Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2248 results about "Piezoelectric substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A piezoelectric polymer multilayer structure formed on a flexible substrate is investigated for mechanical energy harvesting under bending mode.

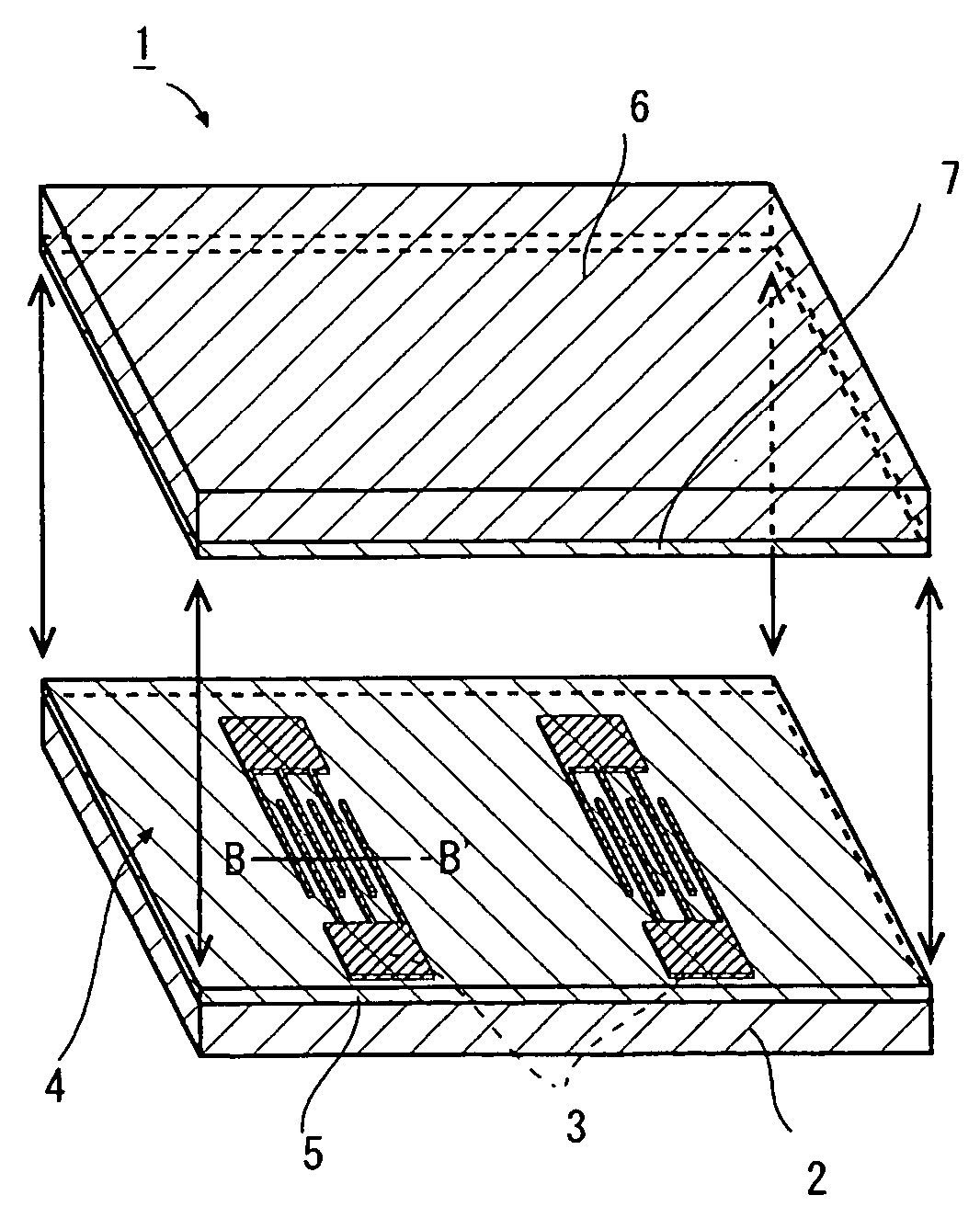

Piezoelectric component and manufacturing method thereof

InactiveUS20100045145A1Small sizeIncrease the number ofPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectrical and Electronics engineeringPiezoelectric substrate

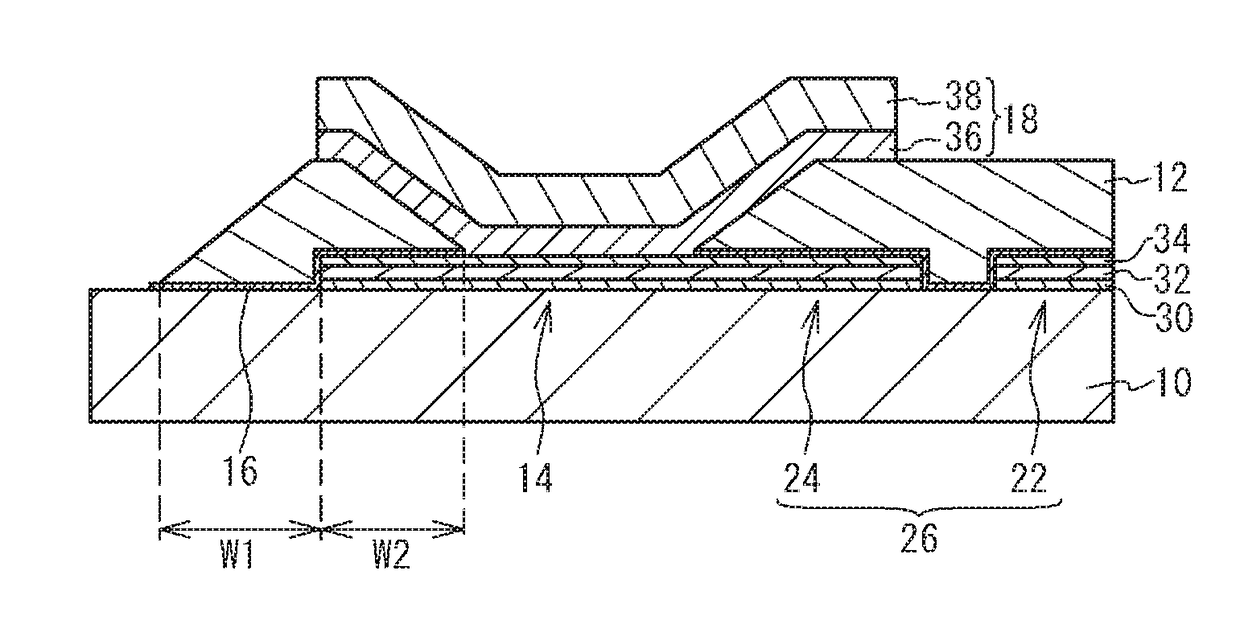

An object of the present invention is to; miniaturize, increase the capacity, and reduce the price of piezoelectric components. The present invention relates to a piezoelectric component and a manufacturing method thereof, characterized in that: there are bonded and laminated at least two or more piezoelectric elements in which comb-teeth electrodes, wiring electrodes having element wirings that are arranged adjacent to the comb-teeth electrodes, and electrode terminals connected to the wiring electrodes, are formed on a principal surface of a plurality of piezoelectric substrates, while forming hollow sections between the respective piezoelectric elements; through electrodes are formed in the respective piezoelectric substrates so as to pass therethrough; the through electrodes are connected to the electrode terminals; and the piezoelectric substrates are sealed by a resin sealing layer.

Owner:NIHON DEMPA KOGYO CO LTD

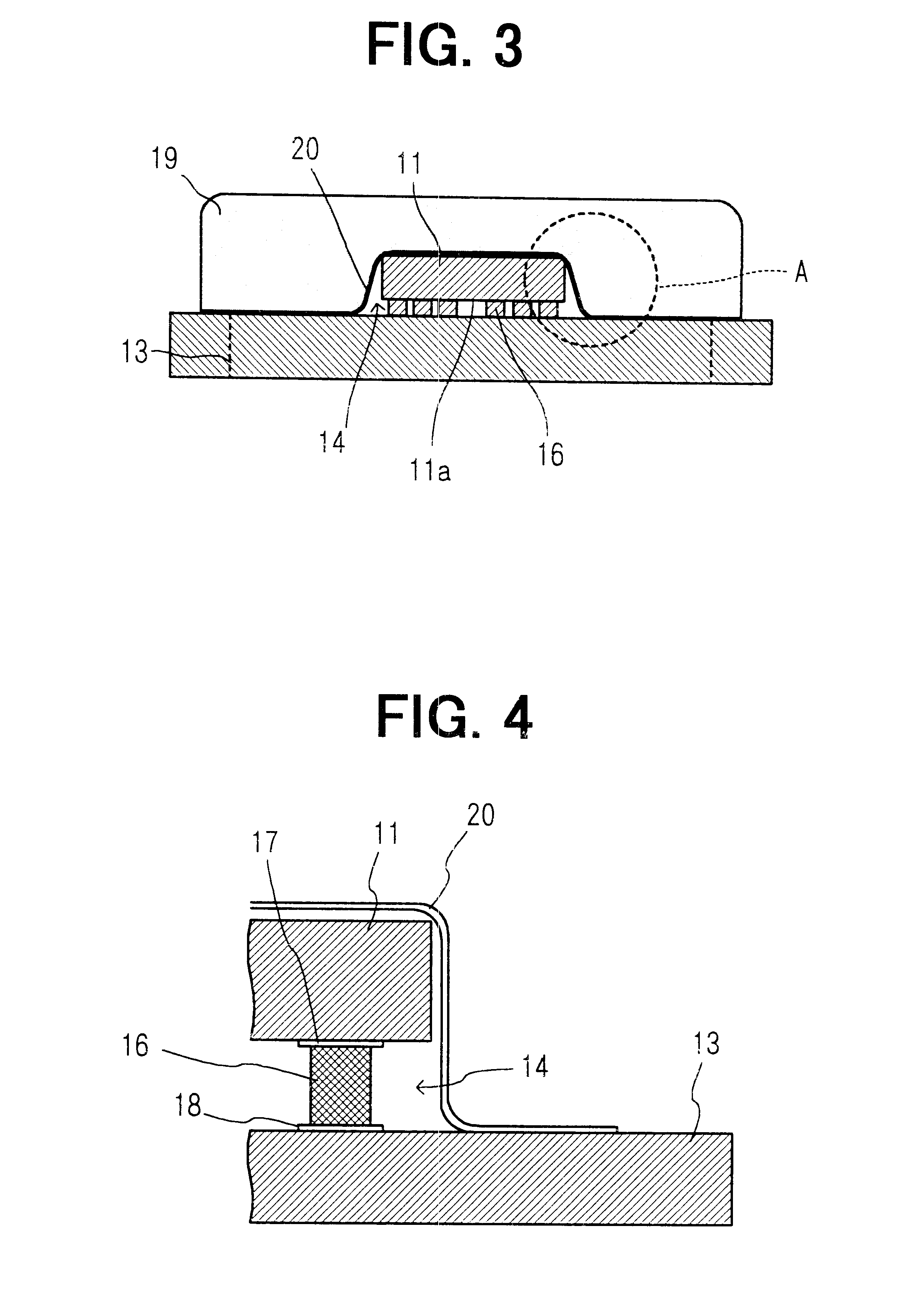

Touch panel input device

InactiveUS7215329B2Thin thicknessAvoid spreadingInput/output for user-computer interactionTransmission systemsElectricityLoudspeaker

A piezoelectric substrate is fixed to the movable plate or the support substrate directly or through a drive electrode of the piezoelectric substrate. When a pressure on an input operation surface is detected, a drive voltage is impressed on the drive electrodes of the piezoelectric substrate. In response, the piezoelectric substrate vibrates the movable plate or the support substrate, thereby providing tactile feedback to an operator. Because the movable plate or the support substrate directly vibrates without an independent vibrating source, there is no energy loss or transmission delay caused by transmitting the vibration, and finely control of the contraction and expansion of the piezoelectric substrate allows fine control of the vibration. In one embodiment, the drive voltage is modulated with signals dependent on the location of the pressure. In another embodiment, the drive voltage is modulated with audio frequencies to create a speaker.

Owner:SMK CORP

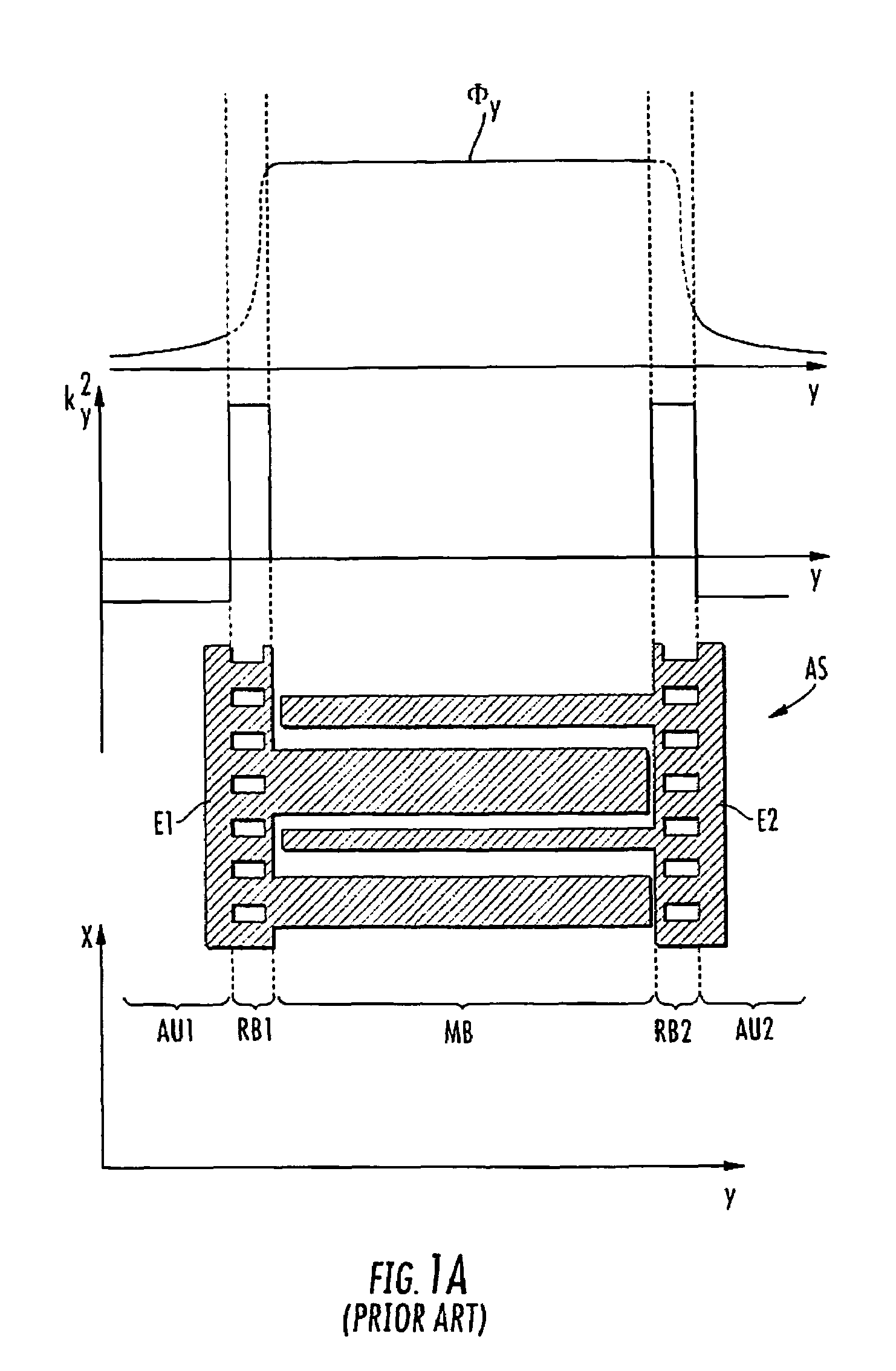

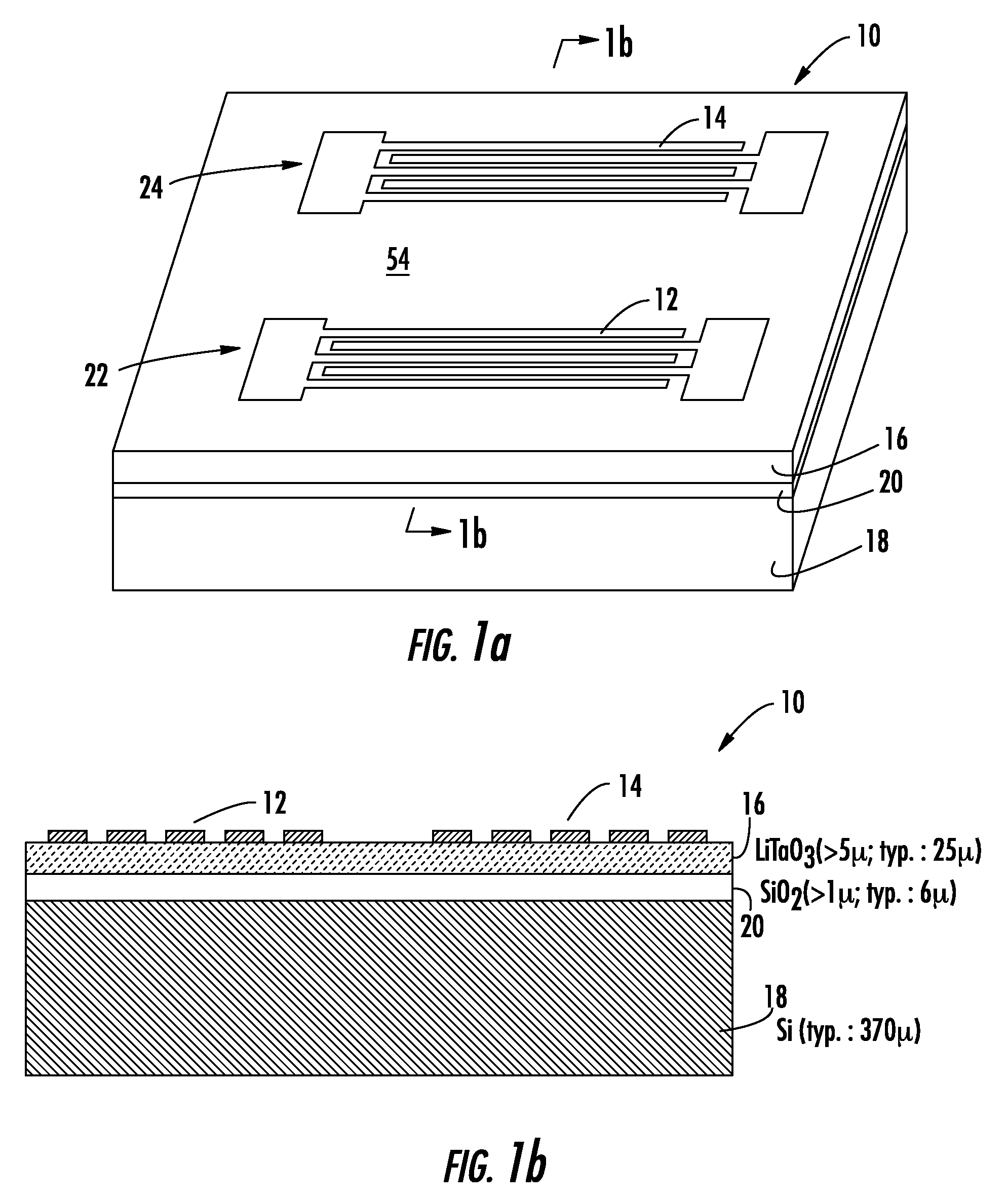

Saw filter device and method employing normal temperature bonding for producing desirable filter production and performance characteristics

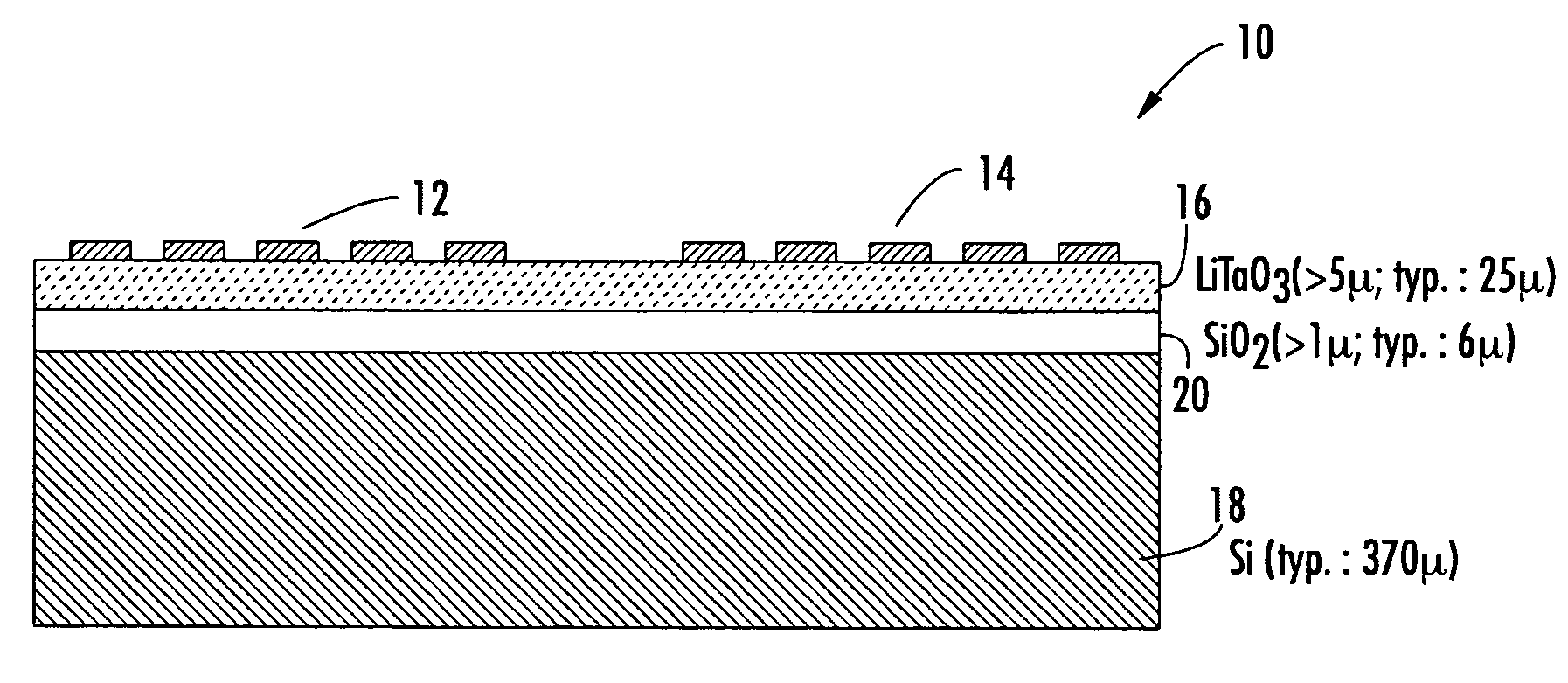

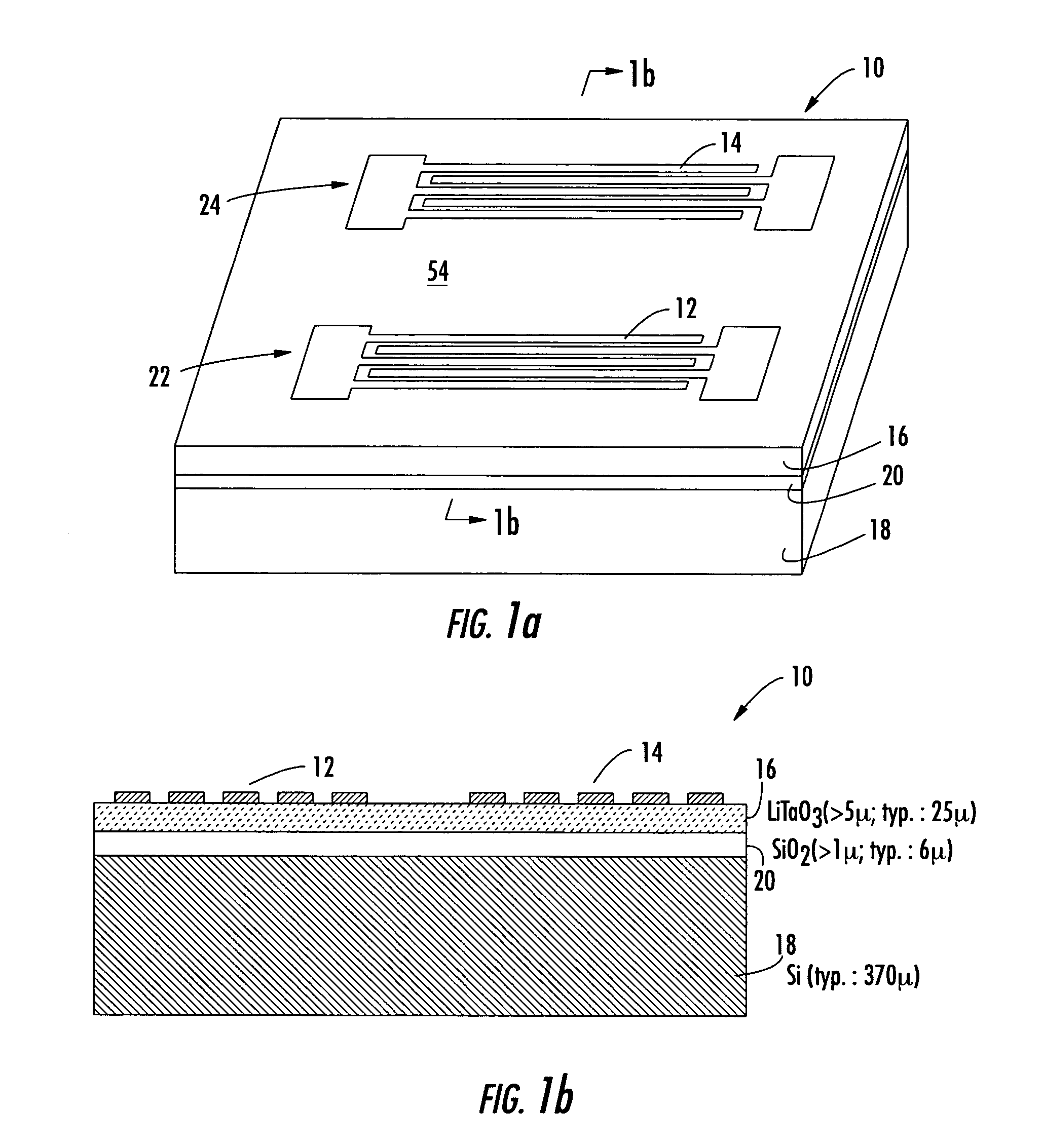

ActiveUS7105980B2Improve reliabilityReduce heat sensitivityImpedence networksPiezoelectric/electrostriction/magnetostriction machinesLength waveSilicon

A SAW filter includes a piezoelectric substrate of Lithium Niobate or optionally Lithium Tantalate having a thickness of at least twice an acoustic wavelength. The piezoelectric substrate is bonded to a surrogate substrate of a silicon material. The surrogate substrate is characterized by a resisitivity of at least 100 ohm-cm and an expansion coefficient compatible with the piezoelectric substrate. A catalytic bonding film between the piezoelectric substrate and the surrogate substrate is formed from a first catalytic bonding film deposited onto a surface of the piezoelectric substrate and a second catalytic bonding film deposited onto a surface of the surrogate substrate. The piezoelectric substrate is bonded to the surrogate substrate through a compression force sufficient for providing a bonding at a normal temperature.

