Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4880results about How to "Avoid wrinkles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacture of minimum porosity, wrinkle free composite parts

A process and associated apparatus used to prepare a thermoplastic composite from a plurality of plies of thermoplastic resin prepregs. The prepregs are formed into a composite structure under two chambers; a rigid outer chamber (of any convenient size or shape) and a second flexible inner chamber containing a prepreg lay-up. The absolute pressures are reduced concurrently in a stepwise method in both chambers. This concurrent, stepped pressure reduction is accomplished at a rate which prevents the vacuum bag from moving far from the prepregs, and prevents wrinkles from forming in the prepregs. Pinching off the diffusion paths required for the removal of unwanted gases is eliminated. The lay-up is then heated and the absolute pressure in the outer rigid chamber is increased. This pressure constrains the flexible inner chamber during out-gassing of the thermoplastic resin, preventing wrinkles from forming in the prepregs. The absolute pressure in the outer rigid chamber is increased to atmospheric pressure or greater causing the prepregs to consolidate. A low absolute pressure is maintained in the flexible inner chamber. The temperature is then increased to the cure temperature of the resin and held for a time sufficient for the resin to cure. The resulting consolidated thermoplastic resin is substantially void free and detectable wrinkles are absent.

Owner:HALE HAROLD P

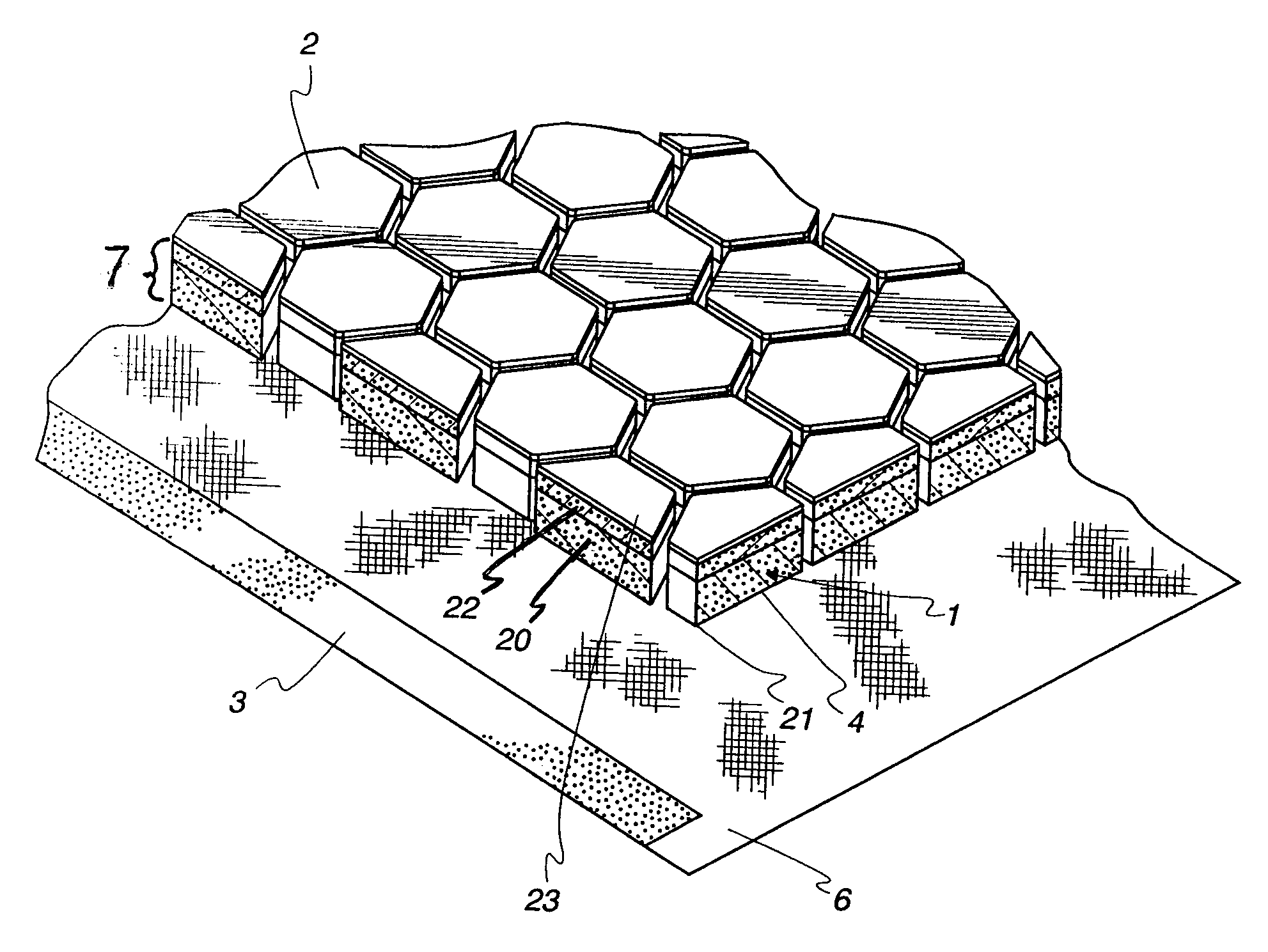

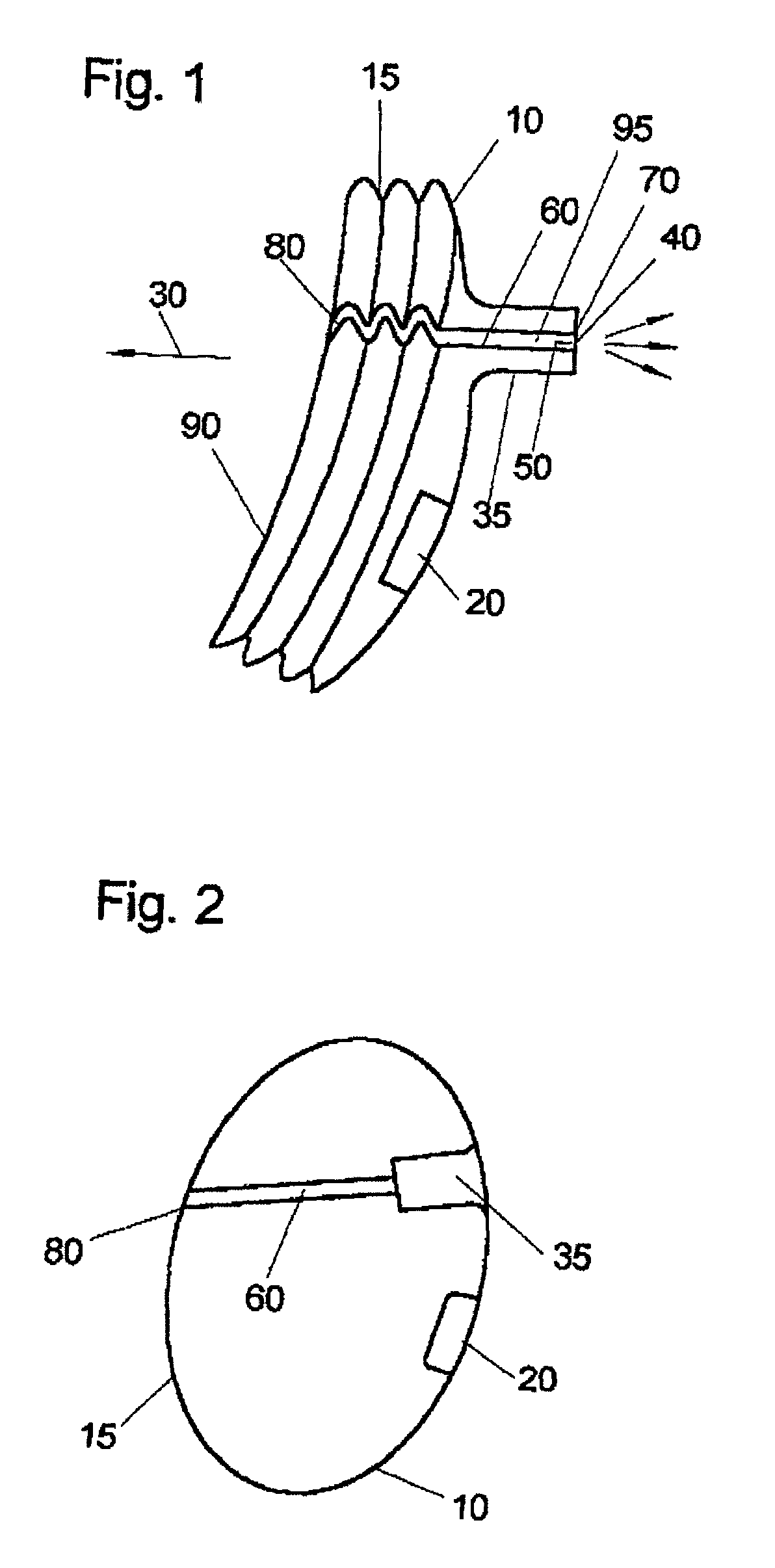

Flexible Material and Method of Manufacturing the Flexible Material

InactiveUS20080113143A1Dissipates blowReduce the impactProtective equipmentLayered productsCompressibilityEngineering

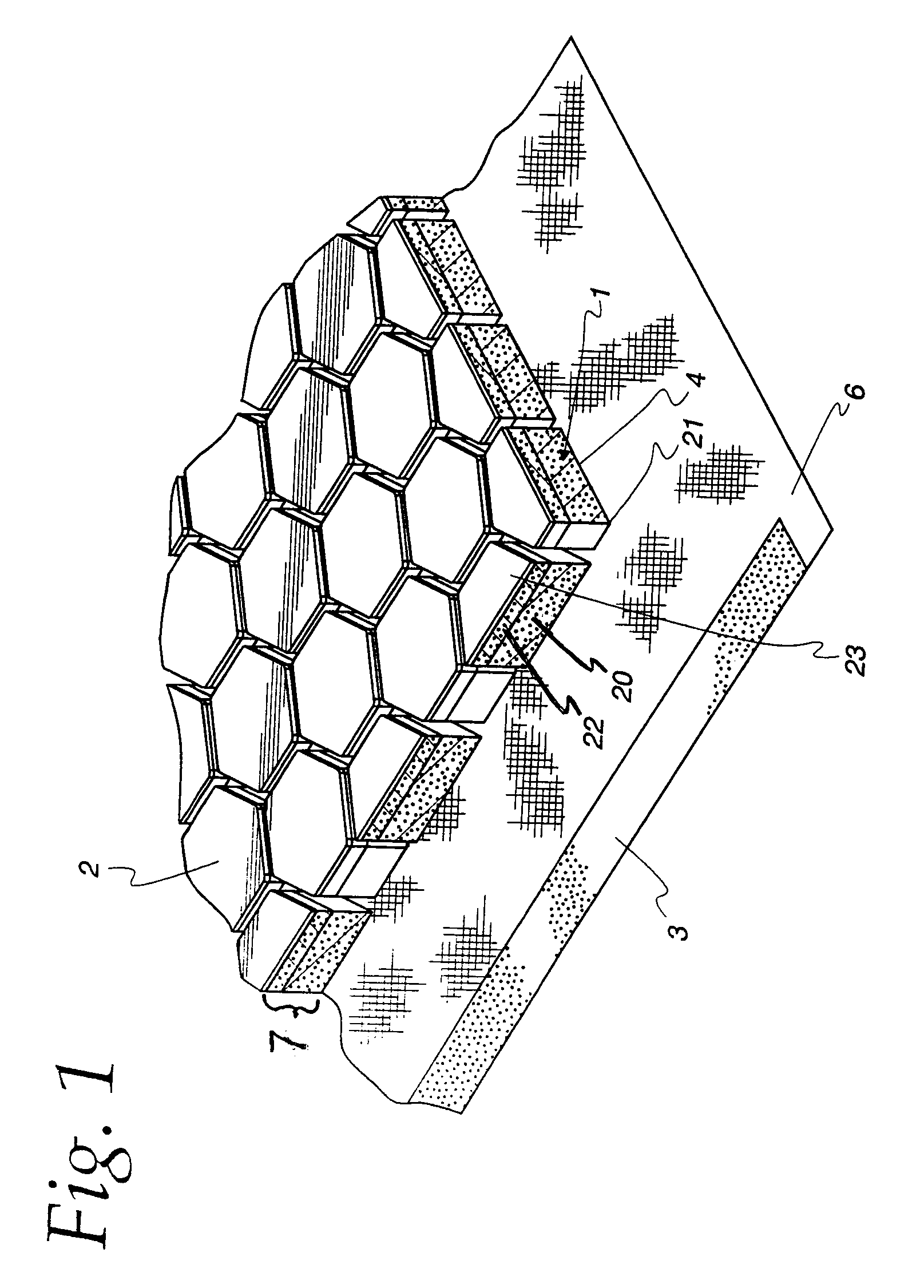

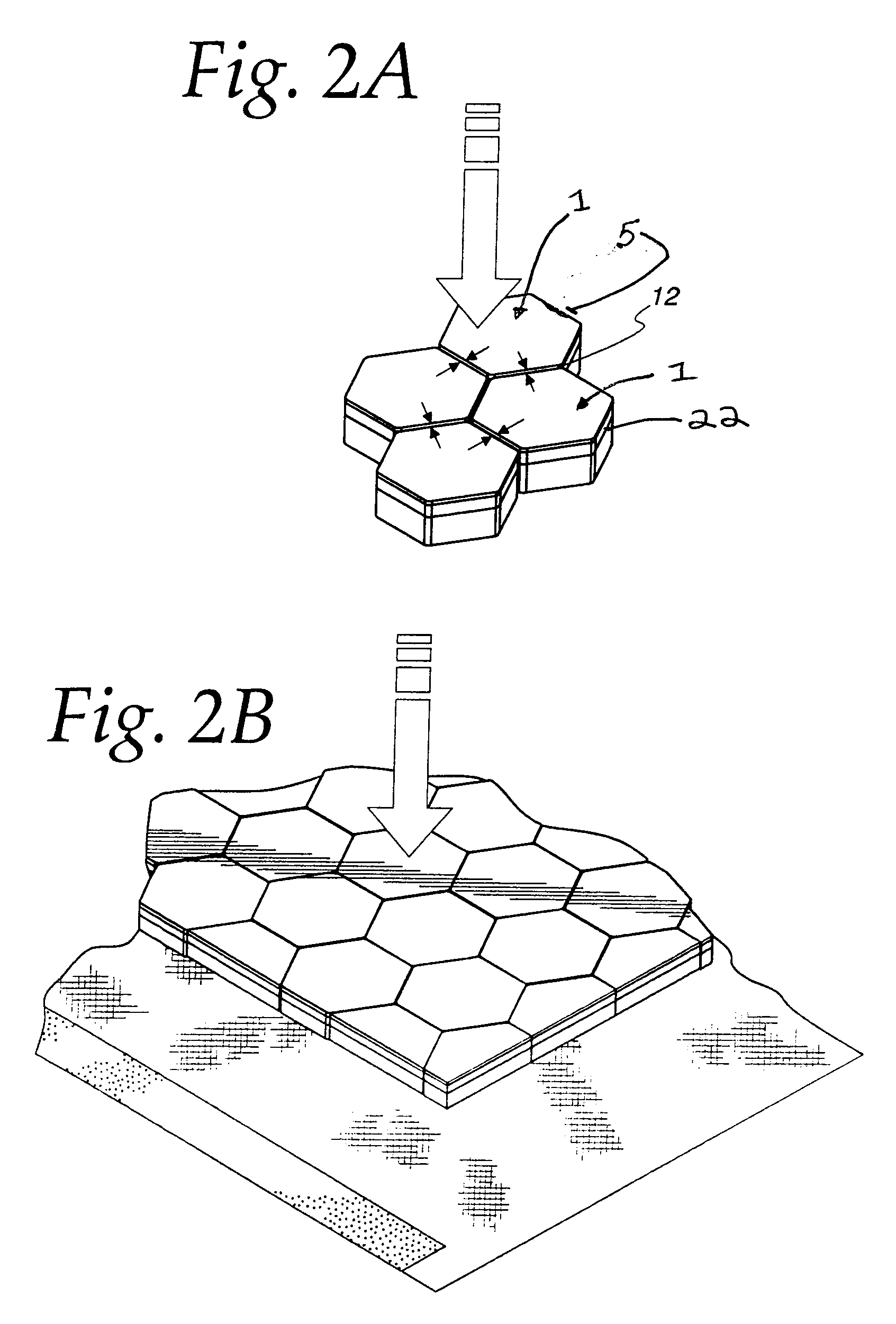

A flexible protective padding material is described and comprises an array of resilient multilayered elements or blocks which have generally planar top and bottom surfaces and each of which have at least two layers which include a first layer bonded to an outer second layer. The total compressibility of each element with the at least two layers, the spacing between the elements and the total thickness of the elements provides the elements with the ability to compress such that at least one side wall of each of adjacent elements move together and touch each other to provide a joined outer surface of elements which dissipates a blow to the protective padding.

Owner:STIRLING MOLDINGS

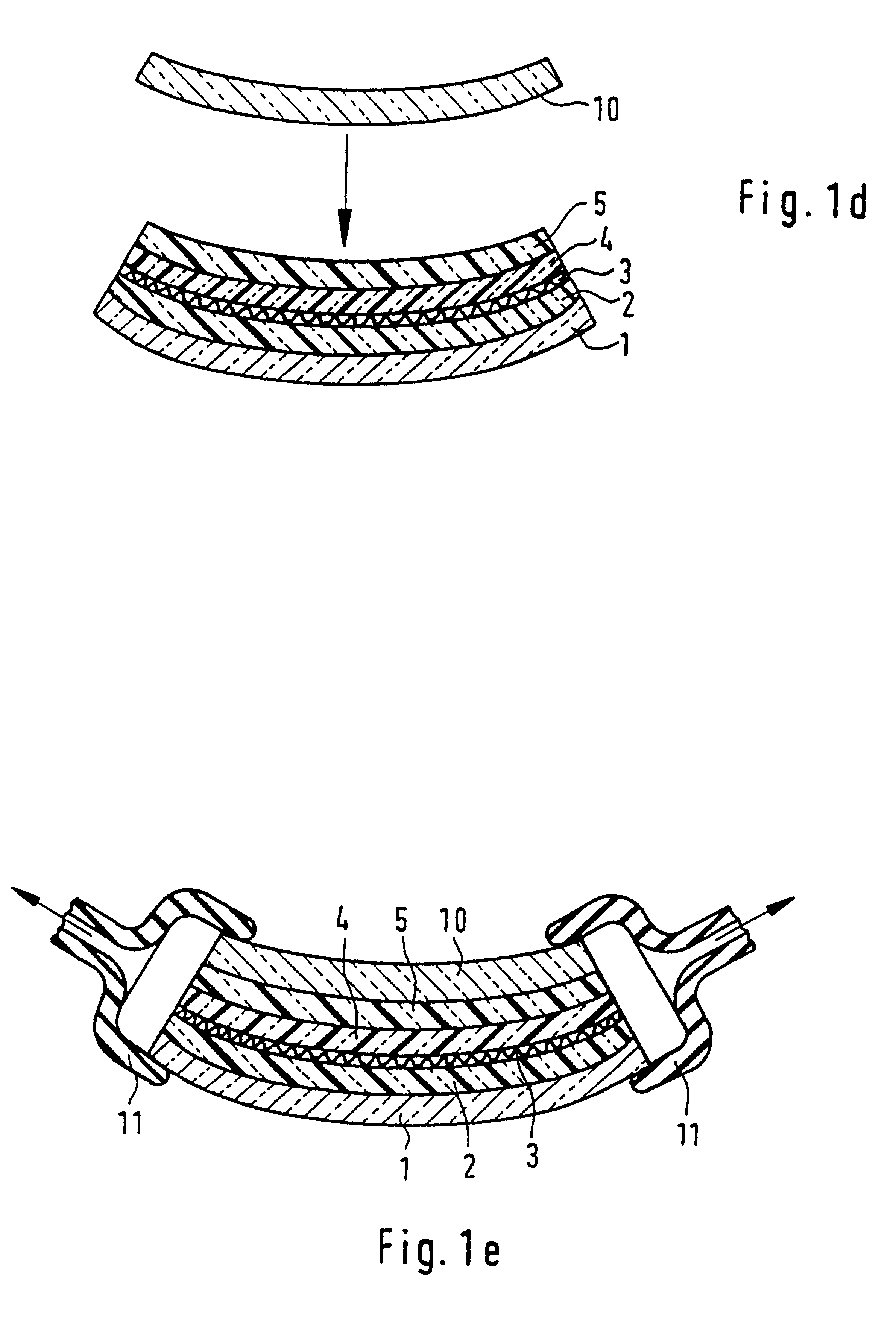

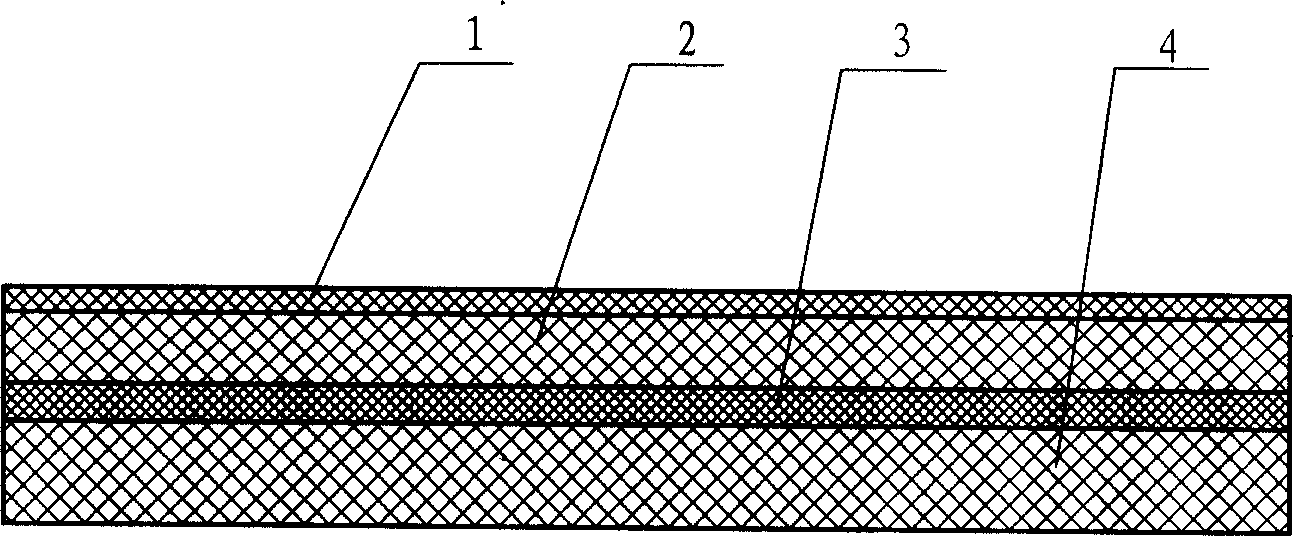

Process for producing a curved laminated safety glass sheet

InactiveUS6261398B1Avoid wrinklesSimple preparation processLaminationLamination apparatusThin layerEngineering

