Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

200results about How to "Improve chlorine resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

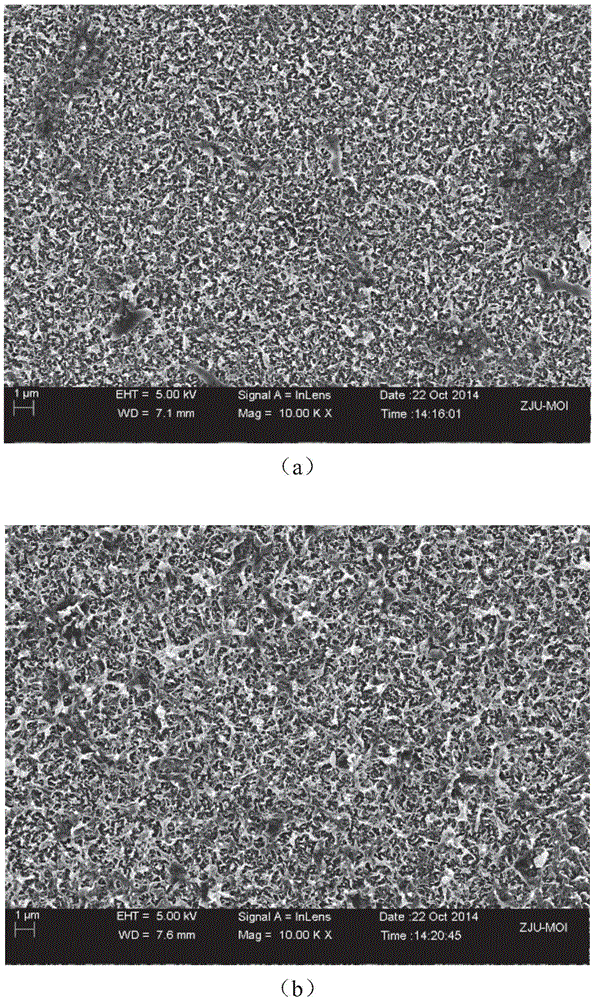

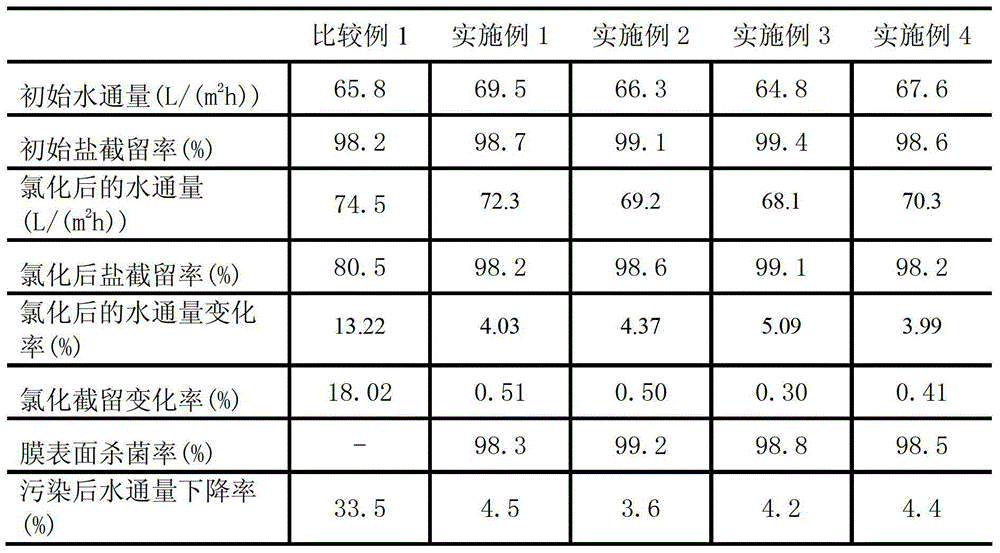

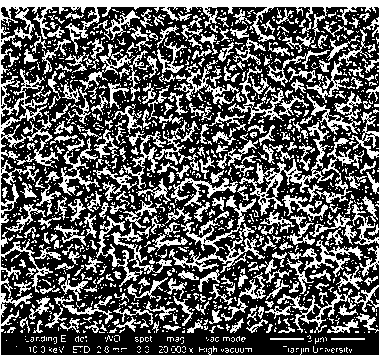

Grafted modified aromatic polyamide composite reverse osmosis membrane and preparation method thereof

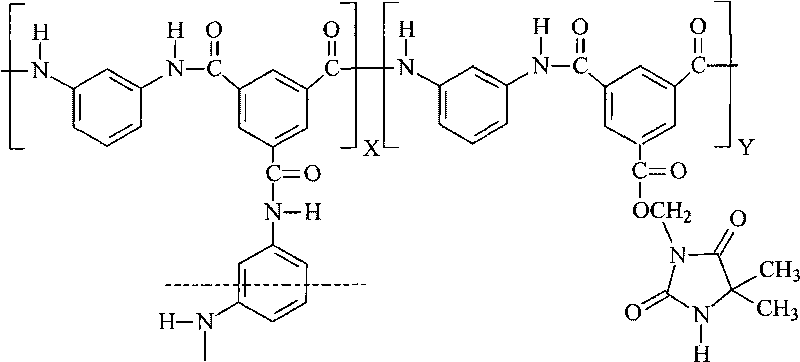

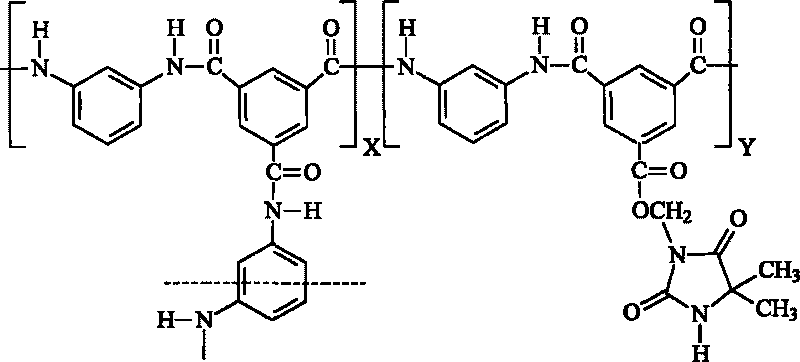

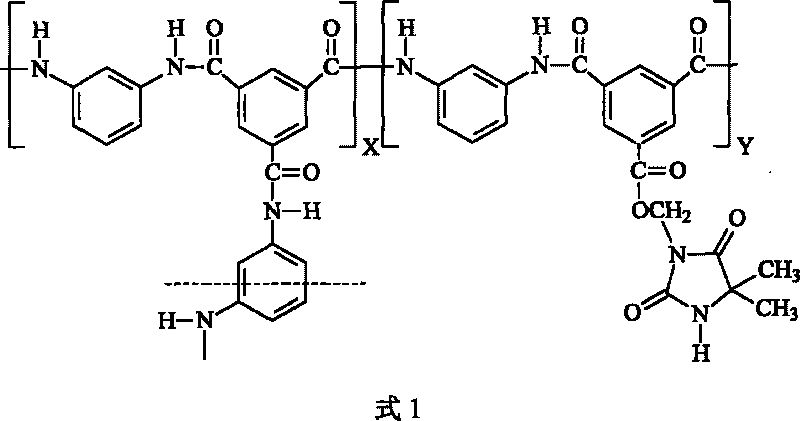

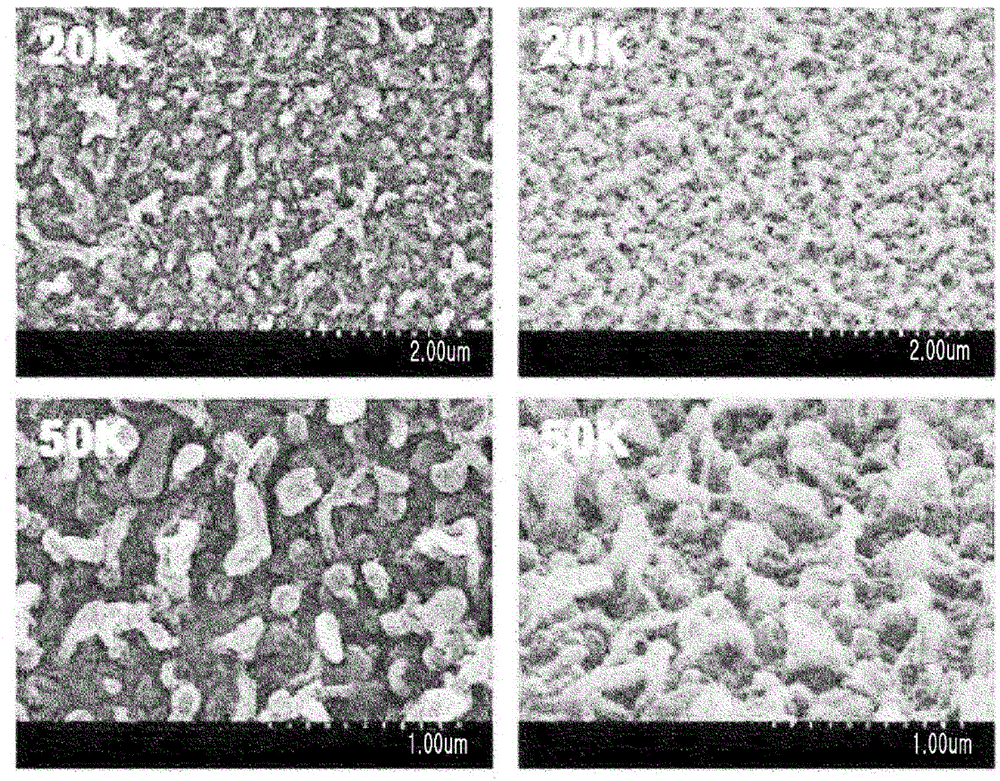

ActiveCN101695636AImprove chlorine resistanceSimple methodSemi-permeable membranesHydantoin derivativesPolysulfone membrane

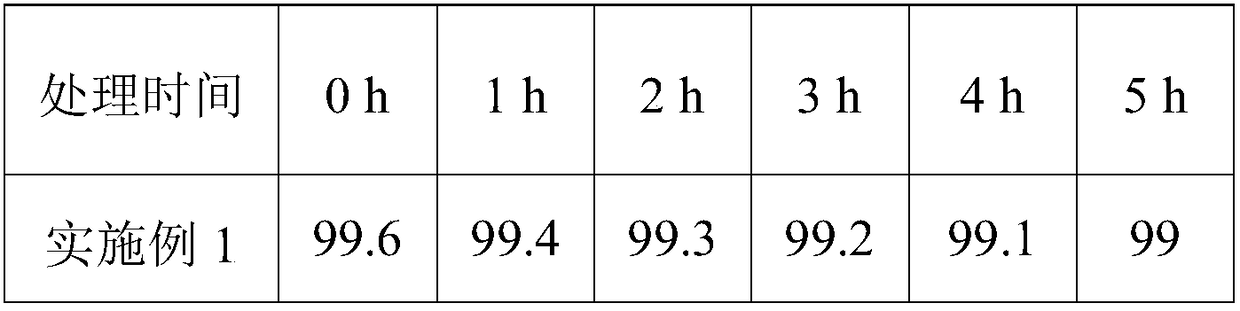

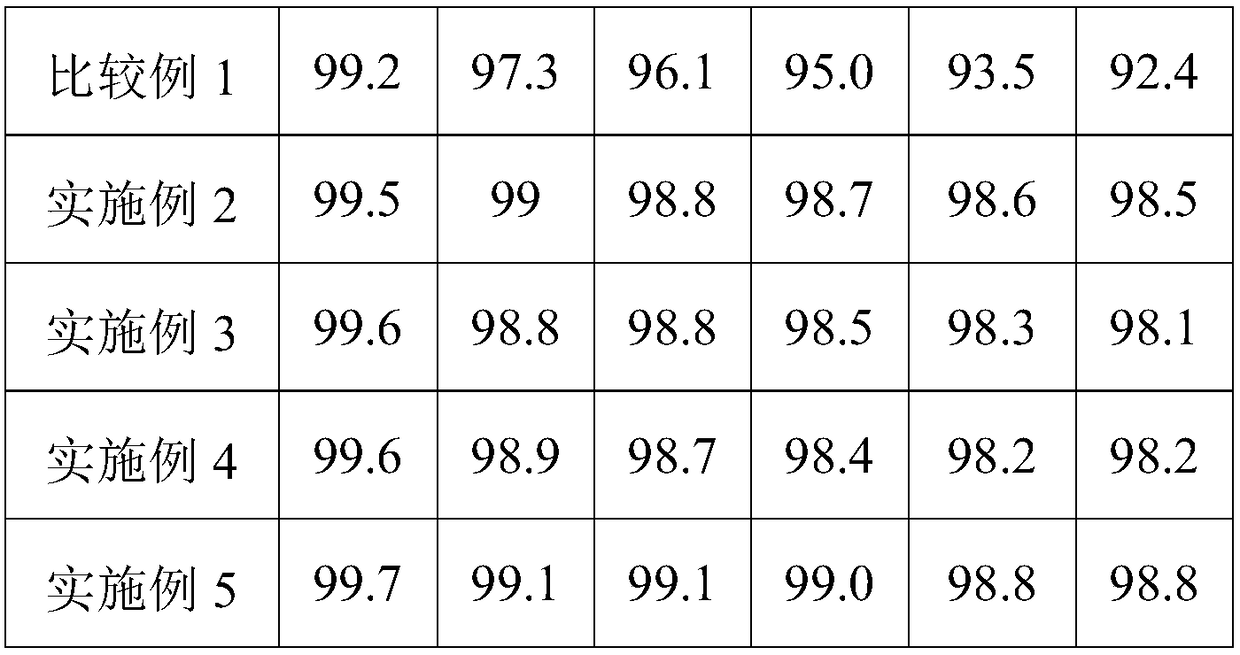

The invention discloses a grafted modified aromatic polyamide composite reverse osmosis membrane and a preparation method thereof, belonging to preparation technology of composite reverse osmosis membranes. The structural formula of the membrane is shown as follow. The preparation process comprises the following steps: taking a polysulphone membrane as a support membrane, preparing an aromatic polyamide composite reverse osmosis membrane to be grafted by an interfacial polymerization; enabling a graft modified solution containing 3-hydroxymethyl-5,5-dimethylhydantoin to contact the surface of the membrane to be grafted quickly for reacting, and conducting heat treatment to obtain the modified aromatic polyamide composite reverse osmosis membrane grafted with hydantoin derivatives. The invention has simple process, and the prepared membrane has the characteristics of good chlorine resistance and good microbial contamination resistance.

