Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Not prone to permanent deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for no-ironing finishing of pure cotton textile

The no-ironing finishing process of pure cotton textile includes the available steps of preparation, preflexibilizing, framing and settling, calendering, preshinking and packing as well as increased rolling supercrosslinking assistant, storing and water washing steps inserted between available preflexibilizing and framing steps. The textile after the said treating process is soft, permeable, water absorbing and no need of ironing and has low formaldehyde content.

Owner:LUTAI TEXTILE

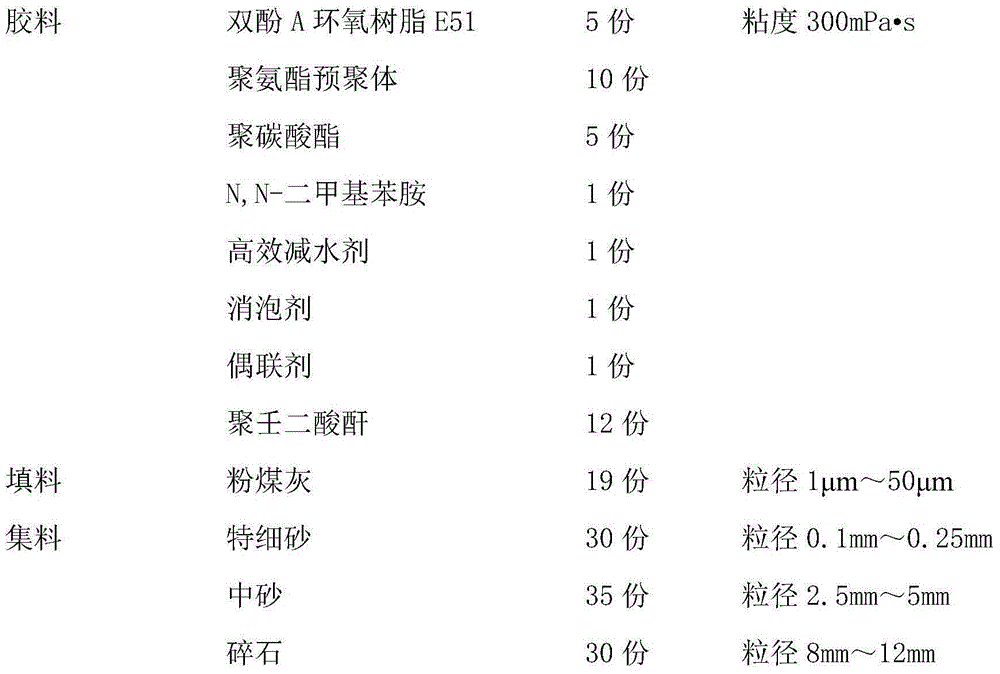

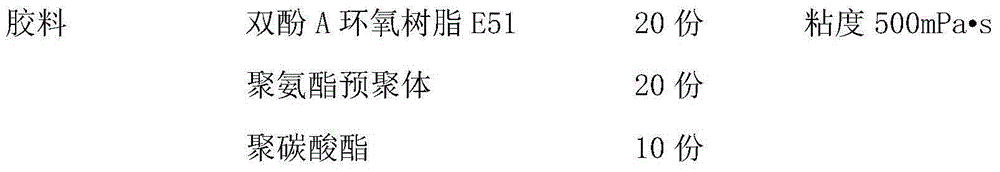

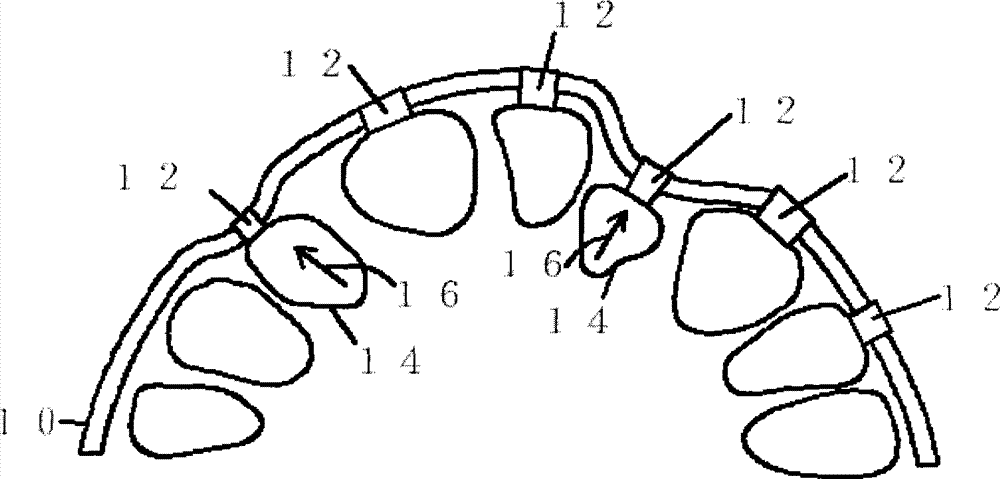

High-strength super-toughness resin concrete and preparing method thereof

The invention discloses high-strength super-toughness resin concrete which is composed of aggregate, packing and a sizing material. The high-strength super-toughness resin concrete is characterized in that the sizing material is composed of resin A and a curing agent B. The resin A is composed of epoxy resin, polyurethane prepolymer, polycarbonate and a functional agent. The weight percentage of the resin A and the curing agent B is 1:1-2:1, and the packing is inorganic powder. The aggregate is composed of super-fine sand, coarse sand and gravel. The epoxy resin is bisphenol A epoxy resin. The functional agent comprises accelerant, a water reducing agent, a defoaming agent and a coupling agent. The curing agent is long-chain aliphatic series anhydride. The high-strength super-toughness resin concrete has the advantages that strength is high and even, cracking and breaking do not happen, the deformation capability is good, the elasticity recovery rate is high, and the high-strength super-toughness resin concrete is not prone to permanent deformation at a high temperature.

Owner:NANJING ROAD KEEPER TECH

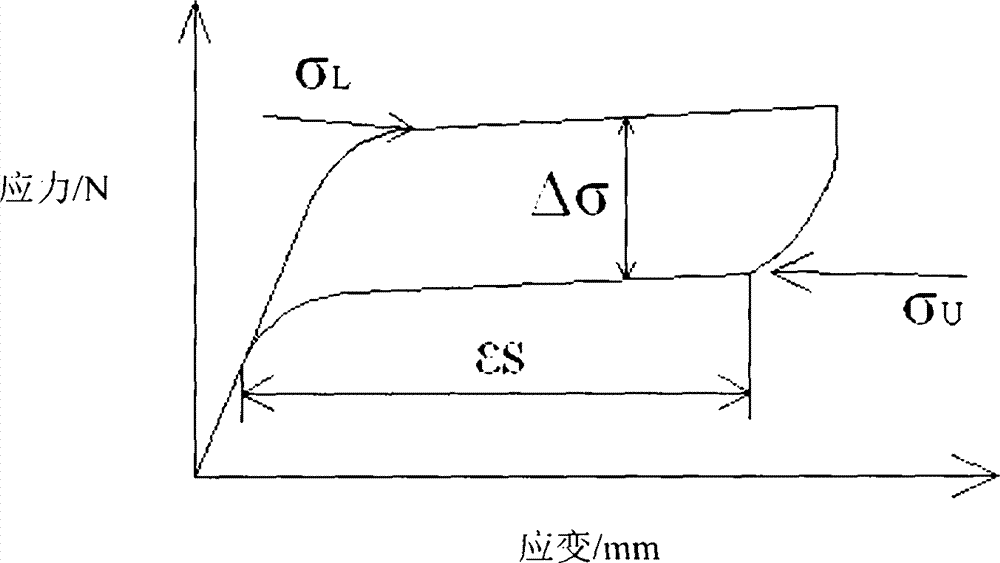

Production technology of novel copper-nickel-titanium orthodontic arch wire

The invention provides a production technology of novel copper- nickel-titanium orthodontic arch wire aiming at the problems that with further development and improvement of orthodontics systems, requirement on orthodontic products is higher gradually, and the traditional stainless steel orthodontic arch wire and nickel-titanium alloy orthodontic arch wire both cannot meet the requirement on clinical operation and therapeutic effect well due to respective certain defects. The orthodontic arch wire has special mechanical property and characteristics, and can be used for solving the detects of the traditional orthodontic arch wires well. Basic production process of the copper-nickel-titanium orthodontic arch wire comprises the steps of: 1. carrying out wire drawing, namely carrying out hot drawing and cold drawing, wherein hot drawing temperature is 650-720 DEG C, and cold deformation after cold drawing is controlled to be 45%+ / -5%; 2. carrying out aging treatment, specifically, placing a preformed orthodontic arch wire into a holding furnace, keeping the temperature to be 480-600 DEG C, preserving heat for 0.5-3.5h, and cooling the orthodontic arch wire with water after being discharged; and 3. carrying out surface treatment, specifically, carrying out acid pickling, polishing and other processing on the orthodontic arch wire subjected to the aging treatment.

Owner:INNOVATIVE MATERIAL & DEVICES

PU foaming shoe material capable of releasing negative ions and preparation method thereof

The invention discloses a PU foaming shoe material capable of releasing negative ions and a preparation method thereof. The PU foaming shoe material is prepared from the following raw materials in parts by weight: 70-80 parts of polyester polyurethane, 12-16 parts of ethylene-vinyl acetate copolymer, 5-7 parts of styrene-ethylene-butadiene-styrene block copolymer, 4-6 parts of a negative ion additive, 1.2-1.7 parts of 4-methylbenzenesulfonyl hydrazine, 0.45-0.55 parts of triethylene diamine, 0.08-0.12 parts of triallyl isocyanurate, 2-3 parts of talcum powder, 2-4 parts of titanium dioxide, 1-2 parts of zinc oxide, 2-4 parts of stearic acid and 1.5-2.7 parts of zinc stearate, wherein the negative ion additive is a mixture of opal powder and medical stone powder, and the mass ratio of opalpowder to medical stone powder is 1: (0.6-0.8). The PU foaming shoe material capable of releasing negative ions is small in density and light in weight; the indentation hardness is high, the tensile strength is high, and the mechanical property is good; the rebound rate is high, the compression set rate is low, the elasticity is good, and permanent deformation is not likely to happen in the usingprocess; and the overall performance is excellent.

Owner:ZHEJIANG SEMIR GARMENT CO LTD +1

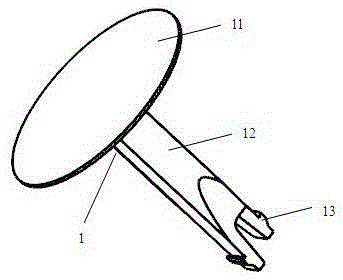

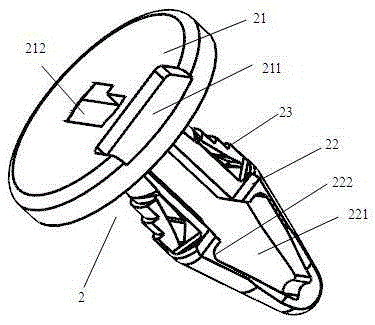

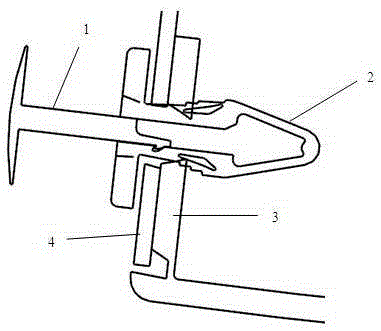

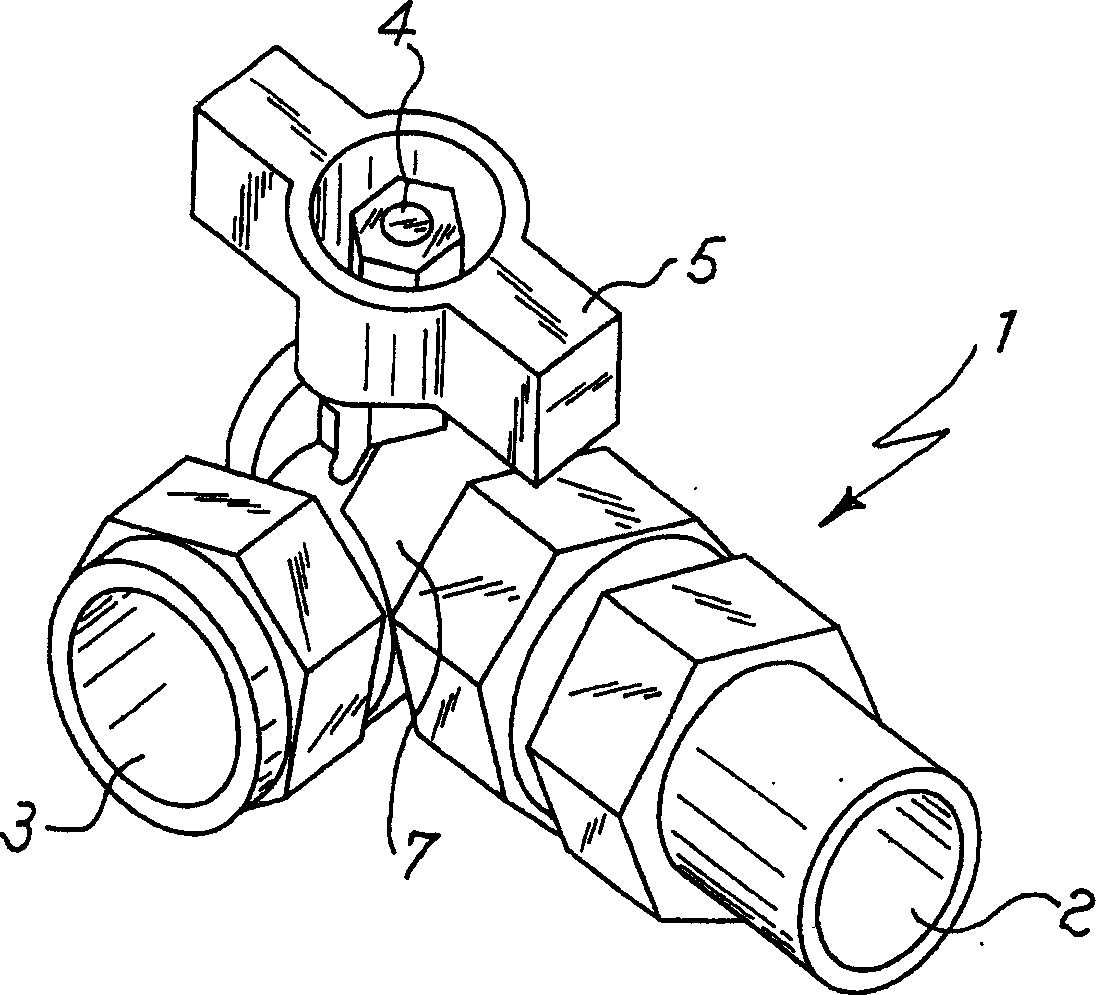

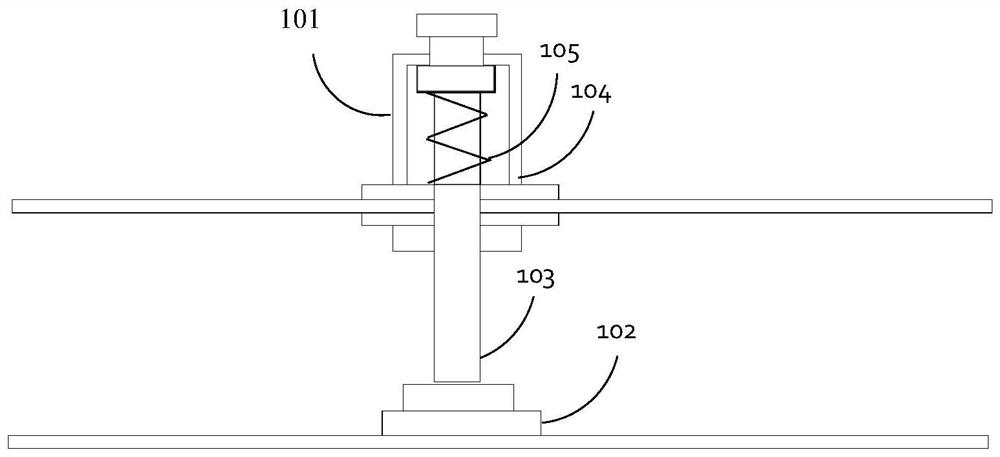

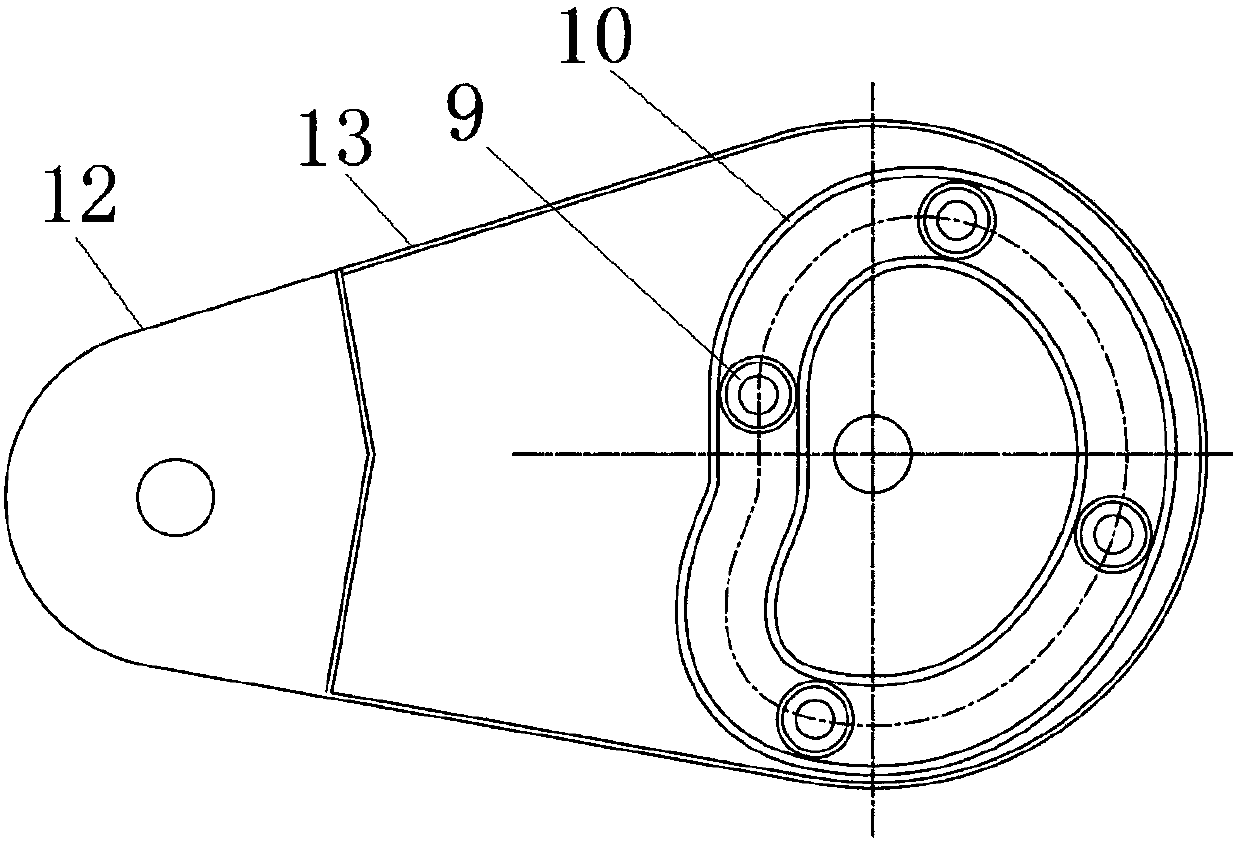

Buckle assembly

InactiveCN105299012ANot easy to failNot easy to looseSnap-action fastenersEngineeringMechanical engineering

