Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

452results about "Rotary slide valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

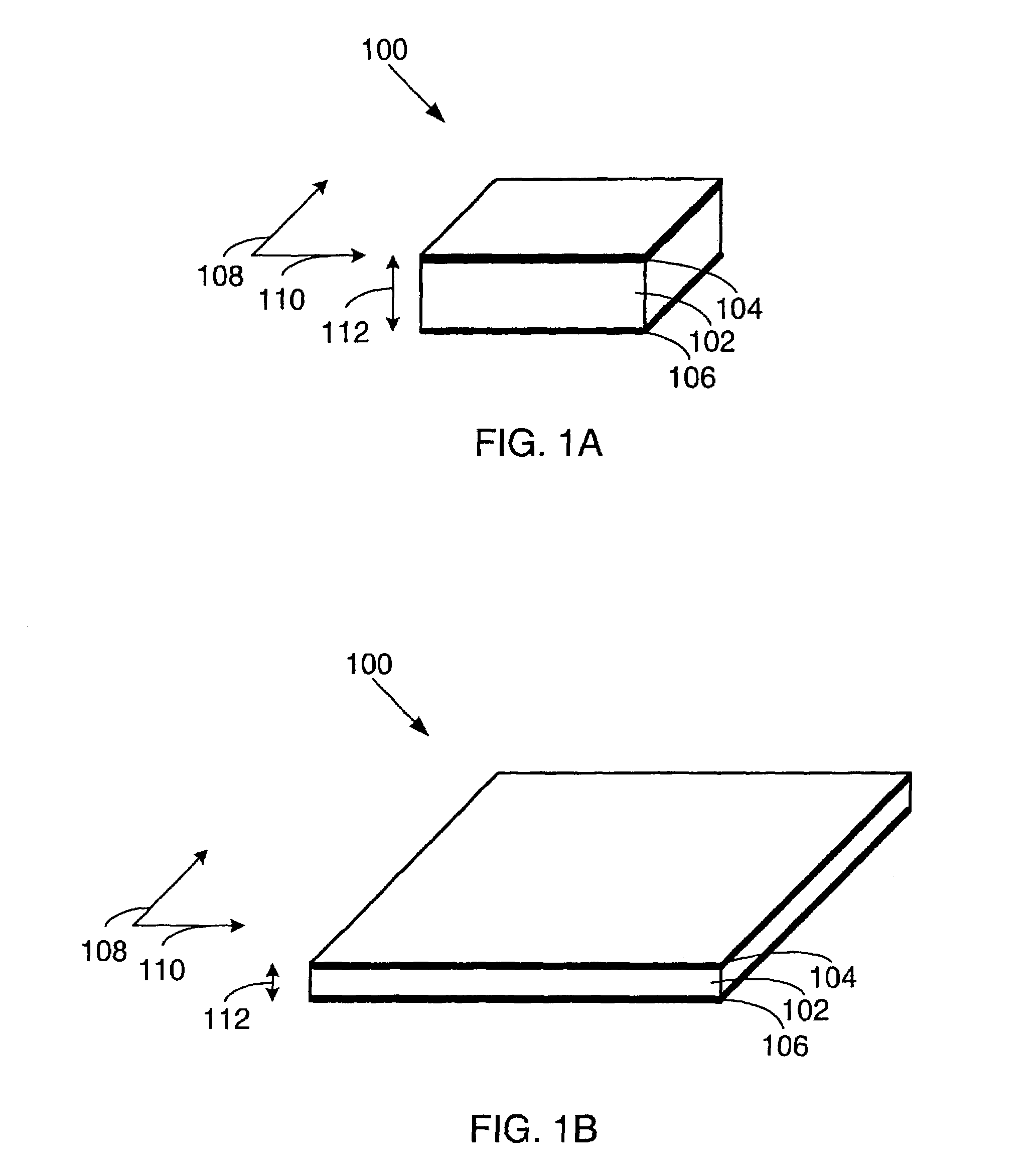

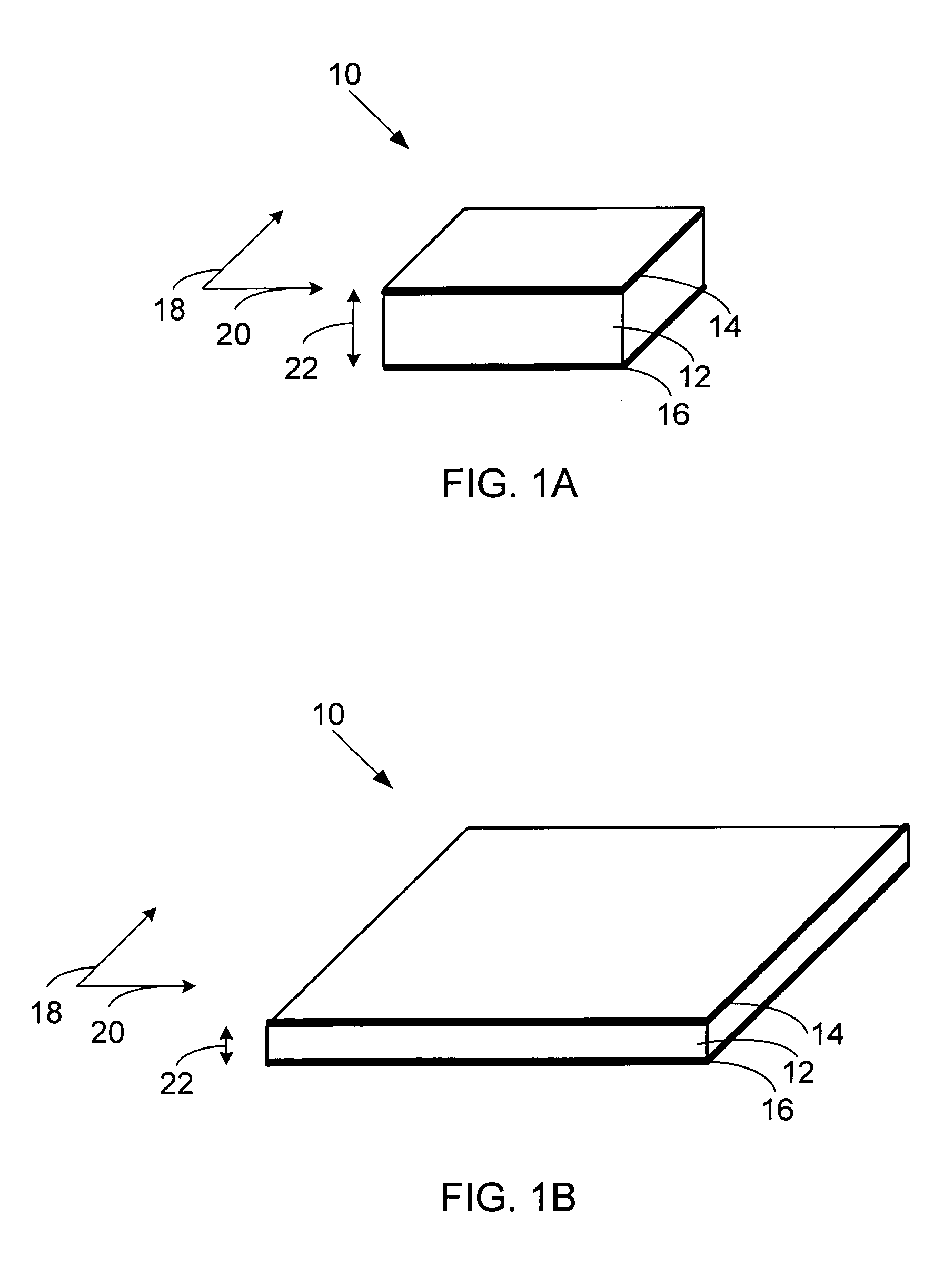

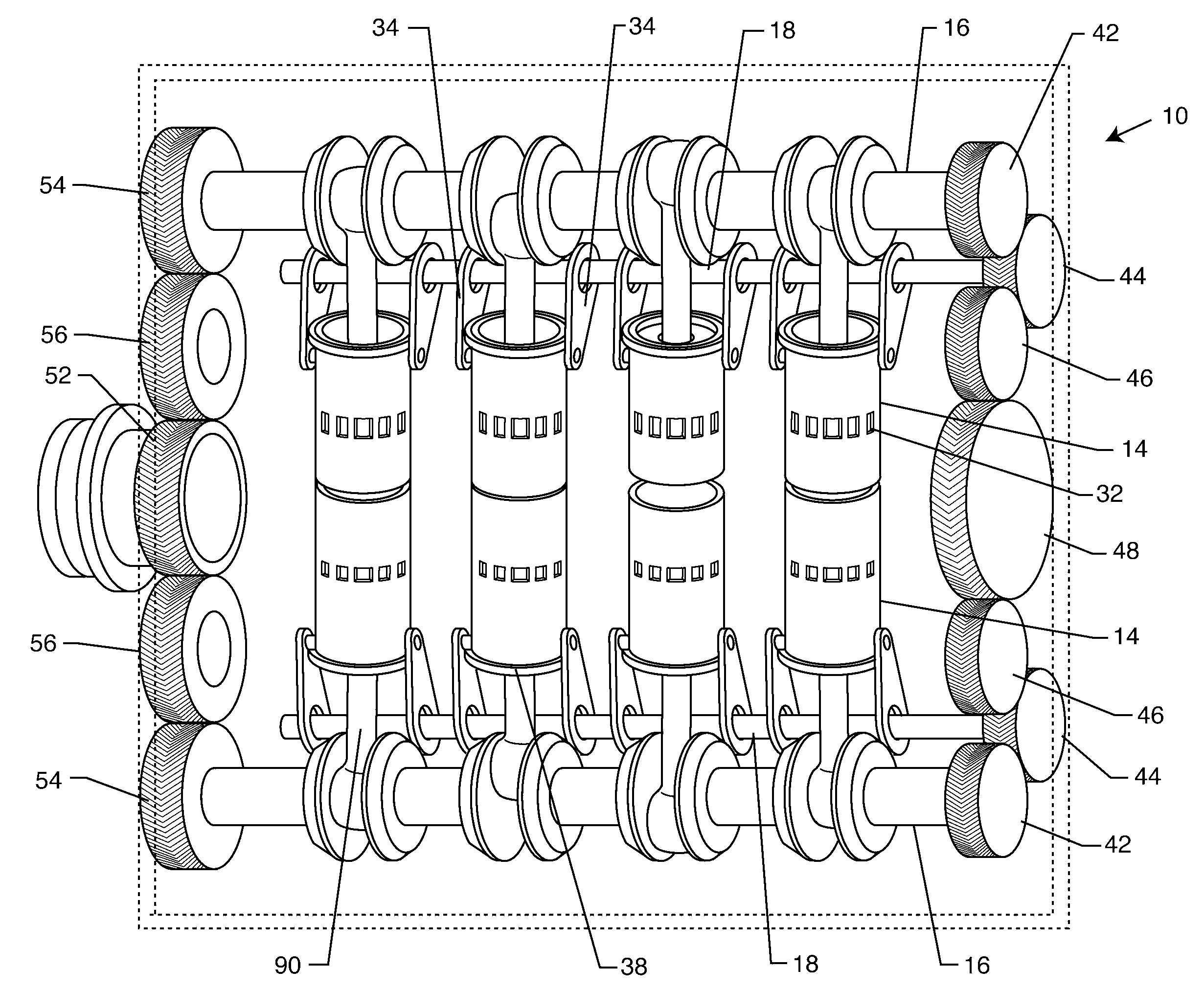

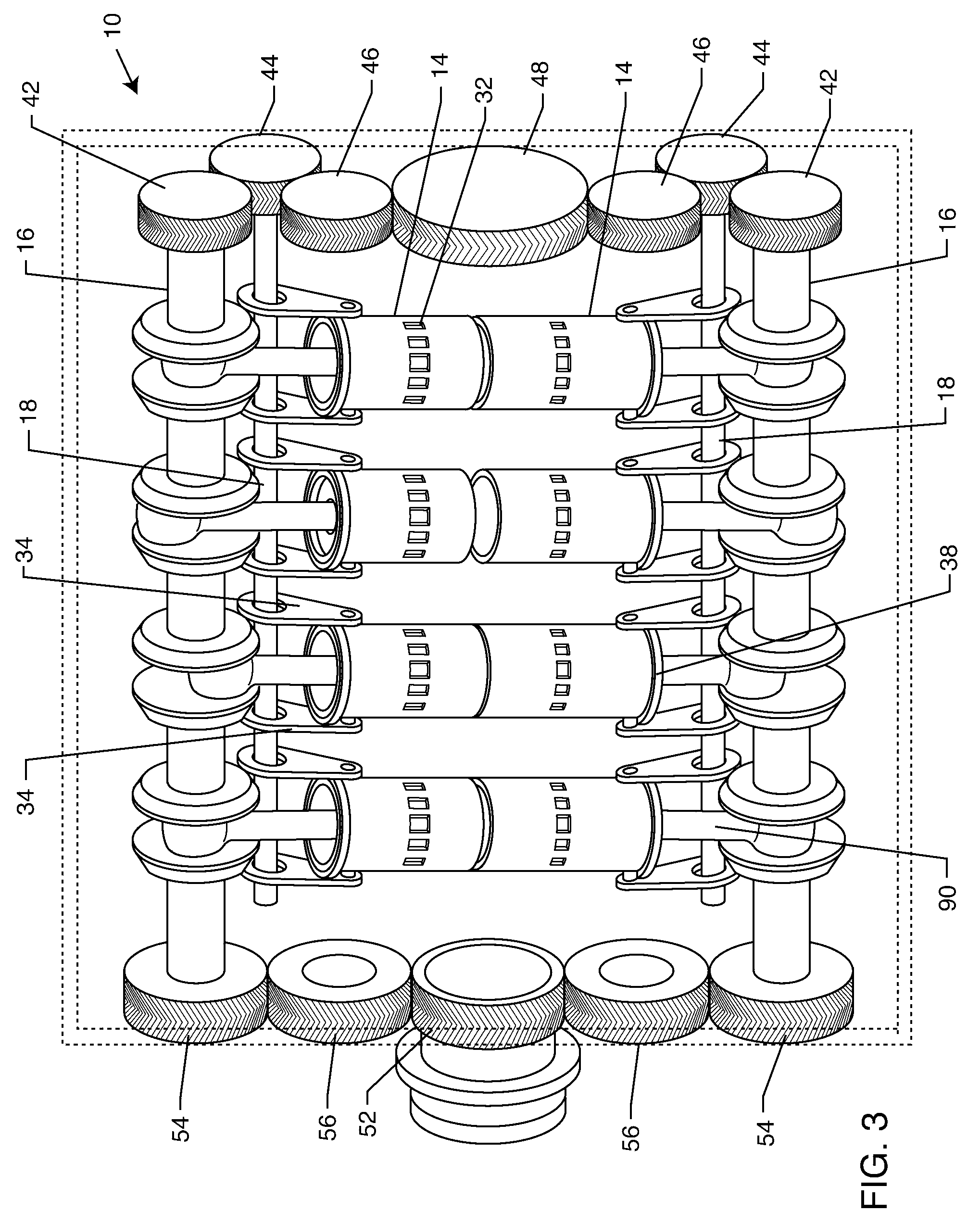

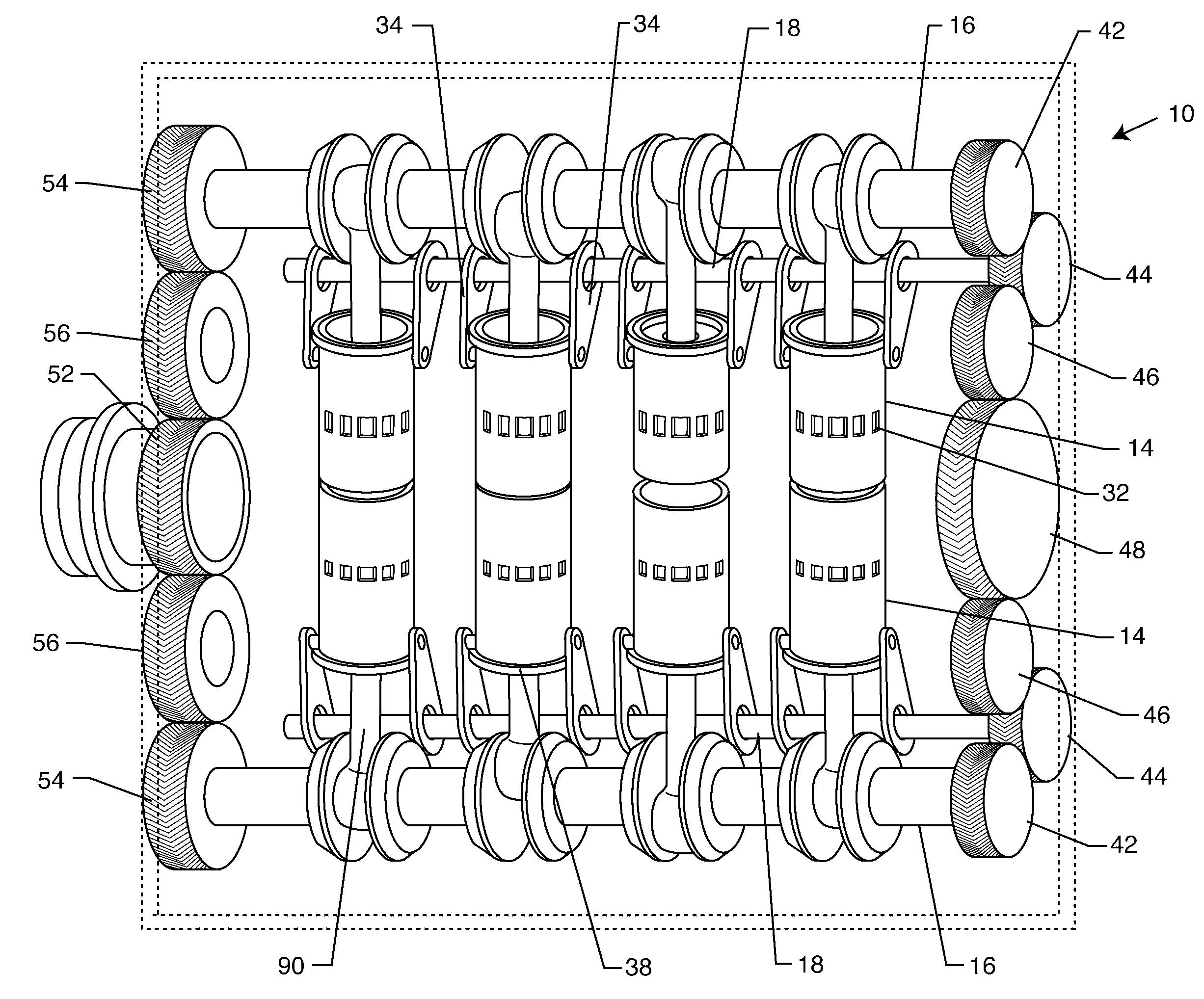

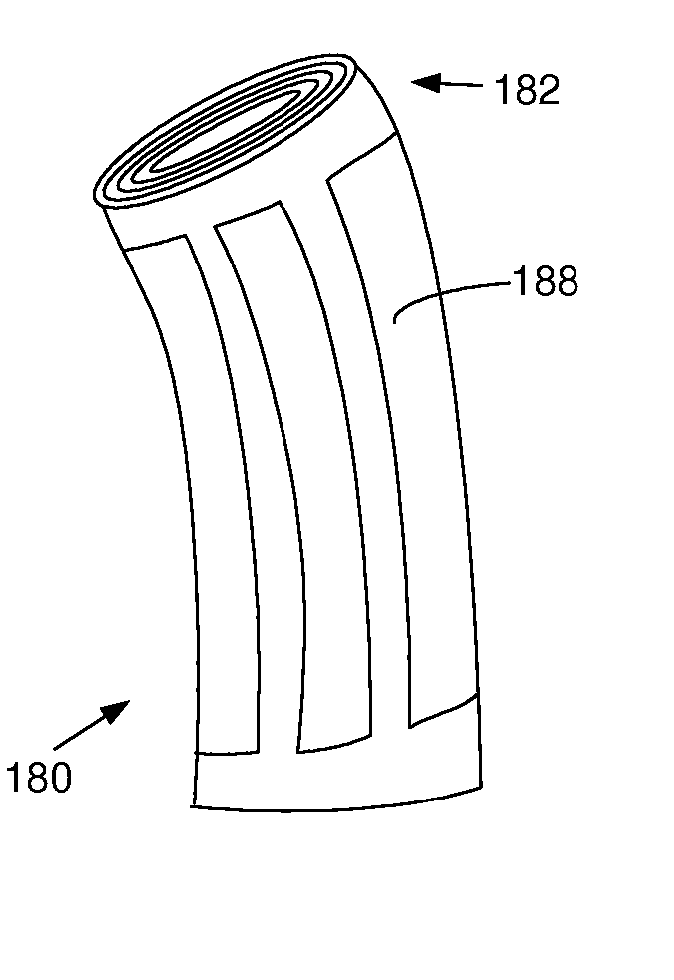

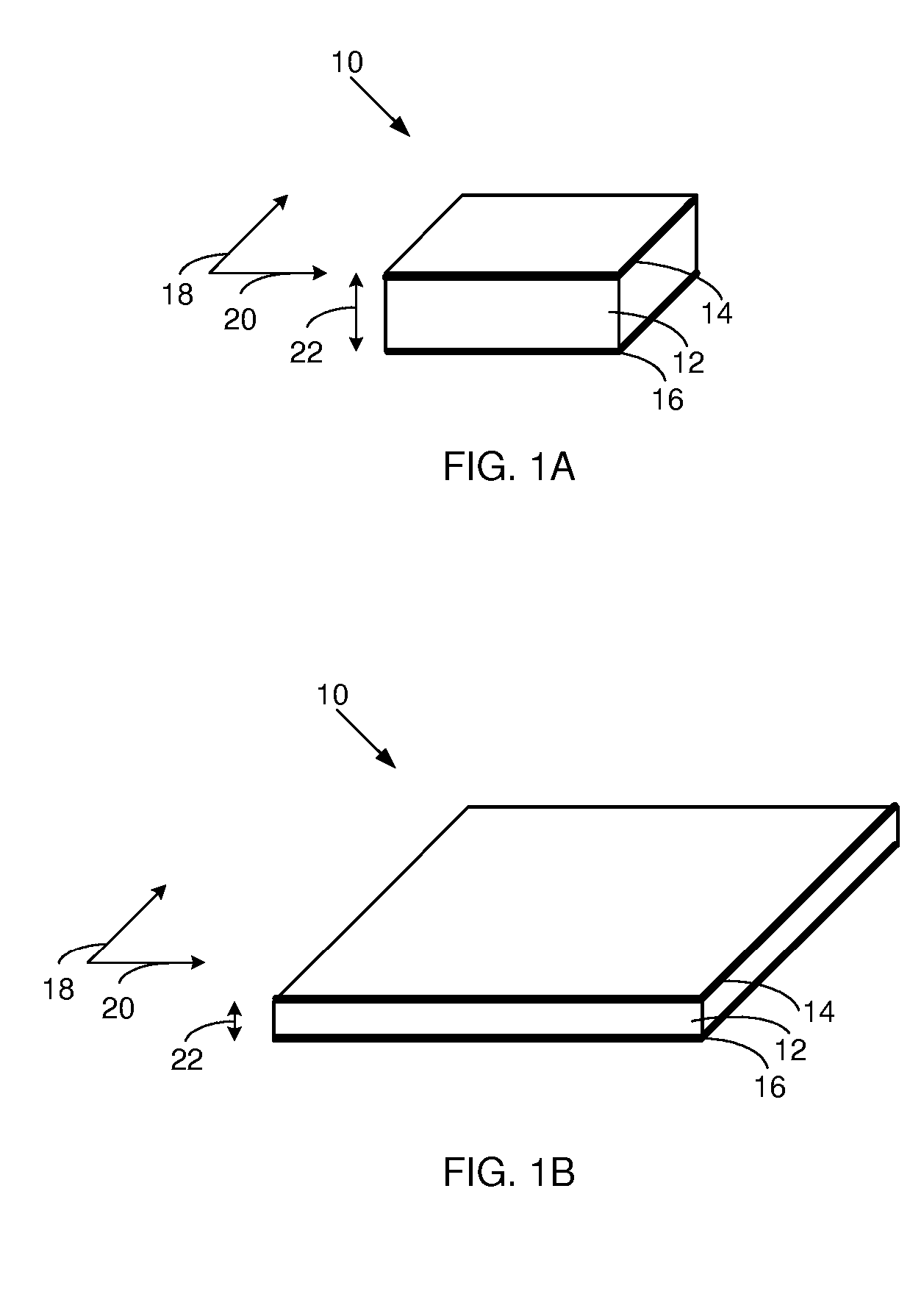

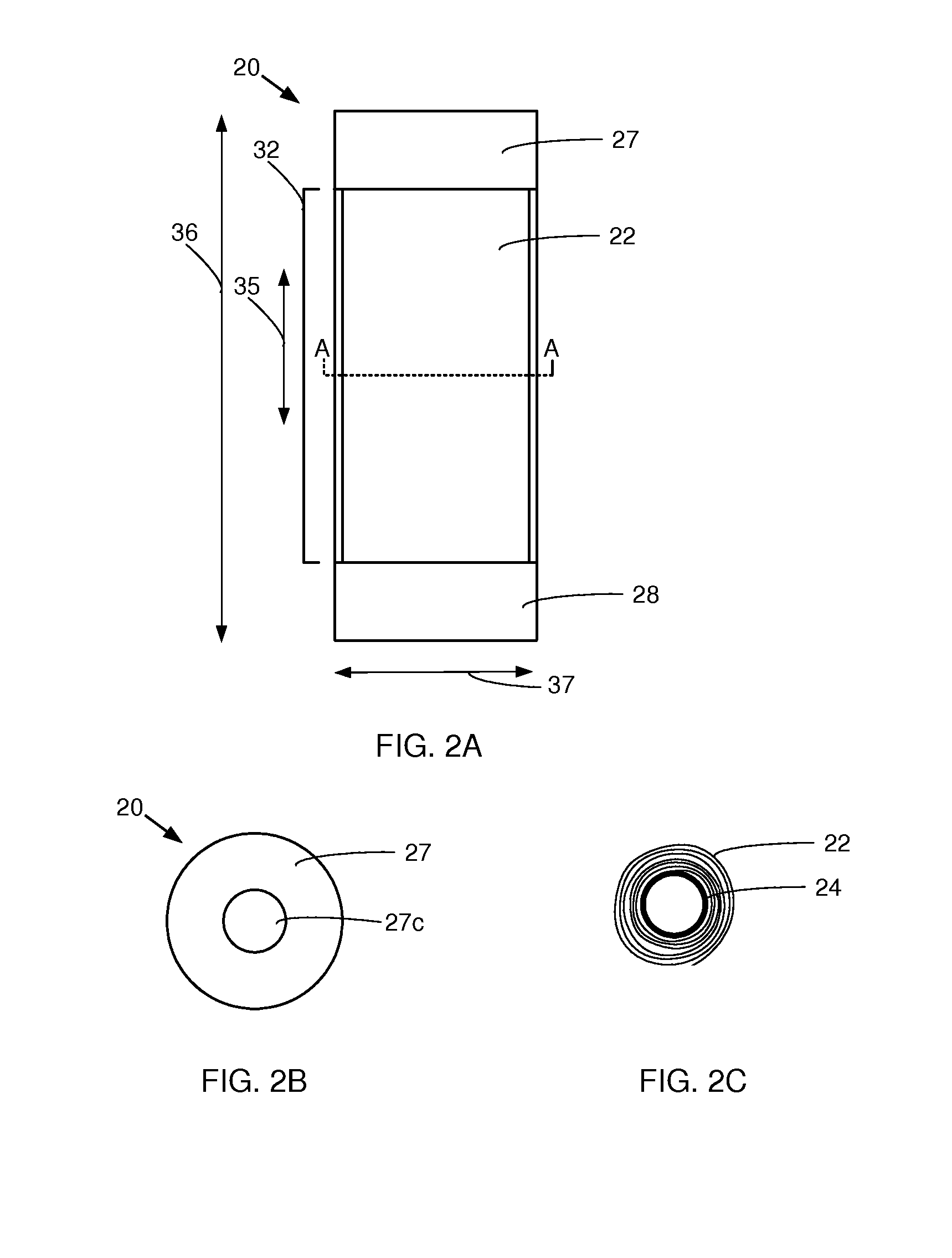

Rolled electroactive polymers

InactiveUS6891317B2Increase conversionsImprove performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPolymer scienceMechanical energy

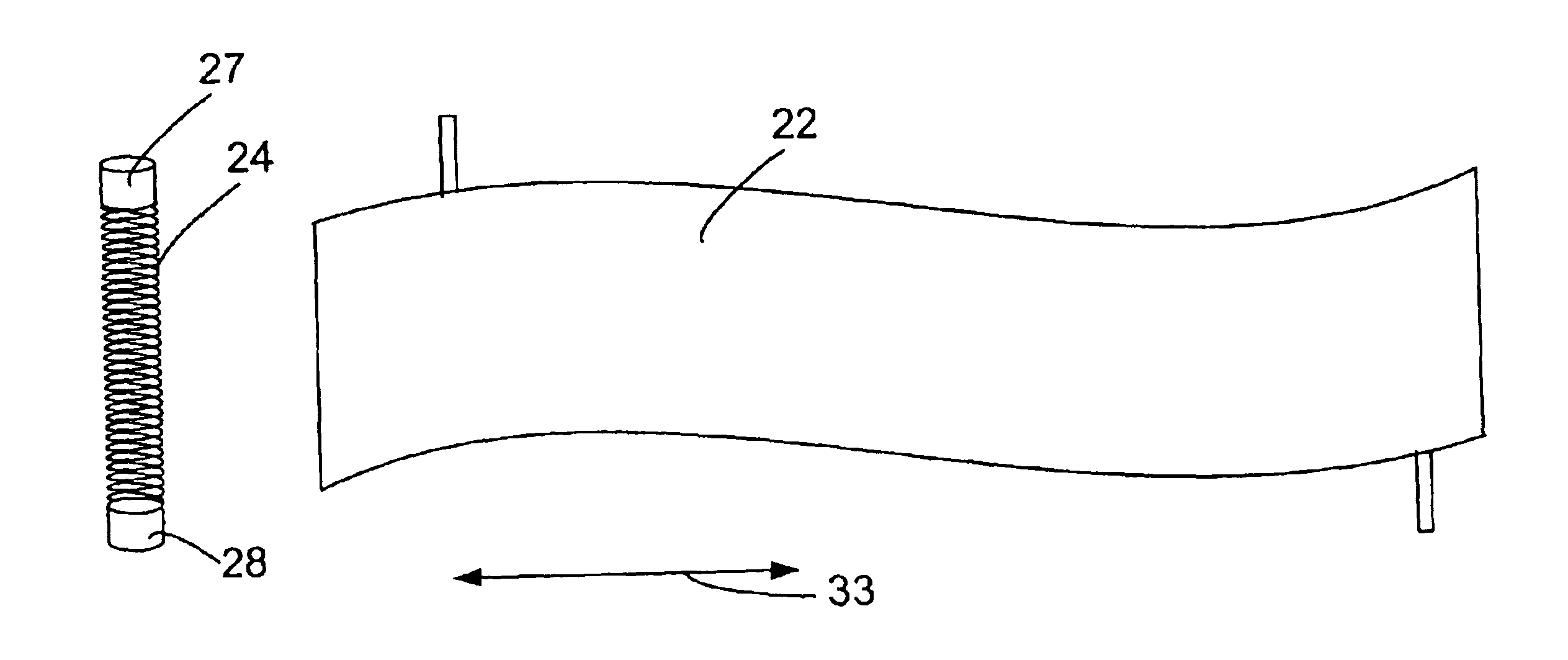

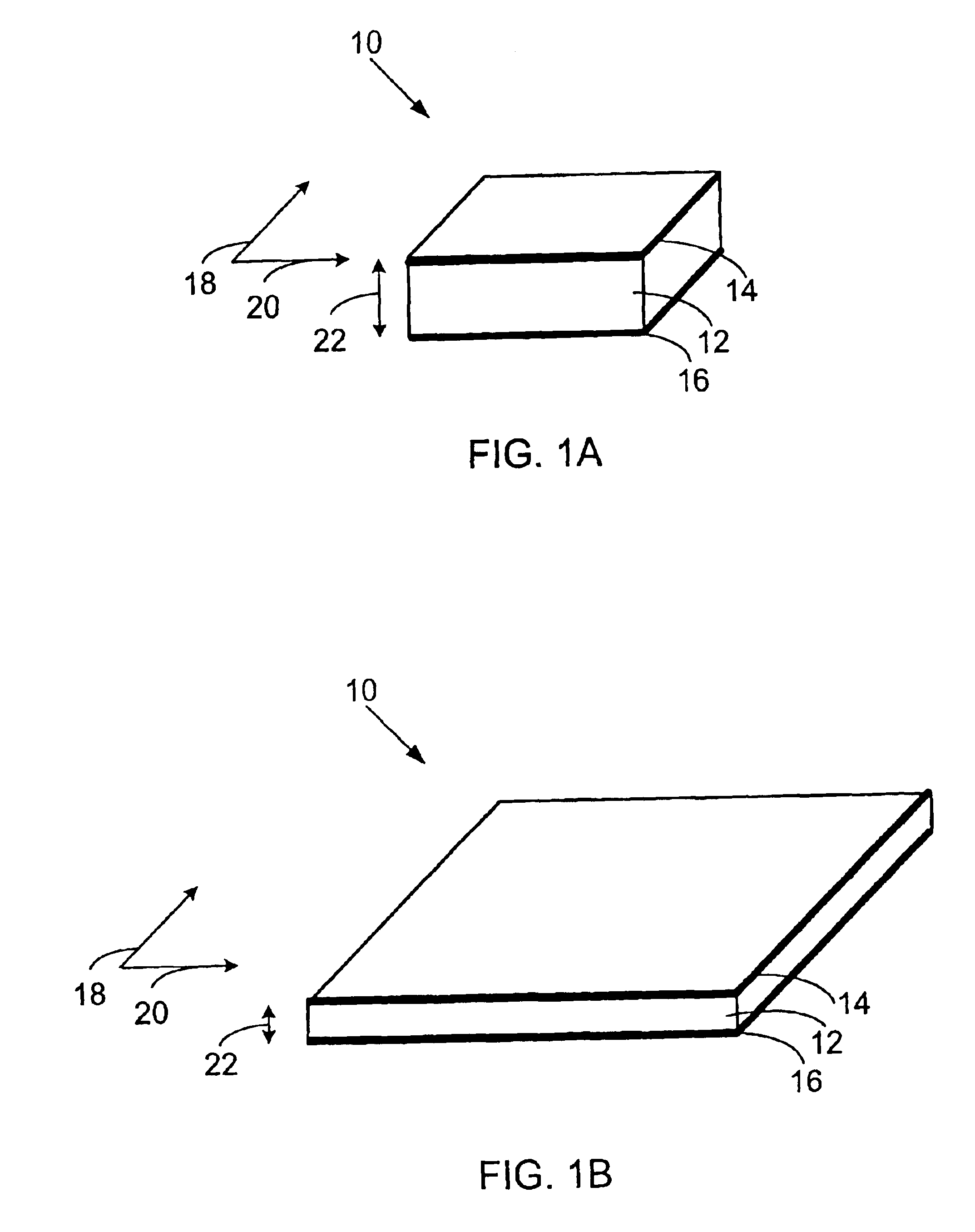

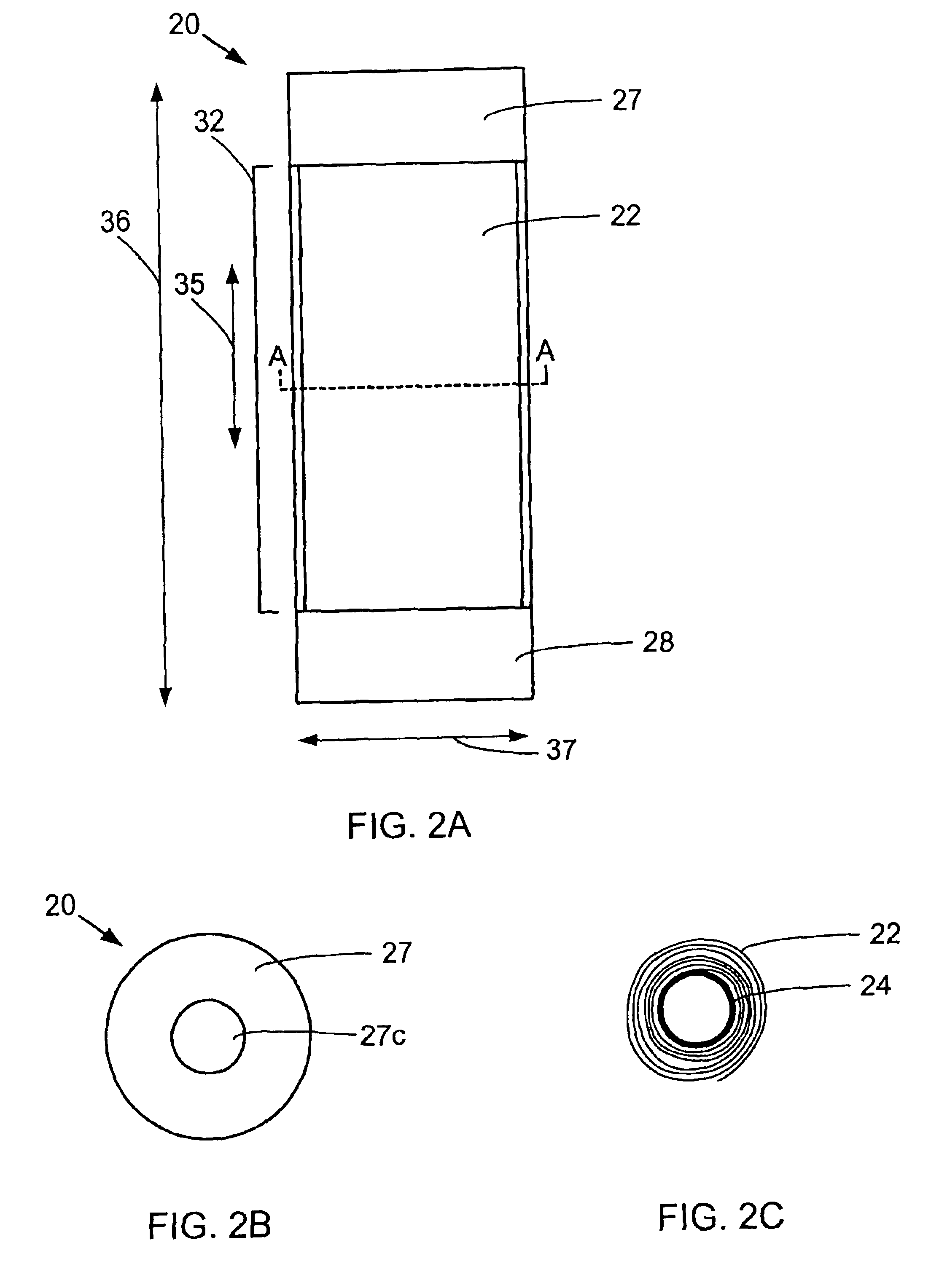

The invention describes rolled electroactive polymer devices. The invention also describes employment of these devices in a wide array of applications and methods for their fabrication. A rolled electroactive polymer device converts between electrical and mechanical energy; and includes a rolled electroactive polymer and at least two electrodes to provide the mechanical / electrical energy conversion. Prestrain is typically applied to the polymer. In one embodiment, a rolled electroactive polymer device employs a mechanism, such as a spring, that provides a force to prestrain the polymer. Since prestrain improves mechanical / electrical energy conversion for many electroactive polymers, the mechanism thus improves performance of the rolled electroactive polymer device.