Owner:TIANJIN UNIV

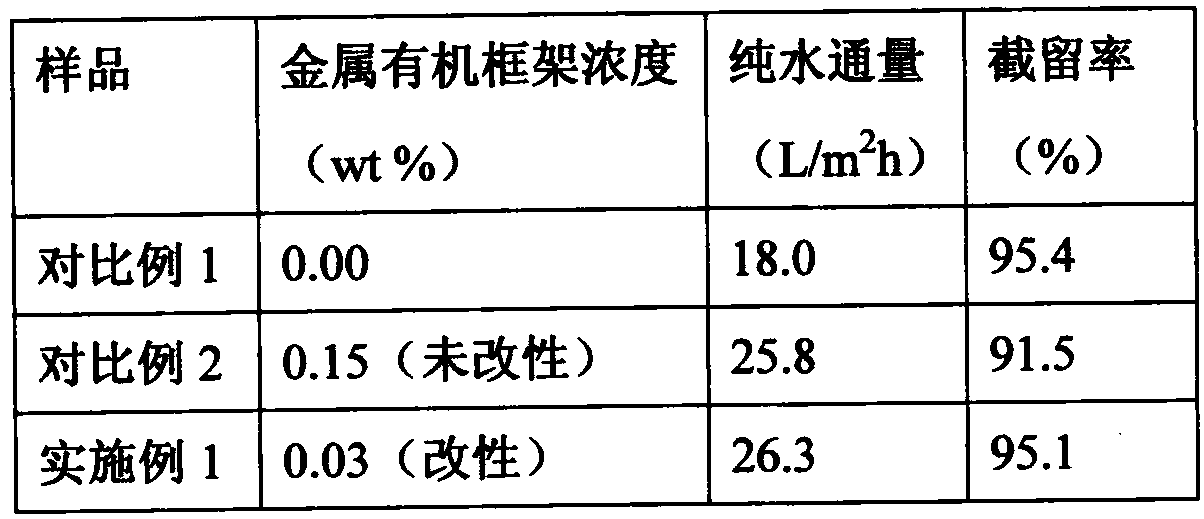

Cellulose acetate nanofiltration membrane and preparing method thereof

The invention discloses a cellulose acetate nanofiltration membrane and a preparing method thereof. The preparing method of the cellulose acetate nanofiltration membrane includes the steps that cellulose acetate serves as a raw material, an organic metal framework compound and a small molecule pore-forming agent serve as a mixed additive, the raw material and the mixed additive are dissolved through a solvent to prepare a cellulose acetate membrane casting solution, a dry and clean glass plate with a supporting layer is coated with the prepared membrane casting solution to form a plate nascent-state membrane or the prepared membrane casting solution and a medium with an inner fiber cavity are extruded through a spinneret plate to obtain a hollow fiber nascent-state membrane, the hollow fiber nascent-state membrane is solidified and subjected to heat treatment, and the cellulose acetate nanofiltration membrane is prepared. As the cellulose acetate nanofiltration membrane is prepared through the organic metal framework compound, the porosity factor of the cellulose acetate nanofiltration membrane is increased, and the water flux is improved; the amine-modified organic metal framework compound is introduced into the formula of the membrane casting solution of the cellulose acetate, the nanofiltration membrane can show charged positive electricity after cross-linking, separation of amino acid with positive charges and protein with positive charges can be promoted, and the reject rate of the nanofiltration membrane is increased.

Owner:INST OF CHEM CHINESE ACAD OF SCI

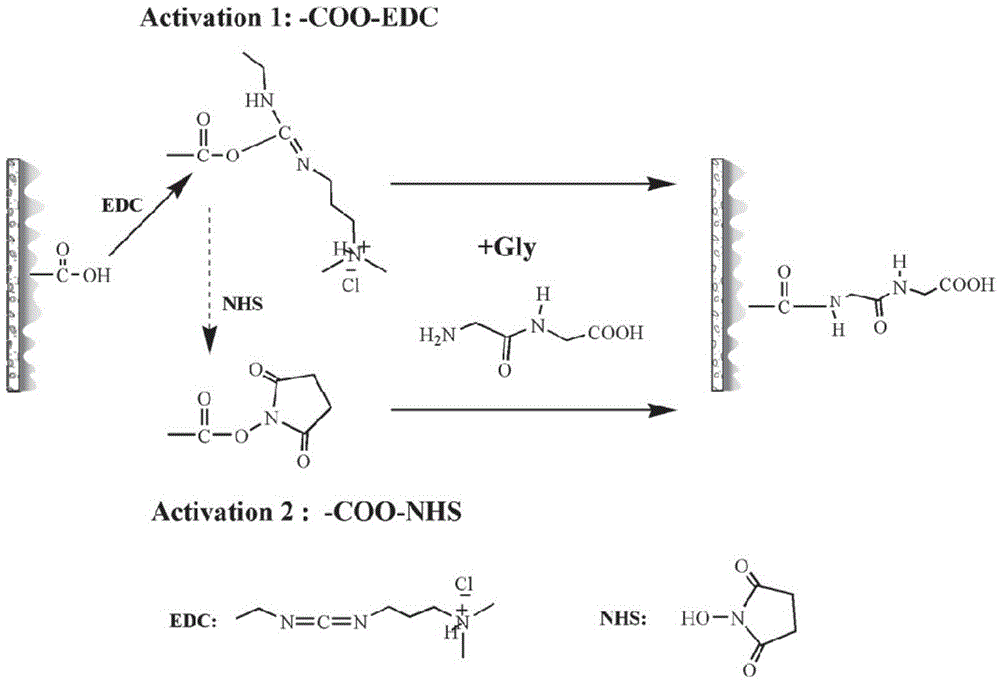

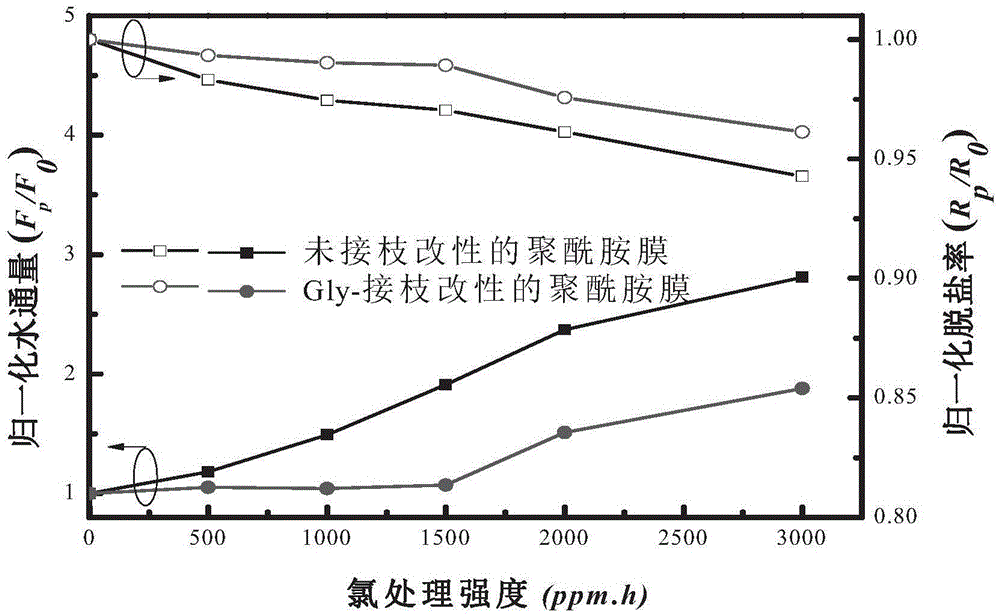

Polyamide reverse osmosis composite membrane having renewable chlorine resistance and preparation method thereof

The invention discloses a polyamide reverse osmosis composite membrane having renewable chlorine resistance and a preparation method thereof, wherein the preparation method comprises the steps: (1) a polyamide reverse osmosis original membrane having the surface with carboxyl is soaked in a catalyst and is subjected to surface activation; and (2) the membrane obtained after surface activation is soaked in a solution containing a graft material and is subjected to surface grafting, wherein the catalyst contains 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide, and the graft material is at least one of glycylglycine, glutamine and tyrosine. According to the preparation method, the surface of the polyamide reverse osmosis original membrane is introduced with aliphatic amide small molecules with the tail end being carboxyl, amide N-H in a structure is used as an sacrificial-layer functional group for preferentially undergoing a reaction with active chlorine, a body polyamide layer is protected, the chlorine resistance of the polyamide reverse osmosis composite membrane is strengthened, and at the same time, the chlorine resistance can be regenerated through reduction.

Owner:ZHEJIANG UNIV

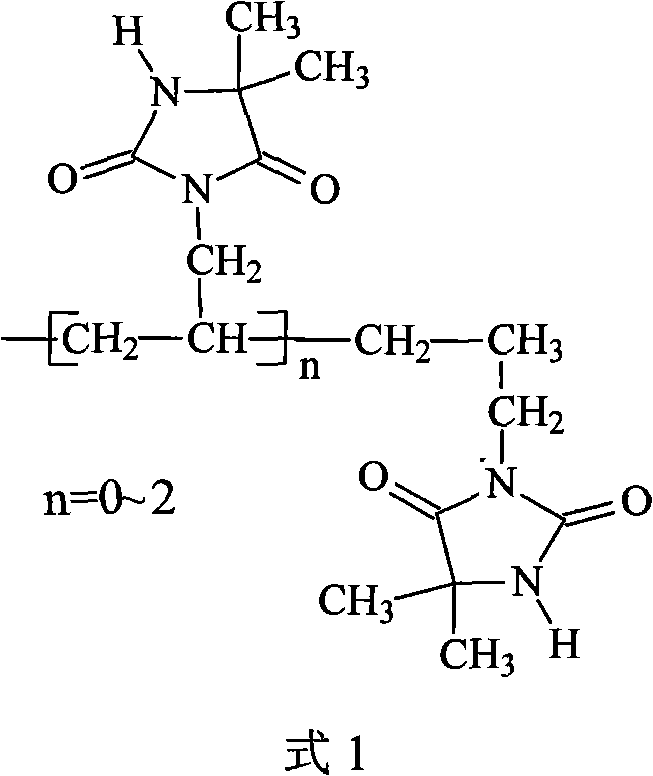

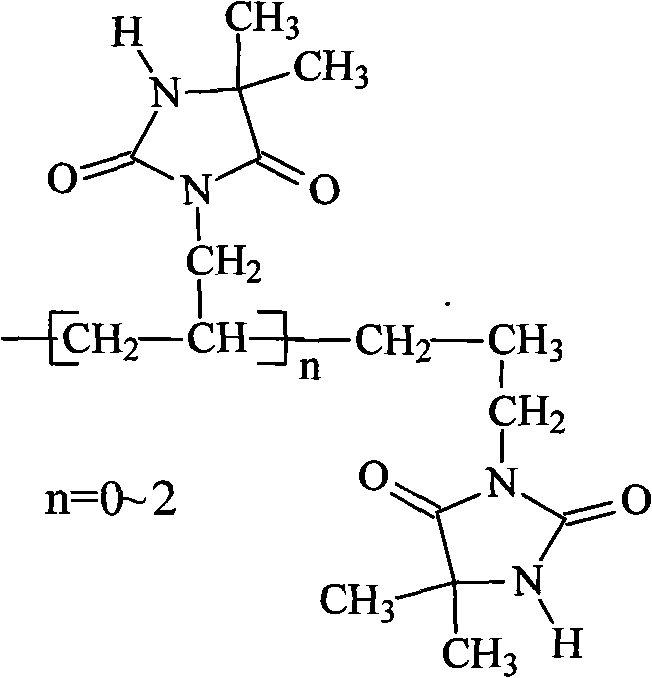

Aromaticpolyamide composite reverse osmosis membrane modified by graft polymerization and preparation method thereof

InactiveCN101816900ASimple processEasy to implementSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisMicrobial contaminationChemistry

The invention discloses an aromaticpolyamide composite reverse osmosis membrane modified by graft polymerization and a preparation method thereof, belonging to a preparation technology of composite reverse osmosis membranes. The surface of the aromaticpolyamide composite reverse osmosis membrane modified by graft polymerization is provided with a 3-allyl-5,5-dimethylhydantion polymer. The preparation method comprises the steps of: reacting 5,5-dimethylhydantion with allyl bromide to prepare the 3-allyl-5,5-dimethylhydantion polymer as a monomer; and introducing the 3-allyl-5,5-dimethylhydantion polymer into the surface of the aromaticpolyamide composite reverse osmosis membrane by adopting zaodiisobutyronitrile amidine hydrochloride as an initiating agent through using a graft polymerization method to prepare the aromaticpolyamide composite reverse osmosis membrane modified by graft polymerization. The invention has simple process; and the prepared aromaticpolyamide composite reverse osmosis membrane modified by graft polymerization has properties of resisting chlorine and preventing microbial contamination.

