Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2484 results about "Gantry crane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gantry crane is a crane built atop a gantry, which is a structure used to straddle an object or workspace. They can range from enormous "full" gantry cranes, capable of lifting some of the heaviest loads in the world, to small shop cranes, used for tasks such as lifting automobile engines out of vehicles. They are also called portal cranes, the "portal" being the empty space straddled by the gantry.

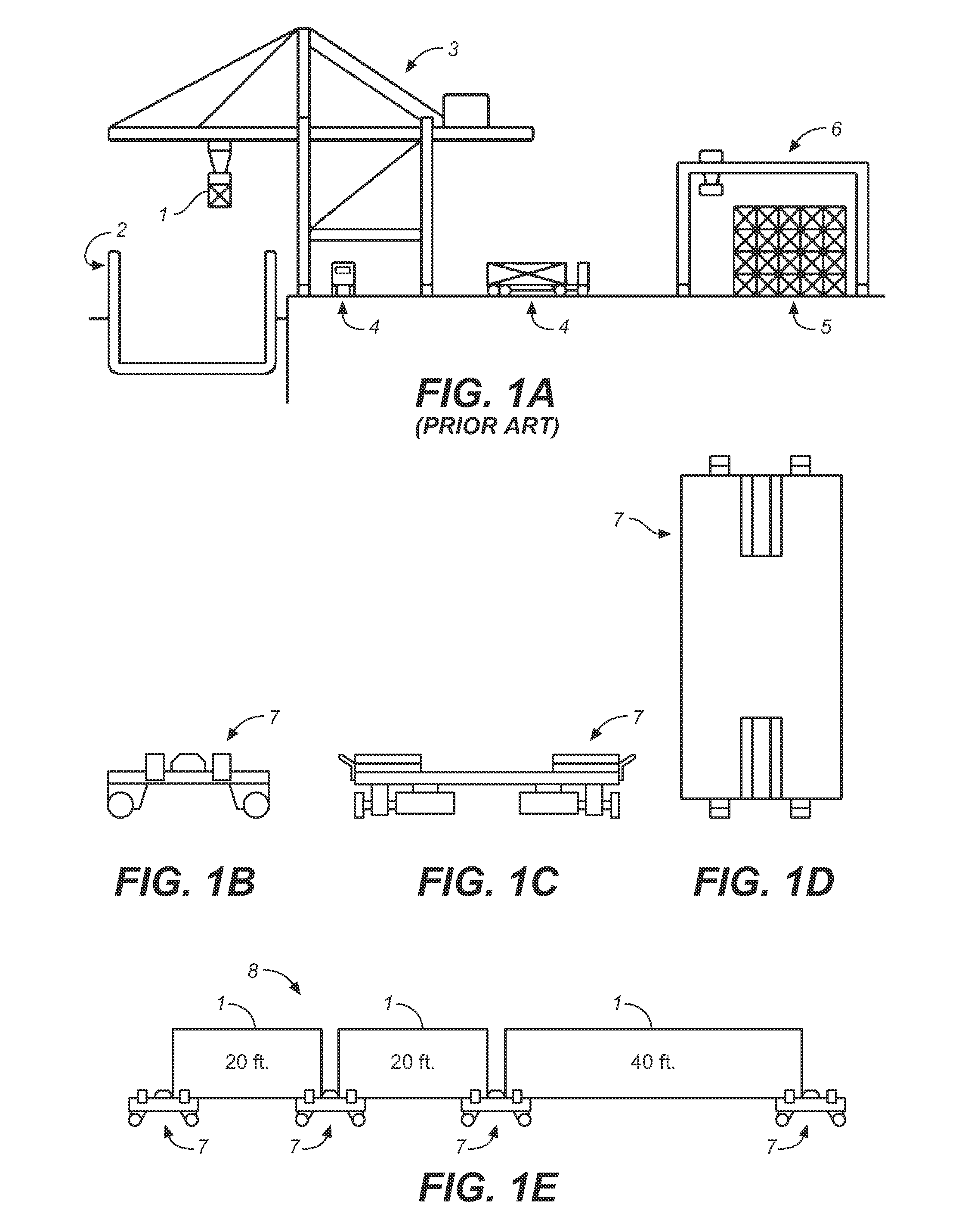

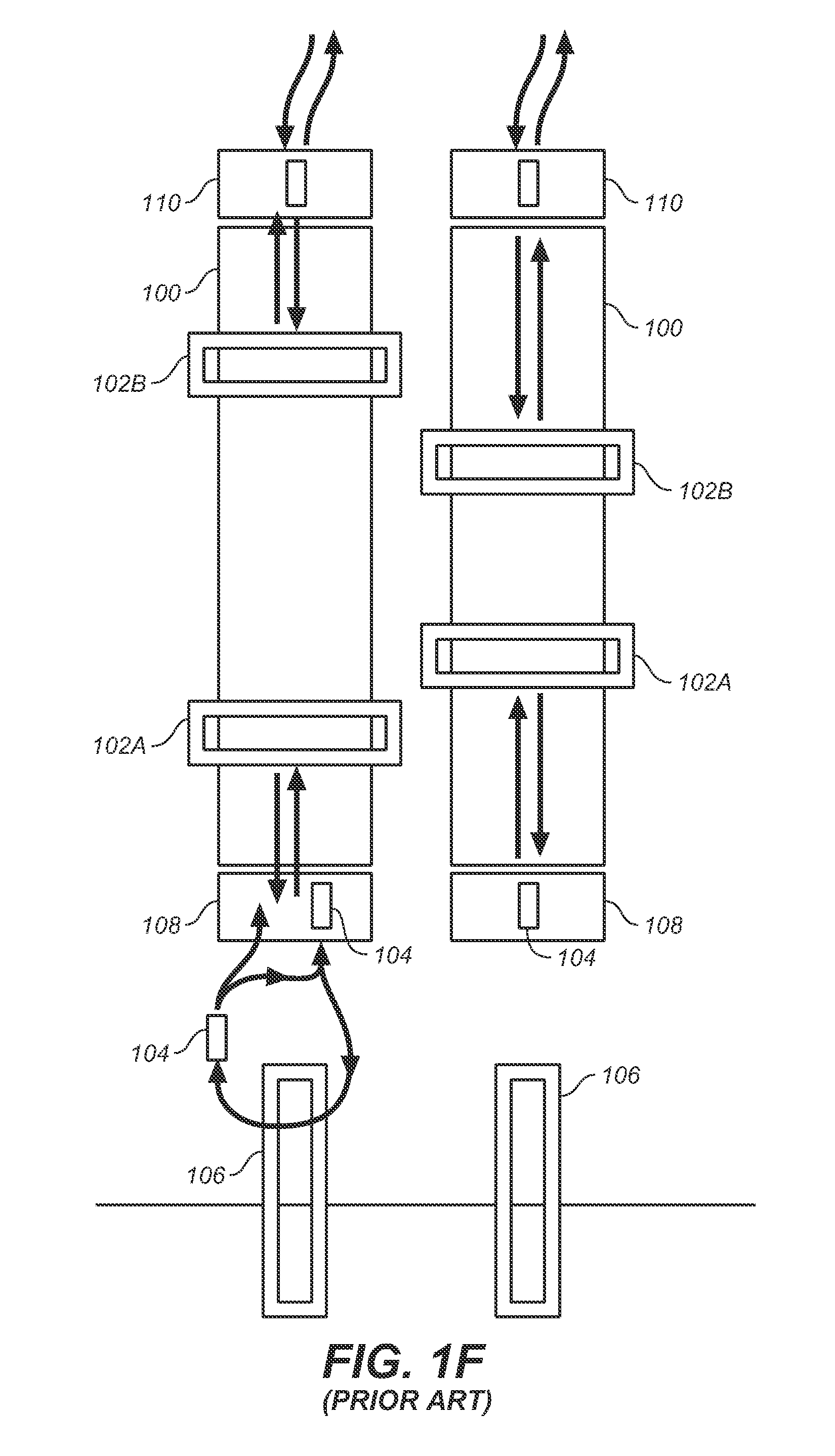

Load-lifting apparatus and method of storing energy for the same

ActiveUS7554278B2Small sizeAlleviate power rating requirementDc motor stoppersDynamo-electric converter controlRegenerative brakeContainer crane

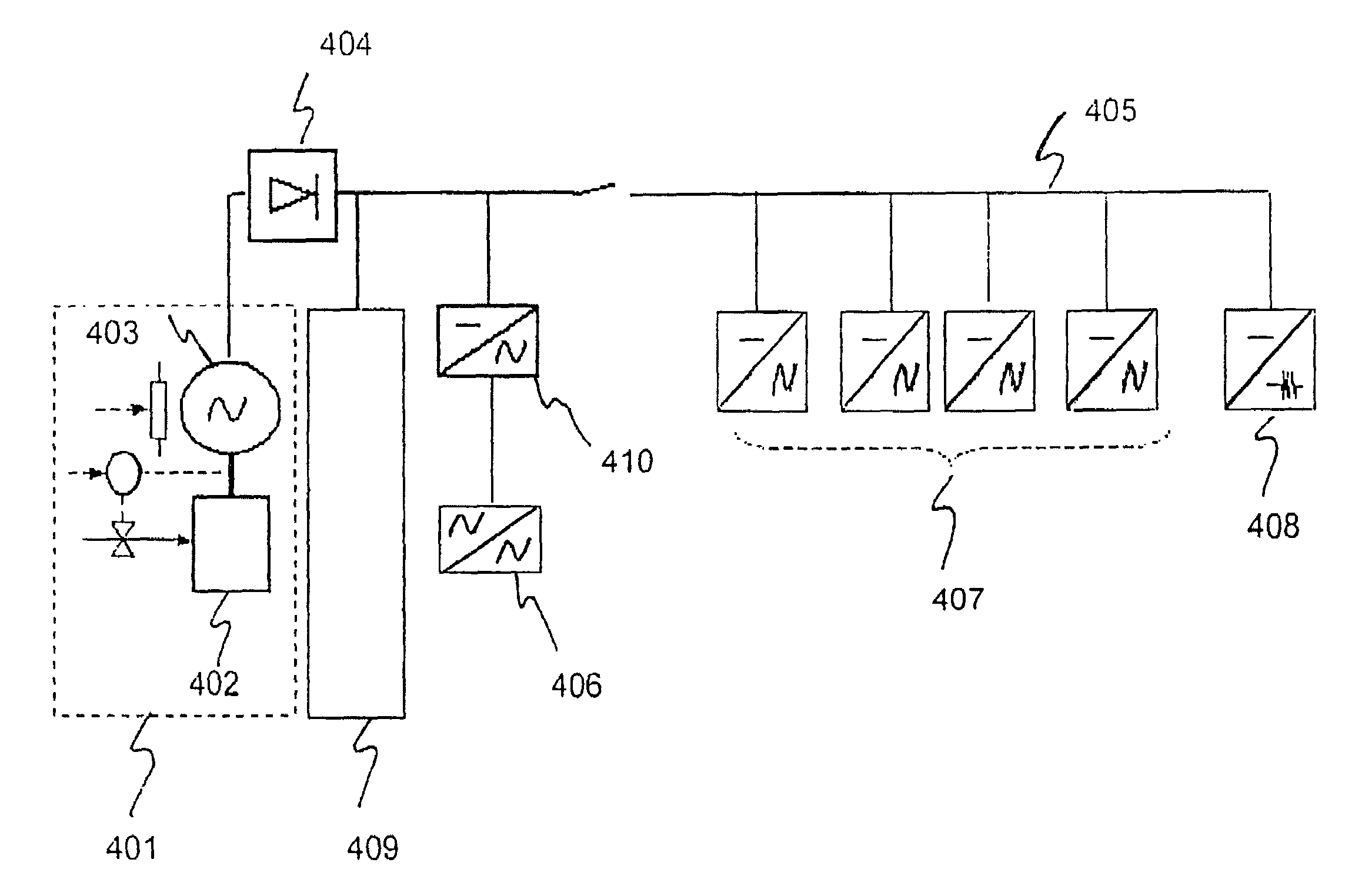

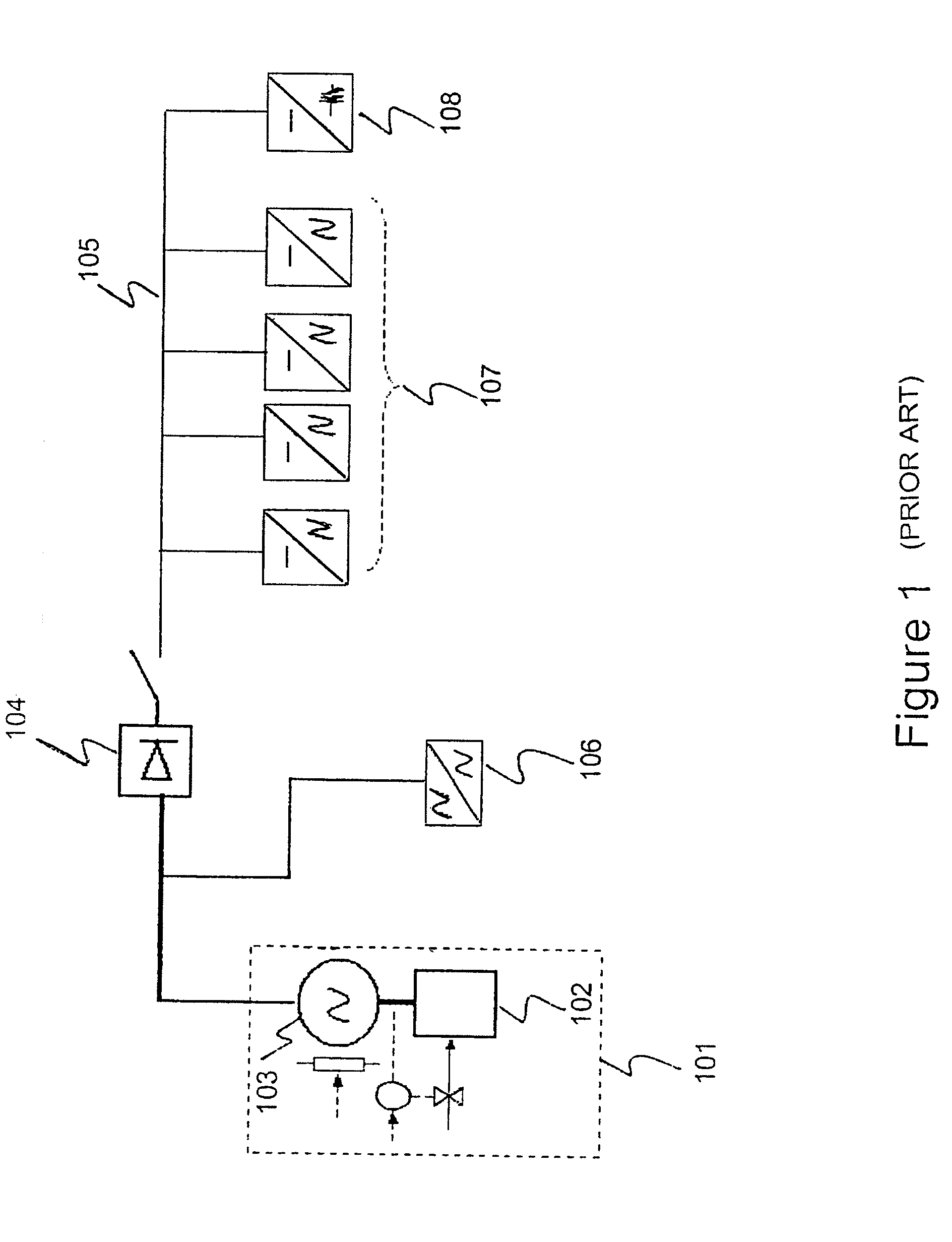

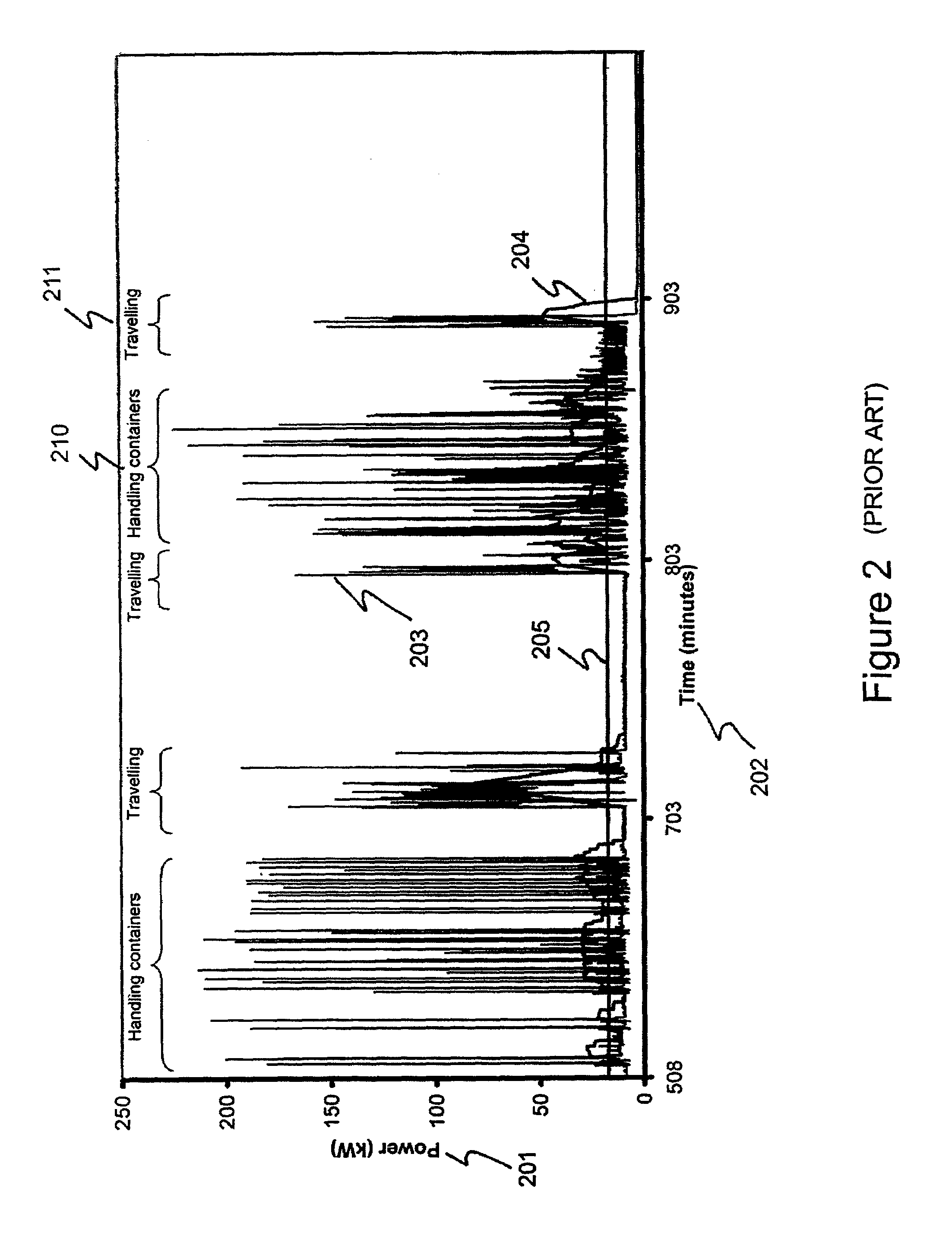

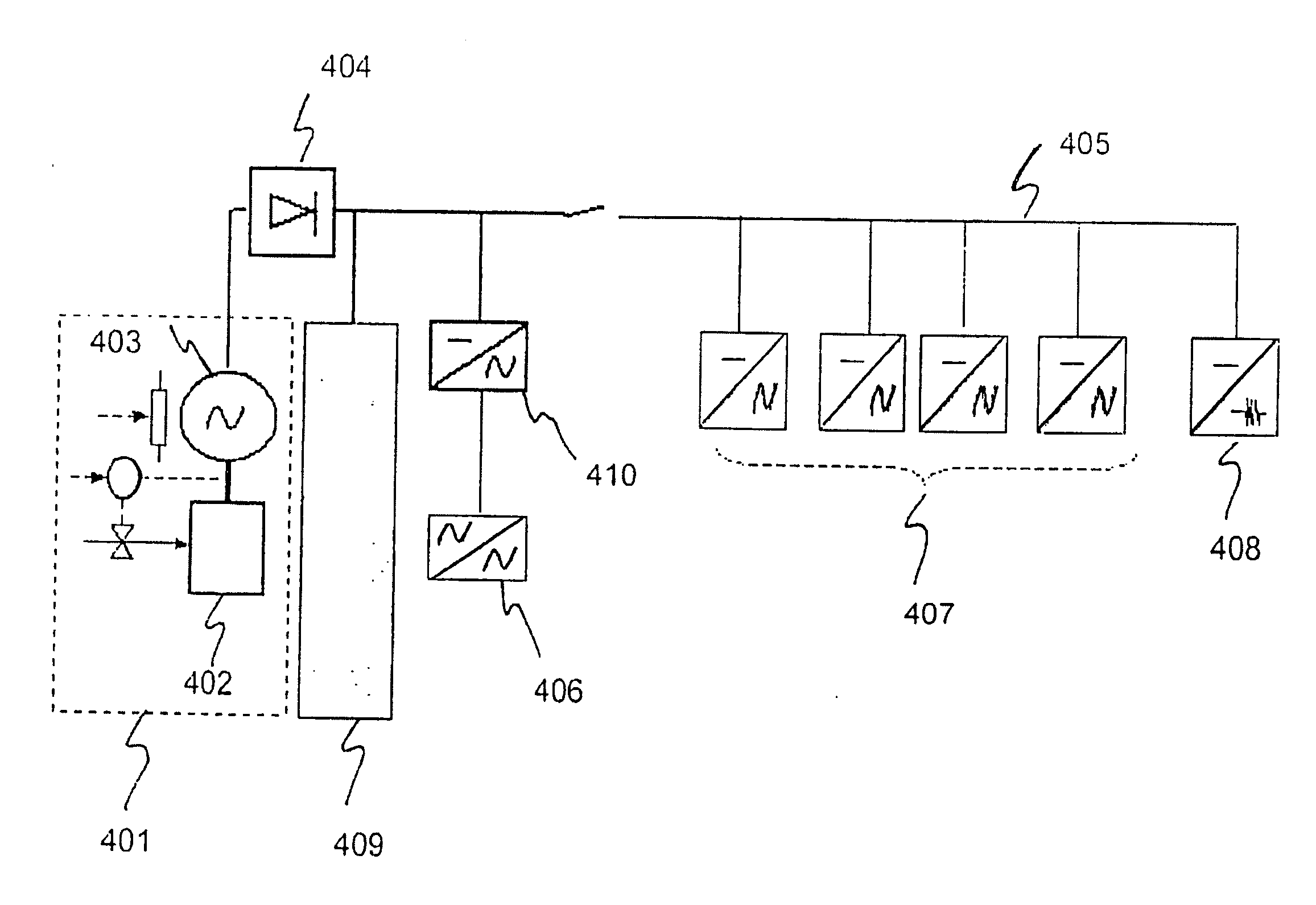

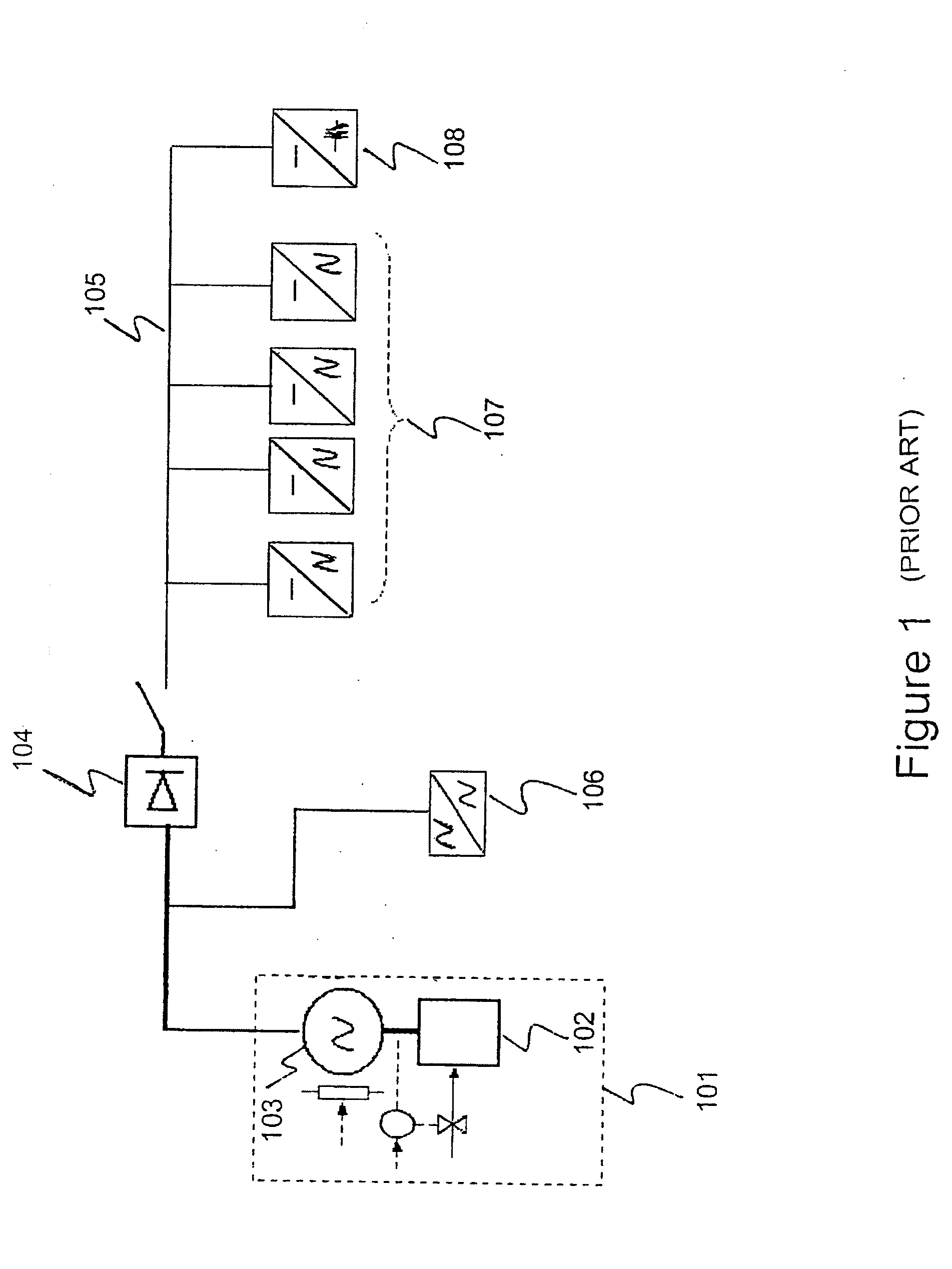

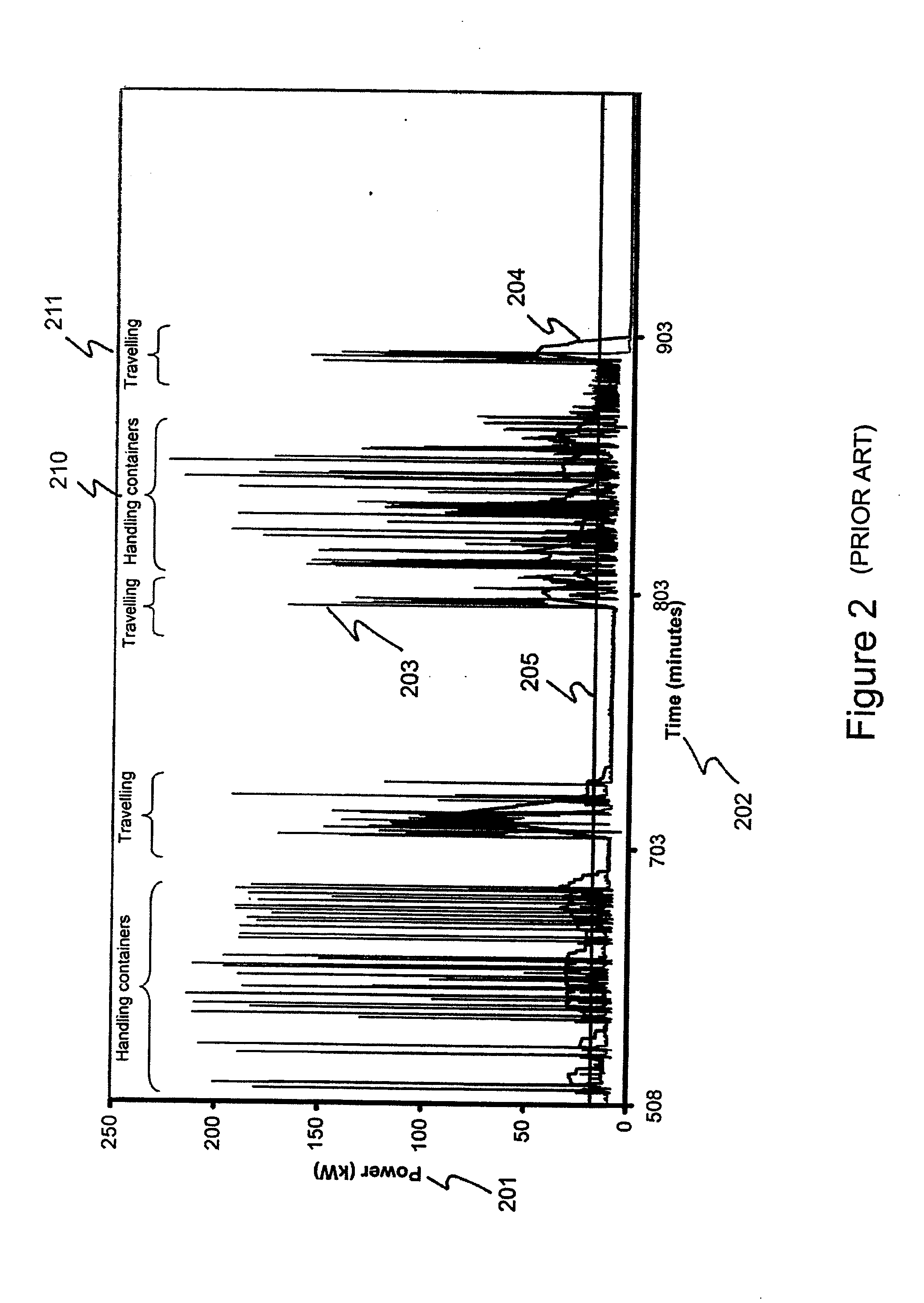

A load-lifting apparatus has one or more prime power sources, one or more energy storage systems and regenerative braking. Regenerative energy is recovered when the load-lifting apparatus lowers its load. The elements of the prime power sources, energy storage devices and electrical components may be distributed to provide stability for the load-lifting apparatus. The general power architecture and energy recovery method can be applied to cranes, rubber-tired gantry cranes, overhead cranes, mobile cranes, ship-to-shore cranes, container cranes, rail-mounted gantry cranes, straddle carrier cranes and elevators. In such an architecture, the energy storage system helps alleviate the power rating requirement of the prime power source with respect to the peak power requirement for lifting a load.

