Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

150results about How to "Enhanced oscillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

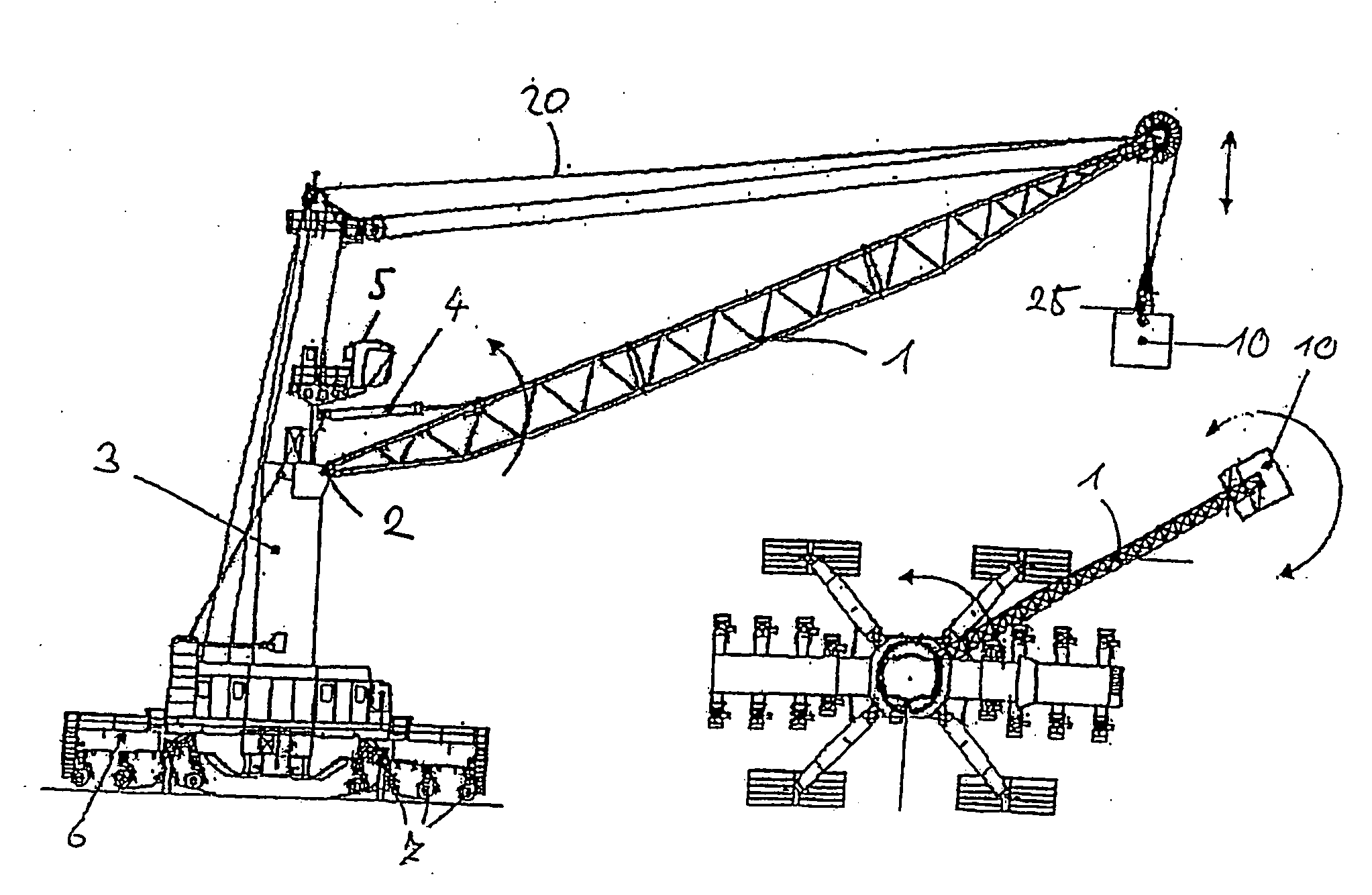

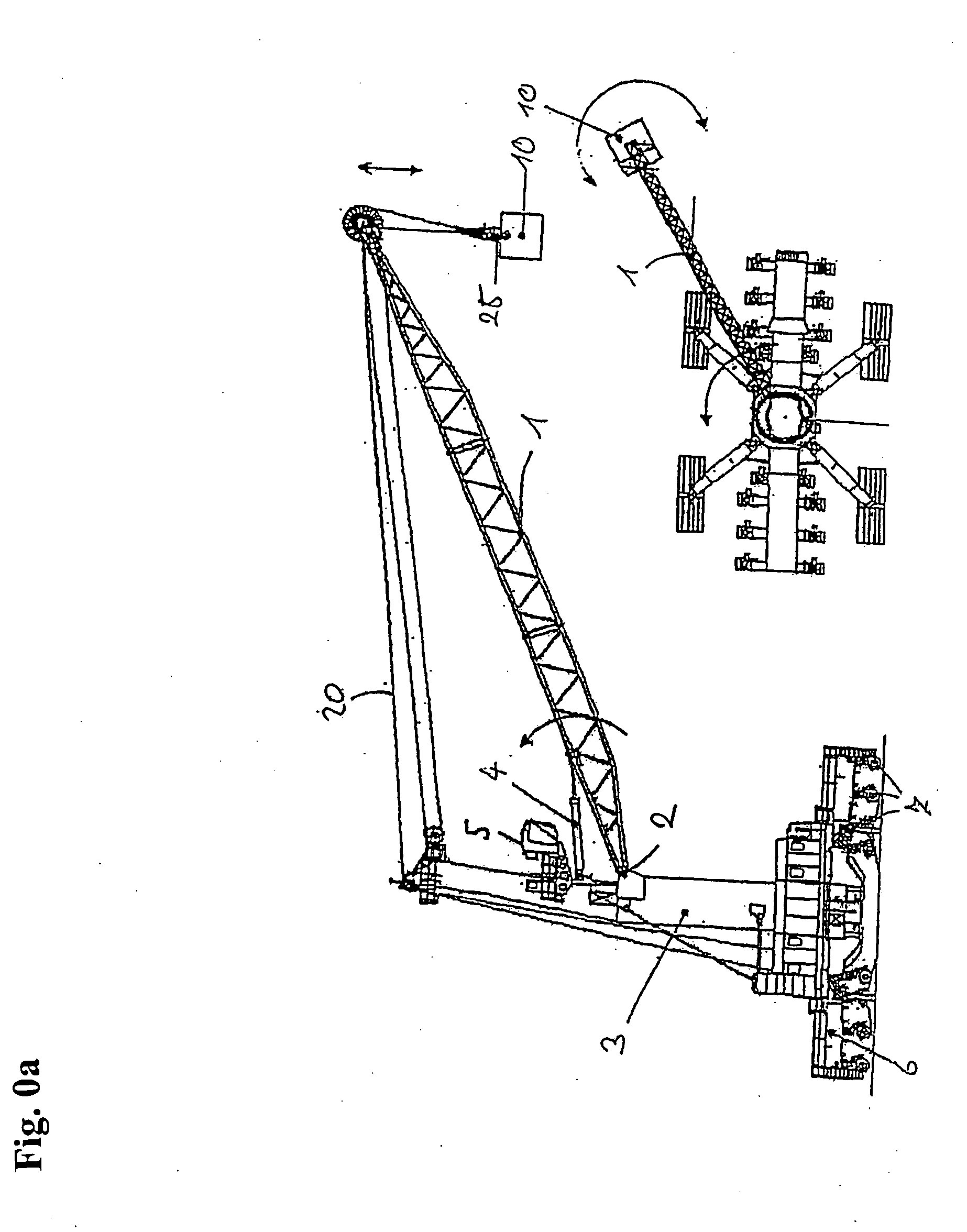

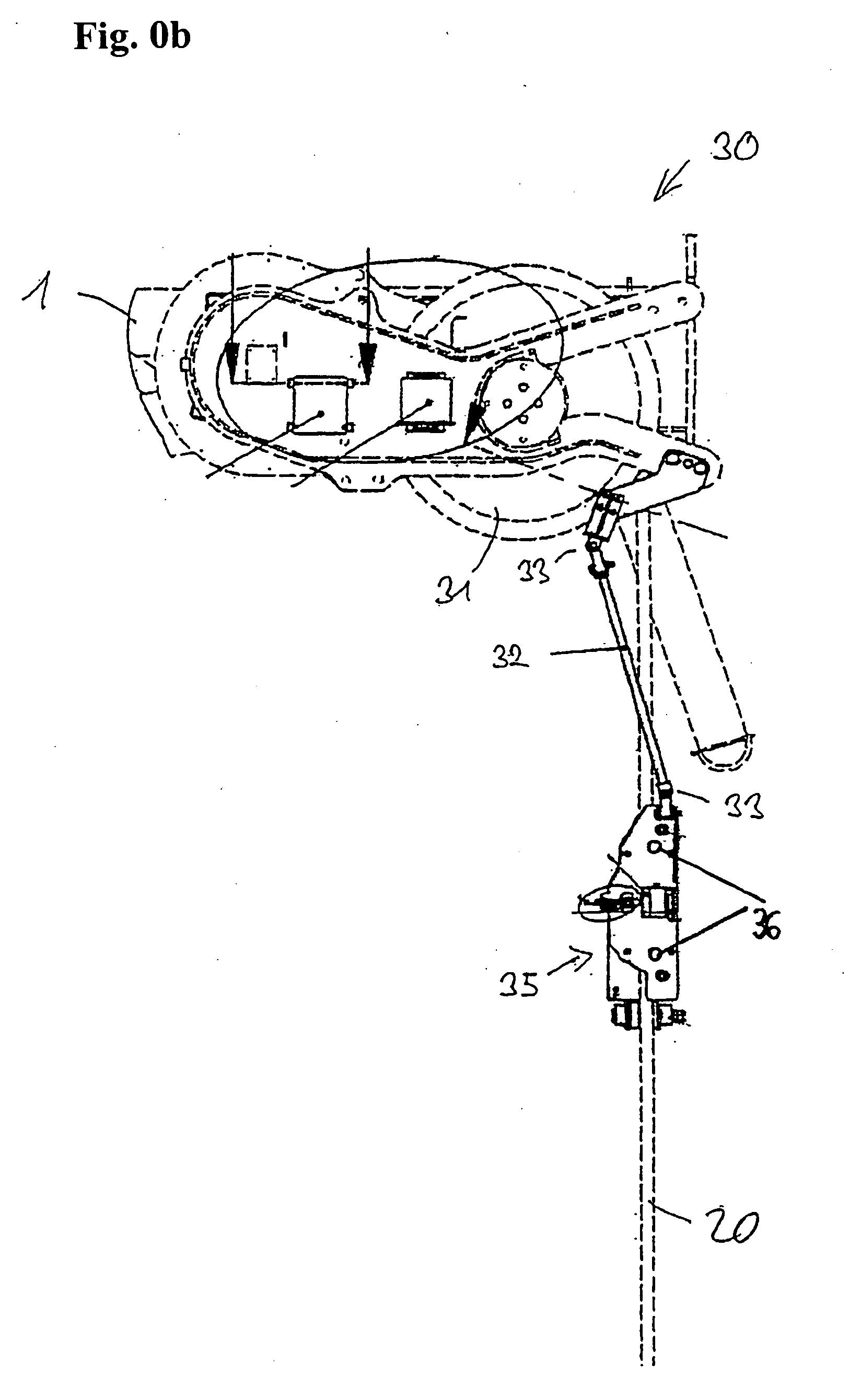

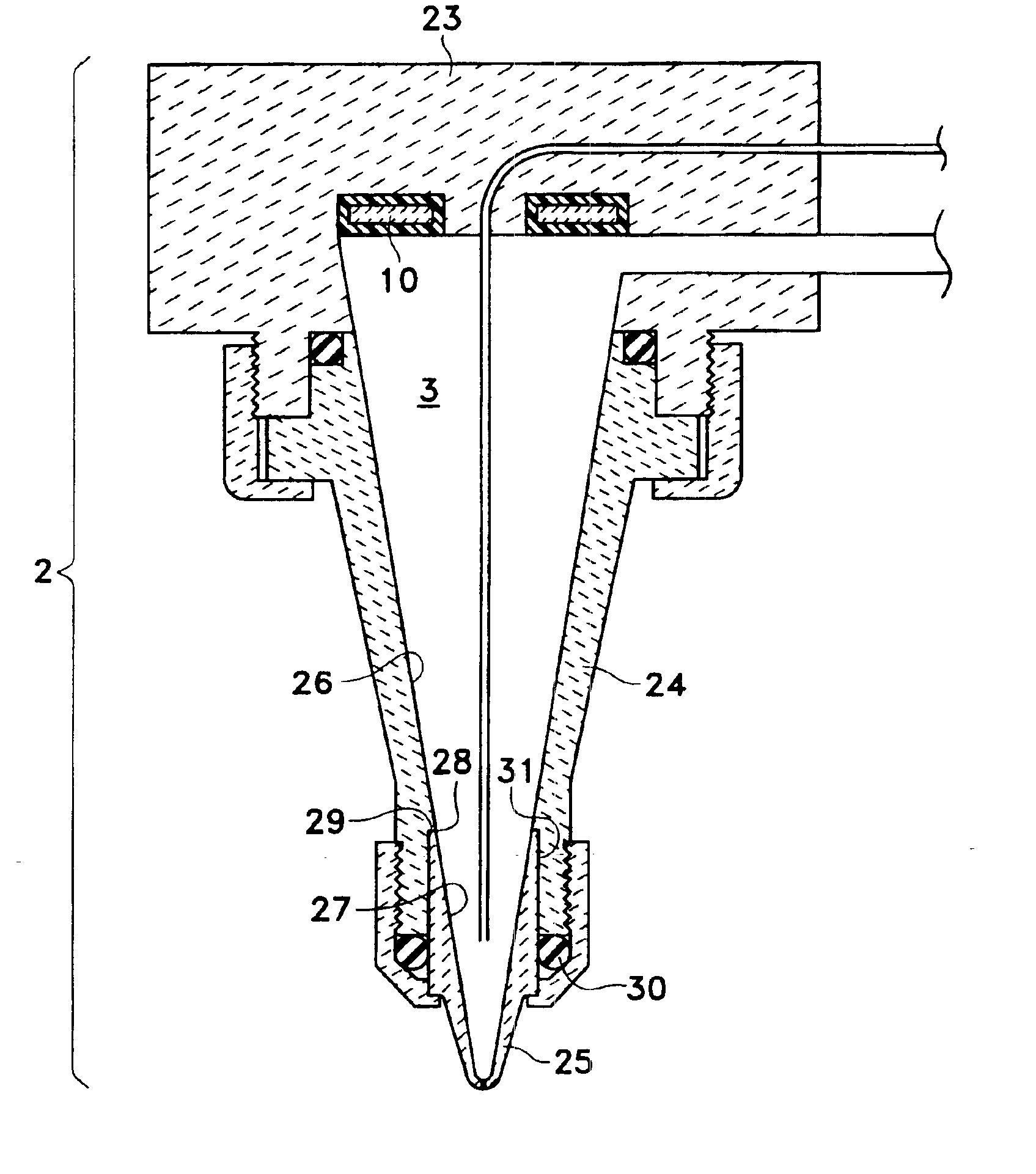

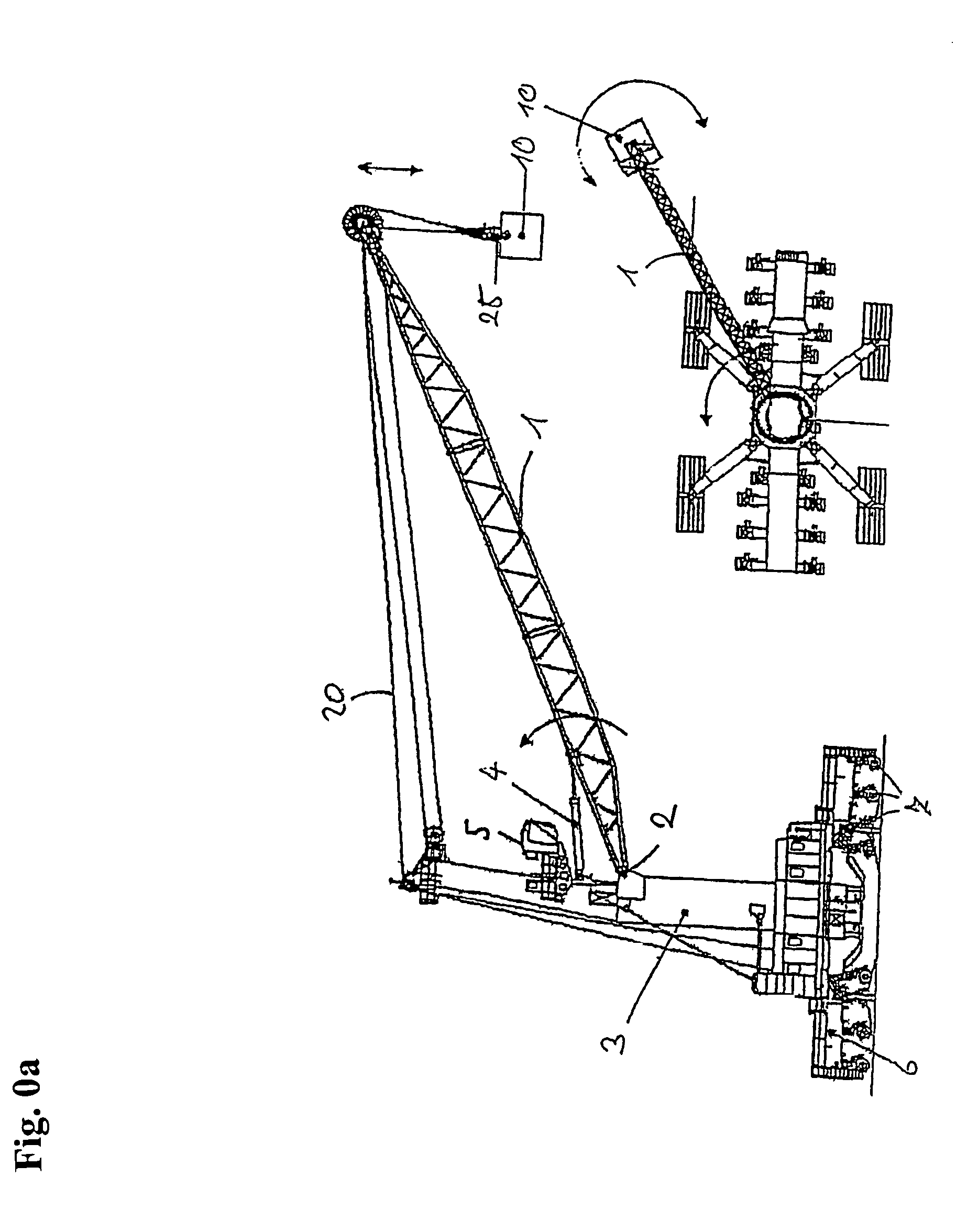

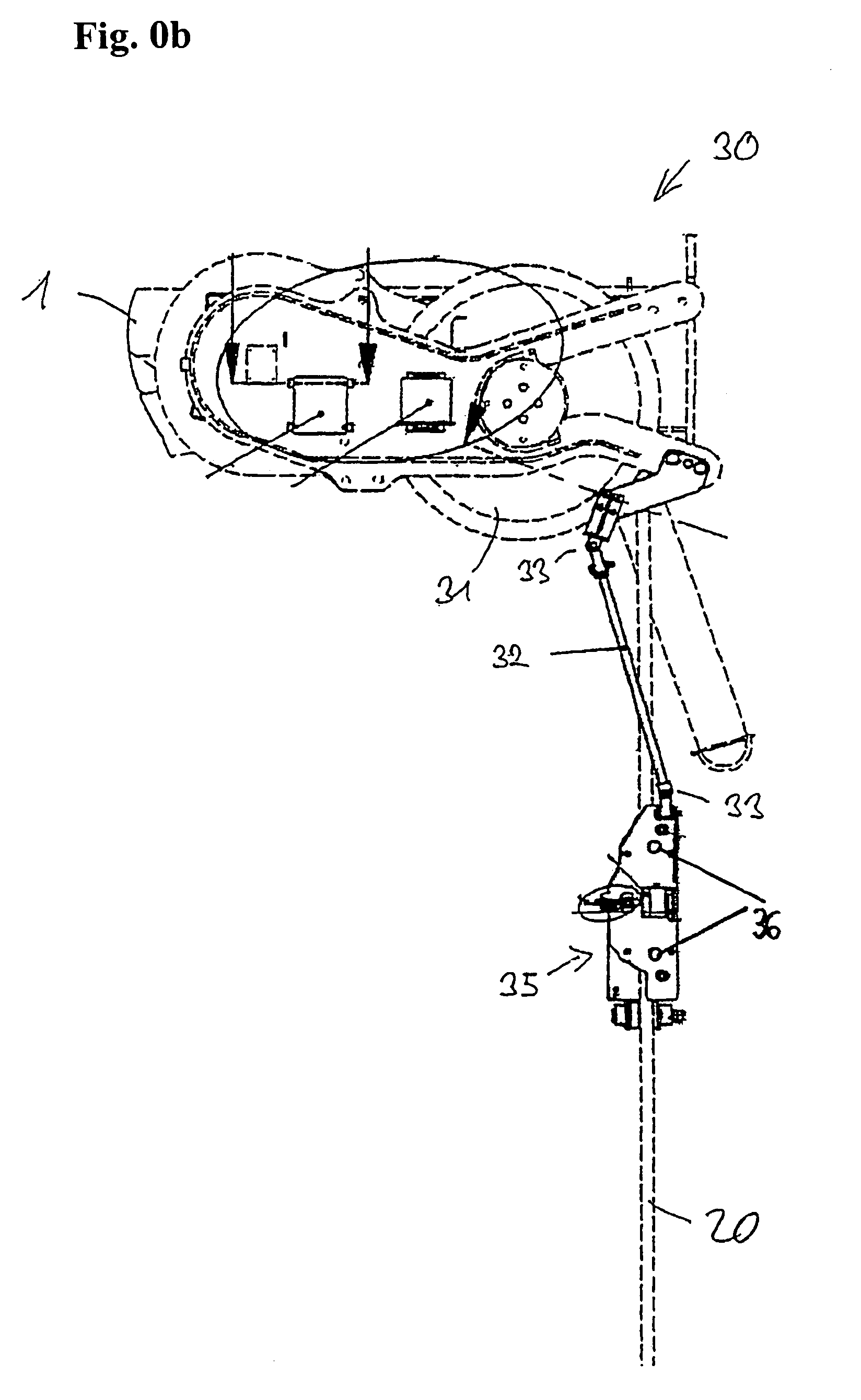

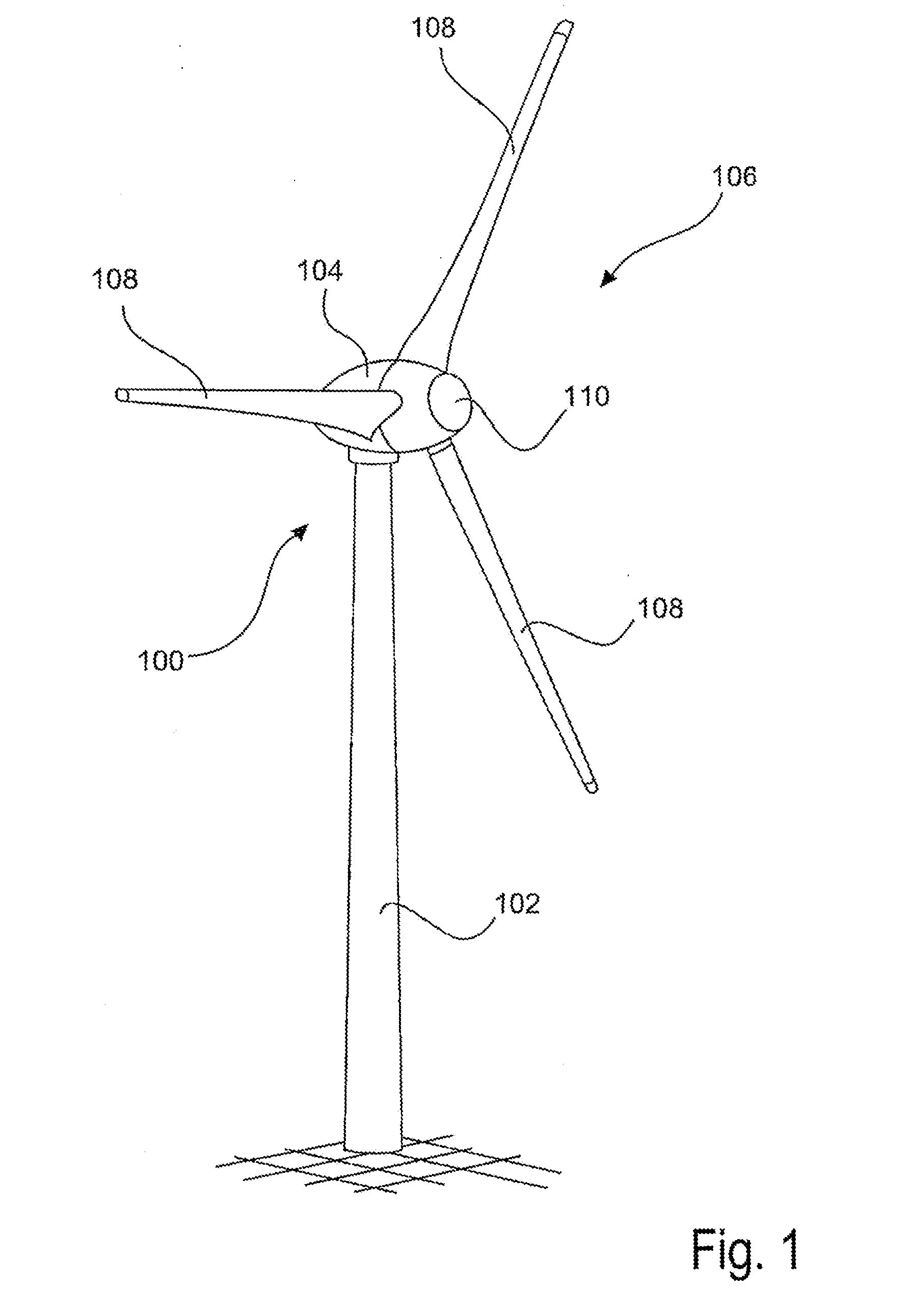

Crane control, crane and method

ActiveUS20090008351A1Easy and safer alignmentEnhanced oscillationCranesSafety gearAngular velocityGravitational force

The present invention shows a crane control of a crane which includes at least one cable for lifting a load, wherein at least one sensor unit is provided for determining a cable angle relative to the direction of gravitational force. Furthermore, there is shown a crane control for driving the positioners of a crane which includes at least one first and one second strand of cables for lifting the load, with a load oscillation damping for damping spherical pendular oscillations of the load, wherein first and second sensor units are provided, which are associated to the first and second strands of cables, in order to determine the respective cable angles and / or cable angular velocities, and the load oscillation damping includes a control in which the cable angles and / or cable angular velocities determined by the first and second sensor units are considered. Furthermore, a corresponding crane and a method are shown.

Owner:LIEBHERR WERK NENZING

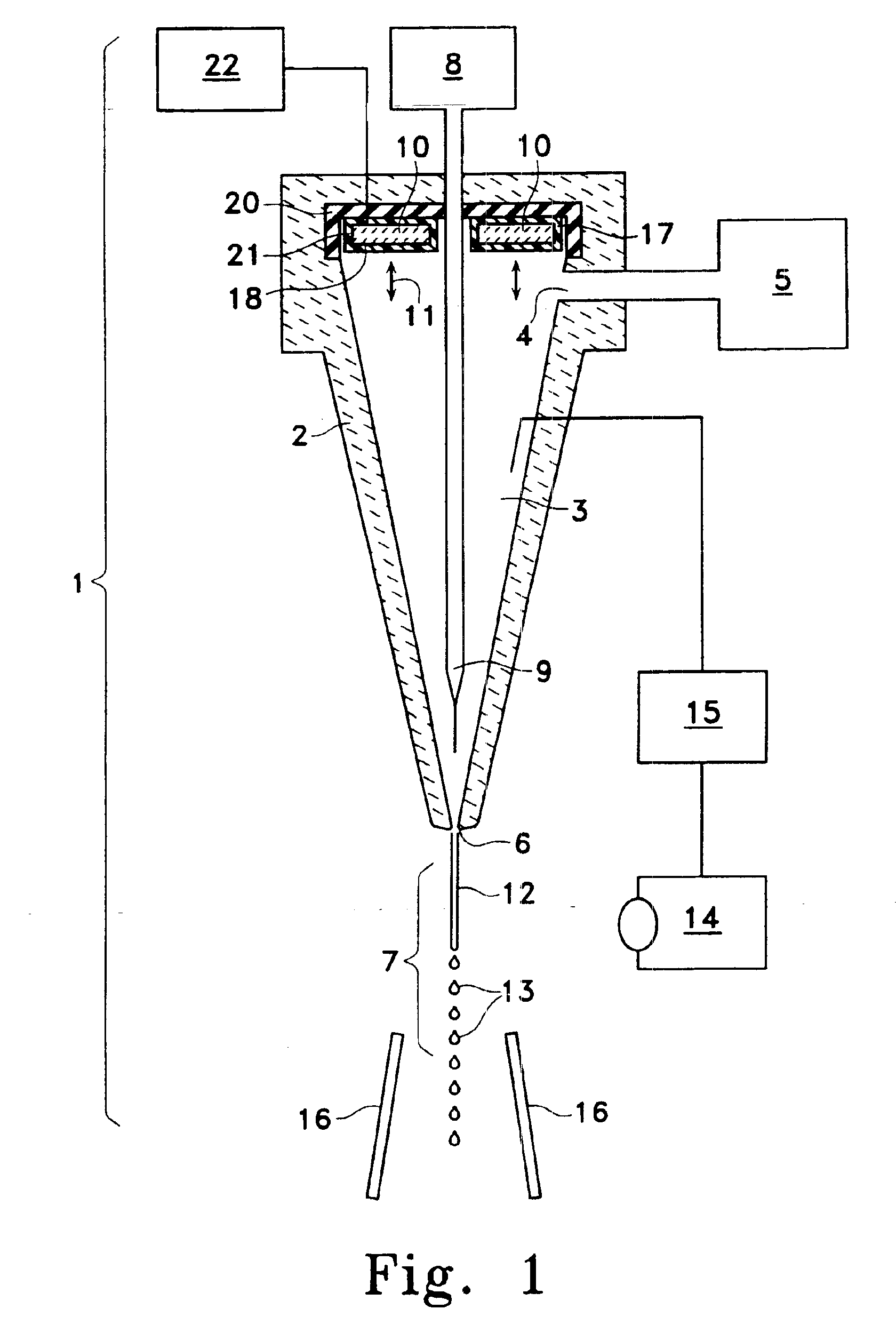

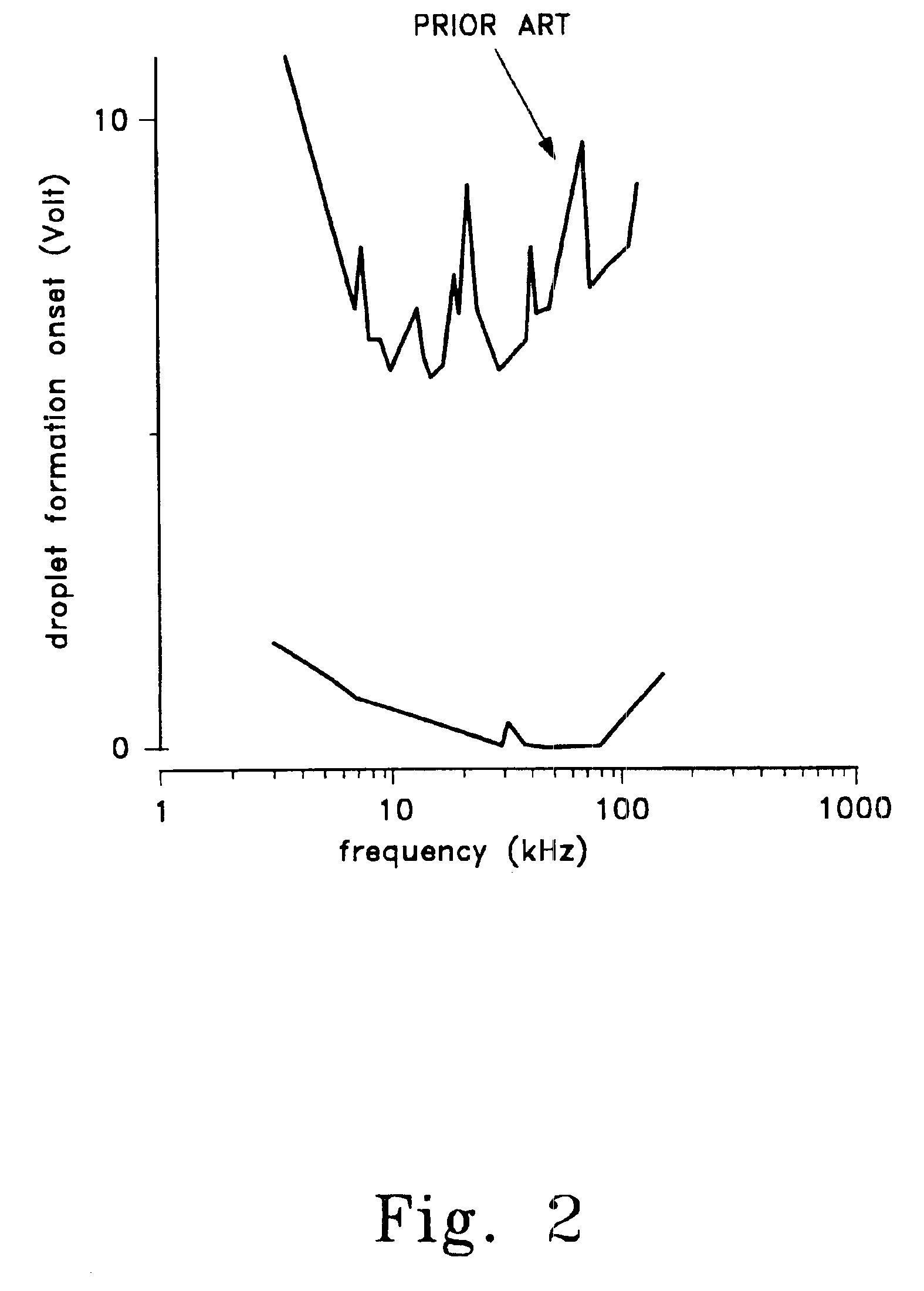

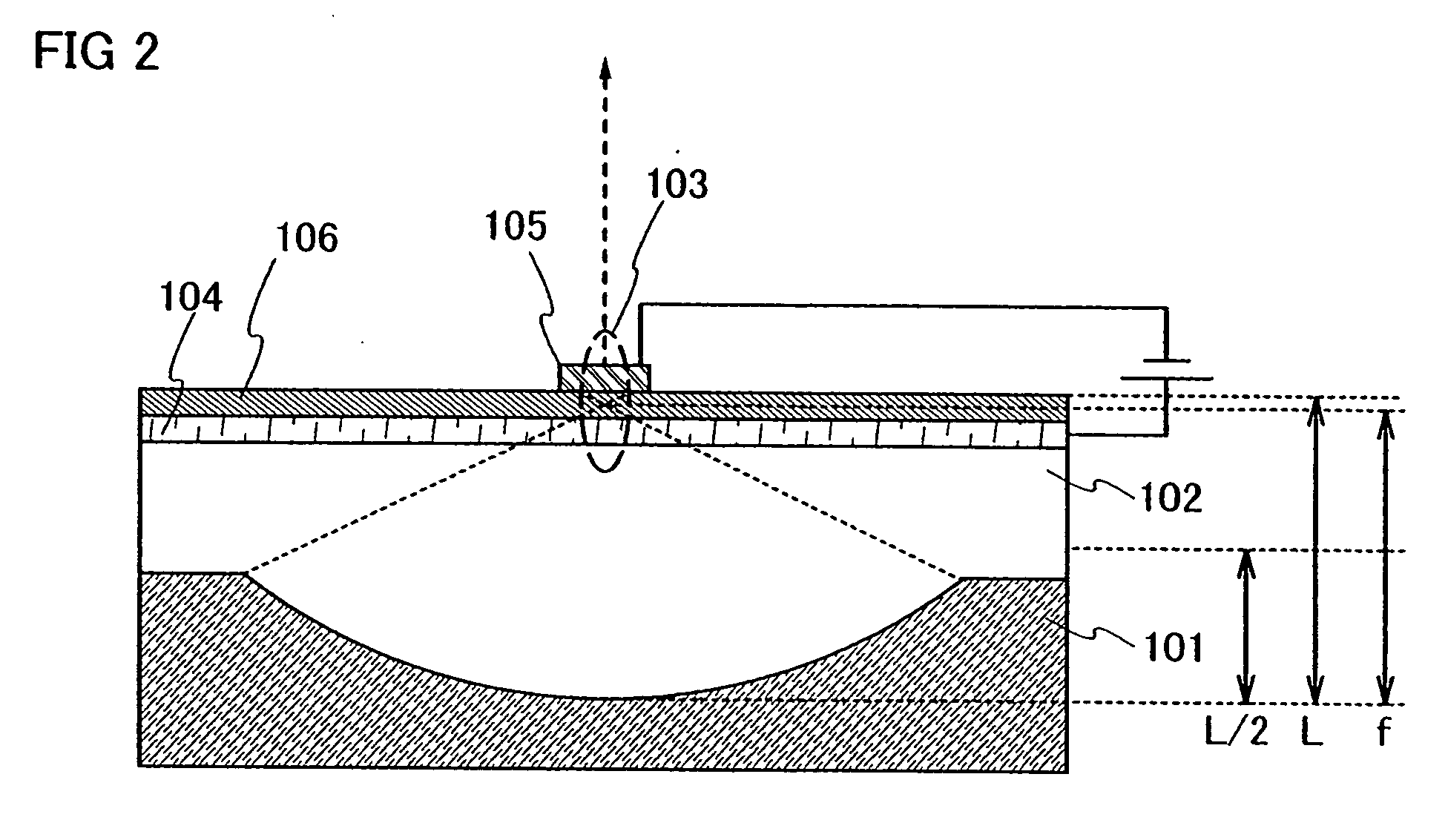

Flow cytometer droplet formation system

InactiveUS6861265B1Improve performanceHigh magnificationMaterial thermal conductivityWithdrawing sample devicesElectricityAutomatic control

A droplet forming flow cytometer system allows high speed processing without the need for high oscillator drive powers through the inclusion of an oscillator or piezoelectric crystal within the nozzle volume and directly coupled to the sheath fluid. The nozzle contain converges so as to amplify unidirectional oscillations which are transmitted as pressure waves through the nozzle volume to the nozzle exit so as to form droplets from the fluid jet. The oscillator is directionally isolated so as to avoid moving the entire nozzle container so as to create only pressure waves within the sheath fluid. A variation in substance concentration is achieved through a movable substance introduction port which is positioned within a convergence zone to vary the relative concentration of substance to sheath fluid while still maintaining optimal laminar flow conditions. This variation may be automatically controlled through a sensor and controller configuration. A replaceable tip design is also provided whereby the ceramic nozzle tip is positioned within an edge insert in the mozzle body so as to smoothly transition from nozzle body to nozzle tip. The nozzle tip is sealed against its outer surface to the nozzle body so it may be removable for cleaning or replacement.

