Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Good non-ironing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for no-ironing finishing of pure cotton textile

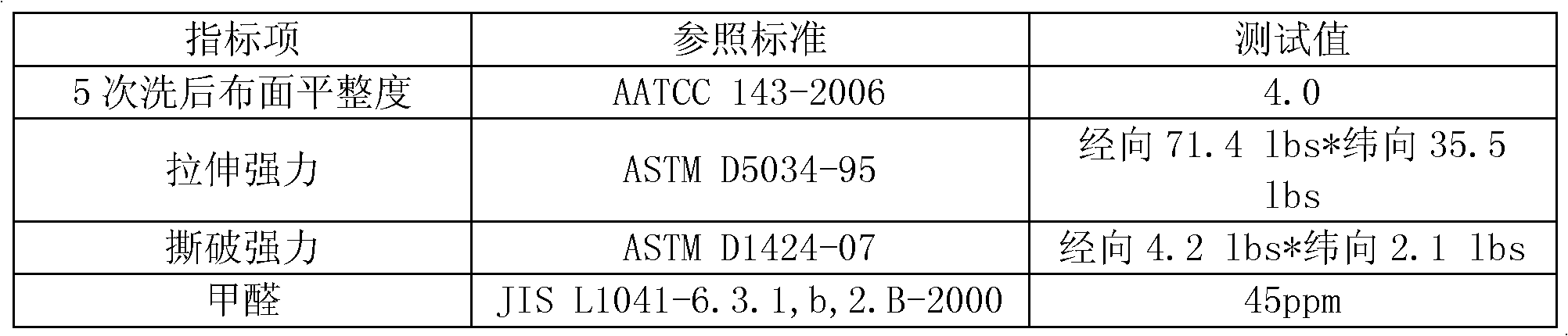

The no-ironing finishing process of pure cotton textile includes the available steps of preparation, preflexibilizing, framing and settling, calendering, preshinking and packing as well as increased rolling supercrosslinking assistant, storing and water washing steps inserted between available preflexibilizing and framing steps. The textile after the said treating process is soft, permeable, water absorbing and no need of ironing and has low formaldehyde content.

Owner:LUTAI TEXTILE

Finishing agent composition for cotton silk fabrics and production method of wash and wear cotton silk shirts

InactiveCN102634984AImprove breathabilityGood hygroscopicityVegetal fibresAnimal fibresEthylene ureaGlyoxal

The invention discloses a finishing agent composition for cotton silk fabrics and a production method of wash and wear cotton silk shirts. The finishing agent composition contains a finishing agent selected from dihydroxyl ethylene urea resin, butanetetracarboxylic acid, propanetricarboxylic acid, citric acid, polymaleic acid, glyoxal and glutaraldehyde, a polyurethane finishing agent and a catalyst. The wash and wear cotton silk shirts produced by the method can simultaneously have such advantages of cotton as good air permeability and strong moisture absorbability and such advantages of silk as good drapability, gloss and outstanding handfeel and can have excellent wash and wear effect while maintaining the peculiar handfeel of the cotton silk fabrics.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Process for knitting towel

The invention discloses a process for knitting a towel, which comprises the procedures of warping, kitting and grey cloth post-processing. The process for knitting a towel is characterized by adopting yarn made from zein fiber and cotton fiber, and after the procedures of the warping, the kitting and the grey cloth post-processing, the yarn is prepared into a finished towel product. The towel prepared by the process has little filoplume, good appearance transparence, soft texture, textural quality, good resiliency, is easy to degrade, has good stability for solvents, such as a dry cleaning agent and can resist the dirt, the sunlight and the weather. The process for knitting a towel can reduce the environmental pollution and prolong the service life of the towel. The towel with the zein fiber feels good on skin and has good permeability, smoothness, better gloss and wash-and-wear effect, thereby being a new generation green product.

Owner:SUNVIM GROUP

Method for processing no-iron 100% bombast

ActiveCN1932137AGood flexibilityDimensionally stableBiochemical fibre treatmentVegetal fibresYarnAfter treatment

The present invention discloses a processing method of all-flax flexible self-smoothing face fabric. It is characterized by adding the processes of tensionless desizing and enzyme treatment in the face fabric finishing stage, and its whole processing method includes the following several steps: loosening yarn, pretreatment, dyeing, after-treatment, coning, weaving, gray inspection, singeing, tensionless desizing, enzyme treatment, liquid ammonia finishing, finalizing design and re-shrinking.

Owner:盛泰智造集团股份有限公司

High-whiteness formaldehyde-free non-ironing cellulose fiber fabric finishing liquid, and application thereof

ActiveCN107142721AHigh whitenessGood non-ironing effectWrinkle resistant fibresVegetal fibresWrinkle skinWhitening Agents

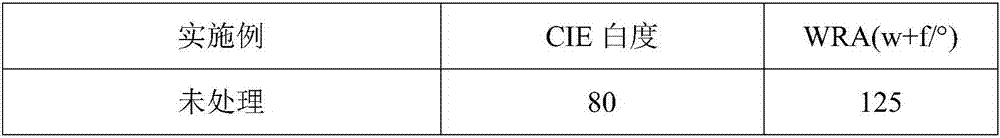

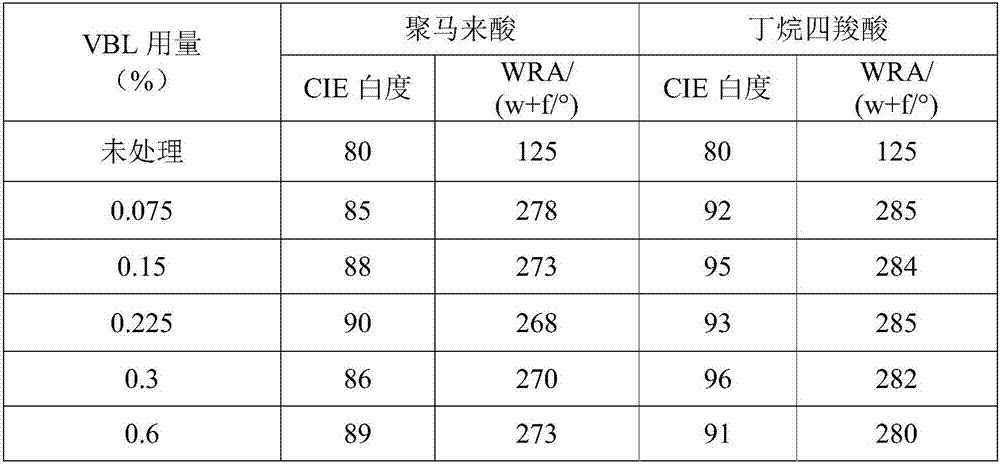

The invention relates to high-whiteness formaldehyde-free non-ironing cellulose fiber fabric finishing liquid, and application thereof. The cellulose fiber fabric is subjected to non-ironing and whitening one-bath finishing by using a polycarboxylic acid formaldehyde-free non-ironing finishing agent and an acid-resistant type fluorescent whitening agent and by the conventional padding-drying-baking method, and a high-whiteness formaldehyde-free non-ironing finishing product can be obtained. The non-ironing and whitening one-bath finishing method provided by the invention is simple and easy to operate and can be conducted on the existing non-ironing processing equipment of the enterprise; the obtained finishing product has a good non-ironing effect, and the wrinkle recovery angle is more than 265 degrees; and the whiteness is high, the whiteness value can reach 135 and above, and the requirements of the market on the high-whiteness formaldehyde-free non-ironing fabric can be met.

