Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4659results about "Safety gear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

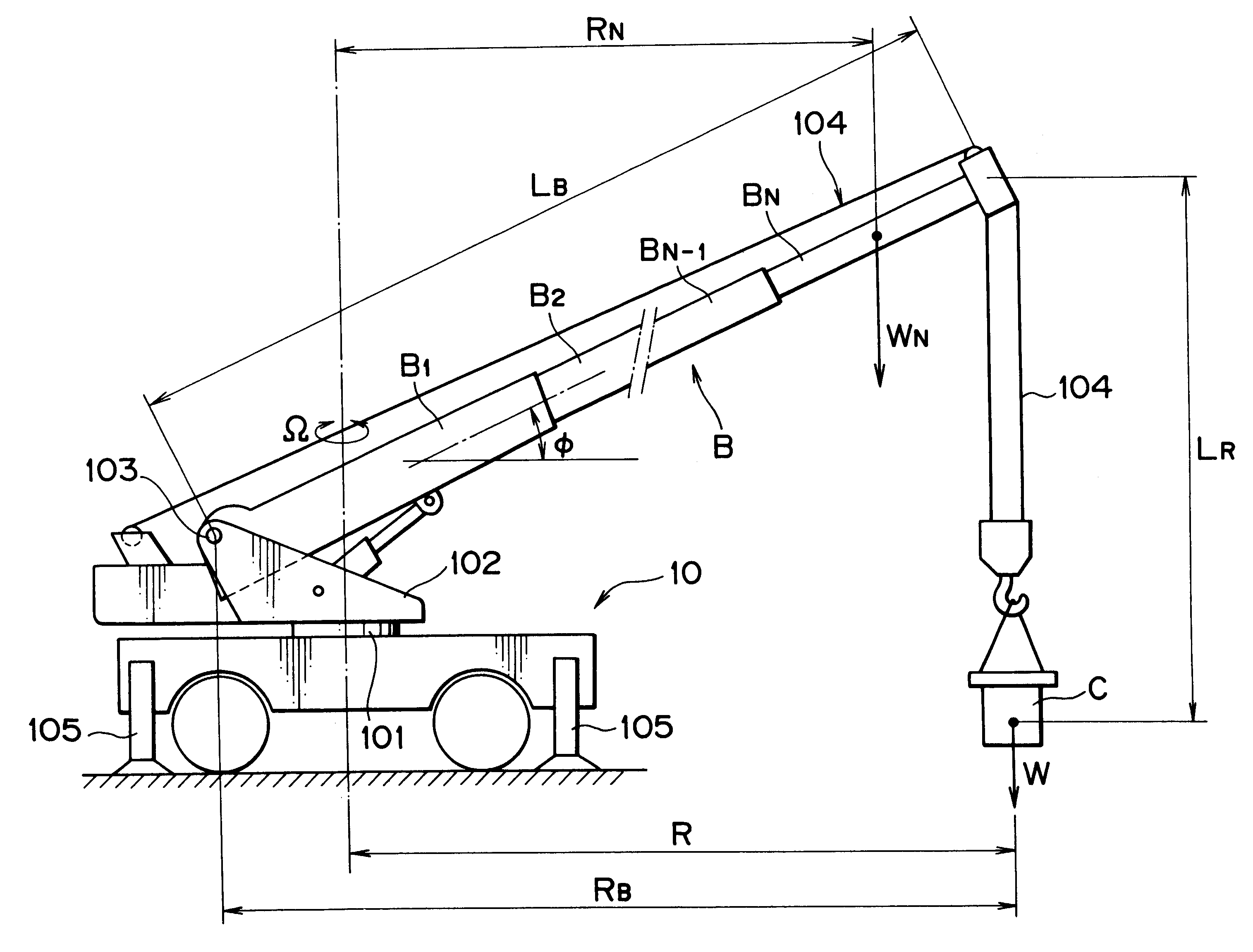

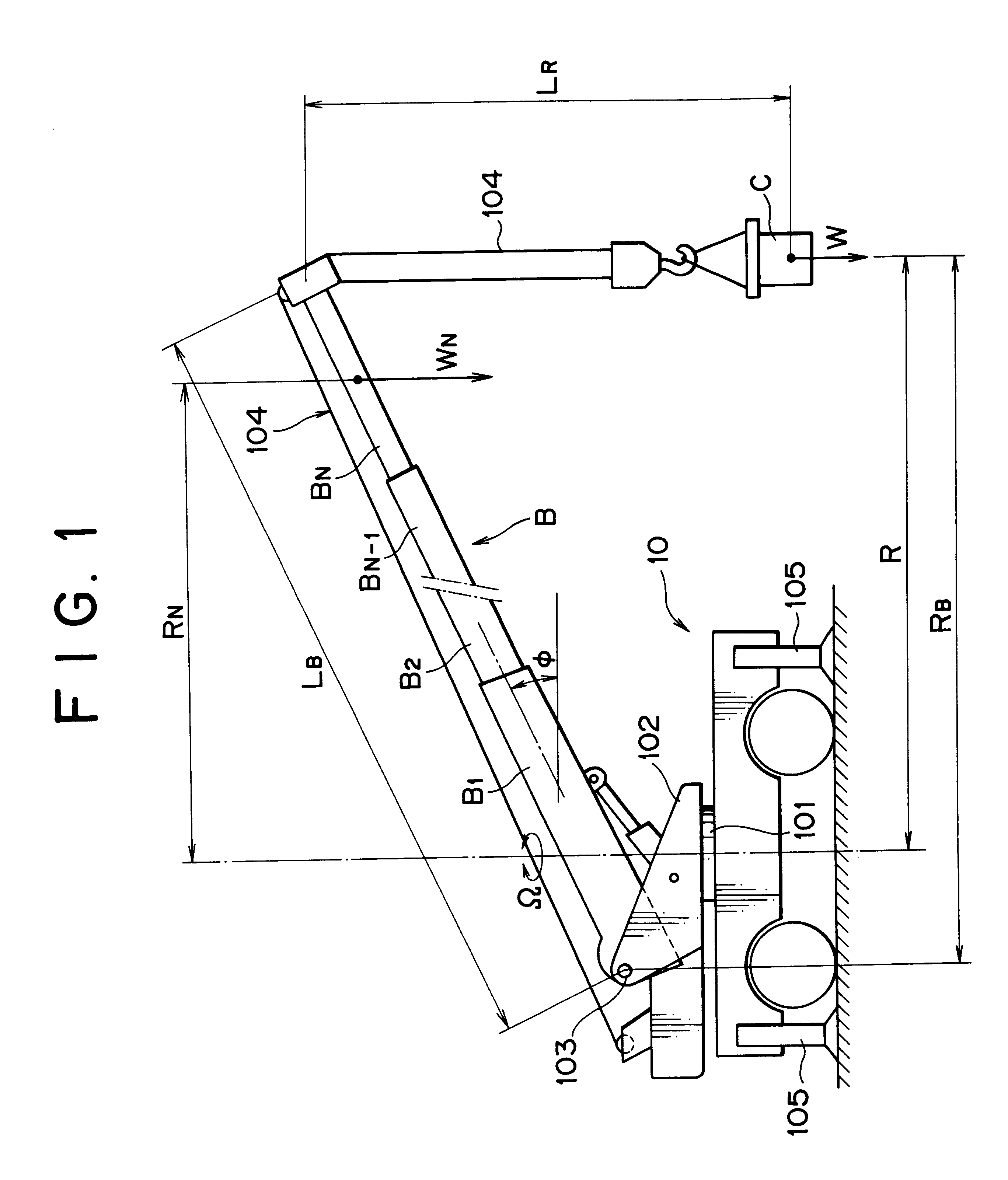

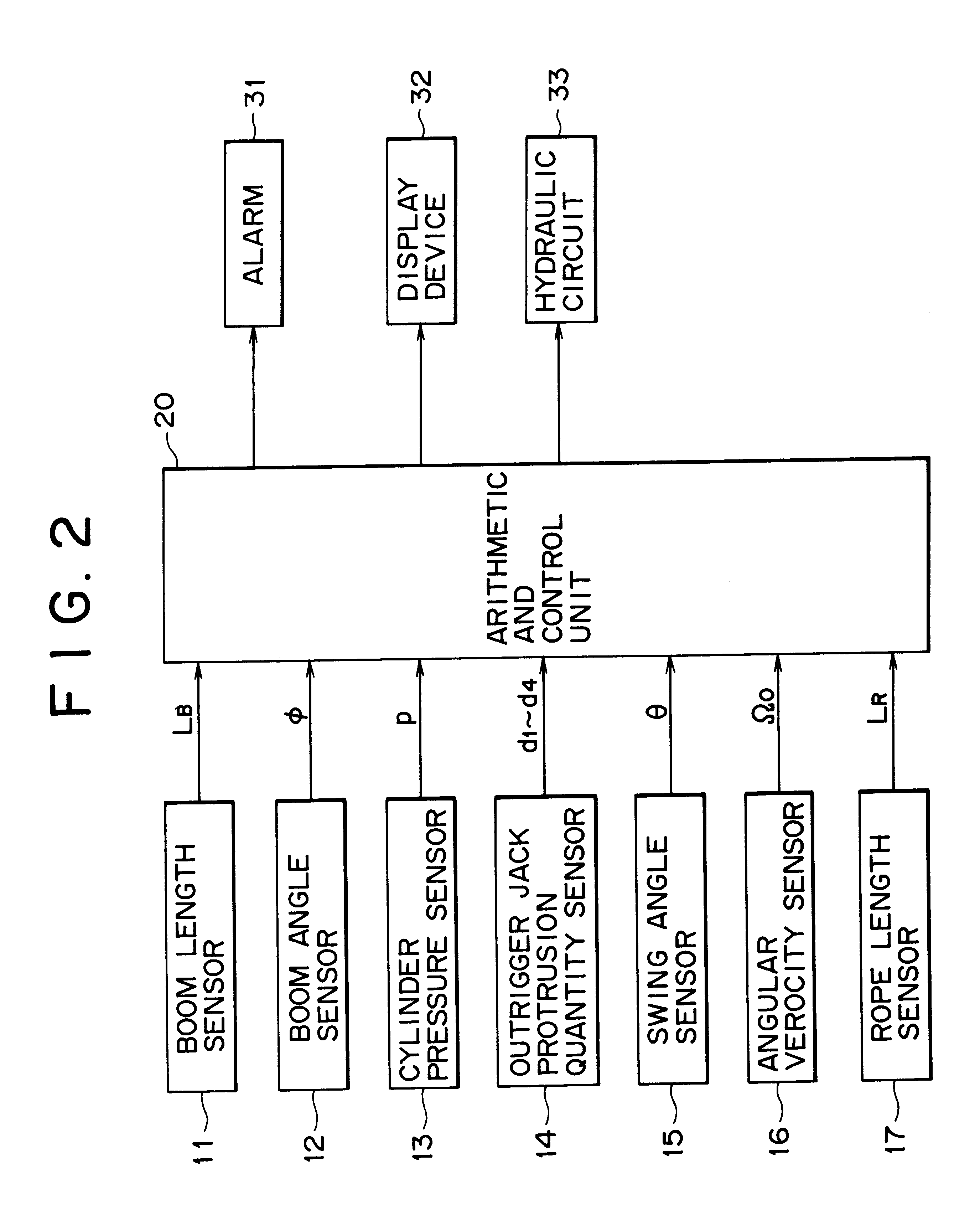

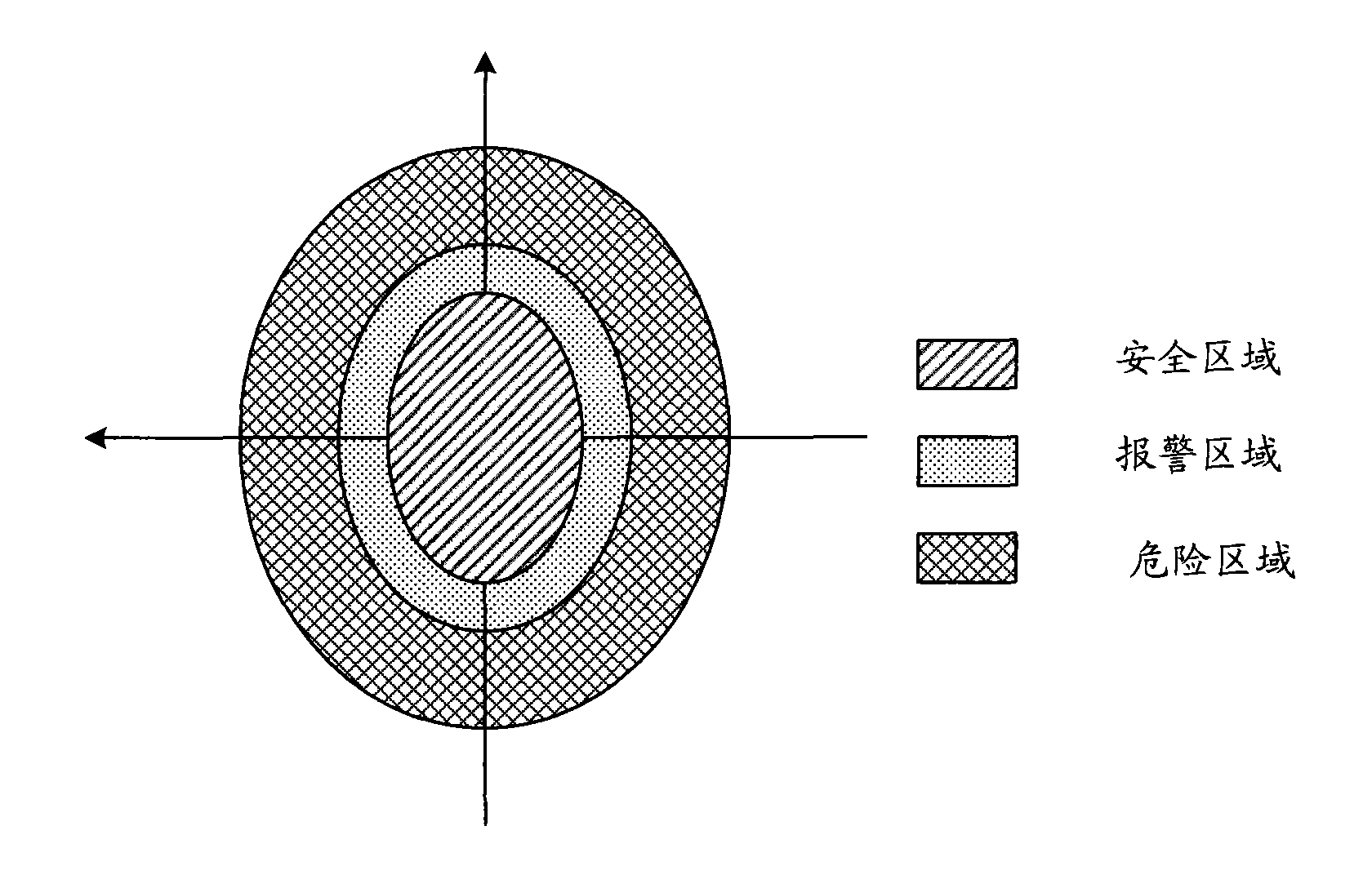

Swing type machine and method for setting a safe work area and a rated load in same

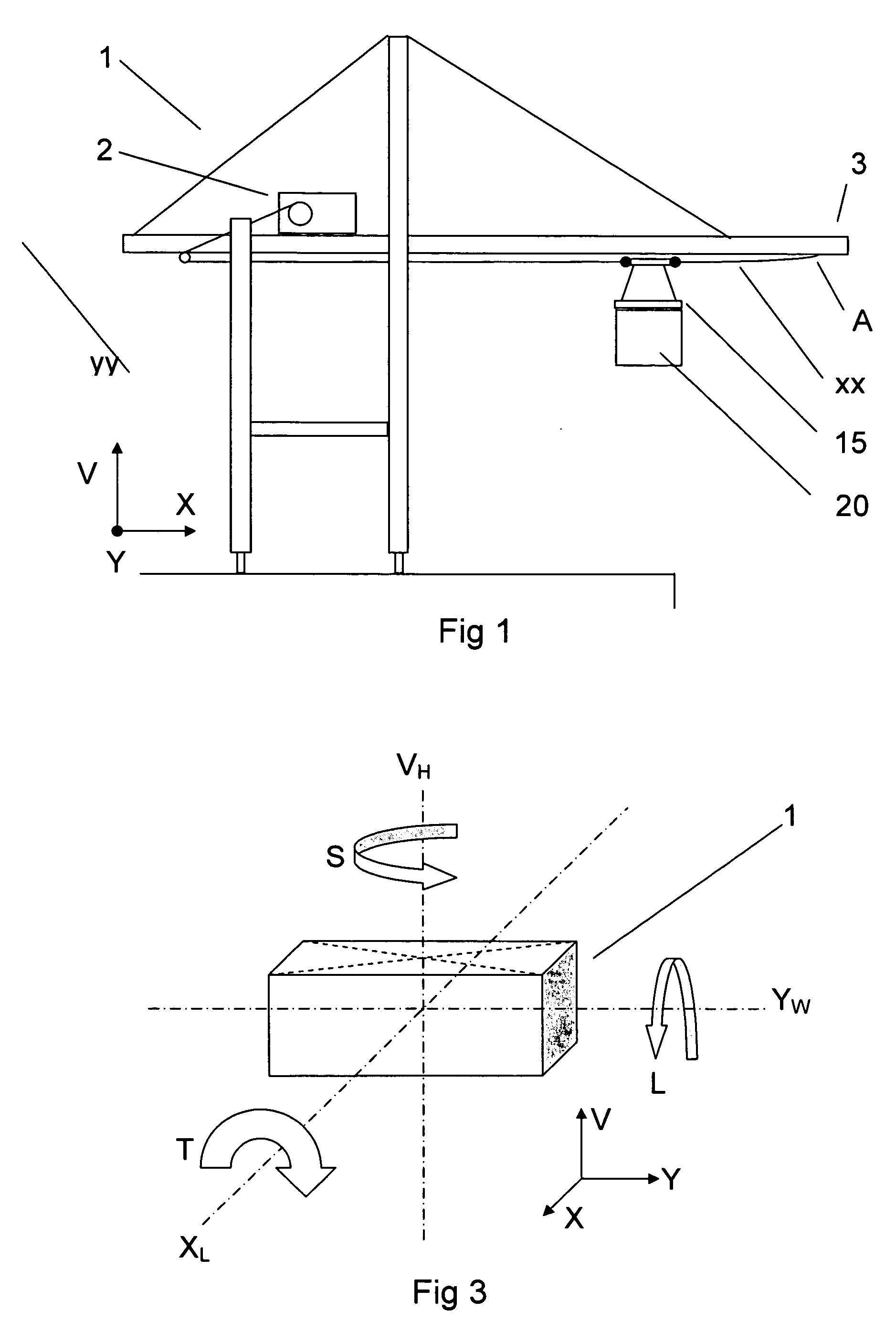

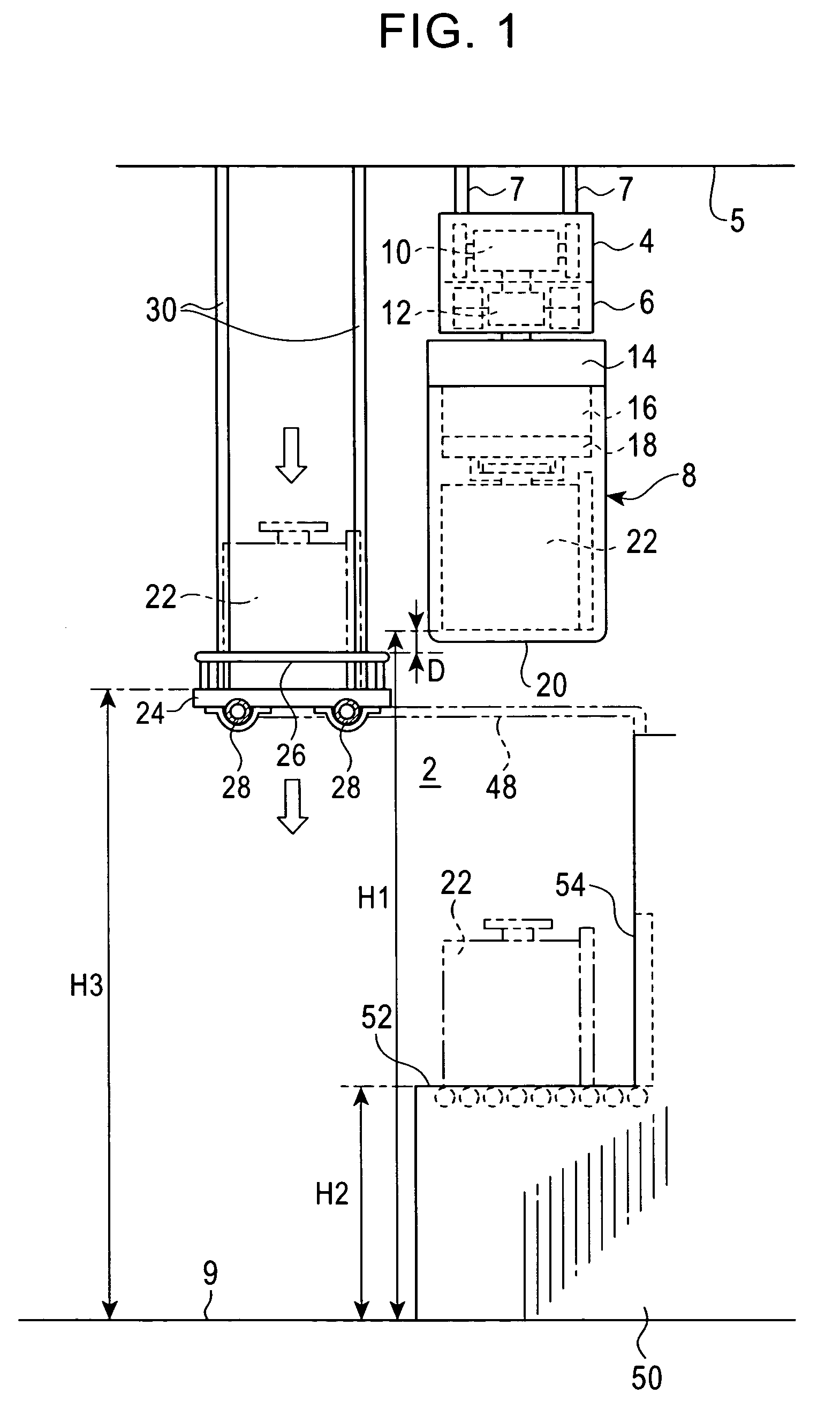

A method for setting a safe work area and a rated load in a swing type work machine, as well as a swing type work machine which utilizes the said method, are disclosed. An area where a strength-based safe work area which is established taking the strength of a swing member into account and a stability-based safe work area which is established taking the stability of the work machine into account overlap each other, is set as a safe work area to be used actually. Likewise, out of a strength-based rated load which is set taking the strength of the swing member into consideration and a stability-based rated load which is set taking the stability of the work machine into consideration, the lower one is set as a rated load to be used actually. Using the safe work area and rated load thus obtained, there are made a safety control and an appropriate display. According to this method, in a swing type work machine such as a crane, it is possible to establish a safe work area and a rated load both matching the actual hoisting capacity of the work machine.