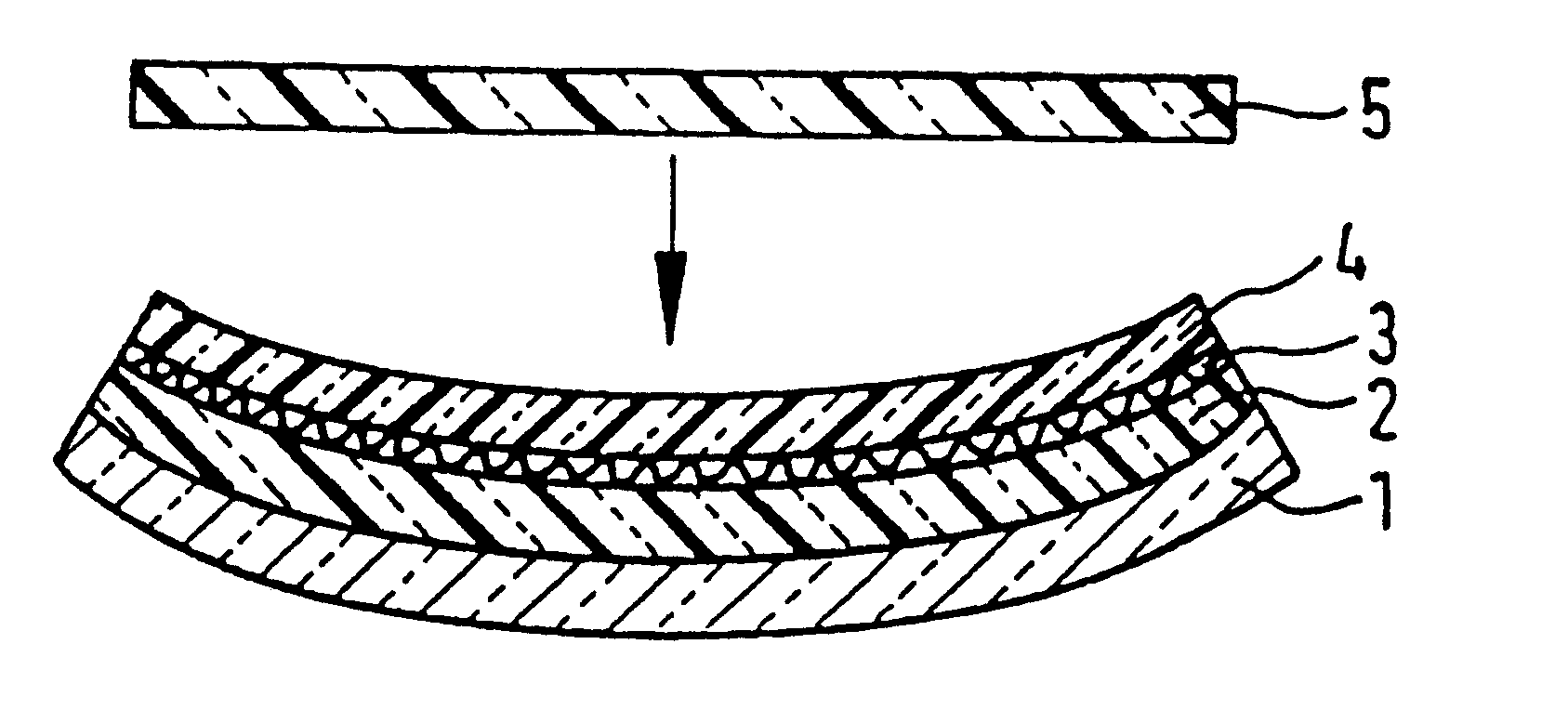

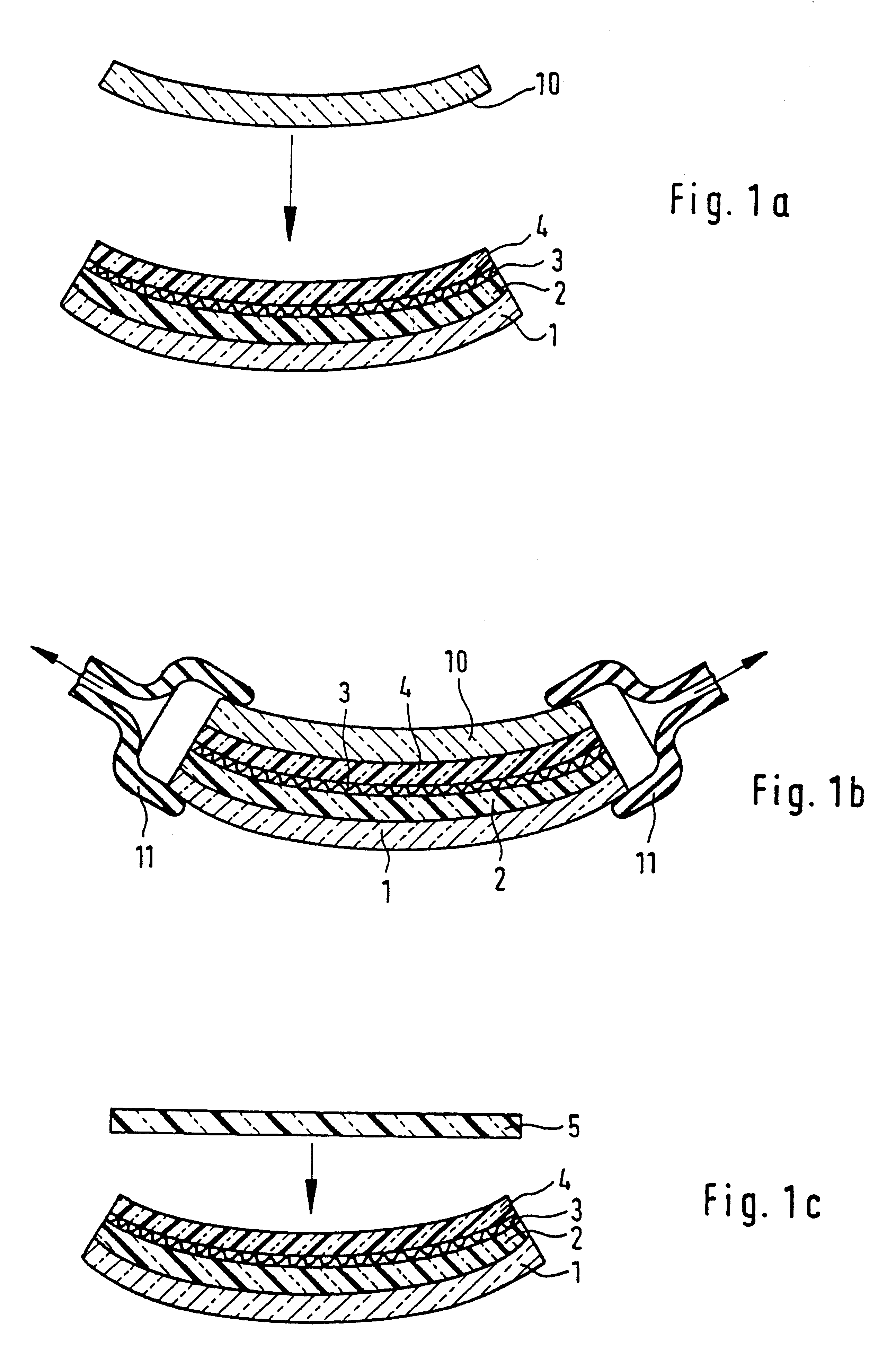

This invention concerns a process for producing a curved, laminated safety glass sheet from a first curved glass sheet (1), a first laminated layer (2), a thermoplastic substrate sheet (4) with a biaxially drawn thin-layer system (3), a second laminated layer (5), and a second curved glass sheet (10) conforming to the first one. To avoid formation of folds in the substrate layer, the process has the following steps: (a) a prelaminated sheet consisting of the first laminated layer (2) and the substrate sheet (4) is superimposed with its laminated layer facing the first glass sheet, (b) a bend-resistant cover sheet (10) conforming to the first glass sheet (1) is superimposed on the prelaminated sheet, (c) the glass layer packet formed out of the first glass sheet (1) and the prelaminated sheet with the cover sheet (10) superimposed upon it is preliminarily bonded by removing the air and subjecting it to pressure and heat, (d) the cover sheet (10) is removed, (e) the second laminated layer (5) and the second glass sheet (10) are superimposed on the preliminarily bonded glass-film pocket, (f) the laminate so formed is preliminarily bonded by removing the air and subjecting it to pressure and heat, (g) the preliminarily bonded laminate is finally bonded into a laminated safety glass sheet by subjecting it to pressure and heat.

Owner:PILKINGTON AUTOMOTIVE DEUT GMBH

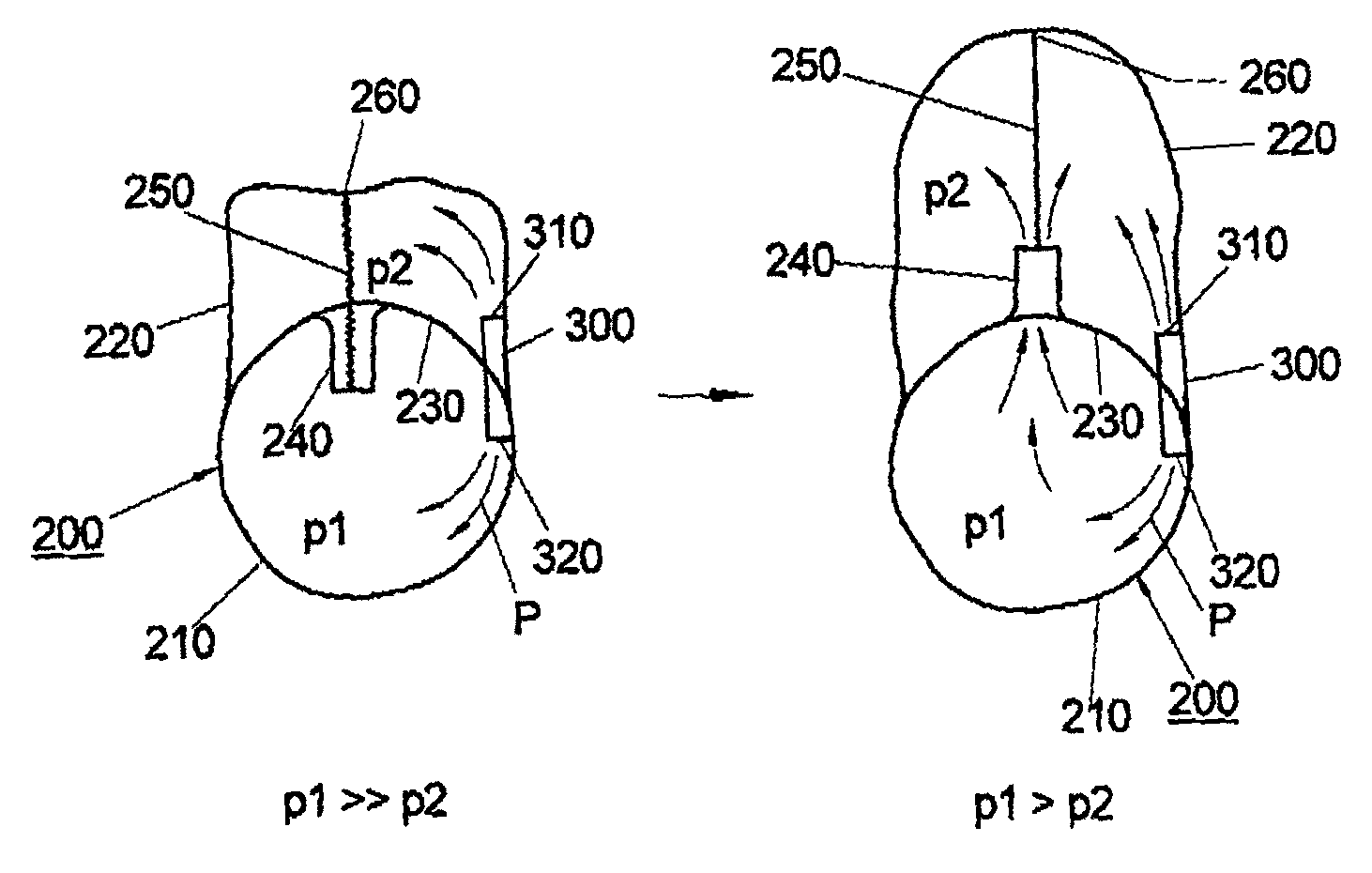

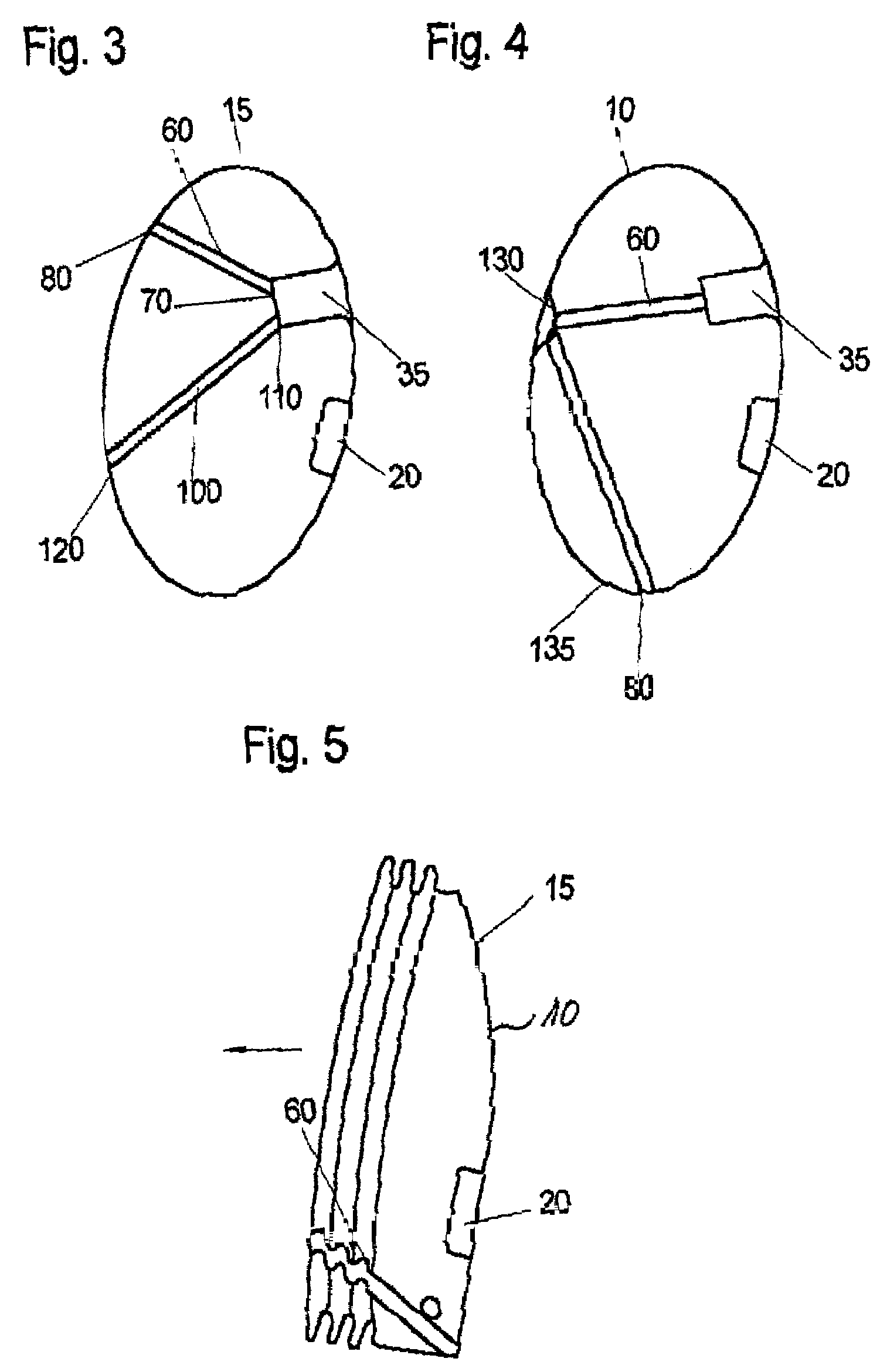

Gas bag for an airbag module

InactiveUS7059634B2Produced cost-effectivelyIncreased riskPedestrian/occupant safety arrangementEngineeringInternal pressure

A gas bag in which an orifice is opened or closed with the aid of a control band as soon as the gas bag has reached a predetermined state of deployment. One end of the control band is fastened to a gas bag envelope in the region of the orifice. The control band is connected at its other end to the gas bag envelope so that, when the predetermined state of deployment is reached, the control band slips into the gas bag envelope so that the orifice is closed by the slipped-in region of the gas bag envelope by the internal pressure of the gas bag, or the control band slips out of the gas bag envelope so that the previously closed orifice is opened.

Owner:TAKATA CORPORATION

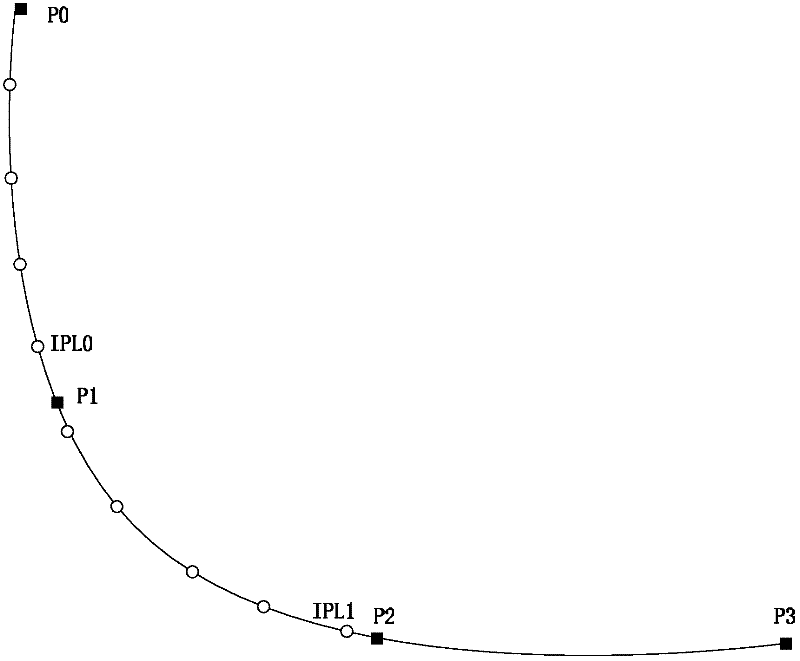

Handwriting generating method for electronic writing brush

ActiveCN102521858AReduce the numberAvoid wrinklesModifying/creating image using manual inputInput/output processes for data processingGraphicsHandwriting

The invention discloses a handwriting generating method for an electronic writing brush, which relates to the technical field of computer image processing and includes the following steps: S1 calculating distance between two adjacent touch points according to touch point coordinates on a touch track delivered by a touch device; S2 if the distance is smaller than a preset threshold, the touch point is obtained according to the preset threshold serving as the distance, and if the distance is larger than the preset threshold, an interpolation point is inserted between the two adjacent touch points; and S3 drawing a preset writing brush shape according to points on the touch track to generate handwriting. The handwriting generating method enables writing brush handwriting input by hands to be smooth and continuous.

Owner:BEIJING SHENGSHI XUANHE INFORMATION TECH

Transparent, coated, shrinkable, oriented polypropylene film

InactiveUS20030157354A1Prevent shrinkageAvoid wrinklesSynthetic resin layered productsPackaging by pressurising/gasifyingWater basedEngineering

A transparent, coated, heat-shrinkable film having controlled shrinkability which includes a biaxially oriented substrate having a polypropylene blend core layer and a water based coating. The shrink during the application on packaging machines is achieved through the balanced MD-TD (machine direction and transverse direction) film retraction in and near the sealed areas. The substrate can also include outer layers of a propylene-ethylene-butylene terpolymer disposed on either side of the polypropylene core layer or on either side of additional intermediate layers that may be disposed between the outer layers and the core layer. The invention also includes a process for making this coated heat-shrinkable film. The coated film is formed under controlled temperature and tension conditions to produce a packaging film having shrinkage within a controlled shrinkability range.

Owner:EXXONMOBIL CORP (US)

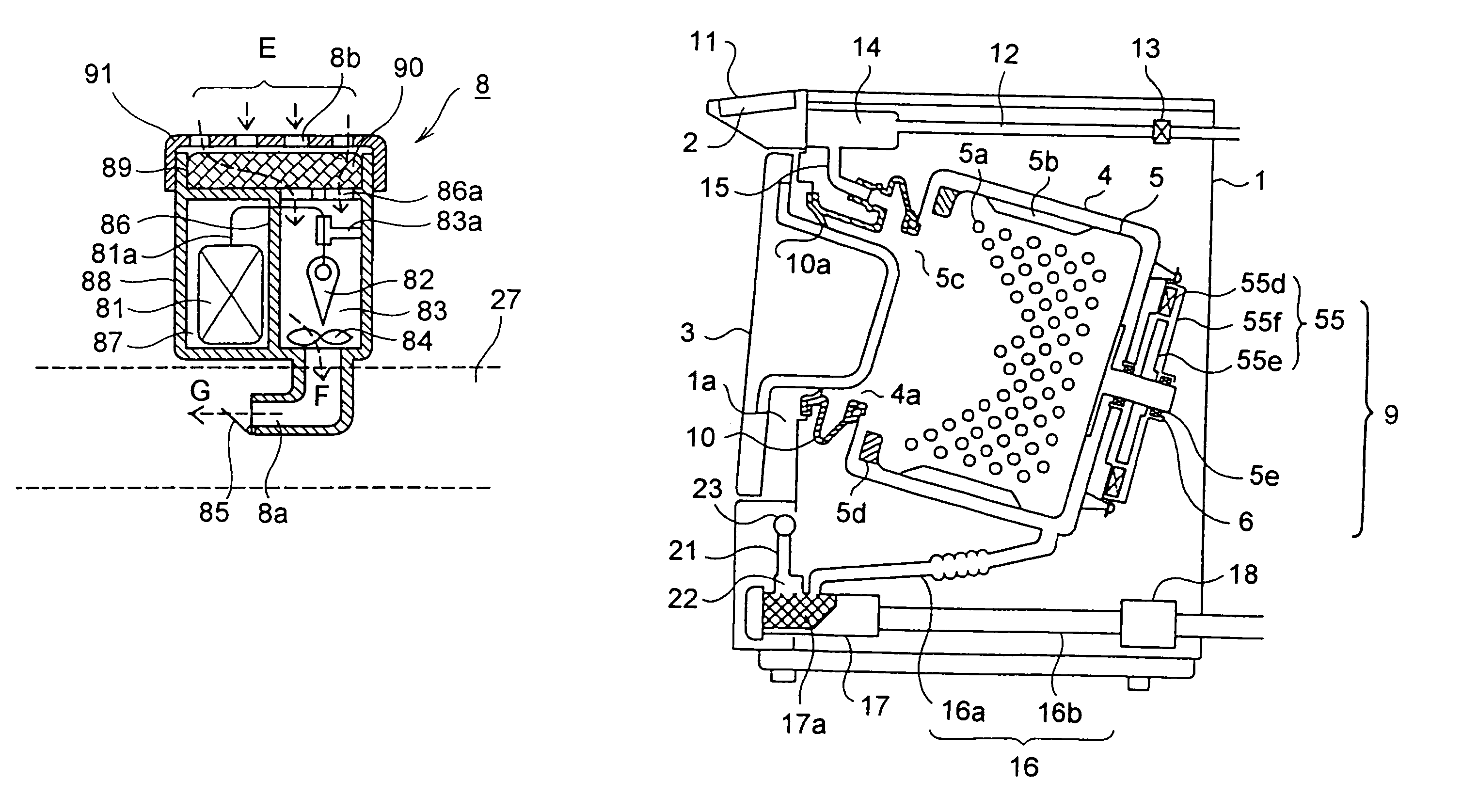

Drying/washing machine

InactiveUS6954995B2Easy to cleanAvoid wrinklesOther washing machinesControl devices for washing apparatusEngineering

A washer-dryer has a tub, a drum rotatably disposed inside the tub, and warm air feeding means for feeding warm air to dry laundry put in the drum. The washer-dryer further has an ion generating device that generates ions for sterilizing the laundry. The ion generating device feeds the ions to the drum and the tub. This makes it possible to realize a washer-dryer that can kill germs attached to clothes or floating in circulated air and thereby keep clothes clean.

