Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1992results about How to "Reduce voids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacture of minimum porosity, wrinkle free composite parts

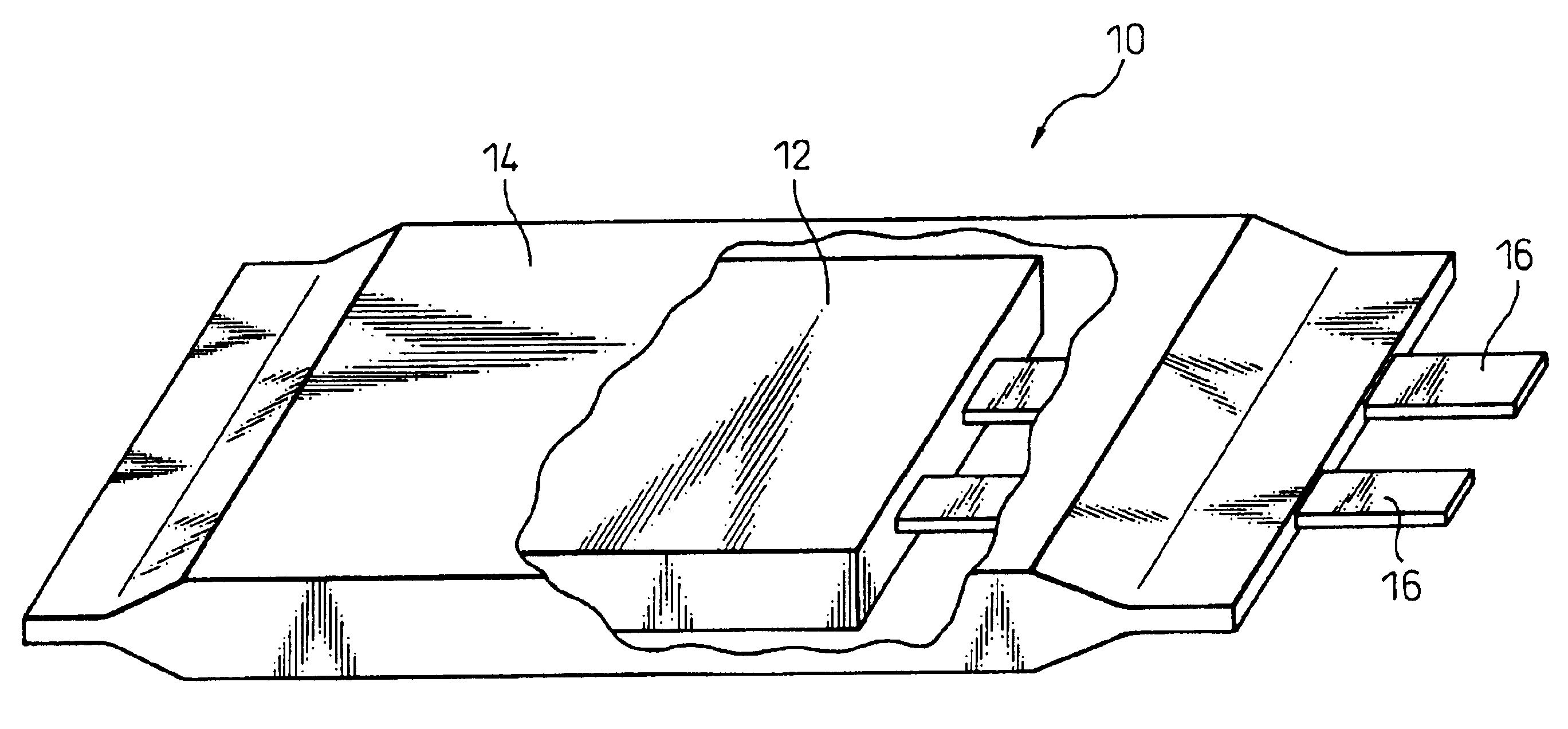

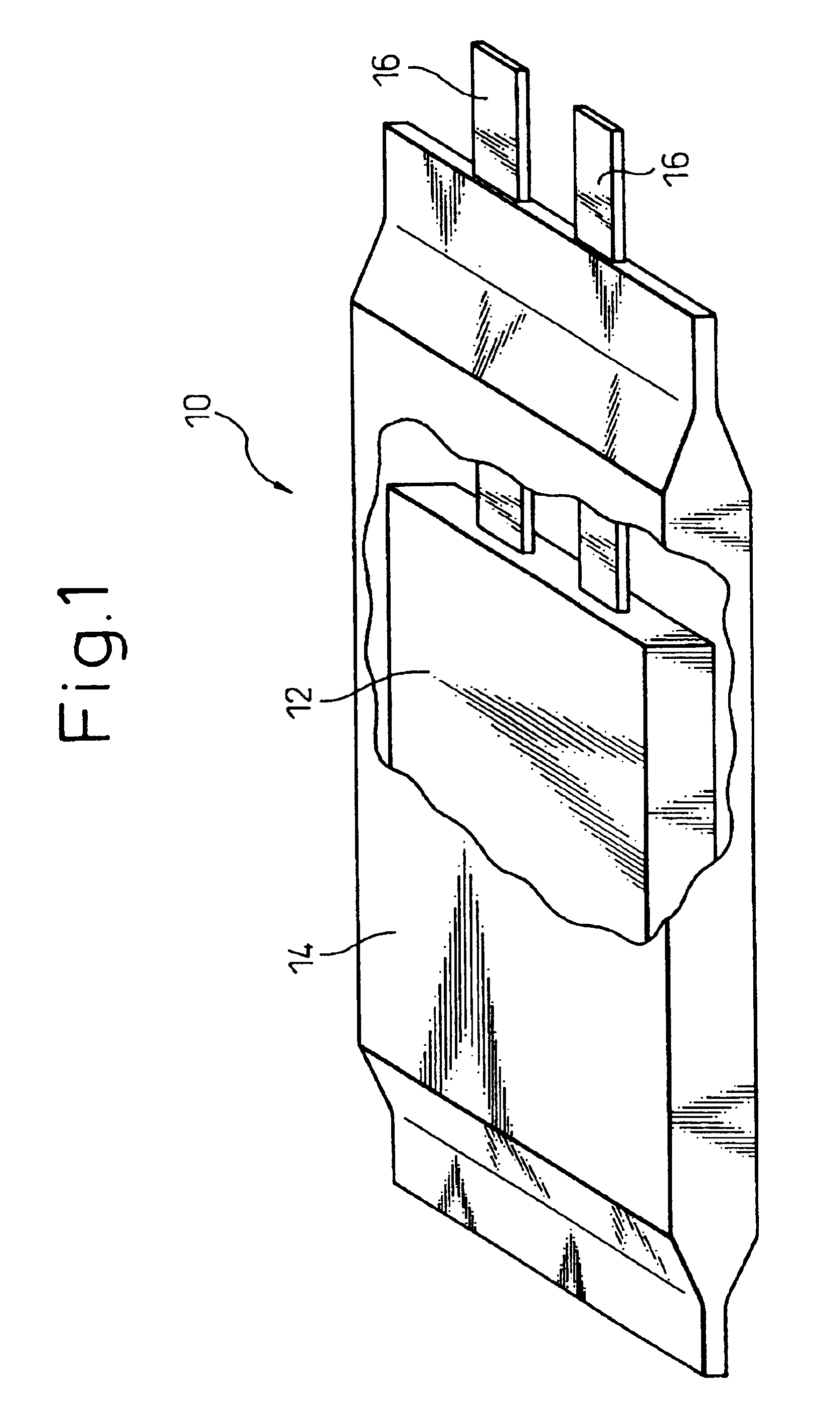

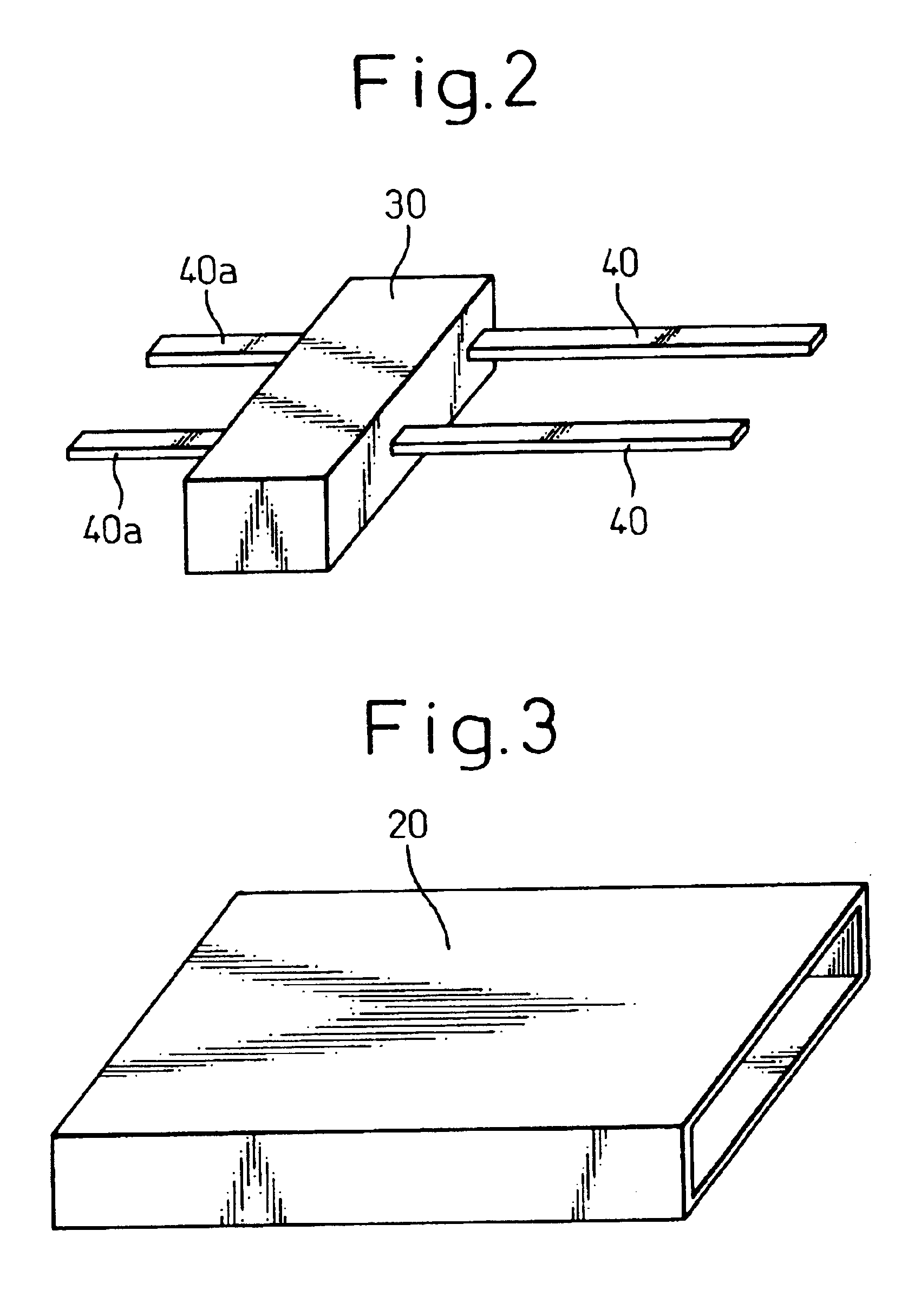

A process and associated apparatus used to prepare a thermoplastic composite from a plurality of plies of thermoplastic resin prepregs. The prepregs are formed into a composite structure under two chambers; a rigid outer chamber (of any convenient size or shape) and a second flexible inner chamber containing a prepreg lay-up. The absolute pressures are reduced concurrently in a stepwise method in both chambers. This concurrent, stepped pressure reduction is accomplished at a rate which prevents the vacuum bag from moving far from the prepregs, and prevents wrinkles from forming in the prepregs. Pinching off the diffusion paths required for the removal of unwanted gases is eliminated. The lay-up is then heated and the absolute pressure in the outer rigid chamber is increased. This pressure constrains the flexible inner chamber during out-gassing of the thermoplastic resin, preventing wrinkles from forming in the prepregs. The absolute pressure in the outer rigid chamber is increased to atmospheric pressure or greater causing the prepregs to consolidate. A low absolute pressure is maintained in the flexible inner chamber. The temperature is then increased to the cure temperature of the resin and held for a time sufficient for the resin to cure. The resulting consolidated thermoplastic resin is substantially void free and detectable wrinkles are absent.

Owner:HALE HAROLD P

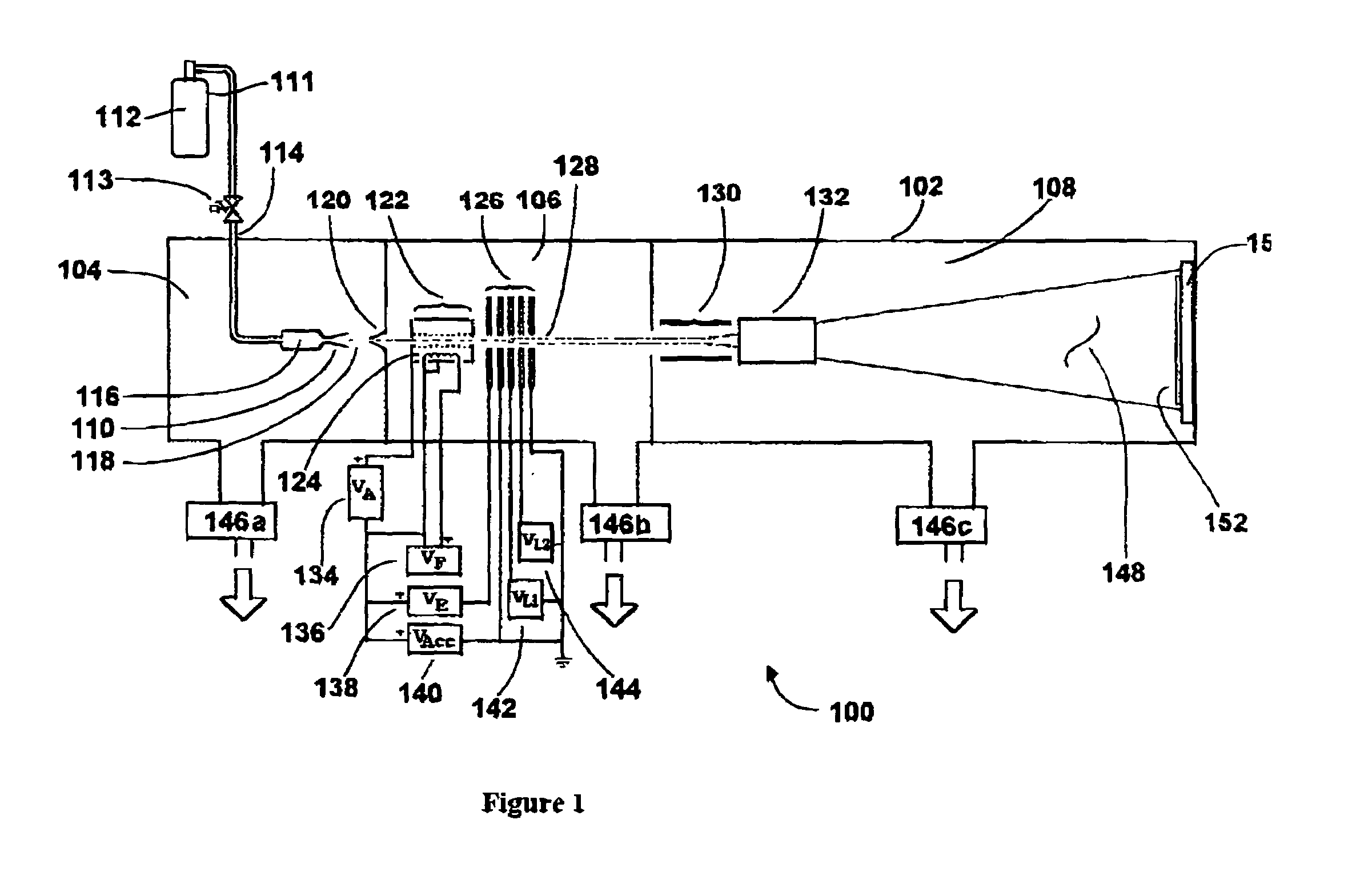

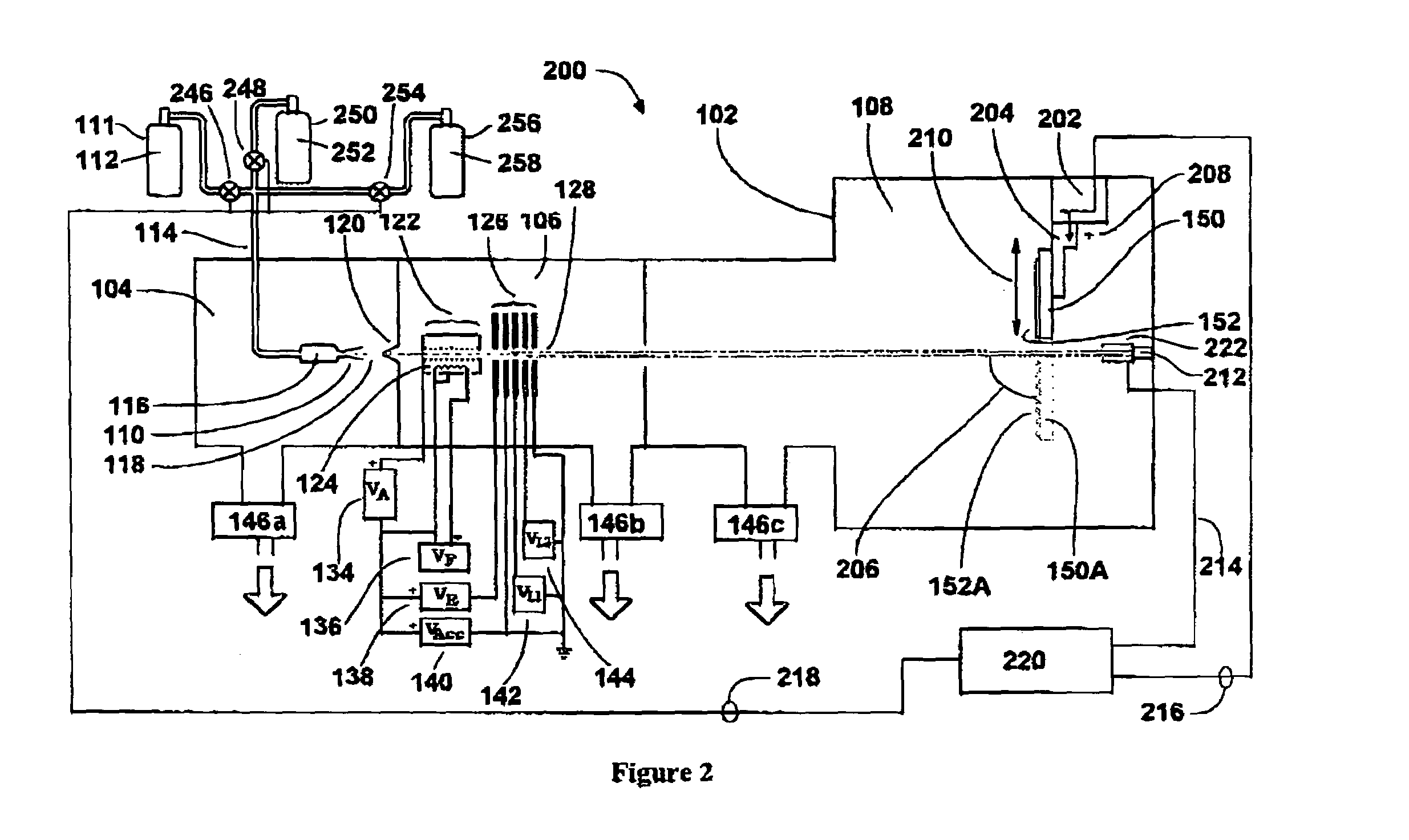

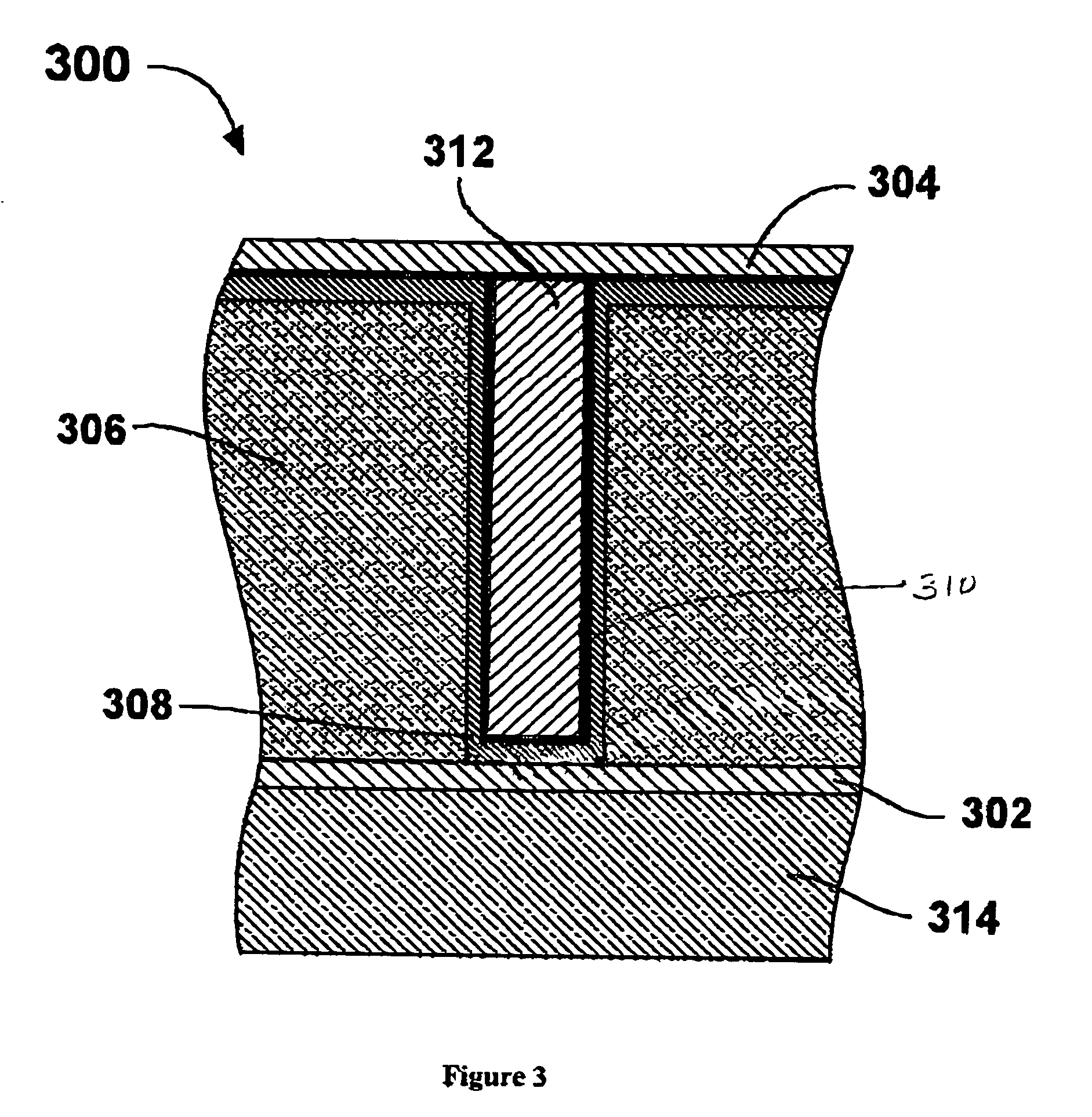

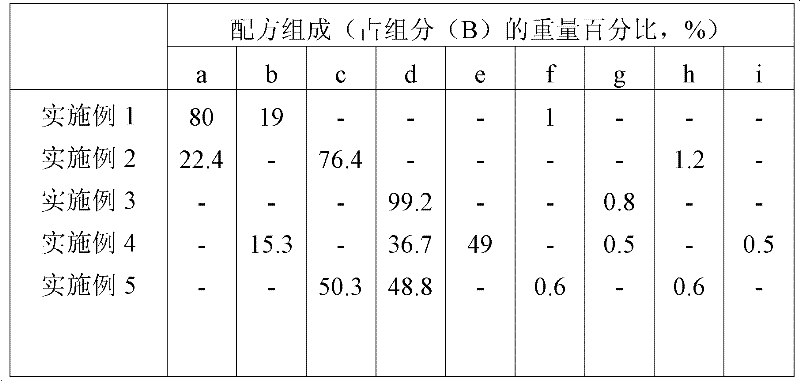

GCIB processing of integrated circuit interconnect structures

InactiveUS7115511B2Improving fabrication process and qualityImprove usabilityElectric discharge tubesSemiconductor/solid-state device manufacturingMetal interconnectIntegrated circuit interconnect