Owner:KOBE STEEL LTD

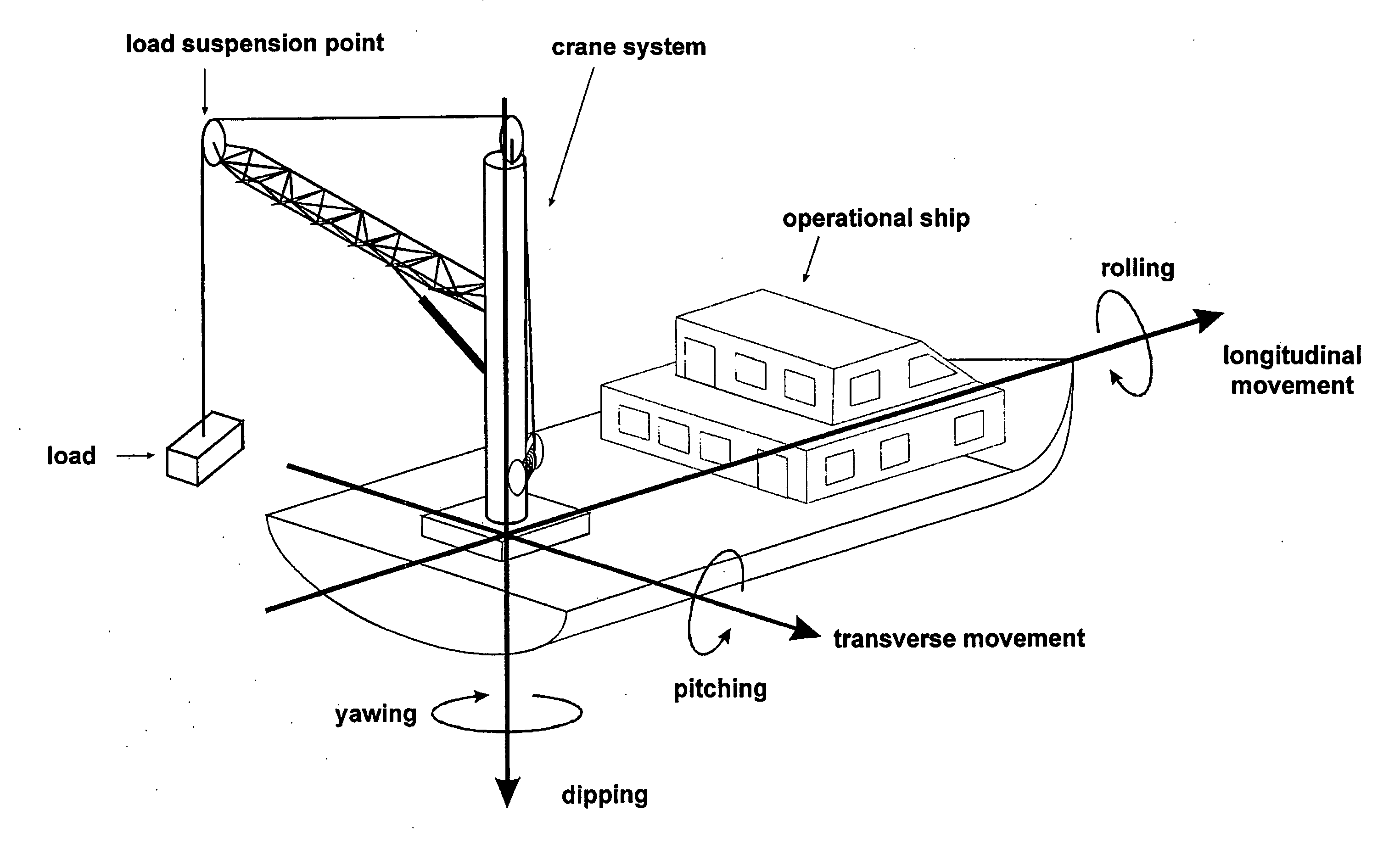

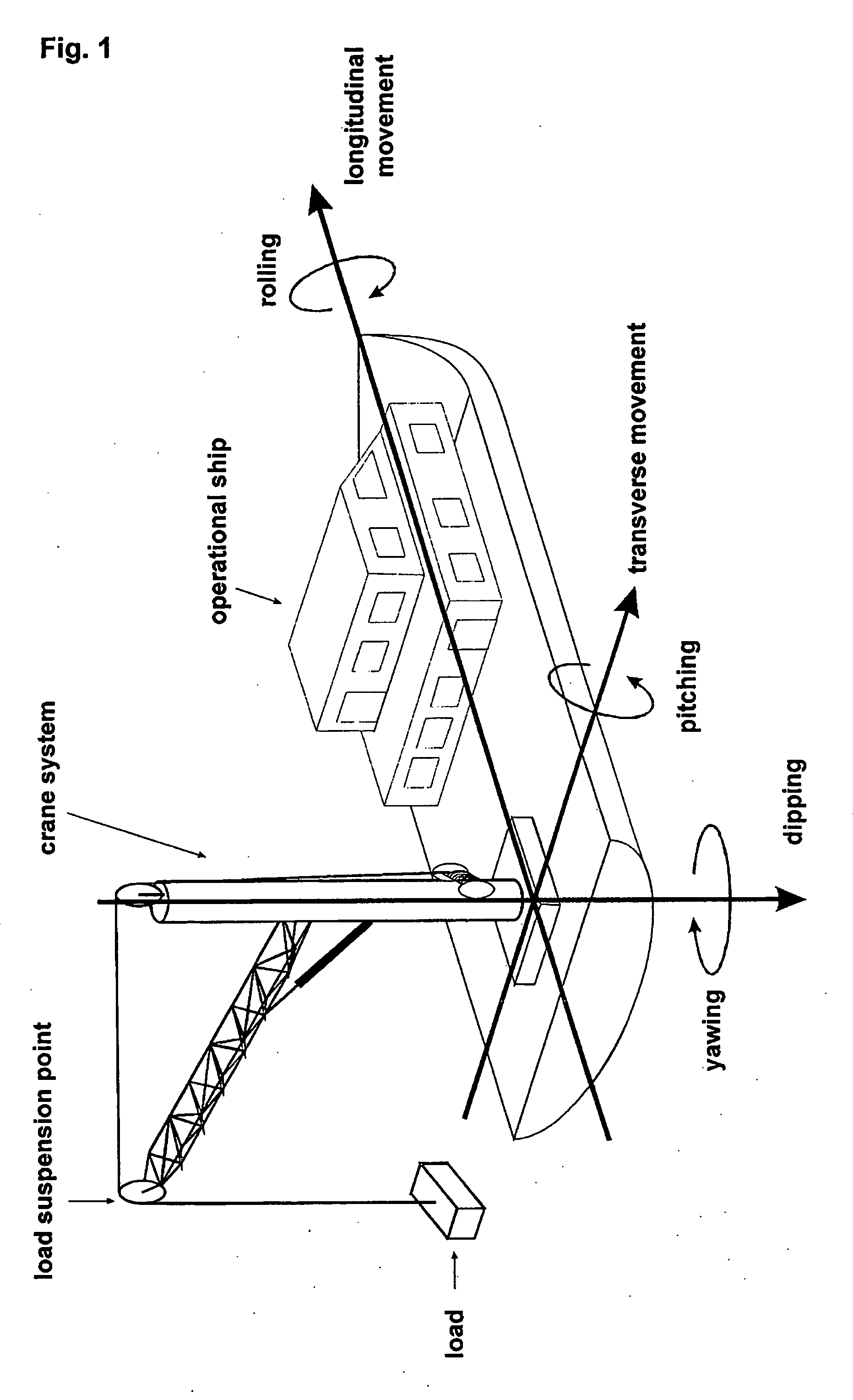

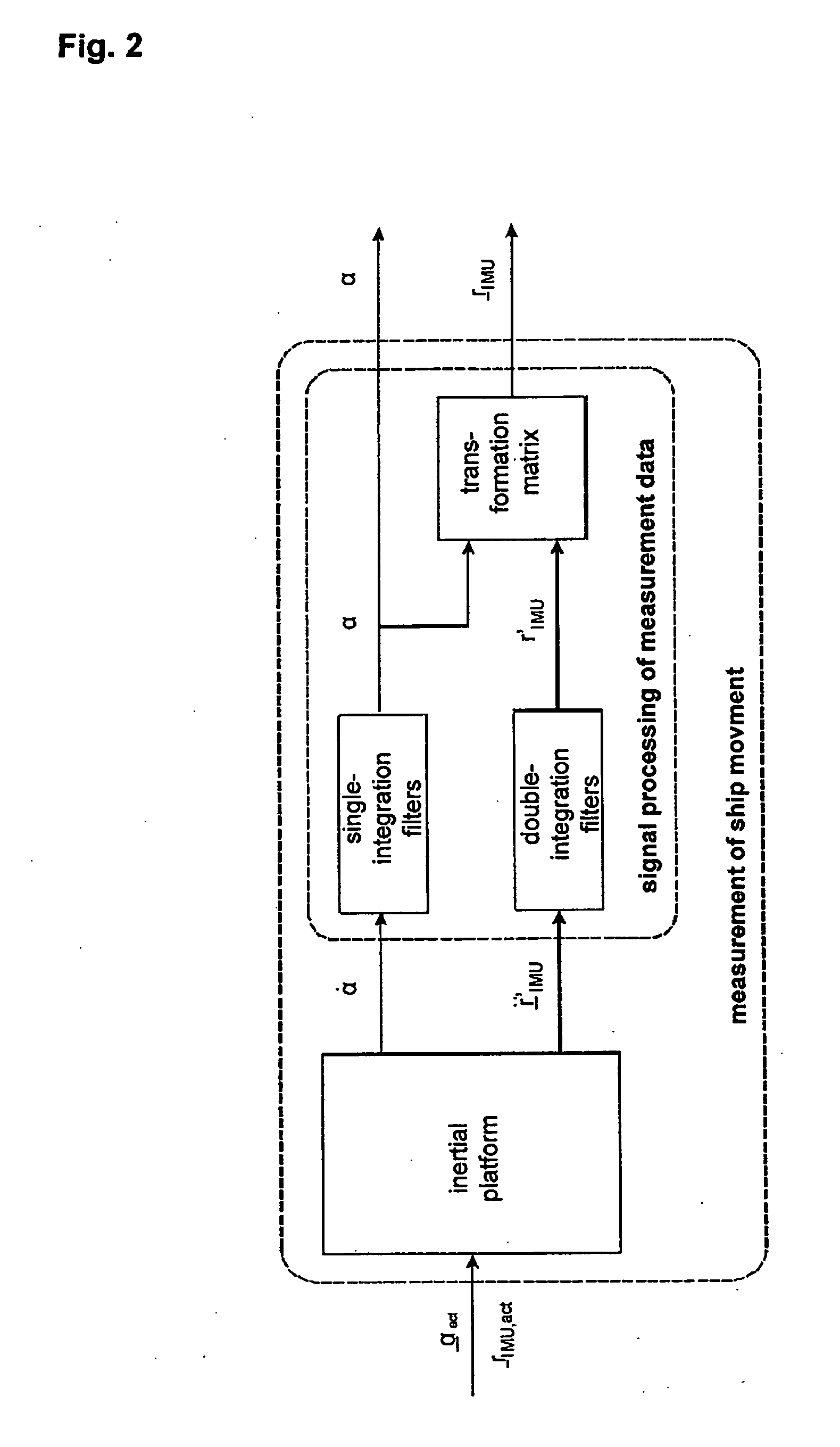

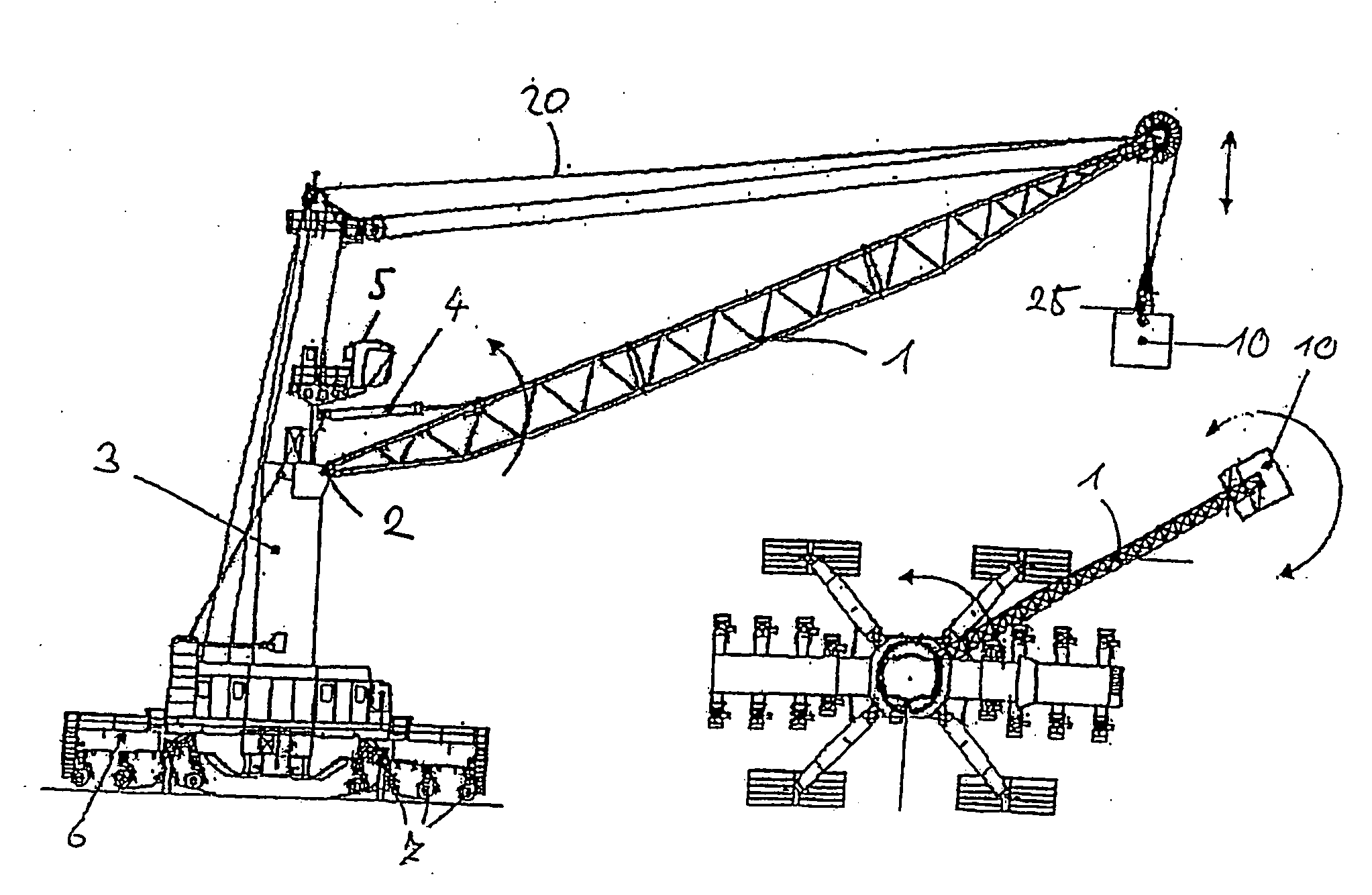

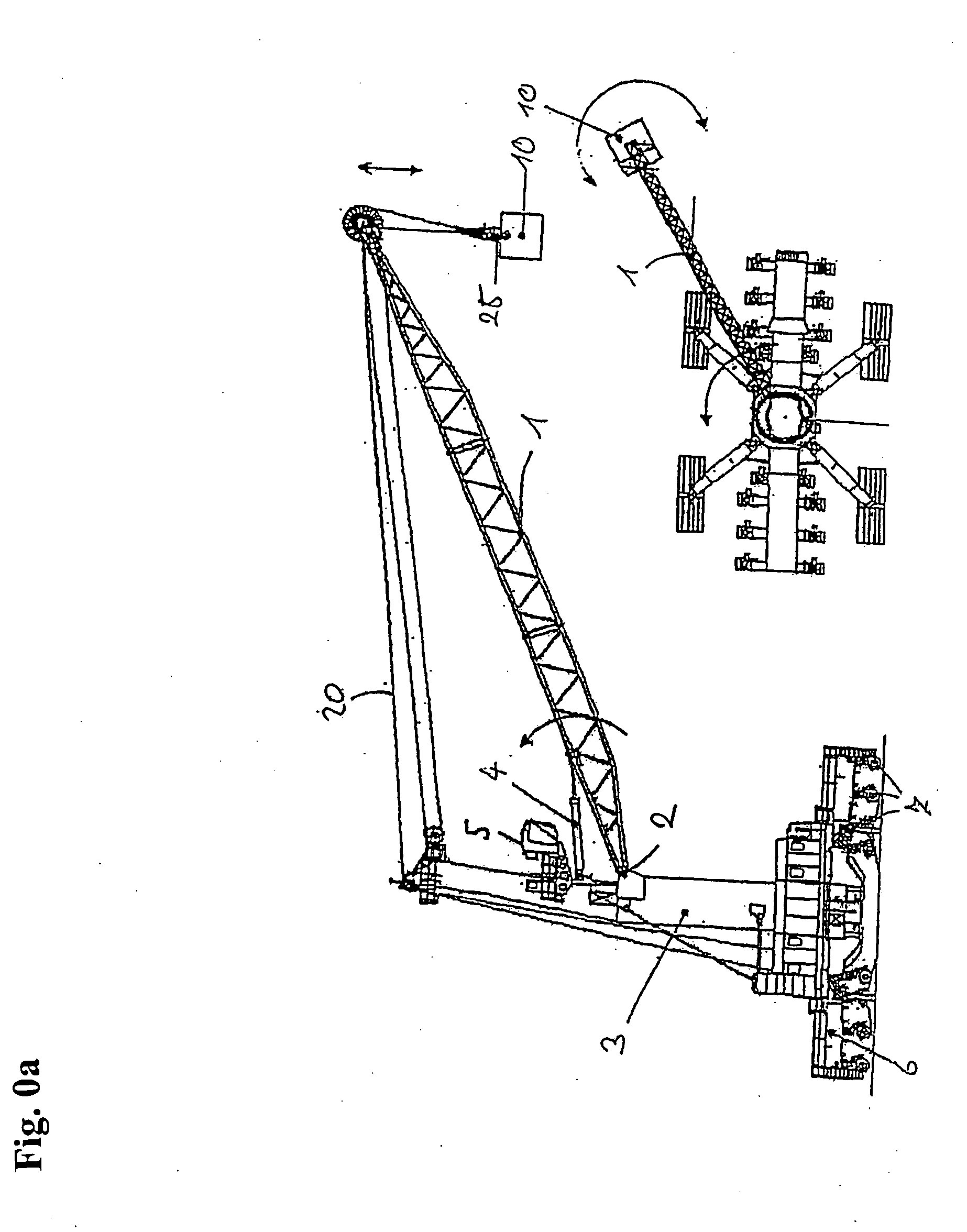

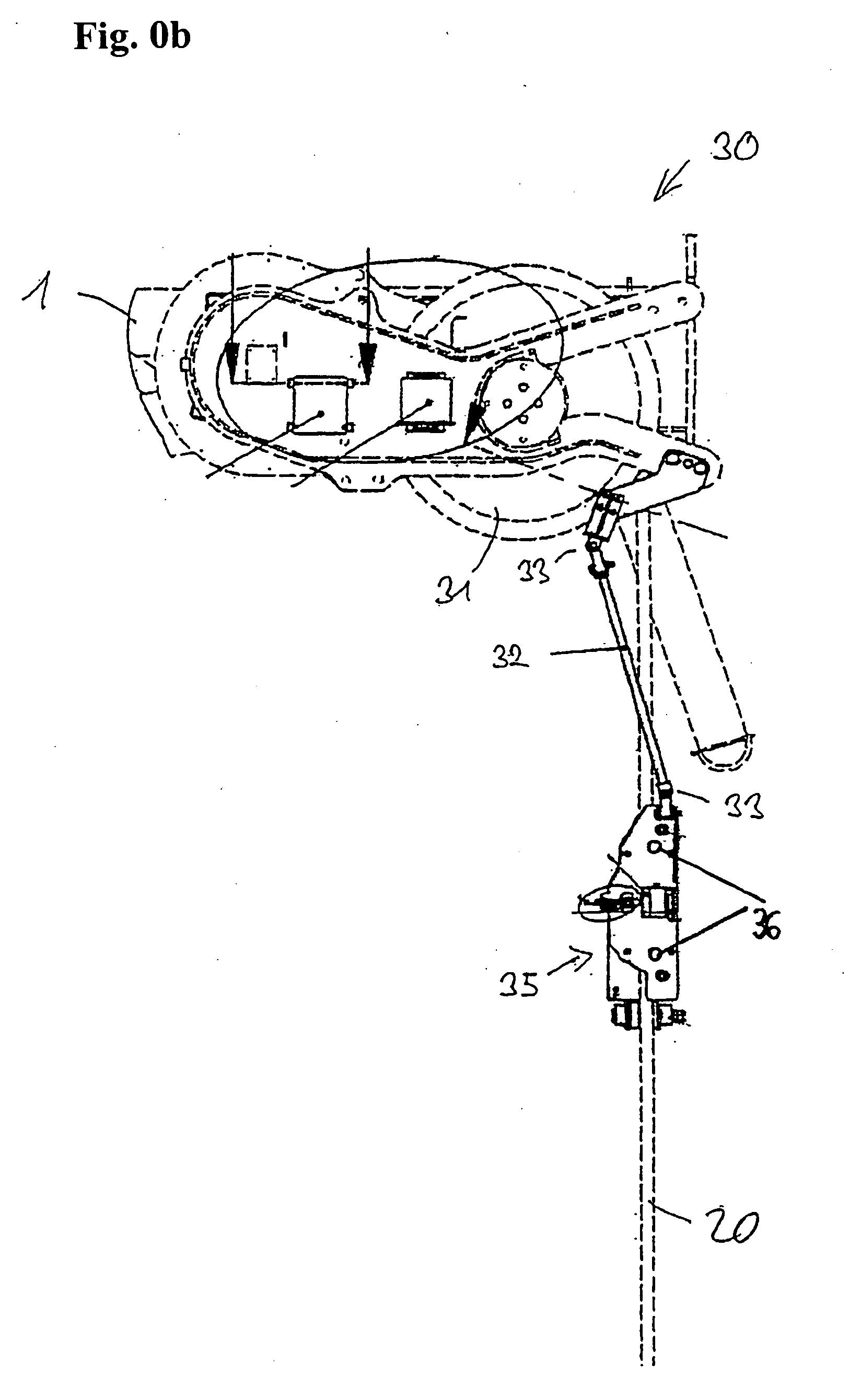

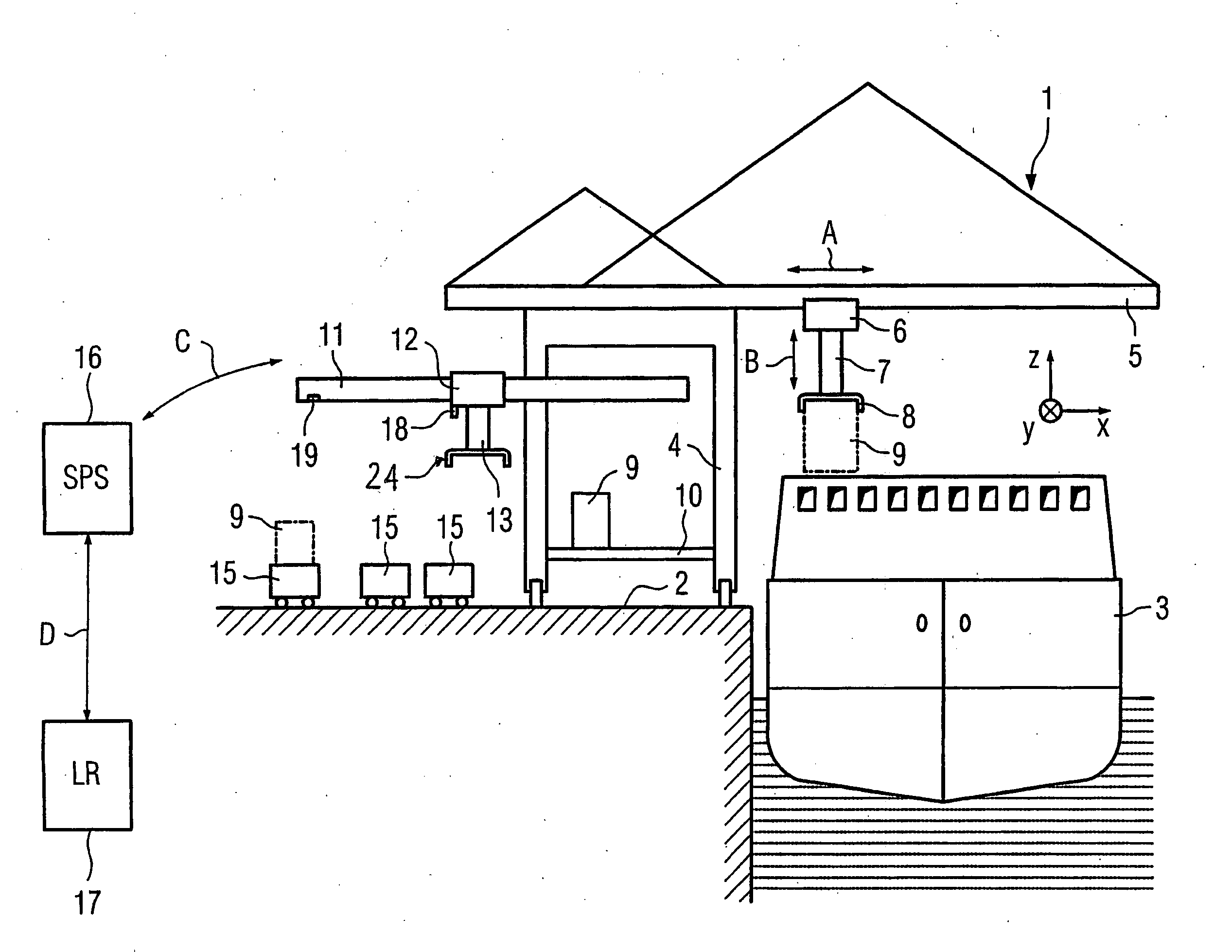

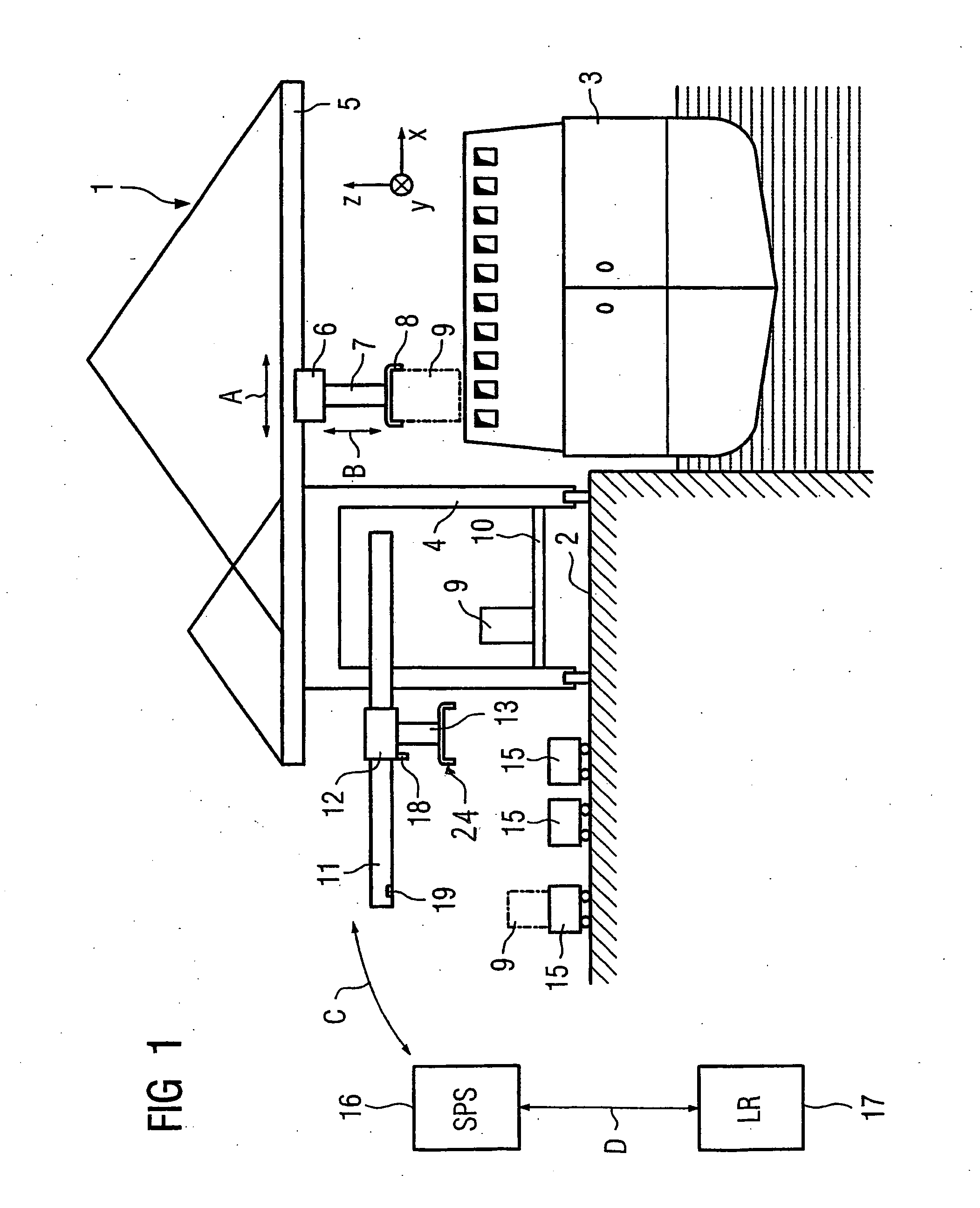

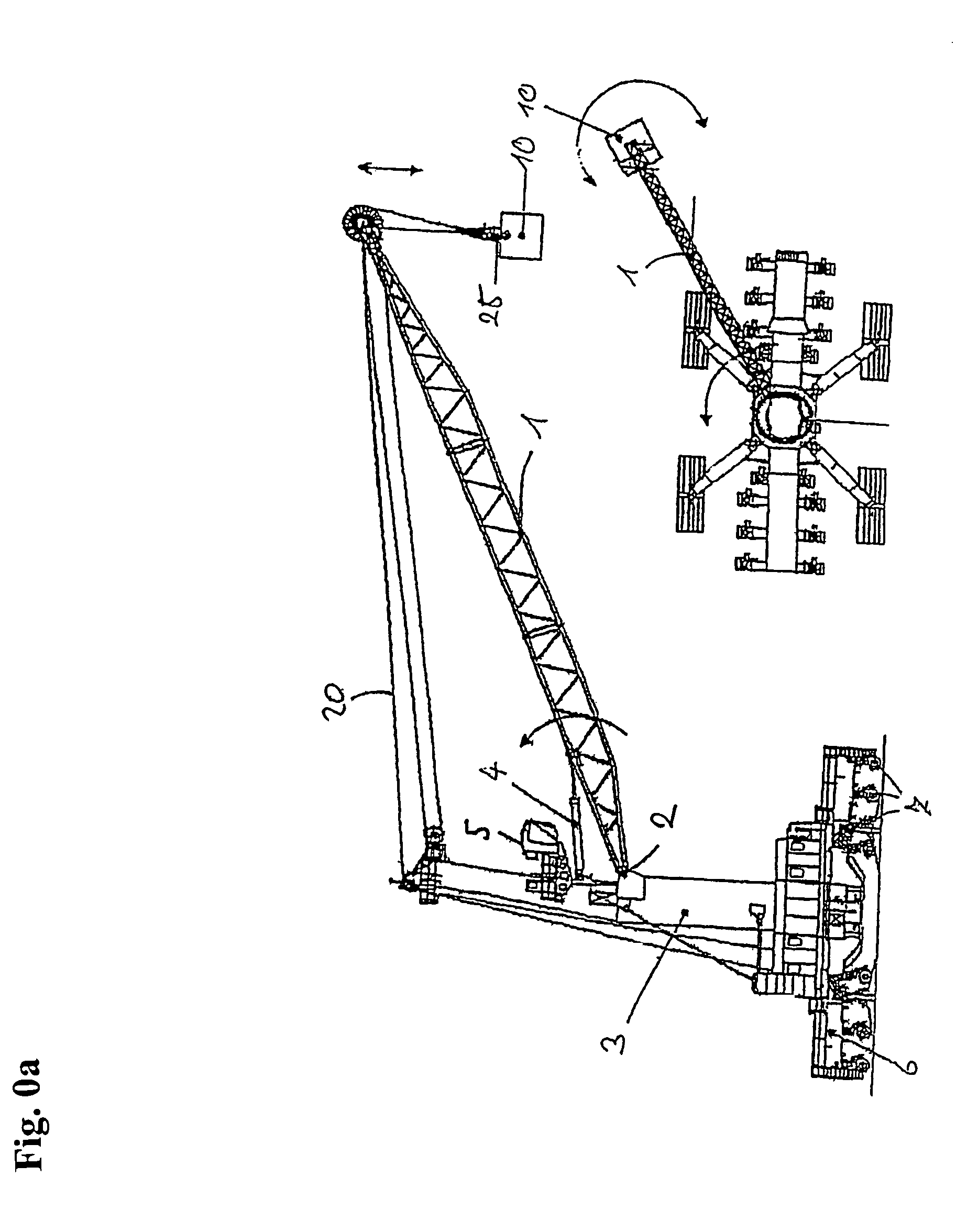

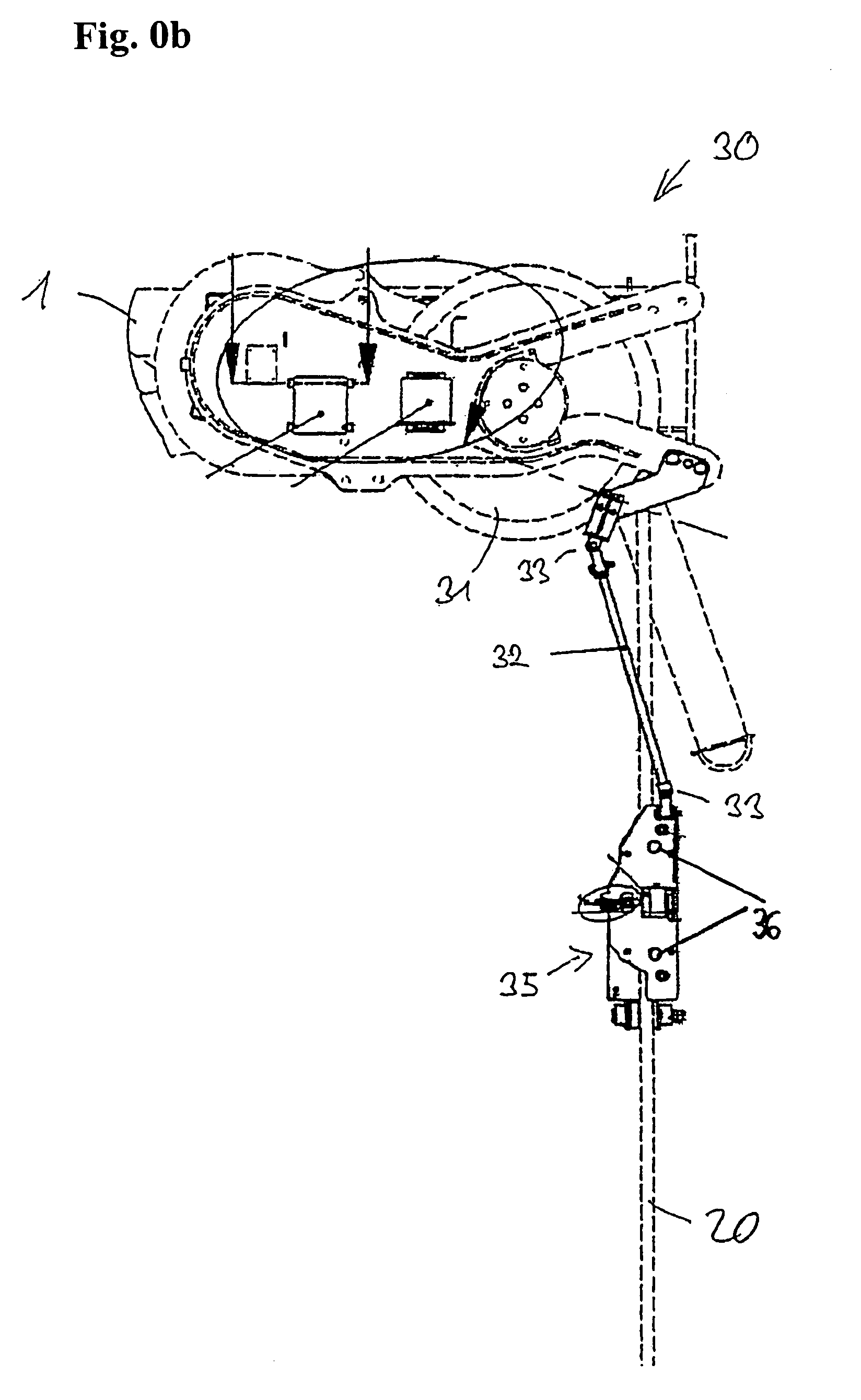

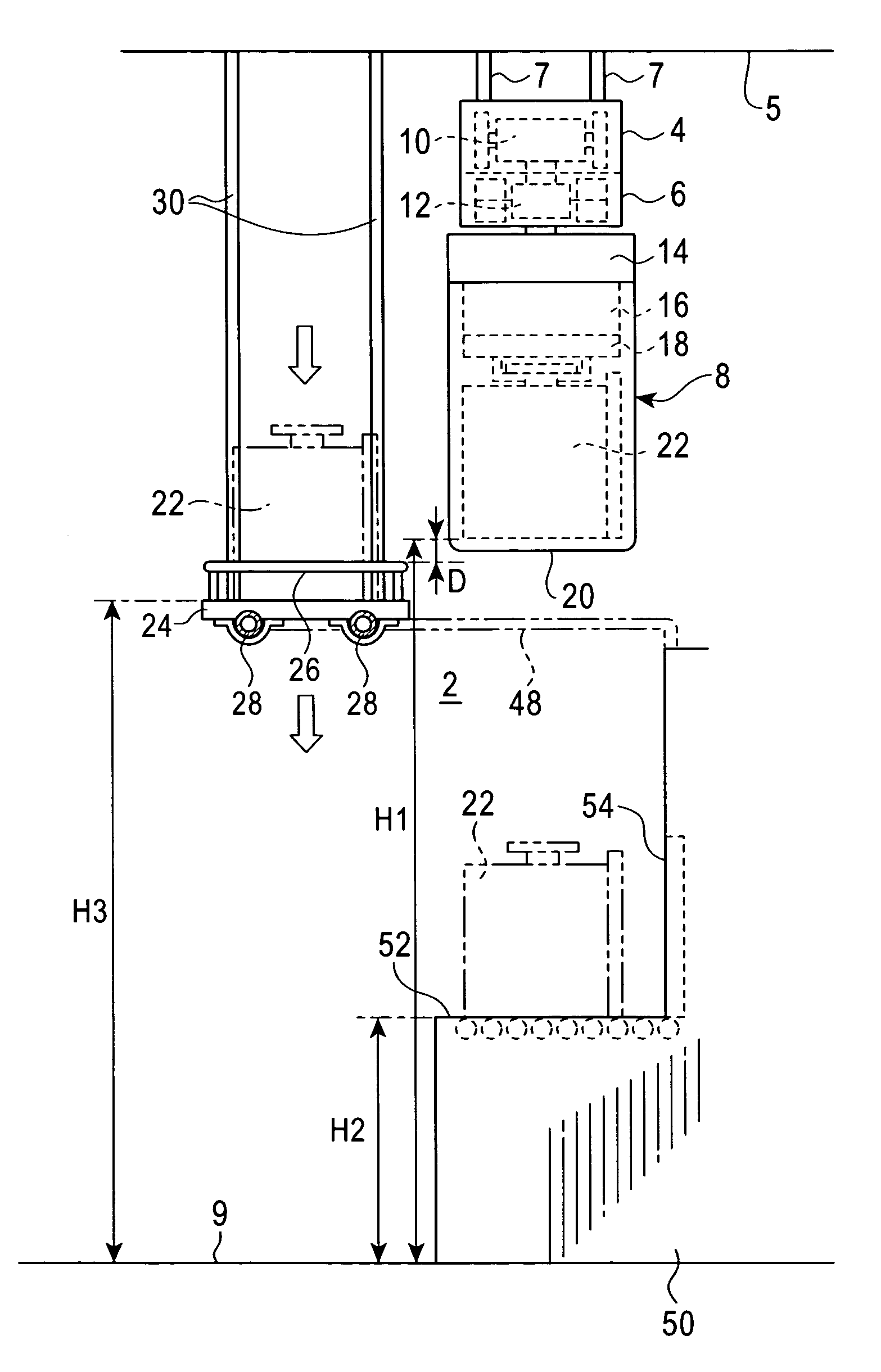

Crane control with active heave compensation

InactiveUS20100230370A1Precise positioningFlexible useCargo handling apparatusAnalogue computers for trafficDynamic modelsActive heave compensation

The present invention represents a procedure for compensating the heave movement of offshore cranes. The dynamic model of the compensation actuator (hydraulically operated winch) and the load hanging on a rope are derived. Based on this model, a path-tracking control unit is developed. To compensate the movement of the ship / watercraft caused by waves, the heave movement is defined as a time-varying disturbance and is analyzed with respect to uncoupling conditions. With a model expansion, these conditions are satisfied, and an inversion-based uncoupling control law is formulated. To stabilize the system, an observer is used for reconstructing the unknown state by means of a force measurement. Furthermore, the compensation efficiency can be improved by predicting the heave movement. There is proposed a prediction method in which no ship / watercraft models or properties are required. The simulation and measurement results validate the heave compensation method.

Owner:LIEBHERR WERK NENZING

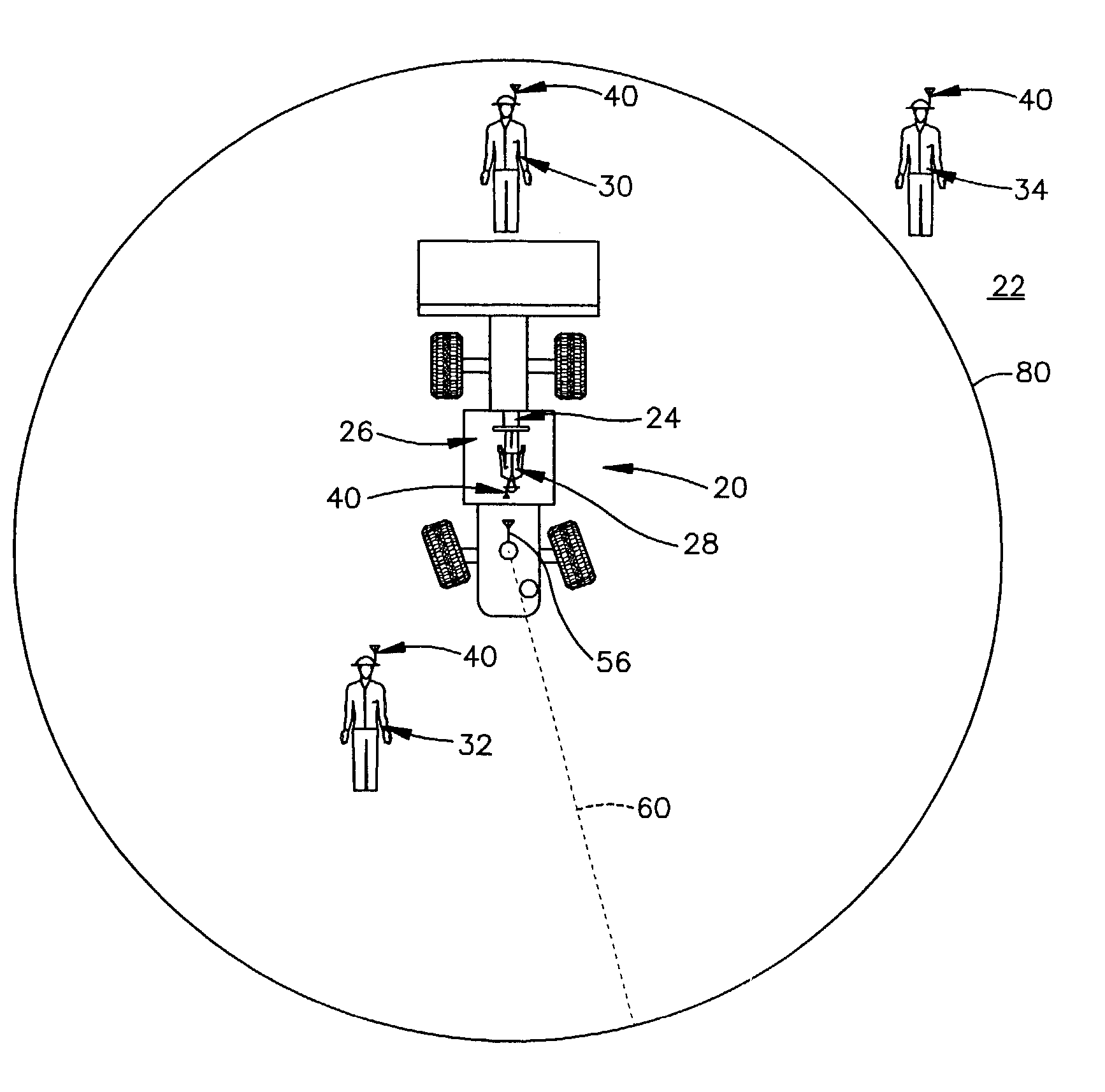

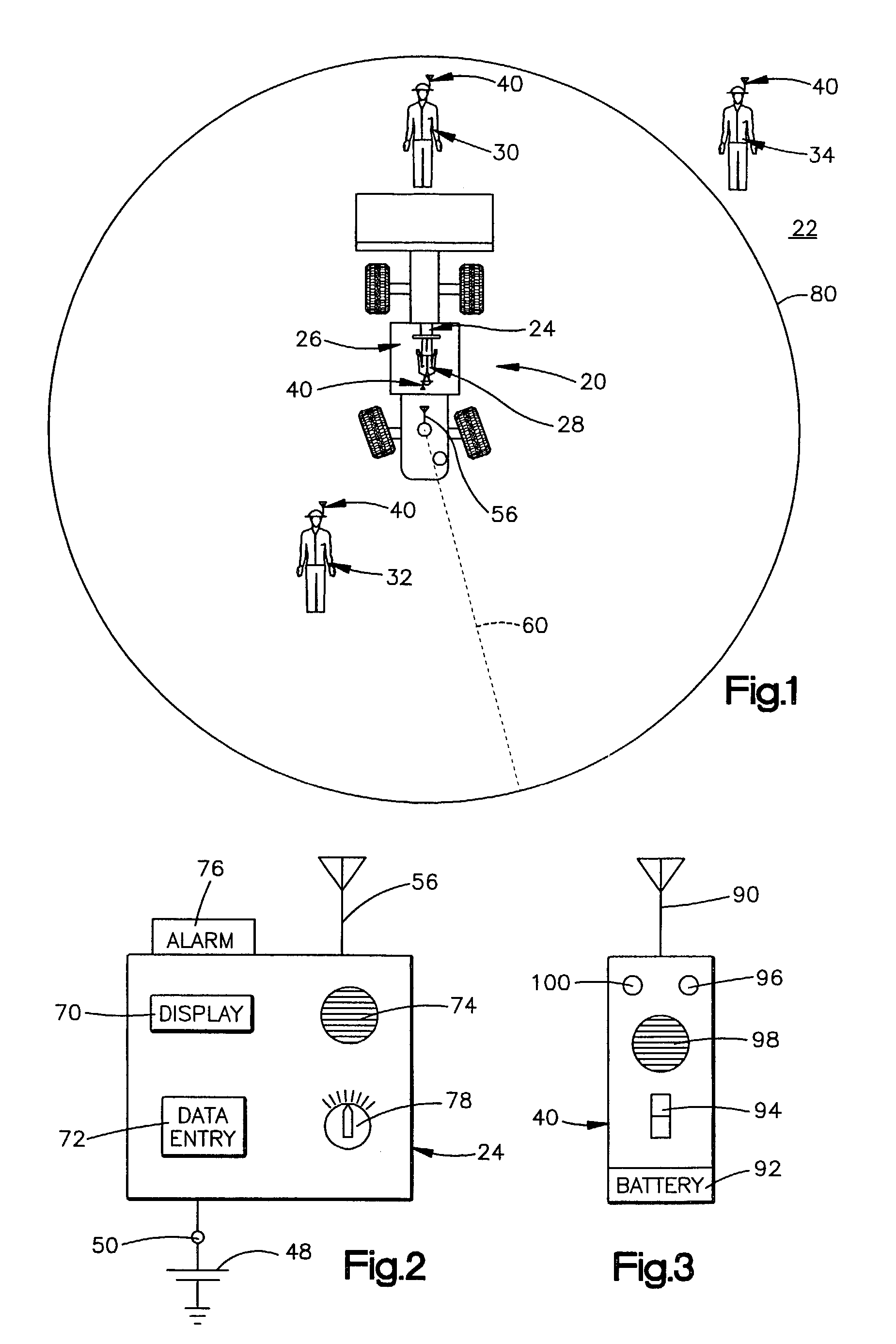

Method and apparatus for enhancing safety within a work zone

ActiveUS6963278B2Improve securityEngineering safety devicesElectric/electromagnetic visible signallingWork zoneIndustrial engineering

Owner:FRAME GARY M

Crane control, crane and method

ActiveUS20090008351A1Easy and safer alignmentEnhanced oscillationCranesSafety gearAngular velocityGravitational force

The present invention shows a crane control of a crane which includes at least one cable for lifting a load, wherein at least one sensor unit is provided for determining a cable angle relative to the direction of gravitational force. Furthermore, there is shown a crane control for driving the positioners of a crane which includes at least one first and one second strand of cables for lifting the load, with a load oscillation damping for damping spherical pendular oscillations of the load, wherein first and second sensor units are provided, which are associated to the first and second strands of cables, in order to determine the respective cable angles and / or cable angular velocities, and the load oscillation damping includes a control in which the cable angles and / or cable angular velocities determined by the first and second sensor units are considered. Furthermore, a corresponding crane and a method are shown.

