Multi-arch bridge rib vertical turning technical method

A vertical rotation and continuous technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of a large number of continuous jacks and buckle towers, and achieve the effect of convenient construction and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

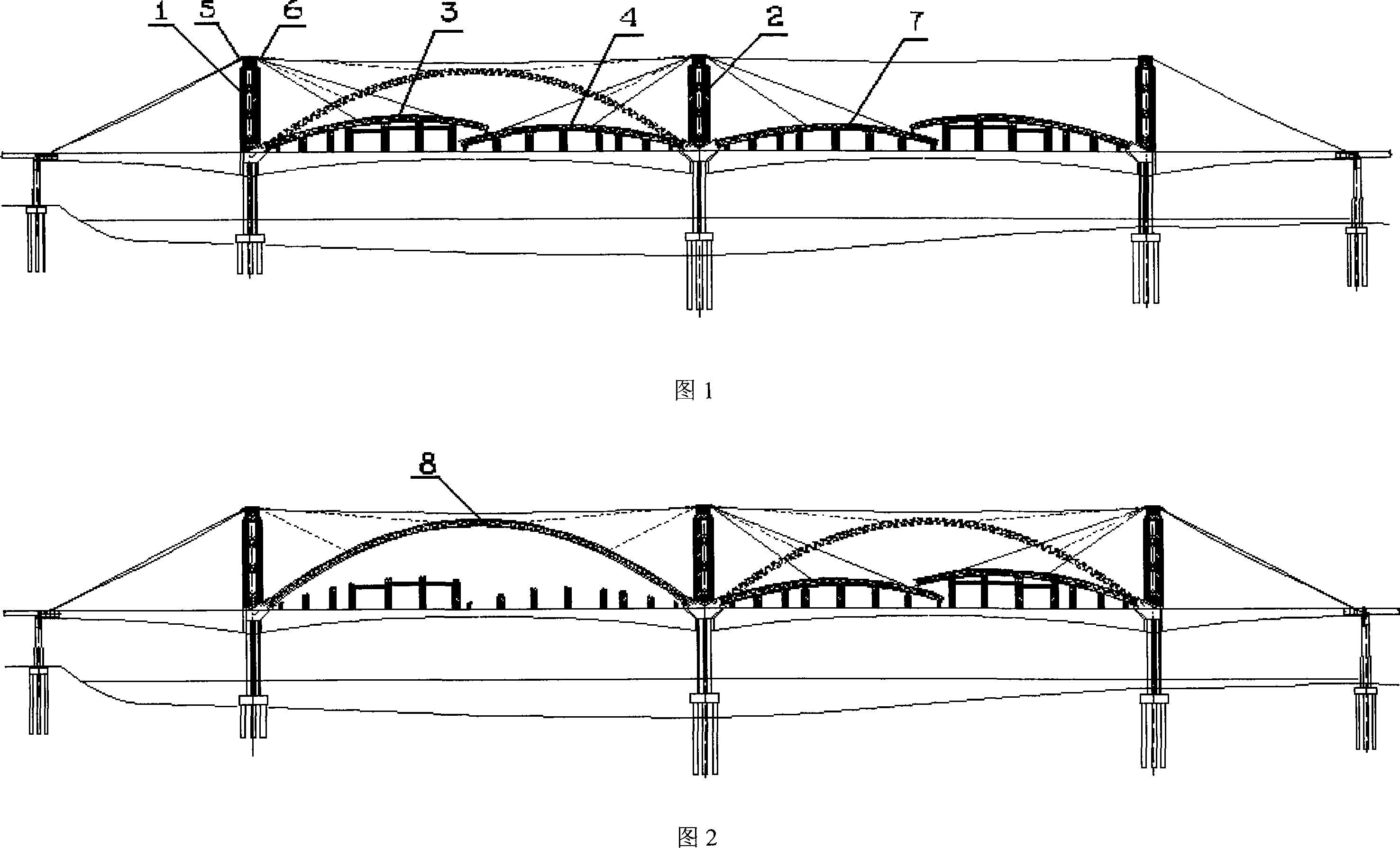

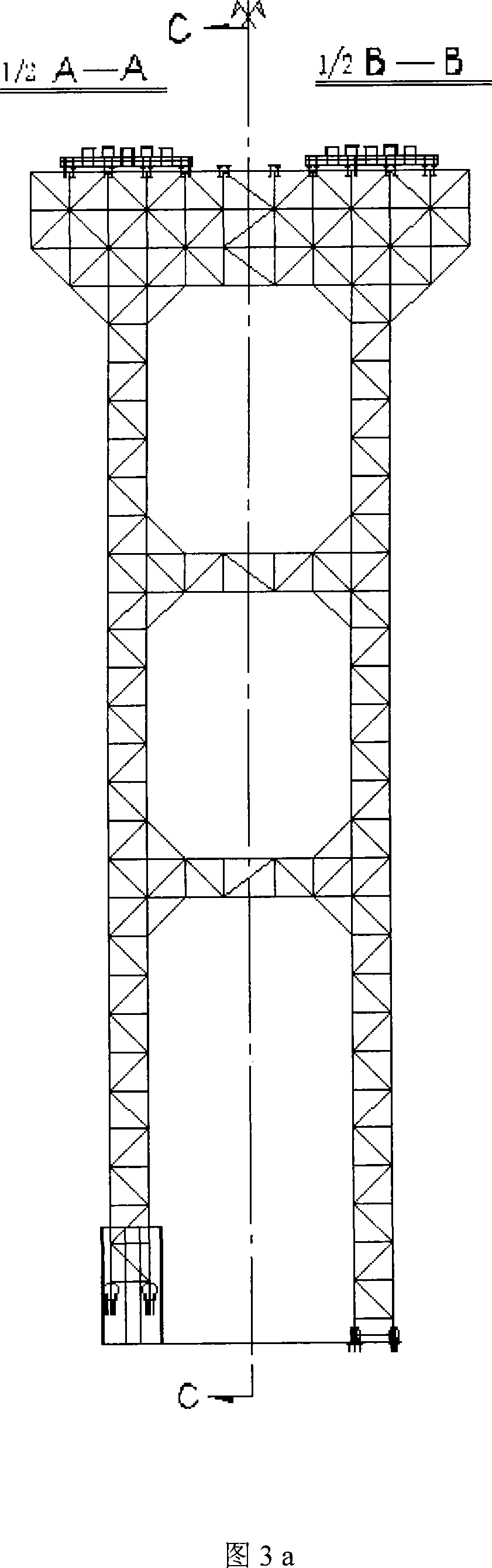

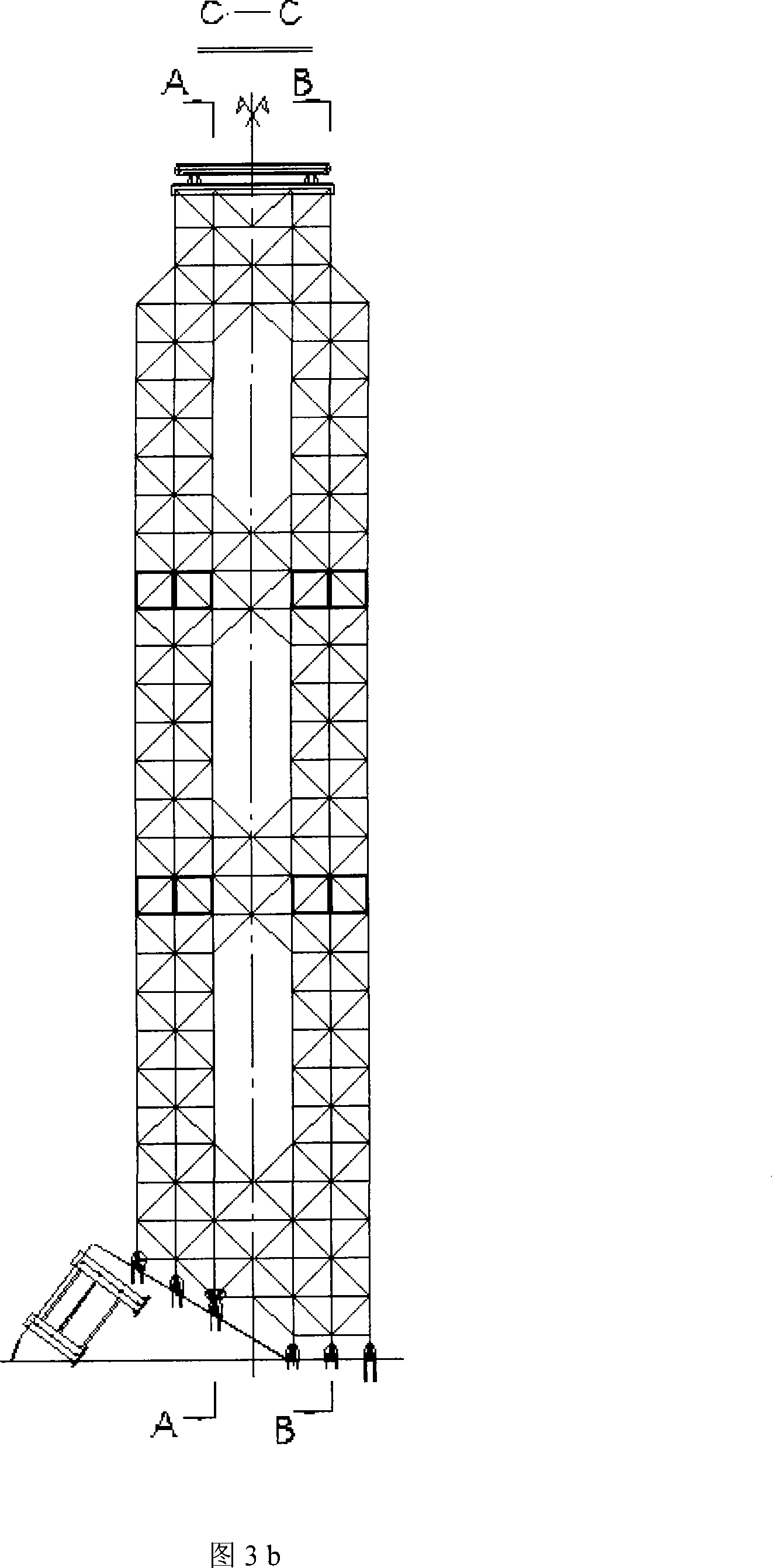

[0027] Taking the bridge with three pylons as an example to illustrate the construction method of the vertical rotation of the arch ribs of the multi-span continuous arch bridge.

[0028] The main steps of this method are:

[0029] 1. The buckle cable tower can be installed with a tower crane after a certain section of the rigid frame beam cantilevered, and it can be changed to a loose assembly after reaching a certain height; after the three towers are assembled, install the pressure tower cable and the rear cable wind, and tension Pull to the design tonnage to form a stable system.

[0030] 2. Assembly of arch ribs

[0031] Set up a door crane lifting station near the side hole with steel pipe arch. After the steel pipe arch rib segment is processed in the factory, it is transported by water to the hoisting station; it is hoisted from the hoisting station to the bridge deck transport vehicle, and transported to the location to be installed. After the parts of the arch rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com