Owner:MI JACK CANADA

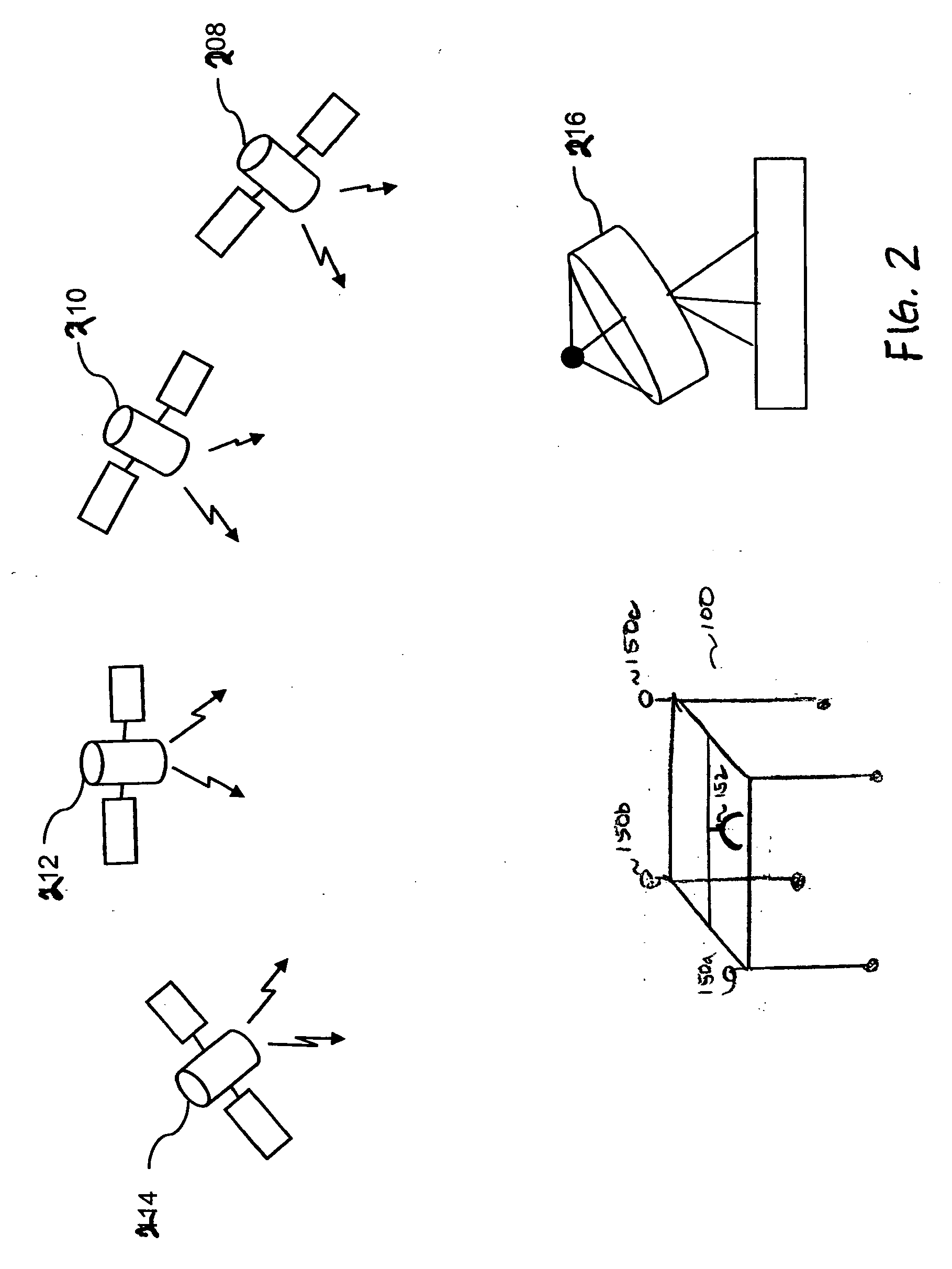

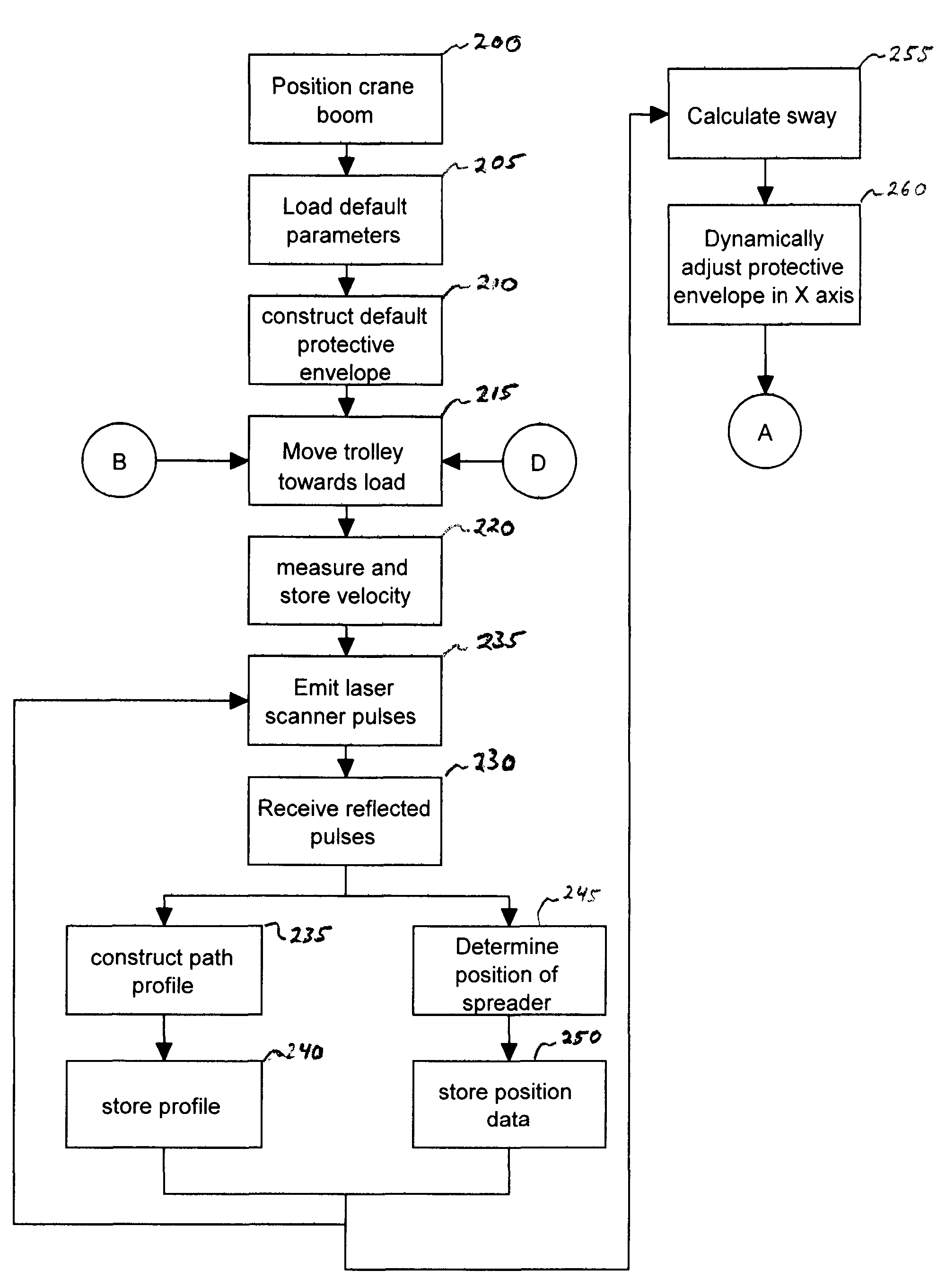

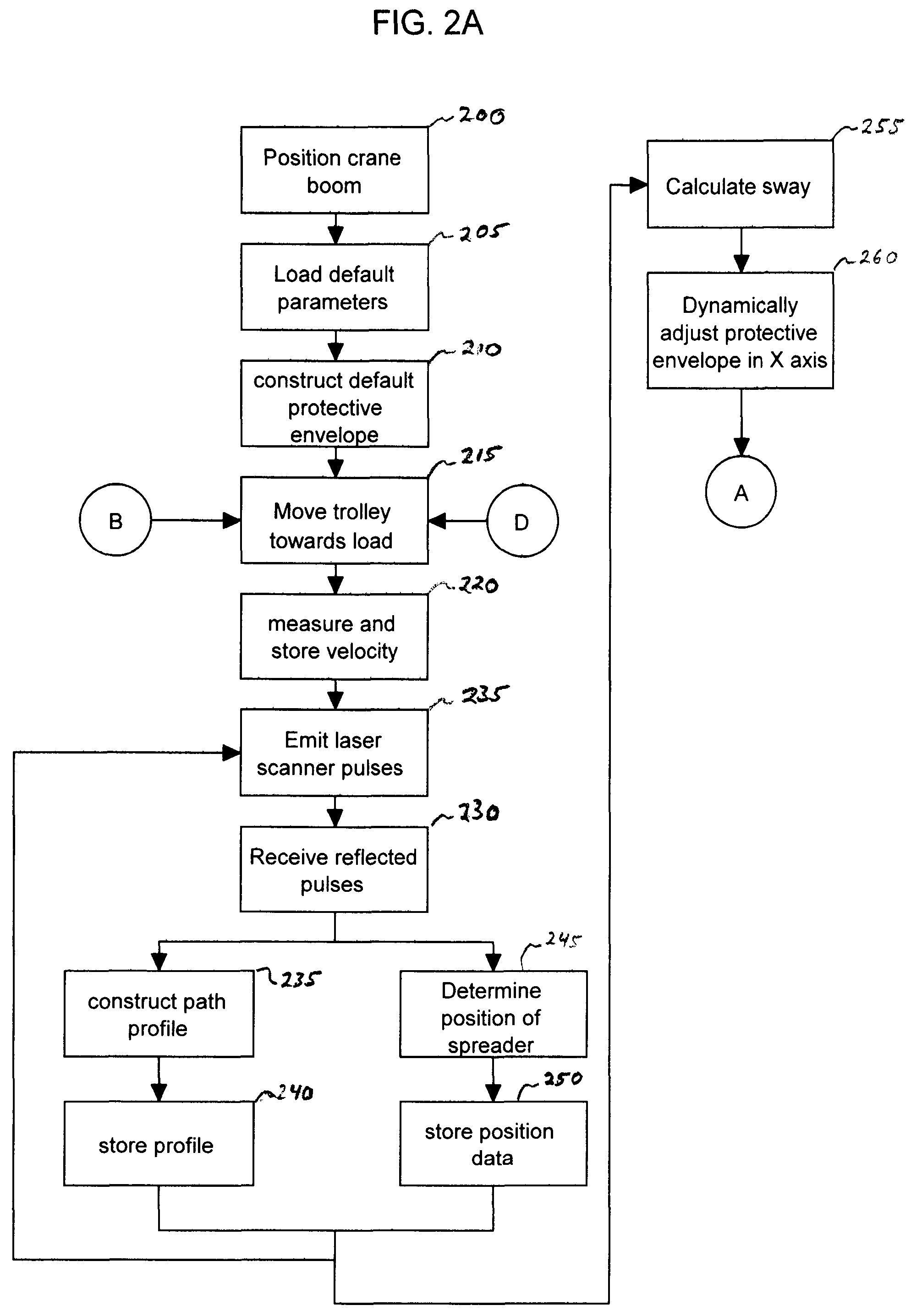

Method and apparatus for gantry crane sway determination and positioning

A gantry crane system includes a frame structure having a plurality of vertical support legs and one or more members interconnecting predetermined pairs of the vertical support legs; and a positioning system including positioning sensors mounted to the frame structure and configured to receive positioning signals from positioning transmitters and a position processing unit configured to use the positioning signals to determine a deflection from vertical of at least one of the vertical support legs. In certain embodiments, the gantry crane system further includes a grappler assembly mounted to the frame structure. The position processing unit is configured to use the positioning signals to determine a location of the grappler assembly.

Owner:NOVARIANT

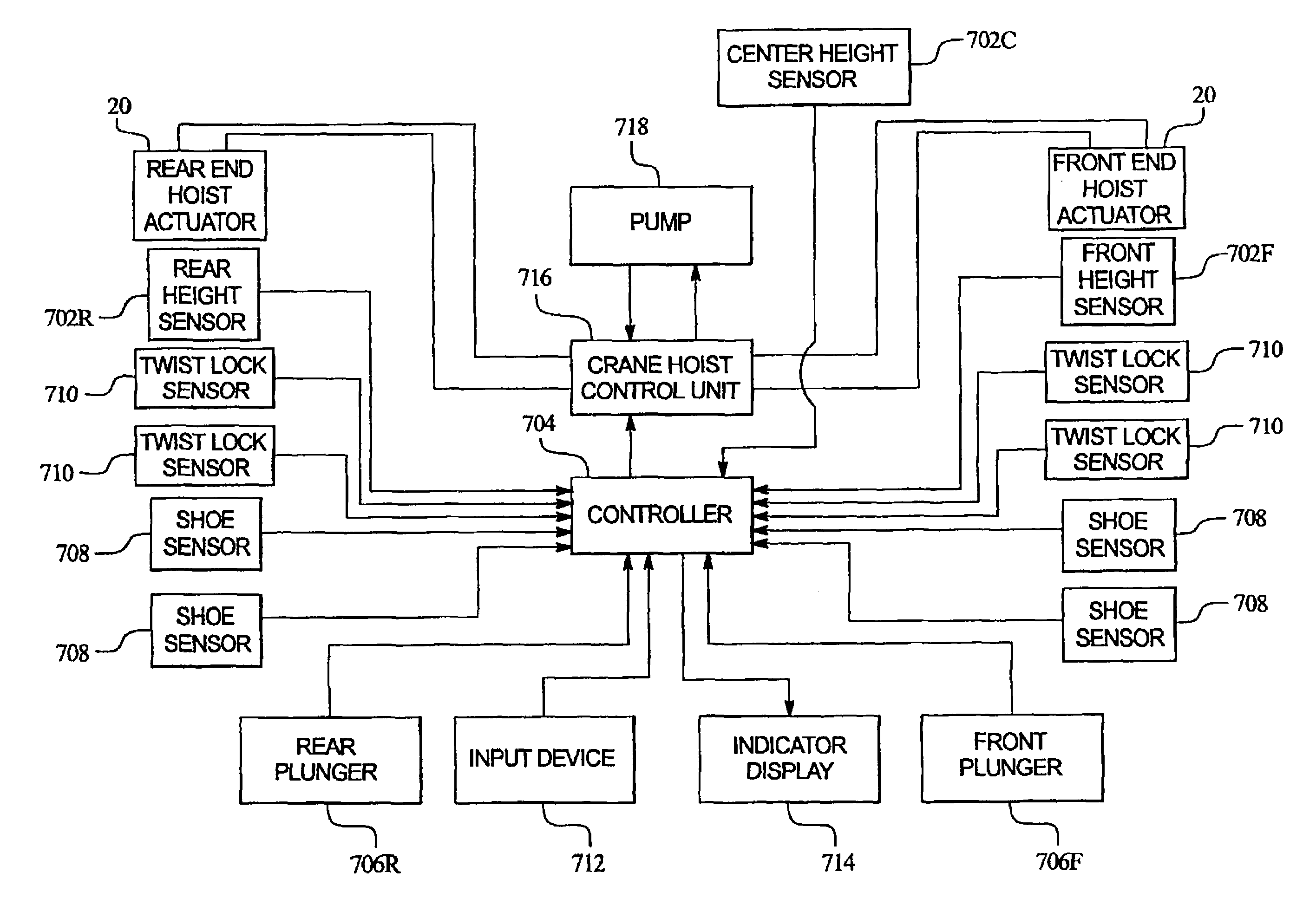

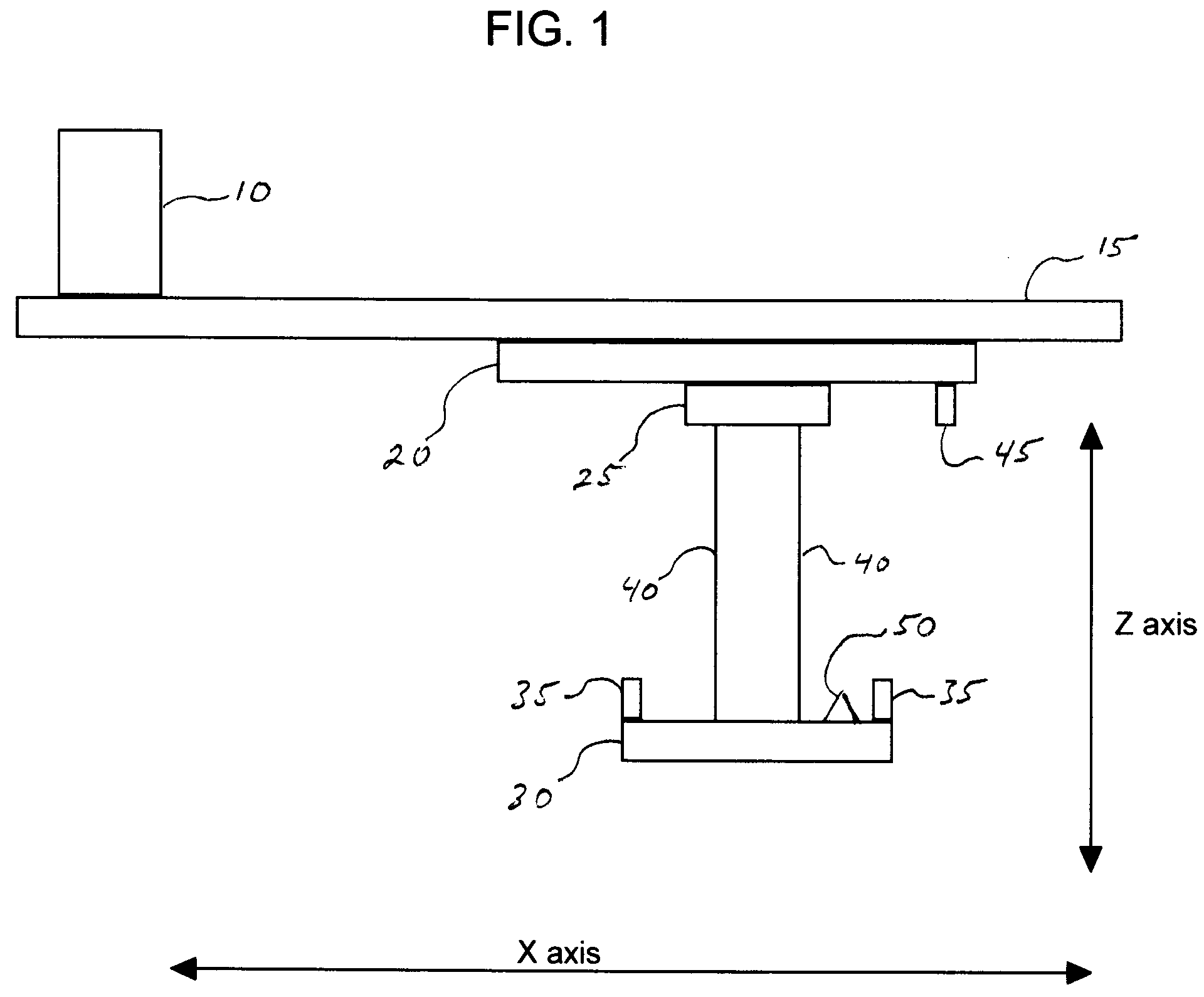

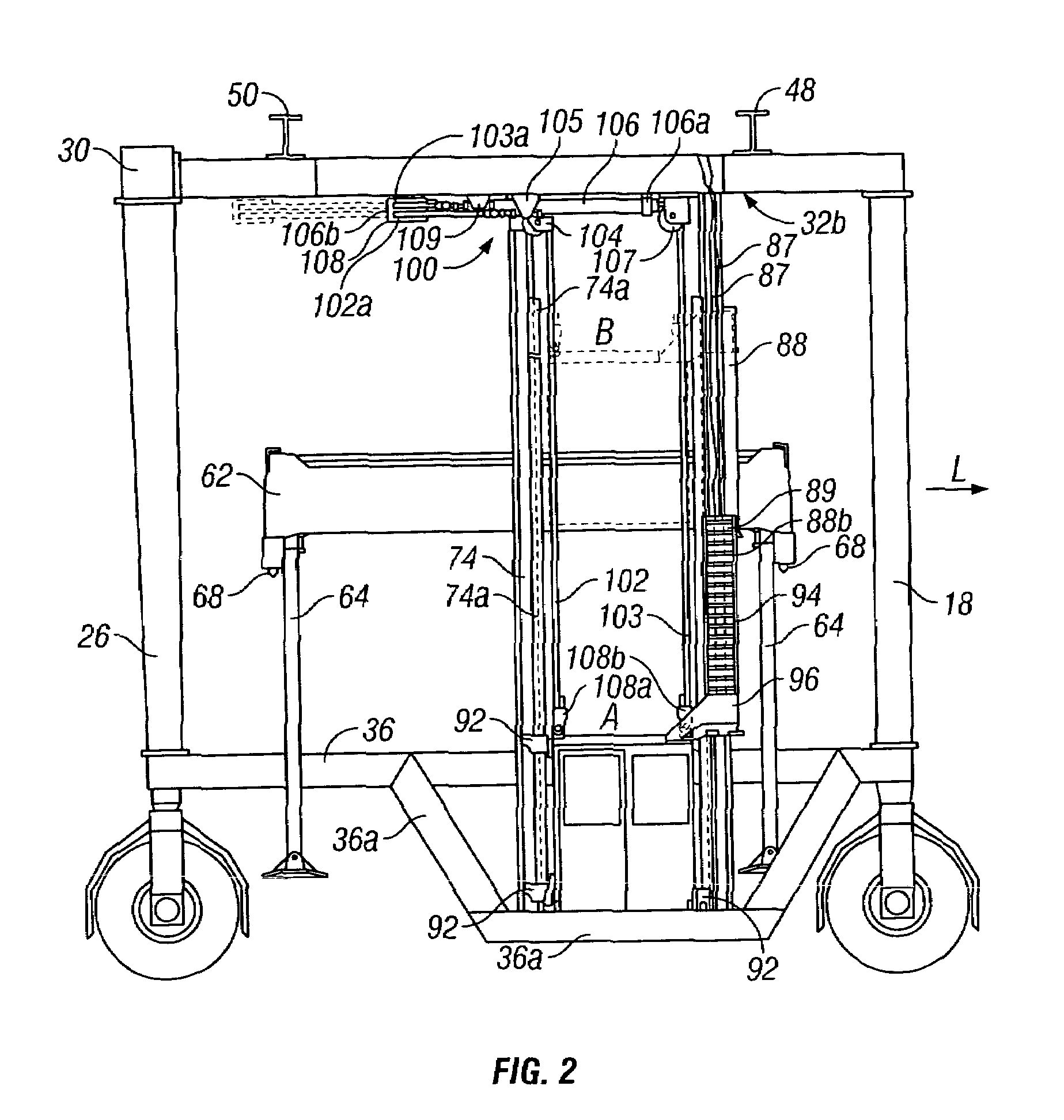

Grappler control system for a gantry crane

InactiveUS6968963B1Potential damageExtended reaction timeTrolley cranesThin material handlingVertical motionGantry crane

A system and process are provided for controlling motion of a grappler of a gantry crane to avoid damaging an object to be lifted. In an embodiment, a speed of grappler movement is automatically reduced when in close proximity to the object. Furthermore, the grappler automatically stops when positioned appropriately to permit a latching mechanism to engage the object for lifting. Normal speed grappler motion is restored when the latching mechanism is fully engaged. In a particular embodiment, the grappler includes a plurality of height sensors at various positions along the grappler to determine the respective height of the grappler above a top of the object. Vertical motion of front and rear ends of the grappler are independently actuated and controlled to permit appropriate control when the grappler and / or the object are not level.

Owner:MI JACK PRODS

Load-lifting apparatus and method of storing energy for the same

ActiveUS20080048497A1Improve fuel efficiencyLower noxious prime power emissionBatteries circuit arrangementsDc motor stoppersPower ArchitectureContainer crane

A load-lifting apparatus has one or more prime power sources, one or more energy storage systems and regenerative braking. Regenerative energy is recovered when the load-lifting apparatus lowers its load. The elements of the prime power sources, energy storage devices and electrical components may be distributed to provide stability for the load-lifting apparatus. The general power architecture and energy recovery method can be applied to cranes, rubber-tired gantry cranes, overhead cranes, mobile cranes, ship-to-shore cranes, container cranes, rail-mounted gantry cranes, straddle carrier cranes and elevators. In such an architecture, the energy storage system helps alleviate the power rating requirement of the prime power source with respect to the peak power requirement for lifting a load.

Owner:MI JACK CANADA

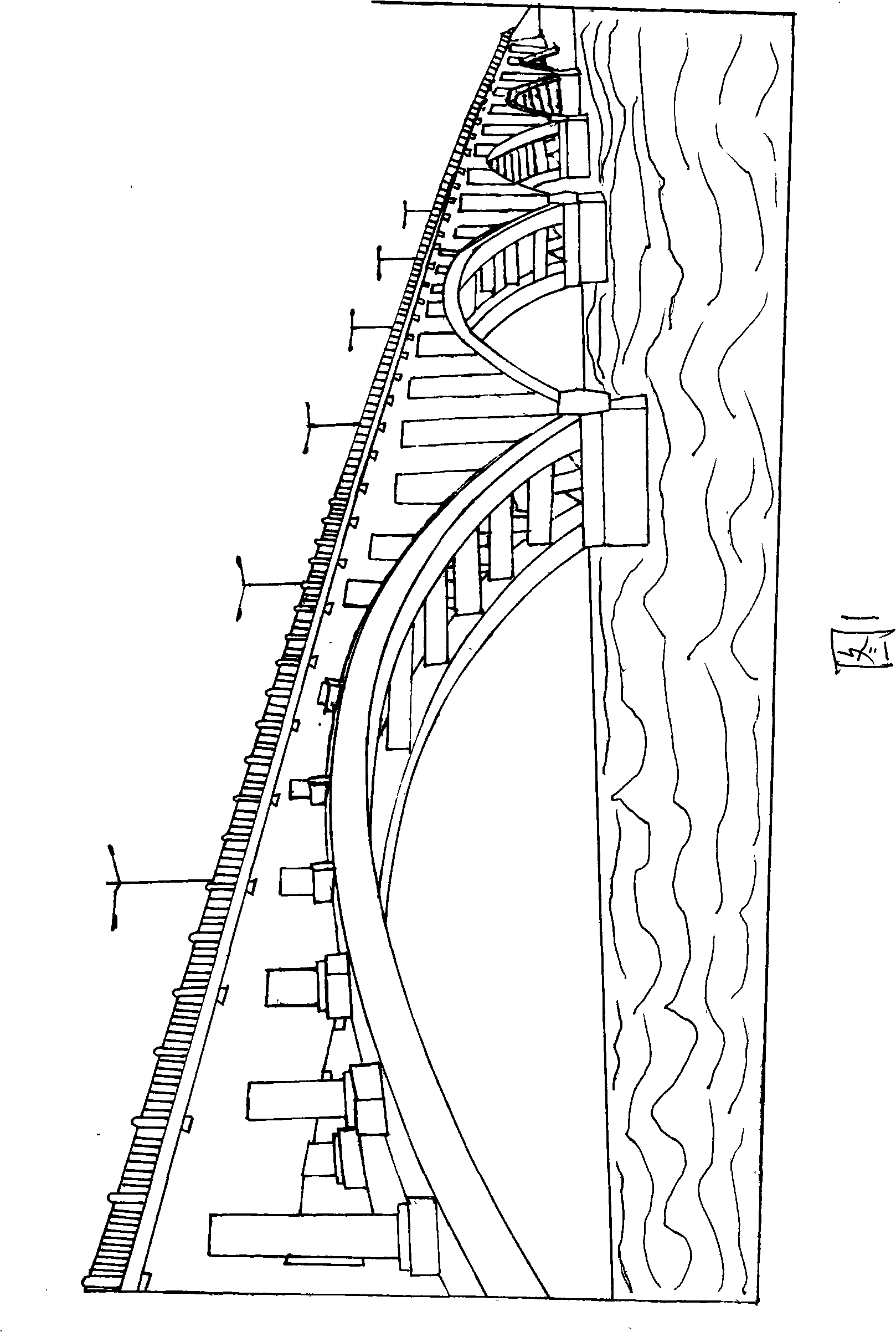

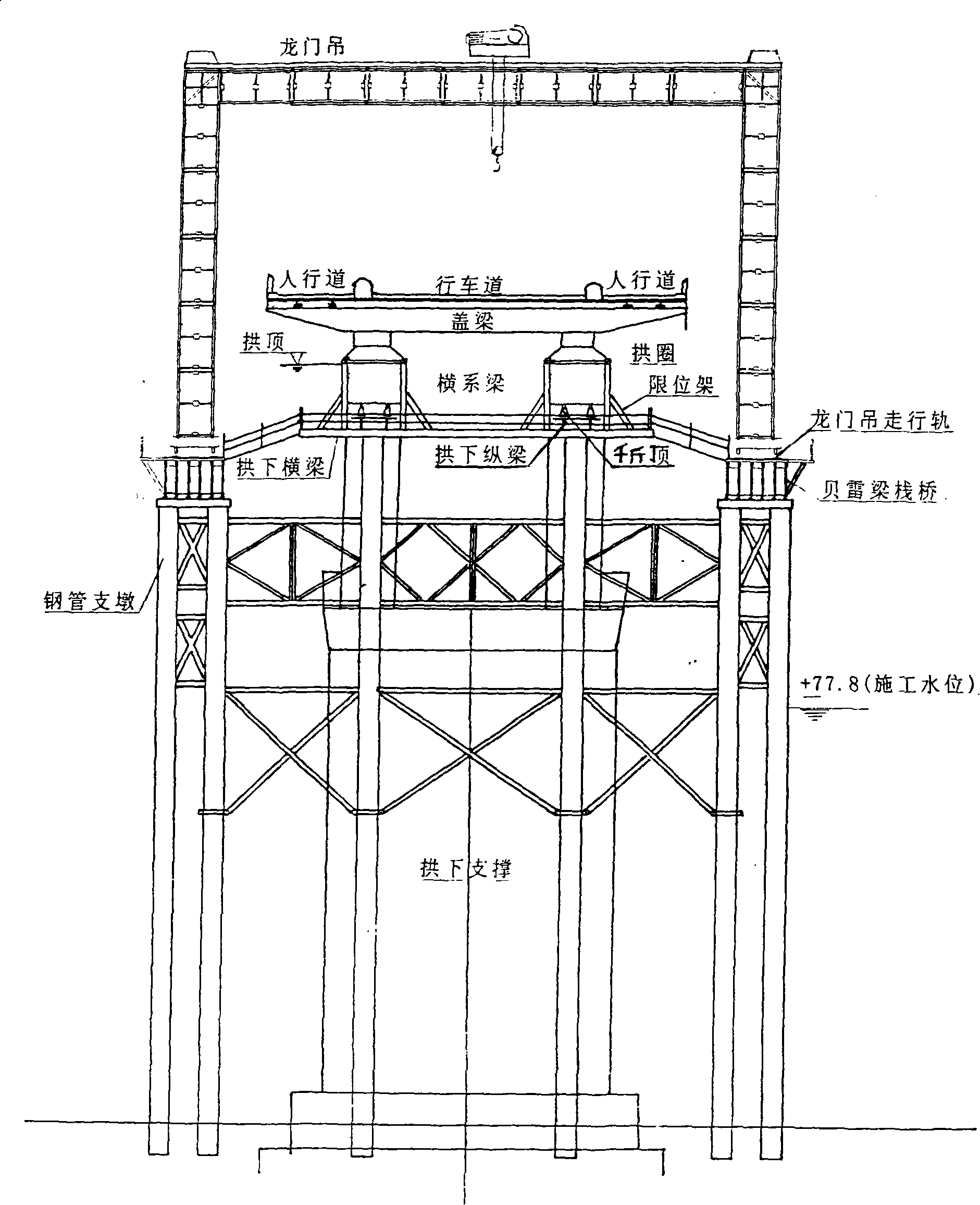

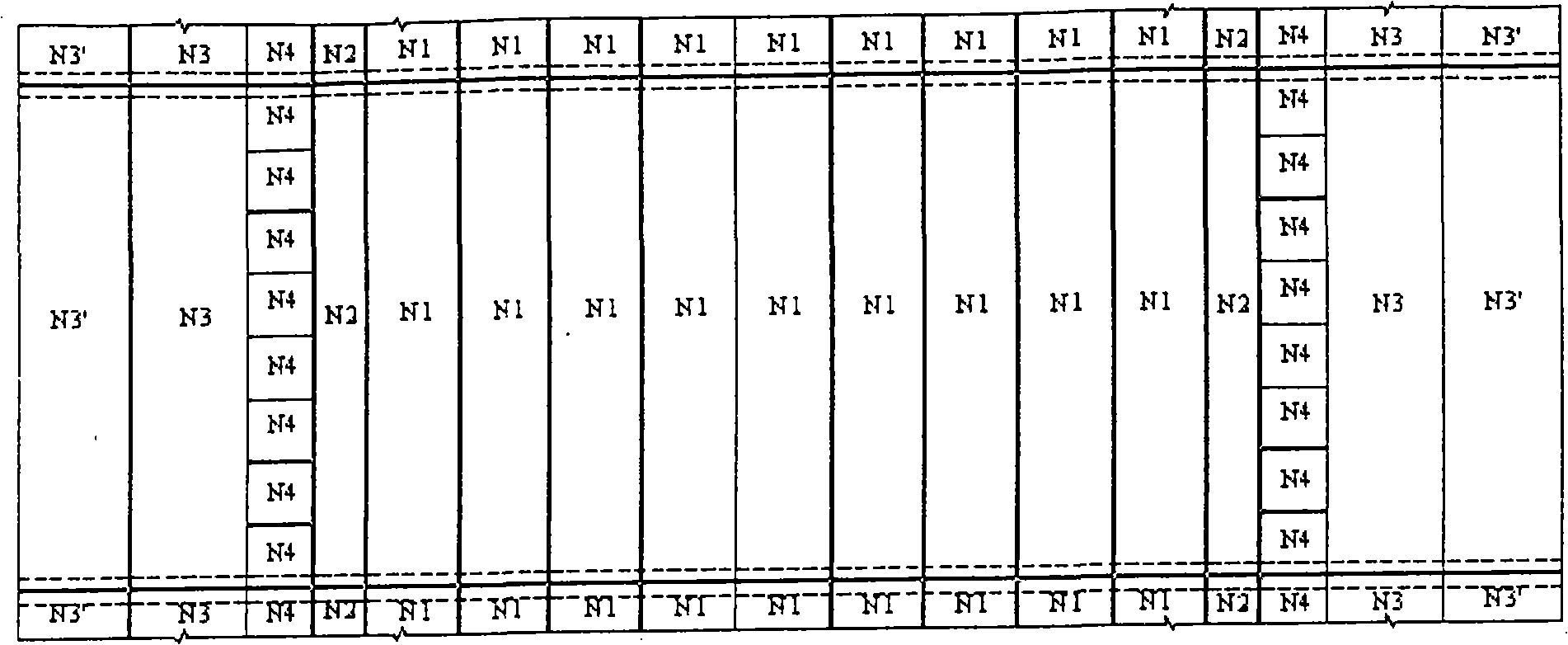

Method for dismantling arch bridge for protection

InactiveCN101265690AShort construction periodEnsure construction safetyBuilding repairsSocial benefitsReverse order

The invention provides a protective method for removing an arch bridge, which belongs to the technology field of bridge removal. The method aims to provide a protective bridge removal method with safety, high efficiency and no pollution. The technical points include: building up a new trestle, erecting a gantry crane, carrying out the bridge removal in a reverse order of the bridge building including bridge decking, coping, column, beam, arch rib and arch support in sequence. The removal stage of the arch rib especially includes removing by adopting methods of top-supporting under the arch, arch box transverse stop and horizontal restraining rope, which better solves the difficult problem of the protective bridge removal with safety, high efficiency and no pollution in a complex construction environment of guaranteeing under-arch navigation, high security level, short construction period and various unpredictable elements, manages to meet the design requirements of the removal safety factor in the protective bridge removal process and the limit control under various removal working conditions and guarantees the removal quality and the construction safety. The removal method has low cost and remarkable social benefit reflected in the direct economic analysis, which is a protective removal method of large-span bridges with safety, high efficiency and practicability.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