Owner:UNIV OF WASHINGTON

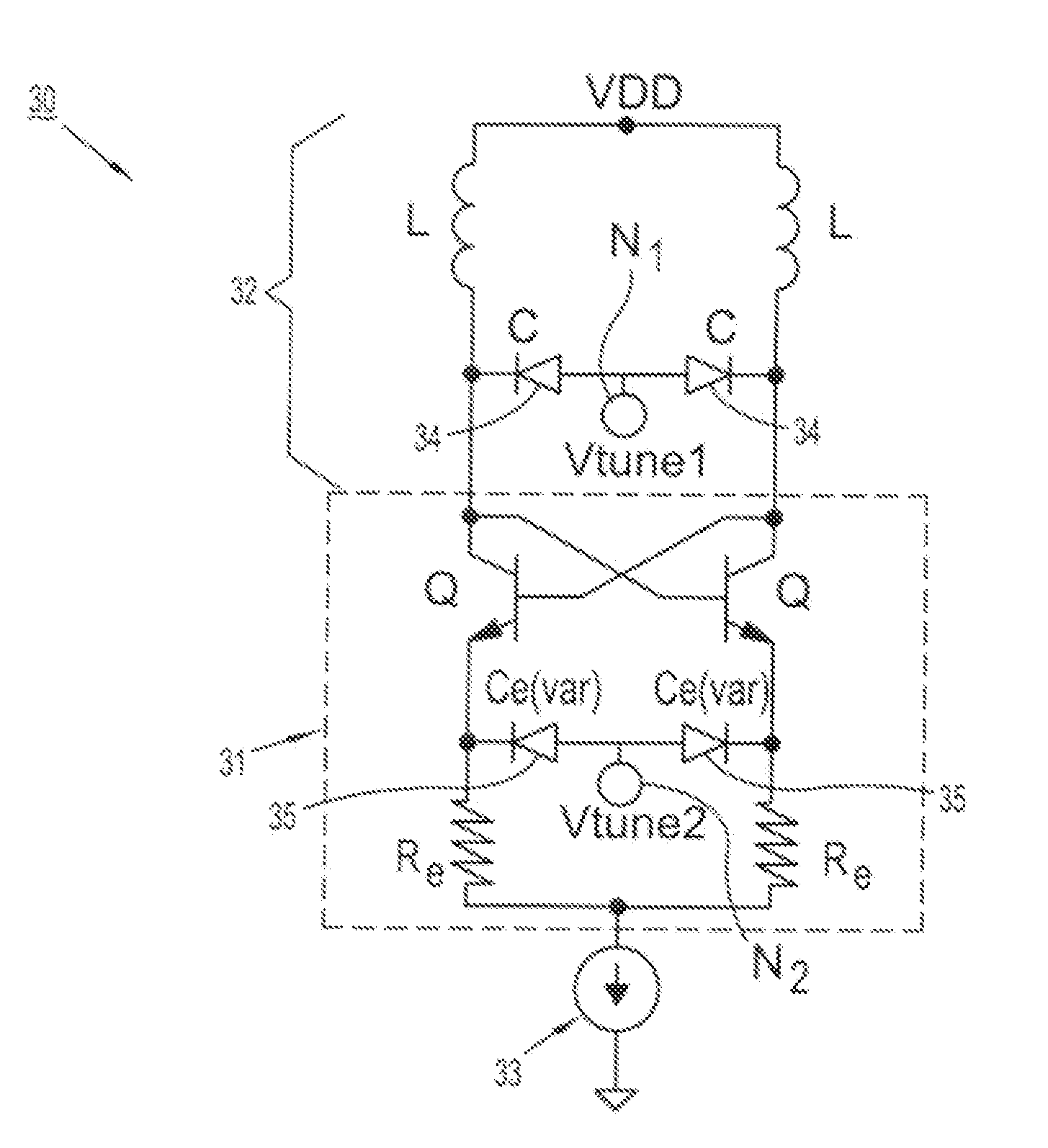

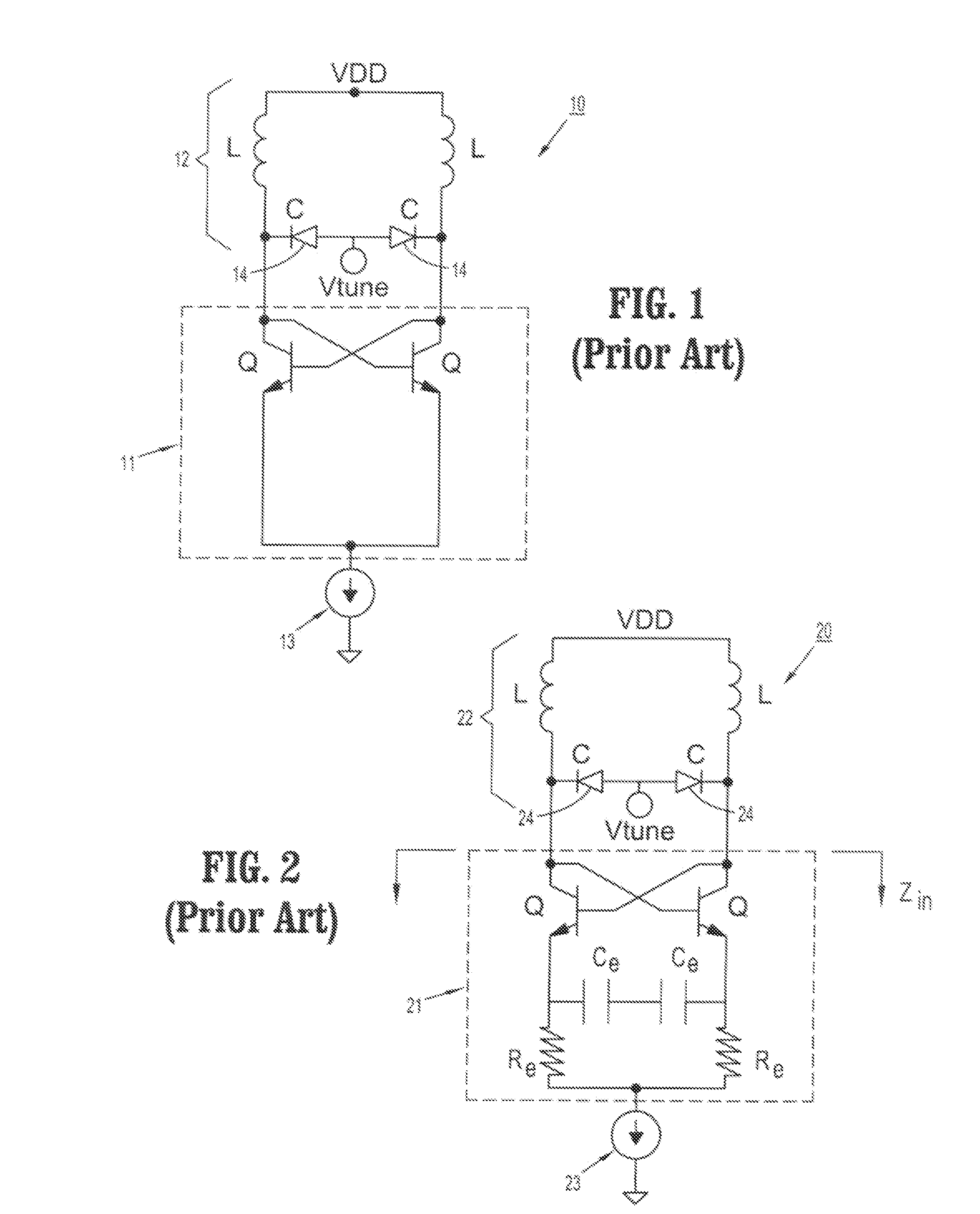

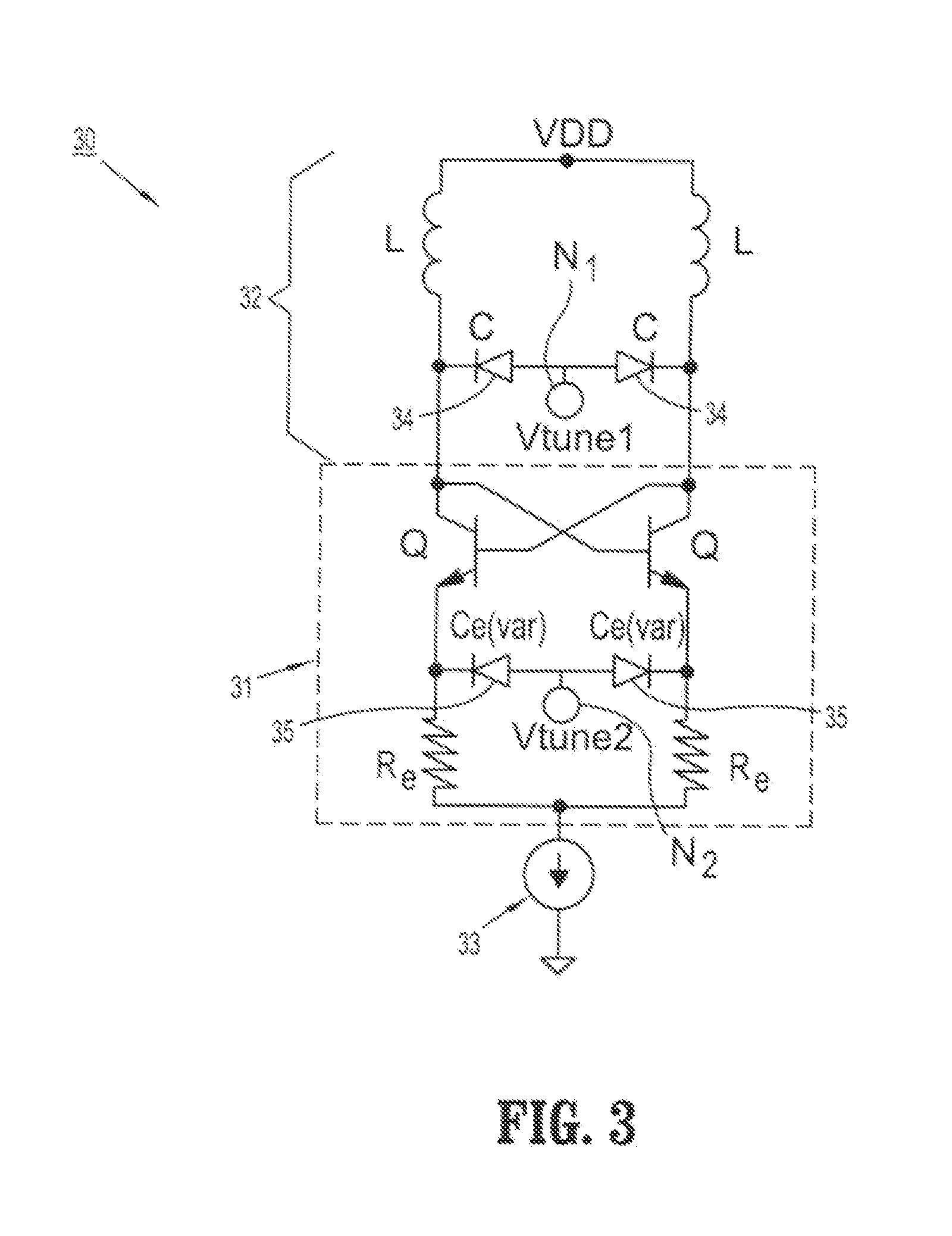

Voltage controlled oscillator circuits and methods using variable capacitance degeneration for increased tuning range

InactiveUS20080164955A1Less powerOscillation suppressionAngle modulation by variable impedenceElectric pulse generatorCapacitanceEngineering

Voltage controlled oscillator circuits are provided in which variable capacitance degeneration is employed to provide increased tuning ranges and output amplitudes for VCO circuits for millimeter wave applications

Owner:IBM CORP

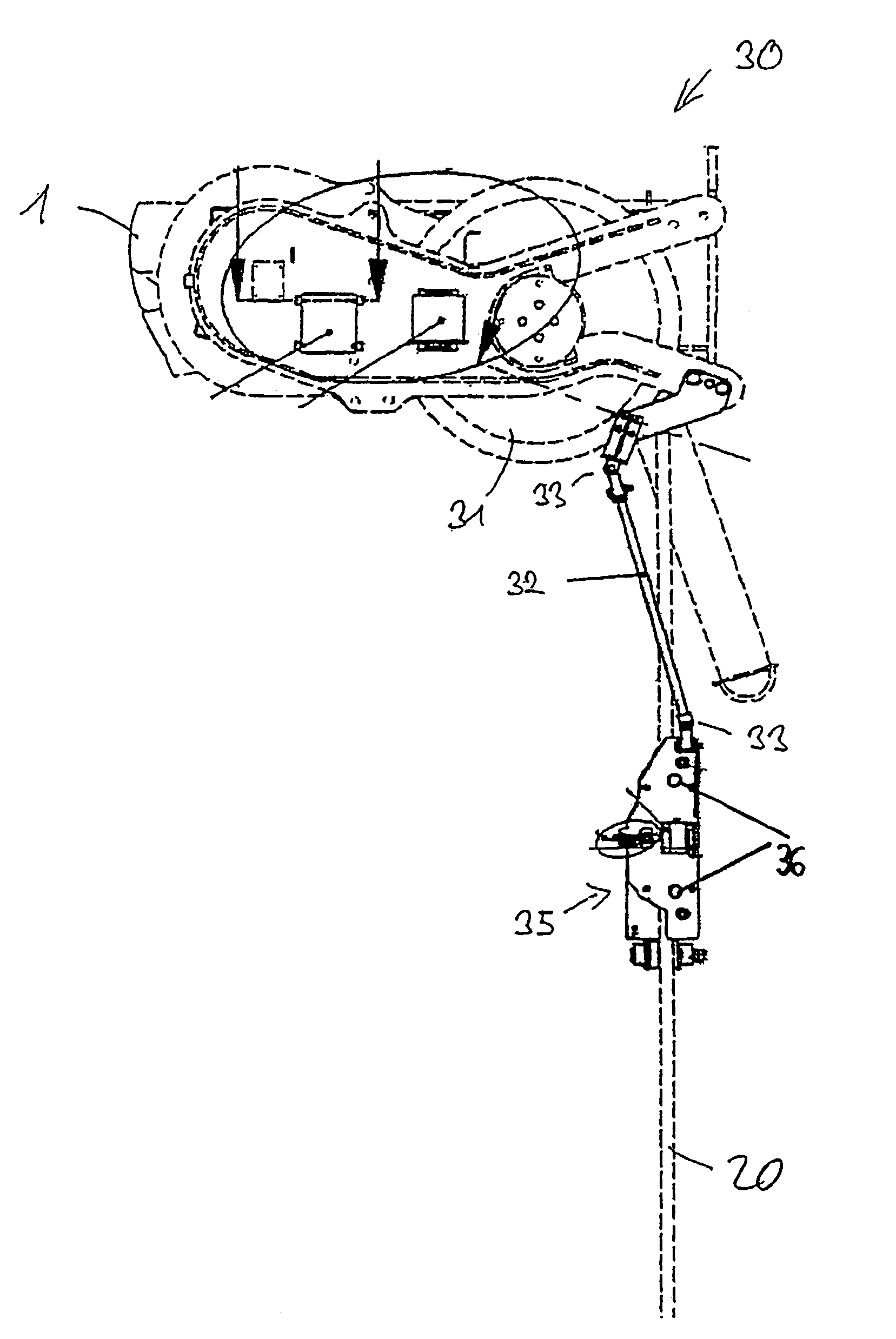

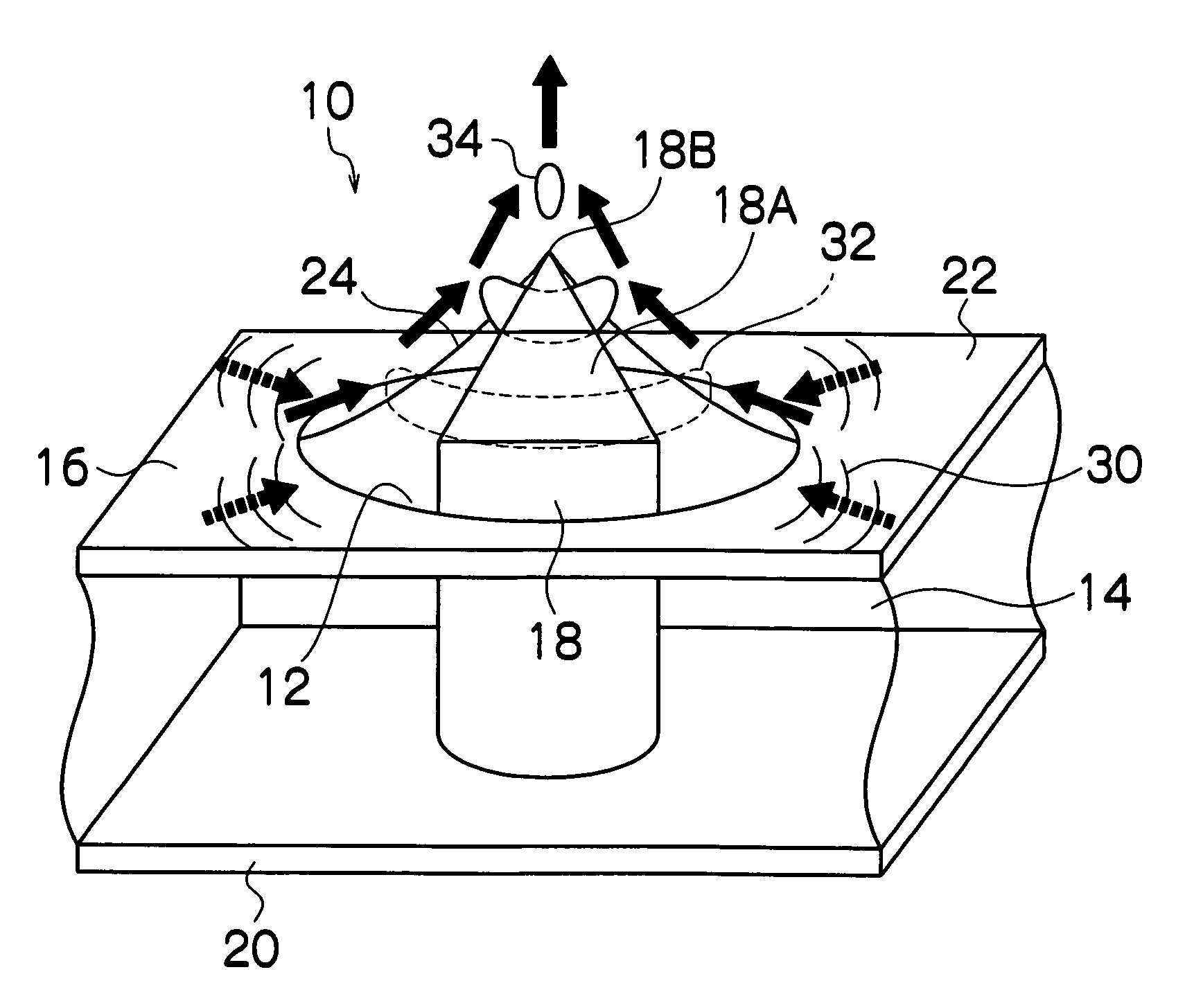

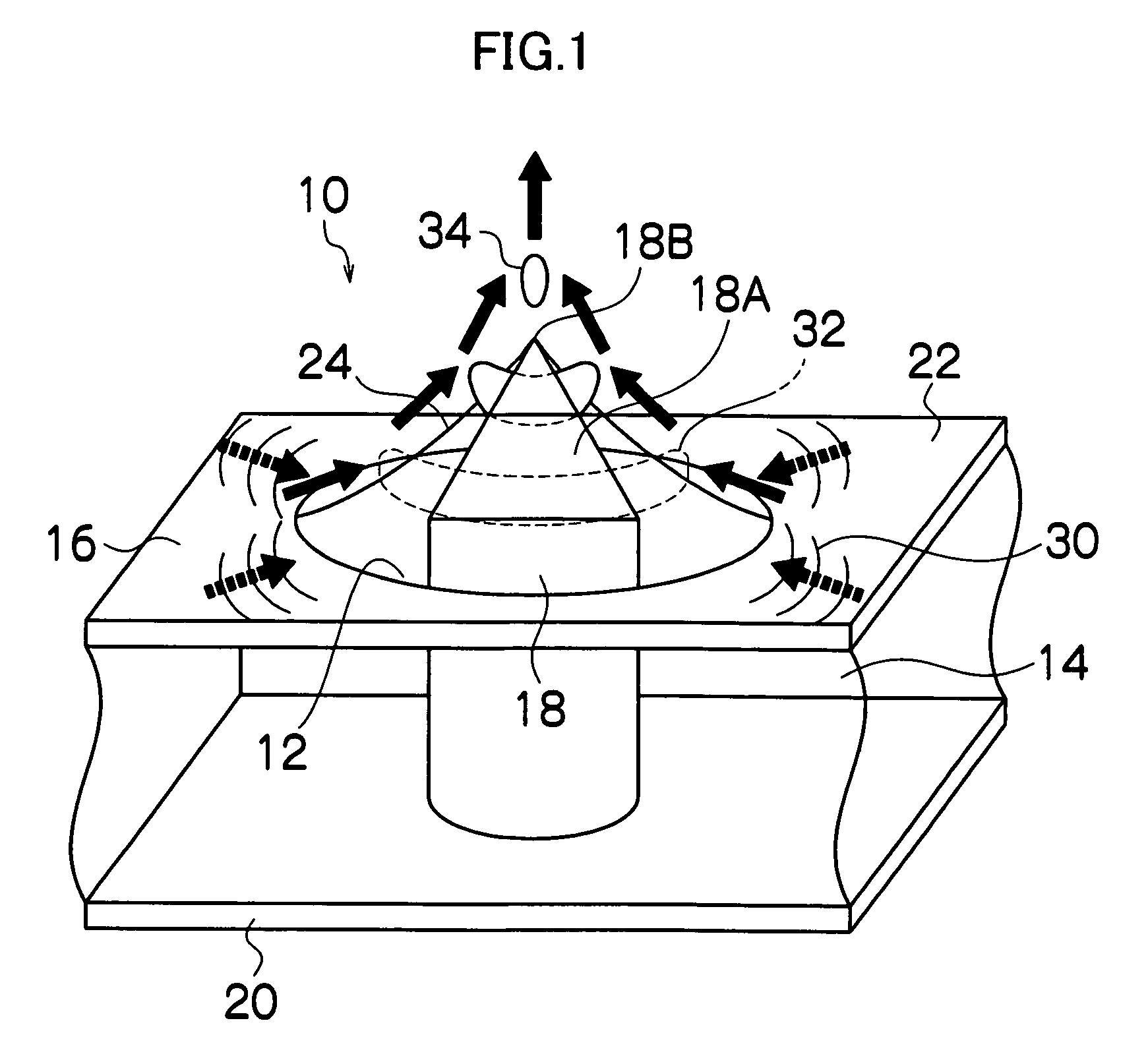

Crane control, crane and method

ActiveUS8025167B2Easy and safer alignmentEnhanced oscillationCranesSafety gearAngular velocityEngineering

The present invention shows a crane control of a crane which includes at least one cable for lifting a load, wherein at least one sensor unit is provided for determining a cable angle relative to the direction of gravitational force. Furthermore, there is shown a crane control for driving the positioners of a crane which includes at least one first and one second strand of cables for lifting the load, with a load oscillation damping for damping spherical pendular oscillations of the load, wherein first and second sensor units are provided, which are associated to the first and second strands of cables, in order to determine the respective cable angles and / or cable angular velocities, and the load oscillation damping includes a control in which the cable angles and / or cable angular velocities determined by the first and second sensor units are considered. Furthermore, a corresponding crane and a method are shown.

