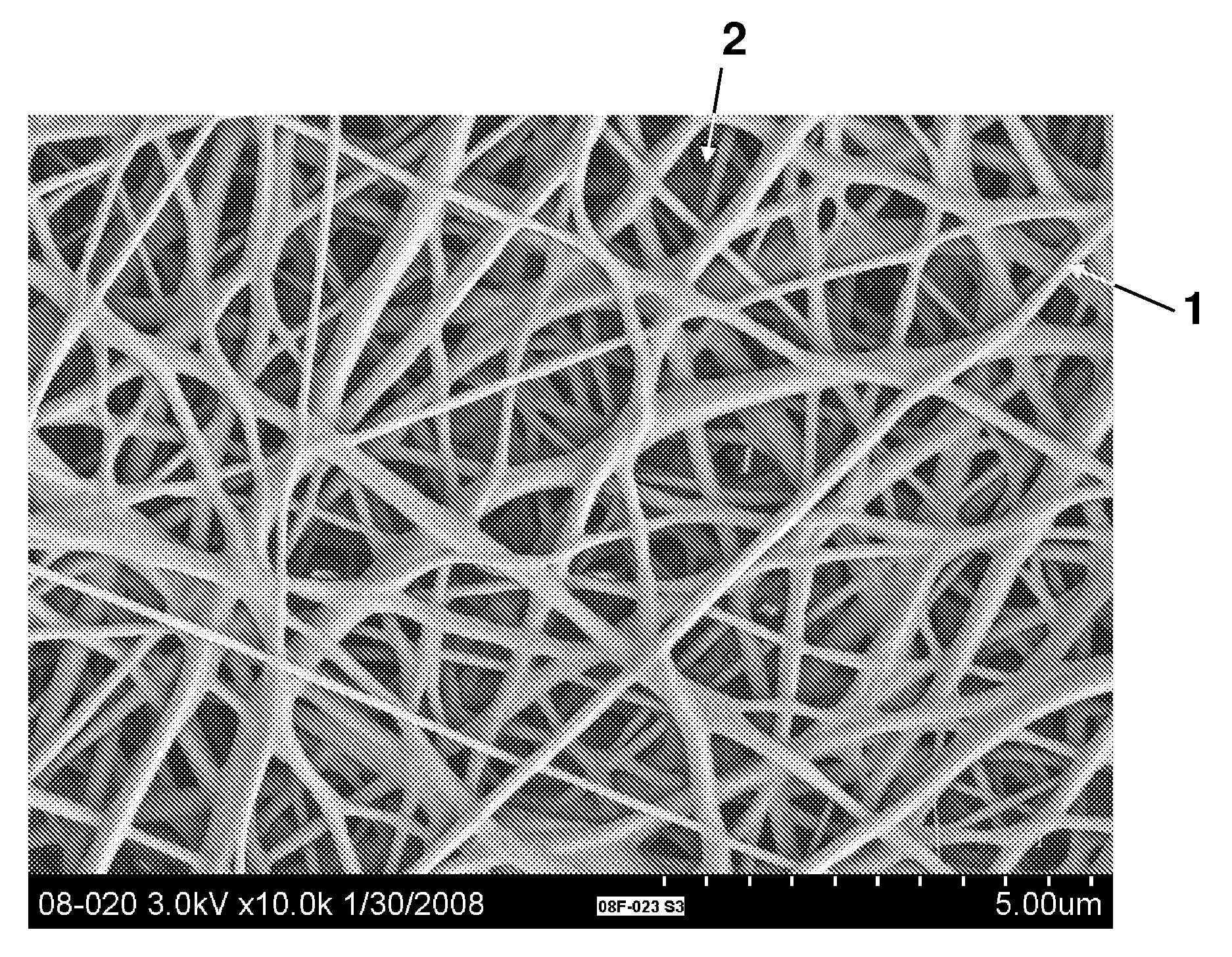

Continuous preparation method for ultra-fine electrostatic spinning fibre yarn

ActiveCN101104970AMonocomponent polyurethanes artificial filamentNew-spun product collectionYarnUltra fine

The invention relates to a continuous preparation method of superfine electrostatic-spinning fiber yarn, which comprises the following steps: (1) dissolving a polymer in a solvent to obtain a homogenous solution; (2) adding additives into the solution; (3) electrostatic spinning: feeding the spinning stock solution into a container, and extruding from a nozzle connected with a high-voltage anode under the control of a microinjection pump while controlling various electrostatic spinning parameters to keep a stable spinning state; (4) approaching a grounded needle tip to the nozzle to induce the electrostatic-spinning fibers to form bundles; (5) dragging the fiber bundles and twisting by a twisting machine; and (6) winding the twisted continuous yarns around a barrel by using a winding machine. The superfine electrostatic-spinning fiber yarn produced by the inventive method has wide application range.