Owner:TIANJIN UNIV

Novel polyamide nanofiltration membrane and preparation method thereof

InactiveCN101829508AImprove hydrophilicityImprove chlorine resistanceSemi-permeable membranesAramidPolymeric membrane

The invention discloses a polymeric membrane and a preparation method thereof, in particular to a polyamide nanofiltration membrane and a preparation method thereof. The membrane comprises a porous support layer membrane and a polyamide ultrathin functional layer, wherein the polyamide ultrathin functional layer simultaneously contains sulfonyl amino, amide, carboxylic and sulfonic functional groups. The preparation method comprises the following step of compounding an aromatic polyamide ultrathin functional layer on a polysulfone support membrane through the interfacial polycondensation between aromatic polyhydric acyl chloride or other aromatic polyhydric acyl chloride mixture with modified acyl chloride groups on aromatic rings and a 4-amino piperidine water solution. The invention has the advantages that: the preparation method is novel and simple; and the nanofiltration membrane has better hydrophilcity and chlorine resistance and keeps higher removal ratio to bivalent ions while maintaining higher reflux. The invention has wide application in liquid separation industry.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

High-temperature resistance polyamide composite membrane and preparation method thereof

InactiveCN103111195AImprove high temperature resistanceGood acid and alkali resistanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceIndustrial waste water

The invention discloses a high-temperature resistance polyamide composite membrane and a preparation method thereof. The high-temperature resistance polyamide composite membrane is composed of a non-woven fabric layer, a porous supporting layer and a polyamide layer, wherein a porous supporting membrane material is prepared by adding one or more of a solubility high-temperature resistance polymer P1 and a commodity polymer P2 for preparation of a porous membrane material to a certain solvent and a pore-foaming agent and at least contains the P1. The polyamide composite membrane prepared by the method has very good high-temperature resistance performance and can be widely applied to water treatment composite membrane treatment devices needing to run at a high temperature in industries such as industrial wastewater treatment, petrochemical wastewater treatment, food, medicines and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Modified thin film composite reverse osmosis membrane and a process for preparation thereof

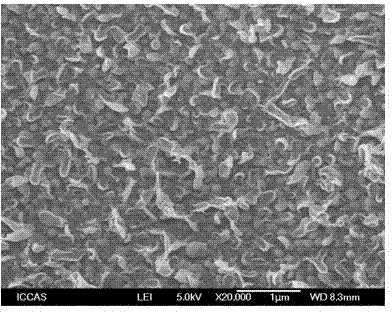

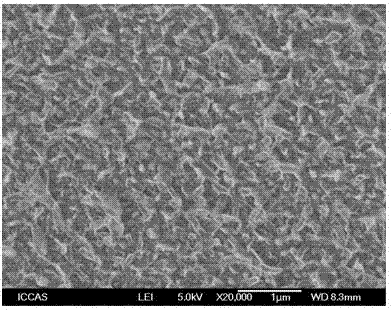

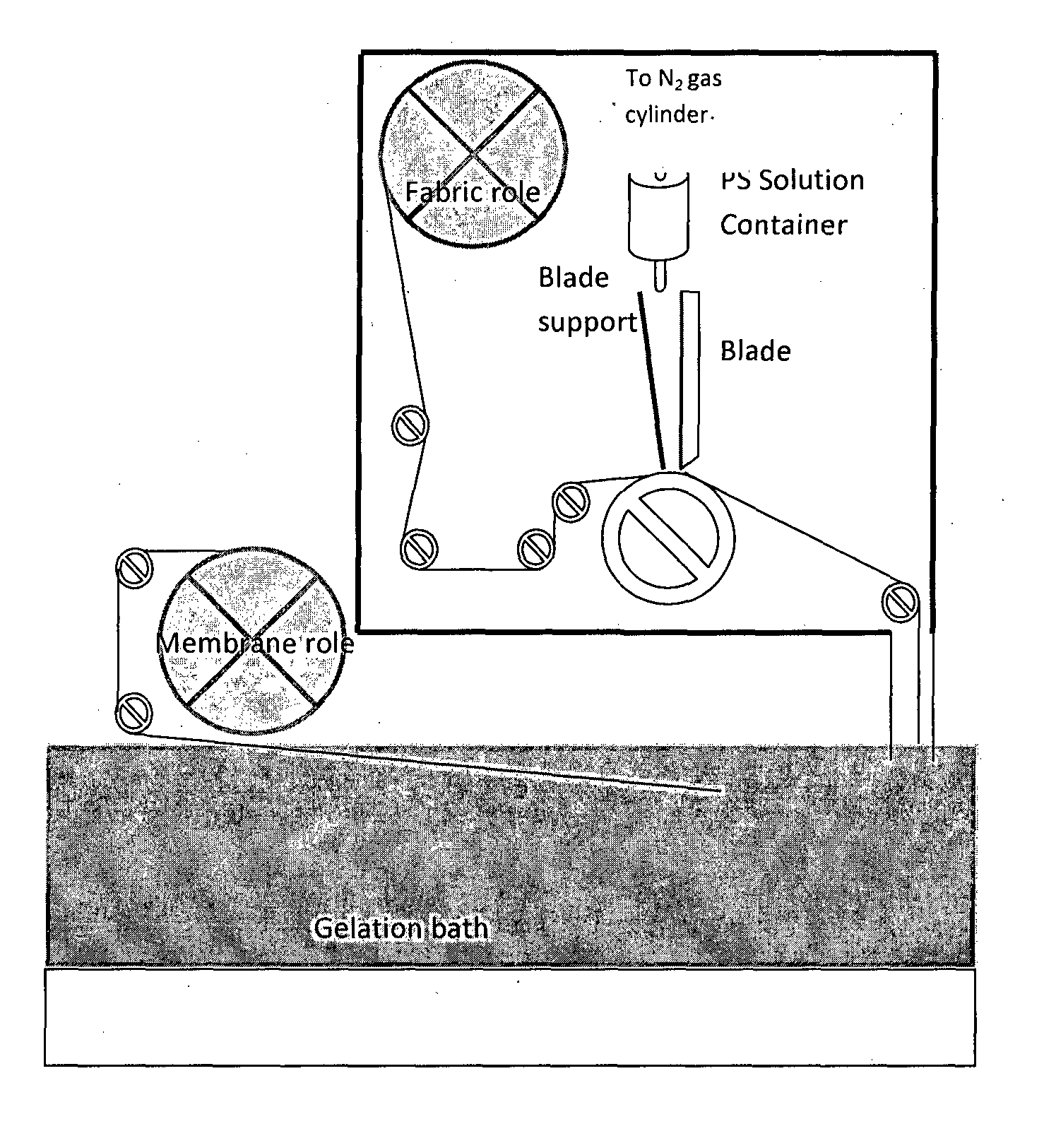

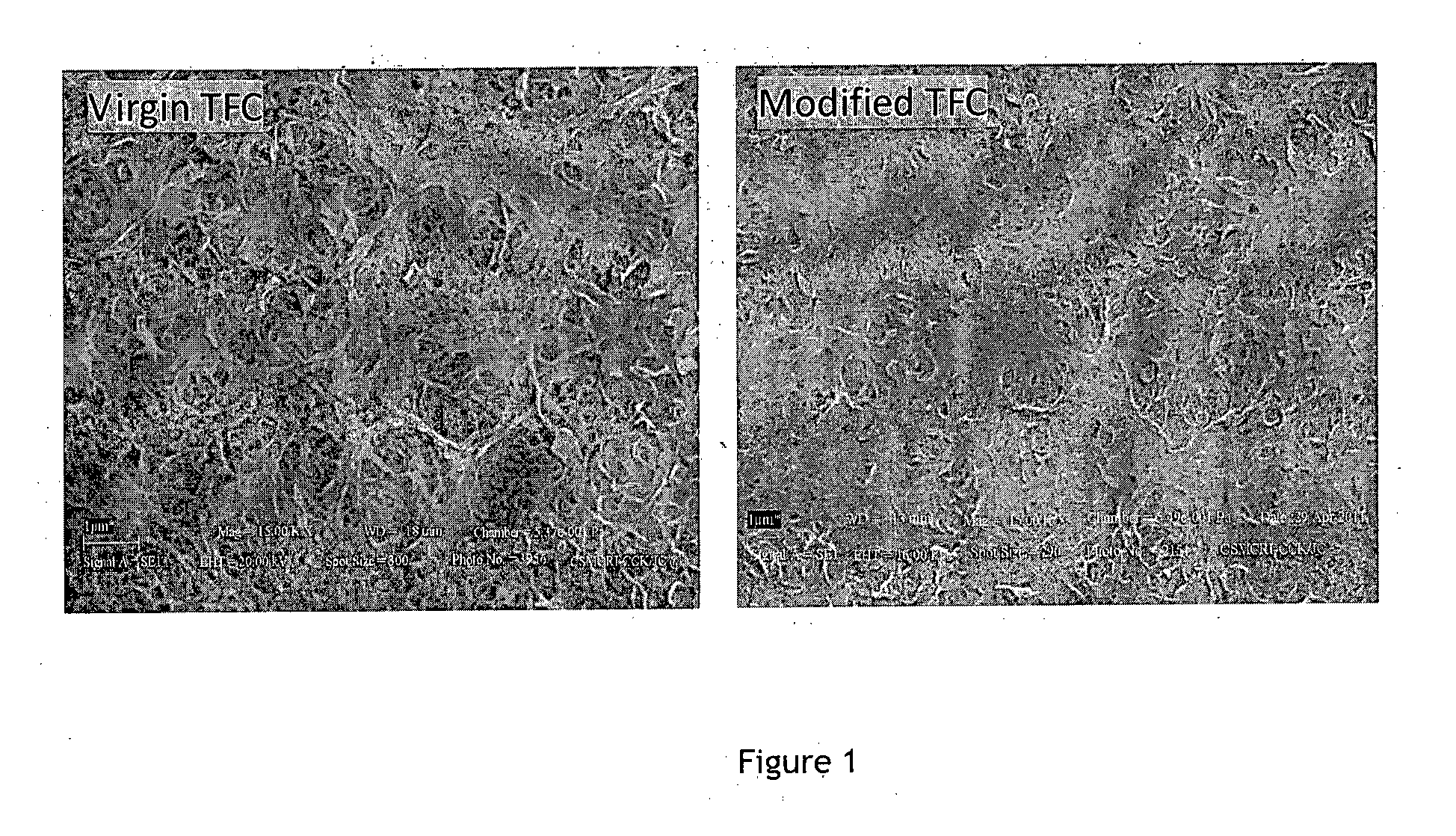

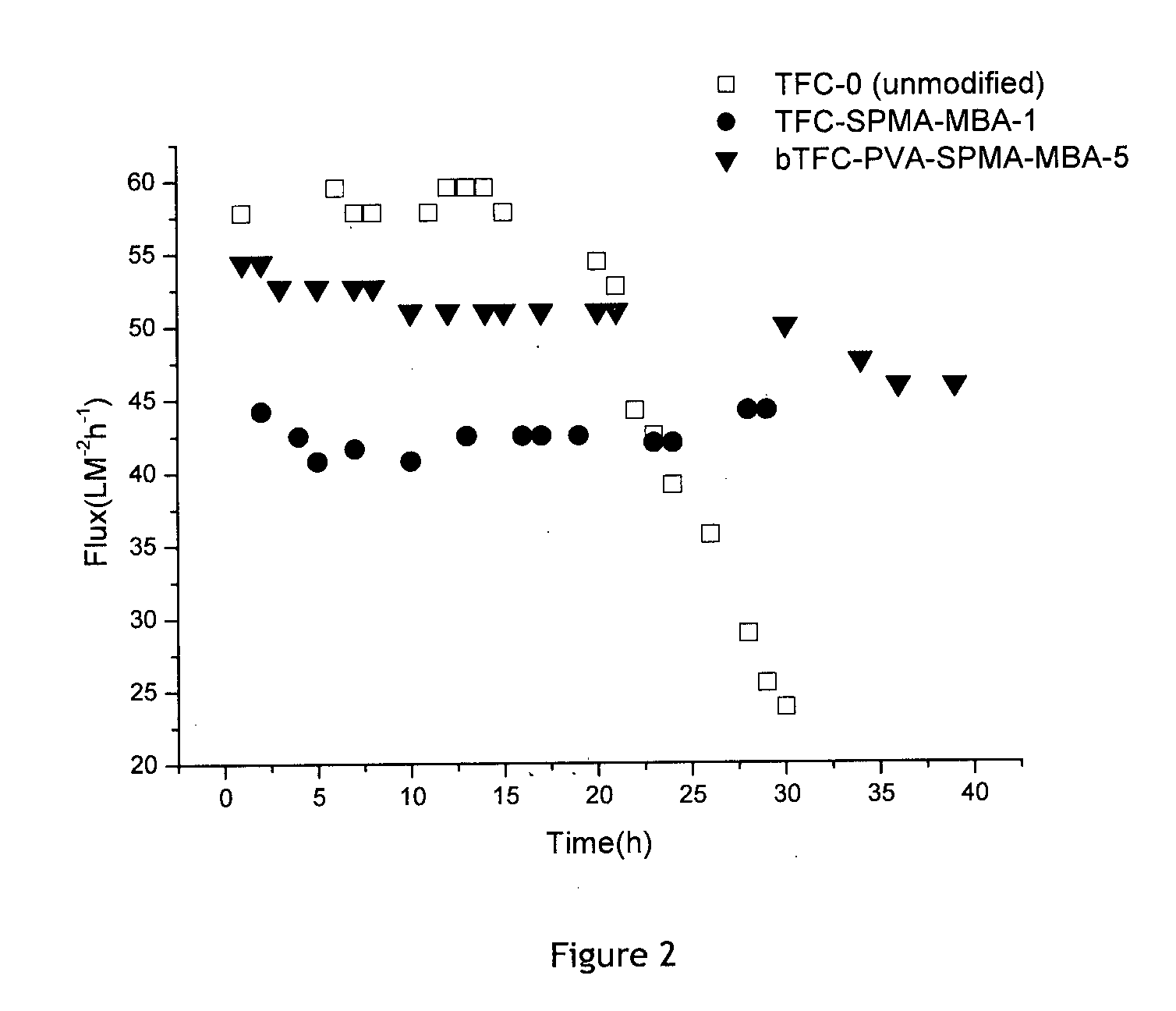

ActiveUS20150290595A1Improved resistant to foulingReduce pollutionMembranesSeawater treatmentUltrafiltrationHigh flux

The present invention relates to a complete process for preparation of high flux and salt rejection thin film composite (TFC) reverse osmosis (RO) membrane including process for preparation of support membrane for thin film, process for thin film coating of support membrane by in-situ interfacial polymerization between diamines and trimesoyl chloride, machine design, chemistry and details of process (engineering+chemistry+ambient) parameter at 1×100 sqm scale upgradable to a scale even 10-20 times higher. The produced membrane is characterized by 96% salt rejection and 48 LM-2H 1 flux with 2000 ppm sodium chloride solution at 250 psi pressure and 95% salt rejection and 46 LM2H 1 flux with 35000 ppm sodium chloride solution at 900 psi pressure. The present invention also relates to complete machine design for PSF ultrafiltration membrane casting and coating for TFC membrane production at commercial level.