Owner:LIEBHERR WERK NENZING

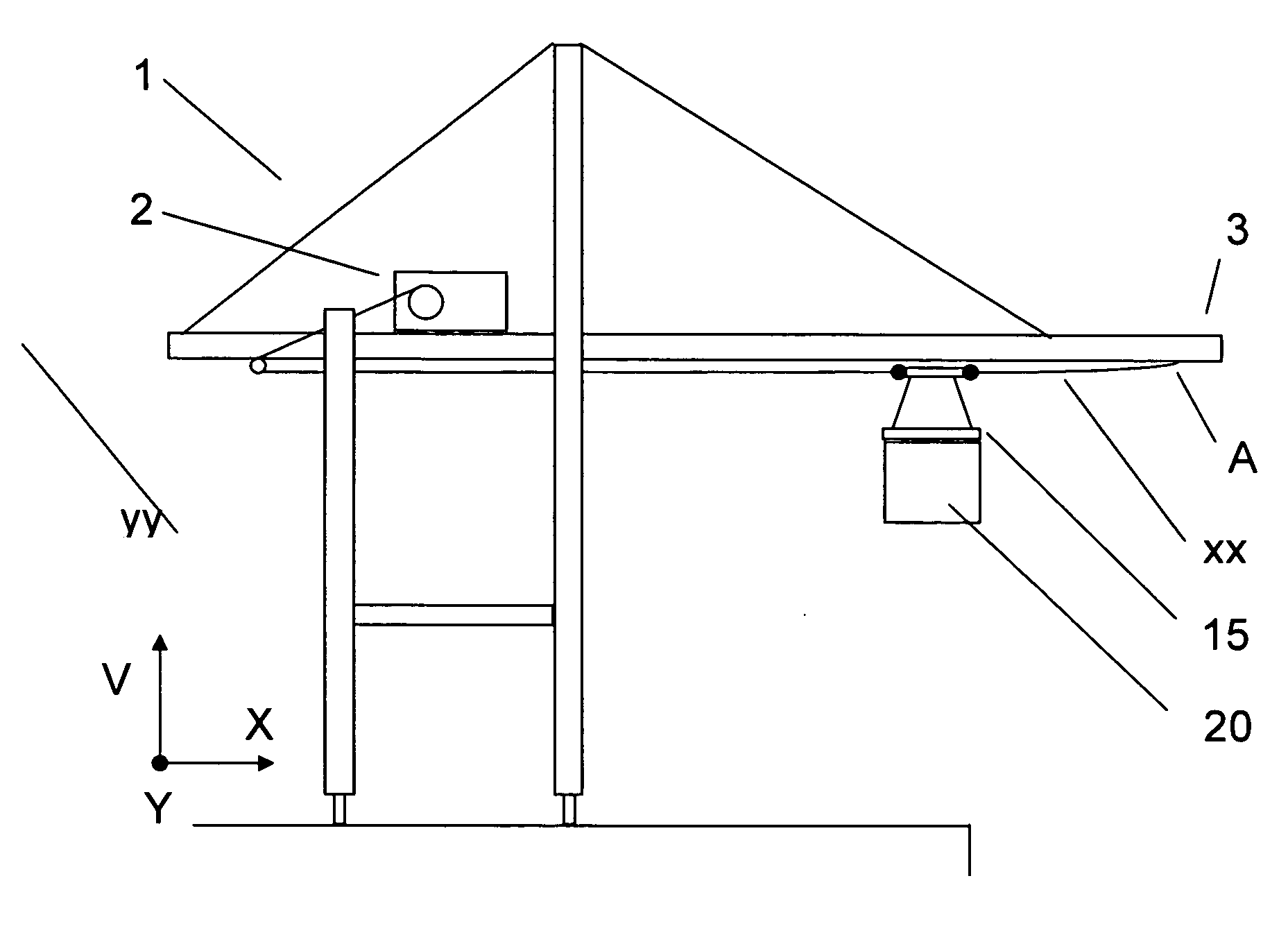

Load control device for a crane

ActiveUS20070289931A1Promote recoveryRapid responseAngle measurementTrolley cranesContainer craneEngineering

A control device and system for controlling a suspended load of a container crane with a trolley, a spreader and load lines arranged in a four point suspension for lifting a load and an optical sensor for sensing a deflection position of an orthogonal axis of a container suspended under the spreader. Two or more actuators are arranged attached to at least one load for moving at least one said suspension point closer to or farther away from an imaginary center line by shortening and / or lengthening the at least one load line.

Owner:ABB (SCHWEIZ) AG

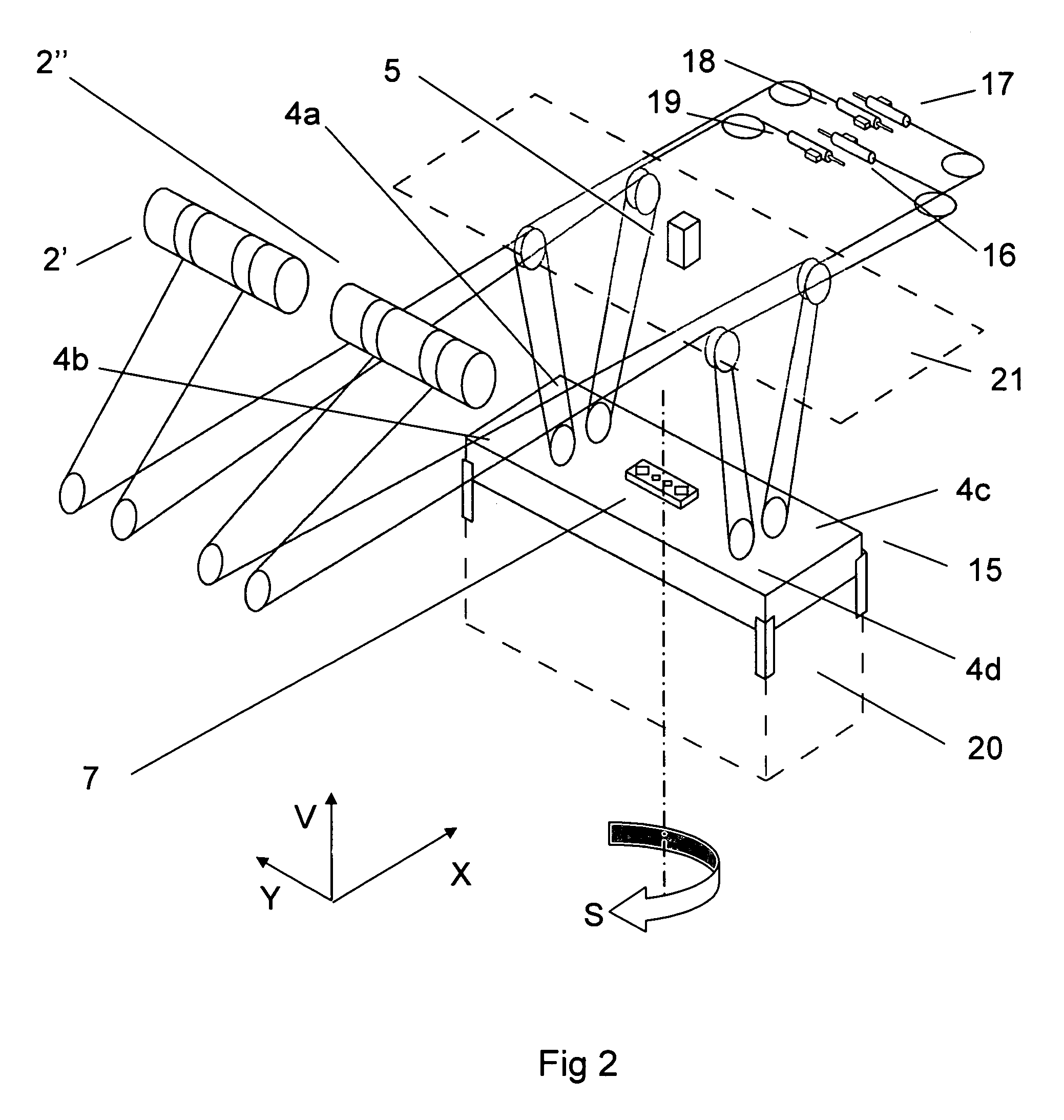

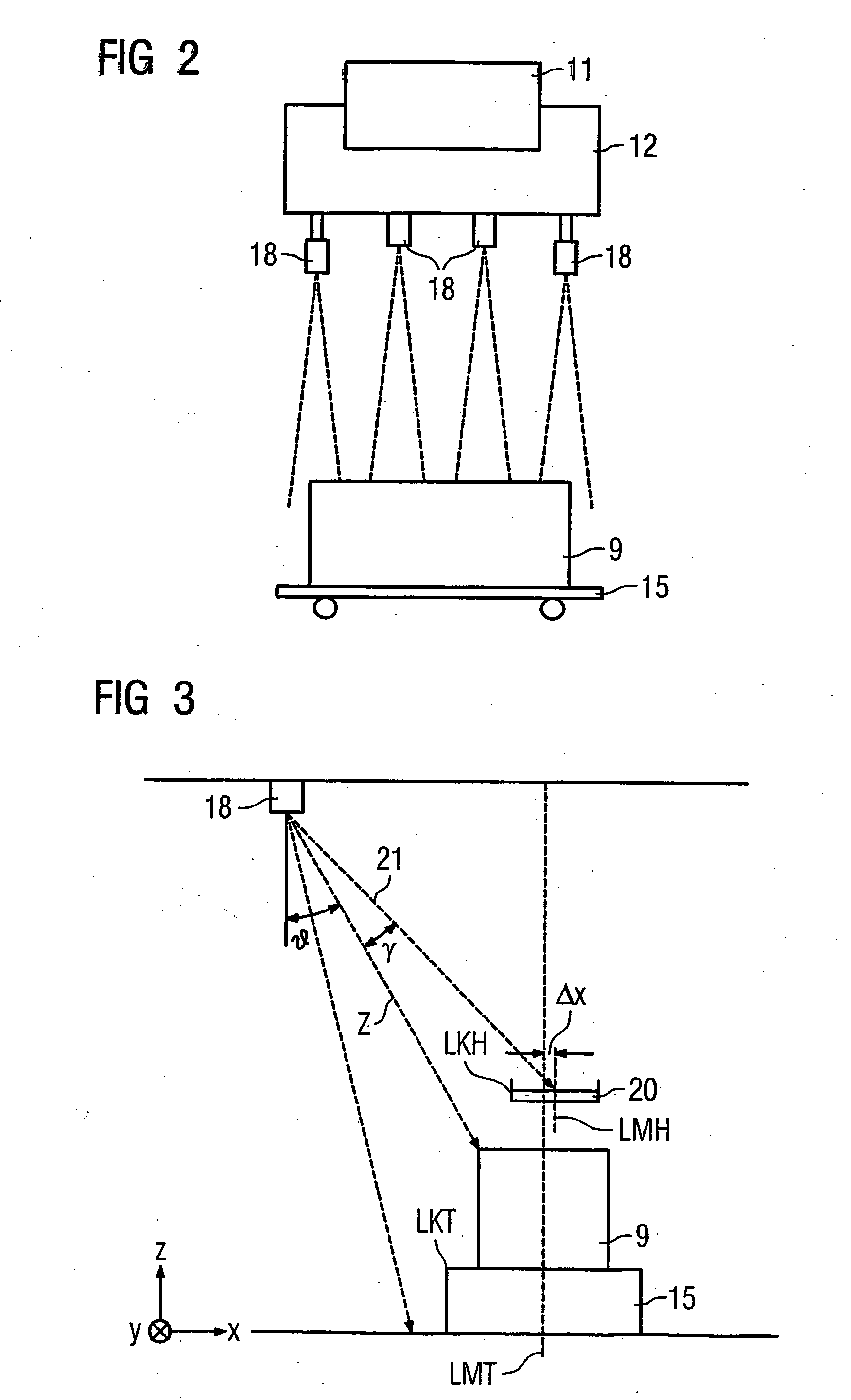

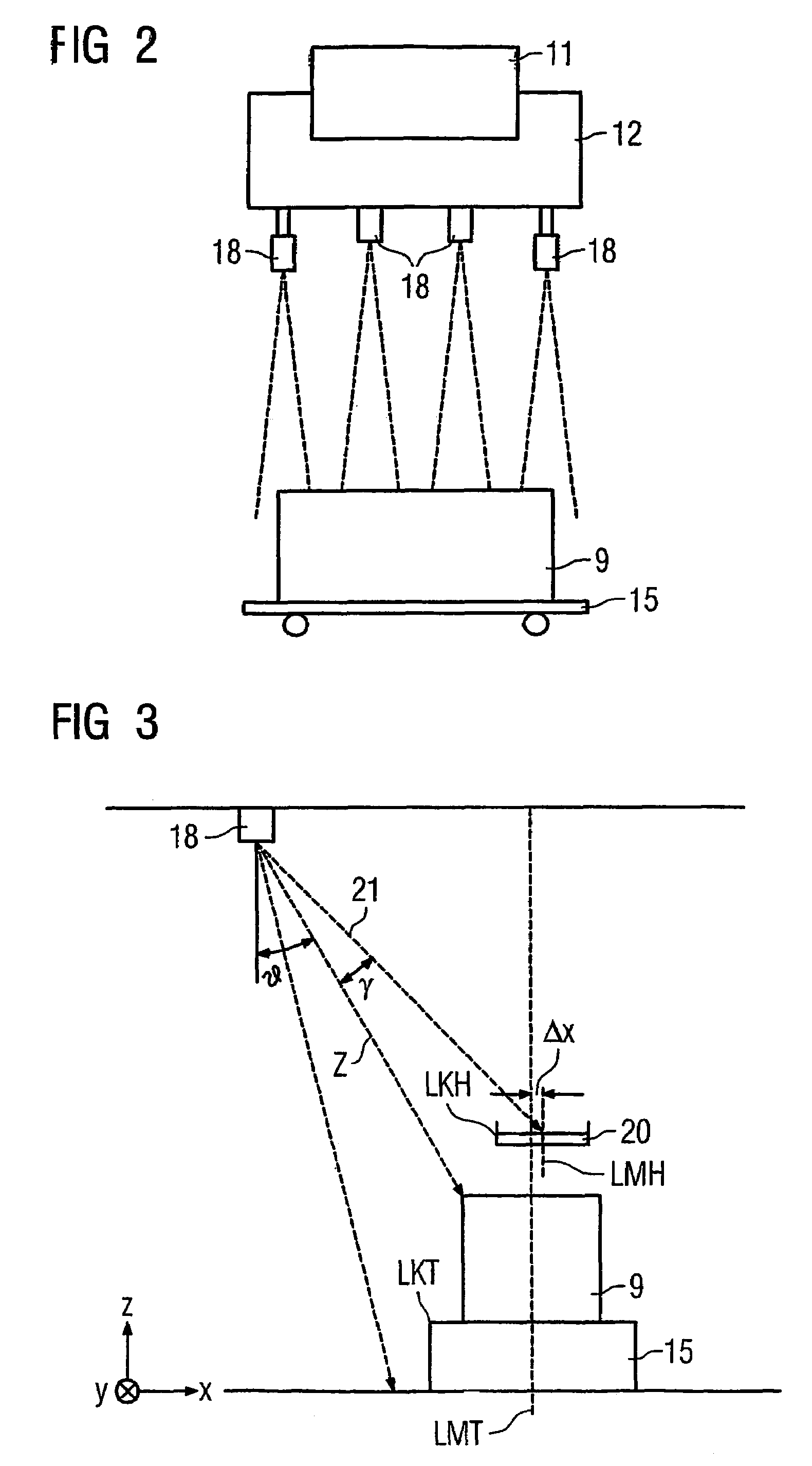

Container crane, and method of determining and correcting a misalignment between a load-carrying frame and a transport vehicle

ActiveUS20050281644A1Large enough scanning areaEnough recording areaDigital data processing detailsArticle unpackingContainer craneEngineering

A container crane includes a movable trolley and a load-carrying frame pendantly connected to the trolley and comprised of a spreader and a head block, for transfer of a container from or to a transport vehicle. Plural optical detectors are mounted on the trolley for identifying longitudinal and transversal edges of the head block or spreader and the transport vehicle. Operatively connected to the detectors is a processing device for determining a spatial position of the edges and calculating a position of longitudinal and transversal center lines of the head block or spreader and the transport vehicle and their spatial positions in relation to one another. In this way a possible offset of the center lines of the head block or spreader with regard to those of the transport vehicle in longitudinal and transversal directions as well as a rotation angle of the center lines can be determined, whereby a detected offset or rotation angle is compensated by displacing the spreader relative to the head block.

