Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3141 results about "Rotary valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

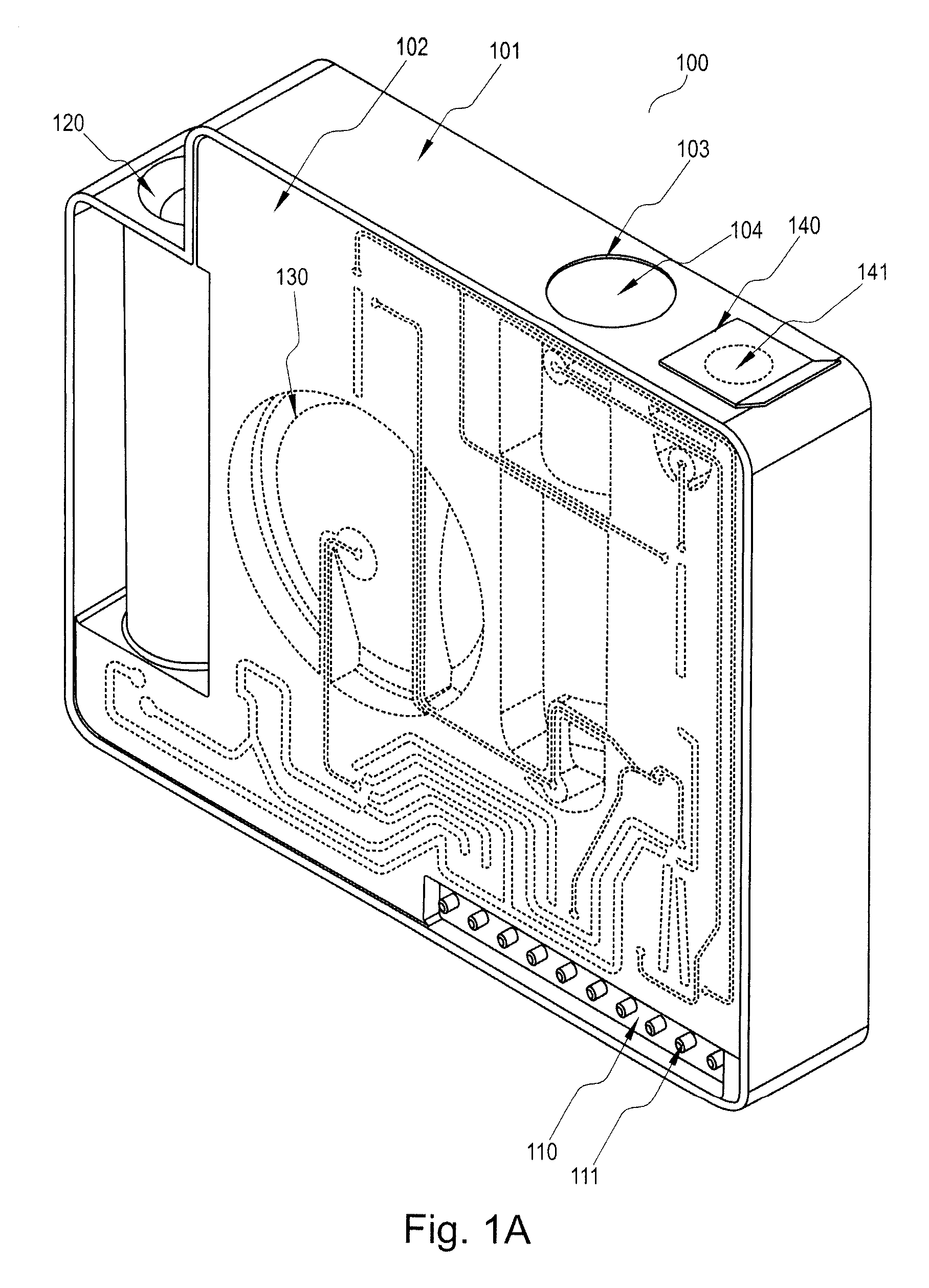

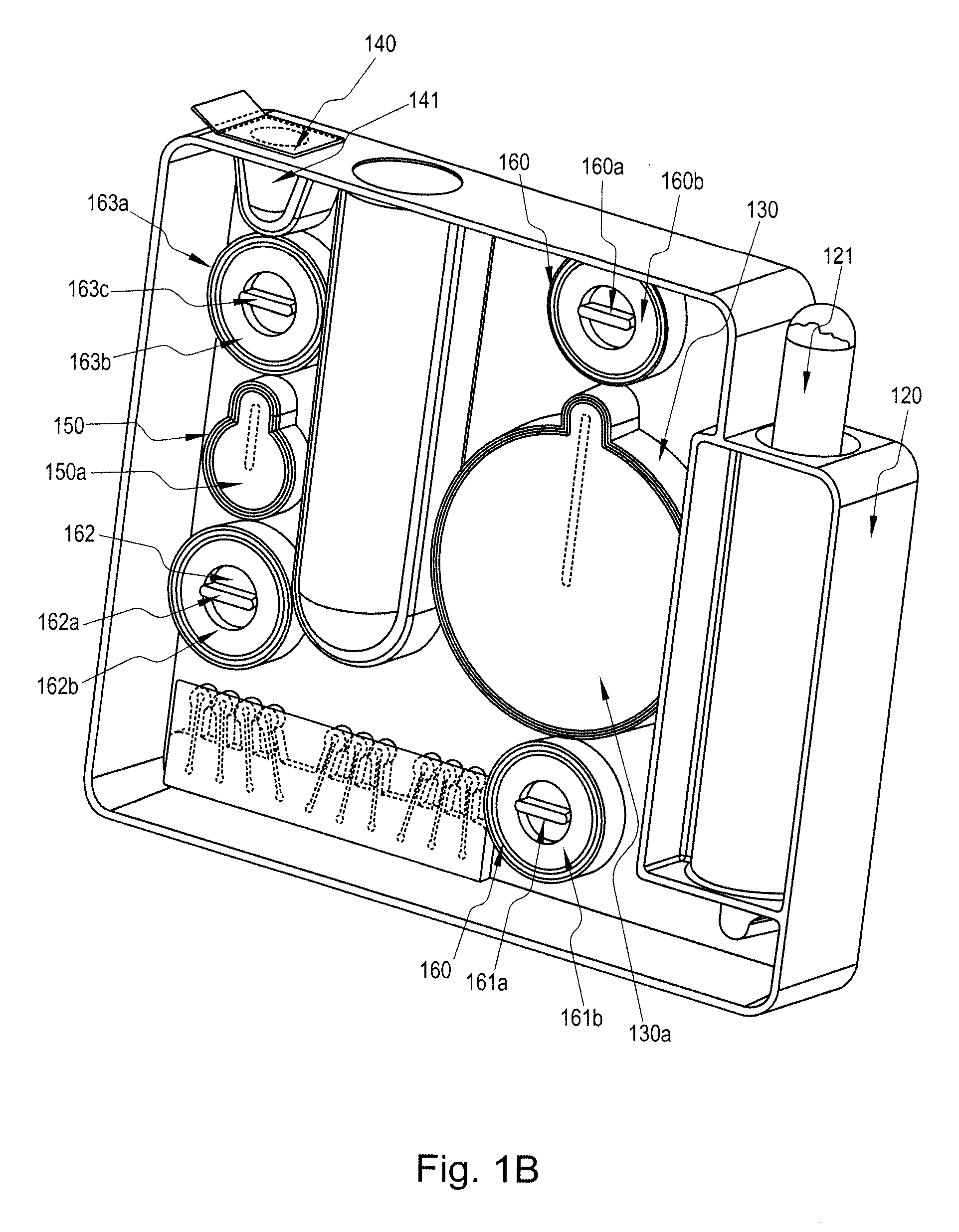

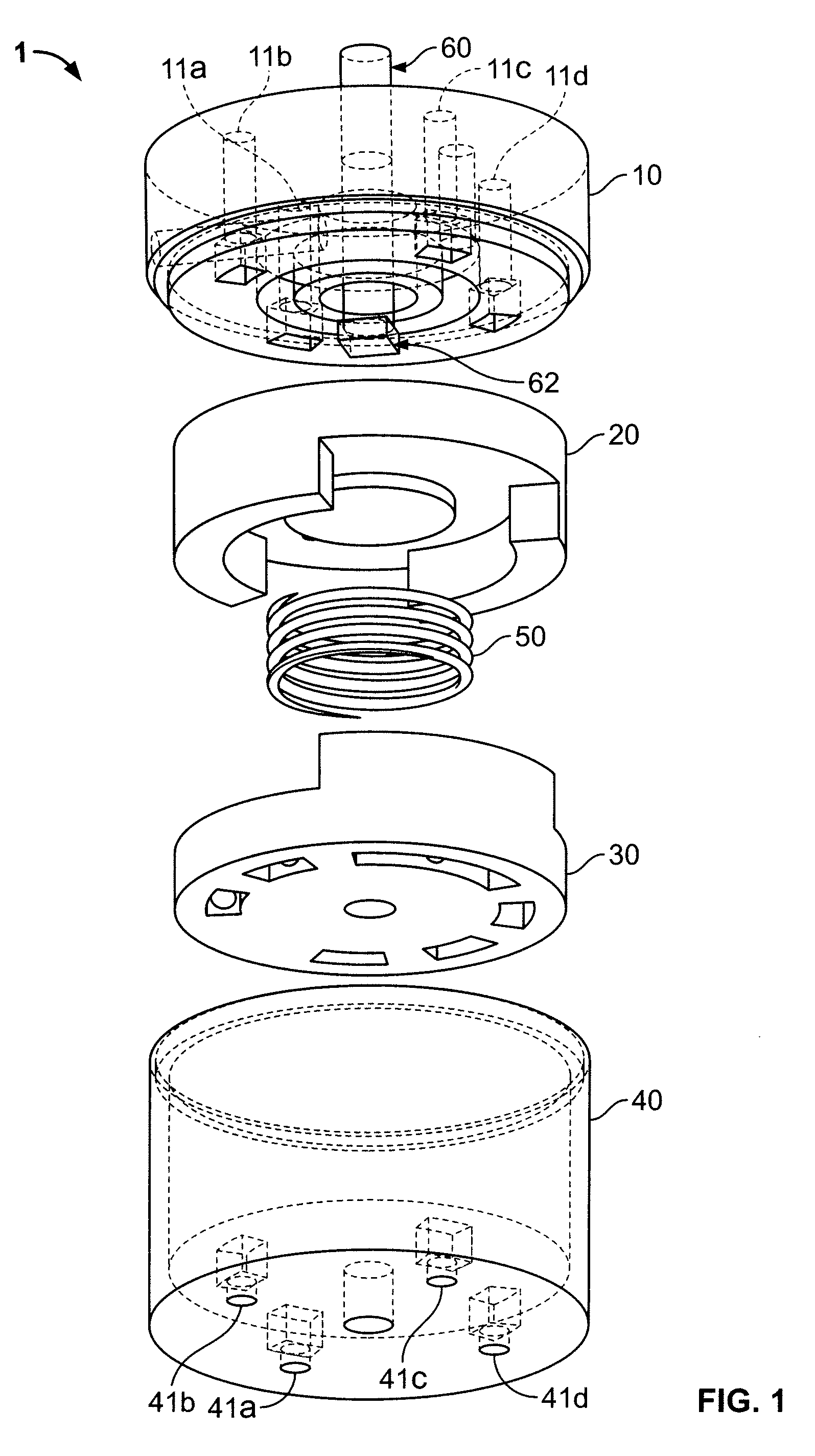

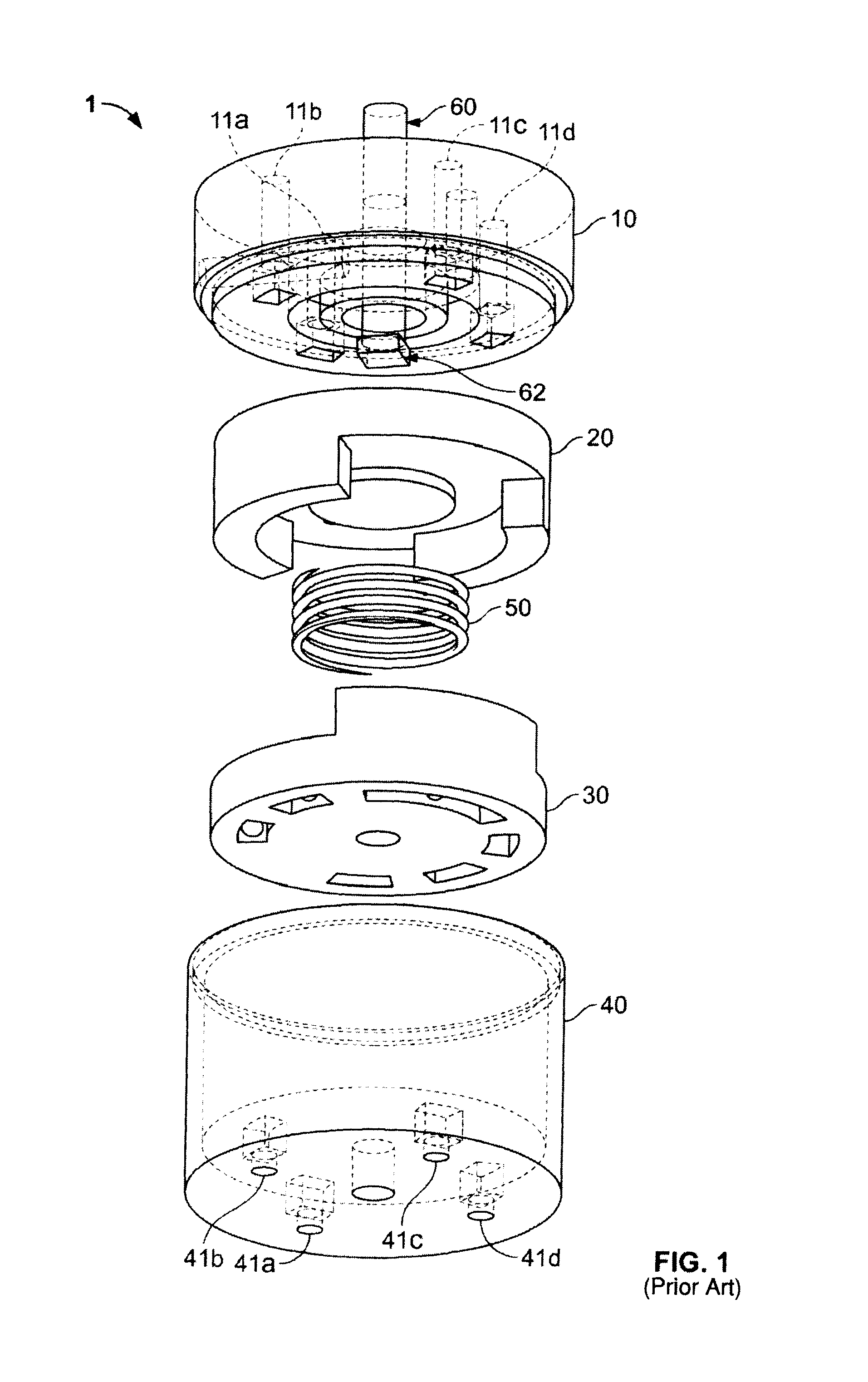

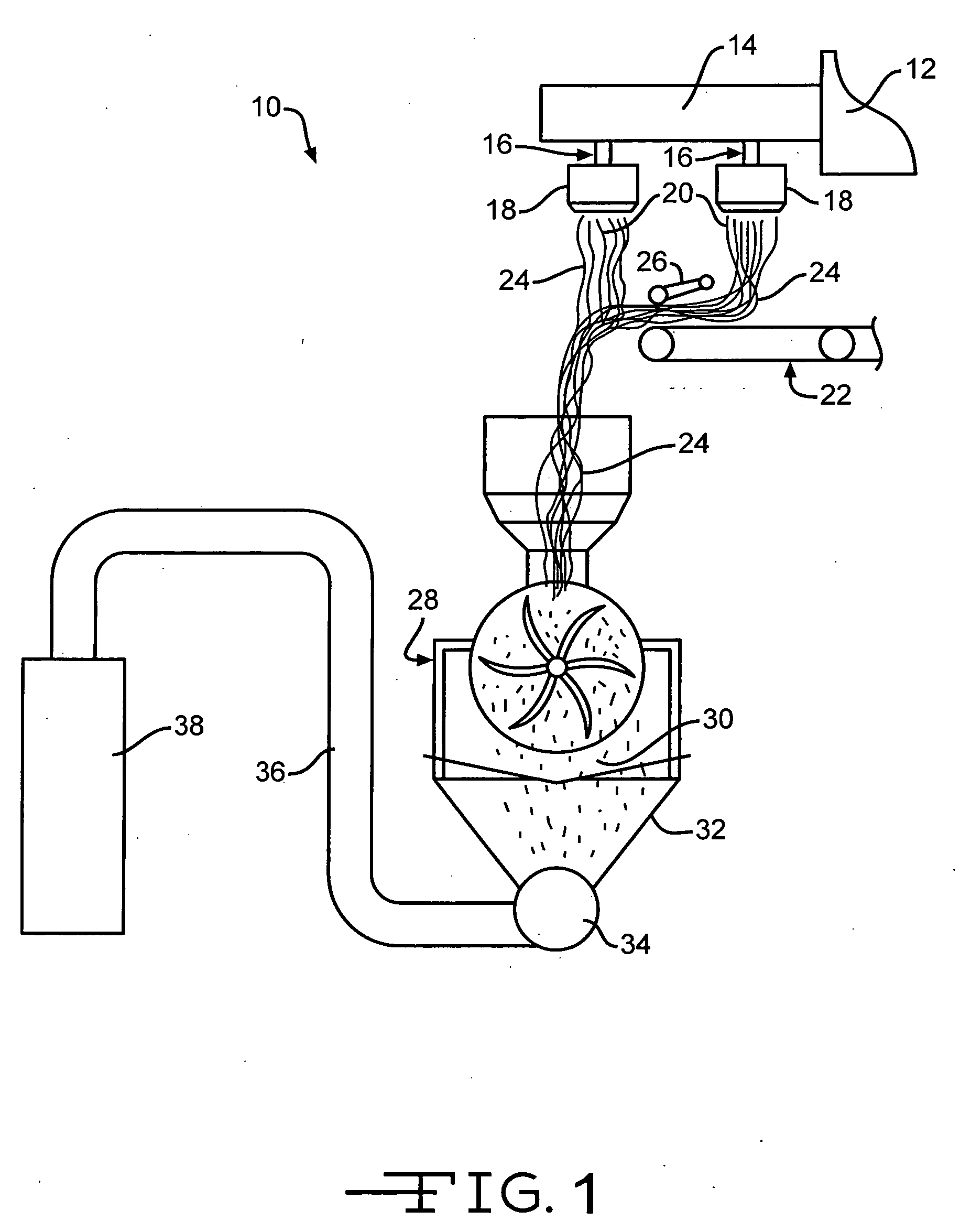

Aerosol generator and methods of making and using an aerosol generator

InactiveUS7117867B2Easy to useEasy to moveRespiratorsControlling ratio of multiple fluid flowsRotary valveEngineering

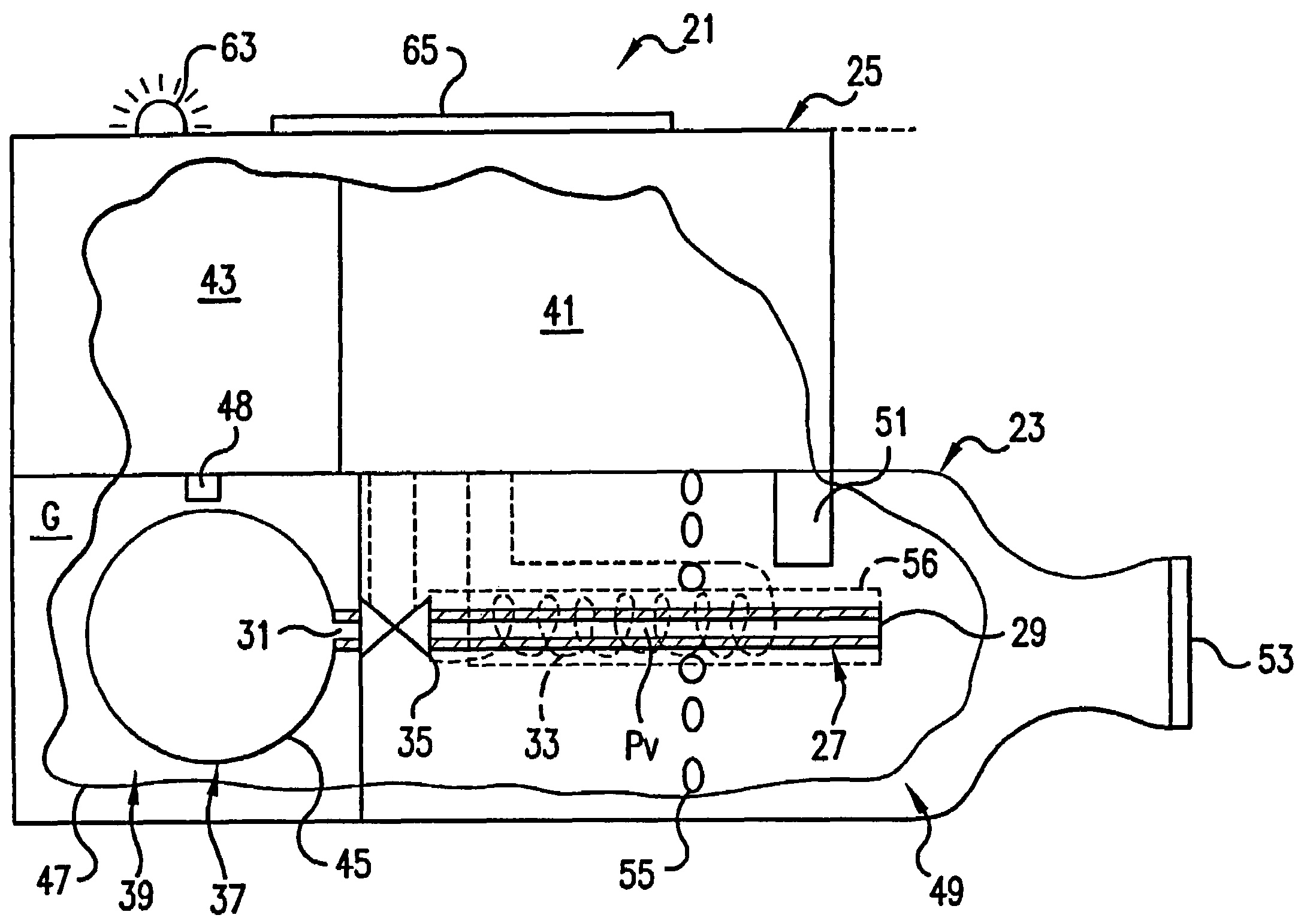

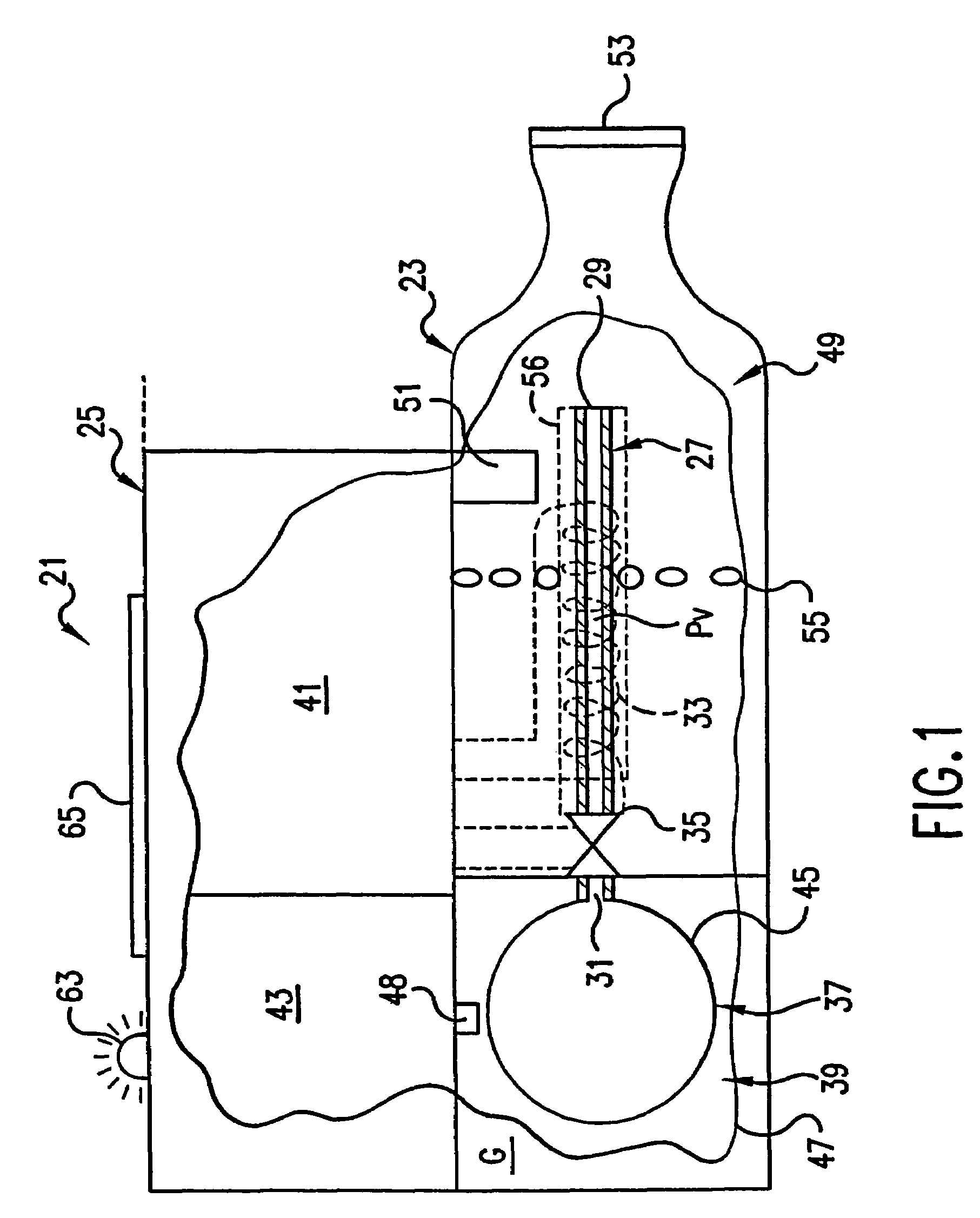

An aerosol generator includes a flow passage having an inlet and an outlet, a heater arranged relative to the flow passage for heating the flow passage, a source of material to be volatilized in communication with the inlet of the flow passage, a valve to open and close communication between the source of material and the inlet of the flow passage, and a pressurization arrangement for causing material in the source of material to be introduced into the flow passage when the valve is in an open position. The aerosol generator further includes a source of power for operating the heater and the valve, and a control device for controlling supply of power from the source of power to the heater and the valve. A metering device in an inhaler includes a pressurized source of medicated fluid and a metering chamber configured to deliver a predetermined volume of fluid to a heated flow passage in the inhaler. The metering chamber can be part of a rotary valve having a bore and a displacement member moveable within the bore from a first position where the fluid is loaded into the bore to a second position where the predetermined volume is ejected out of the bore. Another metering chamber has an elastic portion of a delivery passage in fluid communication with the pressurized source of liquid and the elastic portion of the delivery passage is deformed to eject the predetermined volume.

Owner:PHILIP MORRIS USA INC

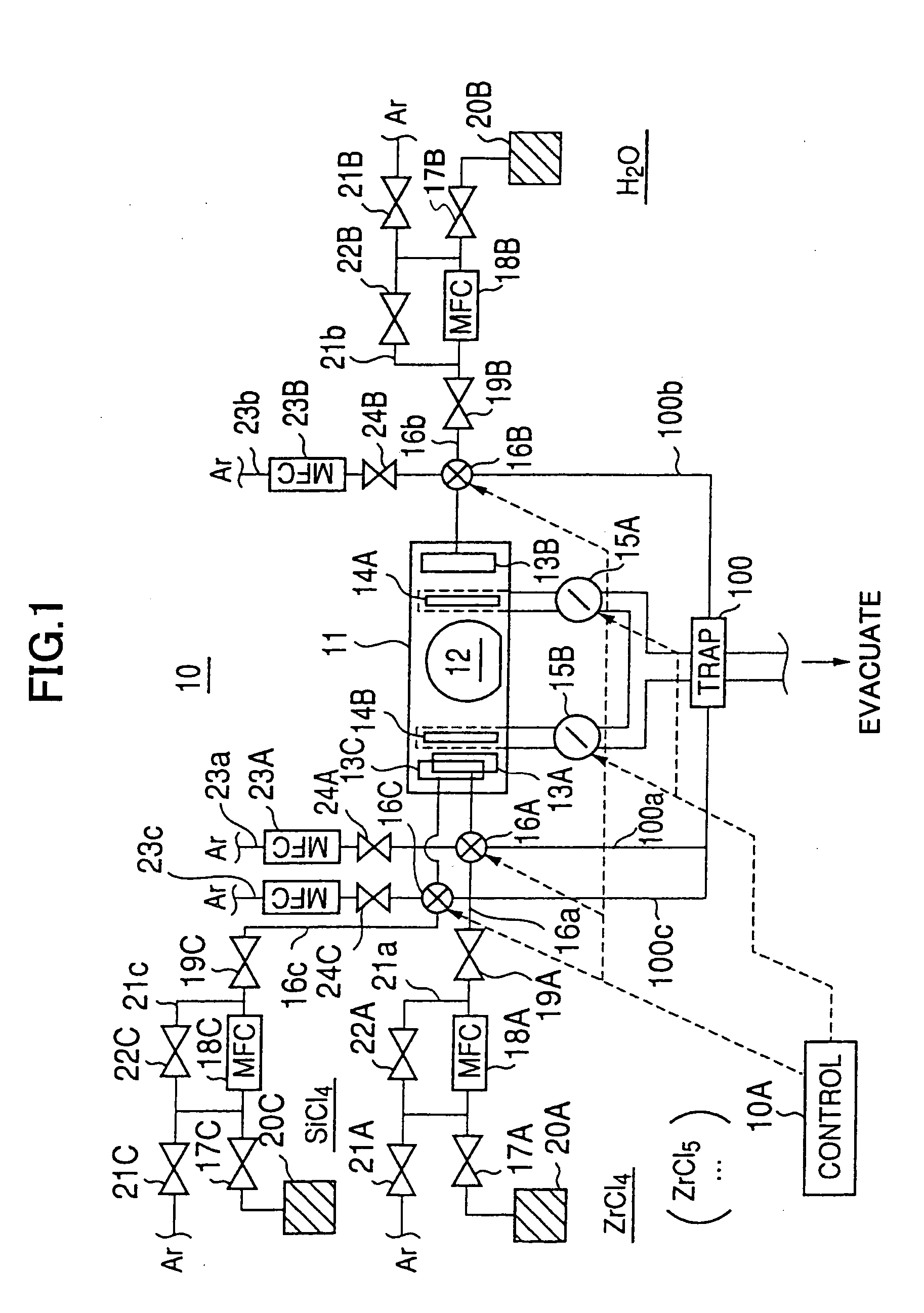

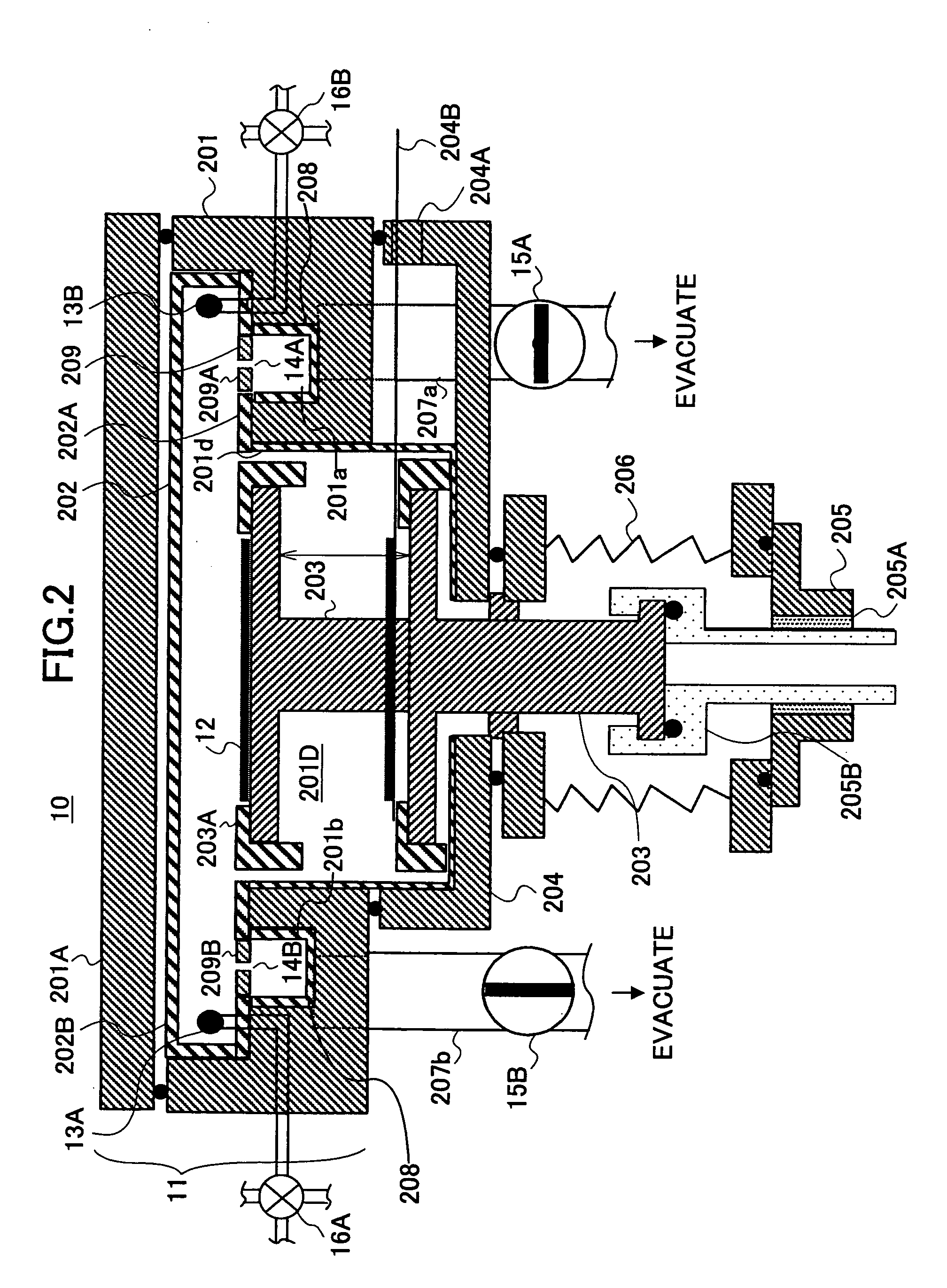

Substrate processing apparatus and substrate processing method, high speed rotary valve, and cleaning method

InactiveUS20050074983A1Increase speedFilm growth efficientlyPlug valvesLiquid surface applicatorsRotary valveEngineering

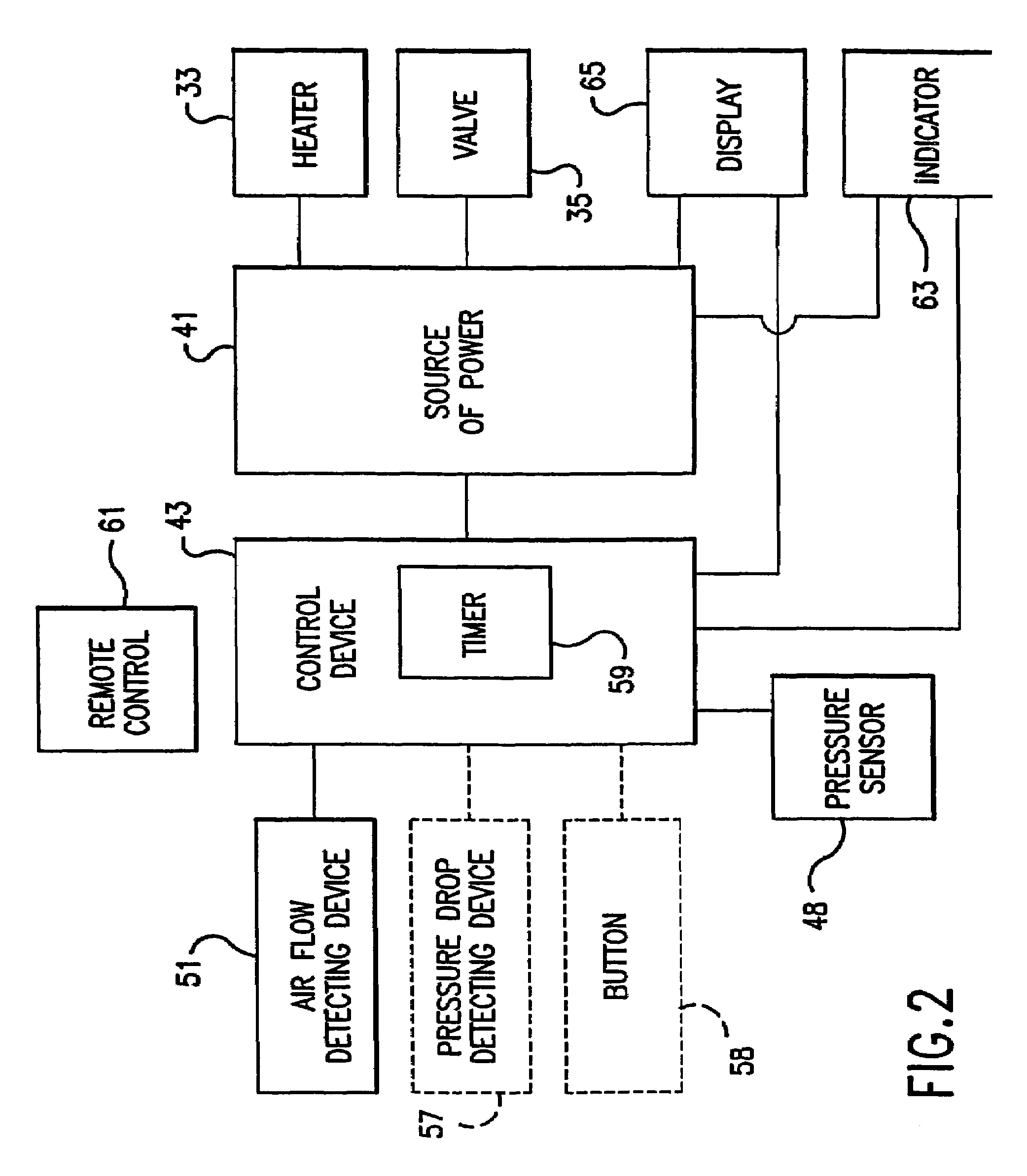

A substrate processing apparatus includes a processing vessel provided with a stage holding thereon a substrate to be processed and evacuated at an evacuation port, and a source gas supplying system that supplies plural source gases to the processing vessel separately in the form of a laminar flow, wherein the evacuation port has a slit-form shape extending in a direction generally intersecting perpendicularly to a direction of the laminar flow, the evacuation port is engaged with a valve having a valve body formed with a slit-form opening corresponding to the slit-form shape of the evacuation port, the slit-form opening being provided so as to cause a displacement with respect to the evacuation port in a direction generally intersecting perpendicularly to an extending direction of the evacuation port, the valve changing a degree of valve opening thereof via displacement of said slit-form opening.