Owner:DONGHUA UNIV

Environment friendly functional fabric finishing process

InactiveCN101021044AImprove washabilityGood non-ironing effectFibre treatmentLiquid/gas/vapor textile treatmentEnvironmental engineeringFormaldehyde

The present invention relates to fabric finishing technology, and is especially environment friendly functional fabric finishing process with low formaldehyde resin. The process includes the steps of soaking and rolling, dewatering, pre-roasting, stoving and roasting. The process is environment friendly, and finished fabric is wash and wear, shape memory, wash fast, flexible and comfortable.

Owner:罗国宏

Weft knitted fabric

InactiveCN1376222AGood non-ironing effectEasy to stretchWeft knittingYarnEngineeringPolyethylene terephthalate

The present invention is a weft-knitted fabric, which is characterized in that it contains polytrimethylene terephthalate fiber strands, and according to JIS-L-1018, the constant load elongation in the weft direction measured at a load of 19.6N per 2.5cm width The percentage ranges from 80 to 250%, and it has a smooth and soft hand feeling, excellent stretch performance and elongation recovery performance, and excellent wearing comfort.

Owner:ASAHI KASEI KK

Method for processing yarn-dyed four-side stretch fabric garment

ActiveCN109097974AClear organizationImprove cohesionLiquid/gas/vapor removalBiochemical treatment with enzymes/microorganismsYarnEngineering

The invention discloses a method for processing a yarn-dyed four-side stretch fabric garment. The method comprises the following steps: (a) alkali soaking; (b) biological enzyme polishing; (c) dyeing;(d) air drying; (e) sizing; (f) weaving; (g) desizing; (h) scouring and bleaching; (i) padding; (j) drying; (k) finishing; and (l) pre-shrinking. The method is simple in process, saves energy and reduces consumption and is easy to control, and an obtained fabric is soft and comfortable in touch and has a fine and soft gloss, good non-ironing property, anti-wrinkle performance and anti-pilling performance and dimensional stability.

Owner:盛泰智造集团股份有限公司

Method for processing non-ironing moisture-absorption pure-cotton fabric

InactiveCN101838930AGood non-ironing effectGood hygroscopicityFibre treatmentFiberMoisture absorption

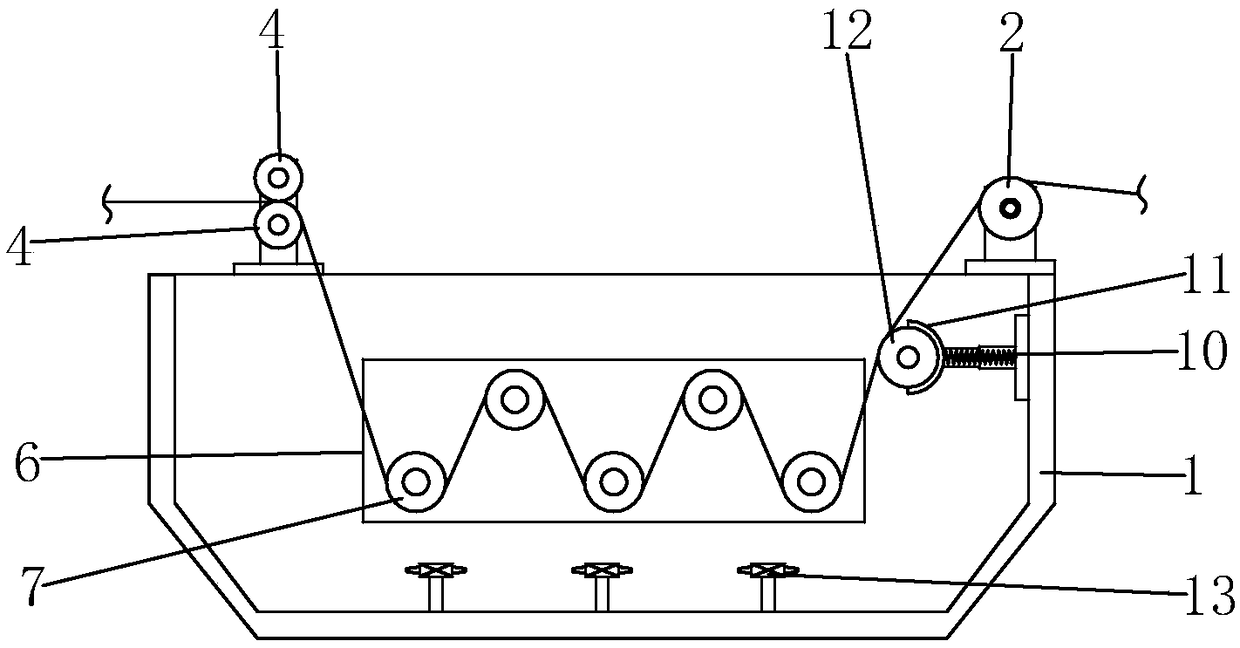

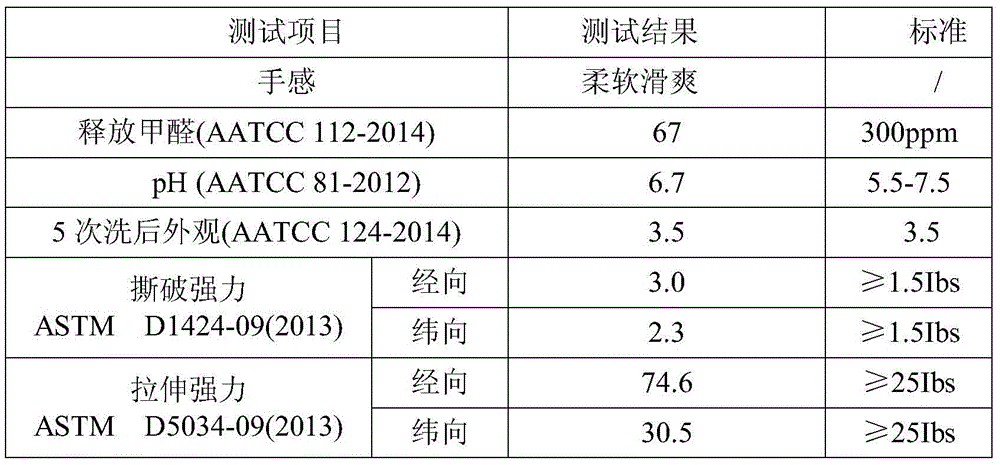

The invention provides a method for processing non-ironing moisture-absorption pure-cotton fabric. The method comprises the procedures in sequence: fabric preparation, pre-softening, rolling of moist crosslinking resin, storage reaction, water washing, tentering formation and pre-shrinking, and is characterized in that: the padding of a moisture-absorption softener is performed during the procedures of the pre-softening, the rolling of moist crosslinking resin and the tentering formation. Through the procedures of the fabric preparation and the pre-softening, cotton fiber is swelled, and undergoes the crosslinking reaction with the resin at the specified temperature, so that the fabric gets the higher-grade non-ironing effect. In the procedures of the rolling of moist crosslinking resin and the tentering formation, the moisture-absorption softener which is added respectively is reacted with the cotton fiber to generate a hydrophilic high polymer which plays a key role in improving the moisture-absorption effect of the fabric. Tests prove that the fabric of the invention has quite good non-ironing and moisture-absorption effects, after the fabric is washed by water for five times, the appearance of the fabric can still reach over 3.5 level of the AATCC 124 standard, and the moisture-absorption property of the fabric is in the range of 7S of the AATCC 79-2000 standard.