Owner:LIEBHERR WERK NENZING

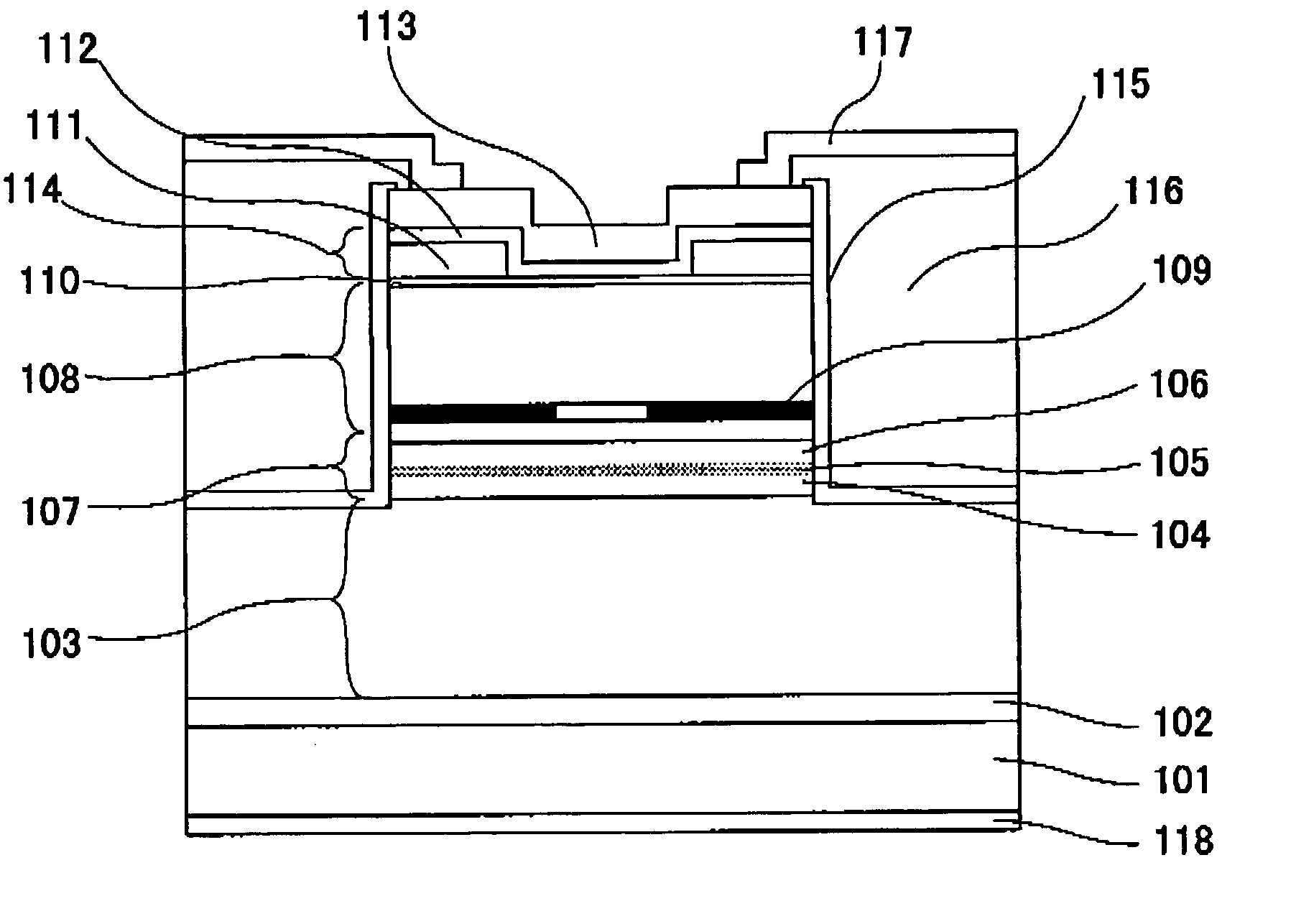

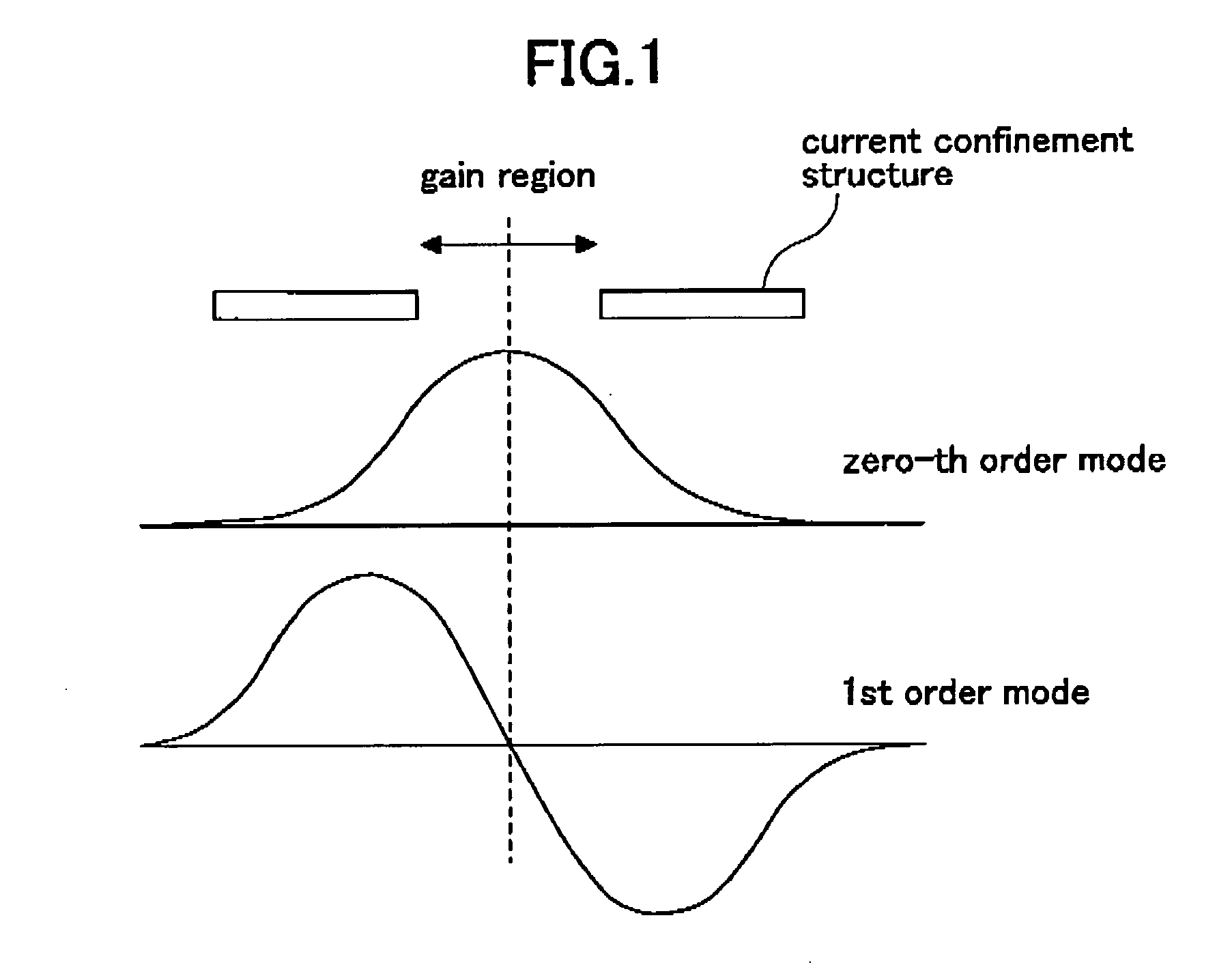

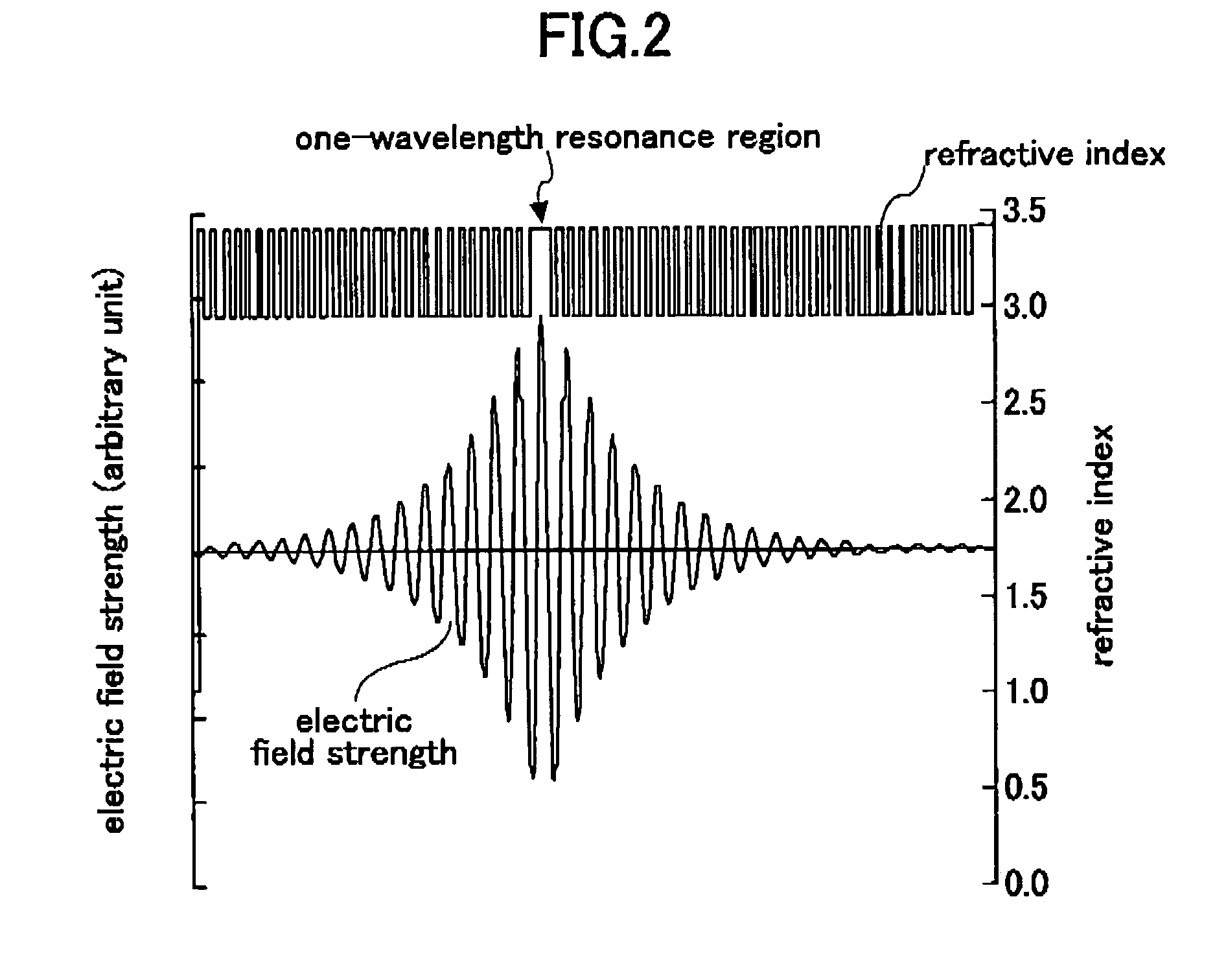

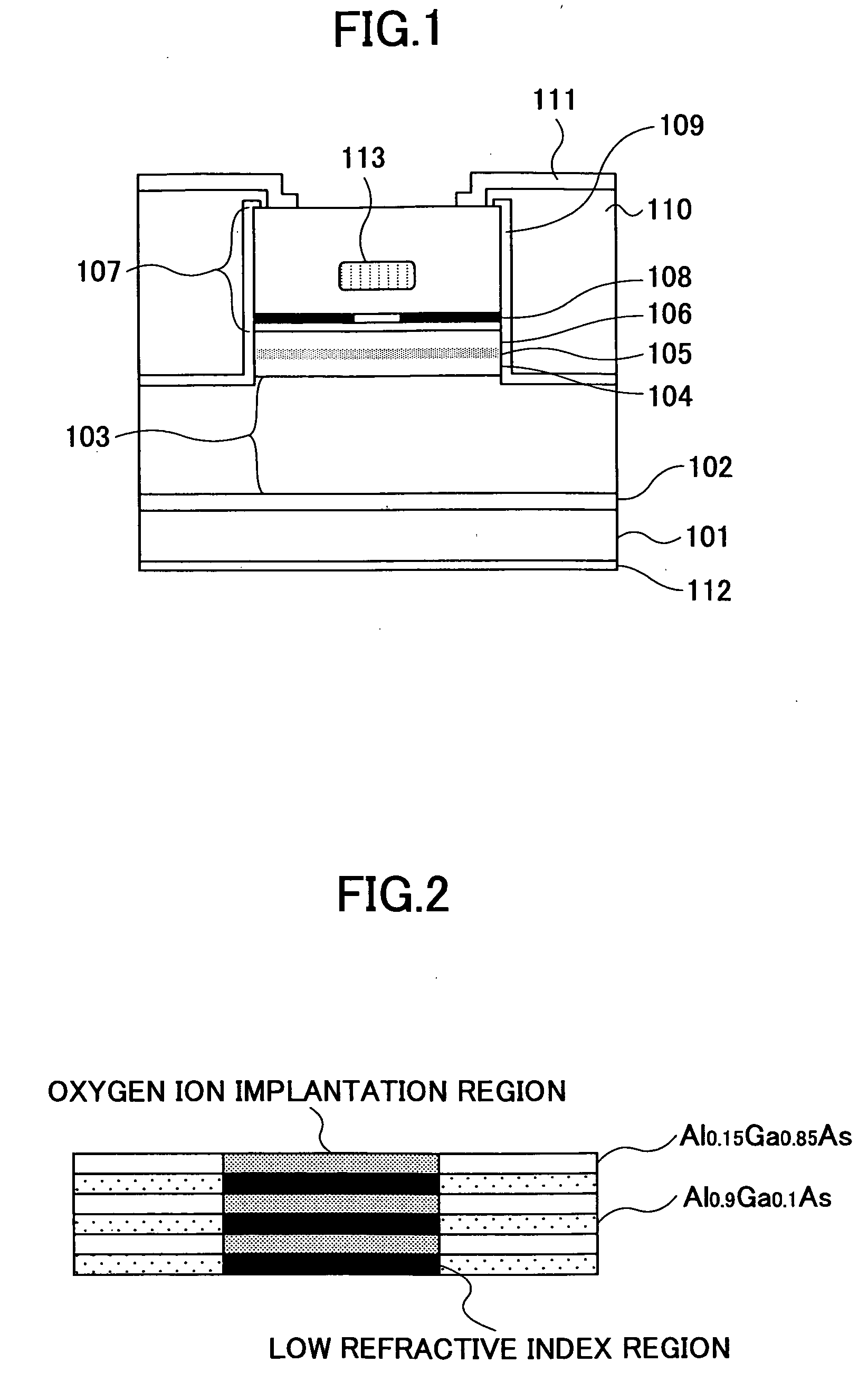

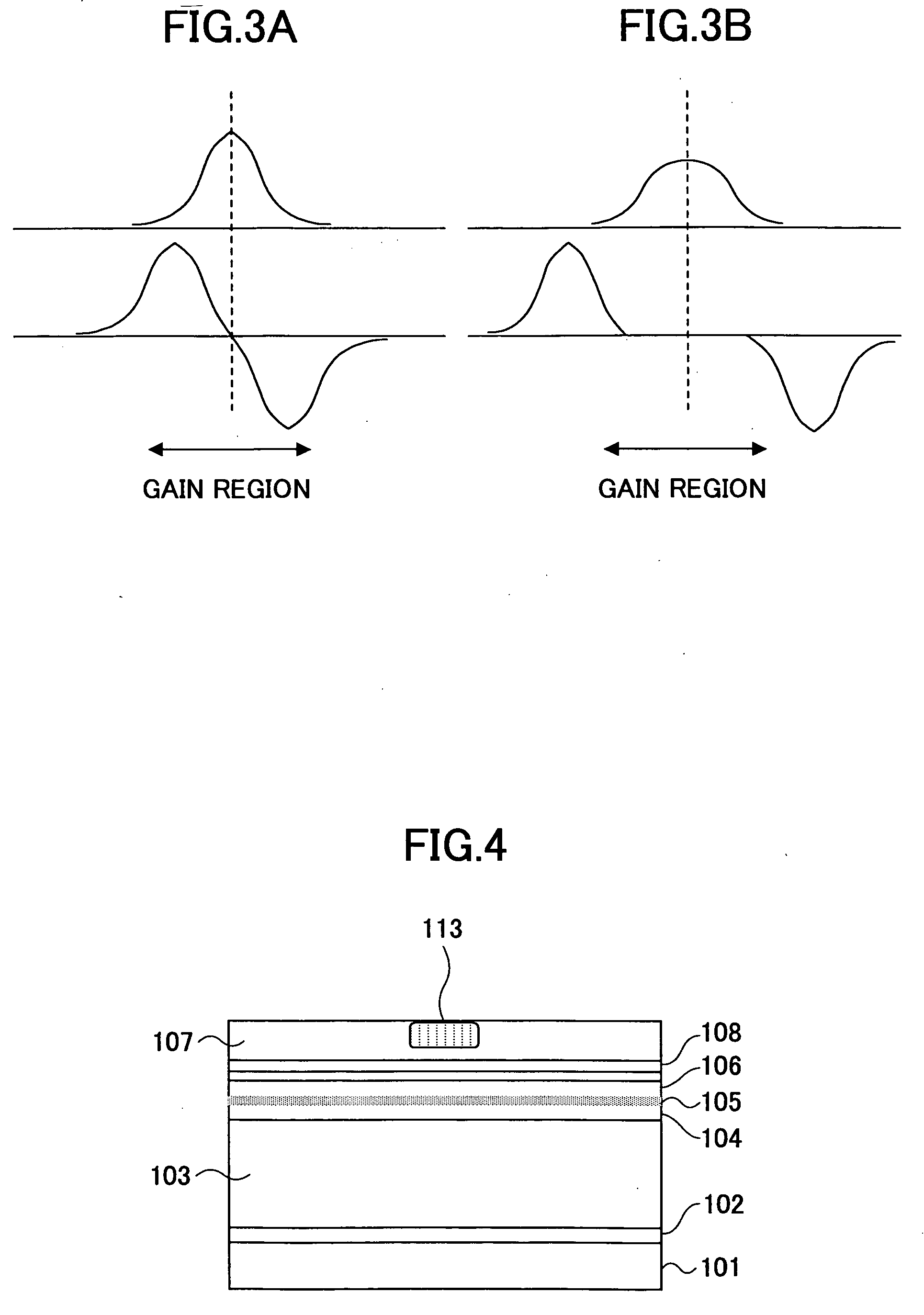

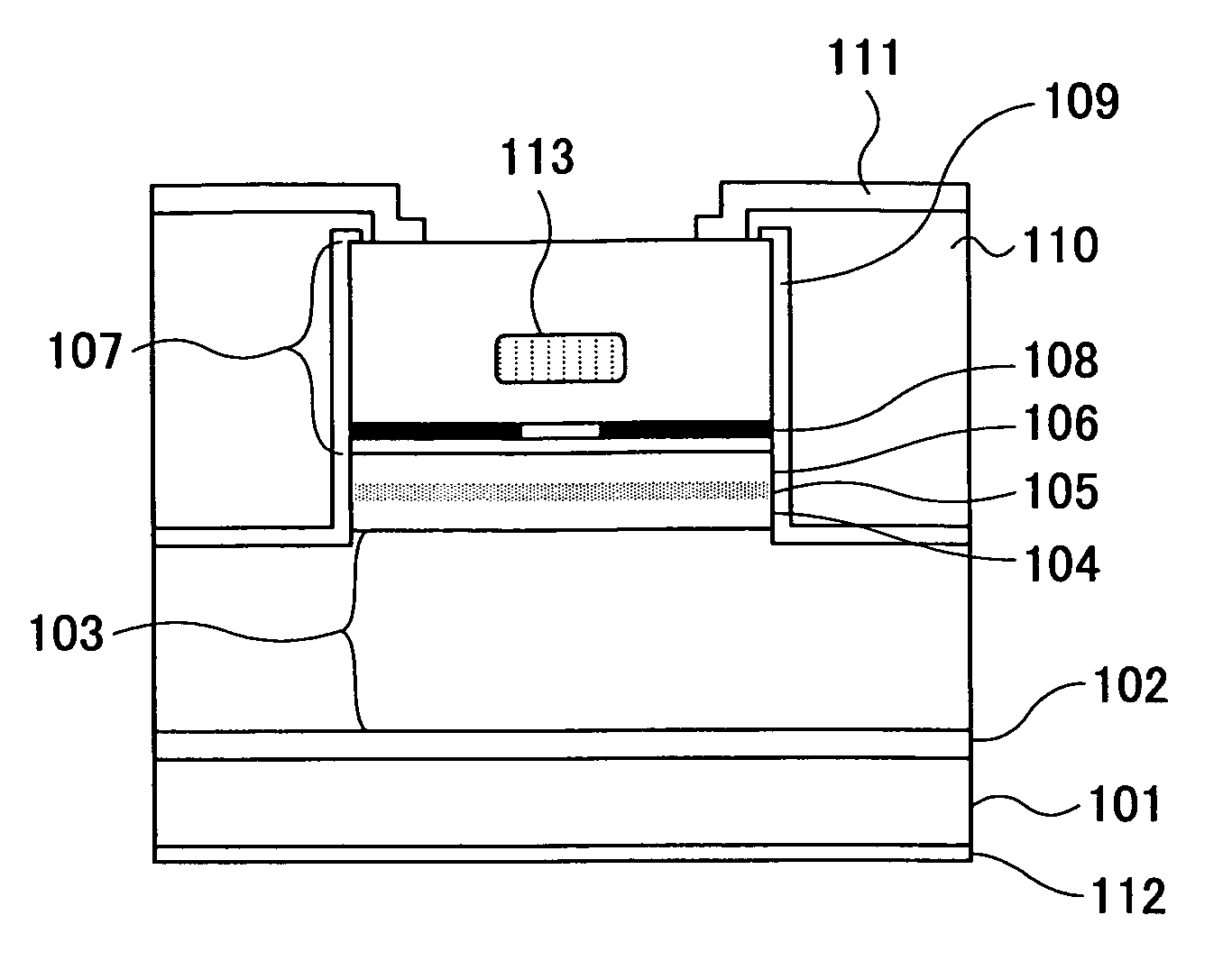

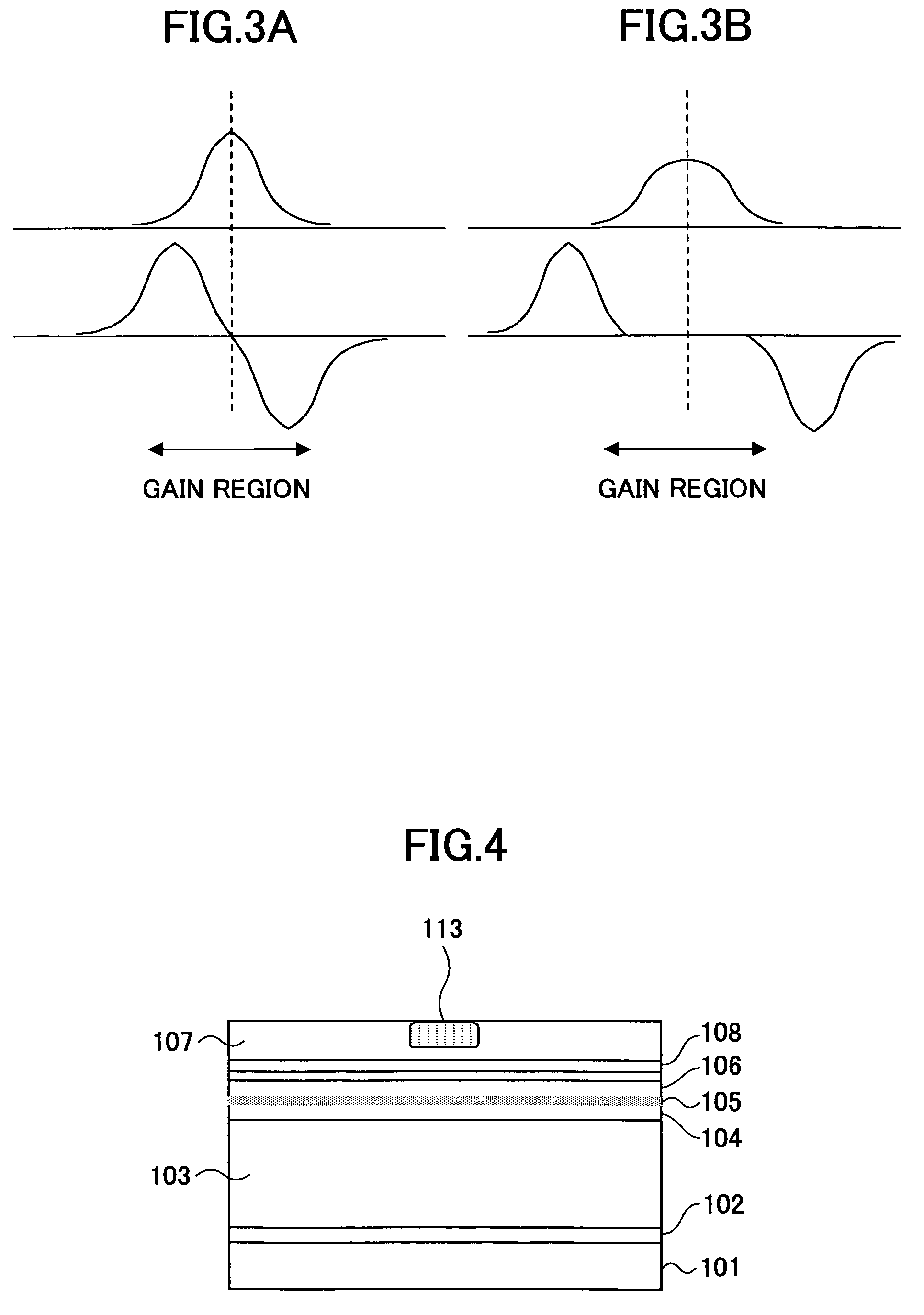

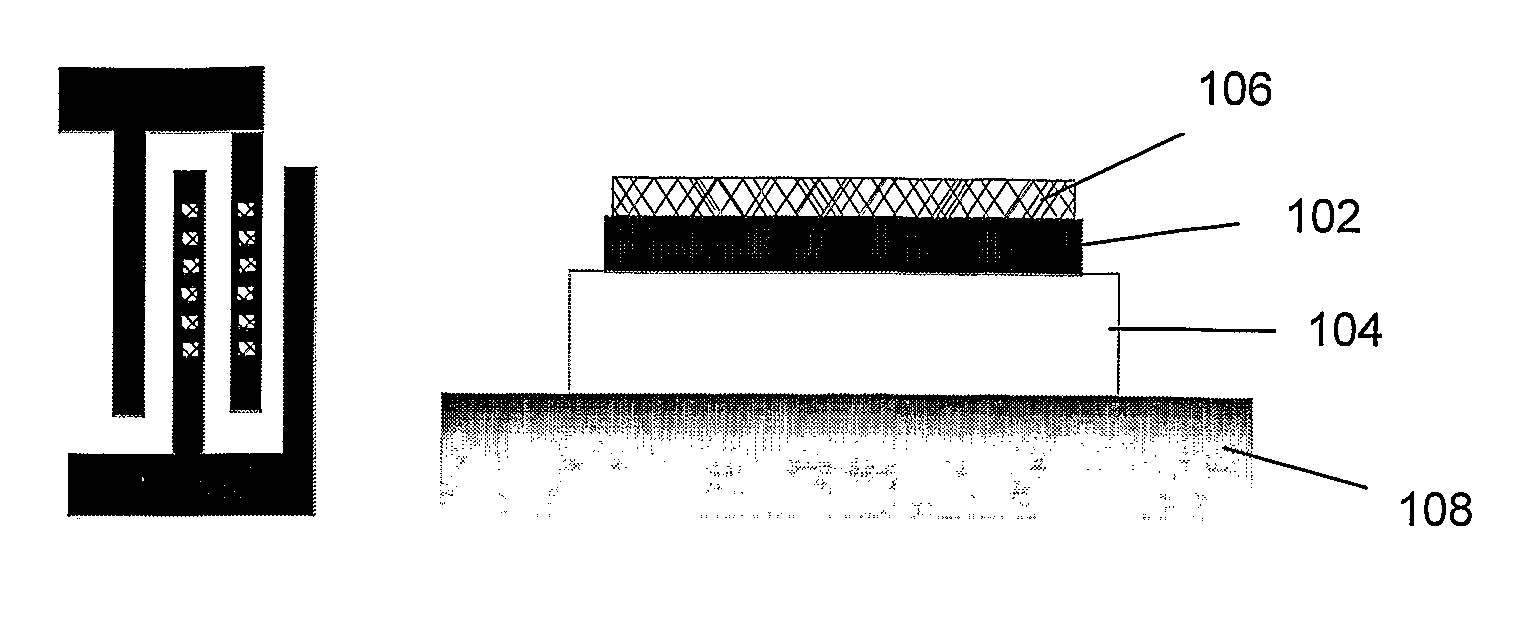

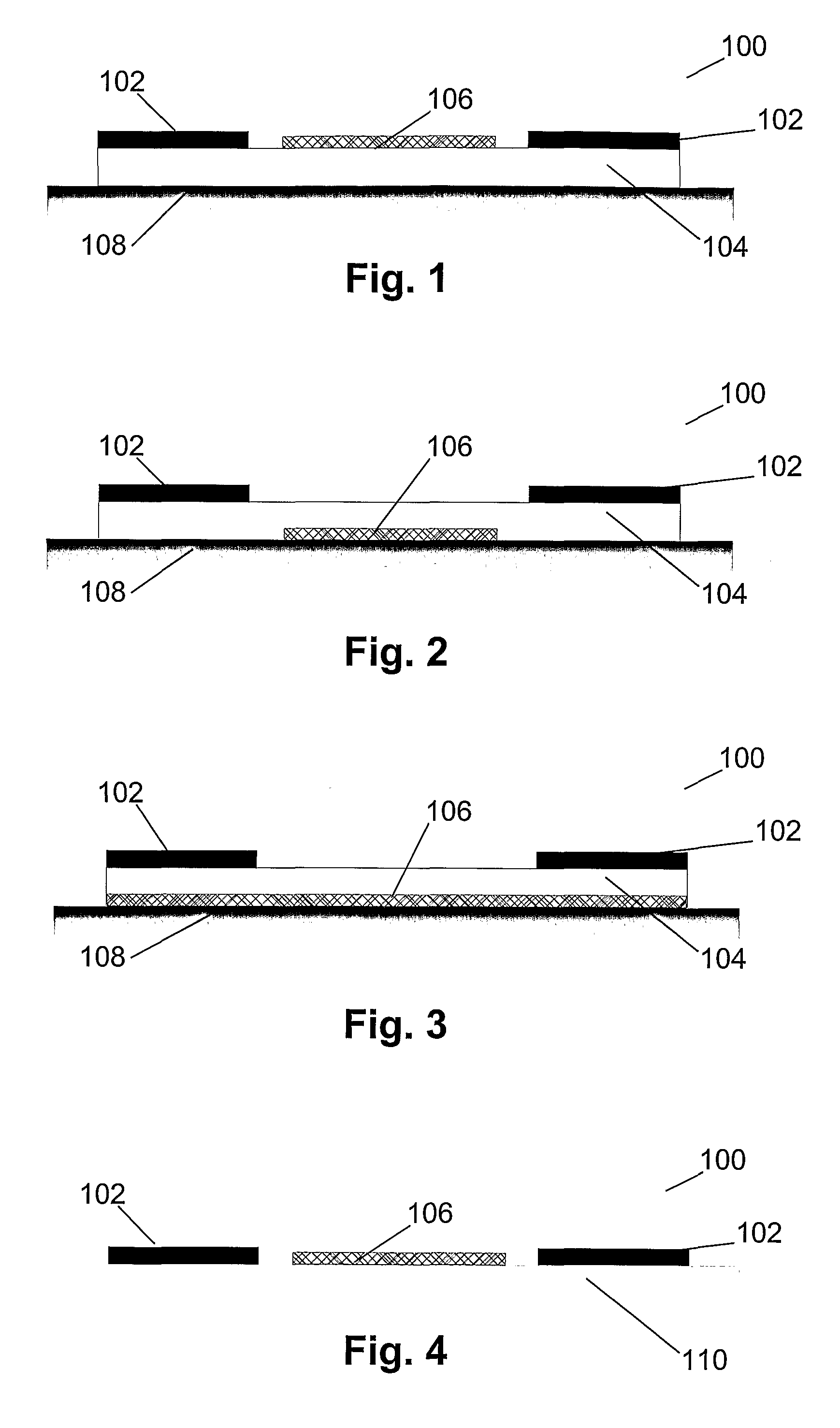

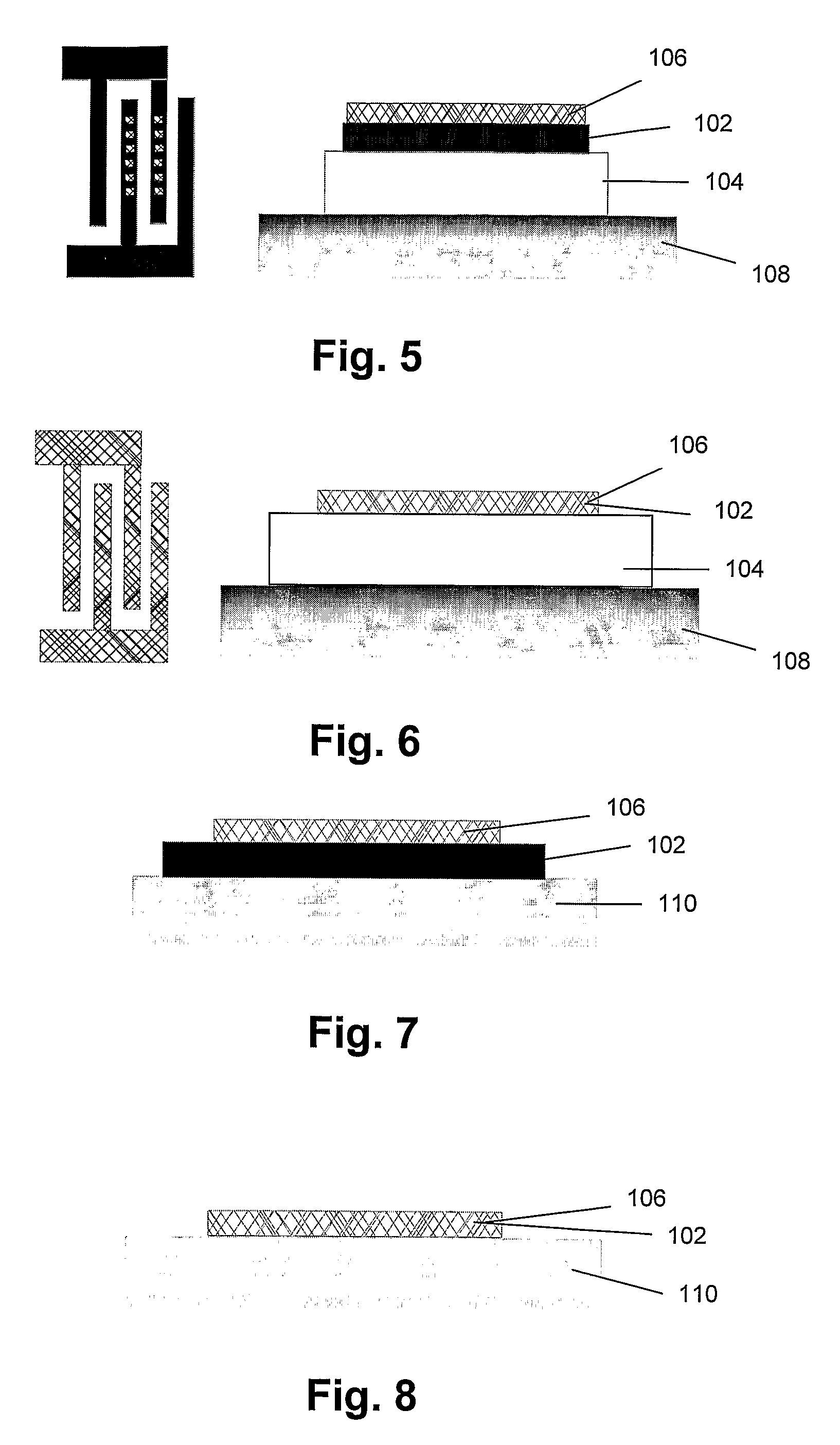

Surface emitting laser device and production method

InactiveUS20060093006A1Well formedIncrease productionLaser detailsSemiconductor lasersCurrent limitingResonance

A surface emitting laser device is disclosed that is able to selectively add a sufficiently large loss to a high order transverse mode so as to efficiently suppress a high order transverse mode oscillation and to oscillate at high output in a single fundamental transverse mode. The surface emitting laser device includes a first resonance region that includes an active layer and spacer layers, two distributed Bragg reflectors that sandwich the resonance region, and a current confinement structure that defines a current injection region for the active layer. At least one of the distributed Bragg reflectors includes a second resonance region arranged in the current injection region excluding a predetermined region surrounding a center of the current injection region.

Owner:RICOH KK

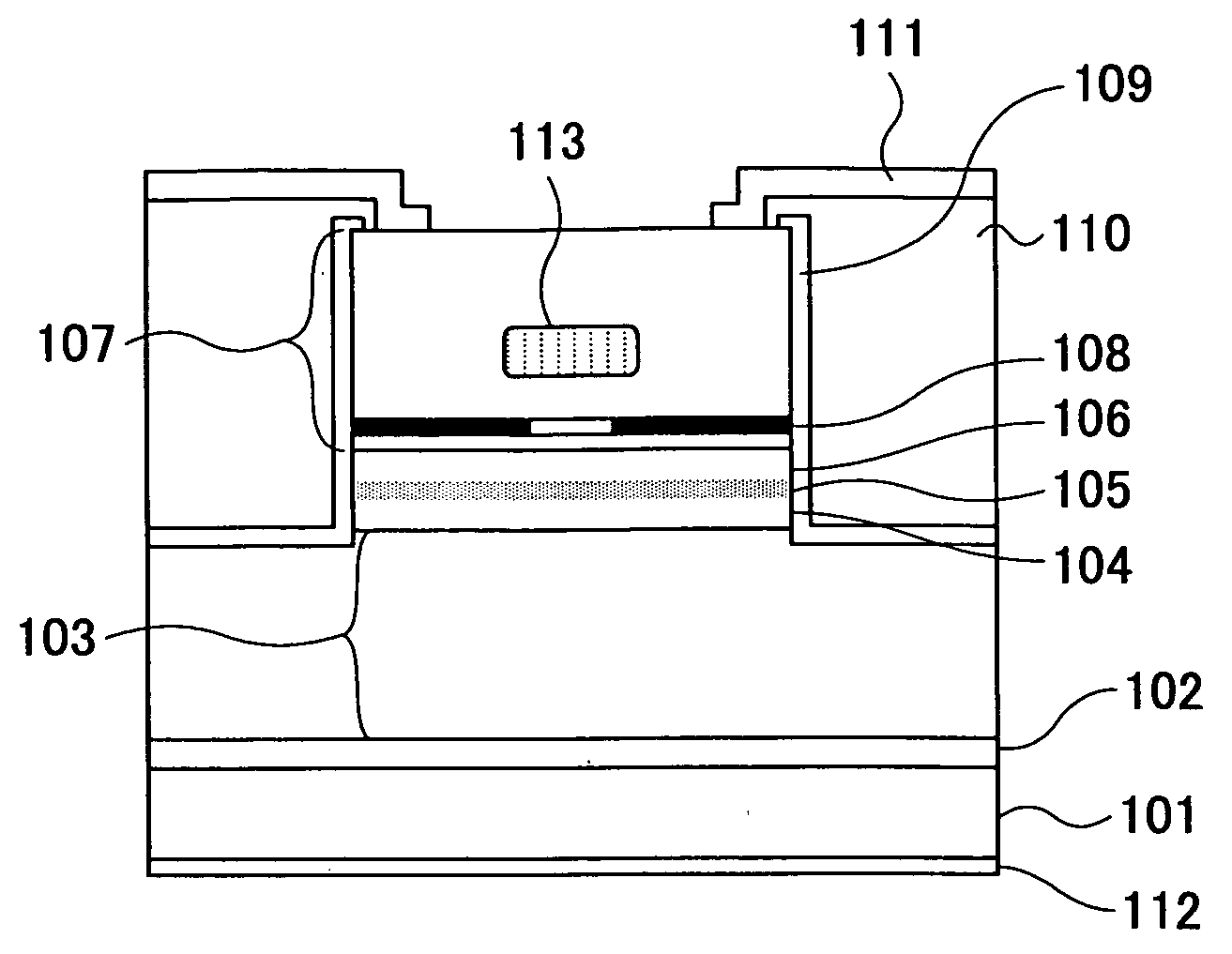

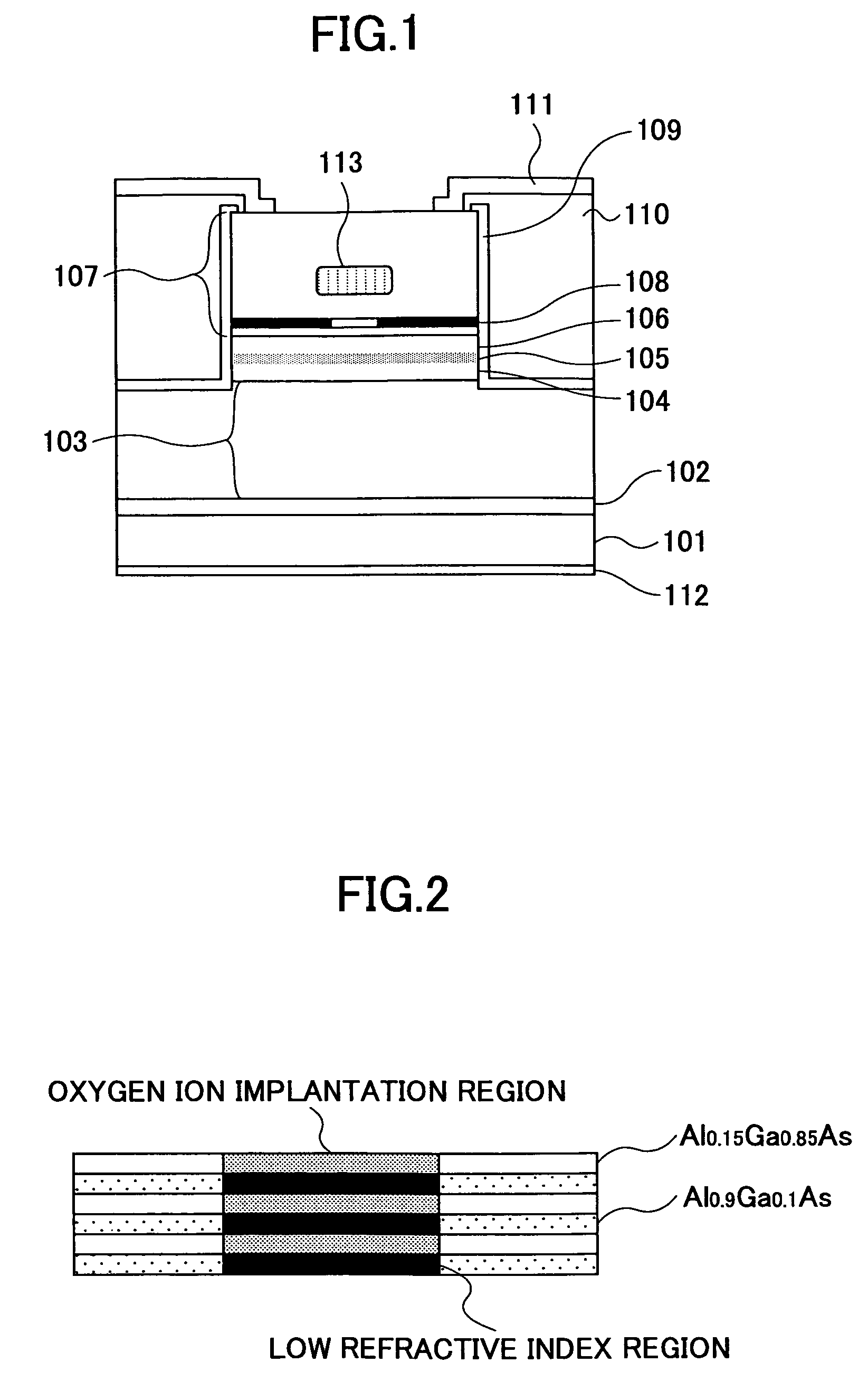

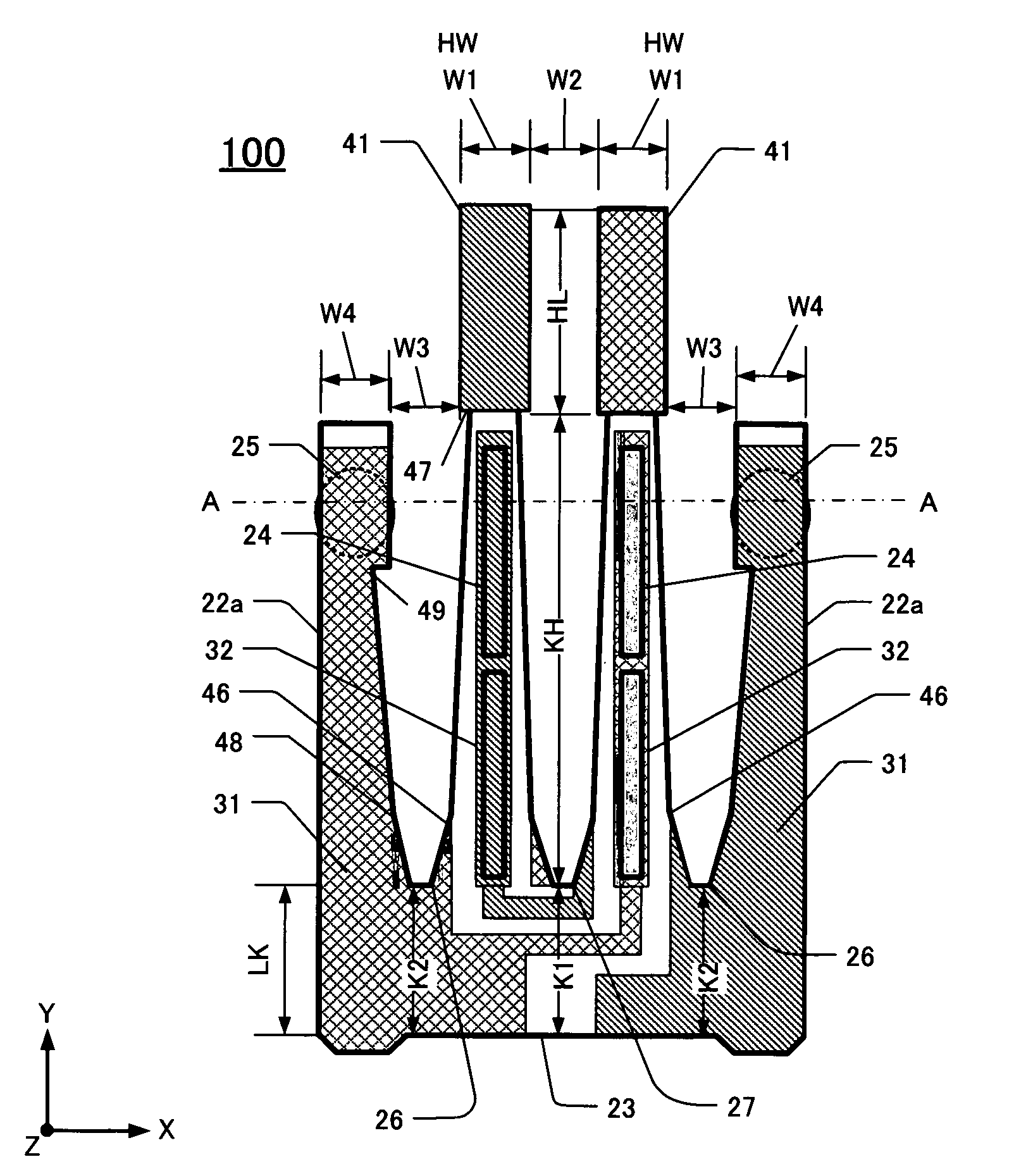

Surface-emission laser diode and surface-emission laser array, optical interconnection system, optical communication system, electrophotographic system, and optical disk system

InactiveUS20050147143A1High power operationIncrease speedOptical wave guidanceLaser cooling arrangementsSemiconductor materialsLaser array

A surface-emission laser diode includes an active layer, a pair of cavity spacer layers formed at both sides of the active layer, a current confinement structure defining a current injection region into the active layer, and a pair of distributed Bragg reflectors opposing with each other across a structure formed of the active layer and the cavity spacer layers, the current confinement structure being formed by a selective oxidation process of a semiconductor layer, the pair of distributed Bragg reflectors being formed of semiconductor materials, wherein there is provided a region containing an oxide of Al and having a relatively low refractive index as compared with a surrounding region in any of the semiconductor distributed Bragg reflector or the cavity spacer layer in correspondence to a part spatially overlapping with the current injection region in a laser cavity direction.

Owner:RICOH KK

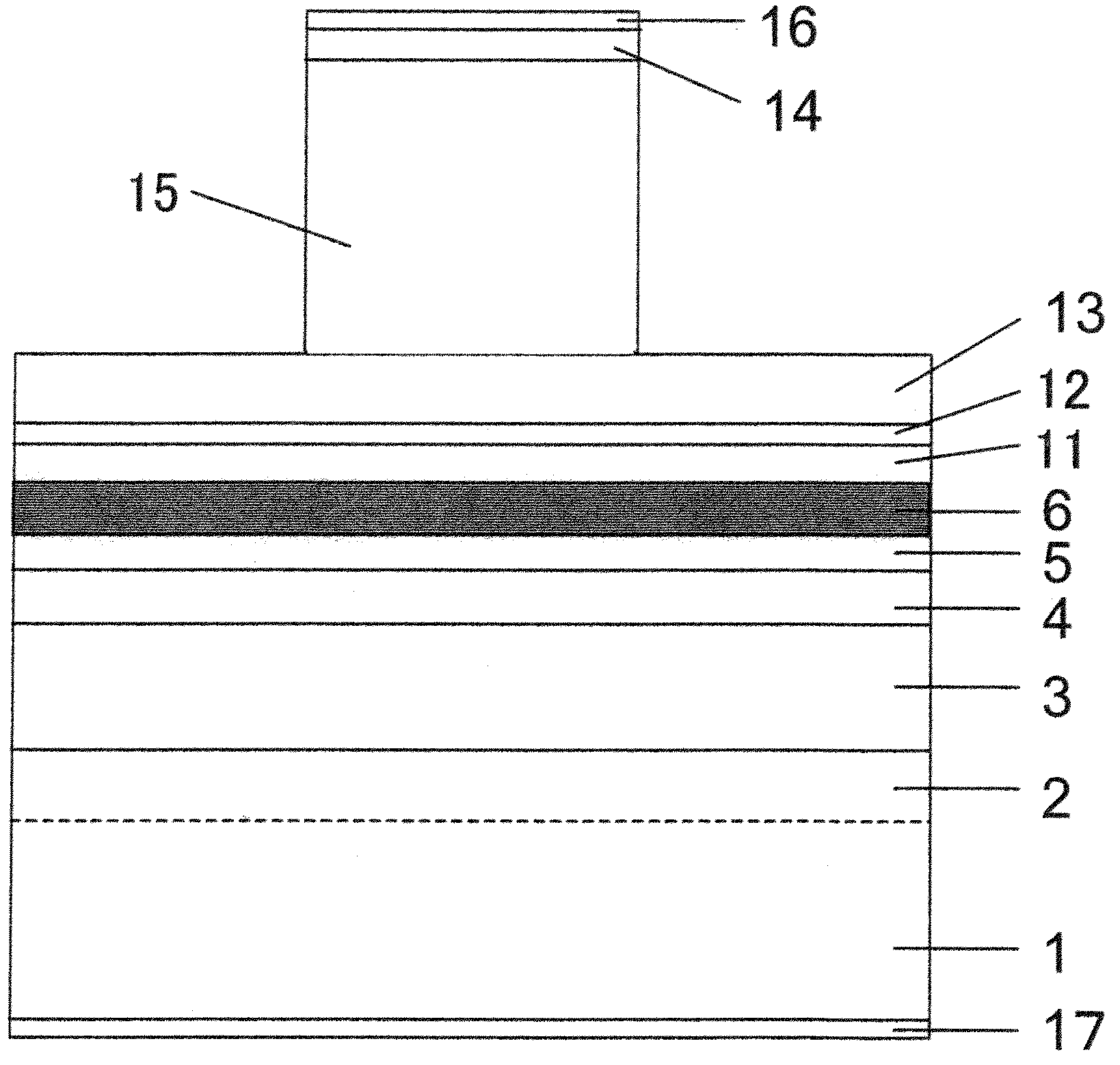

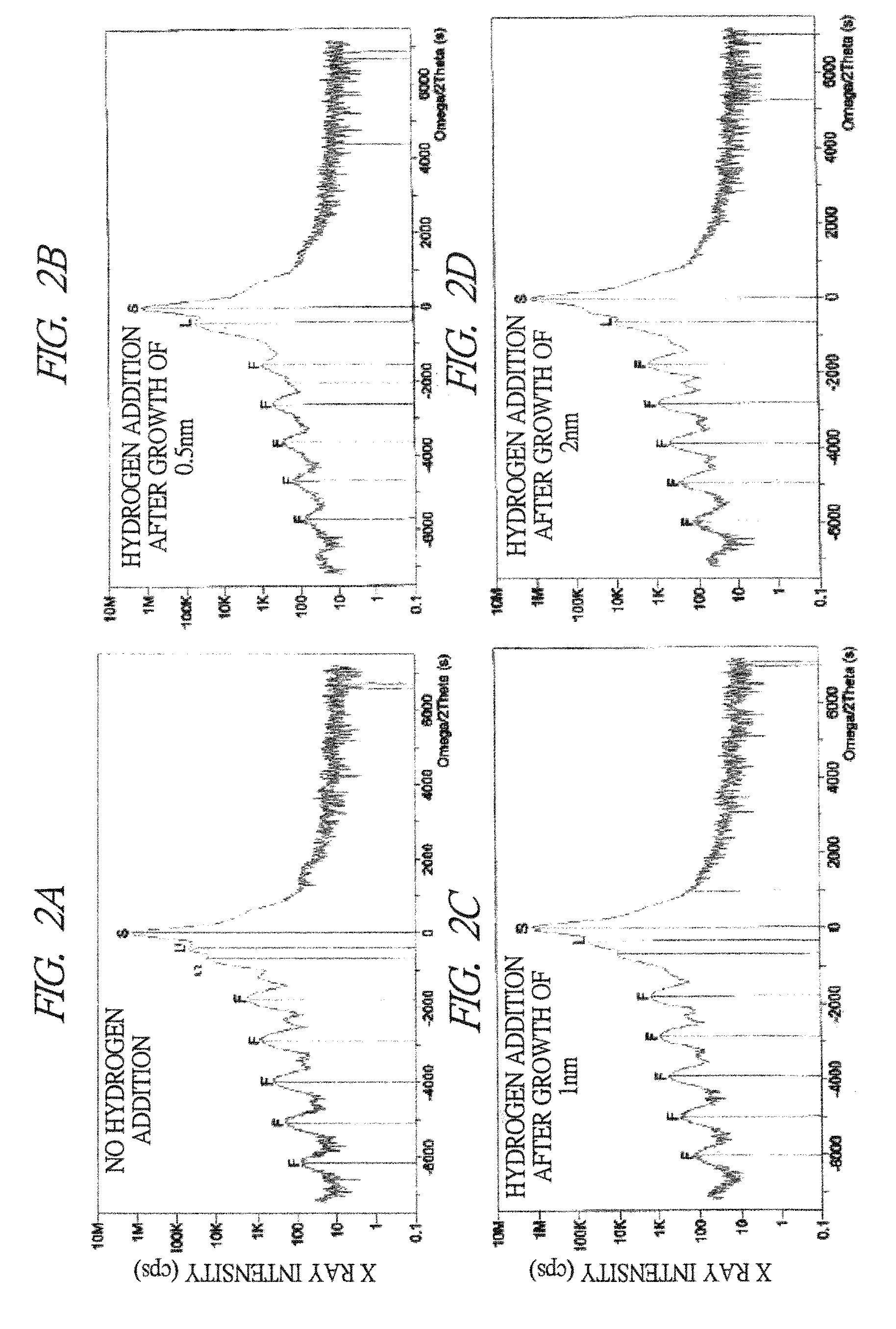

Nitride semiconductor optical element and manufacturing method thereof

ActiveUS20100150194A1High crystallinityEliminate segregationLaser detailsLaser active region structureIndiumHydrogen

In an InGaN-based nitride semiconductor optical device having a long wavelength (440 nm or more) equal to or more than that of blue, the increase of a wavelength is realized while suppressing In (Indium) segregation and deterioration of crystallinity. In the manufacture of an InGaN-based nitride semiconductor optical device having an InGaN-based quantum well active layer including an InGaN well layer and an InGaN barrier layer, a step of growing the InGaN barrier layer includes: a first step of adding hydrogen at 1% or more to a gas atmosphere composed of nitrogen and ammonia and growing a GaN layer in the gas atmosphere; and a second step of growing the InGaN barrier layer in a gas atmosphere composed of nitrogen and ammonia.

