Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2165results about "Braking devices for hoisting equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

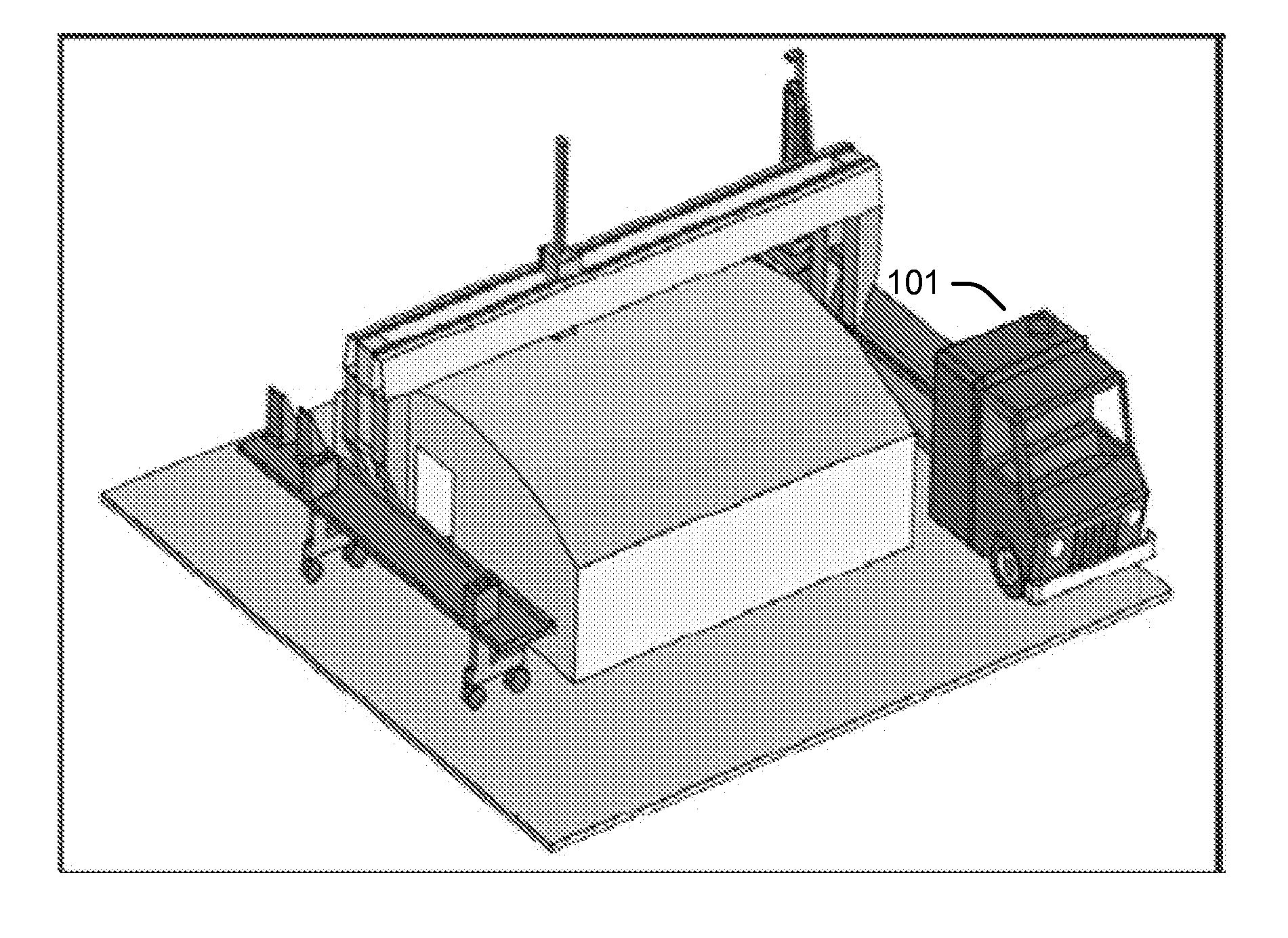

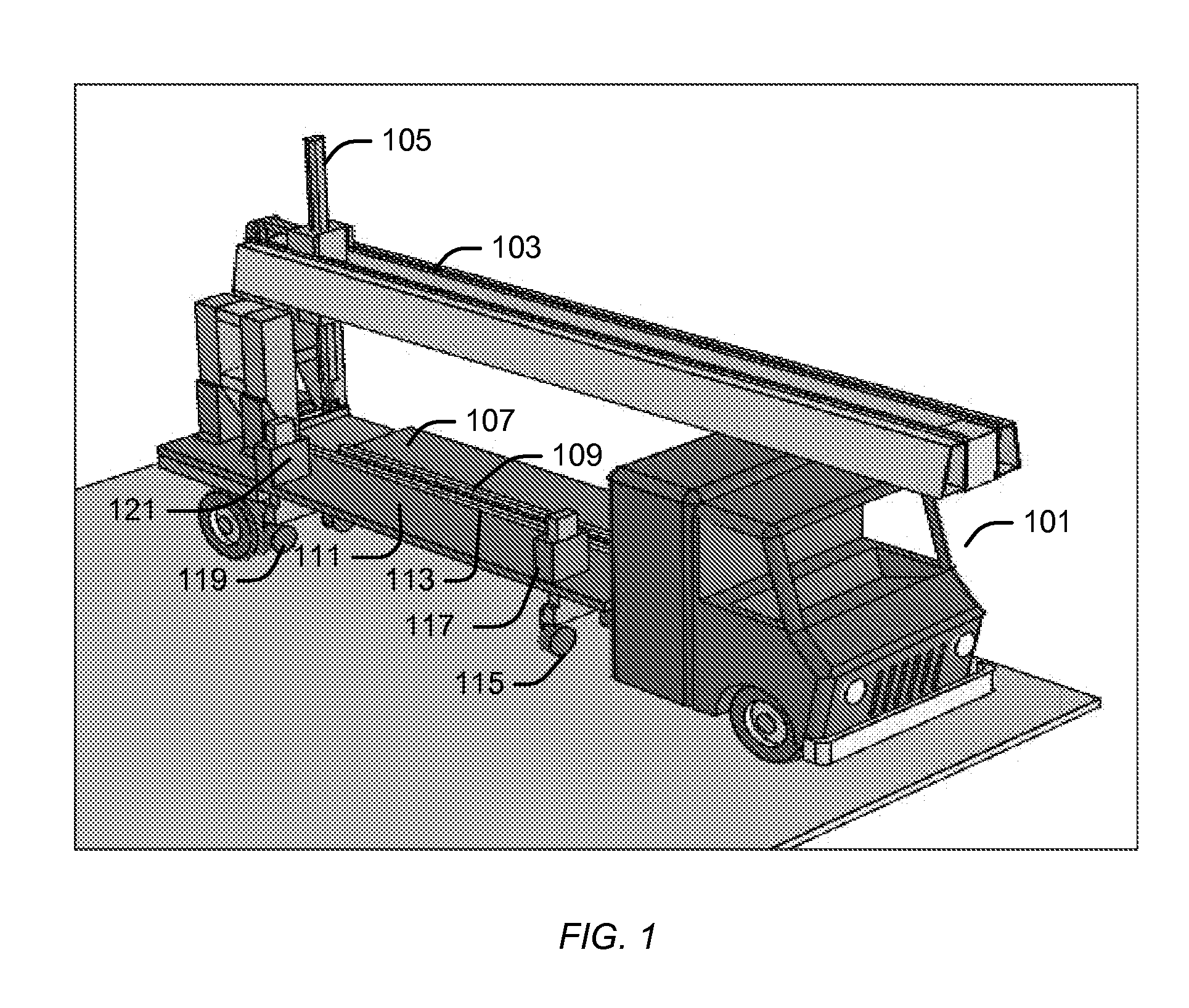

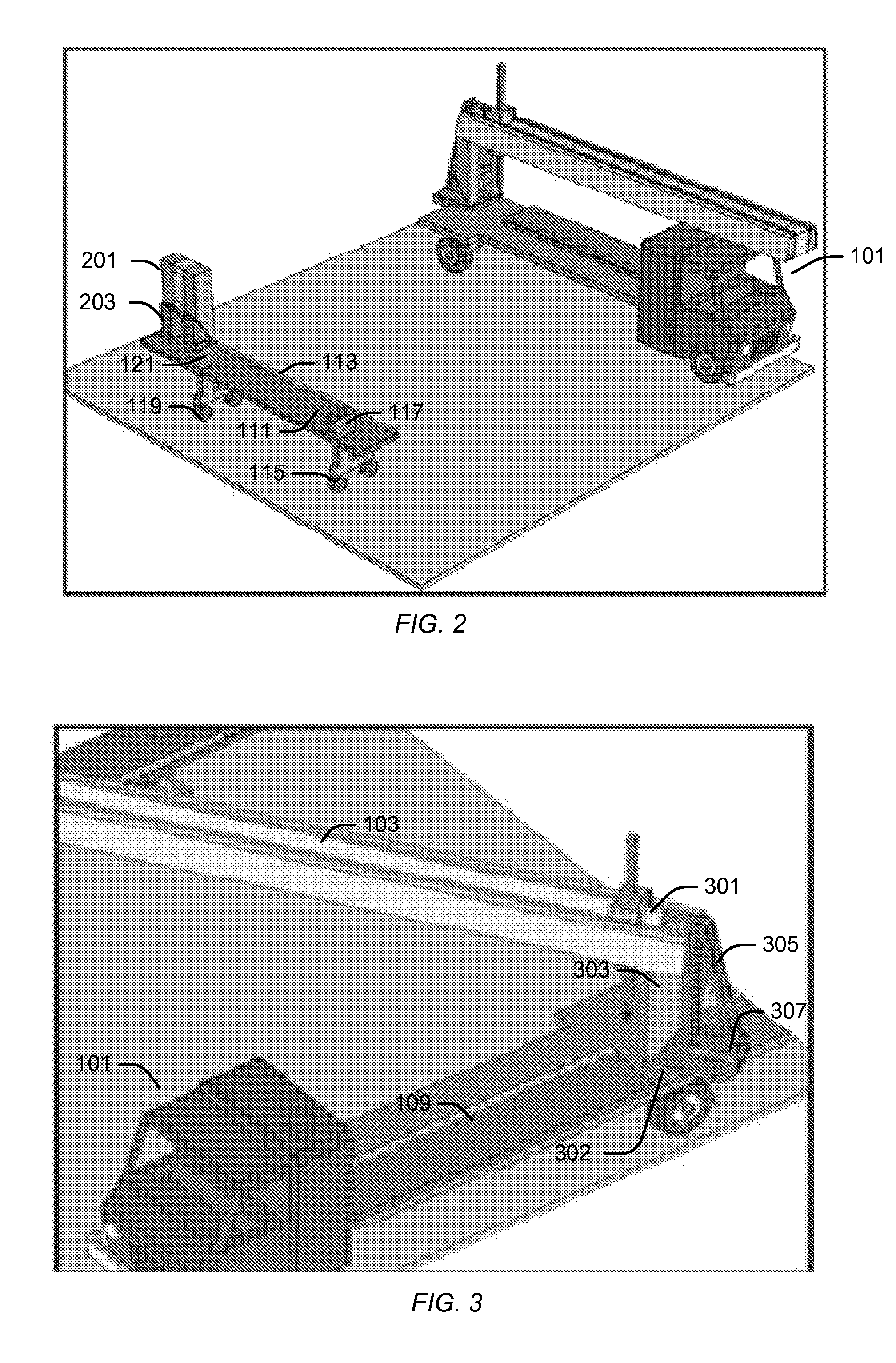

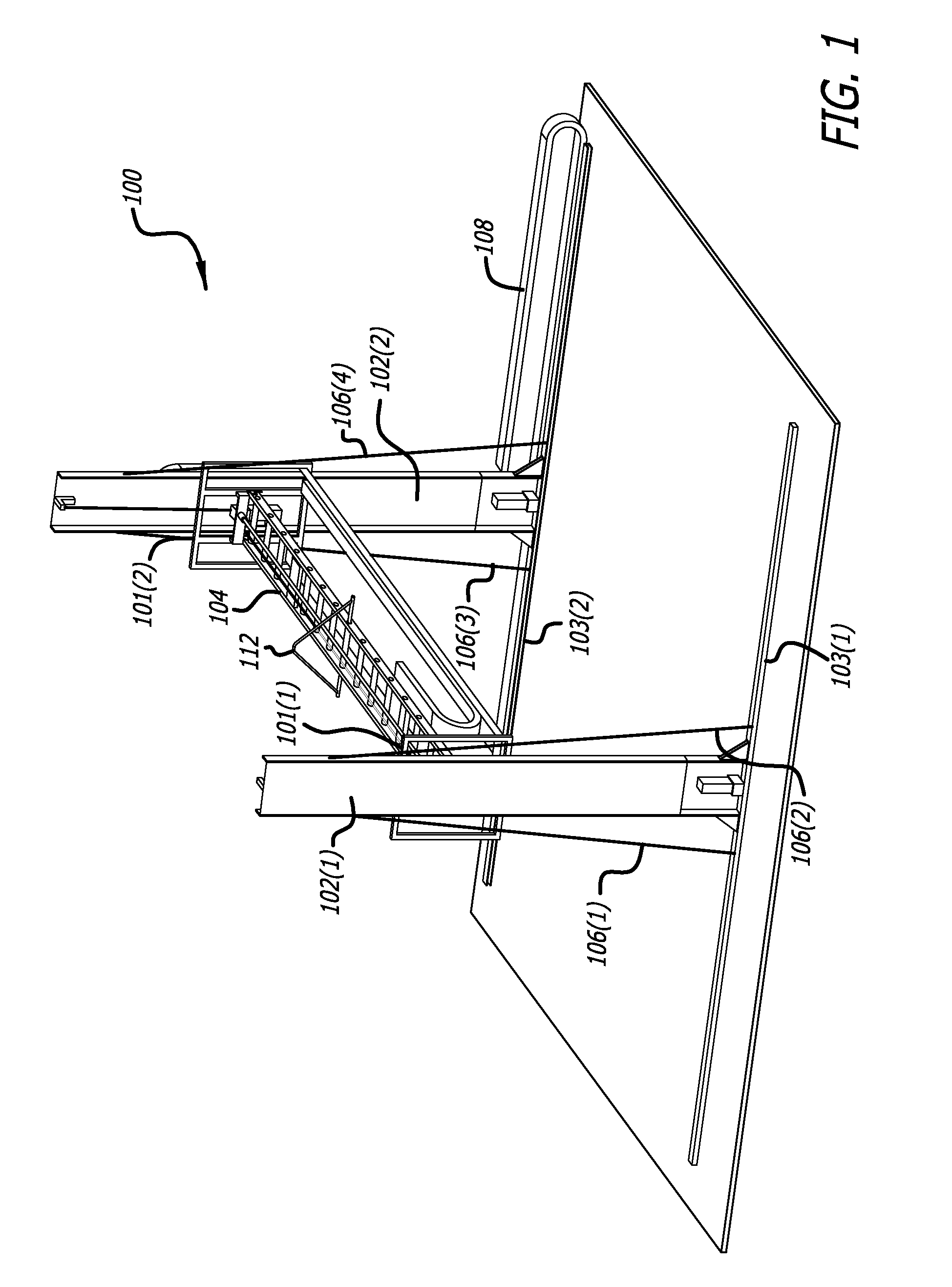

Deployable Contour Crafting

A deployable crafting machine may include a vehicle and a gantry system. The gantry system may be configured to be collapsed on the vehicle during which the gantry system is inoperable and to be expanded during which the gantry system is operable and supported at least in part by the vehicle. A deployable crafting process may include moving a vehicle to a first location while a gantry system is stored on the vehicle in a collapsed and inoperable state and expanding the gantry system into an operable state after the vehicle arrives at the first location during which the gantry system is supported at least in part by the vehicle.

Owner:UNIV OF SOUTHERN CALIFORNIA

Crane apparatus equipped with container security scanning system

InactiveUS6845873B1Improve reliabilityCargo handling apparatusBase supporting structuresEngineeringNeutron

Crane apparatus is equipped with a container security scanning system for scanning containers for radioactive material, such as neutron or gamma ray emissions. The crane apparatus has a crane for unloading containers from a marine vessel and placing the containers on a deck located at the portal girder level of the crane and for transferring the containers from the deck to another location. The container security scanning system comprises one or more scanning units disposed on the deck, each scanning unit having one or more scanning platforms for supporting a container such that a bottom of the container is vertically spaced from the deck. A scanning device is movable beneath the container in a space between the underside of the scanning platforms and the deck for scanning the container to detect whether radioactive material is present. Existing cranes can be retrofitted with the container security scanning system, and newly manufactured cranes can be upgraded to include such a system.