The invention provides a buckle assembly and belongs to the field of mounting and fastening structures. The buckle assembly comprises a secondary buckle and a primary buckle, wherein the secondary buckle and the primary buckle can be connected in a clamped mode. The secondary buckle comprises a pressing part, a guide post and a limiting structure. The limiting structure is arranged at the insertion end of the guide post. The pressing part is arranged at the other end of the guide post. The primary buckle comprises a primary buckle base, a guide part and a step clamping part arranged on the side edge of the guide part. The guide part is arranged on the primary buckle base. The primary buckle base is provided with a through hole for the secondary buckle to be inserted in. The guide part is provided with a hollow portion. The through hole corresponds to the hollow portion. The secondary buckle is connected in the hollow portion in a clamped mode. The buckle assembly has the beneficial effects of being capable of being used repeatedly, low in cost, not liable to generate permanent deformation, suitable for fastening base materials of different thicknesses, reliable in performance and easy to dismount.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

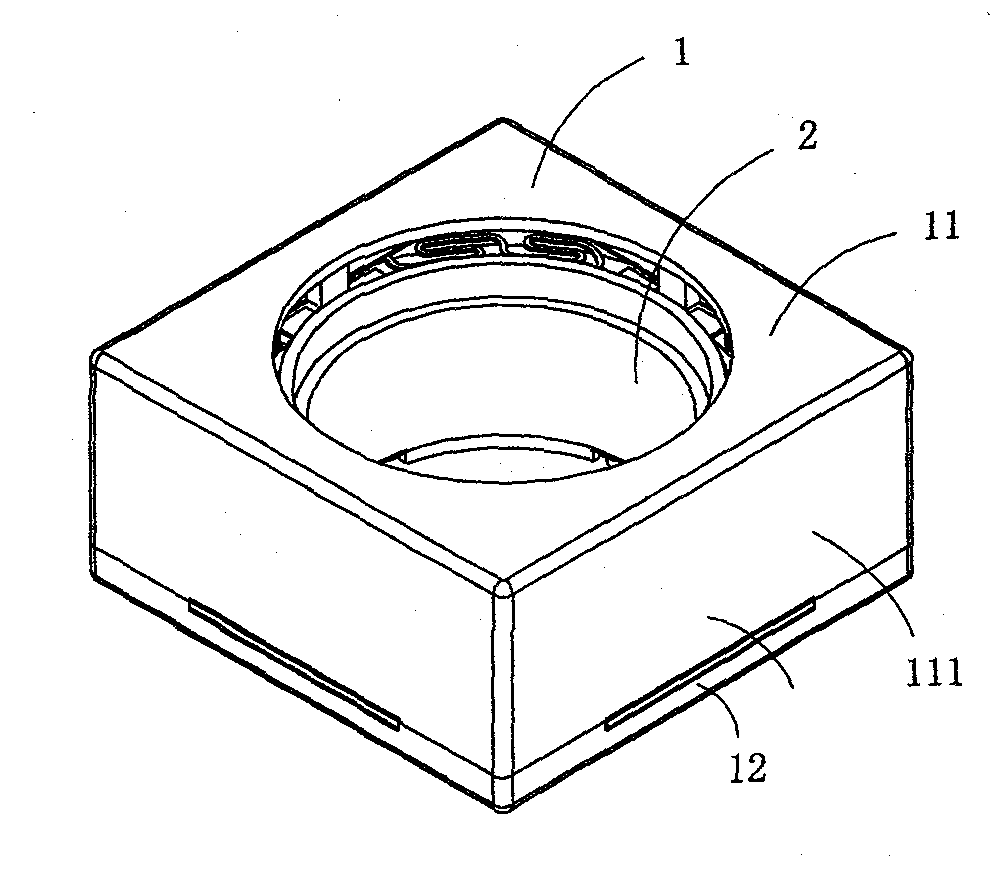

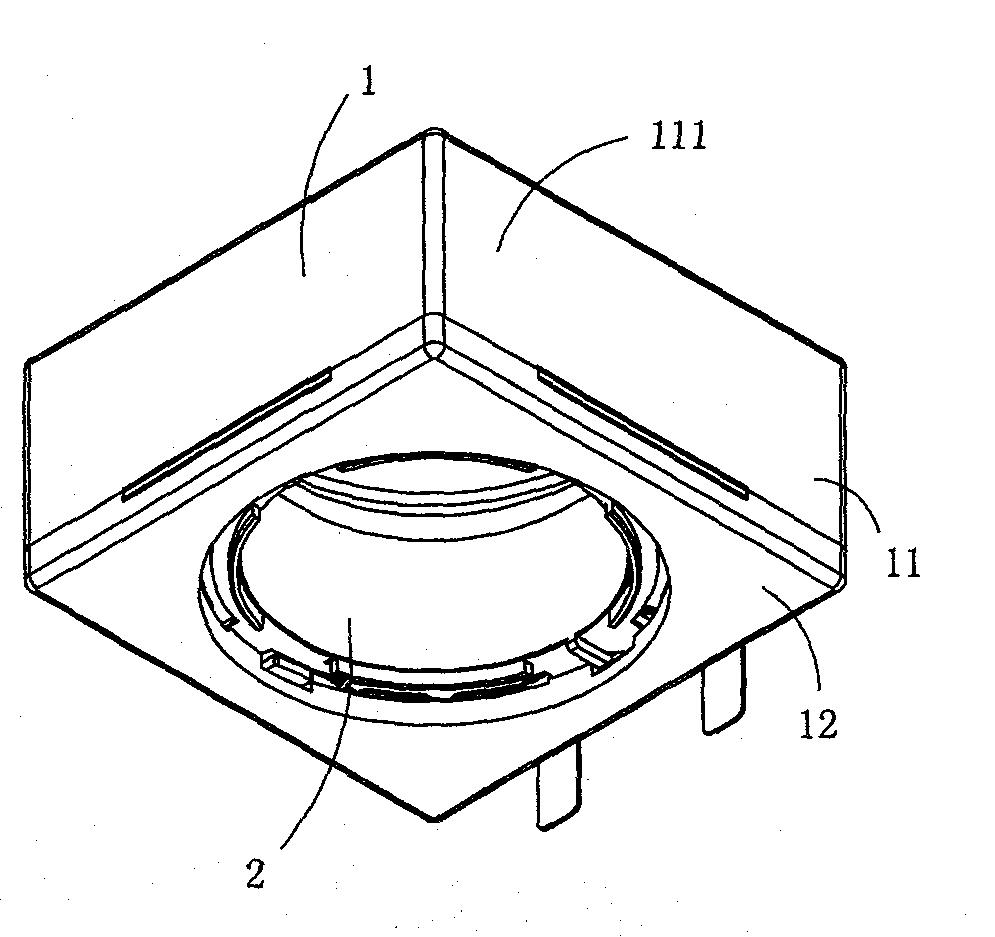

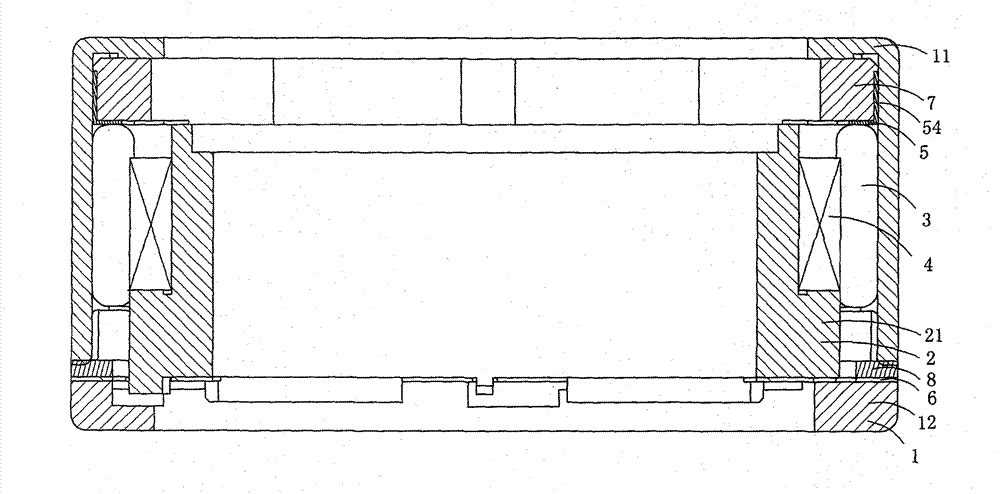

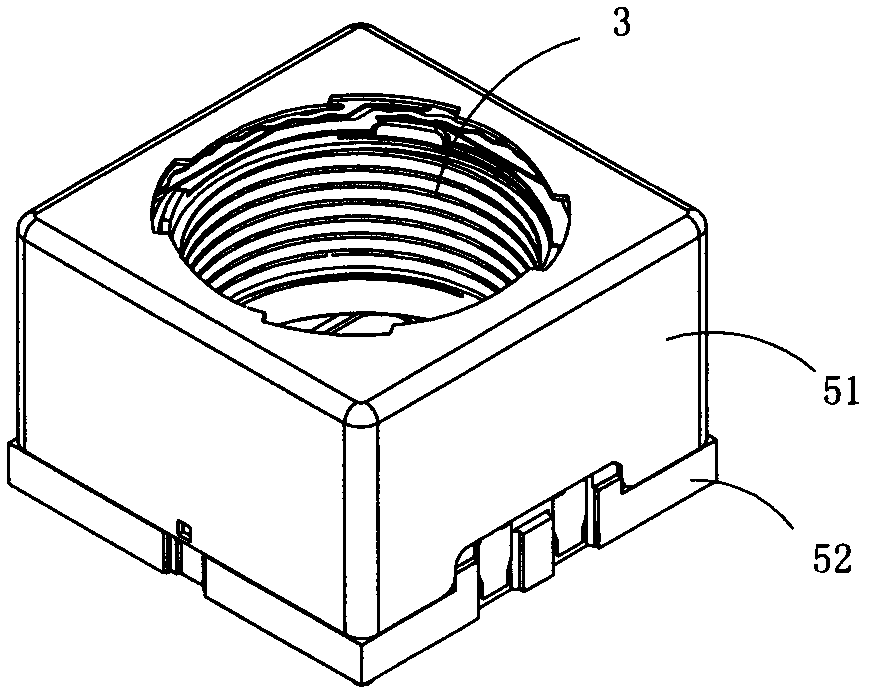

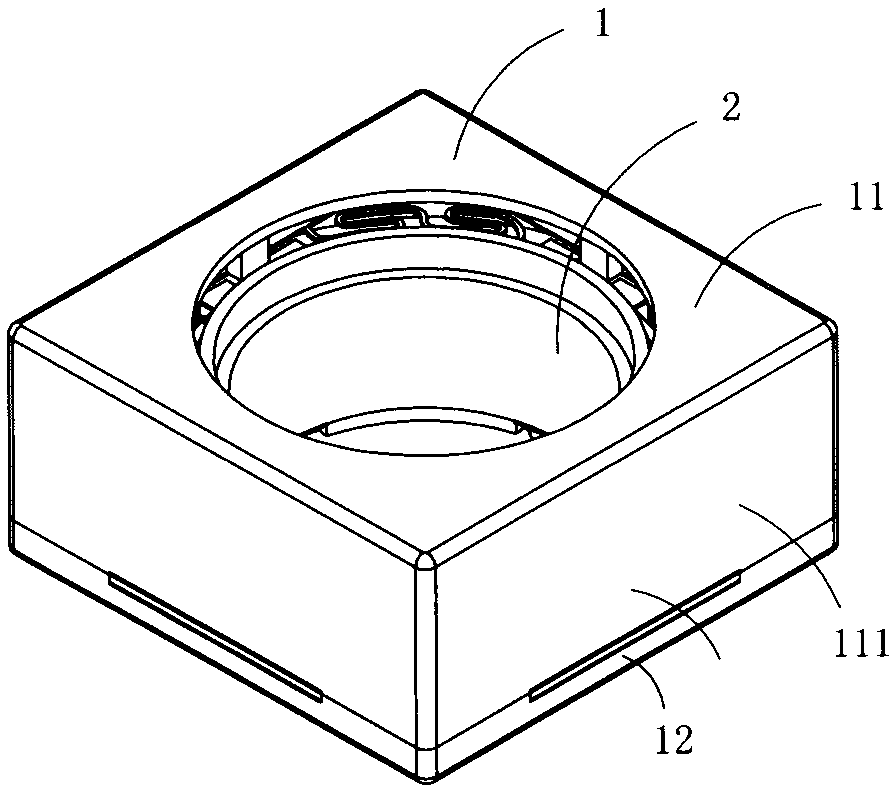

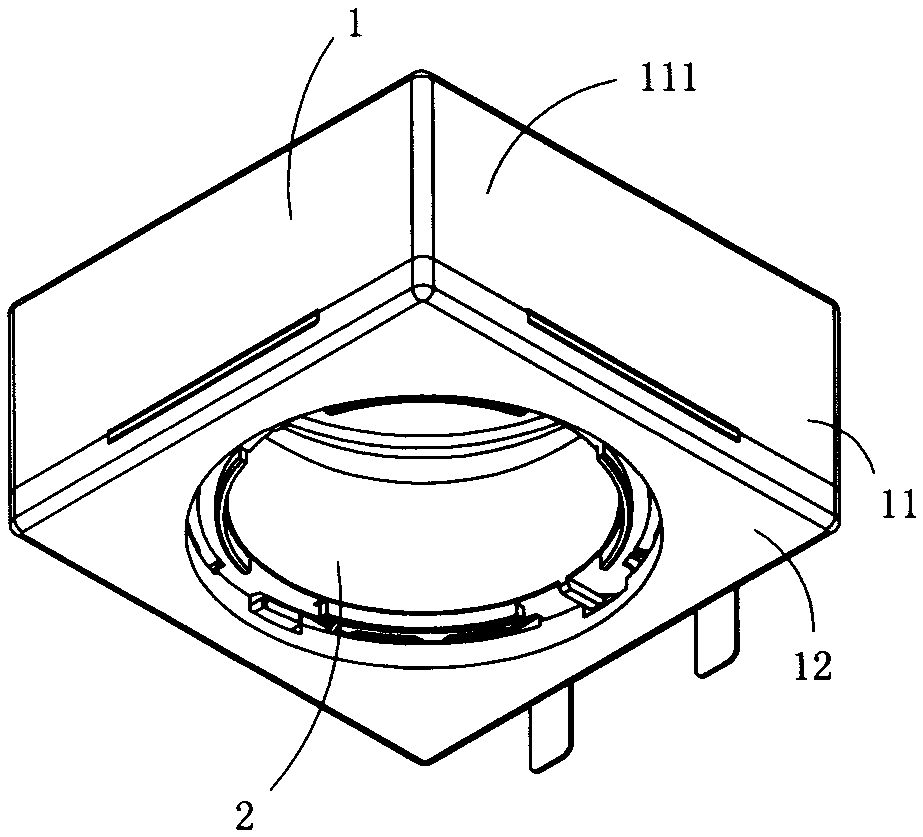

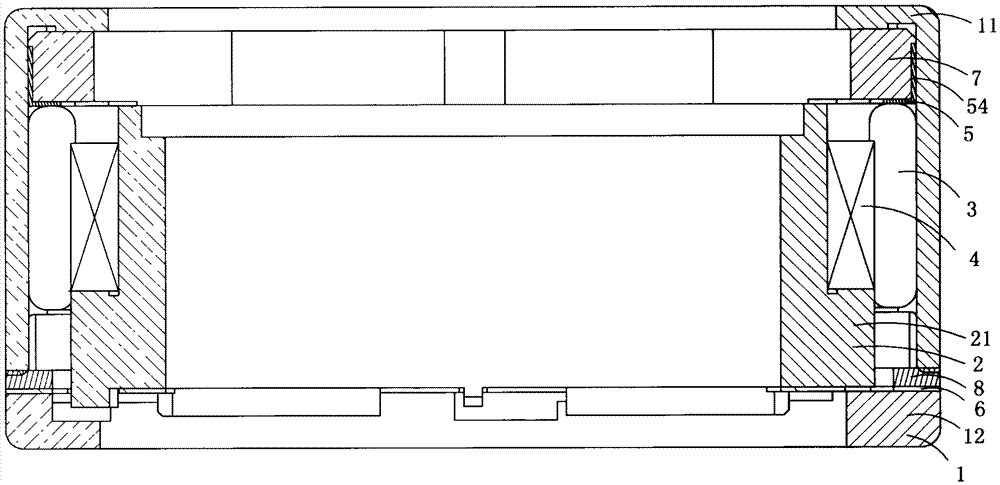

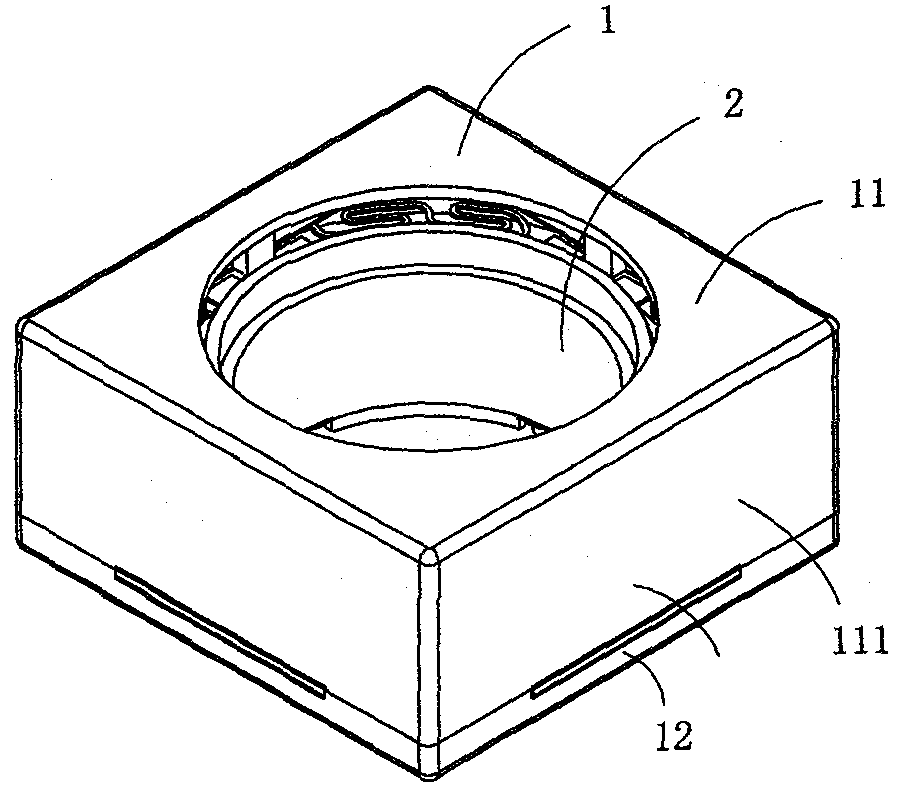

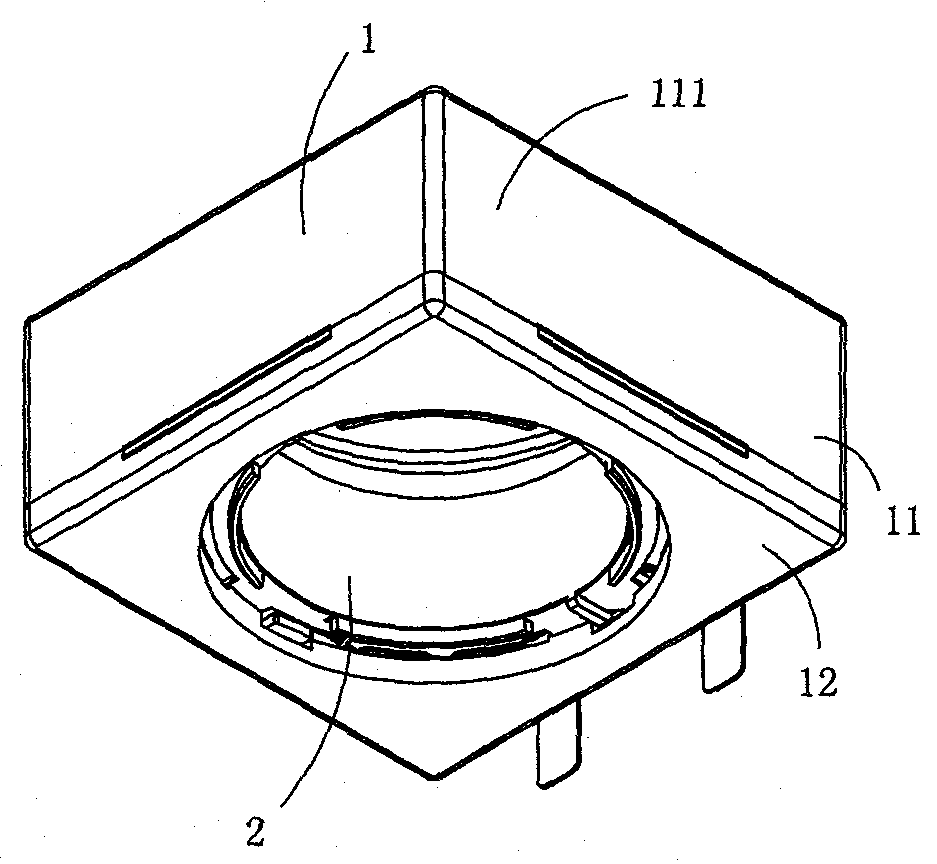

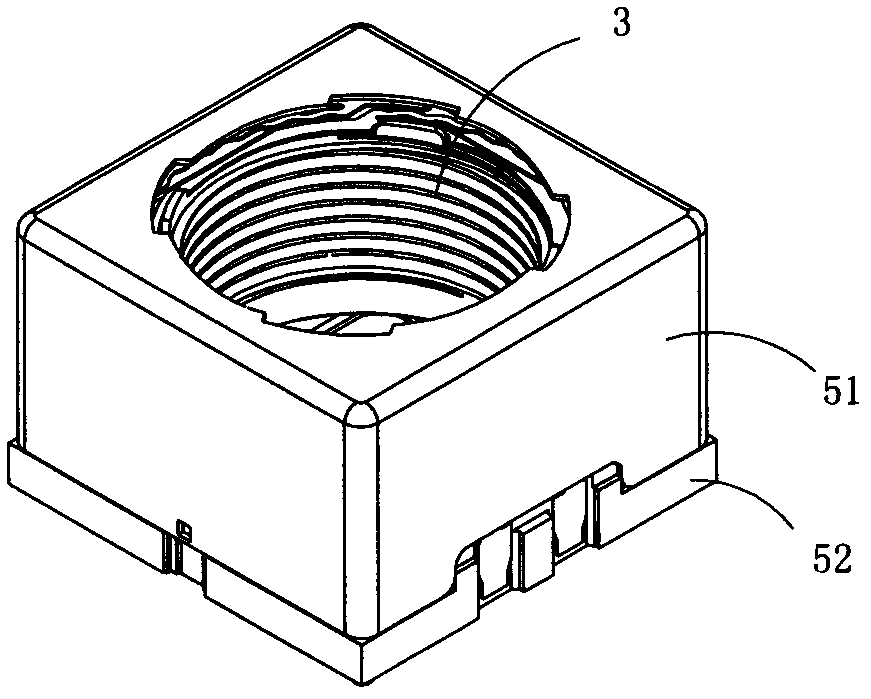

Lens driving device

ActiveCN102967912AAvoid the disadvantages of eccentricityCompact and reasonable structureDynamo-electric machinesMountingsEngineeringMagnetic loop

The invention discloses a lens driving device. The lens driving device comprises a casing, a lens carrier, a magnet assembly, a coil, an upper elastic piece and a lower elastic piece, wherein the lens carrier, the magnet assembly, the coil, the upper elastic piece and the lower elastic piece are arranged in the casing, the lens carrier is arranged between the upper elastic piece and the lower elastic piece, the magnet assembly is arranged on the periphery of the lens carrier, the coil is arranged between the magnet assembly and the lens carrier, the inner wall of the coil is adhered to and fixed on the outer wall of the lens carrier through glue, and a glue containing groove which is used for containing the redundant glue is arranged on the outer wall of the lens carrier. The lens driving device is reasonable and compact in structure, and magnetic conducting rings in traditional lens driving devices are not required, so that defects that lens carriers are eccentric due to the fact that magnetic forces of magnetic conducting rings are too strong can be avoided, the manufacturing process is simplified, and the manufacturing cost can be effectively reduced.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