Owner:USHIO OPTO SEMICON

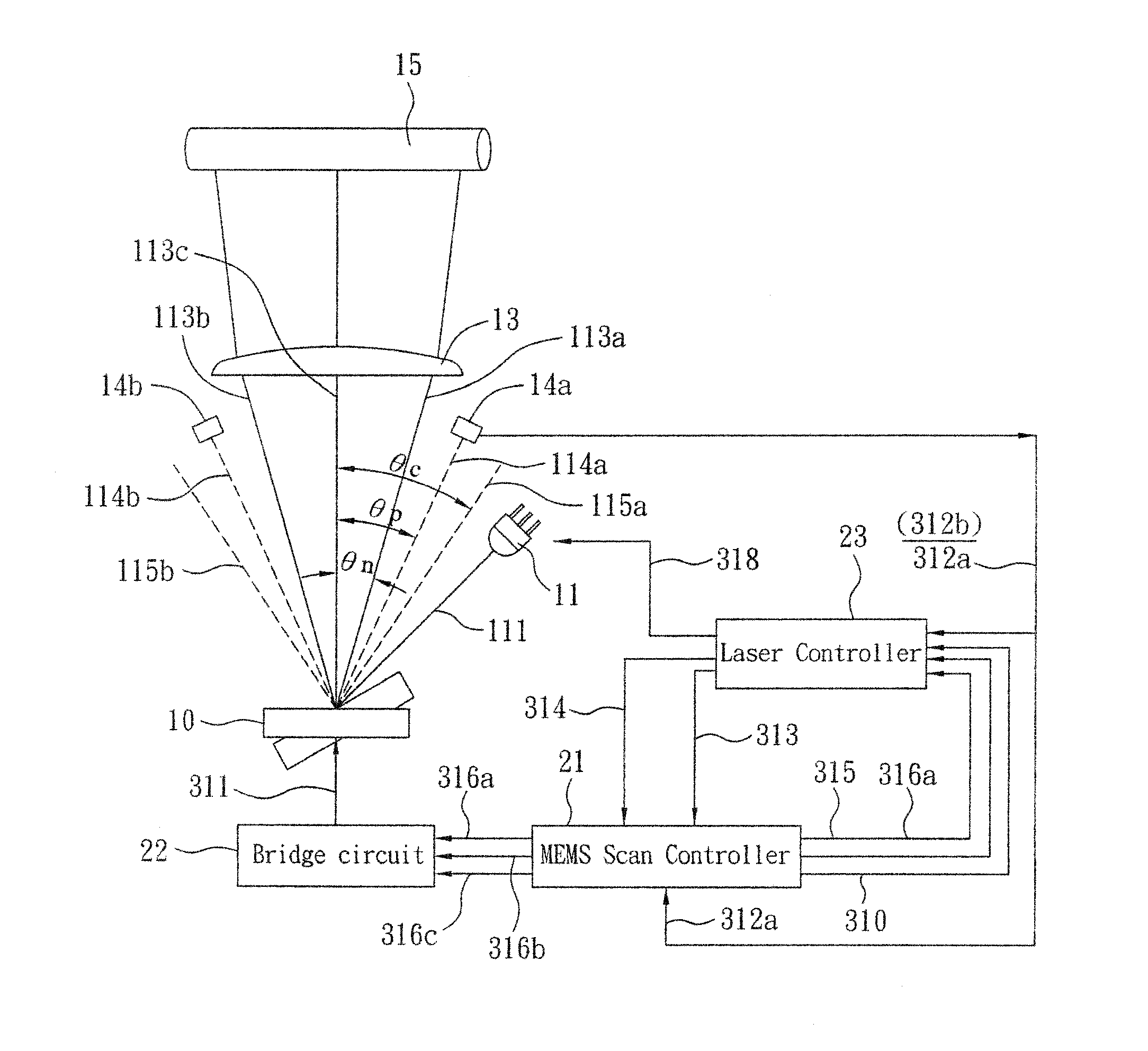

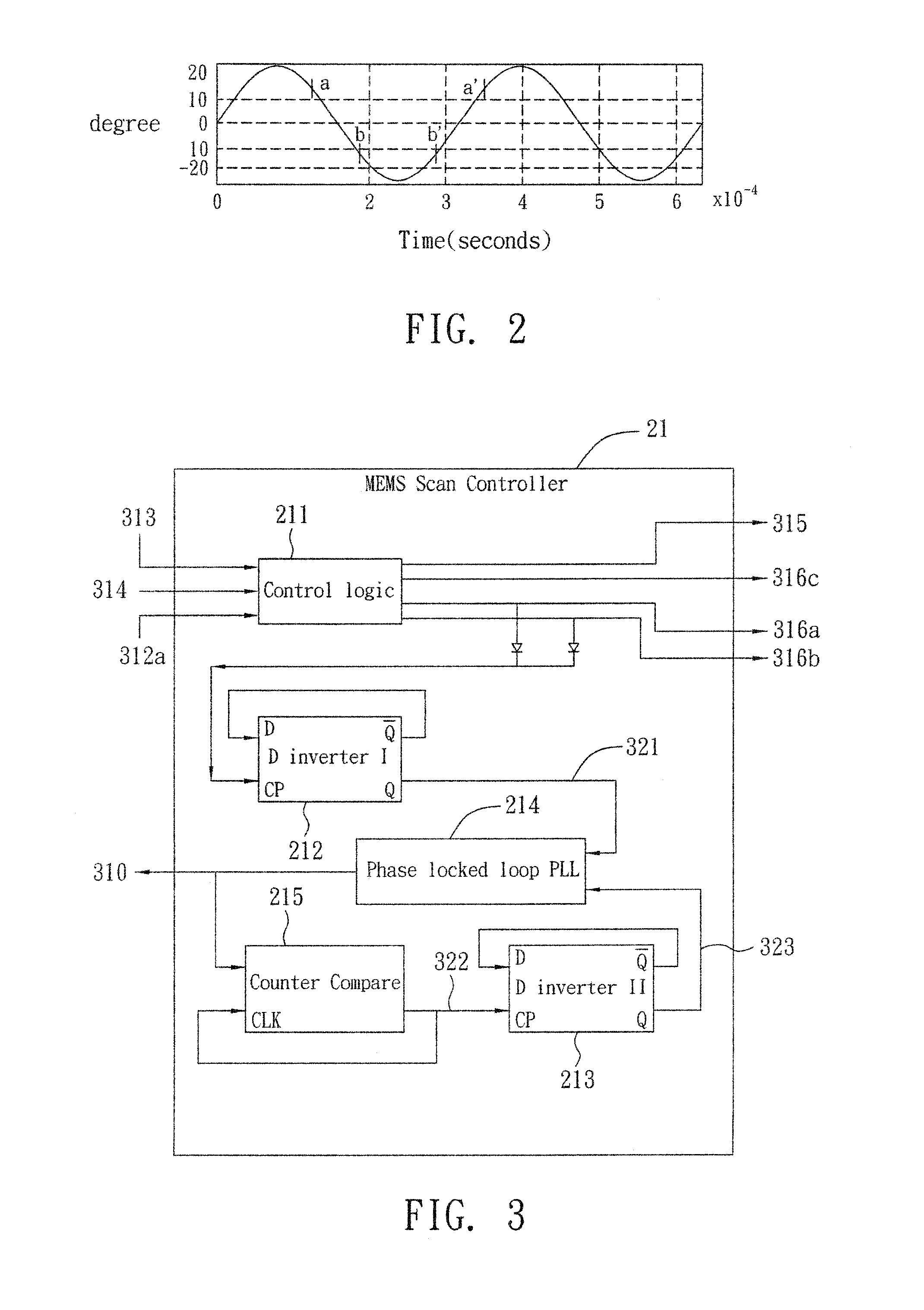

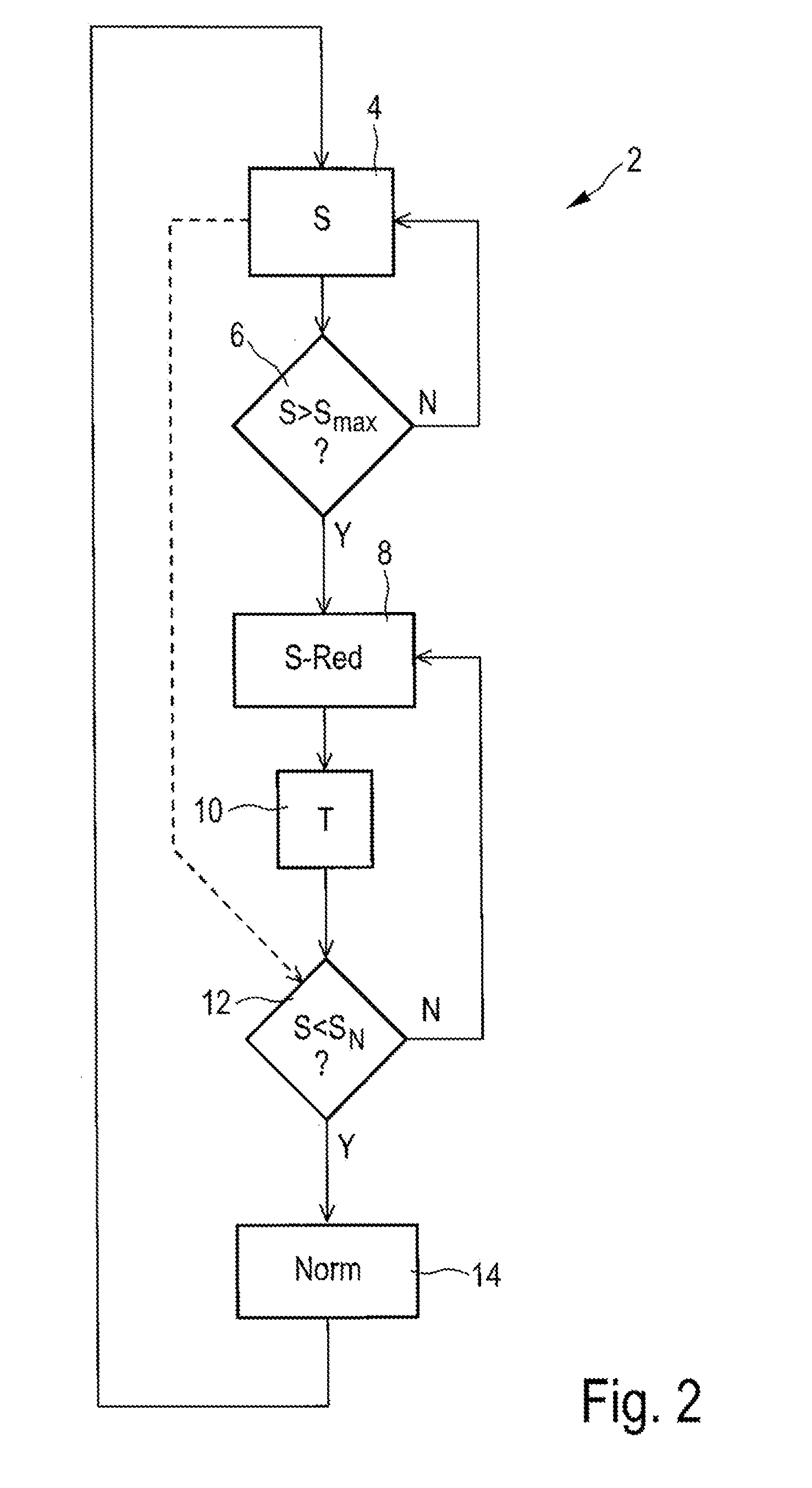

MEMS Scan Controller Generating Clock Frequency and Control Method Thereof

InactiveUS20110127404A1Oscillation stabilityReduce oscillationPhotometry using reference valueMaterial analysis by optical meansClock rateLaser scanning

A Micro Electronic Mechanical System (MEMS) scan controller generating clock frequency and a control method thereof are disclosed. The MEMS scan controller is for a MEMS mirror in a bi-direction laser scanning units (LSU). By detecting resonant frequency of the MEMS mirror, the scan controller sends frequency modulation signal and amplitude modulation signal of the MEMS mirror to a bridge circuit of the MEMS mirror for adjusting and stabilizing the MEMS mirror. A clock signal corresponding to the resonant frequency of the MEMS mirror at the moment is also sent so that scan data is sent within the effective scanning window in forward direction / reverse direction. Thus high-precision scanning is achieved.

Owner:E PIN OPTICAL IND

Surface-emission laser diode and surface-emission laser array, optical interconnection system, optical communication system, electrophotographic system, and optical disk system

InactiveUS7542499B2Increase freedomEnhanced oscillationOptical wave guidanceLaser detailsSemiconductor materialsLaser array

Owner:RICOH KK

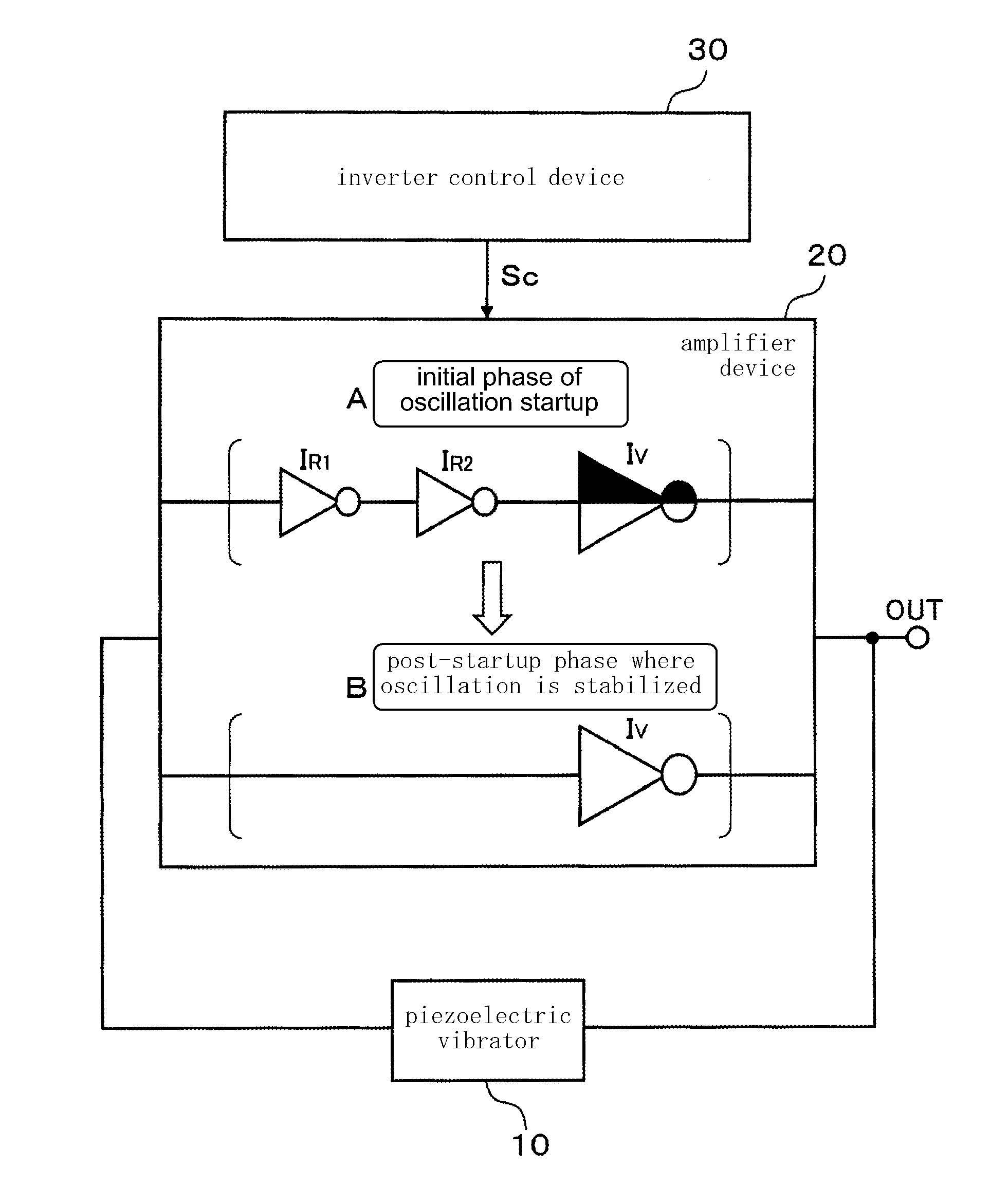

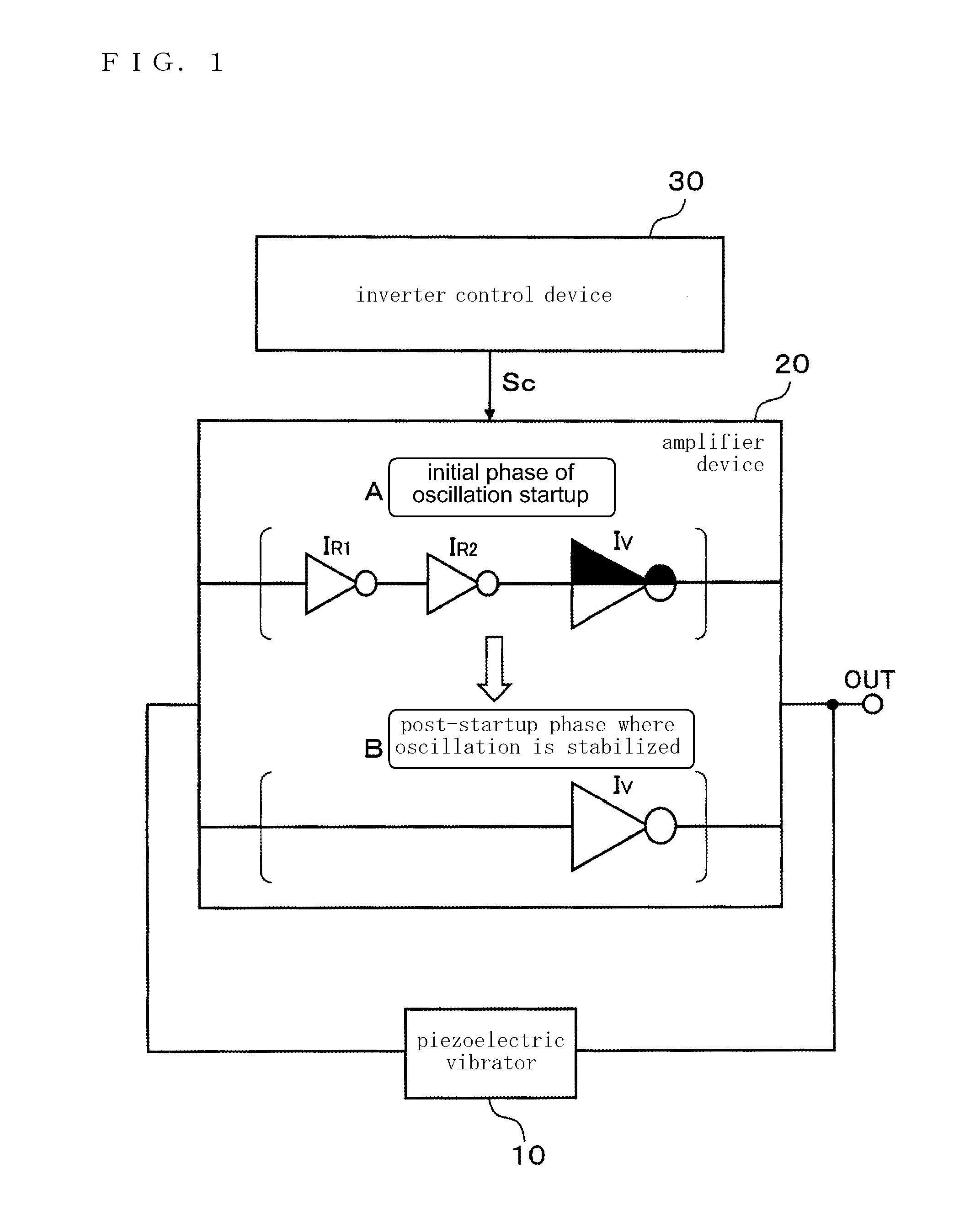

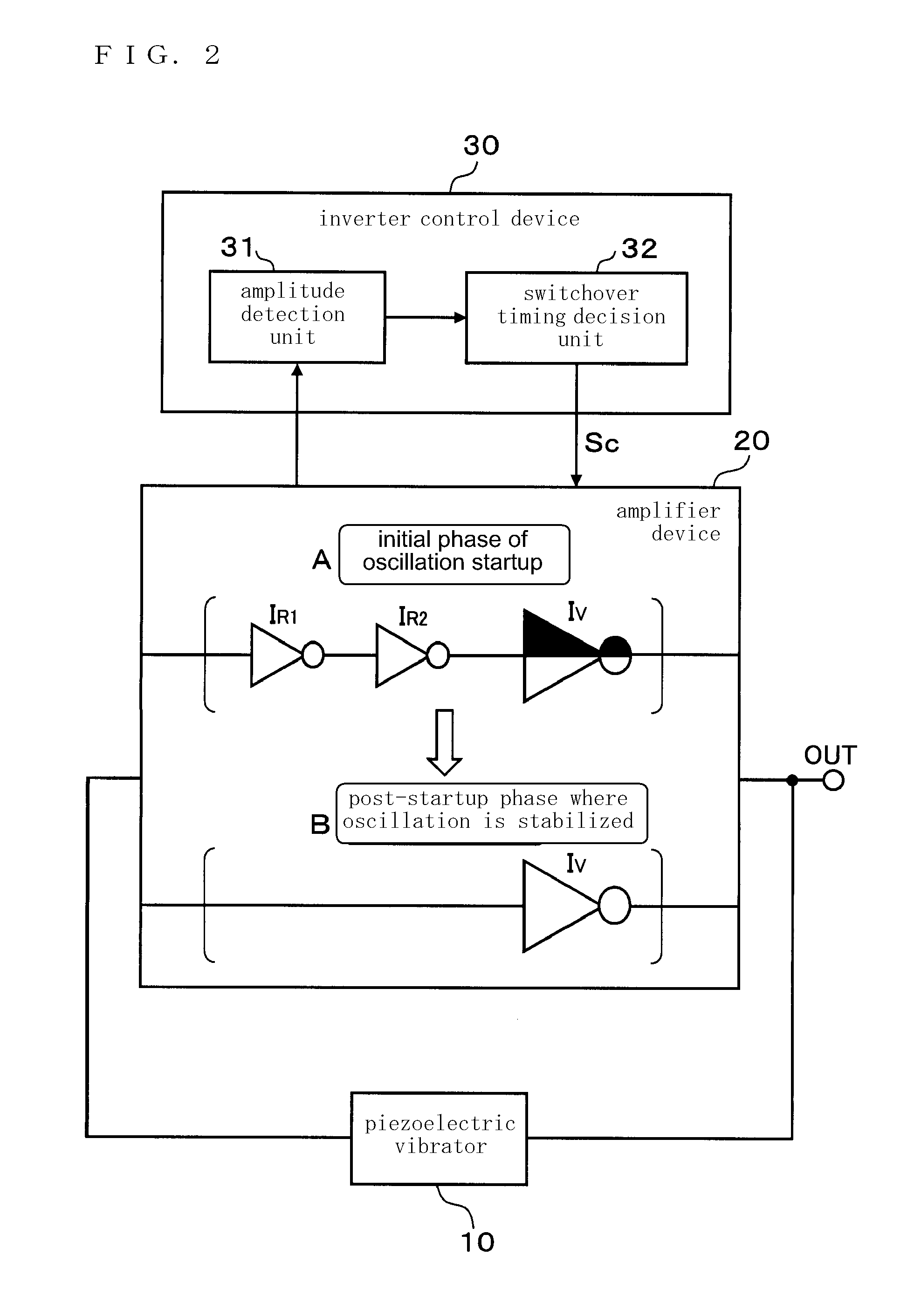

Oscillator circuit

ActiveUS20110291767A1Enhanced oscillationTotal current dropPulse automatic controlGenerator starterAudio power amplifierEngineering

An oscillator circuit comprises a piezoelectric vibrator, an amplifier device including inverters provided in a plurality of stages, and an inverter control device. The inverters provided in the plurality of stages includes a performance-variable inverter configured which is operational in both of an initial phase of oscillation startup and a post-startup phase where the oscillation is stabilized and capable of a variable performance depending on whether the initial phase of oscillation startup or the post-startup phase where the oscillation is stabilized, and an ON / OFF inverter which is operational in the initial phase of oscillation startup and disconnected in the post-startup phase where the oscillation is stabilized. The inverter control device have the performance-variable inverter and the ON / OFF inverter both operational and lowers the performance of the performance-variable inverter in the initial phase of oscillation startup, and the inverter control device disconnects the ON / OFF inverter and increases the performance of the performance-variable inverter in the post-startup phase where the oscillation is stabilized.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

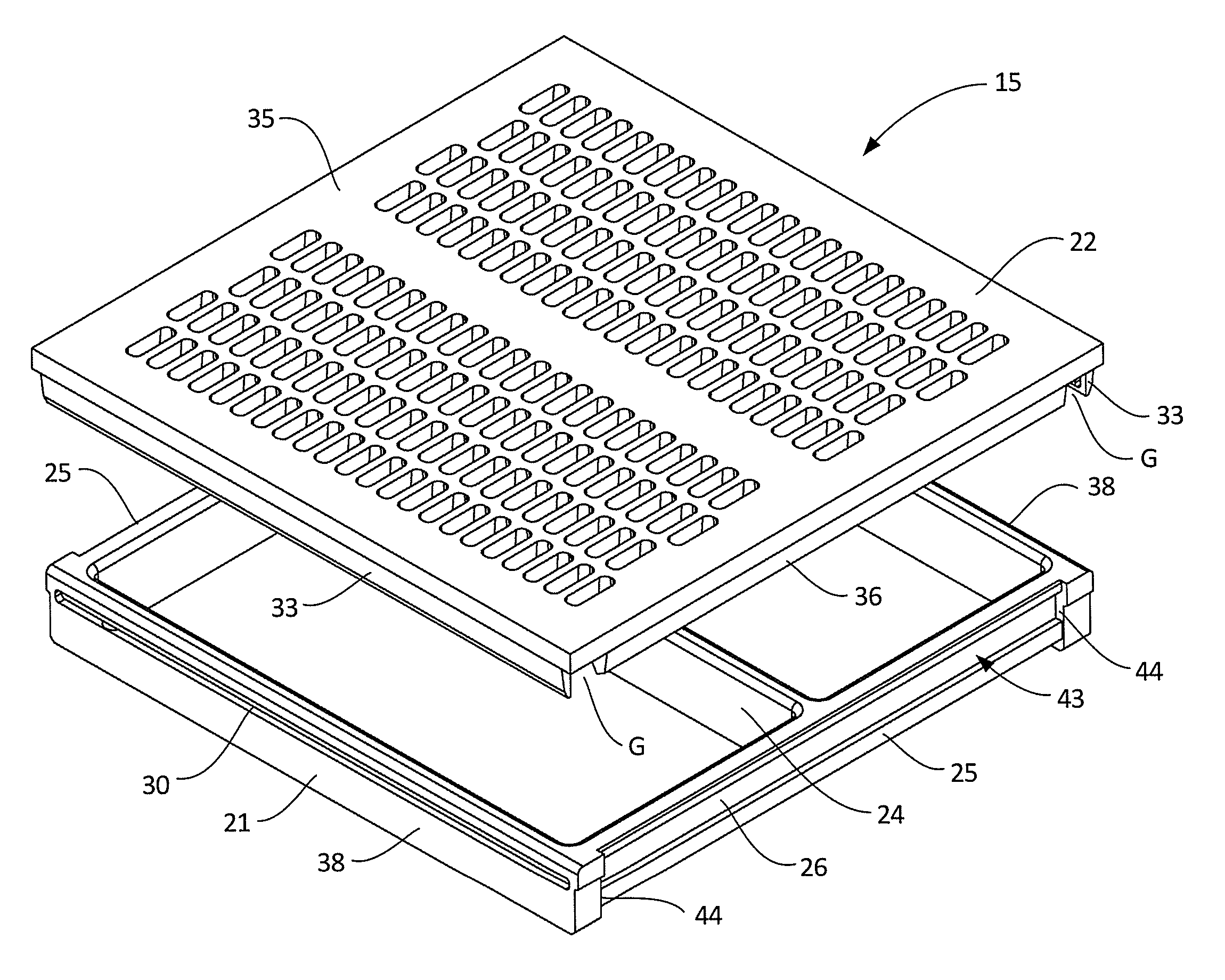

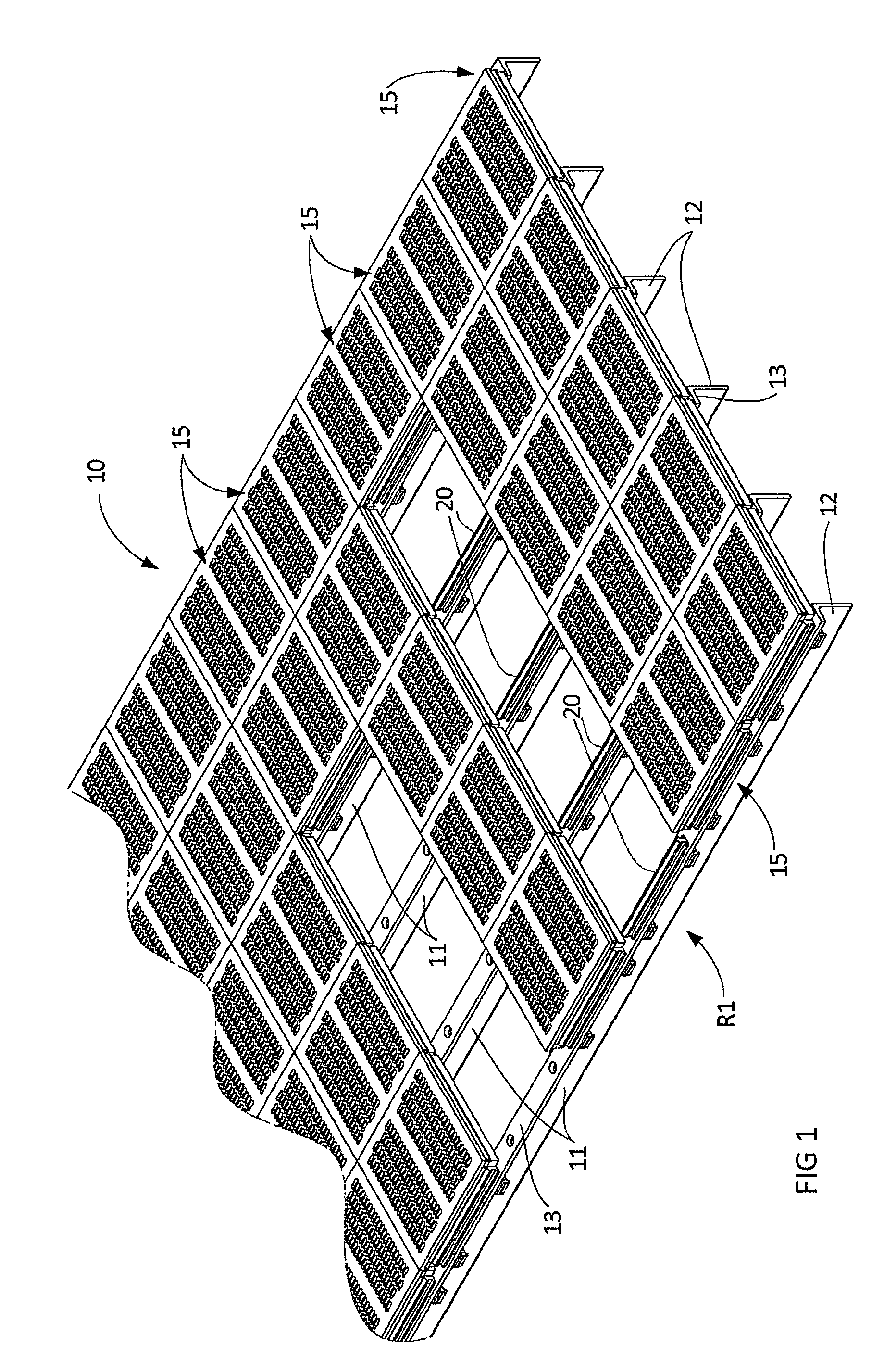

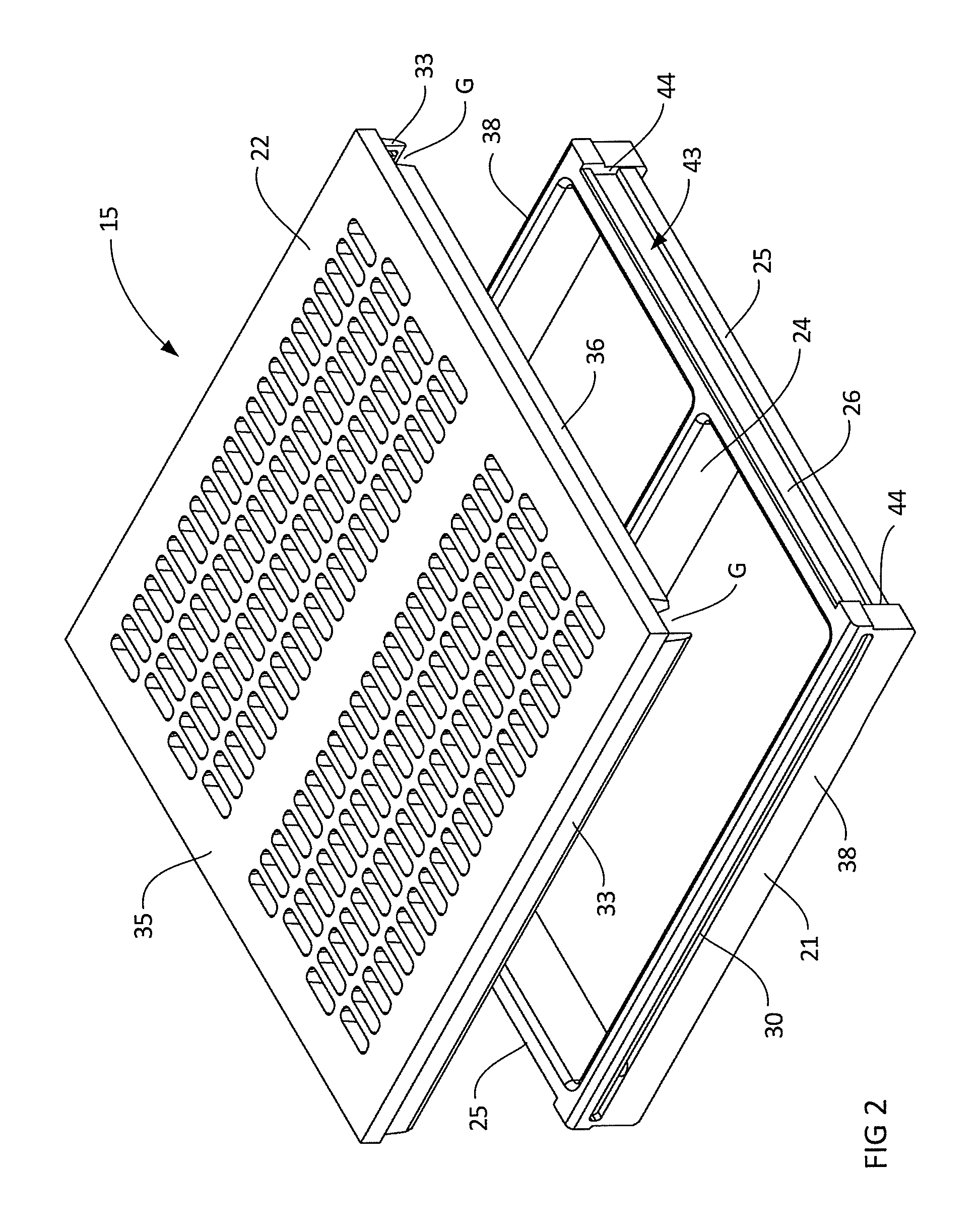

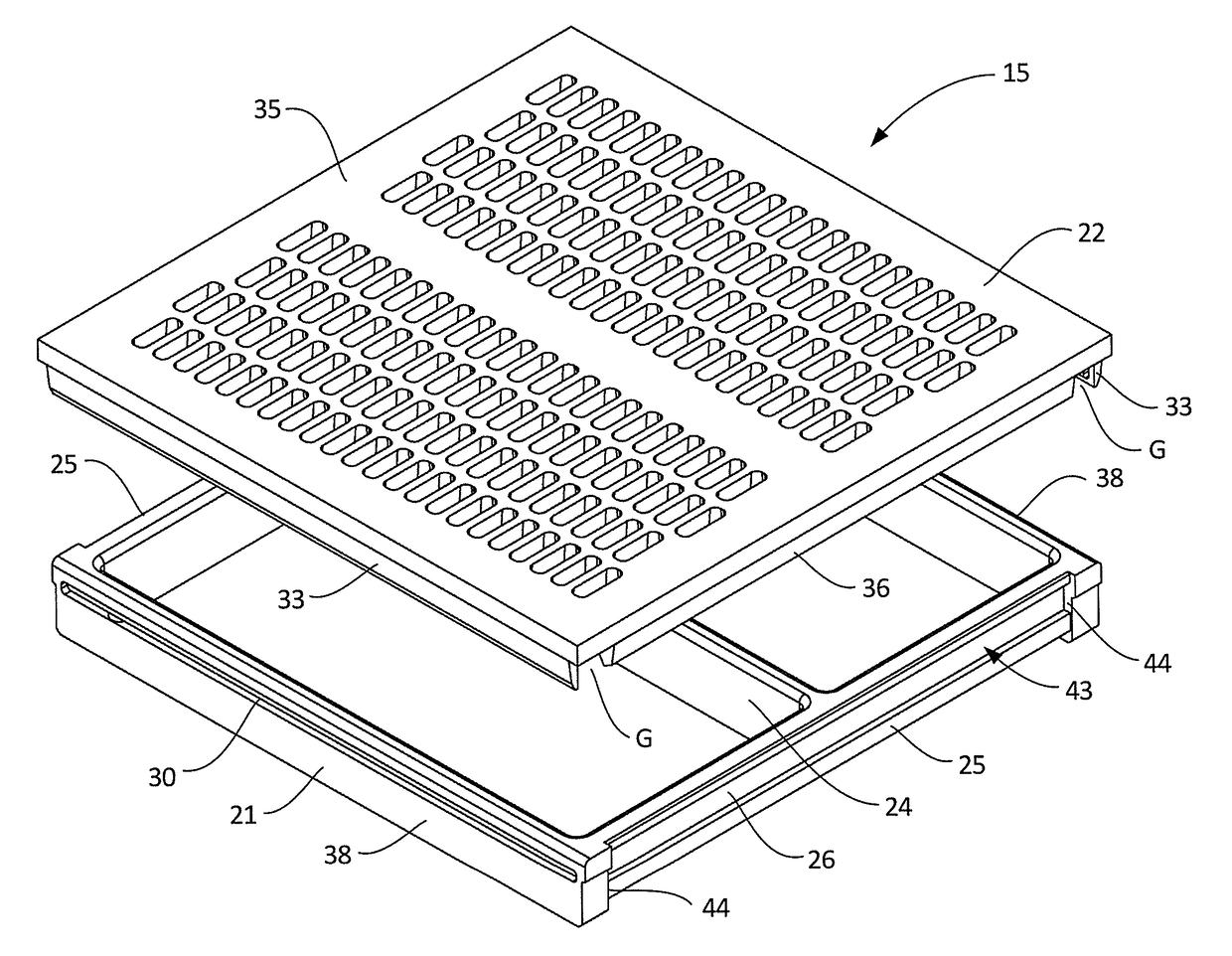

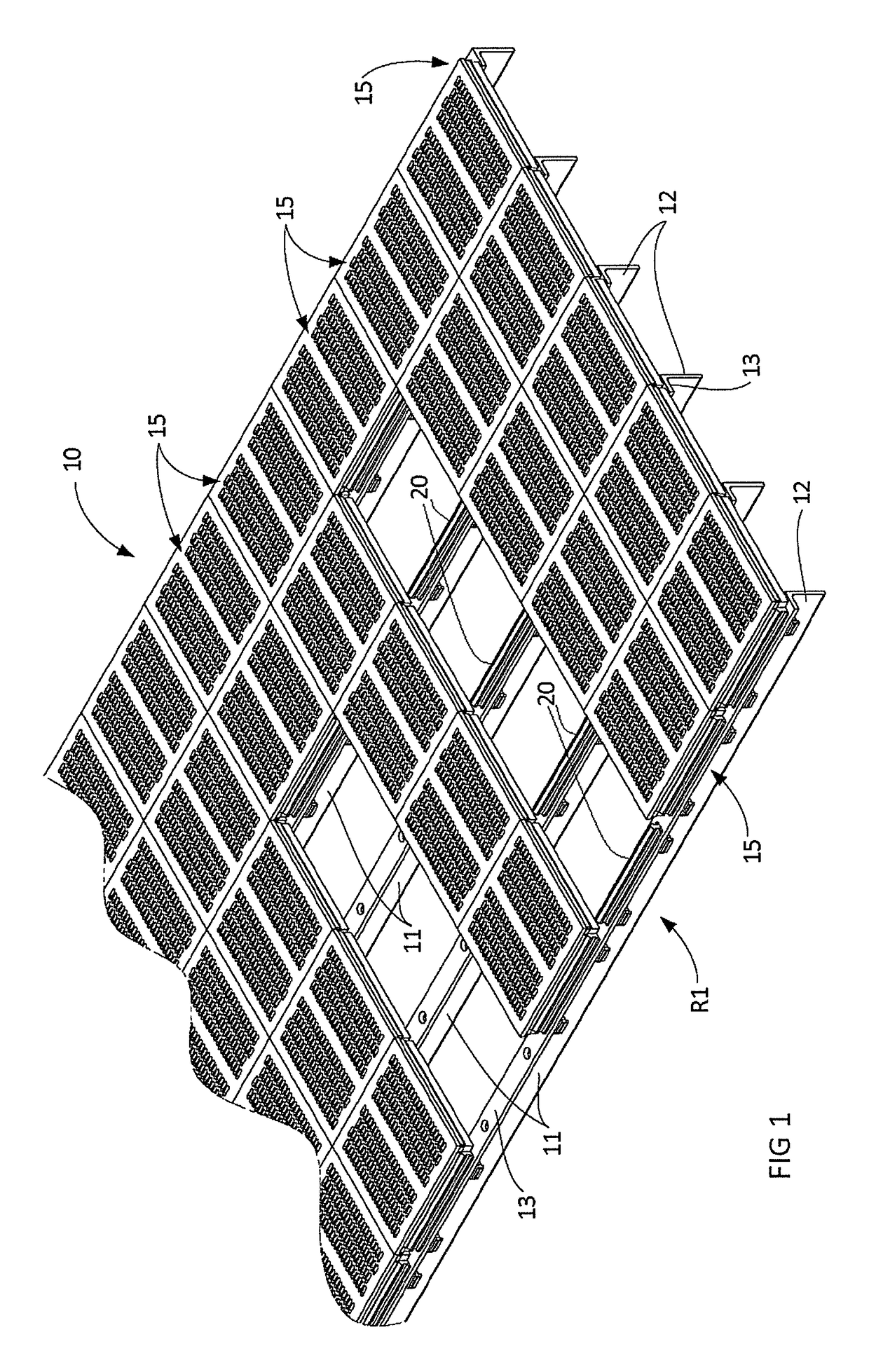

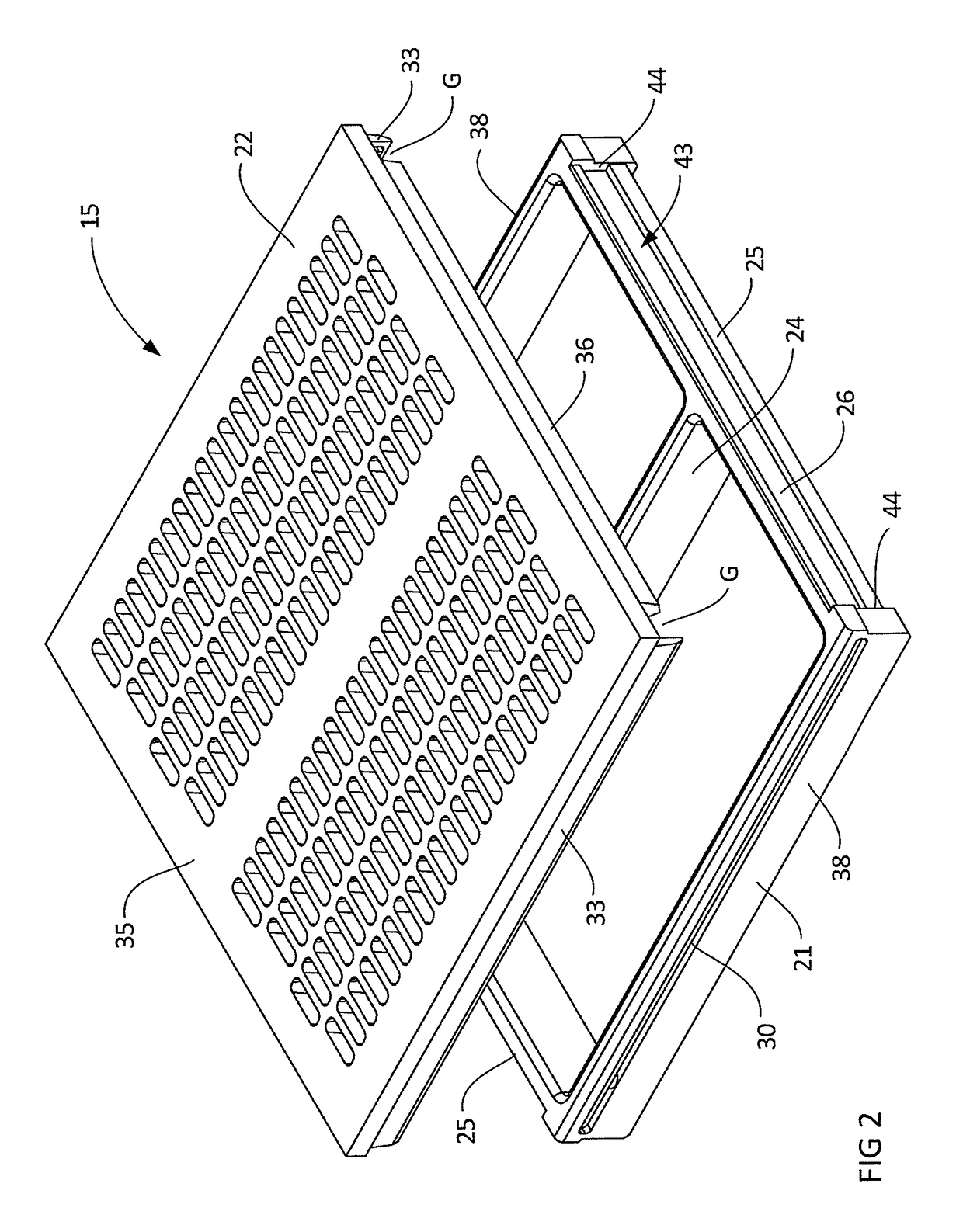

Screening Panel and Method of Fixing

ActiveUS20150283583A1Reduces available flexReduce flexSievingScreeningEngineeringElectrical and Electronics engineering