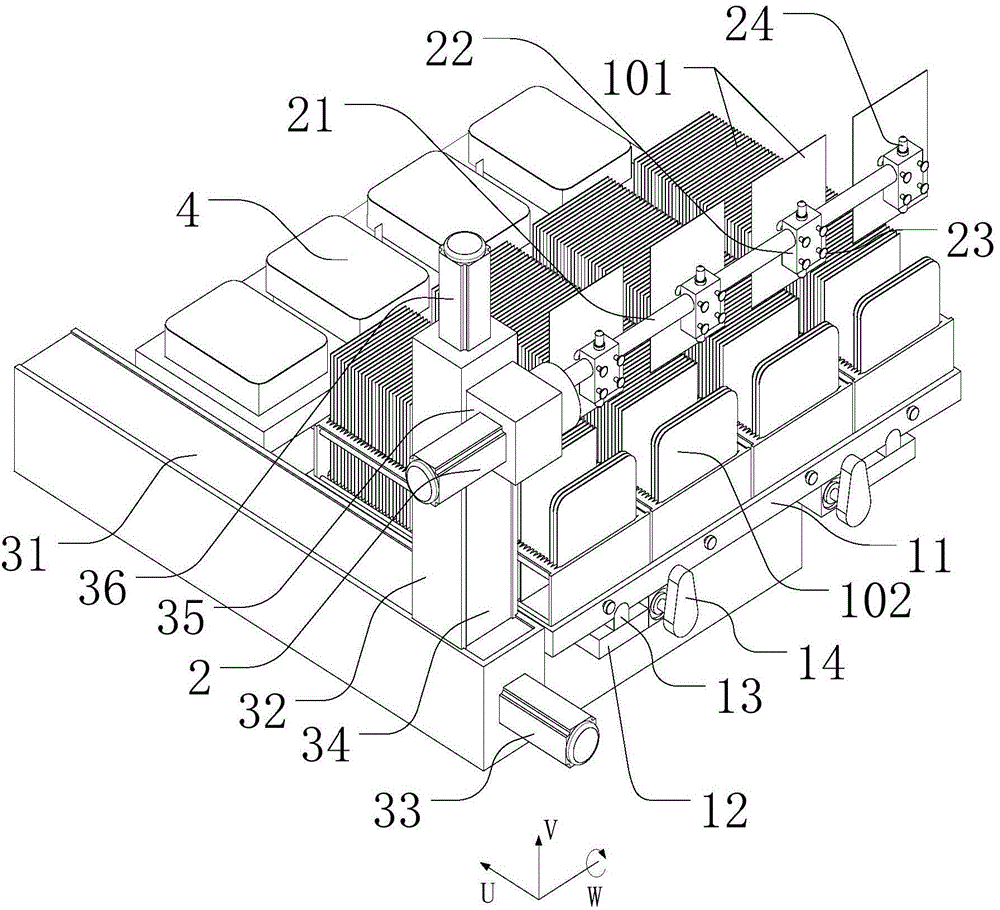

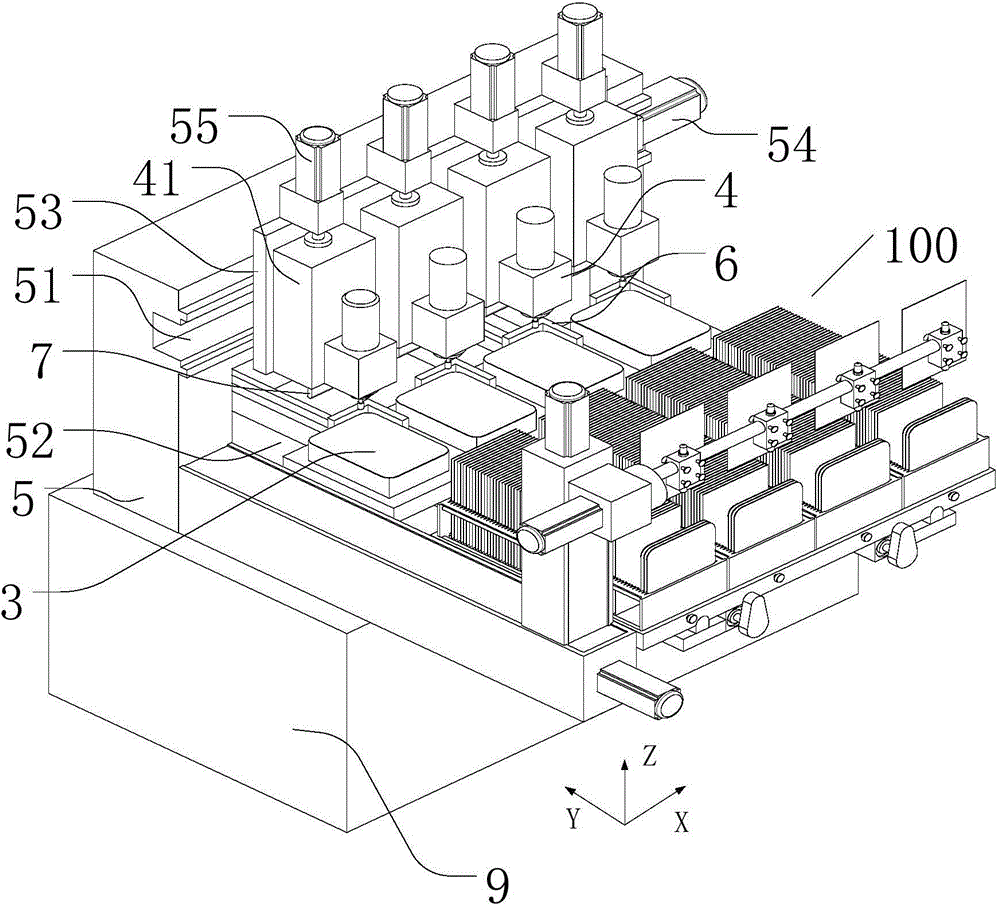

Sheet material feeding and discharging device, mobile phone glass machining center and machining method

ActiveCN104890422AFlexible loading and unloading methodsImprove the efficiency of picking and unloadingGrinding feedersOther artistic work equipmentsEngineeringMachine tool

The invention discloses a sheet material feeding and discharging device, a mobile phone glass machining center and a machining method. The device comprises a material groove, a rotating mechanism provided with a rotating rod, a first drive mechanism and rotating blocks installed on the rotating rod; and taking and placing parts are respectively installed on the front and rear sides of each rotating block, the rotating mechanism is installed on the first drive mechanism, and the rotating blocks are located over the material groove. Two faces of the rotating blocks are provided with the taking and placing parts, the rotating mechanism can drive the rotating blocks to perform 360-degree rotation, a feeding and discharging mode is more flexible, and taking and placing efficiency is greatly improved. After the sheet material feeding and discharging device is applied to the mobile phone glass machining center, a mode that the rotating blocks are fixed to the rotating rod is adopted, and the rotating rod extends to the other side to form a gantry crane type structure, so the rotating blocks can be unlimitedly expanded on the rotating rod, a machining table and the material groove can be correspondingly increased, a plurality of working positions can be increased on one machine tool to the maximum extent, and machining efficiency is greatly improved.

Owner:苏州恒远精密数控设备有限公司

Dynamic Protective Envelope for Crane Suspended Loads

ActiveUS20110076130A1Avoid collisionAnalogue computers for trafficLifting devicesTransceiverMotor control

A system and method for using a gantry crane to efficiently and safely transport loads such as containers and ship hatch covers from one location to another along a known path while avoiding collisions between the loads and obstructing objects which may be situated in the known path. A transceiver emitting laser beams may be used to establish both the position of the spreader and its load and the profile of the known path. Continuous comparisons are made by computer between the location of a dynamic digital protective envelope constructed around the crane spreader and its load, if any, and a digital representation of the profile of the known path to be traveled by the spreader and its load, if any. In the event, the comparison indicates intersection of the protective envelope and the path profile, a speed limit is imposed on the motor controlling the movement in the X axis of the trolley or in the Z axis of the spreader, as required to prevent a collision.

Owner:TMEIC

Powered auxiliary hoist mechanism for a gantry crane

ActiveUS7546929B2Reduce hoist capacityProtection overloadTrolley cranesTrolleysLifting capacityEngineering

Owner:MARINE TRAVEELEVATOR

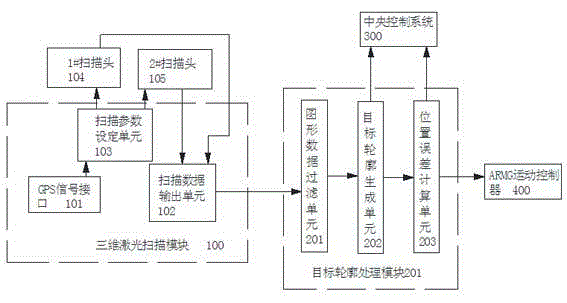

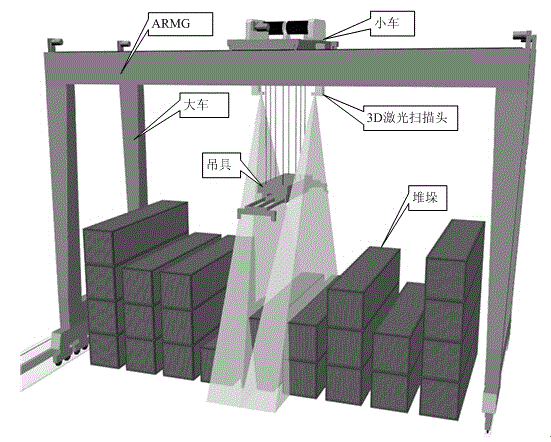

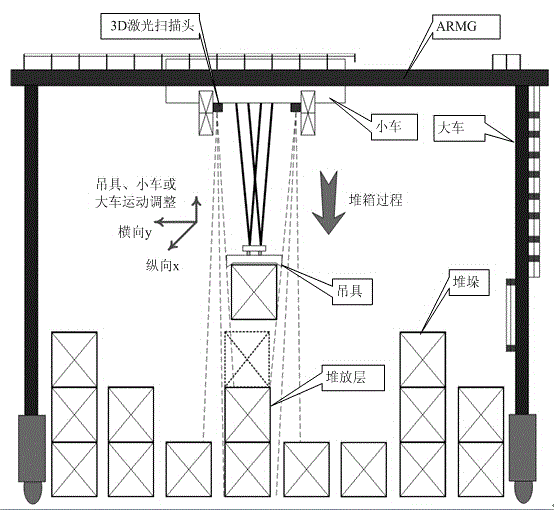

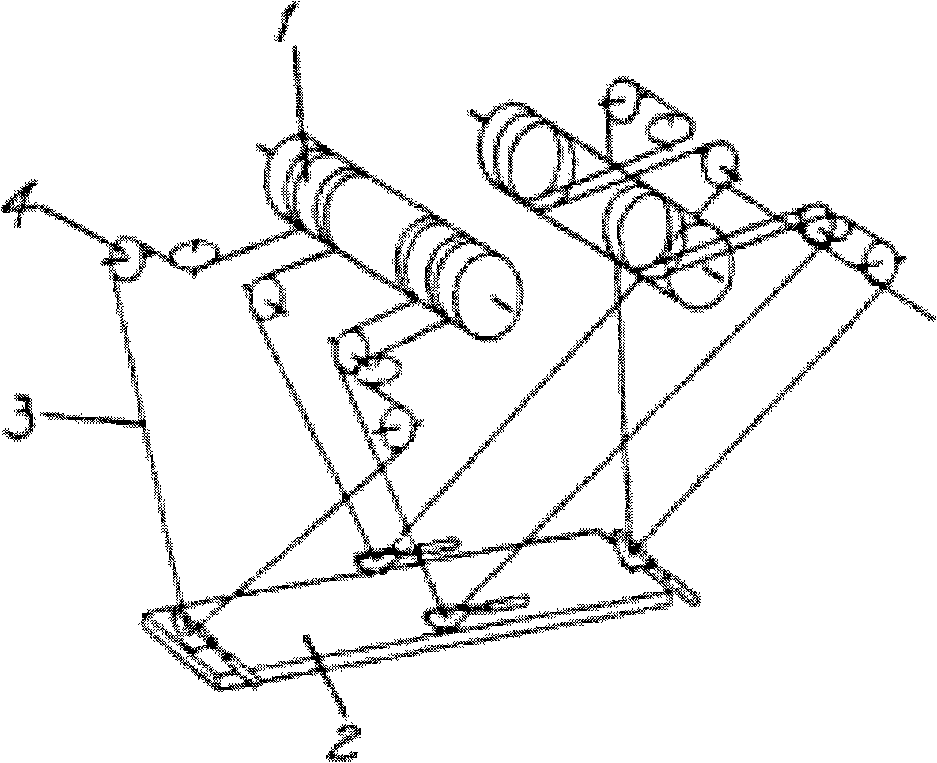

Intelligent detection system and method for distribution profile and position of container

ActiveCN104085794AImprove efficiencyReduce collision accidentsUsing optical meansLoad-engaging elementsLocation detectionThree-dimensional space

The invention discloses an intelligent detection system for a distribution profile and a position of a container. The intelligent detection system comprises a central control system, a three-dimensional laser scanning module, a target profile processing module and an ARMG (Automated Rail Mounted Gantry Crane) movement controller. Meanwhile, the invention discloses a method for detecting the distribution profile and the position of the container by using the intelligent detection system. The method is high in detection speed and high in detection precision by adopting three-dimensional space laser scanning, and overcomes the basic defect of conventional laser single-point scanning or line scanning. A generated container locating position error signal is output to the ARMG movement controller to automatically control movement mechanisms such as a lifting appliance, a trolley and a cart of an ARMG, and thus the accurate control on stacking and grabbing the container by the ARMG is realized; the generated container locating position error signal can be also output to a central monitoring system of an intelligent wharf for remotely monitoring the process of loading or unloading the container by the ARMG. According to the intelligent detection system and method, the accurate container alignment and the container collision in the process of loading or unloading the container are realized, the efficiency of loading or unloading the container is improved, and the accident of collision caused during the loading or the unloading of the container is reduced.

Owner:SHANGHAI MARITIME UNIVERSITY

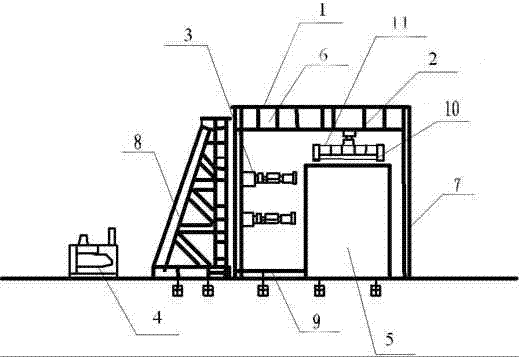

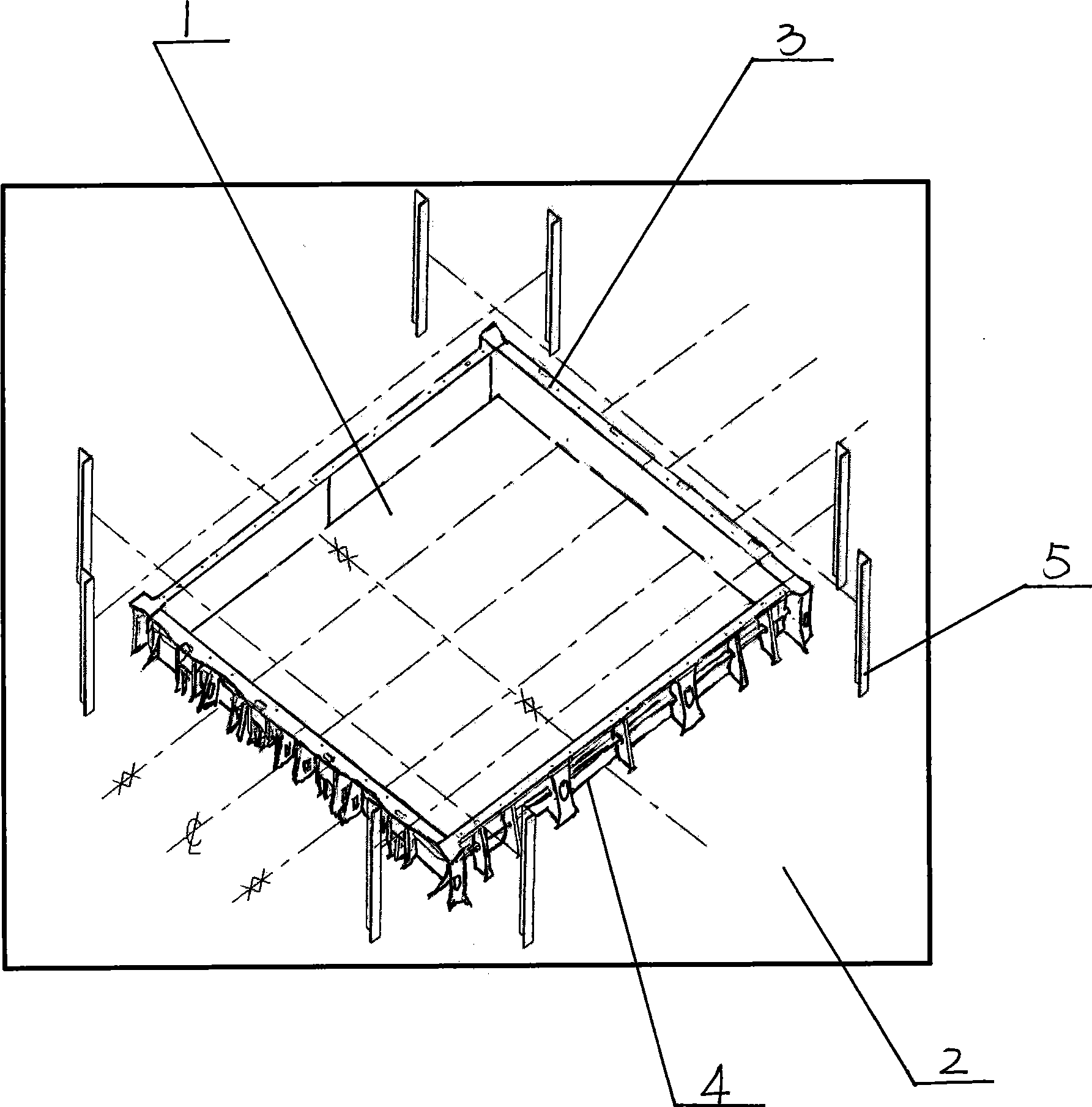

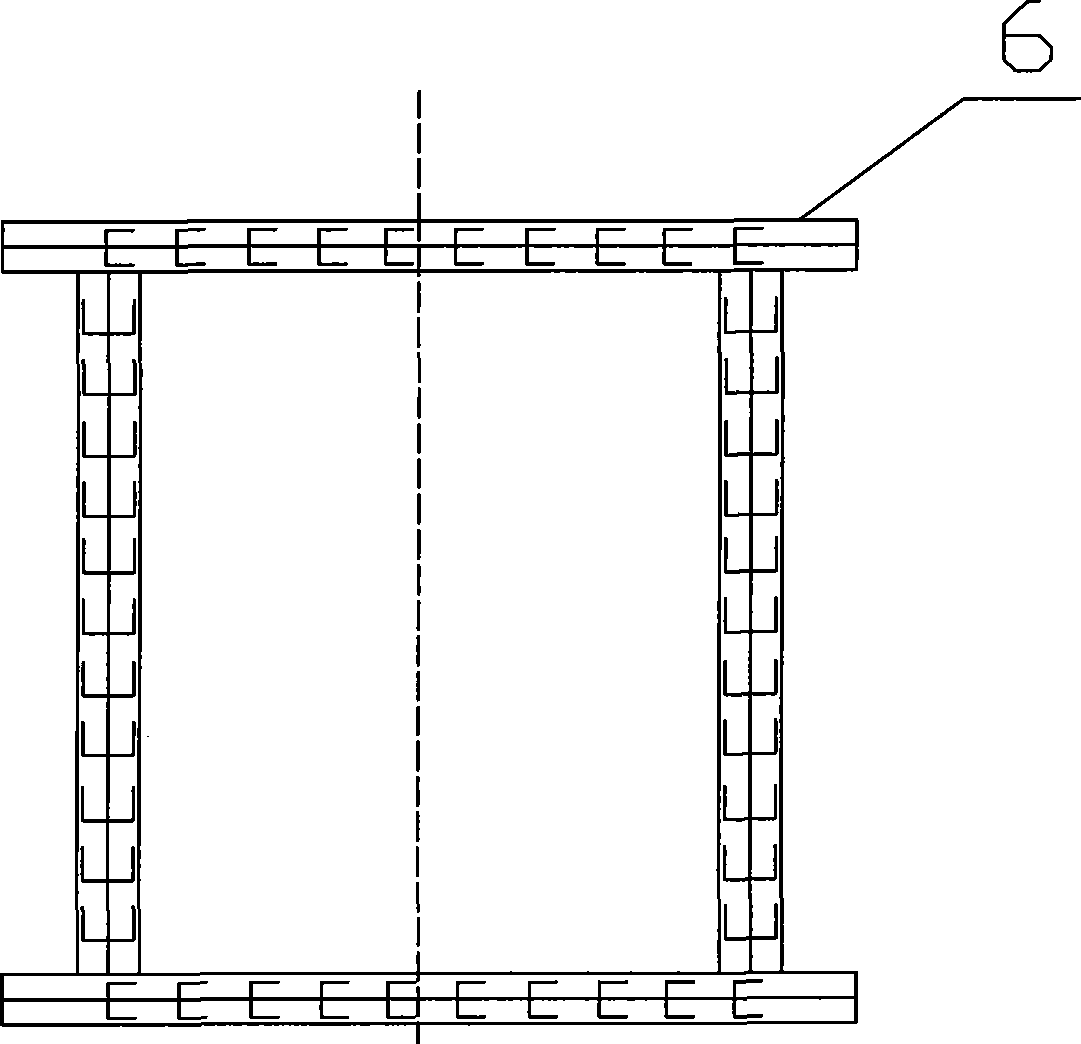

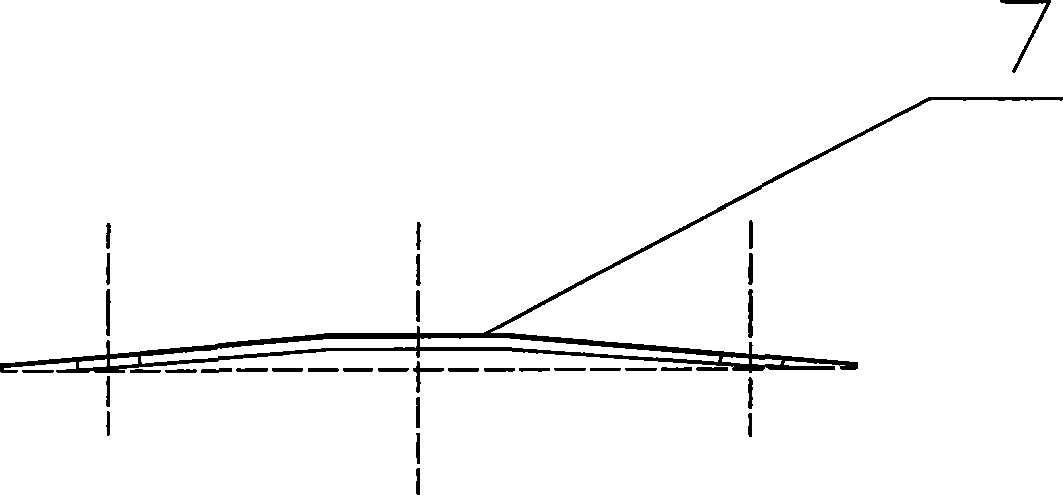

Dynamic and static testing system and method for multifunctional wharf structure

InactiveCN102928293AEasy to assembleStable structureMachine part testingMaterial strength using tensile/compressive forcesActuatorShip load

The invention discloses a dynamic and static testing system for a multifunctional wharf structure. The dynamic and static testing system comprises a detachable large-rigidity bearing frame, a vertical loading actuator, a horizontal loading actuator, a multi-channel controller, an electro-hydraulic servo oil source system, a data collecting system as well as a displacement and force sensor. The maximum clearance size of the loading frame is 4.5m* 4.5m*4.5m (L*W*H); a testing space can be randomly adjusted according to test sample requirements; a loading mode is that vertical and horizontal combined loading can be finished through two 10-100 t static vertical actuators and 3-20t dynamic horizontal actuators; integral or member stress performance tests of the high pile frame wharf structure with large water level difference under a combined effect of various complicated working conditions such as gantry crane load, piling load and ship load are simulated. The invention further provides a dynamic and static testing method for the wharf structure, which can be used for really simulating the stressed deformation performances of the wharf structure under various complicated stressed conditions and can be also used in stress experiments of similar structures.

Owner:CHONGQING JIAOTONG UNIVERSITY

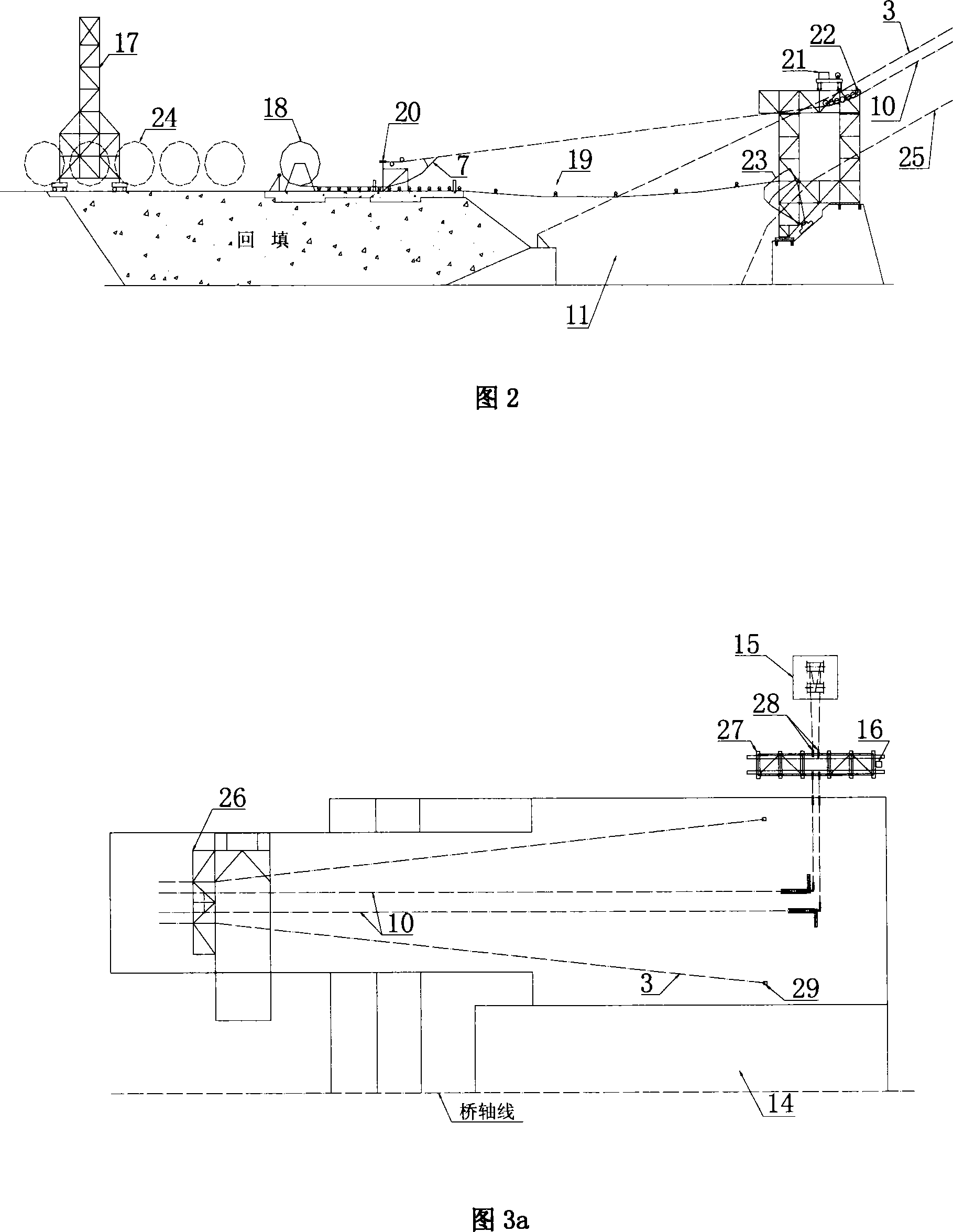

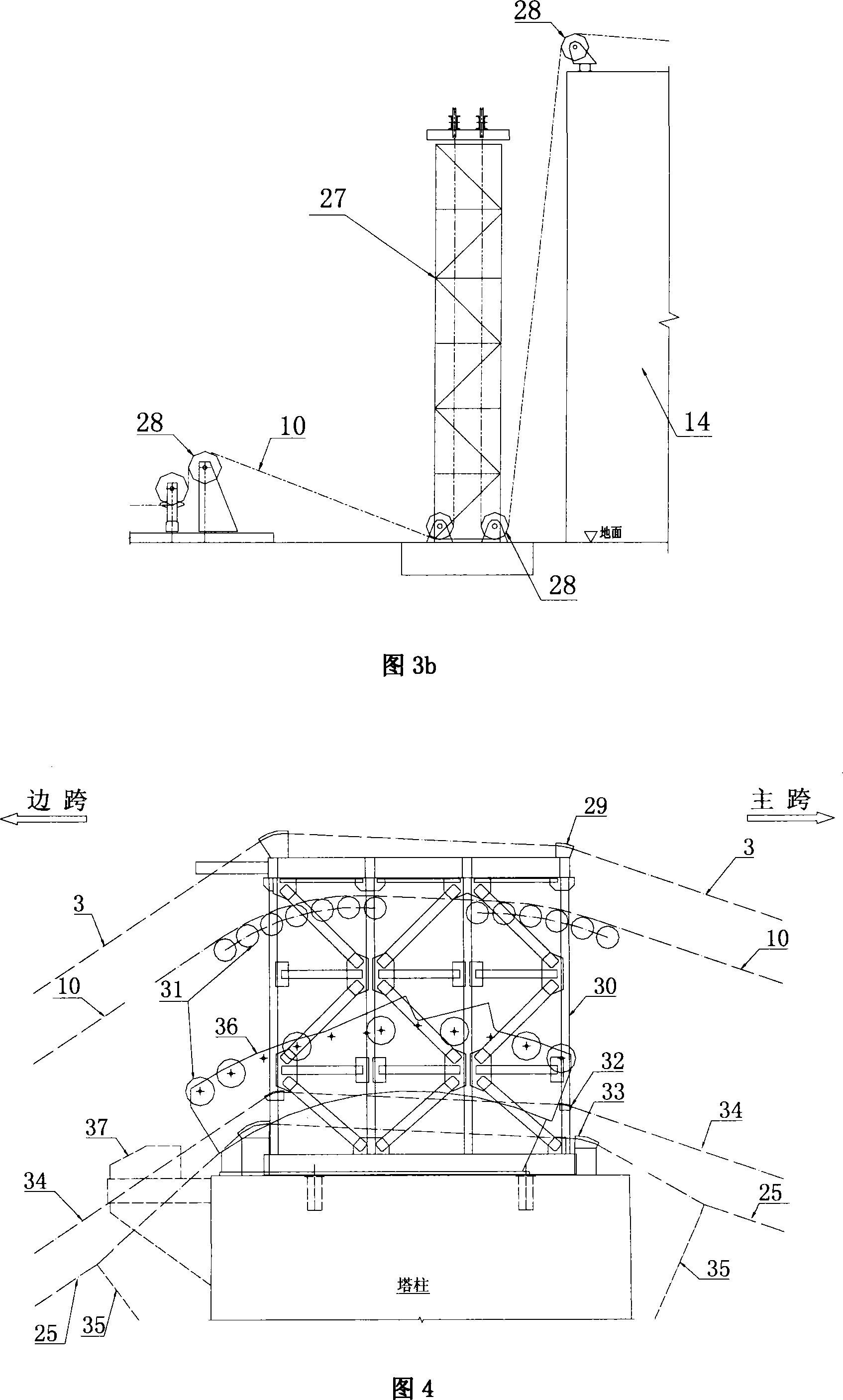

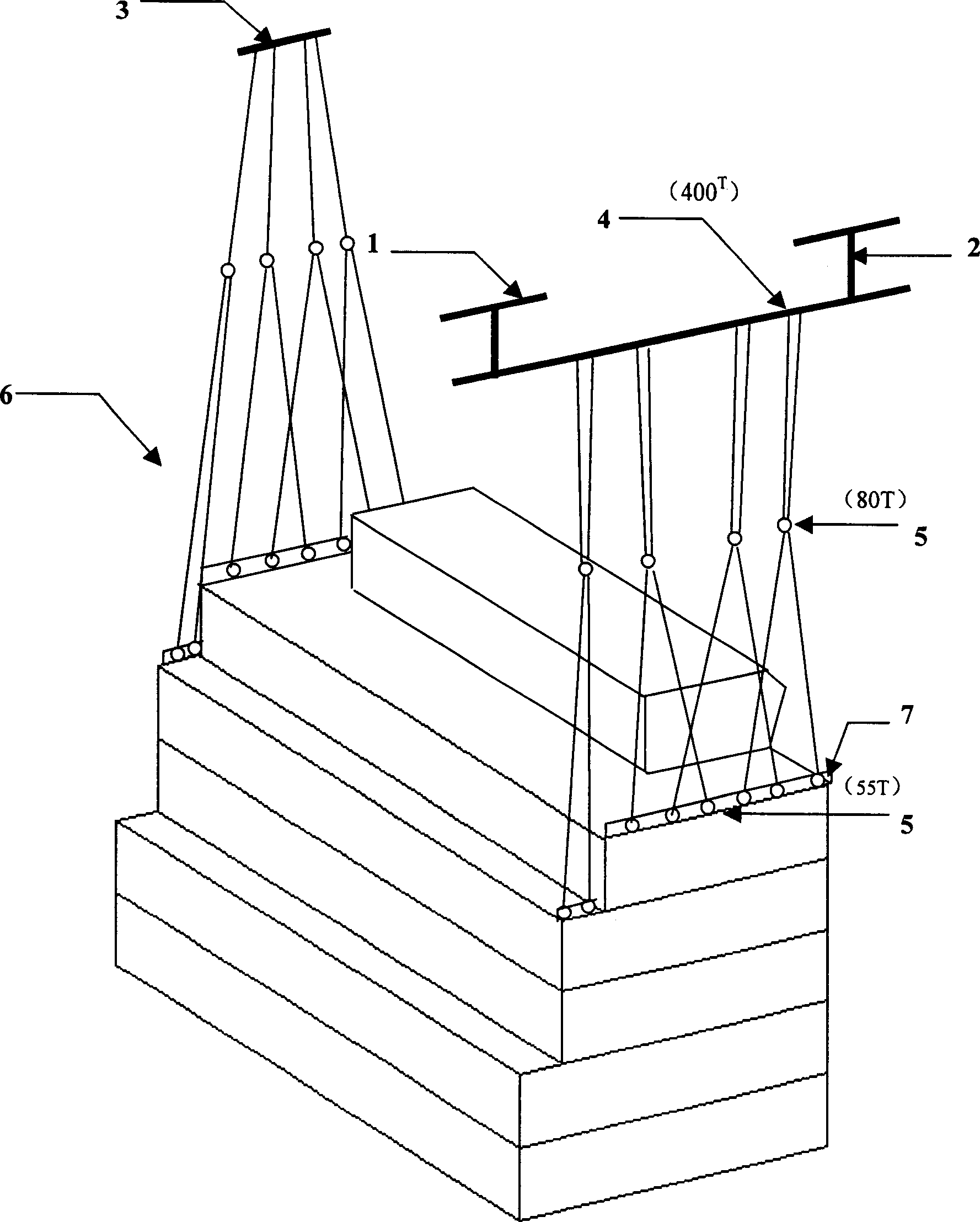

Erection of gantry type small-cycle traction system on large-span suspension bridge main cable