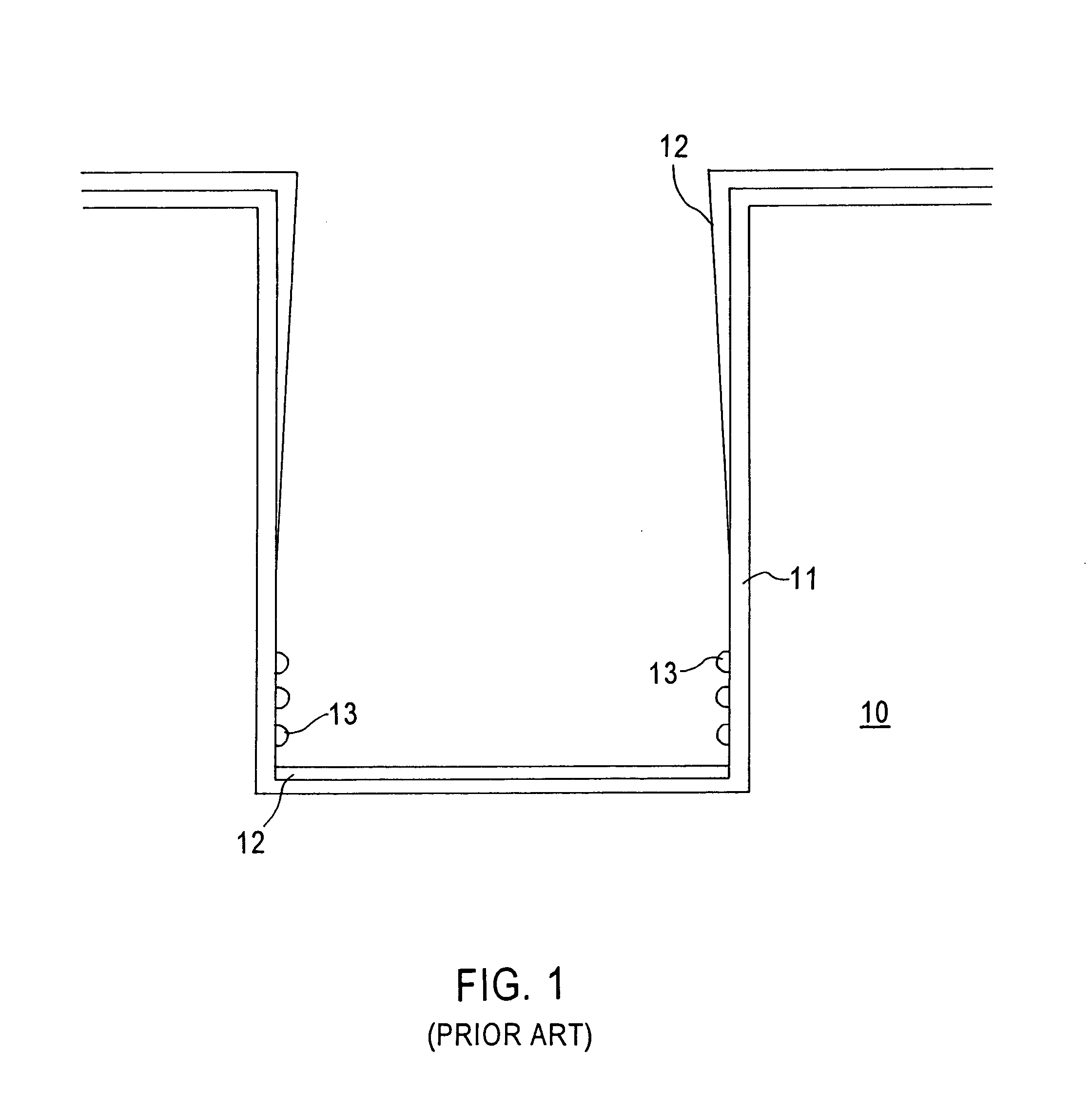

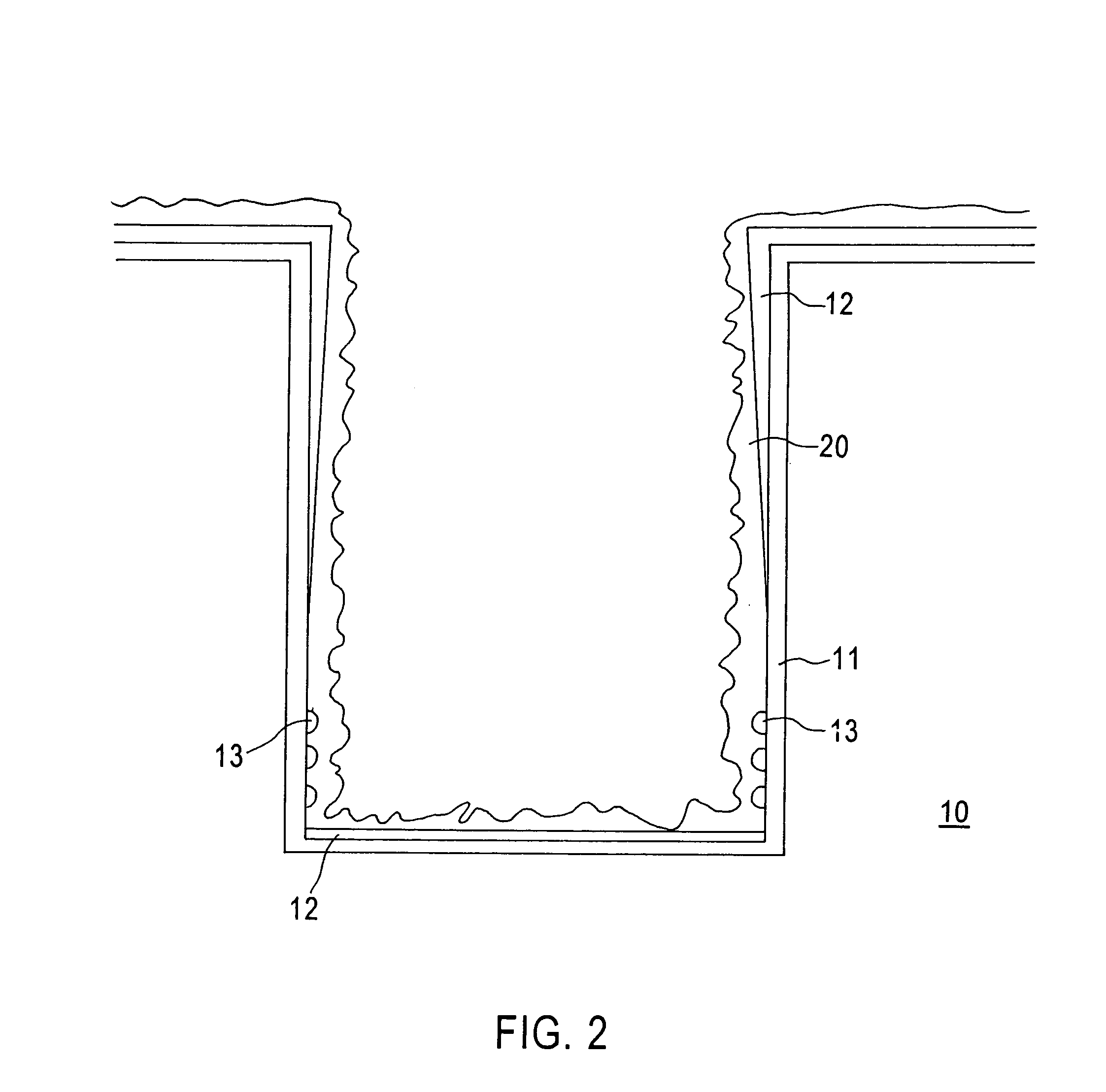

Method for removing and / or redistributing material in the trenches and / or vias of integrated circuit interconnect structures by a gas cluster ion beam (GCIB) is described to improve the fabrication process and quality of metal interconnects in an integrated circuit. The process entails opening up an undesired ‘necked in’ region at the entrance to the structure, re-depositing the barrier metal from thicker areas such as the neck or bottom of the structure to the side walls and / or removing some of the excess and undesired material on the bottom of the structure by sputtering. The GCIB process may be applied after the barrier metal deposition and before the copper seed layer / copper electroplating or the process may be applied after the formation of the copper seed layer and before electroplating. The method may extend the usability of the known interconnect deposition technologies to next generation integrated circuits and beyond.