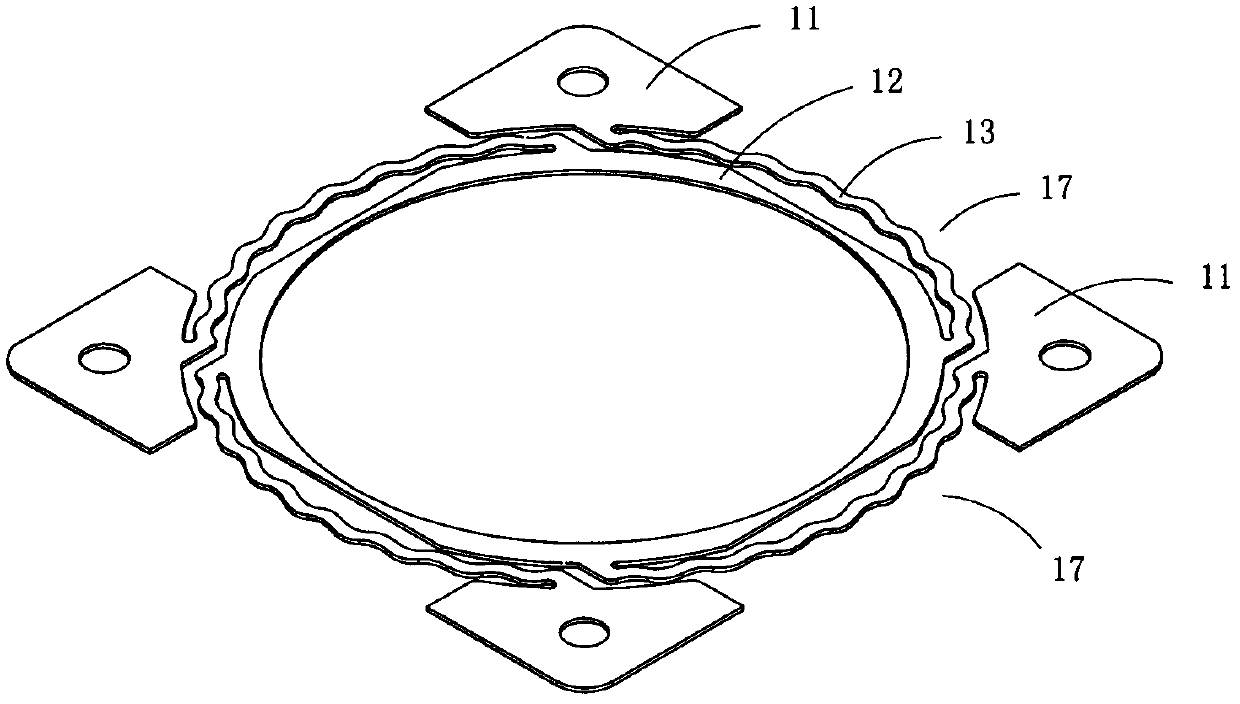

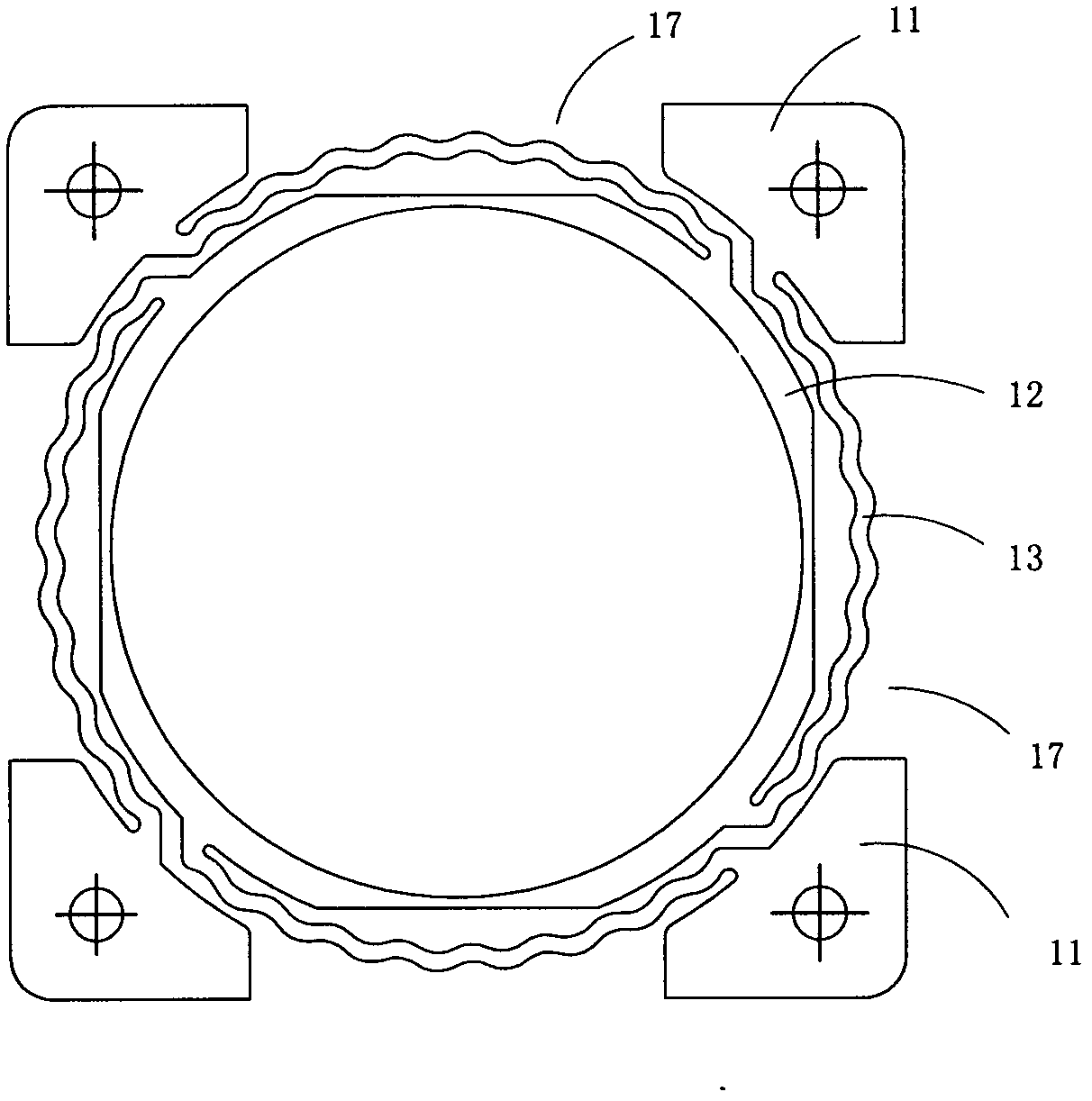

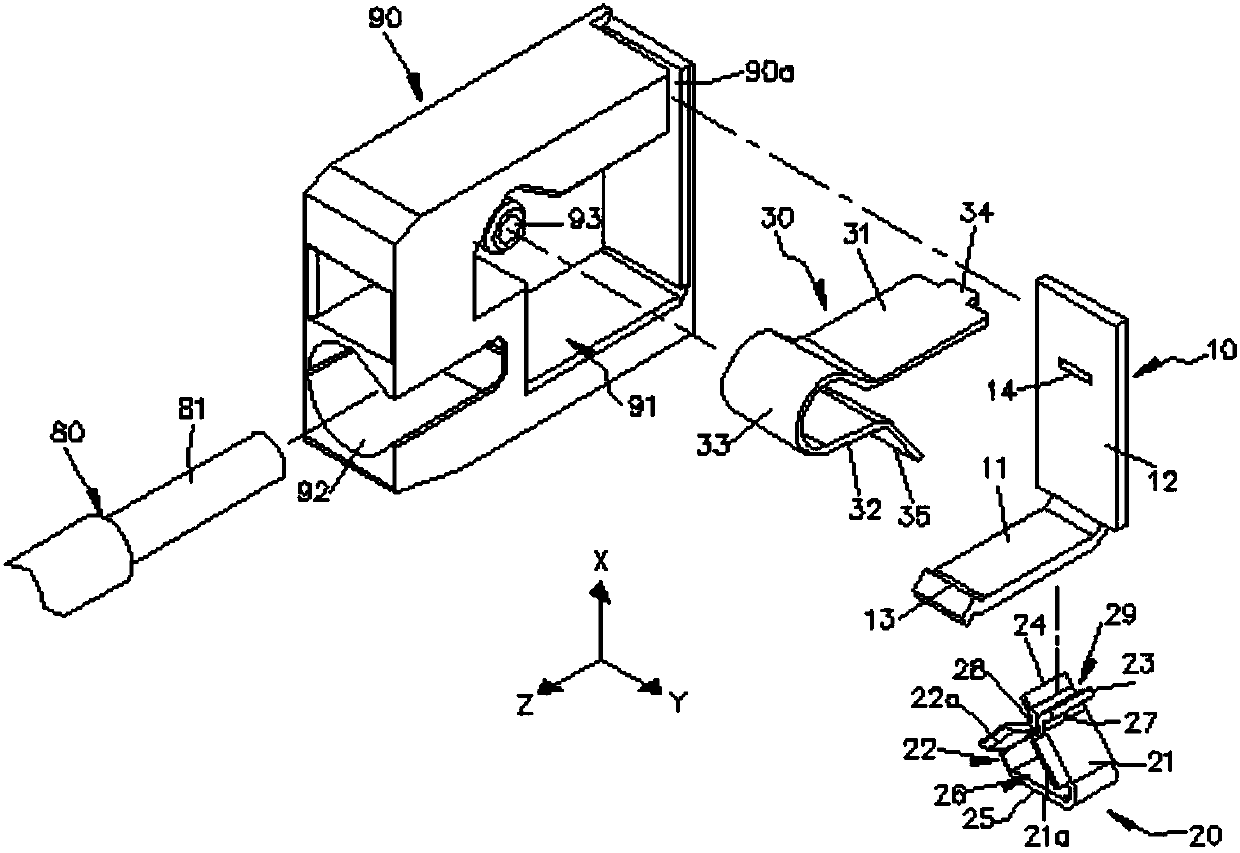

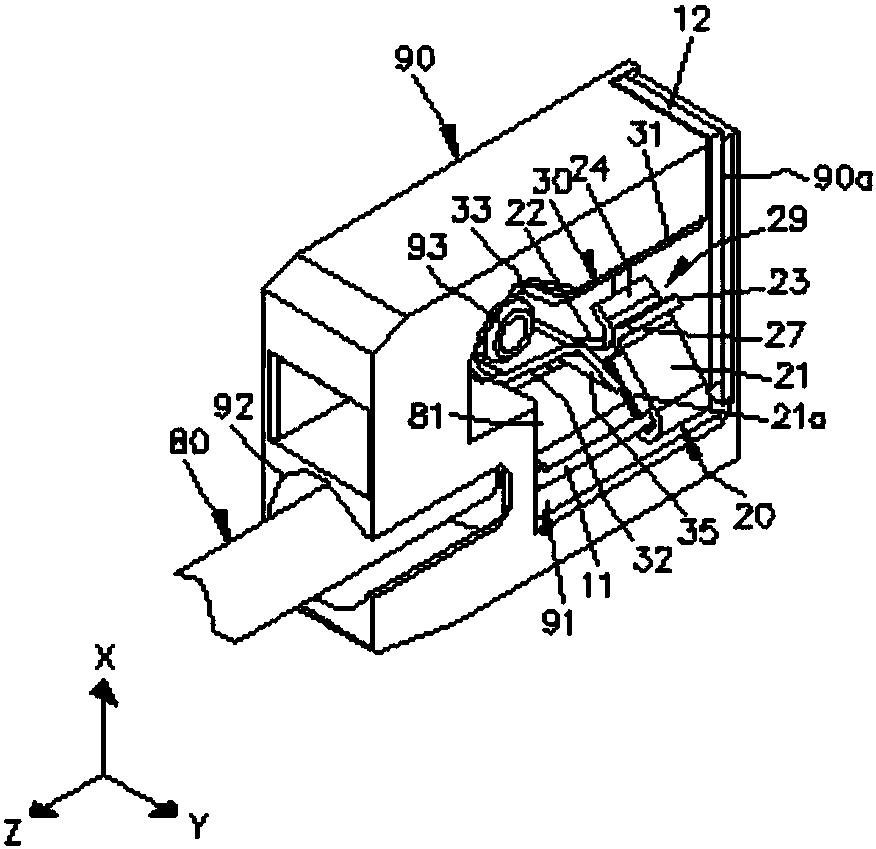

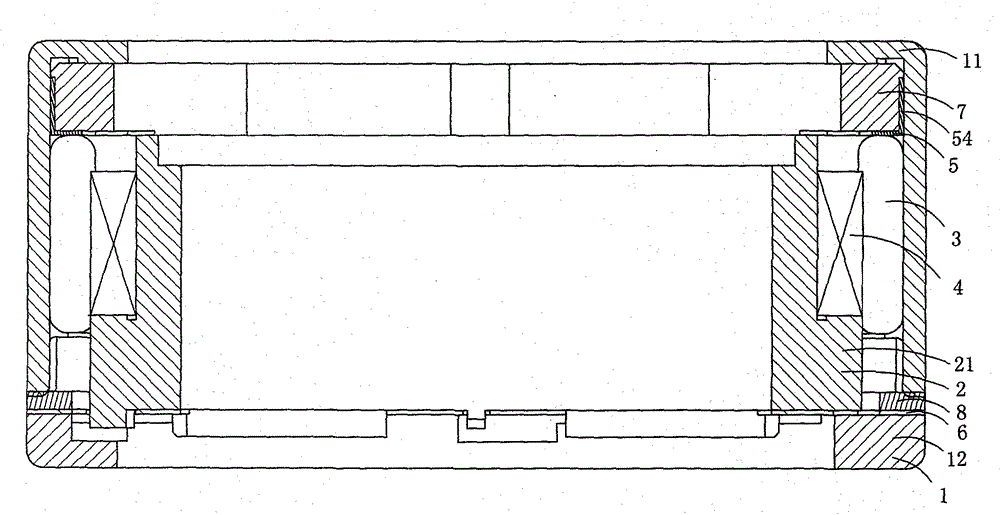

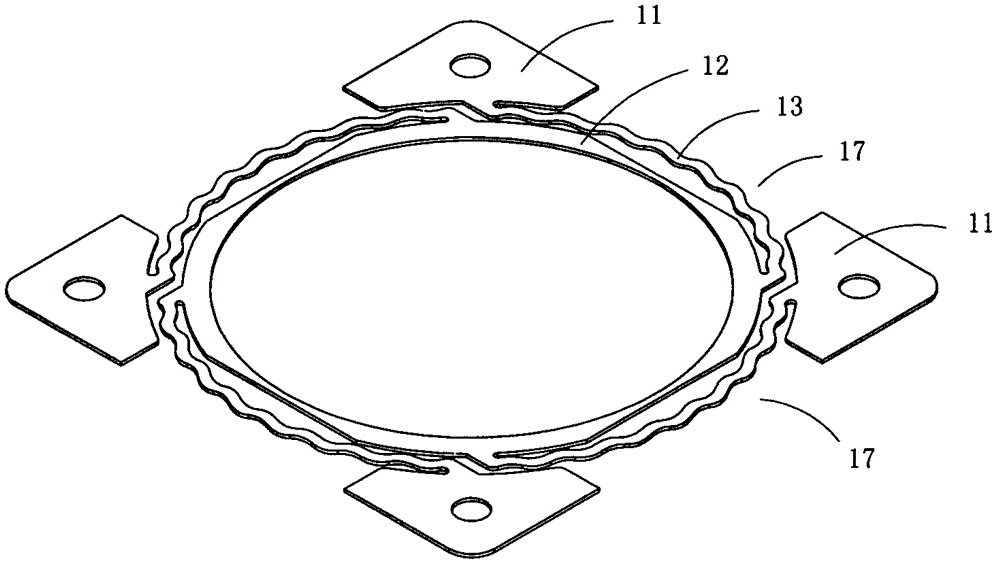

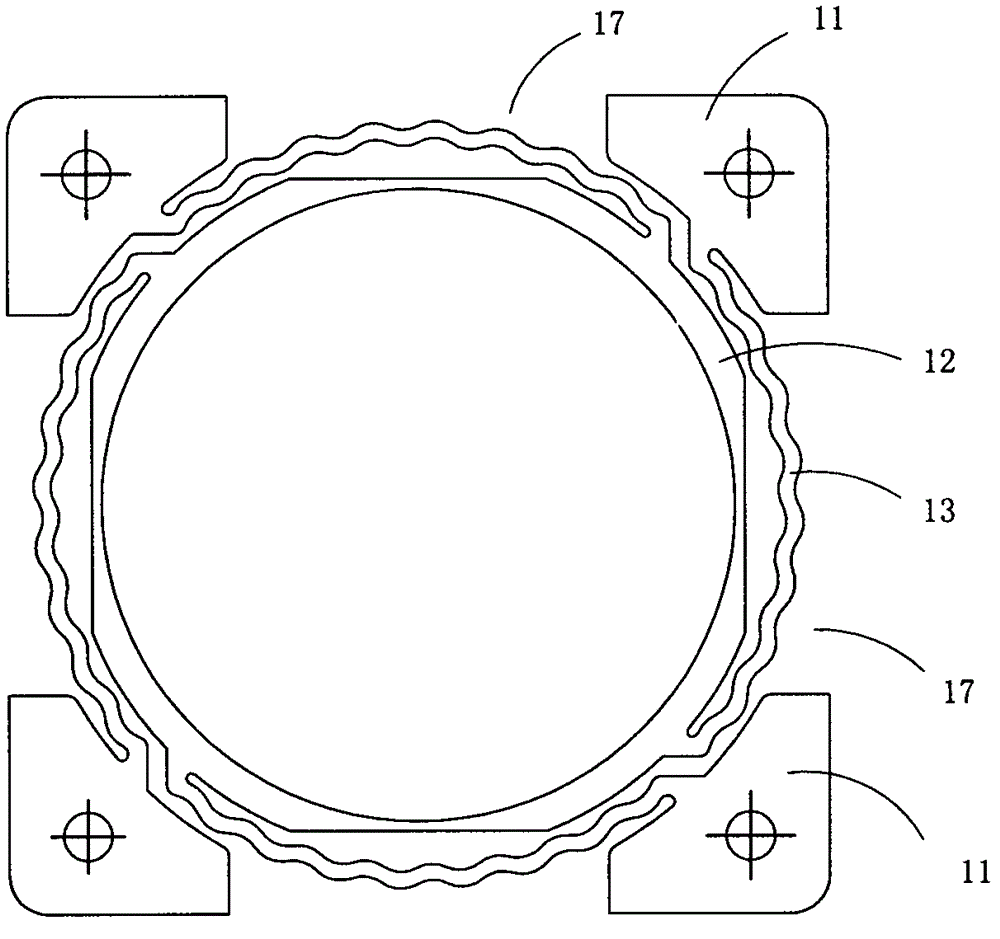

Improved voice coil motor

ActiveCN102710088AHigh strengthNot easy to permanently deformDynamo-electric machinesEngineeringMechanical engineering

The invention discloses an improved voice coil motor. The improved voice coil motor comprises an upper spring plate, an upper spring plate mounting rack and a lens carrier, wherein a plurality of supporting legs are arranged on the upper spring plate mounting rack; the upper spring plate is fixed on the supporting legs; the upper spring plate comprises fixed regions, an inner ring region and a plurality of elastic arm regions; the fixed regions are fixedly arranged on the supporting legs; the inner ring region is fixed on the lens carrier; the elastic arm regions connect the fixed regions and the inner ring region; the upper spring plate also comprises reinforcement plates connecting two adjacent fixed regions; and each reinforcement plate is vertical to the plane where the fixed regions are located. The improved voice coil motor has the following positive effects: the upper spring plate comprises the reinforcement plates connecting two adjacent fixed regions and each reinforcement plate is vertical to the plane where the fixed regions are located; therefore, the reinforcement plates can effectively improve the strength of the upper spring plate on the basis that the floor area is not increased, so that the upper spring plate is not liable to deform permanently during mounting and operation and the yield is effectively improved, thus reducing the manufacture cost to some extent.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

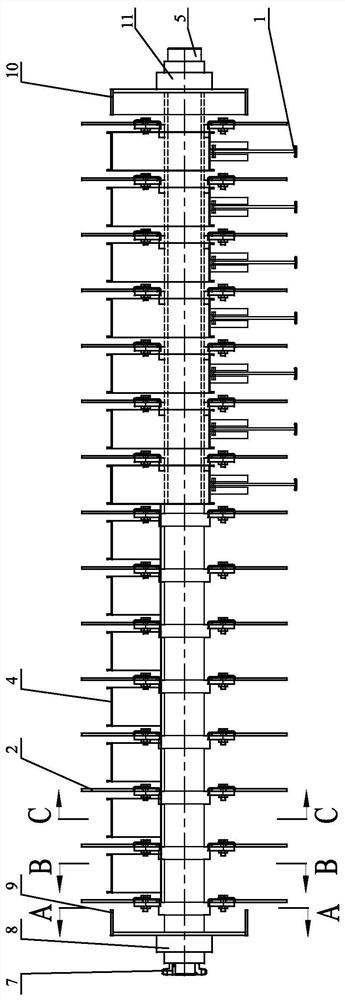