Owner:TRIQUINT

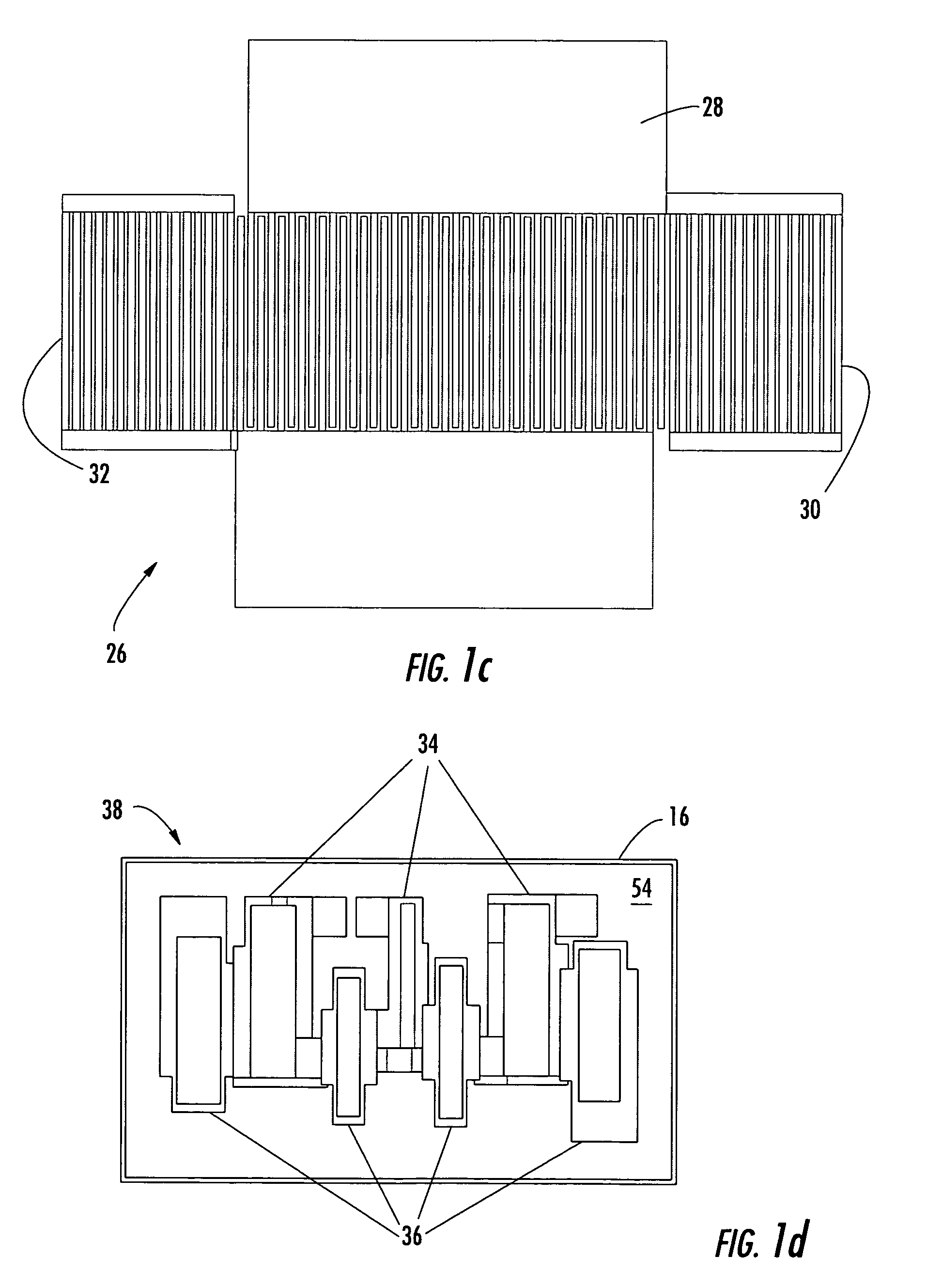

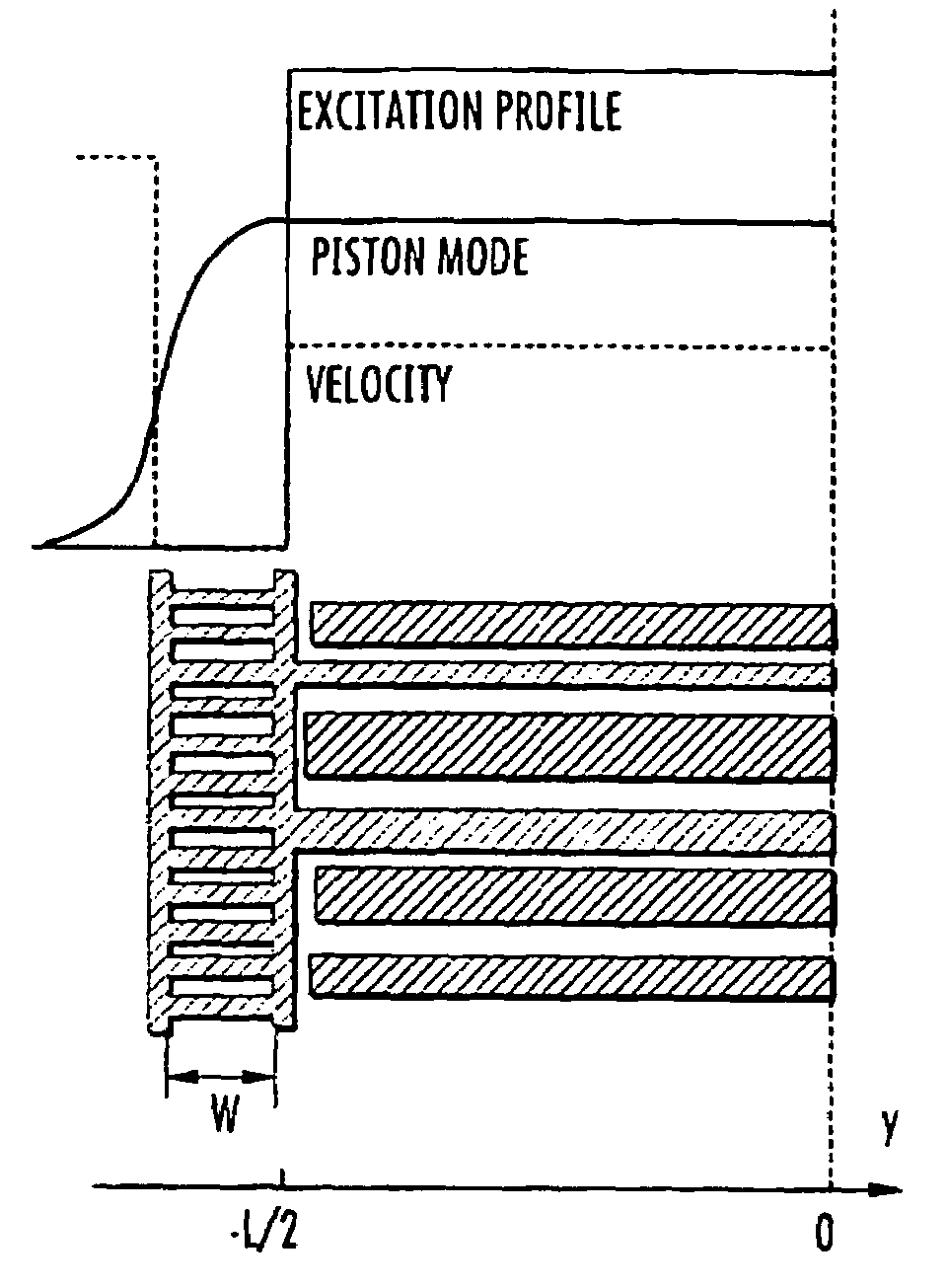

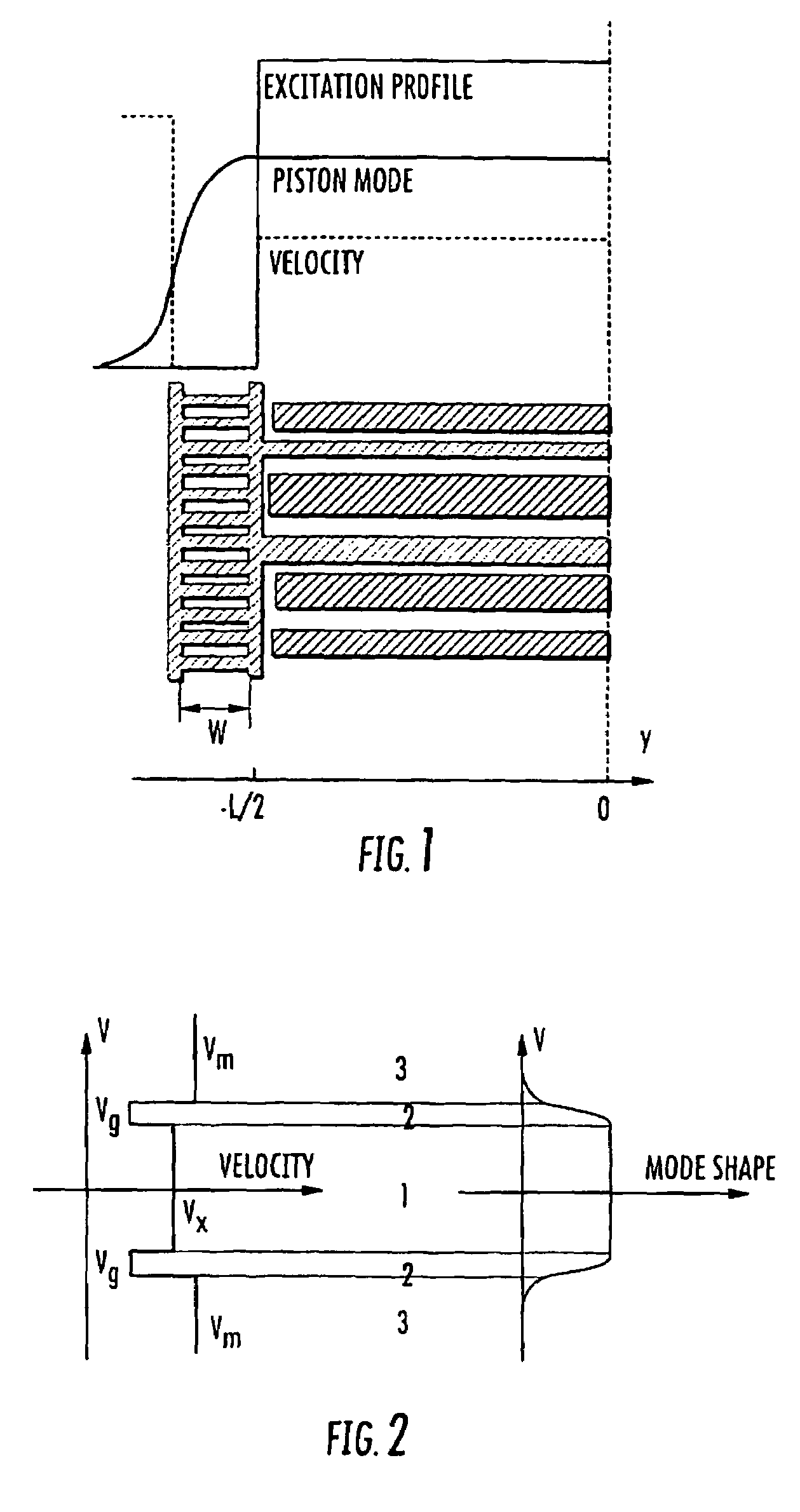

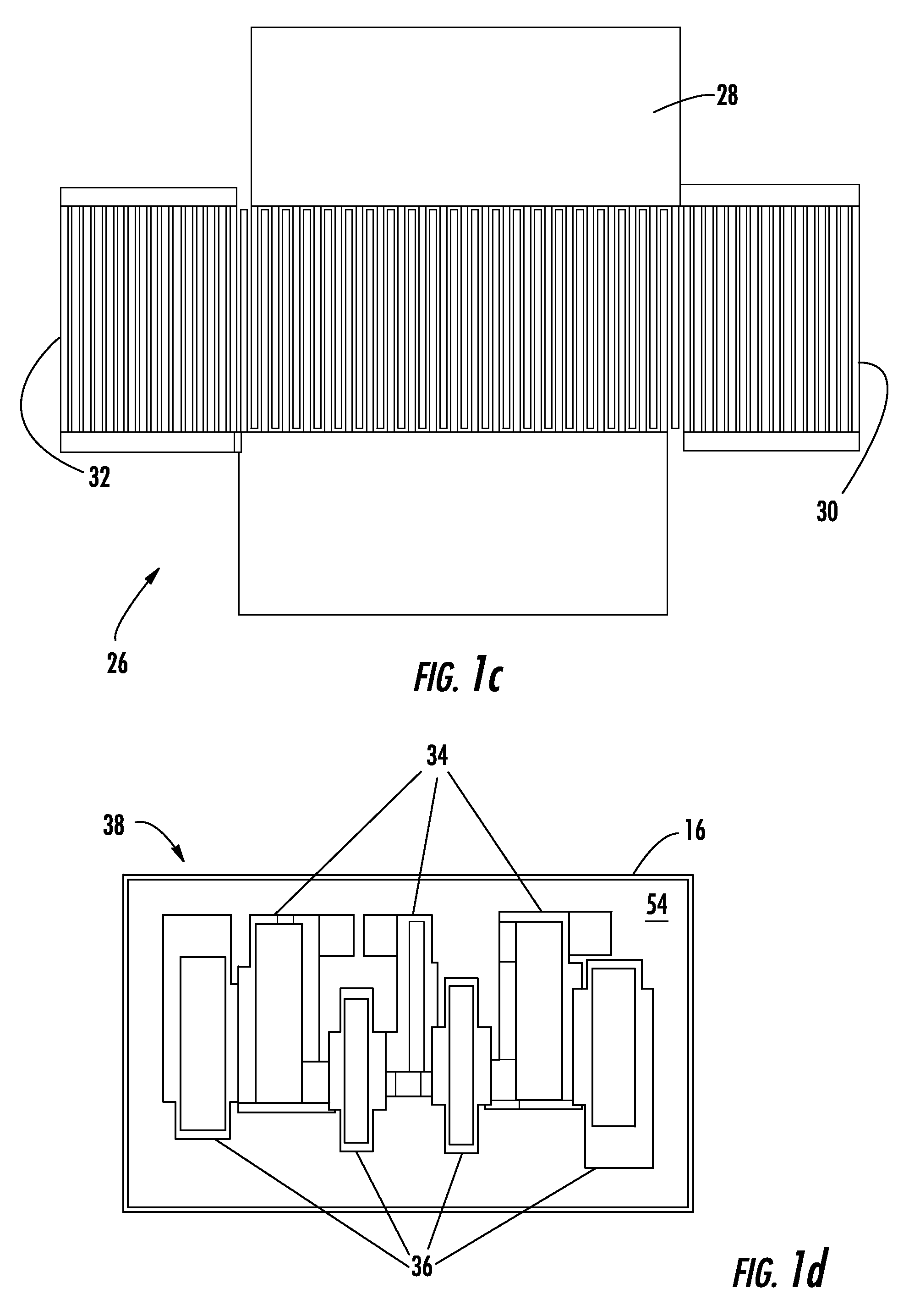

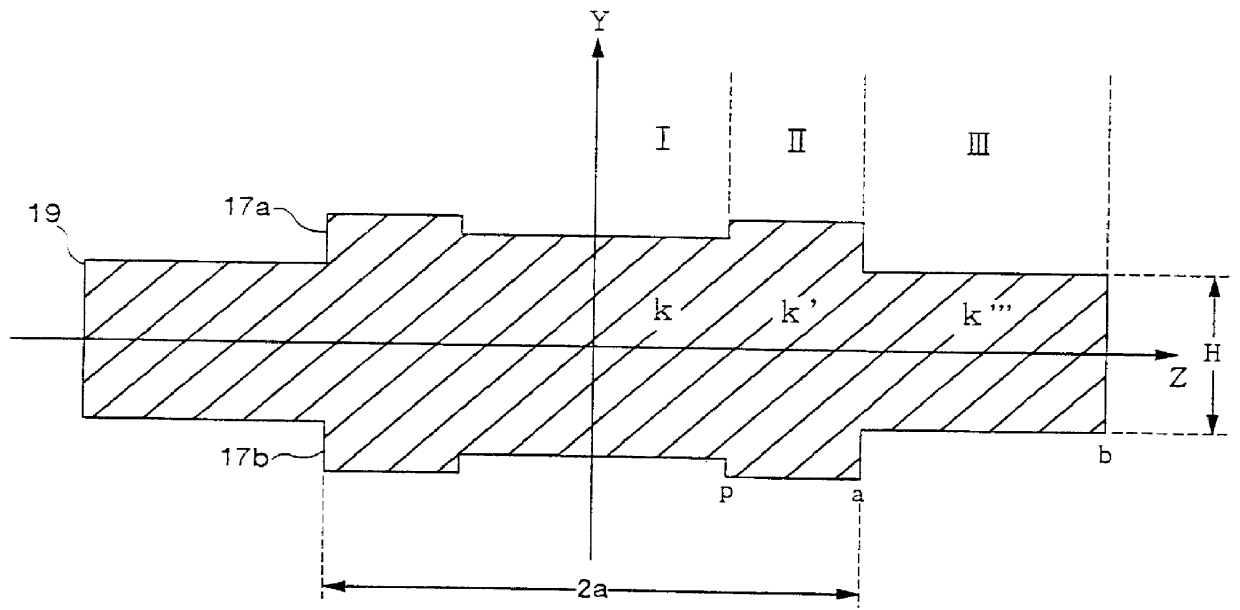

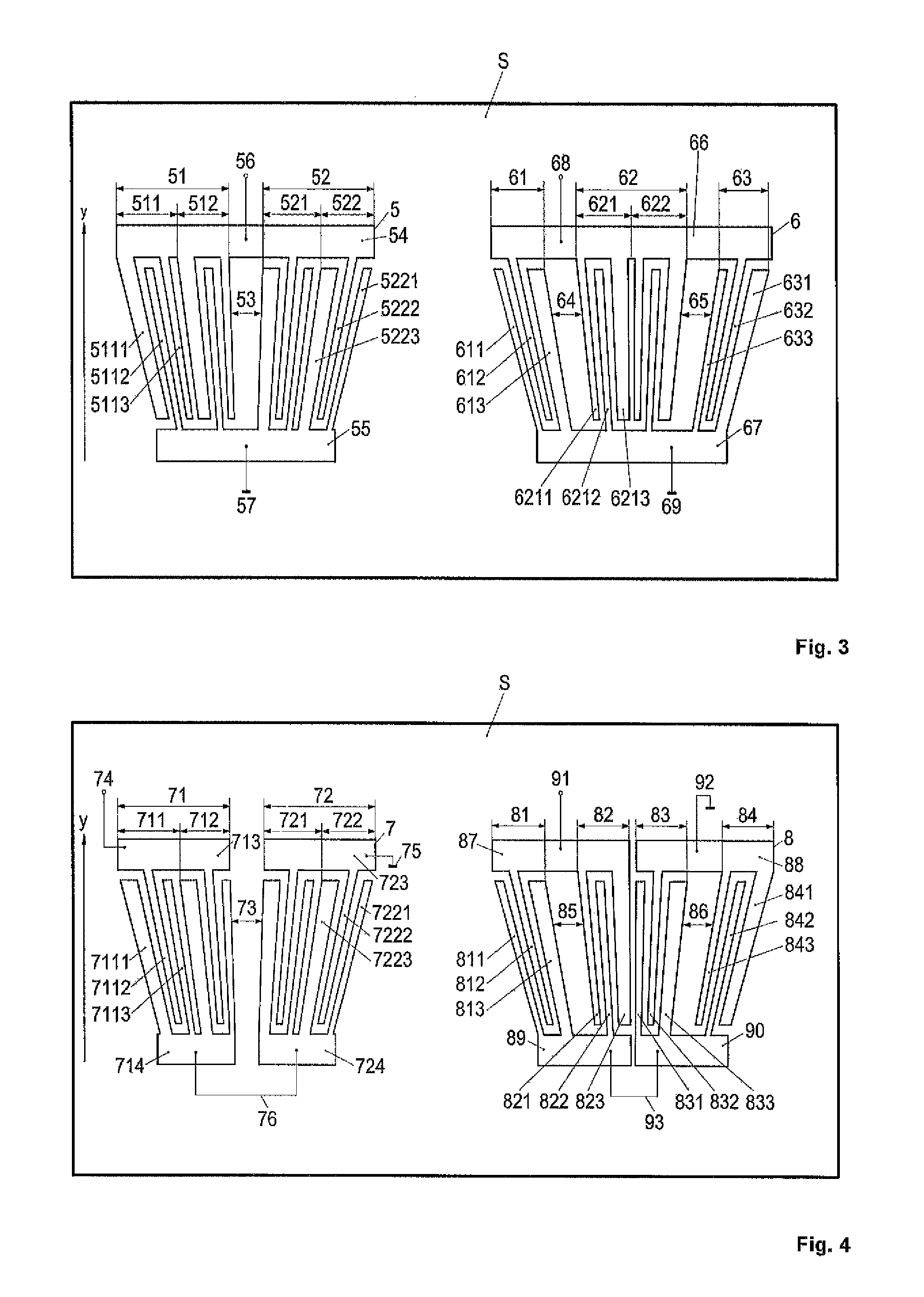

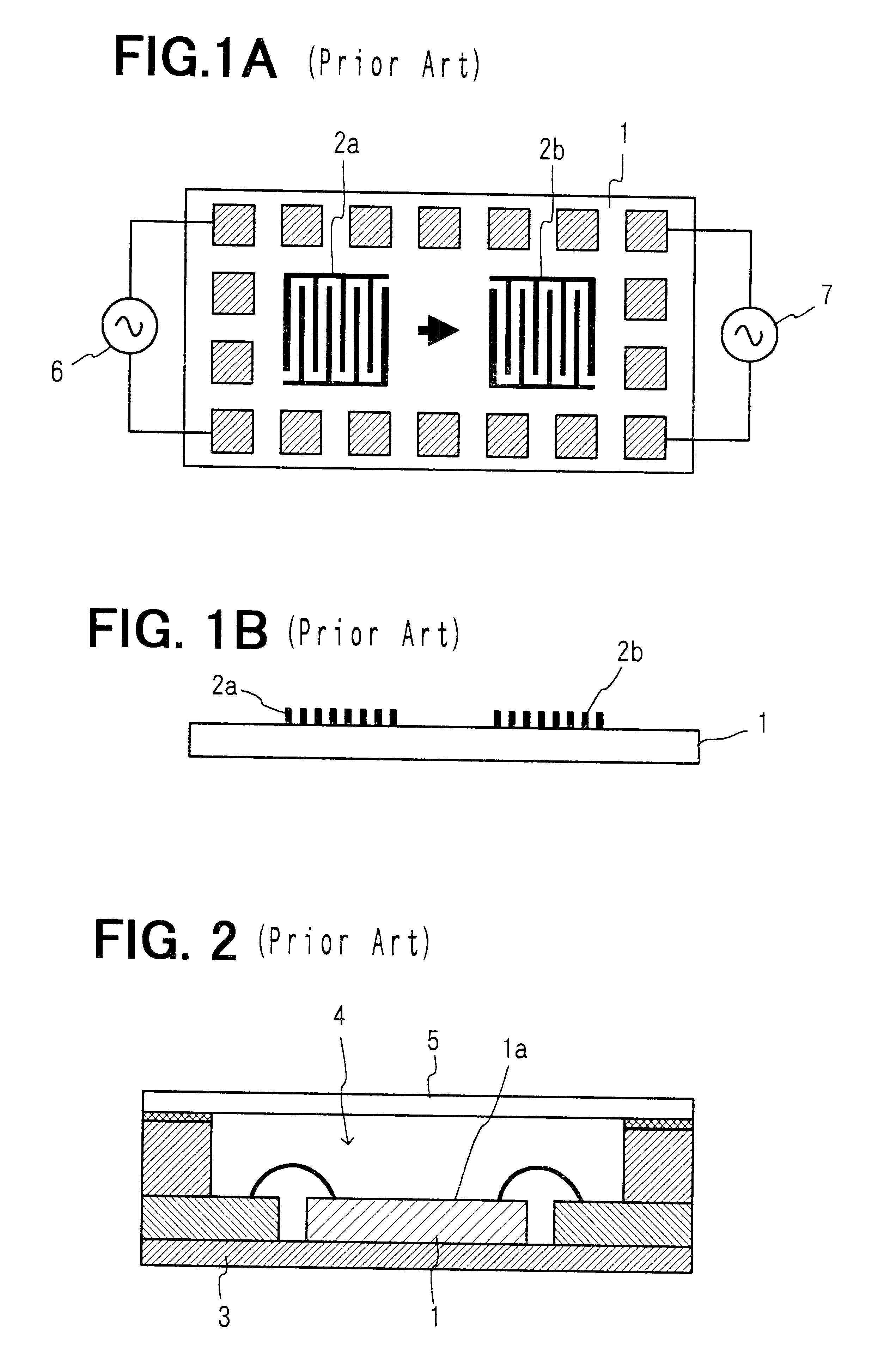

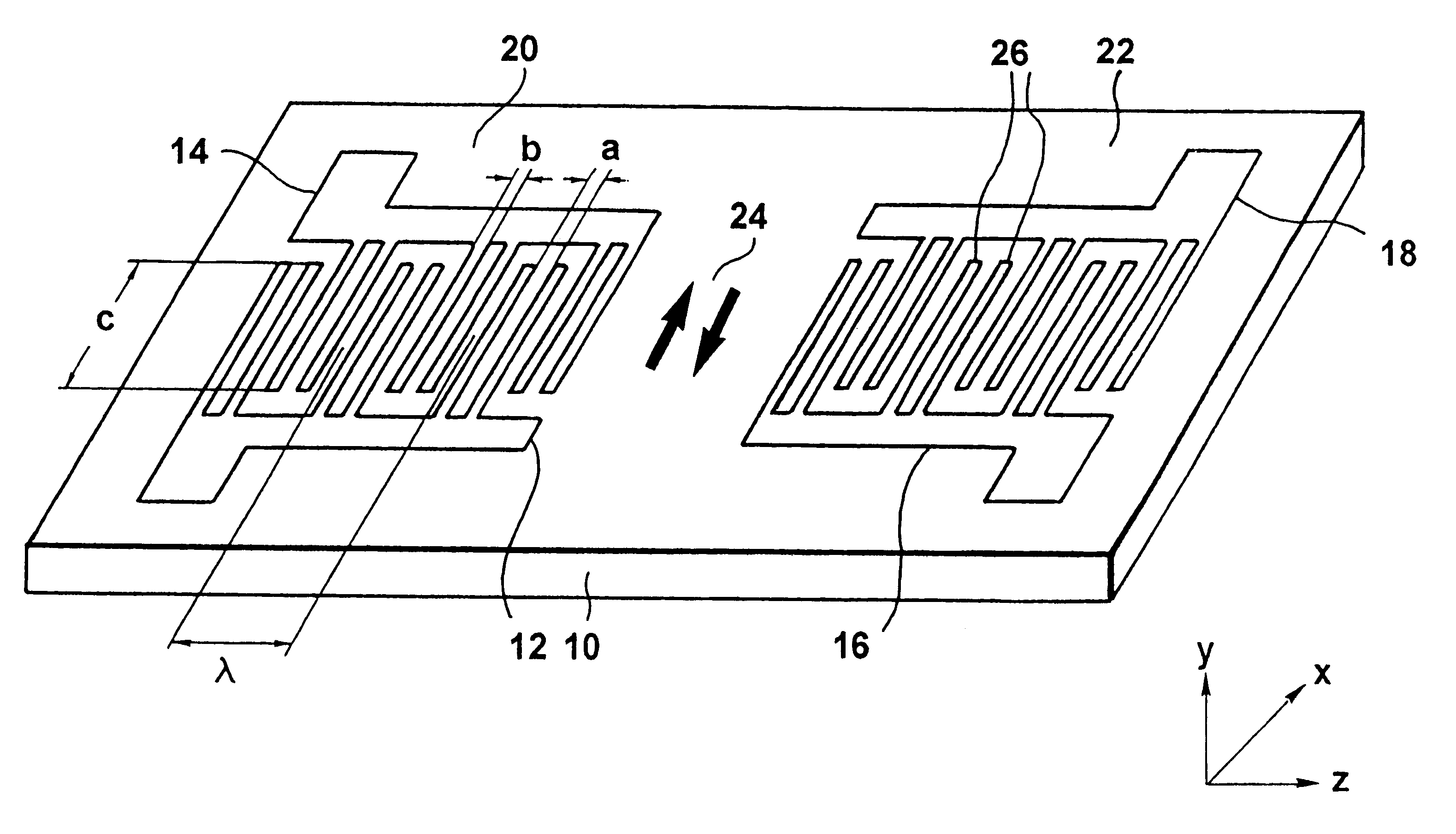

SAW filter operable in a piston mode

ActiveUS7576471B1Piezoelectric/electrostriction/magnetostriction machinesImpedence networksTransducerWave velocity

A SAW transducer includes a pair of opposing bus bars formed on a surface of a piezoelectric substrate with a plurality of interdigital electrodes extending from each of the opposing bus bars. A center region and opposing edge regions are formed, wherein each edge region is proximate each bus bar and includes free end portions of the electrodes such that a wave velocity in each edge region is substantially lower than a wave velocity in the bus bars and in the center region, and wherein electro-acoustic sources extend into the edge regions for providing a SAW transducer having the piezoelectrically excited strongest mode is a piston mode with an amplitude distribution generally flat across most of the resonator area.

Owner:QORVO US INC

Method of forming a surface acoustic wave (SAW) filter device

InactiveUS7213314B2Improve reliabilityReduce heat sensitivityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveLength wave

A SAW filter includes a piezoelectric substrate of Lithium Niobate or optionally Lithium Tantalate having a thickness of at least twice an acoustic wavelength. The piezoelectric substrate is bonded to a surrogate substrate of a silicon material. The surrogate substrate is characterized by a resisitivity of at least 100 ohm-cm and an expansion coefficient compatible with the piezoelectric substrate. A catalytic bonding film between the piezoelectric substrate and the surrogate substrate is formed from a first catalytic bonding film deposited onto a surface of the piezoelectric substrate and a second catalytic bonding film deposited onto a surface of the surrogate substrate. The piezoelectric substrate is bonded to the surrogate substrate through a compression force sufficient for providing a bonding at a normal temperature.

Owner:TRIQUINT

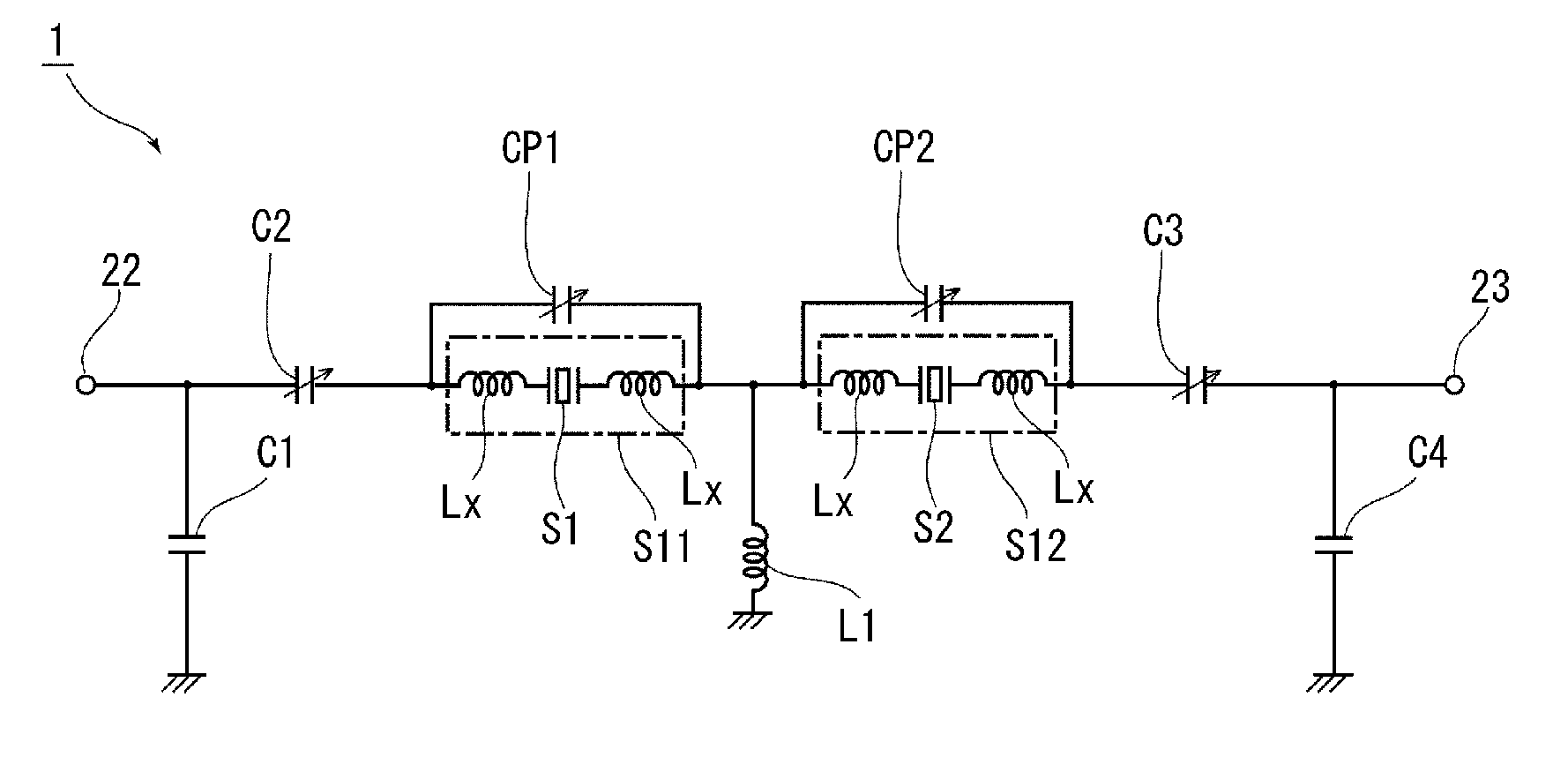

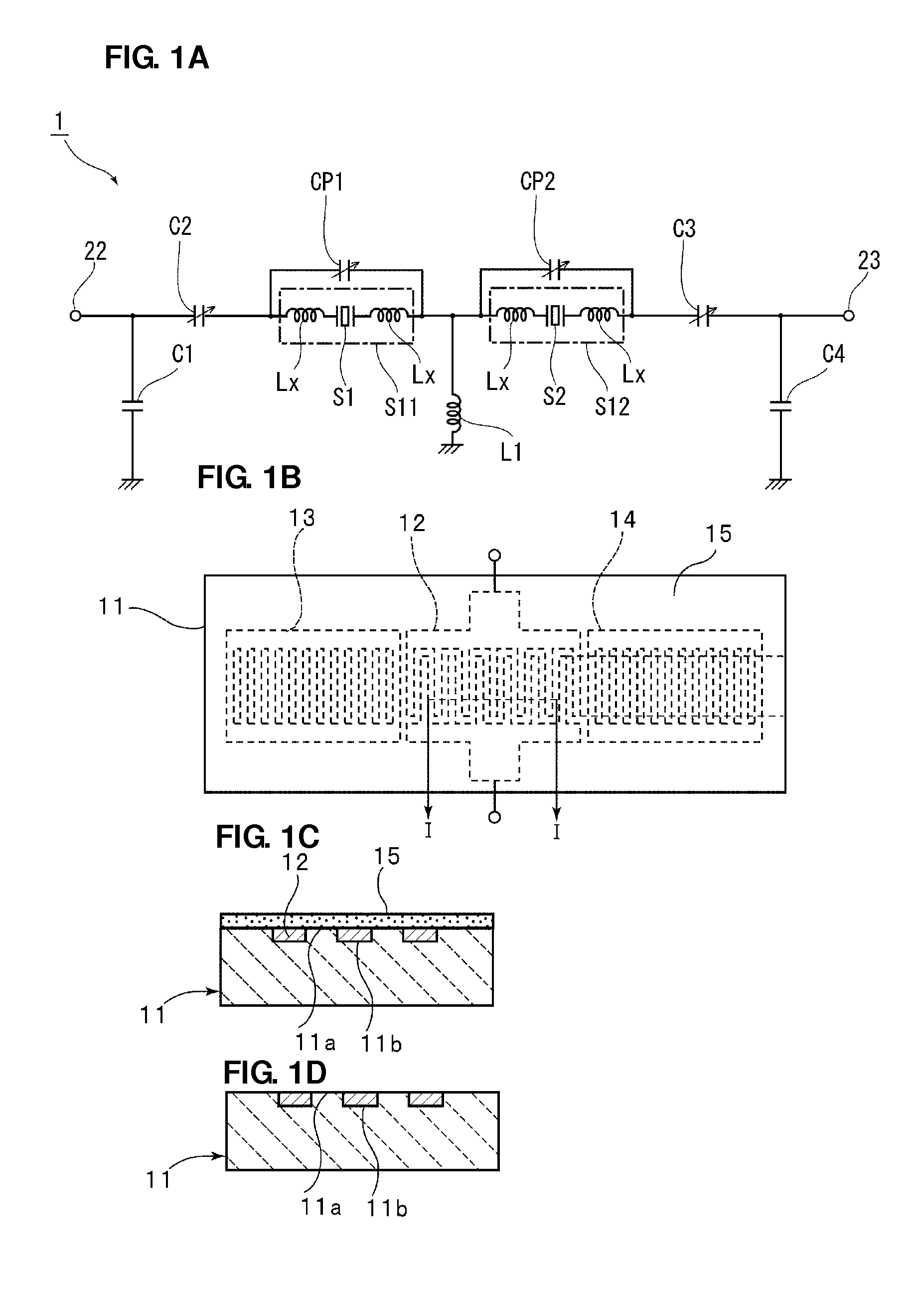

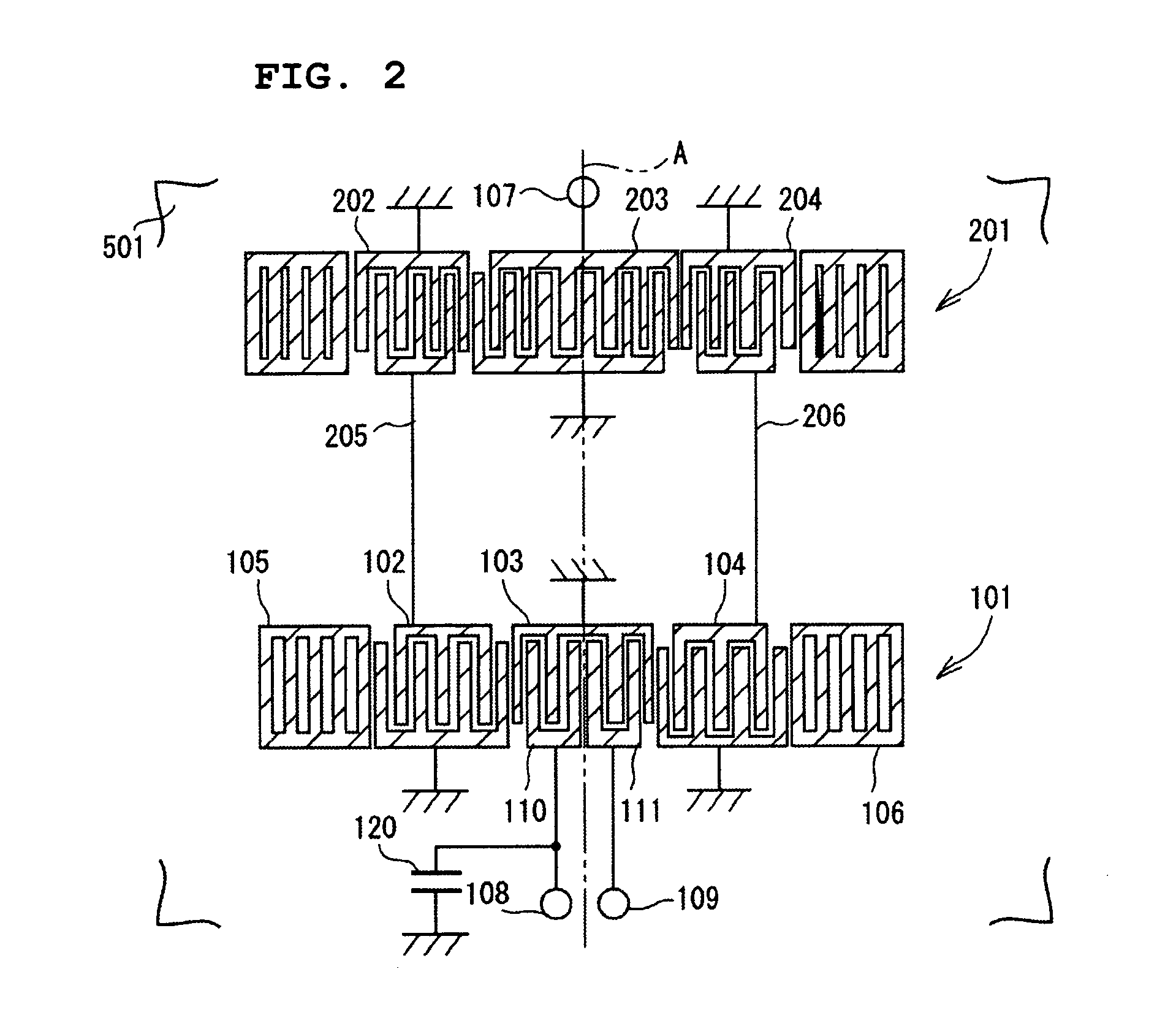

Tunable filter

A tunable filter that is capable of magnifying a pass band width or increasing a frequency variable amount includes a resonator circuit portion provided in at least one of a series arm connecting an input terminal and an output terminal to each other and a parallel arm connecting the series arm and a ground potential to each other, a first variable capacitor is connected in series to the resonator circuit portion and a second variable capacitor is connected in parallel to the resonator circuit portion. The resonator circuit portion includes a piezoelectric substrate including LiNbO3 or LiTaO3, an elastic wave resonator including an electrode located on the piezoelectric substrate, and a bandwidth extending inductance Lx, Lx connected to the elastic wave resonator.

Owner:MURATA MFG CO LTD

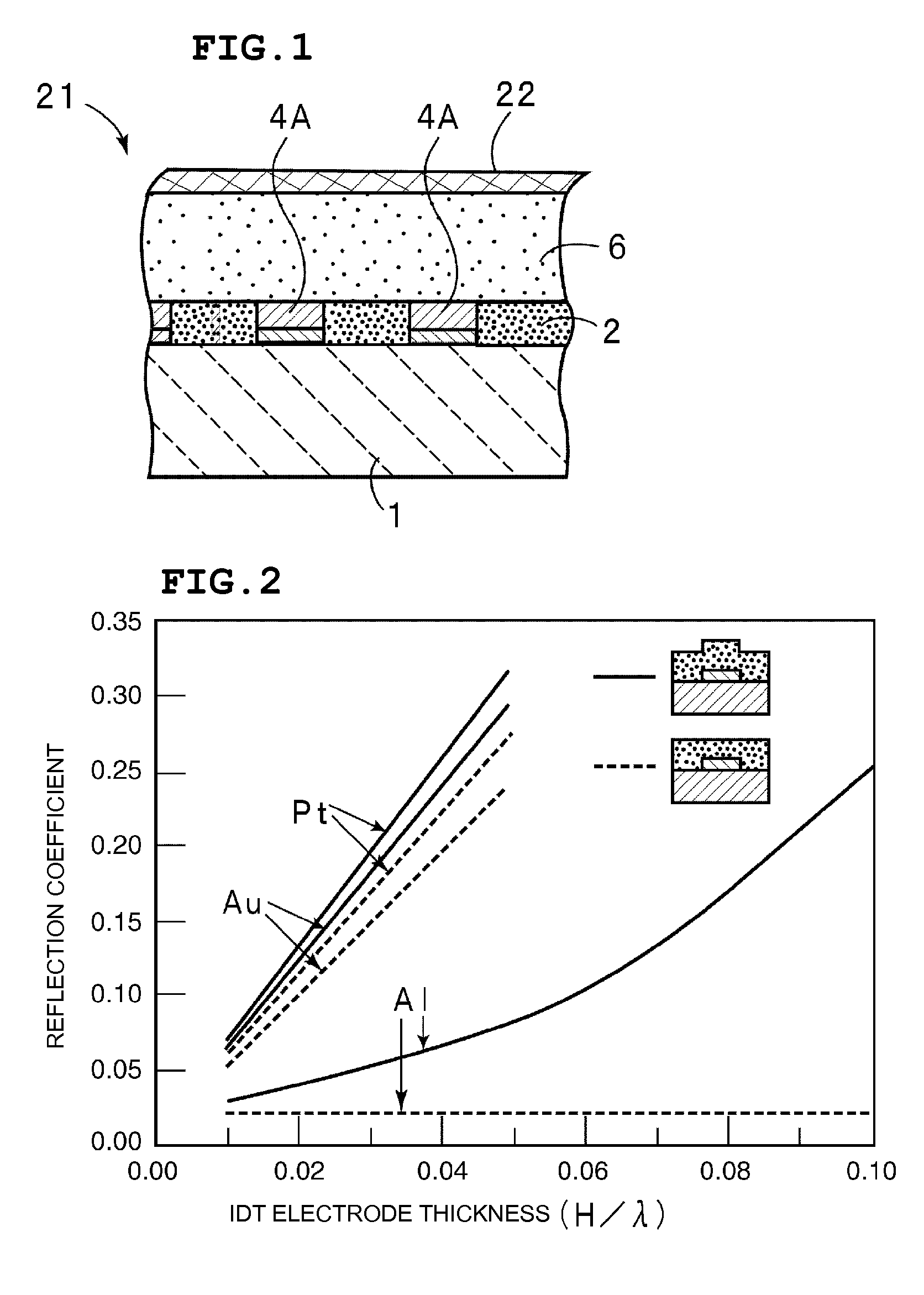

Surface acoustic wave device

ActiveUS7327071B2Improve filtering effectRipples are prevented and minimizedImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAlloyAcoustic wave

A surface acoustic wave device includes a piezoelectric substrate made of LiTaO3 or LiNbO3 having an electromechanical coefficient of about 15% or more, at least one electrode which is disposed on the piezoelectric substrate and which is a laminate film having a metal layer defining a primary metal layer primarily composed of a metal having a density higher than that of Al or an alloy of the metal and a metal layer which is laminated on the primary metal layer and which is composed of another metal, and a first SiO2 layer which is disposed in a remaining area other than that at which the at least one electrode is located and which has a thickness approximately equivalent to that of the electrode. In the surface acoustic wave device described above, the density of the electrode is at least about 1.5 times that of the first SiO2 layer. In addition, a second SiO2 layer disposed so as to cover the electrode and the first SiO2 layer and a silicon nitride compound layer disposed on the second SiO2 layer are further provided.

