Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

194results about How to "Clamp evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

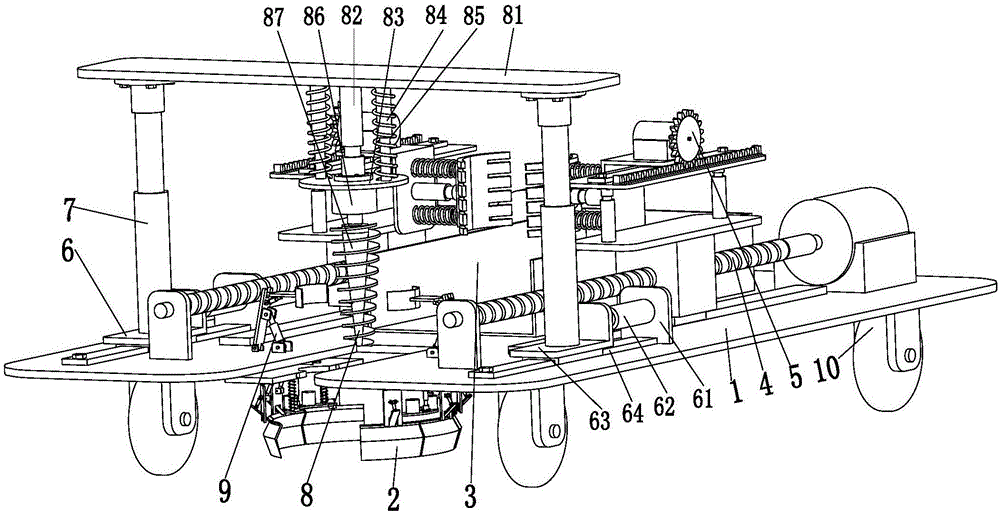

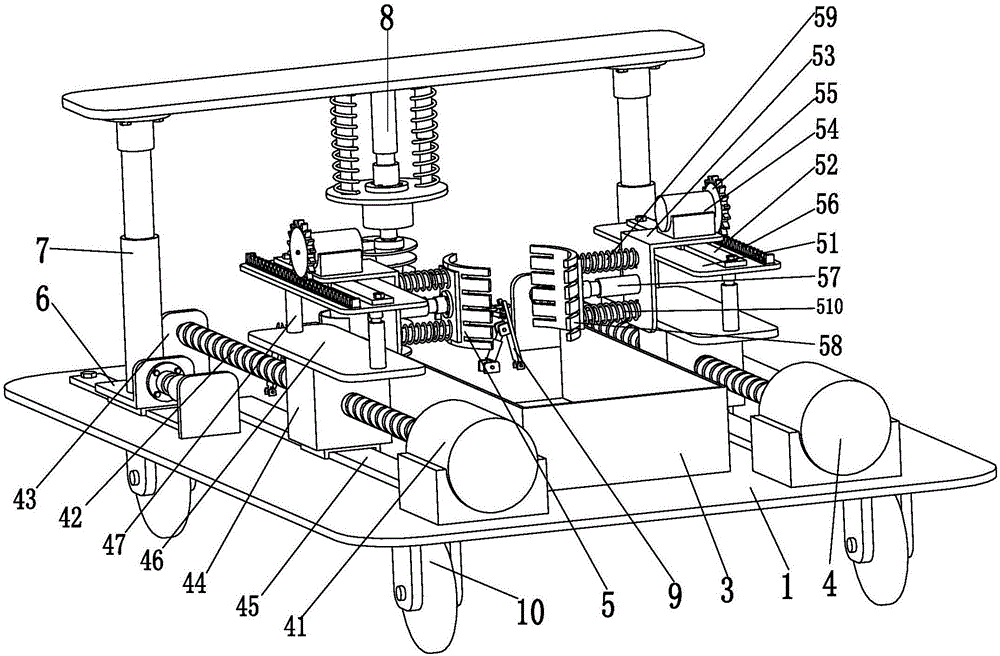

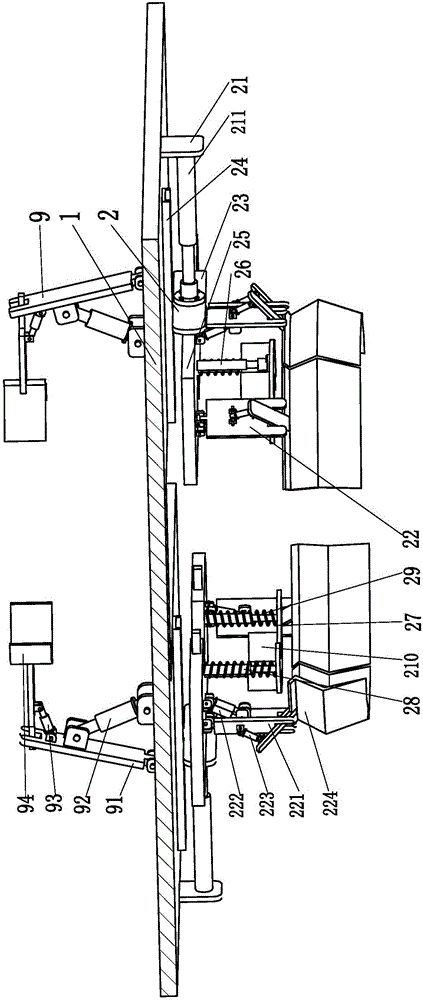

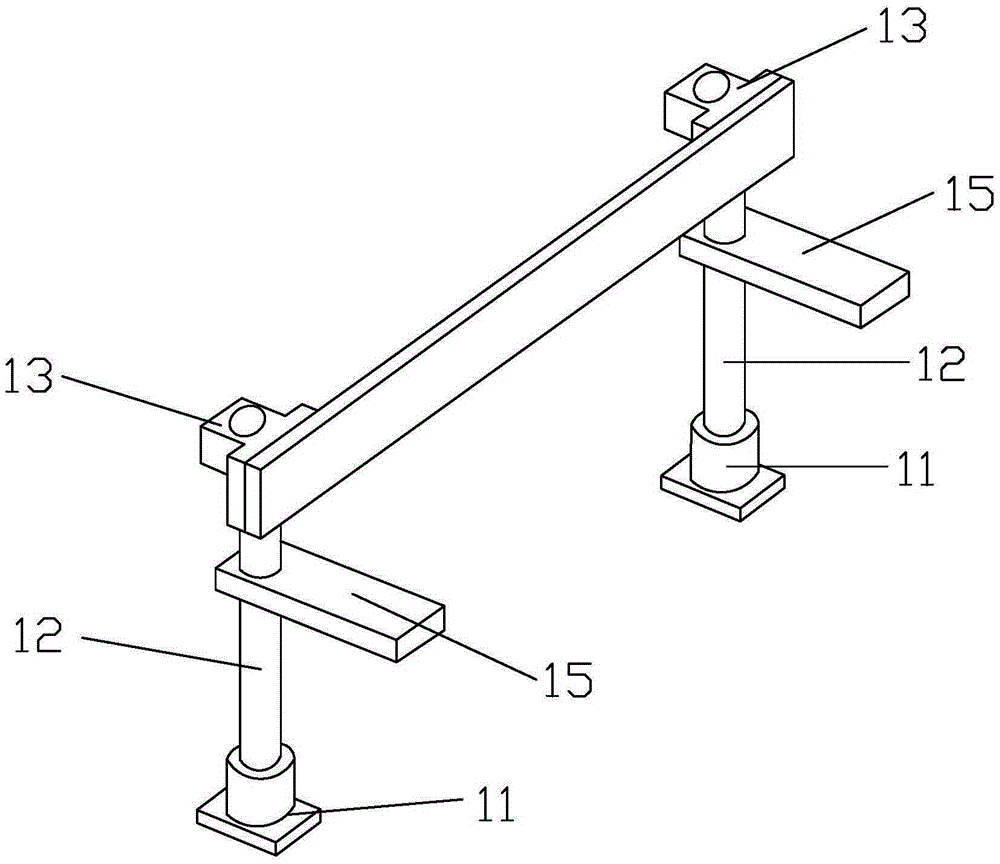

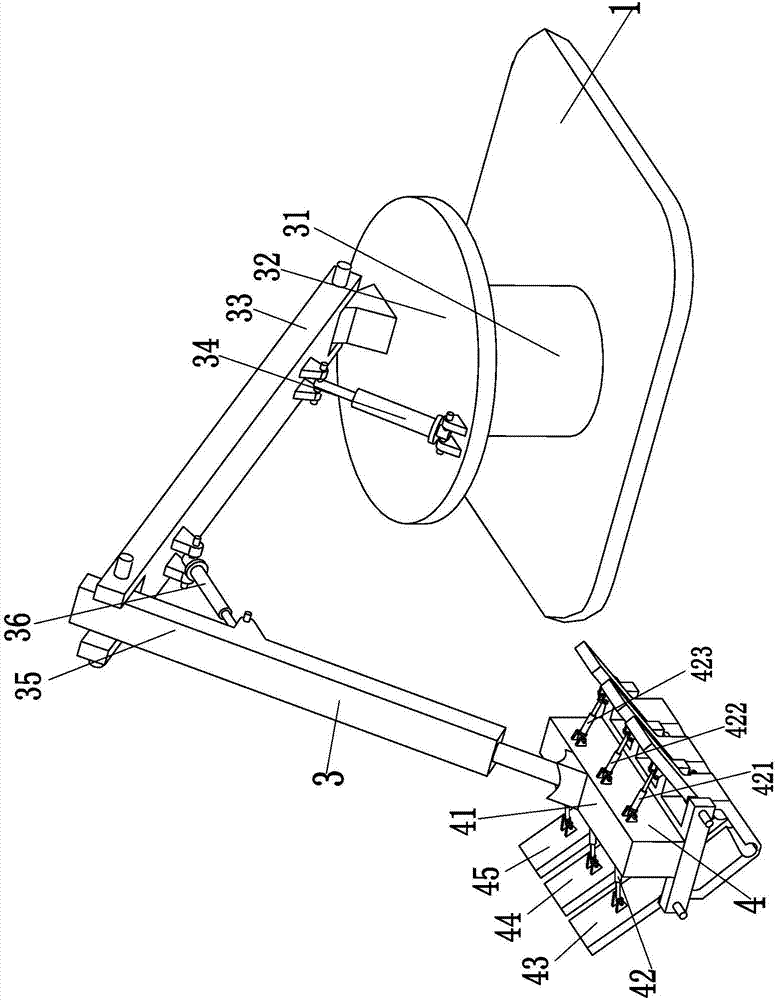

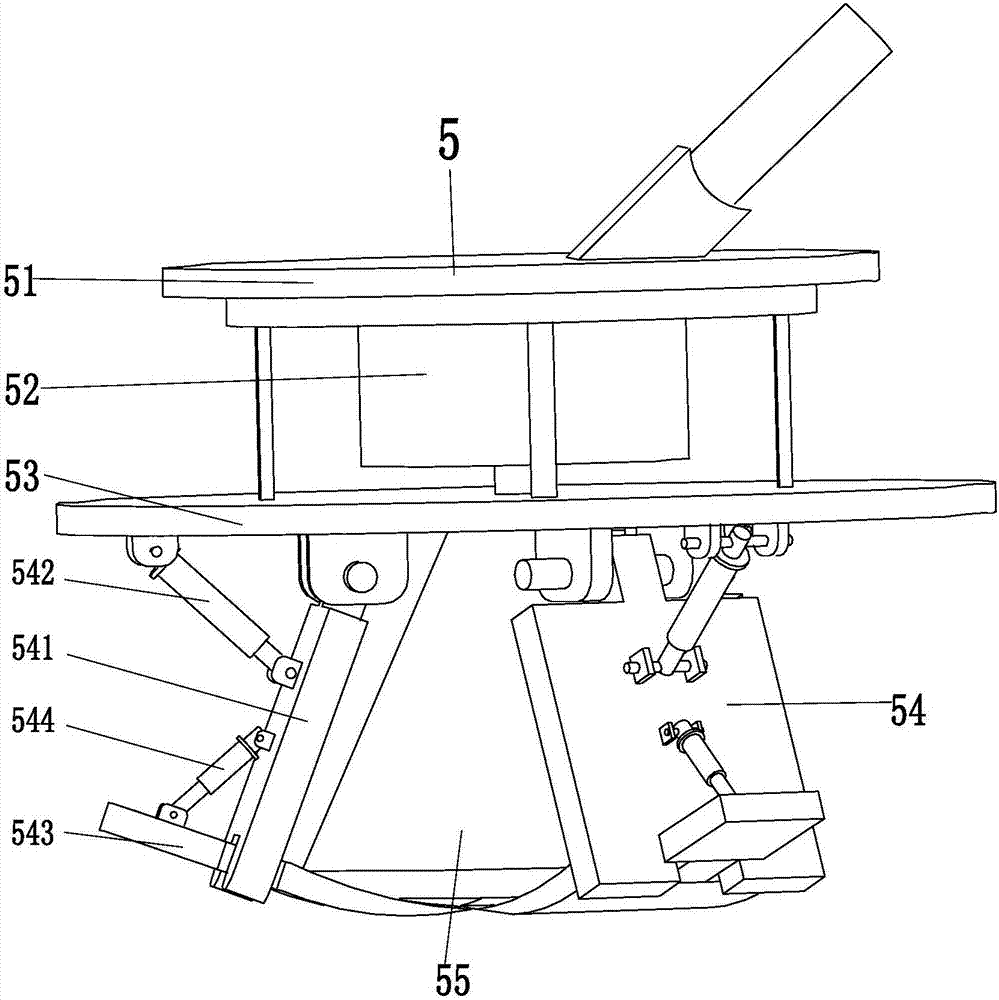

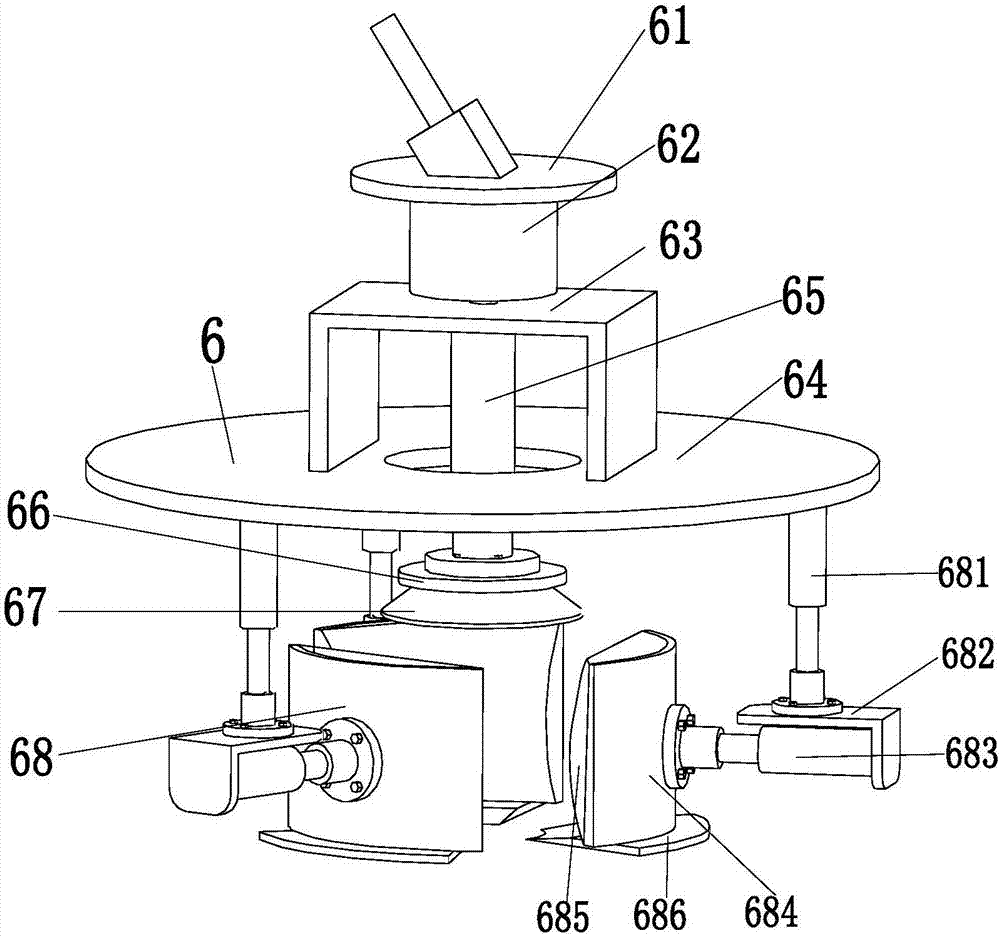

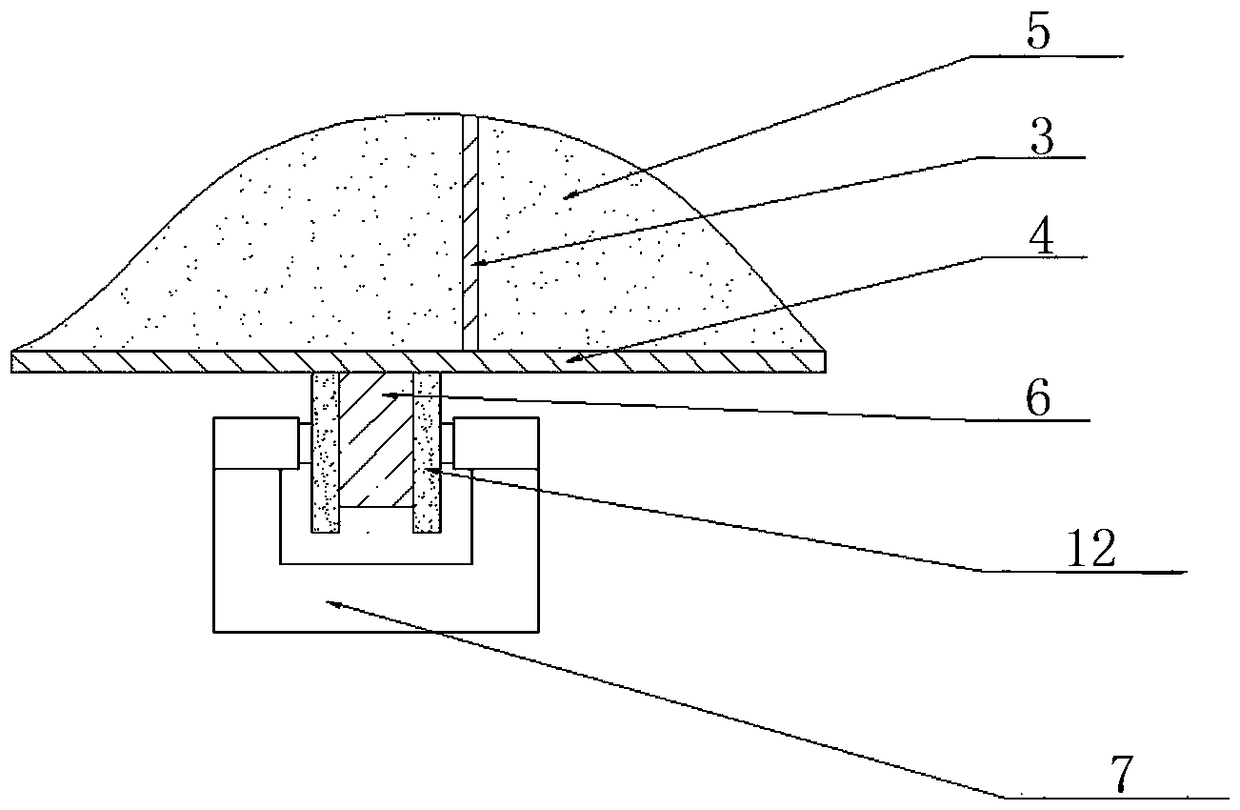

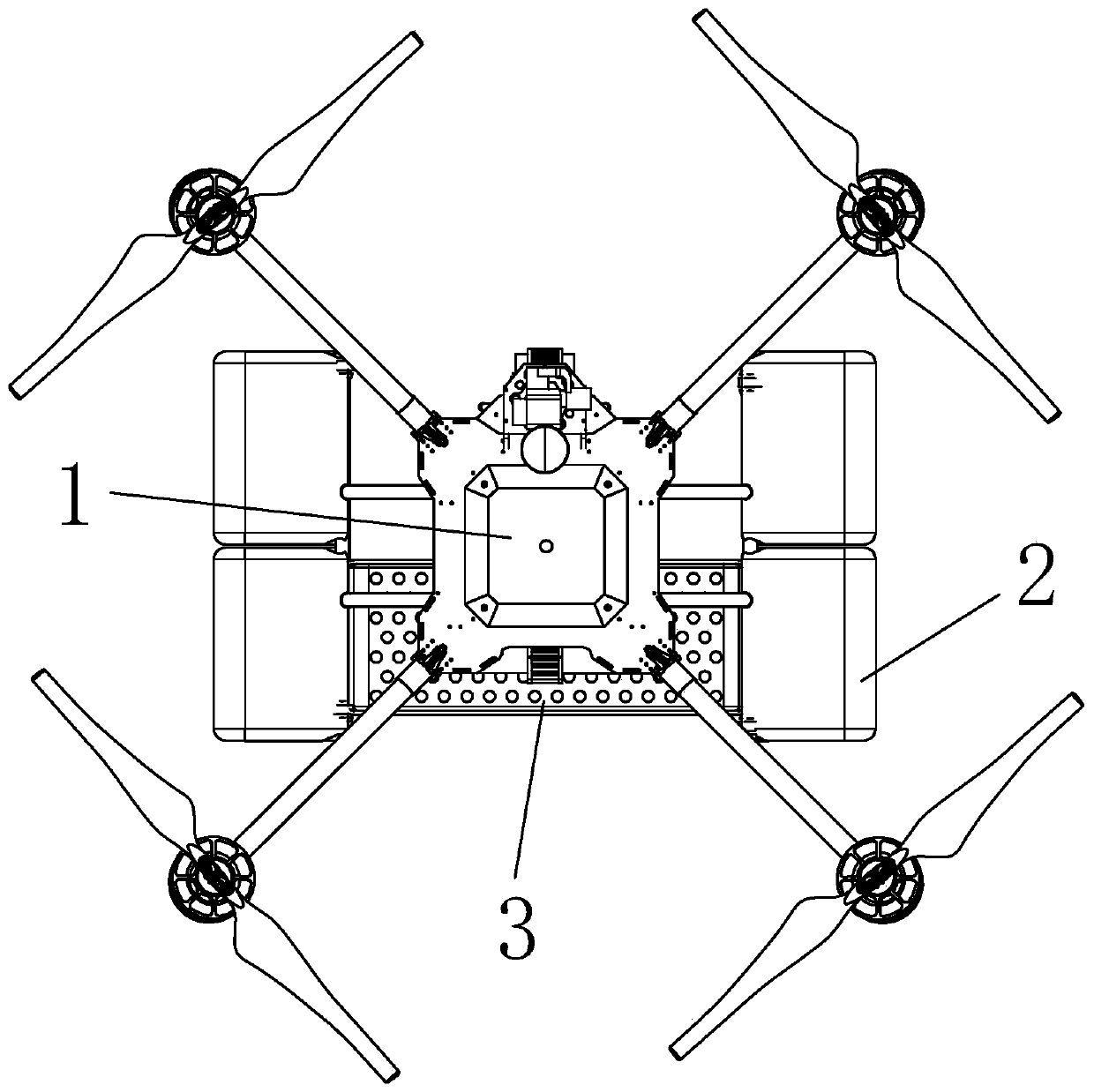

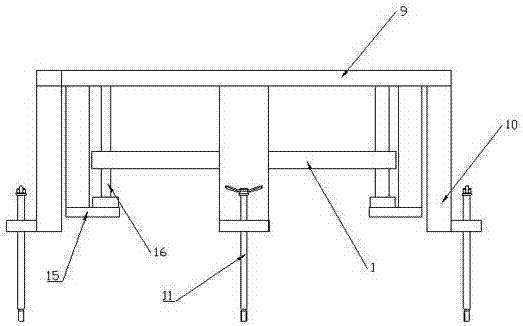

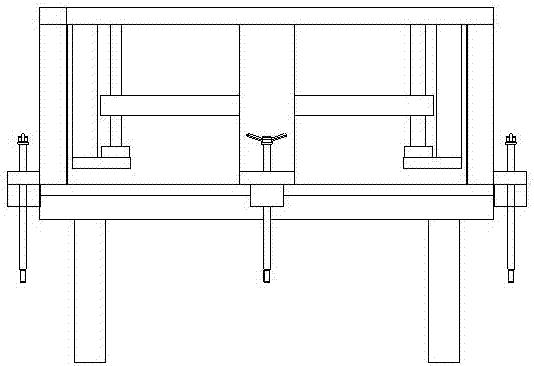

Special automatic digging and planting machine for tree seedlings in urban green belt construction

InactiveCN106665270AClamp evenlyNo manual operationPlantingFurrow making/coveringEngineeringUltimate tensile strength

The invention relates to a special automatic digging and planting machine for tree seedlings in urban green belt construction. The special automatic digging and planting machine comprises a bottom plate, wherein four universal wheels are symmetrically arranged at the lower end of the bottom plate; an opening structure is arranged at the left end of the bottom plate; a placing frame is arranged in the middle of the bottom plate; two horizontal feeding mechanisms are symmetrically arranged at the front side and the rear side of the bottom plate and are respectively provided with a movable clamping mechanism; two pushing mechanism are symmetrically arranged at the left end of the bottom plate and are respectively provided with an electric pushing rod; the two electric pushing rods are arranged on an earth digging mechanism by two flanges; two opposite earth burying mechanisms are arranged at the lower side of the left end of the bottom plate. The special automatic digging and planting machine has the advantages that the difficulties of separated operation for digging and planting, complex operation, high labor intensity of workers and low planting efficiency and the like in the semiautomatic tree seedling planting mode adopted in the existing municipal park and garden construction can be solved, and the full-automatic integrated digging and planting function for the tree seedlings can be realized.