Owner:COUNCIL OF SCI & IND RES

Chlorine-resistant composite nanofiltration membrane and preparation method thereof

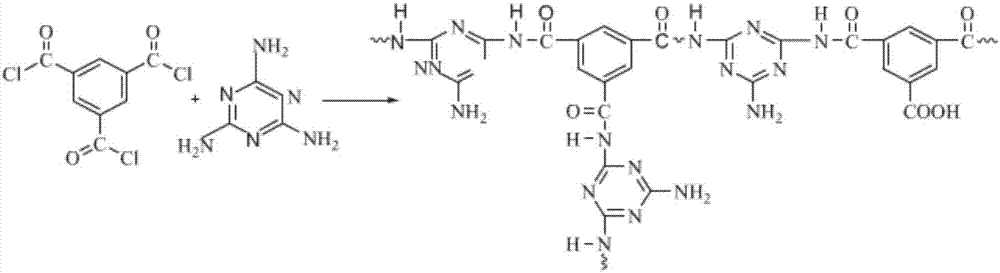

InactiveCN107029558AImprove chlorine resistanceAddresses the limitation that it cannot be used in environments with more oxidizing mediaSemi-permeable membranesMembranesPolyamideMelamine

The invention belongs to the technical field of membrane separation, and provides a chlorine-resistant composite nanofiltration membrane and a preparation method thereof. The chlorine-resistant composite nanofiltration membrane has charge performance, and comprises a separation function layer and a support layer, wherein the support player is positioned under the separation function layer. The chlorine-resistant composite nanofiltration membrane prepared by the preparation method provided by the invention can be a flat membrane and can also be a hollow fiber membrane. The chlorine-resistant composite nanofiltration membrane monomer has melamine of a triazine ring structure and is subjected to crosslinking treatment, so that the composite membrane has significantly higher chlorine resistance than a commercial polyamide composite membrane, the limitation that the current commercial nanofiltration membrane cannot be used in the environment including residual chlorine is broken, and thus complexity of pretreatment can be greatly reduced, and the application environment is wide.

Owner:DALIAN UNIV OF TECH

Method for preparing structure and performance controllable super nanofiltration membrane

InactiveCN104474927AImprove hydrophilicityIncrease water fluxSemi-permeable membranesElectricityHigh flux

The invention provides a method for preparing a structure and performance controllable super nanofiltration membrane. The method comprises the following steps: a pre-treatment step of a base membrane, a preparation step of an aqueous phase solution, a preparation step of an oil phase solution and a treatment step of the base membrane. According to the preparation method provided by the invention, a loose polyamide desalinated layer with adjustable height, electric neutrality on the surface and a high hydrophilic structure is formed by controlling the proportion and concentration of a reaction monomer, the active environment and temperature of the reaction monomer and the molecular weight and alcoholysis degree of a polymer and the like, so that the flux of the membrane is obviously improved. Meanwhile, the charge property of the membrane surface is remarkably reduced, and the high flux anti-pollution super nanofiltration membrane is prepared. The desalinization ratio of the prepared super nanofiltration membrane on NaCl is 10-90% and the effective reject rate for organic molecules with the molar weight ranging from 400 to 5000 is over 90% while high flux is guaranteed.

Owner:BEIJING ORIGIN WATER PURETECH CO LTD

Preparation method of modified metal-organic framework and composite nano-filtration membrane

InactiveCN108409981AImprove hydrophilicityGood dispersionSemi-permeable membranesFiltration membraneSurface layer

The invention discloses a preparation method of a modified metal-organic framework and a composite nano-filtration membrane. The preparation method of the modified metal-organic framework includes thesteps: modifying the surface of the metal-organic framework by the aid of plant polyphenol; forming a hollow structure in the metal-organic framework to obtain the modified metal-organic framework. The preparation method of the composite nano-filtration membrane containing the modified metal-organic framework includes the steps: loading the metal-organic framework into an aromatic polymer function surface layer of a porous supporting membrane by an interfacial polymerization method in situ to obtain the composite nano-filtration membrane. The modified metal-organic framework in the compositenano-filtration membrane is effectively loaded on the membrane and interacted with a surface layer polymer through a chemical bond, water flux, hydrophilcity and pollution resistance of the compositemembrane are improved, and structure stability and chlorine resistance of the composite nano-filtration membrane can be improved. The preparation method is simple and low in production cost and has good industrial production bases and wide application prospects, and the comprehensive performance of the membrane is remarkably improved.

Owner:DONGHUA UNIV

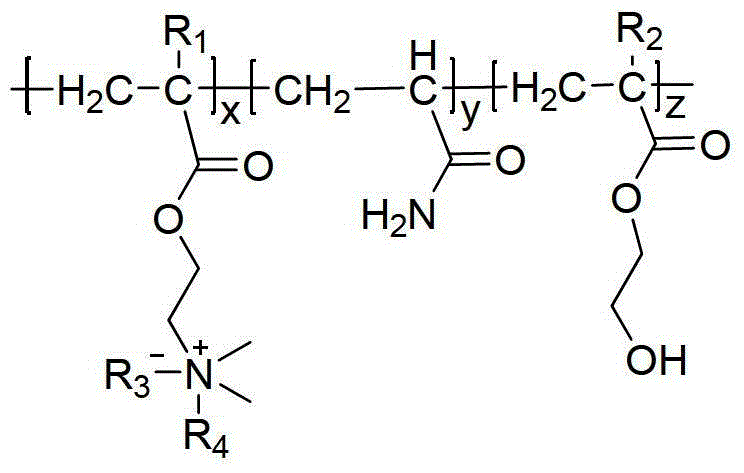

Pollution-resistant chlorine polyamide-resistant reverse osmosis composite membrane and preparation method thereof

InactiveCN103331110AImprove pollutionImprove chlorine resistanceSemi-permeable membranesGeneral water supply conservationPolyamideReverse osmosis

The invention discloses a pollution-resistant chlorine polyamide-resistant reverse osmosis composite membrane and a preparation method thereof. The preparation method comprises the following steps of 1, immersing a polyamide layer of a pollution-resistant chlorine polyamide-resistant reverse osmosis composite membrane raw material in an isopropanol aqueous solution, taking out it, and washing it by pure water, and 2, immersing the treated polyamide layer in a mixed solution, taking out it, putting it into an oven for a certain time, and washing the dried polyamide layer by pure water to obtain the pollution-resistant chlorine polyamide-resistant reverse osmosis composite membrane, wherein the mixed solution is a water solution containing a compound shown in the formula (I) and glutaraldehyde; and in the formula (I) , R1 represents H or -CH3, R2 represents H or -CH3, R3 represents Cl, Br or I, R4 represents -CH3 or -C6H5, X is in a range of 1-100000, Y is in a range of 1-100000 and Z is in a range of 1-100000. The pollution-resistant chlorine polyamide-resistant reverse osmosis composite membrane has high pollution resistance and chlorine resistance. The preparation method has the simple processes.

Owner:四川华创智诚工程设计咨询有限责任公司

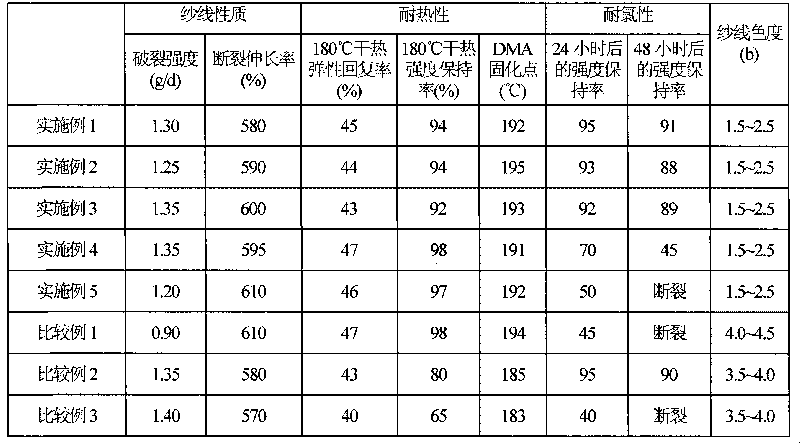

High heat and chlorine resistant polyurethaneurea elastic fiber and preparation of thereof

ActiveCN101724936AImprove heat resistanceImprove chlorine resistanceMonocomponent polyurethanes artificial filamentMonocomponent polyureas artificial filamentFiberPolyester

Owner:TAEKWANG IND CO LTD

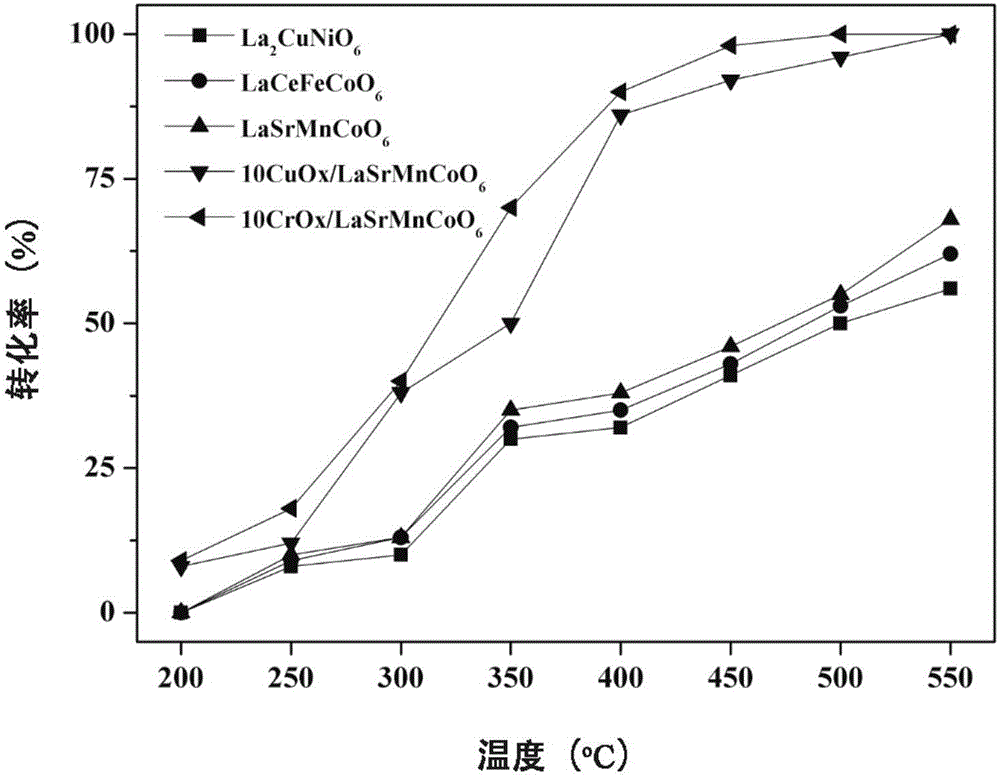

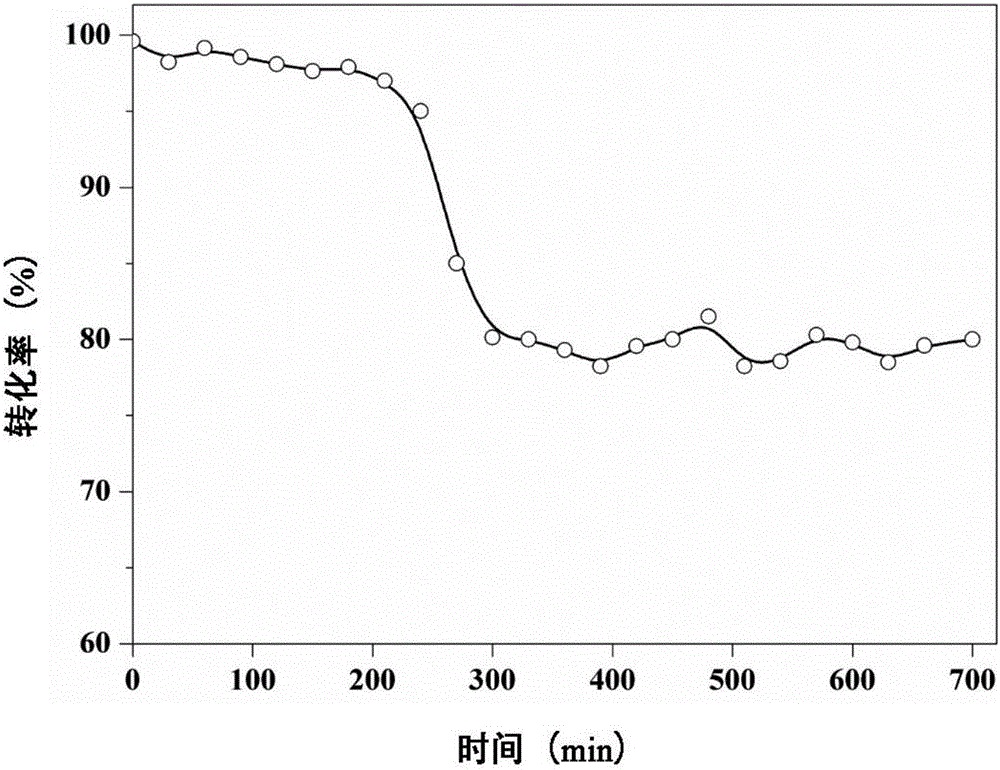

Double-perovskite composite metal oxide catalyst and preparation method and application thereof

ActiveCN106475105AThe synthesis method is simpleLow priceGas treatmentHeterogenous catalyst chemical elementsReaction temperatureTemperature resistance

The invention discloses a double-perovskite composite metal oxide catalyst and a preparation method and application thereof and belongs to the technical field of atmospheric pollution treatment. The condensed structural formula of the double-perovskite composite metal oxide catalyst is A2B2O6, wherein A is La, Sr or Ce, and B is Mn, Fe, Co, Cu or Ni. The double-perovskite composite metal oxide catalyst has the advantages that the catalyst is excellent in high temperature resistance, water resistance and chlorine resistance and applicable to effective degradation of CVOCs under an industrial high-temperature environment; the catalyst can achieve complete oxidization of industrial typical CVOCs (1,2-dichloroethane) under reaction temperature of 500-550 DEG C, reaction air speed of 20000-30000h<-1> and oxygen concentration of 10-20%; meanwhile, by regulating the loading capacity of transition metal oxide, the oxidizing efficiency of the catalyst can be increased effectively, and the selectivity of the reaction product CO2 can be increased greatly. The preparation method of the catalyst is simple, cheap in raw material and promising in industrial application prospect.