Owner:TIANJIN TIANGE TEXTILE

Preparing method for easy-care fabric

InactiveCN106381598AGood non-iron performanceGood moisture absorption and air permeabilityBiochemical treatment with wool-protecting/anti-moth agentsLiquid/gas/vapor removalHemp fiberCotton fibre

The invention discloses a preparing method for an easy-care fabric. High-elastic imitated silk fibers and cotton fibers processed via air low-temperature plasma are blended to form warp yarns; hemp fibers and polyacrylonitrile fibers are blended to form weft yarns; a gray fabric is weaved according to a set tissue structure and thread counts; the acquired gray fabric is ultrasonic wave-padded in finishing liquid, and then washed and dried; and at last, the easy-care fabric can be achieved. The fabric has great easy-care performance and softness and comfortableness; excellent performance of natural fibers can be remained; great moisture-absorbing and ventilating property can be achieved; and the easy-care fabric has great wrinkle resisting, shape-keeping and wash and wear properties.

Owner:EASTERN LIAONING UNIV

No-ironing clothes with lasting shape memory and preparation method thereof

InactiveCN105297429AGood non-ironing effectEasy to integrateFibre treatmentTextile treatment by spraying/projectingCross-linkChloride

The invention discloses no-ironing clothes with lasting shape memory and a preparation method thereof. The clothes is prepared from a cloth material and a resin composition according to the mass ratio of 1:1-1.05, and the resin composition comprises resin, magnesium chloride, an osmotic agent, a strong protective agent, a softener, glacial acetate acid and fluorescent whitening agent. The preparation method for the no-ironing clothes comprises after the clothes is prepared from the cloth material, adding the resin composition, so as to enable the added resin composition to have a cross-linking reaction in the clothes, performing throwing baking on the clothes added with the resin composition, then performing high-temperature pressing on all parts of the clothes, then putting in a high-temperature oven for baking, so as to enable the resin composition to relatively well merge into the clothes material and realize the lasting no-ironing effect of the clothes. The finally-prepared clothes is relatively resistant to washing, and good in no-ironing effect after a person wears the clothes. Cost is relatively saved, operation is convenient, and control on no-ironing effect is relatively direct. A lot of raw materials of the resin composition are saved, water usage is reduced, and energy consumption is saved.

Owner:朱家勇

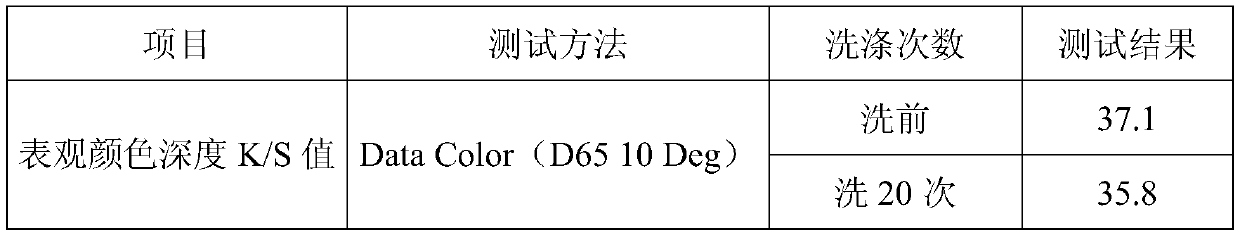

Dark non-ironing washable pure cotton knitted fabric and preparation method and application thereof