Owner:高雅

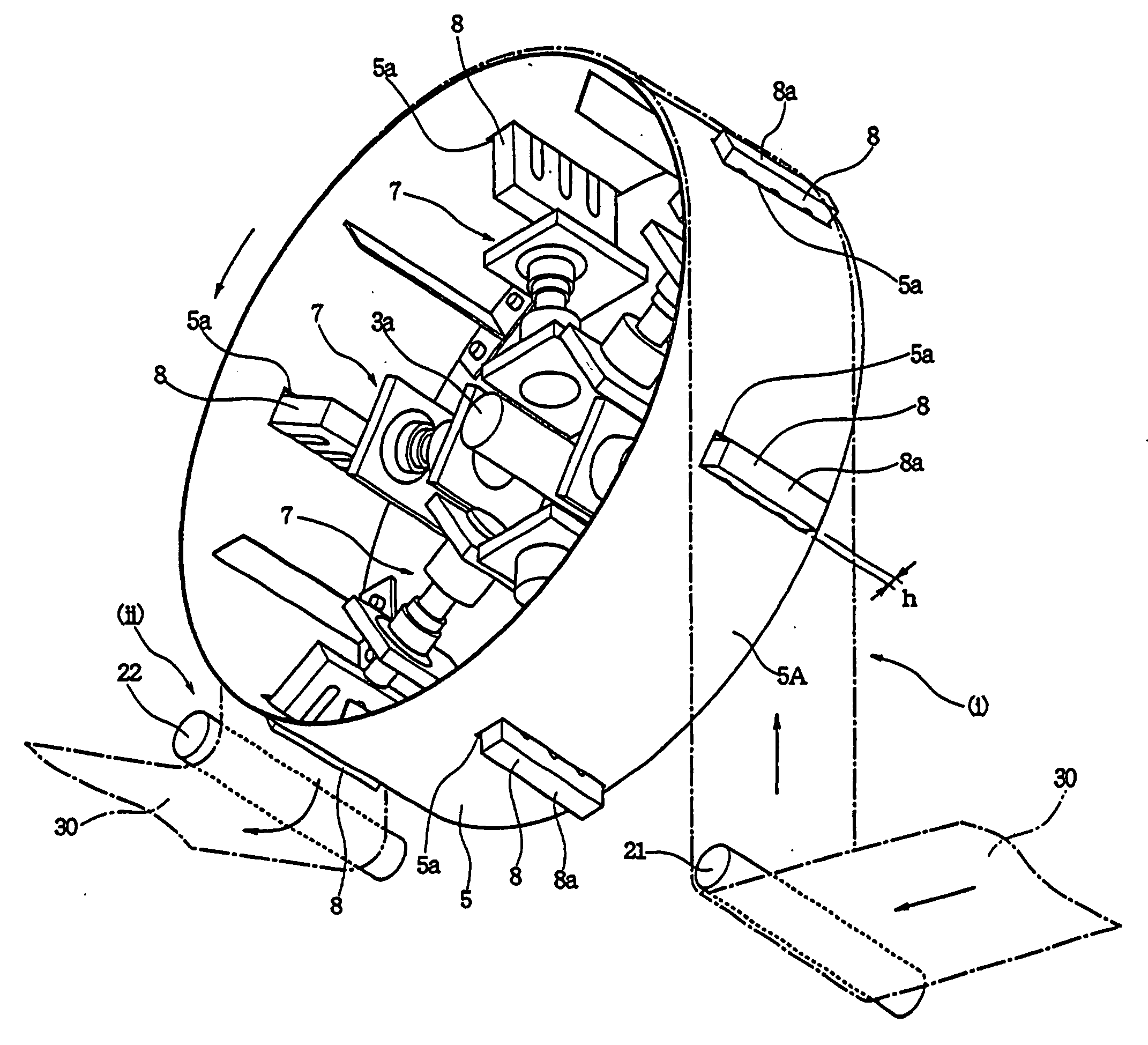

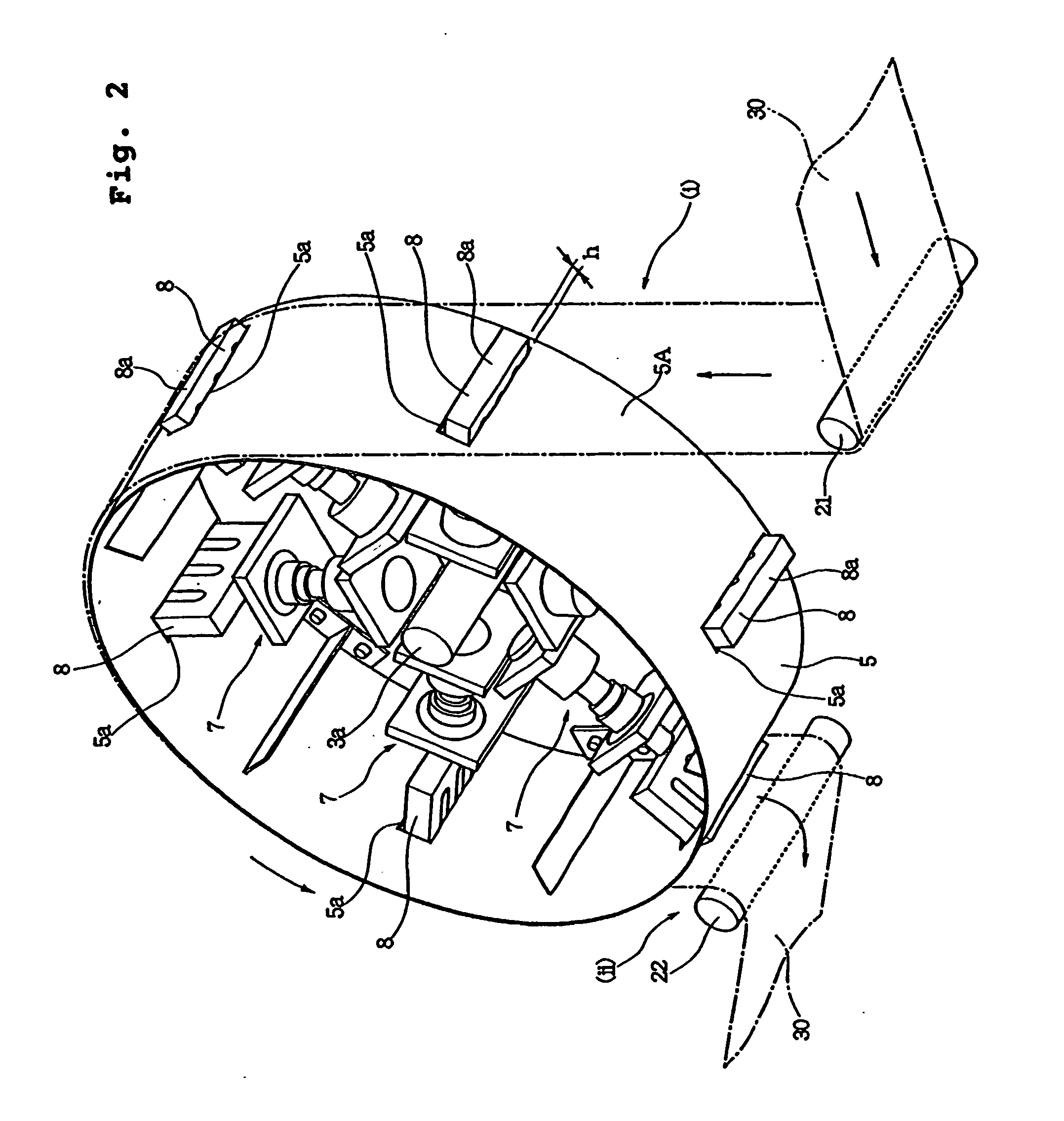

Sealing apparatus and manufacturing process of soft article having sealed portion

InactiveUS20040106506A1Difference in strengthDifference in tastePaper-makingLaminationEngineeringCam

Disclosed is a sealing apparatus wherein, as a drum (5) and a rotary base (6) are rotated together, a follower (10a) of a rocking support member (9) rockably provided on the outer periphery of the rotary base (6) is guided along a cam groove (15c) of a cam member (15) to drive the rocking support member (9) to rock. When the rotary drum (5) reaches a predetermined rotational position, an anvil (14) supported by the rocking support member (9) is urged onto a horn (8), and then, when it reaches another rotational position, the anvil (14) is moved away from the horn (8). Since the anvil (14) is driven by the rocking motion of the rocking support member (9), entire operation becomes quite simple, and a continuous soft work can be certainly clamped between the horn (8) and the anvil (14).