Owner:MURATA MFG CO LTD

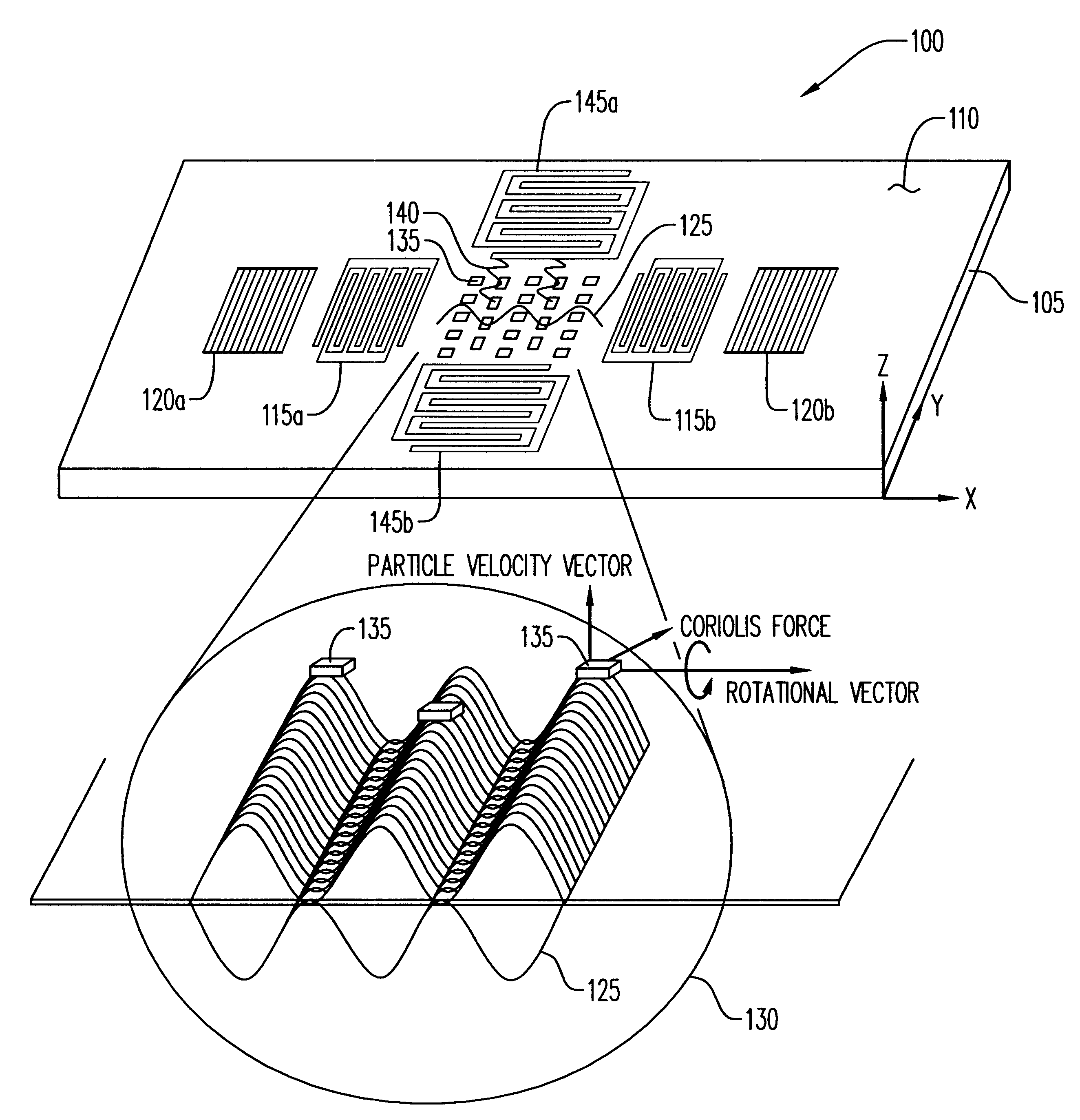

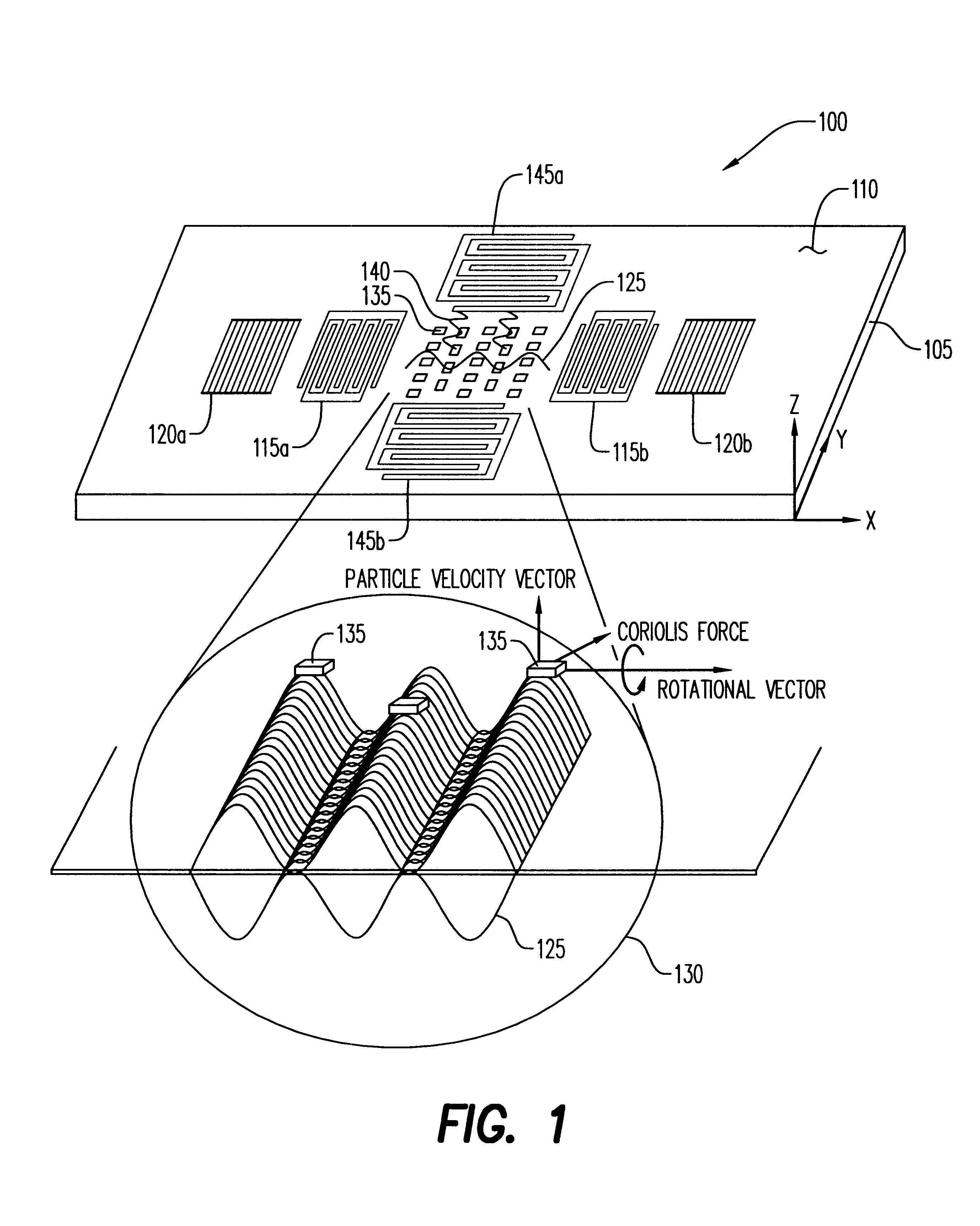

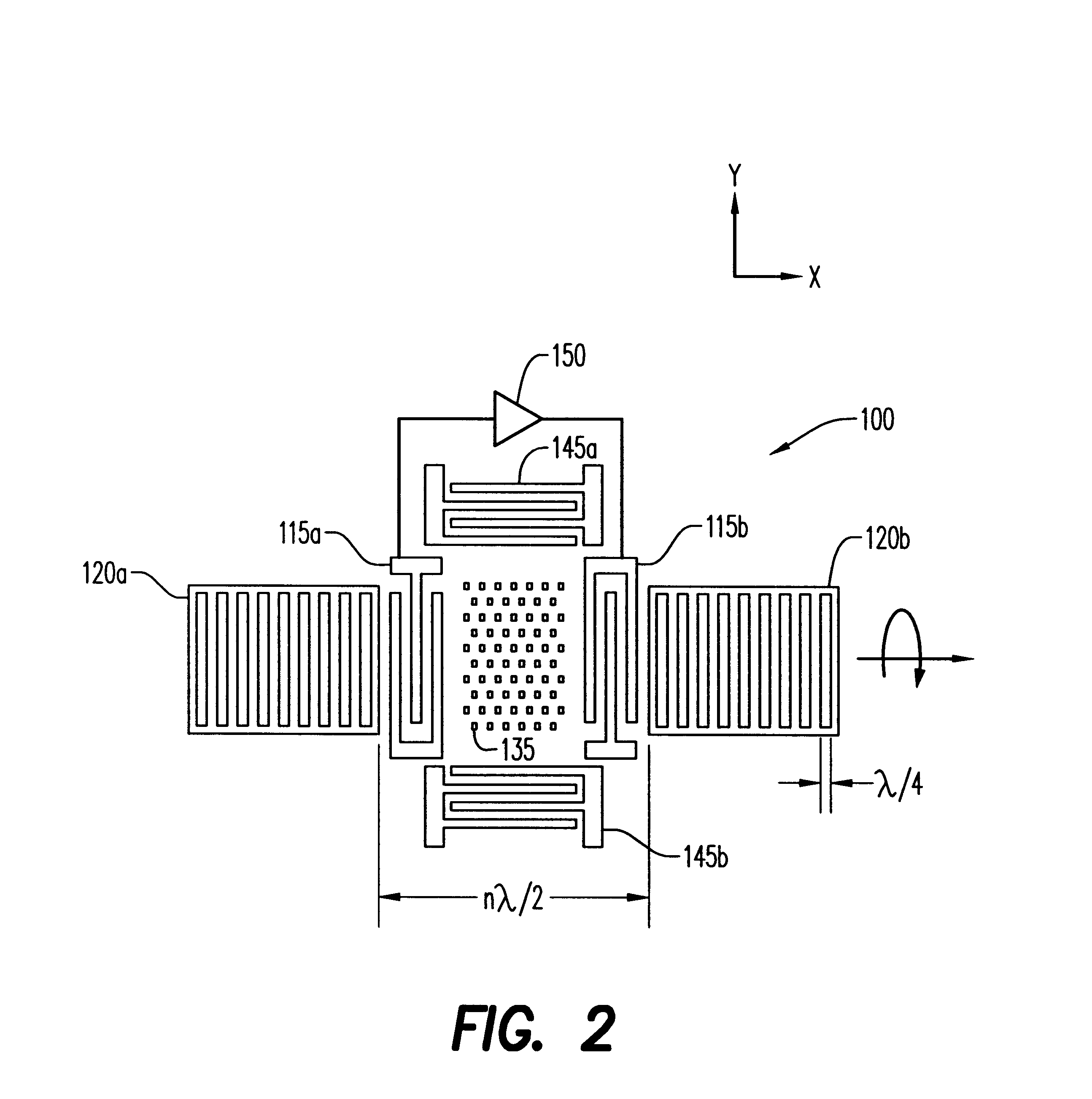

Micro-electro-mechanical gyroscope

InactiveUS6516665B1High sensitivityEasy to detectPiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectricityGyroscope

A gyroscope comprises a piezoelectric substrate having a surface. Disposed on the surface are a resonator transducer, a pair of reflectors, a structure such as a metallic dot, and a sensor transducer. The resonator transducer creates a first surface acoustic wave on the surface. The pair of reflectors reflects the first surface acoustic wave to form a standing wave within a region of the surface between the pair of reflectors. The structure is disposed on the surface within the region, wherein a Coriolis force acting upon the structure creates a second surface acoustic wave. The sensor senses the second surface acoustic wave and provides an output indicative thereof.

Owner:PENN STATE RES FOUND

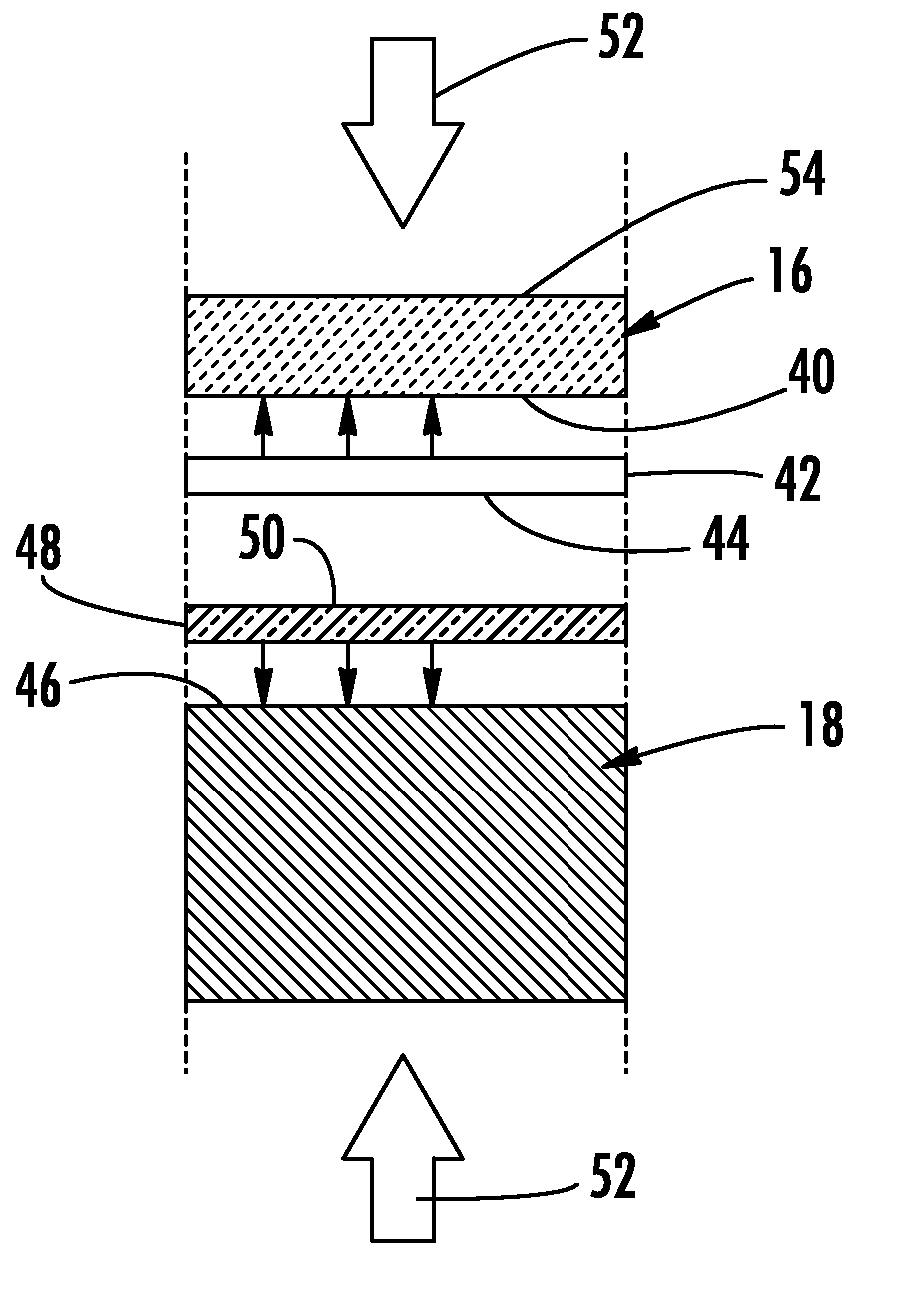

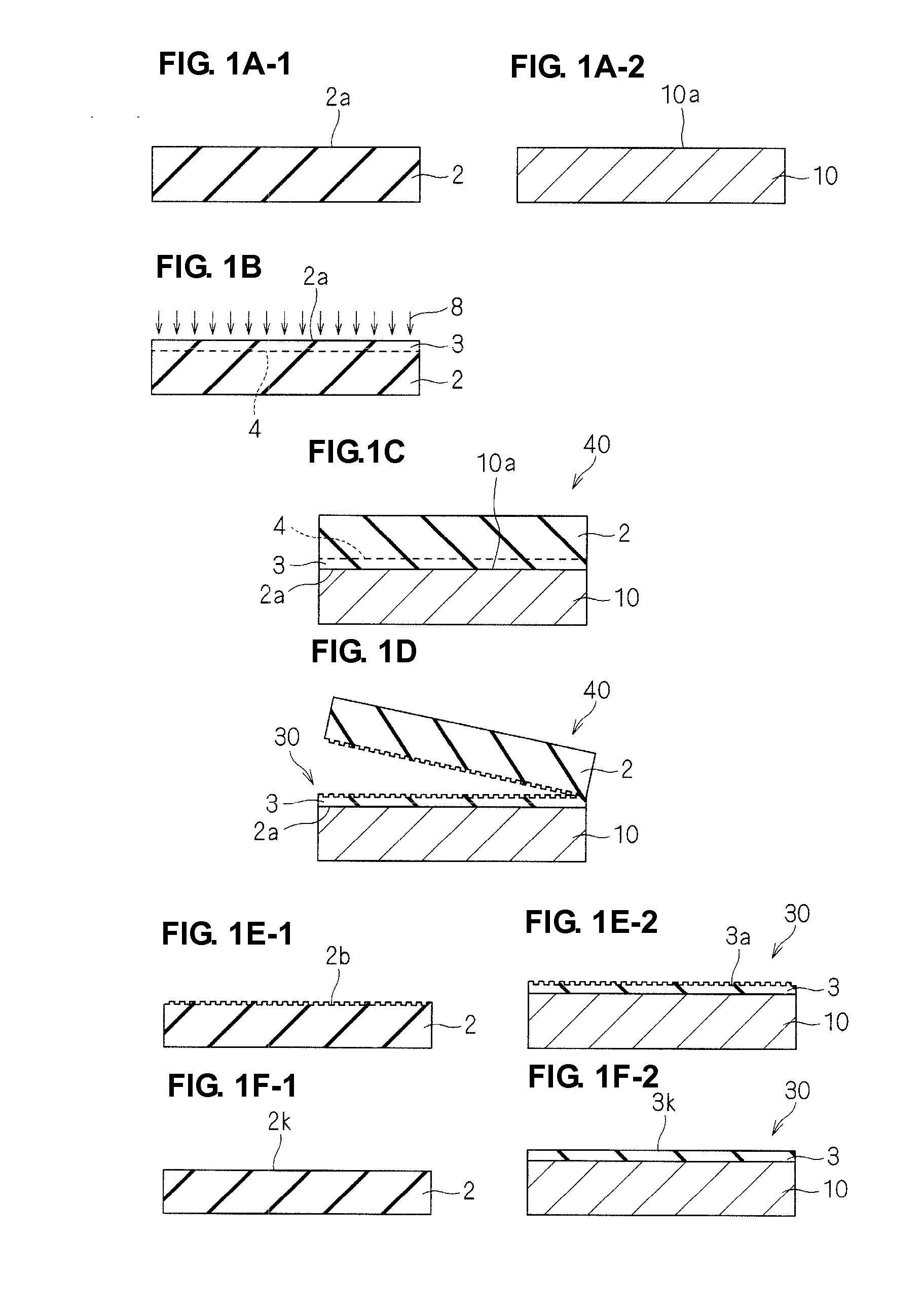

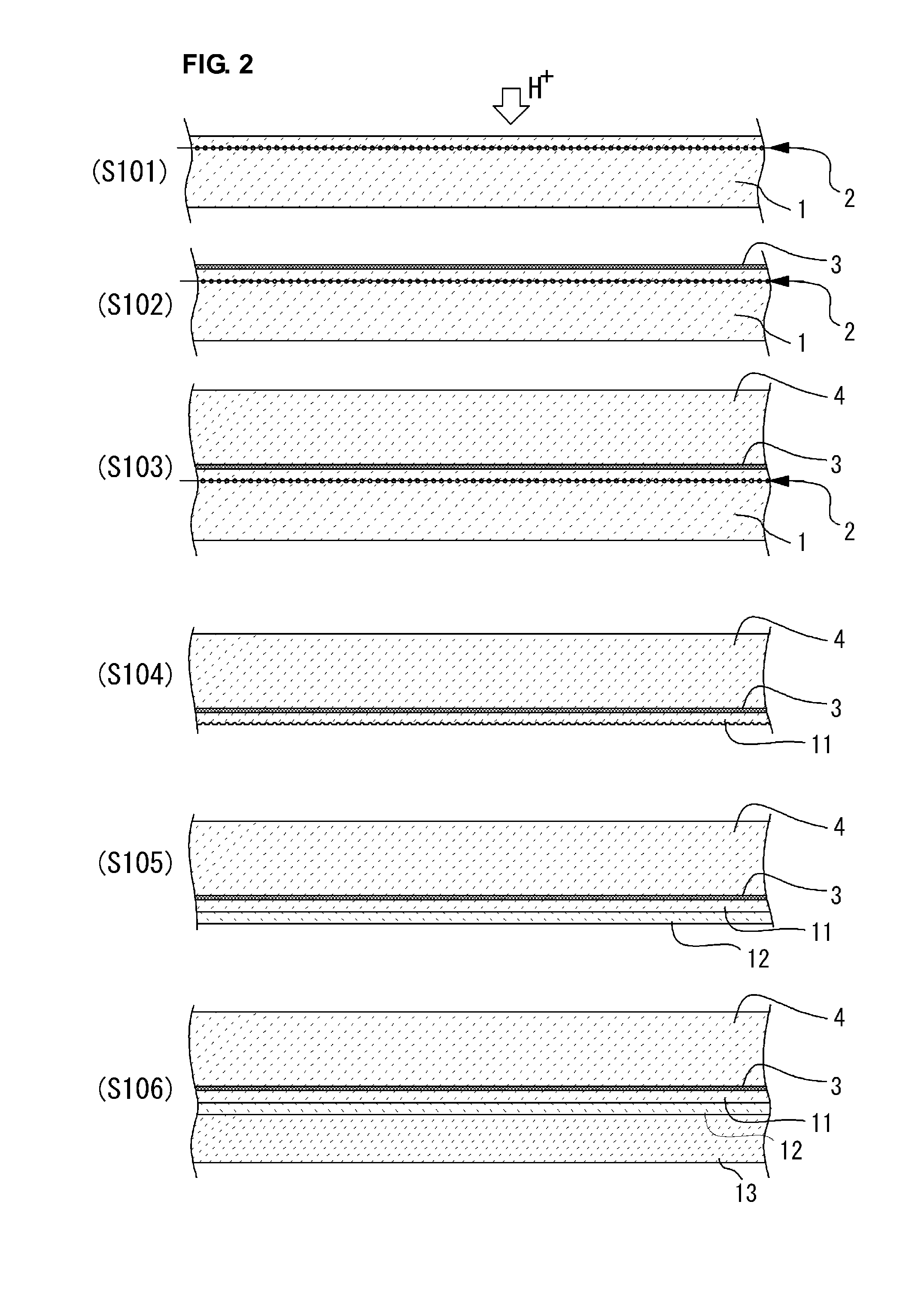

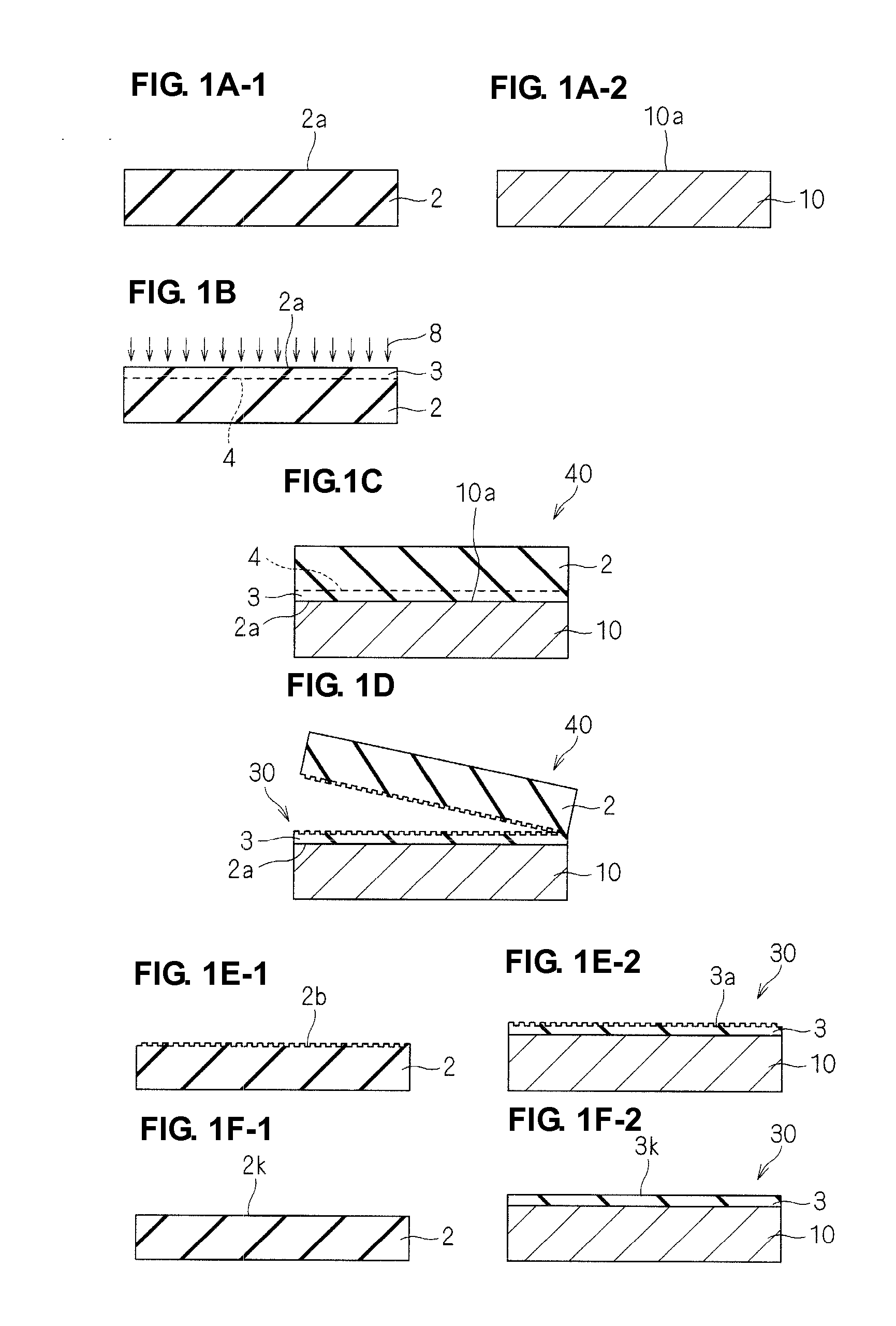

Method for manufacturing composite piezoelectric substrate

ActiveUS20100088868A1Uniform thicknessMaterial efficiencyPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksImpurityNanotechnology

A method for manufacturing a composite piezoelectric substrate is capable of forming an ultra-thin piezoelectric film having a uniform thickness by efficiently using a piezoelectric material. A piezoelectric substrate and a supporting substrate are prepared, ions are implanted from a surface of the piezoelectric substrate to form a defective layer in a region at a predetermined depth from the surface of the piezoelectric substrate, impurities that are adhered to at least one of the surface of the piezoelectric substrate in which the defective layer is formed and a surface of the supporting substrate are removed to directly expose the constituent atoms of the surfaces and to activate the surfaces, the supporting substrate is bonded to the surface of the piezoelectric substrate to form a bonded substrate body, the bonded substrate body is separated at the defective layer formed in the piezoelectric substrate so that a separation layer between the surface of the piezoelectric substrate and the defective layer is separated from the piezoelectric substrate and bonded to the supporting substrate to form a composite piezoelectric substrate, and the surface of the separation layer of the composite piezoelectric substrate is smoothed.