Owner:LETTELA PTY LTD

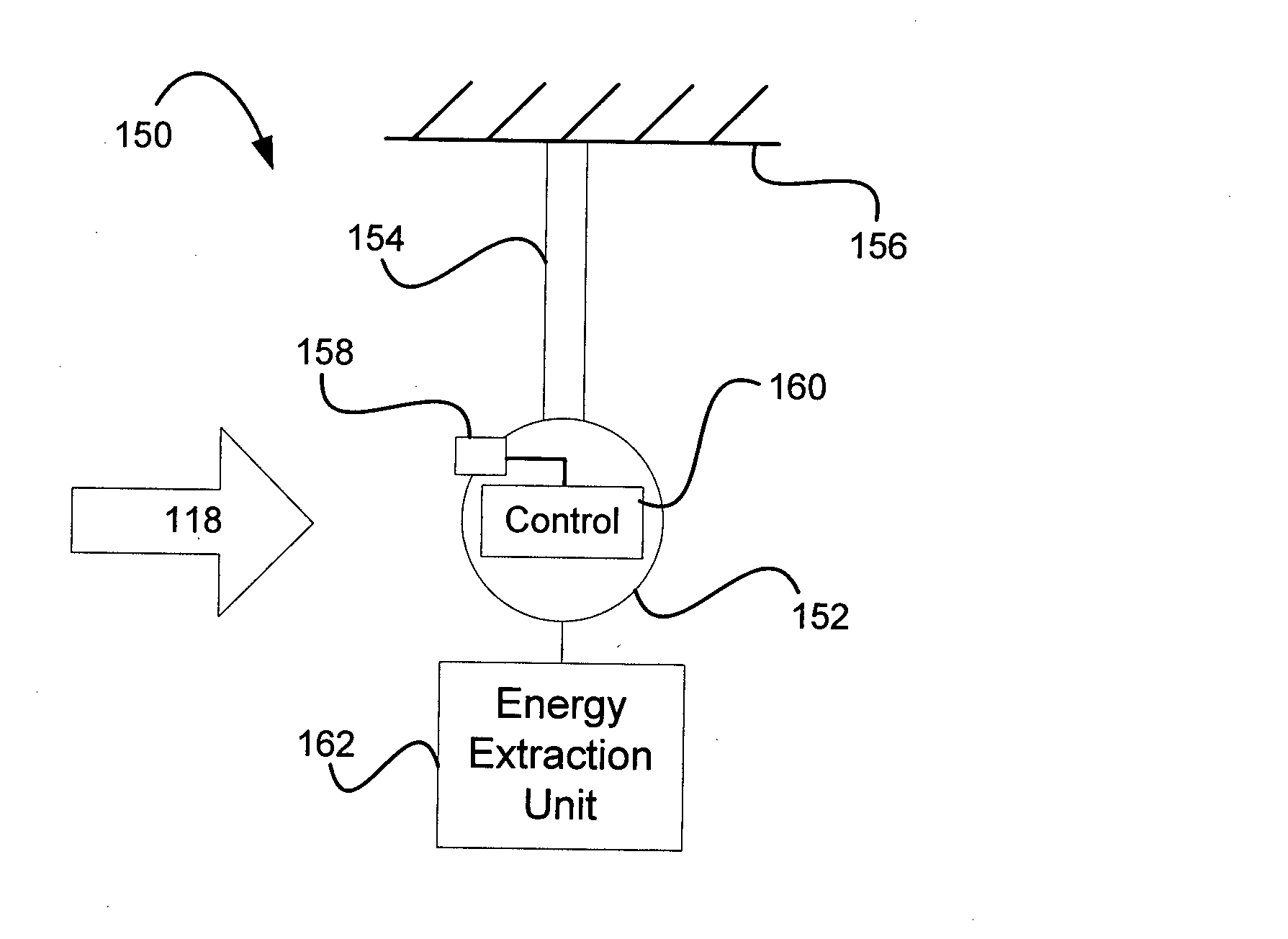

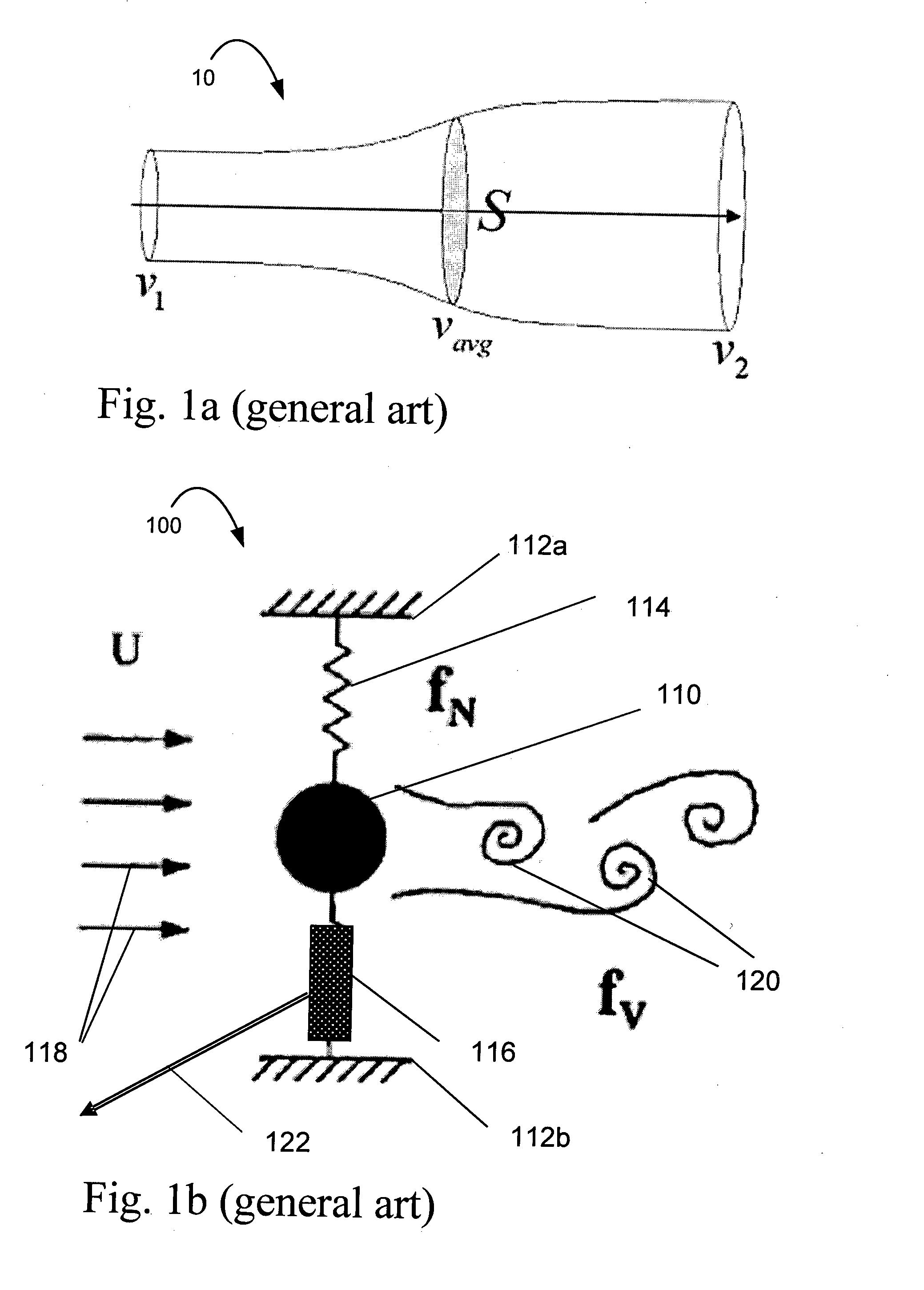

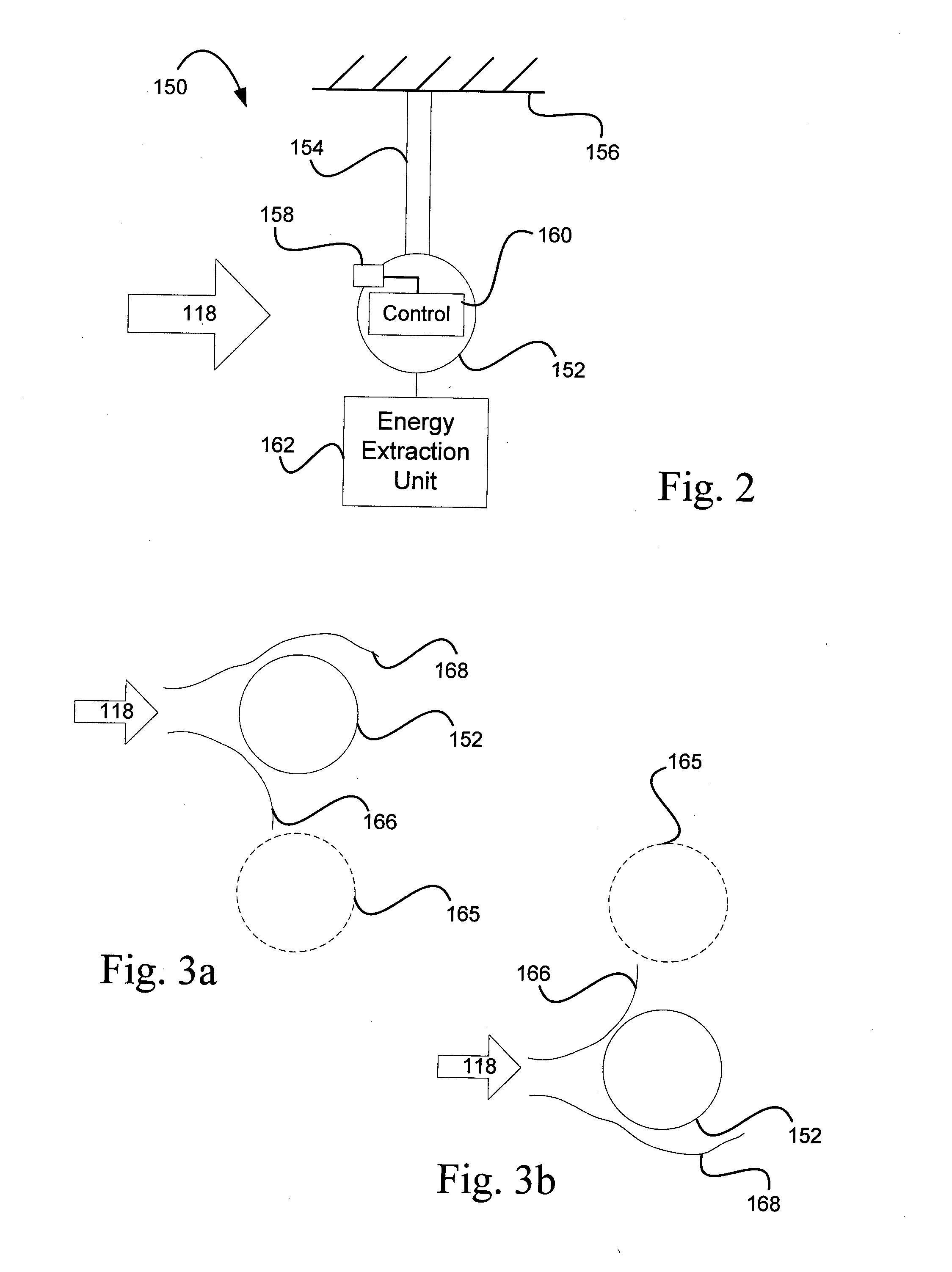

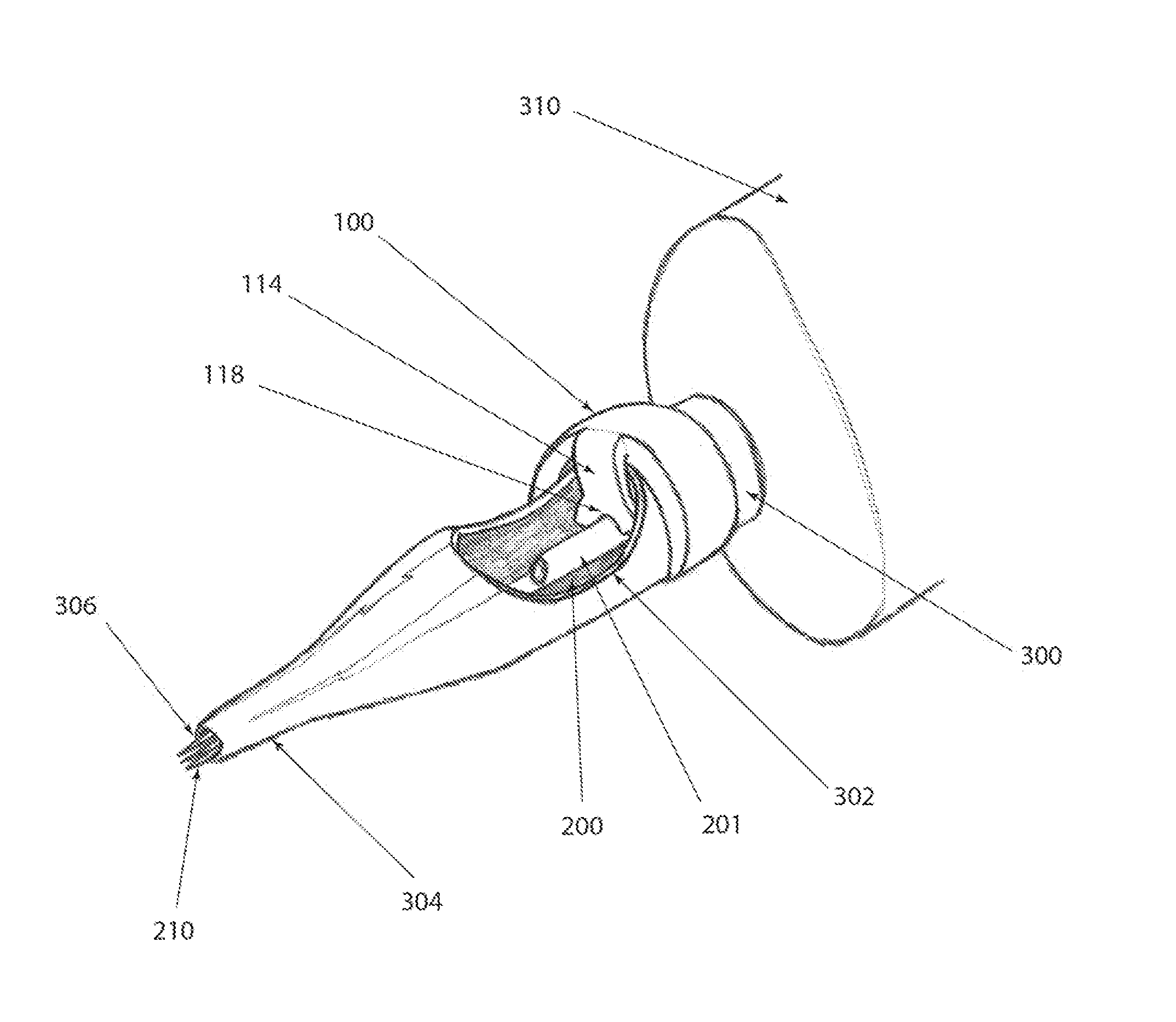

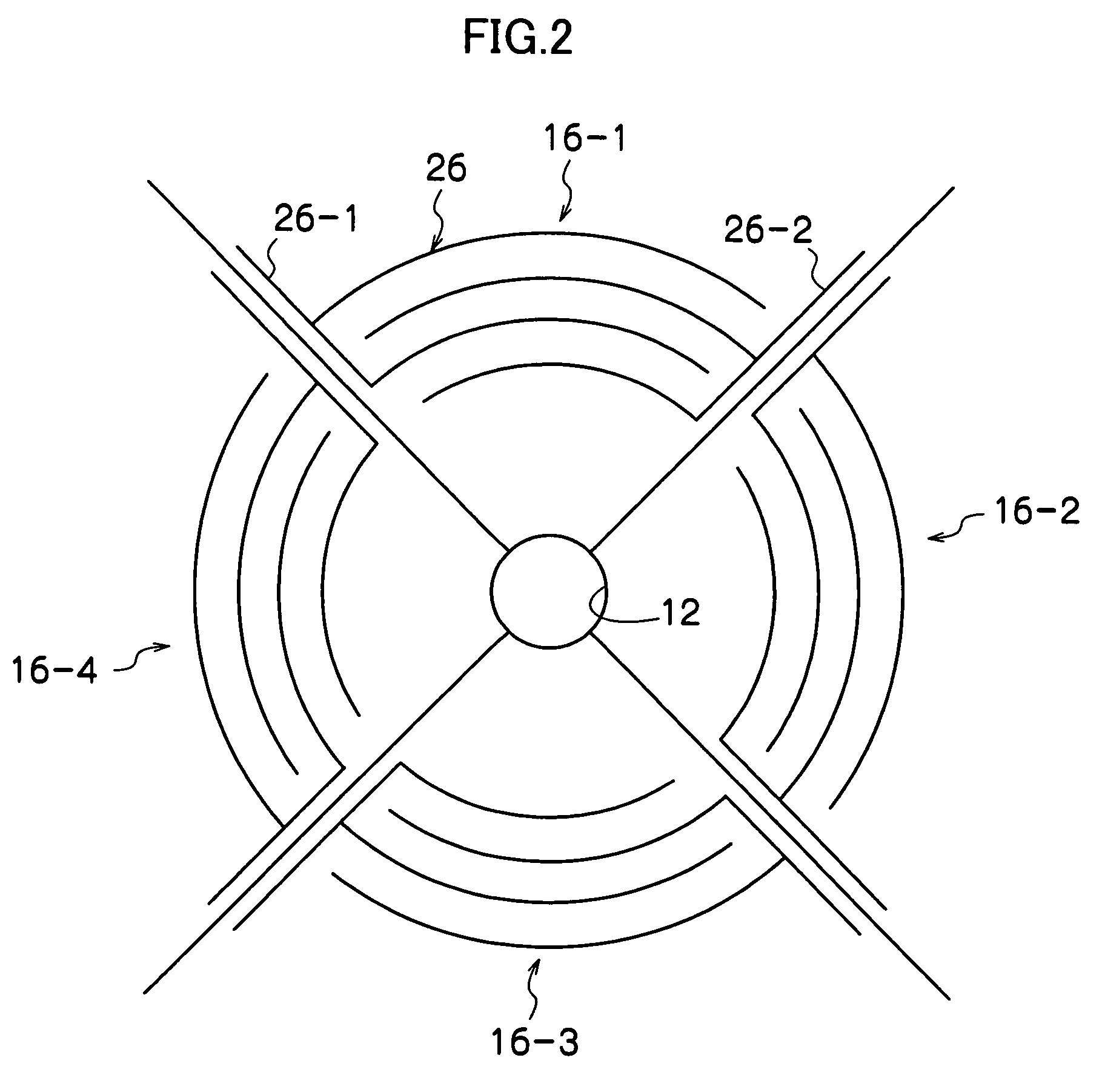

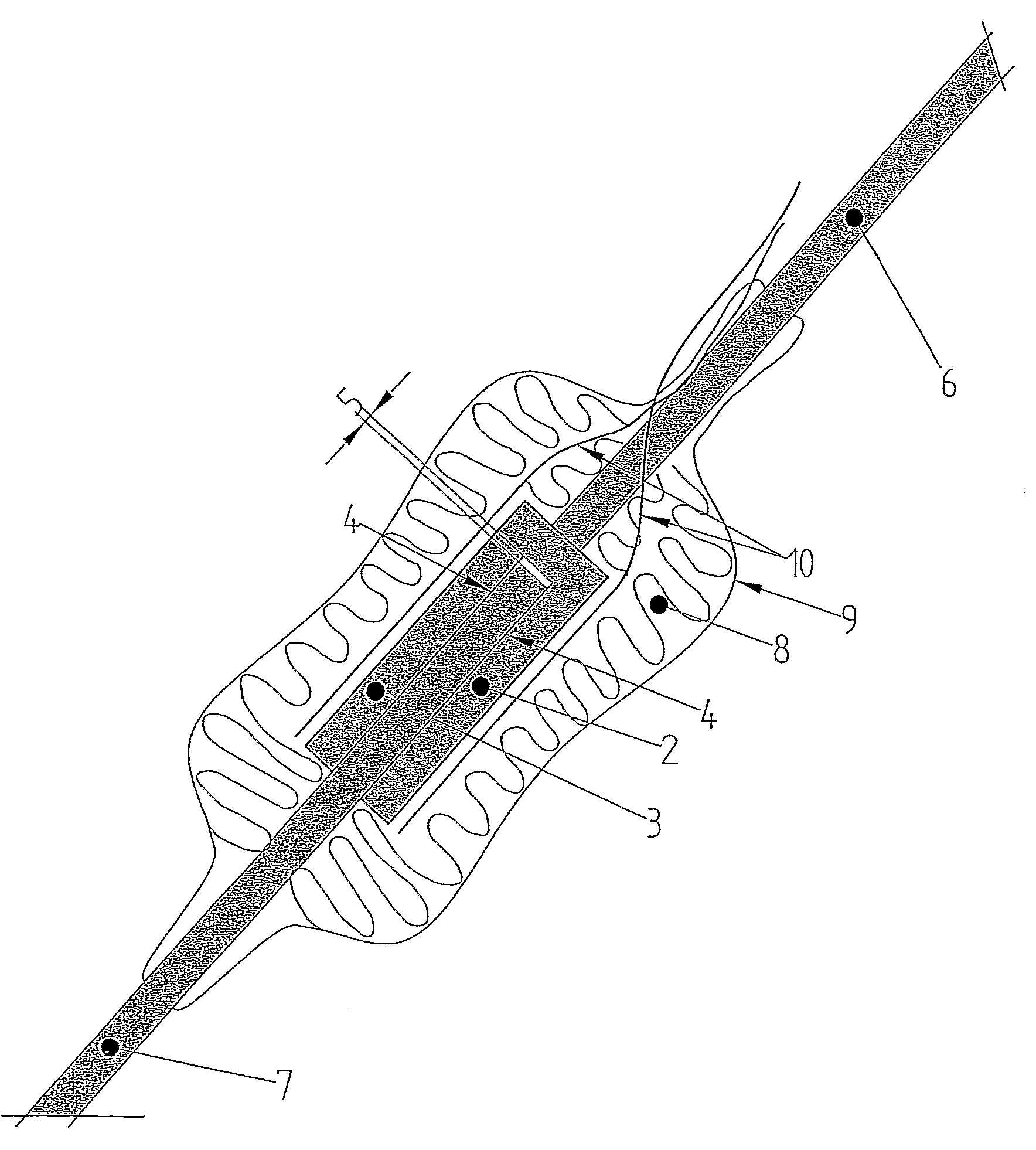

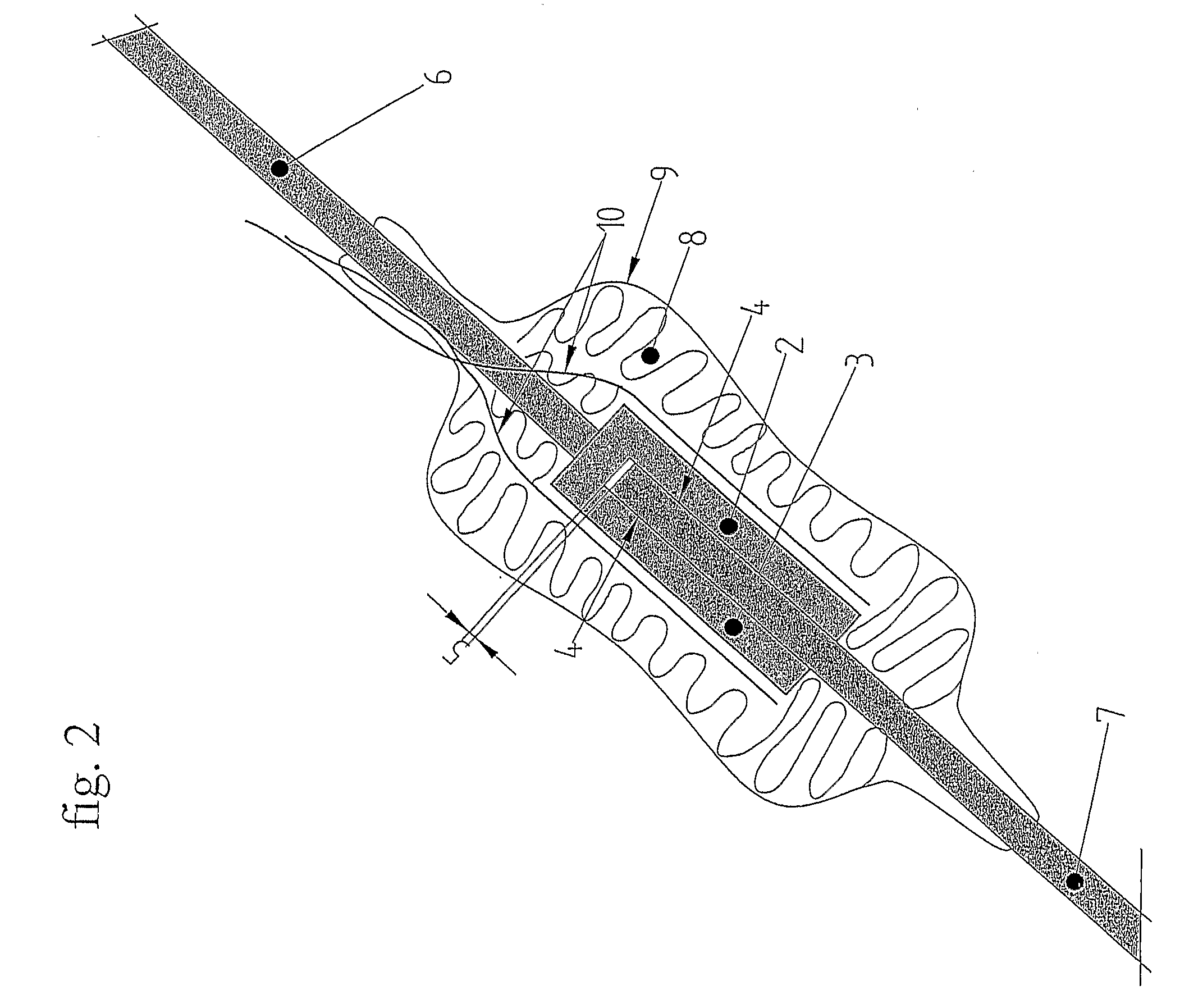

Energy conversion from fluid flow

ActiveUS20130227940A1Increase productionEnhanced oscillationRotary clutchesMachines/enginesEngineeringTime pattern

A device for use in extracting energy from an incoming fluid flow is presented. The device comprises: an oscillator assembly mounted on a base, the oscillator assembly comprising: a main body for exposing to an incoming fluid flow; and a joining element attached to the main body and configured for anchoring the main body to the base and enabling oscillation of the main body with respect to the base; an operative flow affecting unit comprising at least one flow interacting element located in at least one location respectively on a surface of the main body, the operative flow affecting unit being configured and controllably operable for affecting a separation of streams of the fluid flowing over the surface of the main body; a control unit in communication with the operative flow affecting unit, the control unit being configured and operable for activating and deactivating of each of the at least one flow interacting element of the operative flow affecting unit according to a certain time pattern, the time pattern being selected such that interaction between the flow interacting element and fluid streams creates vortices in the fluid streams at a selected vortex formation frequency causing an increase in oscillation of the main body, thereby enabling conversion of motion from the oscillation into useful energy.

Owner:TECHNION RES & DEV FOUND LTD

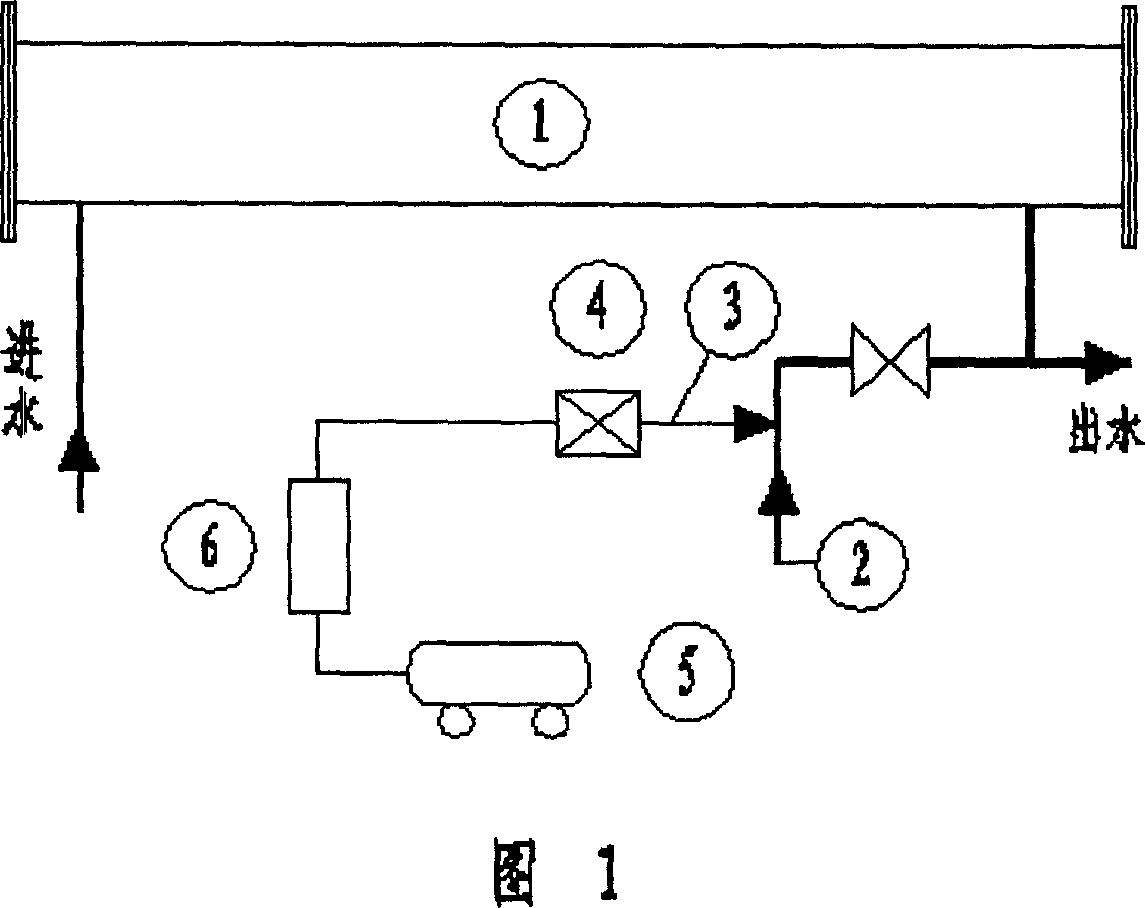

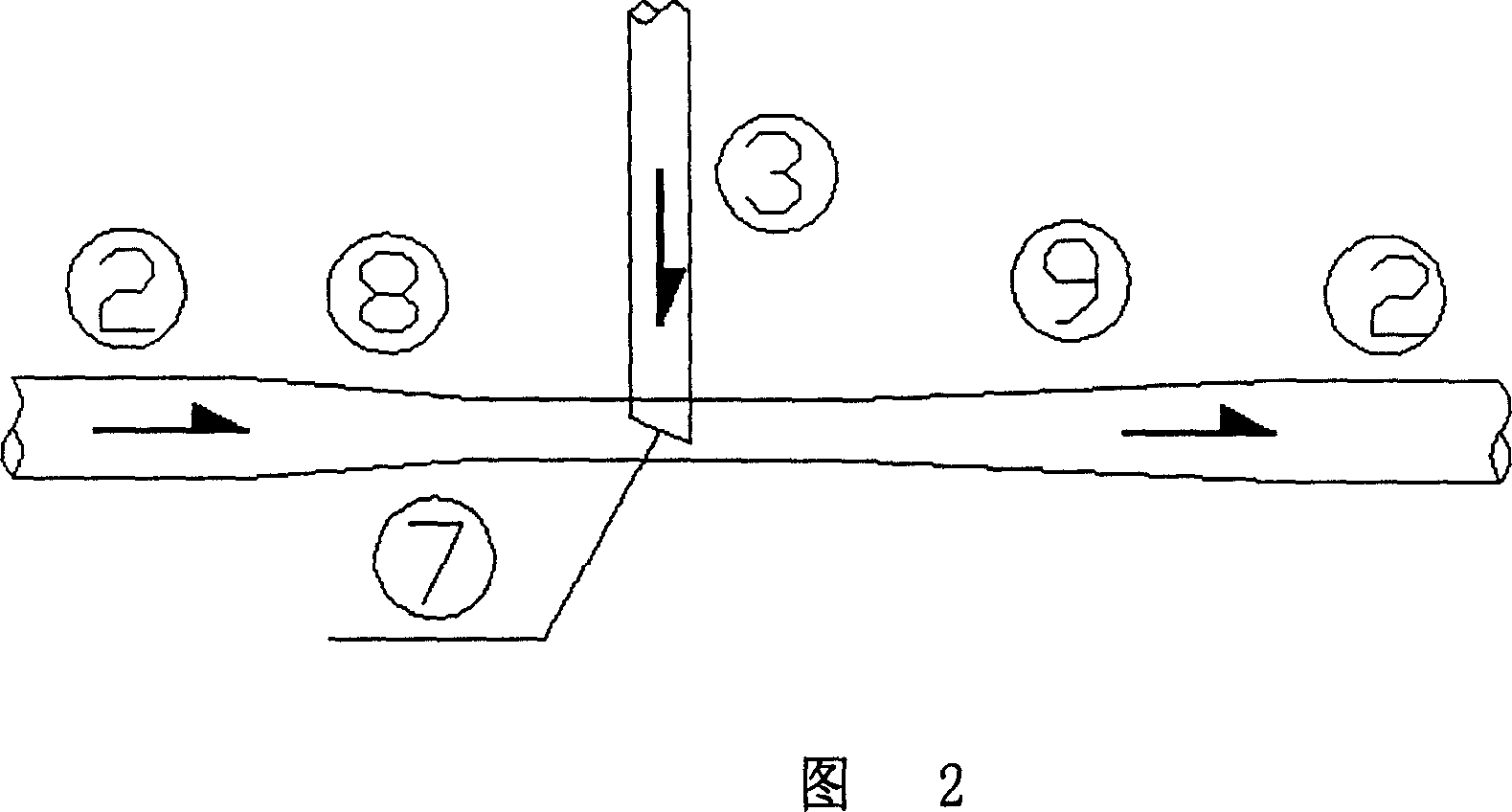

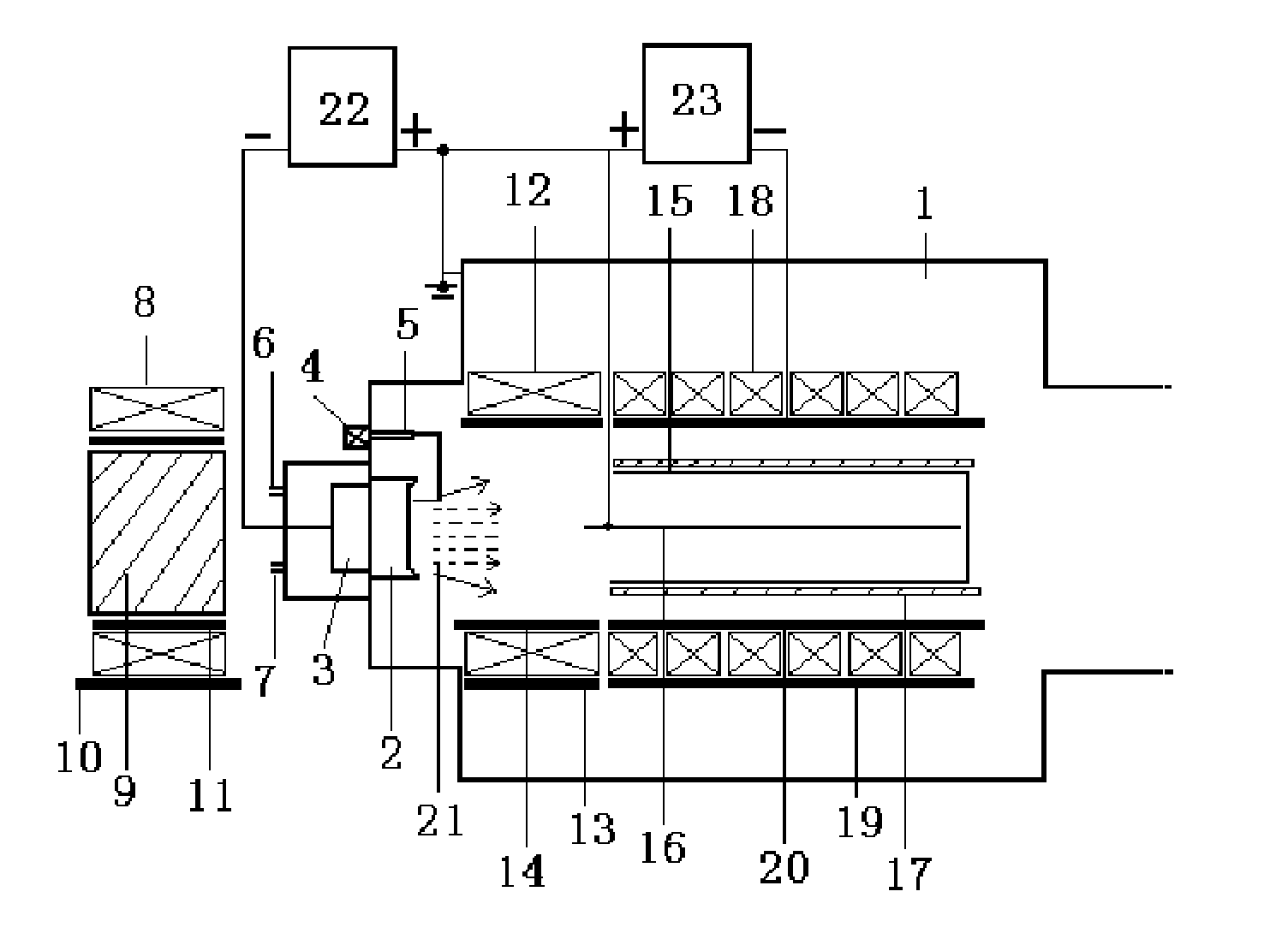

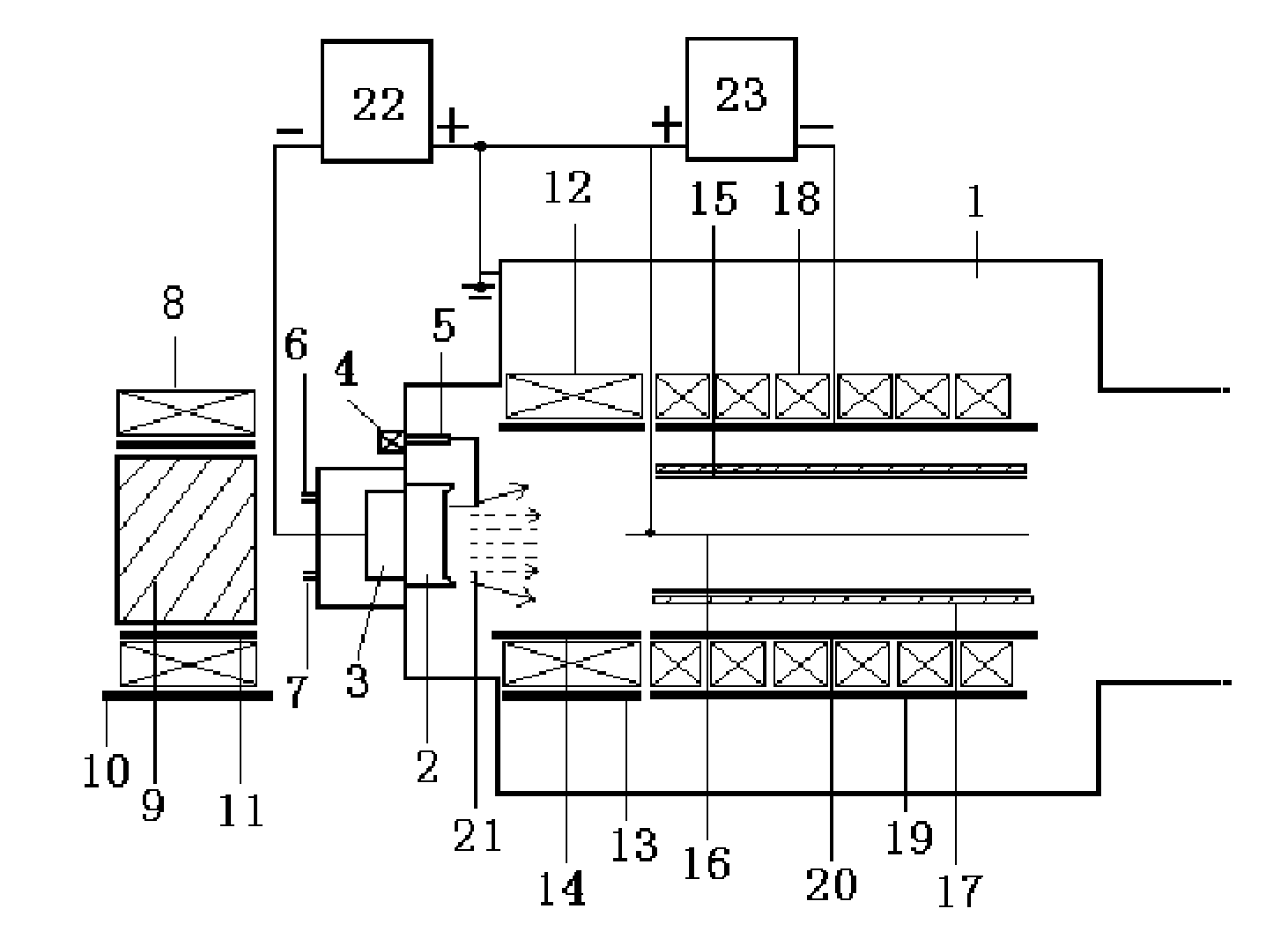

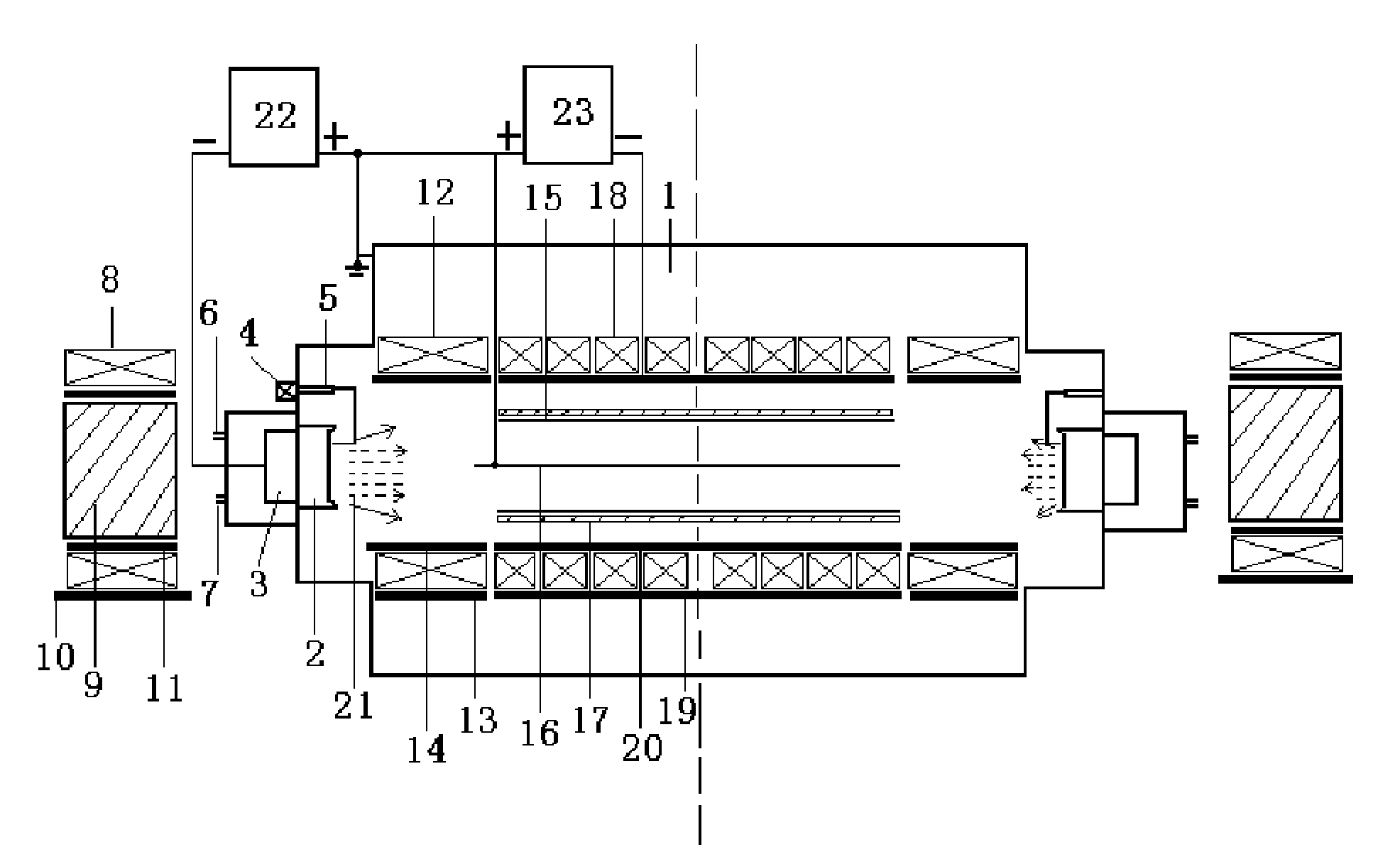

Membrane cleaning device and method in membrane separating technology and its application