Owner:UNI CHARM CORP

Cassava pulling up and holding mechanism

Owner:GUANGXI UNIV

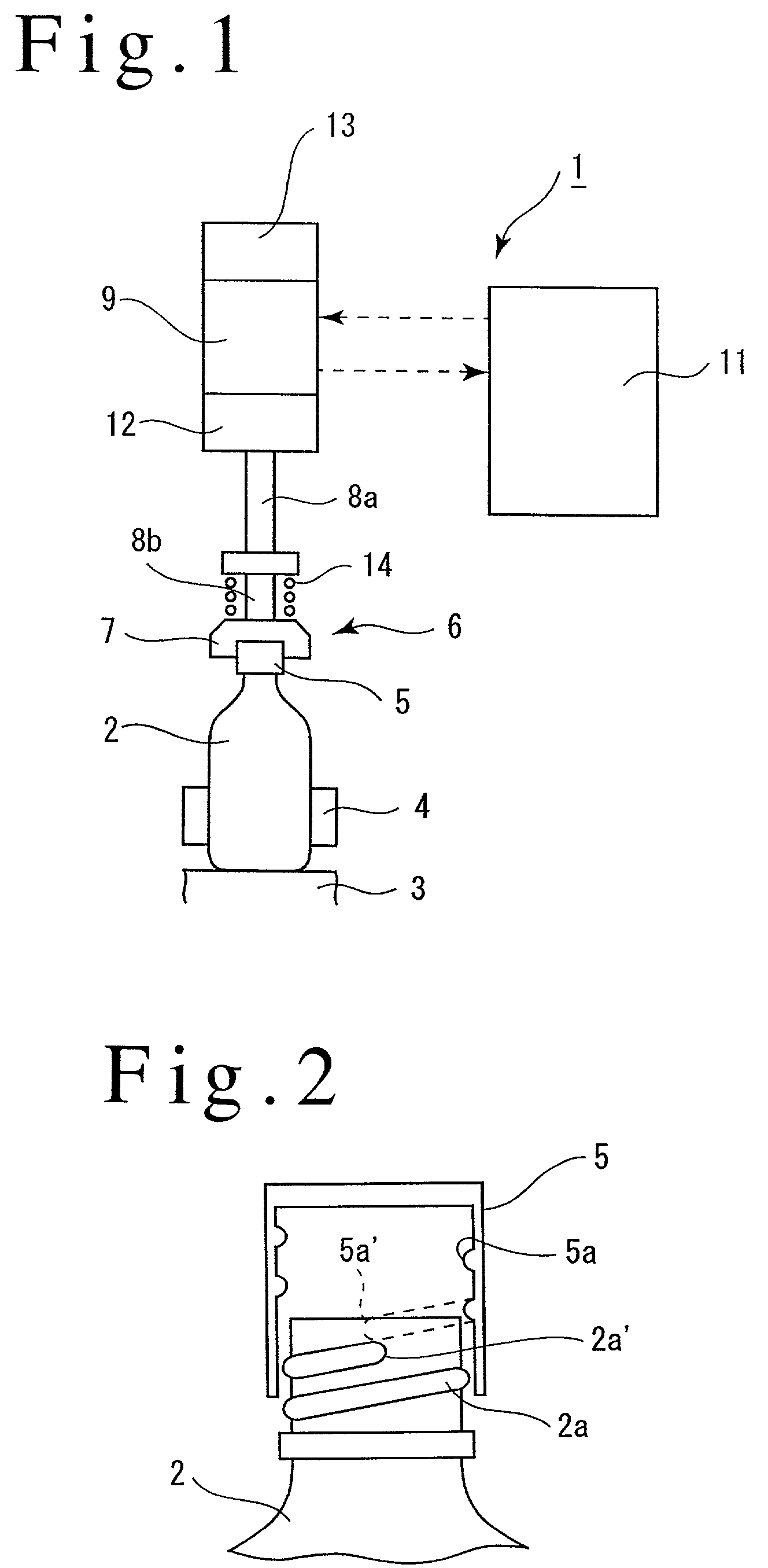

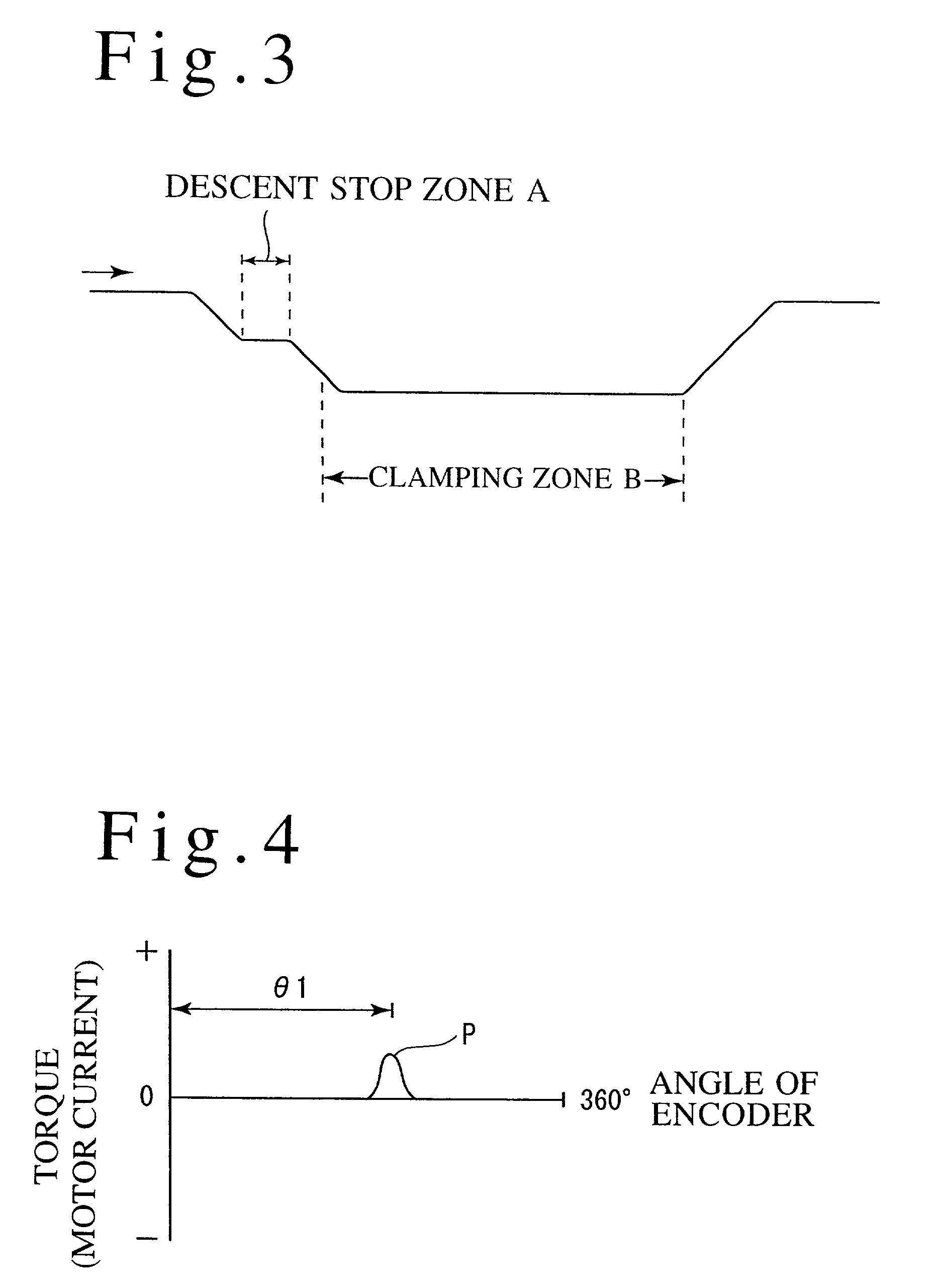

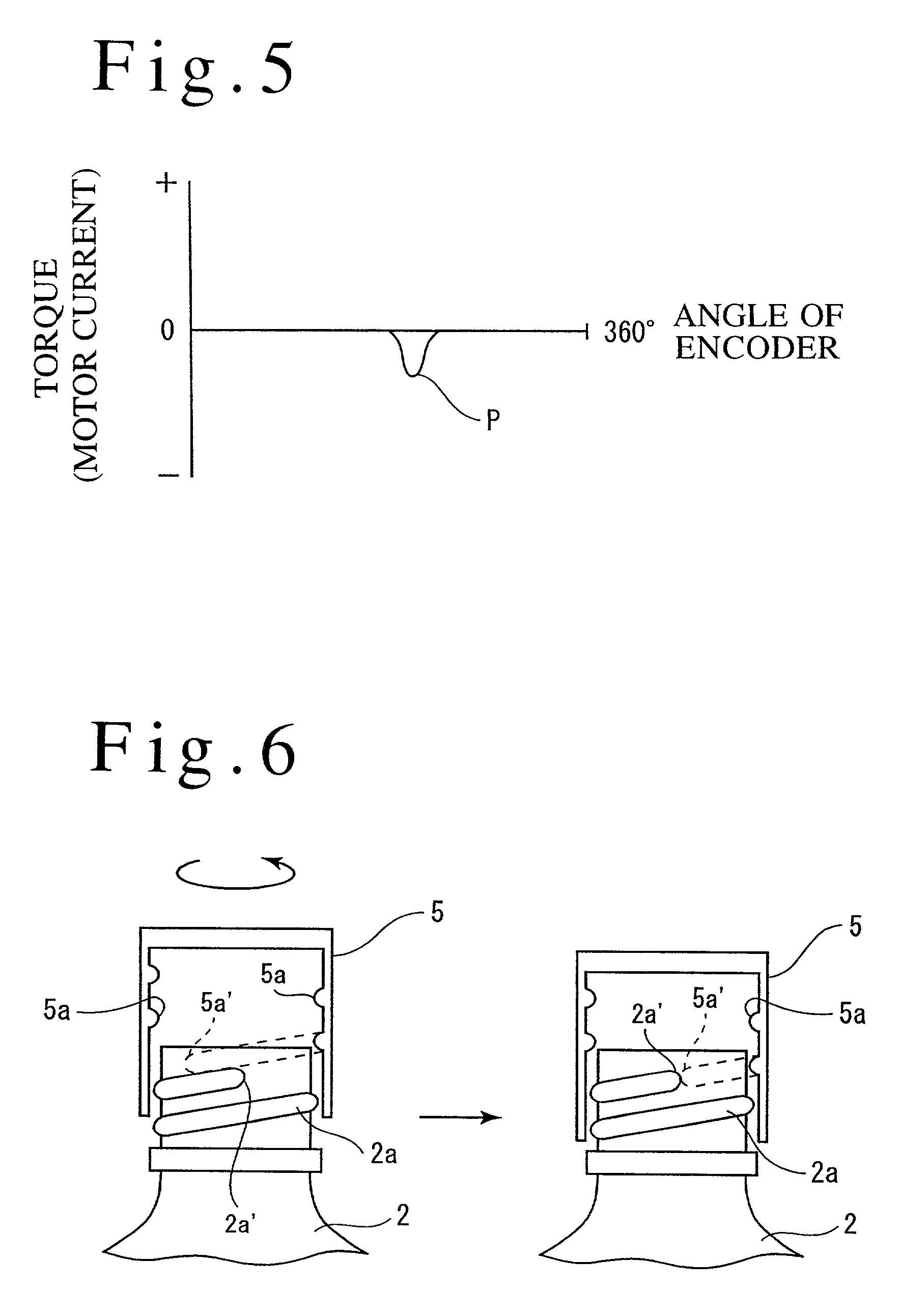

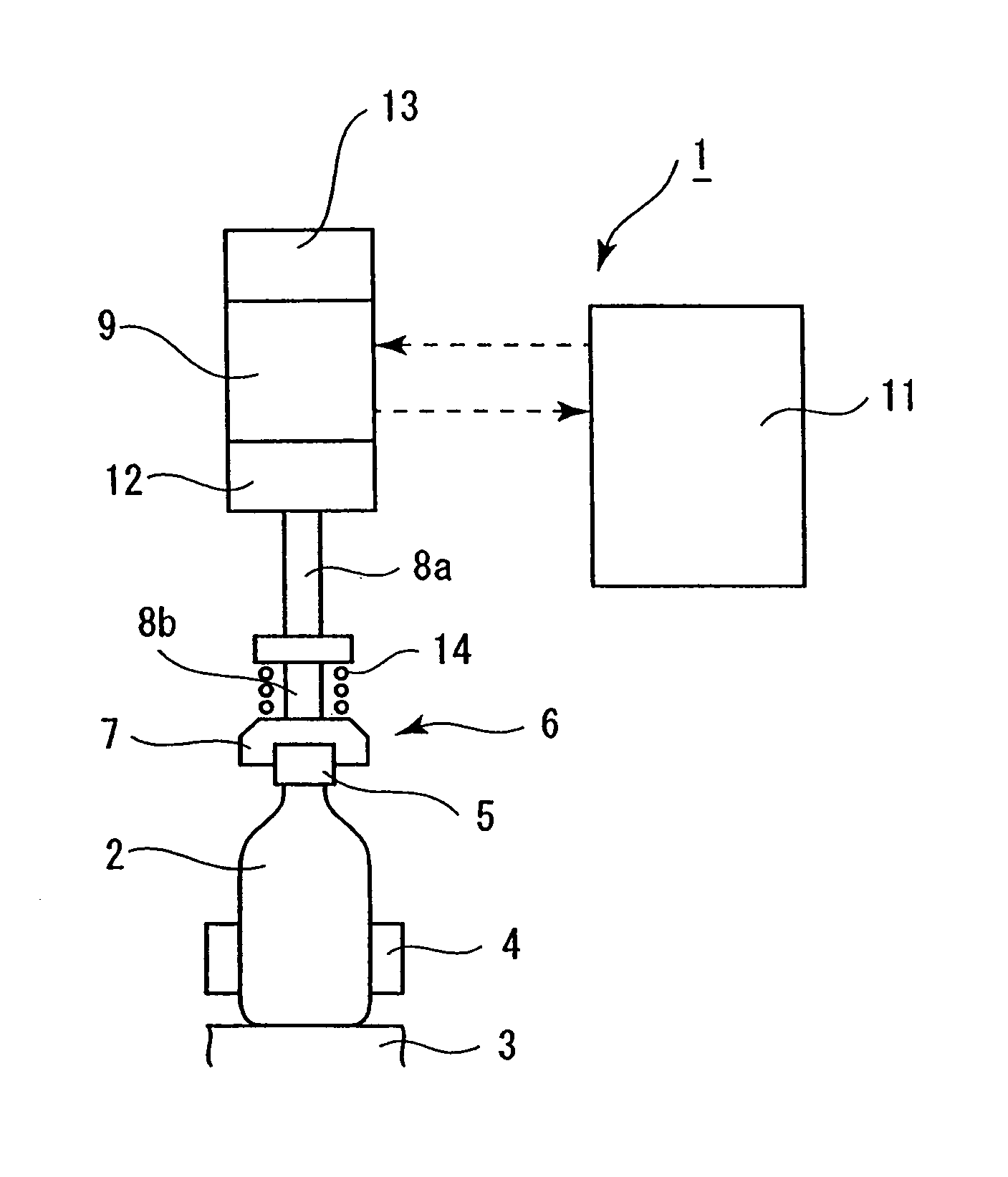

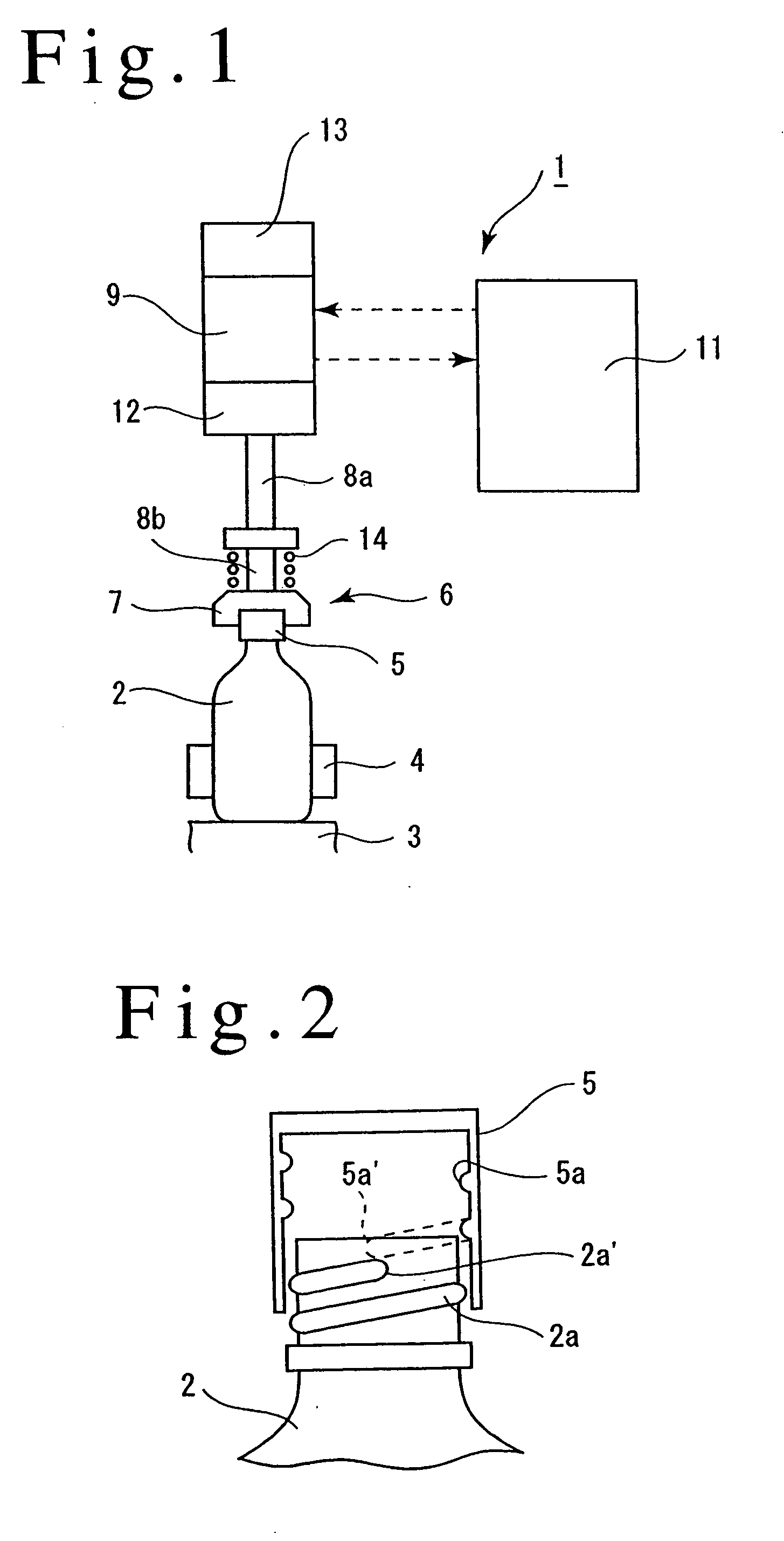

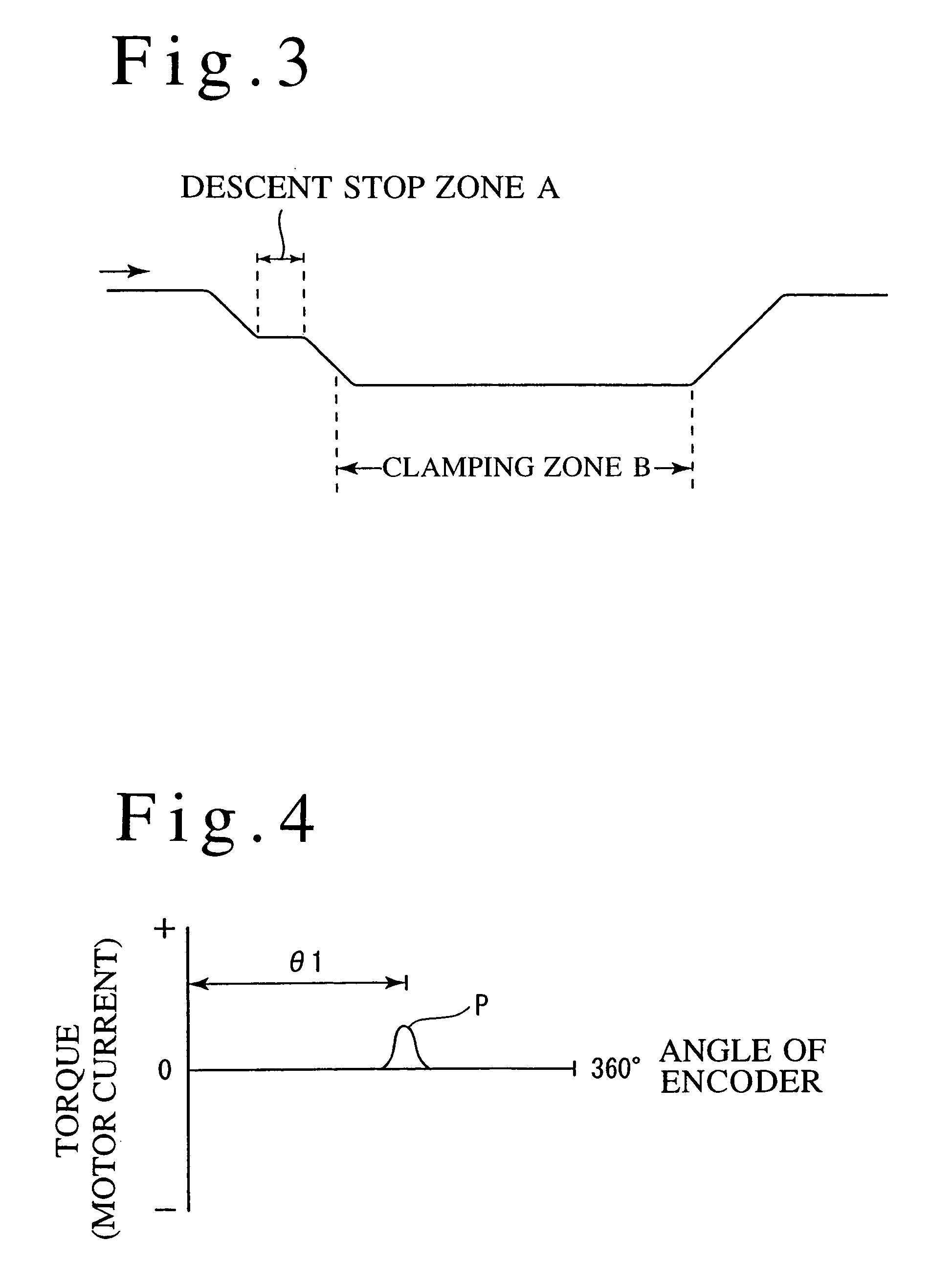

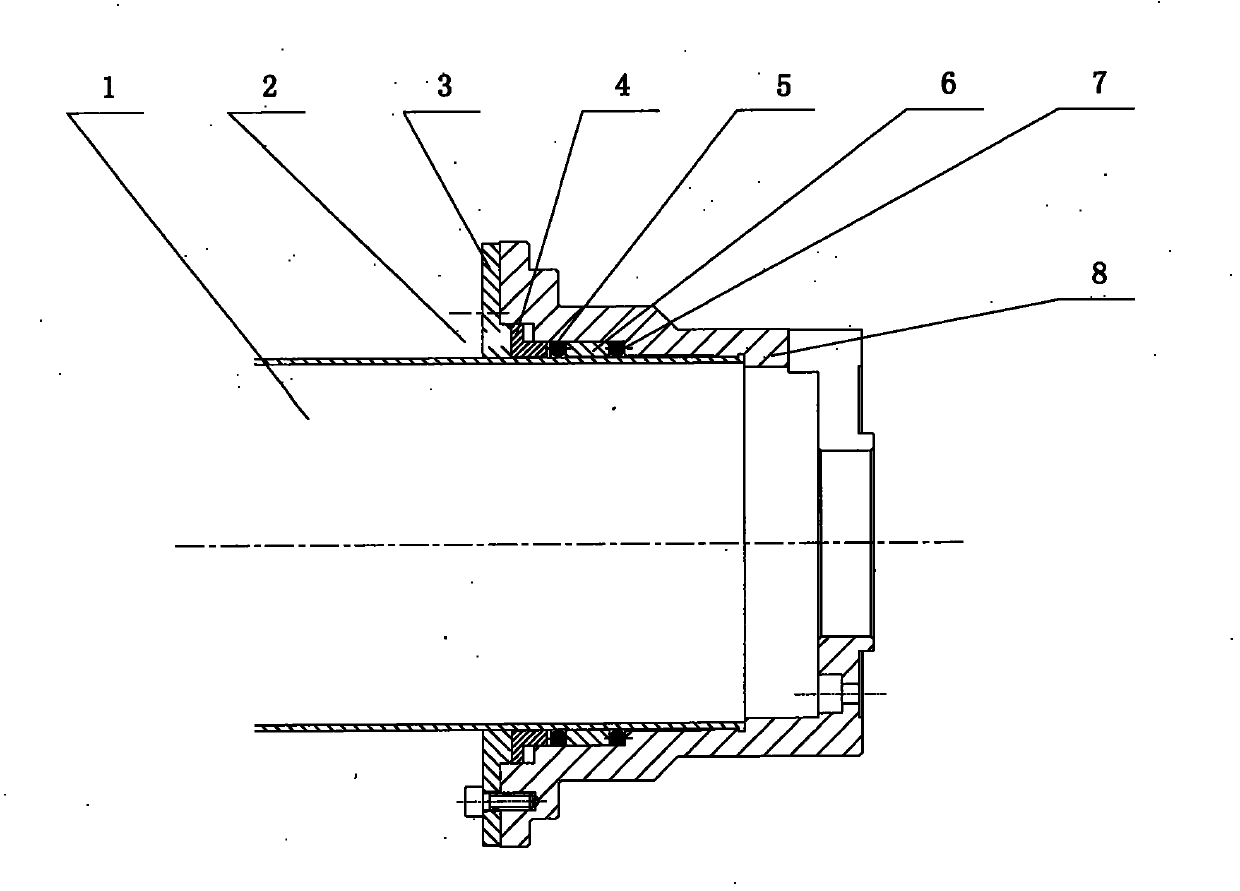

Capping method and apparatus

InactiveUS20010018820A1Accurate detectionClamp evenlyCapsThreaded caps applicationEngineeringControl theory

A capping apparatus 1 includes torque measuring means 12 which detects an output torque when a chuck 7 is driven for rotation by a motor 9. Initially a cap 5 is held by the chuck 7. The cap 5 is fitted over a mouth of a vessel 2, and then the chuck 7 is rotated through one revolution in a clamping direction. A resulting output torque is detected by the torque measuring means 12, and the output torque rapidly increases at the position where the threads on the cap 5 and the vessel 2 abut against each other (an incipient position of meshing engagement P). The cap 5 is rotated through a given angle of rotation as referenced to the incipient position of meshing engagement P, thus threadably engaging the cap 5 with the vessel 2. The invention allows a uniform clamping of cap 5 at the completion of the capping operation.

Owner:SHIBUYA IND CO LTD

Conveying device applied to glass production line

InactiveCN105417152ASolve shipping problemsSimple structureCharge manipulationConveyor partsProduction lineEngineering

The invention discloses a conveying device applied to a glass production line. The conveying device comprises a machine base and conveying belts. The conveying belts are arranged below the machine base. The conveying belts comprise the feeding conveying belt and the production conveying belts. The production conveying belts comprise the first production conveying belt and the second production conveying belt. A carrying device is arranged on the machine base and comprises a horizontal moving mechanism, a vertical lifting mechanism and a clamping mechanism. A horizontal installation plate is arranged on the machine base and provided with a horizontal moving mechanism. The horizontal moving mechanism comprises a horizontal fixing frame and a horizontal moving motor. The horizontal fixing frame is provided with a horizontal moving guide rail which is connected with a vertical lifting mechanism. The vertical lifting mechanism comprises a lifting air cylinder installation seat and a vertical lifting air cylinder. The lifting air cylinder installation seat is provided with the vertical lifting air cylinder. The vertical lifting air cylinder is connected with a clamping mechanism. The conveying device is simple in structure, scientific, convenient to use, high in pertinence, high in automation degree, high in work efficiency and capable of well solving the transportation problem of the glass production line.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

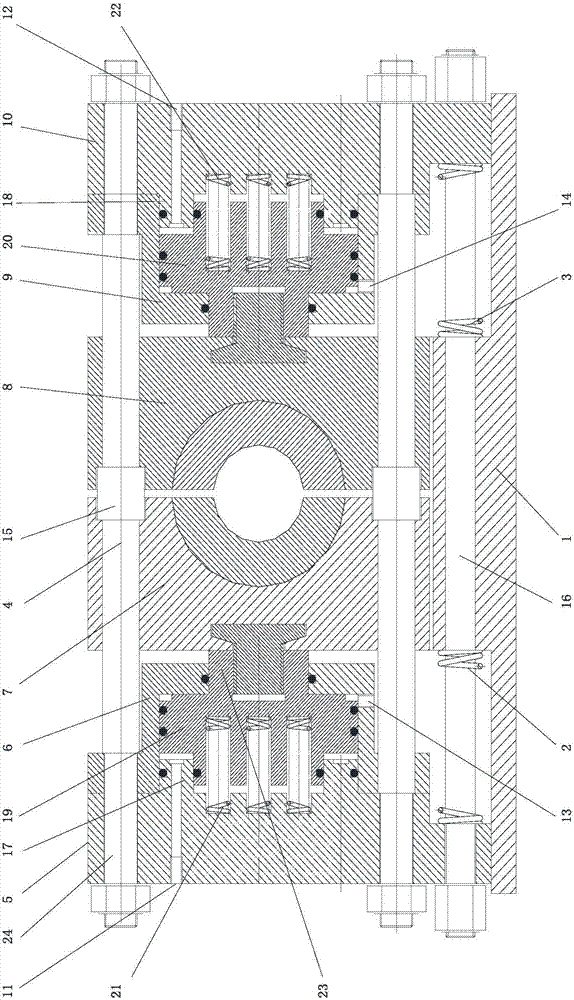

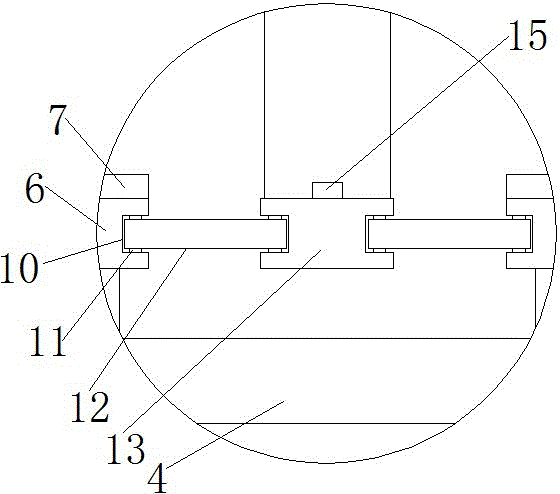

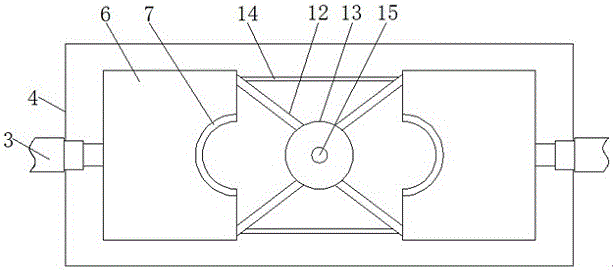

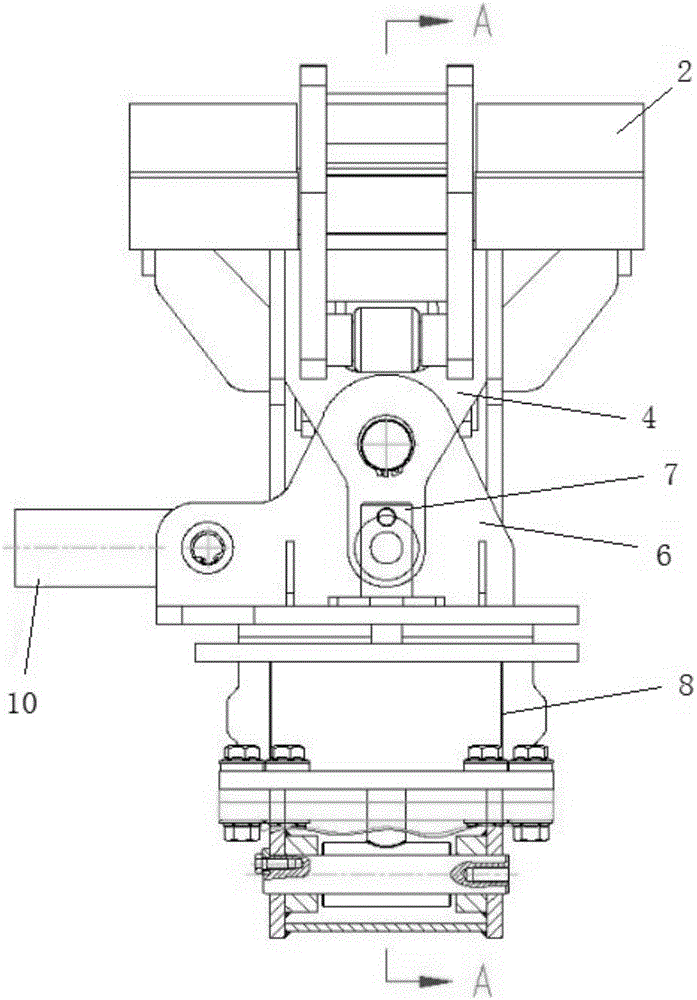

Automatic floating centering hydraulic clamp holder

PendingCN107420051AEliminate wear and tearHigh speedDrilling rodsDrilling casingsSingle degree of freedomEngineering

The invention discloses an automatic floating centering hydraulic clamp holder. The automatic floating centering hydraulic clamp holder comprises a clamping assembly used for clamping a drill rod and a base fixedly matched with a drilling machine rack and used for installing the clamping assembly. The clamping assembly is installed on the base in the radial swing direction of the drill rod in a single-degree-of-freedom sliding mode, and a fixing elastic part used for fixing the clamping assembly to avoid the situation that the clamping assembly slides under the gravity effect is arranged between the base and the clamping assembly in the single-degree-of-freedom sliding direction of the clamping assembly; external force floating centering can be increased, so that the situation that abrasion on the drill rod during clamp holder centering is guaranteed through force generated by rotating of the drill rod is avoided; and meanwhile in a lateral orientation drilling machine, the clamp holder can also be centered under the effect of floating external force, so that the eccentric problem of an existing clamp holder under the gravity effect or the problem that the initial position of the clamp holder is repeatedly adjusted to ensure centering in different orientations is avoided.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Method for detecting incipient position of meshing engagement between thread of vessel and thread of cap

InactiveUS20050022479A1Accurate detectionPrecise positioningCapsThreaded caps applicationEngineeringControl theory

A capping apparatus 1 includes torque sensor 12 which detects an output torque when a chuck 7 is driven for rotation by a motor 9. Initially, a cap 5 is held by the chuck 7. The cap 5 is fitted over a mouth of a vessel 2, and then the chuck 7 is rotated through one revolution in a clamping direction. A resulting output torque is detected by the torque sensor 12, and the output torque rapidly increases at the position where the threads on the cap 5 and the vessel 2 abut against each other (an incipient position of meshing engagement P). The cap 5 is rotated through a given angle of rotation as referenced to the incipient position of meshing engagement P, thus threadably engaging the cap 5 with the vessel 2. The invention allows a uniform clamping of cap 5 at the completion of the capping operation.