ActiveCN101177931AStable tractionImprove erection qualityBridge erection/assemblyTraction systemTraveling block

The utility model relates to a gantry type small circulation traction system for a main cable erection of a large-span suspension bridge, which belongs to the technical field of bridge superstructure construction. Set up a cable storage area behind the A anchorage, and install a 60-ton gantry crane and a cable-laying bracket; set up a traction cable revolving wheel behind this anchorage; set up a 25-ton main traction hoist and a balance weight bracket on the side of the B anchorage. The traction cable is connected by a puller at Anchor Anchor, bypasses the hoist drum at B Anchor Anchor, and is inserted through the balance weight bracket and each steering block to form a ring-shaped endless cable. Make a horizontal circular motion to form an independent small circular traction system. The small circulation system has the advantages of high power, large traction force, high construction efficiency and low cost.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

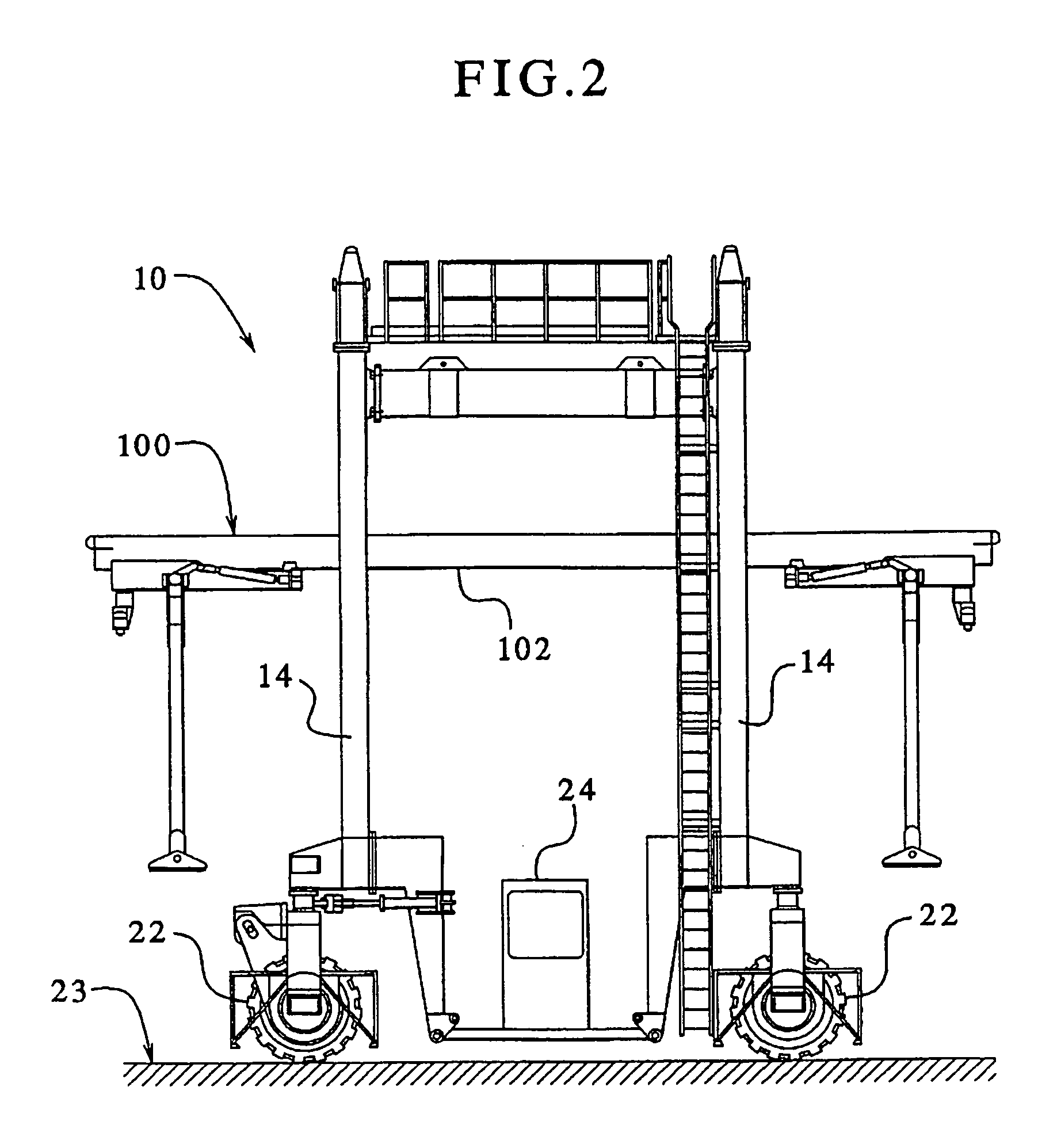

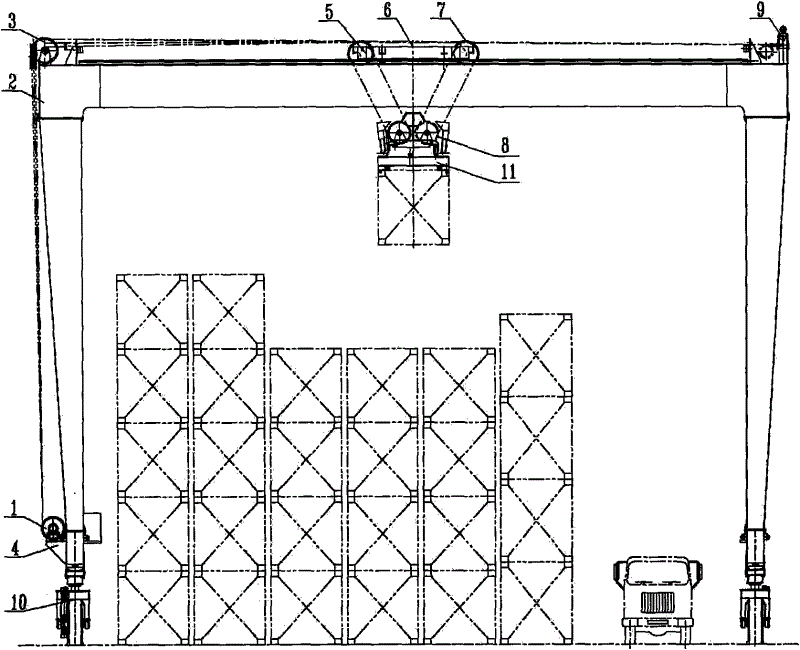

Gantry crane with elevating operator cab

InactiveUS7070060B1Avoid vertical movementReduce stepsTrolley cranesTrolleysHydraulic cylinderMechanical engineering

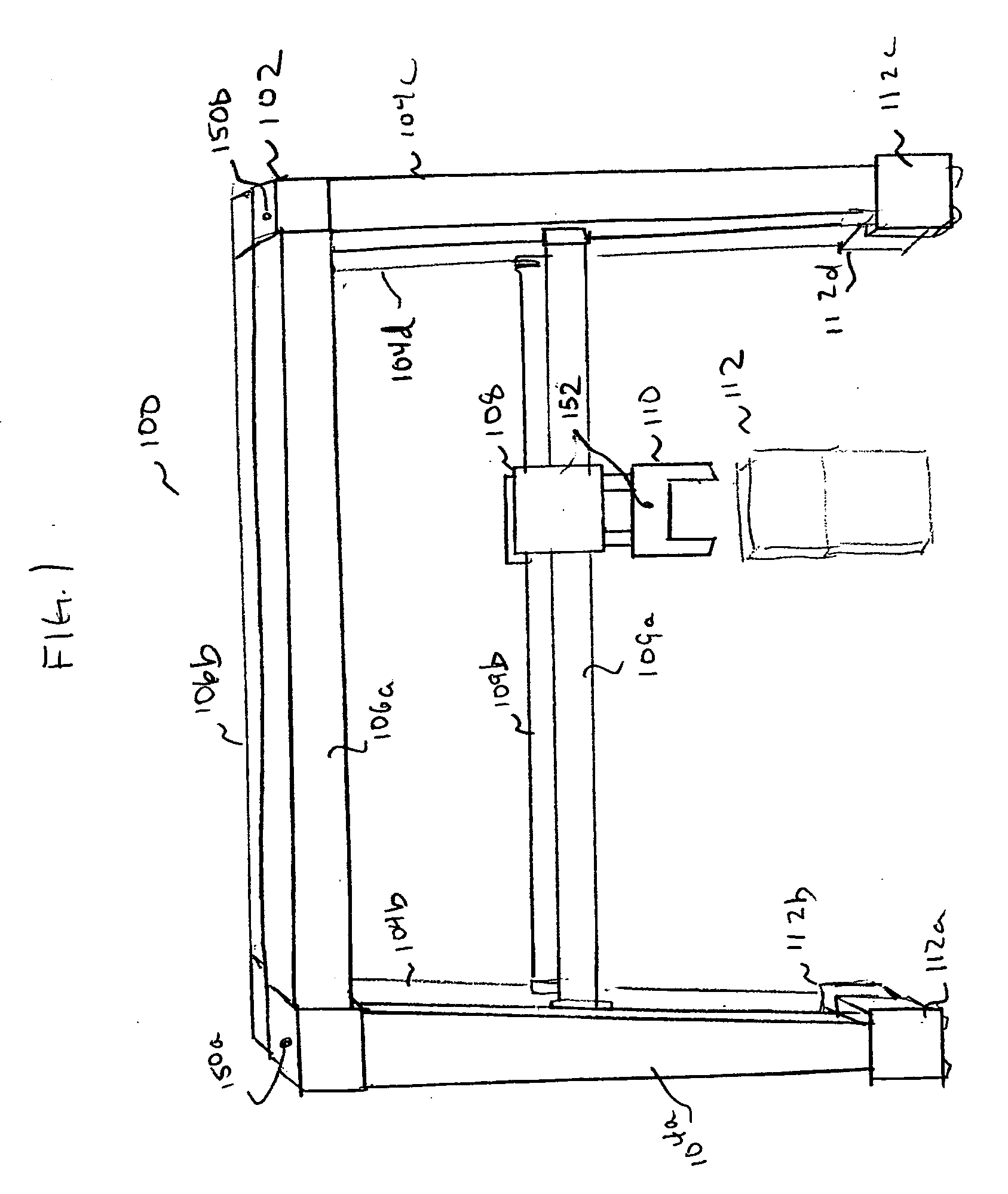

A gantry crane has first and second side support frames spaced by a pair of trolley beams. A load lifting mechanism is connected to the trolley beams and includes a lift frame for engaging a load to be lifted. An operator cab is mounted on the first side support frame and is vertically moveable between a lowermost position and an uppermost position in an operational plane defined by the first side support frame. A cab lift cable has a length and a first end fixed to the operator cab and a second end fixed to the side support frame. A hydraulic cylinder urges the cable between its fixed first and second ends in a direction transverse to a portion of its length. In another embodiment of the invention, an operator cab is adapted to be horizontally moveable. The elevating operator cab of the present invention can be configured to move horizontally. The elevating operator cab is lifted by a carriage beam vertically moveable along vertical legs of the first side support frame. The operator cab is moveable horizontally along the carriage beam.

