Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1155results about "Digger harvesters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

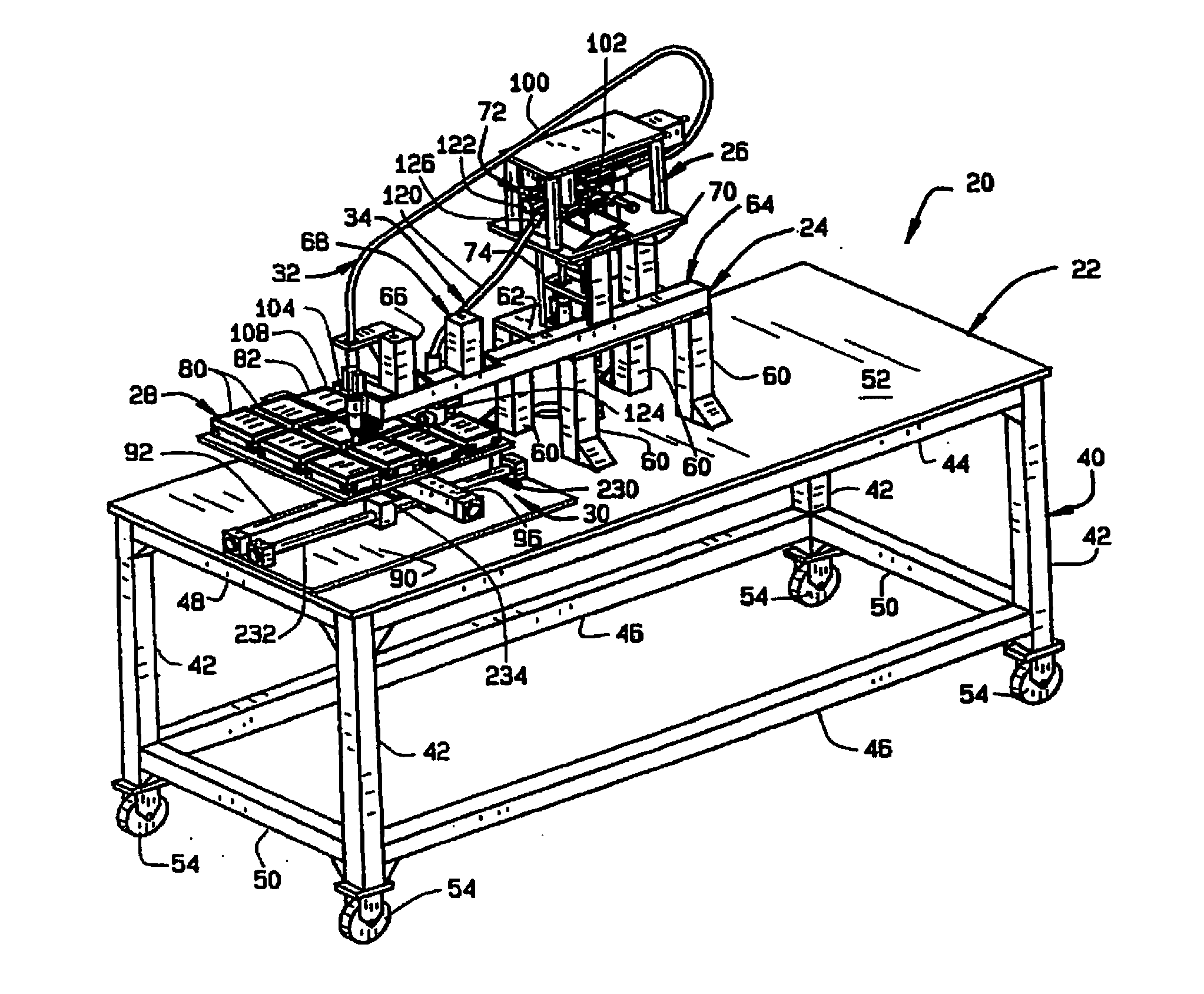

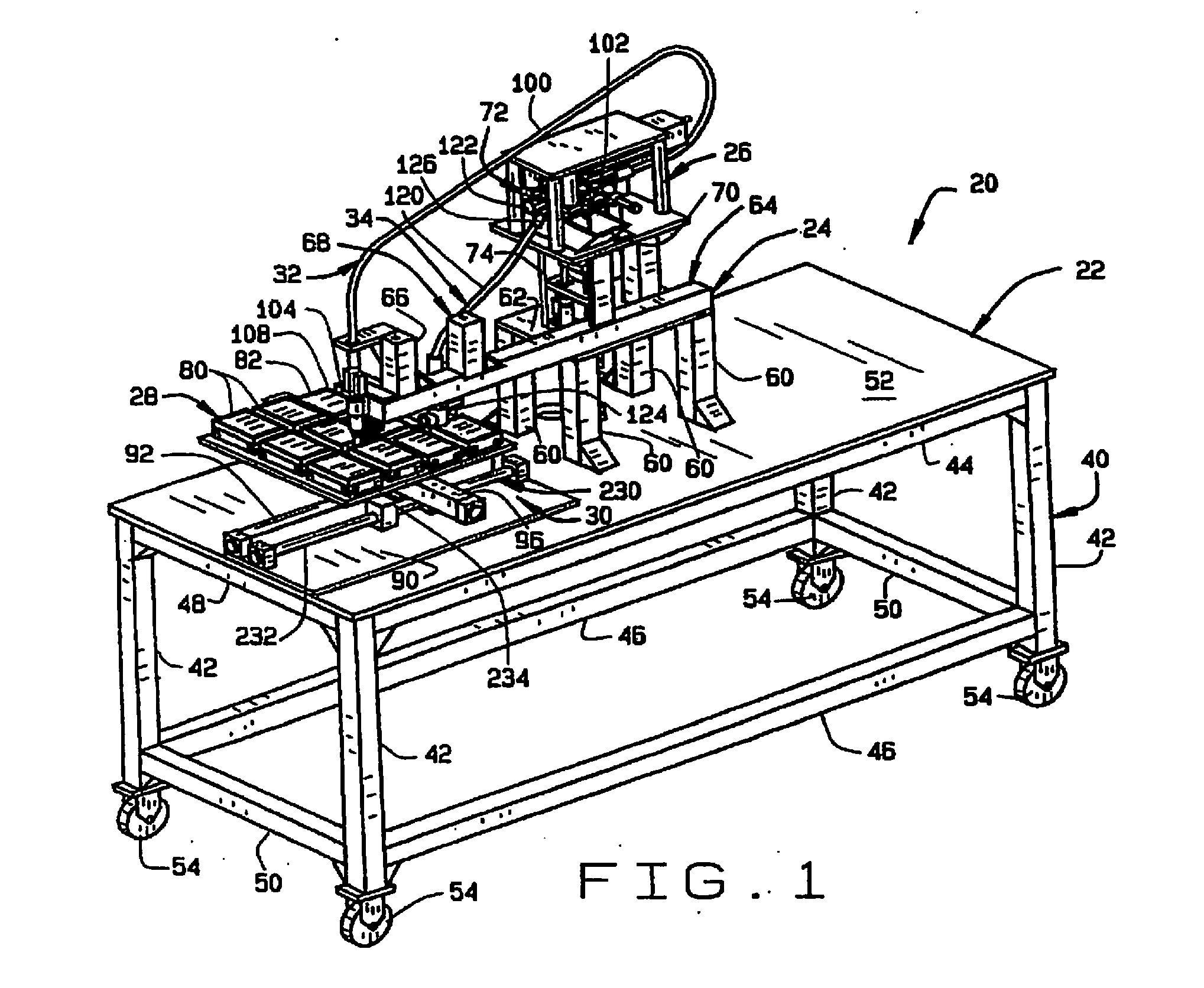

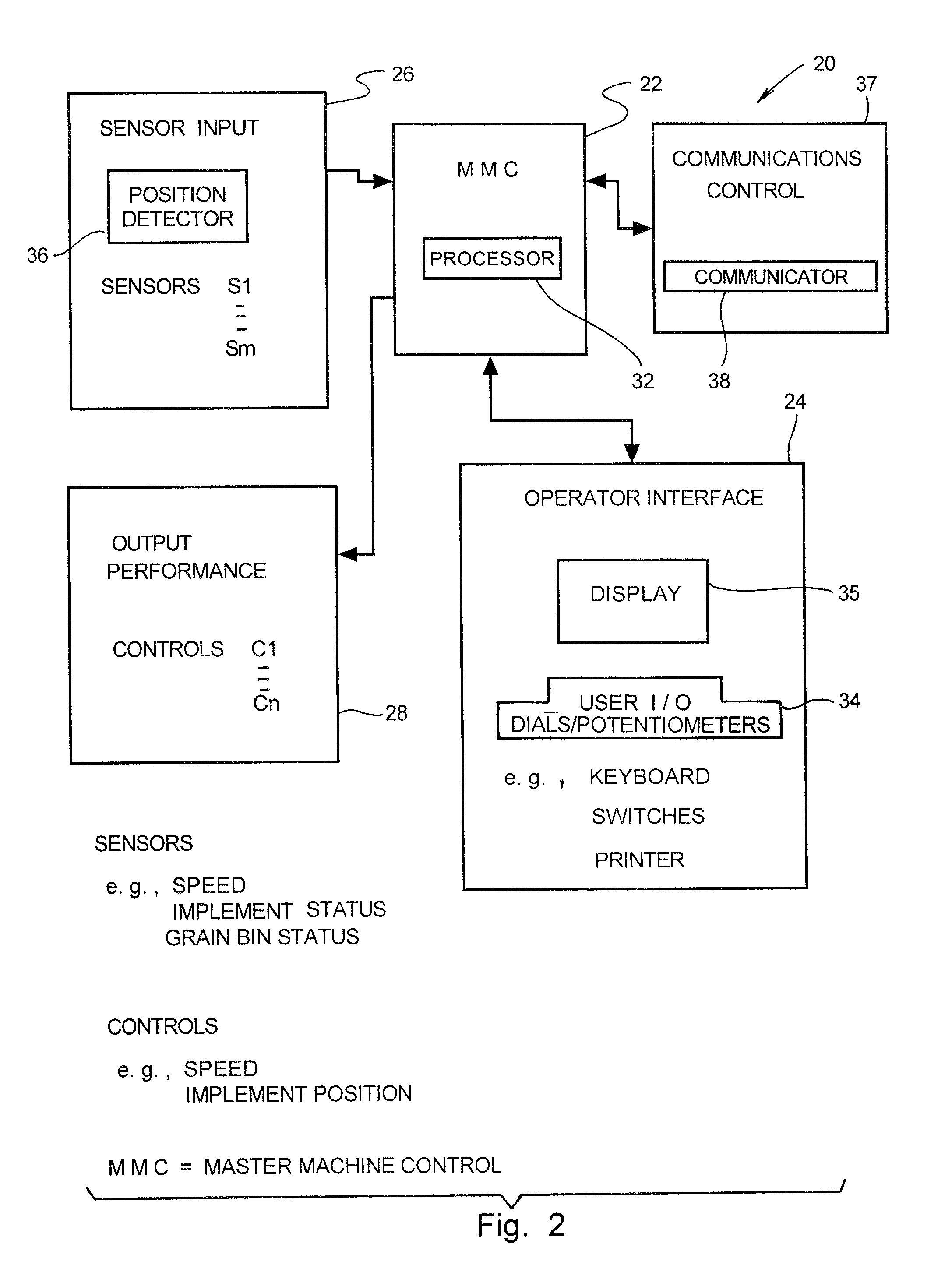

Grain transfer control system and method

ActiveUS20100274452A1Evenly filledDigital data processing detailsRoad vehicles traffic controlAutomatic controlControl system

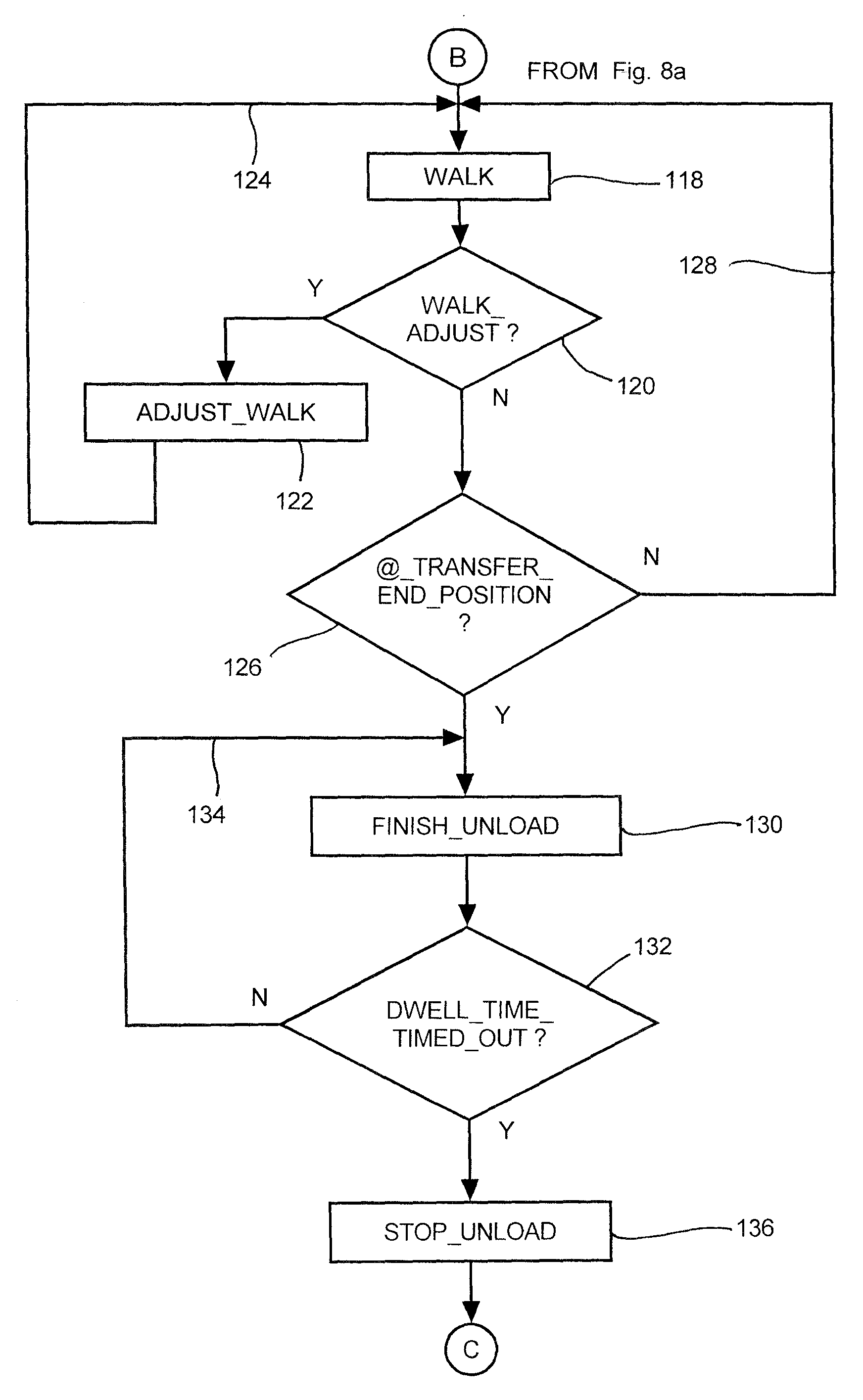

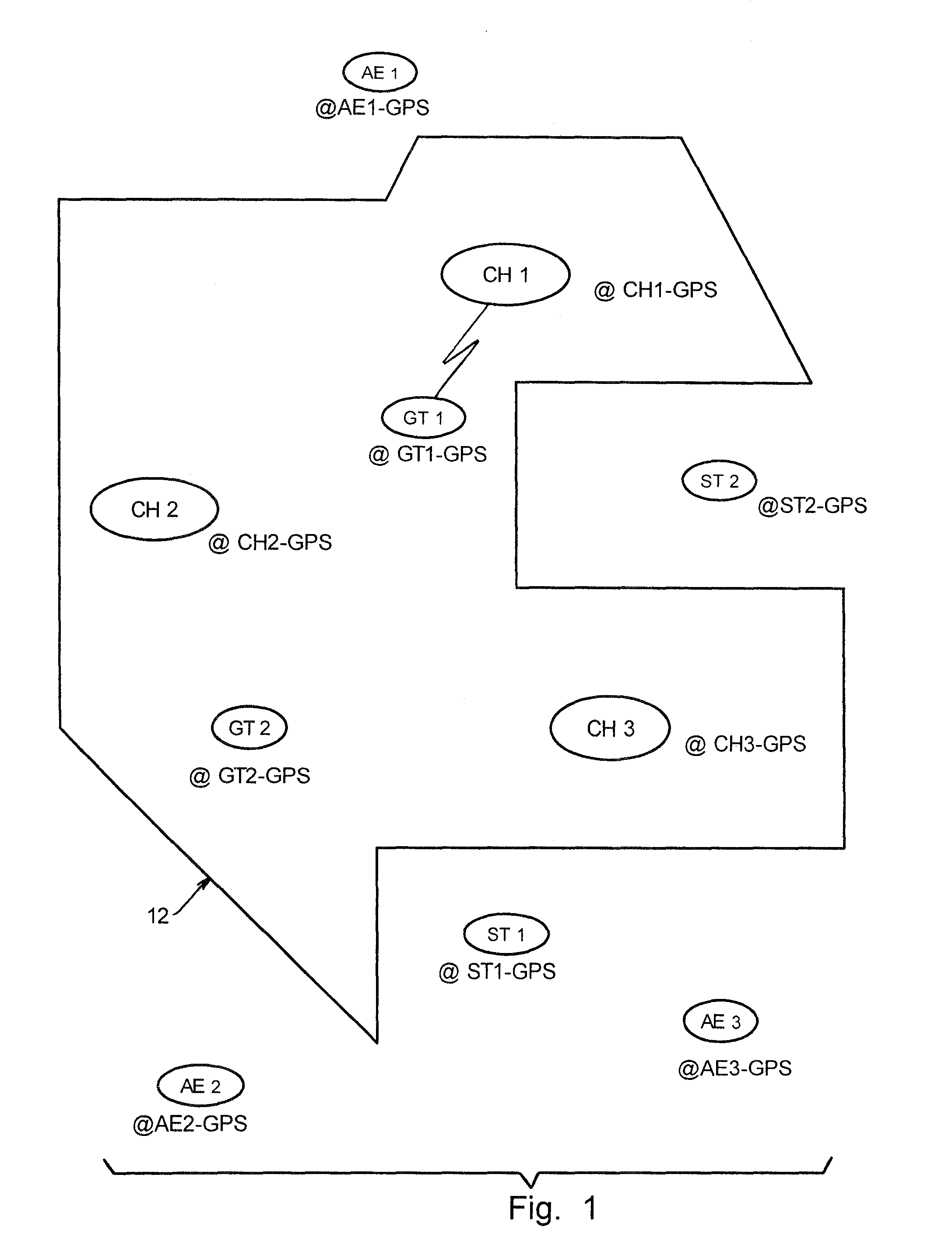

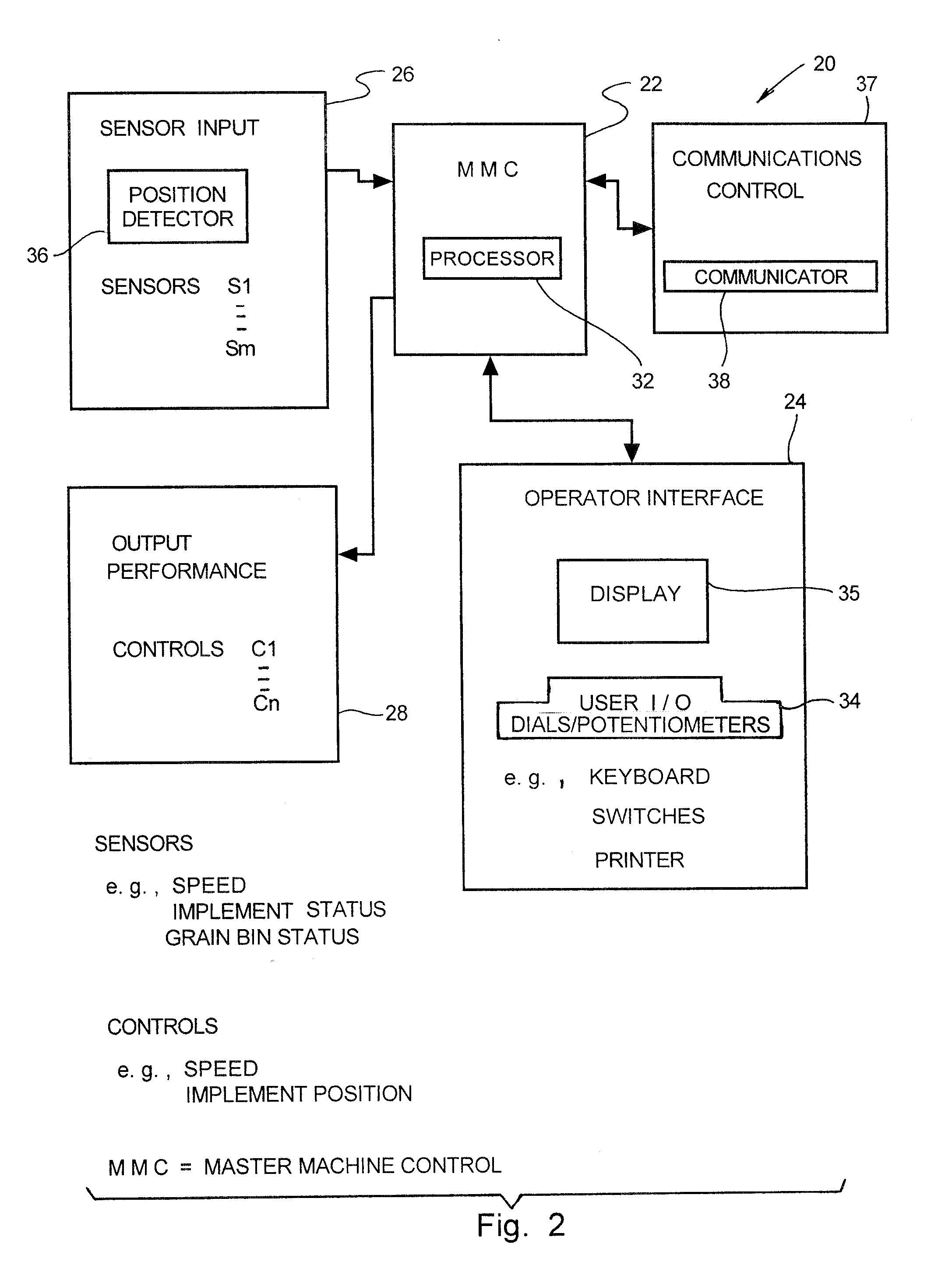

A grain transfer control system, and method of use thereof, for automatedly controlling the transfer of grain from a mobile transferor-type vehicle, such as a combine harvester, to a mobile transferee-type vehicle, such as a crop transport, by varying the position and speed of the transferor-type and transferee-type vehicles relative to one another during the transfer operation, especially by varying the position and rate of walk of the discharge spout along at least a portion of the length of a grain holding receptacle of the transferee-type vehicle, to effect a generally even fill of the grain holding receptacle of the transferee-type vehicle along the length of the grain holding receptacle.