Owner:SHIBUYA IND CO LTD

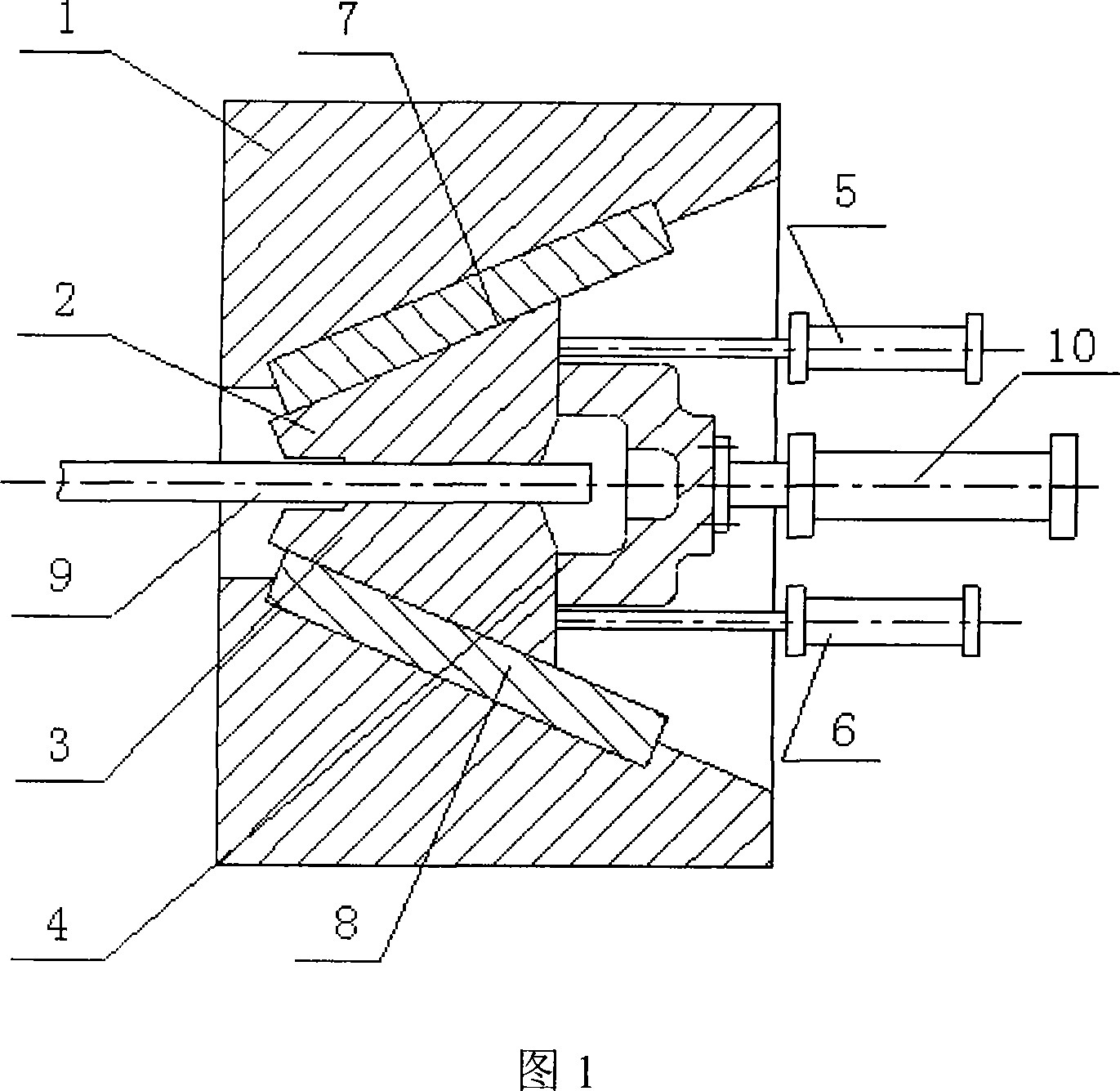

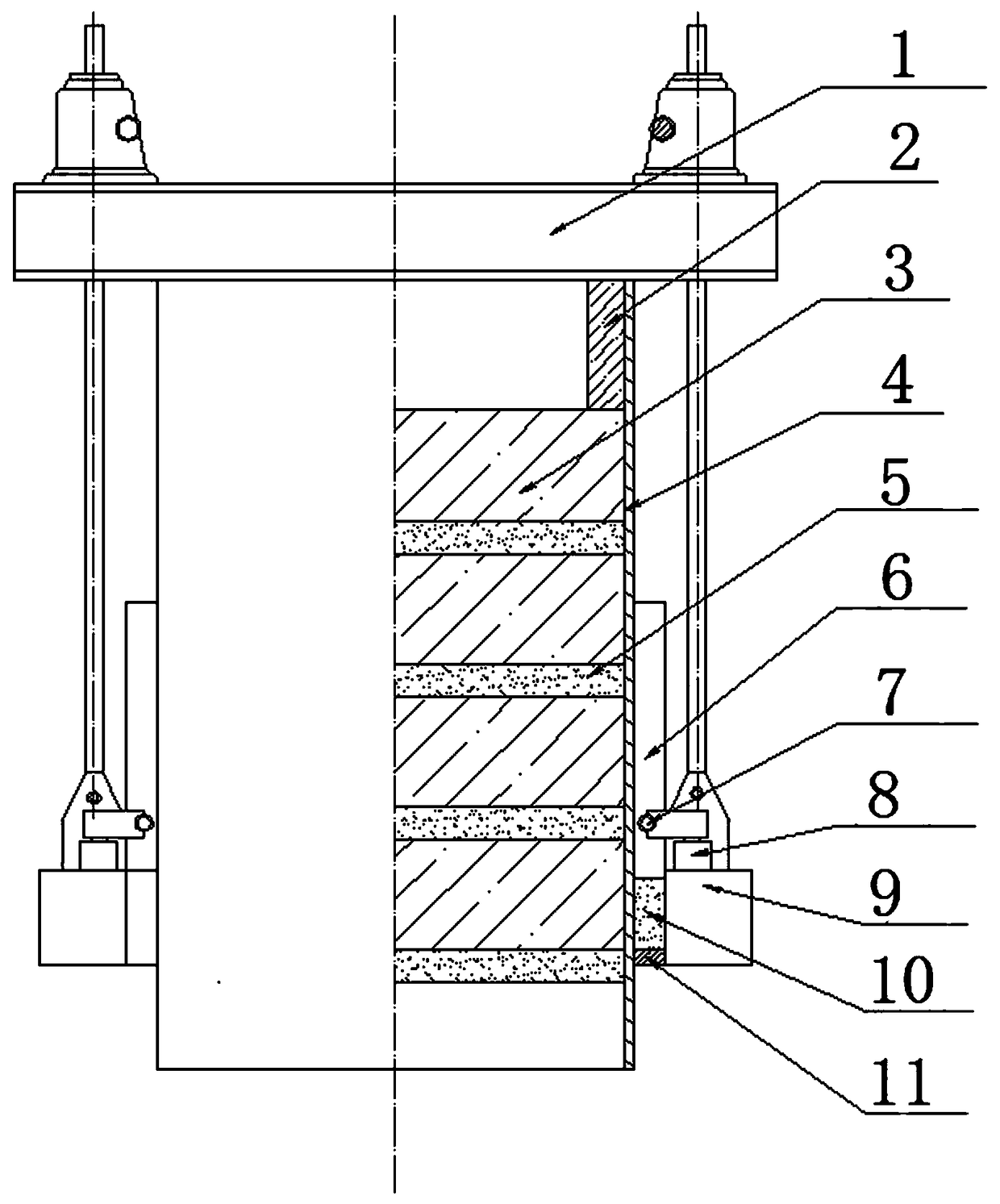

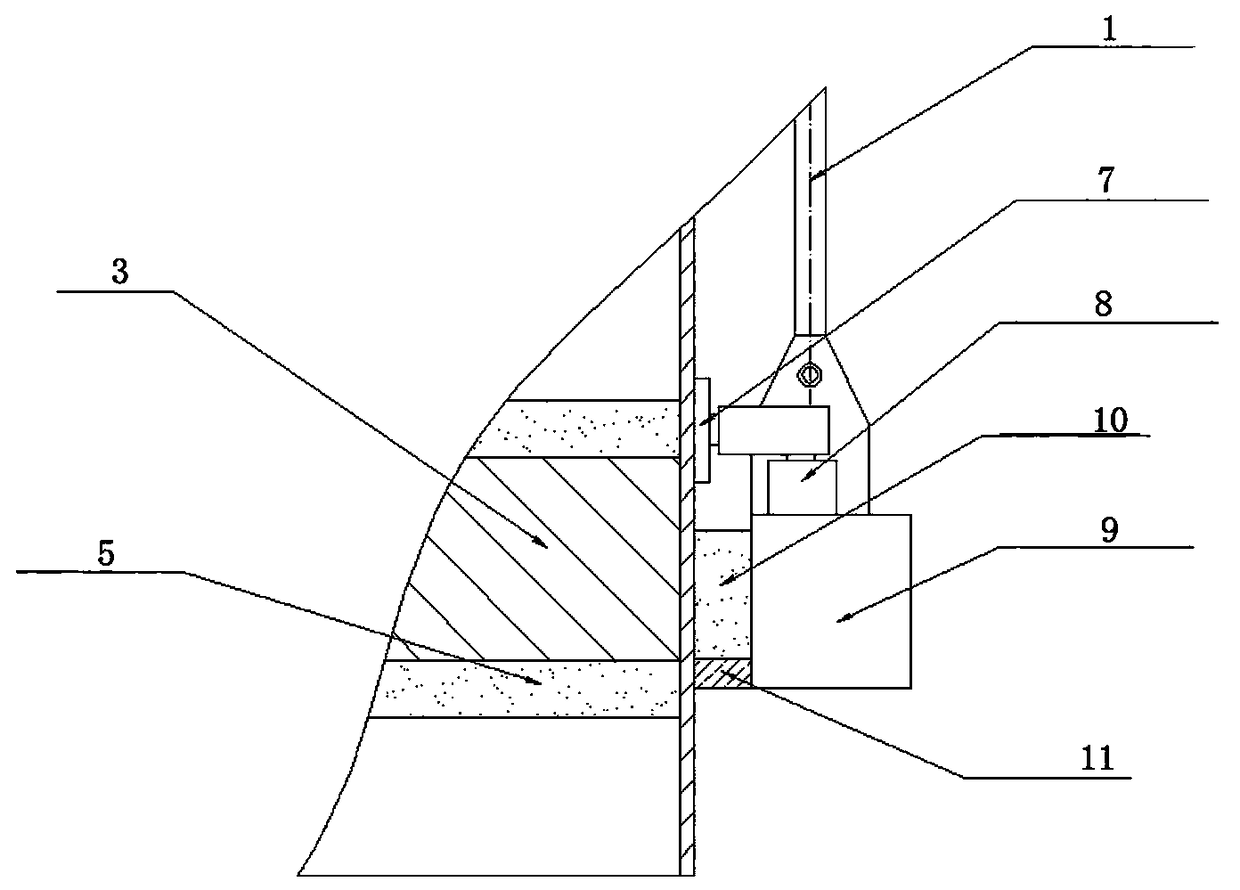

Composite bevel clamping system

The invention belongs to the processing field of nonferrous metal and ferrous metal, which is the clamping system of composite incline. An upper clamp (2) is connected with an upper slide (7) by a hopper chute. The upper slide (7) is connected with a clamping body (1). The upper clamp (2) has incline motion along the upper slide (7) to clamp stretching sheet material (9) downward. A lower clamp (3) is connected with a lower slide (8) by the hopper chute. The lower slide (8) is connected with the clamping body (1). The lower clamp (3) has incline motion along the lower slide (8) to clamp the stretching sheet material (9) upward. The upper clamp (2) and the lower clamp (3) form a clamping jaw together to stretch the stretching sheet material (9). The back end of the upper clamp (2) and the lower clamp (3) is connected with a synchronous clamping device (4). When the driving force of a synchronous clamping drive unit (10) reaches a set value, a synchronous clamping beam stops moving. The invention can make clamping material bear stress evenly, has reliable clamping and is easy to be tested.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

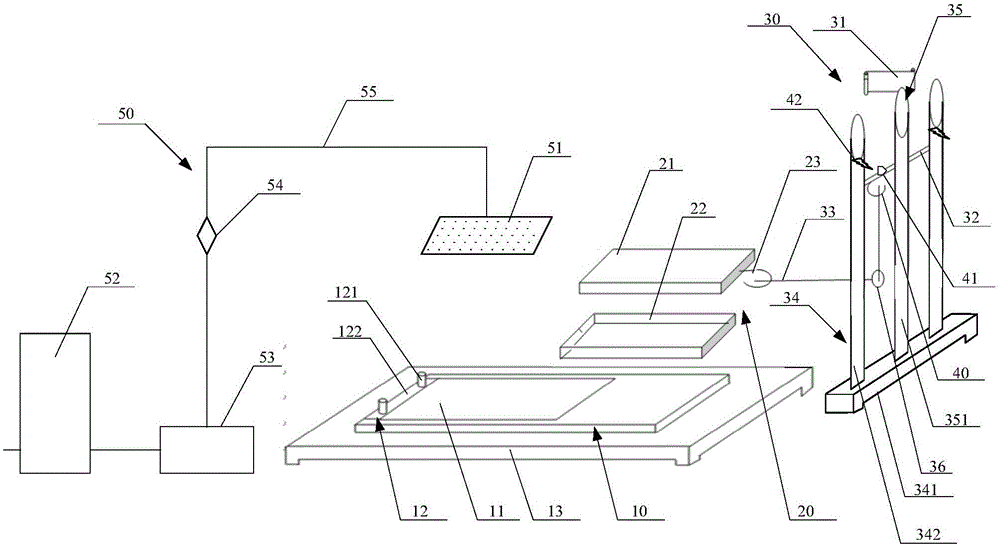

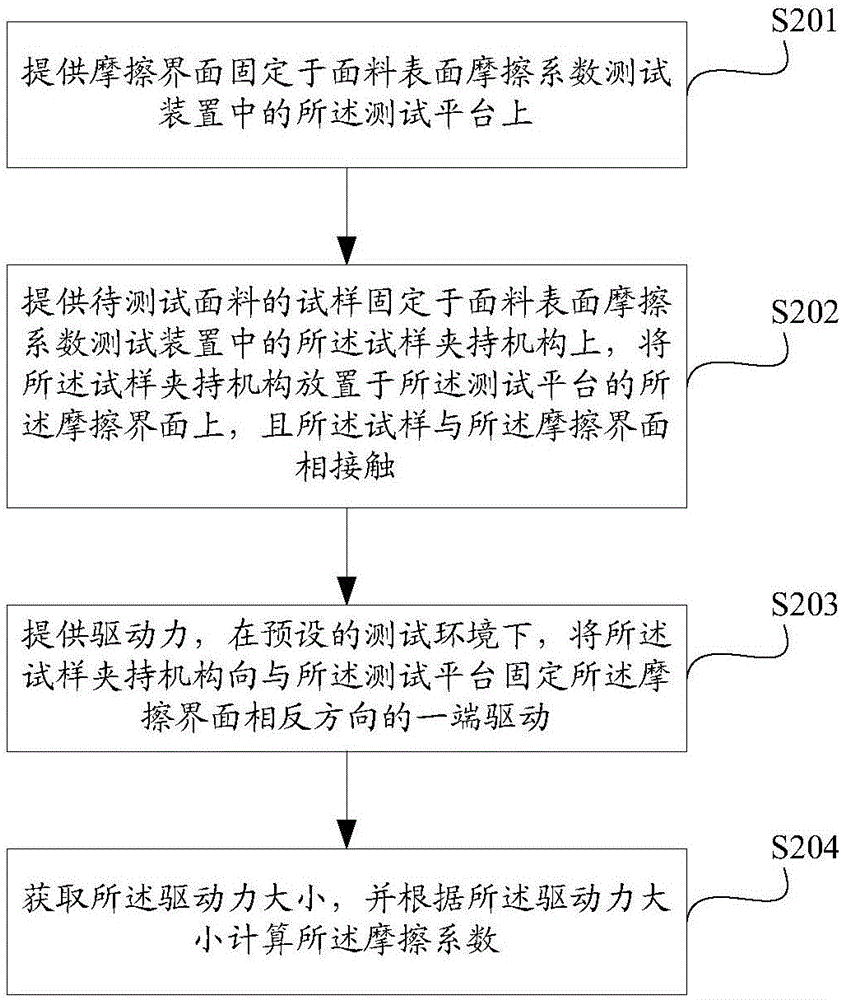

Testing device and method for skin-friction coefficient of fabric

PendingCN106596392AStable clampingClamp evenlyUsing mechanical meansMaterial analysisEngineeringTest fixture

The invention discloses a testing device and method for the skin-friction coefficient of a fabric. The device comprises a testing platform, a sample clamping mechanism, a driving mechanism and a detecting mechanism. The testing platform is provided with a fixing mechanism of a friction interface; the sample clamping mechanism comprises a sample bearing part and a sample fastening part matched with the sample bearing part, the sample fastening part can be embedded into the periphery of the outer wall of the sample bearing part, a sample which is located on the sample bearing part is fastened to the sample bearing part, and the testing face of the sample is opposite to the friction interface; the driving mechanism can drive the sample clamping mechanism to move relative to the testing platform in the detecting direction of the friction coefficient, and the detecting mechanism comprises a force sensor which can detect driving force exerted on the sample clamping mechanism by the driving mechanism when the sample clamping mechanism moves, and the friction coefficient is analyzed according to the driving force; therefore, the accuracy and repeatability of a testing result are improved.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

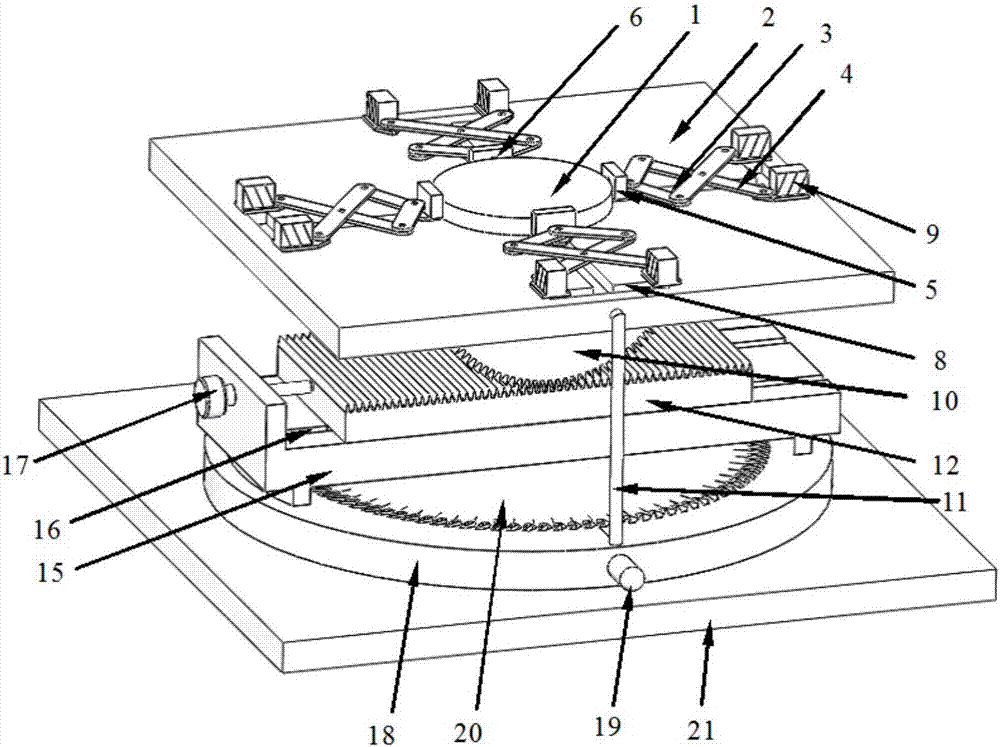

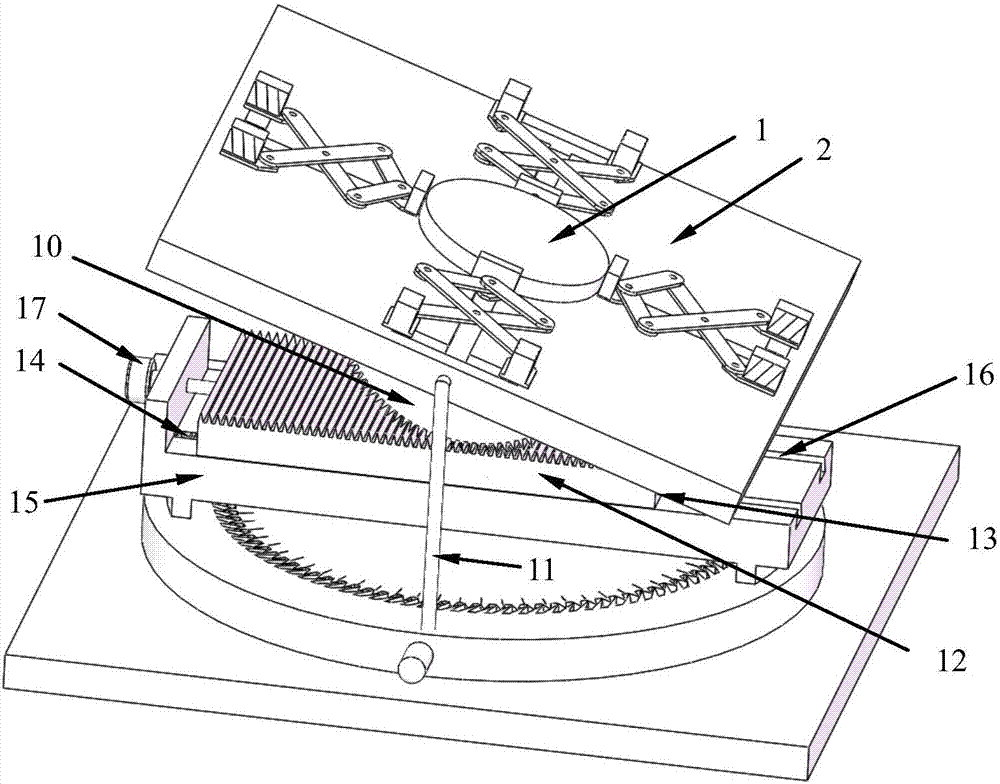

High-efficiency finishing equipment used for recycling different regular wine container resources

ActiveCN107161679ABroken won'tBroken will not causeConveyorsConveyor partsResource recoveryWine bottle

The invention relates to high-efficiency finishing equipment used for recycling different regular wine container resources. The high-efficiency finishing equipment comprises a bottom plate, wherein a rotary regulating device is mounted at the front end of the bottom plate; the tail end of the rotary regulating device is equipped with a regular wine bottle clamping device through threads; the rotary regulating device can drive the regular wine bottle clamping device to perform position regulation; and the regular wine bottle clamping device can be used for stably clamping a regular wine bottle. The high-efficiency finishing equipment can solve the problems that existing mechanical equipment in an existing wine container finishing process only can finish a single regular wine container, is great in labor intensity of manually finishing regular wine bottles, irregular wine bottles and wine jars, easily causes wine bottle breaking as a result of faults after long-time operation, is low in finishing efficiency and the like, can realize the function of finishing different regular wine containers with high efficiency, and has the advantages of being stable in work, not causing wine bottle crushing, saving resources, reducing working strength, improving working efficiency and the like.

Owner:山东尚美网络科技有限公司

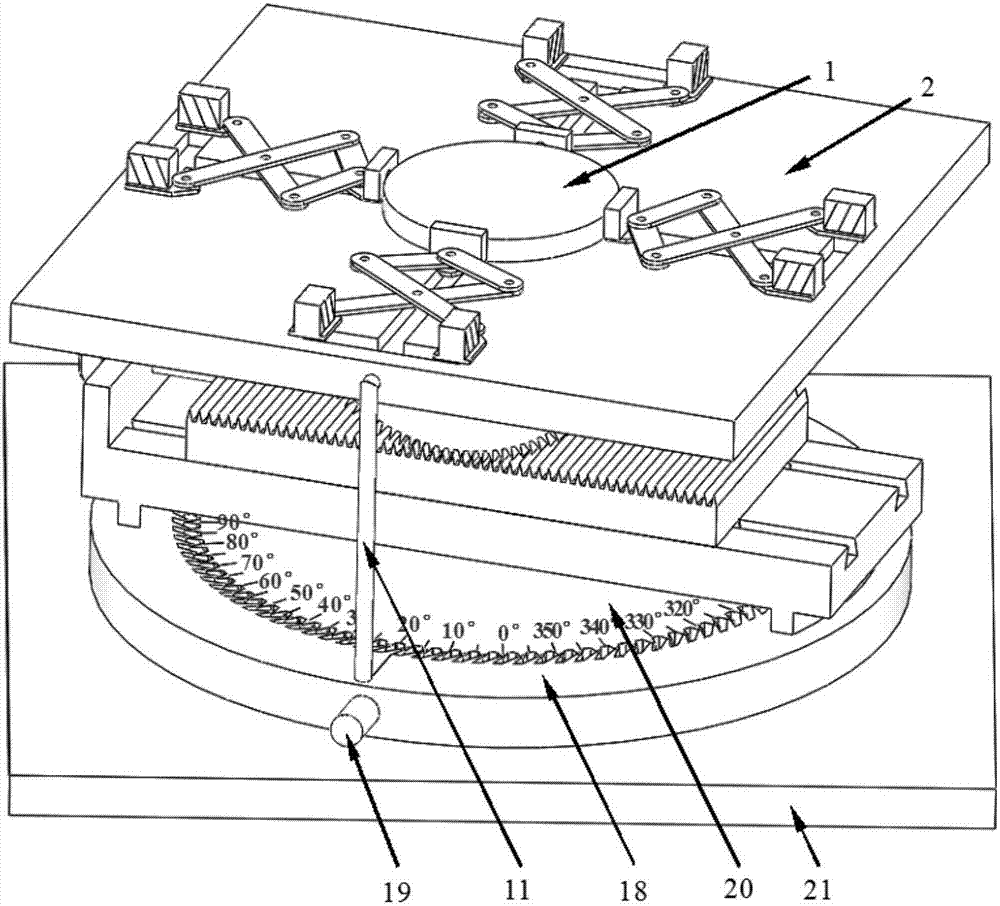

Clamp special for nanoindenter

The invention relates to a clamp special for a nanoindenter. The clamp comprises the following components: four telescoping racks and workpiece clamping blocks are arranged on the upper surface of a workpiece supporting plate, the bottom parts of the telescoping racks are provided with telescoping slide blocks, and the workpiece supporting blocks and the telescoping slide blocks are embedded in atelescoping slide way; the tail ends of the telescoping racks are provided with electromagnets, an inclined gear is arranged below the workpiece supporting plate, and rotation supporting racks are arranged at the side of the workpiece supporting plate; the inclined gear and an inclined tooth bar are connected in engagement, the bottom of the inclined tooth bar is connected to a movable slide way by a movable slide bar, the slide bar is internally provided with a spring, and the end of a micrometer is connected to an inclined tooth bar in contact connection; the rotation supporting rack bottompart and a tooth bar rack are fixed at a rotating disk at the lower part; the inner side of the rotating disk is provided with gear teeth with inclination angles, the outside of a fixed disk is provided with uniformly distributed gear teeth, and the rotating disk is connected to the fixed disk in engagement connection through gear teeth. The clamp has simple operation, can realize multi-freedom motion of the workpiece, and ensures good contact between a pressure head and a workpiece to be measured in the working process of the nanoindenter with accurate and reliable experiment results.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

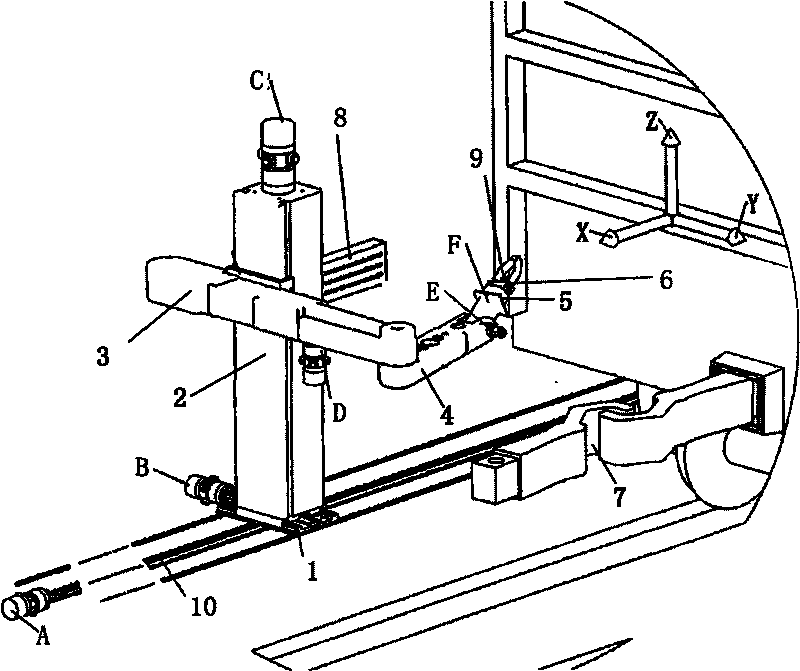

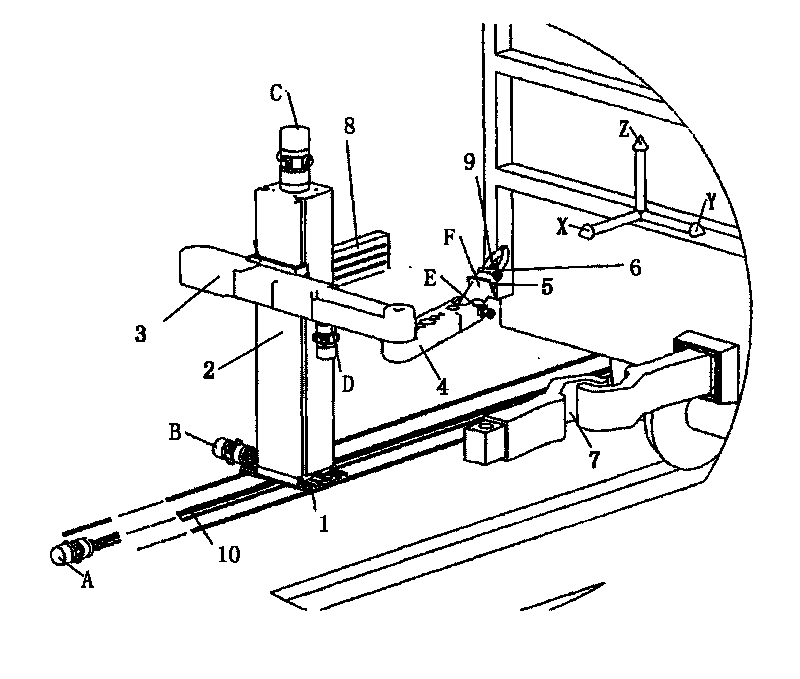

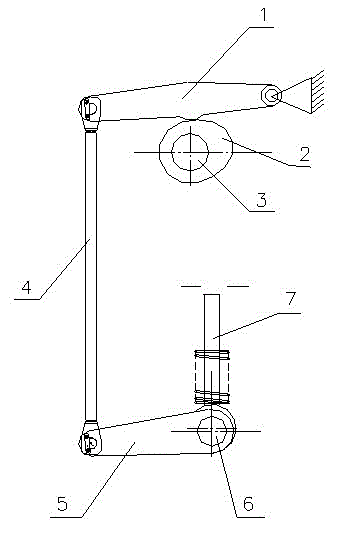

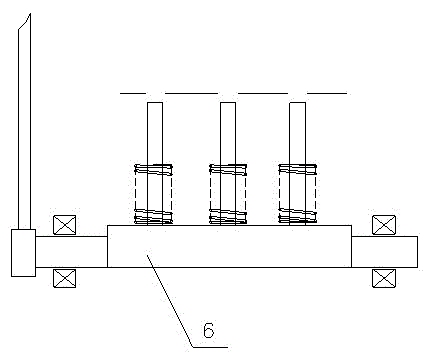

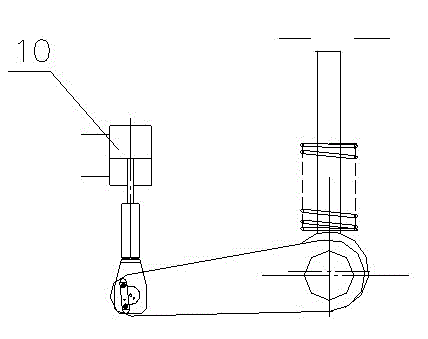

Train coupler uncoupling device

InactiveCN101695925ARealize the removal operationEasy exitRailway coupling accessoriesRelative motionEngineering

The invention relates to a train coupler uncoupling device which is used for uncoupling a coupler between adjacent compartments of a rail train. In order to reliably realize the uncoupling operation of the train coupler, the invention provides the train coupler uncoupling device. The train coupler uncoupling device is characterized by comprising an attached rail, a sliding table, a sliding pole, a big arm, a small arm, a wrist and a clamping jaw which are sequentially matched, wherein the attached rail is fixedly arranged beside a rail in the longitudinal direction; the sliding table longitudinally slides along the attached rail, the sliding pole transversely slides along the sliding table, and the big arm vertically slides along the sliding pole; the small arm is articulated with the end of the big arm approaching the rail by a vertical shaft; the rear end of the wrist is articulated with the other end of the small arm by a transverse shaft; the clamping jaw can be installed at the front end of the wrist in a rotating way around the shafts in the front and rear directions of the wrist; and the relative motions of sequentially matched components are all driven by a motor. The train coupler uncoupling device is provided with a train coupler position detecting device and a train coupler shape recognizing device, wherein the train coupler position detecting device controls the motor according to the detected position of the train coupler so that the wrist can extend beside the train coupler; and the train coupler shape recognizing device controls the motor according to the detected shape of the train coupler so that the clamping jaw can clamp the train coupler and rotate.