Owner:SRI INTERNATIONAL

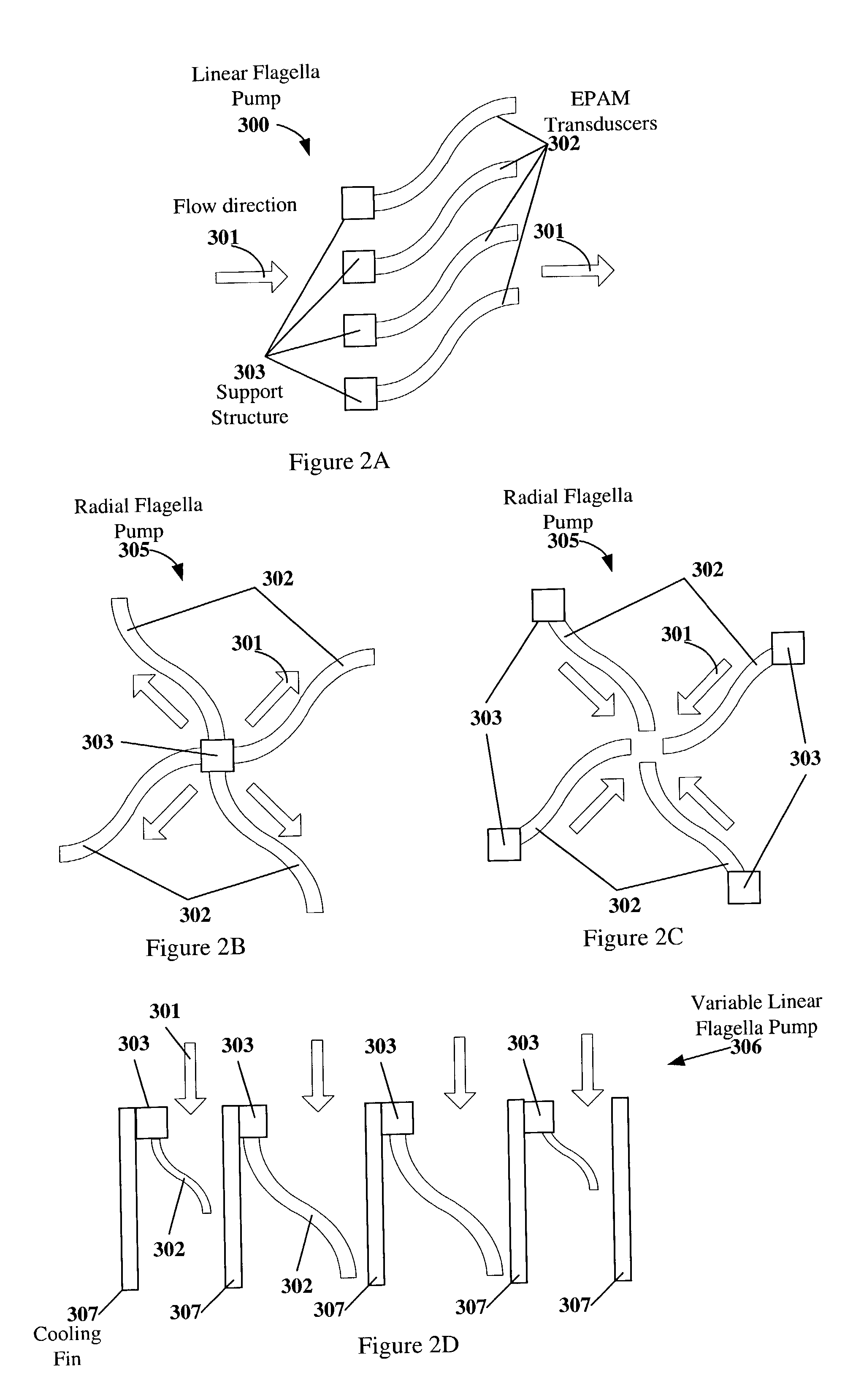

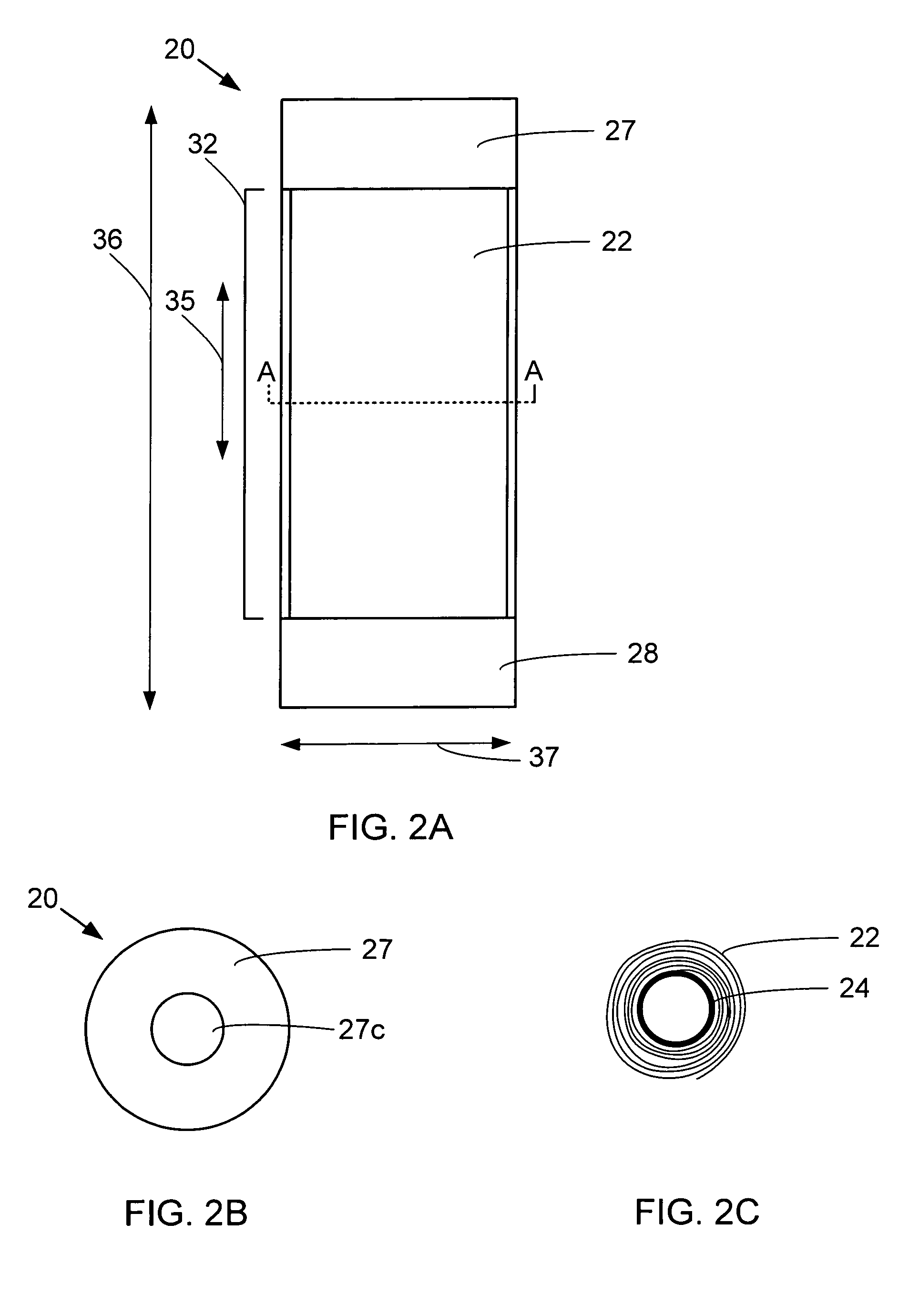

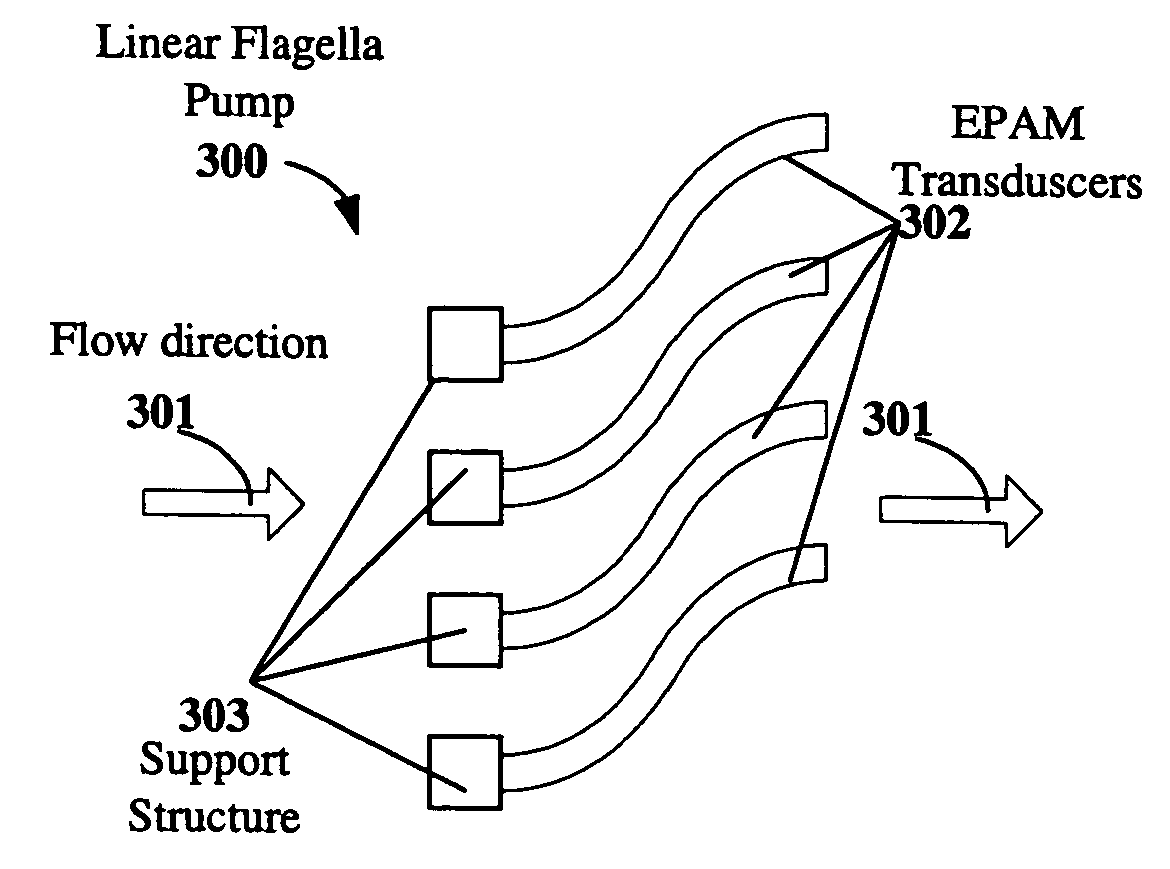

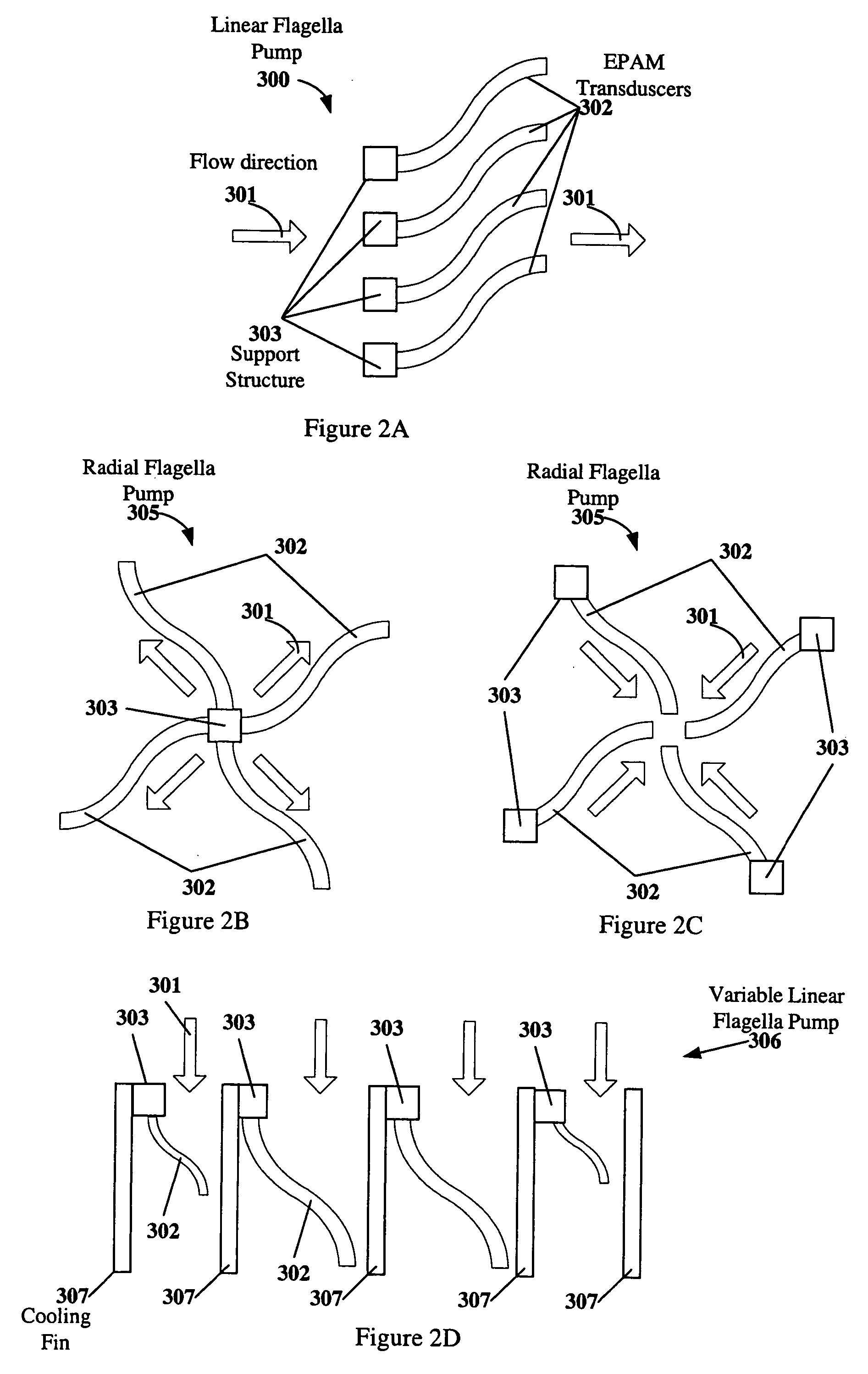

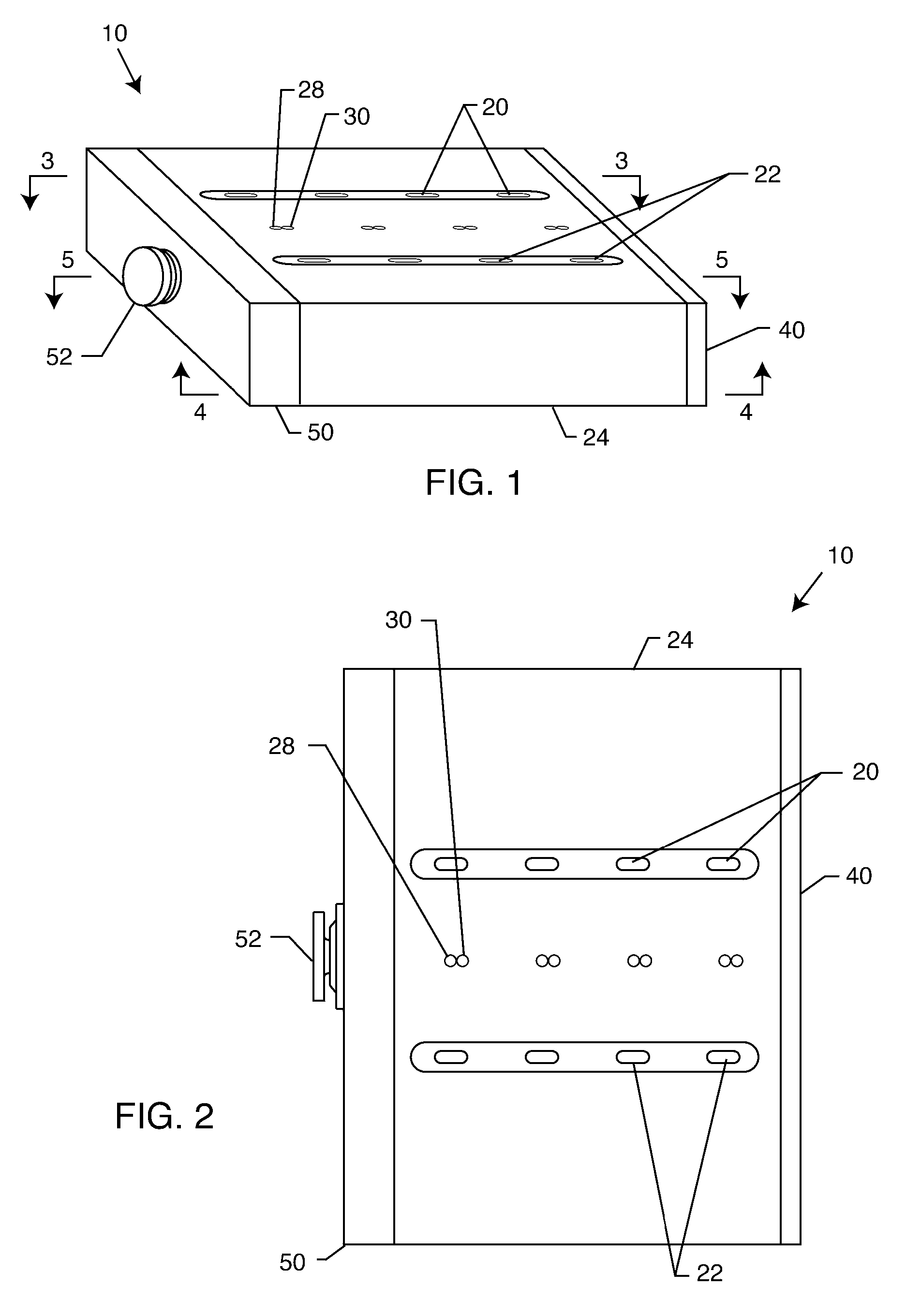

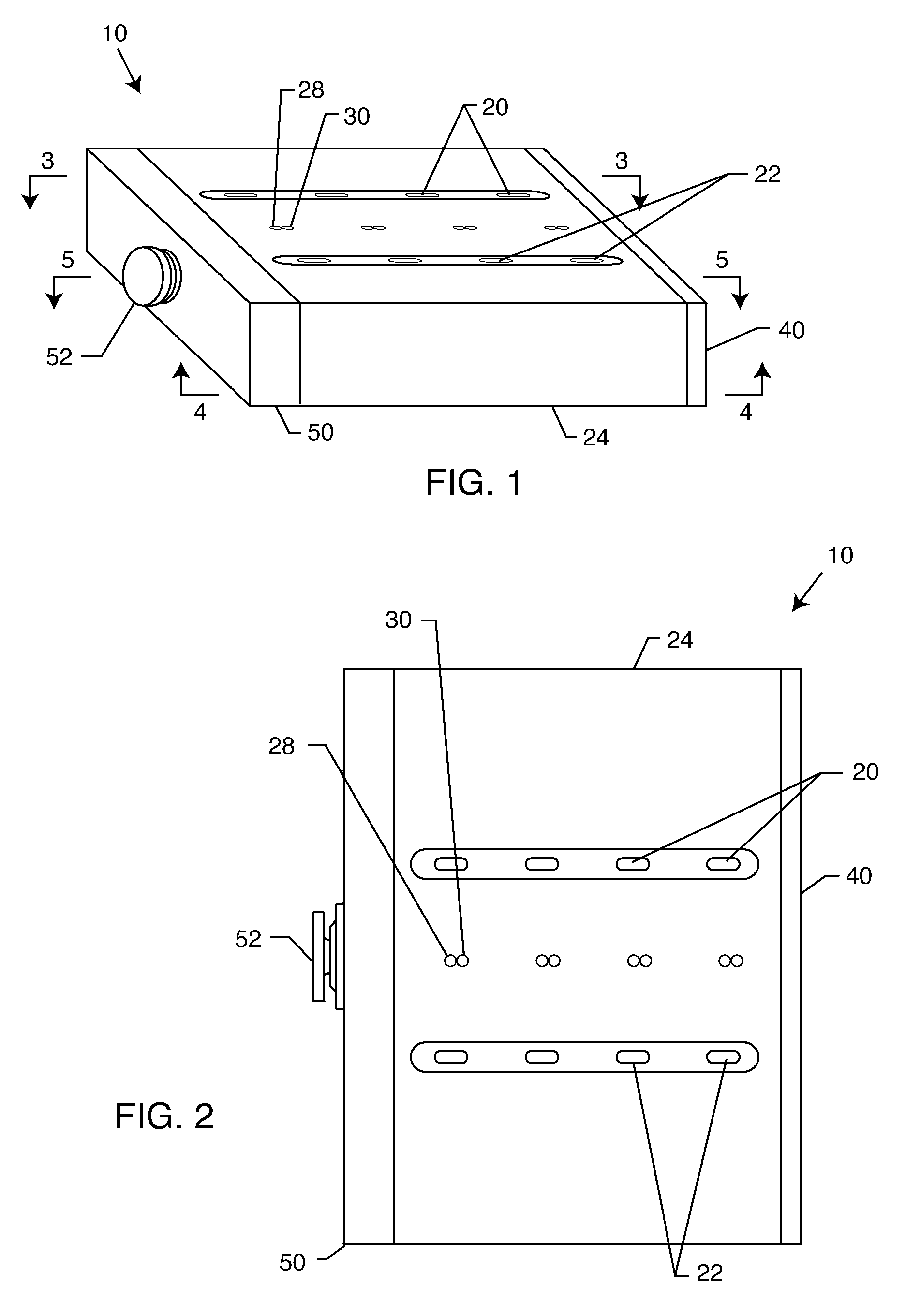

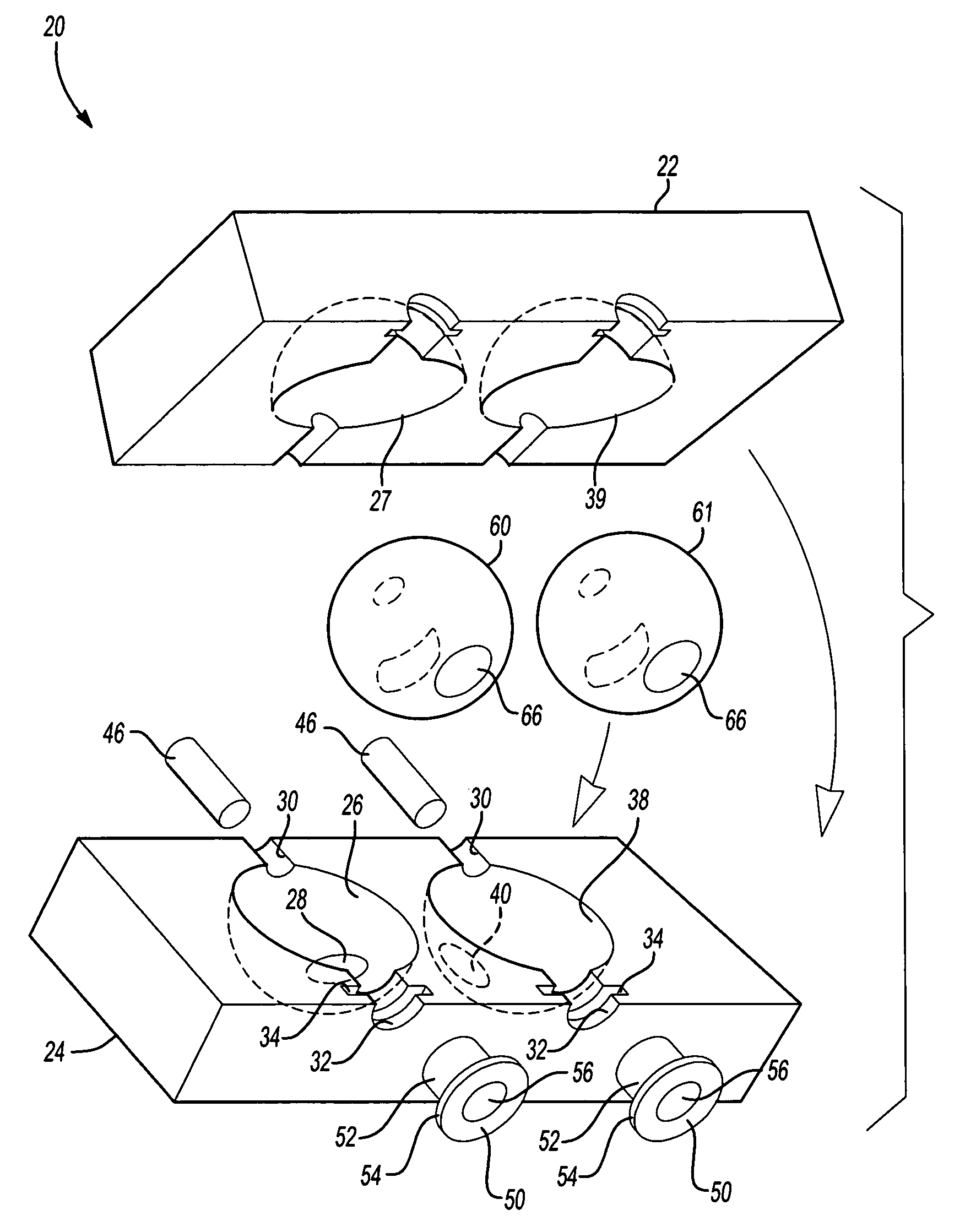

Electroactive polymer devices for moving fluid

InactiveUS7064472B2Improve mechanical responseImprove responseTransducer detailsFlexible member pumpsHearing rangeThermal force

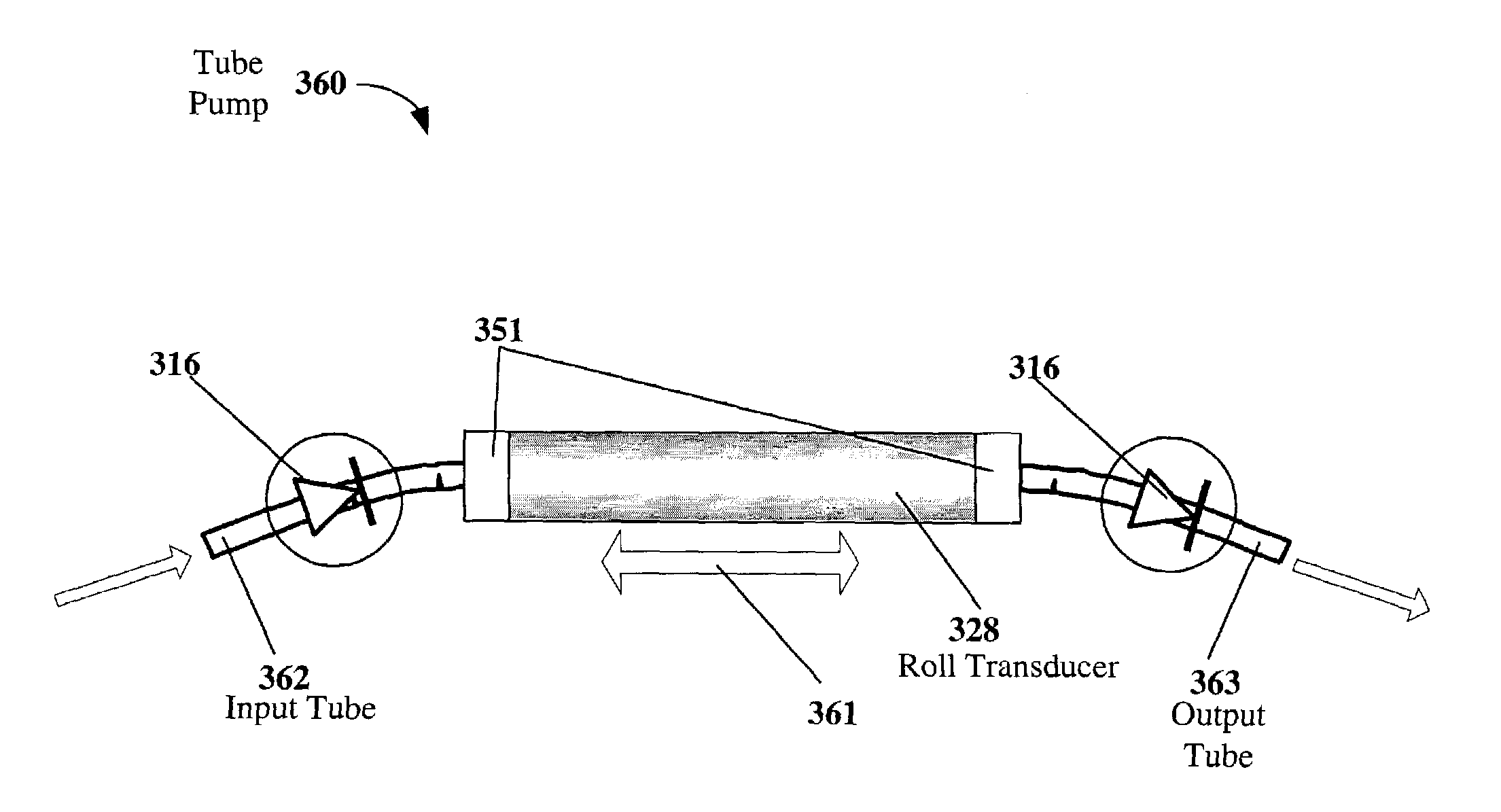

The invention describes devices for performing thermodynamic work on a fluid, such as pumps, compressors and fans. The thermodynamic work may be used to provide a driving force for moving the fluid. Work performed on the fluid may be transmitted to other devices, such as a piston in a hydraulic actuation device. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to perform thermodynamic work on the fluid. The devices may be designed to efficiently operate at a plurality of operating conditions, such as operating conditions that produce an acoustic signal above or below the human hearing range. The devices may be used in thermal control systems, such as refrigeration system, cooling systems and heating systems.