ActiveCN1931419AImprove backwashing effectClear pulseSemi-permeable membranesFiberSeparation technology

The membrane cleaning device includes one back washing water intake pipeline connected to the membrane filter, and one pulse air pipeline connected to the back washing water intake pipeline to adding compressed air into the water flow of the back washing water intake pipeline. The pulse air pipeline includes one pulse valve connected directly to the back washing water intake pipeline, one air compressor with air storing packet and connected to the pulse valve and one PLC control system to control the pulse valve. The device of the present invention can generate high strength pulse air-mixing water flow to clean membrane, especially hollow fiber membrane effectively. The present invention may be used widely in the water flooding treatment of hyposmosis oil field, pure water preparation, product purification, waste water treatment, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

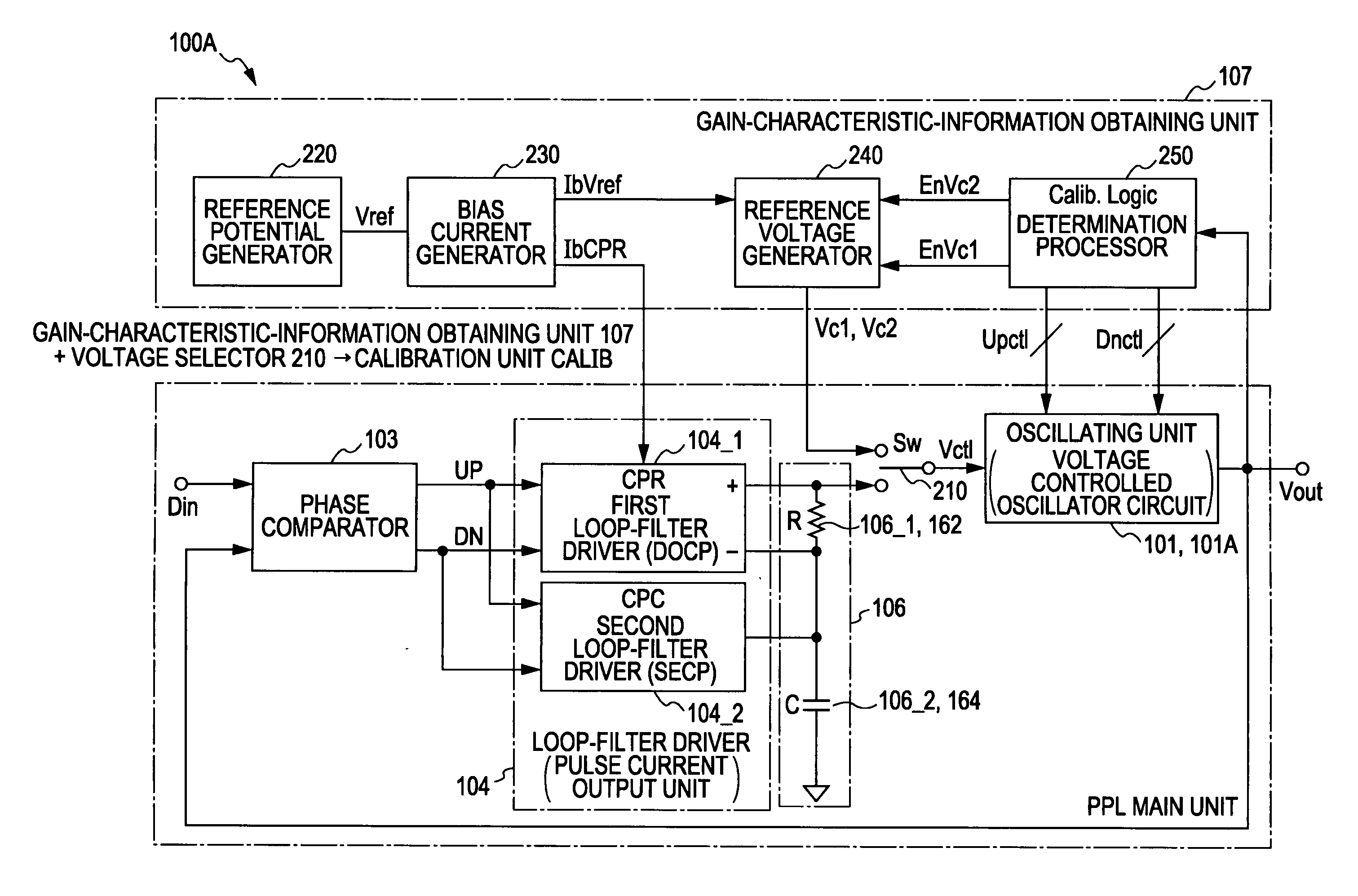

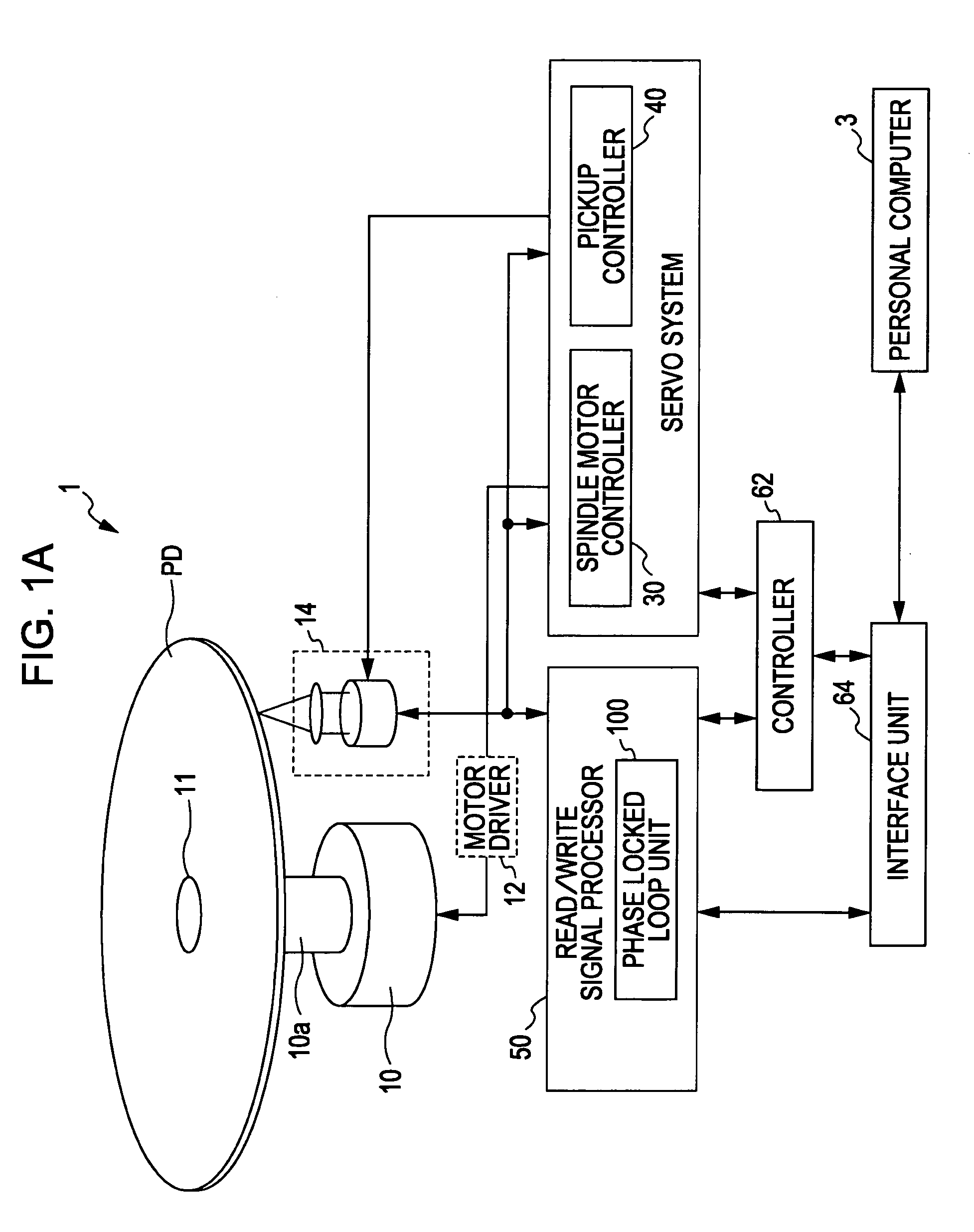

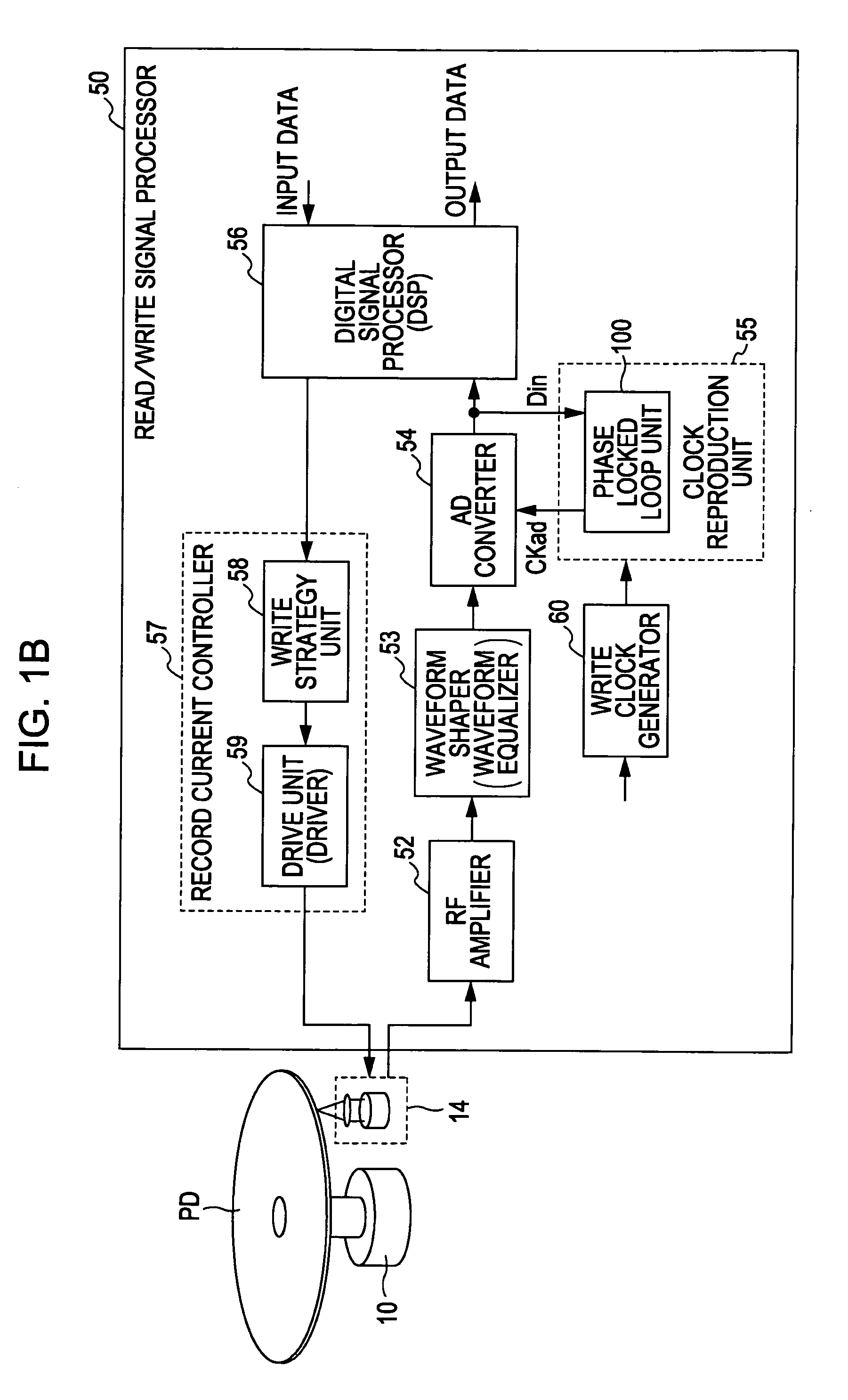

Phase-locked loop circuit, recording-and-reproducing apparatus, and electronic appratus

InactiveUS20100026406A1Noise performanceEasy to operatePulse automatic controlPulse generation by logic circuitsLoop filterPhase locked loop circuit

A phase-locked loop circuit includes a phase detection unit, a loop filter unit including a series circuit of a resistor and a capacitor, first and second pulse-current output units which supply differential and single-end pulse currents corresponding to phase information to the resistor and capacitor, an oscillating unit which varies an oscillation frequency in accordance with a voltage generated at the resistor and capacitor, and a calibration unit which obtains information of an oscillation gain in actual operation and corrects an operation of the oscillating unit on the basis of a difference between the oscillation gain in actual operation and a target oscillation gain. The oscillation gain in actual operation represents a characteristic of oscillation frequency versus input signal of the oscillating unit and is obtained using predetermined oscillation control signals on the basis of a difference between actual oscillation frequencies under the oscillation control signals.

Owner:SONY CORP

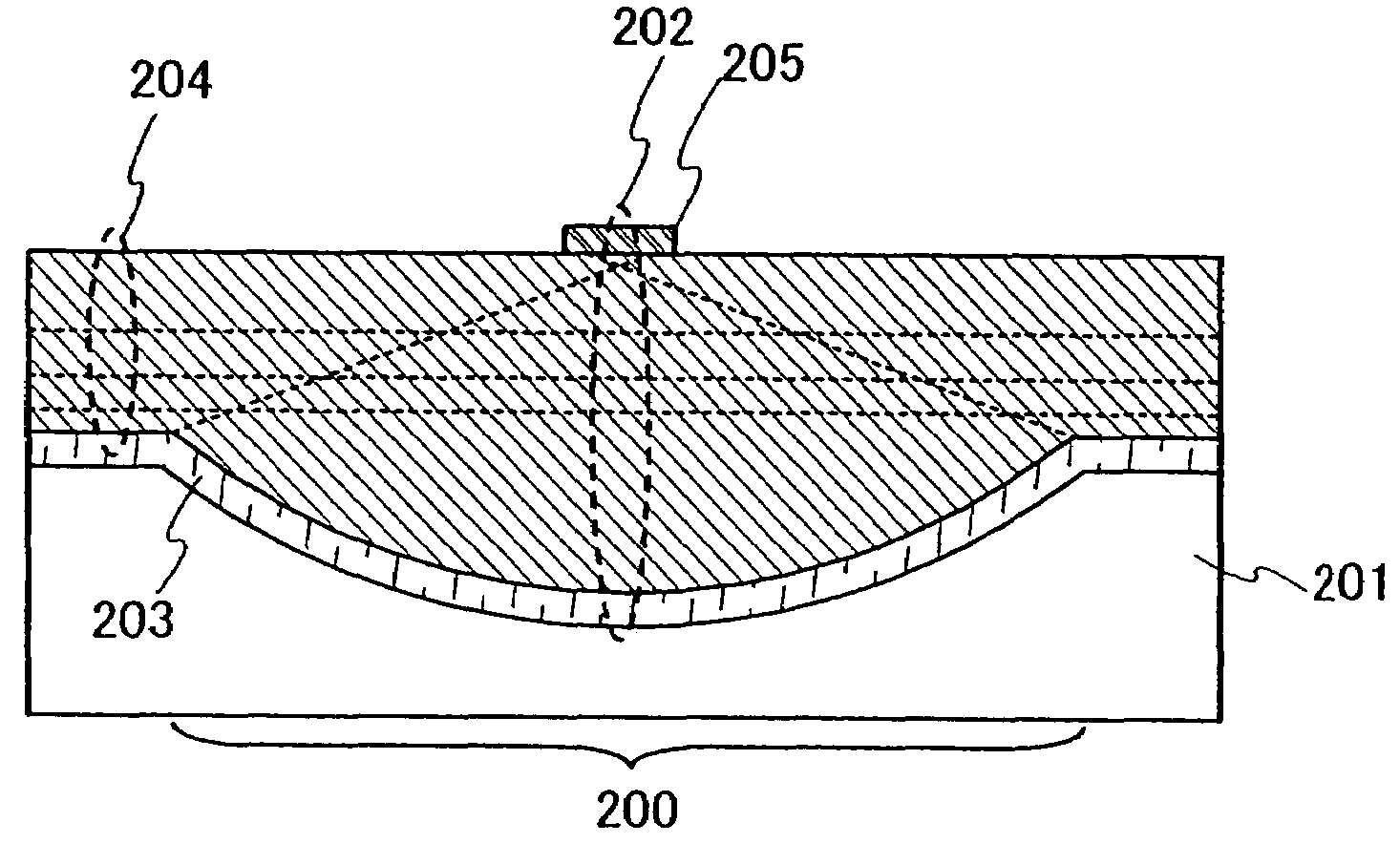

Light-emitting device

InactiveUS7449724B2Improve oscillation efficiencyReduce power consumptionLaser detailsLaser optical resonator constructionOptical axisLaser light

A light-emitting device is disclosed as typified by a laser oscillator formed by an electroluminescent material with improved oscillation efficiency of laser light and even reduced power consumption. The disclosed light-emitting device comprises a light-emitting element including a first electrode having a concave portion, an electroluminescent layer serving as a laser medium formed over the first electrode so as to be overlapped with the concave portion, and a second electrode formed over the electroluminescent layer so as to be overlapped with the concave portion, wherein light generated in the electroluminescent layer is resonated between the first electrode and the second electrode and emitted as laser light from the second electrode, an optical axis of the laser light intersects with the second electrode, the first electrode has a curved surface at the concave portion, and a center of curvature of the curved surface is located at the side of the second electrode above the first electrode.

Owner:SEMICON ENERGY LAB CO LTD

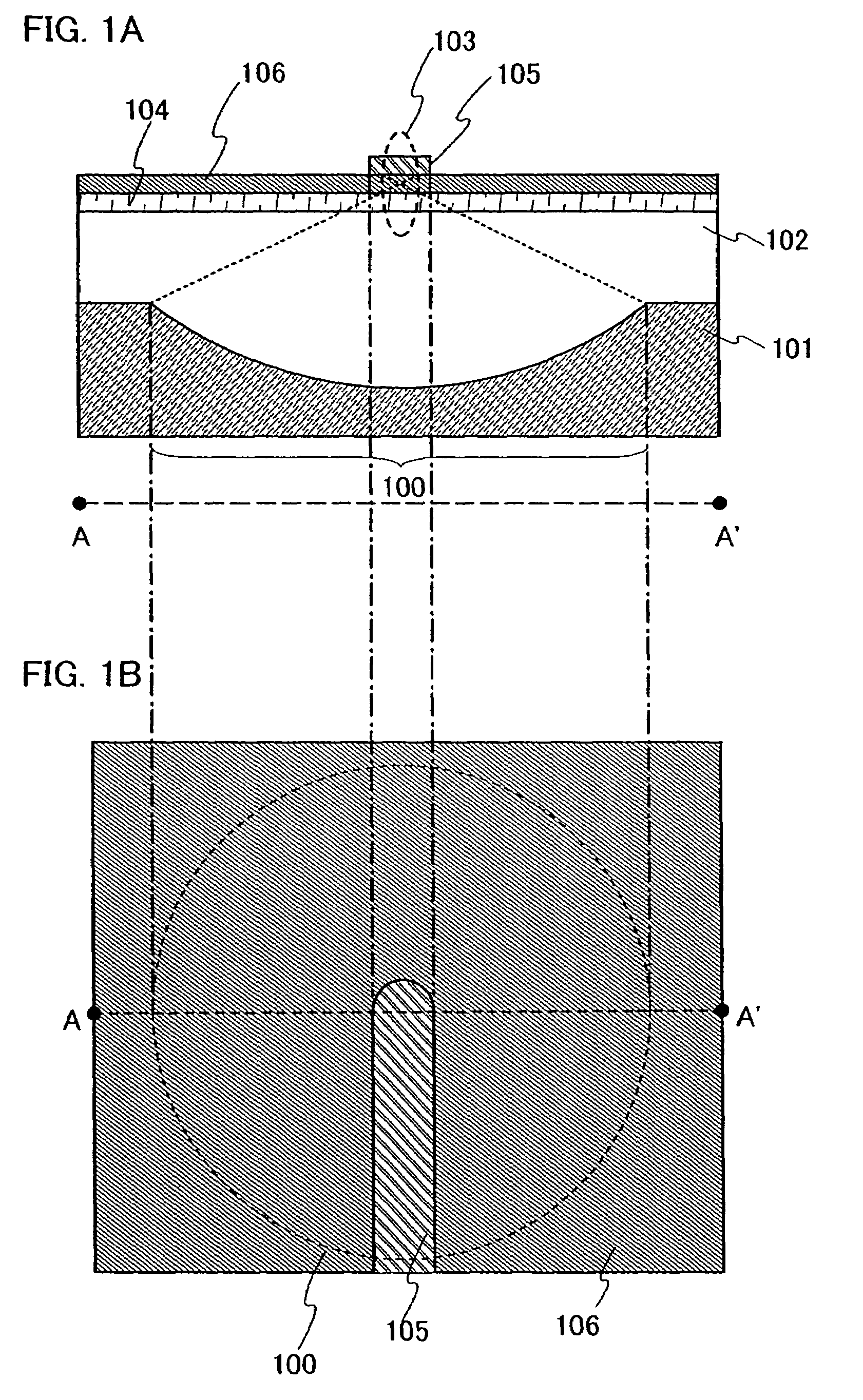

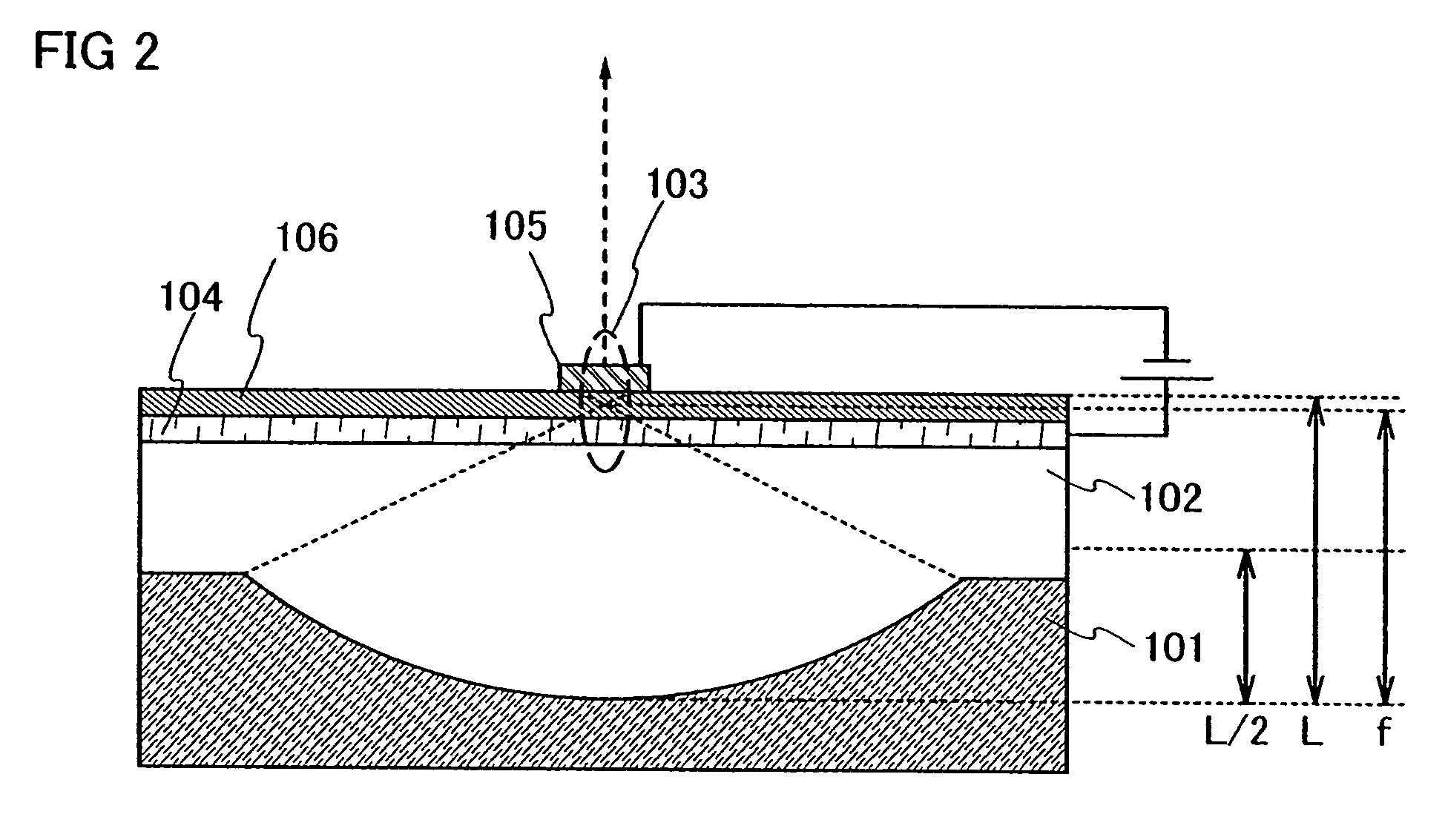

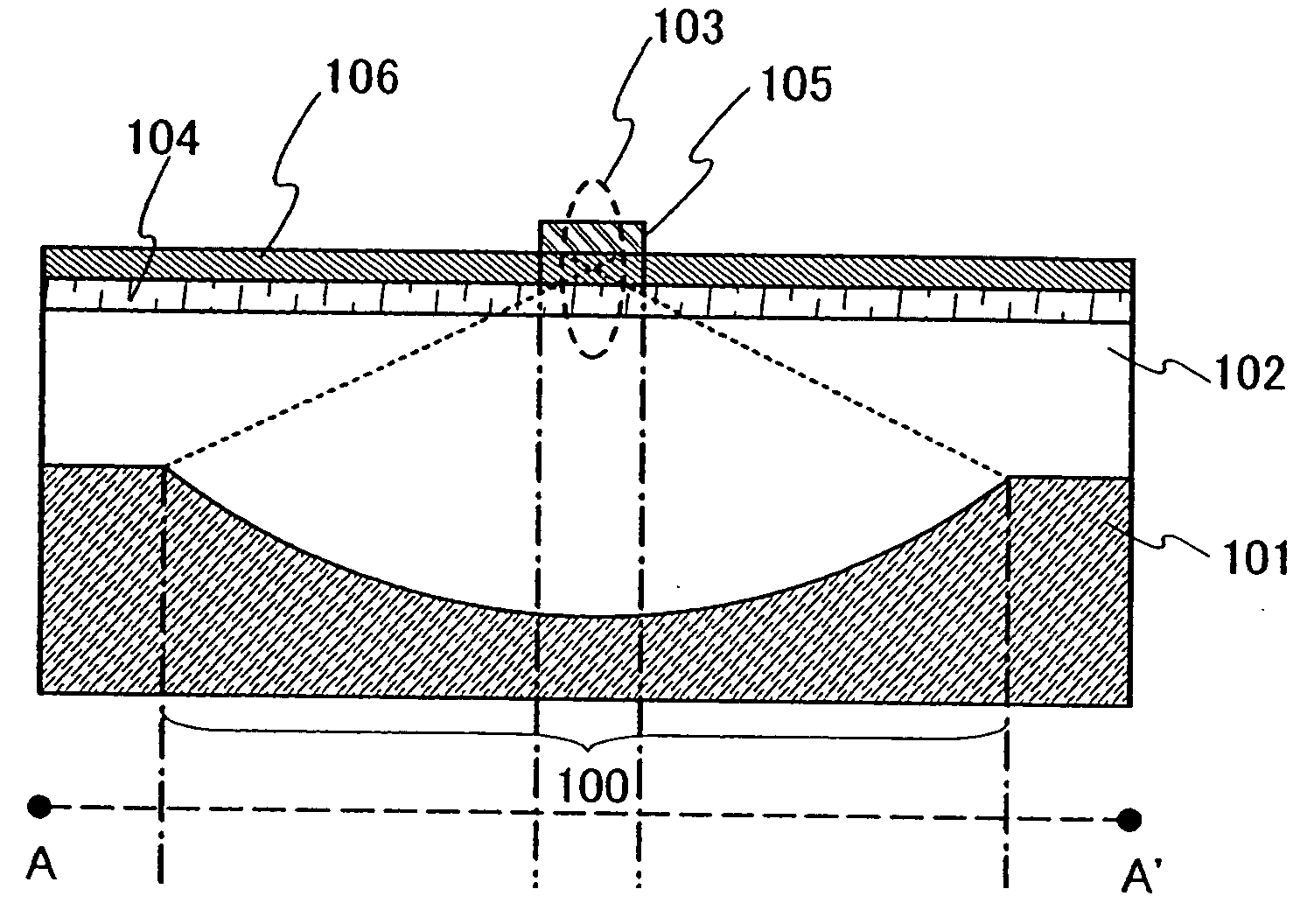

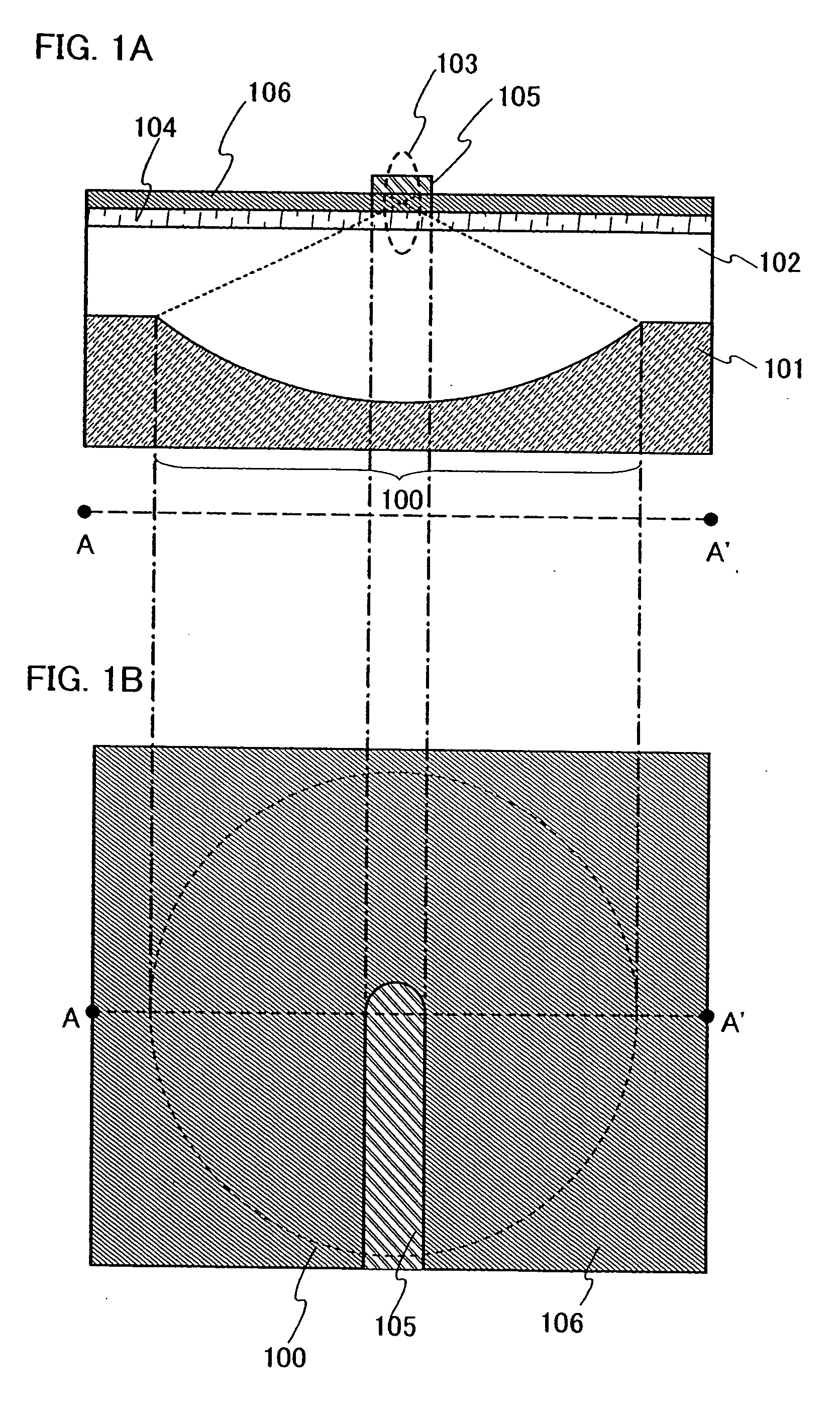

Light-emitting device

InactiveUS20050056856A1Improve oscillation efficiencyReduce power consumptionLaser detailsLaser optical resonator constructionPhysicsLaser light

A light-emitting device is disclosed as typified by a laser oscillator formed by an electroluminescent material with improved oscillation efficiency of laser light and even reduced power consumption. The disclosed light-emitting device comprises a light-emitting element including a first electrode having a concave portion, an electroluminescent layer serving as a laser medium formed over the first electrode so as to be overlapped with the concave portion, and a second electrode formed over the electroluminescent layer so as to be overlapped with the concave portion, wherein light generated in the electroluminescent layer is resonated between the first electrode and the second electrode and emitted as laser light from the second electrode, an optical axis of the laser light intersects with the second electrode, the first electrode has a curved surface at the concave portion, and a center of curvature of the curved surface is located at the side of the second electrode above the first electrode.