Owner:SOUTH CHINA UNIV OF TECH

Polishing clamping device for sealing elements

ActiveCN105904341ASimple structureEasy to useGrinding work supportsEngineeringMechanical engineering

The invention discloses a polishing clamping device for sealing elements. The polishing clamping device comprises a work table, a plate base is arranged in the middle of the top of the work table, two hydraulic telescoping devices are installed at the top end of the work table and are located on the two sides of the plate base, one end of a telescoping rod of each hydraulic telescoping device is fixedly connected to a clamping plate, a sealing element fixing base is arranged in the gap between the two clamping plates, grooves are formed in the right sides of the clamping plates, first rotating shafts are arranged in the grooves, the surfaces of the first rotating shafts are connected to folding supports in a sleeved mode, the right ends of the folding supports are connected to the sealing element fixing base, and clamping rings are arranged at the middle parts of the tops of the clamping plates and are located on one sides of the folding supports. The polishing clamping device for the sealing elements is simple in structure, convenient to use, capable of automatically clamping the sealing elements and more flexible when the clamping plates release or clamp the sealing elements, has better limiting effect on the positions of the sealing elements in the clamping process and has better clamping effect.

Owner:无锡市东特机械科技有限公司

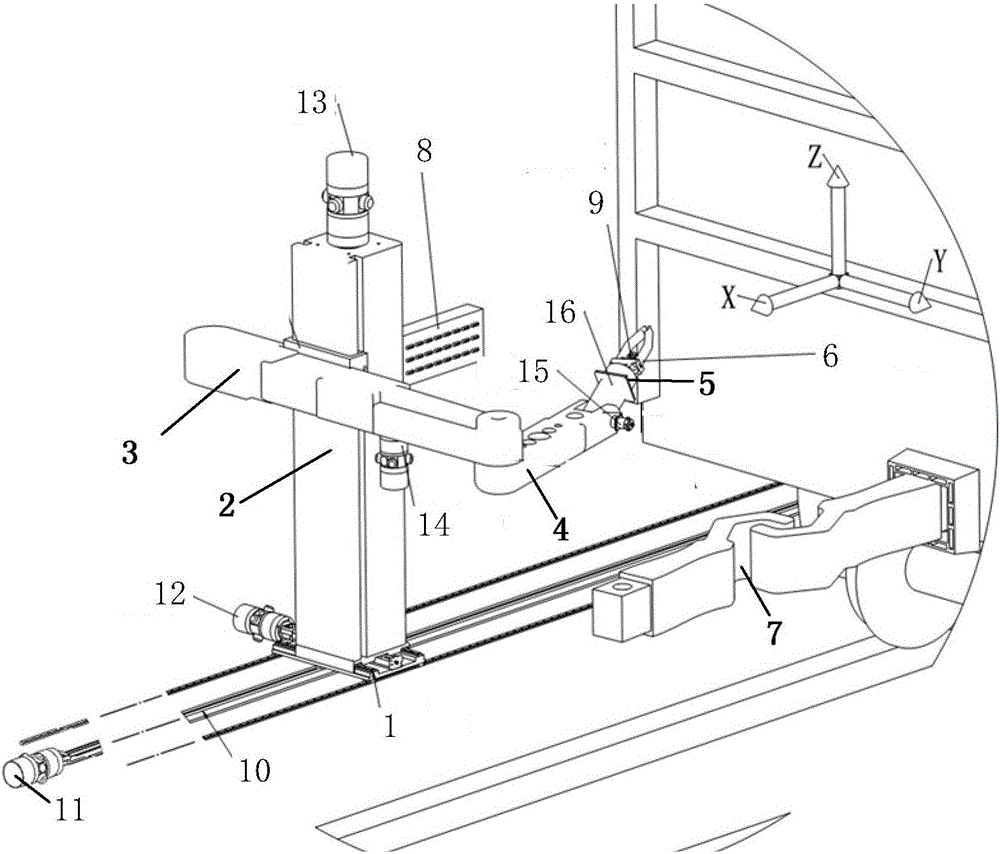

Hook removal robot with improved SCARA

InactiveCN106184275ARealize the removal operationEasy exitRailway coupling accessoriesMachine visionEngineering

The invention discloses a hook removal robot with an improved SCARA. The hook removal robot comprises a tri-axis right-angle coordinate moving mechanism, small arms, wrists, claws, a hook position detecting apparatus and a hook shape machine vision identification apparatus, wherein the tri-axis right-angle coordinate moving mechanism is arranged at one side of a rail in parallel; the small arms are hinged to the end, which is close to the rail, of the tri-axis right-angle coordinate moving mechanism by virtue of a vertical shaft and is driven by a fourth motor to rotate around the vertical shaft; the rear end of each wrist is hinged to the other end of the corresponding small arms by virtue of a transverse shaft and driven by a fifth motor to rotate around the transverse shaft; and the claws are installed at the front ends of the wrists and driven by a sixth motor to rotate around a longitudinal shaft of the wrist so as to be opened and closed. The hook removal robot is provided with multiple parts which are successively matched in multiple directions, and is flexible in action, suitable for different real situations, capable of reliably removing a hook, simple in structure, low in cost, and capable of alleviating the labor intensity and improving the working efficiency.

Owner:SOUTH CHINA UNIV OF TECH +1

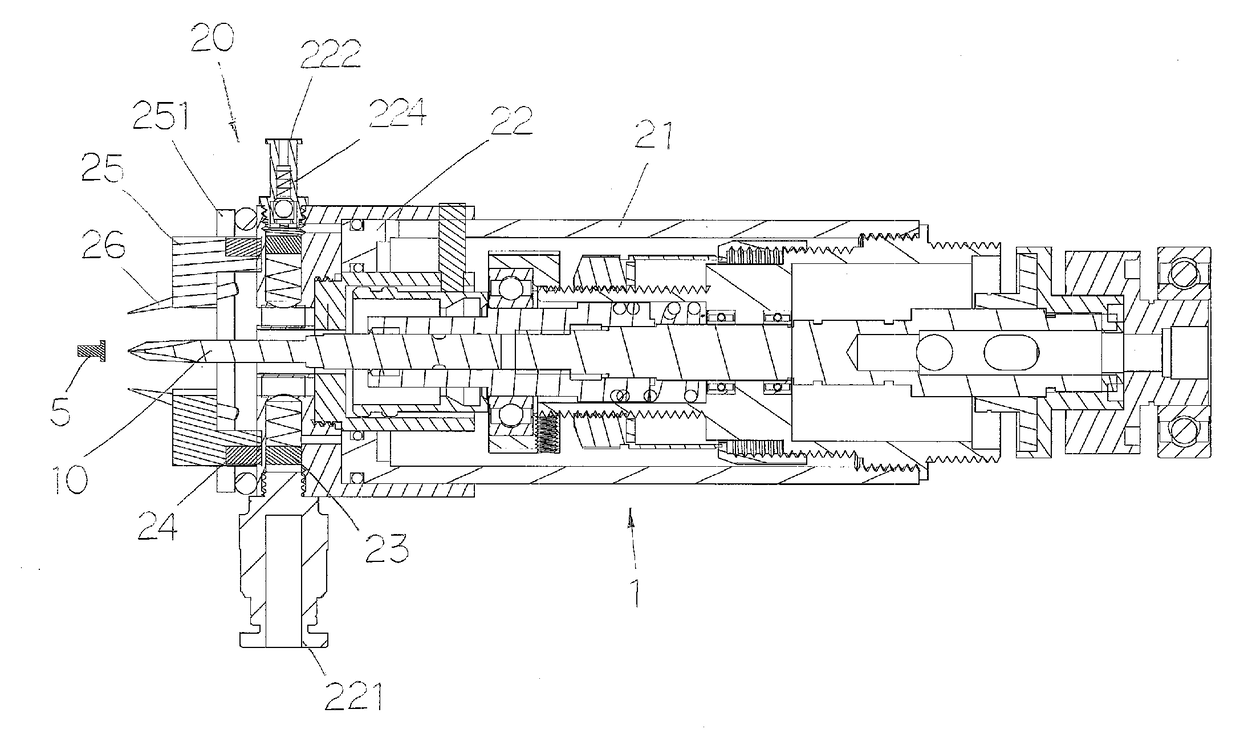

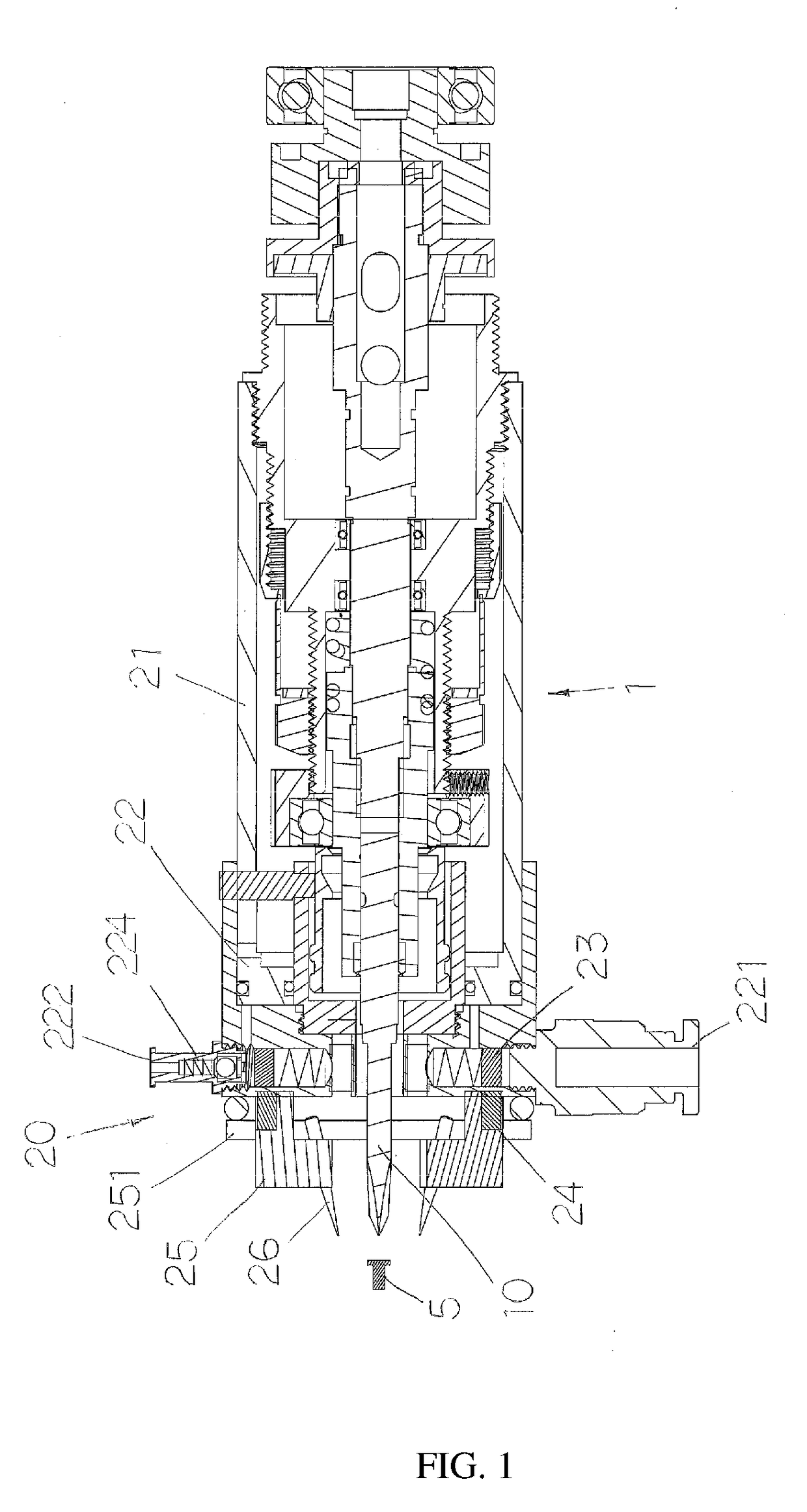

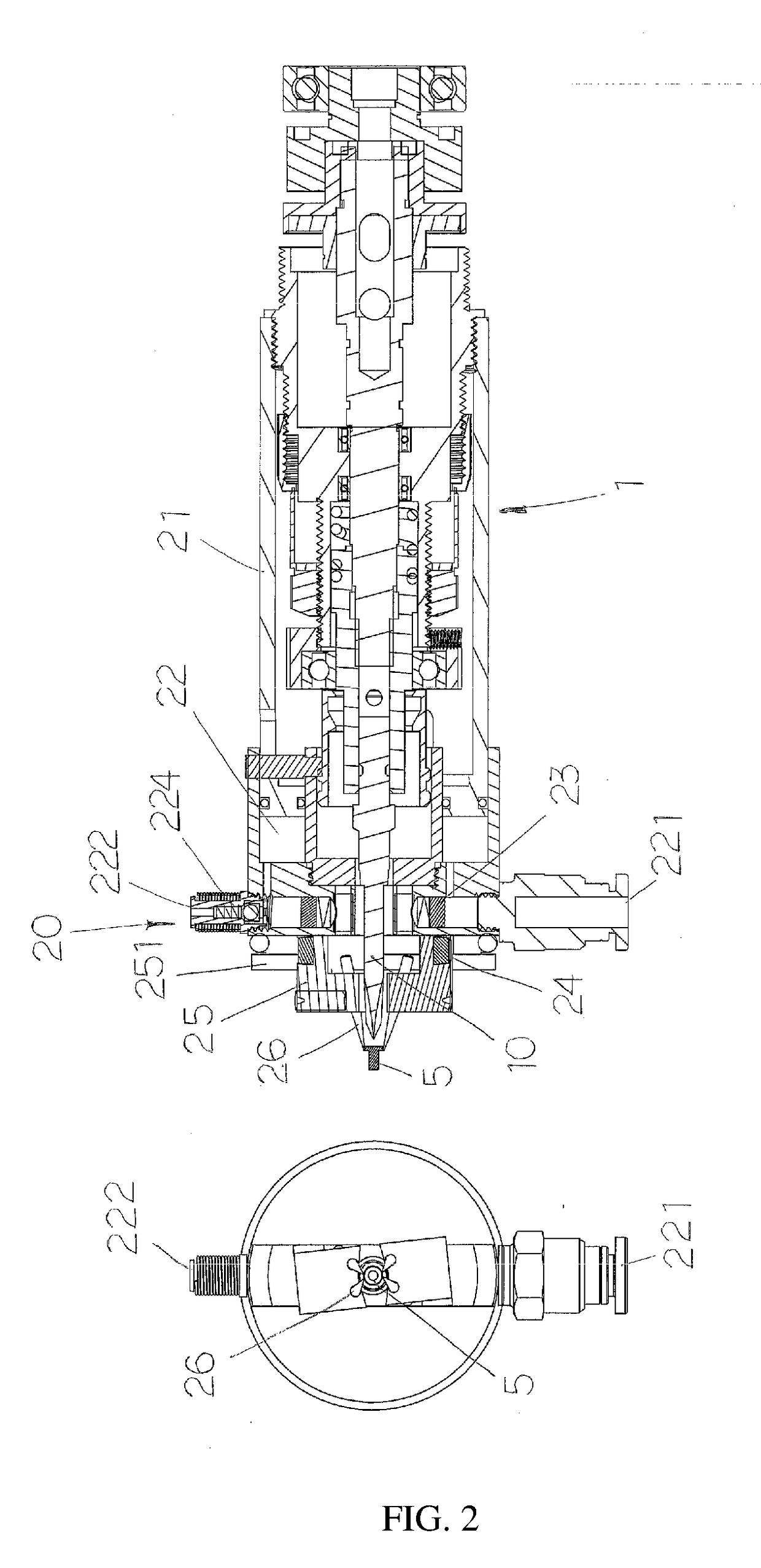

Magnetic levitation screw-clamping jaw for automatic screwdrivers

InactiveUS20170106483A1Easily and quickly and conveniently completeLow production costSpannersWrenchesRelative displacementRepulsion force

A magnetic levitation screw-clamping jaw for automatic screwdrivers. The main feature is a configuration of a magnetic levitation clamping jaw on the front end of the screwdriver bit of an automatic screwdriver. The structure and working principle of the invention include: (1) through pneumatic control, clamp the screw at air intake, and through electromagnetic control, release the screw at air exhaust, meanwhile complete the locking action straightforward with the automatic screwdriver; and with electric power input, the electromagnet can absorb the screw; (2) through the relative displacement with the automatic screwdriver, push the magnet, and as like poles repel, the repulsion force will push the displacement to clamp the screw to immediately conduct the locking action; (3) through the relative displacement with the automatic screwdriver, push the switch to control the magnet excitation of the magnetic chuck to absorb and clamp the screw for the screw-locking action.

Owner:HSU HSIU LIN

Aluminum barrel anode clamping device

PendingCN109355679ADoes not affect normal operationHigh degree of automationElectrical conductorAluminium electrolysis

The invention relates to the technical field of aluminium electrolysis, in particular to an aluminum barrel anode clamping device which comprises a clamping frame / anode bus rack and at least one anodelifting mechanism and further comprises at least one aluminum barrel anode, wherein the at least one anode lifting mechanism is connected with the clamping frame / anode bus rack and is used for lifting the clamping frame / anode bus rack; the at least one aluminum barrel anode is arranged in the clamping frame / anode bus rack and is internally provided with a plurality of conductors; the aluminum barrel anode comprises an aluminum barrel; a plurality of pressing and lifting mechanisms are arranged on the clamping frame / anode bus rack; and at least one first compressing mechanism or conducting element in contact with the aluminum barrel, or the conducting element and the first compressing mechanism are arranged on each of the pressing and lifting mechanisms. The pressing and lifting mechanismsare arranged on the clamping frame / anode bus rack to automatically lift the clamping frame / anode bus rack to an assigned height; and the aluminum barrel anode clamping device is high in degree of automation, simple and steady to operate and high in efficiency.