Owner:SRI INTERNATIONAL

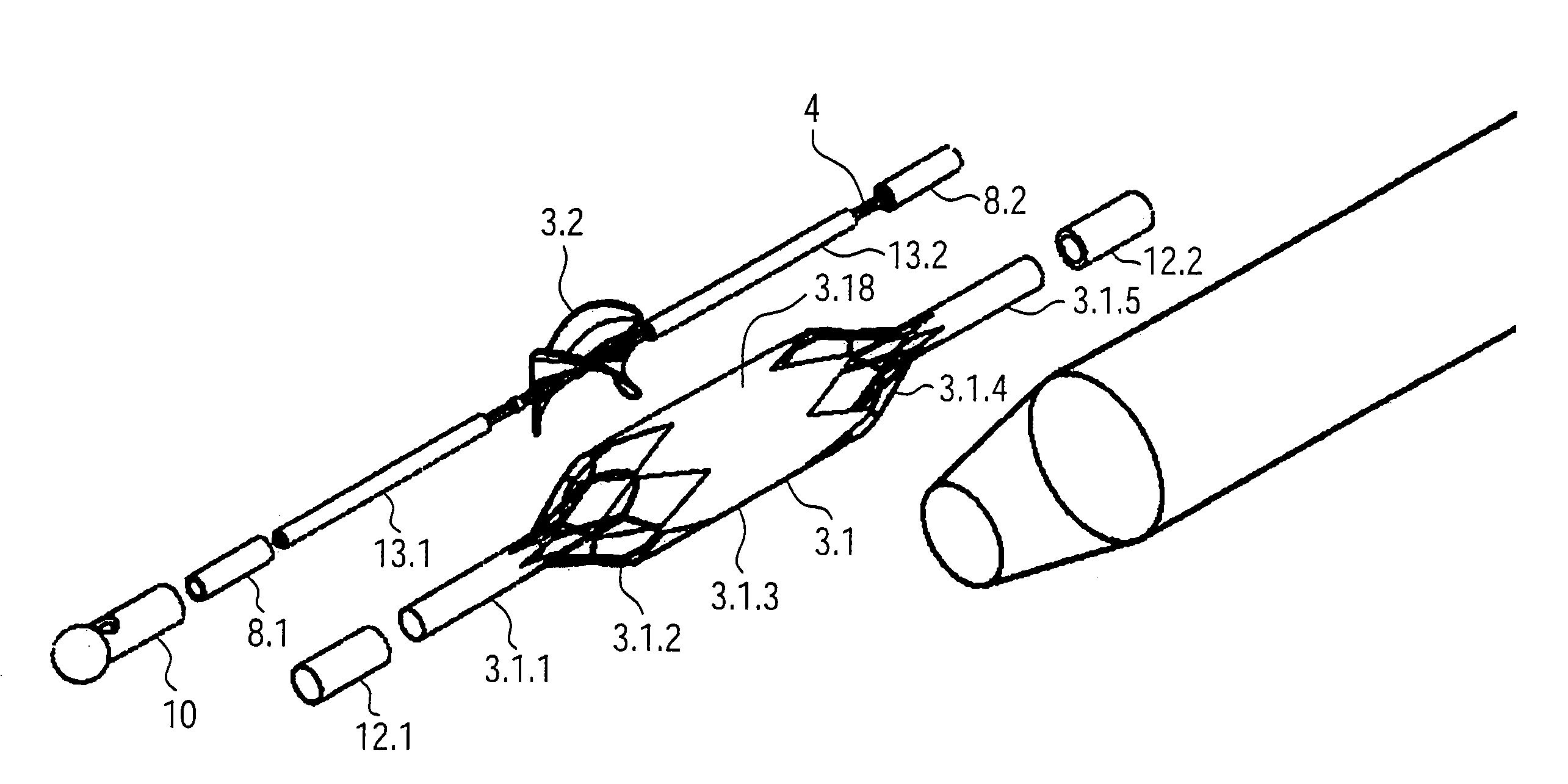

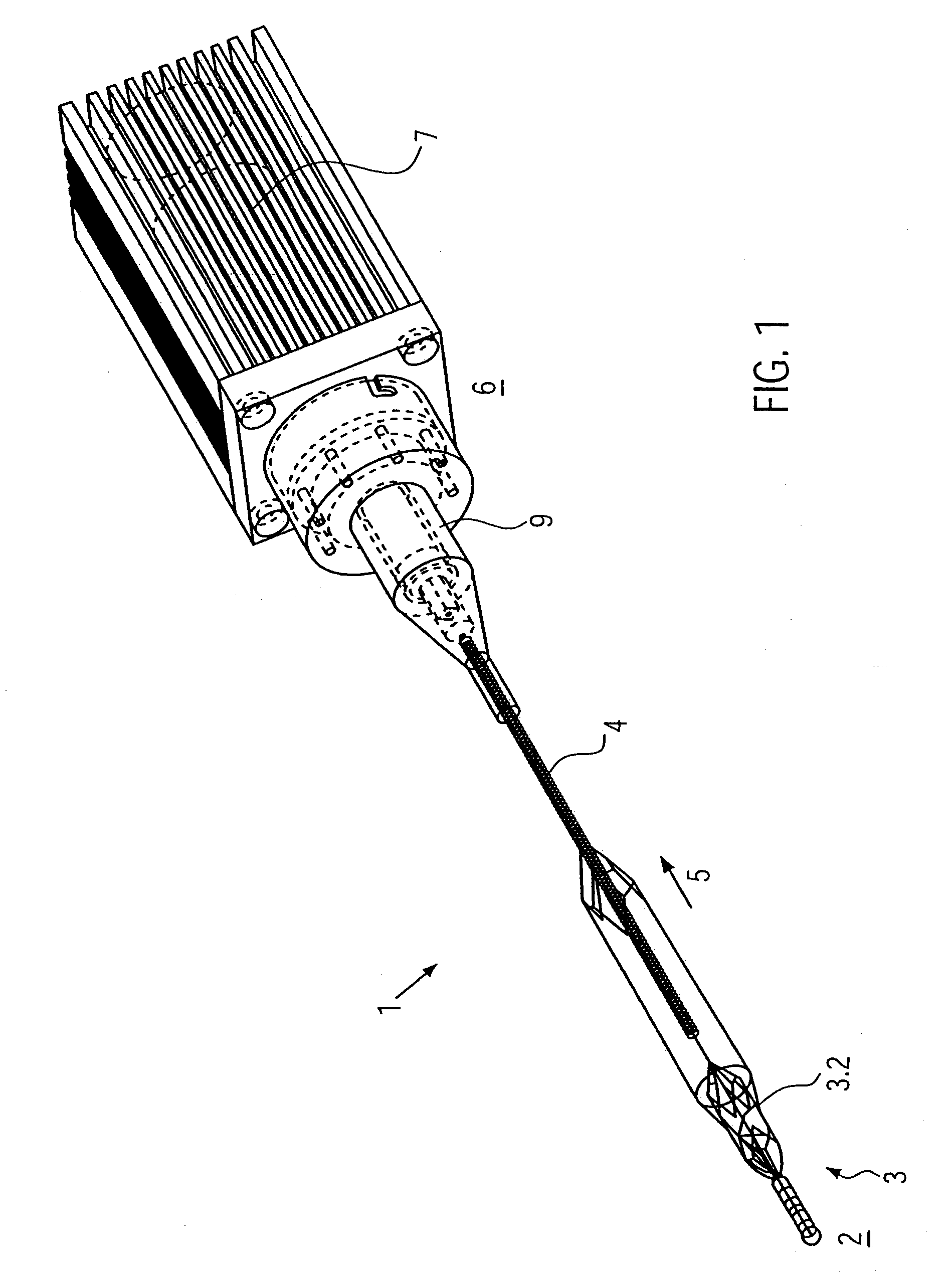

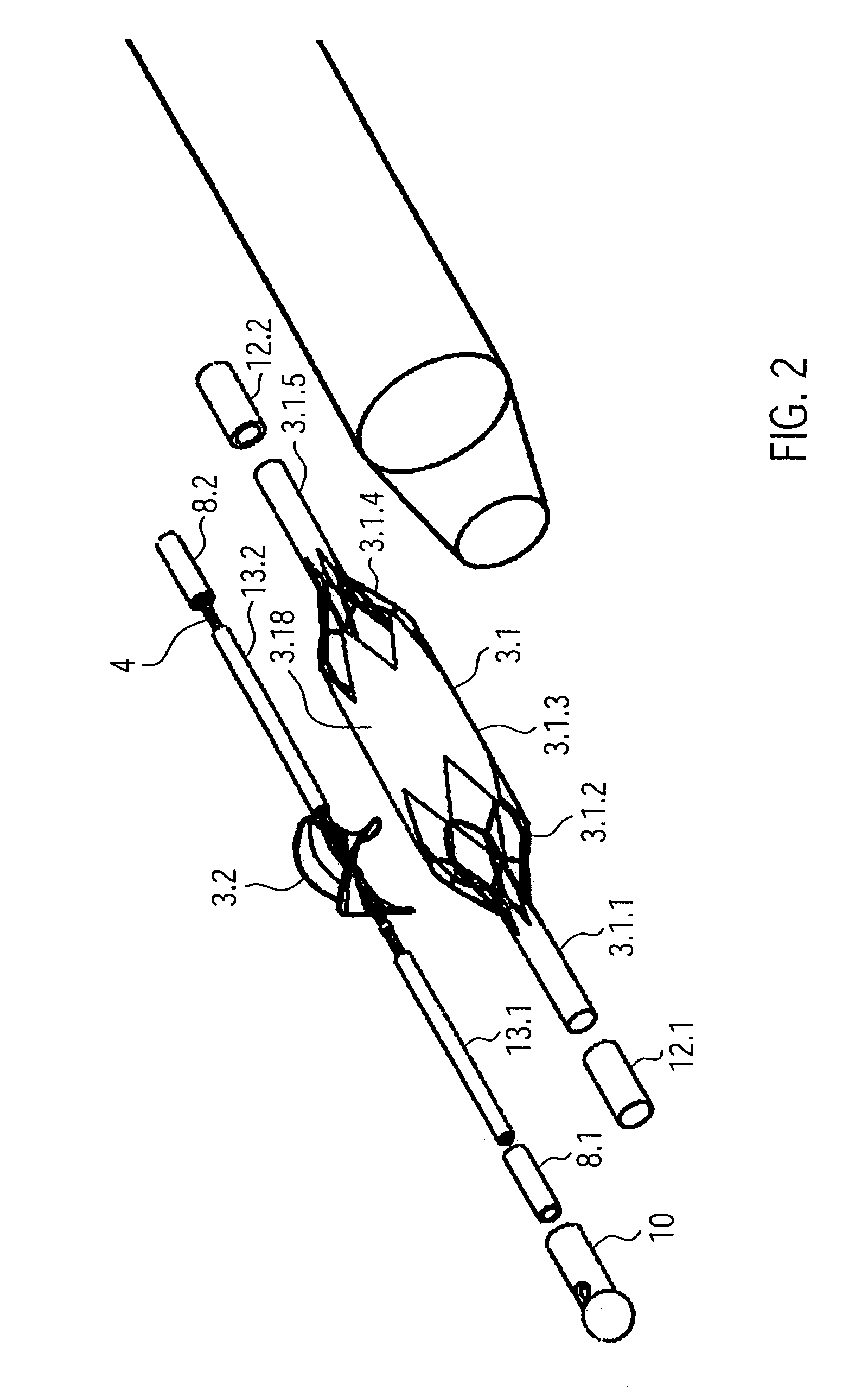

Catheter device

ActiveUS8439859B2Maximum pump performanceImprove performanceStarters with fluid-driven auxillary enginesHeart stimulatorsDrive shaftCatheter device

The catheter device comprises a drive shaft connected to a motor, and a rotor mounted on the drive shaft at the distal end section. The rotor has a frame structure which is formed by a screw-like boundary frame and rotor struts extending radially inwards from the boundary frame. The rotor struts are fastened to the drive shaft by their ends opposite the boundary frame. Between the boundary frame and the drive shaft extends an elastic covering. The frame structure is made of an elastic material such that, after forced compression, the rotor unfolds automatically.

Owner:AIS AACHEN INNOVATIVE SOLUTIONS

Rolled electroactive polymers

InactiveUS7233097B2Improves mechanical/electrical energy conversionImprove performancePiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsPolymer scienceMechanical energy

The invention describes rolled electroactive polymer devices. The invention also describes employment of these devices in a wide array of applications and methods for their fabrication. A rolled electroactive polymer device converts between electrical and mechanical energy; and includes a rolled electroactive polymer and at least two electrodes to provide the mechanical / electrical energy conversion. Prestrain is typically applied to the polymer. In one embodiment, a rolled electroactive polymer device employs a mechanism, such as a spring, that provides a force to prestrain the polymer. Since prestrain improves mechanical / electrical energy conversion for many electroactive polymers, the mechanism thus improves performance of the rolled electroactive polymer device.

Owner:SRI INTERNATIONAL

Electroactive polymer devices for moving fluid

InactiveUS20060158065A1Improve responseTransducer detailsFlexible member pumpsHearing rangeThermal force

The invention describes devices for performing thermodynamic work on a fluid, such as pumps, compressors and fans. The thermodynamic work may be used to provide a driving force for moving the fluid. Work performed on the fluid may be transmitted to other devices, such as a piston in a hydraulic actuation device. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to perform thermodynamic work on the fluid. The devices may be designed to efficiently operate at a plurality of operating conditions, such as operating conditions that produce an acoustic signal above or below the human hearing range. The devices may be used in thermal control systems, such as refrigeration system, cooling systems and heating systems.