Owner:DONGHUA UNIV

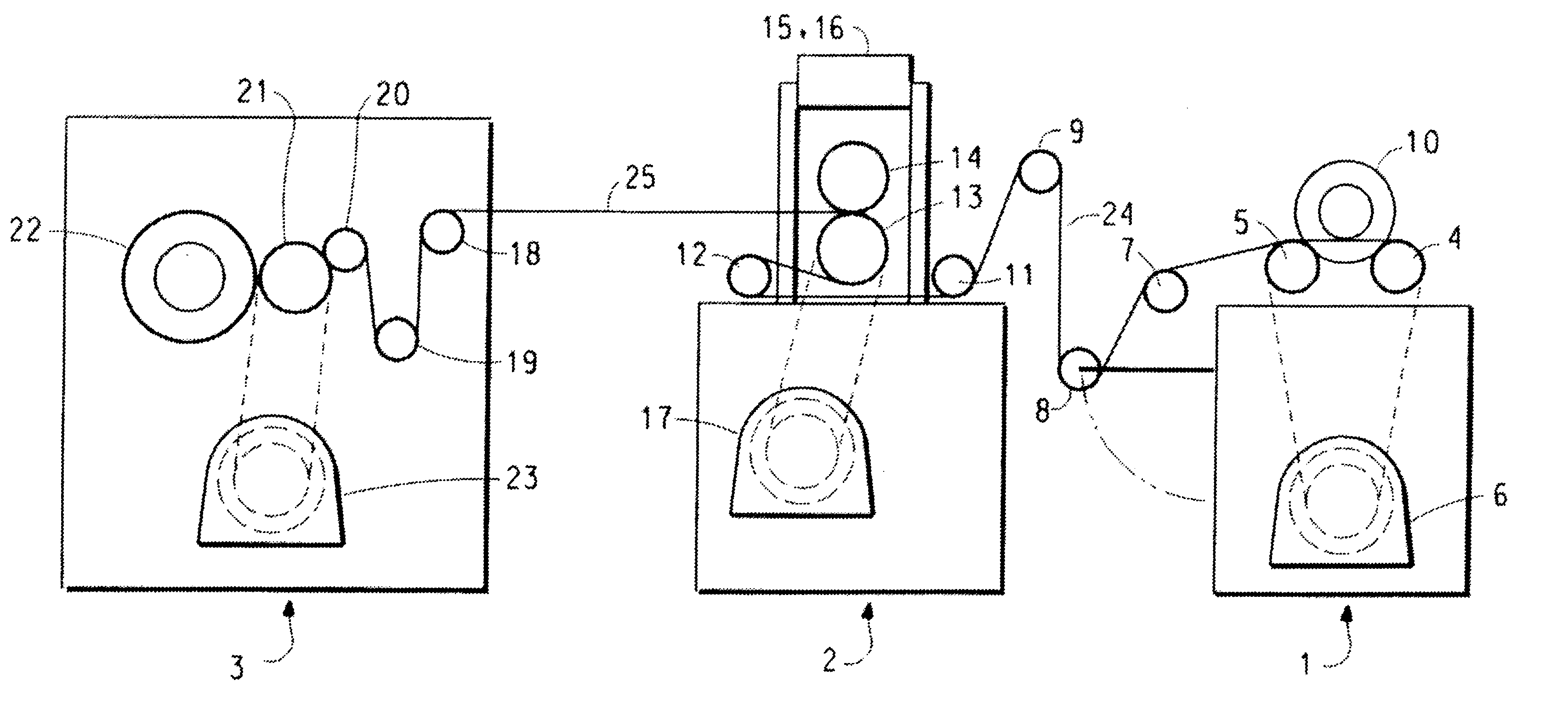

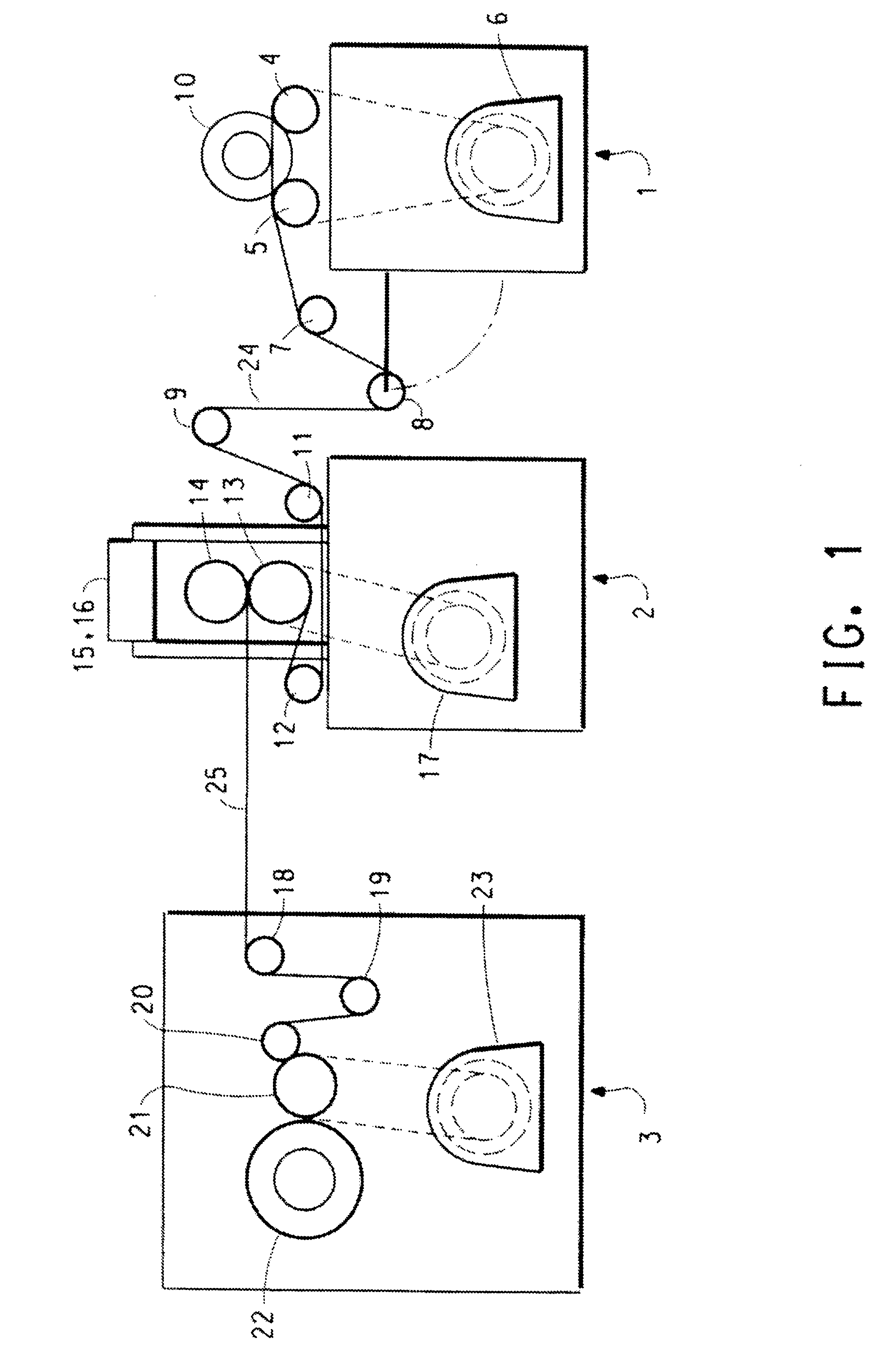

Method for producing a shaped multifilament, non-thermoplastic, elastomeric yarn

InactiveUS6248197B1Good handAdhesive processesMonocomponent polyurethanes artificial filamentYarnEngineering

Owner:DUPONT TORAYCOMPANY LTD +1

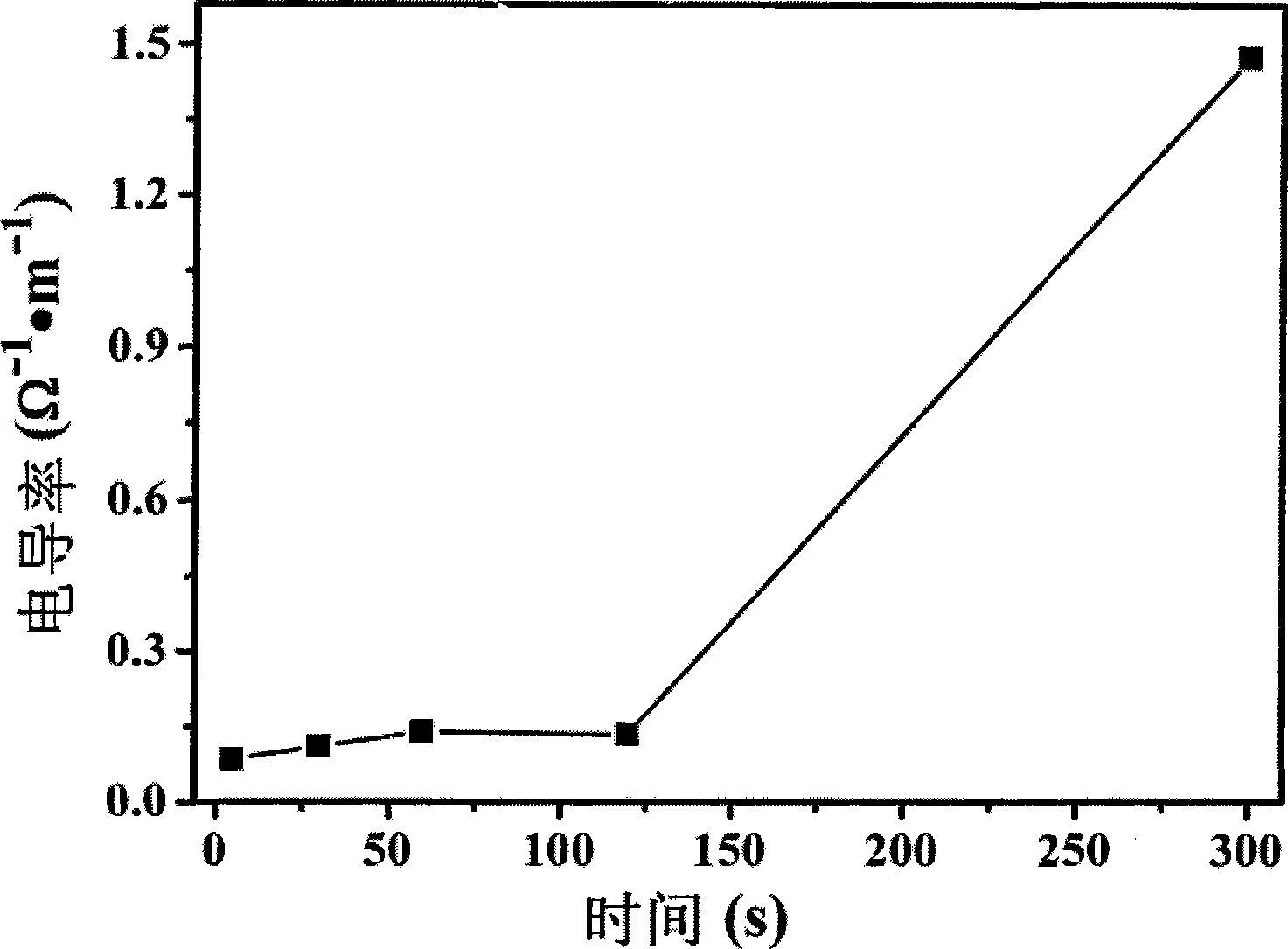

Complex fiber with high conductivity, high elasticity and stress sensing property and preparation thereof

InactiveCN101487148AImprove conductivityIncrease elasticityMonocomponent polyurethanes artificial filamentMonocomponent polyolefin artificial filamentFiberOrganic solvent

The invention relates to a composite fiber with high conductivity, high elasticity and stress sensing performance, and a preparation method thereof, comprising 80-99 parts of high-elastic polymer fiber and 1-20 parts of conductive particles according to weight proportion; the preparation method comprises the steps as follows: a conducting medium bath with ultrasonic vibration is added based on the spinning and forming process of the fiber or during the post-processing of the fiber; and the conductive particles with the concentration of 1-30mg / mL is uniformly dispersed in water or organic solvent by the auxiliary function of the ultrasonic to form a nano-composite conductive fiber, with the dipping time of 5-600 seconds. The conductive composite fiber has the advantages of high conductivity, difficult falling of conductive compositions, durable conductive performance, high elastic performance, soft hand-feeling and the like; the preparation process is simple, the operation is convenient and the cost is low; the composite fiber can be produced continuously in large scale; and the stress sensing element is connected with a corresponding electronic element, thus being applicable to the real-time detection on the physiological status of the human body.