Owner:党星培

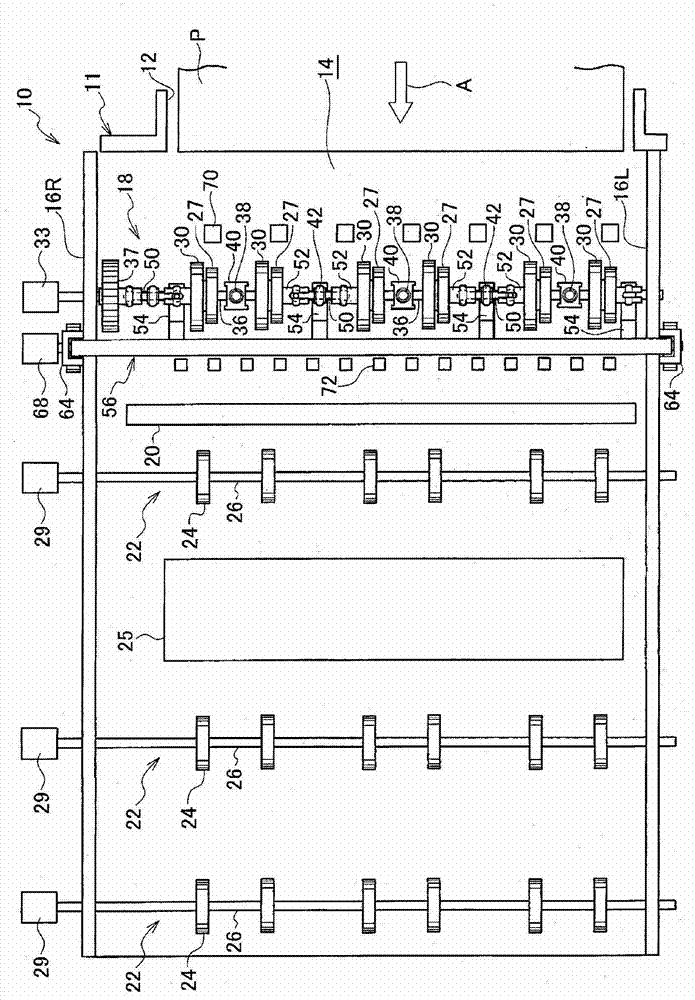

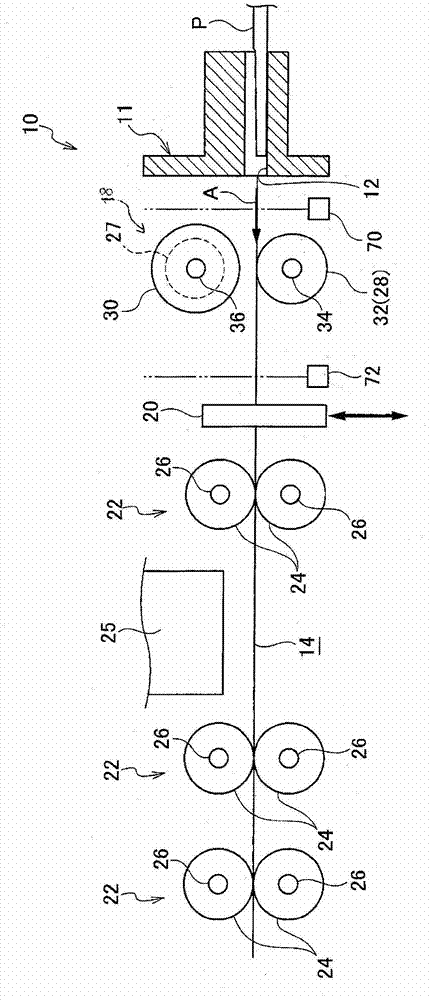

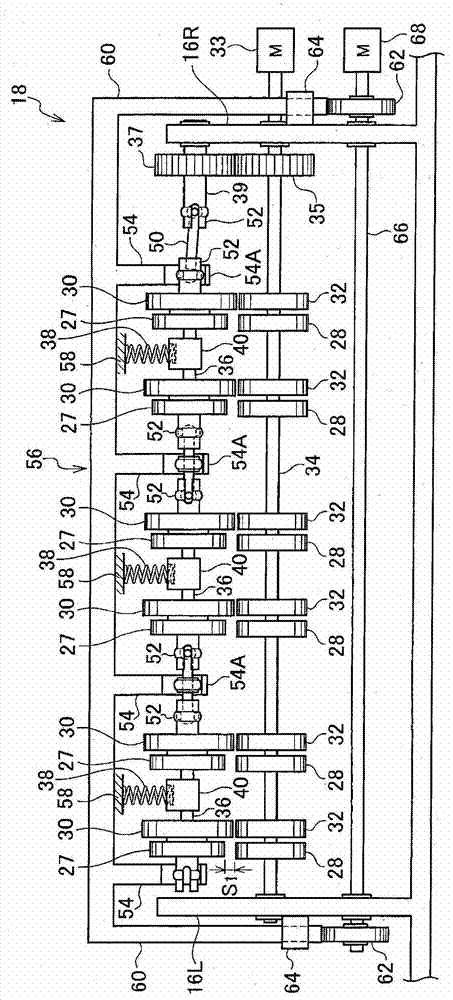

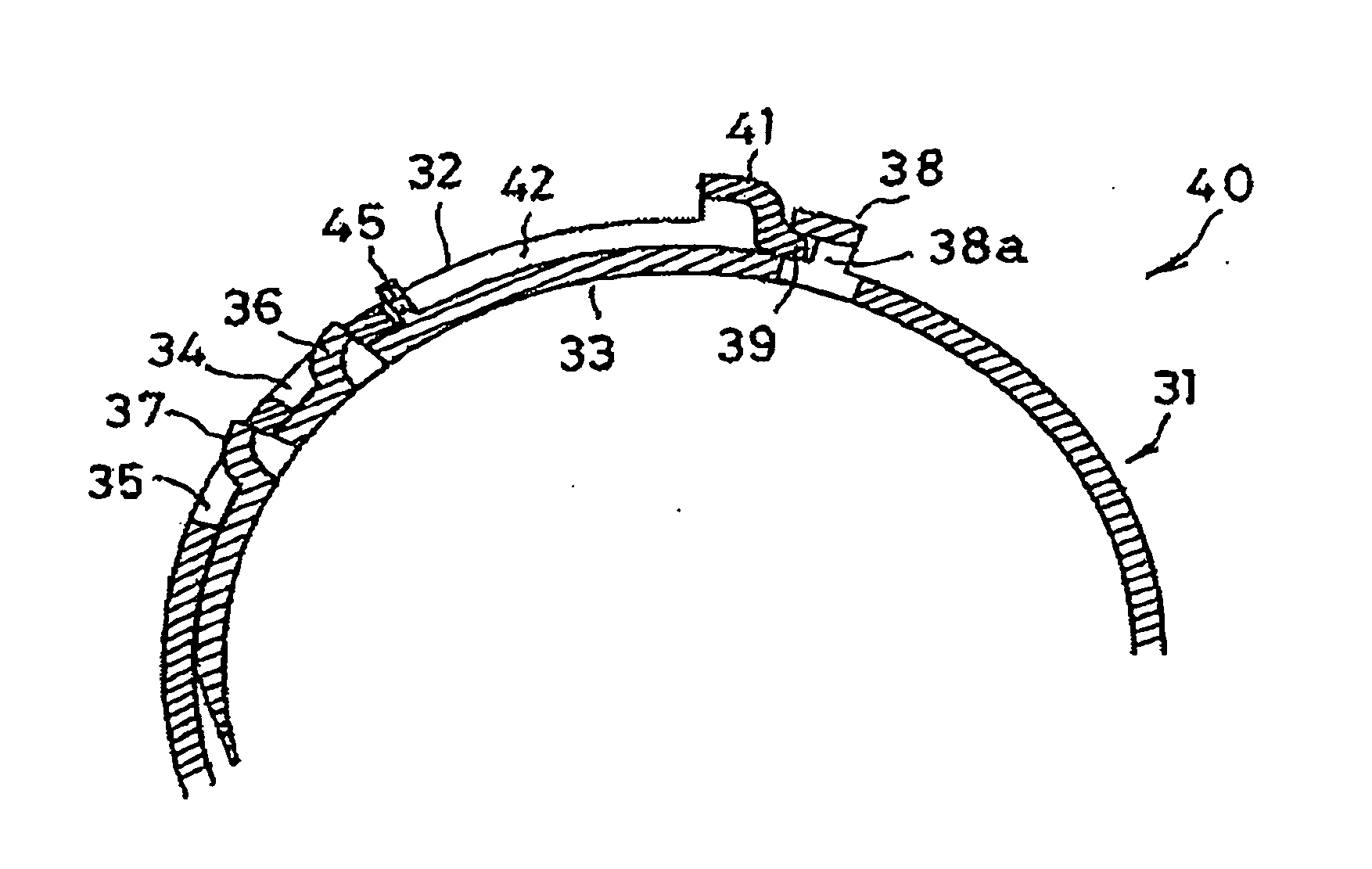

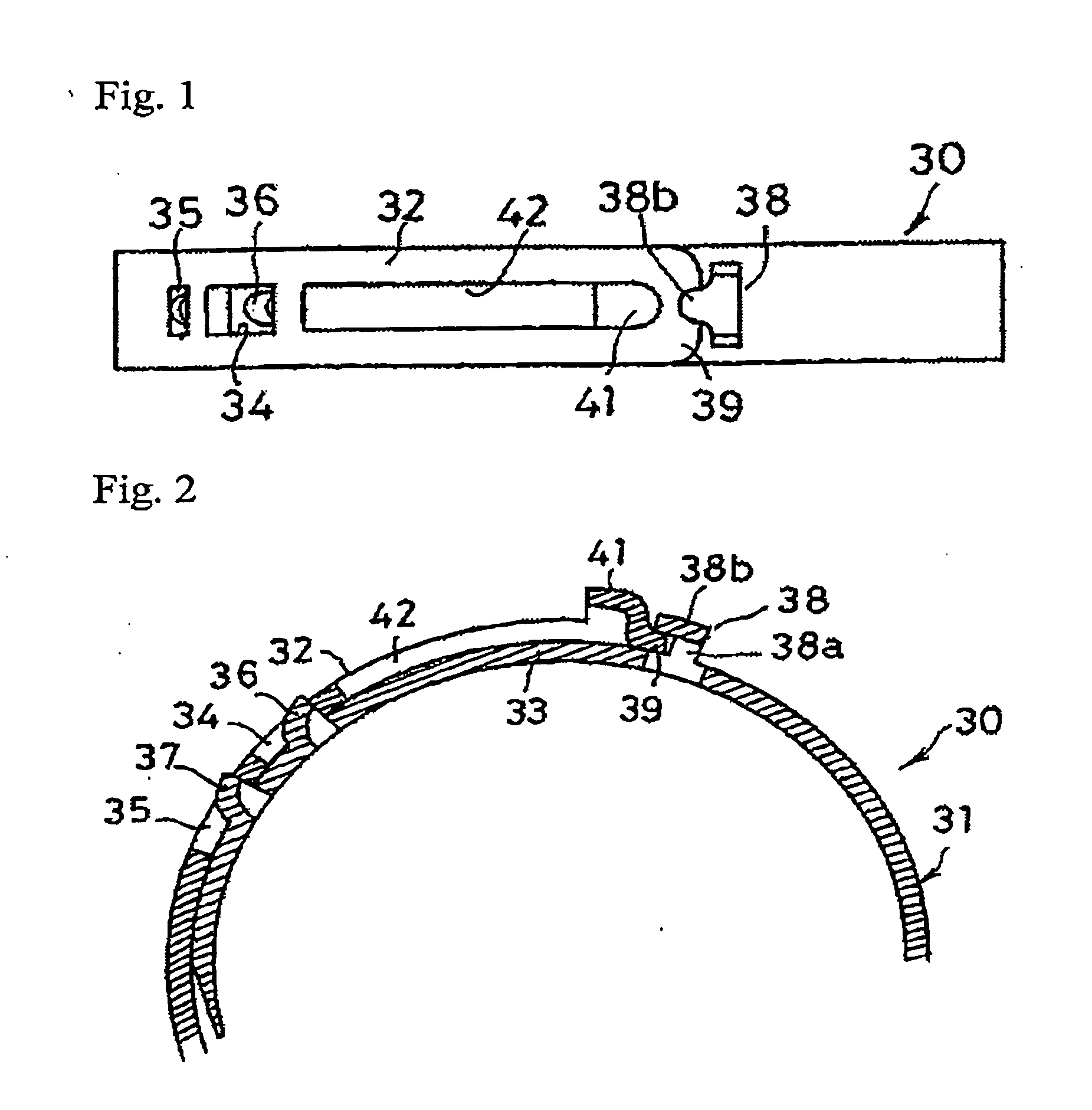

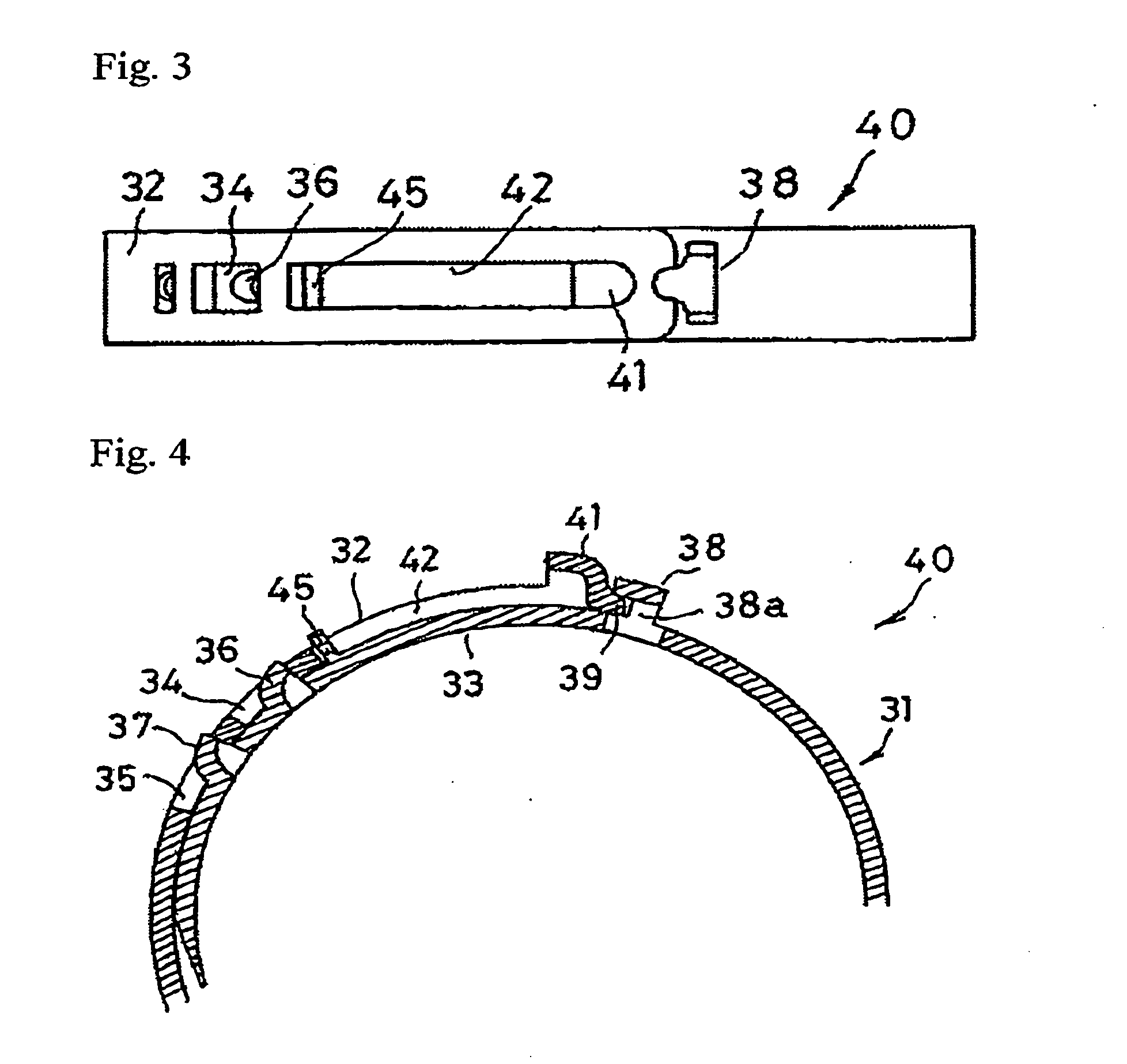

Recording medium conveying mechanism and recording medium processing device

The present invention provides a recording medium conveying mechanism and a recording medium processing device. Recording medium can be clamped and transported uniformly regardless of size and thickness of the recording medium. A rotary shaft (36) of an upper conveying roll (27) which is used for clamping and transporting the recording medium (P)along with an lower part conveying roll (28) is provided with a compressed spiral spring (38) for applying force on the rotary shaft (36) toward the rotary shaft (34) of the lower part conveying roll (28). The end part of the rotary shaft (36) is inclinedly, movably and freely connected by a coupler. A cam (62) is arranged, the cam (62) is connected with a frame (56) for supporting the coupler (50), and the frame (60) is moved along the upper and lower direction.

Owner:OKI ELECTRIC IND CO LTD

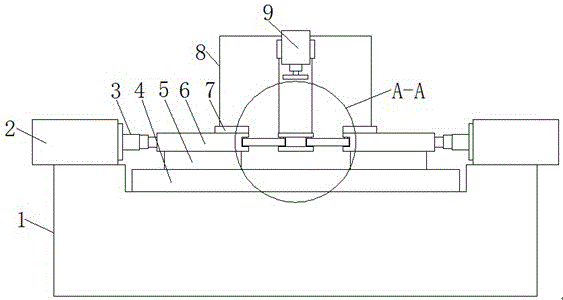

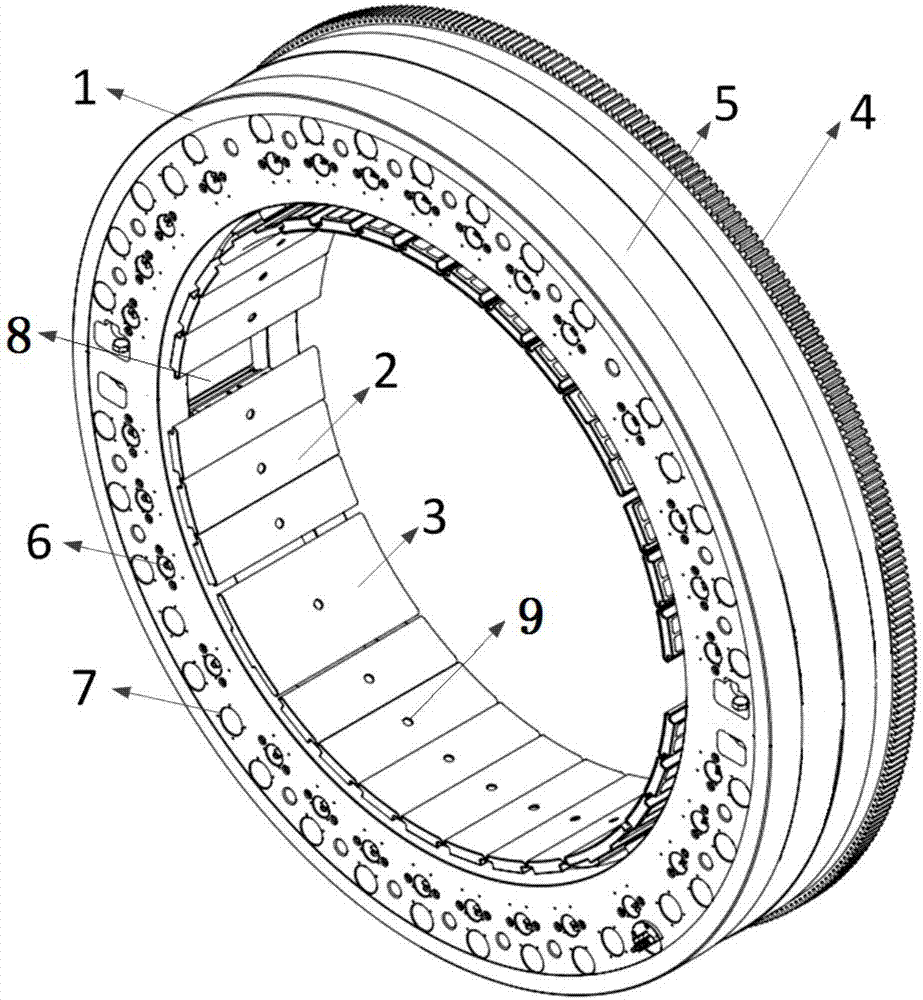

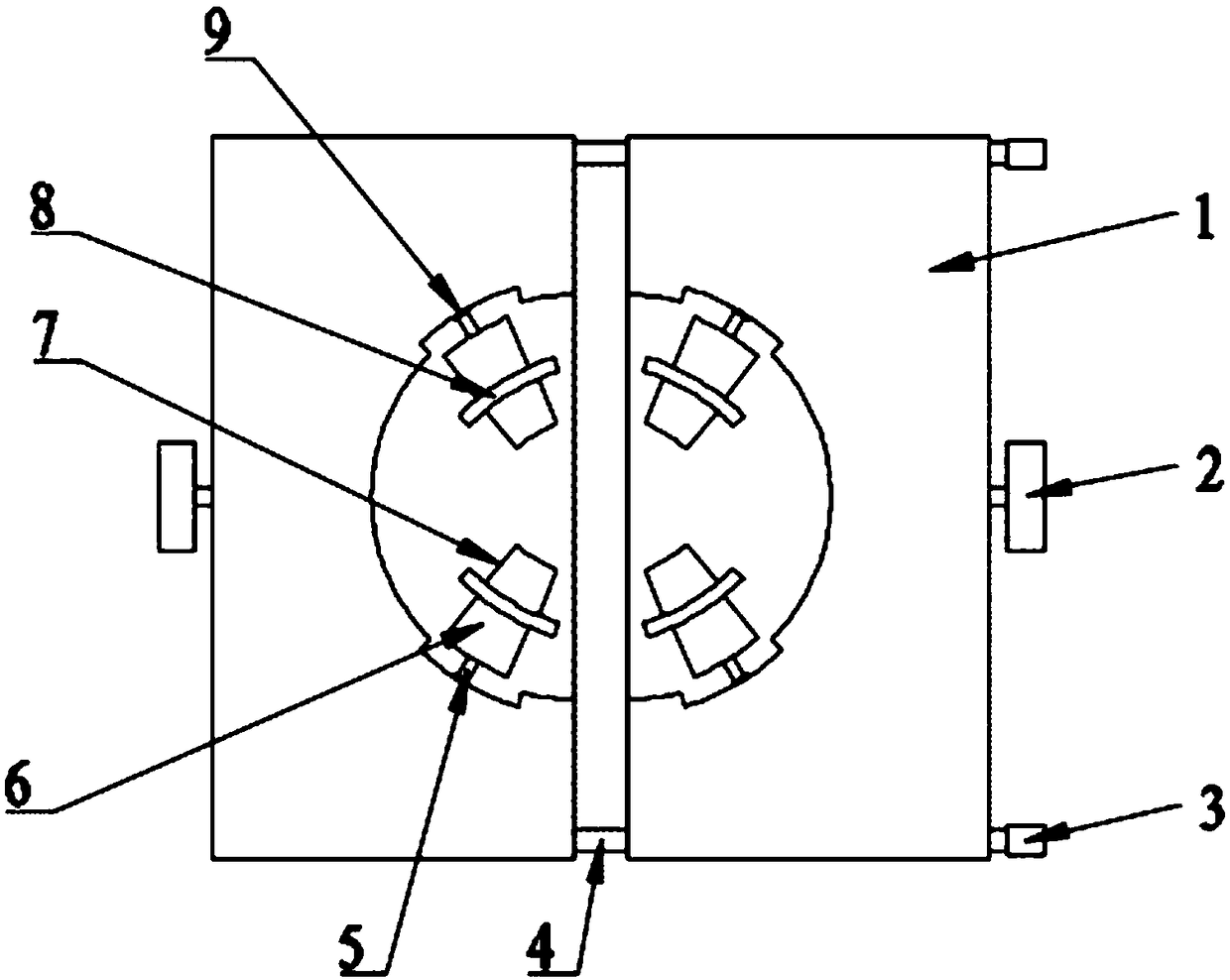

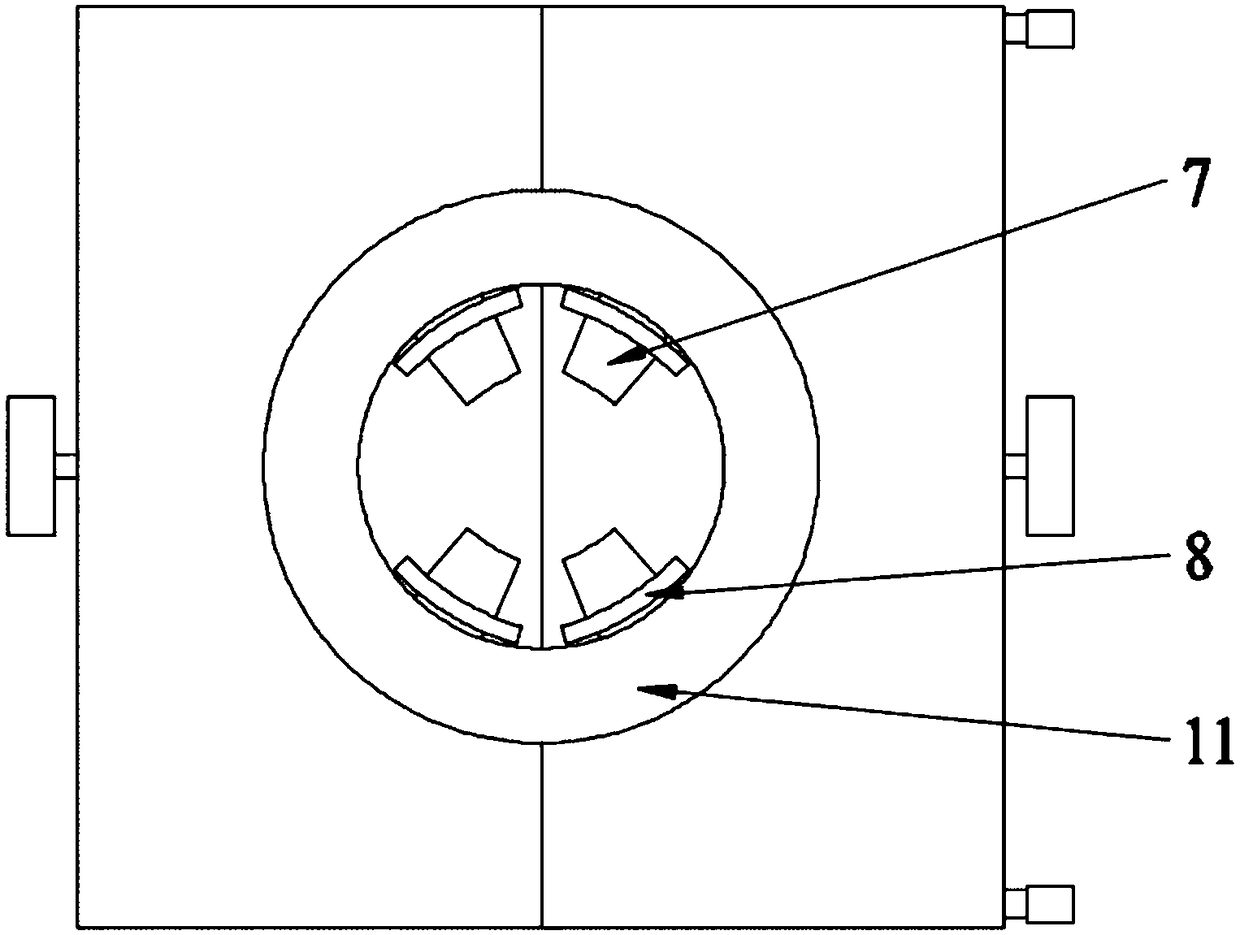

Large workpiece clamping device and clamping system

ActiveCN107309686AIncrease the effective contact areaClamping state effectPositioning apparatusMetal-working holdersRadial motionEngineering

The invention provides a large workpiece clamping device. The large workpiece clamping device comprises a circular clamp body. A mounting groove is formed in the inner ring of the clamp body so that multiple detachable clamping units can be mounted. Each clamping unit comprises a clamping execution device and a clamping drive device. Each clamping drive device is connected with the corresponding clamping execution device and used for driving the corresponding clamping execution device to move in the axial direction and / or the radial direction of a ring of the clamp body. The clamping execution devices are circumferentially distributed along the inner ring of the clamp body. Each clamping drive device comprises a drive device connecting portion fixedly connected with the clamp body. The invention further provides a large workpiece clamping system which comprises the large workpiece clamping device and a bearing platform. Supporting bases are arranged on the bearing platform in parallel. The supporting bases are provided with rolling bearing grooves matched with the outer edge of the clamp body. The large workpiece clamping device and the large workpiece clamping system have the beneficial effects that floating clamping is achieved; the center position of a workpiece does not need to be adjusted repeatedly when the workpiece is clamped; an extra auxiliary supporting structure is not needed; and the clamping efficiency is improved.