Owner:SIEMENS AG

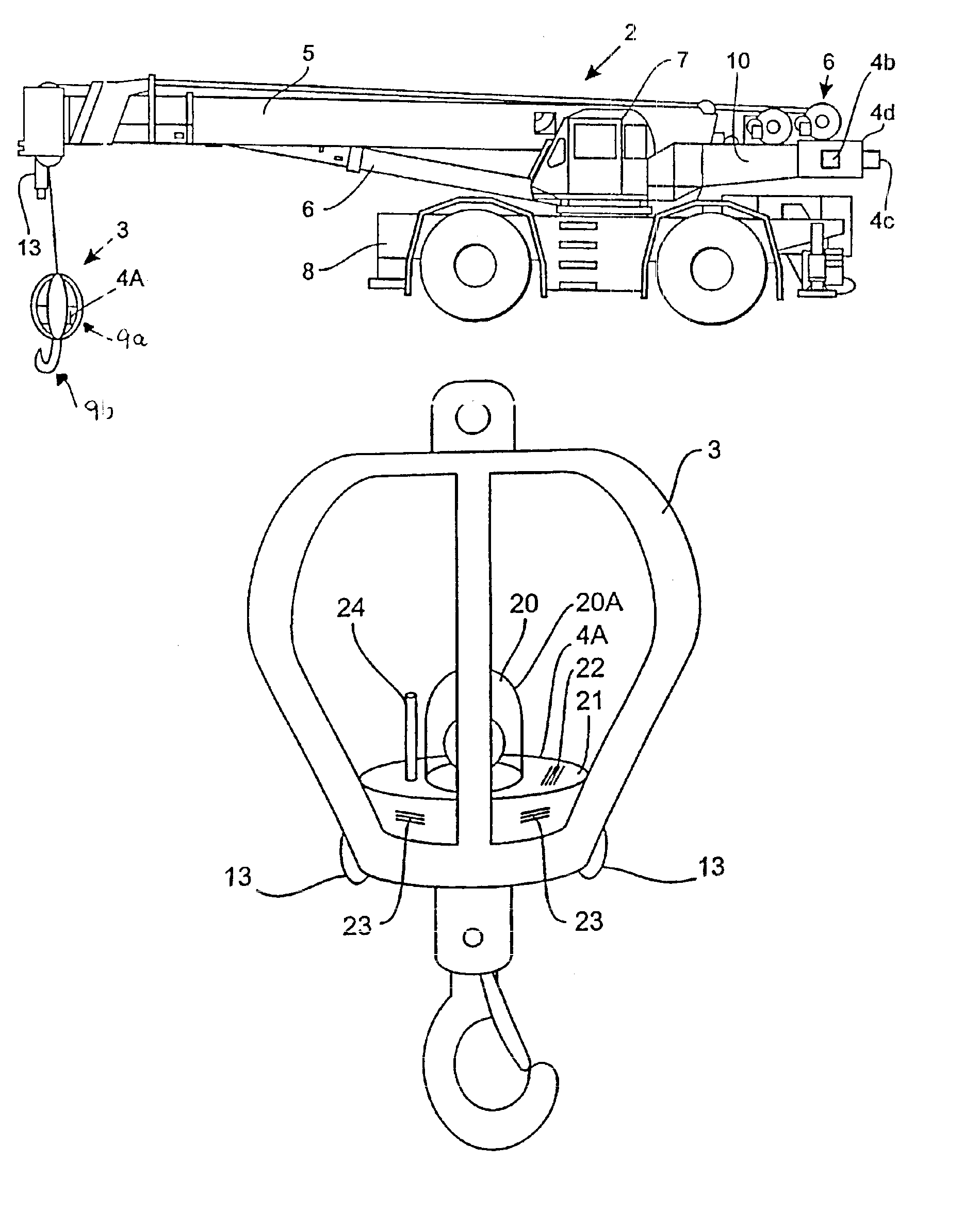

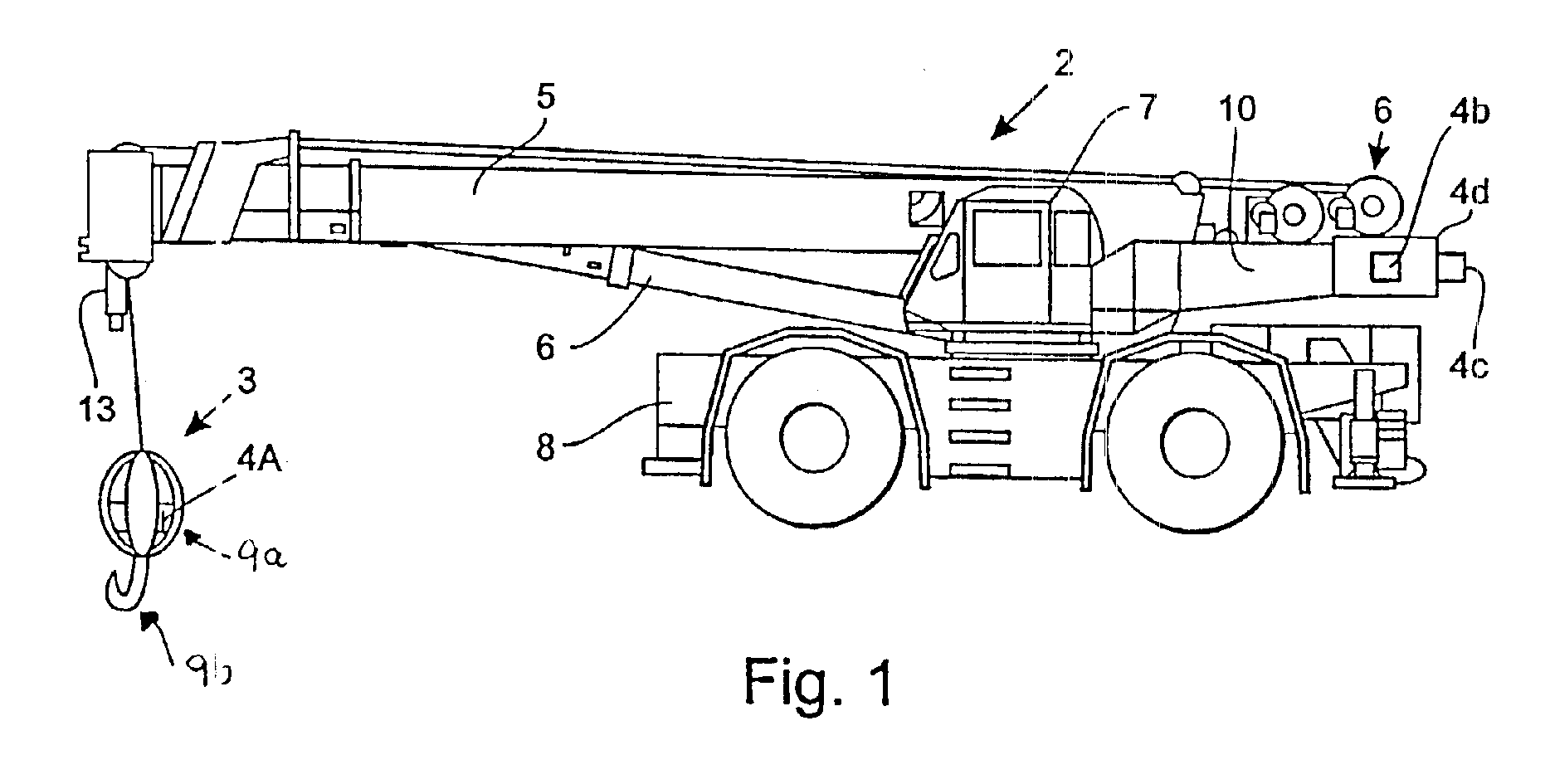

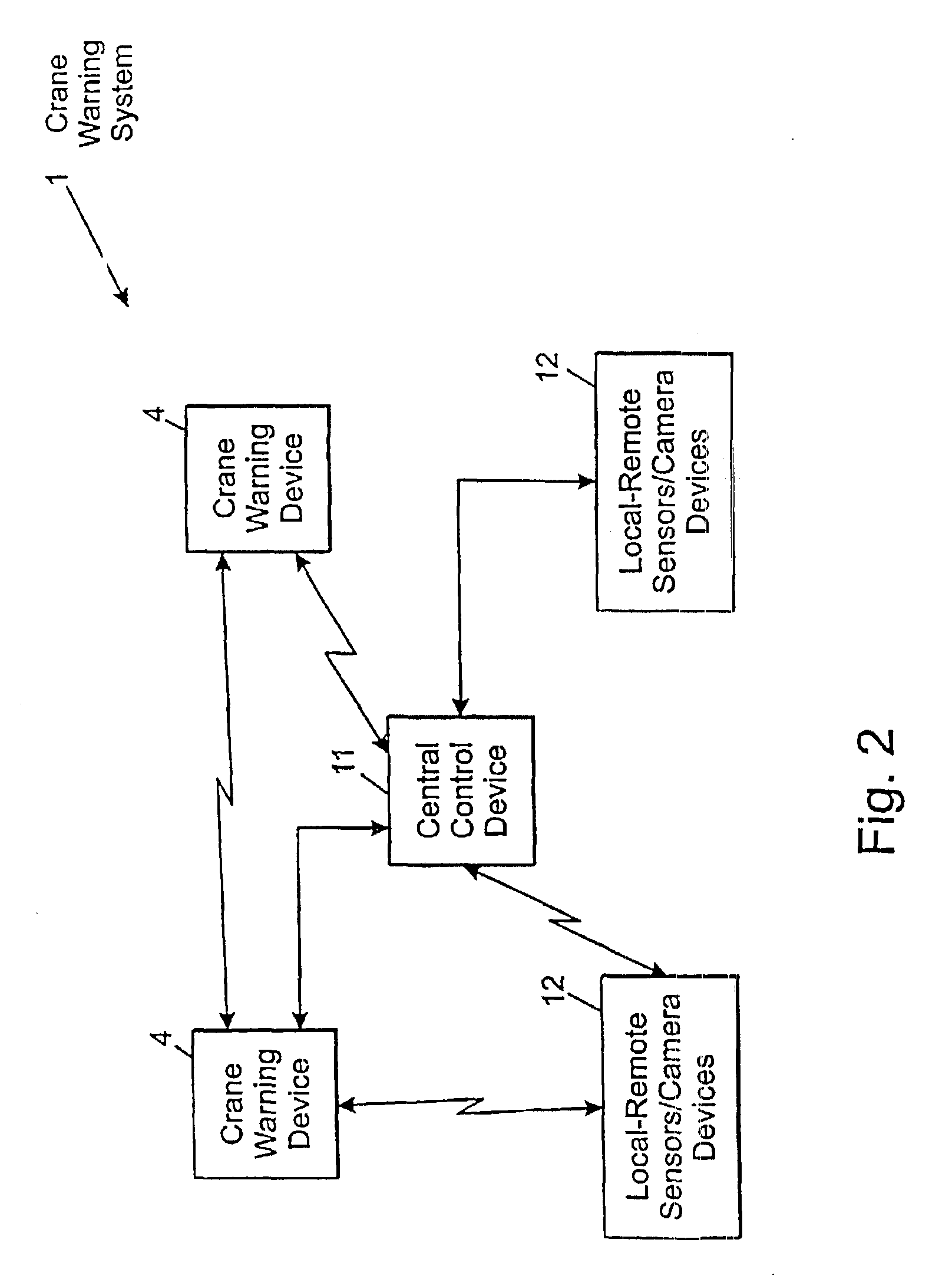

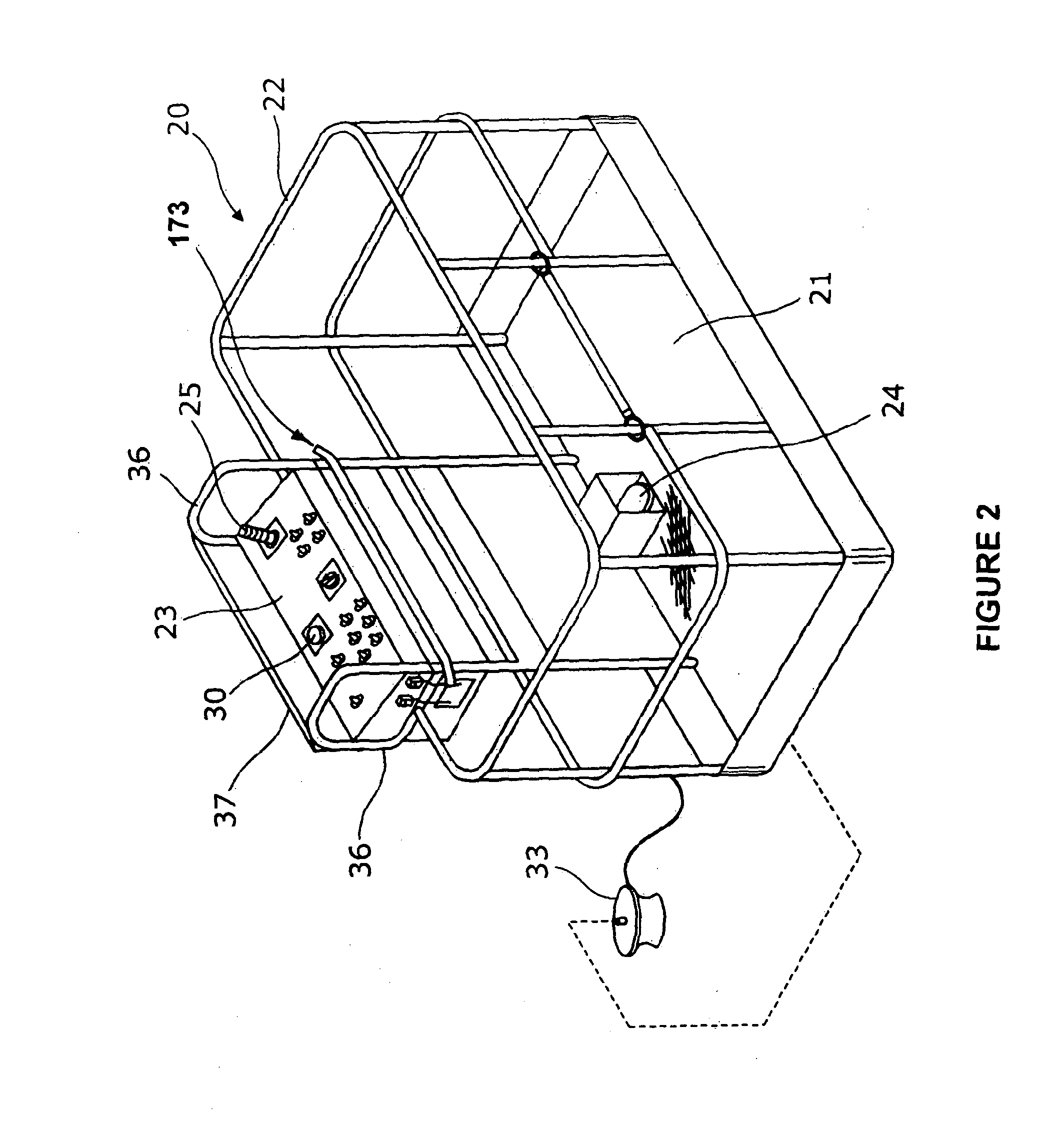

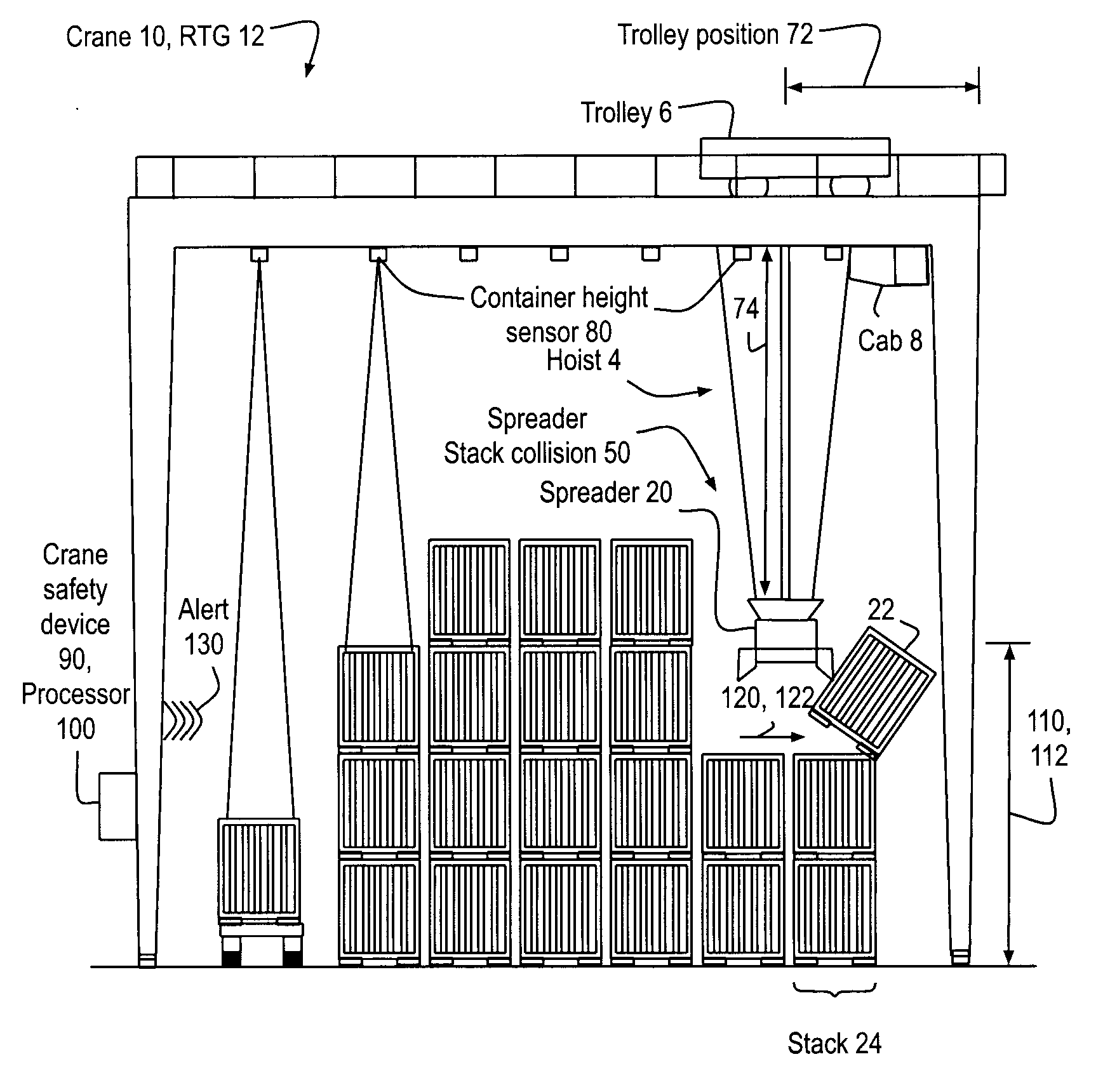

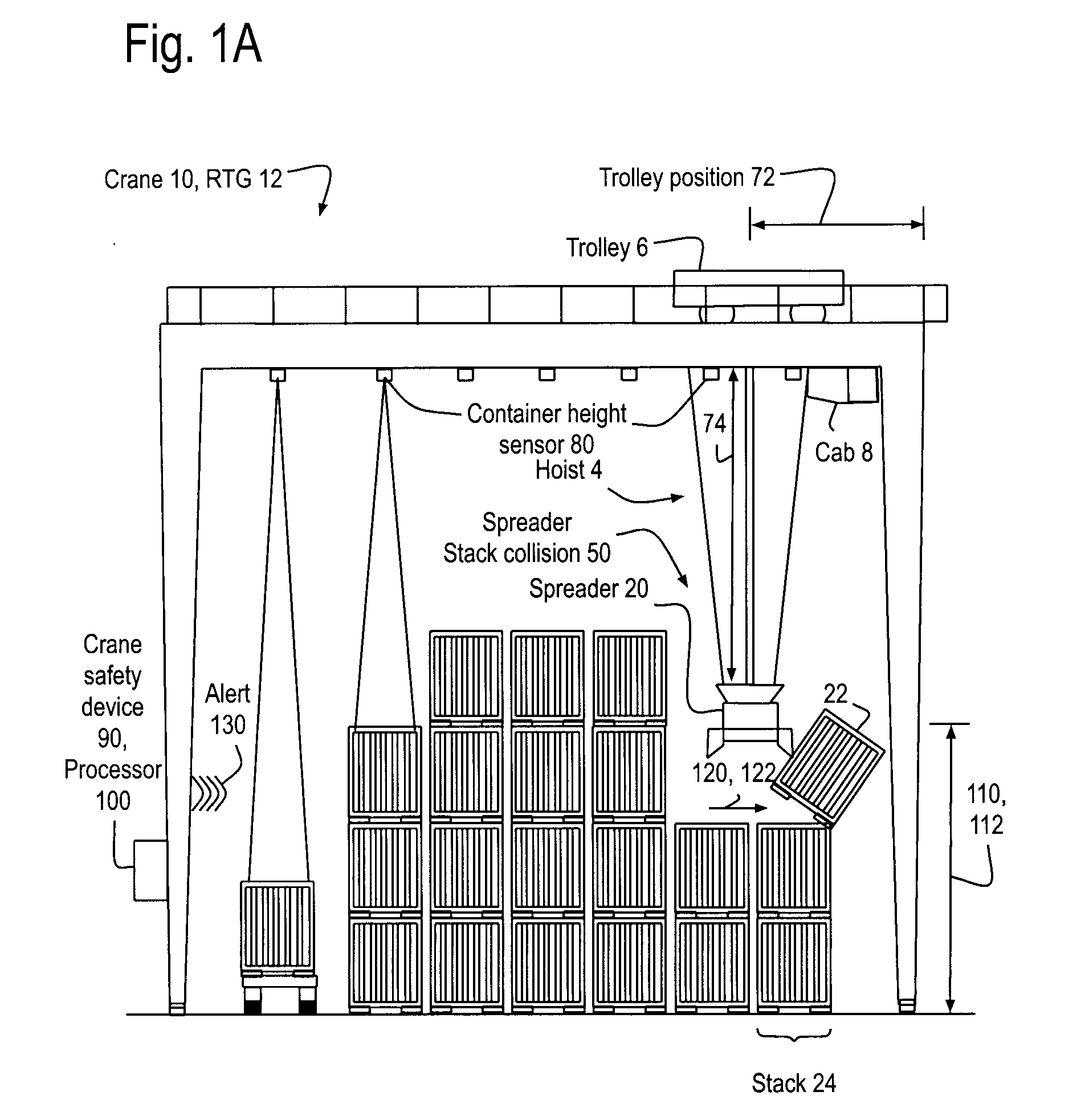

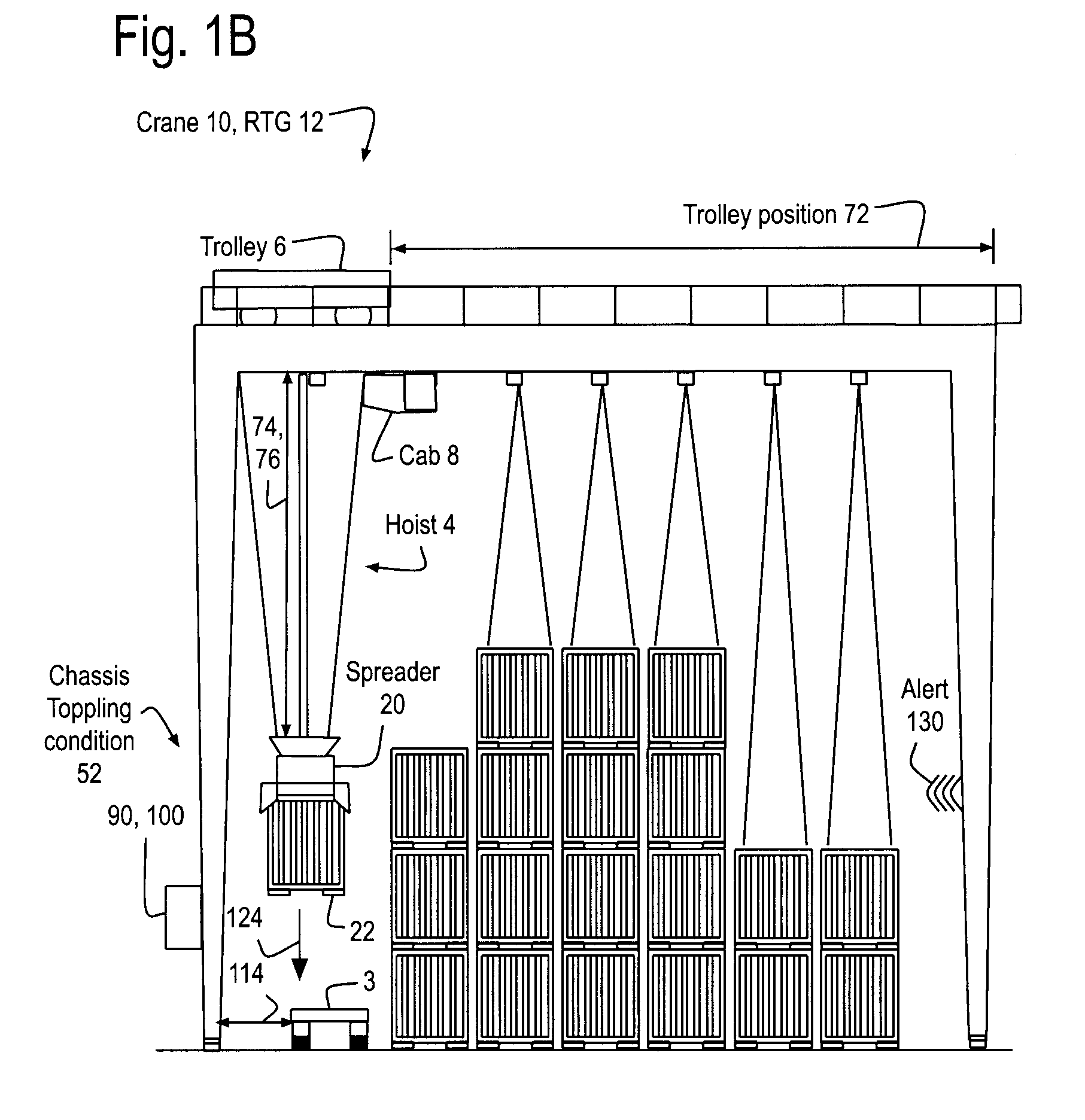

Crane safety devices and methods

InactiveUS6894621B2Minimize background noiseFacilitate communicationAnalogue computers for trafficComputations using stochastic pulse trainsEngineeringRemote communication

An improved crane warning system that includes acceleration sensors, motion sensors, hydraulic sensors, remote communications and / or a camera. The crane warning system may include a crane warning device integrated into the device suspended from the crane.

Owner:SHAW JACK B

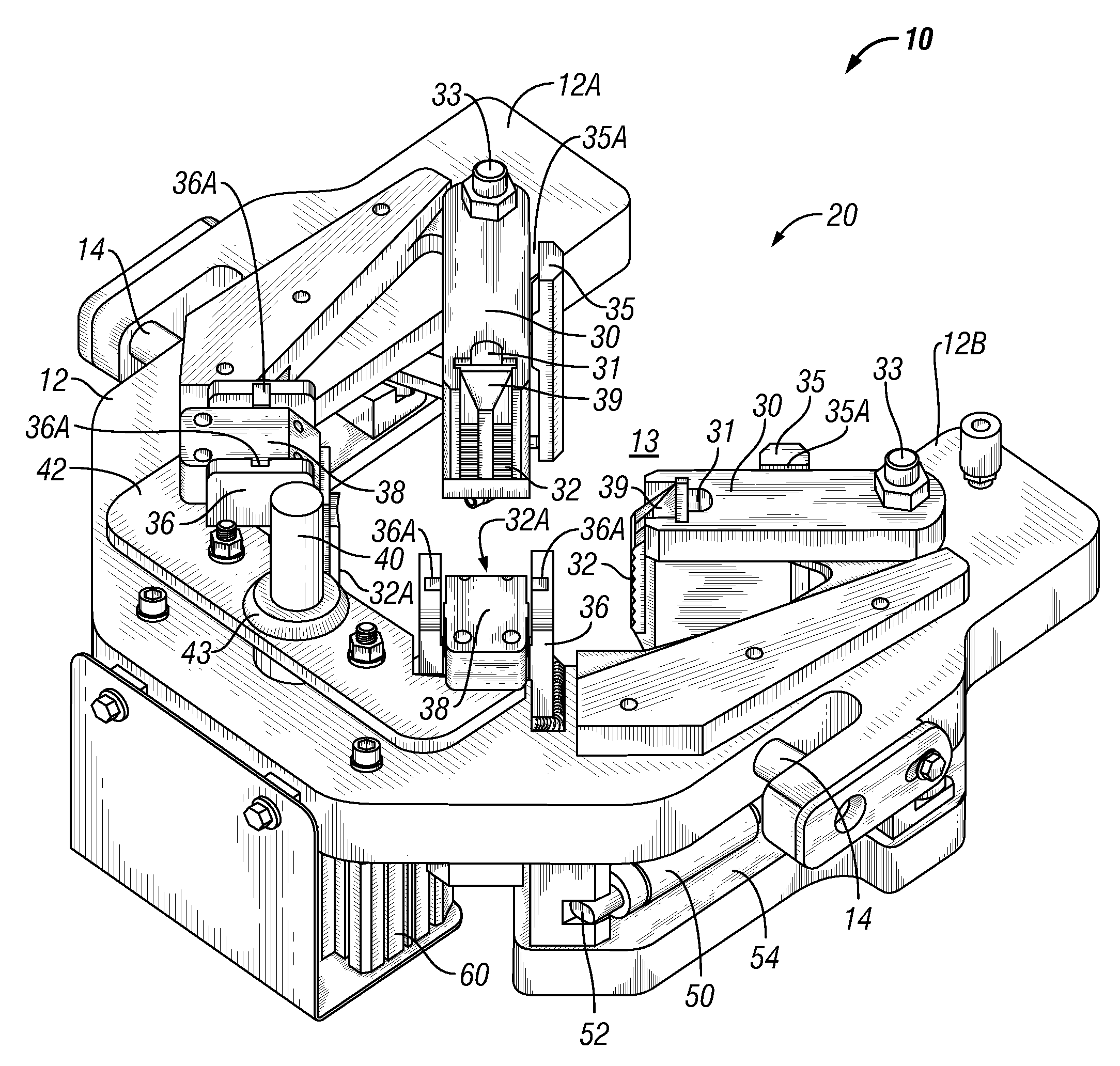

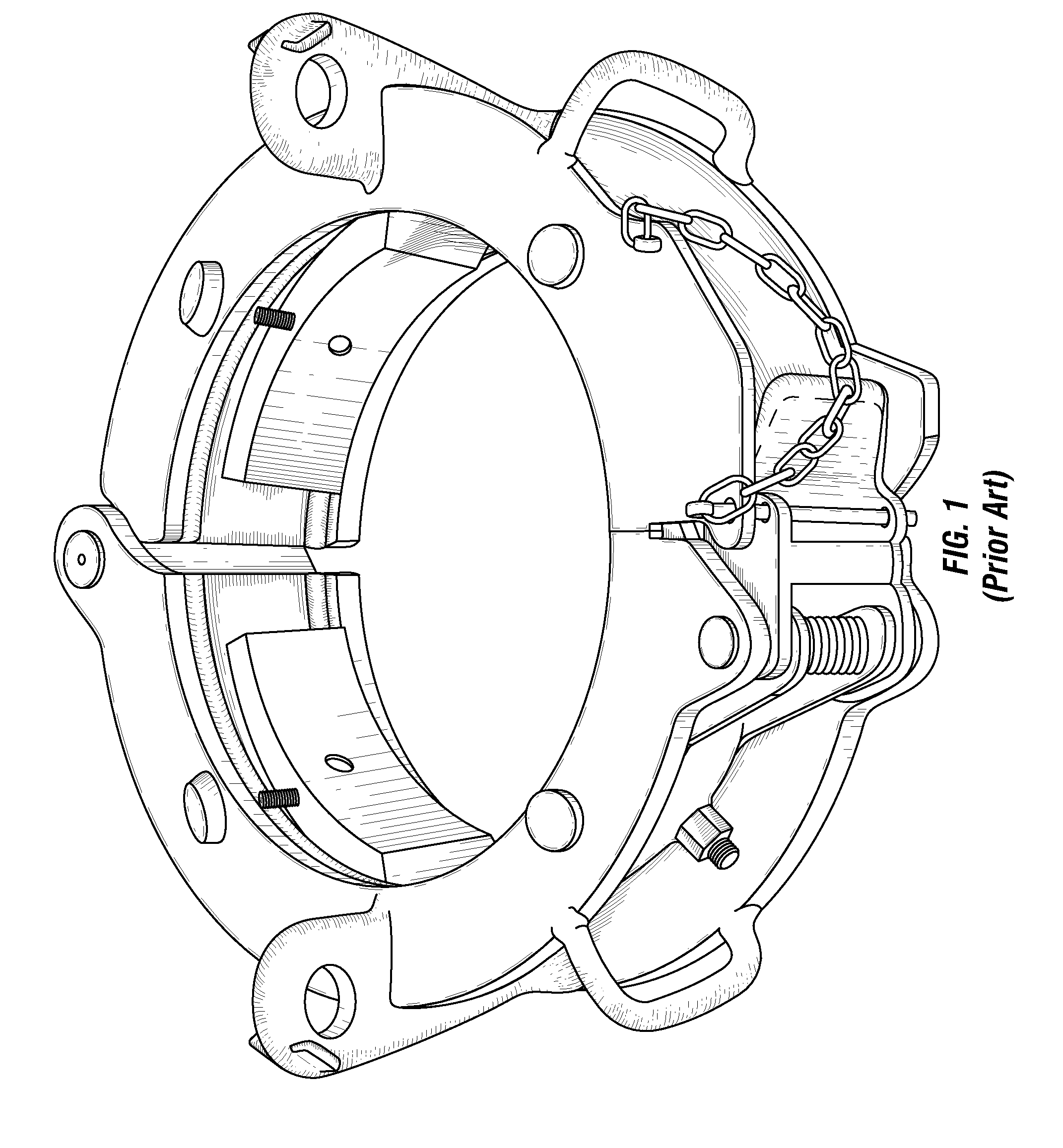

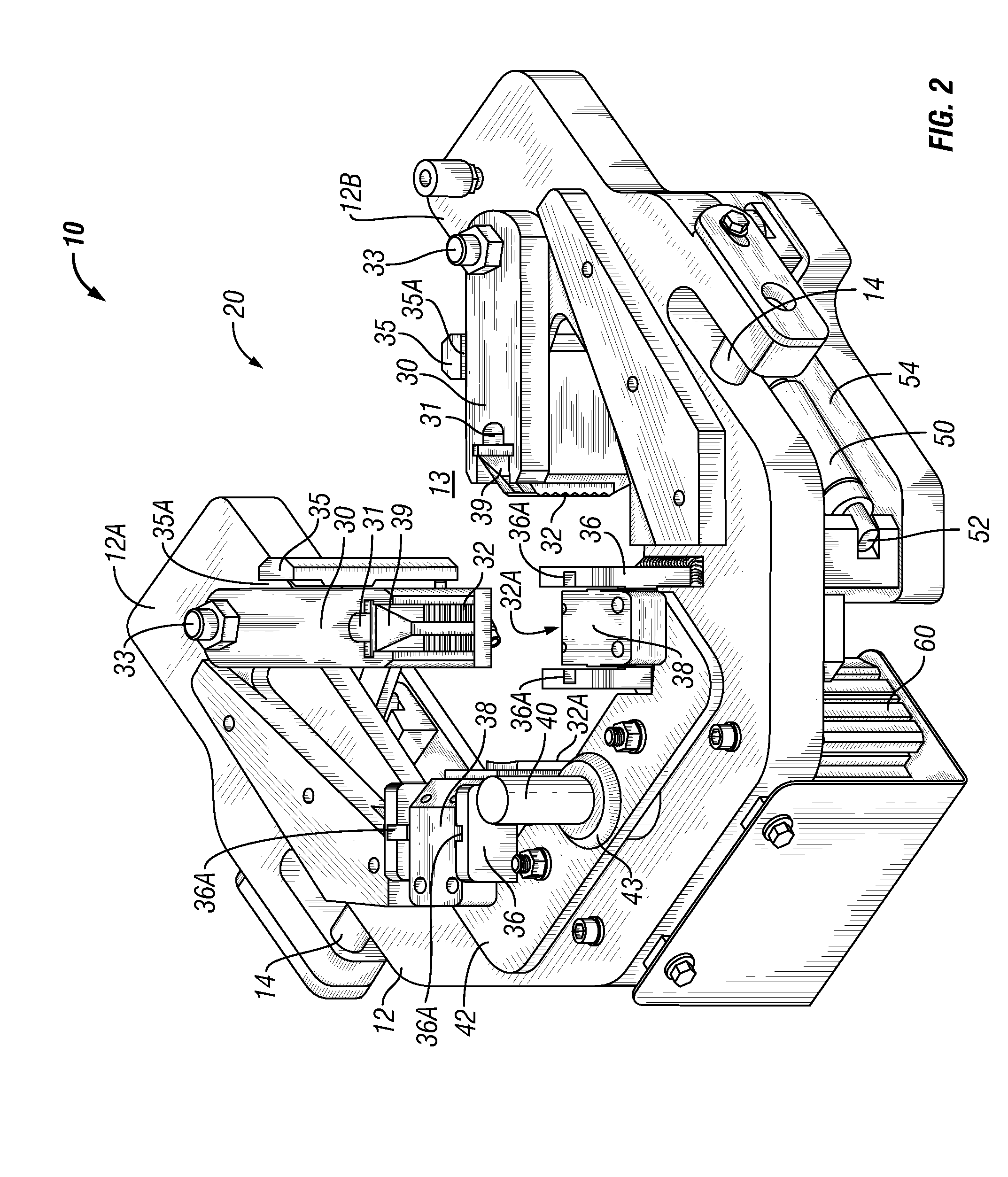

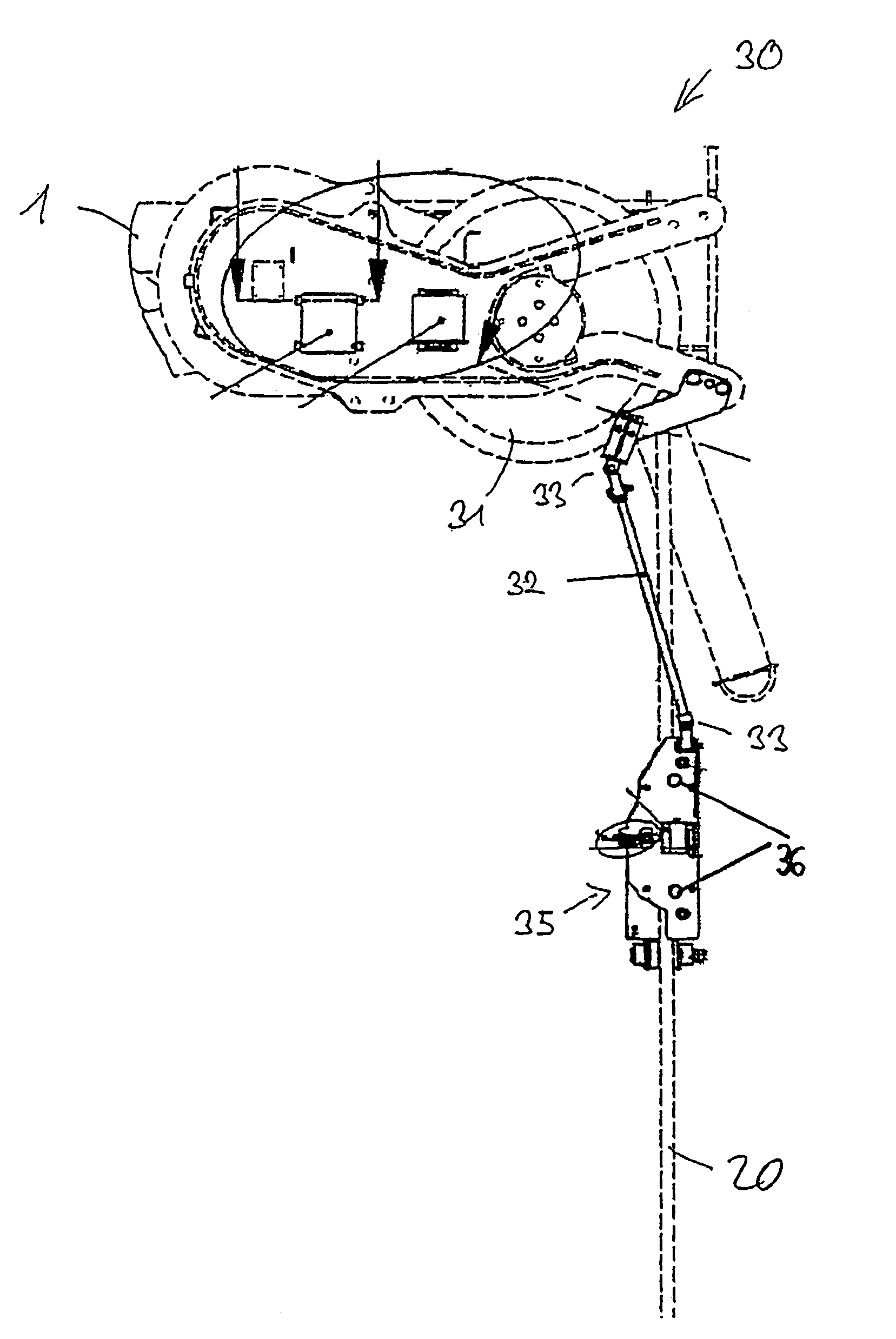

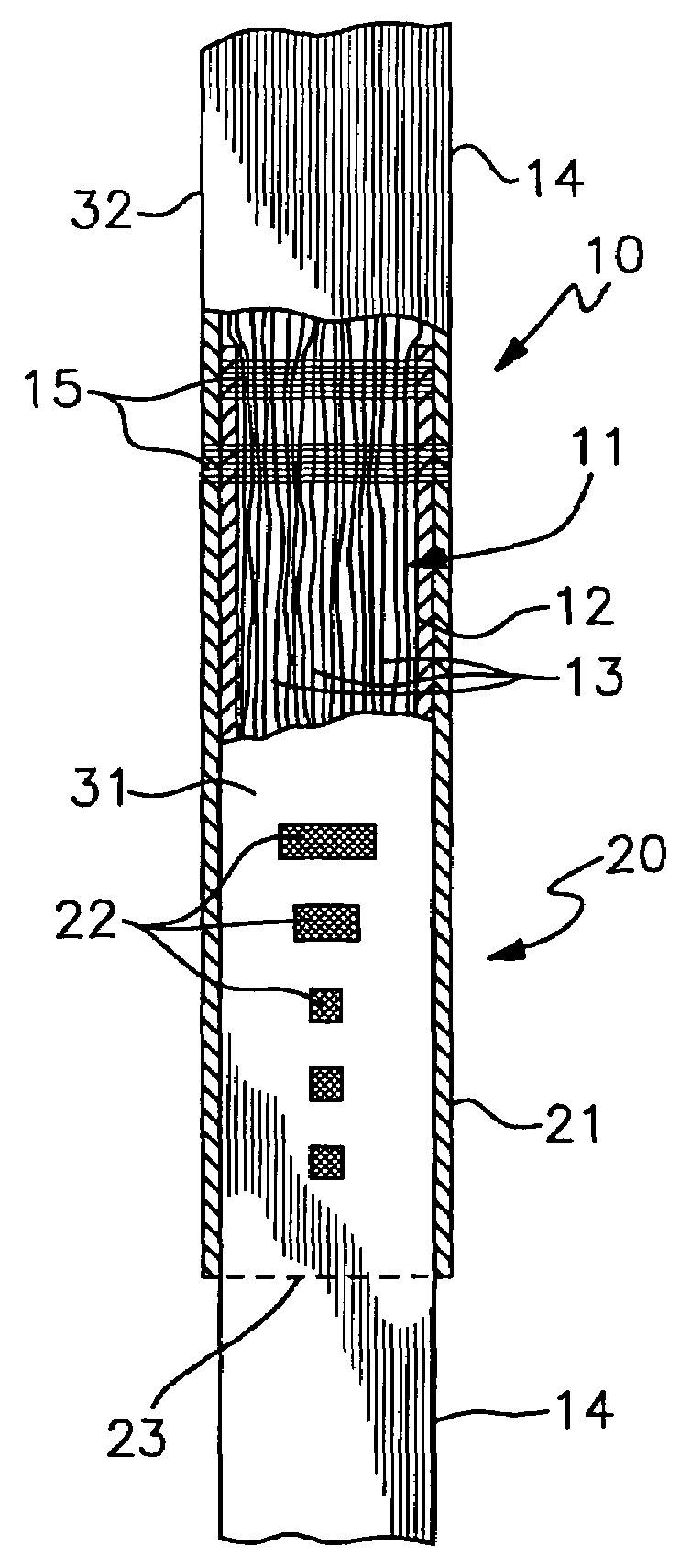

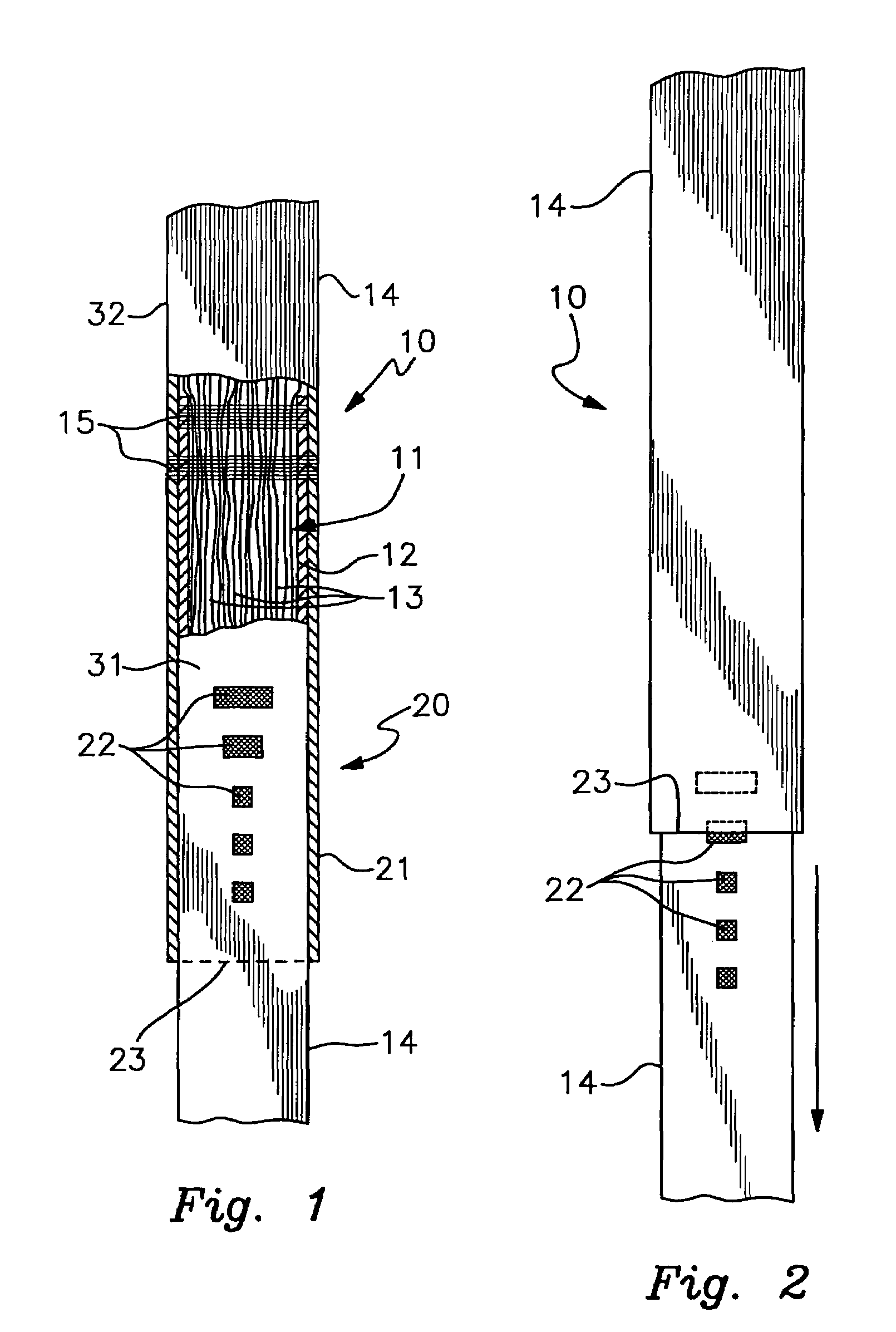

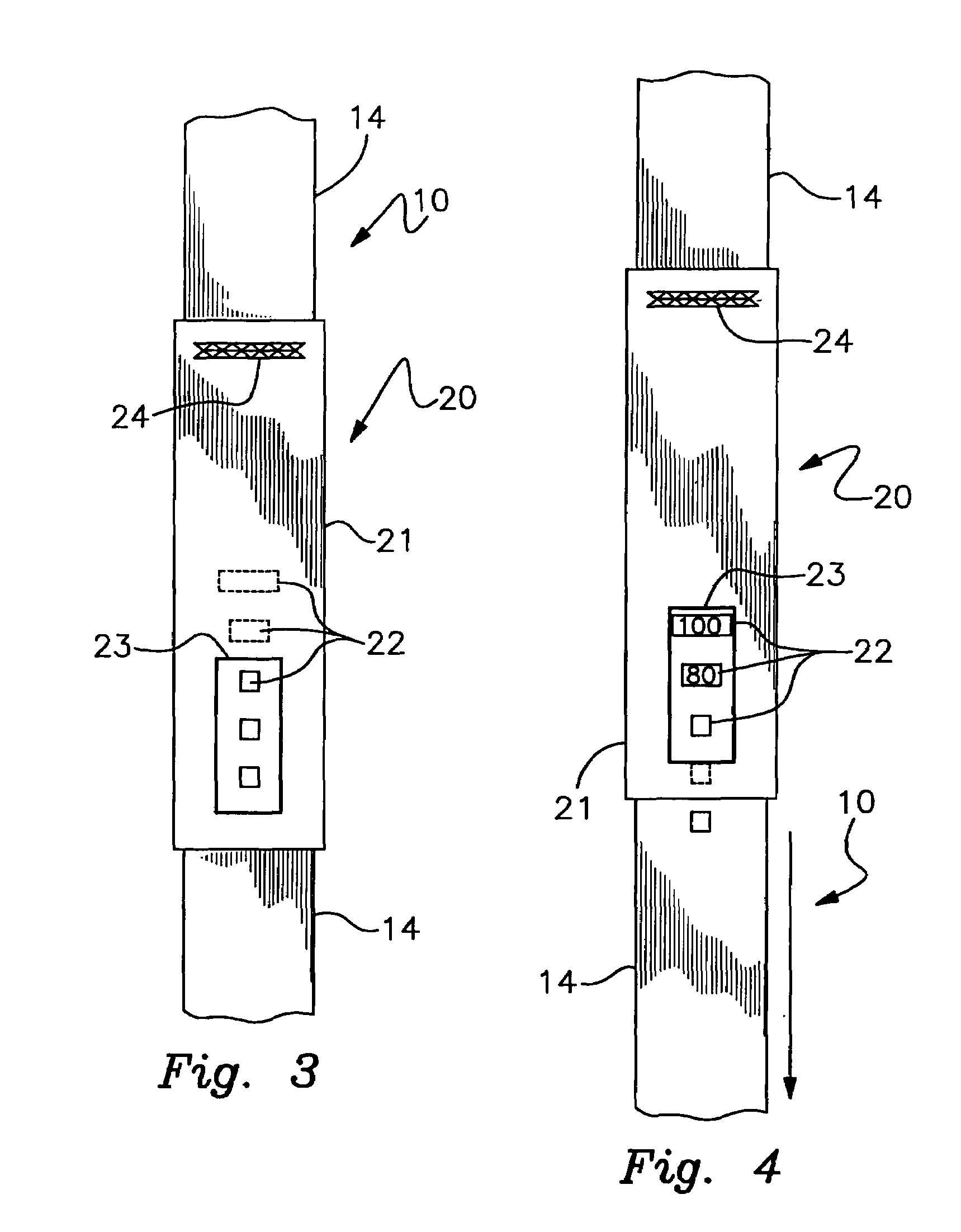

Single Joint Elevator Having Deployable Jaws

The present invention provides an apparatus and a method for lifting a single joint of pipe. The single joint elevator of the present invention comprises, in one embodiment, a pair of deployable jaws cooperating with a pair of static jaws to secure a pipe within the slot of a generally horseshoe-shaped body. The deployable jaws of the single joint elevator of the present invention may be rotatably deployable or translatably deployable, or both. In one embodiment, each jaw, including the static jaws and the deployable jaws, comprises a pipe slip movably disposed within the jaw to secure a pipe segment within the slot and to self-tighten as the weight of the pipe segment secured within the single joint elevator is transferred to the slips and the jaws.