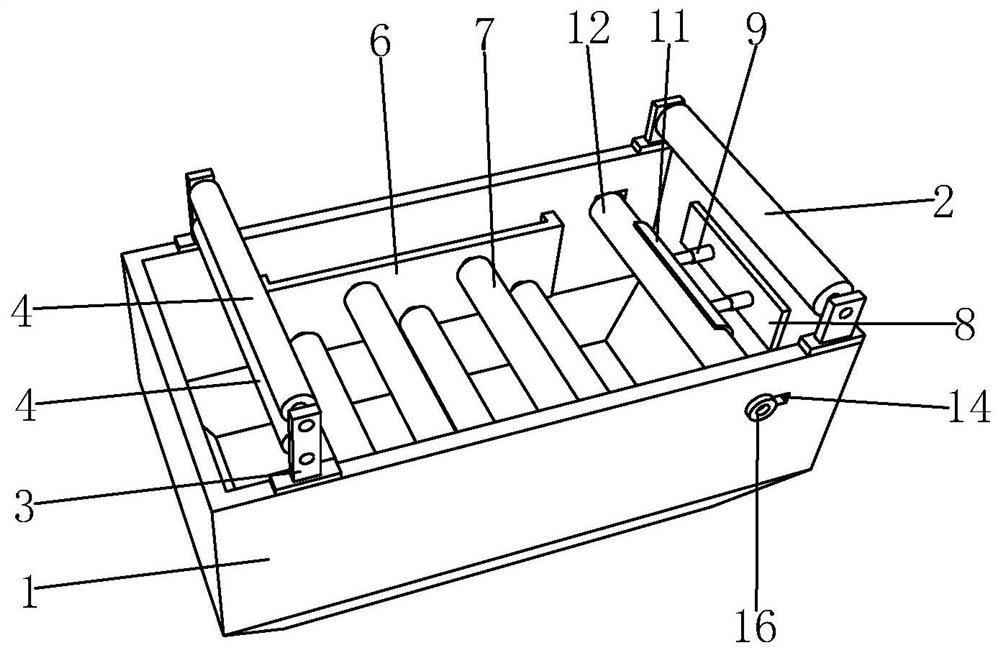

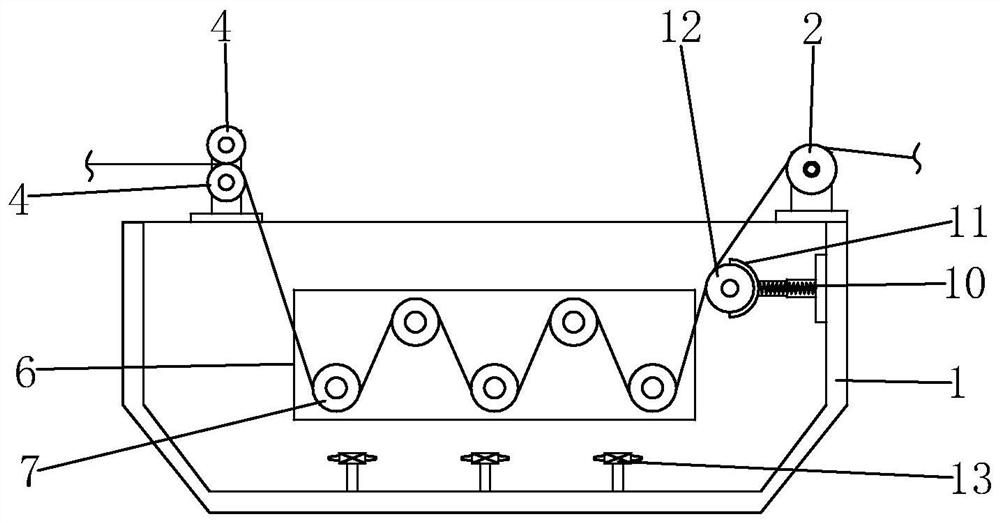

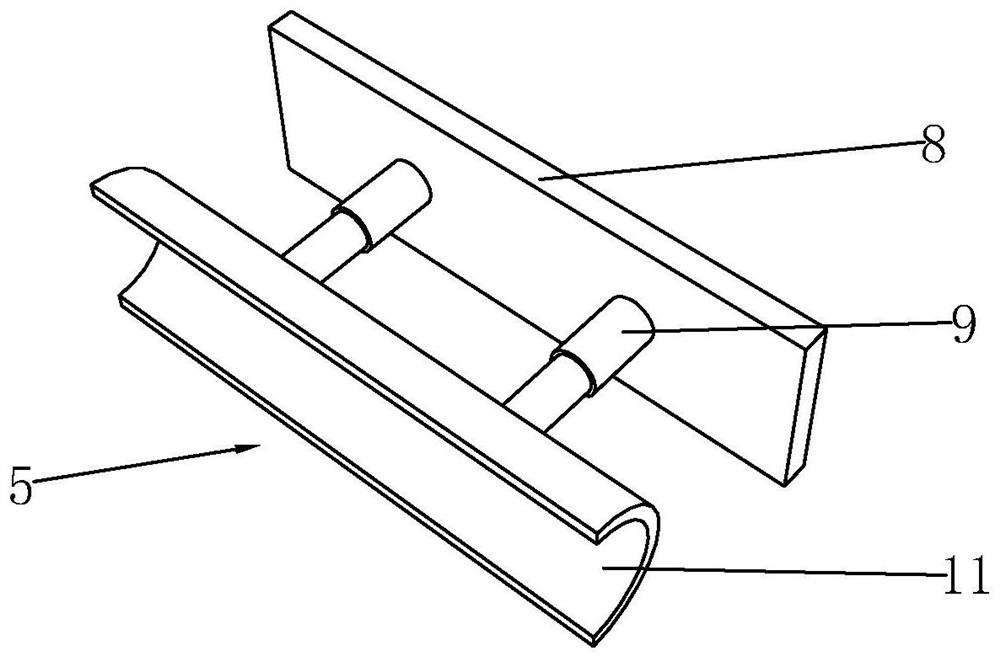

ActiveCN110029501AIncrease the ammonia removal timeIncrease Ⅲ contentSucessive textile treatmentsLiquid/gas/vapor removalYarnChemistry

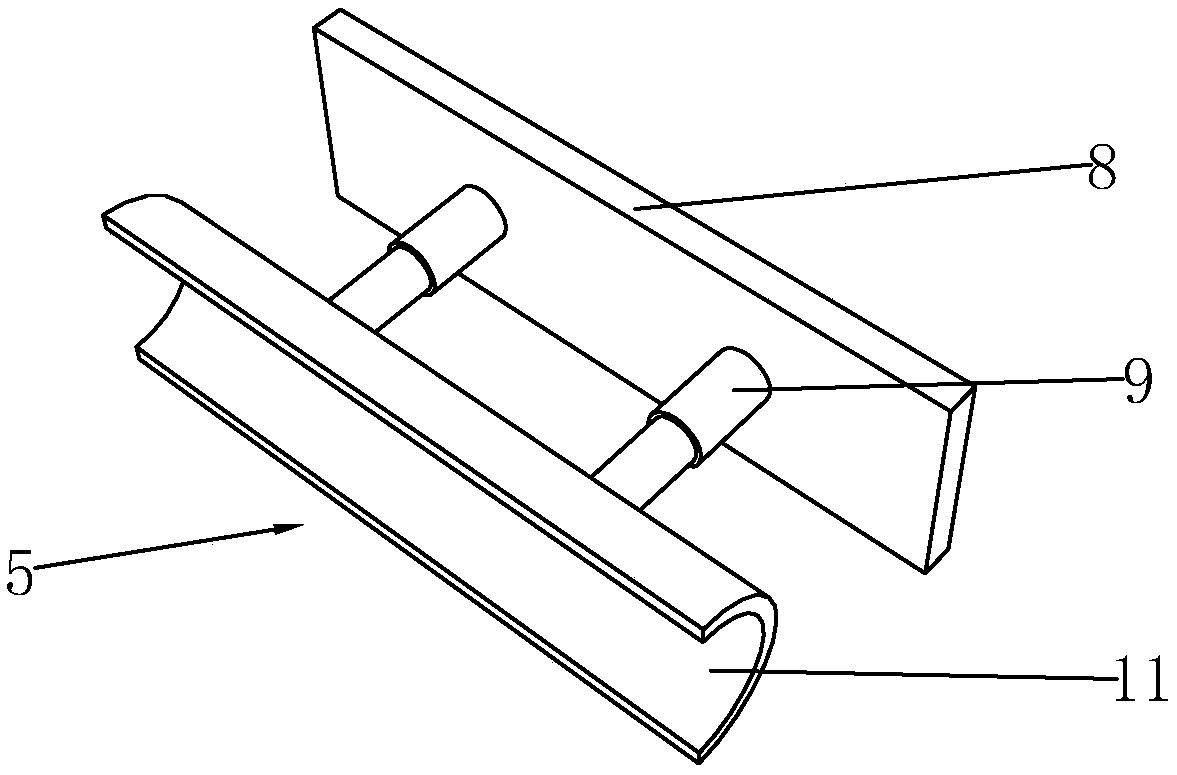

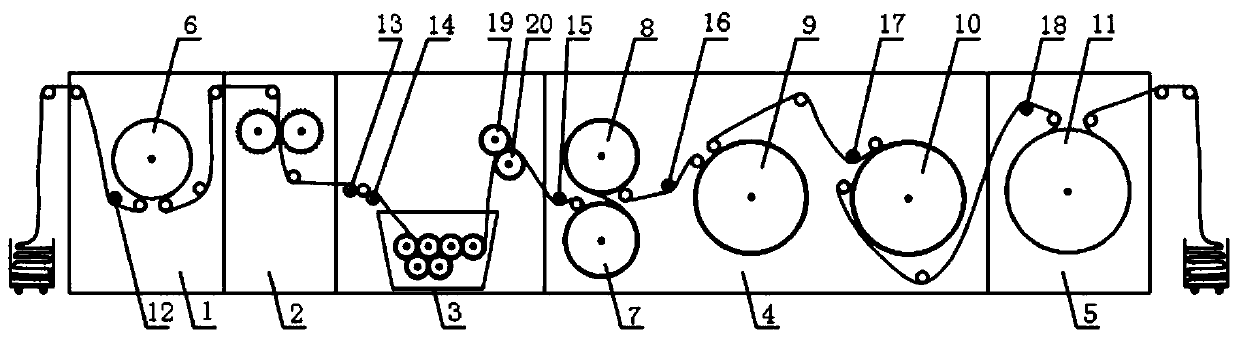

The invention provides a dark non-ironing washable pure cotton knitted fabric and a preparation method and application thereof. The preparation method includes the steps that yarn is subjected to greycloth knitting, scouring, enzyme washing, dyeing, liquid ammonia finishing and resin shaping in sequence to obtain the knitted fabric; during liquid ammonia finishing, a knitted fabric body obtainedafter dyeing, scutching and drying passes through a drying unit, a brushing unit, an ammonia leaching unit, a drying-cylinder ammonia removal unit and a steaming unit in sequence and then is cropped;during liquid ammonia finishing, according to a fabric passing path, the knitted fabric body passes through a fabric guide roller to enter the drying unit and then passes through an edge flattening roller and a fabric guide roller to enter a woolen blanket cylinder body of a drying cylinder of the drying unit; after getting out of the woolen blanket cylinder body, the knitted fabric body passes through a fabric guide roller to enter the brushing unit, passes through an edge flattening roller and a fabric guide roller to enter a liquid ammonia leaching tank of the ammonia leaching unit to passthrough a fabric guide roller and then passes through a first padder roller and a second padder roller; the knitted fabric body enters a plurality of drying cylinders continuously arranged inside thedrying-cylinder ammonia removal unit through the corresponding edge flattening rollers and fabric guide rollers, and then after the knitted fabric body enters a woolen blanket cylinder of a steaming box of the steaming unit through edge flattening rollers and fabric guide rollers, cropping is conducted.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Woven non-ironing fabric with soft and smooth handfeel and processing method thereof