Owner:TOKYO ELECTRON LTD

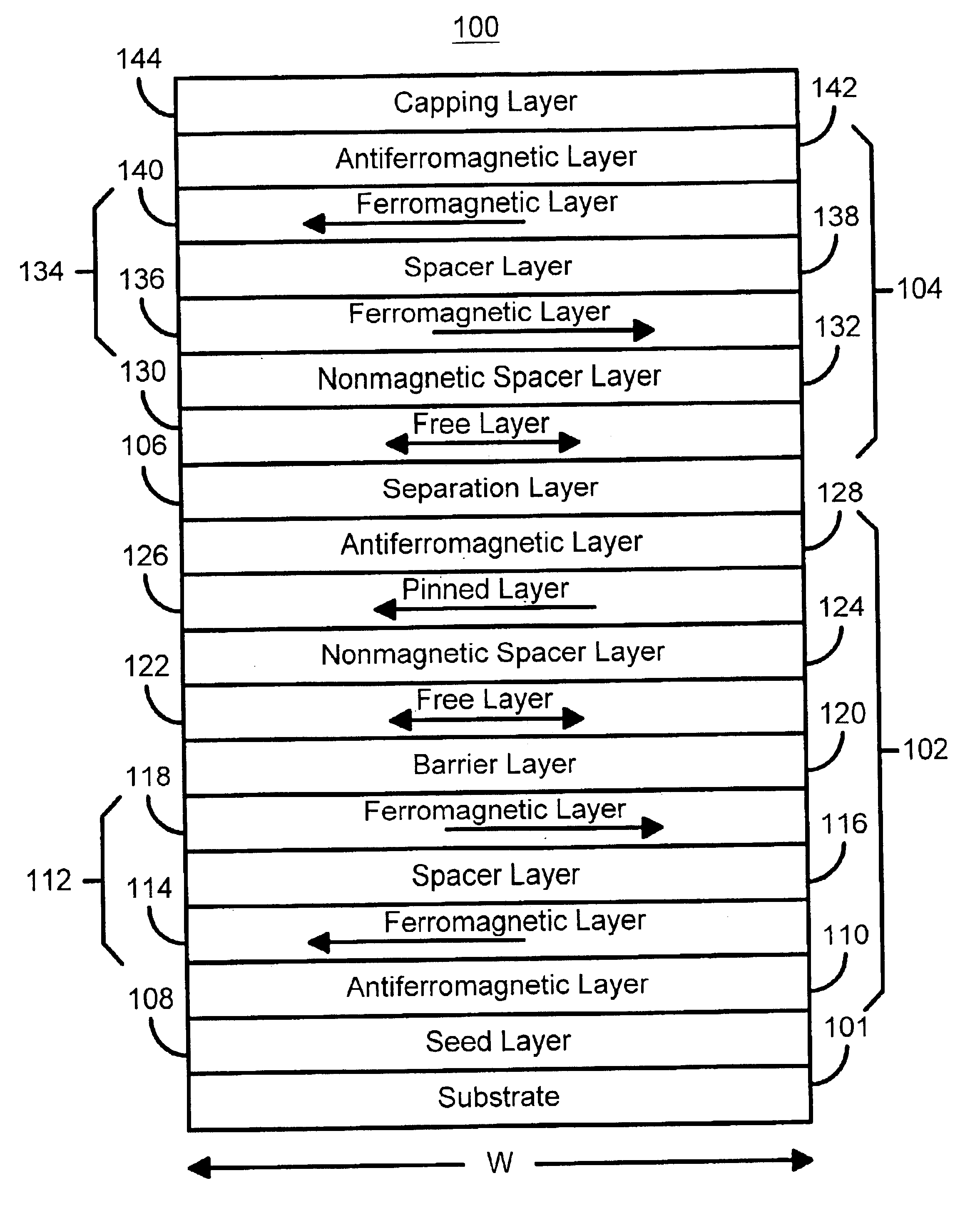

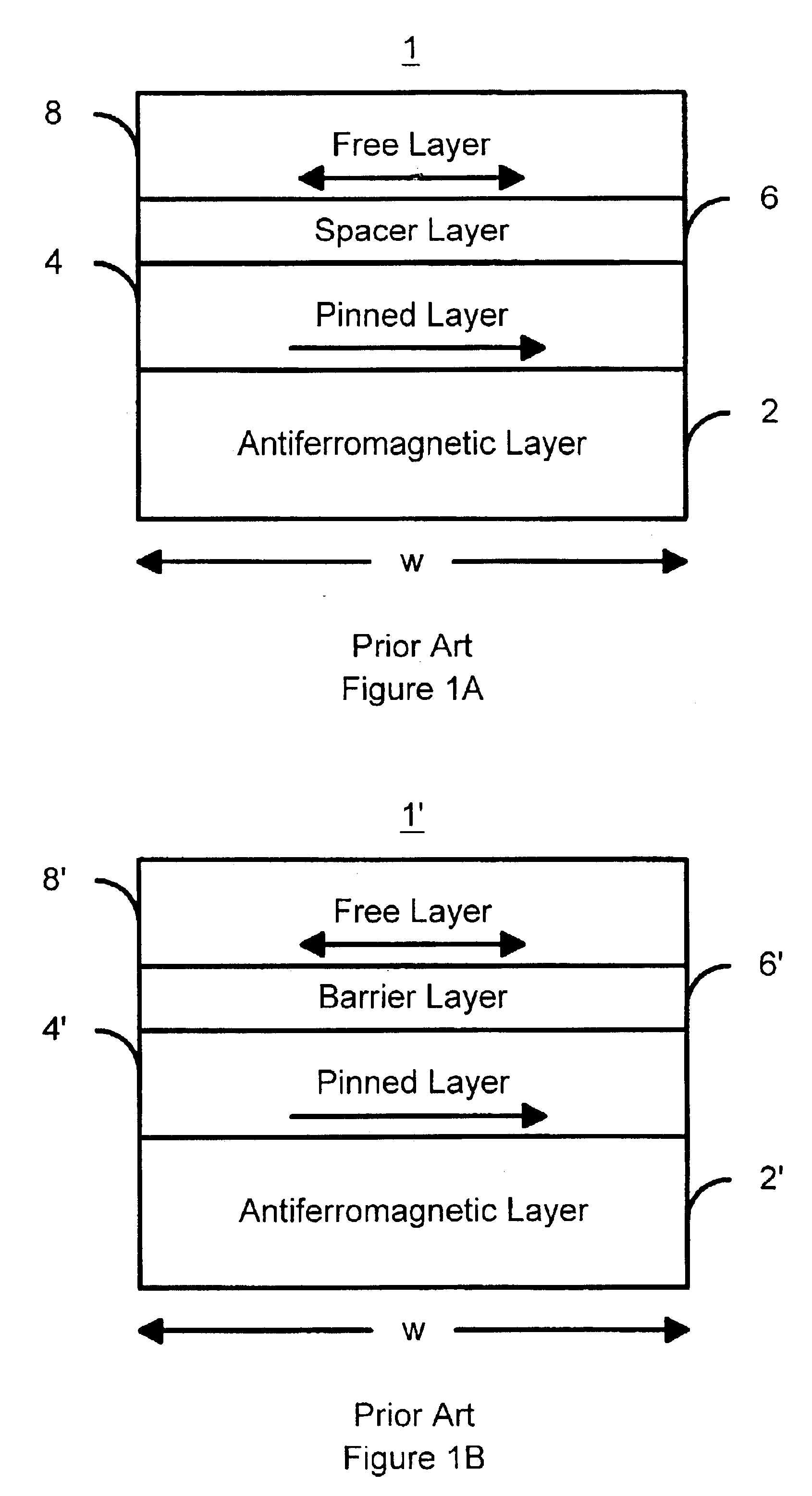

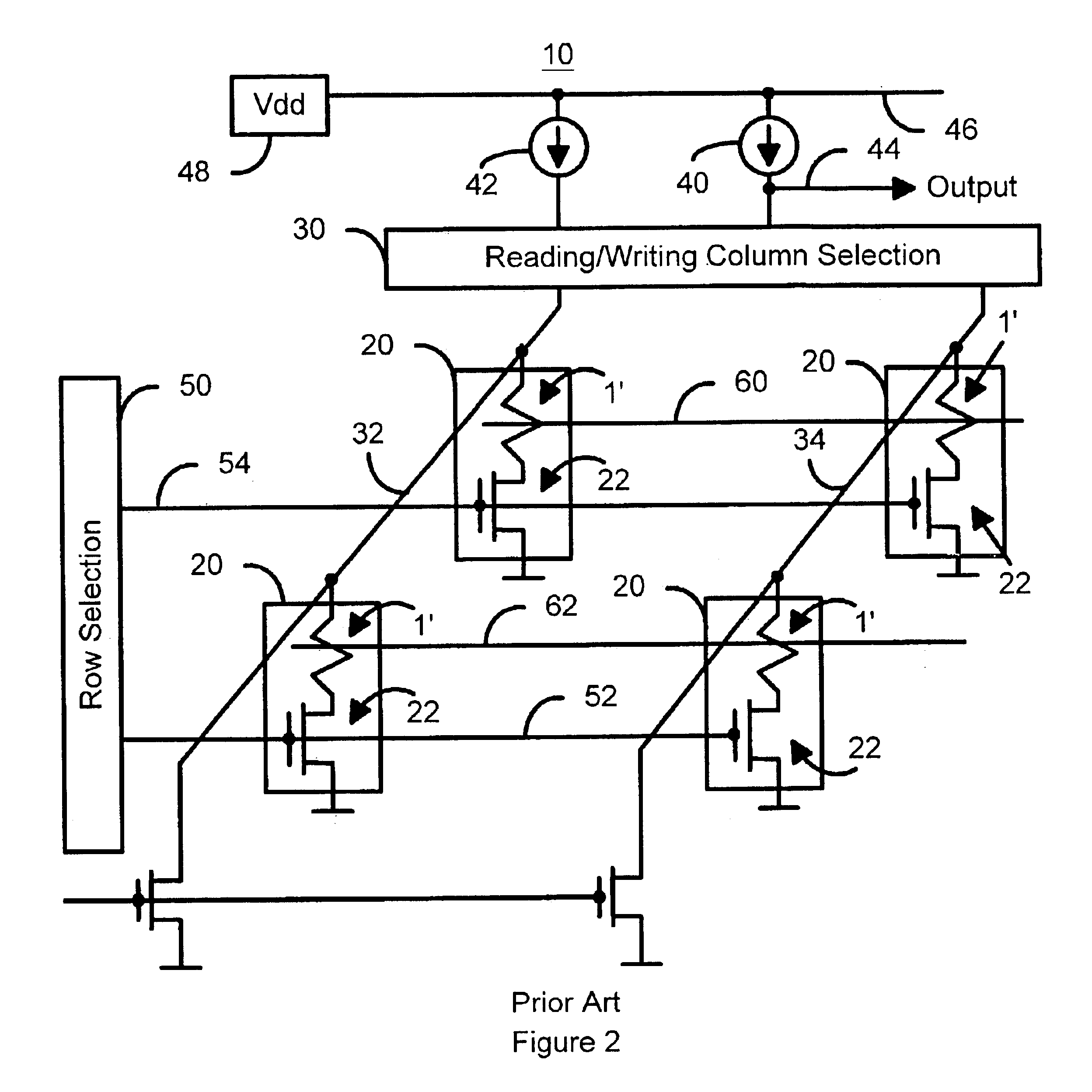

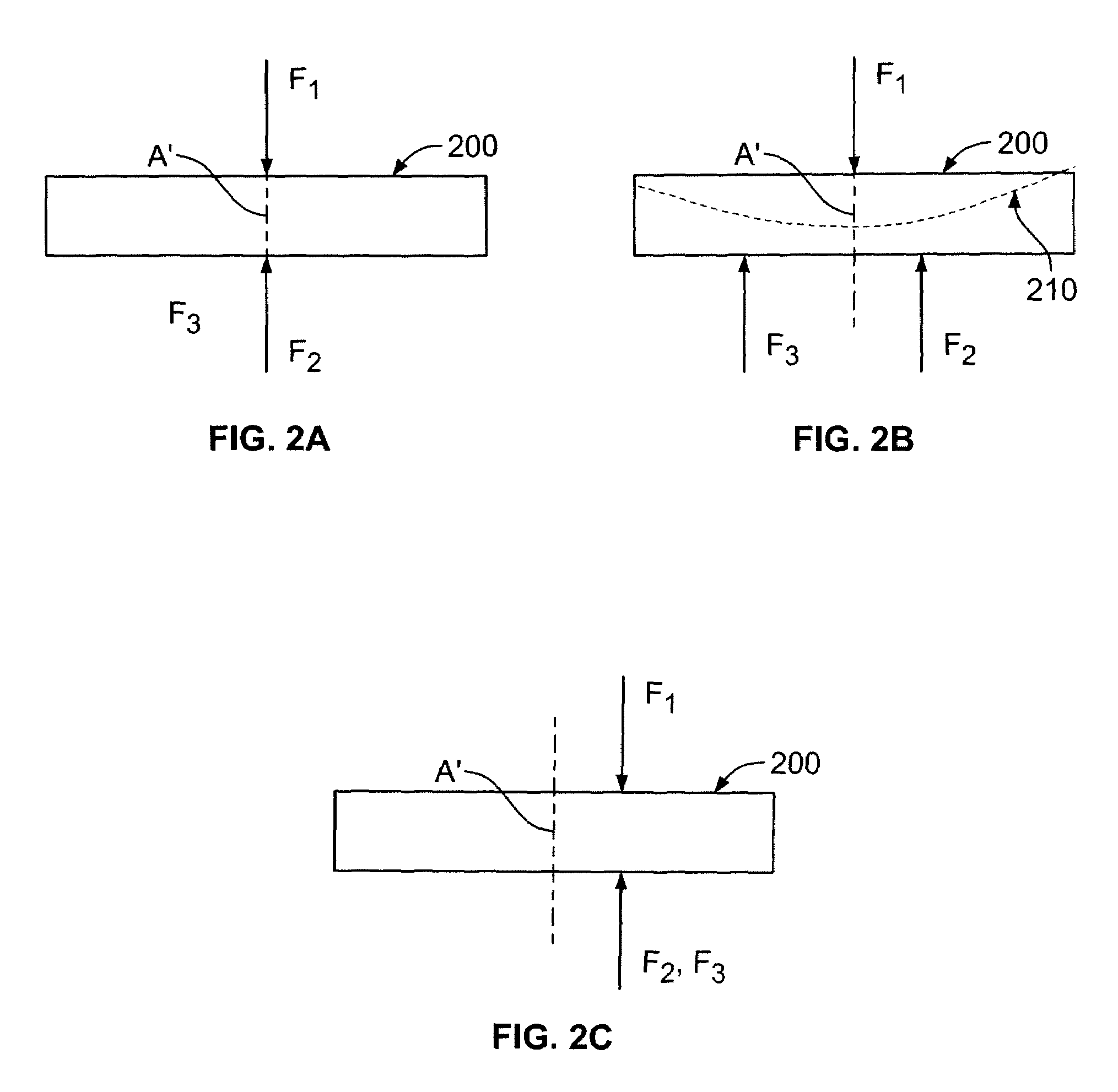

Magnetostatically coupled magnetic elements utilizing spin transfer and an MRAM device using the magnetic element

A method and system for providing a magnetic element and a corresponding memory are disclosed. In one aspect, the method and system include providing a dual spin tunnel / valve structure and at least one spin valve. The dual spin tunnel / valve structure includes a nonmagnetic spacer layer between a pinned layer and a free layer, another pinned layer and a barrier layer between the free layer and the other pinned layer. The free layers of the dual spin tunnel / valve structure and the spin valve are magnetostatically coupled. In one embodiment a separation layer resides between the dual spin tunnel / valve structure and the spin valve. In another aspect, the method and system include providing two dual spin valves, a spin tunneling junction there between and, in one embodiment, the separation layer. In both aspects, the magnetic element is configured to write to the free layers using spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

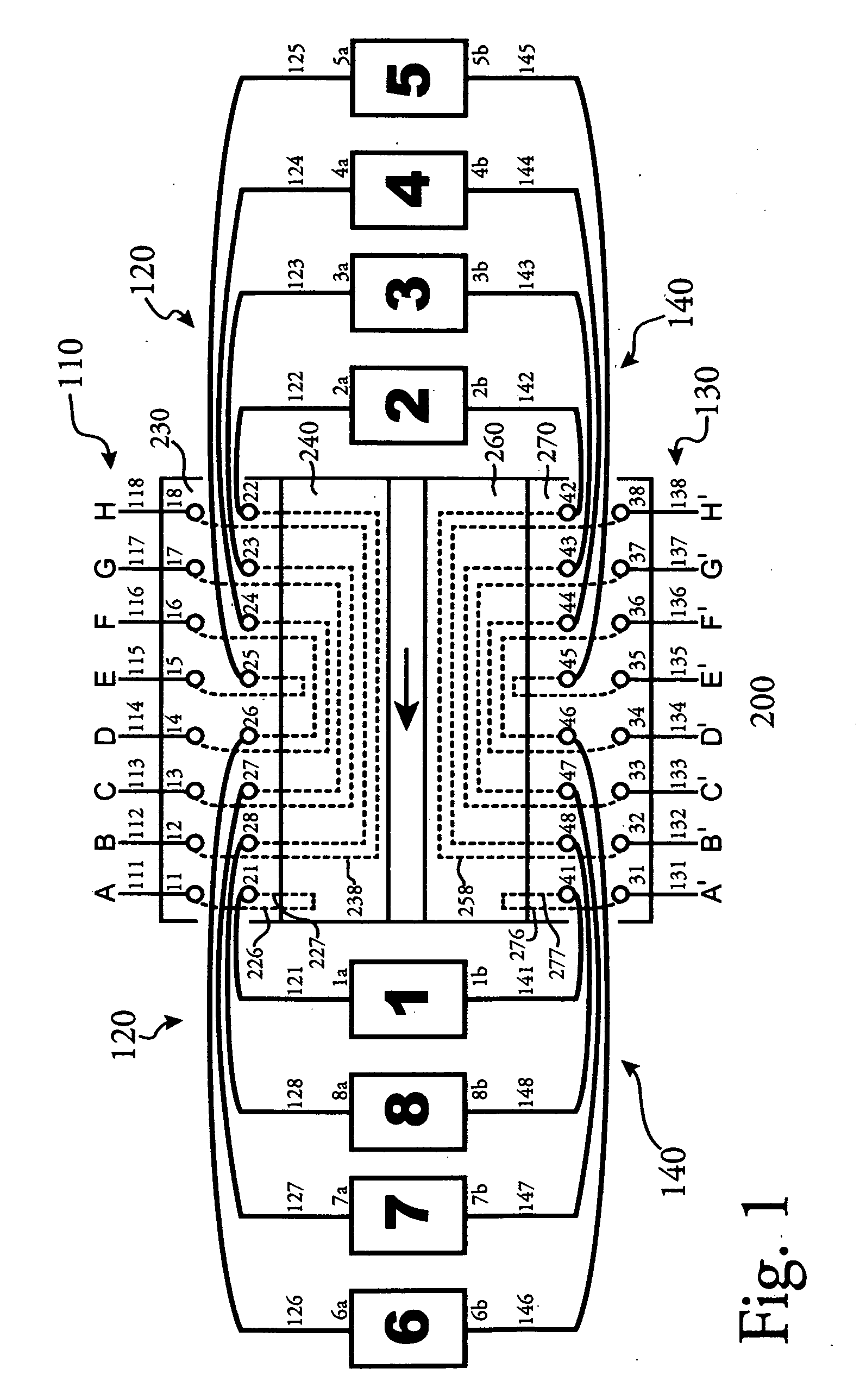

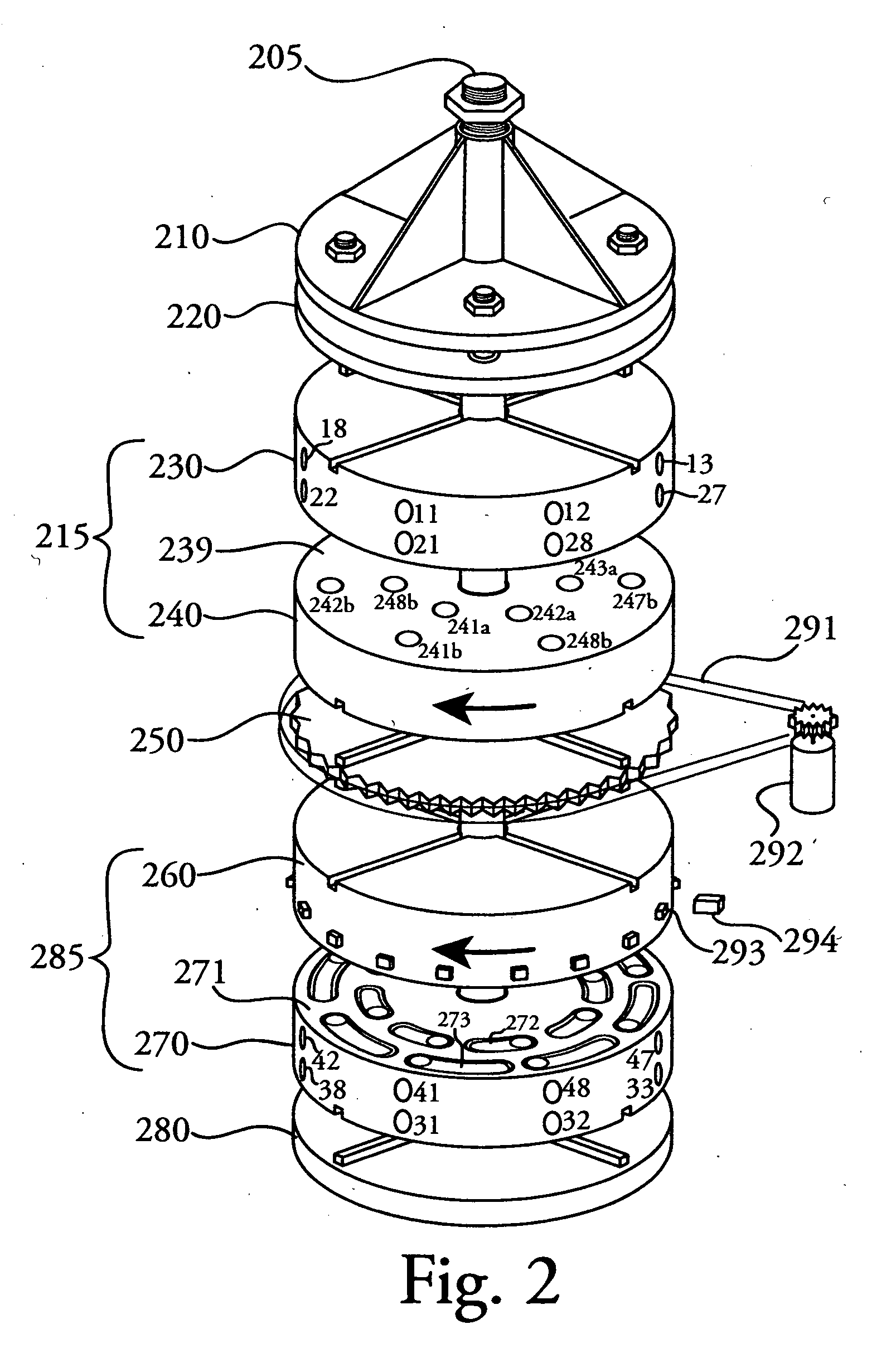

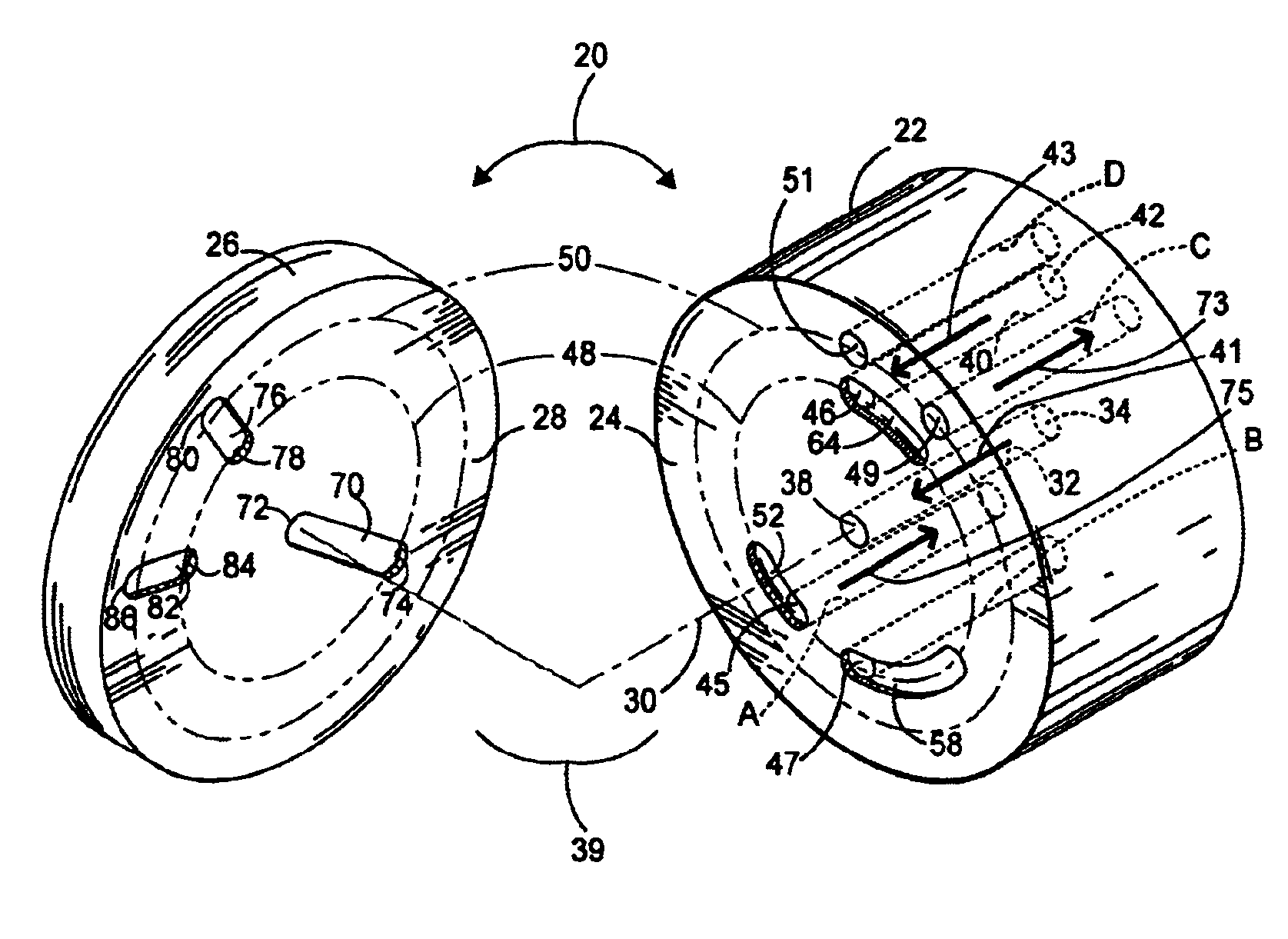

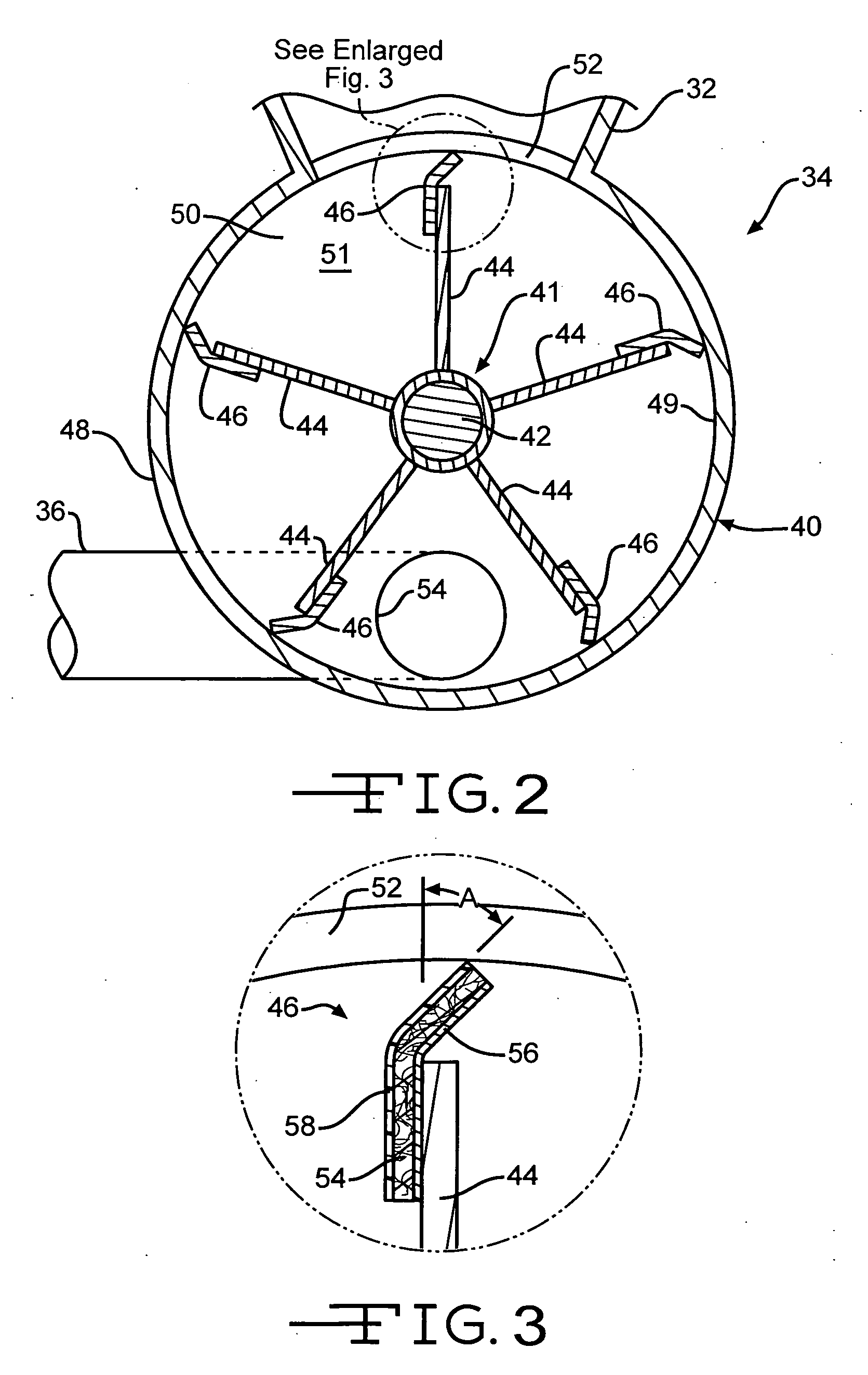

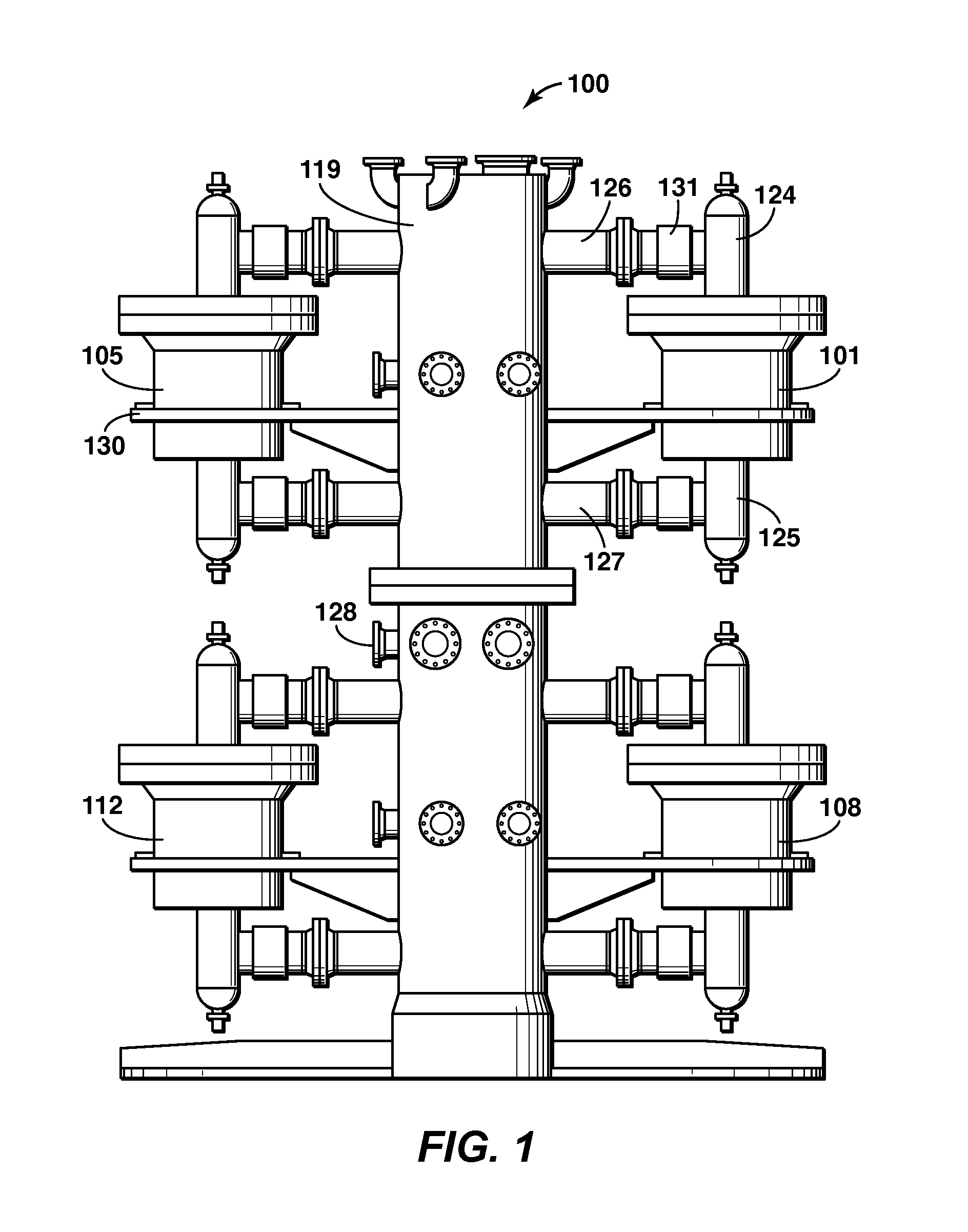

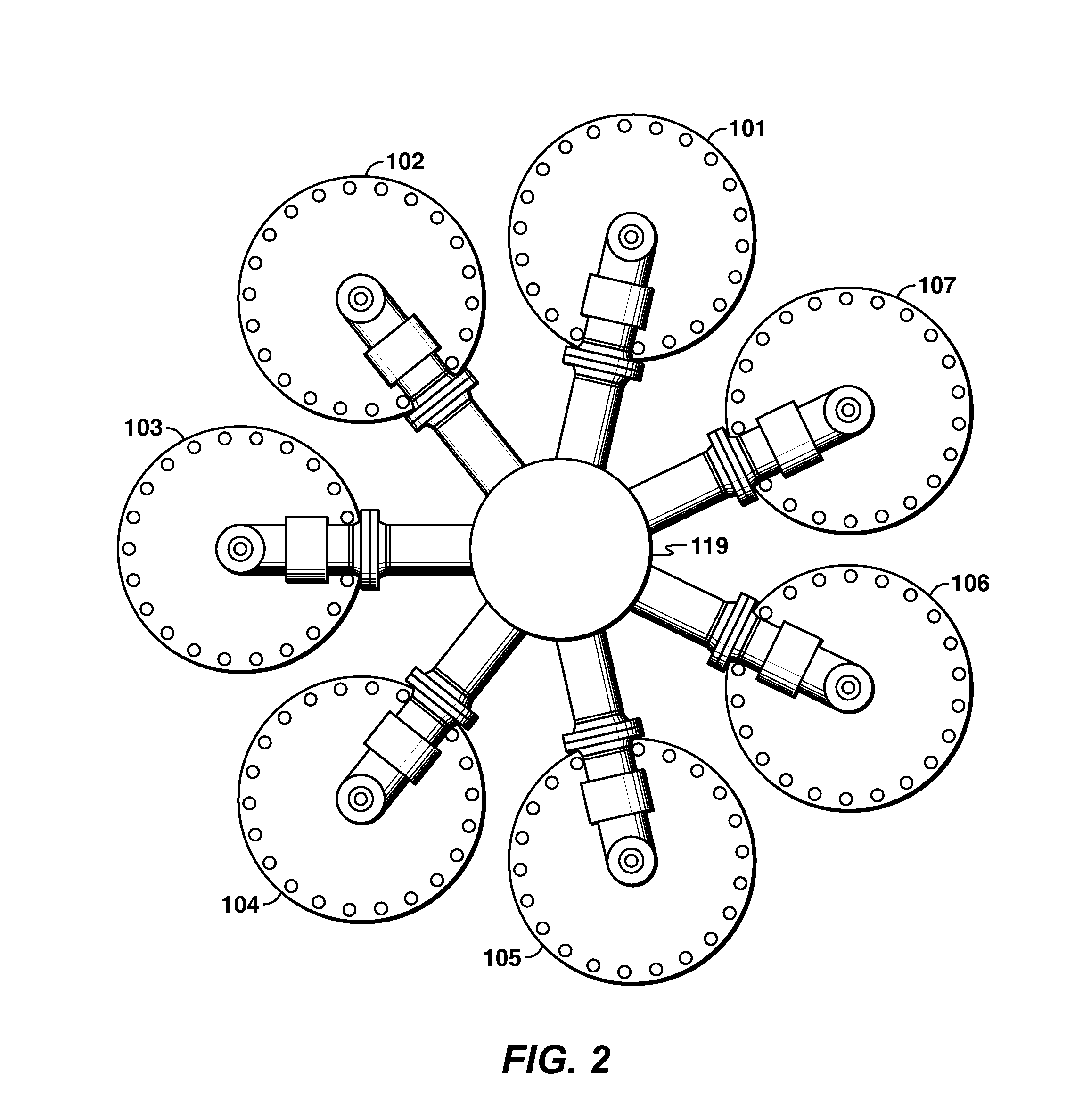

Fluid-directing multiport rotary valve

InactiveUS20110067770A1Simplifying inventorySettling tanks feed/dischargeMultiple way valvesRotary valveEngineering

A multiport rotary valve apparatus for directing fluid streams which has two circular stationary heads and two circular rotating heads. The first stationary head has at least two and preferably more primary ports for connection with fluid streams and a corresponding number of secondary ports for connection to fluid-solid contacting chambers. The second stationary head has the same number of primary ports as the first stationary head (at least two and preferably more) for connection with the fluid streams and the same number of secondary ports for a second connection to the fluid-solid contacting chambers. Each stationary head includes internal conduits for the connection of the primary and secondary ports to a rotating head. The first rotating head is in communication with the first stationary head while the second rotating head is in communication with the second stationary head. Each rotating head has internal transverse conduits formed therein for the purpose of redistributing the flow coming from a primary port in the stationary head back to the secondary port in the same stationary head. In conjunction with offset and recessed arcuate obround windows in either the stationary or rotating heads, the internal transverse conduits in the rotating heads are formed in a very specific pattern that allows each primary port to connect to each secondary port and thereby each fluid-solid contacting chamber in a sequential manner upon one index of the rotating heads. The timing of the index can be varied to accommodate the specifics of each process. The net effect of the apparatus is the simulated movement of each chamber through the various fluid streams without physically moving the chambers.

