U-shaped concrete beam bridge girder erection machine

A technology of girder erecting machine and concrete girder, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve problems such as inaccurate control of the center of gravity, inability to withstand concentrated forces, and excessive moment of bridge pier capping girders, etc., to improve construction quality, reduce construction cost and difficulty, and facilitate bridge construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

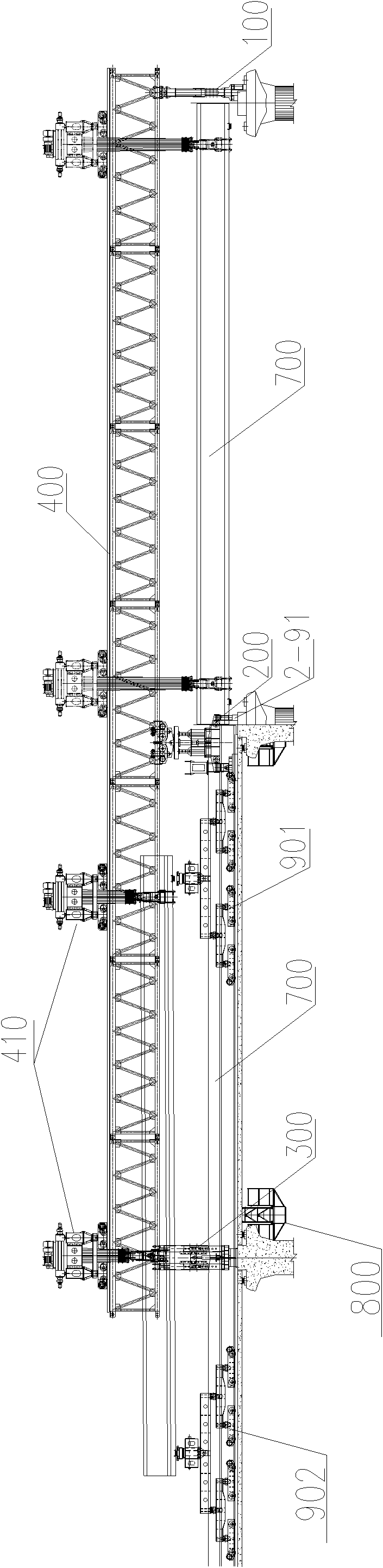

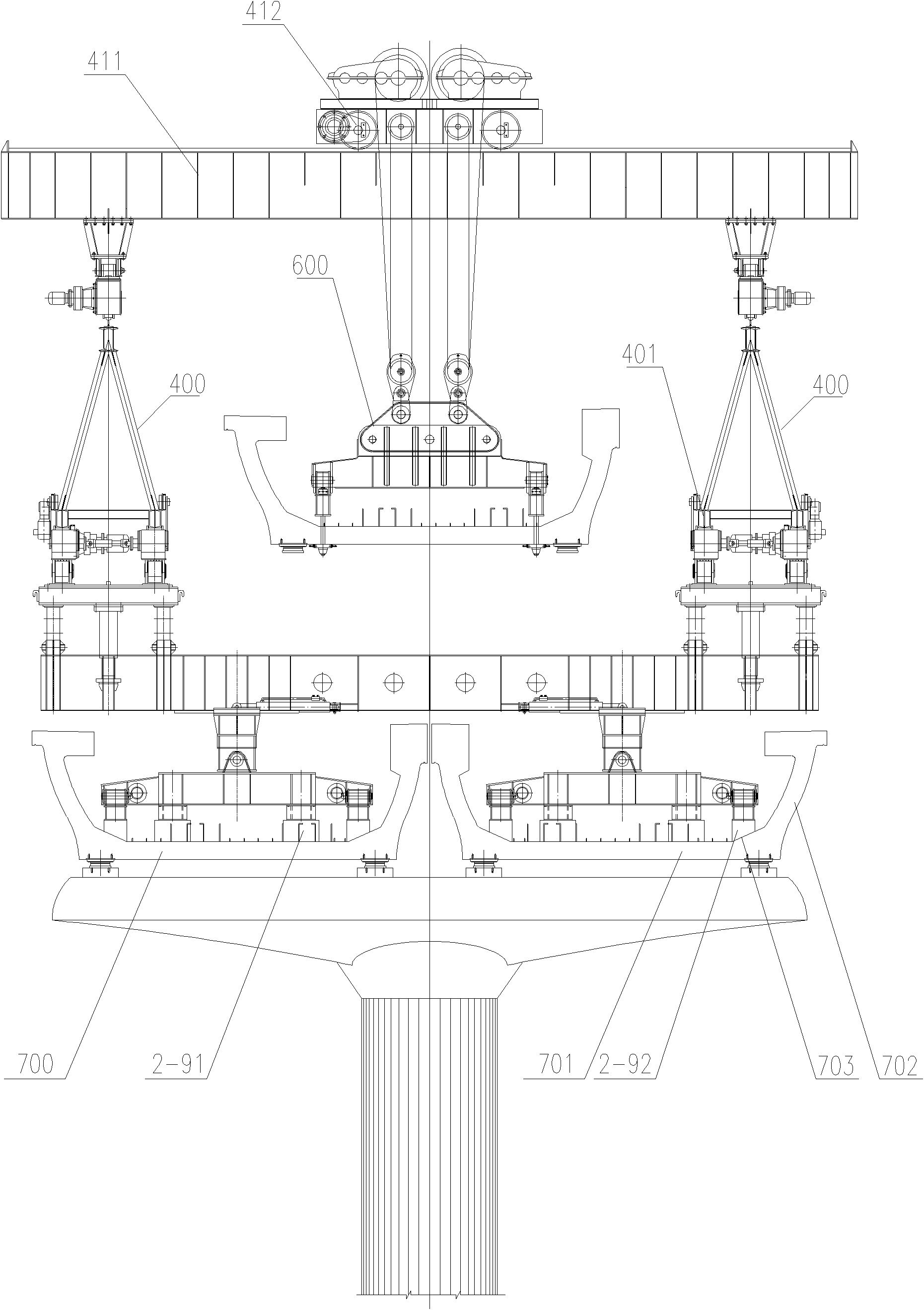

[0043] The present invention includes the main girder 400 of the bridge erecting machine, two cranes 410 traveling on the front and rear of the main girder of the bridge erecting machine, the retractable No. 1 outrigger 100, the No. 2 outrigger 200, the