Owner:SRI INTERNATIONAL

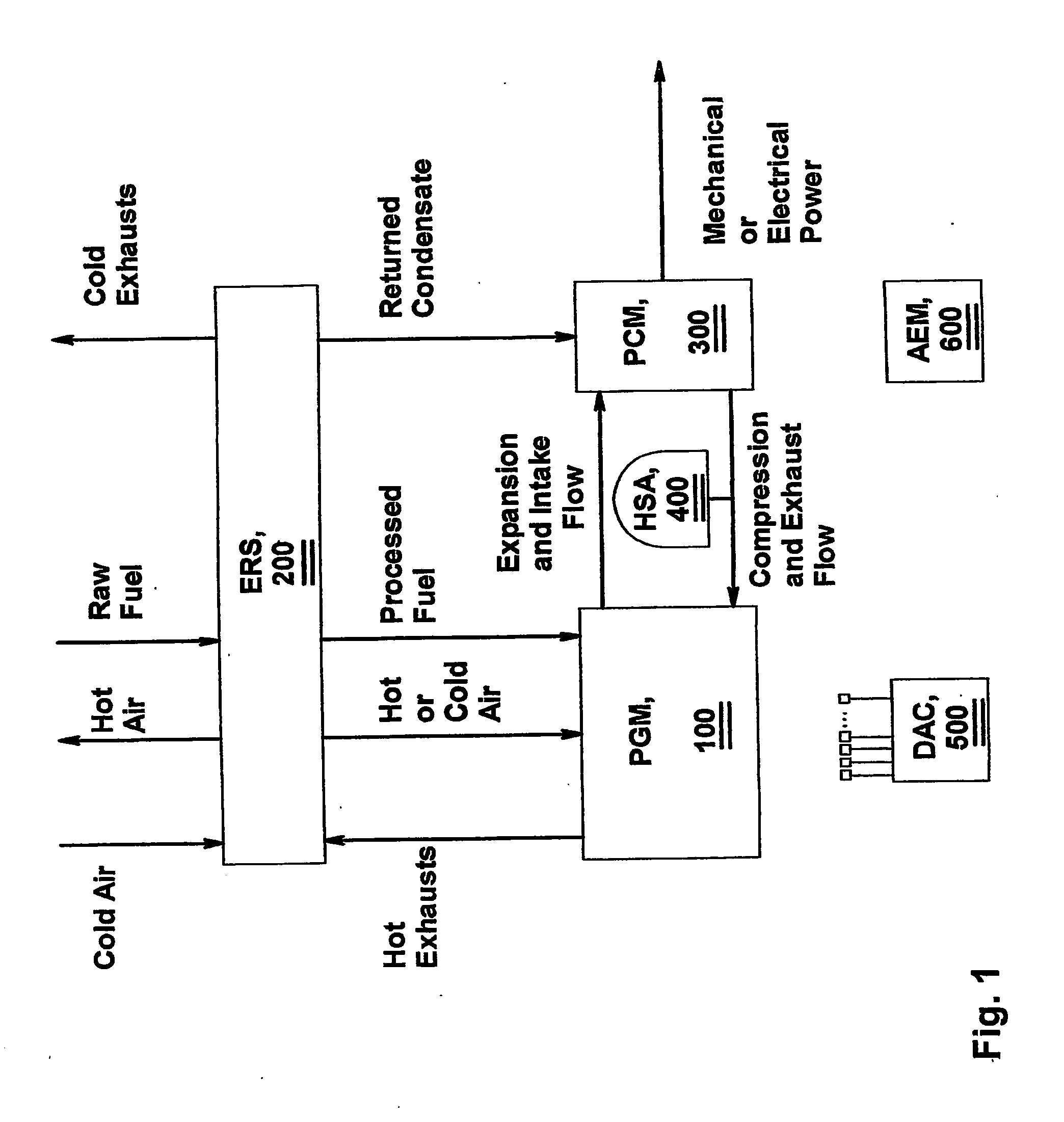

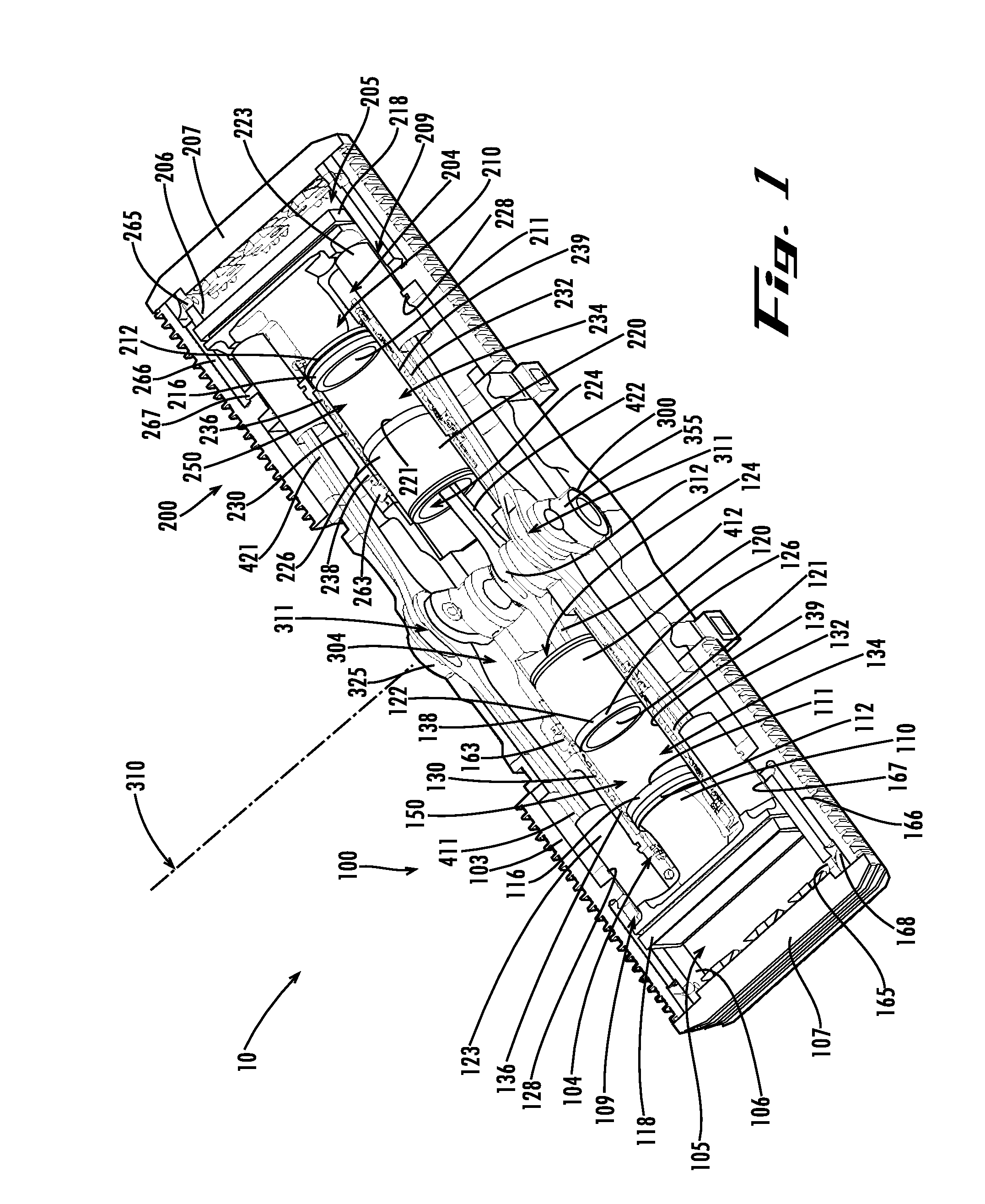

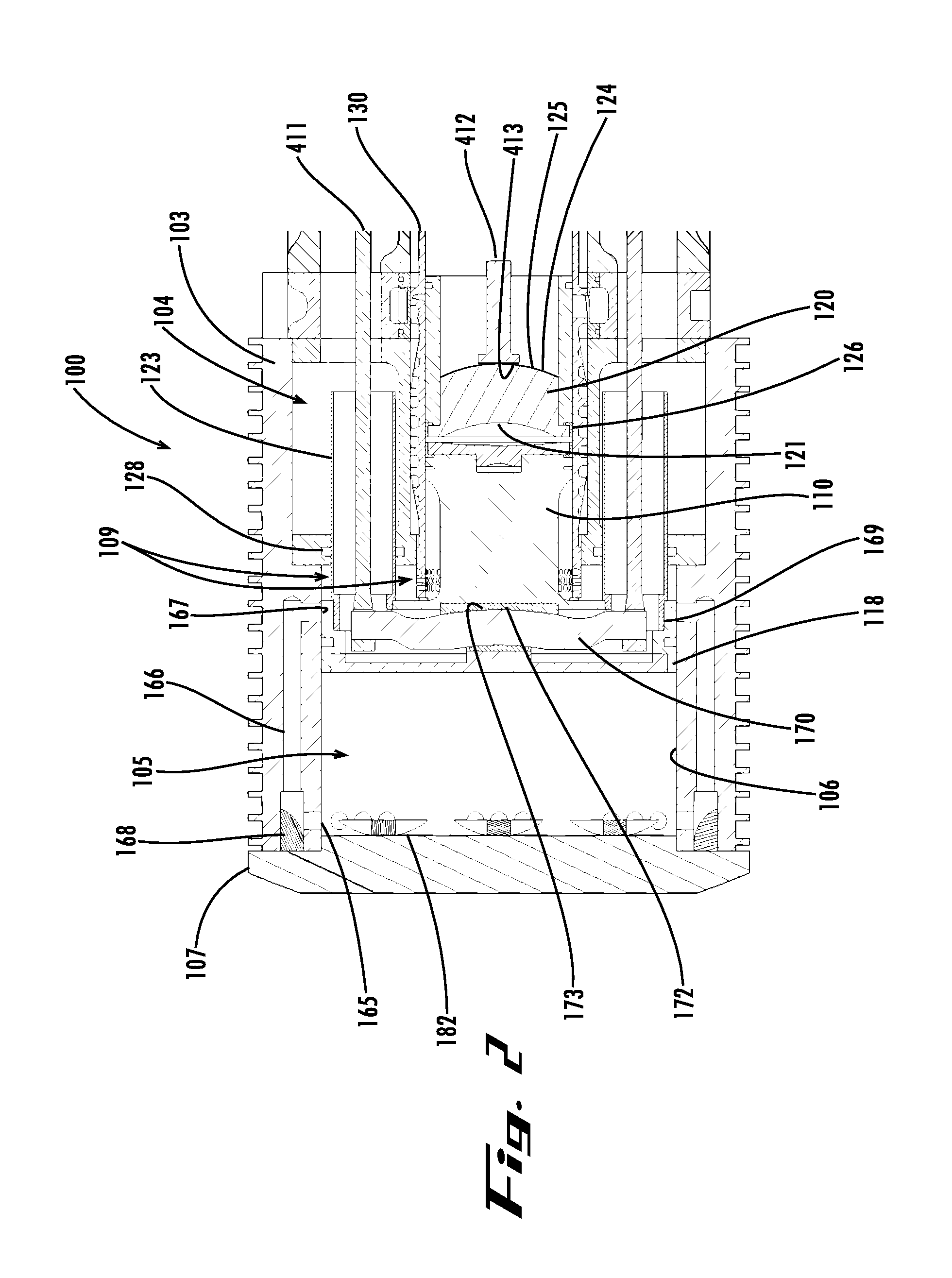

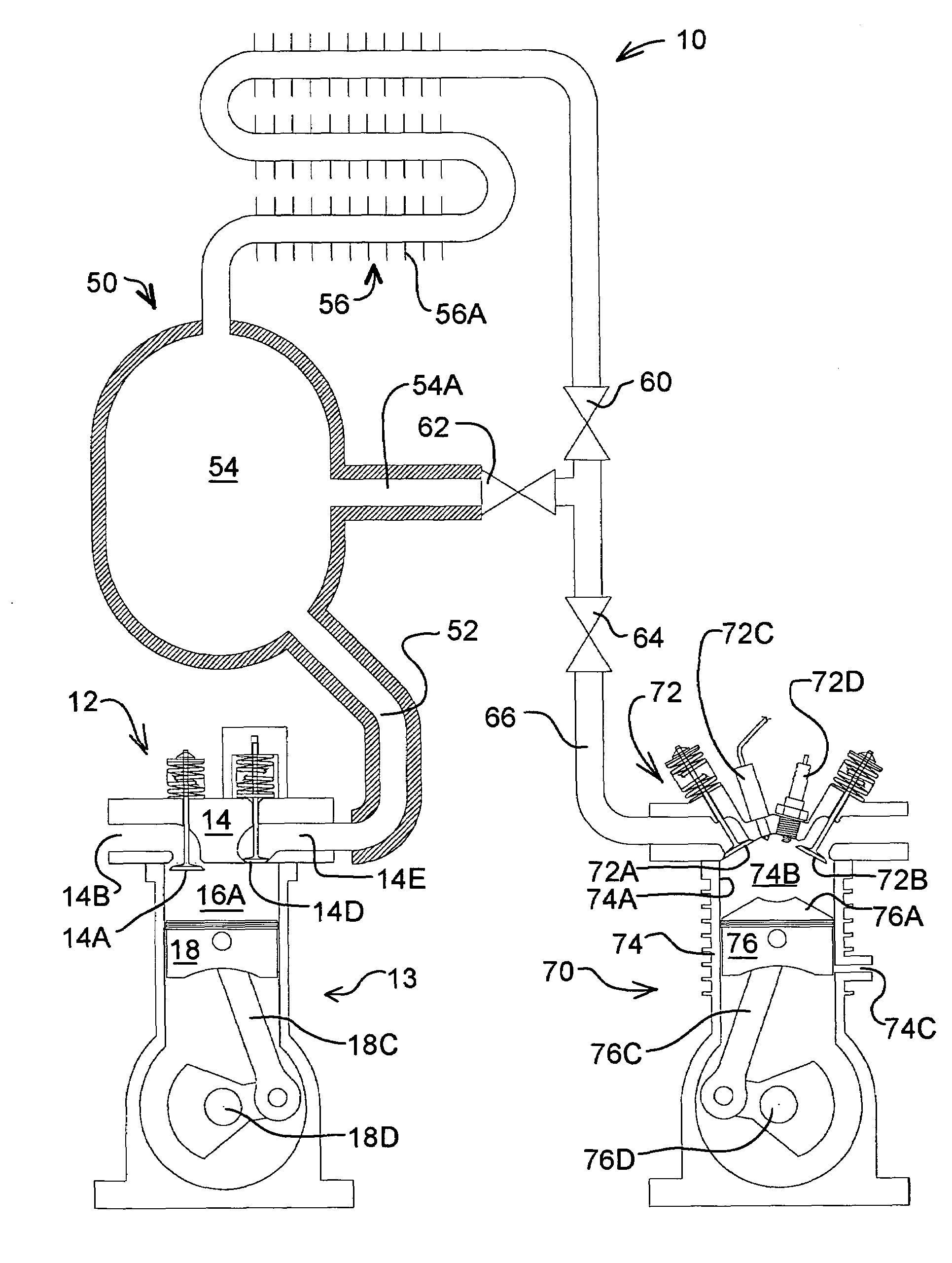

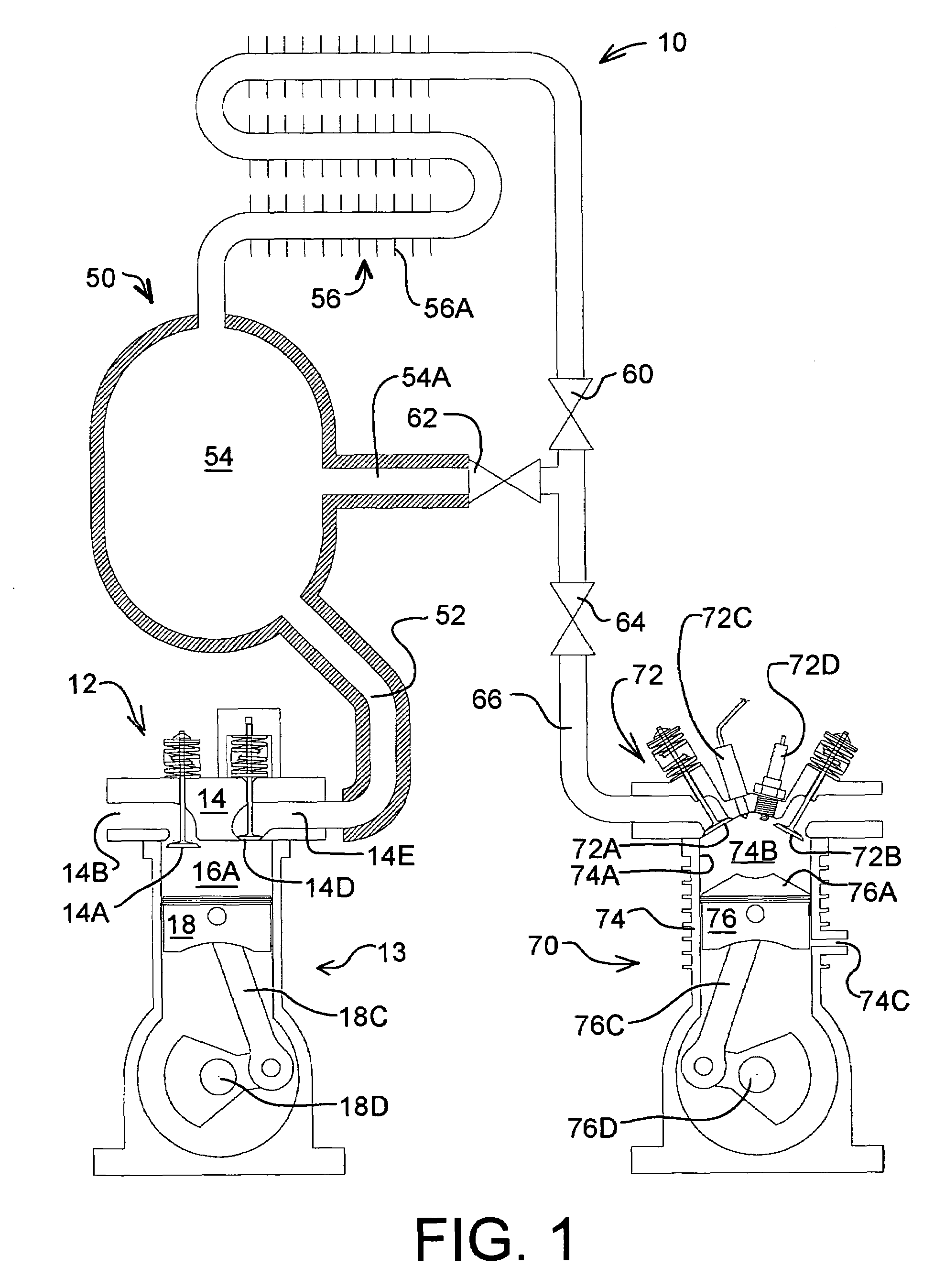

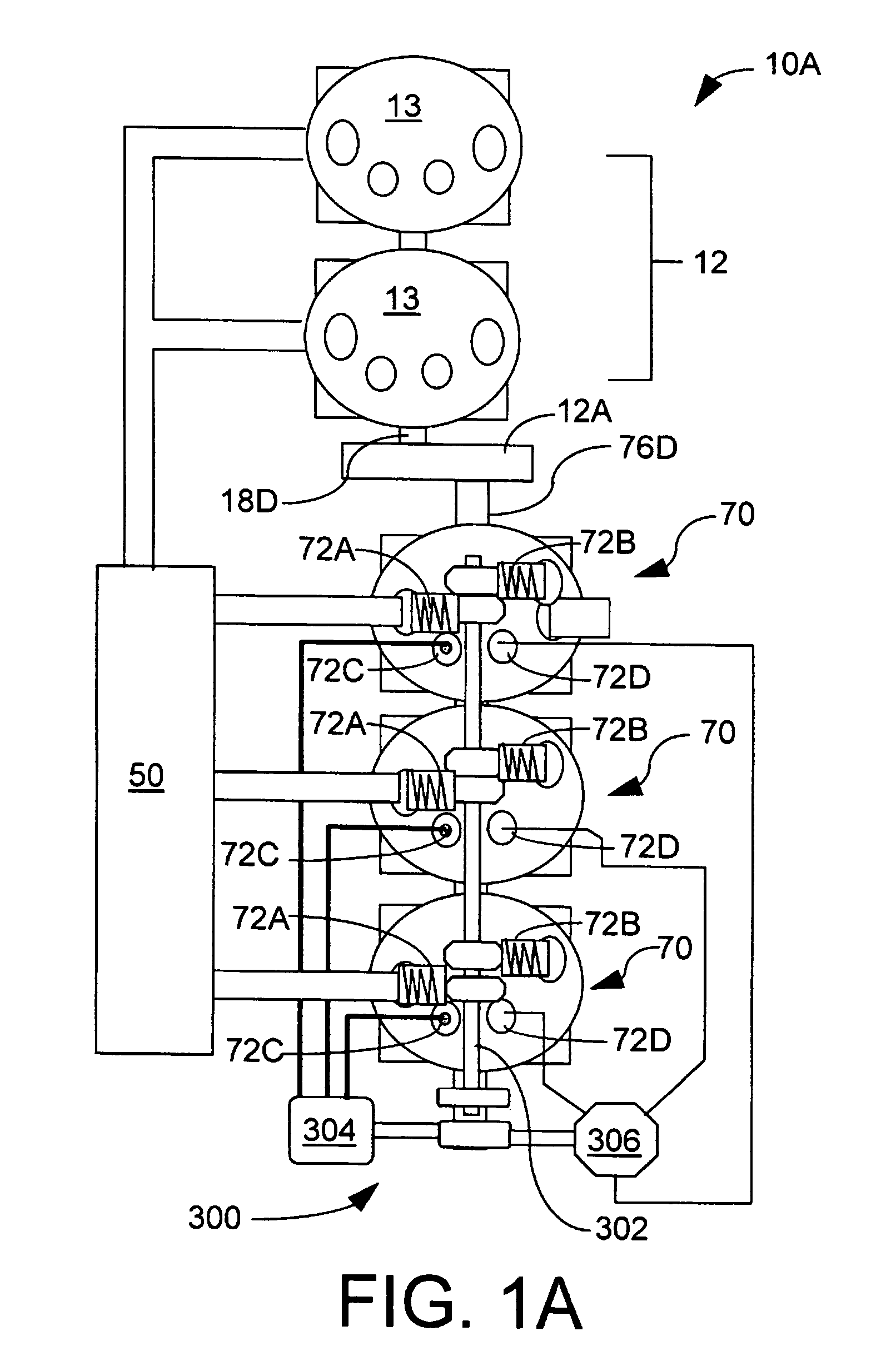

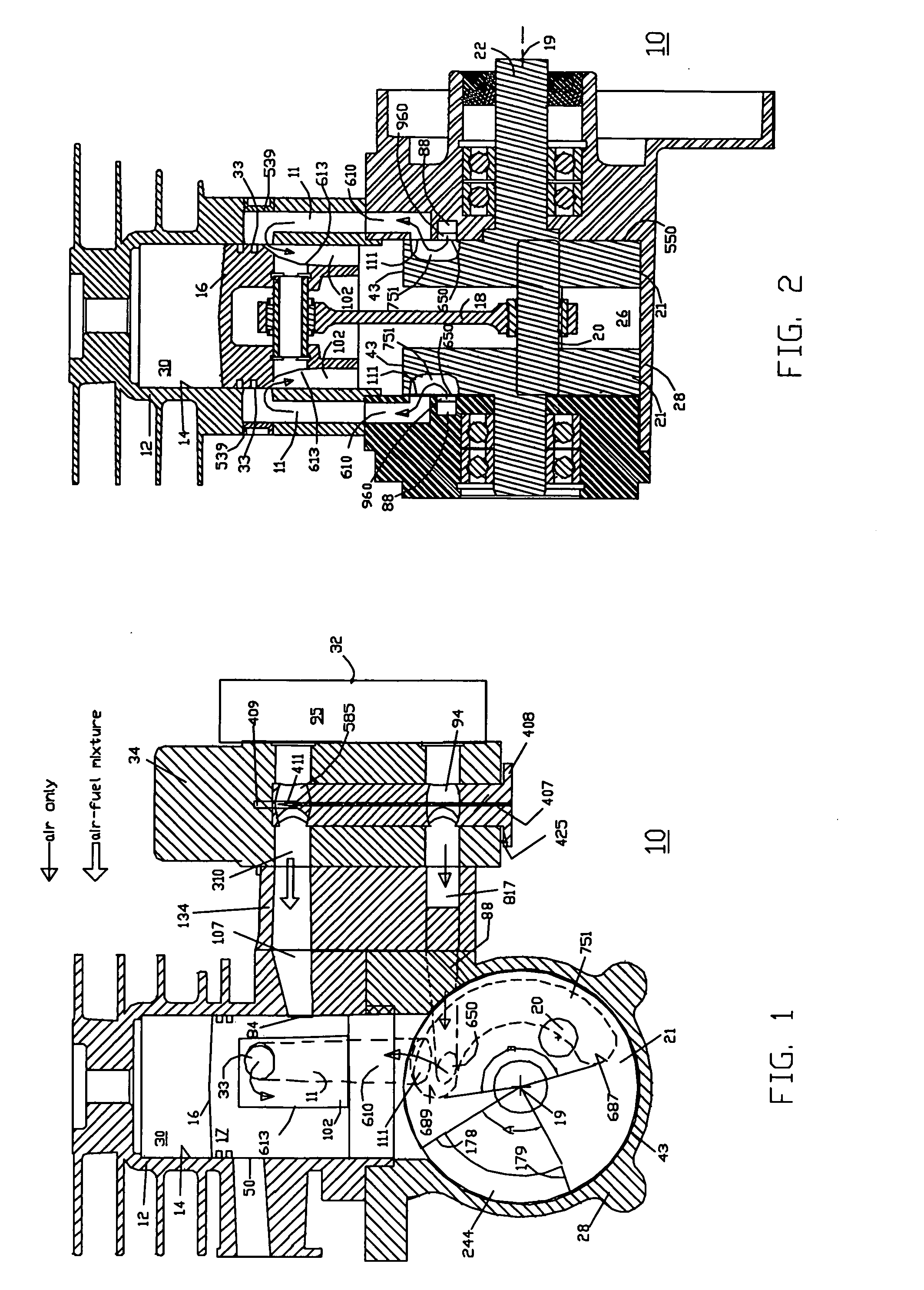

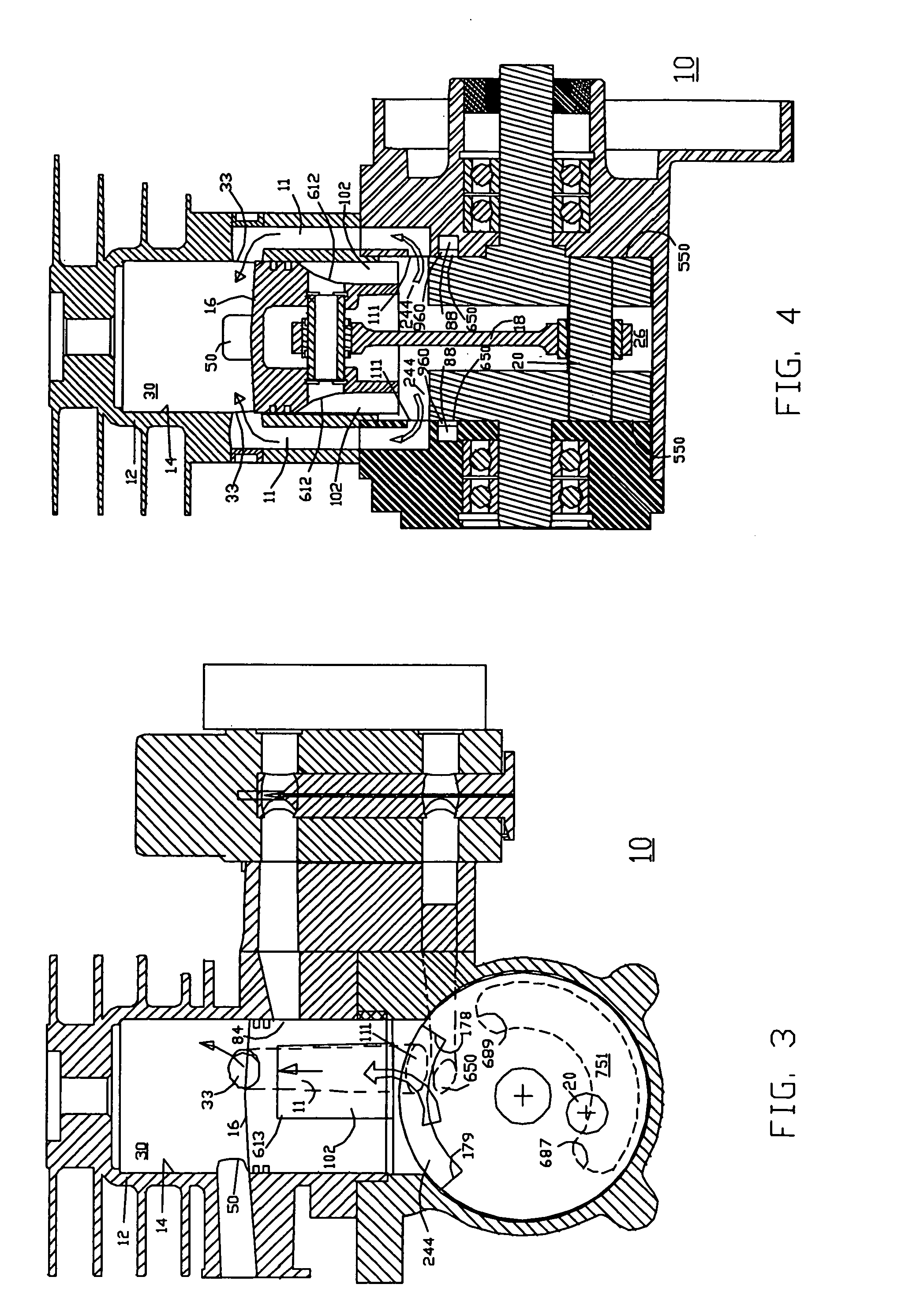

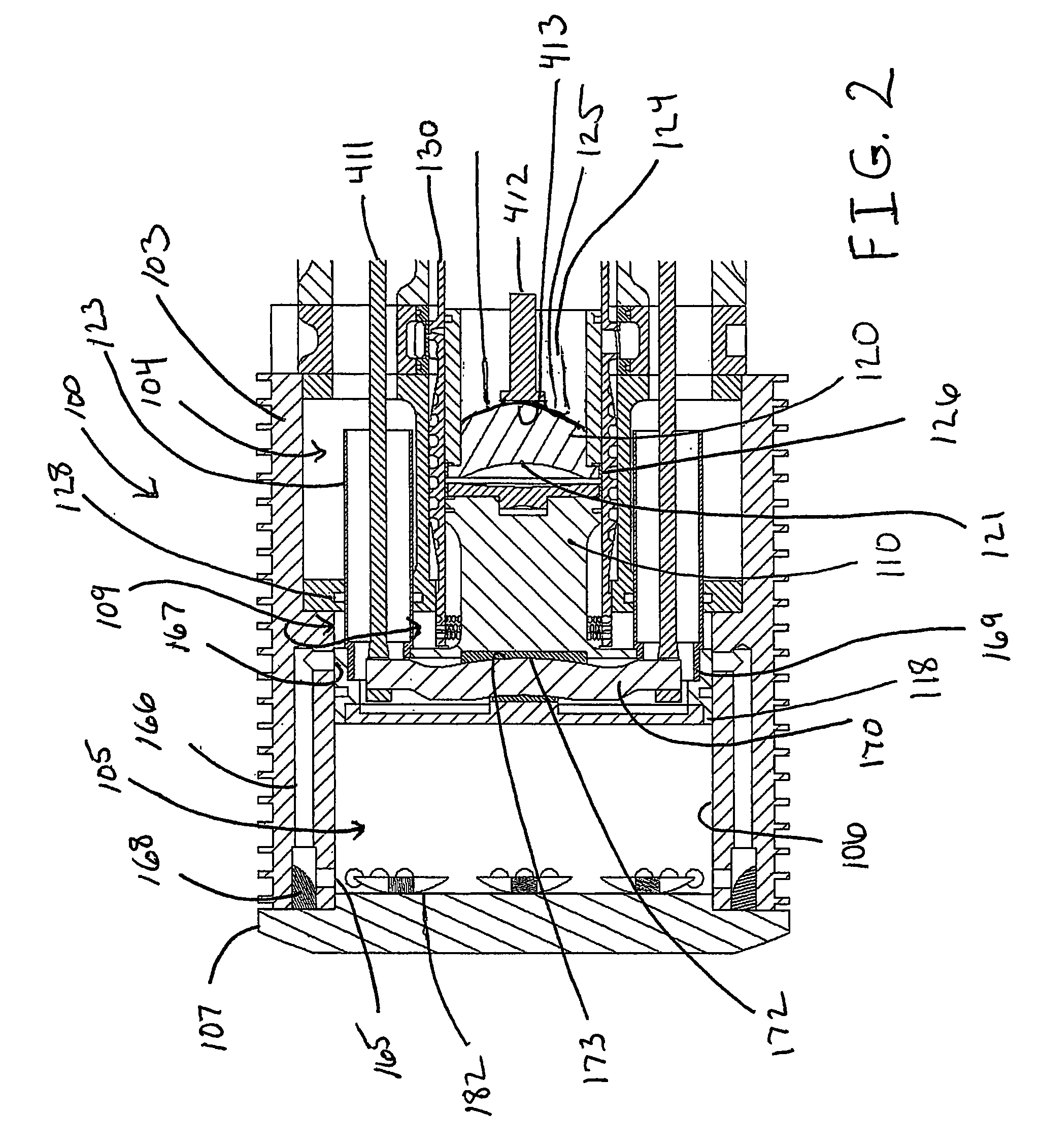

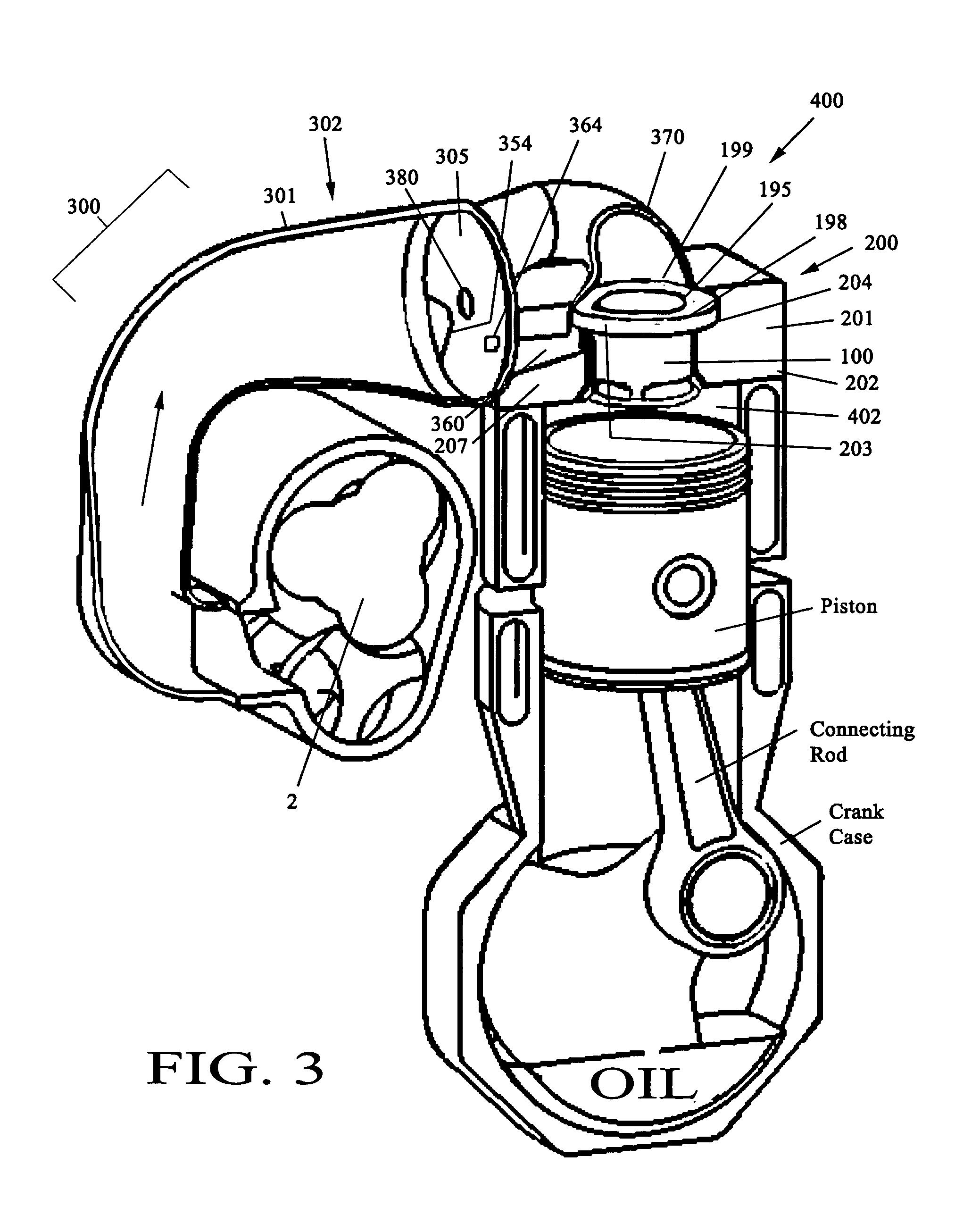

Liquid piston internal combustion power system

InactiveUS20050166869A1Reduce pollutionRotary slide valveSteam engine plantsLiquid pistonEnergy recovery

Methods, devices and systems for power generation through liquid piston internal combustion engine. The liquid piston internal combustion engine of the invention, utilizes a novel, synergetic combination of internal combustion and steam piston engines within the framework of one and the same system. The engine may comprise or a plurality of cylinders, each having a liquid piston. The ICE (Internal Combustion Engine) system comprises six modules viz PGM (Power Generating Module) (100), ERS (Energy Recovery System) (200), PCM (Power Conversion Module) (300), HAS (Hydraulic Shock Absorbers Module) (400), DAC (Data Acquisition & Control Module) (500) and AEM (Auxiliary Equipment Module) (600).

Owner:LIQUIDPISTON INC

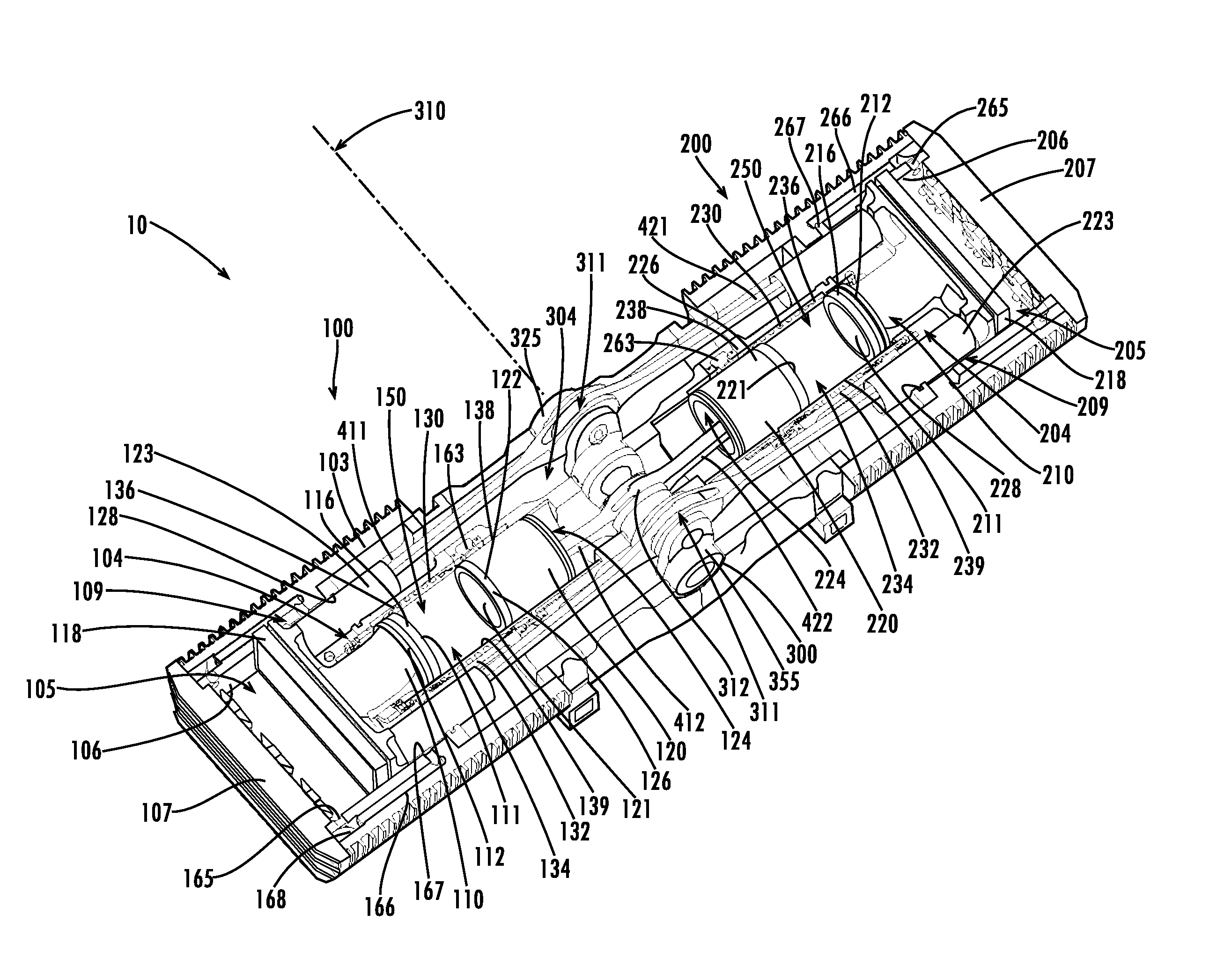

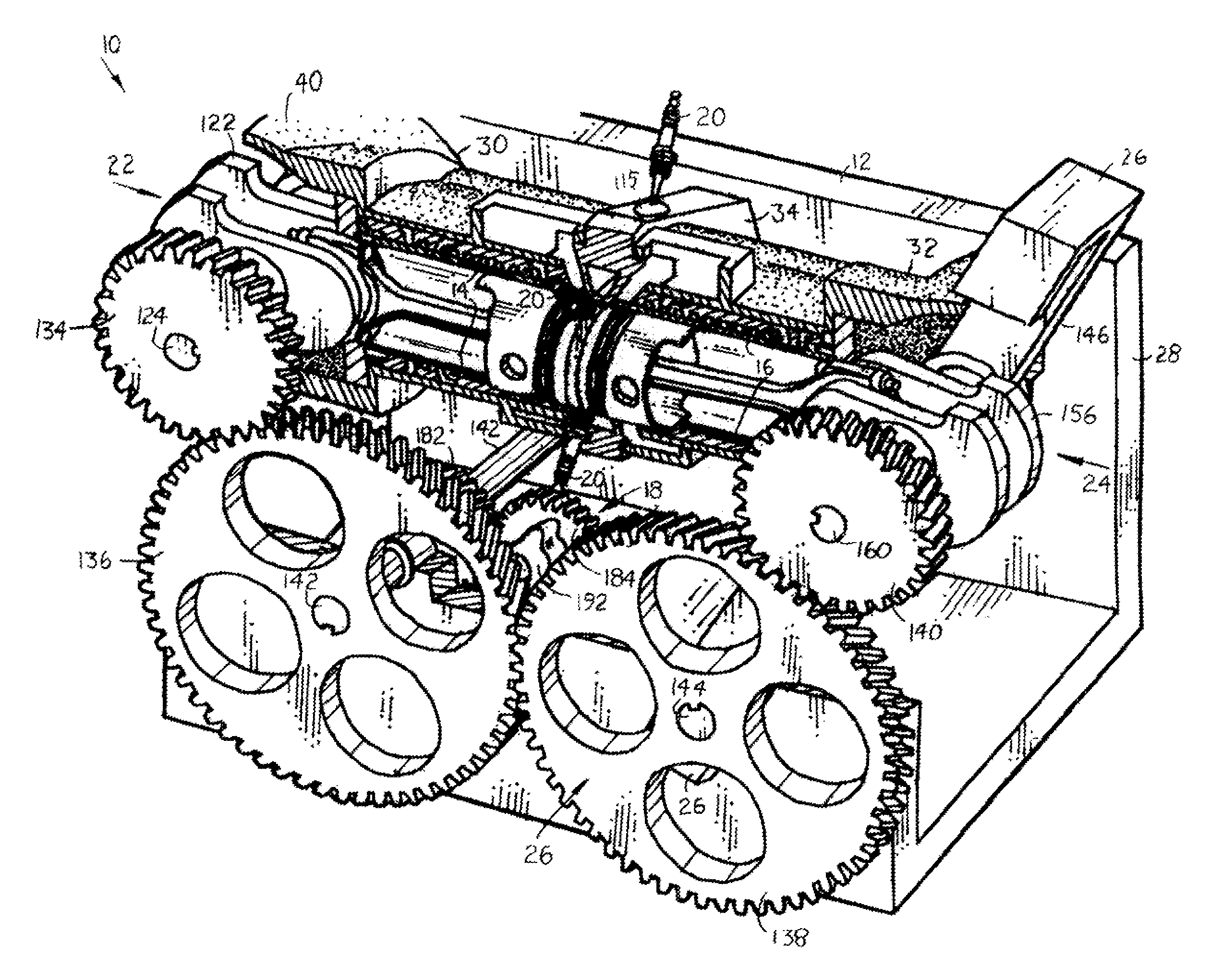

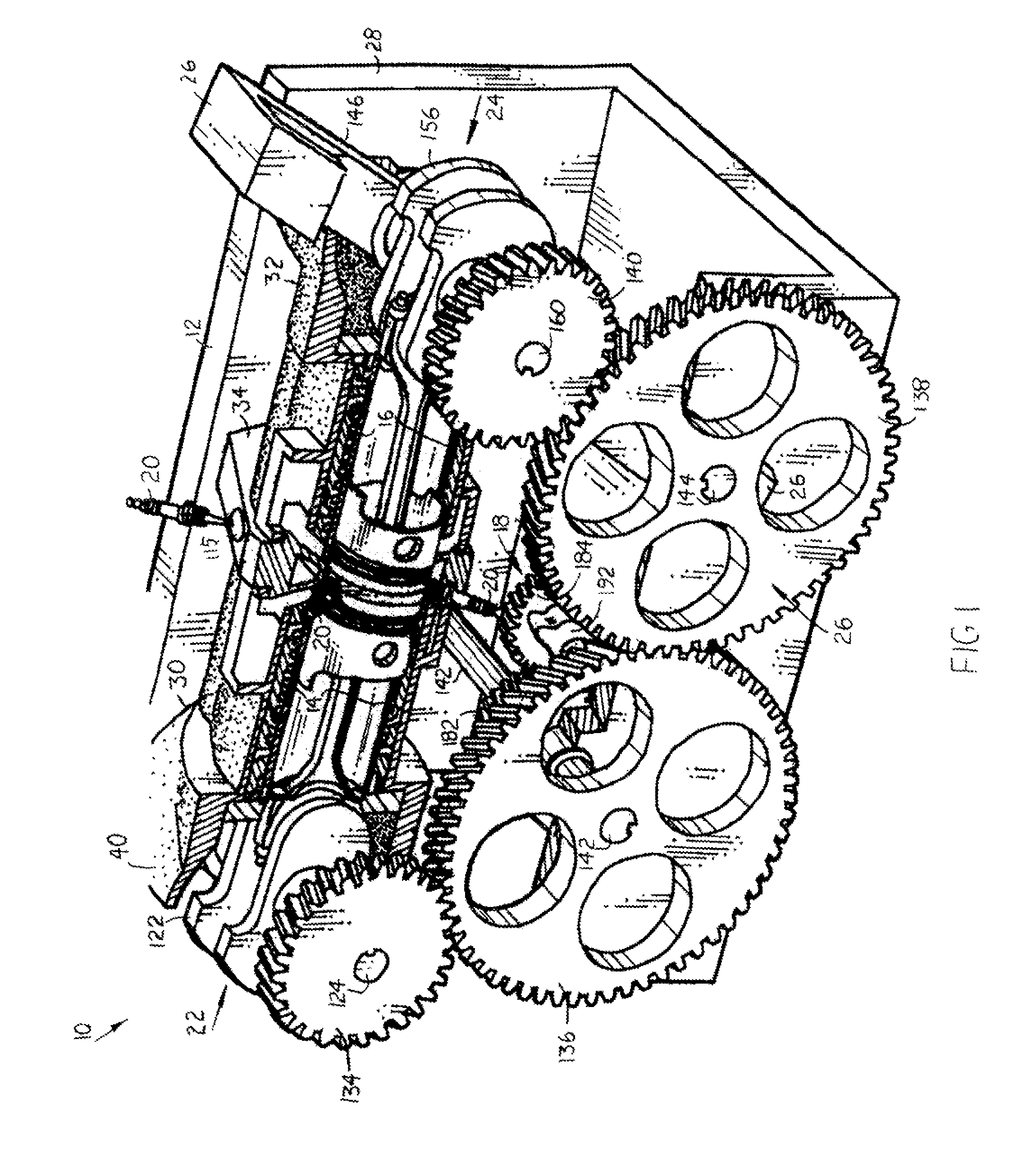

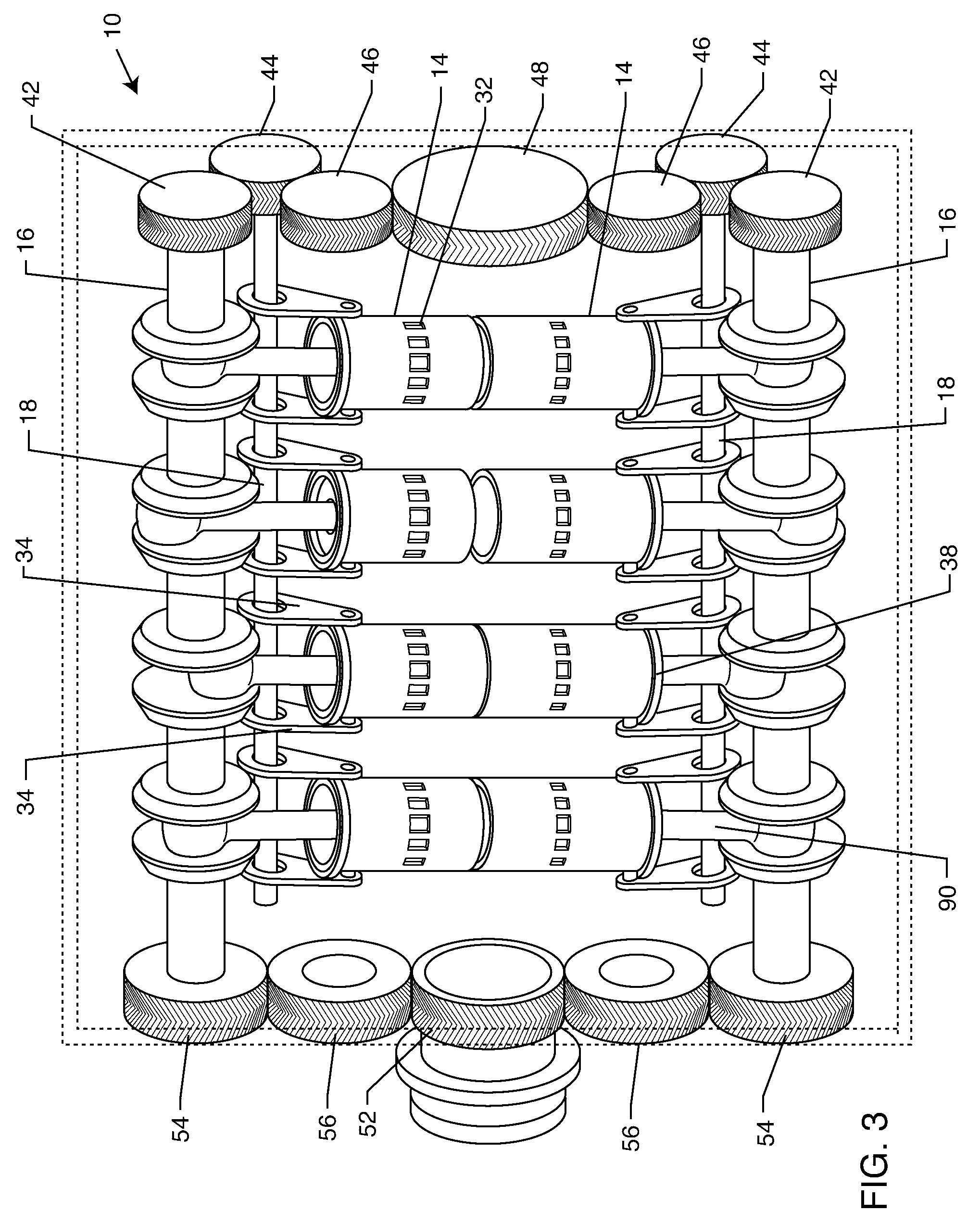

Internal combustion engine

InactiveUS7469664B2Reduce weightImprove efficiencyInternal combustion piston enginesOutput powerExternal combustion engineEngineering

An internal combustion engine is disclosed having opposed cylinders, each cylinder having a pair of opposed pistons. All the pistons may be connected to a common central crankshaft. The inboard pistons of each cylinder may be connected to a common joint on the crankshaft with pushrods and the outboard pistons may be connected to a common joint on the crankshaft with pullrods. Each opposed cylinder may include an integrated scavenge pump for providing positive intake pressure. The engine configuration also allows for asymmetrical timing of the intake and exhaust ports through angular positioning of the journals on the crankshaft.

Owner:ADVANCED PROPULSION TECH

Internal combustion engine

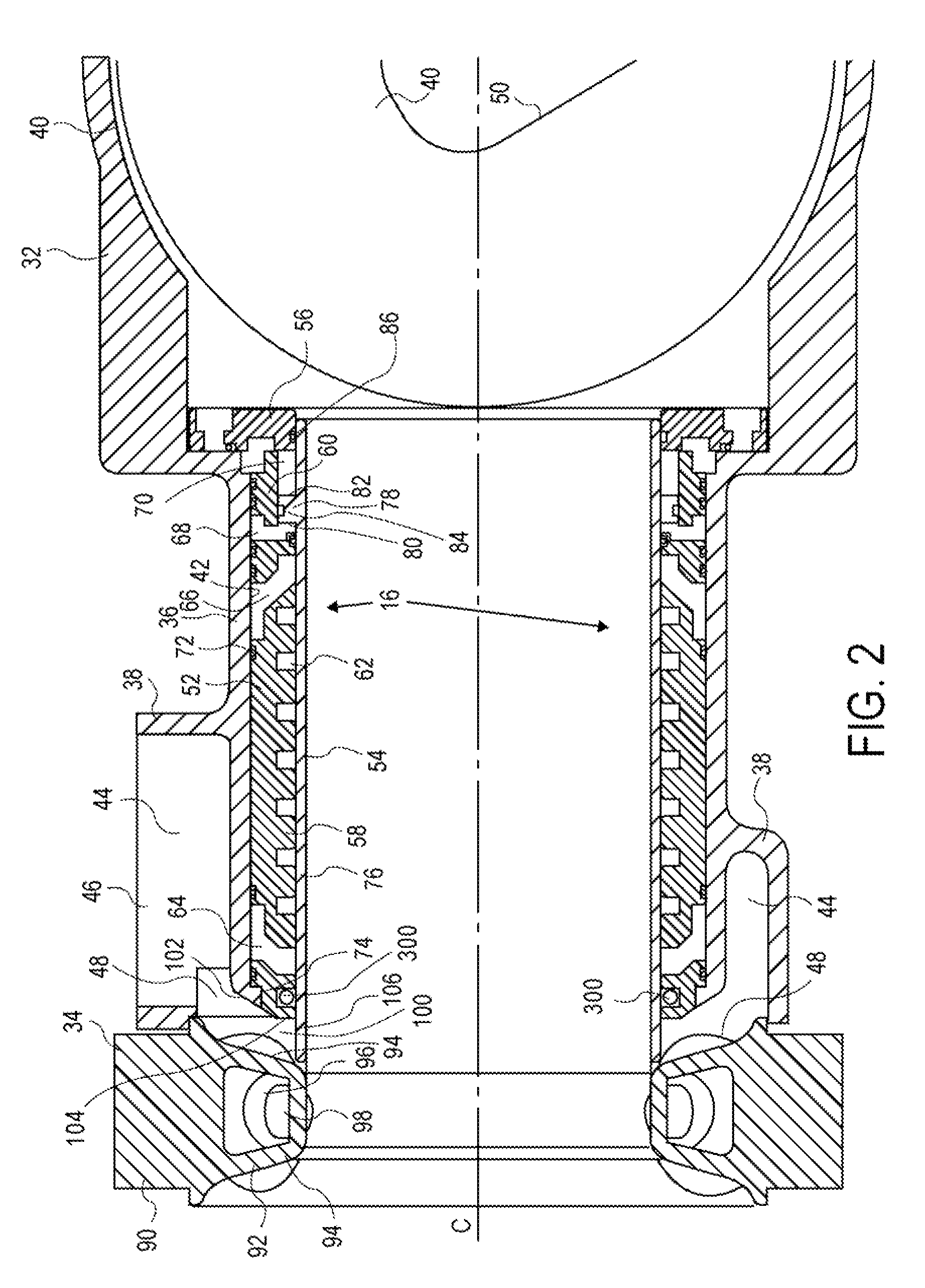

InactiveUS7559298B2Assist in containment of heat energyReduce energy lossLiquid coolingInternal combustion piston enginesCombustion chamberCylinder head

An internal combustion engine is provided. Facing pistons eliminate a cylinder head, thereby reducing heat losses through a cylinder head. Facing pistons also halve the stroke that would be required for one piston to provide the same compression ratio, and the engine can thus be run at higher revolutions per minute and produce more power. An internal sleeve valve is provided for space and other considerations. A combustion chamber size-varying mechanism allows for adjustment of the minimum size of an internal volume to increase efficiency at partial-power operation. Variable intake valve operation is used to control engine power.