ActiveCN105544211ASoft and smoothRaise the level of easy-care appearanceLiquid/gas/vapor removalTextile storagePre treatmentMoisture

The invention provides a processing method of a woven non-ironing fabric with the soft and smooth handfeel. The processing method comprises the following steps that a pretreated gray fabric is placed into enzyme washing liquid for continuous wet beating at the temperature of 35 DEG C-55 DEG C at the speed of 10-20 meters per minute; the fabric treated through the enzyme is placed into an acid pickling solution for acid pickling at the temperature of 20 DEG C-40 DEG C for 5-30 min and then dried until the moisture content of the fabric reaches 30%-60%, wet piling is performed at the temperature of 20 DEG C-35 DEG C for 5-10 hours, and then drying is performed at the temperature of 50 DEG C-100 DEG C at the speed of 40-80 meters per minute; the fabric treated through acid pickling and wet piling is placed into a sizing finishing solution to be treated until the liquid content of the fabric is 30%-60%, non-iron sizing is performed at the temperature of 80 DEG C-110 DEG C at the sizing speed of 40-80 meters per minute, aftertreatment is performed, and then the woven non-ironing fabric with the soft and smooth handfeel is obtained.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

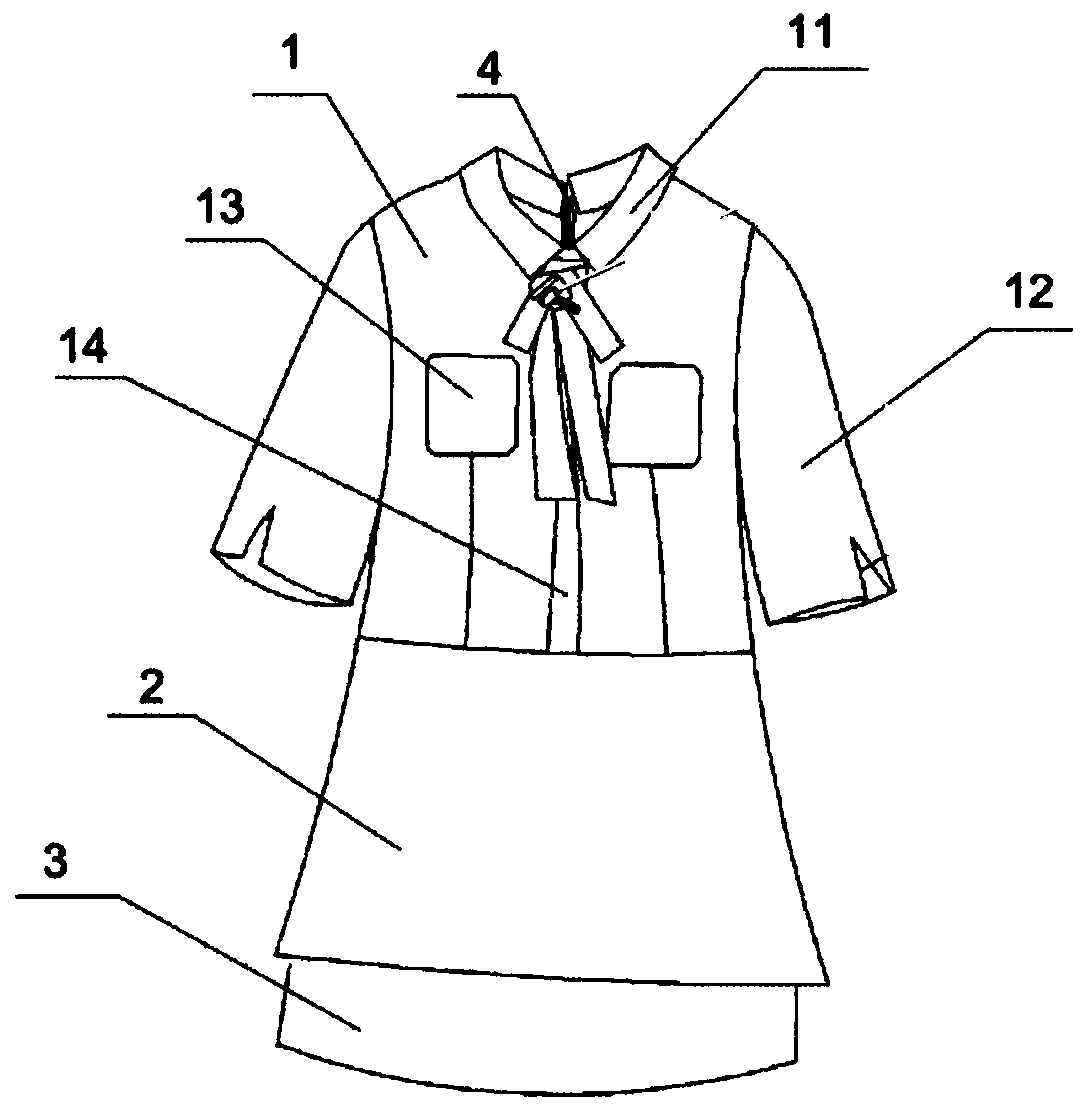

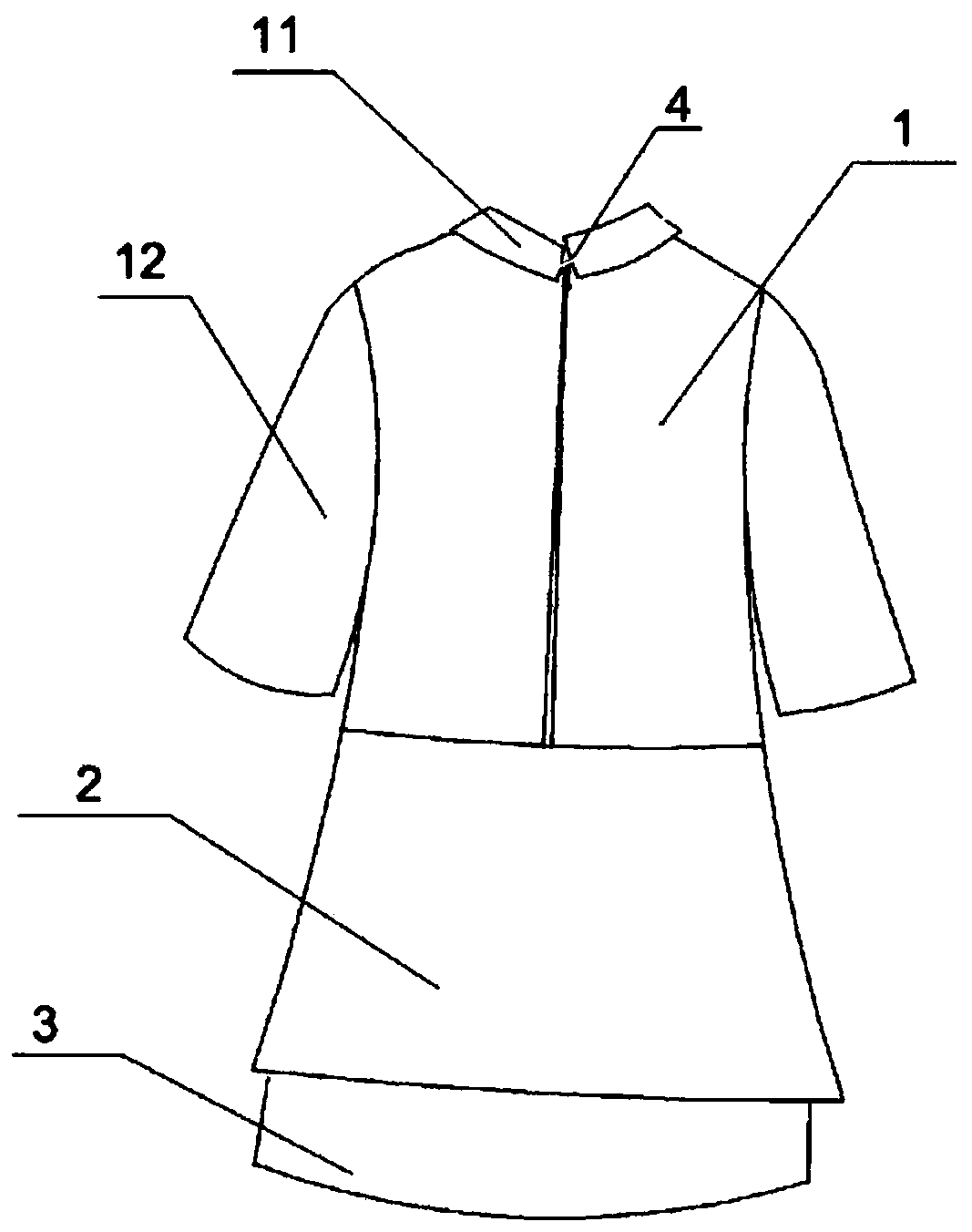

Dress with anti-wrinkle and slimming effect and making process

InactiveCN109924558AExcellent wet and dry wrinkle resistanceGood non-ironing effectFibre treatmentSkirtsEngineeringMechanical engineering

The invention relates to a dress with an anti-wrinkle and slimming effect. The dress comprises a garment part, a skirt part and a lining, the garment part and the skirt part are integrally sewn and provided with a back zipper, and the garment part and the skirt part are combined into a waist-tightening A-shaped dress body; an upper-end collarband of the garment part is a circular collar and is further provided with detachable lapels, the two sides of the garment part are provided with half sleeves, the front end of the garment part is provided with two pockets which are symmetrical left and right, a silver cloth strip extending from the upper end of the garment part to the lower end of the garment part is arranged in the middle of the front panel of the garment part, a collarband, sleevesand shoulders of the lining are fixedly sewn with those of the garment part respectively, silver cloth is sewed to the lower hem, outside the skirt part, of the lining, the lower hem of the lining andthe lower hem of the skirt part form a double-layer skirt hem, the part, above the lower hem, of the lining is black, and the garment part and the skirt part are made of an anti-wrinkle fabric.

Owner:深圳粉蓝衣橱时尚股份有限公司

Preparation method of phenolic yellowing resistant white chinlon non-ironing fabric

PendingCN112127142AFeel goodDoes not affect the fastness to phenol yellowingLight resistant fibresWrinkle resistant fibresTextile technologyDyeing