Owner:MI JACK PRODS

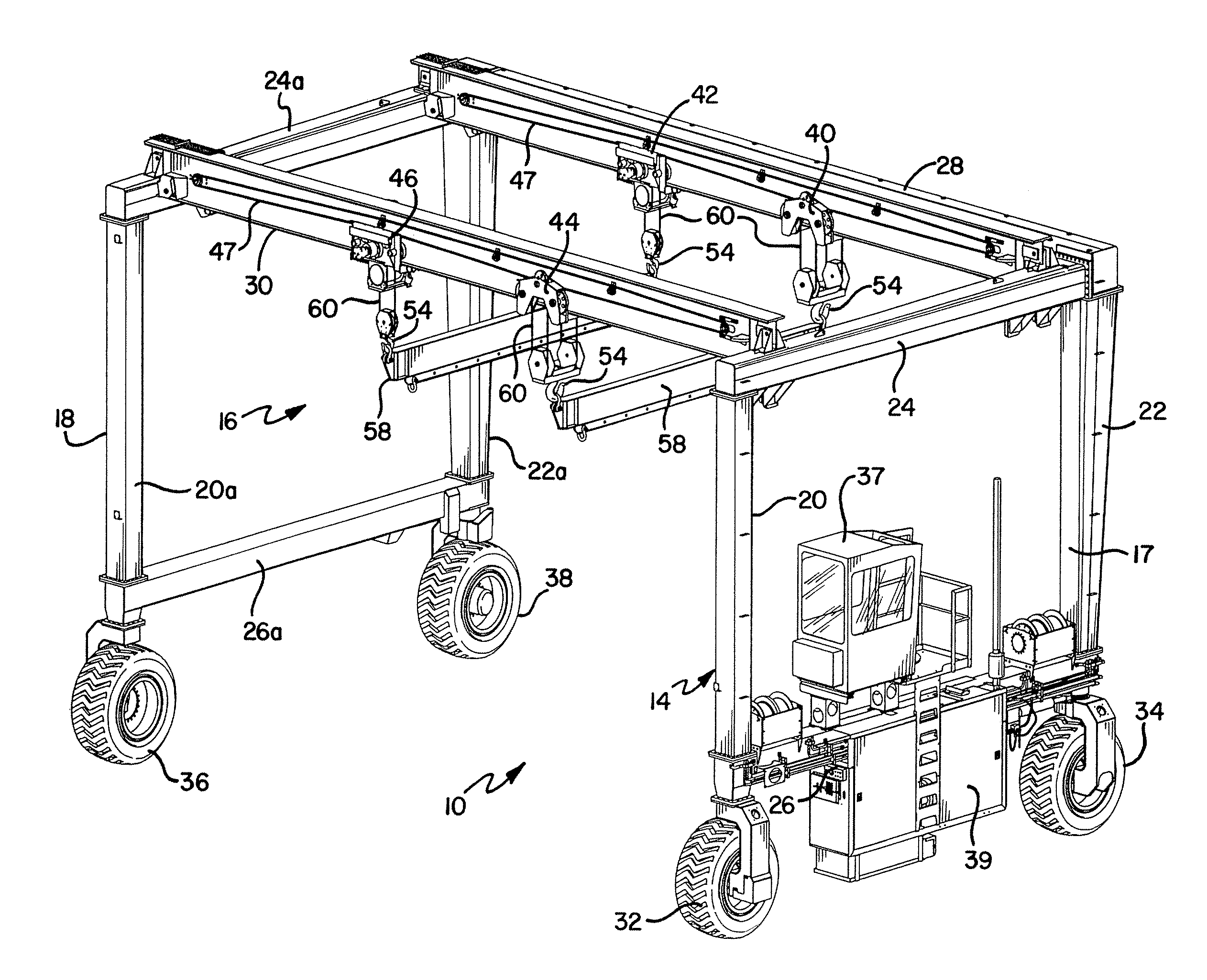

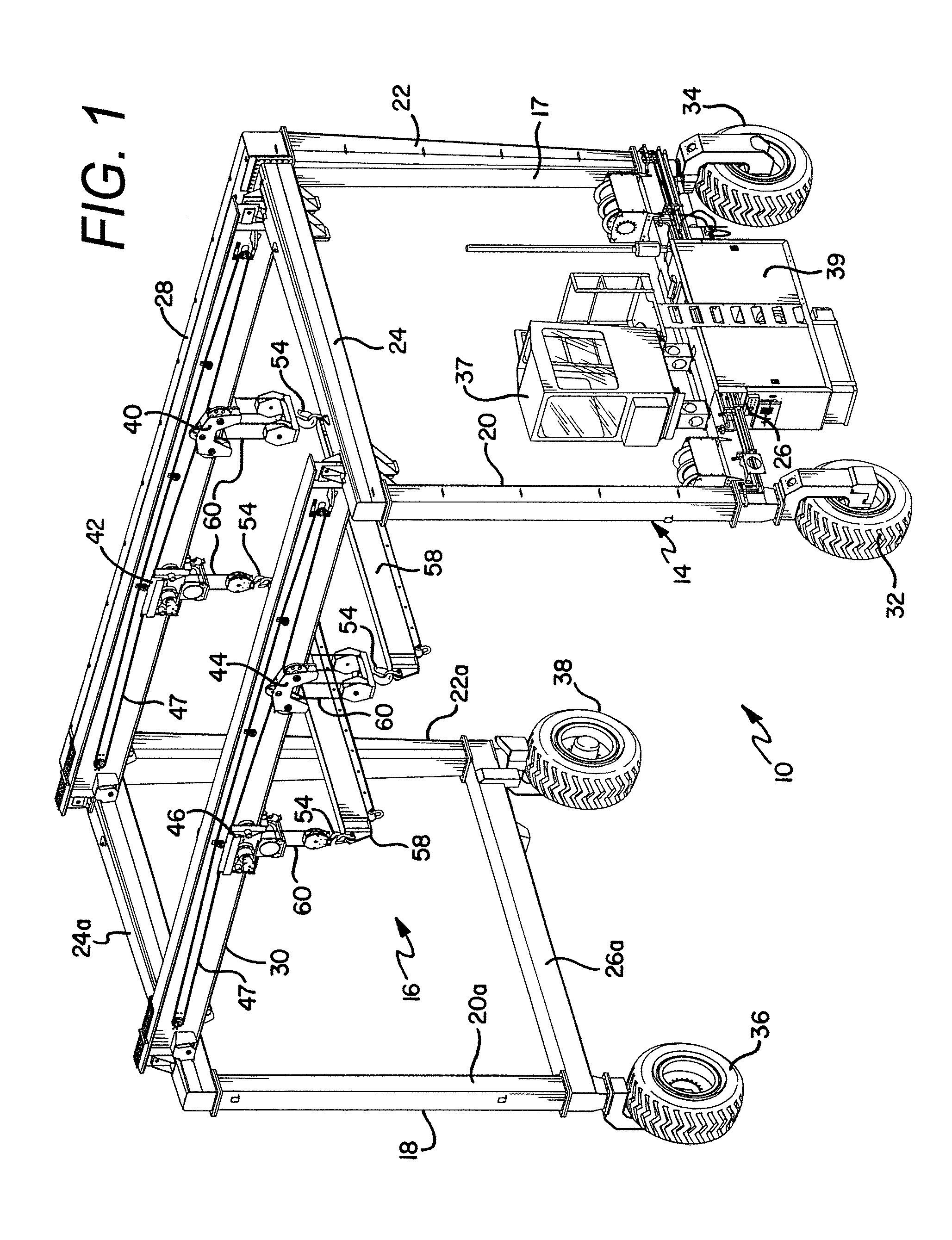

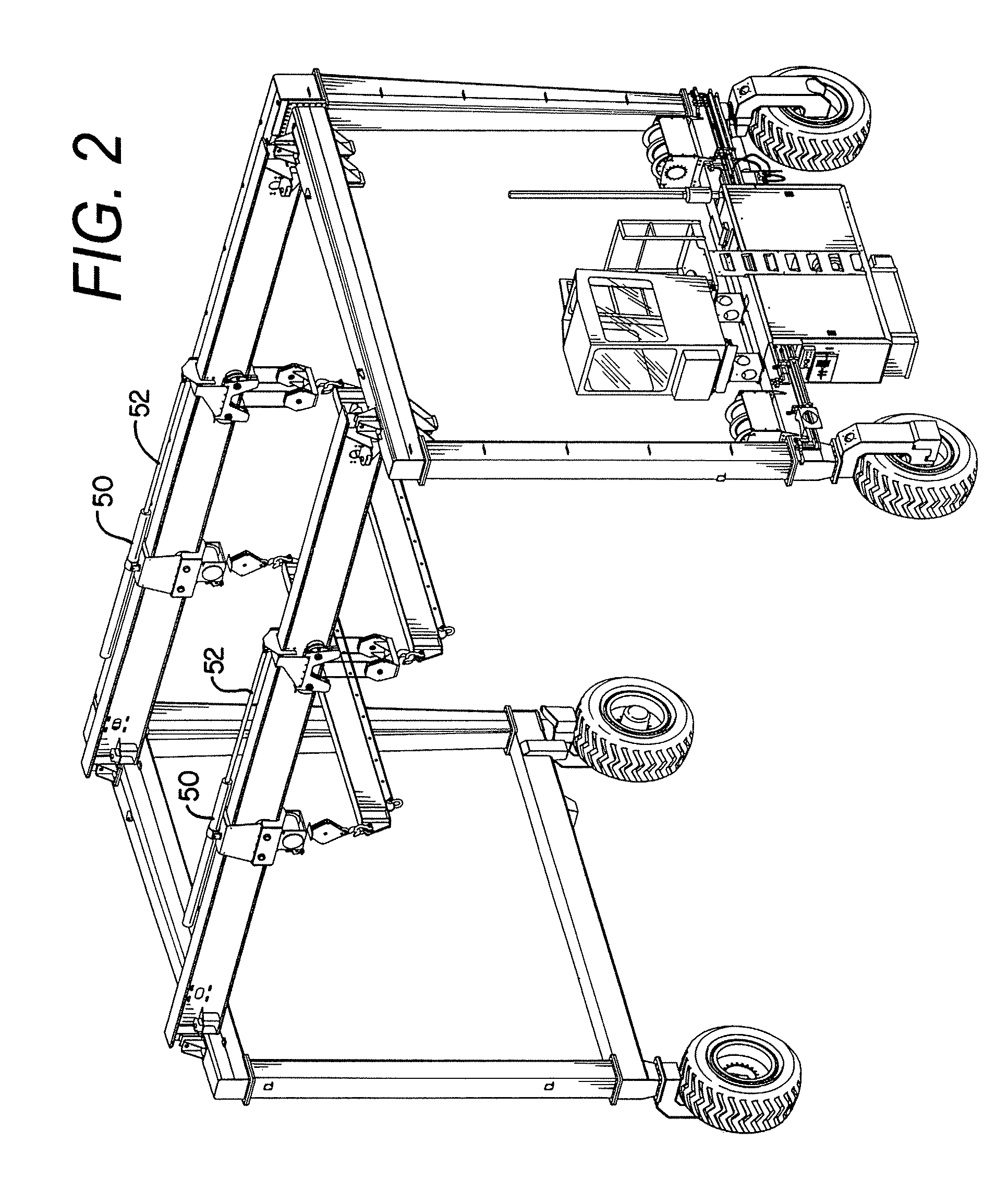

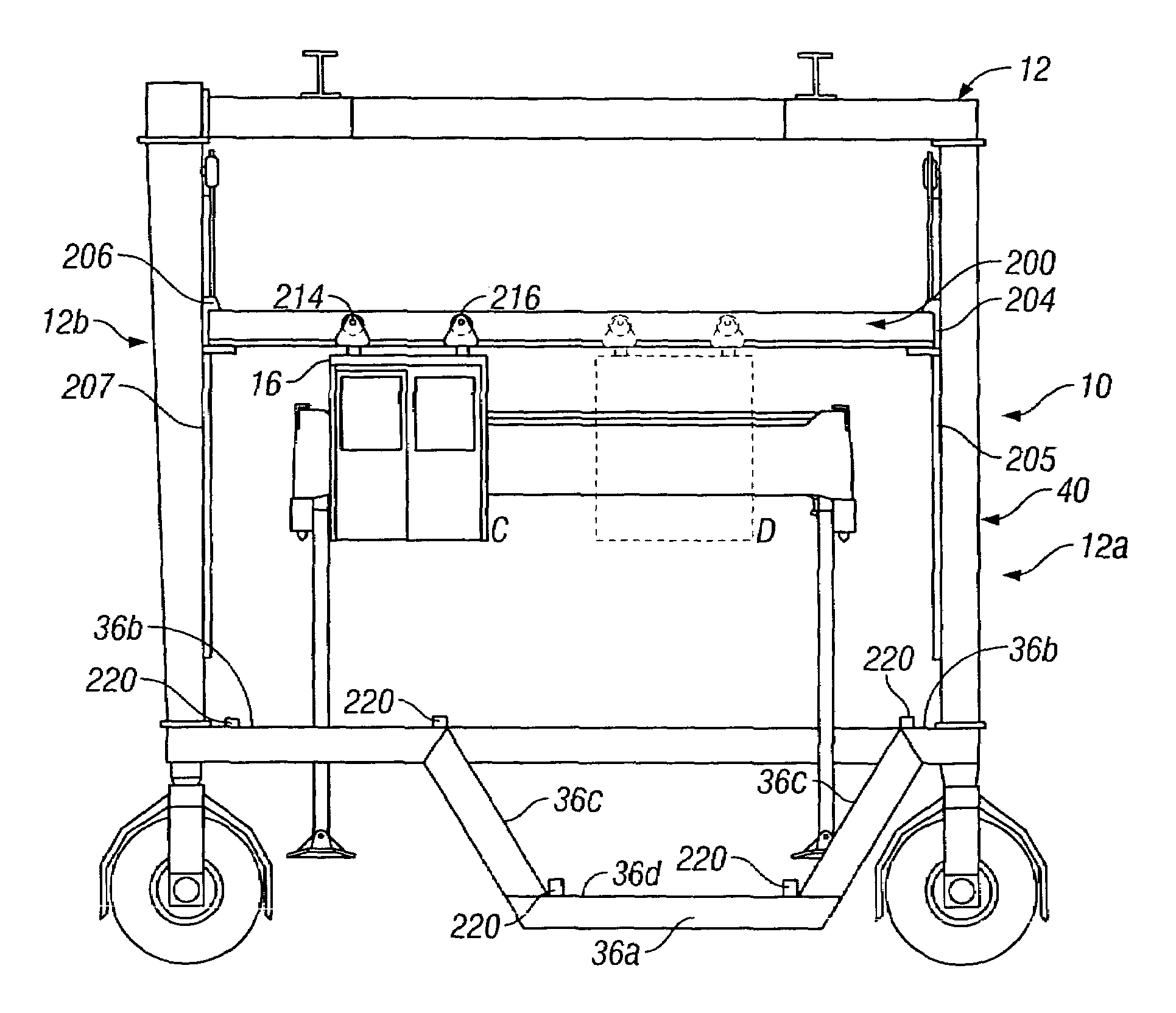

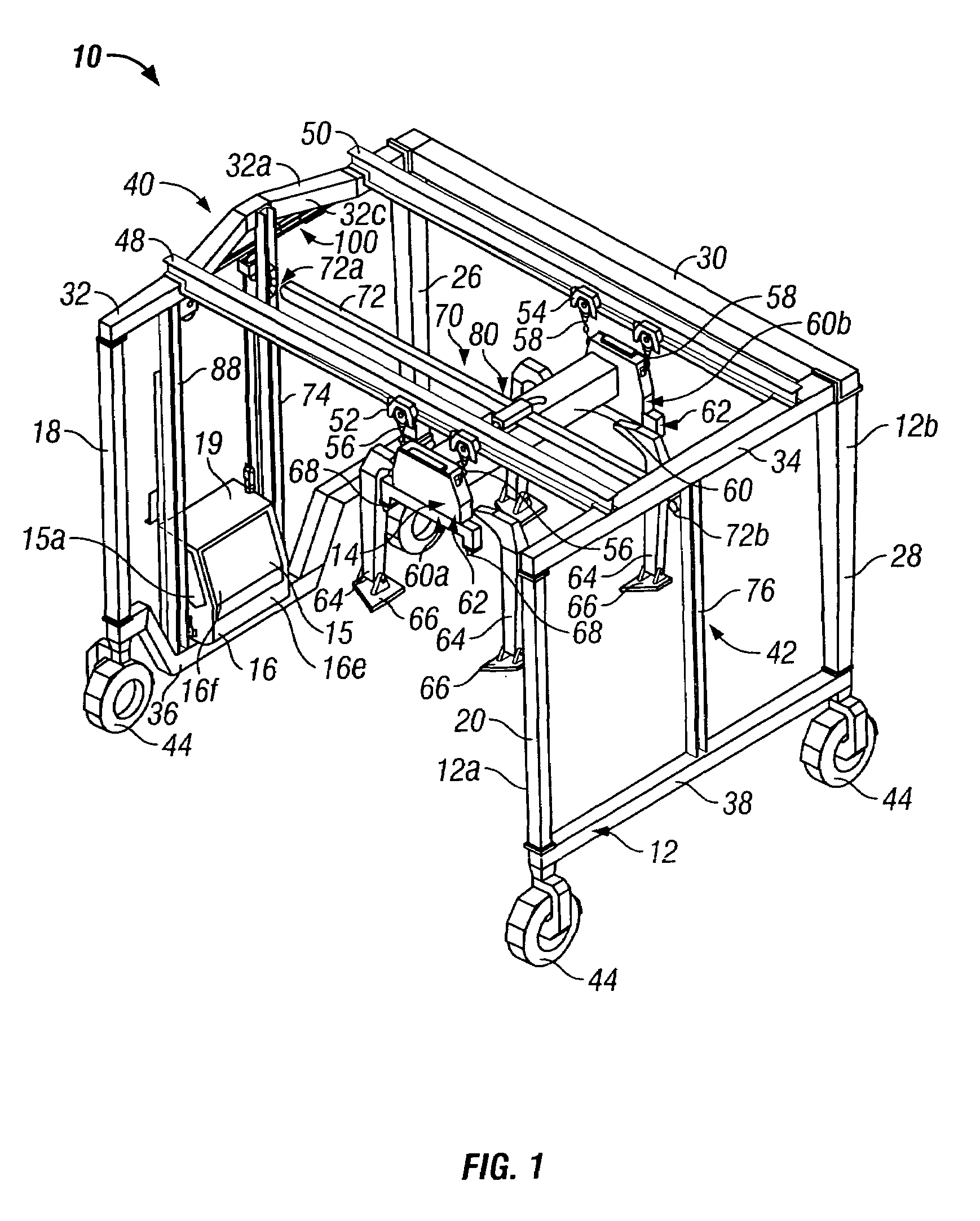

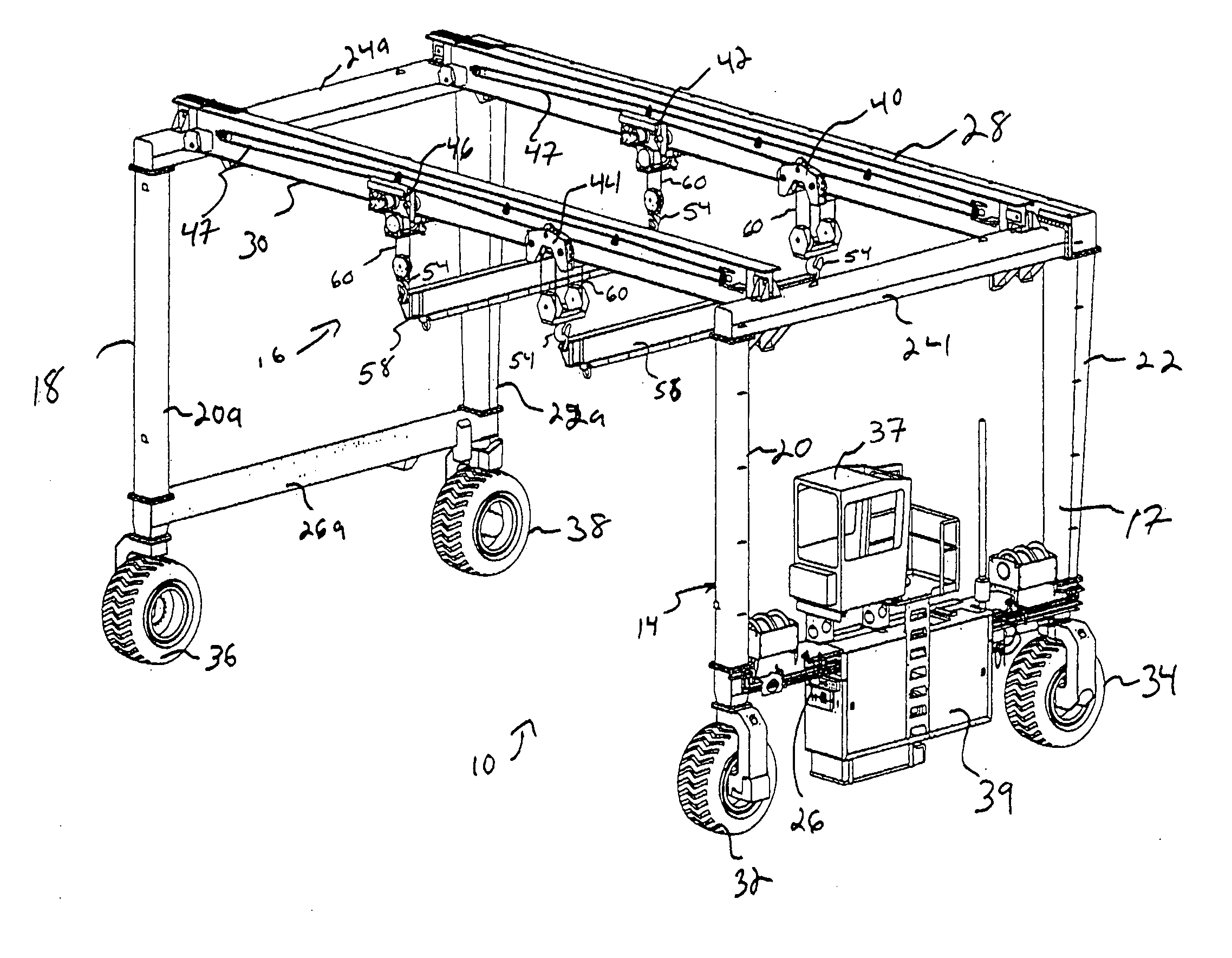

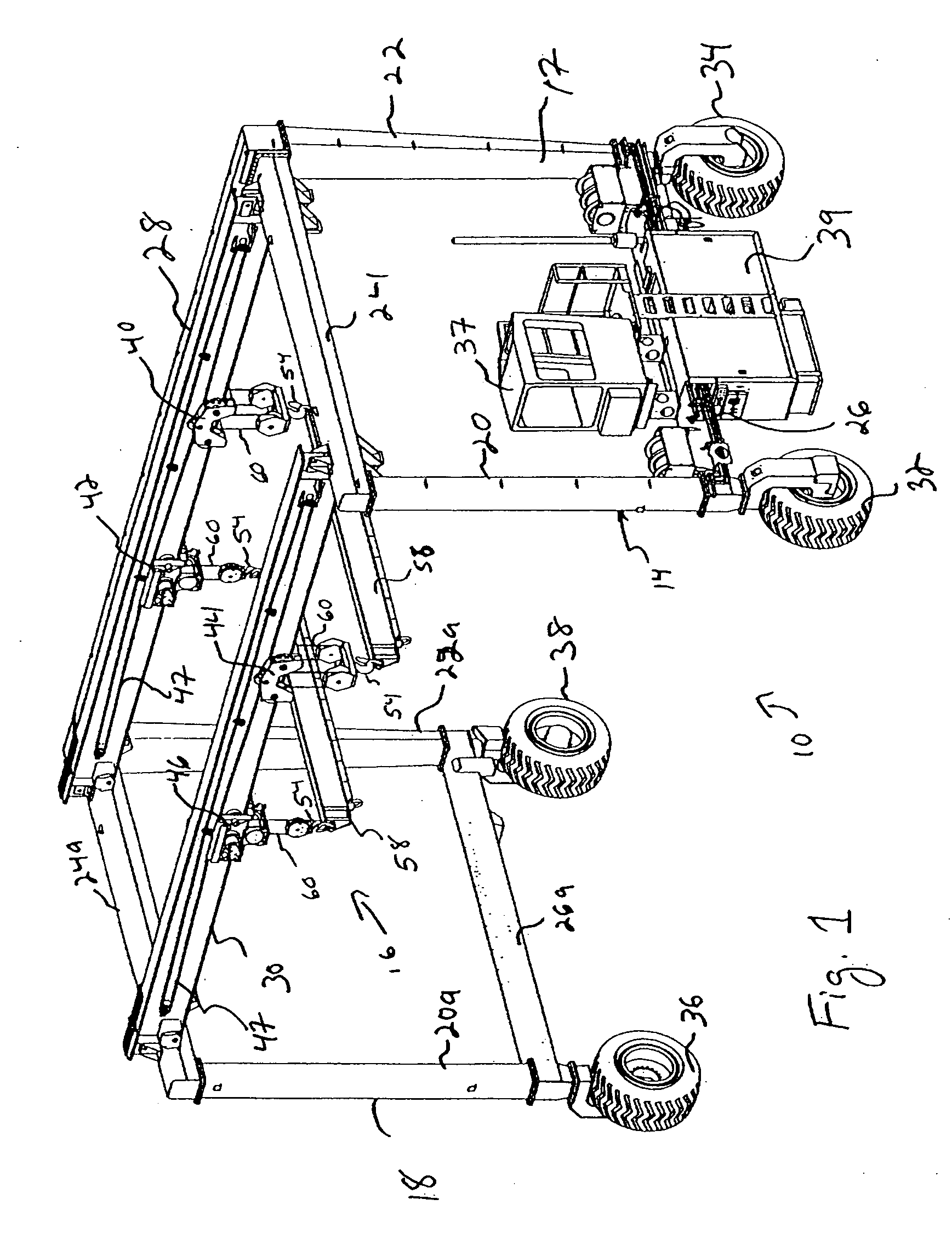

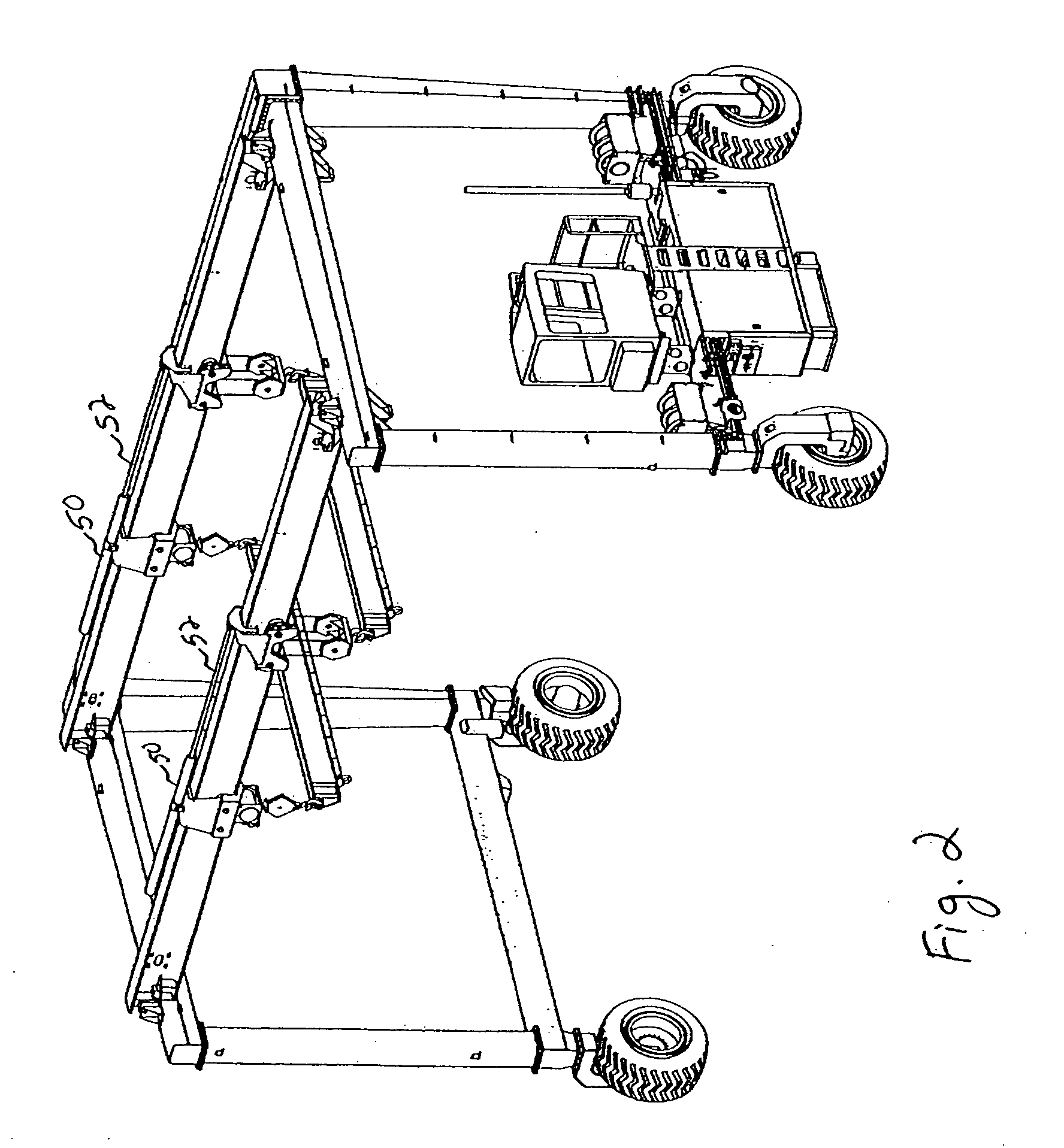

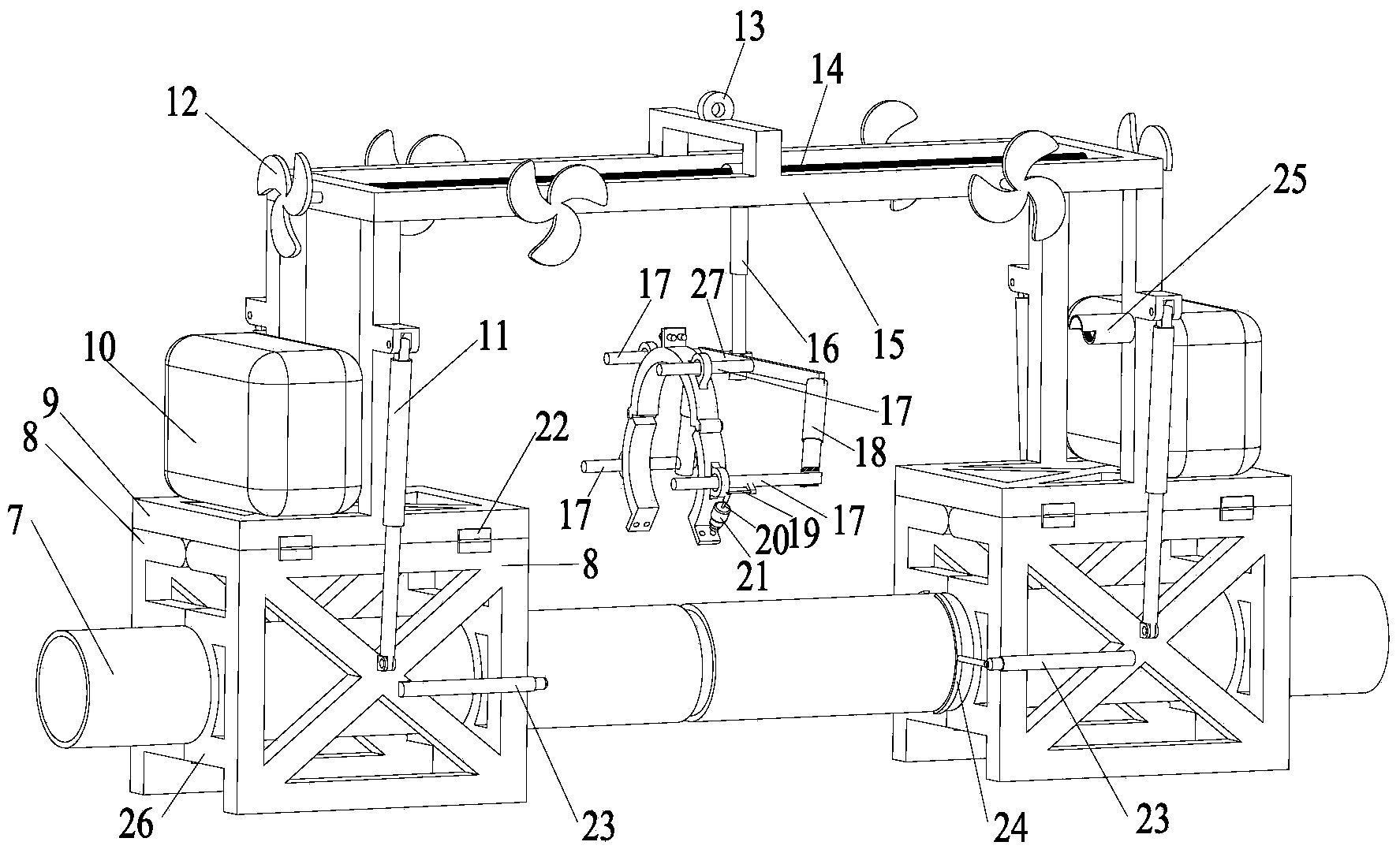

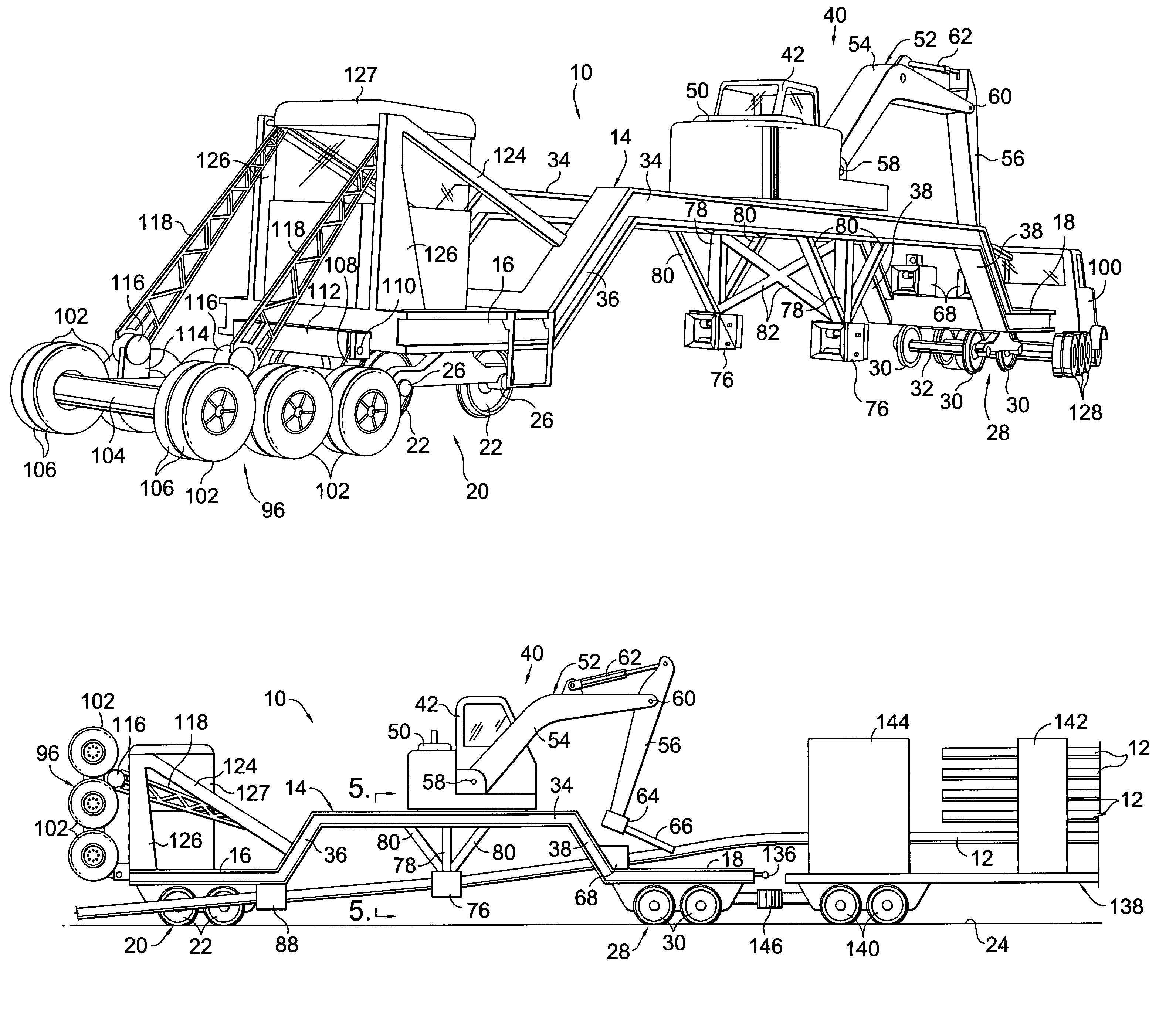

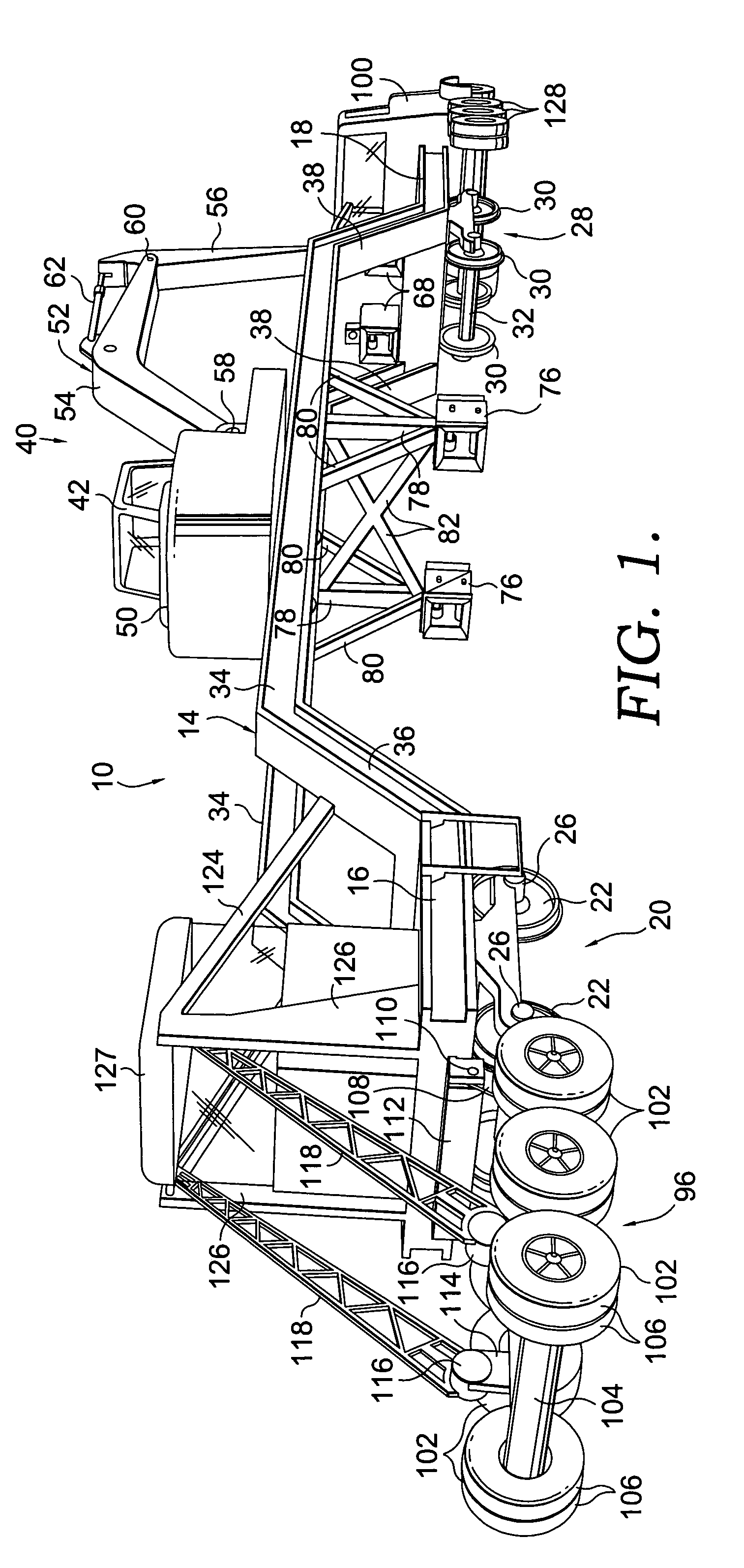

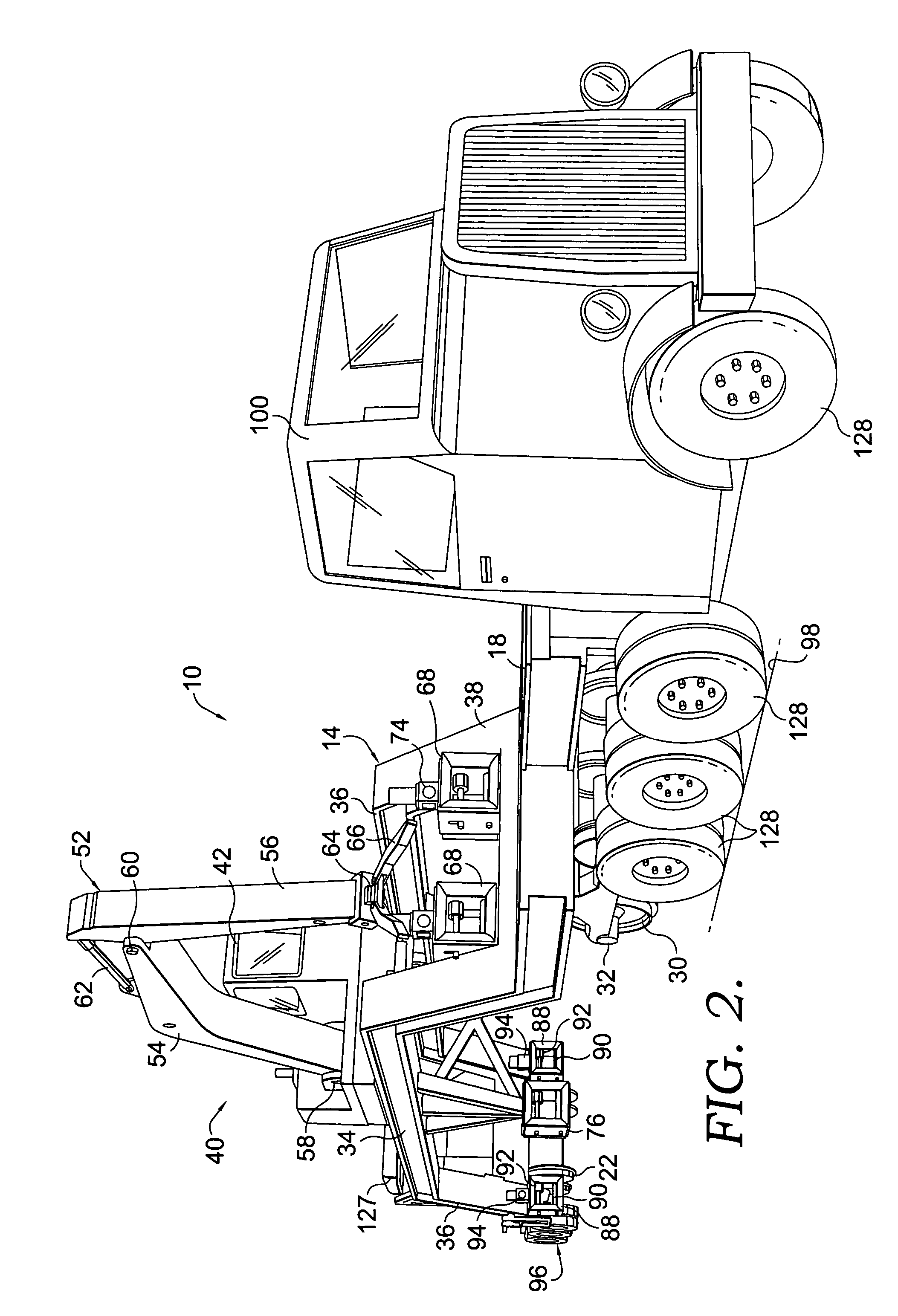

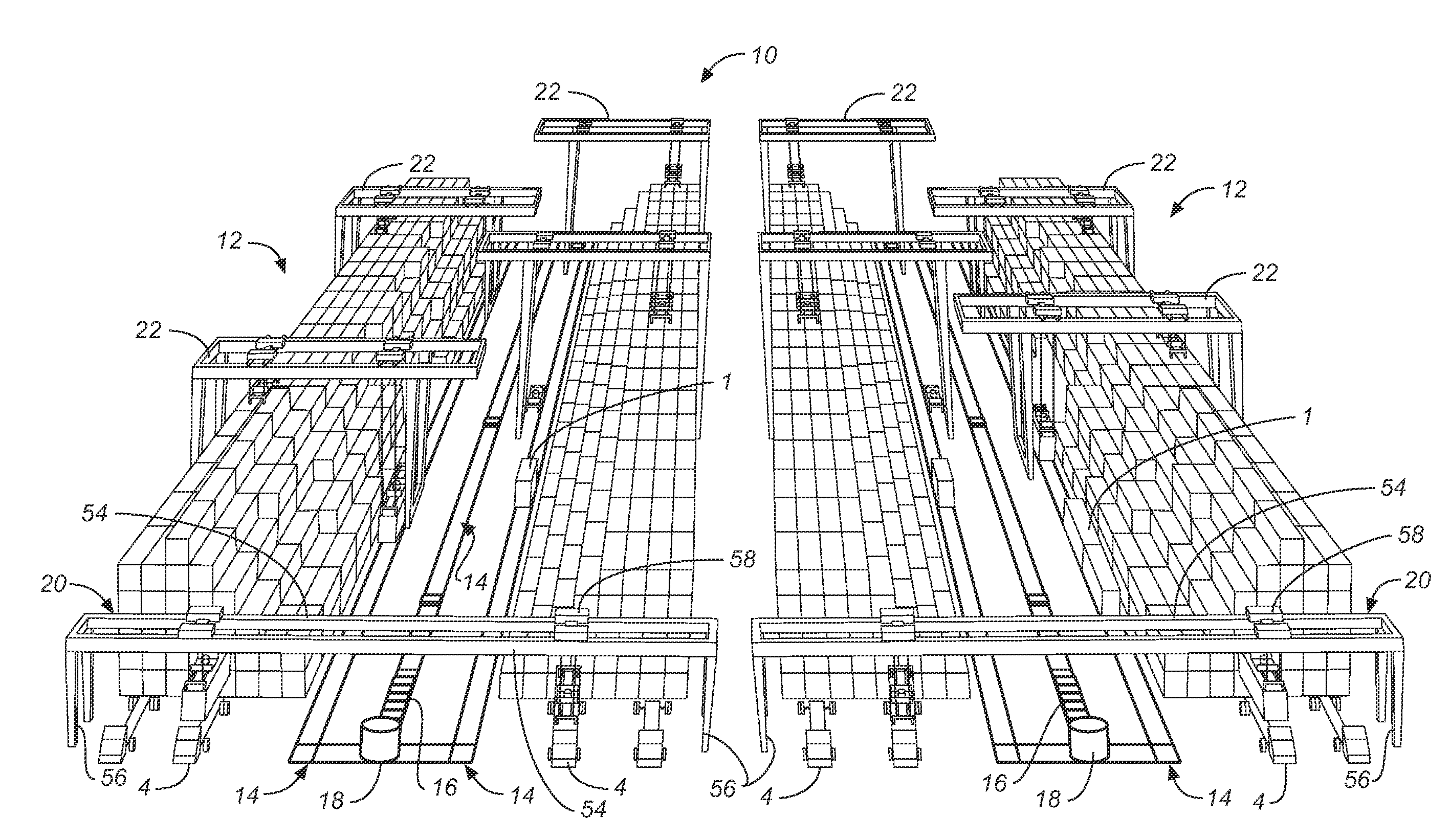

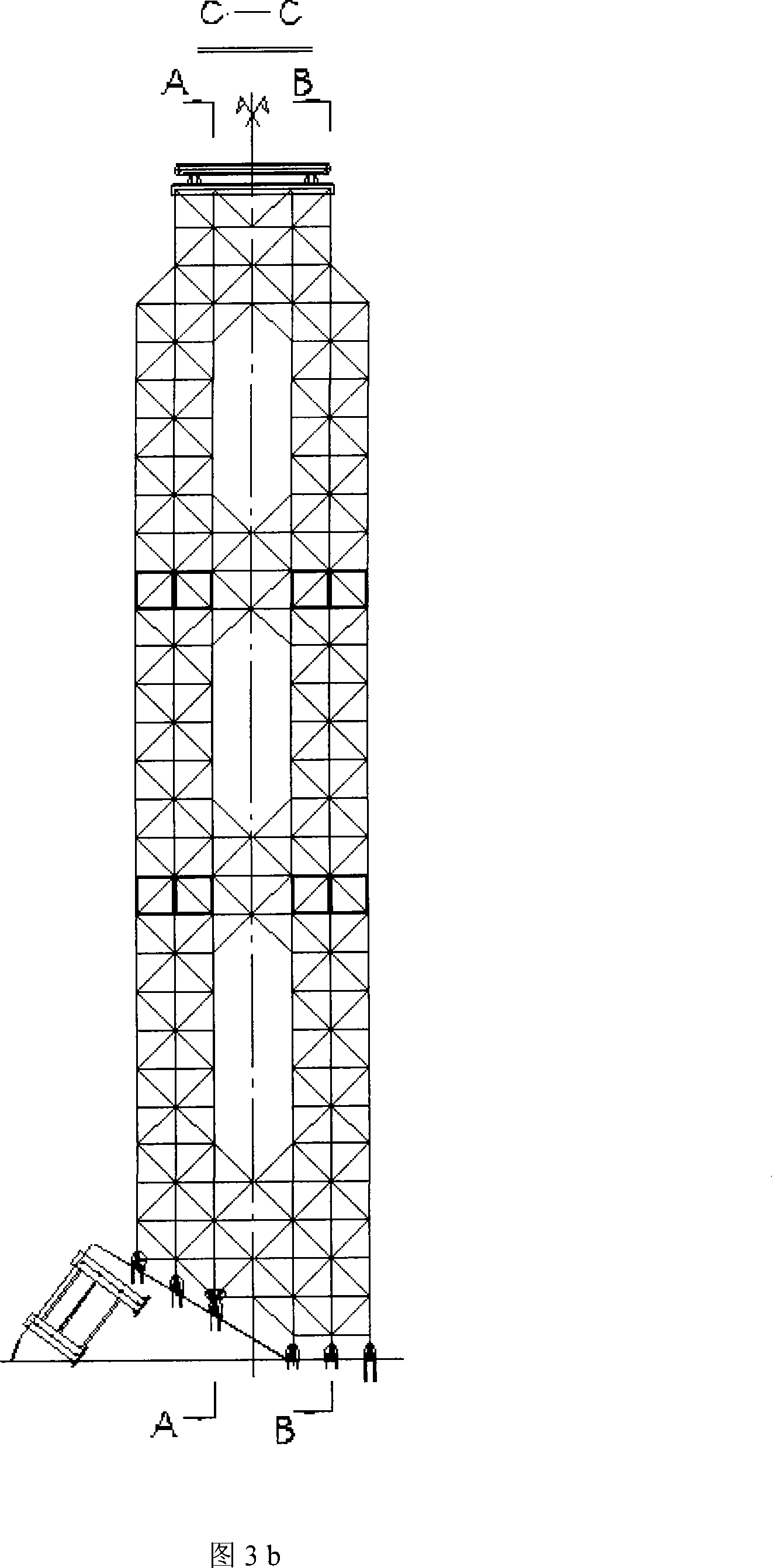

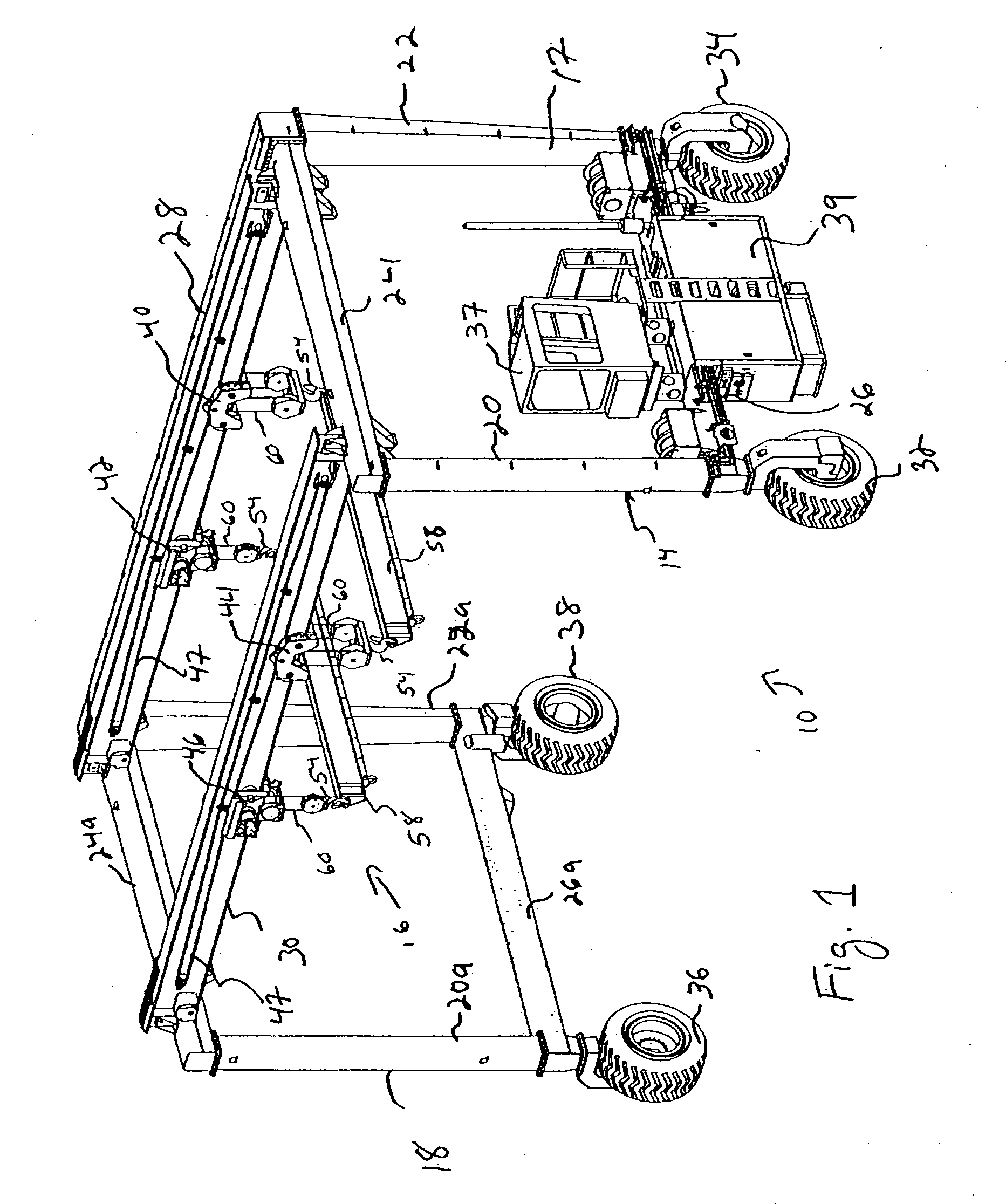

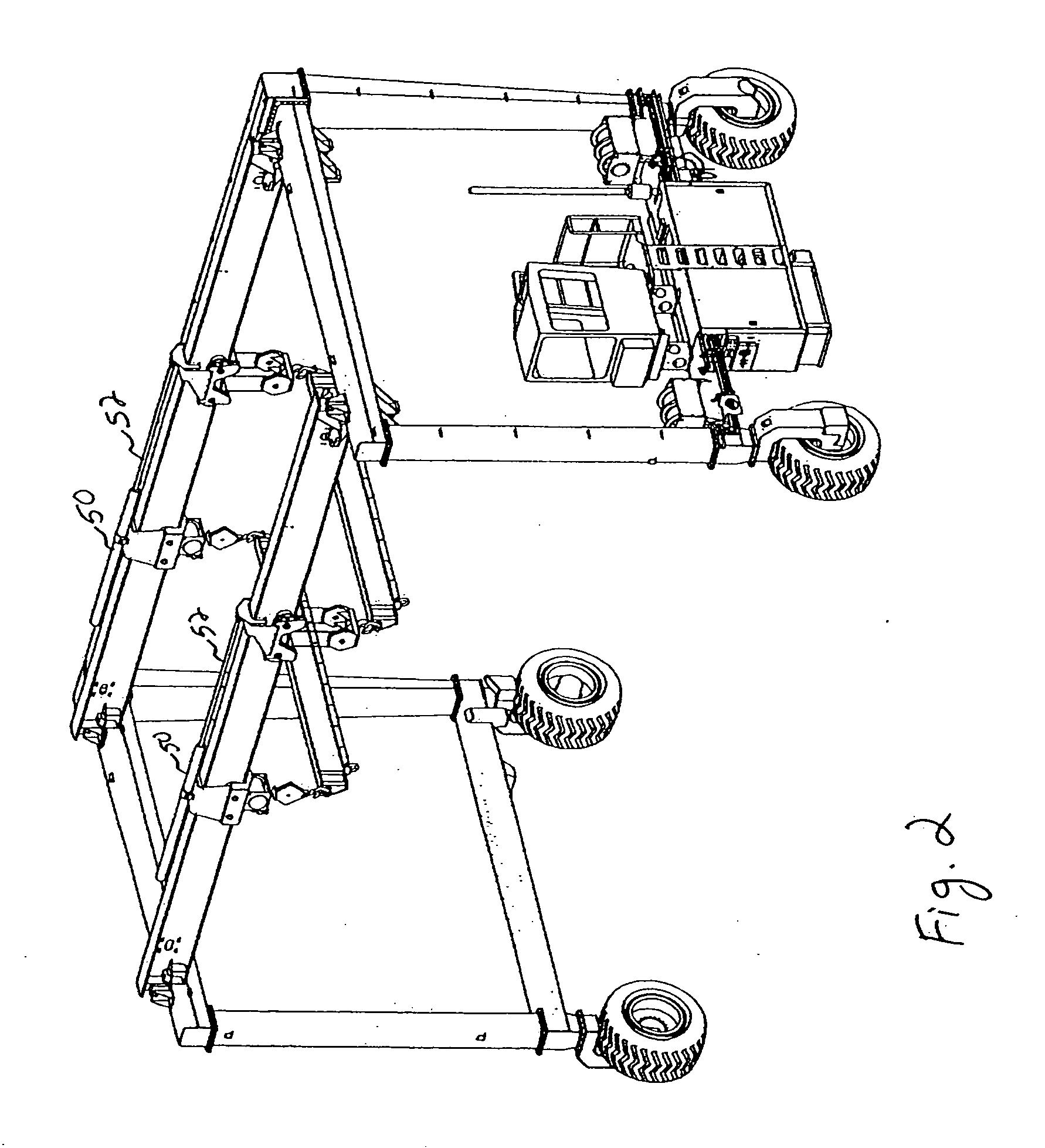

Powered auxiliary hoist mechanism for a gantry crane

ActiveUS20070095777A1Reduce hoist capacityProtection overloadTrolley cranesTrolleysLifting capacityEngineering

A gantry crane (10) is configured in a panel turner application. The gantry crane (10) generally includes a gantry crane structure (14) having a first cross-beam (28) and a second cross-beam (30). A first main hoist mechanism (40) and a first auxiliary hoist mechanism (42) are coupled to the first cross-beam (28), and a second main hoist mechanism (44) and a second auxiliary hoist mechanism (46) are coupled to the second cross-beam (30). The crane (10) includes a hydraulic system configured to reduce the lift capacity of the first and / or second main hoist mechanism (40, 44), and to equalize the hoist capacity between the first and second main hoist mechanisms (40, 44) or the first and second auxiliary hoist mechanisms (42, 46) in certain applications. The auxiliary hoist mechanism (42, 46) are configured for powered movement along the respective cross-beams (28, 30).