Owner:MURATA MFG CO LTD

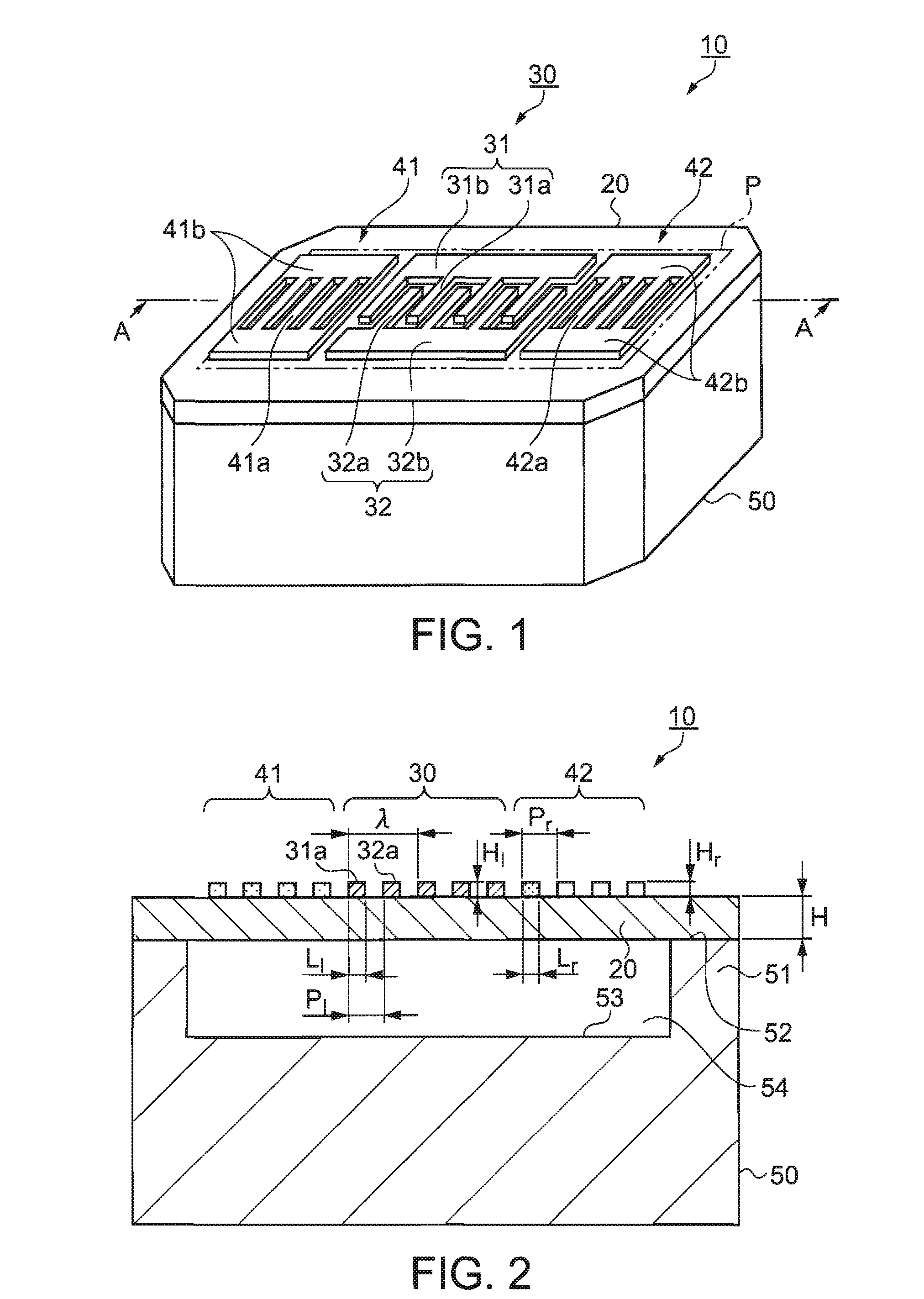

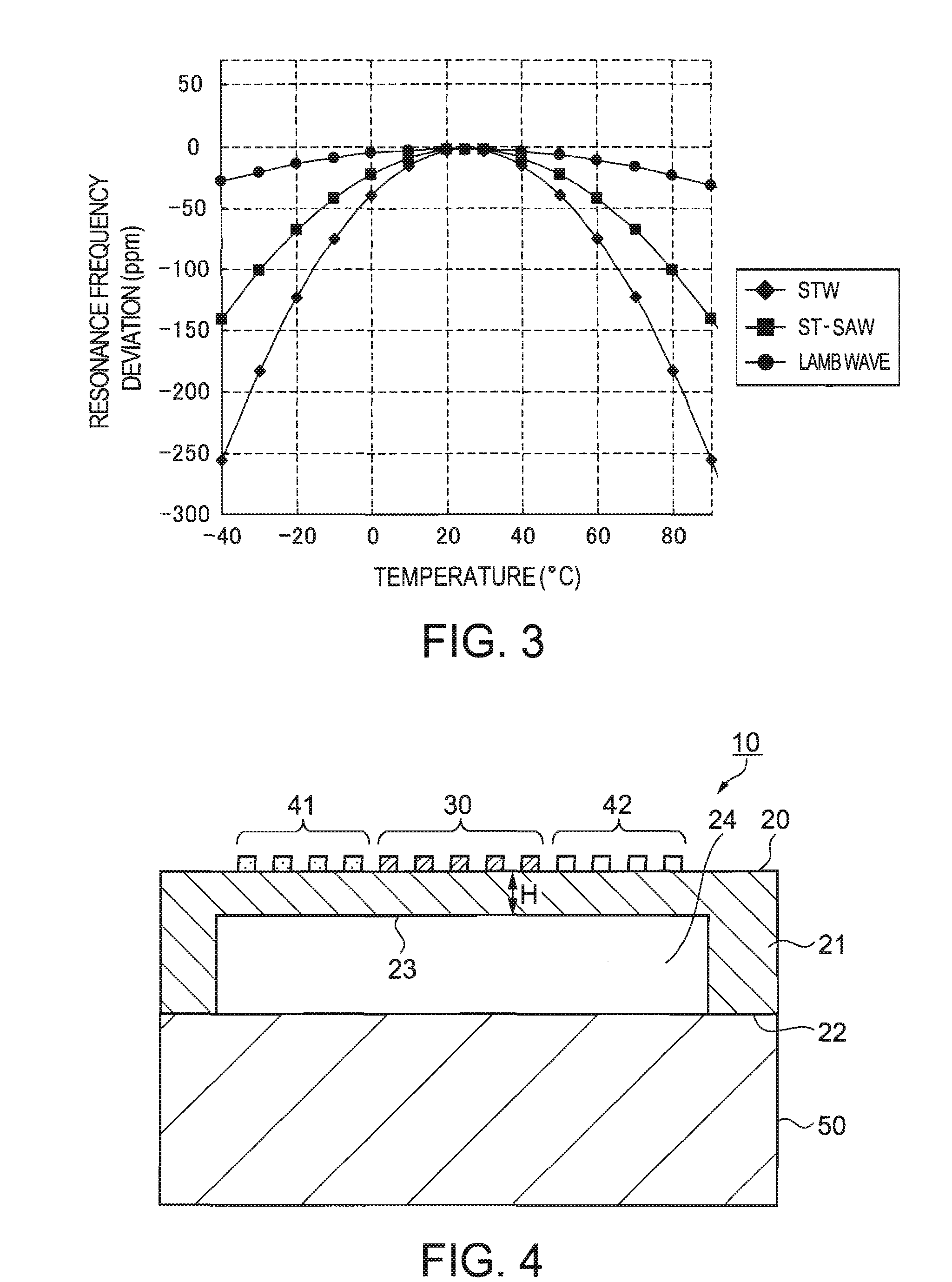

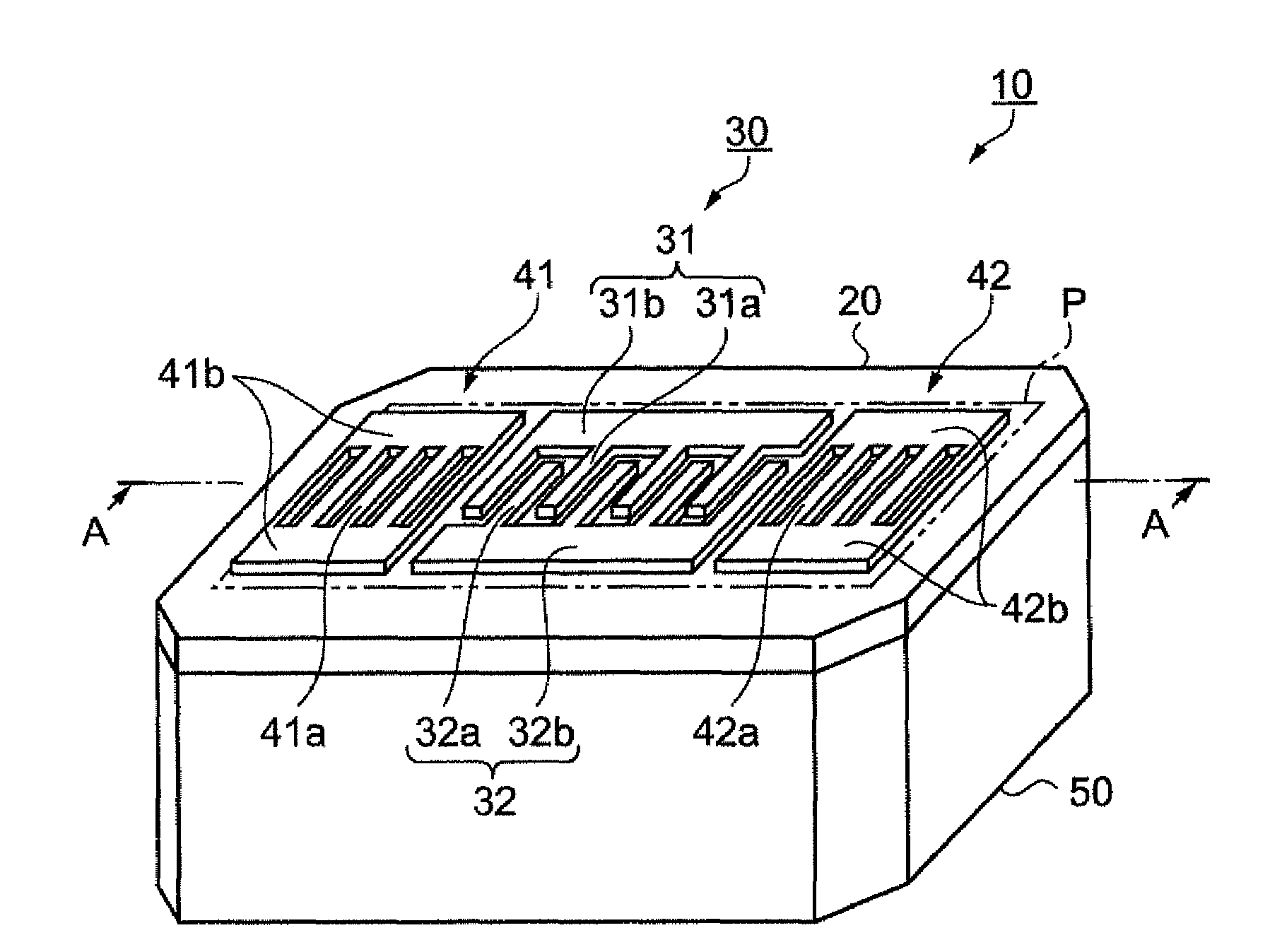

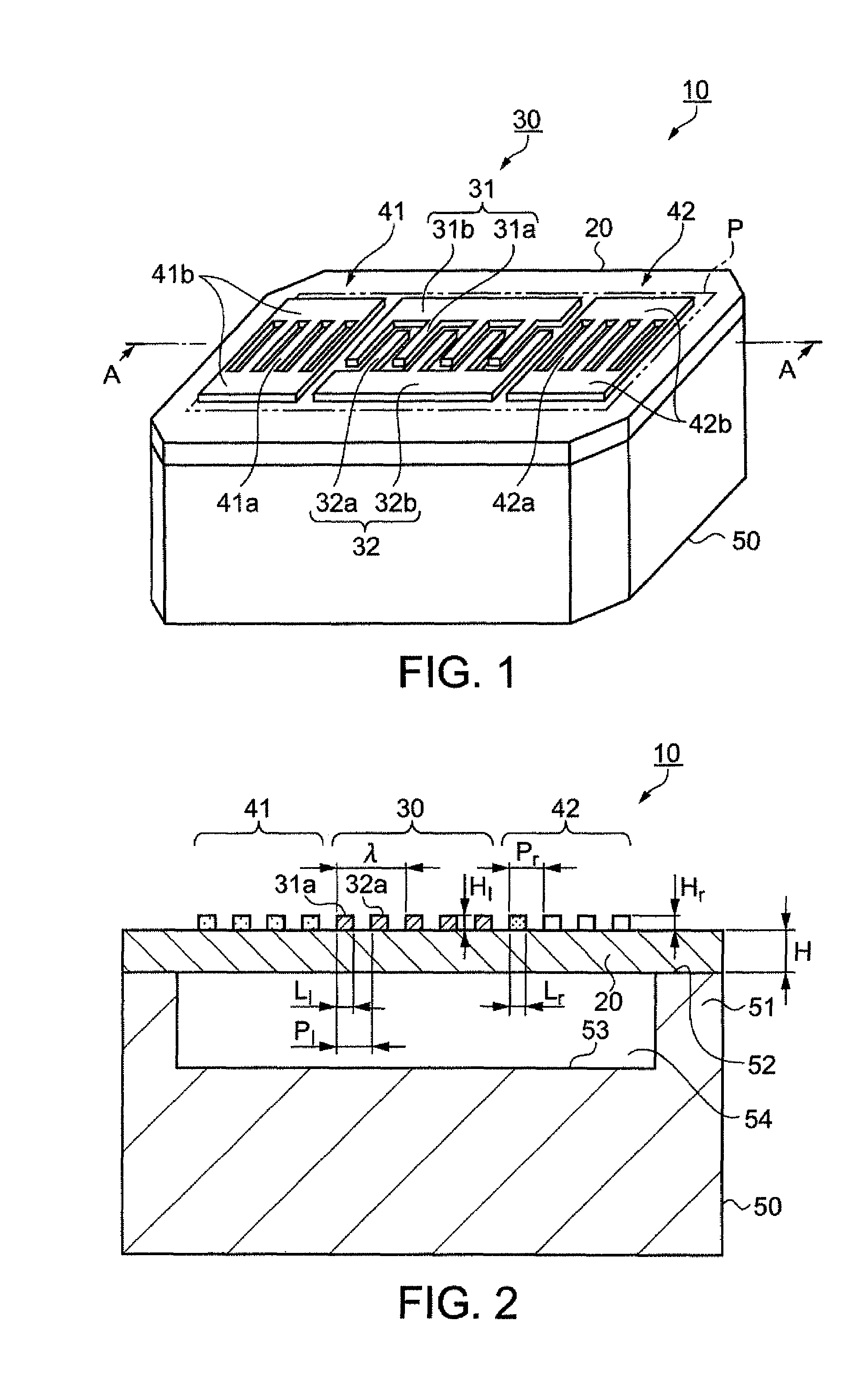

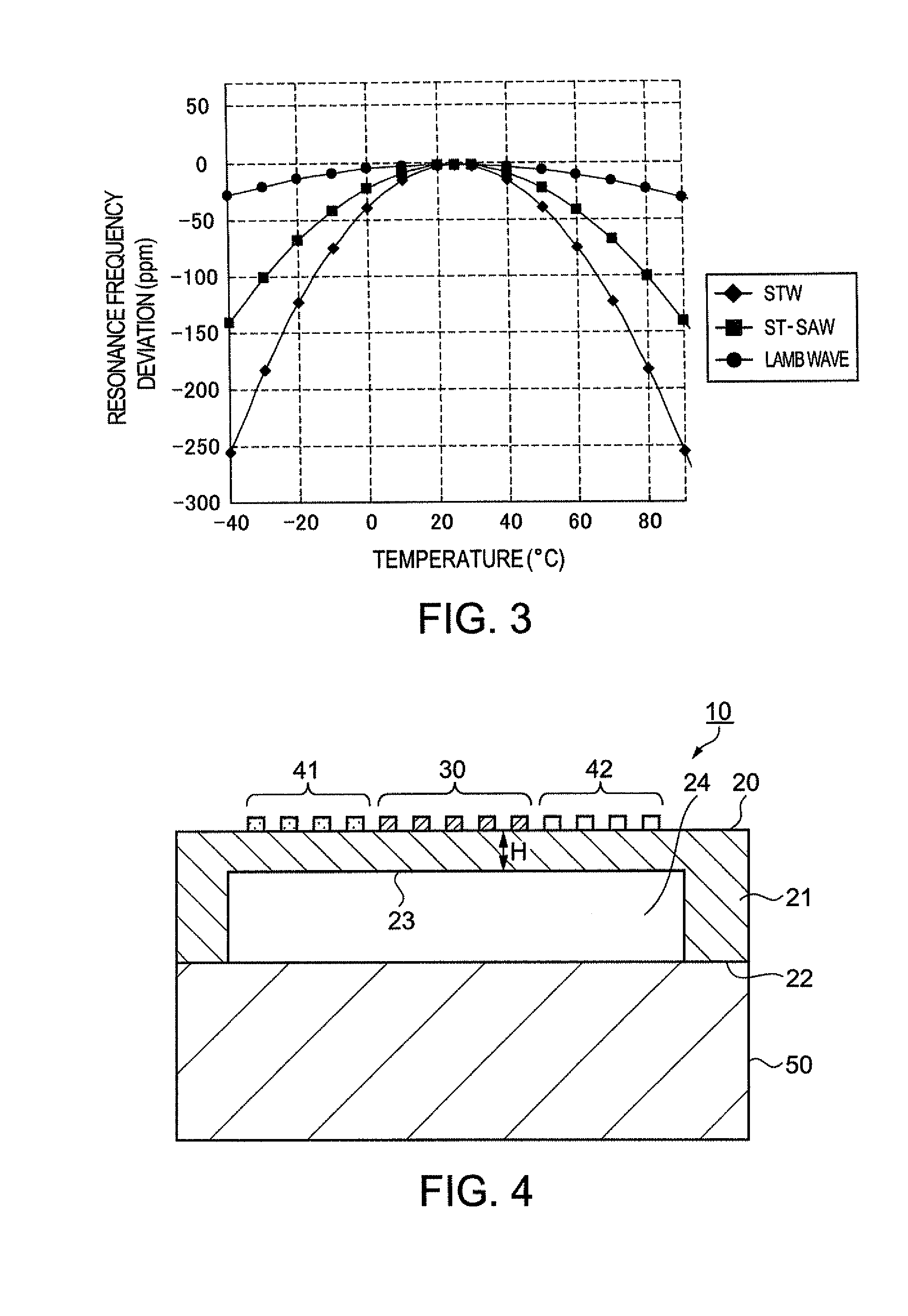

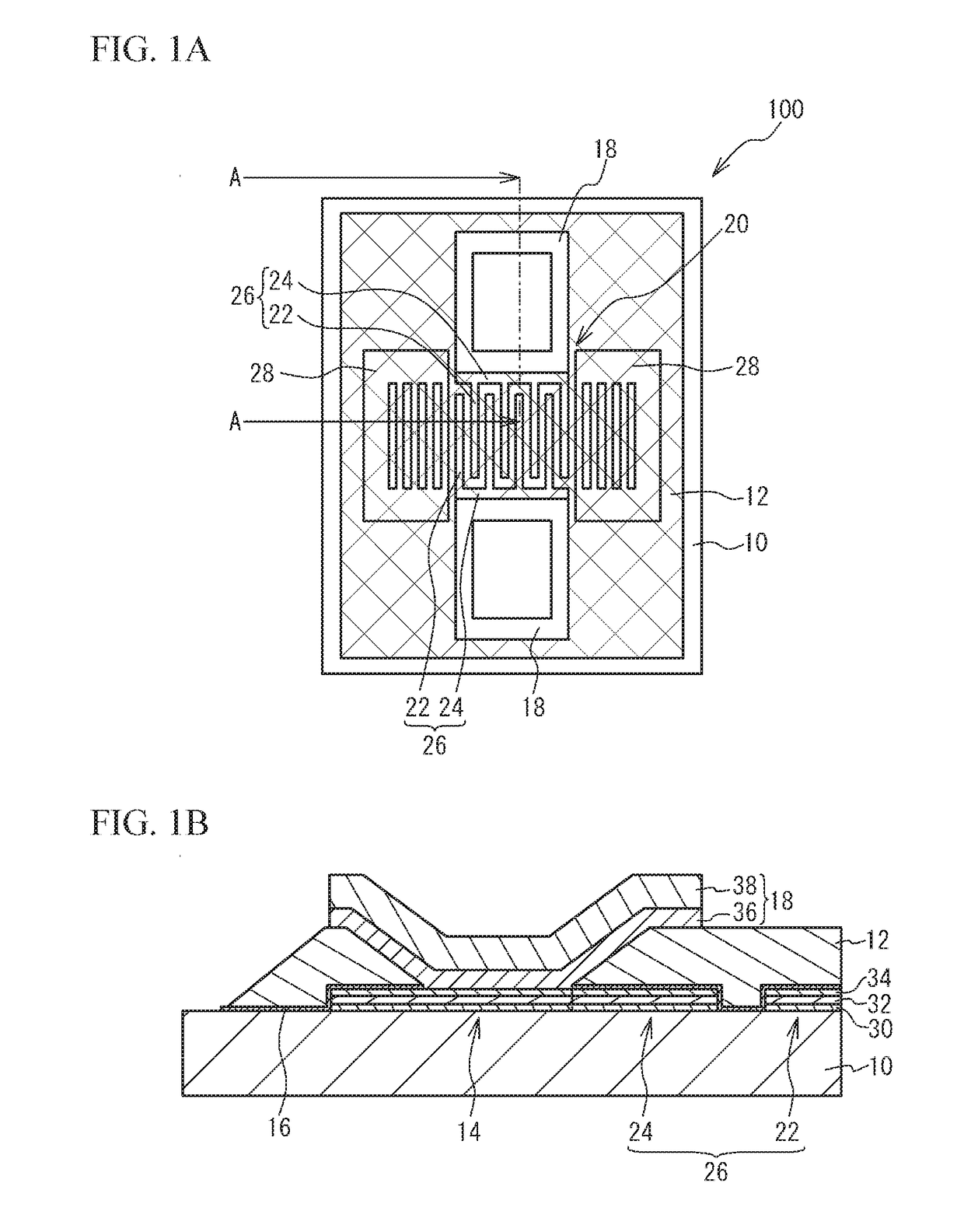

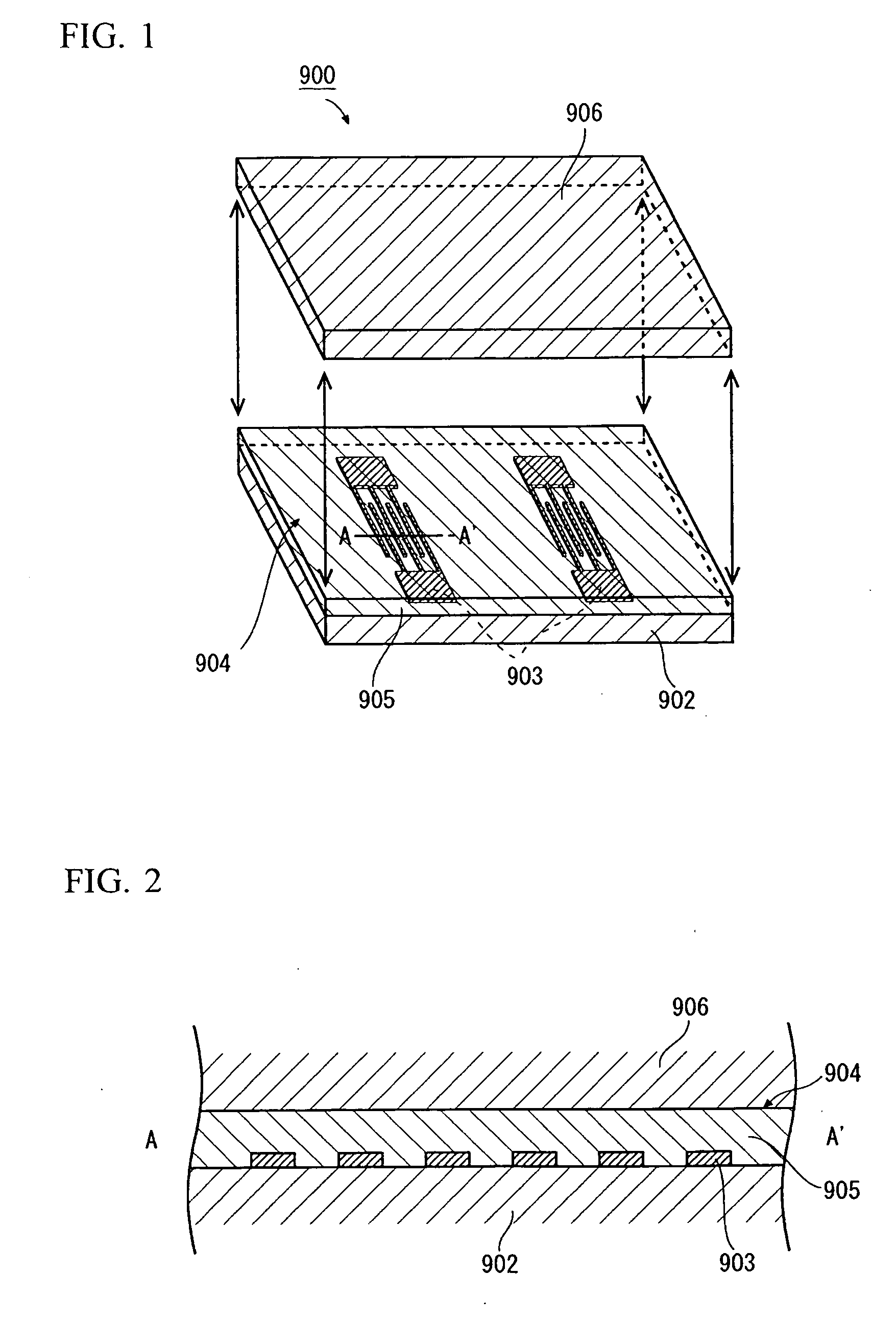

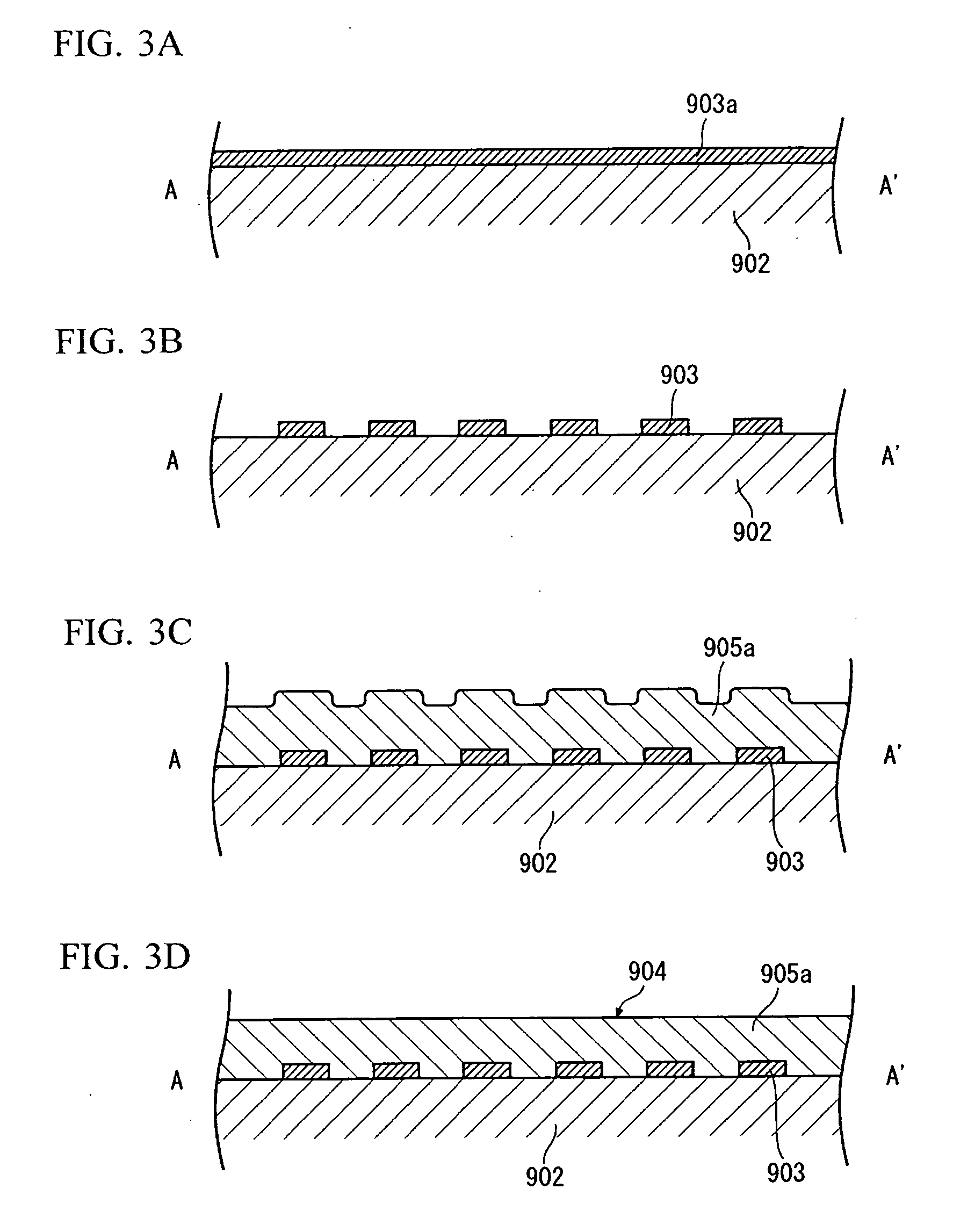

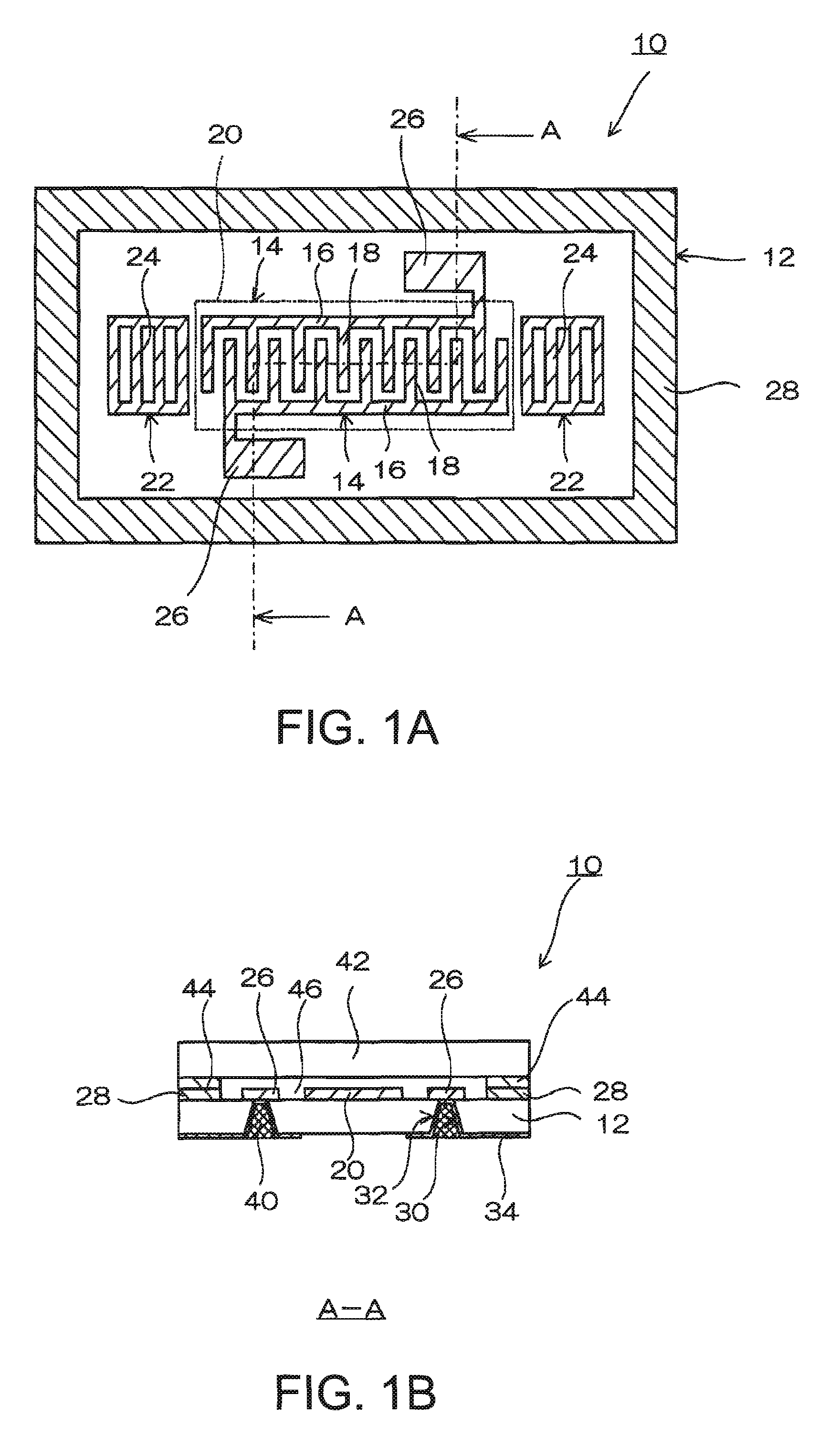

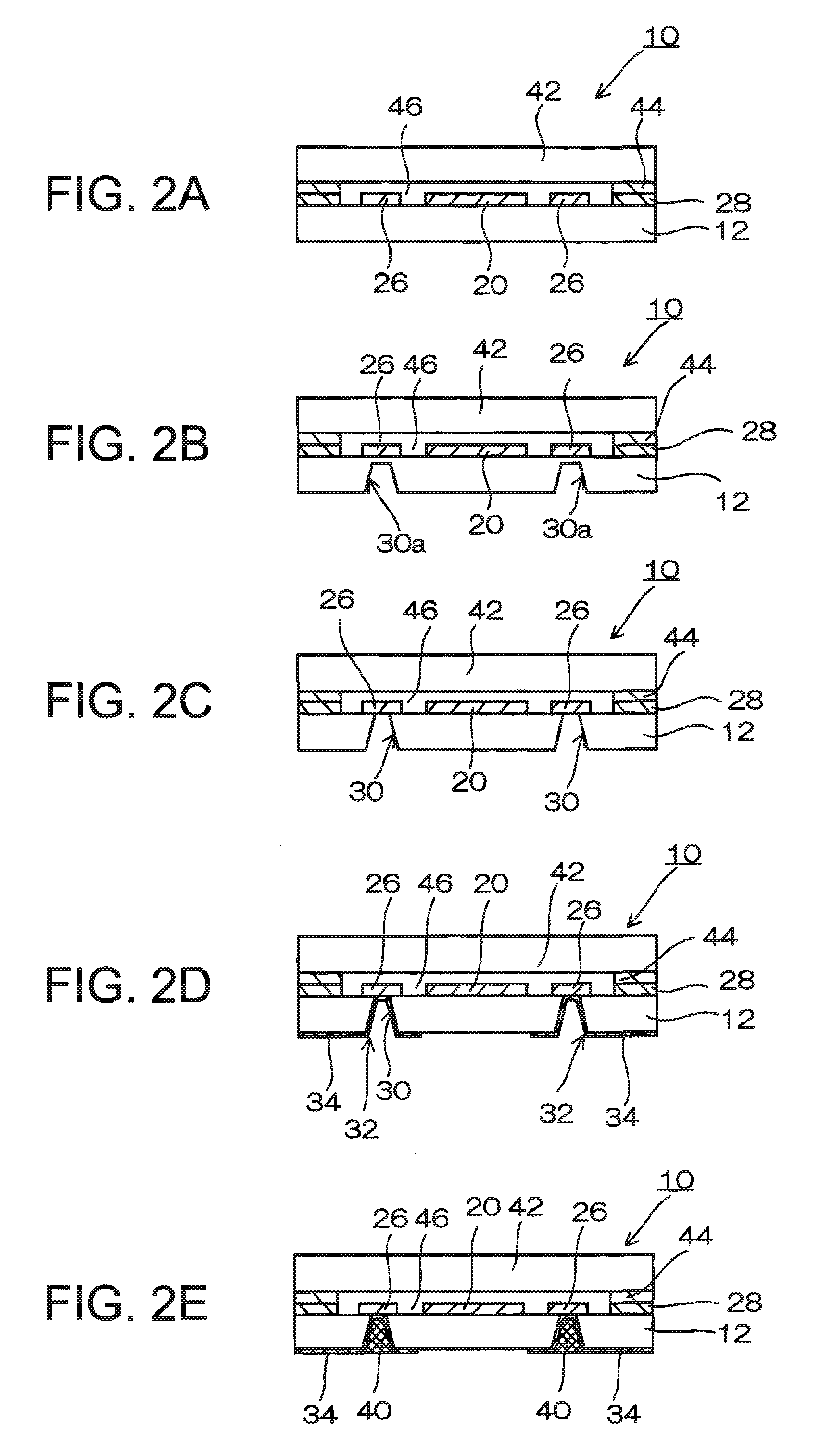

Lamb wave type frequency device and method thereof

InactiveUS20070188047A1Stable resonance propertyImprove structural strengthPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksType frequencyAcoustics

A Lamb wave type high frequency device comprises: a piezoelectric substrate; an interdigital transducer (IDT) electrode formed on a first main surface of the piezoelectric substrates a reinforcing substrate connected to a second main surface of the piezoelectric substrate; a space portion formed in one of the piezoelectric substrate and the reinforcing substrate, an area of the space portion being larger than a region in which a Lamb wave is propagated; and a connecting surface formed in a periphery of the space portion.

Owner:SEIKO EPSON CORP

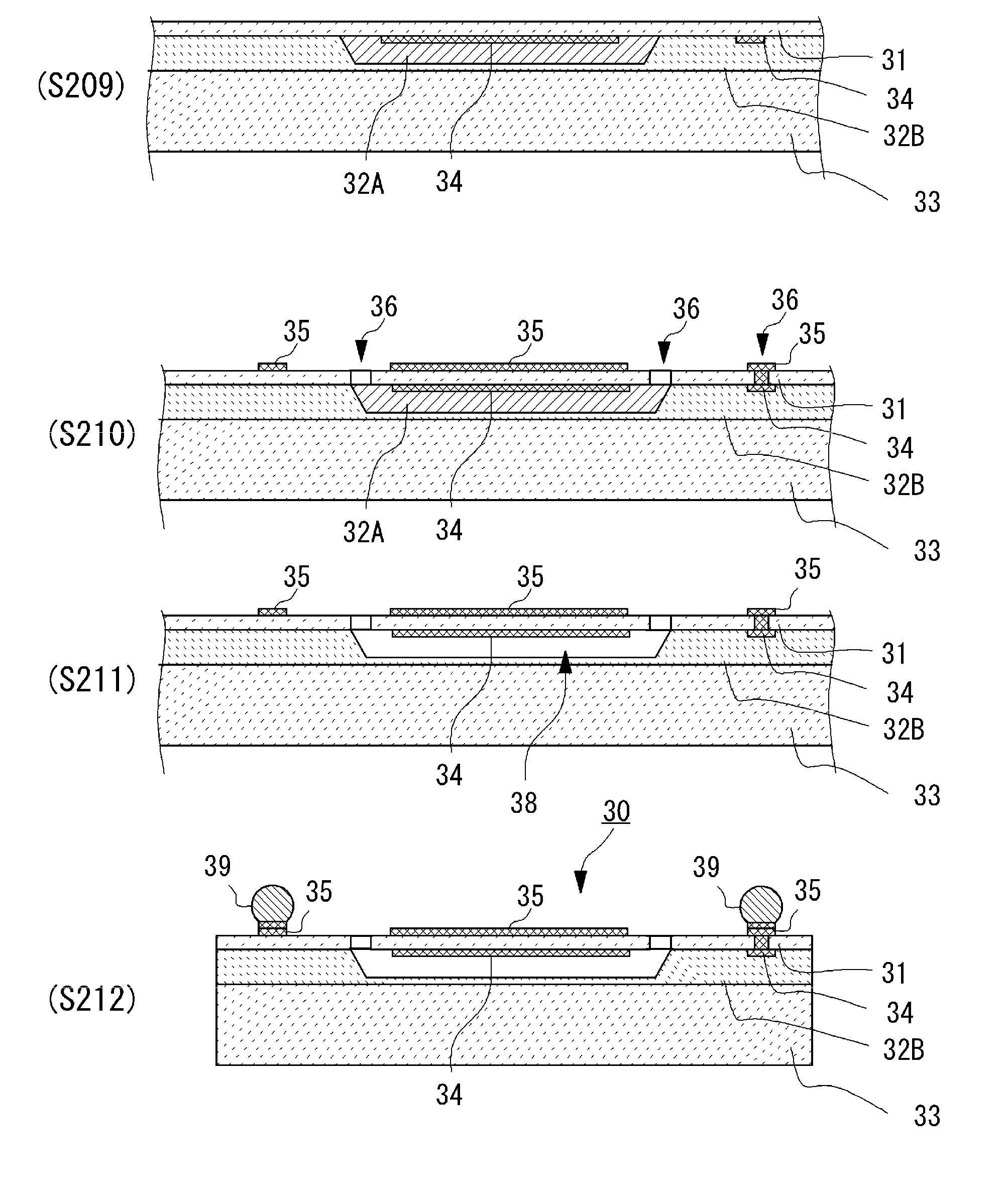

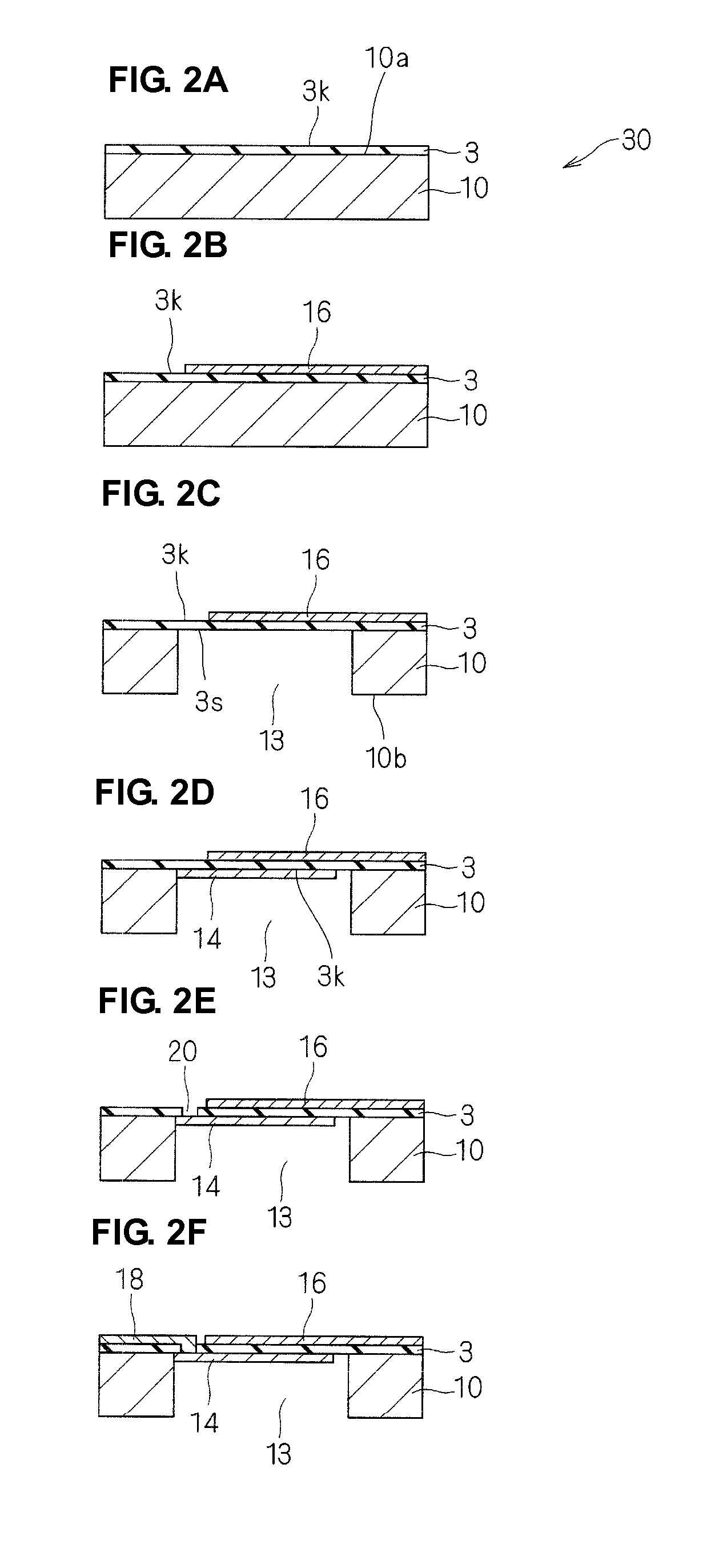

Method for manufacturing composite piezoelectric substrate and piezoelectric device

ActiveUS20110278993A1Improve featuresLess piezoelectric degradationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMetallurgyIon implantation

A piezoelectric device is manufactured in which the material of a supporting substrate can be selected from various alternative materials. Ions are implanted into a piezoelectric substrate to form an ion-implanted portion. A temporary supporting substrate is formed on the ion-implanted surface of the piezoelectric substrate. The temporary supporting substrate includes a layer to be etched and a temporary substrate. The piezoelectric substrate is then heated to be divided at the ion-implanted portion to form a piezoelectric thin film. A supporting substrate is then formed on the piezoelectric thin film. The supporting substrate includes a dielectric film and a base substrate. The temporary supporting substrate is made of a material that produces a thermal stress at the interface between the temporary supporting substrate and the piezoelectric thin film less than the thermal stress at the interface between the supporting substrate and the piezoelectric thin film.

Owner:MURATA MFG CO LTD

Piezoelectric vibrator and method for manufacturing the same

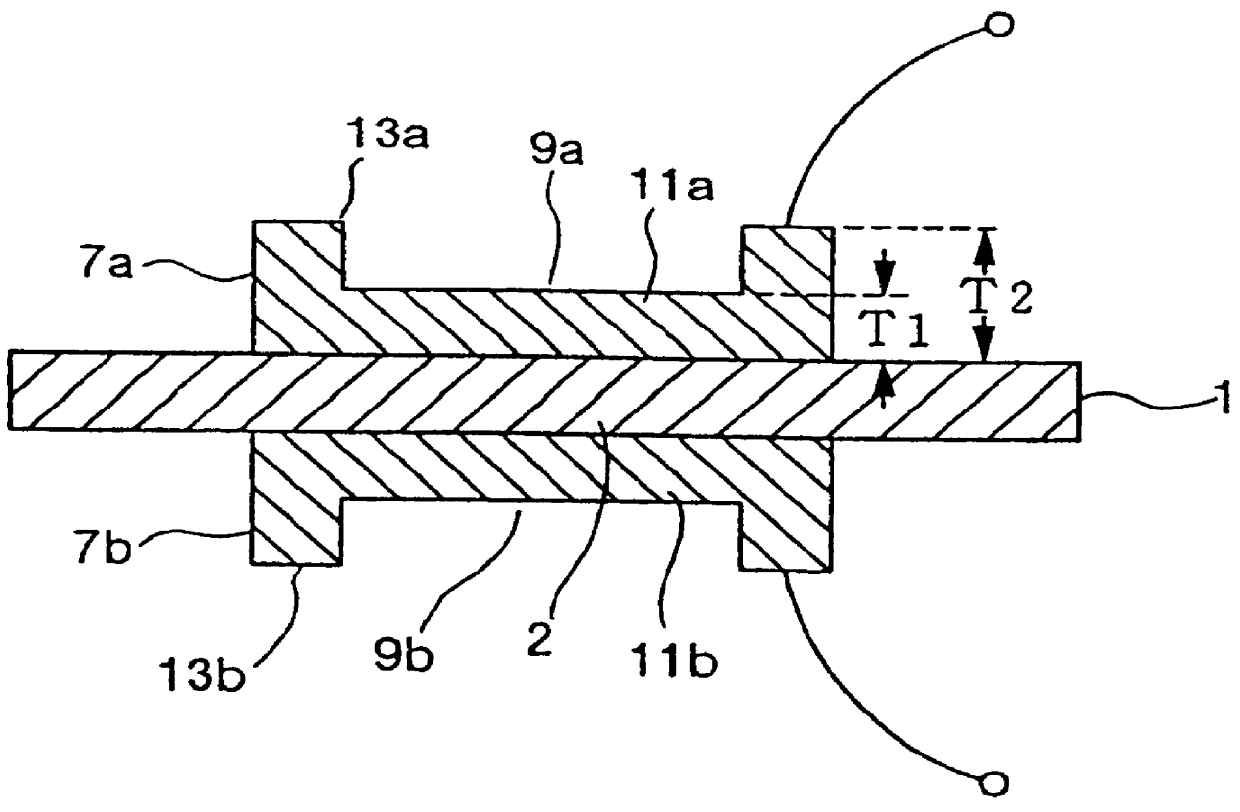

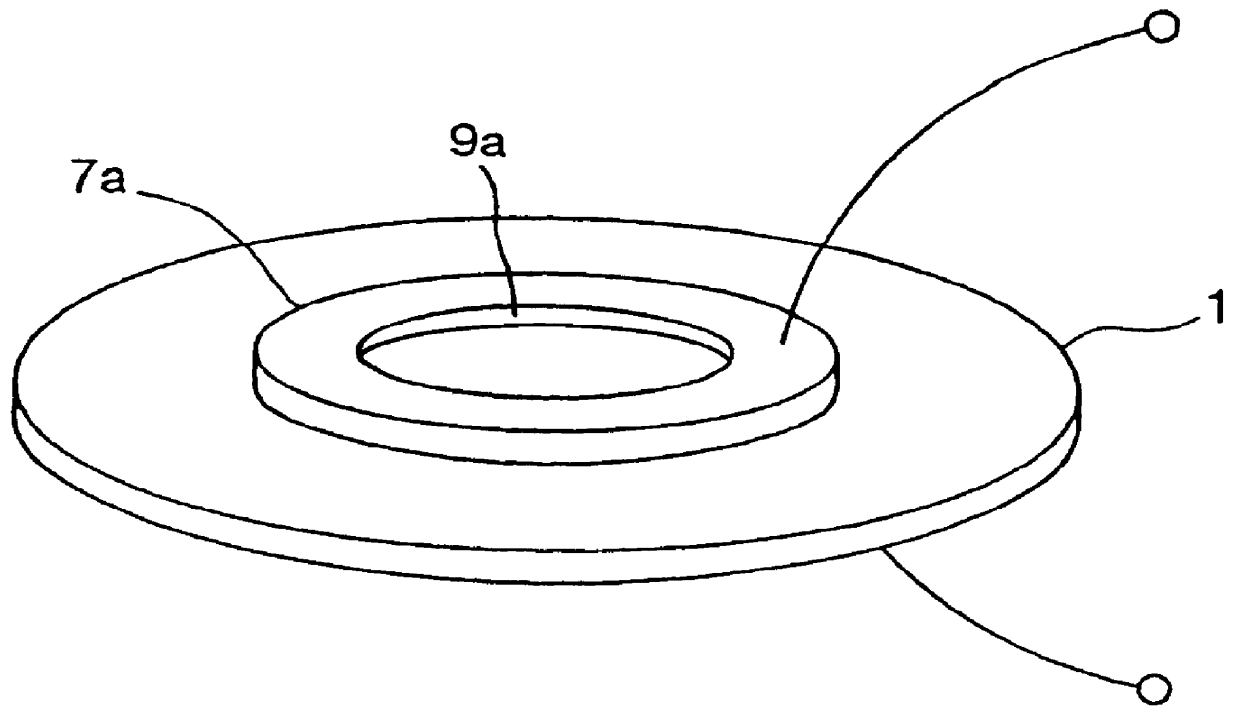

InactiveUS6111341APiezoelectric/electrostriction/magnetostriction machinesImpedence networksCapacitanceLimit value

PCT No. PCT / JP97 / 03807 Sec. 371 Date Dec. 21, 1998 Sec. 102(e) Date Dec. 21, 1998 PCT Filed Oct. 22, 1997 PCT Pub. No. WO98 / 38736 PCT Pub. Date Sep. 3, 1998In a piezoelectric vibrator which has excitation electrodes respectively disposed on the top surface and undersurface of a piezoelectric substrate, at least one of the excitation electrodes being an inverted-mesa electrode that has a recess formed in the opposite side of the electrode from the side which contacts the piezoelectric substrate. Thus, an AT-cut quartz resonator in which the capacitance ratio gamma is reduced to a value below the limit value can be provided as a result of use of the inverted-mesa electrodes as excitation electrodes.

Owner:TOYO TSUSHINKI

Method for manufacturing composite piezoelectric substrate

ActiveUS20140173862A1Uniform thicknessMaterial efficiencyPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksImpurityNanotechnology

In a method for manufacturing a composite piezoelectric substrate, a piezoelectric substrate and a supporting substrate are prepared, ions are implanted from a surface of the piezoelectric substrate to form a defective layer at a predetermined depth, impurities adhered to the surface of the piezoelectric substrate in which the defective layer is formed and / or a surface of the supporting substrate are removed to directly expose the constituent atoms of the surfaces and activate the surfaces, the supporting substrate is bonded to the piezoelectric substrate to form a bonded substrate body, the bonded substrate body is separated at the defective layer so that a separation layer between the surface of the piezoelectric substrate and the defective layer is separated from the piezoelectric substrate and bonded to the supporting substrate to form a composite piezoelectric substrate, and the surface of the separation layer of the composite piezoelectric substrate is smoothed.