Owner:DONGHUA UNIV

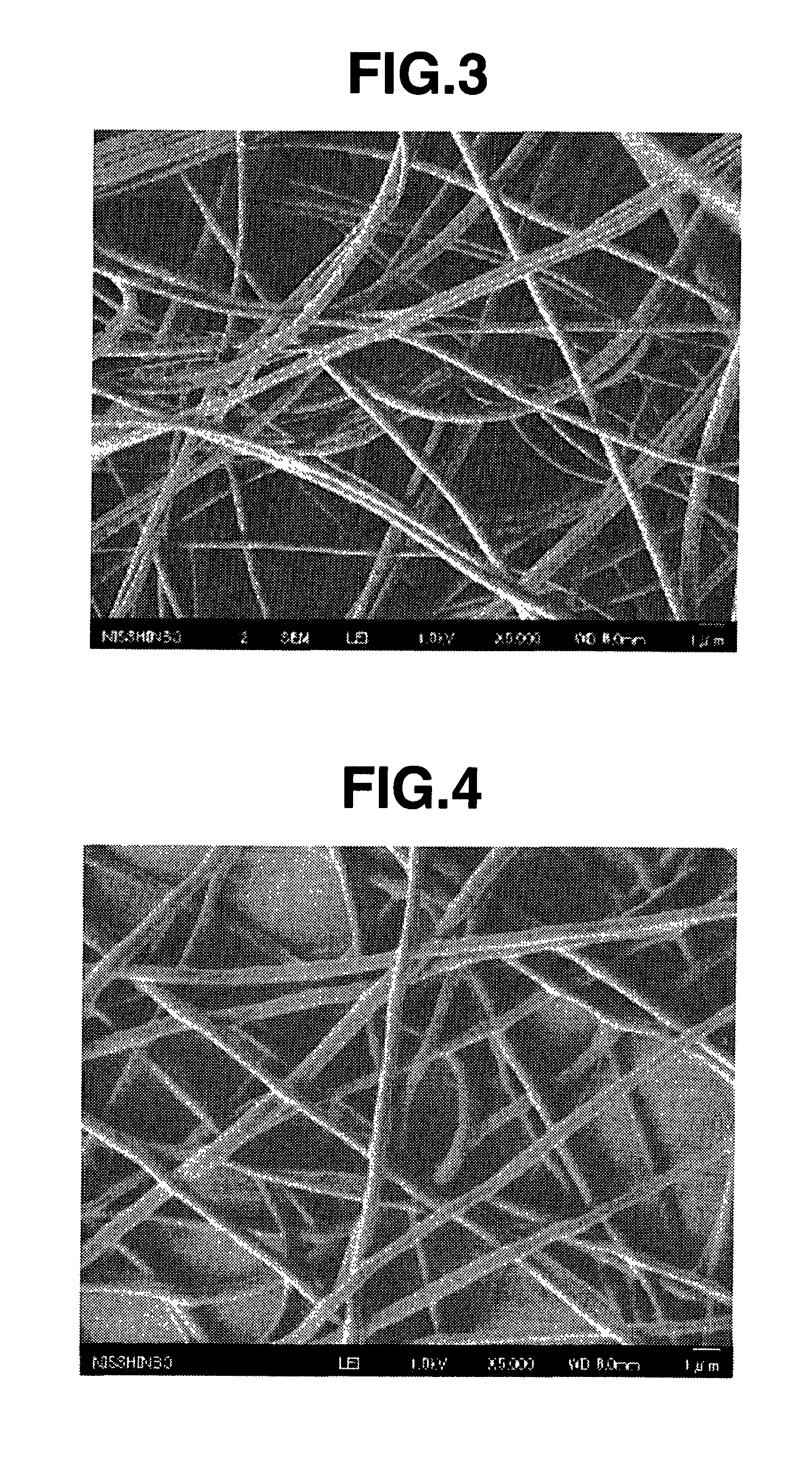

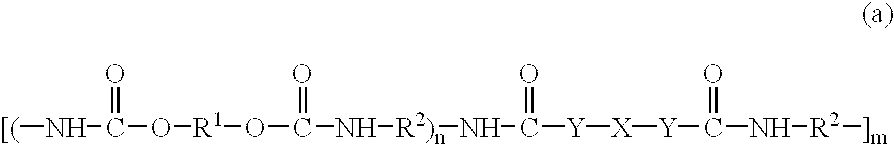

Stretchable nonwoven fabric, method of manufacturing, and products made thereof

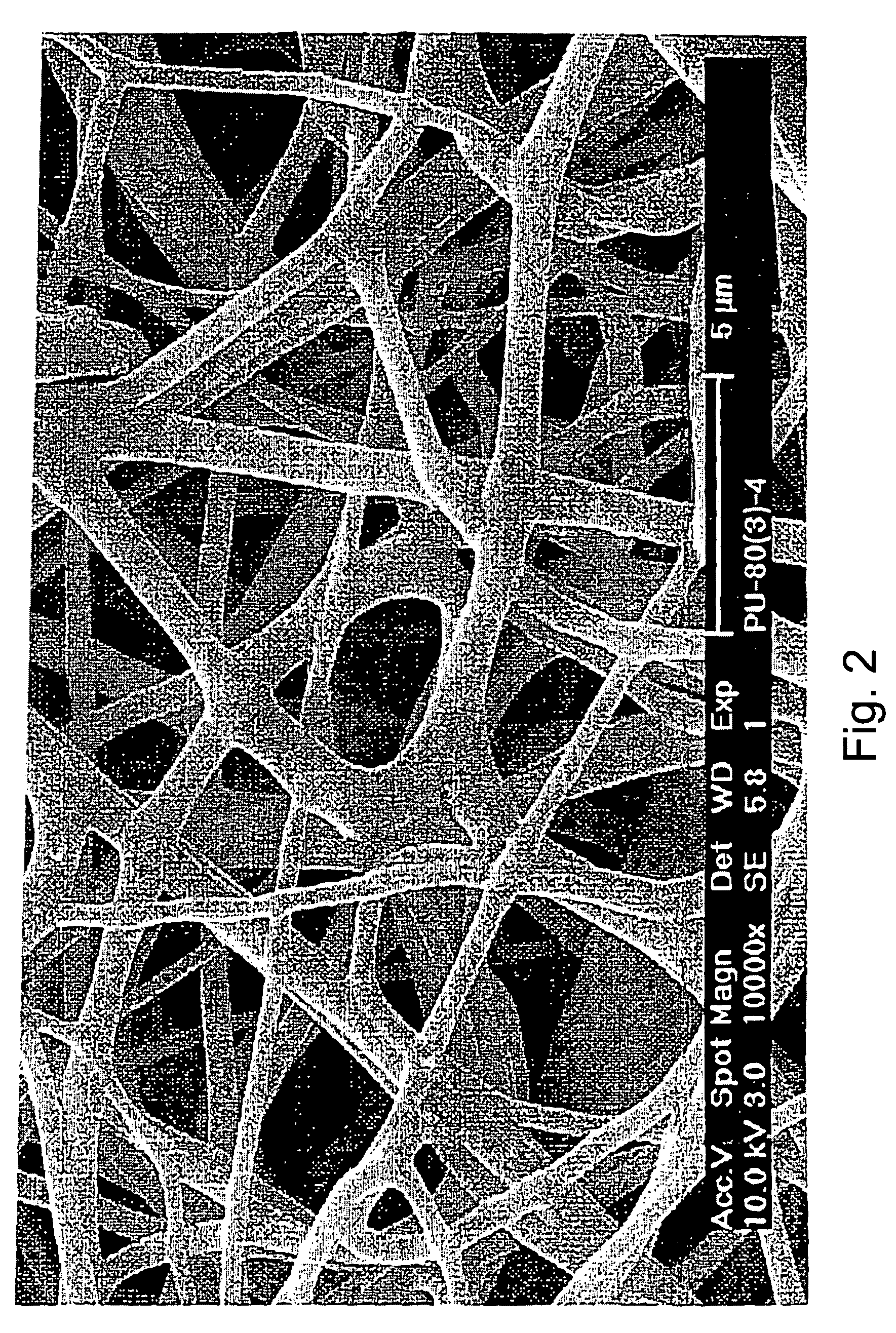

InactiveUS20100304108A1Reduce the possibilityWithout loss of dimensional integrityMonocomponent polyurethanes artificial filamentElectric discharge heatingNanofiberEngineering

The present invention relates generally to textile fabrics, and more particularly, to a stretchable, nonwoven nanofiber fabric which is impermeable to water but allows vapor transport, capable of conforming to body parts, and is particularly useful in high performance apparels and personal care products. The fabric is combined with different substrates to form a laminate. The fabric and its laminate can retain their dimensional integrity on repeated stretching, have relatively high air permeability while maintaining liquid repellency, and have high stretching recovery. Methods of preparing and applying the nanofiber fabric and its laminate are also provided.