Owner:TEL EPION

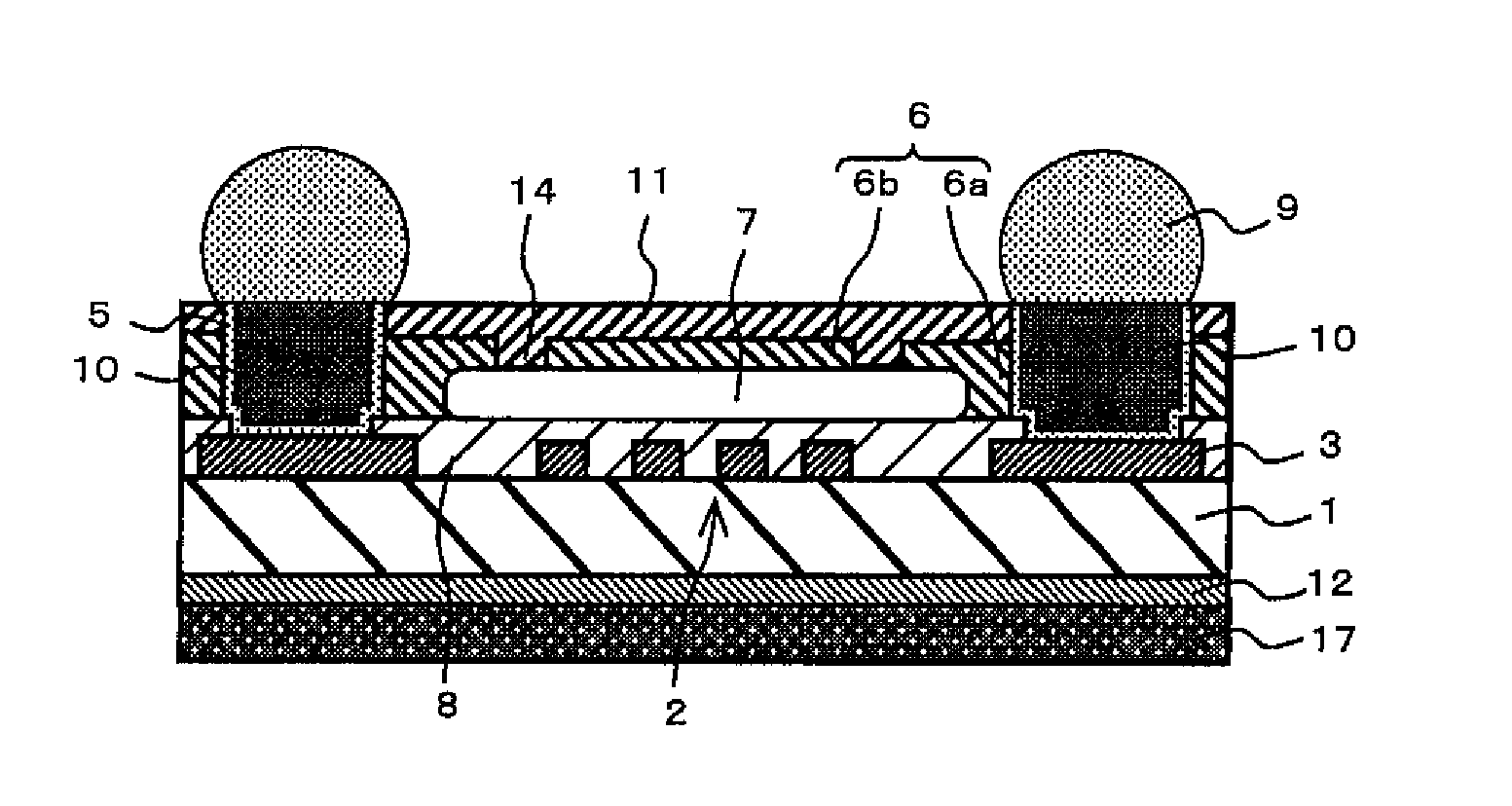

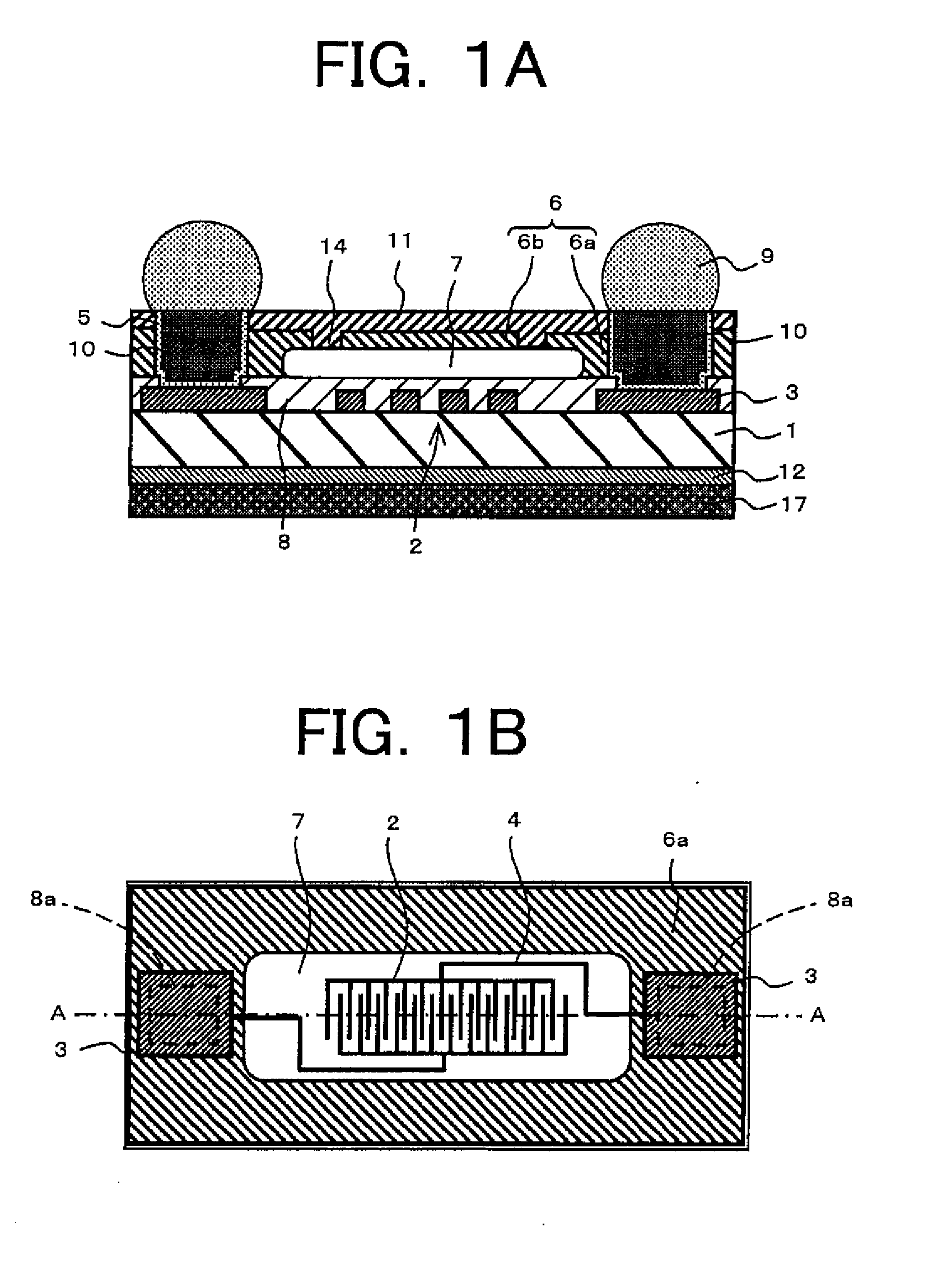

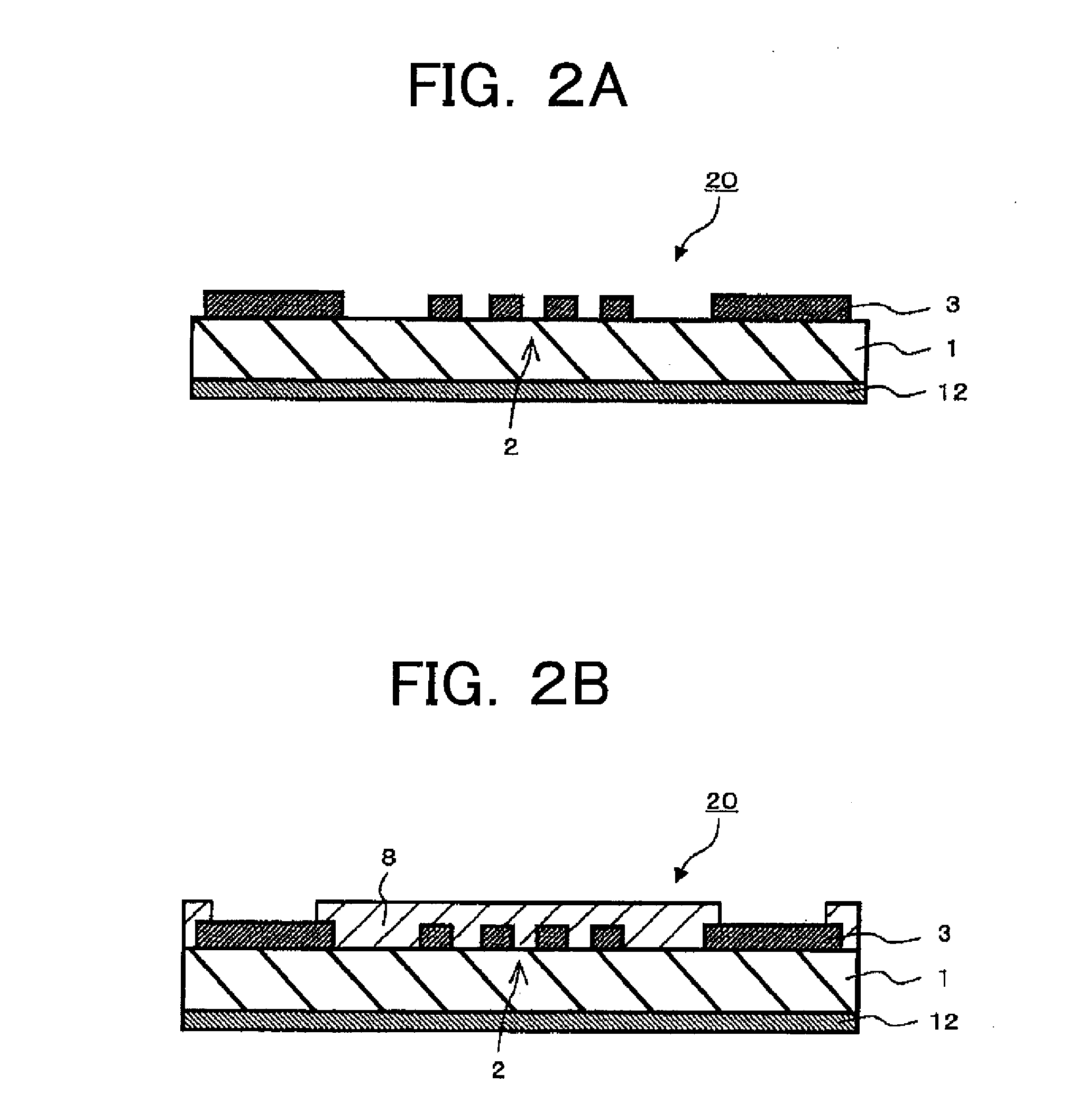

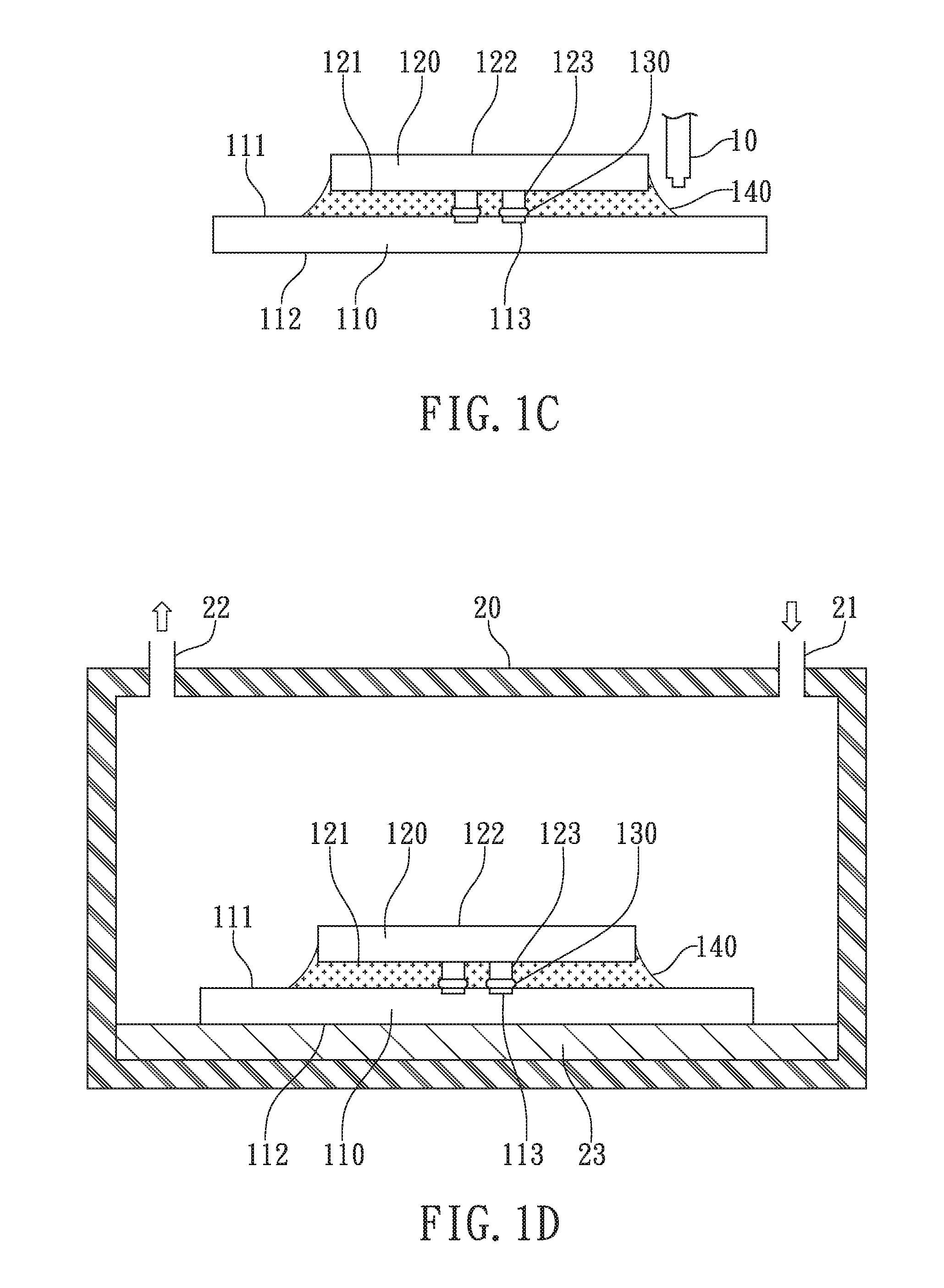

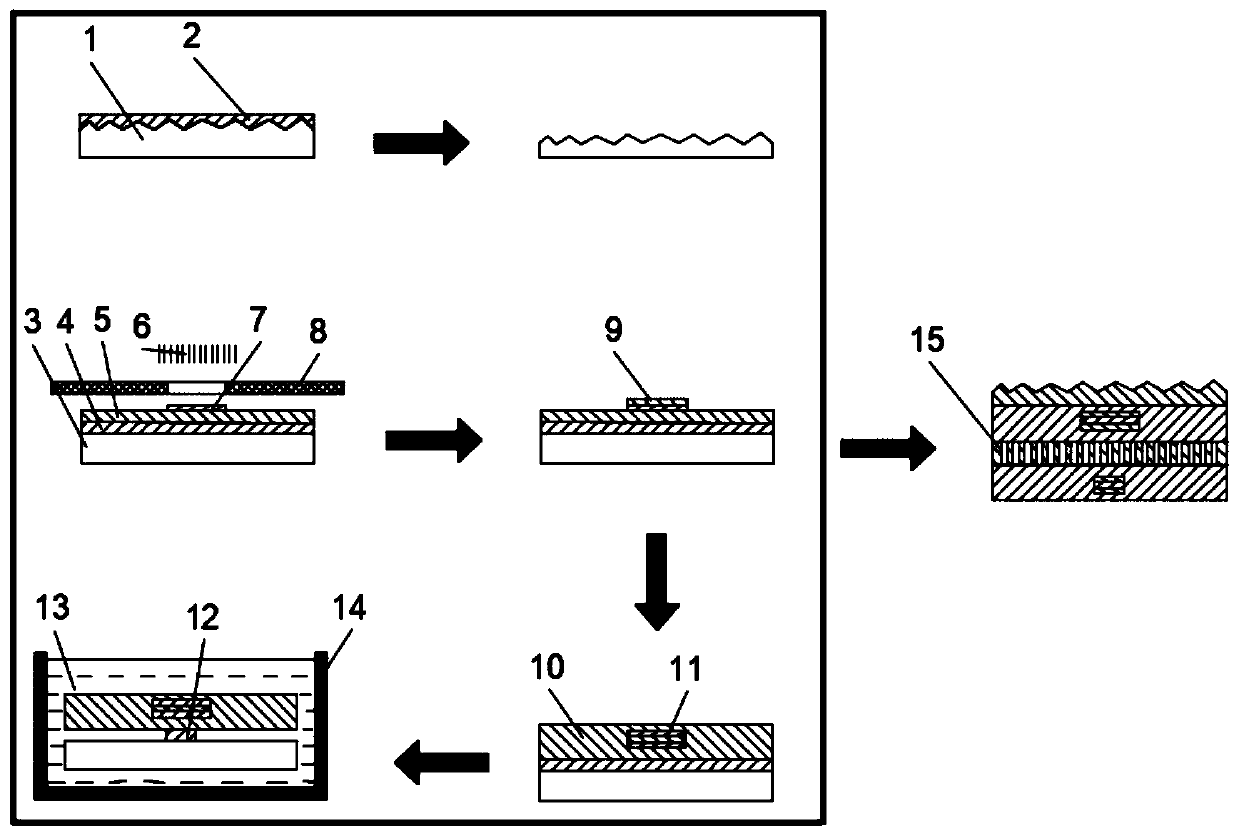

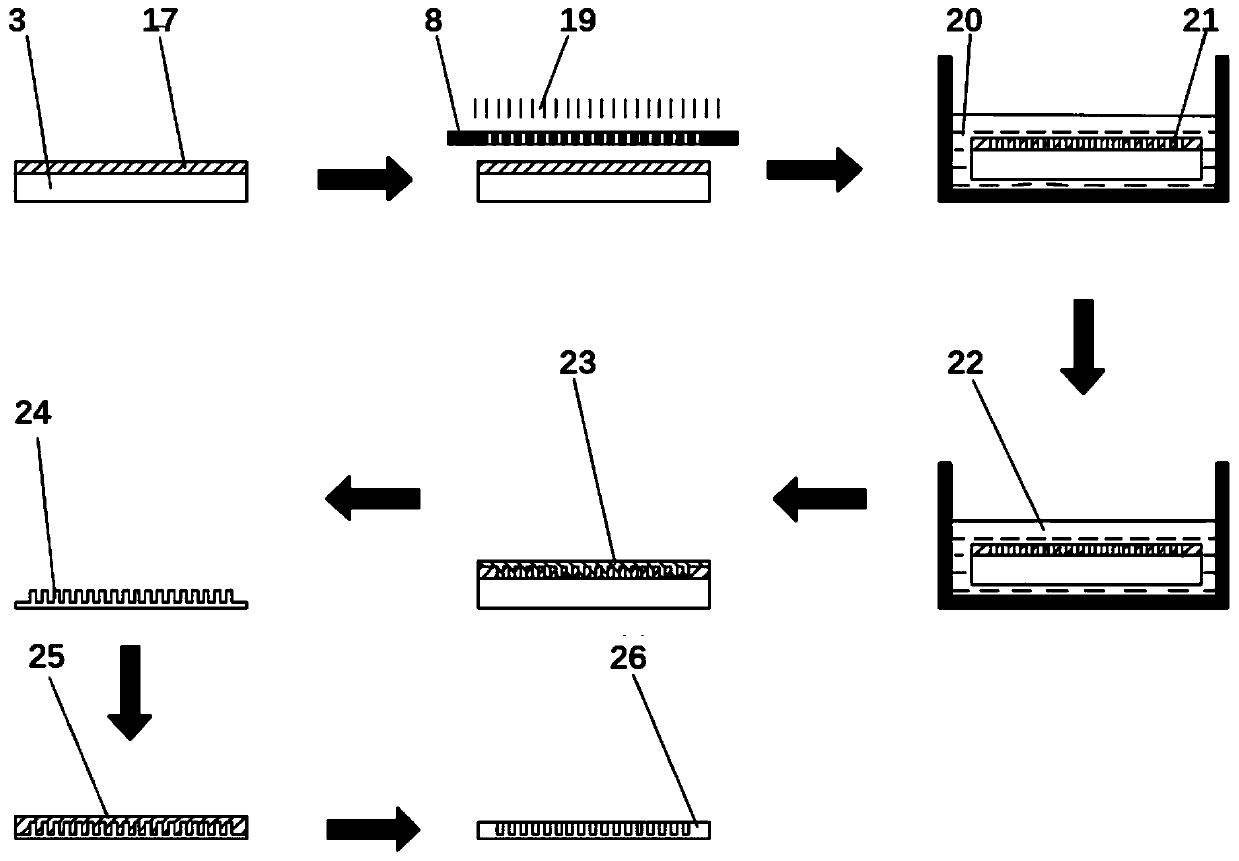

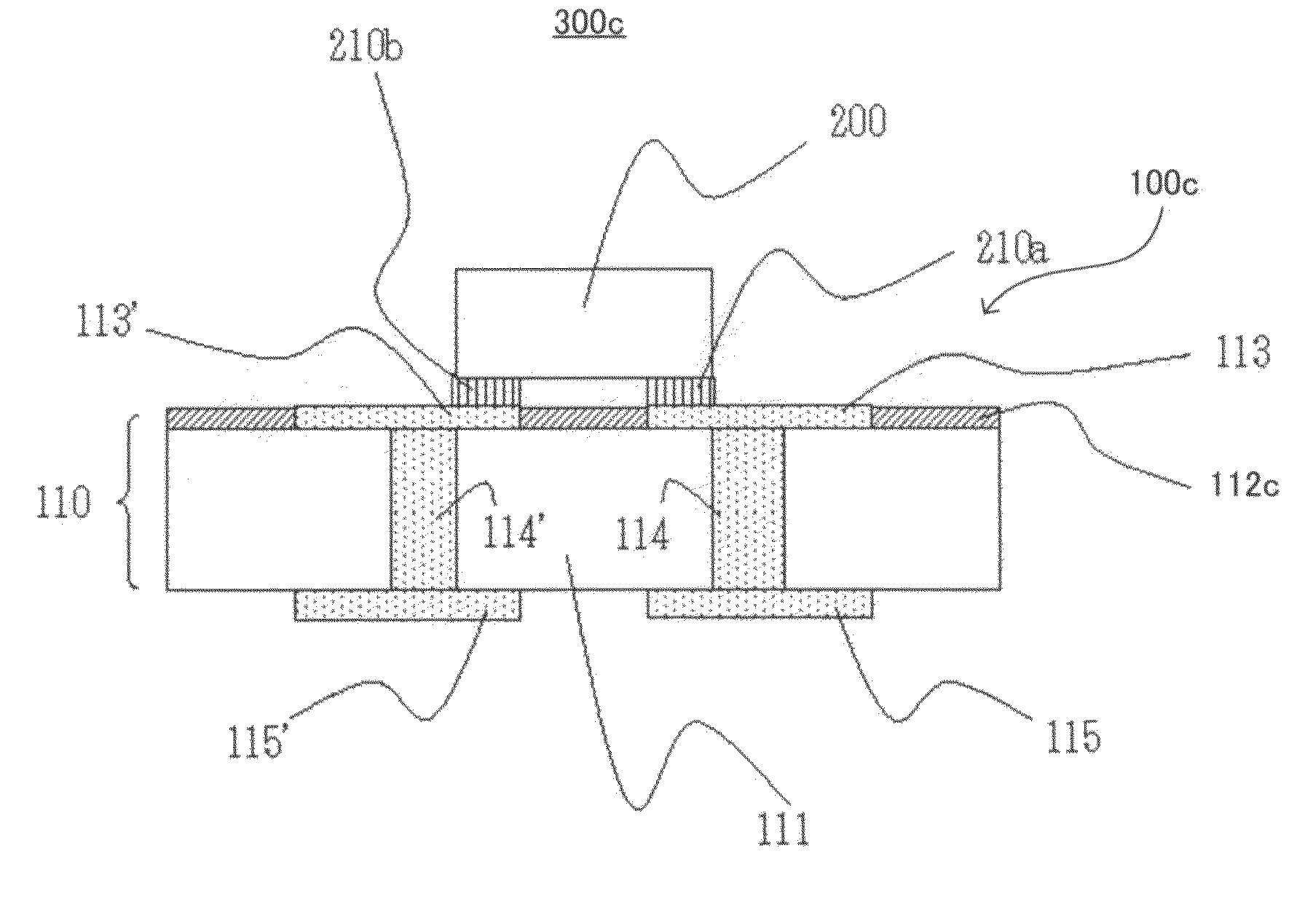

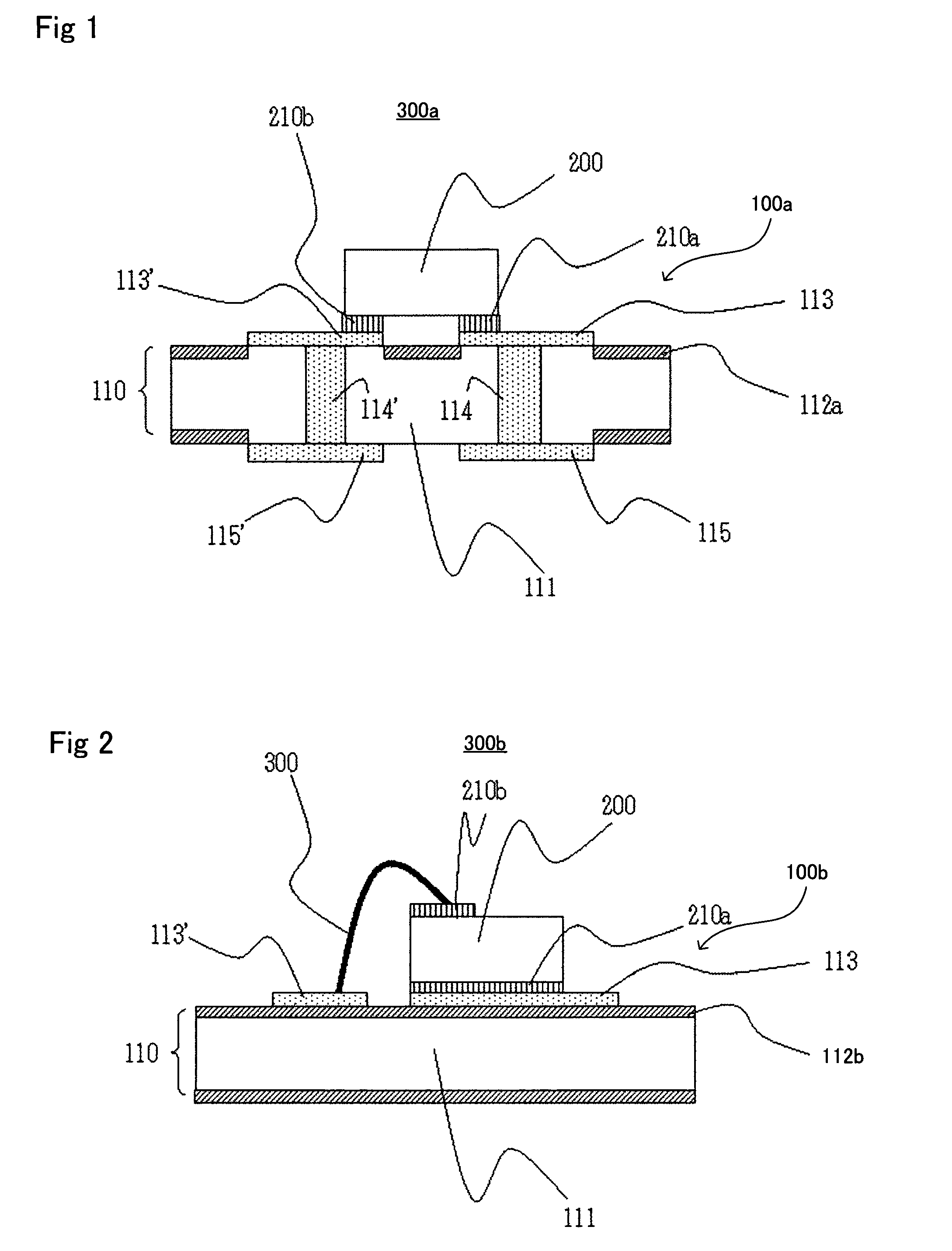

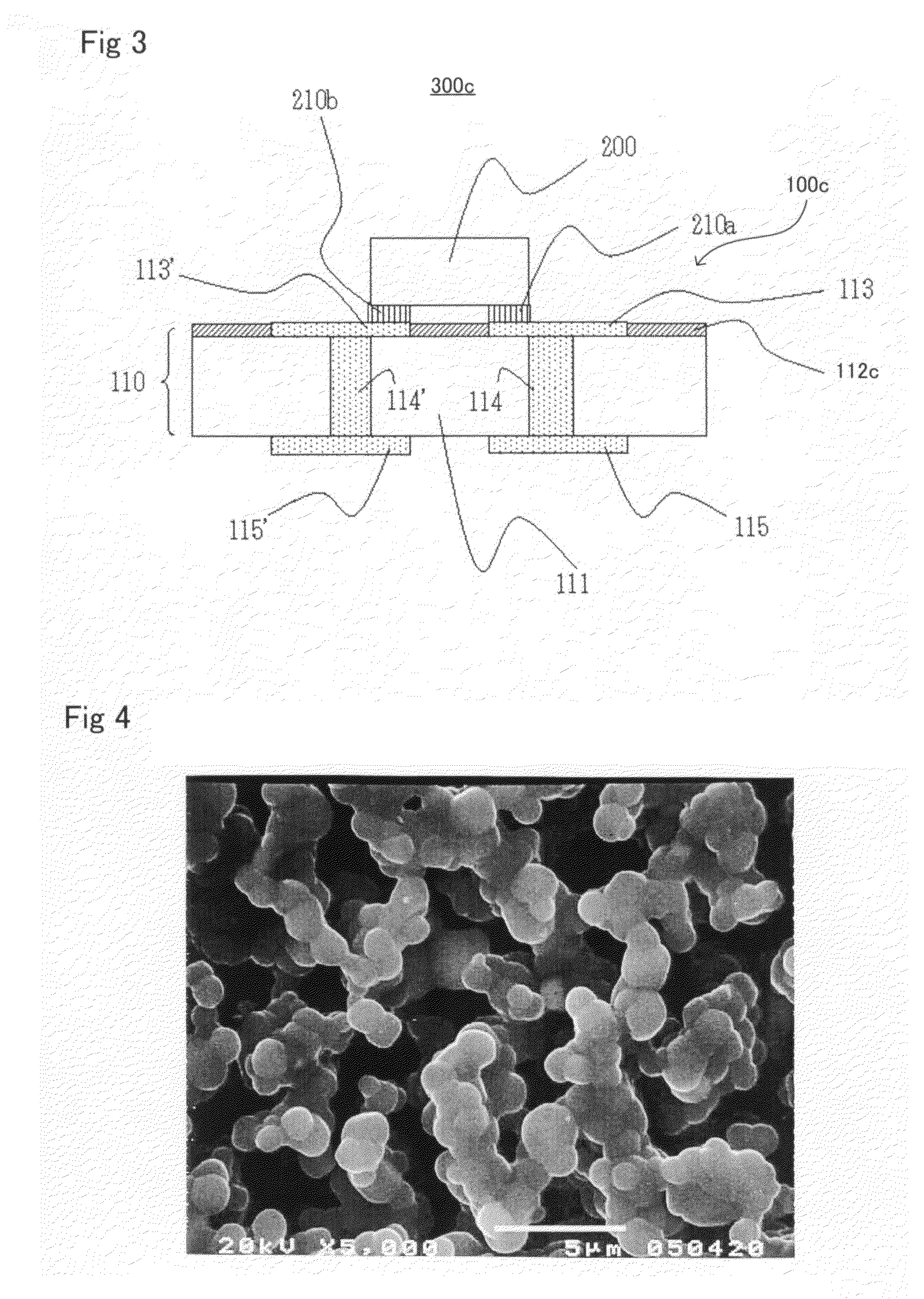

Acoustic Wave Device and Method for Production of Same

ActiveUS20110018389A1Stably keep tight sealImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorAcoustic wave

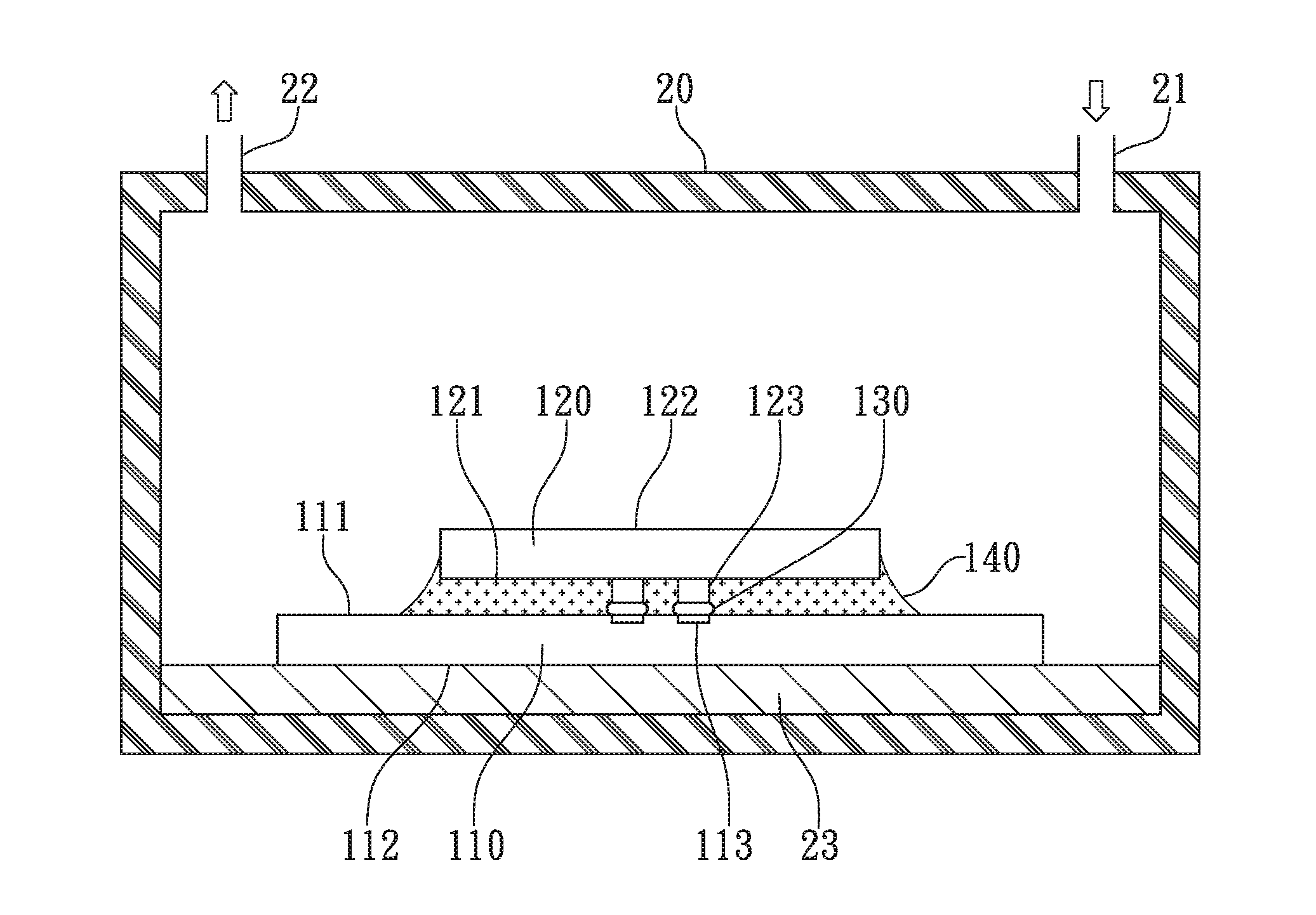

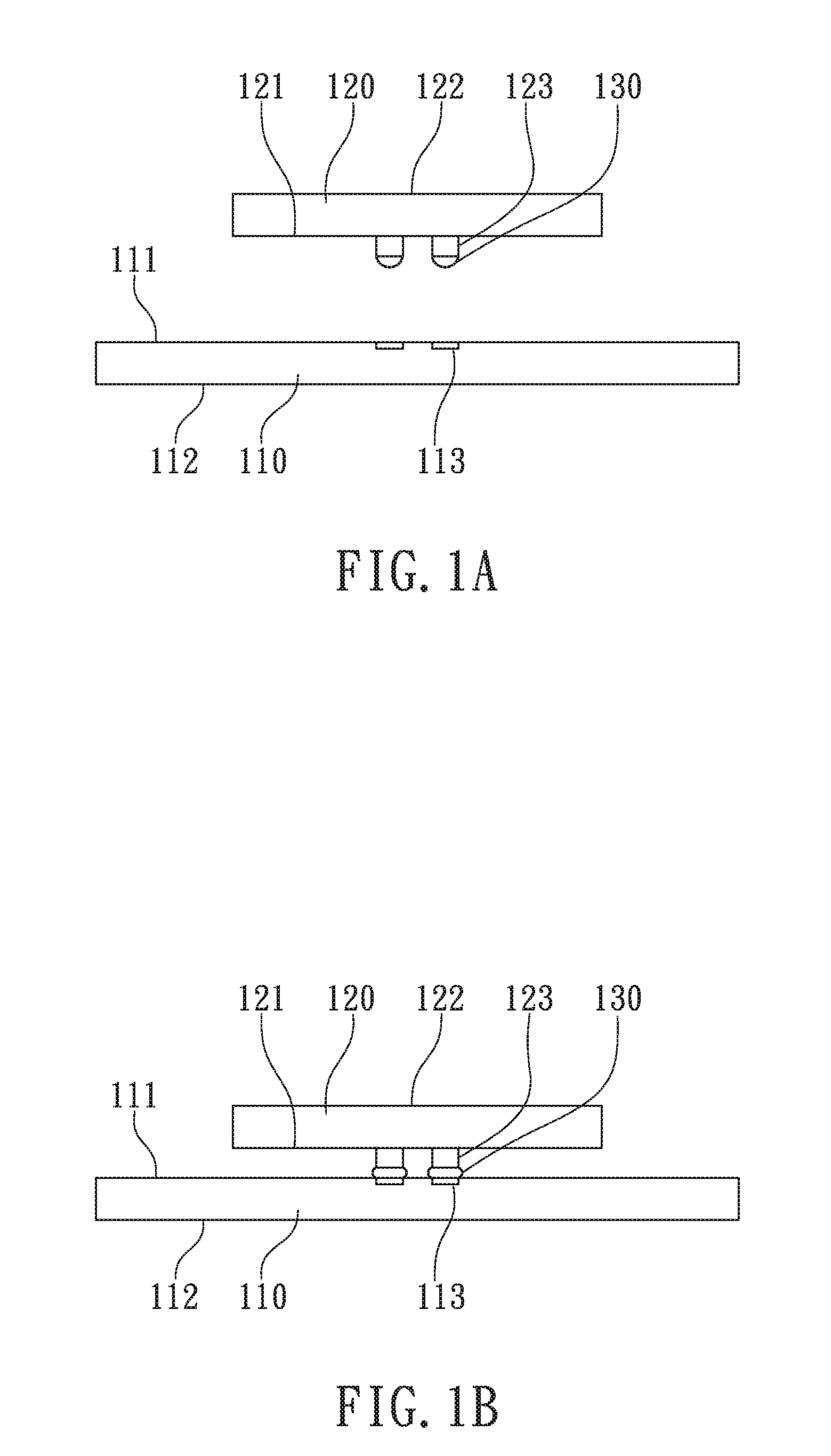

A small and highly reliable acoustic wave device and a method for production of the same will be provided. The acoustic wave device has a piezoelectric substrate 1; a SAW element 2 on one main surface of the piezoelectric substrate 1; an outside connection-use conductor 3 formed on the one main surface of the piezoelectric substrate 1 and electrically connected to the SAW element 2; a columnar electrode 10 on the outside connection-use conductor 3; and a protective cover 6 defining inner walls of a vibration space 7 for vibration of the SAW element 2 and planarly surrounding a side surface of the columnar electrode 10.

Owner:KYOCERA CORP

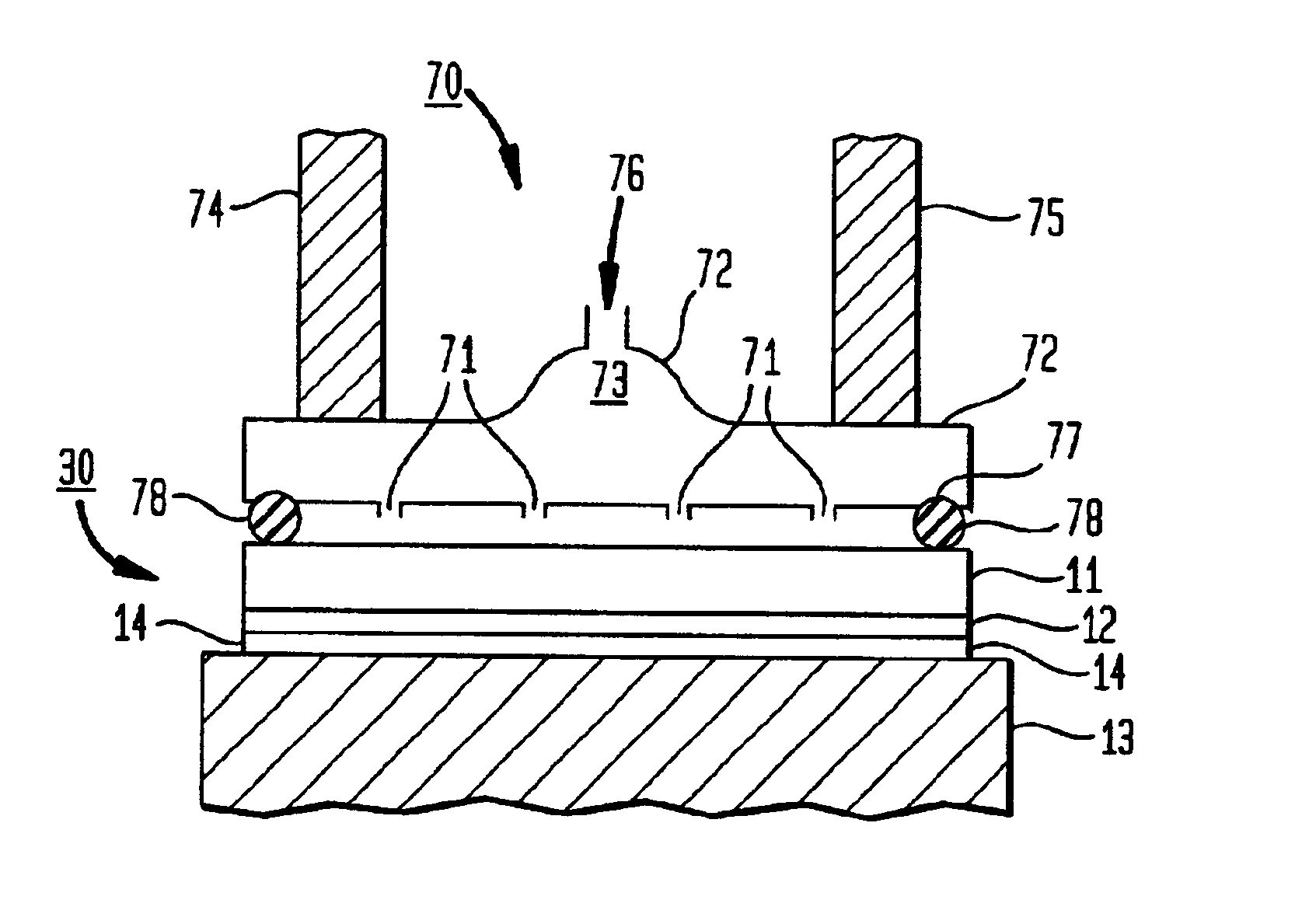

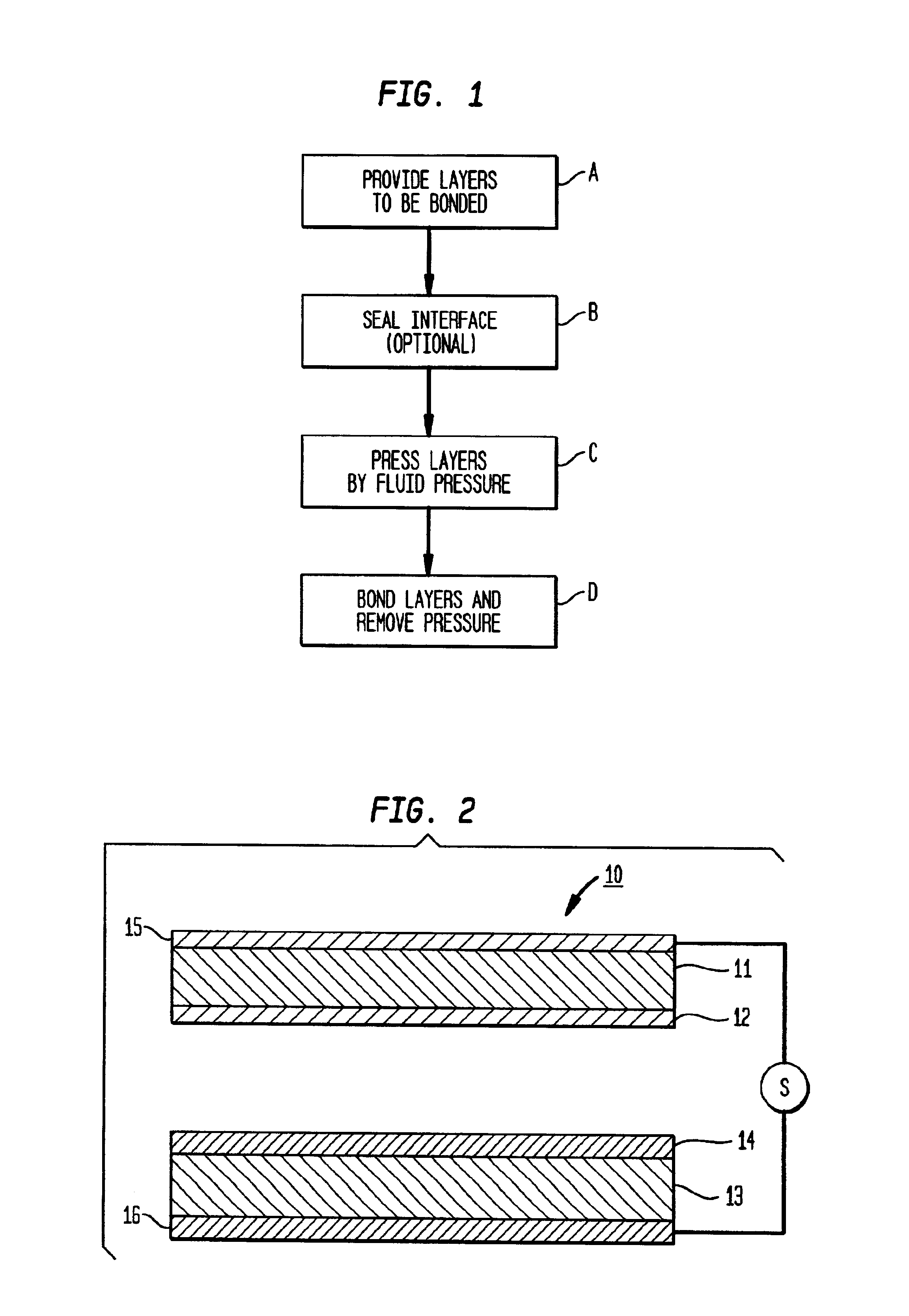

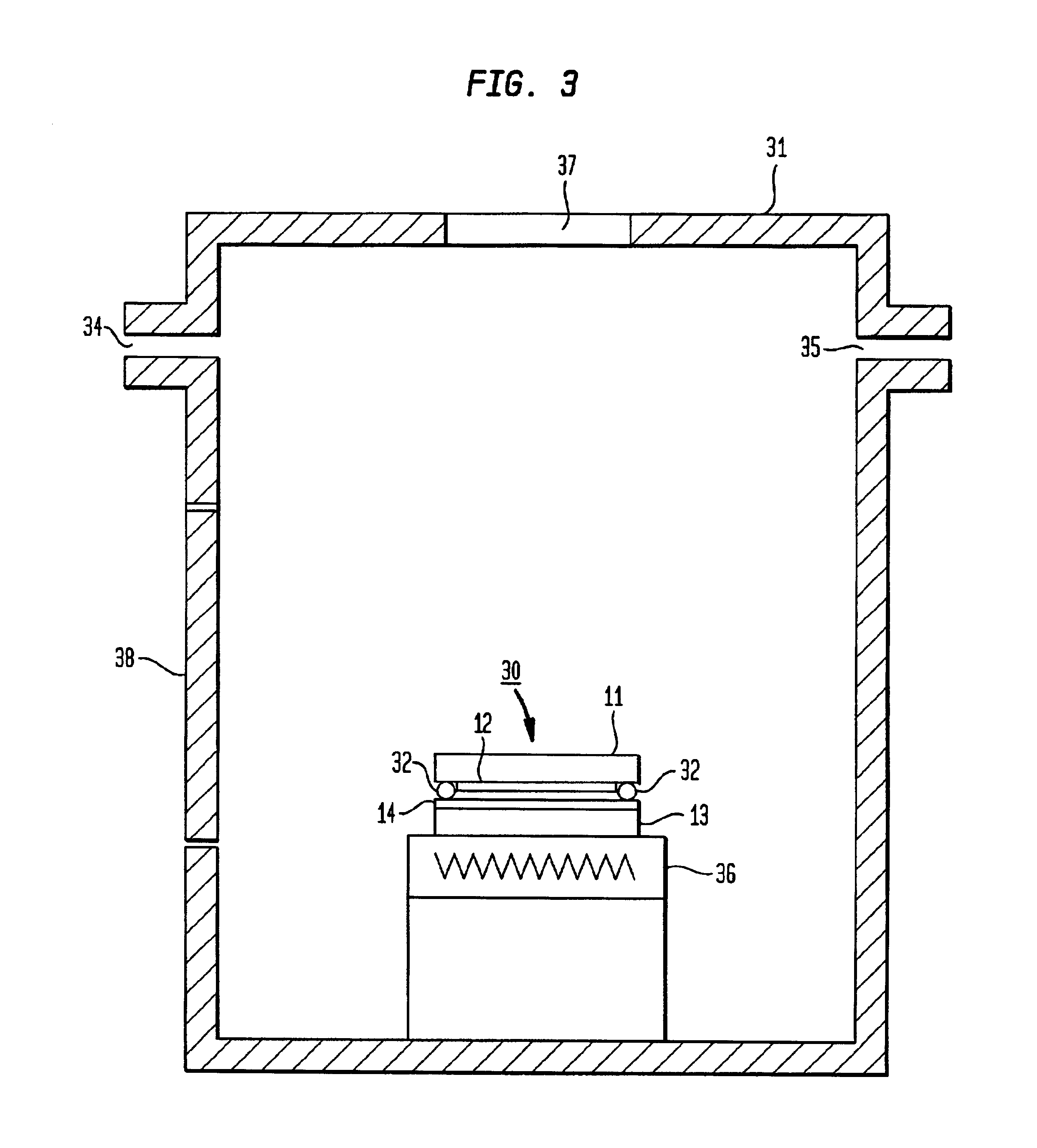

Fluid pressure bonding

InactiveUS6946360B2Reduce voidsImprove uniformityLabelling non-rigid containersNanoinformaticsImproved methodFluid pressure

