Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3846results about "Optical wave guidance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

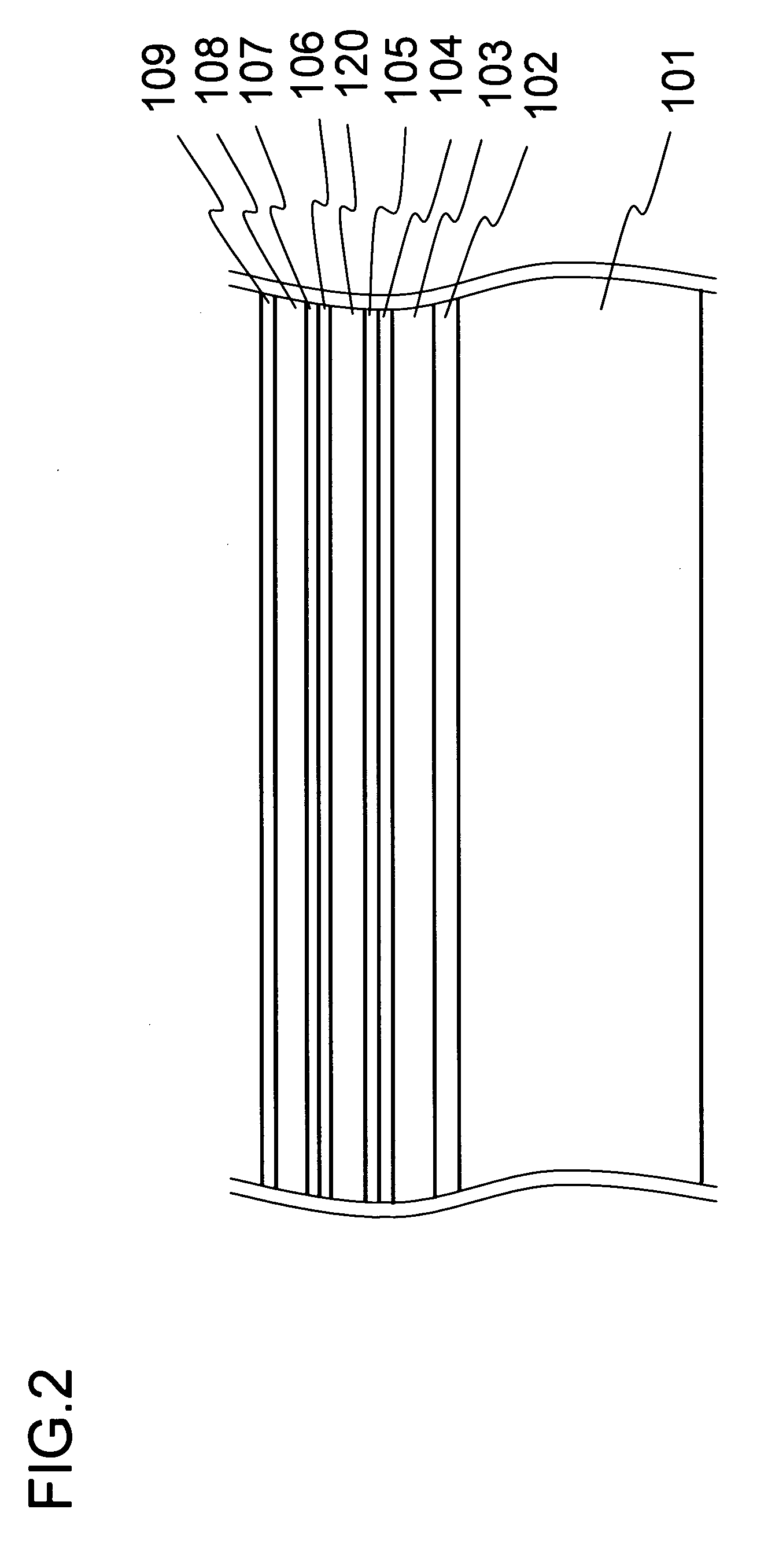

Group-III nitride semiconductor device

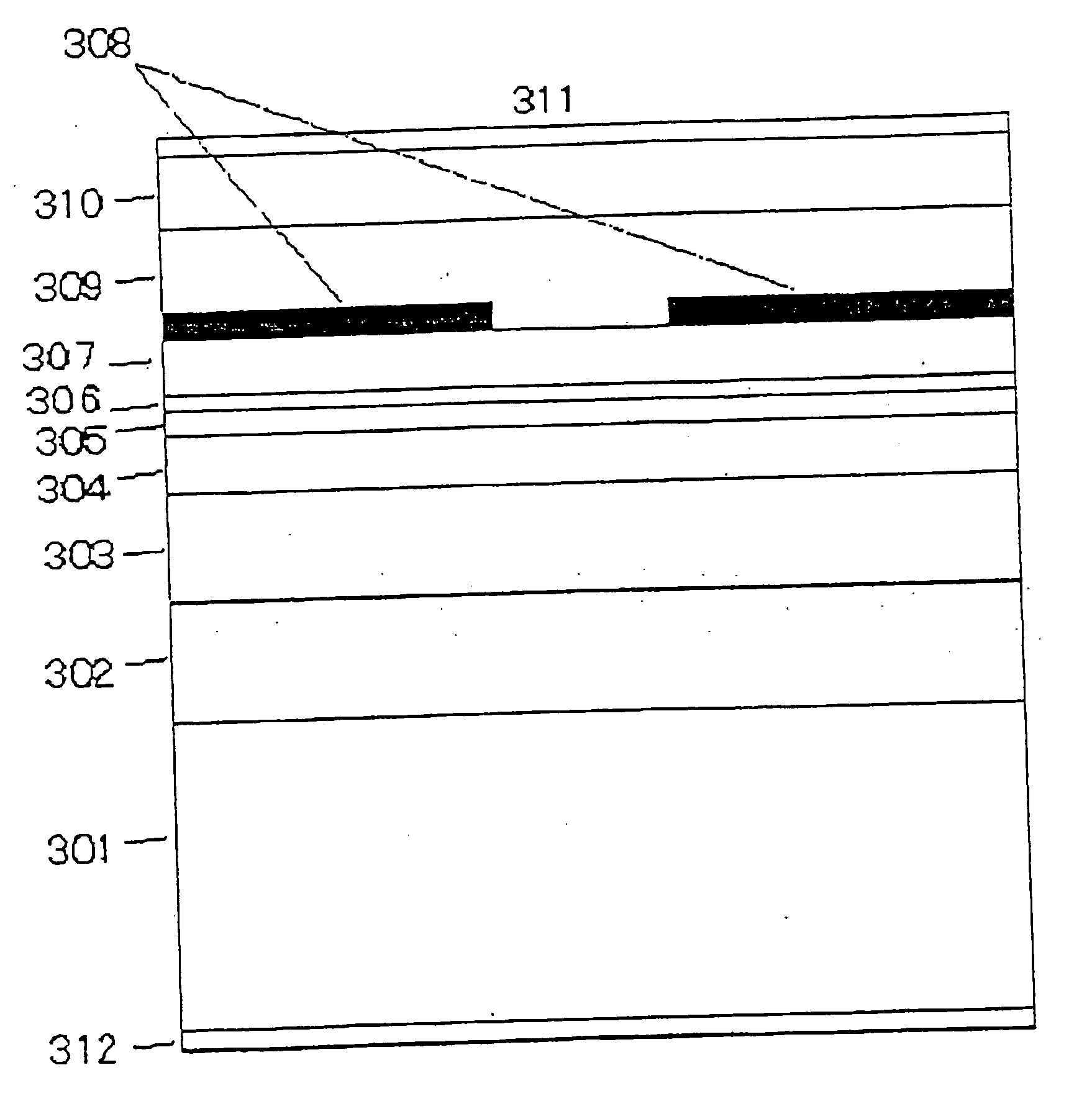

InactiveUS20050072986A1Suppress an undesired mass-transportPrevent surfaceOptical wave guidanceLaser detailsNitride semiconductorsCompound semiconductor

A method of forming a partially etched nitride-based compound semiconductor crystal layer includes the following steps. A non-crystal layer of a nitride-based compound semiconductor is formed. At least a part of the non-crystal layer is then etched to form a partially etched non-crystal layer before the partially etched non-crystal layer is crystallized to form a partially etched nitride-based compound semiconductor crystal layer.

Owner:RENESAS ELECTRONICS CORP

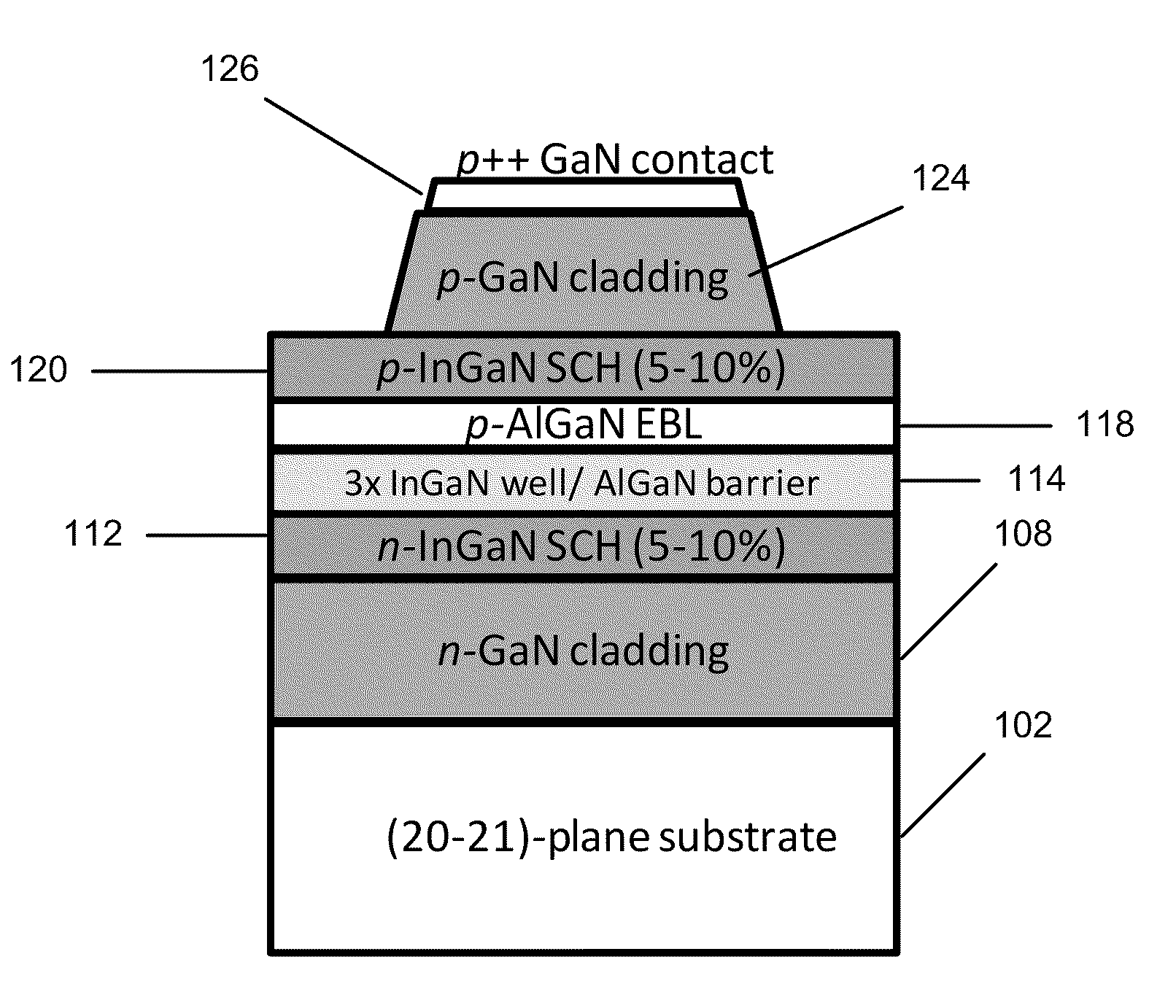

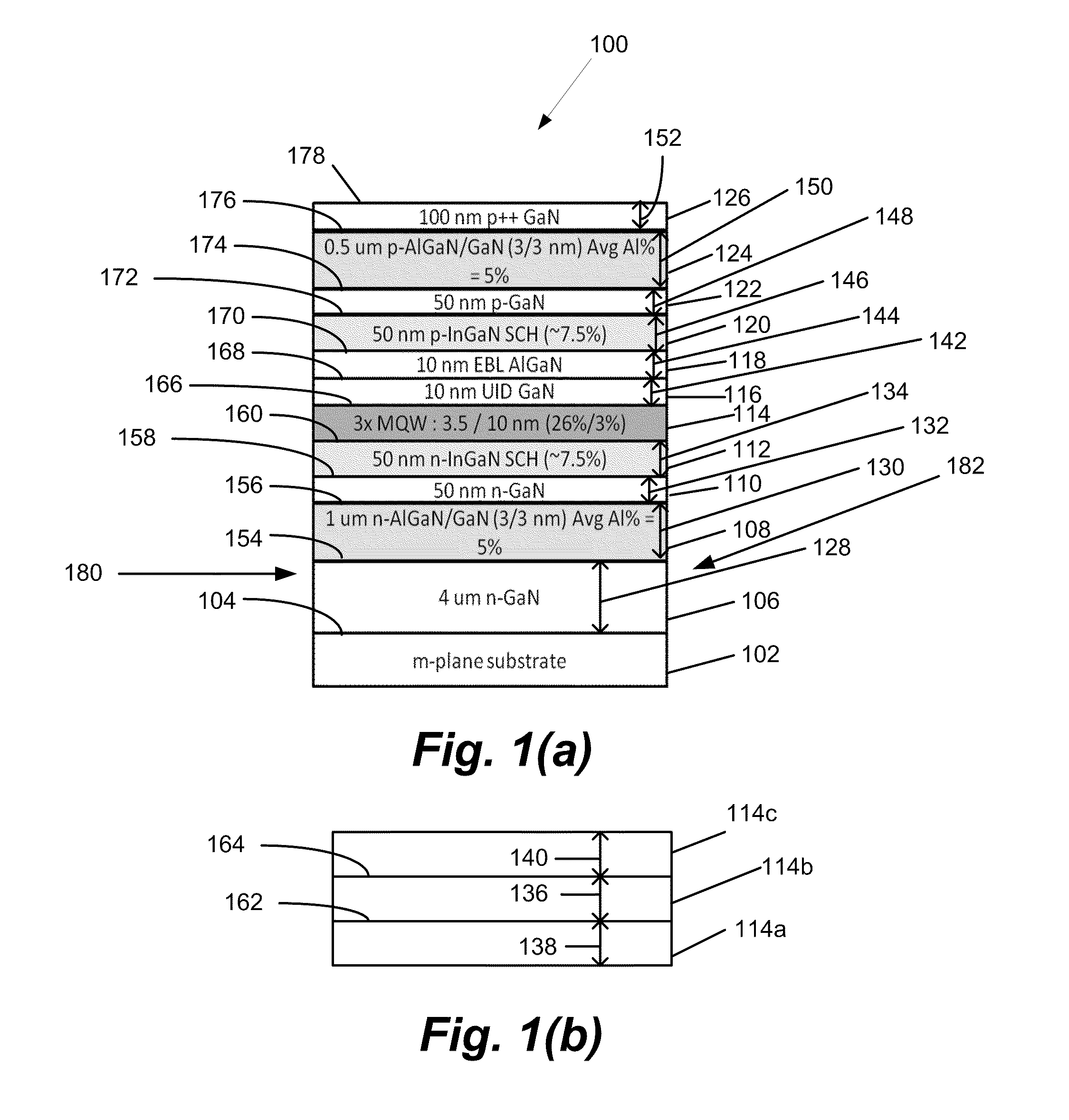

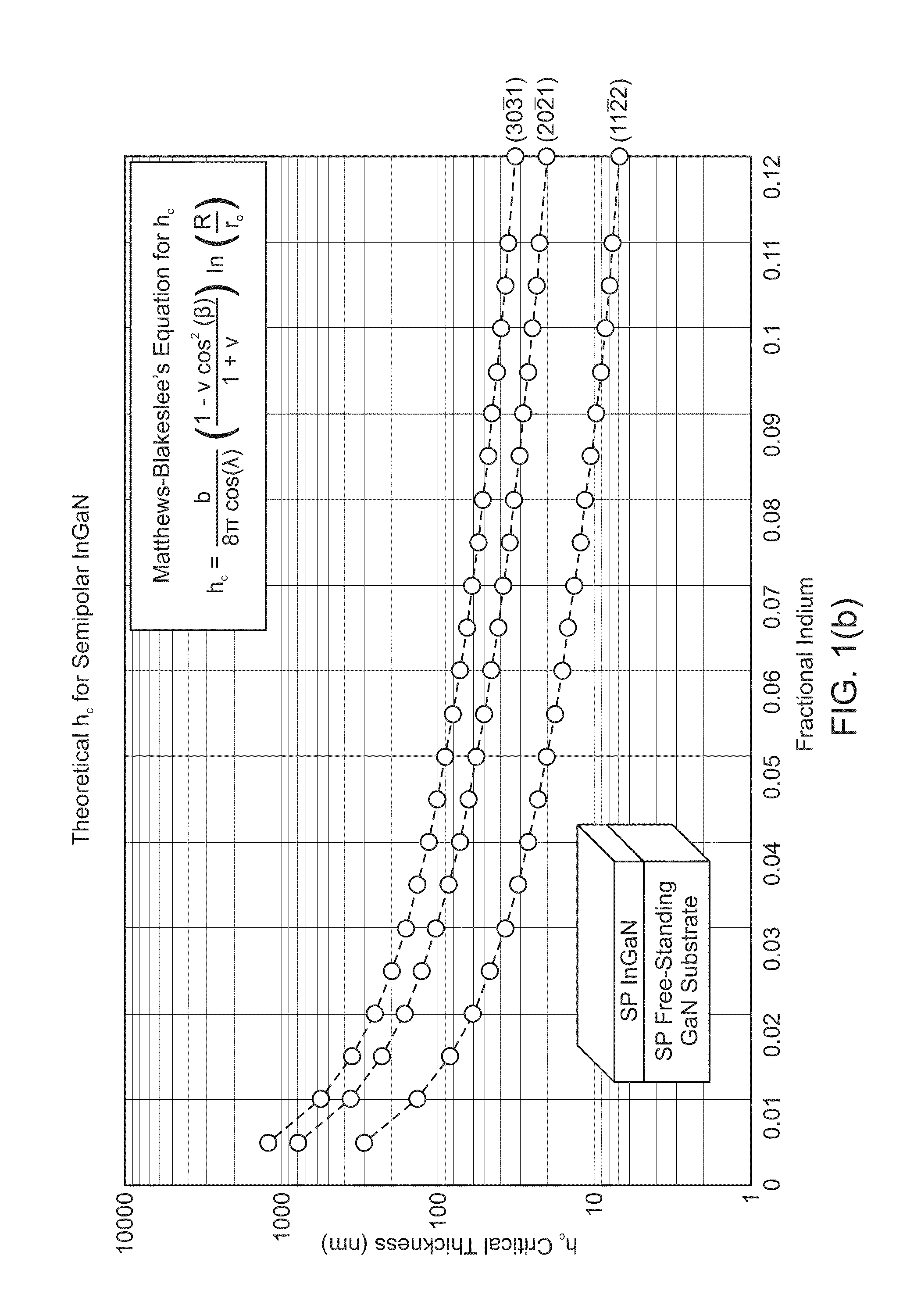

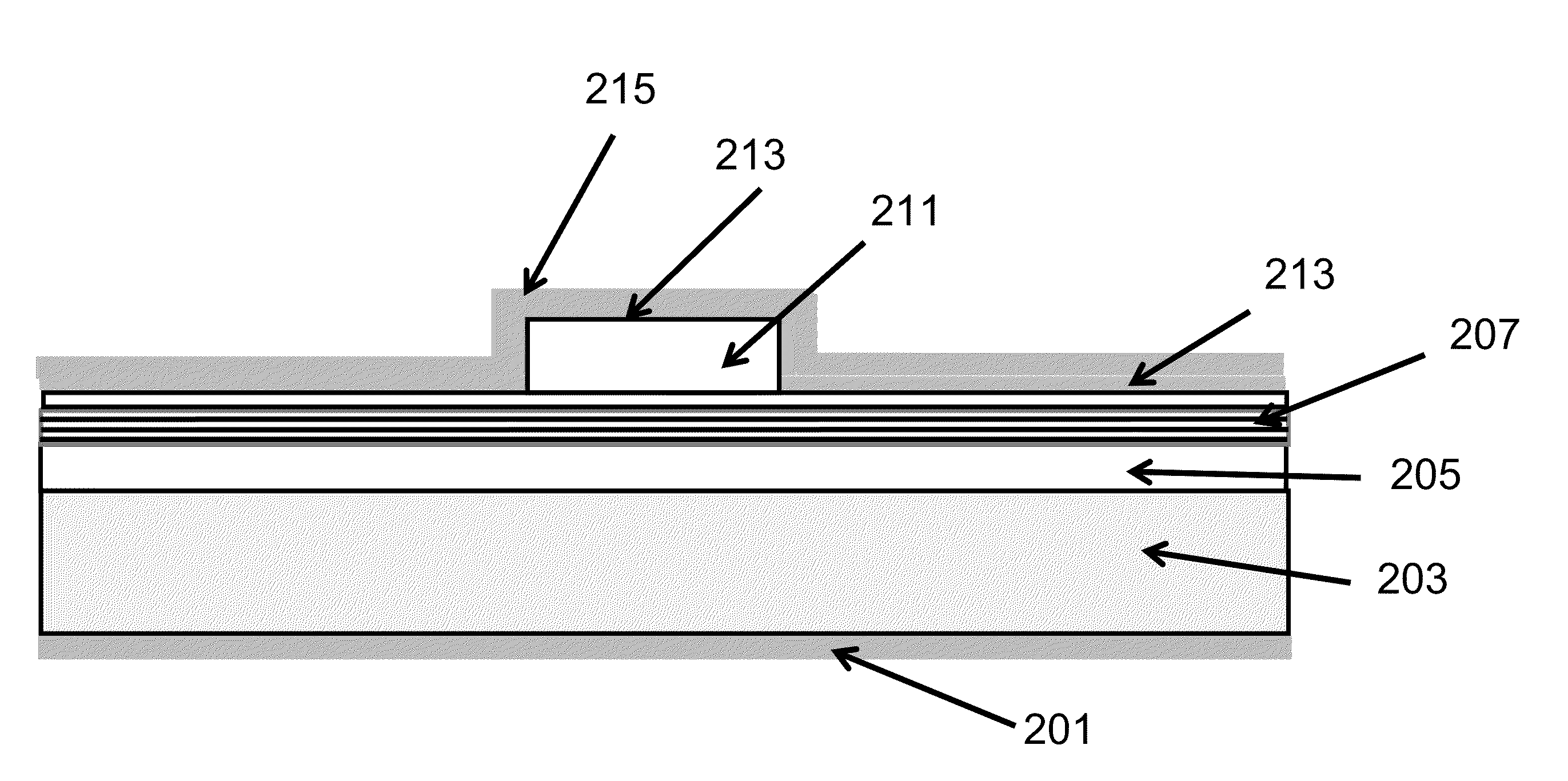

LONG WAVELENGTH NONPOLAR AND SEMIPOLAR (Al,Ga,In)N BASED LASER DIODES

InactiveUS20100309943A1Simple structureImprove electricityOptical wave guidanceLaser detailsContact layerStimulated emission

A laser diode, grown on a miscut nonpolar or semipolar substrate, with lower threshold current density and longer stimulated emission wavelength, compared to conventional laser diode structures, wherein the laser diode's (1) n-type layers are grown in a nitrogen carrier gas, (2) quantum well layers and barrier layers are grown at a slower growth rate as compared to other device layers (enabling growth of the p-type layers at higher temperature), (3) high Al content electron blocking layer enables growth of layers above the active region at a higher temperature, and (4) asymmetric AlGaN SPSLS allowed growth of high Al containing p-AlGaN layers. Various other techniques were used to improve the conductivity of the p-type layers and minimize the contact resistance of the contact layer.