Owner:FRANKS INT

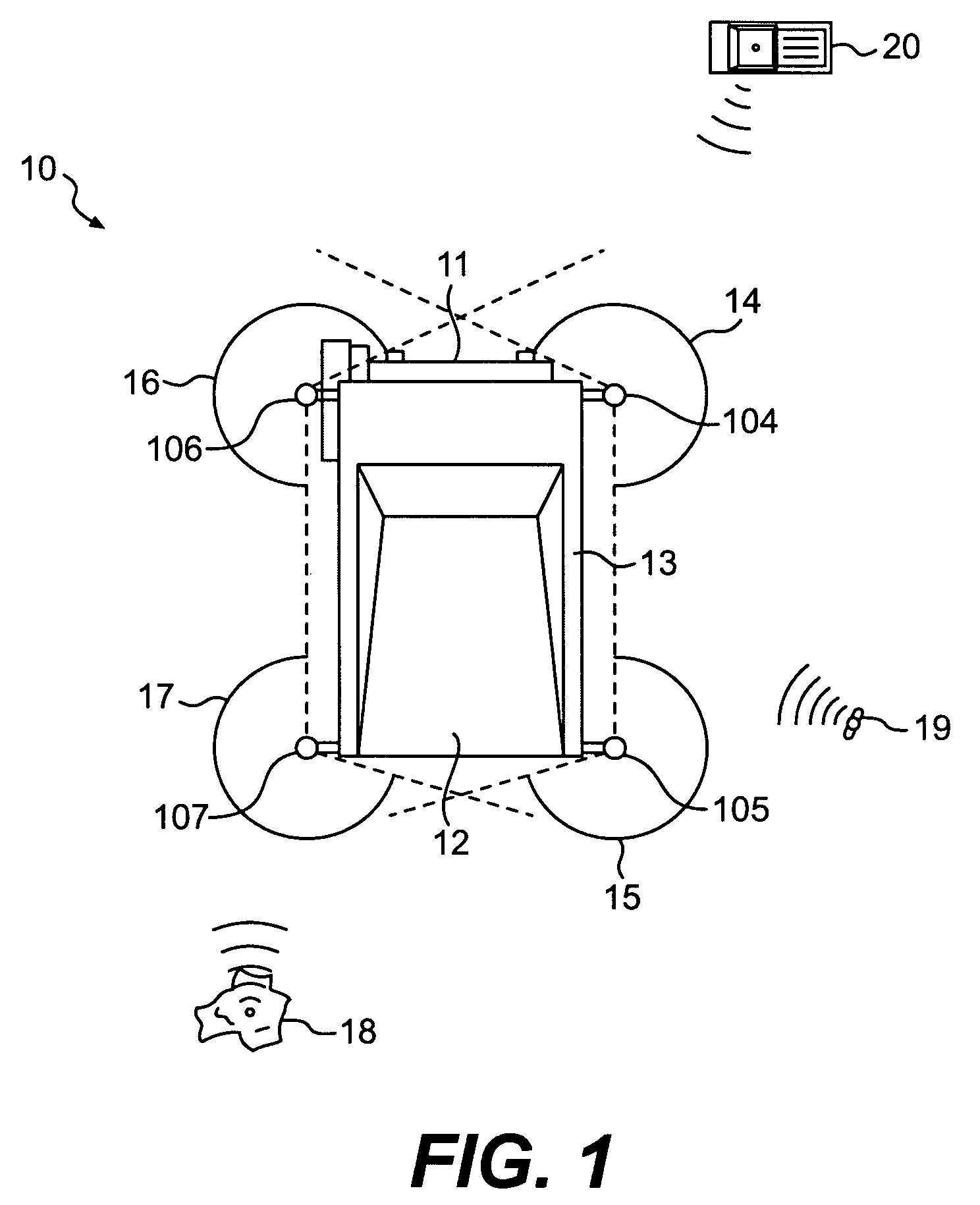

Work site tracking system and method

Owner:CATERPILLAR INC

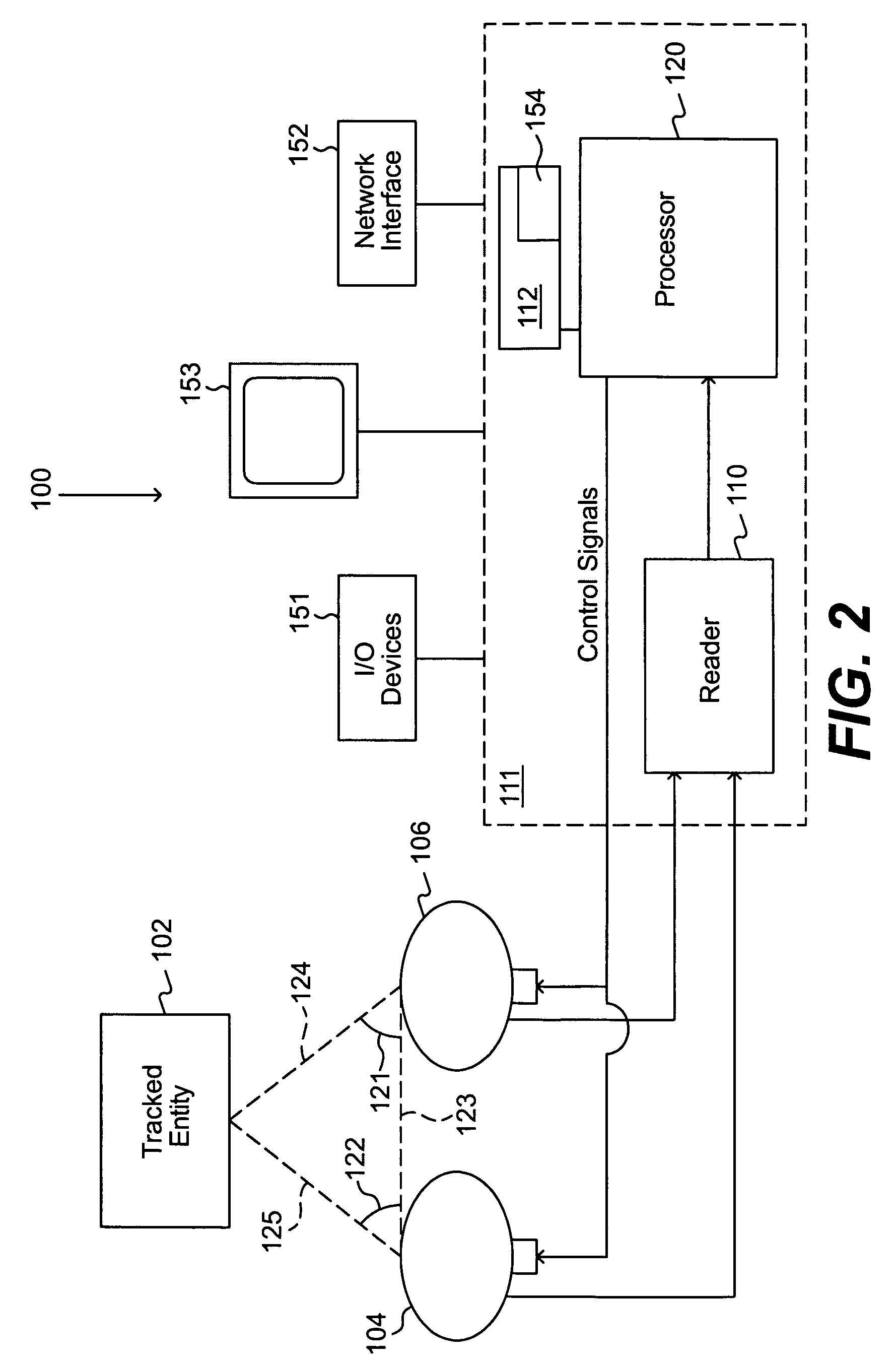

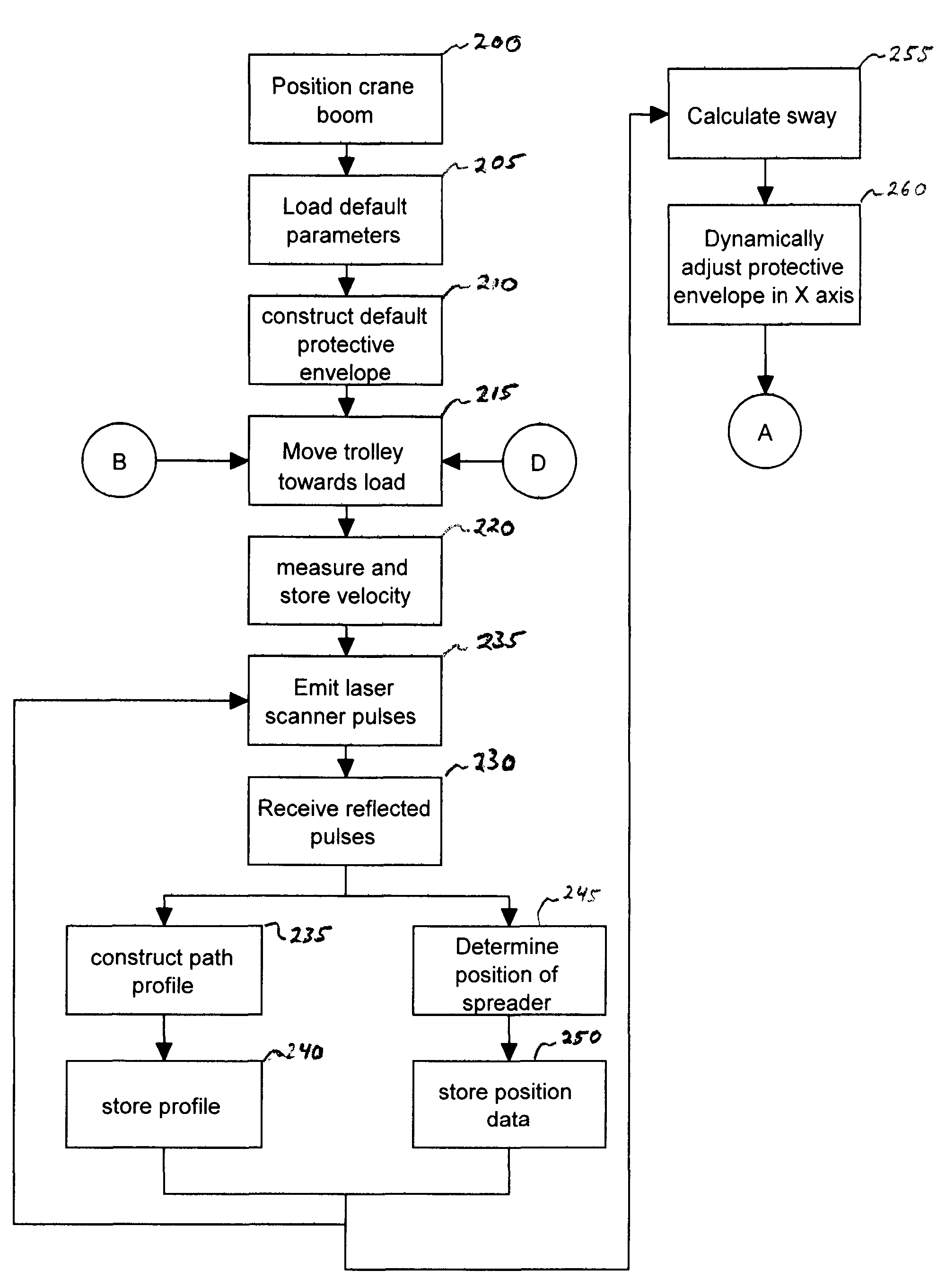

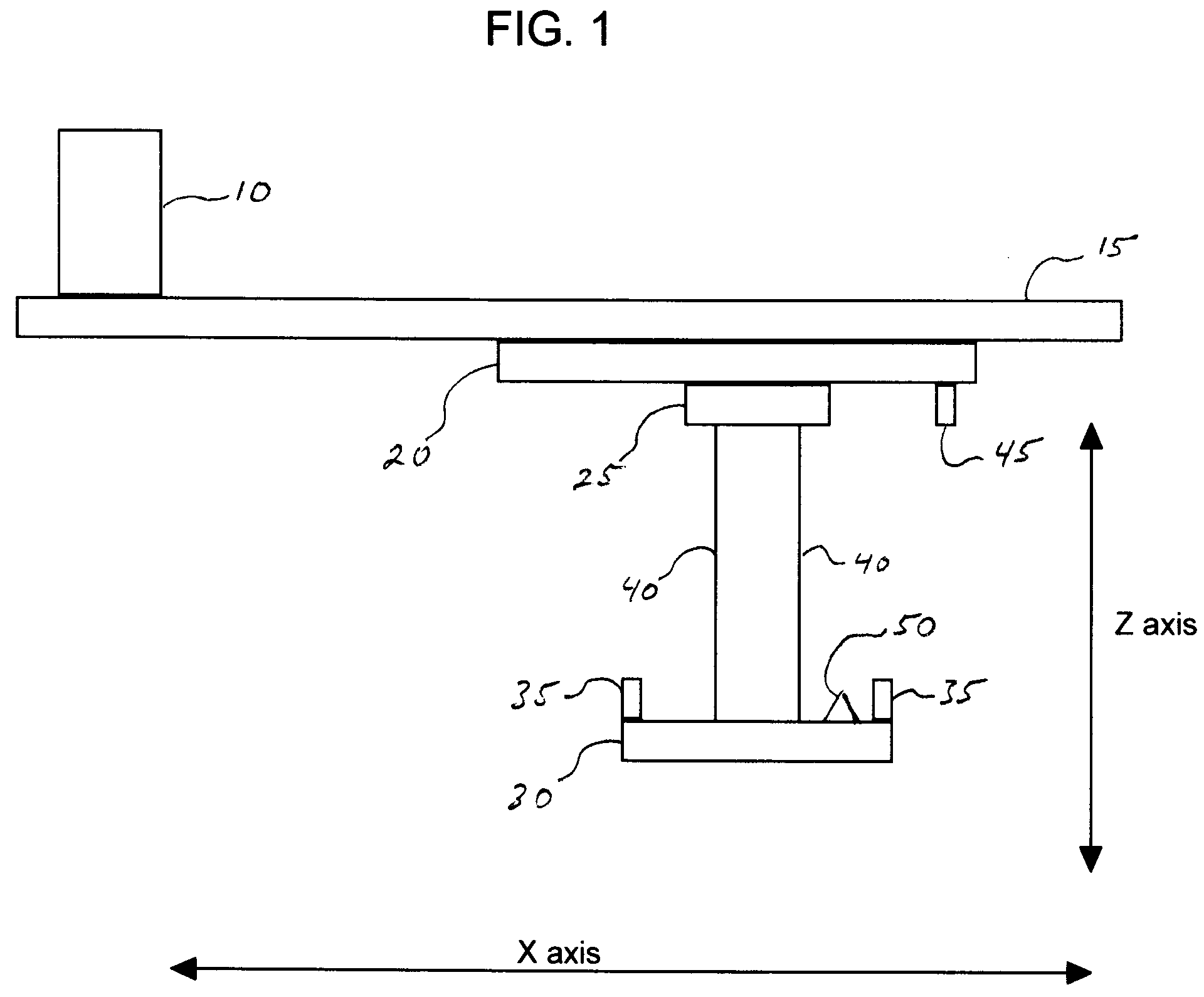

Dynamic Protective Envelope for Crane Suspended Loads

ActiveUS20110076130A1Avoid collisionAnalogue computers for trafficLifting devicesTransceiverMotor control

A system and method for using a gantry crane to efficiently and safely transport loads such as containers and ship hatch covers from one location to another along a known path while avoiding collisions between the loads and obstructing objects which may be situated in the known path. A transceiver emitting laser beams may be used to establish both the position of the spreader and its load and the profile of the known path. Continuous comparisons are made by computer between the location of a dynamic digital protective envelope constructed around the crane spreader and its load, if any, and a digital representation of the profile of the known path to be traveled by the spreader and its load, if any. In the event, the comparison indicates intersection of the protective envelope and the path profile, a speed limit is imposed on the motor controlling the movement in the X axis of the trolley or in the Z axis of the spreader, as required to prevent a collision.

Owner:TMEIC

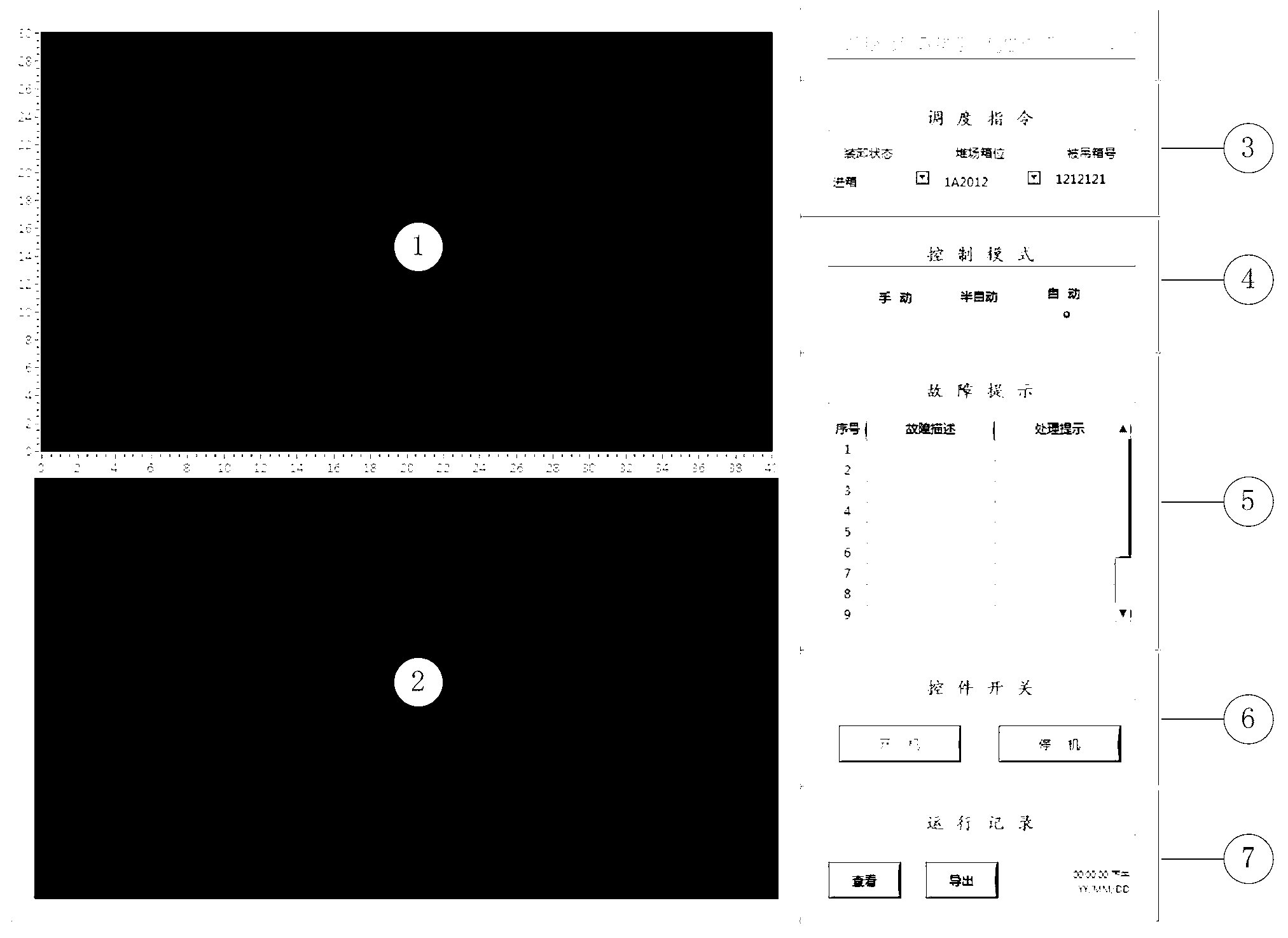

Panorama-visible and controllable intelligent monitoring and protecting integrated system for tower crane

The invention discloses a panorama-visible and controllable intelligent monitoring and protecting integrated system for a tower crane. The panorama-visible and controllable intelligent monitoring and protecting integrated system is characterized by comprising a data collecting module, a data processing module, a control module and a display module; the data collecting module is connected with a video monitoring system on a construction site; the data processing module is connected with the data collecting module; the control module is connected with the data processing module; and the display module is connected with the control module and the data collecting module. Current practical work parameters and rated work capability parameters of the tower crane are displayed in real time through graph numerical values and sounds, and the panorama visible function, the controllable function and the rollover and collision preventing function are integrated.

Owner:SHANDONG LIAOCHENG CONSTR

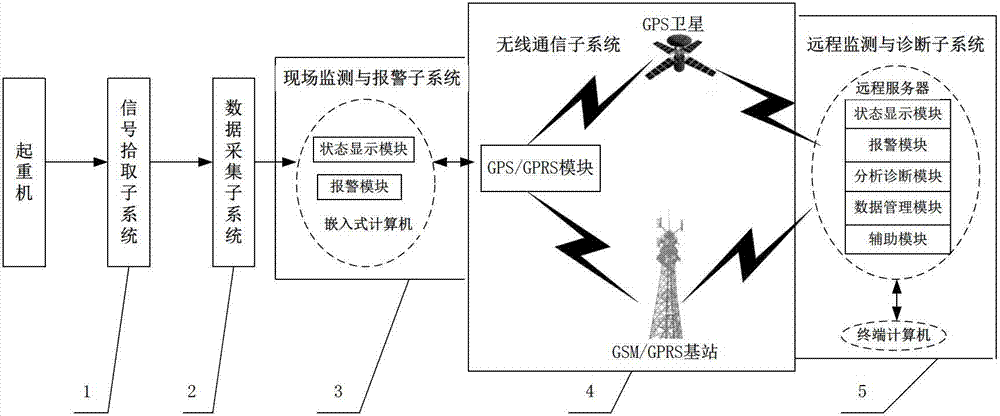

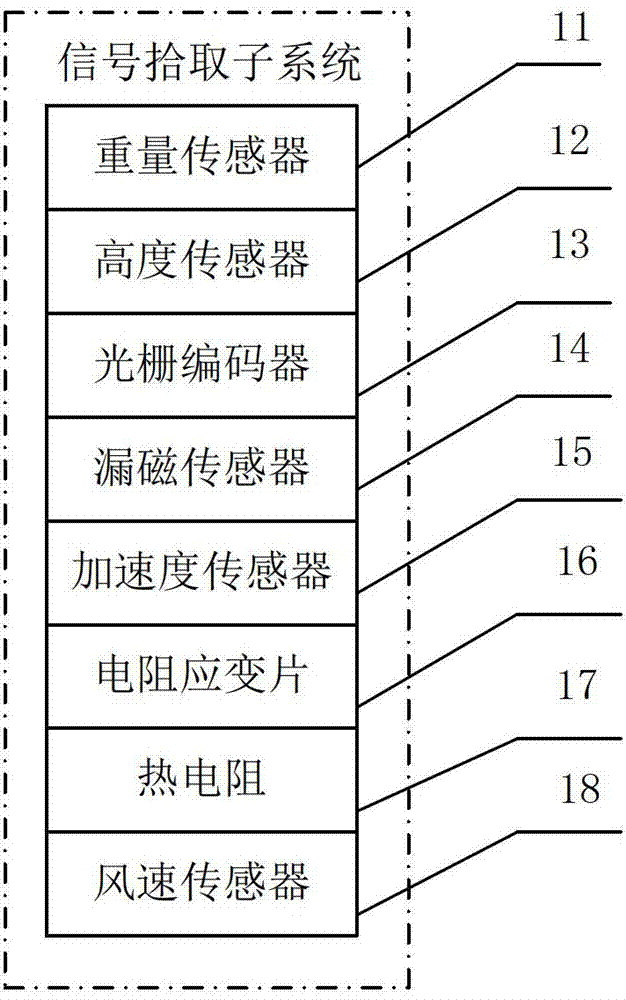

Online monitoring and fault diagnosing system for crane

ActiveCN102730571ARealize online monitoringRealize the alarmSafety gearData acquisitionSafe operation

The invention discloses an online and fault diagnosing system for a crane. The system comprises: a signal collection subsystem which is used for obtaining various state information in the crane operation process; a datum acquisition subsystem which is used for acquiring the information obtained by the signal collection subsystem, preprocessing the information and outputting the information; an online monitoring and alarming subsystem which is used for analyzing the information output by the datum acquisition subsystem, the online monitoring, and the fault alarming; a wireless communication subsystem which is used for positioning the crane and transmitting data input to the online monitoring and alarming subsystem; and a remote monitoring and diagnosing subsystem which is used receiving and analyzing the data transmitted by the wireless communication subsystem to realize online monitoring, fault alarming, fault diagnosing and trend analyzing in a remote manner. The system has the functions of online monitoring, advance warning and alarming, analyzing, diagnosing, wireless communication remote monitoring and the like, so reliable bases are provided for the safe operation of the crane, and safety accidents are avoided or reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Crane control, crane and method

ActiveUS8025167B2Easy and safer alignmentEnhanced oscillationCranesSafety gearAngular velocityEngineering

The present invention shows a crane control of a crane which includes at least one cable for lifting a load, wherein at least one sensor unit is provided for determining a cable angle relative to the direction of gravitational force. Furthermore, there is shown a crane control for driving the positioners of a crane which includes at least one first and one second strand of cables for lifting the load, with a load oscillation damping for damping spherical pendular oscillations of the load, wherein first and second sensor units are provided, which are associated to the first and second strands of cables, in order to determine the respective cable angles and / or cable angular velocities, and the load oscillation damping includes a control in which the cable angles and / or cable angular velocities determined by the first and second sensor units are considered. Furthermore, a corresponding crane and a method are shown.

Owner:LIEBHERR WERK NENZING

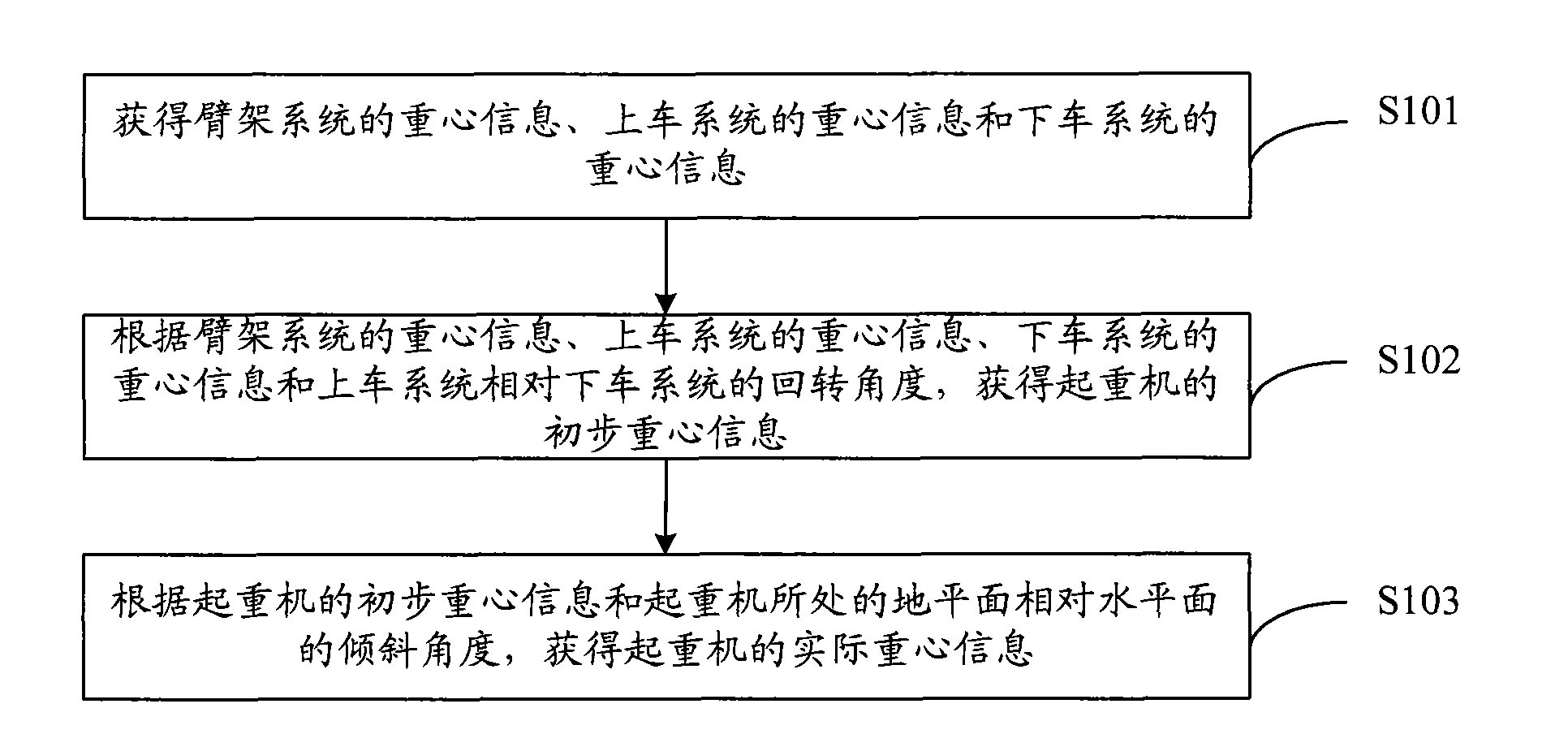

Method for detecting stability of crane and device thereof

ActiveCN101665217AStable and accurate performanceImprove performanceStatic/dynamic balance measurementSafety gearGravity centerEngineering

The invention provides a method for detecting stability of a crane; the crane comprises a cantilever crane system, a mounted system and a dismounted system; the method comprises that: gravity center information of the cantilever crane system, gravity center information of the mounted system and gravity center information of the dismounted system are obtained; initial gravity center information ofthe crane is obtained according to the gravity center information of the cantilever crane system, the gravity center information of the mounted system, the gravity center information of the dismountedsystem and the rotary angle of the mounted system, relative to the dismounted system; practical gravity center information of the crane is obtained according to the initial gravity center informationof the crane and an inclined angle of ground level of the crane, relative to the horizontal level. As the gravity center information of the crane can accurately show the stability degree of the crane, the method and the device can accurately reflect the stability degree of the crane.

Owner:ZOOMLION HEAVY IND CO LTD

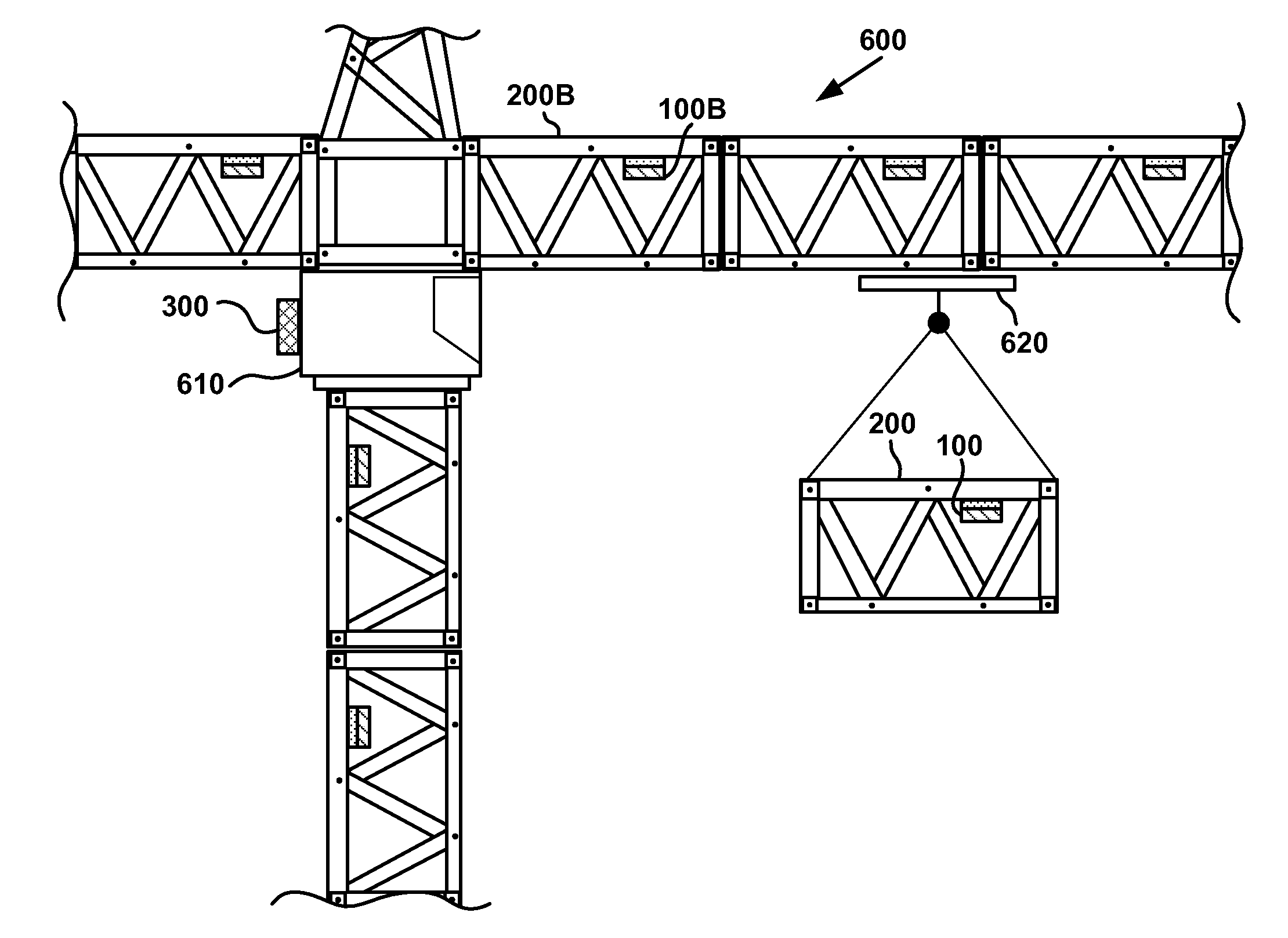

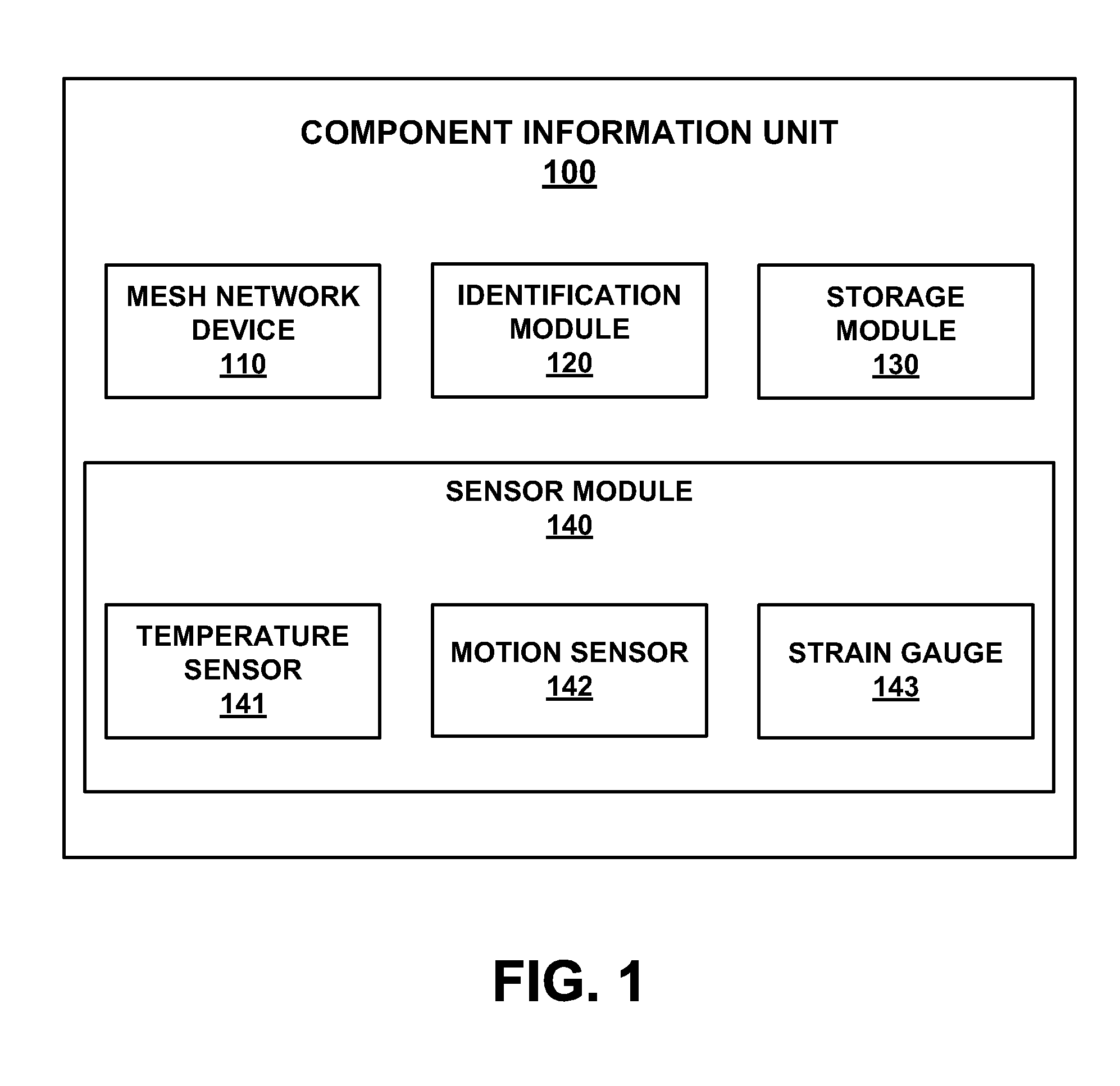

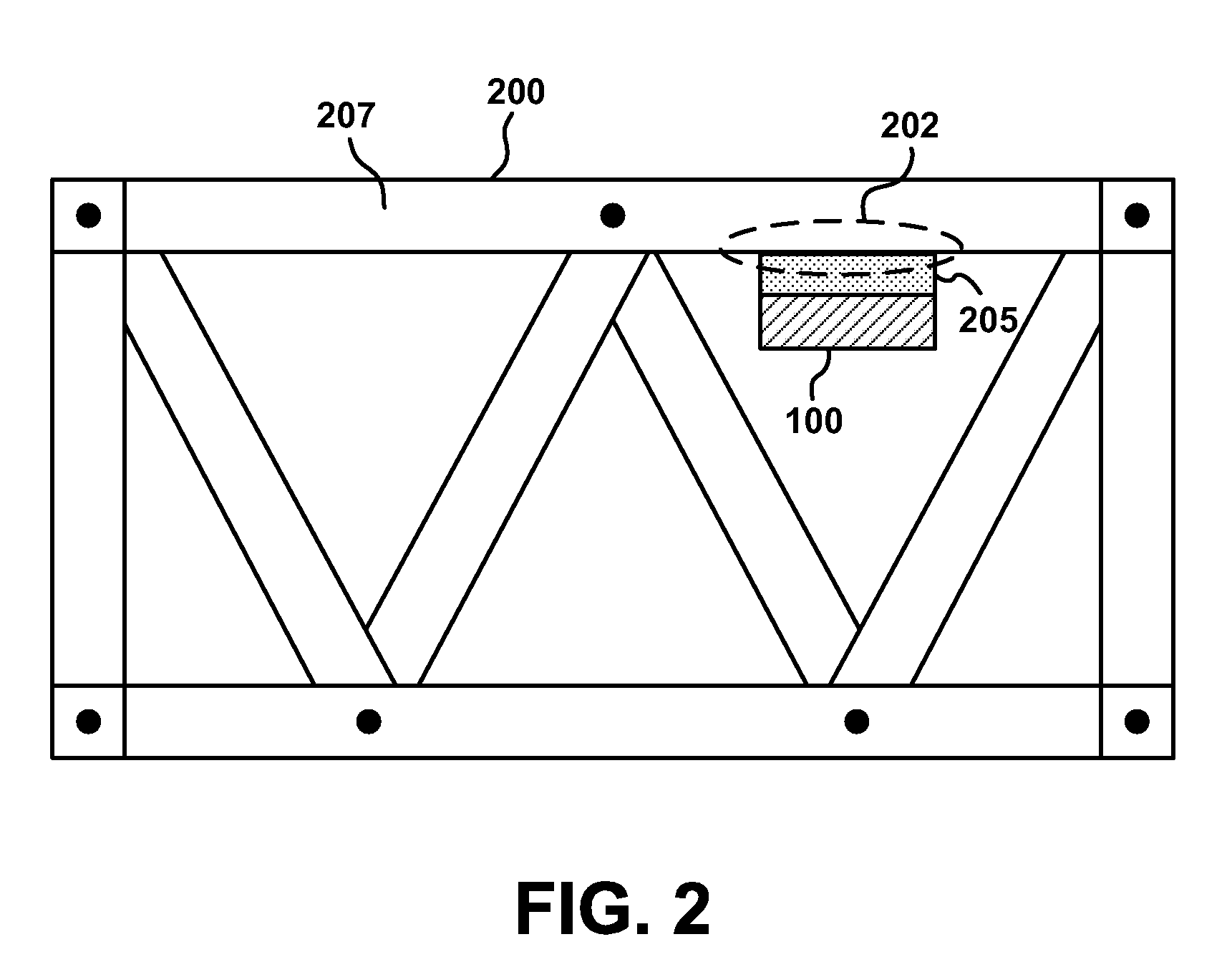

Monitoring crane component overstress

In a method for monitoring overstress conditions experienced by a crane component, a wireless signal is received. The wireless signal is indicative of an overstress condition experienced by a crane of which the crane component constitutes an assembled portion. In response to receiving the wireless signal, a record of the overstress condition is stored in a storage module mechanically coupled with the crane component. Information from the record is provided via a wireless communication to facilitate monitoring of occurrence of overstress conditions experienced by the crane component.