Owner:BLUE LEAF I P INC

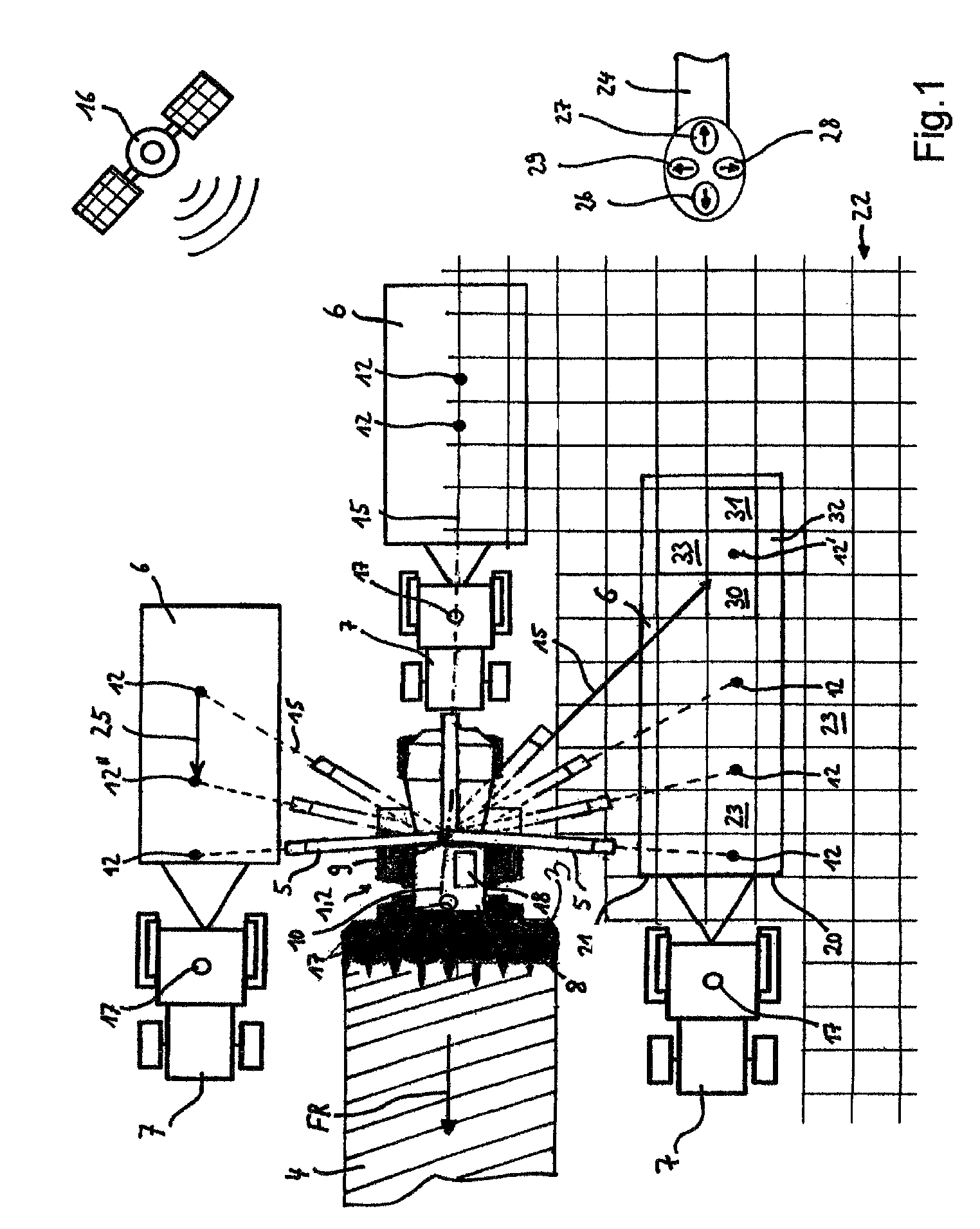

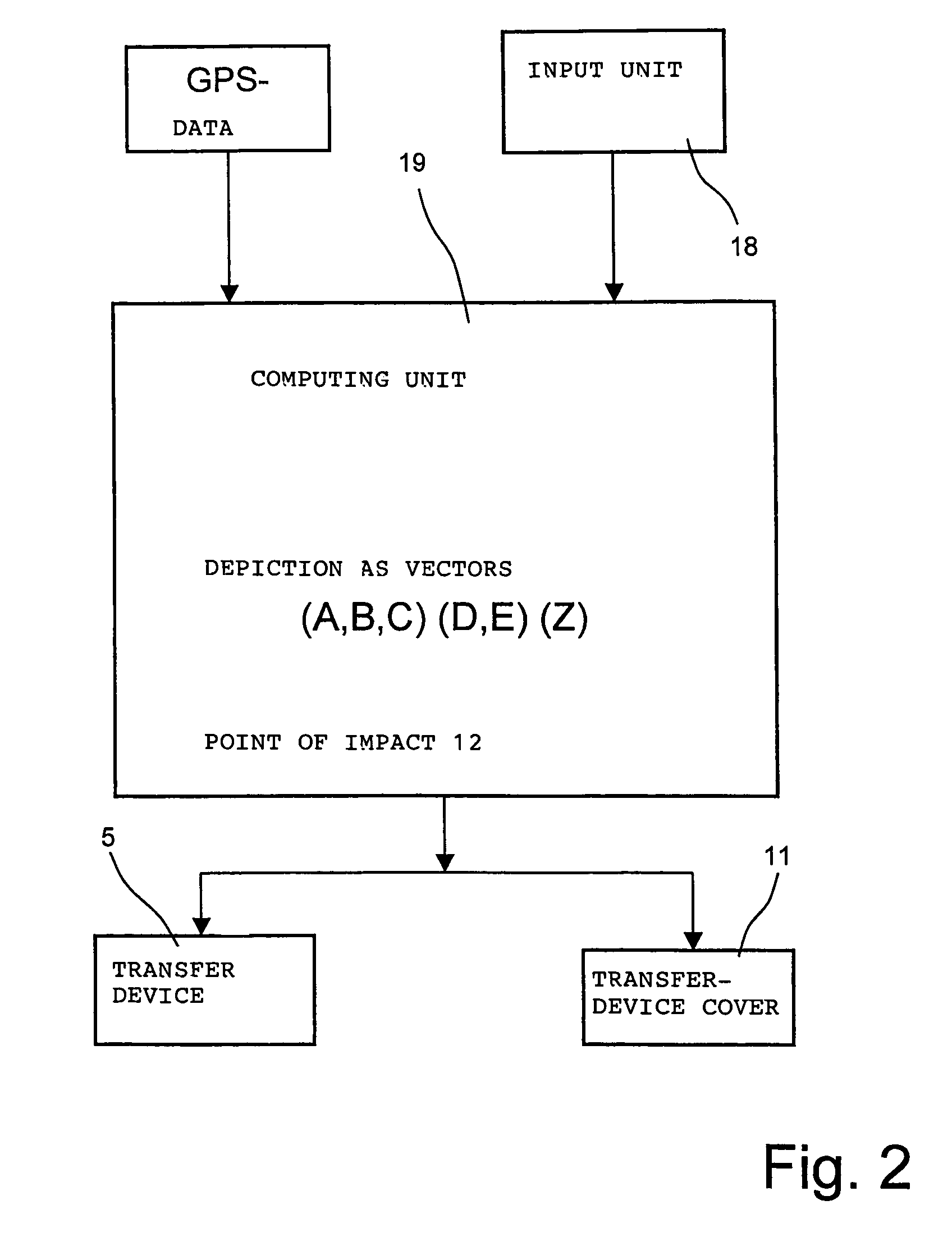

Transfer-assistance system

InactiveUS7537519B2Simple procedureReliable transmissionDigital data processing detailsMowersGuidance systemEngineering

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

High throughput screening of fatty acid composition

ActiveUS20120180386A1Process can be speededEasy to sampleSpectrum investigationSeed and root treatmentHigh-Throughput Screening MethodsSolvent

A method of accumulating a quantity of seeds having a desired fatty acid characteristic is provided. The method includes removing a sample from each seed in a population of seeds while maintaining the germination viability of the seeds; contacting each sample with a solvent to form a mixture comprising fatty acid methyl esters; analyzing the mixture of fatty acid methyl esters from each sample to determine the fatty acid profile of the corresponding seed; selecting seeds having at least one desired fatty acid characteristic based on the analysis of the samples removed from the seeds; cultivating plants from the selected seeds; recovering seeds from the cultivated plants, wherein the recovered seeds are a subsequent generation of the selected seeds; and repeating the operations for one or more generations of the recovered seeds to thereby accumulate the quantity of seeds having the desired fatty acid characteristic.

Owner:MONSANTO TECH LLC

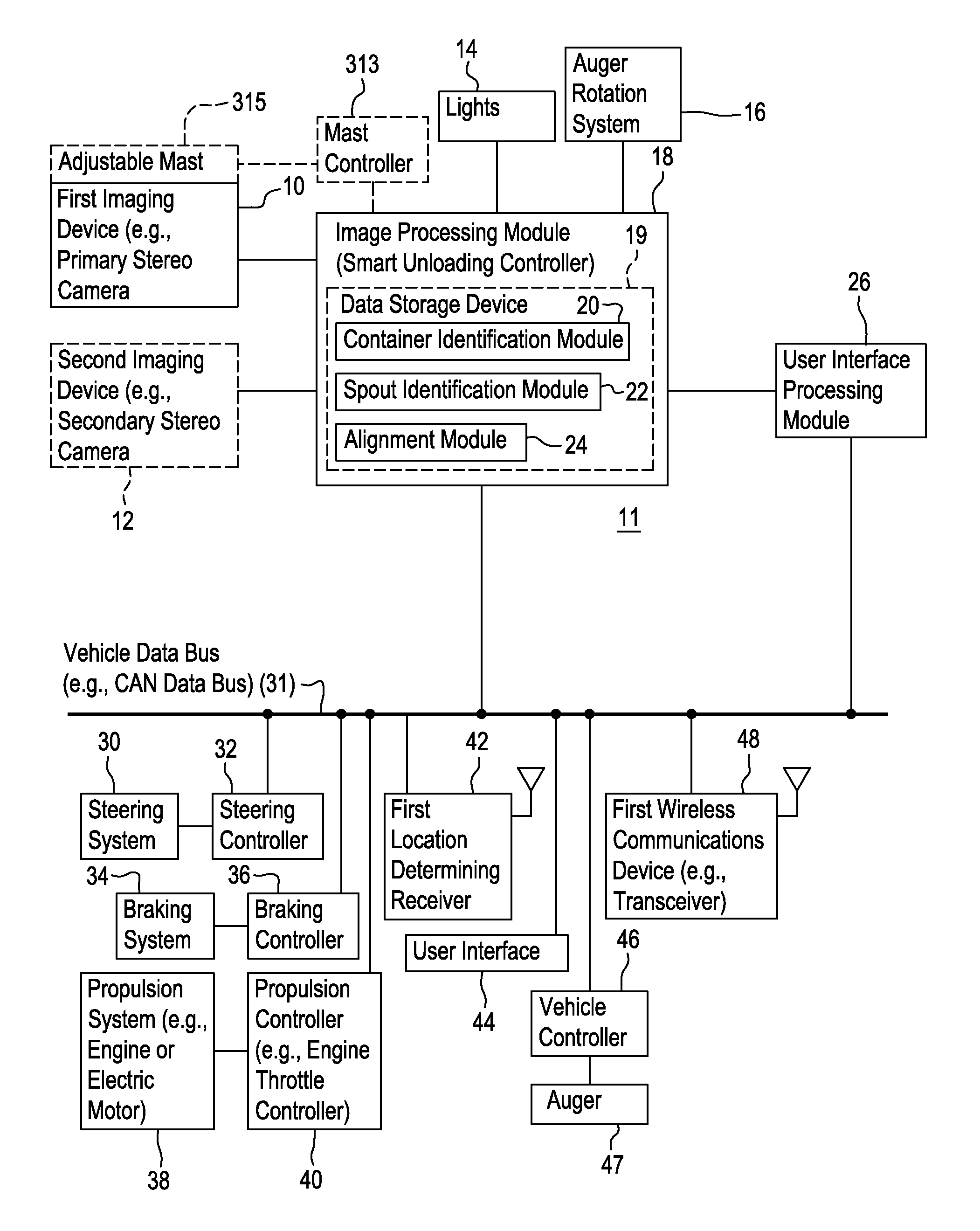

Method and stereo vision system for managing the unloading of an agricultural material from a vehicle

A stereo imaging device on a propelled portion of the receiving vehicle collects image data. A container identification module identifies a container perimeter of a storage portion in the collected image data. A spout identification module is adapted to identify a spout of the harvesting vehicle in the collected image data. An alignment module is adapted to determine the relative position of the spout and the container perimeter and to generate command data to the propelled portion to steer the storage portion in cooperative alignment such that the spout is aligned within a central zone or target zone of the container perimeter. A steering controller is associated with a steering system of the propelled portion for steering the receiving vehicle in accordance with the cooperative alignment.

Owner:DEERE & CO

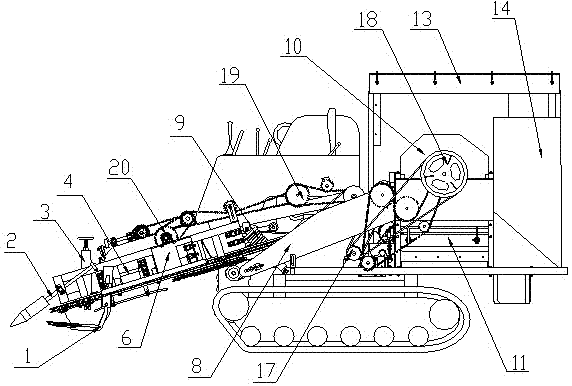

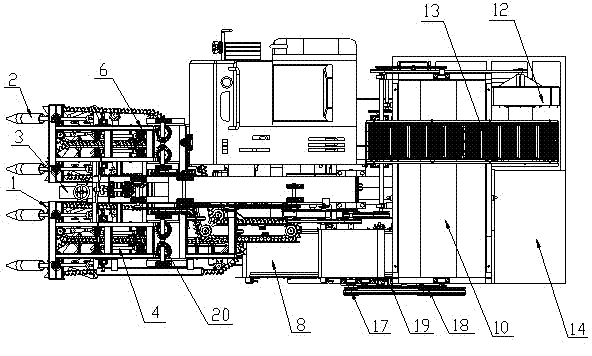

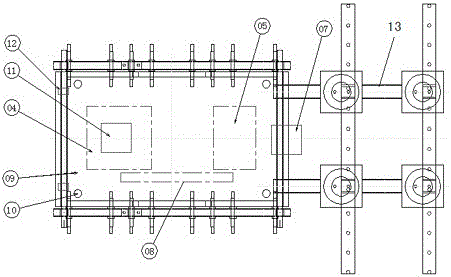

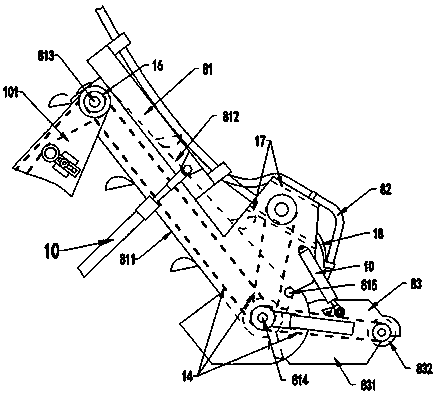

Two-ridge four-row whole-feeding peanut combine harvester

InactiveCN103039175AAchieve harvestRealize the clamping effectDigger harvestersThreshersEngineeringCombine harvester

Disclosed is a two-ridge four-row whole-feeding peanut combine harvester. The two-ridge four-row whole-feeding peanut combine harvester comprises a driving device, a clamping conveying device, a peanut picking sorting device and a peanut lifting device, the clamping conveying device comprises a two-ridge four-row clamping conveying collecting device and a conveying device, the two-ridge four-row clamping conveying collecting device comprises a clamping chain rack and clamping chains I, II, III, IV and V, a peanut vine clamping conveying path A is achieved by meshing of the clamping chain I and the clamping chain II, a peanut vine clamping conveying path B is achieved by meshing of the clamping chain III and the clamping chain IV, the clamping conveying collecting device further comprises a clamping collecting device, and the clamping conveying path A, the clamping conveying path B and conveyed peanut vines are gathered at a position of the clamping collecting device. By means of the two-ridge four-row whole-feeding peanut combine harvester, two-ridge four-row peanut vines can be harvested, clamped and conveyed, peanuts can be picked, sorted and collected, the work efficiency of the peanut combine harvester is improved, and time costs are lowered.

Owner:QINGDAO AGRI UNIV +1

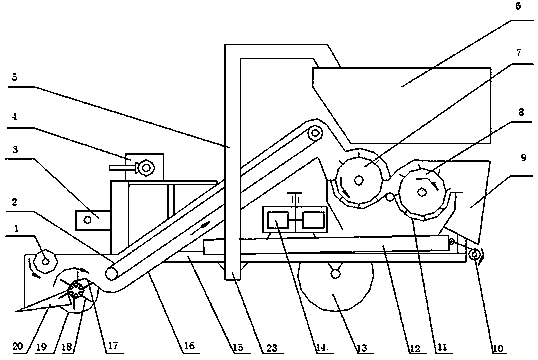

Peanut picking machine

InactiveCN103283373ACompact and reasonable structureImprove space utilizationLoadersDigger harvestersControl systemEngineering

The invention discloses a peanut picking machine which comprises a machine frame, a walking system, a dynamical system, a control system and a peanut collecting box. A picking machine body and a picking device are installed on the front side of the bottom end of the machine frame. A picking lifting adjustment device is installed between the picking machine body and the machine frame. A peanut seedling lifting device is installed behind the picking device. The machine frame is further provided with a peanut seedling feeding device and a peanut picking chamber, a peanut picking device is installed inside the peanut picking chamber, a cleaning chamber extending backwards is arranged on the machine frame below the peanut picking device, a cleaning device is installed inside the cleaning chamber, a peanut transverse conveying assembly is installed on the machine below the cleaning device, an outlet end of the peanut transverse conveying assembly is connected with a peanut lifting device assembly, and an outlet end of the peanut lifting device assembly is connected with the peanut collecting box. The peanut picking machine integrates the functions of picking, peanut-picking and cleaning, the structure is compact and reasonable, the space utilization is high, cost is effectively reduced, operation is convenient, working efficiency is greatly enhanced, and meanwhile, the labor cost is reduced.