Owner:SHARP KK

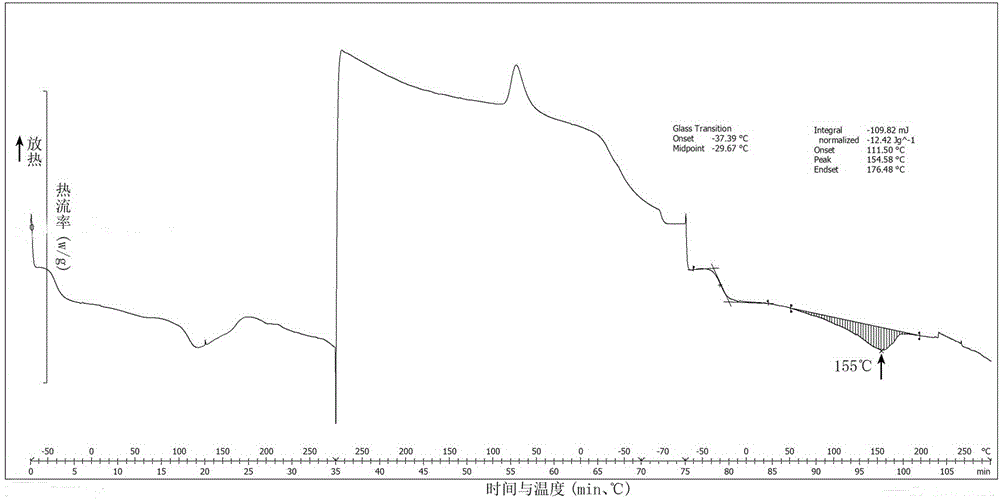

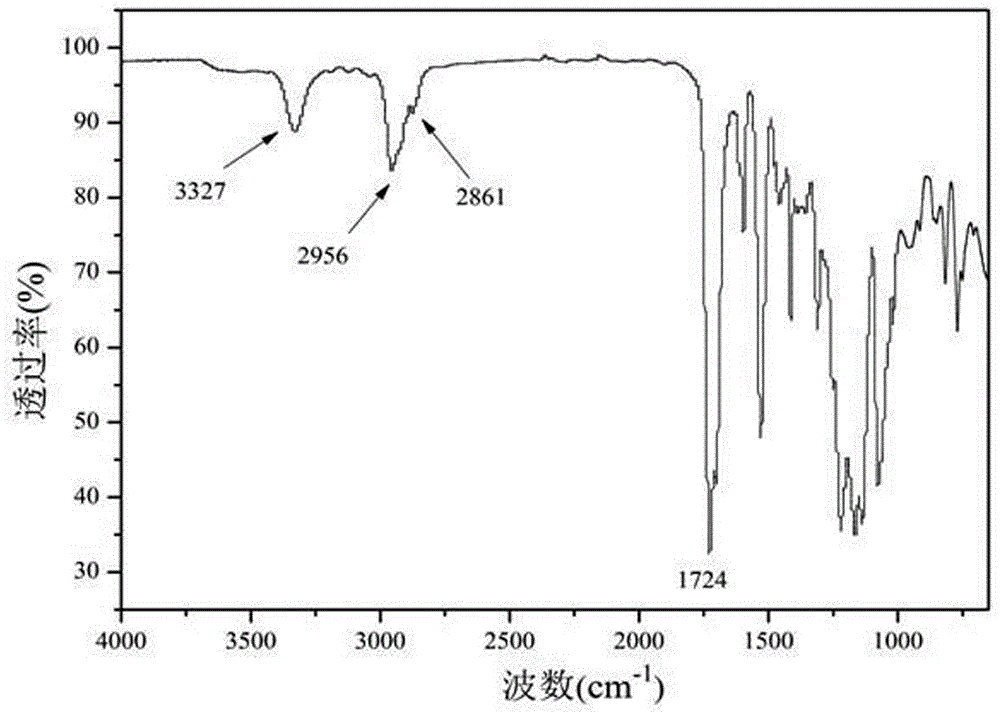

Preparation method of thermoplastic polyurethane beads and bead molding technology

The present invention discloses a preparation method of thermoplastic polyurethane beads and a bead molding technology. High foaming thermoplastic polyurethanes (TPU) beads are obtained through: melting and granulating TPU, melt viscosity modifiers, fillers and age resisters to prepare TPU co-blending granules; using clean, cheap, environmentally-friendly CO2 and / or N2 as foaming agents; and performing medium-temperature and high-pressure soakage, dissolution equilibrium, pressure relief and pre-foaming, saturated steam secondary foaming and other techniques. The obtained high foaming TPU beads are small in shrinkage ratio and smooth in surface. The invention further discloses the bead molding technology which uses a water vapor assisted mould pressing technology to prepare molded bodies of the TPU foaming beads, the prepared molded bodies of the TPU foaming beads are low in density, small in shrinkage ratio and uniform in surface texture, and also have an unique property of TPU resin. The TPU beads can be widely applied in the fields of vibration-absorptive materials, packaging materials, toys for children, sporting goods, aviation models, heat insulating materials, automotive interior materials, etc.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

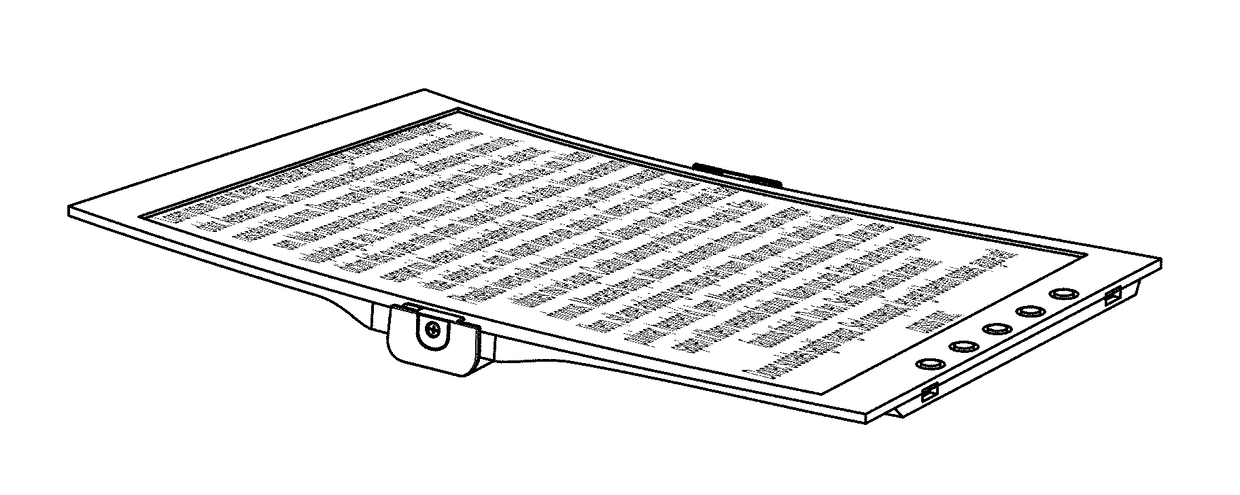

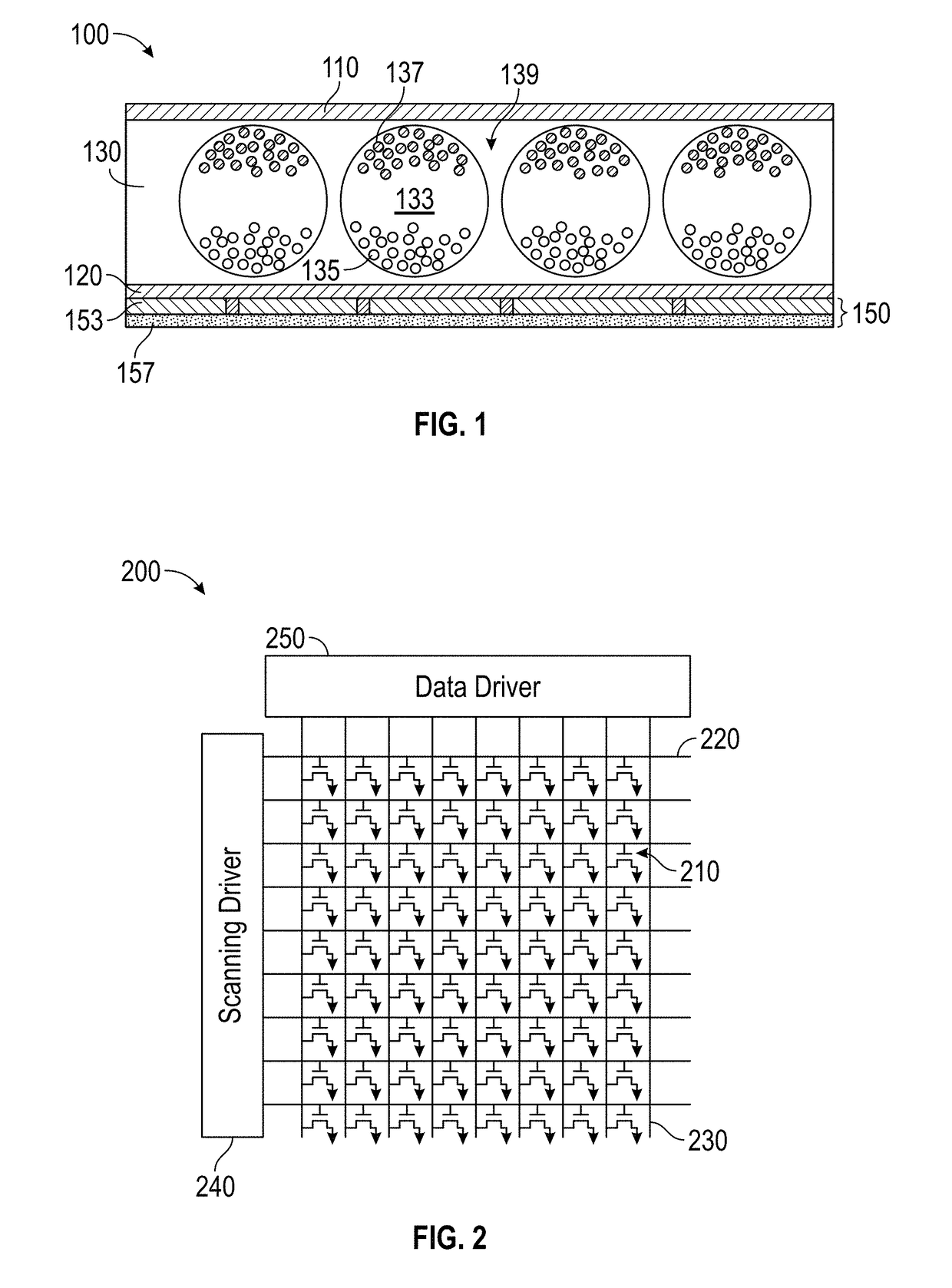

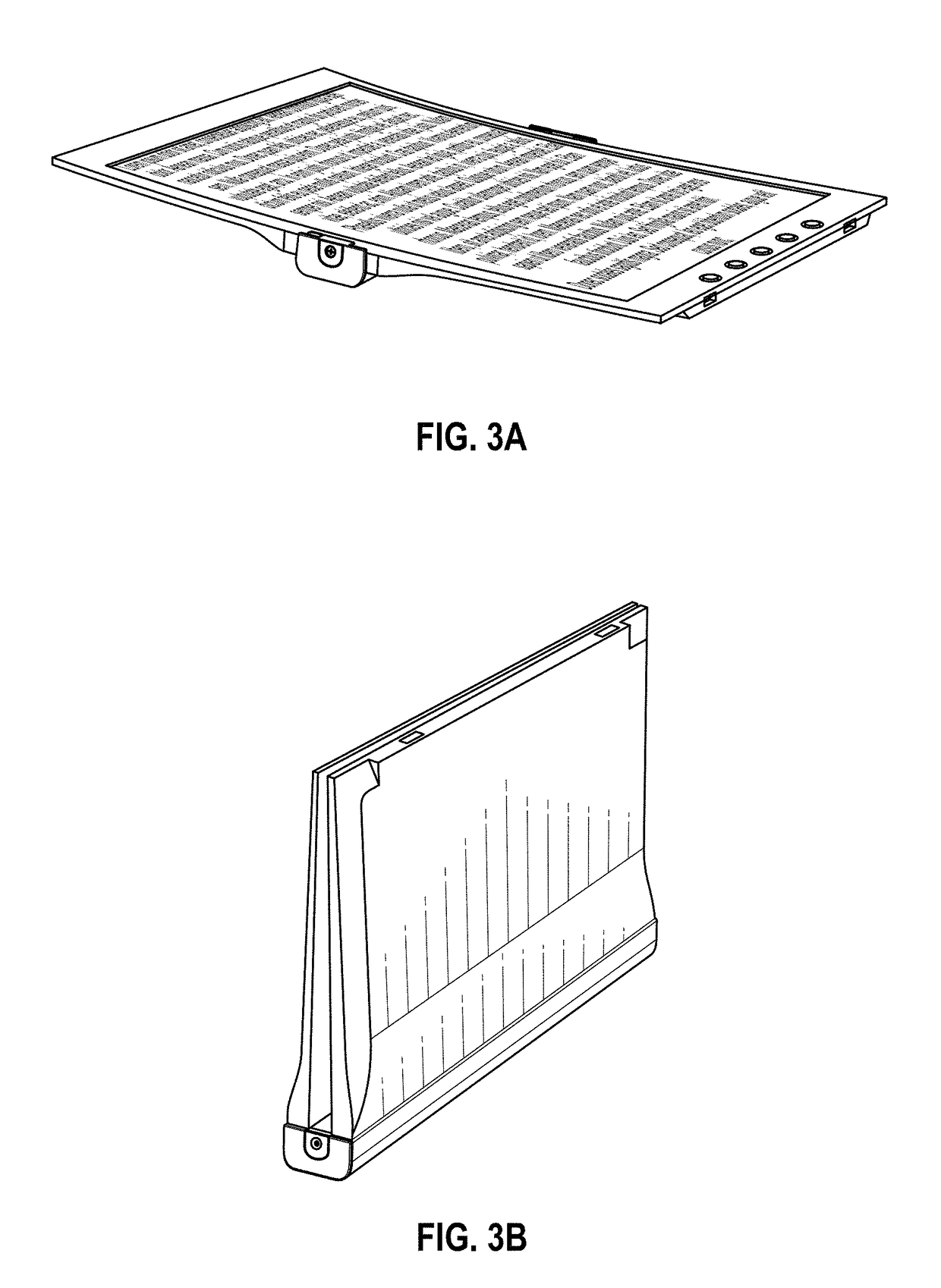

Foldable electro-optic display including digitization and touch sensing

ActiveUS20180335679A1Improve flatnessOpen state stableWing accessoriesDetails for portable computersTouch SensesDisplay device

An electro-optic display that is flexible and may be folded in a book-like fashion. The display apparatus may include a flexible display and a bending mechanism for accommodating the flexible display in a closed state. Portions of the flexible electro-optic display can be coupled to regions of the planar support members so that when the display is in an open state, the display lays flat and smooth. In advanced embodiments, the electro-optic display may include touch sensing or a digitizing layer to record interactions with a stylus.

Owner:E INK CORPORATION

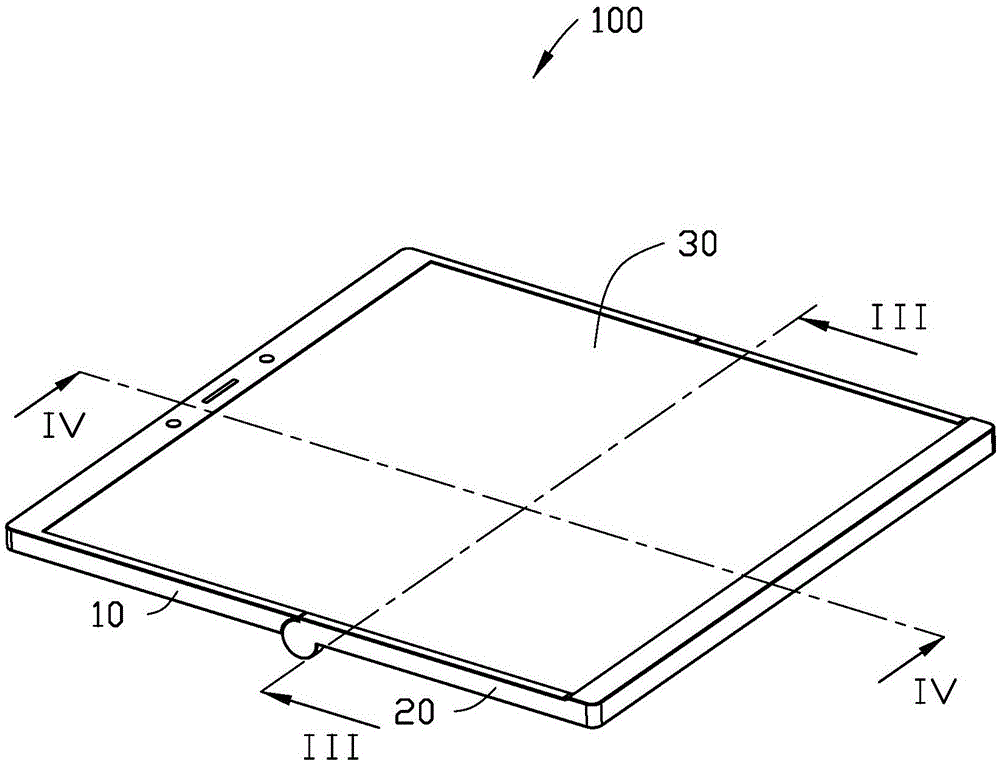

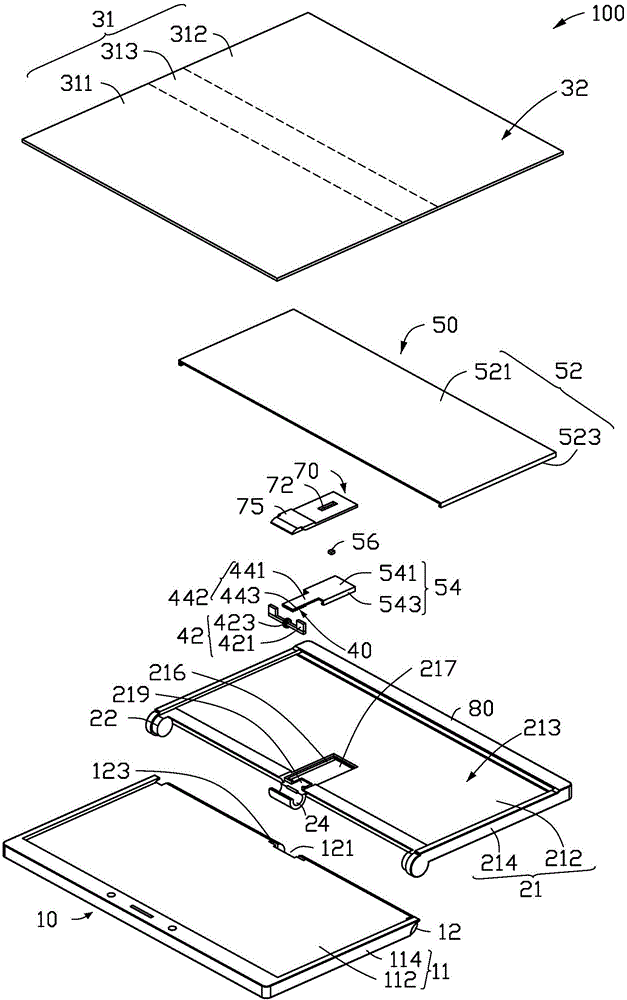

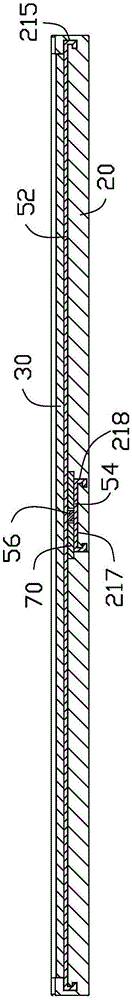

Foldable electronic device

ActiveCN106788536ACompensation length differenceAvoid wrinklesDigital data processing detailsTransmissionWrinkle skinEngineering

The invention discloses a foldable electronic device comprising a first shell, a second shell and a flexible display screen, wherein the first shell and the second shell are rotatably connected, and the flexible display screen is accommodated in the first shell and the second shell. The foldable electronic device further comprises a transmission component and a sliding component, one end of the transmission component is fixedly connected with the first shell, the other end of the transmission component is fixedly connected with the sliding component, the sliding component is arranged on the second shell in a sliding manner and is fixedly connected with the flexible display screen, and when the first shell rotates relative to the second shell, the flexible display screen slides relative to the second shell under the drive of the transmission component and the sliding component. When the foldable electronic device disclosed by the invention is folded or unfolded, the flexible display screen slides with the sliding component, thereby avoiding the wrinkle or stretch of the sliding component.

Owner:MEIZU TECH CO LTD

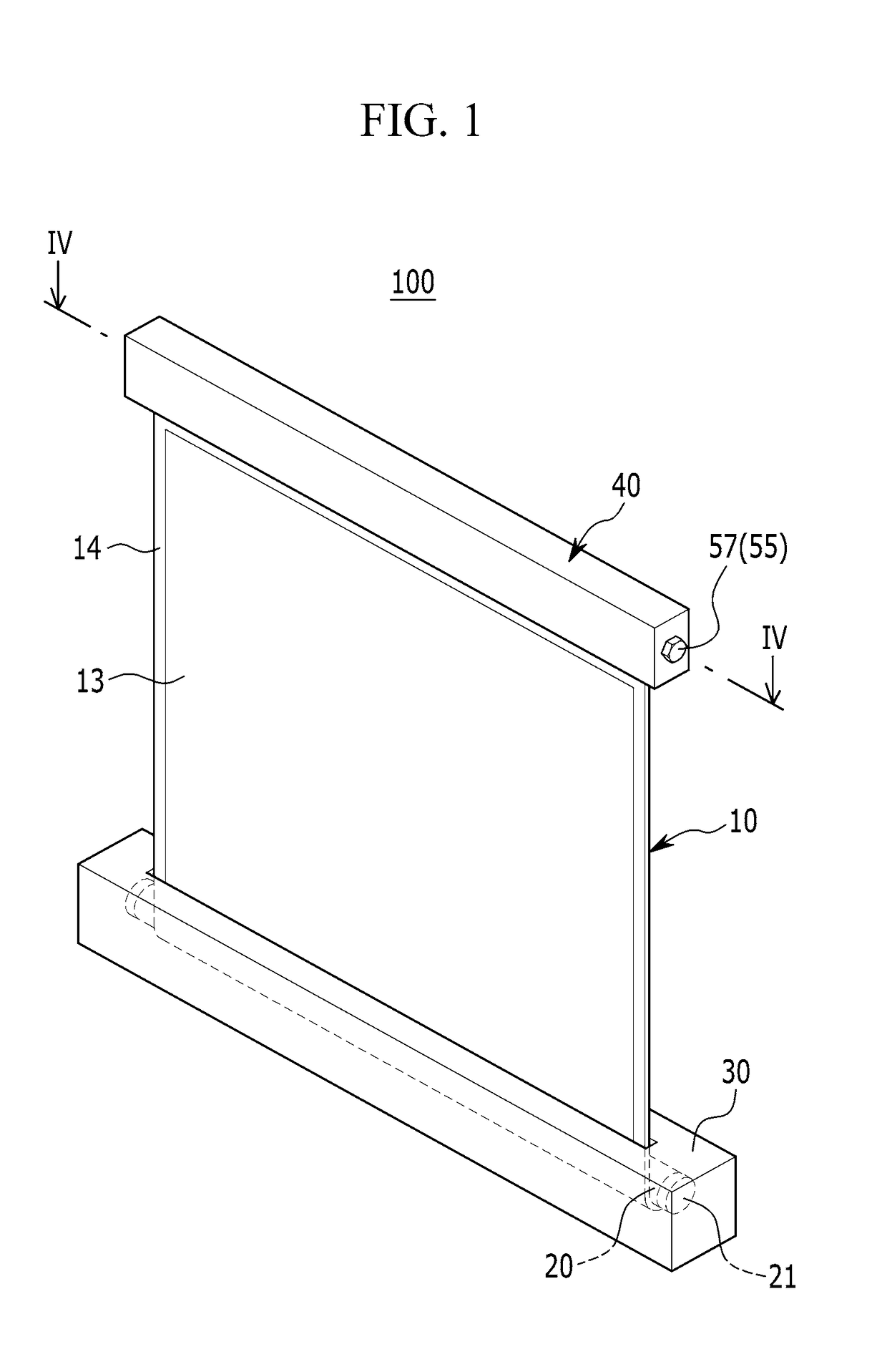

Display device

ActiveUS20170325343A1Satisfactory display qualityAvoid wrinklesDigital data processing detailsCasings with display/control unitsDisplay deviceEngineering

A display device includes a flexible display panel, a roller for winding the flexible display panel, an elastic holder fixed to an edge of the flexible display panel and having a side parallel to the edge of the flexible display panel, and a tension applier set disposed at opposite ends of the elastic holder for tensioning the elastic holder.

