High precision spinning forming method for thin wall closing head with radius-thickness ratio less than three per mille

A technology of spinning forming and aspect ratio, which is applied in the field of spinning forming of the head, can solve the problems of large size of the head, high dimensional accuracy requirements, and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

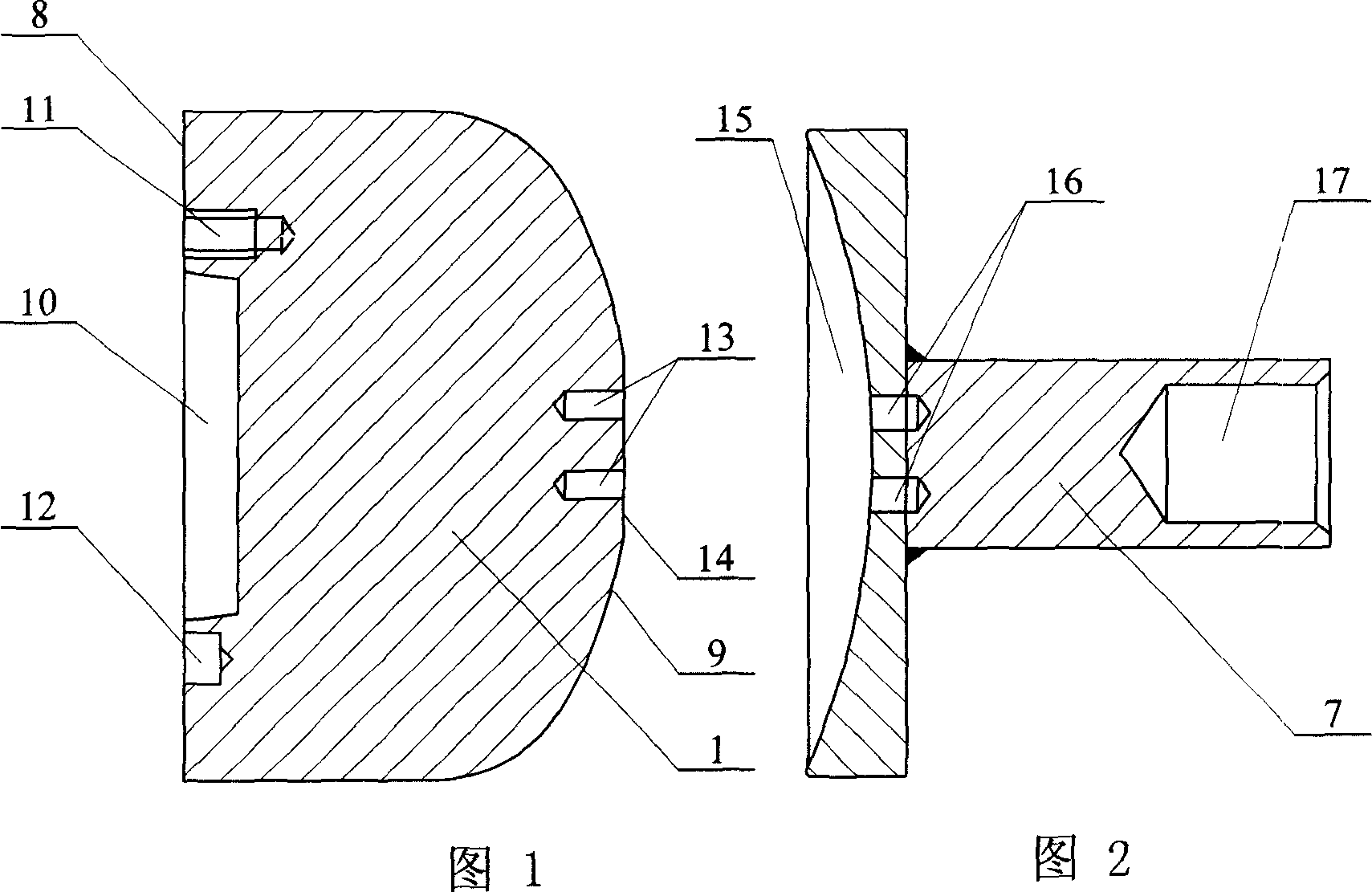

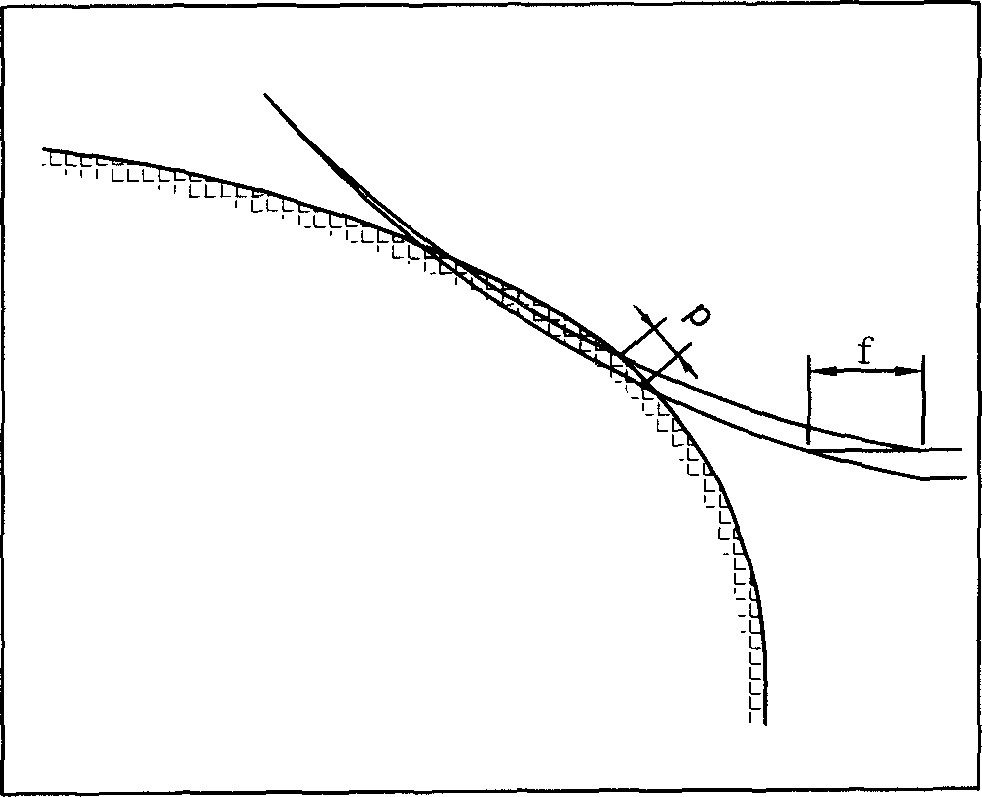

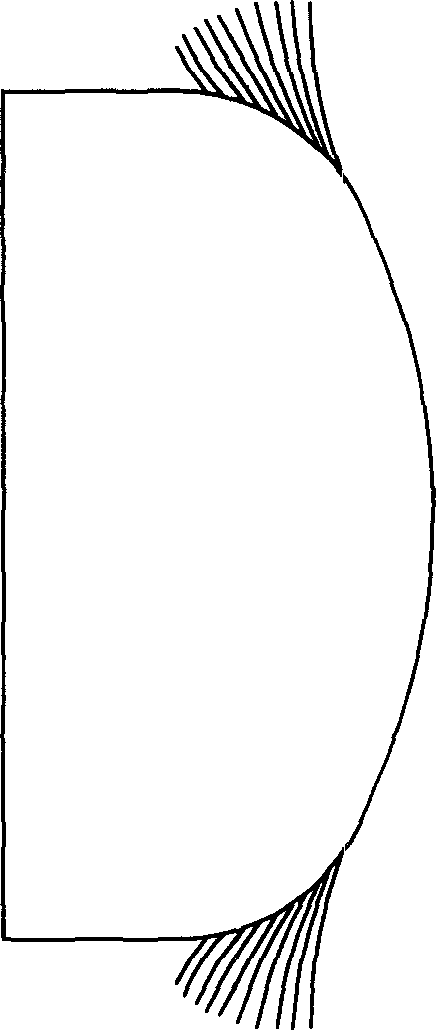

[0005] Specific implementation mode one: (referring to Fig. 1~ Image 6 ) The present embodiment is realized through the following steps: one, the selection of mandrel 1: the material of mandrel 1 is selected the very high carbon steel or tool steel of strength and hardness, and one end of mandrel 1 is plane 8, mandrel 1 The other end of the head is a deep dish-shaped surface 9 whose shape is consistent with the internal shape of the head. There is a tapered blind hole 10 in the center of one end of the flat surface 8. This tapered blind hole 10 is matched with the spindle of the spinning machine. The tapered blind hole At least two threaded blind holes 11 and one avoidance blind hole 12 are evenly distributed around 10. The threaded blind hole 11 is used to fix the spindle of the spinning machine, and the avoidance blind hole 12 is used to avoid the bolt on the spindle. The position is the same as that of the bolt on the spindle. Consistent; the top of the deep dish-shaped su...

specific Embodiment approach 2

[0006] Embodiment 2: In this embodiment, the material of the slab 2 is aluminum alloy. Other methods and specific

Embodiment approach 1

[0007] Embodiment 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com