Owner:CHATTEY NIGEL

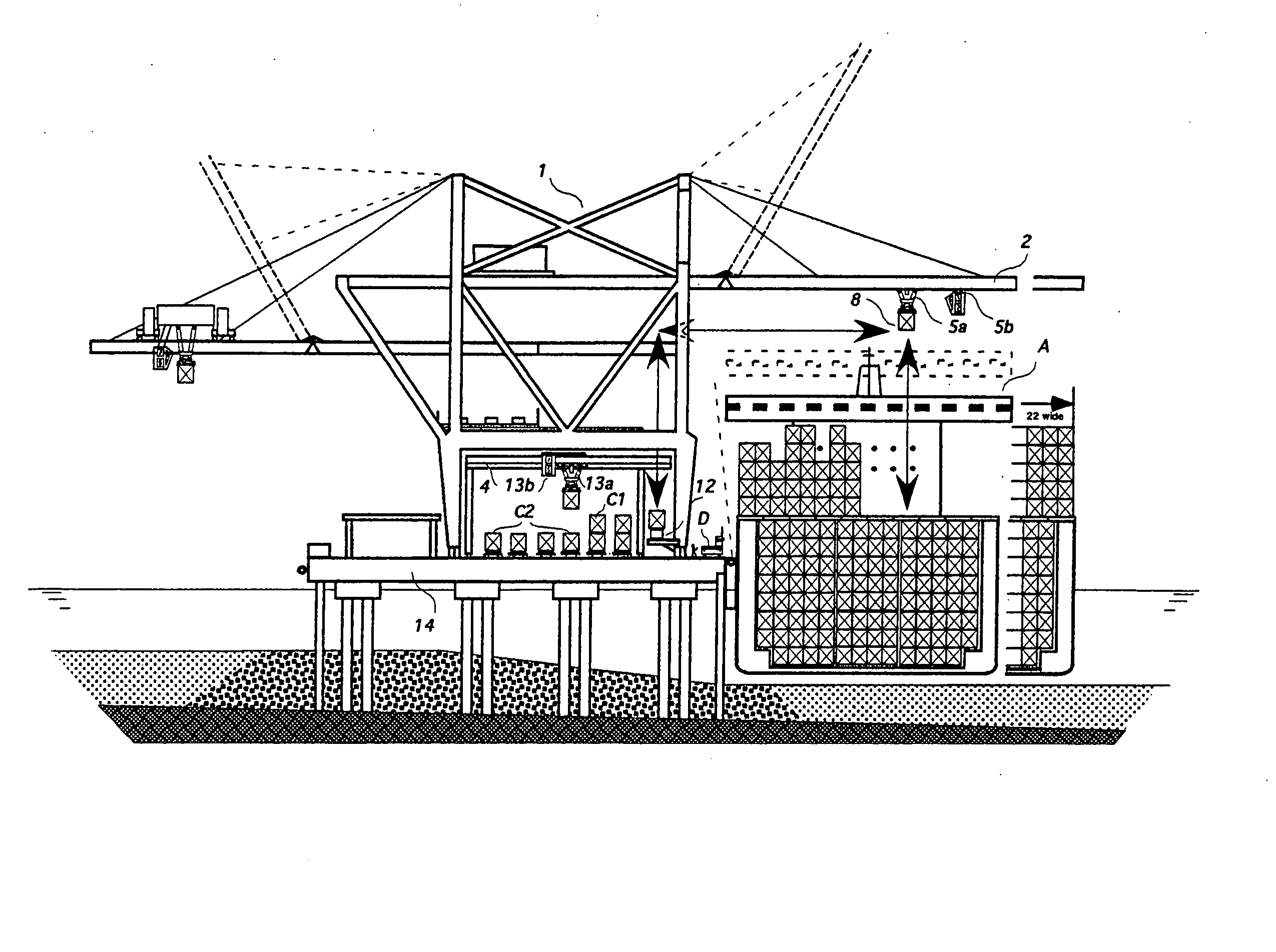

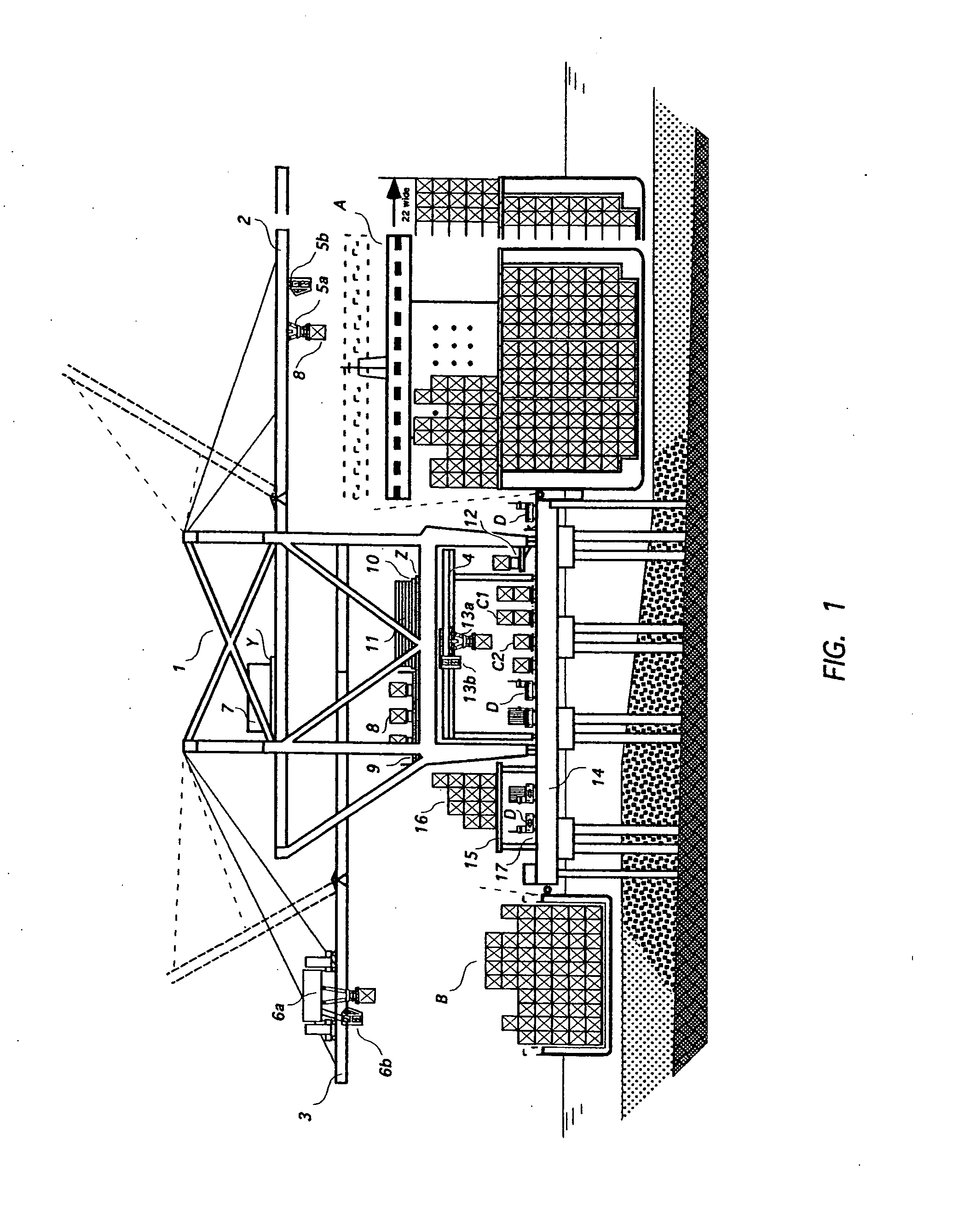

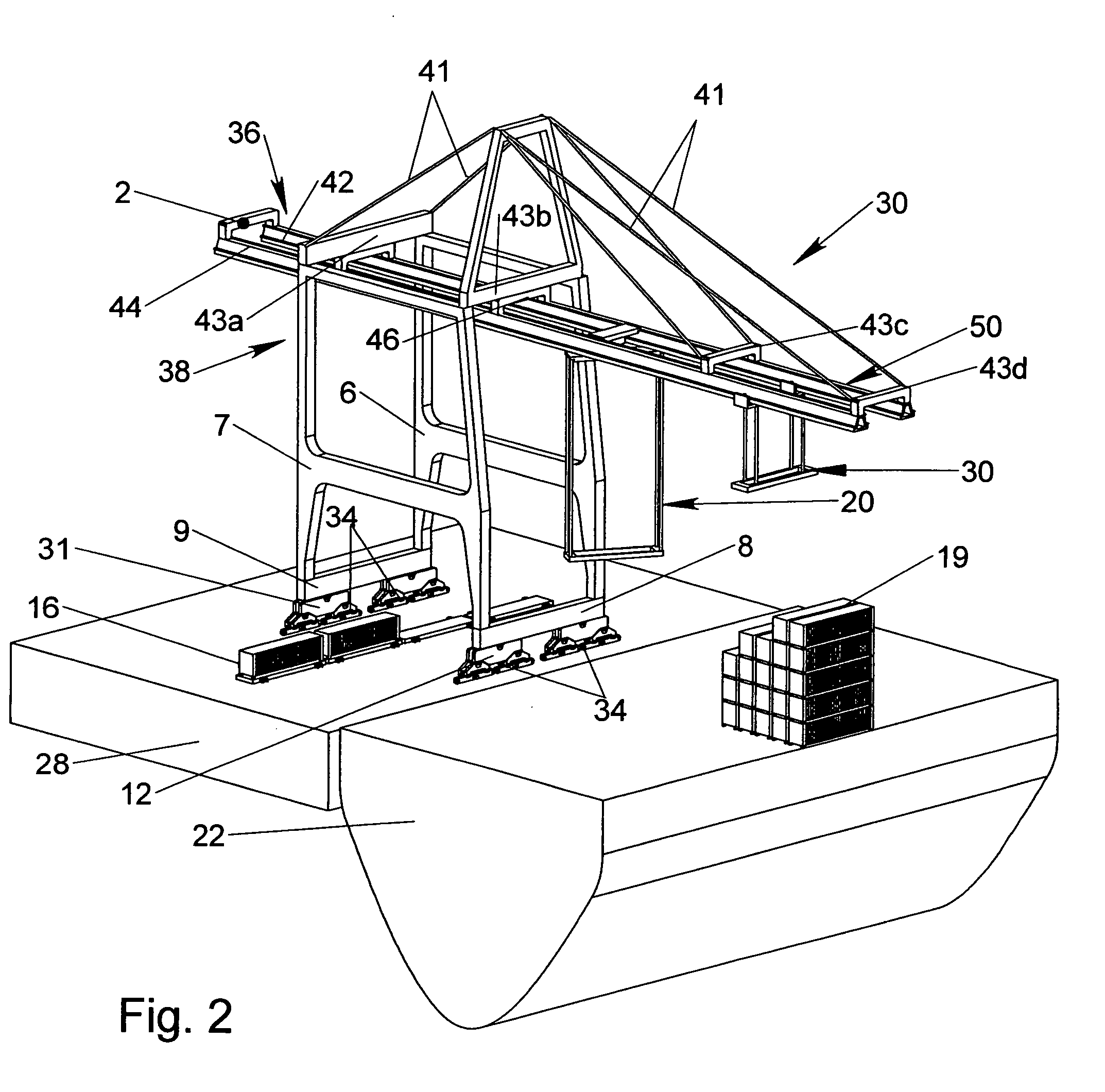

Container crane apparatus and method for container security screening during direct transshipment between transportation modes

InactiveUS20080219804A1Save a lot of costCargo handling apparatusBase supporting structuresContainer craneGround vehicles

A crane apparatus installed on a pier, wharf, bulkhead wharf or other foundation directly transships containers from a vessel moored alongside the foundation to another transportation mode without ground placement of the containers. The crane apparatus includes a parent crane displaceable along the foundation for unloading containers from the vessel and placing them on a first platform of the parent crane, and a sibling crane displaceable along the foundation independently of displacement of the parent crane for loading containers from the first platform directly onto over-the-ground vehicles or onto another vessel moored alongside the foundation. The parent crane has a first trolley-hoist-spreader movable along an outreach boom for unloading containers from the vessel and placing them on either the first platform or a second platform of the parent crane, and a second trolley-hoist-spreader movable along a backreach boom for loading containers from the second platform onto another vessel or onto over-the-ground vehicles. A container security scanning system may be provided on the second platform for scanning the containers while on the second platform to determine whether one or more preselected chemical, biological, explosive or nuclear materials are present in the containers.

Owner:CHATTEY NIGEL

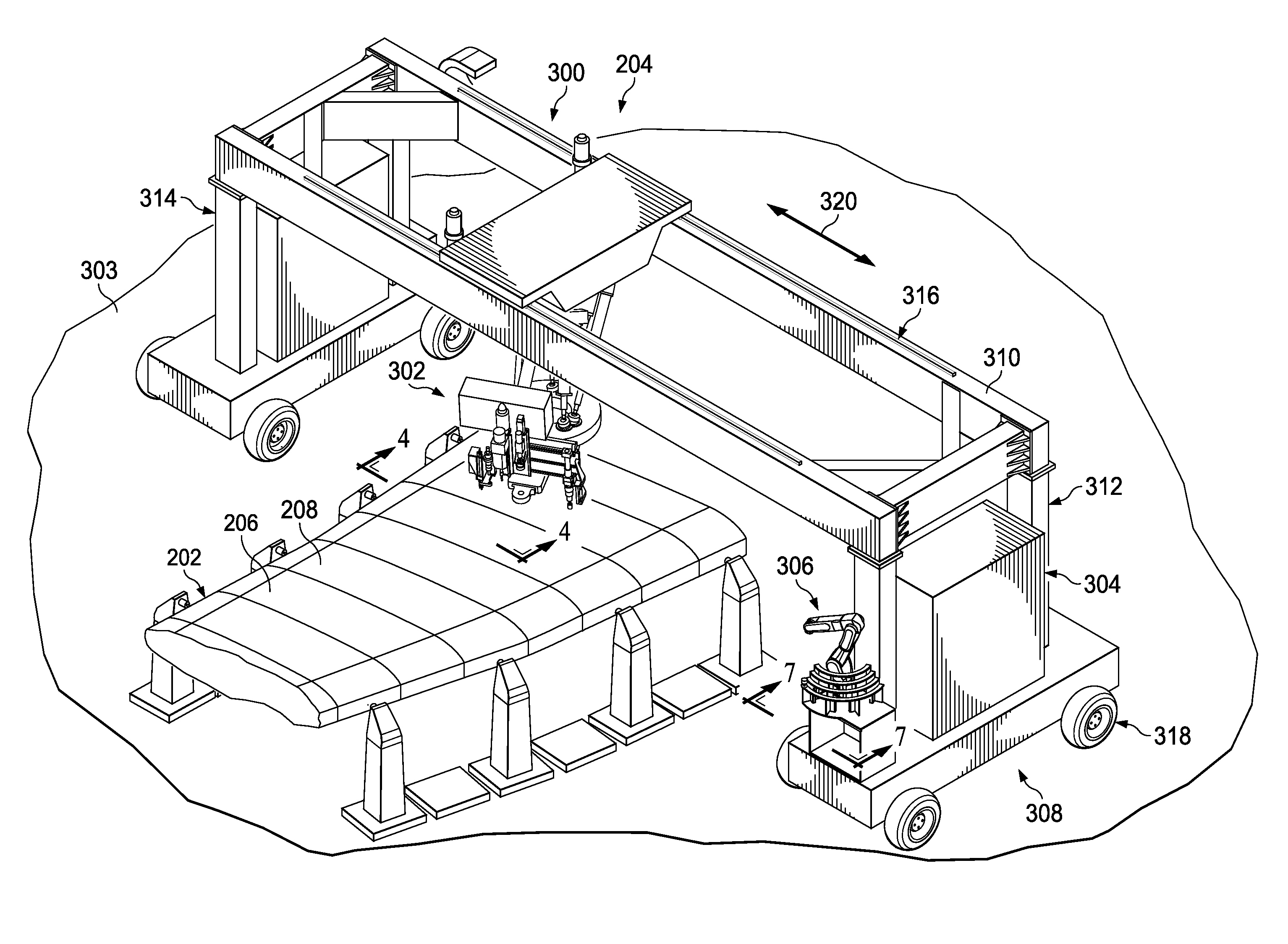

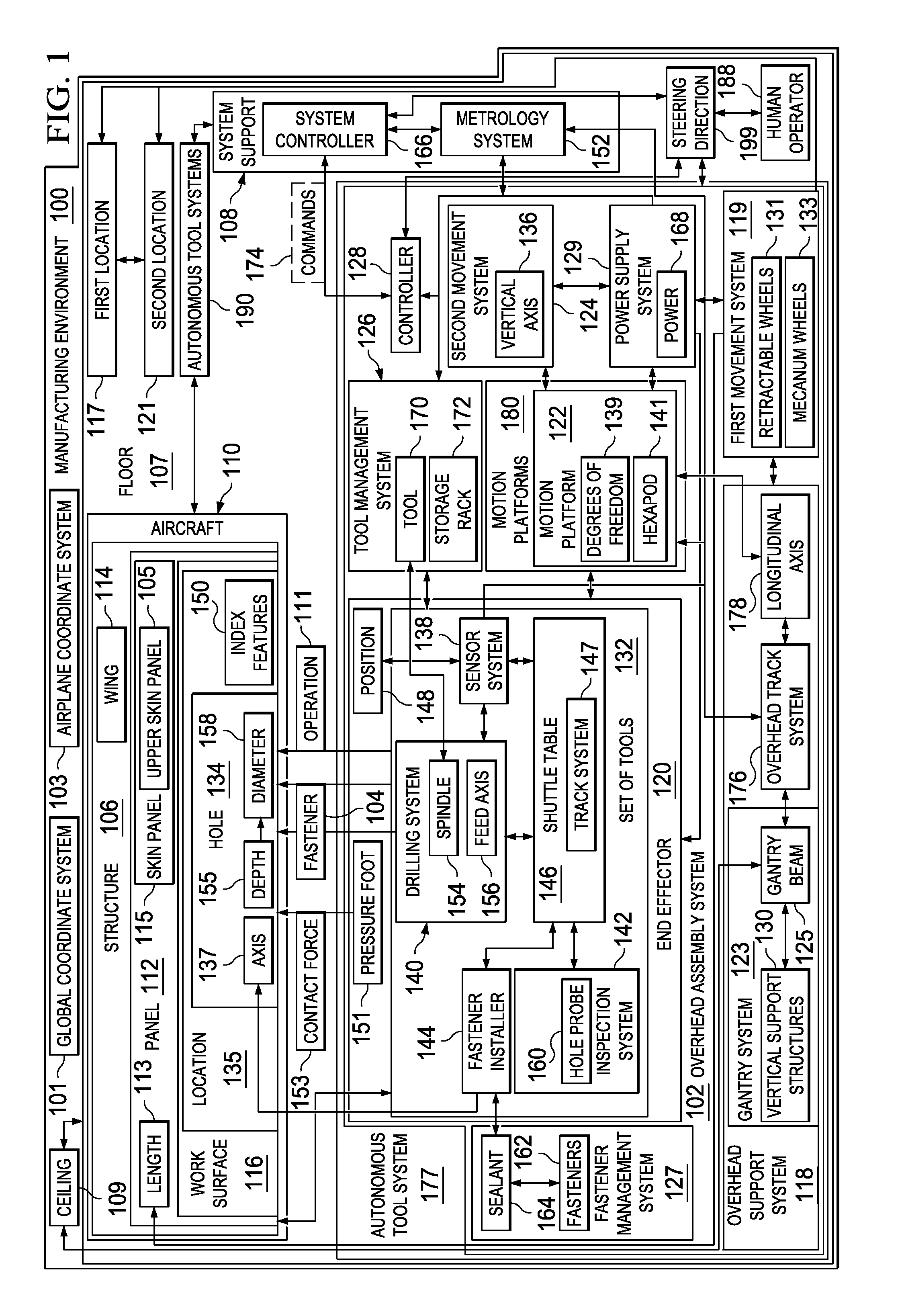

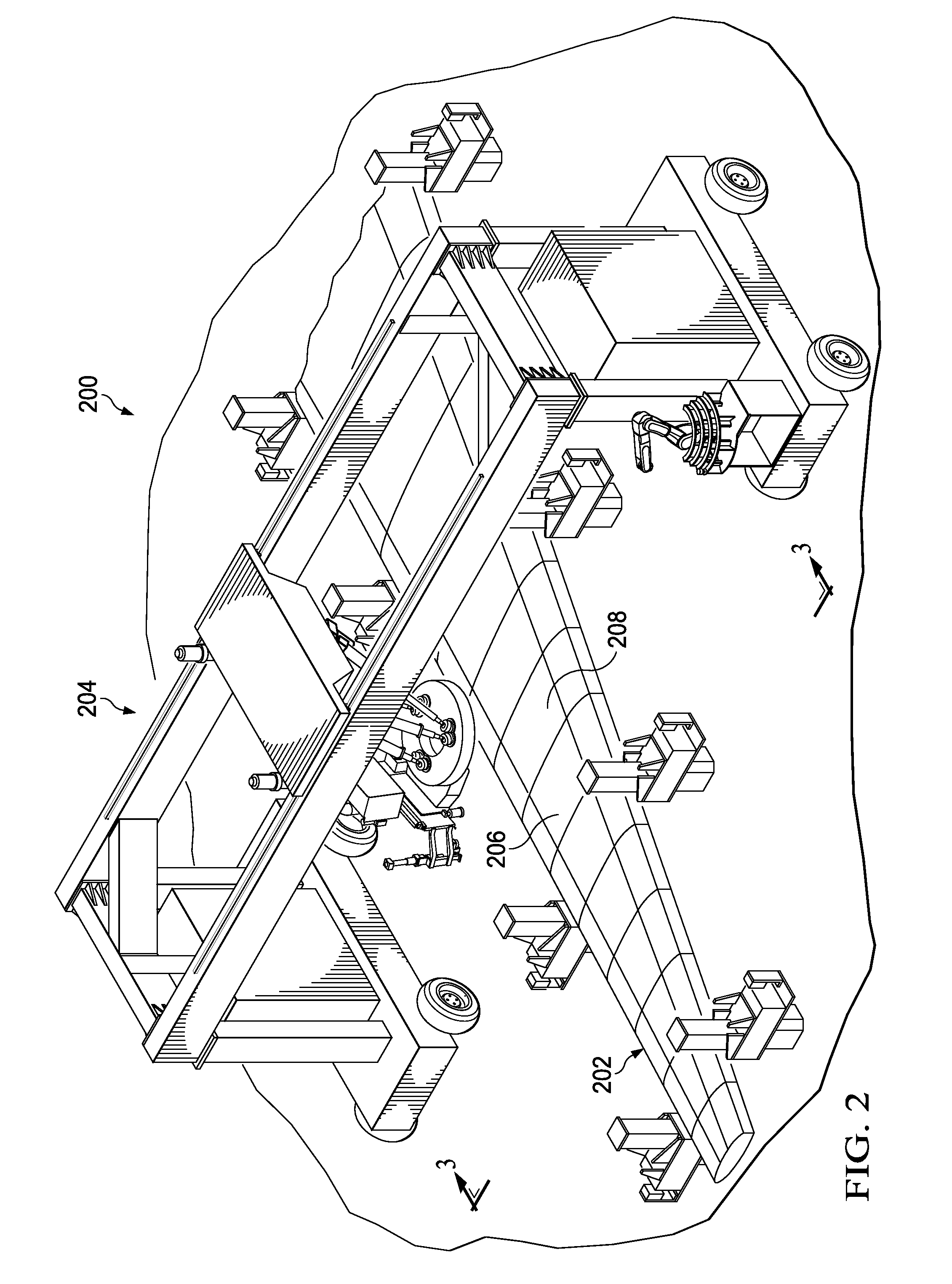

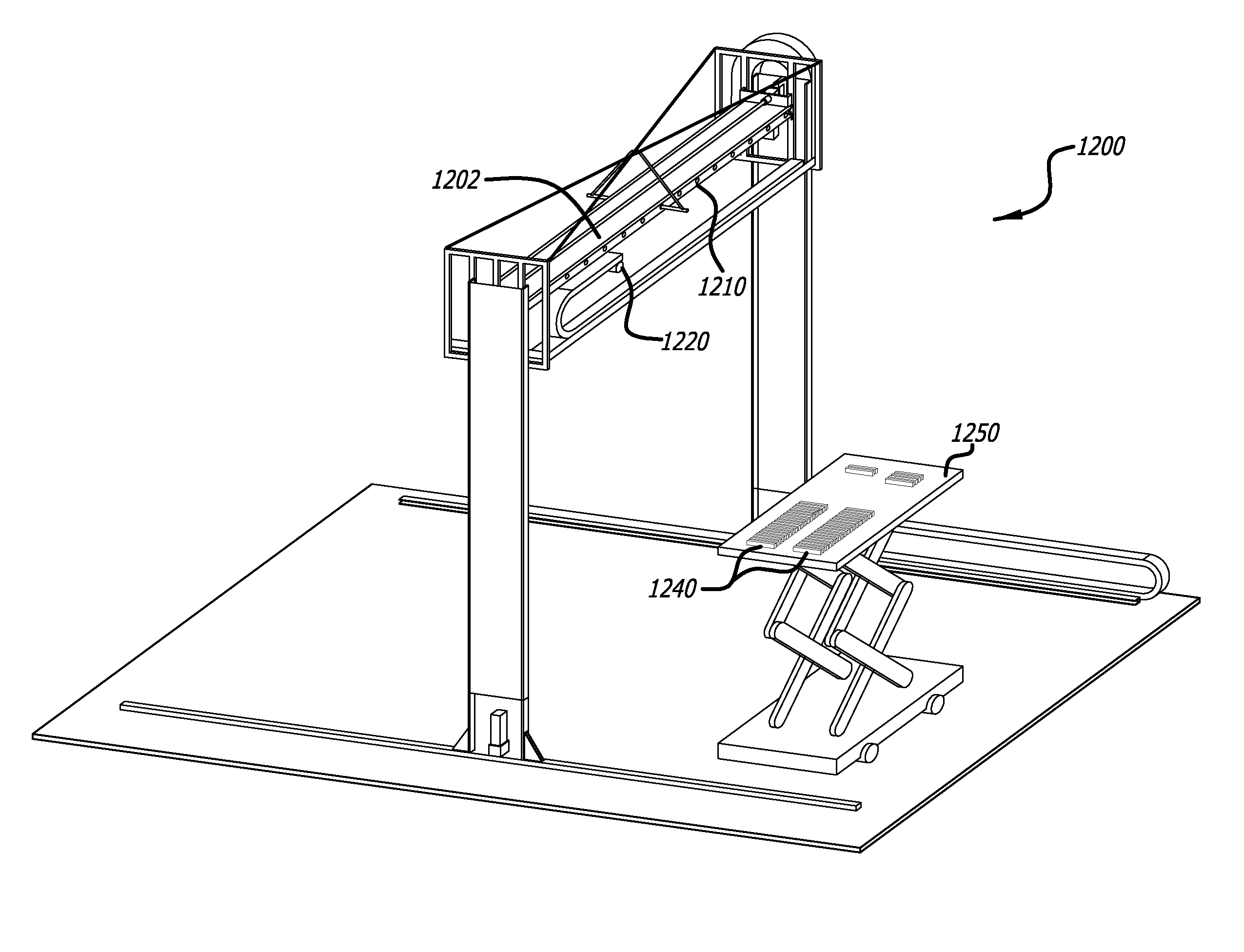

Mobile Automated Overhead Assembly Tool for Aircraft Structures

ActiveUS20150314890A1Precise positioningProgramme-controlled manipulatorBase supporting structuresSupporting systemEngineering

A method and apparatus for performing an operation on a work surface of a structure. The apparatus may comprise a motion platform and an overhead support system. The motion platform may be configured to be positioned above the work surface of the structure to perform the operation on the work surface. The overhead support system may be configured to carry the motion platform across a floor of a manufacturing environment from a first location to a second location.

Owner:THE BOEING CO

Bridge span replacement system

InactiveUS8671490B1Compact configurationPrecise positioningPortable bridgeBase supporting structuresEngineeringSupport surface

A vertically-adjustable gantry assembly installation adapted for removal or placement of a train bridge-span of the type which spans and is supported by two piers, comprises a gantry assembly positioned on load-bearing first ground-support locations, the gantry assembly comprising a gantry and a ground-engaging vertical support and lift system, the vertical support and lift system adapted for supporting a combined weight of the gantry and a bridge span in at least one operational vertical position above respective bridge span support-surfaces of the piers including a position corresponding to a disembarking plane in which the leg portions are extended from a stowed position to an extent at least sufficient for the gantry assembly to self-liftoff the pre-installation conveyance system onto the first ground-support locations to effect the gantry assembly installation.