Owner:WUZHENG +1

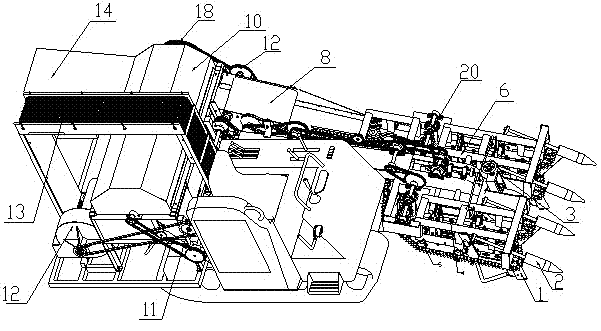

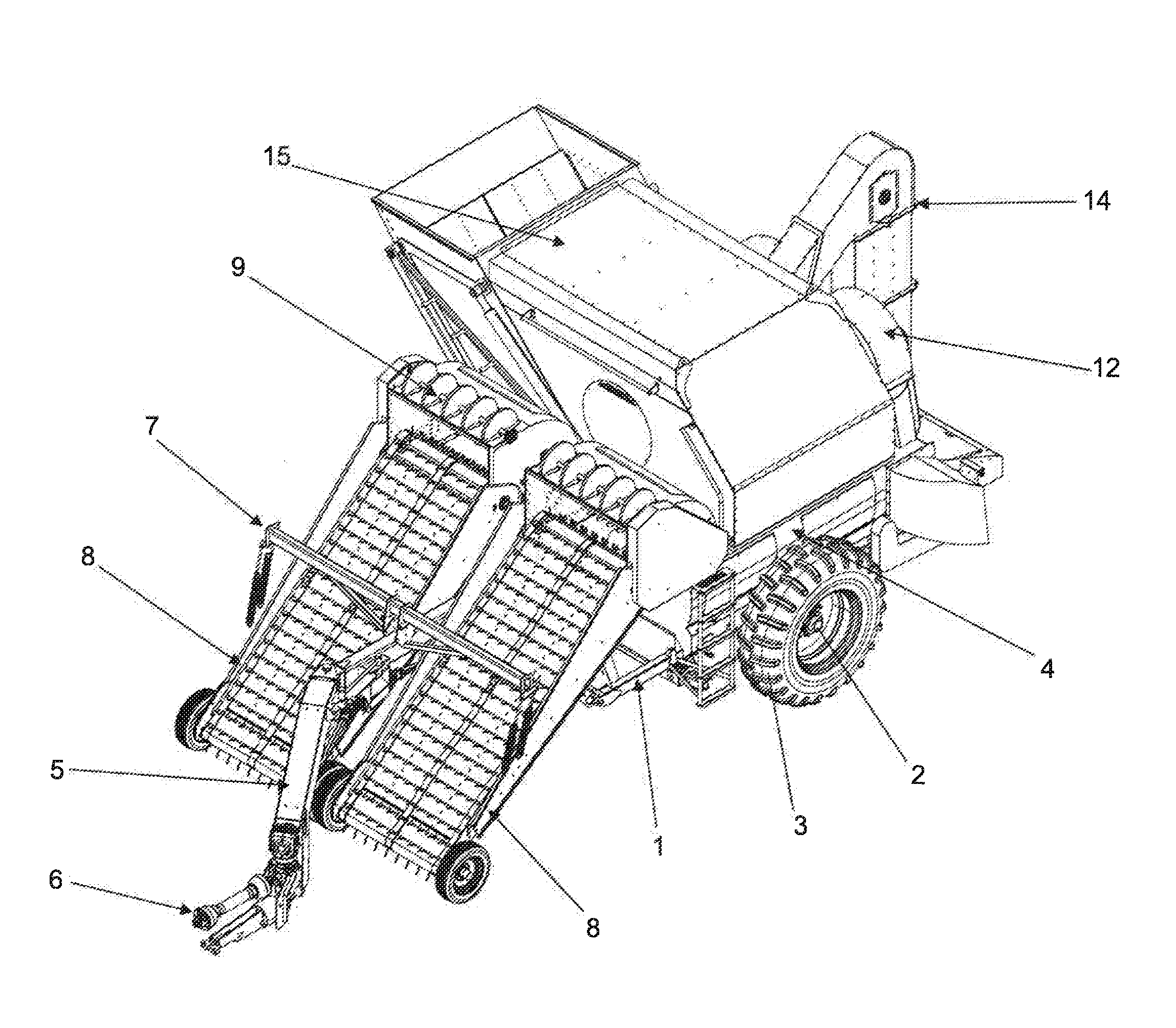

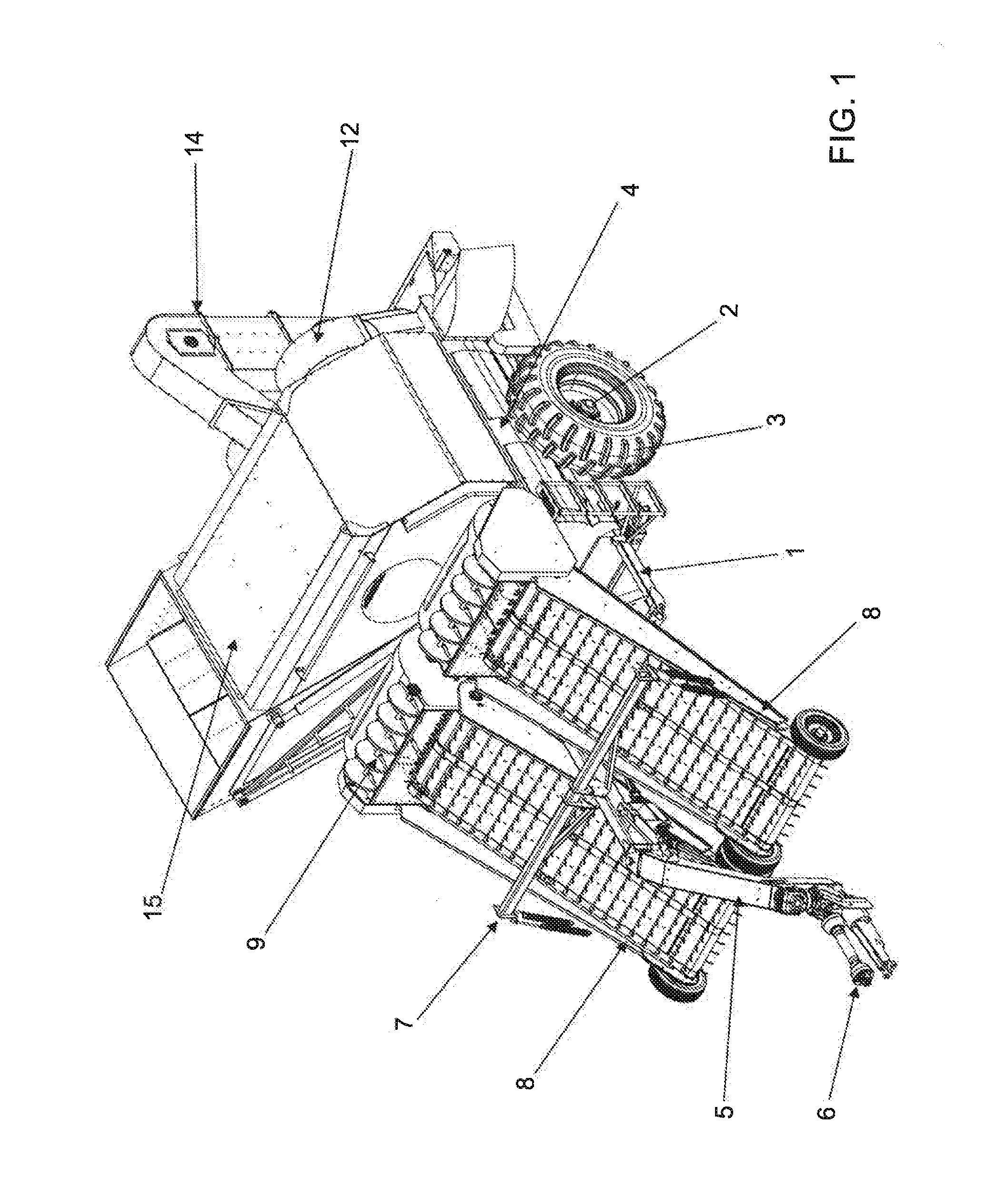

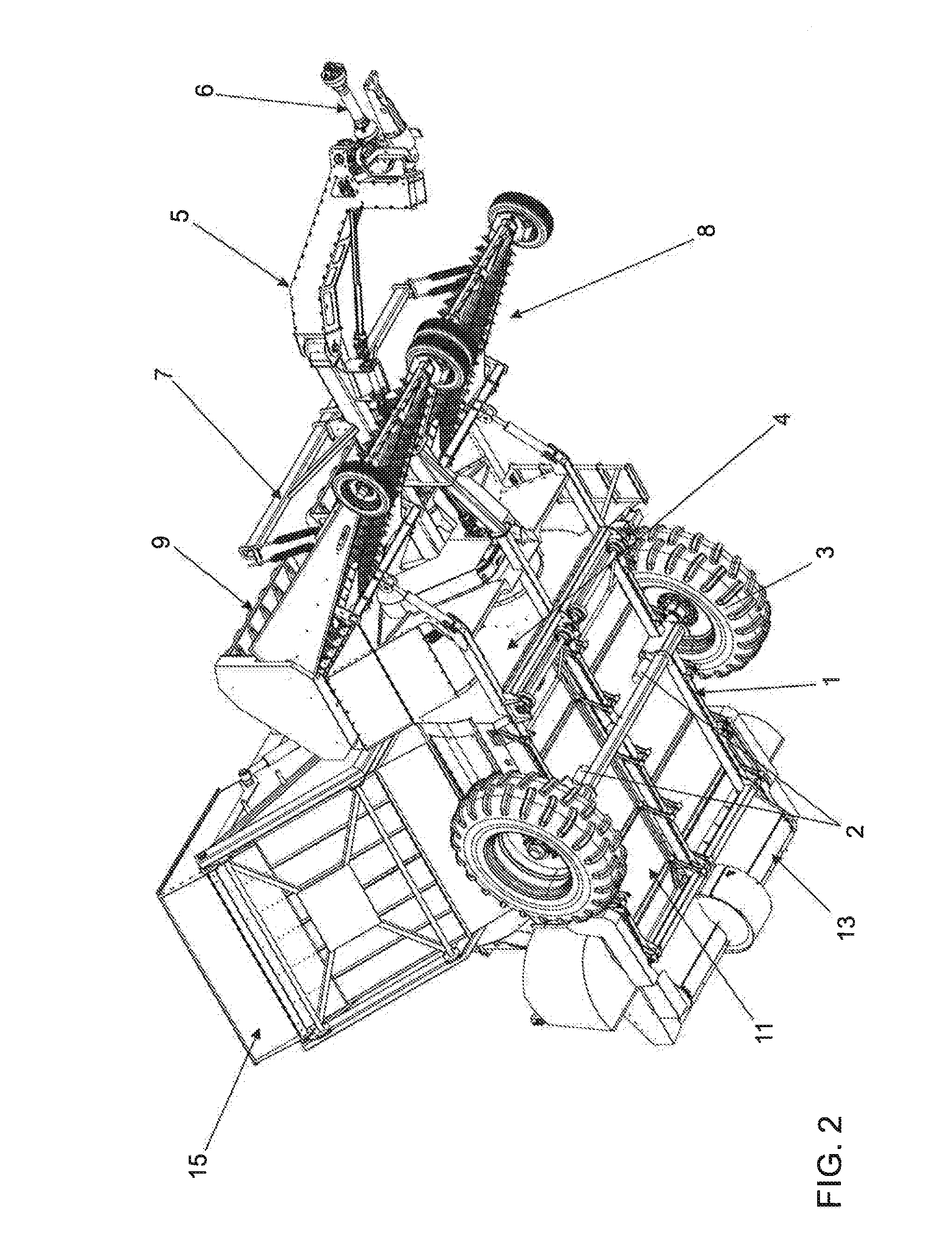

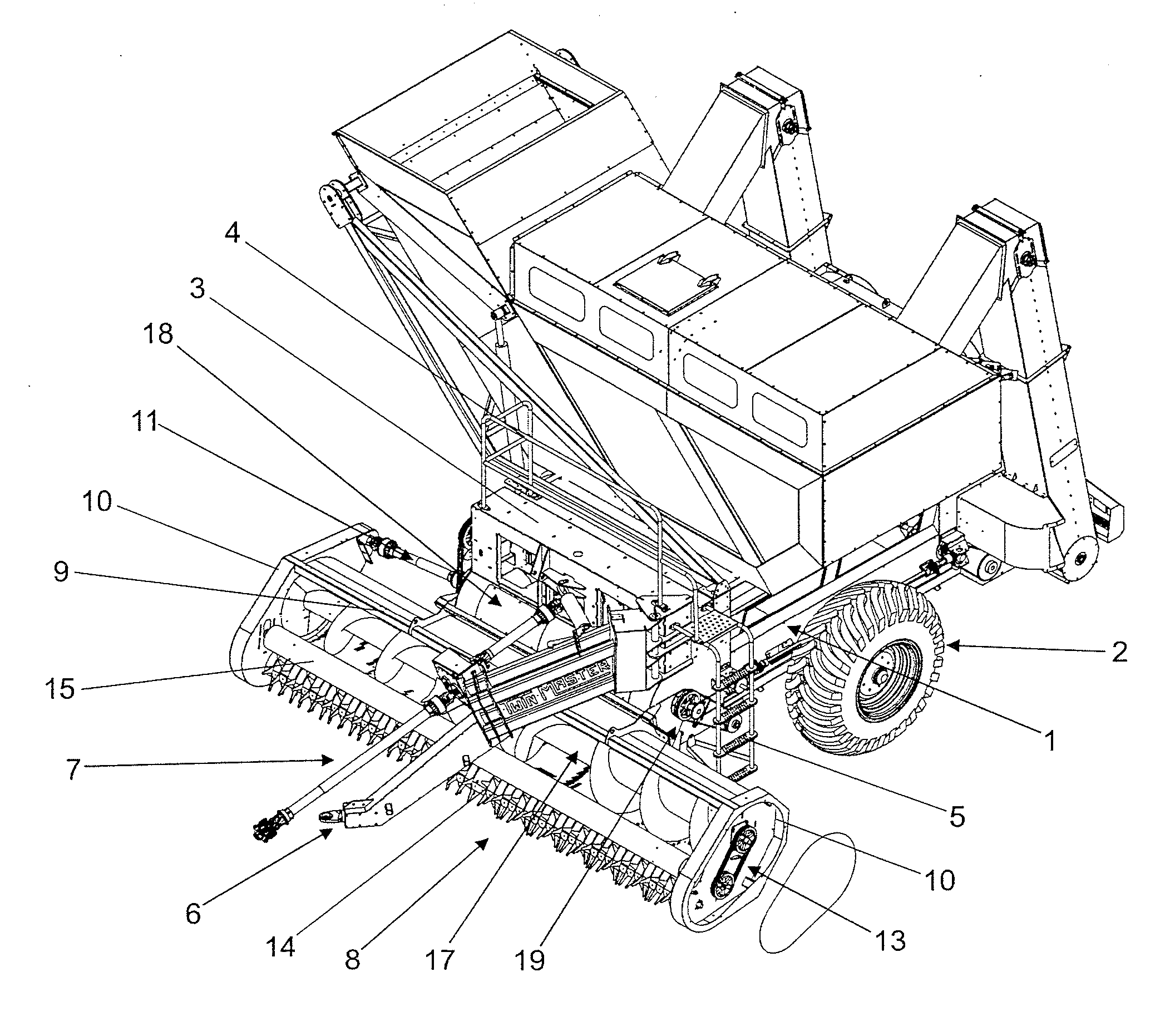

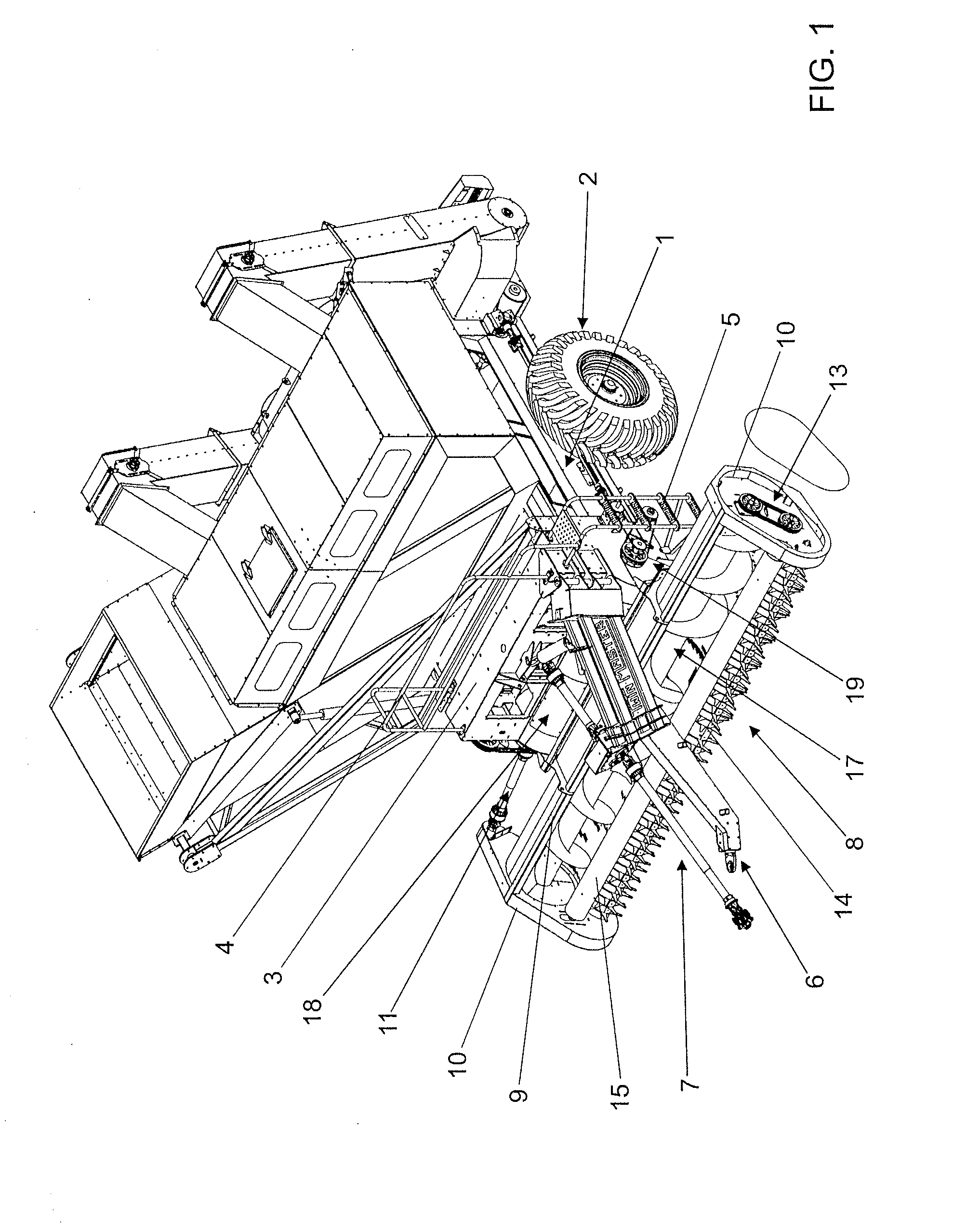

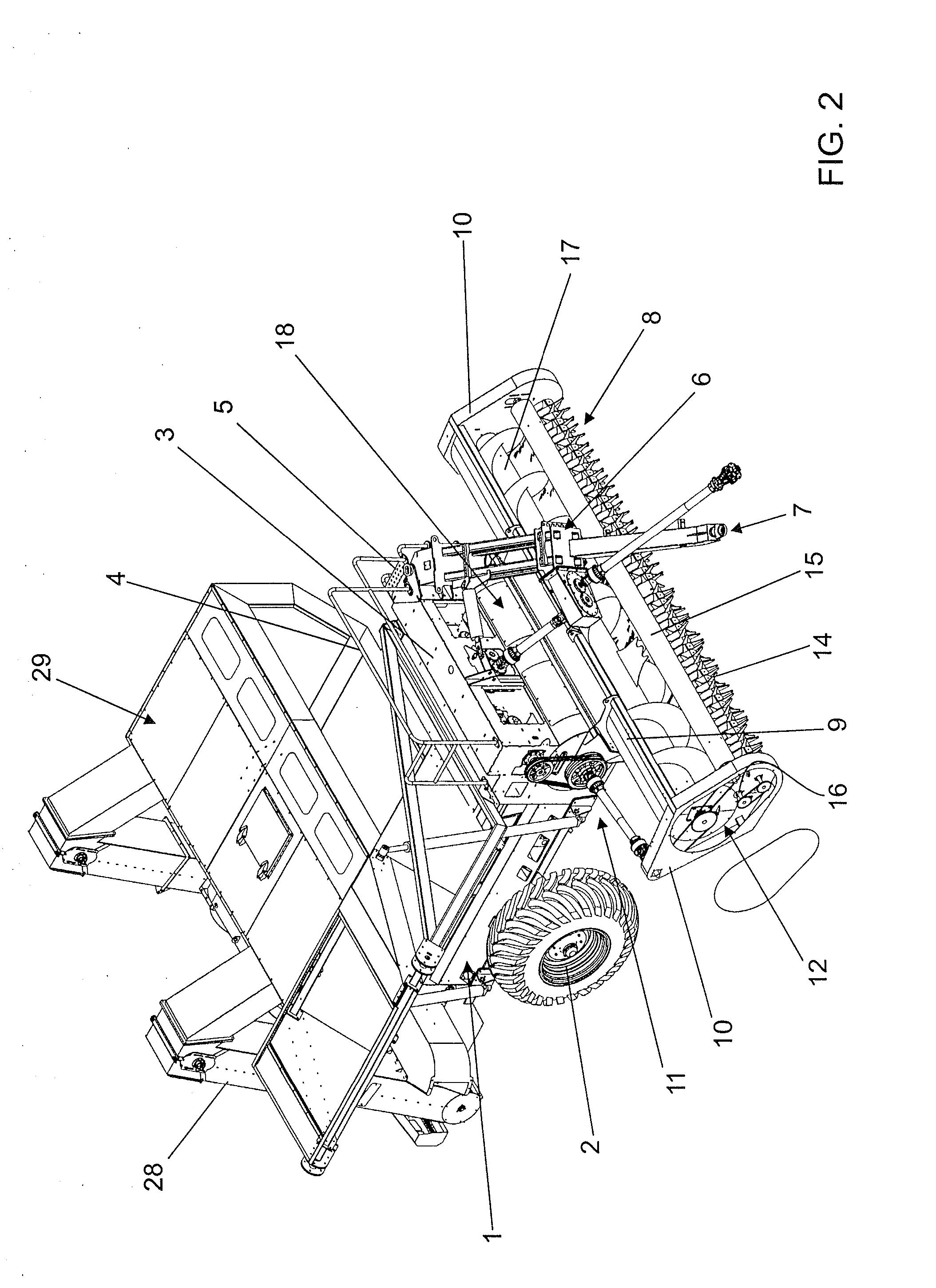

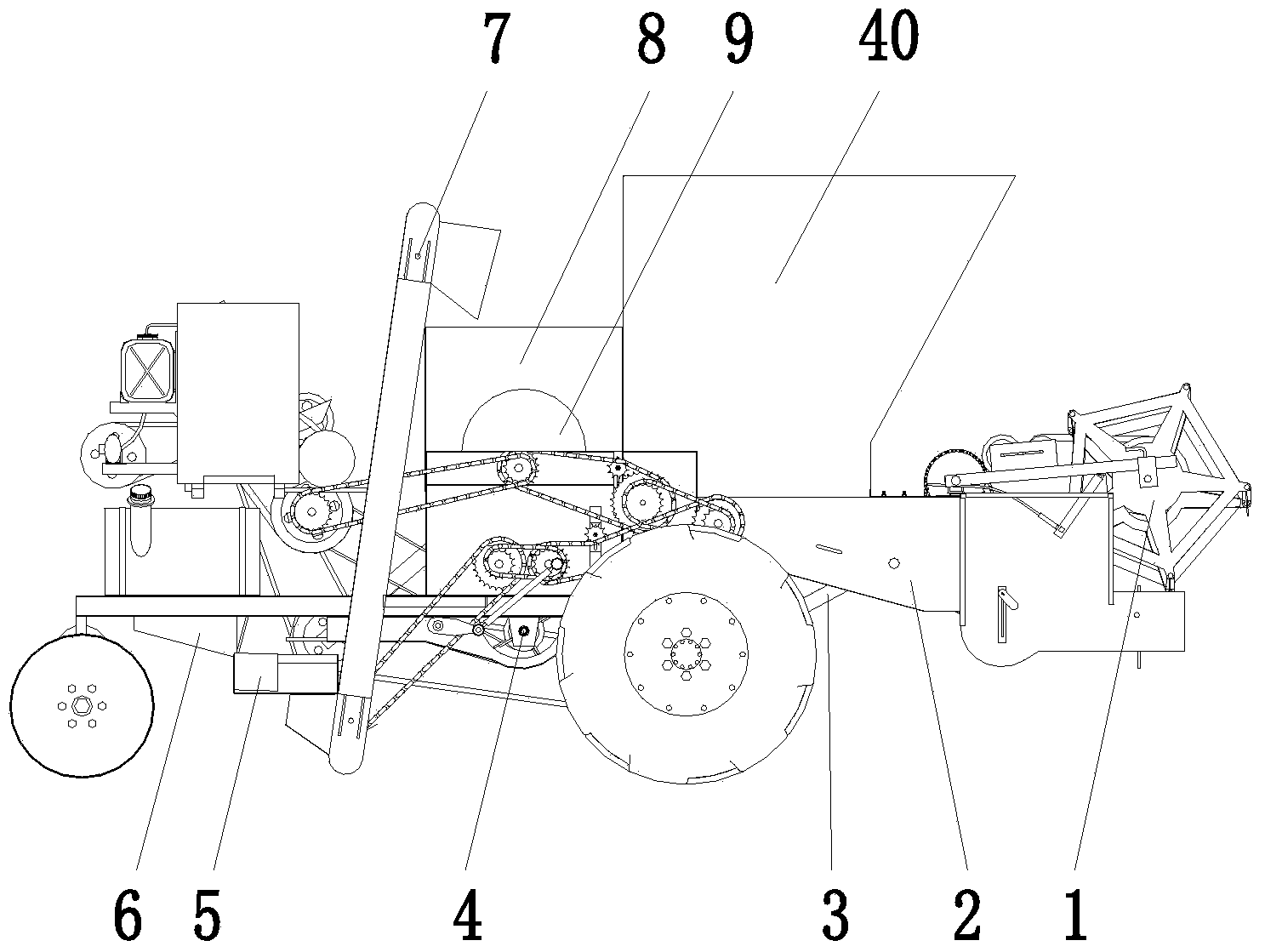

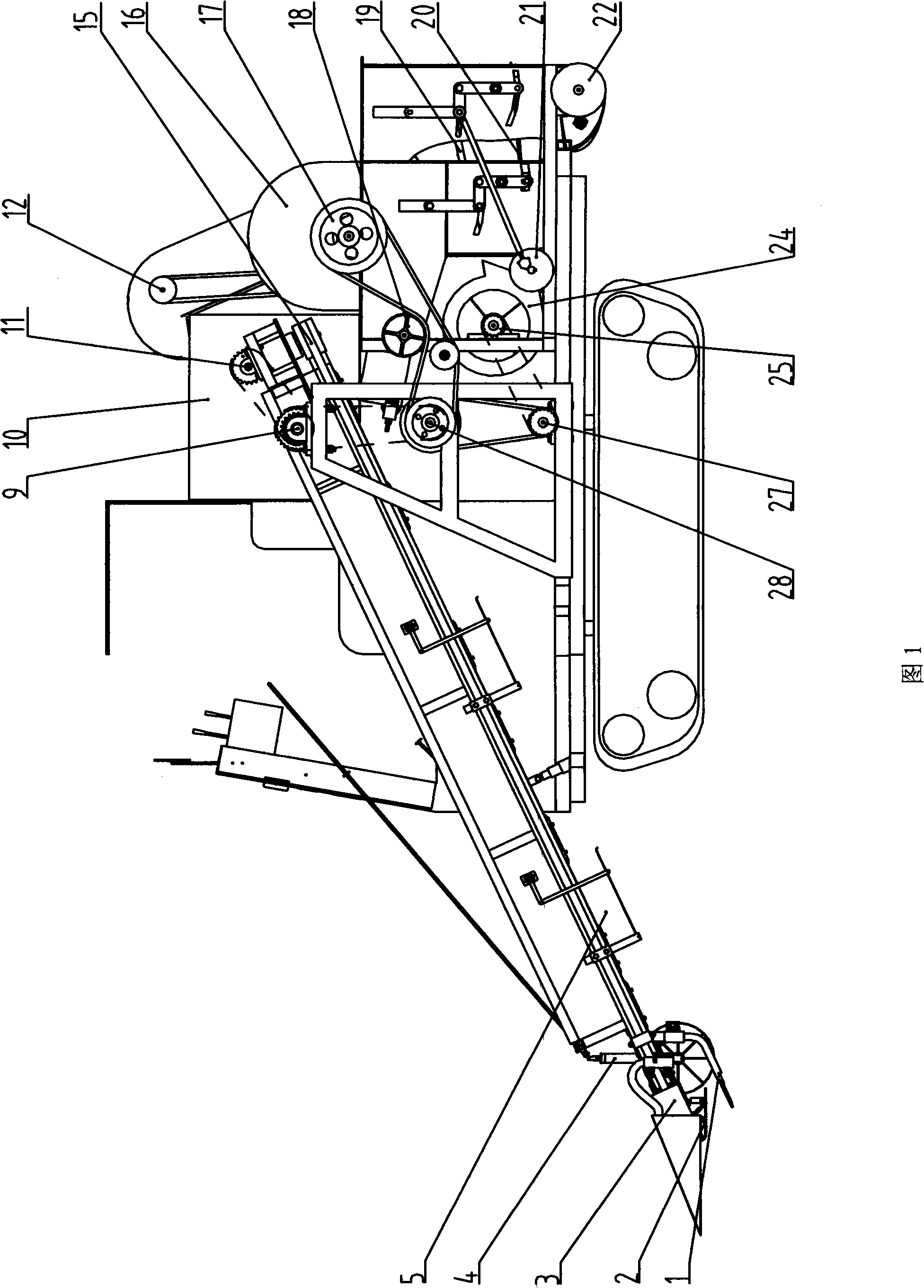

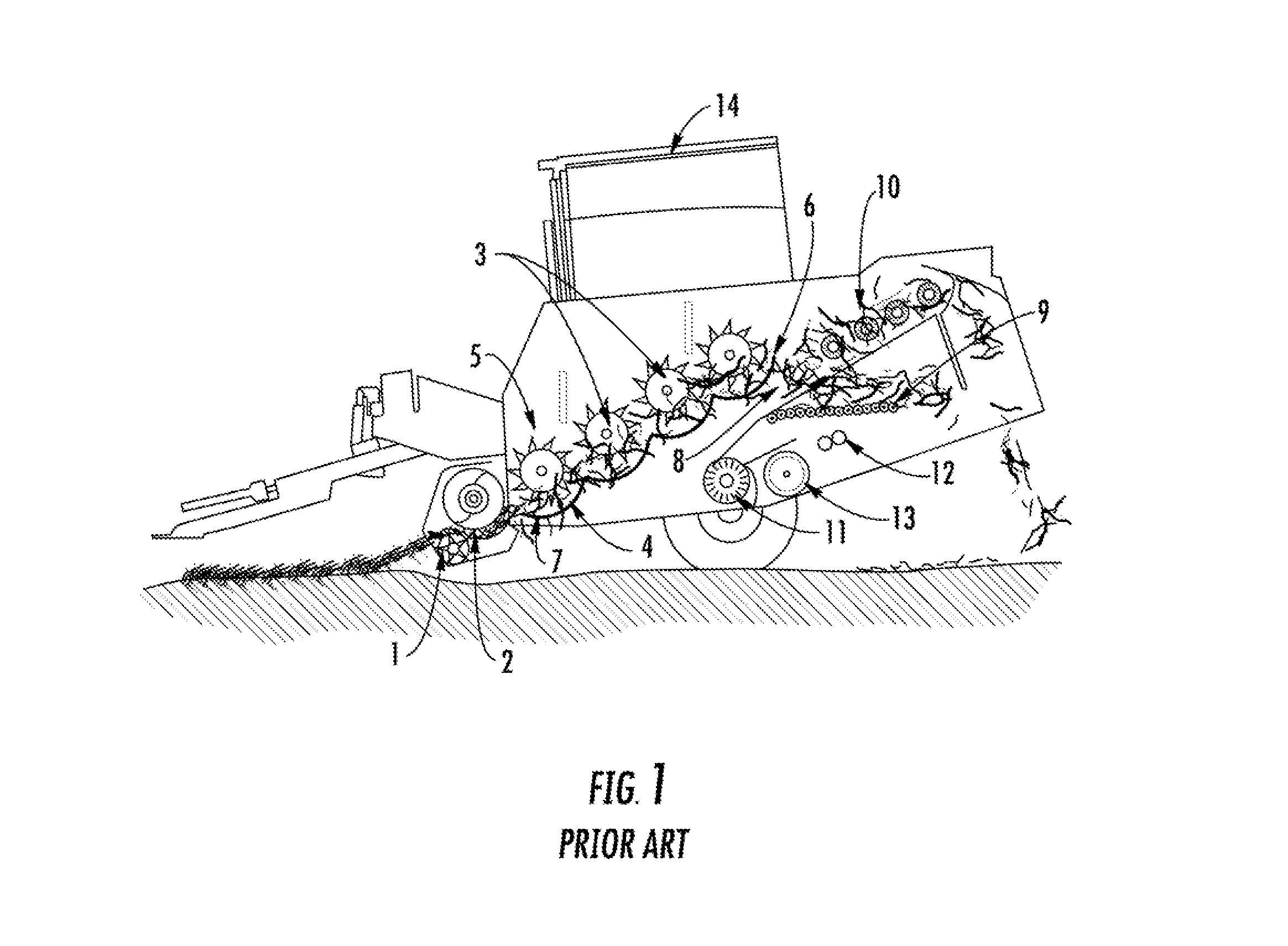

Harvester and processor for peanuts

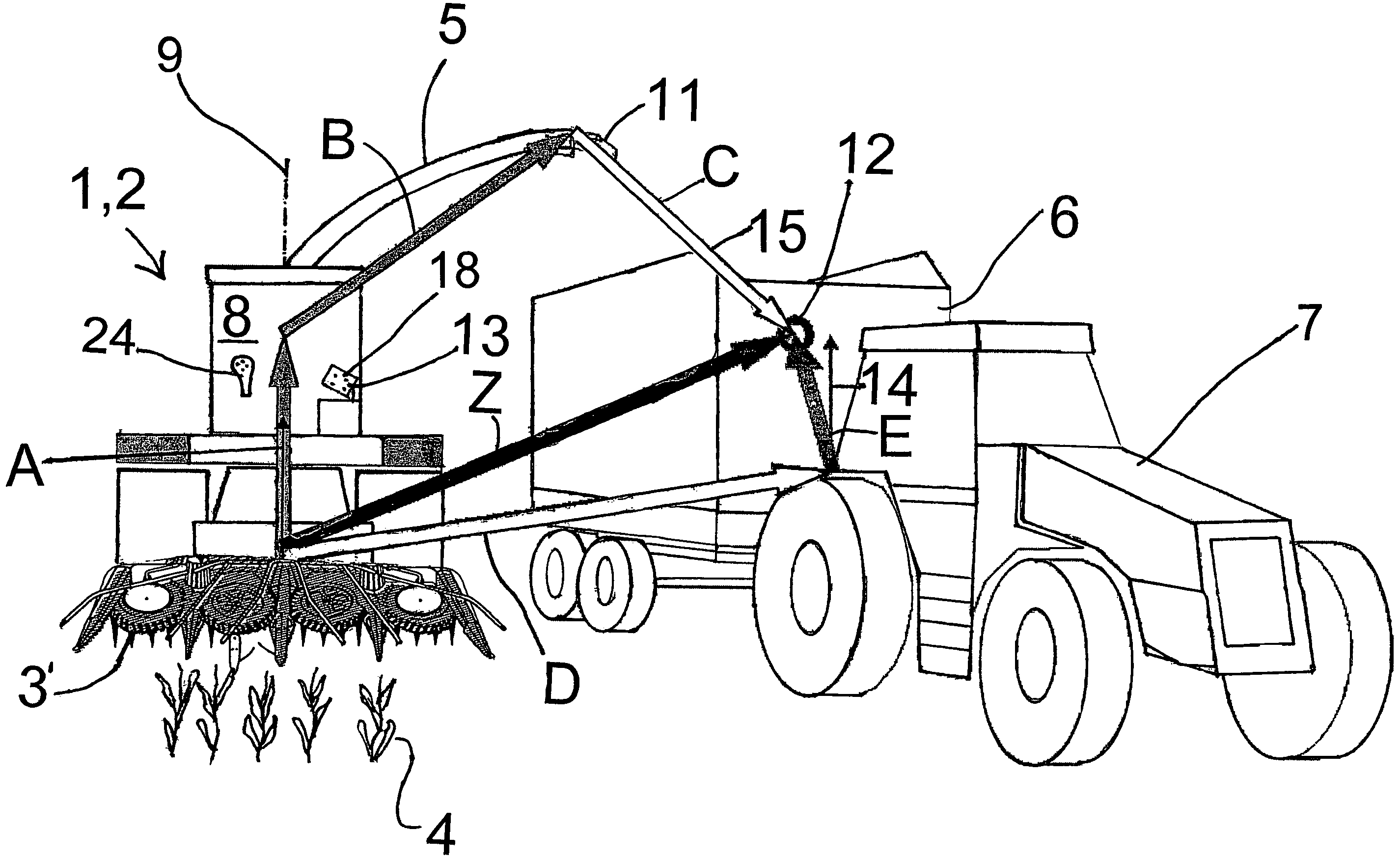

ActiveUS20160316626A1Uniform transitionSpeed up the flowLoadersDigger harvestersAnti jammingEngineering

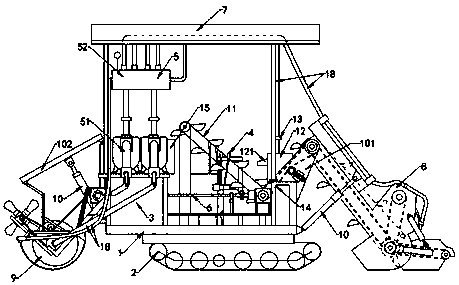

A harvester and processor for peanuts that comprises a drag type machine to be towed and actuated by a conventional tractor, which has various double assemblies to harvest lined up peanuts and process them through various steps of cleaning, up to the separation of the cleaned grains that are stored in an embedded tipper bucket, and to perform all this, said machine contains a chassis (1), that on its bottom side is supported by wheels (3), while on its top side is integrated with a plate body (4) forming a mono block structure for the assembling of all the embedded assemblies, starting with the frontal hitch pole (5) integrated with the transmission assembly (6) which is responsible for the actuation of various parts of the machine, specially two harvesting conveyor belts (8), anti-jamming receptive boxes (9), threshing cylinders (10), and in these