Owner:DOSHI JAYESH N +2

Fire-resistant high-resiliency spandex fabric and method for making same

InactiveCN101113534AIncrease elasticityHigh temperature high elasticityMonocomponent polyurethanes artificial filamentFilament/thread formingYarnPolymer science

The invention discloses a urethane elastic fiber with high temperature resistance and high elasticity and a preparation method thereof, the materials of the urethane elastic fiber comprise: polyether diols, diisocyanate, butanol, amine admixture, anti-oxidant, reelability agent, ultraviolet absorber, yellowing resistant agent and dimethyl acetamide; the preparation method of the urethane elastic fiber is that: a prepolymer is obtained through prepolymerization reation, and macromolecule polymer is also obtained through continuous chain extension reactions, then spinning solution is formed by adding different auxiliary agents; finally winding and dry spinning through round spinning channel are performed to obtain a high temperature high elastic urethane fiber spinning can which has the advantages of high temperature resistance, high elasticity, excellent reelability, outstanding yarn evenness, etc, and the preparation method can realize the continuous process of chain extension reactions and addition of auxiliary agents with continuous and stable production process and high product evenness and can completely meet the requirements of all kinds of novel fabrics and high grade fabrics.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Temperature-regulating fiber and a method of making the same

ActiveUS20100171067A1Monocomponent polyurethanes artificial filamentCeramic shaping apparatusFiberPhase change

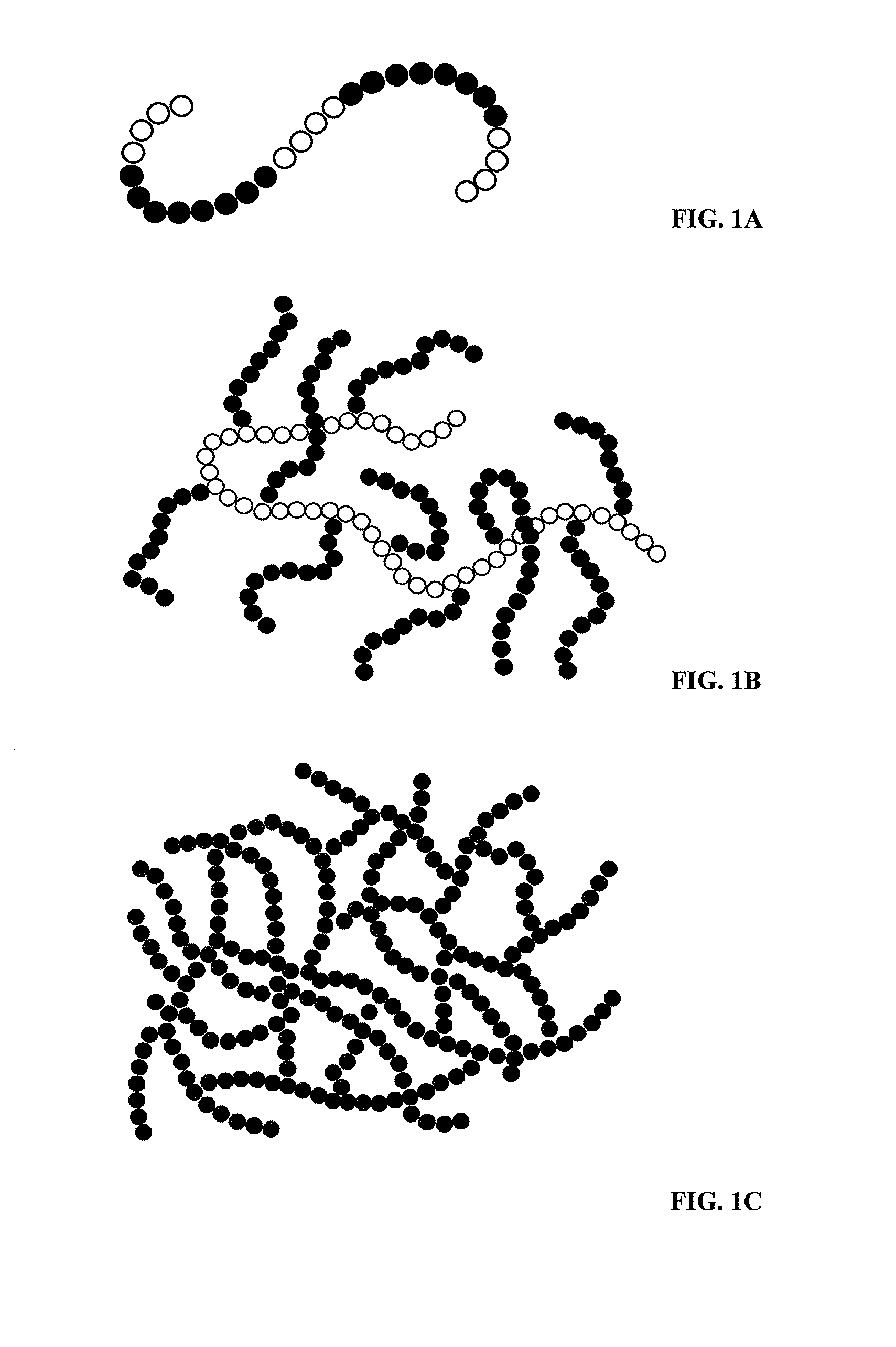

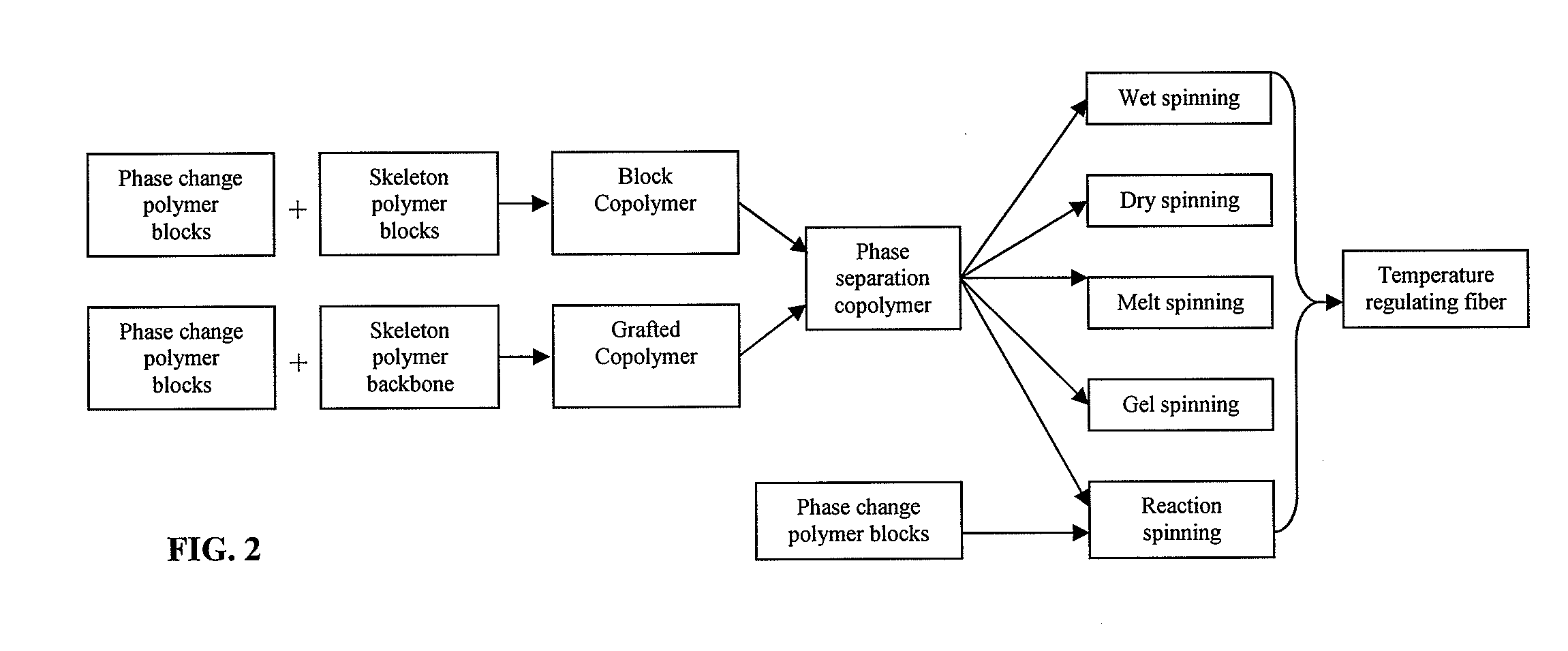

A temperature-regulating fiber may include a spun phase change polymeric material that may include a plurality of phase change polymer blocks. The fiber may have a fixity ratio of at least 80% and a recovery ratio of at least 74%.

Owner:THE HONG KONG POLYTECHNIC UNIV

Process for producing polyether type easy dyeing spandex fiber

InactiveCN101096779AQuality impactImprove dyeing effectMonocomponent polyurethanes artificial filamentArtifical filament manufactureFiberTextile technology

The invention discloses a preparing method of a new spandex fibre with good dyeing behavior in weaving technique domain, which is characterized by the following: choosing polyurethane solution with polyurethanes or polyurethanes urea as main component; proceeding enlargered chain reaction; spinning; producing spandex fibre; possessing organic compound as enlarged chain agent in mixing amine enlarged chain agent solution. This invention possesses the advantages of high dying ratio, big colour stability and stable productive process.