Owner:RGT UNIV OF CALIFORNIA

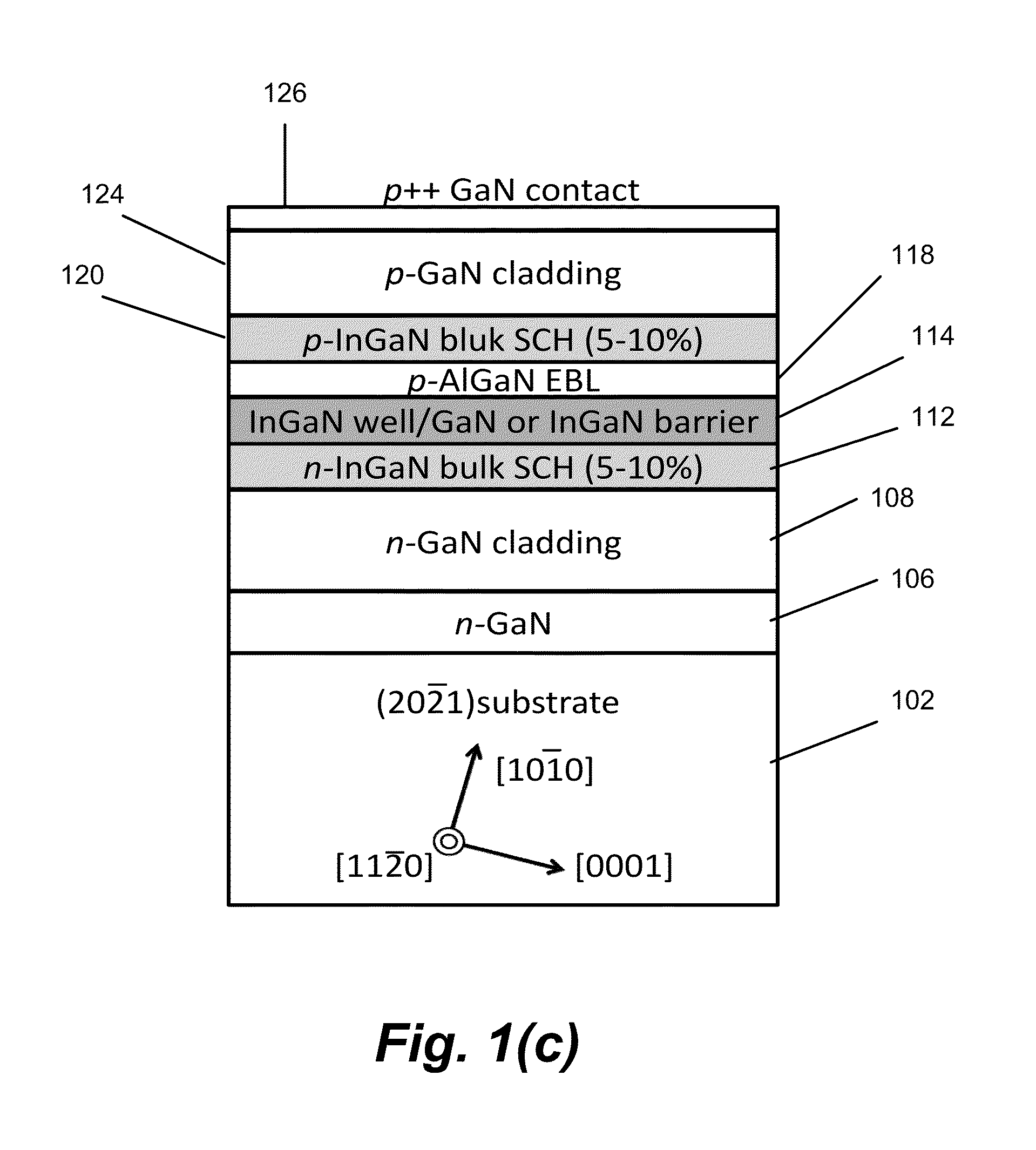

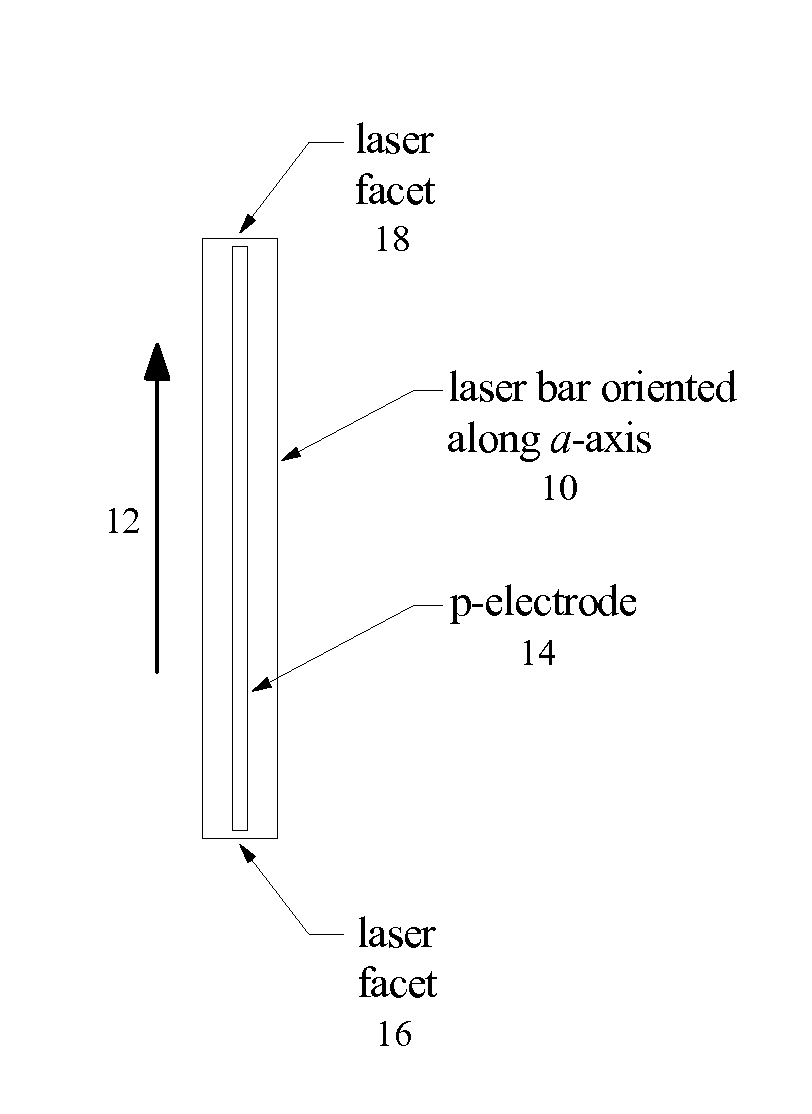

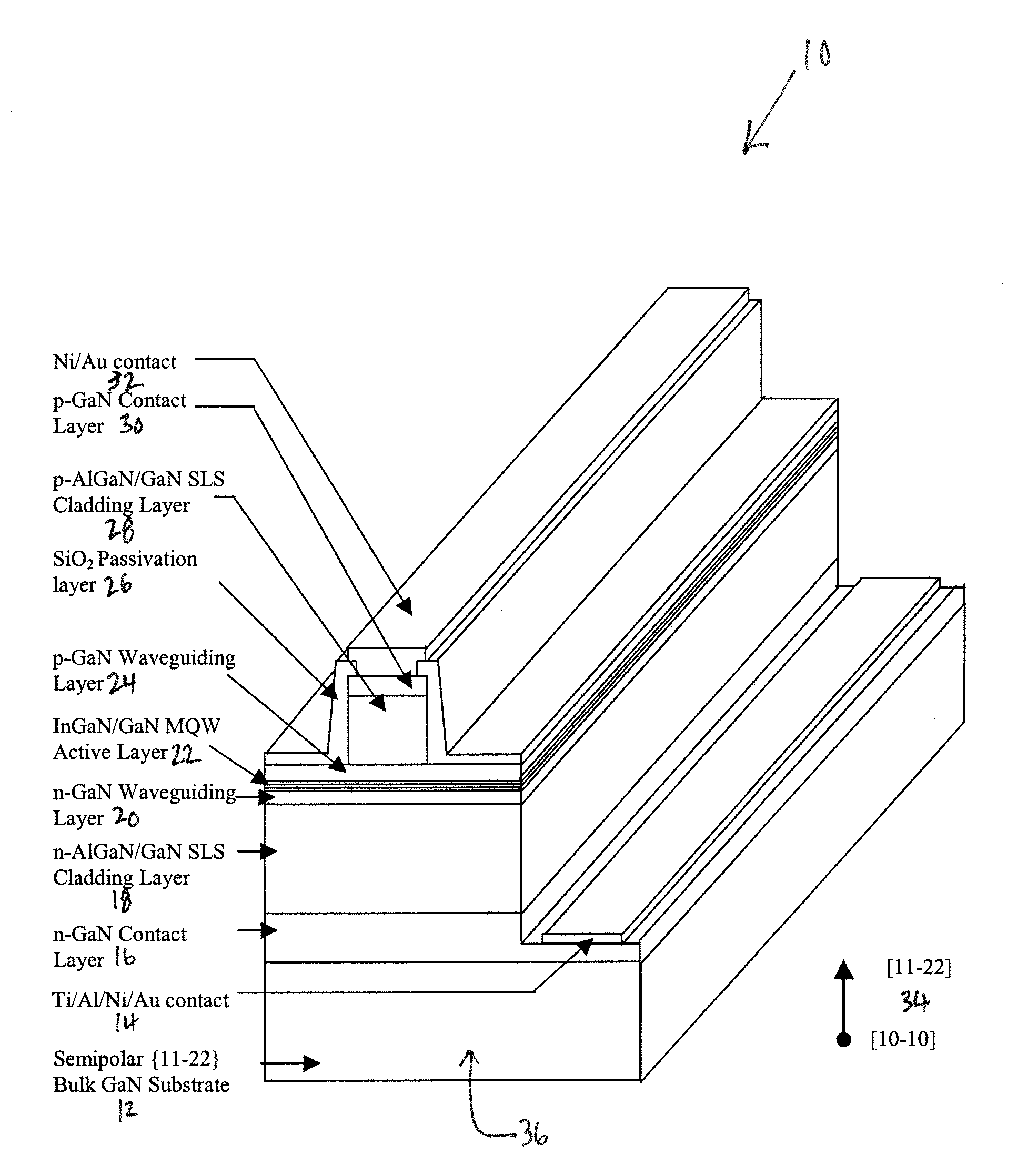

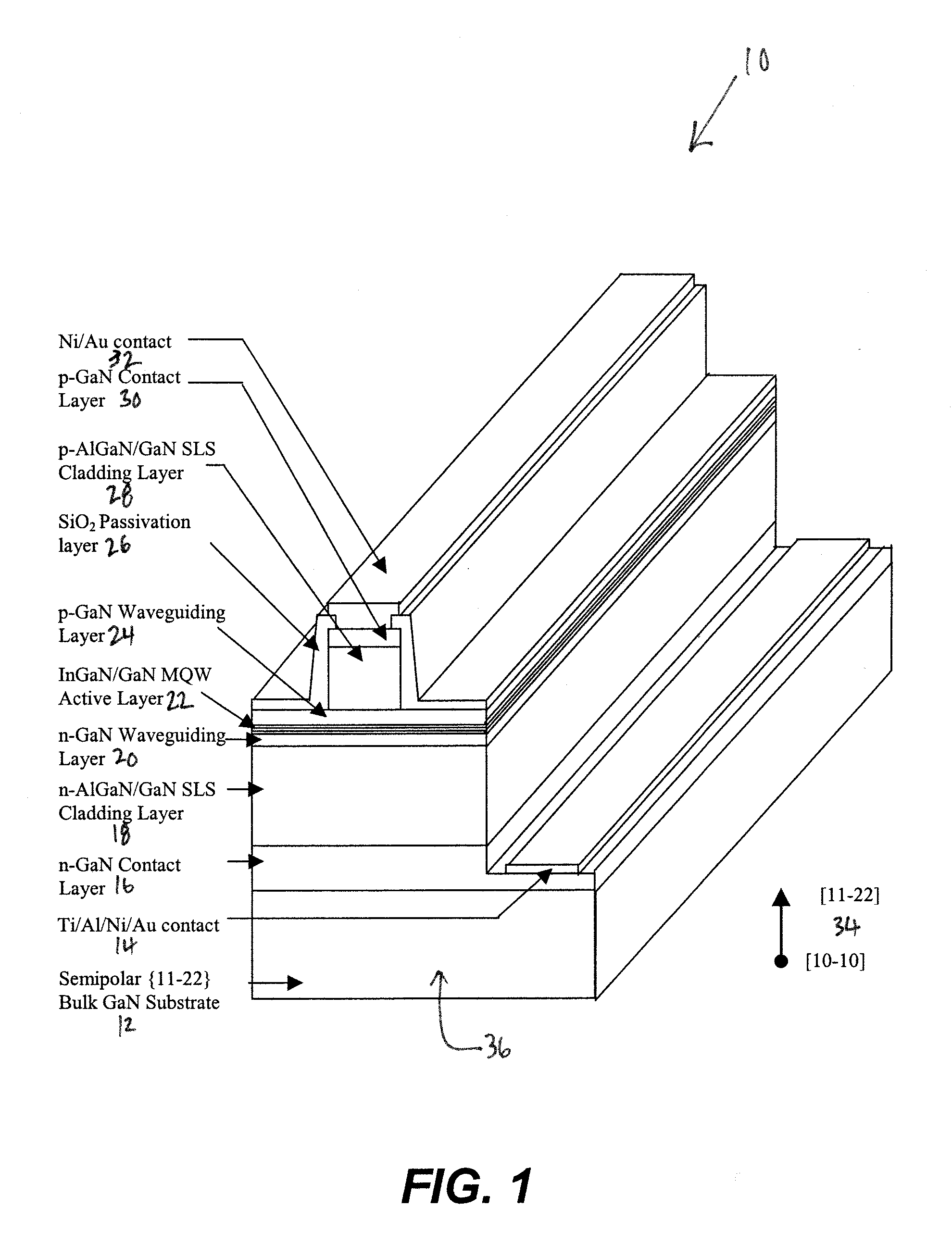

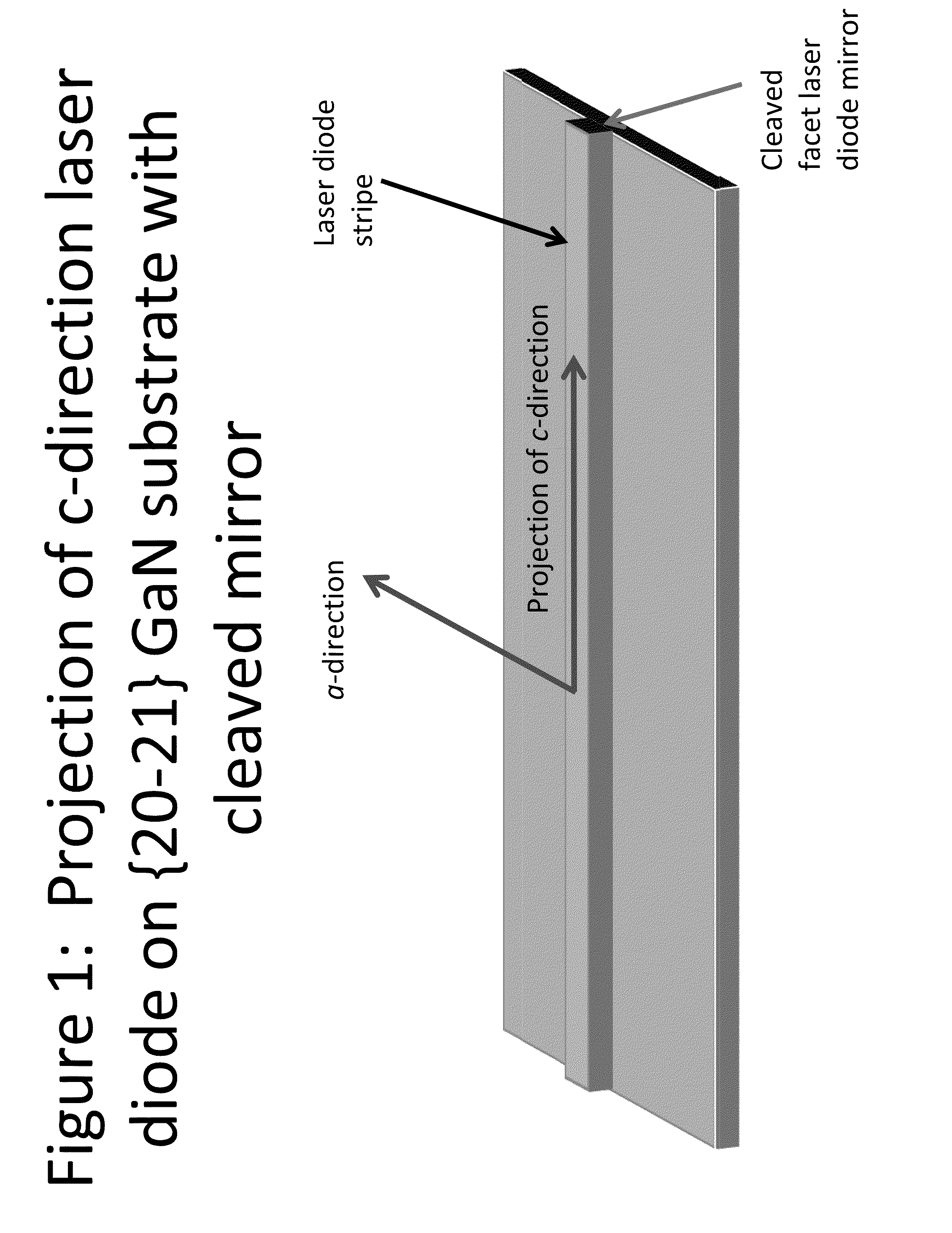

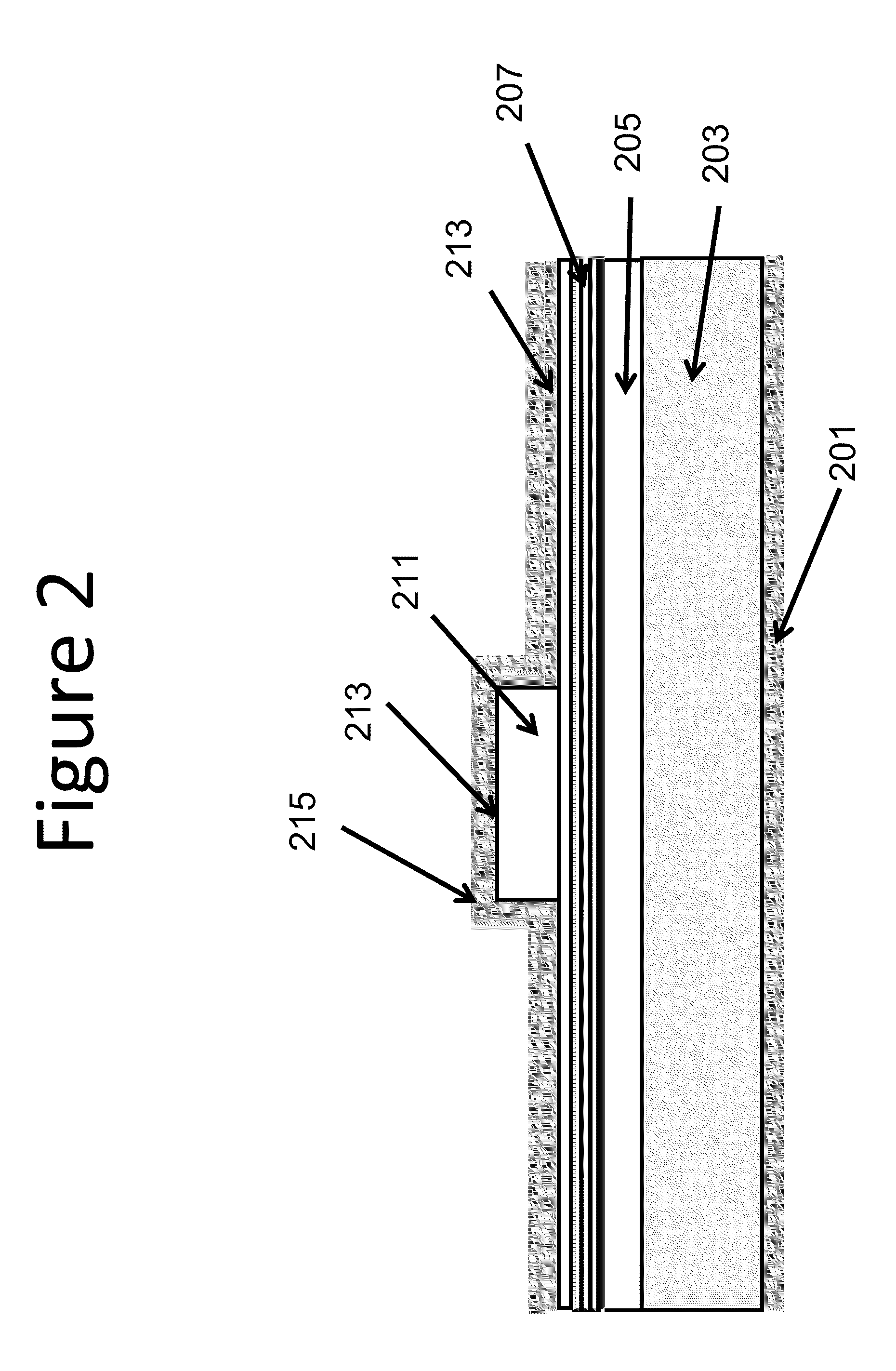

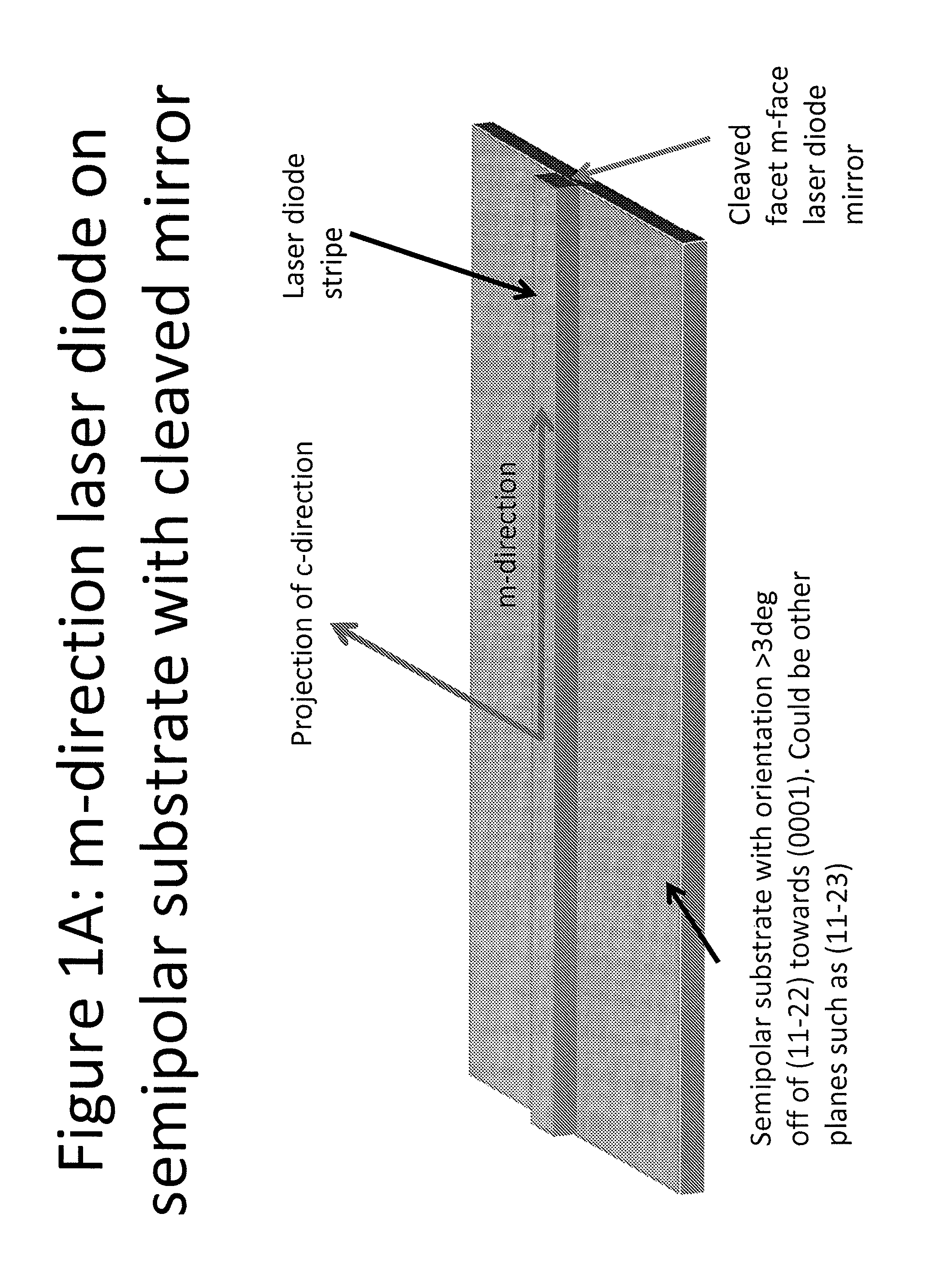

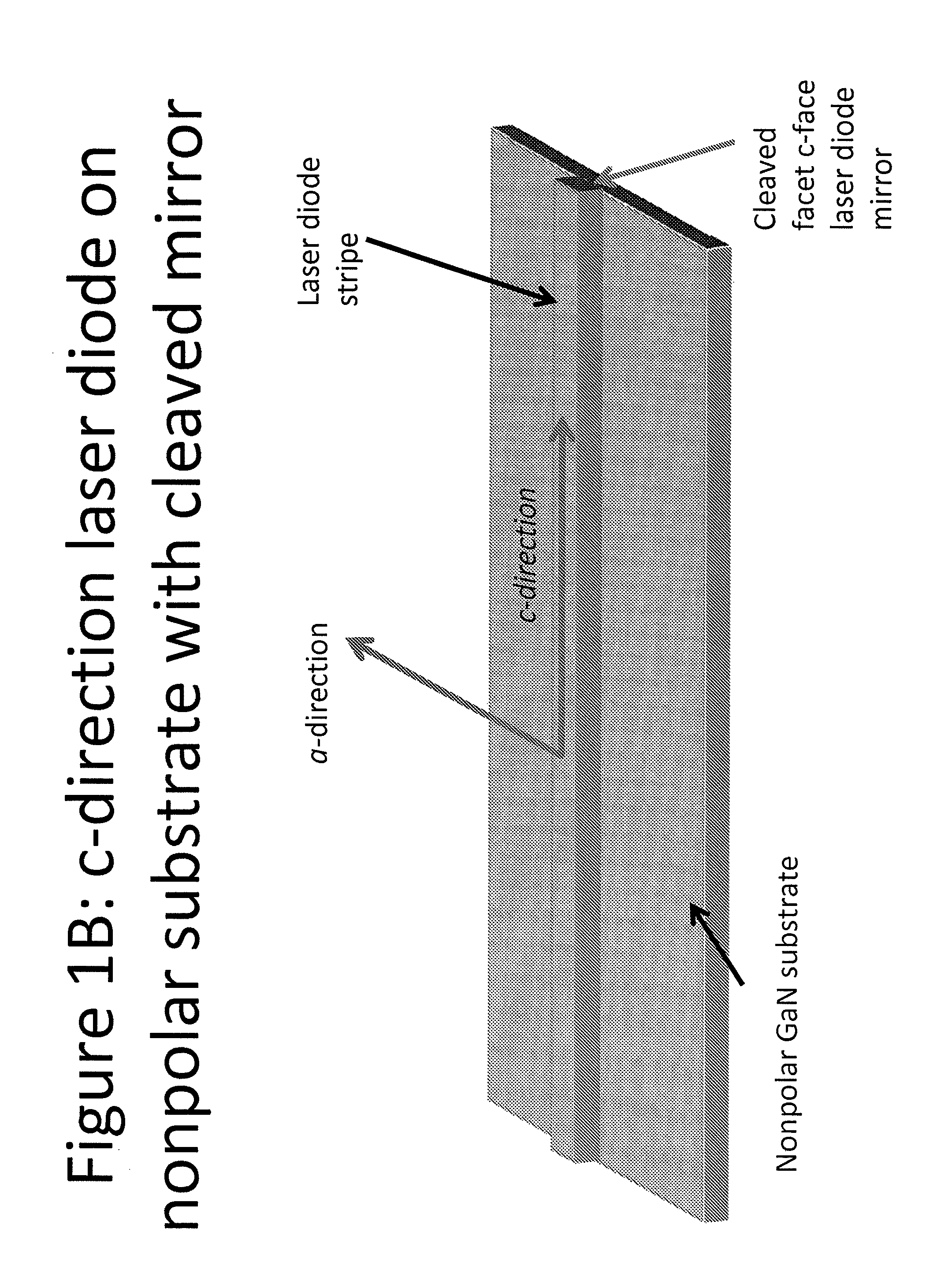

OPTIMIZATION OF LASER BAR ORIENTATION FOR NONPOLAR AND SEMIPOLAR (Ga,Al,In,B)N DIODE LASERS

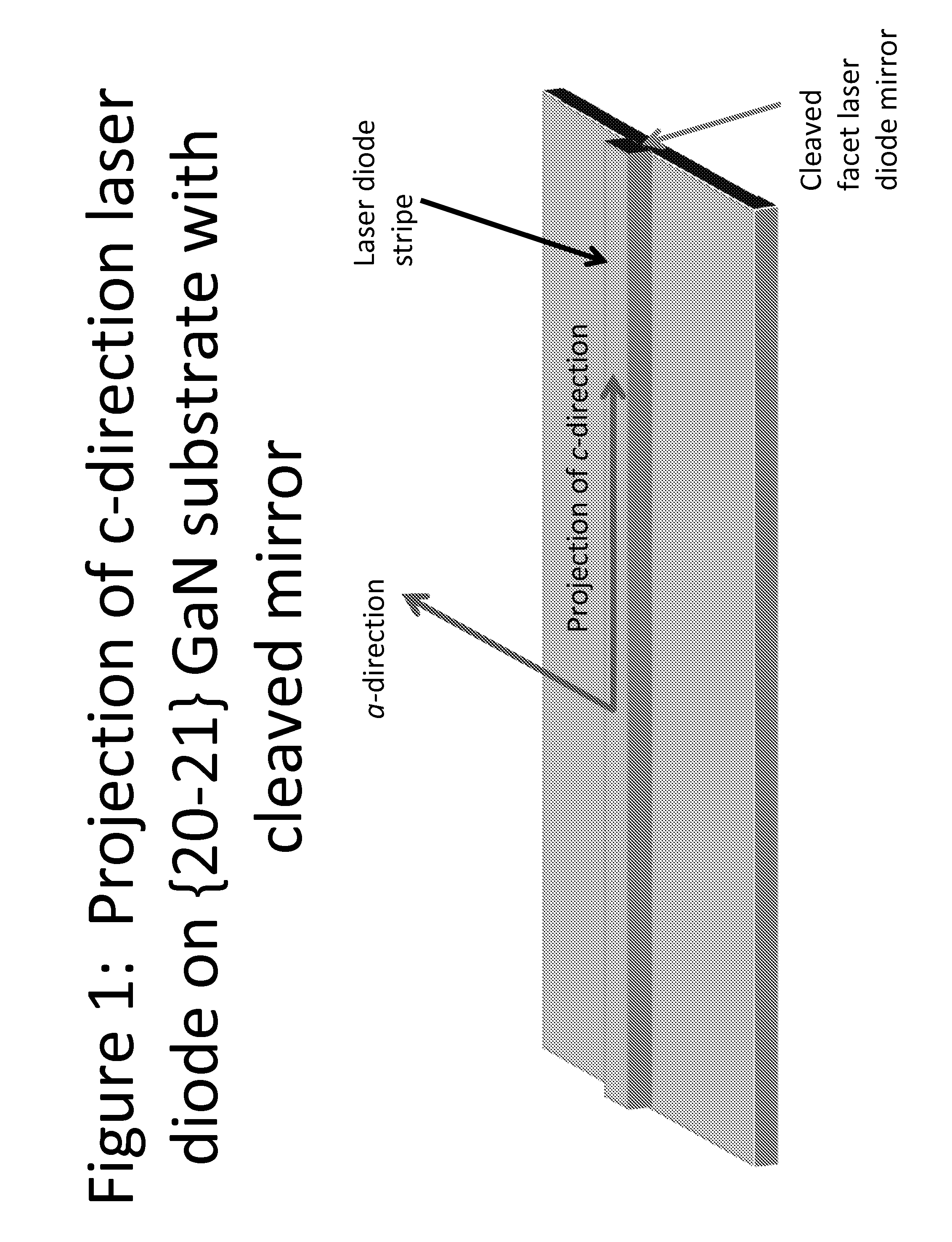

ActiveUS20080198881A1Maximize optical gainOptical wave guidanceLaser detailsNitrideOptical polarization

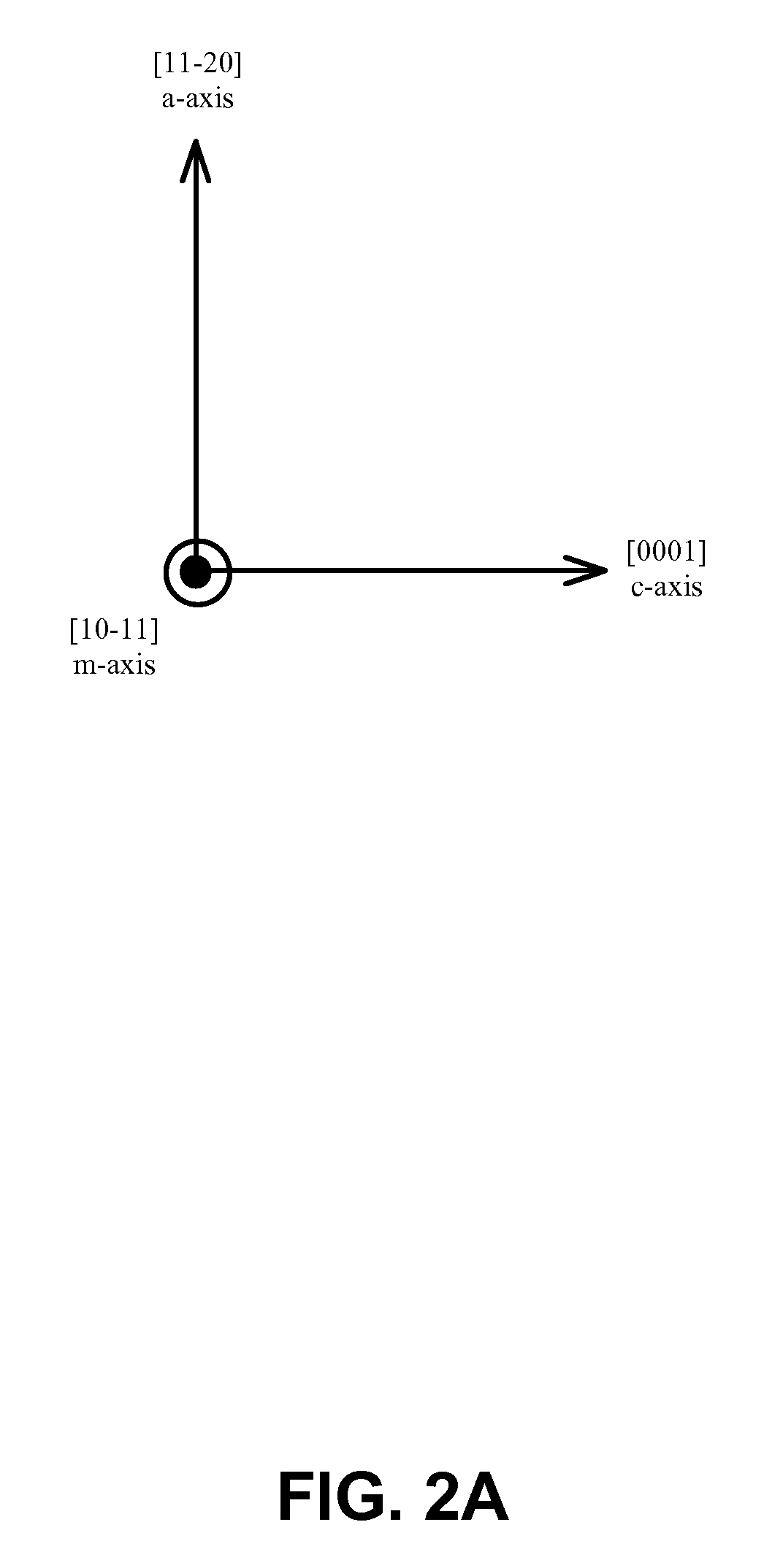

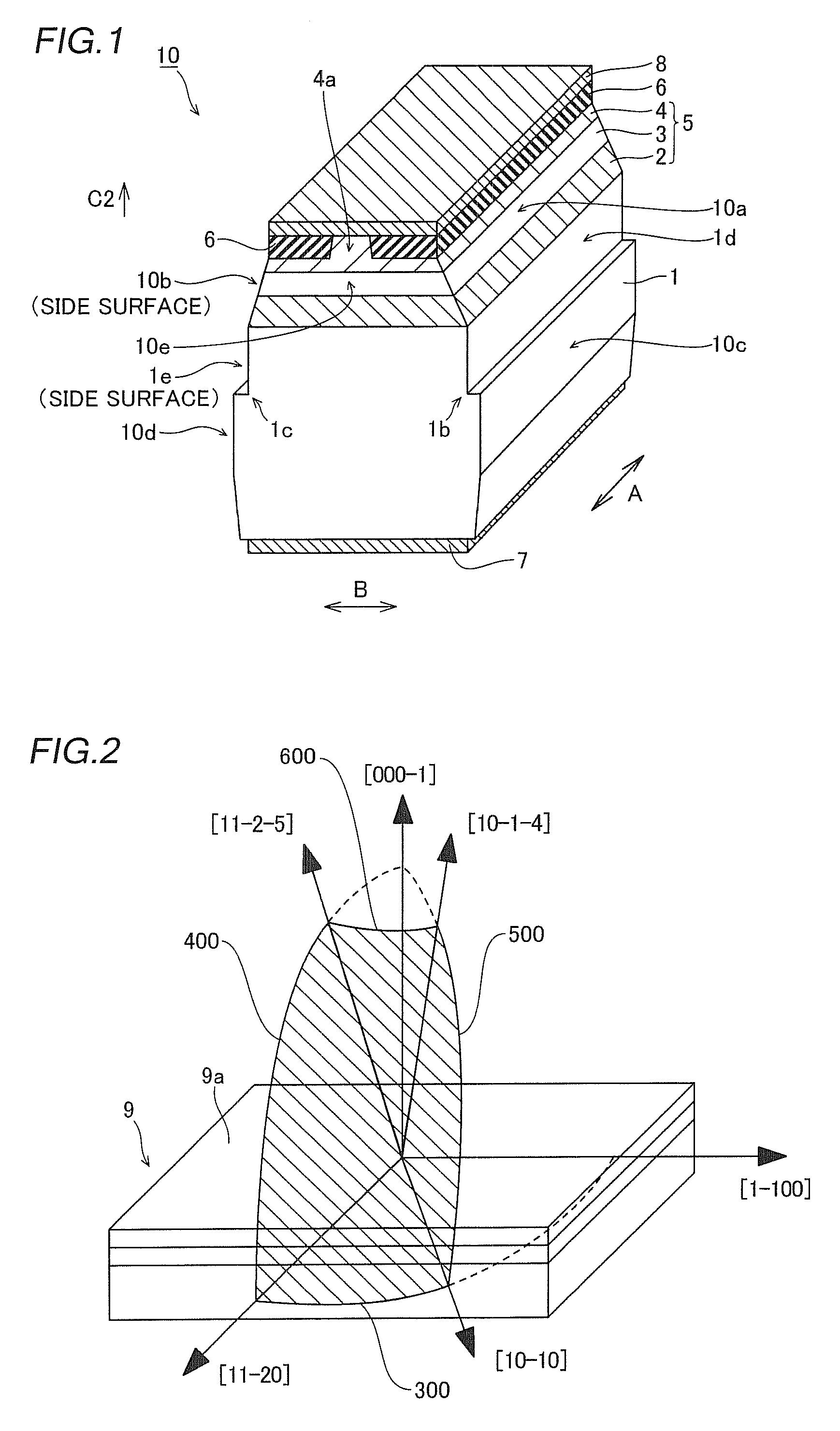

Optical gain of a nonpolar or semipolar Group-III nitride diode laser is controlled by orienting an axis of light propagation in relation to an optical polarization direction or crystallographic orientation of the diode laser. The axis of light propagation is substantially perpendicular to the mirror facets of the diode laser, and the optical polarization direction is determined by the crystallographic orientation of the diode laser. To maximize optical gain, the axis of light propagation is oriented substantially perpendicular to the optical polarization direction or crystallographic orientation.

Owner:JAPAN SCI & TECH CORP

Nitride-based semiconductor device and method of manufacturing the same

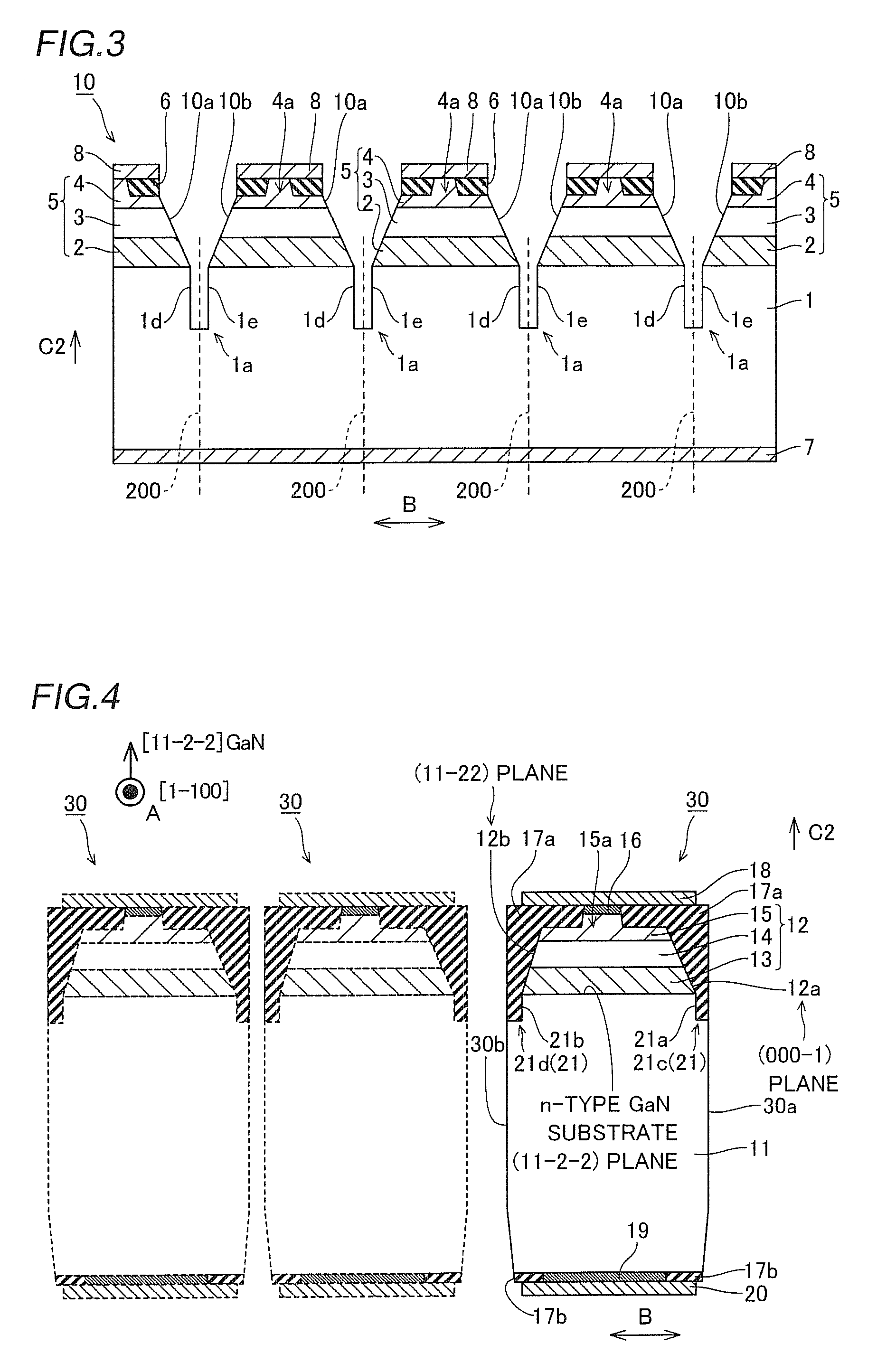

ActiveUS20090267100A1Easy to splitSmall thicknessOptical wave guidanceLaser detailsNitrideSemiconductor

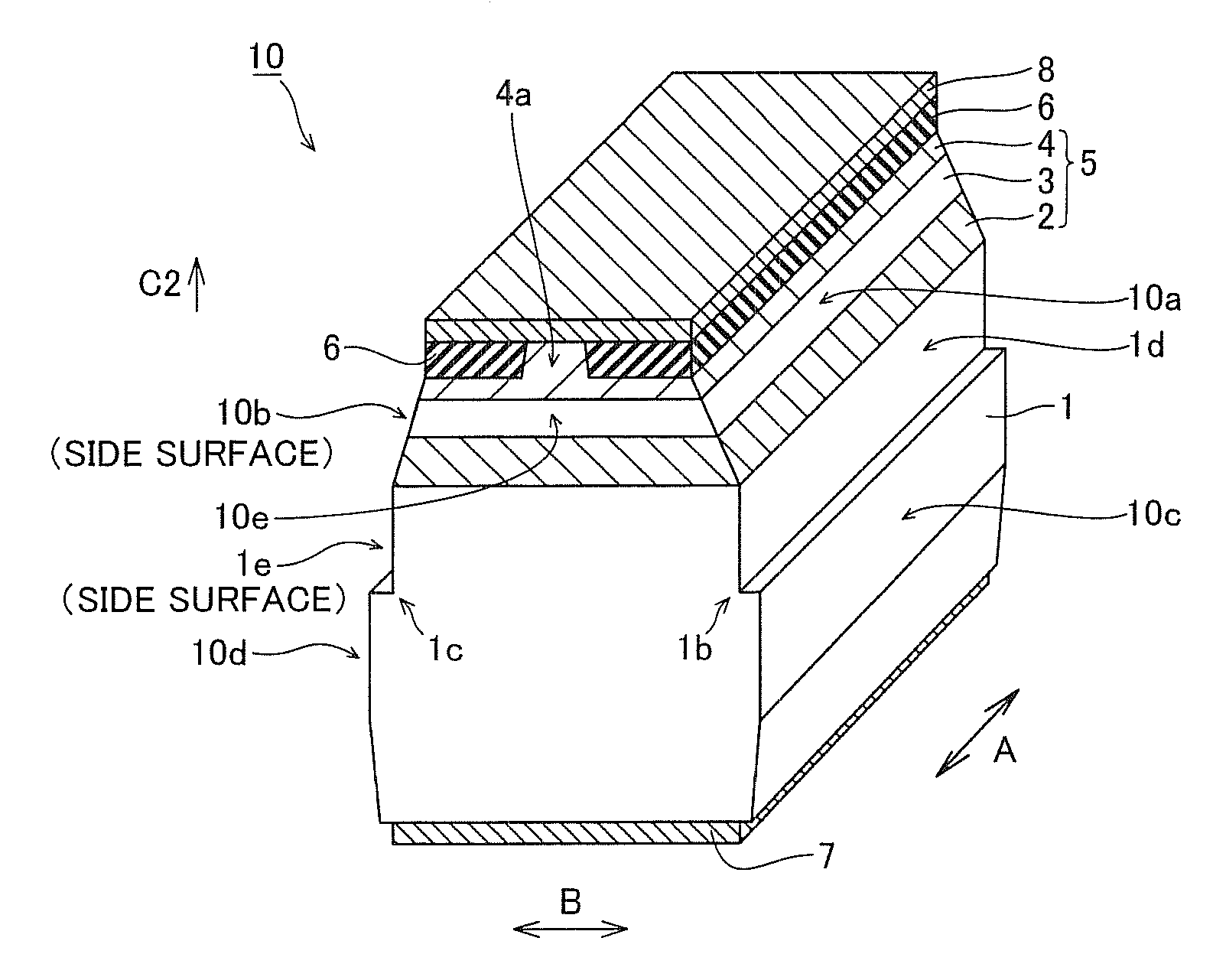

A nitride-based semiconductor device includes a substrate, a first step portion formed on a main surface side of a first side end surface of the substrate, a second step portion formed on the main surface side of a second side end surface substantially parallel to the first side end surface on an opposite side of the first side end surface and a nitride-based semiconductor layer whose first side surface is a (000-1) plane starting from a first side wall of the first step portion and a second side surface starting from a second side wall of the second step portion on the main surface.

Owner:EPISTAR CORP

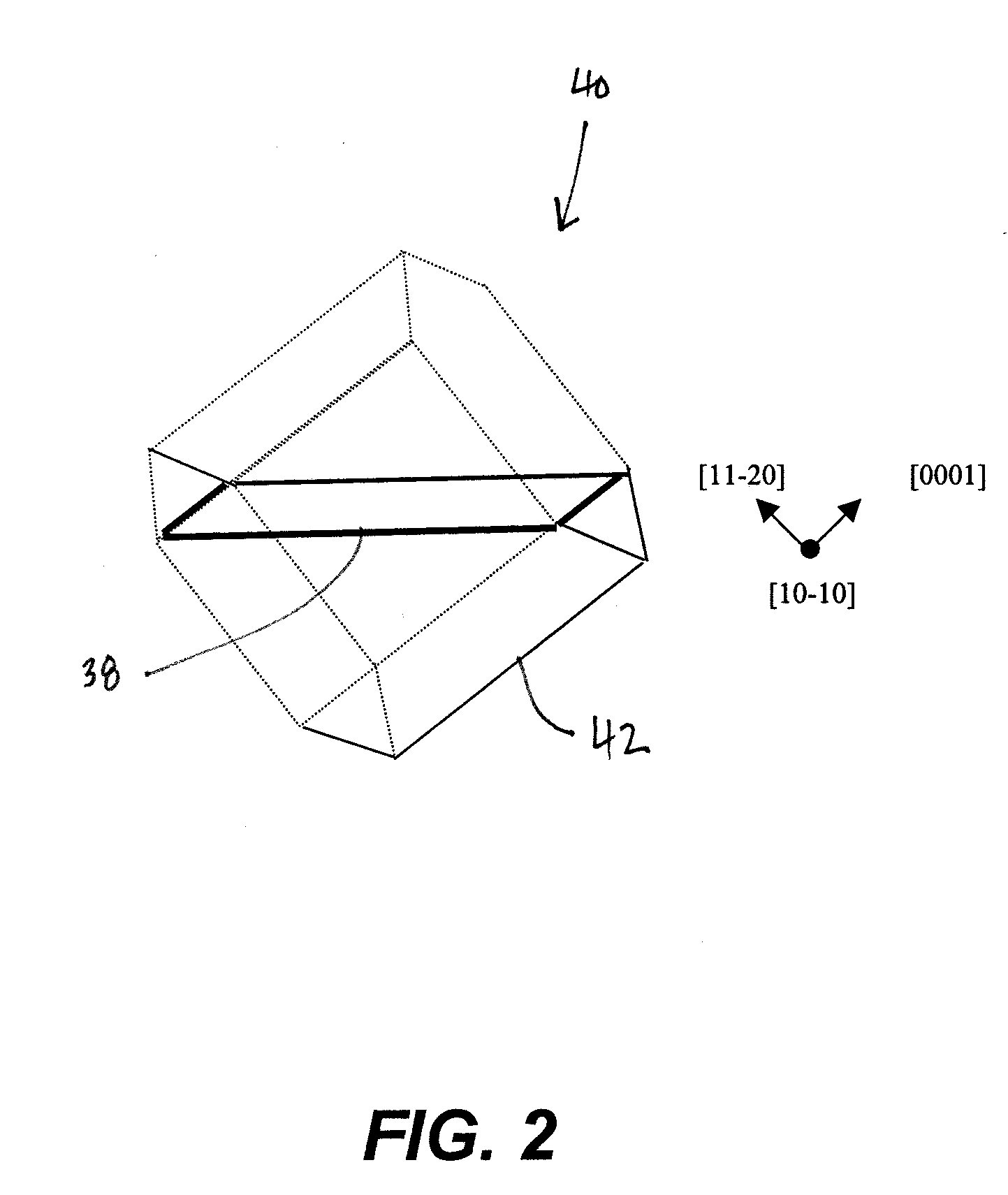

CLEAVED FACET (Ga,Al,In)N EDGE-EMITTING LASER DIODES GROWN ON SEMIPOLAR BULK GALLIUM NITRIDE SUBSTRATES

ActiveUS20080191223A1Optical wave guidanceSemiconductor/solid-state device manufacturingPlane orientationGallium nitride

A III-nitride edge-emitting laser diode is formed on a surface of a III-nitride substrate having a semipolar orientation, wherein the III-nitride substrate is cleaved by creating a cleavage line along a direction substantially perpendicular to a nonpolar orientation of the III-nitride substrate, and then applying force along the cleavage line to create one or more cleaved facets of the III-nitride substrate, wherein the cleaved facets have an m-plane or a-plane orientation.