Owner:GULF SEA VENTURES

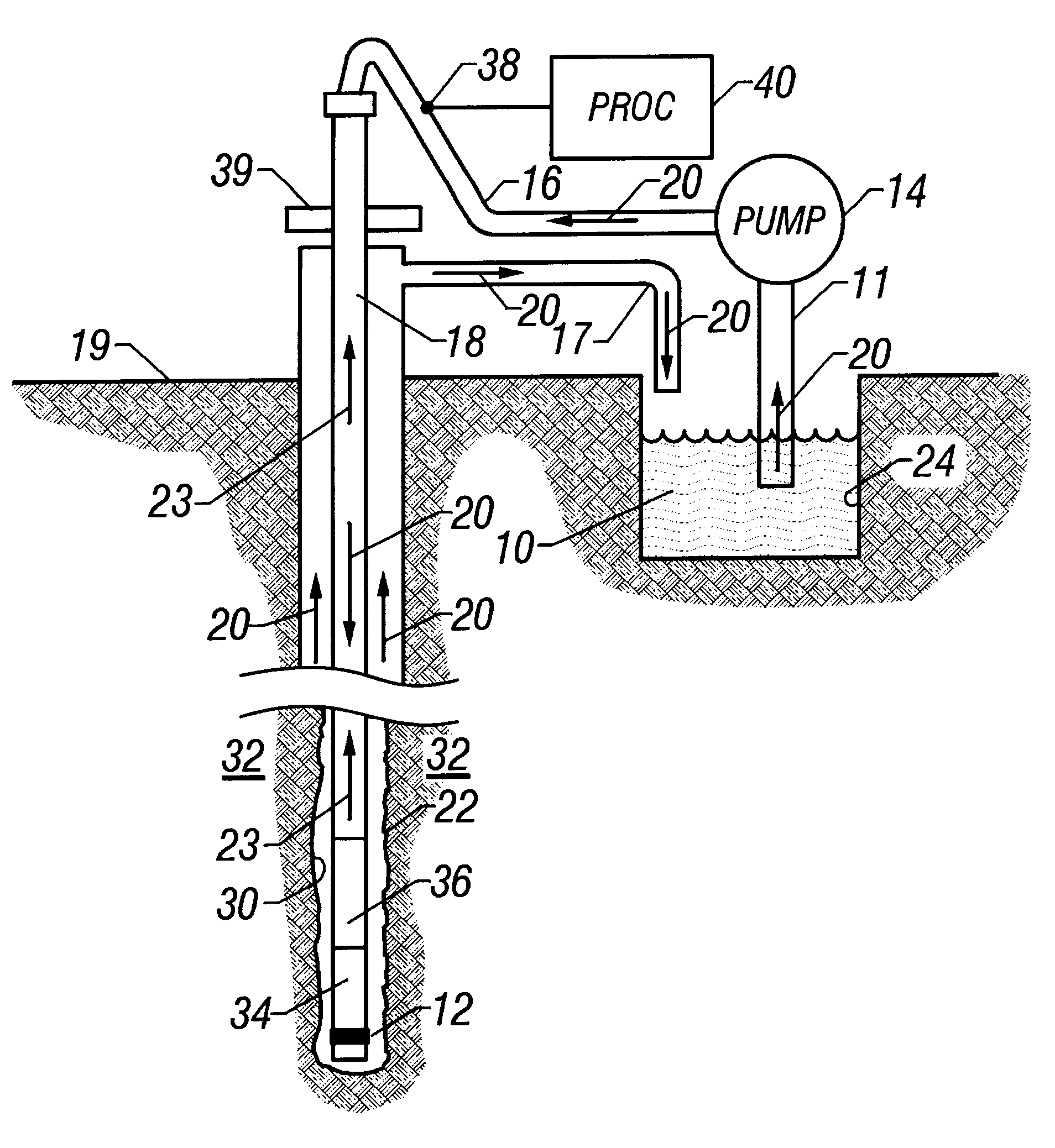

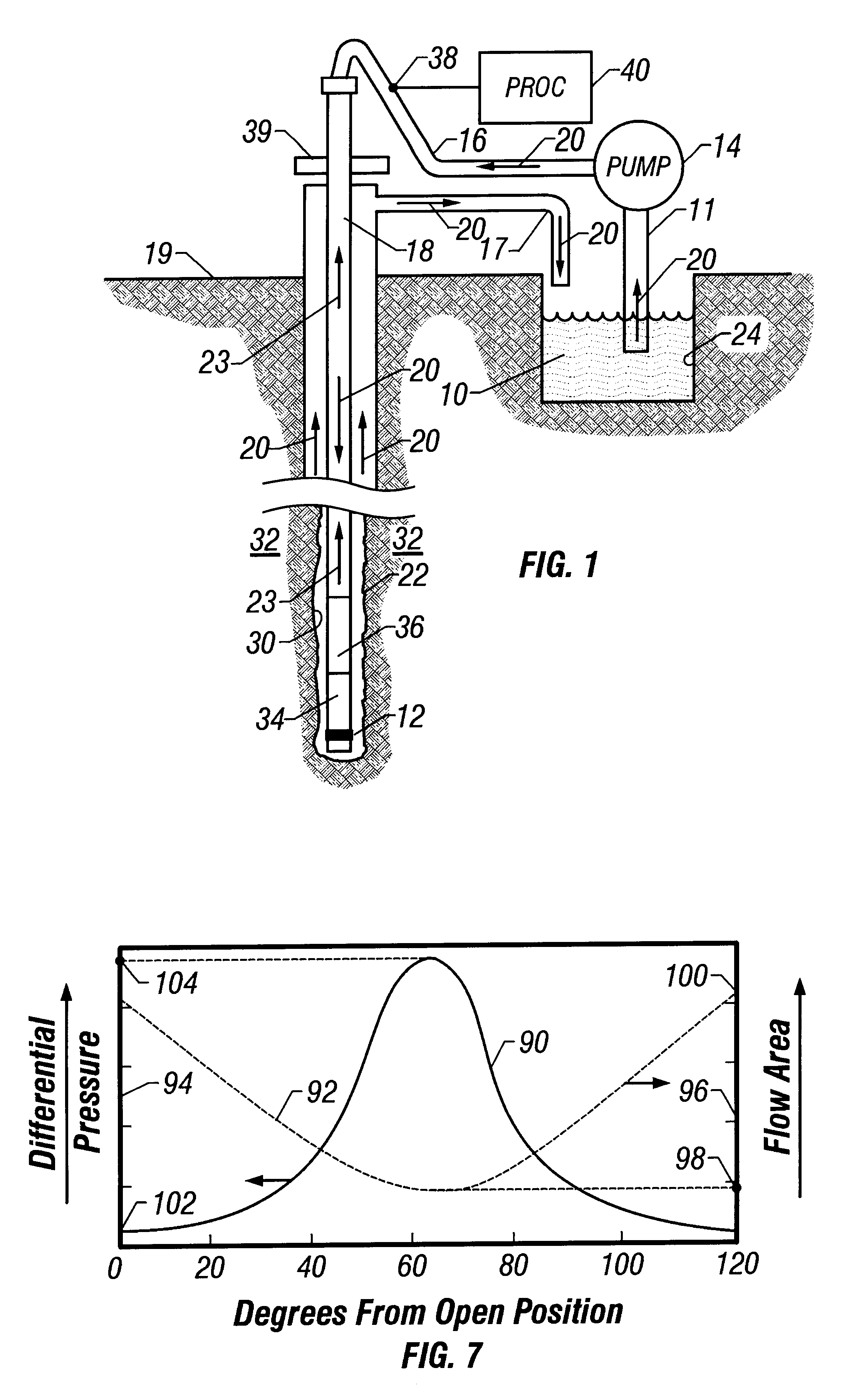

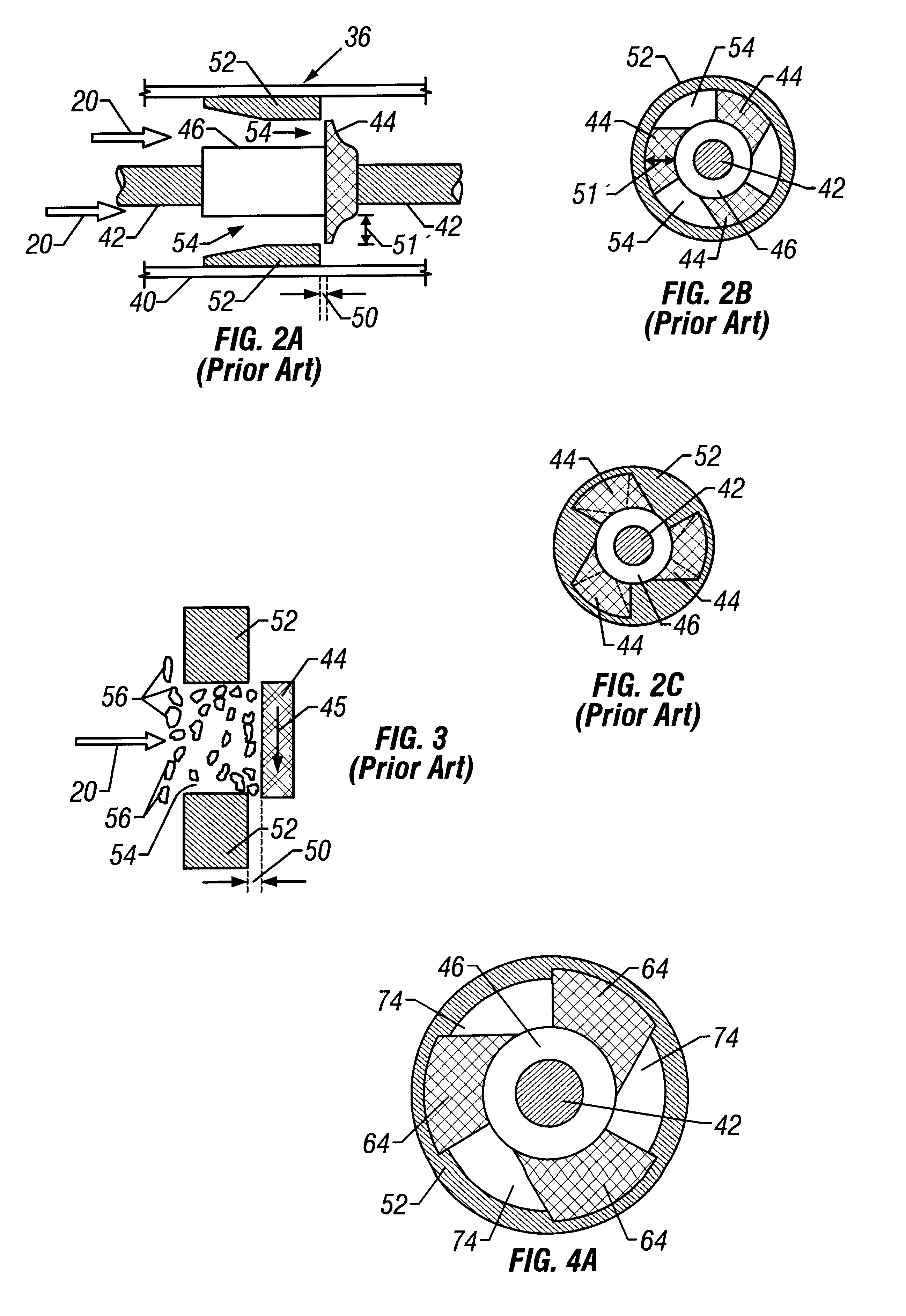

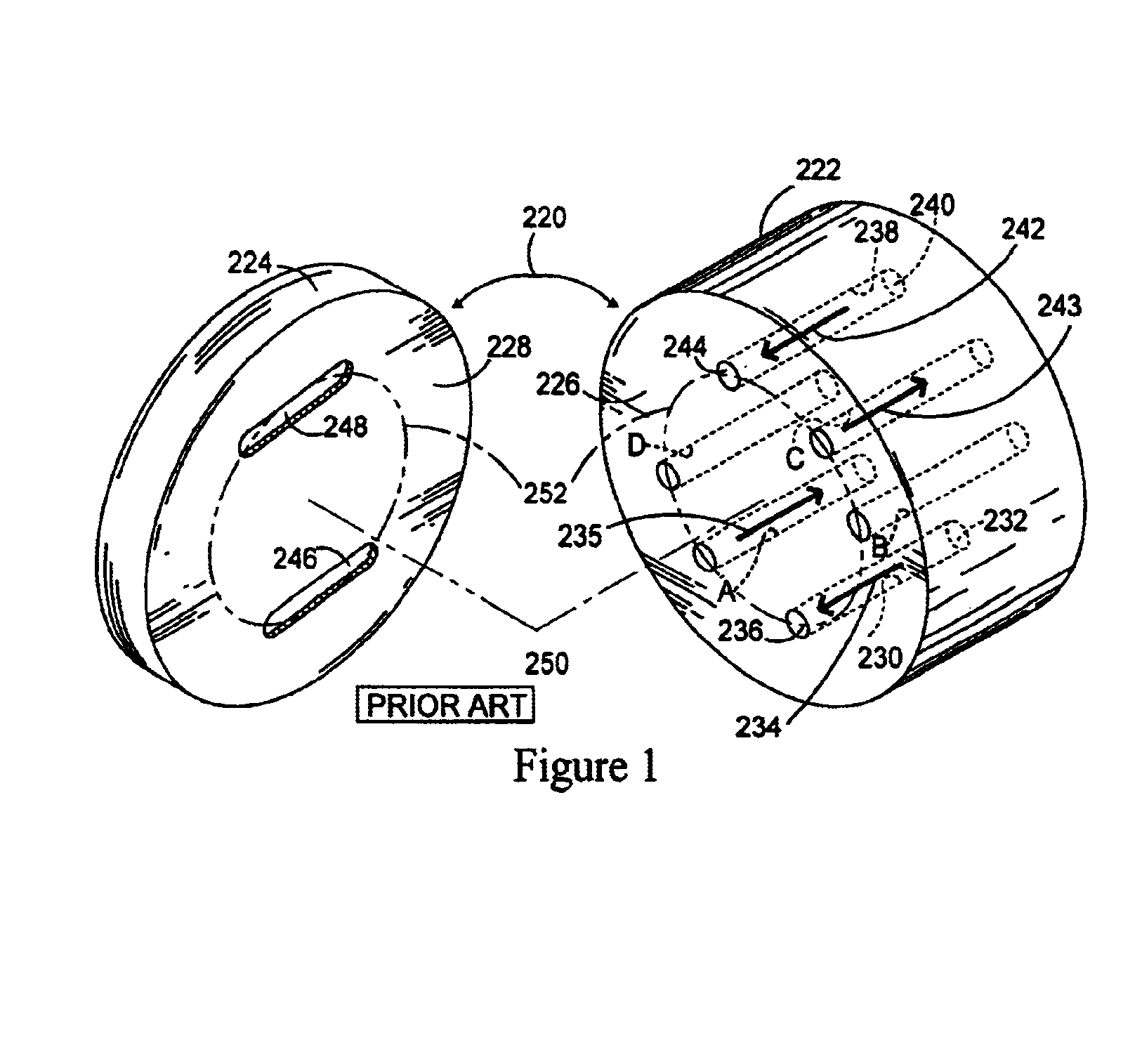

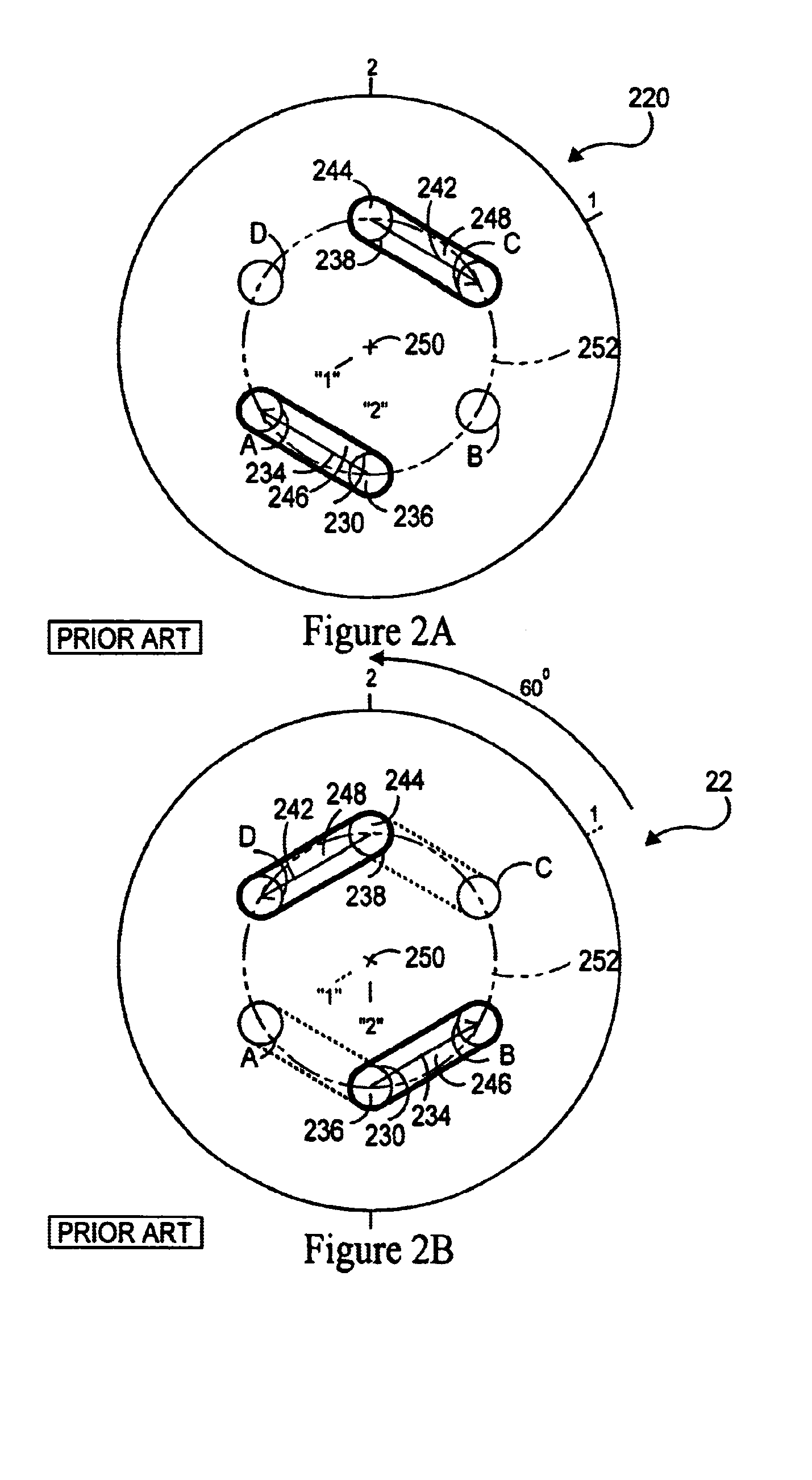

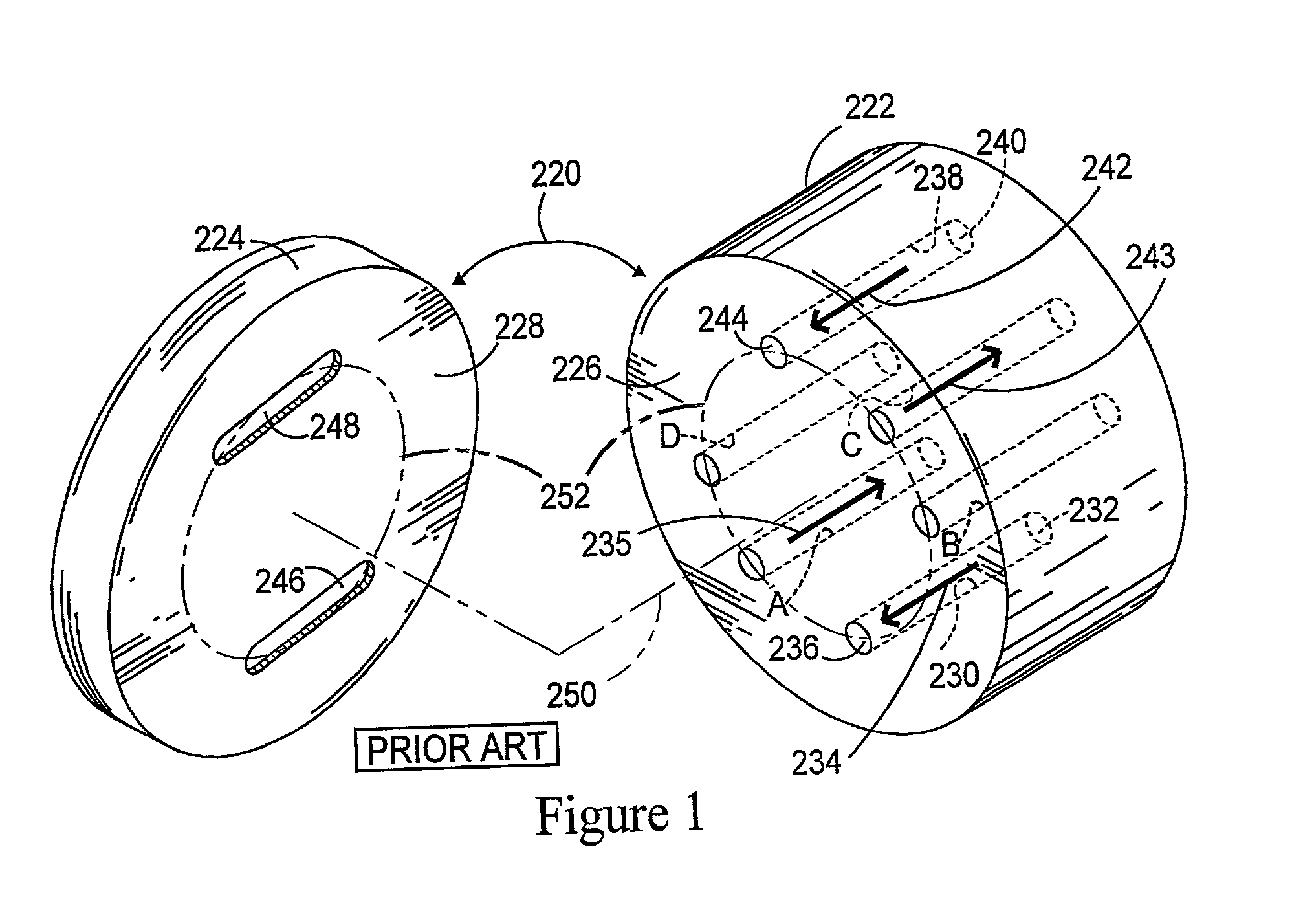

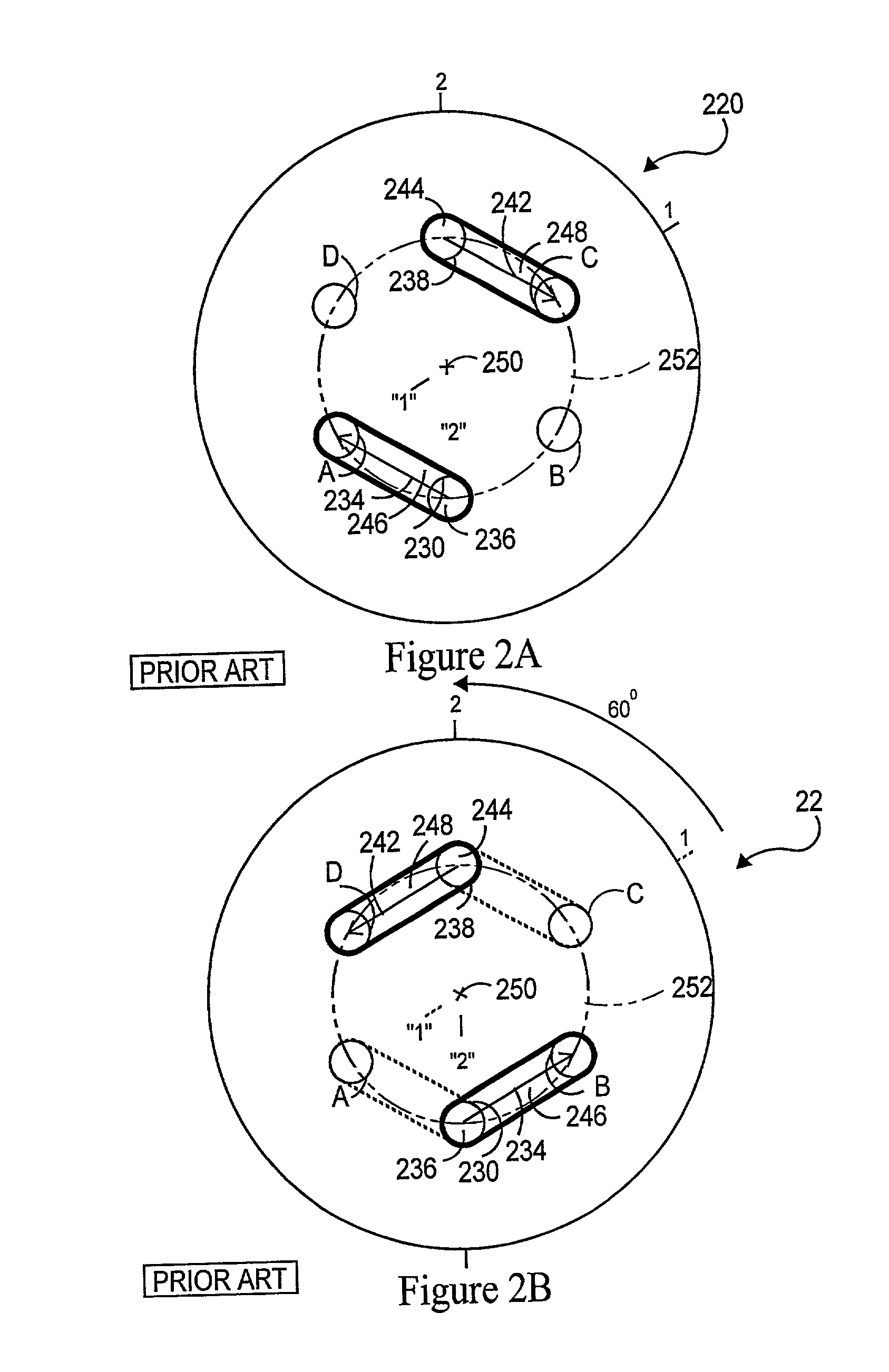

Pressure pulse generator for measurement-while-drilling systems which produces high signal strength and exhibits high resistance to jamming

InactiveUS6219301B1Easy to useIncrease signal strengthSurveyConstructionsHigh resistanceParticulates

A system is disclosed for generating and transmitting data signals to the surface of the earth while drilling a borehole, the system operating by generating pressure pulses in the drilling fluid filling the drill string. The system is designed to maximize signal strength while minimizing the probability of jamming by drilling fluid particulates. The system uses a rotary valve modulator consisting of a stator with flow orifices through which drilling fluid flows, and a rotor which rotates with respect to the stator thereby opening and restricting flow through the orifices and thereby generating pressure pulses. The flow orifices with the stator in a "closed" position are configured to reduce jamming, and to simultaneously minimize flow area in order to maximize signal strength. This is accomplished by imparting a shear to the fluid flow through the modulator, and minimizing the aspect ratio and maximizing the minimum principal dimension of the closed flow area. A preferred embodiment and three alternate embodiments of the modulator are disclosed.

Owner:SCHLUMBERGER TECH CORP

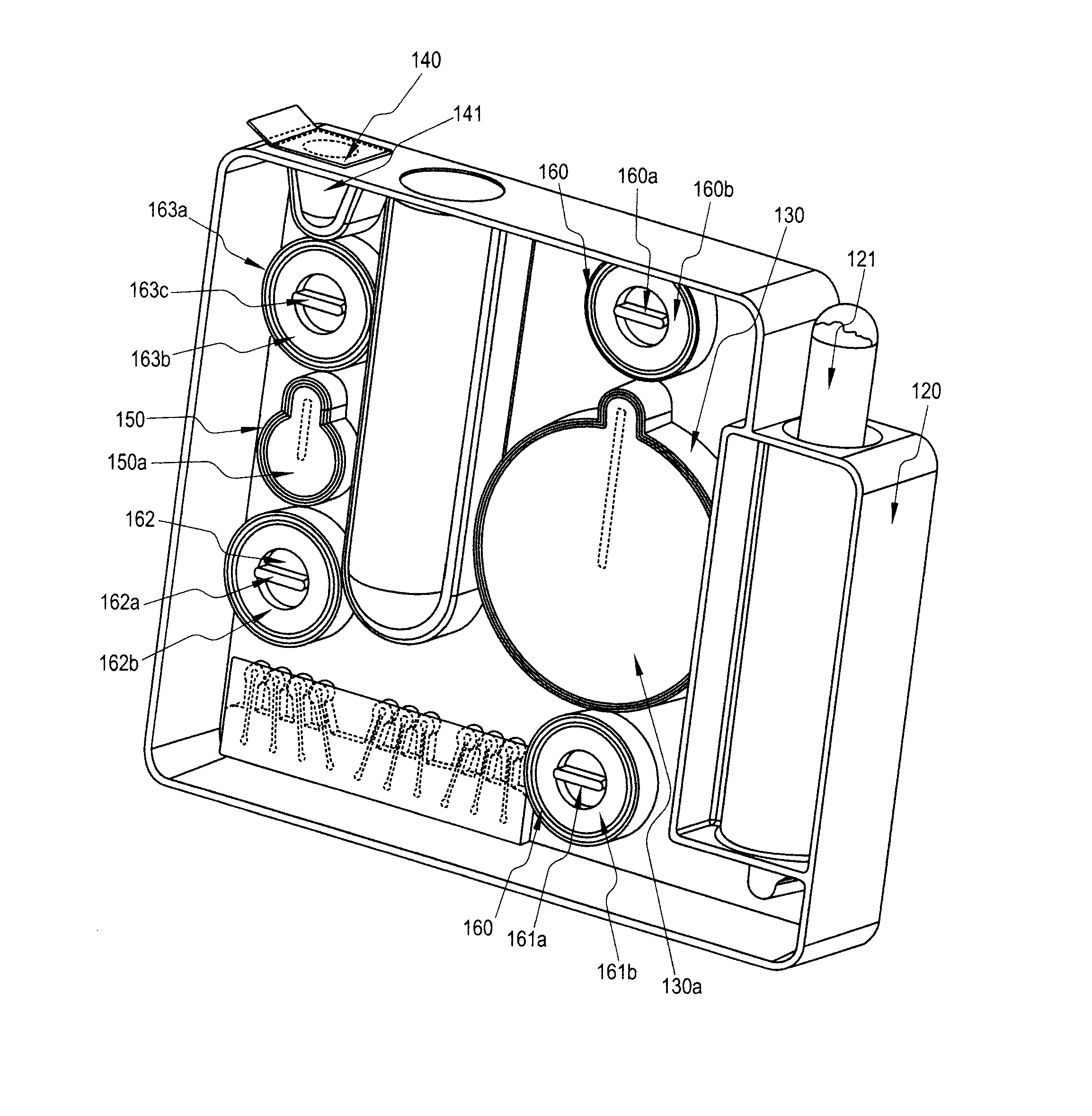

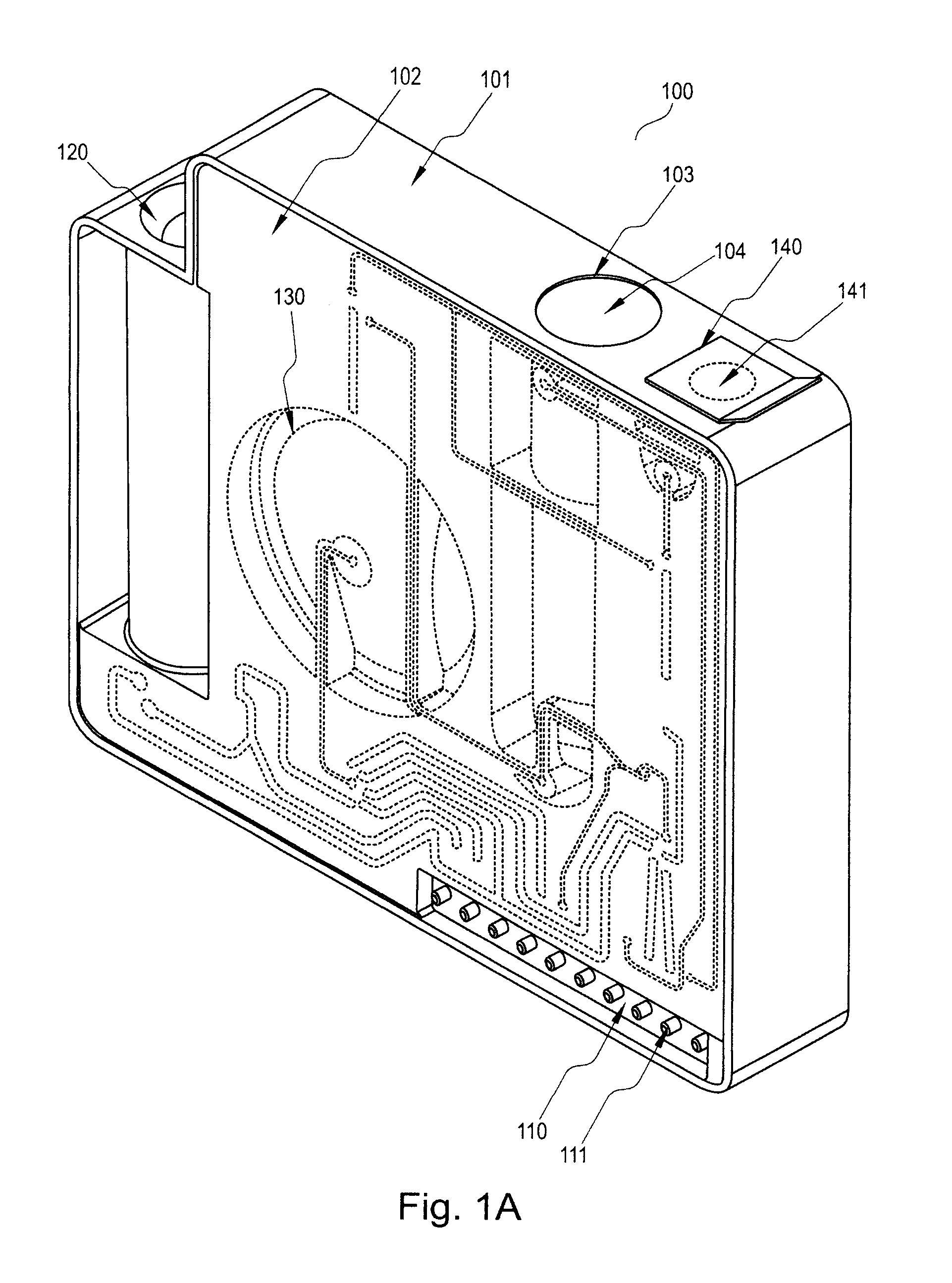

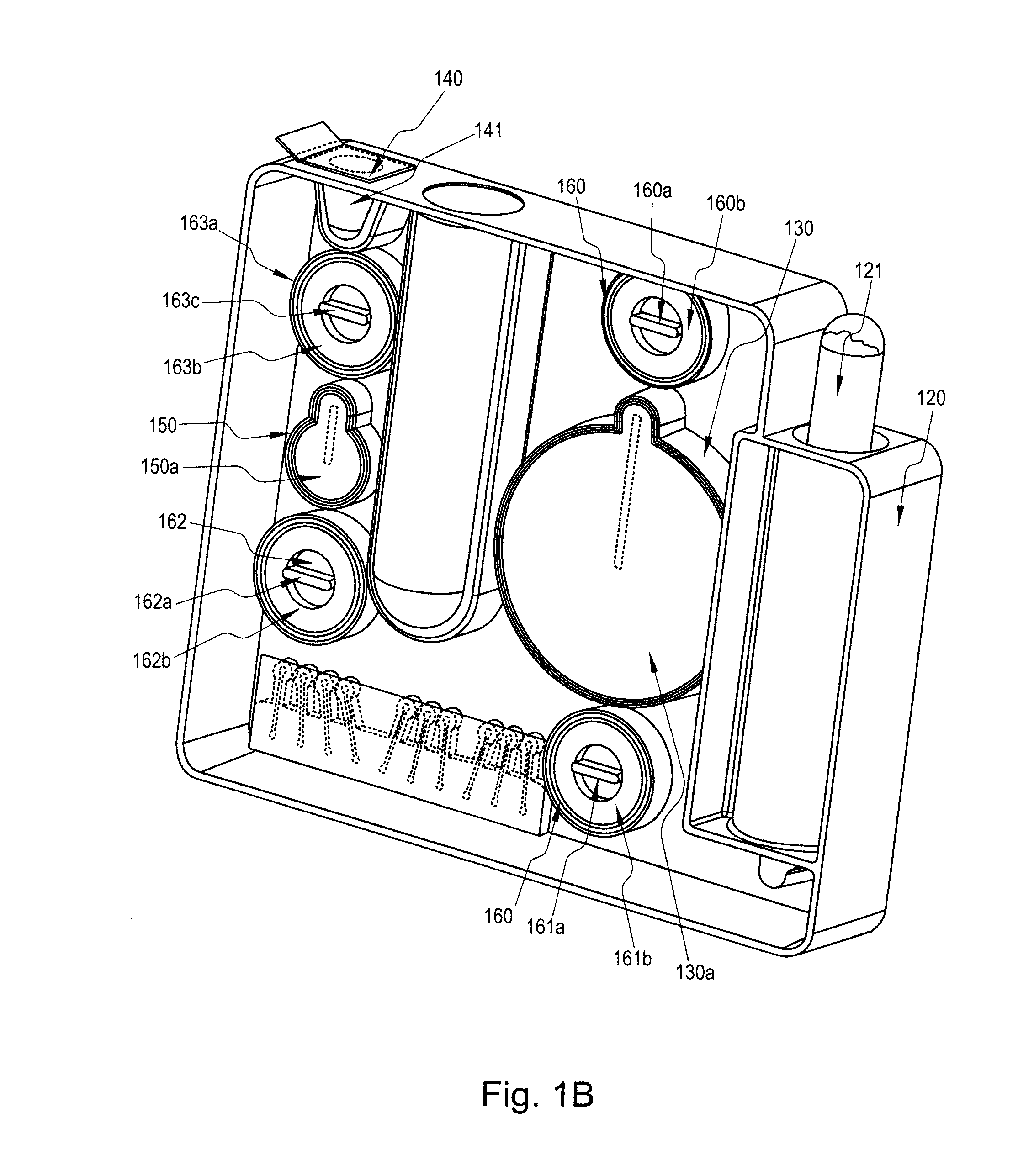

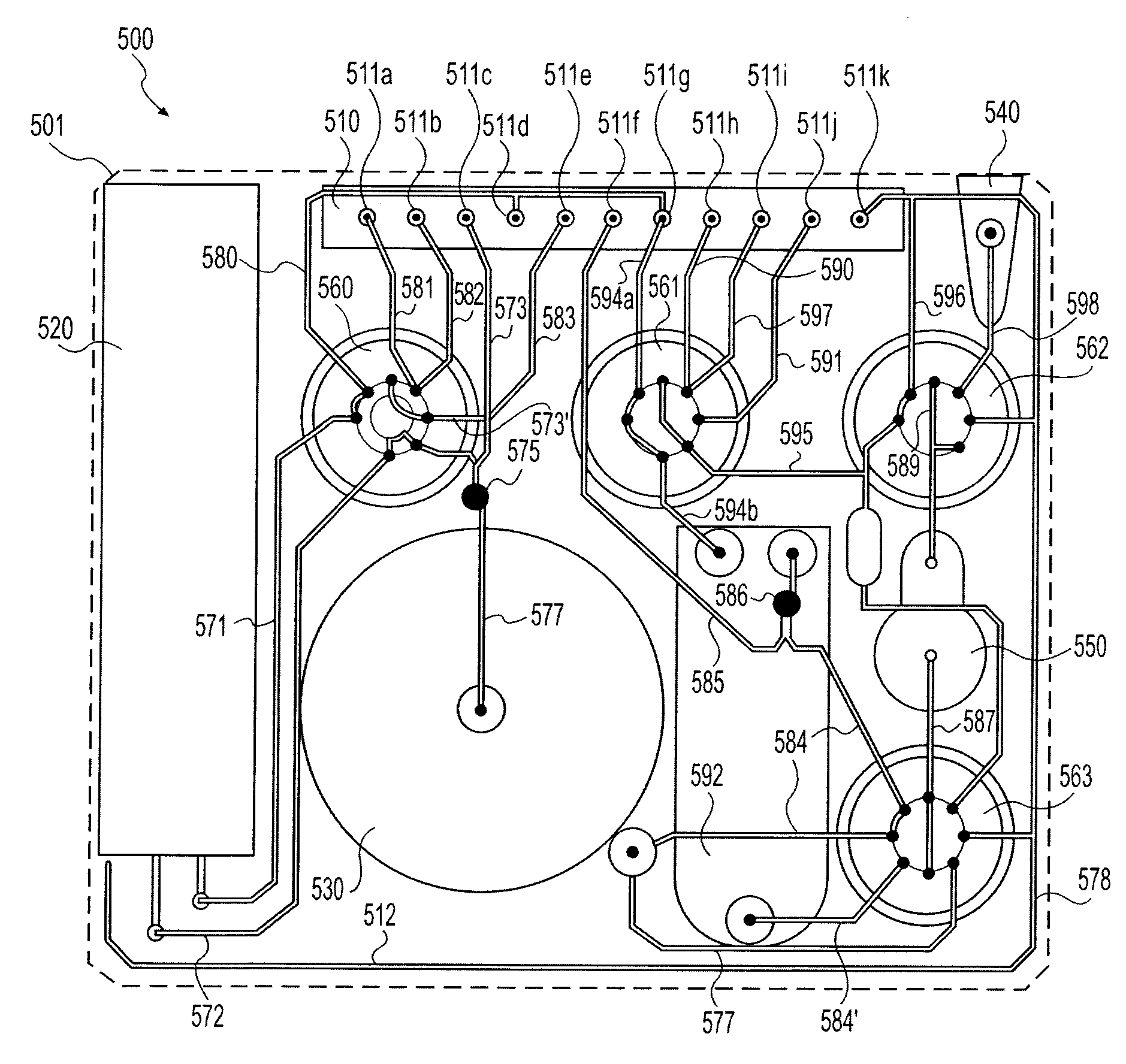

System for isolating biomolecules from a sample

InactiveUS20080026451A1Quality improvementRapid and reproducibleBioreactor/fermenter combinationsBiological substance pretreatmentsFiltrationRotary valve

The present invention provides an automated system for purification of a substance of interest. The system generally comprises an instrument for moving fluids through the system, a reagent pack for storing fluids, and a purification cartridge. The cartridge comprises two filtration units for binding substances based on different physical properties. The cartridge also comprises rotary valves for control of movement of fluids on the cartridge. In preferred embodiments, the system is useful for purifying RNA from blood samples.