Owner:SAMSUNG DISPLAY CO LTD

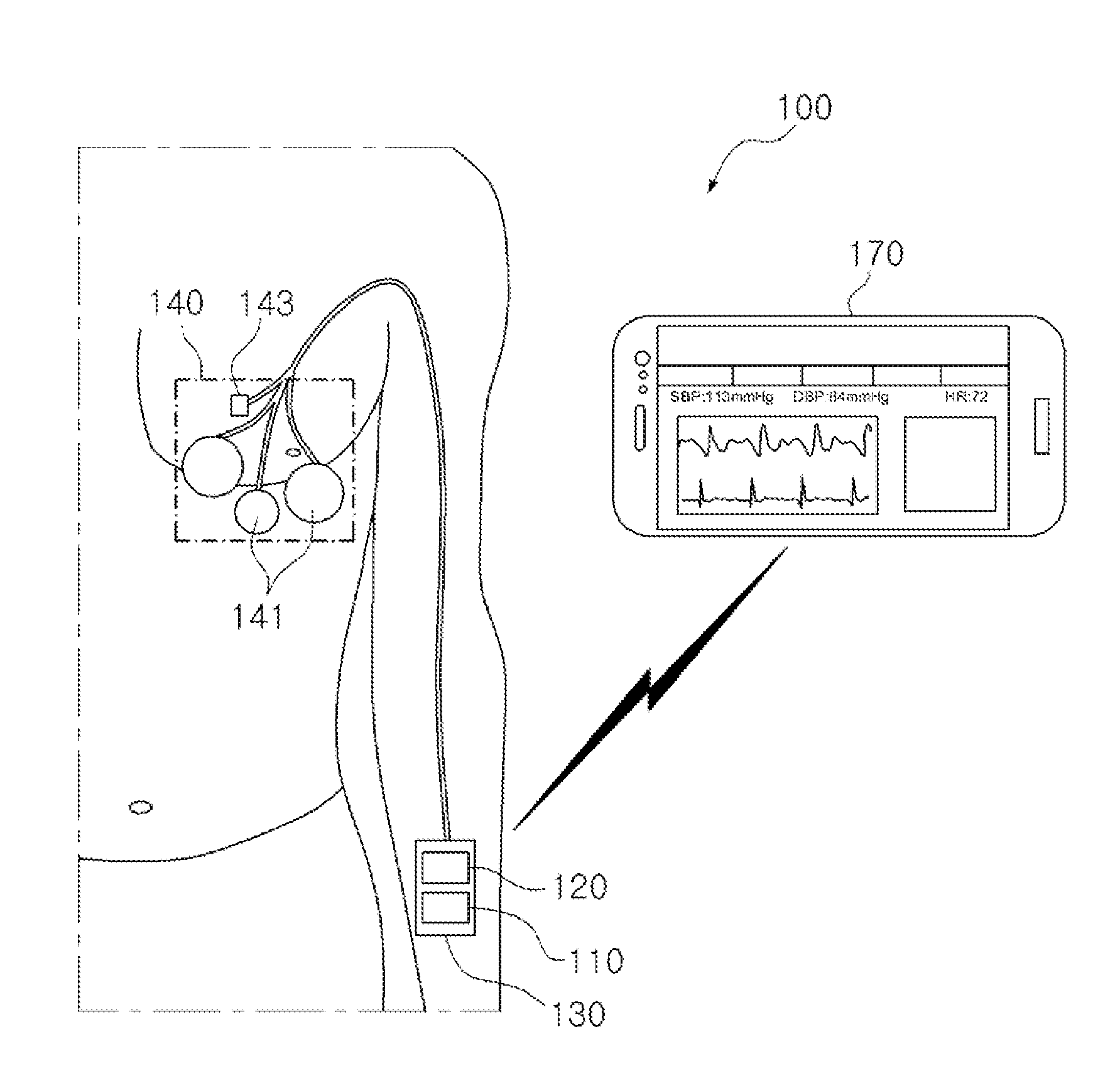

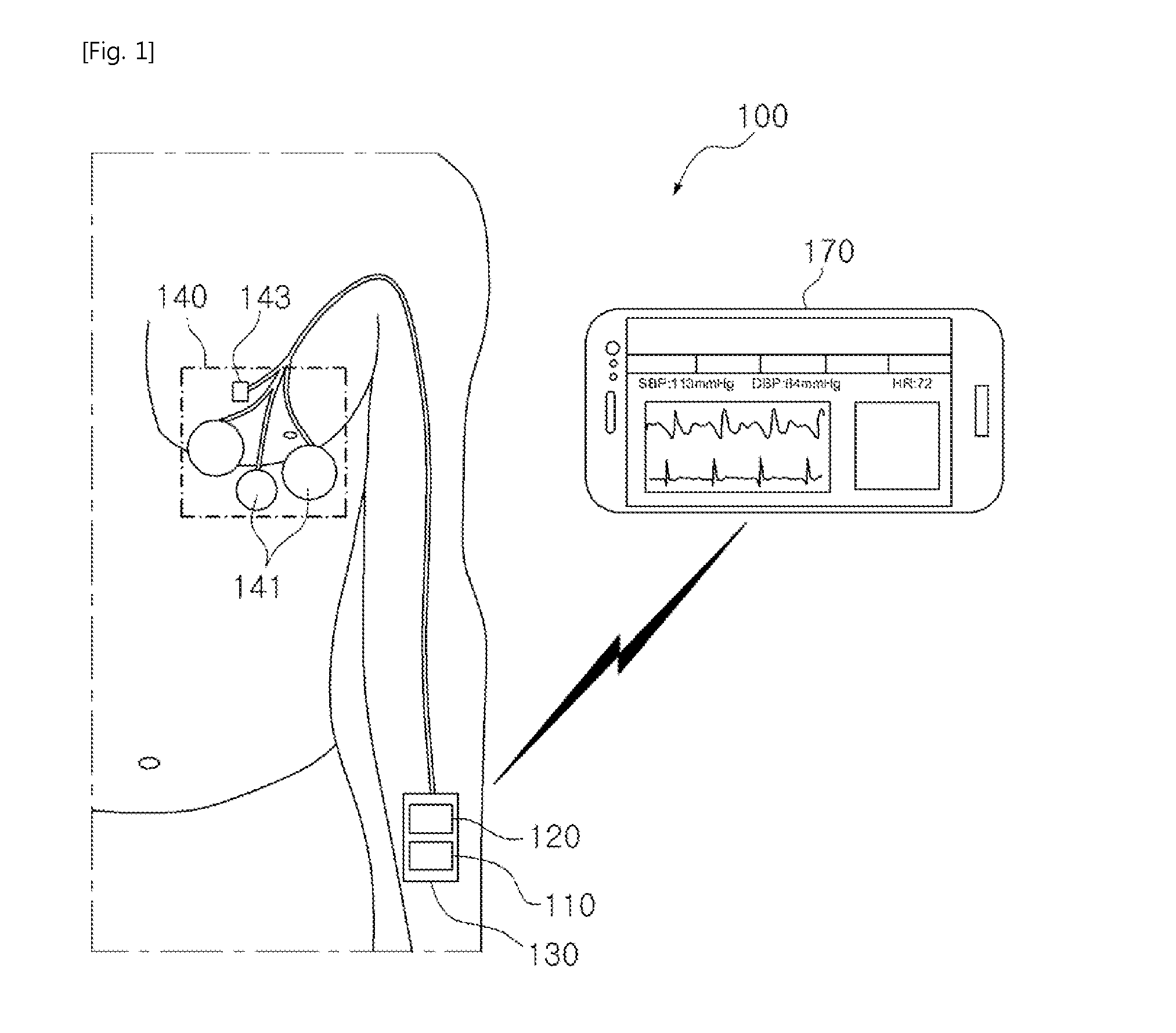

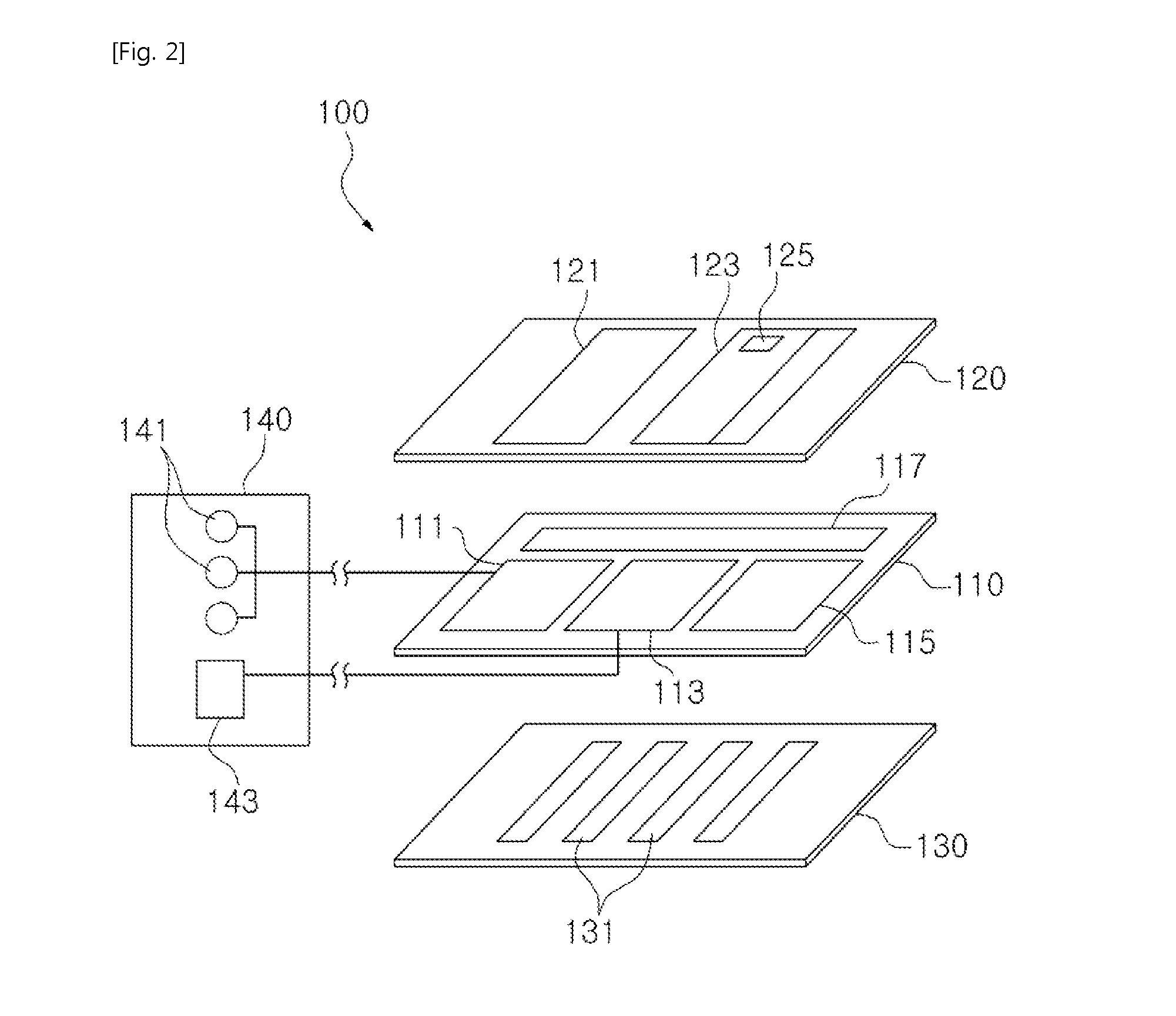

Apparatus for continuously and automatically measuring pulse wave and method for measuring blood pressure

InactiveUS20150374244A1Easy to installSimple configurationElectrocardiographyStethoscopePotential differenceHeart sounds

Disclosed is an apparatus for continuously and automatically measuring a pulse wave by a non-invasive method to know the state of a cardiovascular system. The apparatus includes an integrated measurement module, a communication power module, and a bio-measurement pad. The integrated measurement module includes an electrocardiogram measurement portion for measuring the electrocardiogram of a subject, a bioelectrical impedance measurement portion for measuring the bioelectrical impedance of the subject by a potential difference, a heart sound measurement portion for measuring the heart sound of the subject, and a controller for measuring and controlling the state of the cardiovascular system of the subject on the basis of a pulse transit time calculated by the electrocardiogram signal measured at the electrocardiogram measurement portion, the bioelectrical impedance signal measured at the bioelectrical impedance measurement portion, and the heart sound signal measured at the heart sound measurement portion.

Owner:K HEALTHWEAR

Polarizer, method for producing same, polarizing plate, optical film, and image display

InactiveUS20060227423A1Excellent toneIncreased durabilityPolarising elementsOptical articlesPolyvinyl alcoholTransmittance

A polarizer of the invention comprises a polyvinyl alcohol-based film which is at least dyed with at least iodine and uniaxially stretched, having a single transmittance of 43% or more, a polarizing efficiency of 99.9% or more, and a dichroic ratio of 30 or more, wherein the dichroic ratio is calculated from a parallel transmittance (Tp) and a crossed transmittance (Tc) at a wavelength of 440 nm, and have good hue.

Owner:NITTO DENKO CORP

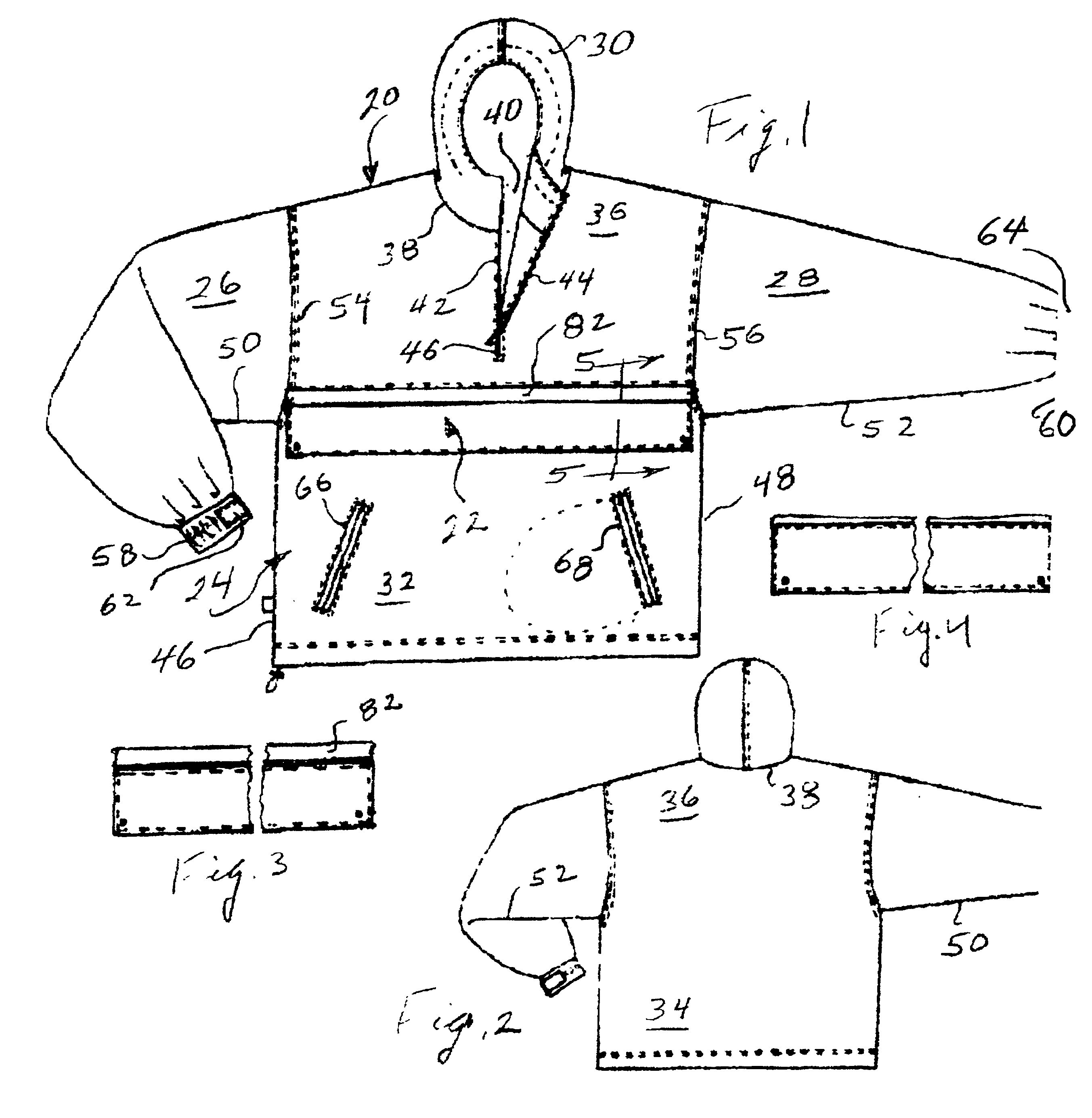

Pullover jacket with customized decorative band

InactiveUS6848118B2Economical inventoryEasy to assembleGarment special featuresJacketsArchitectural engineeringUnit cost

A product and process involve providing customized pullover jackets, units of which are characterized by (1) pullover body construction units of a type having a fabric configuration that facilitates slipping over the head and shoulders; and (2) decorative band construction units of a type having distinguishable color and design for affixation to said pullover body construction. The process comprises acquiring a relatively small inventory of body construction units of different sizes, acquiring a relatively large inventory of band construction units of different colors or designs, and receiving and fulfilling orders for the customized pullover jackets from customers. The body construction units account for the major component of unit cost. The band construction units account for a minor component of unit cost. The customized jackets are assembled by joining mating fasteners on the upper and lower edges of selected band construction and corresponding upper and lower points on selected body constructions. Extending from each body construction is an elongated flap that overlaps the upper edge of the band construction.