Owner:RGT UNIV OF CALIFORNIA

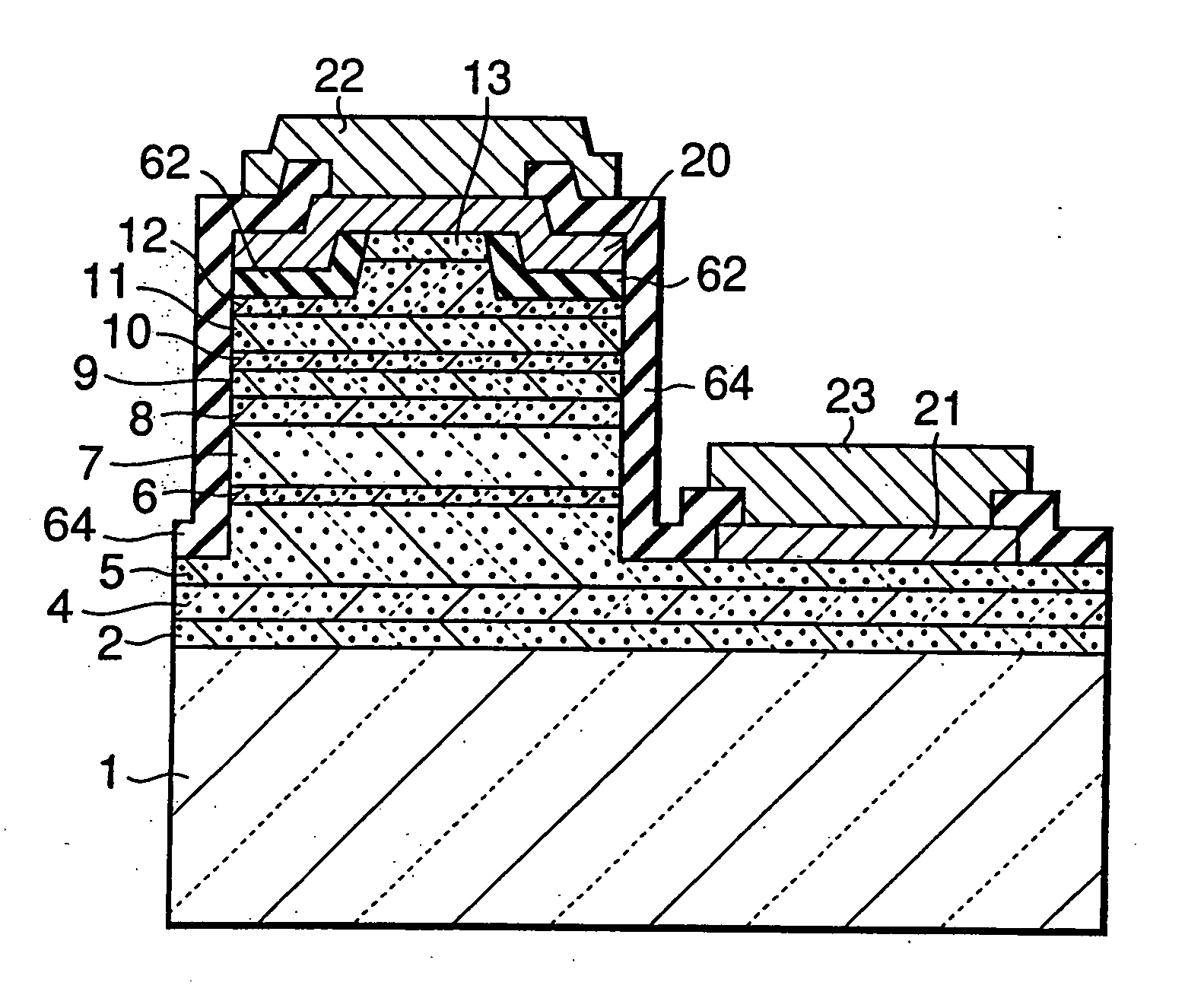

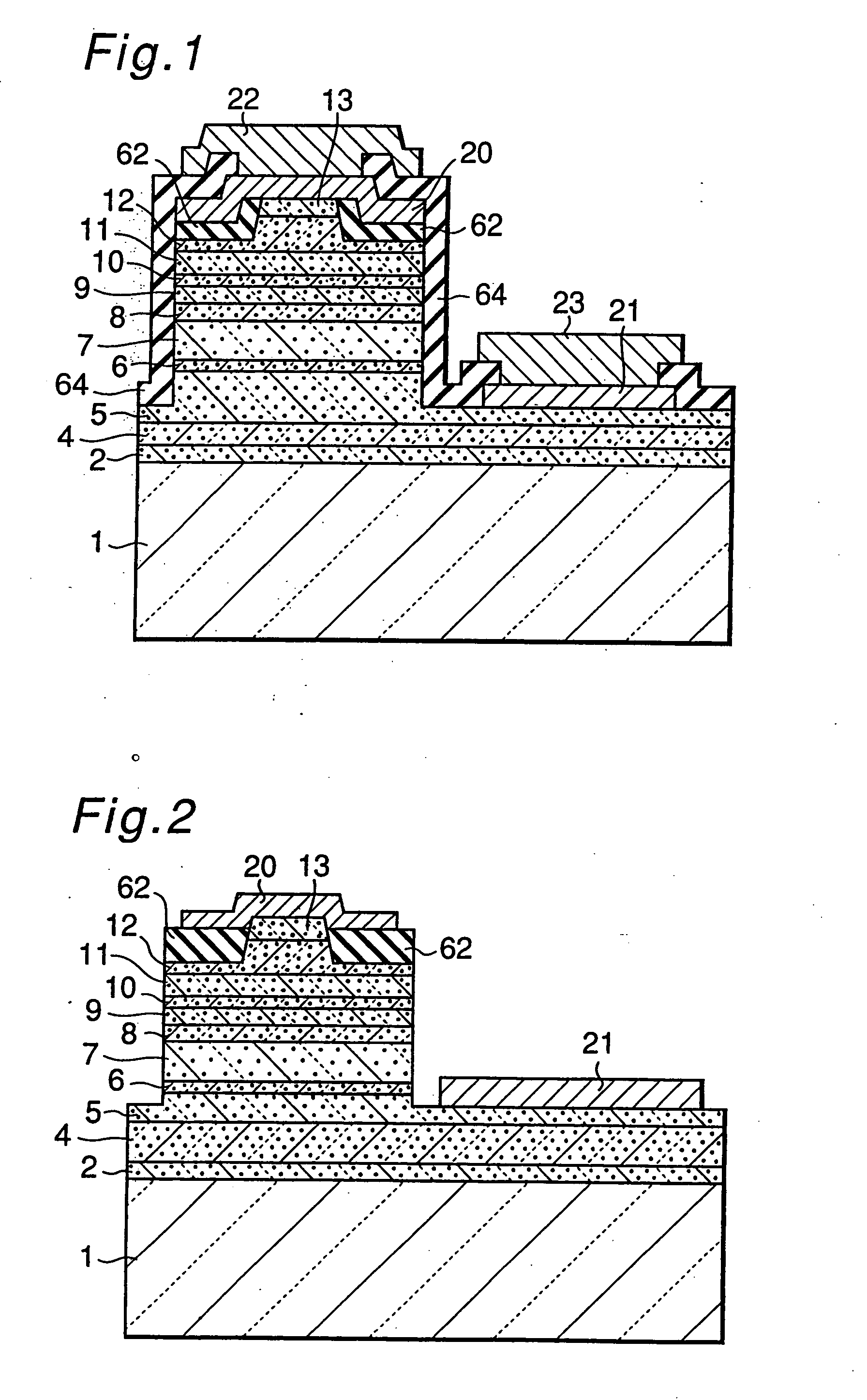

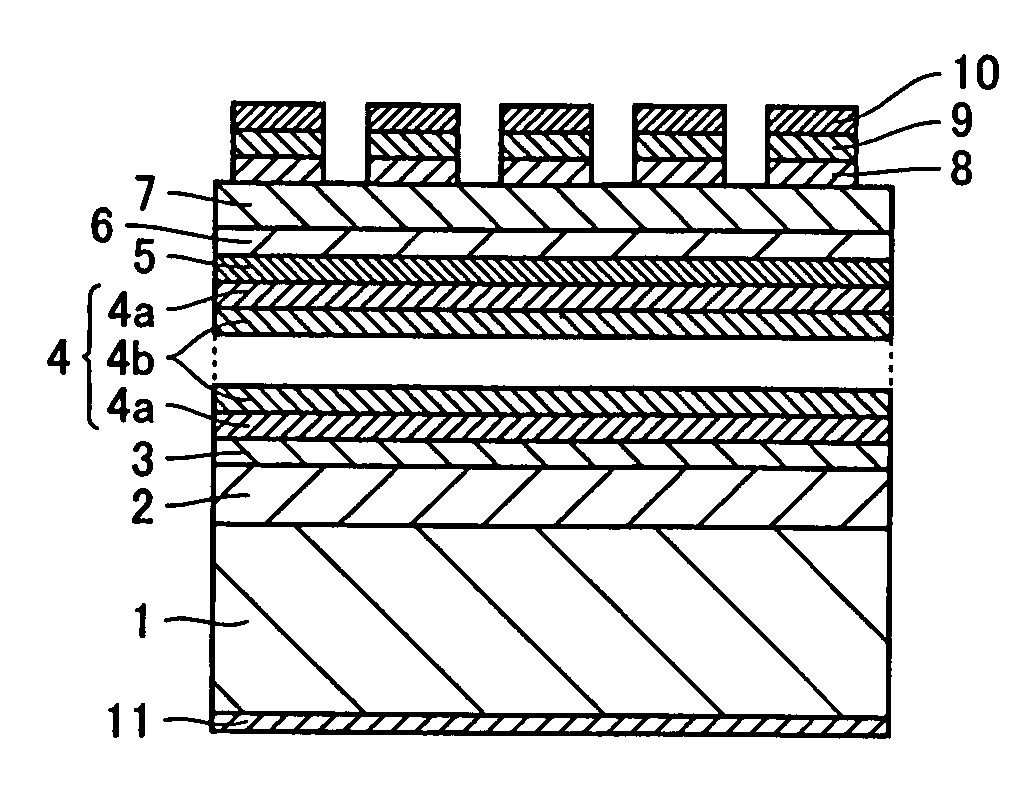

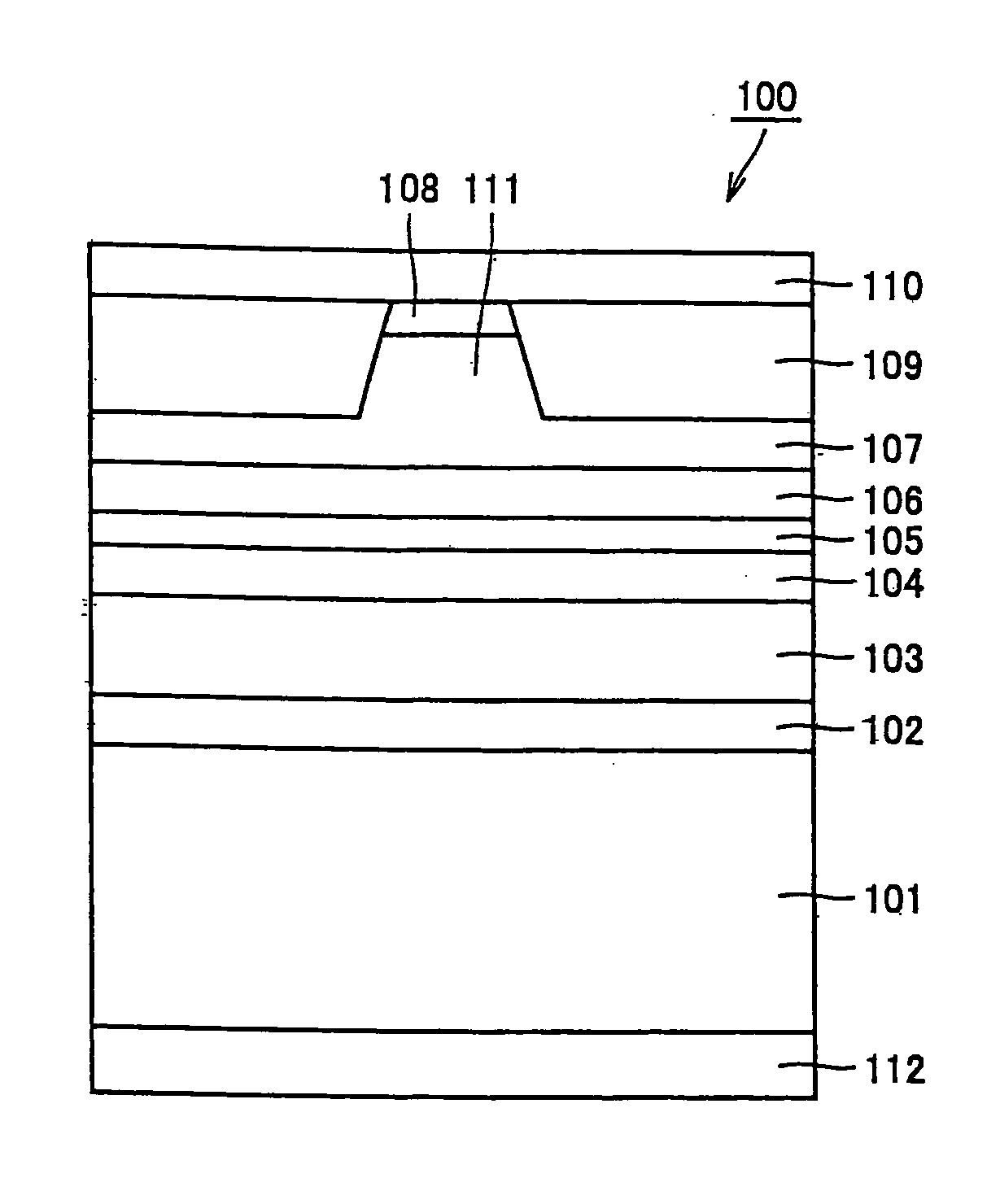

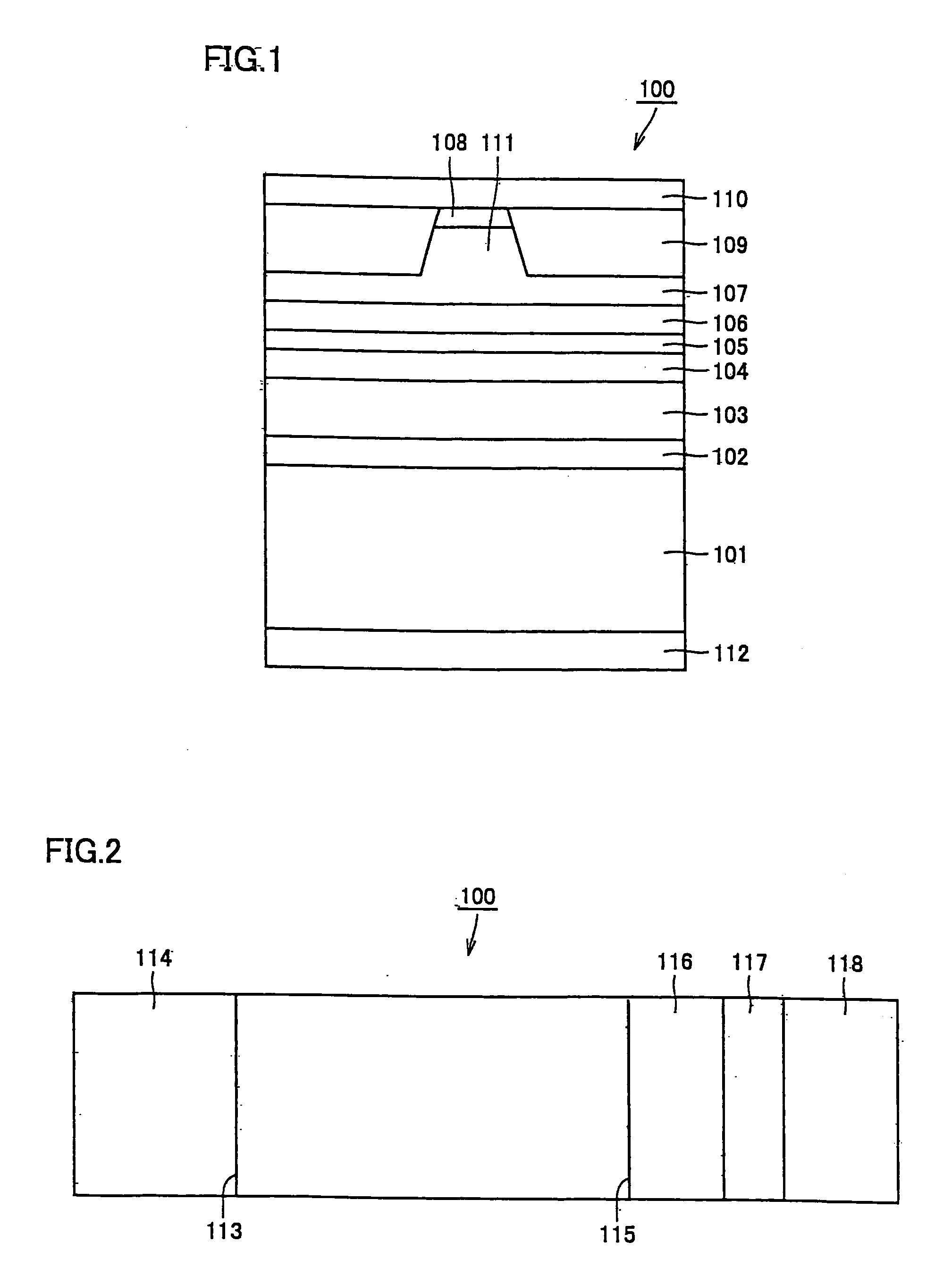

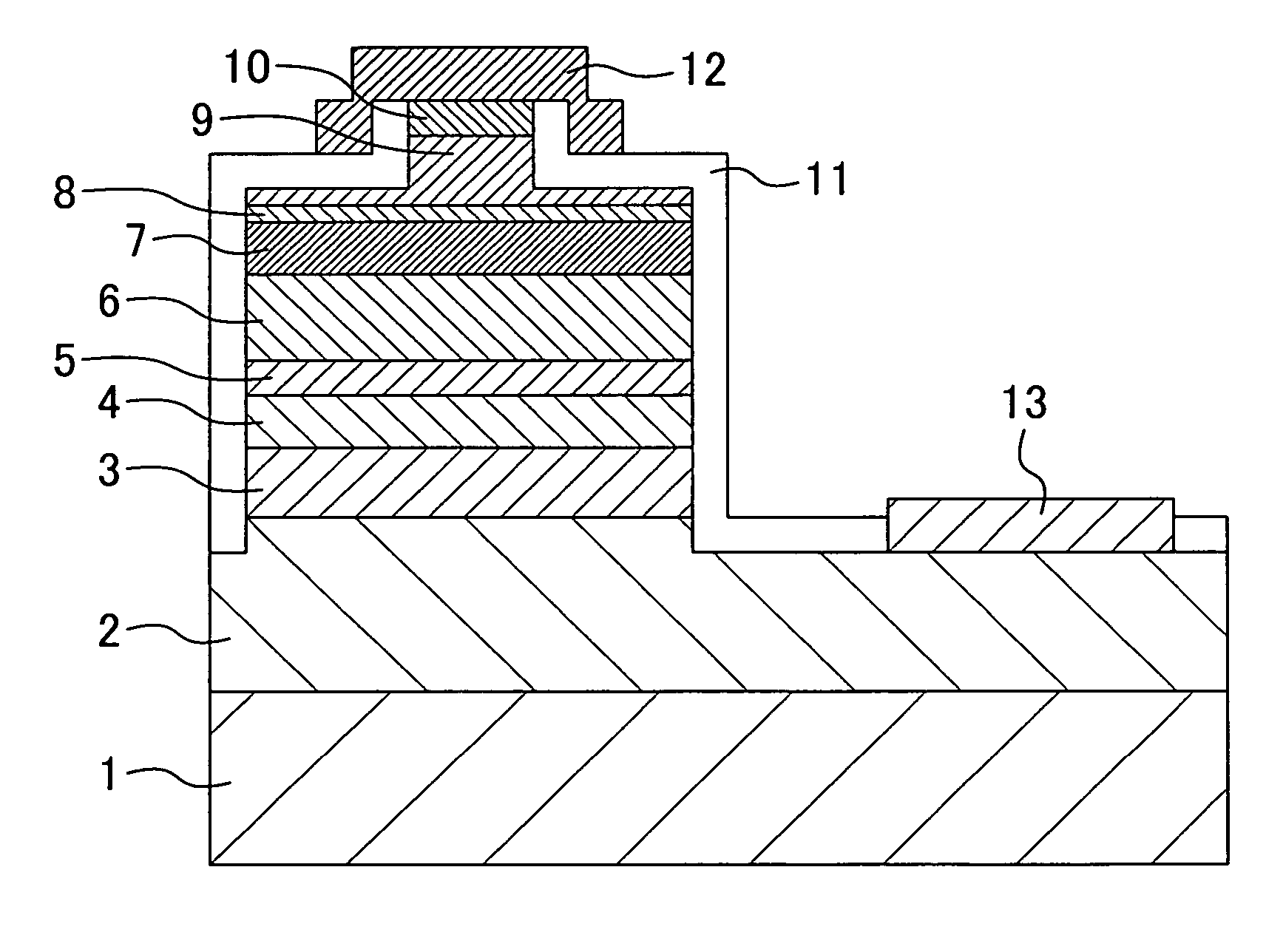

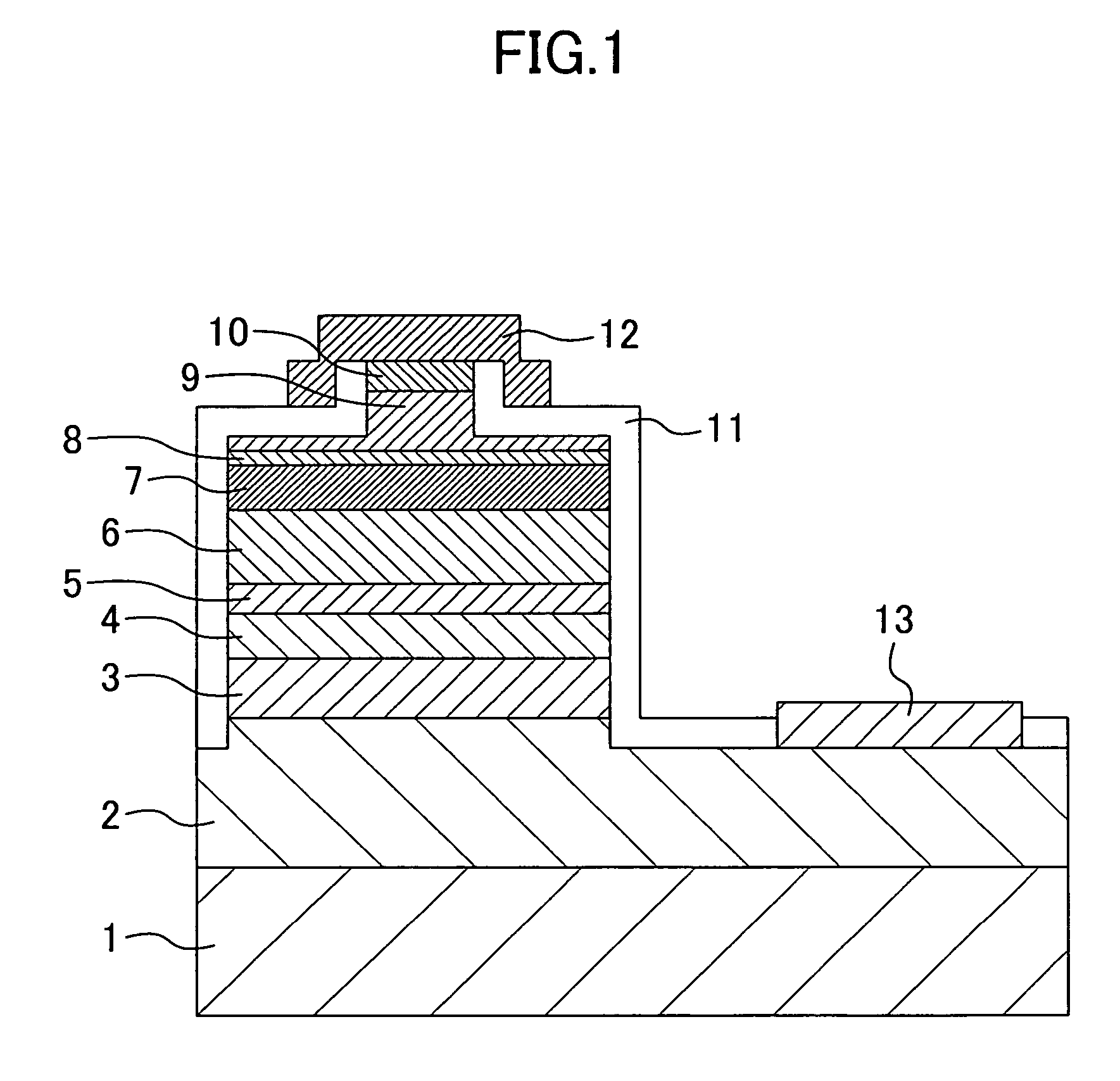

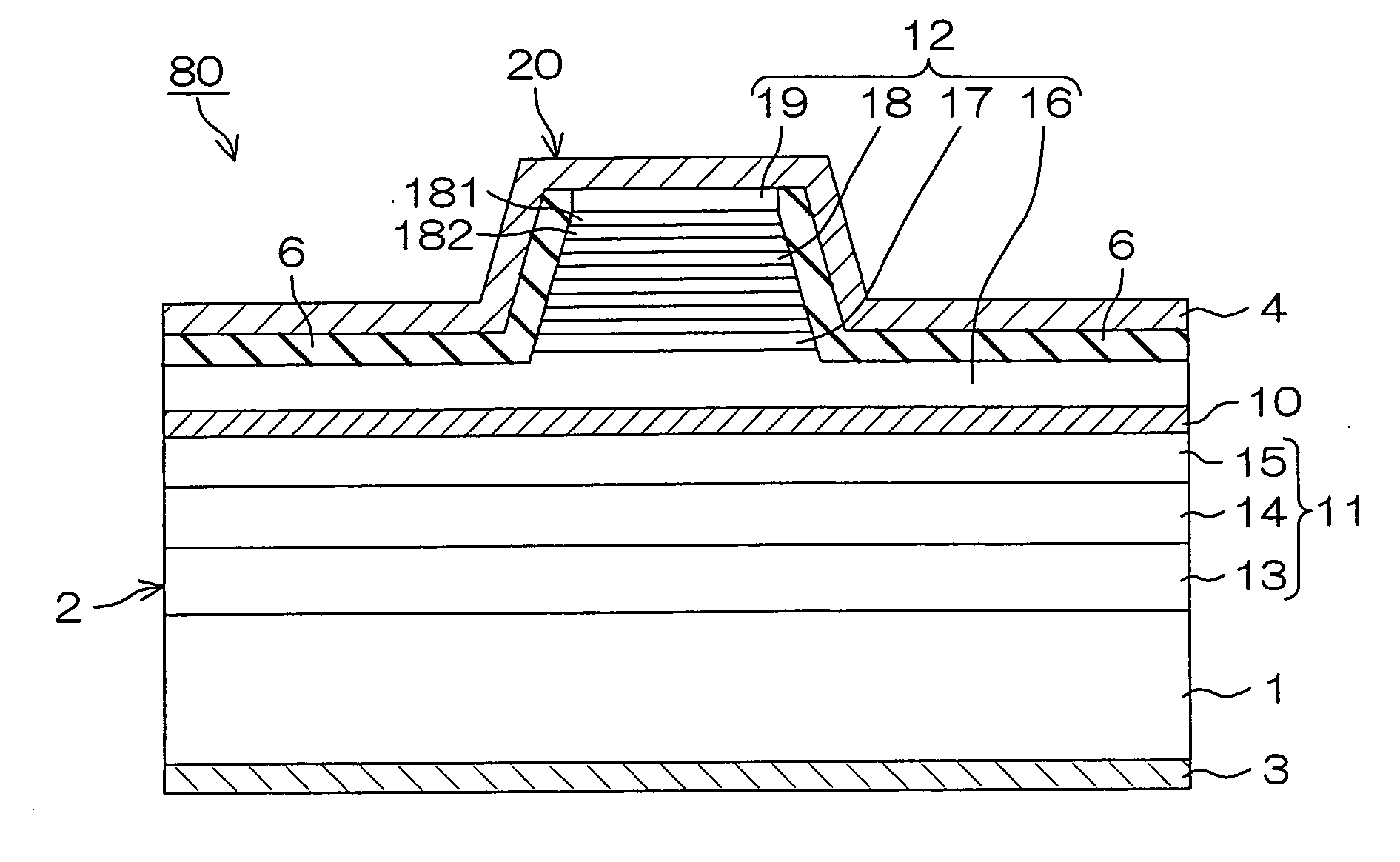

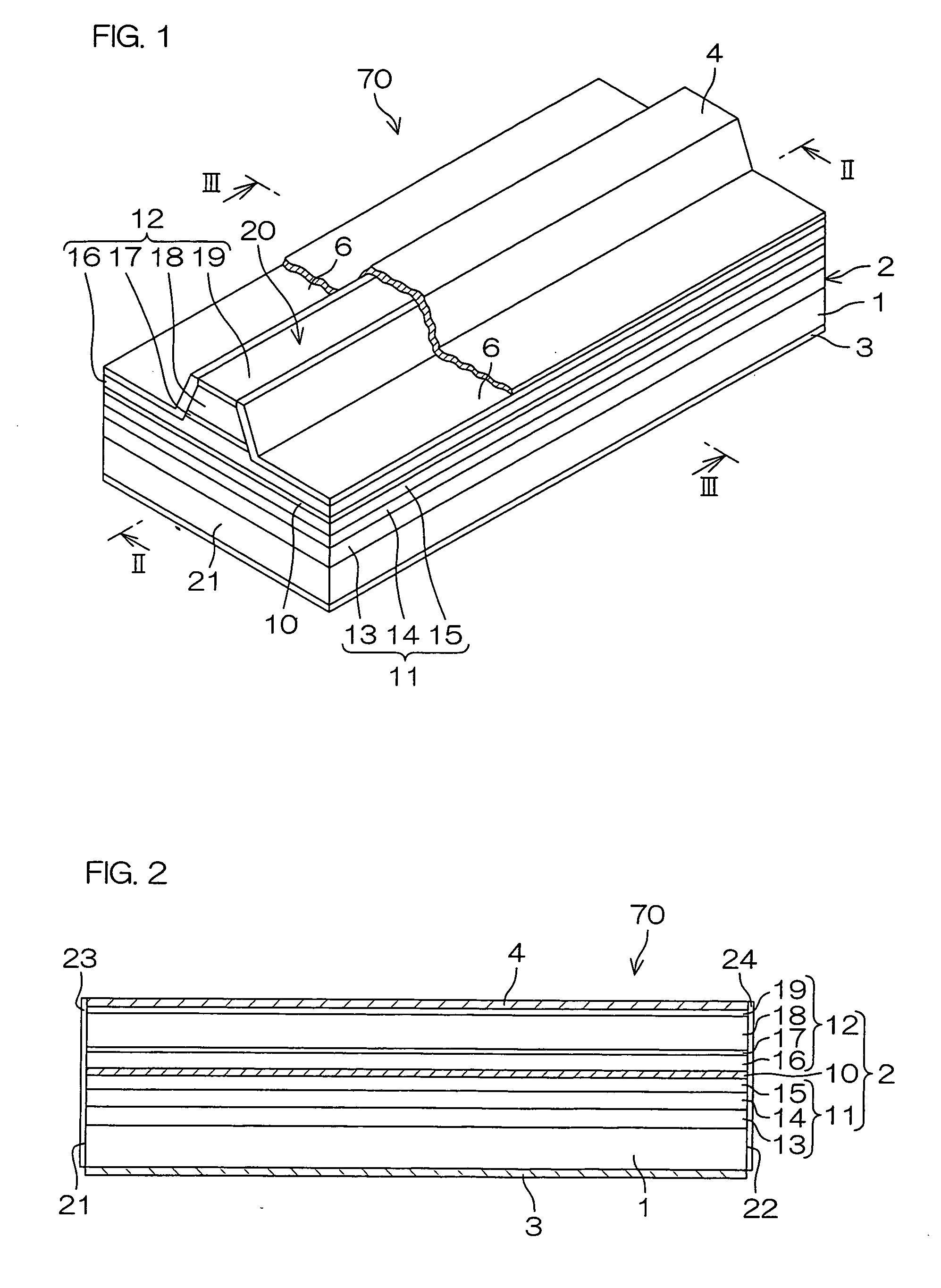

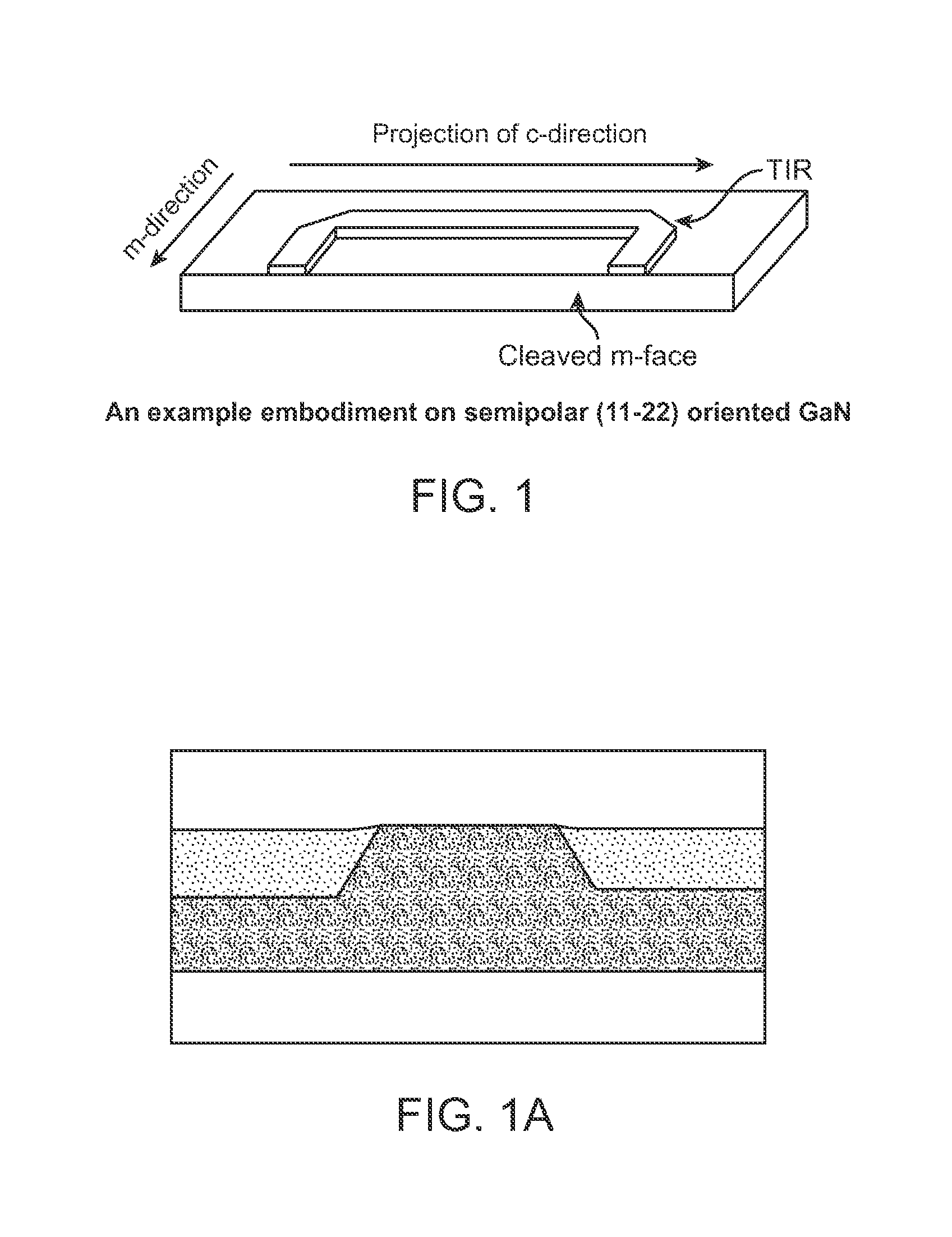

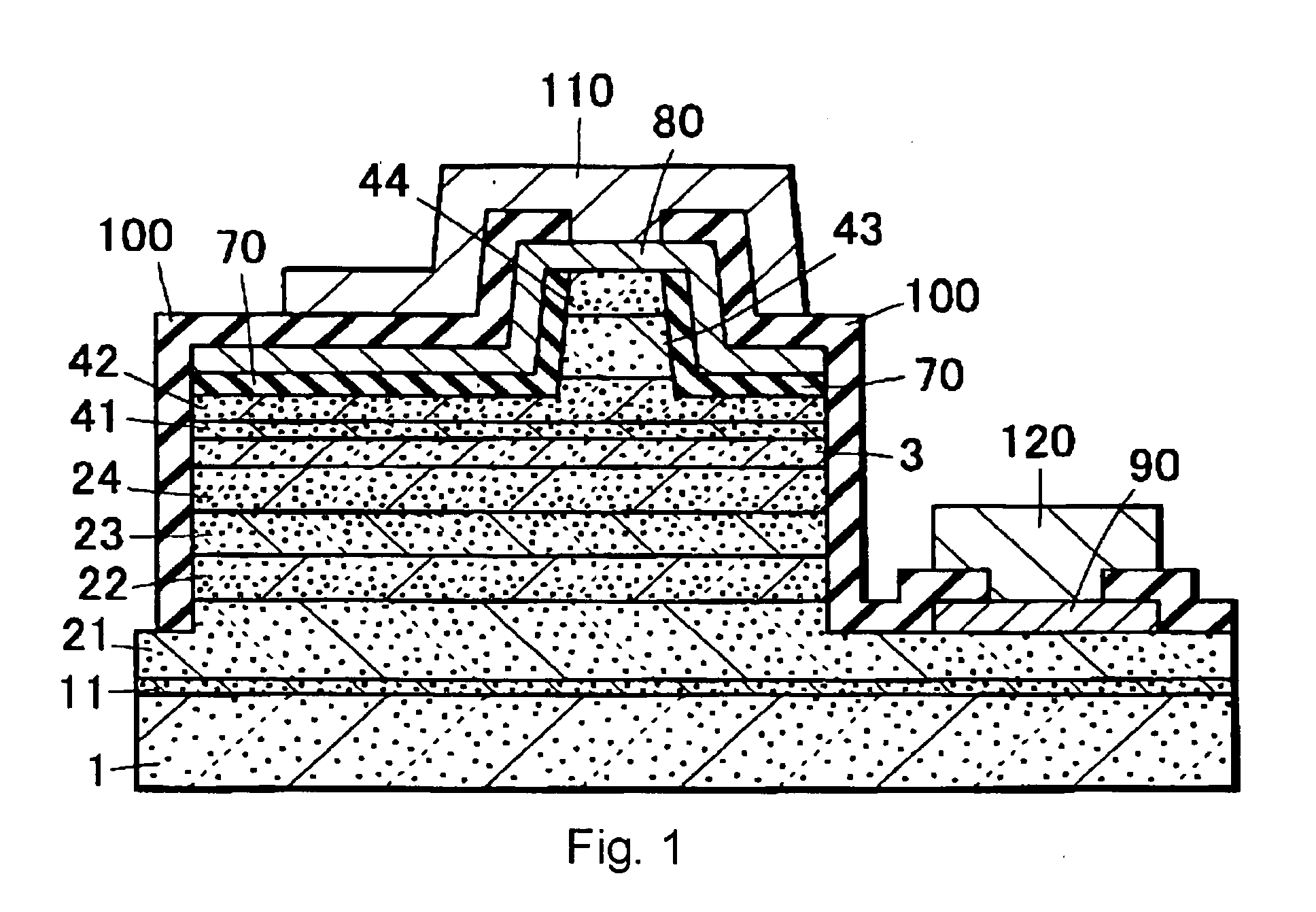

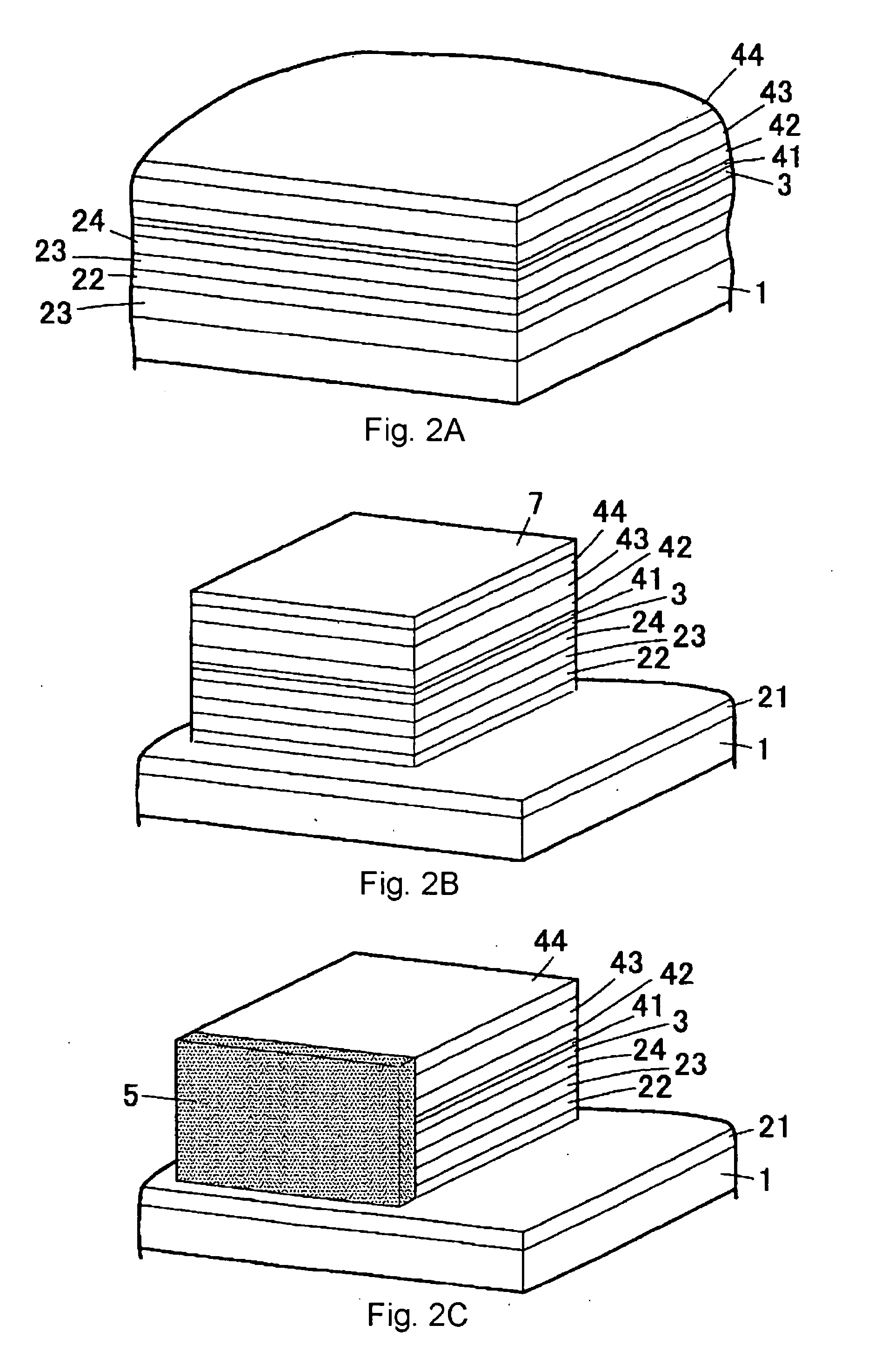

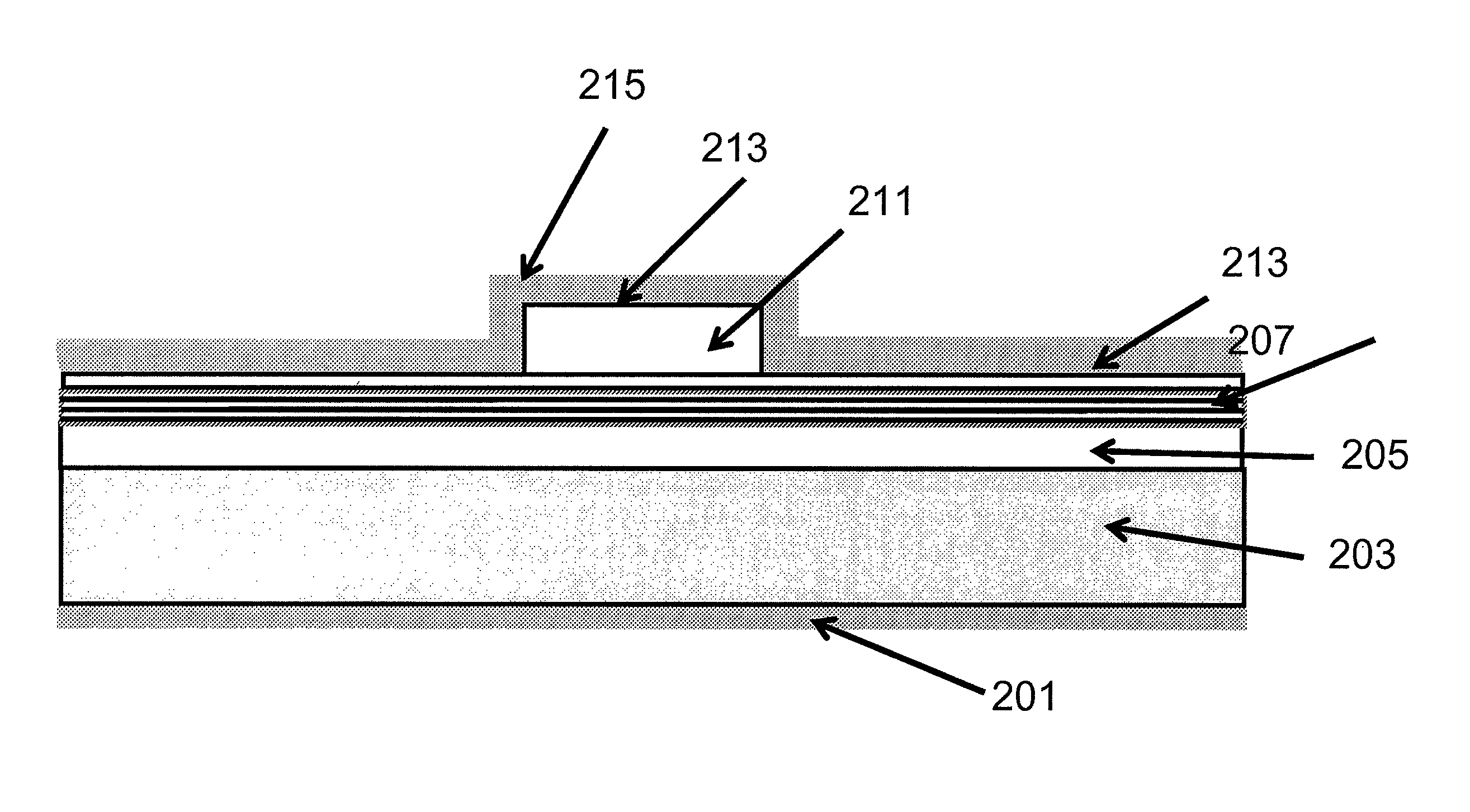

Nitride semiconductor laser device

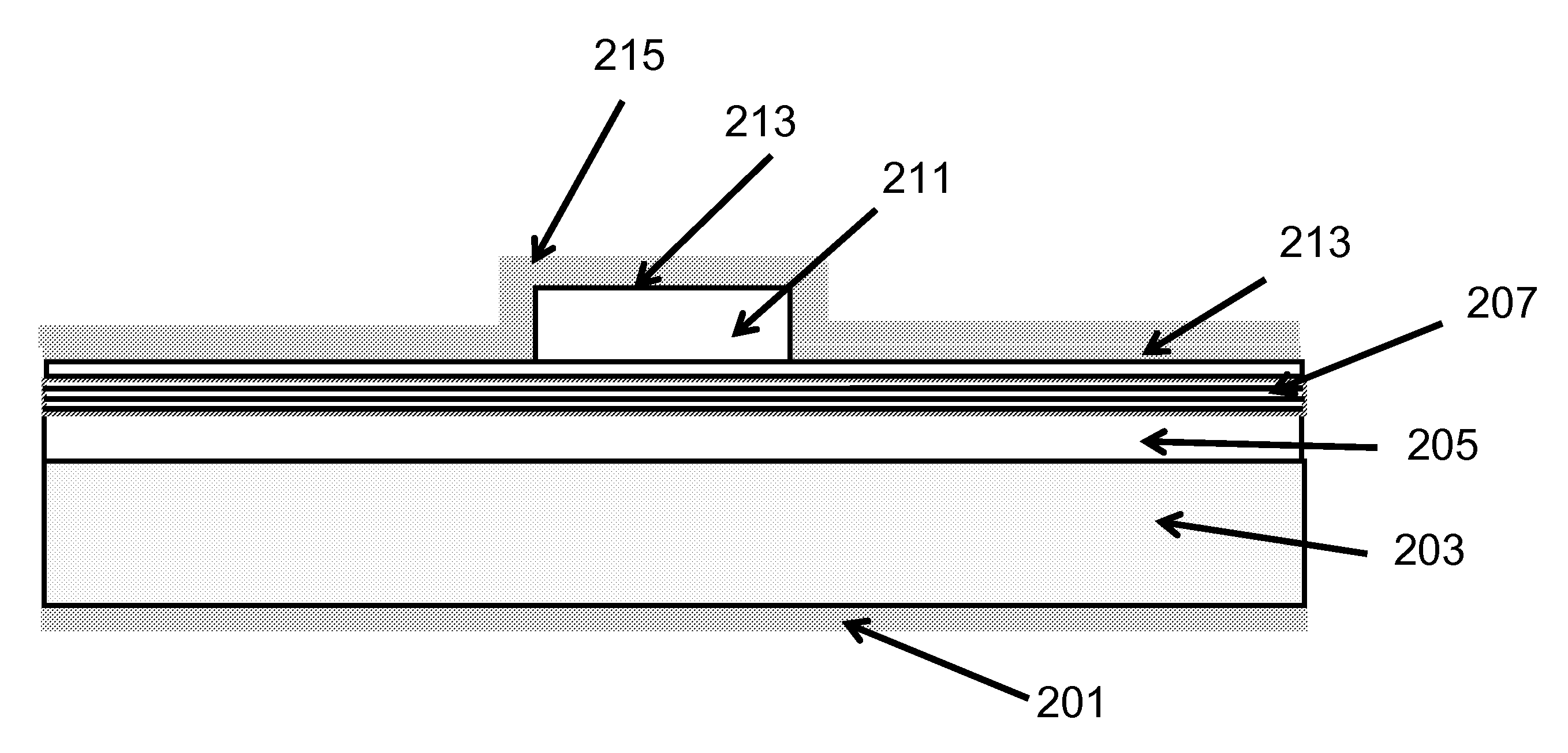

InactiveUS20060078022A1Long lastingStable lateral modeOptical wave guidanceLaser active region structureContact layerTransverse mode

A nitride semiconductor laser device has an improved stability of the lateral mode under high output power and a longer lifetime, so that the device can be applied to write and read light sources for recording media with high capacity. The nitride semiconductor laser device includes an active layer, a p-side cladding layer, and a p-side contact layer laminated in turn. The device further includes a waveguide region of a stripe structure formed by etching from the p-side contact layer. The stripe width provided by etching is within the stripe range of 1 to 3 μm and the etching depth is below the thickness of the p-side cladding layer of 0.1 μm and above the active layer. Particularly, when a p-side optical waveguide layer includes a projection part of the stripe structure and a p-type nitride semiconductor layer on the projection part and the projection part of the p-side optical waveguide layer has a thickness of not more than 1 μm, an aspect ratio is improved in far field image. Moreover, the thickness of the p-side optical waveguide layer is greater than that of an n-side optical waveguide layer.