cylinders starts the cleaning process together with the vibrating sieves (11) and the ventilation assembly (12), being that the cleaned fruits are delivered to a receptive chute (13), where they are collected by a bucket elevator (14) and dropped inside of a tipper bucket (15).

Owner:IND REUNIDAS COLOMBO LTD

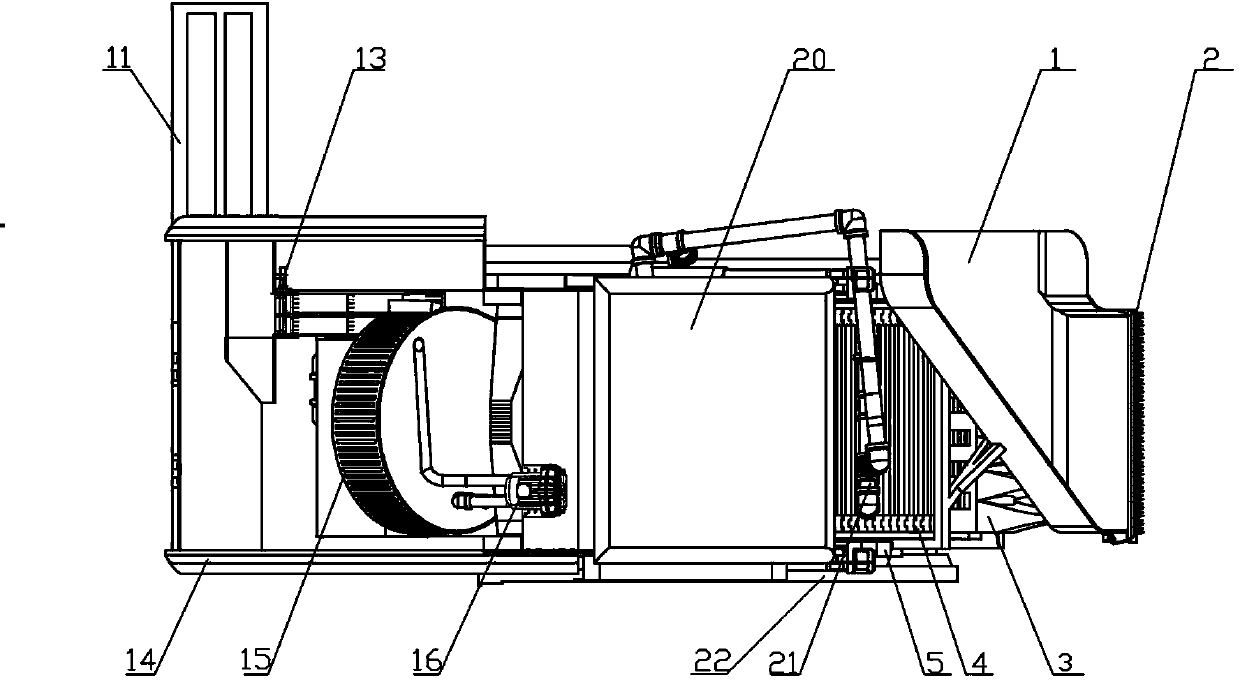

Associative type water chestnut harvesting machine

InactiveCN103749069AMechanizationEasy to storeDigger harvestersWater ChestnutsAgricultural engineering

The invention relates to an associative type water chestnut harvesting machine which comprises a hydraulic type caterpillar band chassis. A cab, a compartment, a diesel engine power mechanism, an excavation conveying device, a vibrating screen, a slush pump washing device, a rotary cage high-pressure air pump air drying device and a field leveling harrow are installed on the caterpillar band chassis through a rack. According to the associative type water chestnut harvesting machine, residual water chestnut straws and weeds in the field can be eliminated, water chestnuts can be excavated out from soil, meanwhile, the soil and water on the water chestnuts are completely removed, and the bumpy field after excavation is recovered to be in an original level state. According to the associative type water chestnut harvesting machine, the water chestnut harvesting mechanization is achieved, and the water chestnut harvesting quality and the water chestnut harvesting working efficiency can be greatly improved.