Owner:CLEEVES ENGINES

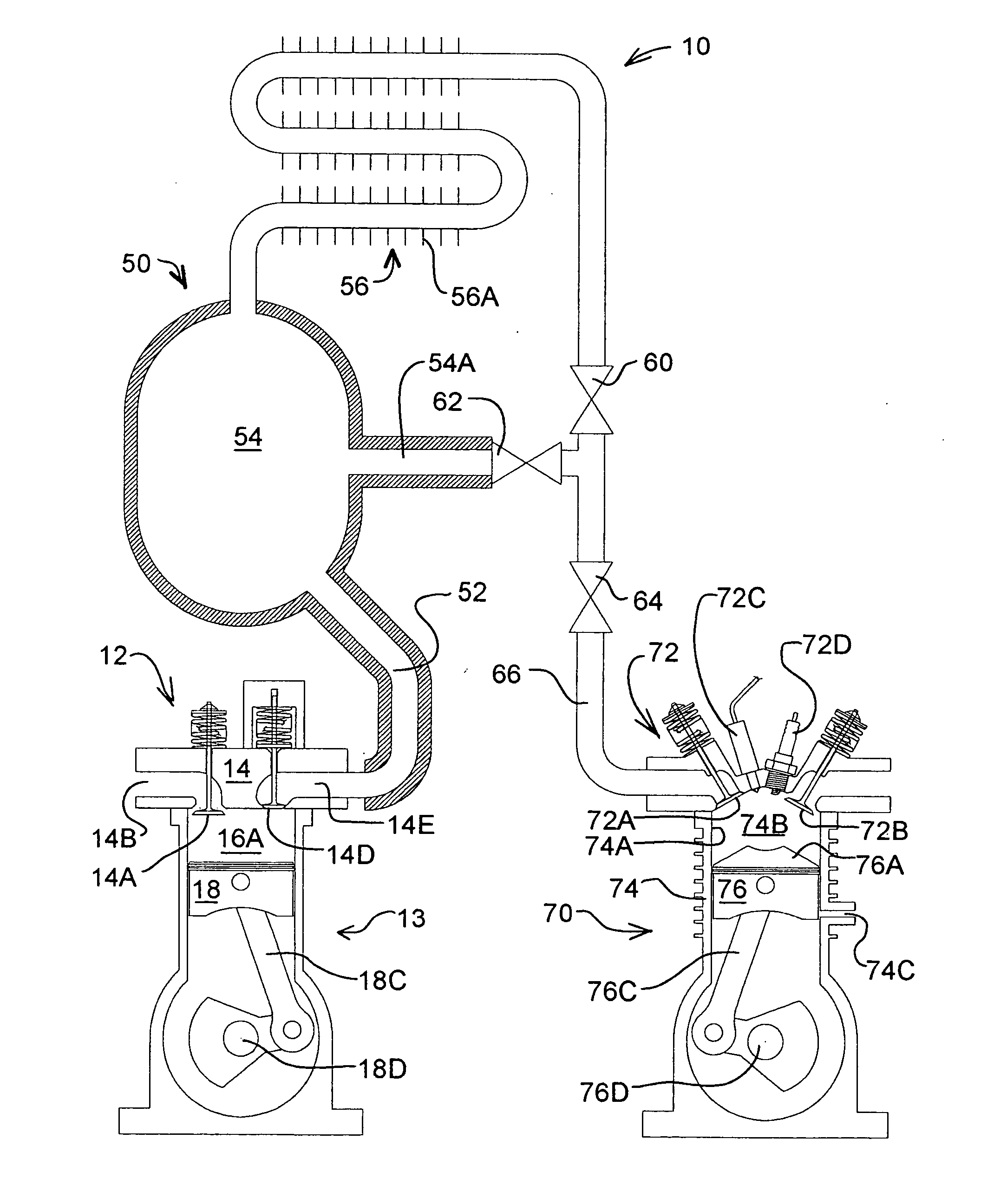

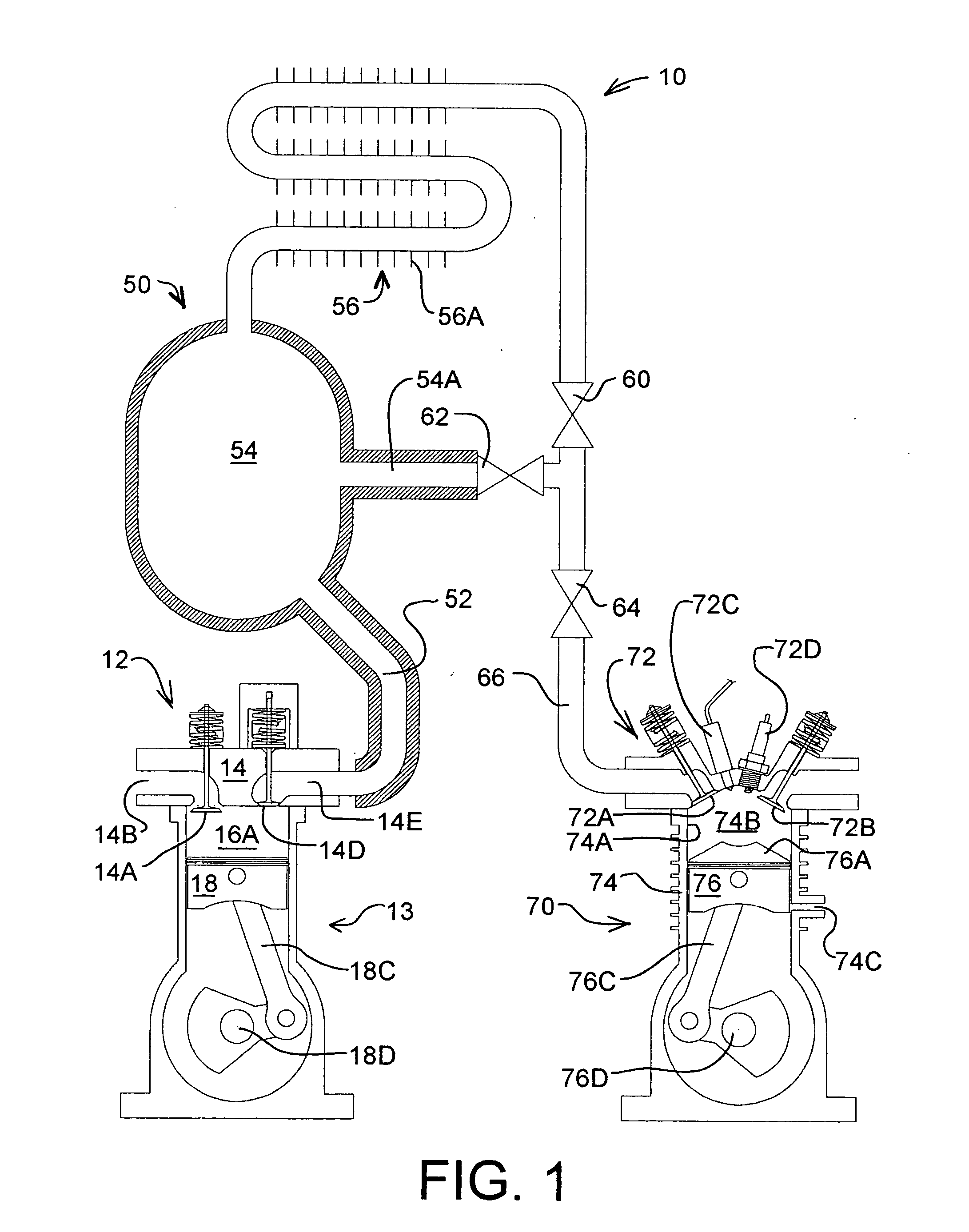

Liquid piston internal combustion power system

InactiveUS7191738B2Reduce pollutionRotary slide valveSteam engine plantsFree-piston engineCombustion

Methods, devices, and systems for power generation through liquid piston internal combustion engine. The liquid piston internal combustion engine of the invention utilizes a novel, synergetic combination of internal combustion and steam piston engines within the framework of one and the same system. The engine may comprise a plurality of cylinders, each having a liquid piston.

Owner:LIQUIDPISTON INC

Exhaust valve arrangement and a fuel system incorporating an exhaust valve arrangement

InactiveUS7533656B2Small diameterSecure attachmentMachines/enginesFuel injecting pumpsCombustion chamberExhaust valve

Owner:DELPHI INT OPERATIONS LUXEMBOURG S A R L

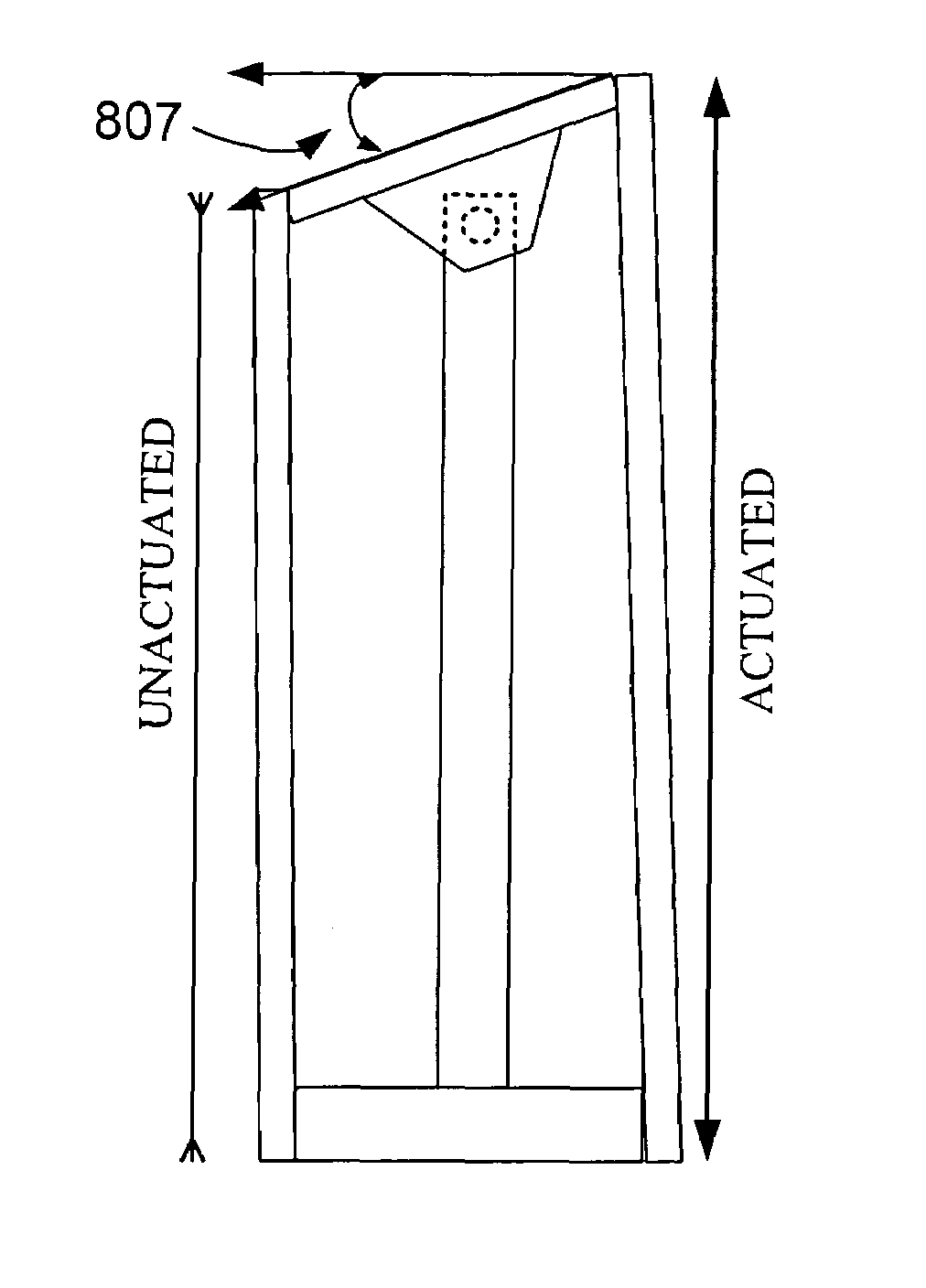

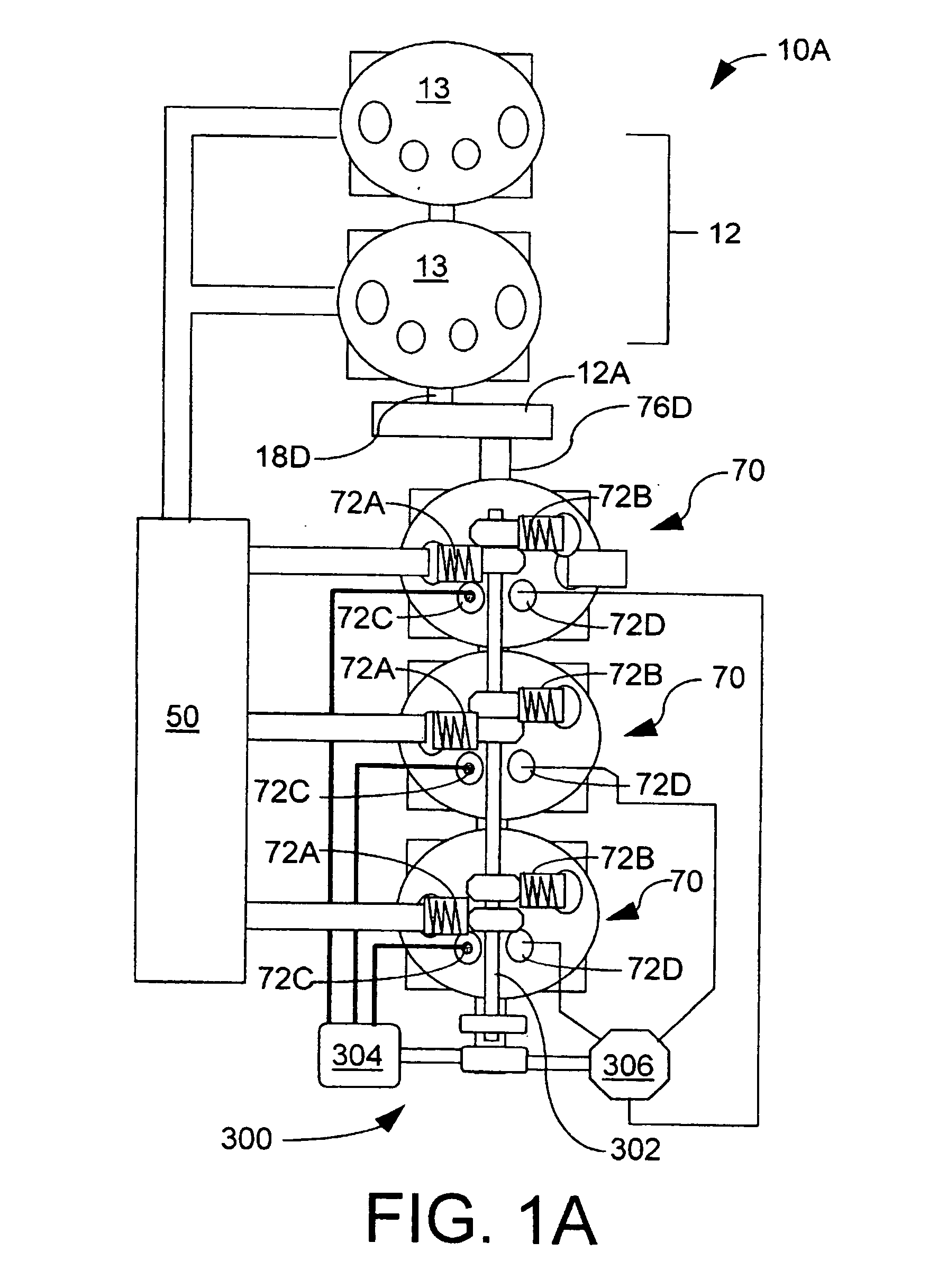

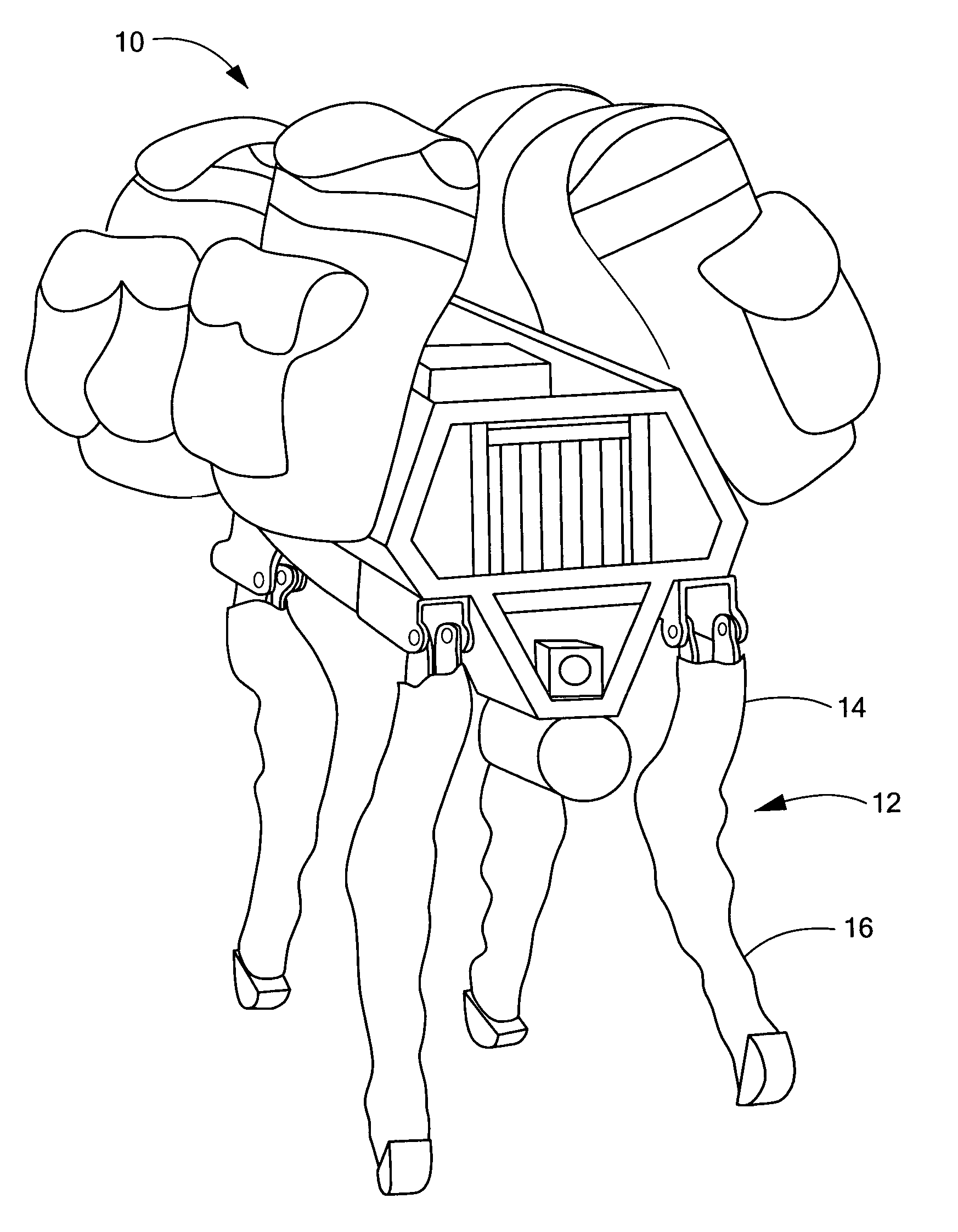

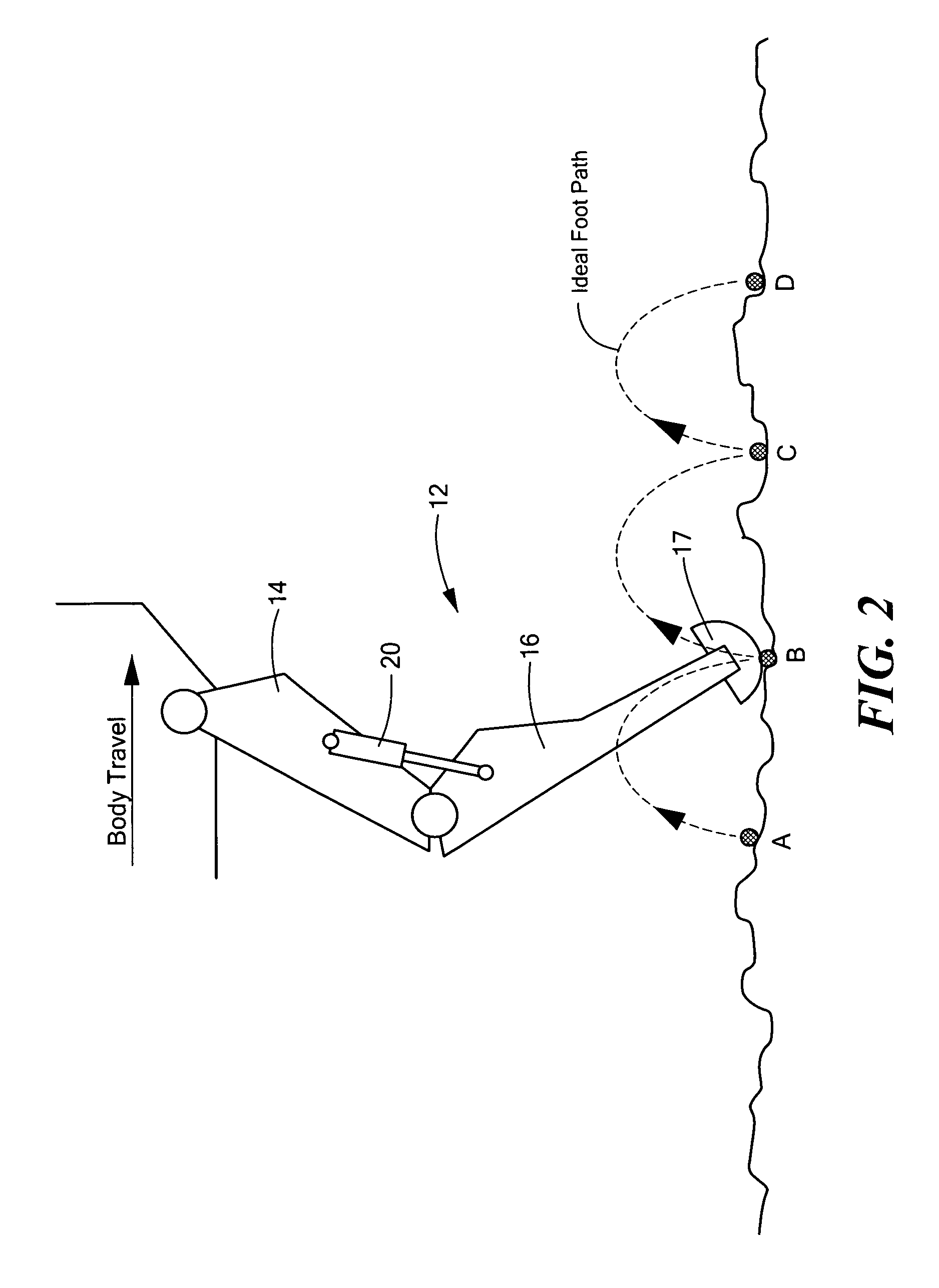

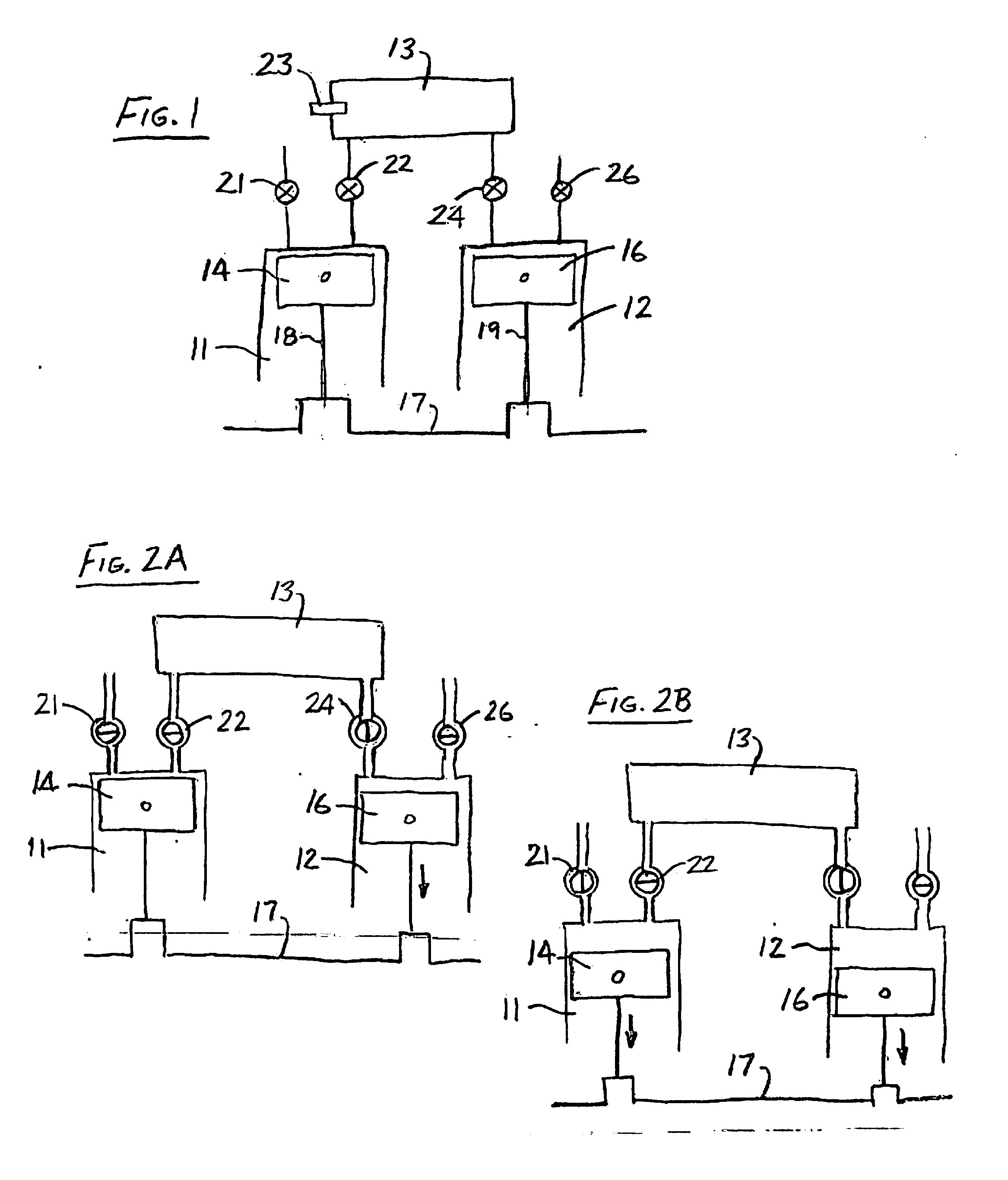

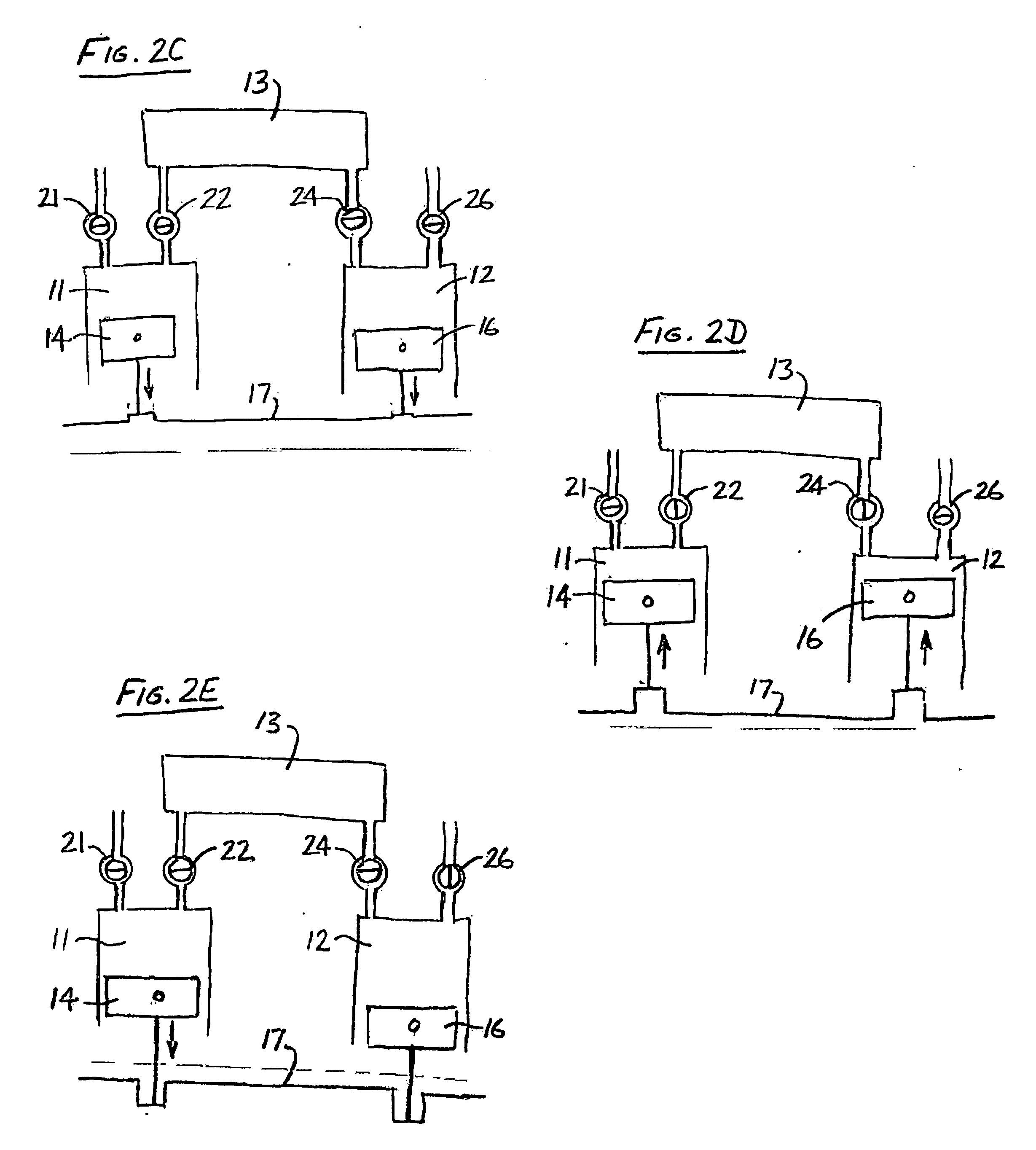

Actuator system

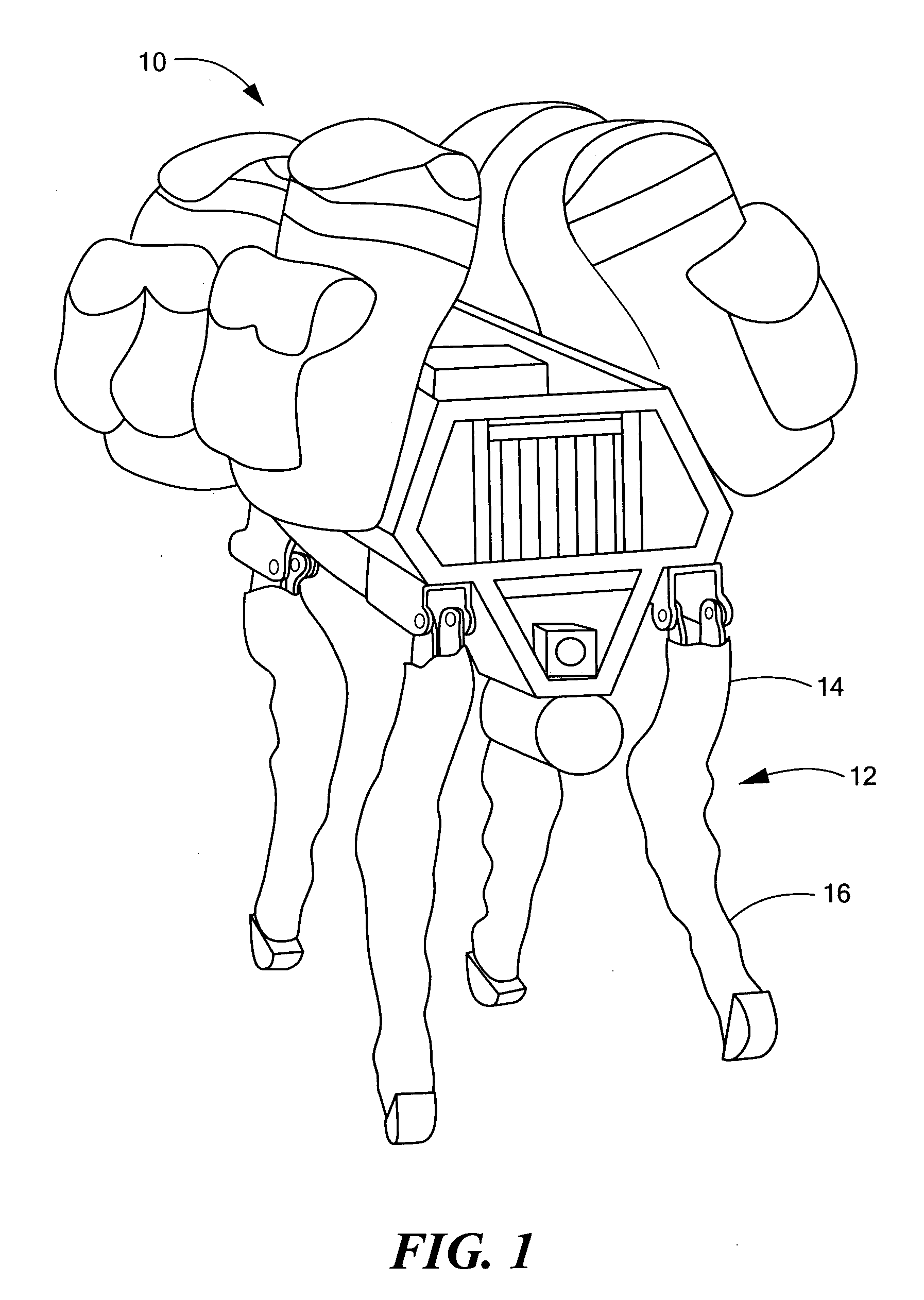

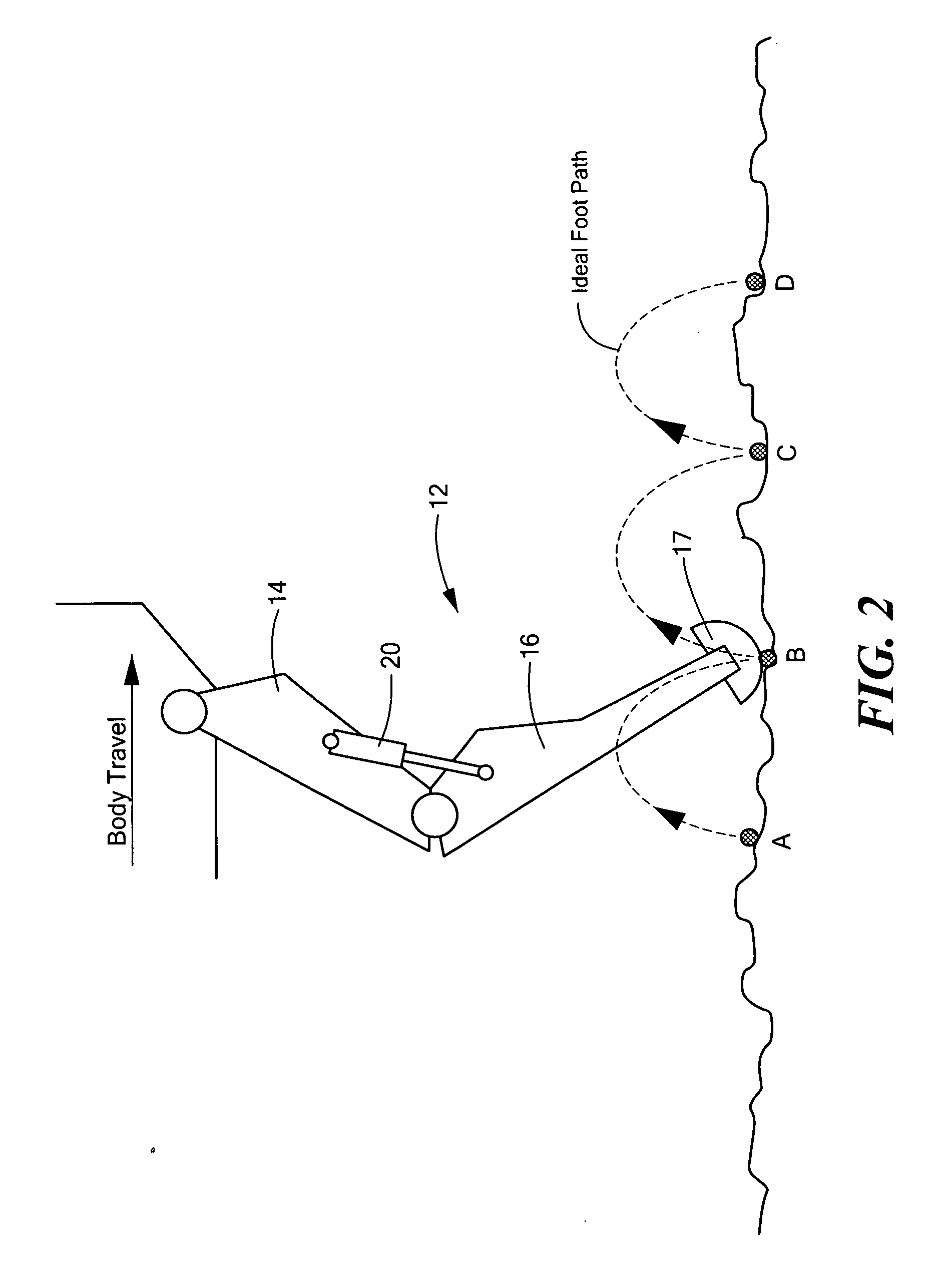

ActiveUS20100090638A1Increase powerFacilitates robots capable of carrying heavier payloadsProgramme-controlled manipulatorServomotorsHydraulic circuitActuator

An actuator subsystem preferably for a robot or bionic linkage. A joint between two robotic or bionic members includes at least first and second actuators such as piston-cylinder assemblies connected between the members. A hydraulic circuit includes a sensor subsystem for sensing the magnitude of the load on the piston-cylinder assemblies and / or members. A fluid supply system includes an actuatable control valve operable to supply fluid to one or both piston-cylinder assemblies. A control circuit is responsive to the sensor and is configured to electronically control the fluid subsystem to supply fluid to the first piston-cylinder assembly when the sensor subsystem senses a load below a predetermined magnitude and to supply fluid to both piston-cylinder assemblies when the sensor subsystem senses a load above the predetermined magnitude.