Owner:XI AN JIAOTONG UNIV

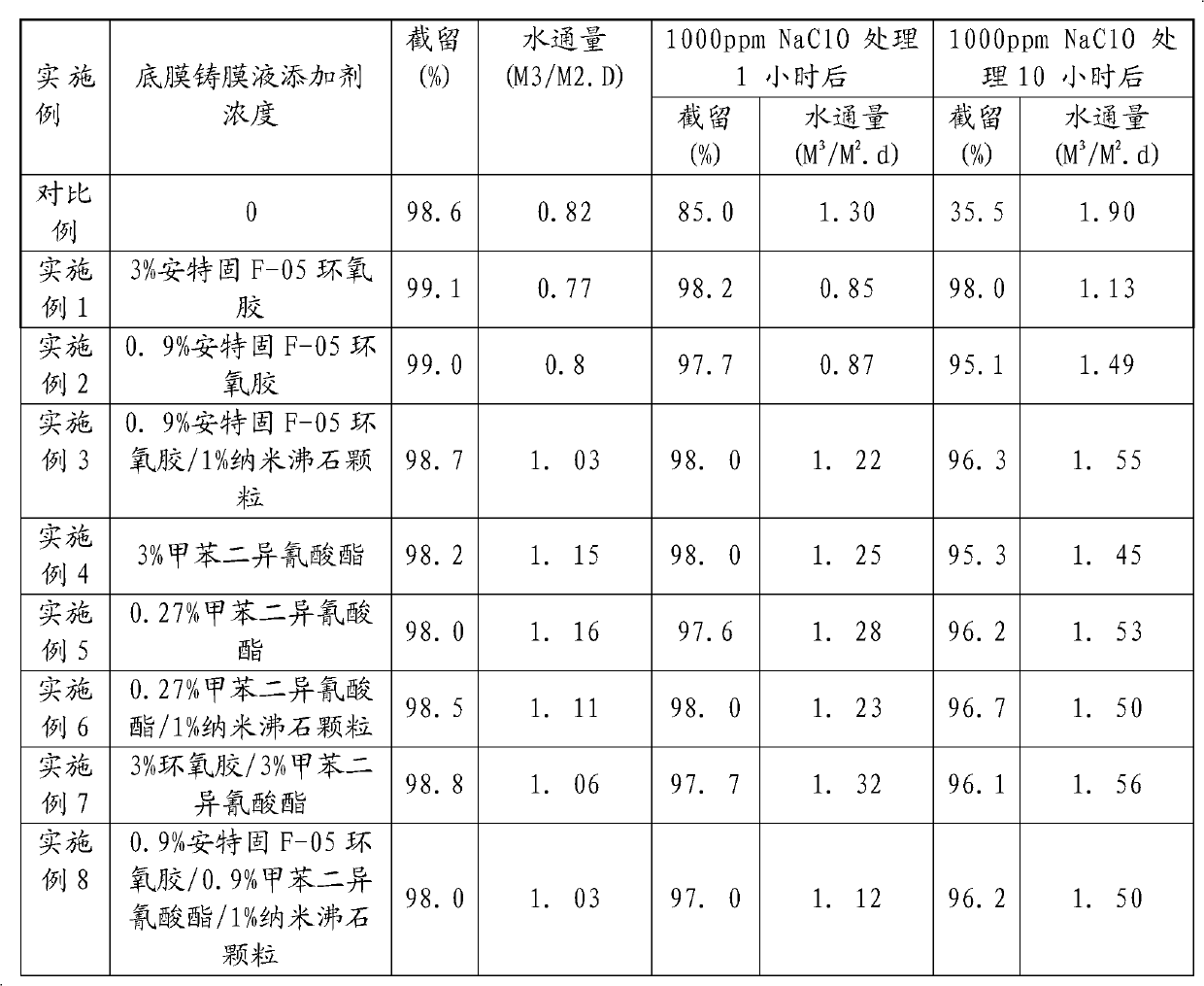

Method for manufacturing anti-chloride polyamide reverse osmosis composite membrane with high flux

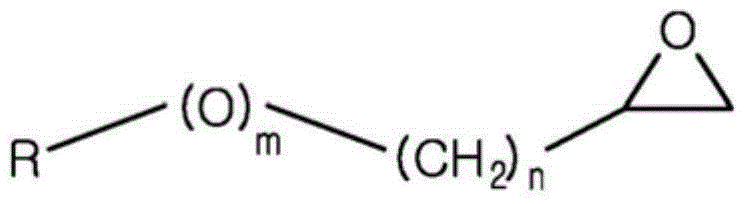

InactiveCN102179191AGood adhesionImprove chemical resistance and stabilityReverse osmosisWater/sewage treatment bu osmosis/dialysisEpoxyReverse osmosis

The invention relates to a method for manufacturing an anti-chloride polyamide reverse osmosis composite membrane with high flux, comprising the following steps of: adding one or two of a compound containing epoxy group and a compound containing isocyanide acid group in a basement membrane casting liquid; manufacturing a support basement membrane with a universal phase inversion method; and then compounding a layer of polyamide reverse osmosis composite membrane on the surface of the obtained support basement membrane with an interface polymerization method. The anti-chloride performance and water flux of the obtained composite membrane are increased. In order to further increase the water flux of the polyamide reverse osmosis composite membrane, nano-particles are further added in the basement membrane casting liquid, and the nano-particles are dispersed in the basement membrane casting liquid. The nano-particles can greatly enhance the roughness of the basement membrane surface and increase the valid surface area of the membrane, thereby being capable of increasing the water flux of the composite membrane.

Owner:NANJING DELNAMEM TECH CO LTD

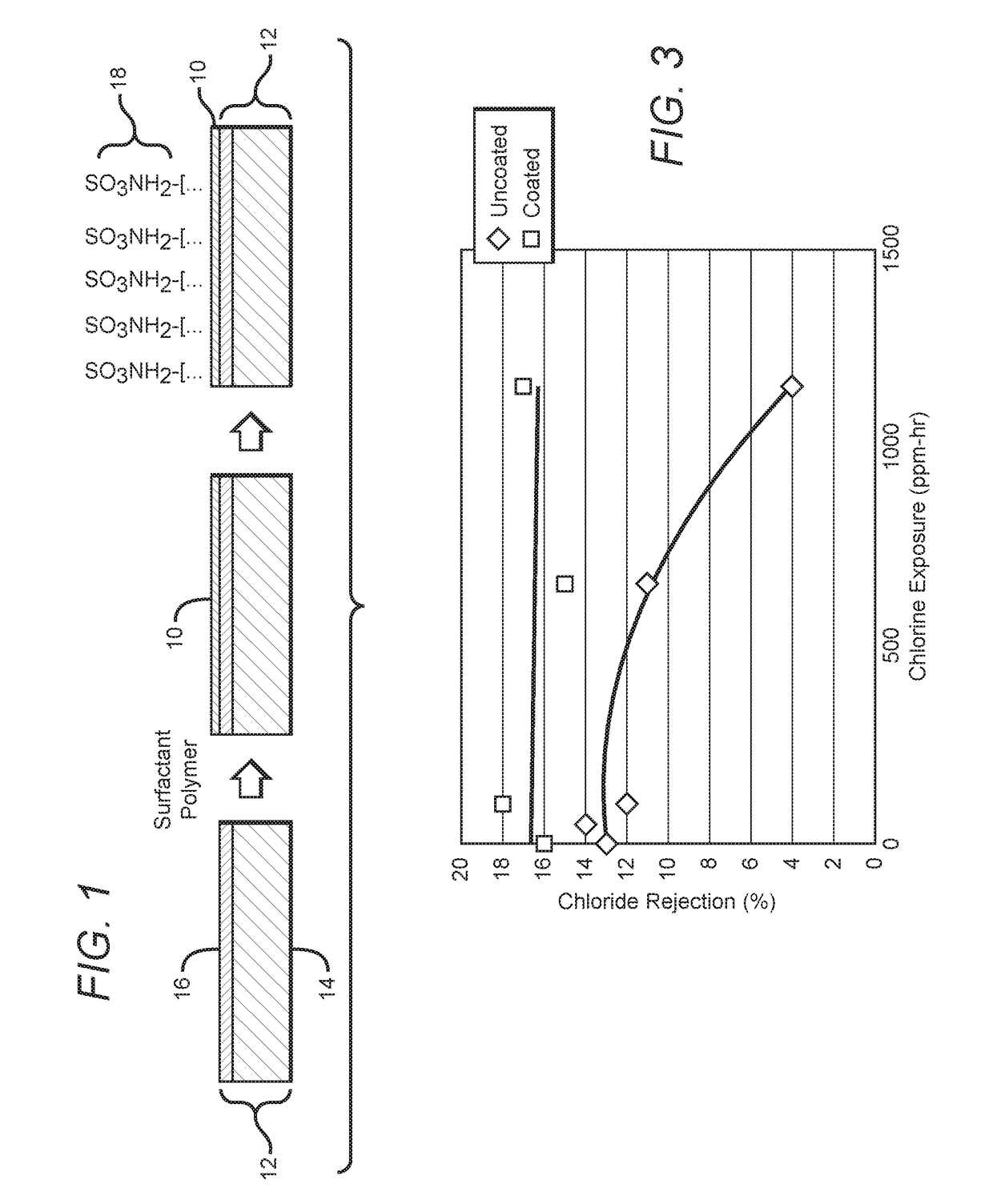

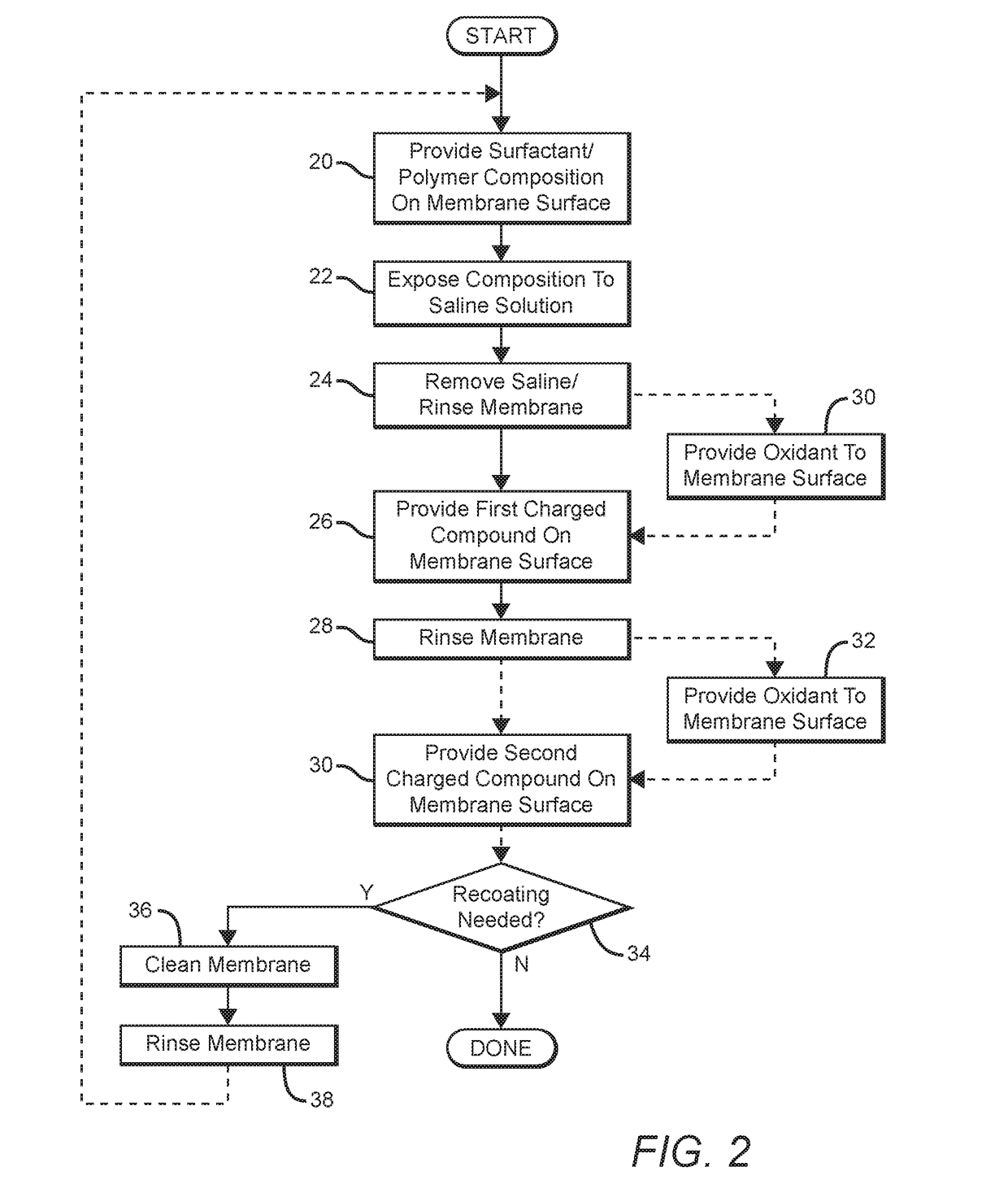

High flux, chlorine resistant coating for sulfate removal membranes

ActiveUS20180369756A1Improve throughputImprove chlorine resistanceMembranesSeawater treatmentFiltration membraneSulfate

A filtration membrane coating comprising a hydrophilic polymer, a surfactant, and one or more charged compounds, each containing one or more sulfonate functionalities and one or more linkable functionalities selected from the group consisting of amine, monochlorotriazine, and dichlorotriazine. The hydrophilic polymer and surfactant form a thin primer layer which is also superhydrophilic. The primer layer improves flux, and enables improved adhesion of the one or more charged compounds, which form a charged dye layer on top of the primer layer when enhances rejection of charged divalent ions. The coating can be applied while the membrane is packaged in its final form, such as in a spiral wound or other configuration.