Owner:YANTAI TAYHO ADVANCED MATERIALS

Method of manufacturing nano-fibers with excellent fiber formation

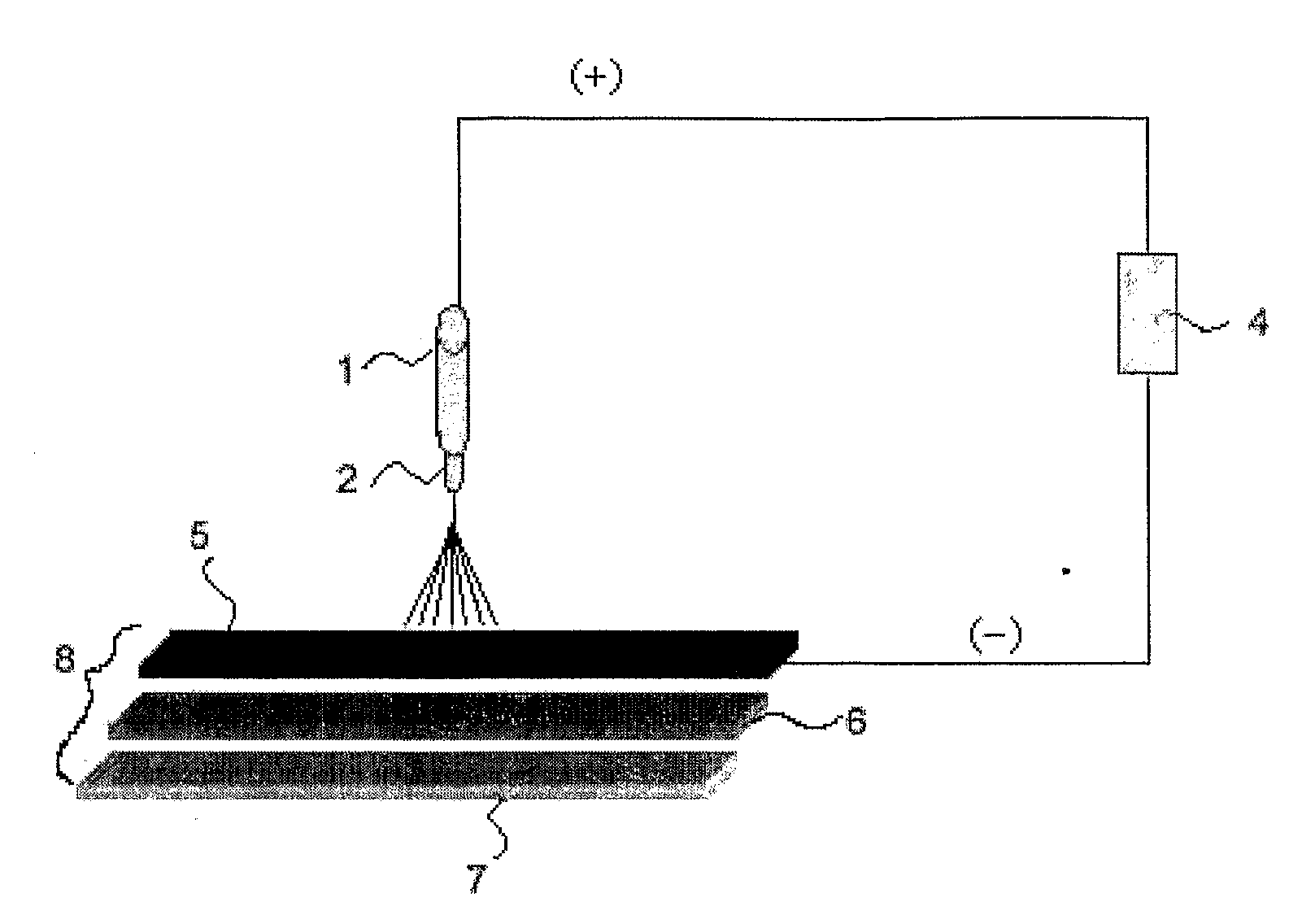

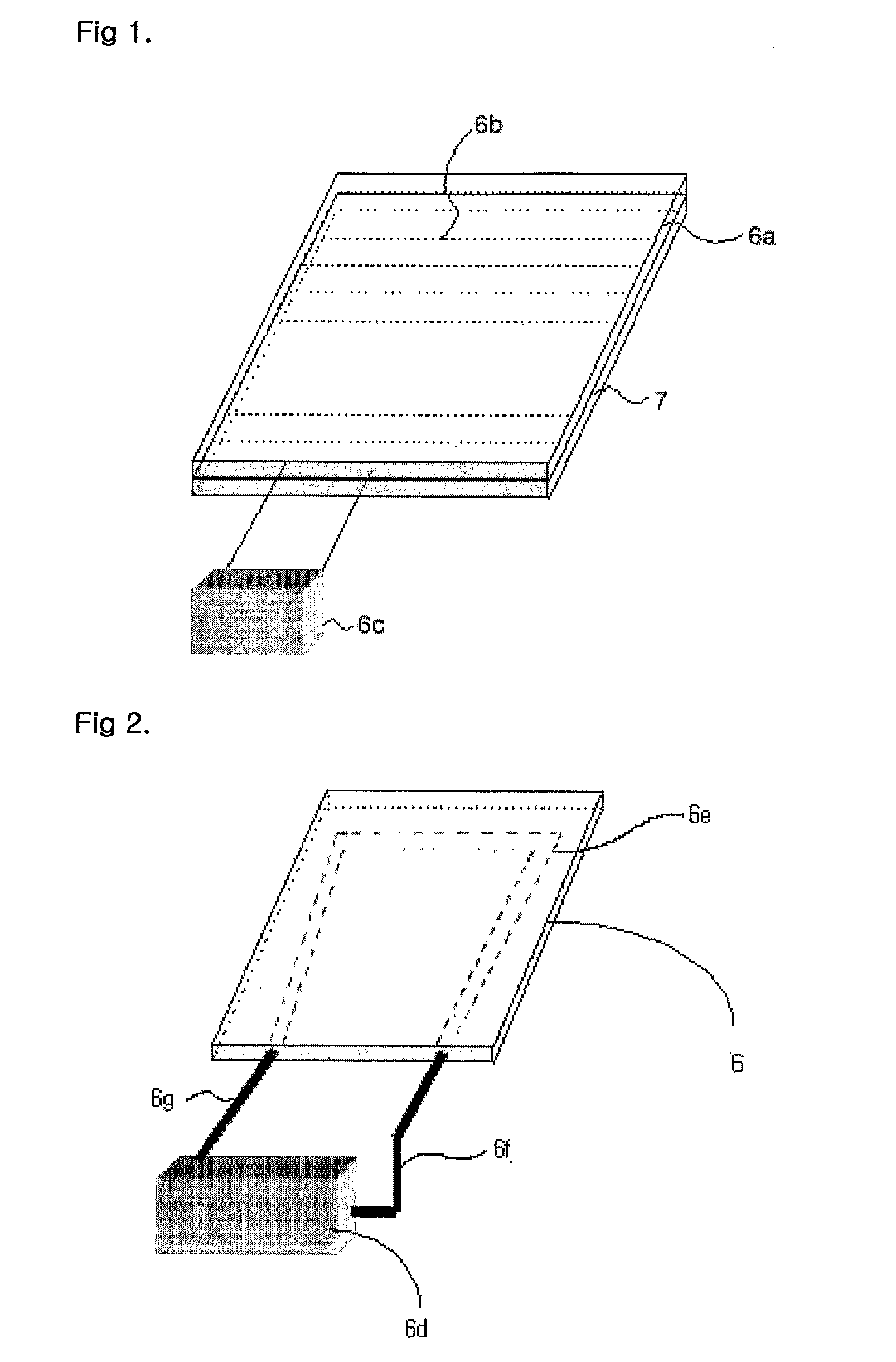

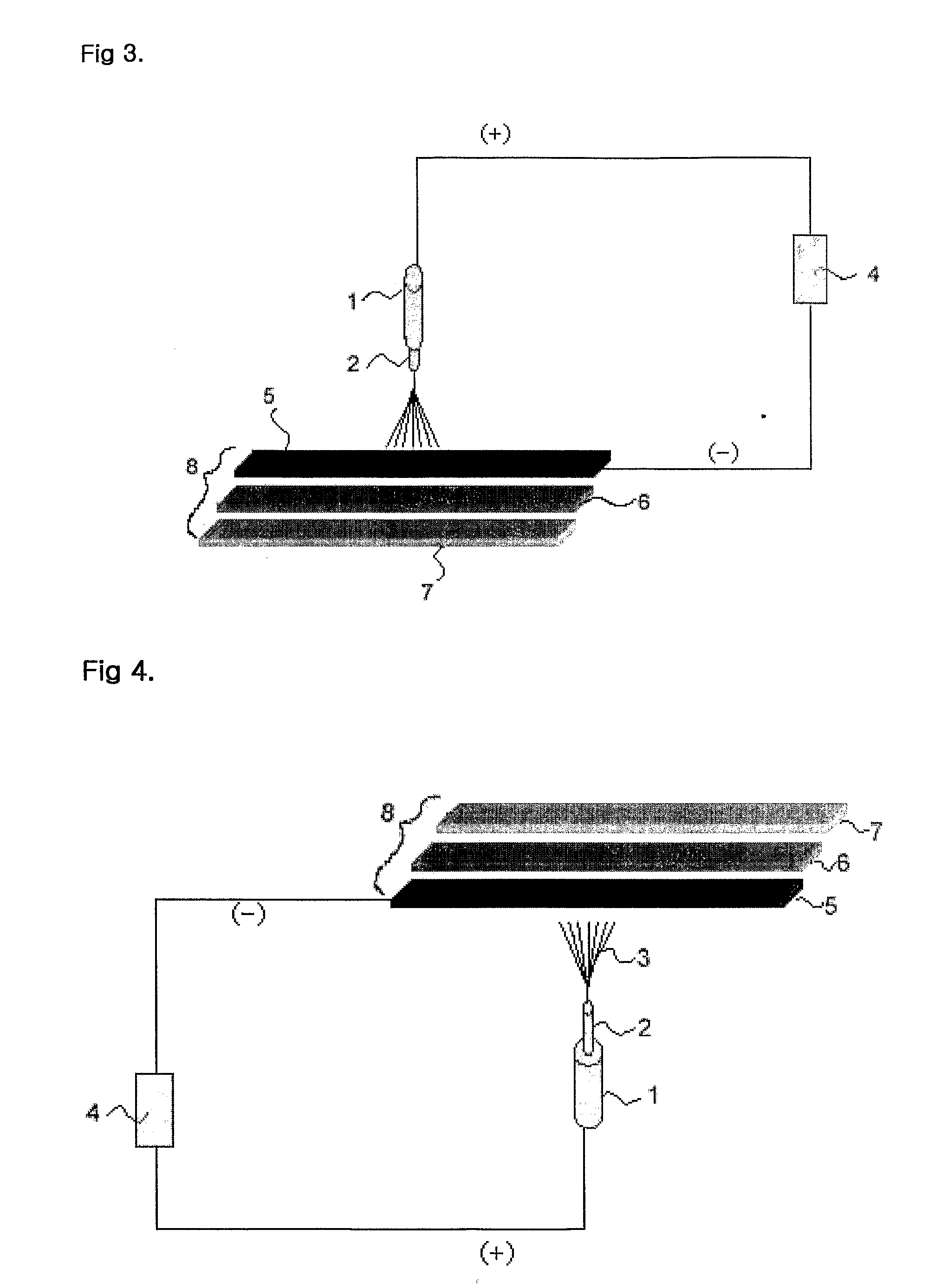

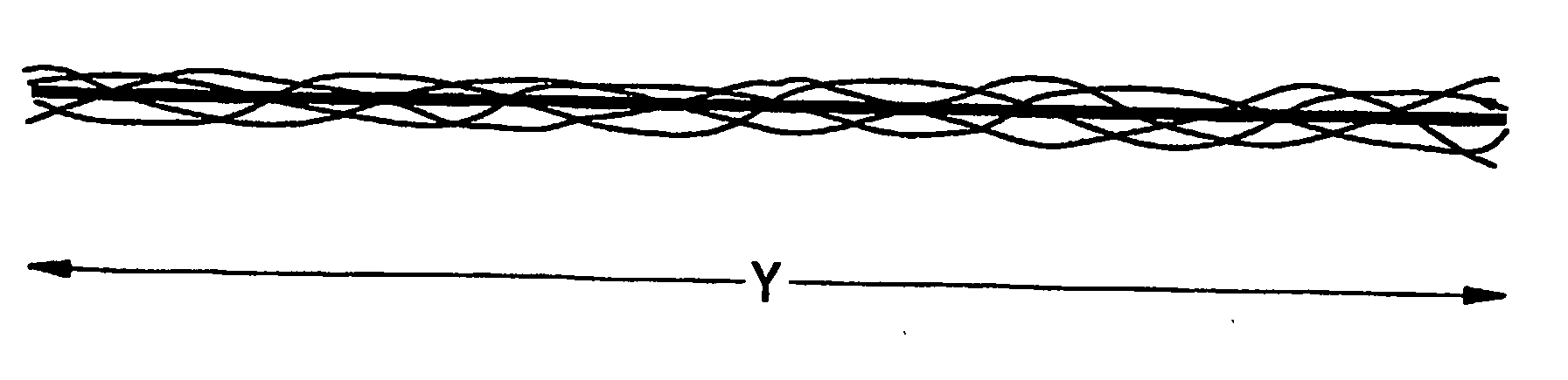

InactiveUS20070152378A1Improving fiber formation efficiencyEffective preventionMonocomponent polyurethanes artificial filamentElectric discharge heatingElectrospinningHigh pressure

The present invention relates to a method for producing nanofibers with an excellent fiber formation property, characterized in that: when nanofibers 3 having a thickness of a nano level are produced by electrostatically spinning a spinning liquid 1 of a polymer resin solution on a collector 8 through a nozzle 2 under a high voltage, a collector 8 with a heater is used as the collector. The present invention can greatly improve the fiber formation property of the nanofibers.

