Fluid pressure bonding

a fluid pressure bonding and pressure bonding technology, applied in the field of bonding, can solve the problems of large area or imperfect planarity limitations of the bonding layer, mechanical presses that are difficult to meet the requirements of high precision bonding, etc., to achieve enhanced uniformity, reduce voids, and expand the effect of area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

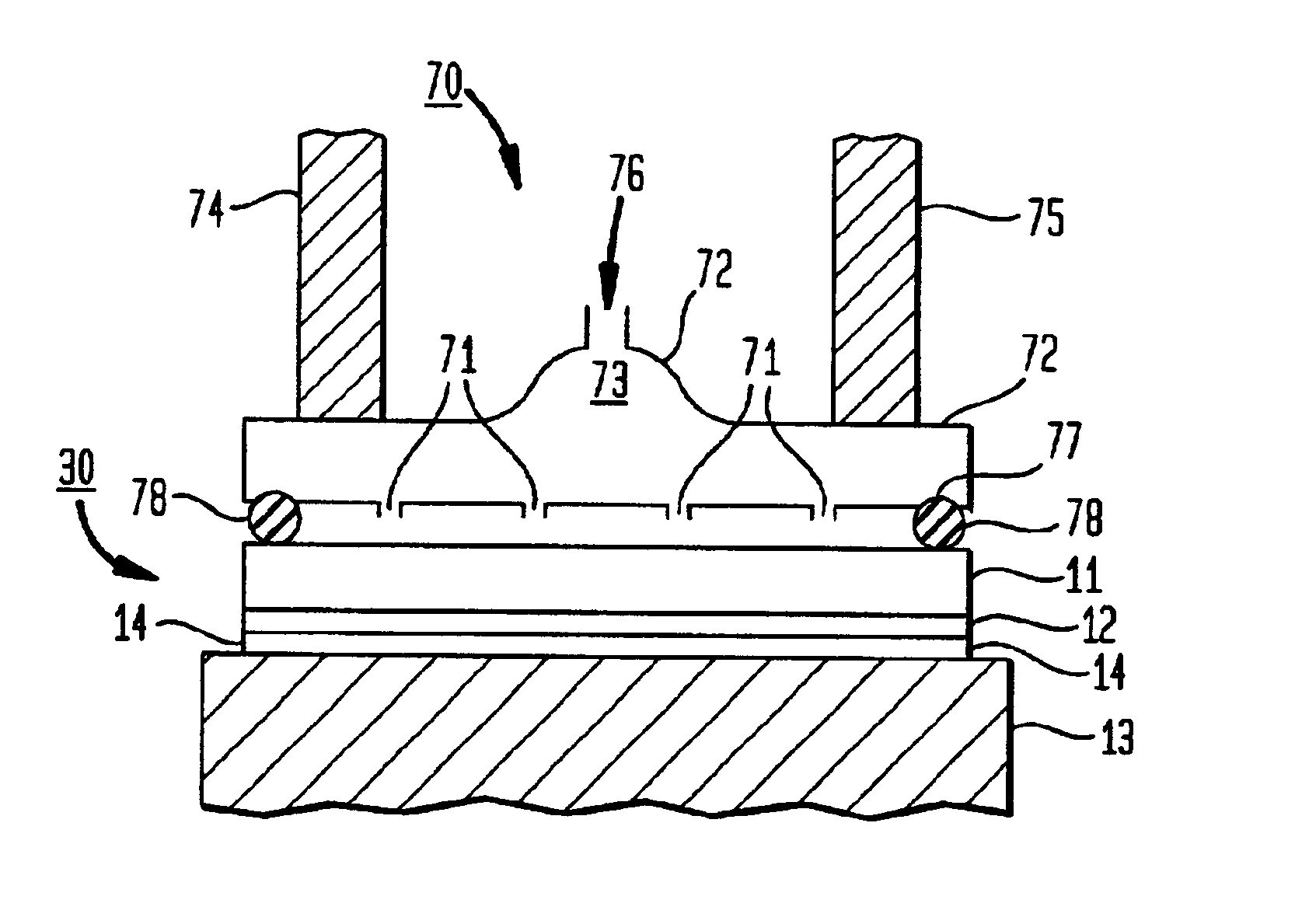

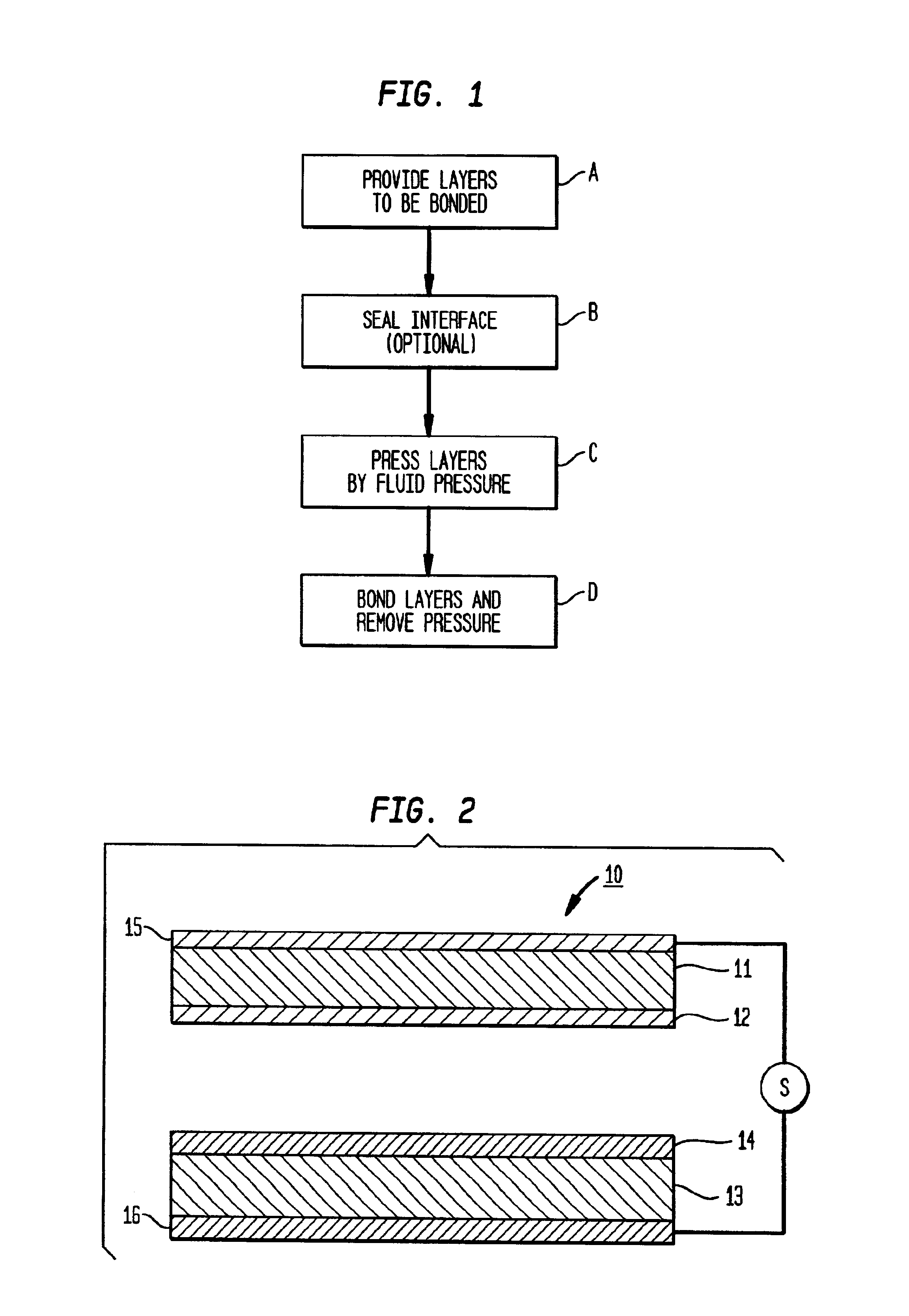