Owner:MURATA MFG CO LTD

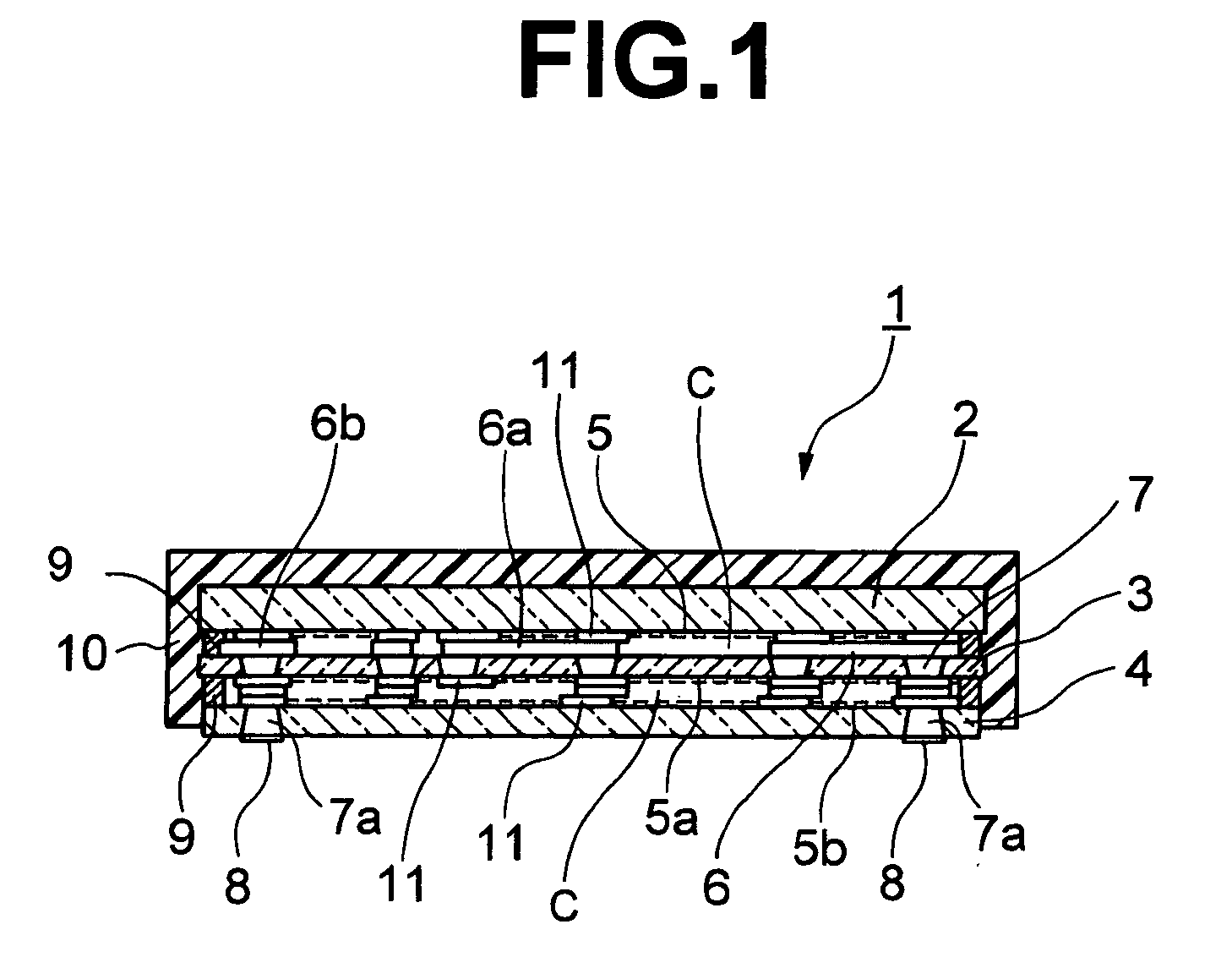

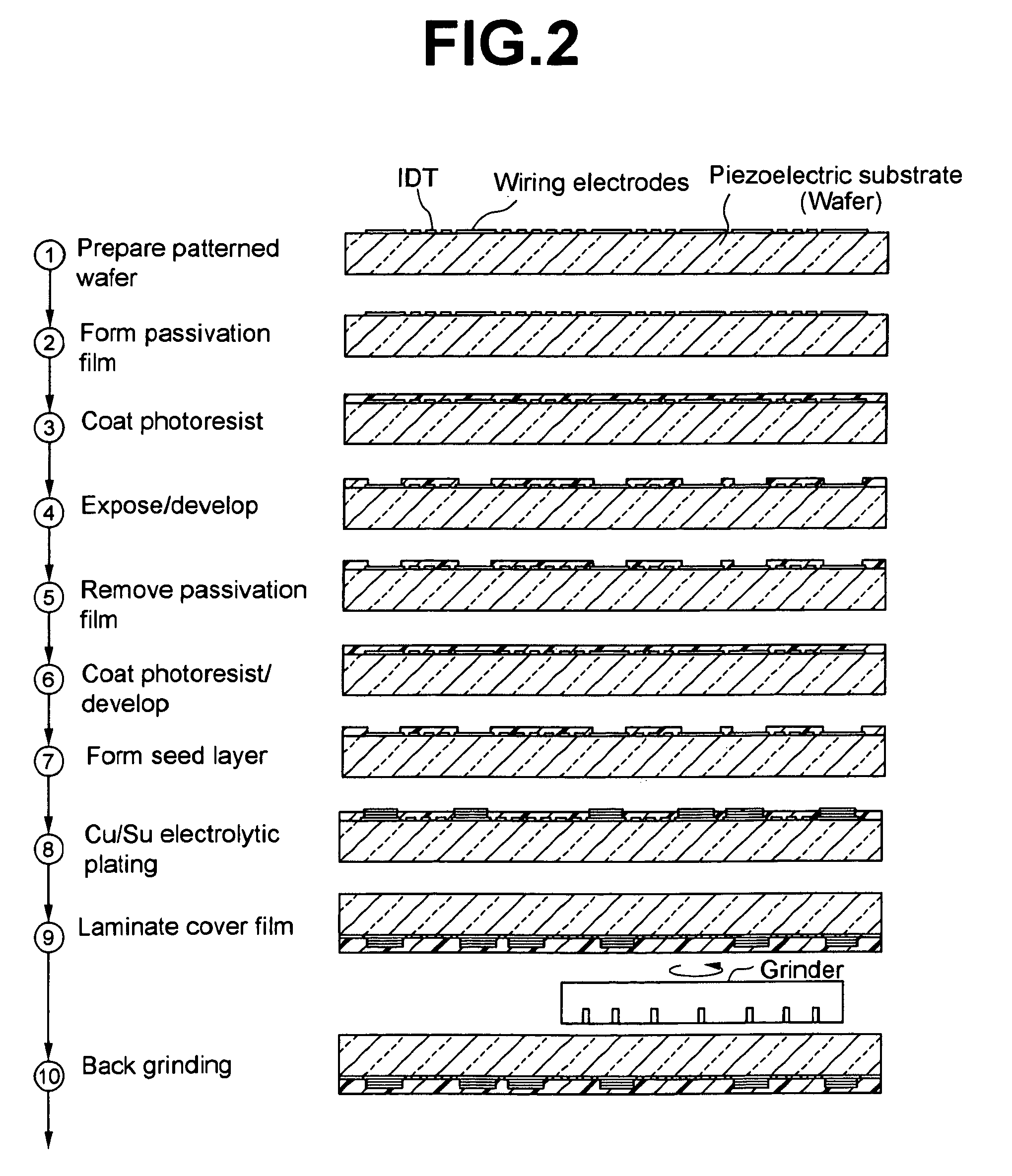

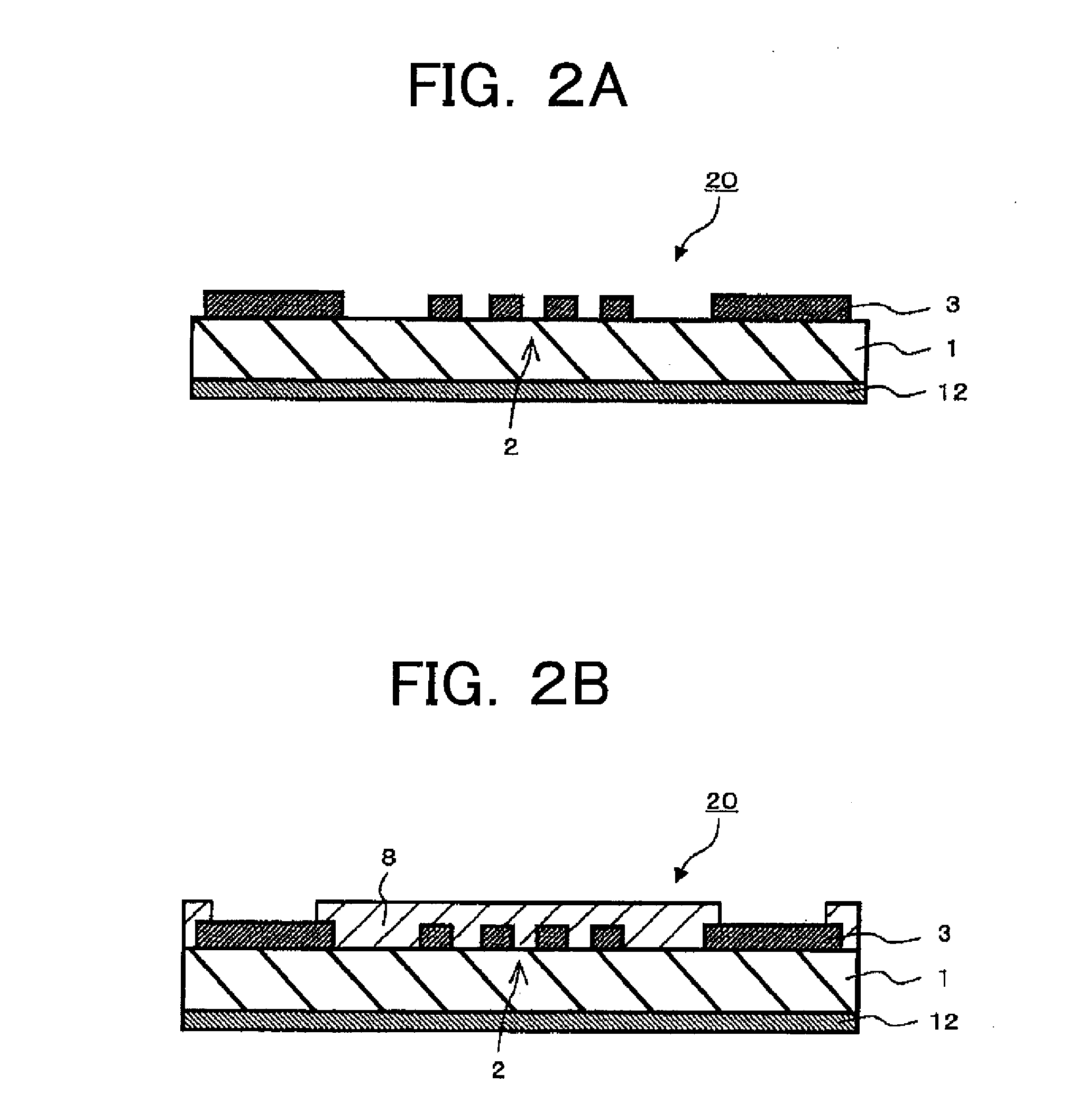

Method for Manufacturing Surface Acoustic Wave Apparatus

InactiveUS20100043189A1Simple manufacturing processEase of mass productionPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveEngineering

Provided is a method for manufacturing a surface acoustic wave apparatus that can reduce degradation of electric characteristics and also reduce the number of manufacturing processes. The method for manufacturing a surface acoustic wave apparatus includes the steps of: forming an IDT electrode on an upper surface of a piezoelectric substrate, forming a frame member surrounding a formation area in which the IDT electrode is formed on the piezoelectric substrate, and mounting a film-shaped lid member on the upper surface of the frame member so as to be joined to the frame member so that a protective cover, used for covering the formation area and for providing a tightly-closed space between it and the formation area, is formed.