Owner:TRIMBLE INC

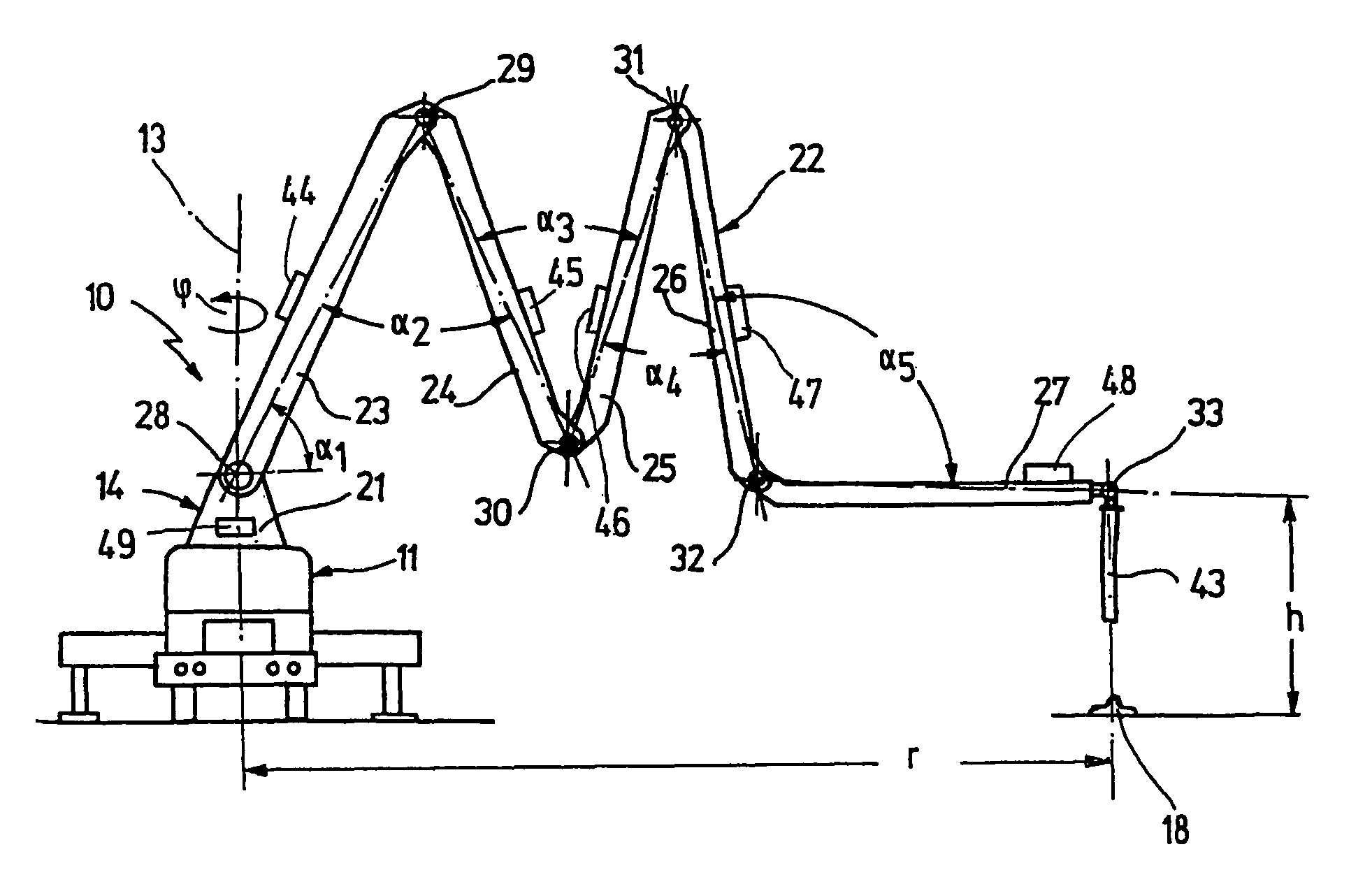

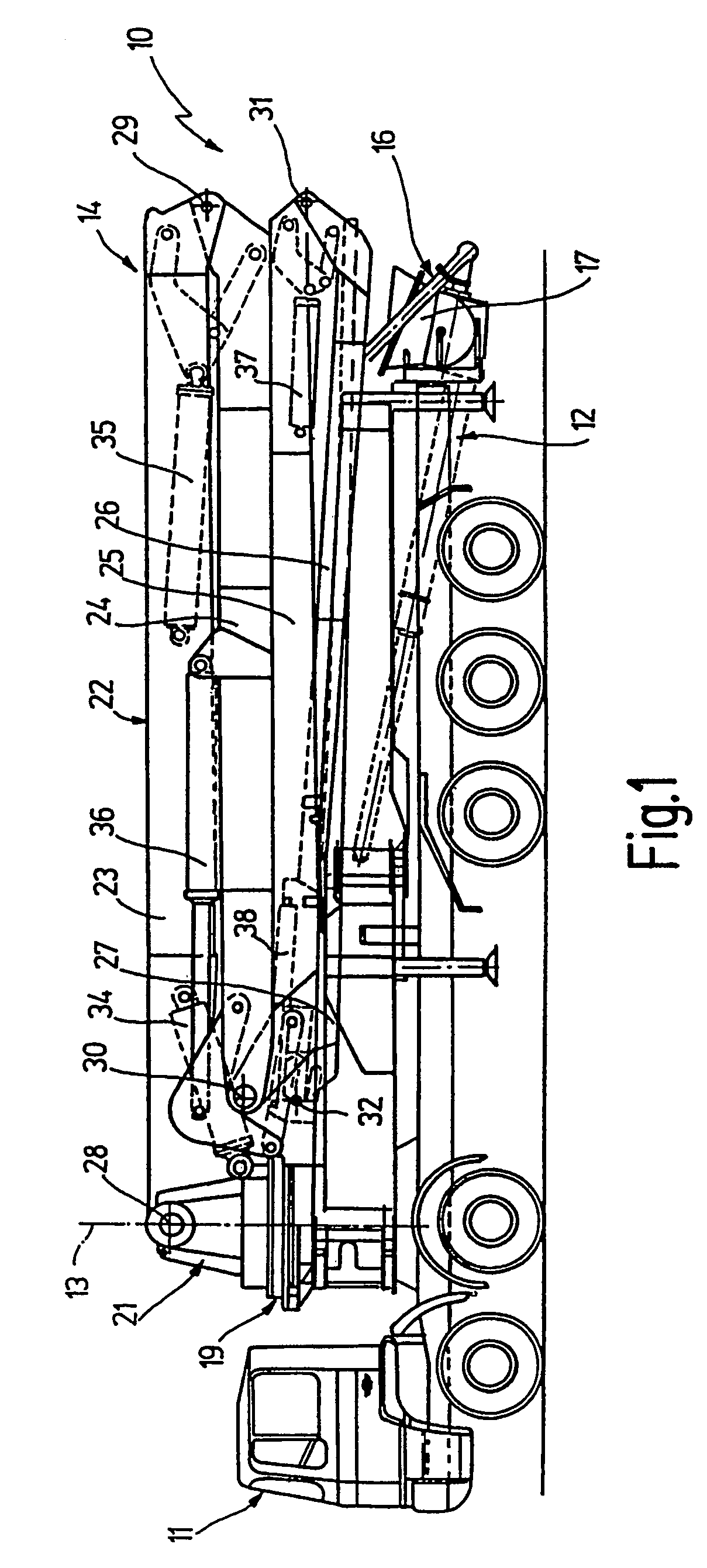

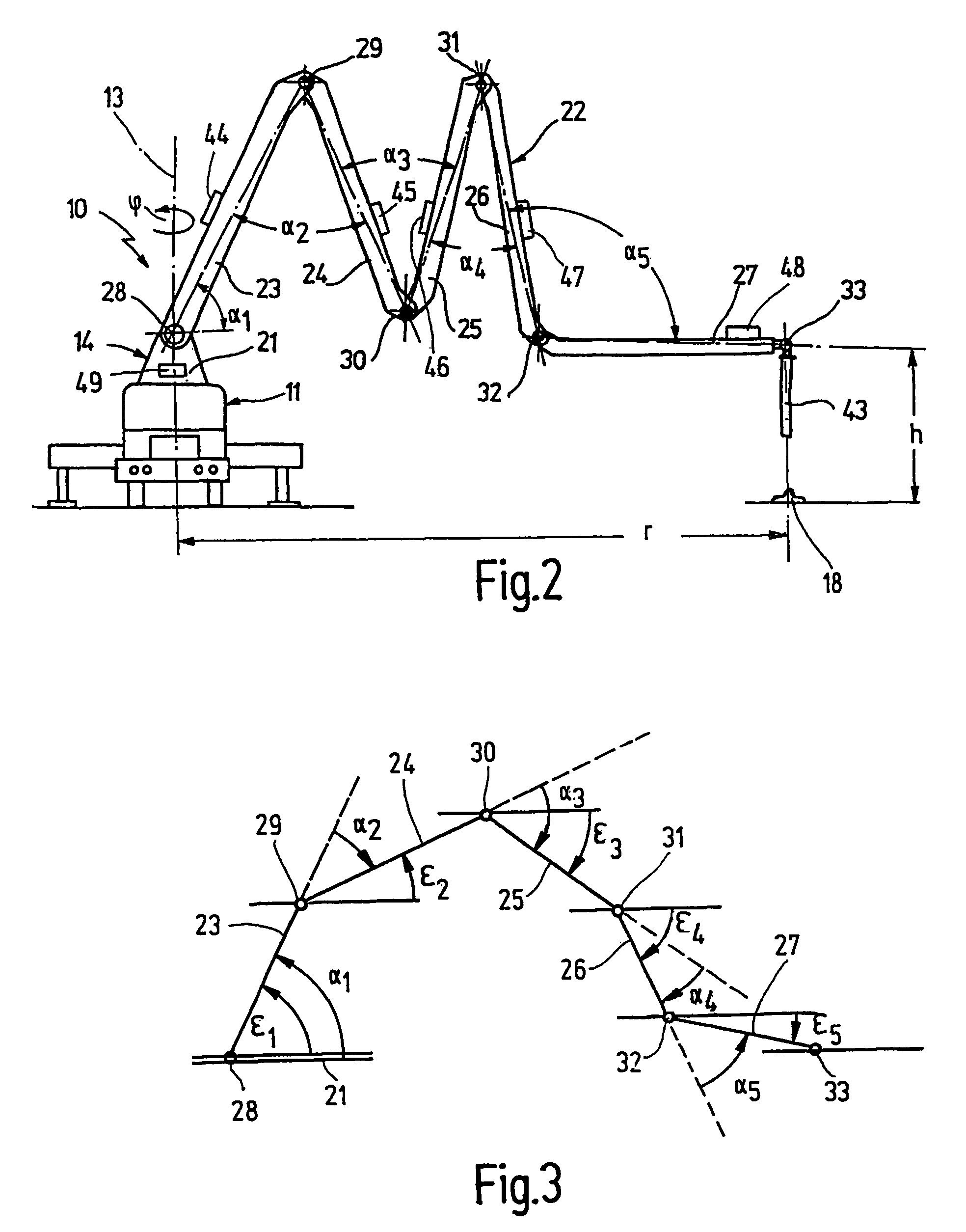

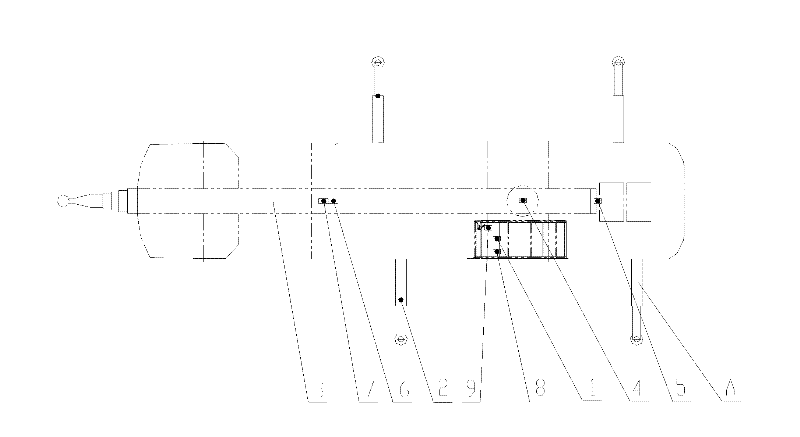

Device for actuating an articulated mast

A large manipulator with an articulated mast (22) is pivotally connected to a mast base (21) that is rotatable about a vertical axis. The mast (22) comprises at least three mast arms (23 to 27) which are pivotable to a limited extent about horizontal articulated axis (28 to 32) that are located parallel to each other, the pivoting movement being relative to the mast base (21) or an adjacent mast arm (23 to 27) and being performed by means of a respective drive unit (34 to 38). A control unit is provided with coordinate transformer (74, 76) which responds to a given guiding parameter (r) and measured angular values (εγ) that are determined by means of angle sensors (44 to 48) located on the mast arms (23 to 27). The coordinate transformer (74, 76) does a conversion into movement signals (Δαv) for the drive units (34 to 38) in accordance with predefined path / slew characteristics, the movement signals being related to the articulation axis. In order to make the inventive device lighter and easier to build, geodetic angle sensors (44 to 48) which determine earth referenced angular values (εγ) that are assigned to the individual mast arms (23 to 27) are disposed in a rigid manner on the mast arms (23 to 27).

Owner:PUTZMEISTER ENG

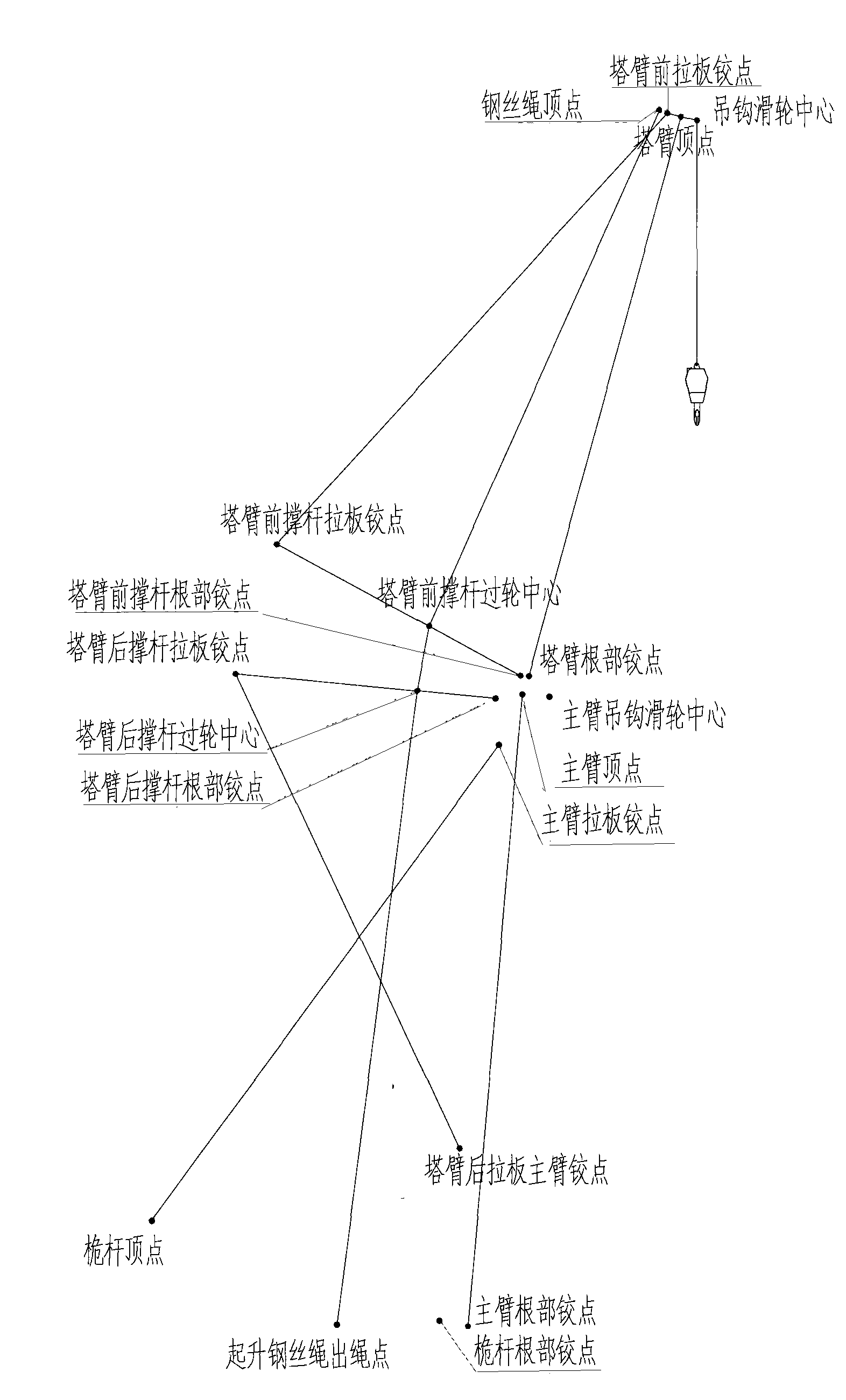

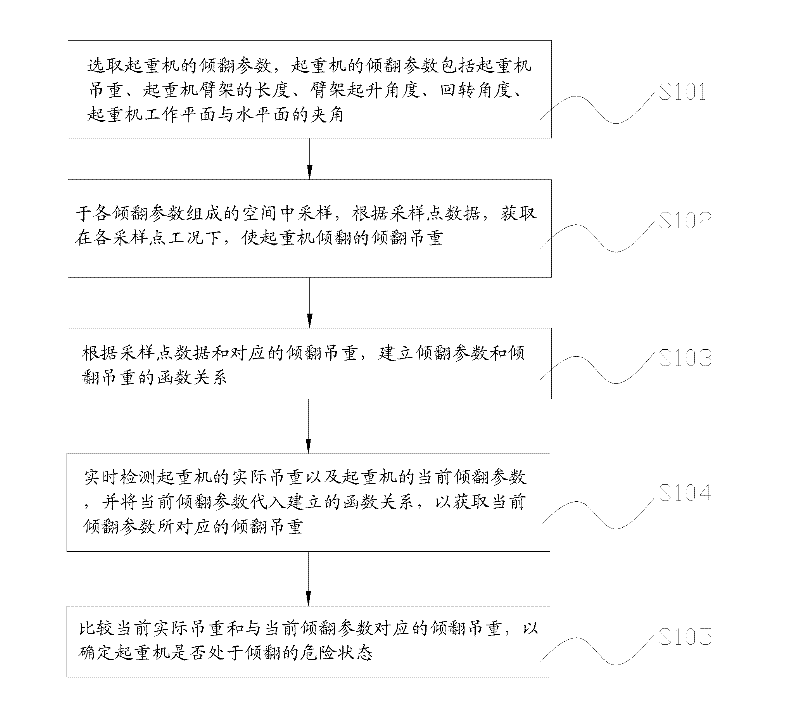

Detection method and detection device for tipping state of crane

InactiveCN102390779AImprove securityAccurate and reliable tipping judgmentCranesSafety gearEngineeringLifting weight

The invention discloses a detection method and a detection device for the tipping state of a crane. The disclosed detection method includes the following steps: 11) selecting tipping parameters comprising a dip angle of a work plane opposite to the level surface, a rotation angle, a lifting angle of a jib, and the length of the jig; 12) obtaining tipping lifting weight by sampling in a space formed by the tipping parameters; and establishing the function relationship between the tipping parameters and the tipping lifting weight; 13) substituting the current tipping parameters into the function relationship so as to obtain the tipping lifting weight corresponding to the current tipping parameters; and 14) comparing the current actual lifting weight with the tipping lifting weight corresponding to the current tipping parameters, thus determining whether the crane is in the dangerous tipping state. With the detection method, operators can know whether the crane is in the dangerous tipping state and the safety property of the crane is improved; in addition, the dip angle of the work plane opposite to the level surface is introduced as one tipping parameter, so that the influence on the judgment on the tipping when the crane is in a non-horizontal state is avoided and the judgment on the tipping of the crane is more correct and reliable.

Owner:SANY HEAVY IND CO LTD (CN)

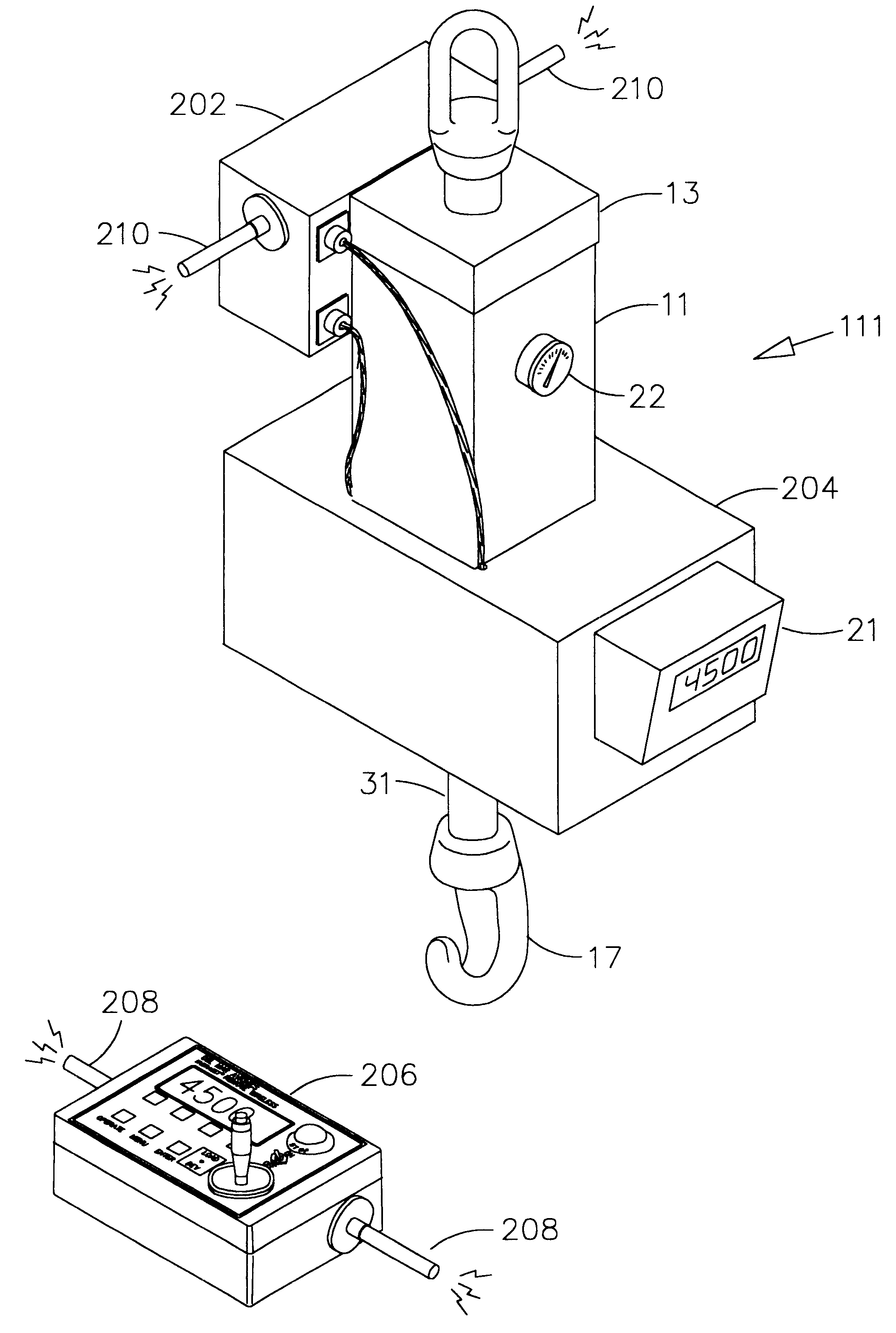

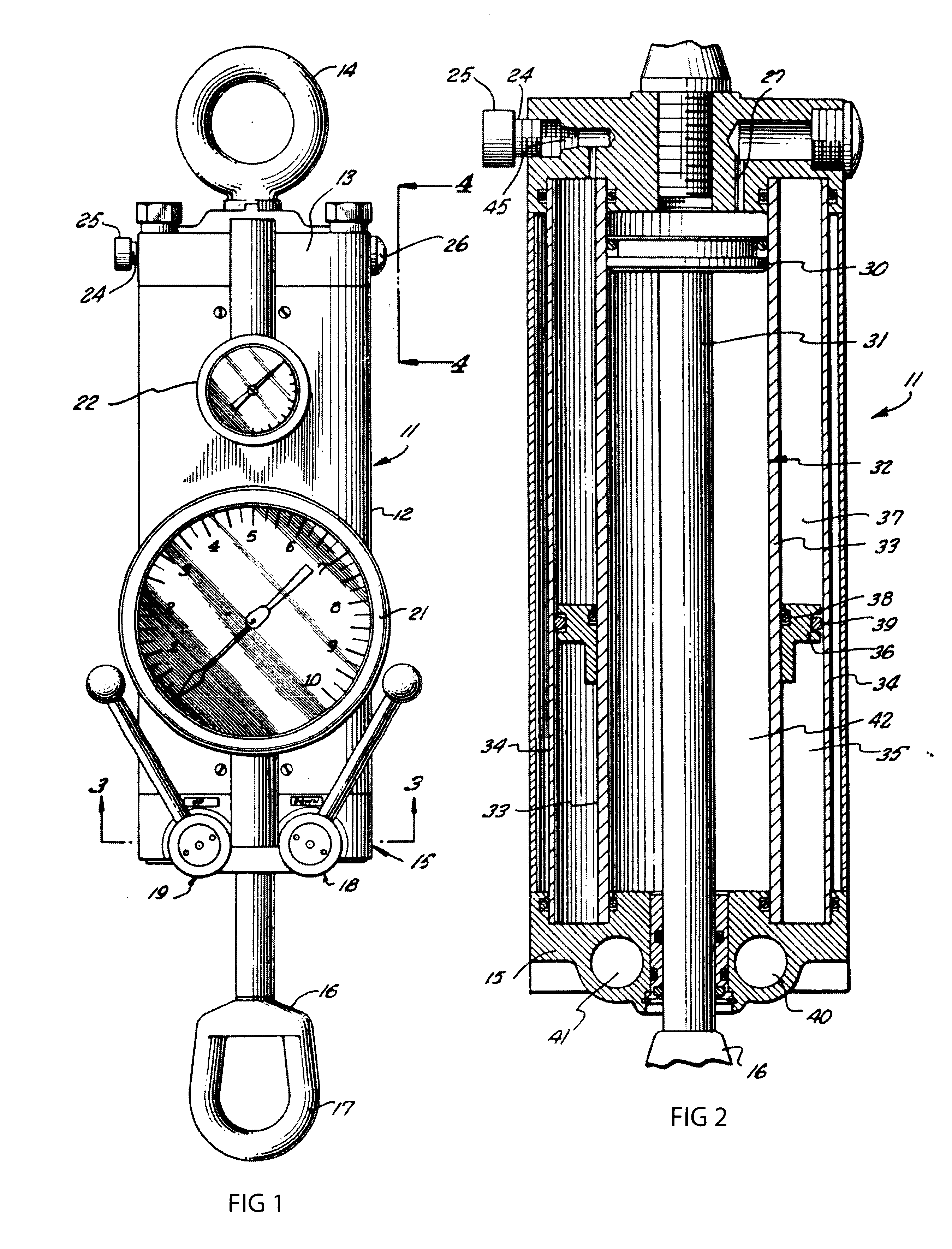

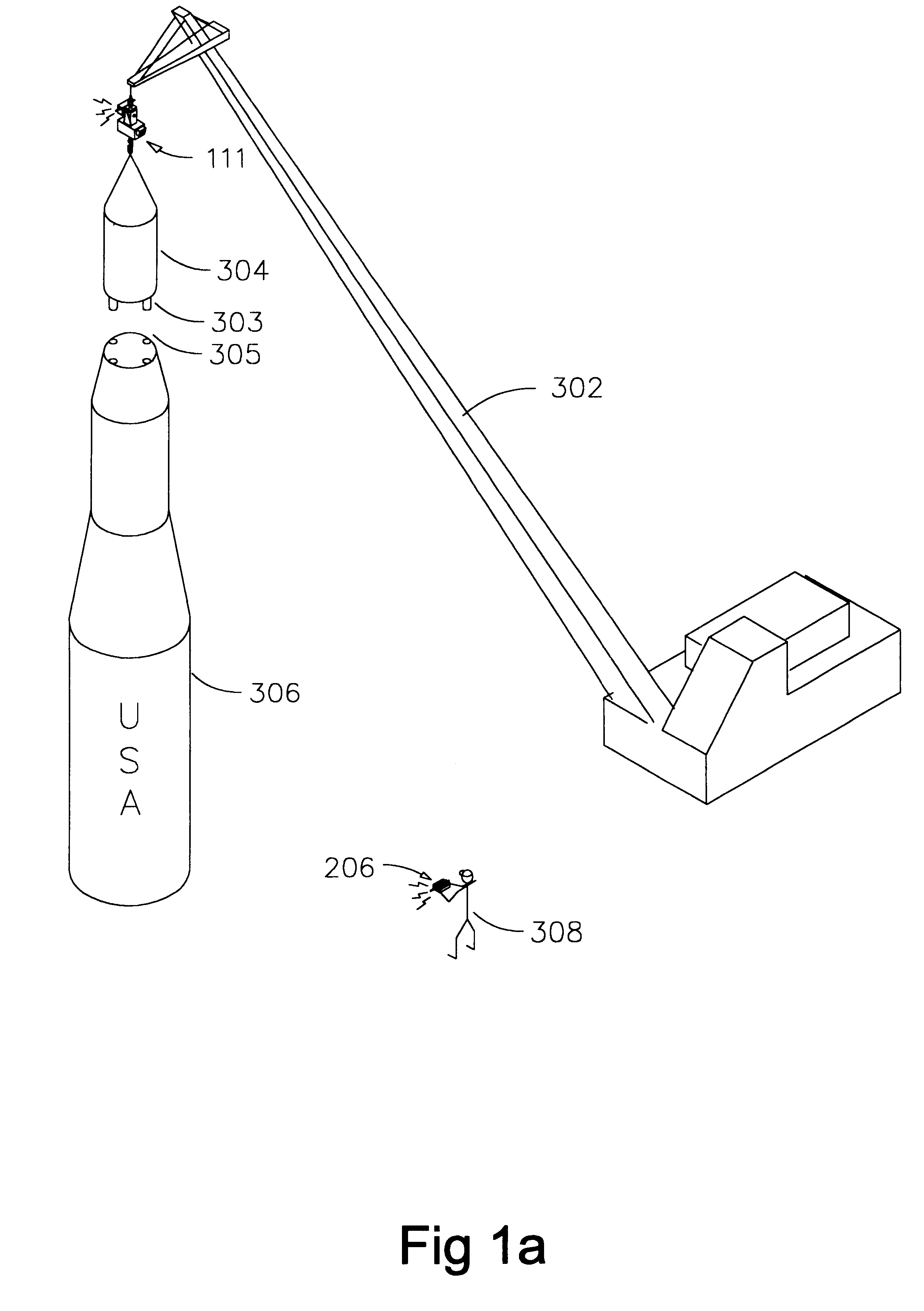

Remote operation auxiliary hoist control and precision load positioner

InactiveUS6474922B2Weighing apparatus with automatic feed/dischargeLoading/unloadingTransceiverRadio frequency

An electromechanical, remotely operated Auxiliary Hoist Control and Precision Load Positioner system and device is disclosed utilizing a Radio Frequency Hand Controller transceiver Unit distal to a Radio Frequency Hoist Controller Transceiver Unit for raising and lowering a large, heavy, bulky, fragile, or expensive piece of equipment by very gradual means to avoid hang ups that might otherwise destroy or seriously damage the equipment.