Owner:FINETEX TECH GLOBAL +1

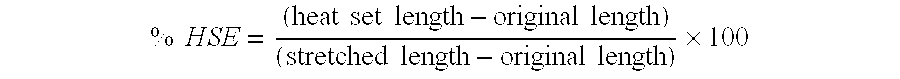

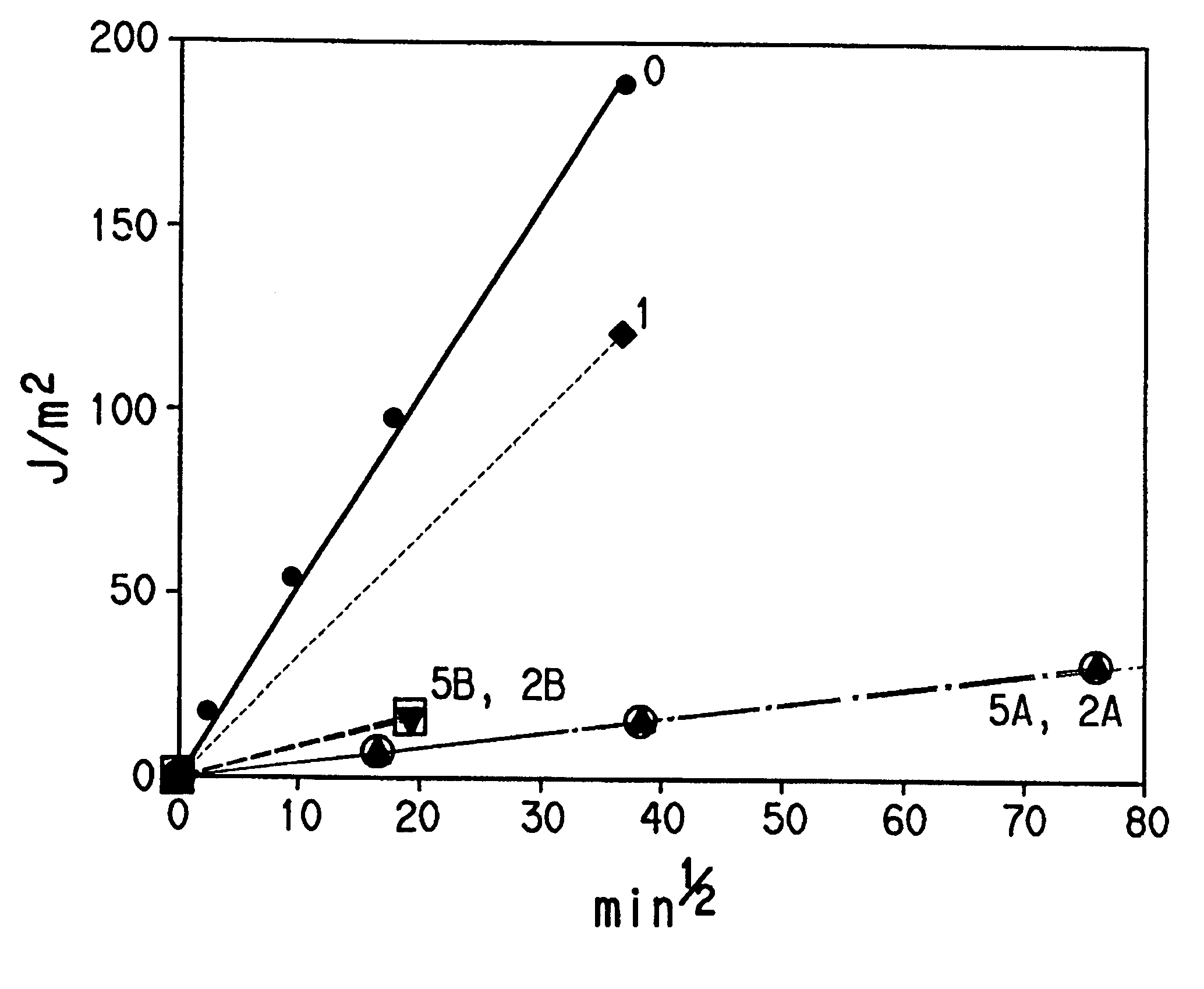

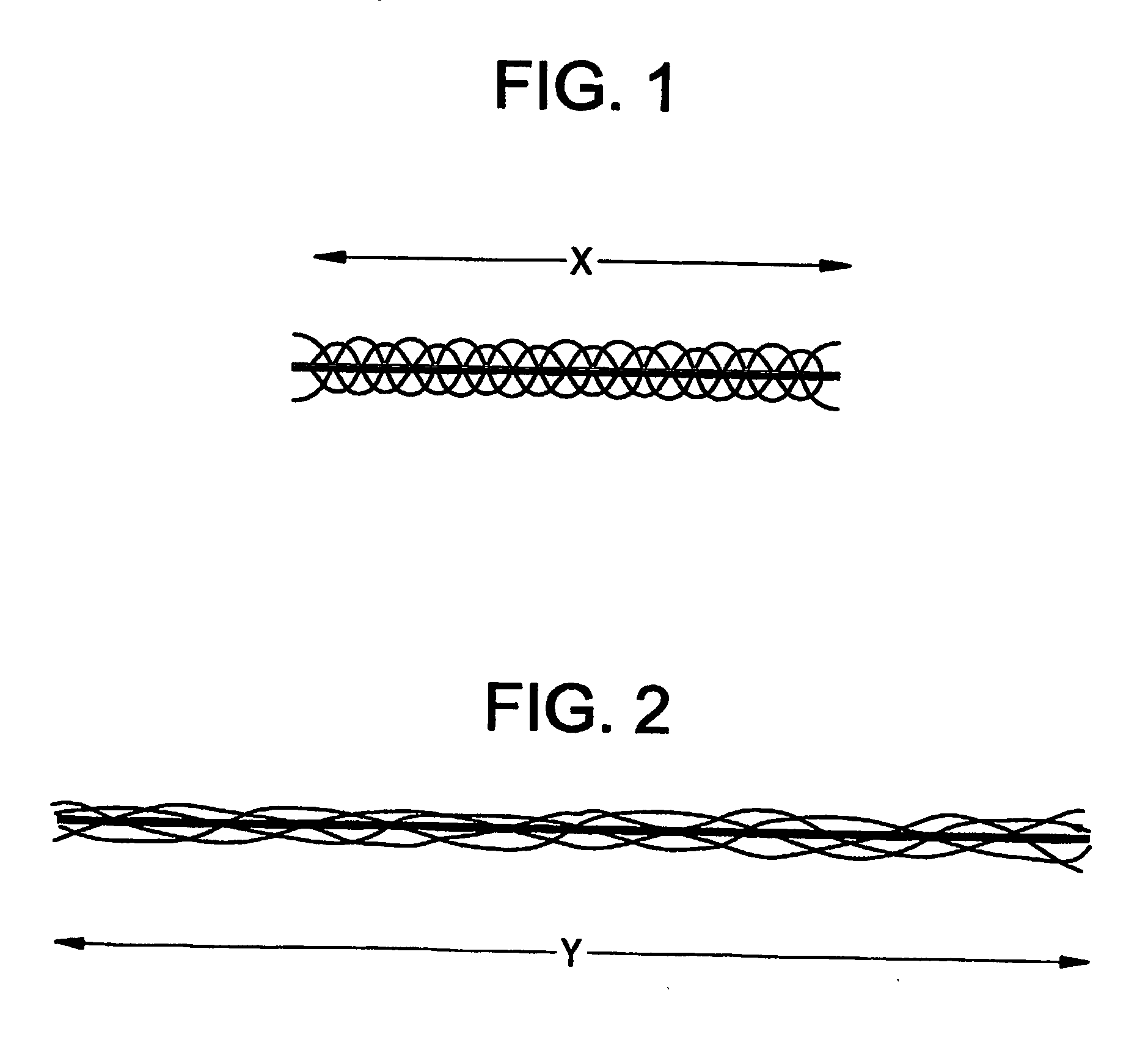

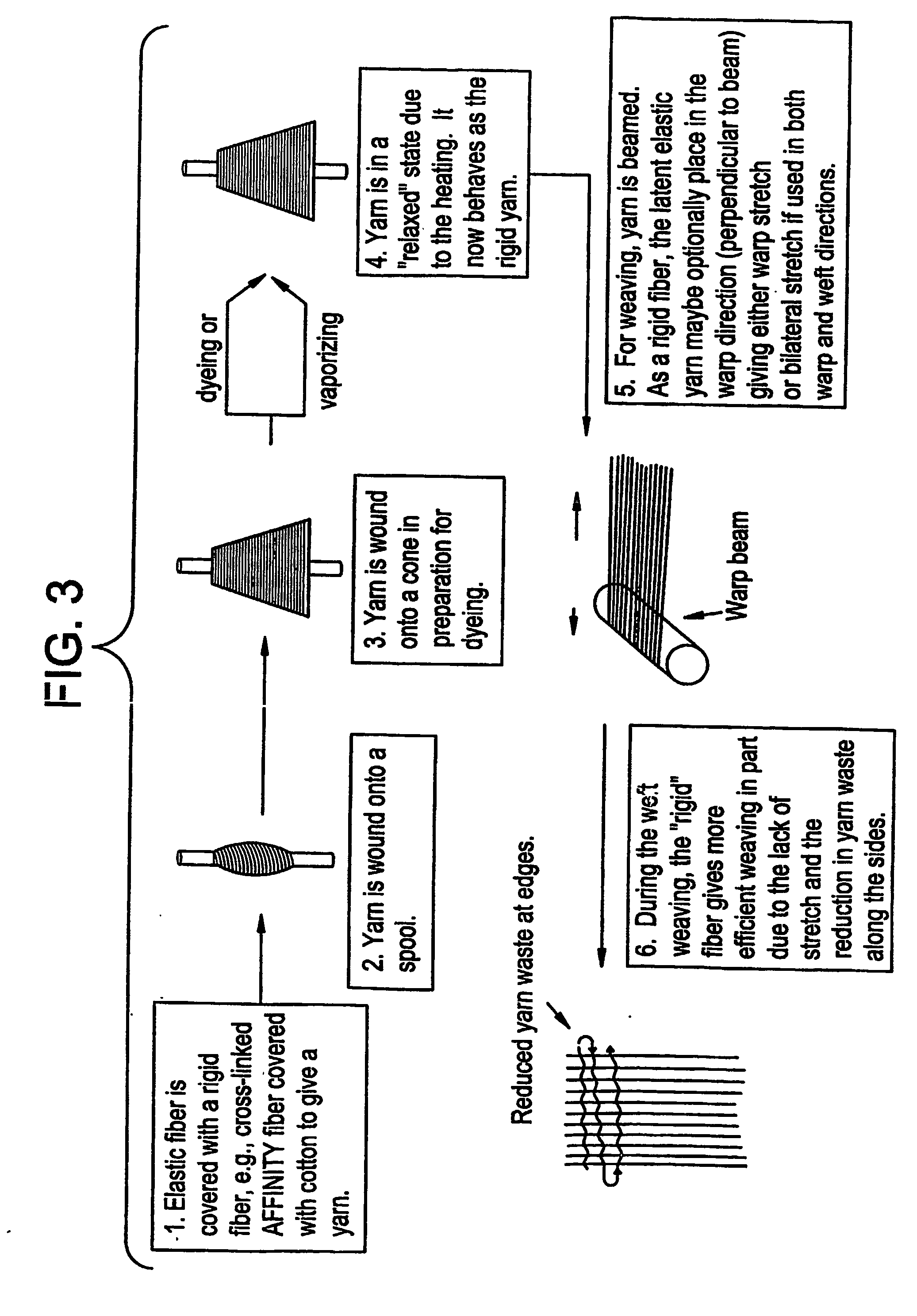

Reversible, heat-set, elastic fibers, and method of making and articles made from same

ActiveUS20050165193A1Reduce stepsReduce the amount requiredShrinkingMonocomponent polyurethanes artificial filamentFiberElastic fiber

A reversible, heat-set covered fiber is described, the covered fiber comprising: A. A core comprising an elastic fiber comprising a substantially crosslinked, temperature-stable, olefin polymer, and B. A cover comprising an inelastic fiber. The fiber is head set by a method comprising: (a) Stretching the covered fiber by applying a stretching force to the covered fiber; (b) Heating the stretched covered fiber of (a) to a temperature in excess of the crystalline melting point of the olefin polymer for a period of time sufficient to at least partially melt the olefin polymer; (c) Cooling the stretched and heated covered fiber of (b) to a temperature below the crystalline melting point of the olefin polymer for a period of time sufficient to solidify the polymer; and (d) Removing the stretching force from the covered fiber.