Owner:NICHIA CORP

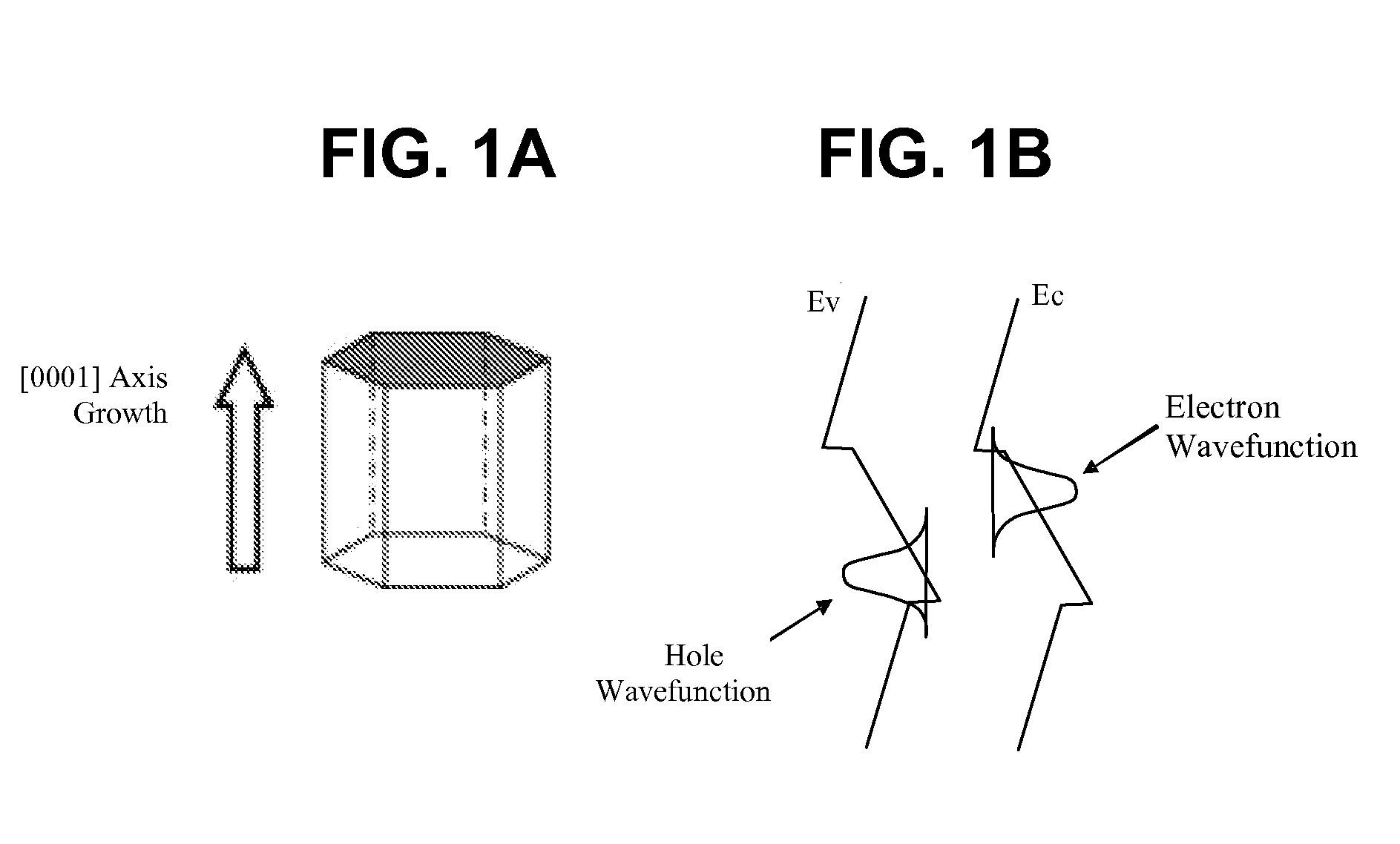

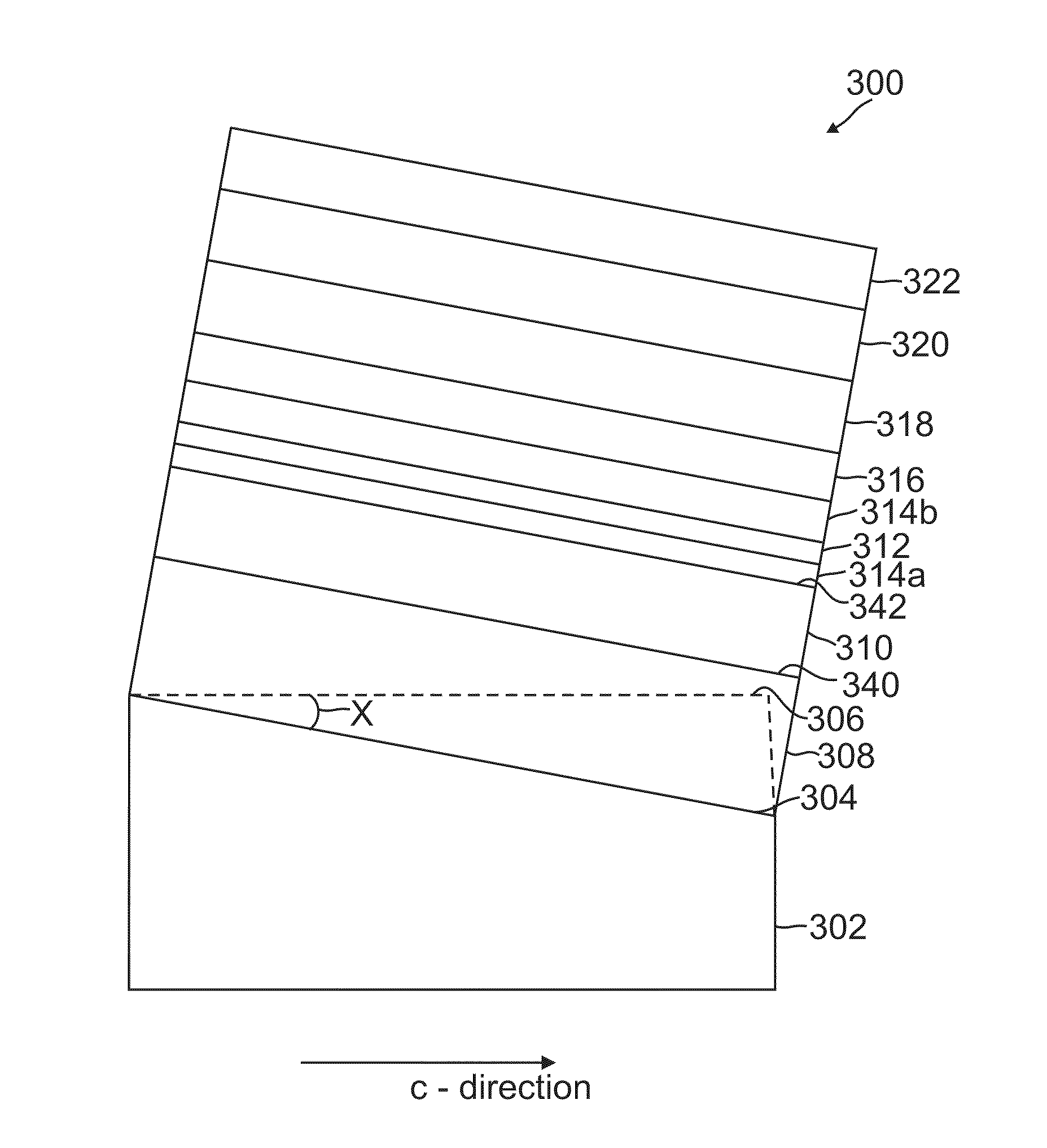

Semi-polar iii-nitride optoelectronic devices on m-plane substrates with miscuts less than +/-15 degrees in the c-direction

ActiveUS20110216795A1QCSE induced dependentIncrease oscillator strengthOptical wave guidanceLaser detailsCrystal planeNitride

An optoelectronic device grown on a miscut of GaN, wherein the miscut comprises a semi-polar GaN crystal plane (of the GaN) miscut x degrees from an m-plane of the GaN and in a c-direction of the GaN, where −15<x<−1 and 1<x<15 degrees.

Owner:RGT UNIV OF CALIFORNIA

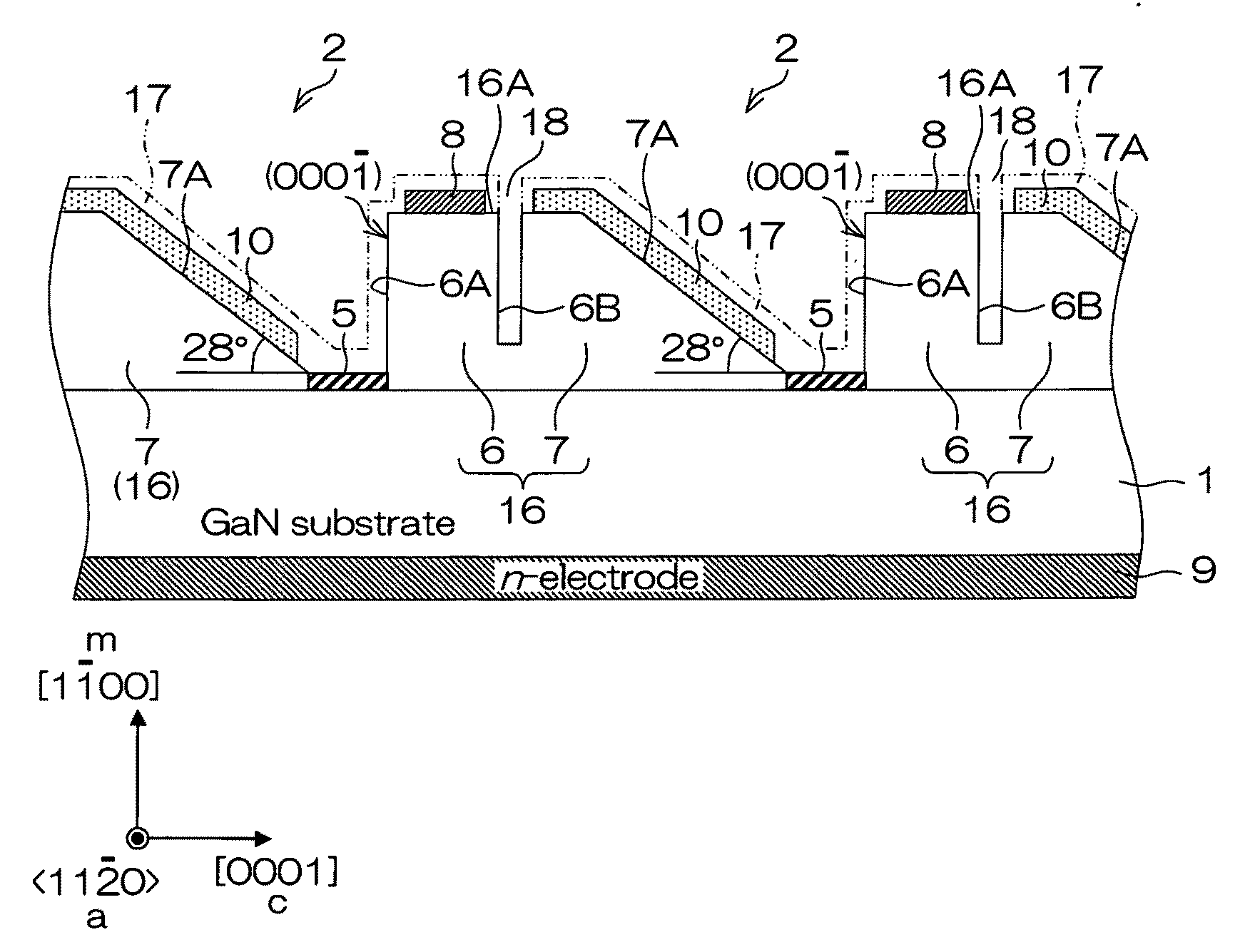

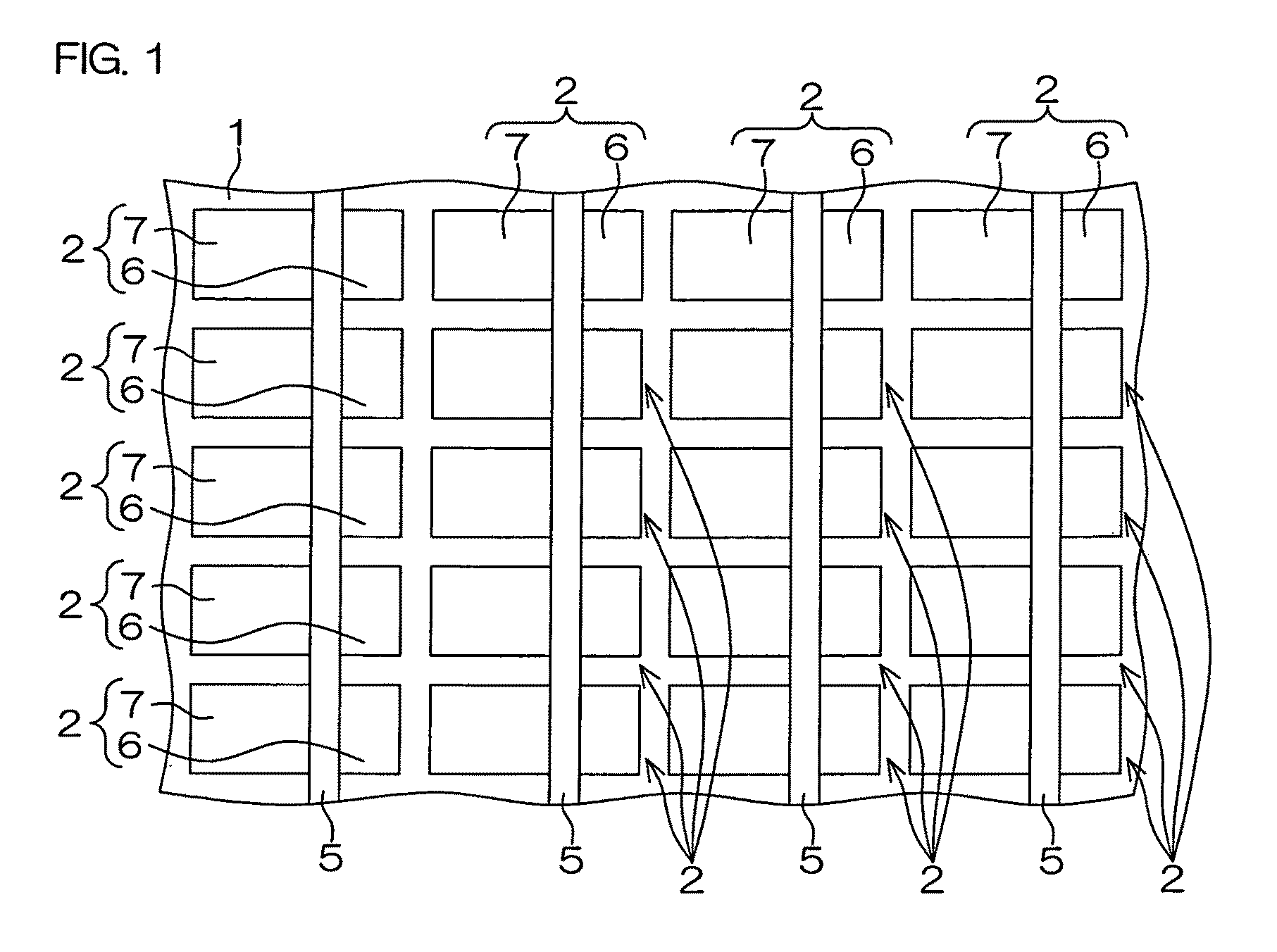

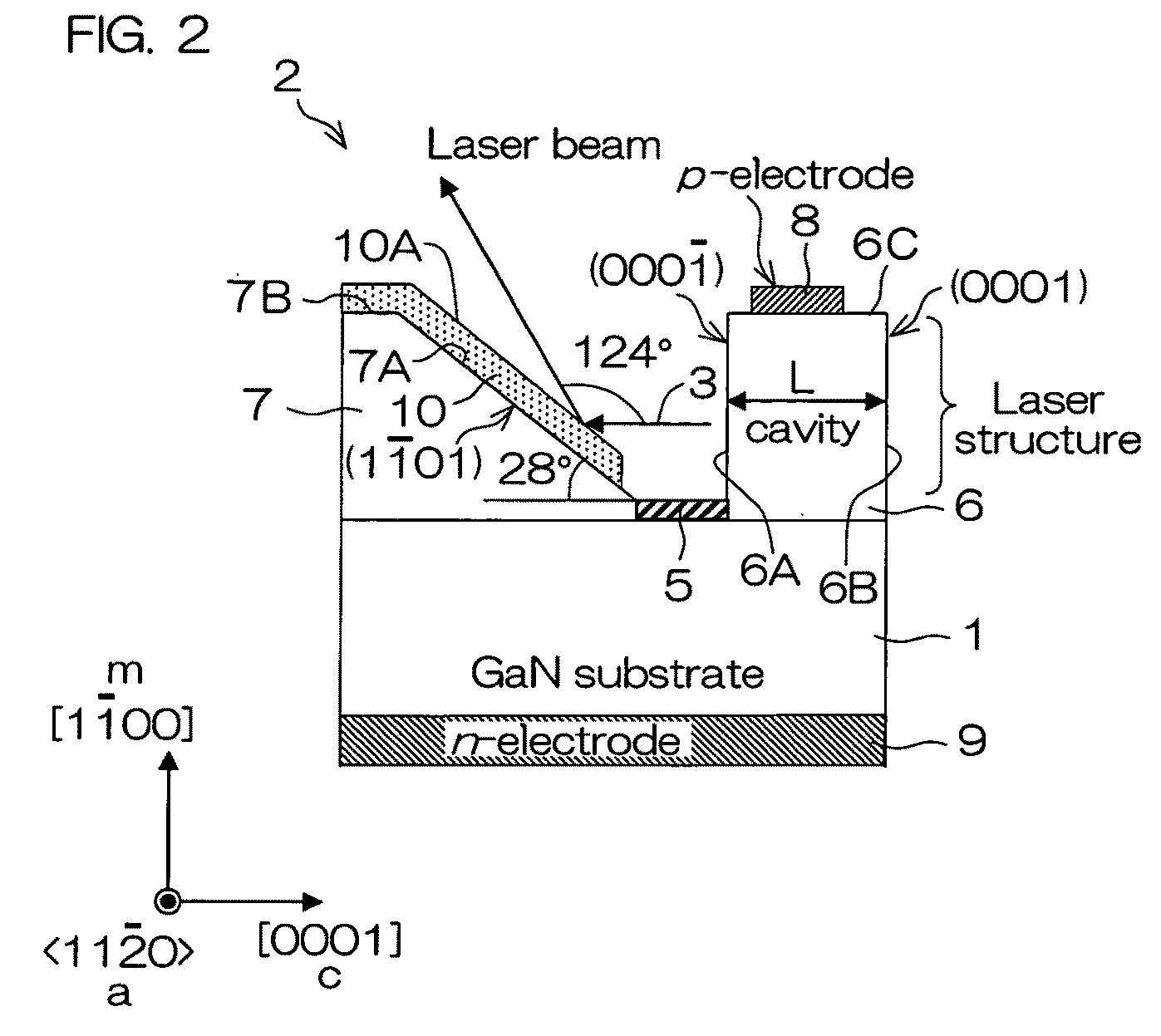

Light emitting device and method of manufacturing the same

InactiveUS20090078944A1High gainSimple stepsOptical wave guidanceLaser detailsOptical cavityLight emitting device

This semiconductor light emitting device includes an optical cavity made of a group III nitride semiconductor having a major growth surface defined by a nonpolar plane and including a pair of cavity end faces parallel to c-planes, and a reflecting portion made of a group III nitride semiconductor having a major growth surface defined by a nonpolar plane and having a reflective facet opposed to one of the pair of cavity end faces and inclined with respect to a normal of the major growth surface. The optical cavity and the reflecting portion may be crystal-grown from the major surface of the substrate. The substrate is preferably a group III nitride semiconductor substrate having a major surface defined by a nonpolar plane.

Owner:ROHM CO LTD

Semiconductor light-emitting device

A semiconductor light-emitting device capable of attaining a surface plasmon effect while attaining excellent ohmic contact is provided. This semiconductor light-emitting device comprises a semiconductor layer formed on an emission layer, a first electrode layer formed on the semiconductor layer and a second electrode layer, formed on the first electrode layer, having a periodic structure. The first electrode layer is superior to the second electrode layer in ohmic contact with respect to the semiconductor layer, and the second electrode layer contains a metal exhibiting a higher plasma frequency than the first electrode layer.

Owner:EPISTAR CORP

Semiconductor light-emitting device

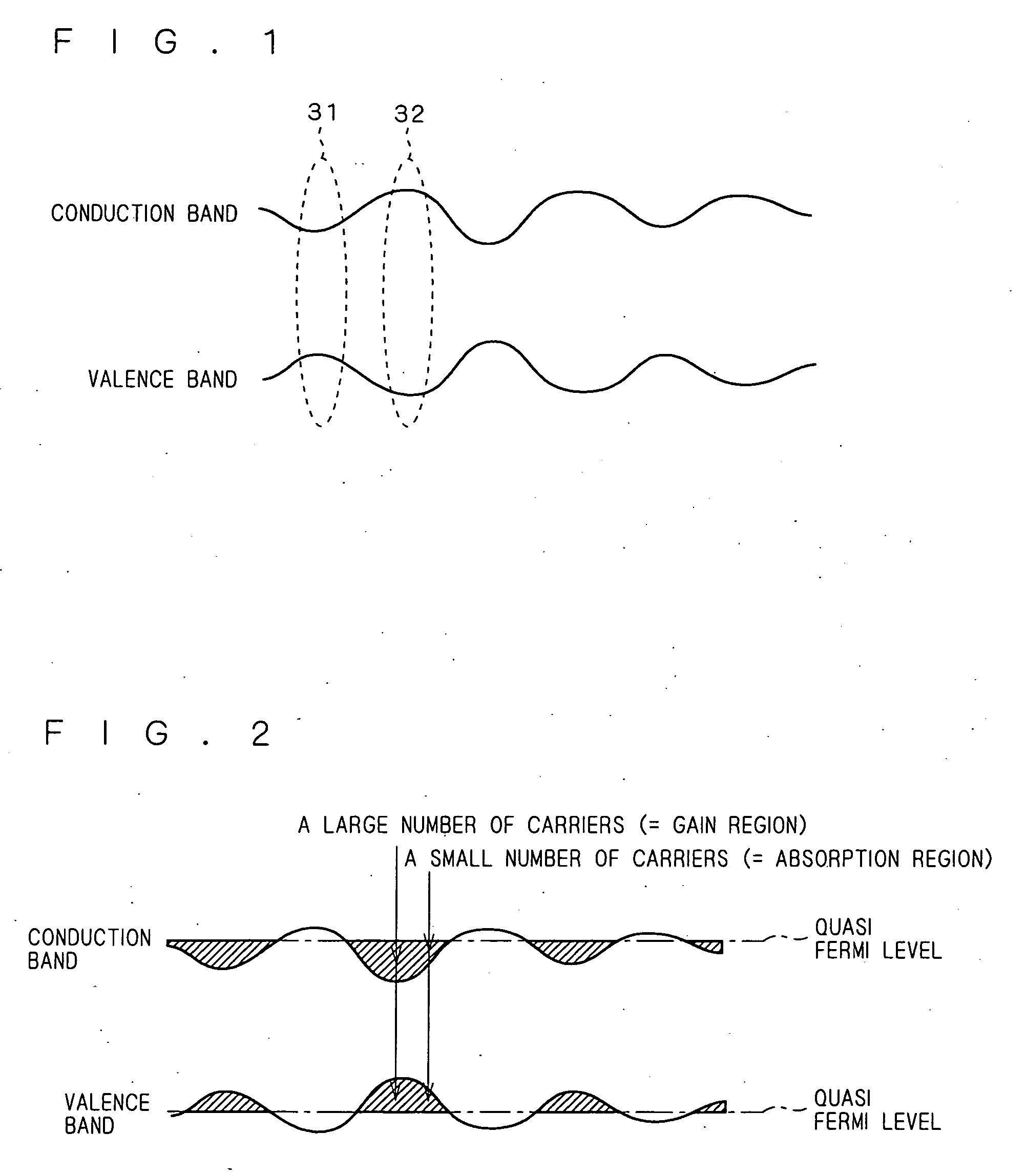

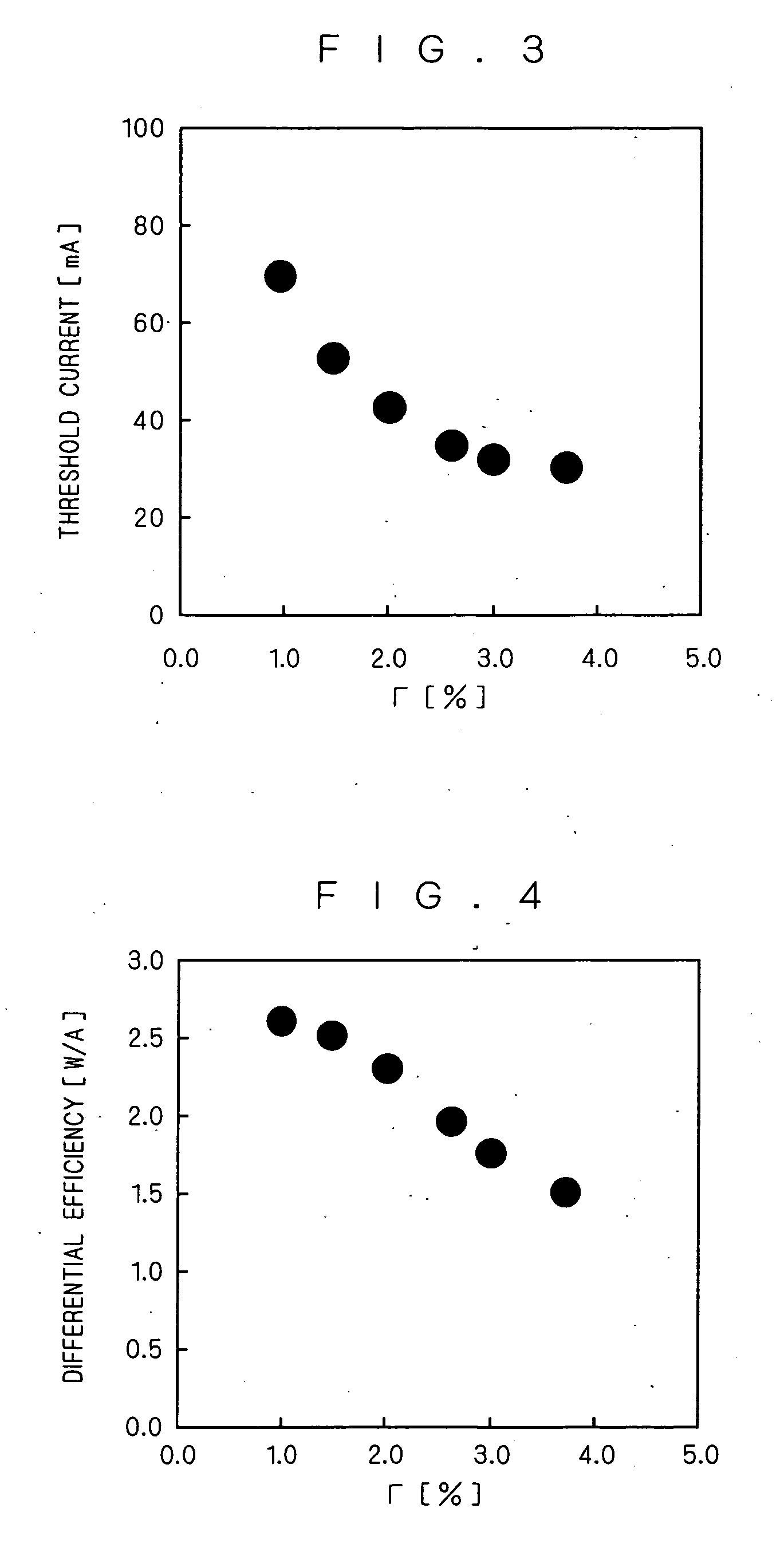

In a semiconductor laser having an active layer of double-quantum-well structure that includes two InGaN well layers each of which has a thickness of 5 nm, a threshold current deteriorates to a relatively small degree while differential efficiency is improved considerably in a region having a light confinement coefficient Γ of 3.0% or less. On the other hand, with the light confinement coefficient Γ becoming less than 1.5%, the threshold current increases considerably while the amount of improvement in differential efficiency becomes small. It is therefore preferable that the lowest limit to the light confinement coefficient Γ be about 1.5%. The differential efficiency of 1.6 W / A or more is obtained with the light confinement coefficient Γ being 3.0% or less, and the differential efficiency of 1.7 W / A or more is obtained with the light confinement coefficient Γ being 2.6% or less.

Owner:MITSUBISHI ELECTRIC CORP

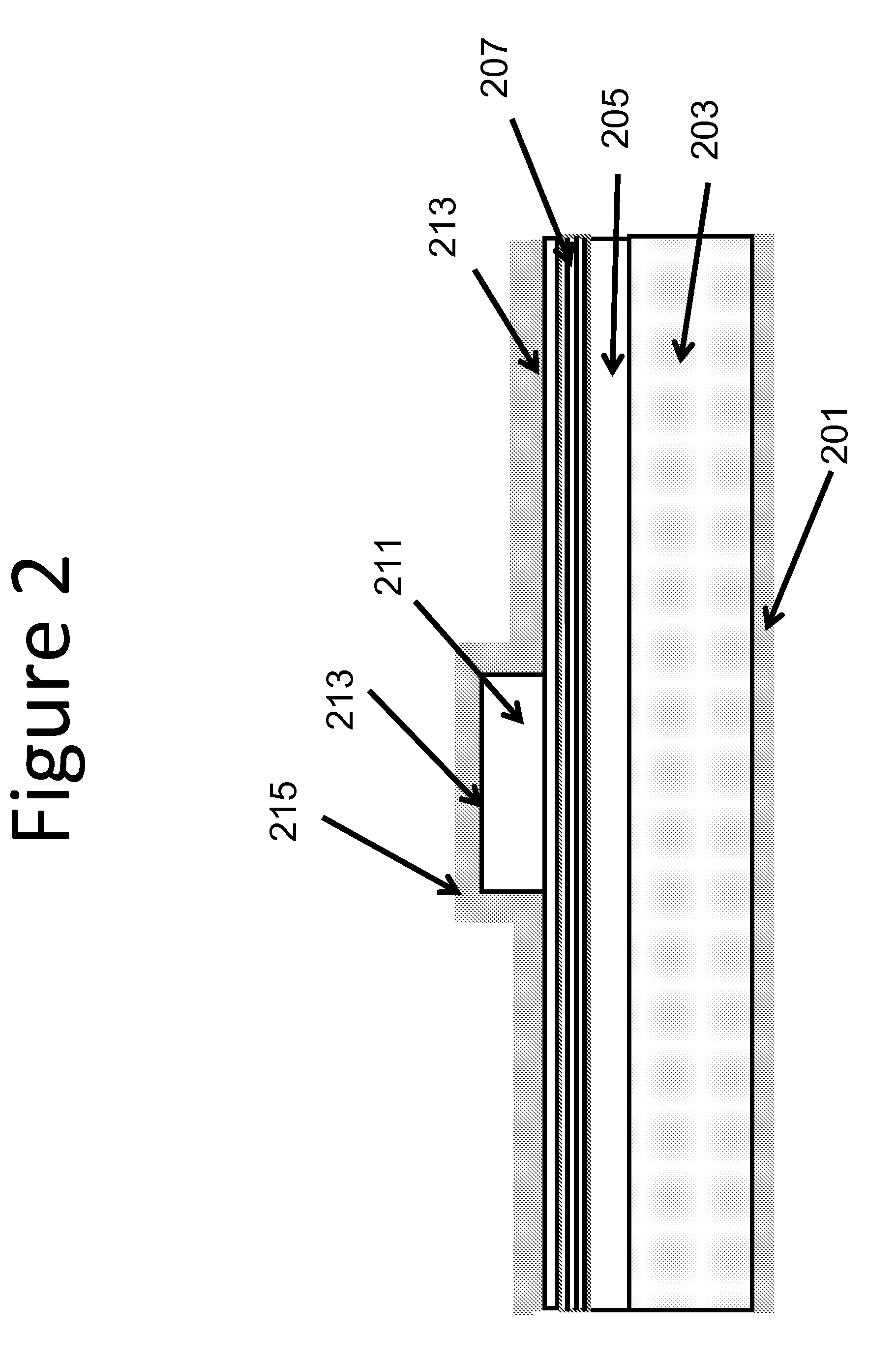

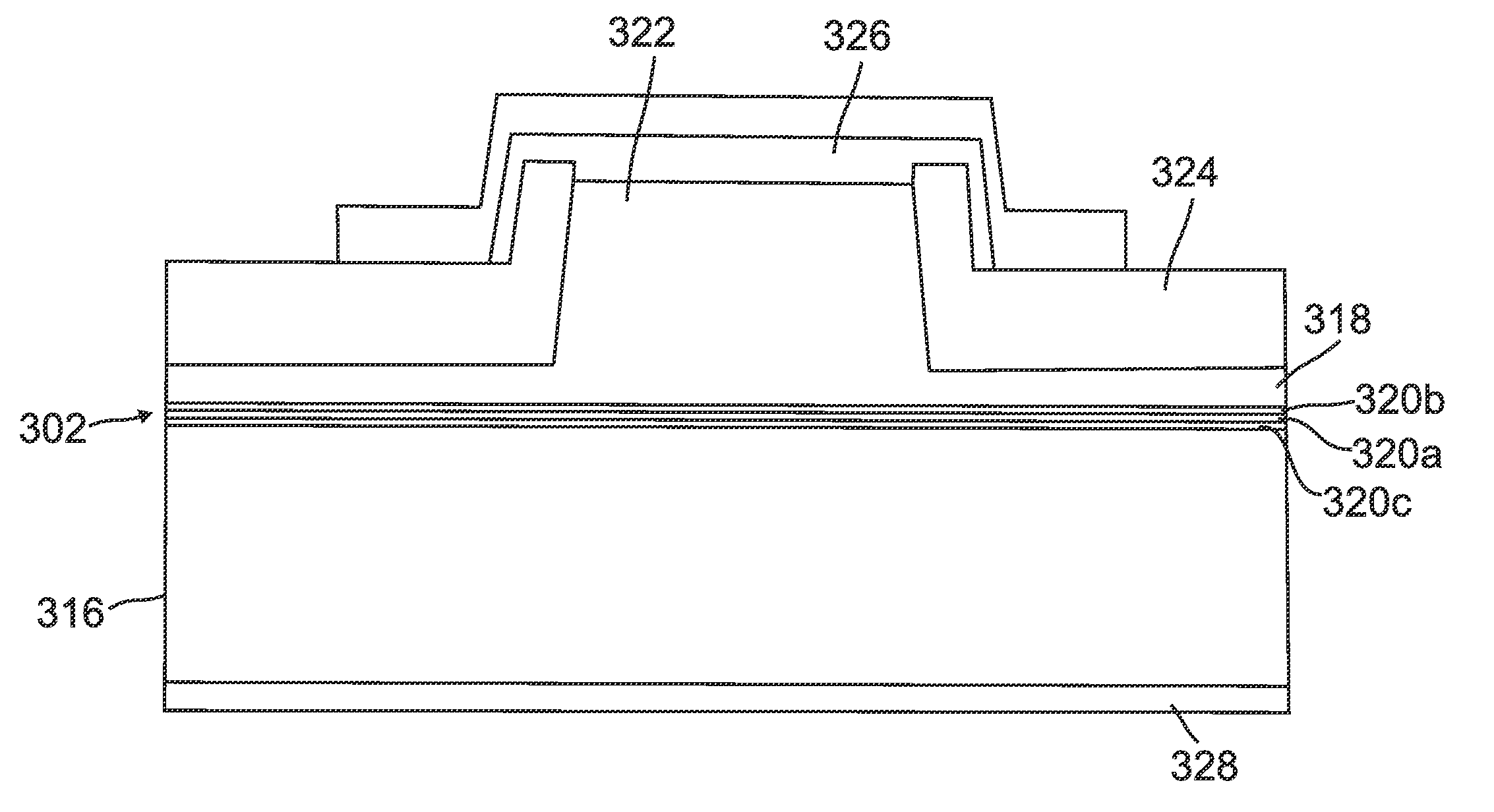

Growth Structures and Method for Forming Laser Diodes on or Off Cut Gallium and Nitrogen Containing Substrates

ActiveUS20110064102A1Improved cleavesCost-effectiveOptical wave guidanceLaser detailsNitrogenLength wave

Owner:KYOCERA SLD LASER INC

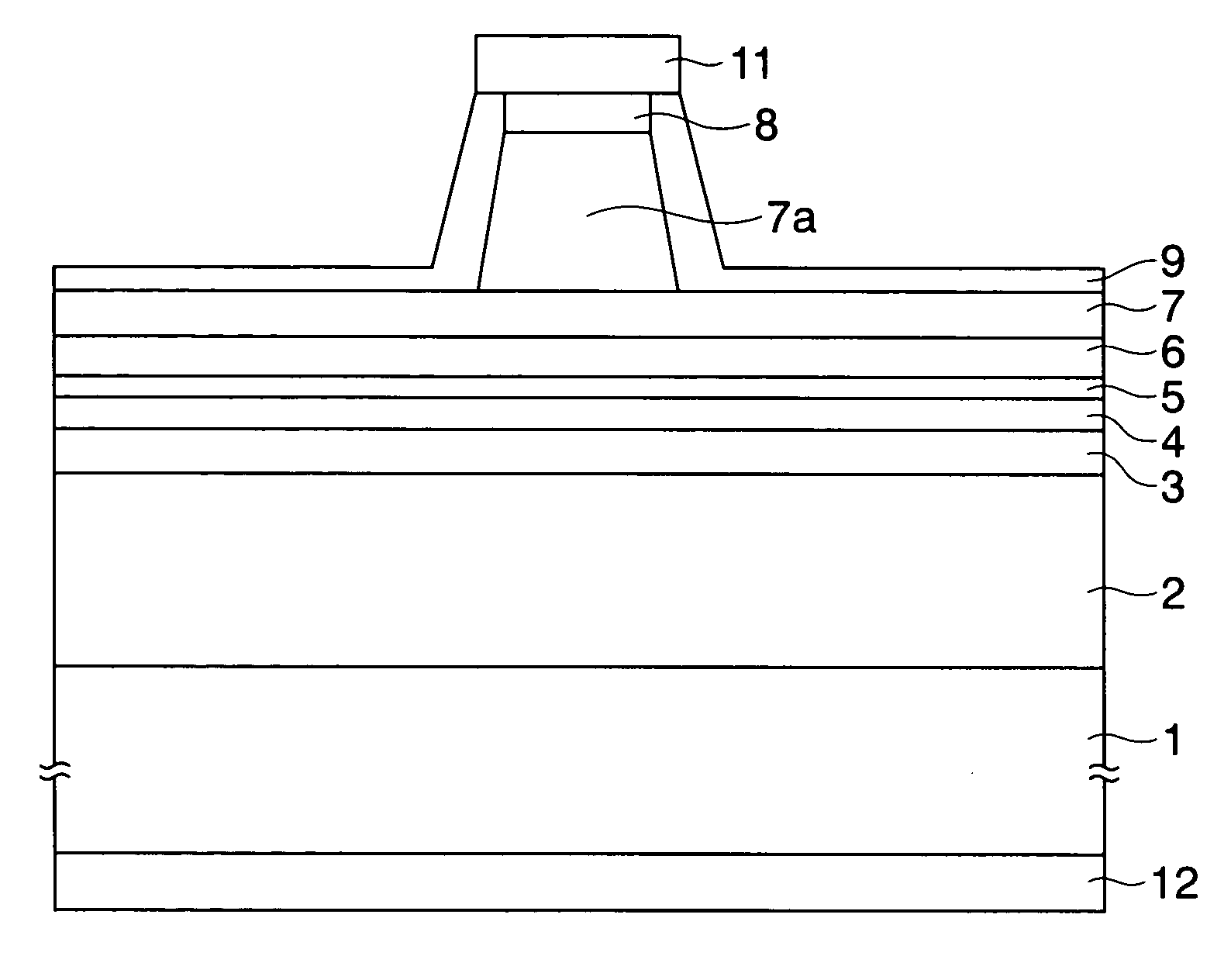

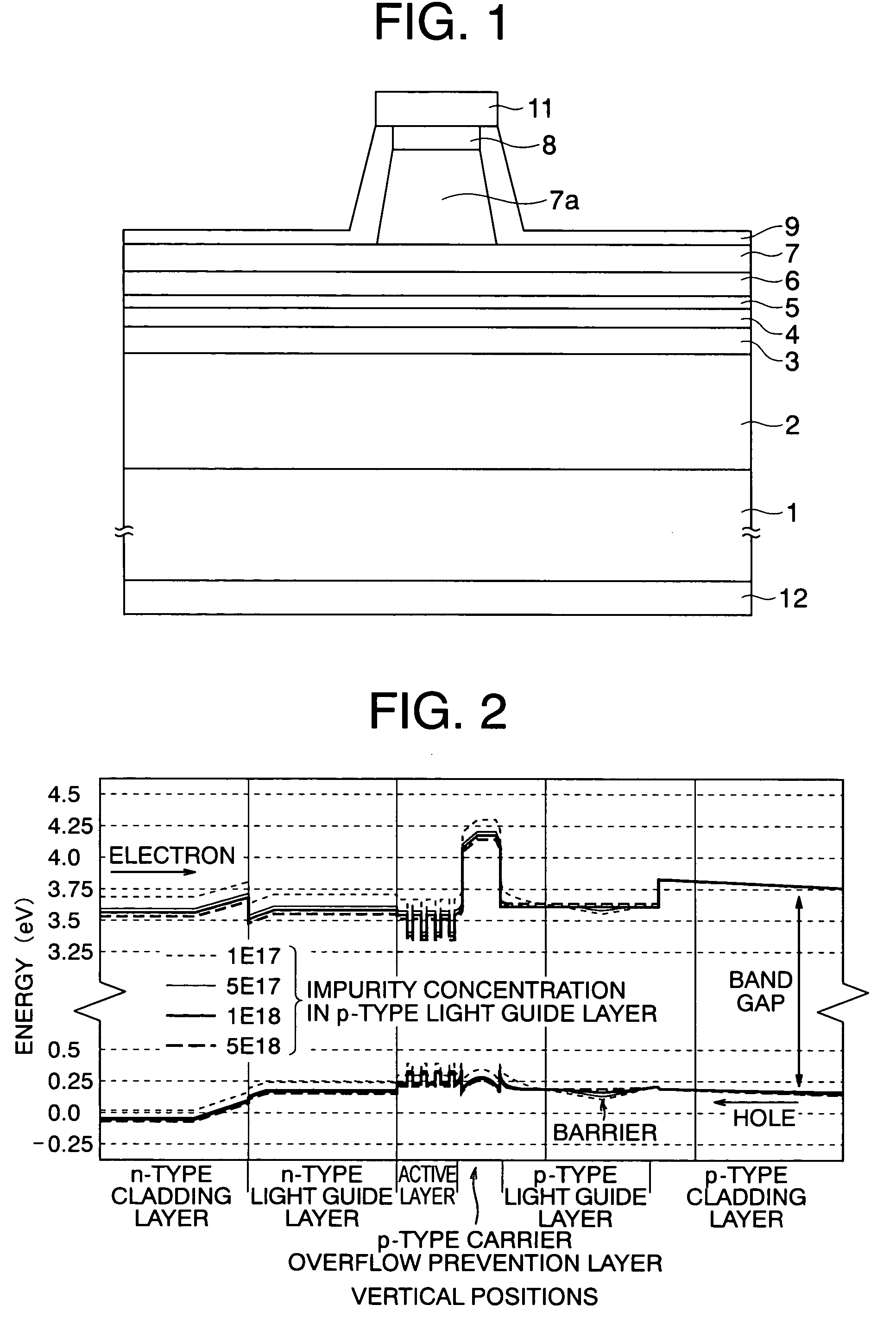

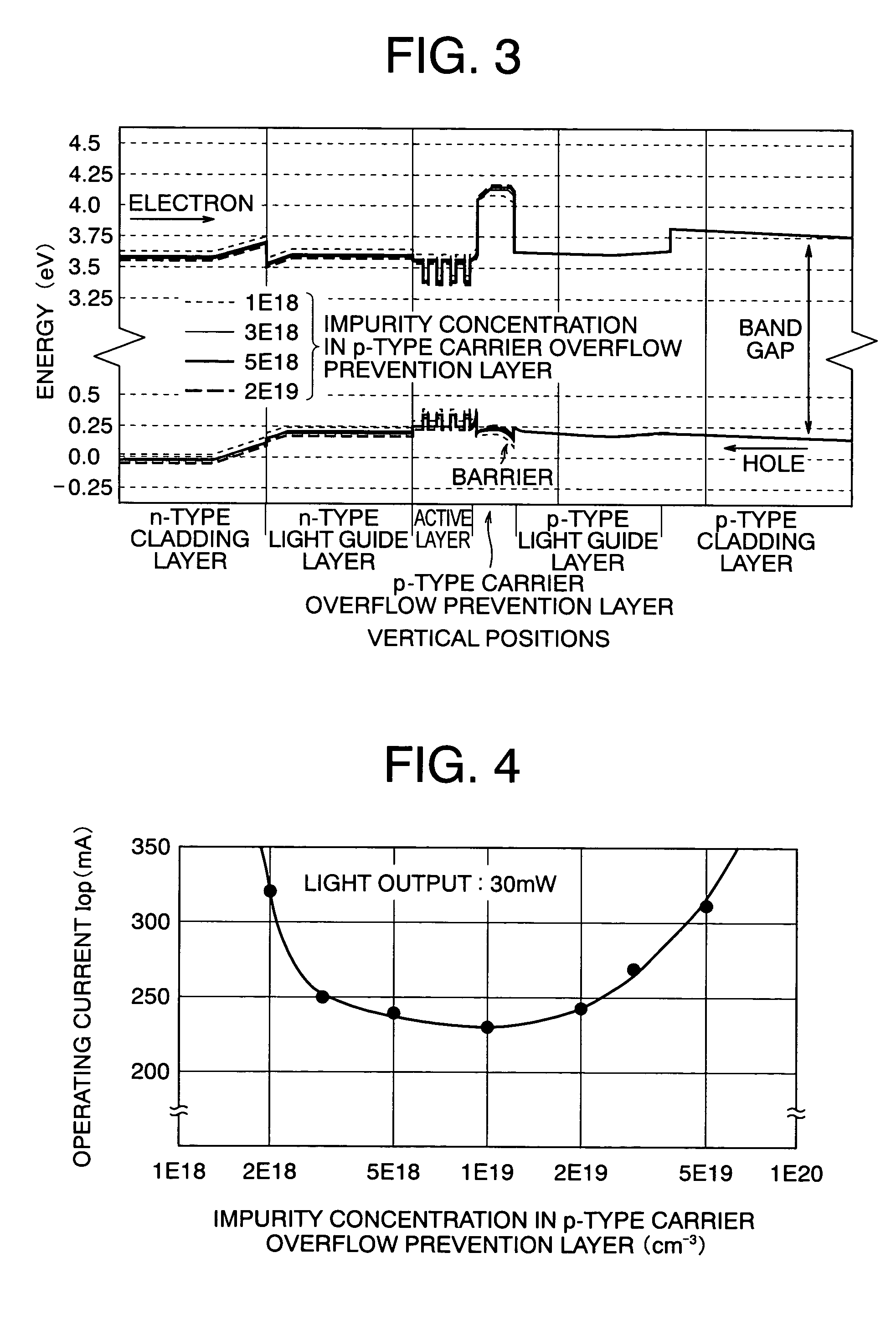

Semiconductor light-emitting element and method of manufacturing the same

Disclosed is a semiconductor light-emitting element, comprising an n-type-cladding layer; a light guide layer positioned on the n-type cladding layer; a multiple quantum well structure active layer positioned on the light guide layer; a p-type carrier overflow prevention layer positioned on the active layer and having an impurity concentration of 5×1018 cm−3 to not more than 3×1019 cm−3; a p-type light guide layer positioned on the p-type carrier overflow prevention layer and-having an impurity concentration of 1×1018 cm−3 or more and less-than that of the p-type carrier overflow prevention layer; and a p-type cladding layer positioned on the p-type light guide layer and having a band gap narrower than the p-type carrier overflow prevention layer, and a method of manufacturing the same.