An improved method of bonding involves using direct fluid pressure to press together the layers to be bonded. Advantageously one or more of the layers are sufficiently flexible to provide wide area contact under the fluid pressure. Fluid pressing can be accomplished by sealing an assembly of layers to be bonded and disposing the assembly in a pressurized chamber. It can also be accomplished by subjecting the assembly to jets of pressurized fluid. The result of this fluid pressing is reduction of voids and enhanced uniformity over an enlarged area.

Owner:NANONEX

Flat aluminum electrolytic capacitor and method of manufacturing the same

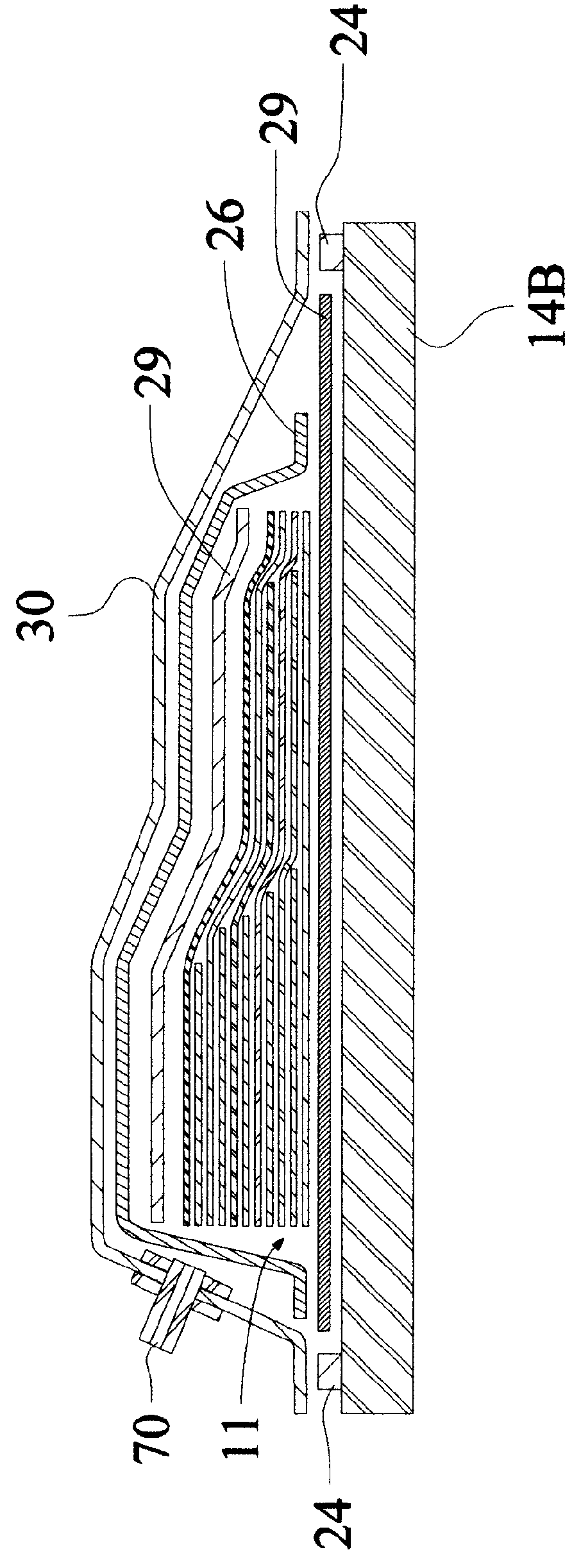

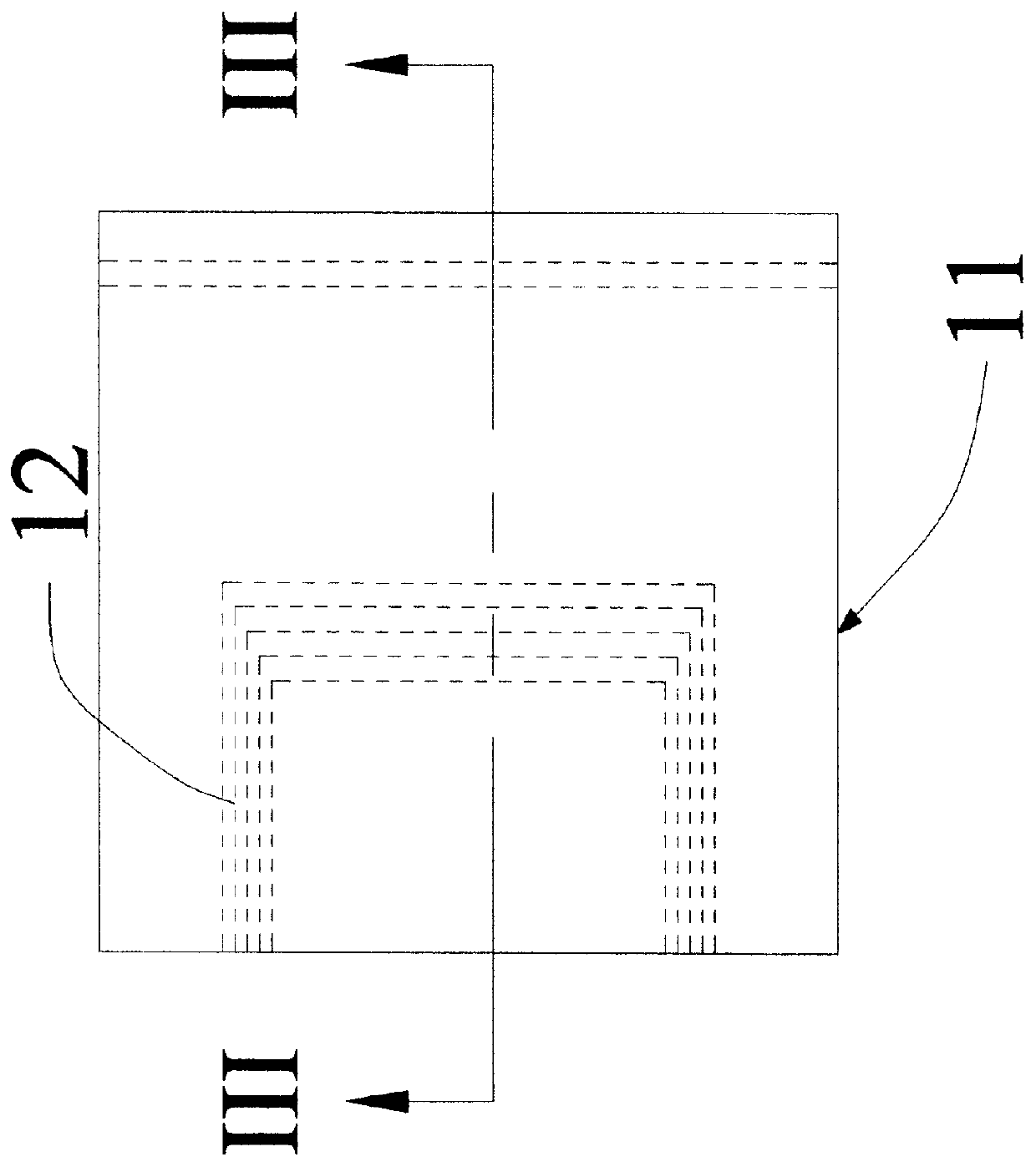

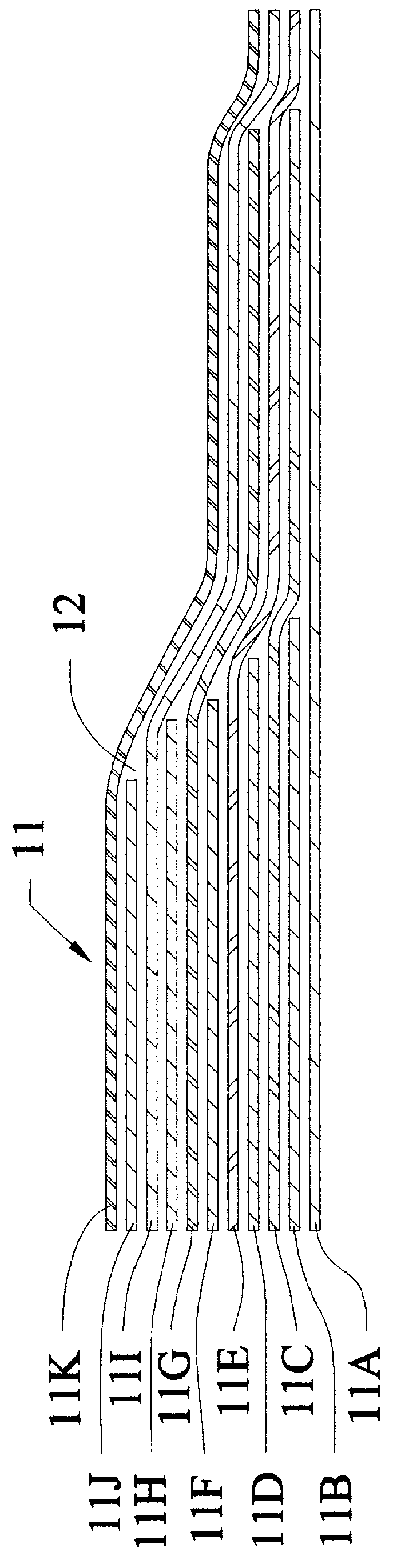

The present invention relates to a method of manufacturing a flat aluminum electrolytic capacitor comprising a separator impregnated with an electrolytic solution, an anode foil and a cathode foil, a flat capacitor element that has external lead-out terminals connected respectively to the anode foil and the cathode foil, and a flexible casing that houses the capacitor element and is hermetically sealed, said method comprising the steps of encasing the capacitor element in the flexible casing and applying aging treatment before hermetically sealing the casing, and hermetically sealing the flexible casing, and also relates to a flat aluminum electrolytic capacitor comprising a separator impregnated with the electrolytic solution, the anode foil and the cathode foil, the flat capacitor element that has the external lead-out terminals connected respectively to the anode foil and the cathode foil, and the flexible casing that houses the capacitor element and is hermetically sealed, wherein the electrolytic capacitor is subjected to an aging treatment before the capacitor element is encased in the flexible casing which is hermetically sealed.

Owner:RUBYCON CORPORATION

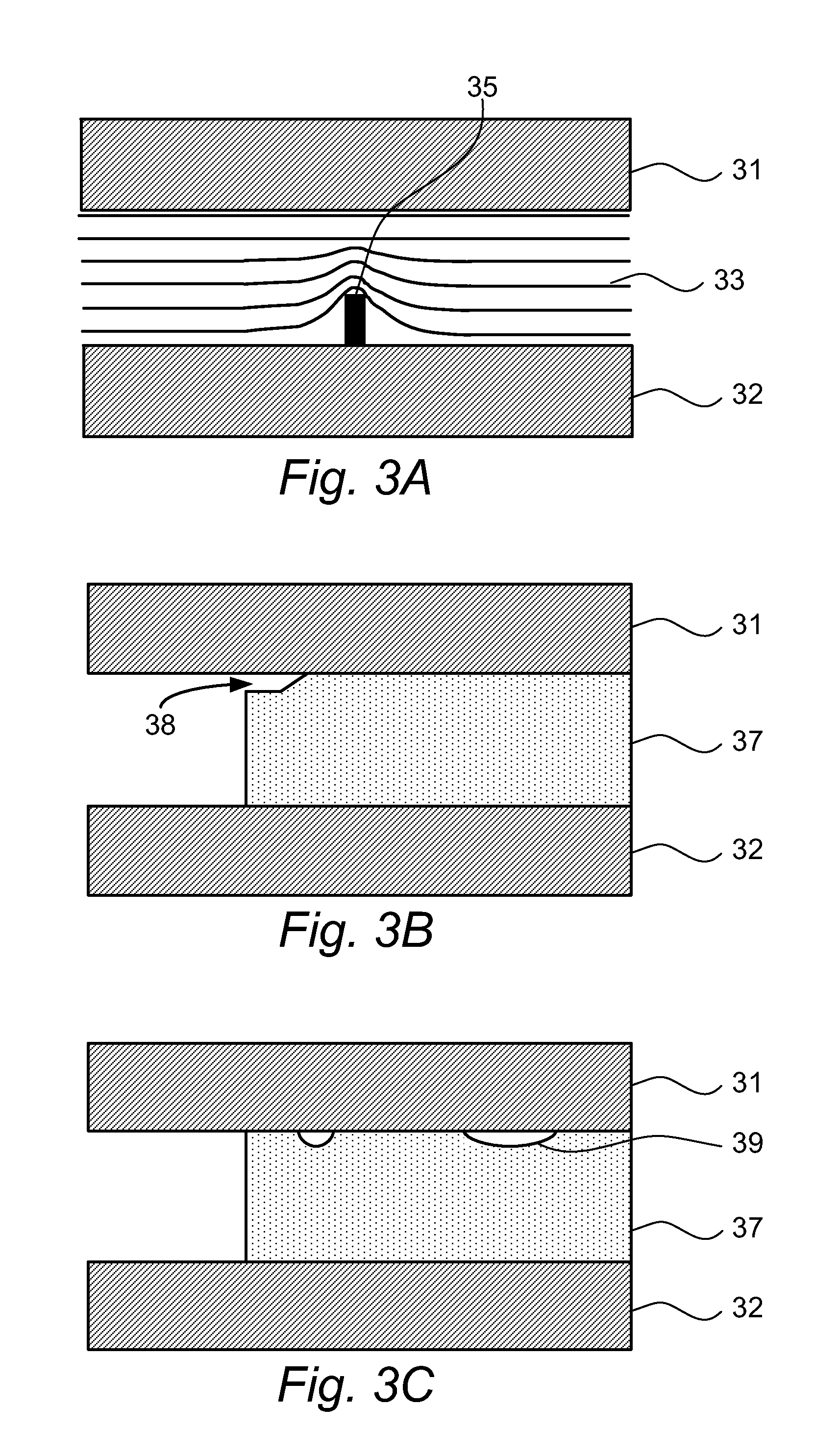

Process and equipment for bonding by molecular adhesion

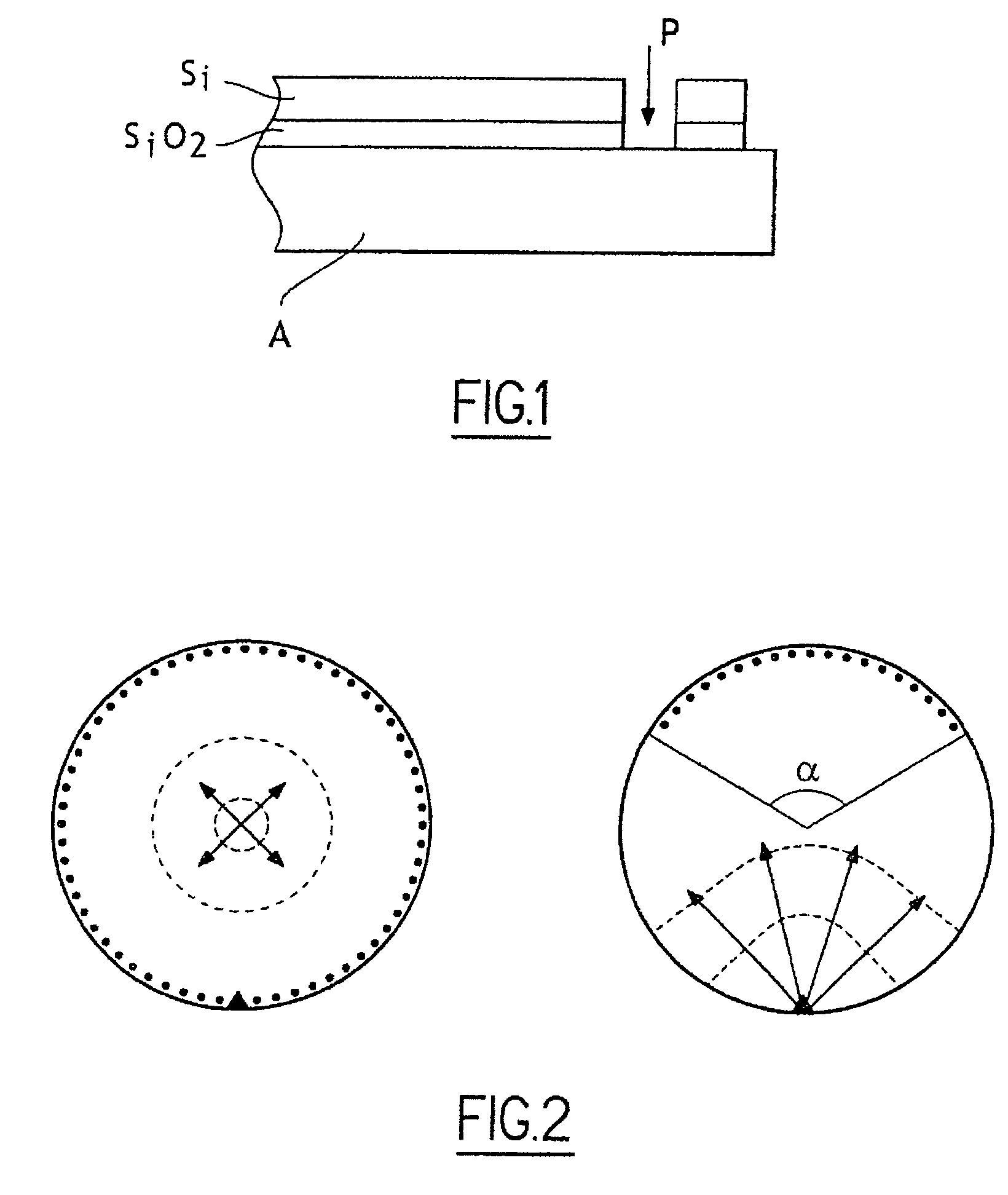

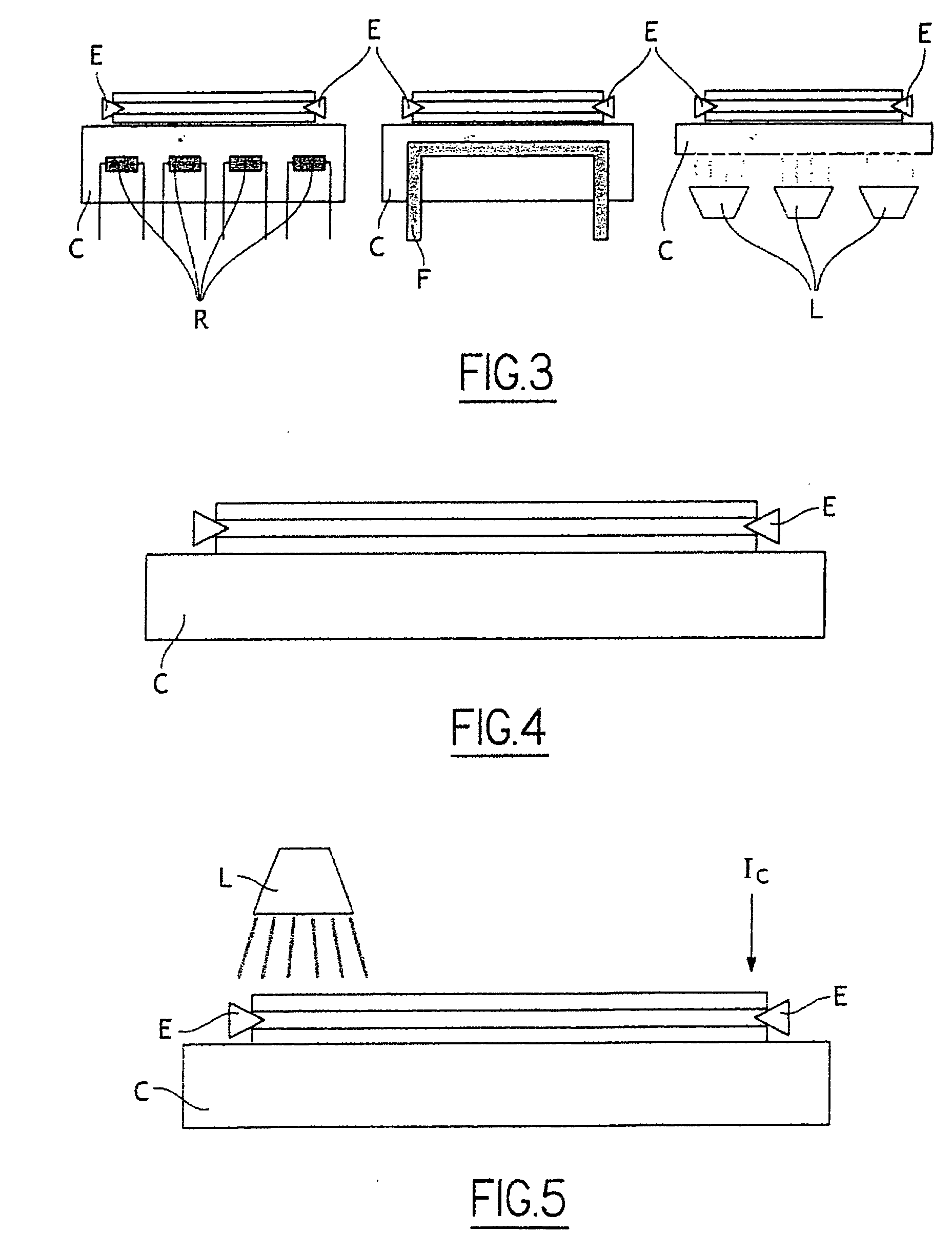

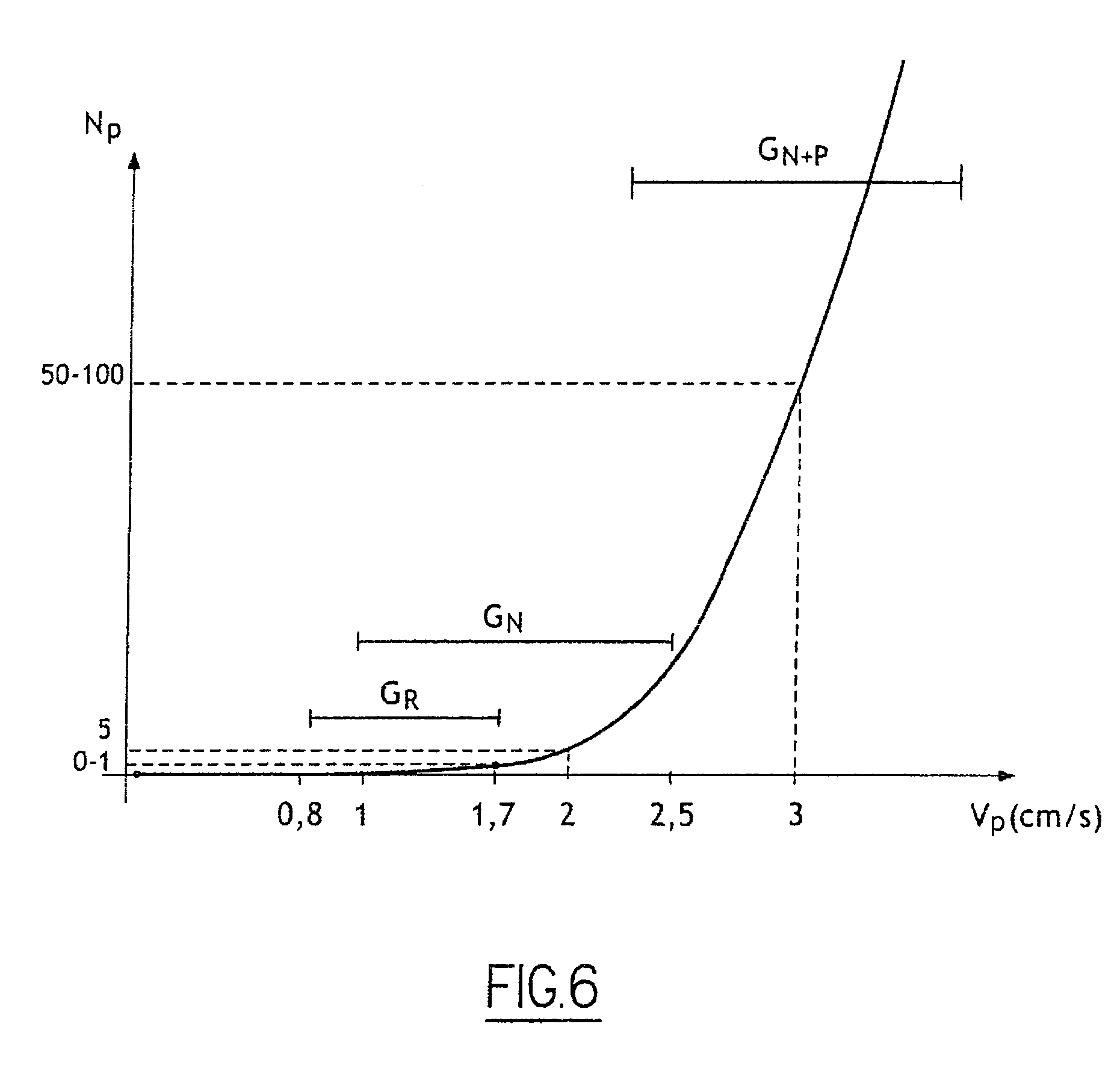

ActiveUS20070119812A1Rectify disadvantageImprove bindingDecorative surface effectsSolid-state devicesSurface statesClose contact

The invention relates to a process for bonding by molecular adhesion of two substrates to one another during which the surfaces of the substrates are placed in close contact and bonding occurs by propagation of a bonding front between the substrates. The invention includes, prior to bonding, a step of modifying the surface state of one or both of the surfaces of the substrates so as to regulate the propagation speed of the bonding front. The surface can be modified by locally or uniformly heating or roughening the surface(s) of the substrate(s).