Owner:WESTERN MECHANICAL ELECTRICAL MILLWRIGHT SERVICES

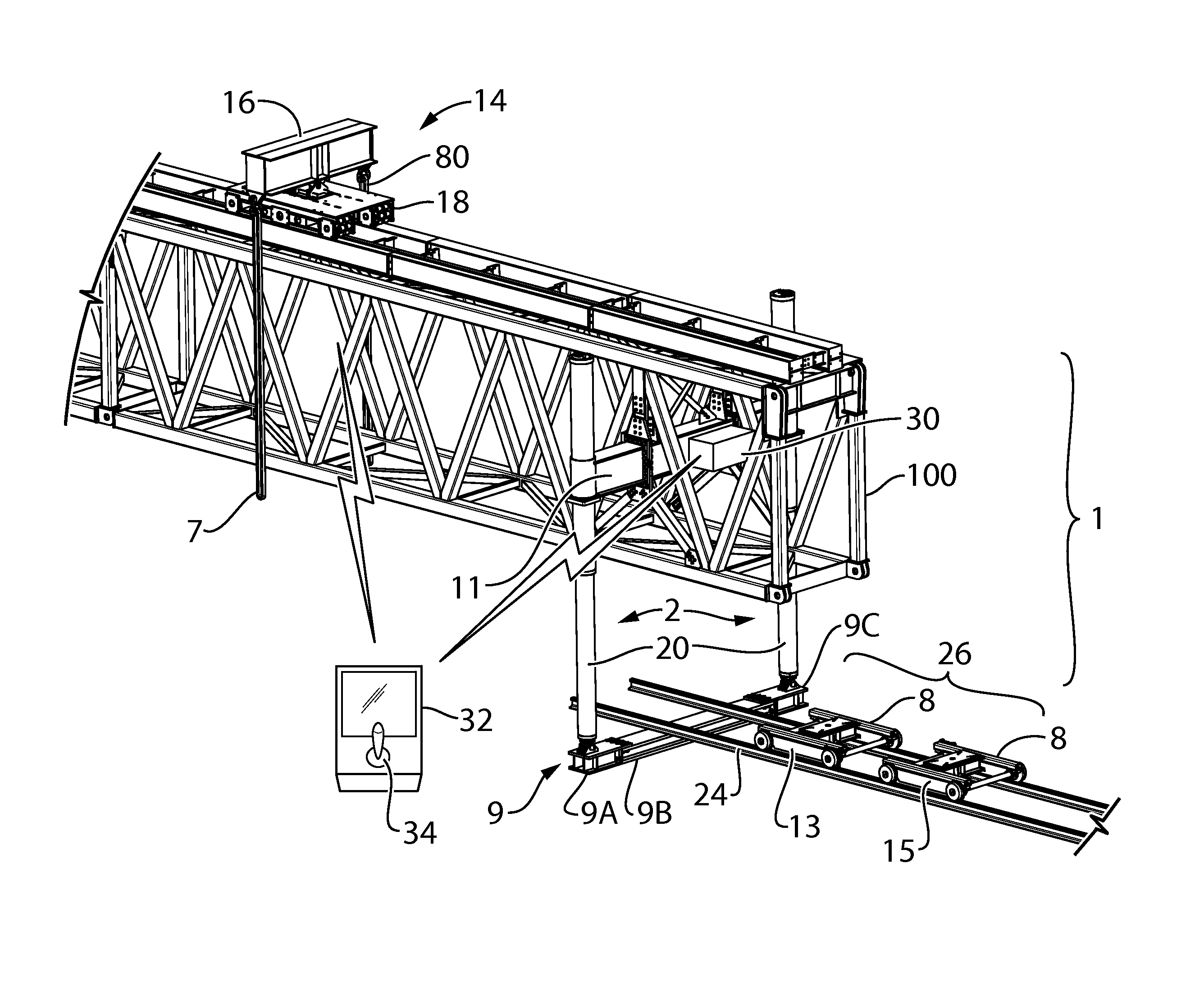

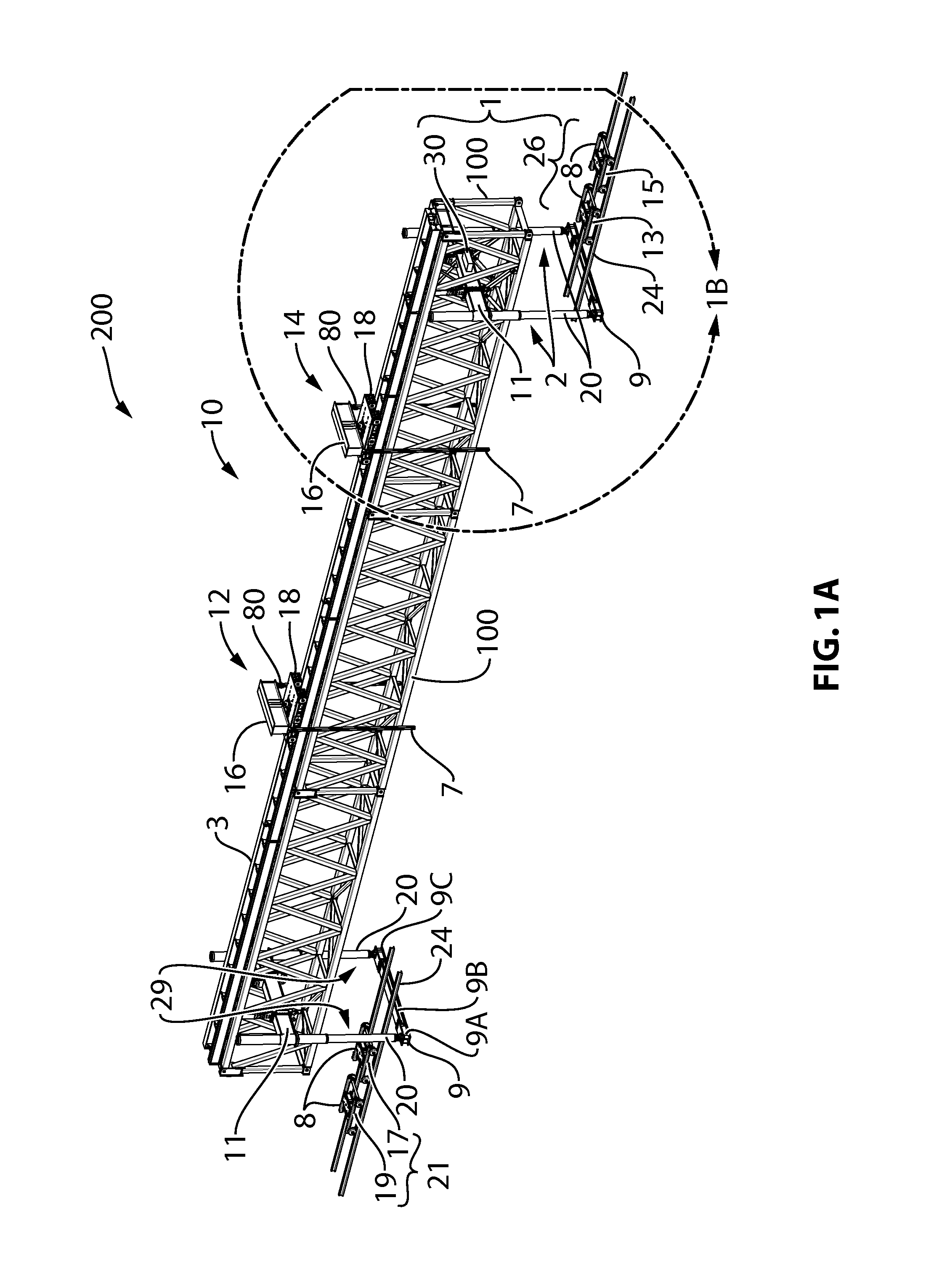

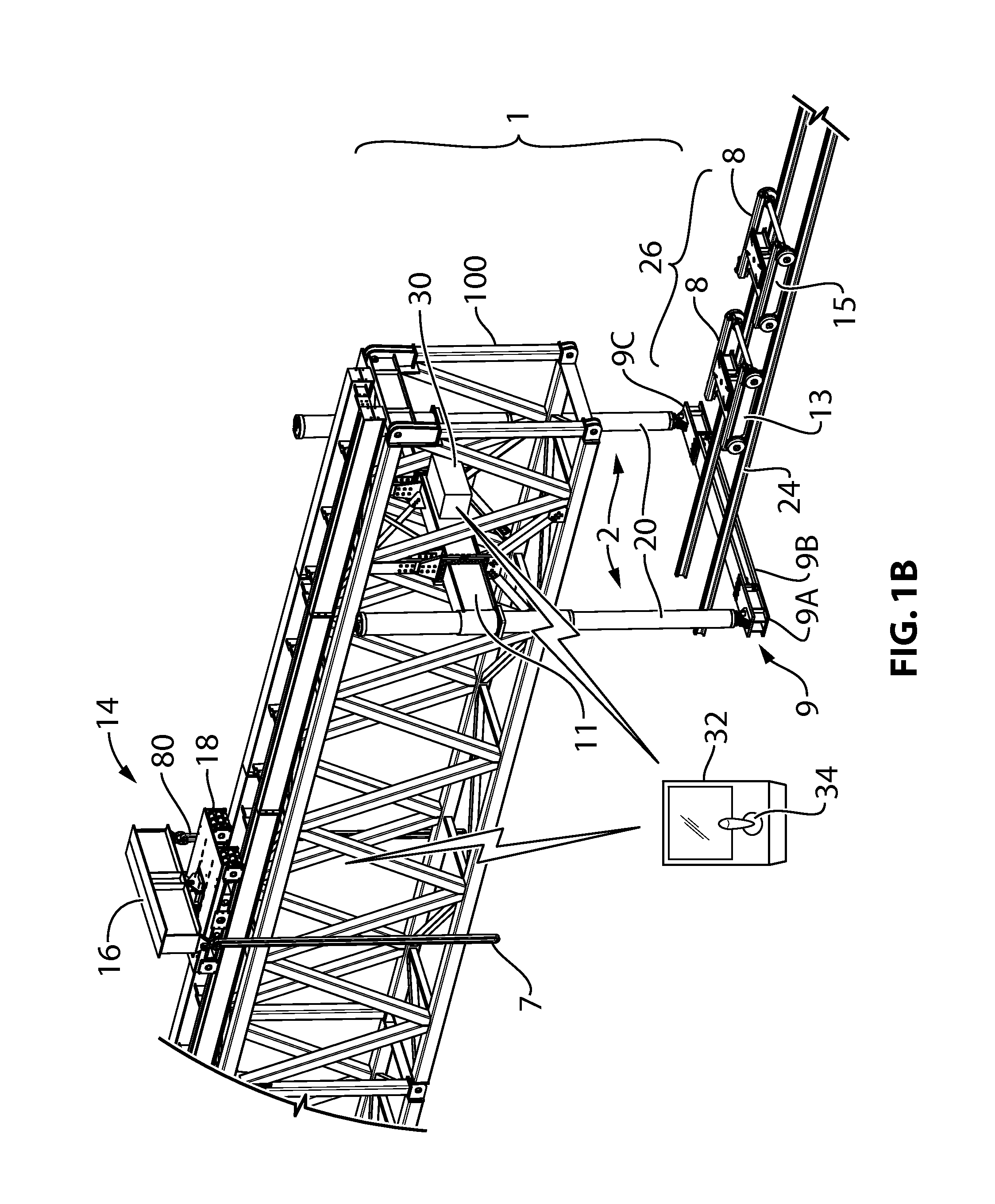

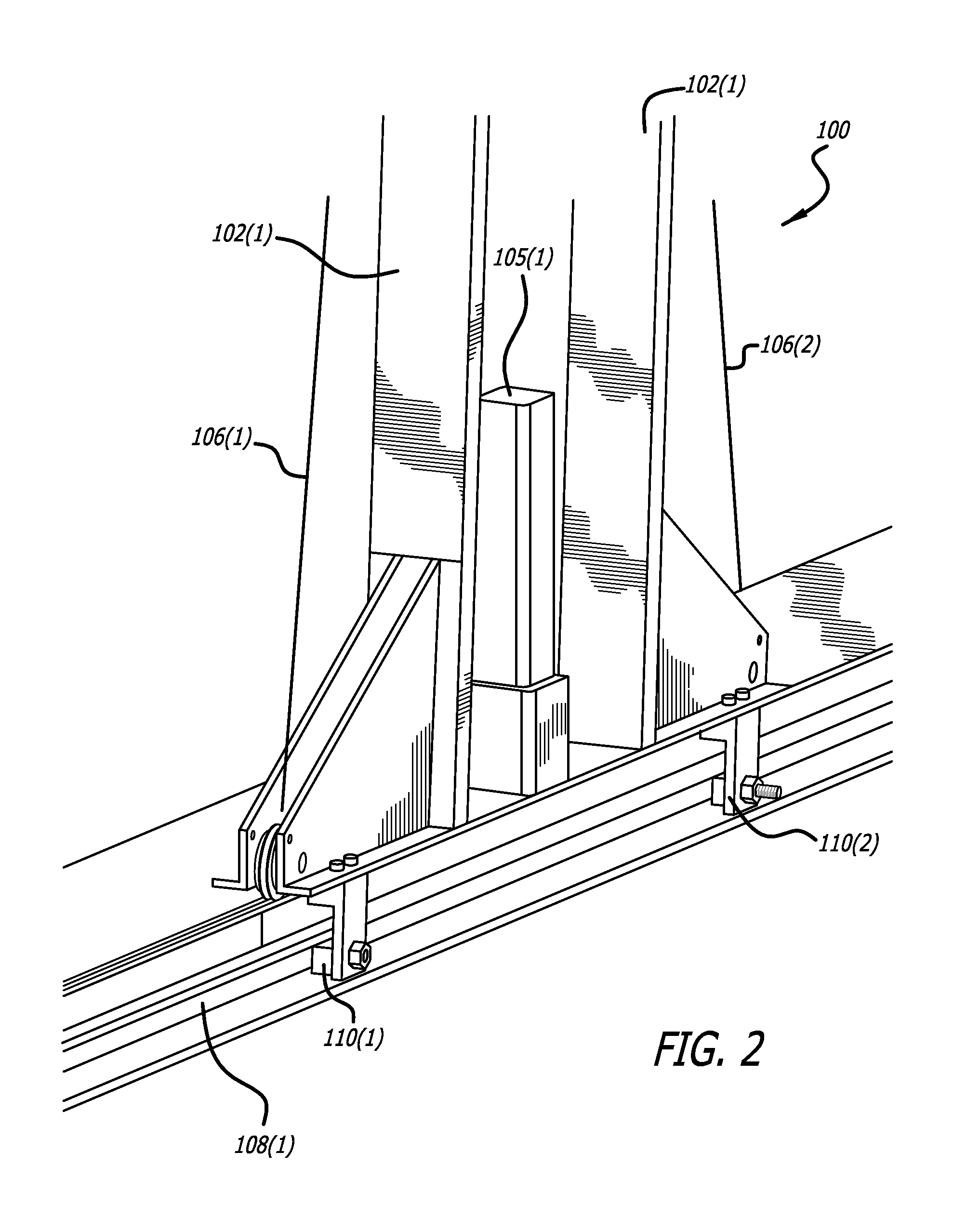

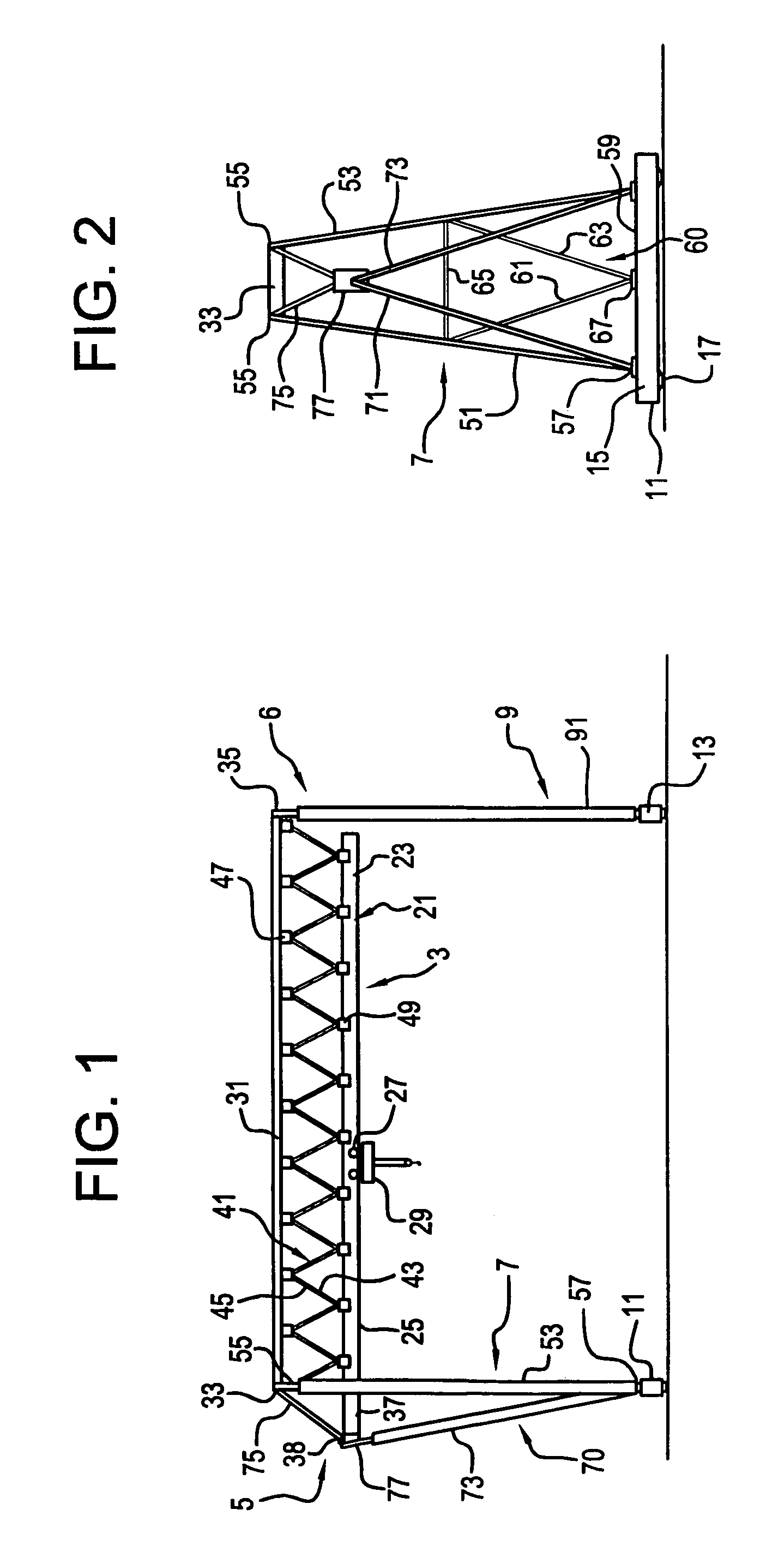

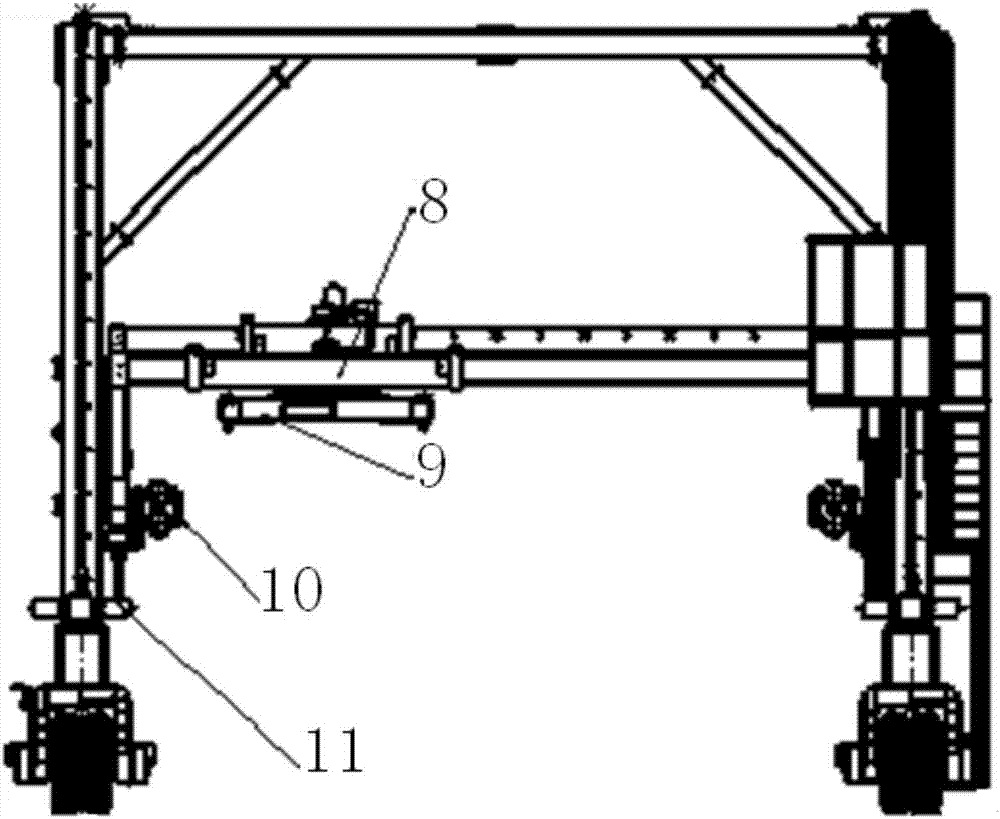

Gantry robotics system and related material transport for contour crafting

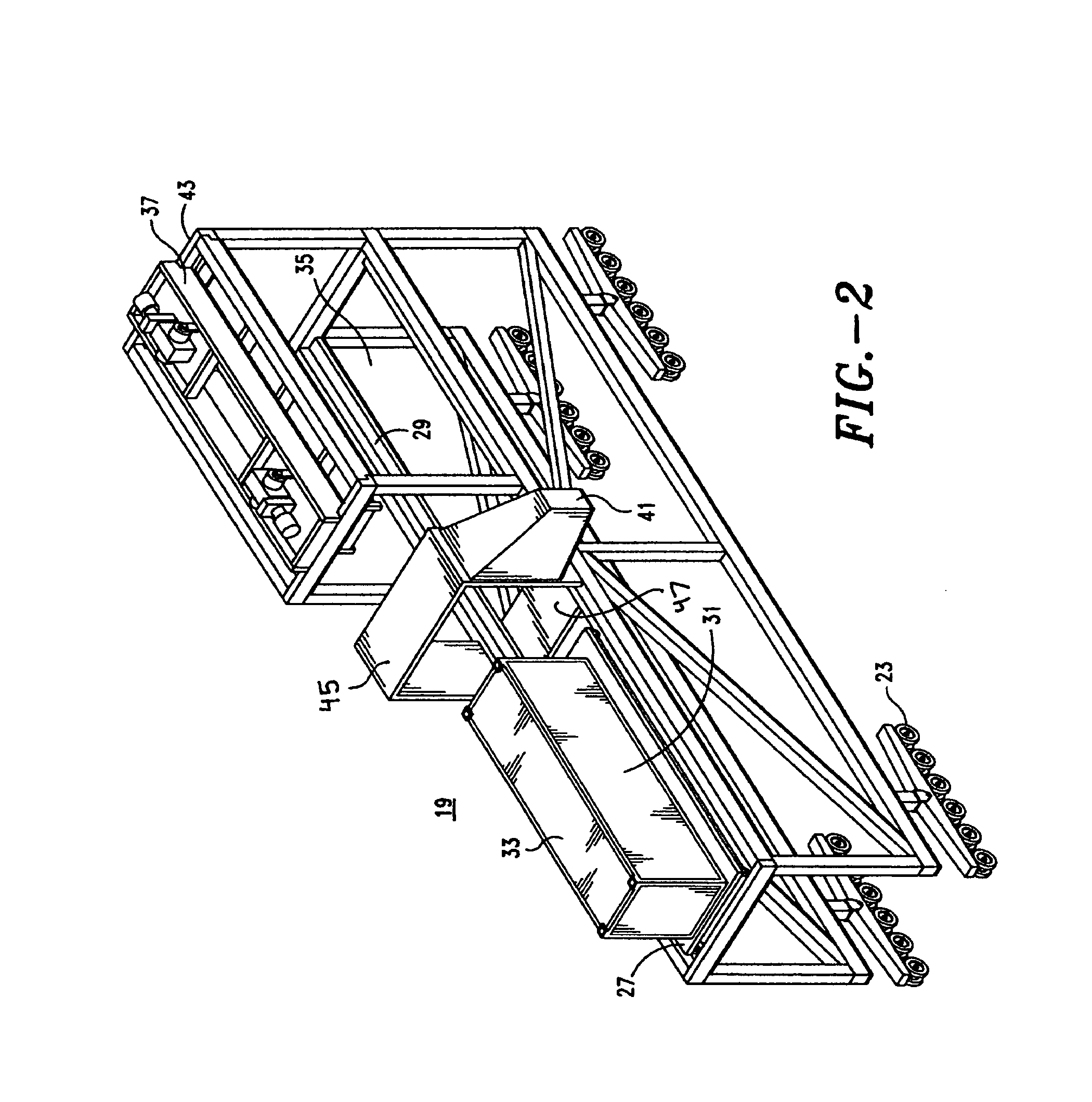

Apparatus and methods are disclosed that are useful for robotic gantry systems that are lightweight while at the same time offering rigidity or stiffness for implementation in Contour Crafting construction and material delivery techniques. The present disclosure is directed to robotic gantry system and material transport apparatus that use of very light structural members that have sufficient compressive strength, but which may otherwise be weak in the presence of bending forces, in conjunction with cables that provide stiffness against bending. Use of such cables provides needed tension while at the same time allowing the robotic gantry system to be very light compared to solid structures, e.g., those with I-beams, etc. Material delivery systems including passive articulated arms are also disclosed.