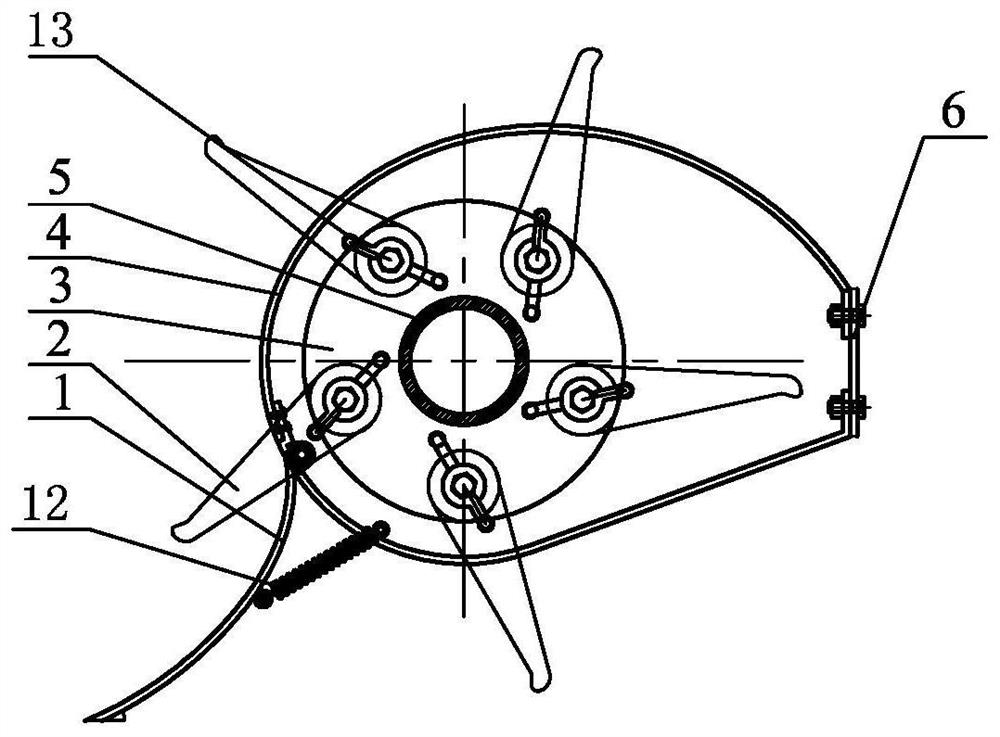

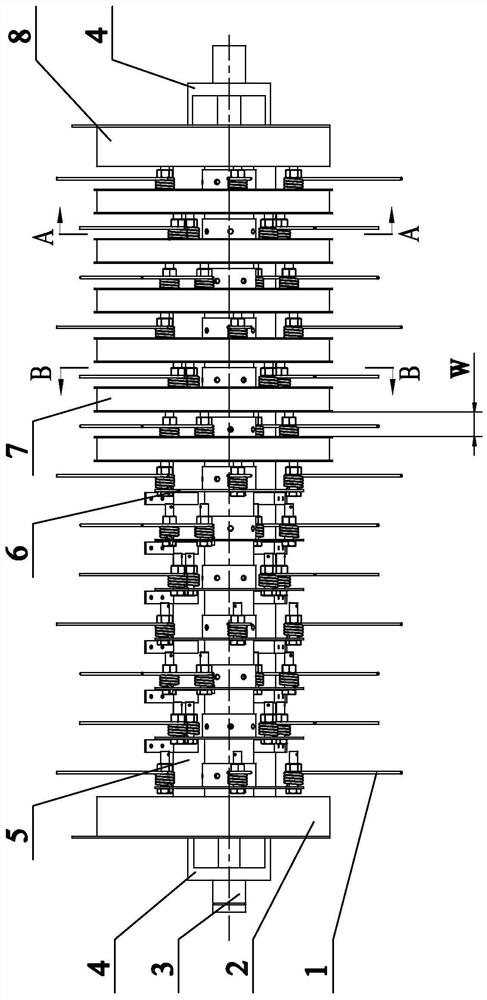

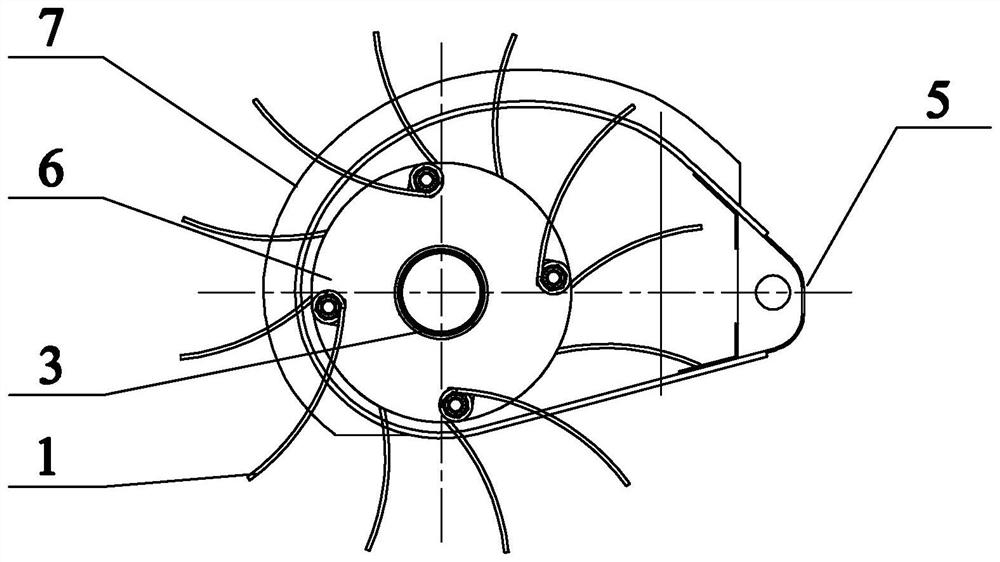

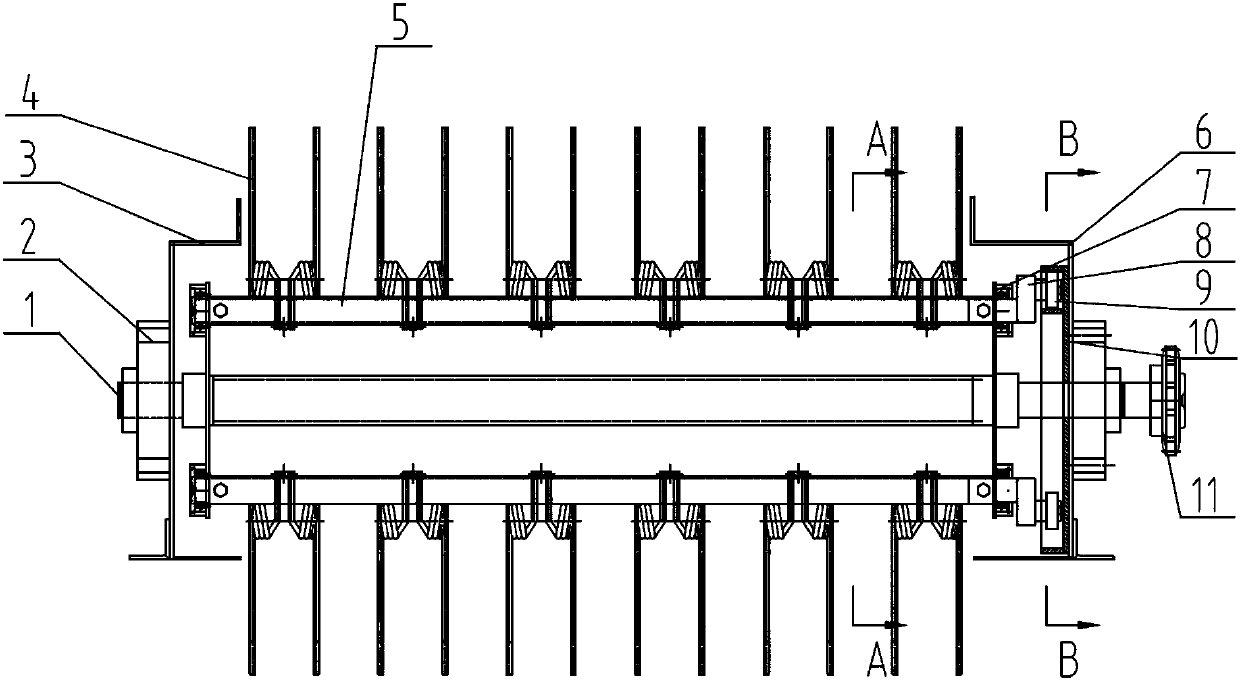

Shovel tooth and elastic tooth roller combined type peanut pickup device

ActiveCN112400478AEasy to pick upExtended service lifeHarvestersAgricultural engineeringStructural engineering

The invention discloses a shovel tooth and elastic tooth roller combined type peanut pickup device, and belongs to the technical field of agricultural machinery. The shovel tooth and elastic tooth roller combined type peanut pickup device comprises picking shovel teeth, roller protection plates, a picking roller, a roller sliding way and side plates; a center shaft of the picking roller penetratesthrough the side plates at the two sides to be installed on bearing pedestals, picking elastic teeth are evenly arranged on an elastic tooth shaft of the picking roller at intervals, and the roller protection plates are arranged between the adjacent picking elastic teeth; at the advancing front end of the pickup device, arc-shaped picking shovel teeth of the same structure are installed at the same position of each roller protection plate to form a row of shovel teeth; and the roller sliding way is fixedly installed in one side plate and is in sliding connection with the elastic tooth shaft on the picking roller. According to the pickup device, the peanut plants are shoveled up through the shovel teeth; the picking roller rotates along the roller sliding way, and the elastic teeth rotatearound the center shaft along with the roller and periodically and repeatedly swing due to the limitation of the roller sliding way, so that actions of lifting, pushing and returning to a station by the elastic teeth are realized; and the impact of the roller on a cam sliding way can be effectively reduced, large stress concentration is avoided, and the service life of the cam sliding way is prolonged.