Owner:KK TOSHIBA

Nitride semiconductor light emitting device and method of fabricating nitride semiconductor laser device

ActiveUS20080291961A1High output without impairing reliabilityImprove the level ofOptical wave guidanceLaser detailsNitrogen oxideLight emitting device

There is provided a nitride semiconductor light emitting device having a light emitting portion coated with a coating film, the light emitting portion being formed of a nitride semiconductor, the coating film in contact with the light emitting portion being formed of an oxynitride. There is also provided a method of fabricating a nitride semiconductor laser device having a cavity with a facet coated with a coating film, including the steps of: providing cleavage to form the facet of the cavity; and coating the facet of the cavity with a coating film formed of an oxynitride.

Owner:SHARP FUKUYAMA LASER CO LTD

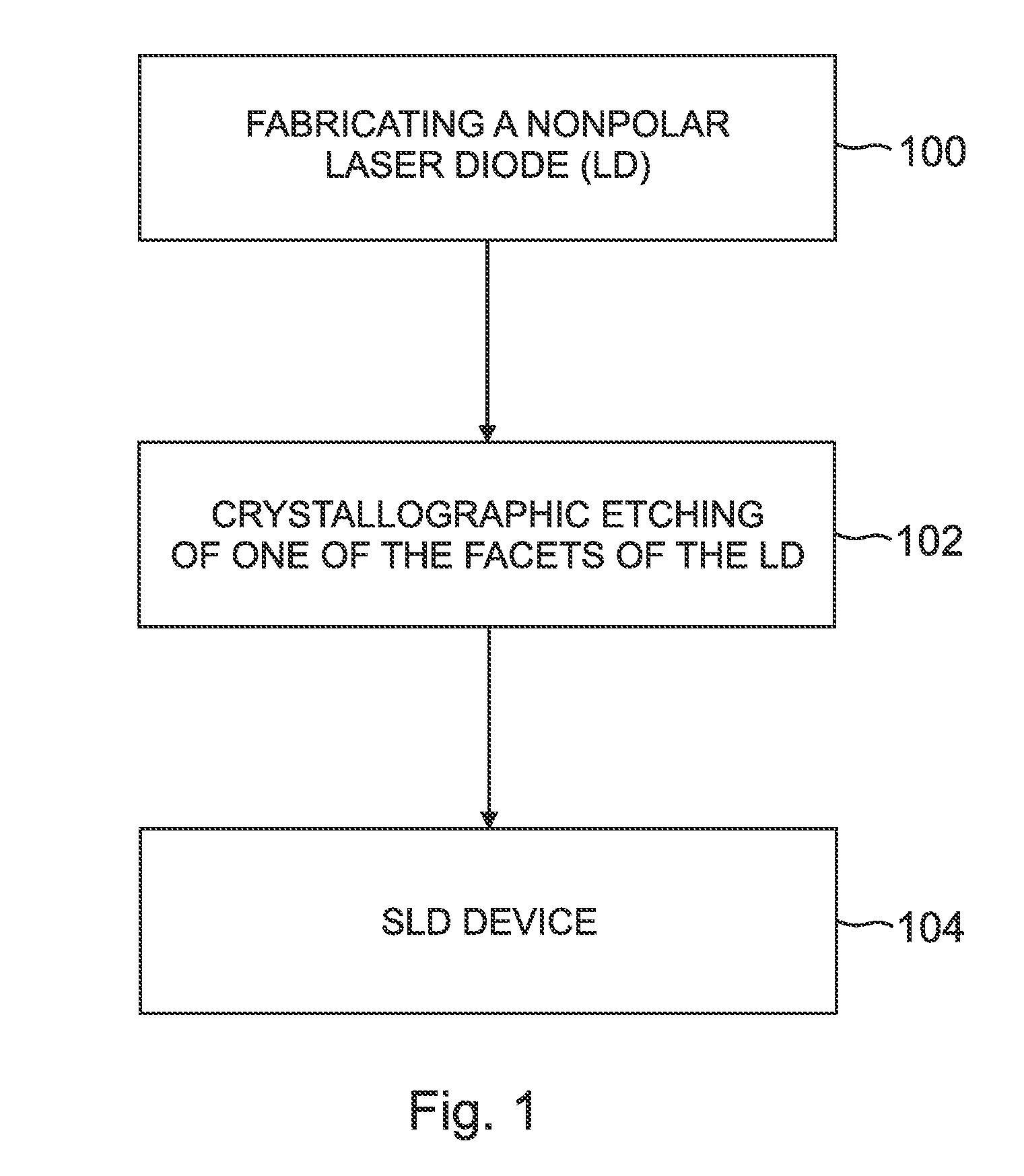

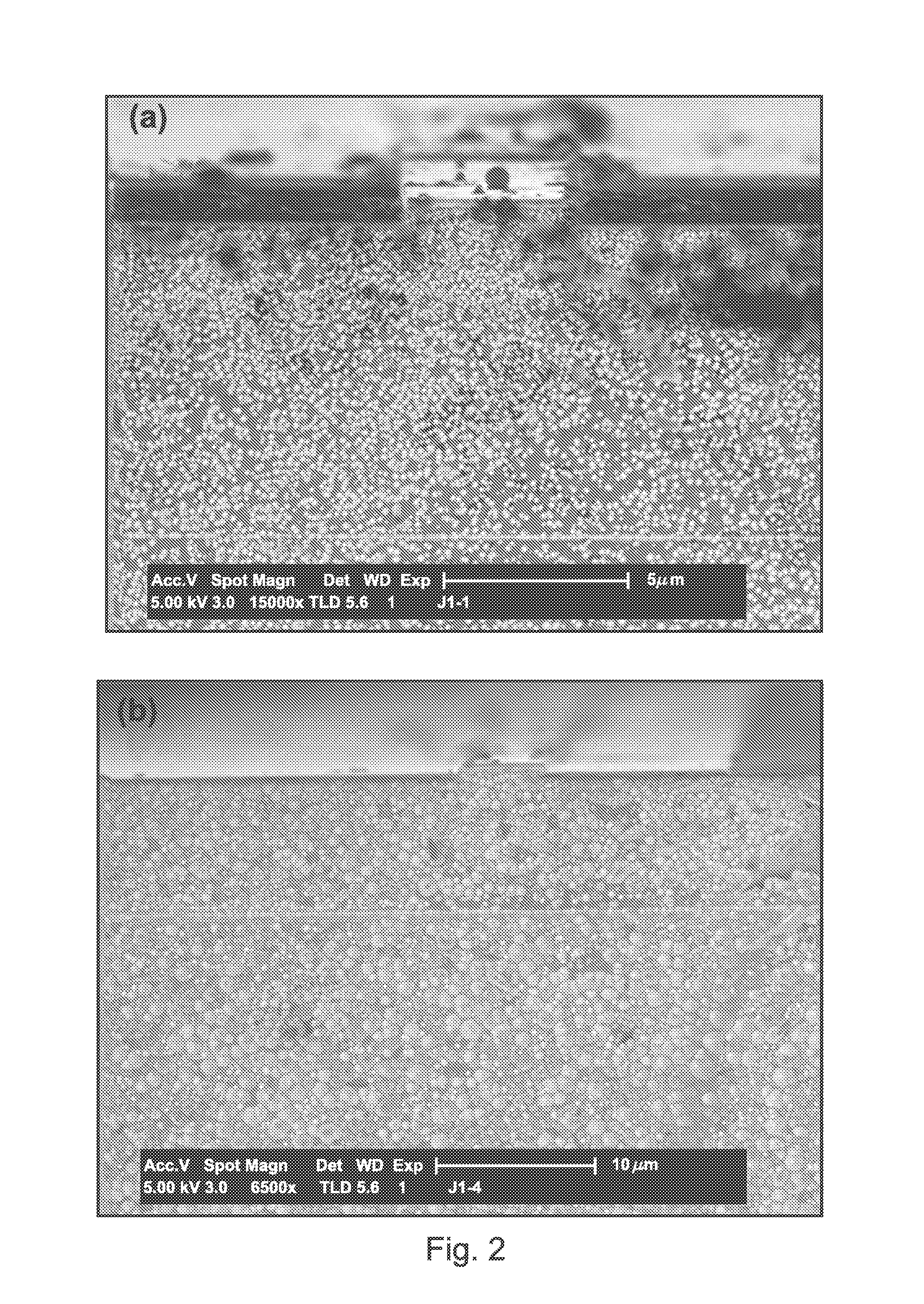

Superluminescent diodes by crystallographic etching

InactiveUS20110103418A1Reduce internal lossSignificant contributionOptical wave guidanceLaser detailsSuperluminescent diodeEtching

An optoelectronic device, comprising an active region and a waveguide structure to provide optical confinement of light emitted from the active region; a pair of facets on opposite ends of the device, having opposite surface polarity; and one of the facets which has been roughened by a crystallographic chemical etching process, wherein the device is a nonpolar or semipolar (Ga,In,Al,B)N based device.

Owner:RGT UNIV OF CALIFORNIA

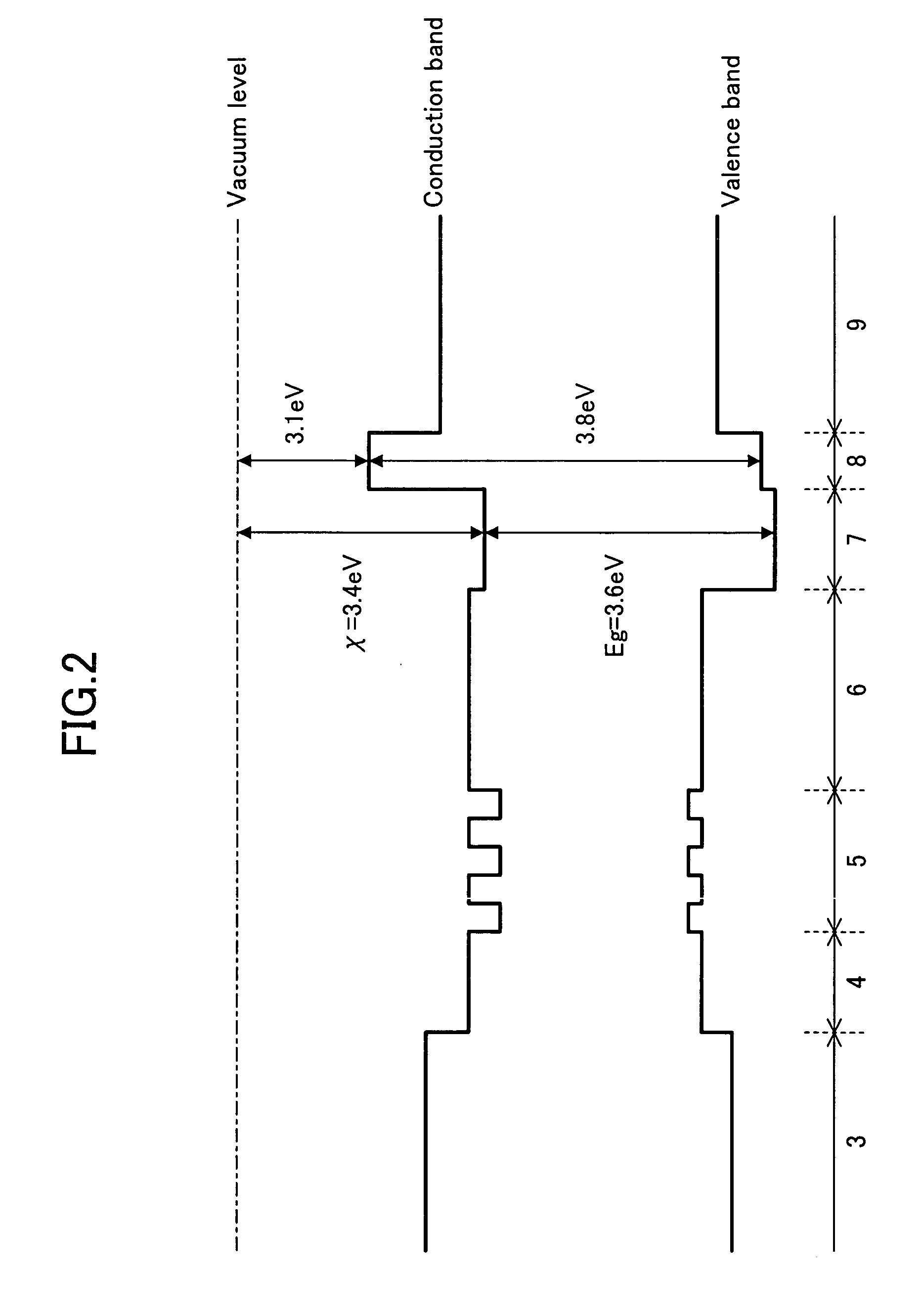

Group III nitride semiconductor light emitting device

InactiveUS20070110112A1Increase fixed chargeEasy to overflowOptical wave guidanceSolid-state devicesElectron blocking layerActive layer

A group III nitride semiconductor light emitting device according to the present invention includes an immediate layer formed of AlxGa1-x-yInyN (0<x<1, 0<y<1, x+y<1) between an active layer and a cladding layer and an electron blocking layer formed of p-type group III nitride semiconductor having a smaller electron affinity than that of the intermediate layer so as to be in contact with the intermediate layer. The semiconductor light emitting layer may be a laser diode or a LED.

Owner:PANASONIC CORP

Nitride semiconductor laser device and method of producing the same

ActiveUS20070217462A1Avoid difficult choicesOptical wave guidanceLaser detailsActive layerArea ratio

A method of producing a nitride semiconductor laser device includes: forming a wafer including a nitride semiconductor layer of a first conductivity type, an active layer of a nitride semiconductor, a nitride semiconductor layer of a second conductivity type, and an electrode pad for the second conductivity type stacked in this order on a main surface of a conductive substrate and also including stripe-like waveguide structures parallel to the active layer; cutting the wafer to obtain a first type and a second type of laser device chips; and distinguishing between the first type and the second type of chips by automatic image recognition. The first type and the second type of chips are different from each other in position of the stripe-like waveguide structure with respect to a width direction of each chip and also in area ratio of the electrode pad to the main surface of the substrate.

Owner:SHARP FUKUYAMA LASER CO LTD

Low Voltage Laser Diodes on Gallium and Nitrogen Containing Substrates

ActiveUS20110064101A1Improved cleavesSimple and cost-effectiveOptical wave guidanceLaser detailsLow voltageNitrogen

A low voltage laser device having an active region configured for one or more selected wavelengths of light emissions.

Owner:KYOCERA SLD LASER INC

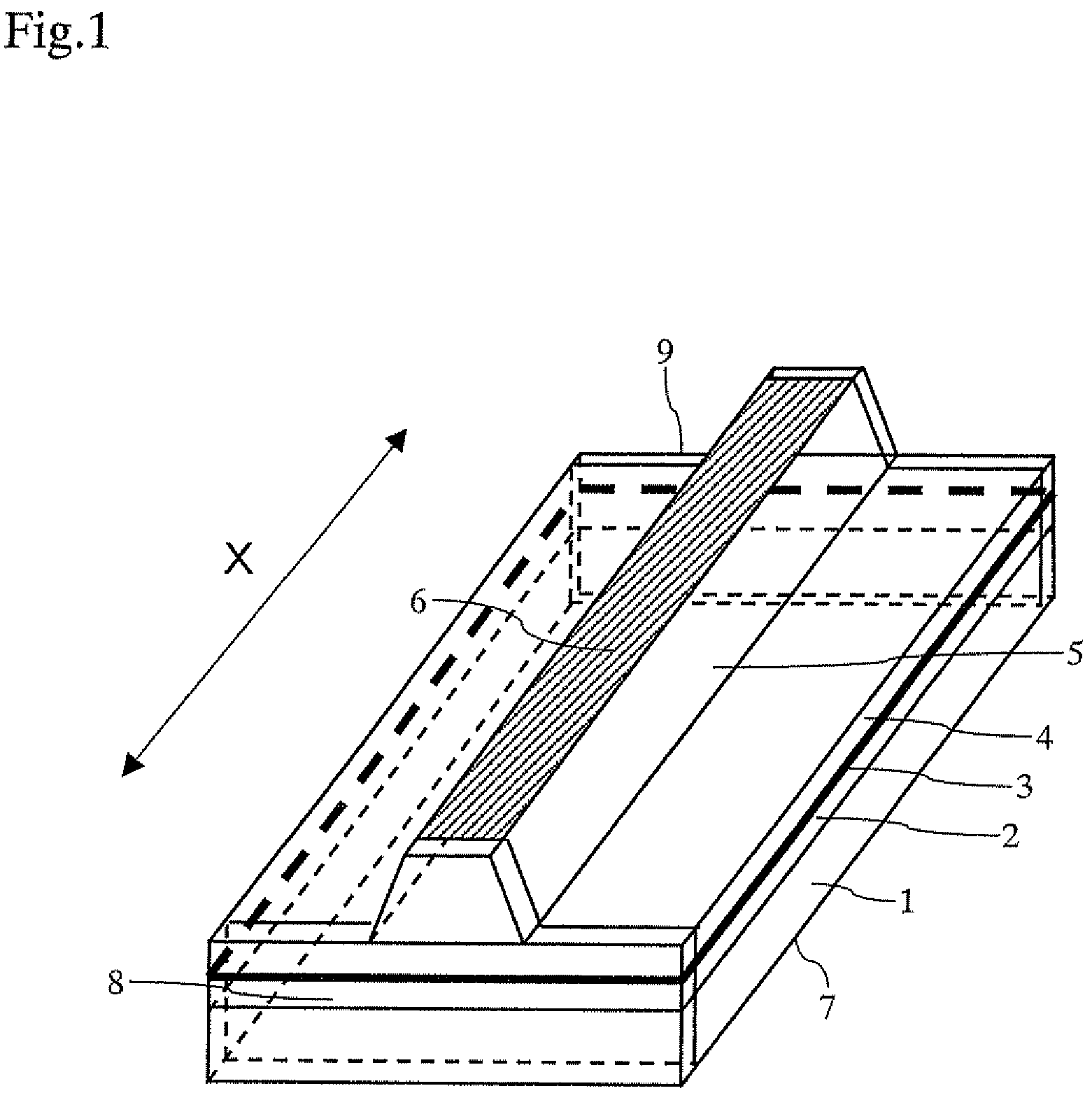

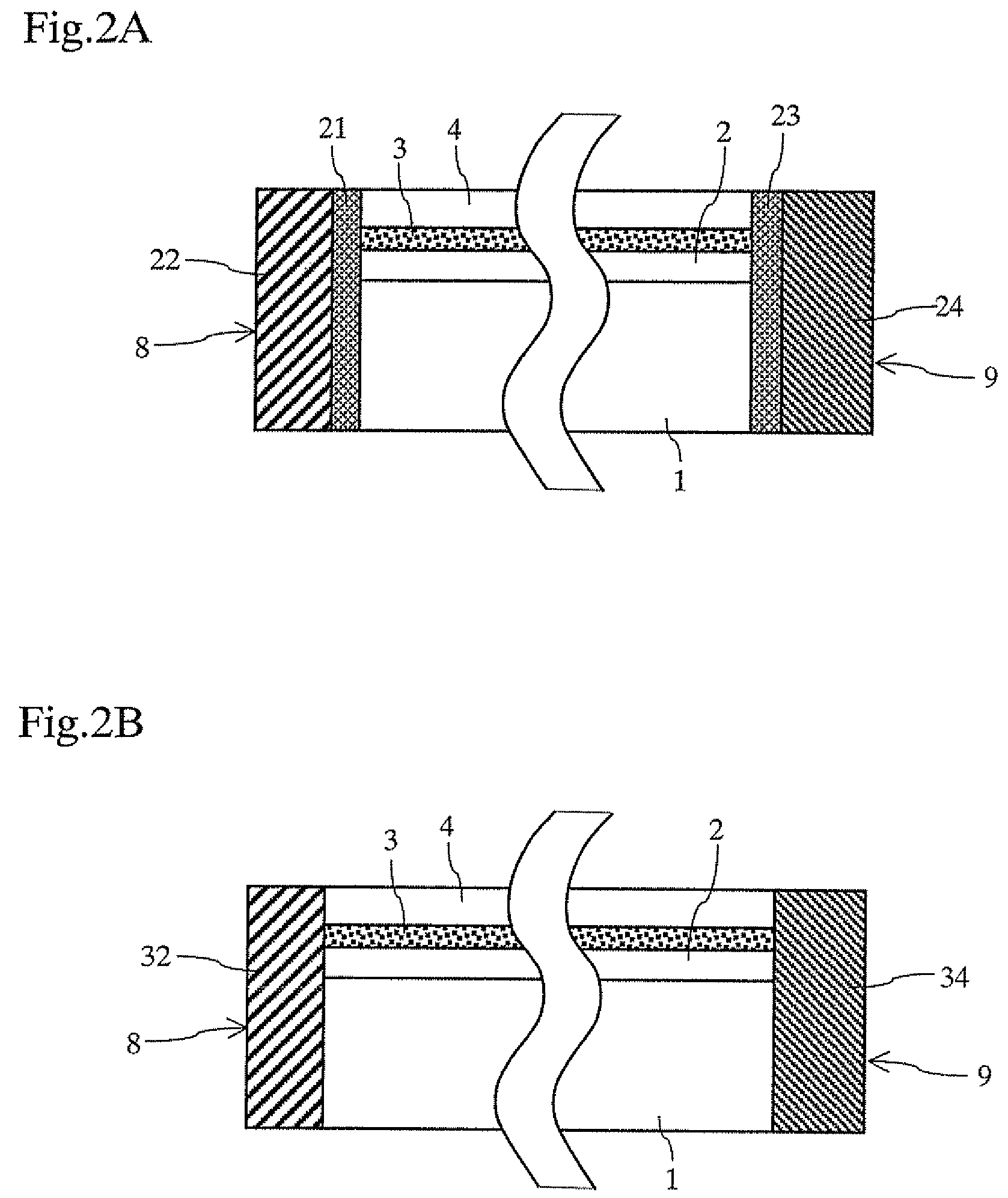

Semiconductor laser device

A semiconductor laser device includes a cavity extending in a propagation direction of a laser beam (X-direction). A front facet is on one end of the cavity through which the laser beam is emitted. A rear facet is on the other end of the cavity. Further, an adhesive layer and a coating film are on the front facet, and an adhesive layer and a coating film are on the rear facet. The adhesive layers preferably have a thickness of 10 nm or less and preferably include an anodic oxide film of one of Al, Ti, Nb, Zr, Ta, Si, and Hf.

Owner:MITSUBISHI ELECTRIC CORP

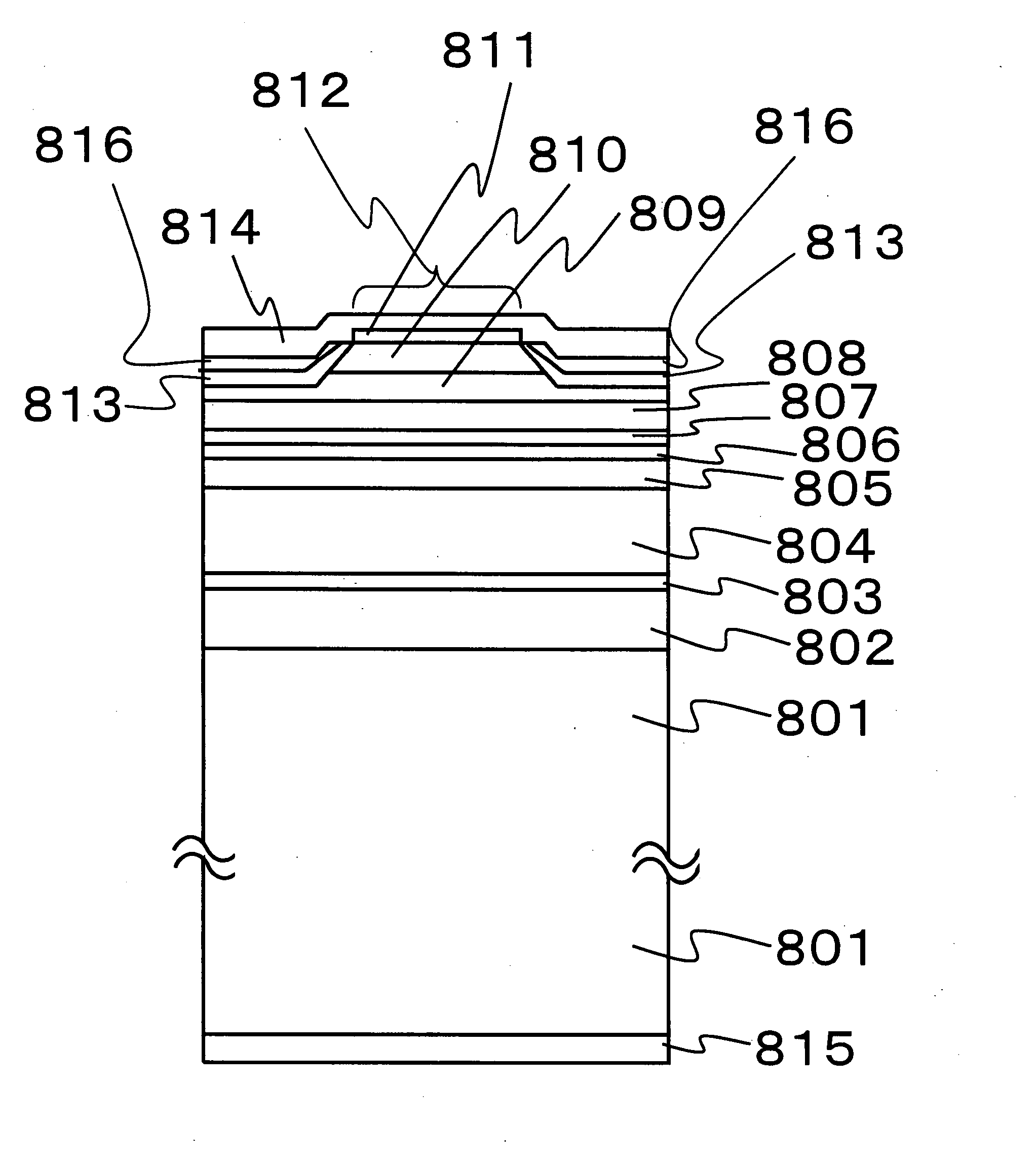

Nitride semiconductor laser device

ActiveUS20090141765A1Improve life characteristicsLow densityOptical wave guidanceLaser detailsElectron blocking layerLaser

A nitride semiconductor laser device has a group III nitride semiconductor multilayer structure. The group III nitride semiconductor multilayer structure includes an n-type semiconductor layer, a p-type semiconductor layer and a light emitting layer held between the n-type semiconductor layer and the p-type semiconductor layer, and the p-type semiconductor layer is formed by successively stacking a p-side guide layer, a p-type electron blocking layer in contact with the p-side guide layer and a p-type cladding layer in contact with the p-type electron blocking layer from the side closer to the light emitting layer. The p-side guide layer is formed by stacking a layer made of a group III nitride semiconductor containing Al and a layer made of a group III nitride semiconductor containing no Al. The p-type cladding layer is made of a group III nitride semiconductor containing Al, and the p-type electron blocking layer is made of a group III nitride semiconductor having a larger Al composition than the p-type cladding layer.

Owner:ROHM CO LTD

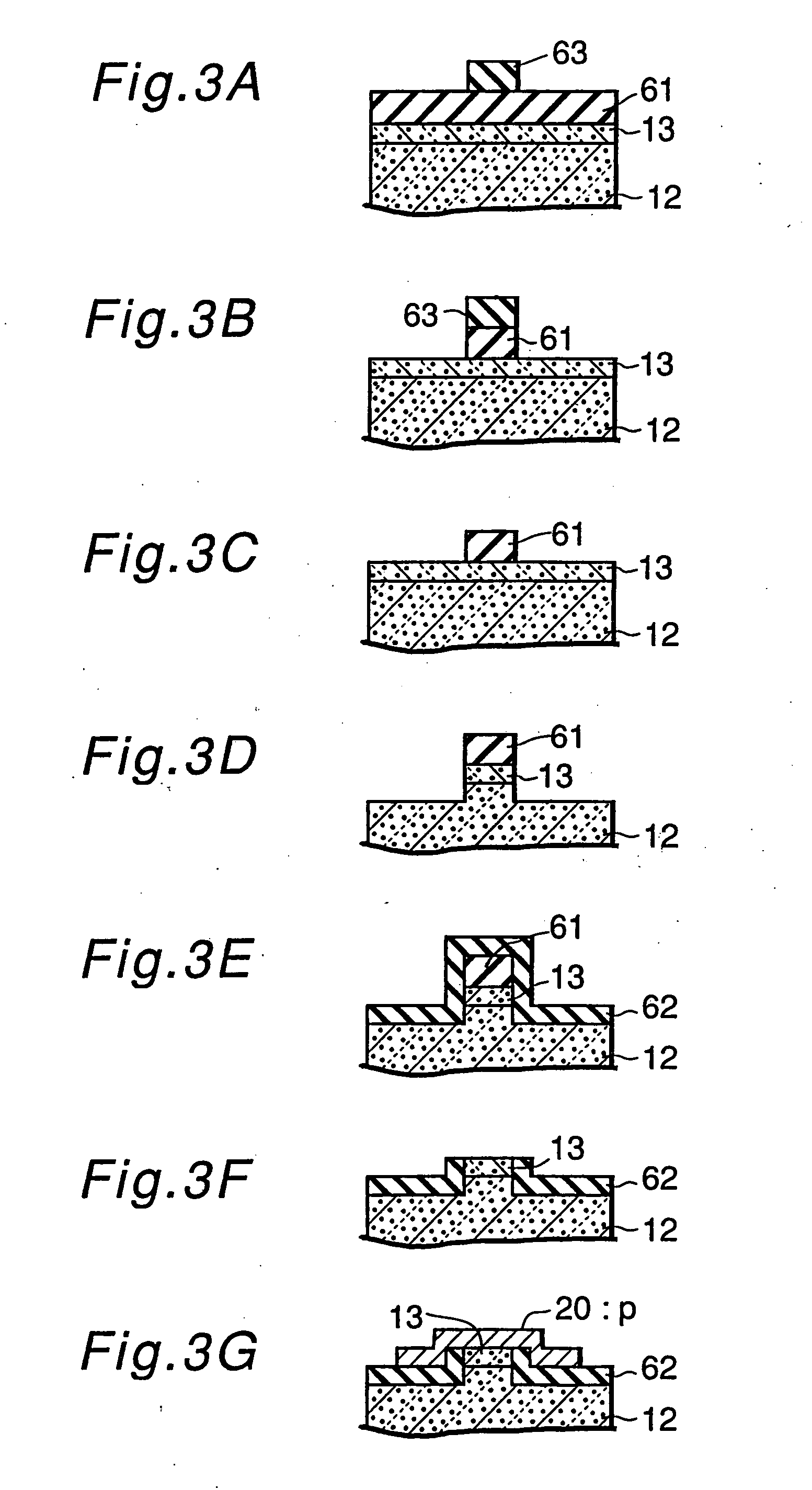

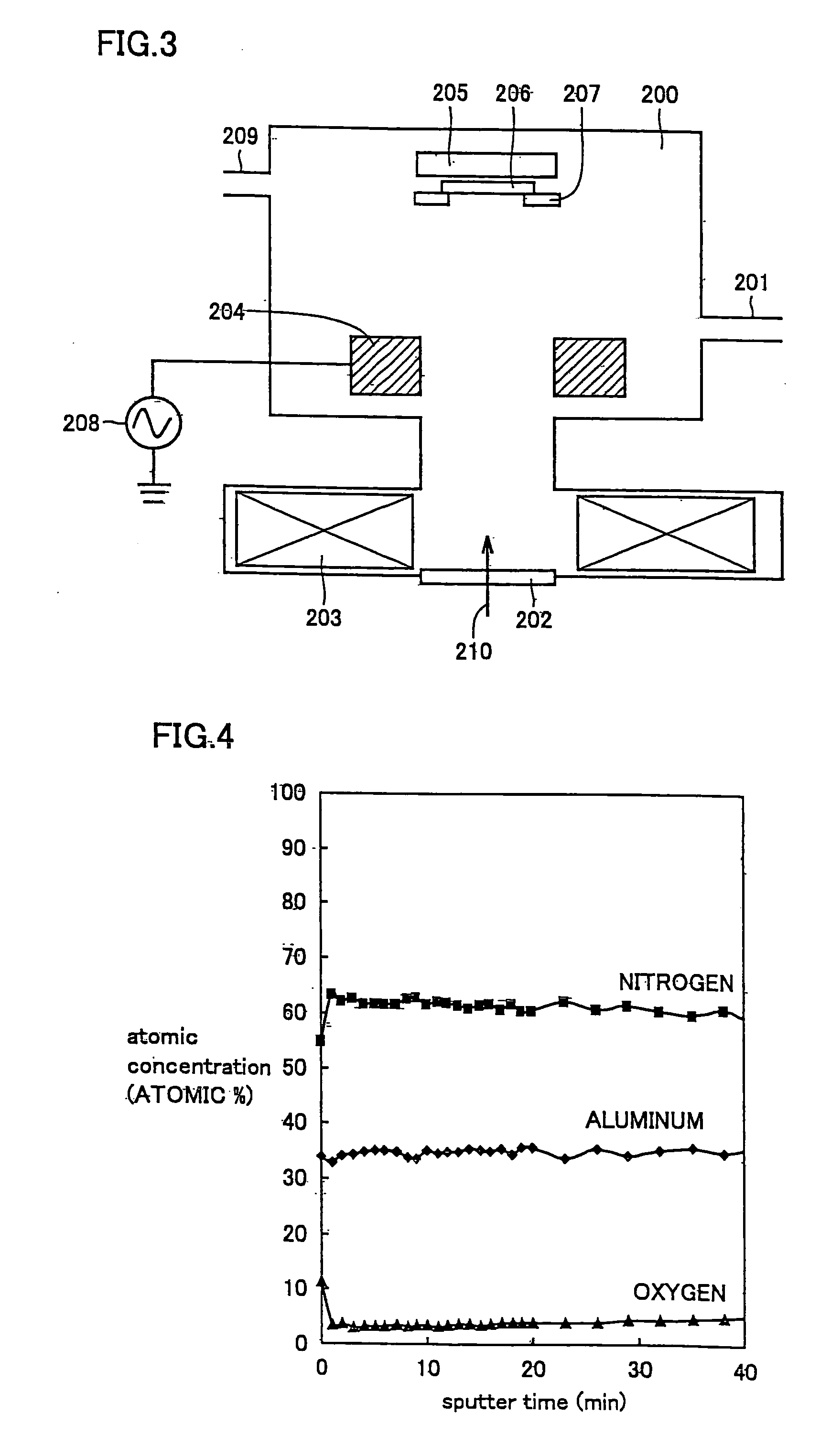

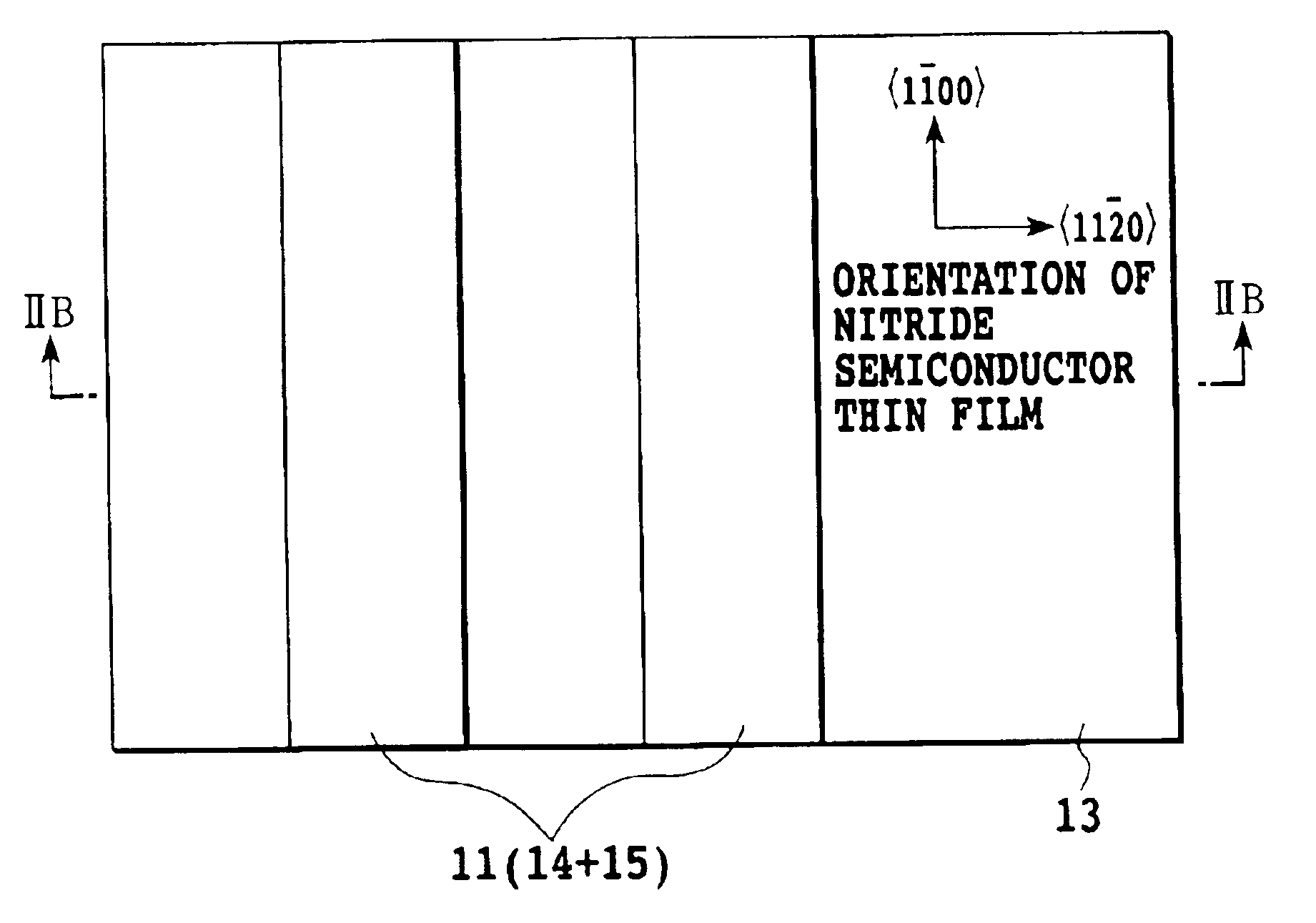

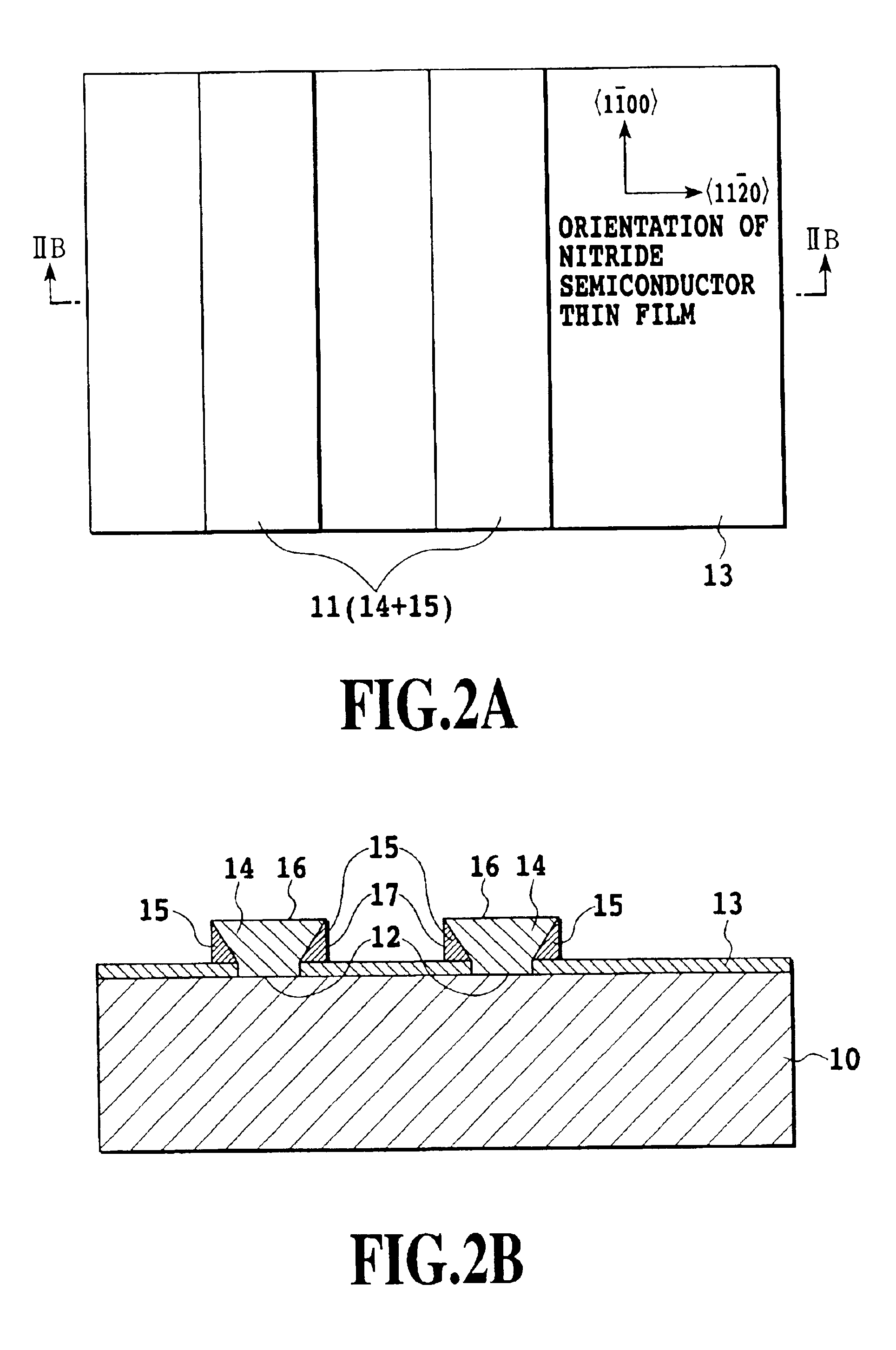

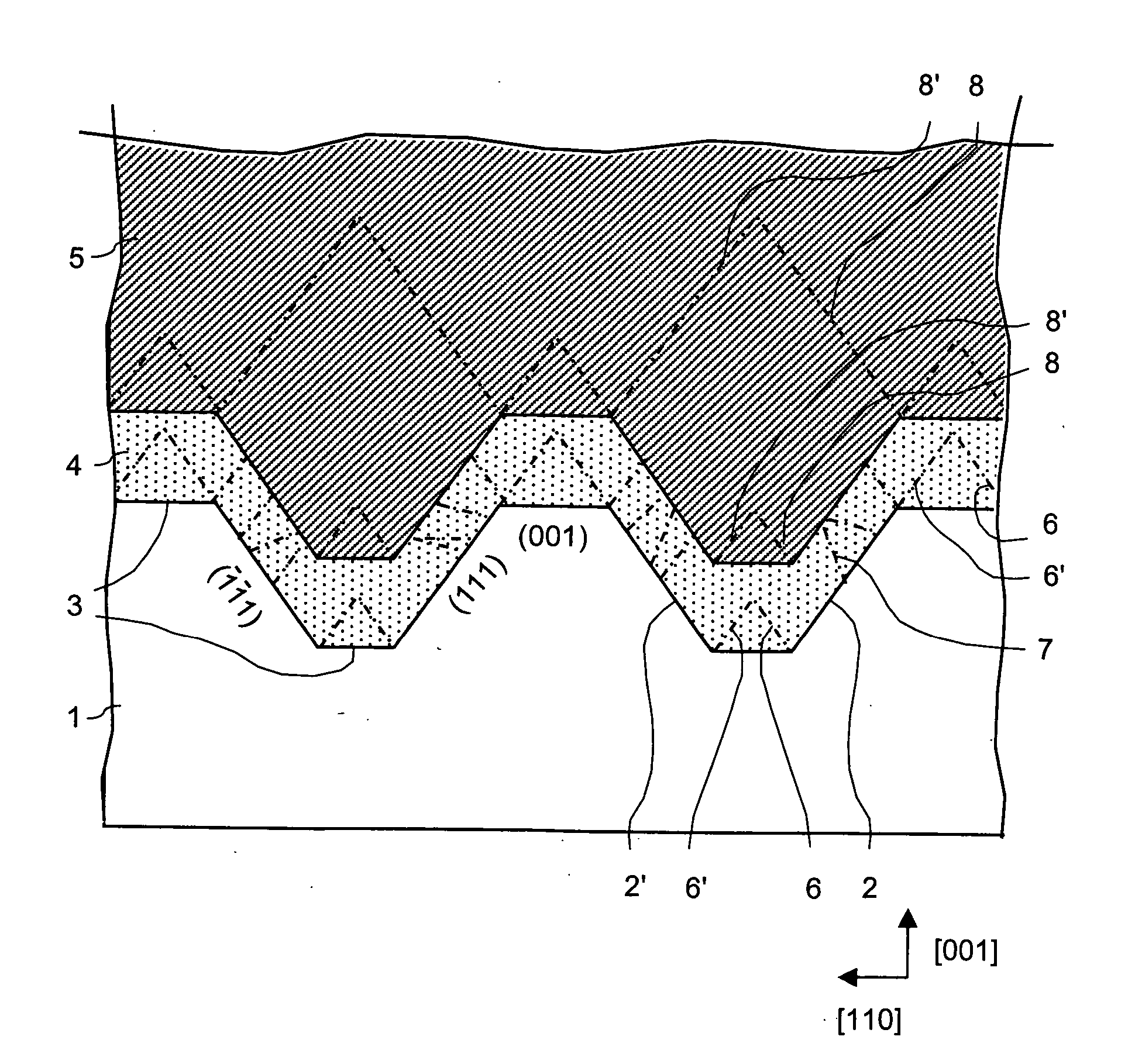

Thin film deposition method of nitride semiconductor and nitride semiconductor light emitting device