Owner:TELEDYNE SCI & IMAGING

Surface grafting modified aromatic polyamide composite reverse osmosis membrane and preparation method thereof

The invention discloses a surface grafting modified aromatic polyamide composite reverse osmosis membrane and a preparation method thereof. The surface grafting modified aromatic polyamide composite reverse osmosis membrane is formed by the connection of carboxyl groups on the surface of the aromatic polyamide composite reverse osmosis membrane and one primary amine of ethidene diamine and the connection of another primary amine of the ethidene diamine and hydroxymethyl groups of imidazolidinyl urea. The preparation method of the surface grafting modified aromatic polyamide composite reverse osmosis membrane comprises the following steps of: activating the carboxyl groups on the surface of the membrane by 1-(3-dimethylamino propyl group)-3-ethyl carbodiimide hydrochloride and N-hydroxyl succinimide, so that the carboxyl groups react with the primary amine of the ethidene diamine, and the ethidene diamine is grafted to the surface of the membrane; and activating imidazolidinyl urea molecules according to the same process, so that the imidazolidinyl urea molecules react with the another primary amine of the ethidene diamine molecule grafted to the surface of the membrane, thus obtaining the surface grafting modified aromatic polyamide composite reverse osmosis membrane. The preparation method has the advantages of mild reaction conditions and simple process; and the prepared surface grafting modified aromatic polyamide composite reverse osmosis membrane has high properties of biological pollution resistance and chlorine-resistance.

Owner:TIANJIN UNIV

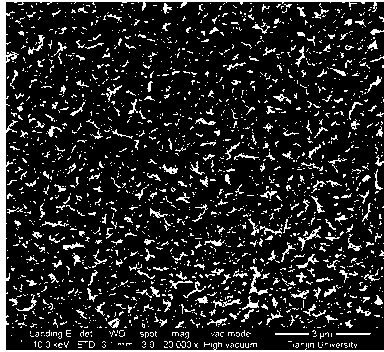

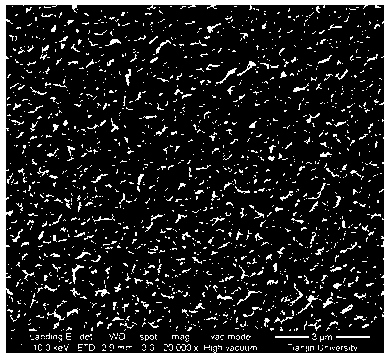

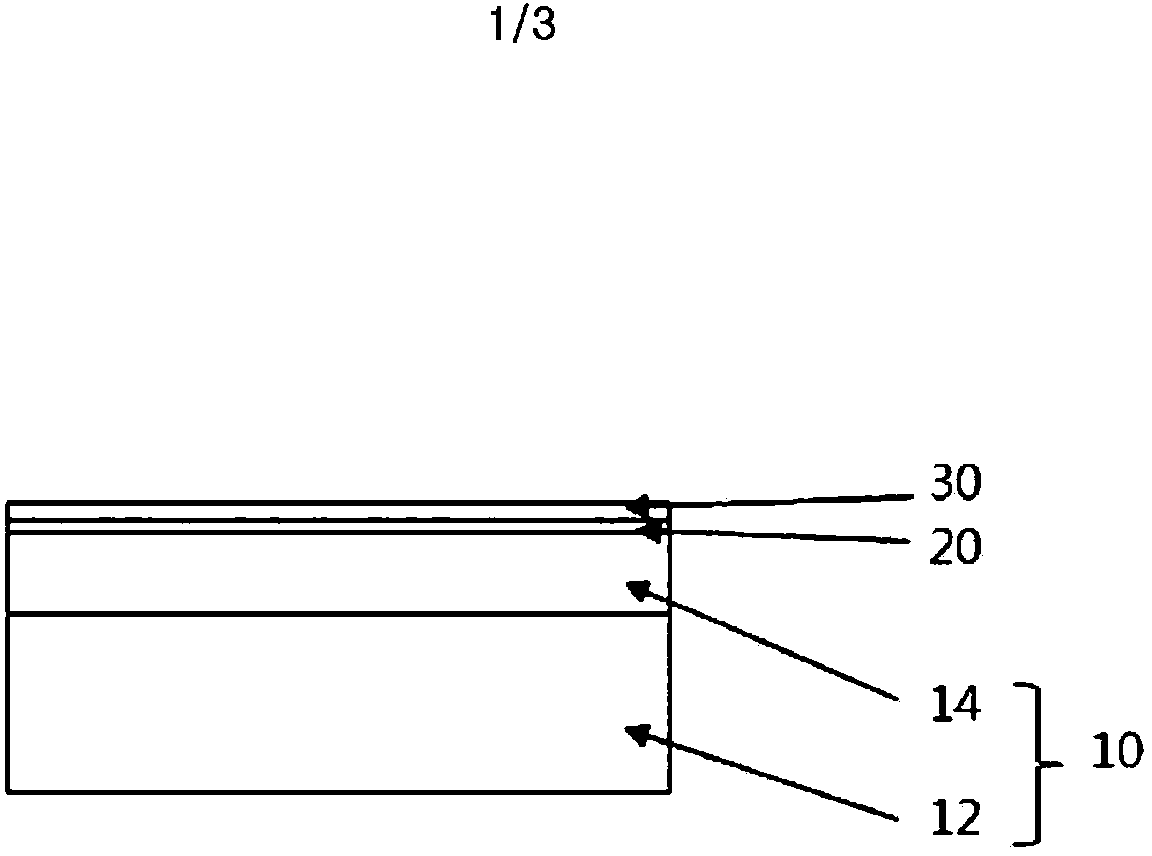

Graphene oxide coating modified aromatic polyamide reverse osmosis membrane and preparation method thereof

InactiveCN105833743AProtect the active reaction siteImprove hydrophilicitySemi-permeable membranesWorking pressurePolyamide

The invention provides a graphene oxide coating modified aromatic polyamide reverse osmosis membrane and a preparation method thereof and belongs to the technical field of water treatment membrane preparation .The reverse osmosis membrane comprises a substrate supporting layer, a middle porous bearing layer, an ultra-thin compact separation layer and a graphene oxide coating .The thickness of the graphene oxide coating is 50-150 nm .The surface of the compact separation layer is coated with the graphene oxide, so that the salt removing rate, antifouling property and chlorine resistance of the composite reverse osmosis membrane can be effectively improved, and meanwhile needed working pressure is lowered.

Owner:TSINGHUA UNIV

Modified polyamide reverse osmosis membrane with chemically grafted GO (graphene oxide) on surface and preparation method of modified polyamide reverse osmosis membrane

InactiveCN108176246AHydrophilicPoor separation performanceSemi-permeable membranesReverse osmosisPolyamide

The invention provides a modified polyamide reverse osmosis membrane with chemically grafted GO (graphene oxide) on the surface and a preparation method of the modified polyamide reverse osmosis membrane. The modified polyamide reverse osmosis membrane is prepared from 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide by catalyzing an amidation reaction of carboxyl and amino, and chemical grafting of layered nano-material GO on a polyamide reverse osmosis membrane; the surface of a polyamide membrane and GO are rich in carboxyl, and layer upon layer connection of membrane surface carboxyl and GO carboxyl is realized by catalysis of a grafting reaction on the basis of a multi-amino substance as an intermediate linker. GO has good oxidation resistance, andthe content of N-H bonds in chlorine reactive groups is increased by the amidation reaction, so that chlorine resistance of the polyamide reverse osmosis membrane can be greatly improved, and the service life is prolonged. The modified polyamide reverse osmosis membrane has the advantages that the flux and the interception rate are basically unchanged, and the modified membrane has good chlorine resistance and can stably run.

Owner:QINGDAO UNIV OF SCI & TECH

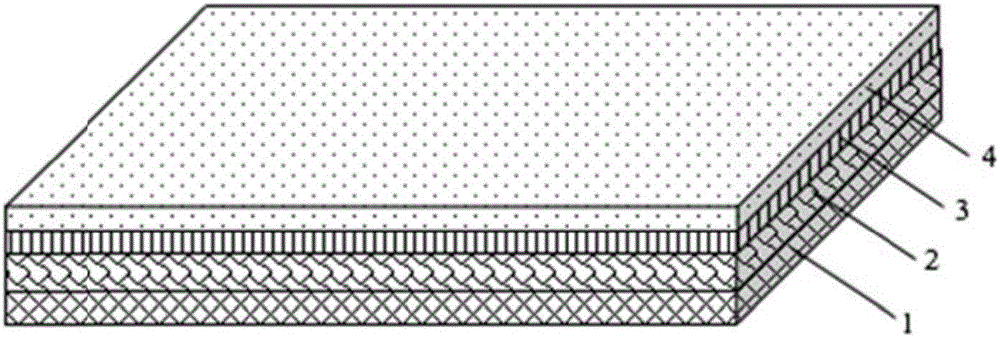

Separating membrane for filtering heavy metal ions as well as preparation method thereof

InactiveCN103977716AStrong complexing abilityTo achieve retentionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFoaming agentCellulose acetate

The invention discloses a separating membrane for filtering heavy metal ions, wherein the separating membrane is composed of a non-woven cloth layer, a porous support layer and an algin layer on the surface of the porous support layer; the non-woven cloth layer is coated with the porous support layer, the porous support layer is a membrane layer formed by mixing cellulose acetate, a pore-foaming agent and a solvent. The separating membrane prepared by the method has a favorable interception performance to heavy metal ions (such as Cd(II), Cu (II) and Fe (III)) in a water solution, and can be applied to waste water treatment in the chemical engineering industry.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Chlorine-resistant reverse osmosis composite membrane and preparation method thereof

ActiveCN108993147AExtended service lifeImprove chlorine resistanceReverse osmosisWater/sewage treatment bu osmosis/dialysisCross-linkPolyamide

The invention discloses a chlorine-resistant reverse osmosis composite membrane and a preparation method thereof. The method is characterized in that an aromatic polyamide separation layer is formed on the surface of a polysulfone microporous membrane by reacting m-phenylenediamine and trimesoyl chloride, an aldehyde compound is used to activate the aromatic polyamide separation layer, the activechlorine attack site is reduced, and a reactive group hydroxyl group is introduced, which provides a basis for fixing the chlorine-resistant protective layer in the form of chemical bonds in a later stage; a hydroxyl group-containing chlorine-resistant polymer material is fixed to the surface of the aromatic polyamide separation layer by a cross-linking agent by means of solvent evaporation and chemical crosslinking to form the chlorine-resistant protective layer, and finally the chlorine-resistant reverse osmosis composite membrane is obtained. The process is simple, and the operationality isstrong.

Owner:HANGZHOU FANGRAN MEMBRANE TECH

Compact chlorine-resistant composite nano-filtration membrane preparation method

InactiveCN107899434AImprove chlorine resistanceImprove interception effectSemi-permeable membranesMembranesFiltration membraneHydroxy compound

The invention relates to a compact chlorine-resistant composite nano-filtration membrane and a preparation method thereof, wherein the compact chlorine-resistant composite nano-filtration membrane comprises a non-woven fabric, a polysulfone support layer and a chlorine-resistant separation layer. According to the present invention, the polypiperazine amide nano-filtration membrane with excellent chlorine resistance is prepared by selecting conventional piperazine / trimesoyl chloride interfacial polymerization, and the compact separation layer with excellent chlorine resistance is formed by using the reaction between the residual acyl chloride at the initial stage of the interfacial polymerization and a hydroxyl-containing macromolecule membrane material with excellent chlorine resistance; the selected membrane materials are chlorine resistant, such that the prepared nano-filtration membrane integrates the high inorganic salt removal rate of the conventional poly aromatic amide compositenano-filtration membrane and the excellent sodium hypochlorite tolerance of the conventional polypiperazine amide composite nano-filtration membrane; and the production method is simple, and the prepared compact chlorine-resistant composite nano-filtration membrane is suitable for wastewater treatment and other fields.