Owner:CHARLES RIVER APPAREL

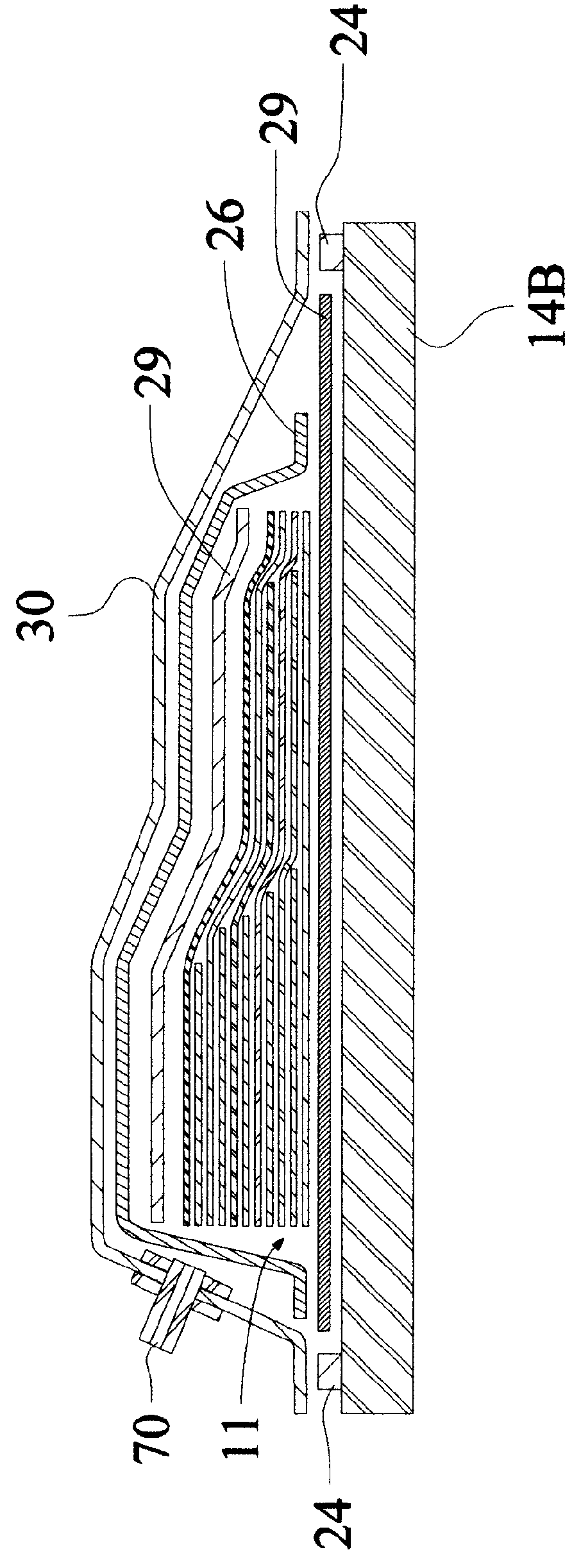

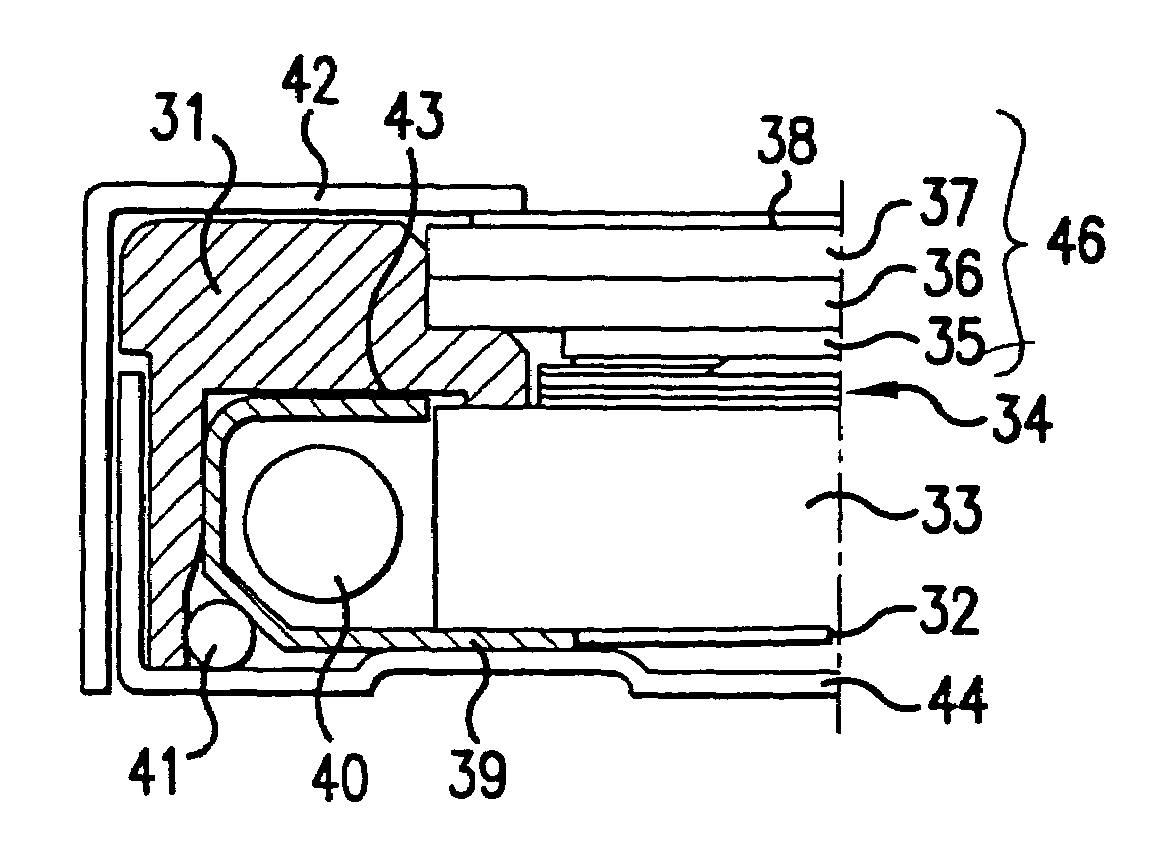

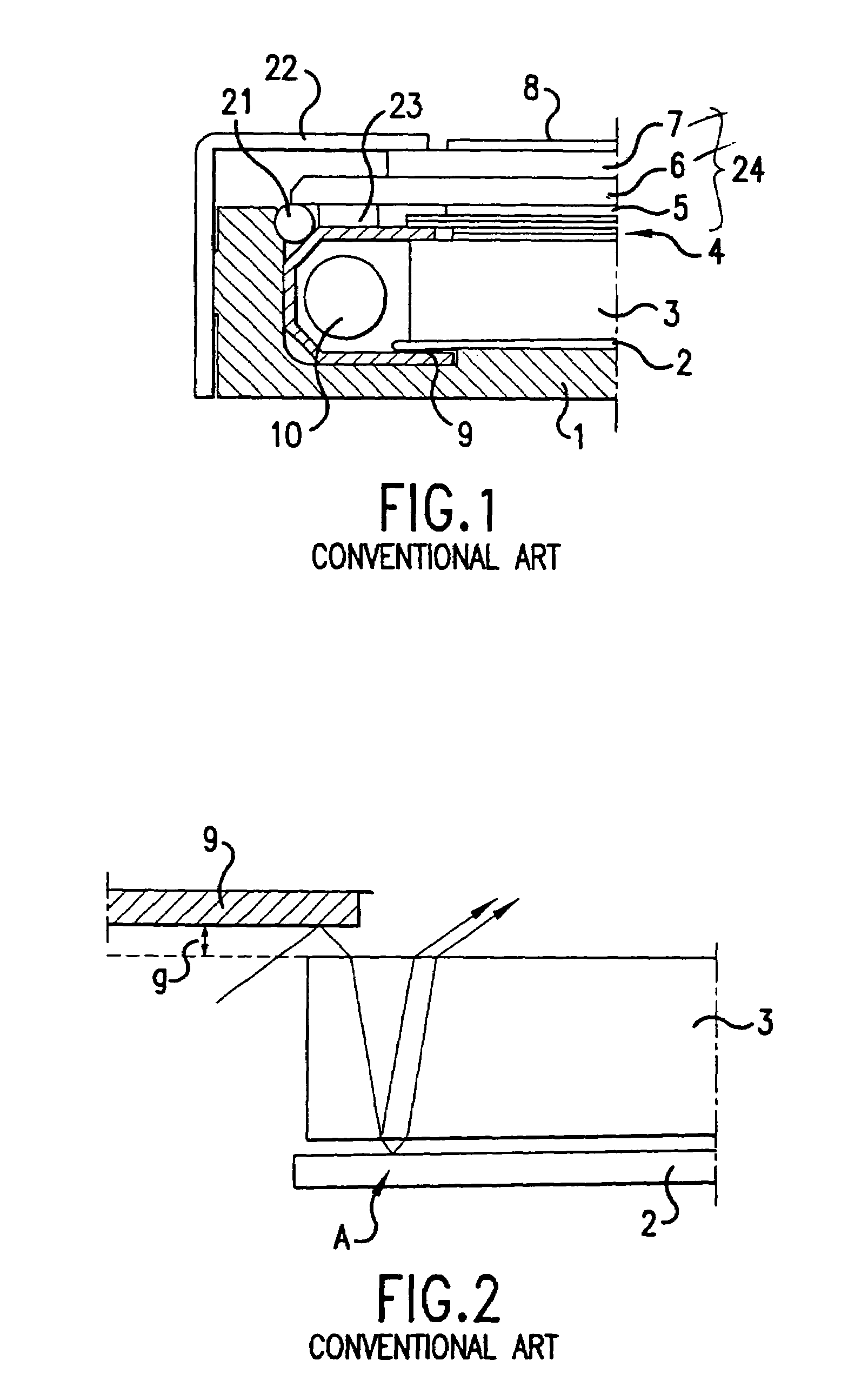

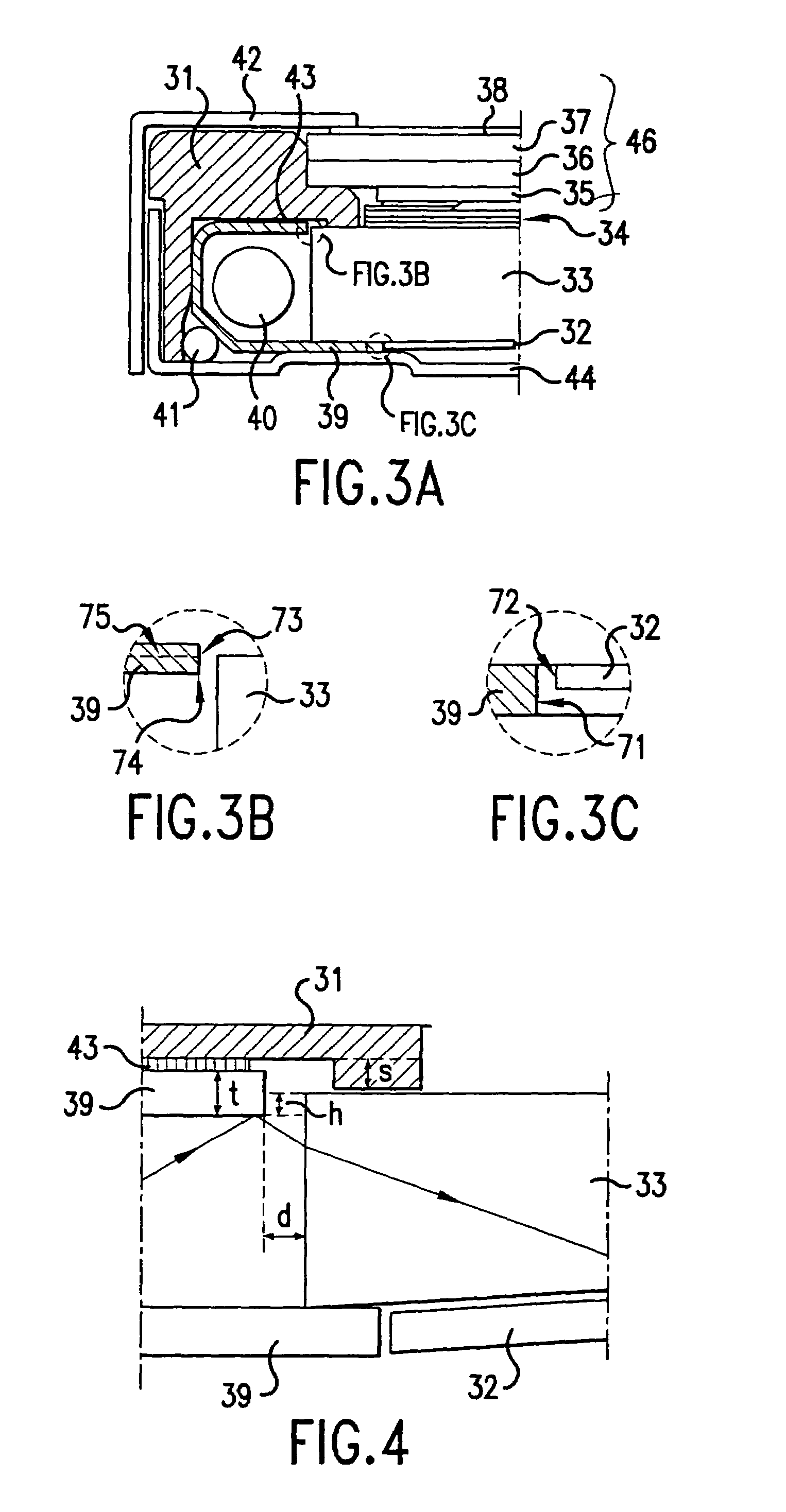

Liquid crystal display device and backlight thereof

InactiveUS7083318B2Avoid it happening againInhibit generation of wrinkleShow cabinetsMechanical apparatusWrinkle skinLiquid-crystal display

In a liquid crystal display device according to the present invention, an upper end portion of a lamp housing is fixed on a main supporter so that the lamp housing can be made to face a side edge of a light guide. Light that can cause bright lines is eliminated or minimized through absorption or scattering by a main supporter. The main supporter is also thermally insulating and is placed between the lamp housing and a liquid crystal panel. Further, a thermally conducting bottom cover is placed under the backlight. Therefore, heat generated from the lamp is effectively channeled away from the light guide to prevent liquid crystal panel deterioration. Still further, although the upper and lower surfaces of the light guide is tightly fit between the lamp housing and the main supporter, wrinkles on a sheet reflector are prevented because the sheet reflector is not stacked between the lamp housing and a lower surface of the light guide.

Owner:LG DISPLAY CO LTD

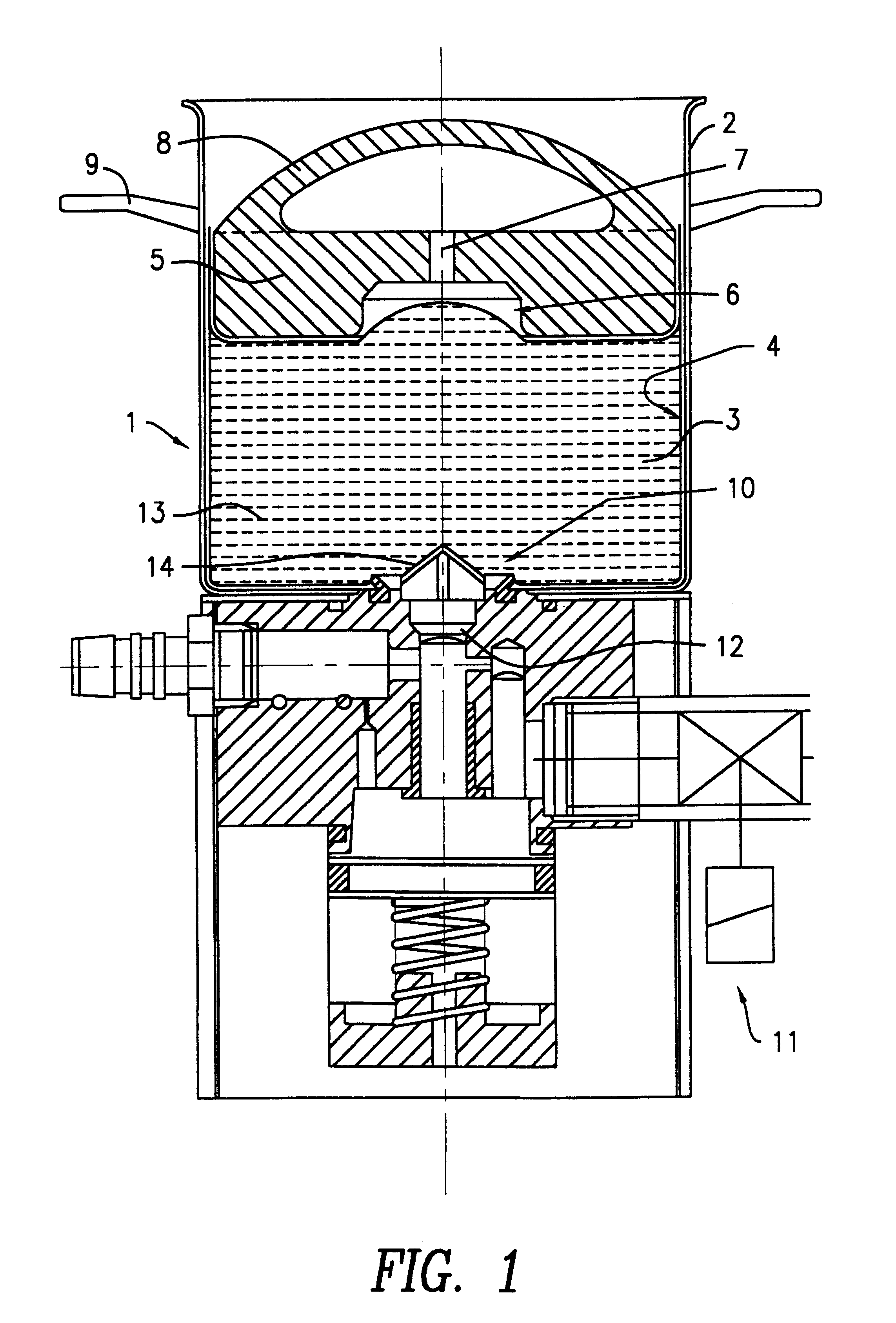

Pot with a flexible storage barrel and follow-up plate

InactiveUS6206242B1Easy to carrySafely and controllably deliveredOpening closed containersBottle/container closureEngineering

The invention relates to a device enabling delivery of a paste from a flexible storage barrel located in a dimensionally stable container. Product is fed to a dosing device which dispenses product under vacuum. A follow-up plate is located on the storage barrel exerting pressure thereon. An opening is located in a central position and surrounds a pressure-sealed connection between the storage barrel and an access passageway to the dosing device.

Owner:HENKEL ECOLAB GMBH & CO OHG

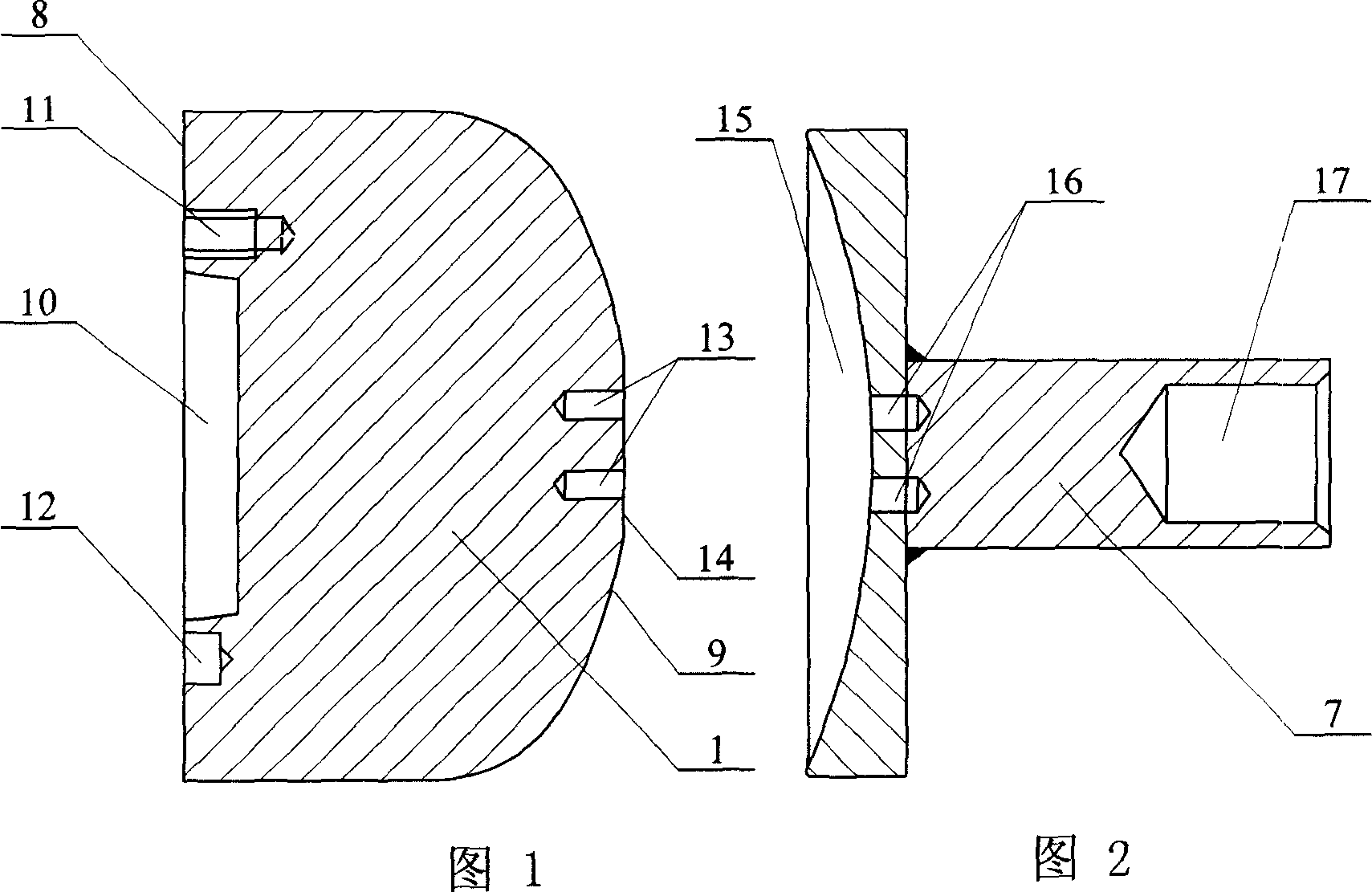

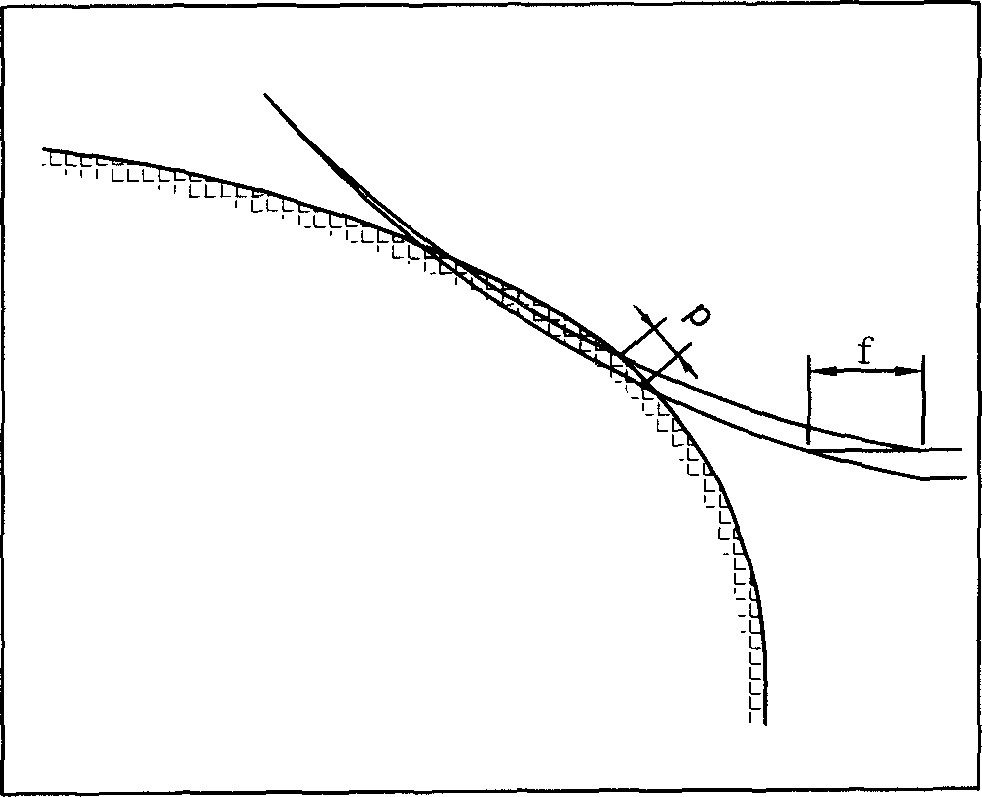

High precision spinning forming method for thin wall closing head with radius-thickness ratio less than three per mille

The invention relates to a thin-walled closure head high accuracy spinning forming method. The invention is to resolve the problem of big size closure head, thin wall thickness, high accuracy size and high difficulty of forming. Spinning machine is started to make rolling wheel do axial and circumferential movement along track loaded into program in head while spinning, meanwhile main axle of spinning machine drives core and bar plate to spin. When rolling wheel rolls to the distance of 20mm from edge it quits. The invention has the advantages of simple process and high accurate product.