No. 3 outrigger 300, and the U-shaped concrete beam Spreader 600, the crane is provided with a crane beam 411 and a crane lateral motion mechanism 412 walking on the beam, the U-shaped concrete beam spreader is connected with the crane lateral motion mechanism, and the bridge erecting machine is also equipped with Front and rear beam transport trolleys 901, 902 and temporary track 500 thereof.

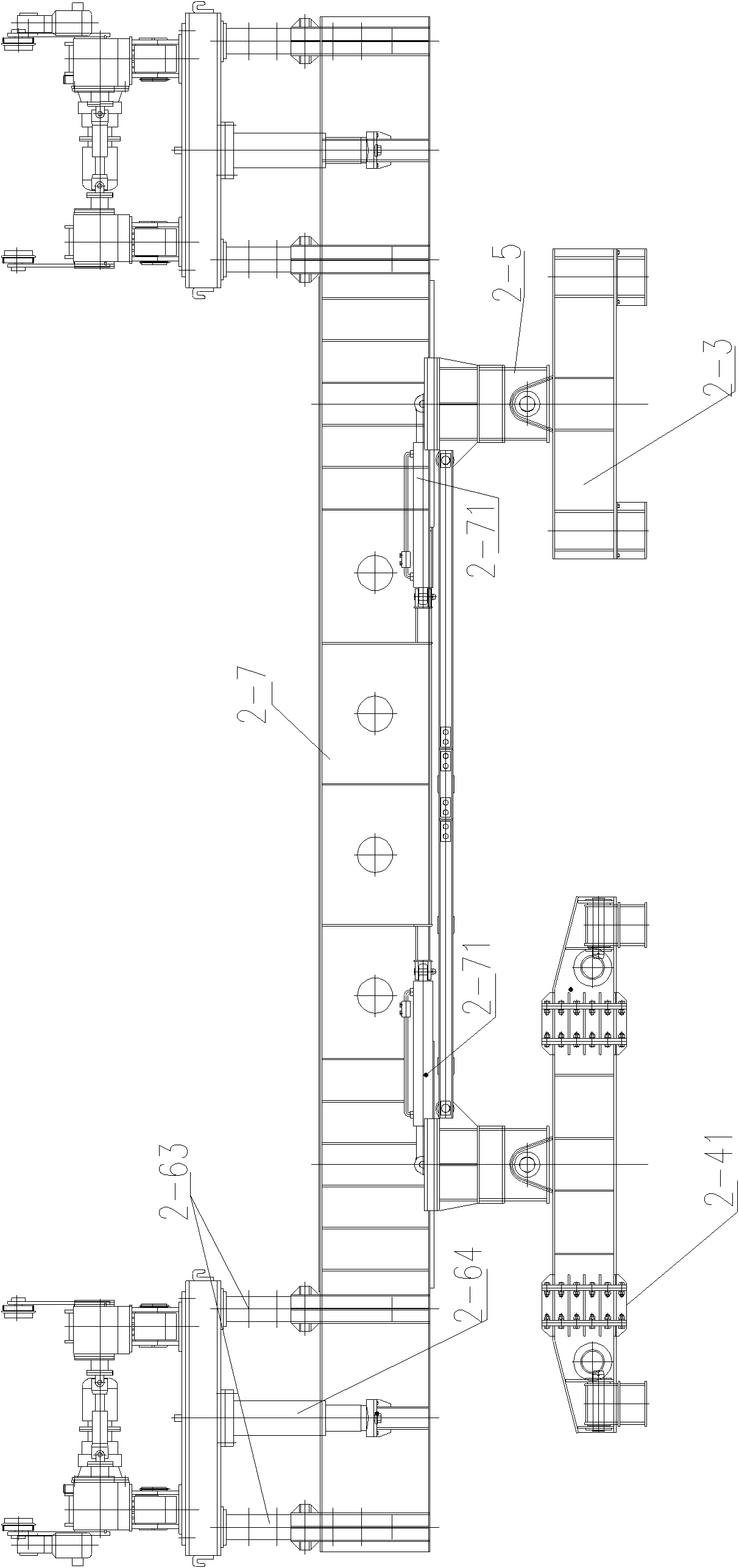

[0044] Refer to attached Figure 1-6 . The second outrigger 200 is the middle outrigger of the bridge erecting machine, which includes two sets of left and right outrigger mechanisms. The outrigger mechanism is provided with a multi-level "distribution beam-pad pier" structure. Including a front pier 2-1 and a rear pier 2-2; the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com