Owner:东北大学秦皇岛分校

Device used to aid in the loading and unloading of vehicles and implements

InactiveUS7034666B2Eliminating potentialEliminate distractionsPortable emergency signal deviceAcoustic signal devicesEngineeringTruck

A communication device is provided which is intended to aid farm workers in the coordination of harvesting and hauling vehicles in the field during crop harvesting operations. This communication device consists of a transmitter and receiver which are mounted at convenient points within the harvesting vehicle and produce hauling truck respectively. The receiver contains four lighted directional arrows representing directional changes of forwards, backwards, left, and right. The transmitter contains four buttons that correspond in location and function to the directional arrows on the receiver. Thus, when a button on the transmitter is depressed by the harvester operator, the corresponding directional arrow on the receiver will light up signaling the truck driver to make a change in the position of his truck relative to the harvester.

Owner:KNUTSON SCOTT WILLIAM

Grain reaper

ActiveUS20080295476A1The process is simple and fastWork resistanceMowersDigger harvestersEngineeringReaper

The present invention relates to a reaper for grains, specially for the bean grains. More specifically, the present invention refers to technical and functional improvements specially developed and introduced which configures a bean reaper that is classified as a trailer to carry out two different operations, the first one of which is gathering various plants, such as bean plants, peanuts and other grains, plants which are previously plucked and aligned, whereas the second function of which is to perform a whole cleaning process by separating the grains (seeds) from the remaining unwanted parts.

Owner:IND REUNIDAS COLOMBO LTD

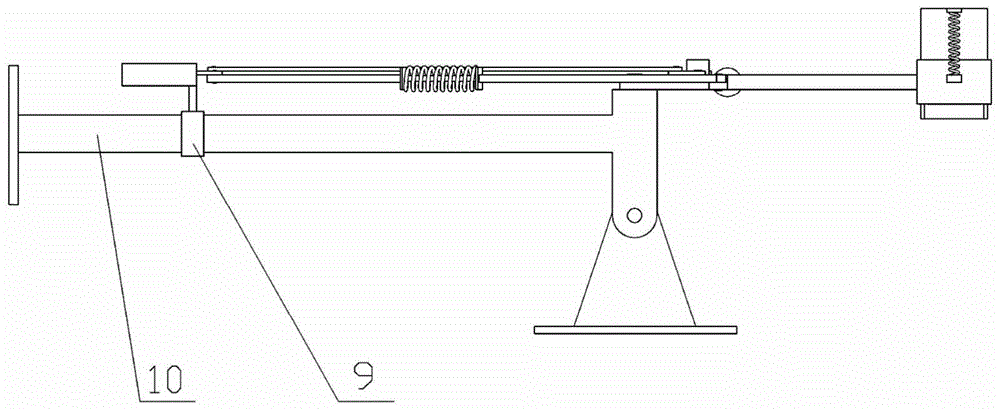

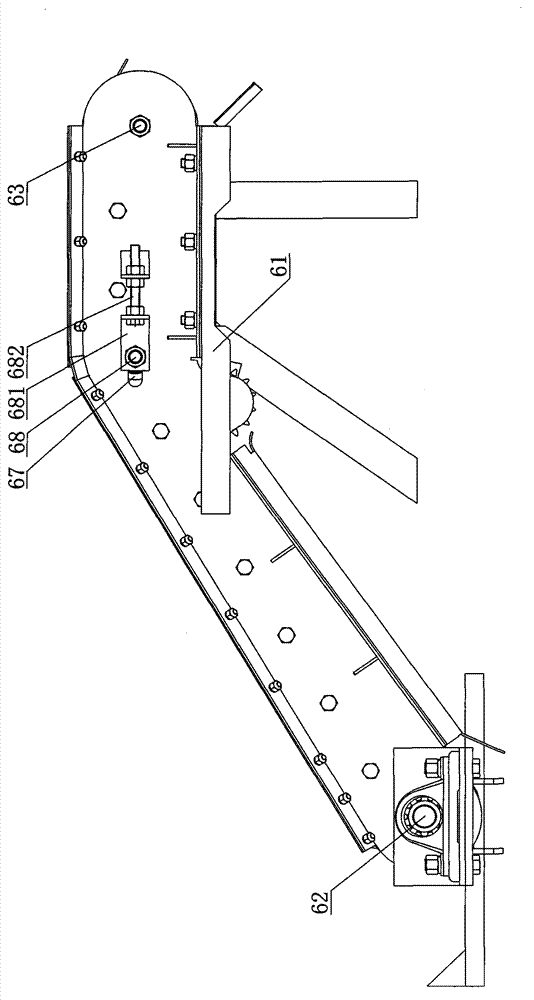

Cassava pulling up and holding mechanism

Owner:GUANGXI UNIV

Cleaning and separation system for tubers

InactiveUS20100096301A1Rapidly and effectively cleaningSimplified descriptionSievingScreeningEngineeringPlant Tubers

An entire harvested ground fruit load is subjected to a first cleaning process on a cleaning table, which separates the smaller ground fruits, soil, stones, clods, vine stems, grasses and other debris from the larger ground fruits. The fall-through burden from the cleaning table is subsequently subjected to a second separation step using a pintle belt conveyor equipped with at least one spinning shear roller. Soil particles, stones, clods, vine stems, grasses and other debris fall between the pintles of the pintle belt conveyor and are discarded, while small ground fruits are moved by the spinning shear roller(s) and either recombined with the main ground fruit load or diverted to a separate path for storage. Operational speed of the pintle belt conveyor and rotational speed of the shear rollers can be adjusted to maximize the breakup of clods which impact the shear roller(s).

Owner:NYBORG BRUCE DAVID +1

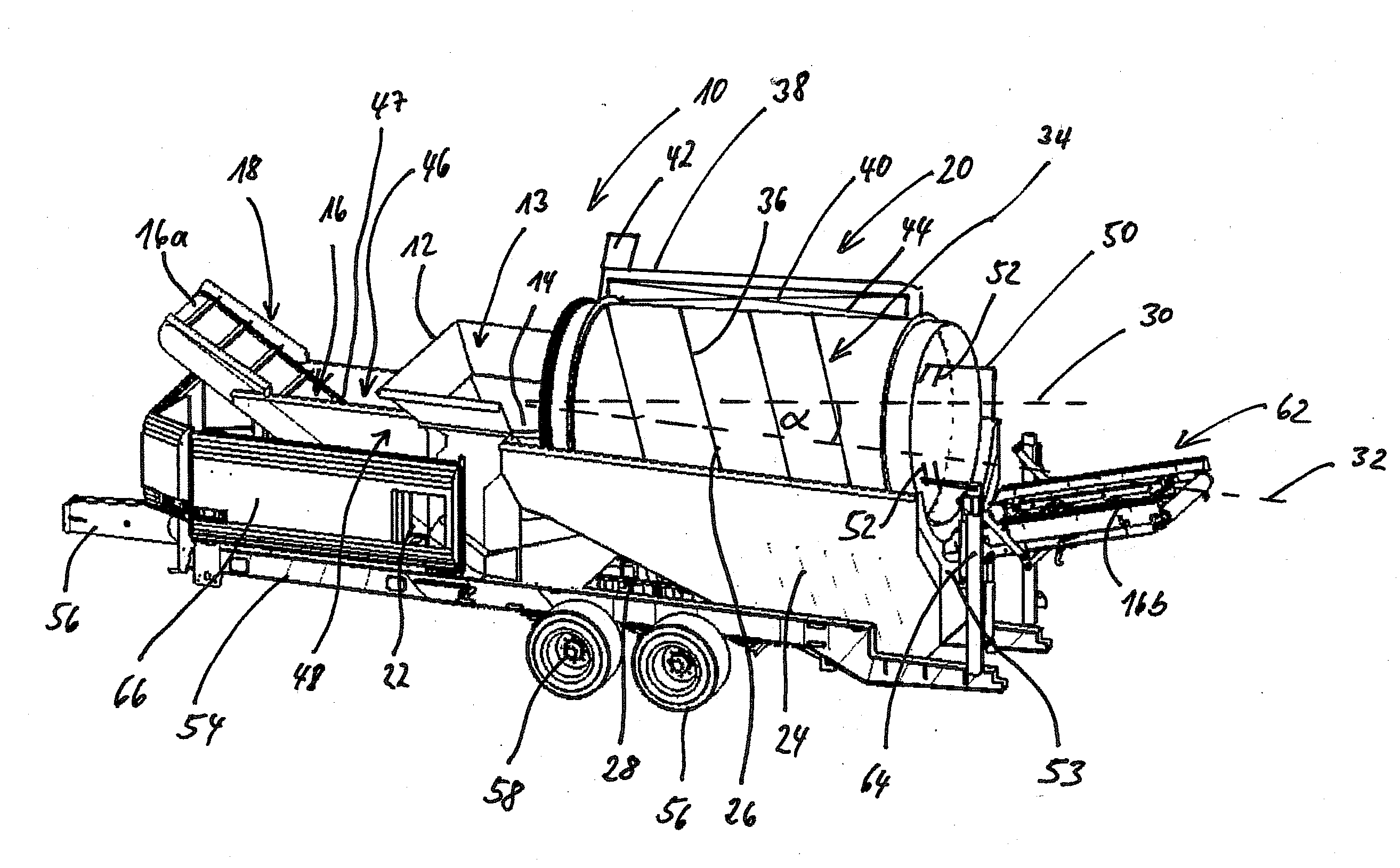

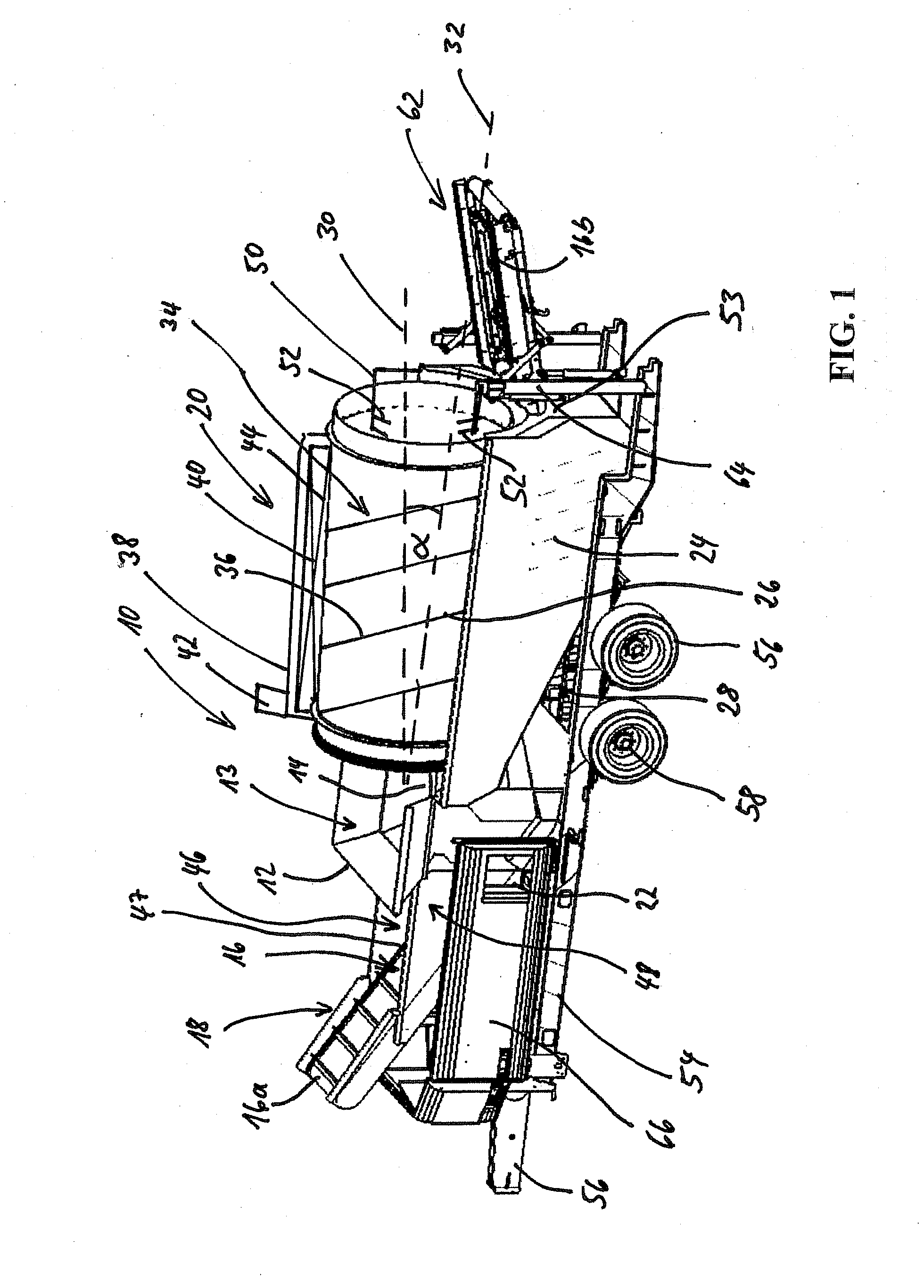

Apparatus for cleaning field crops

A cleaning apparatus is provided for cleaning crops, such as potatoes or beets, with adhering particles of soil and the like. The apparatus comprises a charging and or supply hopper with an opening at its underside from which the crops enter for cleaning; a housing with a cleaning region, wherein the crops are cleaned; a rotating screen drum rotating about an axis of rotation wherein the crops are cleaned; wherein the screen drum is arranged in the cleaning region; the axis of rotation of the rotating screen drum is inclined at an acute angle.

Owner:USG UMWELTSERVICE

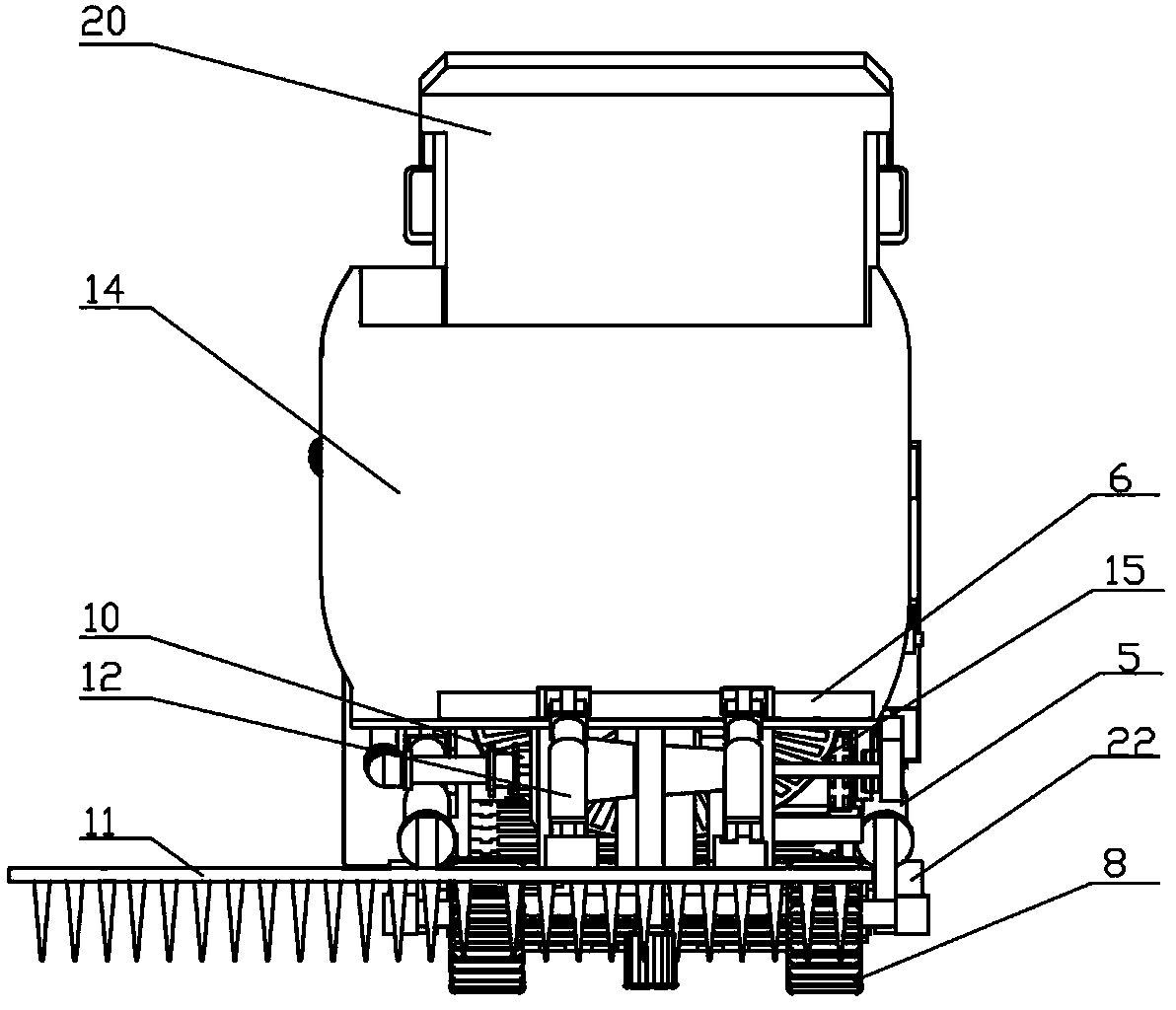

Integrated harvester of water chestnut

The invention relates to the technical field of agricultural machinery, in particular to an integrated harvester of water chestnuts. The integrated harvester of the water chestnuts is characterized inthat the integrated harvester of the water chestnuts comprises a walking machine and a frame; the walking machine is connected with a hydraulic suspension system which is connected with an engine ofthe same; the hydraulic suspension system comprises a transmission case and a hydraulic cylinder; a spindle I is fixed on a smashing mechanism behind the walking machine in drive connection; a shovelboard is arranged at the entrance of a front chamber and in active fit with the front chamber; a push plate vibration mechanism is installed in the front chamber; a mud pump and a high pressure air pump are mounted on the frame and powered by a generator configured by the engine; a water and gas mixing cleaning mechanism is installed in a transport warehouse; a compensatory cleaning mechanism is arranged just below the water and gas mixing cleaning mechanism; a water outlet of the mud pump is connected with a water pipe; a pluarlity of nozzles are mounted on the water pipe; an air outlet of the high pressure air pump is connected with an appendix. The integrated harvester of the water chestnuts has the advantages of being clean after five times of cleaning during work process of the wholemachine, greatly reducing damage during harvesting, improving harvesting efficiency and reducing farmers' harvesting costs.