InactiveUS6920166B2Reduce adverse effectsSuppress loss of internal quantum efficiencyOptical wave guidanceSemiconductor/solid-state device manufacturingLight emitting deviceNitride semiconductors

A masking material 13, which includes stripe-like openings 12 parallel to the [1-100] direction of a nitride semiconductor thin film, is formed on a substrate. Nitride semiconductor thin films 11 doped with Mg are grown on the openings 12 by selective-area growth. The nitride semiconductor thin films 11 are composed of a portion 14 formed as a result of the growth in the direction perpendicular to a (0001) principal plane, and a portion 15 formed as a result of the growth of {11-2x} facets (x=0, 1, 2). The Mg concentration of the portion 15 is made lower than that of the portion 14.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

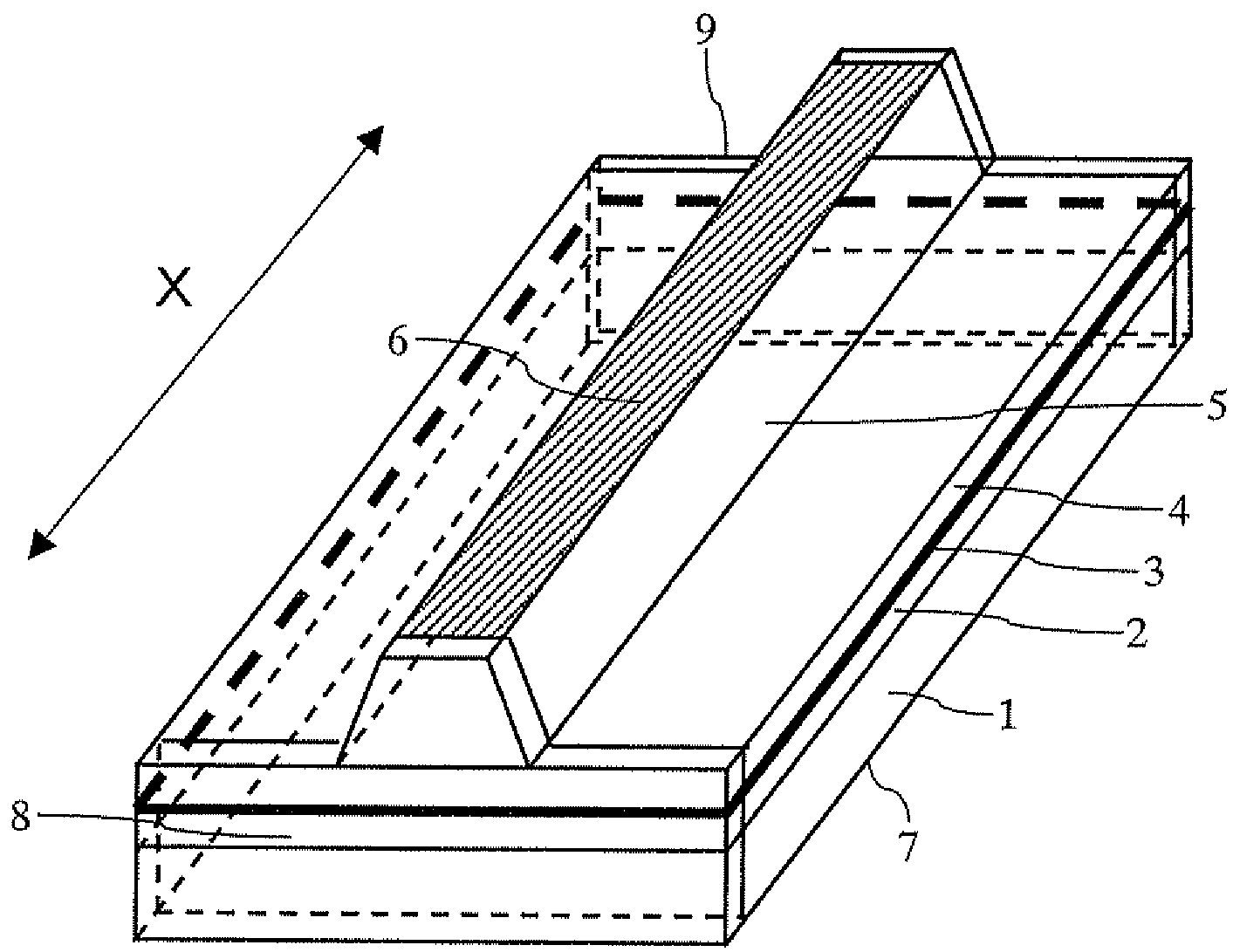

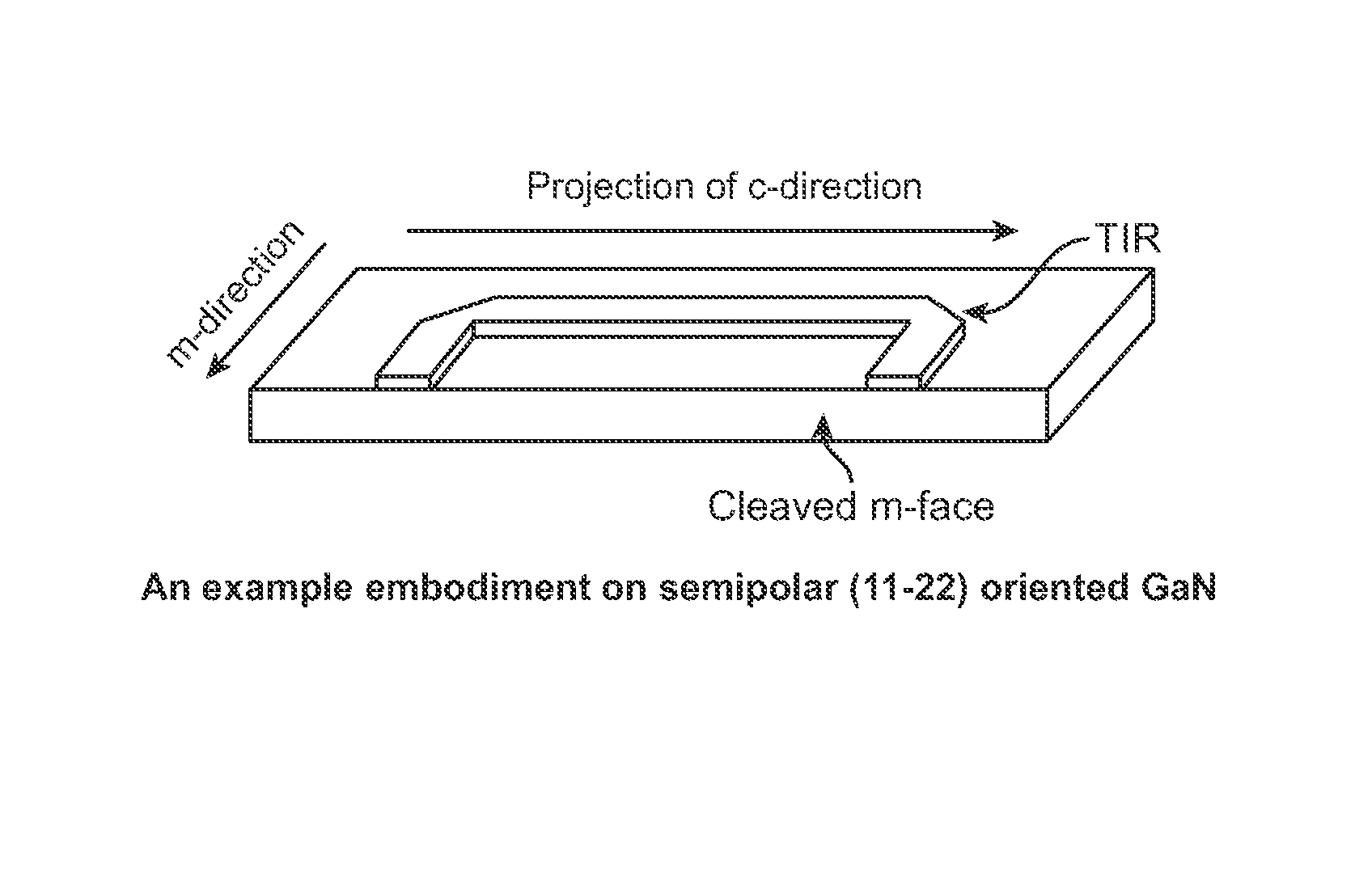

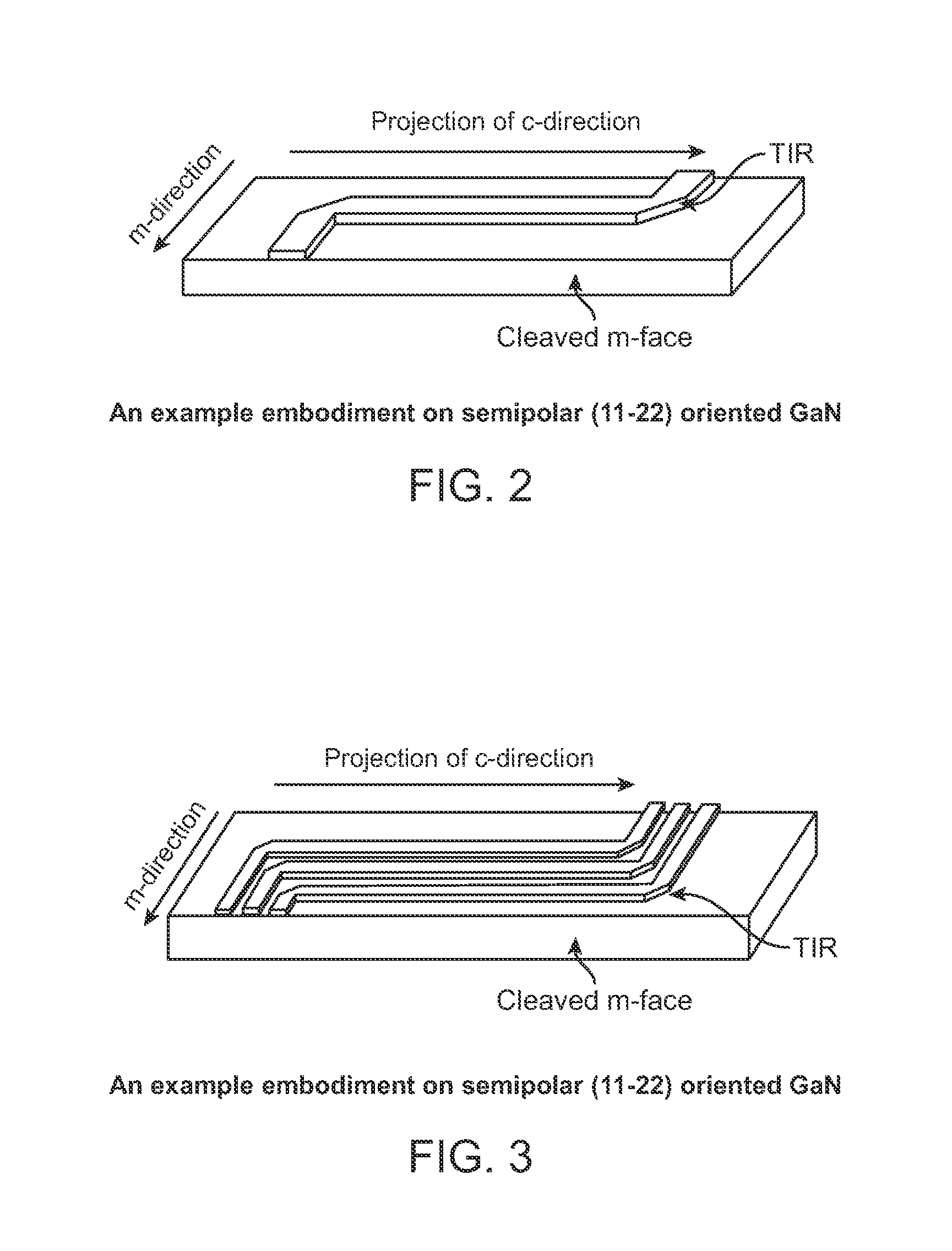

Integrated total internal reflectors for high-gain laser diodes with high quality cleaved facets on nonpolar/semipolar GaN substrates

ActiveUS8259769B1High yieldWell formedOptical wave guidanceOptical resonator shape and constructionTotal internal reflectionCrystal plane

A laser diode device operable at a one or more wavelength ranges. The device has a first waveguide provided on a non-polar or semipolar crystal plane of gallium containing material. In a specific embodiment, the first waveguide has a first gain characteristic and a first direction. In a specific embodiment, the first waveguide has a first end and a second end and a first length defined between the first end and the second end. The device has a second waveguide provided on a non-polar or semipolar crystal plane of gallium containing material. In a specific embodiment, the second waveguide has a second gain characteristic and a second direction. In a specific embodiment, the second waveguide has a first end, a second end, and a second length defined between the first end and the second end. In a specific embodiment, the second waveguide has the first end being coupled to the first end of the first waveguide. The second length is in a different direction from the second length. In a specific embodiment, the device has a cleaved region provided on the second end of the second waveguide, the cleaved region being perpendicular to the second direction of the second waveguide.

Owner:KAAI +1

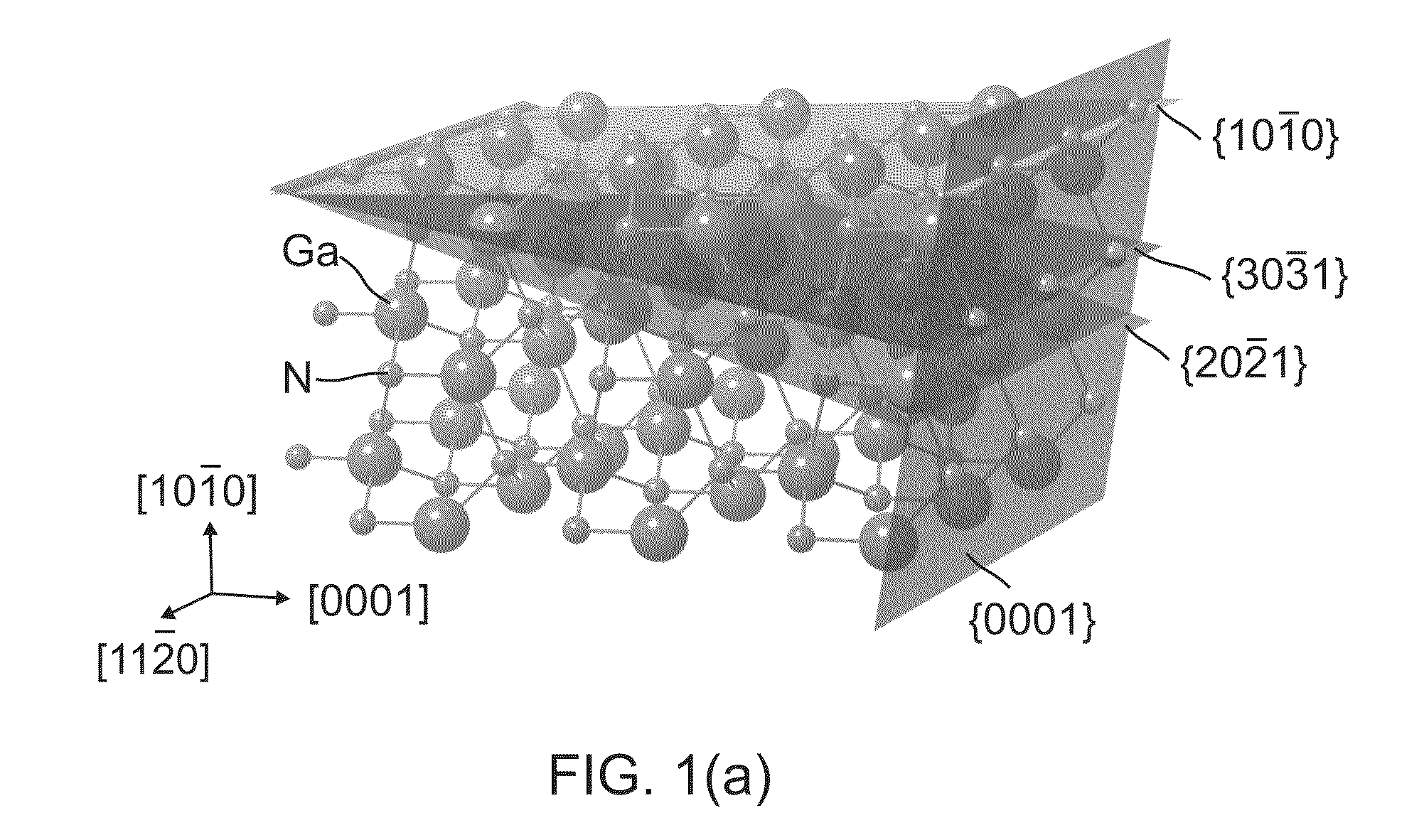

Light emitting element structure using nitride bulk single crystal layer

InactiveUS20040251471A1Improve crystal qualitySimple structureOptical wave guidancePolycrystalline material growthSingle crystalActive layer

The object of this invention is to provide a high-output type nitride light emitting device. The nitride light emitting device comprises an n-type nitride semiconductor layer or layers, a p-type nitride semiconductor layer or layers and an active layer therebetween, wherein a gallium-containing nitride substrate is obtained from a gallium-containing nitride bulk single crystal, provided with an epitaxial growth face with dislocation density of 10<5> / cm<2 >or less, and A-plane or M-plane which is parallel to C-axis of hexagonal structure for an epitaxial face, wherein the n-type semiconductor layer or layers are formed directly on the A-plane or M-plane. In case that the active layer comprises a nitride semiconductor containing In, an end face film of single crystal AlxGa1-xN (0<=x<=1) can be formed at a low temperature not causing damage to the active layer.

Owner:AMMONO SP Z O O (PL) +1

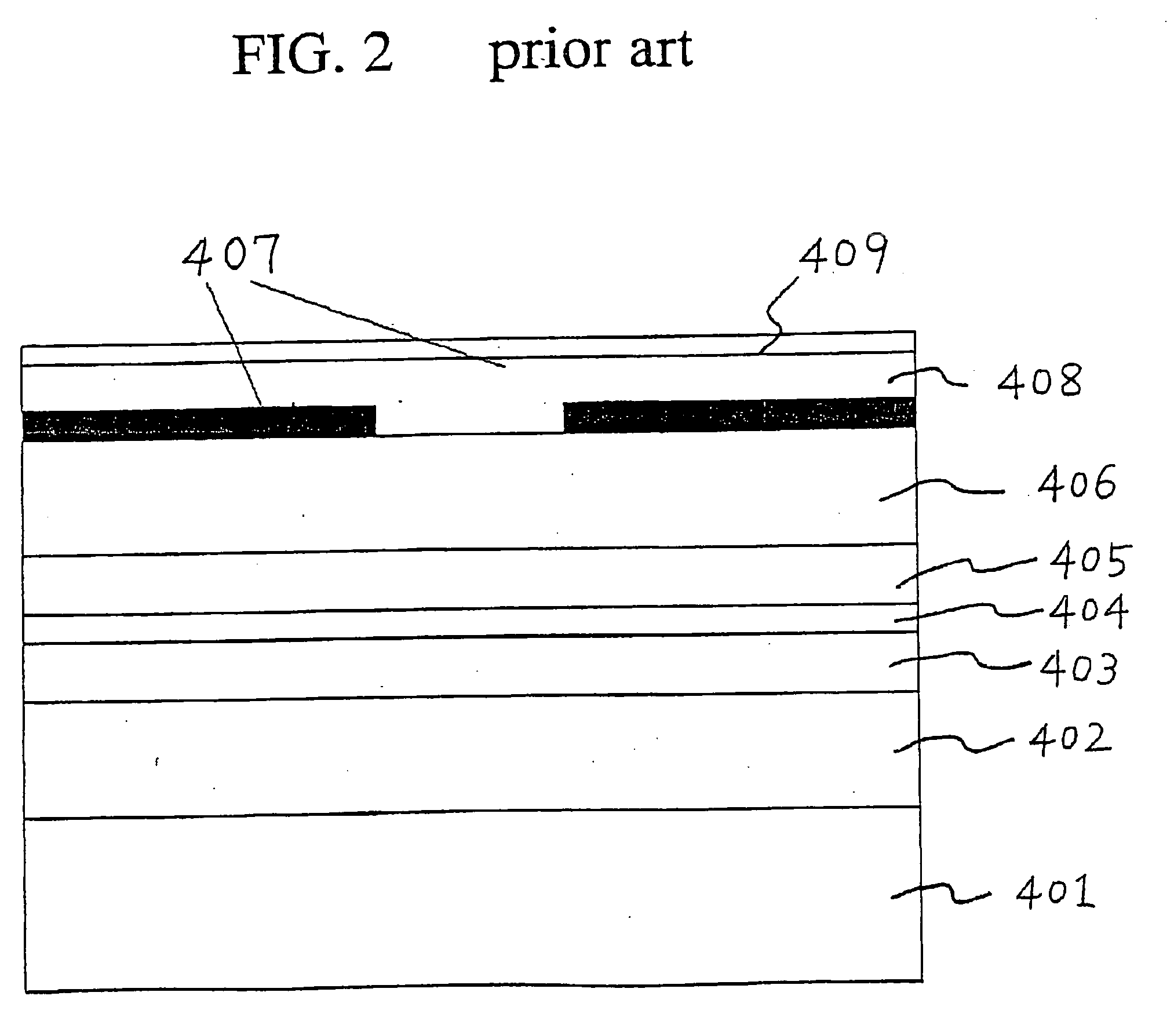

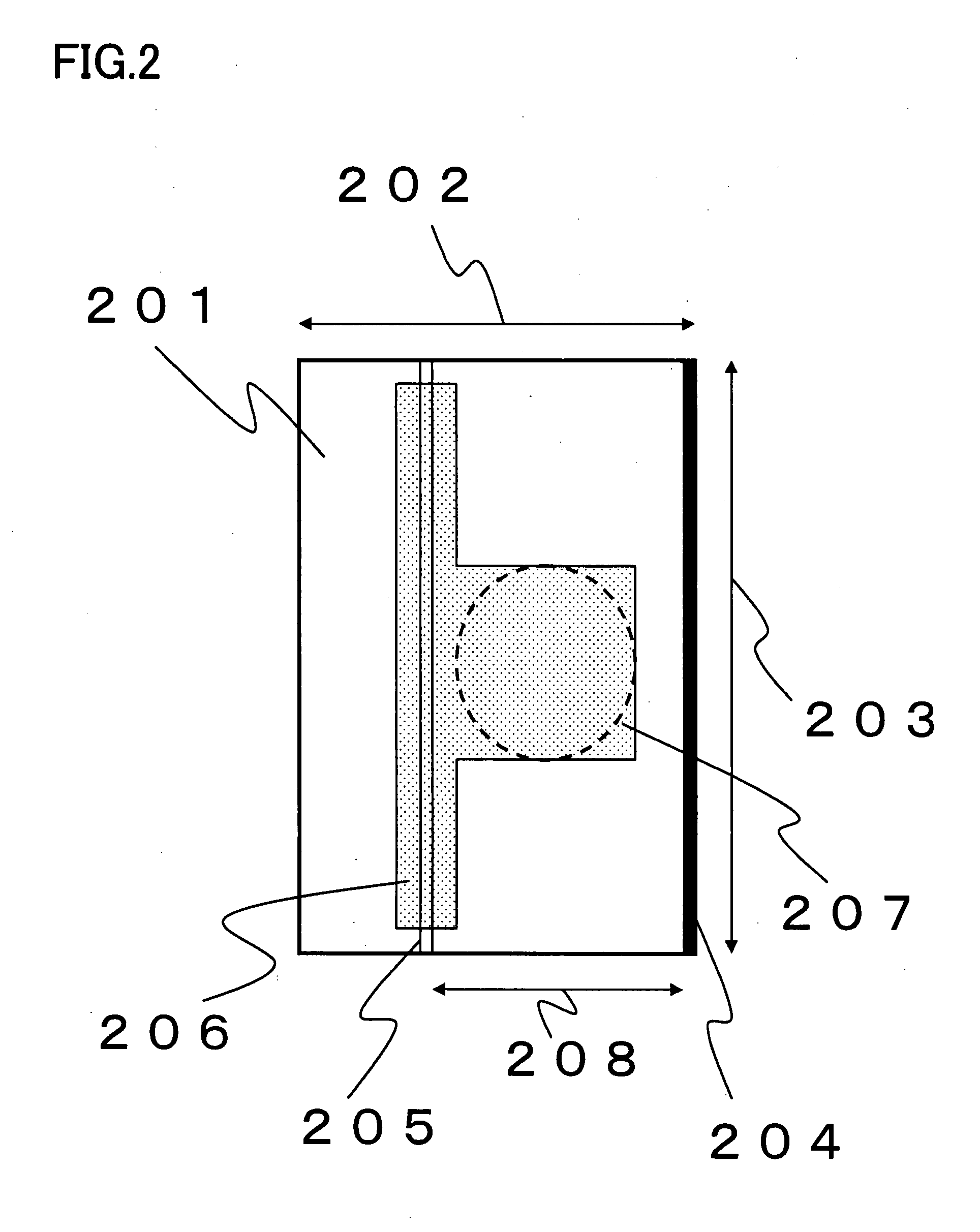

Nitride semiconductor laser chip and fabrication method thereof

InactiveUS20080298409A1Satisfactory reliabilityAvoid damageOptical wave guidanceSemiconductor/solid-state device manufacturingWaveguideNitride semiconductors

In a nitride semiconductor laser chip so structured as to suppress development of a step on nitride semiconductor layers, the substrate has the (1-100) plane as the principal plane, the resonator facet is perpendicular to the principal plane, and, in the cleavage surface forming the resonator facet, at least by one side of a stripe-shaped waveguide, an etched-in portion is formed as an etched-in region open toward the surface of the nitride semiconductor layers.

Owner:SHARP KK

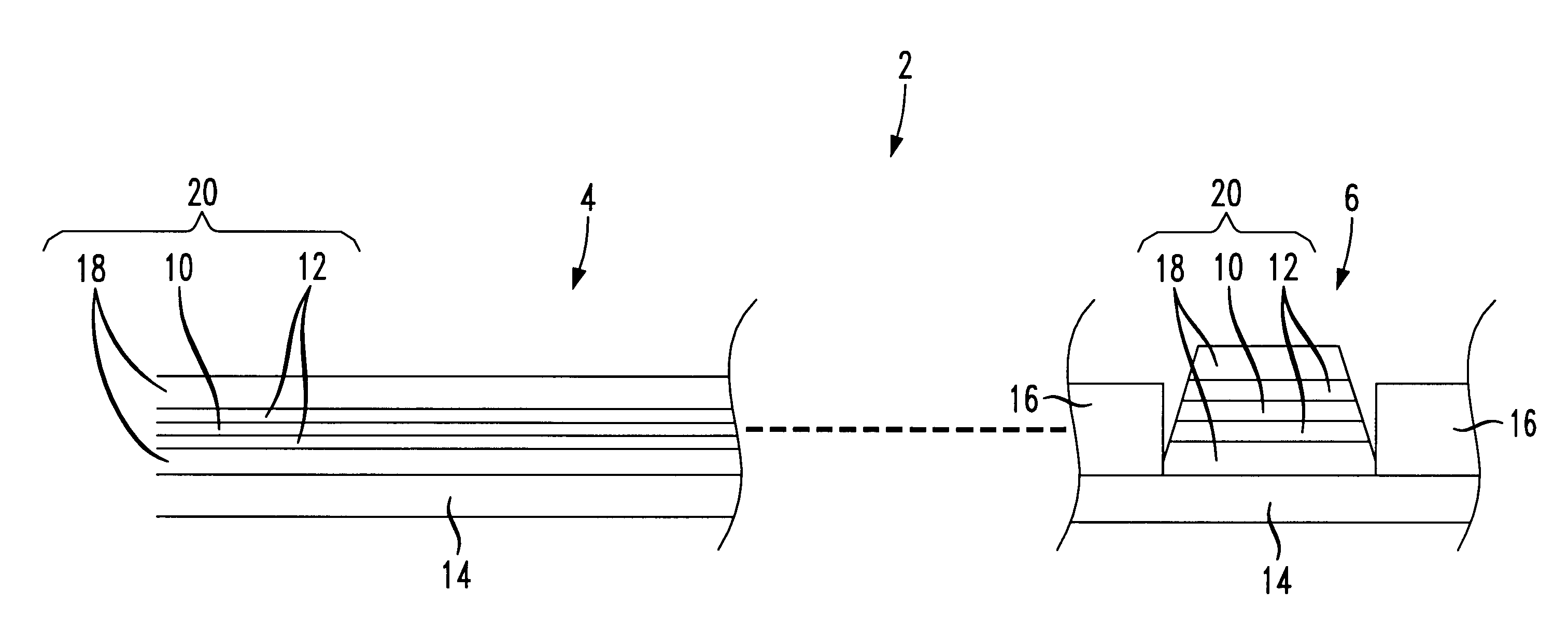

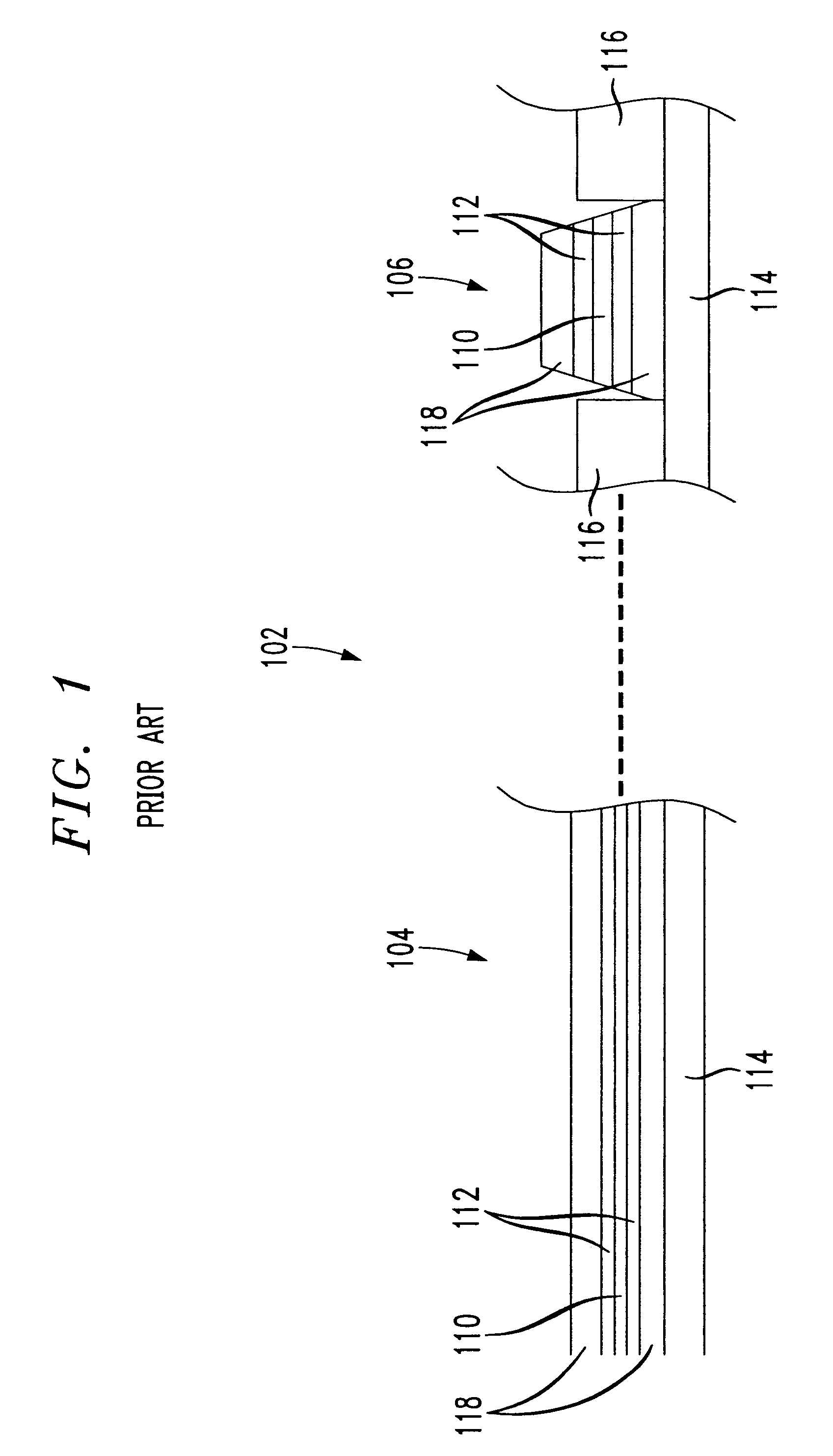

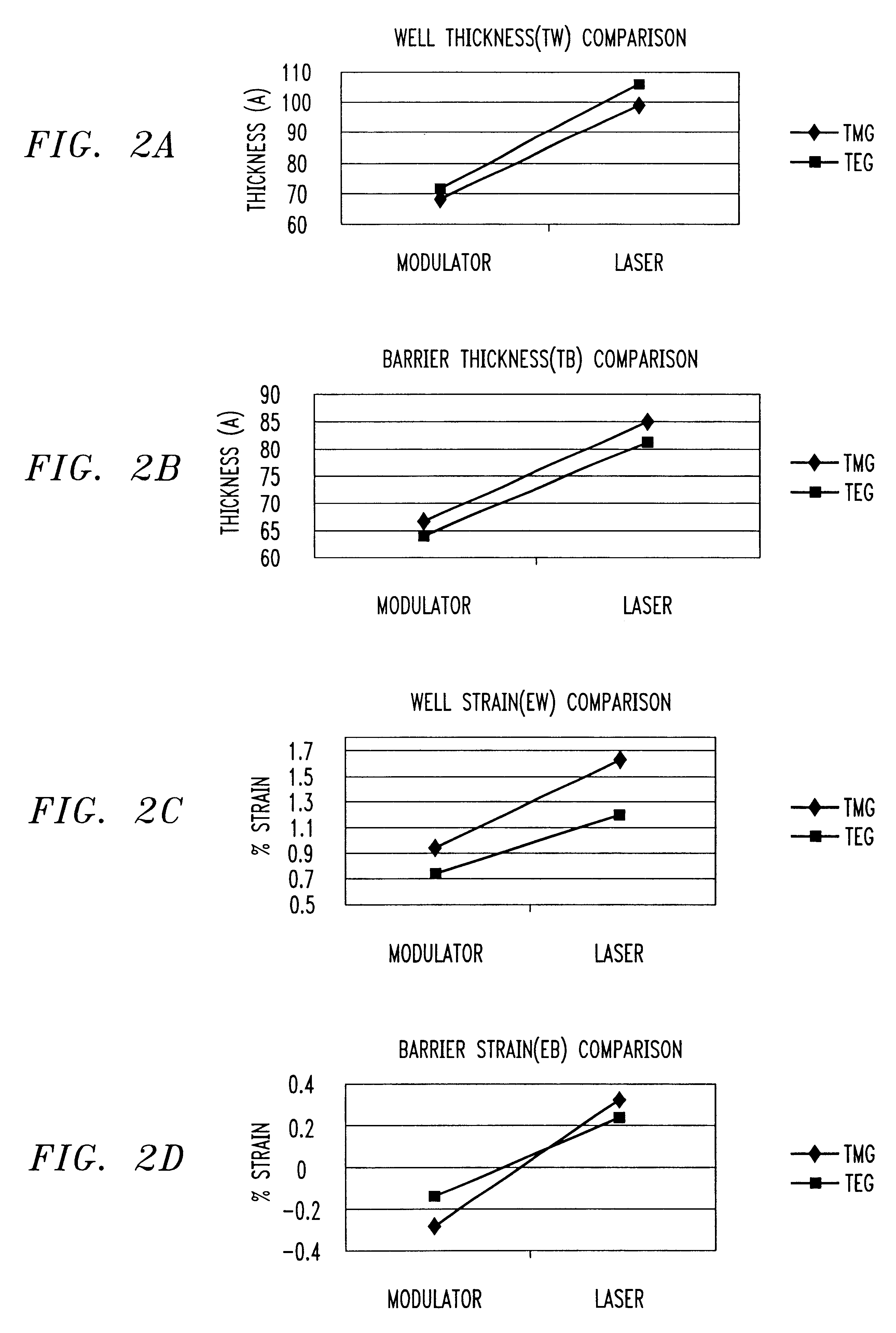

Net strain reduction in integrated laser-modulator

A semiconductor device including first and second epitaxial layers grown in a selective area growth region on a substrate includes an active layer or well layer comprising a first composition formed using a trimethylgallium precursor material and a barrier layer comprising a second composition formed using a triethylgallium precursor material. The use of the first and second compositions in the well layer and barrier layer respectively maximizes the strain in the well layer while simultaneously minimizing the net strain of the selective area growth region.

Owner:LUCENT TECH INC

Optical device structure using GaN substrates and growth structures for laser applications

ActiveUS8294179B1Simple and cost-effectiveCost-effectiveOptical wave guidanceLaser detailsWavelengthLight emission

Owner:KYOCERA SLD LASER INC

Semiconductor device and manufacturing method thereof

InactiveUS20060169987A1Quality improvementReduce defect densityOptical wave guidanceLaser detailsThreading dislocationsDevice material

A high quality silicon carbide (SiC) layer being substantially lower in threading dislocation density than a prior layer is formed on silicon (Si) substrate. A semiconductor device is fabricated in such a way that a semiconductor buffer layer containing Si in part and being higher in defect density than a Si substrate is formed on the Si substrate on the upper portion of which are formed a plurality of pairs of facets being mirror-symmetrical to the surface orientation of a semiconductor substrate, further on the top of the layer a SiC layer is sequentially formed.