Owner:ZHEJIANG SCI-TECH UNIV

Method for regenerating dry-spinning waste polyurethane filament into polyurethane spinning stock solution with chlorine resistance

ActiveCN101922063AWell mixedImprove stabilityArtificial filament recoveryTextile/flexible product manufactureOrganic solventReaction temperature

The invention relates to a method for regenerating dry-spinning waste polyurethane filament into polyurethane spinning stock solution with chlorine resistance, comprising the following technical process: at the temperature of 30 DEG C below zero to 40 DEG C below zero, smashing waste polyurethane filament into short fibre; washing by water and detergent and drying; adding organic solvent accounting for 50-200 wt% of waste polyurethane filament; then adding waste polyurethane filament; finally, adding organic solvent accounting for 46.4-284 wt% of waste polyurethane filament; under the protection of N2, stirring and reacting for 2-4 hours at the reaction temperature of 50-100 DEG C; spraying reaction control agent blended by organic solvent; adding reaction auxiliary agent blended by the organic solvent; stirring for 20-120 minutes; and after curing, obtaining spinning stock solution with proper viscosity. The polyurethane spinning stock solution produced by the method of the invention has good stability, evenness and spinnability and has obvious effect of good chlorine resistance of the product.

Owner:JIANGSU SHUANGLIANG SPANDEX

Polyamide reverse osmosis (RO) membrane modified through bulk doping of CNO, and preparation method and application thereof

InactiveCN109126486AHydrophilicEasy to separateMembranesGeneral water supply conservationHigh fluxPolyamide

The invention belongs to the technical field of functional materials, and relates to a polyamide reverse osmosis (RO) membrane modified through bulk doping of CNO, and a preparation method and application thereof. The preparation method is characterized in that the CNO is added into an aqueous solution for interfacial polymerization reaction of a polyamide RO membrane to prepare the CNO-hybridizedmodified polyamide RO membrane. The polyamide RO membrane and the preparation method and application thereof have the advantages that the CNO, which is rich in oxygen-containing groups and has high water dispersibility and potential oxidation resistance, is added into a polyamide membrane separation layer through bulk doping, so that the chlorine resistance of the prepared hybrid membrane is greatly improved, and the service life of the membrane is prolonged; and the modified polyamide membrane prepared through the method achieves a higher flux, a basically unchanged retention rate, high chlorine resistance, and high stability in use.

Owner:QINGDAO UNIV OF SCI & TECH

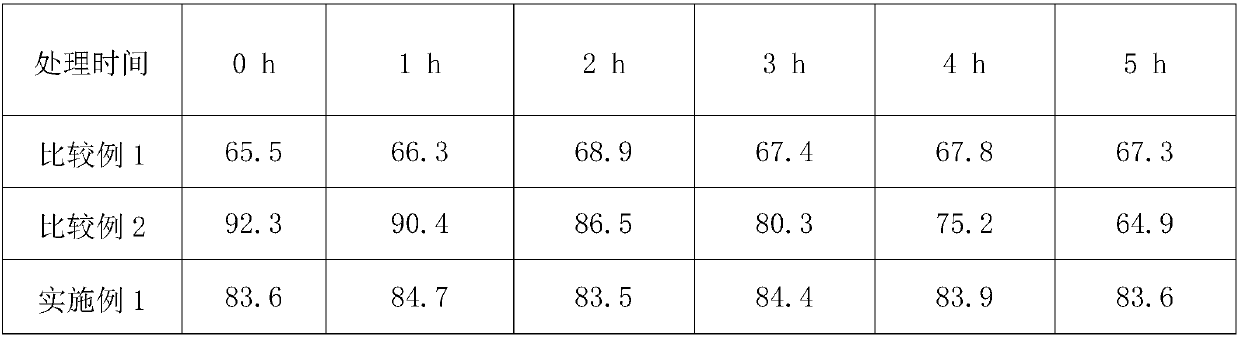

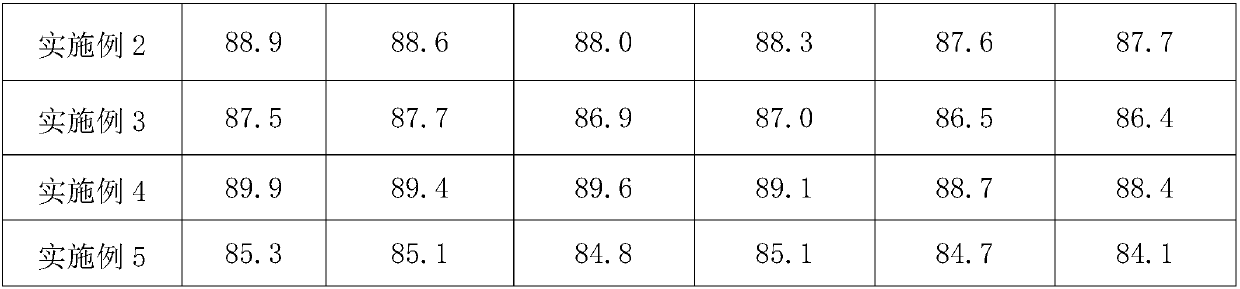

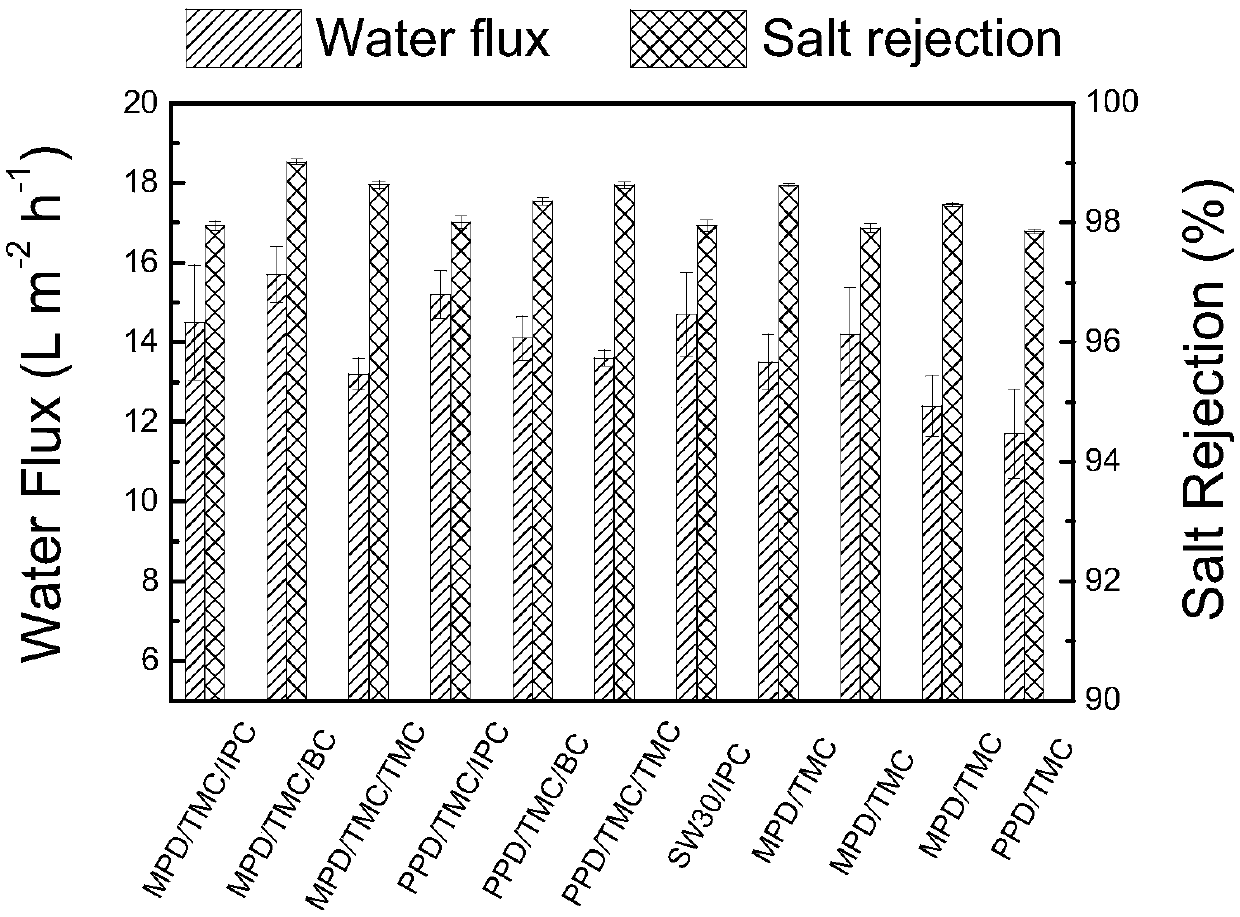

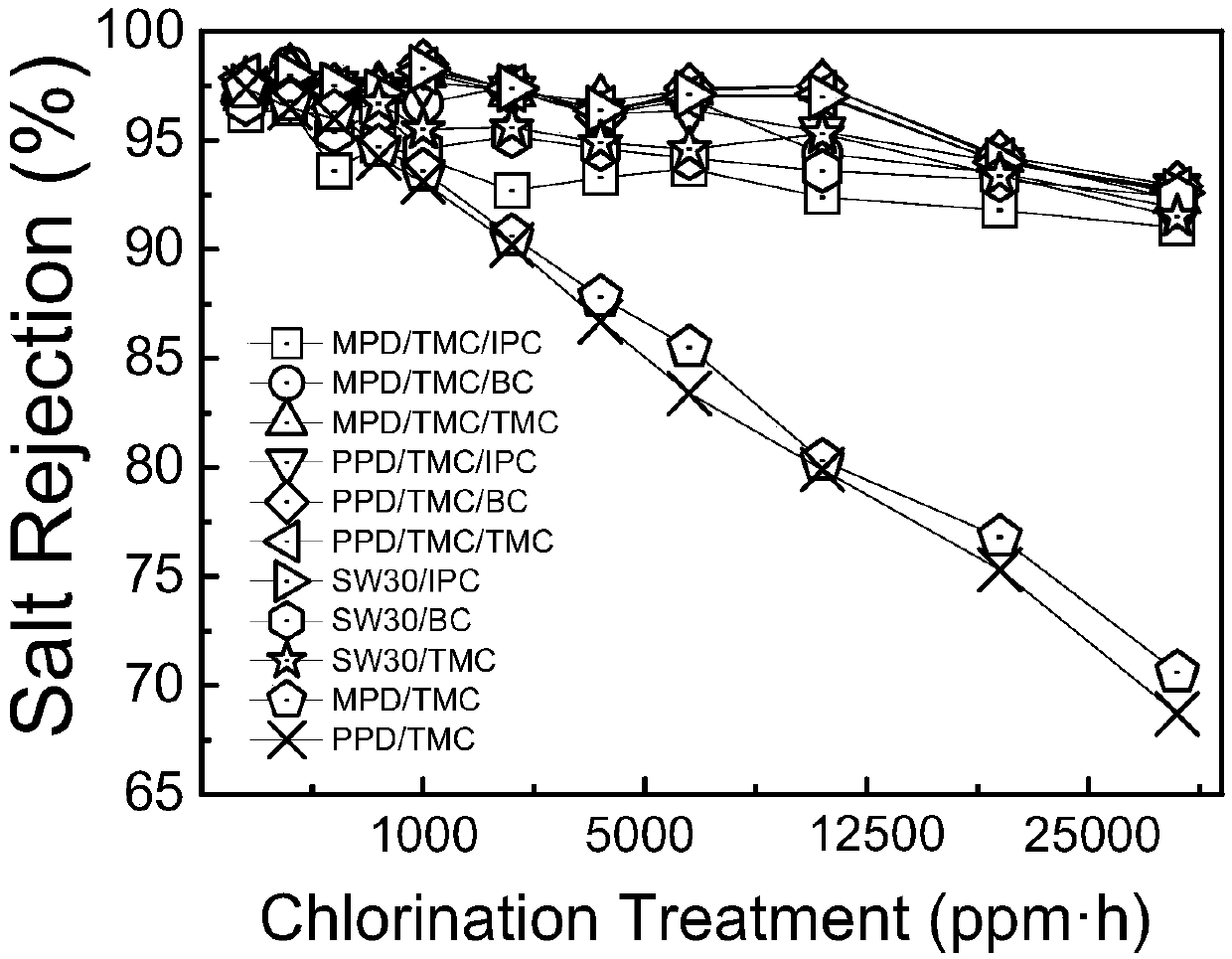

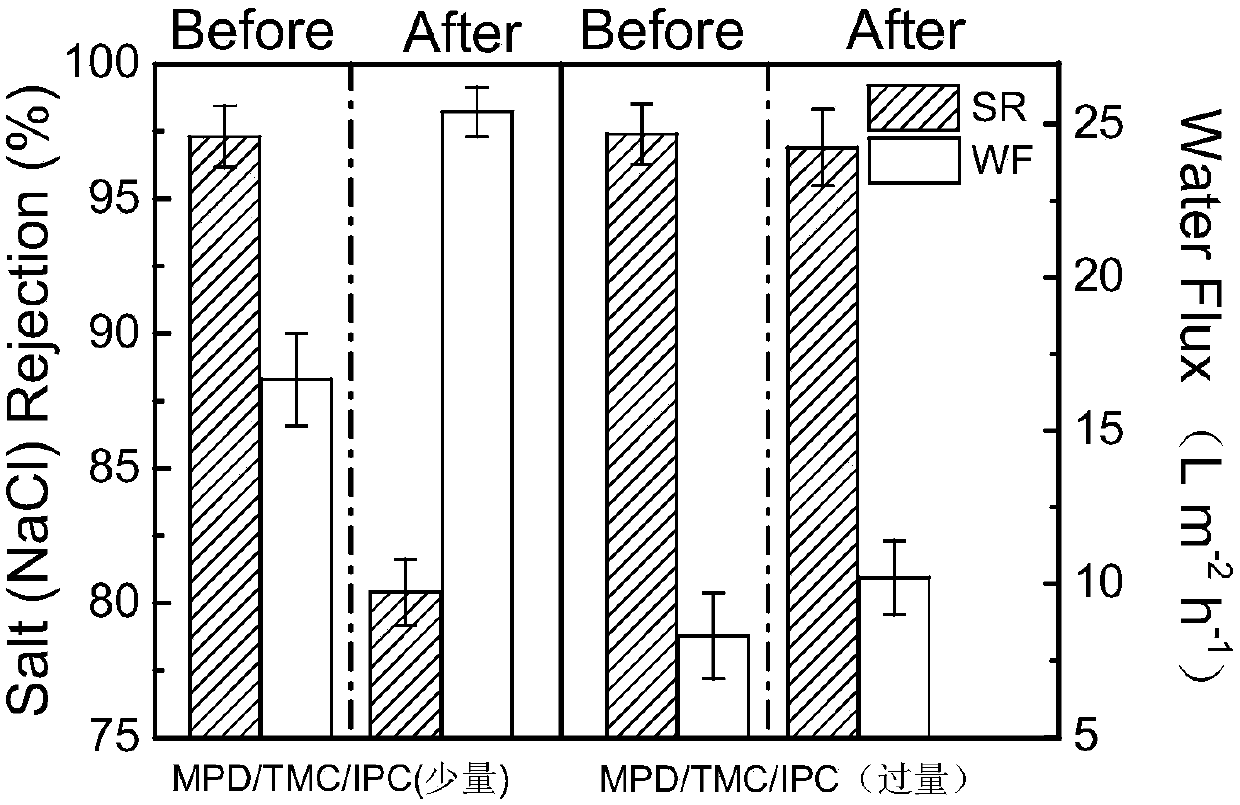

Chlorine-resistant polyamide composite reverse osmosis membrane and preparation method thereof