Owner:BOSTON DYNAMICS INC

Overhead rotary valve for engines

InactiveUS6308677B1Simple sealing deviceImprove sealingMachines/enginesRotary slide valveCombustion chamberExhaust valve

An overhead rotary valve fitted into a cylinder head with diametrical polygonal openings formed therein for use in combination with an internal combustion engine, driven to bring intake and exhaust ports into and out of alignment with passages leading to and from the combustion chamber. Sleeve bearings are fitted in the cylinder head that provide surface sealing, and annular sealing members prevent the air / fuel mixture or exhaust gases from flowing into regions intermediate ports and individual cylinders. Utilizing this overhead rotary valve and associated seals and bearings increases the efficiency and performance of an internal combustion engine. The overhead rotary valve rotating, at one quarter the speed of the crankshaft, minimizes wear and noise levels, self cleans the ports, allows the engine to operate at higher rpm and imparts proper opening and closing of passages at the proper sequence of valve timing without concern of valve float. The instant invention removes the need for reciprocating intake and exhaust valves, camshafts, rocker arms, lifters, push rods, valve guides and retainers, and other related hardware for actuation, significantly increasing the reliability and effectiveness of the internal combustion engine, while reducing overall manufacturing costs.

Owner:BOHACH WILLIAM LOUIS +1

Internal combustion engine

ActiveUS20070028866A1Reduce twistReduce torsion forceInternal combustion piston enginesSlide valveReciprocating motionEngineering

In accordance with the invention, an internal combustion engine having reciprocating piston sleeves is realized comprising an engine block with a pair of cylinders, each cylinder having an intake port, an exhaust port and two linearly opposing pistons connected to two opposing crankshafts. A pair of piston sleeves are reciprocatingly mounted in each cylinder, one piston sleeve around each piston. Each piston sleeve is connected to one of two eccentric shafts that run parallel and adjacent to each crankshaft. The piston sleeves have ported slots in communication with either the intake ports or the exhaust ports of each cylinder. The eccentric shafts are mechanically connected to the crankshafts such that they move in unison.

Owner:STRAIGHT DYNE

Internal combustion engine

ActiveUS7234423B2Little strengthInternal combustion piston enginesSlide valveInternal combustion engineCylinder block

In accordance with the invention, an internal combustion engine having reciprocating piston sleeves is realized comprising an engine block with a pair of cylinders, each cylinder having an intake port, an exhaust port and two linearly opposing pistons connected to two opposing crankshafts. A pair of piston sleeves are reciprocatingly mounted in each cylinder, one piston sleeve around each piston. Each piston sleeve is connected to one of two eccentric shafts that run parallel and adjacent to each crankshaft. The piston sleeves have ported slots in communication with either the intake ports or the exhaust ports of each cylinder. The eccentric shafts are mechanically connected to the crankshafts such that they move in unison.

Owner:STRAIGHT DYNE

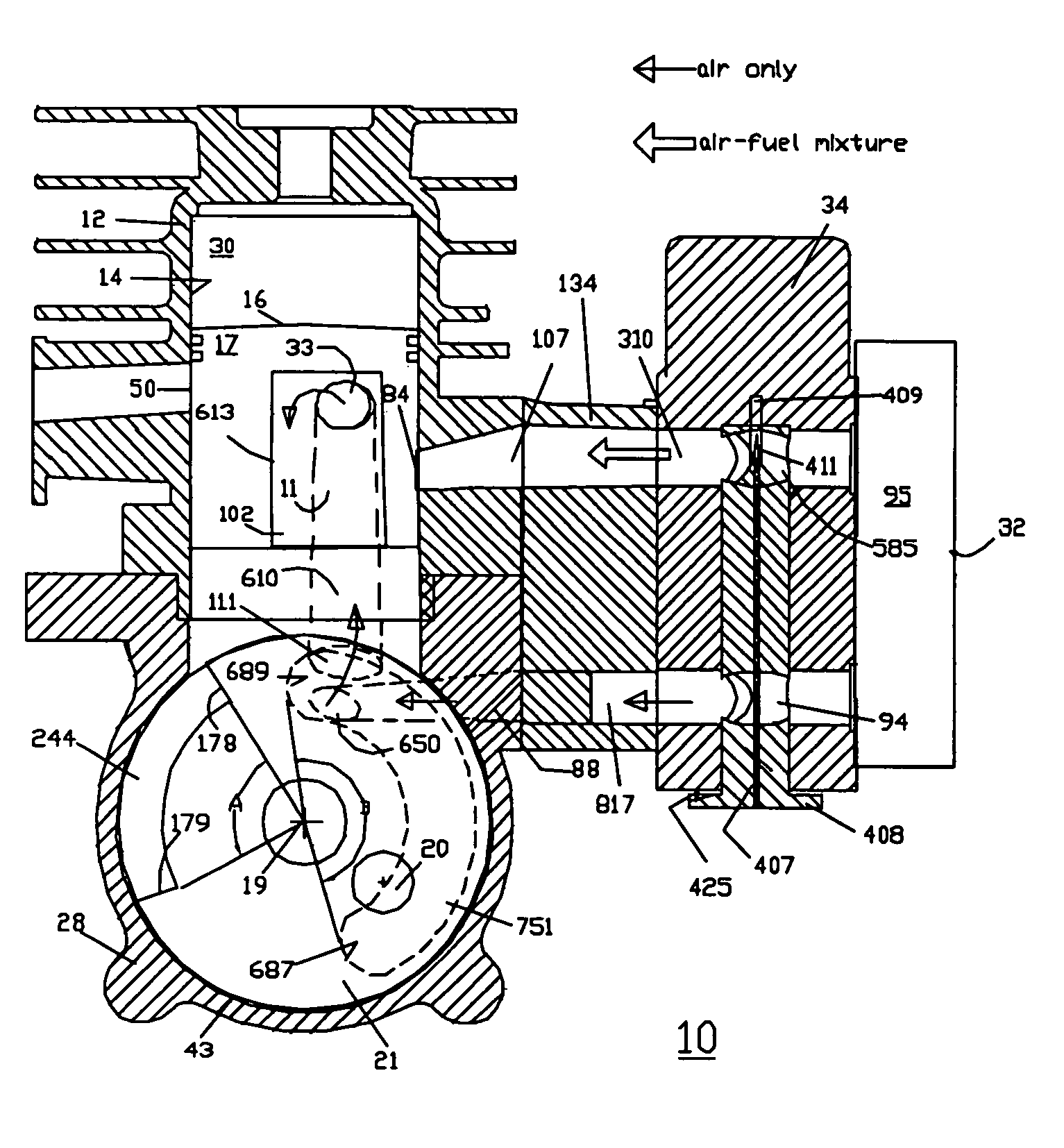

Air injection engine

InactiveUS7007639B1Improve power densityHigh expansion rateInternal combustion piston enginesOutput powerCombustionExternal combustion engine

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

Stratified scavenged two-stroke engine

InactiveUS20050139179A1Increase volumeCombustion enginesEngine controllersCharge injectionFour-stroke engine

A two-stroke internal combustion engine includes at least one gaseous communication charge passage between a crankcase chamber and a combustion chamber of the engine and a piston to open and close the top end of the passage and a rotary valve to open and close the lower end of the transfer passage. The air inlet port to the transfer passage for stratified scavenging is opened and closed by the crank-web that has passages and cutouts. The rotary valve replaces the one-way reed valve used in stratified scavenged and charged two-stroke engines. The air passes from the lower end of transfer passage to the top end and into the crankcase through the piston passage, alternatively air may also pass through the adjacent transfer passage directly or through a passage in the piston into the crankcase. A two-stroke engine also consists of a charge injection system controlled by the crank web eliminating the one-way valve.

Owner:HOMELITE TECH

Internal combustion engine

InactiveUS20060124084A1Improve efficiencyHeight profile of has been reducedInternal combustion piston enginesOutput powerControl theoryMechanical engineering

A two-stroke internal combustion engine is disclosed having opposed cylinders, each cylinder having a pair of opposed pistons, with all the pistons connected to a common central crankshaft. The inboard pistons of each cylinder are connected to the crankshaft with pushrods and the outboard pistons are connected to the crankshaft with pullrods. Each opposed cylinder further comprises an integrated scavenge pump for providing positive intake pressure. This configuration results in a compact engine with a very low profile, in which the free mass forces can be substantially balanced. The engine configuration also allows for asymmetrical timing of the intake and exhaust ports through angular positioning of the journals on the crankshaft.

Owner:ADVANCED PROPULSION TECH

Rolled electroactive polymers

InactiveUS20080022517A1Increase conversionsImprove performanceFlexible member pumpsMedical devicesPolymer scienceMechanical energy

The invention describes rolled electroactive polymer devices. The invention also describes employment of these devices in a wide array of applications and methods for their fabrication. A rolled electroactive polymer device converts between electrical and mechanical energy; and includes a rolled electroactive polymer and at least two electrodes to provide the mechanical / electrical energy conversion. Prestrain is typically applied to the polymer. In one embodiment, a rolled electroactive polymer device employs a mechanism, such as a spring, that provides a force to prestrain the polymer. Since prestrain improves mechanical / electrical energy conversion for many electroactive polymers, the mechanism thus improves performance of the rolled electroactive polymer device.

Owner:SRI INTERNATIONAL

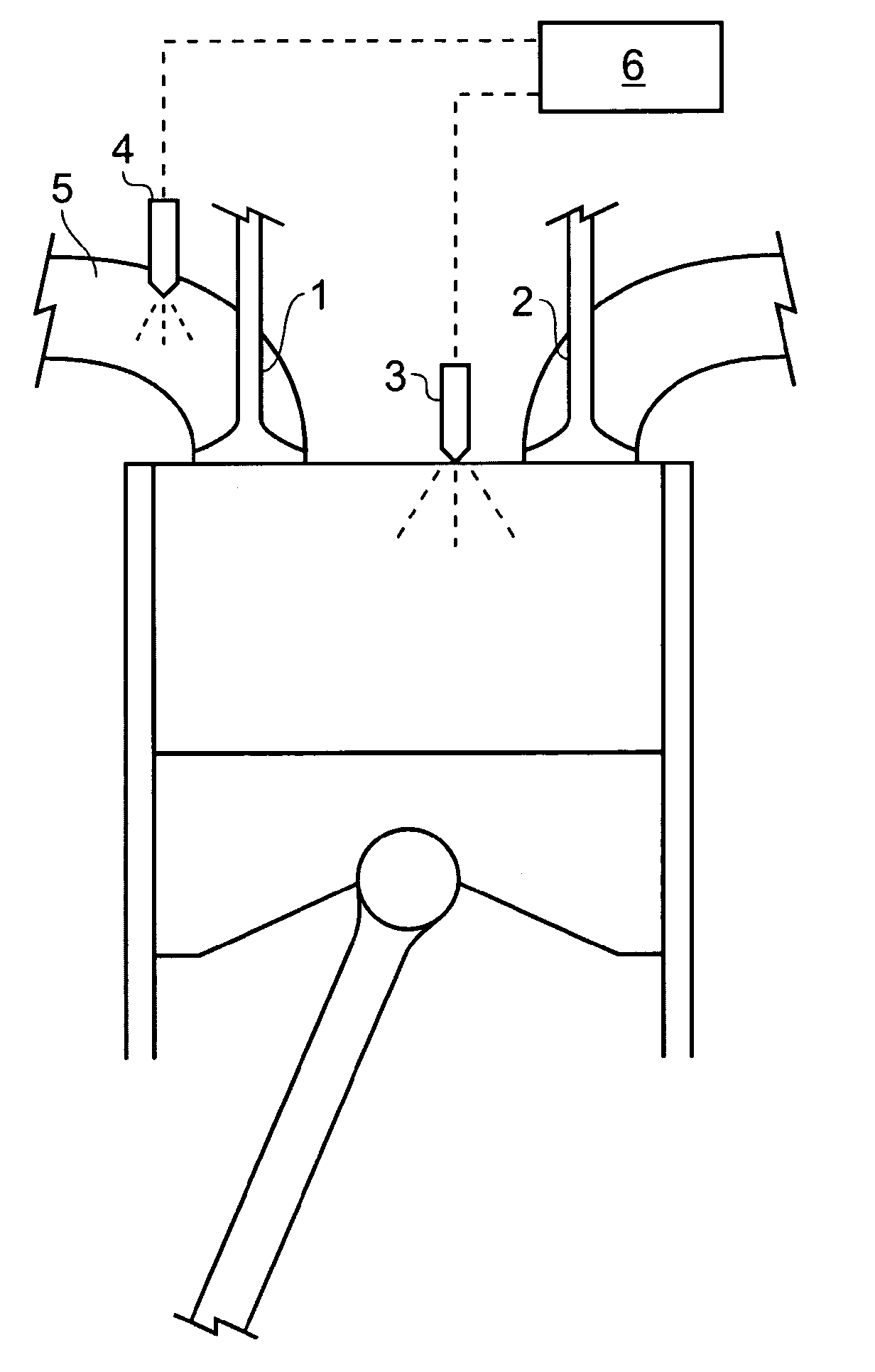

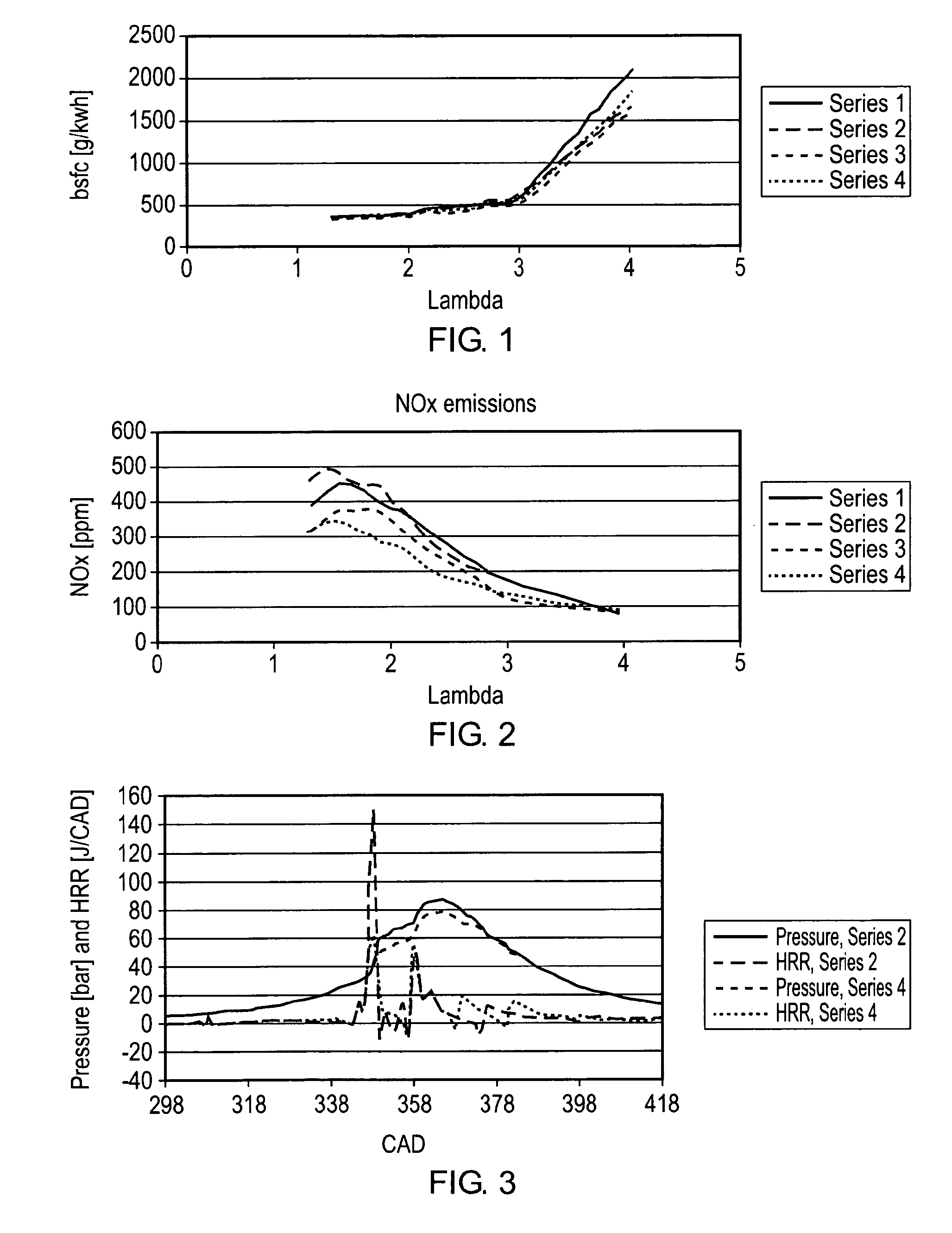

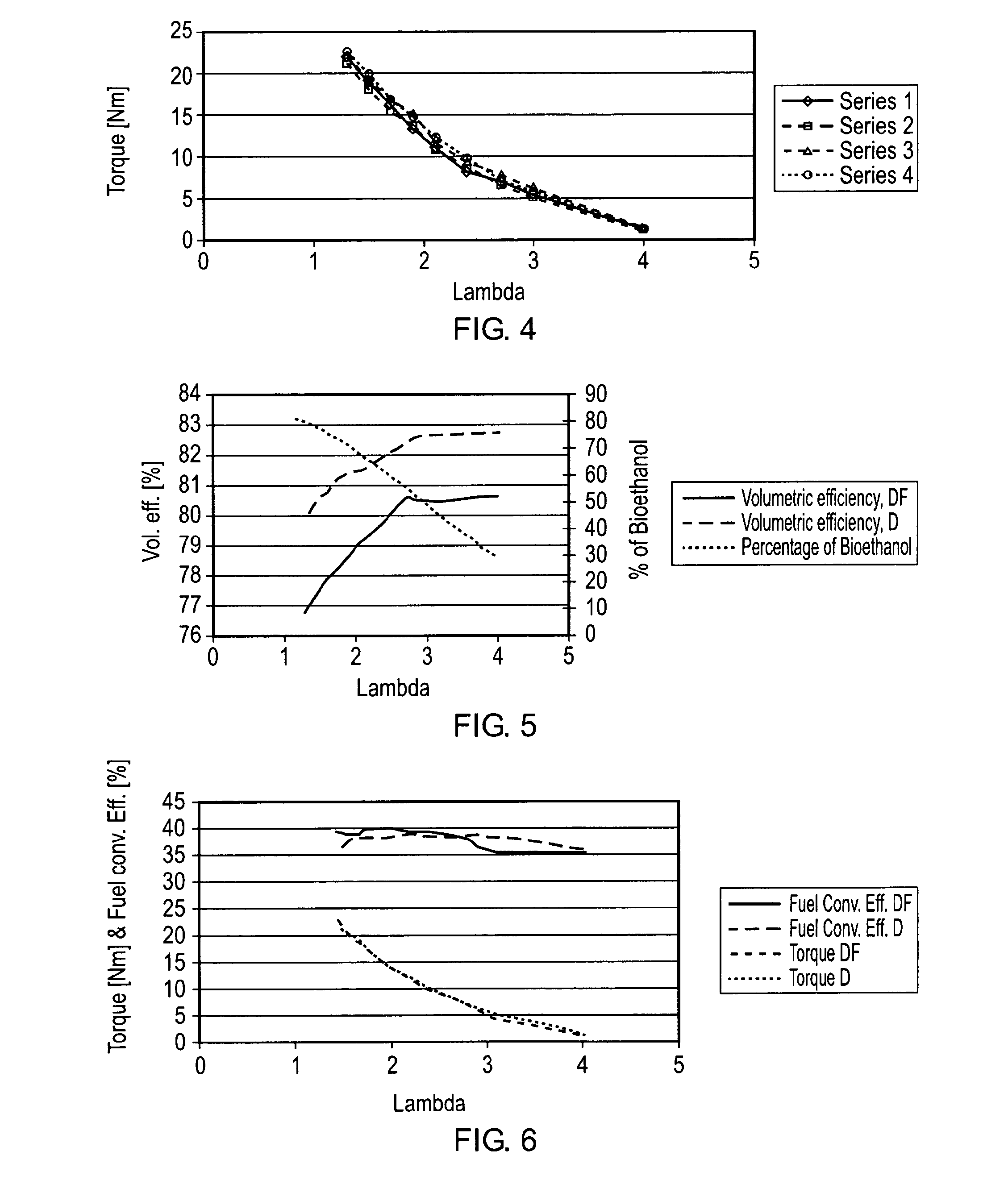

Multi-fuelling an engine

InactiveUS20110088654A1Reduce NOxReduce soot emissionsElectrical controlInternal combustion piston enginesBiodieselCombustion chamber

A compression ignition engine is supplied with a first fuel in a flow of air and a second fuel is injected into the combustion chamber. The first fuel comprises a more volatile fuel than diesel such as ethanol, LPG or other combustible gas; the second fuel comprises diesel or biodiesel; and the second fuel is injected in multiple pulses in each ignition cycle with the first pulse acting as a pilot pulse to trigger ignition, and the timing of the second pulse being such as to modify the temperature through evaporation of the second fuel and thereby reduce the combustion temperature and mitigate knock susceptibility. Preferably the pilot pulse is followed by a single further pulse of the second fuel in the ignition cycle. The engine may be controlled to operate in two different modes, one mode for light and medium load conditions when there is only a pilot pulse injection of the second fuel which reduces NOx and soot emissions, and the other mode for higher load conditions when there is a pilot pulse injection followed by a main pulse injection of the second fuel. The first fuel may comprise bioethanol and or one or more of the following: ethanol, butanol, propanol, lpg, natural gas, hydrogen.

Owner:G VOLUTION

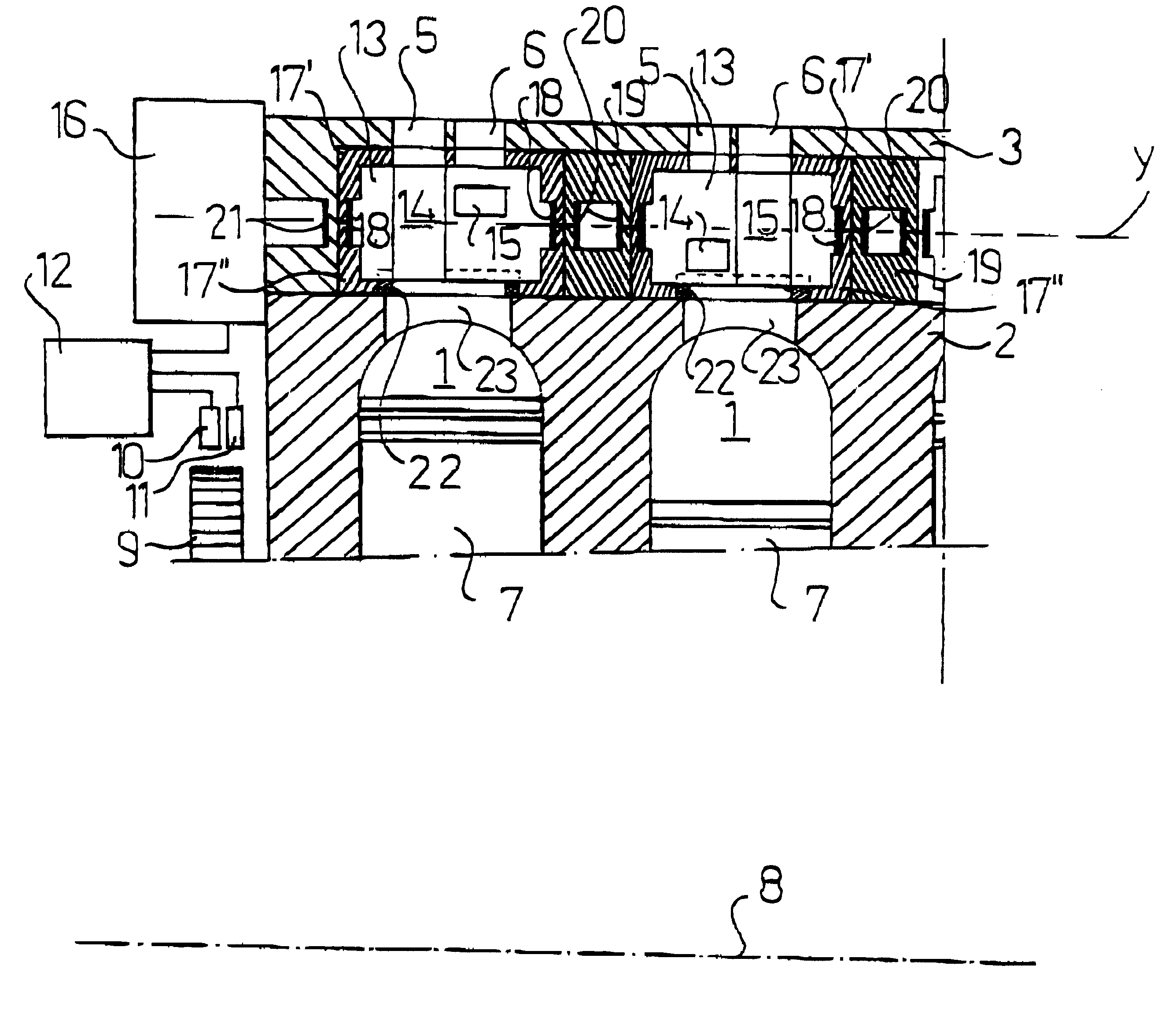

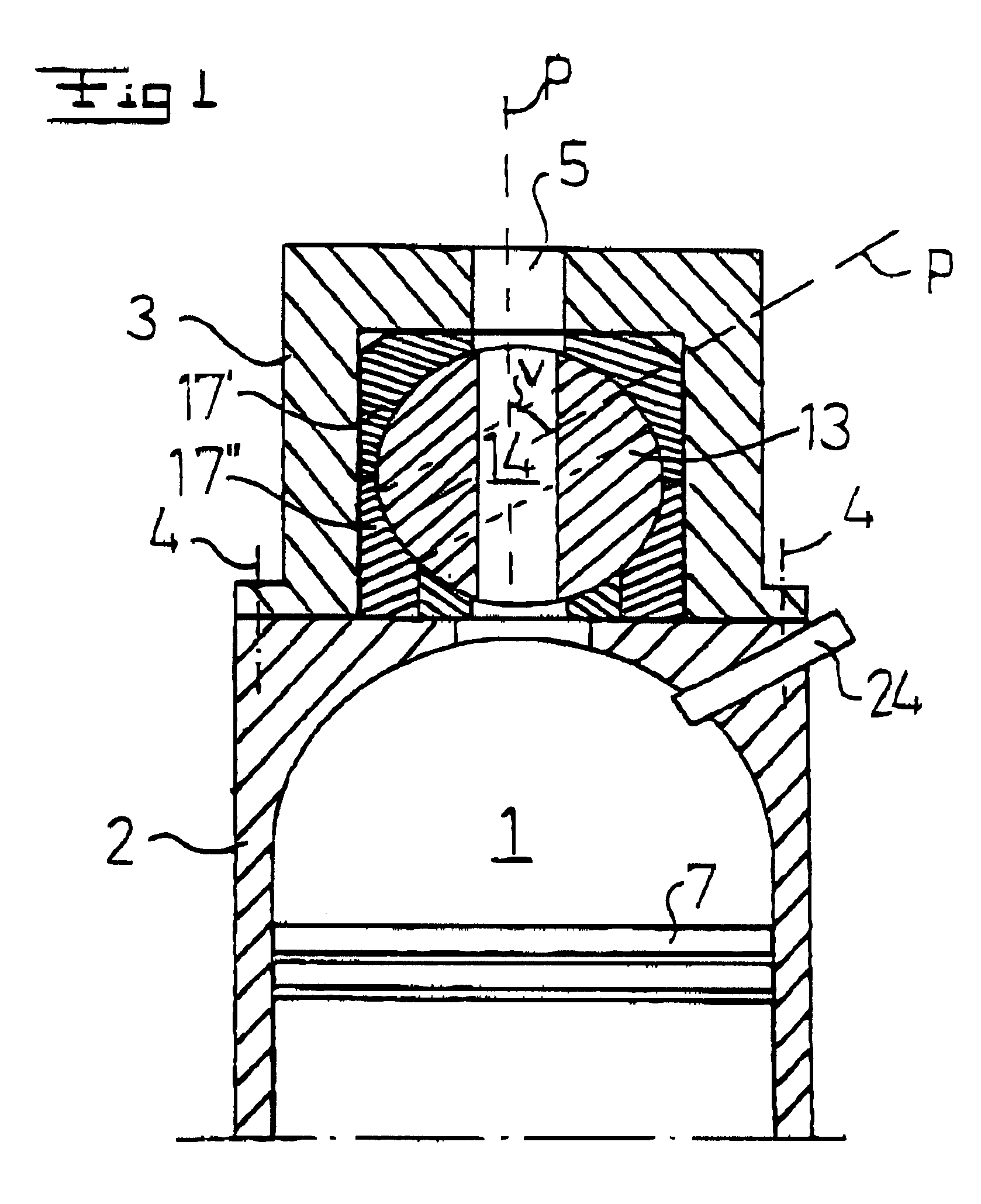

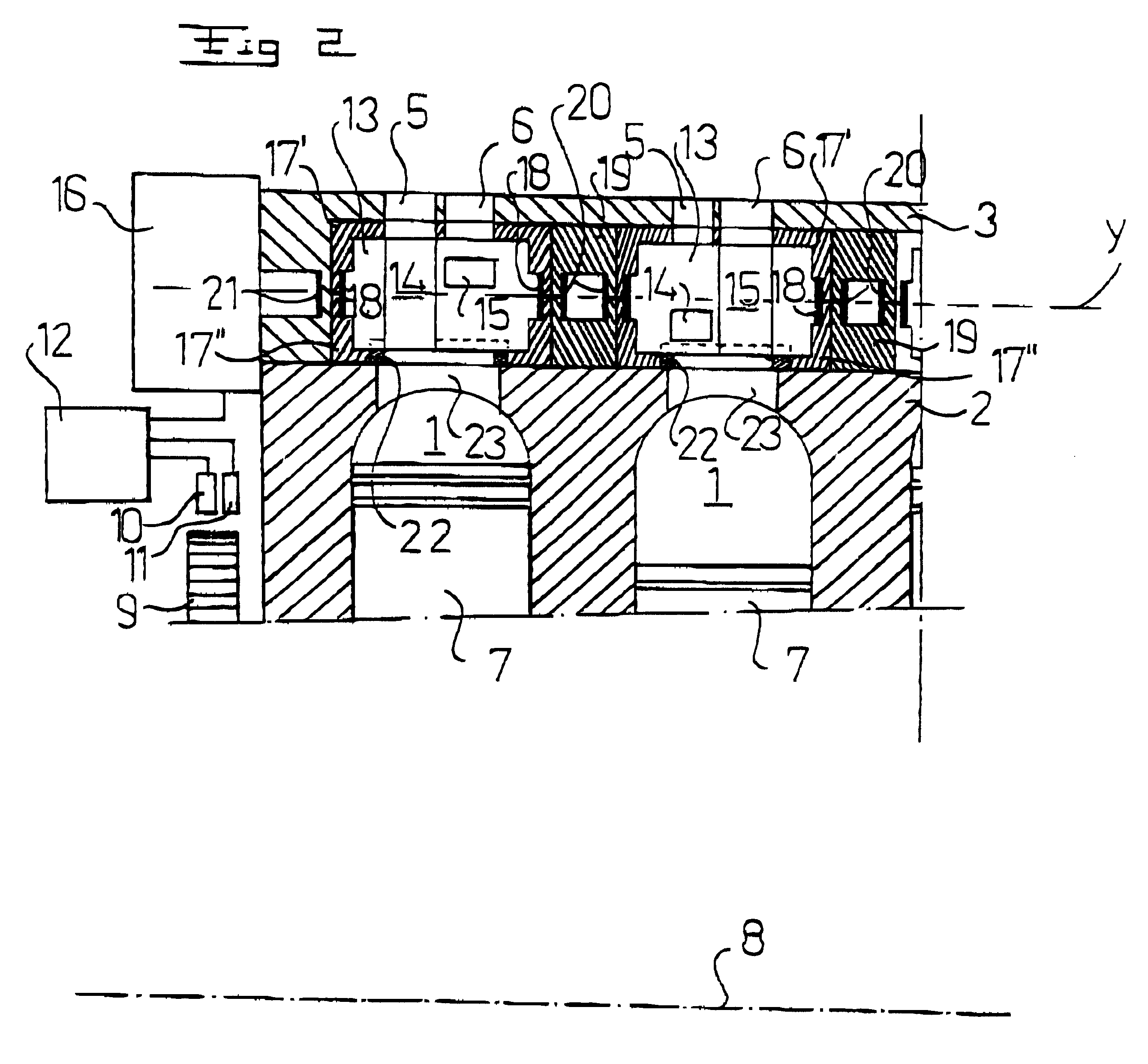

Valve device for an internal combustion engine

InactiveUS6443116B1Slowly successive openingSlowly successive closingMachines/enginesRotary slide valveCombustion chamberInternal combustion engine

The invention refers to a valve device for a combustion engine which includes a combustion chamber (1) and at least one channel (5) for communication between the combustion chamber (1) and an external space. The valve device includes a rotatable valve body (13), which is provided in said channel (5) and includes a passage (14) extending in a direction through said valve body (13). The valve body (13), which is rotatable around an axis of rotation forming an angle to the direction (p) of said passage (14), is arranged to open and close, respectively, said channel (5) by means of said passage (14) by rotation, a rotary motor (16) separated from the combustion engine is provided.