Owner:UNIV OF SOUTHERN CALIFORNIA

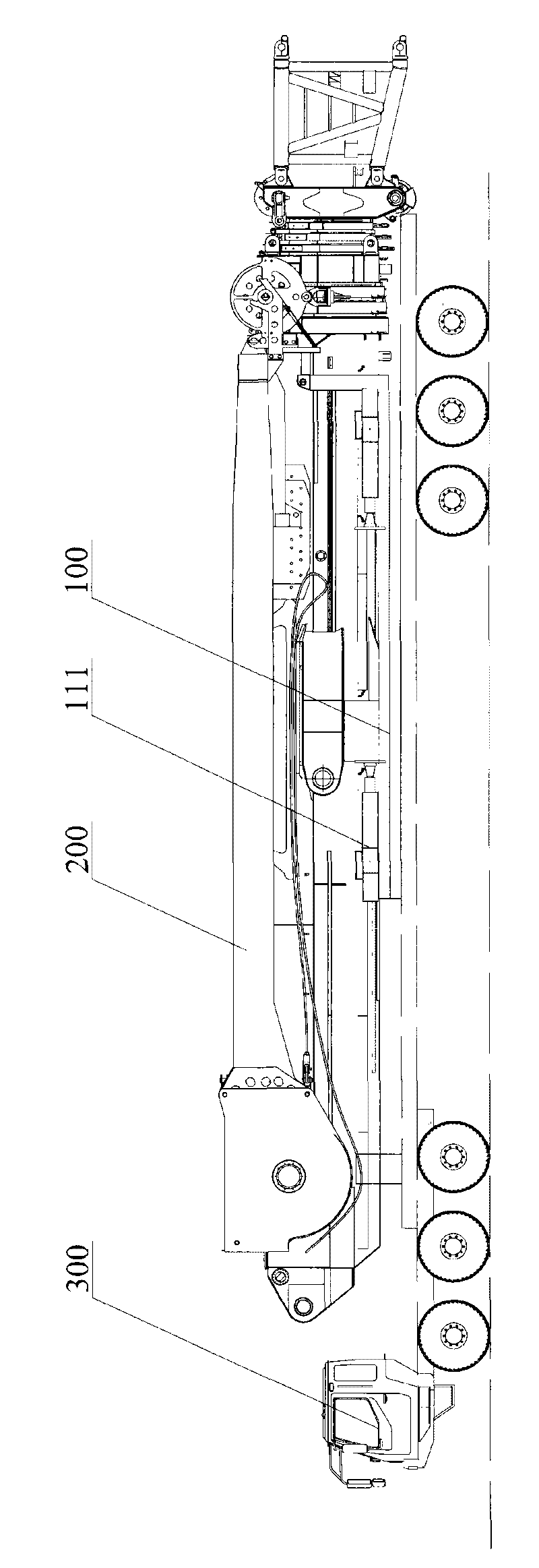

Deployable contour crafting

A deployable crafting machine may include a vehicle and a gantry system. The gantry system may be configured to be collapsed on the vehicle during which the gantry system is inoperable and to be expanded during which the gantry system is operable and supported at least in part by the vehicle. A deployable crafting process may include moving a vehicle to a first location while a gantry system is stored on the vehicle in a collapsed and inoperable state and expanding the gantry system into an operable state after the vehicle arrives at the first location during which the gantry system is supported at least in part by the vehicle.

Owner:UNIV OF SOUTHERN CALIFORNIA

Crane transition auxiliary device, transport trailer and method for dismantling crane

InactiveCN101712439AReduce outline sizeImprove passabilityBase supporting structuresBraking devices for hoisting equipmentsHydraulic cylinderEngineering

The invention discloses a crane transition auxiliary device and also relates to a transport trailer with the auxiliary device and a method for dismantling a crane by utilizing the auxiliary device. The crane transition auxiliary device comprises a bearing frame and a supporting leg arranged on the bearing frame, wherein the supporting leg comprises a hydraulic cylinder extending in a vertical direction; and at least two crane jib brackets which are arrayed along the longitudinal direction of a horizontal plane and used for supporting crane jibs are arranged on the bearing frame. When a large-tonnage wheel crane is disassembled and assembled, the separation or the combination of a crane jib and a rotary table can be realized without an auxiliary hoisting mechanism by utilizing the crane transition auxiliary device so as to further conveniently disassemble and assemble the large-tonnage wheel crane. The transport trailer with the auxiliary device can provide convenience for the carrying of the crane jib, and the method for dismantling a crane by utilizing the auxiliary device can provide convenience for transition operations of the large-tonnage wheel crane.

Owner:SANY AUTOMOBILE MFG CO LTD

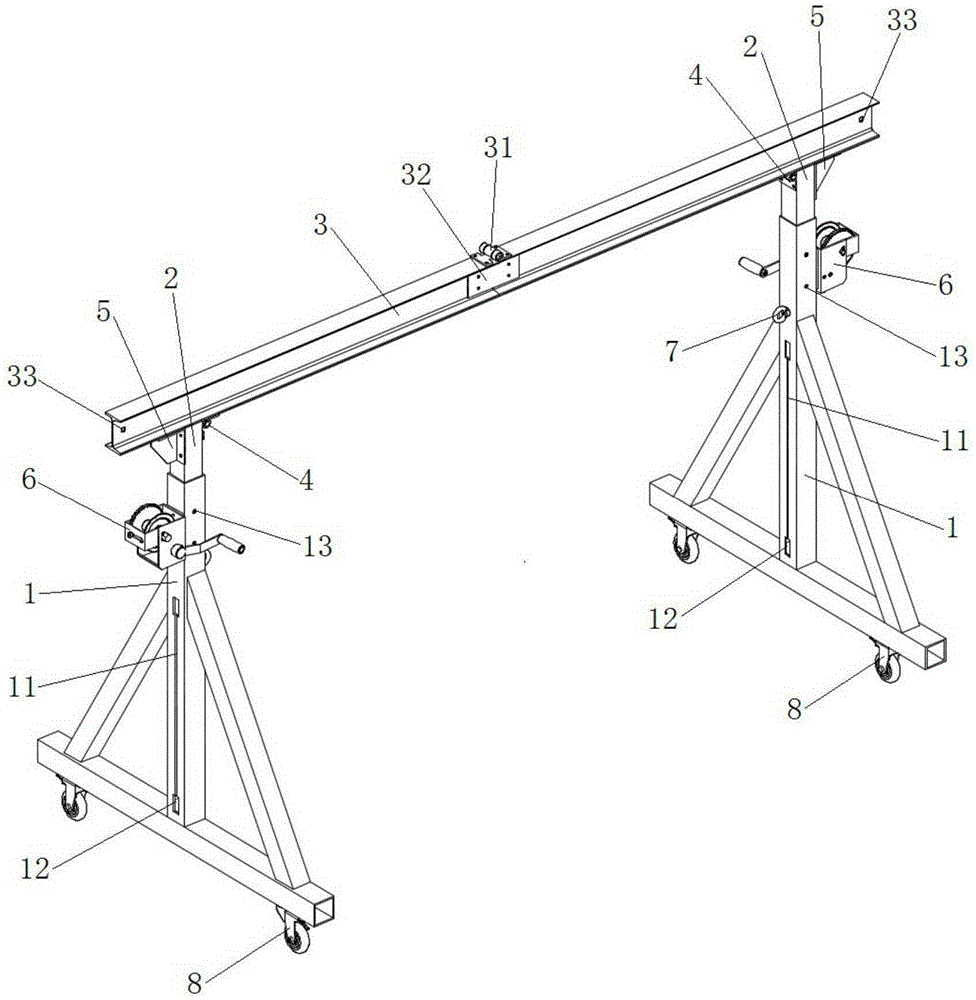

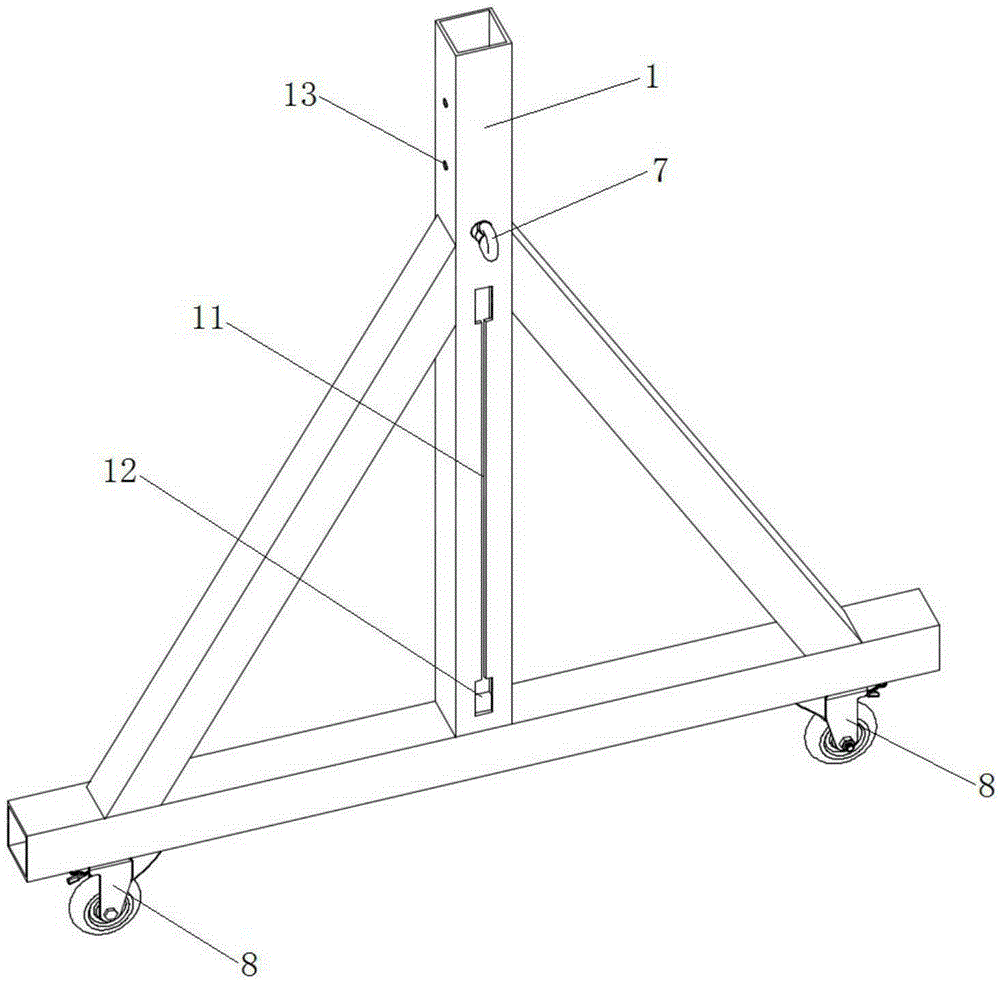

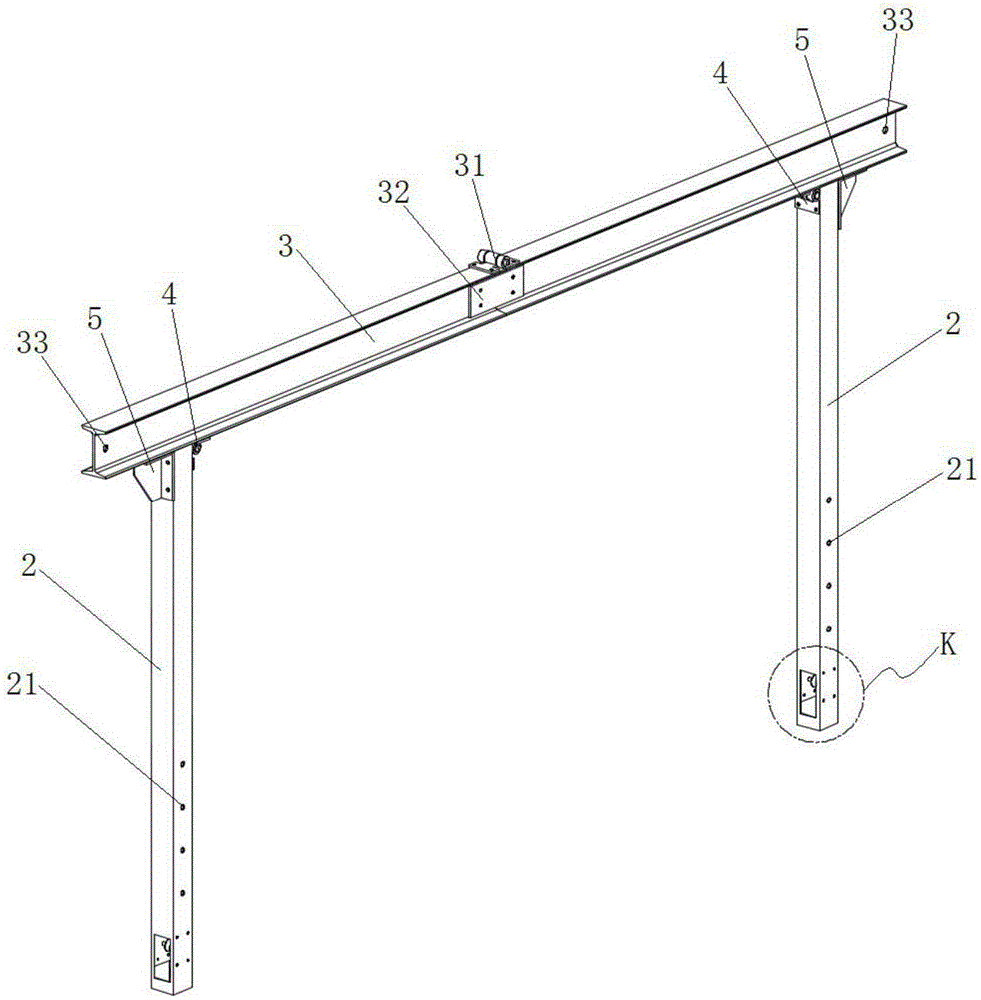

Foldable gantry crane capable of ascending and descending

InactiveCN105236276AEasy to useSmall footprintBase supporting structuresBraking devices for hoisting equipmentsEngineeringGantry crane

The invention discloses a foldable gantry crane capable of ascending and descending, and belongs to the field of carrying tools. The foldable gantry crane capable of ascending and descending comprises a beam and supporting legs arranged on the two sides of the beam. Each supporting leg comprises a lifting supporting rod connected with the beam and a fixed supporting leg in telescopic fit with the lifting supporting rod, wherein a lifting mechanism is arranged between the lifting supporting rod and the fixed supporting leg. The beam is cut off from the middle, the two parts formed after cutting are hinged together, and the hinging portions are fixedly connected through a connecting plate. The two ends of the beam are connected with the upper portions of the lifting supporting rods through hinges respectively. After the connecting plate is detached, the beam can be bent downwards, and then the supporting legs on the two sides of the beam can be retracted inwards. Height adjustment can be performed as needed when the gantry crane is in use, so that use is easy and convenient. The beam can be lowered and folded when the gantry crane is not in use, so that occupied space is reduced, and transport is facilitated. The gantry crane is simple in structure, convenient to operate and low in cost.