Owner:重庆真测科技股份有限公司 +2

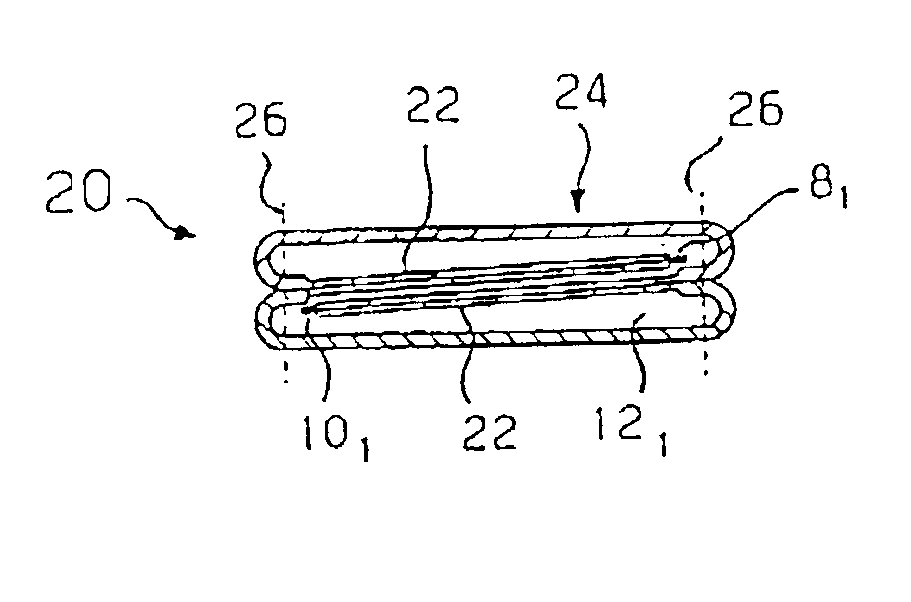

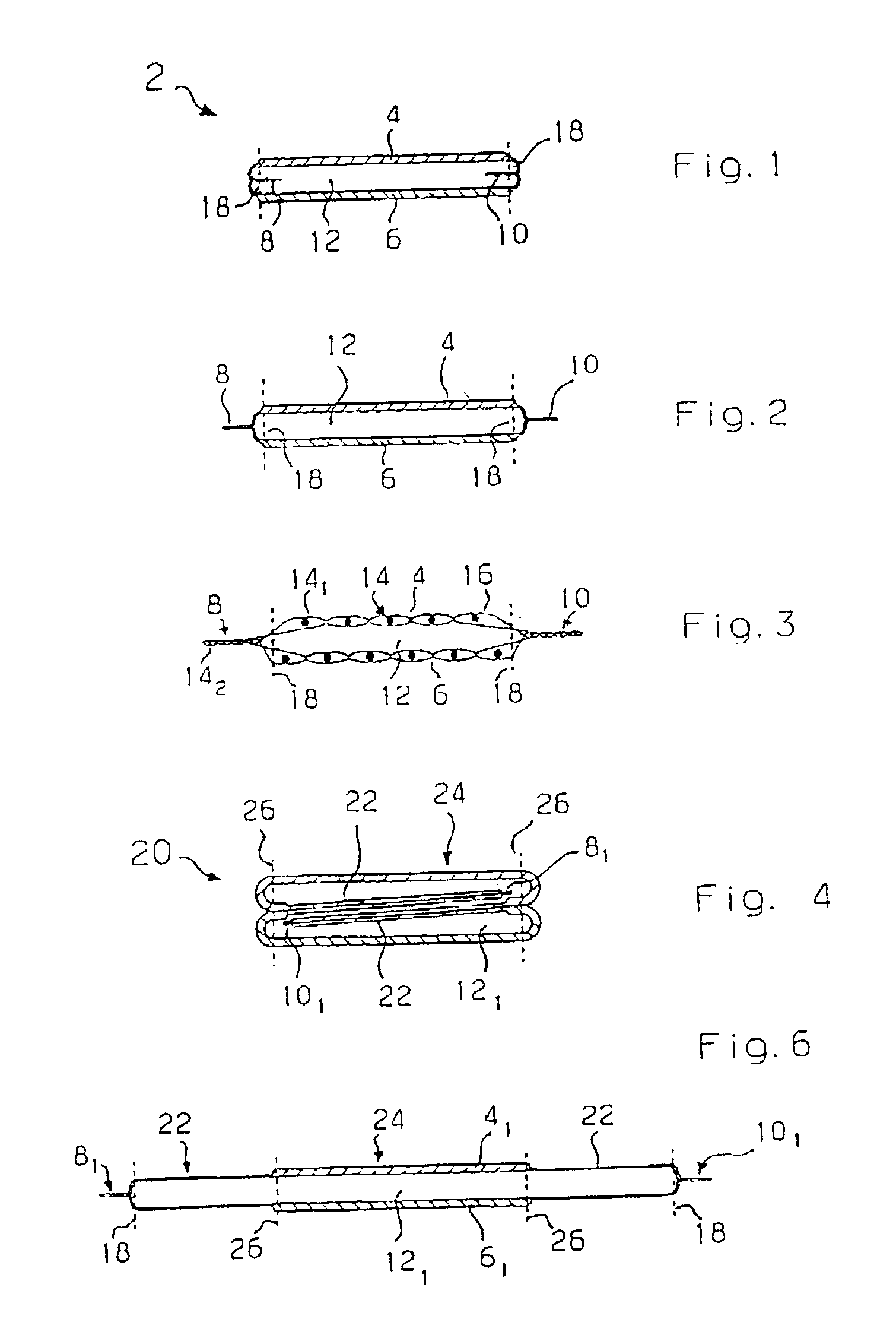

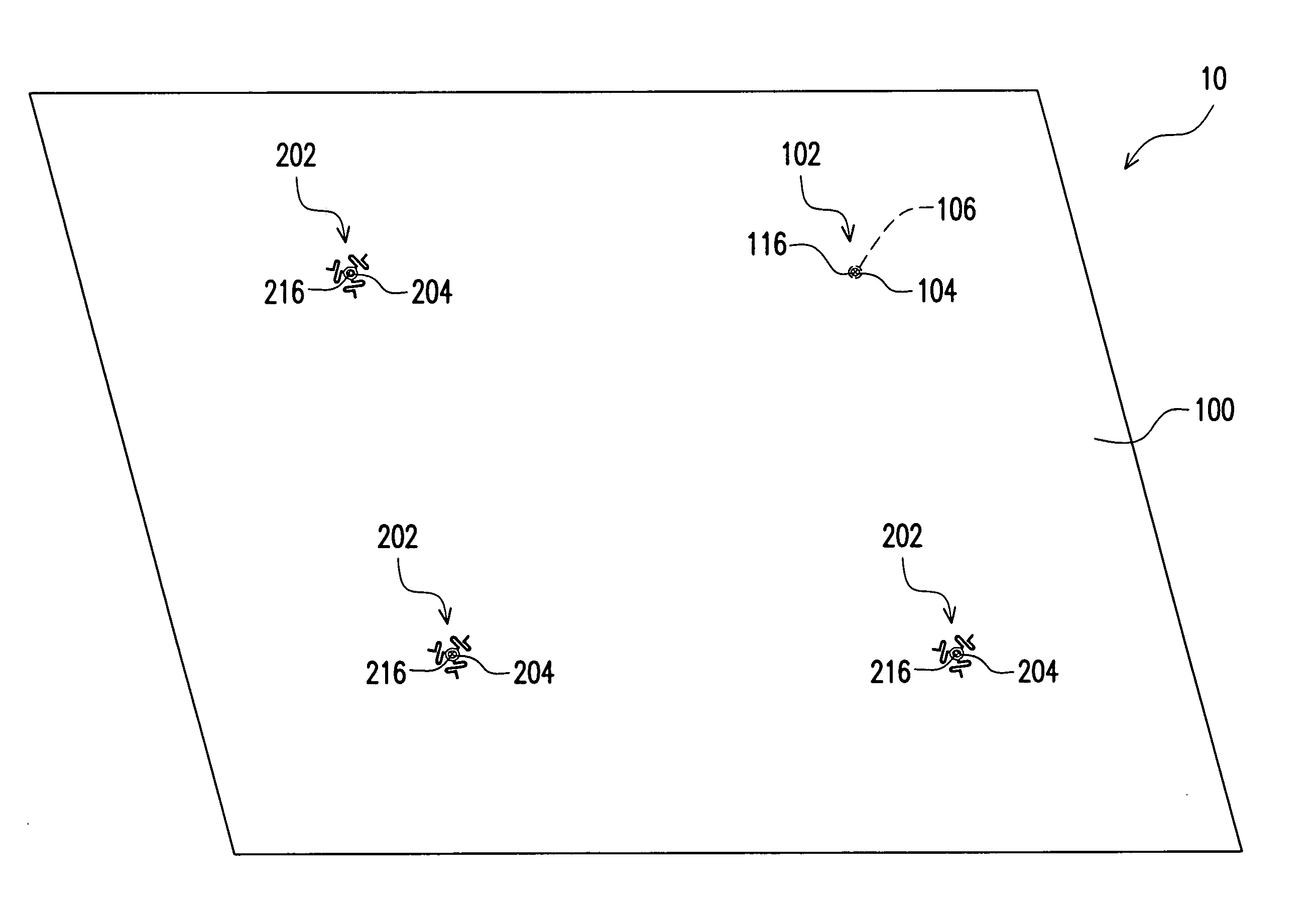

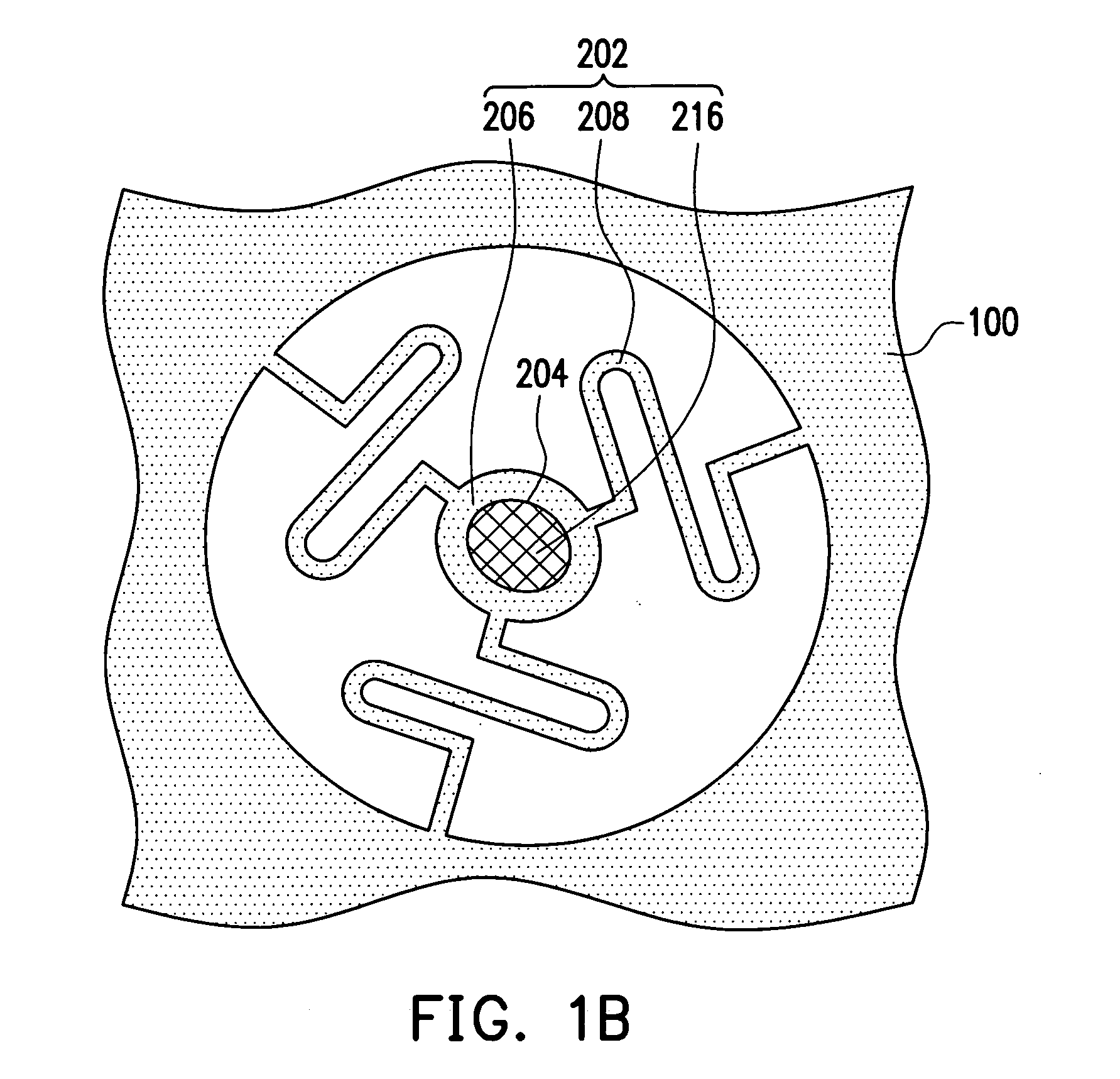

Clamping device for flexible substrate

InactiveUS7591066B2Clamp evenlyIncrease temperatureWorkpiece holdersWave amplification devicesPositioning systemBiomedical engineering

Owner:IND TECH RES INST

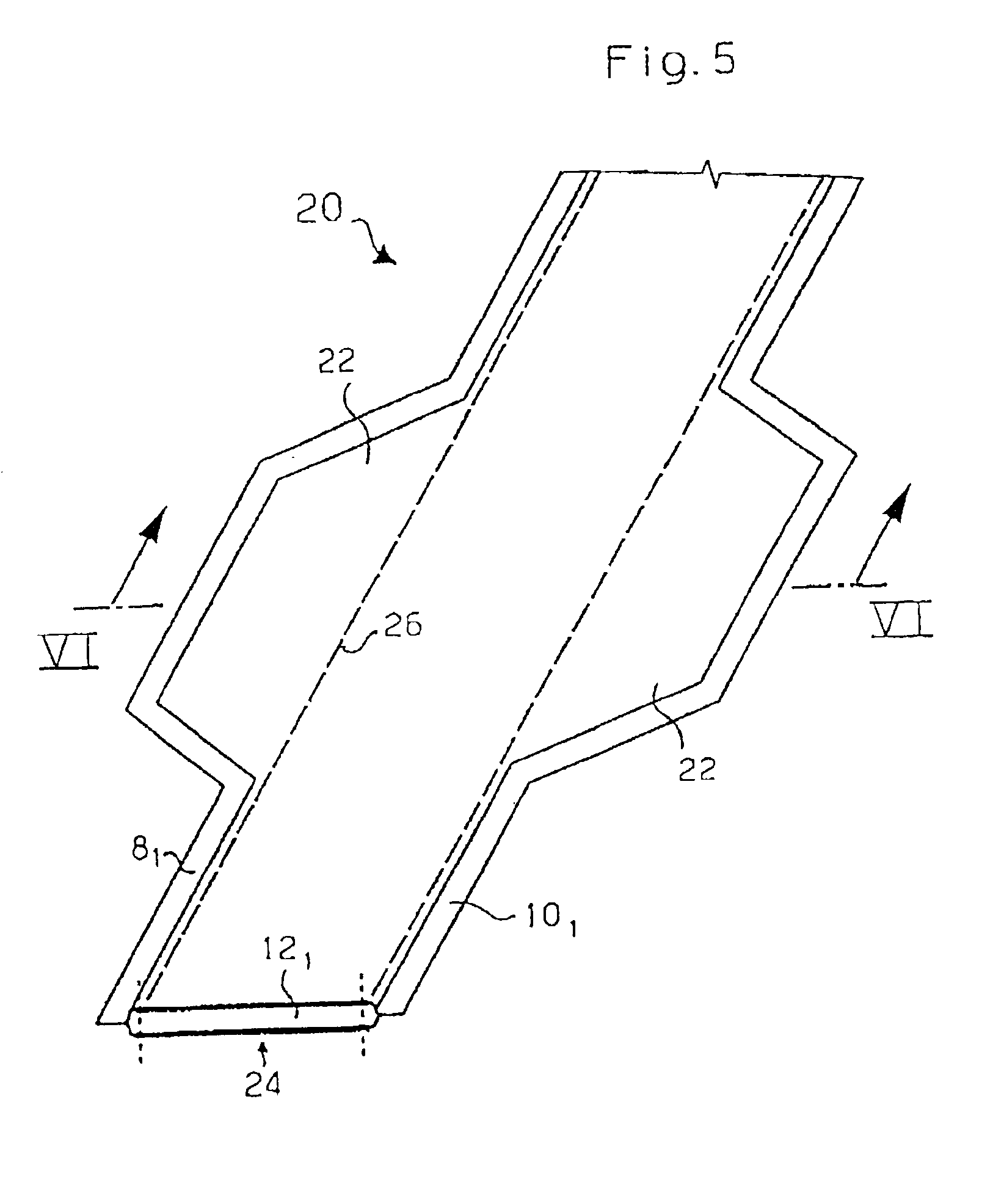

Device for producing a tubular belt band that can be turned inside out

InactiveUS6883555B1Easily and efficiently producedEasy to produceLoomsAuxillary apparatusEngineeringInsertion device

A device for producing at least two tubular belt bands that are turned inside out, where each of the belt bands has two fabric layers on top of one another and connected to each other in a longitudinal direction by woven hems to form a cavity. Warp threads of the layers have a uniform warp thread density over an entire length of the belt bands. The device includes a power loom having a shedding mechanism with a reed with parallel dents, a weft insertion device extending over an entire width of the power loom, a control unit for controlling the shedding mechanism, and an expander extending over the entire width of the power loom. The expander has a smaller diameter in a tubular area than in a hem area in correspondence with the belt bands to be produced so that clamping pressure of the expander is substantially constant over an entire width of the woven fabric. A thermal cutting device has cutting heads that are operative to cut out the belt bands in the hem area from the woven fabric web.

Owner:TEXTILMA AG

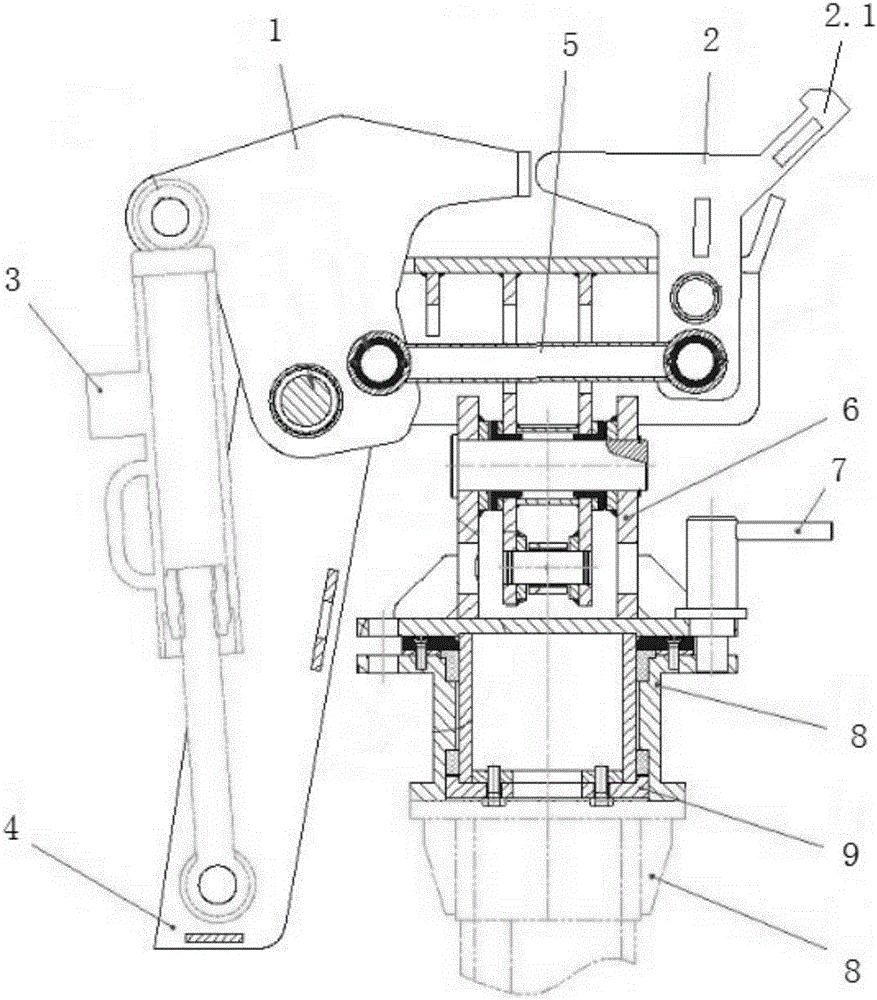

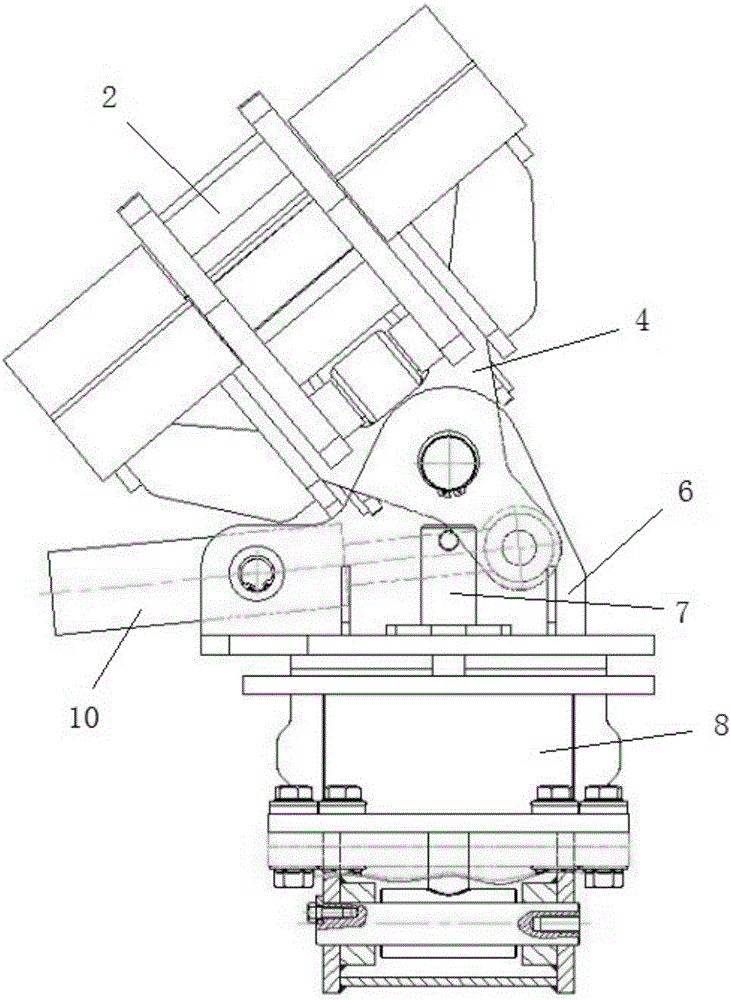

Adjustable corner arch support clamping mechanism

ActiveCN106703844AThe overall structure is simpleEasy to installUnderground chambersTunnel liningEngineeringFree rotation

The invention provides an adjustable corner arch support clamping mechanism. The mechanism comprises a driving clamping head, a driven clamping head, a clamping oil cylinder, a fixing base, a corner fixing seat, a sleeve component and a corner oil cylinder. The driving clamping head and the driven clamping head are both movably arranged on the fixing base, and a connecting rod is arranged between the driving clamping head and the driven clamping head. Two ends of the clamping oil cylinder are connected with the driving clamping head and the fixing base respectively. The fixing base and the corner fixing seat as well as the corner fixing seat and the sleeve component are in movable connection. The sleeve component is provided with an adjusting and positioning part, and two ends of the corner oil cylinder are connected with the fixing base and the corner fixing seat respectively. By application of the technical scheme, the adjustable corner arch support clamping mechanism is integrally simple in structure; by cooperation of the driving clamping head, the driven clamping head, the connecting rod and the clamping oil cylinder, clamping and releasing of an arch support can be realized, openness of the clamping heads can be maximized, and high applicability is achieved; due to connection among the fixing base, the corner fixing seat and the sleeve component, free rotation is realized, and construction requirements under various operating conditions can be met.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

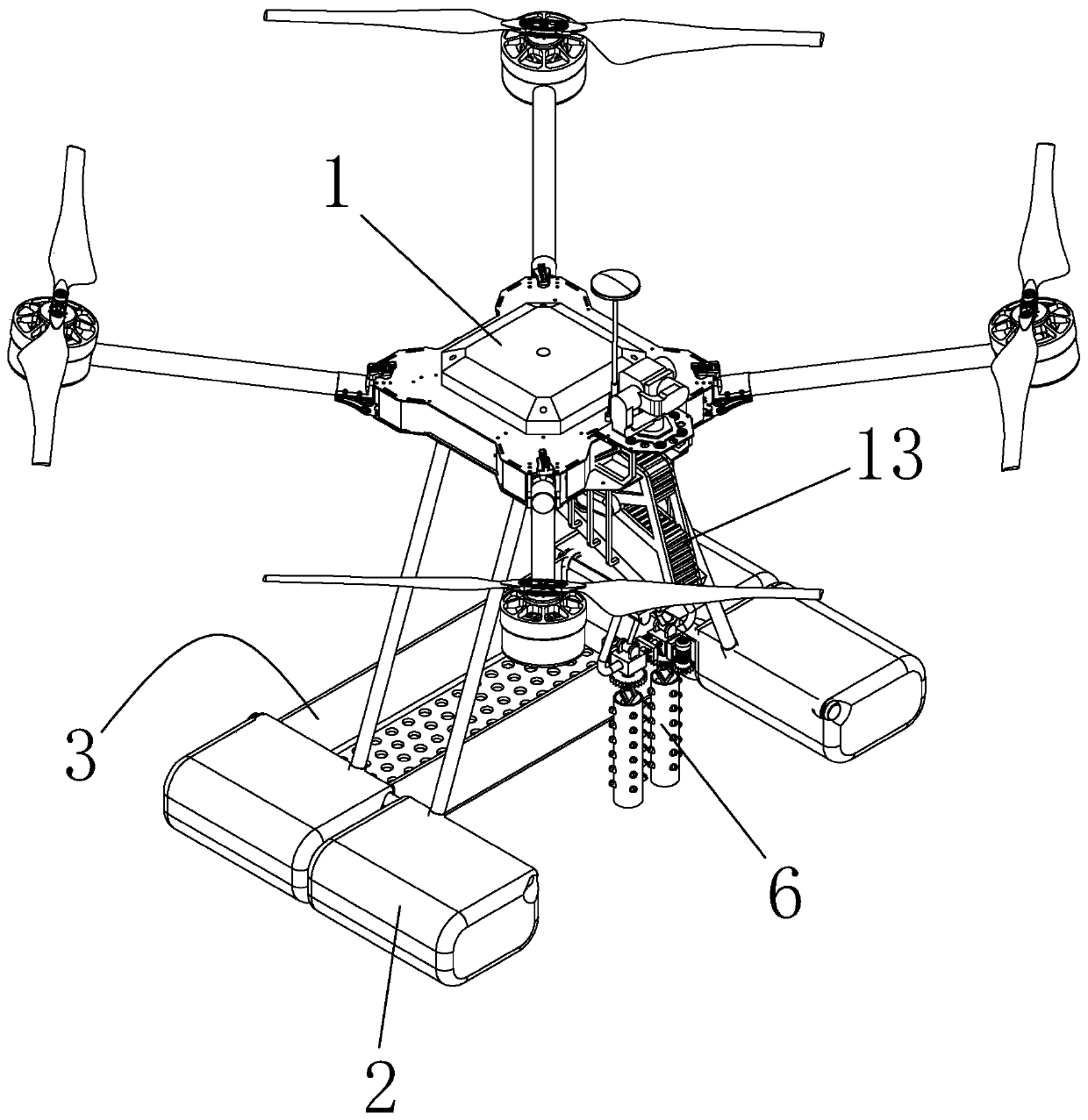

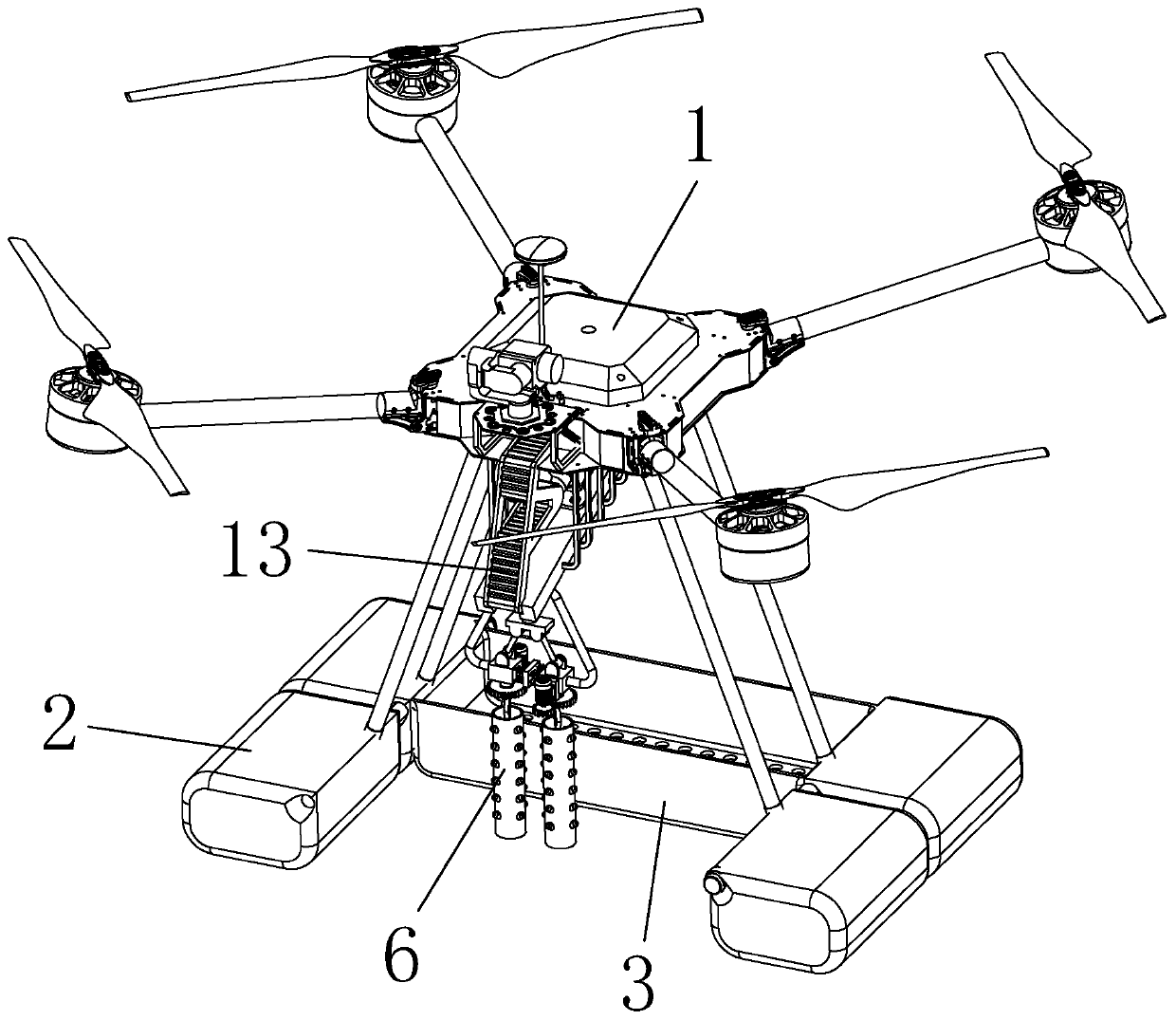

Intelligent unmanned equipment for cleaning dirt on water surface

Intelligent unmanned equipment for cleaning dirt on a water surface comprises a machine body and a collecting box, the collecting box is located on the rear side of the lower portion of the machine body, a conveying mechanism is arranged at the bottom end of the machine body, the conveying mechanism is obliquely distributed downwards towards the front portion of the machine body, and a grabbing assembly used for grabbing floating objects on the water surface is arranged on the bottom face of the conveying mechanism. The grabbing assembly comprises a power mechanism, two driving mechanisms andtwo winding mechanisms, the power mechanism is arranged on the bottom face of the conveying mechanism in a sliding mode, the driving mechanisms and the winding mechanisms are arranged on the power mechanism, the power mechanism can drive the two winding mechanisms to move relatively, and the driving mechanisms can drive the winding mechanisms to rotate around the axes of the driving mechanisms. Apre-clamping force is provided, and it is ensured that a garbage bag can be smoothly clamped; the winding and clamping force is provided, and the garbage bag is prevented from falling off in the fishing process; garbage bags can be stably fished out; the risk of workers is reduced, and the water surface dirt cleaning efficiency is improved.