Owner:惠安县德虹数控设备有限公司

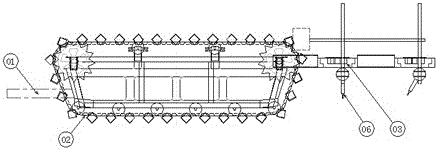

Peanut combine

ActiveCN104025794ASolve the harvesting problem of continuous plantingImprove harvesting efficiencyDigger harvestersTraction frameEngineering

The invention discloses a peanut combine. The peanut combine comprises a machine frame, a traction frame, a transmission gearbox, a peanut picking device, a conveying and collecting device, a peanut collection box, a cleaning and separating device and a peanut collecting trough. The peanut combine is characterized in that the machine frame is supported by land wheels, the front end of the machine frame is provided with a picking-up and conveying device communicated to the peanut picking device, the peanut collection box is arranged on the upper portion of the peanut picking device, and the cleaning and separating device is arranged on the lower portion of the peanut picking device and is communicated to the peanut collecting box through a peanut lifter. The peanut combine automatically picks and collects seedlings and peanuts through the steps of picking-up and conveying, picking, cleaning and separating, and conveying and collecting, is high in harvesting efficiency, makes the harvested peanuts be clean and have few impurities like straw, and is very suitable for management of family farms and cooperatives in China, wide in use range and free of influence of soil texture and planting modes.

Owner:王刚

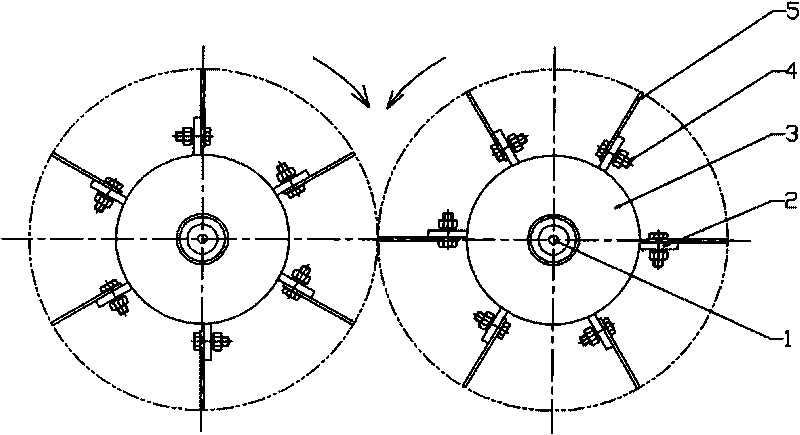

Spring tooth roller type peanut pickup device

The invention relates to a spring tooth roller type peanut pickup device and belongs to the technical field of agricultural machinery. The spring tooth drum type peanut pickup device comprises an open pickup roller, a roller slideway, pickup spring teeth and side plates, wherein the pickup spring teeth are uniformly fixed on a spring tooth shaft at intervals; a center shaft of the pickup roller passes through the left and the right side plates on the two sides and is connected with a bearing pedestal; the roller slideway is fixedly mounted in one of the side plates; one end of the spring tooth shaft is connected with the roller slideway through a crank cam mechanism; a roller of the crank cam mechanism is embedded into the roller slideway and is limited to roll in the slideway; the center shaft rotates and simultaneously drives the pickup roller to rotate; the shape of the roller slideway corresponding to each phase angle ensures the swing posture of each spring tooth on each station in the pickup process, so that the action on spring tooth pickup, lifting, pushing and backlash stations can be realized. According to the peanut plant pickup requirements, the initial posture and the swing rule of each pickup spring tooth on each station are determined. In the pickup process, the spring teeth gradually swing back, so that the strike of the spring teeth for peanut plants is reduced, and the pickup area is increased.

Owner:SHENYANG AGRI UNIV

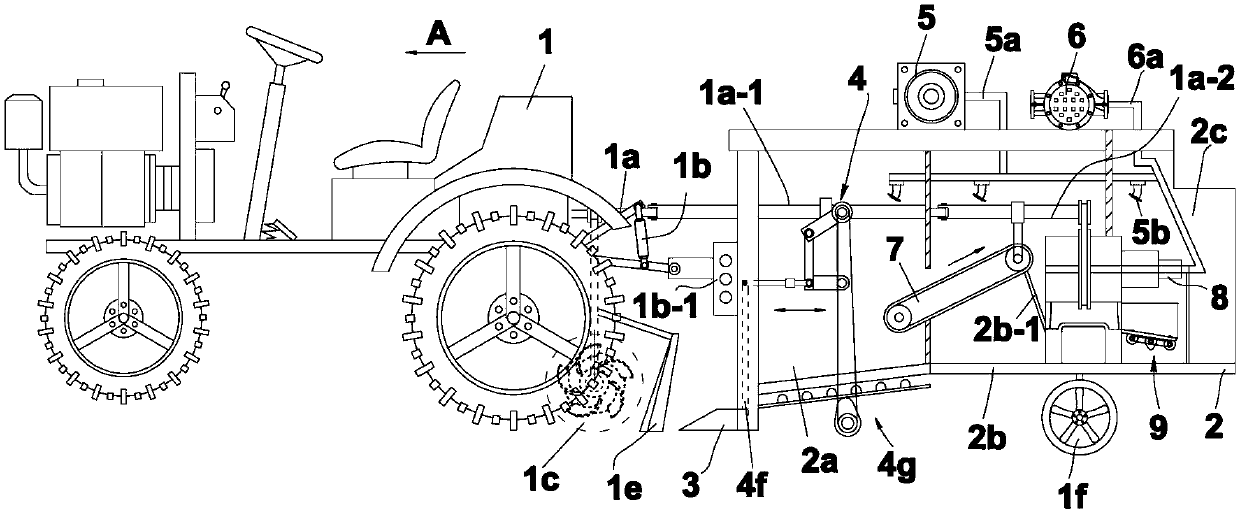

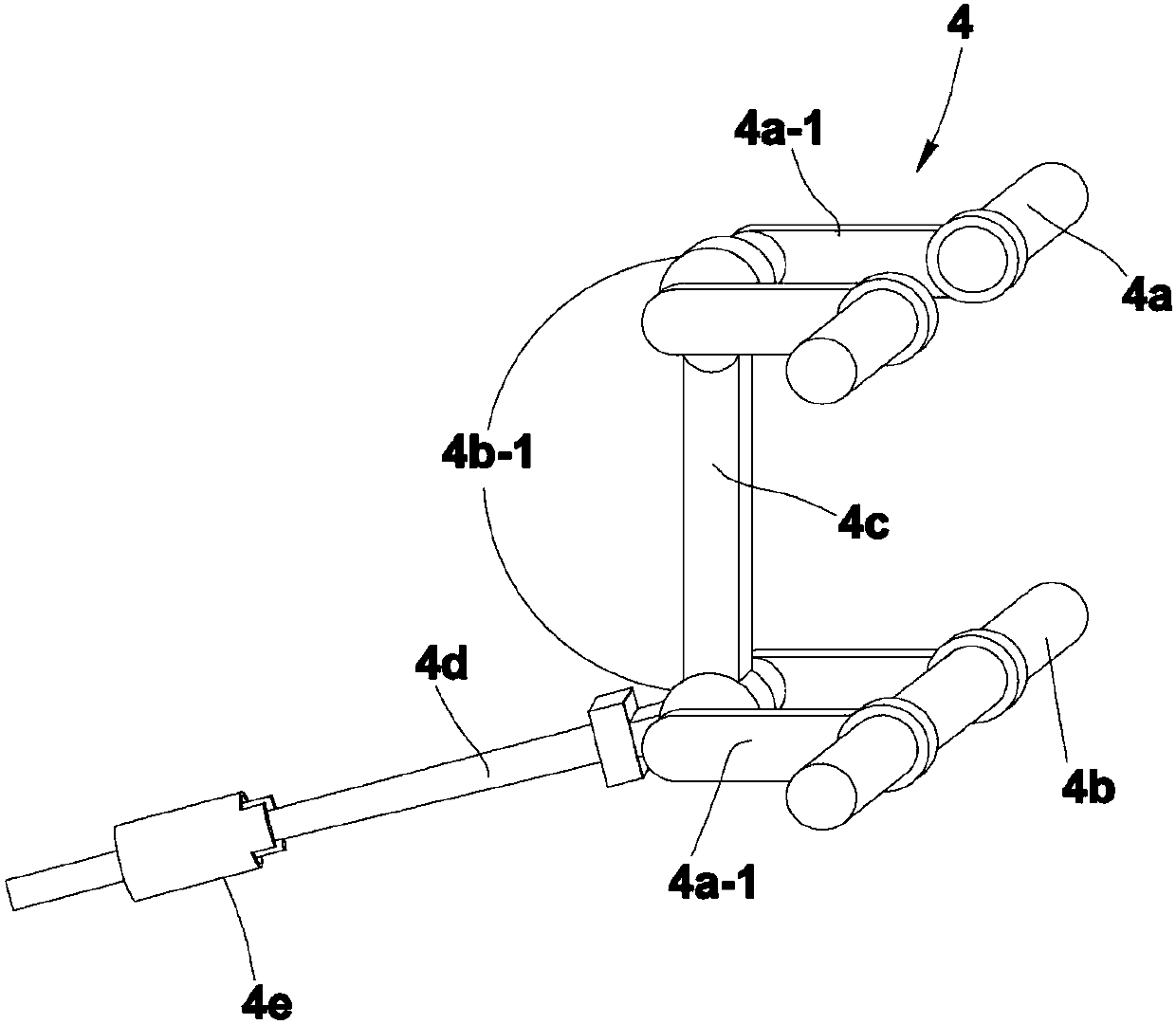

Self-propelled peanut picking-up and fruit picking combine harvester

The invention relates to a peanut combine harvester, in particular to a self-propelled peanut picking-up and fruit picking combine harvester. The self-propelled peanut picking-up and fruit picking combine harvester comprises a picking-up device, a middle conveying device, a fruit picking device, a multi-level cleaning device, a hoisting conveying device and a fruit collecting device which are sequentially connected, and a power device is connected with all the devices respectively. The self-propelled peanut picking-up and fruit picking combine harvester realizes the combined operation integrating picking-up, conveying, fruit picking, cleaning, hoisting and fruit collecting of laid peanuts, is high in picking-up efficiency and picking rate, improves the integrity of the peanuts to the maximum degree, and effectively solves the problem that fruit and seedlings cannot be separated thoroughly or cleaned cleanly.

Owner:QINGDAO AGRI UNIV

Combine for harvesting peanut

InactiveCN101297613AGuaranteed reliabilityReduce weightGearingDigger harvestersEngineeringCombine harvester

The invention relates to a peanut combine harvester, comprising a power travelling mechanism, an excavating mechanism, a gripping conveying mechanism, a fruit-picking mechanism, a cleaning mechanism and a cross conveying elevating and storing mechanism, wherein, the front of the power travelling mechanism is provided with the excavating mechanism connected with the gripping conveying mechanism; the fruit-picking mechanism is positioned at the back part of the gripping conveying mechanism, the lower part of the fruit-picking mechanism is provided with the washing mechanism and one side thereof is provided with the elevating and storing mechanism; power input shafts of the gripping conveying mechanism, the fruit-picking mechanism and the washing mechanism are connected with the output power of the power travelling mechanism by power transmission device. The peanut combine harvester of the invention integrates excavation, conveying, soil-removing, fruit-picking, separation, cleaning and storing into a whole, a machine frame receives pressure evenly, a mulching film is not damaged, the soil pollution is avoided, the operation resistance is little, and the operation is smooth; besides, the peanut combine harvester is characterized by compact mechanism, low cost, low consumption, little harvesting loss and high efficiency.

Owner:QINGDAO AGRI UNIV +1

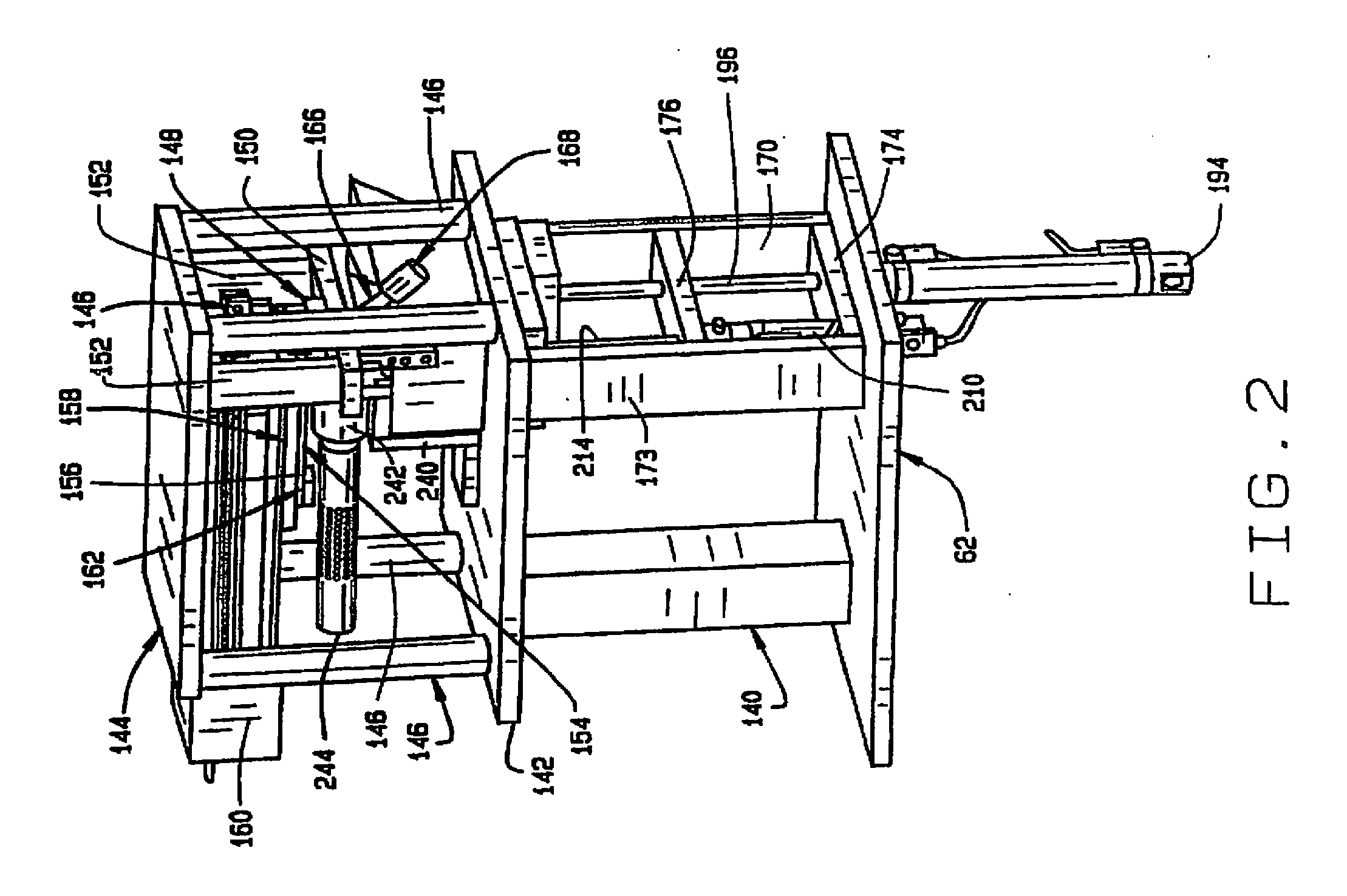

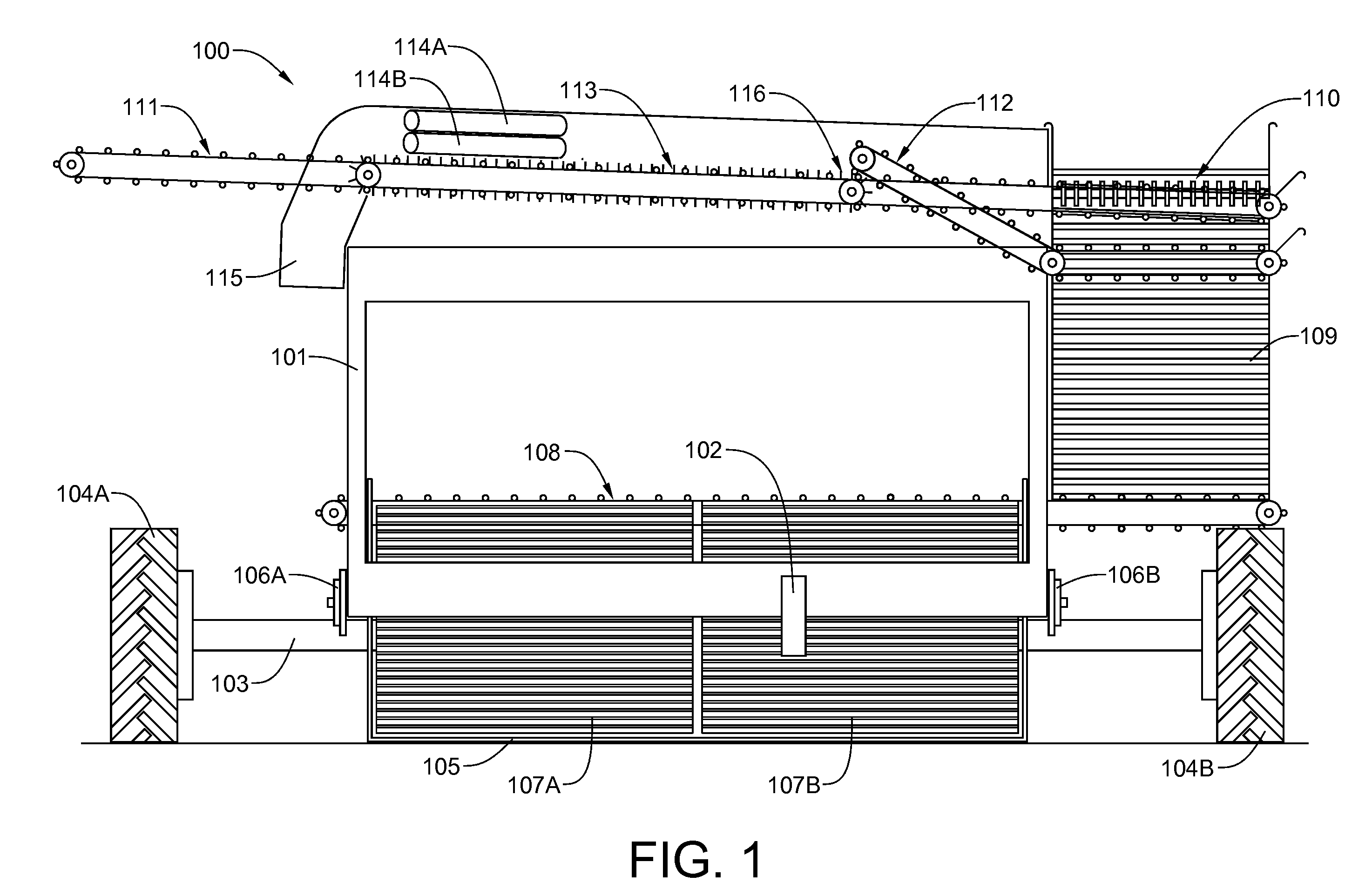

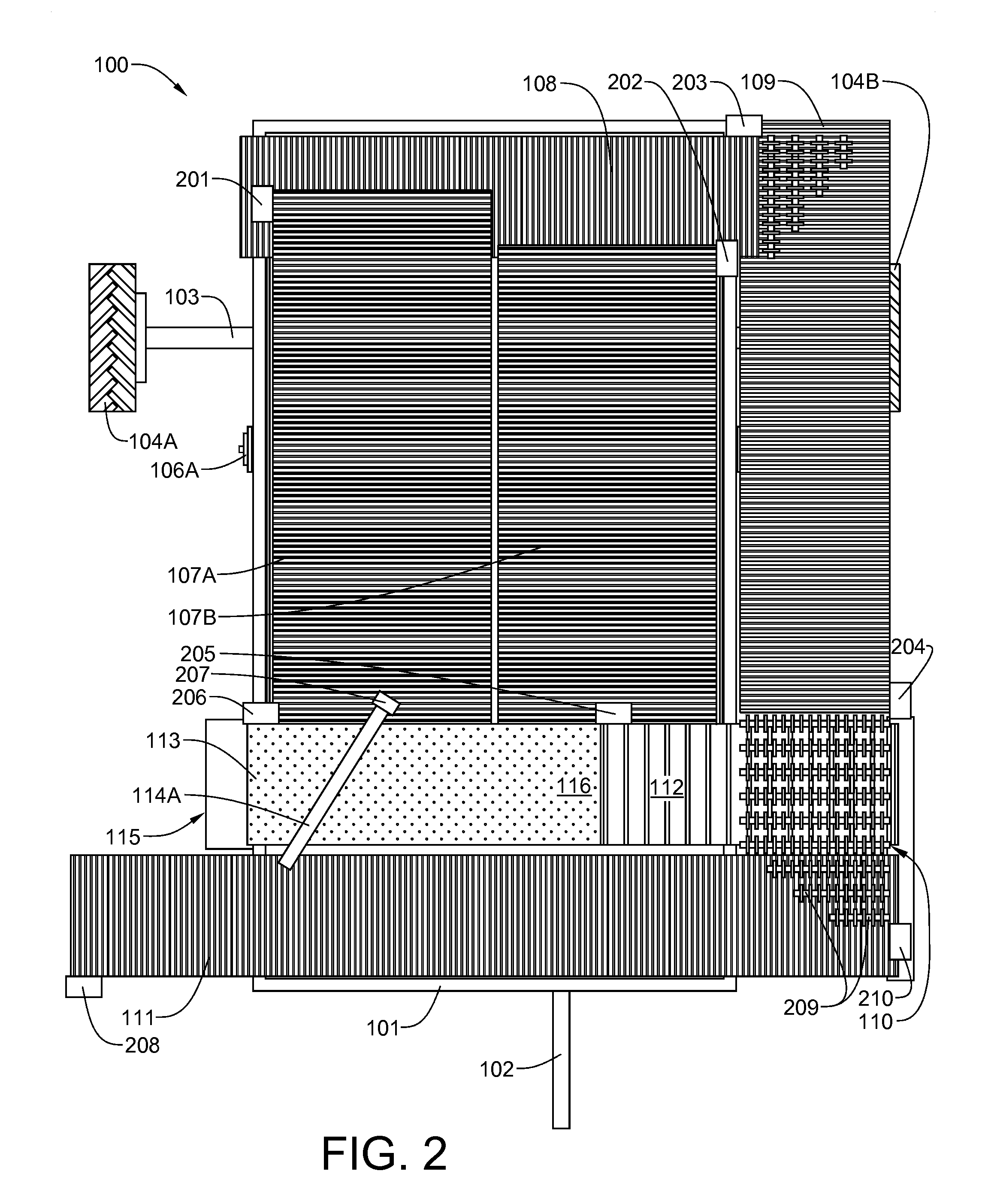

Grain transfer control system and method

ActiveUS8126620B2Evenly filledDigital data processing detailsRoad vehicles traffic controlAutomatic controlControl system

A grain transfer control system, and method of use thereof, for automatedly controlling the transfer of grain from a mobile transferor-type vehicle, such as a combine harvester, to a mobile transferee-type vehicle, such as a crop transport, by varying the position and speed of the transferor-type and transferee-type vehicles relative to one another during the transfer operation, especially by varying the position and rate of walk of the discharge spout along at least a portion of the length of a grain holding receptacle of the transferee-type vehicle, to effect a generally even fill of the grain holding receptacle of the transferee-type vehicle along the length of the grain holding receptacle.

