Ball valve

A ball valve and ball valve technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as damage to sealing parts and their adjacent parts, installation difficulties, etc., to achieve the effect of reducing space and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

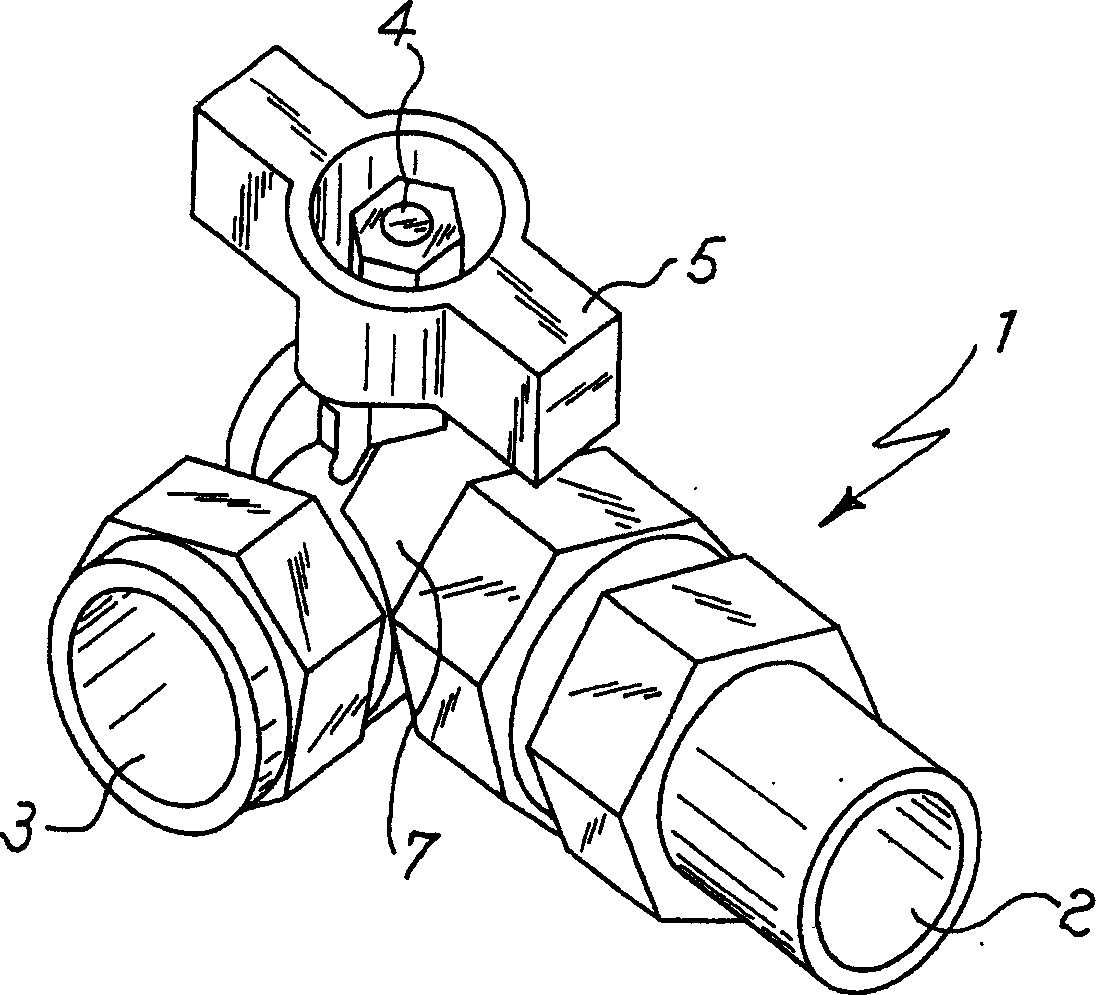

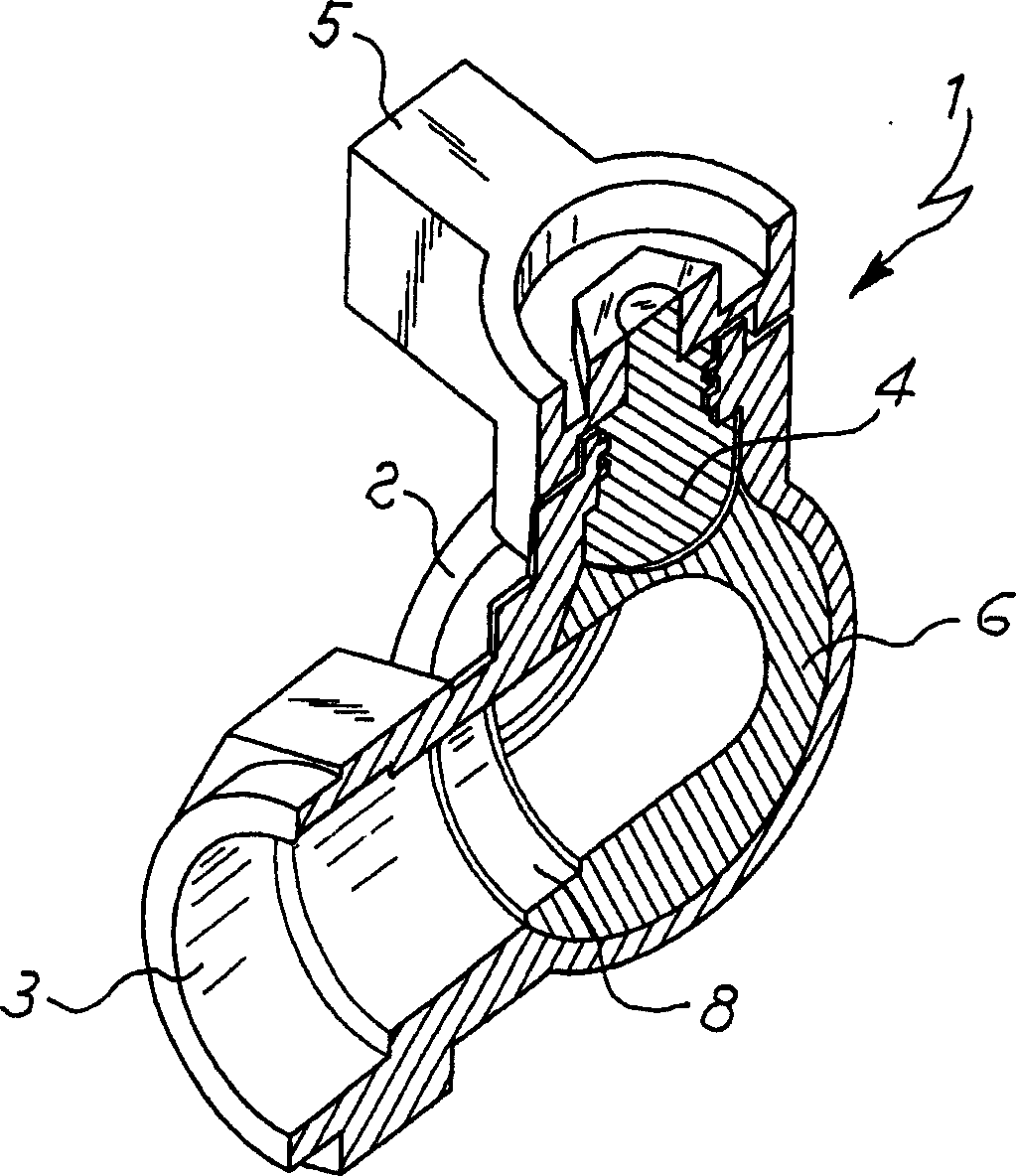

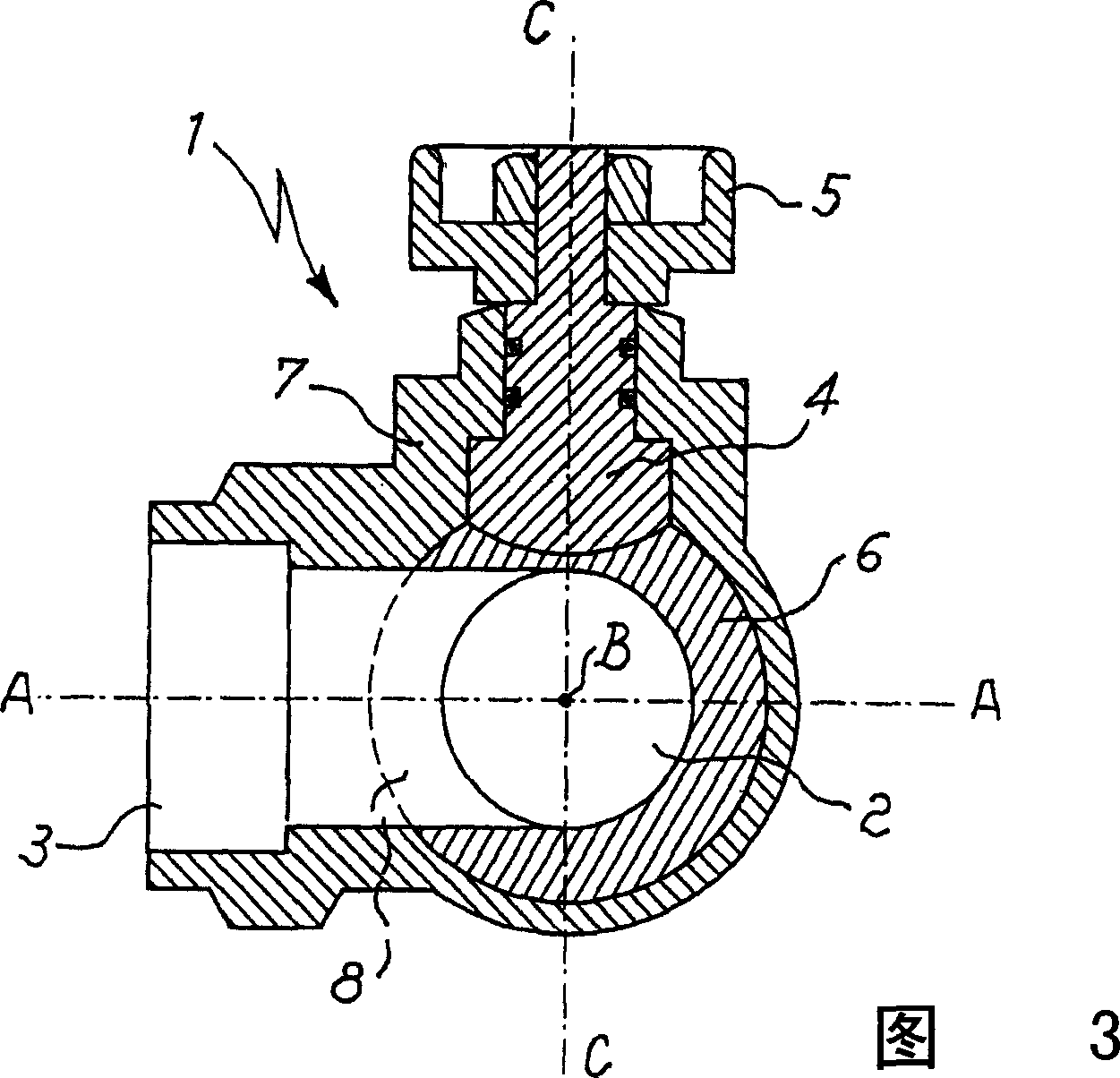

[0023] Referring to the above-mentioned drawings, the ball valve 1 of the present invention includes a cylindrical inflow pipe 2 having an axis B-B and a cylindrical outflow pipe 3 having an axis A-A. As shown, especially as Figure 4 As shown, the axis A-A of the outflow conduit 3 does not coincide with the axis B-B of the inflow conduit 2 . Especially in a particular form of embodiment of the invention as shown, the axis A A of the outflow duct 3 and the axis B-B of the inflow duct 2 intersect at a point (as Figure 4 As shown in C), thus defining the plane where the valve body 7 of the valve 1 is located.

[0024] In the particular embodiment of the invention shown, the axis A-A of the conduit 3 and the axis B-B of the conduit 2 are perpendicular to each other so that the fluid flowing through the valve 1 is deflected by 90 degrees when flowing from the outlet conduit 2 to the outlet conduit 3 .

[0025] However, alternative embodiments of the ball valve in the claimed te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com