Owner:KYOCERA CORP

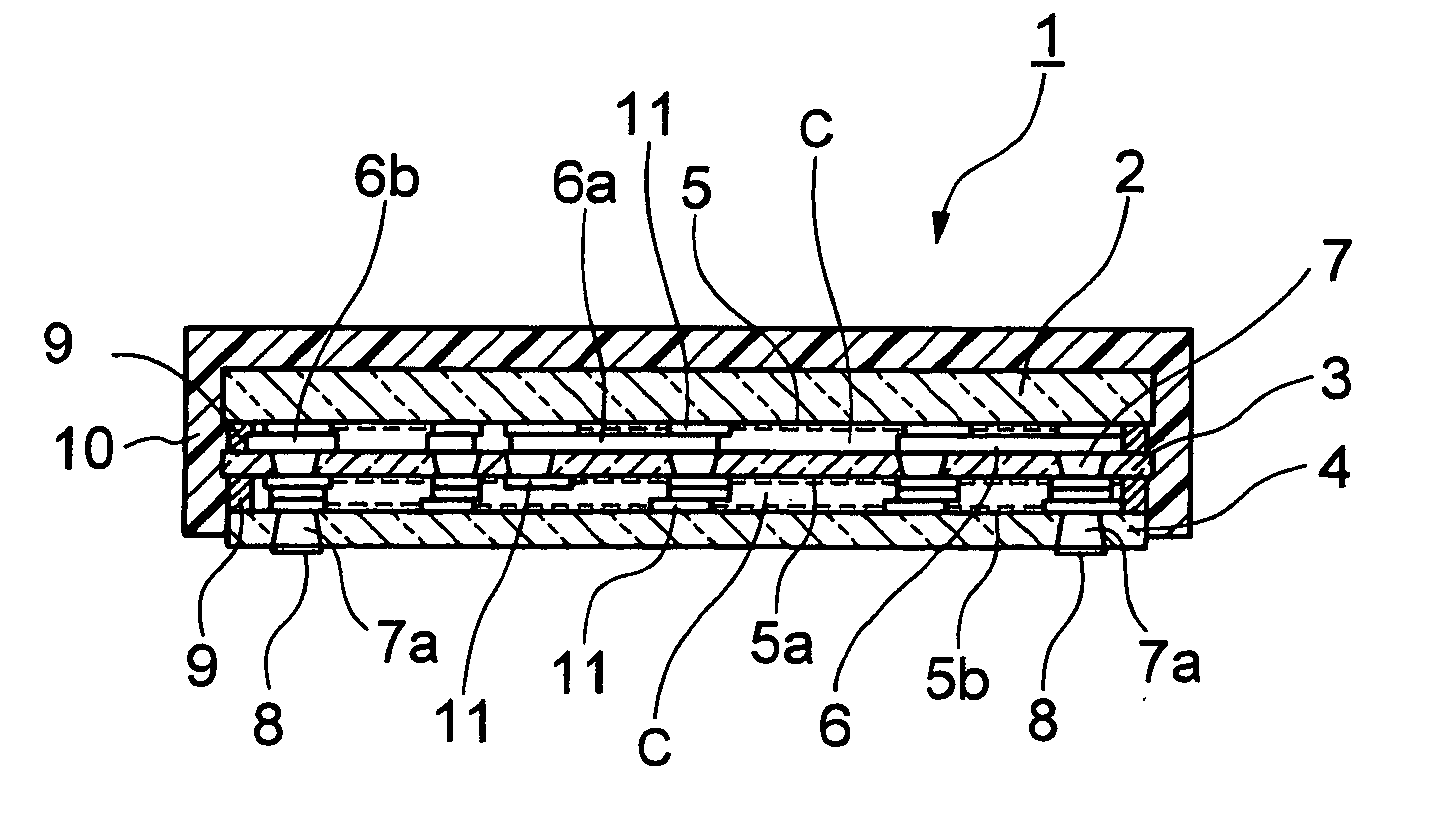

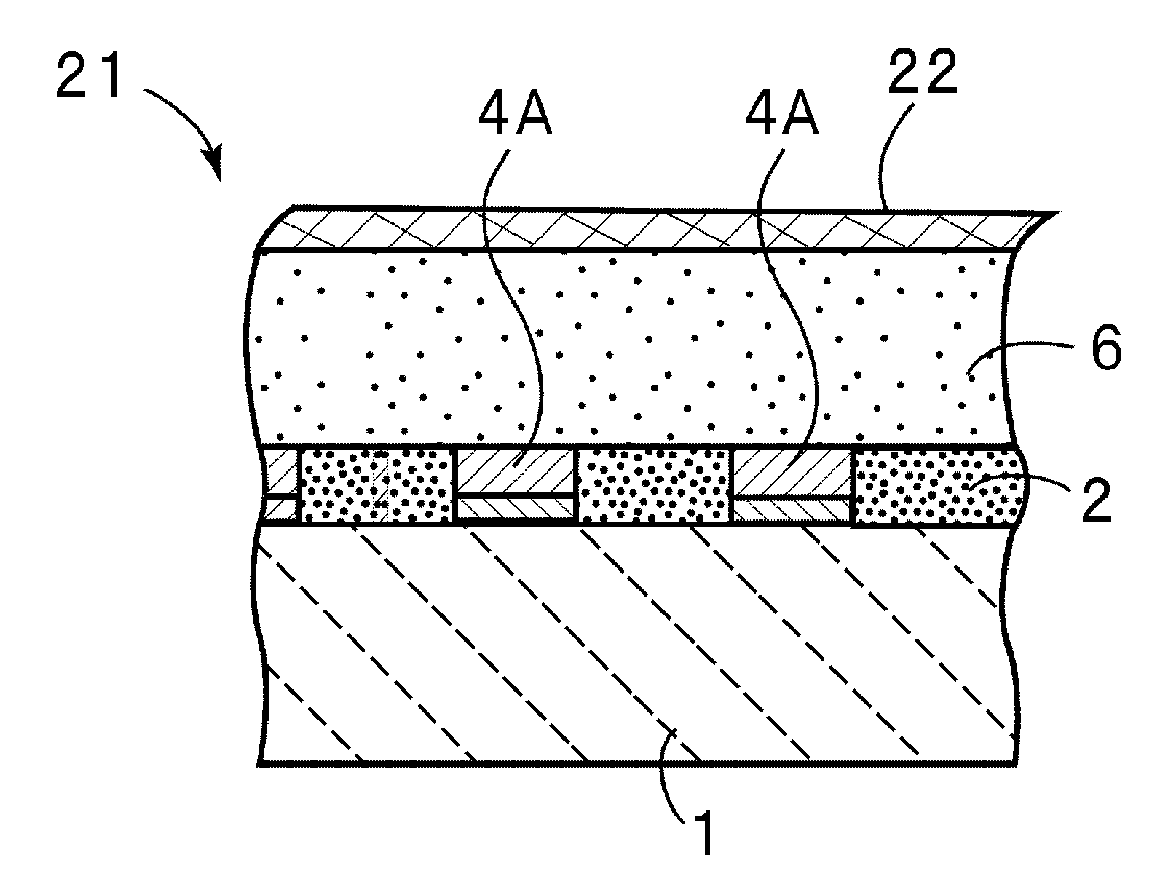

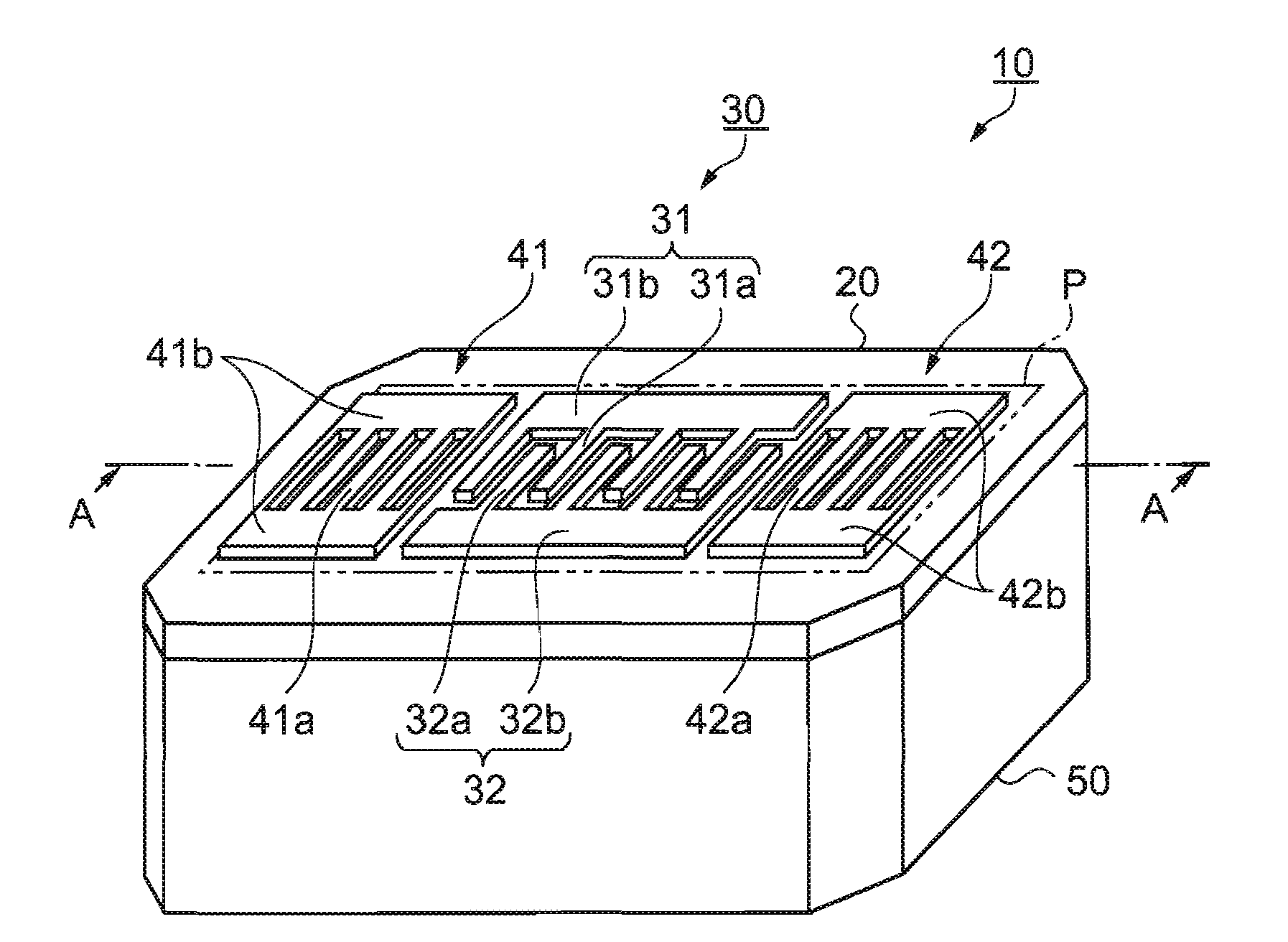

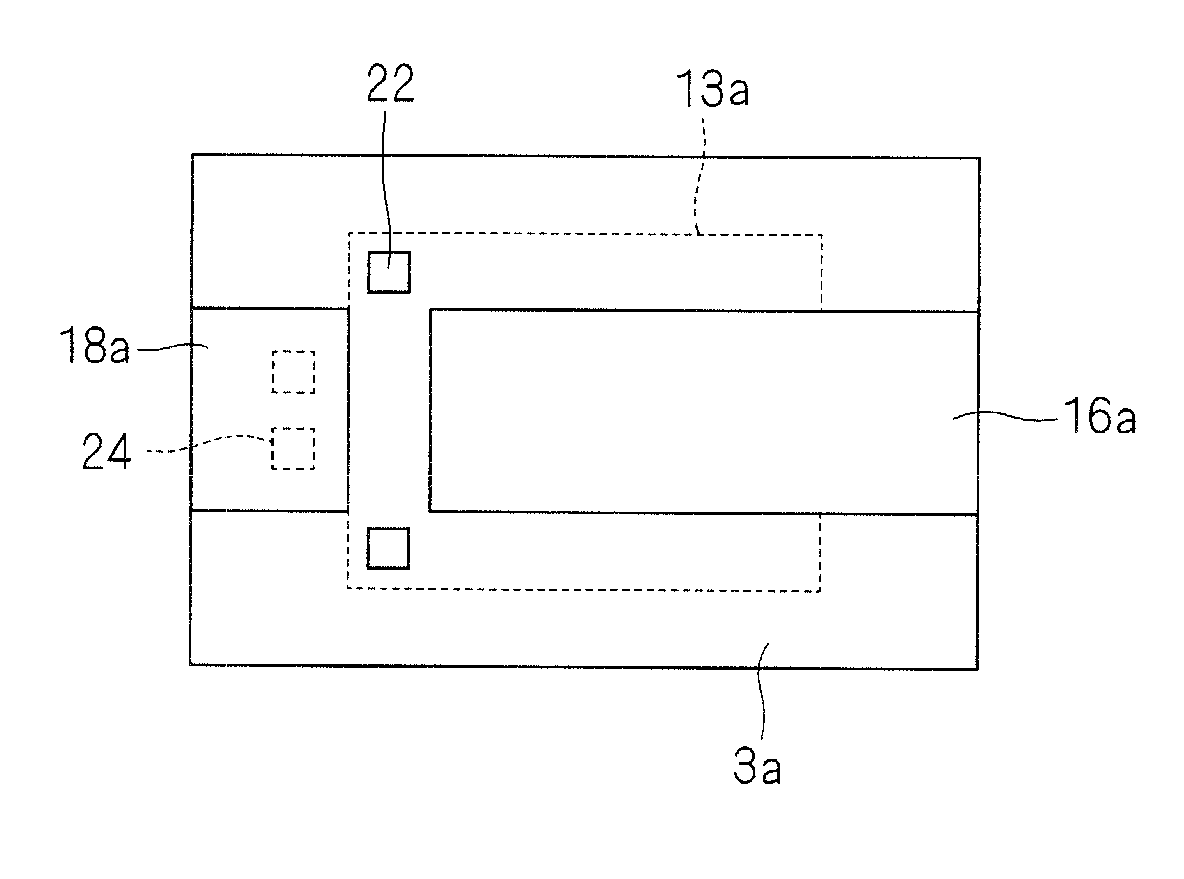

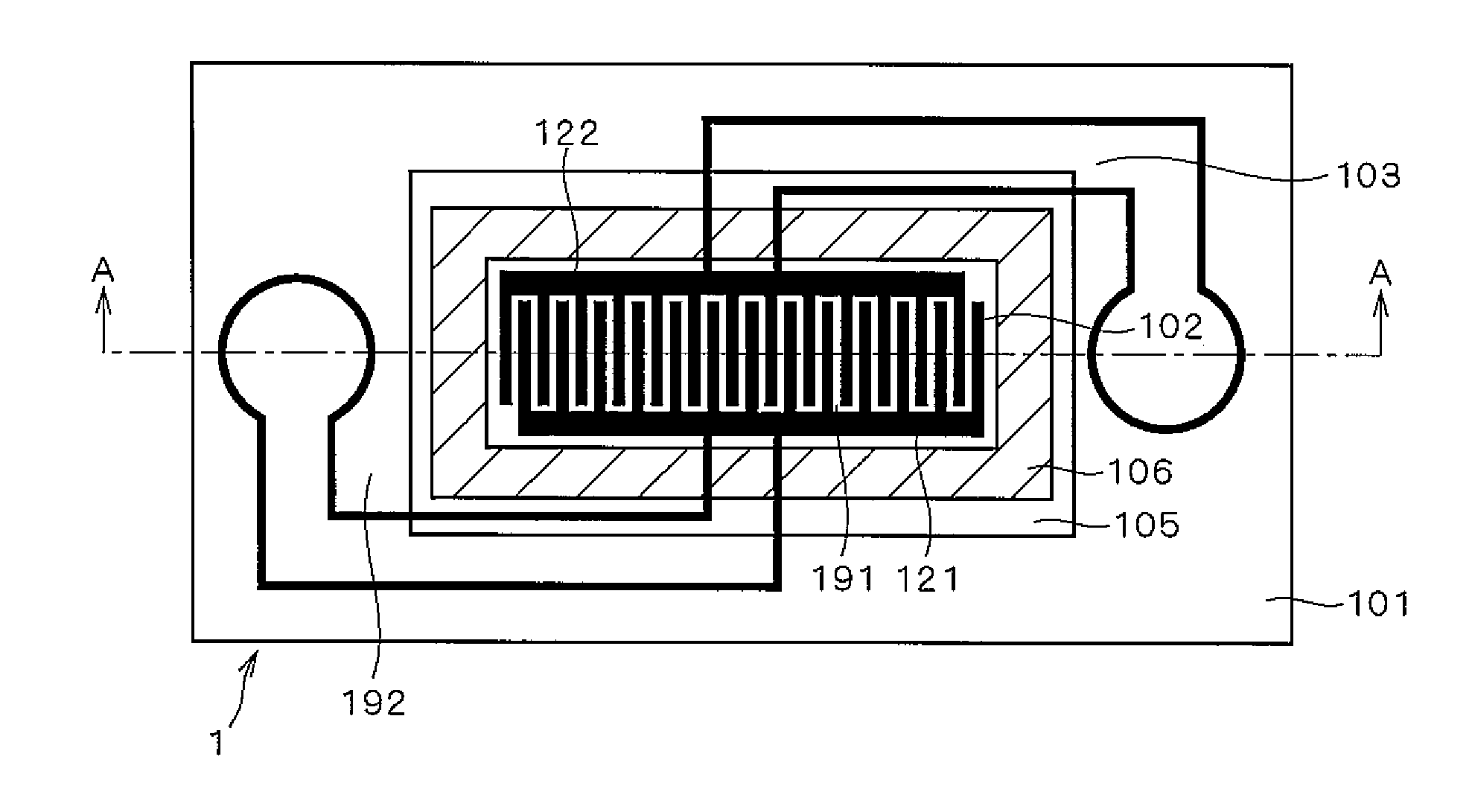

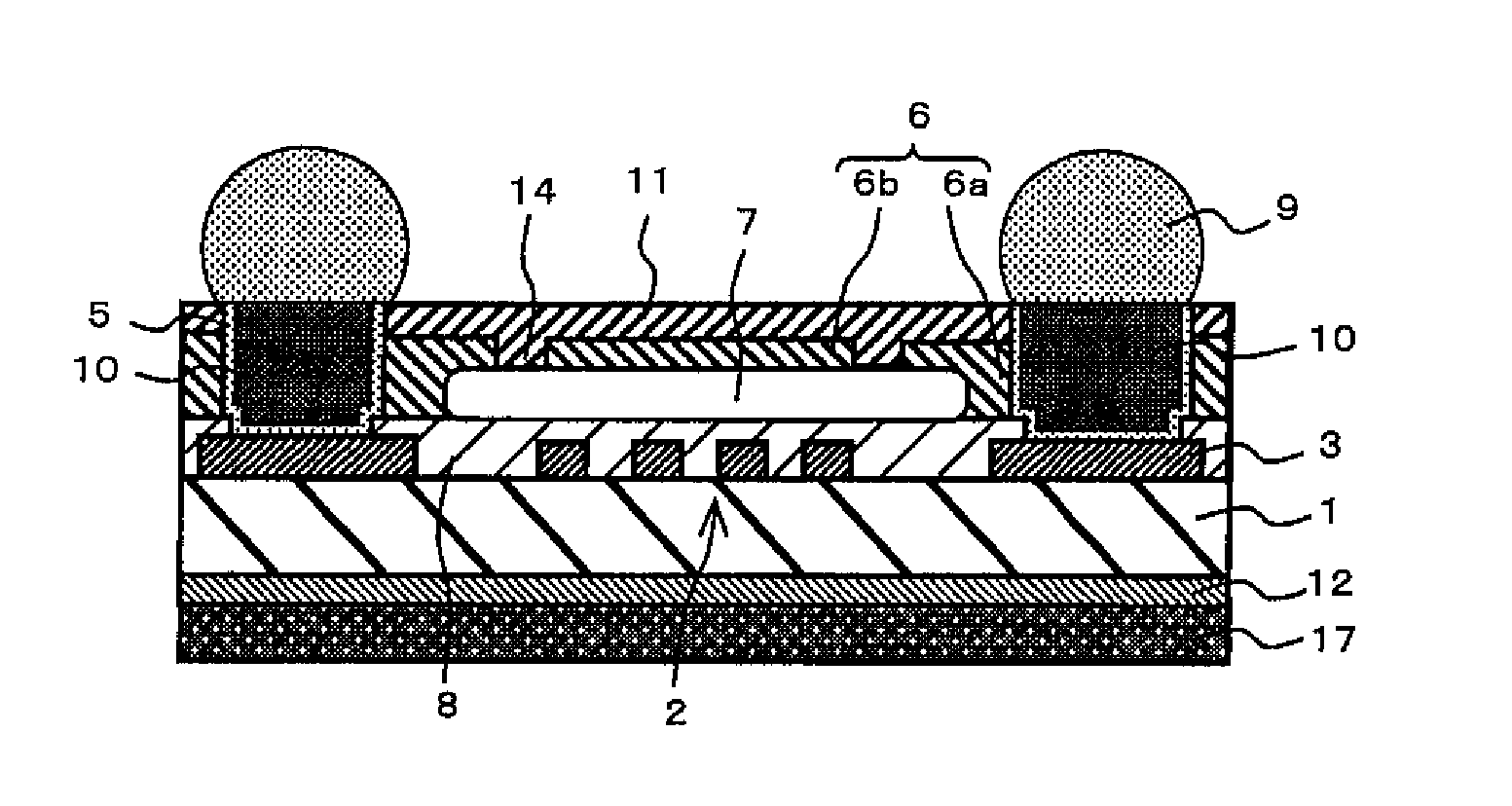

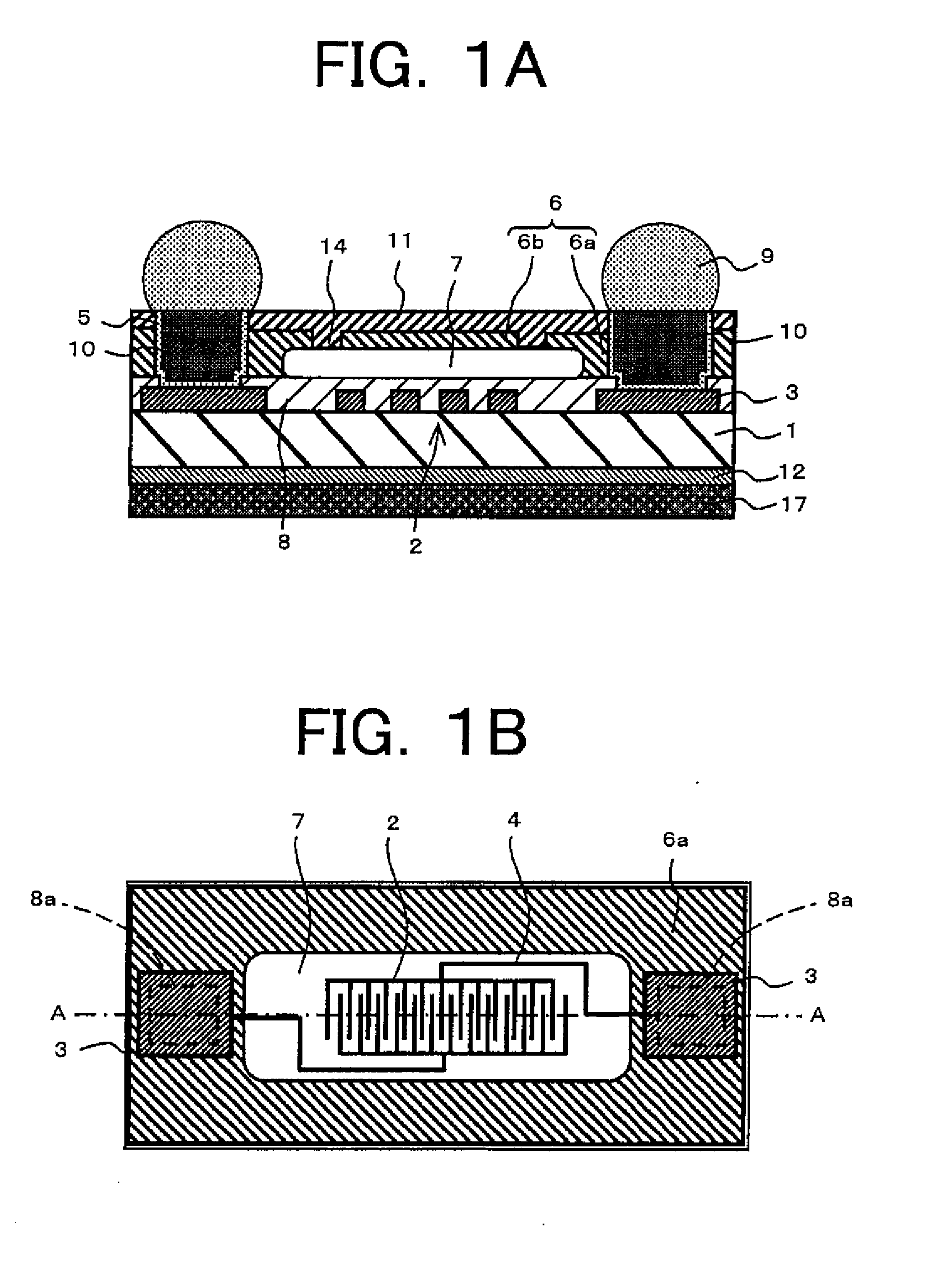

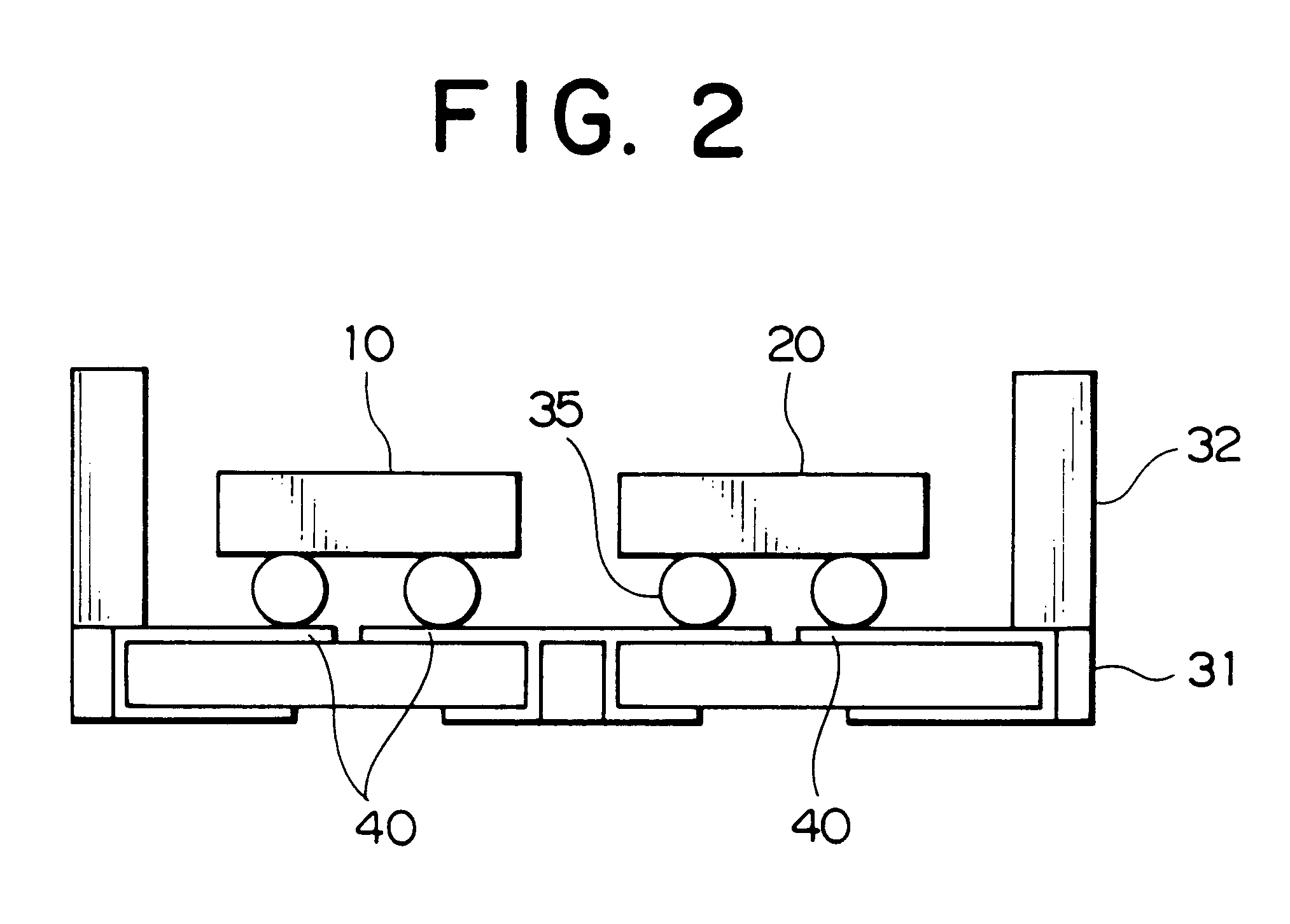

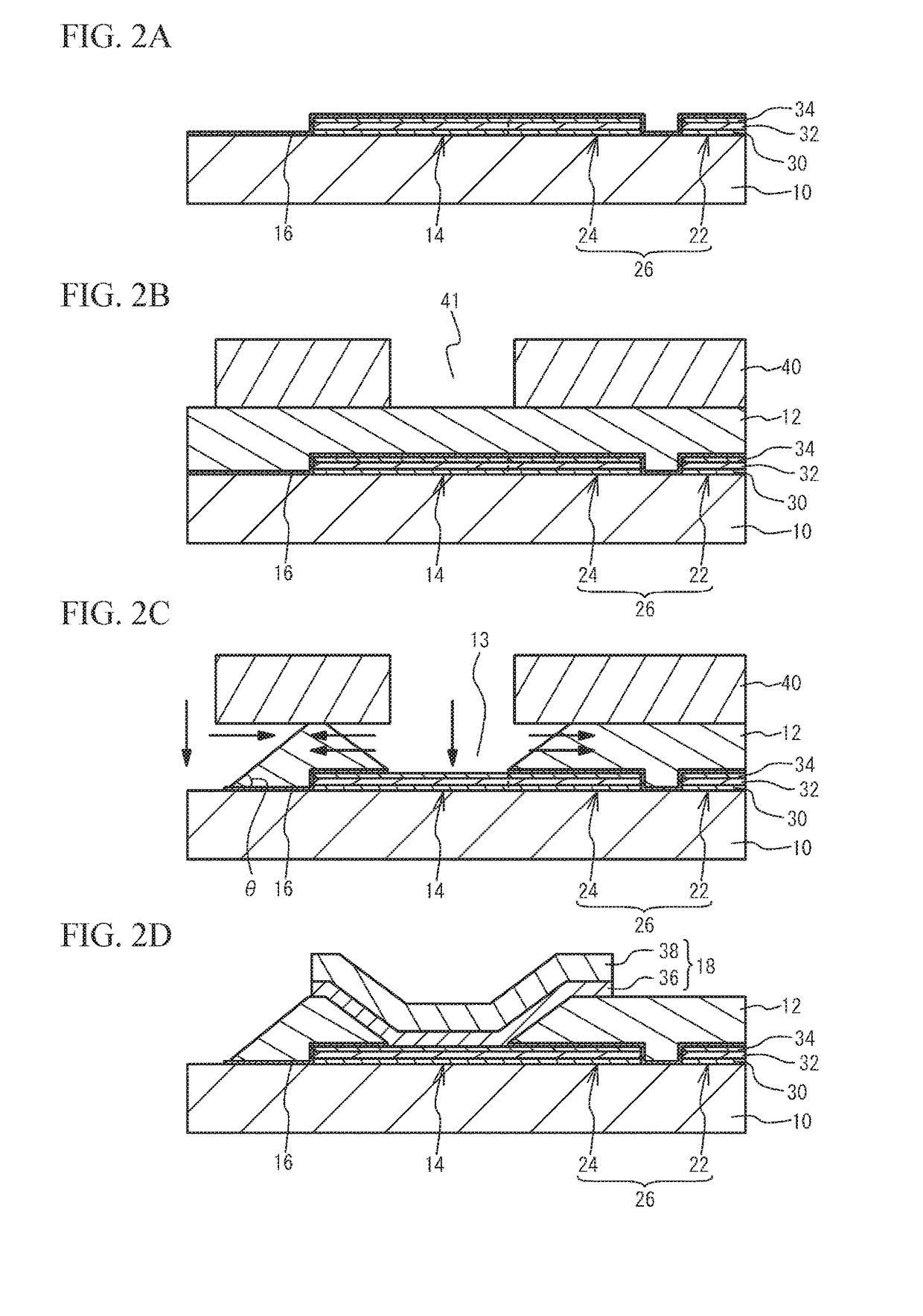

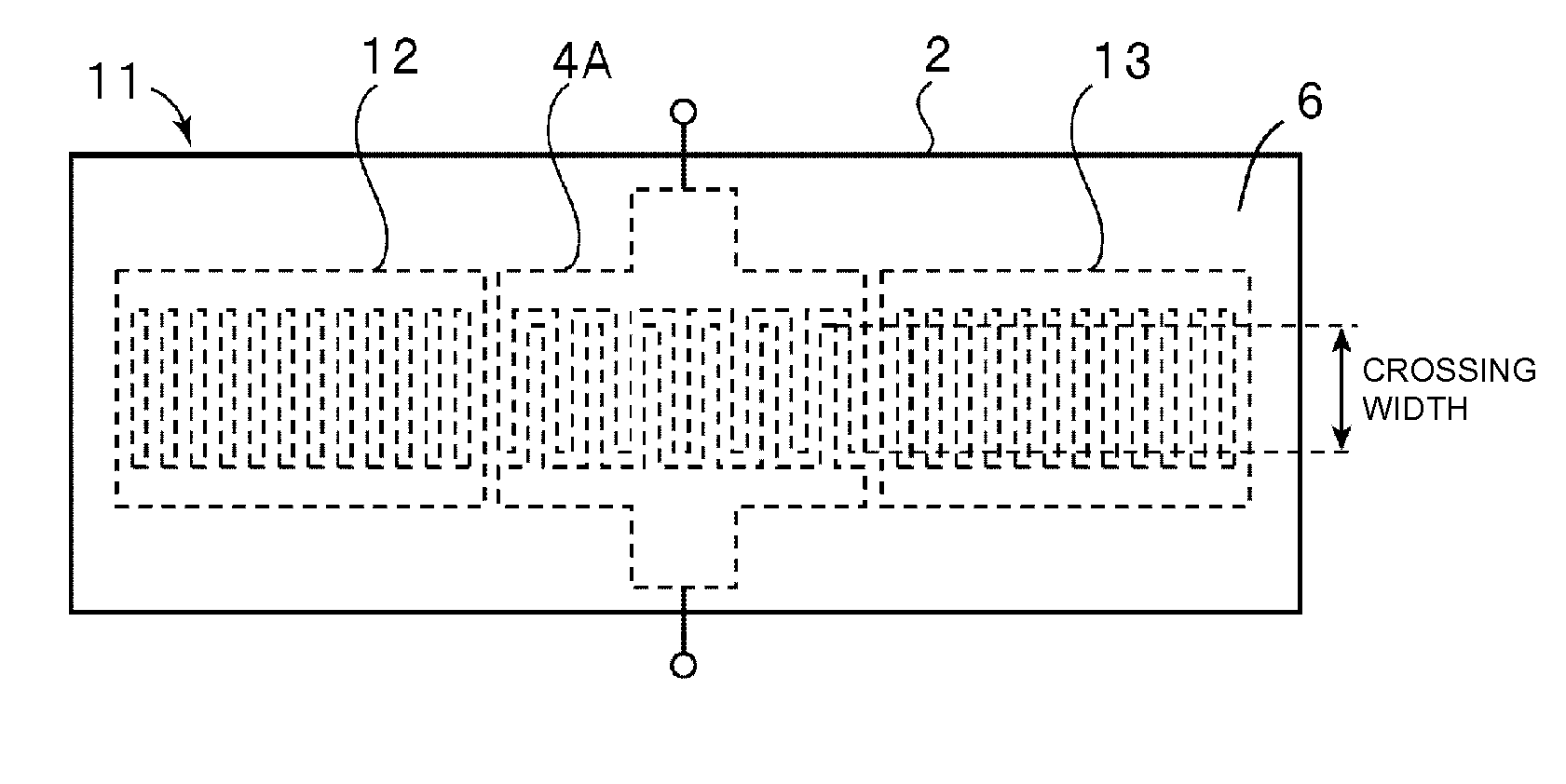

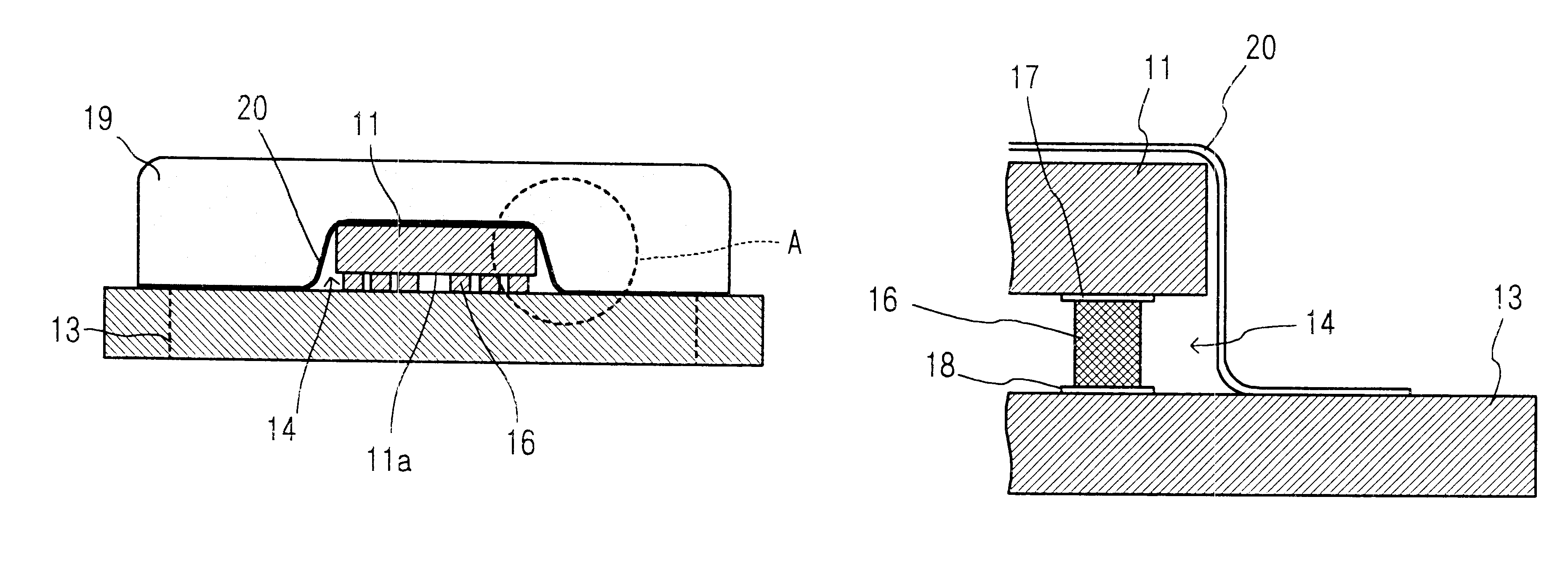

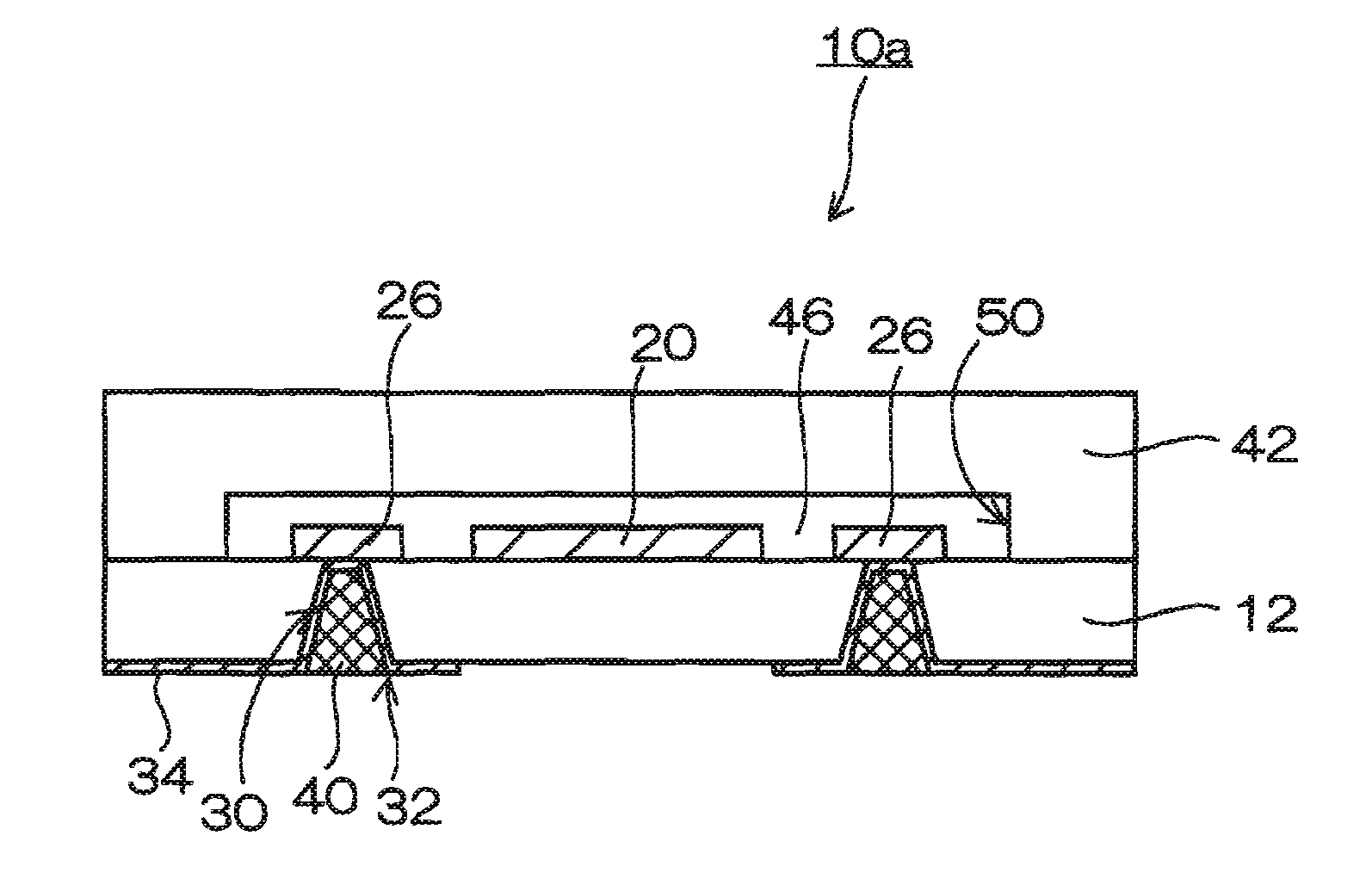

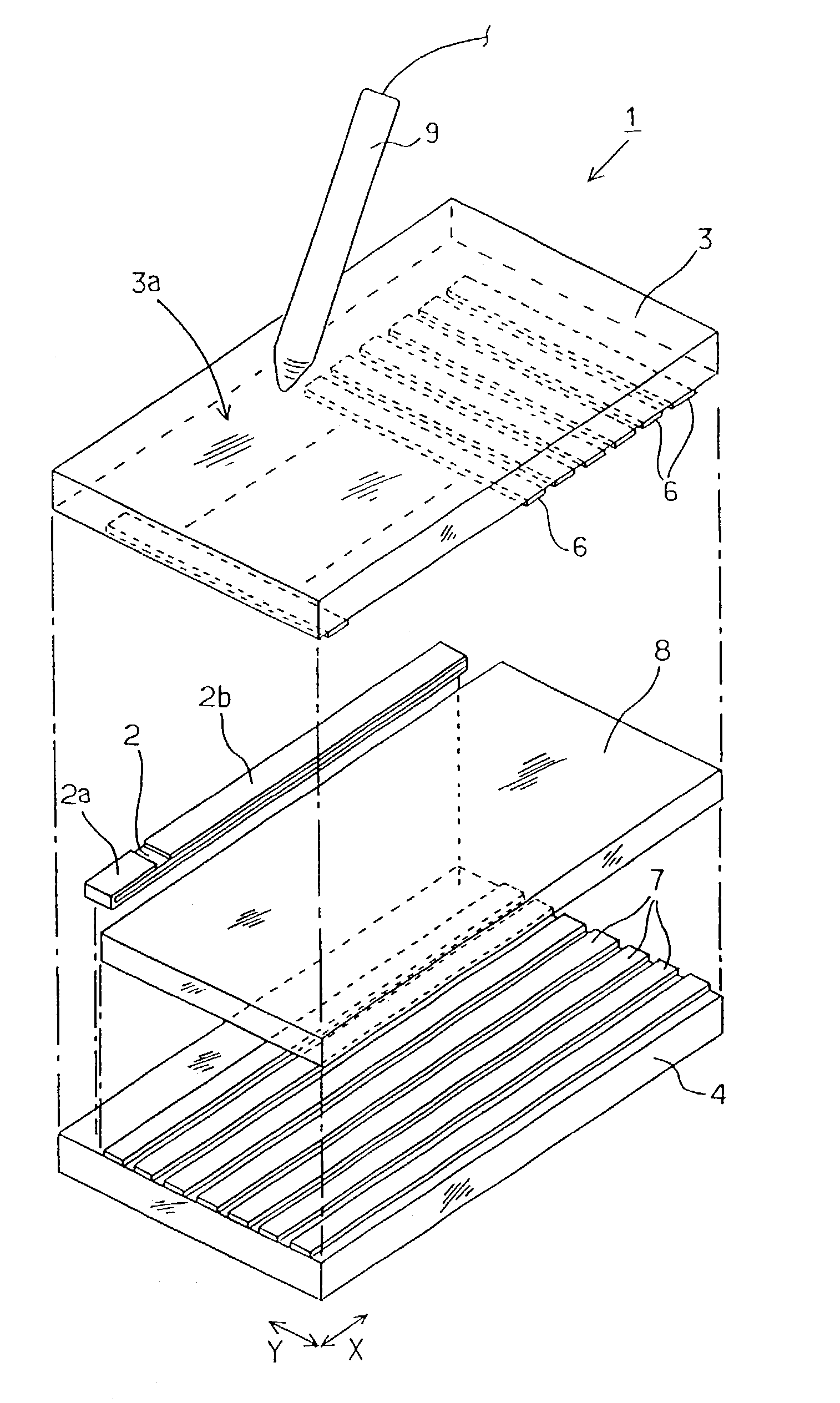

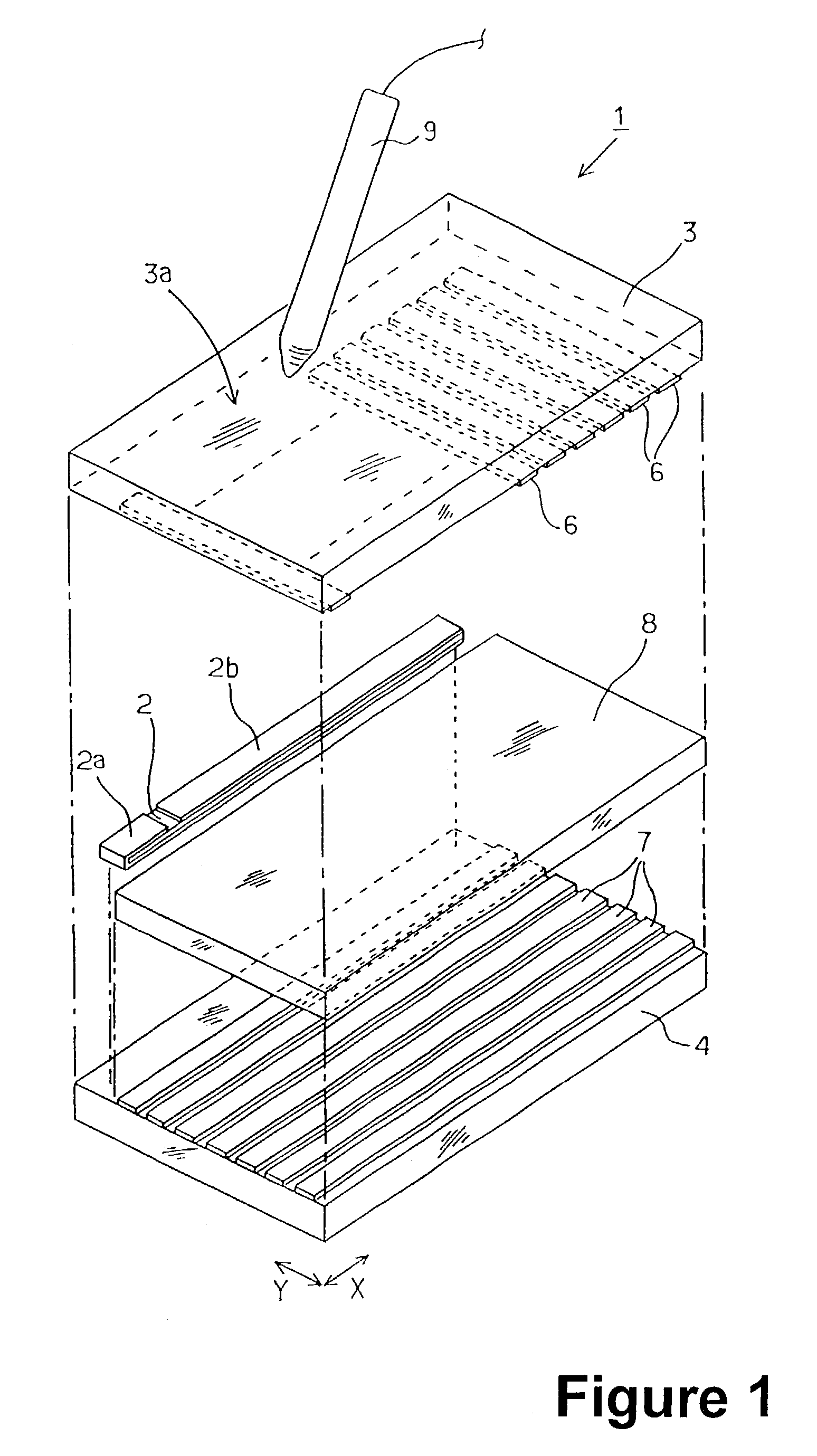

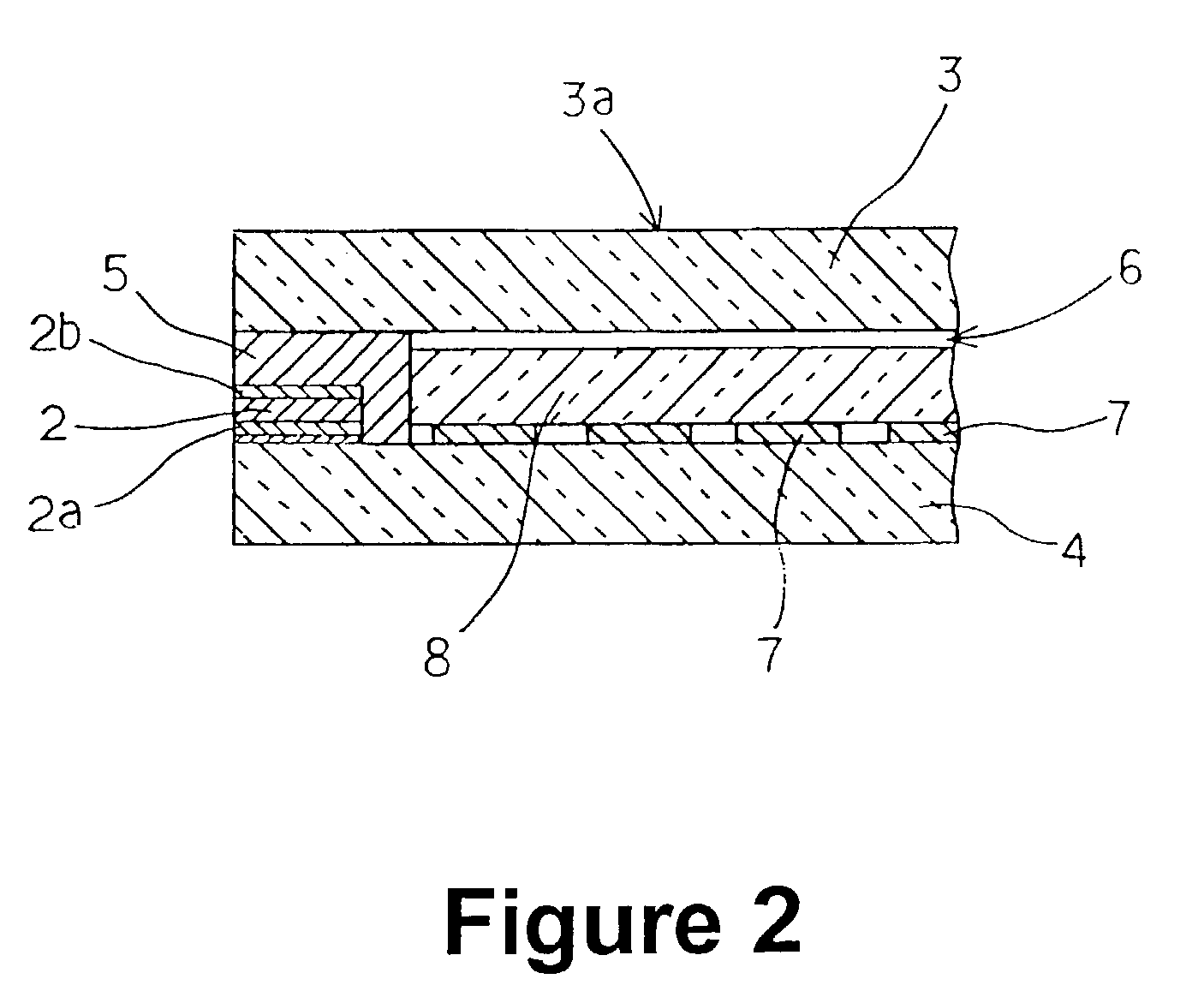

Acoustic Wave Device and Method for Production of Same

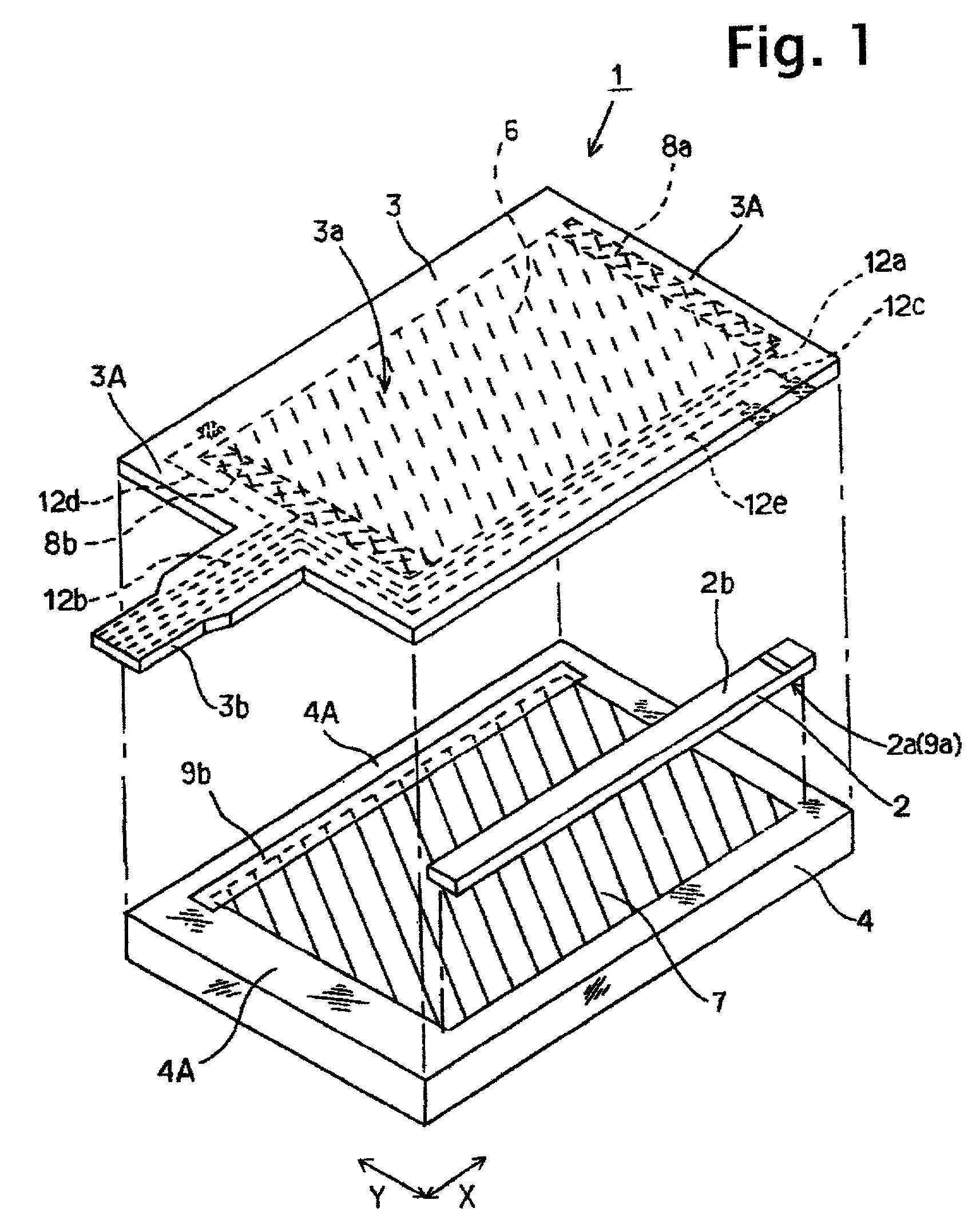

ActiveUS20110018389A1Stably keep tight sealImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorAcoustic wave

A small and highly reliable acoustic wave device and a method for production of the same will be provided. The acoustic wave device has a piezoelectric substrate 1; a SAW element 2 on one main surface of the piezoelectric substrate 1; an outside connection-use conductor 3 formed on the one main surface of the piezoelectric substrate 1 and electrically connected to the SAW element 2; a columnar electrode 10 on the outside connection-use conductor 3; and a protective cover 6 defining inner walls of a vibration space 7 for vibration of the SAW element 2 and planarly surrounding a side surface of the columnar electrode 10.