Owner:SEMICON ENERGY LAB CO LTD

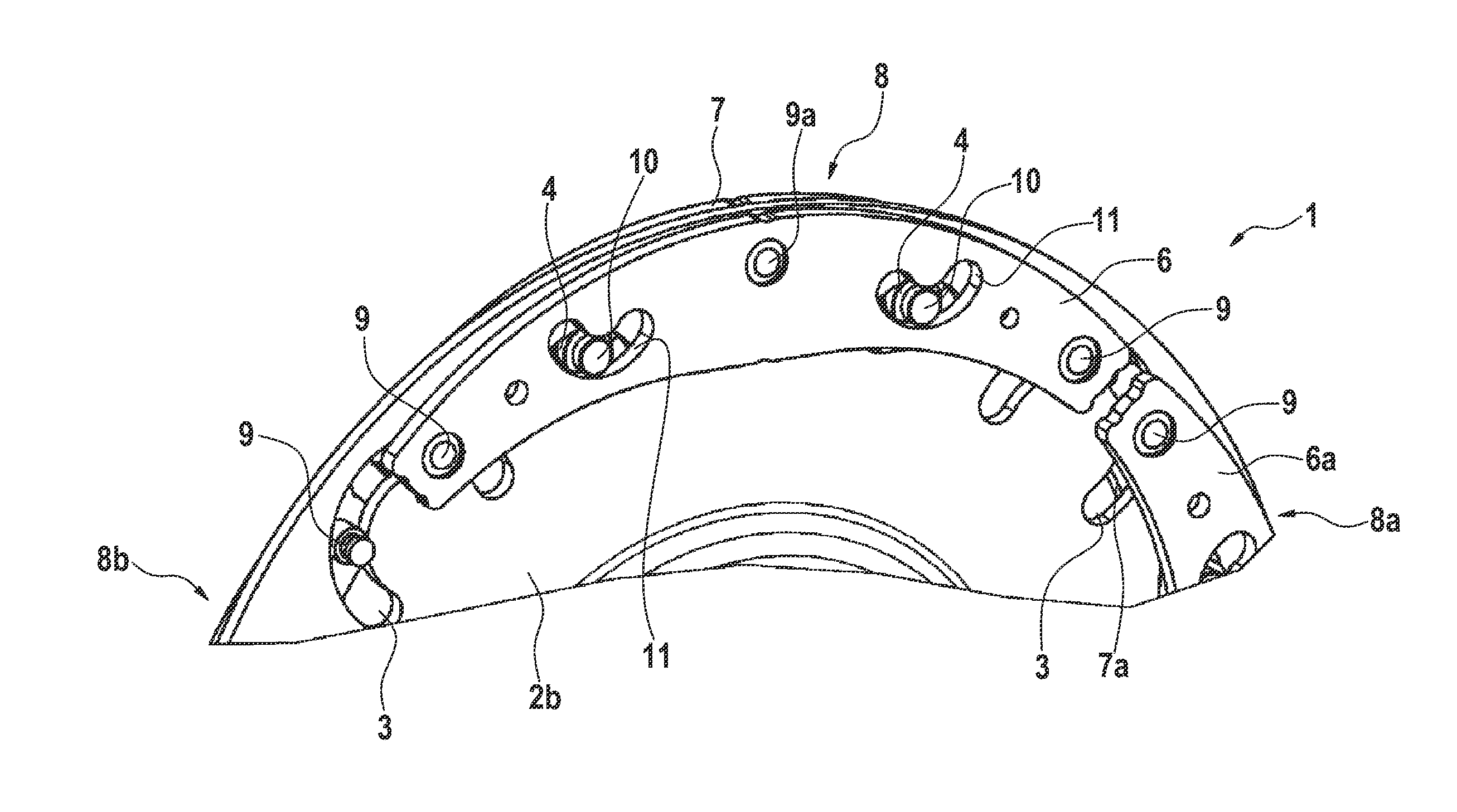

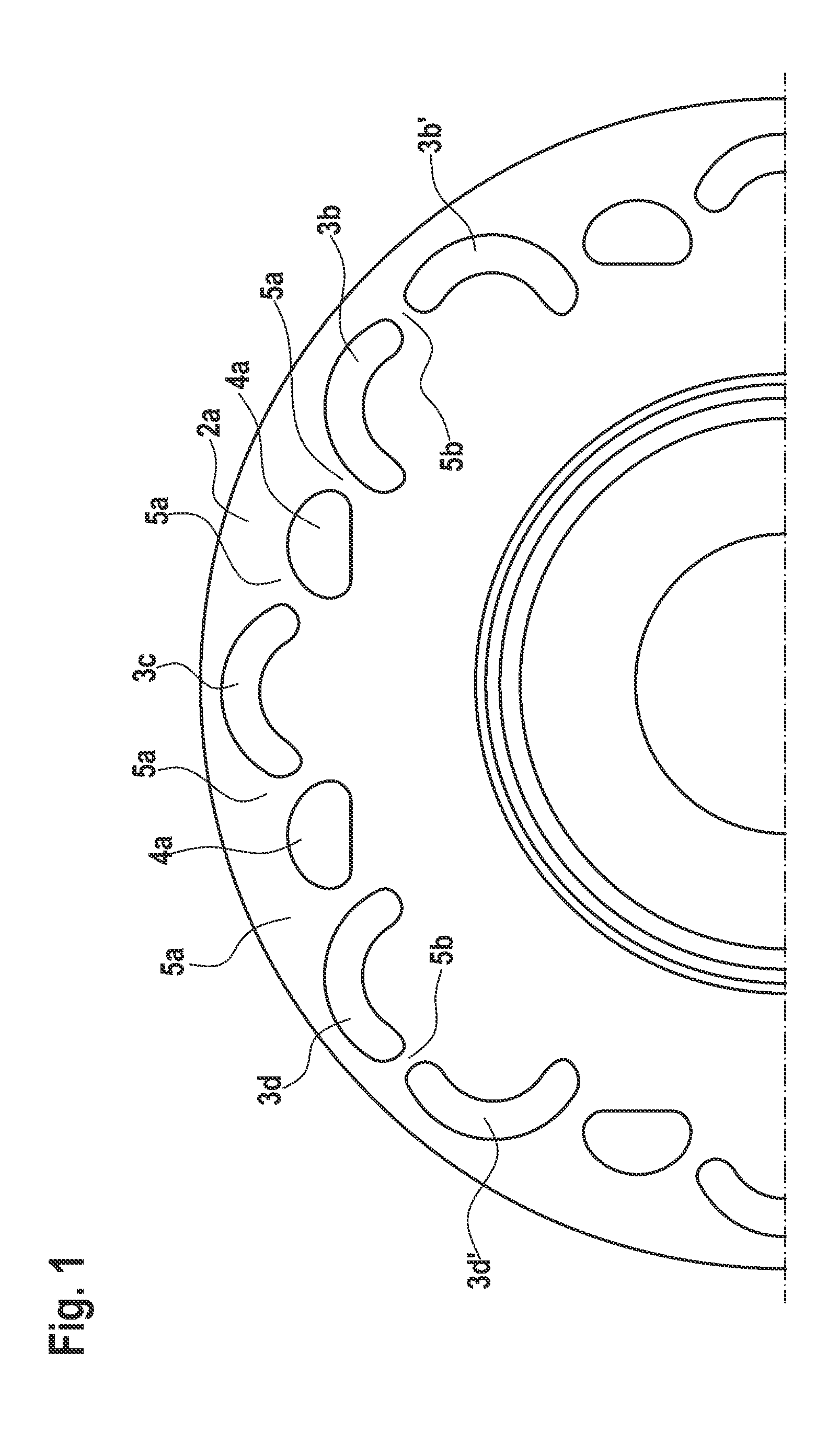

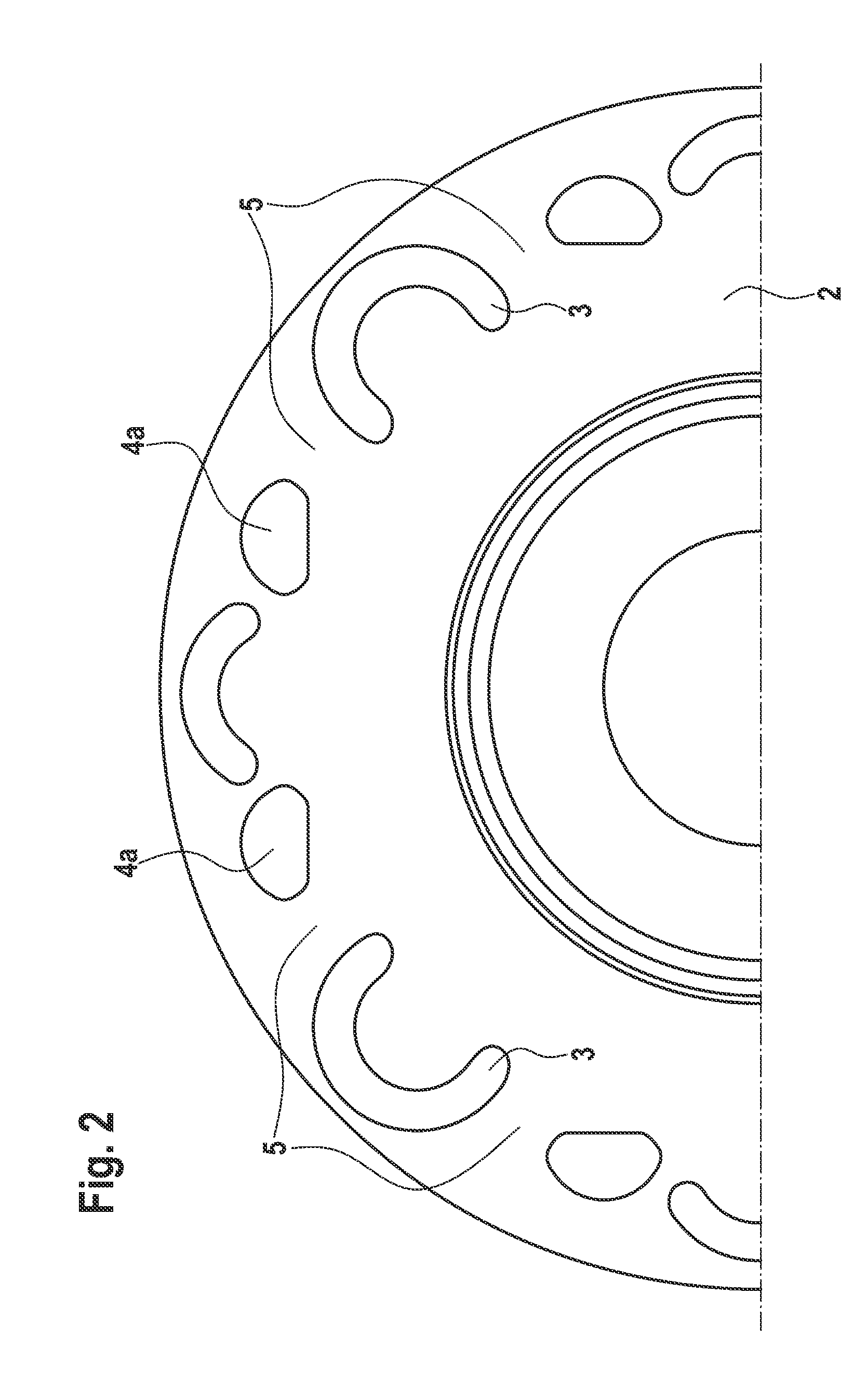

Centrifugal force pendulum

InactiveUS20120055281A1Increased oscillation angleFacilitates for comparable oscillation angles increased distancesRotating vibration suppressionRotational axisCentrifugal force

The invention relates to a centrifugal force pendulum (1), in particular for an arrangement in a drive train of a motor vehicle, comprising a pendulum flange (2) rotating about a rotational axis and a plurality of absorber masses (6) arranged on the flange over the circumference thereof, wherein in each case two absorber masses (6) located opposite of each other on the sides of the pendulum flange are connected to each other through webs (9), which each extend through an opening (3) in the pendulum flange so as to form absorber mass pairs (8). At the same time, cutouts (4) for receiving the absorber masses are provided in the pendulum flange. In order to achieve an optimization of the available circumference of the pendulum flange for accommodating the openings and cutouts, the adjoining webs of two adjoining absorber mass pairs are guided through a single opening.

Owner:SCHAEFFLER TECH AG & CO KG

Method for ultra-fast controlling of a magnetic cell and related devices

InactiveUS20070183190A1Stable and efficientIncrease dampingNanomagnetismOne-port networksResonatorAcoustic wave

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Screening panel and method of fixing

ActiveUS9610614B2Increase the gapEnhanced oscillationSievingScreeningEngineeringMechanical engineering

Owner:LETTELA PTY LTD

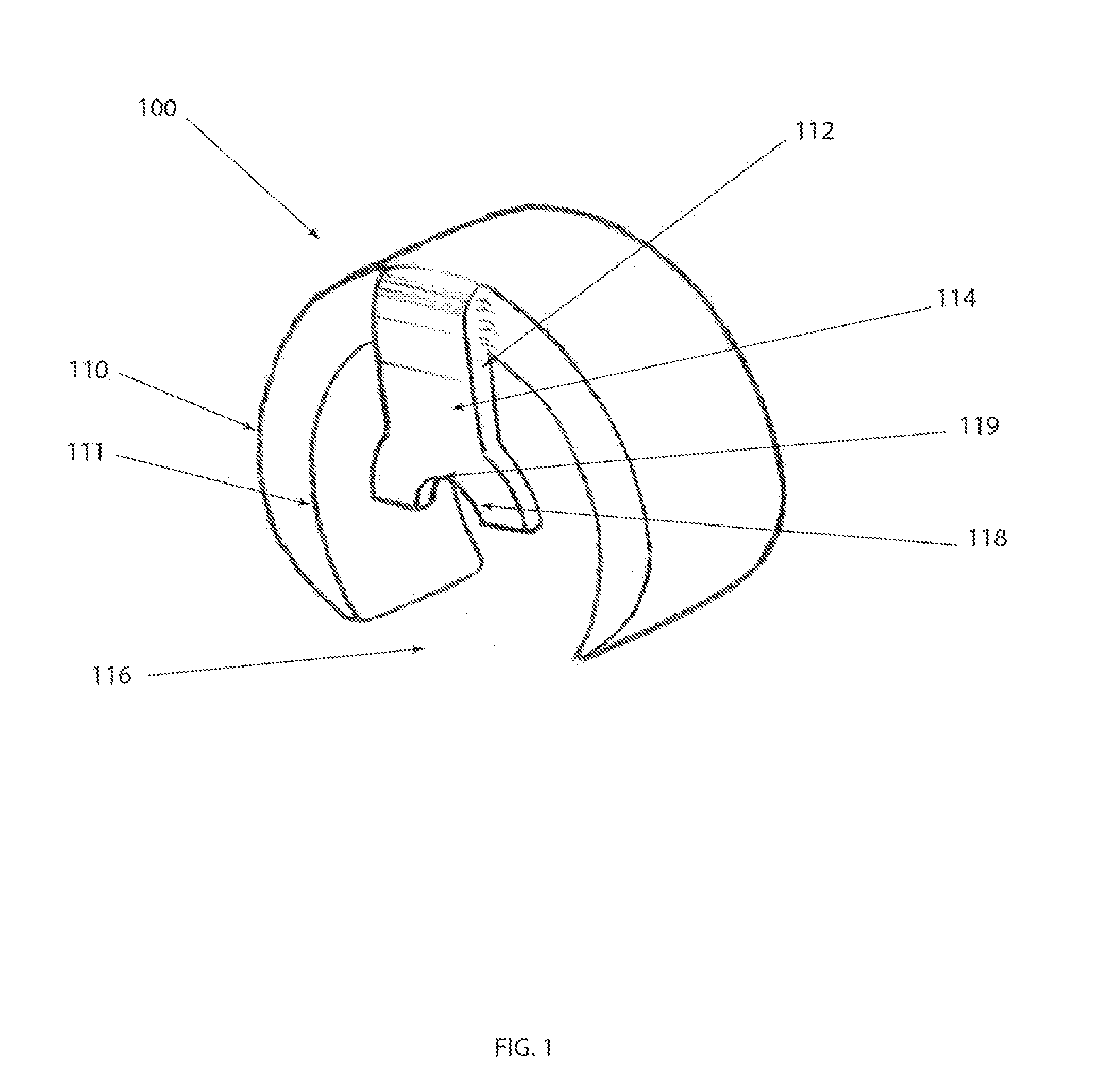

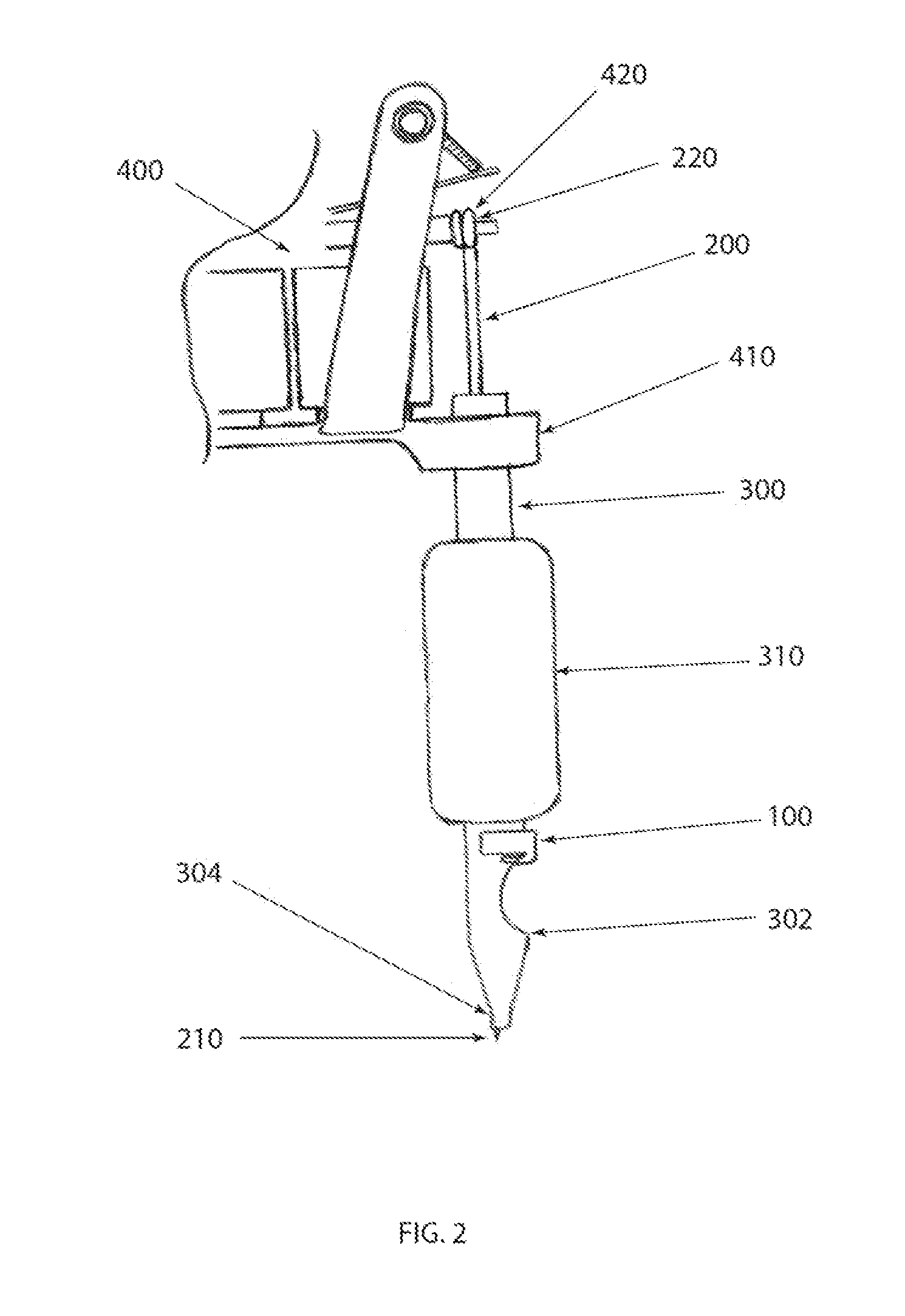

Tattoo needle stabilization device and method of use

InactiveUS20120192681A1Avoid excessive wearStay in shapeMedical devicesInk reservoir pensTattoo needleBiomedical engineering

The present invention relates generally to a tattoo needle stabilization device. More specifically, this disclosure relates to a device that is inserted through the sanitary cutout and engages the shaft of a tattoo needle near the point, biasing the point of the needle against the inside of the tip aperture and stabilizing the needle.

Owner:KLEBS DAVID +1

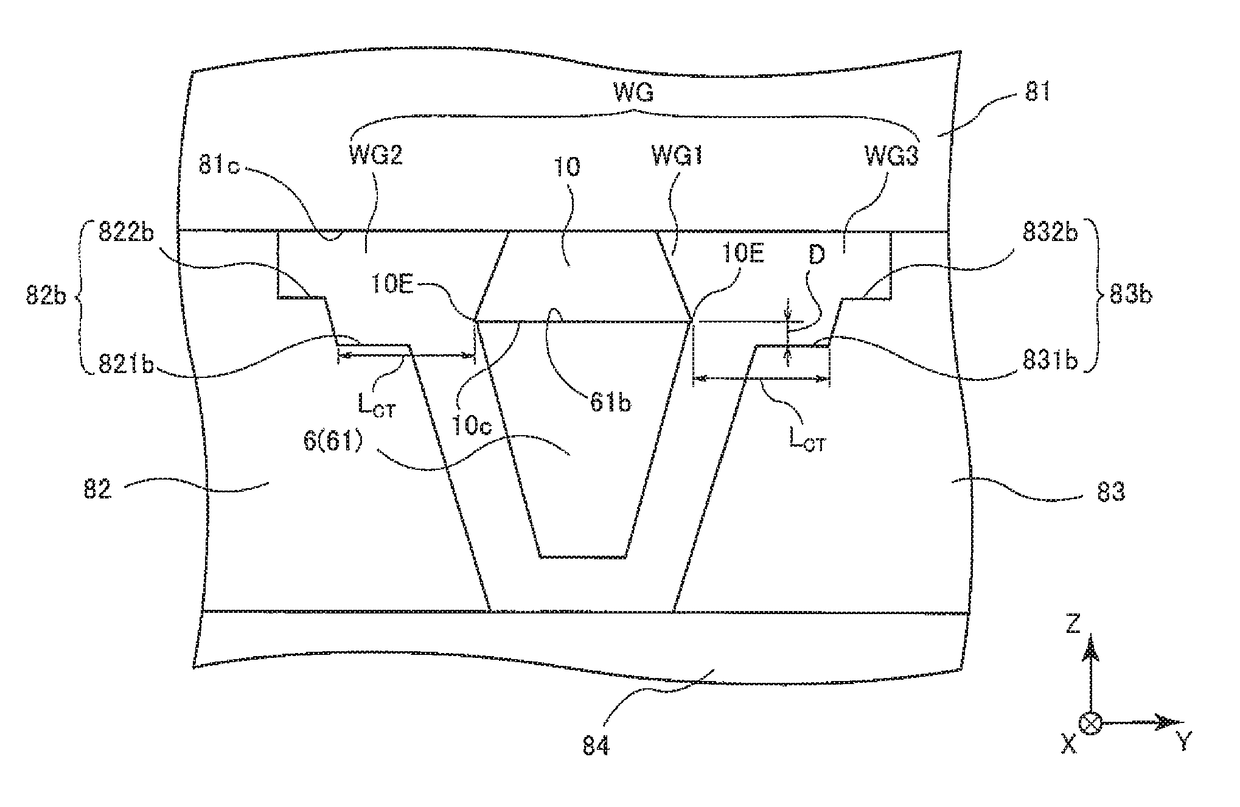

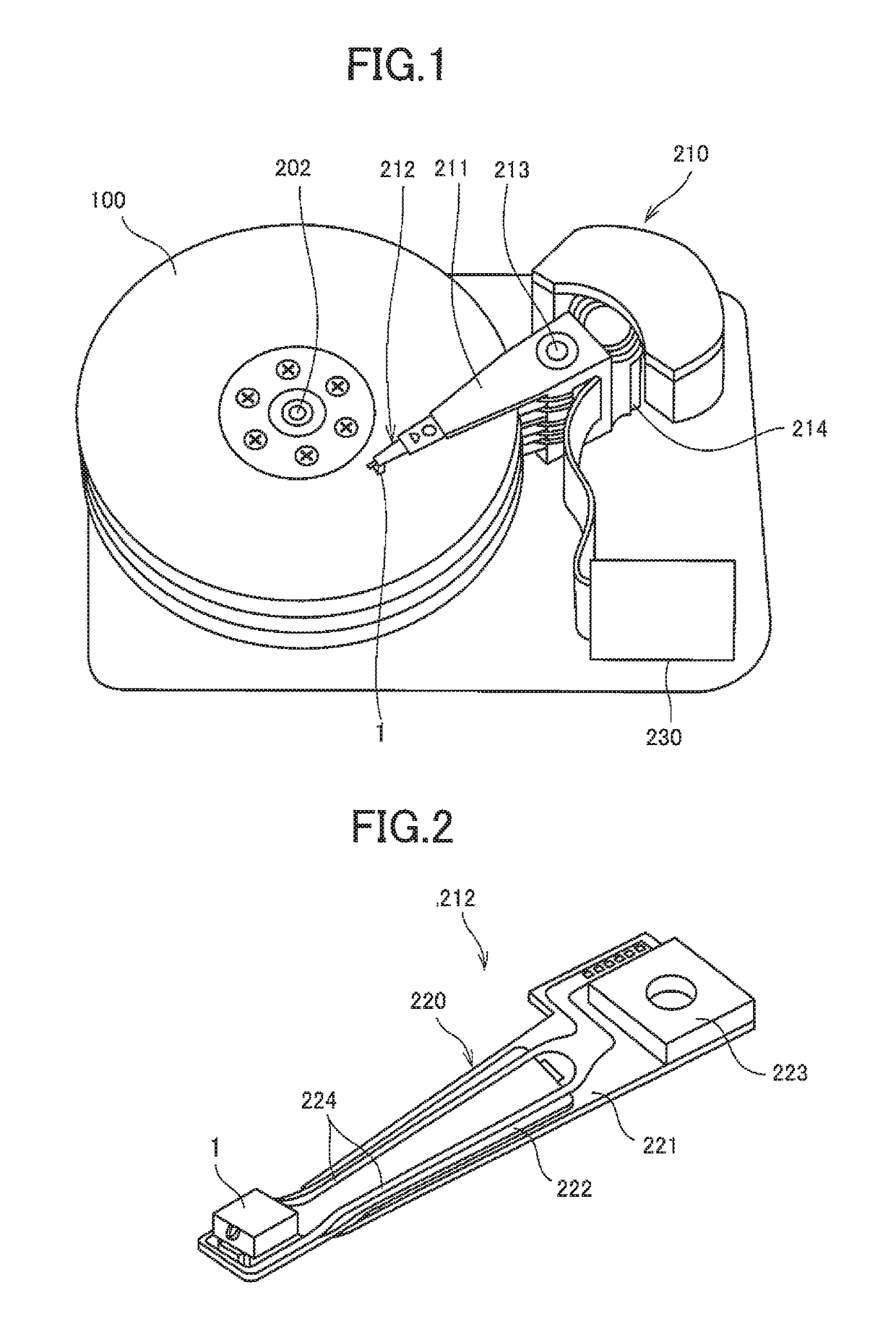

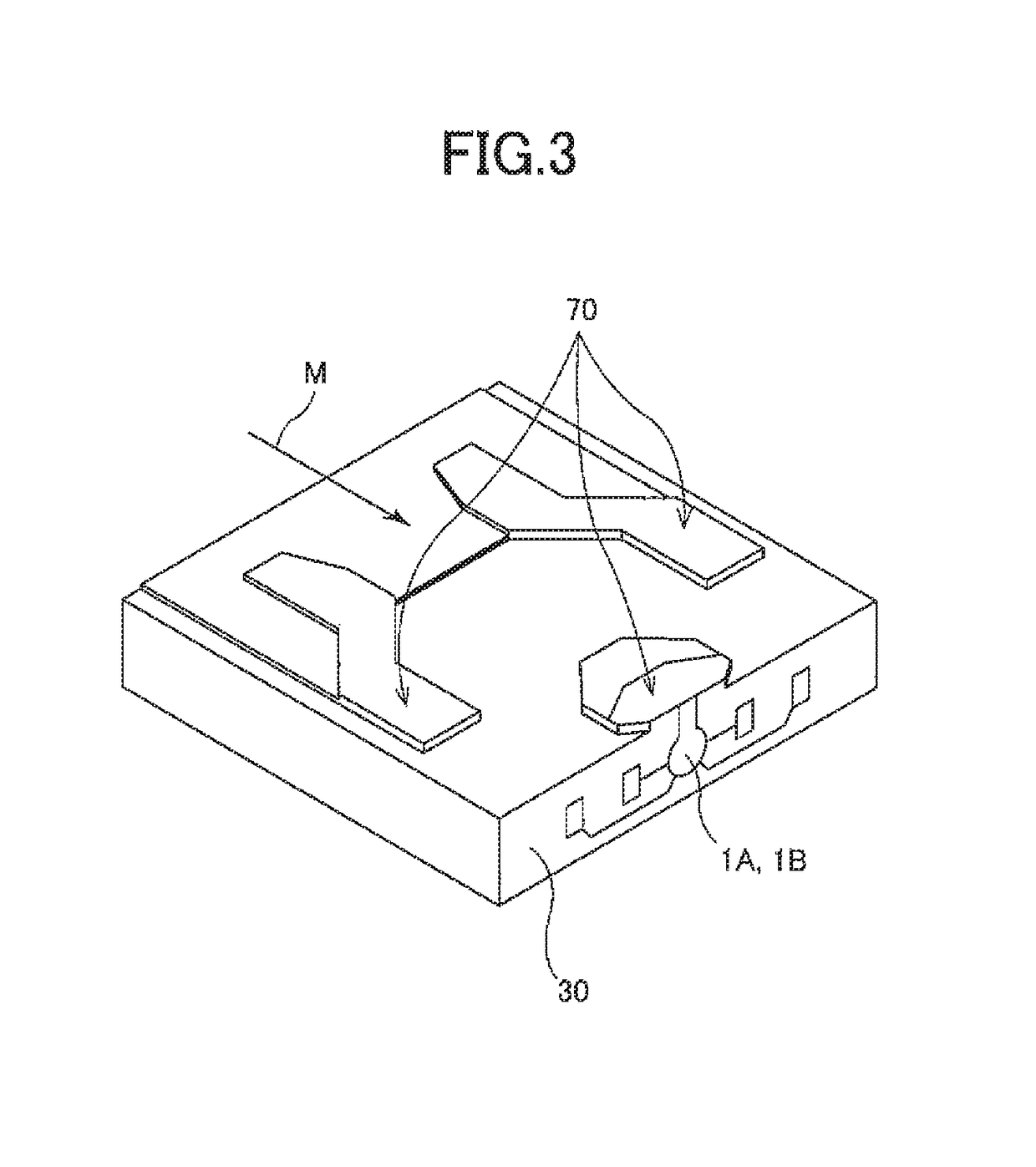

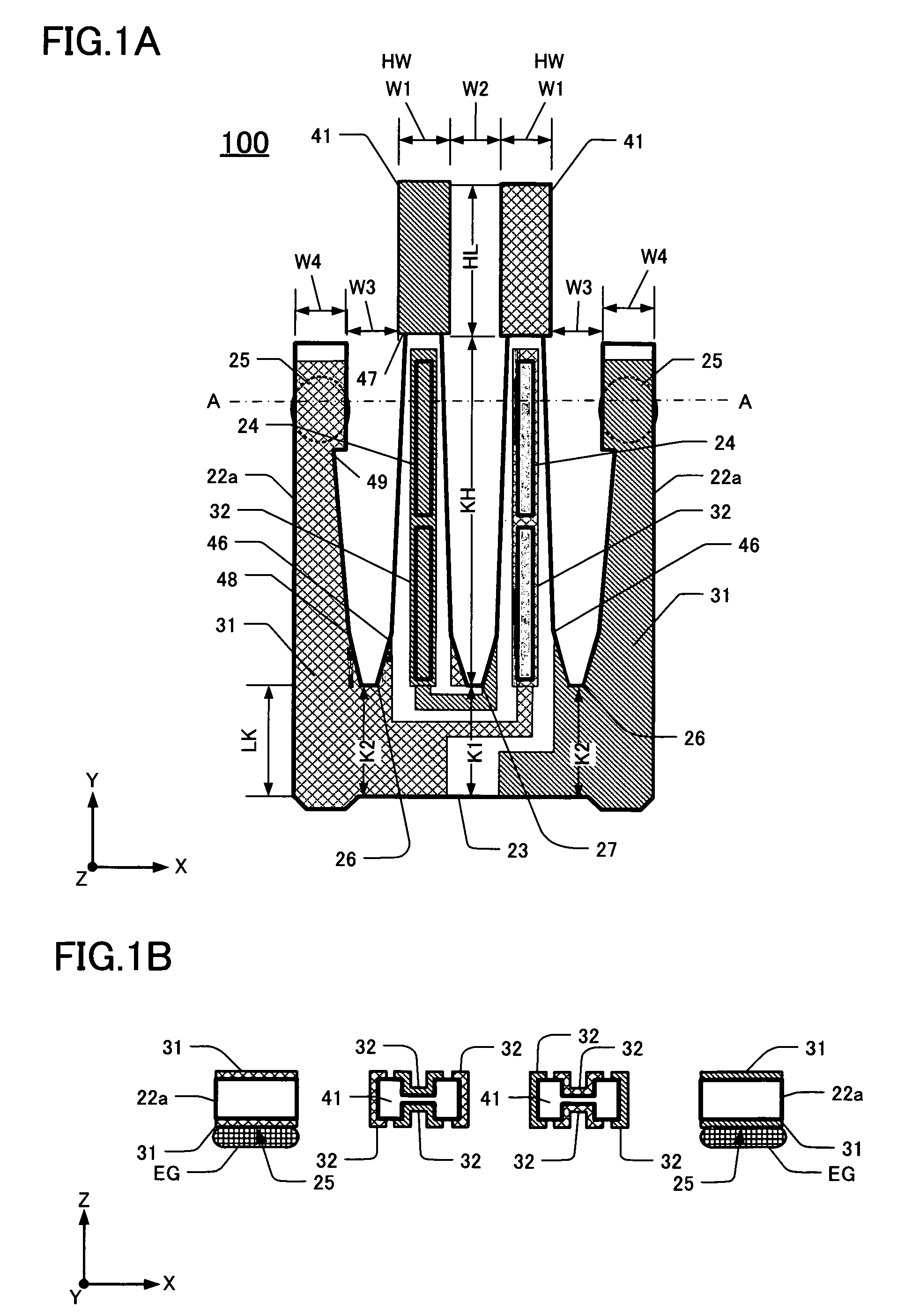

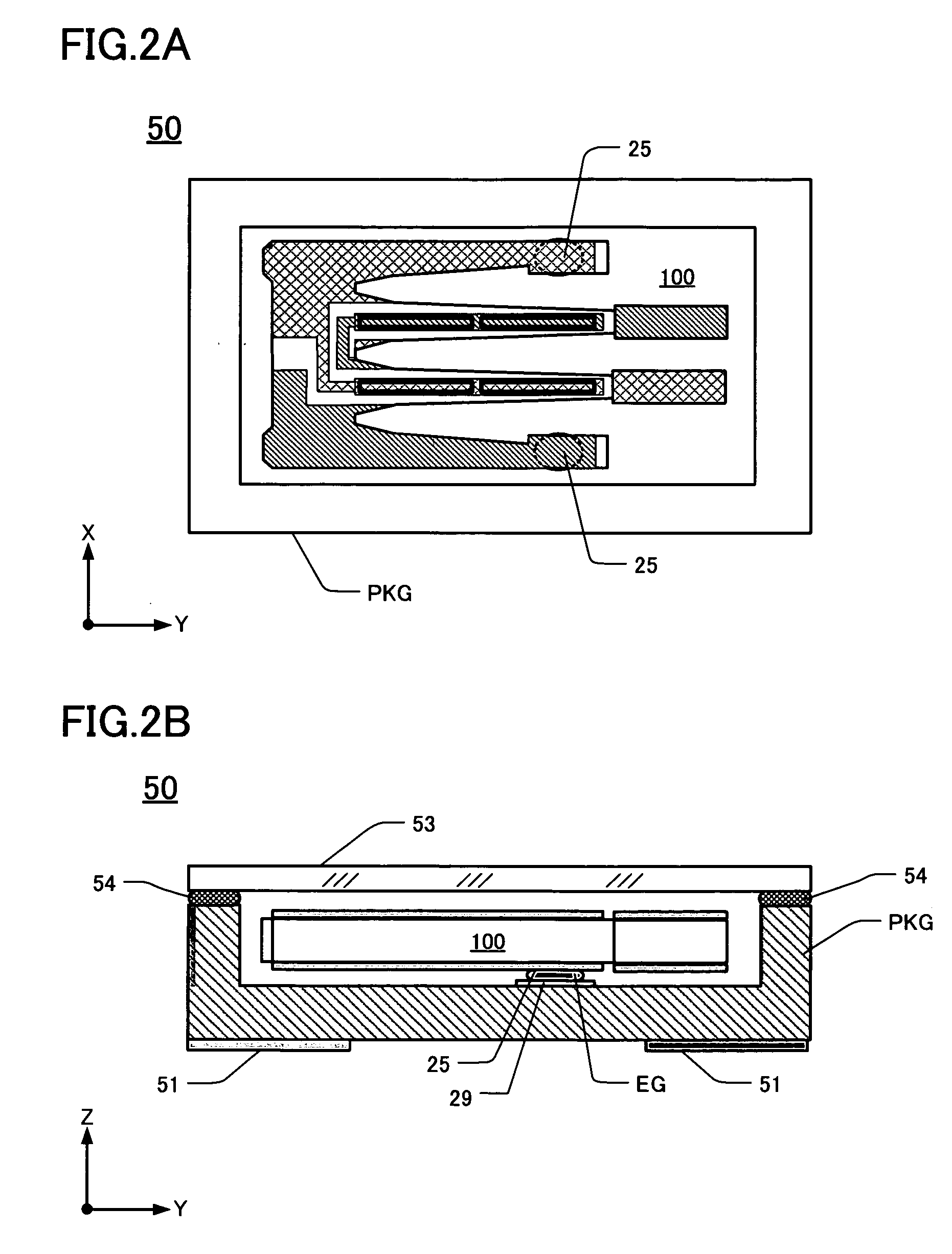

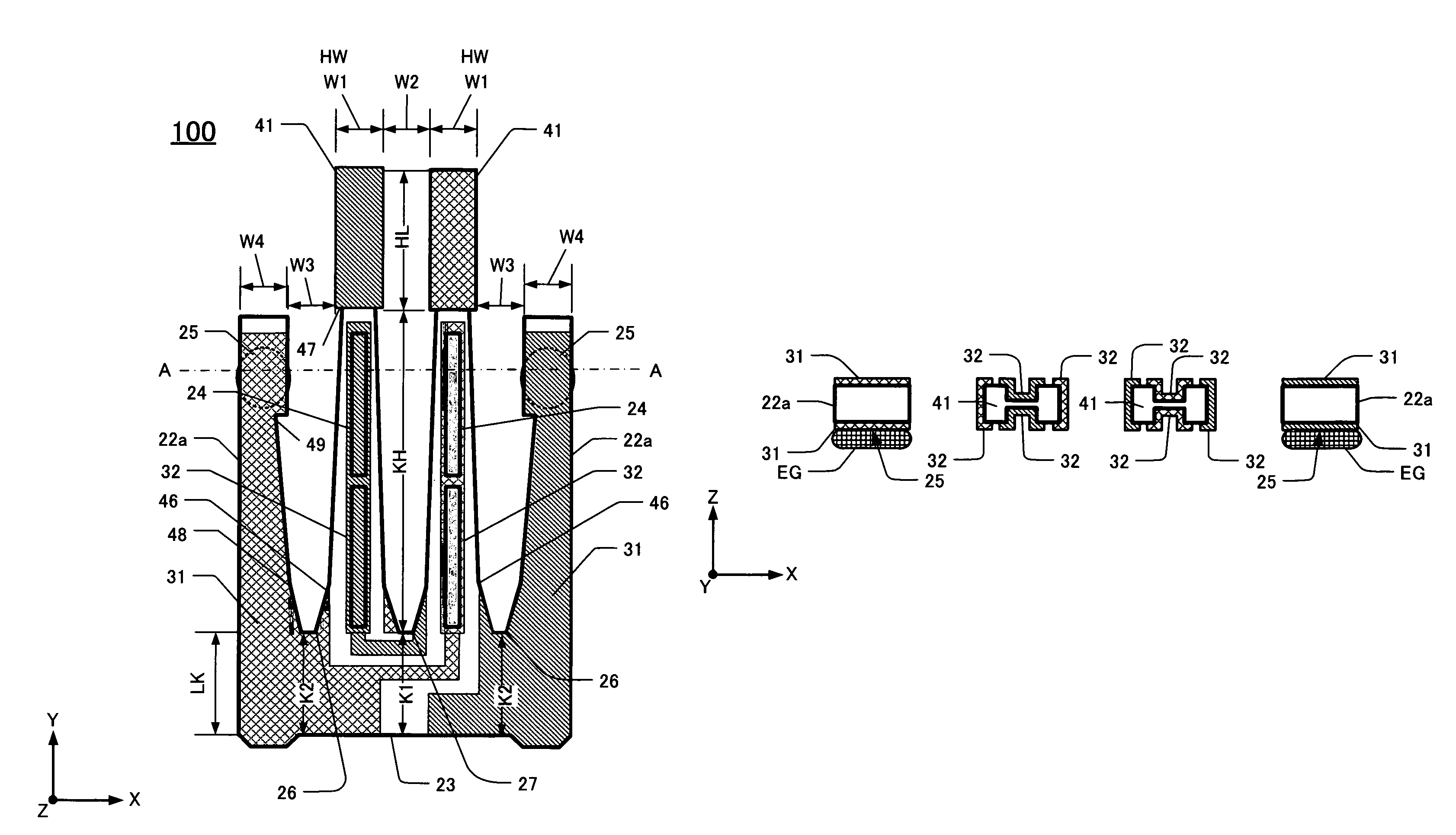

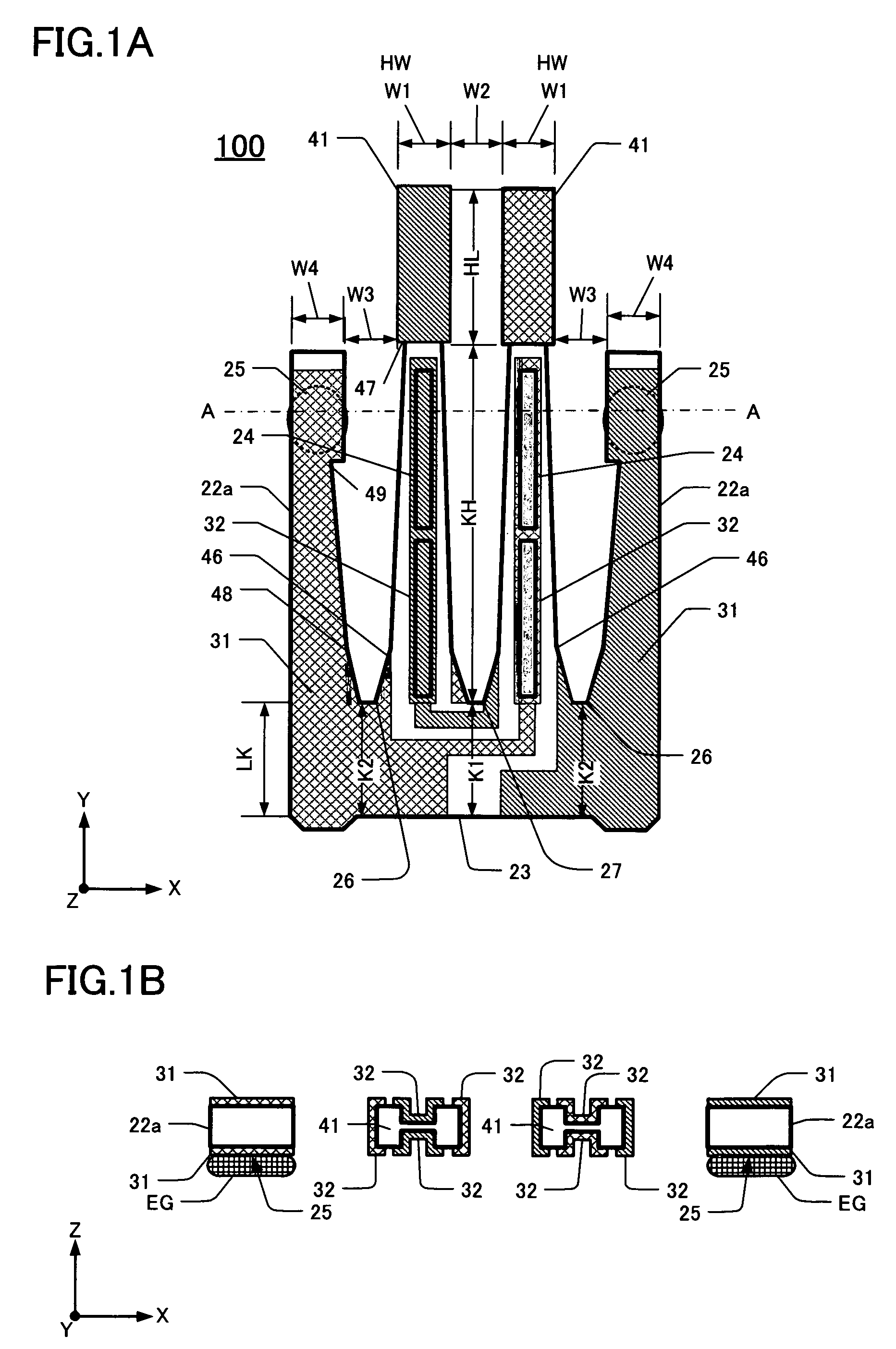

Magnetic recording head with spin torque oscillator, head gimbal assembly and magnetic recording apparatus

ActiveUS10109302B1Enhanced oscillationHeads using thin filmsRecord information storageSpin torque oscillatorsMagnetic poles

A magnetic recording head is provided with a main magnetic pole that generates a recording magnetic field to be applied to a magnetic recording medium from an end surface which makes a portion of an air bearing surface, a trailing shield that is placed by interposing a write gap at a trailing side of the main magnetic pole, a spin torque oscillator that is placed within the write gap to be between the main magnetic pole and the trailing shield, and two side shields that are placed at both sides of the main magnetic pole in the cross track direction, and when viewed from the air bearing surface side, at least a portion of the trailing-side end surfaces of the side shields are offset toward a leading-side of the main magnetic pole from the leading-side end surface of the spin torque oscillator.

Owner:TDK CORPARATION

Liquid ejection head and image forming apparatus

InactiveUS7471028B2Easy to controlIncrease volumePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesAcoustic waveSurface acoustic wave

The liquid ejection head has: a surface acoustic wave propagation body in which a surface acoustic wave propagates; a nozzle orifice formed in the surface acoustic wave propagation body; a surface acoustic wave generation device which is provided on the surface acoustic wave propagation body around the nozzle orifice and excites the surface acoustic wave propagation body so that a surface acoustic wave is generated in the surface acoustic wave propagation body; a liquid supply device which supplies liquid to the nozzle orifice; and a guide member which is provided in a center of the nozzle orifice and has a tapered conical surface shape section that projects from an ejection surface of the nozzle orifice in an ejection direction, the liquid forming a curved liquid surface in the nozzle orifice in accordance with the tapered conical surface shape section due to surface tension, wherein the surface acoustic wave generates a capillary wave which propagates through the curved liquid surface in the nozzle orifice and which ejects the liquid from an apex section of the tapered conical surface shape section.

