Preparation method of high-heat-conduction flexible graphene film

A graphene film, flexible graphite technology, applied in the field of materials science, can solve the problems of high cost, low thermal conductivity, complex preparation process, etc., and achieve the effect of easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Ultrasonic disperse 300 mg of freeze-dried graphene oxide into 1000 ml of ethanol solvent to prepare a graphene oxide dispersion with a concentration of 0.3 mg / mL, and ultrasonically mix it evenly.

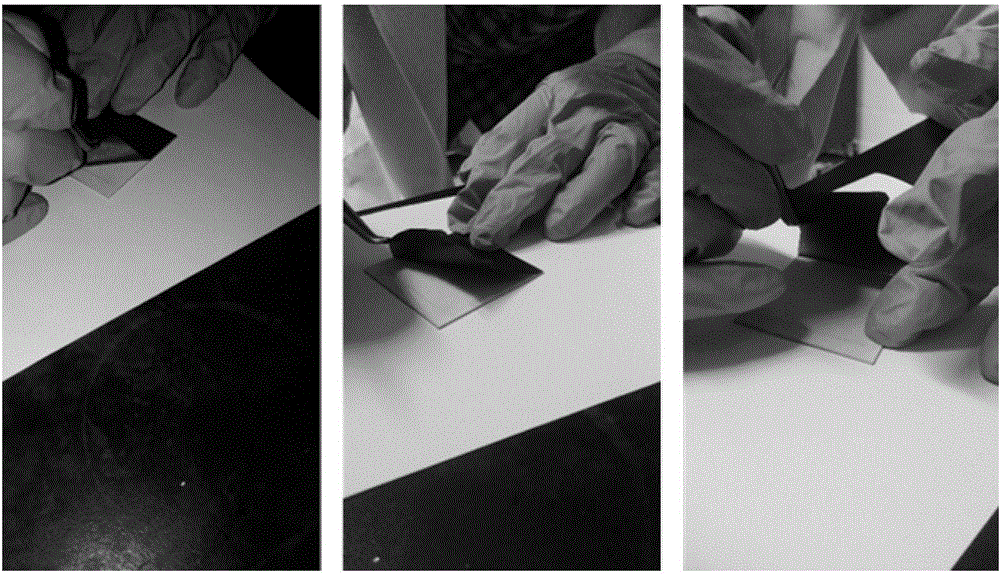

[0026] 2) Add the graphene oxide dispersion liquid into the spraying device, adjust the height and power of the nozzle, and spray on the copper foil substrate to form a film; The thickness of the film is 5-120 μm;

[0027] 3) The graphene oxide film is peeled off from the sprayed substrate.

[0028] 4) After rolling the graphene oxide film with a pressure of 15 MPa, under the condition of nitrogen protection, the temperature is gradually raised to 1000° C. for carbonization.