Owner:DAFAB

Air injection engine

InactiveUS20060124085A1Ratio of compression can be significantly higher or lowerHigh expansion rateInternal combustion piston enginesOutput powerInjection airCylinder (engine)

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

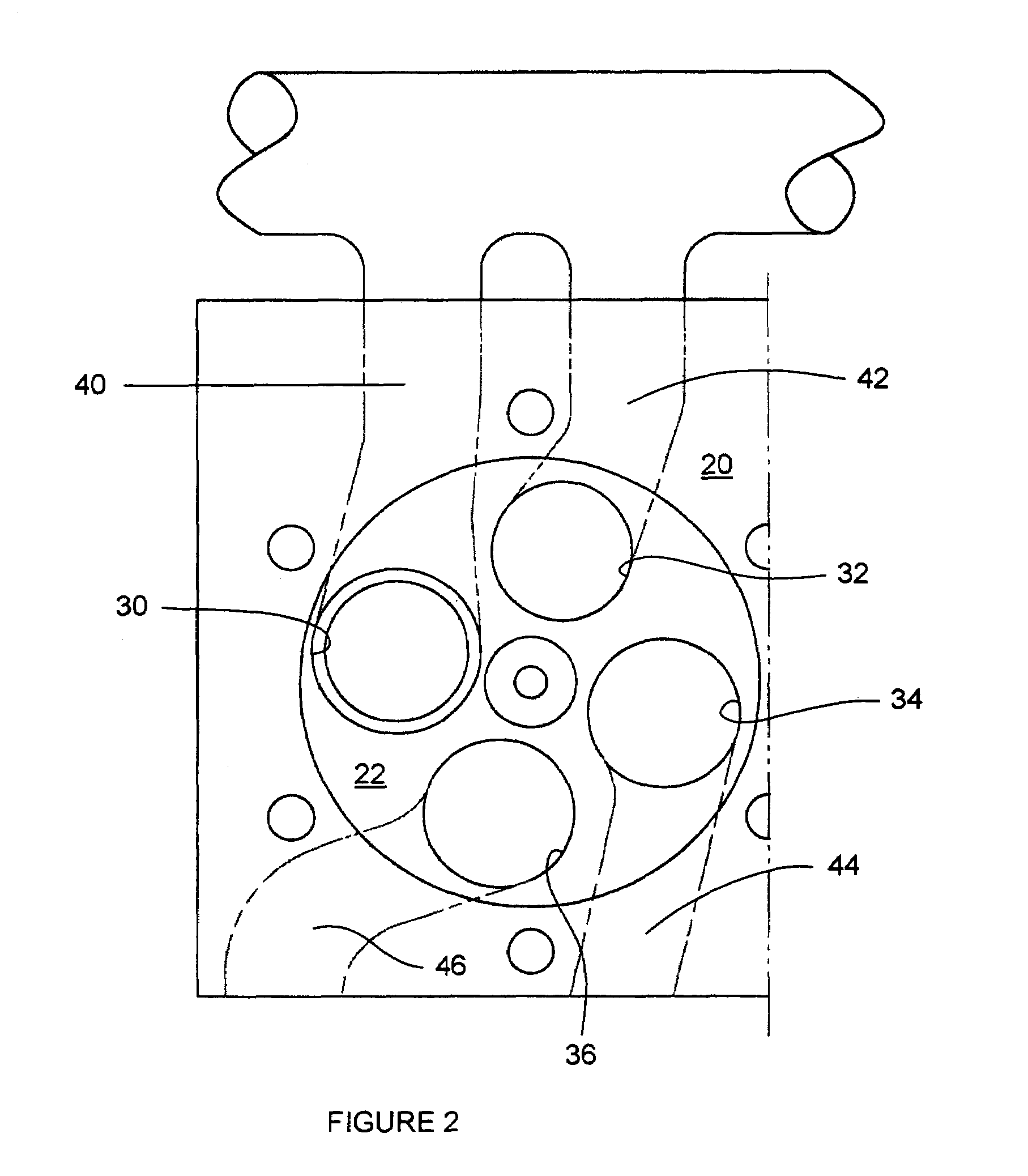

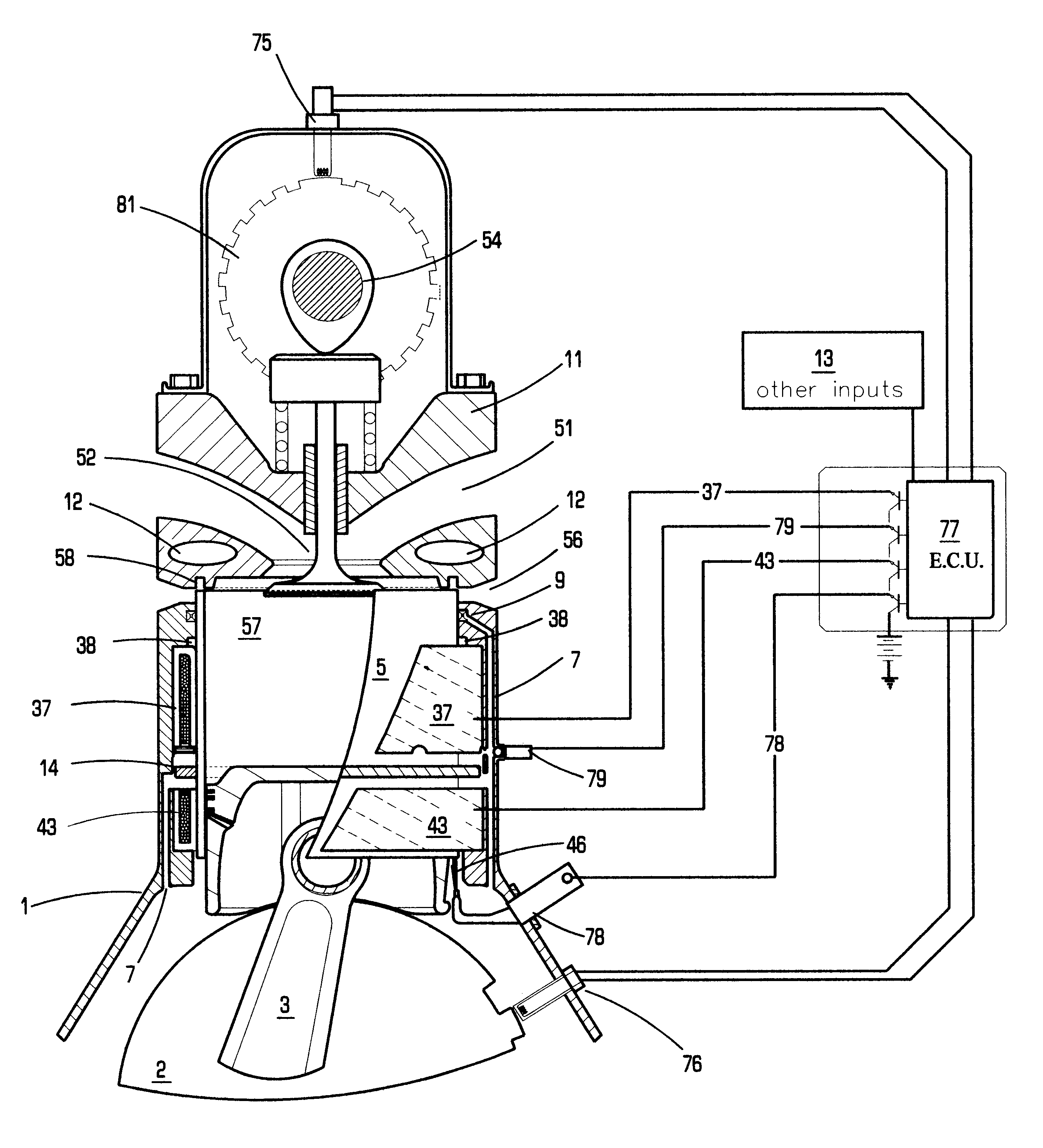

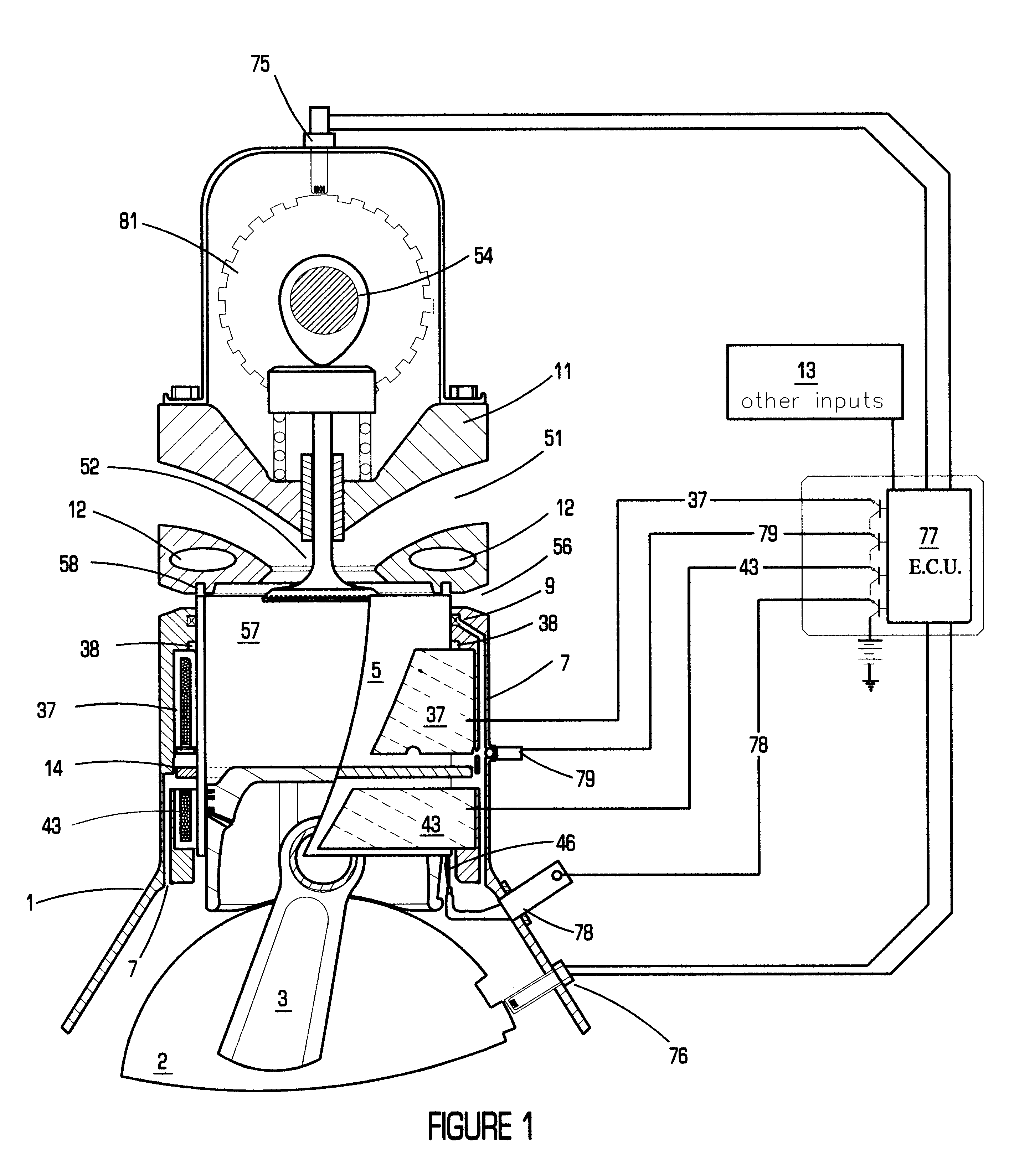

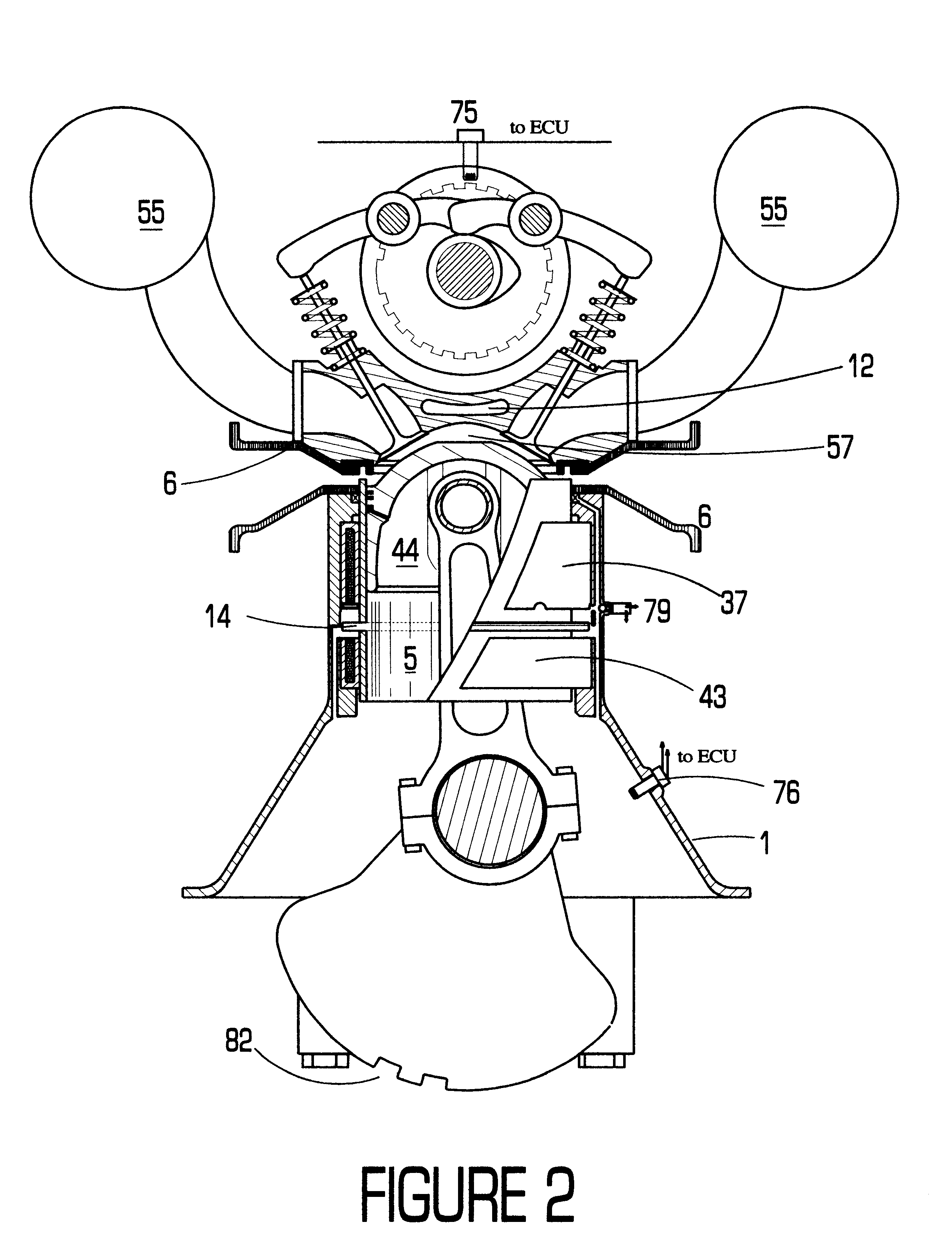

High power density, low emission internal combustion engine

InactiveUS6205963B1Improve power densityEasy constructionCasingsInternal combustion piston enginesWater basedIntermittent motion

An improved internal combustion piston engine that utilizes, in combination at least one poppet valve 52 of known type and a sleeve valve 5 to affect the functions of intake and exhaust gas flow. The resulting gross increase in valve area and volumetric efficiency enables the engine to produce high specific power without large valve opening durations or valve overlap and the resultant undesirable increase in low speed pollution and torque reduction.One embodiment of this invention will use the at least one poppet valve 52 as an intake valve, and the sleeve valve 5 as an exhaust valve. Another embodiment of this invention will use the at least one poppet valve 52 as an exhaust valve, with the sleeve valve 5 performing the intake valve function.Additionally, the sleeve valve may be either constantly or intermittently or incrementally moved to open or close a port through described methods. Intermittent movement of the sleeve valve may be controlled by a computer 77 in known manner, a novel advantage being that a relatively small amount of energy is required for this function because the sleeve is largely moved by friction with the piston 46 or associated parts 47, 48, 49.Another novel feature is the use of engine oil instead of a water based coolant to control heat in the cylinder sleeve area 10. This minimizes friction and significantly simplifies cylinder block design and manufacture.The use of poppet valves which are either intake or exhaust valves simplifies cylinder head design, and the elimination of cold and hot valve and port areas in the confined space of a cylinder head reduces the complexity of design for use of ceramic materials.

Owner:DAVIES JIM W

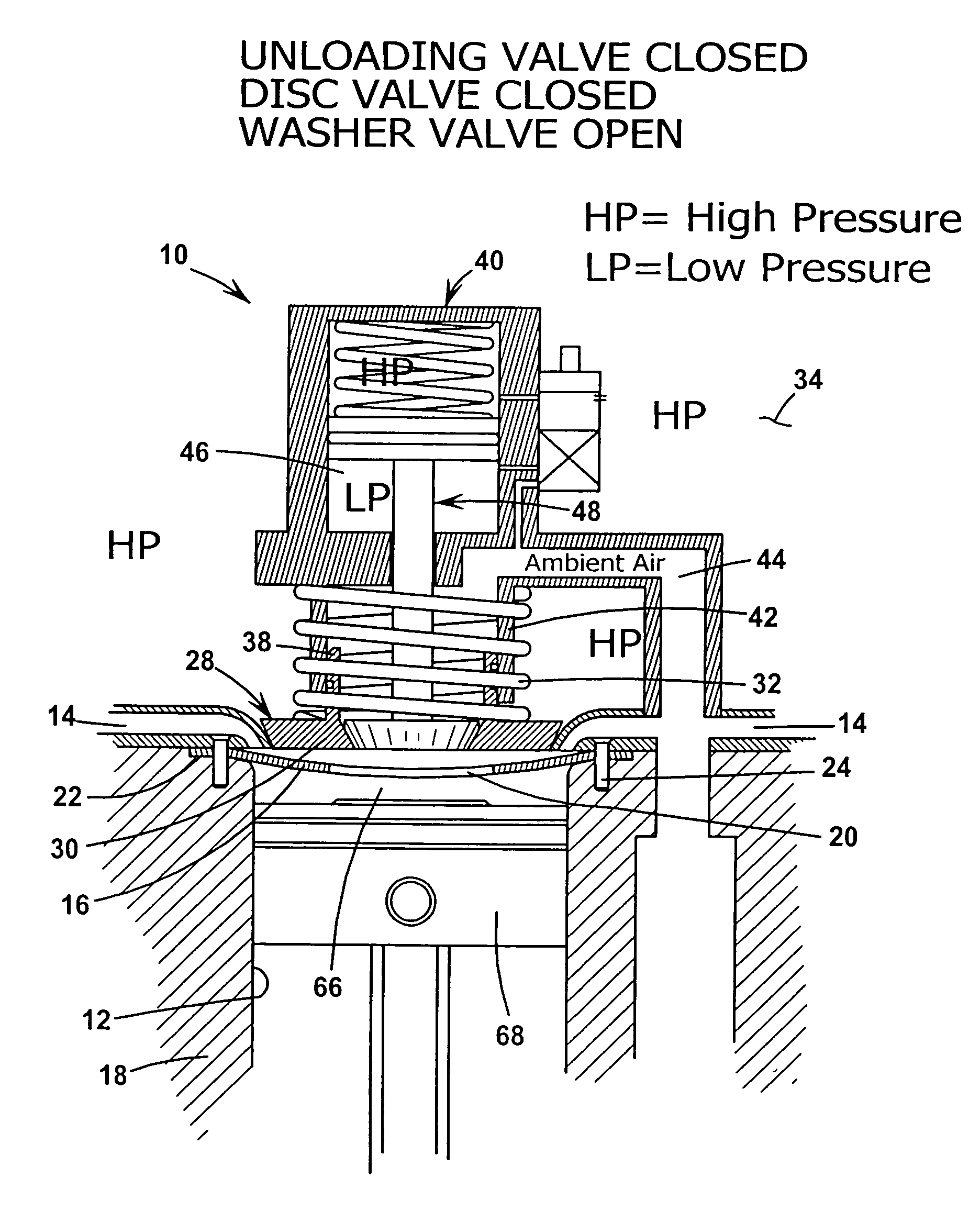

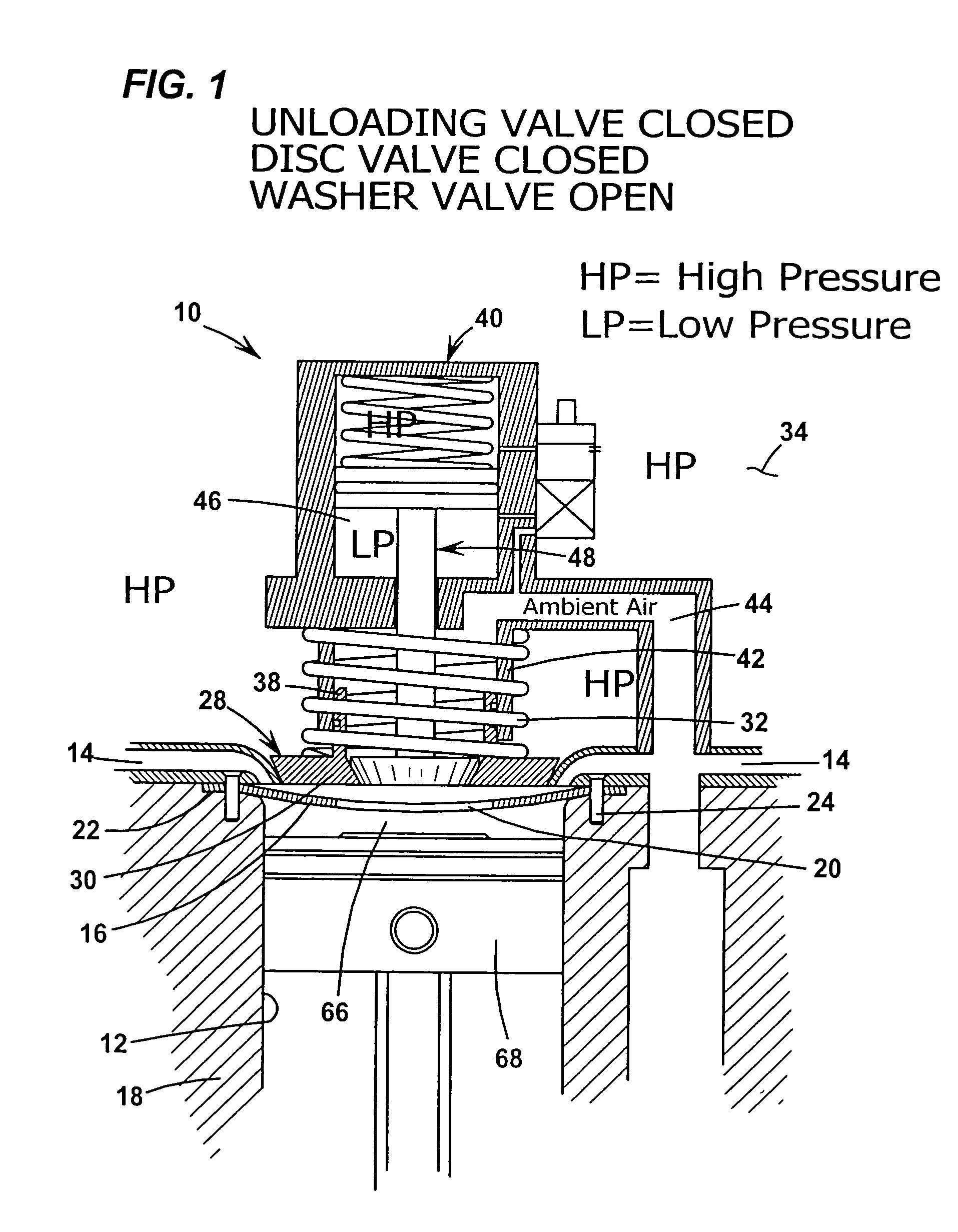

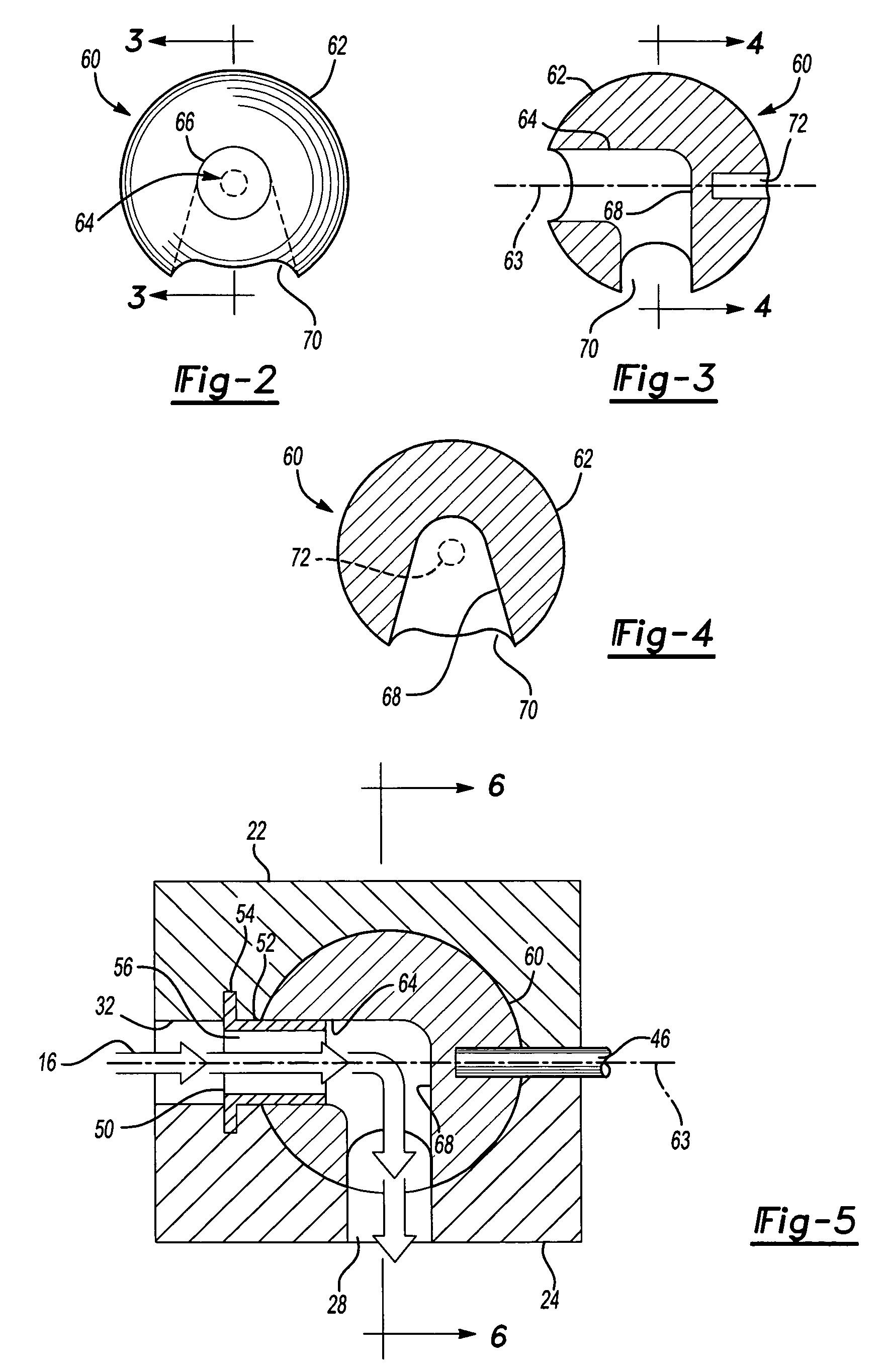

Split-cycle engine with disc valve

InactiveUS7481190B2Lower the volumeImprove efficiencyCombustion enginesRotary slide valveEngineeringValve seat

A split-cycle engine with disc valve includes a crankshaft, a power cylinder and a compression cylinder. A gas crossover passage interconnects the compression cylinder and the power cylinder. An air intake port circumscribes a periphery of the compression cylinder and defines an outer valve seat. An annular ring having a generally central opening is disposed between the compression cylinder and the air intake port and forms a washer valve for opening and closing the air intake port. A disc valve member is concentrically mounted over the central opening of the annular ring. The disc valve member includes a piston portion having a sidewall biased into engagement with the outer valve seat for controlling flow between the compression cylinder and the gas crossover passage.