Owner:CHANGZHOU INST OF TECH

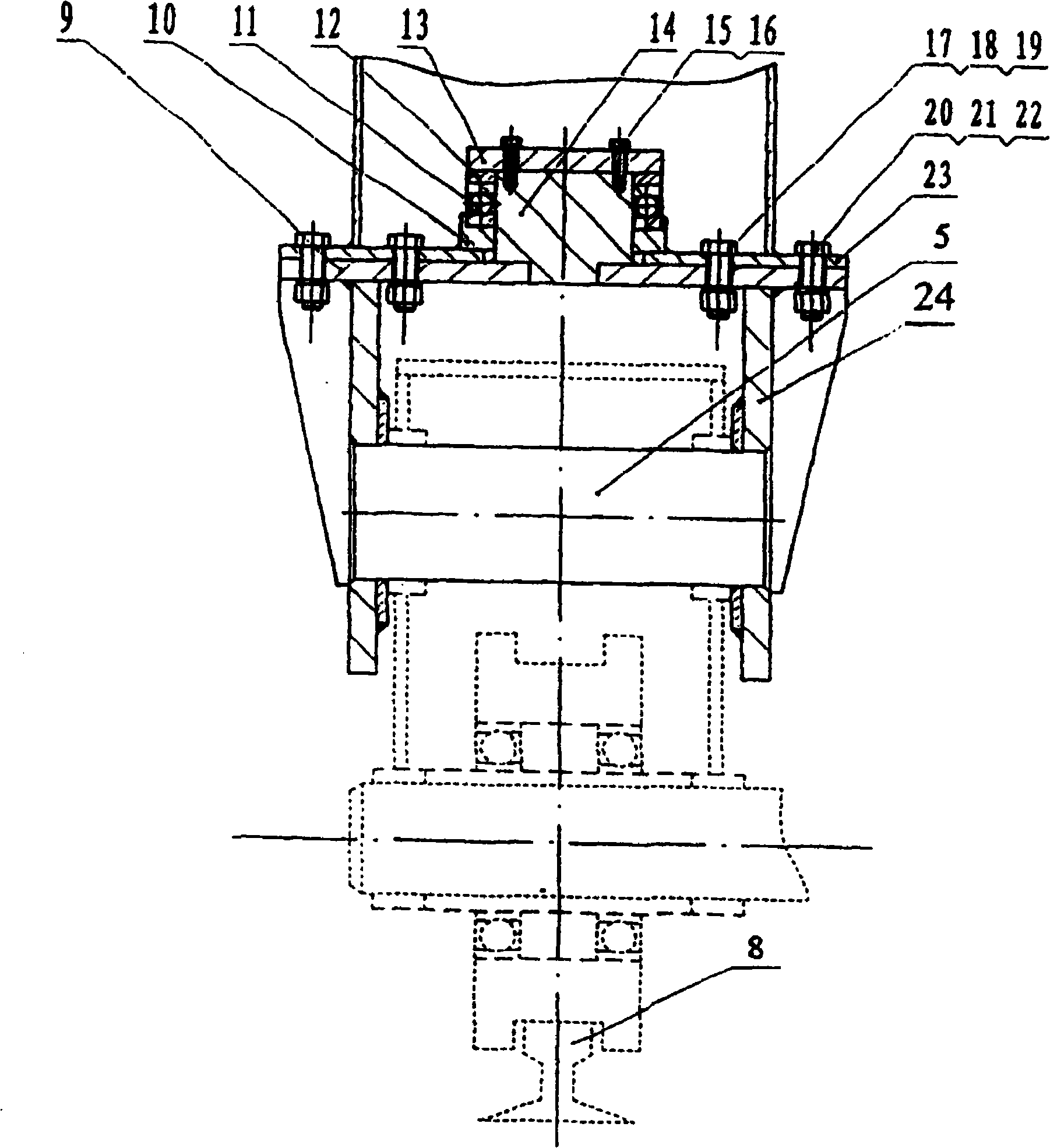

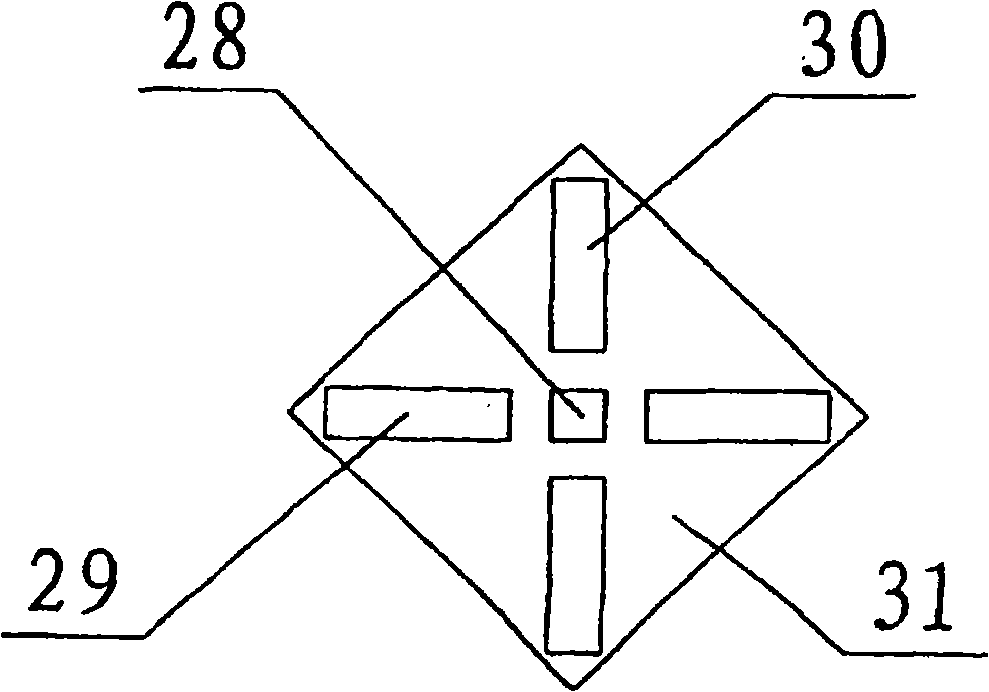

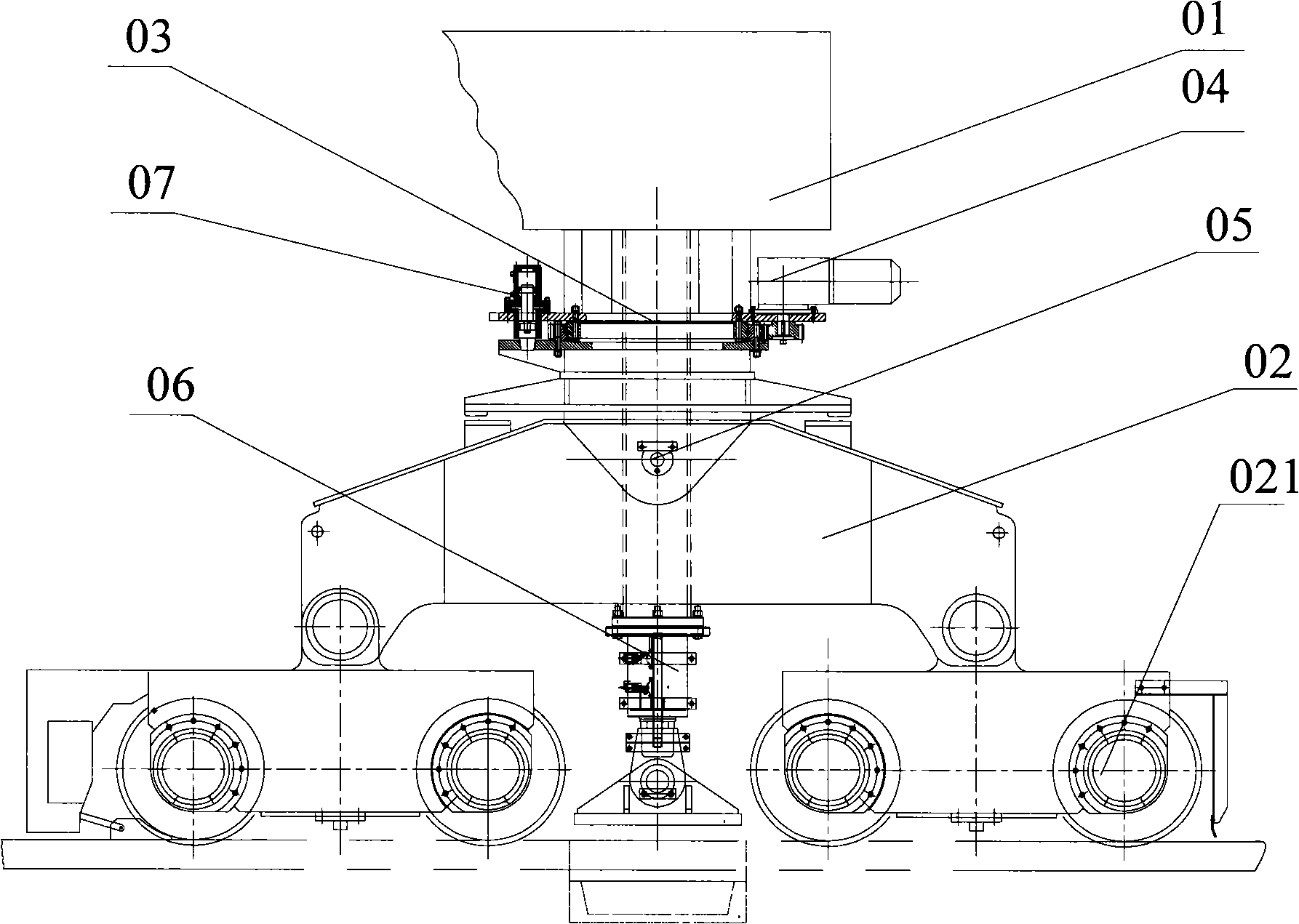

Track transfer apparatus, track transfer connection device, transfer system and method

InactiveCN101348210AImprove transition efficiencyConvenient transition operationBase supporting structuresBraking devices for hoisting equipmentsHydraulic cylinderTransfer system

The invention discloses a rail transfer device. The device comprises a traveling mechanism comprising steel wheels, a first gyration mechanism connecting a saddle beam and the driving mechanism, a first gyration driving mechanism and a jacking-up mechanism, wherein the first gyration mechanism can rotatablely connect the traveling mechanism and the saddle beam; the first gyration driving mechanism can drive the driving mechanism to rotate relative to the saddle beam; the jacking-up mechanism is a jacking-up hydraulic cylinder comprising a cylinder body and a piston; the cylinder body and the saddle beam are relatively fixed; the outer end of the piston is provided with support legs; when the piston of the jacking-up hydraulic cylinder extends out, the support legs can jack the saddle beam up; and the device also comprises a grasping mechanism capable of grasping movable rails. In addition, the invention also discloses a rail transfer connecting device, a rail-type gantry crane transfer system and a transfer method thereof. The rail transfer device provided by the invention can realize the automation of transfer operation and improve the working efficiency of the transfer operation.

Owner:SANY MARINE HEAVY IND

Electric heavy truck battery charging and replacing system

PendingCN110862008AReduce loadImprove interchangeabilityBase supporting structuresElectric propulsion mountingParking areaBattery charge

The invention provides an electric heavy truck battery charging and replacing system. The system comprises a battery box storage platform, a battery to-be-replaced vehicle parking area and a hoistingmechanism, wherein the platform comprises a circulating channel located between the middle and storage areas located on the two sides, the circulating channel is used for transferring a battery box, and providing transfer space; the storage areas are used for storing the battery box, and / or charging the battery box, movable devices are arranged between the storage areas on the two sides and the circulating channel, so that the battery box can move between the circulating channel and the storage areas on the two sides; and the battery to-be-replaced vehicle parking area is used for parking to-be-replaced vehicles, the hoisting mechanism is located above the movable battery box platform and the battery to-be-replaced vehicle parking area and used for lifting the battery box between to-be-replaced battery vehicles and the middle channel to realize the replacement of the battery box of the battery to-be-replaced vehicles. According to the system, the system structure is simplified, the battery replacement time can be controlled to 3 minutes, and the system has the advantages of being small in size, low in cost and the like.

Owner:SHANGHAI ENNEAGON ENERGY TECH CO LTD

Dual trolley, single boom crane system

InactiveUS20080264889A1Valid conversionMinimum amount of downtimeBase supporting structuresBraking devices for hoisting equipmentsEngineeringMechanical engineering

A dual trolley, single boom crane system for loading and unloading containers from ships moored at a dock that effectively doubles the rate of container loading and unloading of conventional prior art single boom crane systems. The present invention also concerns a novel method for retrofitting conventional prior art single boom crane systems to convert them to dual trolley systems, while at the same time retaining the basic geometry of the prior art system so that the same number of multiple cranes may be positioned over the dock side.

Owner:LARSEN STUART

Mobile automated overhead assembly tool for aircraft structures

ActiveUS9708079B2Programme-controlled manipulatorBase supporting structuresSupporting systemEngineering

A method and apparatus for performing an operation on a work surface of a structure. The apparatus may comprise a motion platform and an overhead support system. The motion platform may be configured to be positioned above the work surface of the structure to perform the operation on the work surface. The overhead support system may be configured to carry the motion platform across a floor of a manufacturing environment from a first location to a second location.

Owner:THE BOEING CO

Crossing type double trolley bridge type crane

InactiveCN101323415AImprove loading and unloading speedBase supporting structuresBraking devices for hoisting equipmentsVehicle frameBridge type

The invention relates to a through-typed double-trolley bridge-typed crane, comprising a cart, a main beam arranged on the cart, a first cargo trolley and a second cargo trolley; the first cargo trolley comprises a matter-fetching device, a left flap frame and a right flap frame; the matter-fetching device is hung on the left flap frame and the right flap frame by a lifting sling, and a U-shaped space is formed on the upper surface of the lifting sling and the matter-fetching device of the first loading trolley; the second loading trolley comprises a frame, a traversing mechanism arranged on the frame and the matter-fetching device hung on a traversing part by the lifting sling; rails which support the second loading trolley are arranged between a guide rail for supporting the left flap frame of the first loading trolley and a guide rail for supporting the right flap frame of the first loading trolley; the extending directions of all the guide rails are in parallel and the second loading trolley can pass through the U-typed space.

Owner:樊茂勇 +1

Loading device for ISO containers

InactiveUS20020044854A1Avoid bottlenecksEffective maneuveringCargo handling apparatusBase supporting structuresOverhead craneVertical axis

A loading device for ISO containers in a container terminal with a container bridge for the loading and unloading of ships and with automatic incoming and outgoing transfer of the containers by means of automatic guided vehicles, with at least one container load suspension device in the form of a spreader and devices for the intermediate positioning of the container within the loading device to allow the installation or removal of the twistlocks, and with platforms for the workers performing this task. The loading device consists of a polar bridge crane, which can rotate around its center vertical axis, and which is designed as a bridge crane with a trolley capable of traveling on a crane bridge supported on a circular track located in the rear area of the land-side rail of the container bridge.

Owner:ROCKWELL SOFTWARE +1

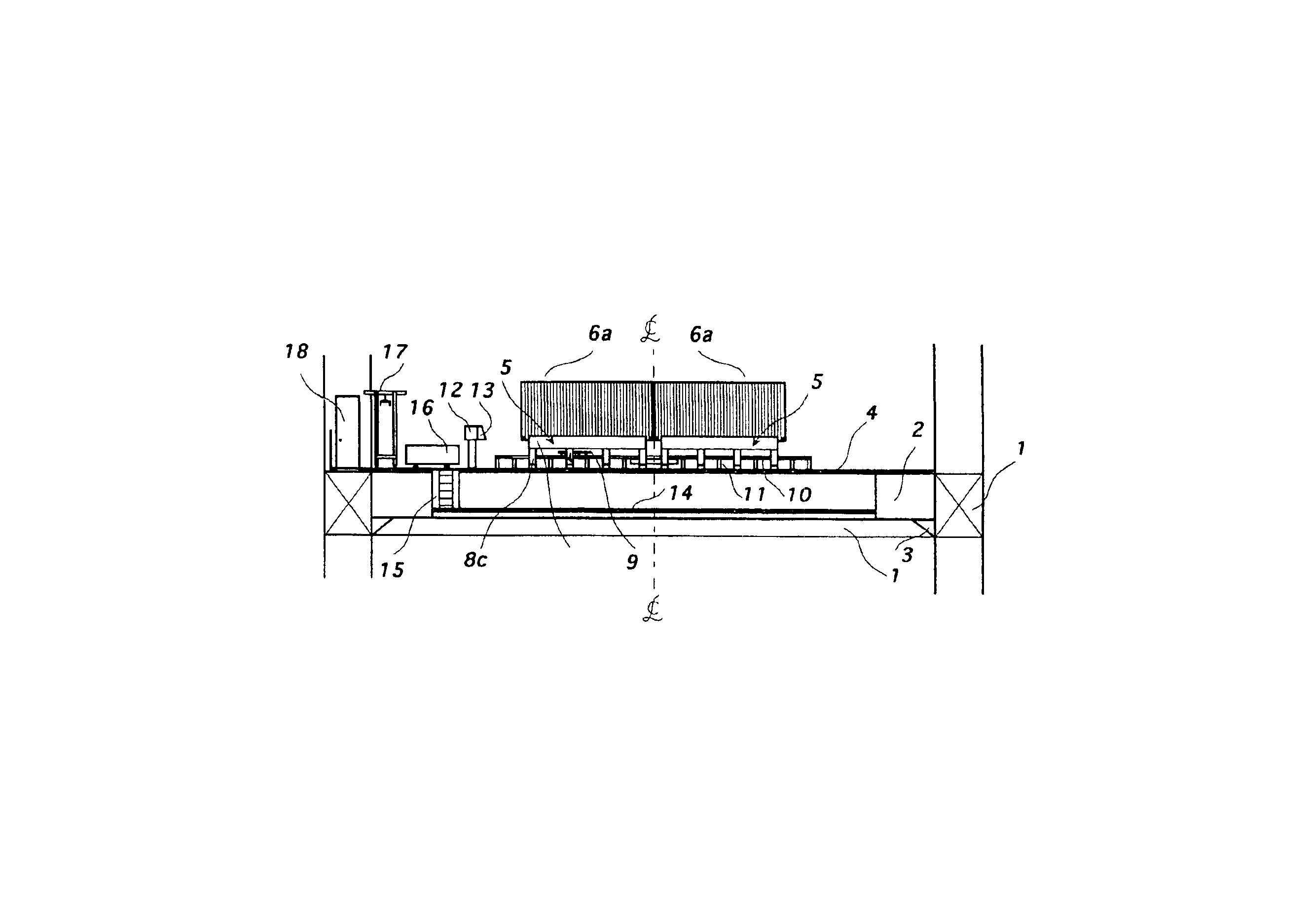

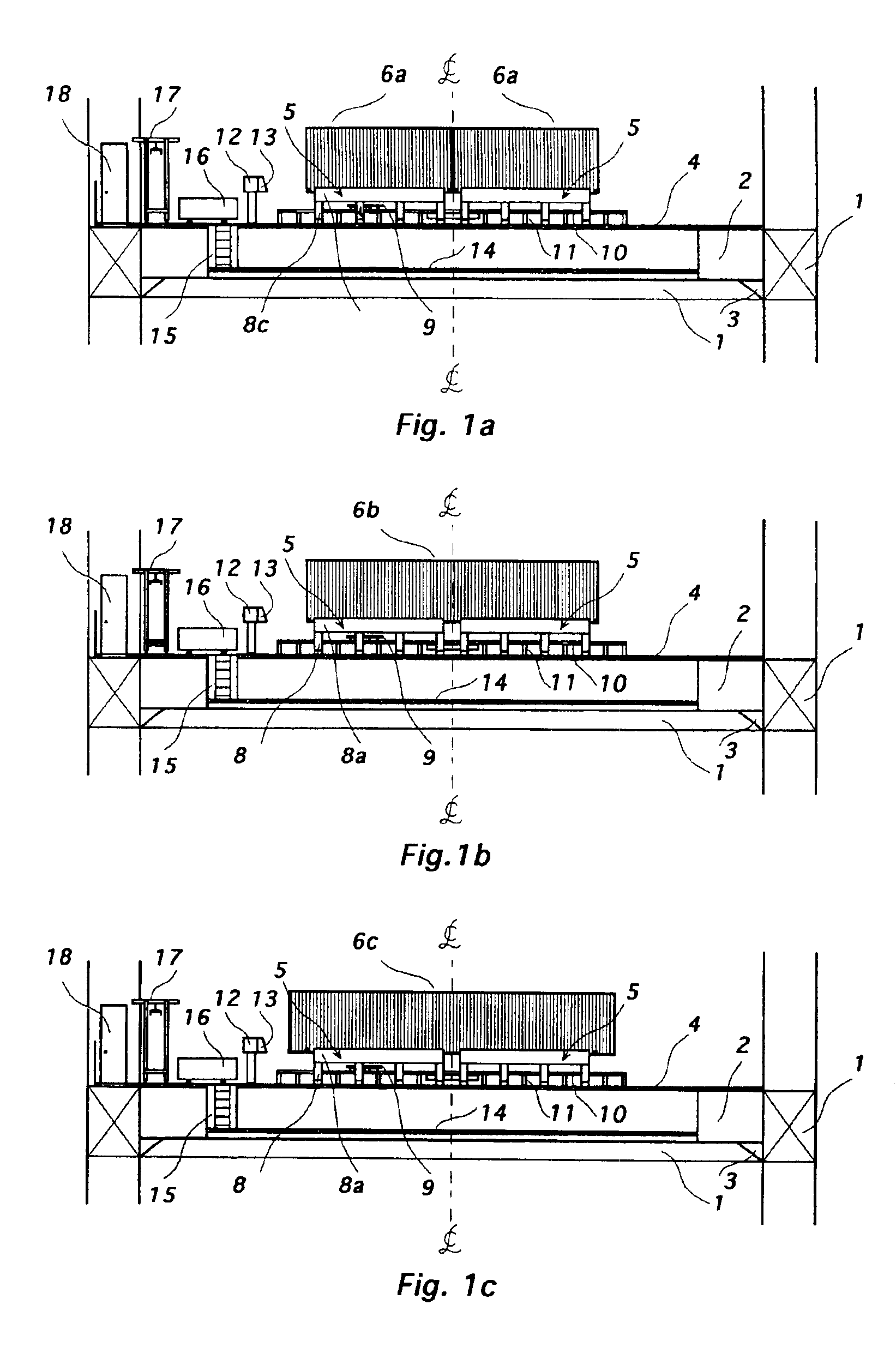

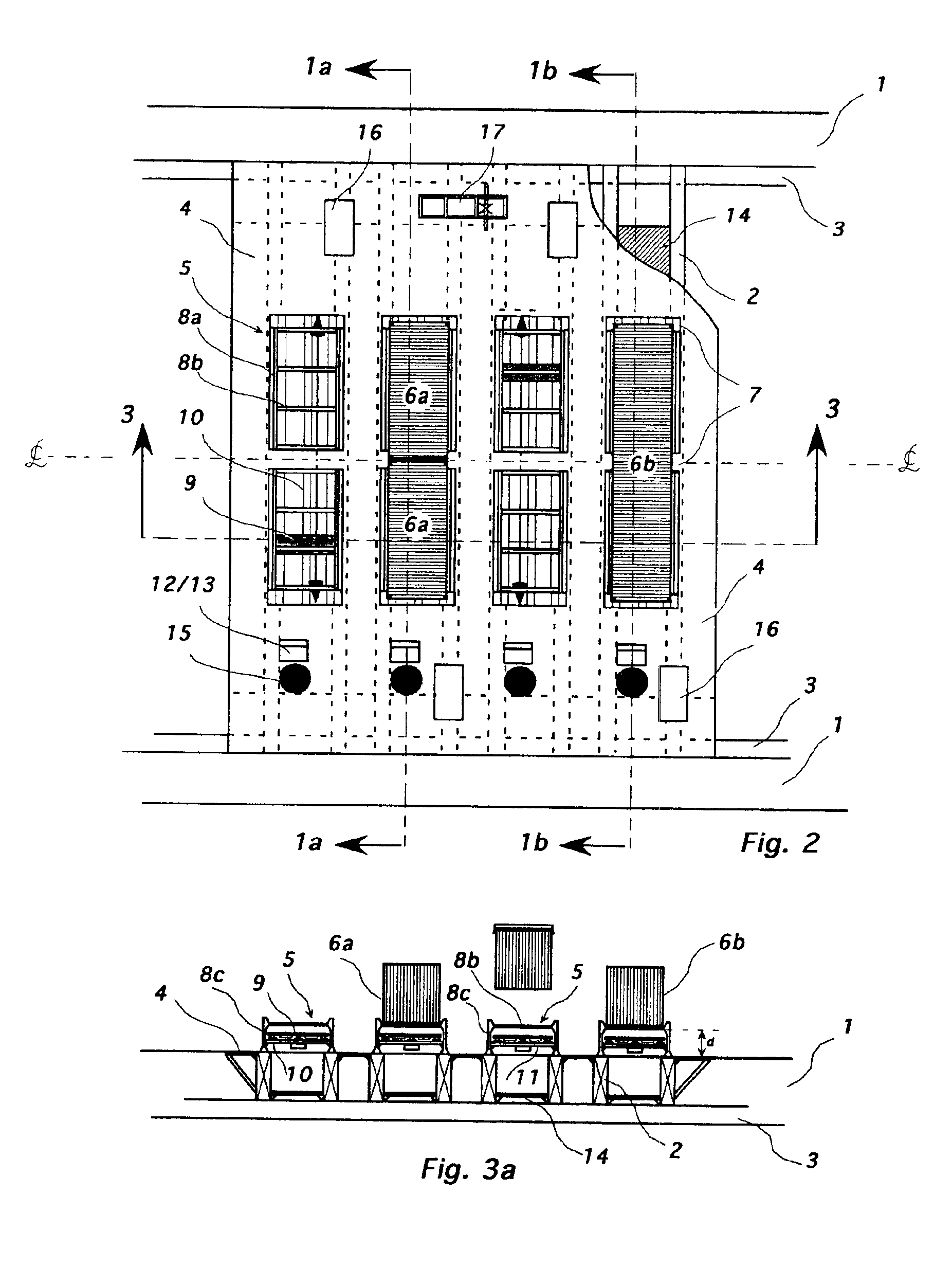

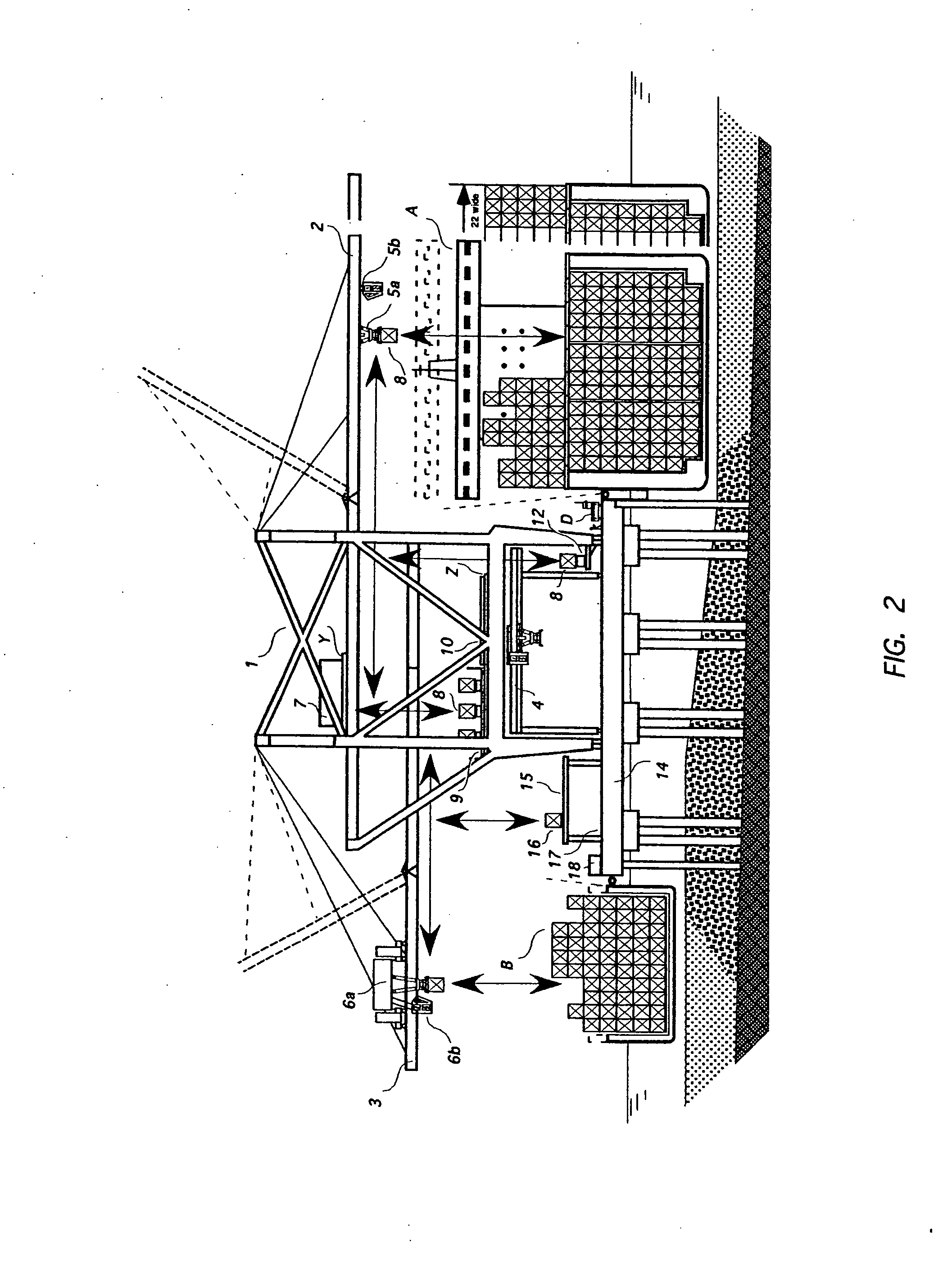

Transfer plant and method for loading and unloading containers from container ships