The invention belongs to the technical field of textiles, and particularly relates to a preparation method of a phenolic yellowing resistant white chinlon non-ironing fabric. Desizing, pre-tentering,dry shaping, non-ironing, padding, jig dyeing, tentering and pre-shrinking are performed to obtain the fabric, wherein an anti-yellowing finishing agent is added in the pre-tentering process, the non-ironing temperature is 155-165 DEG C, and an anti-phenolic yellowing agent is added in the jig dyeing process. Compared with the conventional white chinlon fabric, the white chinlon non-ironing fabricobtained by the method adopts a high-temperature non-ironing process, has the characteristics of good non-ironing property and washability, and is padded and bleached by using an Ostbook stacking method according to the whiteness requirement, so that the stability of the whiteness of the fabric is improved. The anti-phenolic yellowing agent is added in the jig dyeing process, and a weak cation softener with small influences on yellowing is used for tentering, so that the hand feeling of the fabric is improved, the anti-phenolic yellowing fastness of the fabric is not influenced, the anti-phenolic yellowing fastness of the fabric reaches the grade 4 or above, and the requirement for high quality of high-grade fabrics can be met.

Owner:LUTAI TEXTILE

Interwoven fabric of nylon yarn and Modal and weaving method thereof

The invention relates to an interwoven fabric of nylon yarn and Modal and a weaving method thereof. The interwoven fabric is of a plain weave structure and is formed by interweaving 20-30D of ultrafine nylon monofilament yarns as warp yarns and pure Modal yarns as weft yarns according to a certain proportion, and the interwoven fabric also greatly enhances the draping property and the smoothness on the basis of retaining the advantages of soft hand-feeling of the Modal, wet absorption, permeation, coloring effect, and the like, therefore, the problem that the application range is limited due to the characteristics of the Modal is solved. The cloth cover of the interwoven fabric not only has the fine, smooth and comfortable hand feeling similar to the natural silk fabric and is bright in color after being dyed, but also is flat, has good clothing effect, better crease resistance and noiron and can be suitable for coat or decorative cloth fabrics.

Owner:WUJIANG HANTONG TEXTILE

Process for manufacturing novel yarns

InactiveCN103451825AEasy to produceIncrease elasticityWoven fabricsYarnMoisture absorptionFilament yarn

The invention discloses a process for manufacturing novel yarns, and relates to the field of textile manufacture and processing. The process includes steps of mixing yarns; manufacturing carded silver; manufacturing rolls; drawing the silver; manufacturing rough yarns; mixing filaments; manufacturing finished products; packaging and storing the finished products. The process has the advantages that cotton and hemp blended yarns and the filaments are mixed with one another to manufacture the novel yarns, a production mode is simple and convenient, the novel yarns have all characteristics of cotton, hemp and the filaments, shortcomings of an elastic textile made of spandex core-spun yarns are overcome, a textile made of the novel yarns is good in elasticity and high in dimensional stability, a garment made of the novel yarns is good in comfortableness, and the novel yarns are easy to manage, high in moisture absorption and breathability, easy to dye and good in draping performance, stretching restoration performance and easy-care performance, have a sterilization function and are odor-resistant.