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

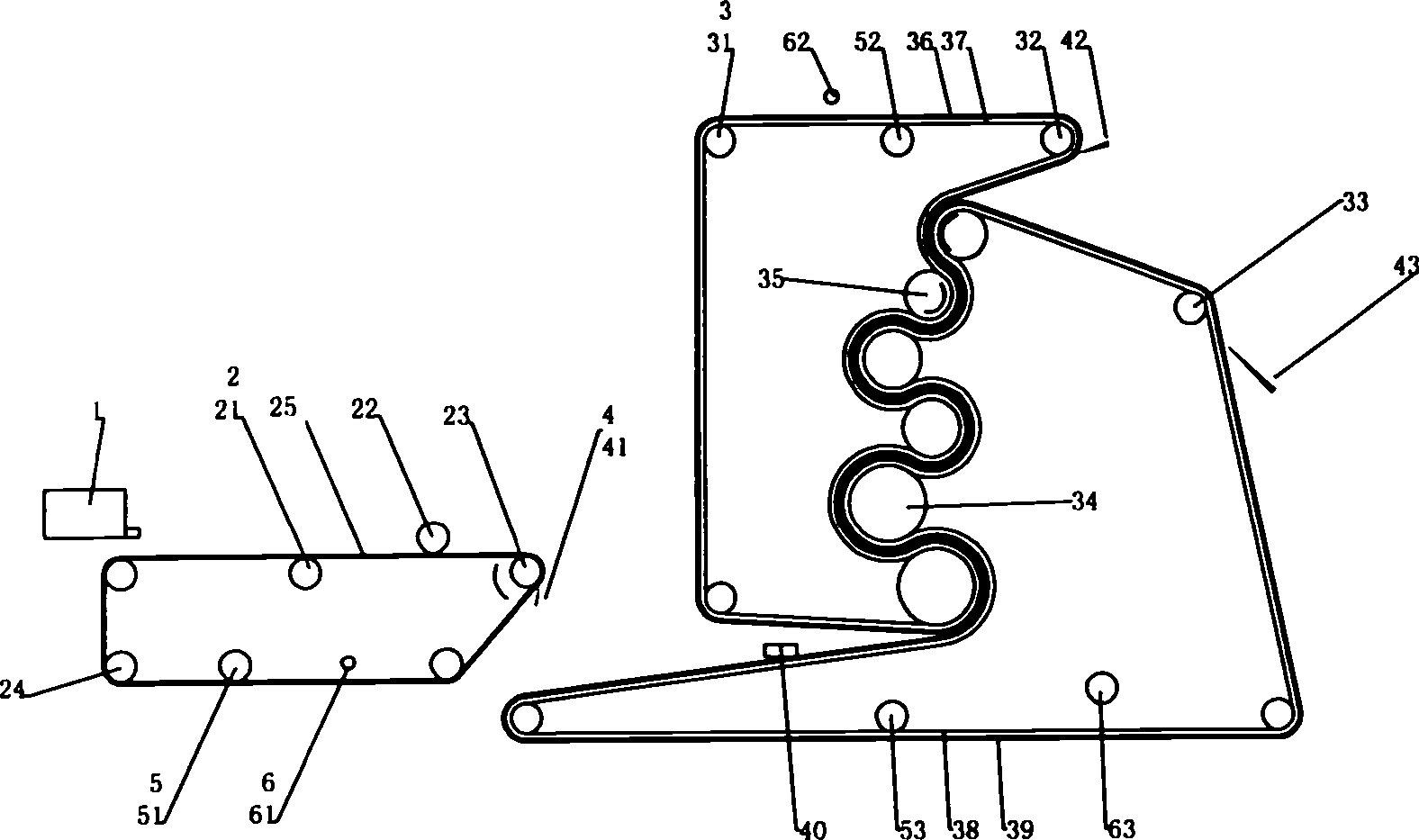

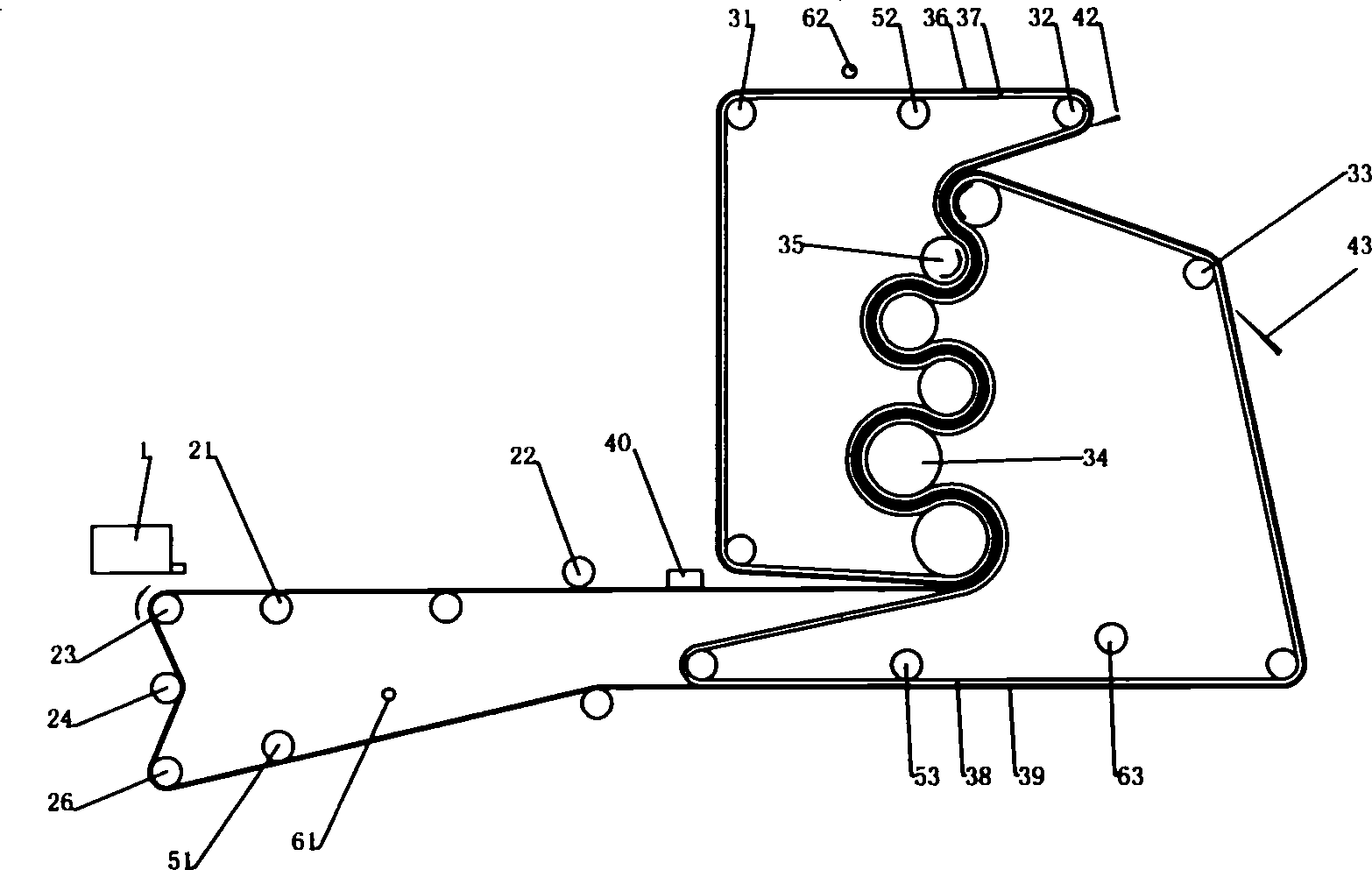

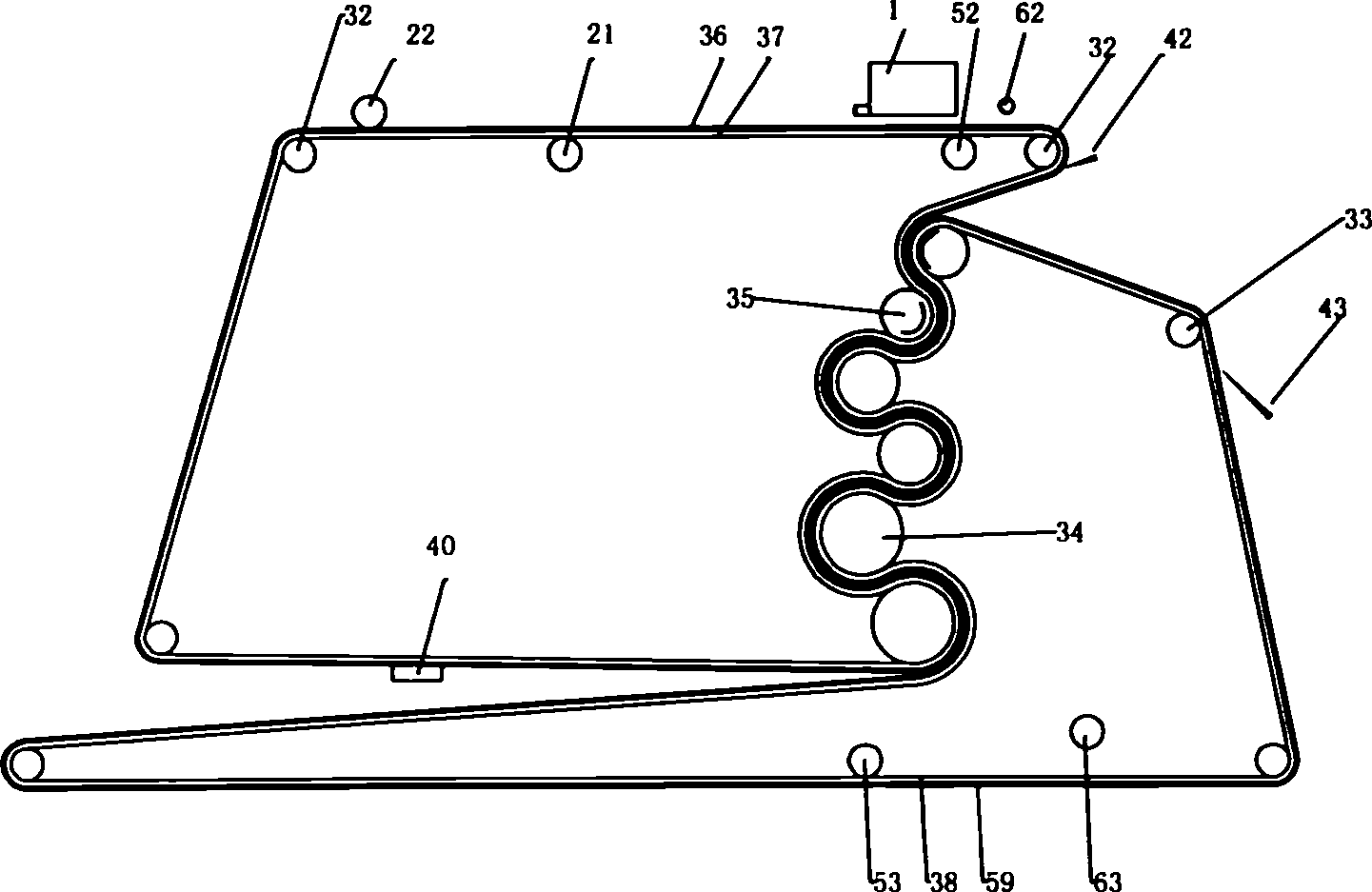

Belt type filter press

ActiveCN1879932AHigh filtration pressureHigh filter pressureMoving filtering element filtersEngineeringFilter press

The invention relates to a belt compress filter for dewatering the micro grains, wherein it is formed by a frame, a driver, a feeding device, a compress area and an auxiliary device; said compress area comprises a compress filtering roller and a filtering belt; the driver comprises a motor and a gear box; the auxiliary device comprises a tension roller, a scrape device, a water collector, a corrector, and a filter belt washer. The invention is characterized in that: the back of filter belt is lined with steel compress belt; the compress filtering rollers are compacted arranged. The invention can improve the filter pressure of compress filter to improve the balance point between the filter pressure and the filter resistance, to overcome the defects of present technique, while it can improve the dewatering efficiency and the yield.

Owner:ZHEJIANG HUAZHANG TECH

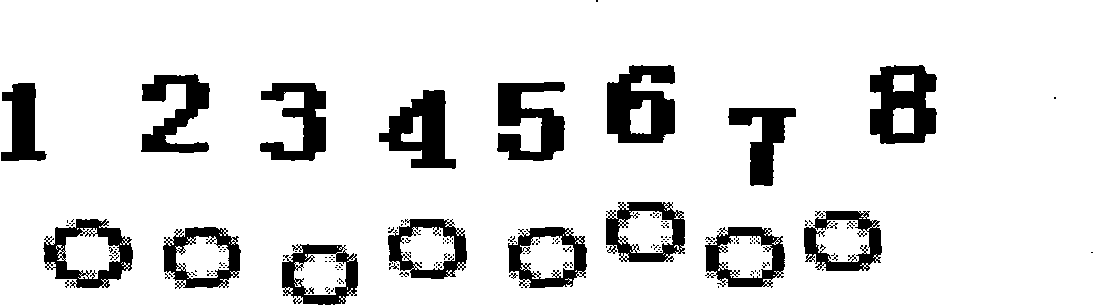

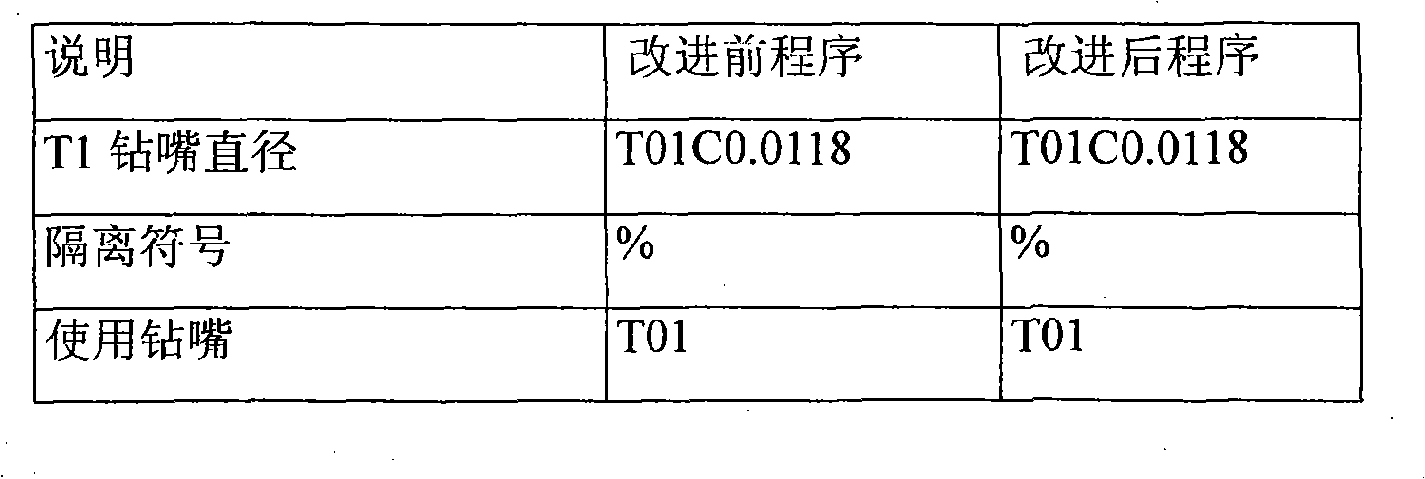

Small-aperture high-density drilling method of printed circuit board

InactiveCN101537505AIncrease working edge lengthReduce the spindle dynamic yaw valuePrinted circuit manufactureHigh densityEngineering

The invention aims at the technical state of the prior printed circuit board drilling method to provide a mechanically drilling method of a high-density and small-aperture multilayer printed circuit board, which improves the drilling machine yield and has good drilling quality by improving drilling parameters. The method mainly comprises the following steps of adjusting zero-position, setting drilling parameters, drilling positioning holes, installing bearing plate, substrate and aluminum sheet, drilling, grinding raw edges, blowing holes and inspecting, wherein the drilling order is set by a leap-frog method with coordinate hole space not smaller than 4 mm; the hole position requirements are converted into a PCB drilling program by CAM, the original hole positions are arranged in sequence, and the drilling sequence is deigned according to the standard of the coordinate hole space not smaller than 4 mm; the pressure foot gasket of a main shaft of a drilling machine is a soft plastic pressure foot gasket; and the bit is a UC-type bit with good chip removal effect, and the total thickness of the drilled substrate is up to 4.5 to 4.8 mm.

Owner:NANJING ELEC & ELTEK ELECTRON

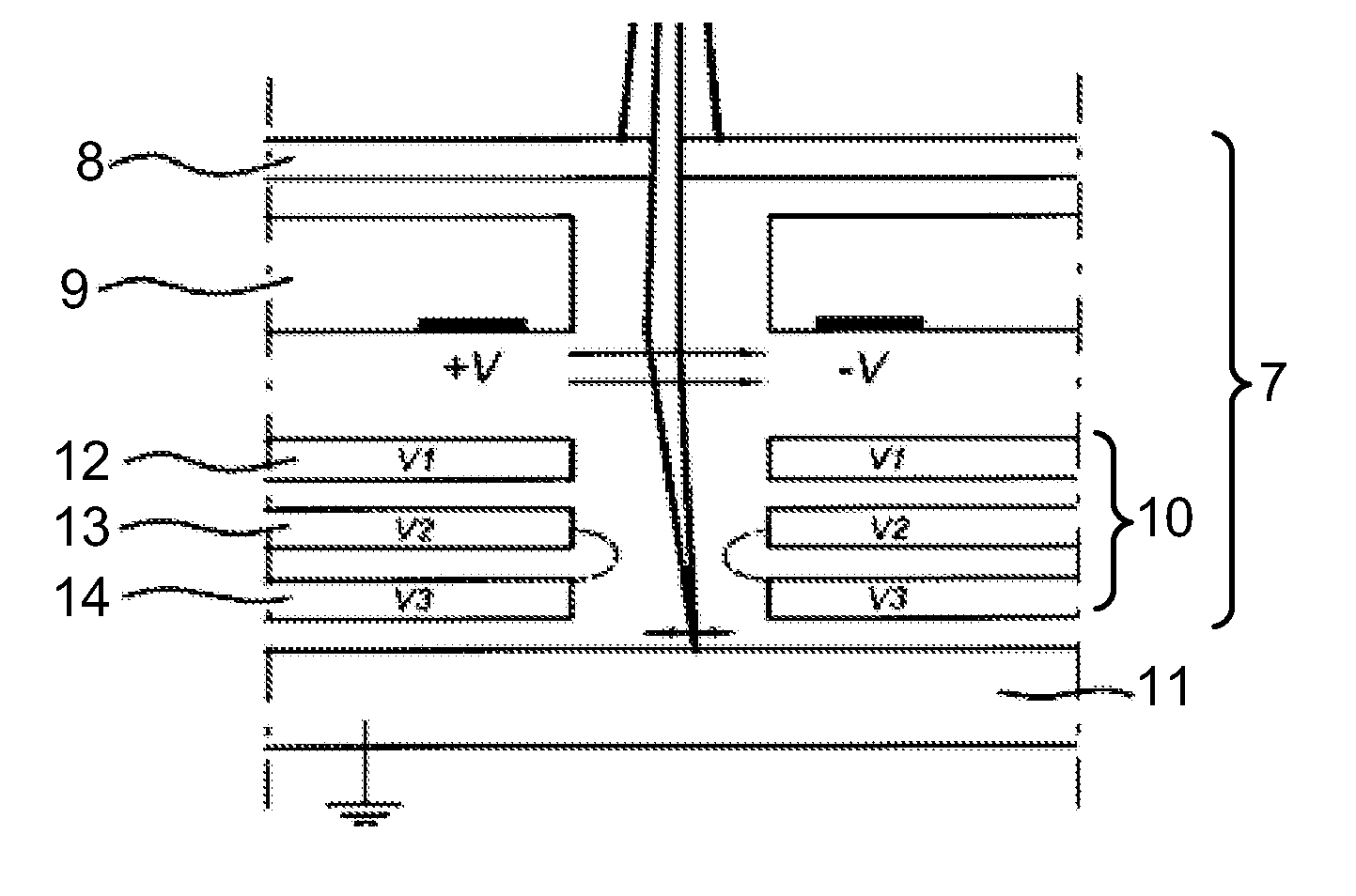

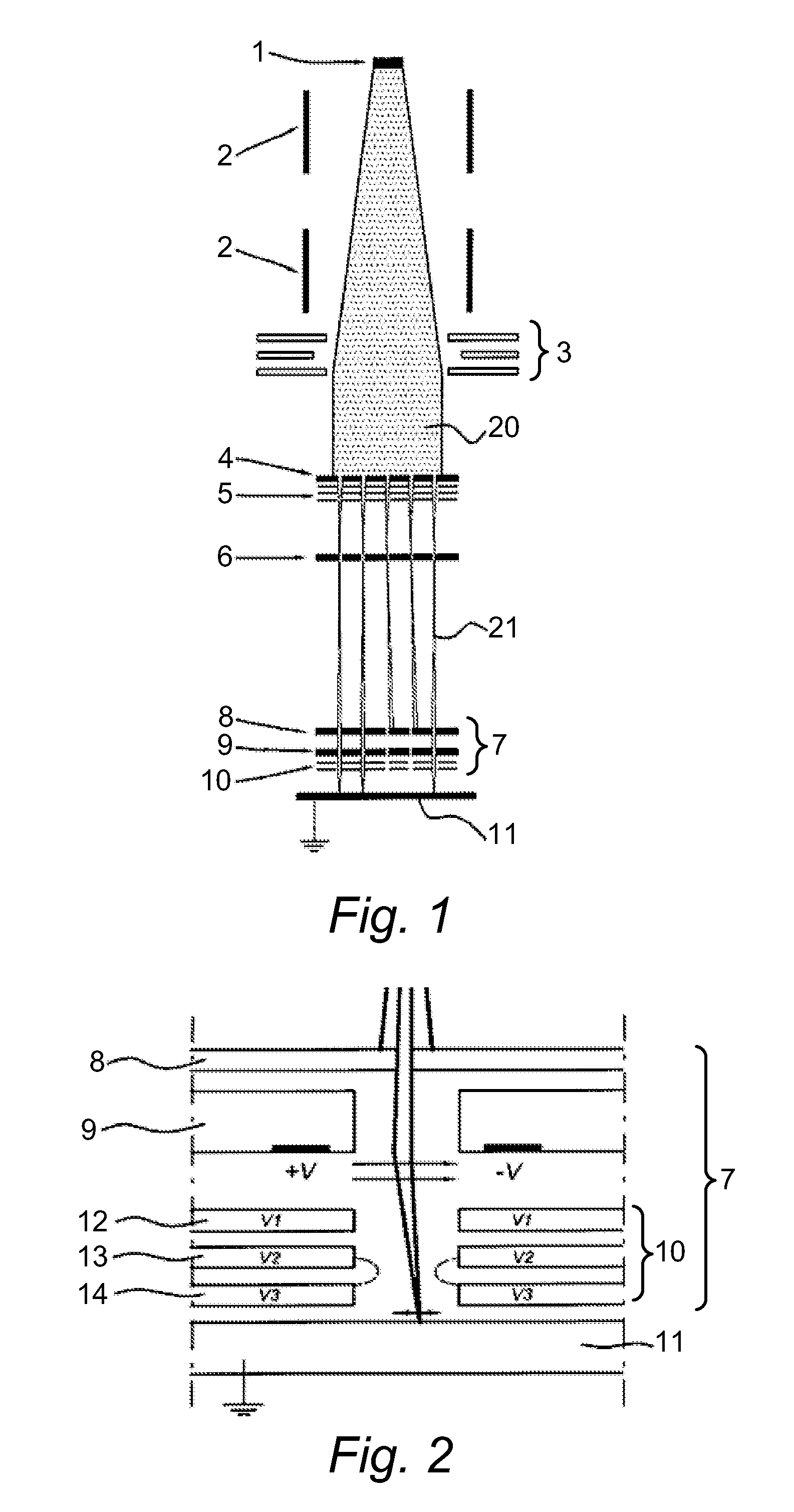

Electrostatic lens structure

ActiveUS20110216299A1Enhancement and elevation of electric fieldRaise the possibilityStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsEngineeringVoltage

An electrostatic lens comprising a first conductive plate with a first aperture, a second conductive plate with a second aperture, the second aperture being substantially aligned with the first aperture, a voltage supply for supplying a first voltage to the first conductive plate and a second voltage to the second conductive plate, the first voltage being lower than the second voltage, and an insulating structure for separating the first conductive plate from the second conductive plate. The insulating structure comprises a first portion in contact with the first conductive plate and a second portion in contact with the second conductive plate, the first portion having an overhanging portion and the second portion having an indented portion at an edge of the insulating structure, so that a gap is formed between the overhanging portion and the second conductive plate.