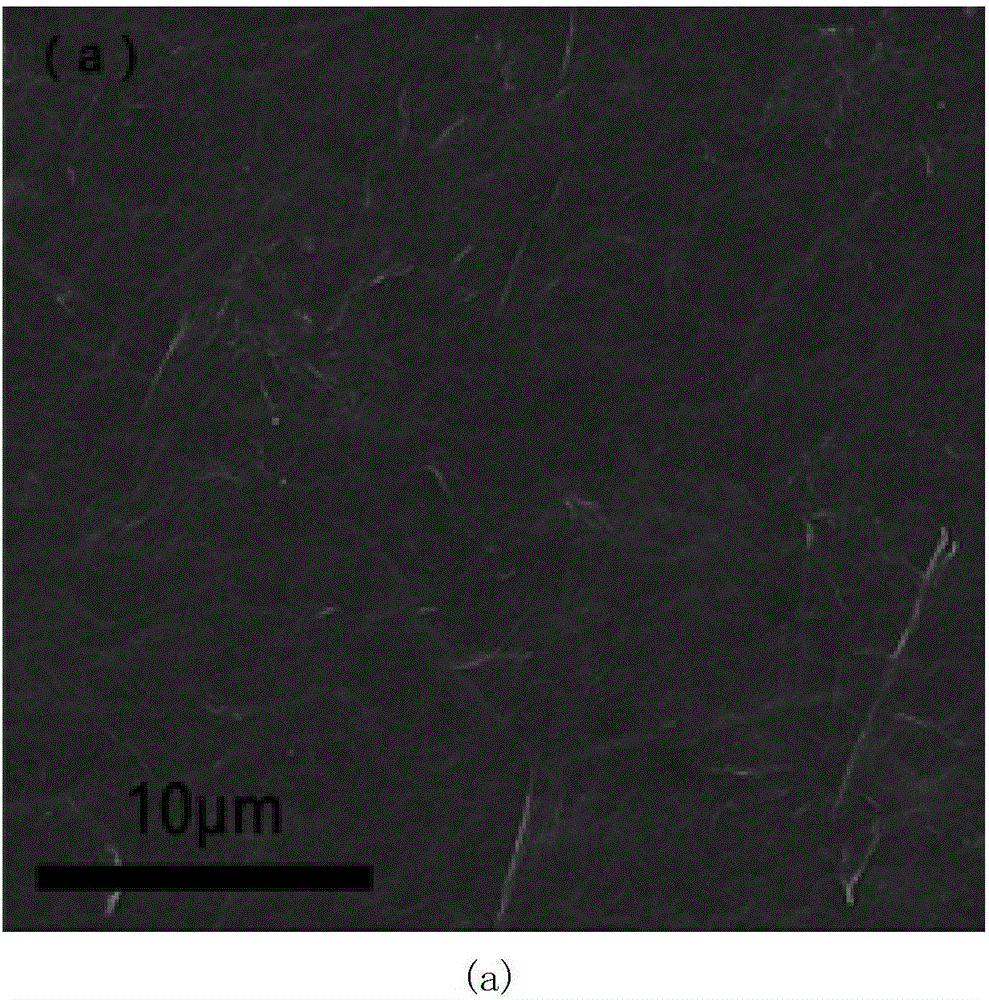

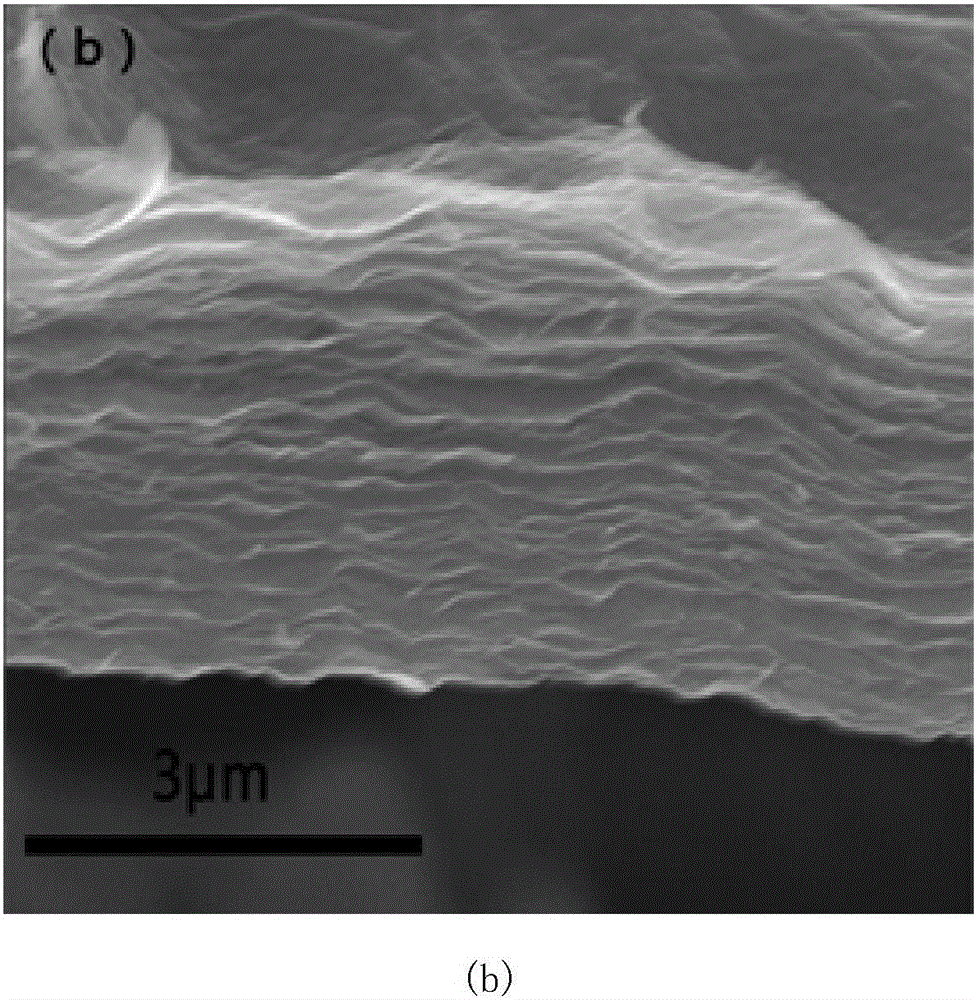

[0029] 5) Finally, put the film into a high-temperature graphitization furnace, raise the temperature to 2800° C., and keep it warm for 45 minutes. A graphene film was prepared with an in-plane thermal conductivity of 1206W m -1 K -1 , and has good flexibility, no damage after repeated bending...

Embodiment 2

[0031] 1) Ultrasonic disperse 300 mg of freeze-dried graphene oxide into 100 ml of DMF solvent to prepare a graphene oxide dispersion with a concentration of 3 mg / mL, and ultrasonically mix it uniformly.

[0032] 2) Add the graphene oxide dispersion into the spraying device, adjust the height and power of the nozzle, and spray the film on the glass substrate; The thickness of the film is 5-120 μm;

[0033] 3) The graphene oxide film is peeled off from the sprayed substrate.

[0034] 4) After the graphene oxide film is rolled with a pressure of 10 MPa, under the condition of nitrogen protection, the temperature is gradually raised to 1200° C. for carbonization.

[0035] 5) Put the final film into a high-temperature graphitization furnace, raise the temperature to 2800° C., and keep it warm for 45 minutes. A graphene film was prepared with an in-plane thermal conductivity of 1475W m -1 K -1 , and has good flexibility, no damage after repeated bending.

Embodiment 3

[0037] 1) Ultrasonic disperse 300 mg of freeze-dried graphene oxide into 50 mL of deionized water solvent to prepare a graphene oxide dispersion with a concentration of 6 mg / mL, and ultrasonically mix it uniformly.

[0038] 2) Add the graphene oxide dispersion liquid into the spraying device, adjust the height and power of the nozzle, and spray on the copper foil substrate to form a film; The thickness of the film is 5-120 μm;

[0039] 3) The graphene oxide film is peeled off from the sprayed substrate.

[0040] 4) After rolling the graphene oxide film at a pressure of 20 MPa, under the protection of argon, the temperature is gradually raised to 1200° C. for carbonization.

[0041] 5) Finally, put the film into a high-temperature graphitization furnace, raise the temperature to 2800° C., and keep it warm for 90 minutes. A graphene film was prepared with an in-plane thermal conductivity of 1509W m -1 K -1 , and has good flexibility, no damage after repeated bending.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com