Owner:六安市凯旋大麻纺织有限责任公司

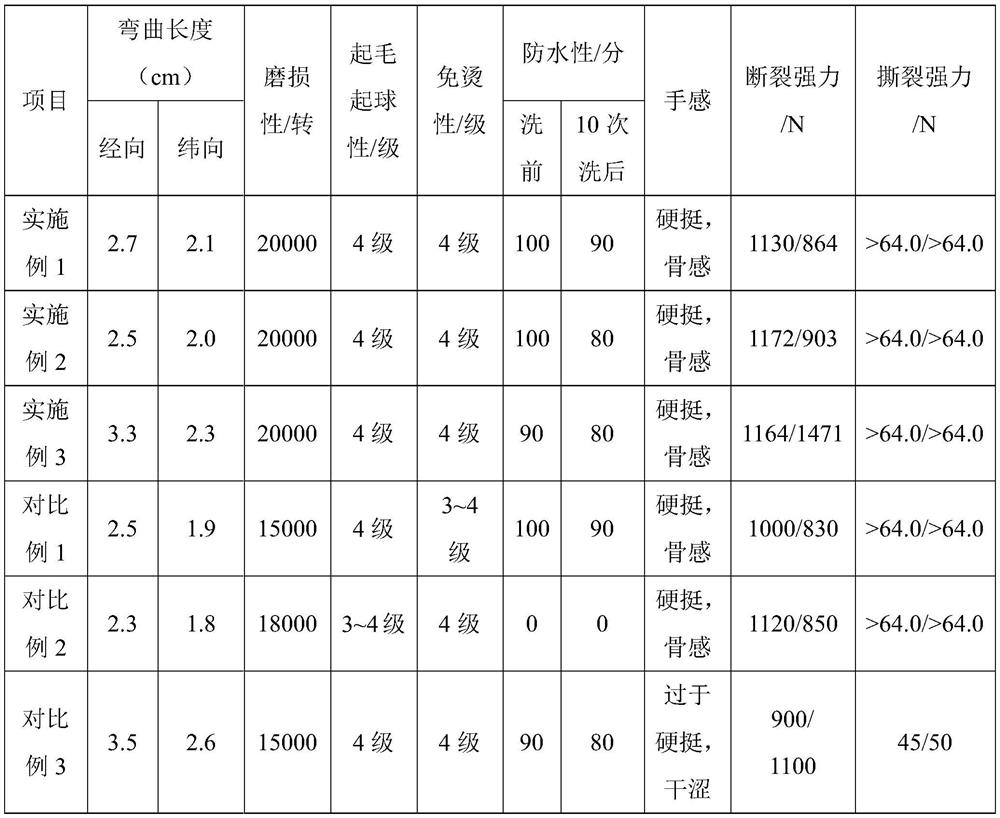

Stiff wear-resistant and waterproof regenerated yarn-dyed fabric and production method thereof

InactiveCN113235208AImprove wear resistanceGood non-ironing effectLiquid repellent fibresAbrasion resistant fibresPolyesterPolymer science

The invention relates to the technical field of textile fabrics, in particular to a stiff wear-resistant and waterproof regenerated yarn-dyed fabric and a production method thereof. According to the stiff wear-resistant and waterproof regenerated yarn-dyed fabric, warp and weft yarns are formed by interweaving cotton and regenerated polyester staple fibers; and the weight percentage of the cotton fibers is 30-50%, and the weight percentage of the regenerated polyester fibers is 50-70%. The warp yarns and the weft yarns are cotton / regenerated polyester blended yarns prepared from the cotton fibers and the regenerated polyester fibers in a compact spinning manner. The stiff wear-resistant and waterproof regenerated yarn-dyed fabric provided by the invention is stiff in hand feeling, and has excellent wear resistance, pilling resistance, non-ironing property and waterproofness. The invention also provides the production method of the stiff wear-resistant and waterproof regenerated yarn-dyed fabric.

Owner:LUTAI TEXTILE

Preparation method of deodorant no-iron functional finishing fabric

The invention provides a preparation method of a deodorant no-iron functional finishing fabric, comprising the following steps of: a, preprocessing a cotton-fiber fabric; b, preparing a finishing solution, sequentially adding a W100 type penetrating agent, a R412 type finishing agent, an H550 type softening agent, 518E type resin and a 515M type catalyst into water in the preparing process of the finishing solution; and c, padding the preprocessed cotton-fiber fabric into the finishing solution at normal temperature, then, tentering, drying, baking, washing with water, drying, tentering, finishing and preshrinking. In the preparation method of the functional finishing fabric, the prepared functional finishing fabric has efficient and durable no-iron wrinkle resistance, the cotton fabric not only has the characteristics of comfortableness, ventilation, soft hand feel, and the like of natural fibers, but also has good no-iron performance and dry-wet-state wrinkle resistance, has good anti-bacterial deodorizing effect, excellent deodorizing function and good washing fastness, and can reduce putrid odor caused by microbial propagation.

Owner:SHANDONG WEIQIAO PIONEERING GROUP

Polyester viscose blended fabric

The invention discloses a polyester viscose blended fabric which is prepared from the following raw materials in parts by weight: 60 to 70 parts of polyester filaments, 10 to 15 parts of polyester staple fibers, 12 to 15 parts of viscose, 8 to 13 parts of selenite fibers, 5 to 9 parts of modified polyacrylonitrile fibers, 2 to 5 parts of bamboo carbon fibers, 3 to 5 parts of acetate fibers, 0.5 to 2 parts of soybean protein fibers, 1 to 3 parts of graphene oxide, 0.3 to 0.5 part of epsilon-polylysine, 2 to 5 parts of nano titanium dioxide, 5 to 8 parts of carboxymethylcellulose, 0.1 to 0.5 part of Arabic gum and 1 to 4 parts of sodium tetraborate. The polyester viscose blended fabric is high in strength, crease-resistant, anti-wear, less prone to pilling, high in moisture absorption performance and good in non-ironing property.

Owner:QINGDAO TOPLINK INFORMATION TECH

Wash and wear finisher for fabric and method for finishing fabric by using wash and wear finisher

The invention discloses a wash and wear finisher. The wash and wear finisher is prepared from the following components in concentration: 100 to 120g / L of QD-WR, 15 to 20g / L of catalyst, 10 to 15g / L of softening agent, 3 to 5g / L of penetrating agent and 10 to 15g / L of waterborne polyurethane elastic enhancer. According to the wash and wear finisher disclosed by the invention, by adopting a special finisher formula, final experiments of wrinkle resistance, shrinking, whiteness, DP grade and strength test show that the treated fabric has good wash and wear effect and high DP grade; the strength accords with the requirement of the fabric; in addition, the fabric is soft and good in hand feeling, is not easy to wrinkle, and is free of shrinking, so the wash and wear finisher for fabric and the method for finishing the fabric by using the wash and wear finisher have a good application prospect.

Owner:JIANGSU SUYANG SERVICE CAP CO LTD

Degradable corn blending fabric

A degradable corn blending fabric is characterized in that firstly a high molecular weight nanometer titanium dioxide composite poly butylene succinate is obtained by utilizing an effective synthesisprocess and spined into a polyester fiber, and then a corn fiber with specification of 1.56-1.65detx multiplied by 38mm is elected to be blended with a nanometer titanium dioxide composite poly butylene succinate fiber with specification of 1.56-1.65detx multiplied by 38mm, thus obtaining the degradable corn blending fabric.