Owner:FUJIFILM CORP

Method for operating a wind turbine

The invention relates to a method for operating at least a first wind turbine including the steps of: recording a tower oscillation, initiating a measure to reduce oscillation if the tower oscillation is or contains a longitudinal oscillation, and if the amplitude of the longitudinal oscillation exceeds a predefined threshold value, and the measure for reducing the oscillation comprises freezing the current pitch angle at the current value for a predefined freezing period, switching the pitch control algorithm used, in particular in such a way that the control speed is reduced, adjusting the yaw position by a predefined yaw angle, switching the operation of the first wind turbine from a first operating mode based on a first power curve to a second operating mode based on a second power curve, and / or if, with regard to the current wind direction, the first wind turbine in a wind park is located behind a second wind turbine, adjusting the rotational speed of the first wind turbine to the rotational speed of the second wind turbine in such a way that the rotational speed of the first wind turbine differs from the rotational speed of the second wind turbine by at least a predefined differential rotational speed.

Owner:WOBBEN PROPERTIES GMBH

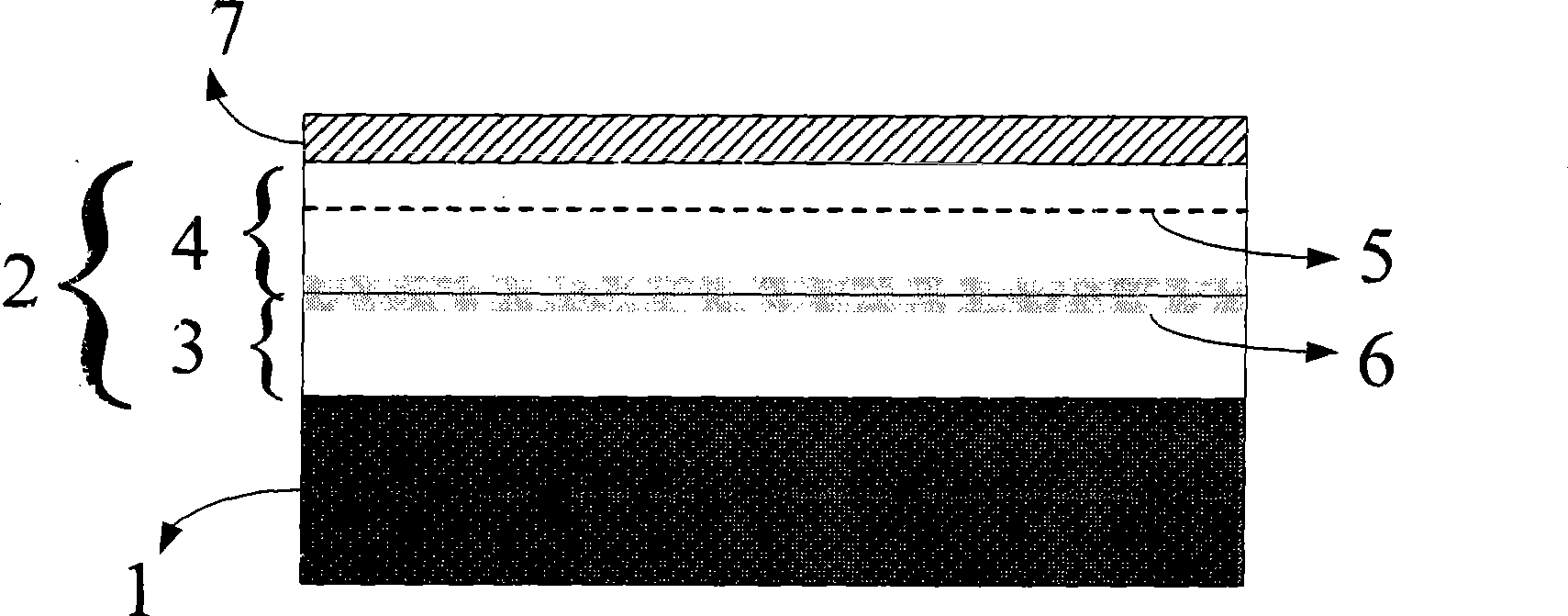

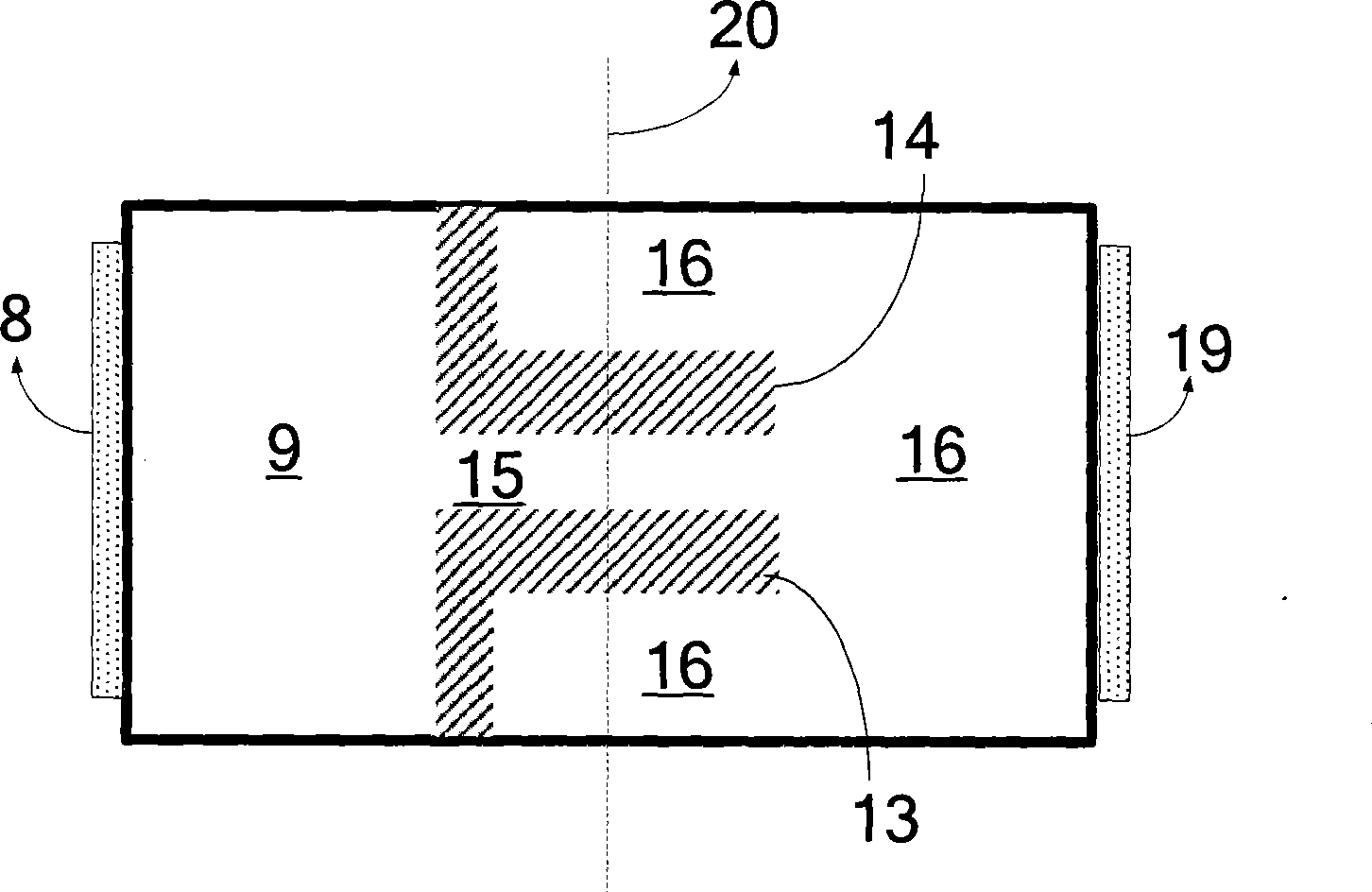

Plane nano electromagnetic radiator structure based on negative differential mobility

InactiveCN101431106AImprove fullyEnhanced oscillationMaterial analysis using wave/particle radiationSolid-state devicesElectrical resistance and conductanceHigh resistance

The invention discloses a plane nanometer electromagnetic radiation device structure based on negative differential mobility, the plane nanometer electromagnetic radiation device structure sequentially comprises an insulating underlay, an active layer and an insulating protective layer from bottom to top, wherein the active layer has negative differential mobility; both sides of the active layer are respectively provided with side electrodes; the active layer comprises low resistance areas and a high resistance area, the low resistance areas are positioned on the left and right ends of the active layer, and the high resistance area is positioned on the middle of the active layer and the distribution of electric field strength is not uniform; and the two low resistance areas are communicated through the high resistance area. The plane nanometer electromagnetic radiation device structure has the advantages of simple technology, easy integration, high power, good thermal property, and the like.

Owner:SUN YAT SEN UNIV

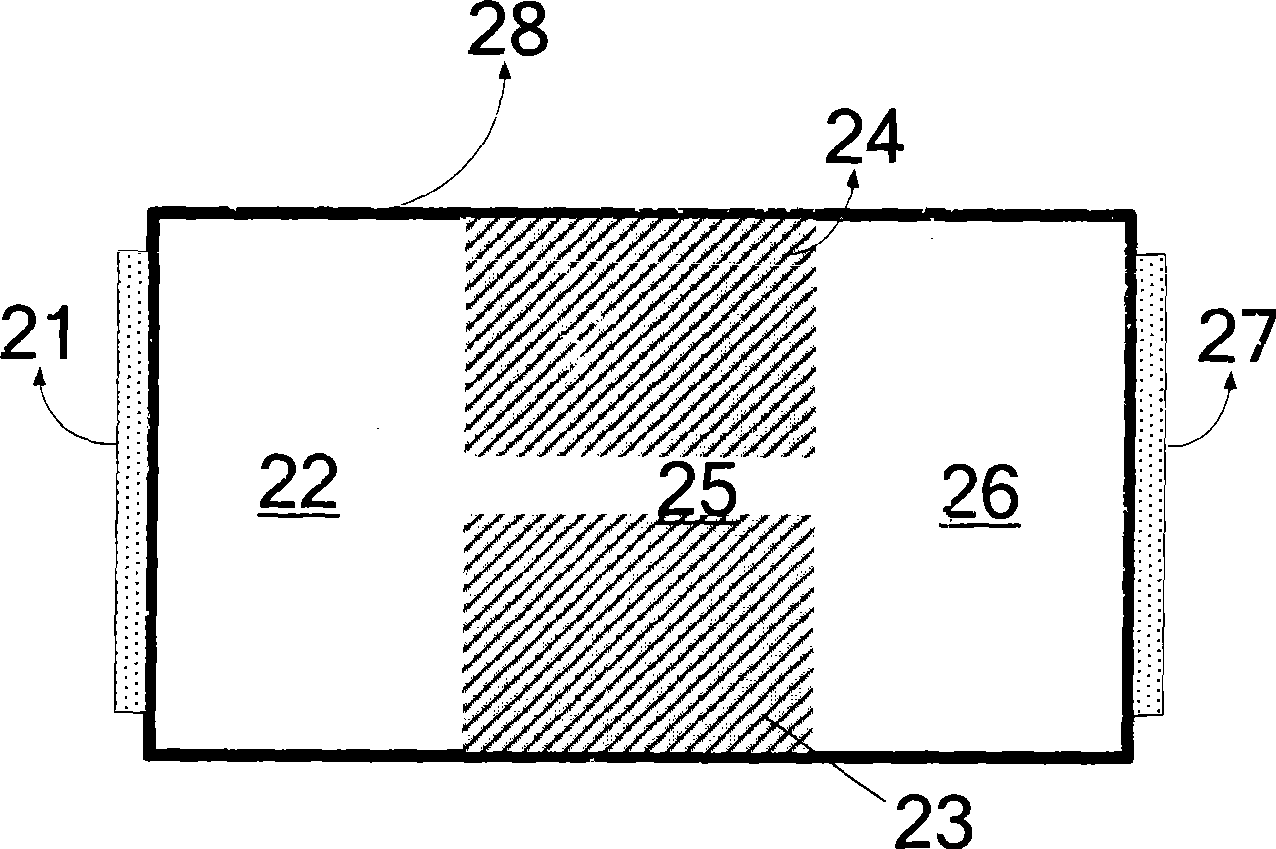

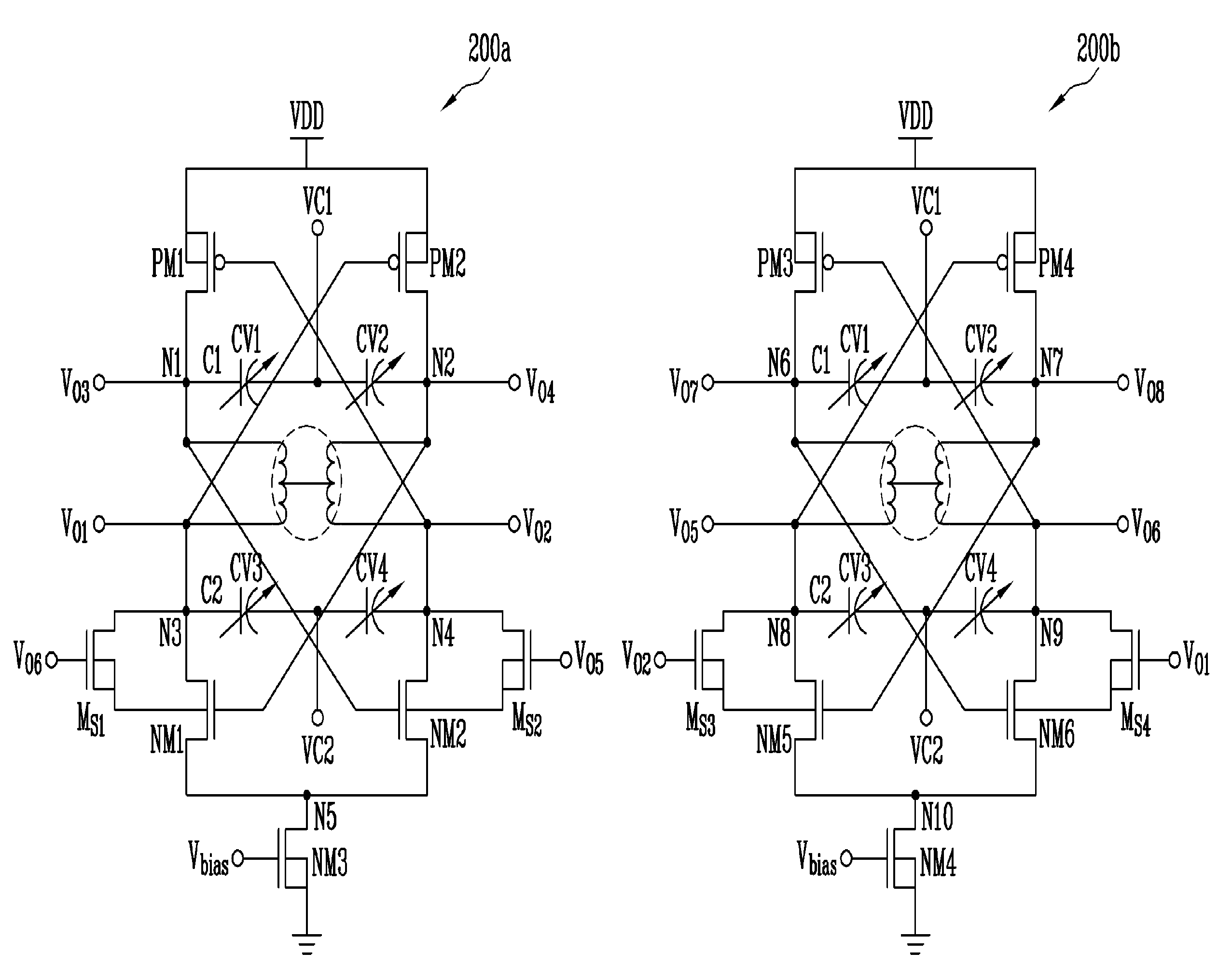

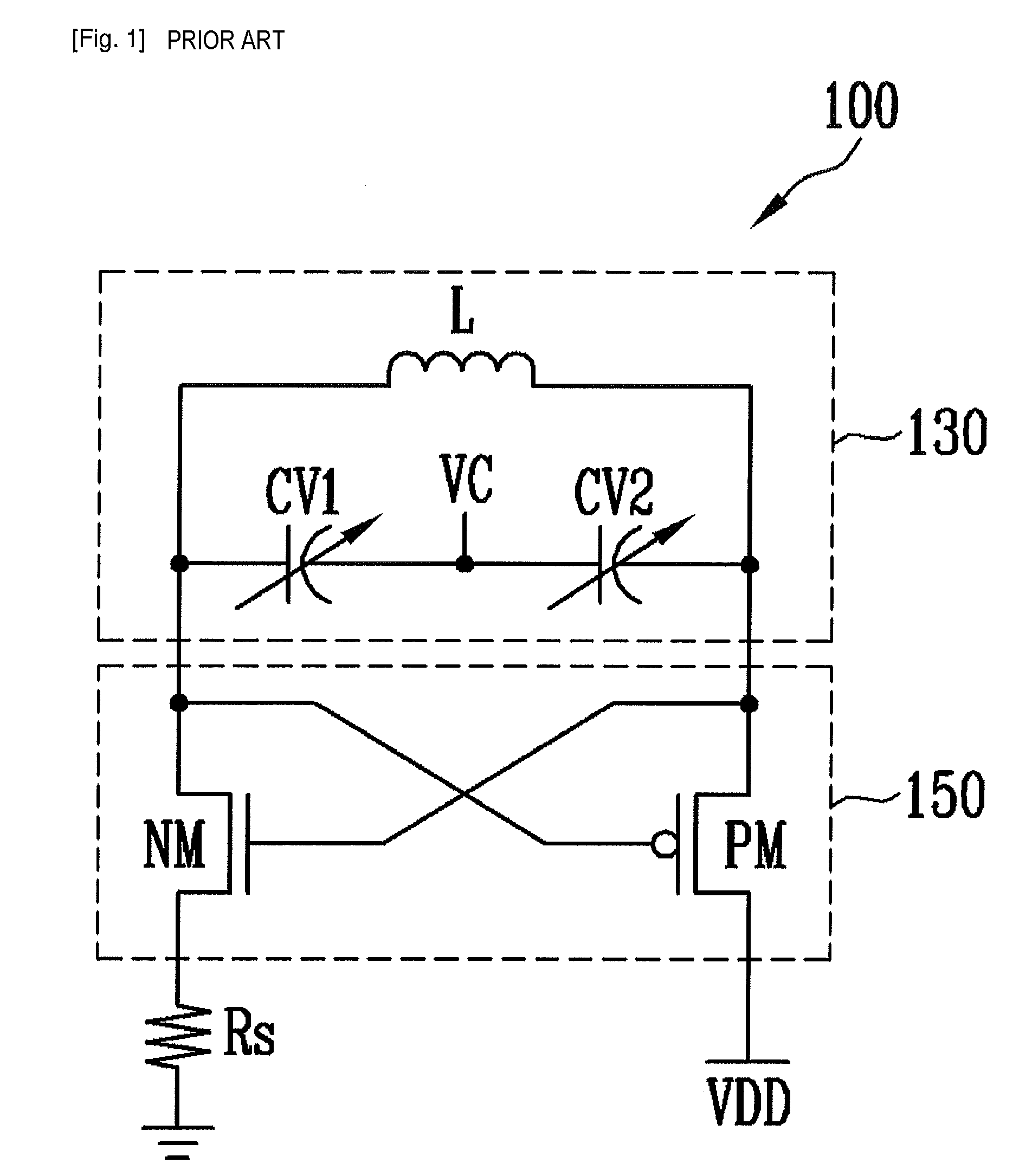

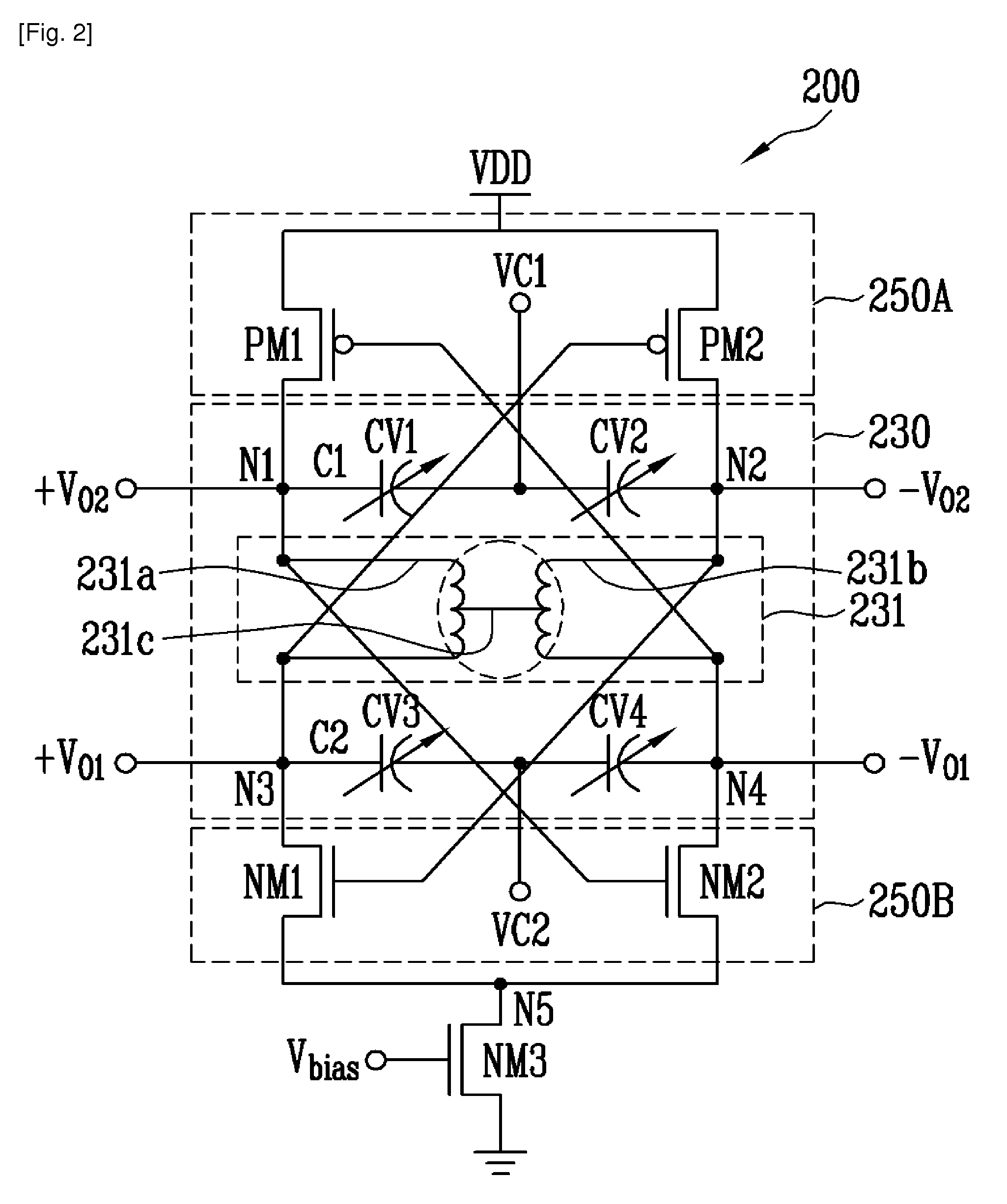

Differential VCO and quadrature VCO using center-tapped cross-coupling of transformer

InactiveUS8212625B2Improve phase noiseEnhanced oscillationAngle modulation by variable impedencePulse generation by logic circuitsCapacitanceLinear control

Provided are a differential voltage-controlled oscillator (VCO) and a quadrature VCO using center-tapped cross-coupling of a transformer. The differential VCO and the quadrature VCO can be driven by low power through a current reuse structure and have an excellent phase noise characteristic by center-tapped cross-coupling through a transformer. Further, variable capacitance units for frequency variation are divided into variable capacitance units for coarse tuning and variable capacitance units for fine tuning. Therefore, it is possible to obtain a wide tuning range while voltage oscillation gain is reduced. Further, the differential VCO and the quadrature VCO are configured in such a manner that the respective variable capacitance units operate linearly throughout the entire capacitance region due to control voltage distribution by resistors. Accordingly, it is possible to obtain a linear control voltage-oscillation frequency characteristic. The quadrature VCO according to the present invention can output four-phase quadrature signals while having an excellent phase noise characteristic, without substrate loss and current consumption caused by the switching transistors.

Owner:ELECTRONICS & TELECOMM RES INST

Electric arc ion plating apparatus

InactiveCN102758186ASolving Deposited Thin FilmsSolve the technical problems of coatingVacuum evaporation coatingSputtering coatingVacuum chamberLarge particle

The invention relates to the field of film and coating preparation, and relates to an electric arc ion plating apparatus which is used for depositing a film or a coating on the inner surface of a long pipe or on the inner wall of a deep-hole device. The electric arc ion plating apparatus comprises three sets of magnetic field generation apparatuses. A first magnetic field generation apparatus used for beaming a metal ion flow emitted by a cathode target is arranged outside a vacuum chamber at a position corresponding to the back of the cathode target. A second magnetic field generation apparatus used for beaming the metal ion flow is arranged between the cathode target and a workpiece in the vacuum chamber. A third magnetic field generation apparatus used for diffusing the beamed metal ion flow and for making the metal ions move with a high speed towards the inner surface of the long pipe or the inner wall of the deep-hole device is arranged on the periphery of the workpiece in the vacuum chamber. The electric arc ion plating apparatus also comprises a pulse bias power supply used for further accelerating the metal ions moving towards the inner surface of the long pipe or the inner wall of the deep-hole device. With the apparatus provided by the invention, a technical problem for depositing a film or a coating on the inner surface of the long pipe or the inner wall of the deep-hole device is solved. Film or coating uniformity and quality are ensured, and the content of large particles in the deposited film or coating is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Piezoelectric vibrating pieces and piezoelectric devices comprising same

InactiveUS20100079036A1Prevent increases in CIReduce leakagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesTuning forkEngineering

Owner:NIHON DEMPA KOGYO CO LTD

Piezoelectric vibrating devices having bisymmetric vibrating arms and supporting arms, and devices comprising same

InactiveUS8174171B2Prevent increases in CIReduce leakagePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringFork tuning

Owner:NIHON DEMPA KOGYO CO LTD

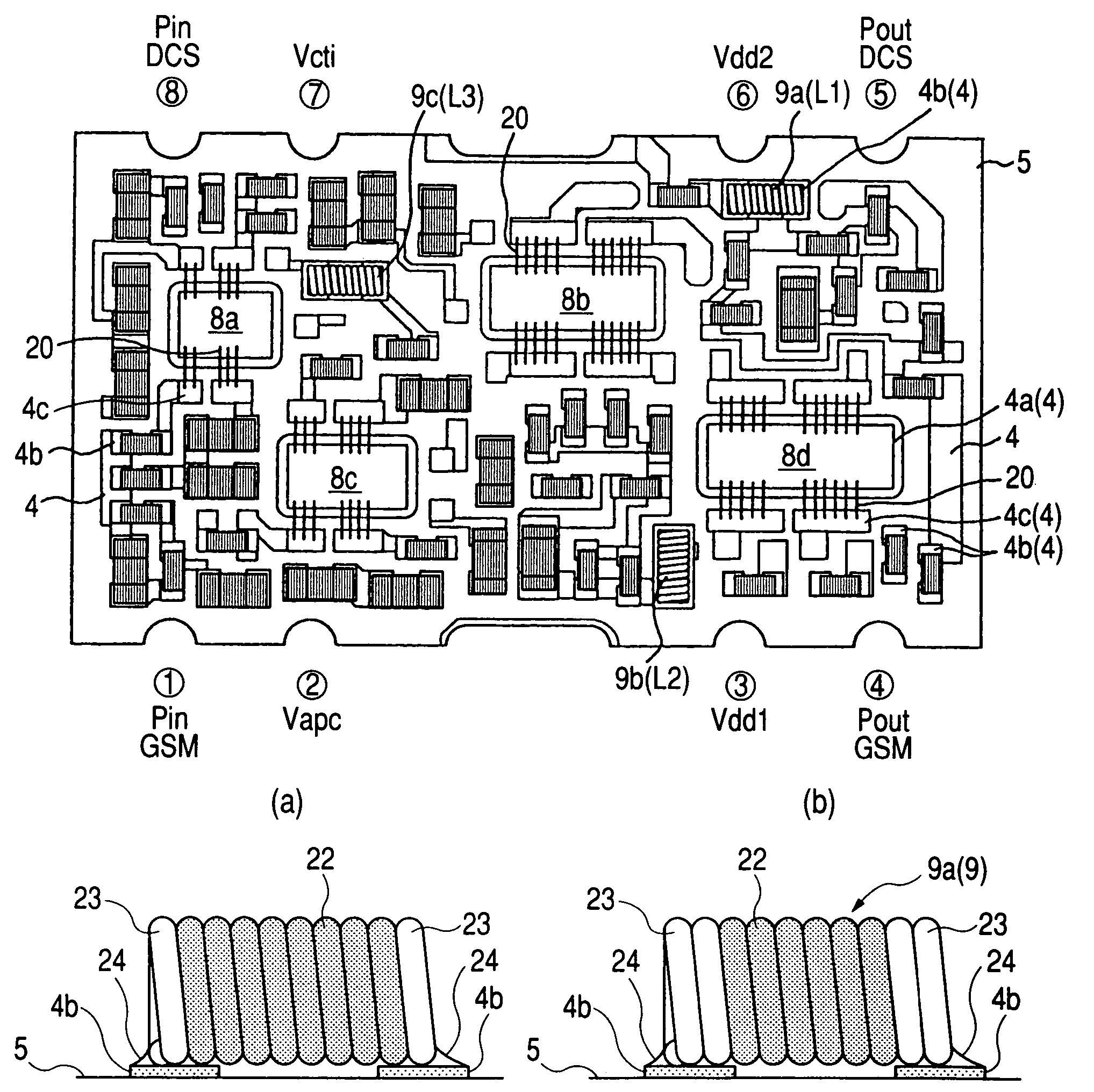

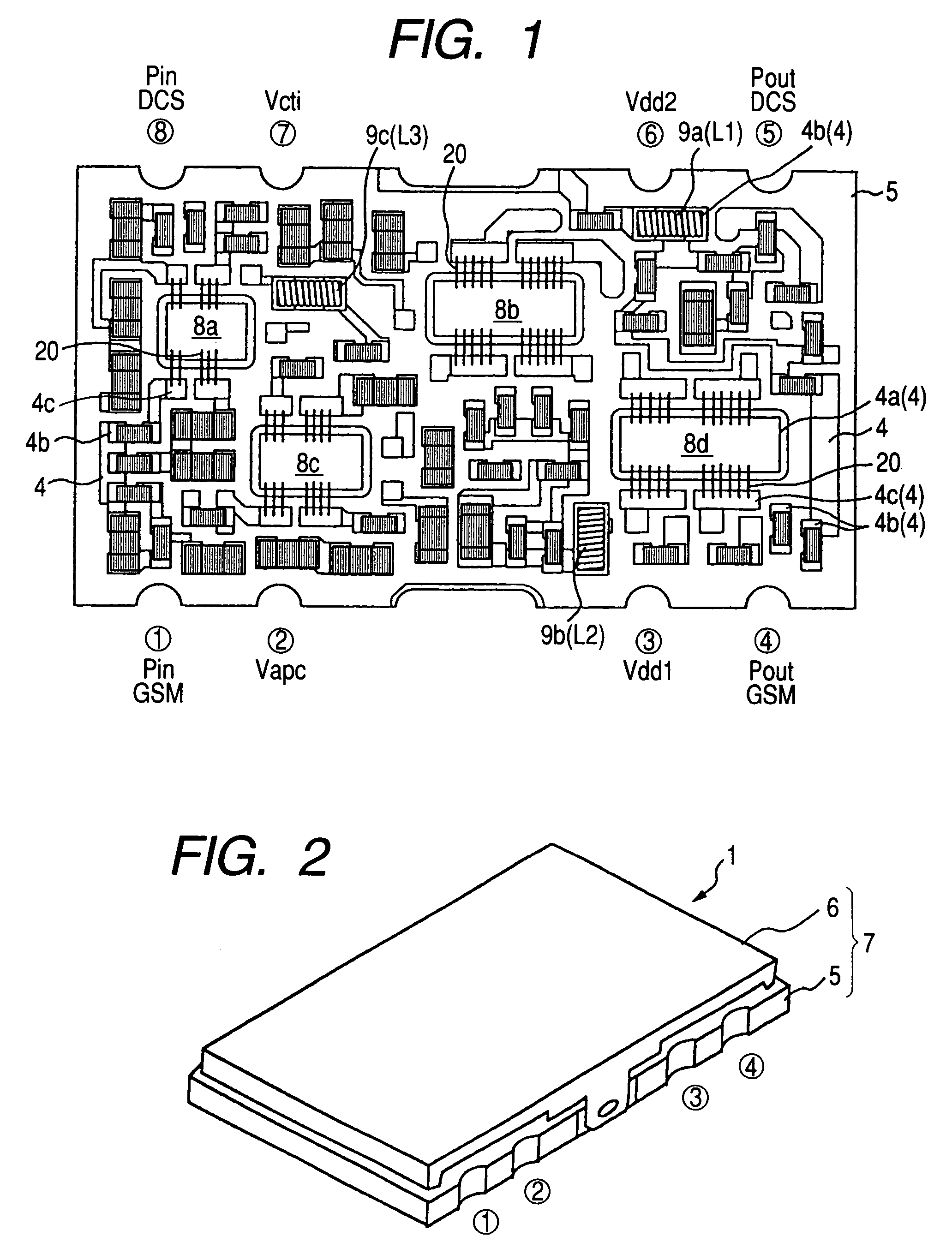

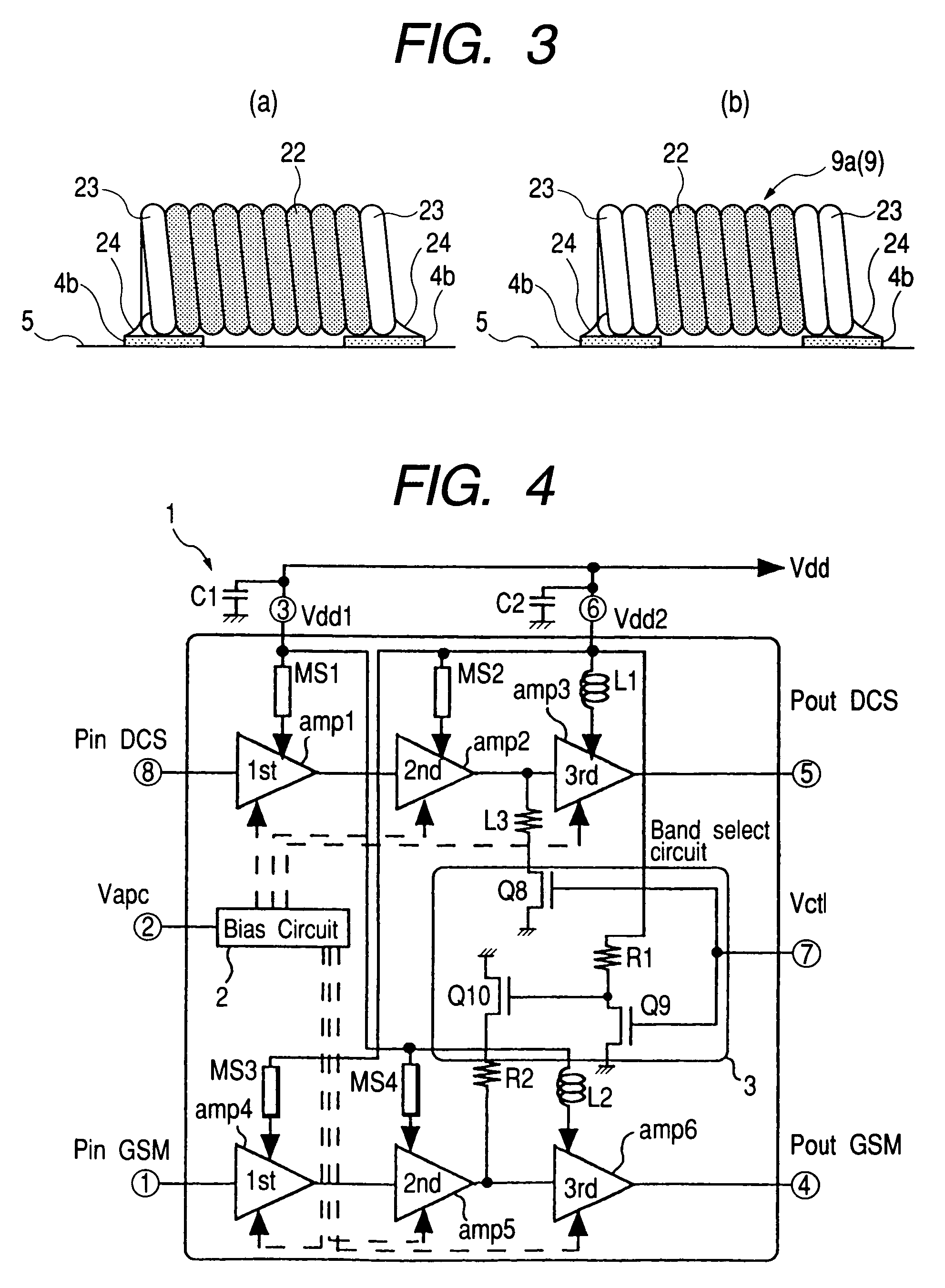

Semiconductor device, and method and apparatus for manufacturing semiconductor device

InactiveUS7262480B2Improve package yieldAccurate and secure packagingFinal product manufactureGated amplifiersHigh frequency powerCopper wire

A high frequency power amplifying device has two amplifying lines. Each amplifying line has a configuration in which a plurality of amplifying stages are connected in cascade having two source voltage terminals, of which one is connected to the first amplifying stage of one amplifying line and to the remaining amplifying stages of the other amplifying line, and the other, to the first amplifying stage of the latter amplifying line and to the remaining amplifying stages of the former amplifying line. An air core coil with a low D.C. resistance, formed by spirally winding a copper wire of about 0.1 mm in diameter, is connected in series between the final amplifying stage of each amplifying line and the source voltage terminal.

Owner:HITACHI LTD +2

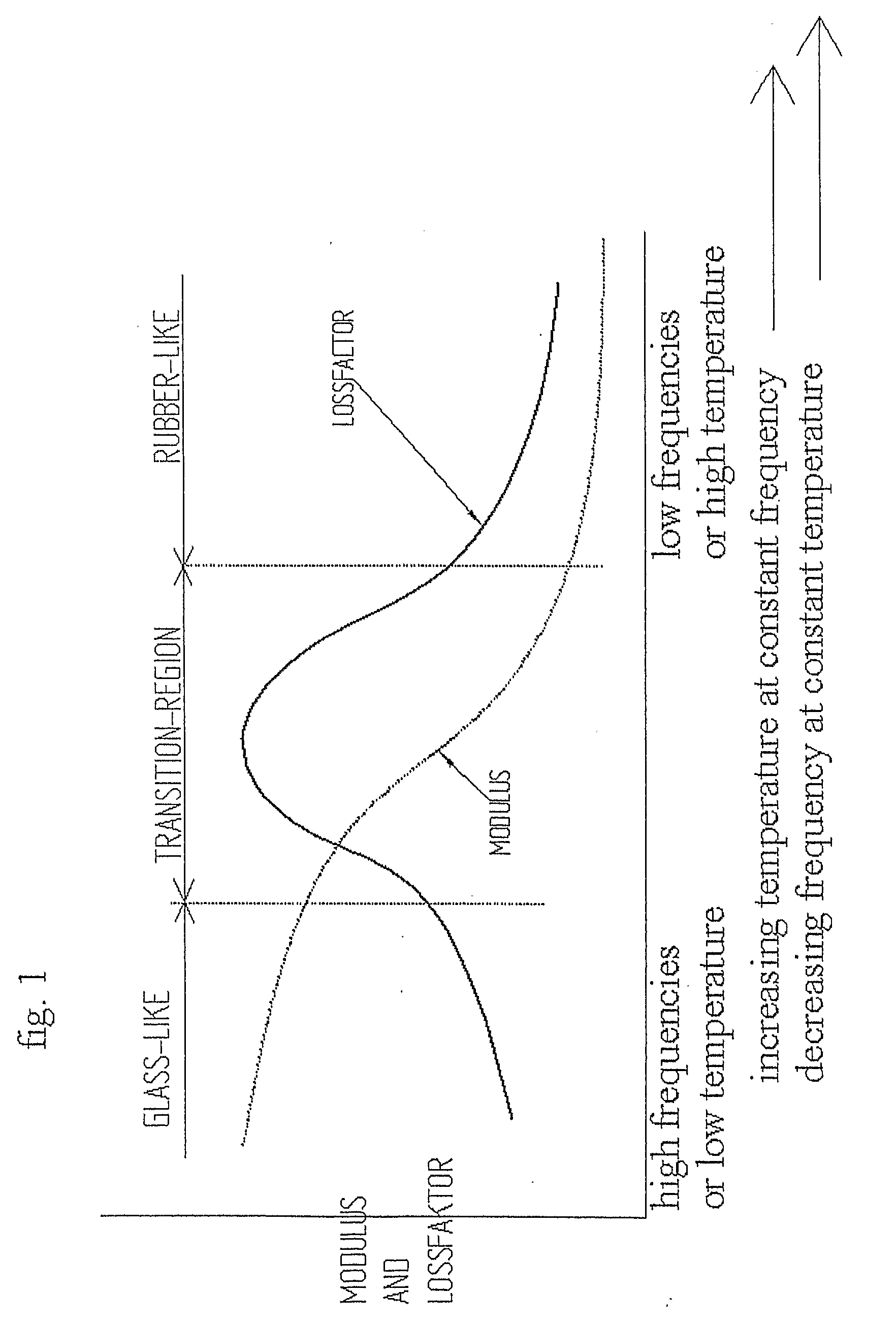

Visco Elastic Damping In A Piping System

InactiveUS20080036200A1Reduce vibrationSimple structurePipe supportsSpringsViscoelastic dampingTemperature control

A piping system for visco elastic damping, which system oscillates with high frequency, small amplitude oscillations. The system includes one or more autonomous visco elastic dampers that includes one or more layers of visco elastic damping material fixedly bonded between stiff members. The visco elastic dampers may be provided with a temperature controlling element.

Owner:INGEMANSSON TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com