Owner:HITACHI LTD

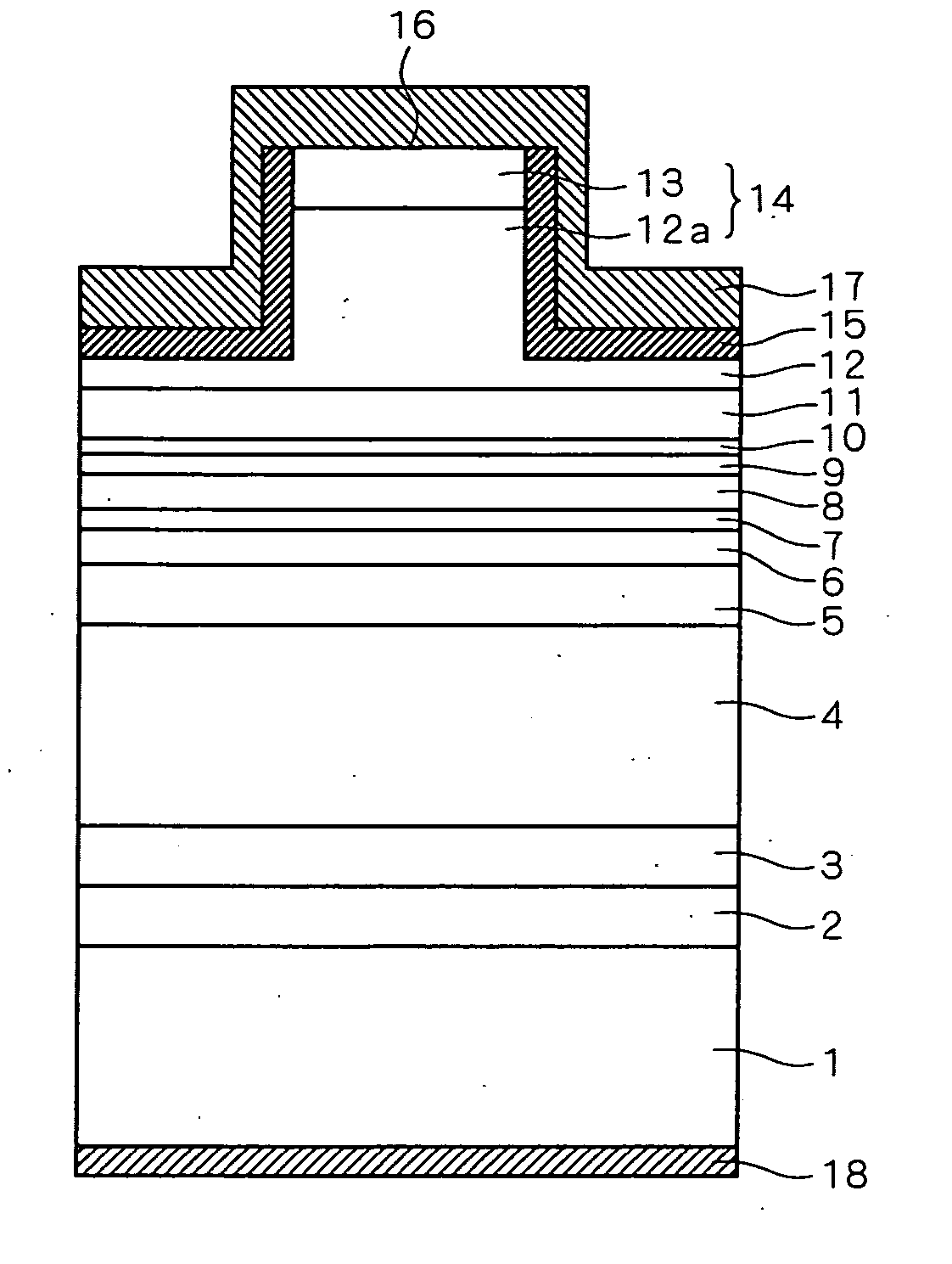

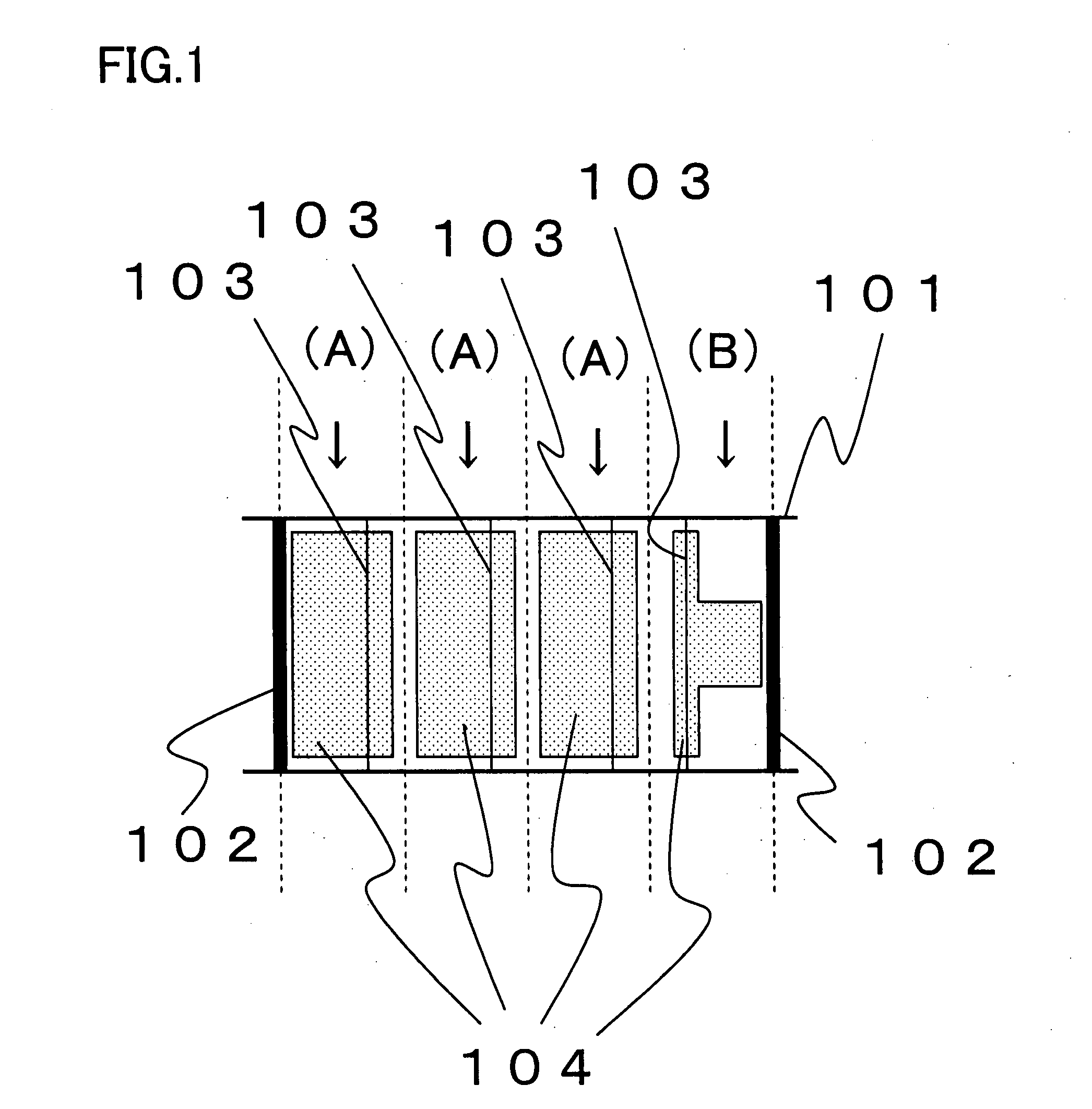

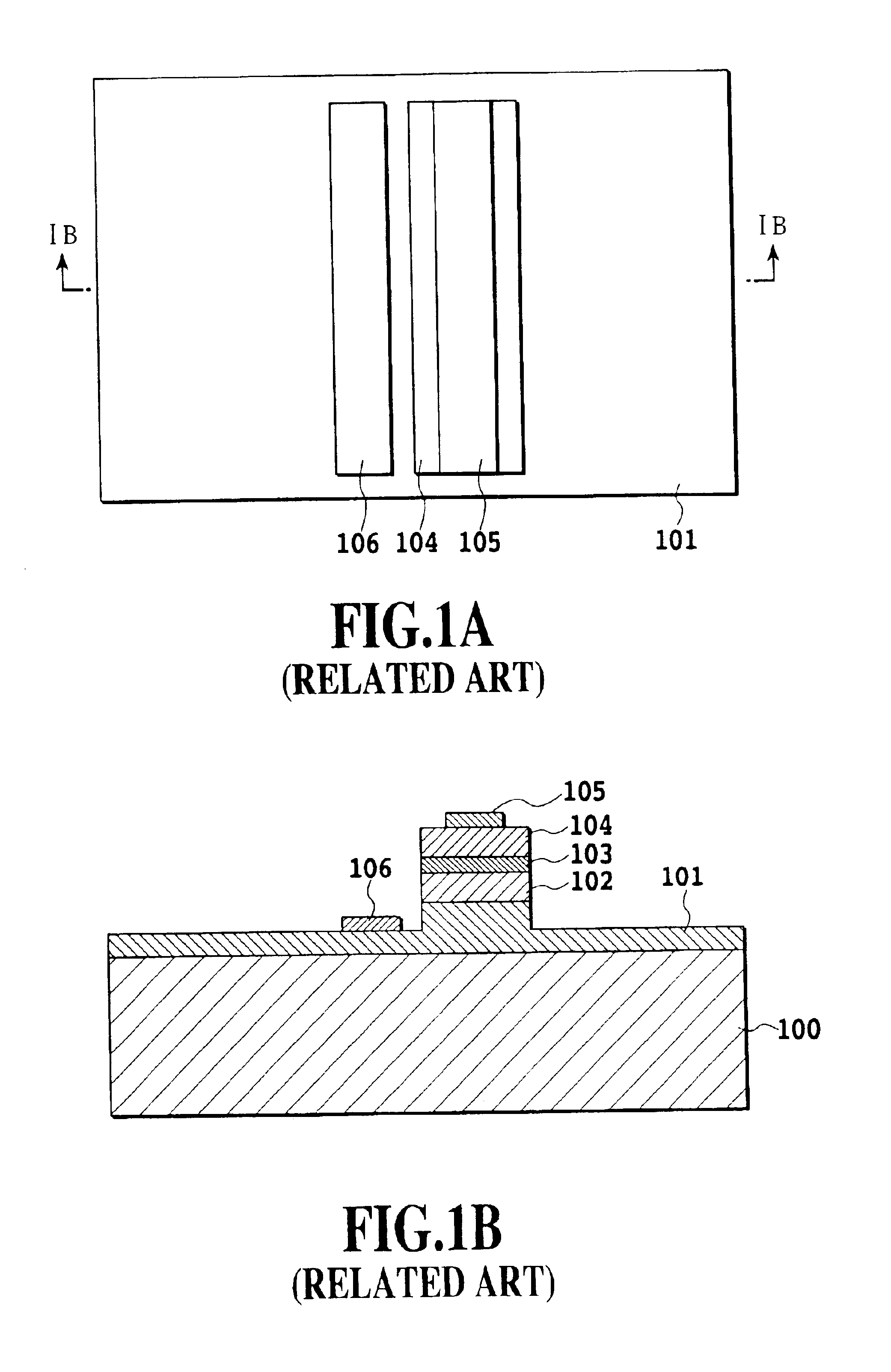

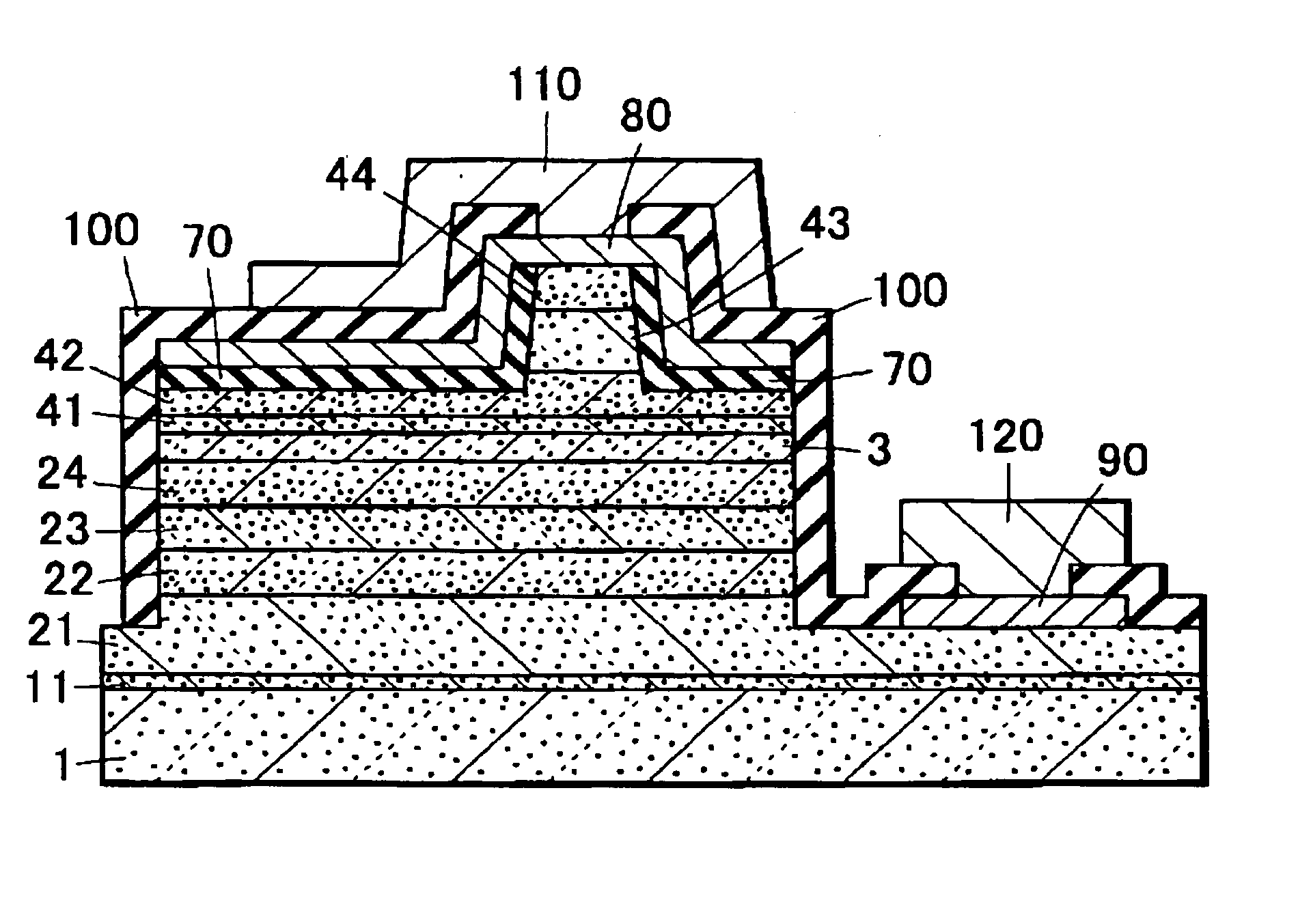

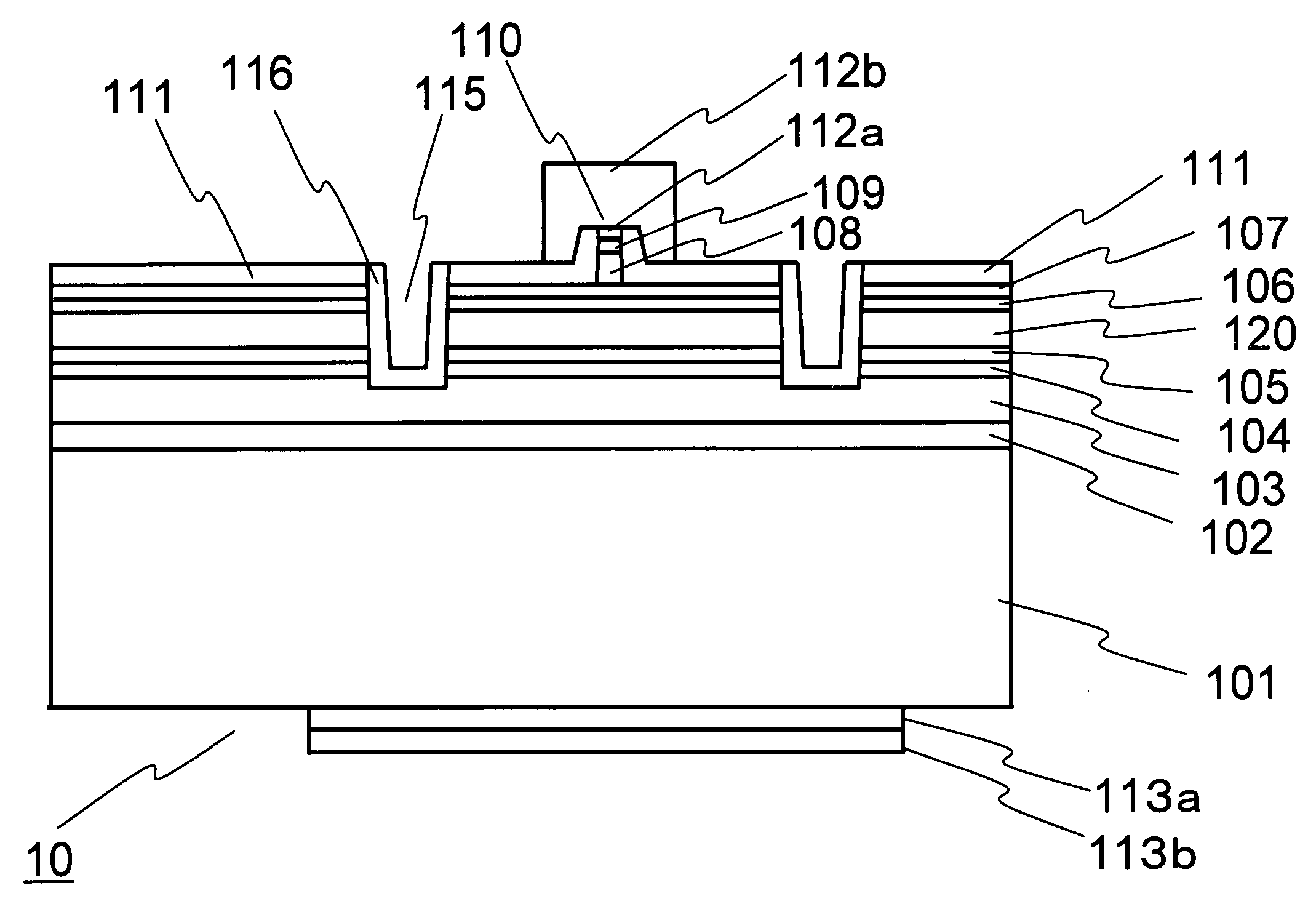

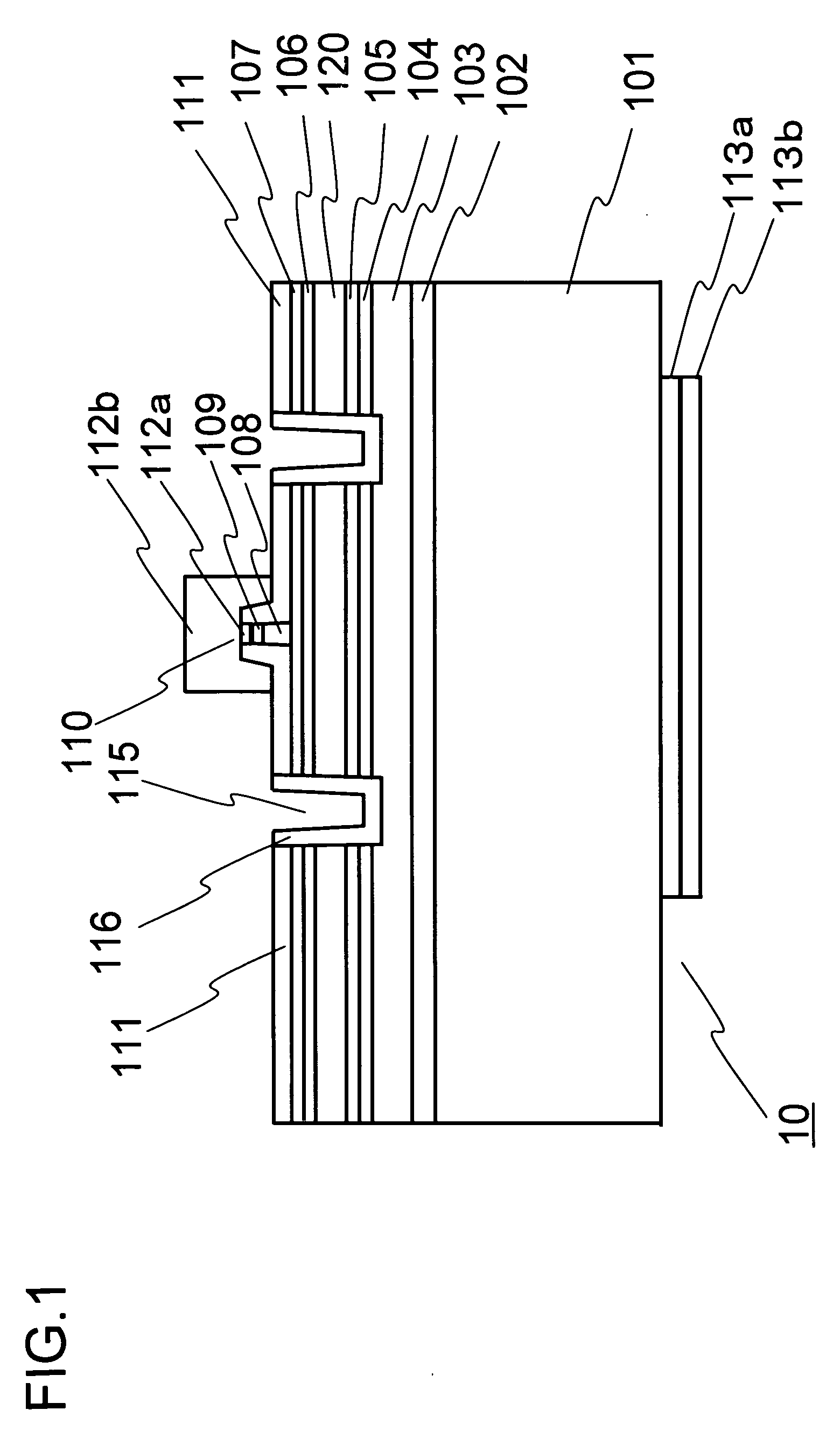

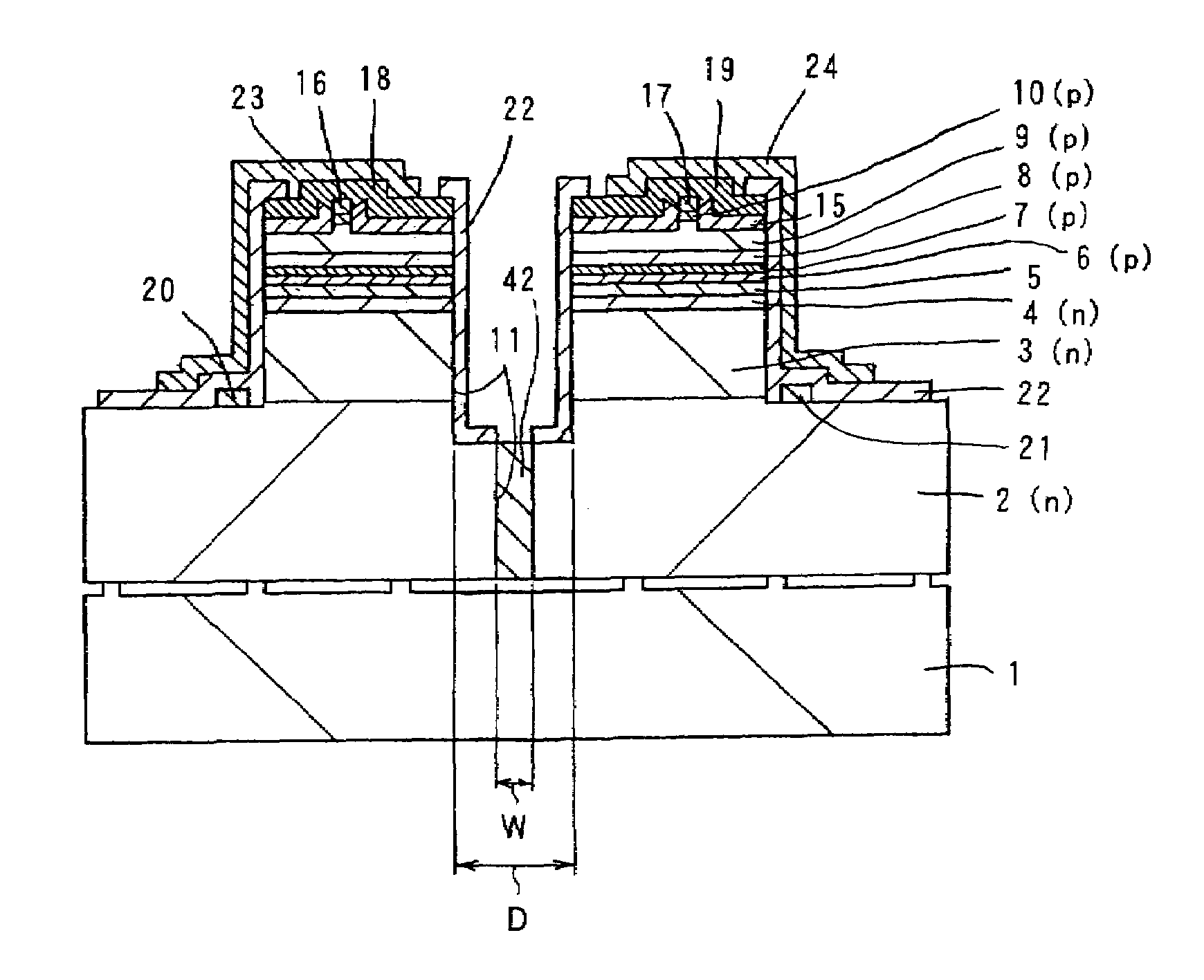

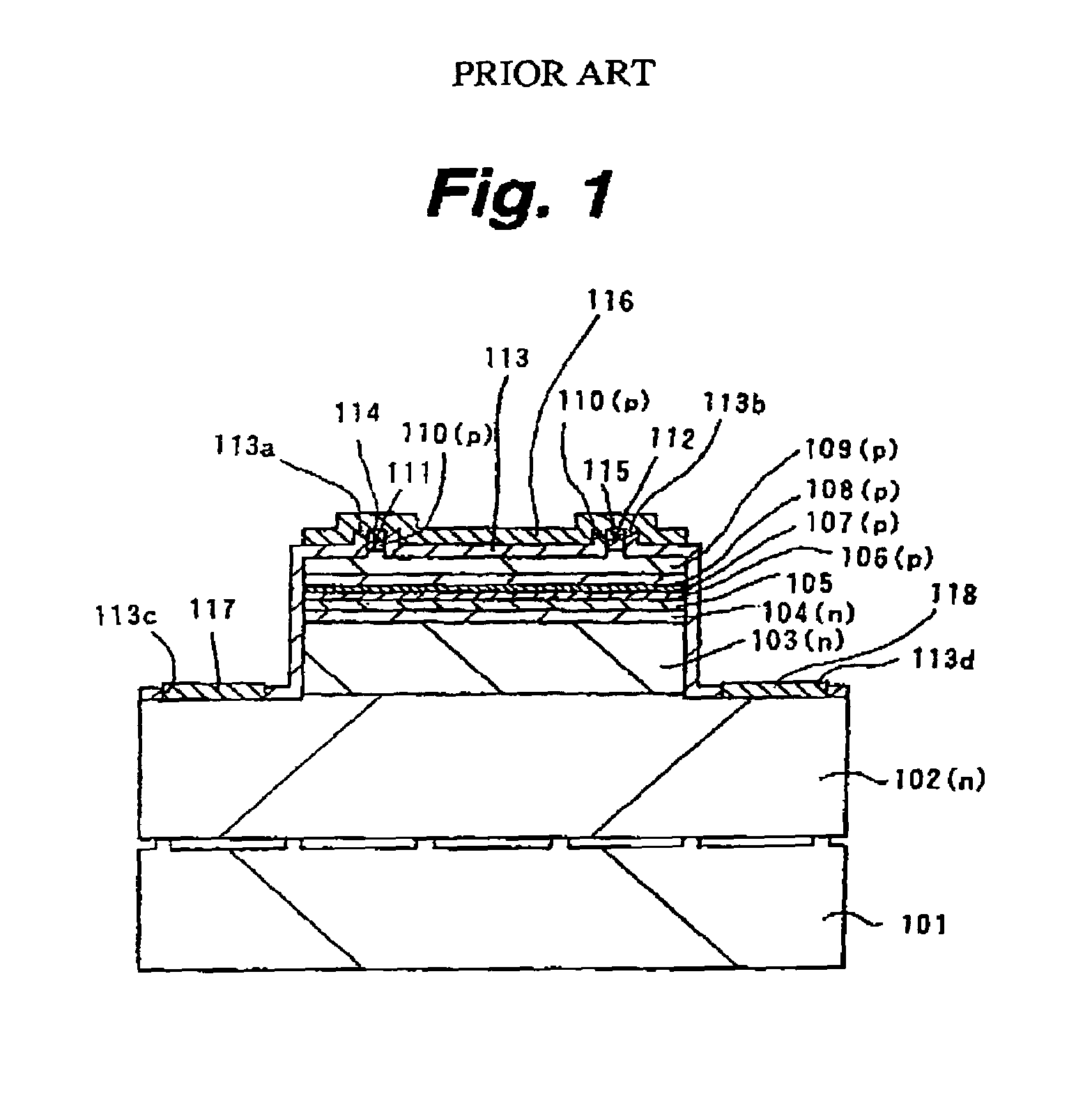

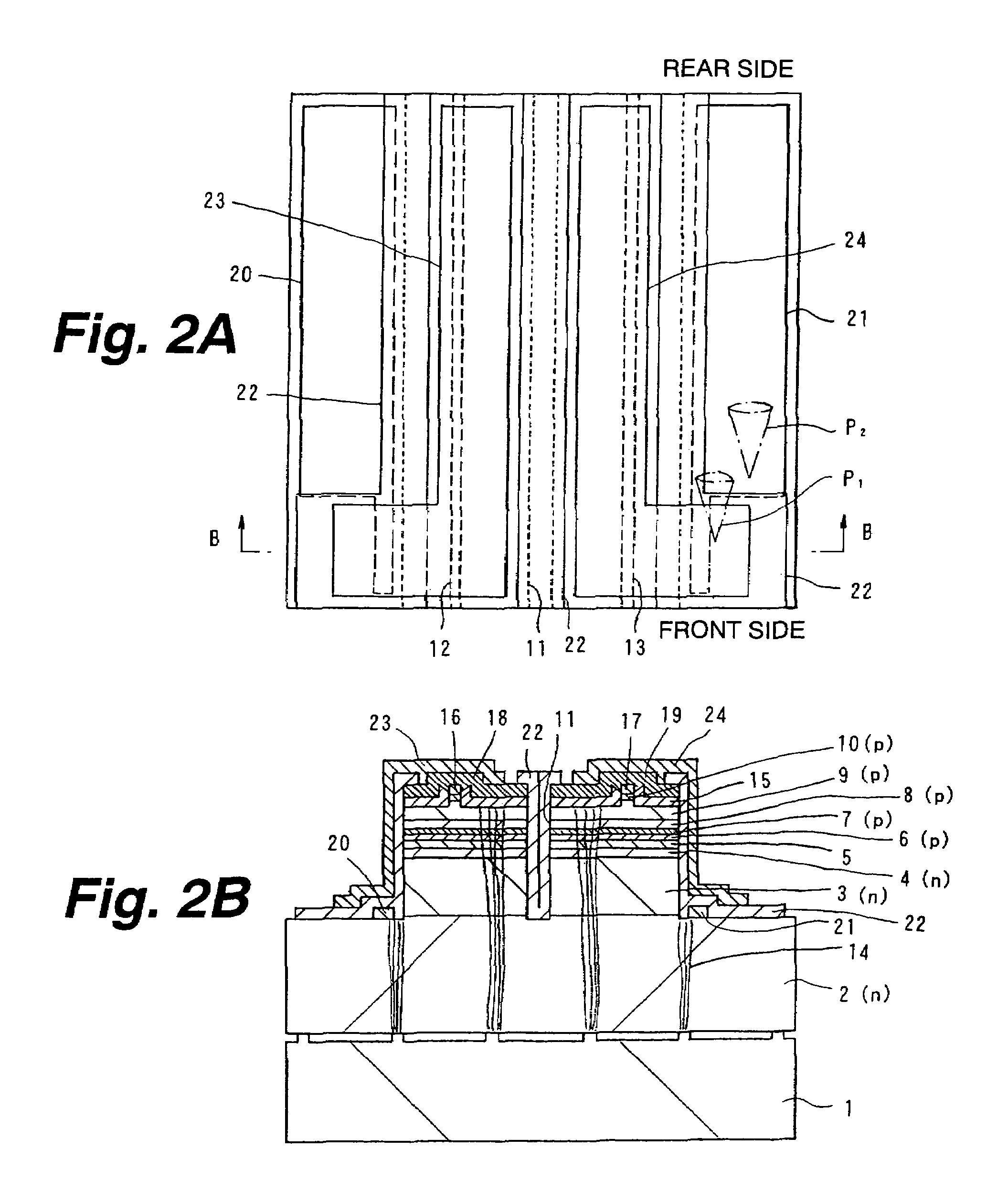

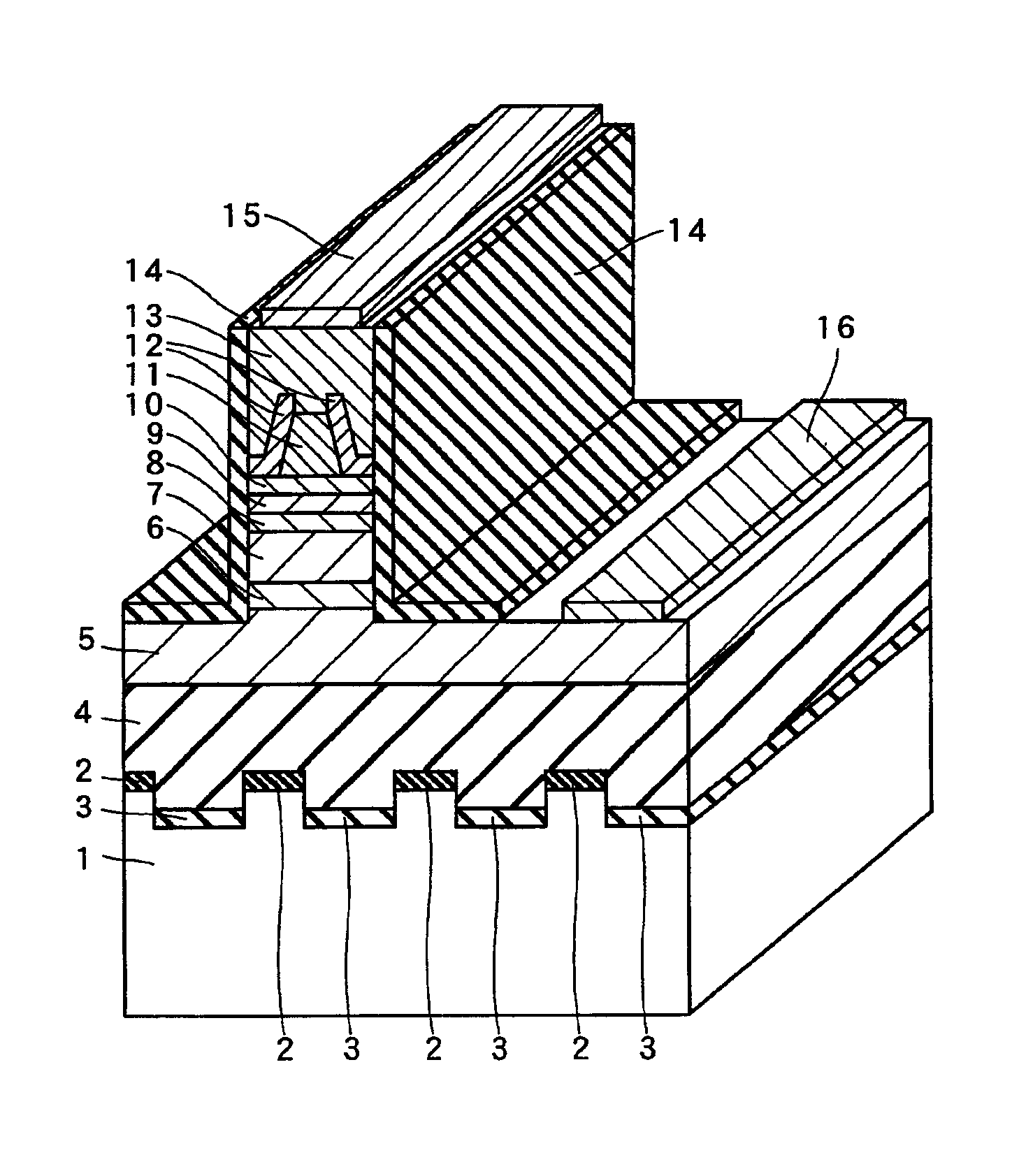

Multibeam semiconductor laser, semiconductor light-emitting device and semiconductor device

InactiveUS6995406B2Easy to checkReduce electrical and thermal cross talkOptical wave guidanceSemiconductor laser arrangementsLight emitting deviceNitride

In a multi-beam semiconductor laser including nitride III–V compound semiconductor layers stacked on one surface of a substrate of sapphire or other material to form laser structures, and including a plurality of anode electrodes and a plurality of cathode electrodes formed on the nitride III–V compound semiconductor layers, one of the anode electrodes is formed to bridge over one of the cathode electrodes via an insulating film, and another anode electrode is formed to bridge over another of the cathode electrodes via an insulating film.