Owner:ASML NETHERLANDS BV

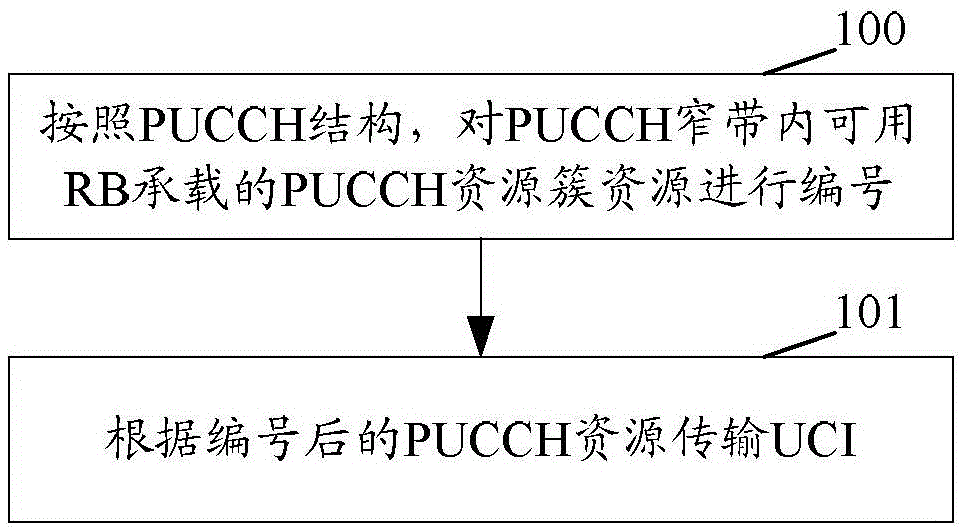

Transmission method and device for transmitting uplink control information

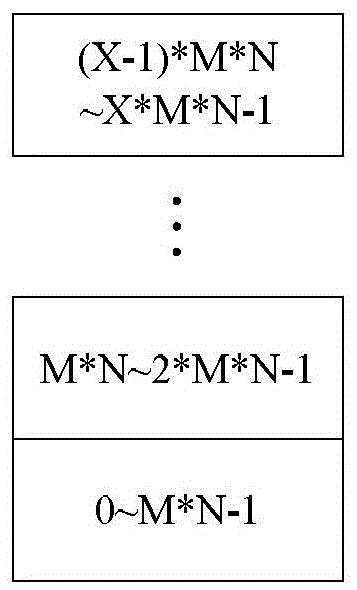

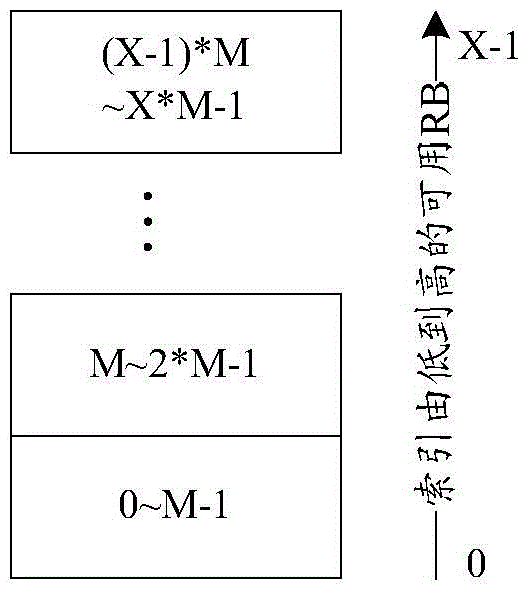

ActiveCN105827371AGuaranteed normal transmissionReduce resource holesError prevention/detection by using return channelError prevention/detection by diversity receptionResource blockUplink transmission

The invention discloses a transmission method and a device for transmitting the uplink control information. The method comprises the steps of according to a PUCCH structure, numbering the PUCCH resource loaded on an available resource block (RB) in a PUCCH narrow band; and transmitting the UCI according to the numbered PUCCH resource. The PUCCH structure includes but not limited to a 1x structure and a 2x structure, wherein the 1x structure and the 2x structure are in PUCCH format. According to the technical scheme of the invention, all 1x structures and all 2x structures, designed in PUCCH format and loaded on all available resource blocks in the PUCCH narrow band, are numbered respectively according to the above 1x structure and the above 2x structure. Meanwhile, according to the uniformly numbered 1x and 2x structures in the PUCCH format, the UCI is transmitted, so that the same resource region in the PUCCH narrow band can be shared by the 1x and 2x resources in the PUCCH format. Therefore, unnecessary PUCCH resource cavities are reduced to a certain extent. Moreover, the UCI transmission efficiency within the range of the PUCCH narrow band is improved. As a result, the efficient transmission of the UCI in the newly introduced PUCCH narrow band in the uplink transmission can be realized.

Owner:ZTE CORP

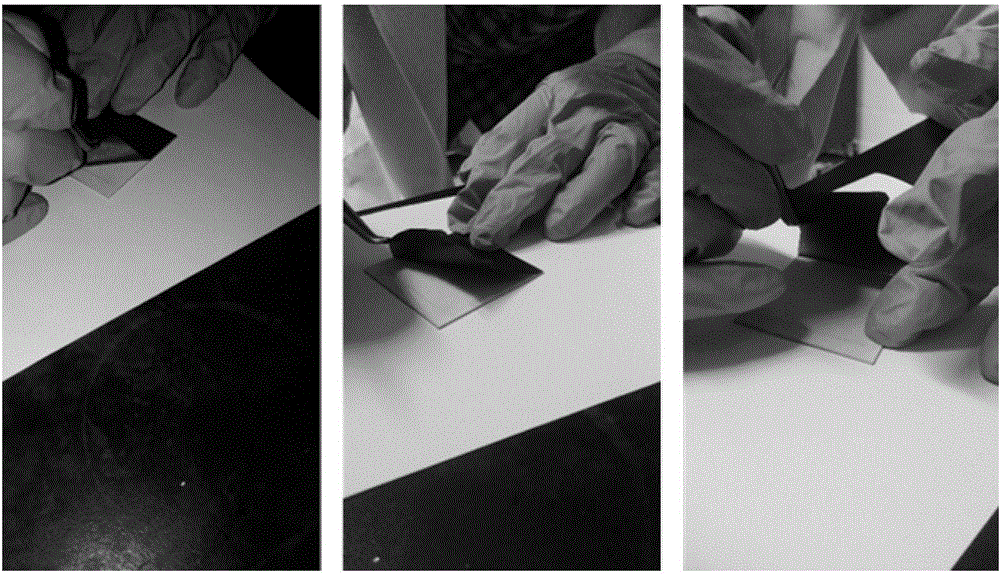

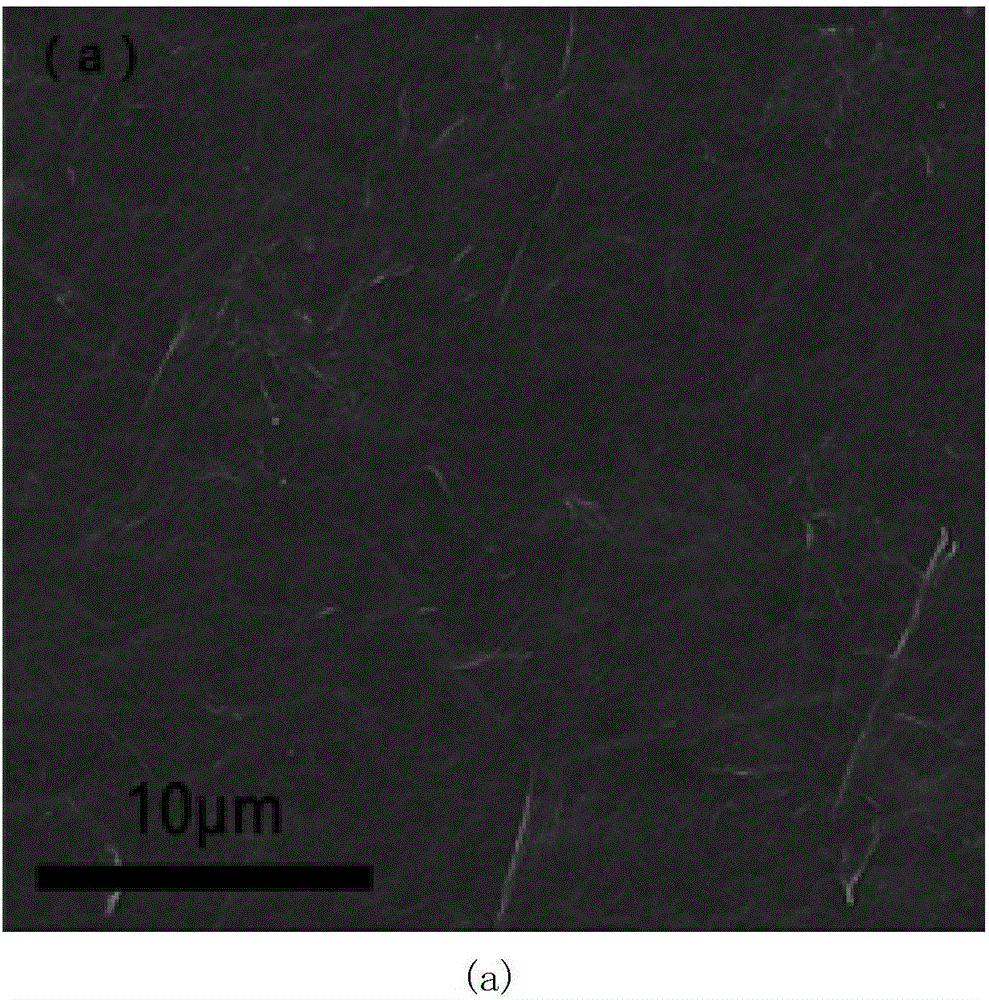

Preparation method of high-heat-conduction flexible graphene film

The invention provides a preparation method of a high-heat-conduction flexible graphene film. Oxidized graphene powder is frozen, dried and dispersed in a solvent, and an oxidized graphene dispersion liquid with the concentration being 0.1-10 mg / ml is obtained; the oxidized graphene dispersion liquid is added to a spraying device and sprayed on a substrate, the substrate is heated at the temperature of 50-150 DEG C for 0.5-5 h, and the oxidized graphene film is formed on the substrate after the dispersion liquid is evaporated; the oxidized graphene film is peeled off and rolled; hot-pressing carbonization and high-temperature graphitization are performed under the protection of a protective atmosphere, and the heat-conduction graphene film is obtained. With the adoption of the method, the high-heat-conduction flexible graphene film with the size and the thickness being controllable can be effectively prepared to meet requirements of different heat dissipation devices and can be applied to various wearable equipment, smart phones, smart televisions and LEDs on a large scale to improve the heat dissipation effect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Straw fiber reinforced foam concrete and preparation method thereof

ActiveCN104130006AUniform porous structureReduce voidsSolid waste managementCeramicwareFoam concreteFoaming agent

The invention discloses straw fiber reinforced foam concrete and a preparation method thereof, and belongs to the technical field of building materials. The straw fiber reinforced foam concrete comprises the following components by mass: 40-80 parts of a cementitious material; 1-20 parts of a fine lightweight aggregate; 0.05-0.6 part of straw fiber; 2-8 parts of a chemical foaming agent; 0.5-4 parts of a physical foaming agent; 0.02-0.14 part of a foam stabilizing agent; 0.1-0.8 part of a catalyst; 0.05-0.6 part of a thickening agent and 15-30 parts of water. The preparation method is as follows: mixing and stirring the cementitious material, the straw fiber and the thickening agent, then adding the water, the chemical foaming agent, the foam stabilizing agent and the catalyst, stirring to obtain a slurry mixture, then adding expanded vermiculite, stirring to obtain chemically foamed foam concrete; adding the physical foaming agent into the chemically foamed foam concrete, stirring, pouring into a mould, and demoulding after concrete is solidified and hardened to prepare the straw fiber reinforced foam concrete. The straw fiber reinforced foam concrete has a more uniform multihole structure, and the water proof, sound insulation and heat insulation effects are better than that of foam concrete in the prior art.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

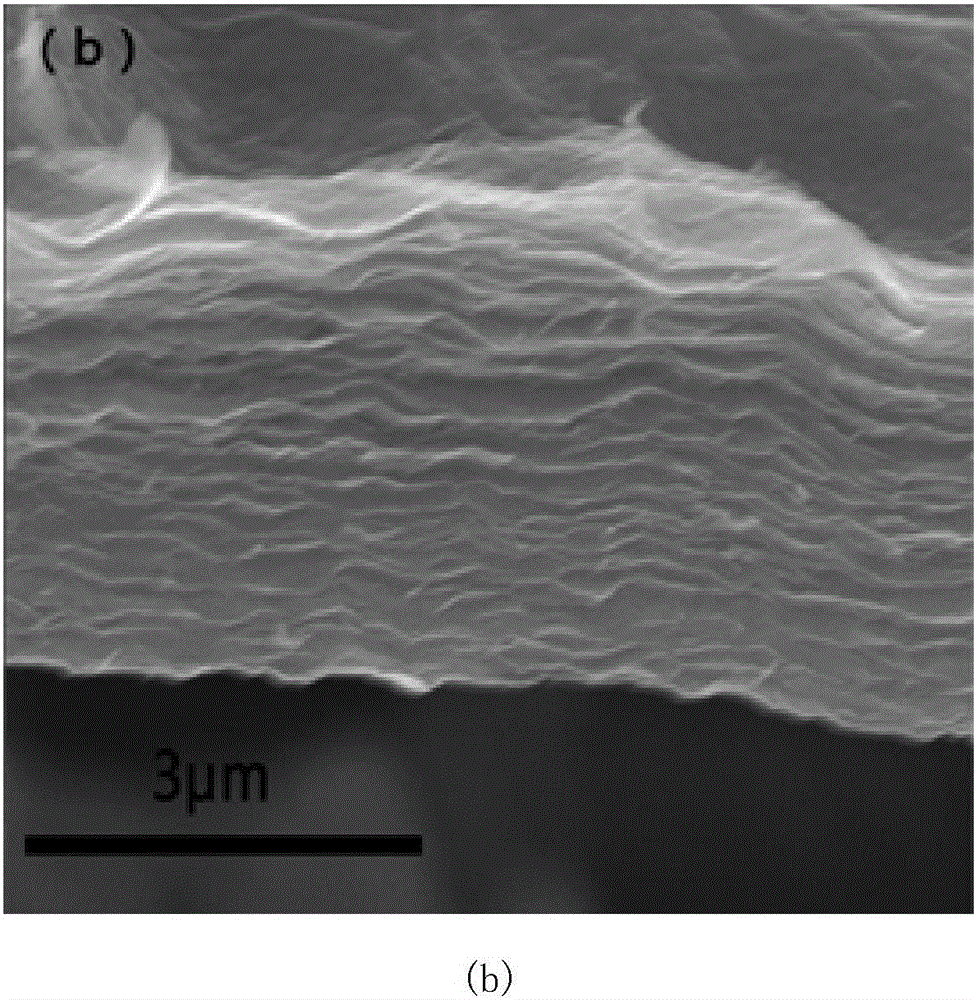

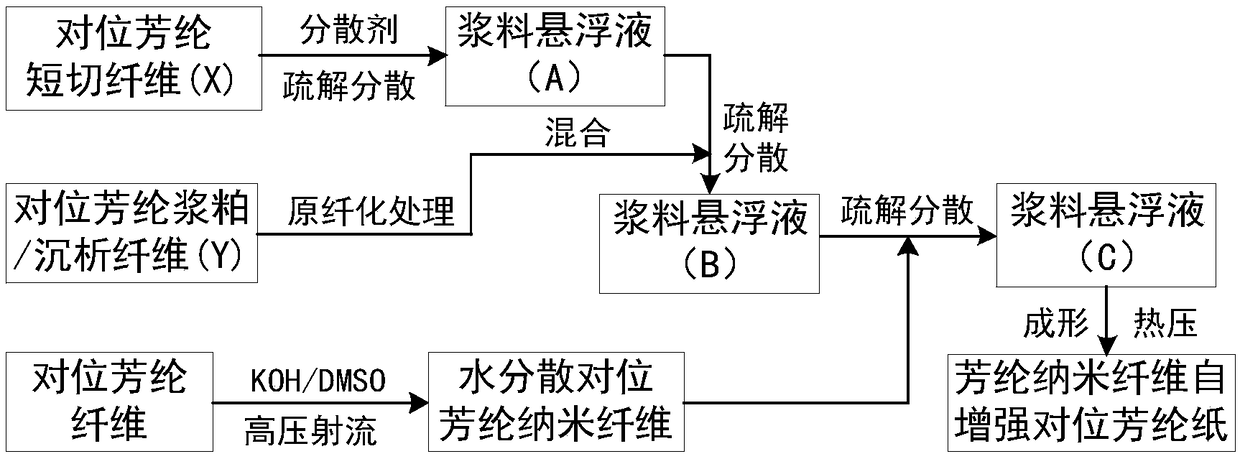

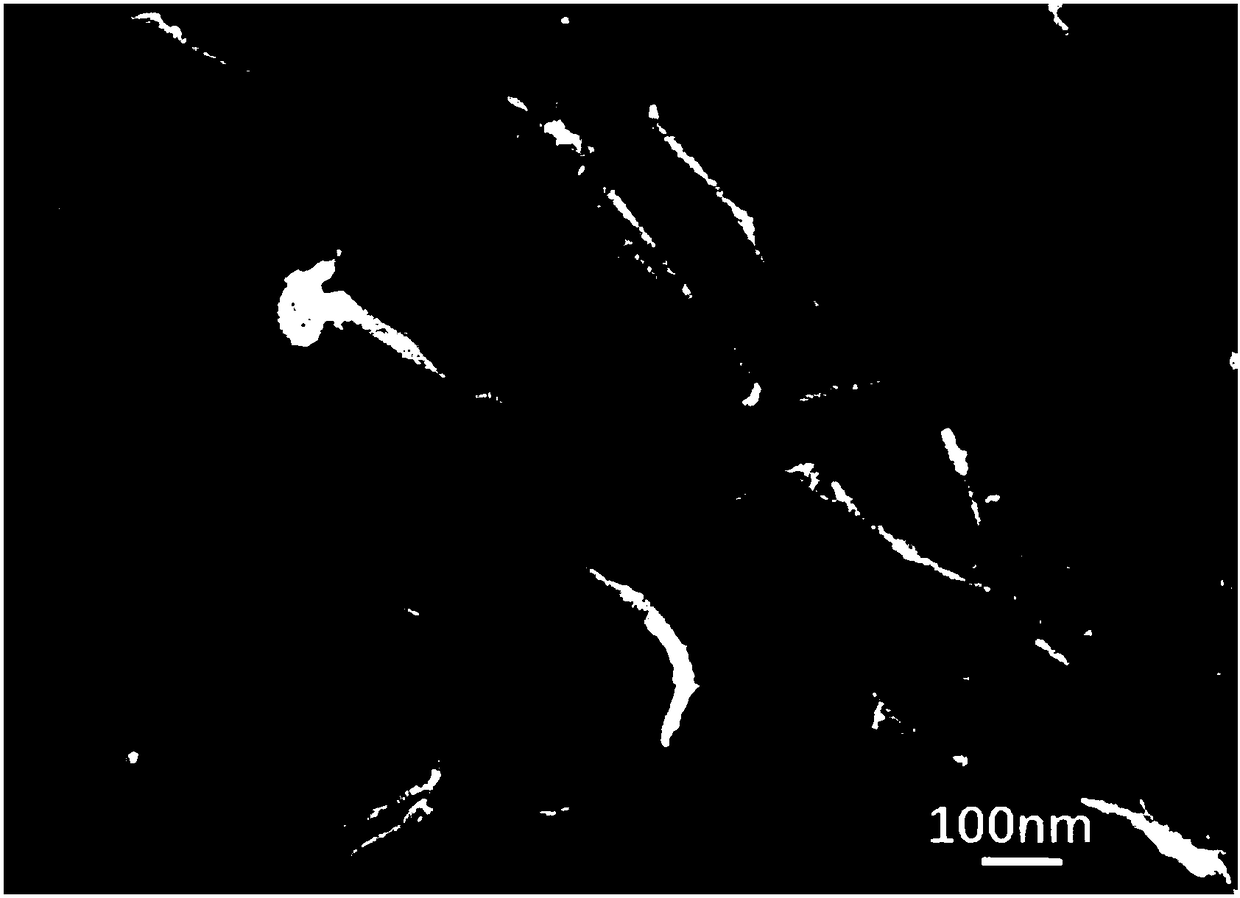

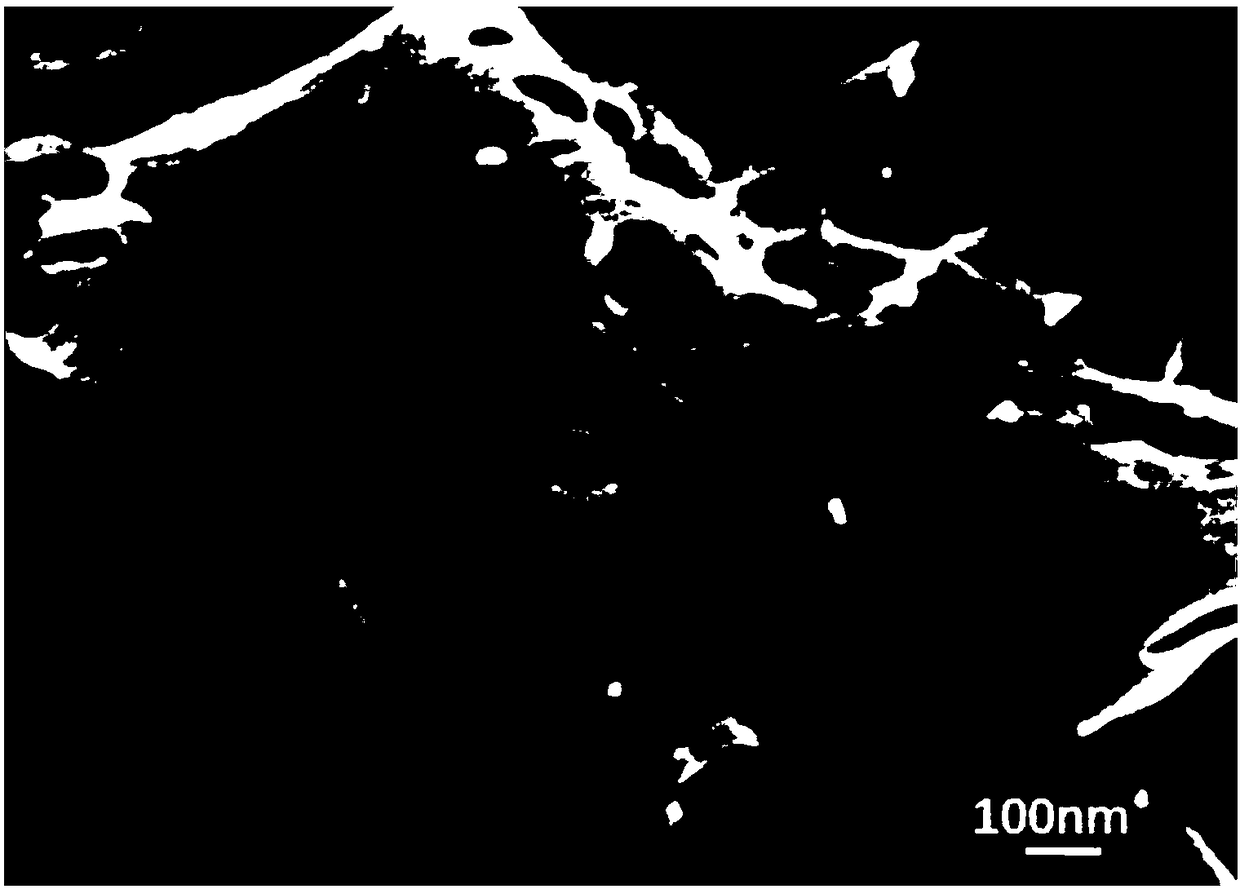

PPTA paper using aramid nanofiber for self-reinforcement and preparation method thereof

ActiveCN108265566AUnique nanoscale structureLarge aspect ratioSpecial paperPaper/cardboardNano structuringHigh surface

The invention discloses a PPTA paper using aramid nanofiber for self-reinforcement and a preparation method thereof. The preparation method includes: utilizing para-aramid paper nanofiber with the advantages of special nano-structure, small fiber diameter, large length-diameter ratio, high surface activity, excellent heat resistance and the like as the self-reinforcement material of para-aramid paper, conducting mixing, defibering and dispersion on aramid chopped fiber, pulp or fibrid and aramid nanofiber to make a uniform suspension, carrying out papermaking shaping, squeezing and drying, andfurther performing hot-pressing on a hot press to obtain aramid paper. The introduced aramid nanofiber enables nanoscale aramid fiber and an aramid nanofilm formed thereby to reach the good interfacefilling, coating and enhancement effects, provides more binding sites for the combination of components, at the same time reduces the pores and holes between components, significantly improves the bonding strength between the aramid paper components, and greatly enhances the mechanical and insulation properties.