Owner:AGILENT TECH INC

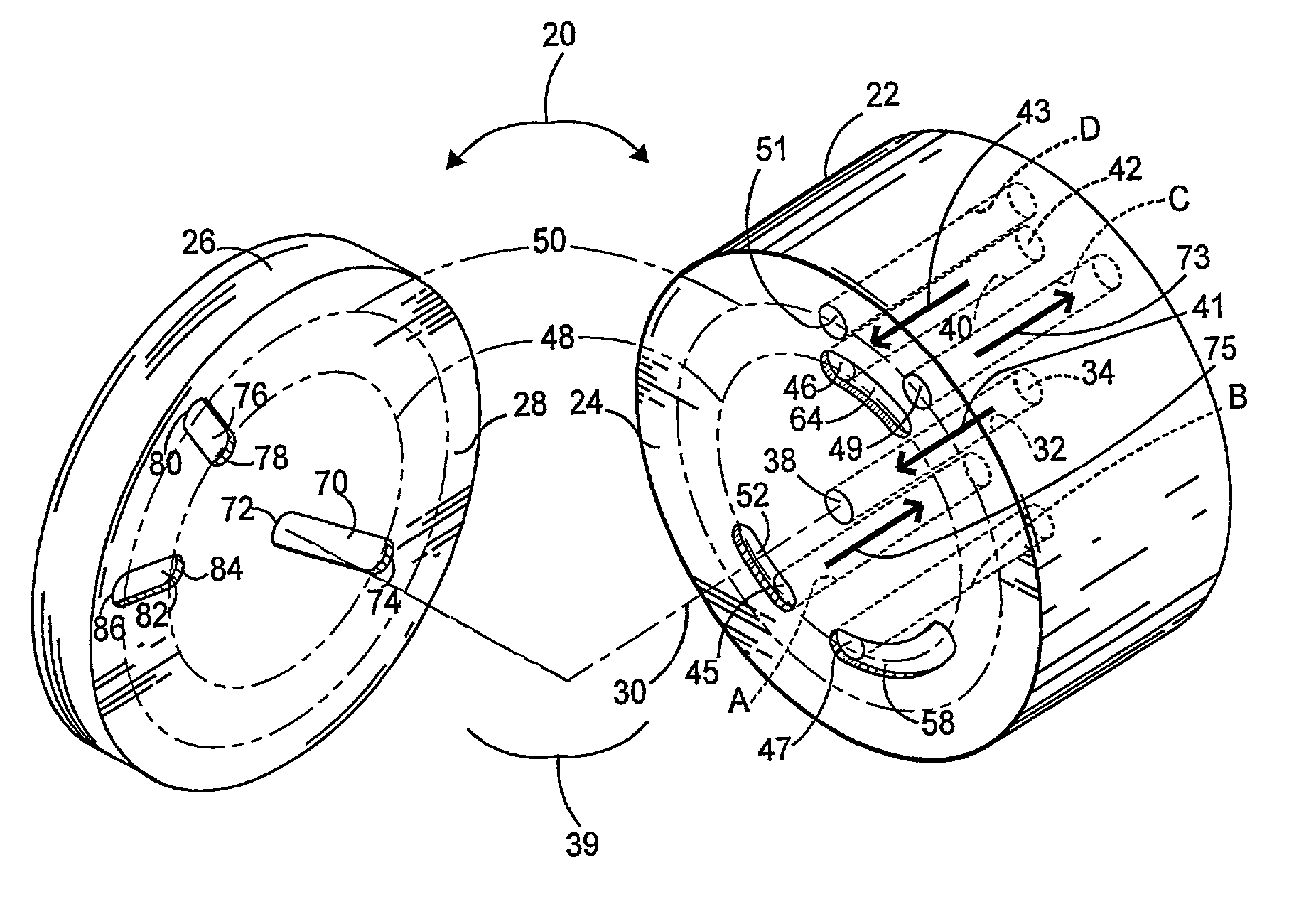

Dual random access, three-way rotary valve apparatus

Owner:IDEX HEALTH & SCI

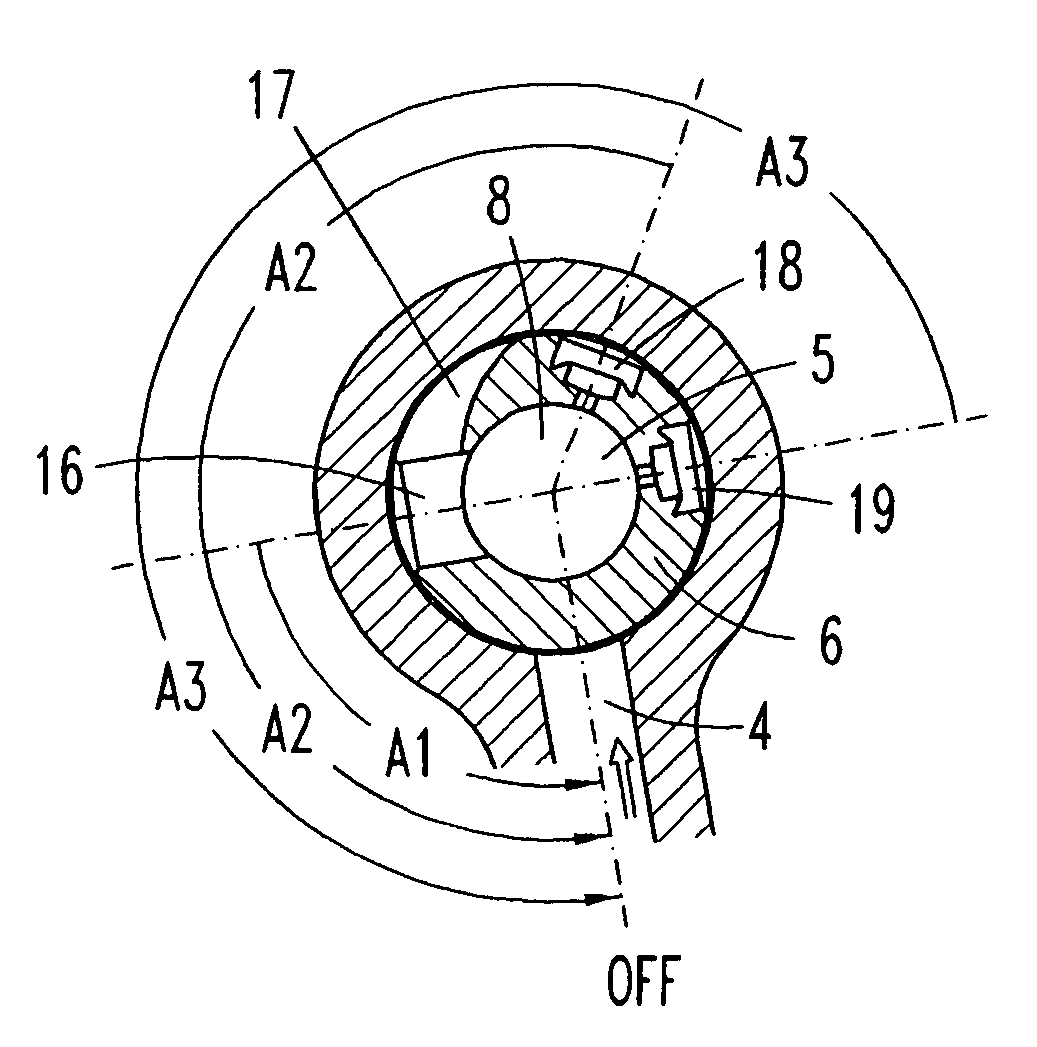

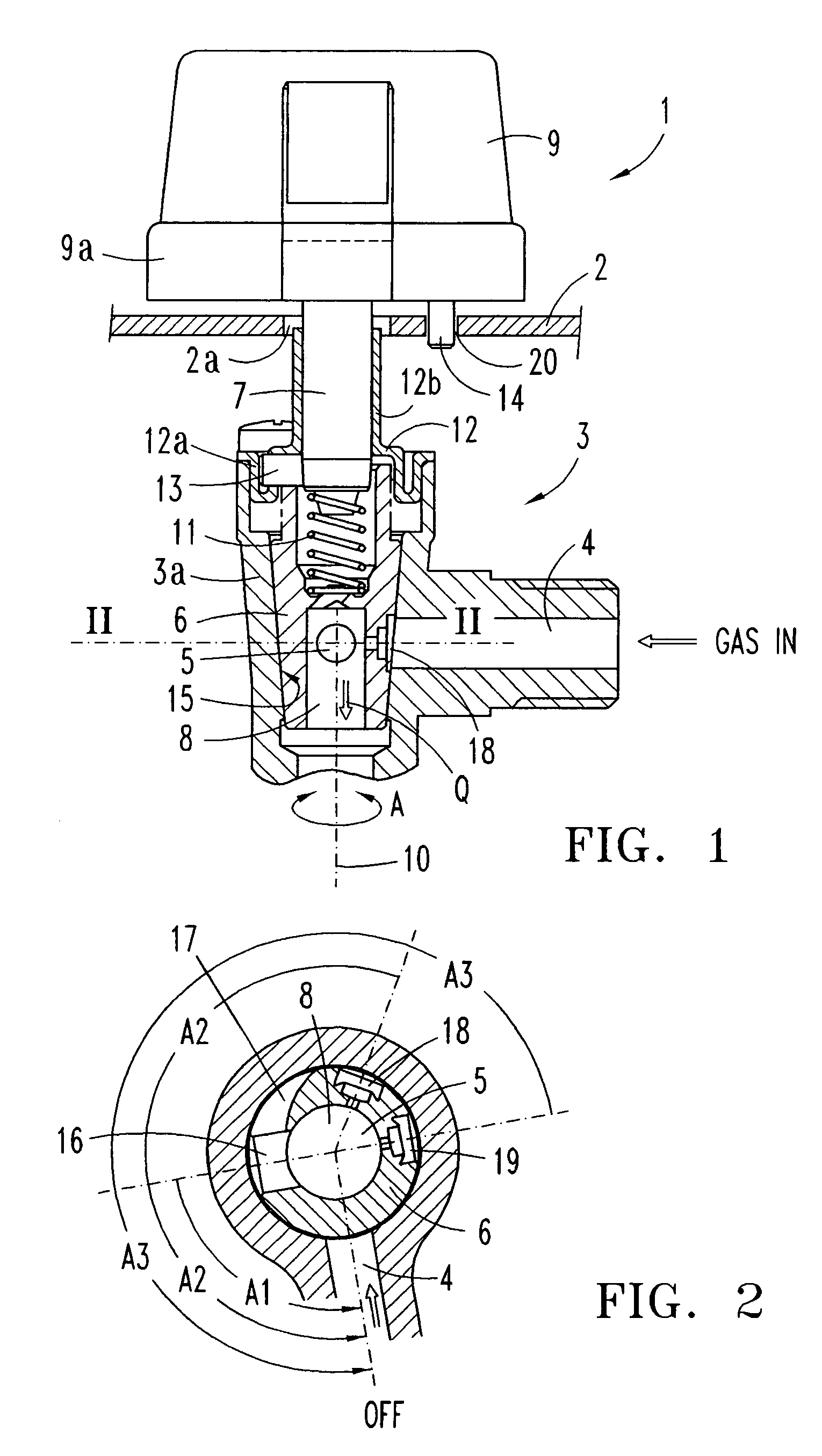

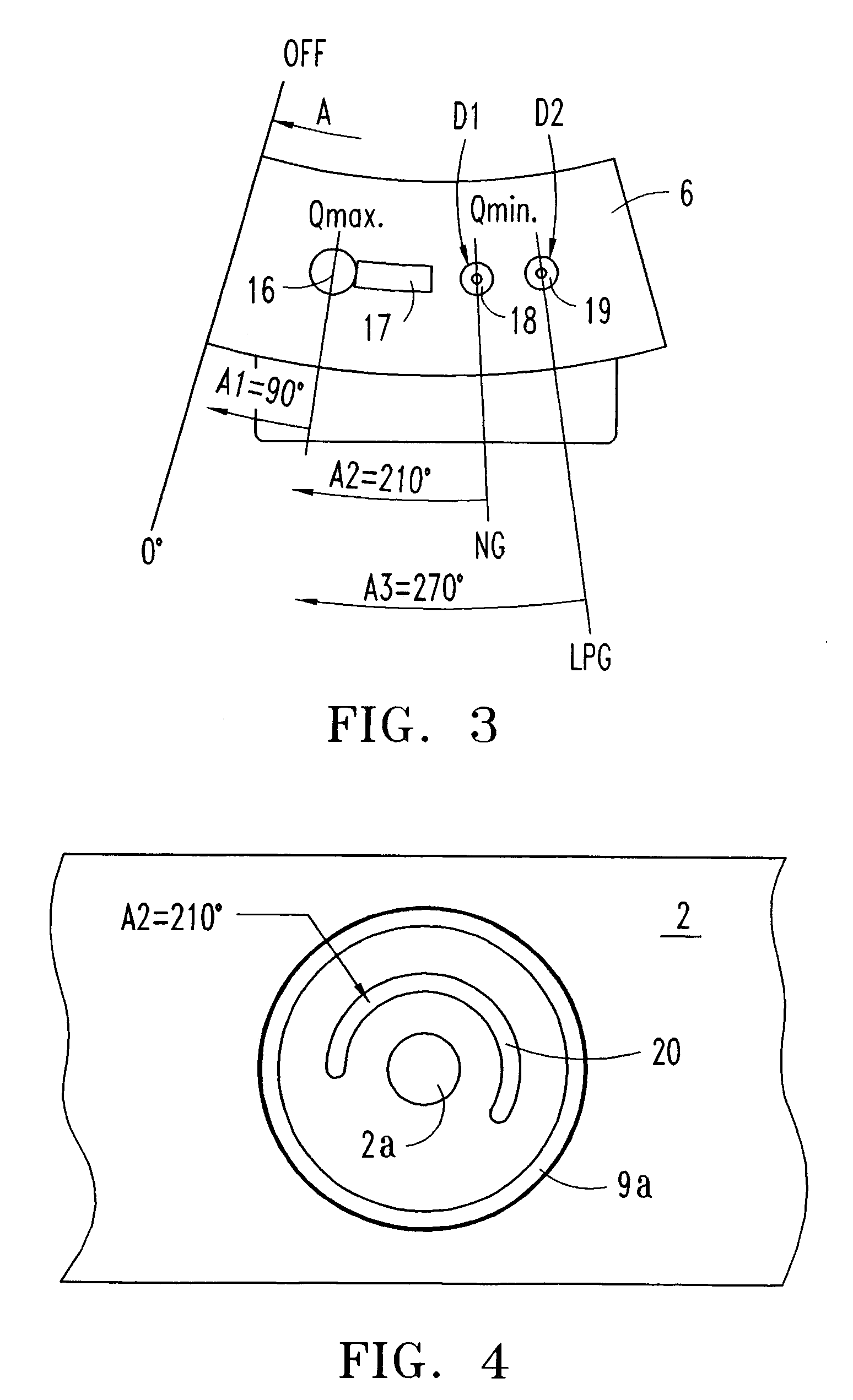

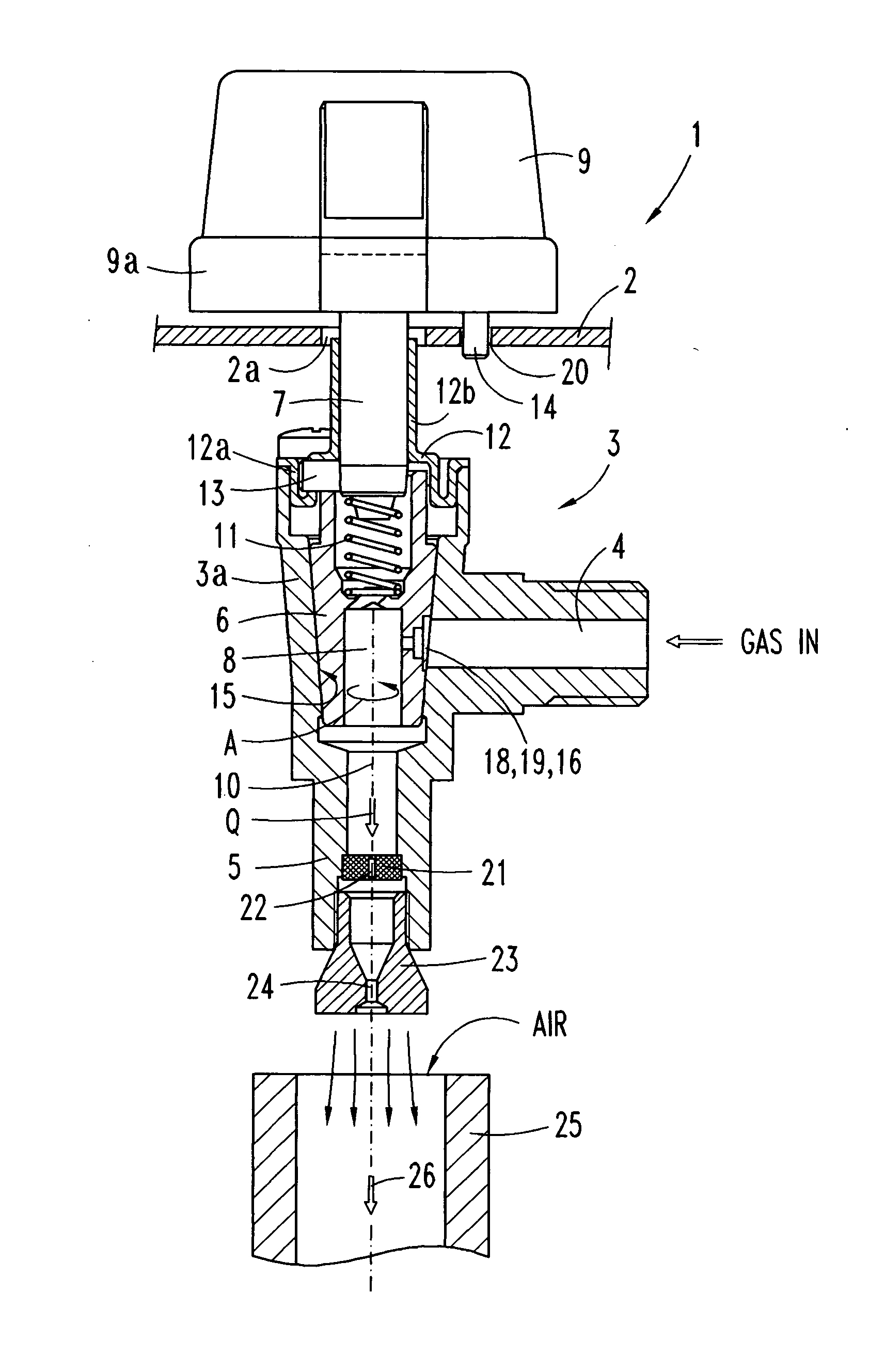

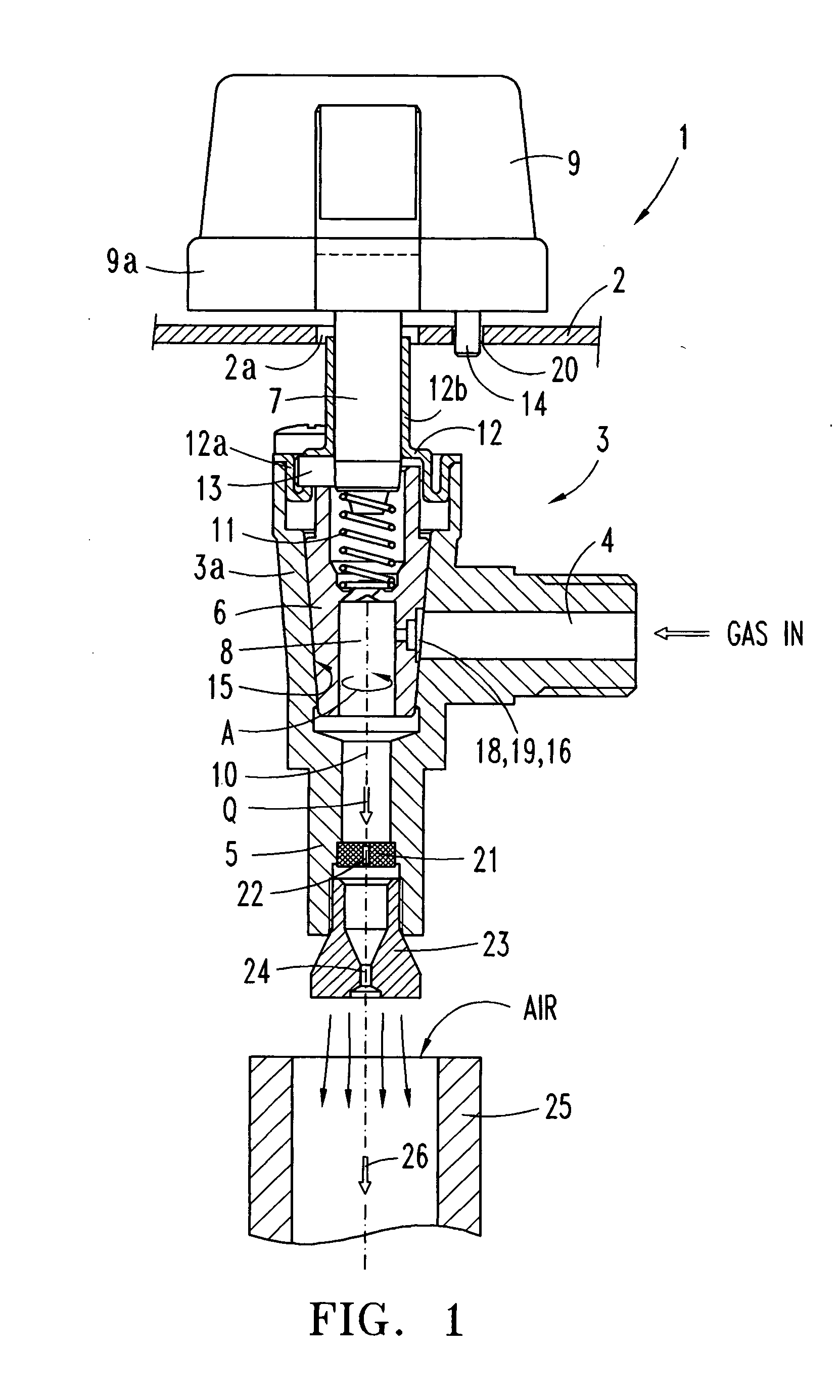

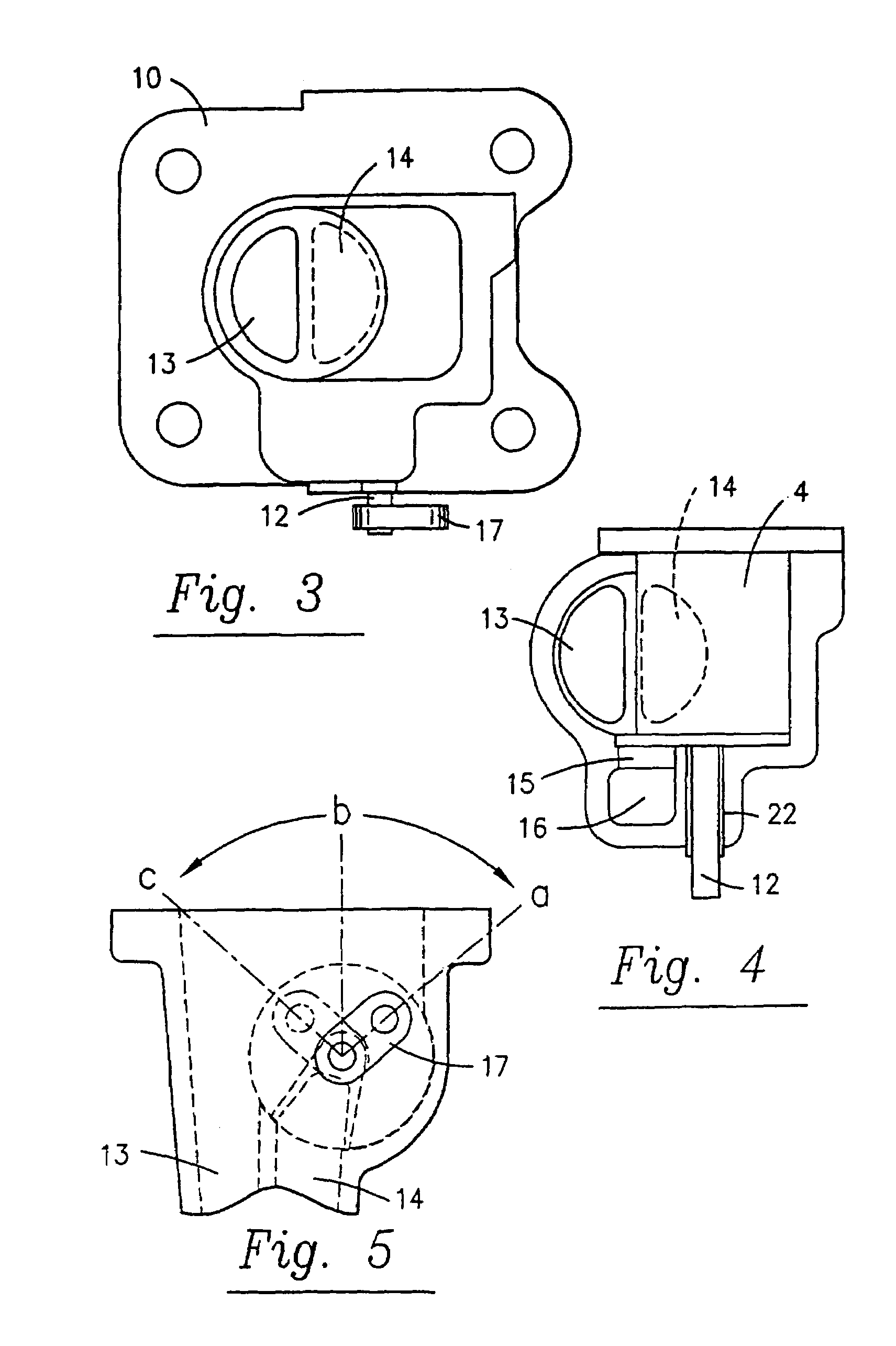

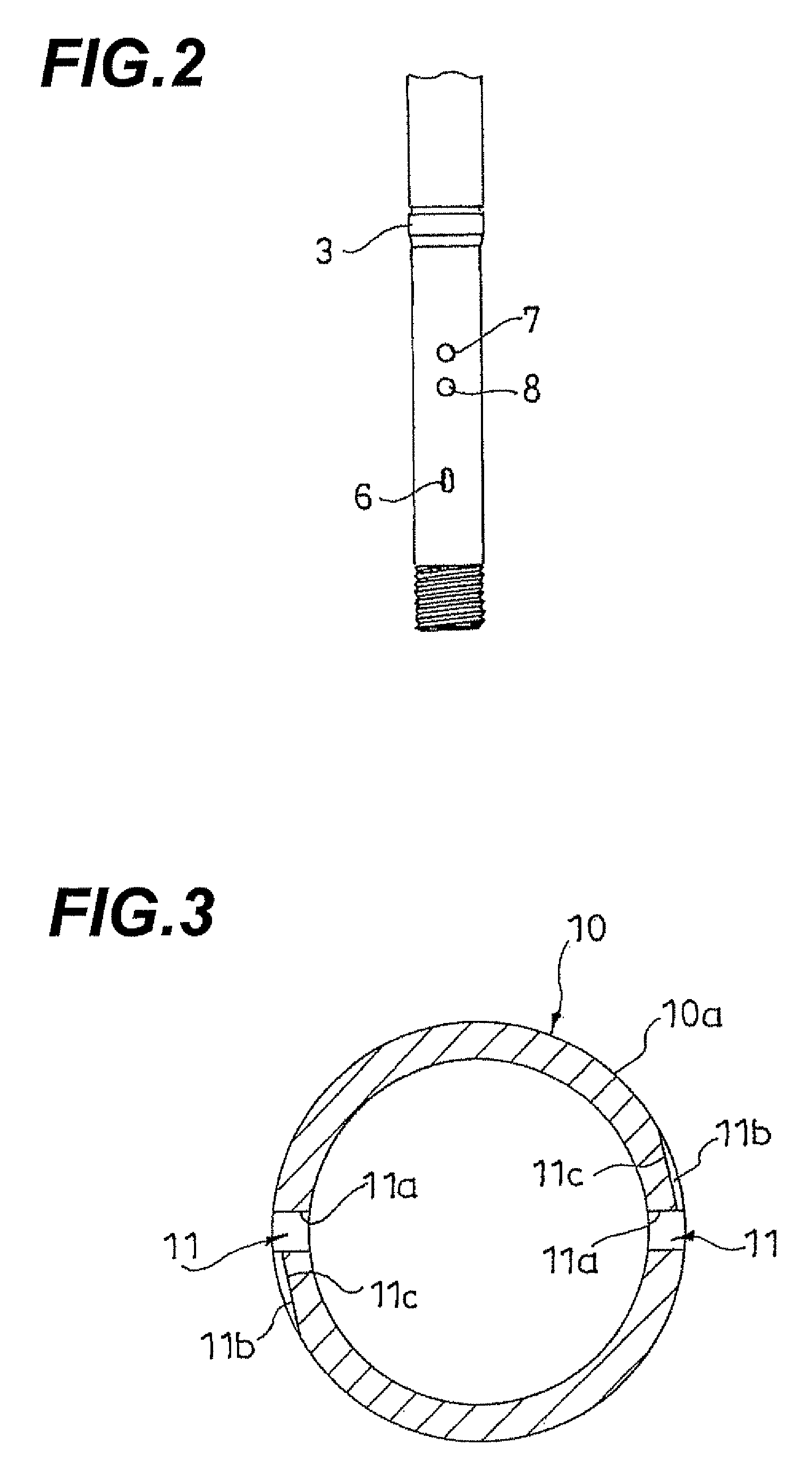

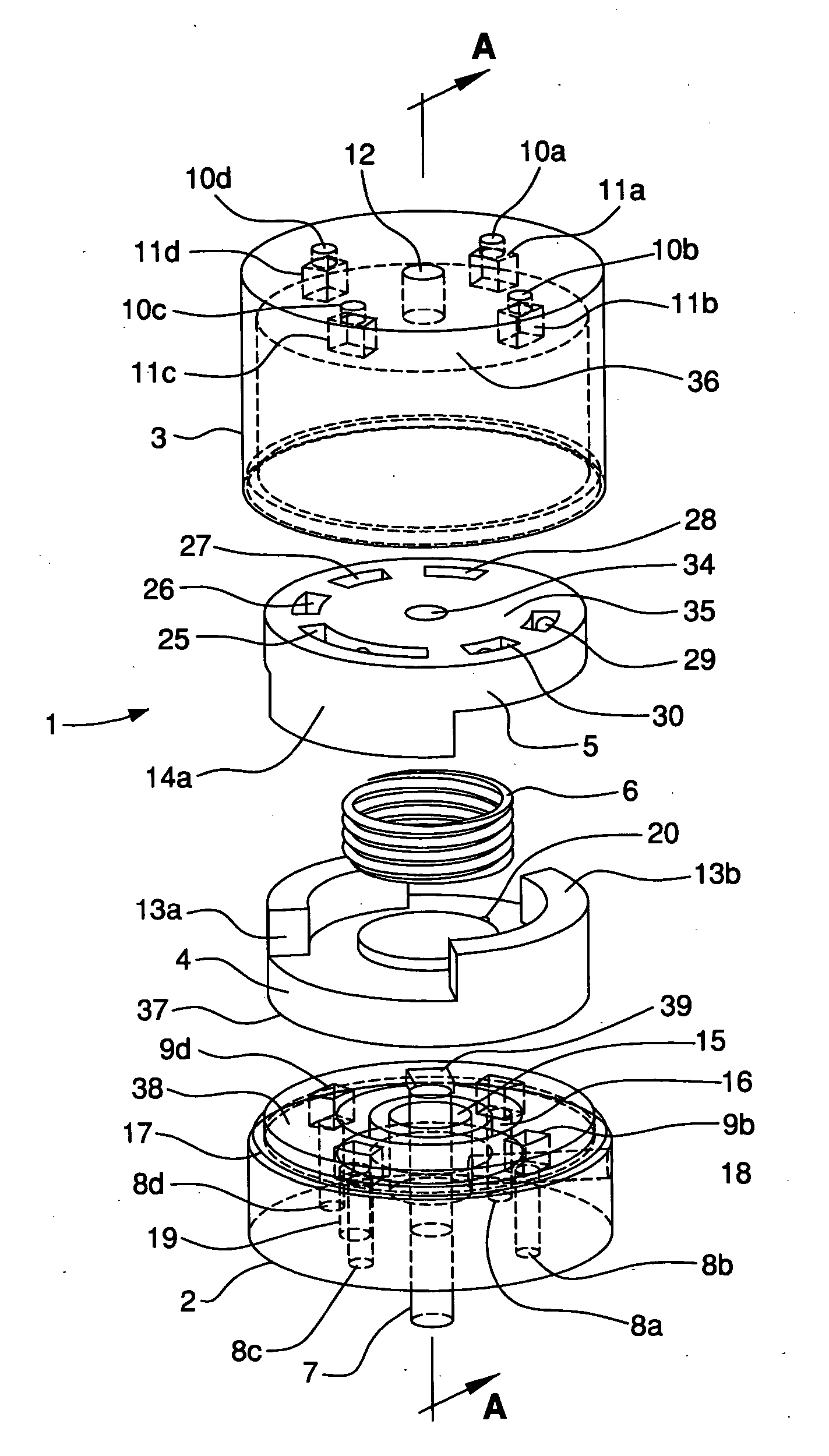

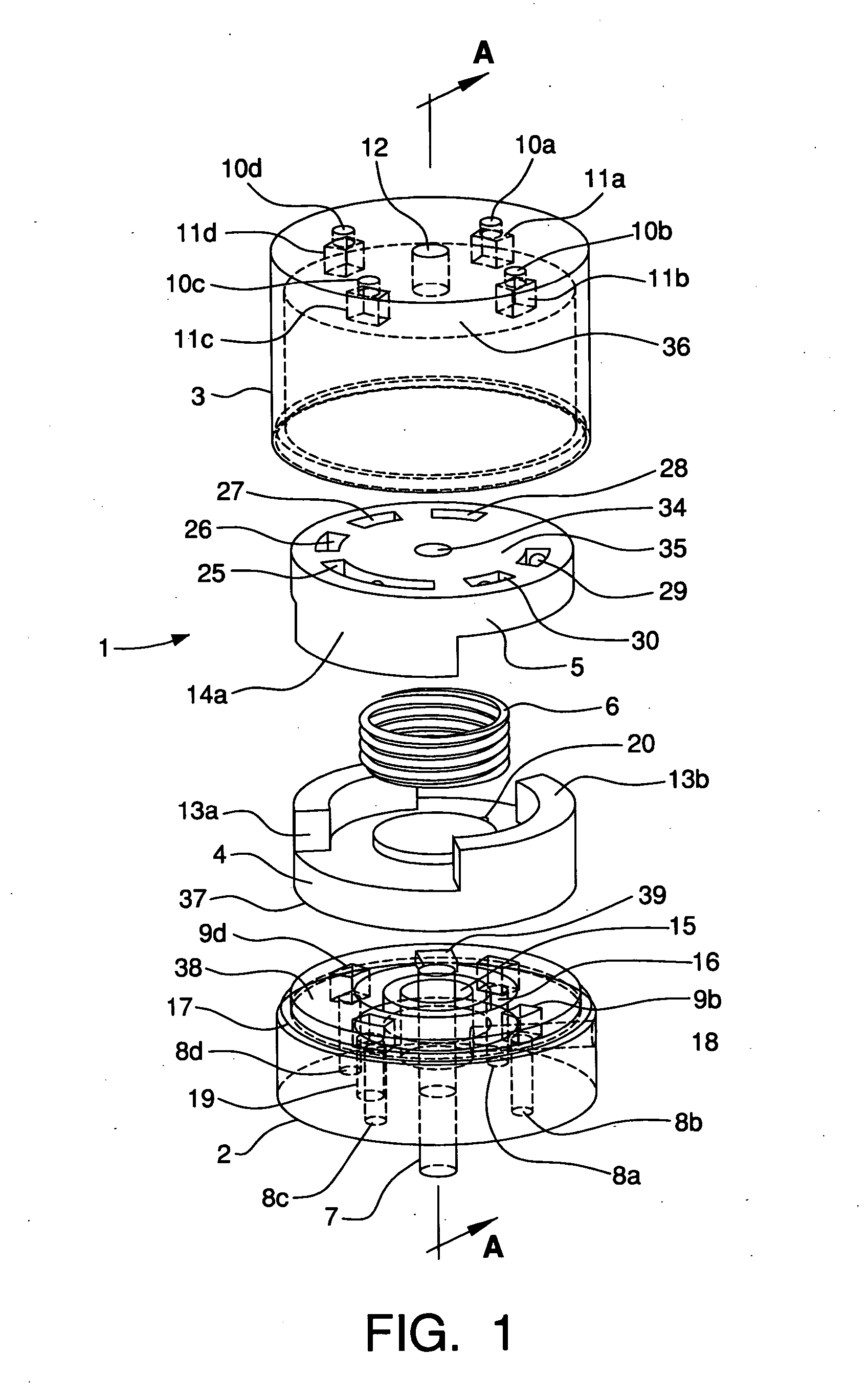

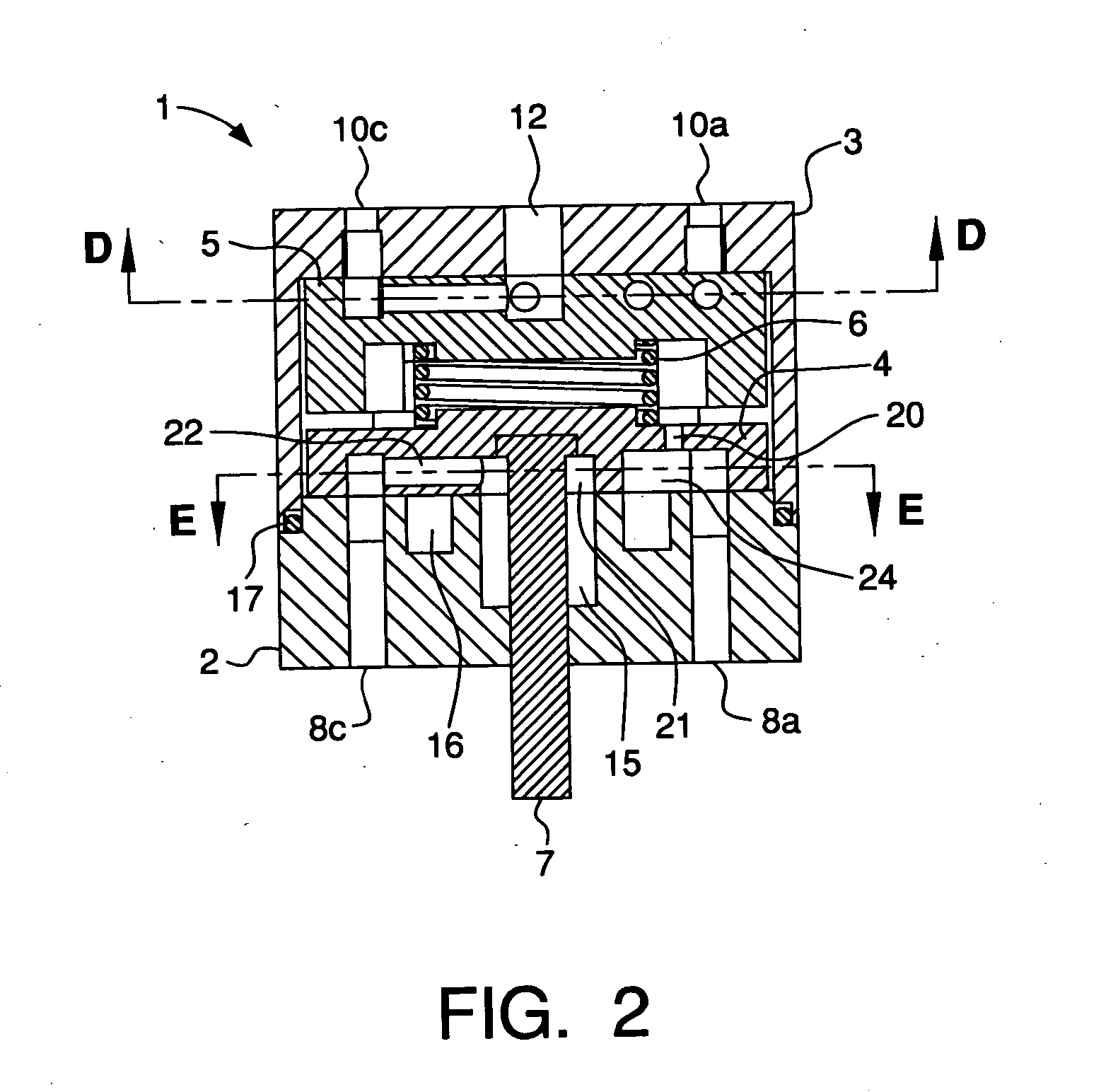

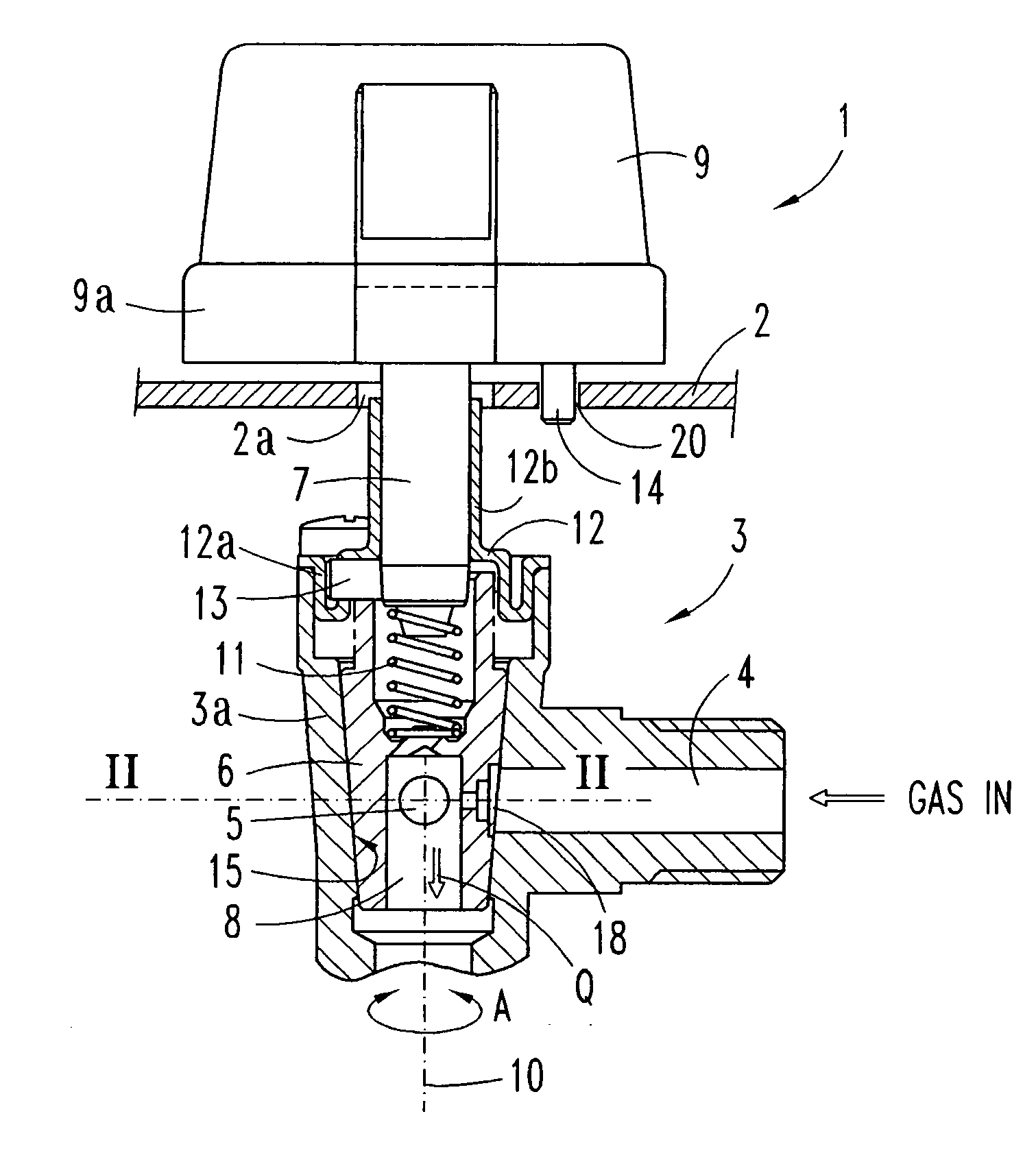

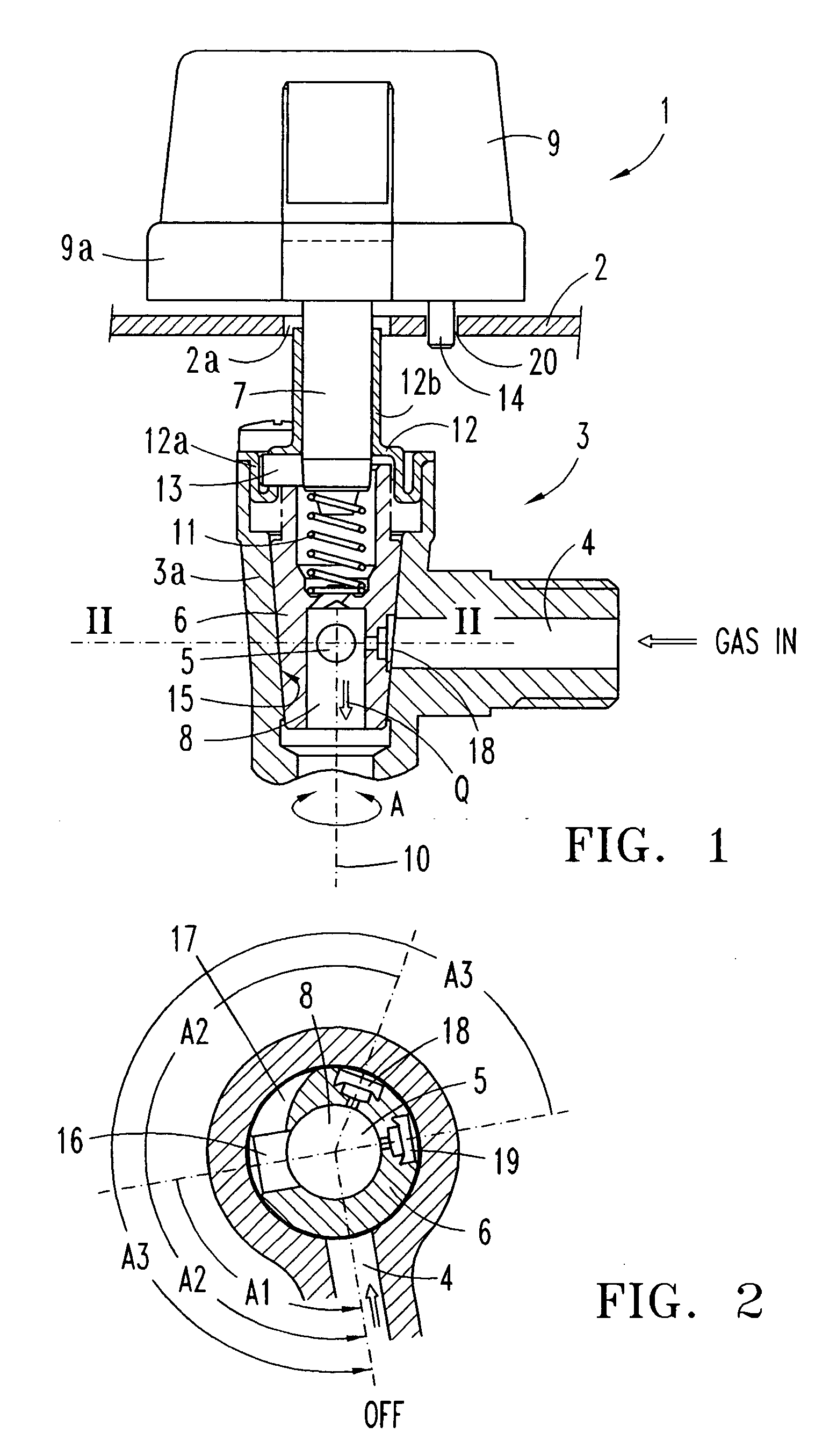

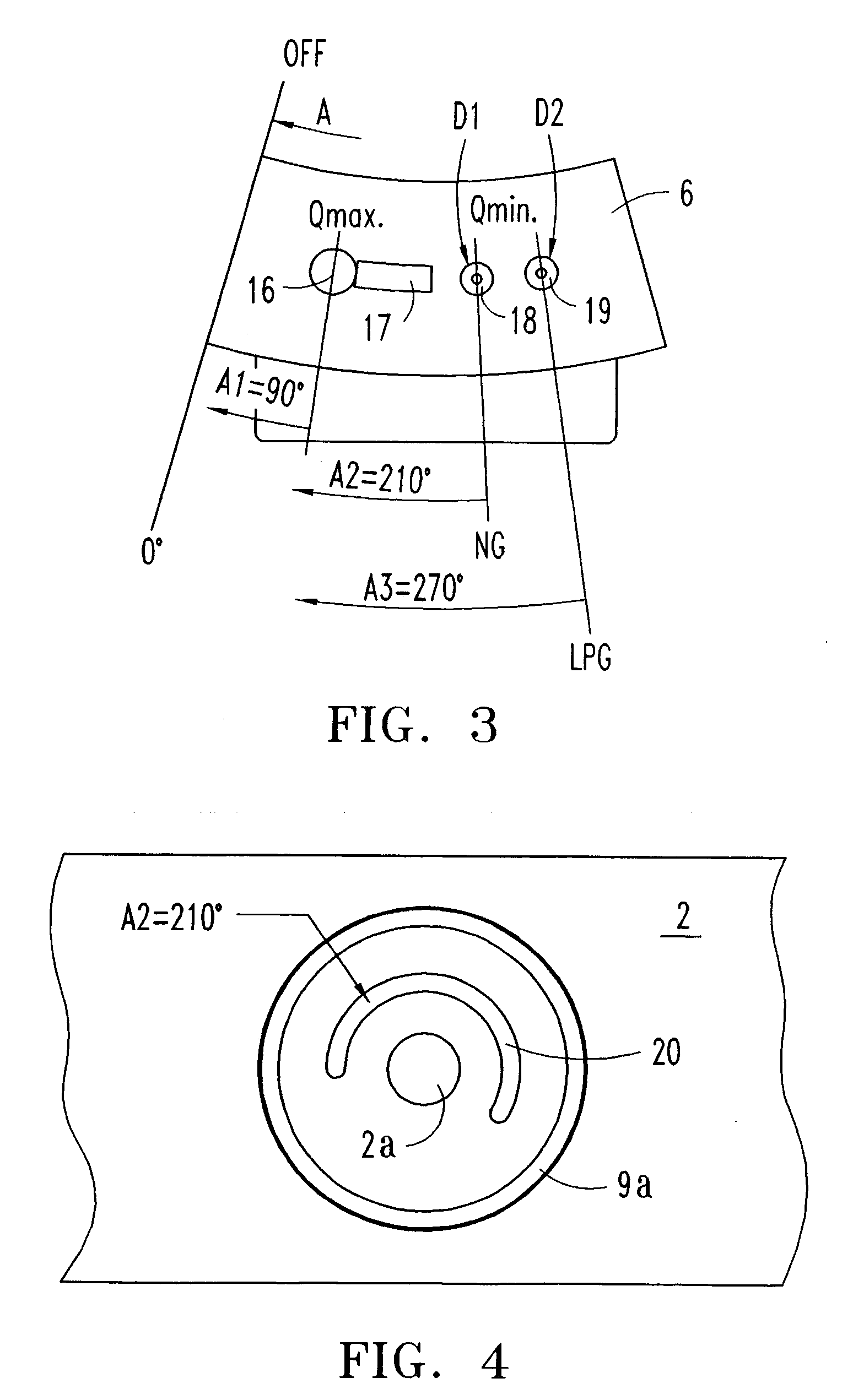

Rotary valve in a multi-gas cooker

The cooking appliance (1) having a control panel (2) is equipped with one or more gas flow (Q) regulating valves, wherein the rotary regulator organ (6) is provided with various peripheral through holes (16–19). The control knob (9) being interchangeable for fitting to the actuating shaft (7), is chosen from the two units available, one and the other permitting different angular limit positions (A2, A3) for the supply of a constant minimum gas flow Qmin, through one of two successive holes (18, 19) calibrated each one for a different type of gas NG or LPG, one or the other hole being superimposed to a valve inlet duct (4) at a different angular position A2, A3. An integral lug (14) on the control knob (9) running into a slide groove (20) in the control panel (2), establishes a first rotation stop A2.

Owner:ALBIZURI INIGO

Dual random access, three-way rotary valve apparatus

A multi-function, random access, dual, three-way valve for use with fluid switching and the like is provided, whereby a first fluid flow to the valve is selectively placed in fluid communication with a first or a second outlet passage from the valve for selectively transferring the first fluid flow and a second fluid flow to the valve is, independent of the flow path of the first fluid, selectively placed in fluid communication with a third or a fourth outlet from the valve for simultaneously transferring the second fluid flow. A rotor element rotatably movable relative to a stationary stator element to at least four discrete angular positions actuates to multi-function switching capabilities of the valve when the rotor element is selectively placed in one of the at least four discrete positions. The valve directs the first fluid flow to one of two alternate outlet passages and, simultaneously and independently, directs the second fluid flow to one of at least two different outlet passages.

Owner:IDEX HEALTH & SCI

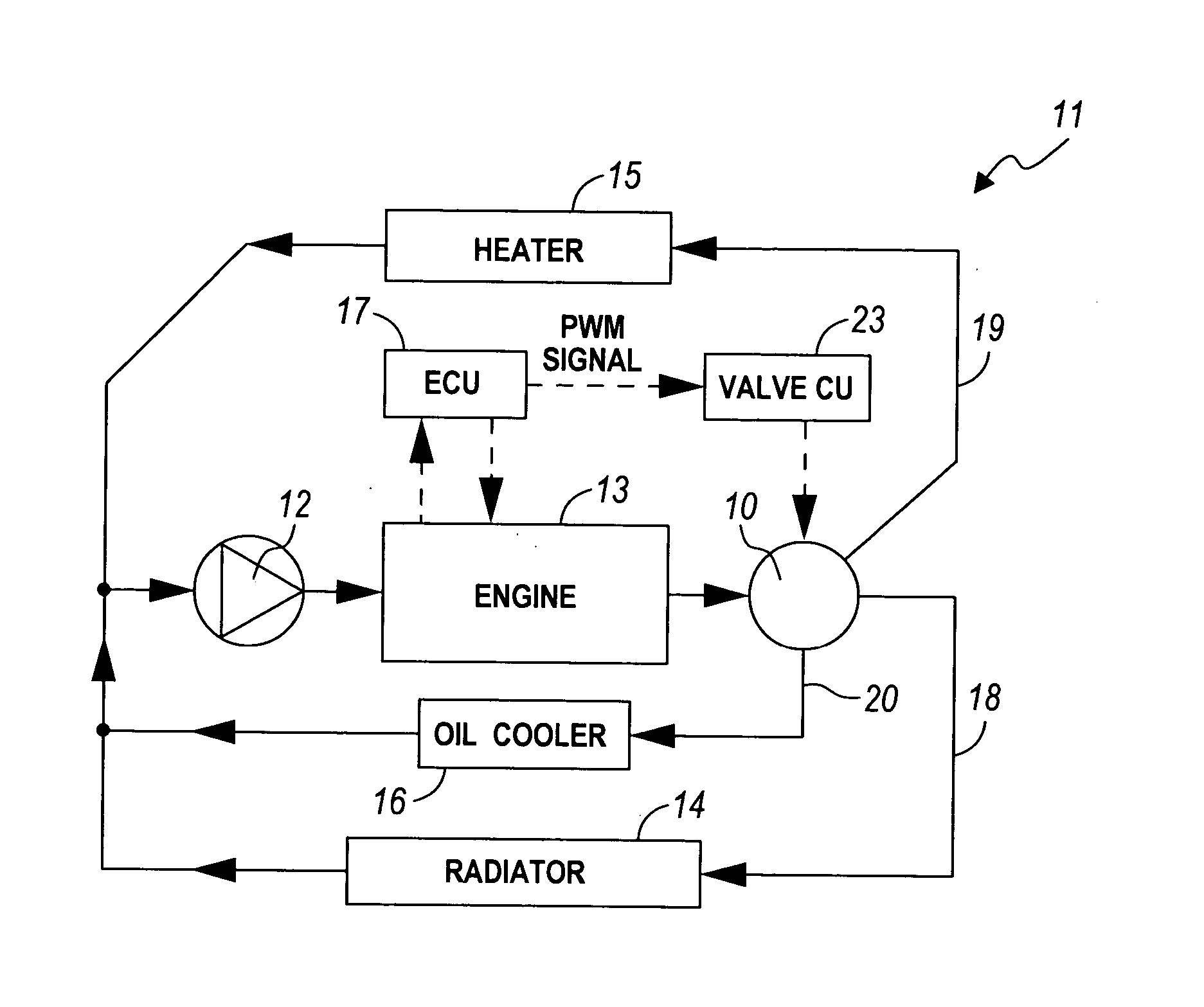

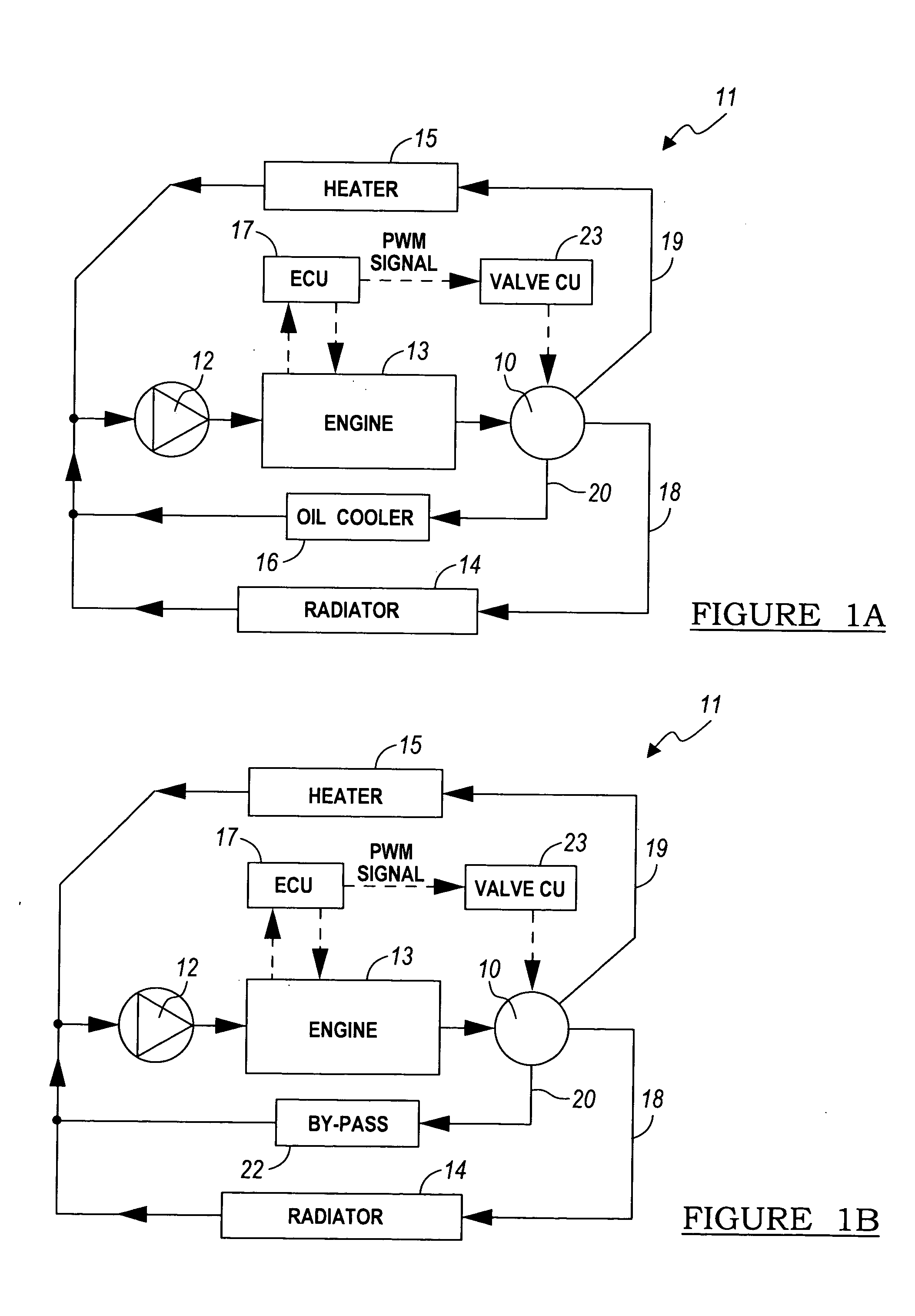

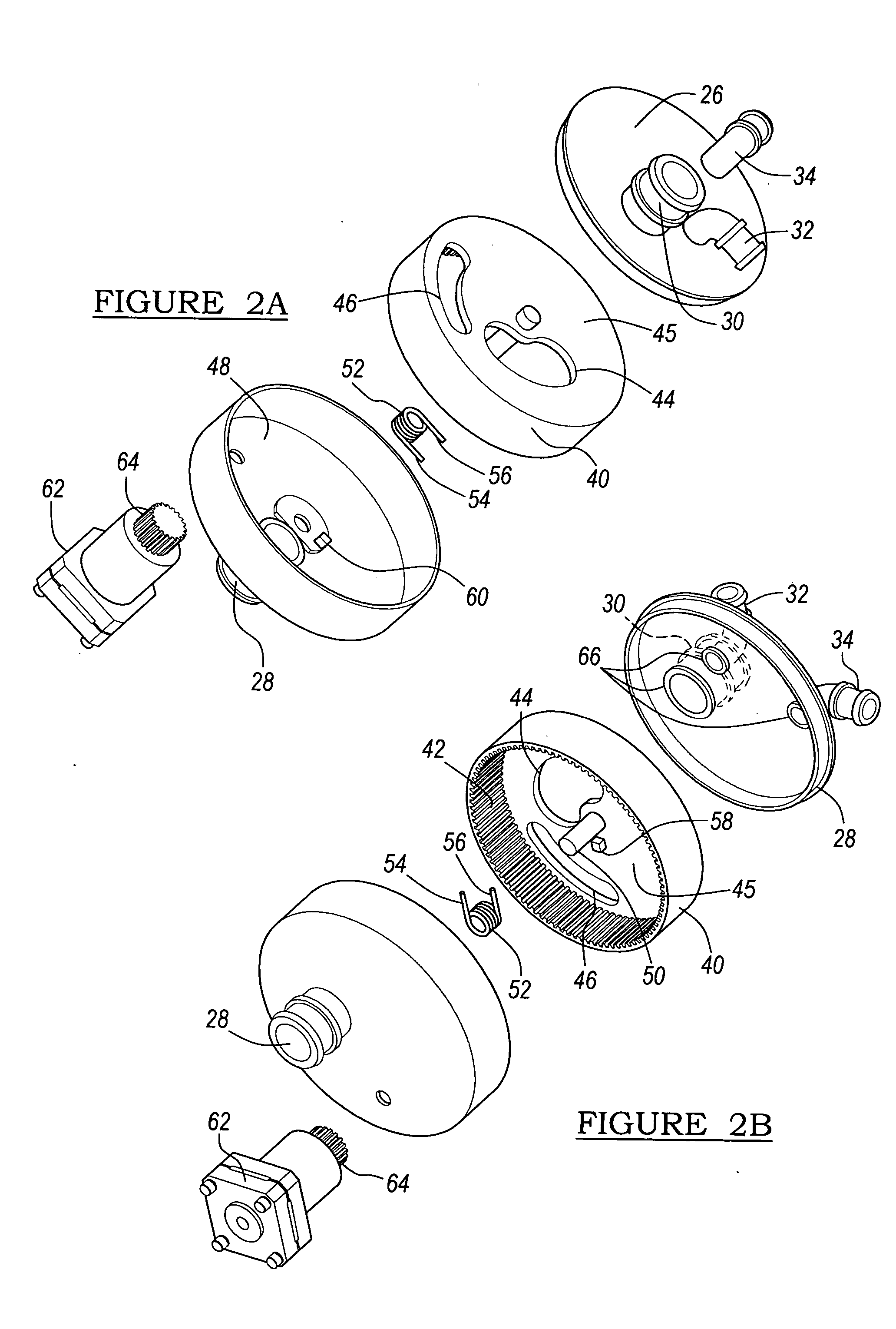

Engine cooling disc valve

A multi-port rotary valve used to distribute coolant to an engine cooling system comprises a valve body having a plurality of outlet ports for directing coolant flow to a radiator circuit, a heater circuit, and an auxiliary circuit. An internal gear driven rotary disc includes a gear driven mechanism located on an inner circumference of the rotary disc. The rotary disc includes two apertures positioned on a top surface of the rotary disc for regulating predetermined flow paths and flow rates to the plurality of ports. An inlet housing body which includes an inlet port mates with the valve body and encases the rotary disc. An actuator which is coupled to a drive gear mounted internal to the inlet housing body is responsive to a control signal for transmitting a torque to the internal drive gear for rotating the rotary disc to regulate coolant flow.