Owner:DEL MAR AVIONICS

Overhead travelling carriage system

ActiveUS7441999B2Easy transferEffectively utilize a space located below the overhead bufferRailway heating/coolingSemiconductor/solid-state device manufacturingTrackwayEngineering

An overhead buffer 24 is provided on a side of a running rail 4 for an overhead travelling carriage 8. The height level of an article on the overhead buffer 24 is slightly lower than that on the running overhead travelling carriage 8. This height is at least such that the overhead buffer 24 does not interfere with an operator. According to the present invention, the overhead buffer can be installed even if load ports are consecutively provided.

Owner:MURATA MASCH LTD

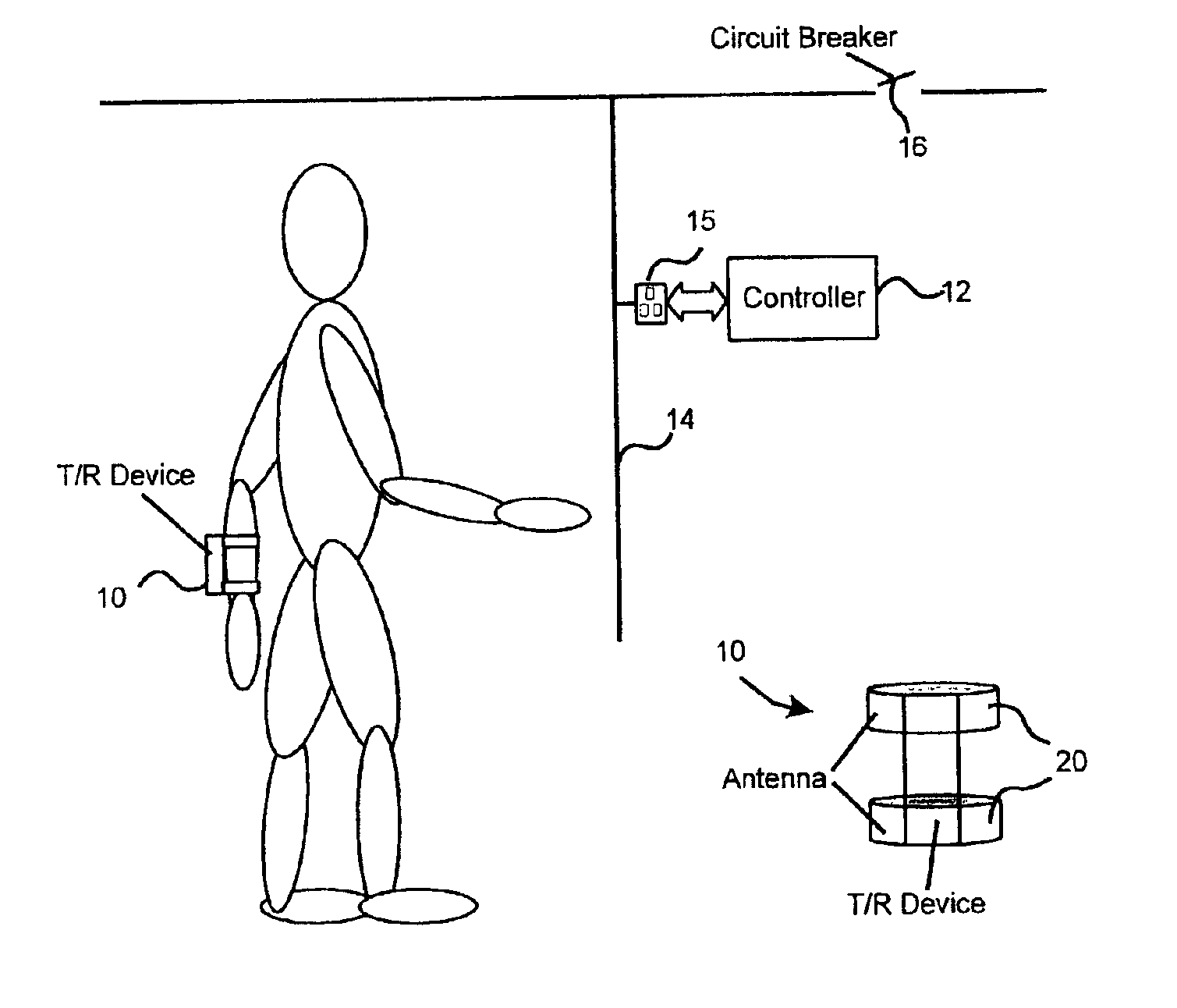

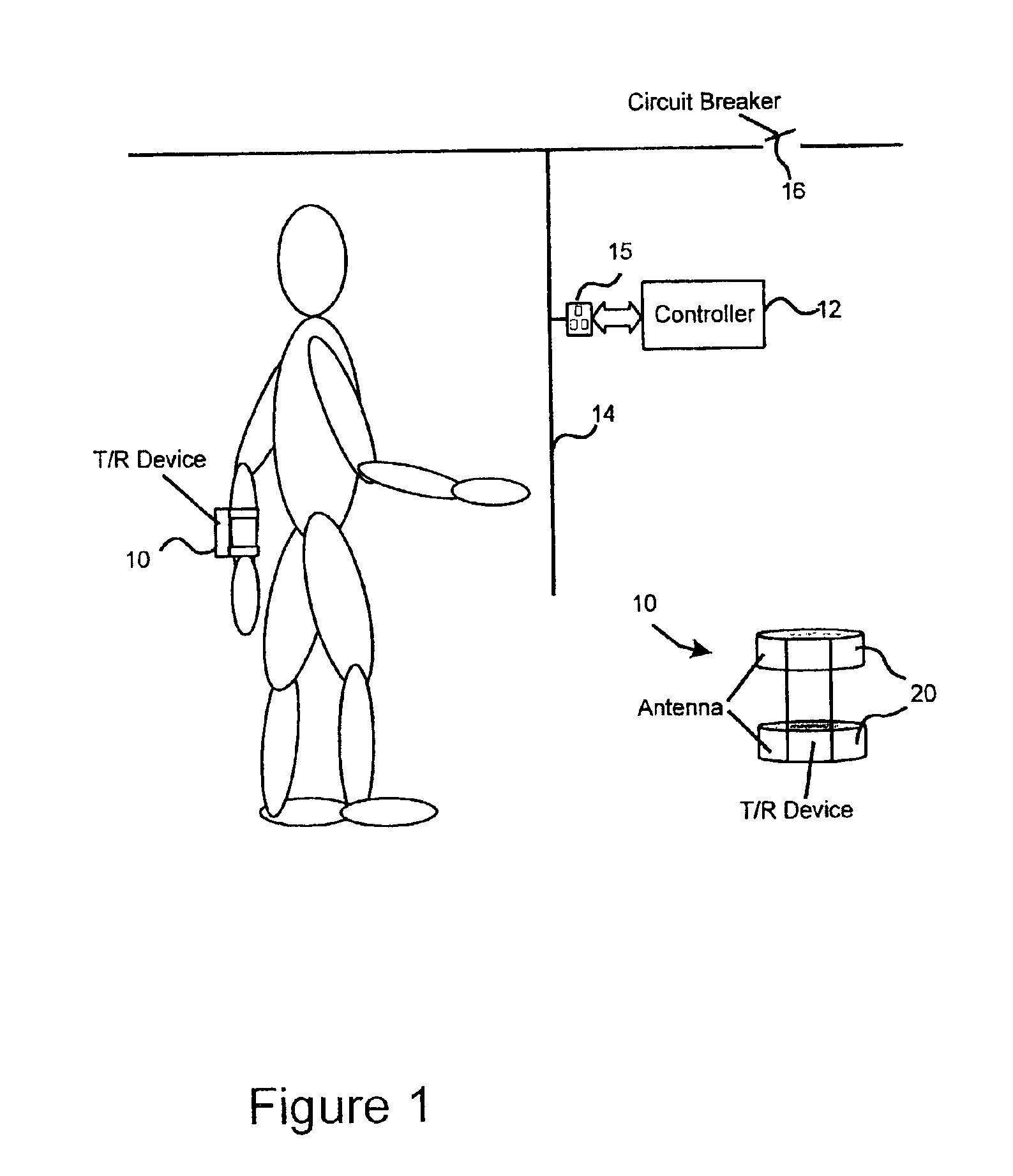

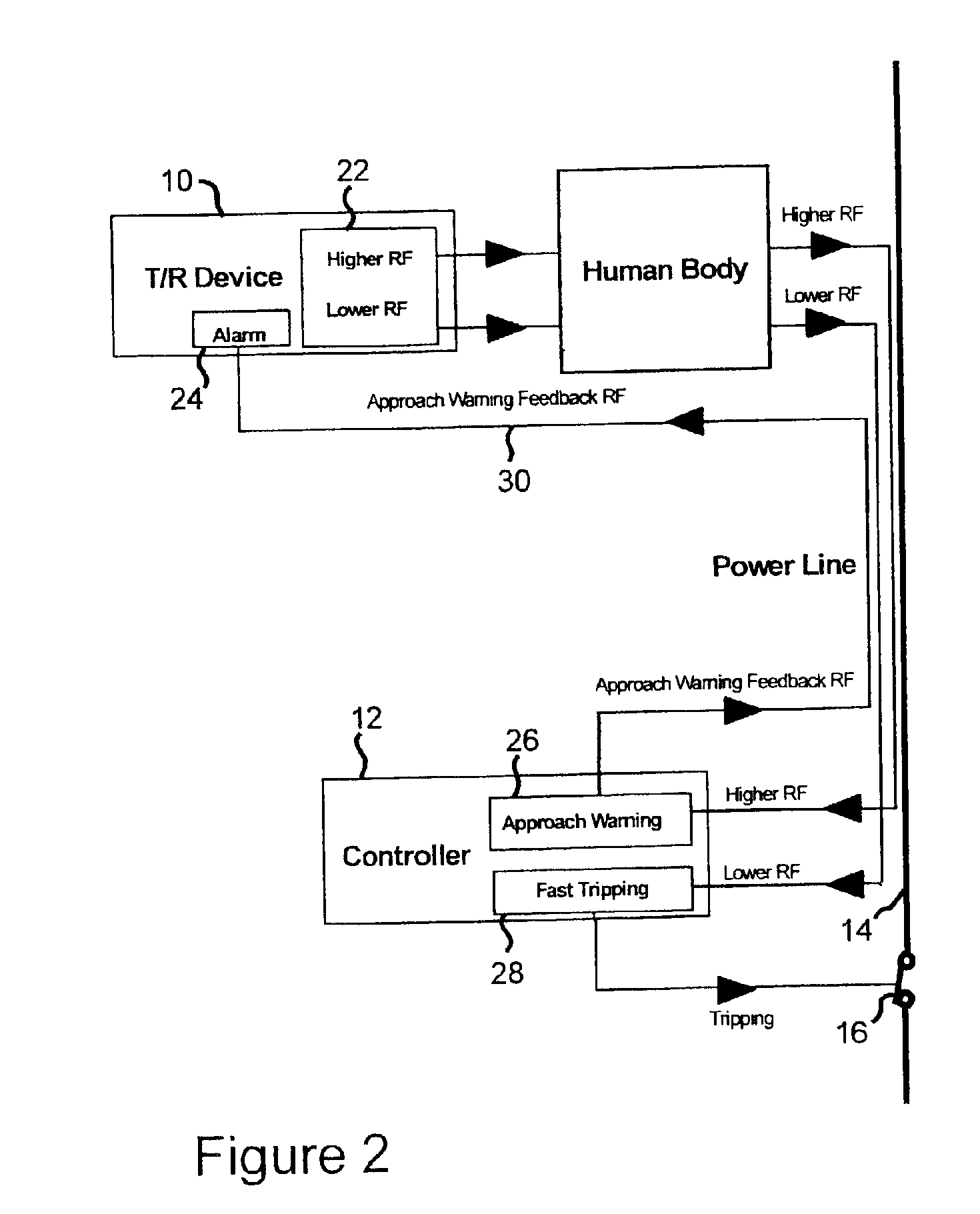

Electrical injury protection system using radio frequency transmission

InactiveUS6897783B2Improve protectionThe method is simple and convenientEmergency protective arrangements for automatic disconnectionAlarmsRadio receiverRadio reception

A personal electrical injury protection system is provided which can be worn by electricians, construction workers, or other individuals working around or with low-voltage lines (i.e. generally less than about 600 volts). The personal electrical injury protection system has both a proximity warning component which provides a warning of potential electrical hazards upon close approach to the low-voltage power line and an electrical contact protection component which turns off the power upon actual electrical contact with the power line. The present personal electrical protection system relies on a radio frequency transmitter attached to the worker or person to be protected and a radio receiver / controller connected to the power line. The radio frequency transmitter has a low frequency generator which is used for electrical-contact protection and a high frequency generator which is used for proximity warning.

Owner:HEALTH & HUMAN SERVICES CENTS FOR DISEASE CONTROL & PREVENTION GOVERNMENT OF THE UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE DEPT OF

Lifting sling with excessive elongation warning indicator

Owner:MUELLER DEWAYNE

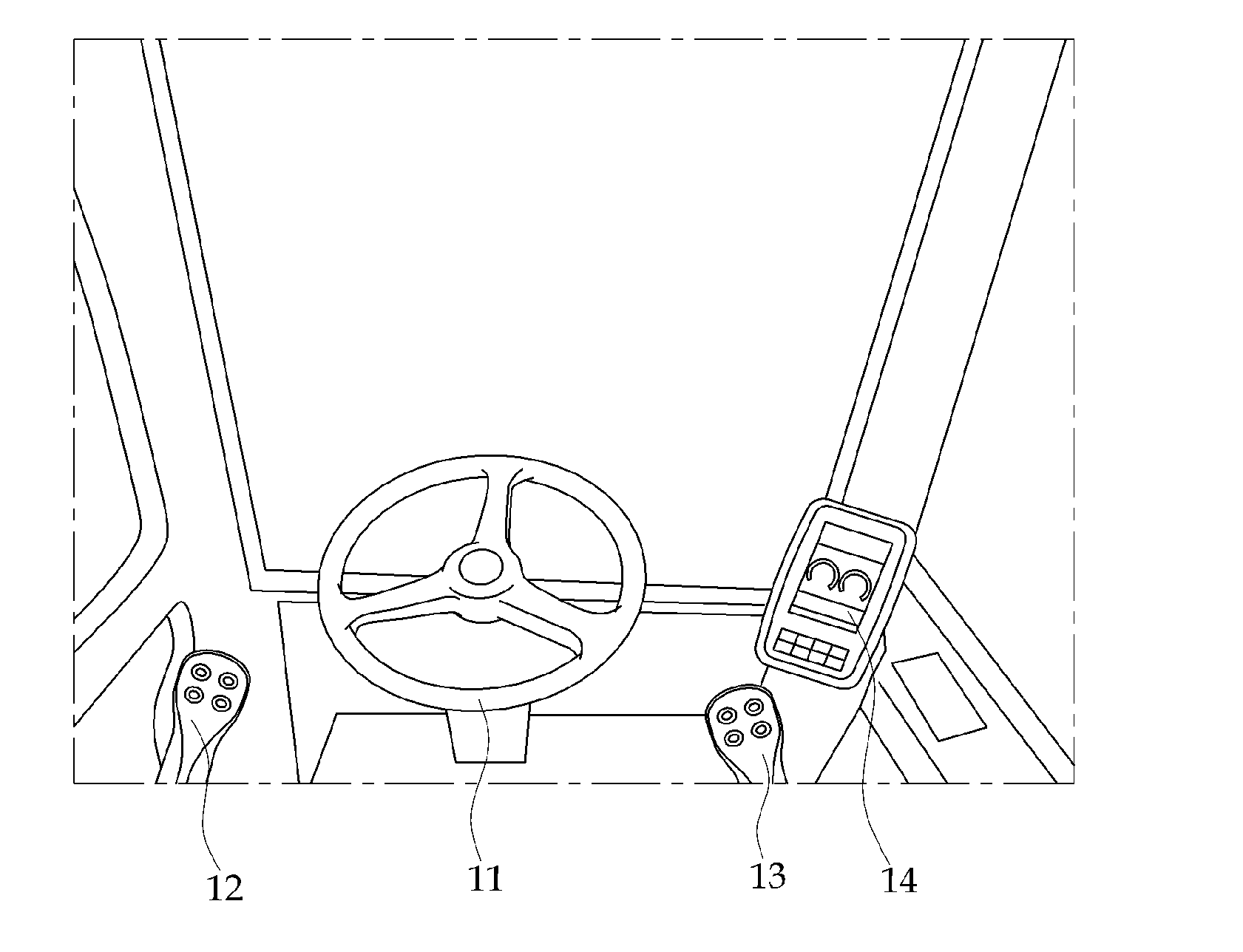

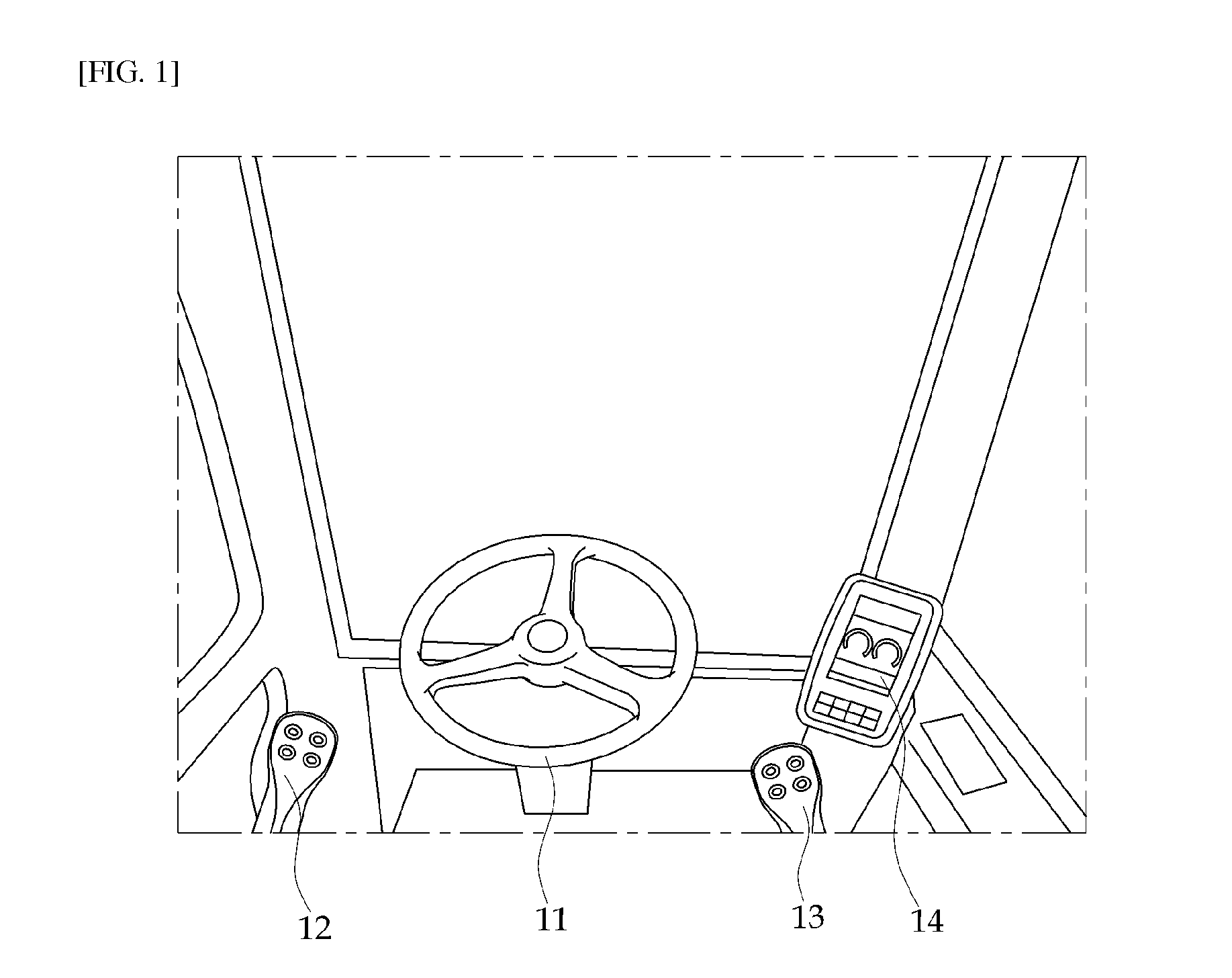

Sensing device and method of construction equipment

ActiveUS20150343976A1Provide conveniencePedestrian/occupant safety arrangementSoil-shifting machines/dredgersWork patternArchitectural engineering

The present invention relates to a device and a method for sensing (detecting) rear and side areas of construction equipment. The present invention comprises: setting a certain distance from the construction machine (or vehicles) as a safe-distance area (work pattern area); patterning fixed objects within the set safe-distance area; sounding an alarm and / or displaying a captured (or detected) image on a display when other objects excluding the fixed objects that are sensed by the construction machine (that is, the fixed objects that are patterned) are sensed.

Owner:DOOSAN INFRACORE CO LTD

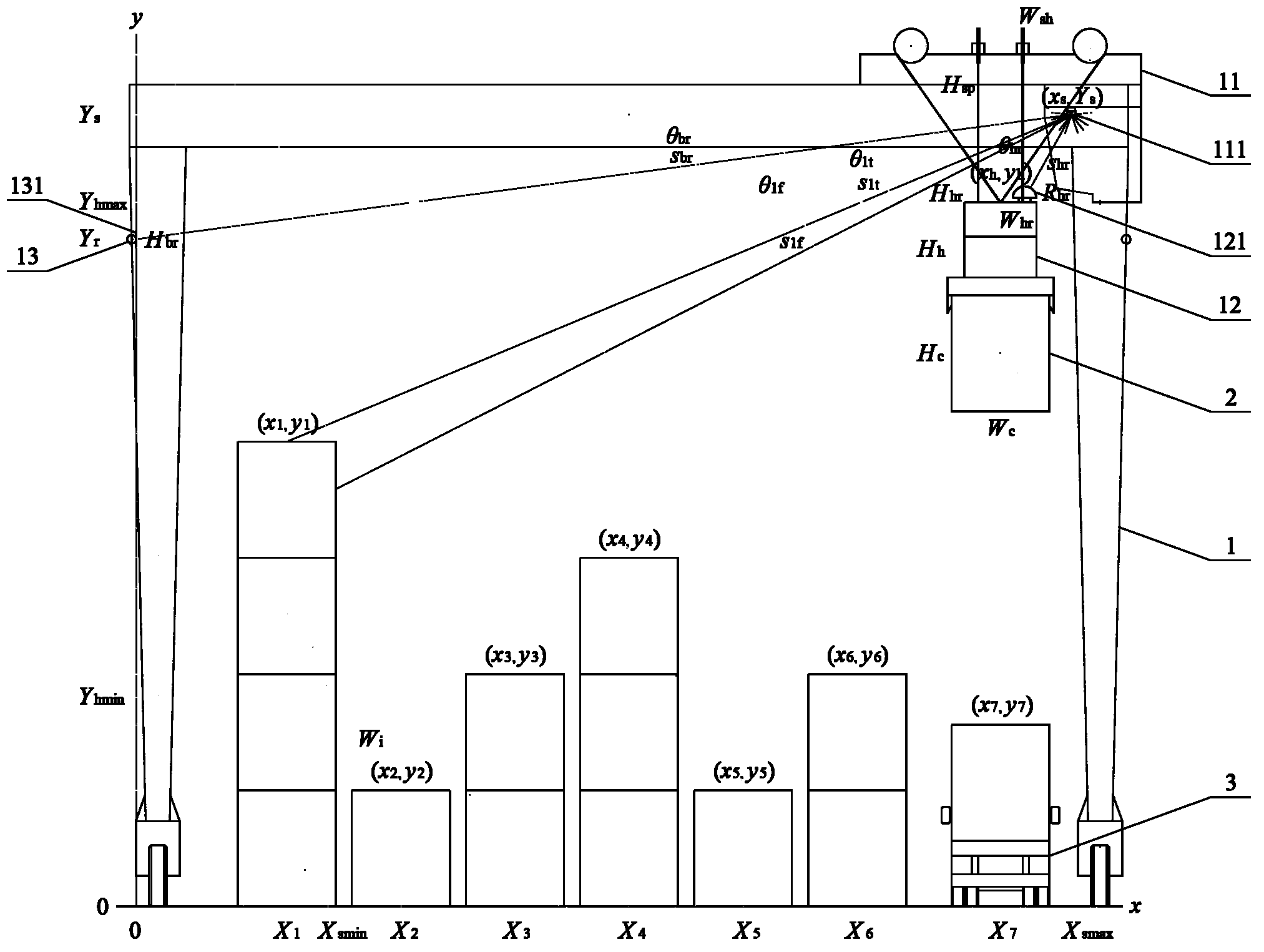

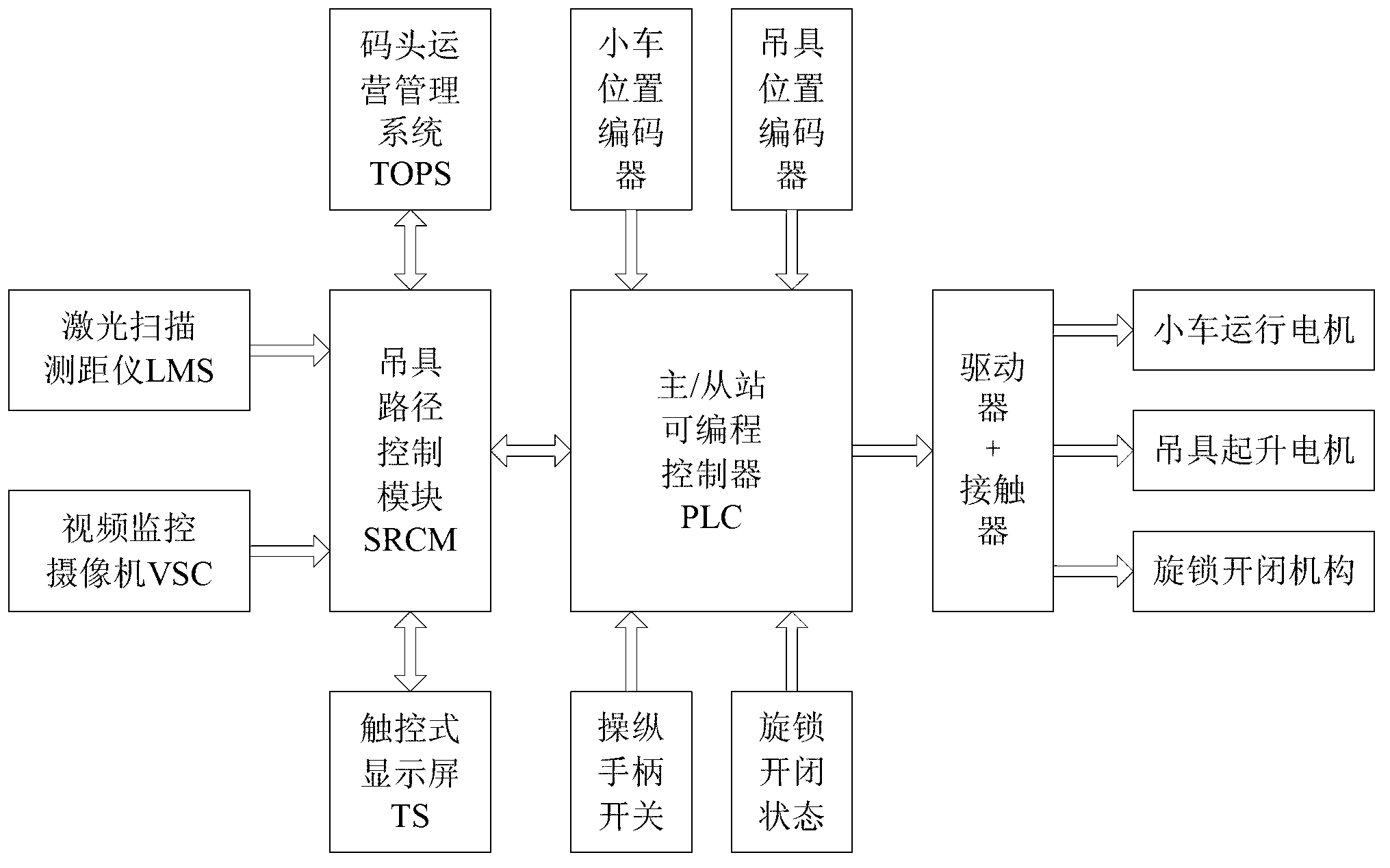

Lifting appliance path optimization control system used for container gantry crane

InactiveCN103231990AExtended Scheduling CapabilitiesImprove work efficiencySafety gearScheduling functionScheduling instructions

The invention relates to a container gantry crane lifting appliance path optimization control system based on a laser scanning positioning technology. The lifting appliance path optimization control system mainly comprises components such as a lifting appliance path control module, a laser scanning range finder, a video surveillance camera and a touch control type display screen, and can carry out positioning identification and path optimization on the contour of a storage yard and a lifting appliance (or a lifted container) according to a scheduling instruction of a wharf operating system and range finding information of a small vehicle-borne laser scanning range finder by using intelligent algorithms such as scanning positioning identification and path optimization control, so that the lifting appliance (or the lifted container) can be loaded and unloaded in place along an optimized path. The lifting appliance path optimization control system can significantly improve the operation efficiency, and reduce the operation energy consumption, container collision accidents and the labor intensity, thus further expanding the scheduling function of the wharf operating system, and being widely used for various tire type and rail type gantry cranes in container yards.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

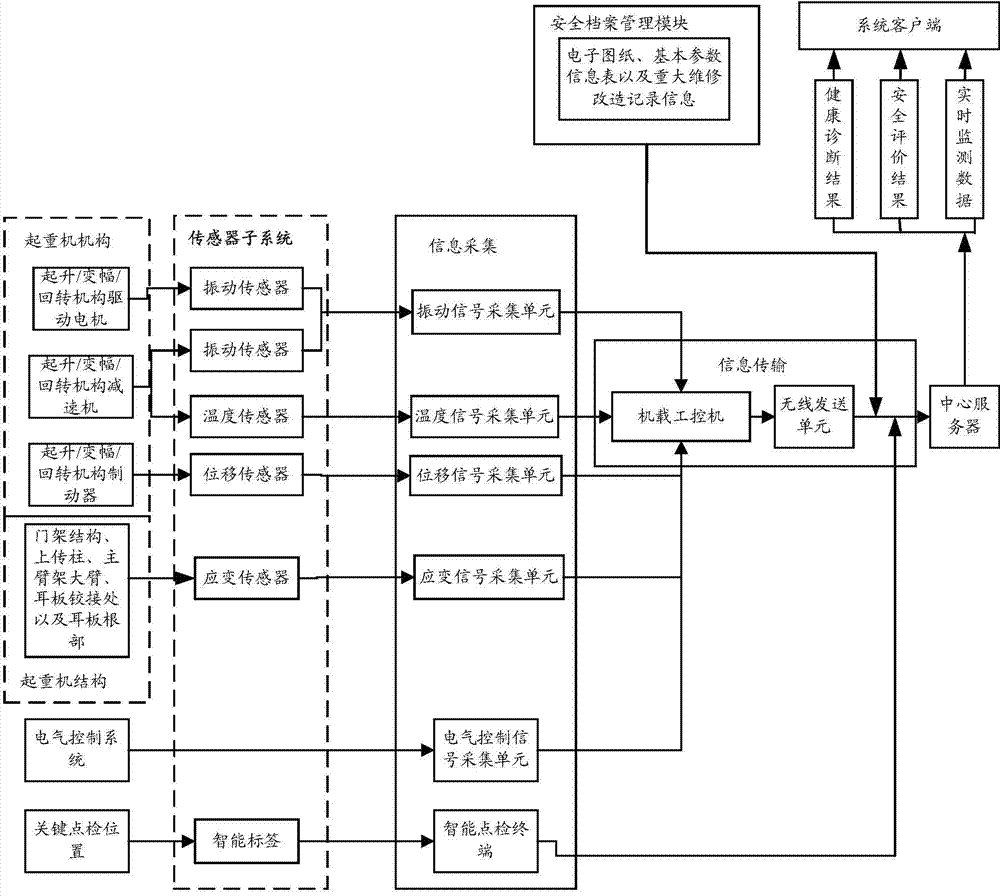

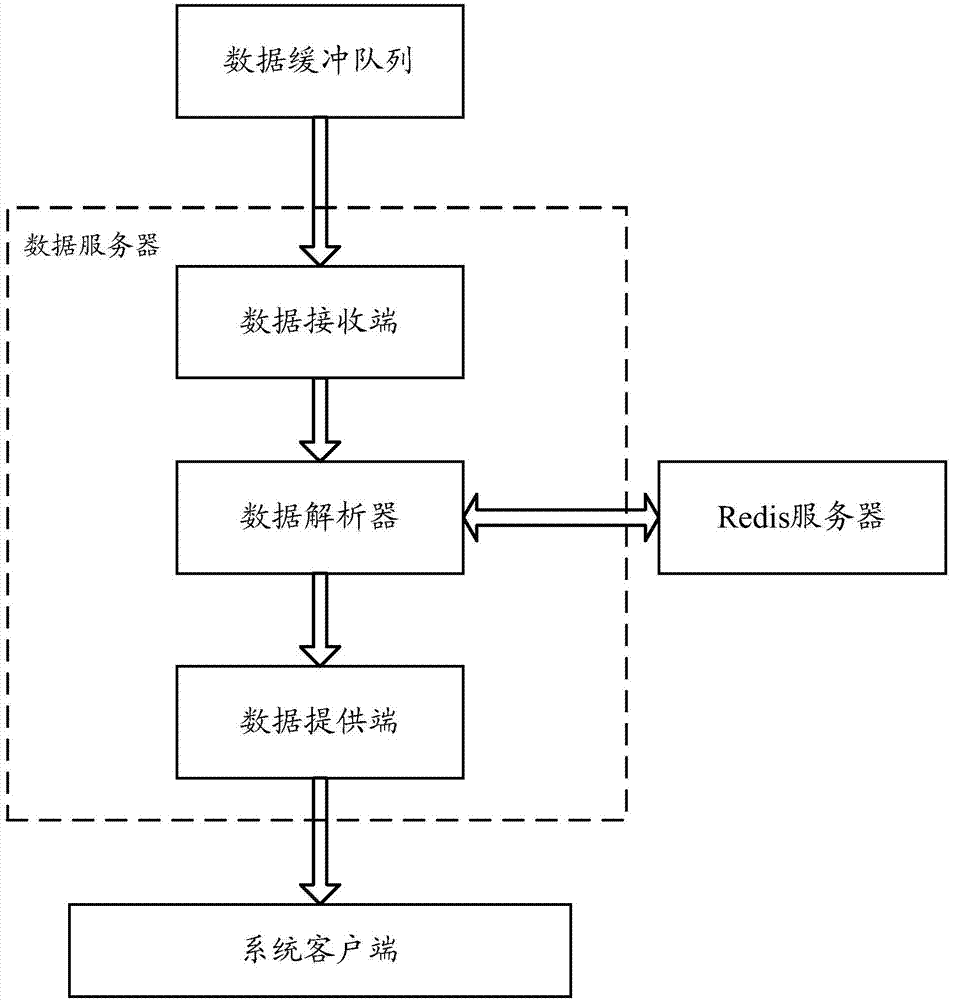

Harbor crane health monitoring and forecasting visualization system

InactiveCN104760892AImprove safety management levelOvercome efficiencySafety gearBusiness forecastingHealth condition