Owner:HARBIN INST OF TECH

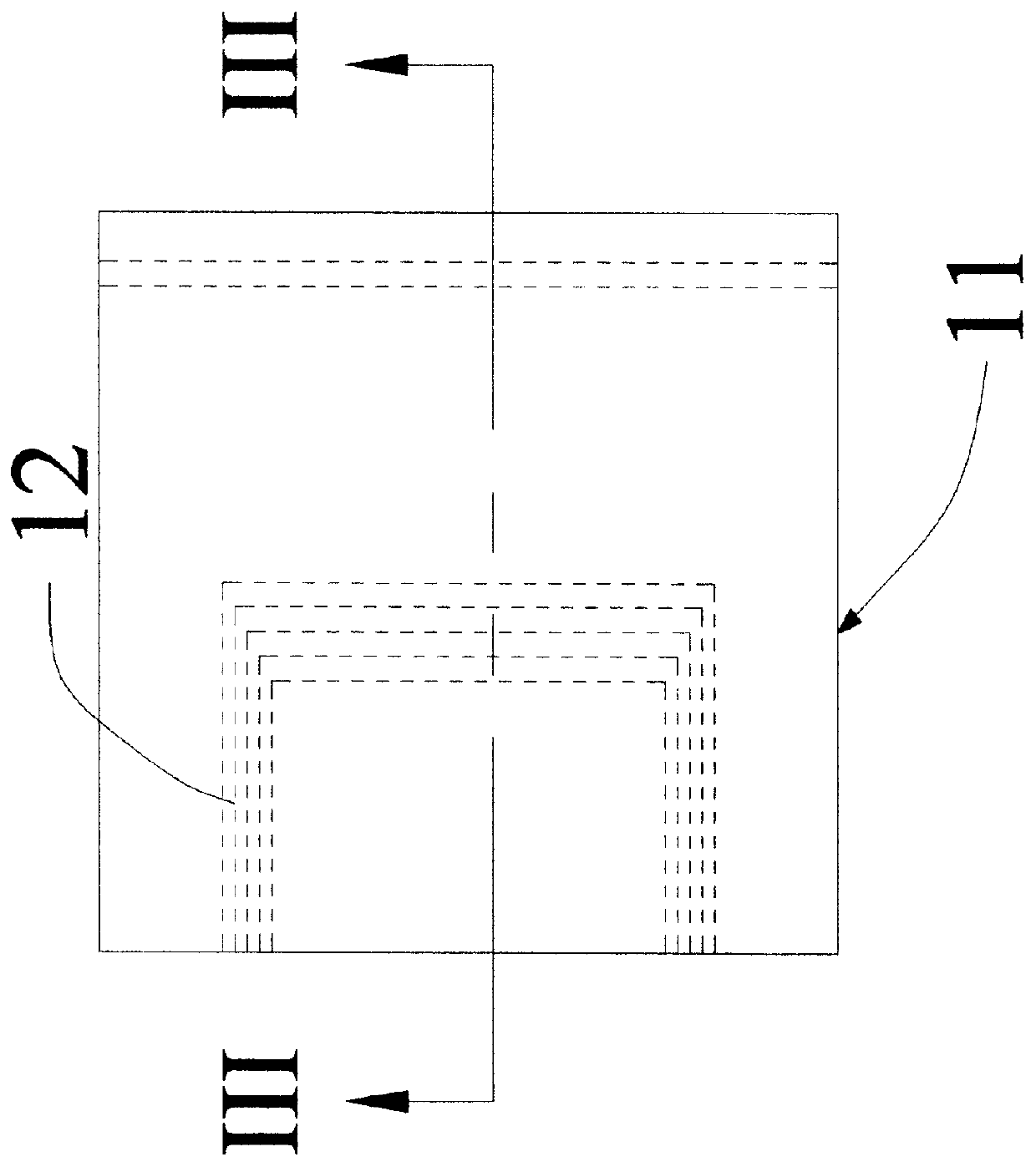

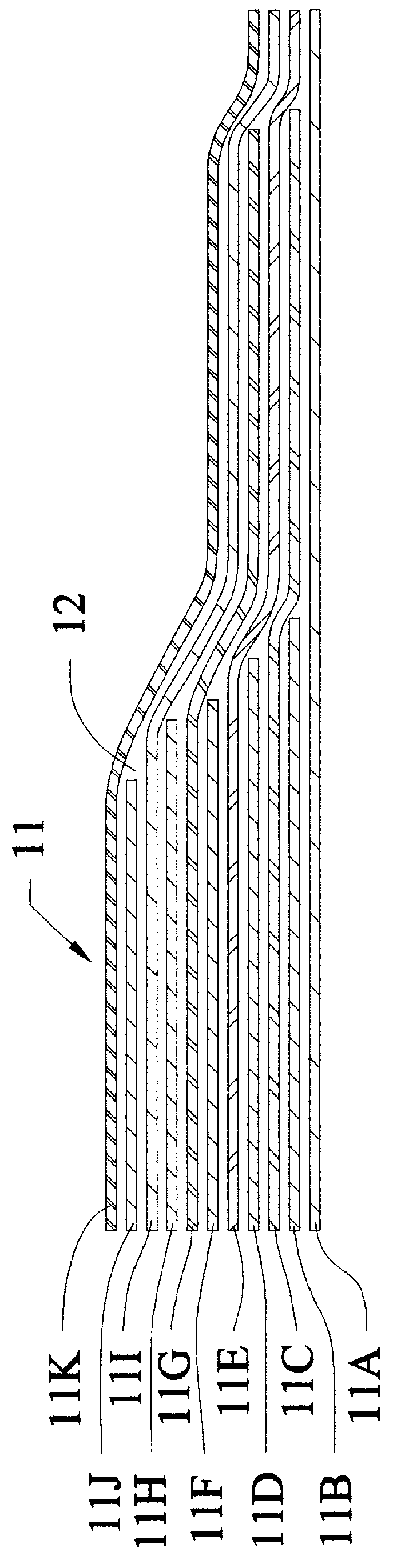

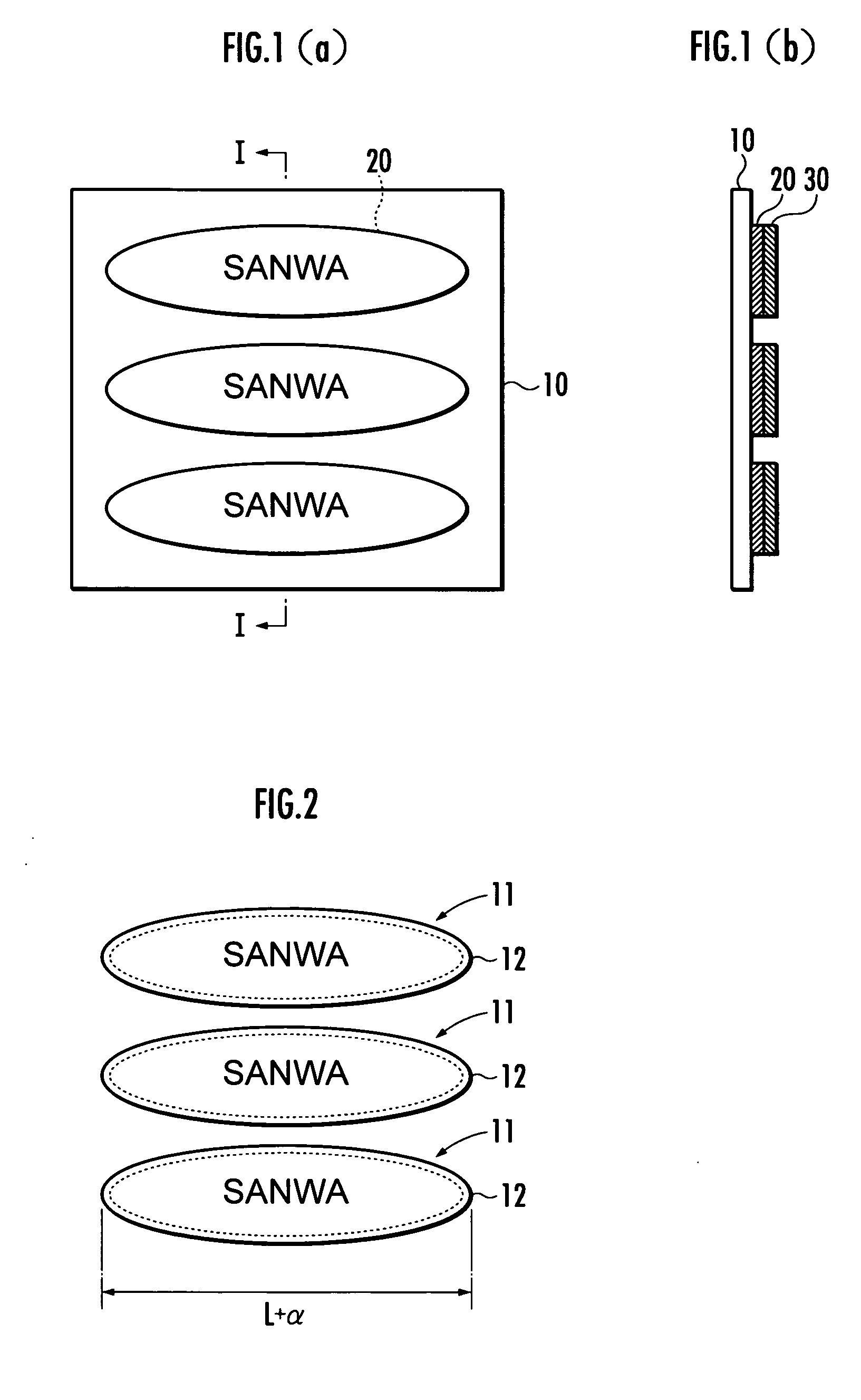

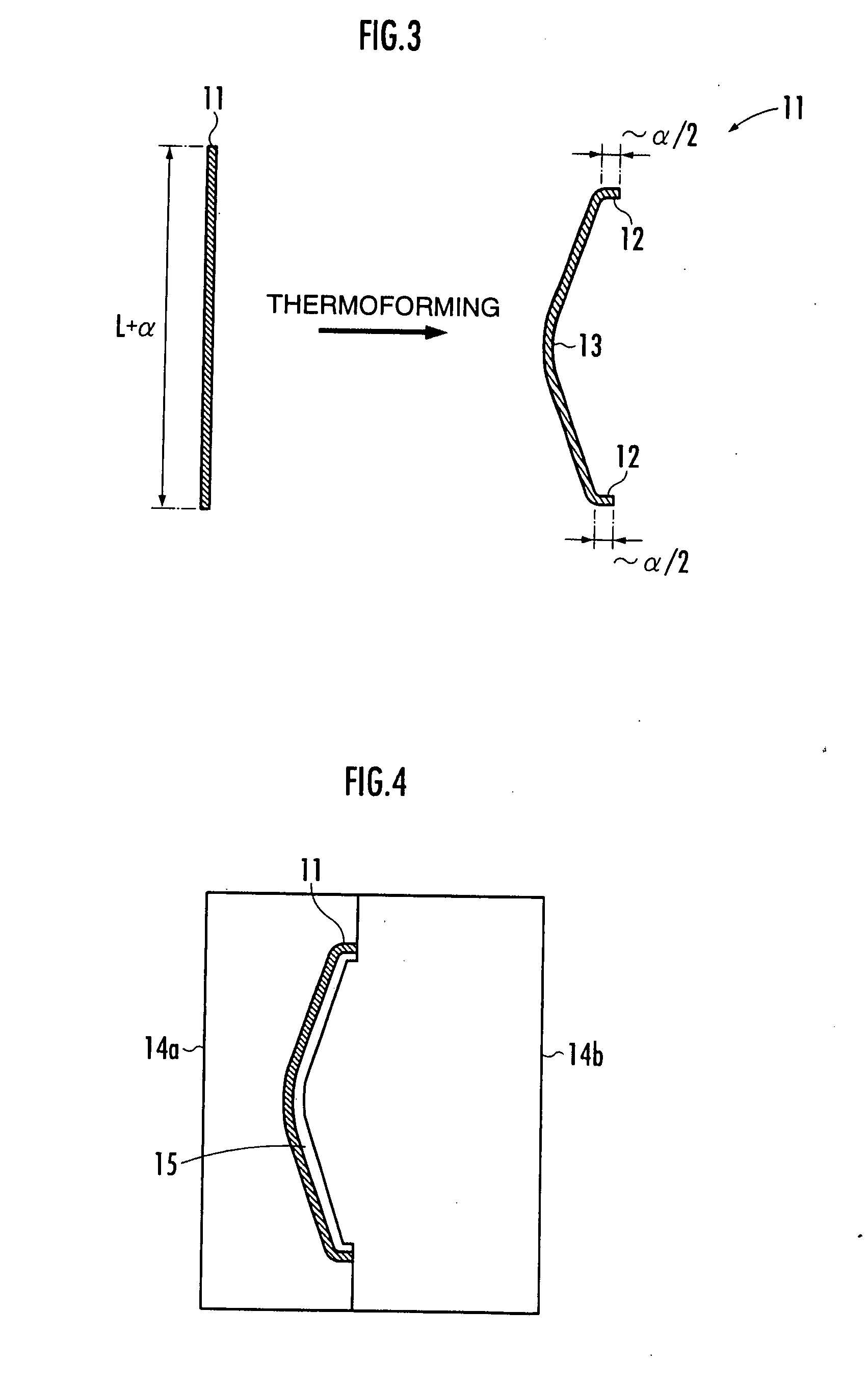

Manufacturing method of film insert molded article

ActiveUS20080277823A1Small sizeAvoid wrinklesButtonsLamination ancillary operationsThree dimensional shapePrinting ink

A manufacturing method of a film insert molded article in which no resin layer is seen in the front and no wrinkle is generated in a film is provided. A thermoformed film (11) for coating is arranged within a cavity (15), and molten resin is injected so that a film insert molded article (50) molded integrally with the film (11) for coating and having a coating plane coated with the film (11) for coating is obtained. A printing ink layer (20) and a binder layer (30) are formed in a raw material film (10). The raw material film (10) is cut out and the film (11) for coating is formed so as to have a size for coating the coating plane and being able to form an outer circumferential bending portion (12) arranged in an outer circumferential side portion (41) by adding a width exceeding a heat shrinking amount of the film. After the film (11) for coating is preheated, the film (11) for coating is thermoformed so that a predetermined three-dimensional shape (13) and the outer circumferential bending portion (12) are formed. The film (11) for coating in which the three-dimensional shape (13) and the outer circumferential bending portion (12) are formed, is arranged within the cavity (15) such that the binder layer (30) comes into contact with molten resin. The molten resin is then injected.

Owner:SANWA SCREEN

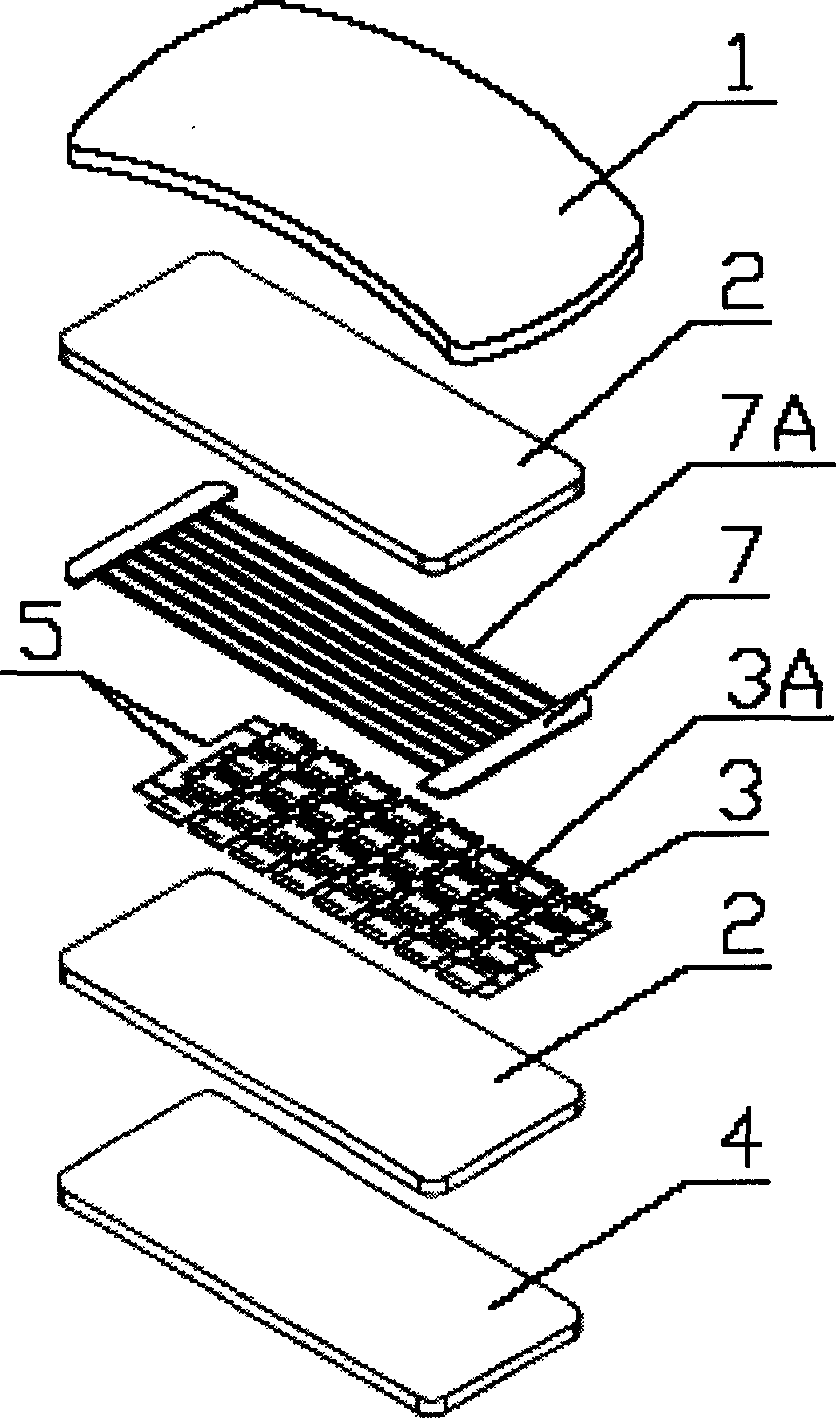

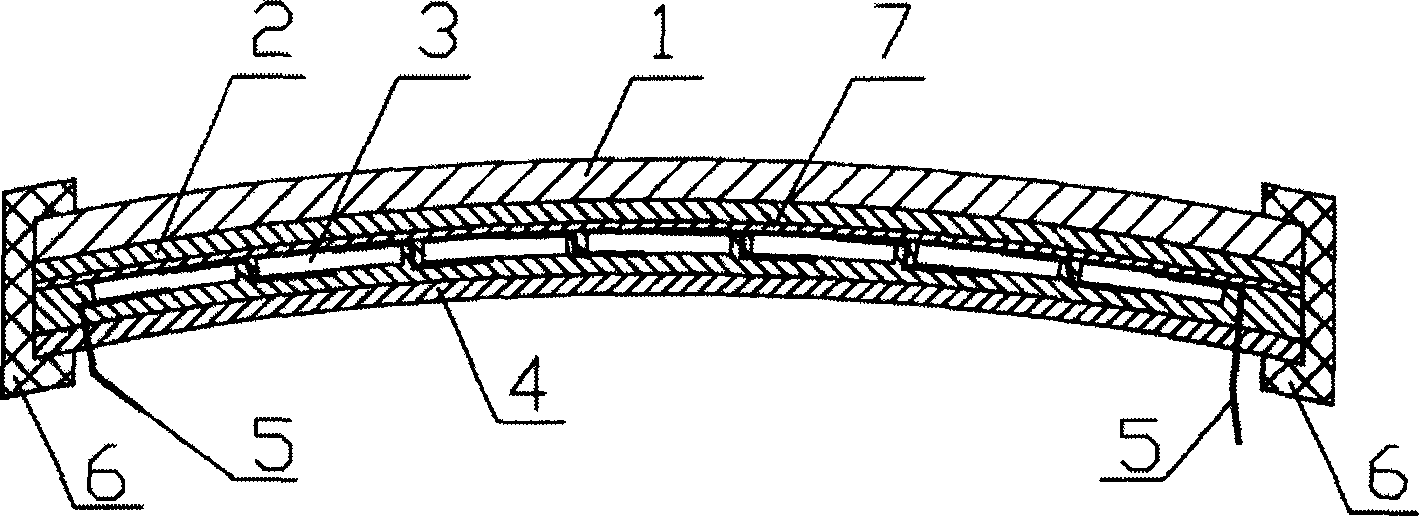

Solar energy battery skylight and its manufacturing method

InactiveCN1794472AIncrease the effective areaEffective area is beautifulPhotovoltaic supportsFinal product manufactureElectrical batterySkylight

This invention discloses a solar energy battery skylight and its manufacturing method aiming at producing a solar energy car skylight with arc by an arc lamination technology and turning the solar energy batteries serial or parallel on the arc of a car skylight glass to an integral arc structure and having the function of generation to improve the outlook of the skylight and overcome crisp in the large amplitude arc lamination.