Owner:MARINE TRAVEELEVATOR

Production technology of hatch coaming and hatch cover

InactiveCN101362505AReduce the number of liftingReduce workloadHull decksVessel hatches/hatchwaysManufacturing technologyHydraulic equipment

Owner:江苏熔盛重工有限公司 +1

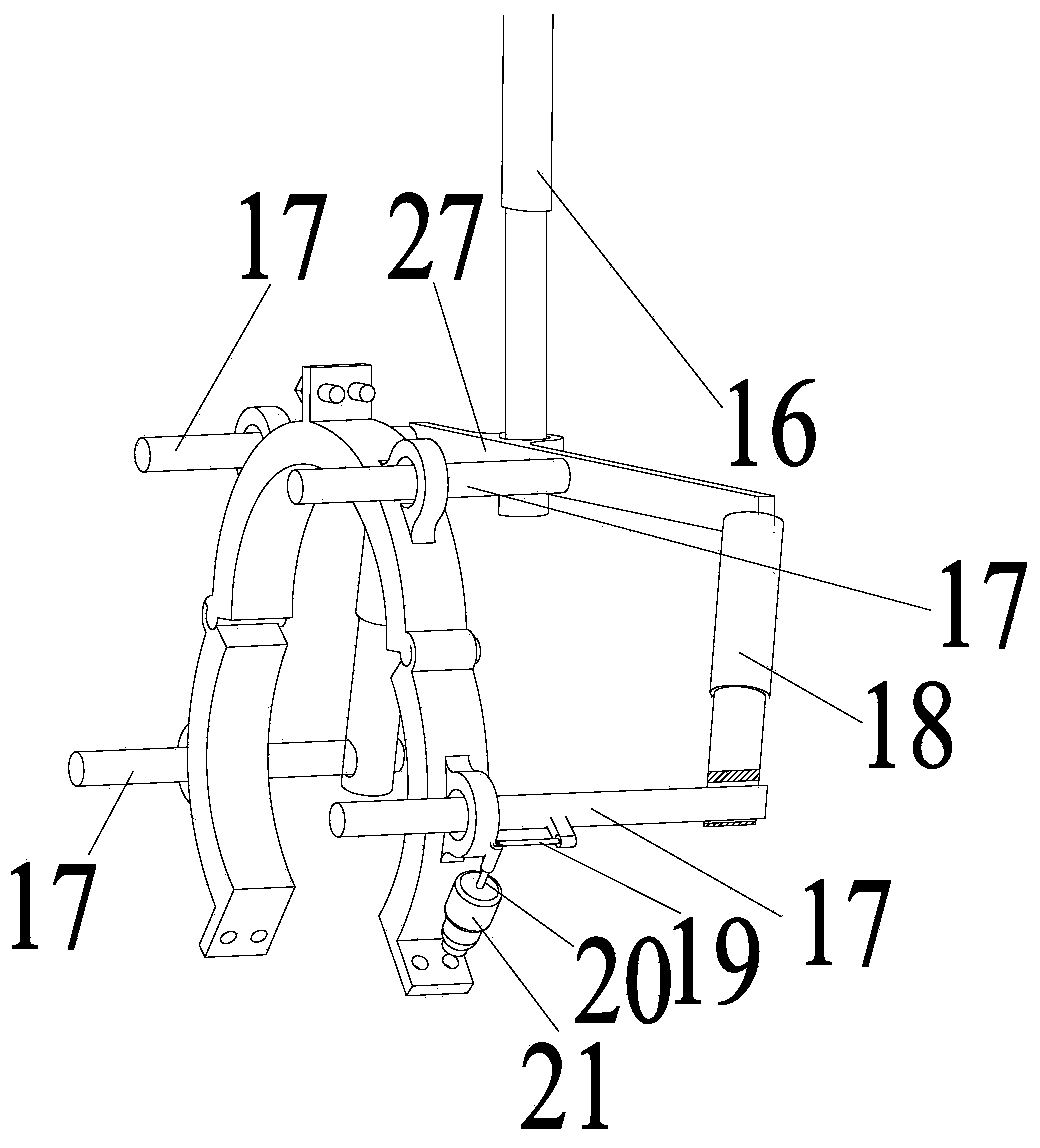

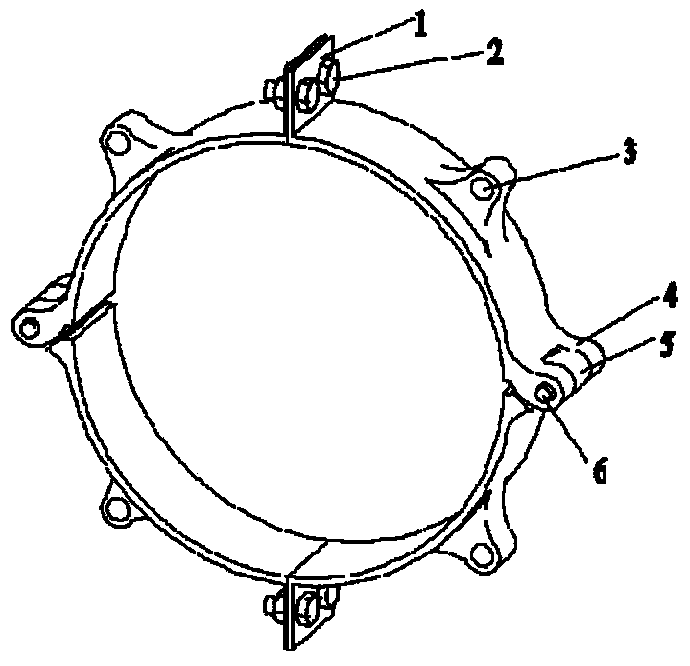

Robot for installing groove-type large-caliber pipeline connector in deepwater complex environment

The invention discloses a robot for installing a groove-type large-caliber pipeline connector in a deepwater complex environment. The robot is integrally shaped similarly as a portal crane; fixing side wings of the robot adopt openable and closable structures, open and close through clamping parts and clamp two pipelines to be connected around a connection point; mechanical arms of the robot form reciprocable movable connection with a screw sliding table. Due to adoption of a series of technical measures, the robot can connect horizontal pipelines and inclined or even vertical pipelines; the mechanical arms and the fixing devices of the robot can be flexibly adjusted according to pipe diameters of the specific connected pipelines, so that needs of connection construction of different models of connectors can be met; through coordination of an airbag and a driving propeller, adjustment on an underwater posture of the robot is achieved, so that the robot has relatively high mobility and flexibility; a main control device of the robot is arranged on a mother ship, so that the structure of an underwater working part is simplified.

Owner:SHANDONG UNIV OF SCI & TECH

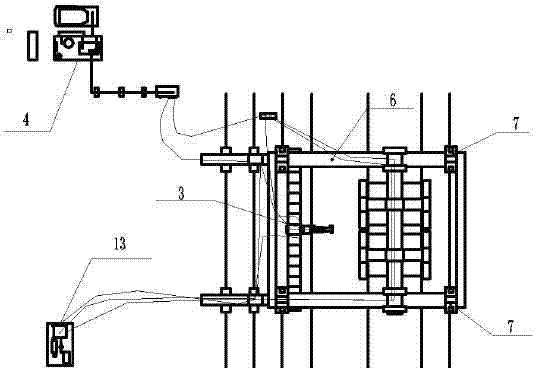

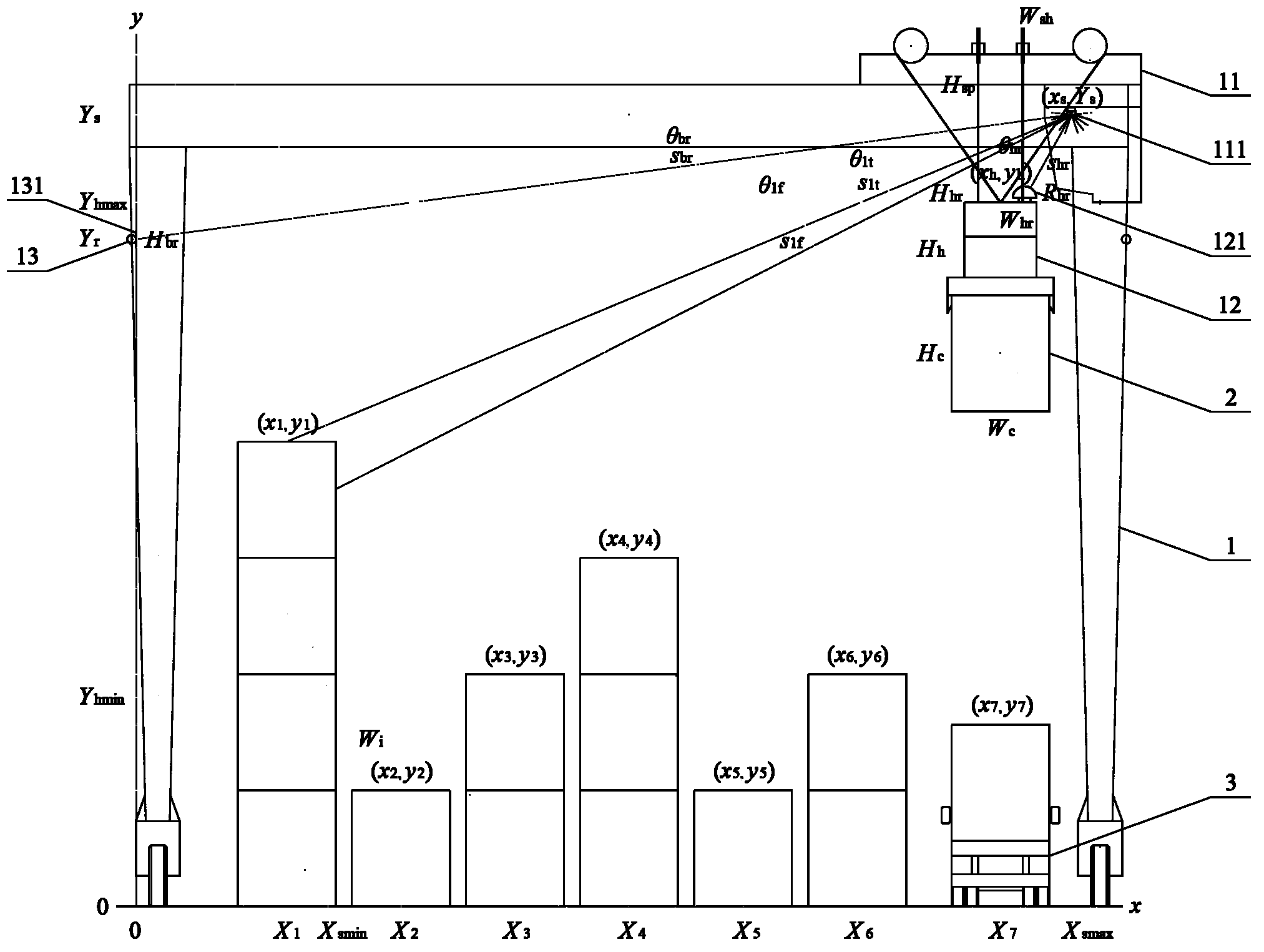

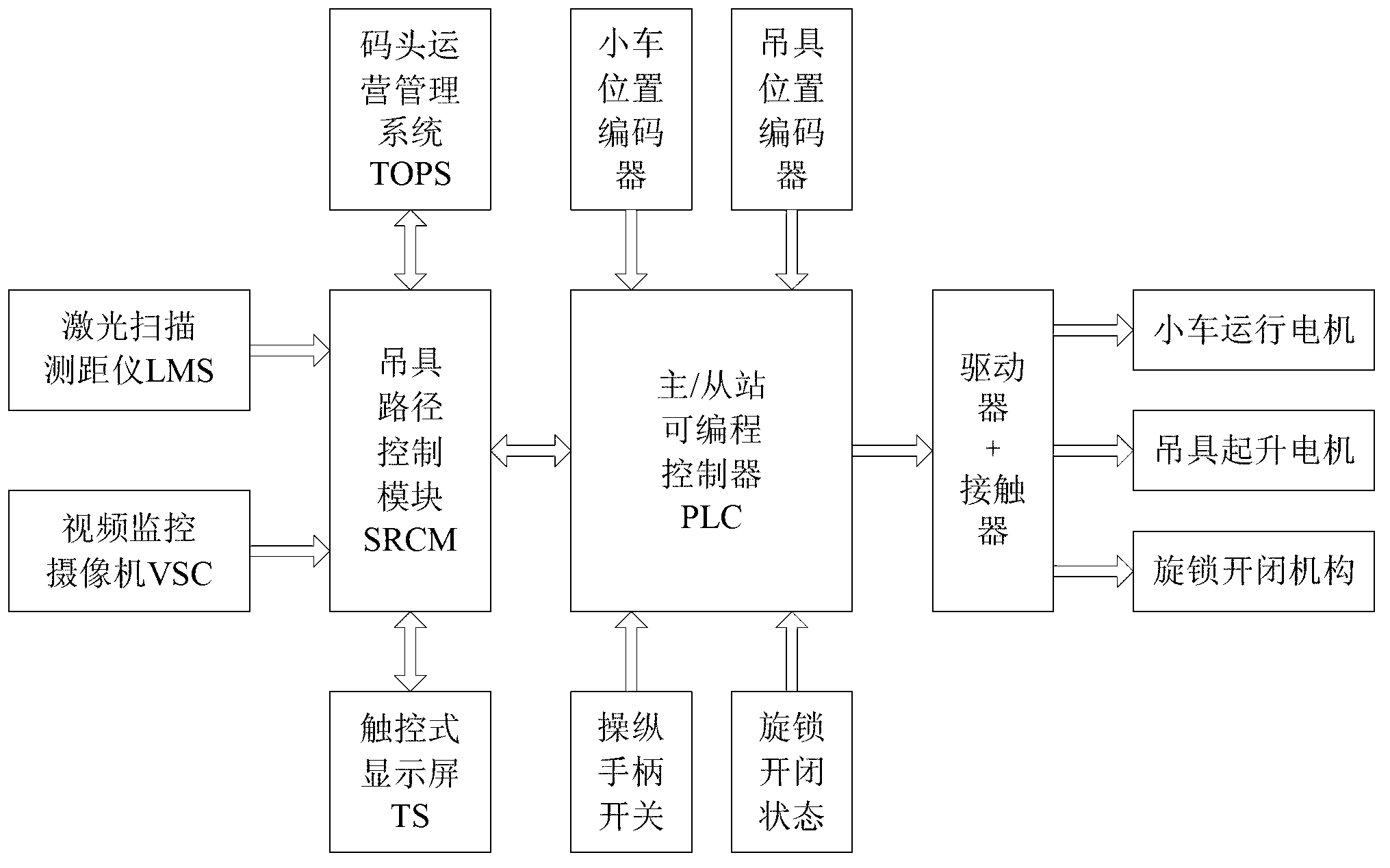

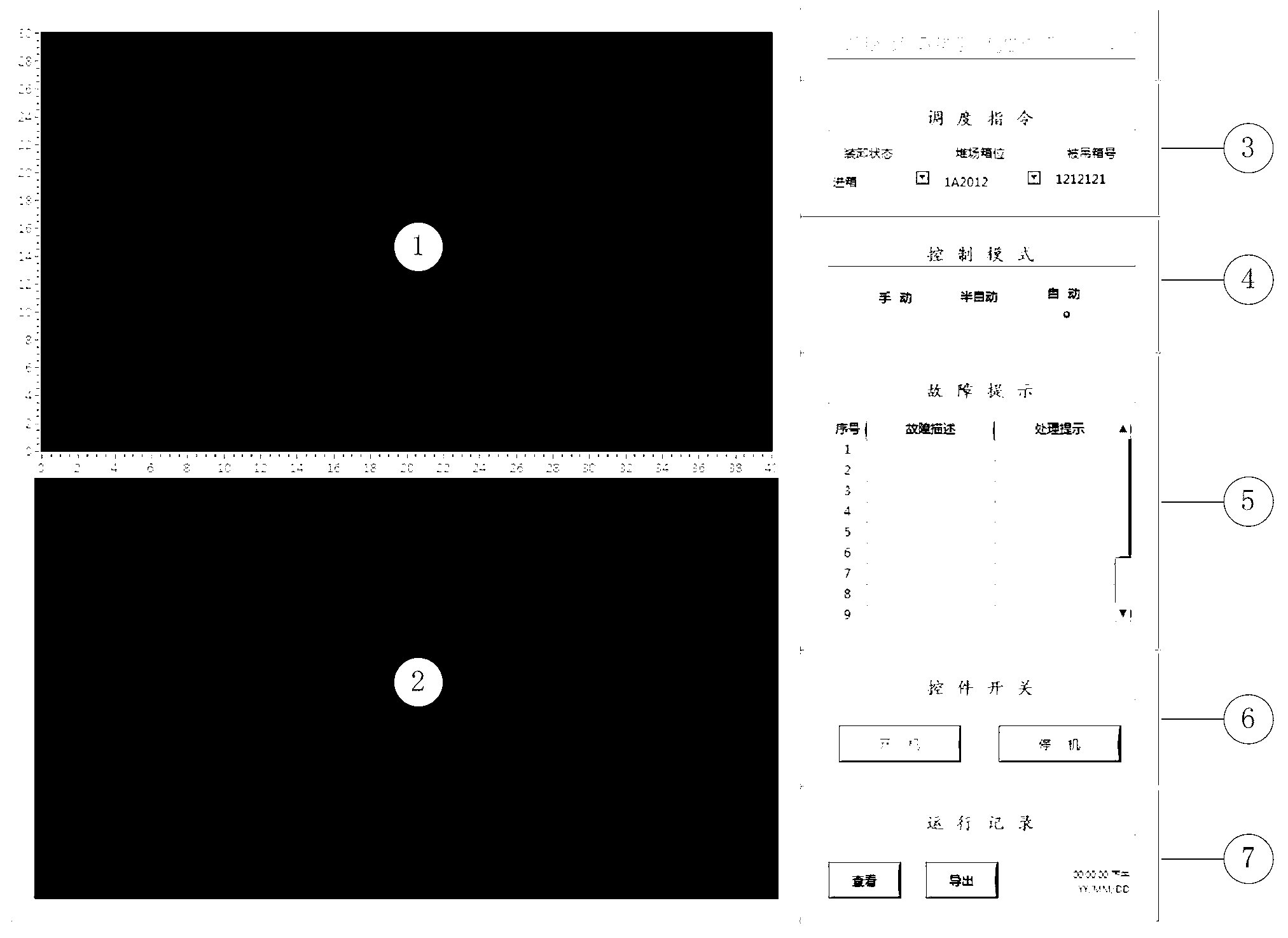

Lifting appliance path optimization control system used for container gantry crane

InactiveCN103231990AExtended Scheduling CapabilitiesImprove work efficiencySafety gearScheduling functionScheduling instructions

The invention relates to a container gantry crane lifting appliance path optimization control system based on a laser scanning positioning technology. The lifting appliance path optimization control system mainly comprises components such as a lifting appliance path control module, a laser scanning range finder, a video surveillance camera and a touch control type display screen, and can carry out positioning identification and path optimization on the contour of a storage yard and a lifting appliance (or a lifted container) according to a scheduling instruction of a wharf operating system and range finding information of a small vehicle-borne laser scanning range finder by using intelligent algorithms such as scanning positioning identification and path optimization control, so that the lifting appliance (or the lifted container) can be loaded and unloaded in place along an optimized path. The lifting appliance path optimization control system can significantly improve the operation efficiency, and reduce the operation energy consumption, container collision accidents and the labor intensity, thus further expanding the scheduling function of the wharf operating system, and being widely used for various tire type and rail type gantry cranes in container yards.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

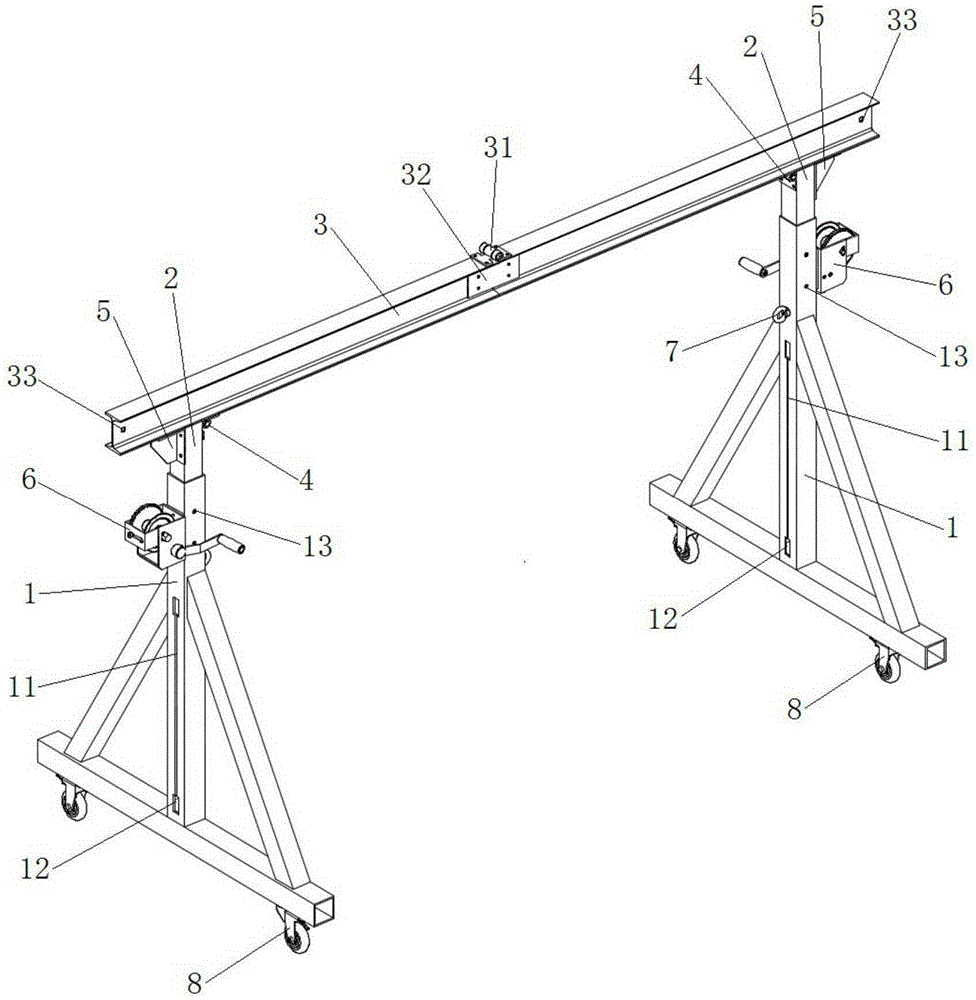

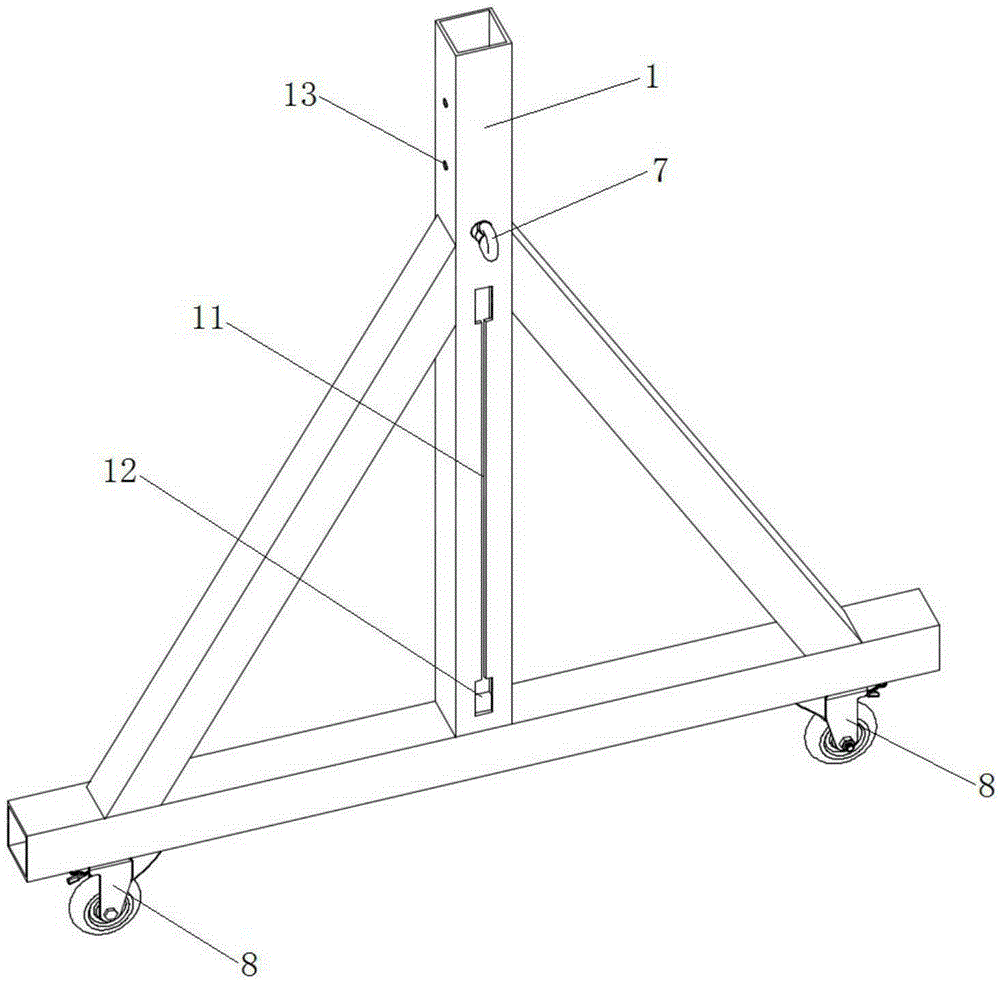

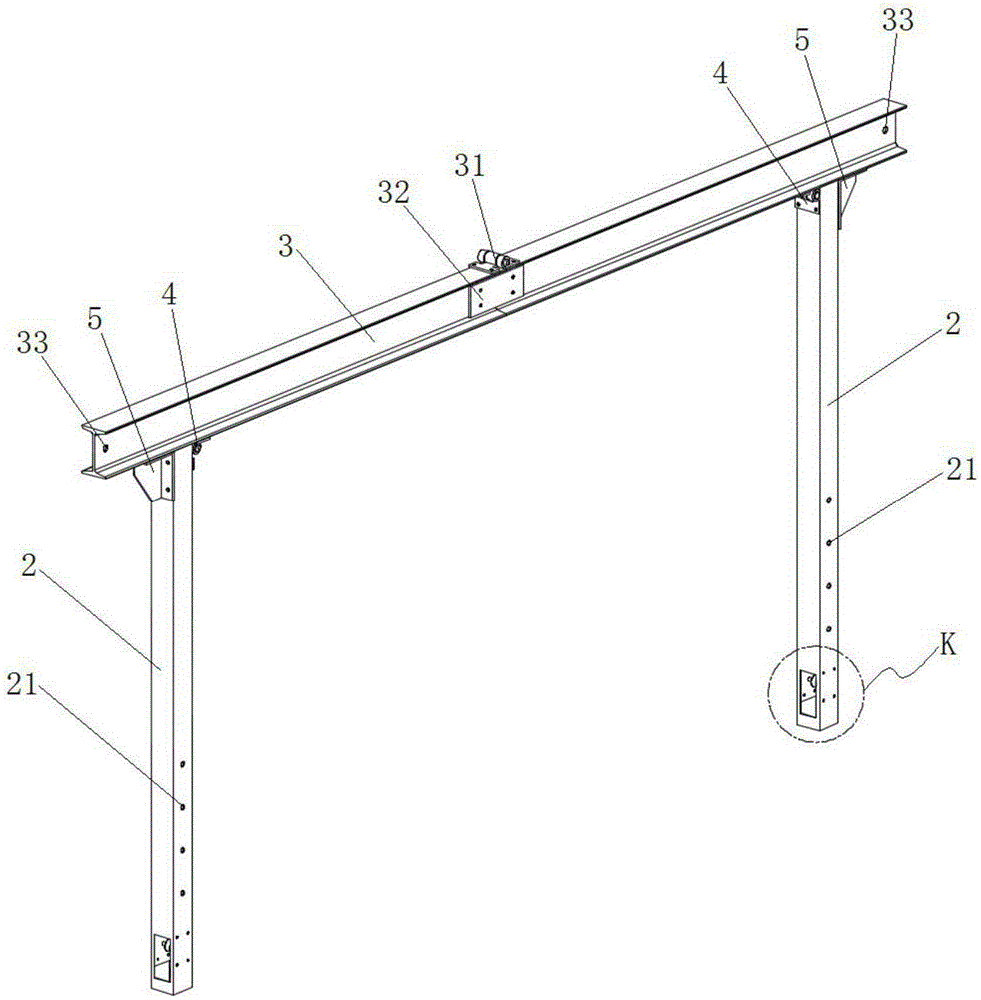

Foldable gantry crane capable of ascending and descending

InactiveCN105236276AEasy to useSmall footprintBase supporting structuresBraking devices for hoisting equipmentsEngineeringGantry crane

The invention discloses a foldable gantry crane capable of ascending and descending, and belongs to the field of carrying tools. The foldable gantry crane capable of ascending and descending comprises a beam and supporting legs arranged on the two sides of the beam. Each supporting leg comprises a lifting supporting rod connected with the beam and a fixed supporting leg in telescopic fit with the lifting supporting rod, wherein a lifting mechanism is arranged between the lifting supporting rod and the fixed supporting leg. The beam is cut off from the middle, the two parts formed after cutting are hinged together, and the hinging portions are fixedly connected through a connecting plate. The two ends of the beam are connected with the upper portions of the lifting supporting rods through hinges respectively. After the connecting plate is detached, the beam can be bent downwards, and then the supporting legs on the two sides of the beam can be retracted inwards. Height adjustment can be performed as needed when the gantry crane is in use, so that use is easy and convenient. The beam can be lowered and folded when the gantry crane is not in use, so that occupied space is reduced, and transport is facilitated. The gantry crane is simple in structure, convenient to operate and low in cost.