Owner:JILIN AGRICULTURAL UNIV +2

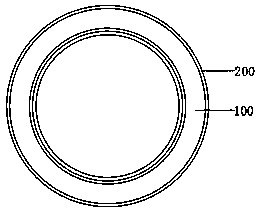

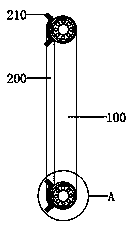

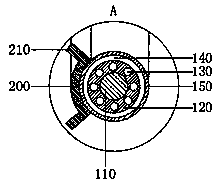

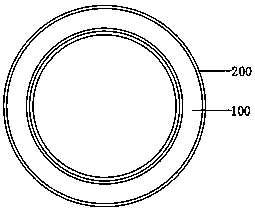

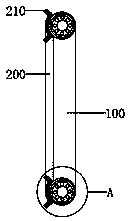

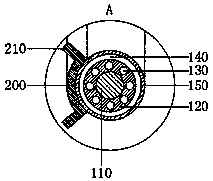

O-shaped seal ring of automobile fuel oil pump and manufacturing method thereof

ActiveCN109737206AAvoid wear and tearImprove cold resistanceEngine sealsDomestic articlesEngineeringFuel oil

The invention discloses an O-shaped seal ring of an automobile fuel oil pump and belongs to the technical field of fuel oil pumps. The O-shaped seal ring of the automobile fuel oil pump comprises a seal ring body and a dustproof strip. The dustproof strip is fixedly connected to the back side of the seal ring body. A manufacturing method of the O-shaped seal ring of the automobile fuel oil pump comprises the following steps of rubber inner ring formation, snap cage fixation, injection molding and dustproof strip fixation. The O-shaped seal ring of the automobile fuel oil pump is provided withthe dustproof strip, so that during installation and use, external dust can be prevented from entering the O-shaped seal ring installation portion, and it is avoided that the dust enters the O-shapedseal ring and accelerates wear of the O-shaped seal ring; the seal ring body adopts multi-layer design and is provided with a cold-resistant outer sheath, so that the cold resistance of the O-shaped seal ring is greatly improved, and the O-shaped seal ring can be used under cold conditions; multiple snap cages are annularly arranged in the O-shaped seal ring, so that the O-shaped seal ring has good rebound resilience, when the O-shaped seal ring is used and squeezed for a long time, the O-shaped seal ring is not prone to generating permanent deformation, and the O-shaped seal ring can always keep good seal performance.

Owner:安徽沃尔顶密封工业股份有限公司

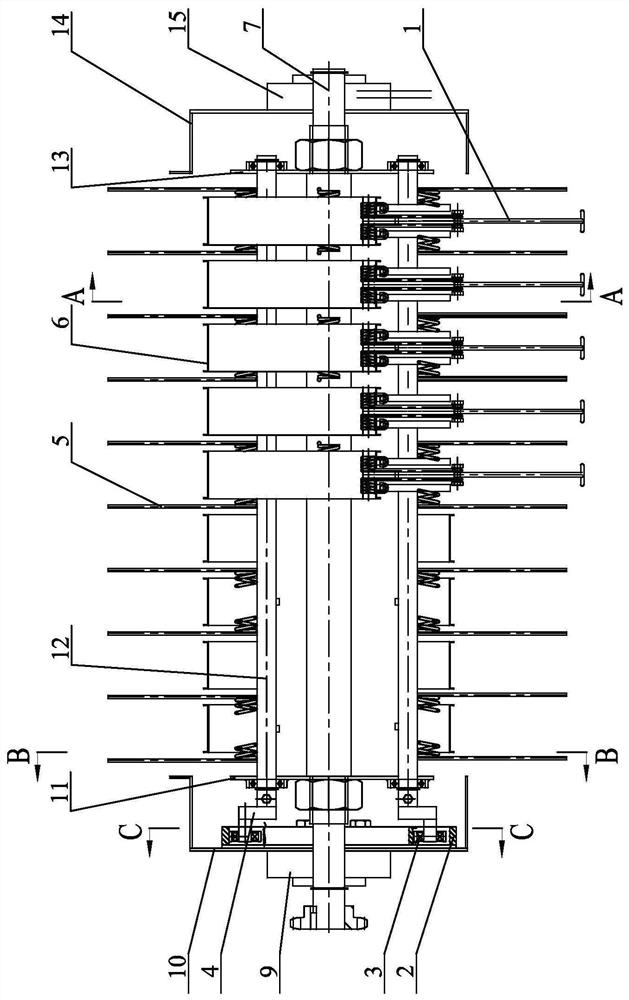

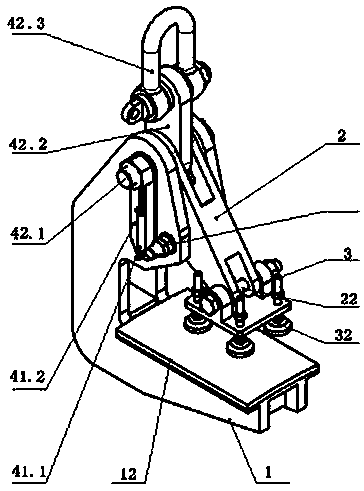

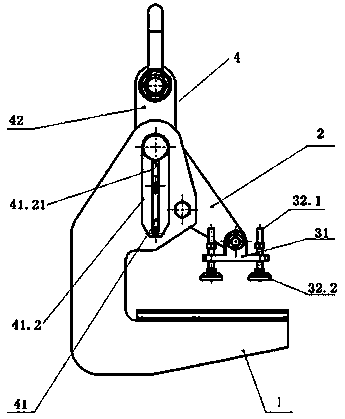

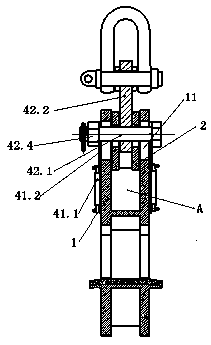

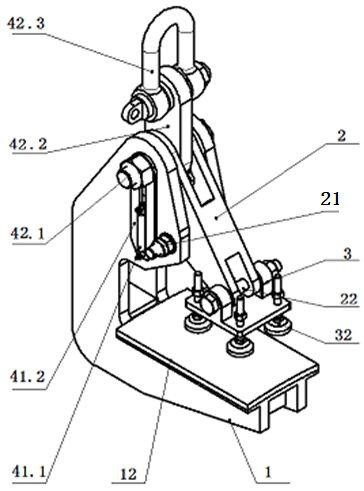

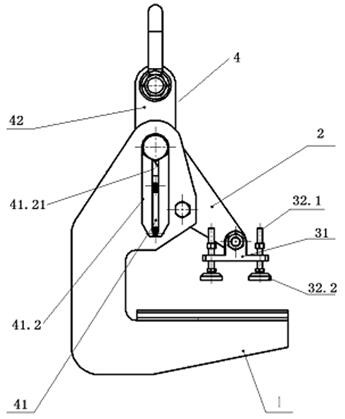

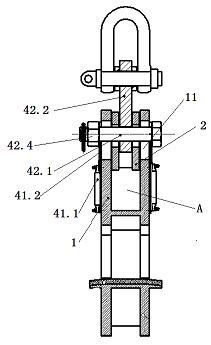

Wind power blade demoulding hoisting clamp and wind power blade demoulding method

ActiveCN111573494AImprove demoulding efficiencyImprove reliabilitySafety gearEngineeringStructural engineering

The invention provides a wind power blade demoulding hoisting clamp. The wind power blade demoulding hoisting clamp comprises a C-shaped seat, a pressing block connecting rod obliquely arranged and installed on the C-shaped seat in a swinging mode and a pressing block assembly installed at the lower end of the connecting rod and used for compressing a blade on the C-shaped seat. The wind power blade demoulding hoisting clamp is characterized by further comprising an elastic hoisting assembly capable of driving the pressing block connecting rod to swing, the elastic hoisting assembly is movablyinstalled on the C-shaped seat and enables the initial spacing between the pressing block assembly and the C-shaped seat to be the largest through an initial oblique angle of an elastic positioning pressing block connecting rod, the blade extends between the C-shaped seat and the pressing block assembly, blade gravity is located on the C-shaped seat with the upward hoisting of the elastic hoisting assembly, and the pressing block connecting rod swings downwards with the hoisting of the elastic hoisting assembly to enable the spacing between the pressing block assembly and the C-shaped seat tobe reduced and pressed on the blade. According to the wind power blade demoulding hoisting clamp, the blade is effectively protected from being damaged in the demoulding process due to clamping, thereliability and safety of the clamp are improved, the demoulding efficiency of the blade is improved, and the service life is long.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Shovel tooth and tooth roller combined type peanut pickup device

ActiveCN112400477AEasy to pick upIncreased pickup widthHarvestersSaving energy measuresAgricultural engineeringStructural engineering

The invention discloses a shovel tooth and tooth roller combined type peanut pickup device, and belongs to the technical field of agricultural machinery. The shovel tooth and tooth roller combined type peanut pickup device comprises picking shovel teeth, roller protection plates, a picking roller and side plates; the side plates are arranged at the two sides of the picking roller, a center shaft of the picking roller penetrates through the side plates at the two sides to be installed on bearing pedestals, cattail wheels of the picking roller are evenly arranged on the center shaft at intervals, and the roller protection plates are arranged between the adjacent cattail wheels; at the advancing front end of the pickup device, arc-shaped picking shovel teeth of the same structure are installed at the same position of each roller protection plate, and a row of picking shovel teeth are formed; during working, the arc-shaped picking shovel teeth move forwards, the working front ends of the shovel teeth go deep into the ground surface to shovel up peanut plants, and a picking action is achieved; and the cattail wheels of the picking roller rotate along with the center shaft, so that actions of lifting, pushing and returning to a station of the cattail wheels are realized. According to the shovel tooth and tooth roller combined type peanut pickup device, the peanut plants are shoveledby the shovel teeth; and the subsequent picking actions such as lifting and pushing are completed by the roller with the cattail wheels. The pickup device has the characteristics of small size, high pickup rate, low loss rate and the like.

Owner:JILIN AGRICULTURAL UNIV +2

Method for no-ironing finishing of pure cotton textile

The no-ironing finishing process of pure cotton textile includes the available steps of preparation, preflexibilizing, framing and settling, calendering, preshinking and packing as well as increased rolling supercrosslinking assistant, storing and water washing steps inserted between available preflexibilizing and framing steps. The textile after the said treating process is soft, permeable, water absorbing and no need of ironing and has low formaldehyde content.

Owner:LUTAI TEXTILE

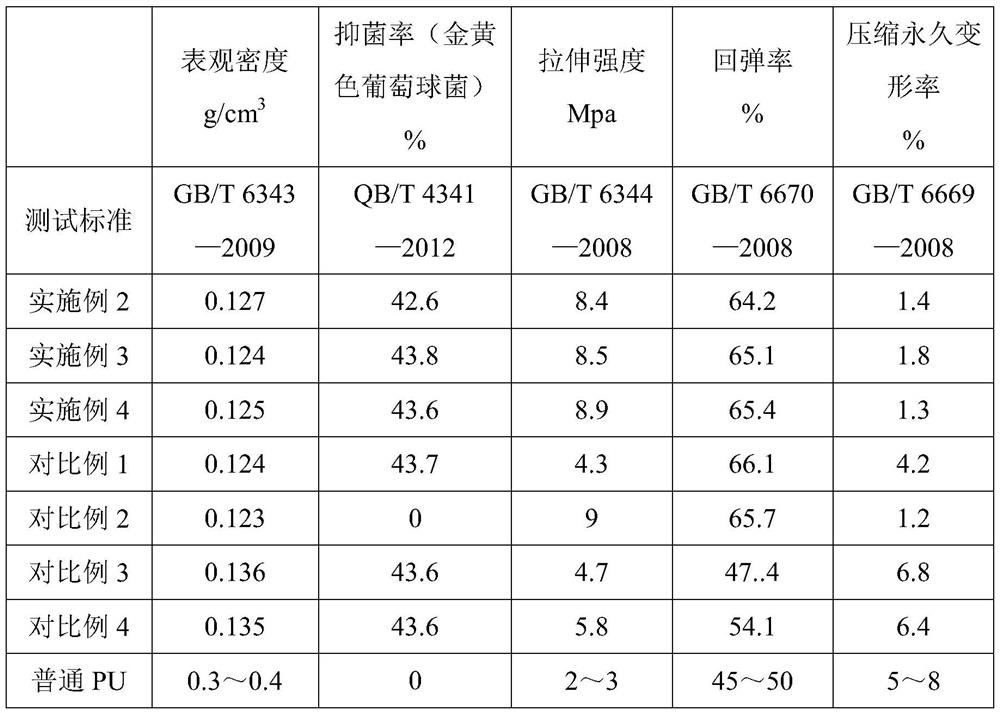

Traditional Chinese medicine antibacterial PU foaming shoe material with good moisture absorption performance and preparation method thereof

The invention discloses a traditional Chinese medicine antibacterial PU foaming shoe material with good moisture absorption performance and a preparation method thereof. The material is prepared fromthe following raw materials in parts by weight: 80-90 parts of polyurethane, 10-14 parts of styrene-ethylene-butadiene-styrene block copolymer, 4-6 parts of polyethylene oxide, 4-6 parts of epoxidizedsoybean oil, 2-2.6 parts of fructus cnidii, 1.4-1.8 parts of dandelion, 2.4-3.6 parts of carboxymethyl cellulose, 1.8-2.2 parts of 4-methylbenzenesulfonyl hydrazine, 0.6-0.75 part of triethylene diamine, 0.08-0.1 part of triallyl isocyanurate, 5-9 parts of a filling material, 1.2-1.6 parts of zinc oxide, 2.5-4 parts of stearic acid and 1.5-2.7 parts of zinc stearate. The traditional Chinese medicine antibacterial PU foaming shoe material with the good moisture absorption performance is small in density and light in weight; the antibacterial rate is high, and the antibacterial performance is good; the tensile strength is high and the mechanical property is good; the resilience rate is high, the compression set rate is low, and the elasticity is good; the comprehensive performance is excellent, and durability and antibiosis are achieved.