Owner:SONY CORP

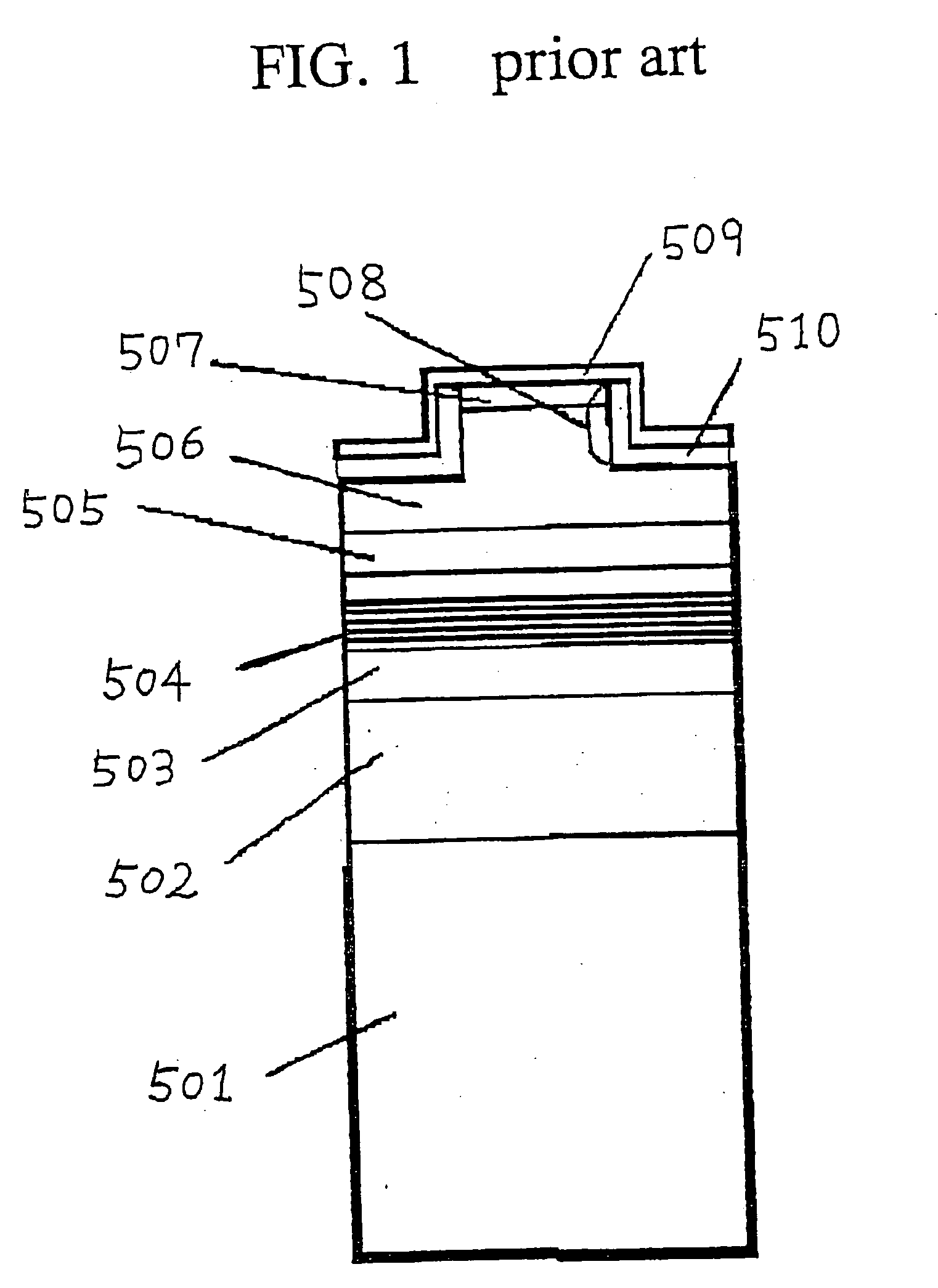

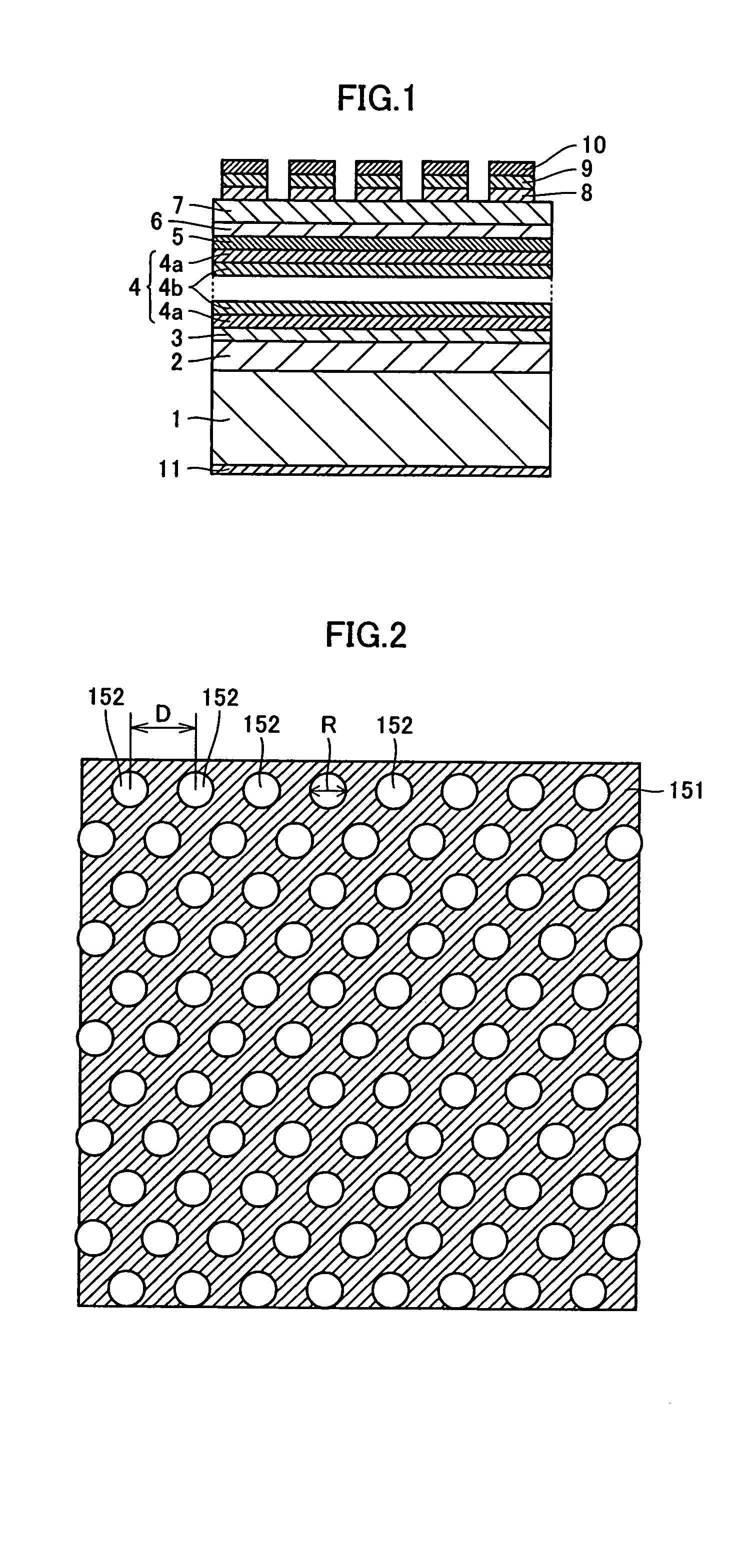

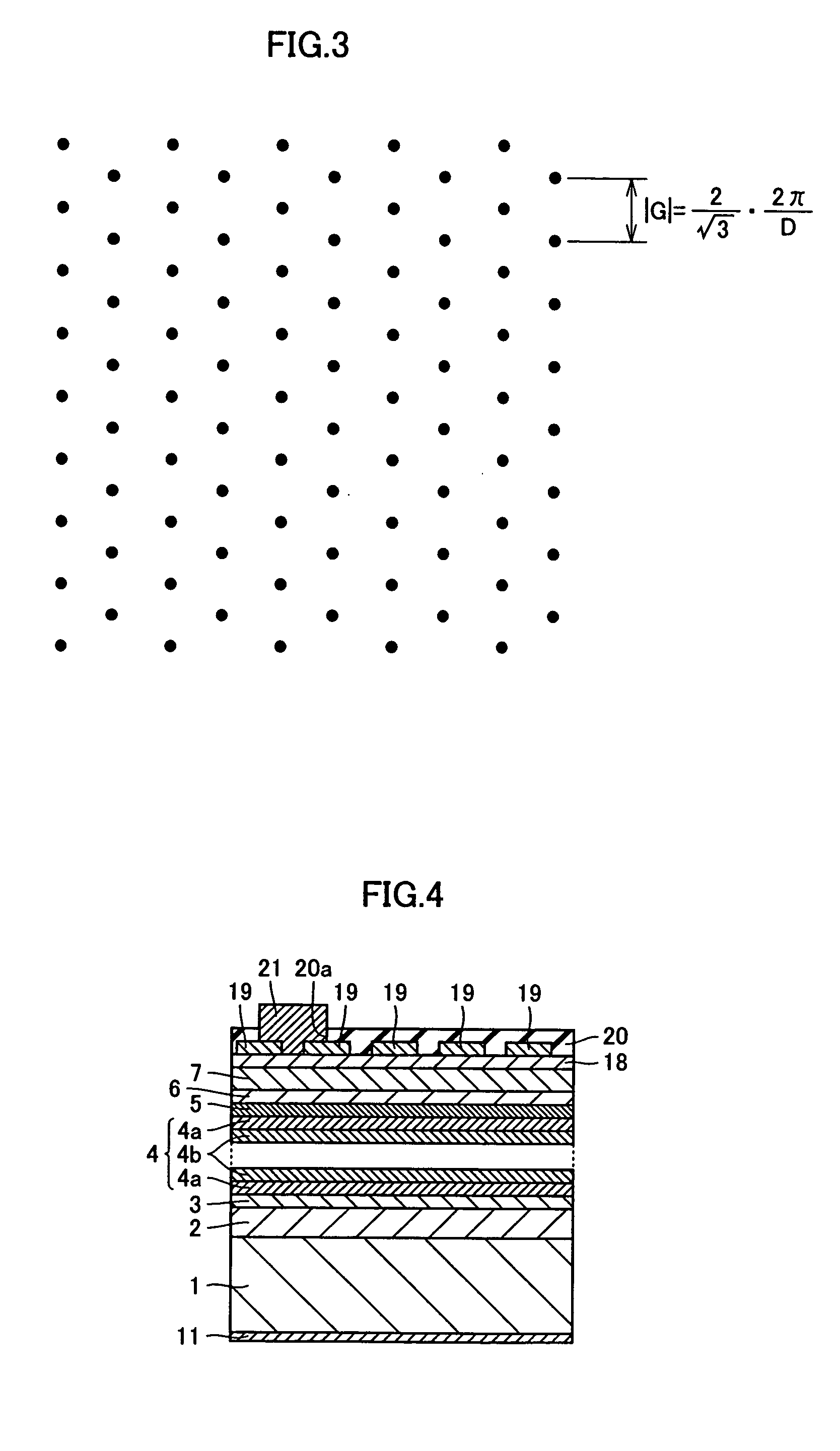

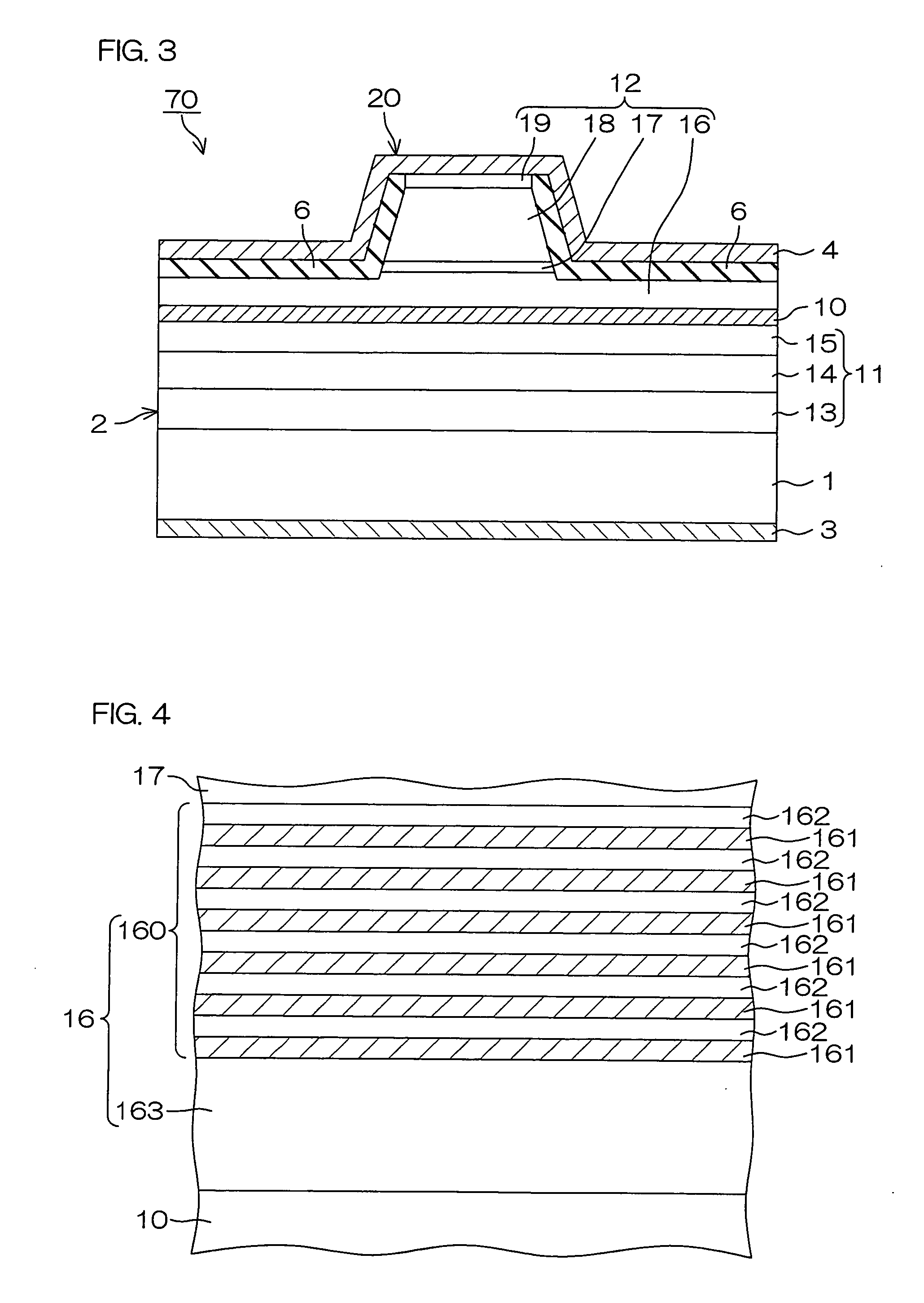

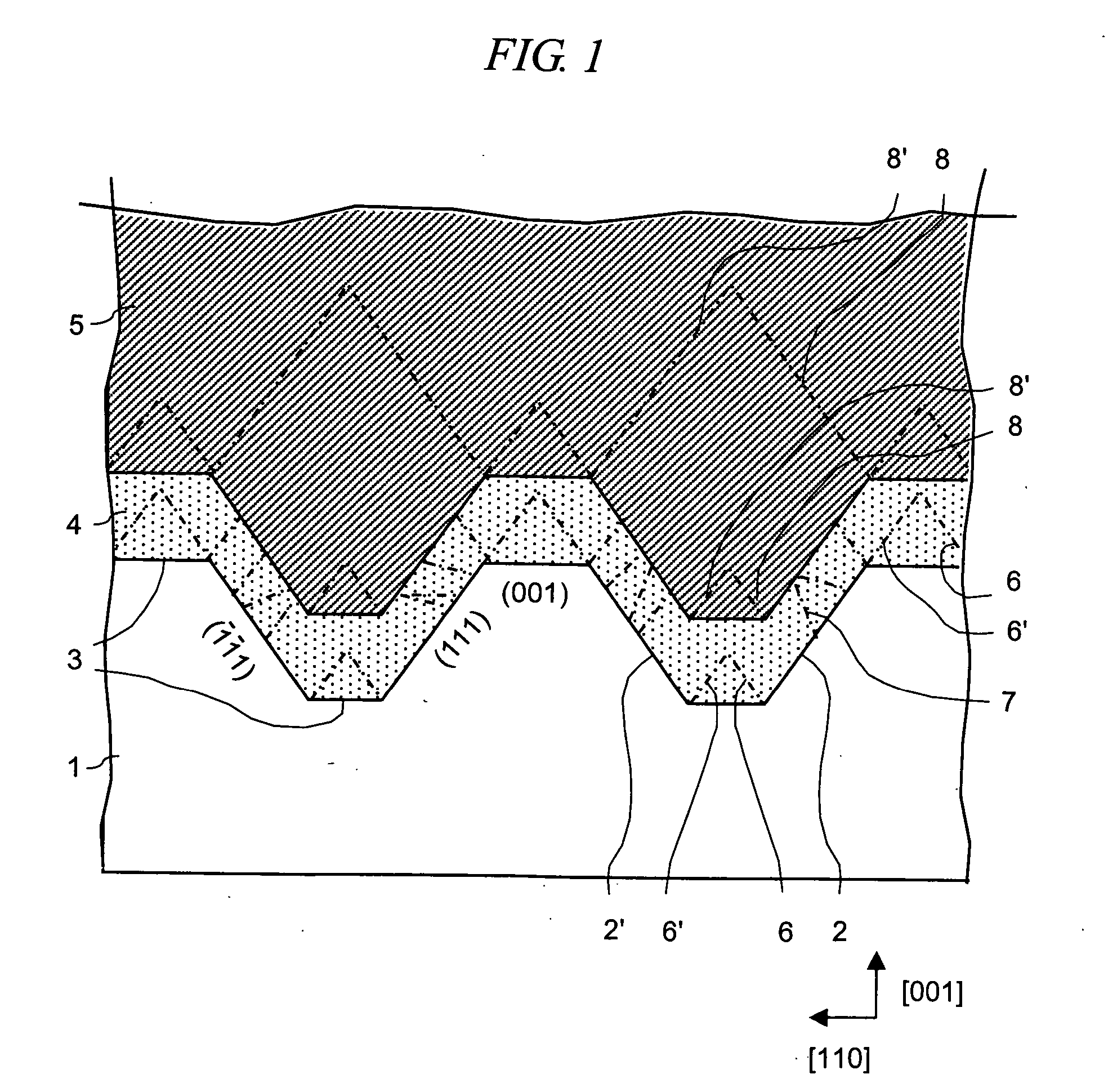

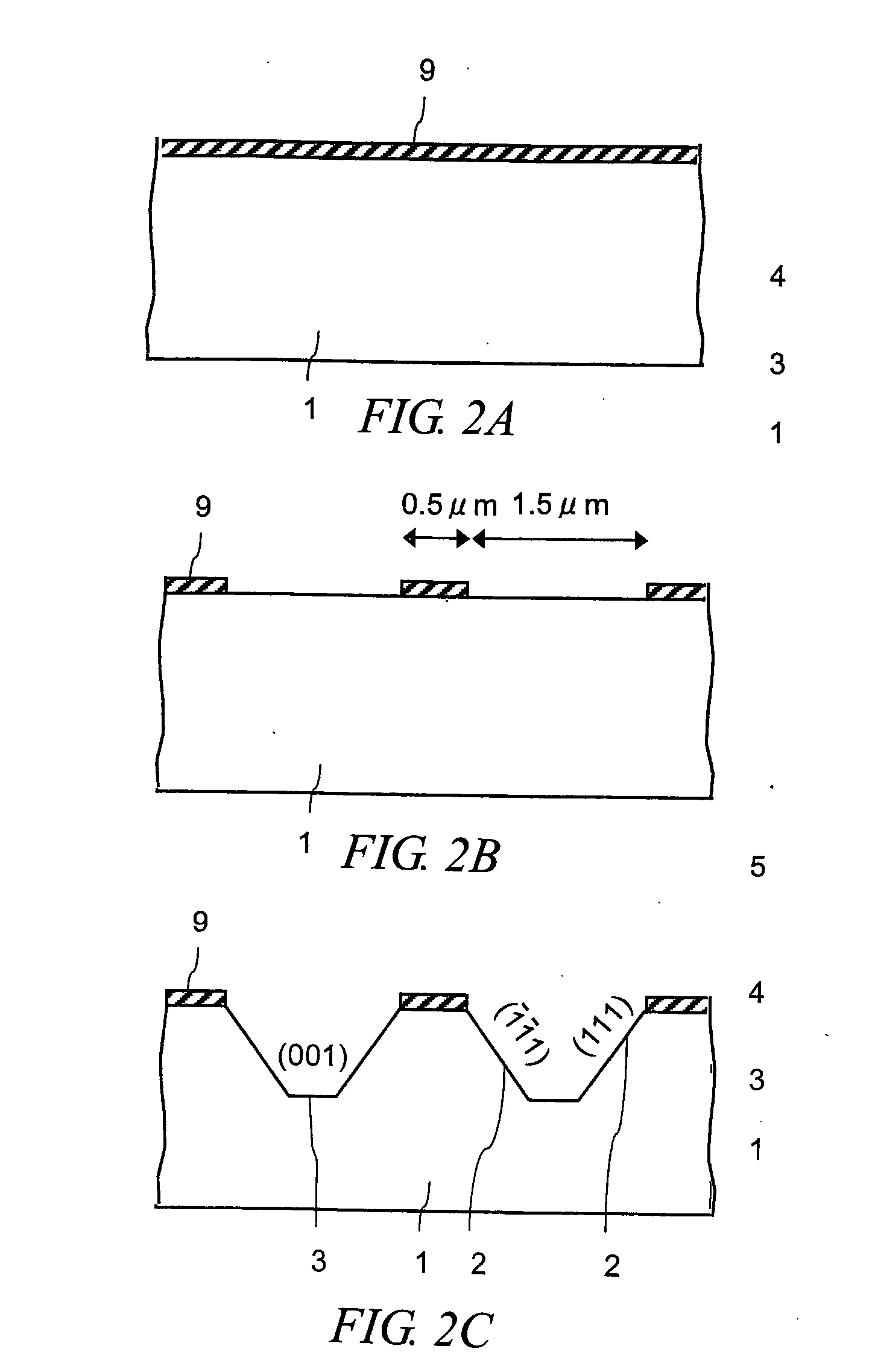

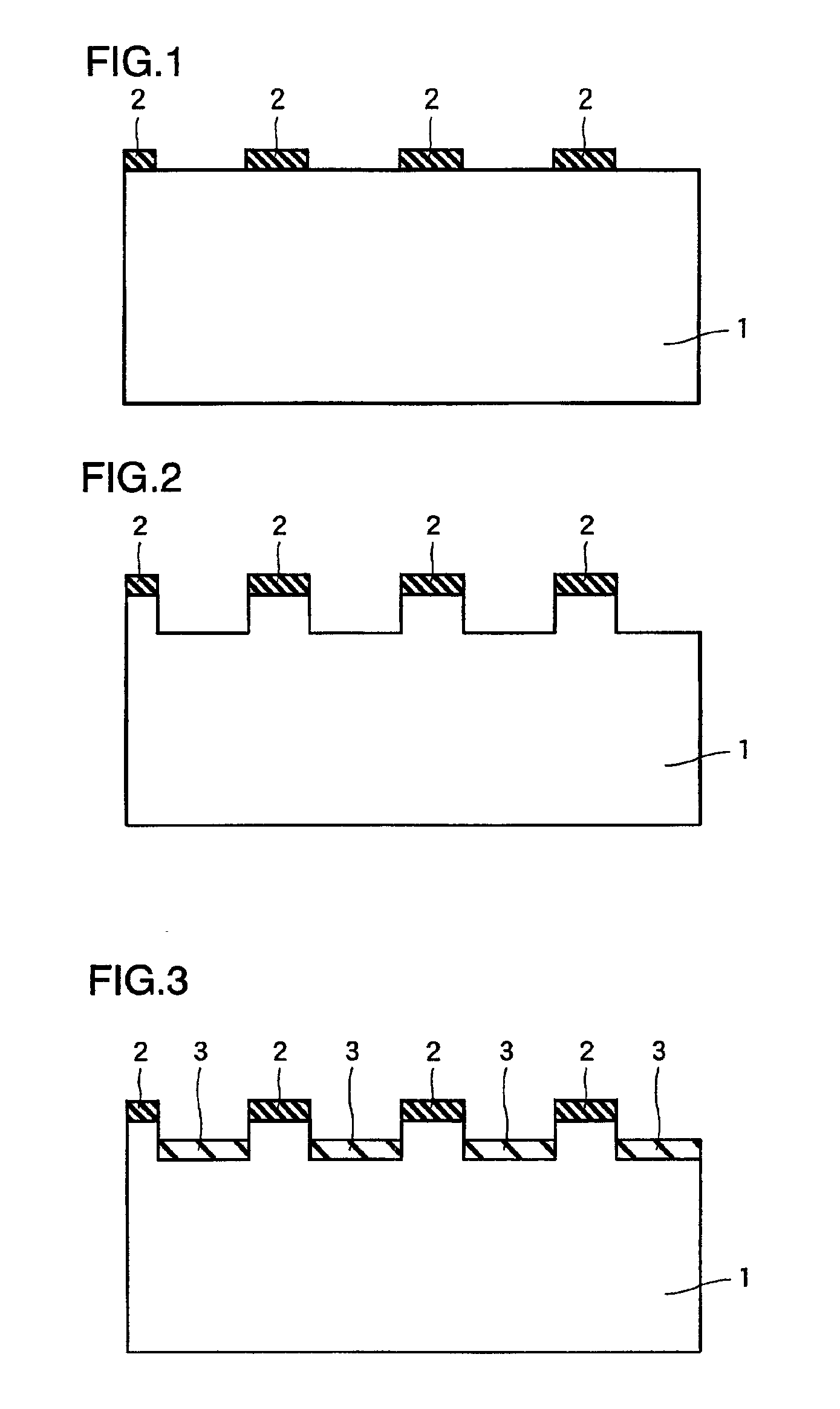

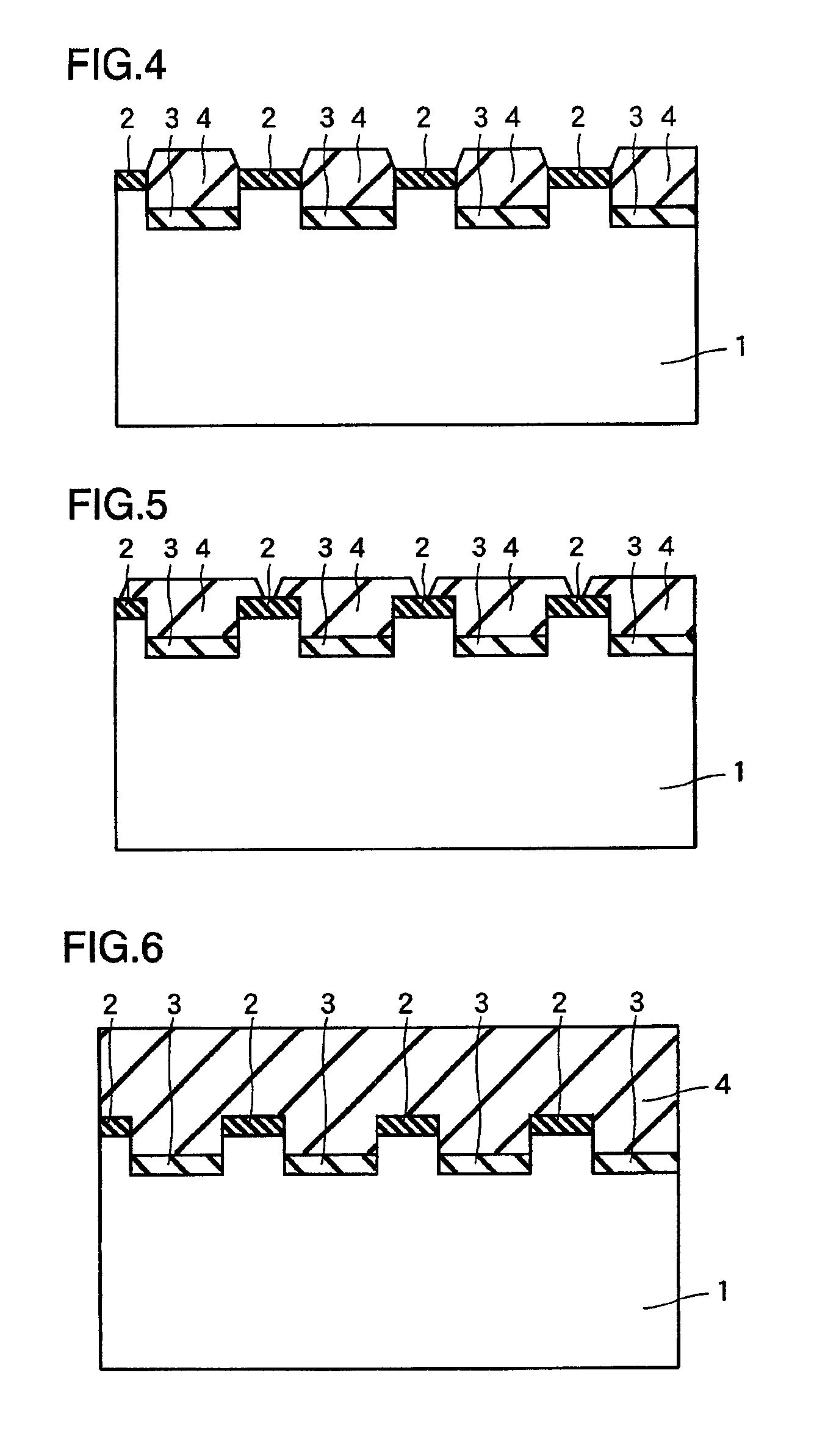

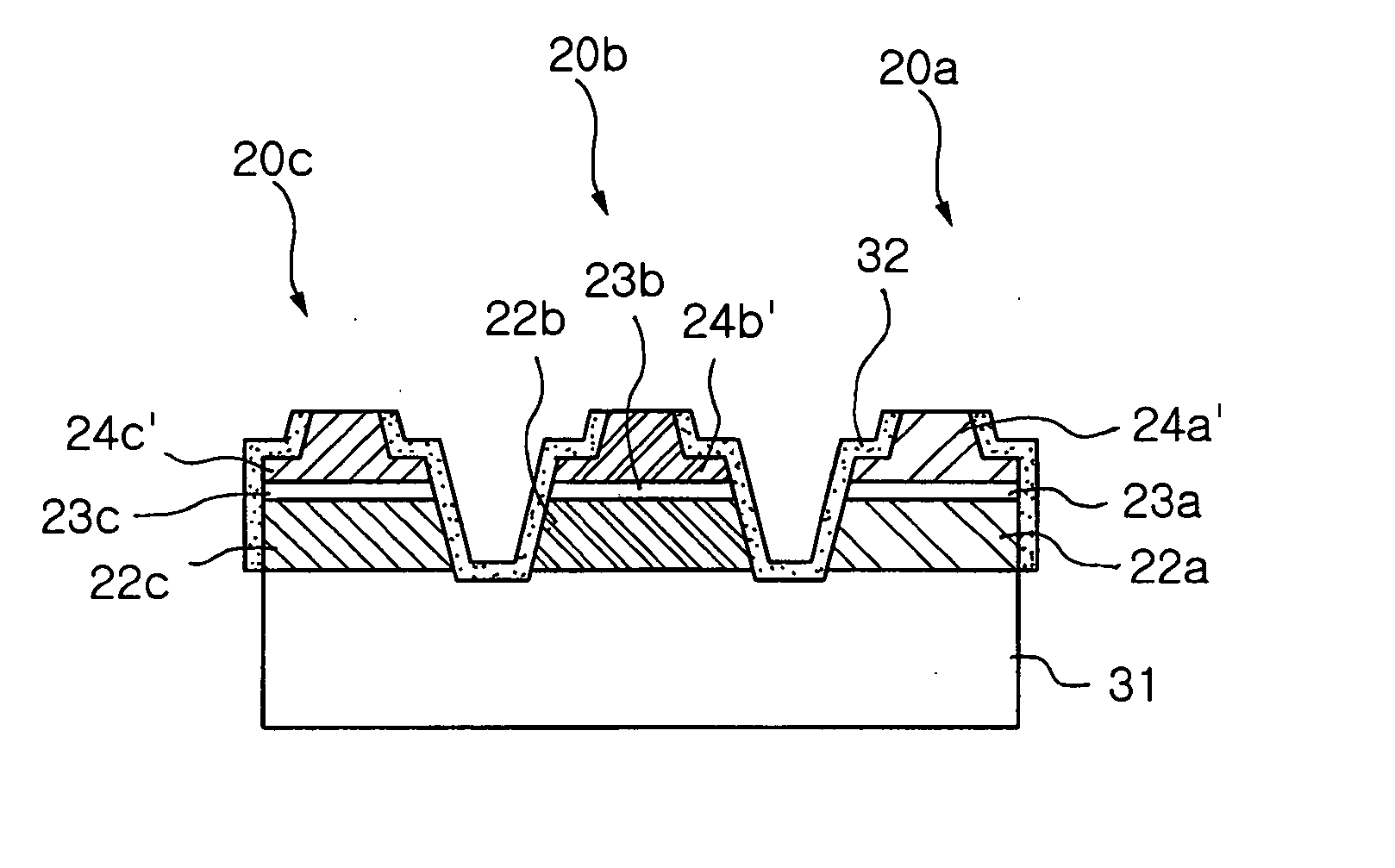

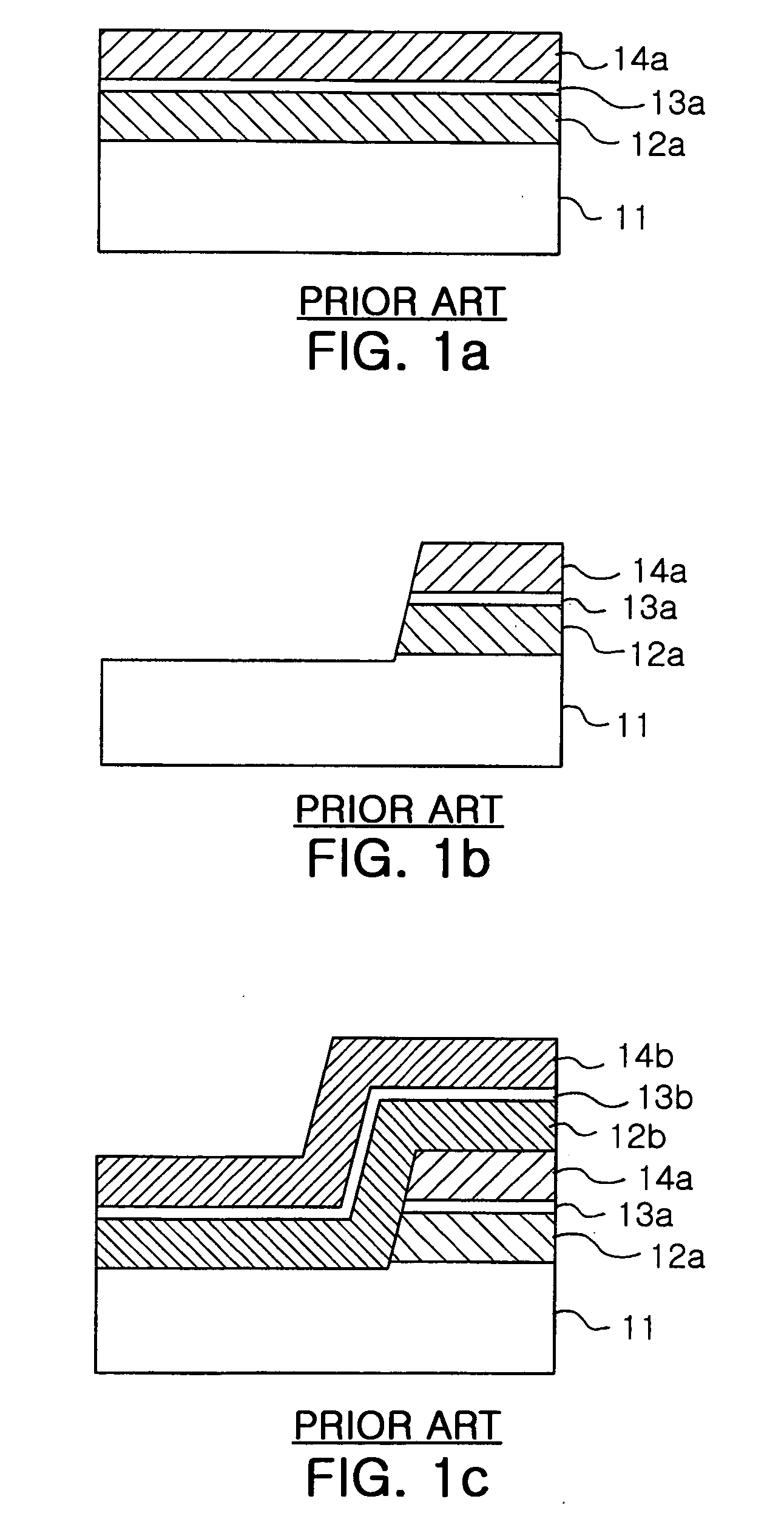

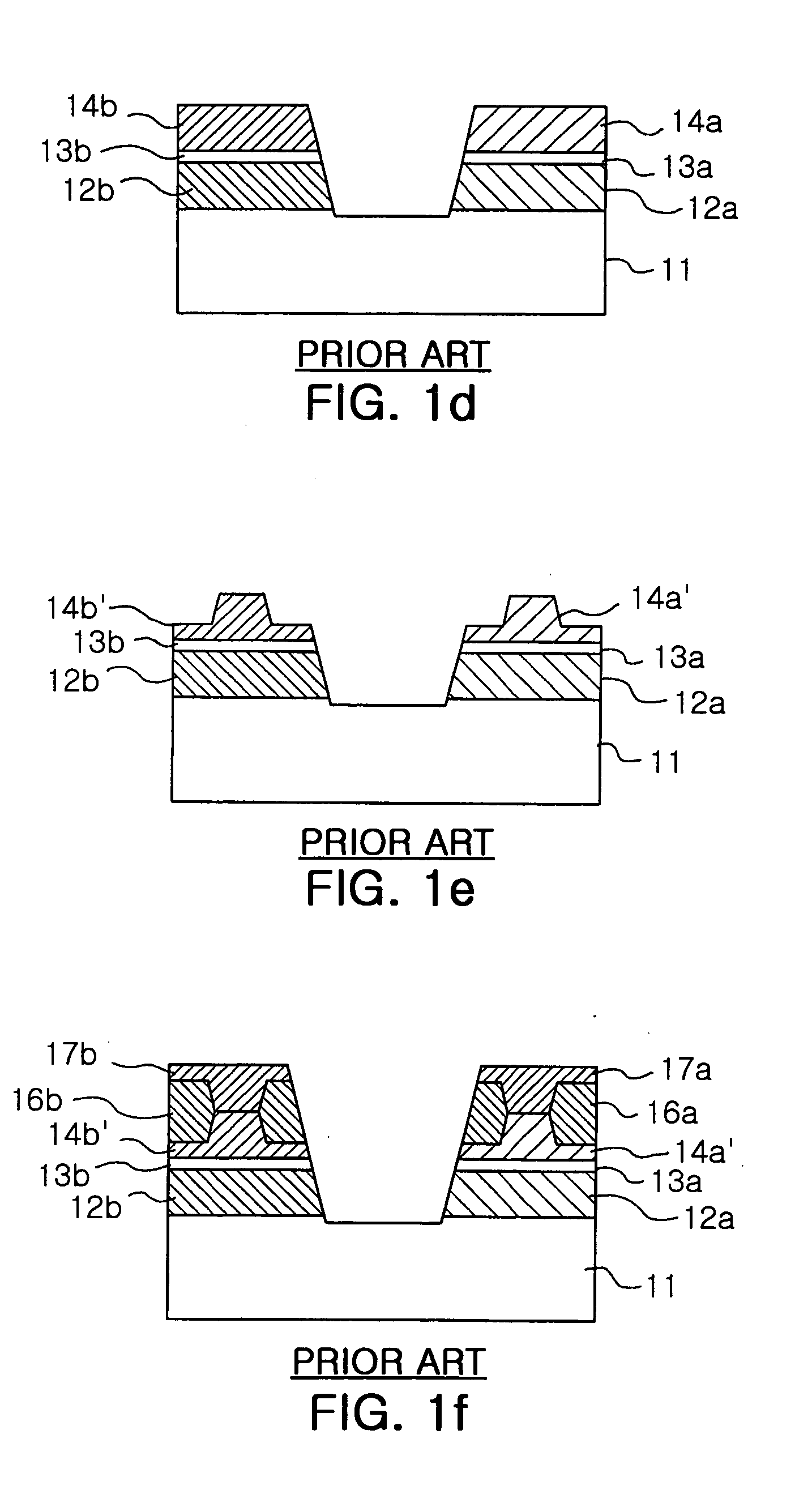

Nitride-based semiconductor element and method of forming nitride-based semiconductor

InactiveUS6994751B2Improve batch productivityExcellent element characteristicOptical wave guidancePolycrystalline material growthProduction rateDislocation

A nitride-based semiconductor element having superior mass productivity and excellent element characteristics is obtained. This nitride-based semiconductor element comprises a substrate comprising a surface having projection portions, a mask layer formed to be in contact with only the projection portions of the surface of the substrate, a first nitride-based semiconductor layer formed on recess portions of the substrate and the mask layer and a nitride-based semiconductor element layer, formed on the first nitride-based semiconductor layer, having an element region. Thus, the first nitride-based semiconductor layer having low dislocation density is readily formed on the projection portions of the substrate and the mask layer through the mask layer serving for selective growth. When the nitride-based semiconductor element layer having the element region is grown on the first nitride-based semiconductor layer having low dislocation density, a nitride-based semiconductor element having excellent element characteristics can be readily obtained. The first nitride-based semiconductor layer is formed through only single growth on the substrate, whereby a nitride-based semiconductor element having excellent mass productivity is obtained.

Owner:LEDVANCE GMBH

Method of producing multi-wavelength semiconductor laser device

InactiveUS20050286591A1Easy alignmentReduce thicknessOptical wave guidanceSemiconductor laser arrangementsSingle crystalMaterials science

Disclosed herein is a method for producing a multi-wavelength semiconductor laser device. The method comprises the steps of: forming first and second nitride epitaxial layers in parallel on a substrate for growth of a nitride single crystal; separating the first and second nitride epitaxial layers from the substrate; attaching the separated first and second nitride epitaxial layers to a first conductivity-type substrate; selectively removing the first and second nitride semiconductor epitaxial layers to expose a portion of the first conductivity-type substrate and to form first and second semiconductor laser structures, respectively; and forming a third semiconductor laser structure on the exposed portion of the first conductivity-type substrate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

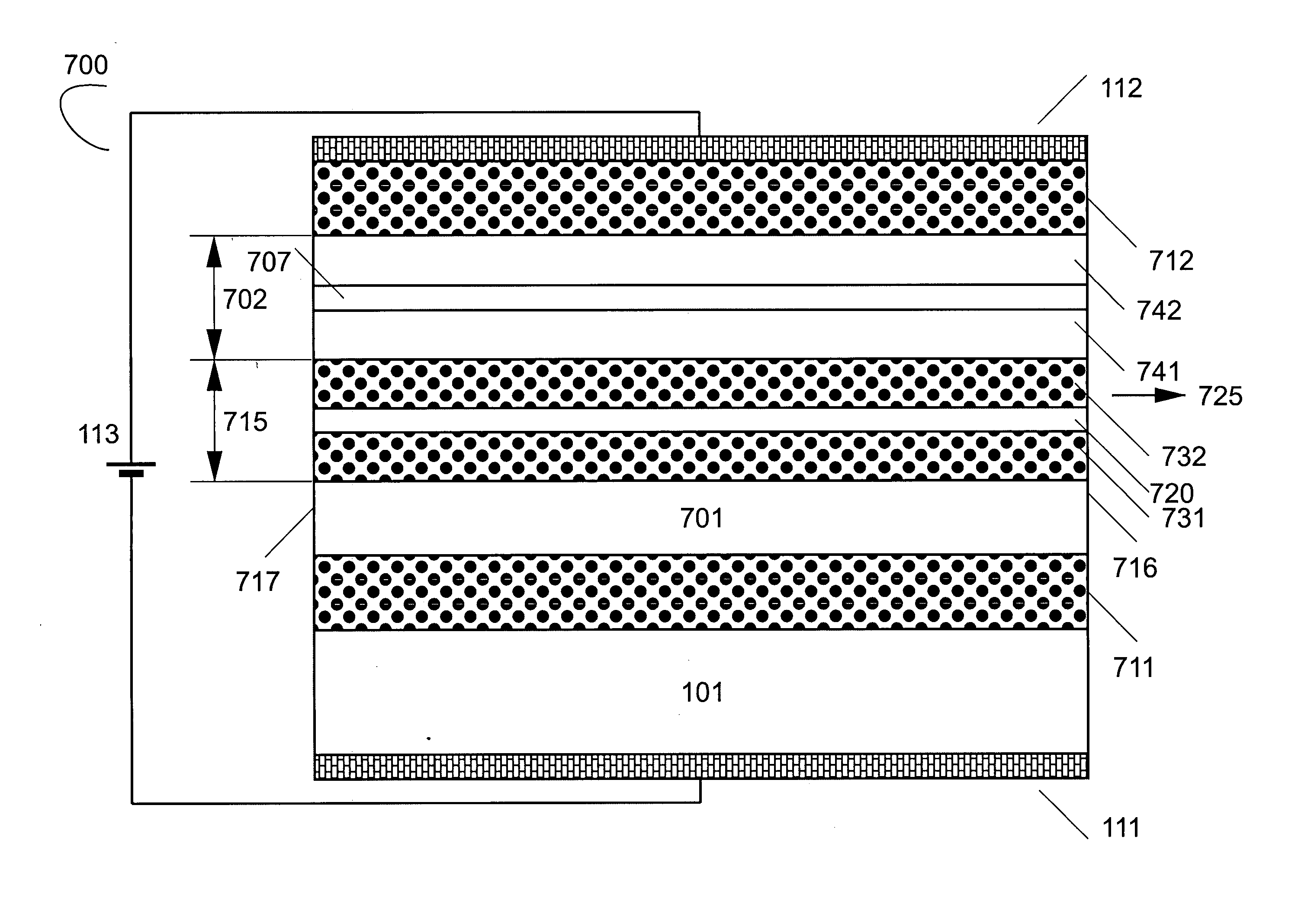

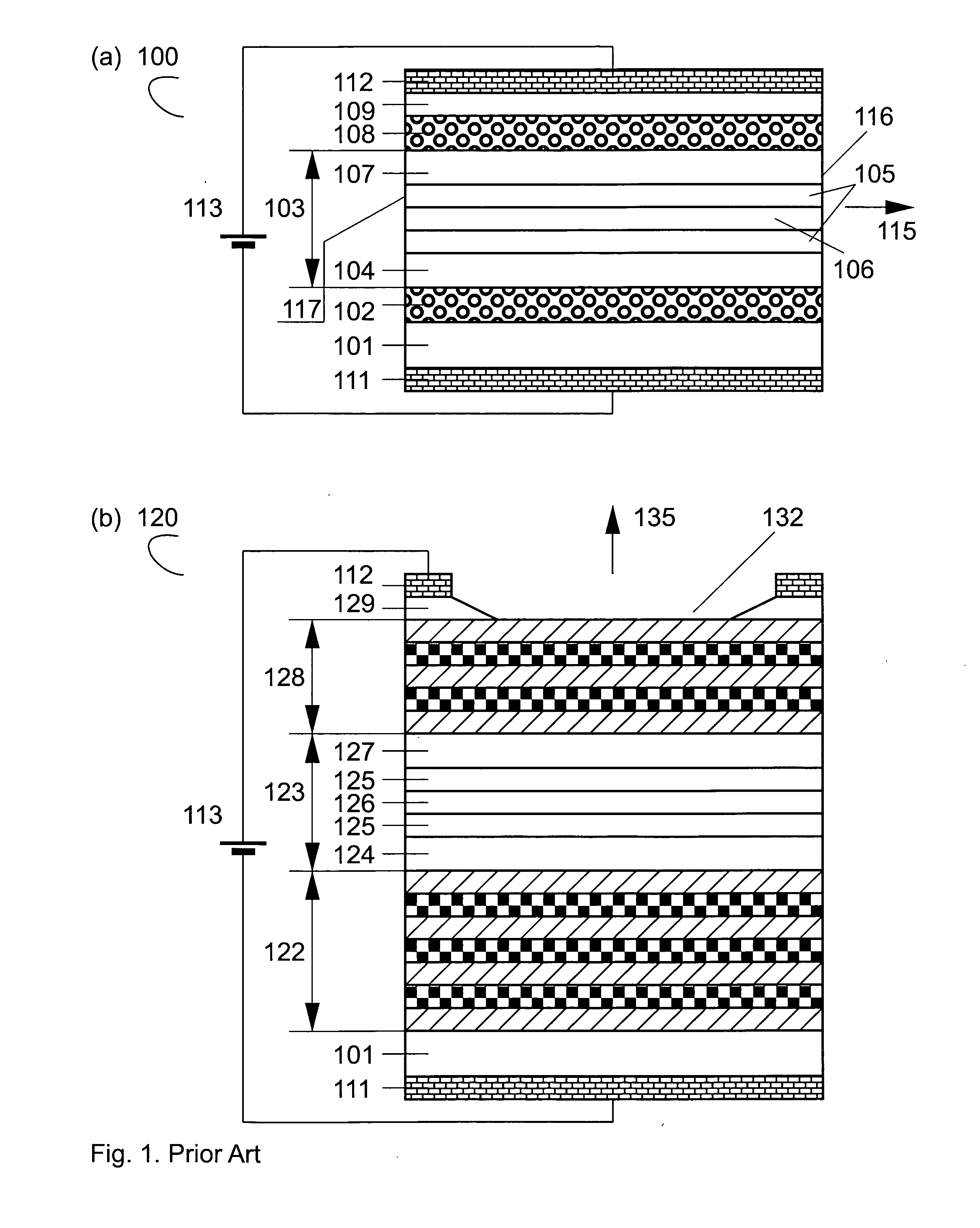

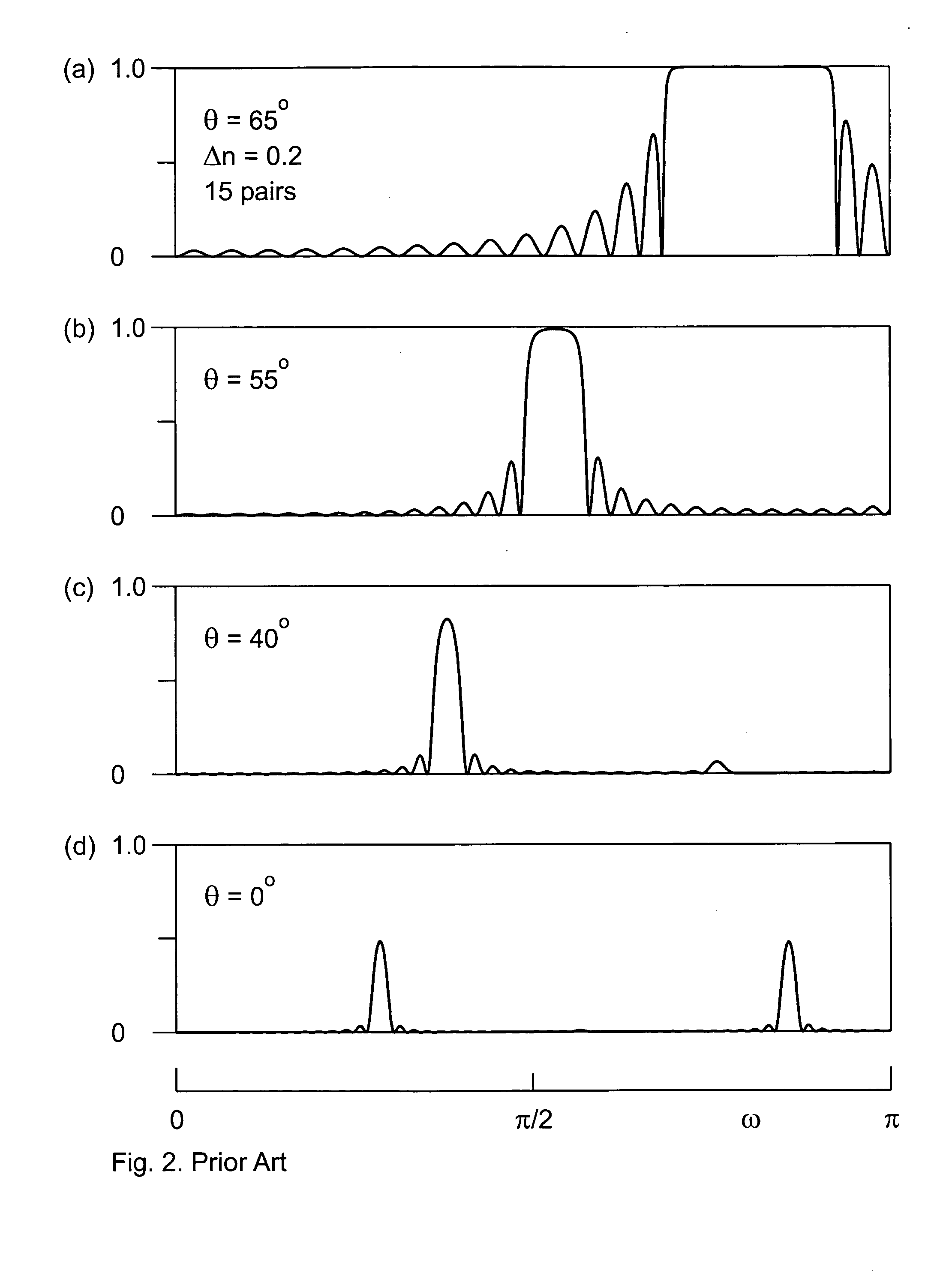

Optoelectronic device incorporating an interference filter

InactiveUS20050117623A1Optical wave guidanceLaser optical resonator constructionOptical cavityResonance

A novel class of optoelectronic devices incorporate an interference filter. The filter includes at least two optical cavities. Each of the cavities localizes al least one optical mode. The optical modes localized at two cavities are at resonance only at one or at a few discrete selective wavelengths. At resonance, the optical eigenmodes contain one mode having a zero intensity at a node position between the two cavities, where this position shifts as a function of the wavelength. A non-transparent element, which is preferably an absorbing element, a scatterer, or a reflector, is placed between two cavities. At a discrete selective wavelength, when the node of the optical mode matches with the non-transparent element, the filter is transparent for light. At other wavelengths, the filter is not transparent for light. This allows for the construction of various optoelectronic devices showing a strongly wavelength-selective operation.

Owner:INNOLUME

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com