InactiveUS7410339B2Improve handlingShorten the timeCargo handling apparatusBase supporting structuresEngineeringRe engineering

The invention relates to a transfer plant, especially for loading and unloading ISO containers from container ships at seaports, comprising a vertical support which is propped up on the land side and on which a horizontal extension arm is braced. Said horizontal extension arm, along which a horizontal conveying device can be displaced, protrudes across the ship that is to be unloaded on the sea side. The horizontal conveying device cooperates with hoisting and lowering devices which pick up and put down the containers. The aim of the invention is to create a redesigned transfer plant and a method for loading and unloading containers, preferably ISO containers, from container ships in seaports, which allow the transfer rate to be significantly increased and consequently the lay times of the container ships at the pier to be substantially reduced. Said aim is achieved by disposing at least two horizontal conveying devices (9, 10) on the horizontal extension arm (1.4, 1.5, 1.6), which can be displaced independently of each other along said horizontal extension arm (1.4, 1.5, 1.6) between the hoisting and lowering devices (11, 13) that are located on the land side and the sea side. In addition, intermediate storage devices (12, 14), into which the containers can be placed and from which said containers can be picked up by the hoisting and lowering devices (11, 13) that are located on the land side and the sea side and the horizontal conveying devices (9, 10), are disposed on the horizontal extension arm in the area of the hoisting and lowering devices (11, 13) that are located on the land side and the sea side.

Owner:GOTTWALD PORT TECH

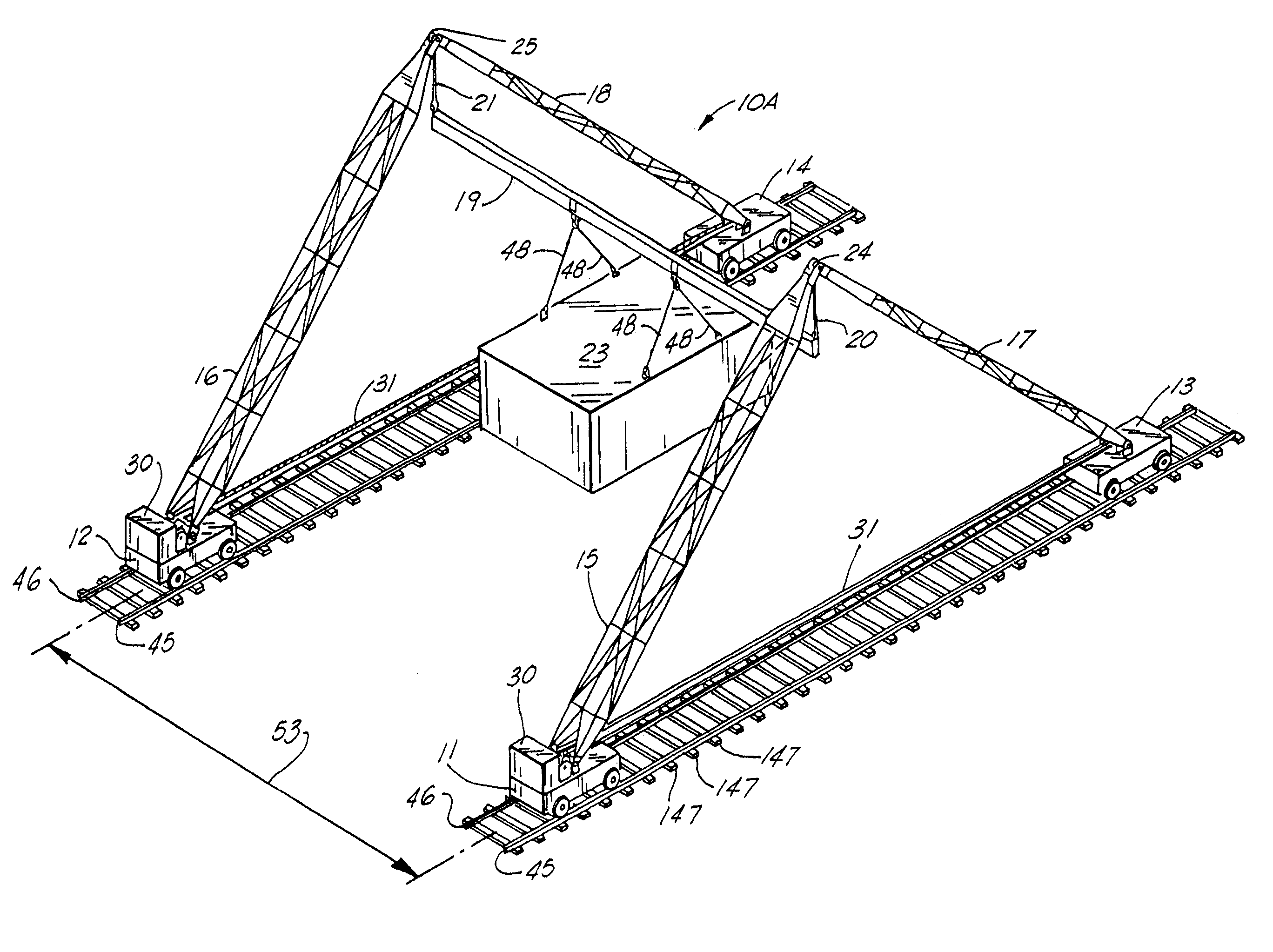

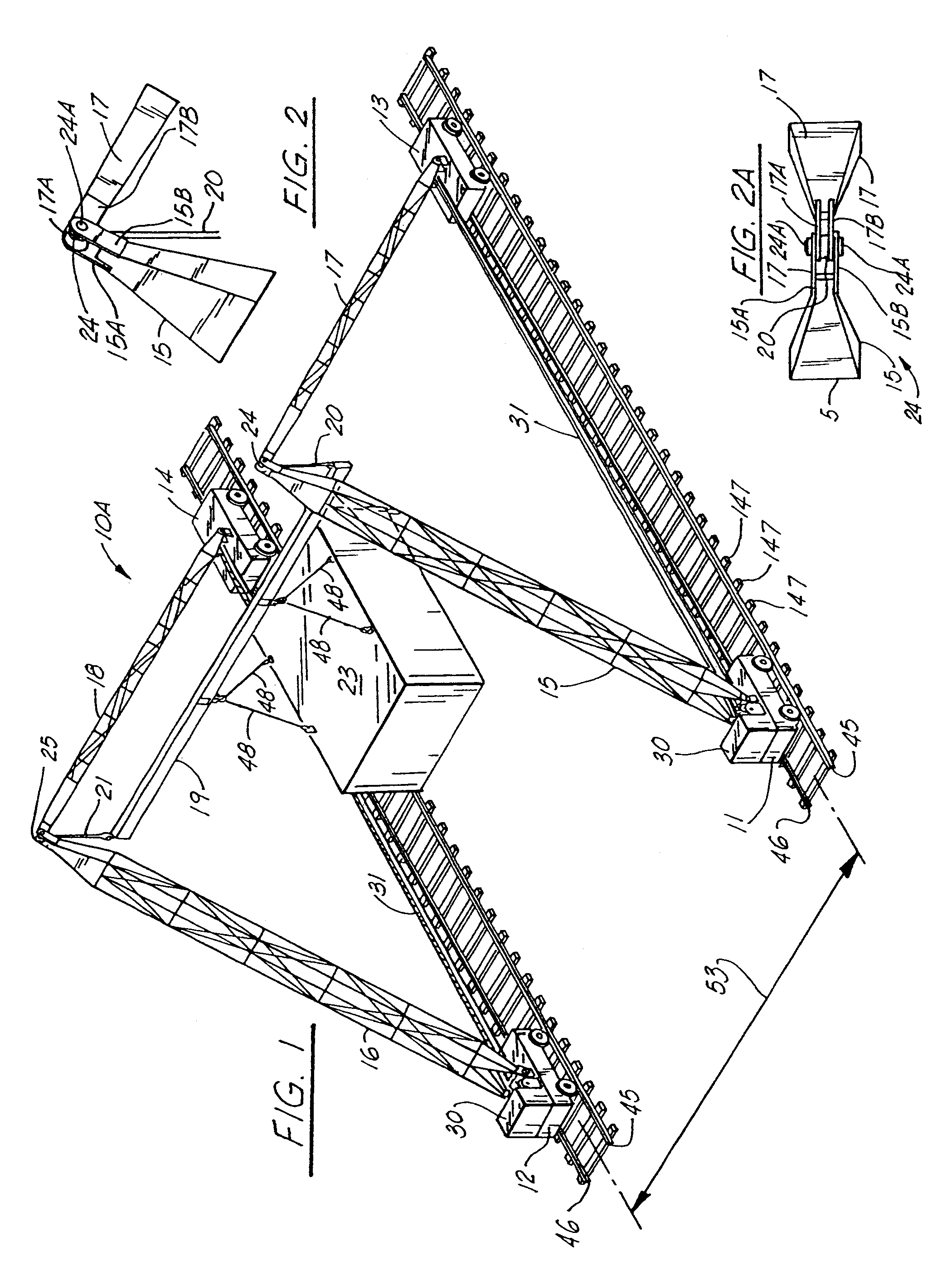

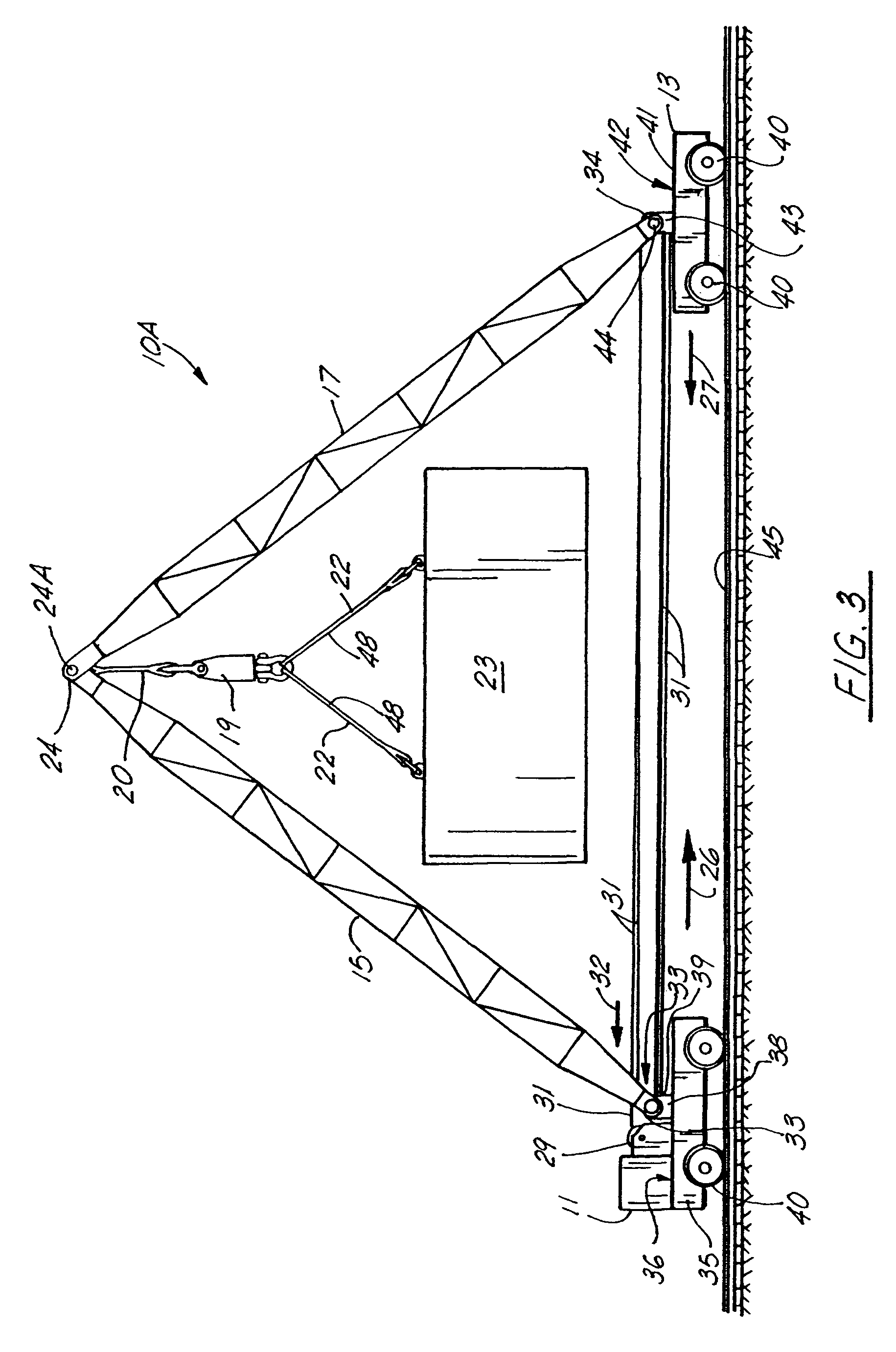

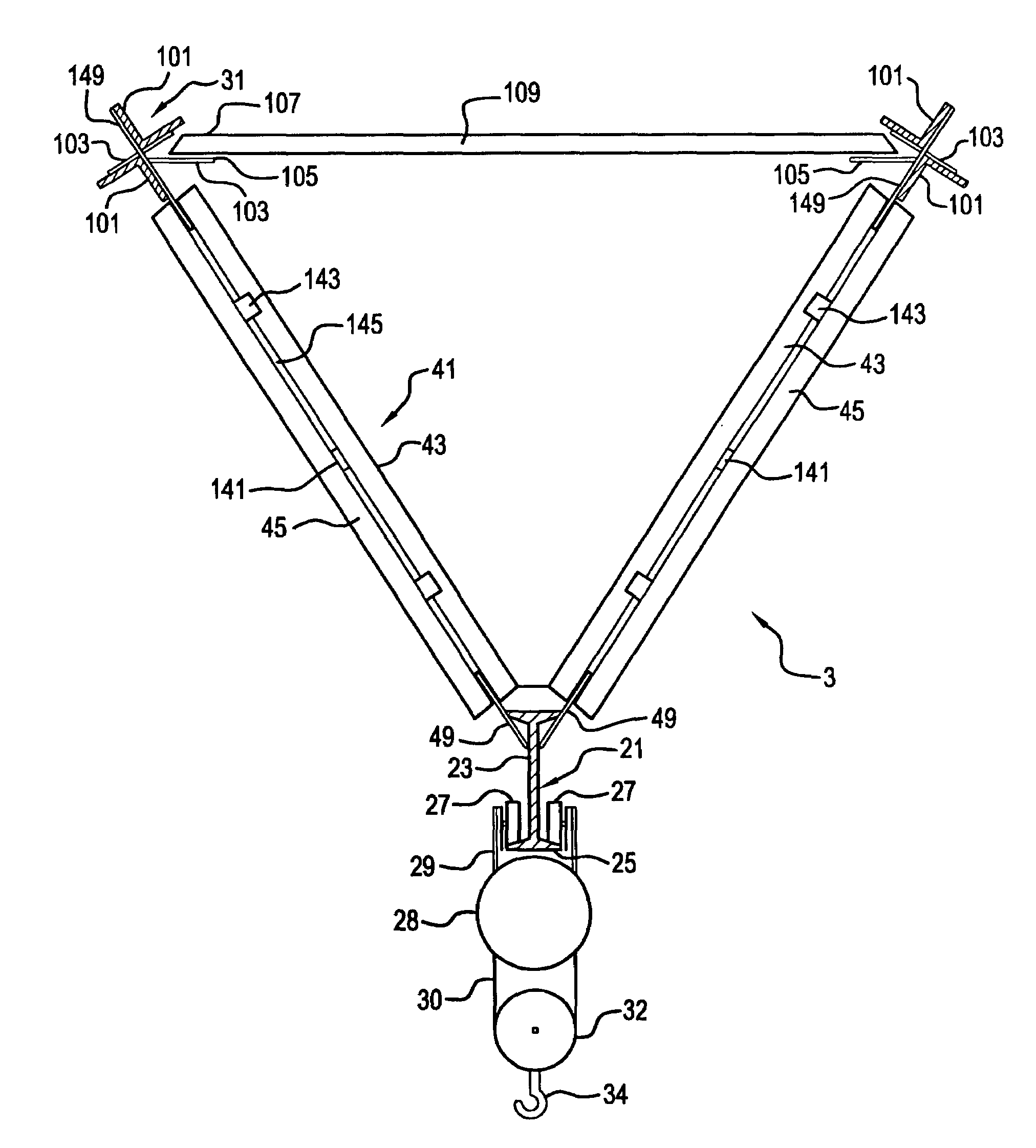

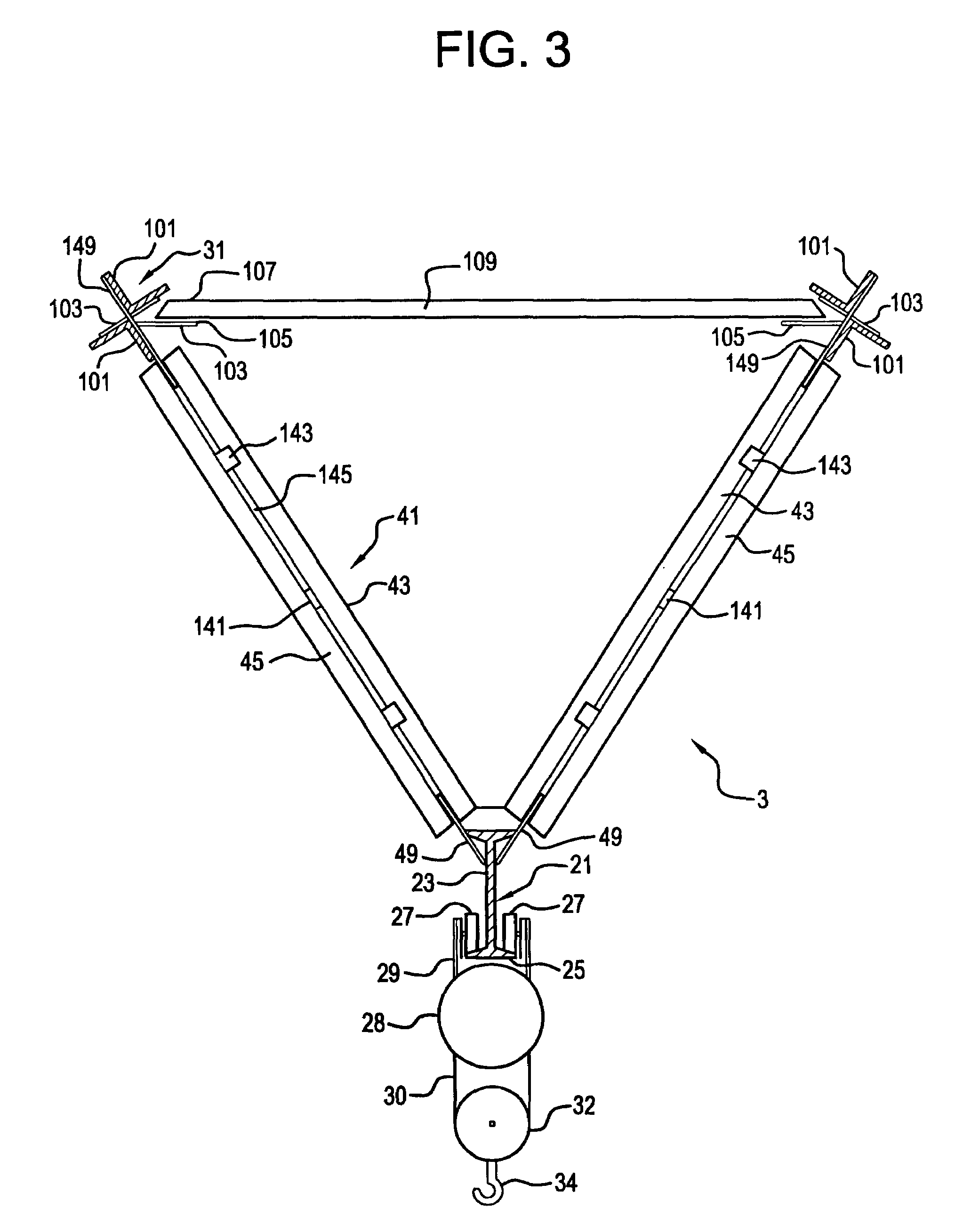

Powered lifting apparatus using multiple booms

InactiveUS7066343B1Costly to transportCostly to assembleBase supporting structuresBraking devices for hoisting equipmentsMotor driveEngineering

A lifting apparatus includes a plurality of preferably four carriages, each carriage supporting a lifting boom. Two booms are pinned together to define a first pair, a second two booms being pinned together to define a second pair. Each pair of booms and connected carriages are placed on a preferably common travel path. Rigging can include a horizontal beam that extends between the first pair of booms and the second pair of booms. The beam can be attached to the pinned connection of each pair of booms with a sling. A powered motor-driven winch is used to power a cable that is wound between sheaves on the lower end portions of a pair of booms that are connected together. During use, the winches are simultaneously or nearly simultaneously operated to elevate the first pair of the booms and the second pair of booms at about the same time. The horizontal beam that spans in between booms is elevated. Packages can be lifted with the horizontal beam by depending one or more slings from the horizontal beam to the package to be lifted. The apparatus can use carriages that are provided with wheels that travel on rails. Carriages can use rubber tires, or can be sled or skid-mounted without the use of wheels or tires.