Owner:QUANZHOU YUANLI SHOES MATERIAL

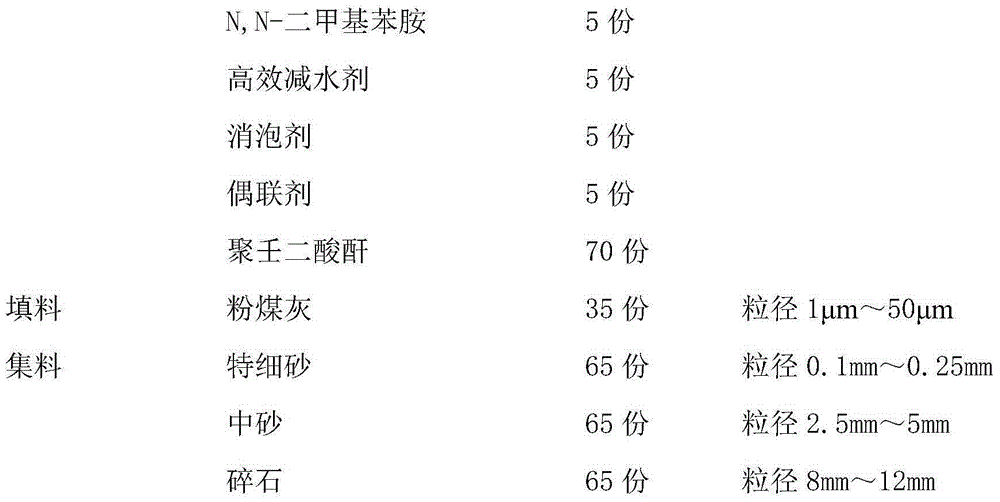

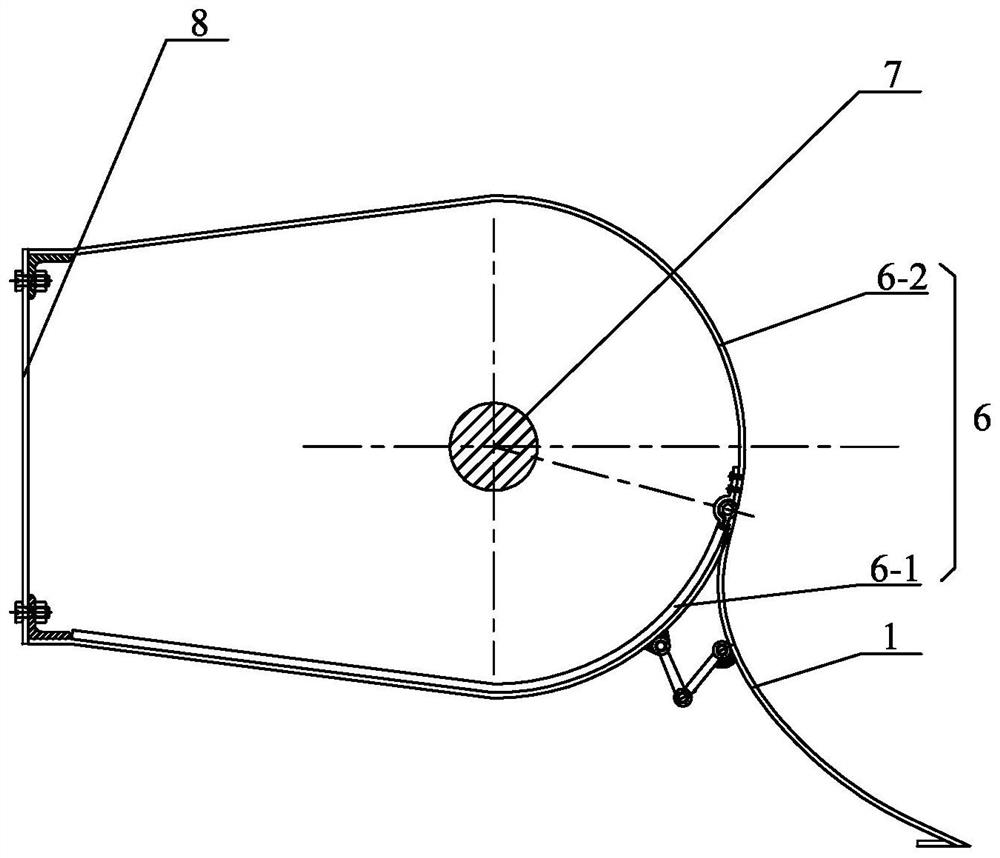

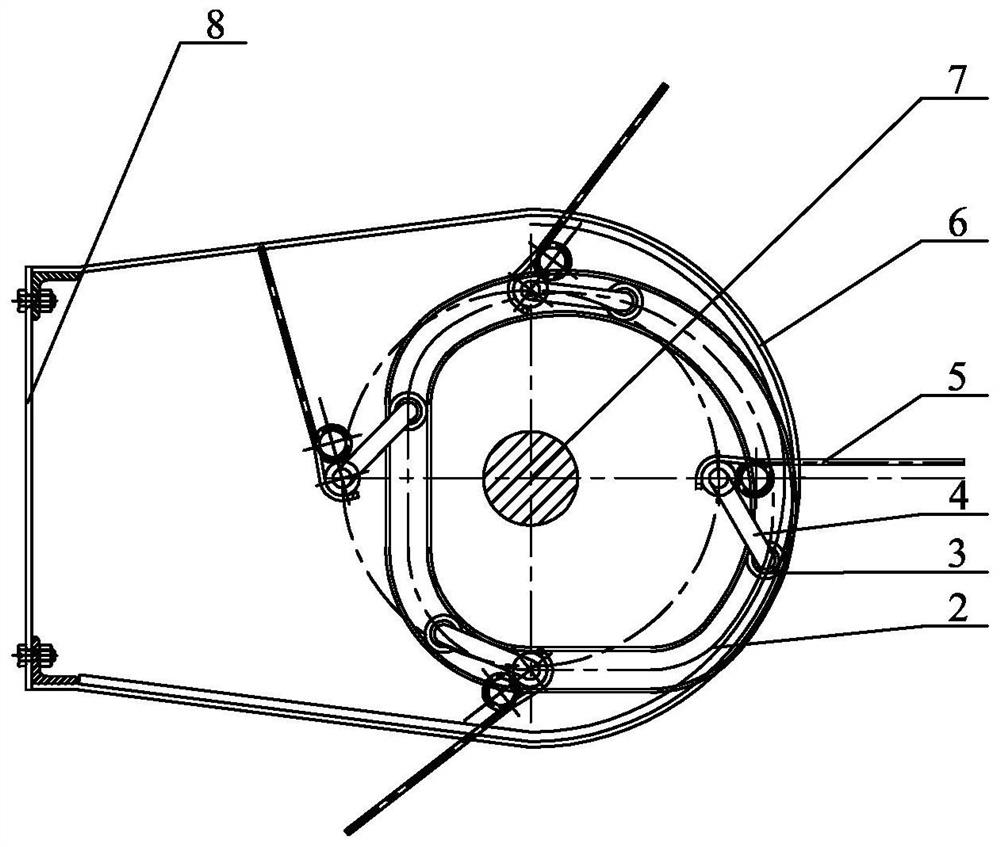

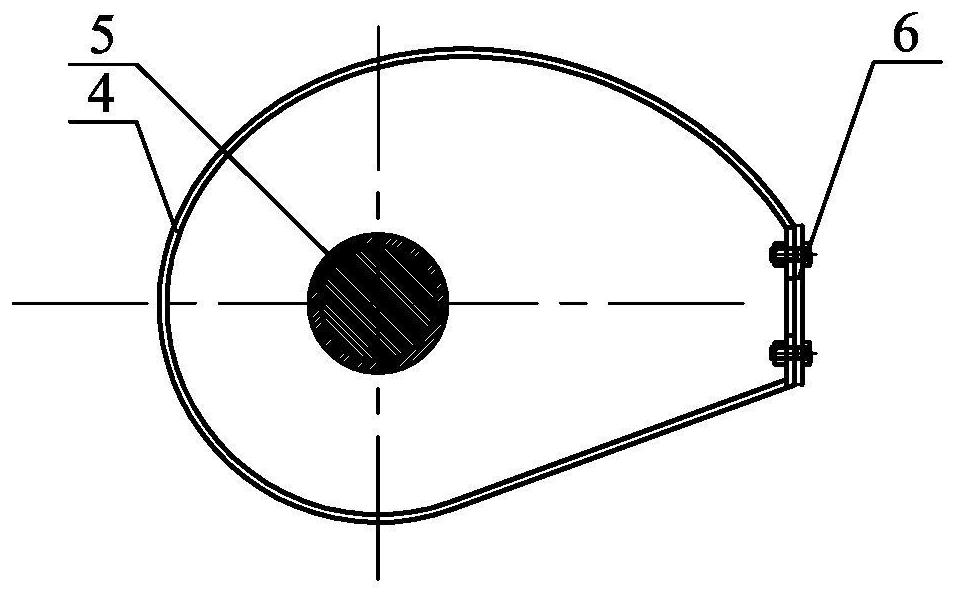

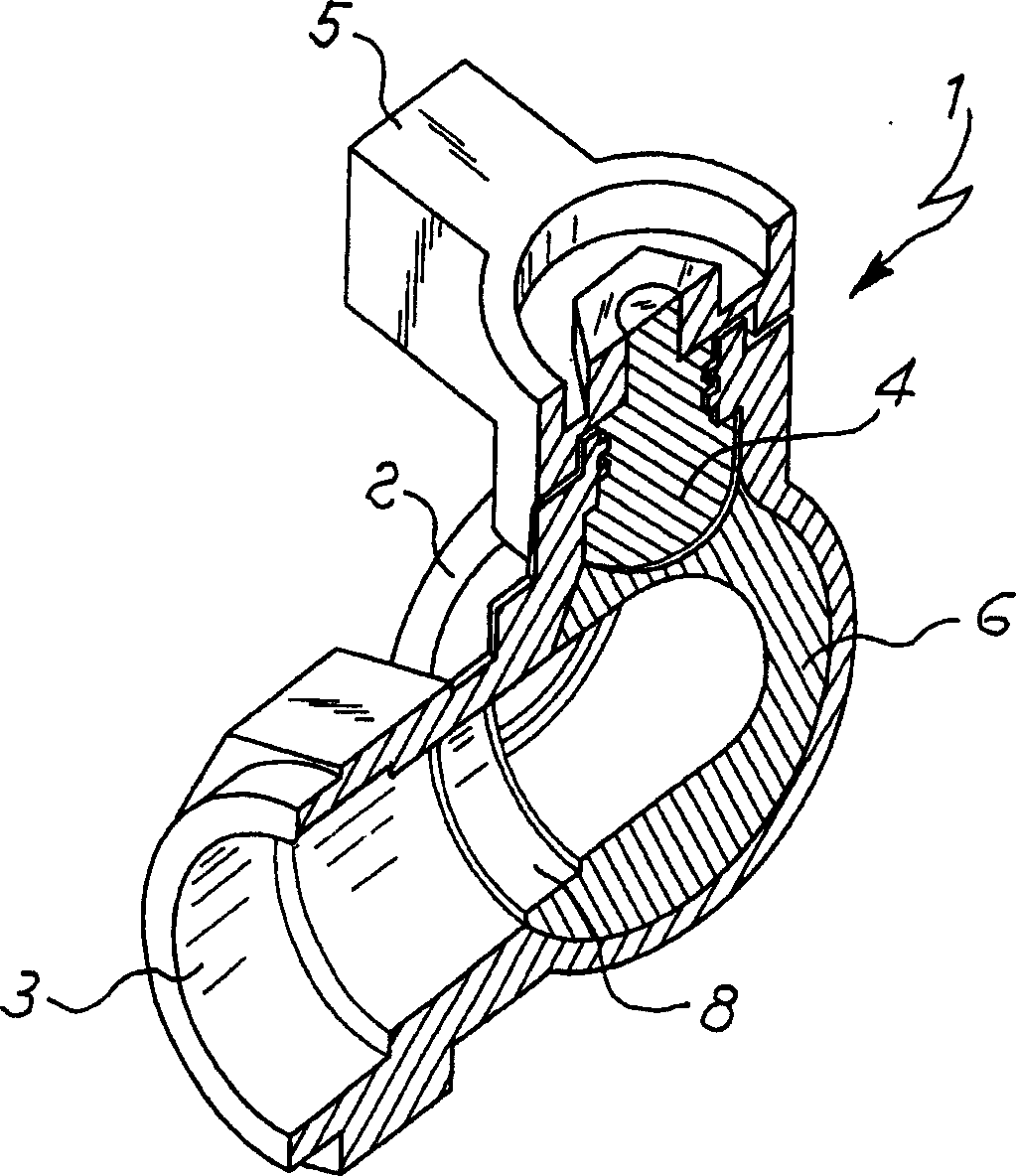

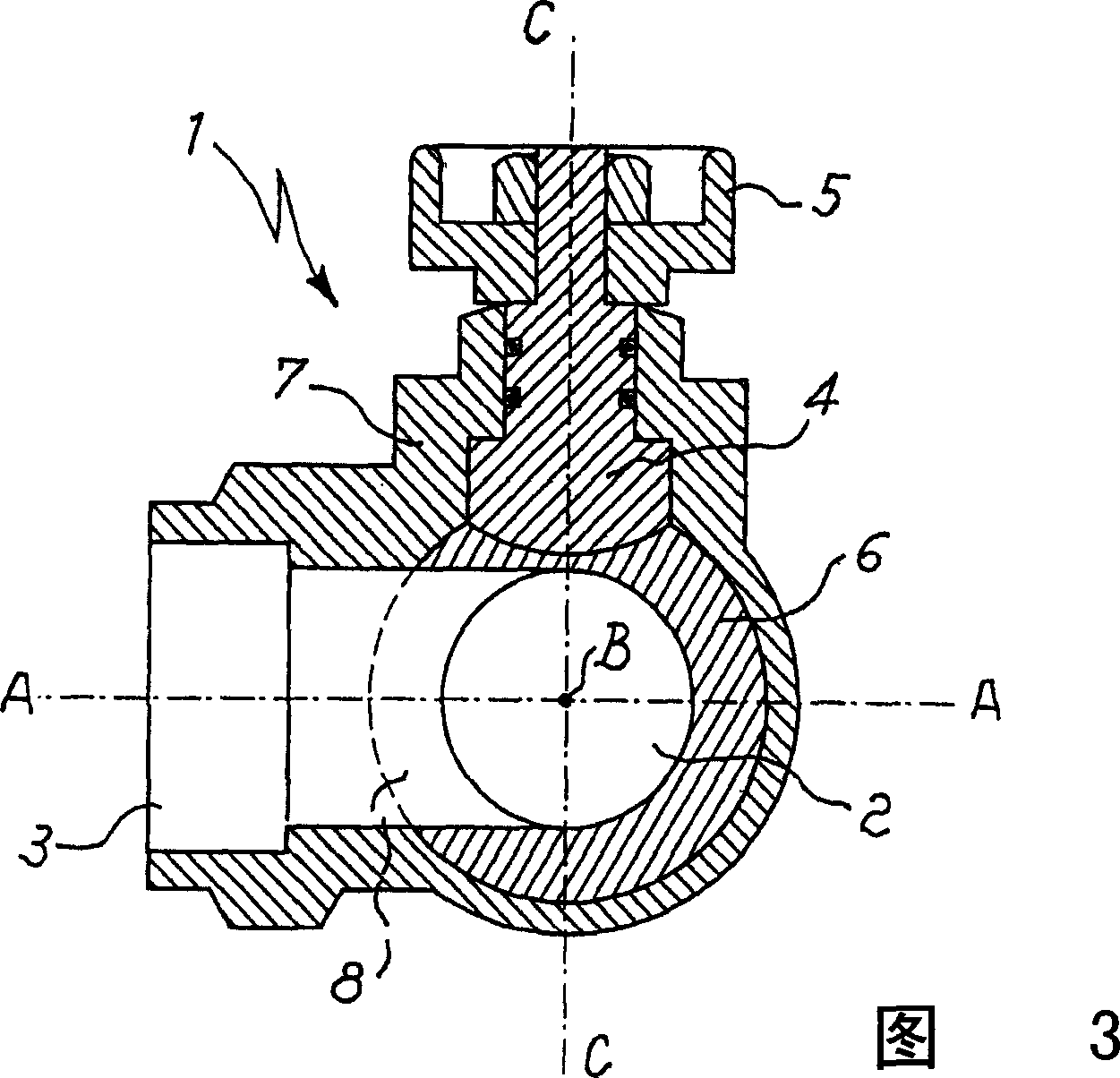

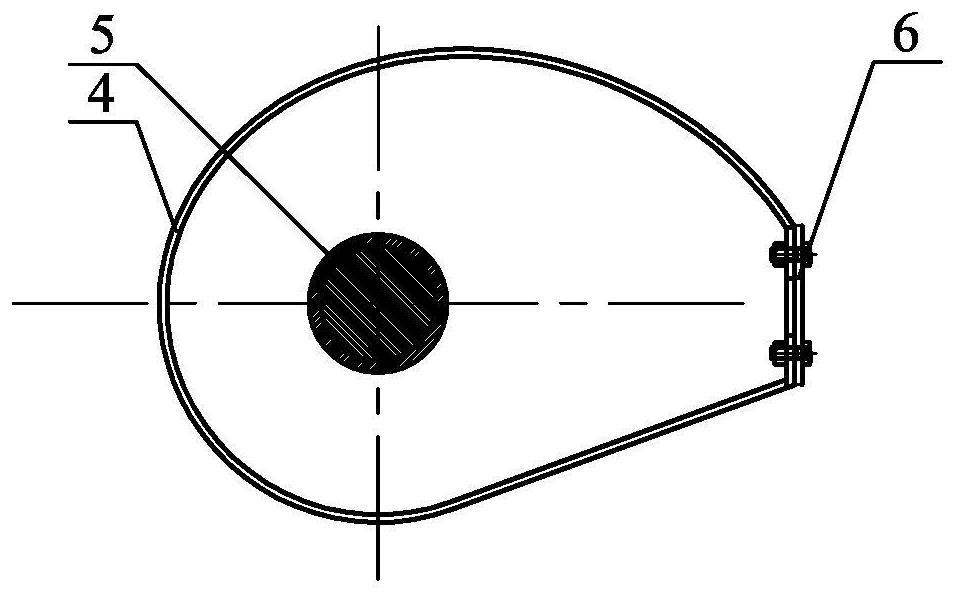

Ball valve

InactiveCN1766381ANot prone to permanent deformationSave spacePlug valvesRotational axisRotary valve

A ball valve (1), comprising at least one fluid inflow pipe (2) and at least one fluid outflow pipe (3), the axes (BB: AA) of the inflow and outflow pipes do not coincide, and at least one Rotating spherical valve plate (6) is used to cut / regulate the flow rate of fluid from the inflow pipe to the outflow pipe. Advantageously, the axis of rotation (CC) of said at least one spherical valve plate substantially intersects the axis (A-A) of said outflow duct (3) and the axis (BB) of said inflow duct (2) .

Owner:EFFEBI SPA

Production process of cushion rubber

A production process of cushion rubber is related to the technical field of rubber and comprises the following steps: burdening: preparing materials, including, by weight: 20-30 parts of natural rubber, 16 parts of cis-butadiene rubber, 10 parts of tread reclaimed rubber, 3 parts of a toughener, 3 parts of an elastic agent, 0.2-0.8 part of calcium silicate, 1 part of zinc oxide, 0.05 part of stearic acid, 0.3 part of a plasticizer, 20 parts of an antiaging agent, and 10 parts of calcium carbonate, the toughener being polyvinyl butyral and dioctyl phthalate having an addition ratio of 2:1, and the elastic agent being butadiene copolymer, ethyl acetate and maleic anhydride having an addition ratio of 2:1.5:1; mixing: blending well the materials, and mixing in a mixer at 40 DEG C for 30 min; mold forming: forming the mixed materials with a mold, and cooling. The rubber produced herein has low price, high elasticity, high toughness, long service life and permanent deformation resistance.