The invention provides a harbor crane health monitoring and forecasting visualization system including a sensor subsystem, an information collection and transmission subsystem, a central server and a system client; the sensor subsystem is used for acquiring real-time operation parameters of a crane; the information collection and transmission subsystem is used for sending the real-time operation parameters of the crane to the central server through a wireless sending unit; the central server is used for storing and managing the real-time operation parameters of the crane, then performing health diagnosis on the crane to obtain a health condition diagnosis report, also forecasting whether the crane is failed or goes wrong according to the diagnosis result, and evaluating the operation safety of the crane to obtain a safety evaluation report; the system client is used for displaying the real-time operation parameters of the crane, the health condition diagnosis report and the safety evaluation report. The system can comprehensively, efficiently and real-timely monitor the harbor crane health condition, so as to ensure the safety operation of the harbor crane.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

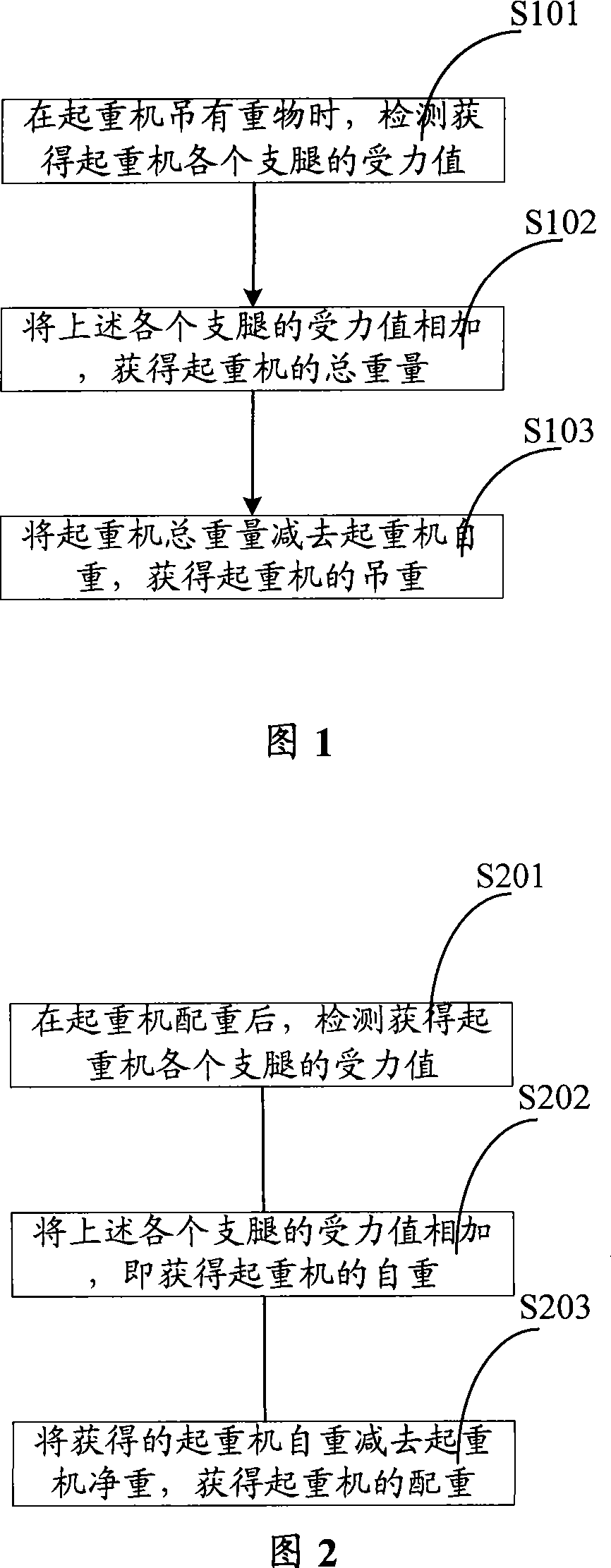

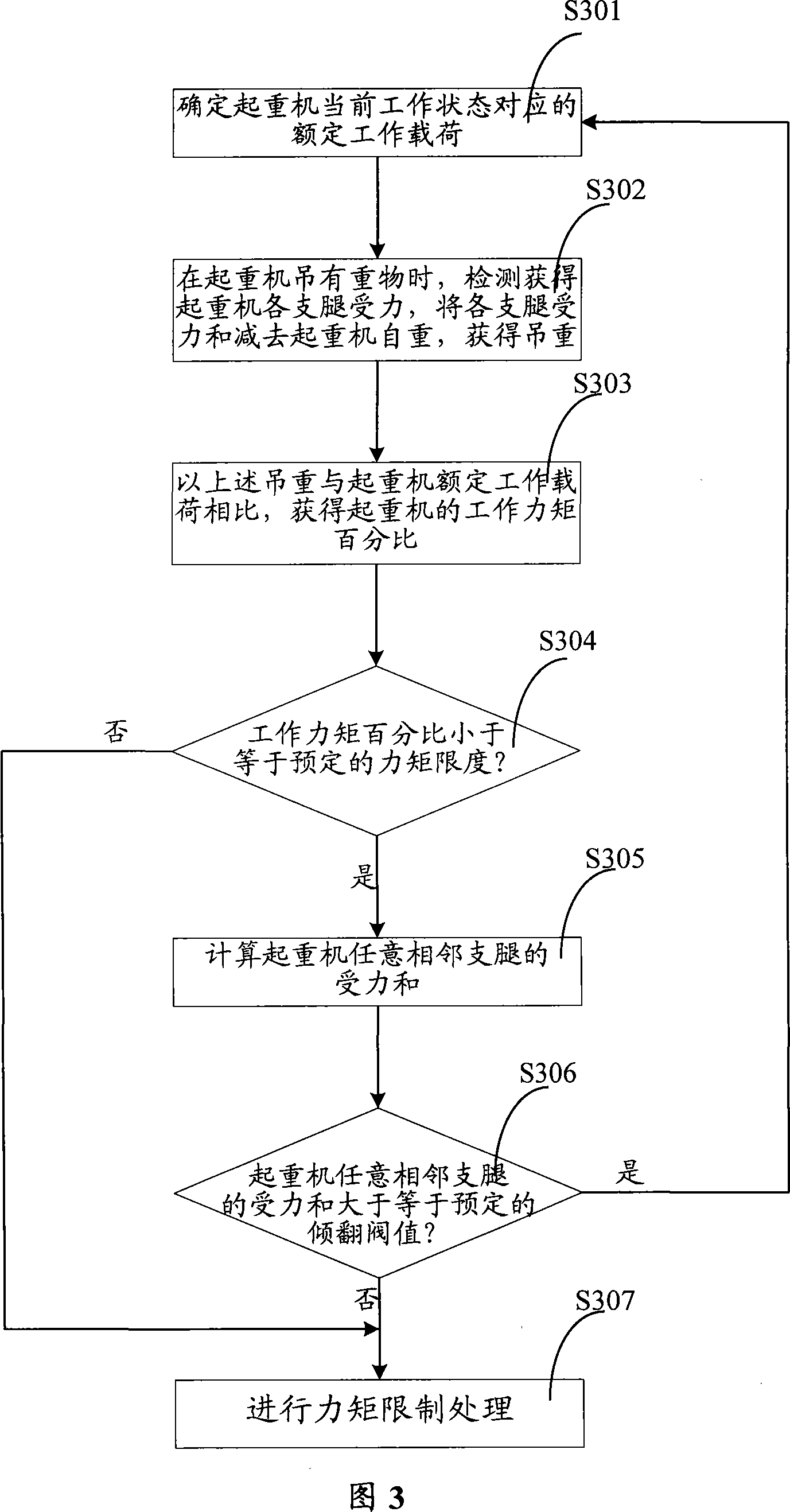

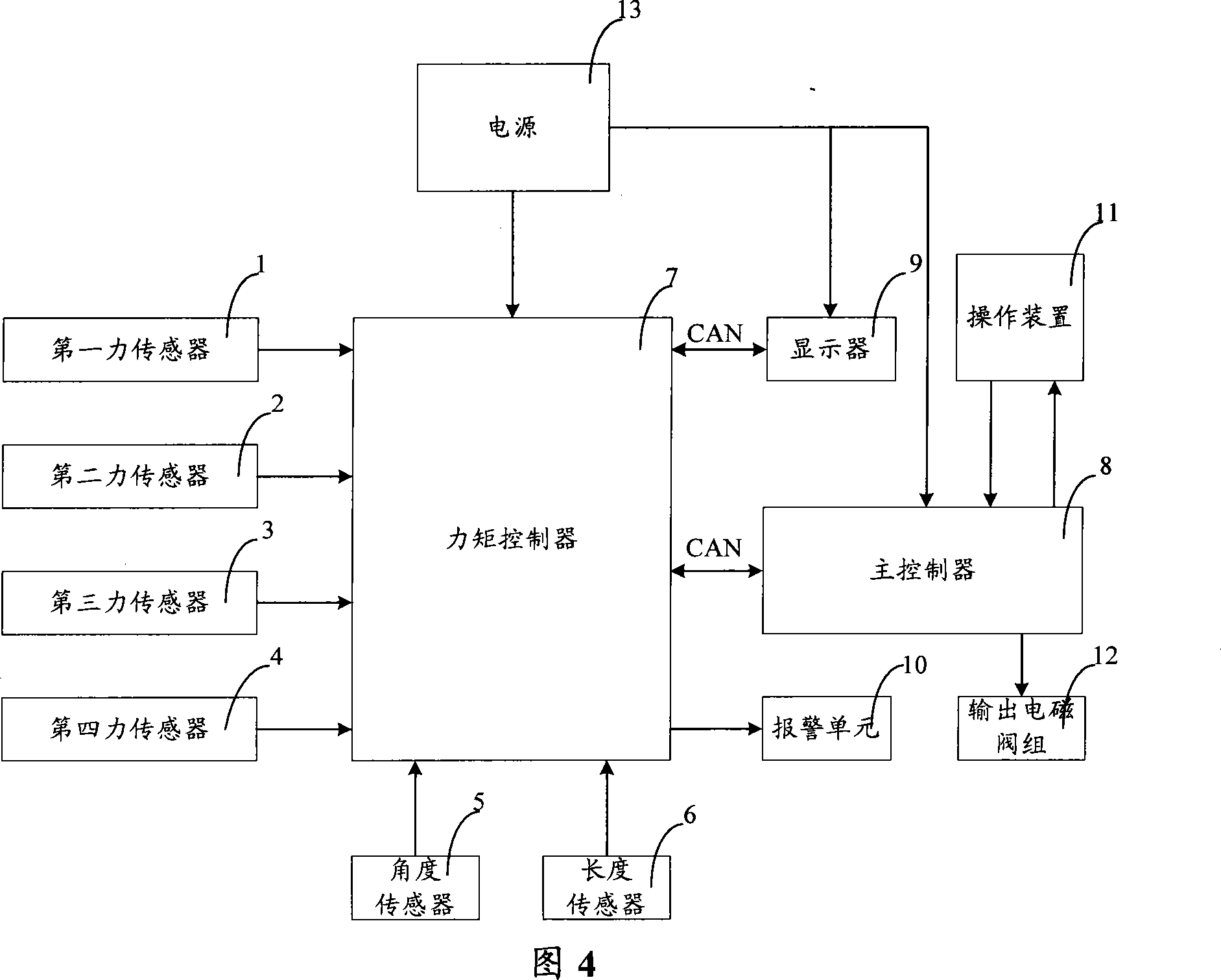

Method for measuring crane hoisting weight and counter weight and force moment controlling method and system

InactiveCN101214903AHigh precisionEasy to detectForce measurementWork measurementControl systemEngineering

The present invention discloses a method of measuring the lifted weight of a crane, comprising that: when the crane lifts a heavy article, the borne-force values of each outrigger of the crane are tested and obtained to be added to obtain the total weight of the crane; the self weight of the crane is subtracted from the tested and obtained total weight of the crane to obtain the lifted weight of the crane. The present invention also discloses a method of measuring the balance weight of the crane which has the same technical characteristic as the method. The present invention also discloses a crane moment control method which adopts the method of measuring the lifted weight and a crane moment control system. Compared with the prior art, the method of measuring the lifted weight of the crane provided by the present invention has better testing effect.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

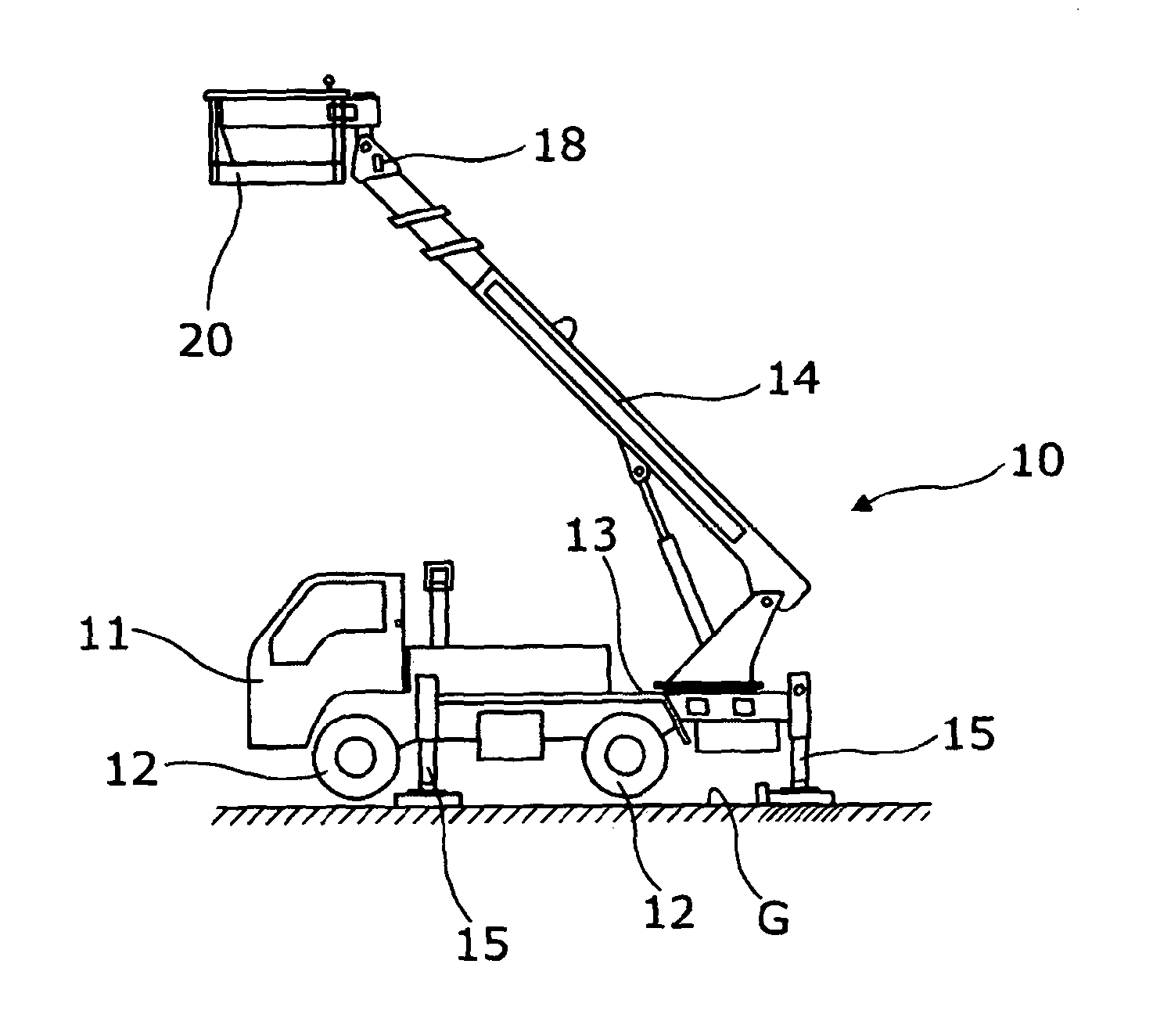

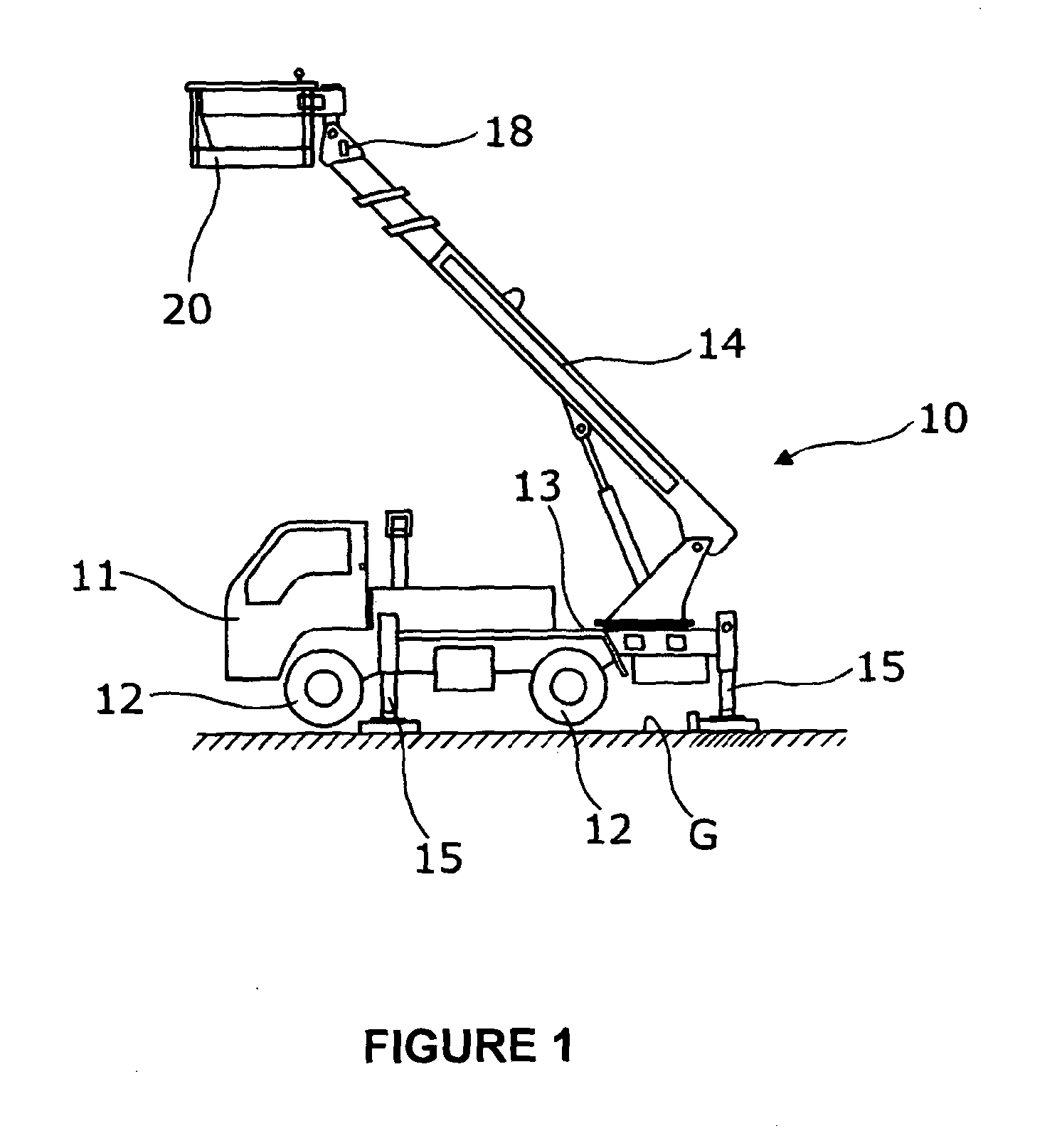

Aerial Lift with Safety Device and Alarm

ActiveUS20150008073A1Safety devices for lifting equipmentsSafety gearAerial liftManual fire alarm activation

A safety device for an aerial lift having a basket with controls which permit an operator standing in the basket to manoeuvre the basket. The safety device comprises an alarm, a switch activation device proximate to the controls and two solenoid operated relays, one connected with a normally-closed manually operable emergency switch means which is operable to cut electrical supply and prevent further movement of the basket, and one connected with a foot operable safety switch, which must be held closed by an operator to activate the controls. Each relay is held in a closed condition (switch on) unless caused to change to an open condition (switch off) to cut electrical supply. The relays are controlled by a programmable control box connected to the switch activation device, foot switch and alarm. The control box causes the alarm to operate in accordance with the condition of the foot operable safety switch.

Owner:NATIONWIDE PLATFORMS LTD

Method and apparatus for crane topple/collision prevention

Methods and apparatus are disclosed for a crane safety device configured to operate a processor estimating a trajectory for the crane, determining a potentially dangerous event in response to a yard estimate and the trajectory, and sending alert messages in response to the potentially dangerous event. The processor may further generate the yard estimate. The embodiments may include means for implementing these operations, sensors of the yard estimate to generate the yard estimate, computer readable devices and / or a server containing a program system to instruct a computer to at least partly operate the processor and / or an installation package to create the program system.

Owner:PACECO

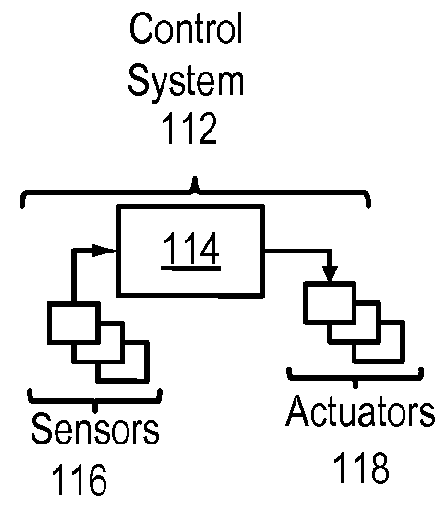

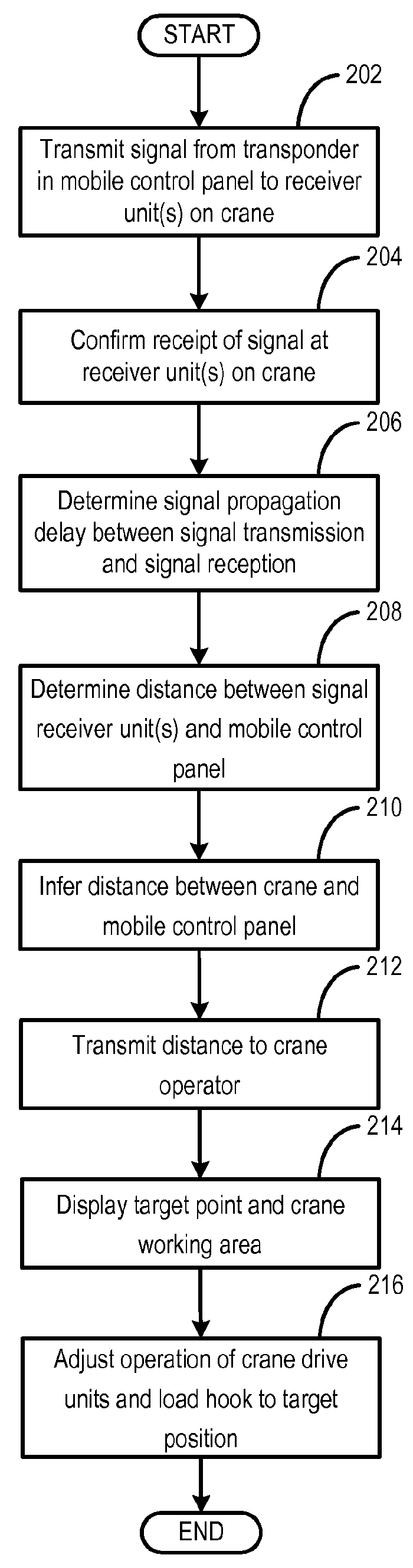

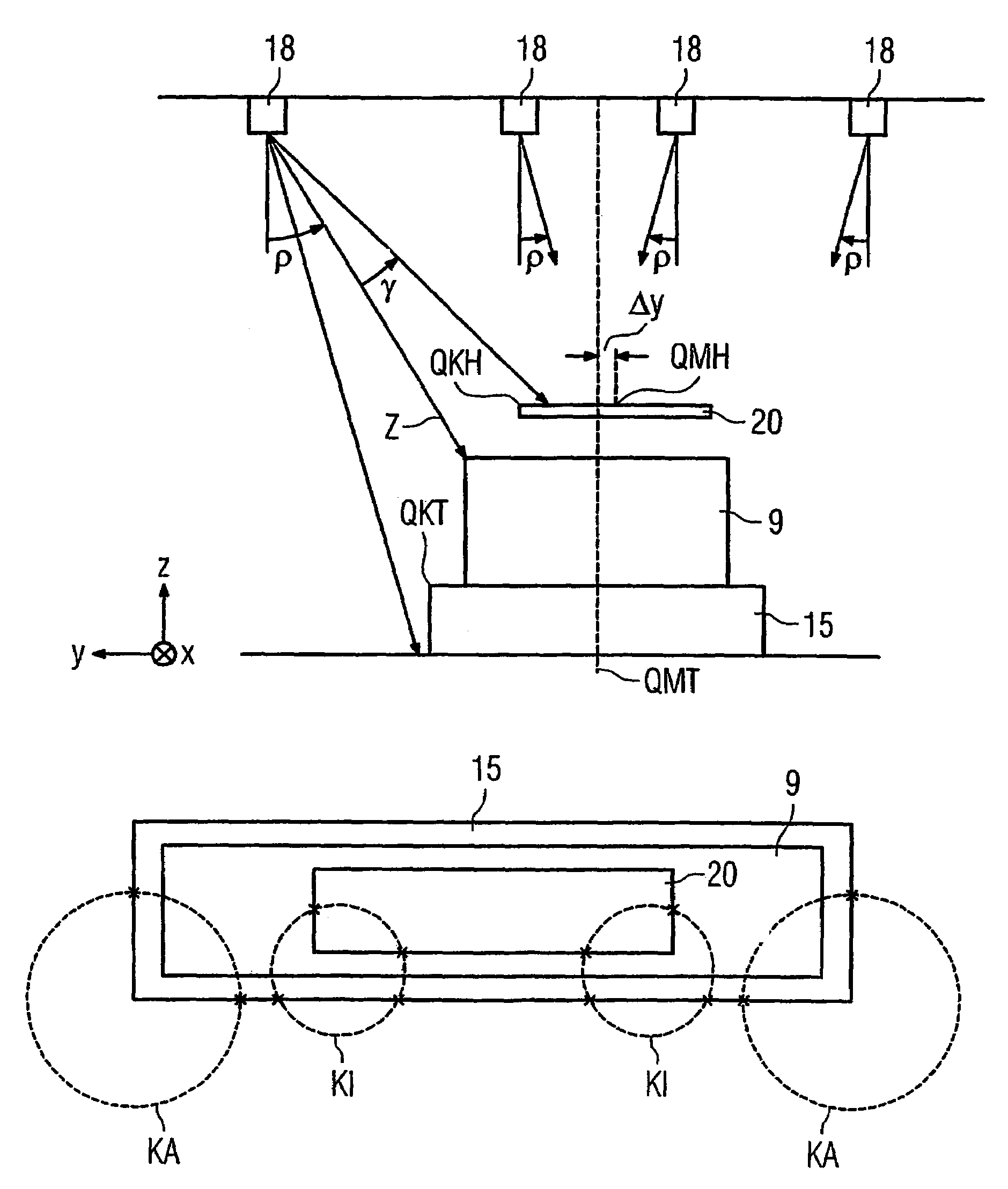

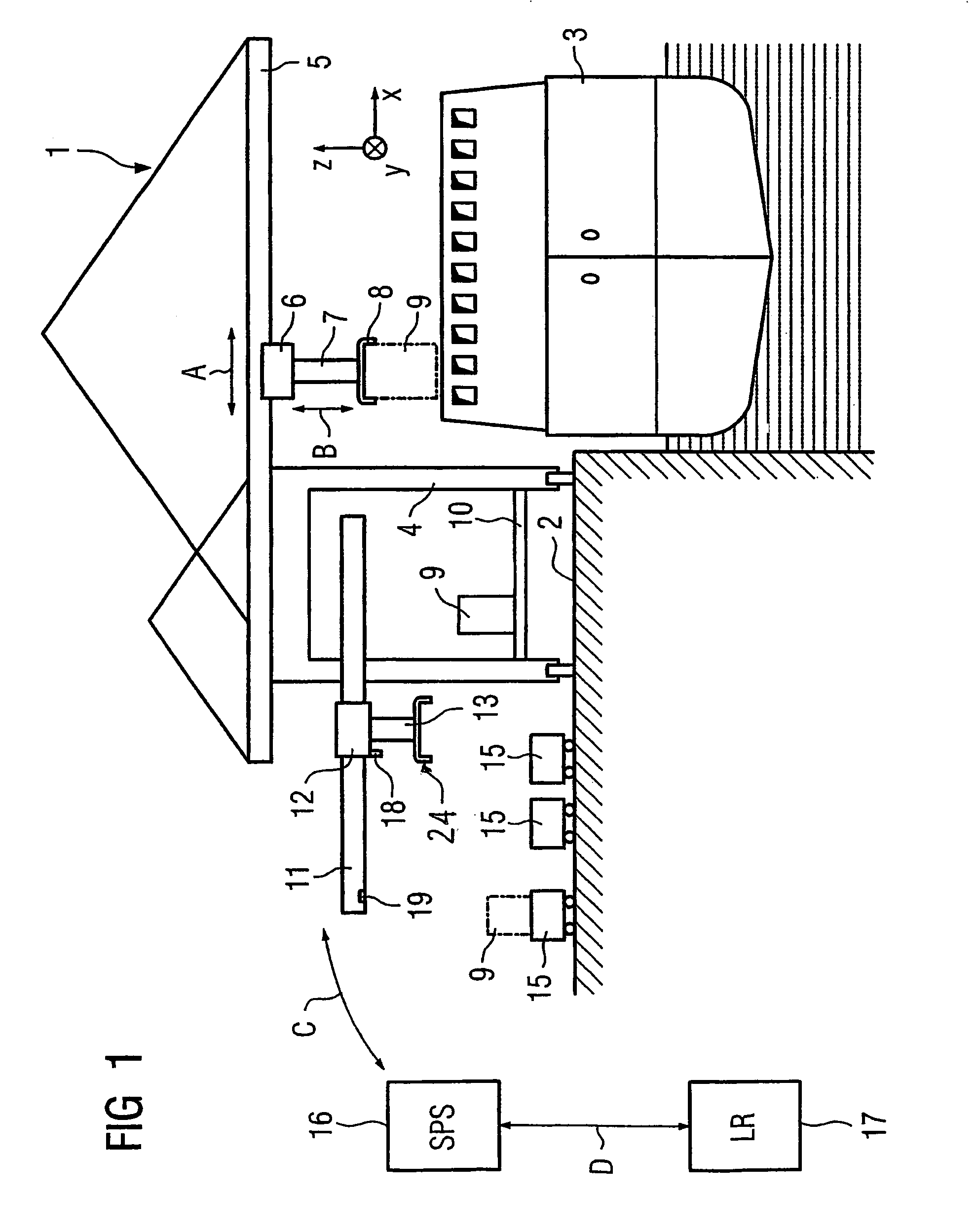

Remote-controlled crane

The present disclosure concerns a crane, in particular a tower crane, telescopic boom crane, harbour crane and the like, with a load hook that can be raised or lowered via movable crane elements, and moved within a crane working area by operating drive units associated with the crane elements. The crane is provided with a control unit with input means to control the drive units. According to the present disclosure, the crane uses a mobile portable target signal transmitter that can be variably positioned in the crane working area, and positioning means for automatically determining the current position of the target signal transmitter relative to the load hook and / or a crane element, and target control means for automatically controlling the drive units in response to a signal from the positioning means, such that the load hook is automatically moved to the mobile target signal transmitter.

Owner:LIEBHERR WERK BIBERACH

Container crane, and method of determining and correcting a misalignment between a load-carrying frame and a transport vehicle

ActiveUS7289876B2Quick correctionQuick identificationDigital data processing detailsArticle unpackingContainer craneEngineering

A container crane includes a movable trolley and a load-carrying frame pendantly connected to the trolley and comprised of a spreader and a head block, for transfer of a container from or to a transport vehicle. Plural optical detectors are mounted on the trolley for identifying longitudinal and transversal edges of the head block or spreader and the transport vehicle. Operatively connected to the detectors is a processing device for determining a spatial position of the edges and calculating a position of longitudinal and transversal center lines of the head block or spreader and the transport vehicle and their spatial positions in relation to one another. In this way a possible offset of the center lines of the head block or spreader with regard to those of the transport vehicle in longitudinal and transversal directions as well as a rotation angle of the center lines can be determined, whereby a detected offset or rotation angle is compensated by displacing the spreader relative to the head block.

Owner:SIEMENS AG

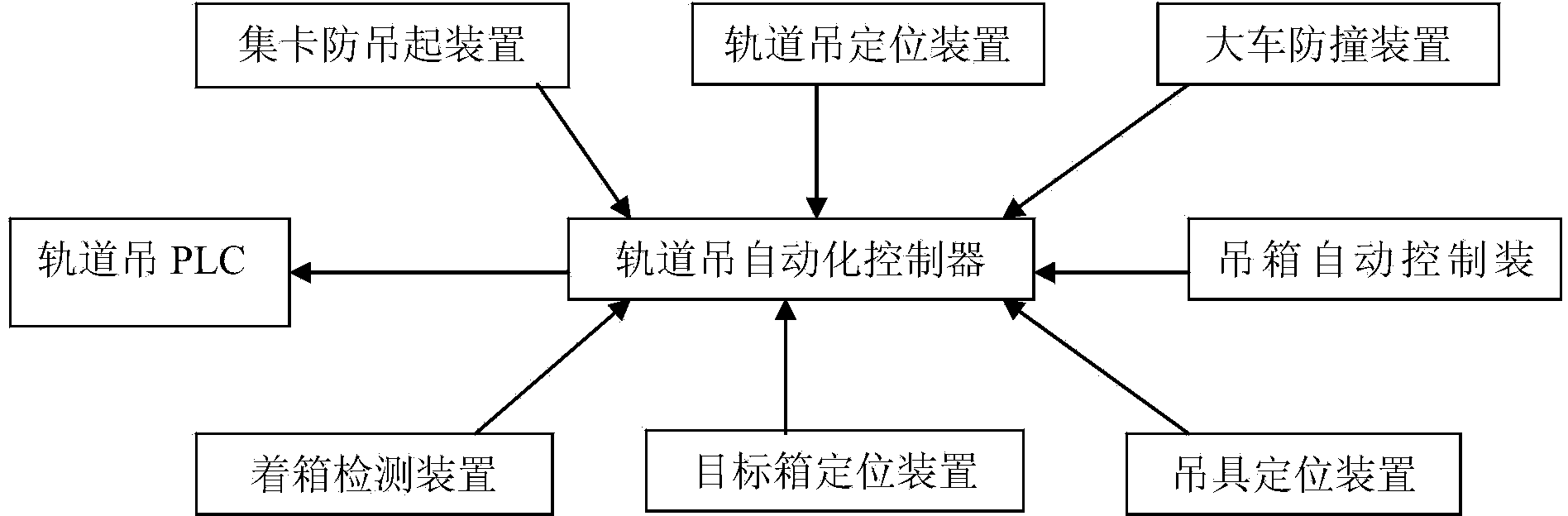

Rail-mounted gantry crane automatic yard operation control system and automatic loading and unloading method

ActiveCN103523675AImprove work efficiencyReduce labor costsSafety gearAutomatic controlControl system

The invention discloses a rail-mounted gantry crane automatic yard operation control system and an automatic loading and unloading method, and the control system and the automatic loading and unloading method can reduce investment for reconstruction and enables technological process to be simplified. The system comprises a rail-mounted gantry crane automatic controller, a rail-mounted gantry crane PLC controller, a hanger PLC controller, a container truck hoist-preventing device, a rail-mounted gantry crane positioning device, a container landing detection device, a hoisting box automatic control device, a target container positioning device and a hanger positioning device. The system refits a conventional rail-mounted gantry crane into an automatic rail-mounted gantry crane and can carry out container landing, locking, hanger rising, container dropping, unlocking, hanger rising and the like on containers through controlling by the automatic loading and unloading method, a cycle of operation can be automatically finished without intervention by a remote operator, so work efficiency is improved, labor cost is reduced and work cost is lowered down; moreover, equipment investment is small, and operation is simple and convenient.

Owner:TIANJIN PORT CONTAINER TERMINAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com