Owner:DOW GLOBAL TECH LLC

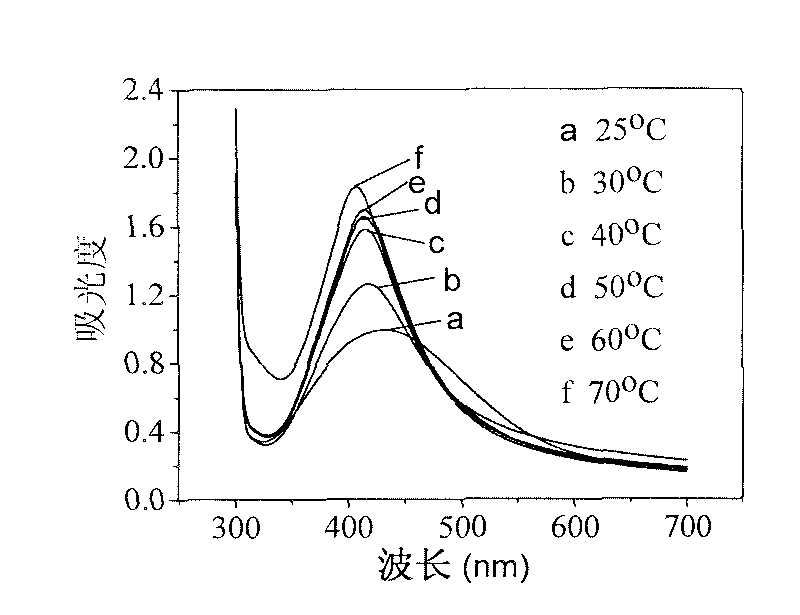

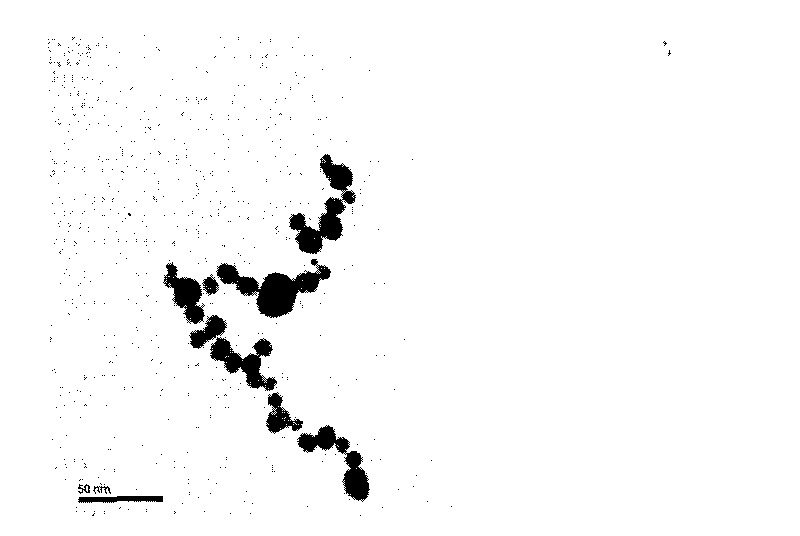

Antibacterial nano-silver composite polyurethane material and preparation method thereof

InactiveCN101760000ASimple methodEasy to operateMonocomponent polyurethanes artificial filamentArtifical filament manufactureSilver ionAqueous solution

The invention discloses an antibacterial nano-silver composite polyurethane material and a preparation method thereof. The silver salt solutions with different concentrations are slowly added in polyurethane stock solutions with different concentrations at the normal temperature, then stirred for 0.5-1 hour to gradually rise to the preset temperature, and then continuously stirred for 2-16 hours until full reaction, so as to obtain golden yellow nano-silver polyurethane solution; the reaction liquid stands after being cooled to obtain the antibacterial nano-silver composite polyurethane material, and then the antibacterial nano-silver composite polyurethane material is bottled in a sealed manner and can be used for spinning or film making; in the provided antibacterial nano-silver composite polyurethane material, the nano-sliver is regularly spherical, the grain size distribution is narrow, the dispersion is uniform, and the weight percent is 0.01 percent to 5.0 percent; and other reducing agents are not required to be added under the nonaqueous solution, the silver ions can be reduced into silver nanoparticles, therefore, the operation is simple, and the antibacterial nano-silver composite polyurethane material and the preparation method thereof are suitable for popularization and application.

Owner:LUDONG UNIVERSITY

Heat resistant high moisture vapor transmission thermoplastic polyurethane

ActiveUS7202322B2Good moisture permeabilityMonocomponent polyurethanes artificial filamentSynthetic resin layered productsFiberPolyether polyurethane

A thermoplastic polyether polyurethane having high moisture vapor transmission, high melting point and static dissipative properties is disclosed. The thermoplastic polyether polyurethane is prepared by reacting a hydroxyl terminated polyether intermediate, an aromatic chain extender glycol, and a polyisocyanate. The polymers formed are useful for melt-spun fibers, fabric coatings for breathable garments, house wrap, roofing membranes, and other applications requiring high vapor transmission and high melting points.

Owner:NOVEON INC

Polyurethane composite material releasing negative ion and preparation technique thereof

InactiveCN101457017AMonocomponent polyurethanes artificial filamentPolyureas/polyurethane adhesivesFiberChemical industry

The invention adopts nano-silica and a series of superfine powder body which can release anion and creates Anion series anion additive using a doping and blending method, which can be added to the polymer materials such as polyurethane fibers, plastics, dopes and additives, etc, and the modified polyurethane composite provided with releasing anion functions is successfully produced. The invention can be applied in the fields of Chemistry and Chemical industry, the spinning, the rag trade, the automotive trim, the health and the environment protecting, the nano-silica and the superfine powder which can release anions have a good dispersivity in the composite and no technical defaults exist in the processing process.

Owner:赵勐

Antibacterial nanofiber

InactiveUS20100120315A1Easy to handleMonocomponent polyurethanes artificial filamentNanotechBinding energyAtomic group

Disclosed is an antibacterial nanofiber which comprises a polymer having an electron-withdrawing group and / or an electron-withdrawing atomic group and has an average fiber diameter of not less than 1 nm and less than 1000 nm, wherein the ratio of the binding energy of the minimum unit of the polymer at 25° C. to the binding energy of the electron-withdrawing group and / or the electron-withdrawing atomic group contained in the minimum unit of the polymer at 25° C. is 0.13 or greater. The nanofiber has an antibacterial activity by itself, and therefore can exhibit an antibacterial activity without the need of adding any antibacterial agent.

Owner:NISSHINBO IND INC

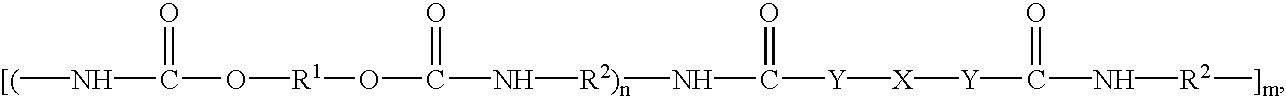

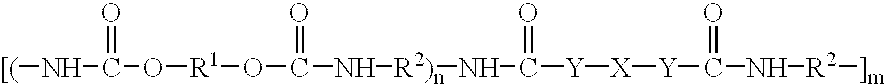

Polyurethane elastomers, method of producing them and their use

InactiveUS6458866B1Advantageous low-temperature behaviorImprove hydrolytic stabilityMonocomponent polyurethanes artificial filamentPhysical treatmentPolyurethane elastomerHeat deflection temperature

The invention concerns a polyurethane elastomer containing structural units of type (a), in which: the group -O-R1-O-is a macrodiol group with a molecular weight of approximately 500 to 10000, R2 is a bivalent aliphatic, cycloaliphatic and / or aliphatic-cycloaliphatic group; and X is a short-chain olefinically unsaturated group, Y is NH or O, n is an integer from 1 to 10 and m is an integer of at least 4. The invention also concerns a method of preparing this polyurethane elastomer which can be melt-spun to form fibres or melt-extruded to form foils. The fibres or foils can be exposed to energy-rich radiation such that crosslinking of the polyurethane occurs. Fibres according to the invention display superior properties in terms of textile-mechanical properties, in particular good tensile strength, elongation at tear, residual elongation and heat distortion temperature.

Owner:RHODIA SA

Thermoplastic polyurethanes comprising polytrimethylene ether soft segments

Provided are hermoplastic polyurethanes prepared from reactants comprising: (a) polytrimethylene ether glycol; (b) diisocyanate; (c) diol chain extender; and (d) monofunctional isocyanate reactive alcohol or amine. Also provided are methods of manufacturing the polyurethanes.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com