Owner:SANLIAN PUMP IND CO LTD

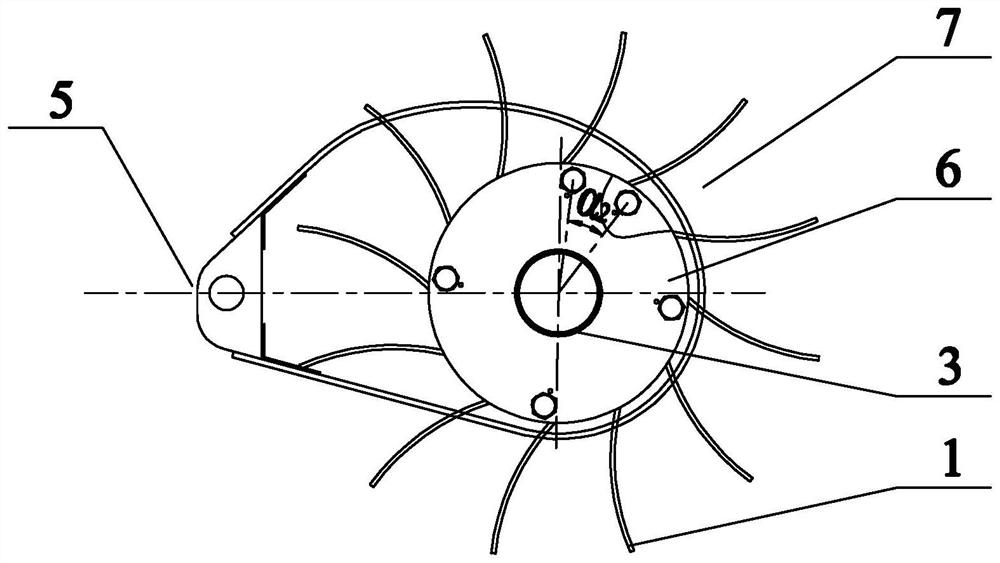

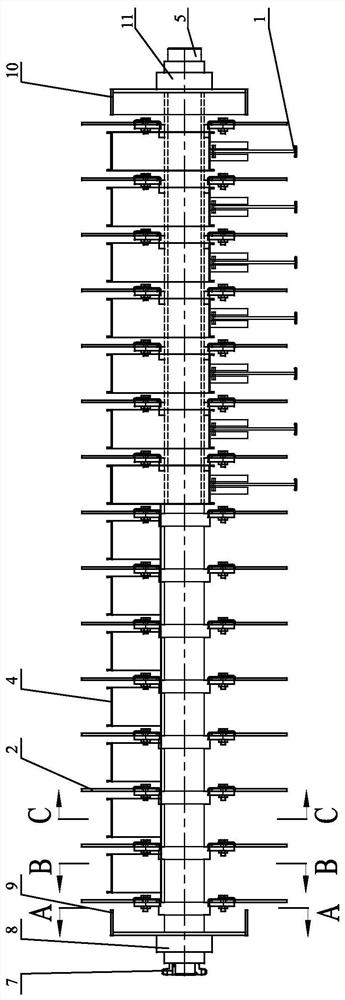

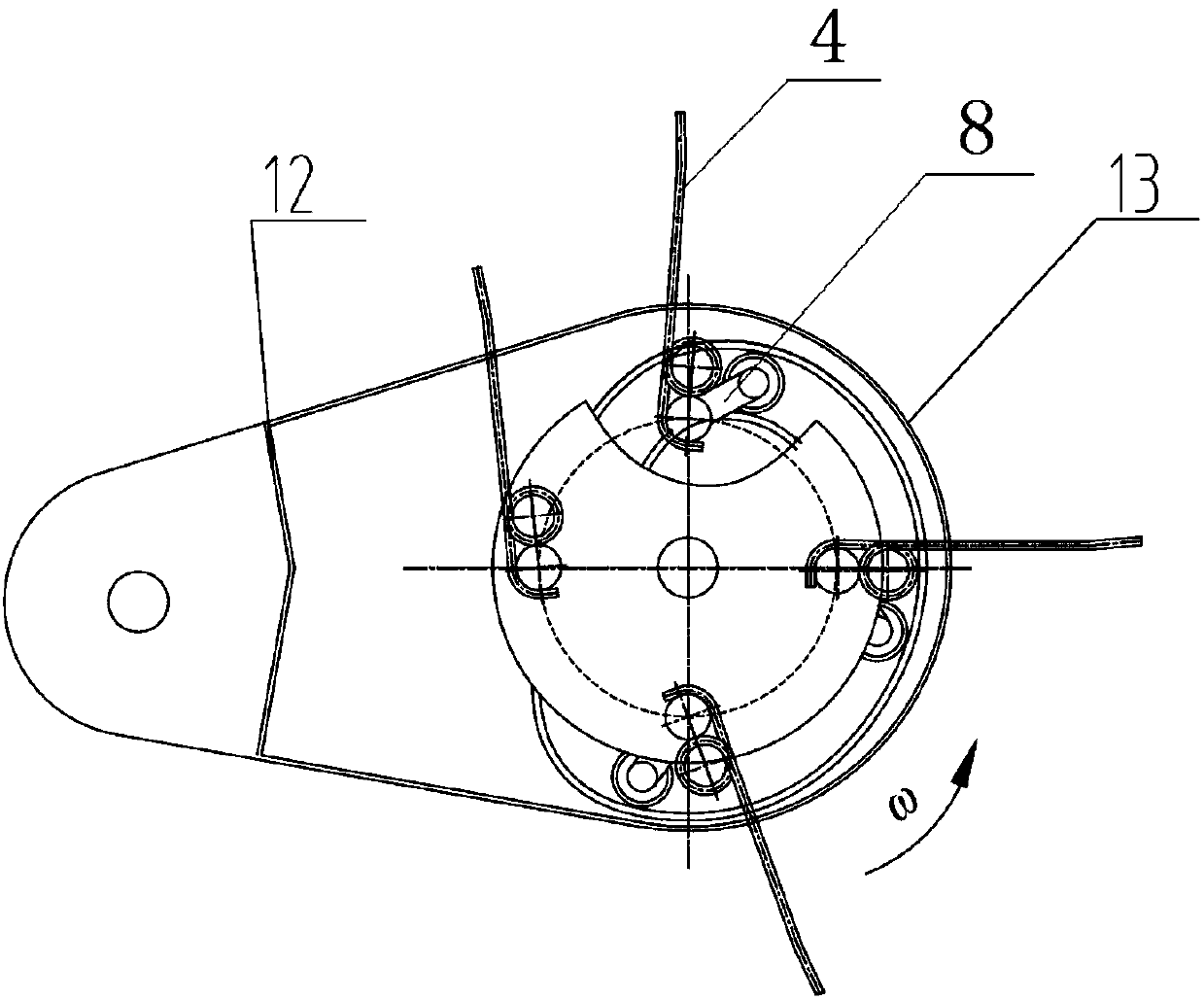

Helical tooth roller type peanut picking device

PendingCN114793595ASolve the \"blocking pile\"Solve the problem of \"throwing up\"LoadersDigger harvestersWork cycleAgricultural engineering

The invention discloses a spiral tooth roller type peanut picking device, and belongs to the technical field of agricultural machinery. Comprising picking teeth, a roller protection plate, a spiral picking roller, a left side plate, a right side plate and a rear side plate, a center shaft of the picking roller is installed on bearings of the left side plate and the right side plate, and the left side plate and the right side plate are fixedly connected with the rear side plate. Four to eight pick-up teeth are evenly arranged on the tooth roller discs in the circumferential direction of the tooth roller discs, the pick-up teeth are fixed on the tooth roller seat, the tooth roller discs are installed on the center shaft at equal intervals in the axial direction of the center shaft, and the pick-up teeth of the adjacent tooth roller discs are arranged in the same rotating direction in the circumferential direction in a staggered mode by 15 degrees to 30 degrees. During picking operation, the picking teeth are in contact with peanut plants in sequence, and the phenomenon of'heap 'can be effectively avoided. And the protective plates are arranged between the adjacent tooth roller seats and are mounted on the rear side plate. The roller rotates along with the center shaft and is matched with the unit to move forwards, the elastic teeth pick up peanut plants from bottom to top, and a working cycle of picking, lifting, pushing and backlash is completed in sequence.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY +1

A shovel tooth-tooth roller combined peanut picking device

ActiveCN112400477BEasy to pick upIncreased pickup widthHarvestersSaving energy measuresAgricultural engineeringEngineering

A shovel tooth-tooth roller combined peanut picking device belongs to the technical field of agricultural machinery. It includes pick-up shovel teeth, roller guards, pick-up rollers and side plates. Side plates are arranged on both sides of the pick-up drum. The wheels are evenly spaced on the central axis, and there are roller guards between adjacent pulleys. At the front end of the pick-up device, arc-shaped pick-up shovel teeth with the same structure are installed at the same position on each of the roller guards to form a Rows of pick-up shovel teeth; when working, the arc-shaped pick-up shovel teeth move forward, and the working front end of the shovel teeth goes deep into the ground to shovel up the peanut plants to realize the picking action; the pick-up roller rotates with the central axis to realize the pick-up wheel lifting The actions of lifting, pushing and emptying back to the station. In the present invention, the peanut plants are scooped up by the shovel teeth; the follow-up lifting, pushing and other picking actions are completed by the pulley roller. It has the characteristics of small size, high pick-up rate and low loss rate.

Owner:JILIN AGRICULTURAL UNIV +2

A kind of automobile fuel pump O-shaped sealing ring and preparation method thereof

ActiveCN109737206BAvoid wear and tearImprove cold resistanceEngine sealsDomestic articlesFuel oilFuel pump

Owner:安徽沃尔顶密封工业股份有限公司

A lens driving device

ActiveCN103018871BAvoid the disadvantages of eccentricityCompact and reasonable structureDynamo-electric machinesMountingsMagnetic tension forceEngineering

The invention discloses a lens driving device, which comprises a casing, and a lens carrier, a magnet assembly, a coil, an upper elastic piece and a lower elastic piece arranged in the casing; the lens carrier is arranged between the upper elastic piece and the lower elastic piece, so The magnet assembly is arranged on the periphery of the lens carrier; the coil is arranged between the magnet assembly and the lens carrier. The structure of the present invention is relatively reasonable and compact, and no longer needs the magnetic conducting ring in the traditional lens driving device, thereby avoiding the ills of lens carrier eccentricity caused by the excessive magnetic force of the magnetic conducting ring, not only simplifying the manufacturing process, but also effectively reducing the manufacturing cost. cost.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

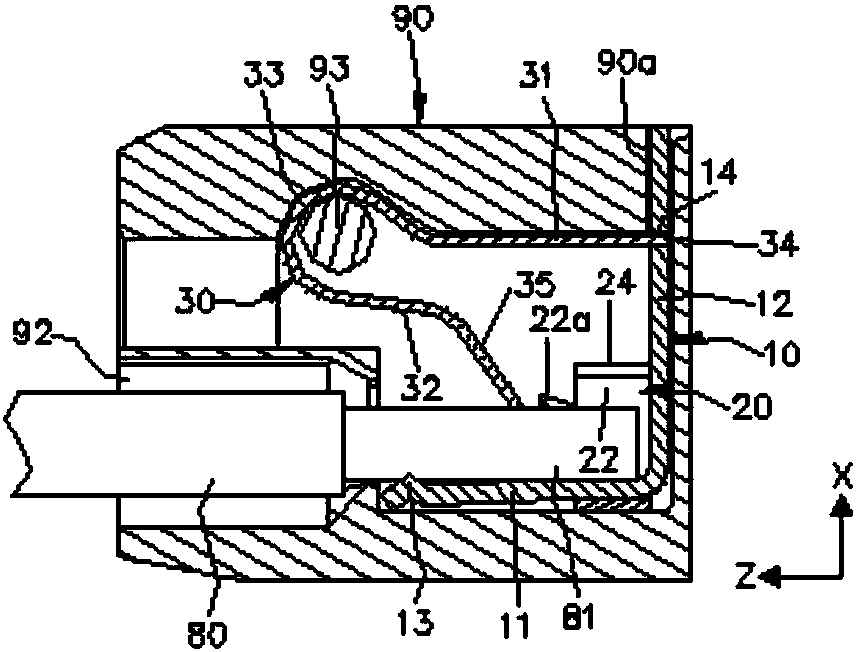

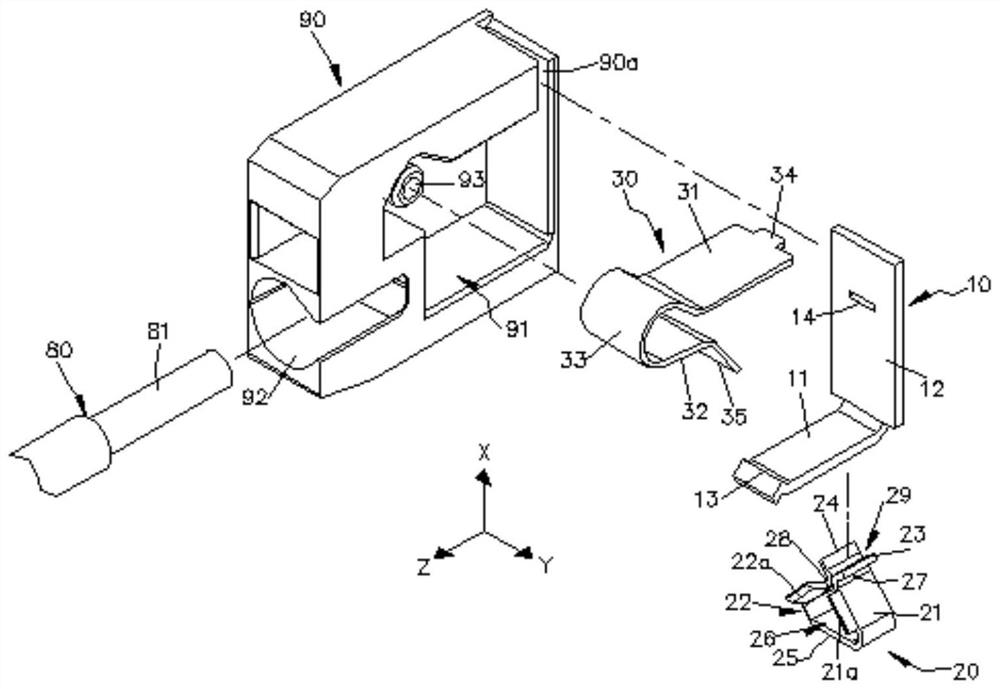

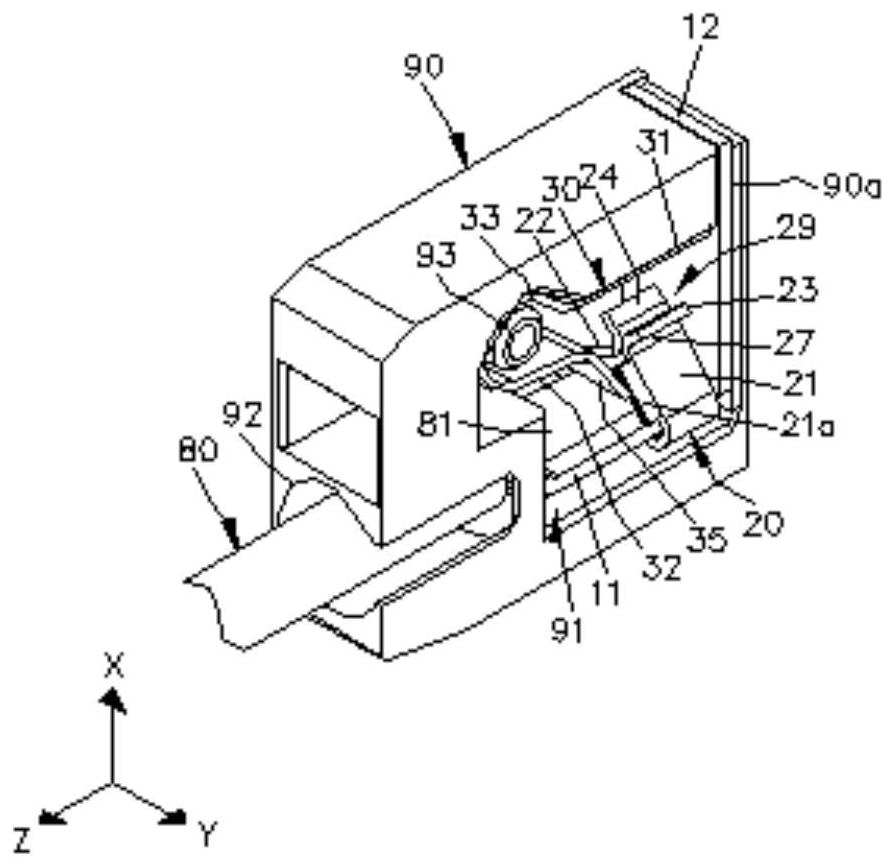

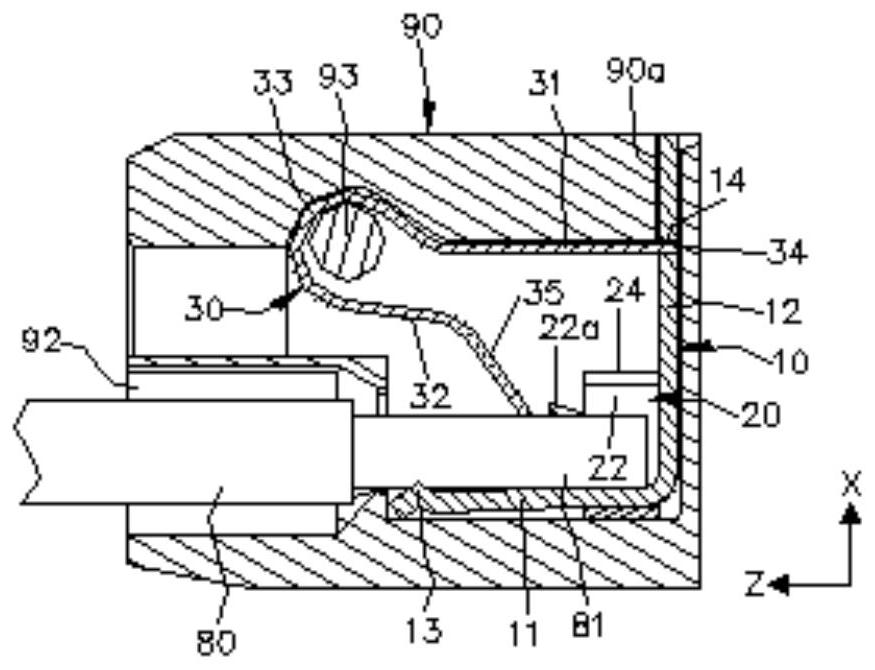

Conductive assembly structure of wire connecting device

ActiveCN110277687ALarge amount of elastic deformationNot prone to permanent deformationCoupling contact membersEngineeringAssembly structure

The invention relates to a conductive assembly structure of a wire connecting device, which plays a role of increasing the conductive efficiency and the stability of a combined wire. The conductive assembly comprises a plate-shaped body and a restriction body connected to the body, and the restriction body is provided with a first base portion, a first arm and a second arm which are connected to the base portion and a free segment connected to the first arm and the second arm, thereby enabling the restriction body to have an elastic clamping function together. When a wire is inserted into and contacted with the conductive assembly, the tail end of the wire is enabled to at least be pressed between the first arm and the second arm of the restriction body to form fixation, thereby improving the situation that the conductive efficiency and safety of the wire are affected by deflection or shaking and unstable contact due to an external force.

Owner:SWITCHLAB SHANGHAI +1

Production technology of elastic rubber pad

The invention relates to the technical field of rubber, in particular to a production technology of an elastic rubber pad. The production technology includes the following steps of preparation, wherein raw materials are prepared and include natural rubber, butadiene-styrene rubber, nitrile-butadiene rubber, a toughener, an elasticizer, calcium zincate, quartz powder, bentonite, zinc oxide, stearic acid, a plasticizer and an antiager, and the elasticizer includes butyl conjugated diene, pentaerythritol oleate and maleic anhydride at the addition proportion of 1:2:1; mixing, wherein the substances, except the elasticizer, in the raw materials are fully mixed and then put into a mixer for mixing treatment; mould forming, wherein the raw materials obtained after mixing are subjected to forming treatment with a mould and then cooled; vertical stress removing treatment, wherein formed rubber is soaked in clear water and then cooked for 5-10 min at 80-100 DEG C. The rubber produced with the production technology is low in price, high in elasticity and toughness, long in service life and not prone to permanent deformation.