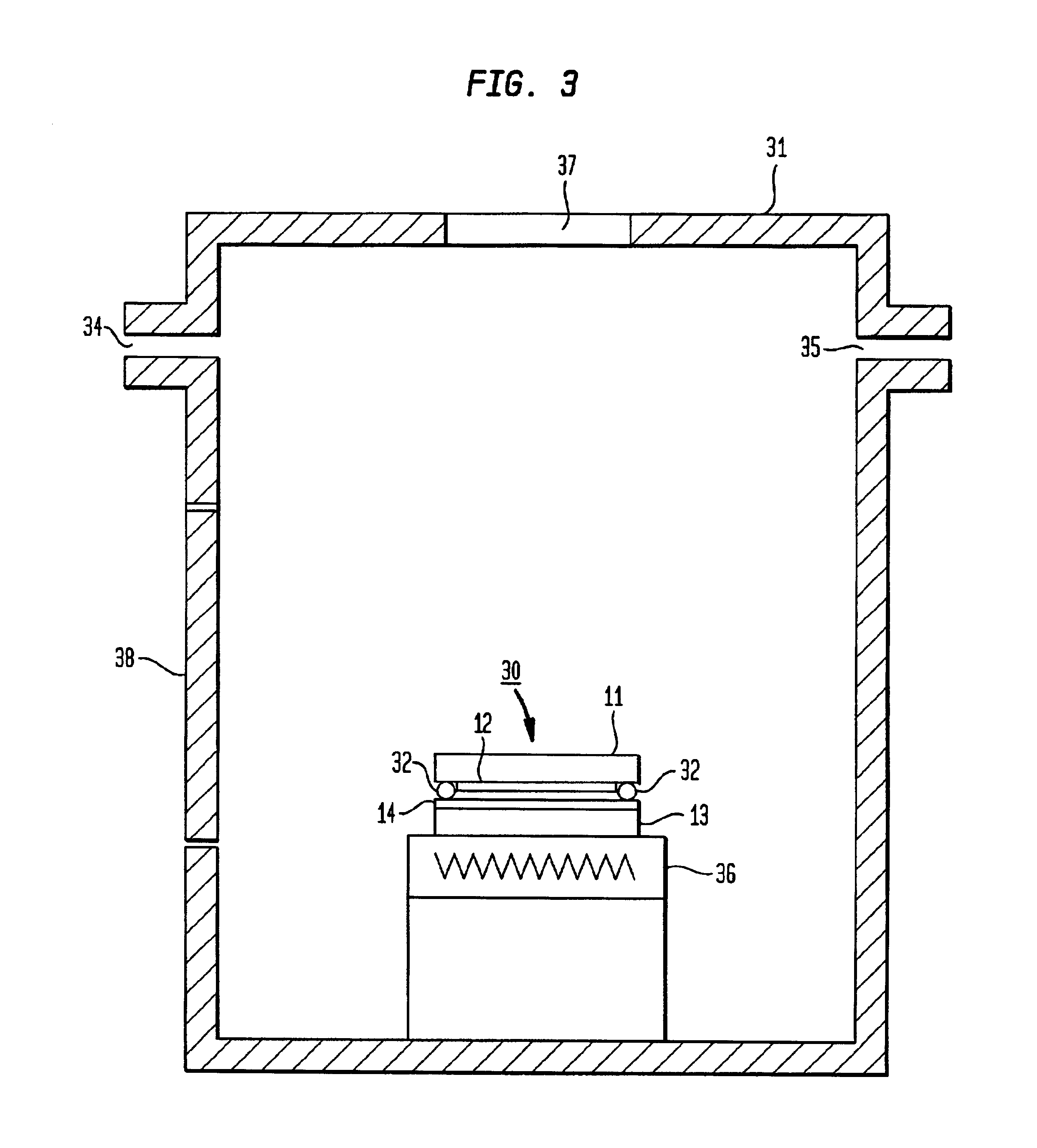

[0013]In accordance with the invention, the problem of unwanted lateral movements of mechanical presses in bonding is ameliorated by using direct fluid pressure to press together the layers to be bonded. The inventive method applies fluid pressure over the assembly of layers to be bonded. Because the fluid pressure is isostatic, no significant unbalanced lateral forces are applied. Direct fluid pressure also includes fluid pressure transmitted to the assembly via a flexible membrane, as the membrane does not interfere with the transmission of isostatic pressure from the fluid. And streaming pressurized fluid from openings in a pressure vessel can also apply nearly isostatic direct fluid pressure on the plates or assembly.

[0014]It is contemplated that the invention will have important applications in the bonding of previously patterned layers. The layers can be aligned with respect to previous patterns using conventional alignment techniques, and be pressed by direct fluid pressure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com