Owner:KYOCERA CORP

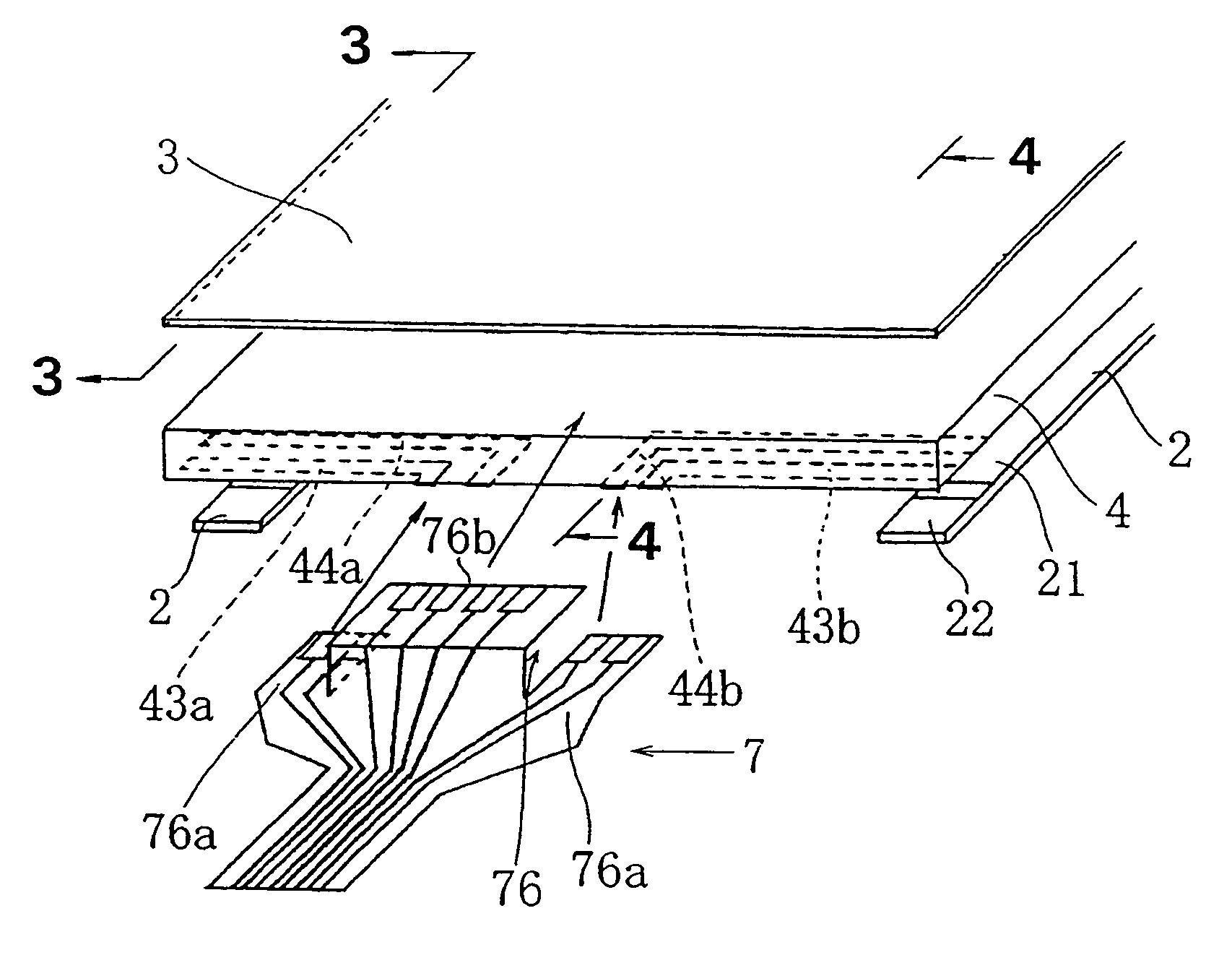

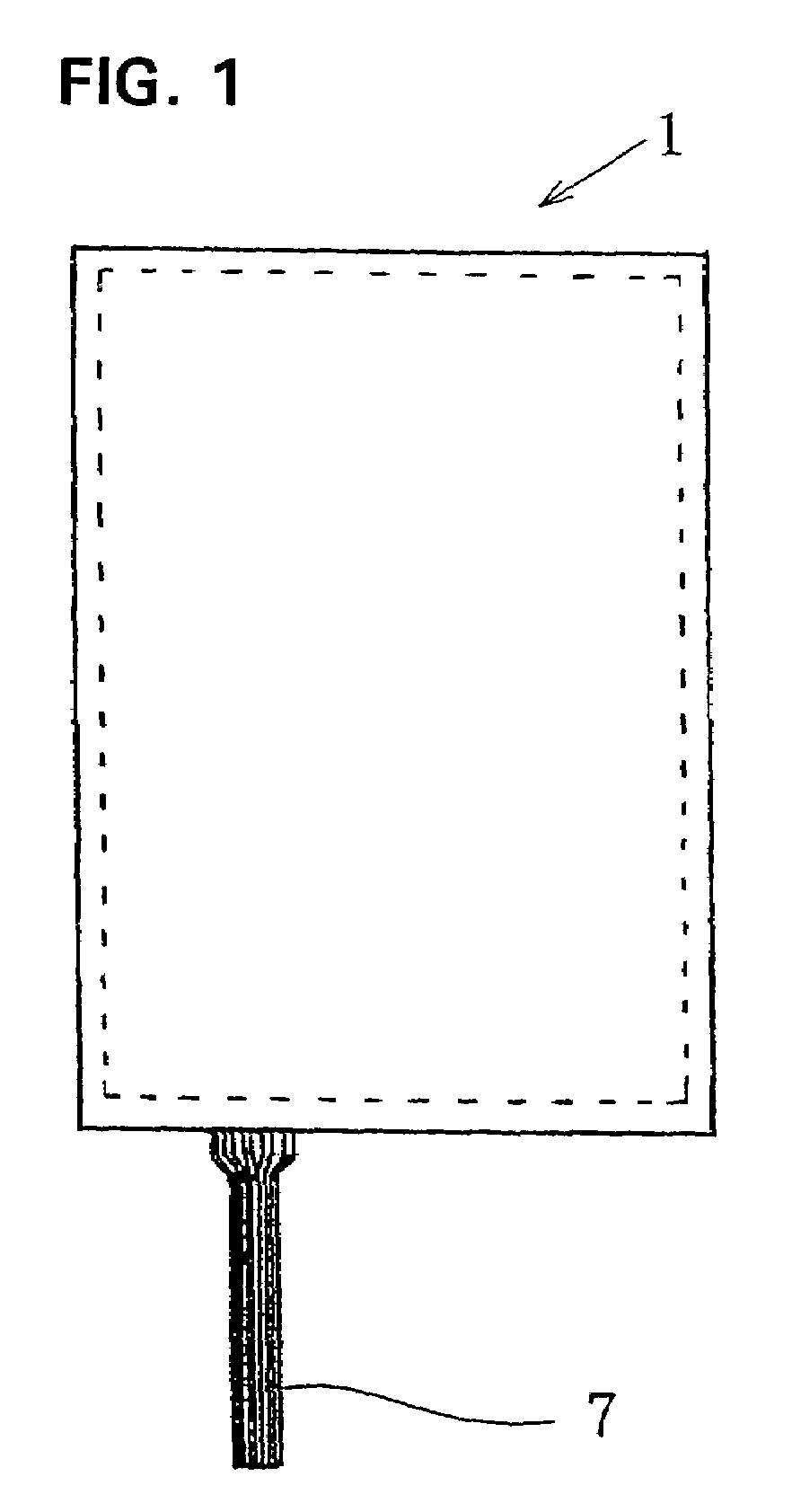

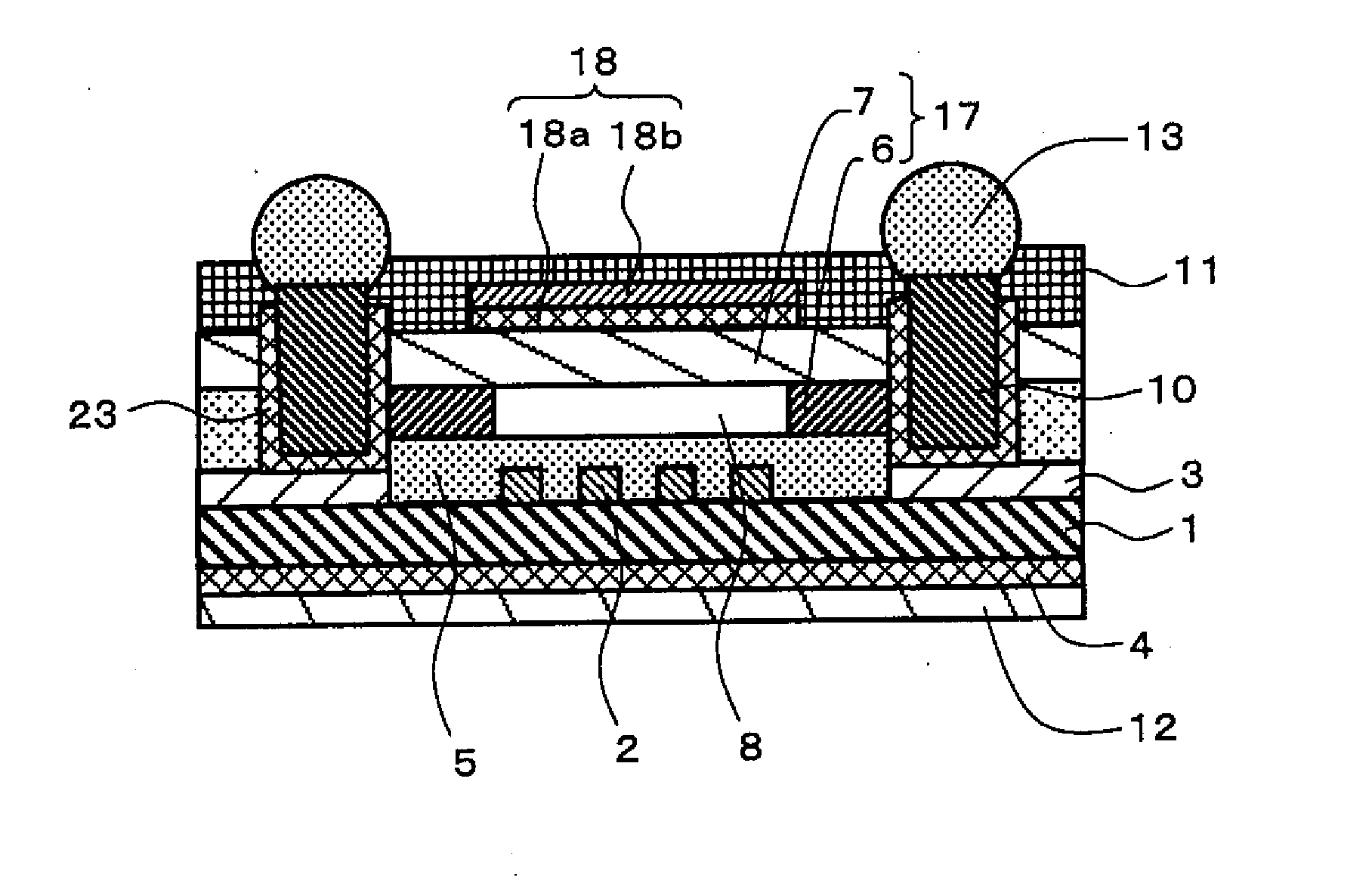

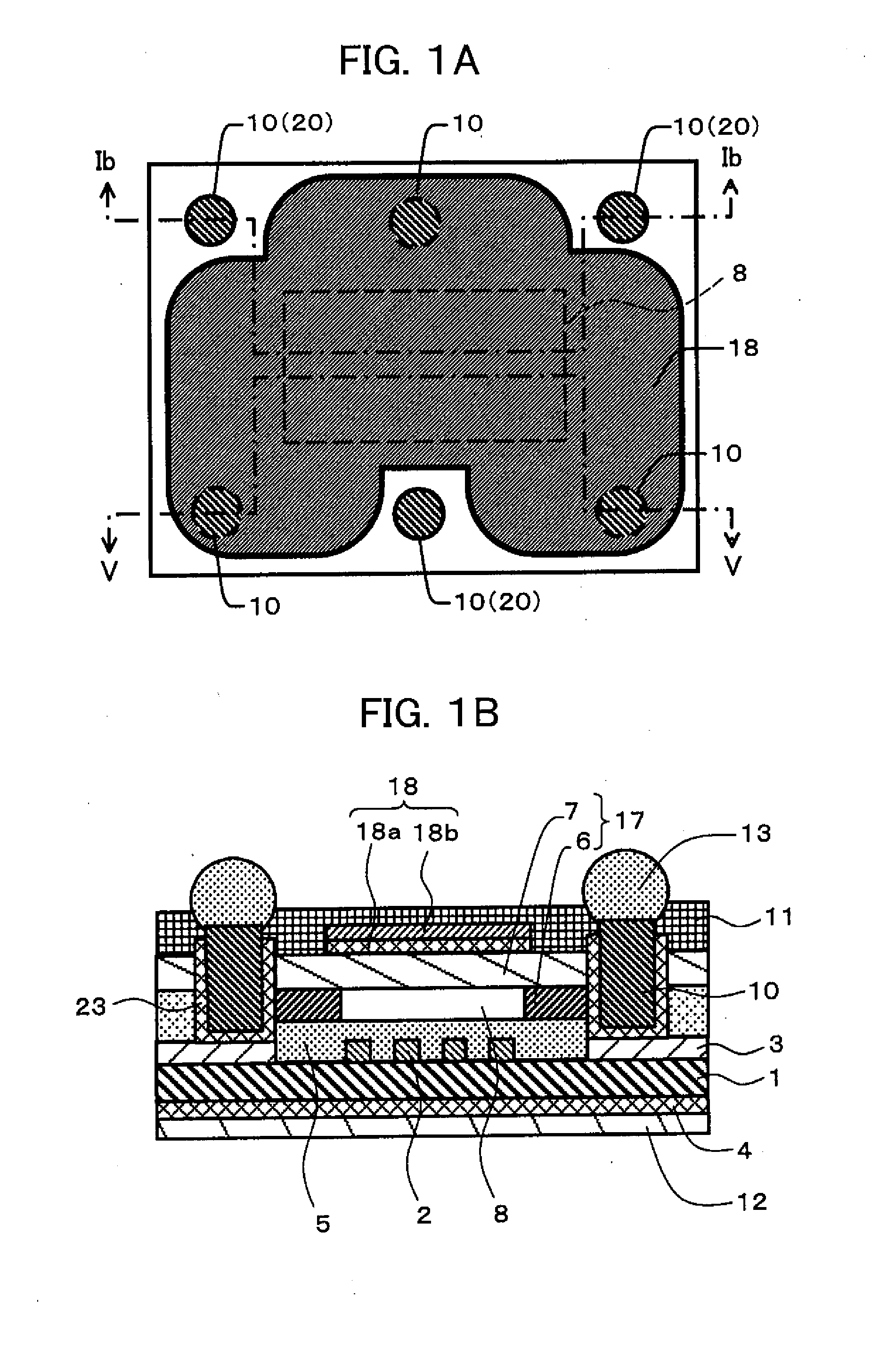

Touch panel

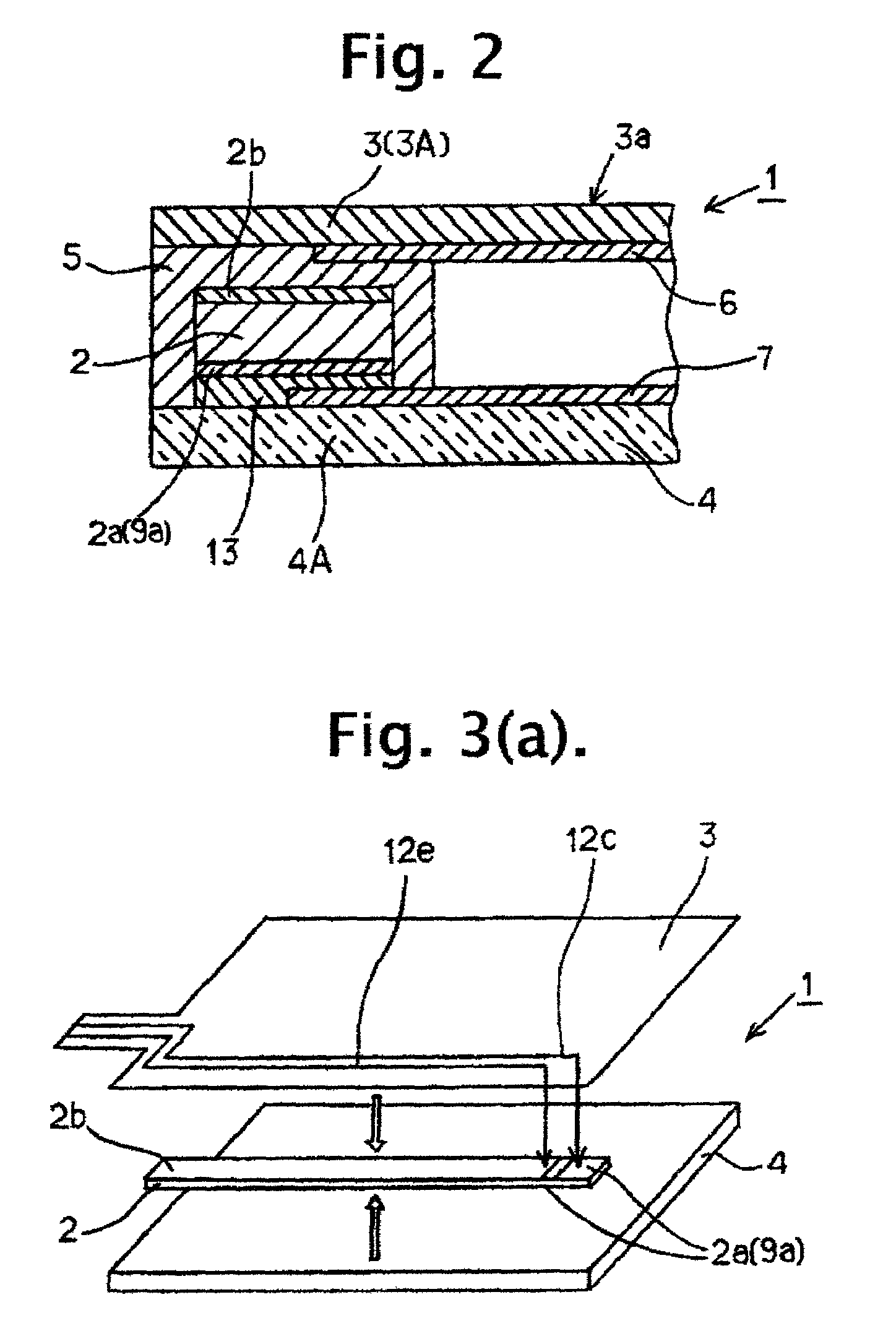

InactiveUS7227537B2Reduce weightSmall sizeInput/output for user-computer interactionCathode-ray tube indicatorsTouchpadEngineering

A touch panel of the present invention in which a piezoelectric substrate is fixed to a movable plate or a supporting substrate has a reduced weight, size, and thickness by providing simpler wiring. The touch panel comprises: a movable plate having an input manipulation surface; a supporting substrate, disposed with a slight insulation gap from the movable plate, for supporting the movable plate from a back surface thereof; conductive layers on the movable plate and the supporting substrate on their respective opposing surfaces; and a piezoelectric substrate fixed to the movable plate or the supporting substrate. A pair of driving electrodes on the piezoelectric substrate are fixed to respective opposing surfaces of the piezoelectric substrate. A conductive layer electrode of the movable plate, a conductive layer electrode of the supporting substrate, and the pair of driving electrodes of the piezoelectric substrate are withdrawn integrally using a single connector tail.

Owner:SMK CORP

Lamb wave type frequency device and method thereof

InactiveUS20100064492A1Stable resonance propertyImprove structural strengthPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksType frequencyAcoustics

A Lamb wave type high frequency device comprises: a piezoelectric substrate; an interdigital transducer (IDT) electrode formed on a first main surface of the piezoelectric substrate; a reinforcing substrate connected to a second main surface of the piezoelectric substrate; a space portion formed in one of the piezoelectric substrate and the reinforcing substrate, an area of the space portion being larger than a region in which a Lamb wave is propagated; and a connecting surface formed in a periphery of the space portion.

Owner:SEIKO EPSON CORP

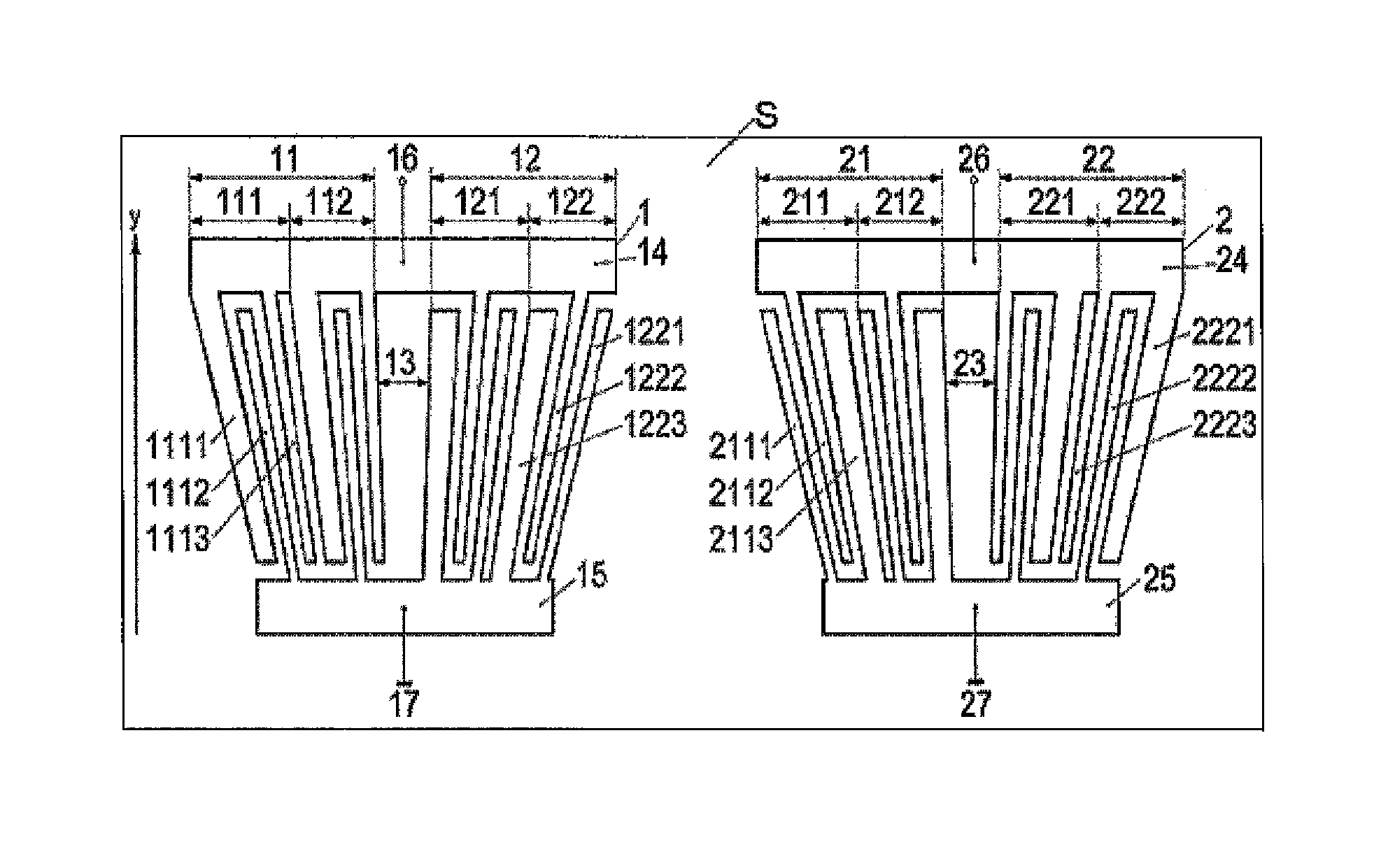

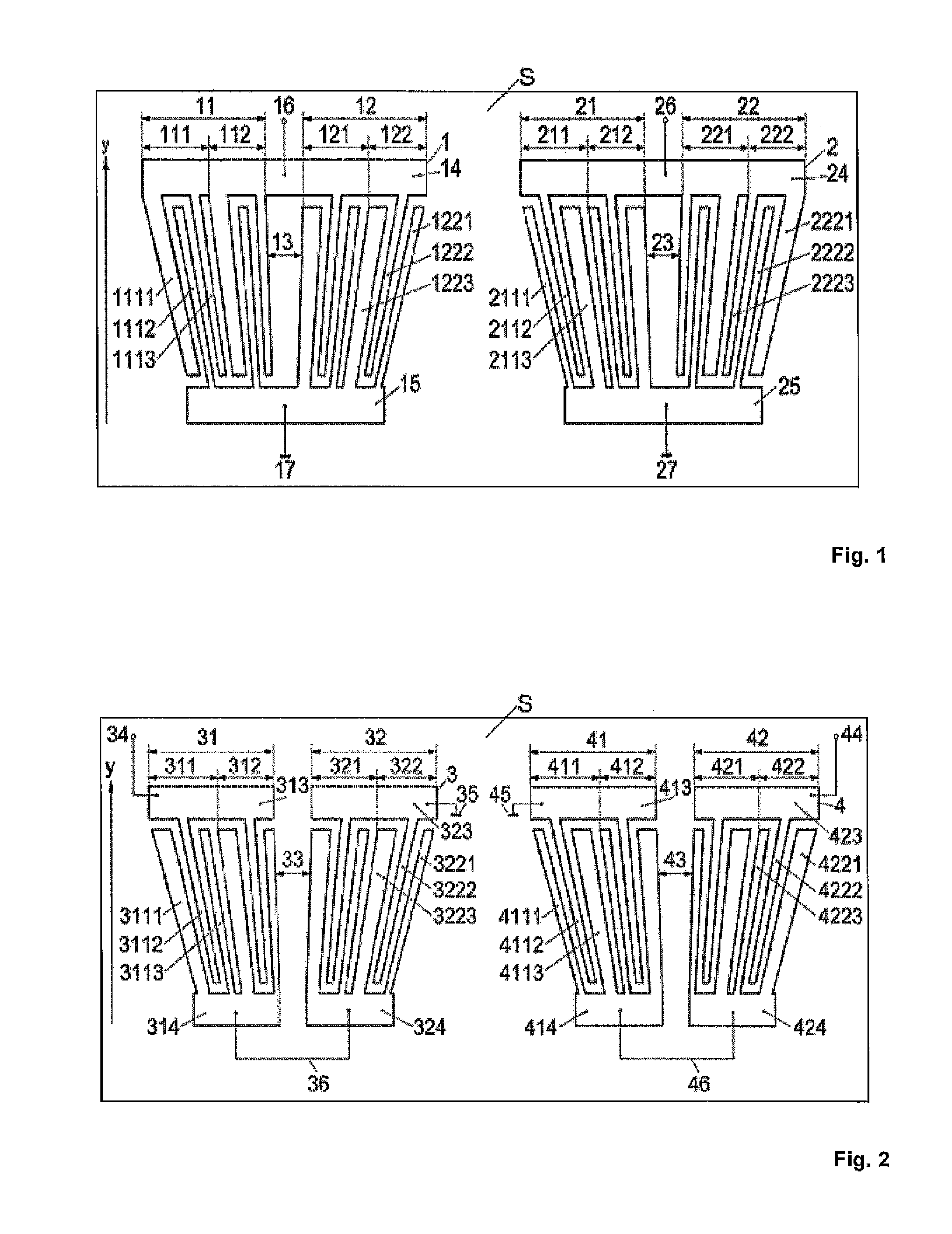

Surface acoustic wave component

InactiveUS9130145B2Maintain good propertiesImpedence networksPiezoelectric/electrostrictive/magnetostrictive devicesInterdigital transducerPiezoelectric substrate

A surface acoustic wave component contains two fan-shaped interdigital transducers disposed on a piezoelectric substrate, the prongs and gaps of which transducers forming groups having the same length, called cells, between them, and narrow in the averaged prong direction. The cells are structured like cells of unidirectional transducers, and at least one of the fan-shaped interdigital transducers is composed of partial transducers. The partial transducers are disposed one behind the other, perpendicular to the averaged prong direction.

Owner:MICROCHIP FREQUENCY TECH GMBH

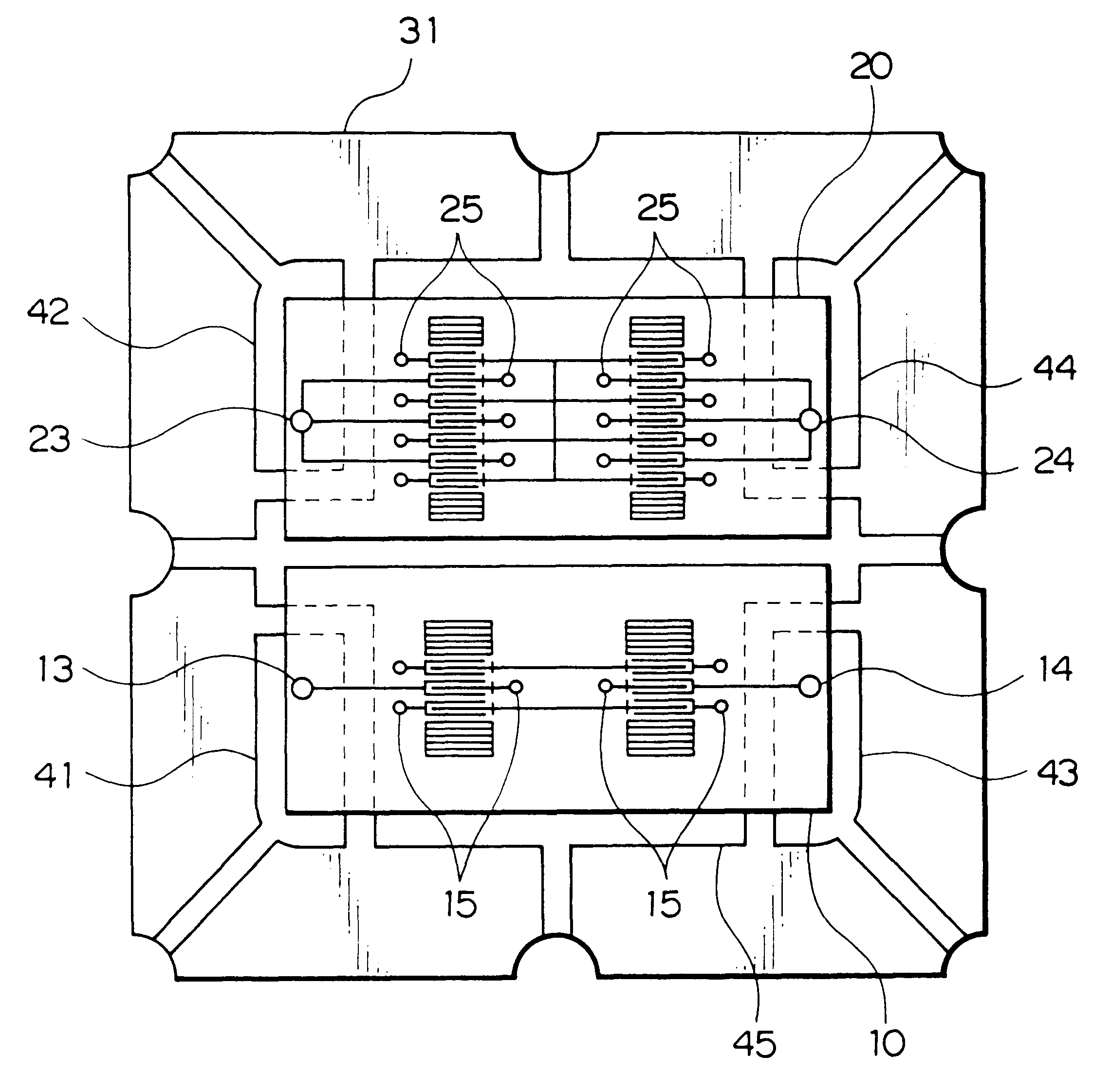

Surface acoustic wave device comprising first and second chips face down bonded to a common package ground

InactiveUS6339365B1Easy to distinguishLow costImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorEngineering

An object of the present invention is to provide a filter that enables to manufacture in a multi-chip package with ease and that is of small size and multi-function or multi-mode. In a constitution of the present invention, a filter comprises a package comprising a base on one main surface thereof a conductor is formed, and a plurality of surface acoustic wave chips comprising a plurality of interdigital transducers formed on one main surface of a piezoelectric substrate, signal terminals disposed on facing sides on the piezoelectric substrate, and ground terminals disposed on the piezoelectric substrate. Here, the plurality of surface acoustic wave chips, at the signal terminals and the ground terminals, is bonded to the conductor in a face down way.

Owner:KK TOSHIBA

Acoustic waves in microfluidics

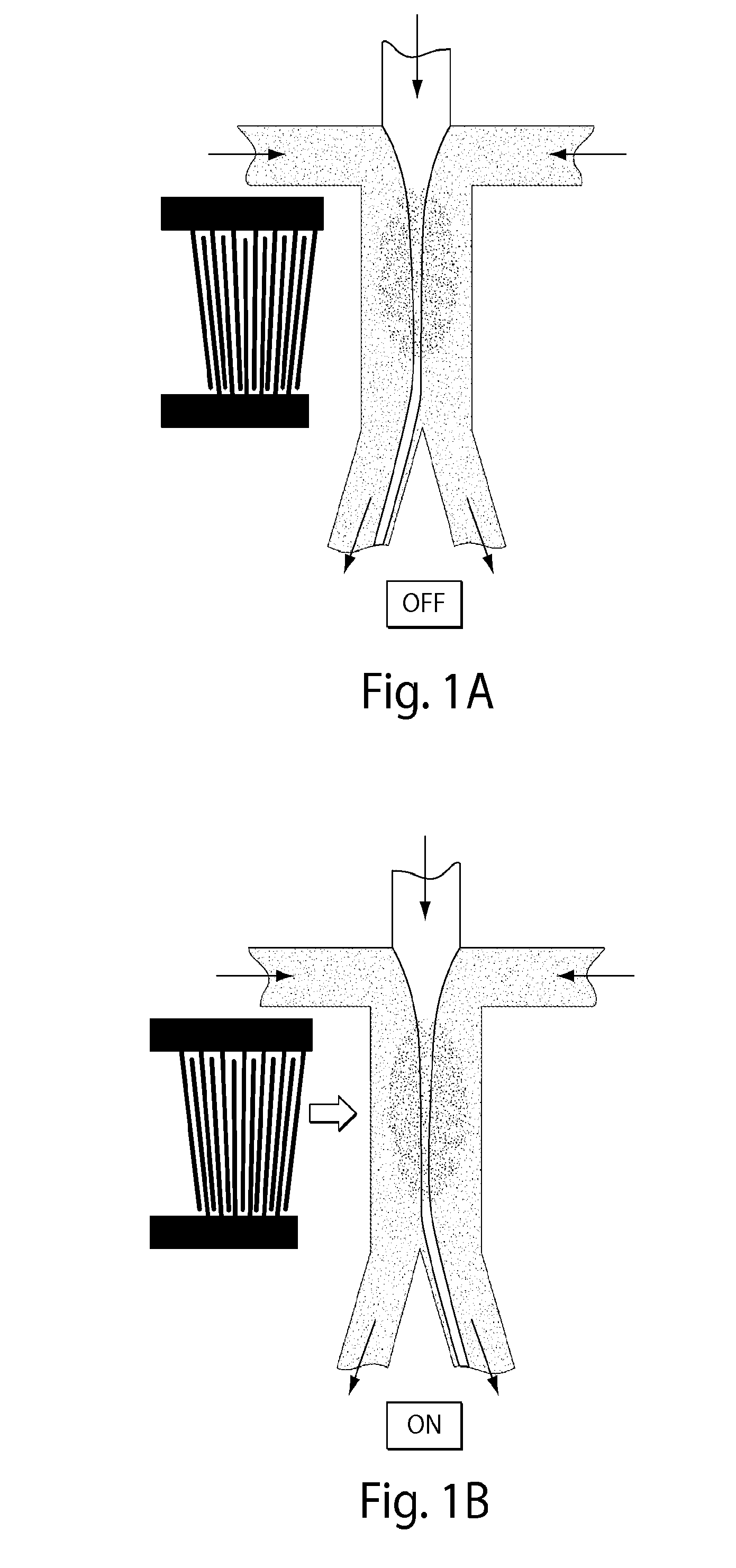

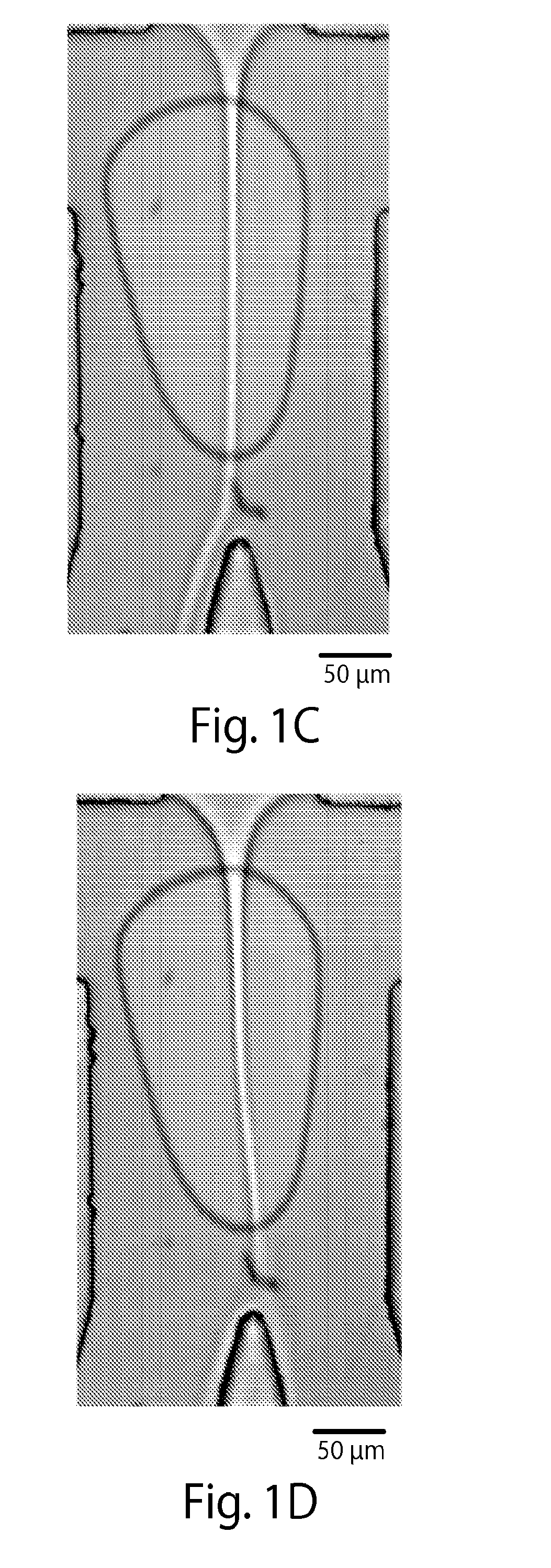

Various aspects of the present invention relate to the control and manipulation of fluidic species, for example, in microfluidic systems. In one set of embodiments, droplets may be sorted using surface acoustic waves. The droplets may contain cells or other species. In some cases, the surface acoustic waves may be created using a surface acoustic wave generator such as an interdigitated transducer, and / or a material such as a piezoelectric substrate. The piezoelectric substrate may be isolated from the microfluidic substrate except at or proximate the location where the droplets are sorted, e.g., into first or second microfluidic channels. At such locations, the microfluidic substrate may be coupled to the piezoelectric substrate (or other material) by one or more coupling regions. In some cases, relatively high sorting rates may be achieved, e.g., at rates of at least about 1,000 Hz, at least about 10,000 Hz, or at least about 100,000 Hz, and in some embodiments, with high cell viability after sorting.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

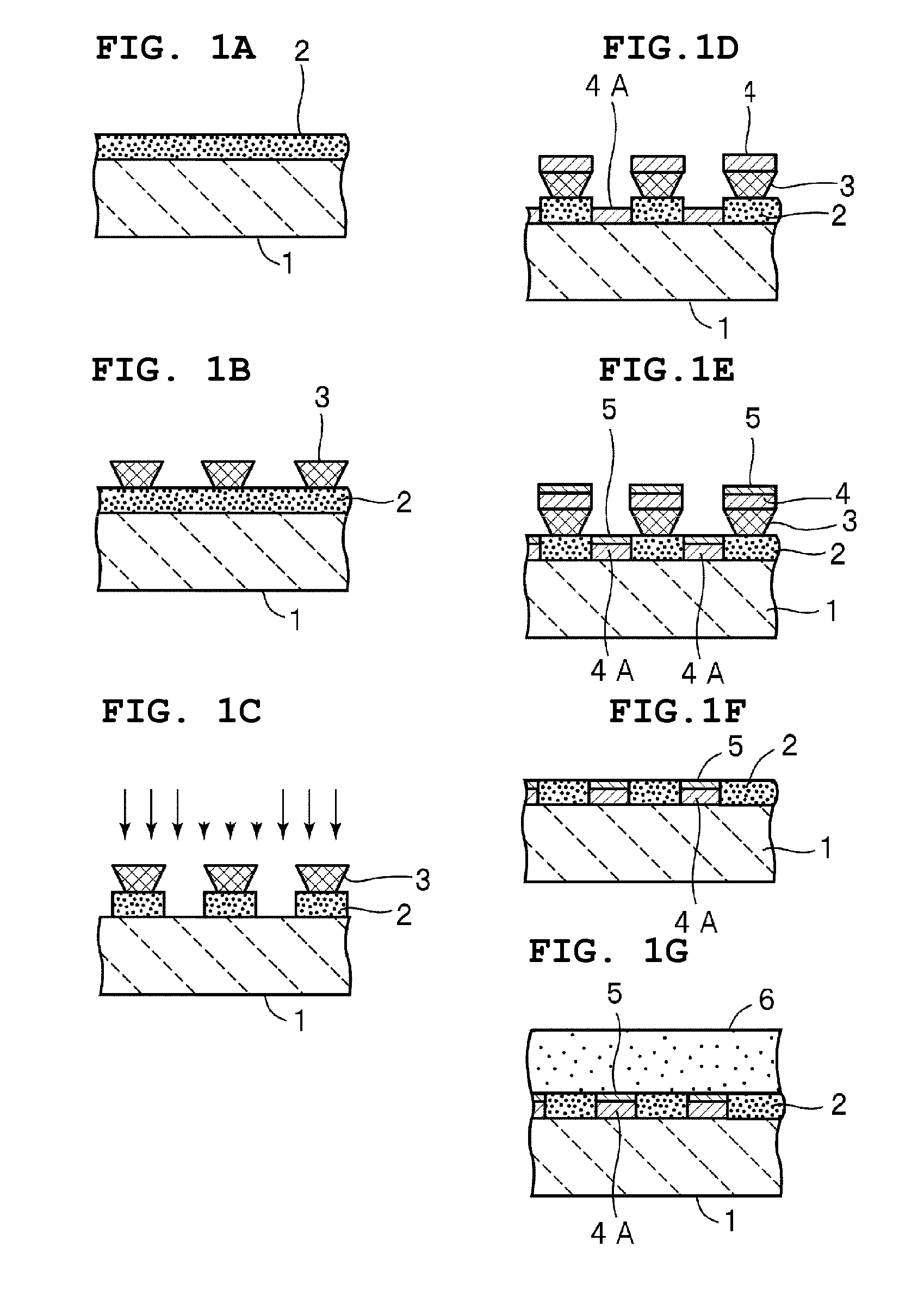

Method of fabricating acoustic wave device and acoustic wave device

ActiveUS20170370791A1Impedence networksFluid pressure measurement by electric/magnetic elementsSilicon oxideAcoustic wave

An acoustic wave device fabrication method includes: forming on a piezoelectric substrate a comb-shaped electrode and a wiring layer coupled to the comb-shaped electrode; forming on the piezoelectric substrate a first dielectric film having a film thickness greater than those of the comb-shaped electrode and the wiring layer, covering the comb-shaped electrode and the wiring layer, and being made of silicon oxide doped with an element or undoped silicon oxide; forming on the first dielectric film a second dielectric film having an aperture above the wiring layer; removing the first dielectric film exposed by the aperture of the second dielectric film by wet etching using an etching liquid causing an etching rate of the second dielectric film to be less than that of the first dielectric film so that the first dielectric film is left so as to cover an end face of the wiring layer and the comb-shaped electrode.

Owner:TAIYO YUDEN KK

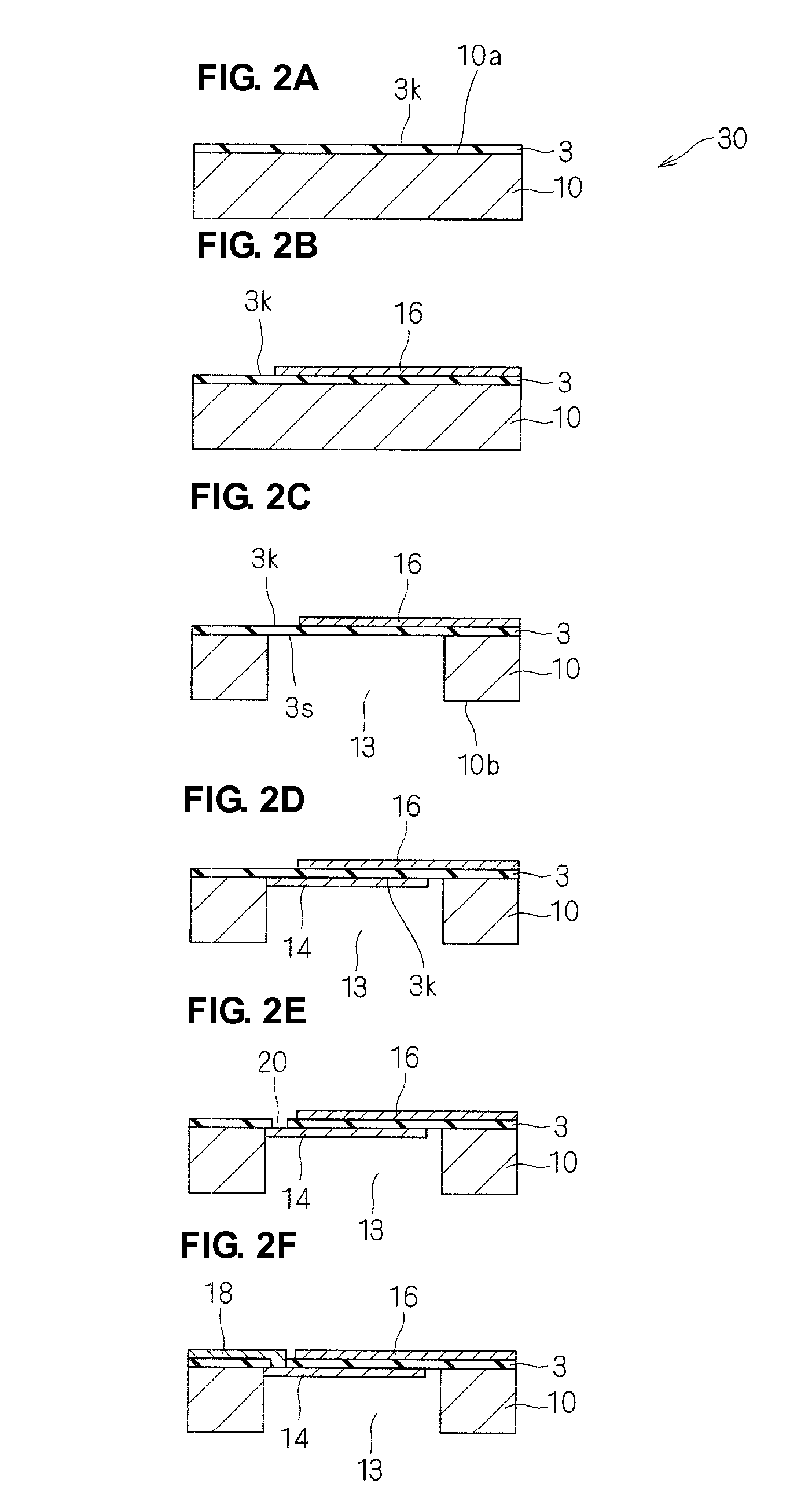

Acoustic Wave Device

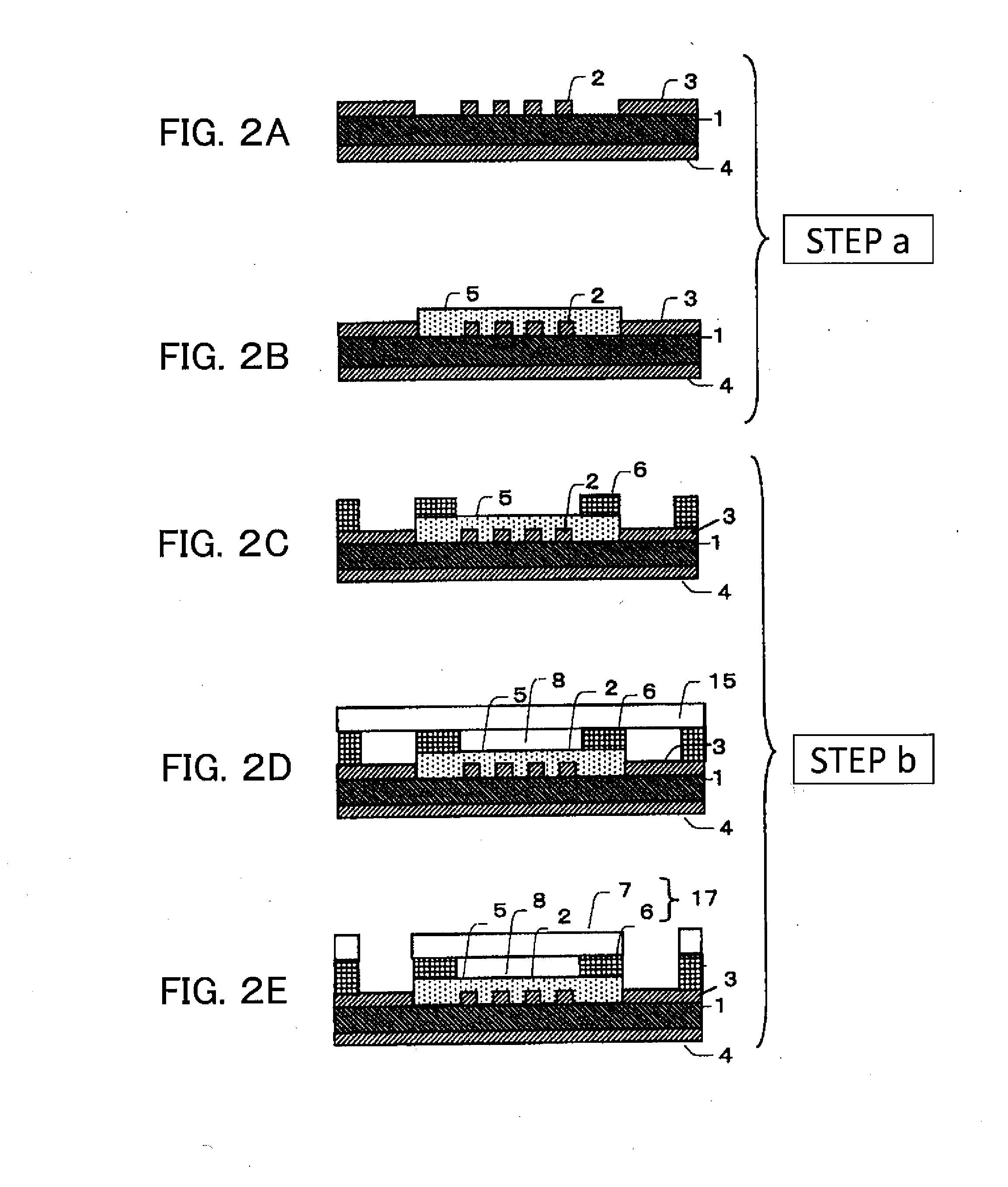

ActiveUS20100225202A1Little changeImprove moisture resistanceImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAcoustic waveBulk acoustic wave

Provided is a highly reliable acoustic wave device wherein deterioration of electrical characteristics due to deformation of a protective cover is suppressed. A method for manufacturing such acoustic wave device is also provided. The acoustic wave device has a piezoelectric substrate 1 propagating an acoustic wave; an excitation electrode arranged on a first main surface of the piezoelectric substrate 1; a columnar outside connection-use electrode 10 electrically connected to the excitation electrode; a protective cover 17 having a hollow accommodating space 8 in which the excitation electrode is accommodated on the first main surface; and a conductive layer 18 connected to the electrode 10 on the protective cover 17.