Owner:WUJIANG YINGXIANG CHEM FIBER

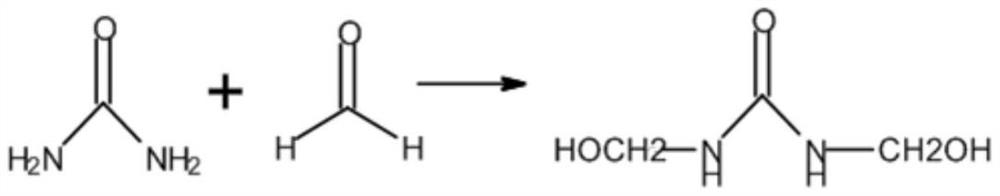

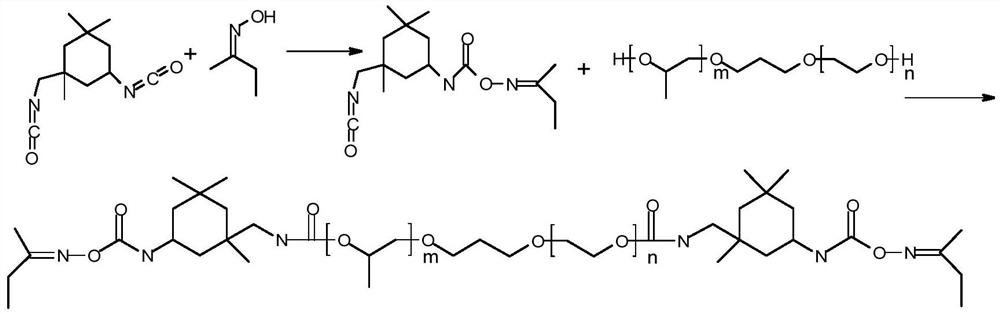

Preparation method of polyurethane modified non-ironing resin with improved strong hand feeling

InactiveCN111793202AGuaranteed validityGood non-ironing effectWrinkle resistant fibresGrip property fibresCelluloseFiber

The invention belongs to the technical field of preparation of textile assistants, and particularly relates to a preparation method of polyurethane modified non-ironing resin with improved strong handfeeling. The preparation method comprises the following steps: preparing dimethylol urea from urea and formaldehyde; preparing a polyurethane prepolymer from aliphatic diisocyanate and a sealing agent, carrying out a reaction on propylene glycol polyoxyethylene polyoxypropylene ether, the polyurethane prepolymer and a catalyst, adding the dimethylol urea and dioxane, and carrying out a reaction;and finally adding glyoxal, continuously reacting, and adding water to adjust the water content after the reaction is finished so as to obtain the product. According to the invention, the product of areaction of a polyoxyethylene polyoxypropylene ether block copolymer and isocyanate is cross-linked with a traditional 2D resin, wherein the polyether block is attached to the surface of the fiber soas to enhance the lubricity of the fiber, improve the hand feeling of the fabric and make the fiber slide within a limited range when being stressed to achieve the purpose of reducing strength loss,and the effectiveness of cross-linking of resin and cellulose is ensured through polyhydroxy structures at the two ends, so that the non-ironing property is still good.

Owner:ZIBO LURUI FINE CHEM CO LTD

Fabric non-ironing finishing liquid and method for finishing of fabric using same

The invention discloses fabric non-ironing finishing liquid. The fabric non-ironing finishing liquid is prepared from RCT with the concentration being 100-120 g / L, amino silicon oil with the concentration being 10-15 g / L, a catalyst with the concentration being 15-20 g / L, a softening agent with the concentration being 10-15 g / L and a penetrating agent with the concentration being 3-5 g / L. Meanwhile, the invention discloses a method for finishing of fabric using the finishing liquid. According to the fabric non-ironing finishing liquid and the method for finishing of the fabric using the finishing liquid, a special finishing liquid formula is adopted, it is proved by final anti-wrinkle, shrinkage, whiteness and DP grade and brute force testing experiments that the fabric finished through the method has a good non-ironing effect, the DP grade is high, and brute force meets the fabric requirement; the fabric is soft, good in handfeeling, not prone to wrinkling and free of shrinkage; good application prospects are achieved.

Owner:SUZHOU SHUNTANG CHEM FIBER

A non-ironing fabric and a manufacturing process therefor

InactiveCN107313154AGood non-ironing effectGood moisture absorption and air permeabilityUltrasonic/sonic fibre treatmentWoven fabricsPolyesterCotton fibre

The invention provides a non-ironing fabric and a manufacturing process therefor. The non-ironing fabric is formed by interweaving warp yarn and weft yarn. The warp yarn is made of cotton fibers and the weight accounts for 80% of the weight of the fabric. The weft yarn is made of polyester fibers and bast and leaf fibers. The novel non-ironing fabric is formed by performing plasma processing first and them non-ironing finish and has the advantages of being good in moisture absorption and breathability, being soft and comfortable, maintaining excellent properties of natural fibers, having good non-ironing performance, being stable in size, easy to care, and free of formaldehyde, and causing no harm to human bodies.

Owner:RUGAO WANLI CHEM IND

Method for no-ironing finishing of pure cotton textile

The no-ironing finishing process of pure cotton textile includes the available steps of preparation, preflexibilizing, framing and settling, calendering, preshinking and packing as well as increased rolling supercrosslinking assistant, storing and water washing steps inserted between available preflexibilizing and framing steps. The textile after the said treating process is soft, permeable, water absorbing and no need of ironing and has low formaldehyde content.

Owner:LUTAI TEXTILE

A non-ironing processing method for yarn-dyed four-way stretch fabric garments

ActiveCN109097974BClear organizationImprove cohesionLiquid/gas/vapor removalBiochemical treatment with enzymes/microorganismsYarnProcess engineering

Owner:盛泰智造集团股份有限公司

Method for processing no-iron 100% bombast

ActiveCN100404750CGood flexibilityDimensionally stableBiochemical fibre treatmentVegetal fibresYarnAfter treatment

The present invention discloses a processing method of all-flax flexible self-smoothing face fabric. It is characterized by adding the processes of tensionless desizing and enzyme treatment in the face fabric finishing stage, and its whole processing method includes the following several steps: loosening yarn, pretreatment, dyeing, after-treatment, coning, weaving, gray inspection, singeing, tensionless desizing, enzyme treatment, liquid ammonia finishing, finalizing design and re-shrinking.

Antibacterial and non-ironing processing method for denim shirt

ActiveCN104452273BImprove flatnessGood non-ironing effectSucessive textile treatmentsBiochemical fibre treatmentDenimProcess engineering

The invention relates to an antibacterial and non-ironing processing method of jean shirts. The antibacterial and non-ironing processing method comprises the steps: performing biological enzyme desizing, performing enzyme washing, cleaning, spraying or soaking a finishing liquid, dehydrating, pre-drying, pressing and molding, roasting, cooling and dampening as well as cleaning and drying to treat the jean shirt fabric. Compared with the prior art, the antibacterial and non-ironing processing method has the advantages of antibacterial and non-ironing effects, easy sorting, comfortable wearing and the like.

Owner:FIBER CHEM BIOLOGICAL CHEM

A kind of dark non-ironing and washable pure cotton knitted fabric and its production method and application

ActiveCN110029501BImprove washabilityGood non-ironing effectSucessive textile treatmentsLiquid/gas/vapor removalYarnPolymer science

The invention provides a dark color non-ironing and washable pure cotton knitted fabric and its production method and application. The method comprises making the yarn successively undergo weaving, scouring, enzyme washing, dyeing, liquid ammonia finishing, and resin setting to obtain knitted fabrics. Fabrics; liquid ammonia finishing is to make knitted fabrics dyed and dried in open width sequentially through the drying unit, brushing unit, ammonia soaking unit, drying cylinder ammonia removal unit, and steaming unit, and then drop the cloth; the liquid ammonia finishing process wears The cloth route is that the knitted fabric enters the cloth drying unit through the cloth guide roller, and then passes through the edge roller, and the cloth guide roller enters the felt cylinder of the drying cylinder of the cloth drying unit; after exiting the cylinder, it enters the brush unit through the cloth guide roller; The rollers and cloth guide rollers enter the cloth guide rollers of the liquid ammonia dipping tank of the ammonia soaking unit, and then pass through the first padding roller and the second padding roller; the knitted fabric enters the drying cylinder sequentially through the corresponding edge rollers and cloth guide rollers In several drying cylinders set continuously in the ammonia removal unit; the knitted fabric enters the blanket cylinder of the steam box of the steaming unit through the edge roller and cloth guide roller, and then falls off.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com