Owner:VISTEON GLOBAL TECH INC

System for isolating biomolecules from a sample

InactiveUS20080153078A1Maintaining suitable pressureBioreactor/fermenter combinationsBiological substance pretreatmentsFiltrationRotary valve

The present invention provides an automated system for purification of a substance of interest. The system generally comprises an instrument for moving fluids through the system, a reagent pack for storing fluids, and a purification cartridge. The cartridge comprises two filtration units for binding substances based on different physical properties. The cartridge also comprises rotary valves for control of movement of fluids on the cartridge. In preferred embodiments, the system is useful for purifying RNA from blood samples.

Owner:AGILENT TECH INC

Rotary valve assembly for fluid filtration system

A valve assembly is disclosed for use in conjunction with a replaceable filter cartridge system. The valve assembly includes a head member having an interior valve chamber defining a central axis, and inlet and outlet passages extending parallel to and communicating with the interior valve chamber. The valve assembly further includes a valve member having an inlet path and an outlet path, adapted for rotation within the interior valve chamber of the head member between a filter position wherein the inlet path of the valve member is in communication with the inlet passage of the head member and a bypass position wherein the inlet path of the valve member is out of communication with the inlet passage of the head member. The valve assembly further includes a seal member seated in an upper surface of the valve member and positioned to seal against an opposing surface of the interior valve chamber. The seal member sealingly isolates untreated and treated fluid streams flowing through the inlet and outlet paths of the valve member, respectively, when the valve member is in the filter position, and sealingly isolates the inlet and outlet passages of the head member from the atmosphere when the valve member is in the bypass position to permit fluid to flow therebetween.

Owner:3M INNOVATIVE PROPERTIES CO

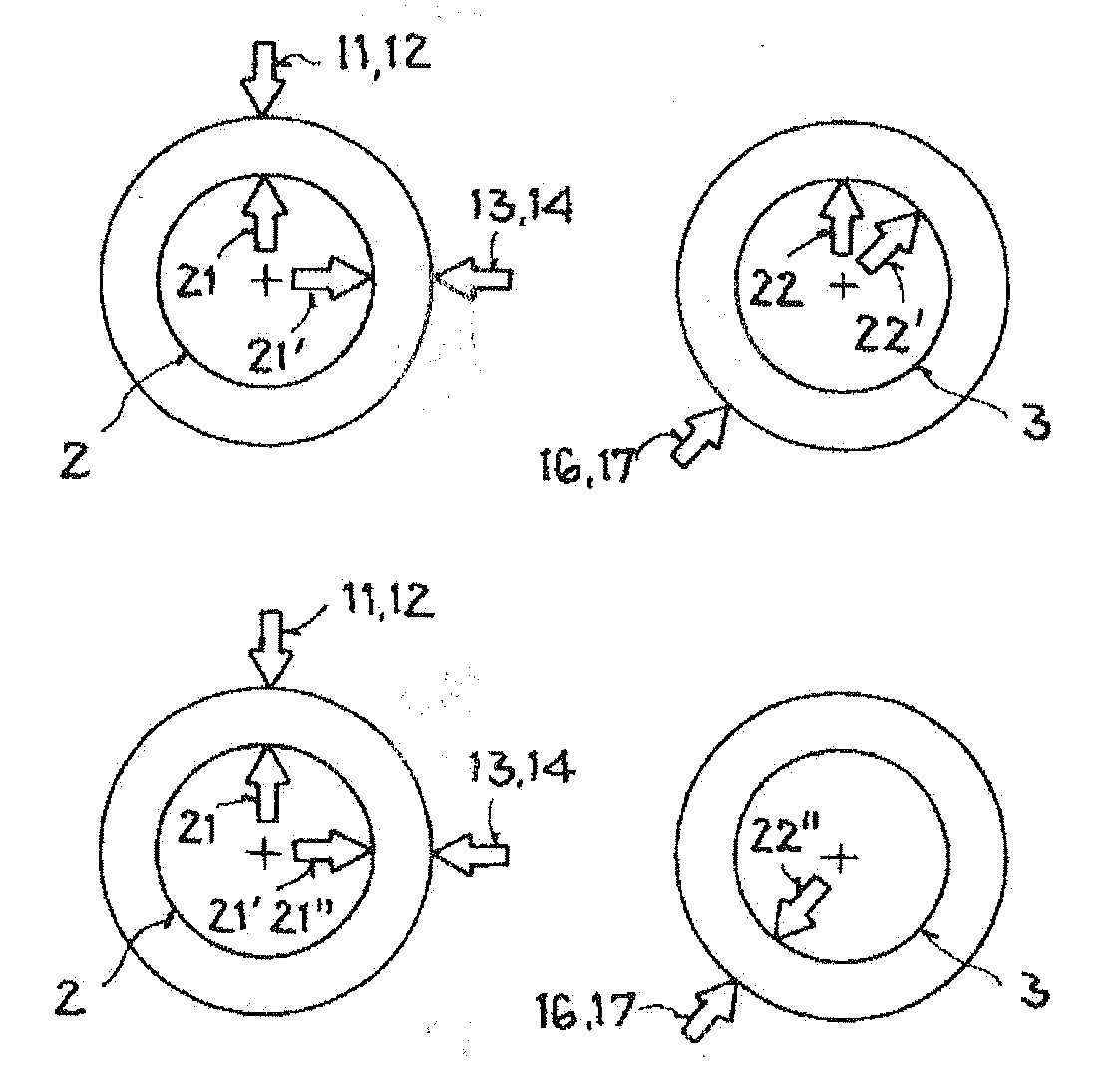

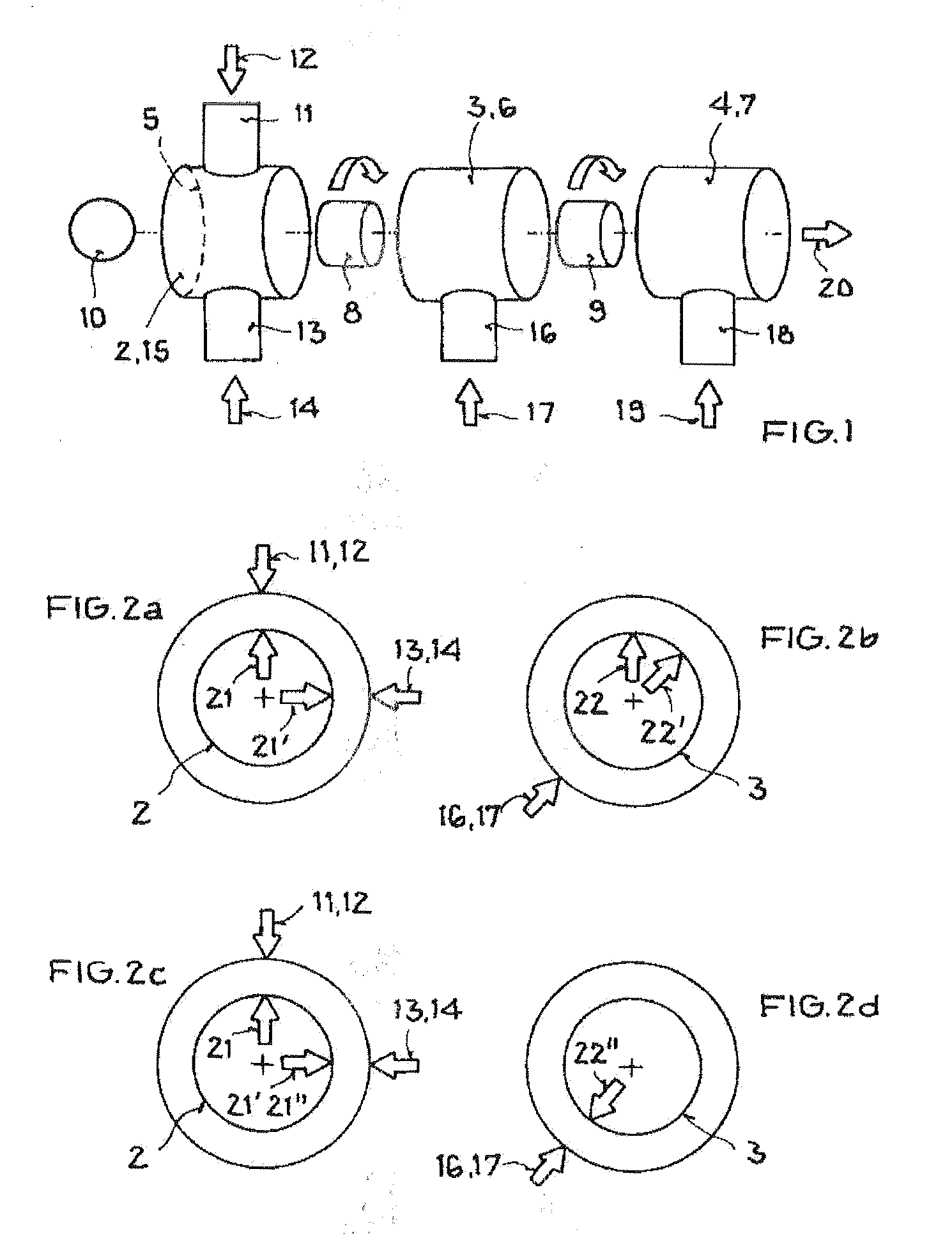

Multi-gas cooker, with a rotary valve provided with interchangeable regulating means

The cooking appliance (1) having a control panel (2) is equipped with one or more gas flow (Q) regulating valves, wherein the rotary regulating plug (6) is provided with various peripheral through holes (16-19). The control knob (9) being interchangeable for fitting to the actuating shaft (7), is chosen from the two units available, one and the other permitting different angular limit positions of the regulating plug (6) for the supply of a constant minimum gas flow Qmin, adjusted each one for a different type of gas N gas or LP gas. The outlet conduit (5) of the valve is equipped with a further injector nozzle (21,23) for adjusting a constant gas flow Qmax to be fed into the conduit (25) of the correspondent burner, when the cooking appliance is supplied with a LP gas.