Owner:SHAANXI UNIV OF SCI & TECH

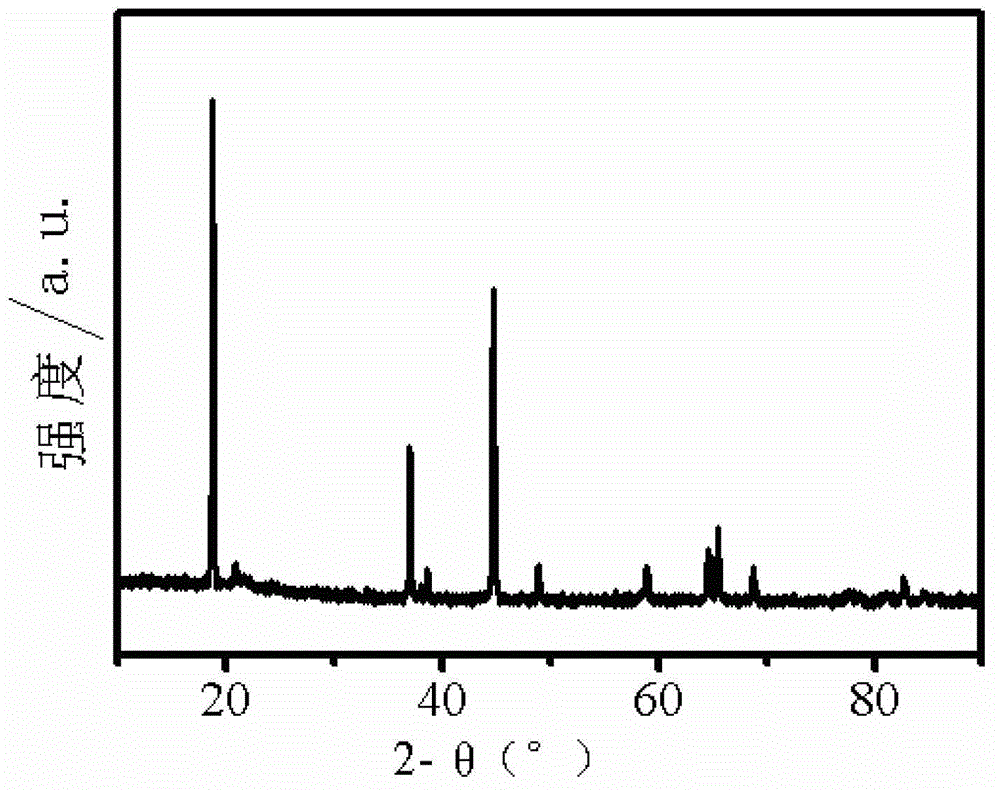

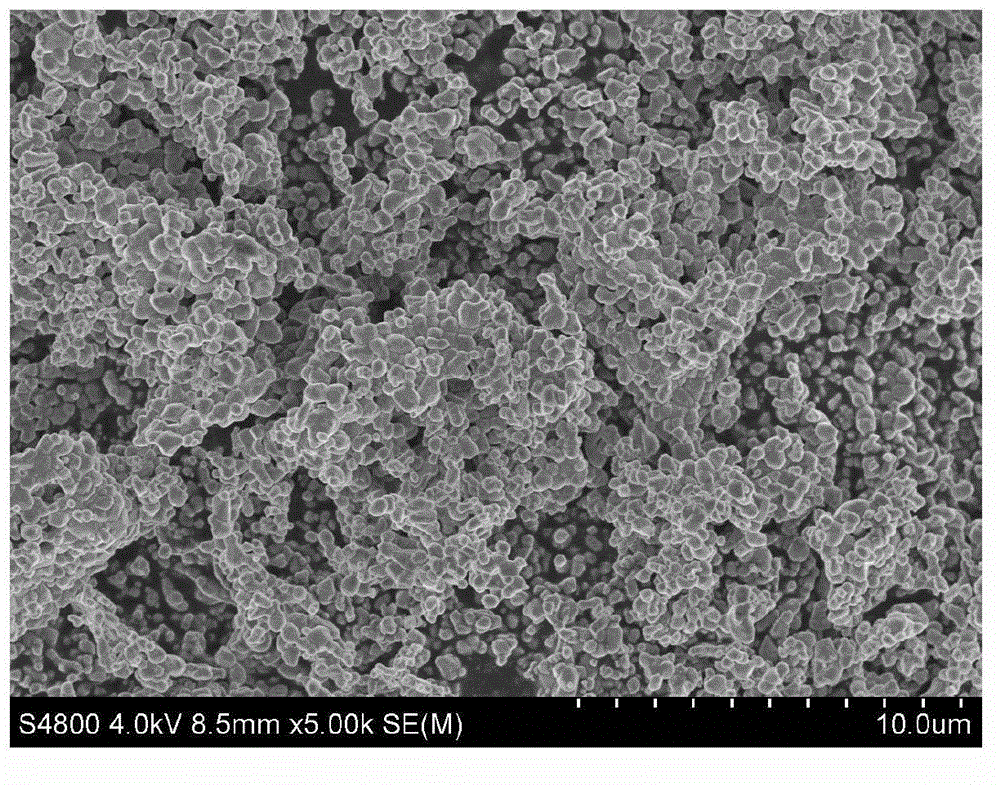

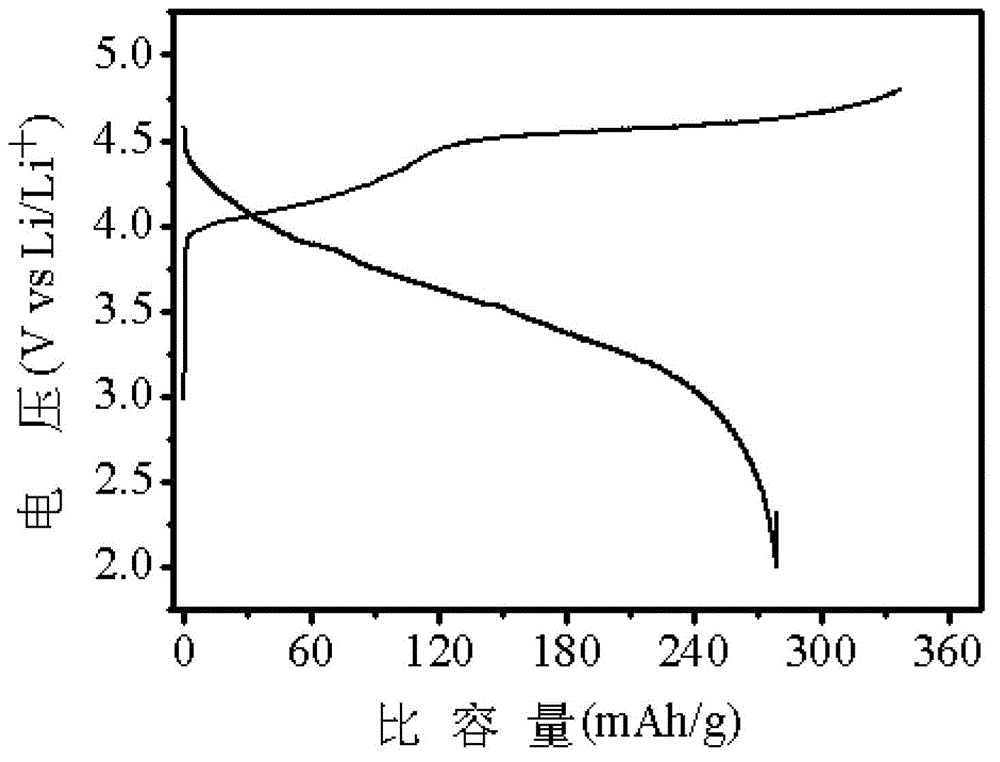

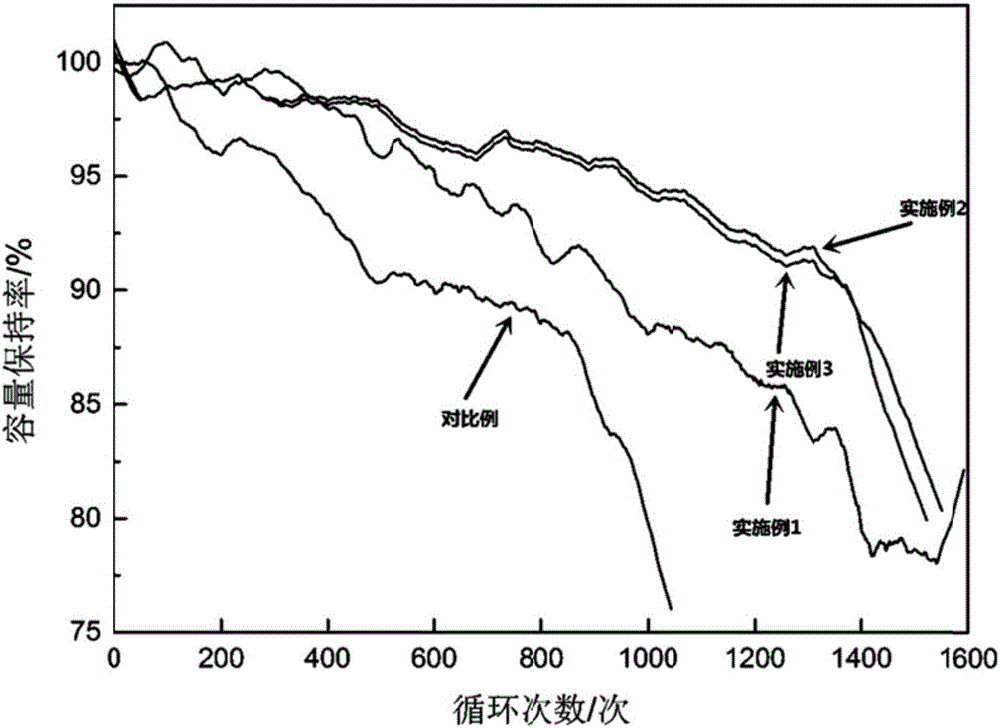

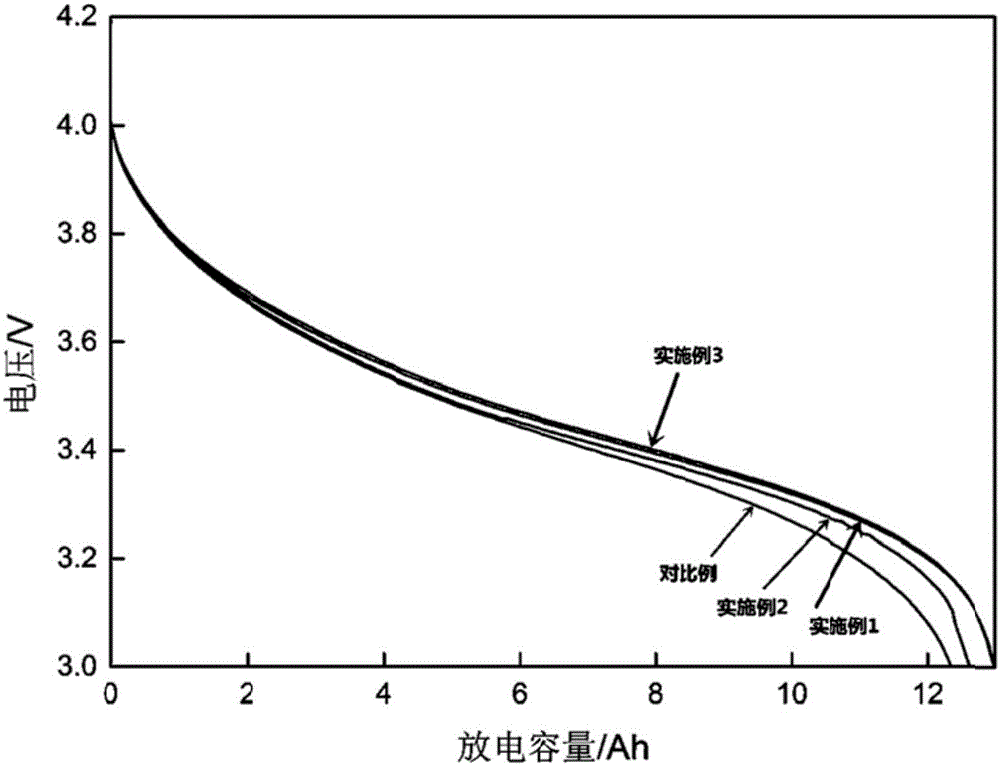

Lithium-rich manganese-based anode material and method for manufacturing same

ActiveCN102916169AImprove featuresUniform structureCell electrodesSecondary cellsPtru catalystActive agent

The invention discloses a lithium-rich manganese-based anode material and a method for manufacturing the same. The method includes steps of (a), providing mixed solution containing lithium compounds, nickel compounds and manganese compounds, optional titanium compounds, optional iron compounds, optional cobalt compounds or an optional combination of the titanium compounds, the ion compounds and the cobalt compounds; (b), adding complexing agents, catalysts and surfactants into the mixed solution to form pre-coagulated substances; and (c), calcining the pre-coagulated substances to obtain the lithium-rich manganese-based anode material Li[LixNiaMnbM1-a-b-x]O2 or a combination of lithium-rich manganese-based anode materials. The complexing agents, the catalysts and the surfactants are used for forming the pre-coagulated substances, the complexing agents contain resorcinol and formaldehyde, in the molecular formula of the lithium-rich manganese-based anode material, the M represents Ti, Fe, Co or a combination of the Ti, the Fe and the Co, the x is larger than 0 and is smaller than or equal to 0.4, the a is larger than 0 and is smaller than or equal to 0.5, the b is larger than or equal to 0.33 and smaller than or equal to 0.6, and a result of 1-a-b-x is larger than or equal to 0. The lithium-rich manganese-based anode material is of a multi-channel porous structure, is small in grain size, uniform in grain distribution, advanced in porosity and stable in electrochemical performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Treatment method for improving performance of 3D printing metal workpiece

The invention discloses a treatment method for improving the performance of a 3D printing metal workpiece. The treatment method comprises the following steps of sequentially carrying out primary cryogenic treatment and primary tempering treatment; carrying out secondary cryogenic treatment and secondary tempering treatment on a metal for 3D printing. The 3D printing metal workpiece treated by the treatment method disclosed by the invention has the micro-structural characteristic that when the 3D printing metal workpiece is subjected to cryogenic treatment, due to ultra-low temperature effect, the internal microstructure of the metal workpiece is shrunk, the gap is reduced, and thus the density of the product is increased; meanwhile, under cryogenic treatment conditions, ultrafine carbides are precipitated, the fine dispersed carbides can hinder the movement of dislocation in the plastic deformation of the material, and thus the wear resistance of the metal workpiece is enhanced; the lattice of martensite is promoted to be changed at an ultra-low temperature environment, the internal microstress of the metal workpiece is reduced, and the microstructure is strengthened, so that the hardness, impact toughness and wear resistance of the metal workpiece are significantly increased, and the microstructure and overall performances of the metal workpiece are finally improved, thereby enhancing the mechanical properties of the 3D printing metal workpiece.

Owner:NANTONG HUDA MASCH EQUIP CO LTD

Slurry-homogenizing process for positive electrode slurry of lithium ion battery, positive electrode plate and lithium ion battery

ActiveCN106654166AImprove uniformity and stabilityReduce evaporationSecondary cellsNon-aqueous electrolyte accumulator electrodesCurrent collectorLithium electrode

The invention discloses a slurry-homogenizing process for positive electrode slurry of a lithium ion battery, a positive electrode plate and the lithium ion battery, and belongs to the technical field of manufacturing of the lithium ion battery. The slurry-homogenizing process for the positive electrode slurry of the lithium ion battery comprises the steps of preparing an adhesive solution, stirring by a V-shaped stirrer, performing pre-mixing and stirring, performing high-speed stirring, performing viscosity adjustment, performing vacuum defoaming and the like; the positive electrode plate of the lithium ion battery comprises a positive electrode current collector and the positive electrode slurry for coating the positive electrode current collector; the positive electrode current collector adopts an aluminum foil; the positive electrode slurry is prepared by the slurry-homogenizing process for the positive electrode slurry of the lithium ion battery; and the lithium ion battery adopts the positive electrode plate of the lithium ion battery prepared by the method. By adoption of the slurry-homogenizing process, the solid content of the slurry is increased, so that solid granule friction in stirring can be improved, and the uniformity and the stability of the slurry can be improved; and by lowering a baking temperature in a drying oven in coating and drying, gaps formed between active material granules, conducive carbon granules and a binder can be reduced, thereby enhancing an adhesive effect and improving the performance of the lithium ion battery.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

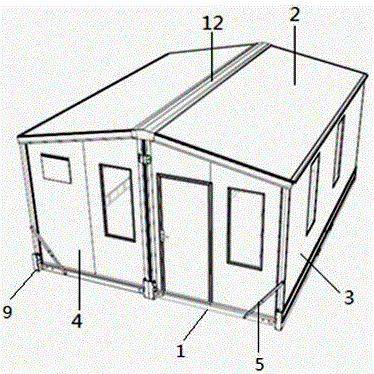

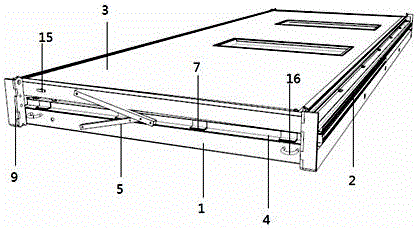

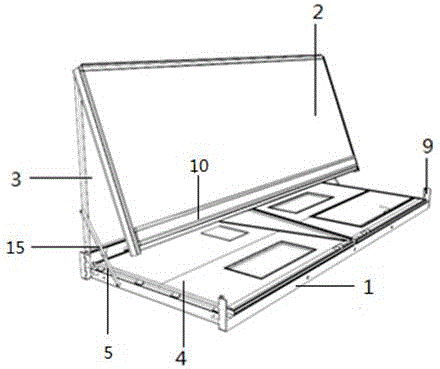

Foldable house and assembling and disassembling method thereof

ActiveCN105735480AReasonable structural designIncrease the usable areaBuilding constructionsEngineeringWall plate

The invention relates to a foldable house and an assembling and disassembling method thereof, and belongs to the technical field of moveable house structures. The foldable house comprises a first unit and a second unit, wherein the first unit and the second unit are structurally symmetric and can be integrally assembled with each other to form the foldable house; the first unit and the second unit both comprise bottom plates and mountain wall plates which are hinged to two opposite sides of the bottom plates; side wall plates are arranged between the two mountain wall plates; the bottoms of the side wall plates are hinged to the bottom plates; a top plate is hinged to the tops of the side wall plates; side surface connecting parts and top connecting parts of both the first unit and the second unit are respectively assembled integrally through detachable side connecting members and top connecting members. The foldable house is smart in structural design, small in space, light in weight, rapid in assembly and disassembly, and convenient and rapid in transport, and can be repeatedly assembled and disassembled for use.

Owner:WANHUA MODULAR PROJECTS

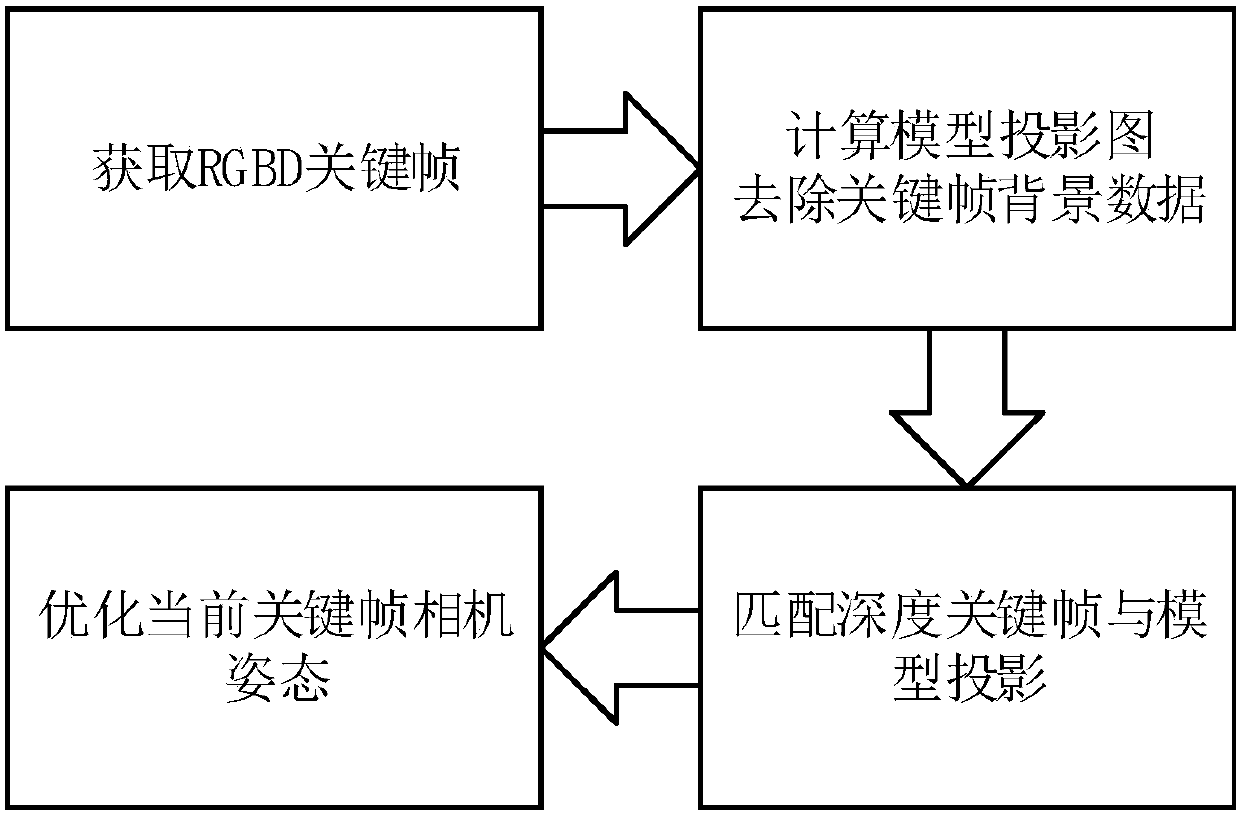

Camera attitude optimization method for RGBD three-dimensional reconstruction texture generation

The invention belongs to the technical field of computer vision and computer graphics image processing, and in particular relates to a camera attitude optimization method for RGBD three-dimensional reconstruction texture generation. The method comprises the steps that S1 a depth image fusion keyframe is acquired; S2 a three-dimensional mesh model point cloud depth projection map is calculated; S3background data in a point cloud depth projection map are removed; and S4 depth data matching and camera pose optimization are carried out. The method is based on the known three-dimensional mesh model and keyframe, is combined with the requirements of a texture generation process, uses the geometric features of the mesh model and depth data in the keyframe to study an optimization method for thecamera pose under the view point of the keyframe in the RGBD three-dimensional reconstruction texture generation process, and provides a guarantee for high-quality texture image generation.

Owner:QINGDAO RES INST OF BEIHANG UNIV +1

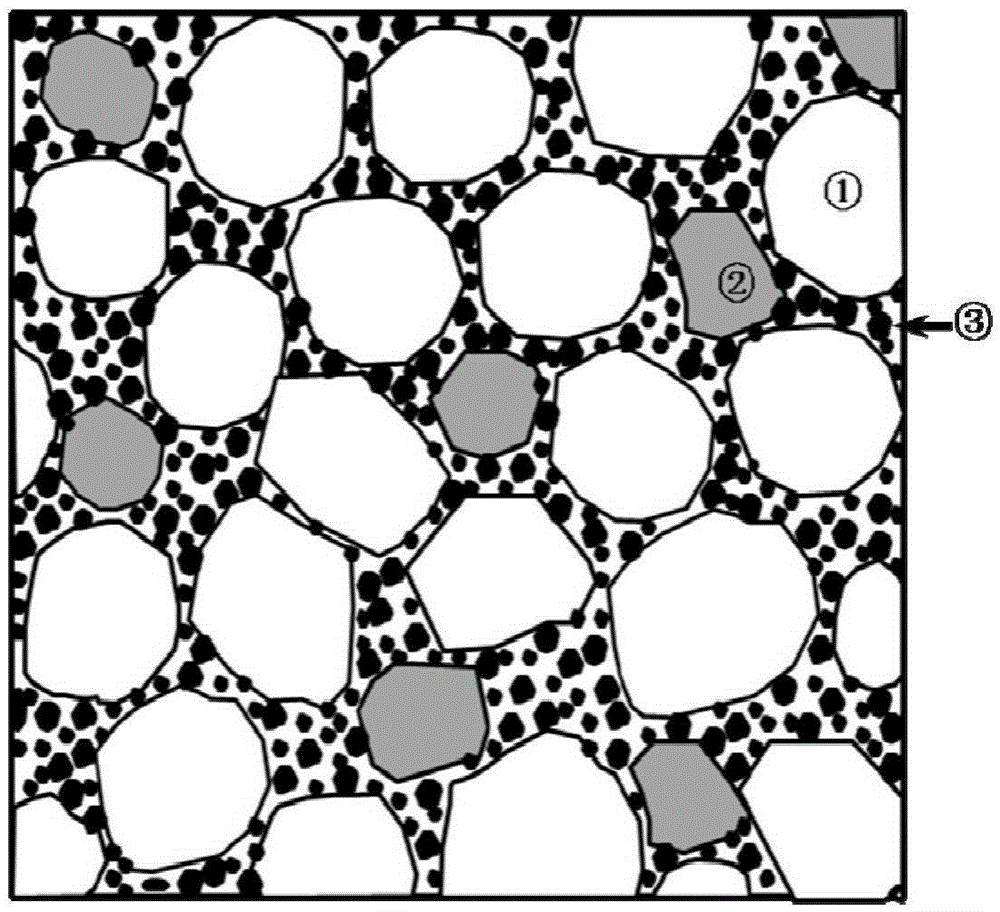

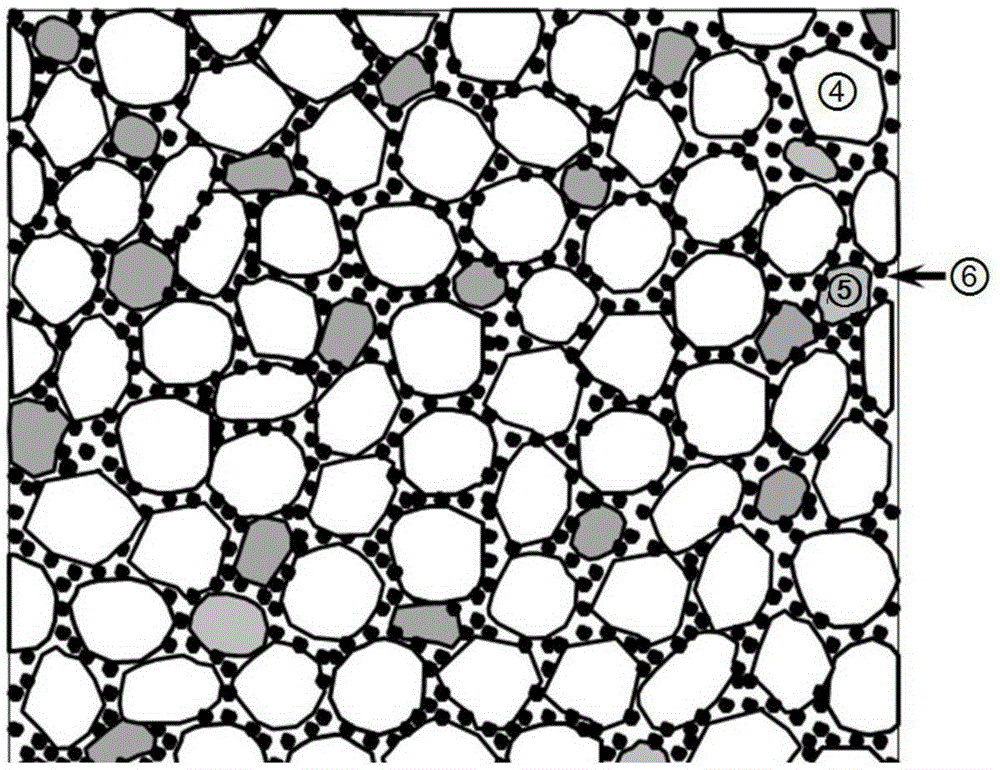

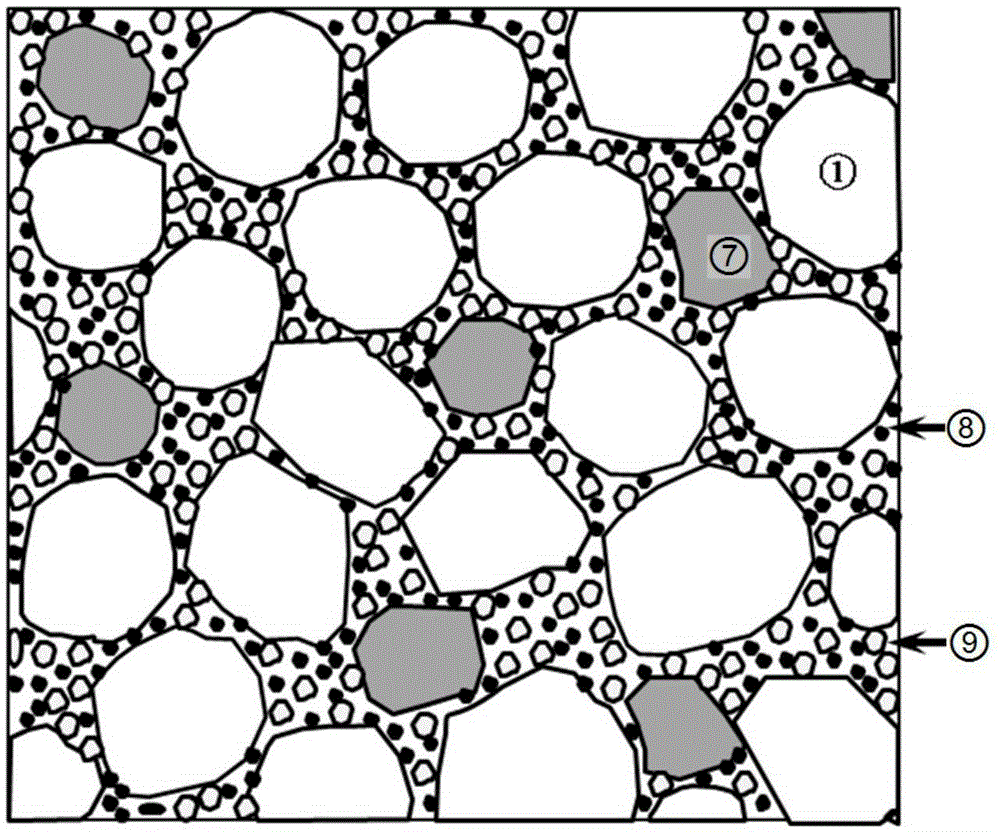

Production method of polycrystalline ceramic body

InactiveUS20060091588A1Improve relationshipHigh porosityPiezoelectric/electrostrictive device manufacture/assemblyCeramic shaping apparatusVolumetric Mass DensityCoarse particle

To provide a production method of a polycrystalline ceramic body with excellent density, a preparation step, a mixing step, a forming step and a heat-treating step are performed. In the preparation step, a coarse particle ceramic powder, and a fine particle powder having an average particle diameter of ⅓ or less of the average particle diameter of the coarse particle ceramic powder are prepared. In the mixing step, the coarse particle ceramic powder and the fine particle powder are mixed to produce a raw material mixture. In the forming step, the raw material mixture is formed to a shaped body. In the heat-treating step, the shaped body is heated and thereby sintered to produce a polycrystalline ceramic body. In the heat-treating step, a temperature elevating process and a first holding process are performed and at the same time, a second holding process and / or a cooling process are performed. In the temperature elevating process, heating is started to elevate the temperature and in the first holding process, the shaped body is held at a temperature T1° C. In the second holding process, the shaped body is held at a temperature T2° C. lower than the temperature T1° C. In the cooling process, the shaped body is cooled at a temperature dropping rate of 60° C. / h or less from the temperature T1° C.