Owner:李毅

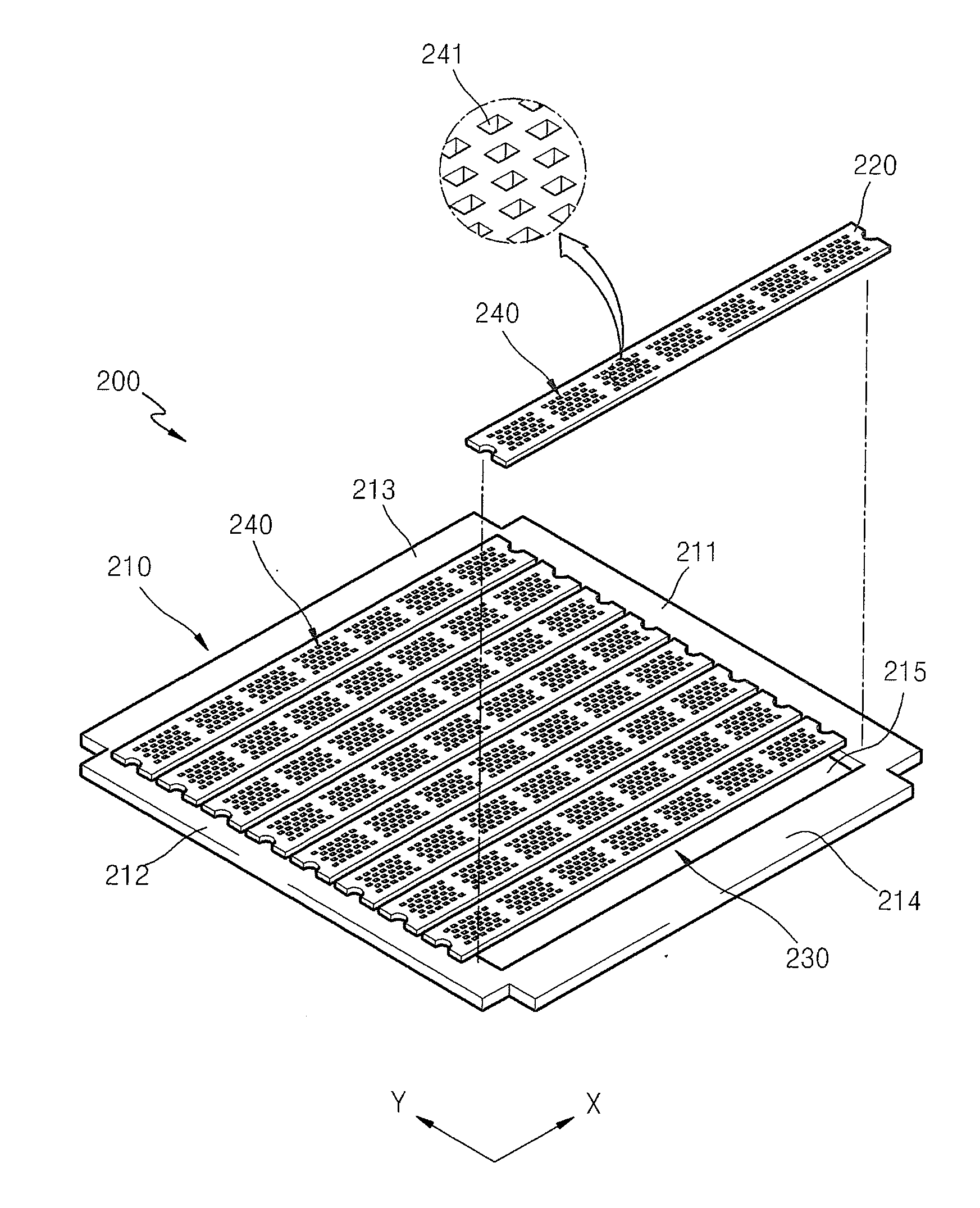

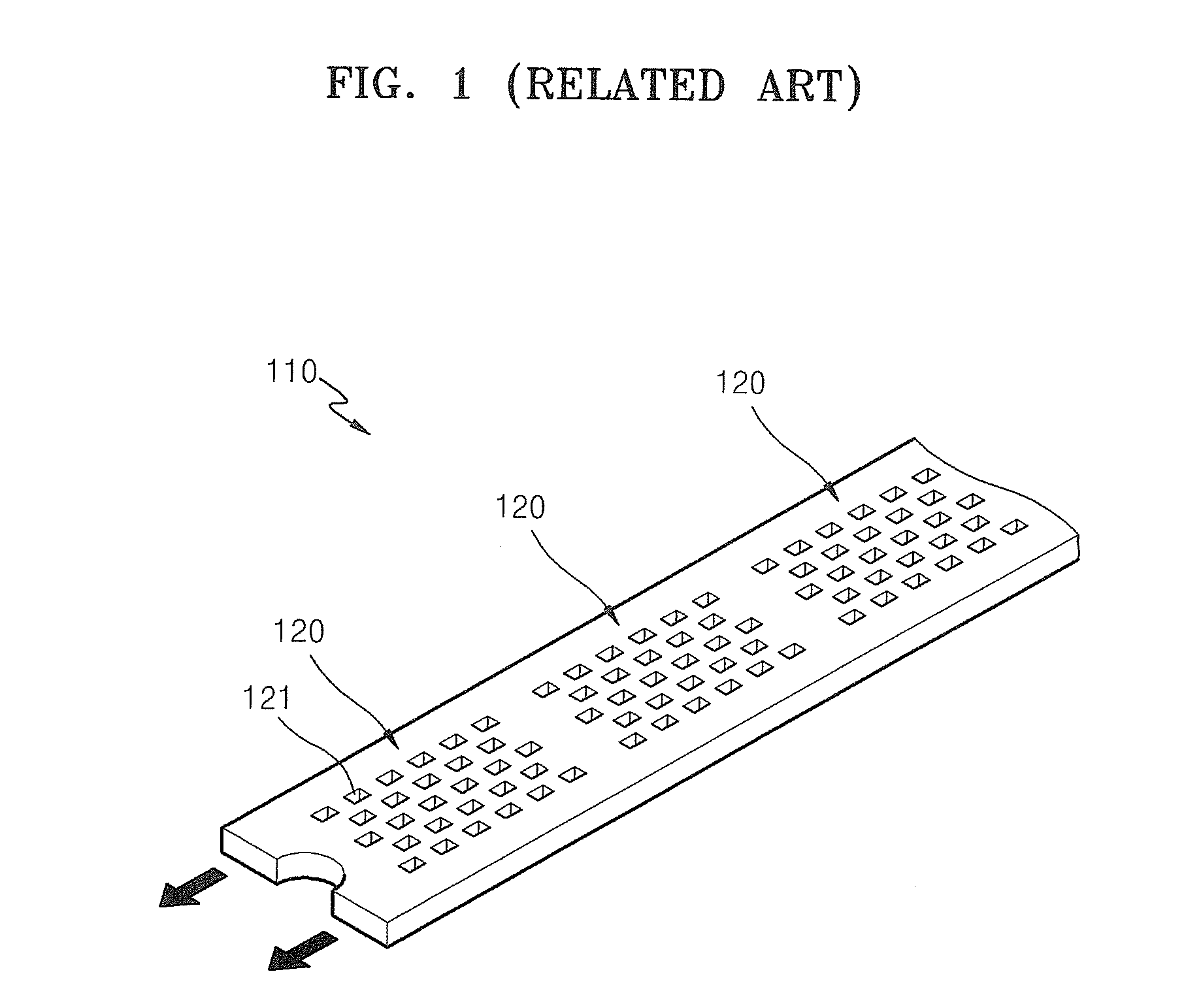

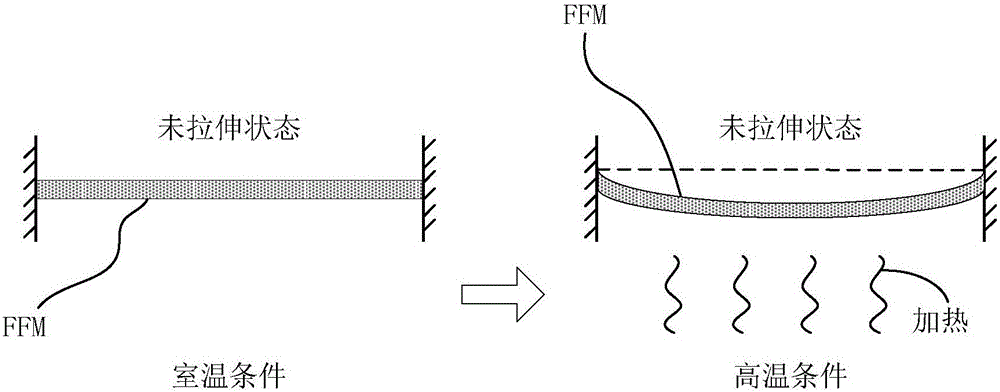

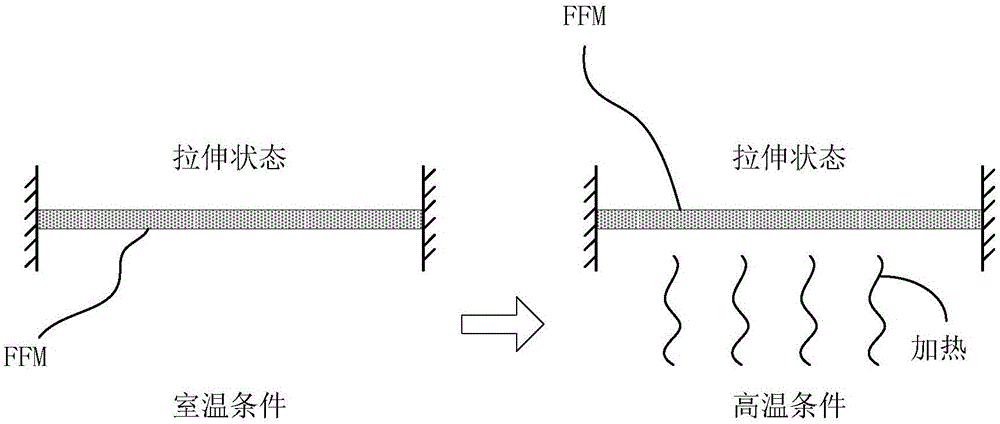

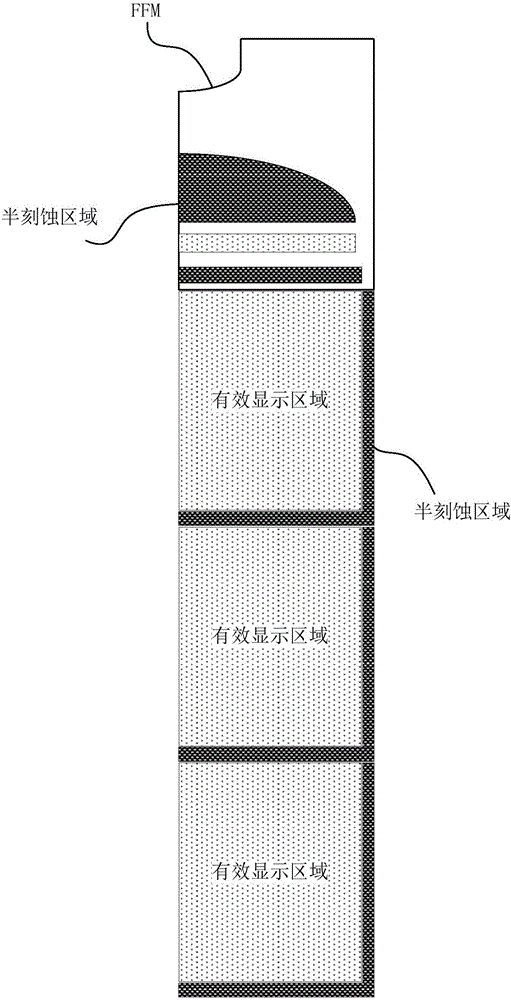

Mask frame assembly for thin film deposition

ActiveUS20110168087A1Reduce the overall heightAvoid wrinklesLiquid surface applicatorsSolid-state devicesWrinkleEngineering

A mask frame assembly for thin film deposition includes a frame having an opening and at least two unit masks having end parts in a longitudinal direction fixed to the frame, each of the unit masks comprising first regions and second regions, the first regions having unit masking patterns, each of the unit masking patterns having a plurality of openings for thin film deposition, the unit masking pattern being spaced apart from each other, each of the second regions being interposed between a pair of adjacent ones of the first regions, the first regions having a first thickness from a first surface of the unit masks, and at least a portion of the second regions having a second thickness from a second surface of the unit masks opposite to the first surface of the unit masks, such that the first regions and the at least the portion of the second regions are offset from each other in a direction normal to the first and second surfaces. A plurality of unit masks are each half etched from different surfaces and thus a height of wrinkles generated in the mask of the mask frame assembly may be reduced.

Owner:SAMSUNG DISPLAY CO LTD

Mobile terminal

ActiveCN105611012AEasy to fixFlatten outMouthpiece/microphone attachmentsTelephone set constructionsComputer terminalEngineering

The invention provides a mobile terminal. The mobile terminal provided by the invention comprises a shell; a pickup hole is formed in the shell; a microphone, a circuit board, a waterproof membrane bracket, a waterproof membrane and a sound receiving bracket are arranged in the inner cavity of the shell; the waterproof membrane is stuck on the waterproof membrane bracket and is supported against the pickup hole which is located at the inner sidewall of the shell; the microphone is arranged on the circuit board; a sound receiving through hole which is opposite to the waterproof membrane is formed in the waterproof membrane bracket; the sound receiving bracket is connected with the shell; the sound receiving bracket is provided with a through hole; one end of the through hole is opposite to the sound receiving through hole of the waterproof membrane bracket while the other end thereof is opposite to the receiving end of the microphone, so that a sound conduction channel is formed between the pickup hole and the receiving end of the microphone; and the circuit board is electrically connected with the microphone to drive the microphone to receive sound. According to the mobile terminal, a microphone sealing and waterproof structure with good sealing and high reliability can be realized.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

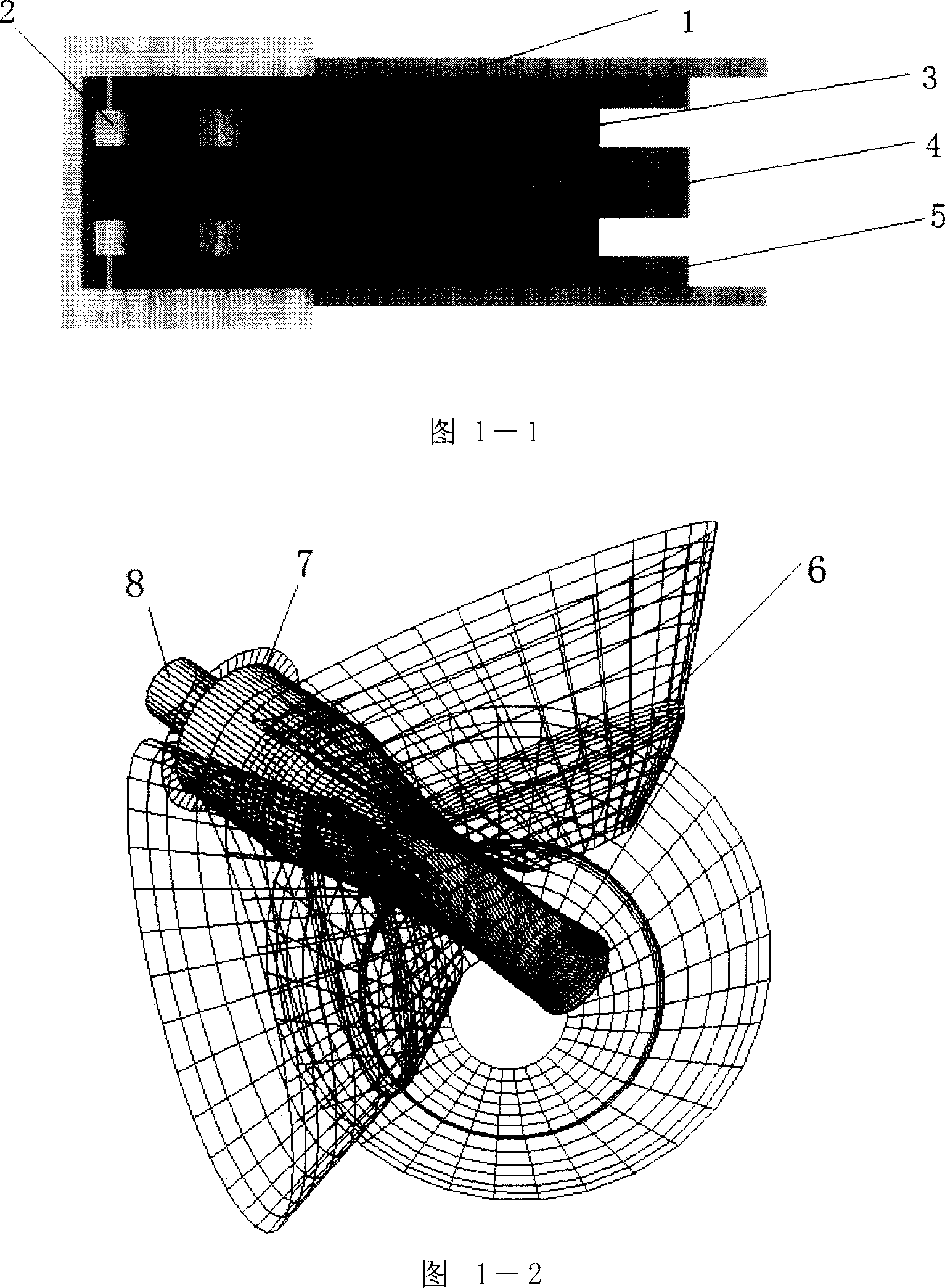

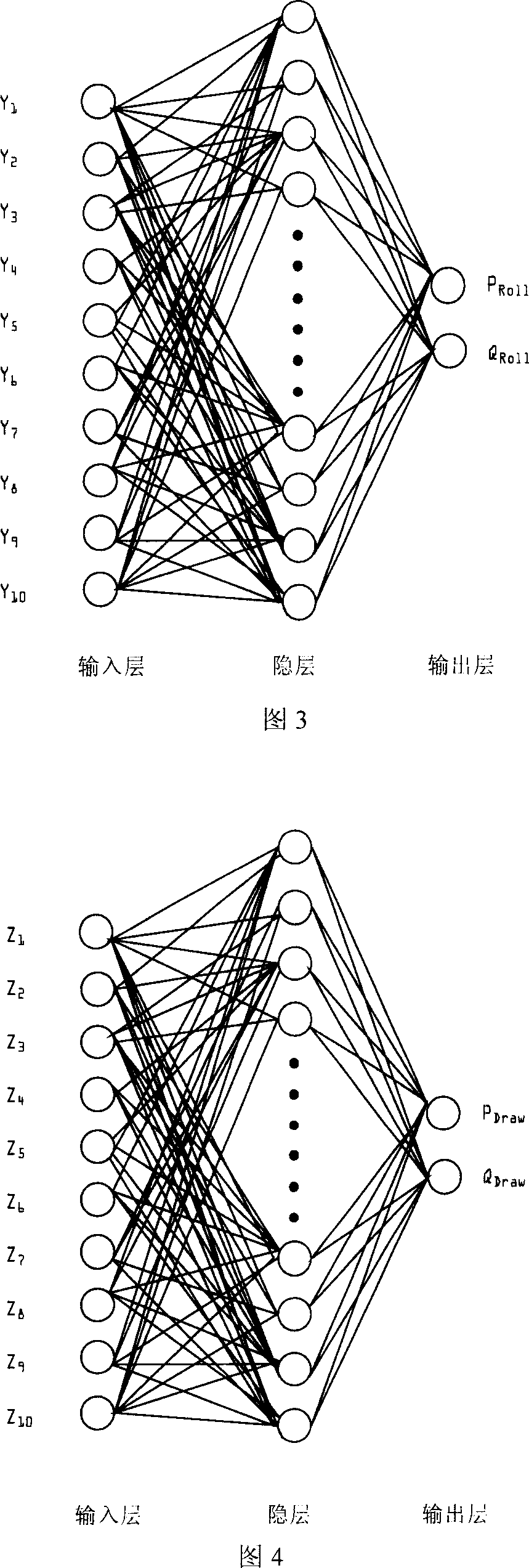

Copper-alloy pipe-material casting-milling technology parameter designing and optimizing method

InactiveCN1979496AOptimizing Graphical Result ExpressionAvoid breakingPhysical realisationSpecial data processing applicationsNerve networkMachining deformation

The invention discloses a method for designing and optimizing cast-rolling process parameters of copper alloy tubing, using database as design basic, using nerve network as design method of process parameters and indexes, and using genetic algorithm as process parameter optimizing means, integrating nerve network, genetic algorithm, finite element simulation, experiment design, CAD parameterized design and database technique into the process design and parameter optimization, designing and optimizing the cast-rolling process parameters of the copper alloy tubing. And the invention has high automation degree, and can be applied to machining deformation of copper alloy tubing, and make personnel short of special knowledge able to make accurate and standard machining process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Thermally expandable microcapsule,process for producing molded foam, and molded foam

ActiveUS20060063000A1Improve performanceImprove heat resistanceFatty substance preservation using additivesGlass/slag layered productsFoaming agentSide chain

Thermo-expansive microcapsule comprising: a polymeric shell produced by polymerizing 15 to 75 weight % of a nitrile monomer, 10 to 65 weight % of a monomer having a carboxyl group, 0.1 to 20 weight % of a monomer having an amide group and 0.1 to 20 weight % of a monomer having a cyclic structure in its side chain; and a blowing agent encapsulated in the polymeric shell.