Owner:KYOCERA CORP

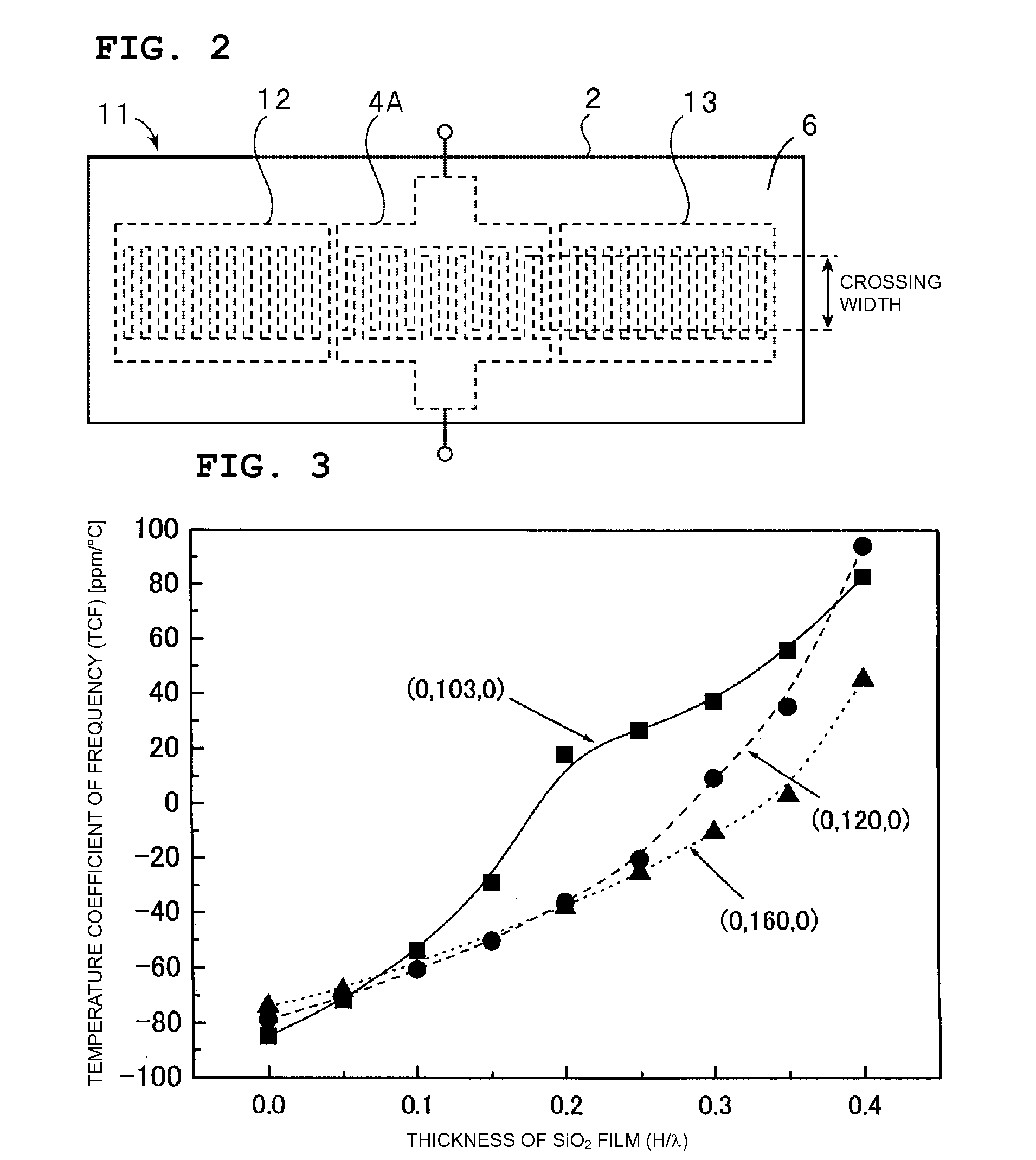

Surface acoustic wave device

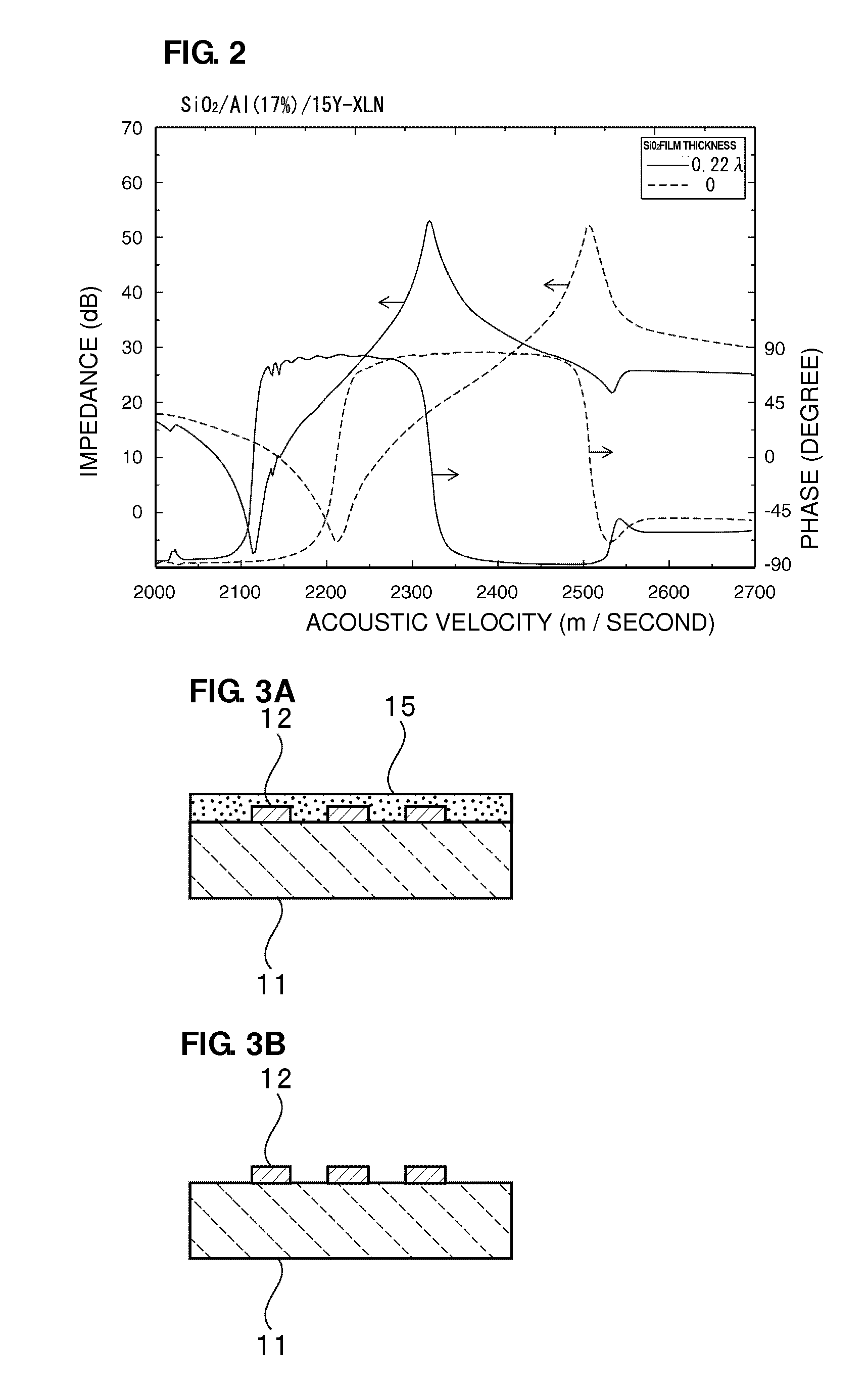

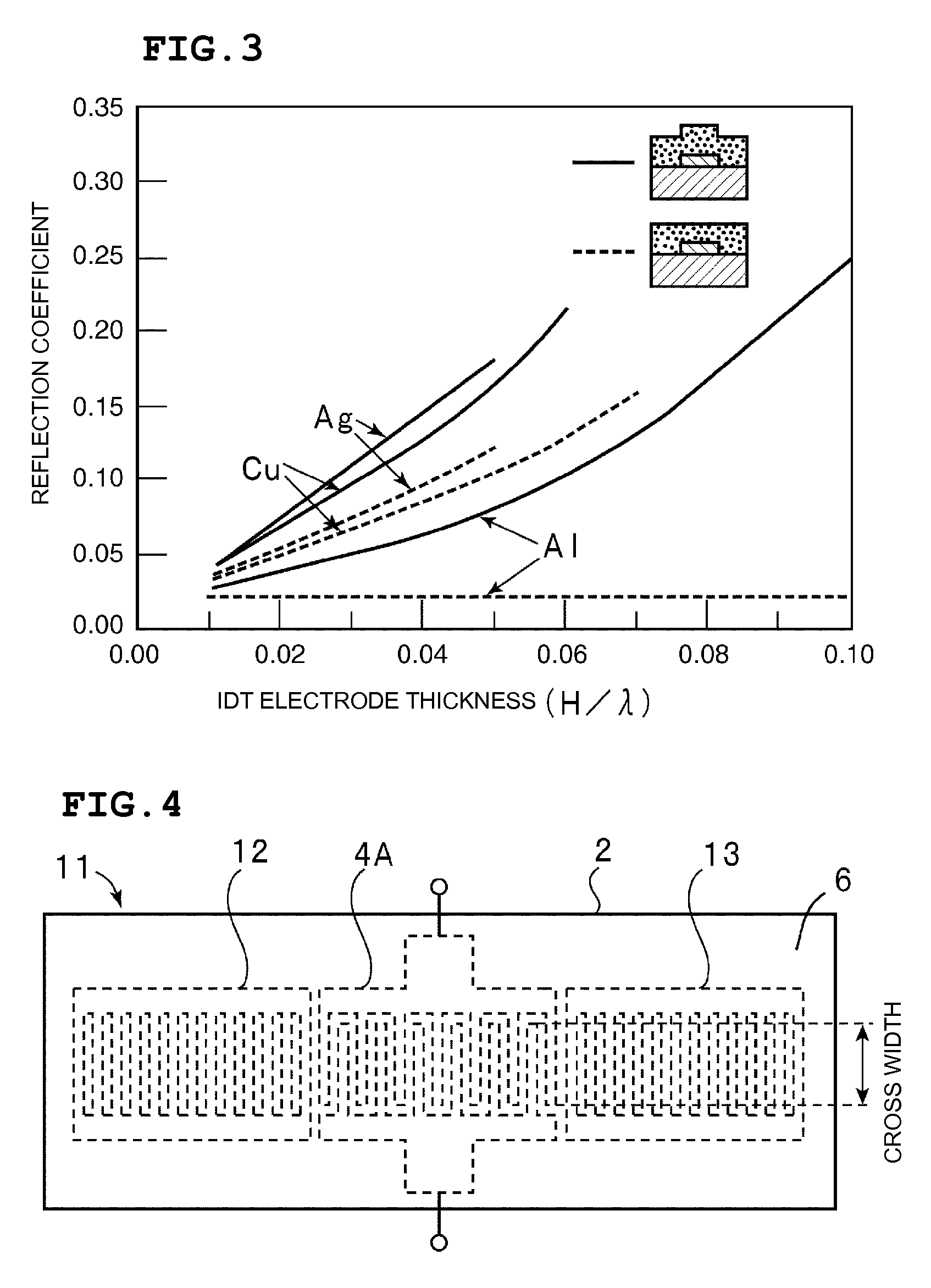

ActiveUS20070096592A1Improve featuresHigh reflection coefficientImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectromechanical coupling coefficientAcoustic wave

A surface acoustic wave device includes a piezoelectric substrate made of LiNbO3 having an electromechanical coupling coefficient k whose square is at least about 0.025, at least one electrode that is made of a metal whose density is greater than that of Al or an alloy primarily including the metal or that is composed of laminated films made of a metal whose density is greater than that of Al or an alloy primarily including the metal and another metal, the electrode being disposed on the piezoelectric substrate, a first insulating layer disposed in a region other than a region where the at least one electrode is disposed, the thickness of the first insulating layer being substantially equal to that of the electrode, and a second insulating layer covering the electrode and the first insulating layer. The density of the electrode is at least about 1.5 times greater than that of the first insulating layer.

Owner:MURATA MFG CO LTD

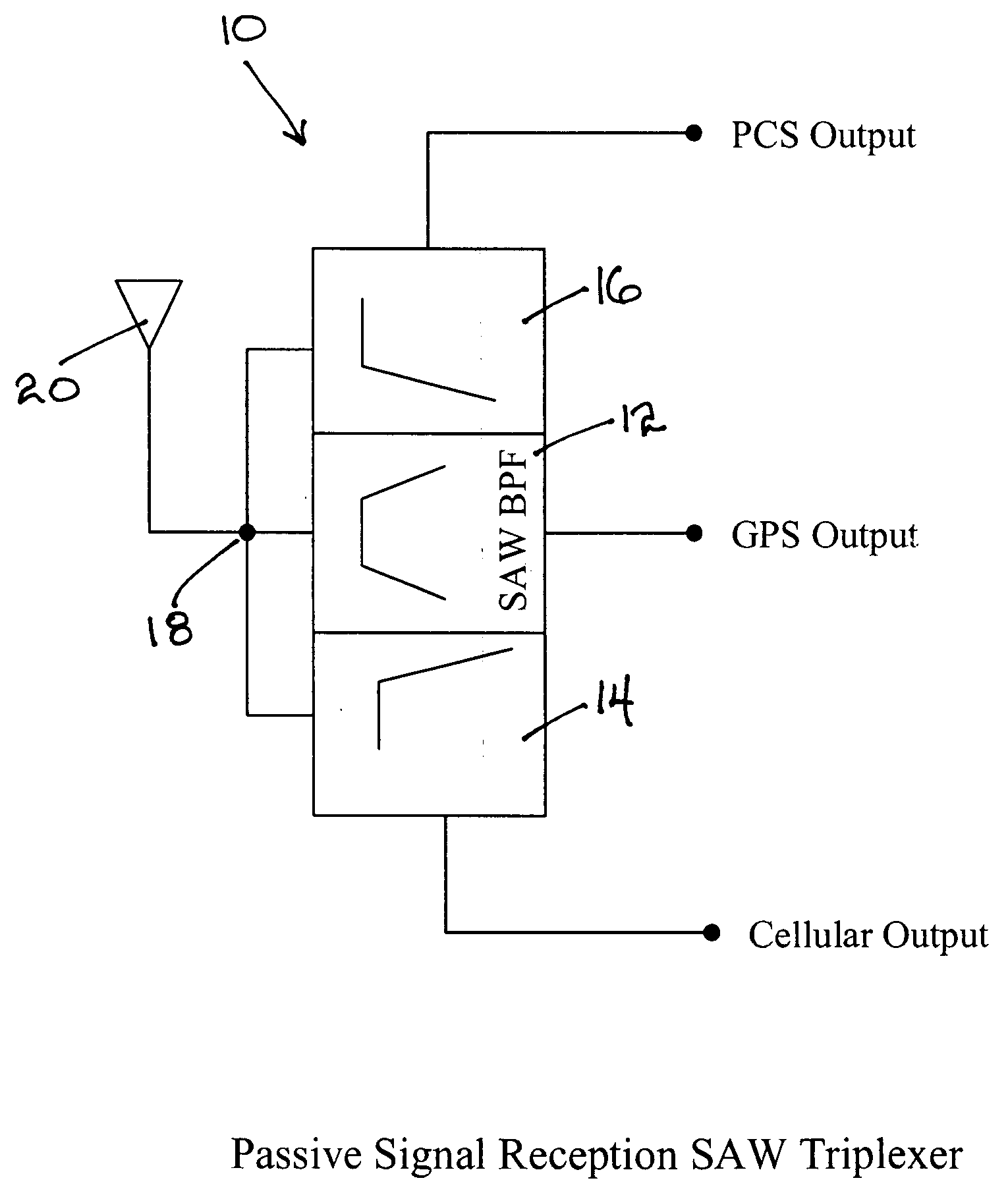

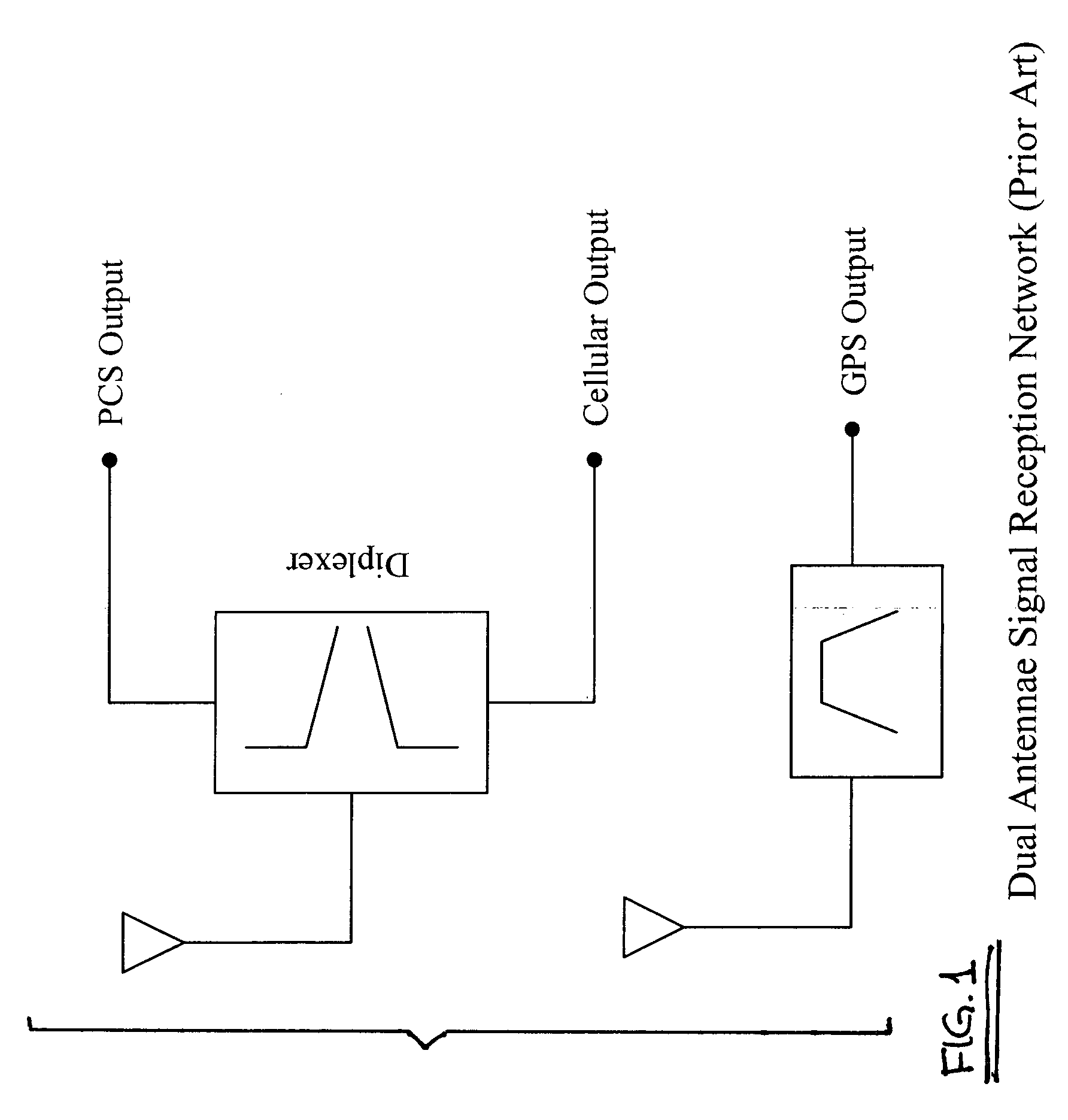

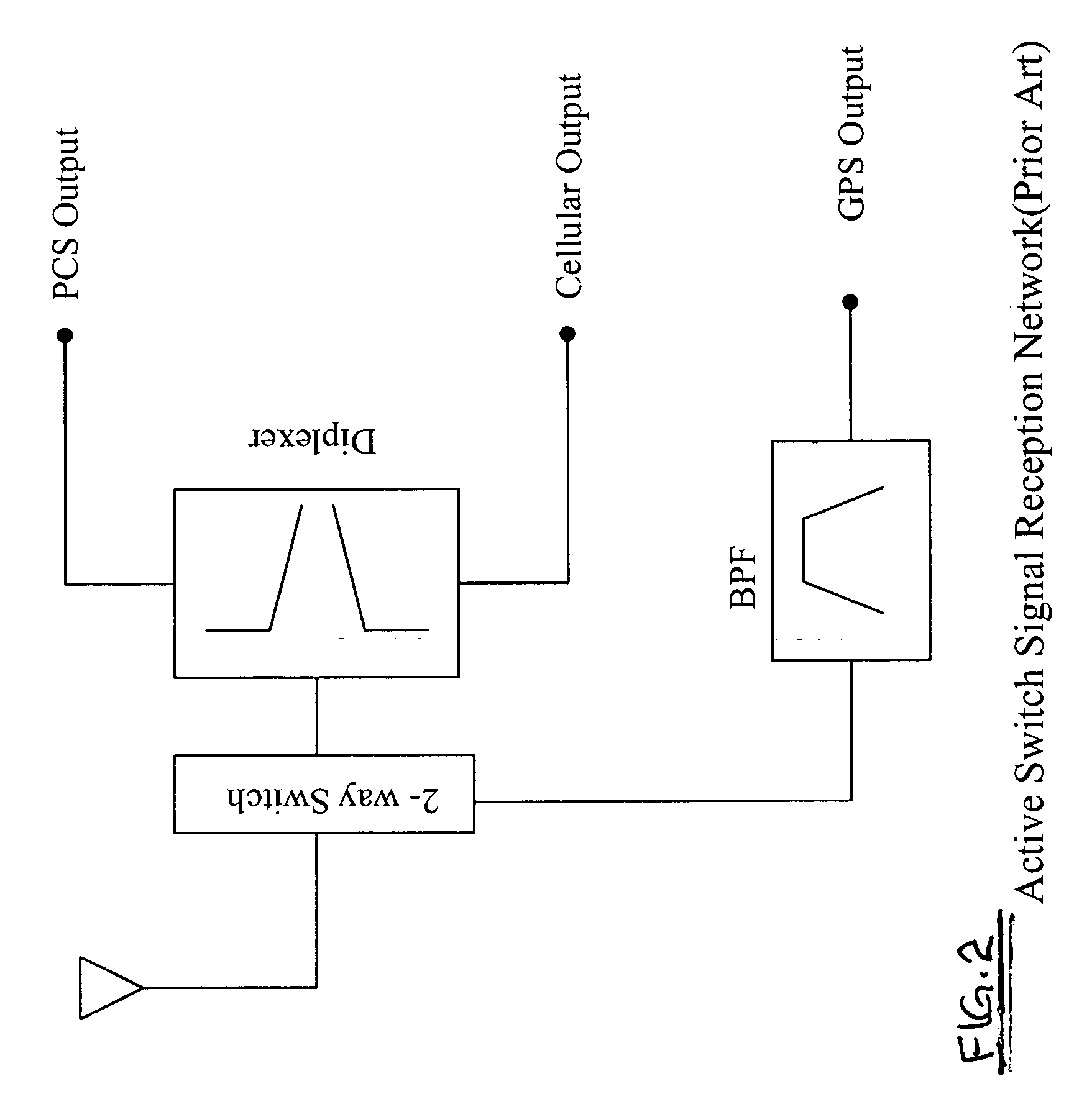

Triband passive signal receptor network

InactiveUS20060067254A1Low insertion lossLarge isolationImpedence networksRepeater circuitsBandpass filteringLow-pass filter

A surface acoustic wave (SAW) triplexer receives radio frequency signals in three bands and provides output signal components for PCS, GPS, and cellular signal processing ports. The triplexer includes low pass filter and a high pass network operating with an antenna terminal for reception and separation of an incoming signal in a low and high frequency bands, and a SAW filter connected to the input terminal for reception and separation of the incoming signal within a frequency band located between that of the low and the high bands. A low insertion loss bandpass filter is provided by the SAW filter having a transducer and reflectors fabricated on a piezoelectric substrate.

Owner:SAWTEK

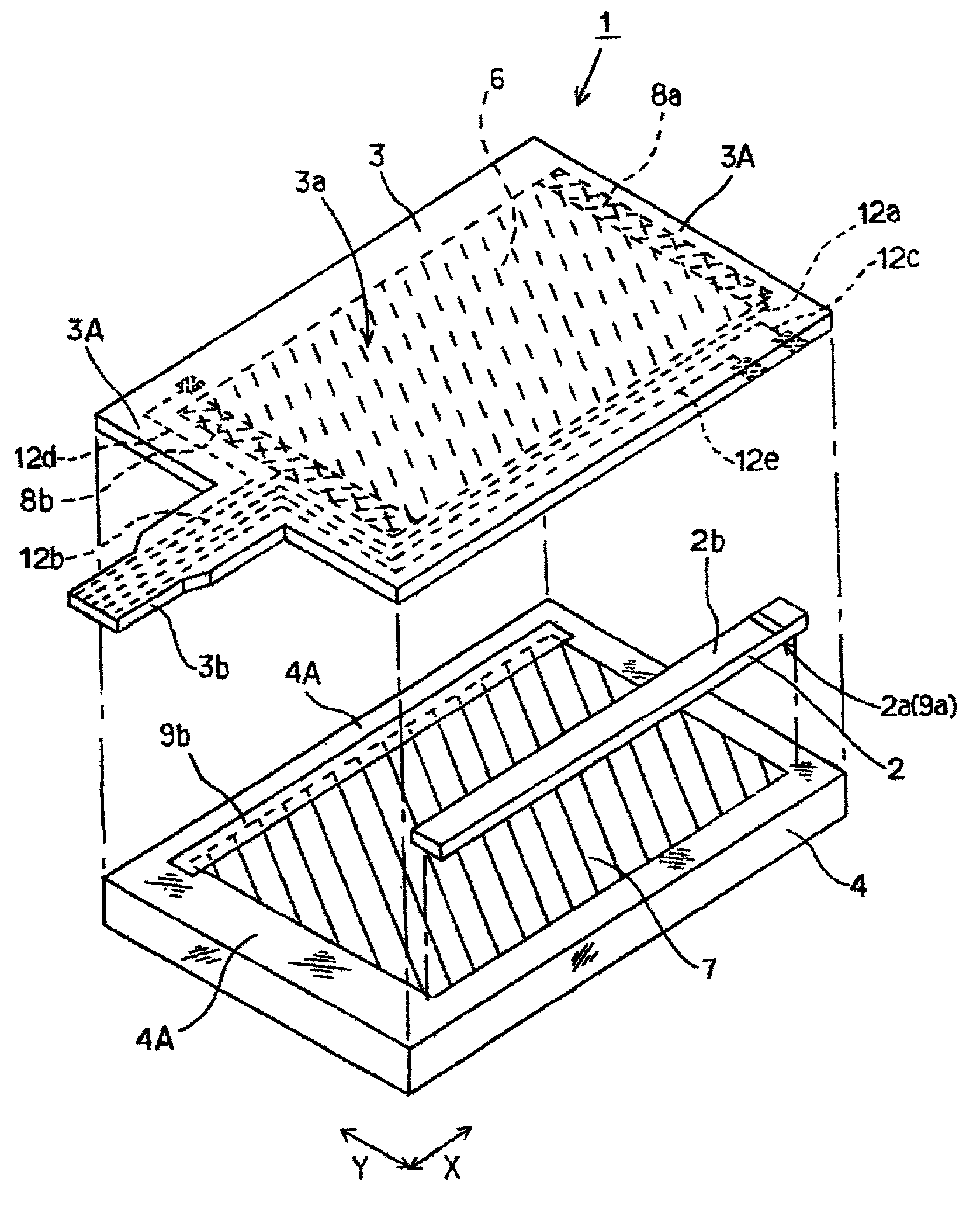

Elastic boundary wave device and method of manufacturing the same

ActiveUS20050099091A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDielectric surfaceOptics

An elastic boundary wave device includes a first piezoelectric substrate, IDTs arranged thereon, a first dielectric film having a smoothed surface that covers the IDTs, a second substrate that is a silicon-based substrate, and a second dielectric film provided on a main surface of the second substrate. The smoothed surface of the first dielectric surface and a surface of the second dielectric film are joined together.

Owner:TAIYO YUDEN KK

Surface-acoustic wave device package

InactiveUS6329739B1MiniaturizationSmall packagePiezoelectric/electrostriction/magnetostriction machinesImpedence networksAcoustic waveEngineering

A surface-acoustic-wave device package includes a cover film which covers a piezoelectric substrate to provide an air gap around the functional surface of the surface-acoustic-wave device. The surface-acoustic-wave device package also includes a seal material which is provided over the cover film to seal the surface-acoustic-wave device.

Owner:HANGER SOLUTIONS LLC

Surface wave liquid sensor

InactiveUS6186005B1Reduce distractionsHigh measurement sensitivityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesSurface shearShear waves

A liquid sensor has comb-shaped electrodes, applied to a piezoelectric substrate, as interdigital transducers for generating an electroacoustic wave from a transmitting transducer to a receiving transducer. The number of finger pairs of the interdigital transducers and the material out of which the electrodes are made are so chosen that a surface shear wave generated by the transmitting transducer and a bulk shear wave generated by the transmitting transducer have different frequencies.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

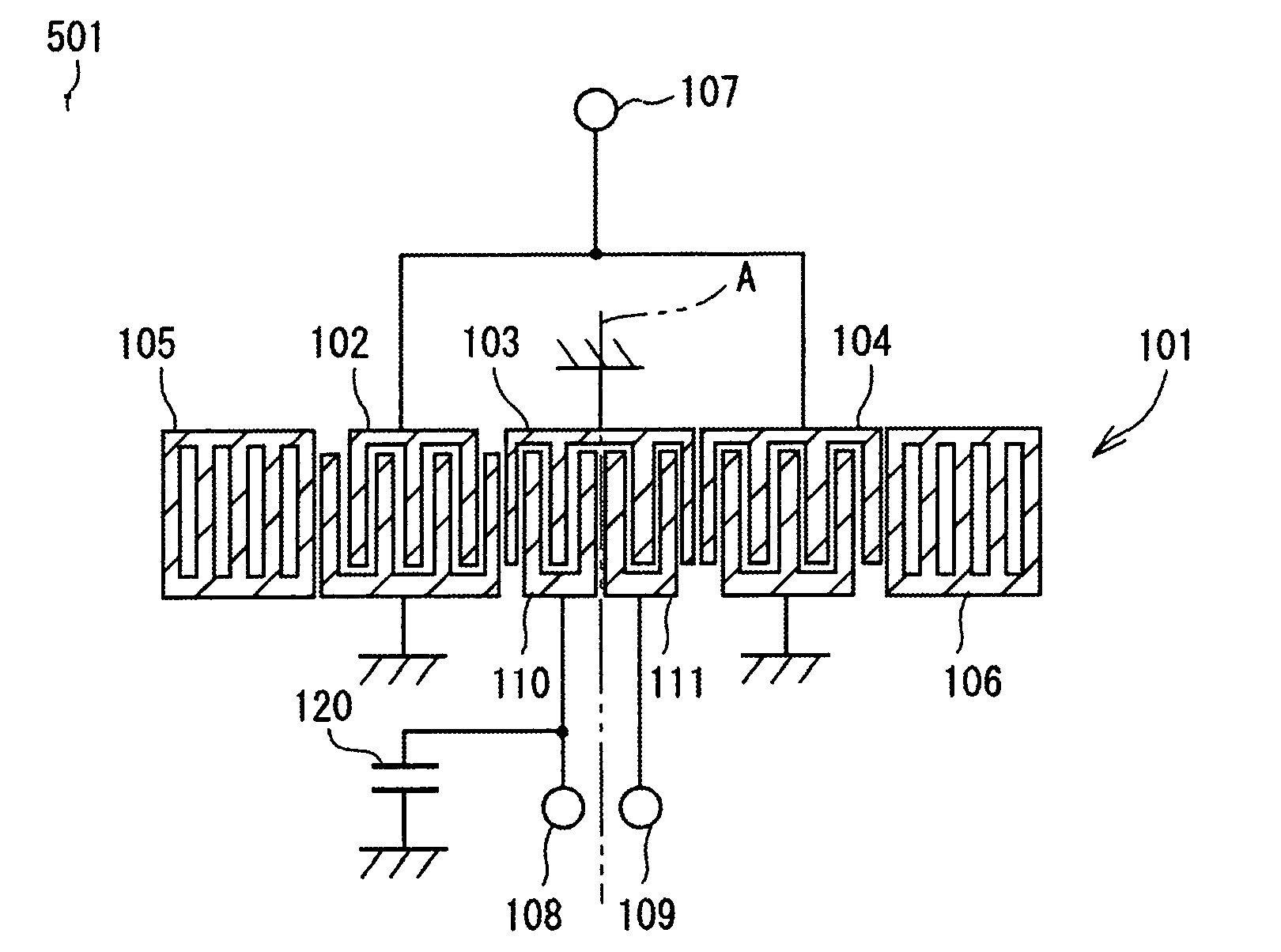

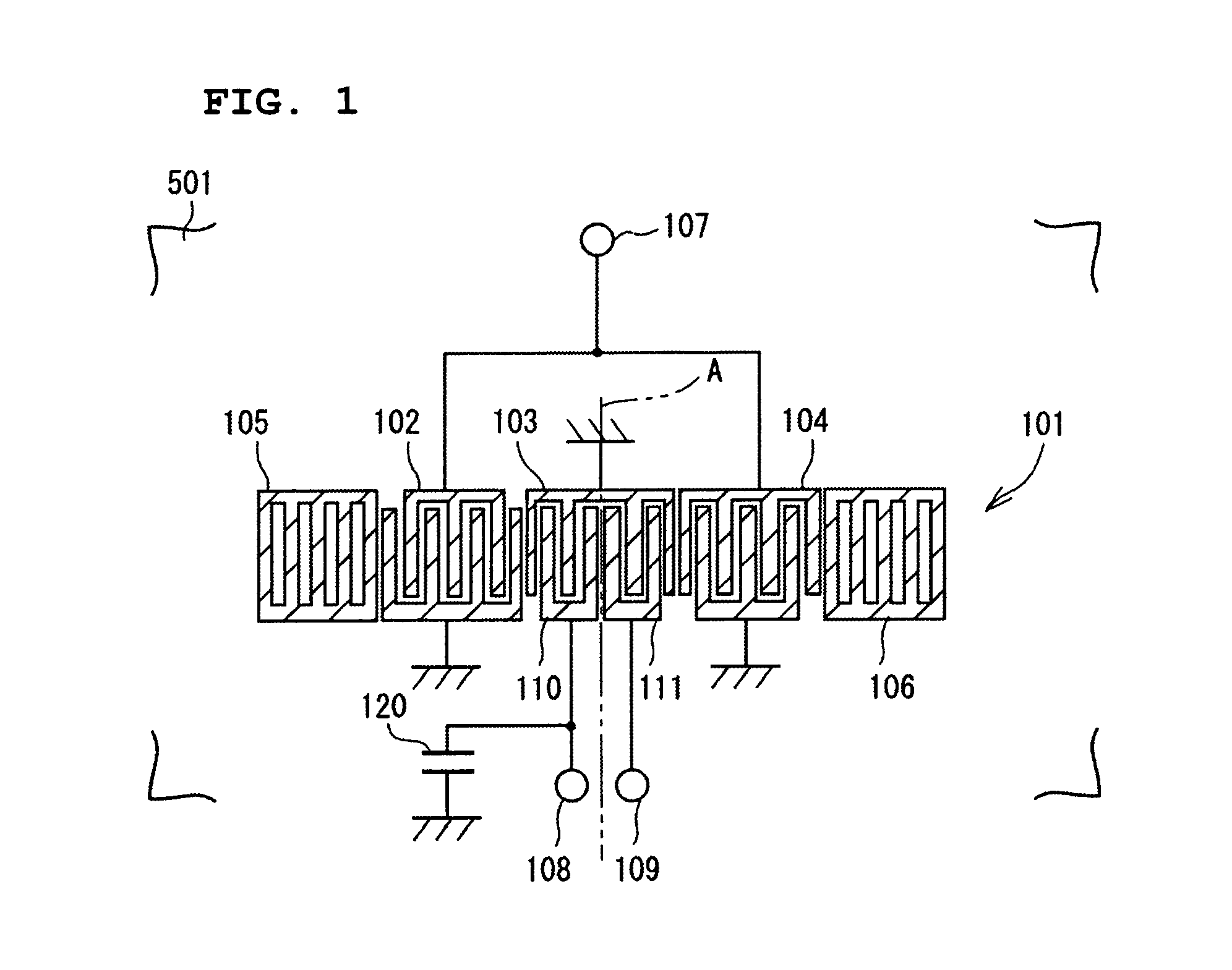

Surface acoustic wave apparatus and communication apparatus

InactiveUS20040080385A1Good communication characteristicsGreat degreeImpedence networksSolid-state devicesSurface acoustic wave sensorResonator

A longitudinally-coupled-resonator-type surface acoustic wave filter includes three interdigital transducers provided on a piezoelectric substrate in the direction in which surface acoustic waves propagate. An interdigital transducer disposed at the approximate center among the three interdigital transducers of the longitudinally-coupled-resonator-type surface acoustic wave filter is divided into two parts substantially symmetrically in the propagation direction of the surface acoustic waves and the two parts are connected to balanced signal terminals, respectively. Left and right interdigital transducers of which the polarities are inverted relative to each other are connected to an unbalanced signal terminal to provide a balanced-to-unbalanced conversion function. A reactance component provided on the piezoelectric substrate, inside a package, or outside the package is connected to either of the balanced signal terminals.

Owner:MURATA MFG CO LTD

Through-hole forming method, and piezoelectric device manufacturing method and piezoelectric device manufactured thereby

InactiveUS20070058003A1Improve airtightSpace with easePrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyThin metalConductive materials

In a method of forming a part of a through-hole for a piezoelectric substrate having an excitation electrode and a leading electrode which are formed on a first surface of the piezoelectric substrate and are made of a thin metal film in order to establish a conductivity, the method includes: blasting a position on a second surface of the piezoelectric substrate corresponding to the leading electrode to form a preliminary hole by boring the piezoelectric substrate in its halfway; etching a bottom of the preliminary hole to form a part of a through-hole through which a part of the leading electrode is exposed; and placing a conductive material in the part of a through-hole, the conductive material contacting the leading electrode from a side of the second surface of the piezoelectric substrate.

Owner:SEIKO EPSON CORP

Digitizing tablet

ActiveUS7119798B2Without increasing size of tabletDesign is limitedInput/output for user-computer interactionCathode-ray tube indicatorsSoftware engineeringMechanical engineering

A digitizing tablet that can control the vibration of an operation panel or a support substrate is disclosed. A piezoelectric substrate having a pair of drive electrodes fixed to the front and rear surfaces of the piezoelectric substrate is fixed directly or via one of the drive electrodes to the operation panel or the support substrate. A drive voltage is applied to the pair of drive electrodes after an input as been detected, and the drive voltage causes the expandable piezoelectric substrate to vibrate the operation panel or the support substrate. An additional vibration source is not required. Therefore, the vibration energy is not dissipated and there is no time delay in transmission since the operation panel or the support substrate are vibrated directly by the piezoelectric substrate. The expansion and contraction of the piezoelectric substrate can be controlled so that the vibration can be controlled precisely.

Owner:SMK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com