Owner:SKADERI GRUP LLC

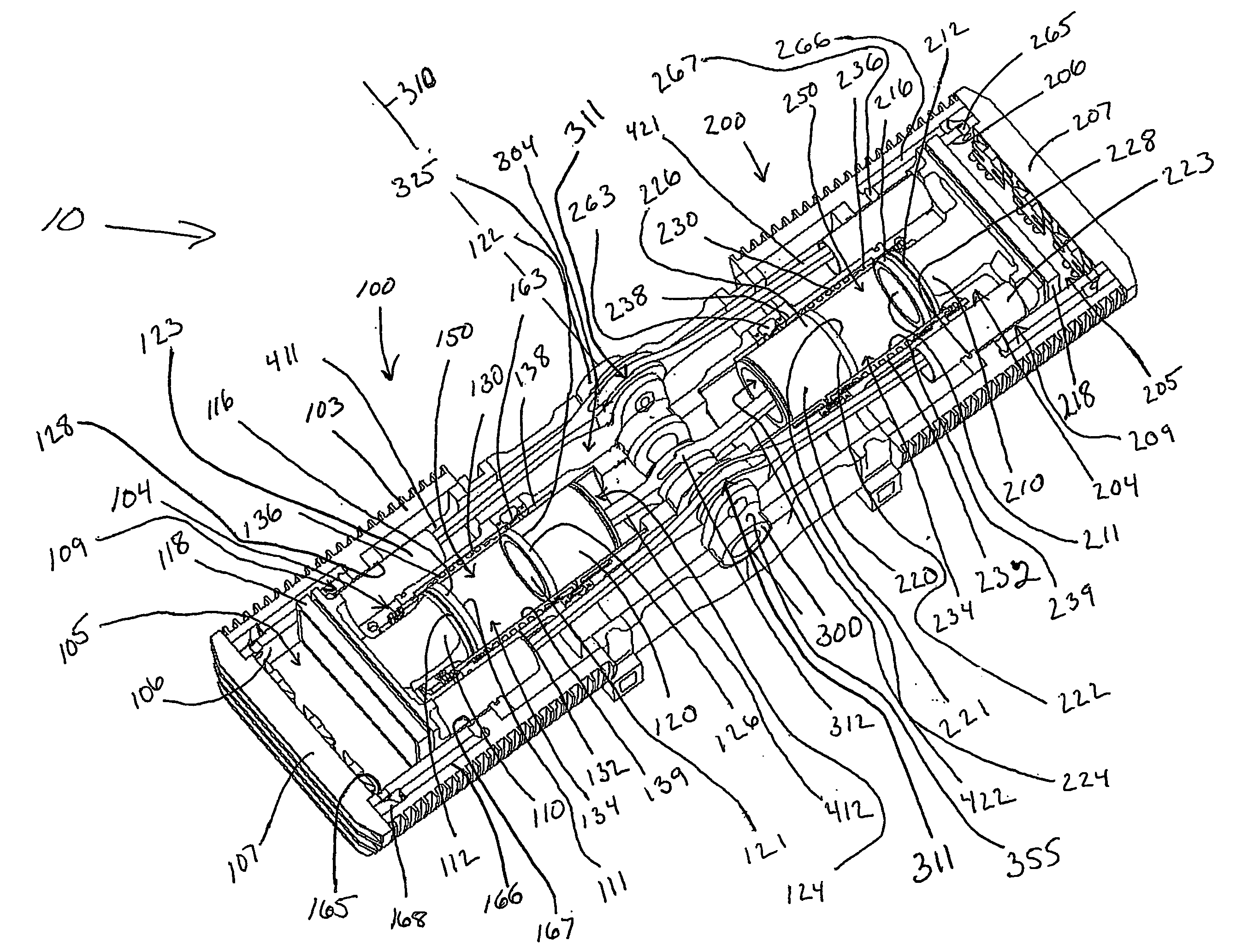

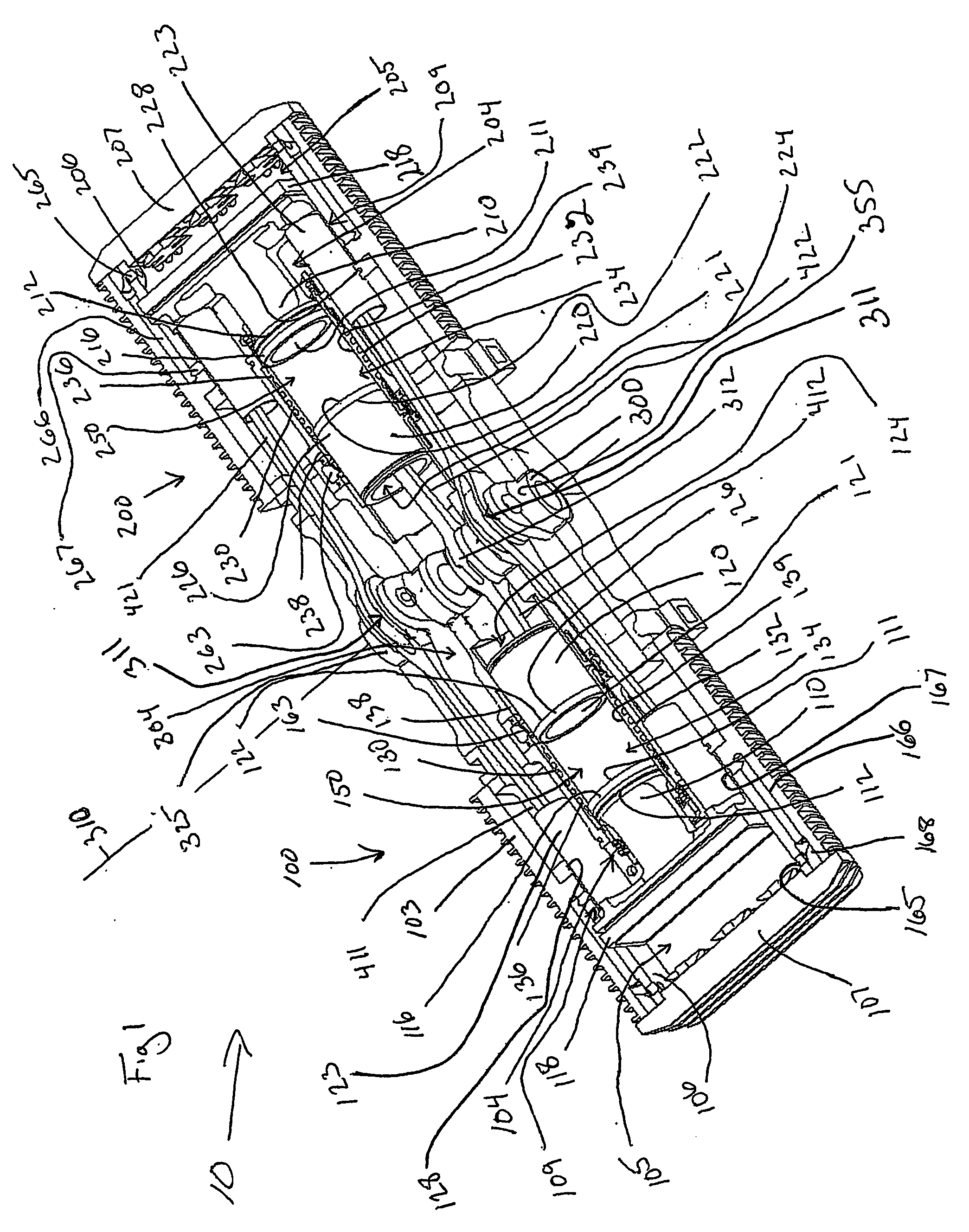

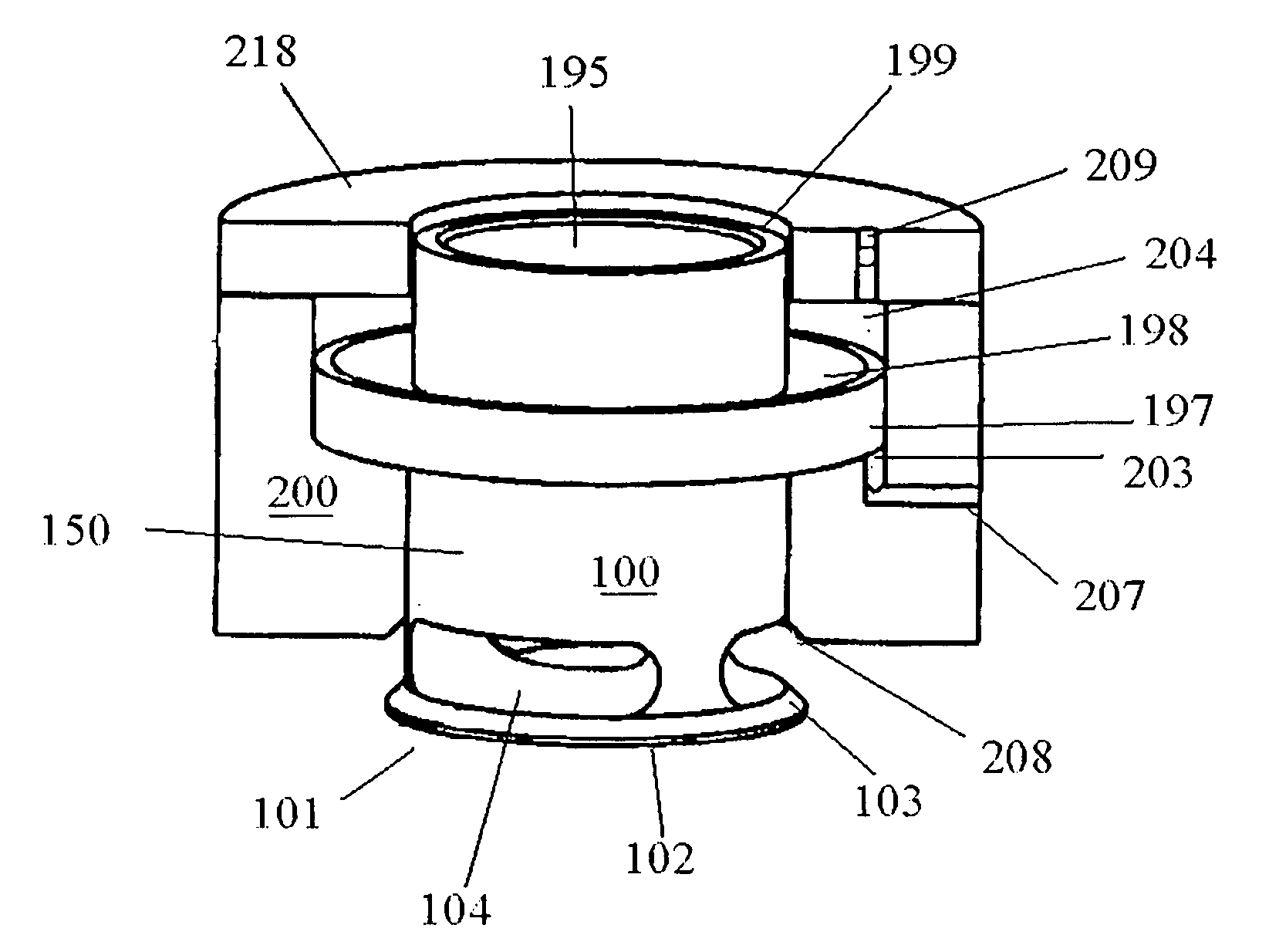

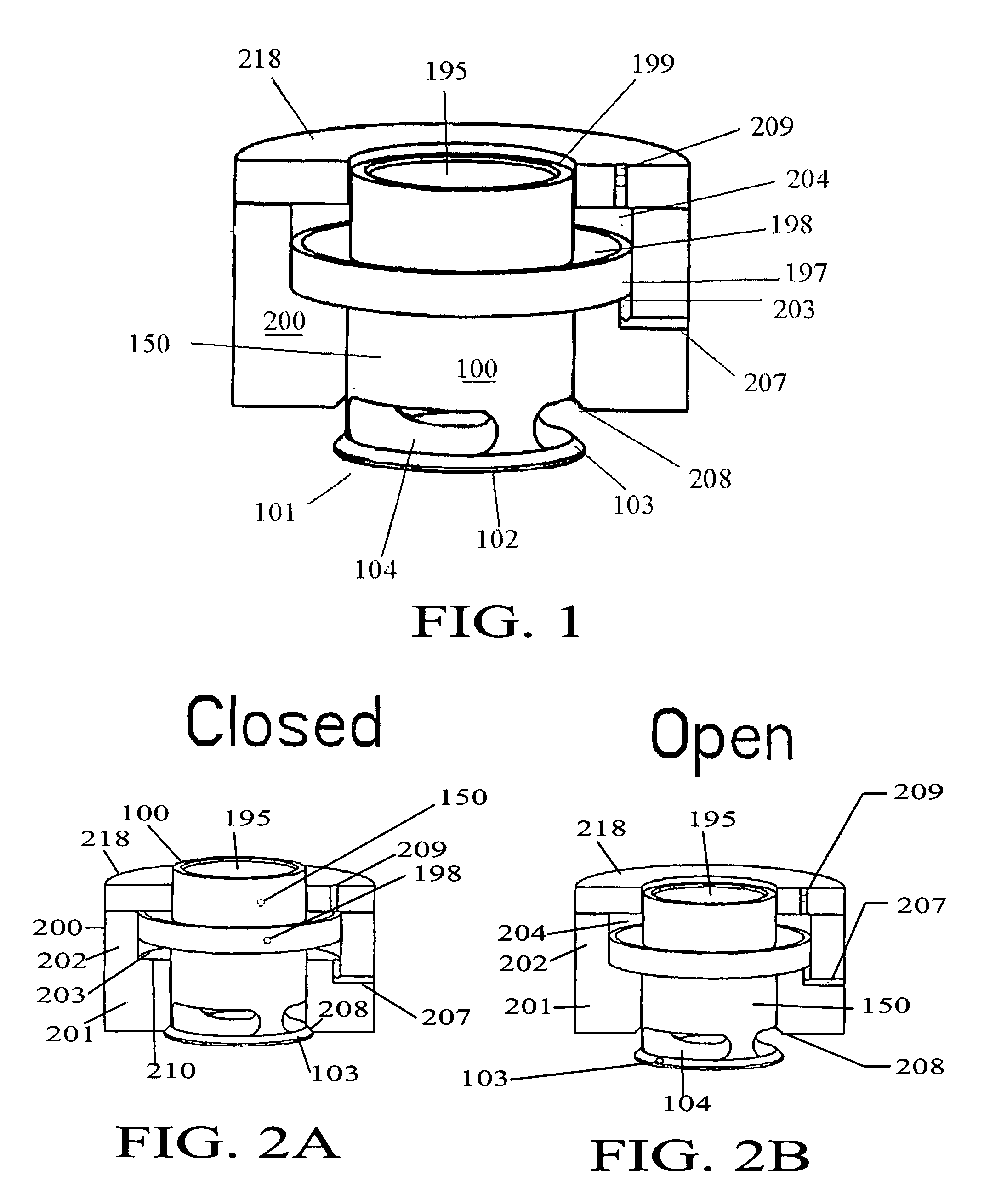

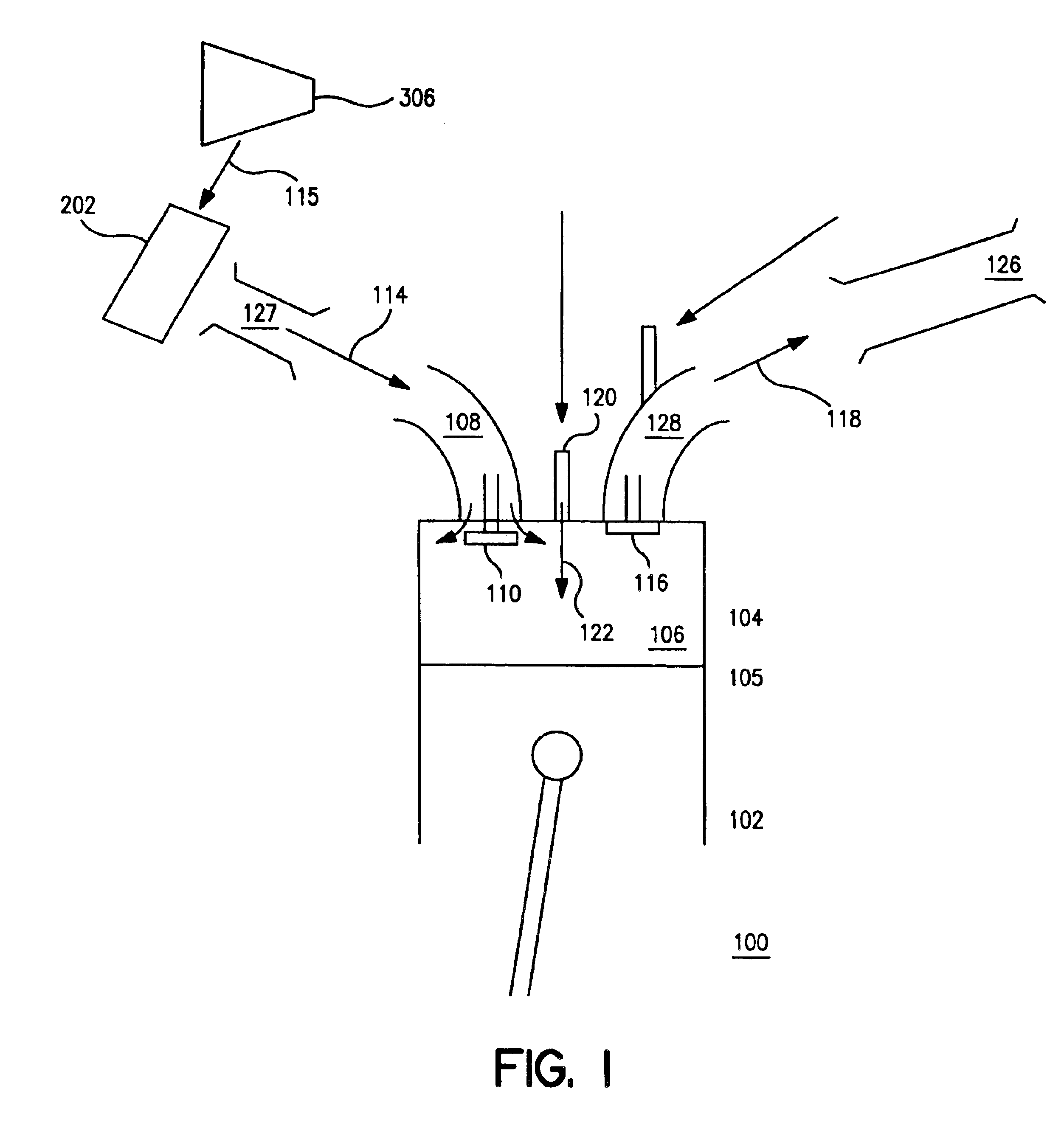

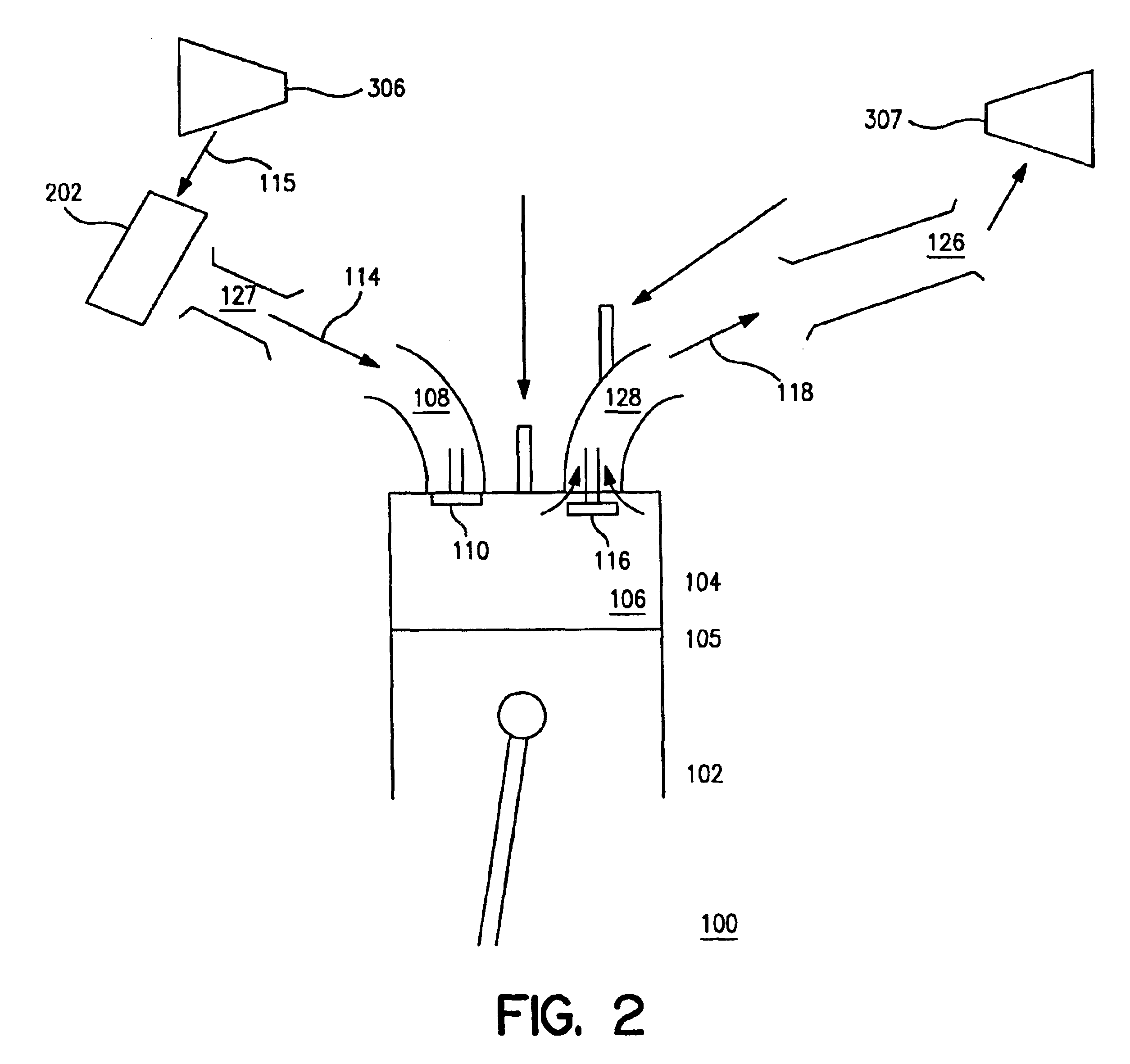

Pneumatically actuated valve for internal combustion engines

A pneumatically actuated valve assembly for use as intake and / or exhaust valves on two- or four-stroke internal combustion engines. The assembly includes a valve (100), valve housing (200), and compressed gas distribution and timing mechanisms (FIGS. 5–8). The valve (100) is comprised of a short light weight hollow cylindrical body with a capped lower end and an opened upper end. The valve is further defined by a plurality of ports (104) adjacent to the lower end and a collar (198) encircling the body adjacent the upper end. The valve housing (200) is hollow and tubular having a larger diameter upper section and a smaller diameter lower section in which the valve (100) slides up to close and down to open. The housing (200) further includes hollow channels which direct compressed gas, managed by the distribution and timing mechanism, alternately towards the areas above and below the valve collar at regular intervals to open and close the valve, respectively.

Owner:KLEIN JEFFREY F +1

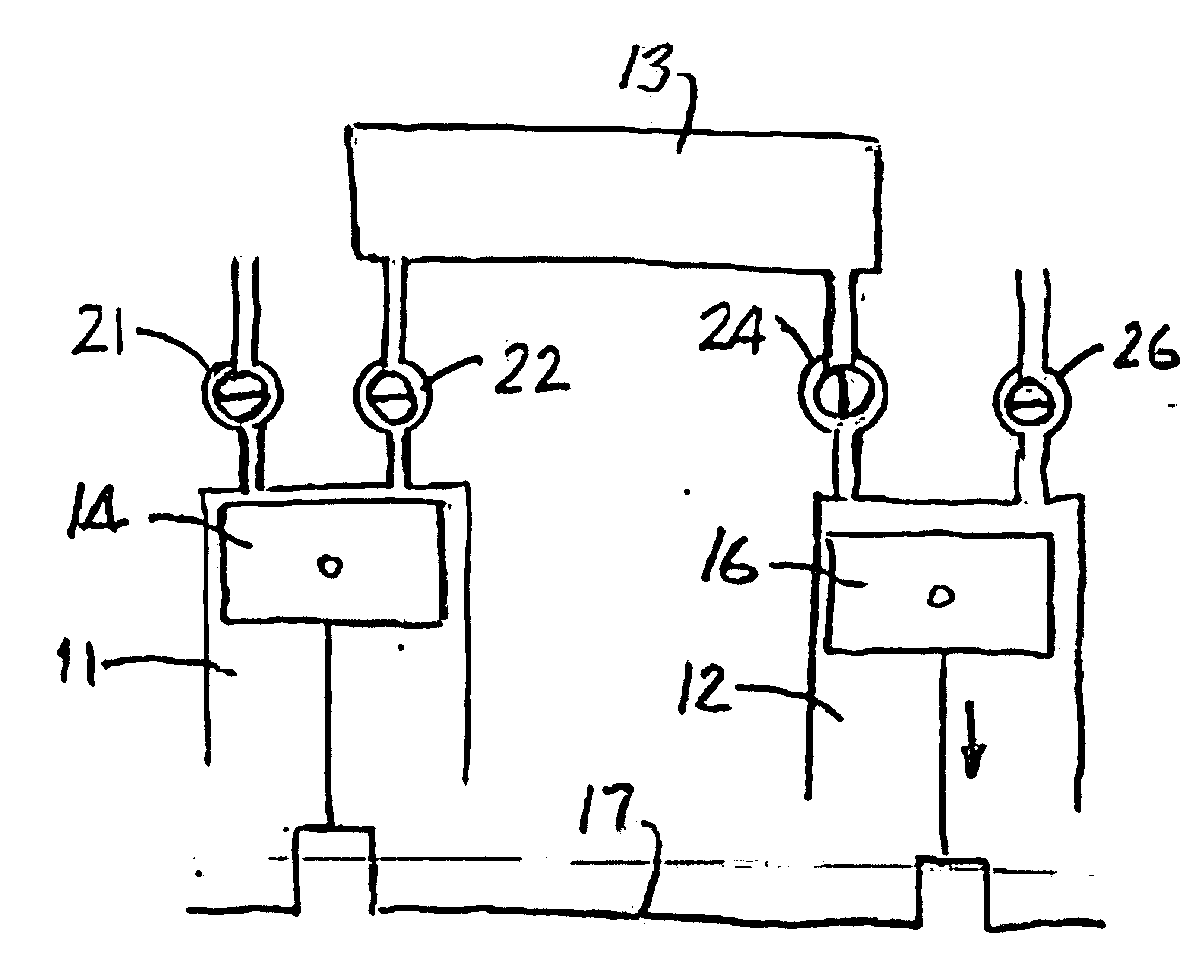

Actuator system

ActiveUS8126592B2Increase powerFacilitates robots capable of carrying heavier payloadsProgramme-controlled manipulatorServomotorsHydraulic circuitActuator

An actuator subsystem preferably for a robot or bionic linkage. A joint between two robotic or bionic members includes at least first and second actuators such as piston-cylinder assemblies connected between the members. A hydraulic circuit includes a sensor subsystem for sensing the magnitude of the load on the piston-cylinder assemblies and / or members. A fluid supply system includes an actuatable control valve operable to supply fluid to one or both piston-cylinder assemblies. A control circuit is responsive to the sensor and is configured to electronically control the fluid subsystem to supply fluid to the first piston-cylinder assembly when the sensor subsystem senses a load below a predetermined magnitude and to supply fluid to both piston-cylinder assemblies when the sensor subsystem senses a load above the predetermined magnitude.

Owner:BOSTON DYNAMICS INC

Cylinder head assembly and spherical valve for internal combustion engines

InactiveUS7328680B1Easy to movePlug valvesMachines/enginesReciprocating motionExternal combustion engine

A cylinder head assembly includes a spherical valve for an internal combustion engine having at least one cylinder defining a combustion chamber and housing a piston reciprocally movable therein throughout successive intake, compression, power, and exhaust strokes for facilitating the flow of engine gasses between a manifold and the combustion chamber. The cylinder head assembly comprises a cylinder head defining therein a spherical valve race in gaseous communication with the combustion chamber. A spherical valve is disposed in the spherical valve race and has a spherical body defining a central axis of rotation and further defining a passageway therethrough. The passageway has a first opening substantially coaxial with the central axis for gaseous communication with a manifold and has a second opening substantially transverse from the central axis. The spherical valve is rotatable in the spherical valve race about the central axis of rotation to selectively place the second opening in gaseous communication with the combustion chamber.

Owner:DIAMOND GARY

Valve seal assembly for rotary valve engine

ActiveUS6880511B1Regulating pressureExtend your lifeMachines/enginesRotary slide valveExternal combustion engineCylinder head

A valve seal for a rotary valve assembly for use in an internal combustion engine of the piston and cylinder type, wherein the cylinder head / combustion chamber is designed for high compression and of long stroke, such as a diesel engine, the rotary valves and the valve seals being positioned in relationship so as to permit charging of the cylinder with a fuel / air mixture and evacuation of spent gases, and to regulate the pressure within the valve seal and valve seat and hence regulate the pressure between the valve seal and the rotary valve.

Owner:COATES GEORGE J

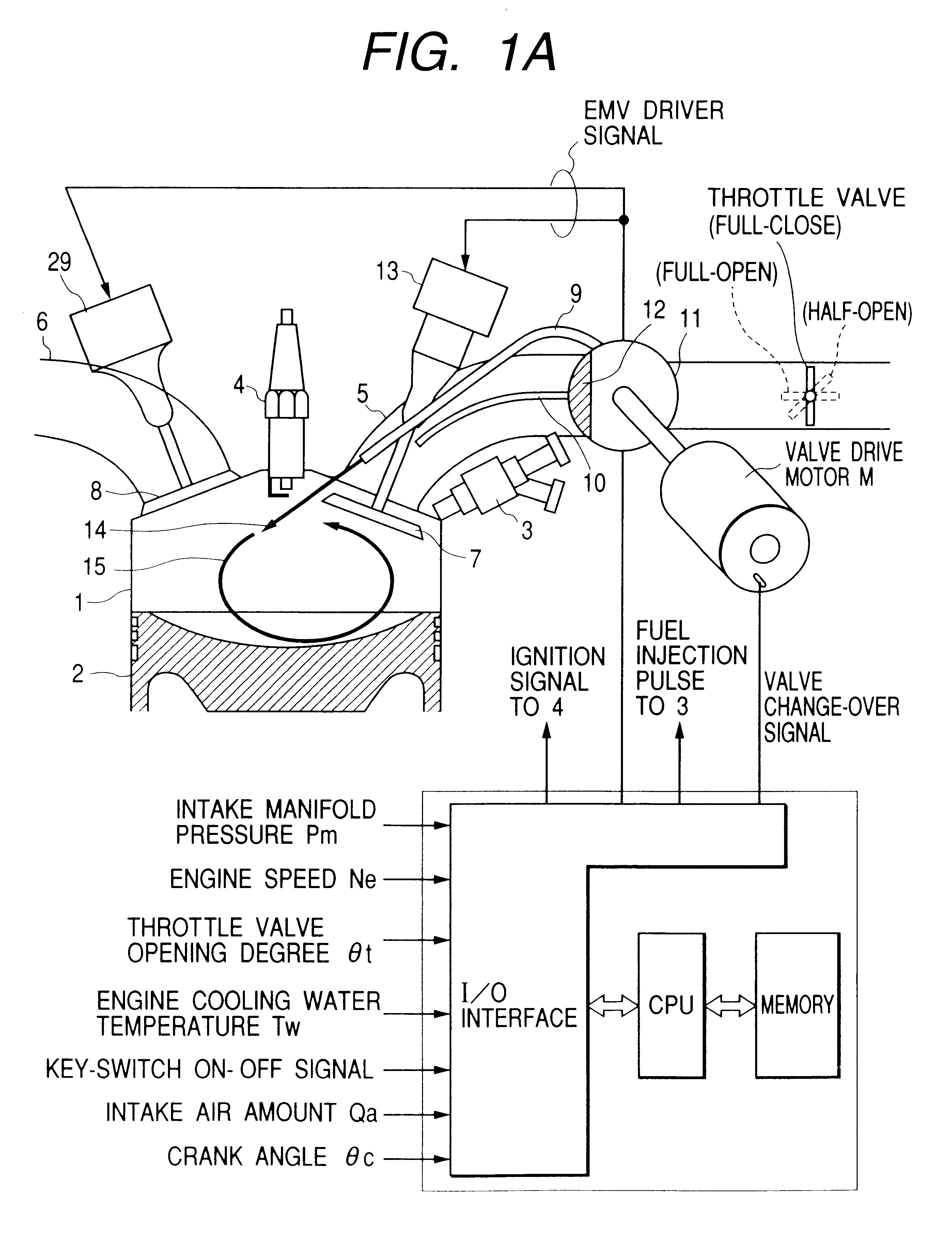

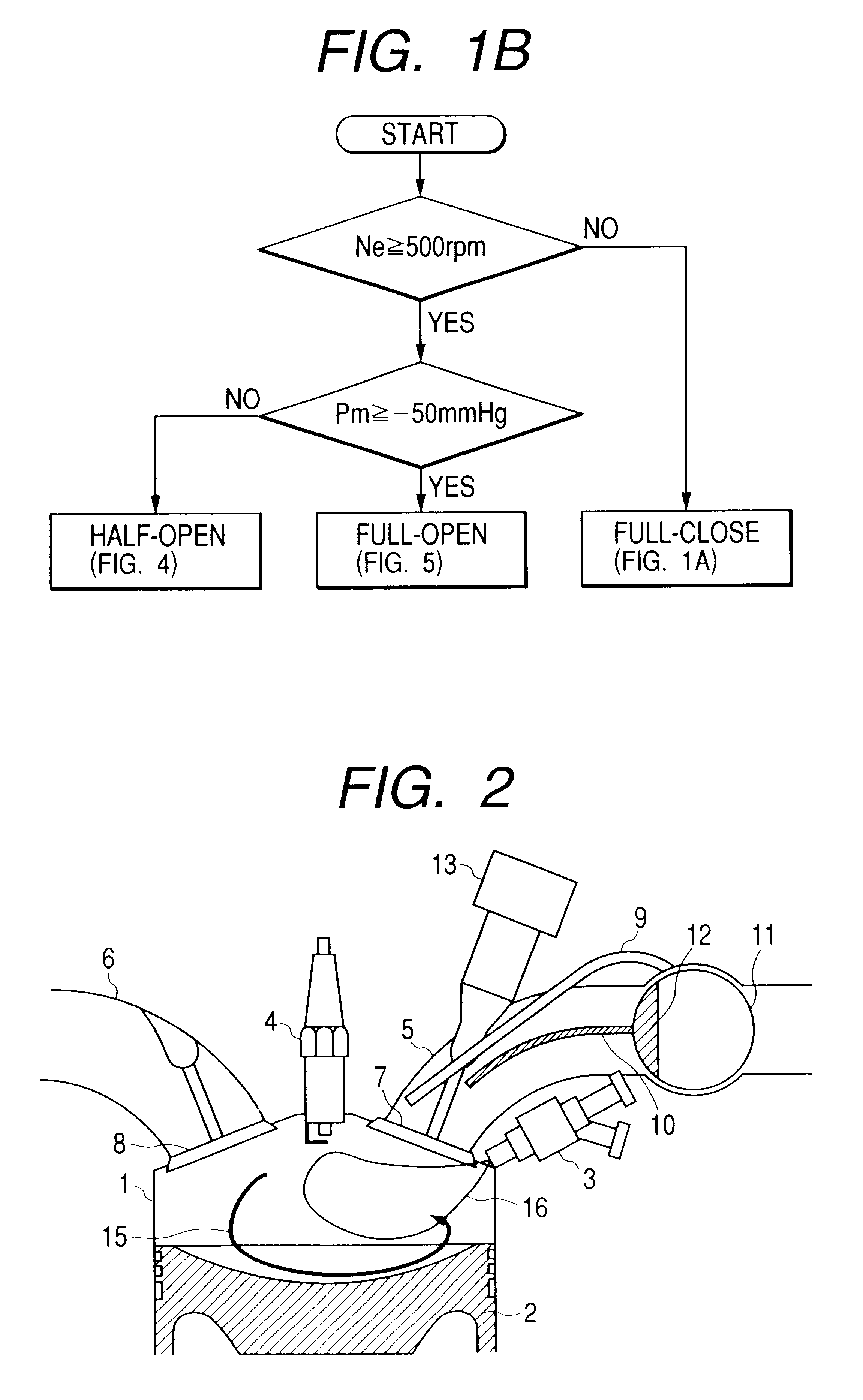

Direct injection type internal combustion engine

InactiveUS6634333B2Easy dischargeElectrical controlInternal combustion piston enginesStart timeCombustion

In a starting time in which an air motion is little, a means for heightening the motion is added, from the starting time a stratification combustion operation is enable to carry out, and a discharge of an unburned fuel is minimized. From the starting time of an engine (from the firstly combustion cylinder) it is possible to carry out a stable stratification combustion. In accordance with the stratification combustion in the exhaust air a large quantity of the surplus oxygen remains. In the engine in the exhaust stroke twice (two time) fuel injection is carried out and the after burn phenomenon is caused in the exhaust port and then the exhaust gas temperature can be raised.

Owner:HITACHI LTD

Internal combustion engine and method

InactiveUS20060243229A1Easy to operateReduce the amount of fuelInternal combustion piston enginesGas turbine plantsCombustion chamberEngine efficiency

Internal combustion engine and method with compression and expansion chambers of variable volume, a combustion chamber, a variable intake valve for controlling air intake to the compression chamber, a variable outlet valve for controlling communication between the compression chamber and the combustion chamber, means for introducing fuel into the combustion chamber to form a mixture of fuel and air which burns and expands in the combustion chamber, a variable inlet valve for controlling communication between the combustion chamber and the expansion chamber, a variable exhaust valve for controlling exhaust flow from the expansion chamber, means for monitoring temperature and pressure conditions, and a computer responsive to the temperature and pressure conditions for controlling opening and closing of the valves and introduction of fuel into to the combustion chamber to optimize engine efficiency over a wide range of engine load conditions. The relative volumes of the compression and expansion chambers and the timing of the valves are such that the pressure in the combustion chamber remains substantially constant throughout the operating cycle of the engine, and exhaust pressures are very close to atmospheric pressure regardless of the load on the engine. The engine runs so quietly and burns so cleanly that in some applications it may not require a muffler and / or a catalytic converter.

Owner:ZAJAC OPTIMUM OUTPUT MOTORS

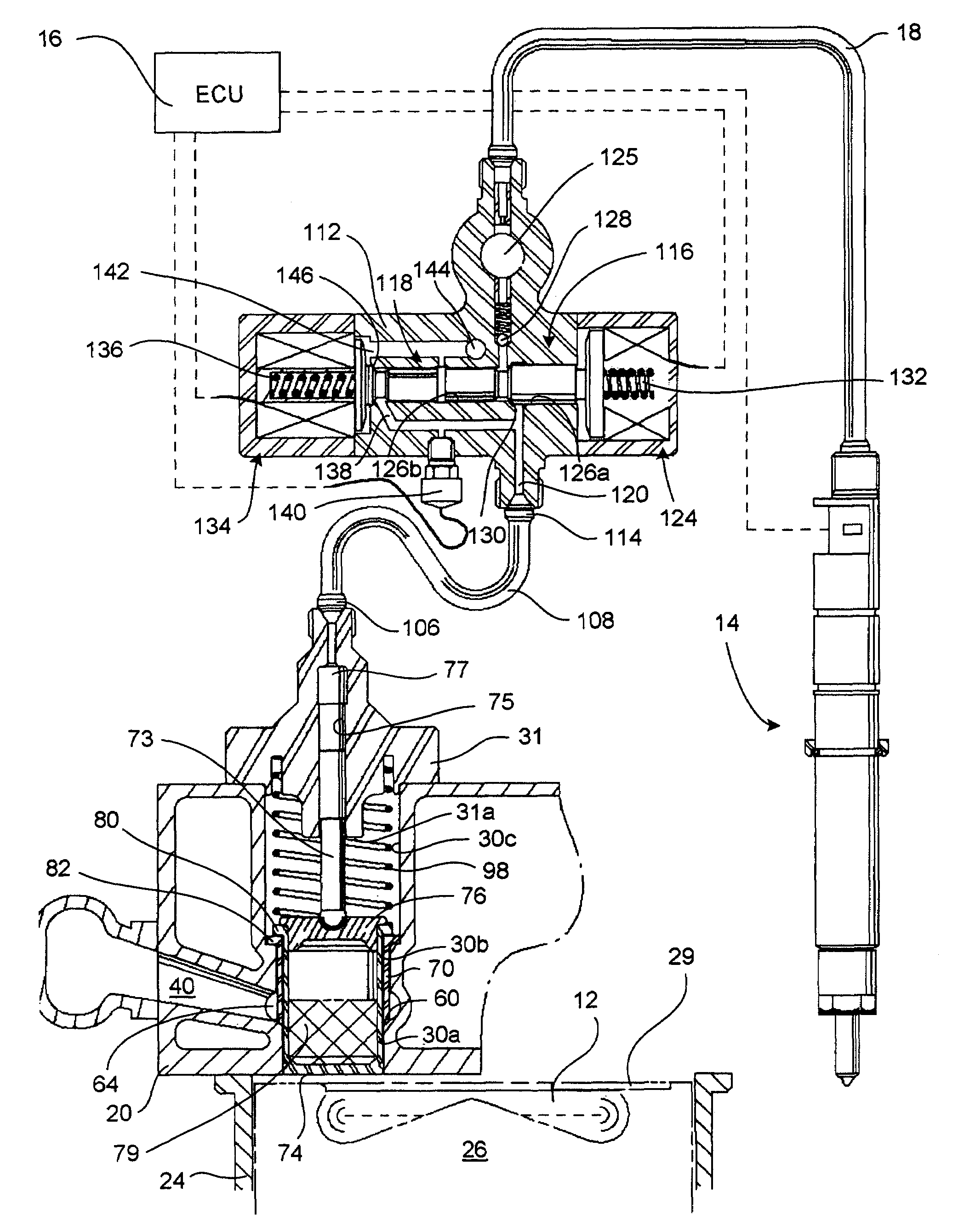

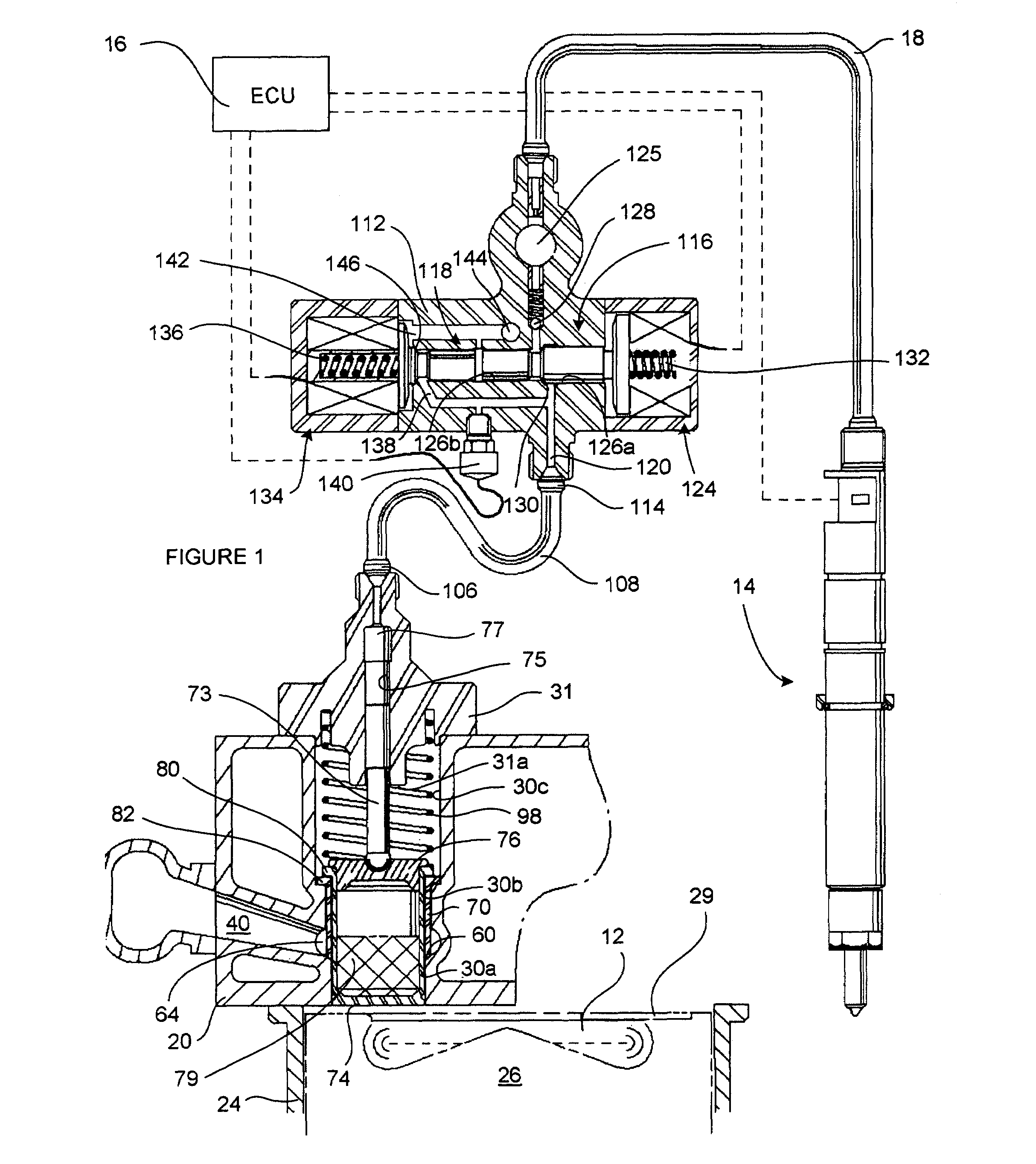

Turbo-charged internal combustion engine with in-cylinder EGR and injection rate shaping

InactiveUS6968831B2Improve efficiencyImprove transient responseInternal combustion piston enginesCylinder headsExhaust valveExternal combustion engine

A turbo-charged internal combustion cylinder assembly includes a combustion chamber which may be communicably connected to a compressor via an intake port through an intake manifold and aftercooler so the compressor may provide pre-combustion gases to the combustion chamber when the intake valve is open. An exhaust port communicably connects the combustion chamber to an exhaust manifold. An exhaust valve may open to exhaust post-combustion gases to the exhaust manifold while an intake valve is substantially closed, and the exhaust valve may open to admit post-combustion gases to the combustion chamber while the intake valve is substantially open and an exhaust port pressure in the exhaust port is higher than a combustion chamber pressure in the combustion chamber. A fuel injector may admit fuel to the combustion chamber. A spill valve may control a rate of fuel injection to the combustion chamber, the spill valve having a first position providing a maximum fuel injection rate, a second position providing a substantially zero fuel injection rate, and at least one intermediate position providing an intermediate fuel injection rate between the maximum fuel injection rate and the zero fuel injection rate.

Owner:VOLVO LASTVAGNAR AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com