Owner:DENSO CORP

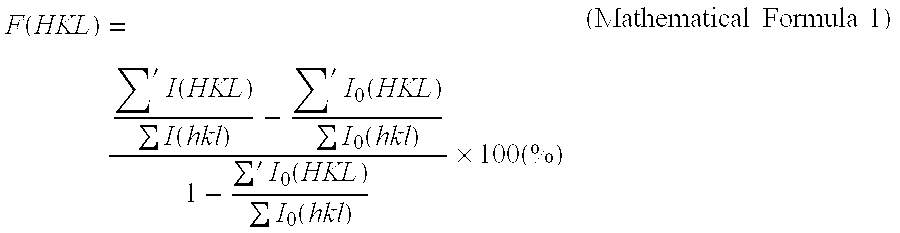

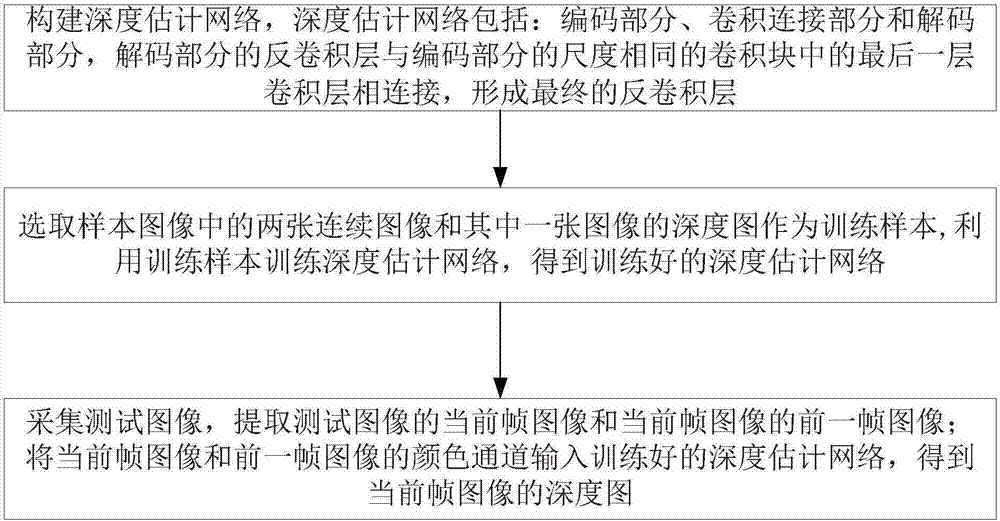

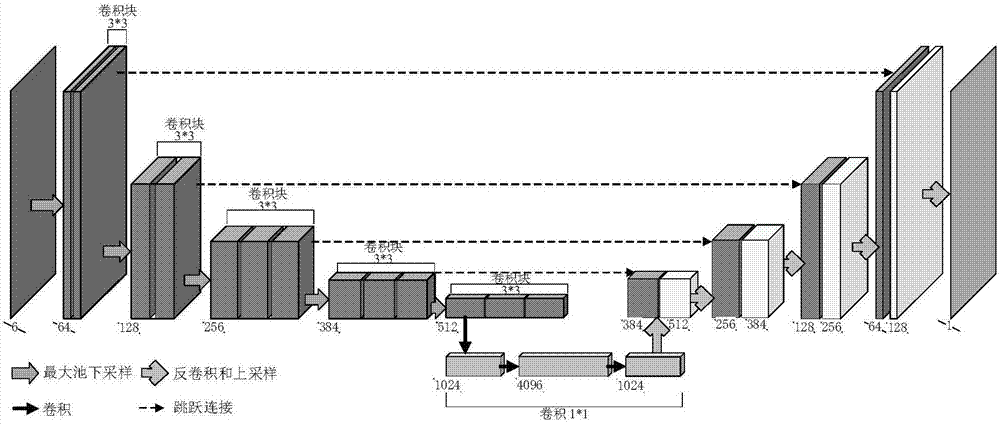

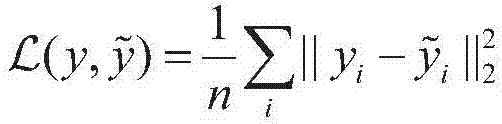

Image depth estimation method and system

ActiveCN107274445AReduce volumeImprove accuracyImage enhancementImage analysisEstimation methodsSample image

The invention discloses an image depth estimation method and system. The method is implemented by comprising the steps of establishing a depth estimation network, wherein the depth estimation network comprises a coding part, a convolutional connection part and a decoding part, and a deconvolutional layer of the decoding part is connected with a last convolutional layer in a convolutional block with the same scale as the coding part to form a final deconvolutional layer; selecting two continuous images in sample images and a depth image of one image as training samples, and training the depth estimation network by utilizing the training samples to obtain a trained depth estimation network; collecting a test image, and extracting a current frame image of the test image and a previous frame image of the current frame image; and inputting color channels of the current frame image and the previous frame image to the trained depth estimation network to obtain a depth image of the current frame image. The method is high in efficiency; and the obtained depth image is high in accuracy and high in compactness.

Owner:HUAZHONG UNIV OF SCI & TECH

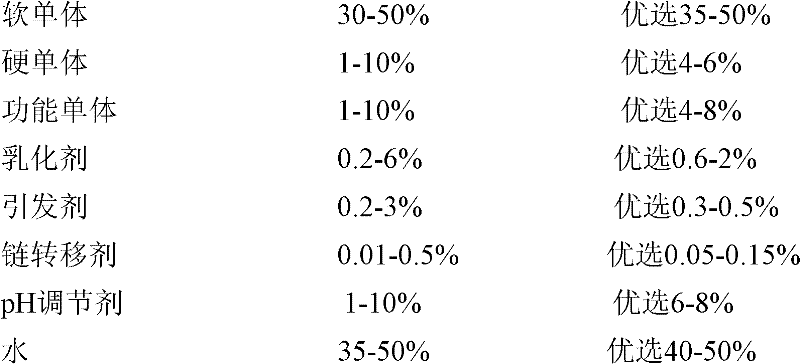

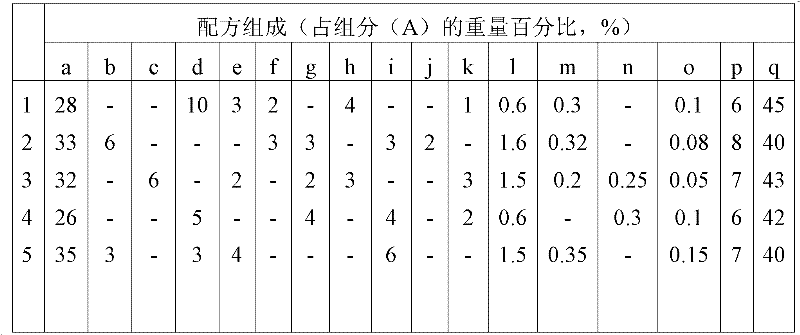

High water resistance emulsion polyacrylate pressure-sensitive adhesive and preparation method and application thereof

ActiveCN102533177AReduce voidsHinder entryFilm/foil adhesivesEster polymer adhesivesPressure sensitiveEmulsion

A high water resistance emulsion polyacrylate pressure sensitive adhesive and a preparation method and application thereof relate to the field of acrylate pressure sensitive adhesive tapes. The emulsion polyacrylate pressure sensitive adhesive is characterized in that by weight, the pressure sensitive adhesive is formed by mixing a component (A) and a component (B). The component (A) is 92% to 97% of polyacrylate emulsion, and the component (B) is 3% to 8% of water-soluble monomer and free radical initiating agent. The prepared emulsion polyacrylate pressure sensitive adhesive is coated on the surface of a carrier to form an adhesive coating, the thickness of the adhesive coating ranges from 25mum to 50 mum, and the adhesive coating is in thermal polymerization for 30 minutes to 40 minutes at the reaction temperature of 30 DEG C to 50 DEG C, and is dried to obtain a pressure sensitive adhesive tape with the adhesive thickness ranging from 25mum to 35mum. The pressure sensitive adhesive tape prepared by the emulsion adhesive is good in each performance, simple in preparing process, free of pollution, low in cost and suitable for massive industrial production.

Owner:SHENZHEN YUTO PACKAGING TECH +1

Thermal annealing for Cu seed layer enhancement

InactiveUS6998337B1Low resistance CuReduce voidsSolid-state devicesSemiconductor/solid-state device manufacturingAdamiteReducing atmosphere

Semiconductor devices with highly reliable Cu interconnects exhibiting reduced resistance are formed by sequentially depositing a seed layer by PVD, depositing a conformal seed layer enhancement film by electroplating, and then thermal annealing the seed layer enhancement film in an inert or reducing atmosphere to expel impurities, enhance film conductivity, reduce film stress, increase film density, and reduce film roughness. Embodiments include single and dual Cu damascene techniques formed in dielectric layers having a dielectric constant no greater than about 3.9.

Owner:ADVANCED MICRO DEVICES INC

Flip-chip bonding method to reduce voids in underfill material

InactiveUS20120077312A1Reduce materialImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesFilling materialsElectrical and Electronics engineering

Disclosed is a flip-chip bonding method to reduce voids in underfill material. A substrate with connecting pads is provided. At least a chip with a plurality of bumps is bonded on the substrate and then an underfill material is formed between the chip and the substrate. Finally, the substrate is placed in a pressure oven in which a positive pressure greater than one atm is provided, meanwhile, the underfill material is thermally cured with exerted pressures to reduce bubbles or voids trapped inside the underfill material to avoid popcorn issues due to CTE mismatch between the chip and the substrate. In one embodiment, another underfill material is further formed between a plurality of chips and bubbles or voids trapped between the chips are also reduced by the pressurized curing.

Owner:WALTON ADVANCED ENG INC

Lignosulfonate series air entraining and water reducing admixture for concrete and its prepn process and application

The present invention relates to preparation process of serial lignosulfonate air entraining and water reducing admixtures for concrete. The preparation process includes the following steps: dissolving solid lignosulfonate in water of the same weight, adding catalyst and oxidant, heating after reaction, adding amine and partial aldehyde to aminate, and dropping the rest aldehyde for condensation reaction to obtain the product; adding surfactant and polymer through stirring, and cooling to obtain liquid phase lignosulfonate as air entraining and water reducing admixture. The present invention is used as the admixture for concrete, and has relatively high water reducing rate, capacity of raising the strength of concrete, and certain setting retarding effect to delay the appearance of cement setting heat peak and reduce crack caused by temperature change.

Owner:SOUTH CHINA UNIV OF TECH

Electromagnetic wave interference preventive material and production thereof

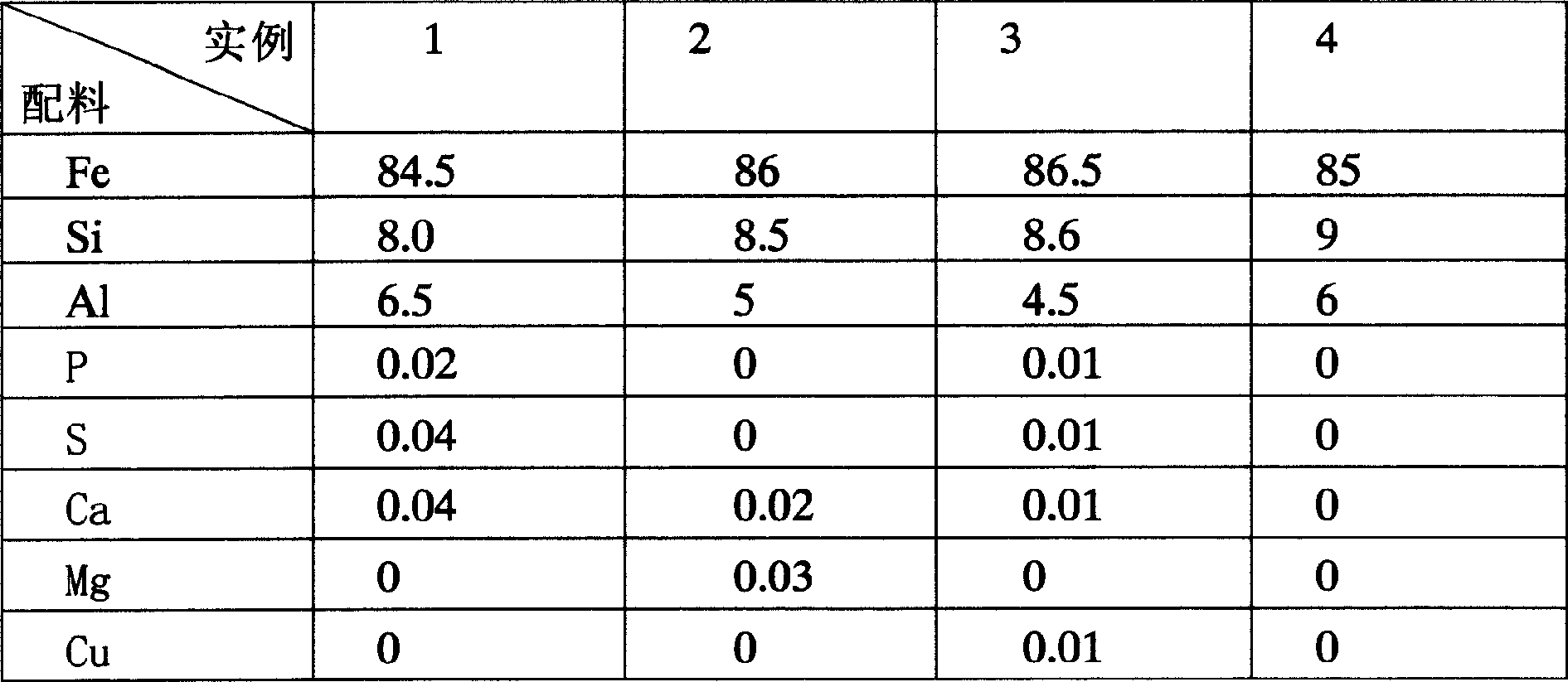

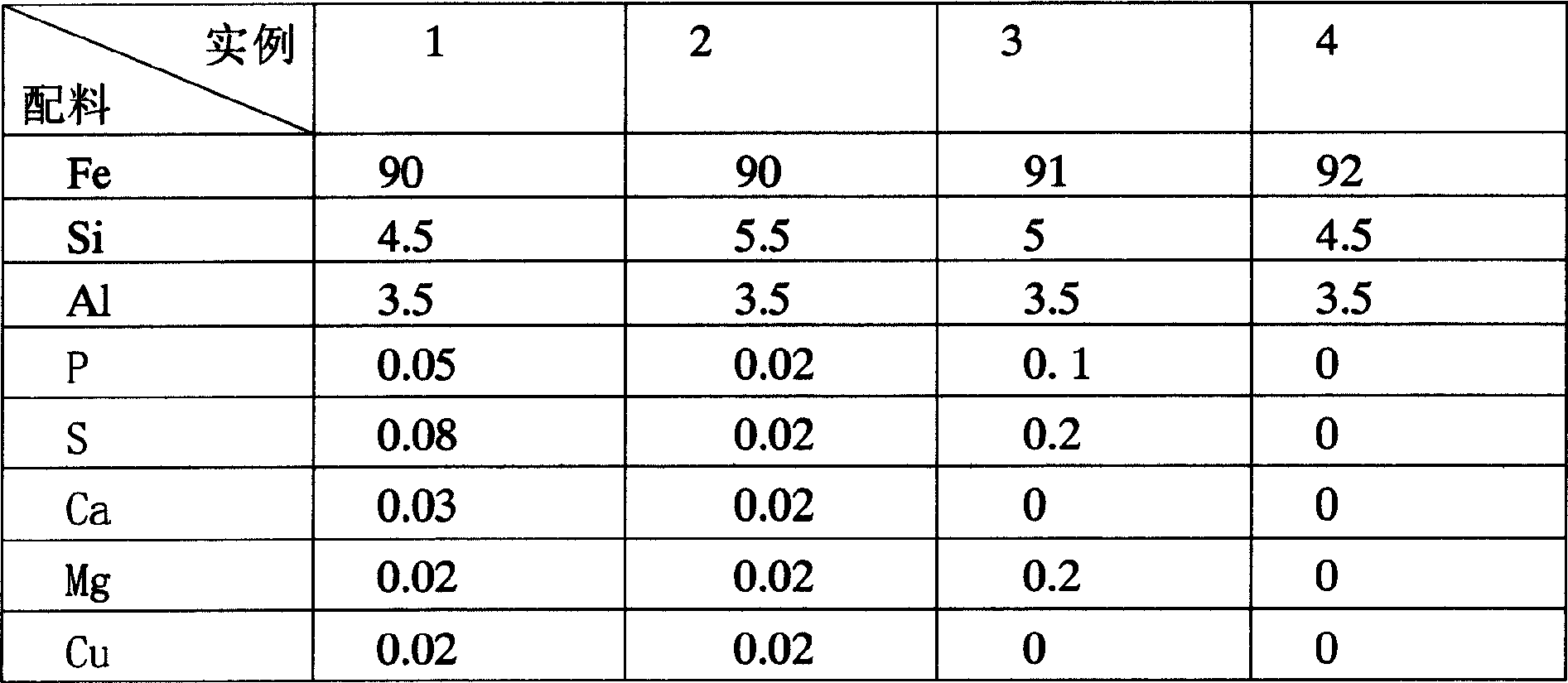

InactiveCN1646000AHigh specific surface areaIncrease reflectionMagnetic/electric field screeningIron powderSendust

The anti electromagnetic interference material is composed of several layers: the impedance matching layer is made of absorbing type sendust powder, manganese-zinc ferrite and resin; the absorbing layer is made of absorbing type sendust powder, nickel zinc ferrite and resin; the reflecting layer is made of reflection type sendust powder, iron powder and resin.

Owner:横店集团东磁有限公司

Novel patching material

The invention relates to a novel patching material which comprises the following components in percentage by mass: 70-75% of ash, 20-22% of polymer emulsion and 5-8% of fiber, wherein the ash comprises quick-hardening sulphoaluminate cement, a water reducing agent, an expanding agent and a setting accelerator. The patching material prepared according to the proportion can be used for quick patching of concrete bridges, dams, roads and buildings, and has the advantages of close bonding with concrete, high strength, endurable water resistance and corrosion resistance. When in use, the patching material of the invention does not need to level the construction base level or make a protective layer, thereby saving time and labor and being a nontoxic no-pollution environment-friendly patching material.

Owner:TONGJI UNIV

Multifunctional sensing flexible sensor and preparation method thereof

PendingCN110132457AIncreased pressure measurement rangeImprove linearityForce measurementUsing electrical meansCapacitanceElectrical conductor

The invention belongs to the field of flexible sensors, and discloses a multifunctional sensing flexible sensor and a preparation method thereof. The sensor comprises a top electrode layer, a middle dielectric layer and a bottom electrode layer, wherein the top electrode layer and the bottom electrode layer are the same in structure, and each of the top electrode layer and the bottom electrode layer comprises a flexible base material and liquid metal inlaid in the base material; the middle dielectric layer is arranged between the top electrode layer and the bottom electrode layer, and a plurality of micron-sized holes are arranged in the middle dielectric layer; when the sensor bears the pressure, the tensile or is close to a conductor, the pressure, the tension or a distance between the conductor and the sensor can be obtained by measuring the change of the capacitance of the sensor; when the friction between an object to be measured and the top electrode layer occurs, the pressure applied to the top electrode by the object to be measured is obtained by measuring the change of the voltage in the top electrode layer. The invention also discloses a preparation method of the sensor.According to the multifunctional sensing flexible sensor and the preparation method thereof, the high-sensitivity and multifunctional measurement of the flexible sensor are realized by combining two sensing principles of capacitive sensing and friction power generation.

Owner:HUAZHONG UNIV OF SCI & TECH

Multi-main-phase Nd-Fe-B type permanent magnet with high crack resistance and high coercive force and preparation method thereof

ActiveCN105244131AAvoid wastingReduce defectsInductances/transformers/magnets manufactureMagnetic materialsHigh resistanceCrack resistance

The invention pertains to the technical field of rare earth magnetically hard material, in particular to a multi-main-phase Nd-Fe-B type permanent magnet with high crack resistance and high coercive force and a preparation method thereof.A final magnet contains multiple differently-sized hard-magnetic main-phase particles having different anisotropic fields HA. Different main-phase particles account for different volume fractions and are differently distributed, wherein Nd denotes a red earth element having the most content based on the mass percent. According to mass percent, the chemical formula of the permanent magnet is expressed as (Dd, Re) aFe100-a-b-cBbTmc. By respective selection, different types of main-phase materials such as (Nd, Pr)-Fe-B, (PR, La, Ce)-Fe-B, (Dy, Tb, Ho, Gd, Er)-Fe-B in the ratio of 2:14:1 in order to prepare corresponding coarse magnetic powder, thin magnetic powder and magnetic nanocrystalline powder. Power is utilized for absorbing hydrogen and controlling oxygen. Liquid-phase sintering technology on the pressurized condition at low temperature is adopted for preparation. The multi-main-phase Nd-Fe-B type permanent magnet with high crack resistance and high coercive force and the preparation method thereof have following beneficial effects: a large piece of magnet does not easily have crack; crack resistance of the magnet is improved; high coercive force and high magnetic energy product are obtained; and the preparation technology is suitable for scale production in engineering.

Owner:CENT IRON & STEEL RES INST

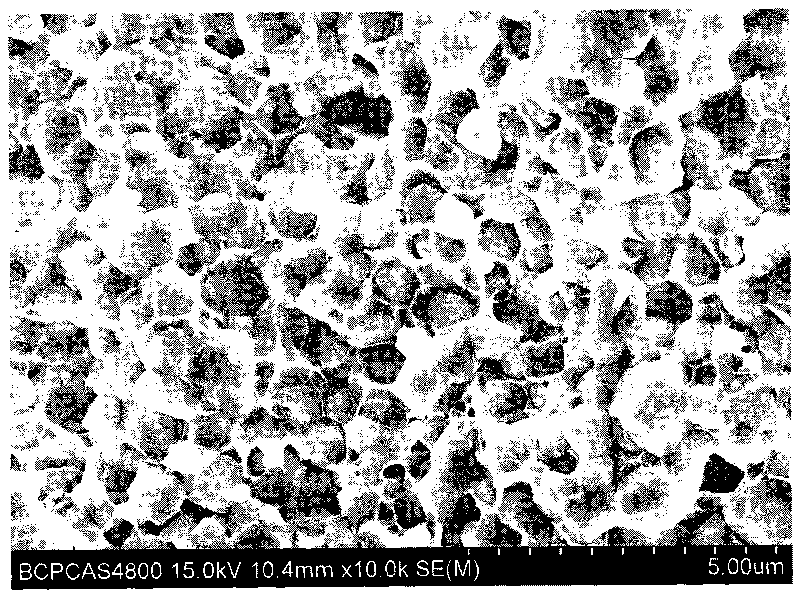

Method for preparing molybdenum-copper alloy

The invention belongs to the technical field of powder metallurgy. The invention prepares molybdenum-copper alloy by the following steps: (1) adding a copper nitrate solution and a complexing agent citric acid solution into an ammonium molybdate solution, heating at the temperature of 70-95 DEG C after regulating the pH to 1-2 to form colloidal sol, drying at the temperature of 100-150 DEG C to form gel and heating and decomposing in air at the temperature of 500-600 DEG C to form molybdenum-copper composite oxide powder; (2) after keeping the molybdenum-copper composite oxide powder in hydrogen gas for heat preservation at the temperature of 500 DEG C for 90min, keeping the molybdenum-copper composite oxide powder in hydrogen gas for heat preservation at the temperature of 700 DEG C for 90min; and (3) after compacting a molybdenum-copper composite powder body in a graphite sharper, perfroming heat preservation at the temperature of 1100-1200 DEG C and the pressure of 30-50MPa for 0-5min in a discharge plasma sintering device. A preparation method provided by the invention has low sintering temperature, short sintering time, no need of powder pre-forming, energy saving and environmental protection properties, high density of an obtained product, finer and uniform size of crystal grains and little impurities.

Owner:BEIJING UNIV OF TECH

Ceramic substrate for mounting a light emitting element and method for manufacturing the same

InactiveUS7825422B2Improve luminanceReduce voidsDischarge tube luminescnet screensCircuit optical detailsLight reflectanceNitride

A ceramic substrate for mounting a light emitting element. The ceramic substrate has a placement surface for placing a light emitting element having an electrode; and an electrode electrically-connected with the electrode of the light emitting element, wherein the ceramic substrate comprises a substrate body consisting of a nitride ceramics; and a coat layer coating at least a part of a surface of the substrate body and consisting of a ceramics different from the nitride ceramics forming the substrate body; and the coat layer has an optical reflectance of 50% or more for any light having a wavelength of from 300 to 800 nm, which can increase a luminance of the light emitting element by reflecting the light emitted from the element efficiently with certainty, and which has a high heat radiation property; and a manufacturing method therefor.

Owner:TOKUYAMA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com