Owner:CHANGZHOU INST OF TECH

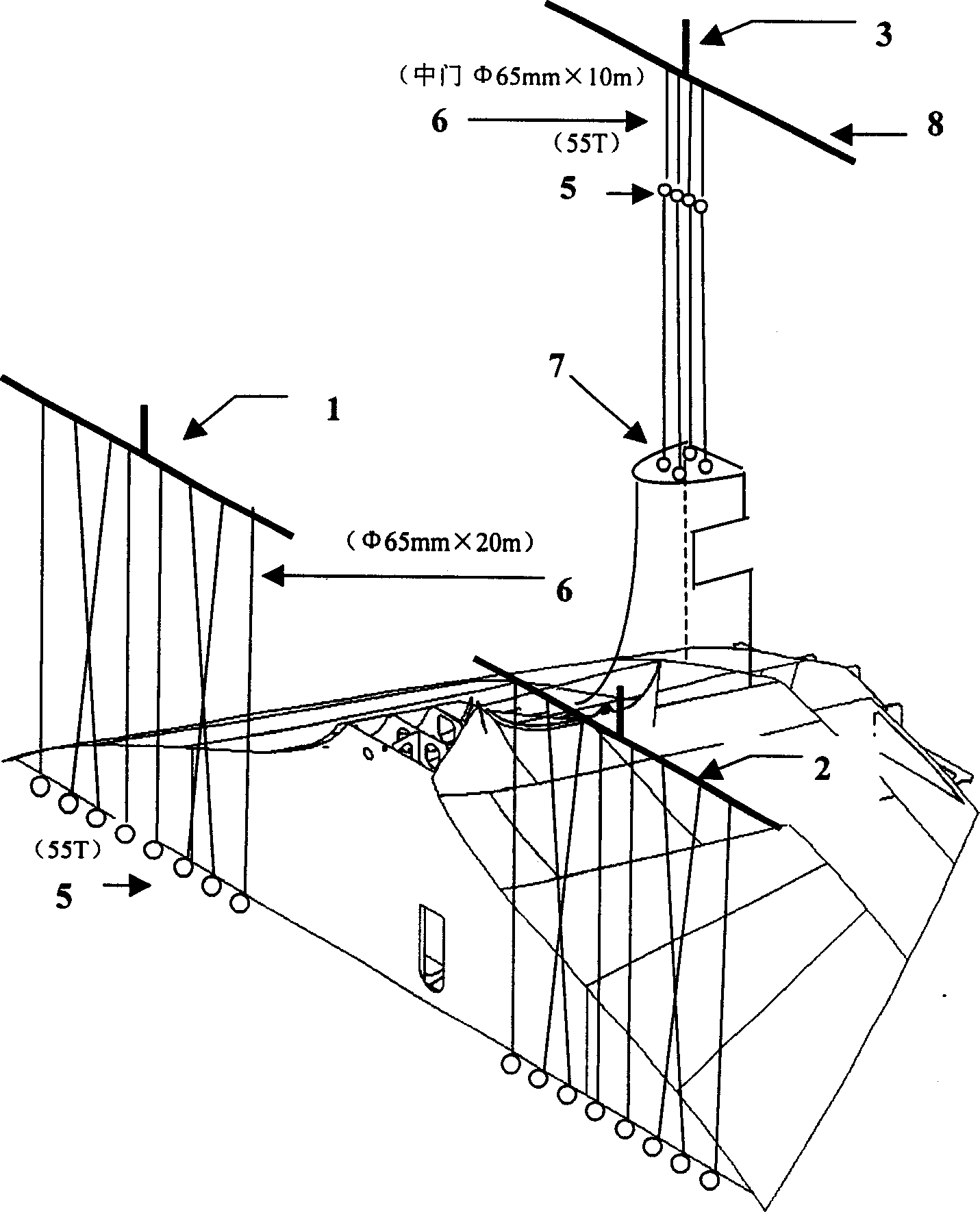

Sectional hoisting method

The invention relates to one sectional hoisting technique, which may be applied to series disperses freighter with 17.5 or 177000 tons, this hoisting technique includes: The district embarkation hoisting technique and the body section embarks the hoisting technique, respectively partitions the hoisting technique carries out the following step: a) determines the partition the actual tonnage; b) hanging establishment and hanging rigging equipment, which includes the selection steel wire's diameter, length, quantity, docking way and unloading gram, the load bearing tonnage and the material with which the suspenders corresponds; c) selects and arranges three gantry cranes hook; d) partitions stands up from failure the total group and the embarkation; e) controls partitions the time which the total group and the embarkation need. This invention partition hoisting technique, the host hung row of small, the hoisting working procedure are few, which causes the hull hoisting process and the tool utilization and the manpower arrangement which obtains the optimization, partitioned one time of arrive rate is high, the error was quite small, 100% guaranteed the hoisting success ratio.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Track transfer apparatus, track transfer connection device, transfer system and method

InactiveCN101348210AImprove transition efficiencyConvenient transition operationBase supporting structuresBraking devices for hoisting equipmentsHydraulic cylinderTransfer system

The invention discloses a rail transfer device. The device comprises a traveling mechanism comprising steel wheels, a first gyration mechanism connecting a saddle beam and the driving mechanism, a first gyration driving mechanism and a jacking-up mechanism, wherein the first gyration mechanism can rotatablely connect the traveling mechanism and the saddle beam; the first gyration driving mechanism can drive the driving mechanism to rotate relative to the saddle beam; the jacking-up mechanism is a jacking-up hydraulic cylinder comprising a cylinder body and a piston; the cylinder body and the saddle beam are relatively fixed; the outer end of the piston is provided with support legs; when the piston of the jacking-up hydraulic cylinder extends out, the support legs can jack the saddle beam up; and the device also comprises a grasping mechanism capable of grasping movable rails. In addition, the invention also discloses a rail transfer connecting device, a rail-type gantry crane transfer system and a transfer method thereof. The rail transfer device provided by the invention can realize the automation of transfer operation and improve the working efficiency of the transfer operation.

Owner:SANY MARINE HEAVY IND

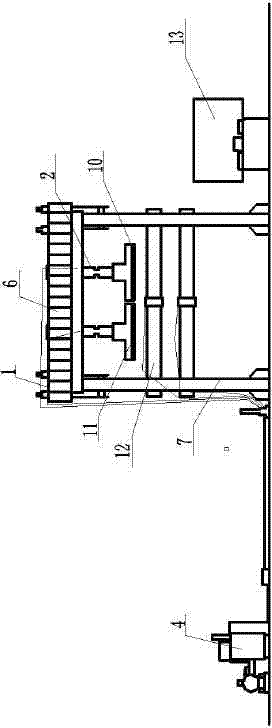

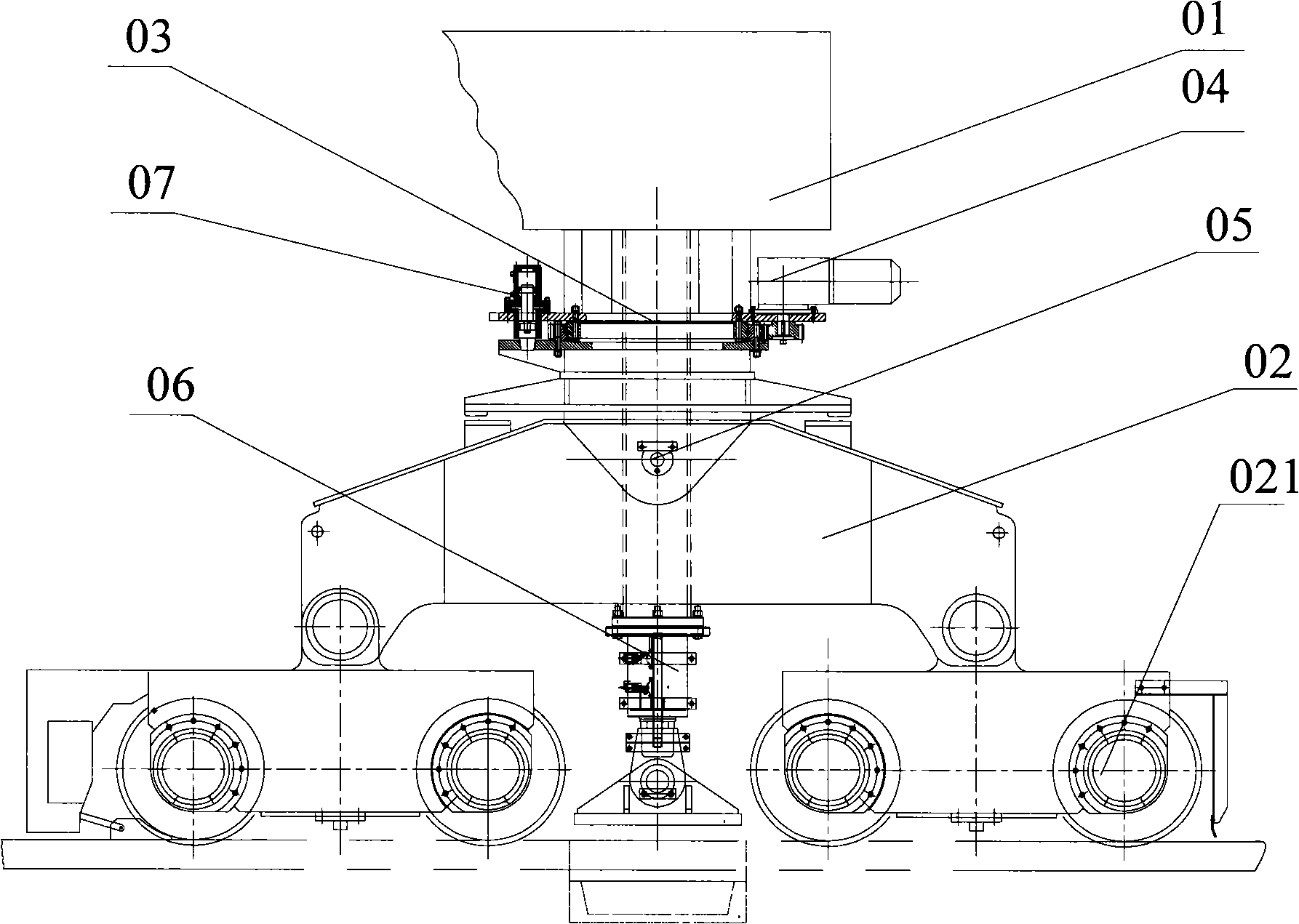

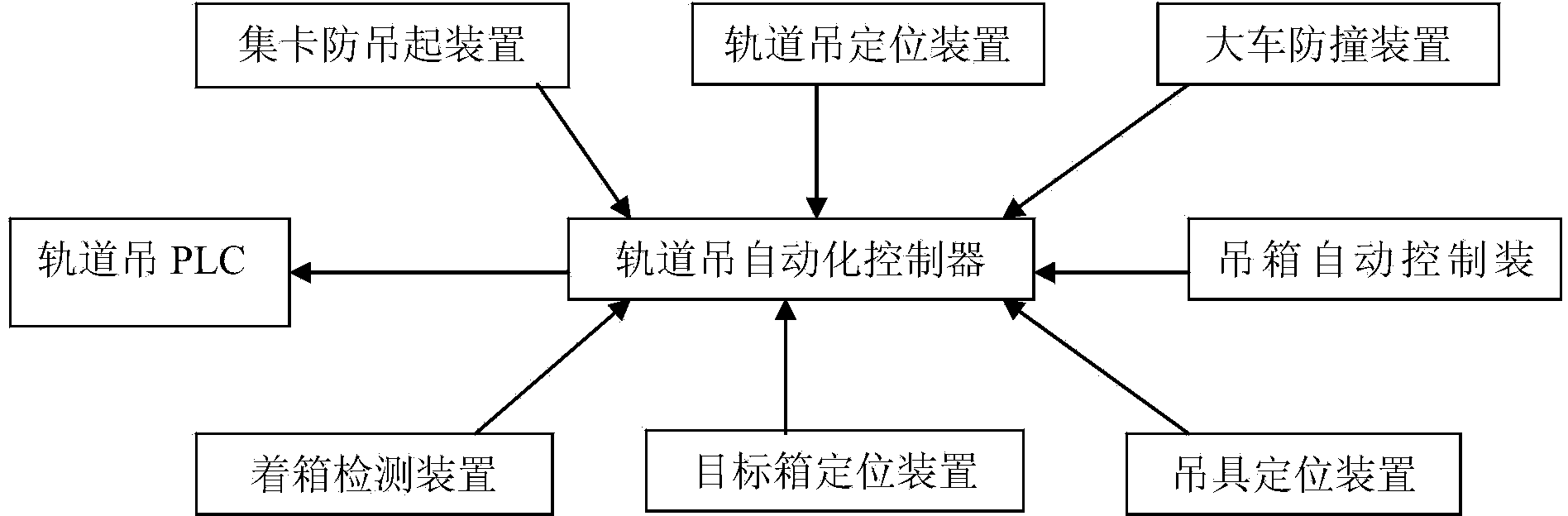

Rail-mounted gantry crane automatic yard operation control system and automatic loading and unloading method

ActiveCN103523675AImprove work efficiencyReduce labor costsSafety gearAutomatic controlControl system

The invention discloses a rail-mounted gantry crane automatic yard operation control system and an automatic loading and unloading method, and the control system and the automatic loading and unloading method can reduce investment for reconstruction and enables technological process to be simplified. The system comprises a rail-mounted gantry crane automatic controller, a rail-mounted gantry crane PLC controller, a hanger PLC controller, a container truck hoist-preventing device, a rail-mounted gantry crane positioning device, a container landing detection device, a hoisting box automatic control device, a target container positioning device and a hanger positioning device. The system refits a conventional rail-mounted gantry crane into an automatic rail-mounted gantry crane and can carry out container landing, locking, hanger rising, container dropping, unlocking, hanger rising and the like on containers through controlling by the automatic loading and unloading method, a cycle of operation can be automatically finished without intervention by a remote operator, so work efficiency is improved, labor cost is reduced and work cost is lowered down; moreover, equipment investment is small, and operation is simple and convenient.

Owner:TIANJIN PORT CONTAINER TERMINAL

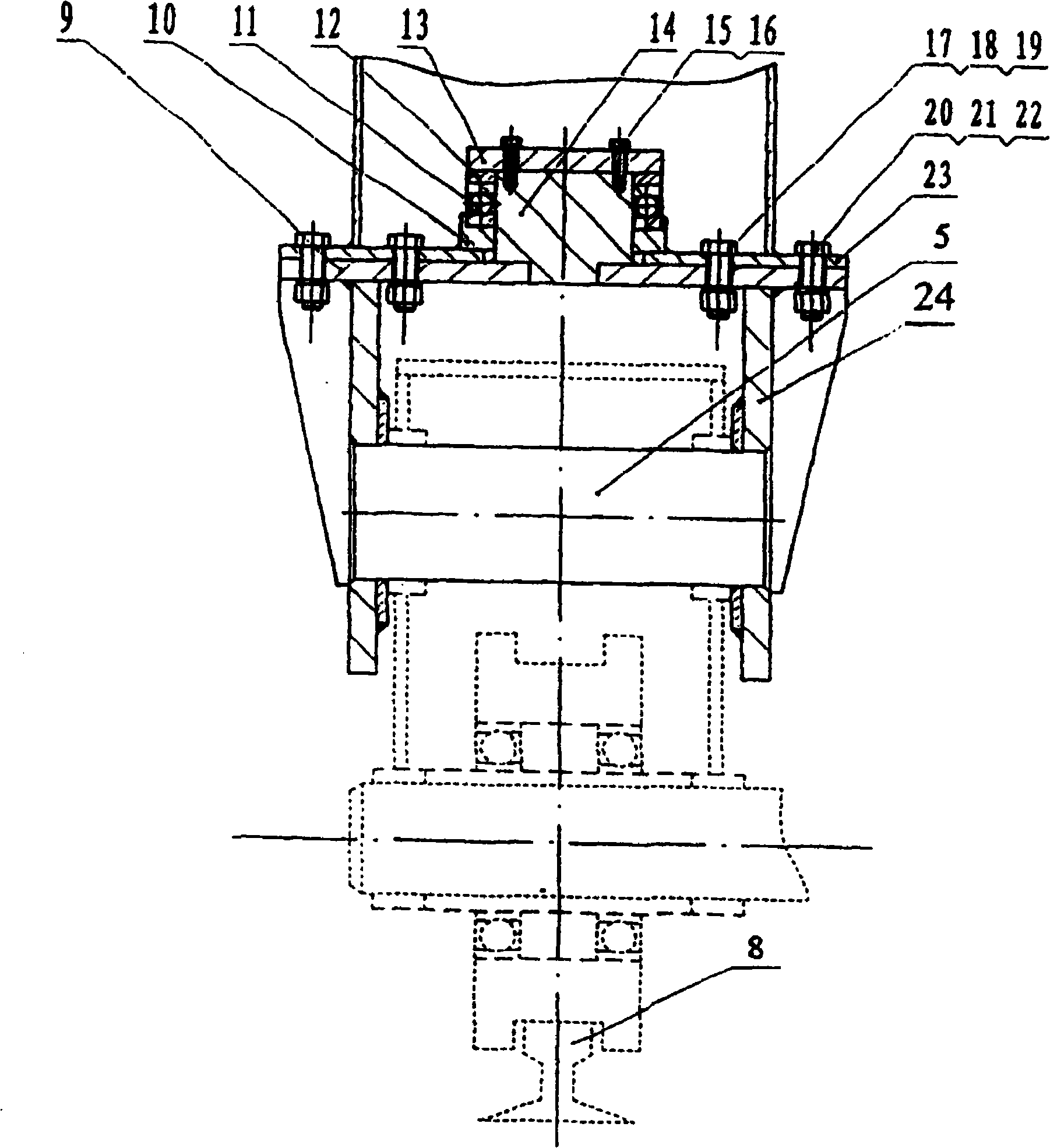

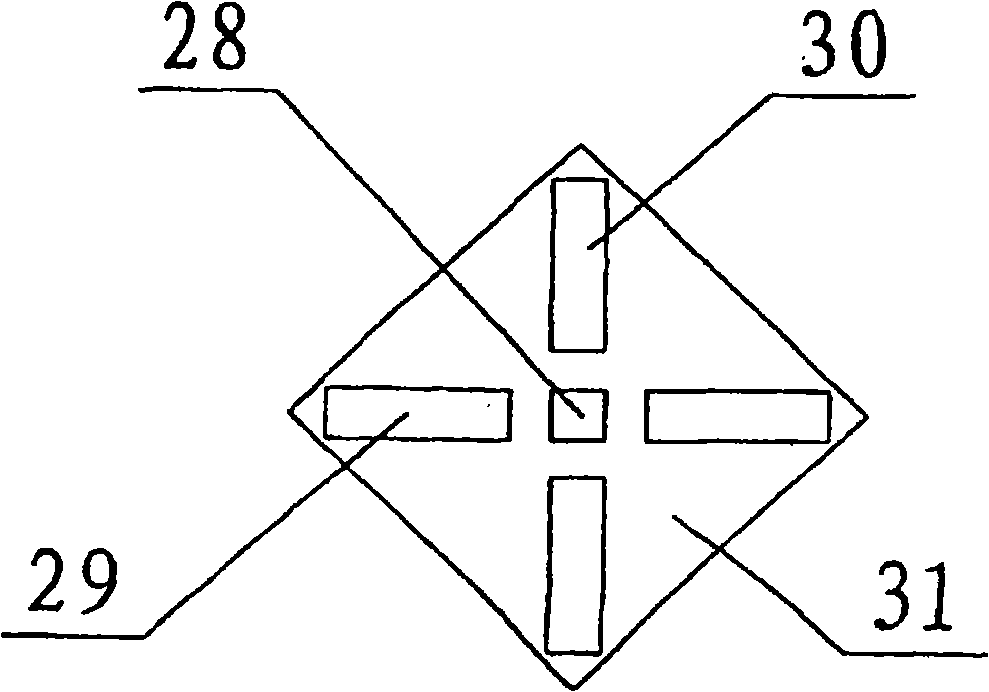

Anti-swing mechanism of container gantry crane sling

InactiveCN101323417AAdd geometric interference dampingPrevent rocking back and forthTravelling cranesLoad-engaging elementsAcute angleBlock and tackle

The invention discloses a spreader stabilizing mechanism of a container gantry crane, comprising a drum group, a pulley block, a spreader upper frame and a steel wire rope group wound on the drum group and the pulley block; the steel wire rope forms four congruent inverse triangles at the space between the spreader upper frame and a pulley frame; the bottom points of the four inverse triangles are distributed at the four corners of the spreader upper frame symmetrically; included angles which are formed by the planes of the four inverse triangles and the moving direction of a cart and a trolley are all acute angles. Therefore, in the moving direction of the cart and the trolley, the motion damping of the four space triangles exists, thus reducing the swing of the spreader; when the load of the spreader is not balance and the swing of opposite angles is generated, namely, twisting and vibration are generated, the space triangle forms the motion damping in the diagonal direction of the upper surface of the spreader upper frame and forms damping component in three directions of the space, thus offsetting the swing of the opposite angles. The invention has simple structure, convenient maintenance and use and high safe reliability.

Owner:SANY MARINE HEAVY IND

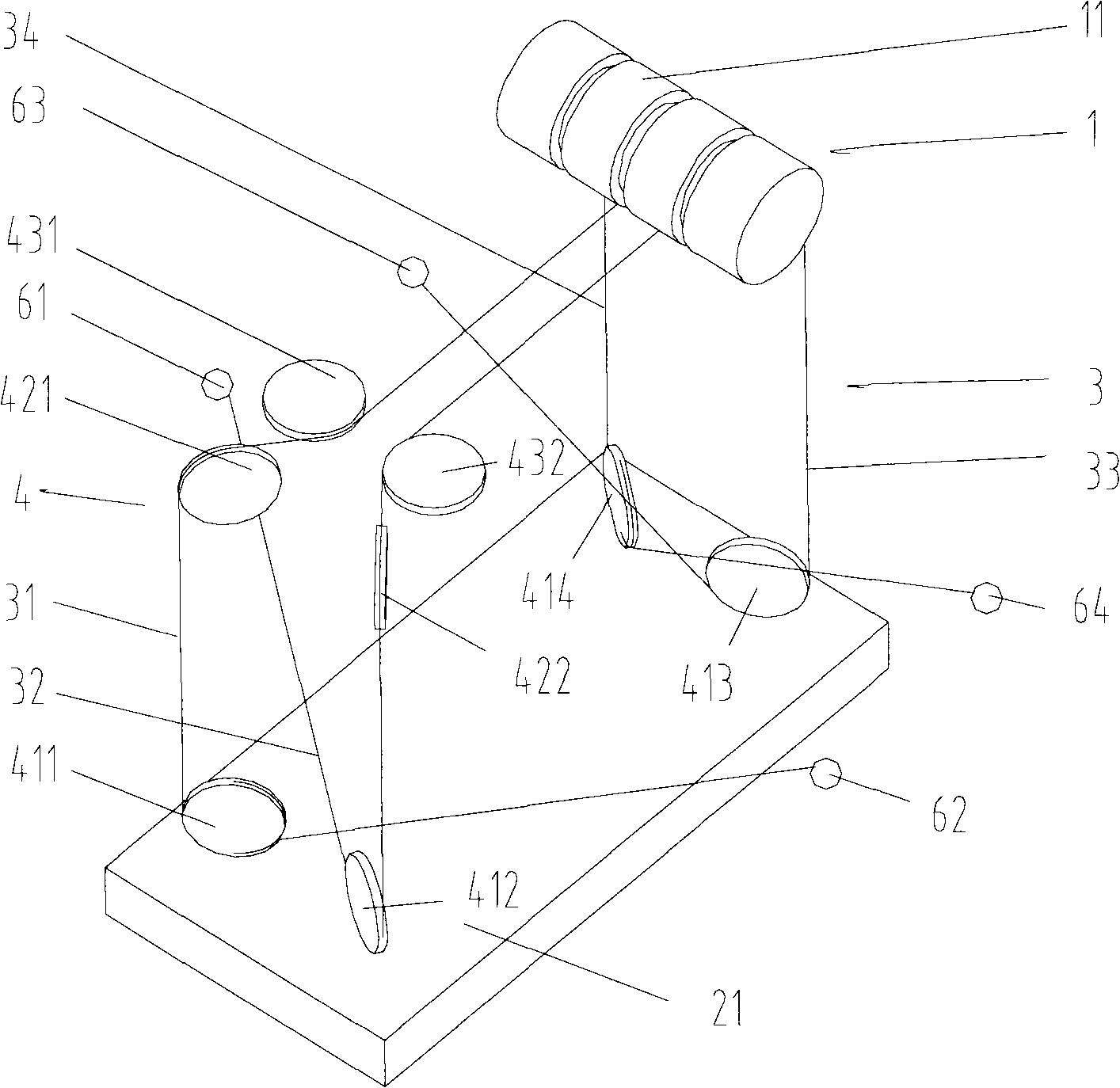

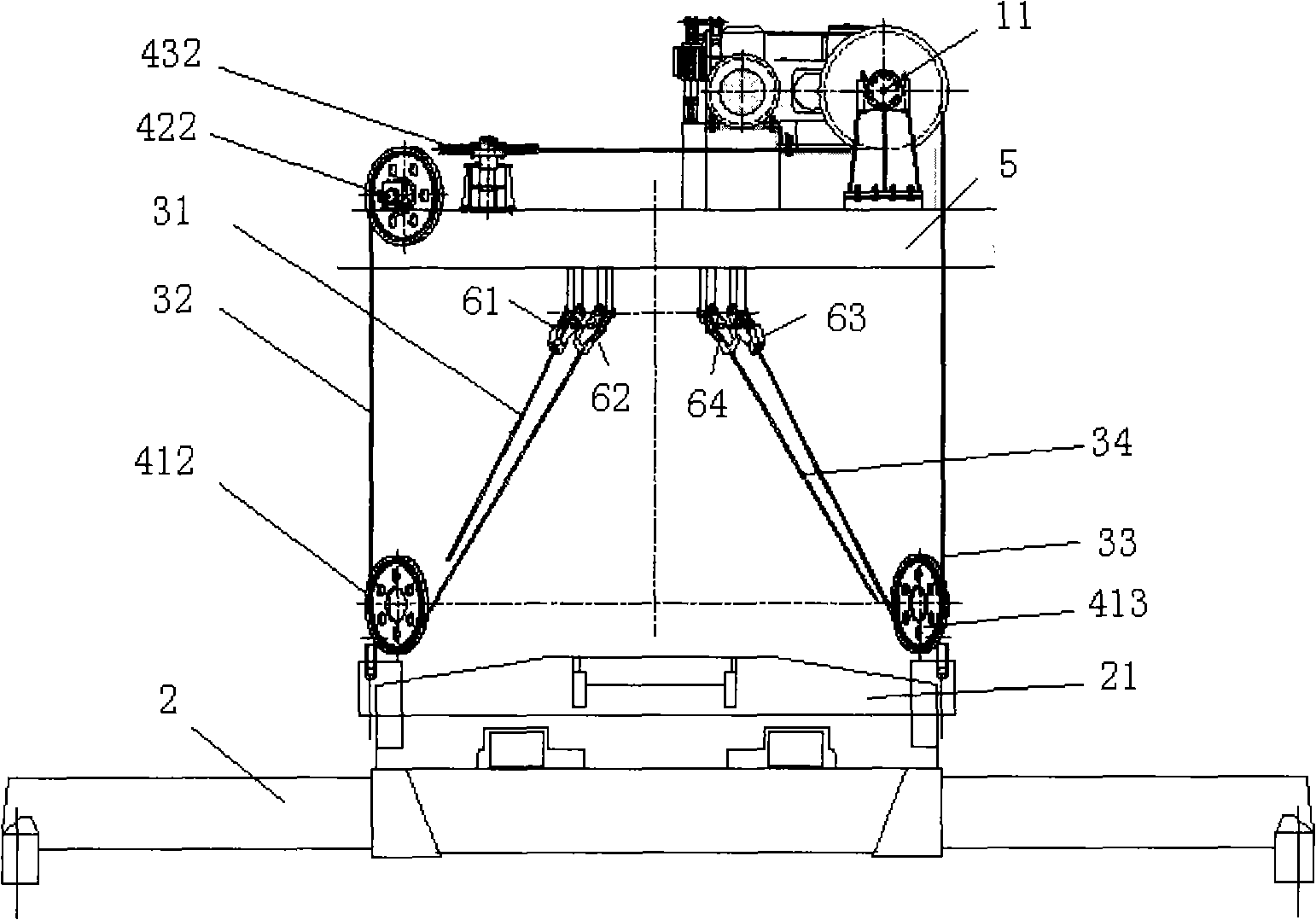

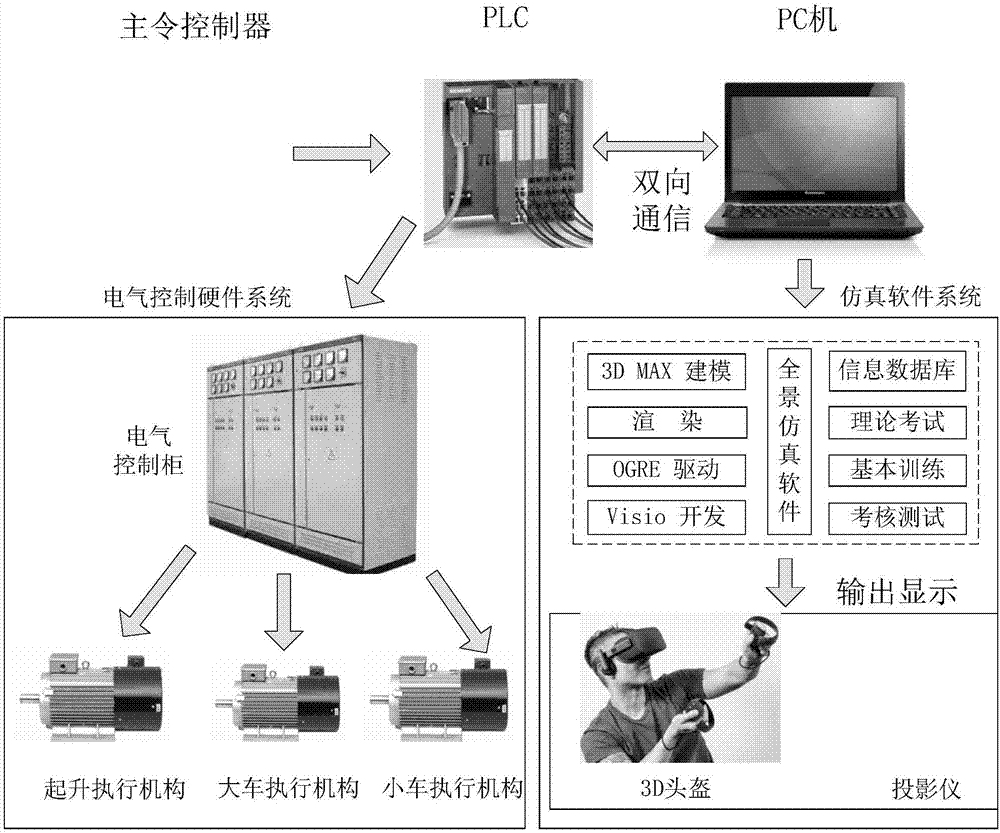

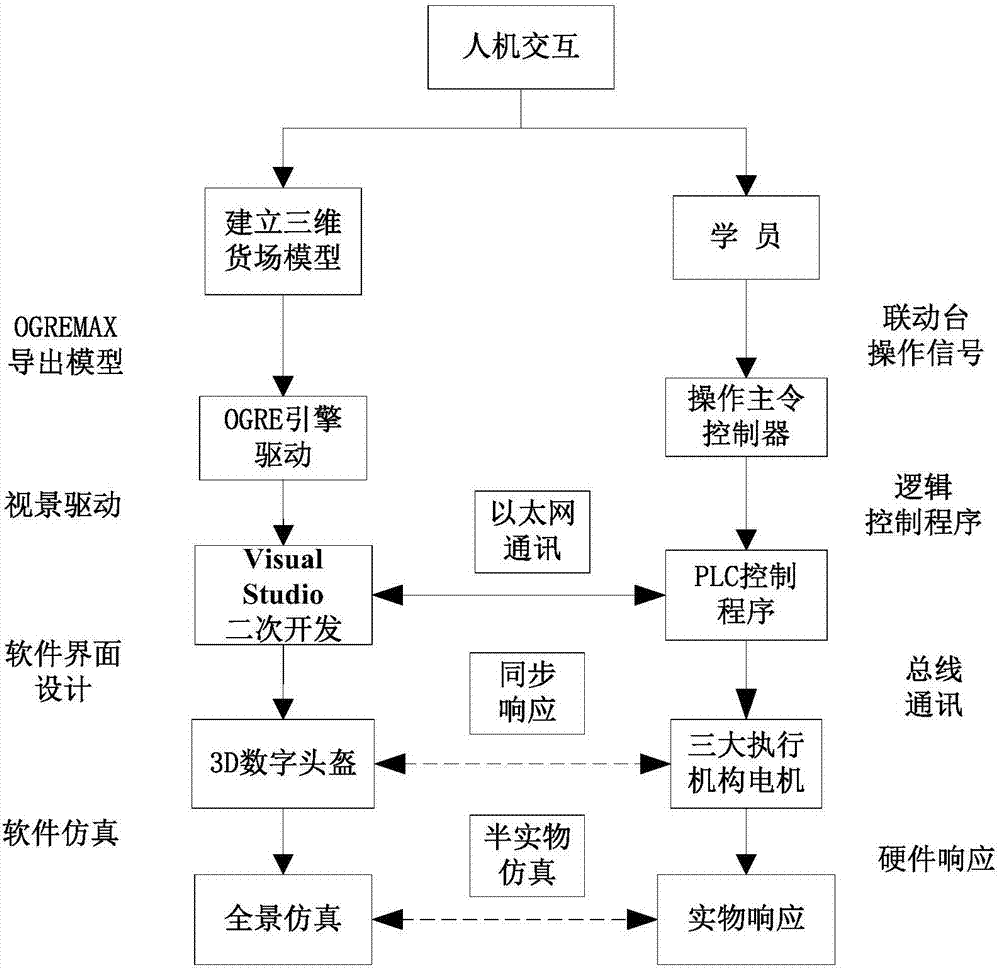

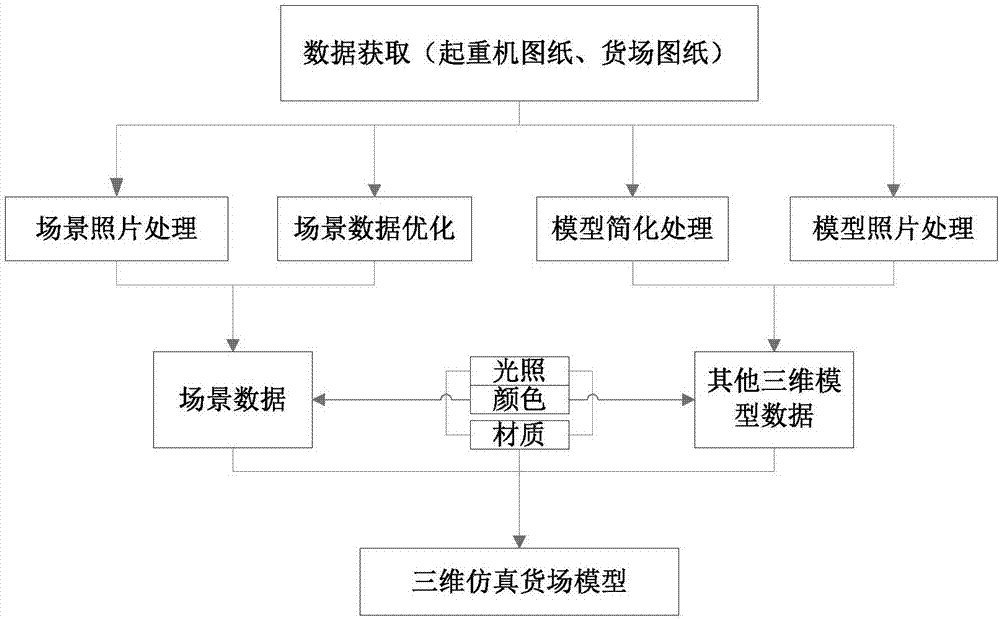

Container-door-type crane simulation operation panorama simulation system and method thereof

InactiveCN107331235AImprove training efficiencyImprove securityCosmonautic condition simulationsSimulatorsSoftware systemDigital mockup

The invention provides a container-door-type crane simulation operation panorama simulation system and a method thereof. The system comprises an electrical control hardware system and a panorama simulation software system. The electrical control hardware system comprises a crane operation linkage bench, a PLC control system, an electrical control cabinet, a driving motor, a 3D helmet system and a PC. The panorama simulation software system comprises a virtual three-dimensional modeling system, a virtual reality simulation software system, a three-dimensional virtual scene output display system, a student information recording database, a theory examination module, an operation training module and an evaluation system. A student operates a crane linkage bench and other external hardware, through using an Ethernet, operation command and the PC carry out bidirectional communication and a set of crane simulation digit model is established. A three-dimensional graph rendering engine is used to drive visual motion and a crane driver controls electrical equipment so that loading and unloading work panorama simulation operation training is performed on a container of a virtual environment. In the invention, training efficiency and training safety of a crane student are increased.