Owner:KHACHATURIAN JON E

Gantry crane

InactiveUS7503460B1Easy erectionReduced flexibilityLoad-engaging girdersBase supporting structuresGusset plateMechanical engineering

A gantry crane has a rigid open three-dimensional truss cross-beam. A lower I-beam and parallel upper X-beams are interconnected with angular gussets and angle irons forming a triangular open beam bounded by three trusses. Angular gussets on the sides are as parallel members to provide maximum strength. One end support is rigid, with upper ends of legs having plates bolted to one end plate extending between the X-beams. Outrigger legs have an upper plate bolted to a sloped plate at an extended end of the I-beam. Vertical support legs at the other end have a strengthening cross-member and upper vertical plates which are bolted to the end plate on the X-beams. The unusual cross-beam structure and the unusual rigid leg structure and rigid interconnection provide rigidity of the entire crane. The vertical support legs accommodate variations in tracks.

Owner:PETRICIO YAKSIC DAVOR

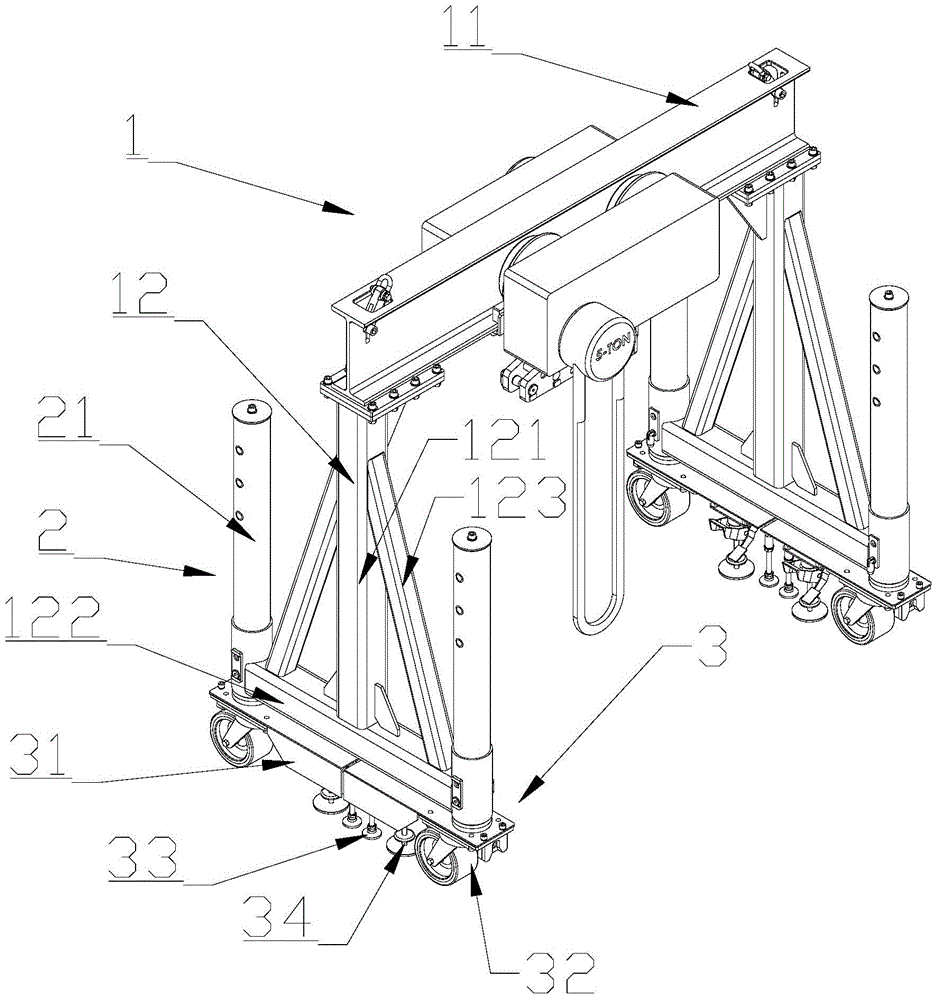

Folding-lifting type movable small-scale portal crane

ActiveCN104016242AGuaranteed stabilityReduced footprintBase supporting structuresBraking devices for hoisting equipmentsEngineeringFixed position

The invention provides a folding-lifting type movable small-scale portal crane. The portal crane is characterized by comprising a lifting part, a shaft fixing part and rotary support parts, wherein the lifting part can be fixed on a fixed position on the shaft fixing part in a detachable connection manner, and the fixed position can be adjusted in the vertical direction; the shaft fixing part is fixedly connected with the rotary support parts, and the rotary support parts can rotate in the horizontal plane by taking the shaft fixing part as the axis; the lifting part comprises chain blocks, a cross beam and multiple groups of side support parts; the shaft fixing part comprises multiple groups of lifting support legs, and each group comprises multiple support legs; the rotary support parts comprise bodies and wheels. The folding-lifting type movable small-scale portal crane has the beneficial effect of being capable of being unfolded in the working process, so that the stability of the crane is guaranteed; the portal crane is folded and packed up in the daily storage process, so that the occupied area and volume of the crane are reduced; multiple working states of the portal crane can be adapted to different space sizes and channel sizes; as the crane is provided with the wheels, the crane can conveniently move in the small-range movement process.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Bridge span replacement system

InactiveUS20140251936A1Precise positioningBase supporting structuresError detection/correctionEngineeringDelivery system

A vertically-adjustable gantry assembly installation adapted for removal or placement of a train bridge-span of the type which spans and is supported by two piers, comprises a gantry assembly positioned on load-bearing first ground-support locations, the gantry assembly comprising a gantry and a ground-engaging vertical support and lift system, the vertical support and lift system adapted for supporting a combined weight of the gantry and a bridge span in at least one operational vertical position above respective bridge span support-surfaces of the piers including a position corresponding to a disembarking plane in which the leg portions are extended from a stowed position to an extent at least sufficient for the gantry assembly to self-liftoff the pre-installation conveyance system onto the first ground-support locations to effect the gantry assembly installation.

Owner:WESTERN MECHANICAL ELECTRICAL MILLWRIGHT SERVICES

Rubber-tyred gantry crane with suspension crane and construction method thereof

InactiveCN101863422AImprove structural stabilityWide range of operationsBase supporting structuresBraking devices for hoisting equipmentsMature technologyElectrical control

The invention relates to hoisting equipment, in particular to a rubber-tyred gantry crane with a suspension crane and a construction method thereof. The crane consists of a gantry and a hoisting device arranged on the gantry, wherein a walking mechanism is arranged at the lower part of the gantry; a balancing weight block is arranged at the rear end of the gantry which is also provided with a generating unit and an electric control device which are connected with the hoisting device and the walking mechanism; the rubber-tyred crane is novel hoisting equipment which combines cranes of tyre type, gantry type and suspension arm type; the rubber-tyred walking mechanism ensures that an LTD10 type crane has more flexible forward, backward and steering and wide running range and is not limited by tracks; the steering mechanism adopts an electric push rod as steering power, has sensitive reaction and is beneficial to improving the operation efficiency; a gantry structure has favorable stable performance, small volume, can be integrally transported and is convenient to install on site; and in a winch mechanism of the rubber-tyred crane, an electric hoist with mature technology is used, so that the manufacturing construction period and the cost can be saved.

Owner:ZHENGZHOU HUAZHONG CONSTR MACHINERY CO LTD

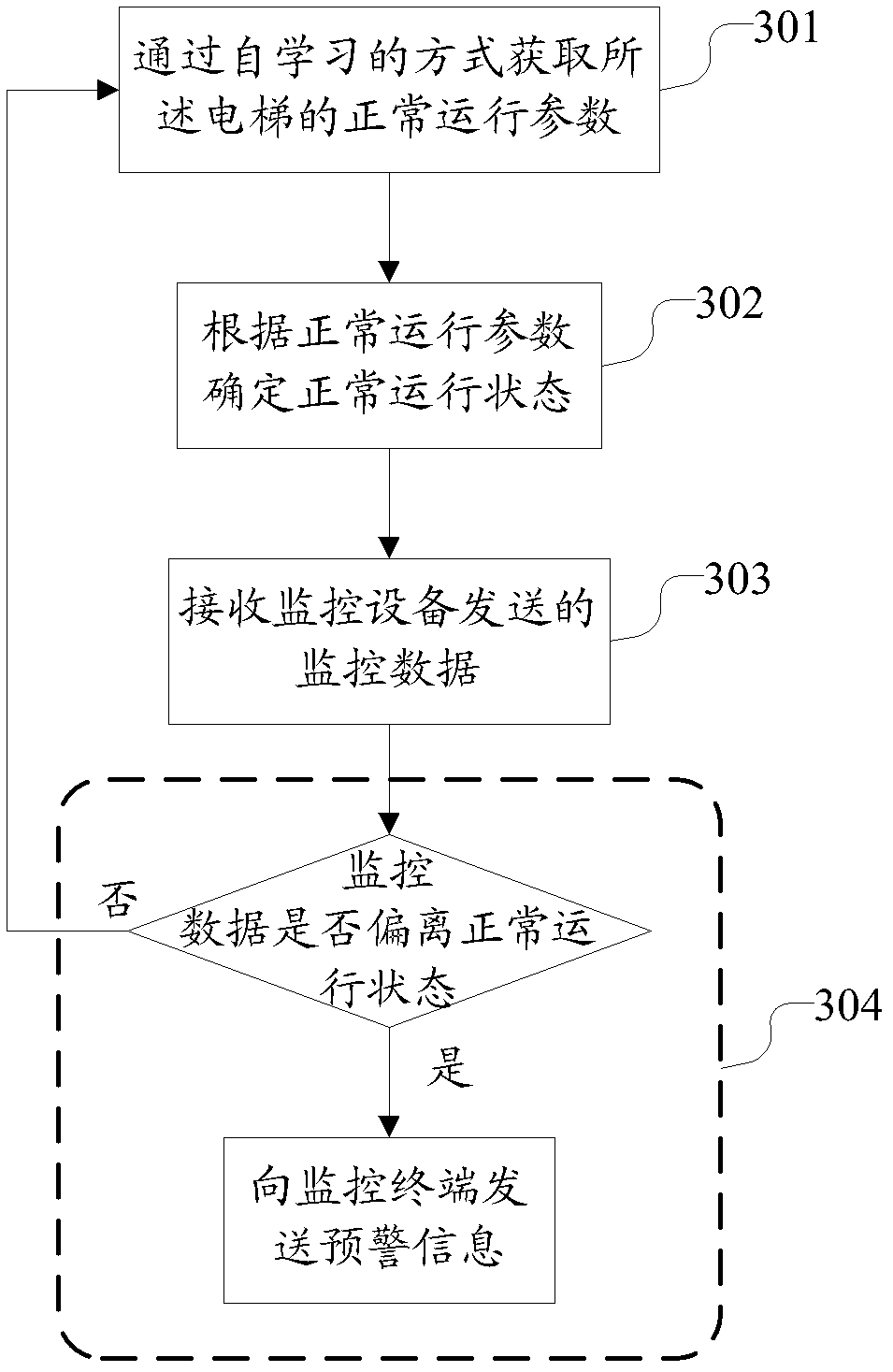

Elevator fault early warning method and relevant server

InactiveCN103130095ABase supporting structuresBraking devices for hoisting equipmentsState dependentComputer terminal

An embodiment of the invention discloses an elevator fault early warning method and a relevant server. The elevator fault early warning method and the relevant server are used for analyzing monitoring data relevant to operation states of an elevator, and sending early warning information to monitoring equipment when the current operation states are judged to be abnormal. The method comprises that normal operation parameters of the elevator are obtained and are used for indicating normal operation states of the elevator; the normal operation states of the elevator are confirmed according to the normal operation parameters; the monitoring data sent by the monitoring equipment are received and are the current elevator operation parameters acquired by the monitoring equipment; whether the monitoring data deviate the normal operation states or not are judged, if the monitoring data deviate the normal operation states, the early warning information is sent to a monitoring terminal. The elevator fault early warning method can prompt monitoring stuff to troubleshoot fault hidden danger of the elevator, and solves the problem that the fault hidden danger can not be warned early.

Owner:ALTUS TECH

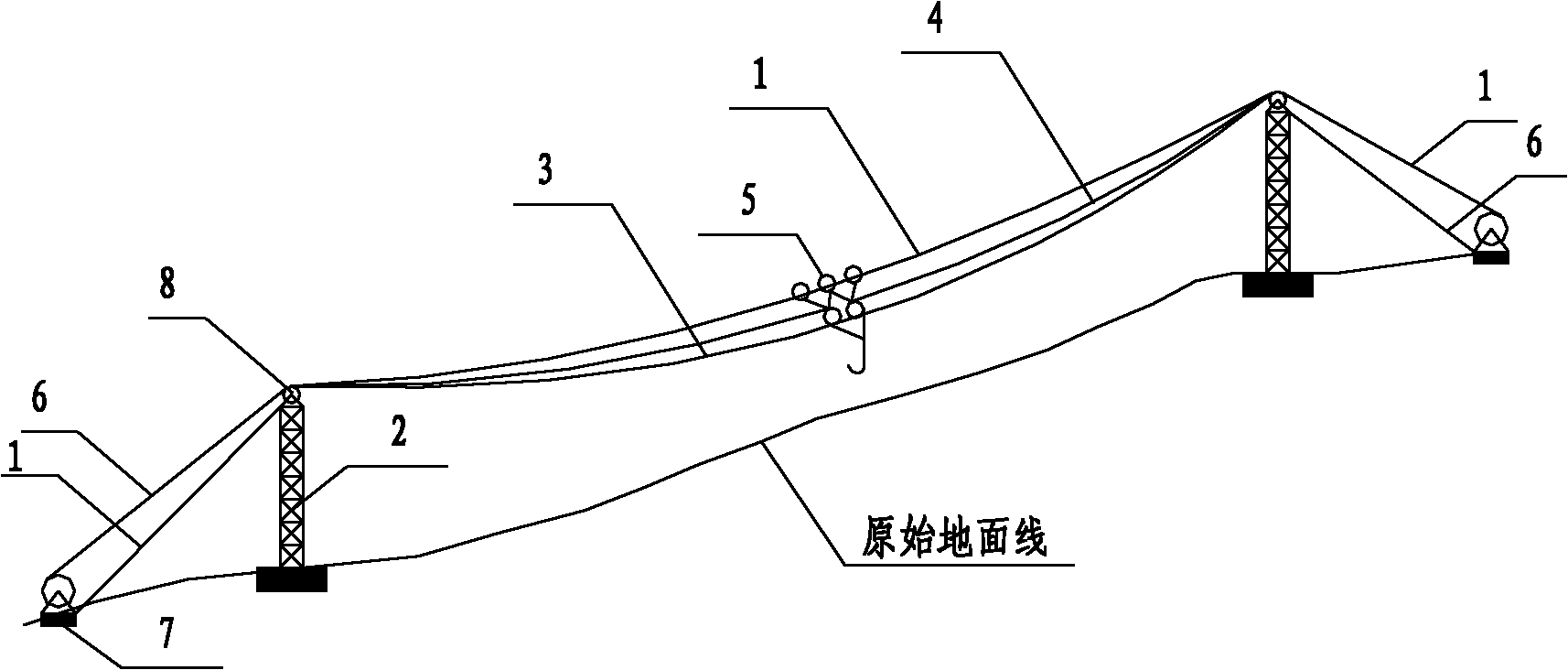

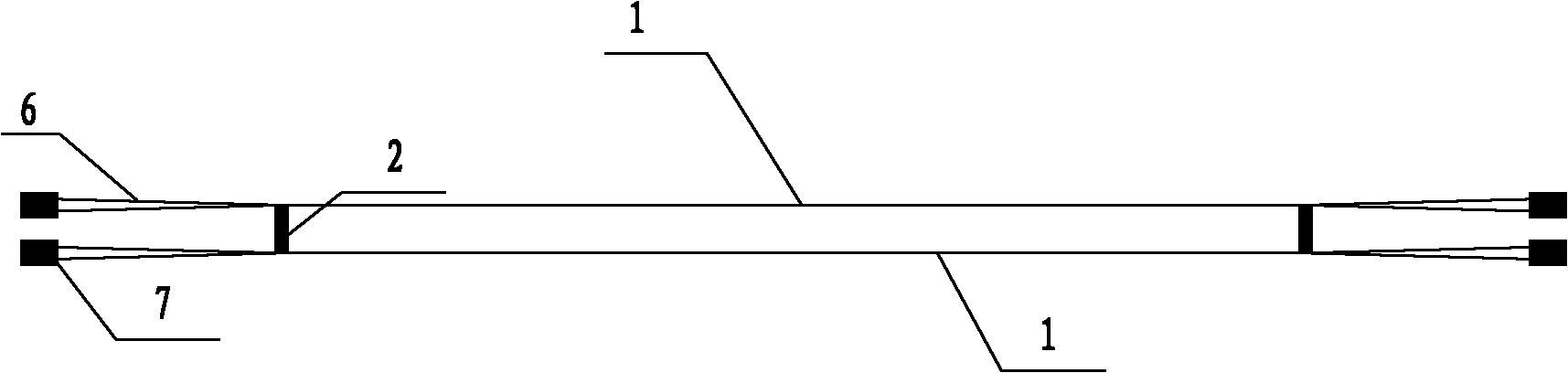

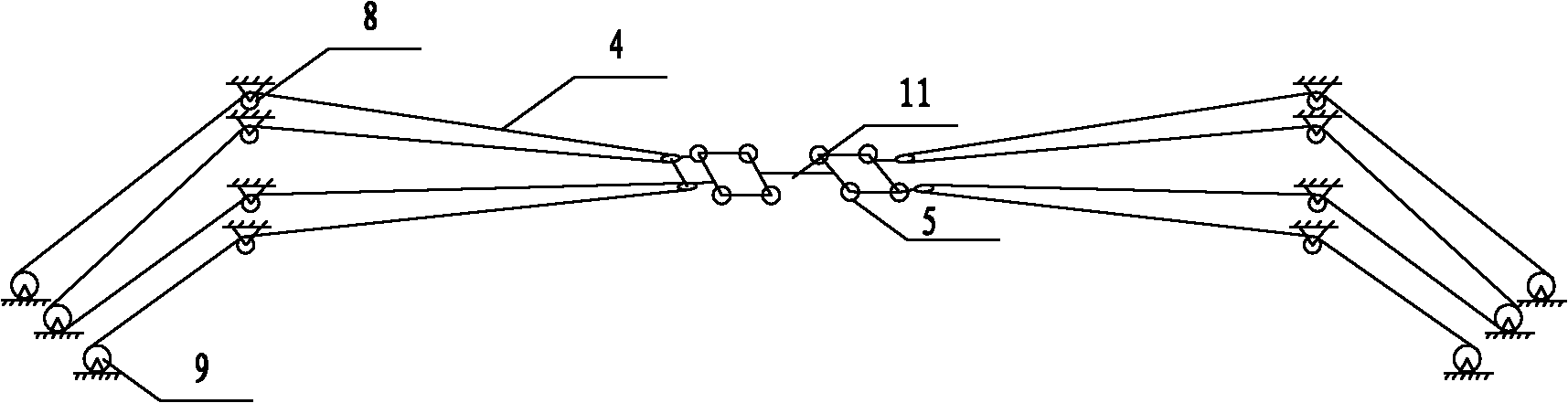

Ropeway transport system of long-span steep terrain wind power device

InactiveCN102020206ABase supporting structuresBraking devices for hoisting equipmentsElectricityTerrain

A ropeway transport system of a long-span steep terrain wind power device comprises a main cable (1), a tower (2), a hoisting cable (3), a pulling cable (4), a crane carriage (5), a rack winch (9), a steel cable (6), an anchor (7) and a tower top steering pulley (8); the tower top steering pulley (8) is installed on the tower (2); the main cable (1) and the steel cable (6) are fixed on the anchor (7); the other ends of the main cable (1) and the steel cable (6) are fixed on the tower top steering pulley (8); two ends of the pulling cable (4) are connected with the rack winch (9); and two ends of the hoisting cable (3) are connected with a hoisting winch (10). The system overcomes the problems of big construction difficulty, high project construction cost and serious environment damage when construction roads are built in the mountainous area by using a traditional technique. The invention provides a transport solution for a heavy cargo device of a steep terrain wind power device in a mountainous area and designs a device for realizing the solution.