Owner:BLUE LEAF I P INC

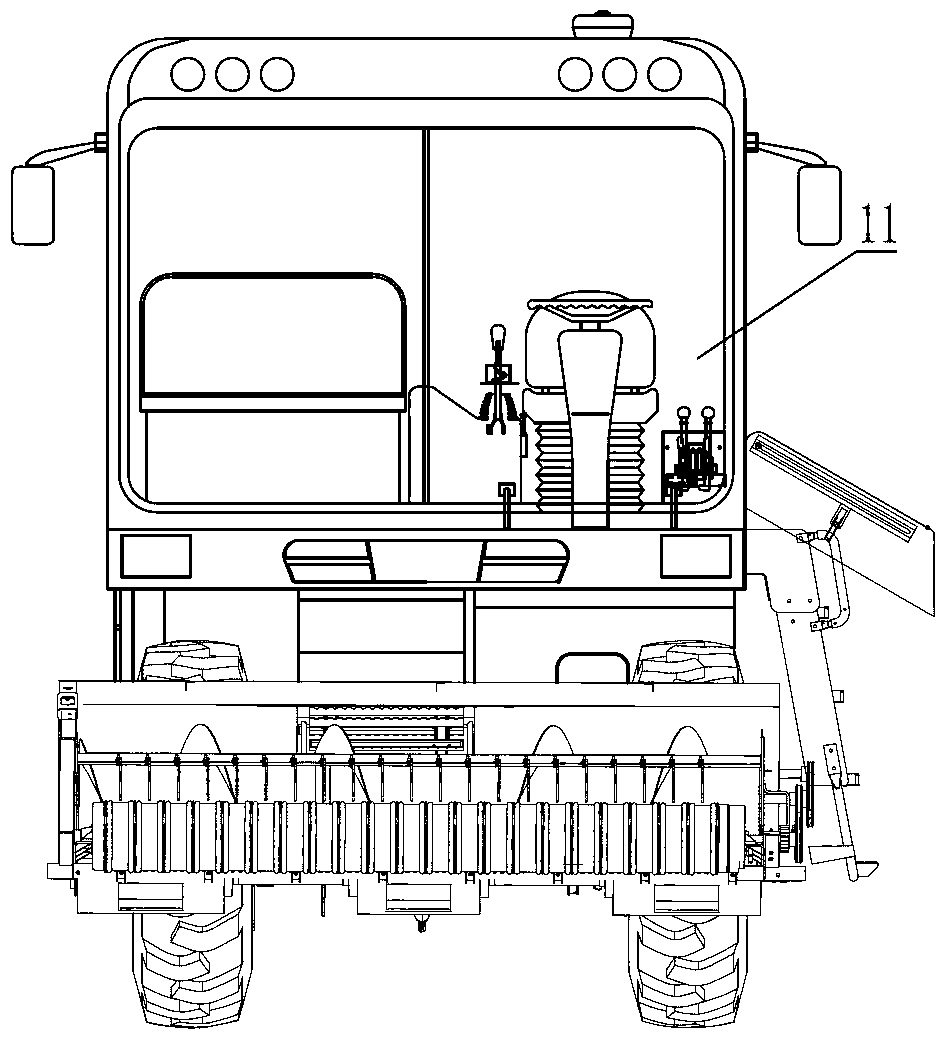

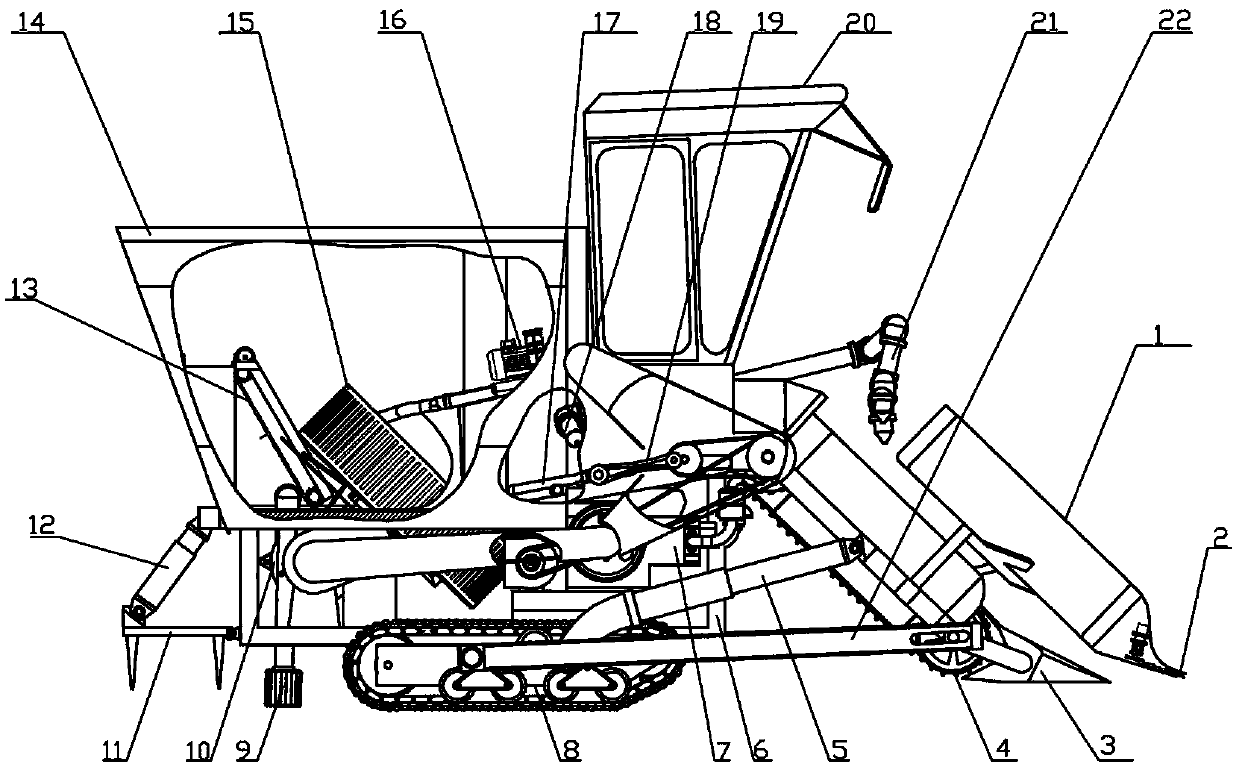

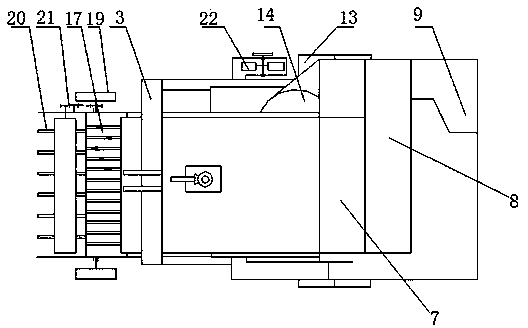

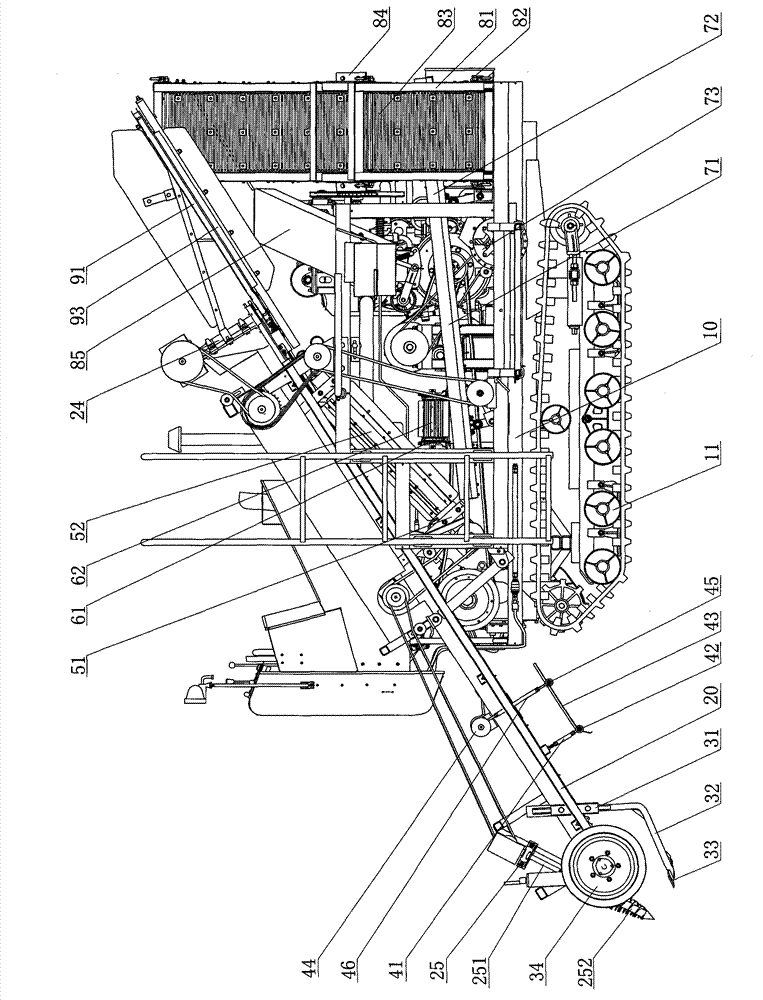

Peanut combine harvester

InactiveCN102812811AEasy to pick fruitEasy to collect and storeDigger harvestersBalingEngineeringCombine harvester

The invention discloses a peanut combine harvester, which comprises a frame, clamping and conveying devices, digging devices, soil removing devices, fruit picking devices, a transverse conveying device, a cleaning device, a lifting and flow guide device, and a peanut plant discharge device, wherein a power walking device is installed at the bottom of the frame; the clamping and conveying devices are obliquely installed on the frame; the digging devices are respectively installed at the front lower ends of the two clamping and conveying devices; the soil removing devices are respectively installed at the rear parts of the two digging devices; the fruit picking devices are respectively installed at the rear parts of the two soil removing devices; the transverse conveying device is installed between the fruit picking devices on two sides; the cleaning device is installed below the outlet end of the transverse conveying device; the lifting and flow guide device is installed at the outlet end of the cleaning device; and the peanut plant discharge device is installed at the rear part of the fruit picking devices and is connected with the clamping and conveying devices. The peanut combine harvester has the advantages that the structure is reasonable, the harvester works stably, the soil adaptability is strong, the fruit crushing rate during operate is low, the fruits are thoroughly picked, the harvesting rate is high, the peanut plants are tidily discharged, the treatment after harvesting is facilitated, the automation level and the operating efficiency are high, and the harvester is suitable for harvesting peanuts planted in large area.

Owner:WUZHENG

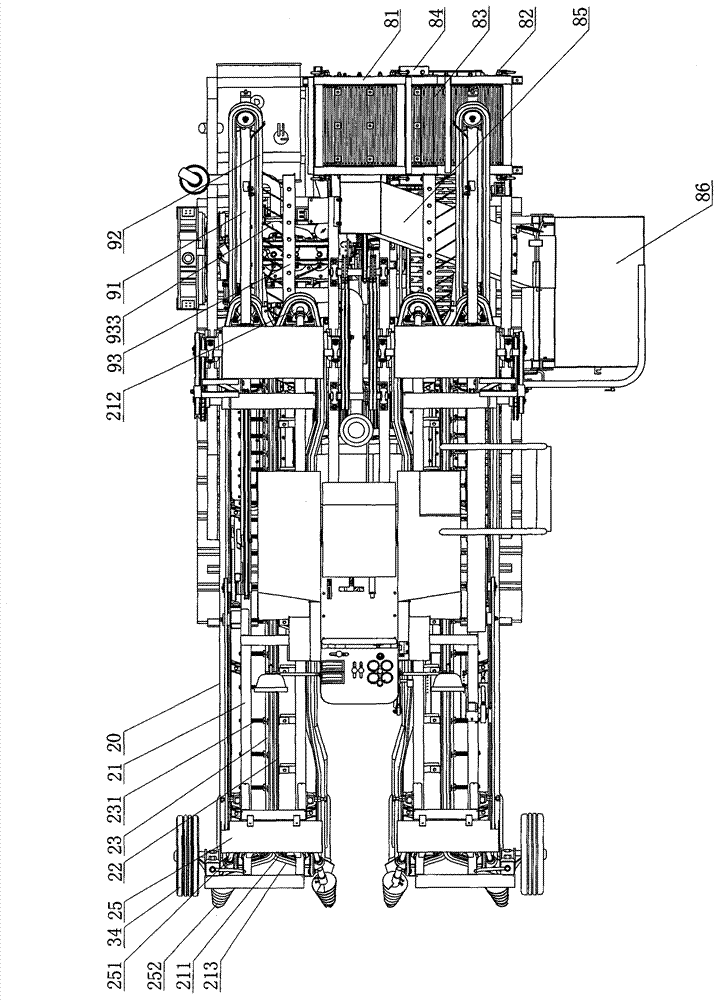

Self-propelled peanut harvester

InactiveCN107114051AImprove efficiencyGood fruit picking effectLoadersDigger harvestersControl systemEngineering

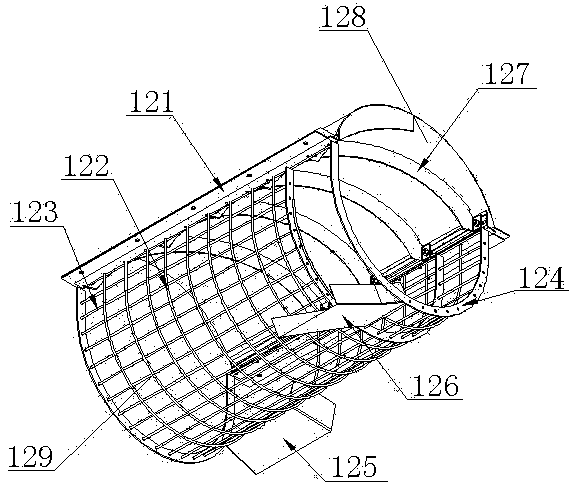

The invention belongs to the field of agricultural machines, and particularly relates to a self-propelled peanut harvester. The self-propelled peanut harvester includes a working chassis assembly, wherein the working chassis assembly is composed of a power system, a walking chassis system and a driving control system; the working chassis assembly includes a machine frame, and the machine frame is provided with a harvesting work assembly; the harvesting work assembly includes a peanut pickup harvesting device, a fruit picking roller and a straw chopping, conveying and collecting device which are arranged in sequence from front to back; cylindric concave grids are arranged on the upper portion and lower portion of the fruit picking roller, the lower portion of the fruit picking roller is provided with a picking device, the lower portion of the picking device is provided with a fruit conveying device, the outlet end of the fruit conveying device is correspondingly provided with a fruit box, the fruit box is located above the fruit picking roller of the peanut harvester, and an outlet of the picking device is communicated with the straw chopping, conveying and collecting device. According to the self-propelled peanut harvester, picking, full-feeding and harvesting are adopted, the efficiency is greatly improved compared with line cutting and harvesting. The fruit picking roller is optimally designed, aiming at peanuts; the fruit picking effect is good, and the breakage rate is effectively reduced.

Owner:SHANDONG JUMING MASCH CO LTD

Crawler-type self-walking lotus root harvesting machine and method

ActiveCN105917838AChange the problem of difficult transportationWon't hurtDigger harvestersHydraulic motorMarine engineering

The invention relates to a crawler-type self-walking lotus root harvesting machine and method. The technical scheme of the crawler-type self-walking lotus root harvesting machine is characterized in that a crawler-type walking device is arranged on the outer side of a ship body, a hydraulic motor is arranged at the tail portion of the ship body, the lower side of the tail portion of the ship body is connected with a water collecting device, a pressure adjusting and distributing device is arranged at the head of the ship body, the other side of the ship body is connected with a gun head installing rod, an indexing adjusting high-pressure gun head is arranged on the gun head installing rod through a gun body swinging device, a power transmitting device is arranged on the front side in the ship body, a power device and a high-pressure water supplying device are arranged on the rear side in the ship body, and a hydraulic lifting system is arranged on the ship body. The crawler-type self-walking lotus root harvesting machine has the advantages of being high in lotus root digging efficiency, good in passing ability and suitable for a plurality of road situations, completely reaching barrier-free pass, daring to walk on abrupt slops, also serving as a transporting tool, solving the problem of transporting difficulty in lotus root pools, being suitable for a plurality of water areas with a depth of 15 centimeters or above, only waking on the upper surfaces of lotus roots without damaging the lotus roots and avoiding a situation that the quality of the lotus roots declines due to abrasion.

Owner:徐州嘉农农业发展有限公司

Vine Stripping Apparatus and Method

An apparatus for removing plant material from a vine. The apparatus generally comprises a support frame, a pair of counter-rotating wheels, and a vine stripping component. In an embodiment, the vine stripping component includes interchangeable stripping dies. In an additional embodiment, the apparatus is incorporated in a mobile harvesting unit. The invention further includes a method for removing plant material from vines.

Owner:WILDWOOD FARM INVESTMENTS LLC

Soil and potato separation device of potato harvester

ActiveCN107087468AAvoid damageDoes not affect the separation effectDigger harvestersEngineeringSolanum tuberosum

The invention relates to the technical field of agricultural machinery, in particular to a soil and potato separation device of a potato harvester. The device comprises a frame; a flexible anti-damage mechanism and a clay soil cleaning mechanism are sequentially installed on the frame from front to rear; a rod bar soil and potato separation mechanism is arranged below the flexible anti-damage mechanism and the clay soil cleaning mechanism; a transport channel between the rod bar soil and potato separation mechanism and the flexible anti-damage mechanism and the clay soil cleaning mechanism is gradually reduced; the bottom of the frame is provided with a depth wheel; the clay soil cleaning mechanism is not less than three groups; the flexible anti-damage mechanism, the clay soil cleaning mechanism, the rod bar soil and potato separation mechanism are connected by power through a transmission mechanism respectively. According to the device, the flexible anti-damage mechanism is utilized to hold and transport potatoes, the soil and potato separation effect is not affected, and the damage of the potatoes on an ascending transport chain caused by mechanical collisions is greatly reduced at the same time, and the clay soil cleaning mechanism further improves the soil and potato separation effect, and improves the potato-exposing rate.

