High water resistance emulsion polyacrylate pressure-sensitive adhesive and preparation method and application thereof

A technology of polyacrylate and pressure-sensitive adhesives, applied in adhesives, ester copolymer adhesives, N-vinylpyrrolidone copolymer adhesives, etc., can solve problems such as water whitening, whitening, and blurring, and achieve improved and water resistance, improved cohesion, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

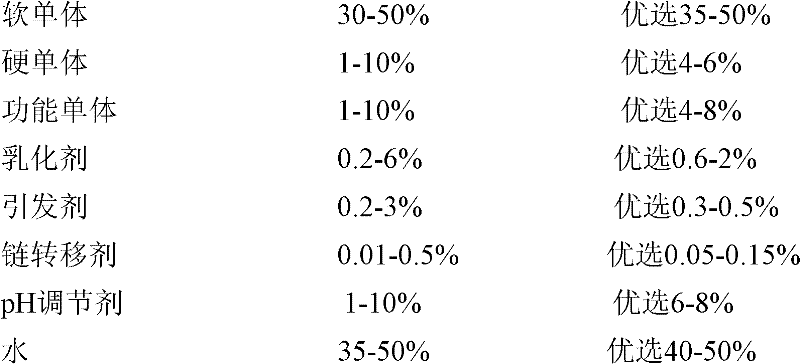

Method used

Image

Examples

Embodiment 1

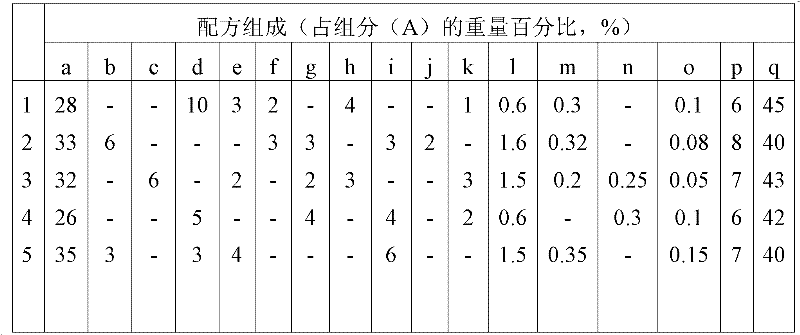

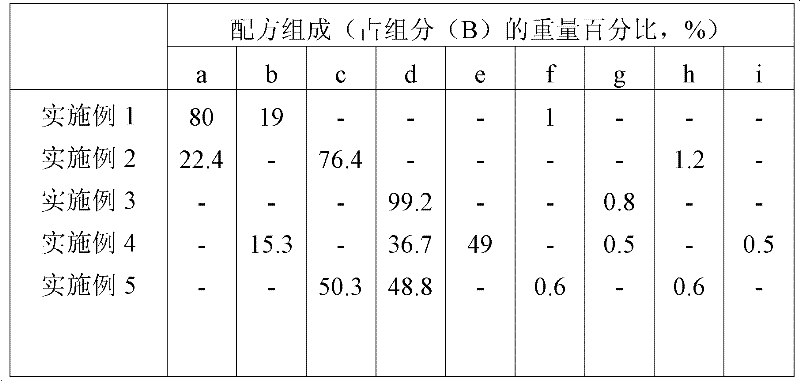

[0029] According to the formula in Table 1, component (A) is formed by emulsion polymerization. According to the formulation in Table 2, component (B) is formed by stirring and mixing water-soluble monomers and low-temperature free radical initiators at room temperature. According to the formulation in Table 3, slowly add component (B) to component (A) and stir and mix evenly at room temperature to prepare an emulsion polyacrylate pressure-sensitive adhesive. The adhesive is ready-to-use and has the best performance.

[0030] Coat the pressure-sensitive adhesive on the PET film with an RK wire bar coater, the thickness of the adhesive layer is about 35 μm, raise the temperature to 45°C to polymerize the monomer in component (B) for 30 minutes, and the thickness of the adhesive layer is about 25 μm after drying , Paste the silicone protective paper to get the pressure sensitive tape. Cut the pressure sensitive tape into a spline with a width of 25mm and a length of 200mm for ...

Embodiment 2

[0032] According to the formula in Table 1, component (A) is formed by emulsion polymerization. According to the formulation in Table 2, component (B) is formed by stirring and mixing water-soluble monomers and low-temperature free radical initiators at room temperature. According to the formulation in Table 3, slowly add component (B) to component (A) and stir and mix evenly at room temperature to prepare an emulsion polyacrylate pressure-sensitive adhesive. The adhesive is ready-to-use and has the best performance.

[0033] Coat the pressure-sensitive adhesive on the PET film with an RK wire bar coater, the thickness of the adhesive layer is about 40 μm, raise the temperature to 30°C to polymerize the monomer in component (B) for 30 minutes, and the thickness of the adhesive layer after drying is about 25 μm , Paste the silicone protective paper to get the pressure sensitive tape. Cut the pressure sensitive tape into a spline with a width of 25mm and a length of 200mm for ...

Embodiment 3

[0035] According to the formula in Table 1, component (A) is formed by emulsion polymerization. According to the formulation in Table 2, component (B) is formed by stirring and mixing water-soluble monomers and low-temperature free radical initiators at room temperature. According to the formulation in Table 3, slowly add component (B) to component (A) and stir and mix evenly at room temperature to prepare an emulsion polyacrylate pressure-sensitive adhesive. The adhesive is ready-to-use and has the best performance.

[0036] Coat the pressure-sensitive adhesive on the BOPP film with an RK wire bar coater, the thickness of the adhesive layer is about 35 μm, raise the temperature to 40°C to polymerize the monomer in component (B) for 30 minutes, and the thickness of the adhesive layer is about 25 μm after drying , Paste the silicone protective paper to get the pressure sensitive tape. Cut the pressure sensitive tape into a spline with a width of 25mm and a length of 200mm for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com