Owner:COPRECITEC

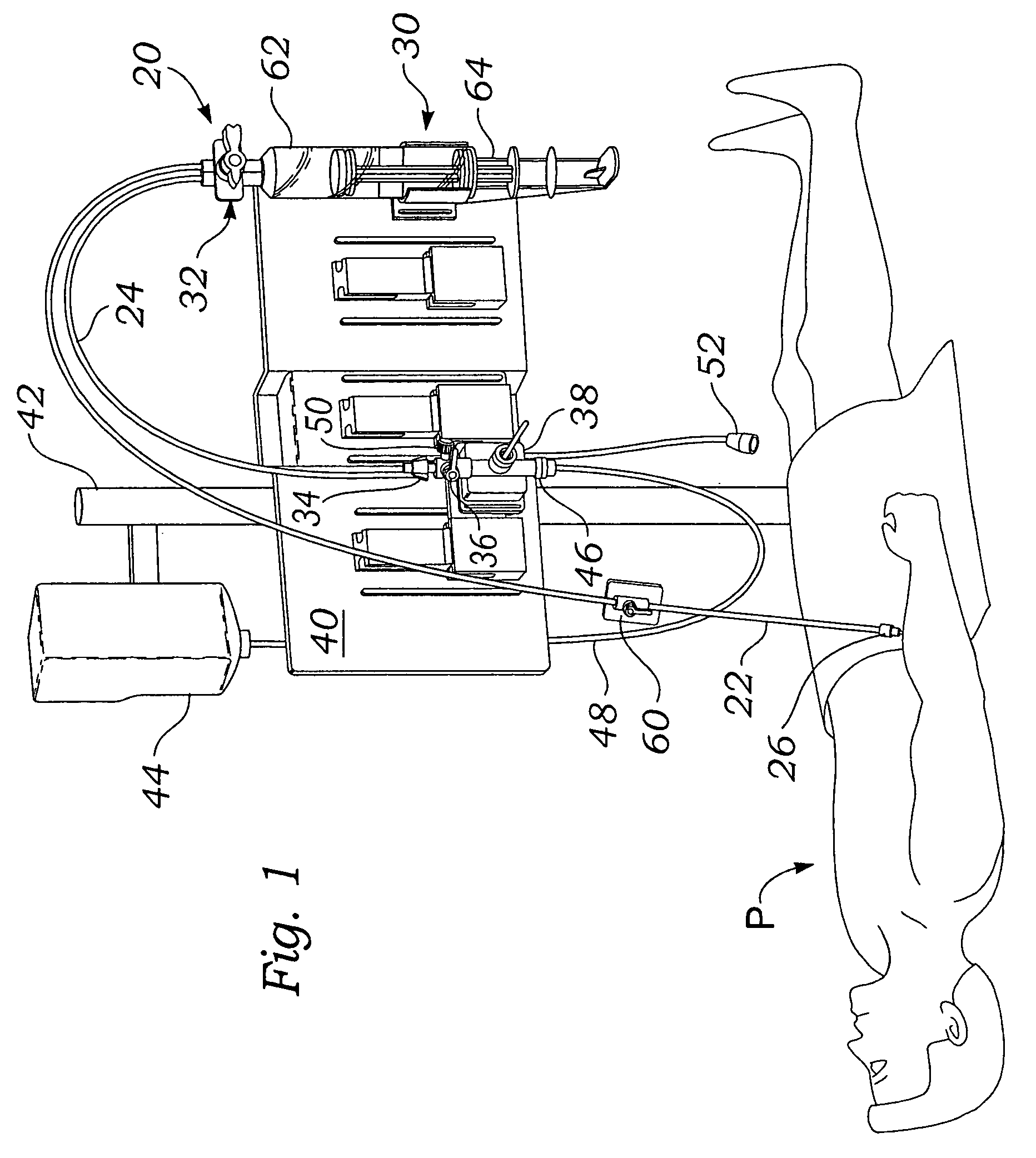

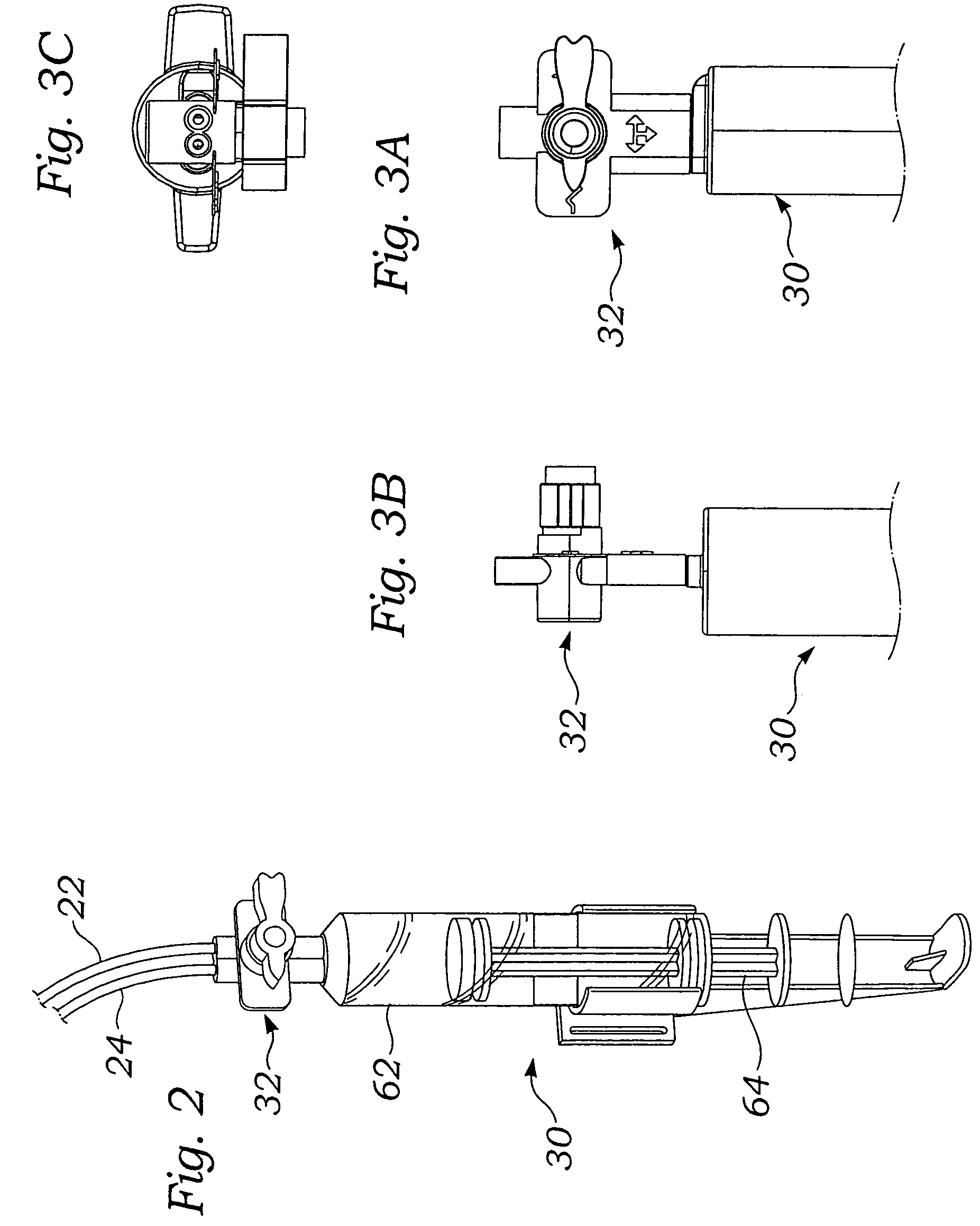

Closed blood sampling system with isolated pressure monitoring

ActiveUS7744573B2Easy to optimizeImprove pressure qualityCatheterIntravenous devicesMedical intensive care unitIntensive care

Owner:EDWARDS LIFESCIENCES CORP

Rotary Valve

ActiveUS20090107332A1Reduce the amount requiredLeak preventionProductsOxygen/ozone/oxide/hydroxideRotary valveEngineering

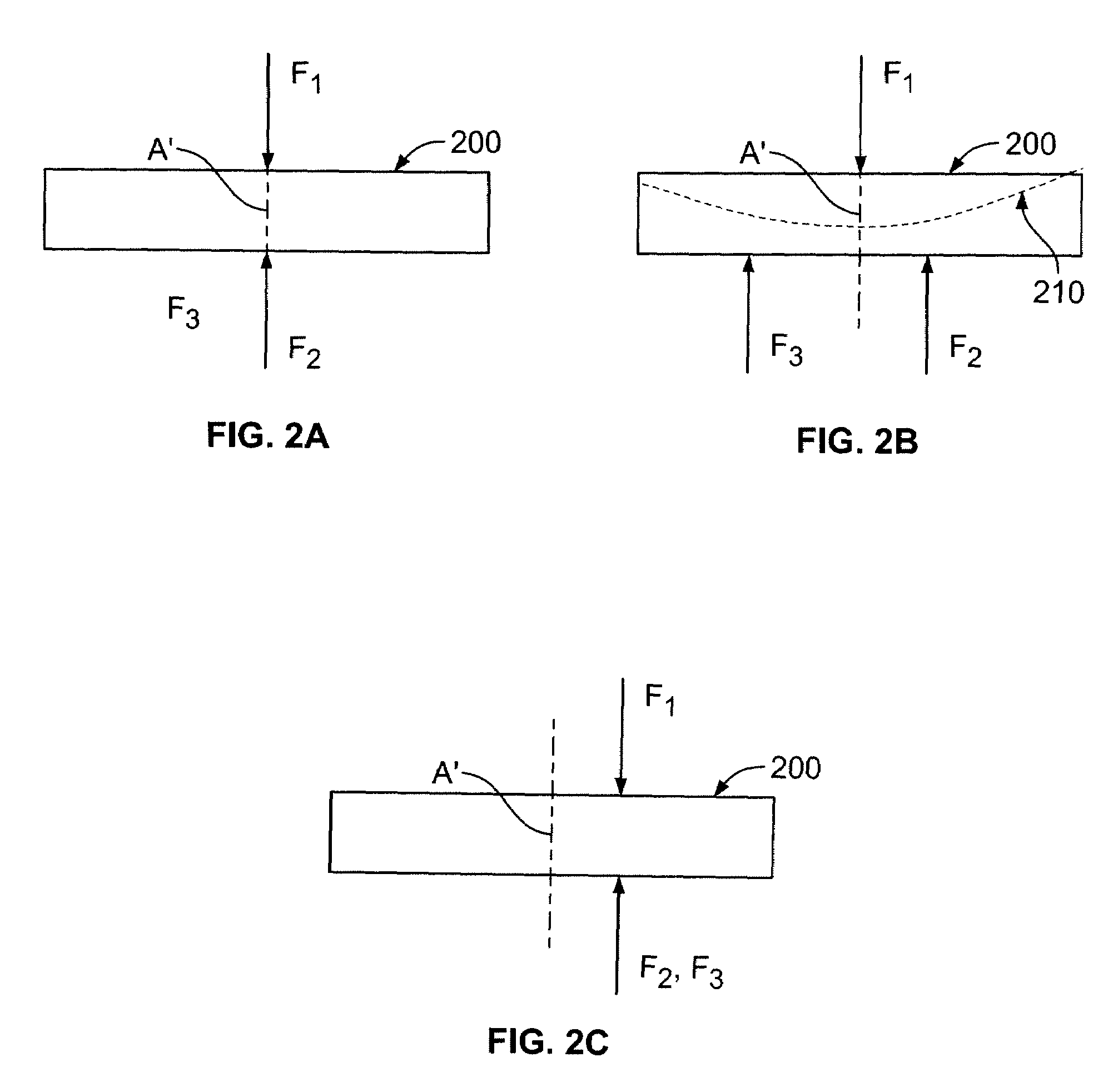

A rotary valve is disclosed having a rotor and stator that utilizes at least one compression spring to provide contact between the rotor and stator. The spring(s) is configured to oppose the pressure forces that urge the rotors and stators apart and reduce the amount of torque necessary to turn the rotors in the valve while preventing leakage from between the rotor and stator. The spring(s) may be positioned within the valve by a spring locating features.

Owner:AIR PROD & CHEM INC

Rotary valve

ActiveUS7819948B2Reduce the amount requiredMinimize torqueProductsOxygen/ozone/oxide/hydroxideRotary valveEngineering

A rotary valve is disclosed having a rotor and stator that utilizes at least one compression spring to provide contact between the rotor and stator. The spring(s) is configured to oppose the pressure forces that urge the rotors and stators apart and reduce the amount of torque necessary to turn the rotors in the valve while preventing leakage from between the rotor and stator. The spring(s) may be positioned within the valve by a spring locating features.

Owner:AIR PROD & CHEM INC

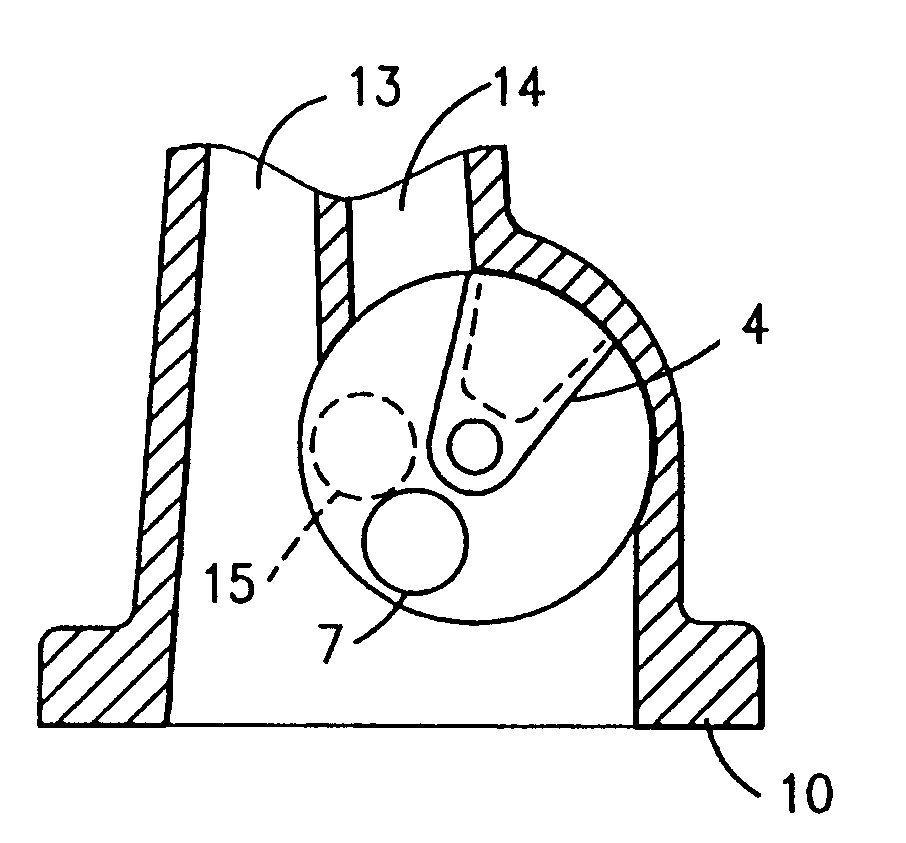

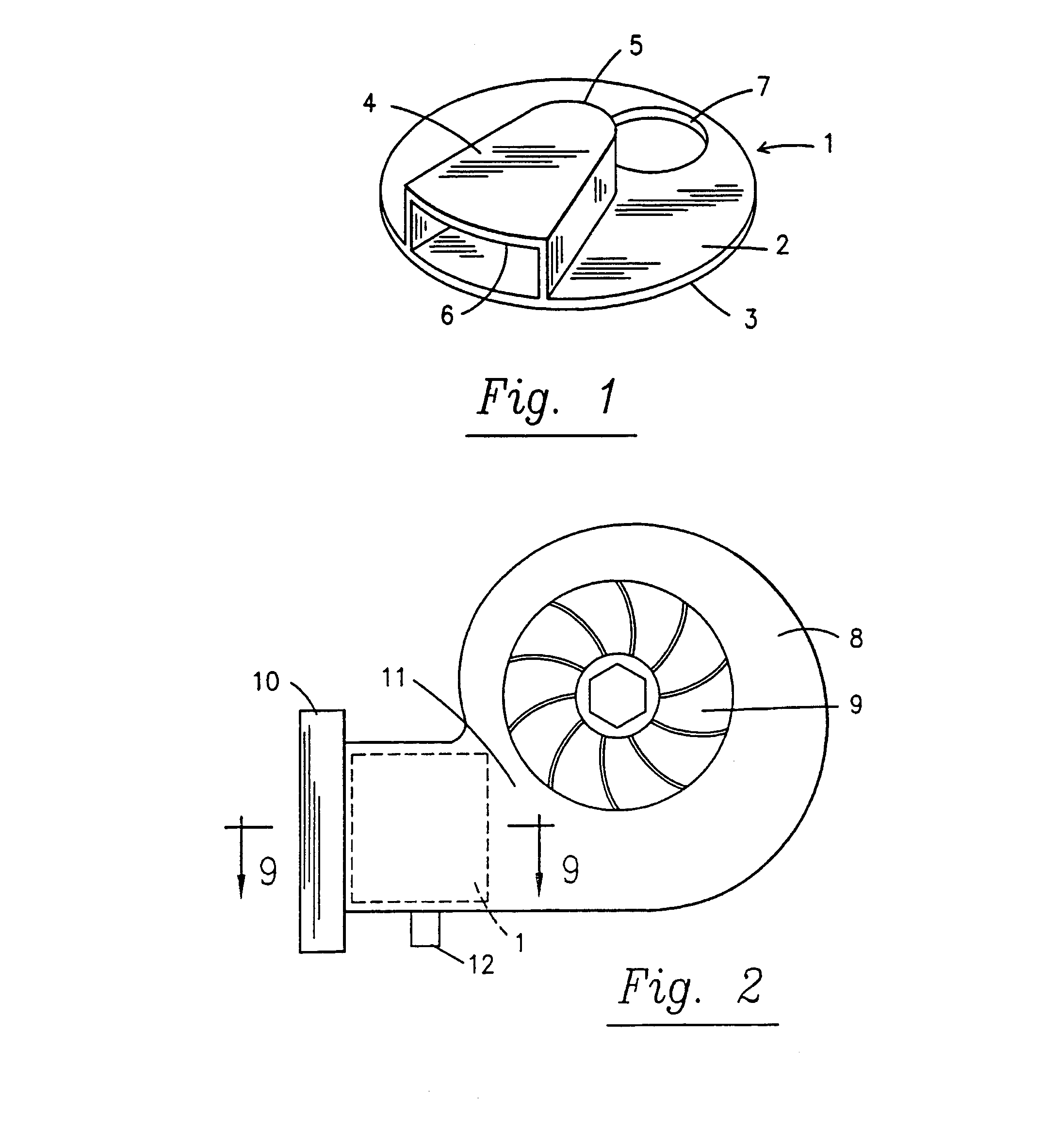

Controlled turbocharger with integrated bypass

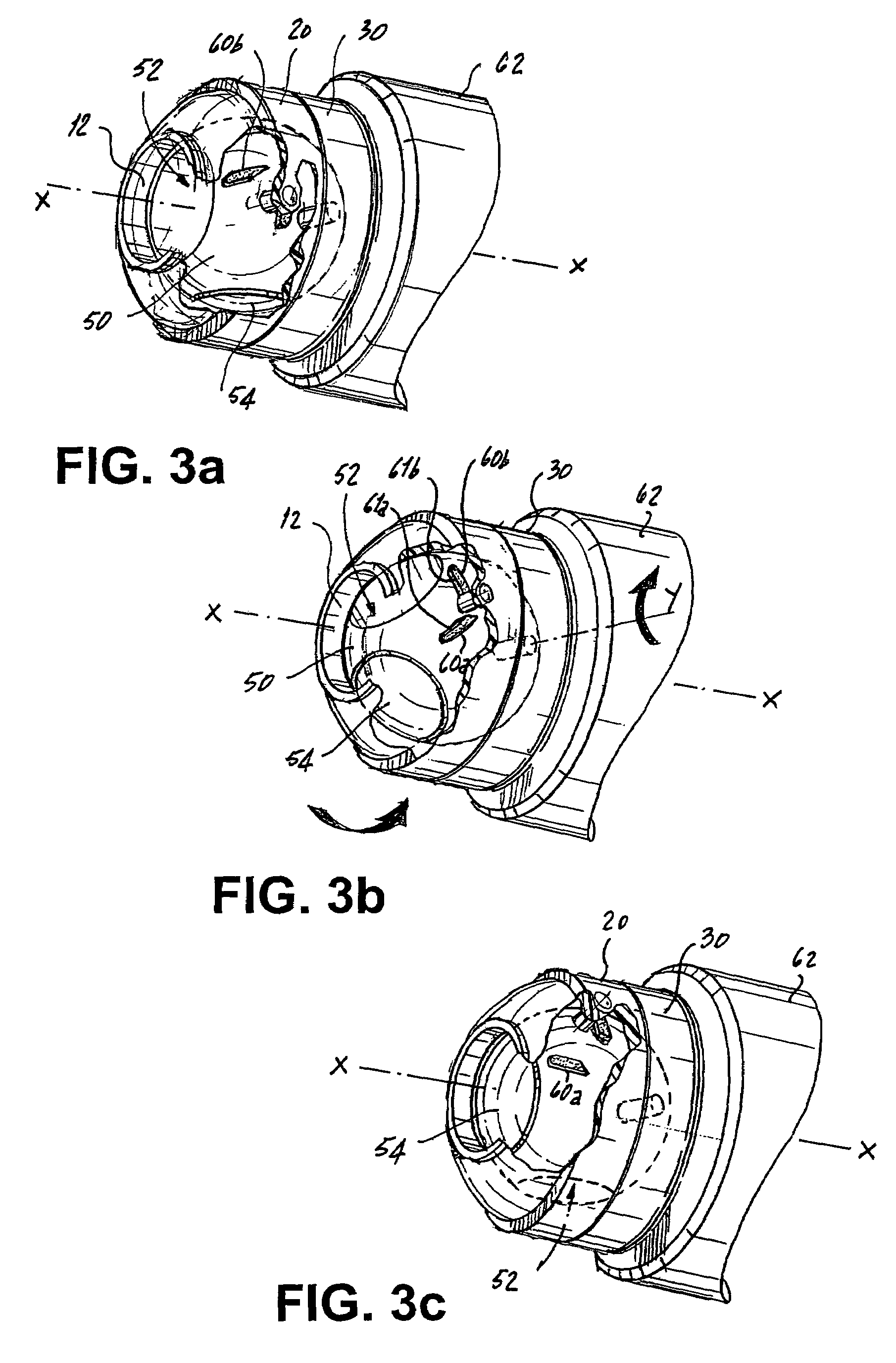

InactiveUS6983596B2More responsiveGreat ease of controlInternal combustion piston enginesEngine controllersTurbochargerRotary valve

A rotary valve (1) particularly suitable for use in a turbocharger for an internal-combustion engine, the rotary valve provided between a turbocharger inlet port (10) and at least first and second scroll passages (13, 14), the rotary valve rotatable between (a) a position at which at least one scroll passage is blocked and a bypass outlet is blocked, (b) a position at which no scroll passage is blocked and the bypass outlet is blocked, and (c) a position at which no scroll passage is blocked and the bypass outlet is not blocked. The control valve is rotatable about a central axis, includes a disk-shaped base (2) and a control surface (4) provided upon said base, the control surface preferably being generally wedge shaped, and the disk optionally having an aperture (7) for communication with the bypass outlet. The rotary valve is preferably mounted on both sides via a shaft (112a, 112b) extending through the axis of rotation.

Owner:BORGWARNER INC

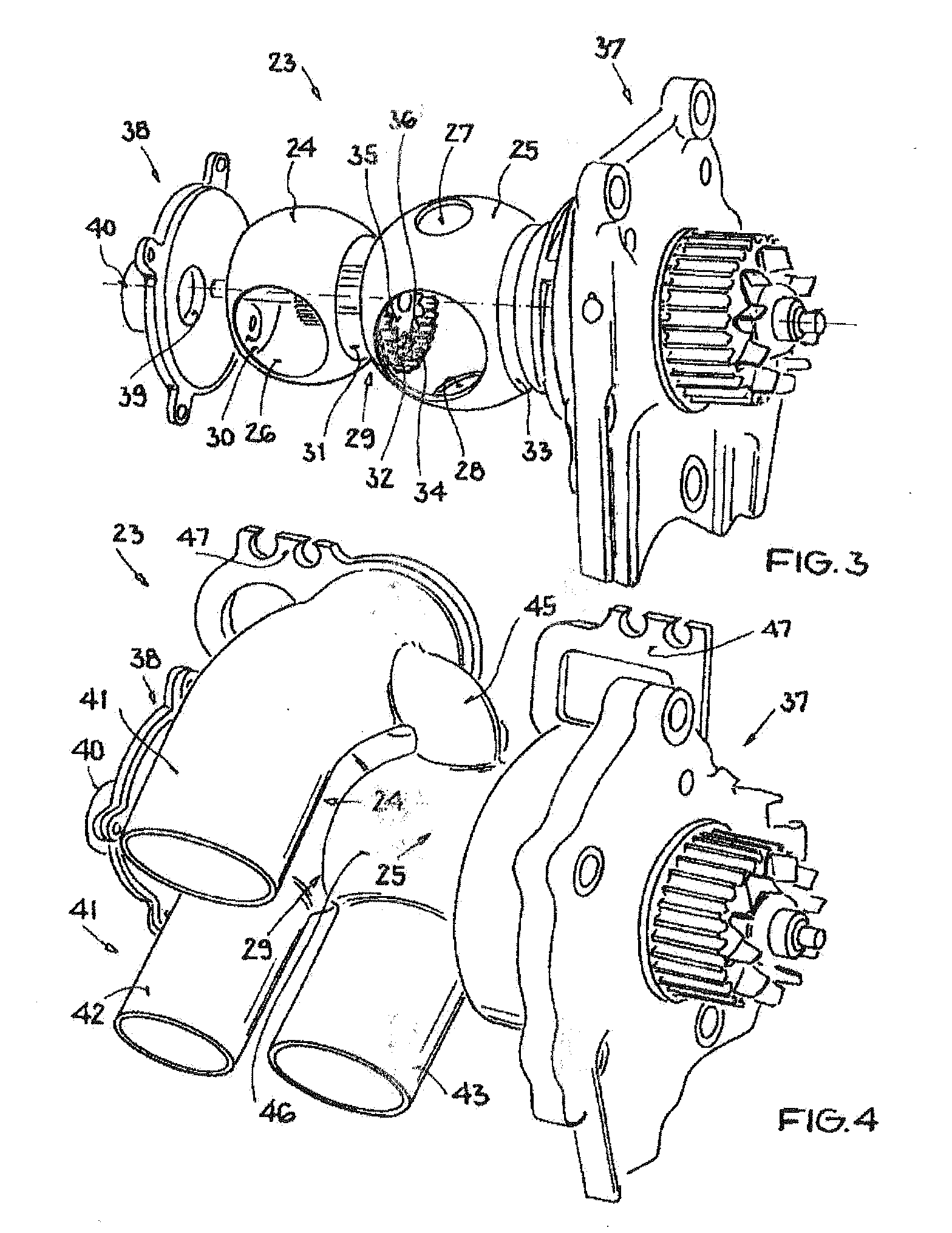

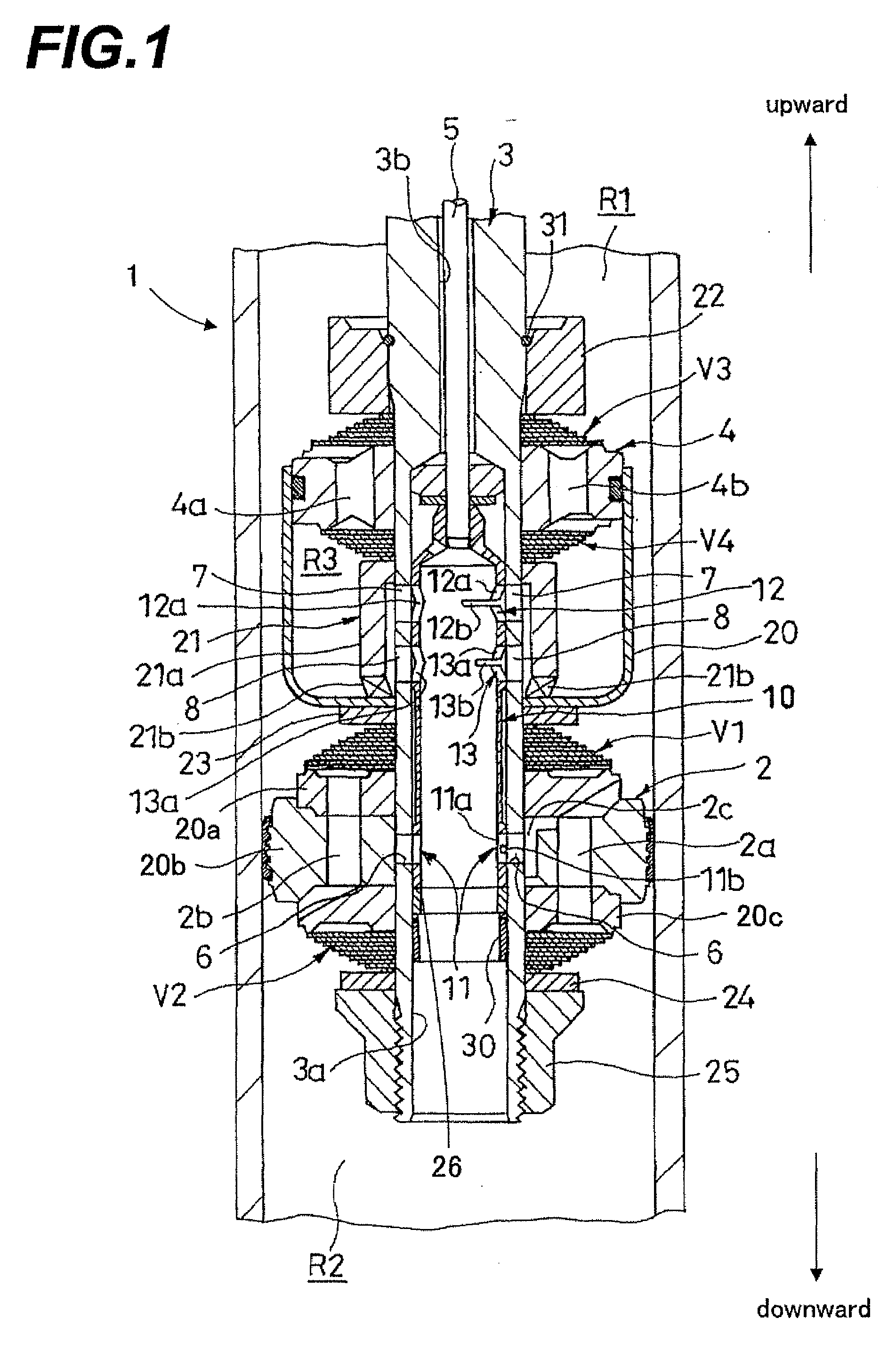

Rotary slide valve, in particular for a coolant circuit, which has a plurality of branches, of an internal combustion engine; electromechanical assembly

A valve assembly for the coolant system of an internal combustion engine including a housing, at least two coaxially disposed rotary valves journaled in such housing, each of such valves having an axially disposed fluid passageway communicable with an inlet port of such housing and at least one passageway communicating with the axially disposed passageway and communicable with an outlet port of the housing upon a particular orientation of such valve, and a drive gear operatively connected to such valves, operative to rotate such valves to different degrees.

Owner:AUDI AG

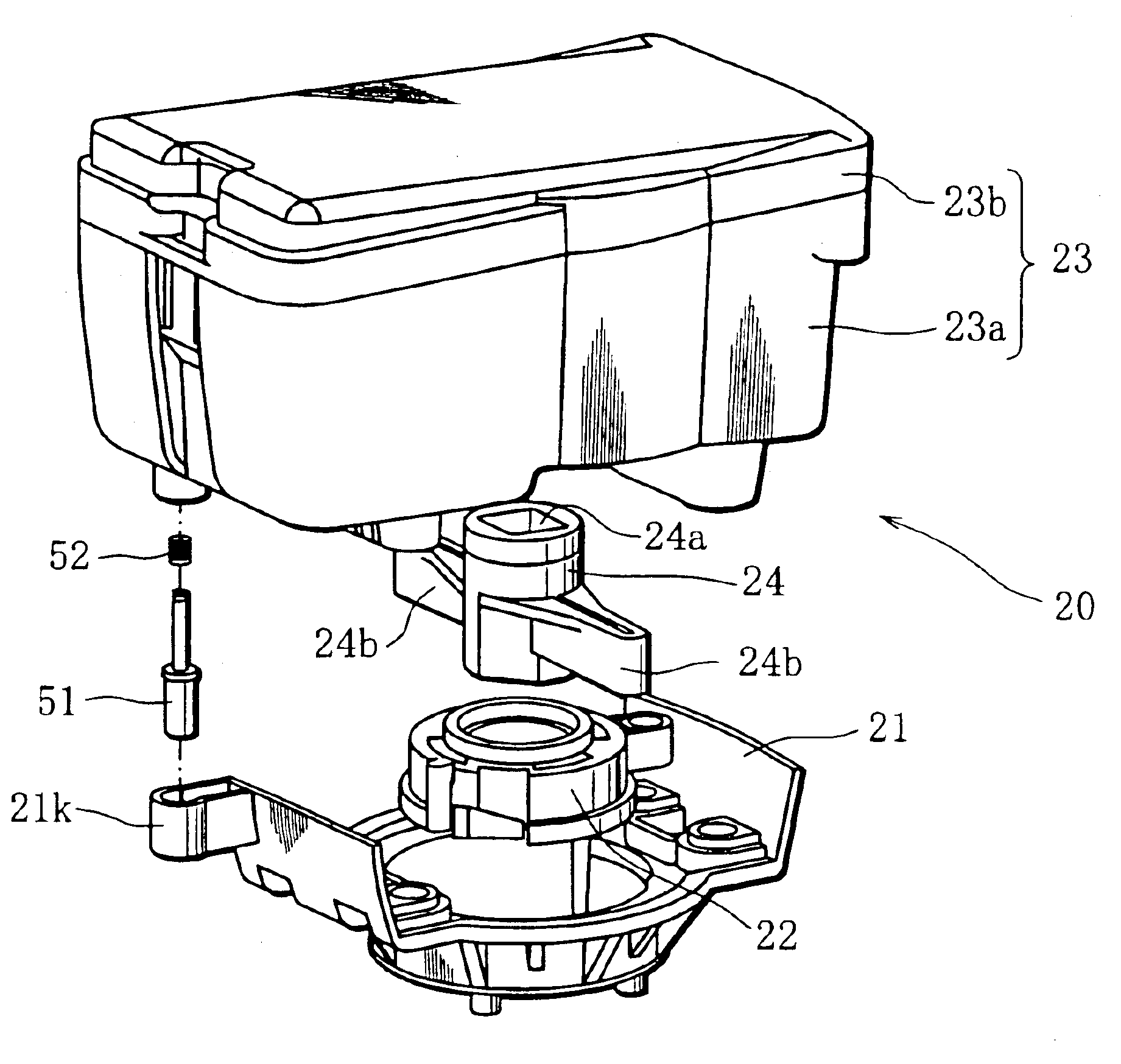

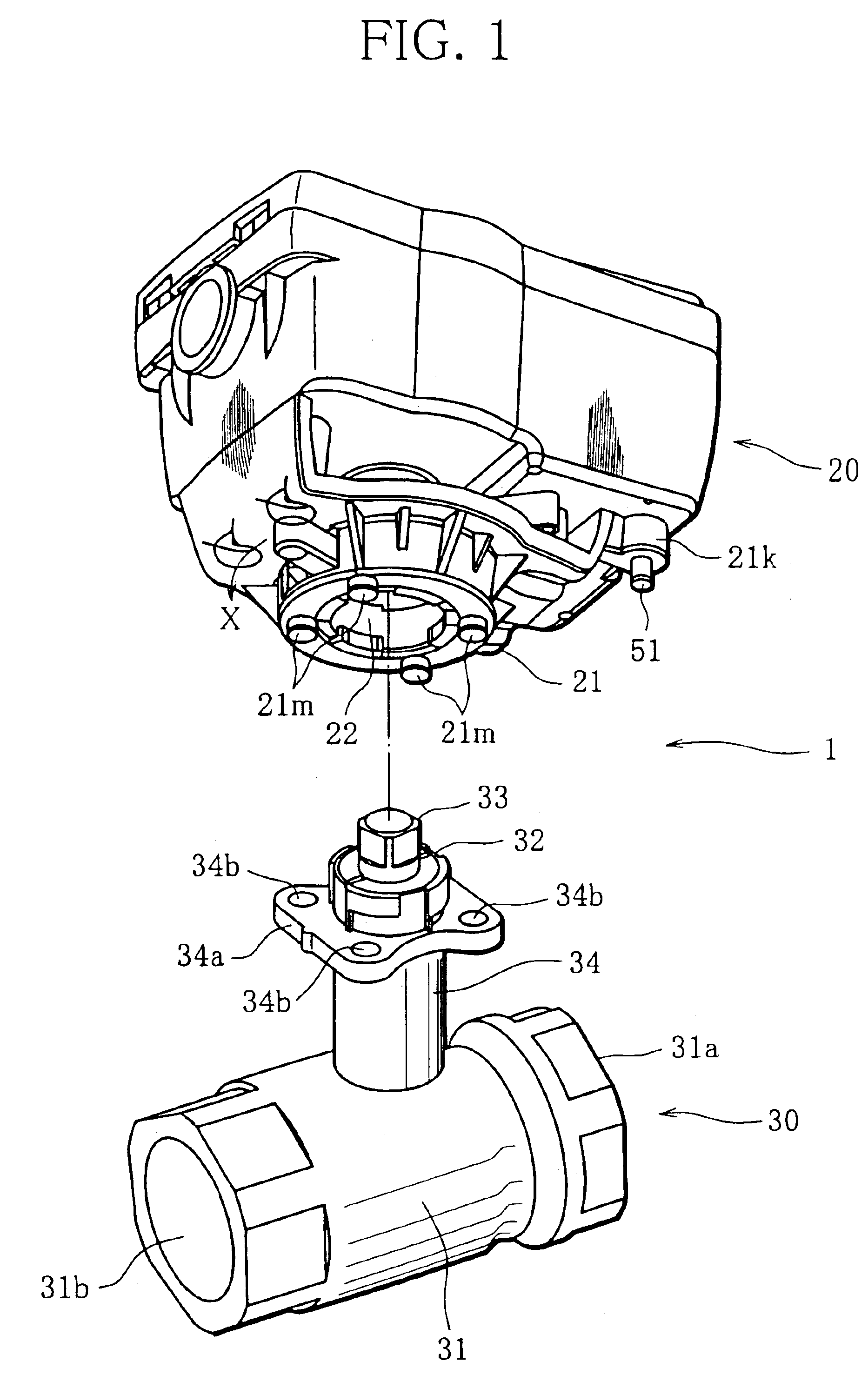

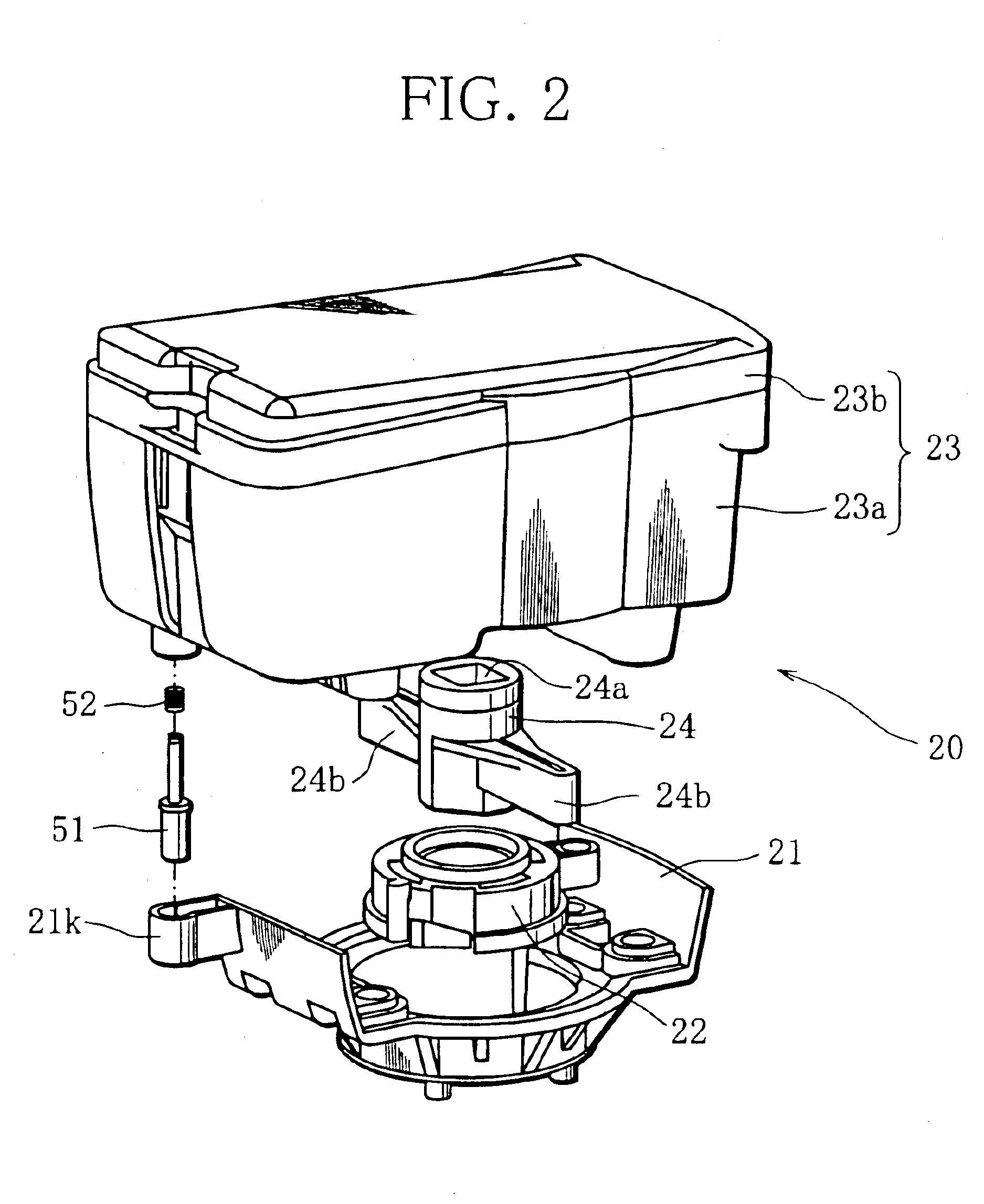

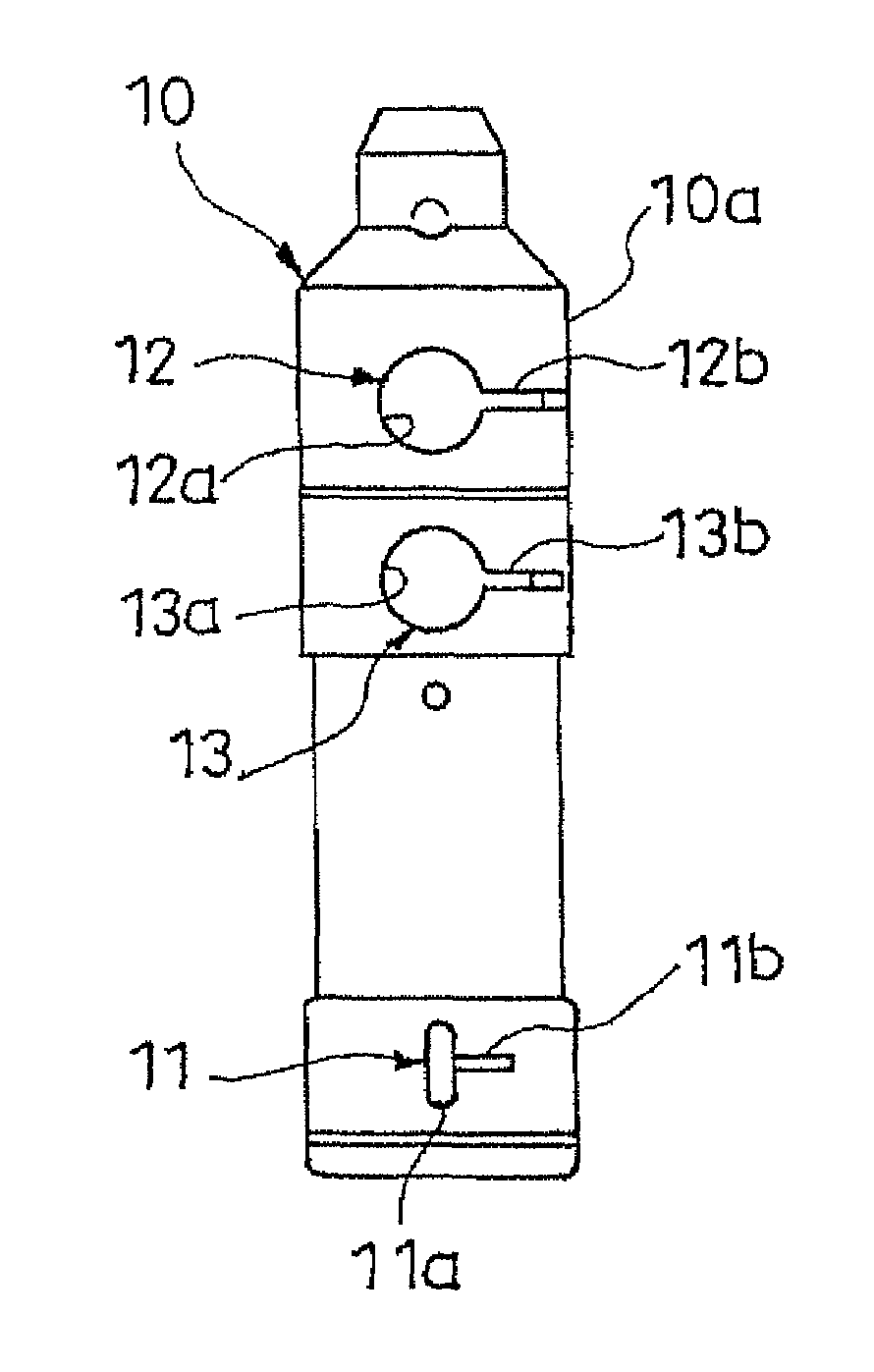

Actuator for driving rotary valve actuator and valve device with the actuator

InactiveUS6880806B2Improve securityImprove machinabilityOperating means/releasing devices for valvesPipeline systemsRotary valveEngineering

A valve gear includes a valve (30), which controls a flow rate of a fluid and an opening of which is determined according to a rotational position of a valve element, an actuator (20) for providing a rotational force to a rotary valve shaft that changes the opening of the valve (30), and attaching / detaching means. The attaching / detaching means includes a locking element (32) formed at its prescribed positions with locking concave / convex portions and an engaging element (22) formed at its prescribed positions with engaging concave / convex portions. The locking element (32) and the engaging element (22) are relatively rotatable around the rotary valve shaft up to a prescribed angle, and prevent the actuator (20) from coming off the valve (30) at an engaging position where the engaging concave / convex portions and the locking concave / convex portions are engaged with one another, and allow the actuator (20) and the valve (30) to be detached from each other at a disengaging position.