InactiveCN109647224AImprove chlorine resistanceSeparation performance comparable toSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisOscillatory reactionReverse osmosis

The invention discloses a chlorine-resistant polyamide composite reverse osmosis membrane and a preparation method thereof. The chlorine-resistant polyamide composite reverse osmosis membrane is prepared by immersing a polyamide reverse osmosis membrane in an active acyl chloride reactant solution with the concentration of 1 wt%-4 wt%, oscillating for reaction, carrying out secondary interfacial polymerization and forming a polyamide separation layer structure completely terminated by carboxyl groups. The chlorine-resistant polyamide composite reverse osmosis membrane overcomes the shortcomingof poor chlorine resistance of a conventional commercial reverse osmosis membrane, and the obtained composite reverse osmosis membrane has good salt rejection and chlorine resistance, can still maintain the rejection rate of more than 90% of NaCl under the chlorination condition of 30,000 ppm.h, can work for a long time under the condition of residual chlorine, and has wide application prospects.

Owner:NANJING UNIV OF SCI & TECH +1

Antibacterial and non-ironing processing method of jean shirts

ActiveCN104452273AImprove flatnessGood non-ironing effectSucessive textile treatmentsBiochemical fibre treatmentChemistryProcess engineering

The invention relates to an antibacterial and non-ironing processing method of jean shirts. The antibacterial and non-ironing processing method comprises the steps: performing biological enzyme desizing, performing enzyme washing, cleaning, spraying or soaking a finishing liquid, dehydrating, pre-drying, pressing and molding, roasting, cooling and dampening as well as cleaning and drying to treat the jean shirt fabric. Compared with the prior art, the antibacterial and non-ironing processing method has the advantages of antibacterial and non-ironing effects, easy sorting, comfortable wearing and the like.

Owner:FIBER CHEM BIOLOGICAL CHEM

Chlorine-resistant highly permeable water-treatment membrane, and method for preparing same

ActiveCN104023830AImprove chlorine resistanceExcellent permeate flux performanceMembranesWater/sewage treatmentPolyamideCompounds of fluorine

The present disclosure relates to a method of manufacturing a water treatment membrane having high chlorine resistance and high permeability, the method including: forming an aqueous amine solution layer on a porous support, using an aqueous amine solution including a fluorine compound having an epoxy group in a terminal thereof and an amine compound; and forming a polyamide layer containing the fluorine compound by bringing an organic solution containing acyl halide into contact with the aqueous amine solution layer, and a water treatment membrane manufactured using the same.

Owner:LG CHEM LTD

Reverse osmosis membrane comprising silver nanowire layer, and preparation method thereof

ActiveCN103492051AImprove antifouling performanceImprove chlorine resistanceMembranesReverse osmosisReverse osmosisNanometre

Owner:LG CHEM LTD

Positively charged composite nano filtration membrane and preparation method

ActiveCN109794166AImprove chlorine resistanceIncreased pure water fluxReverse osmosisFiltration membranePolyamide

The invention discloses a positively charged composite nano filtration membrane. The nano filtration membrane is characterized in that a modified meta-aramid hollow fiber membrane is taken as a base membrane, an ultra-thin polyamide layer is formed by positively charged polyelectrolyte, polyamine and polyacyl chloride through interfacial polymerization, and a method for preparing the composite nano filtration membrane is prepared. According to the composite nano filtration membrane, pure water throughput under 0.3 MPa is greater than or equal to 24 L (m2 h), the desalting rate of 2g / L divalentcation salt solution is greater than or equal to 90%, the needed cost is lower, and industrialization is easy. The preparation method is simple, operation is easy, reaction conditions are mild, the performance is stable, and the market application prospects are wider.

Owner:OCHEMATE MATERIAL TECH CO LTD

Fluorescent colorant compositions, coloring process and colored articles

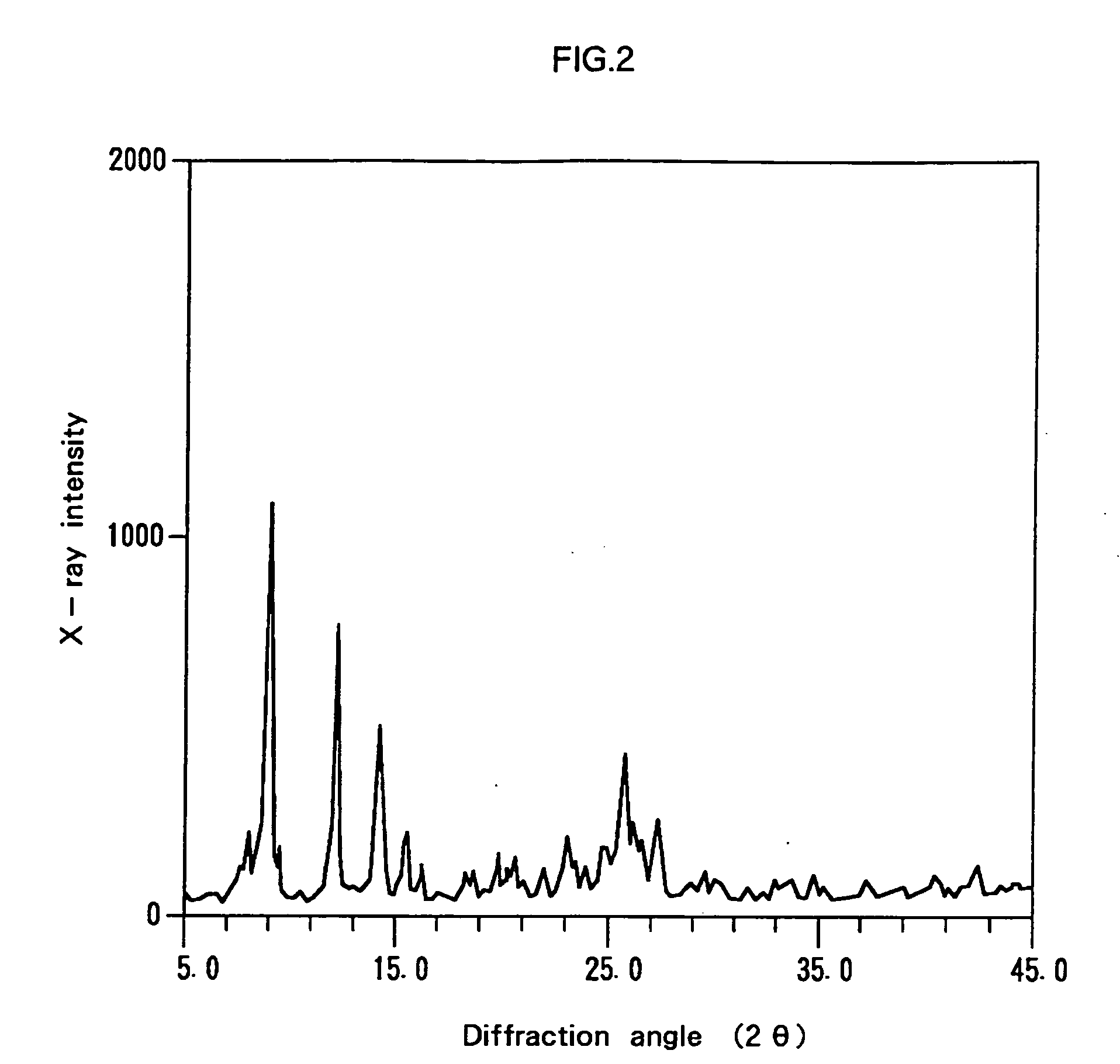

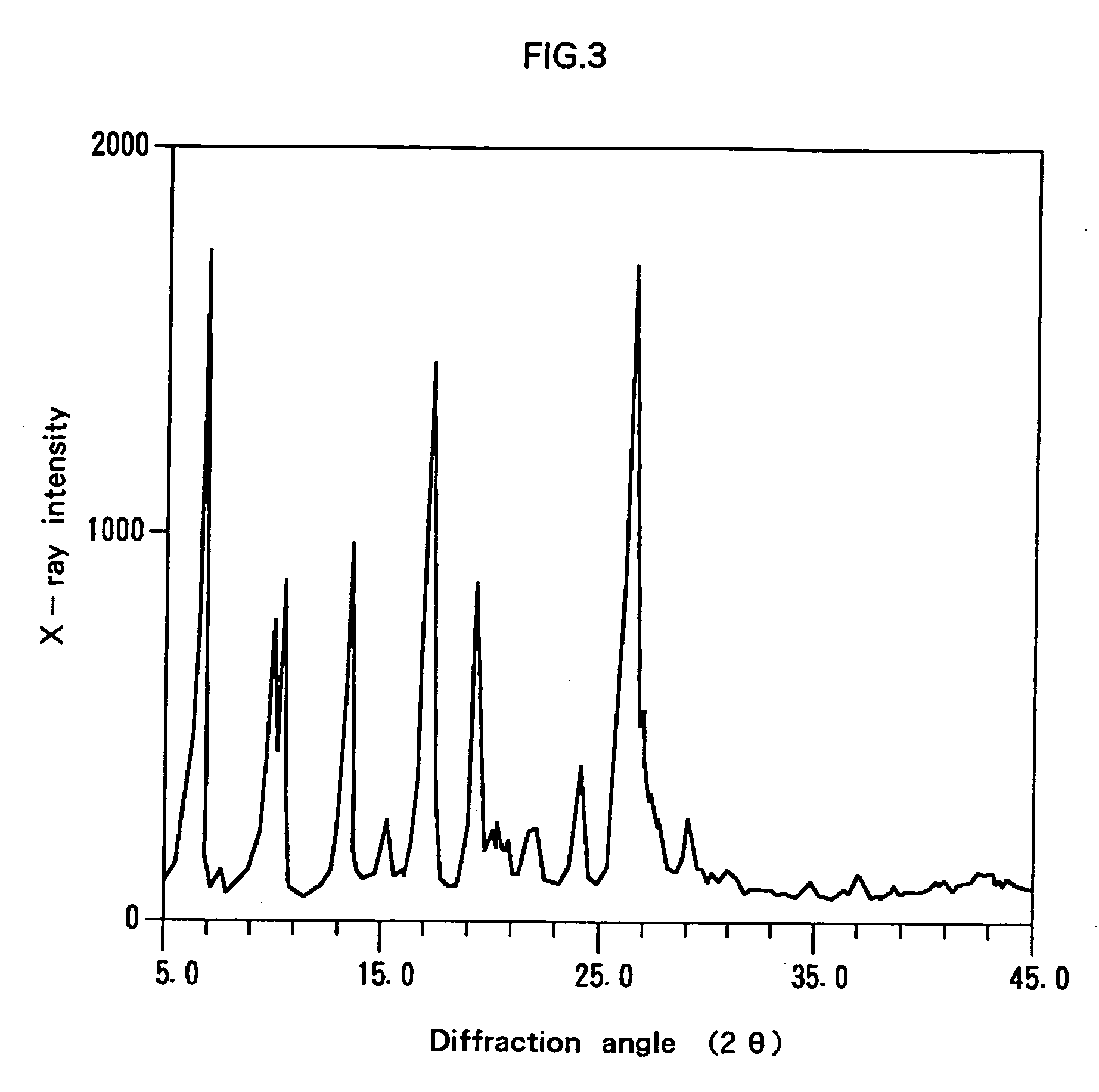

InactiveUS20060219976A1High hiding powerExcellent in water proofnessMonoazo dyesInksFluorescenceX-ray

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Composite nano-filtration membrane and preparation method thereof

ActiveCN109663511AImprove chlorine resistanceImprove throughputSemi-permeable membranesFiltration membraneDesalination

The invention discloses a composite nano-filtration membrane, wherein a modified meta-aramid hollow fiber membrane is used as a base membrane, and polyamine, a diaminobenzene fluoride and polyacyl chloride are subjected to an interface polymerization reaction on the base membrane to form an ultra-thin polyamide layer. The invention further provides a preparation method of the composite nano-filtration membrane. With the technical scheme of the present invention, the pure water flux of the prepared composite nano-filtration membrane is more than or equal to 50 L / (m<2>.h) at 0.5 MPa, the desalination rate of the prepared composite nano-filtration membrane to the 2 g / L divalent cation salt solution is more than or equal to 80%, the required cost is low, and the method is suitable for industrial production; and the preparation method has characteristics of simpleness, mild reaction condition, stable product performance and wide market application prospect.

Owner:OCHEMATE MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com