Owner:BENGBU LONGHUA DIE CASTING MACHINE CO LTD

Conductive component structure of wire connection device

ActiveCN110277687BLarge amount of elastic deformationNot prone to permanent deformationCoupling contact membersClassical mechanicsEngineering

The invention relates to a conductive component structure of a wire connecting device, which provides functions such as increasing the conductive performance and the stability of the combined wire. The conductive assembly includes a plate-shaped body and a limiting body connected to the body; and, the limiting body has a base, a first arm connected to the base, a second arm and a free section connected to the first arm and the second arm, and the common The restricting body has an elastic clamping effect. When the wire is inserted into the contact conductive component, the end of the wire is at least pressed between the first arm and the second arm of the restricting body to form a fixation; to improve the wire is easy to shift or shake due to external force, and the contact is not stable, which affects the conduction efficiency and safety, etc.

Owner:SWITCHLAB SHANGHAI +1

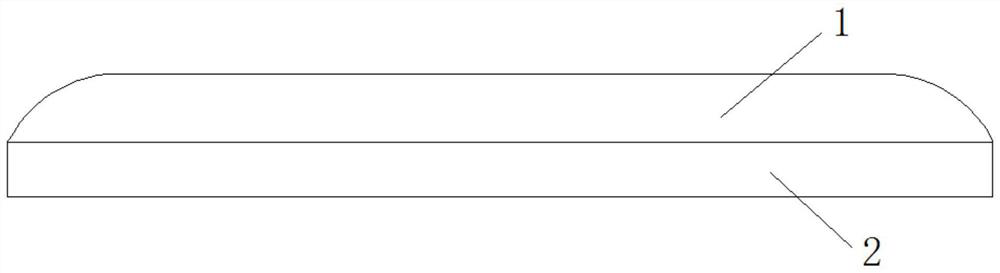

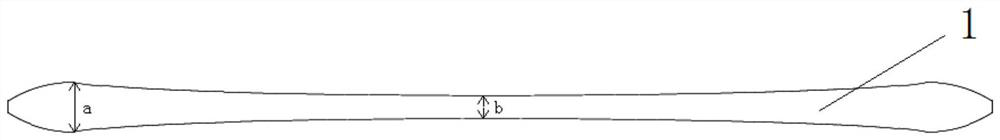

Narrow-waist ice skate blade pipe rack

The invention discloses a narrow-waist ice skate blade pipe rack and belongs to the technical field of ice skate blade racks. The ice skate blade pipe rack comprises a blade pipe and a clamping wall, wherein an upper part of the blade pipe is provided with a bridge connected with the bottom of the skate, a lower part of the blade pipe is provided with a clamping wall for clamping an ice skate blade, and at least one of two side surfaces of the blade pipe is a smooth cambered surface which is sunken inwards. The narrow waist design with different size ratios in the middle of the blade pipe can increase the contact area between the ice blade and the ice surface by changing the deformation degree of the blade pipe when an athlete kicks ice, so an athlete can apply more sufficient force when kicking the ice, the force is converted into kinetic energy required for advancing to the greatest extent, the sliding speed of the athlete is increased, in addition, the ice skate blade can be in complete contact with the ice surface, so the probability of sideslip in the advancing process is reduced, and situations of collision and injury of athletes are effectively avoided. The ice skate blade pipe rack is advantaged in that the force bearing position of an original ice skate blade pipe frame is not changed, resilience is high, permanent deformation is not likely to happen, the weight is lighter, the wearing comfort is higher, and the service life is long.

Owner:长春百凝盾体育用品器材有限公司

Wind power blade demoulding hoisting fixture and wind power blade demoulding method

Wind power blade stripping hoisting fixture, including a C-shaped seat, an inclined and swingable pressure block connecting rod mounted on the C-shaped seat, and a pressure block installed at the lower end of the pressure block connecting rod and used for pressing the blade on the C-shaped seat. The block assembly is characterized in that it also includes an elastic lifting assembly that can drive the connecting rod of the pressure block to swing, the elastic lifting assembly is movably mounted on the C-shaped seat, and the initial inclination angle of the connecting rod of the pressure block is positioned by the elastic force to make the pressure block assembly. The initial distance between the C-shaped seat and the C-shaped seat is the largest, the blade extends between the C-shaped seat and the pressing block assembly, and the blade is gravitationally loaded on the C-shaped seat with the upward lifting of the elastic lifting assembly. The lifting assembly is hoisted and swings downward to reduce the distance between the pressing block assembly and the C-shaped seat and press on the blade. The invention effectively protects the blade from being damaged by clamping during the demolding process, improves the reliability and safety of the clamp, improves the demolding efficiency of the blade, and has a longer service life.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Lens driving device

ActiveCN102967912BAvoid the disadvantages of eccentricityCompact and reasonable structureDynamo-electric machinesMountingsMagnet

The invention discloses a lens driving device. The lens driving device comprises a casing, a lens carrier, a magnet assembly, a coil, an upper elastic piece and a lower elastic piece, wherein the lens carrier, the magnet assembly, the coil, the upper elastic piece and the lower elastic piece are arranged in the casing, the lens carrier is arranged between the upper elastic piece and the lower elastic piece, the magnet assembly is arranged on the periphery of the lens carrier, the coil is arranged between the magnet assembly and the lens carrier, the inner wall of the coil is adhered to and fixed on the outer wall of the lens carrier through glue, and a glue containing groove which is used for containing the redundant glue is arranged on the outer wall of the lens carrier. The lens driving device is reasonable and compact in structure, and magnetic conducting rings in traditional lens driving devices are not required, so that defects that lens carriers are eccentric due to the fact that magnetic forces of magnetic conducting rings are too strong can be avoided, the manufacturing process is simplified, and the manufacturing cost can be effectively reduced.

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

Improved voice coil motor

ActiveCN102710088BHigh strengthImprove yieldDynamo-electric machinesEngineeringUltimate tensile strength

Owner:JINLONG MACHINERY & ELECTRONICS CO LTD

Production technology for elastic rubber

A production process of elastic rubber, relating to the technical field of rubber, comprising the following steps: batching: preparing raw materials, the raw materials include natural rubber, butyl rubber, toughening agent, 3-8 parts of elastic agent, calcium silicate, oxidized Cobalt, plasticizer, anti-aging agent and boron trifluoride; the elastic agent is butane conjugated diene, pentaerythritol oleate and maleic acid glycoside; mixing: after fully mixing other substances in the raw materials except the elastic agent Put it into the mixer for mixing treatment; mold forming: use the mold to shape the mixed raw materials, and then cool them; stress treatment: soak the formed rubber in clean water, then boil, boil The temperature is 80-100° C., and the time is 5-10 minutes. The rubber produced by the invention is cheap, has high elasticity, high toughness, long service life and is not easy to be permanently deformed.

Owner:BENGBU LONGHUA DIE CASTING MACHINE CO LTD

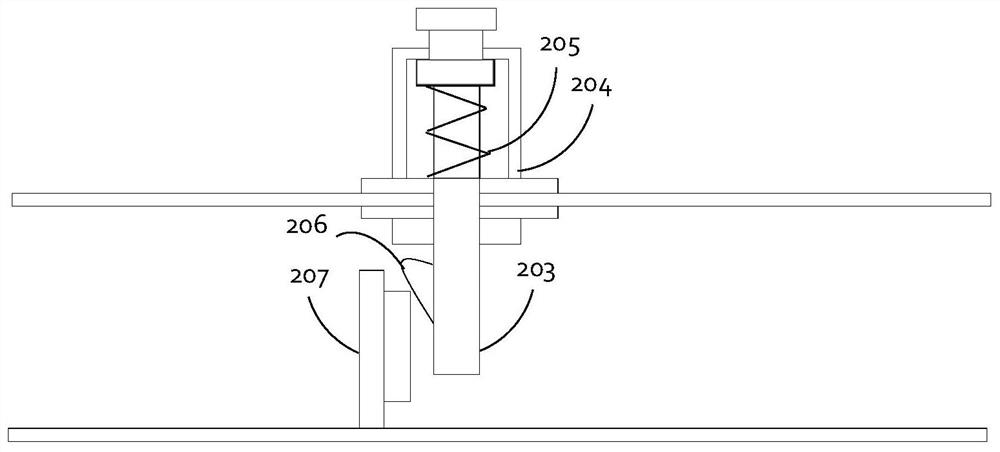

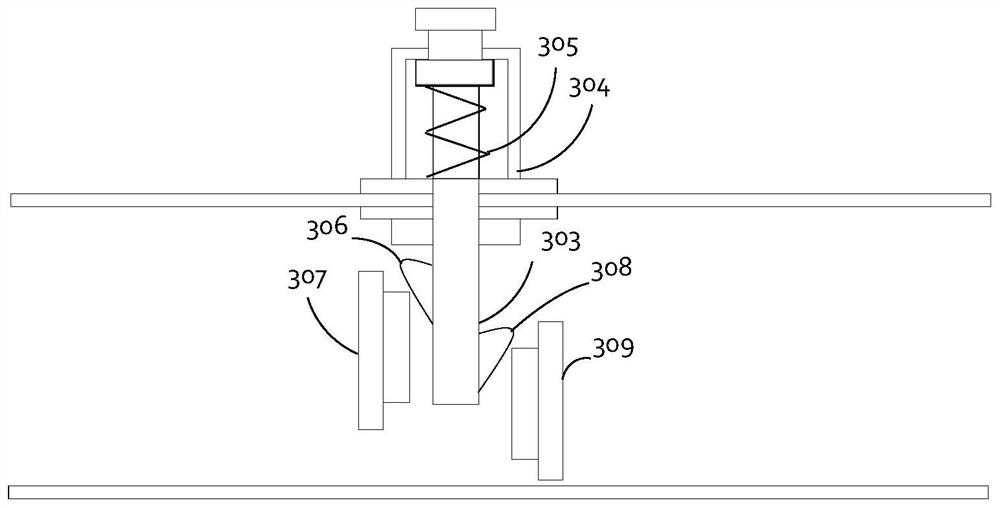

Laterally triggered musical instrument switch pressing assembly and musical instrument control switch

ActiveCN112164607AExtended service lifeNot prone to permanent deformationElectric switchesEngineeringControl switch

The invention relates to a laterally triggered musical instrument switch pressing assembly, a musical instrument control switch and a musical instrument control device. The musical instrument switch pressing assembly comprises a shell, an elastic reset mechanism and a pressing shaft, the pressing shaft penetrates through the shell through a through hole, one end of the pressing shaft is a pressingend, the other end of the pressing shaft is a triggering end, the elastic reset mechanism is arranged in the shell, and the pressing shaft can move relative to the shell from the initial position inthe stroke direction of the musical instrument switch pressing assembly. The surface of the trigger end is provided with a projection in a direction perpendicular to the stroke direction of the musical instrument switch pressing assembly. When the musical instrument switch pressing assembly is used, the pressing type switch can be arranged according to the shape of the protrusion and the stroke distance of the pressing type switch, so that the protrusion extrudes the pressing type switch in the moving process to be switched on, and excessive pressure on the pressing type switch due to excessive pressing force of a user is avoided; permanent deformation of an elastic mechanism in the push-type switch is avoided, and the service life of the musical instrument control switch can be prolonged.

Owner:长沙幻音电子科技有限公司

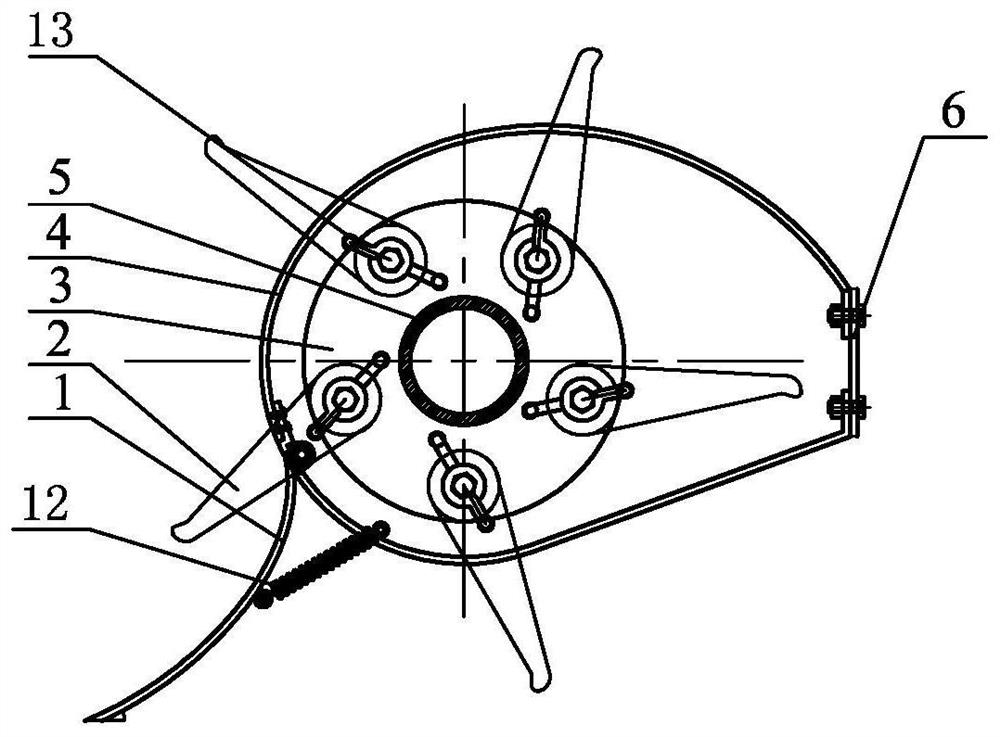

A spring tooth drum type peanut picking device

The invention relates to a spring tooth roller type peanut pickup device and belongs to the technical field of agricultural machinery. The spring tooth drum type peanut pickup device comprises an open pickup roller, a roller slideway, pickup spring teeth and side plates, wherein the pickup spring teeth are uniformly fixed on a spring tooth shaft at intervals; a center shaft of the pickup roller passes through the left and the right side plates on the two sides and is connected with a bearing pedestal; the roller slideway is fixedly mounted in one of the side plates; one end of the spring tooth shaft is connected with the roller slideway through a crank cam mechanism; a roller of the crank cam mechanism is embedded into the roller slideway and is limited to roll in the slideway; the center shaft rotates and simultaneously drives the pickup roller to rotate; the shape of the roller slideway corresponding to each phase angle ensures the swing posture of each spring tooth on each station in the pickup process, so that the action on spring tooth pickup, lifting, pushing and backlash stations can be realized. According to the peanut plant pickup requirements, the initial posture and the swing rule of each pickup spring tooth on each station are determined. In the pickup process, the spring teeth gradually swing back, so that the strike of the spring teeth for peanut plants is reduced, and the pickup area is increased.

Owner:SHENYANG AGRI UNIV

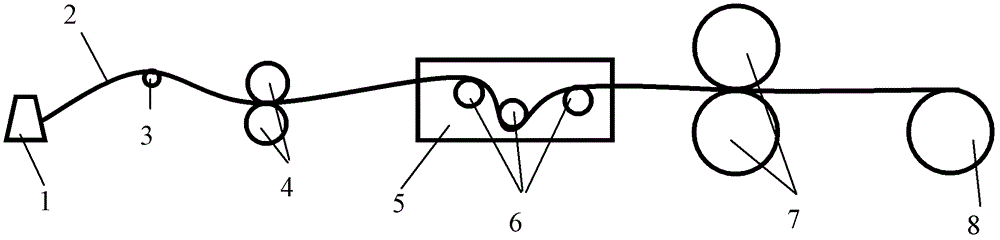

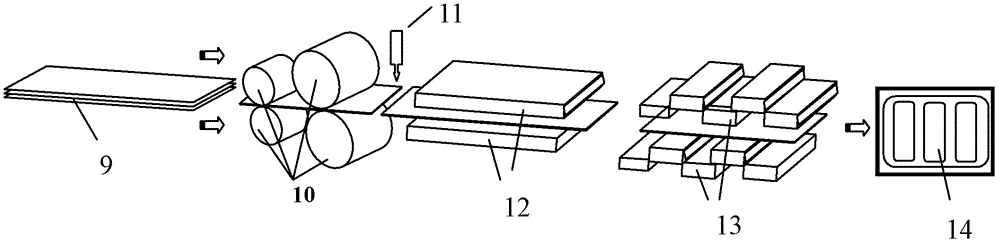

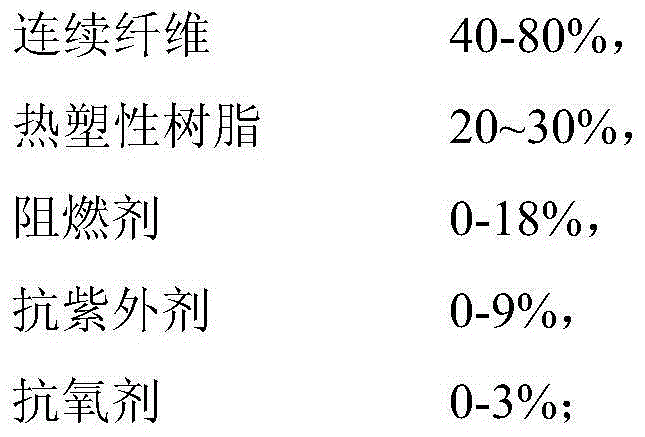

A kind of thermoplastic resin composite material, preparation method and application thereof

The invention falls into the technical field of resin material, and discloses thermoplastic resin composite material and a preparation method and application thereof. The thermoplastic resin composite material comprises 40-80 wt.% of continuous fibers, 20-30 wt.% of thermoplastic resin, 0-18 wt.% of a flame retardant, 0-9 wt.% of an anti-ultraviolet agent and 0-3 wt.% of an antioxidant. The preparation method of the thermoplastic resin composite material includes unreeling, spreading and laying fibers; impregnating unidirectional fiber fabrics; cooling and flattening; and coiling and forming. Also disclosed is a method for manufacturing an automobile door from the thermoplastic resin composite material, which includes laying impregnated unidirectional fiber tapes; molding the impregnated tapes under heating and pressing into composite sheet material; preheating the composite material; and press molding the composite material in a mold. The inventive composite automobile door has the advantages of integral molding, excellent overall properties, good impact resistance, resistance to damage, resistance to permanent deformation, etc.

Owner:滁州格美特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com