Owner:SOUTHWEST JIAOTONG UNIV

Method and apparatus for unloading ribbon rails from rail cars

ActiveUS6981452B2Reduce labor requirementsReduce riskBallastwayRefuse receptaclesEngineeringMechanical engineering

Owner:HERZOG CONTRACTING

Cabin entry process for main diesel generating set of 50,000-ton semi-submerged ship

InactiveCN102030076AReduce disassembly workIntegrity guaranteedVessel partsMarine engineeringDiesel generator

The invention discloses a cabin entry process for a main diesel generating set of a 50,000-ton semi-submerged ship. The cabin entry process comprises the following steps of: 1) selecting a cabin entry position and entering from a sectional folding port; 2) determining a cabin entry mode and horizontally pulling in by using a tool; 3) preparing for a cabin entry condition of the main diesel generating set; 4) preparing for cabin entry of the main diesel generating set, and arranging a rail, wherein two strips of sectional transverse H-shaped steel are arranged on the two sides of the rail; 5) lifting the main diesel generating set by using a gantry crane; 6) connecting a hoist, slowly pulling the main diesel generating set into a cabin by using the hoist, and checking a folding condition of a host pedestal and the rail at any time to prevent paint on a base of the main diesel generating set from being scratched; and 7) dragging the main diesel generating set out of the rail when completely reaching a preset mounting position. By the cabin entry process, the disassembly work of a cabin structure and pipe outfitting can be reduced, safe and high-efficiency cabin entry and completeness of the structure and the outfitting are guaranteed, and the workload is reduced.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

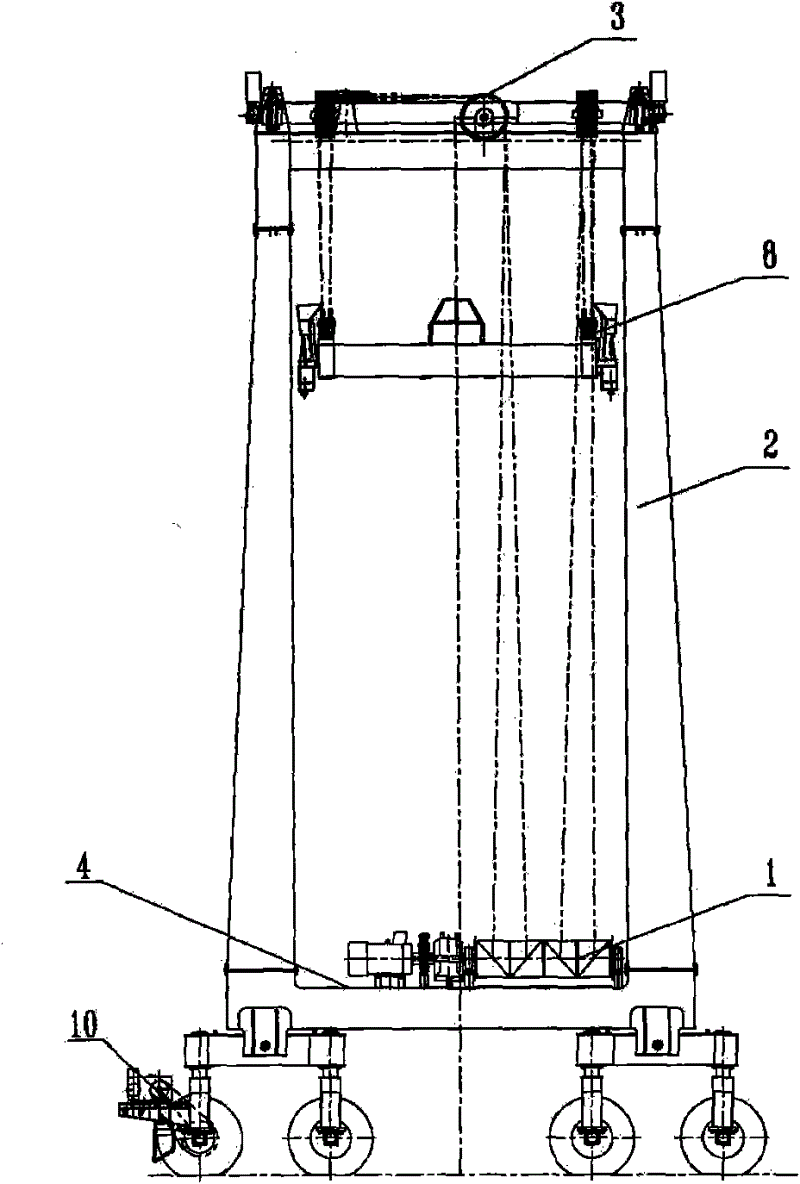

Semi-traction dolly type light-weight portal crane

InactiveCN102616666AReduce weightImprove stabilityTrolley cranesWinding mechanismsVehicle frameEngineering

The invention which discloses a semi-traction dolly type light-weight portal crane aims to provide a fixed or rubber-tyred or rail-mounted lifting loading and unloading apparatus with the advantages of simple structure, light weight, and economy and utility. The crane comprises a hoisting mechanism arranged at the bottom platform of a frame, a dolly frame and a dolly operation mechanism arranged on the kingpost track of the frame, a suspender connected with the dolly frame through first, second, third and fourth wire ropes, and a suspender rotary tilting device arranged at the rear side of the frame, wherein first ends of the first to fourth wire ropes are respectively connected to the reel of the hoisting mechanism; and second ends of the first to fourth wire ropes, which respectively slidingly go through the frame, the dolly and the assembly pulley of the suspender, are respectively connected to both ends of the suspender rotary tilting device or directly fixed on the wire rope fixing end at the rear side of the frame. The portal crane has the characteristics of light weight, saved investment, low energy consumption, low wheel pressure, low maintenance and use cost, and the like.

Owner:CHINA WATERBORNE TRANSPORT RES INST

Container storage yard transporation system

A container storage yard transportation system comprises a container storage yard having at least one container stacking area, at least one container handling cart delivery lane disposed alongside the container storage area, a container handling cart return lane associated with the delivery lane, a plurality of container handling carts disposed in the delivery and return lanes, gate handling equipment for transferring containers from ground transportation vehicles to handling carts in a loading position in the delivery lane such that the containers 1 an be transported to the container stacking area on the handling carts via the delivery lane, one or more yard gantry cranes for transferring the containers from the handling carts to the container stacking area, and cart shifting equipment for shifting empty handling carts between the delivery and return lanes such that the empty carts can be returned to the loading position via the return lane.

Owner:PACECO

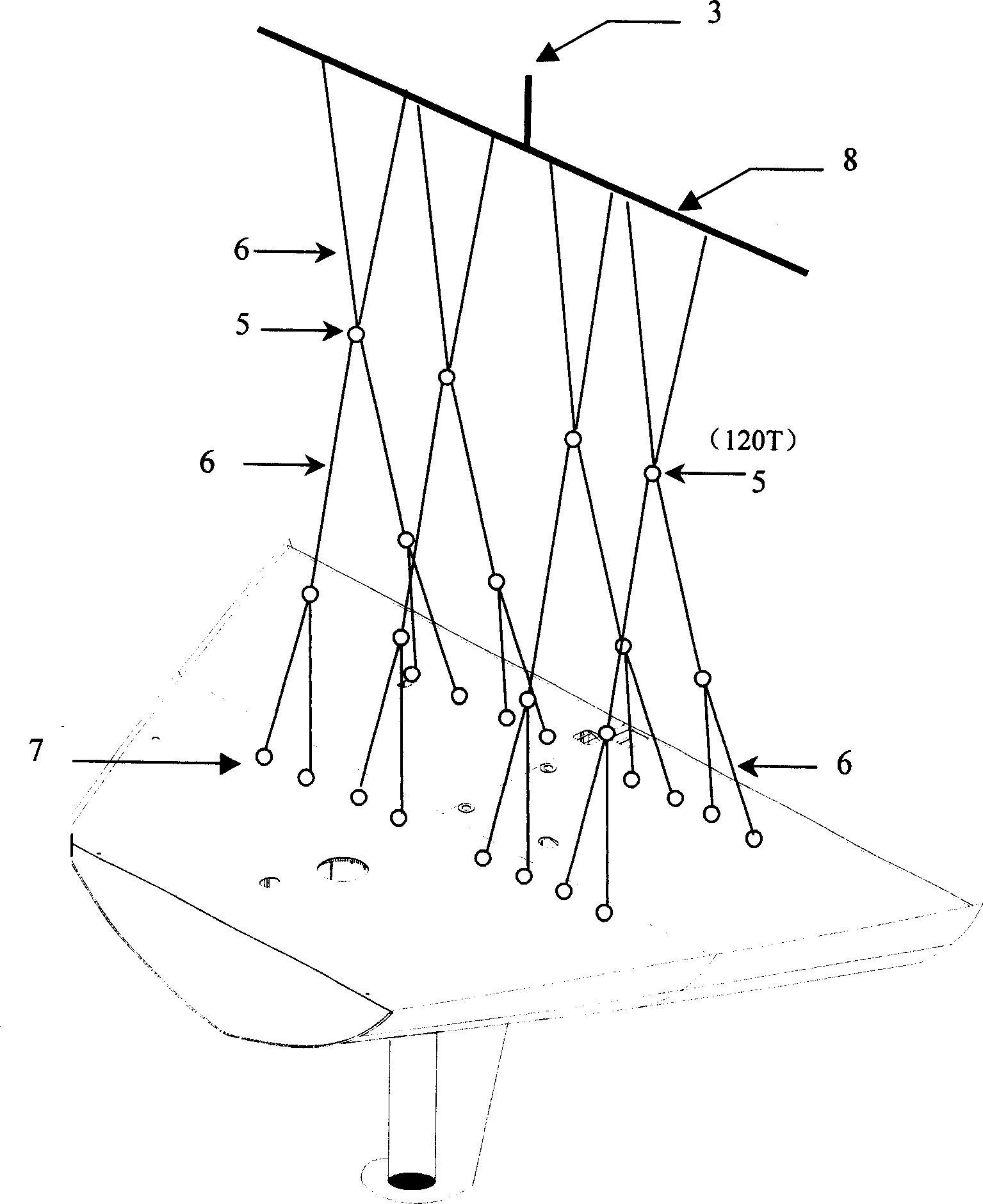

Large ship superstructure hoisting method

InactiveCN102452603AInsufficient reliefShorten the dock cycleVessel partsLoad-engaging elementsElement modelSimulation

The invention provides a large ship superstructure hoisting method which is implemented through the following steps: 1, calculating the whole weight and gravity center of the superstructure, configuring a hoisting point according to gantry crane equipment parameters and calculating the length and included angle of steel wire ropes; 2, designing a hoisting ring according the hoisting point and the whole weight; 3, carrying out reinforcement arrangement on the superstructure according to the hoisting point and stress distribution thereof; 4, establishing finite element modeling, carrying out whole strength check through finite element strength calculation, establishing a whole reinforced superstructure finite element model comprising the hoisting ring in MSC.Patran simulation software according to a structural drawing, and checking the whole and local strength through calculation; 5, reinforcing and modifying the steps 2 and 3 according to finite element calculation and strength check results, and rechecking; and 6, hoisting. Compared with the prior art, the method provided by the invention has the advantages of fully meeting technical indexes, obviously shortening the dock period at the same time, greatly relieving the defects of a ship integral assembly field and steadily improving the annual ship building quantity.

Owner:JINHAI INTELLIGENT MFG CO LTD

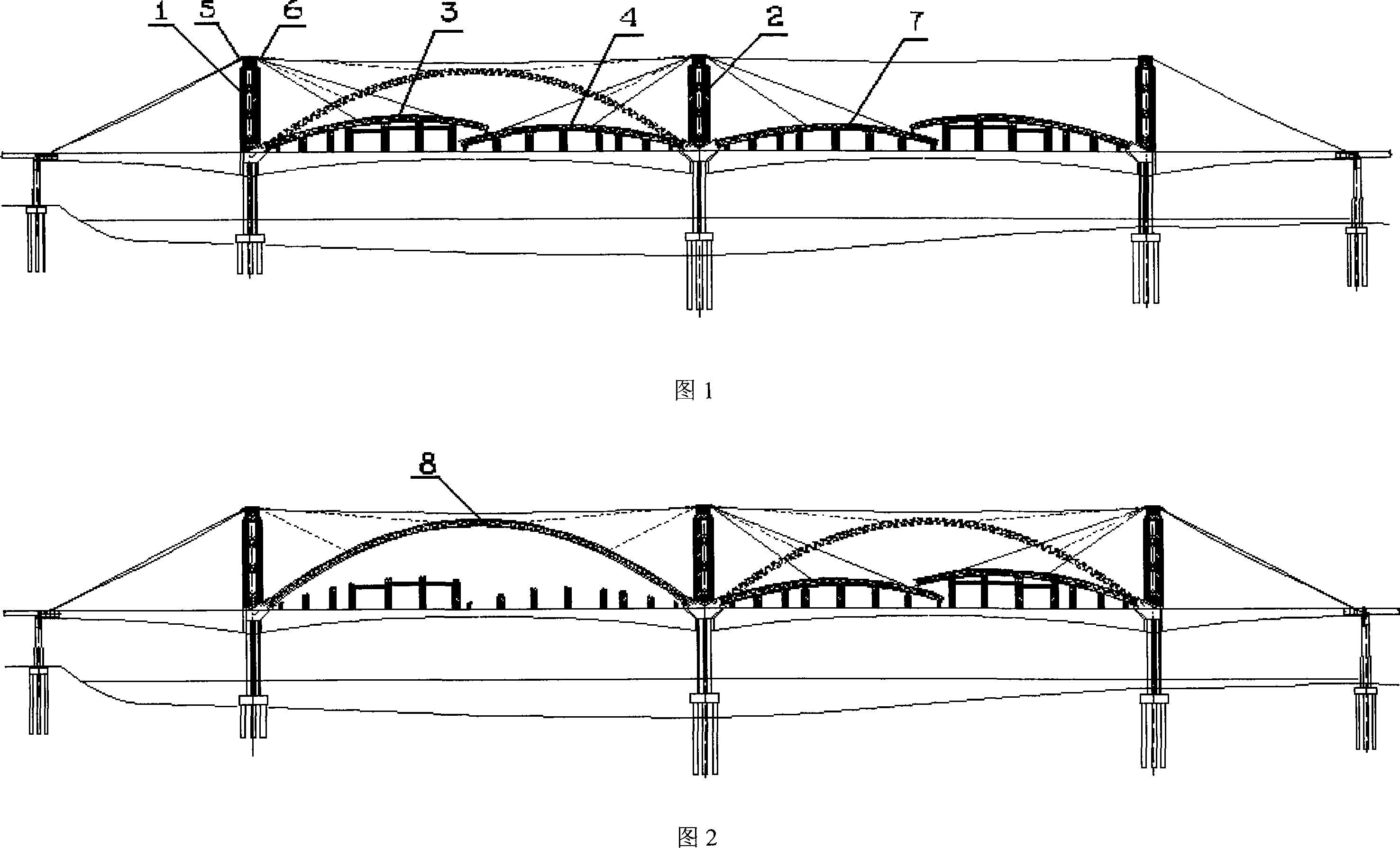

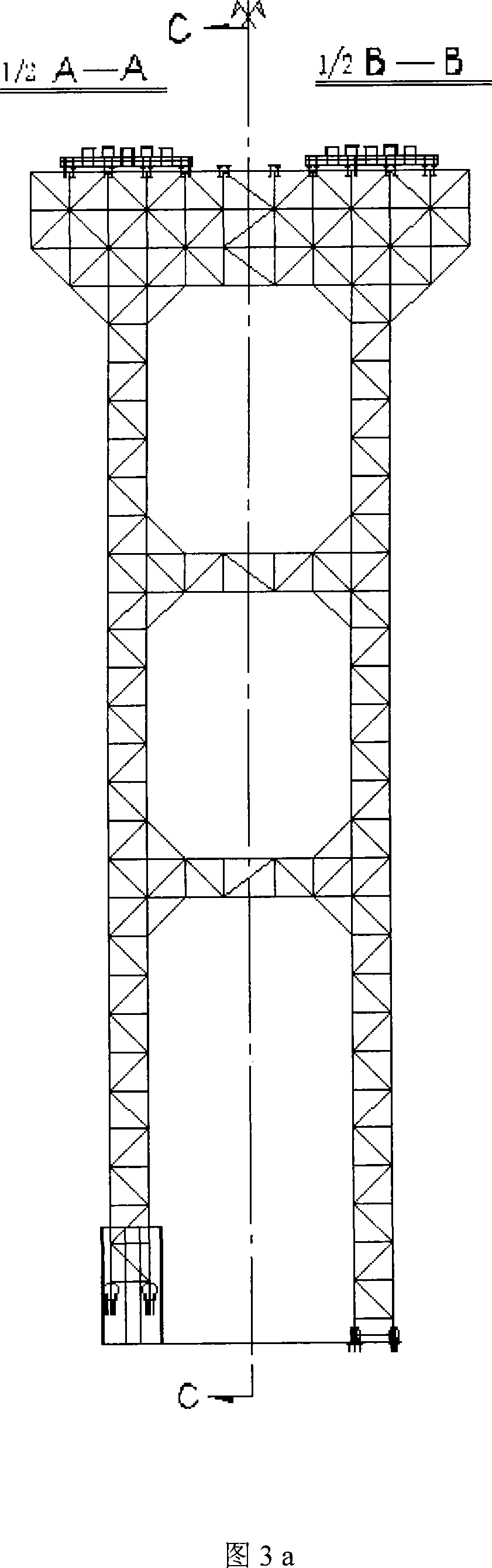

Multi-arch bridge rib vertical turning technical method

ActiveCN101200879AEasy constructionReduce construction costsBridge erection/assemblyRotation methodTower

The present invention relates to a construction method of bridges, in particular to a vertical rotation method of the arch ribs of a multi-span continuous arch bridge. The construction method includes seven steps: (1) the tower frames of a side tower and a middle tower, a hoisting station, a mobile gantry crane and an arch rib trestle are assembled, and a rear archorage system is installed; (2) arch ribs are assembled on the arch rib trestle; (3) the fastening anchorage cables of the steel pipe arch ribs of a first span are hung, and a swivel tensioner is installed; (4) the steel pipe arch ribs of the first span are rotated and closed; (5) the fastening anchorage cables of the steel pipe arch ribs of a second span are hung; (6) the steel pipe arch ribs of the second span are rotated and closed, and the working procedure is repeated until the rotation and the closure of the steel pipe arch ribs of the nth span are finished; (7) arch feet are closed, steeves are adjusted and the construction equipment is disassembled. The present invention has the advantages of convenient construction, safety, reliability and low construction cost.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

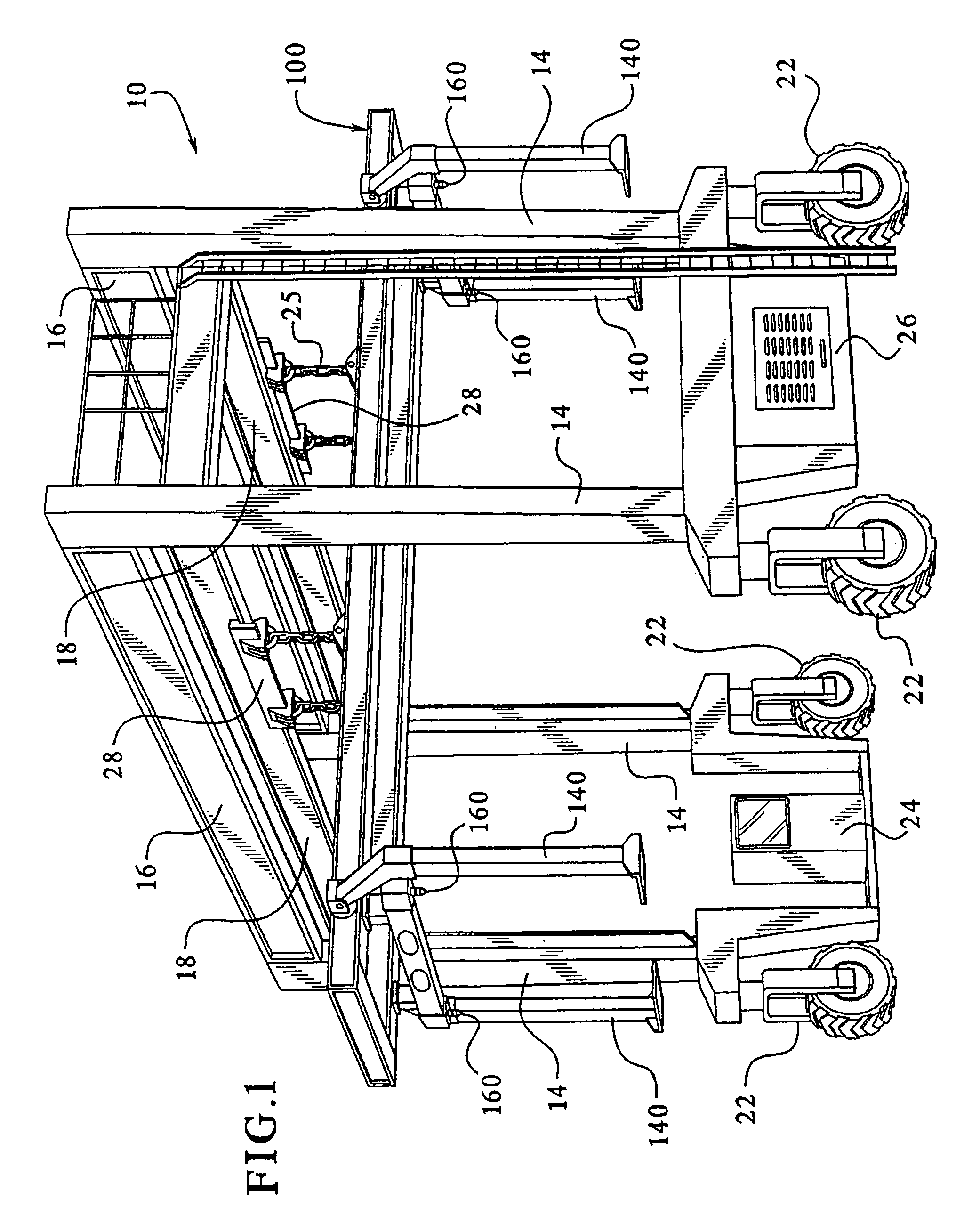

Panel turner for gantry crane

ActiveUS20070095776A1Reduce hoist capacityProtection overloadMechanical apparatusTrolley cranesEngineeringGantry crane

A gantry crane (10) is configured in a panel turner application. The gantry crane (10) generally includes a gantry crane structure (14) having a first cross-beam (28) and a second cross-beam (30). A first main hoist mechanism (40) and a first auxiliary hoist mechanism (42) are coupled to the first cross-beam (28), and a second main hoist mechanism (44) and a second auxiliary hoist mechanism (46) are coupled to the second cross-beam (30). The crane (10) includes a hydraulic system configured to reduce the lift capacity of the first and / or second main hoist mechanism (40, 44), and to equalize the hoist capacity between the first and second main hoist mechanisms (40, 44) or the first and second auxiliary hoist mechanisms (42, 46) in certain applications. The auxiliary hoist mechanism (42, 46) are configured for powered movement along the respective cross-beams (28, 30).

Owner:MARINE TRAVEELEVATOR

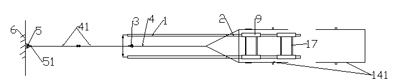

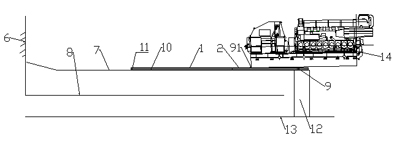

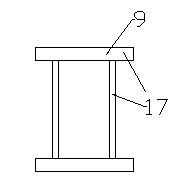

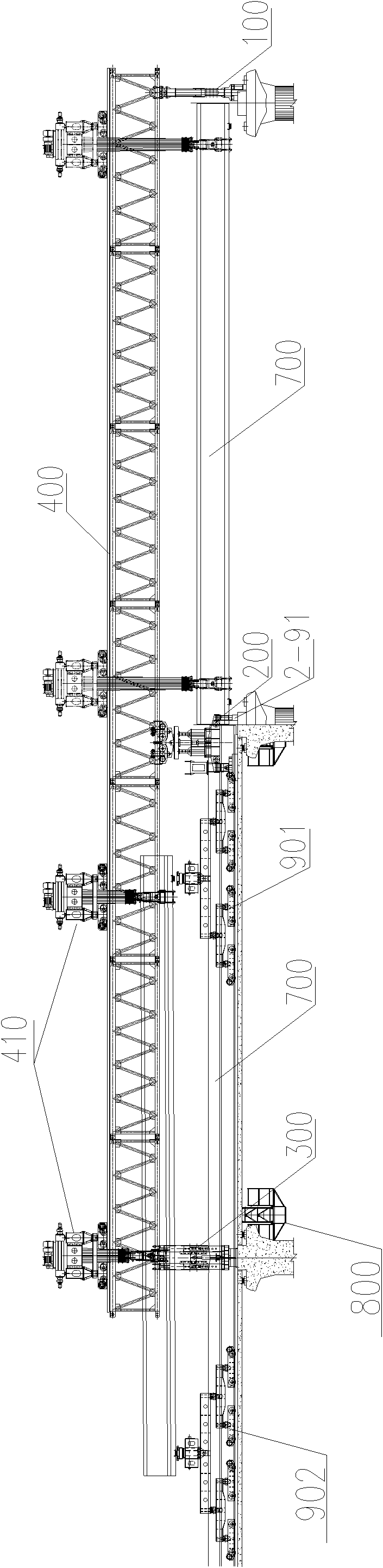

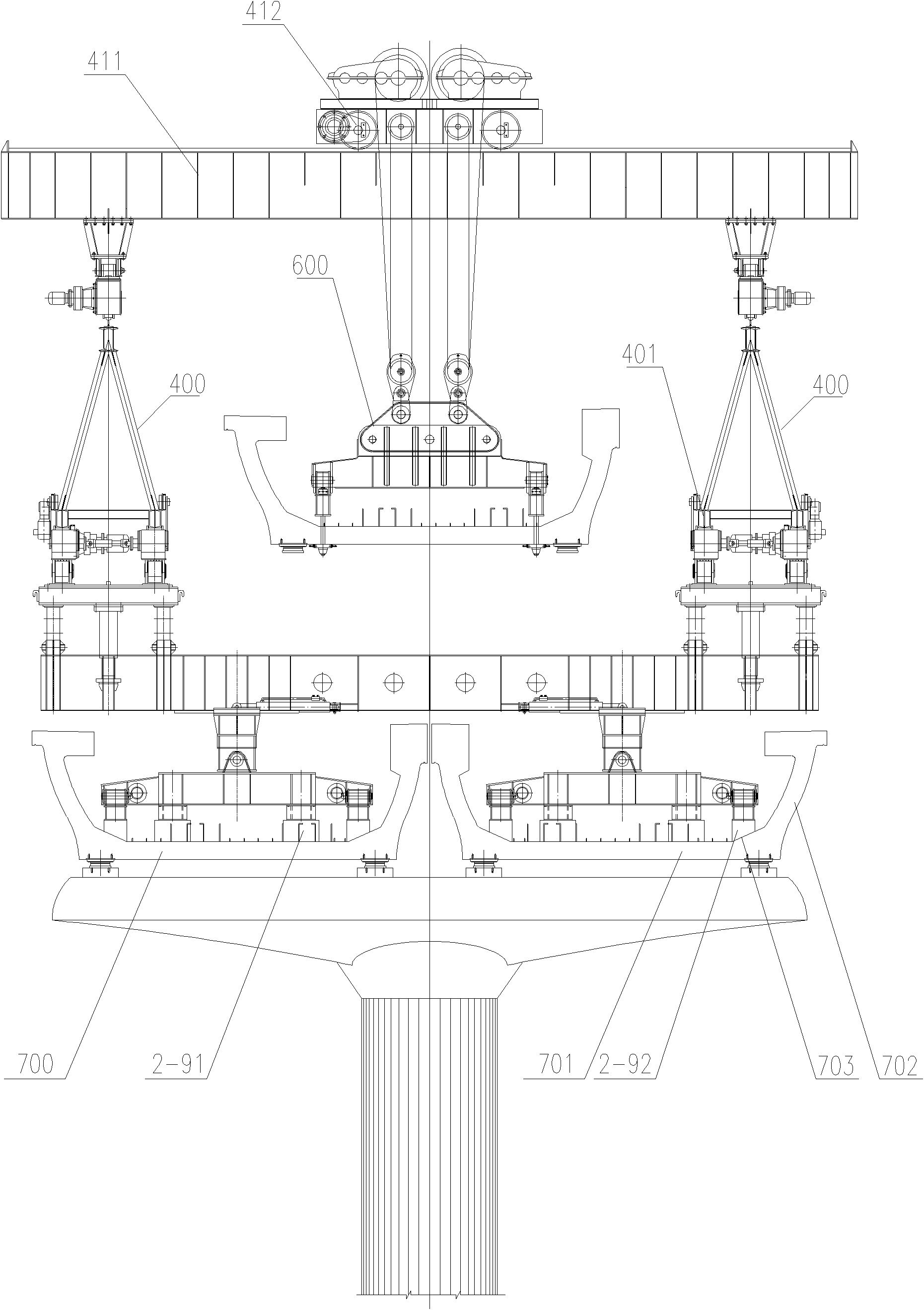

U-shaped concrete beam bridge girder erection machine

InactiveCN102367651AOvercoming bridging problemsConvenient for bridge constructionBridge erection/assemblyShaped beamConcrete beams

The invention provides a U-shaped concrete beam bridge girder erection machine, which comprises a bridge girder erection machine main beam, a front crown block, a back crown block, a telescopic No. 1 landing leg, a telescopic No. 2 landing leg, a telescopic No. 3 landing leg and a U-shaped concrete beam hanger, wherein the front crown block and the back crown block walk on the bridge girder erection machine main beam, and are provided with crown block transverse beams and crown block transverse moving mechanisms walking on the transverse beams; the U-shaped concrete beam hanger is connected with the crown block transverse moving mechanisms; and the bridge girder erection machine is further provided with a hanging construction platform, a front beam conveying trolley, a back beam conveyingtrolley and a temporary rail. In the invention, an original bridge girder erection machine can be improved specific to the characteristics of a U-shaped concrete beam, so that the problem of bridge girder erection caused by a U-shaped beam structure can be solved; convenience is brought to bridge girder erection construction according to the characteristics of the U-shaped beam structure, so thatthe bridge girder erection machine provided by the invention is suitable for U-shaped concrete beams; and crane hoisting or gantry crane installation is not required in U-shaped concrete bridge girder erection, so that the construction cost and difficulty can be greatly lowered, and the construction quality can be improved.

Owner:TENGDA CONSTR GROUP CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com