Owner:MATSUMOTO YUSHI SEIYAKU

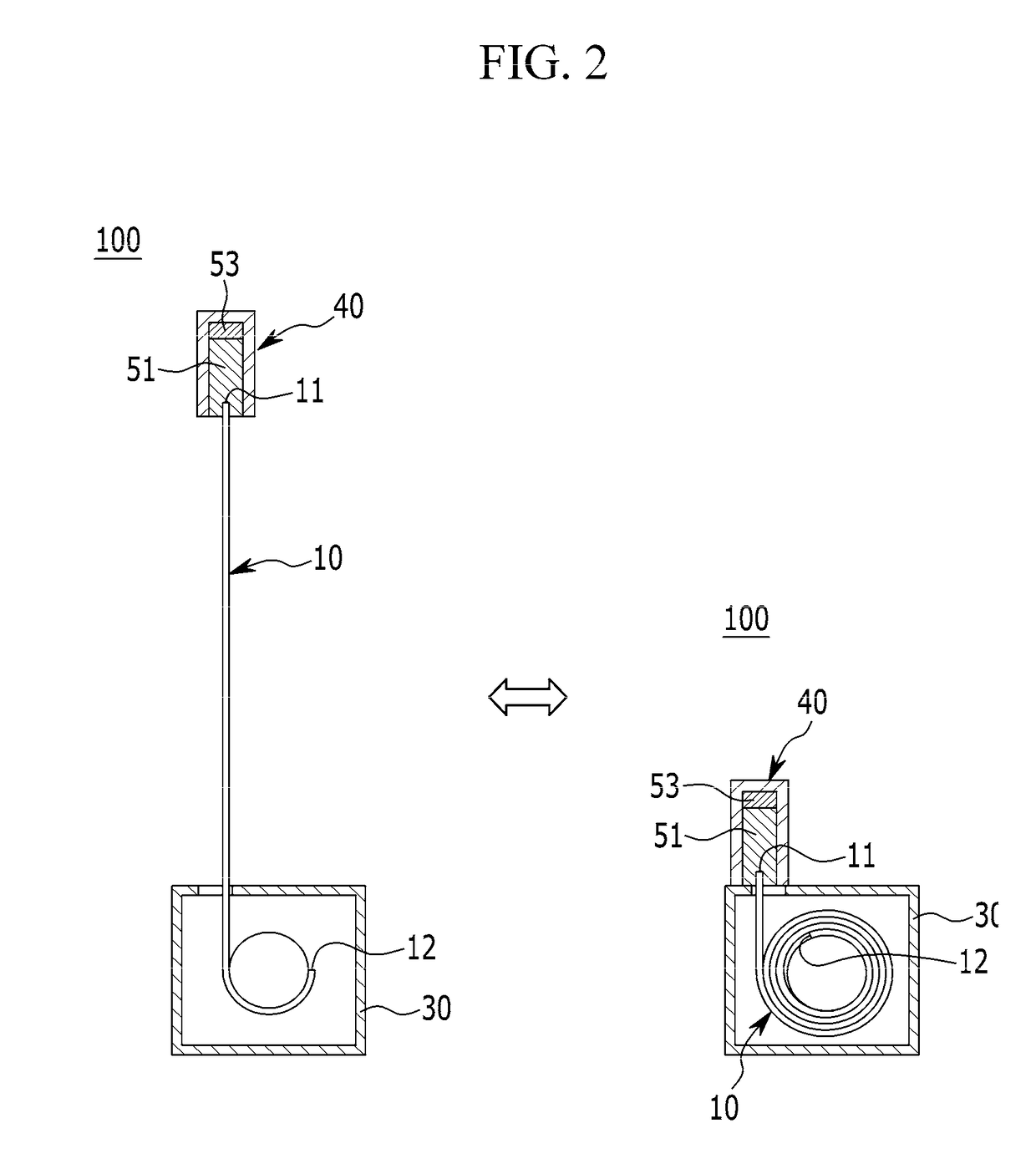

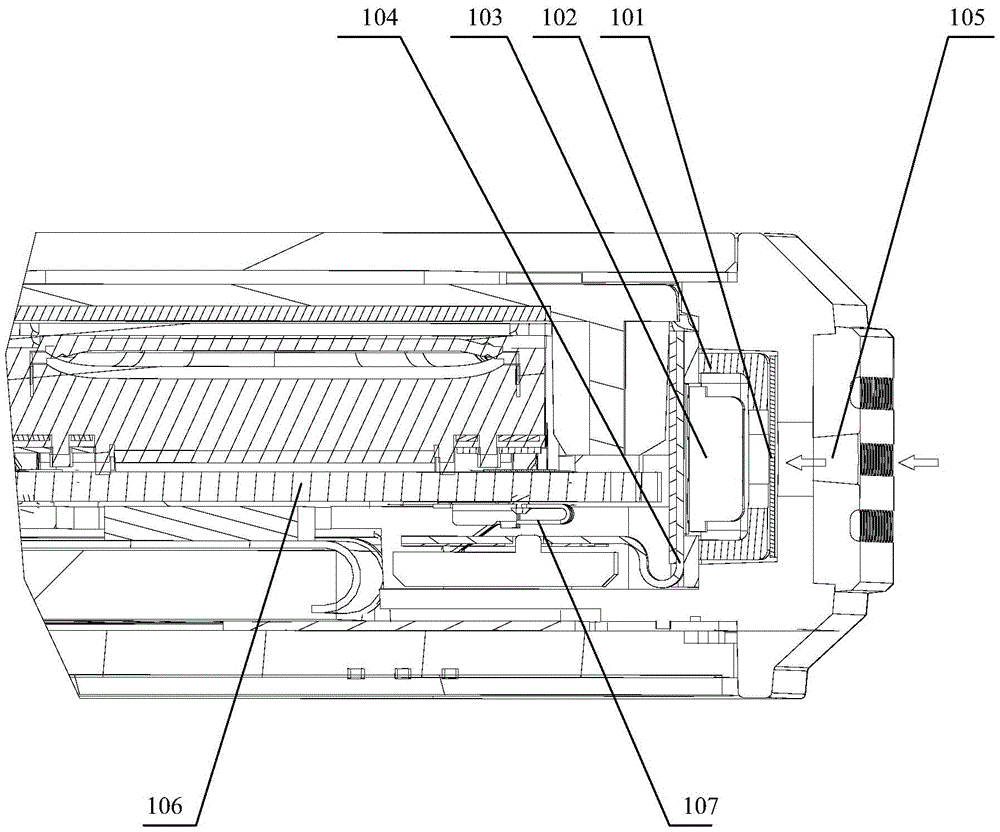

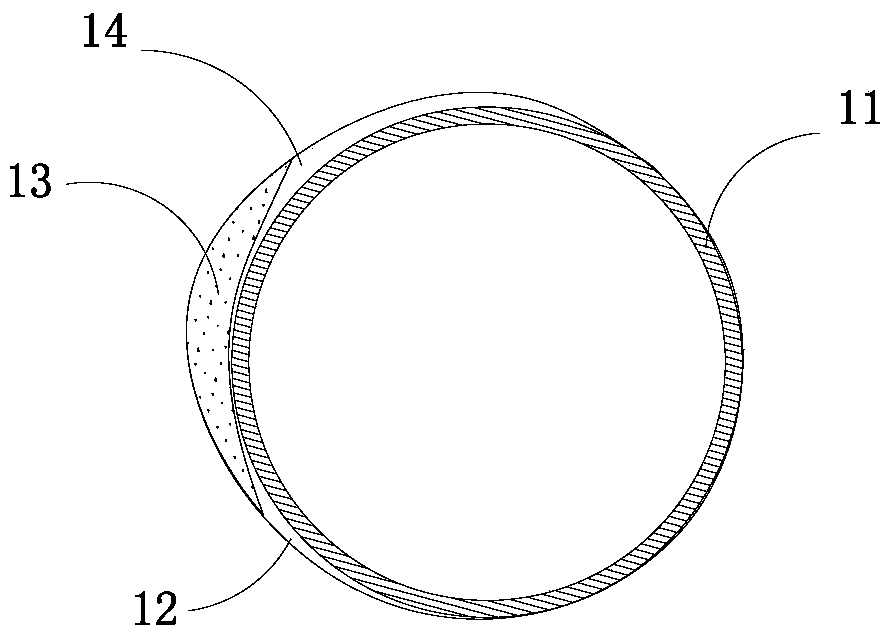

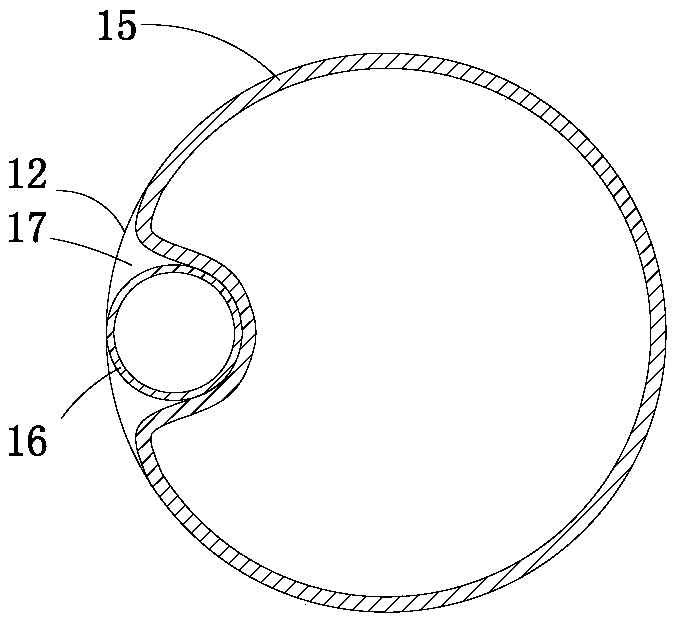

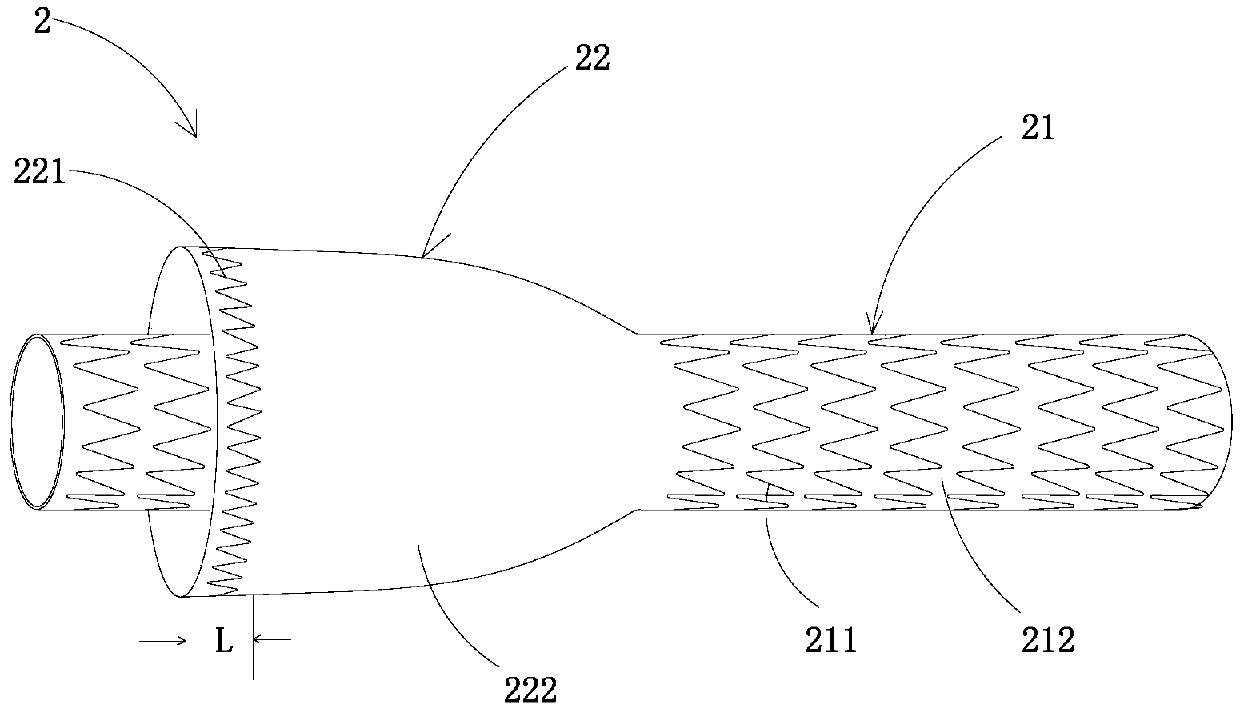

Pipe cavity bracket

The invention discloses a pipe cavity bracket. The pipe cavity bracket comprises a first pipe body and a second pipe body which sleeves the first pipe body, wherein at least one end of the second pipe body is in sealed connection with the outer surface of the first pipe body; in a radial supporting section of the pipe cavity bracket, the first pipe body comprises at least one first radial supporting structure which is arrayed along the peripheral direction of the first pipe body; the second pipe body comprises at least one second radial supporting structure which is arrayed along the peripheral direction of the second pipe body and a covering membrane covering the second radial supporting structure; a radial deformation capability of the second radial supporting structure is greater than that of the first radial supporting structure. After the pipe cavity bracket is planted, a semi-sealed gap can be formed between the first pipe body and the second pipe body or between the second pipe body and a pipe cavity wall; blood flowing into the gap can be used as a filling material to block an I type inner leakage channel, so that the blood is prevented from flowing into tumors or an interlayer. Under the impact of the blood, the first pipe body and the second pipe body both can keep a radial supporting shape and the end faces of near ends of the first pipe body and the second pipe body are not deformed, so that the blood flowing into the pipe cavity is prevented from being blocked.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

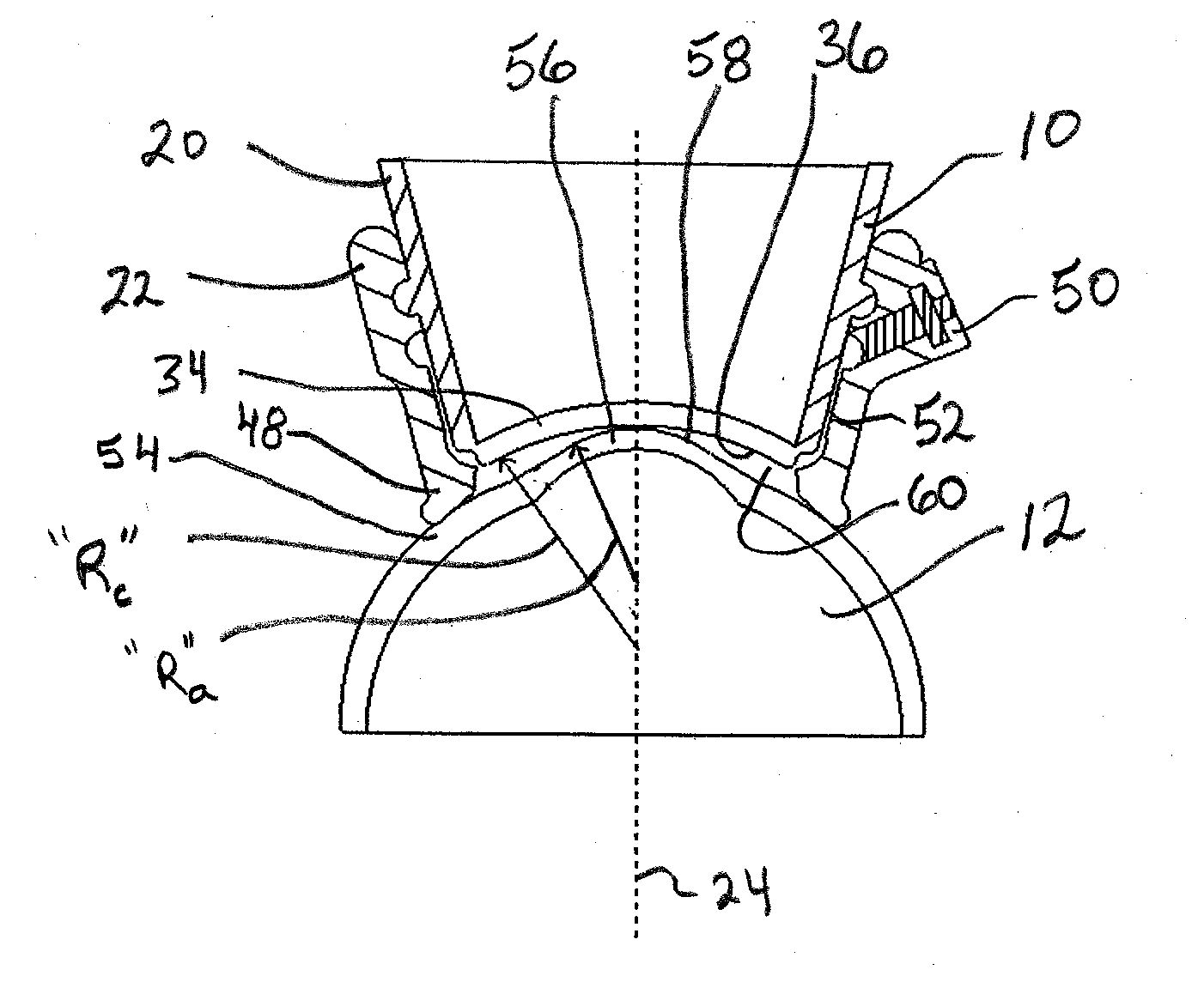

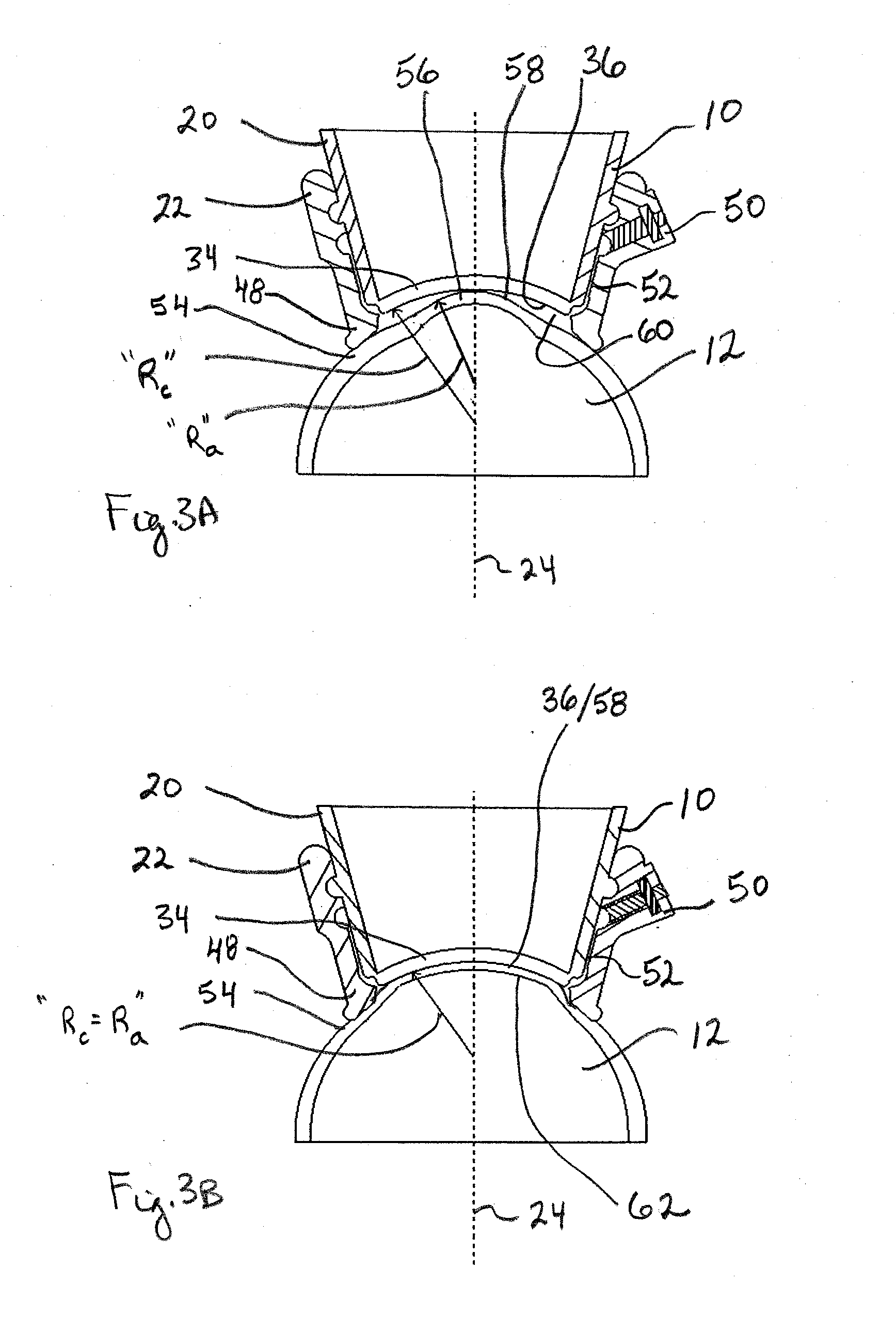

System and Method for Docking a Cornea with a Patient Interface Using Suction

InactiveUS20130053837A1Avoid occurrenceAvoid and minimize creationLaser surgeryHollow article cleaningAbutmentCornea

A system and method are provided for docking a patient interface device to the eye of a patient using suction. The patient interface device is formed by the structural cooperation of a base member and an attachment member, both of which have an open distal end. A contact lens is formed onto the open distal end of the base member, and a continuous abutment is formed onto the open distal end of the attachment member. When the interface device is placed onto the eye of a patient, only the continuous abutment contacts the sclera of the patient. An air pocket is formed between the contact lens and the continuous abutment. The air pocket is in fluid communication with a vacuum channel. A vacuum pump is then employed to suction the air from the air pocket and draw the surface of the eye into contact with the contact lens.

Owner:TECHNOLAS PERFECT VISION

Mask film plate and manufacturing method thereof

ActiveCN105803389AImprove flatnessQuality assuranceVacuum evaporation coatingSputtering coatingEngineering

The invention discloses a mask film plate and a manufacturing method thereof. The mask film plate is used for evaporating a display substrate, and comprises a pattern part and a stress buffer part, wherein the pattern part corresponds to a display area of the display substrate; the stress buffer part corresponds to at least one part of a non-display area of the display substrate; multiple first grooves are formed in one side of the stress buffer part; multiple second grooves are formed in the other side of the stress buffer part; and first projections of the first grooves on the plane where the mask film plate is located do not intersect with second projections of the second grooves on the plane where the mask film plate is located. The quality of the mask film plate in the evaporating process is guaranteed, so that the effect of improving the AMOLED product quality is achieved.

Owner:BOE TECH GRP CO LTD +1

Hand-care disposable disinfection gel and preparation method thereof

ActiveCN104873432ASimple preparation processHigh sterilization rateCosmetic preparationsToilet preparationsSolventChemistry

The invention relates to a hand-care disposable disinfection gel and a preparation method thereof. The hand-care disposable disinfection gel comprises ethanol, a bactericide, a cosolvent, a thickener, an emollient, essence and a PH regulator, wherein the essence is used as a carrier to cover pungent odor of ethanol. The hand-care disposable disinfection gel has the advantages of being bactericidal, washing-free, not sticky and greasy, and comfortable in smell, and caring hands. The preparation method comprises the following steps: the thickener swells in purified water fully to prepare a liquid A; meanwhile, the bactericide and the cosolvent are added in ethanol to be mixed uniformly to prepare a liquid B; then, the liquid B is poured into the liquid A; the emollient and the essence are poured in the liquid A, after purified water is supplemented to be sufficient, the PH regulator is added to regulate the PH value to 6.0-8.0, and the uniform mixing is performed.

Owner:HENAN HUIBO MEDICAL CO LTD

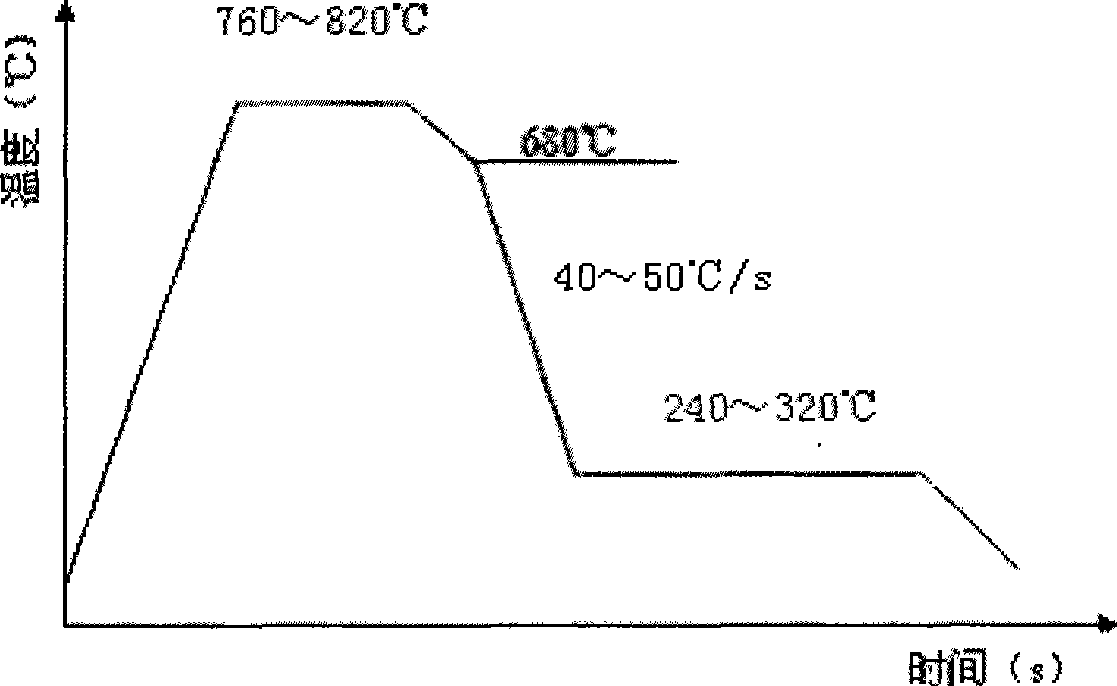

Cold rolled dual-phase sheet steel with 1000MPa grade tensile strength and preparation method thereof

A cold-rolled biphase steel plate with 1000 MPa of tensile strength and a production method thereof belong to the technical field of high-intensity cold-rolled biphase steel. The steel plate comprises the following chemical components by mass percentages: 0.14%-0.21% of C, 0.40%-0.90% of Si, 1.5%-2.1% of Mn, 0.01%-0.05% of Nb, less than 0.02% of P, less than 0.01% of S, and Fe and inevitable impurities. The production method is as follows: a billet is treated by the conventional hot rolling, pickling, cold rolling and continuous annealing, the annealing temperature is 760-820 DEG C and is kept for 70-120s, the fast cooling speed is 40-50 DEG C per second, the aging temperature is 240-320 DEG C and the aging time is 180-300s. The cold-rolled biphase steel plate has the advantages of high tensile strength, low tensile ratio, high initial work hardening rate, no yield elongation which avoids wrinkles on the formed parts. The cold-rolled biphase steel plate has a biphase organization with fine grain ferrite and martensite, wherein, the volume fraction of the martensite is 30%-40% and the average grain size of the ferrite is 2mum.

Owner:UNIV OF SCI & TECH BEIJING +1

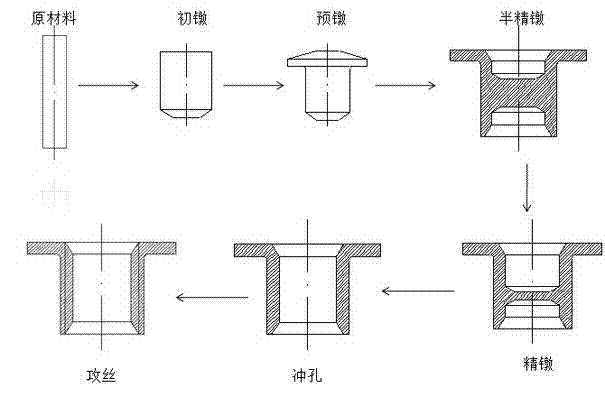

Forming method of thin-wall nut

The invention discloses a forming method of a thin-wall nut. The forming method comprises the following steps: (1) treatment of raw materials, namely aligning wires used as the raw materials by virtue of a cold upsetting machine, conveying the aligned wires to a material cutting mechanism and cutting the wires into small sections of wire blanks; (2) primary upsettig, namely putting the small sections of wire blanks into a female die, performing end surface reshaping on the wire blanks by virtue of a reshaping punch and the female die, so as to obtain a cylinder and frustum combination body; (3) pre-upsetting, namely overturning the blank subjected to primary upsetting so as to enter into a cavity of the female die, and reshaping the blank as a mushroom shape; (3) semi fine supsetting, namely forming a tray part by use of a semi fine upsetting die and forming pre-upset holes; (5) fine upsetting, namely deepening the hole by virtue of a fine upsetting die; (6) punching; (7) threading. According to the forming method disclosed by the invention, a wire upsetting process is used for replacing a sheet material deep-drawing process, area deformation is replaced by volume deformation, and various problems such as drawing breakage and wrinkling caused by area formation in the deep-drawing process can be effectively avoided.

Owner:AVIC STANDARD PARTS MFG

Anti-splitting paster and preparation method thereof

InactiveCN100999893AHigh viscoelasticityLow temperature flexiblePaving detailsRoads maintainencePolymer modifiedBituminous materials

The anticracking patch includes protecting film layer, upper coating layer, high strength base layer and lower coating layer arranged successively from the top to the bottom. Both the upper coating layer and the lower coating layer are made of polymer modified asphalt material comprising asphalt 48-58 wt%, SBS 5-10 wt%, tackifying resin 7-13 wt%, engine oil 4-8 wt%, rubber powder 9-11 wt%, tackifying petroleum resin 1-3 wt% and intensifier 3-13 wt%. The present invention is industrially produced and has excellent anticracking and waterproofing functions.

Owner:BAIHE INT HIGHWAY SCI & TECH HENAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com