Owner:YAMATAKE HONEYWELL CO LTD

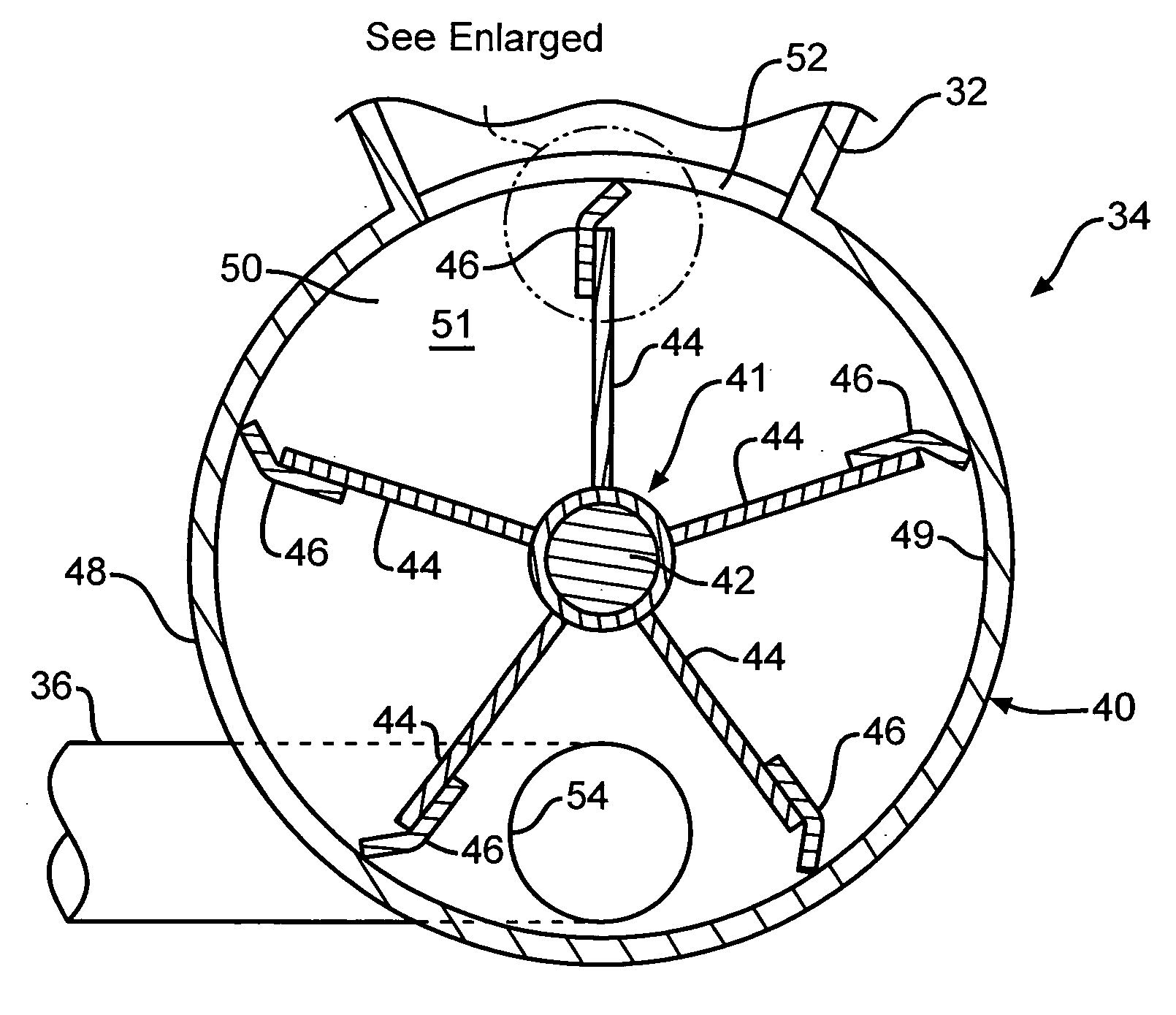

Rotary valve for handling solid particulate material

A rotary valve including a housing having an inner surface. A rotary assembly is positioned for rotation within the housing. The rotary assembly includes a plurality of radially outwardly extending vanes. The vanes extend toward the inner housing surface and are configured to transport material along the inner housing surface. Seal members are mounted upon the vanes. Spring members are secured to the vanes urging the seal members into contact with the inner housing surface.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

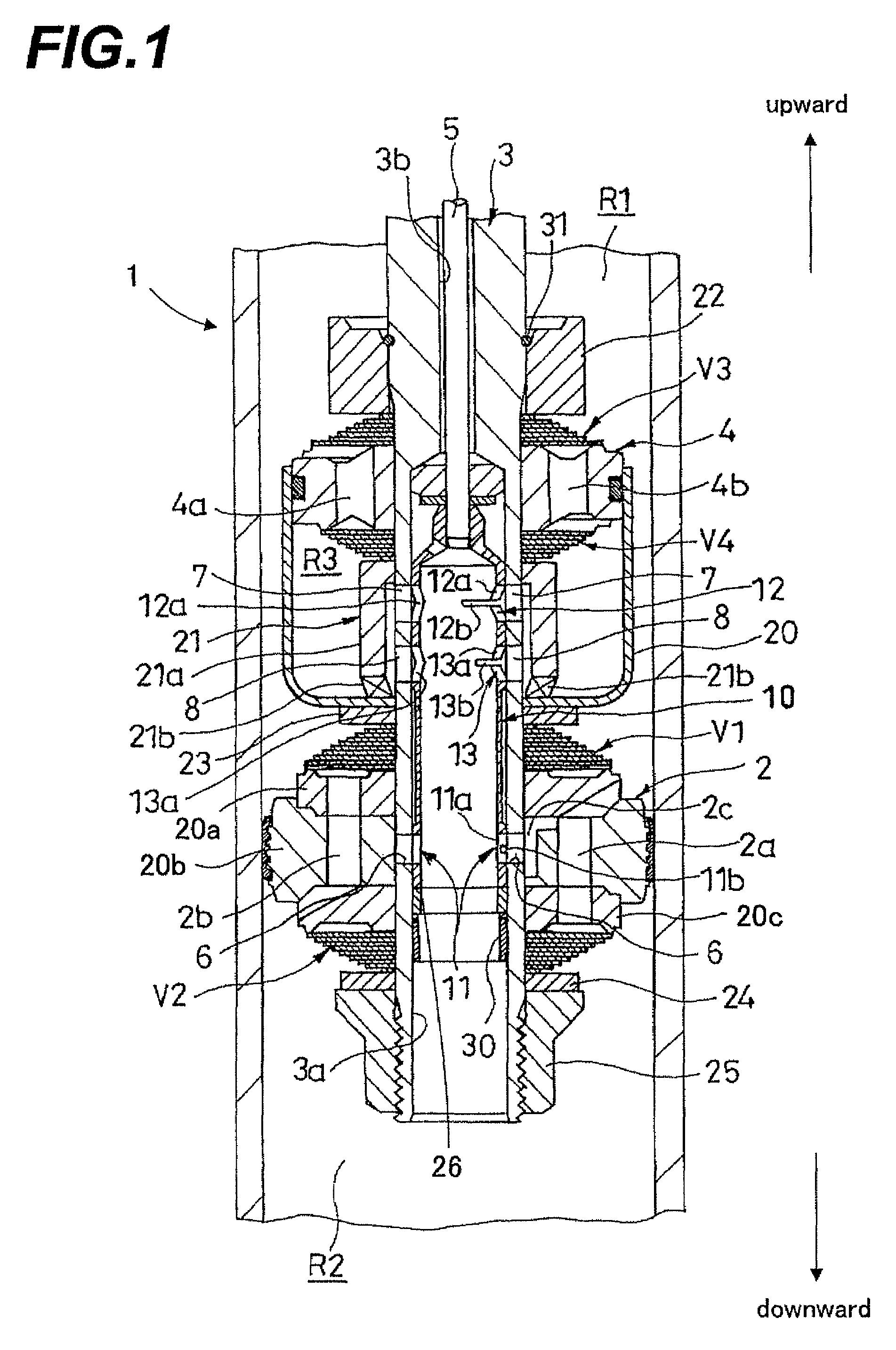

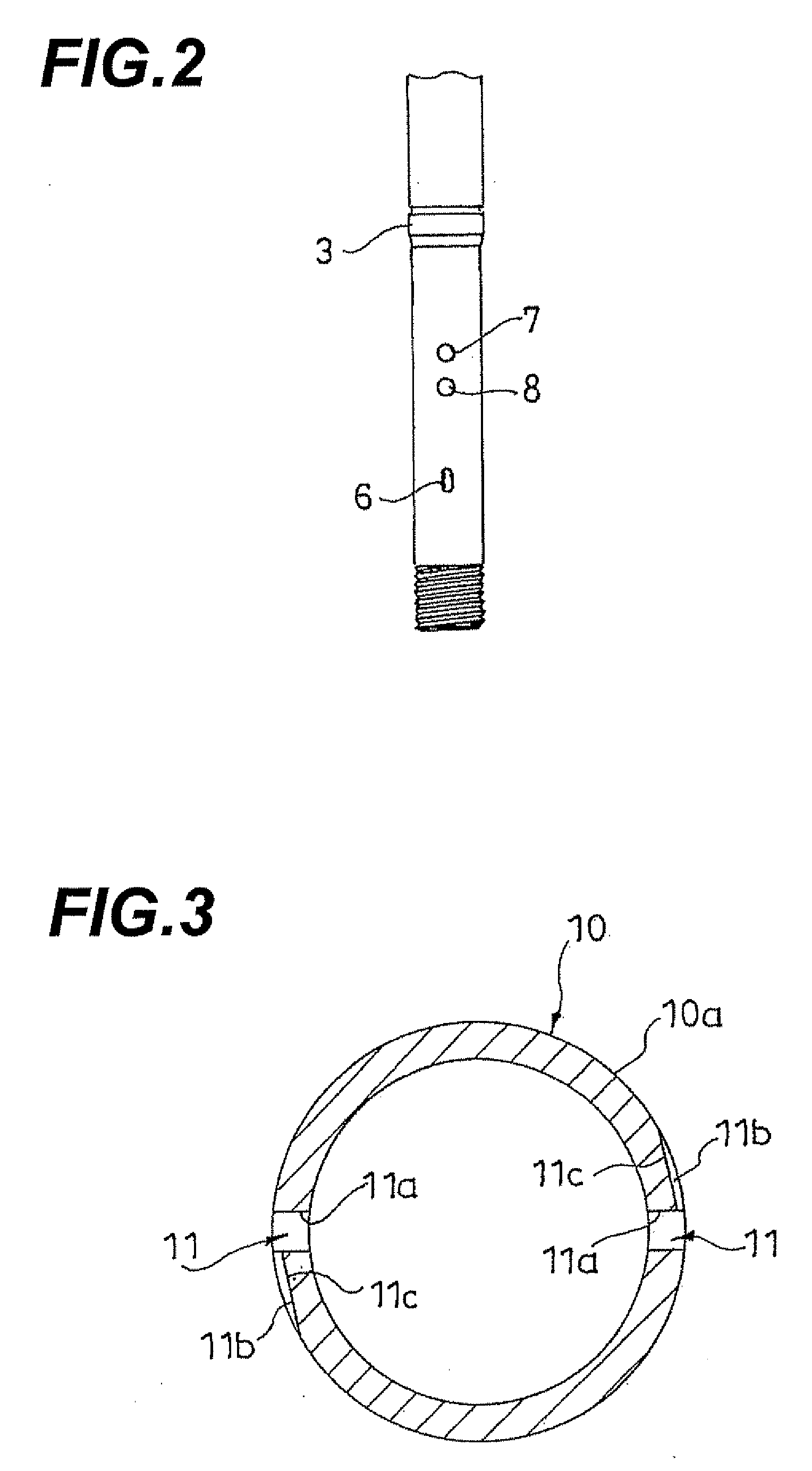

Rotary valve

In a rotary valve comprising a tubular housing (3) having, at the side part, a port (6) for communicating the inside and the outside thereof, and a tubular valve body (10) which is contained within the housing rotatably and has, at the side part, an orifice hole (11) capable of opposing to the port (6), the rotary valve of which the flow channel area formed by communicating the port (6) and the orifice hole (11) is changed by rotating the tubular valve body, at least one rotation stopping position with which the angle between the rotation stopping position at which the flow channel area is minimized and the rotation stopping position at which the flow channel area is maximized is equally divided, and the pressure loss differences between the adjacent rotation stopping positions are the same on condition that the passing flowing rate remains constant is provided.

Owner:KYB CORP

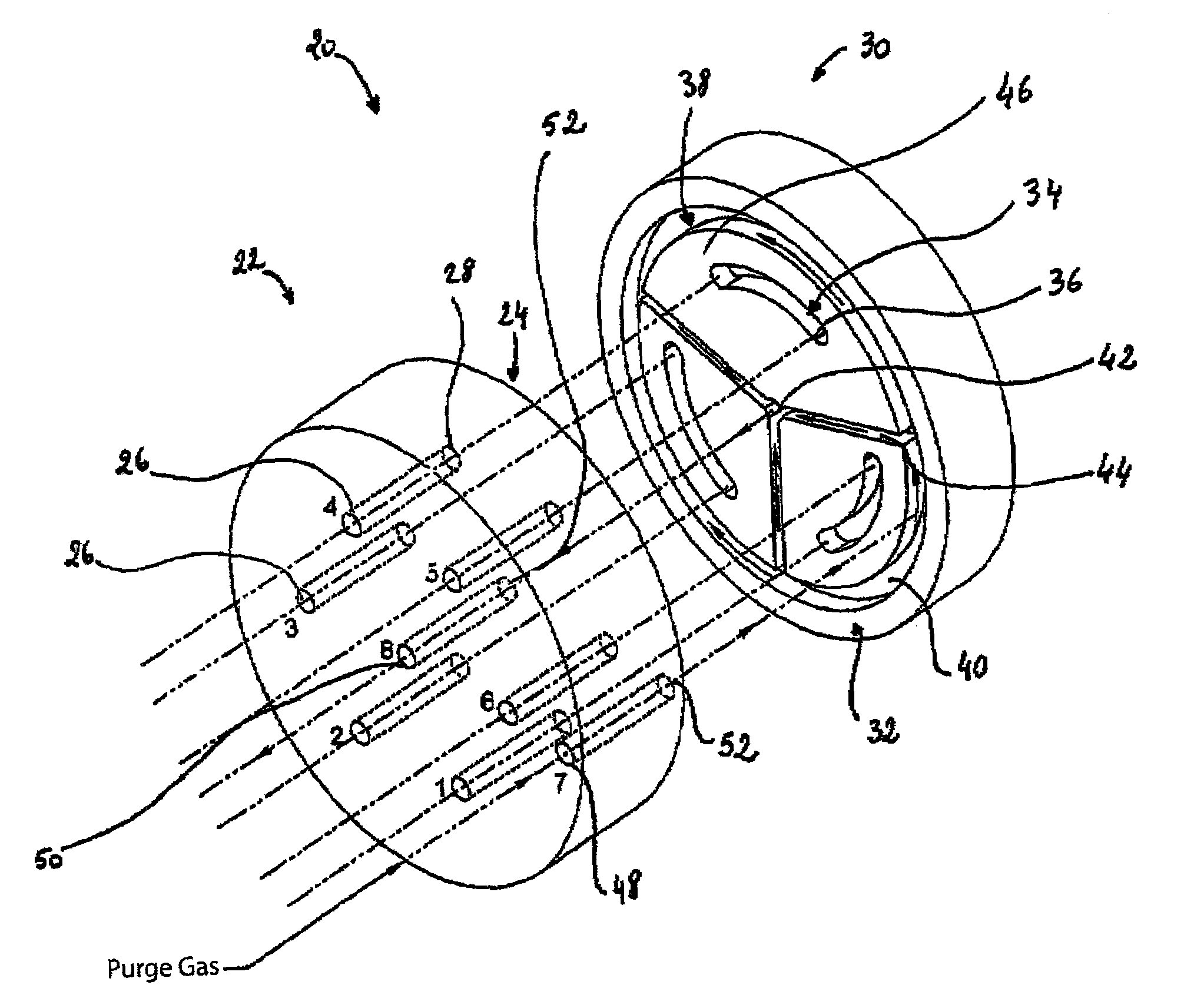

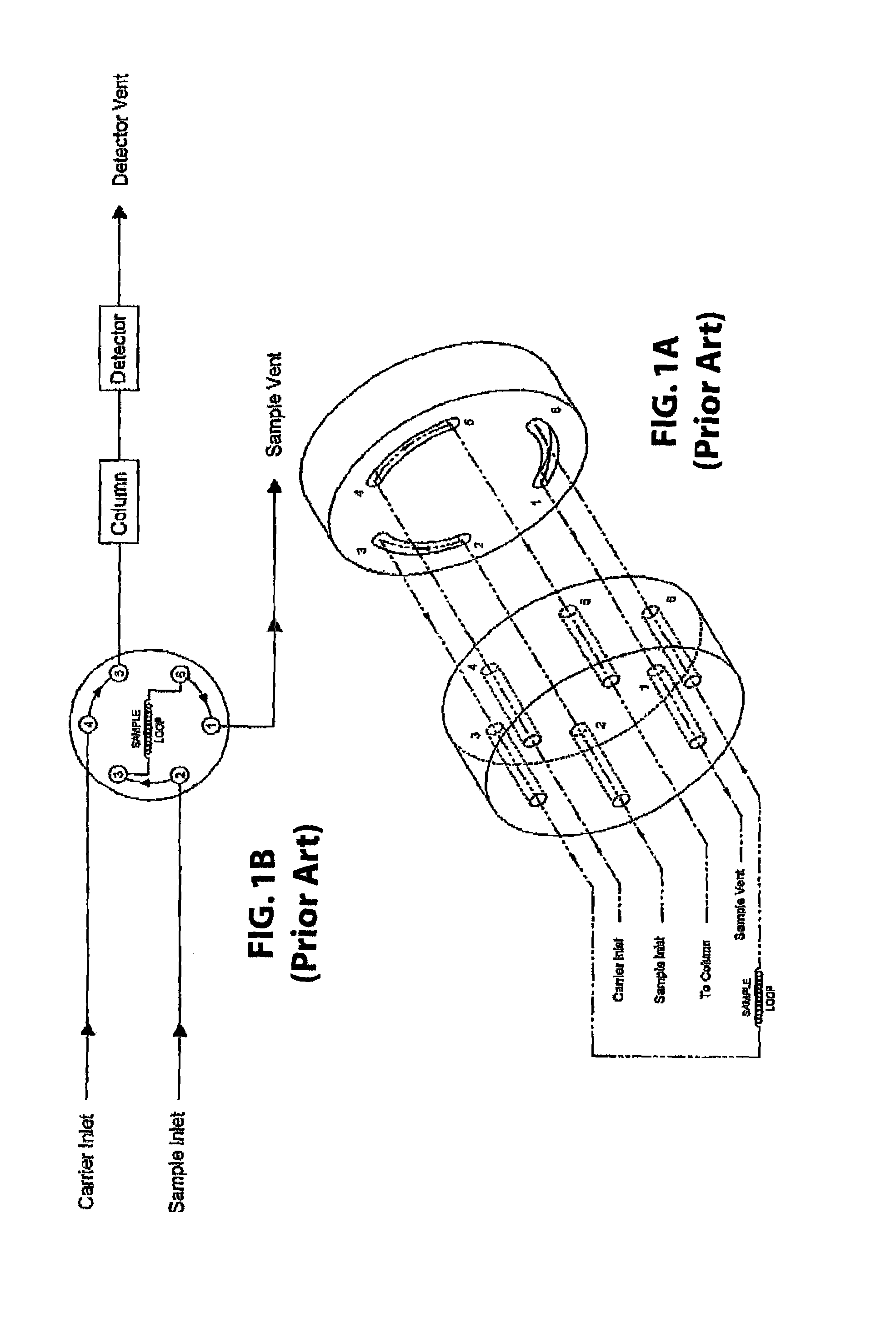

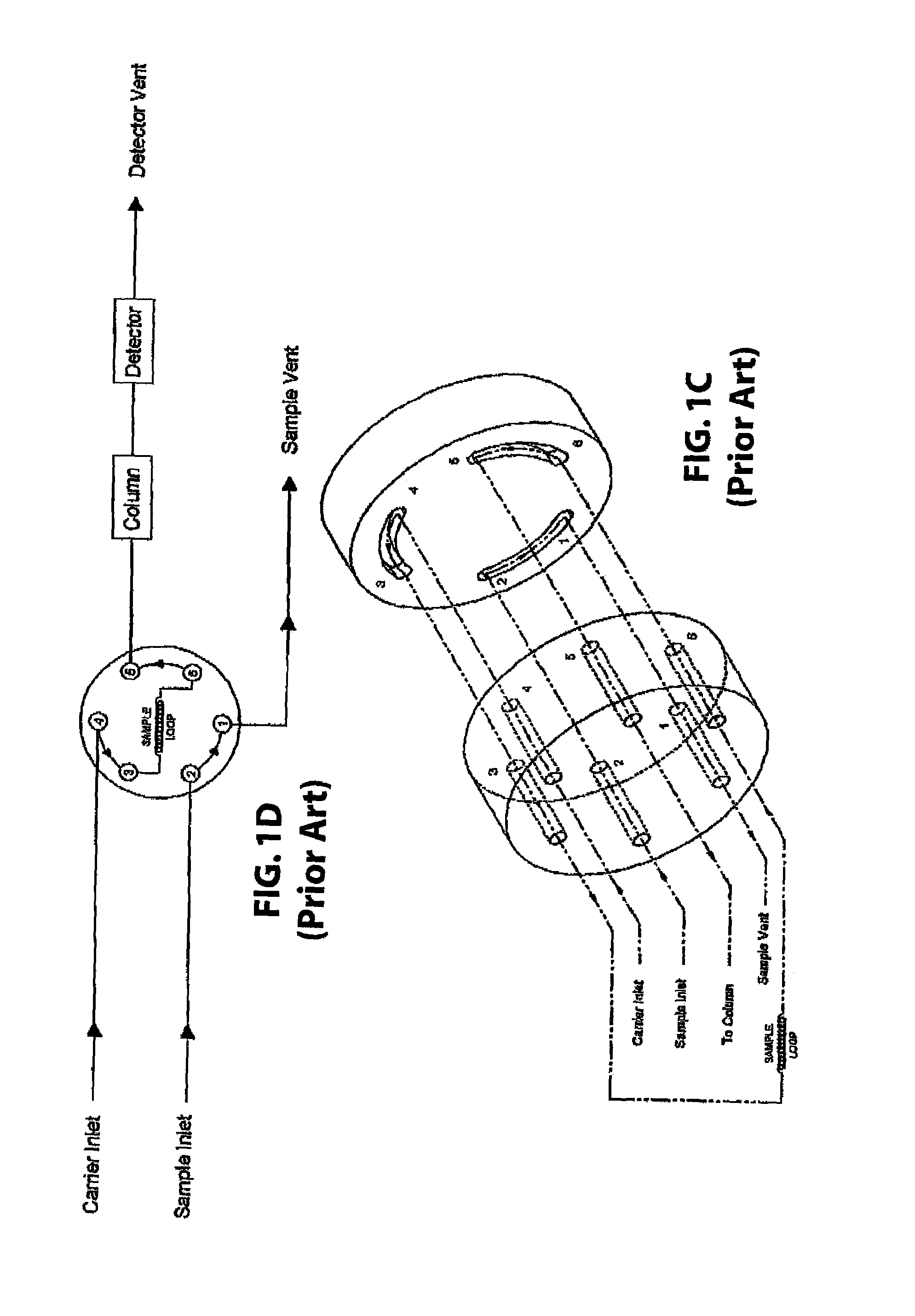

Rotary valve and analytical chromatographic system using the same

ActiveUS7503203B2Eliminate buildupReduce the possibilityComponent separationMultiple way valvesRotary valveEngineering

There is provided a rotary valve for fluid analytical systems. The present valve provides improved characteristics such as an extended lifetime. The valve can fulfil different fluid analytical functions and can be a multi-ports and / or multi-positions valve. The valve is provided with extra recesses in the rotor and extra ports in the stator. These recesses allow to cancel the effect of any possible leaks by evacuating them. Such a valve then prevents cross-port leaks and can advantageously be used in highly critical applications. Moreover, the present valve can be used in an analytical system which is advantageously self-diagnostic.

Owner:APN INC

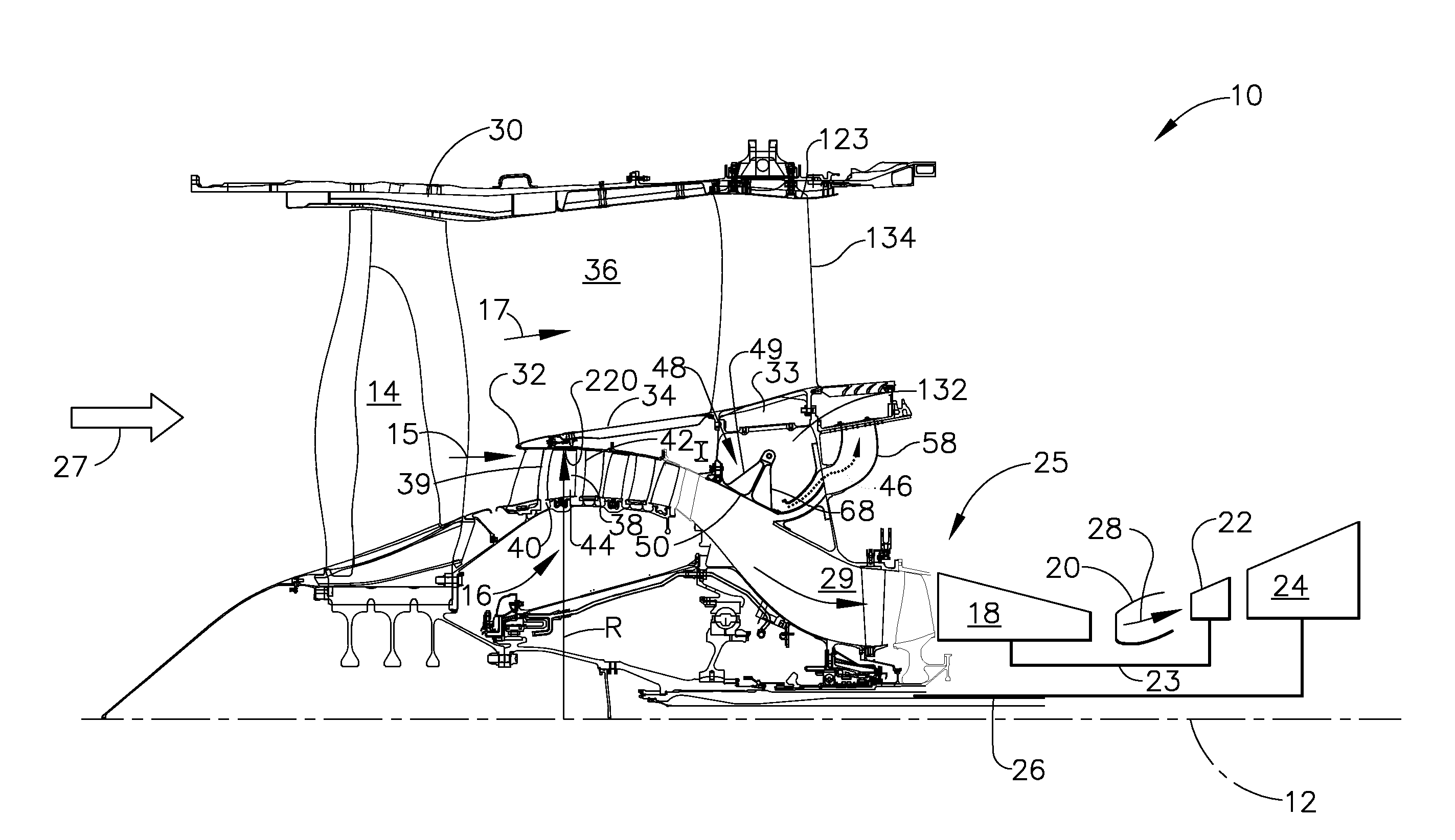

Gas turbine engine variable bleed valve for ice extraction

A variable bleed valve includes a variable bleed valve door disposed in a bleed inlet in transition duct and rotatable about an axis at or near a forward end of door. Valve is operable to open and close a bleed slot open to a booster bleed flowpath located outwardly of transition duct and having an airflow restrictor. Airflow restrictor may be variable such as a flapper valve. Booster bleed flowpath may pass through a bifurcated bleed duct including an inner passage radially bound by spaced apart inner and middle bleed walls and an outer passage radially bound by middle bleed wall and an outer bleed wall. Airflow restrictor may include an outlet area smaller than an inlet area of inner passage. Door seals against middle bleed wall to open inner passage and against outer bleed wall to open both passages.

Owner:GENERAL ELECTRIC CO

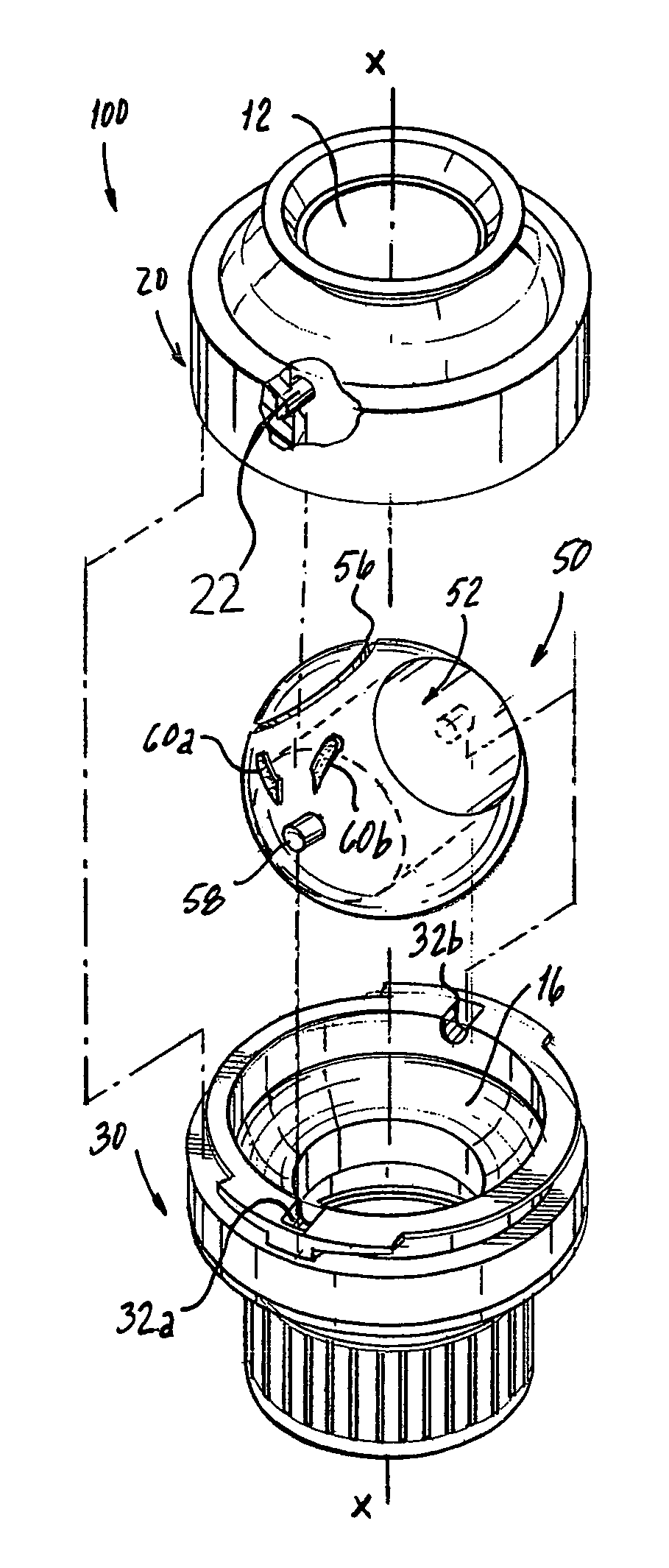

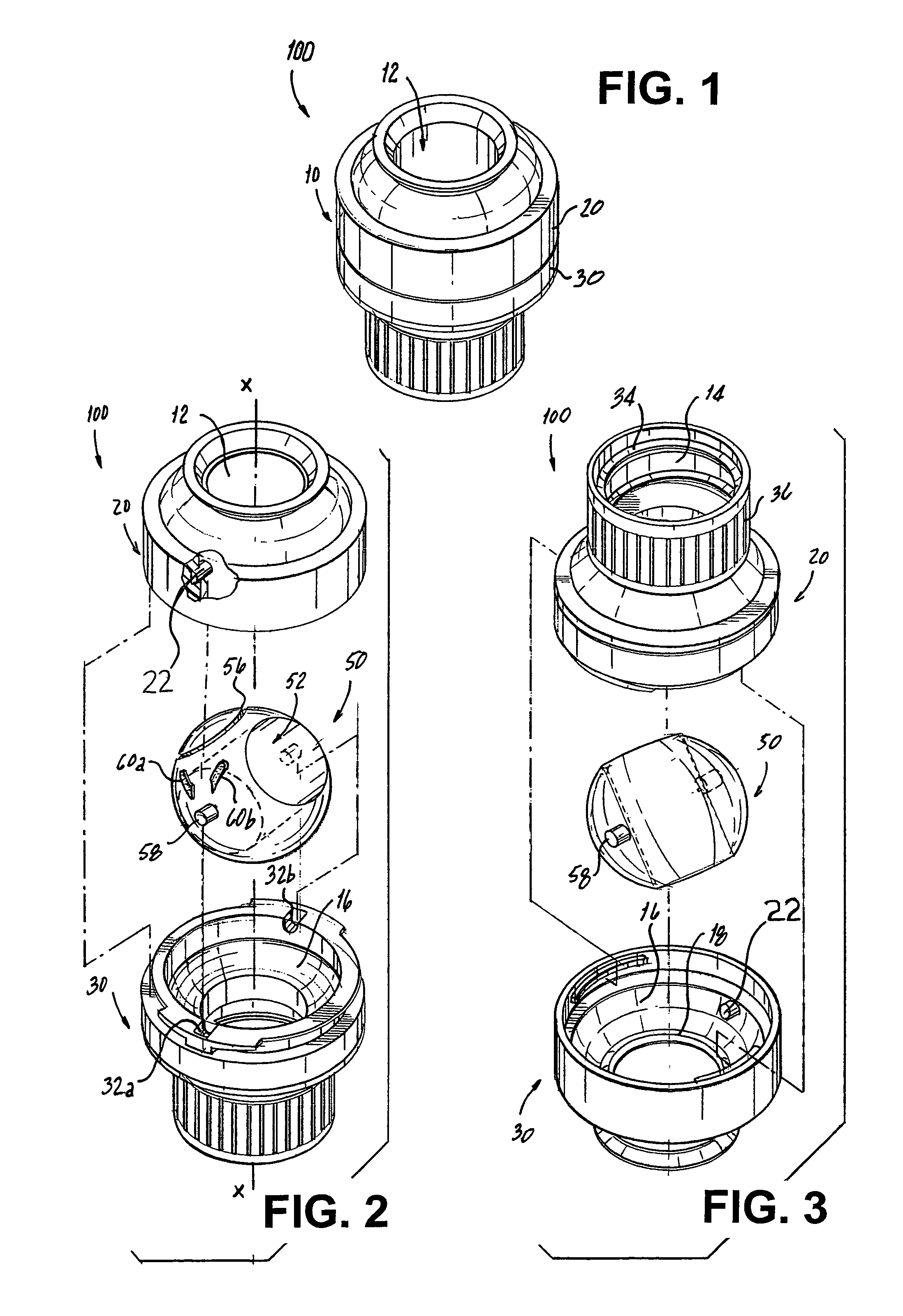

Rotating valve assembly

Disclosed is a valve / seal assembly that is adapted for use in a variety of applications, such as for example, medical, consumer beverage, pharmaceutical containers, automobile, household appliance and marine. The disclosed valve includes, inter alia, a valve housing having an upper body portion and a lower body portion and a generally spherical valve member. The upper and lower body portions of the housing define an internal chamber for accommodating the valve member and a central axis for the valve. The generally spherical valve member is seated within the internal chamber of the valve housing and has an axial bore extending therethrough. The valve member is mounted for movement between an open position; wherein the axial bore of the valve member is axially aligned with the inlet and outlet ports of the valve housing, and a closed position; wherein the axial bore of the valve member is out of alignment with the inlet and outlet ports of the valve housing. The valve assembly further includes a camming mechanism that is operatively associated with the valve housing and the valve member for moving the valve member between the open position and the closed position.

Owner:AXIAL TECH

Rotary valve with internal leak control system

Rotary valve comprising (a) a rotor having a rotor face rotatable about an axis perpendicular to the rotor face, a plurality of openings, and at least one passage connecting at least one pair of the plurality of openings; (b) a stator having a stator face in sealing contact with the rotor face to form a planar rotary valve seal with an outer periphery, a plurality of openings in the stator face that are connected to respective passages through the stator, and wherein at least one of the passages through the stator is a stator vacuum passage directly connected to a vacuum pump; (c) a sealed valve chamber having an interior volume contiguous with the outer periphery of the rotary valve seal, which chamber is sealed from the atmosphere surrounding the rotary valve; and (d) a vacuum vent passage connected to the sealed valve chamber.