Owner:XIHUA UNIV

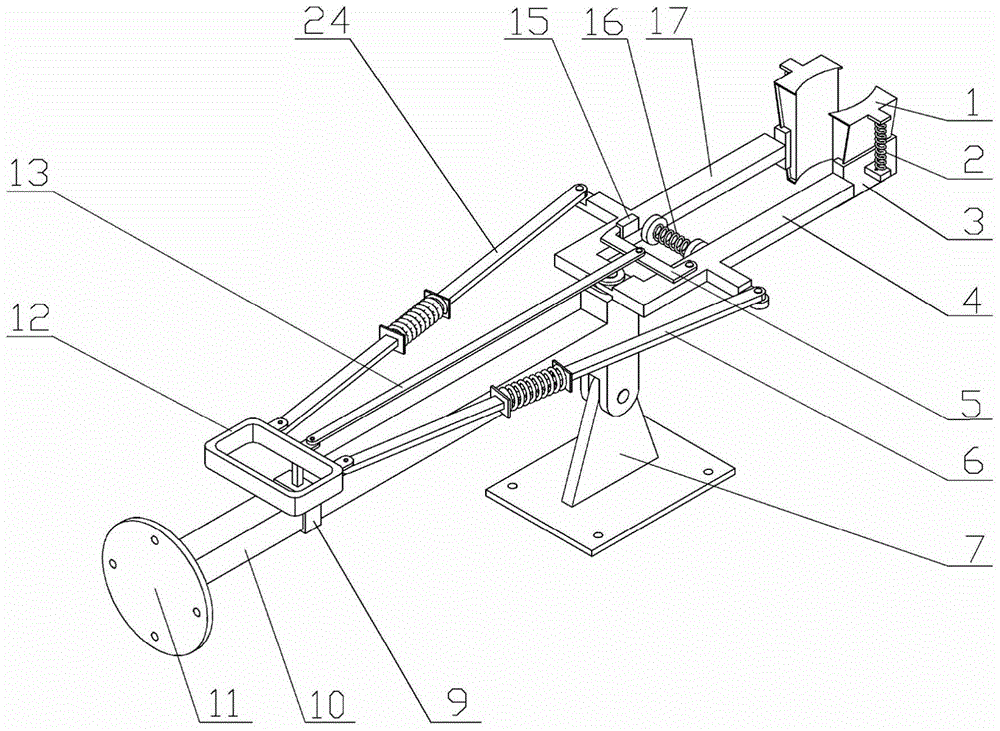

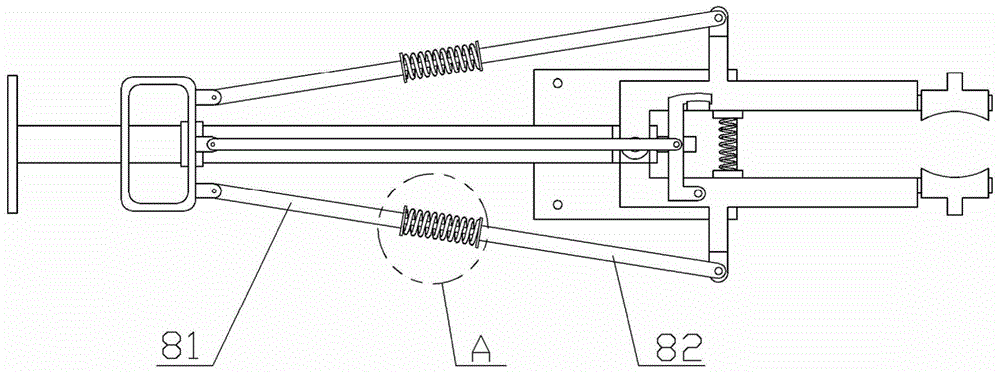

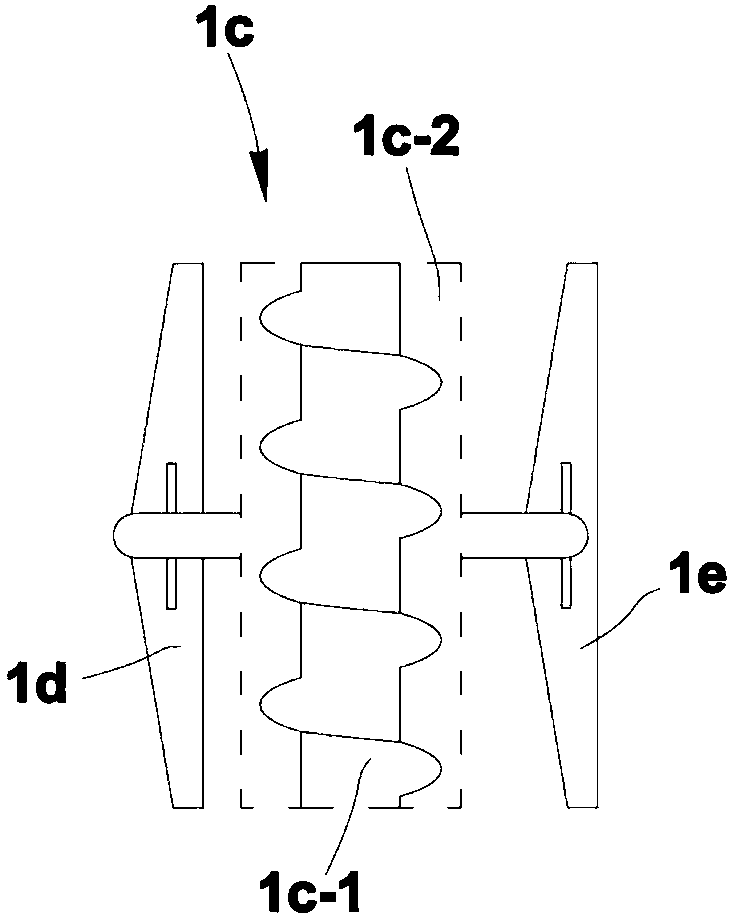

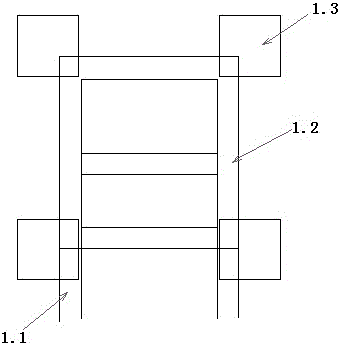

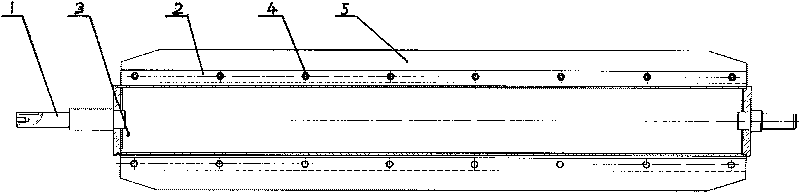

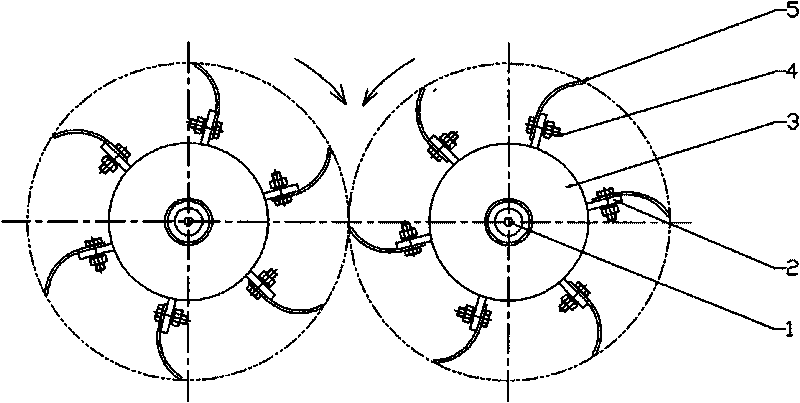

Semi-feeding device for harvesting peanut and picking fruit

InactiveCN101699948AImprove harvest qualityForce softeningDigger harvestersDifferential phaseEngineering

The invention relates to a semi-feeding device for harvesting peanuts and picking fruits, belonging to the technical field of agricultural machinery. The device comprises a pair of rollers racially provided with fruit-picking blades in differential phase distribution at intervals; the fruit-picking blades present continuous curved surfaces which gradually bend deviating from the rotary direction of the roller. For the convenient manufacture, the curved surface is in a circular arc shape. The device of the invention not only keeps high picking rate, but also effectively reduces the stem carrying rate of fruit pods and the rates of seedling breaking and root breaking, thus the harvest quality of a semi-feeding peanut combine harvester can be significantly improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Impact Mass Flow Sensor For Monitoring Peanut Harvest Yields

Yield monitoring systems for harvesting machines and methods that can provide yield monitoring of crops are described. Machines include those that pneumatically convey crop through the machine such as peanut harvesting machines. The yield monitoring system includes a force sensor that can be located in conjunction with a duct of the harvesting machine such that impact of the crop materials on an impact plate within the duct will be registered by the force sensor. This registration can be used to determine a mass flow rate for the crop, which can be correlated to yield of the crop. The systems can include additional components such as optical monitors, moisture sensors, and pressure sensors.

Owner:CLEMSON UNIV RES FOUND +1

Full-feeding type peanut combined harvester

InactiveCN104160818AReduce impurityQuick and efficient removalDigger harvestersThreshersReciprocating motionAgricultural engineering

The invention discloses a full-feeding type peanut combined harvester and belongs to the field of agricultural harvesting machinery. The full-feeding type peanut combined harvester comprises a vibrating digging shovel, a soil distributing and conveying device, a peanut picking device, a cleaning device, a peanut collecting device and the like. The vibrating digging shovel performs reciprocating vibration and is a sawtooth type vibrating digging shovel, a belt wheel transfers power to the vibrating digging shovel through a crankshaft and a connecting rod to achieve reciprocating vibration of the vibrating digging shovel. The soil distributing and conveying device is located at the rear portion of the digging shovel, and soil on peanut vines is screened while the soil is conveyed backwards. A feeding conveying belt is located under the back of the soil distributing and conveying device, the tail portion of the conveying belt extends into the peanut picking device, and the peanut vines are fed into the peanut picking device through the feeding conveying belt. The full-feeding type peanut combined harvester has the advantages that digging, soil screening, peanut picking, cleaning, peanut collecting and the like are finished in one time, the harvesting efficiency is improved, and peanut picking gaps of peanut picking rollers can be adjusted according to peanut varieties, planting density, maturity and the harvesting speed.

Owner:JIANGSU UNIV

Chinese yam harvesting and planting dual-purpose machine

InactiveCN102144450AEasy to take outImprove planting efficiencyPlantingDigger harvestersRootstockDual purpose

The invention relates to the technical field of harvesting and planting machinery for agricultural products, in particular relates to a Chinese yam harvesting and planting dual-purpose machine. The soil requires to be loosened deeply before the planting of long-rootstock crops; because the crops grow deeply in the soil and especially the growing situations of Chinese yam, burdock and the like are difficultly known, most of the crops are harvested manually so as to avoid damage of the crops during the harvesting, and thus the labour intensity is high and the work efficiency is low. The technical scheme of the Chinese yam harvesting and planting dual-purpose machine disclosed by the invention is characterized by comprising a frame, a power device and a furrowing device; the upper end of a shaft sleeve of a vibrating device is assembled at the rear part of the furrowing device, and the lower end of the shaft sleeve of the vibrating device is fixedly provided with a wedge-shaped vibrating box. During the harvesting of the crops such as Chinese yams and the like, the soil at two sides of a crop ridge is dug to be loose by using the furrowing device, then the soil below or around the crop is vibrated to be loose by using the vibrating device, and finally, the crop is ejected upwards, so that the intactness of the crop in the digging process is guaranteed and the work efficiency is improved greatly. The Chinese yam harvesting and planting dual-purpose machine further can be used for digging the soil to be loose by only using the furrowing device and improves the planting efficiency of the agricultural crops.

Owner:张家口茂盛创新科技有限公司

Work machine and components thereof

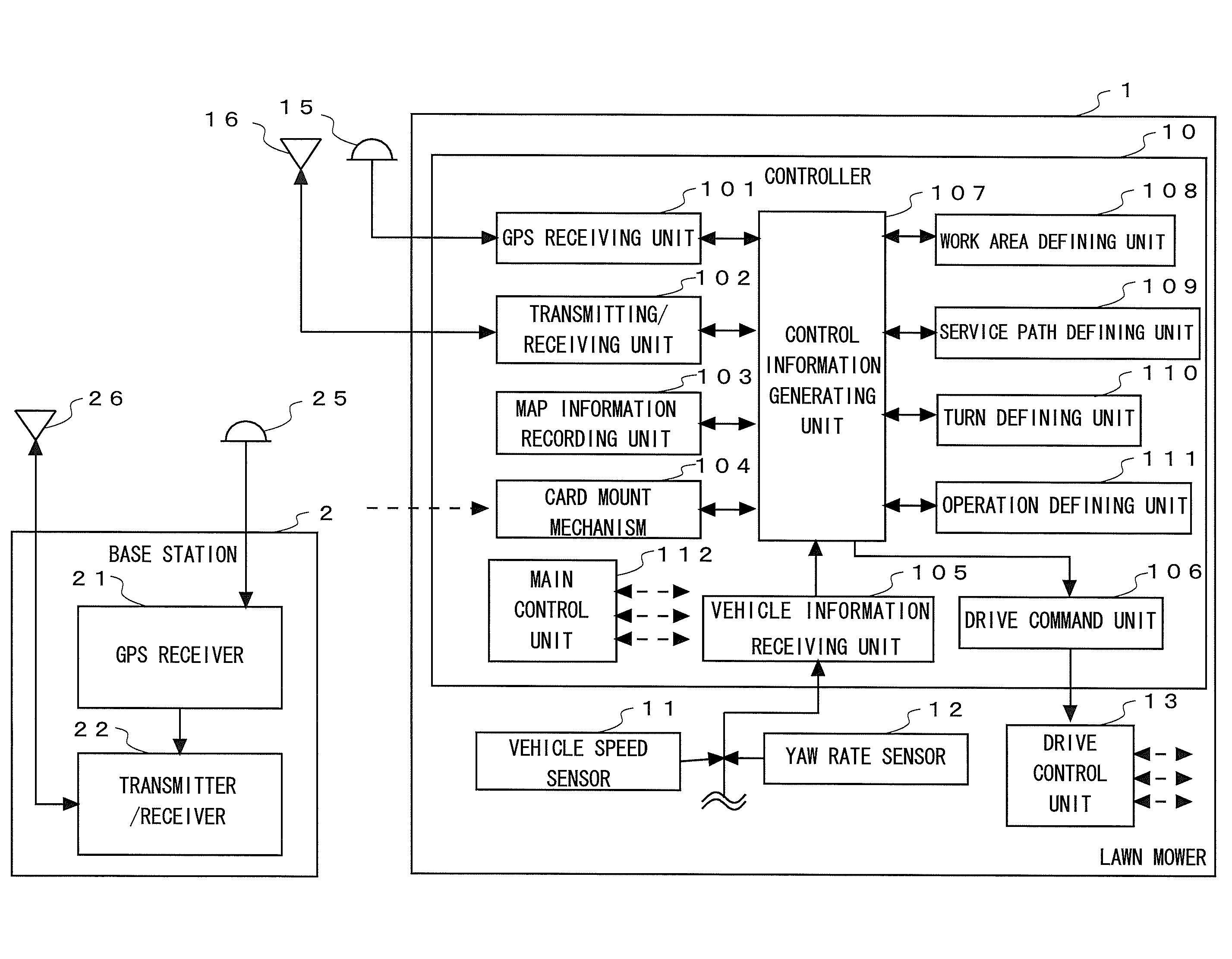

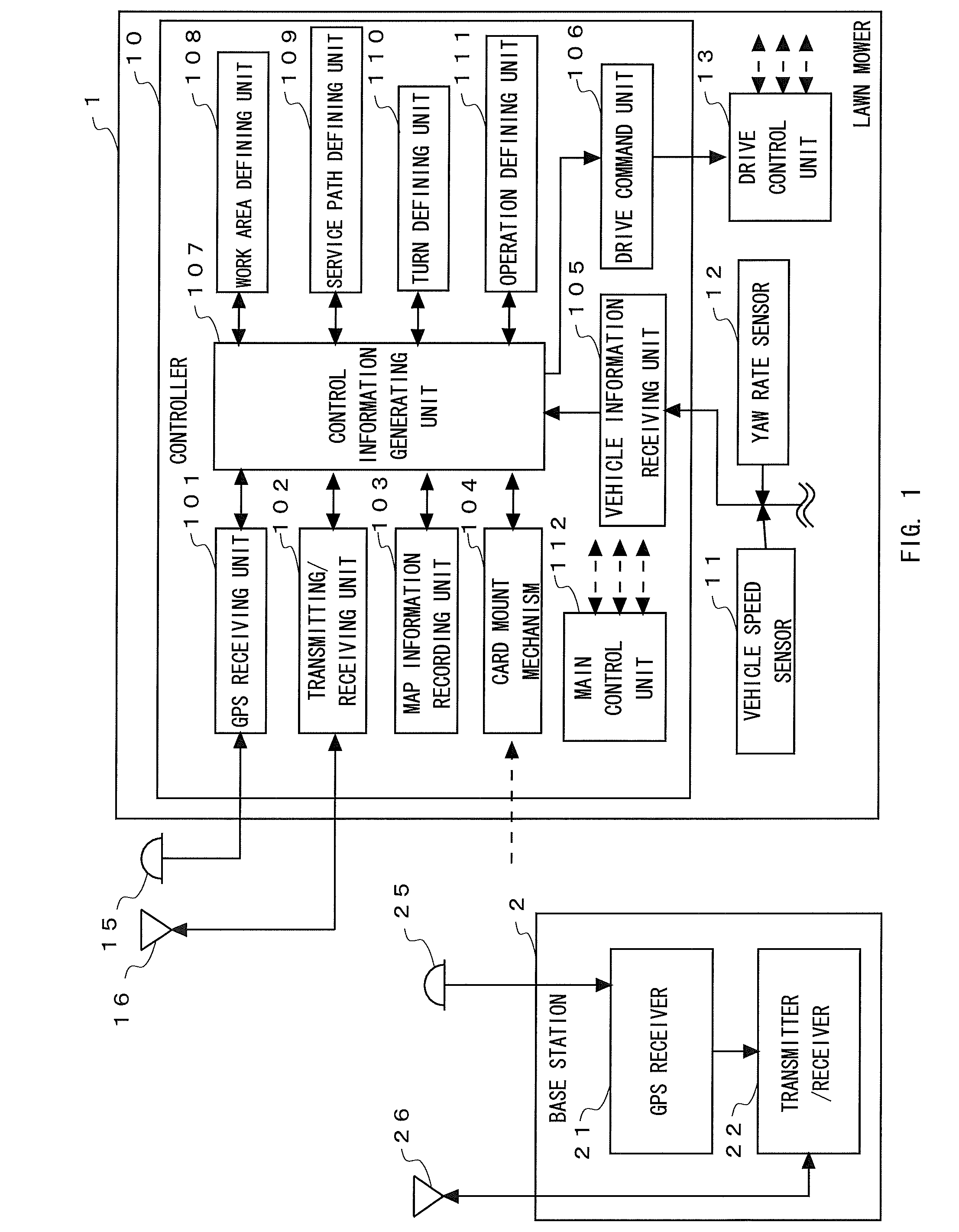

To provide a work machine that can make minimum passes over a target area without leaving any tasks with flexible steering operations. A controller 10 mounted on a motor-driven lawn mower 1 determines intersections between a contour service path and a pair of straight service paths that are adjacent to each other in which the motor-driven lawn mower 1 travels along the straight service paths in opposite directions, and sets (records) a turning behavior including backward movement of the motor-driven lawn mower connecting the adjacent intersections in a configuration file. The information recorded in the configuration file is read during the operation to move the motor-driven lawn mower along the contour service path 50 and the straight service paths on anywhere other than the aforementioned intersections and to turn in accordance with the turning behavior when the motor-driven lawn mower reaches one of the intersections.

Owner:MAMIYA

Improved water chestnut harvester

InactiveCN108260399AIntegrity guaranteedEasy to useDigger harvestersMoving filtering element filtersHydraulic cylinderWater Chestnuts

The invention provides an improved water chestnut harvester. The improved water chestnut harvester is characterized in that a collecting mechanism (8) controlled and lifted by a hydraulic cylinder (10) and a filtering water intake device (9) are arranged at two ends of a rack (1); a conveying mechanism (11) is arranged in the middle of the rack (1), a water tank (12) is arranged between the conveying mechanism (11) and the collecting mechanism (8), and a discharge port (121) is formed in the water tank (12); an engine controls operation of a transmission device (6) through a reduction gearbox,the transmission device (6) drives the collection mechanism (8), the conveying mechanism (11) and the filtering water intake device (9) to work, and the engine drives a water pump (51) to work; the engine drives the collecting mechanism (8) to collect water chestnuts, the collected water chestnuts with mud are sent to the water tank (12) for high pressure washing, the washed water chestnuts are output from the discharge port (121) and poured into a collecting basket (15) by the conveying mechanism (11). The collected water chestnuts are good in integrity, and the process of cleaning again inthe later stage is omitted.

Owner:马锁才

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com