A non-ironing processing method for yarn-dyed four-way stretch fabric garments

A processing method and four-way elastic technology, applied in the field of fabric processing, can solve the problems of weak anti-pilling performance, hard hand feeling of the fabric, and uneven surface, so as to achieve a clear structure, reduce pilling, and reduce the probability of forming agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

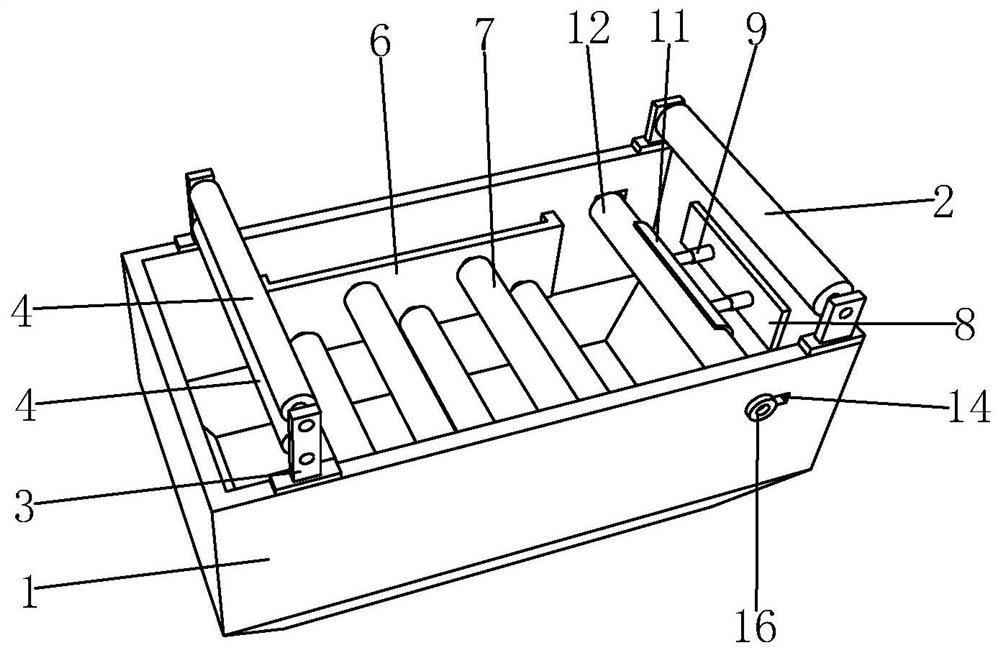

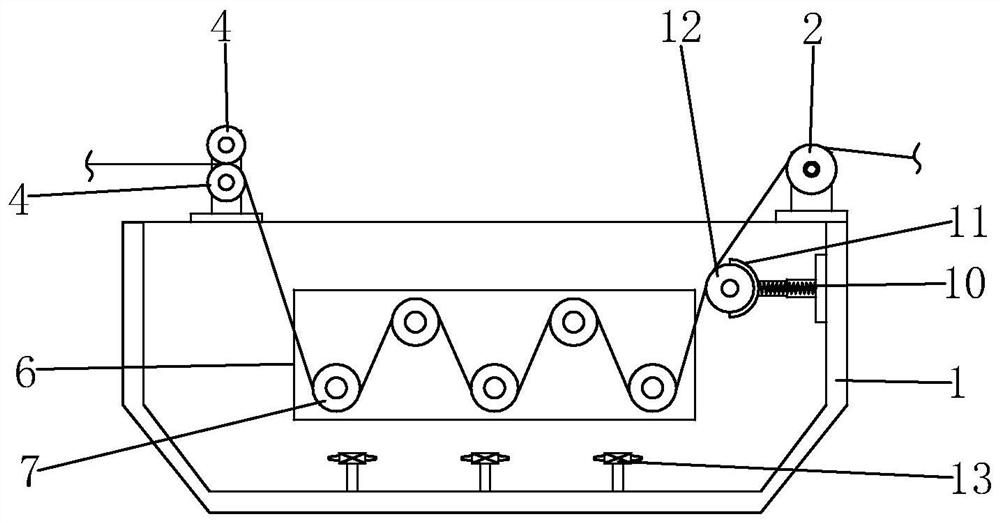

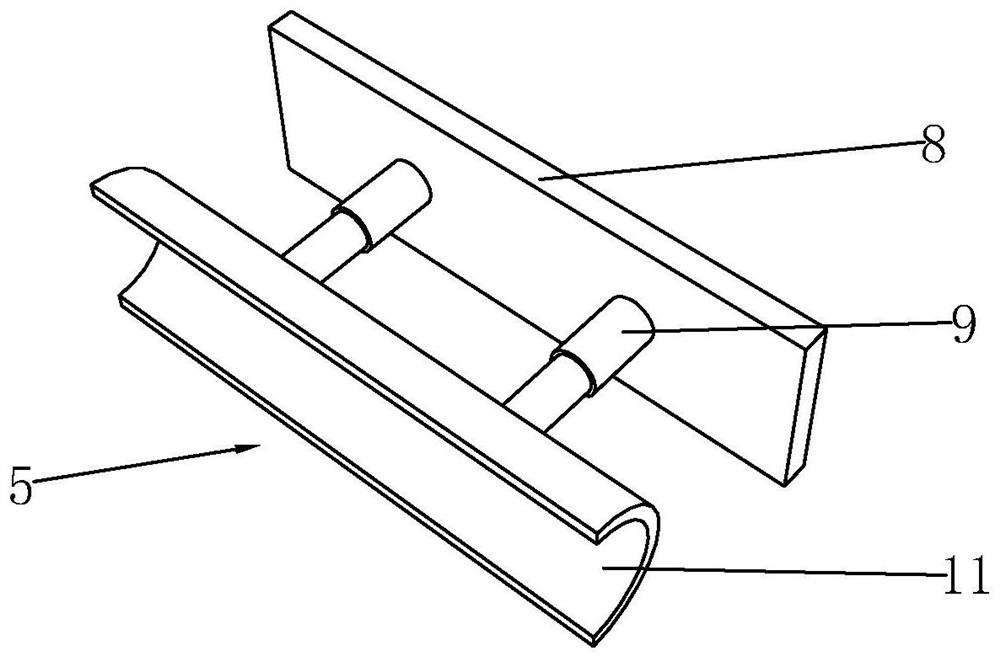

[0039] like Figure 1 to Figure 4 Shown, be the non-ironing processing method of a kind of yarn-dyed four-way stretch fabric ready-made garment of the present invention, comprise the steps:

[0040] (a) Alkali dipping: place the yarn in an alkali dipping tank containing 45-55g / L NaOH and 1-3g / L penetrating agent for alkali treatment, the time of alkali dipping is 60-70s, the temperature of the alkali dipping tank The temperature is 20-25°C, and the surface of the yarn is made more shiny by alkali treatment, and the cohesion force between fibers is increased, so as to achieve the effect of anti-pilling. Then the yarn is placed in an alkali steamer at a temperature of 50-60°C and rinsed with hot water to remove the alkali solution.

[0041] (b) Enzyme polishing: Add acetic acid with a concentration of 0.2-0.5g / L to the constant temperature water bath, then raise the temperature to 50°C, and add neutral enzyme. The dosage of neutral enzyme is 0.4-0.6%, which is neutral enzyme P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com