Owner:长江水利委员会长江勘测规划设计研究院

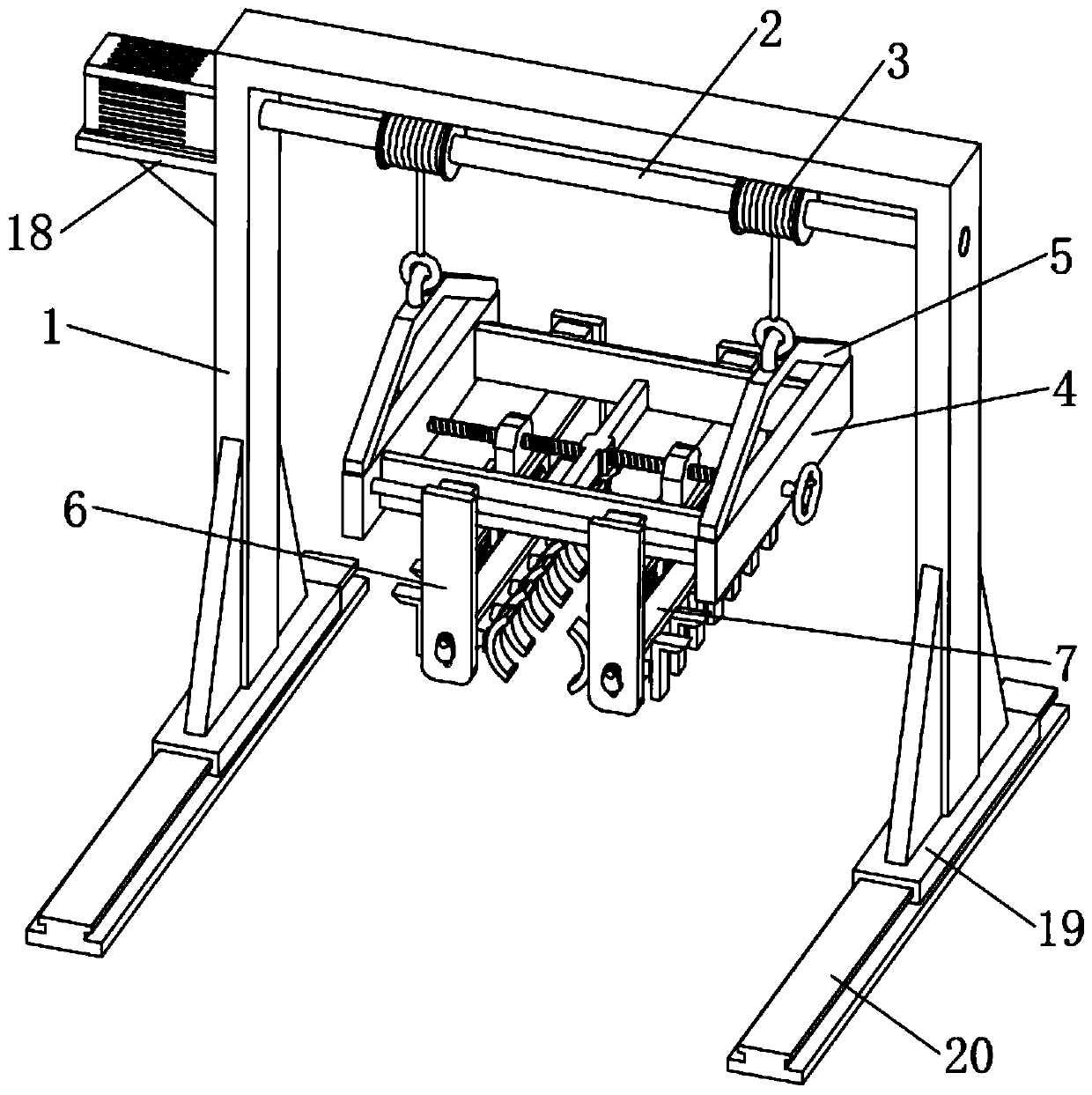

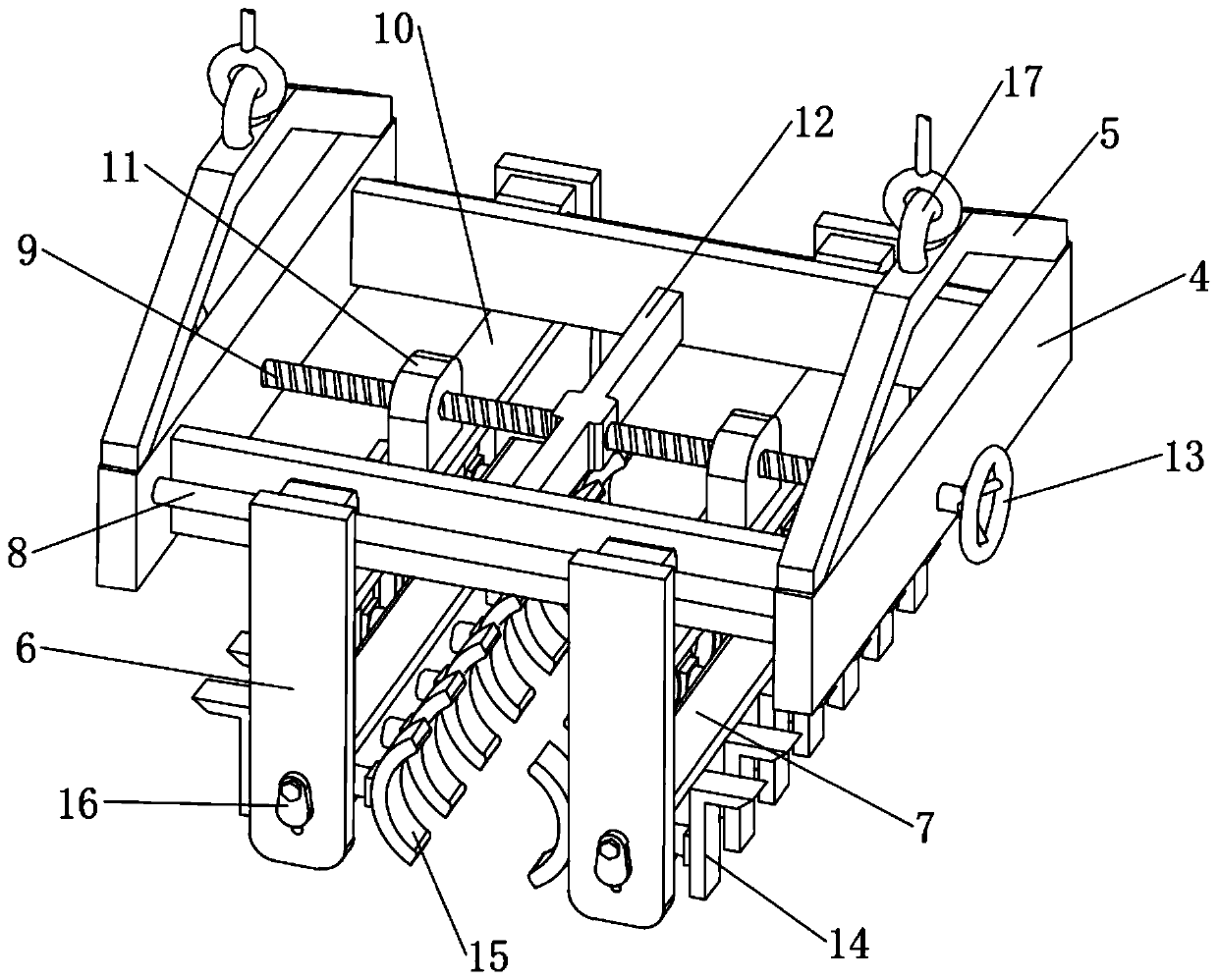

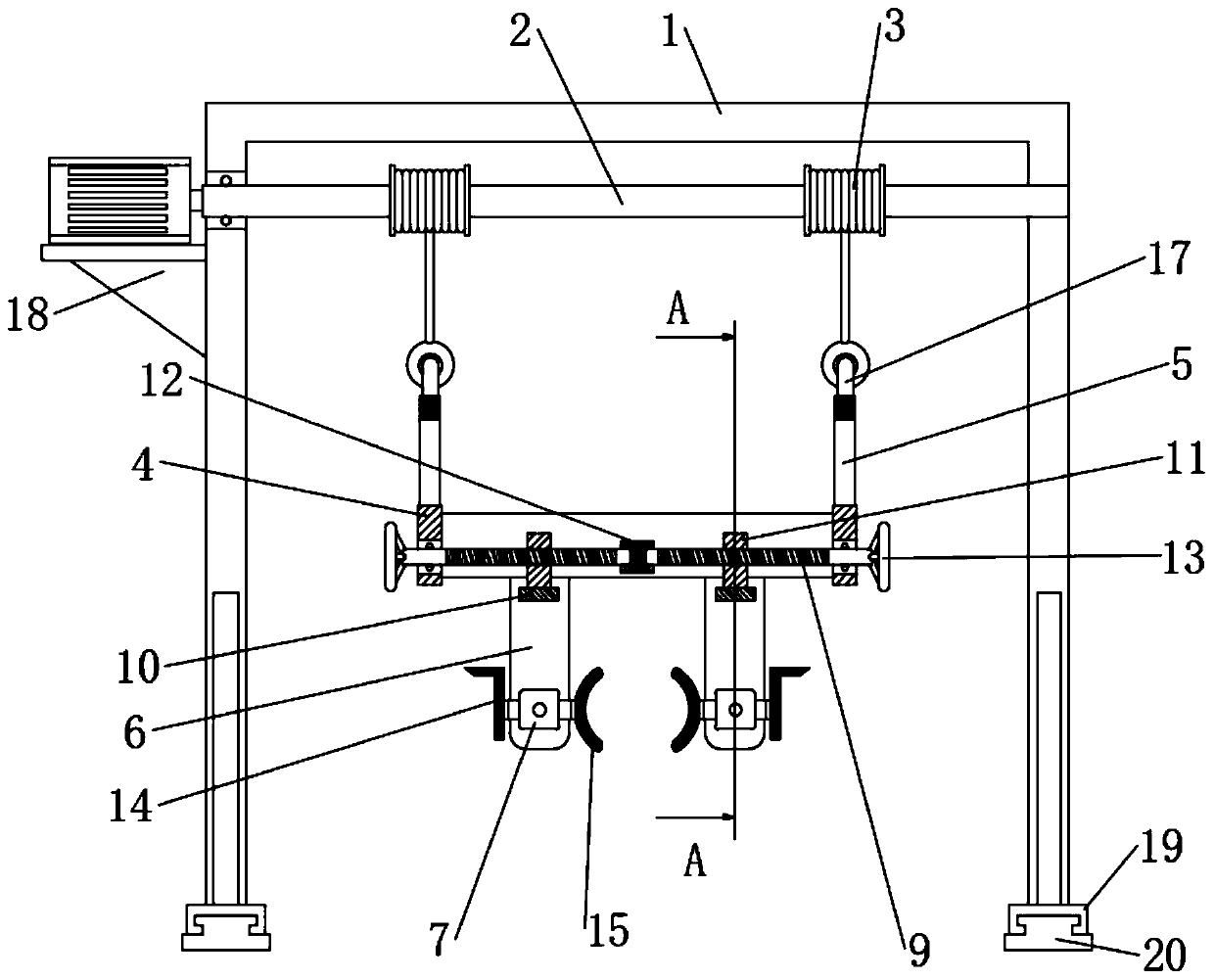

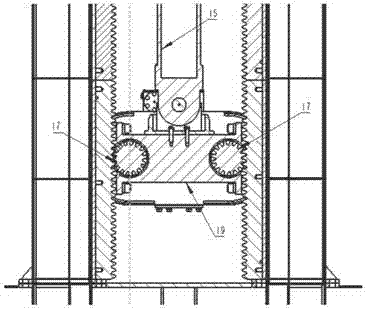

Portal crane capable of switching over clamps and used for hardware pipe fitting

ActiveCN110329903AFlexible deletionMulti-job environmentBase supporting structuresBraking devices for hoisting equipmentsPipe fittingEngineering

The invention discloses a portal crane capable of switching over clamps and used for a hardware pipe fitting, and relates to the field of hardware machining equipment. The portal crane capable of switching over clamps and used for the hardware pipe fitting comprises a crane frame, a clamp hoisting frame and clamp switchover rolls, wherein a winding reel arranged on a hoisting shaft on the crane frame is wound with traction ropes; the hoisting shaft is connected with the clamp hoisting frame through two traction ropes; the clamp hoisting frame is connected with two pairs of clamp switchover roll support columns through slide rods; one clamp switchover roll is rotationally connected between the lower ends of each pair of the clamp switchover roll support columns; a square pipe clamping groupis arranged at one side of each clamp switchover roll; and a circular pipe clamping group is arranged at the other side of each clamp switchover roll. According to the portal crane capable of switching over the clamps and used for the hardware pipe fitting, a rotary wheel is rotated, each pair of the clamp switchover roll support columns is controlled to move under the condition of adjusting thethread relationship of a screw rod and a screw rod seat, a distance between the clamp switchover rolls arranged at the lower ends of the two pairs of clamp switchover roll support columns is adjusted,the clamps arranged on the two groups of clamp switchover rolls clamp the pipe fitting, and the operation is convenient.

Owner:滨州高新材料产业园有限公司

Hydraulic portal crane

ActiveCN106927371AReduce volumeReduce weightBase supporting structuresBraking devices for hoisting equipmentsYardPortal frame

Owner:王亚光

Gantry positioning system

ActiveUS20070170140A1Base supporting structuresBraking devices for hoisting equipmentsEngineeringMechanical engineering

A gantry system is provided that comprises a gantry beam having a first section and a second section and first and second motors cooperating to drive the respective first and second sections in parallel directions to position the gantry beam along a linear axis. A flexure is connected between the first and second sections about which the second section is deflectable relative to the first section, which is advantageous to reduce any stresses that may be caused in the gantry system when driving the gantry beam.

Owner:ASMPT SINGAPORE PTE LTD

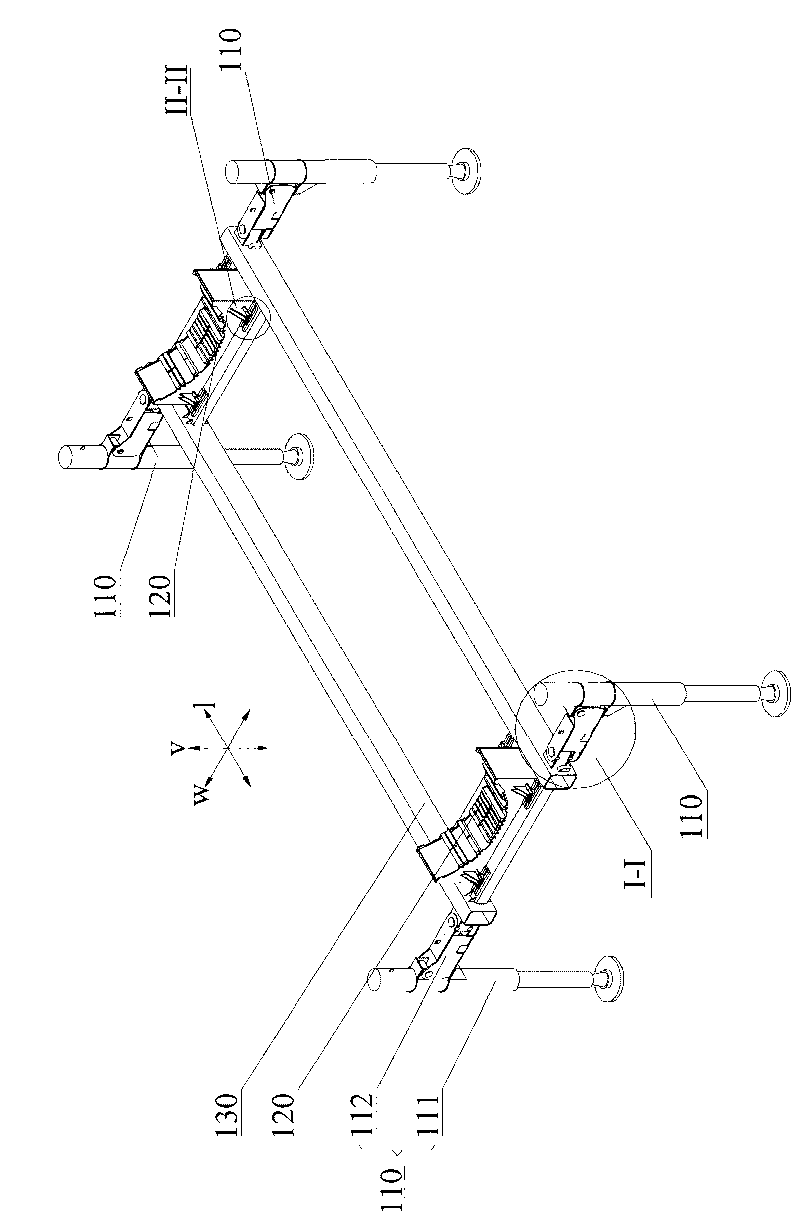

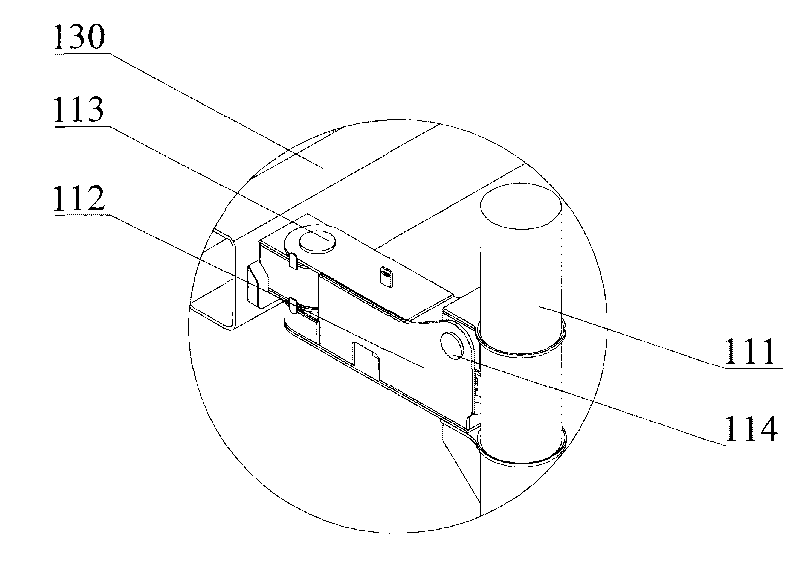

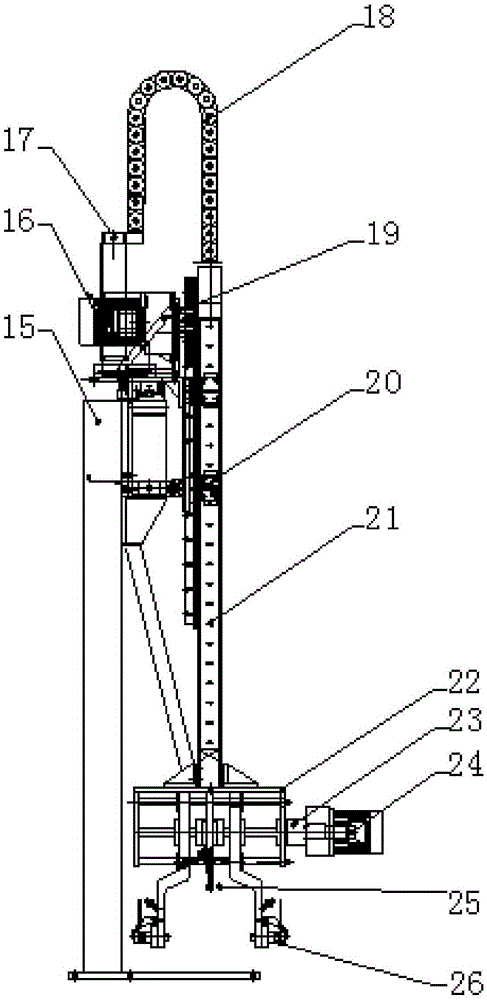

Mechanical Bar Conveying Device

ActiveUS20170123405A1Simple mechanical structureStable bar clamping operationProgramme controlComputer controlHorizontal axisReducer

The invention provides a mechanical bar conveying device consisting of a horizontal travel limiting device (1), a vertical axis servo reducer (2), a vertical descent depth detector (3), a vertical axis travelling mechanism (4), a horizontal axis servo reducer (5), a horizontal drive gear (6), a horizontal tow chain (7), a horizontal moving mechanism (8), a manipulator torque detector (9), a safety detection mechanism (10), a main frame (11), a horizontal frame (12), a vertical movement mechanism (16), a tow chain bracket (17), a tow chain (18), a vertical rack-and-pinion mechanism (19), a horizontal linear guide track (20), a vertical beam (21), a claw clamping mechanism (22), a claw ball screw (23), a manipulator servo reducer (24), a manipulator depth detector (25), and a claw and travel limiting combined mechanism (26). The device realizes automatic conveying of bars, and avoids the problems of manual conveying process, such as high environmental temperature, large intensity, low work efficiency and high risk of industrial accidents.

Owner:CITIC DICASTAL

Slant-truss crane rail

ActiveUS20110180507A1Reduce the total massPromote sportsBase supporting structuresBraking devices for hoisting equipmentsMomentumDrive motor

In one aspect, the invention is directed to an overhead crane with one or more bridge rails, that incorporates a reinforcement truss into its one or more bridge rails so as to reduce the overall mass of the one or more bridge rails. This facilitates movement of a load carried by the bridge by an operator to a destination point, particularly in embodiments wherein the one or more bridge rails do not have any bridge drive motors thereon. Reducing the mass of the bridge can increase the amount of lifted load that can comfortably be maneuvered by an operator, particularly when the bridge is manually moved along the runway. Additionally, reducing the mass of the bridge reduces the momentum associated with the bridge, which can increase the amount of control that the operator has when it is desired to stop the bridge when the load has been maneuvered to its desired destination point. The second reinforcement members may have first and second ends that are inserted into receiving apertures in the first reinforcement member and in a bracket that mounts to the bridge rail respectively. In embodiments wherein the bridge includes two rails and is capable of supporting a load in such a way as to generate a downward force that is offset from the bridge axis, the second reinforcement members may be connected to the first reinforcement member and to brackets in such a way as to prevent the withdrawal of the second reinforcement members from the receiving apertures.

Owner:GIVENS RAY

Bar material mechanical carrying device

InactiveCN105415360AReal-time detection of gripping torqueSimple mechanical structureProgramme controlProgramme-controlled manipulatorReducerUltimate tensile strength

The invention provides a bar material mechanical carrying device. The bar material mechanical carrying device is composed of a horizontal stroke limiting device (1), a vertical shaft servo speed reducer (2), a vertical descending depth detector (3), a vertical shaft walking mechanism (4), a horizontal shaft servo speed reducer (5), a horizontal driving gear (6), a horizontal drag chain (7), a horizontal moving mechanism (8), a tong torque detector (9), a safety detecting mechanism (10), a main machine frame (11), a horizontal machine frame (12), a vertical moving mechanism (16), a drag chain supporting frame (17), a drag chain (18), a vertical gear rack (19), a horizontal linear guide rail (20), a vertical beam body (21), a clamp jaw screwing mechanism (22), a clamp jaw ball screw rod (23), a tong servo speed reducer (24), a tong depth detector (25), and clamp jaw and stroke limiting combined mechanisms (26). According to the bar material mechanical carrying device, automatic carrying of bar materials is achieved, and the problems that the temperature of the environment where workers carry the bar materials is high, the intensity is high, the work efficiency is low, industrial injury risks exist and the like are solved.

Owner:CITIC DICASTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com