Owner:AIR PROD & CHEM INC

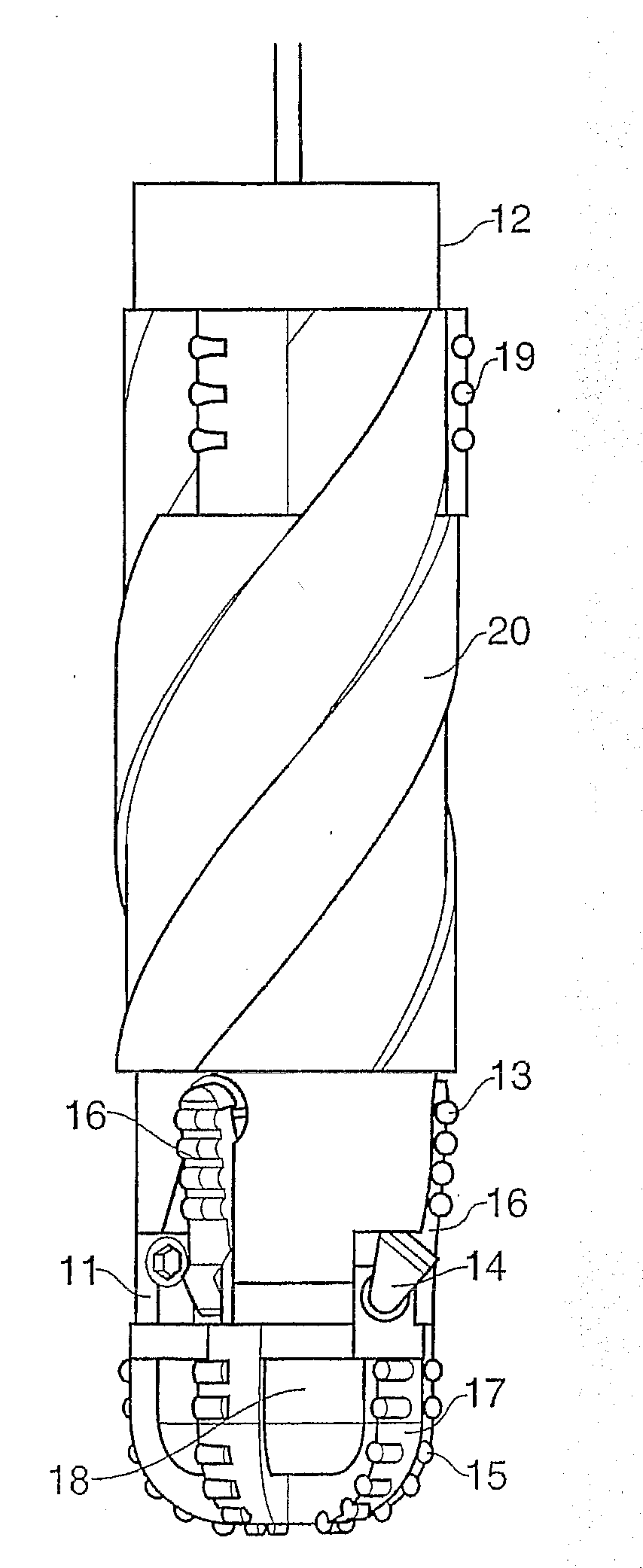

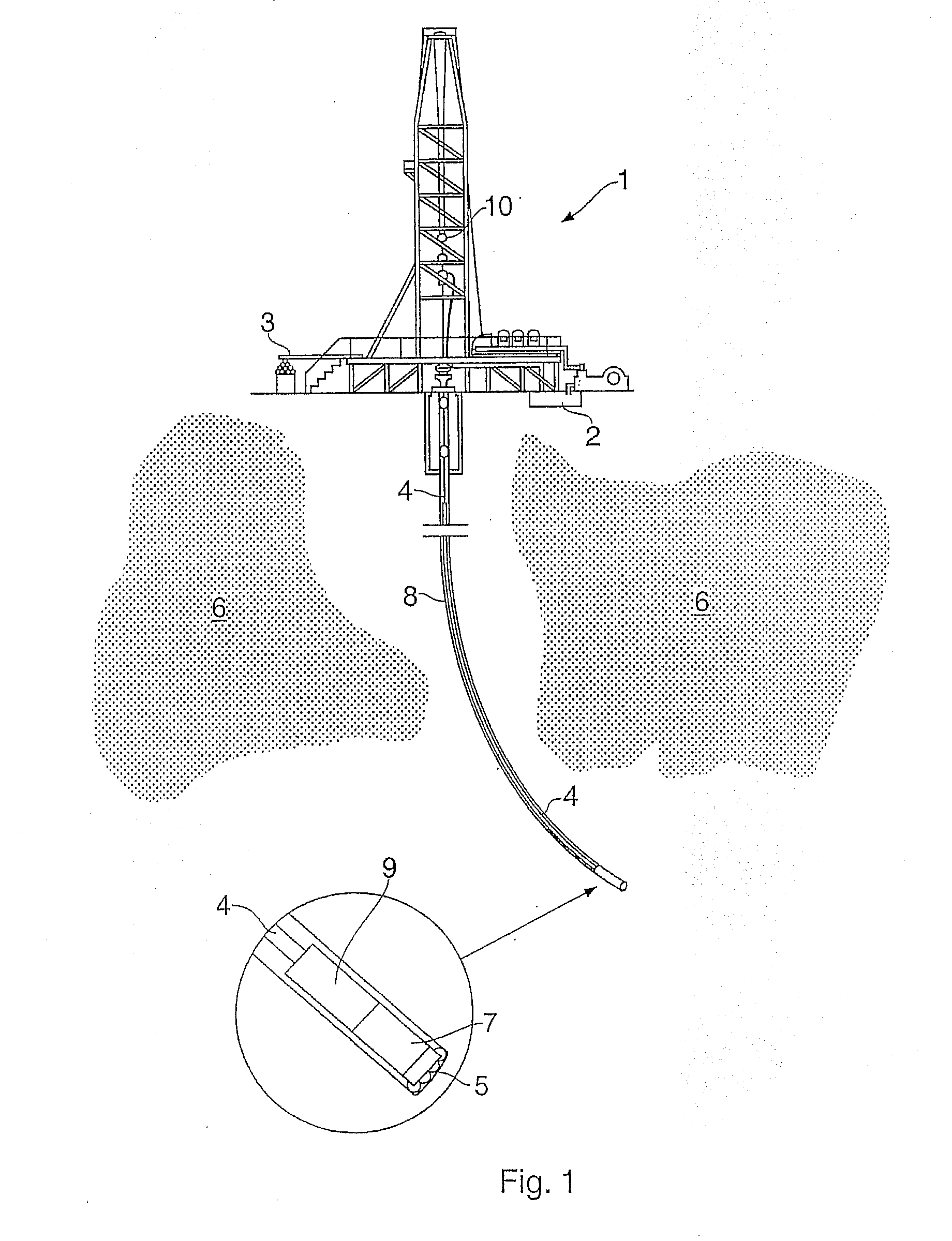

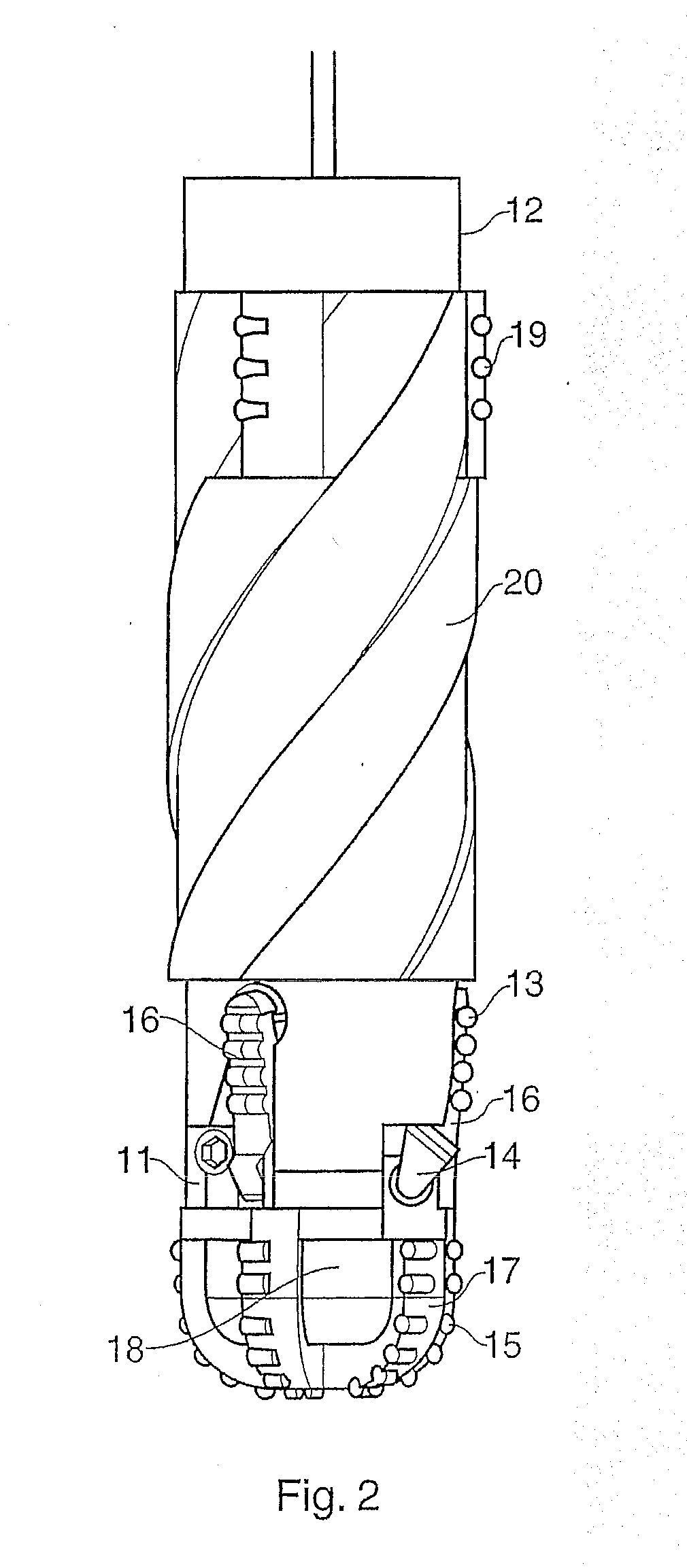

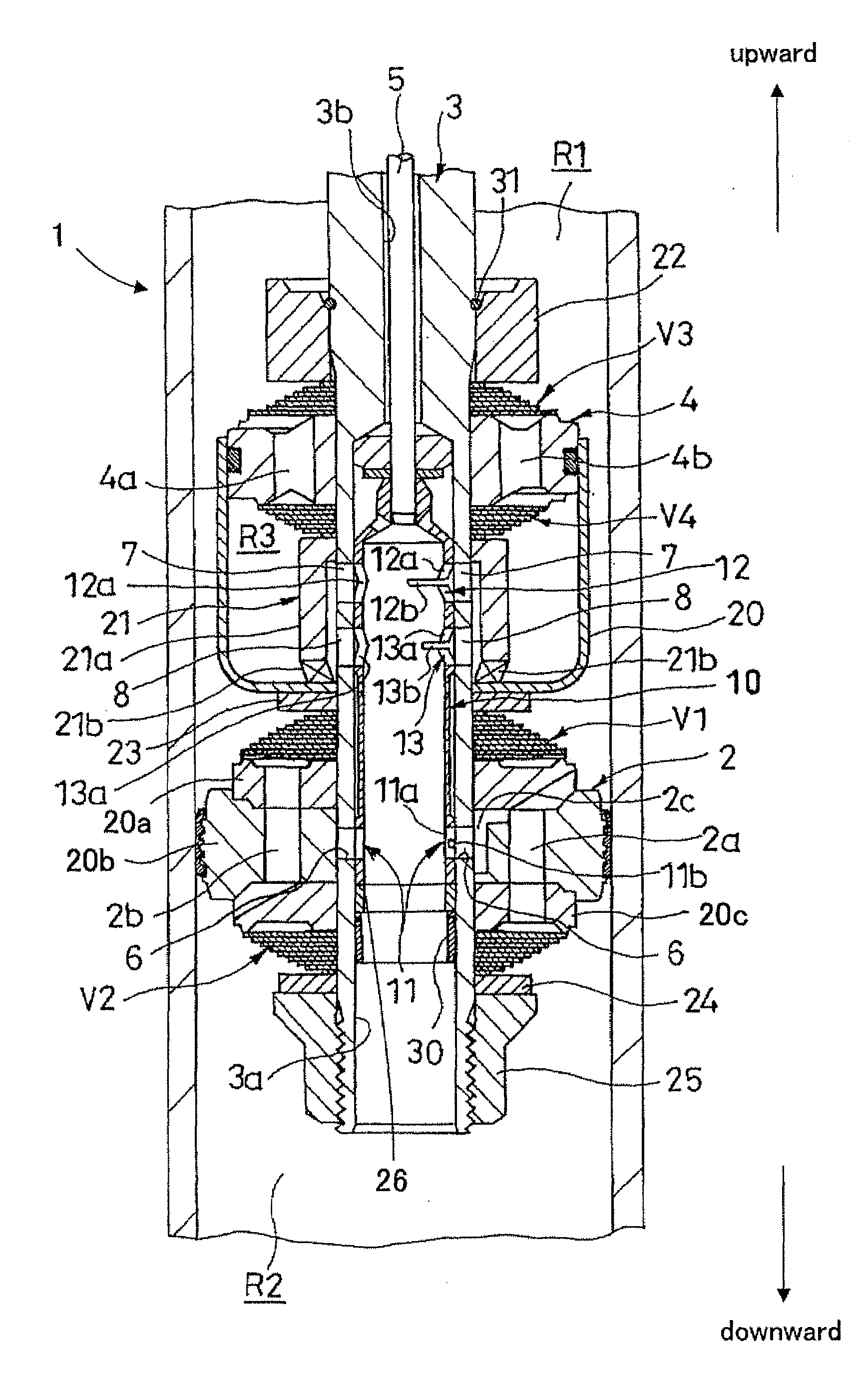

Steerable rotary directional drilling tool for drilling boreholes

The present invention provides a directional drilling apparatus and method for use in drilling bore holes. The apparatus comprises a plurality of movably mounted cutting elements, wherein the cutting elements are movable between radially retracted and extended cutting positions. A rotary valve is provided for synchronizing the movement of the cutting elements between their respective extended and retracted positions. Control of the directional drilling system is affected by synchronized movement of the cutting elements from an inner to an outer radial position in accordance with the angular position of the drill bit. Means are provided for directing high pressure cutting fluid to the region between the cutting elements and the rotatable body to prevent the accumulation of debris that could prevent movement of the cutting elements. The cutting elements enlarge the bore hole formed by the drill bit, so that the cutting elements continuously engage the wall of the bore hole.

Owner:MECIRIA LTD

Overhead rotary valve for engines

InactiveUS6308677B1Simple sealing deviceImprove sealingMachines/enginesRotary slide valveCombustion chamberExhaust valve

An overhead rotary valve fitted into a cylinder head with diametrical polygonal openings formed therein for use in combination with an internal combustion engine, driven to bring intake and exhaust ports into and out of alignment with passages leading to and from the combustion chamber. Sleeve bearings are fitted in the cylinder head that provide surface sealing, and annular sealing members prevent the air / fuel mixture or exhaust gases from flowing into regions intermediate ports and individual cylinders. Utilizing this overhead rotary valve and associated seals and bearings increases the efficiency and performance of an internal combustion engine. The overhead rotary valve rotating, at one quarter the speed of the crankshaft, minimizes wear and noise levels, self cleans the ports, allows the engine to operate at higher rpm and imparts proper opening and closing of passages at the proper sequence of valve timing without concern of valve float. The instant invention removes the need for reciprocating intake and exhaust valves, camshafts, rocker arms, lifters, push rods, valve guides and retainers, and other related hardware for actuation, significantly increasing the reliability and effectiveness of the internal combustion engine, while reducing overall manufacturing costs.

Owner:BOHACH WILLIAM LOUIS +1

Rotary valve

In a rotary valve comprising a tubular housing (3) having, at the side part, a port (6) for communicating the inside and the outside thereof, and a tubular valve body (10) which is contained within the housing rotatably and has, at the side part, an orifice hole (11) capable of opposing to the port (6), the rotary valve of which the flow channel area formed by communicating the port (6) and the orifice hole (11) is changed by rotating the tubular valve body, at least one rotation stopping position with which the angle between the rotation stopping position at which the flow channel area is minimized and the rotation stopping position at which the flow channel area is maximized is equally divided, and the pressure loss differences between the adjacent rotation stopping positions are the same on condition that the passing flowing rate remains constant is provided.

Owner:KYB CORP

Rotary valve in a multi-gas cooker

ActiveUS20060175566A1Gaseous fuel feeder/distributionDomestic stoves or rangesRotary valveEngineering

The cooking appliance (1) having a control panel (2) is equipped with one or more gas flow (Q) regulating valves, wherein the rotary regulator organ (6) is provided with various peripheral through holes (16-19). The control knob (9) being interchangeable for fitting to the actuating shaft (7), is chosen from the two units available, one and the other permitting different angular limit positions (A2, A3) for the supply of a constant minimum gas flow Qmin, through one of two successive holes (18, 19) calibrated each one for a different type of gas NG or LPG, one or the other hole being superimposed to a valve inlet duct (4) at a different angular position A2, A3. An integral lug (14) on the control knob (9) running into a slide groove (20) in the control panel (2), establishes a first rotation stop A2.

Owner:ALBIZURI INIGO

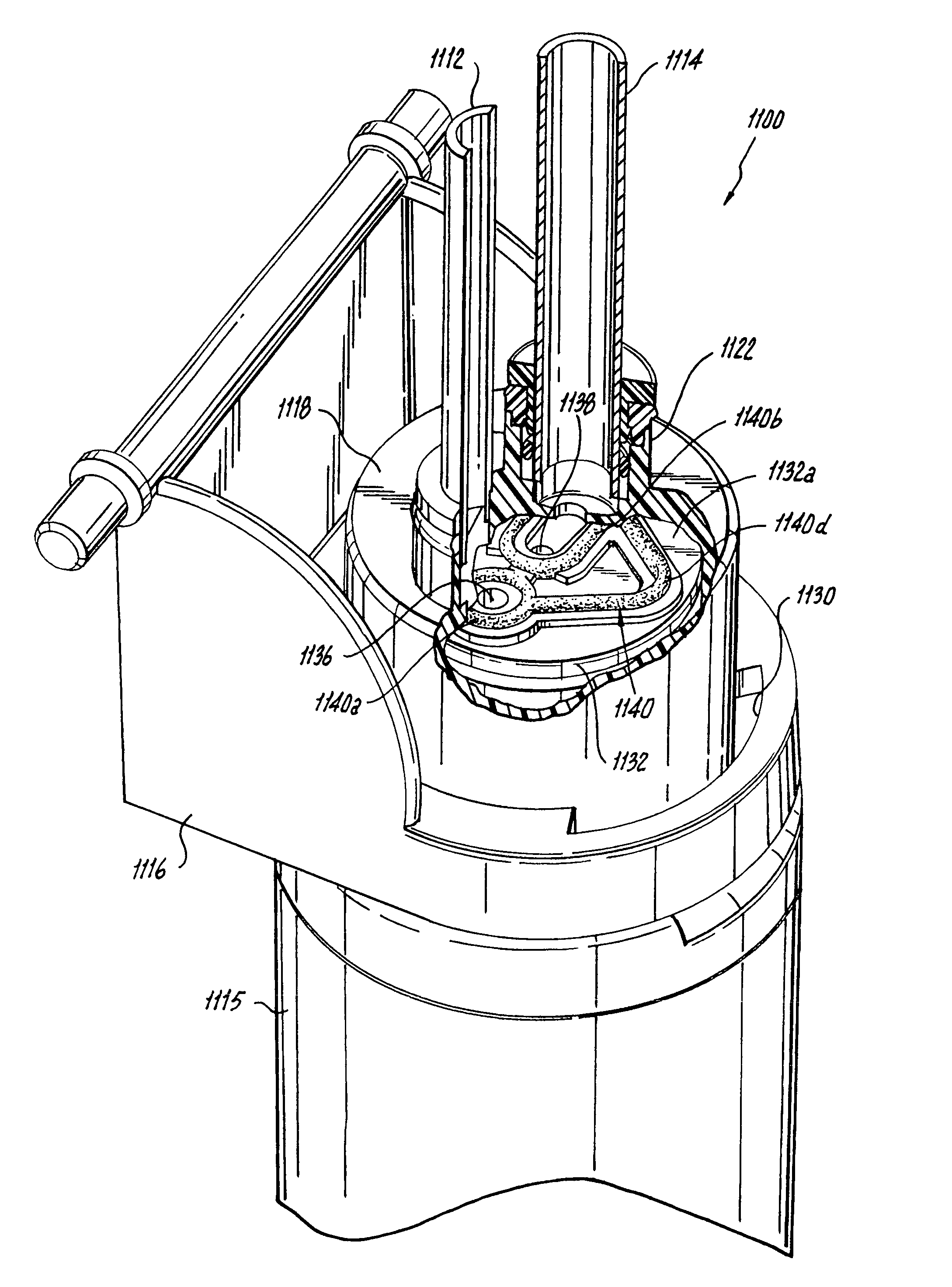

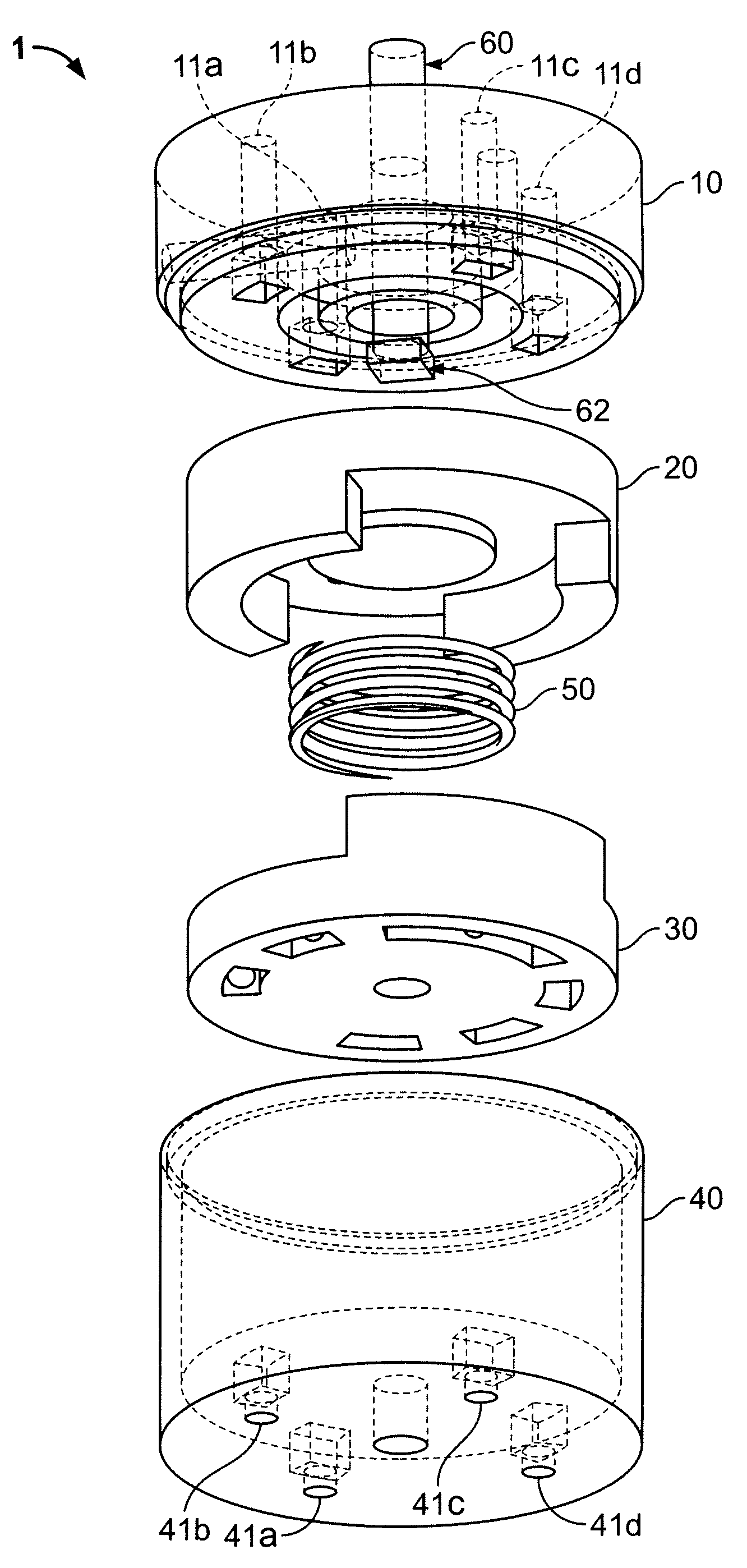

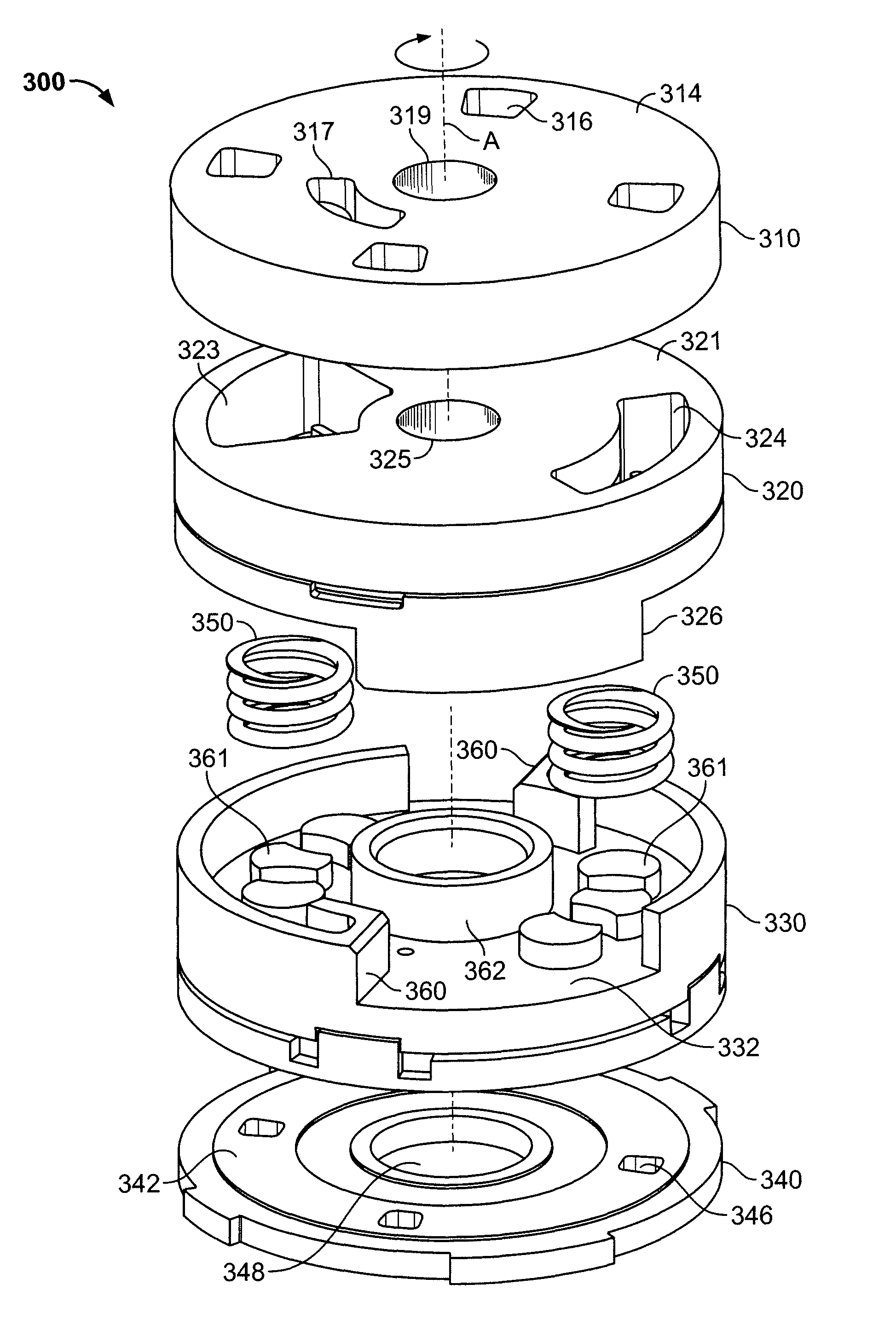

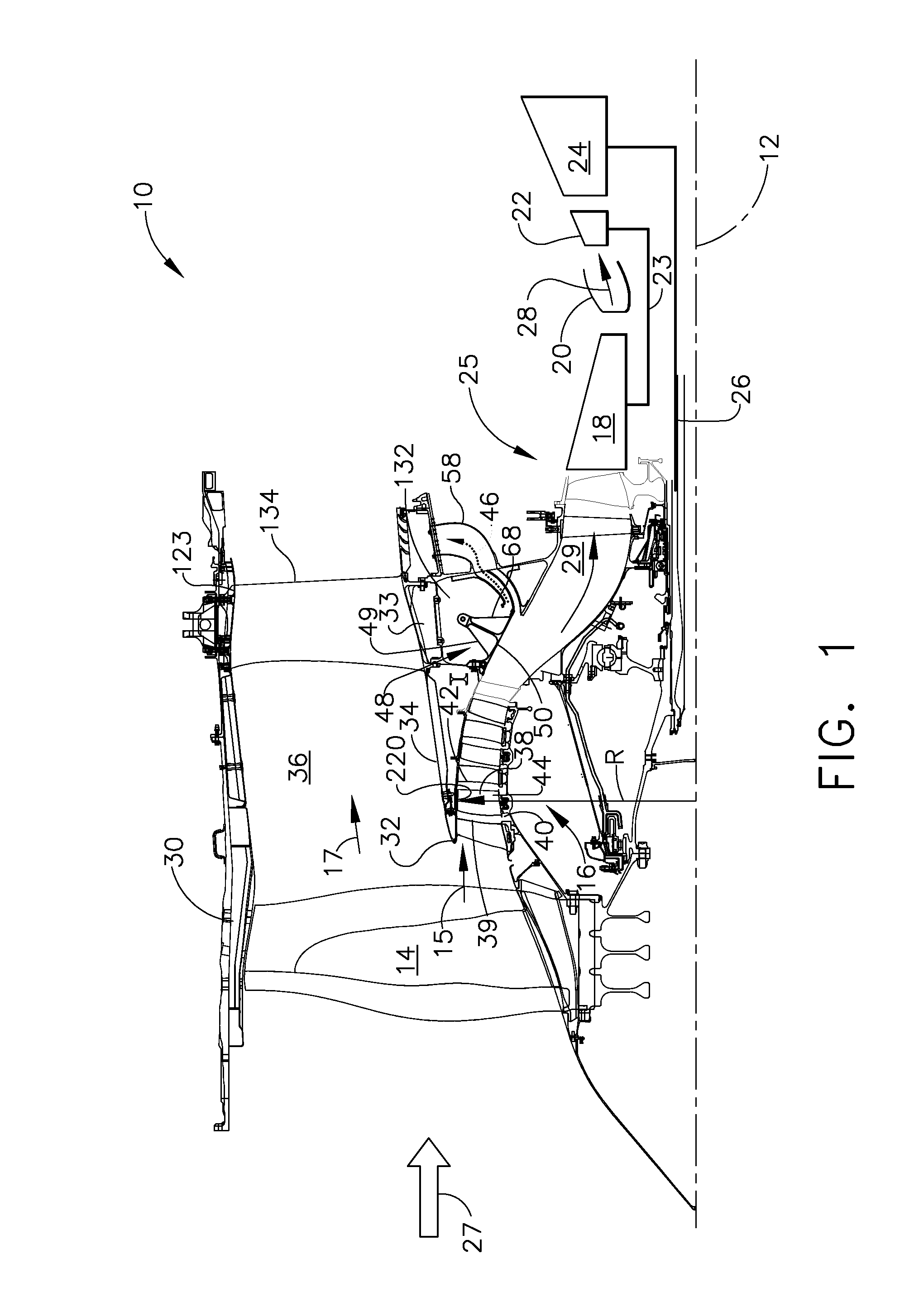

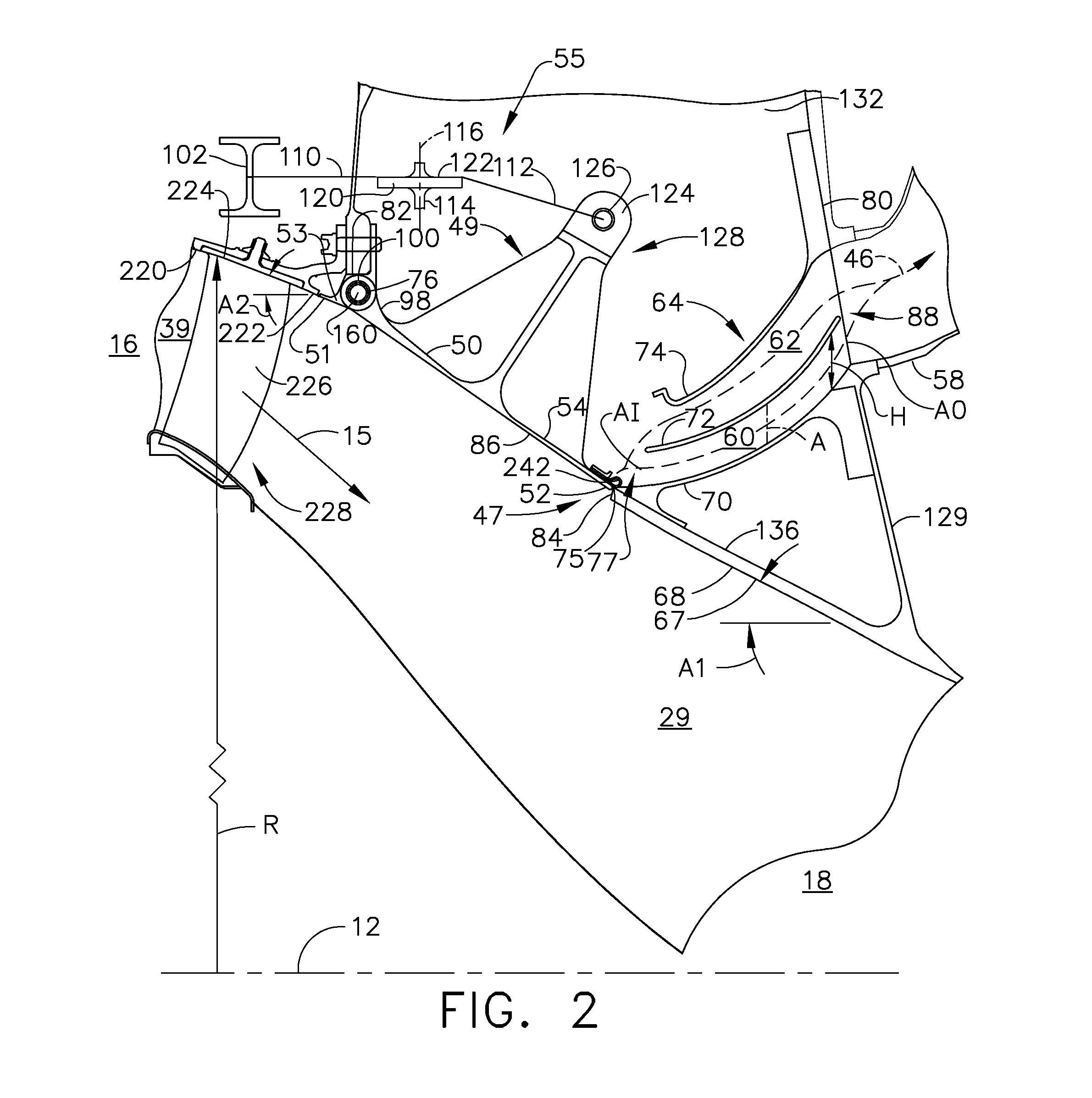

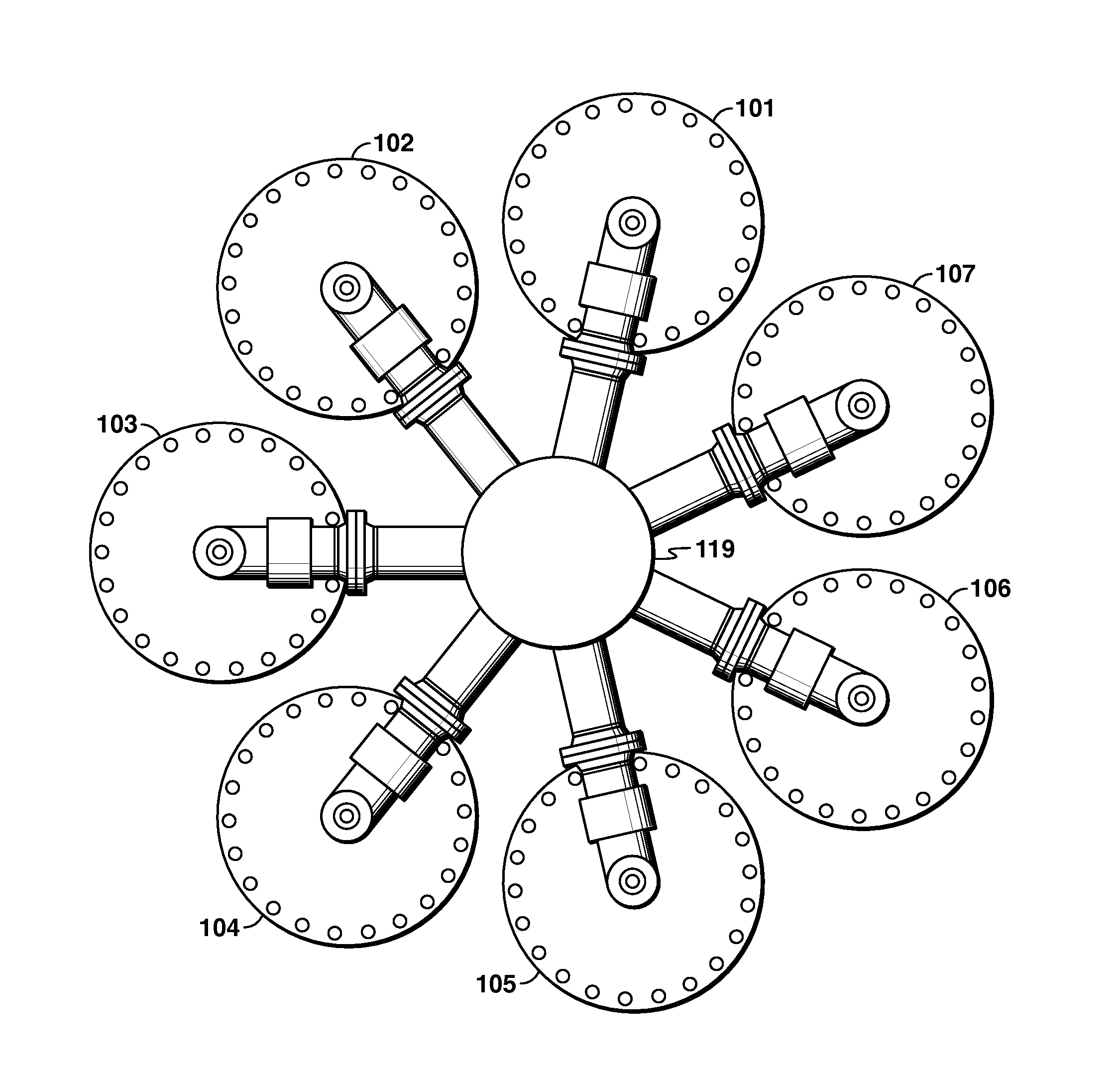

Apparatus and Systems Having a Rotary Valve Assembly and Swing Adsorption Processes Related Thereto

Provided are apparatus and systems having a rotary valve assembly integrated with a reciprocating valve assembly to perform swing adsorption processes. The rotary valve assembly is utilized with the reciprocating valve assembly to manage the flow of streams through the system in an enhanced manner.

Owner:EXXONMOBIL UPSTREAM RES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com