Owner:韩慧

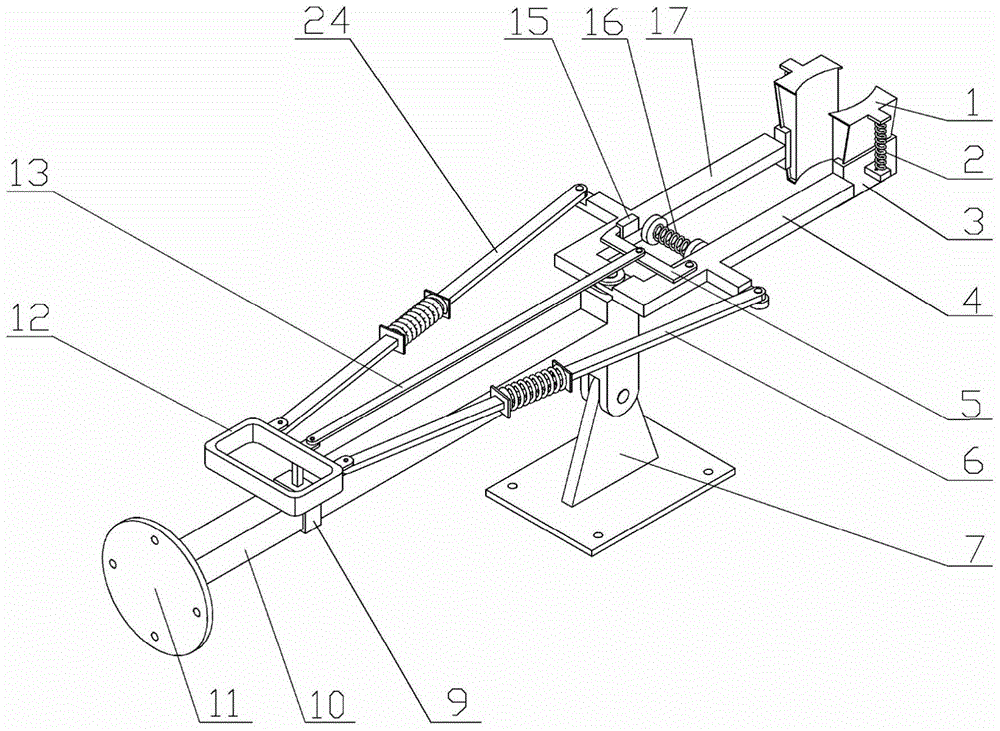

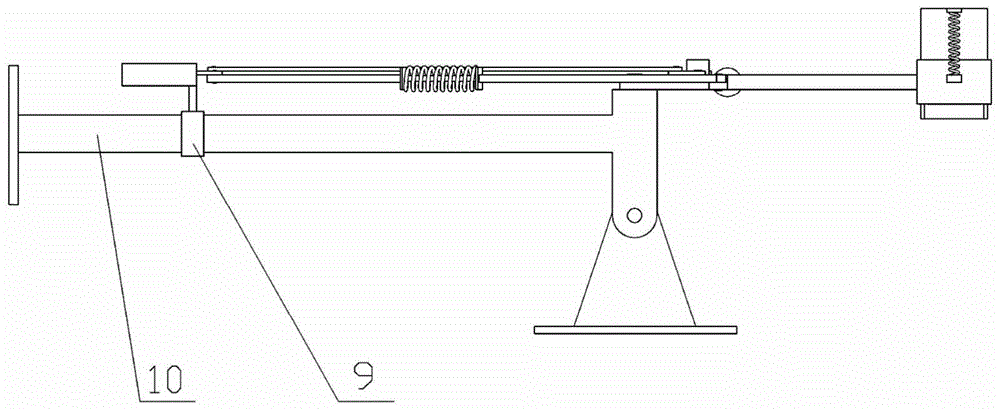

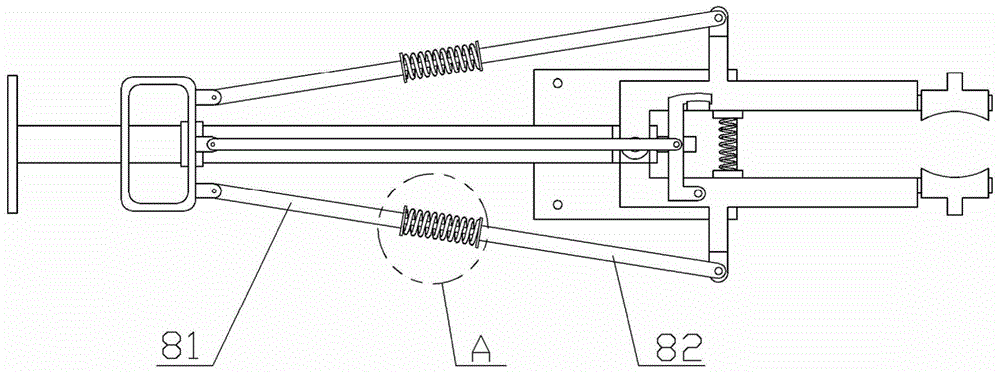

Inertia ejection device for pressing machine and inertia ejection method for workpiece on pressing machine

InactiveCN102615855AChange positionClamp evenlyForging/hammering/pressing machinesPressesMachine pressInertia

The invention relates to an inertia ejection device for a pressing machine. The inertia ejection device for the pressing machine comprises an ejector pin (7) and an ejector pin driving mechanism for driving the ejector pin (7) to move back and forth vertically and linearly; a balance weight (8) is arranged on the ejector pin (7); and the mass of the balance weight (8) is not less than 10 times of that of the ejector pin (7). According to the inertia ejection device for the pressing machine, through the arrangement of the balance weight (8) on the ejector pin (7), when being ejected, a workpiece is controlled to bound in a cavity, so that automatic and smooth workpiece conveying can be is ensured.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

Boot band

Owner:NHK SPRING CO LTD

Core unloading device of sand core assembly

ActiveCN107127303AReduce generationEasy pre-assemblyFoundry mouldsFoundry coresStructural engineeringHot working

The invention relates to a core unloading device of sand core assembly; and the core unloading device is used for assembling and clamping a combined sand core to achieve subsequent lifting by using a trolley. The core unloading device comprises a sand core moving unit positioned at the upper end; the sand core moving unit comprises a sanding core moving bracket; a clamping mechanism for clamping the sand core is mounted on the sand core moving bracket; a sand core fixing unit is positioned at the lower end, and comprises a sand core fixing bracket; a core assembly worktable is mounted on the sand core fixing bracket; and a sand core bracket is movably supported on the core assembly worktable. The core unloading device has the following advantages: firstly, the sand core is preassembled on the core assembly worktable; then, the assembled sand core is clamped by using the clamping mechanism; finally, the trolley is used for shifting the sand core moving bracket and the clamped sand core to a machining place; and by dint of mechanical clamping and movement, such bad conditions as unstable core unloading and sand scratch caused by hot working sand unloading can be effectively prevented, and casting wastes are reduced.

Owner:江苏力源金河铸造有限公司

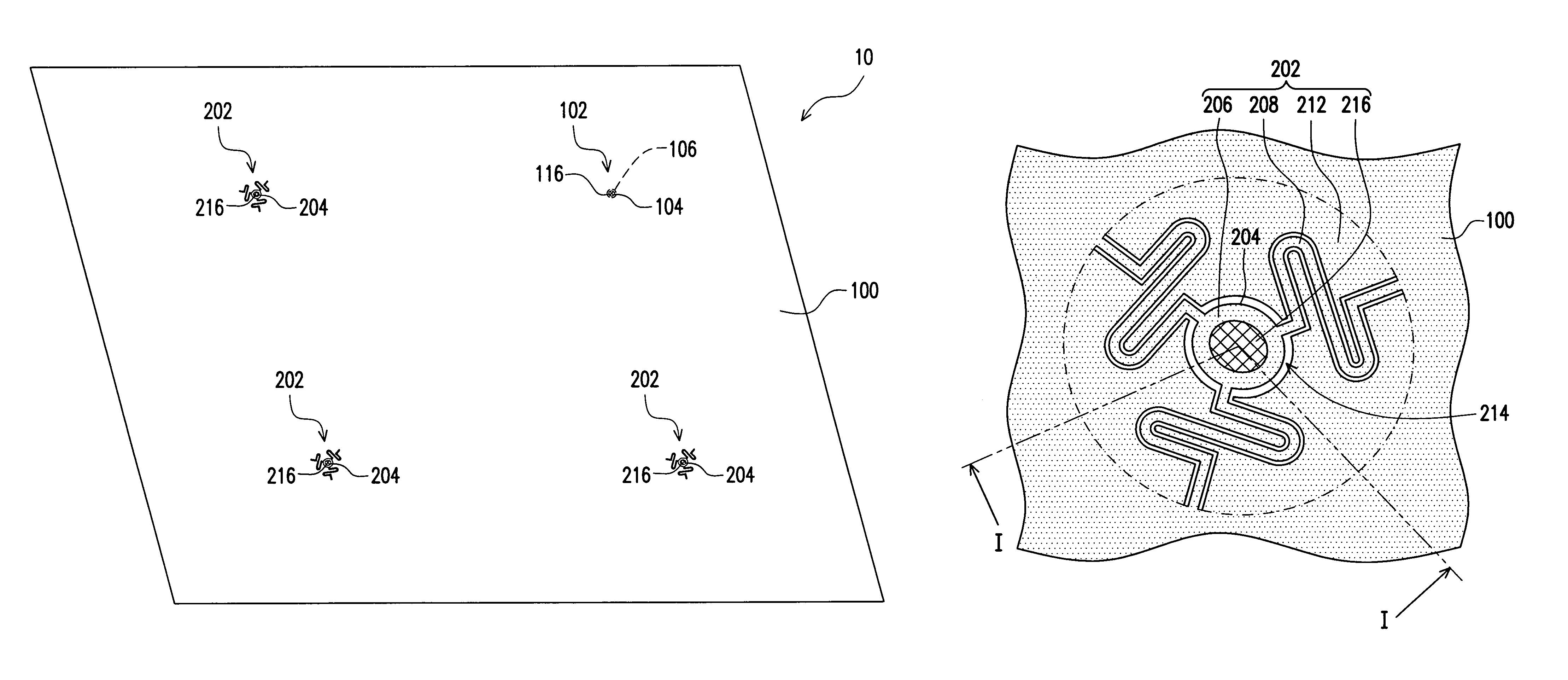

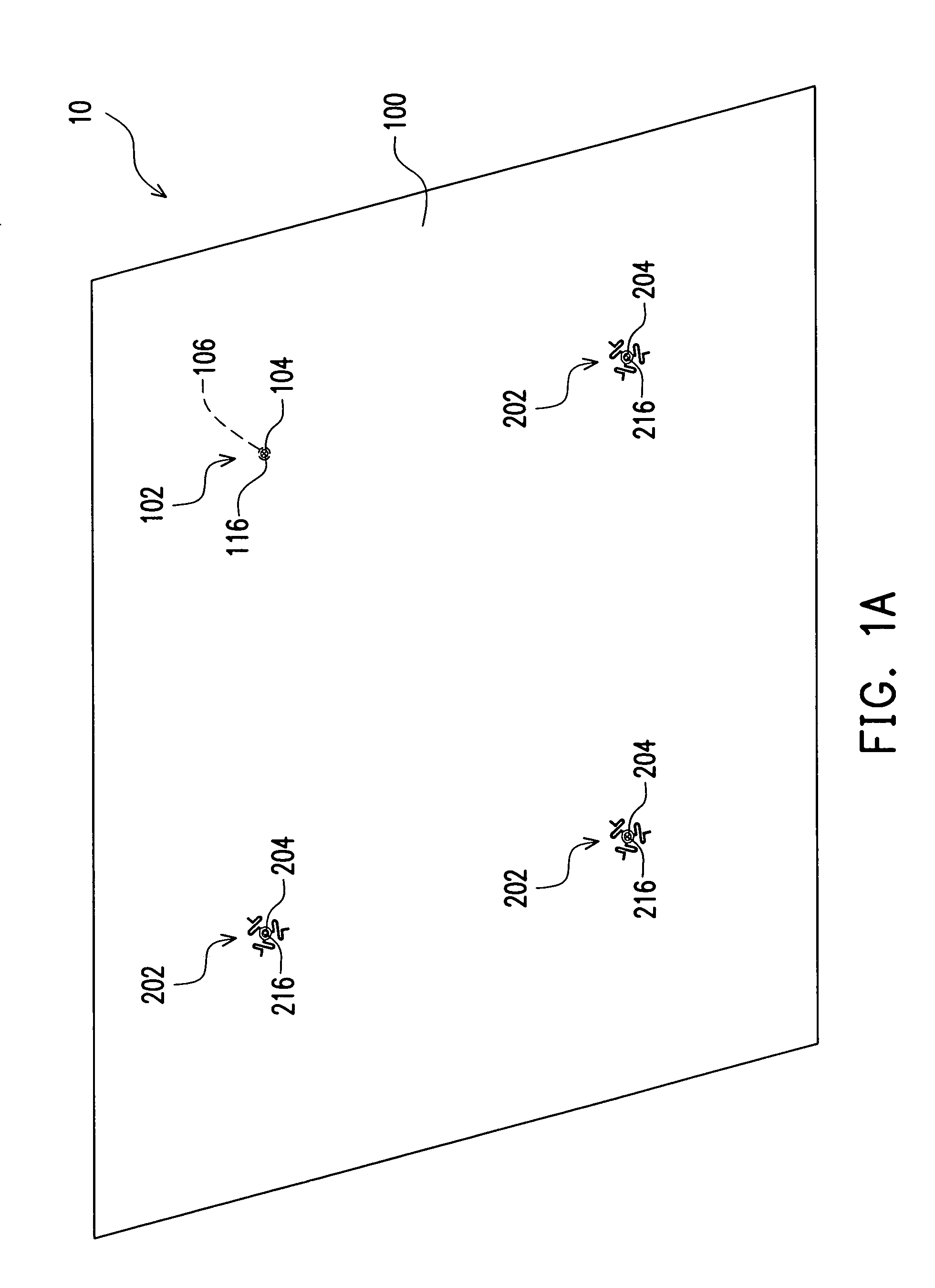

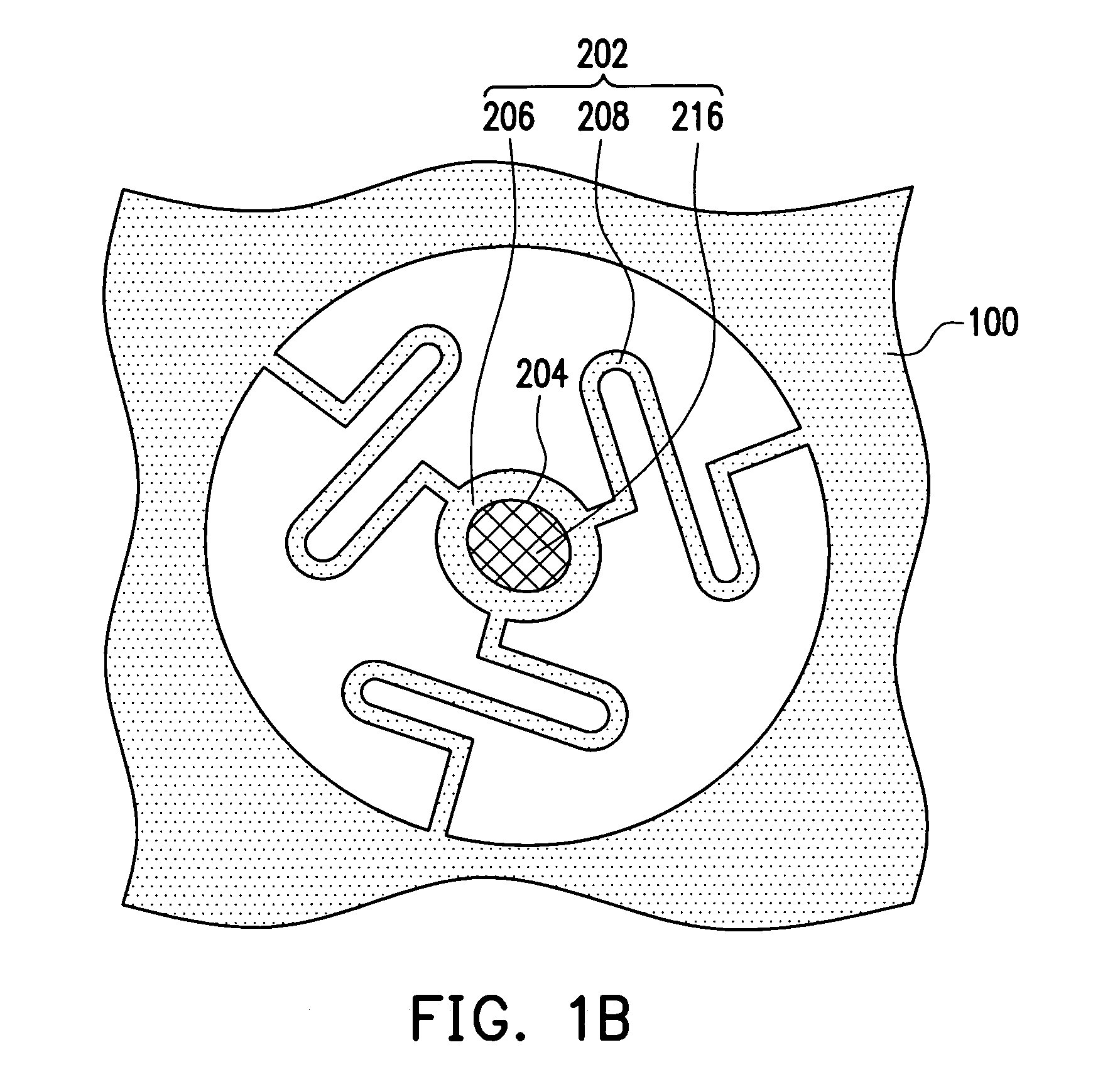

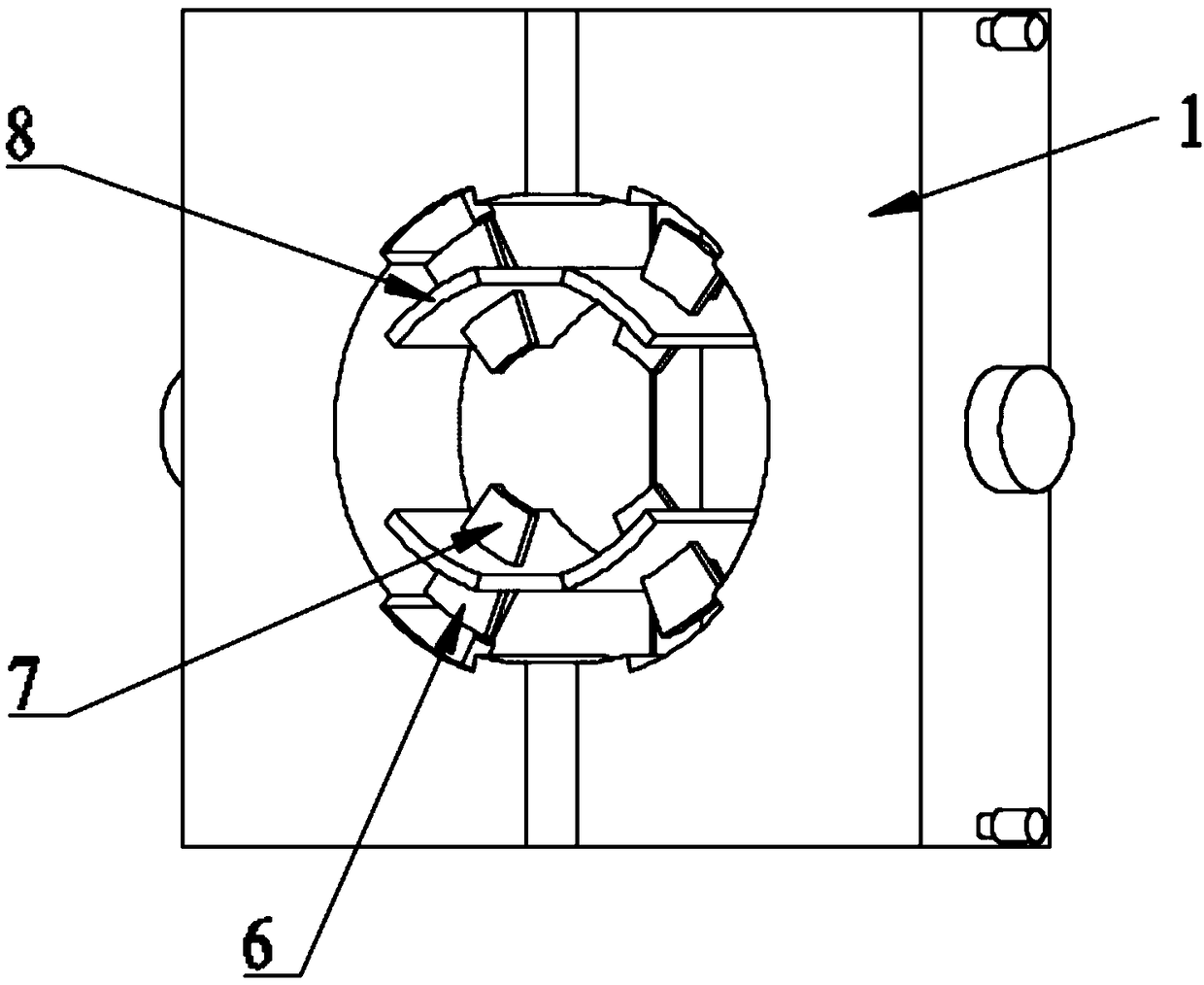

Clamping device for flexible substrate and method for fabricating the same

InactiveUS20070119044A1Clamp evenlyIncrease temperatureWorkpiece holdersWave amplification devicesEngineeringPositioning system

A clamping device for a flexible substrate is provided. The clamping device includes a carrier board. The carrier board has a fixed positioning assembly and a plurality of movable positioning assemblies. The fixed positioning assembly and the movable positioning assemblies are disposed in locations that almost correspond to a plurality of through holes on the flexible substrate. The fixed positioning assembly includes a hole body with a positioning hole and a dowel pin. Each movable positioning assembly includes a hole body with a positioning hole, a plurality of curved extending arms and a dowel pin. Each curved extending arm is connected to the hole body and the carrier board and the dowel pin is inserted into the positioning hole.

Owner:IND TECH RES INST

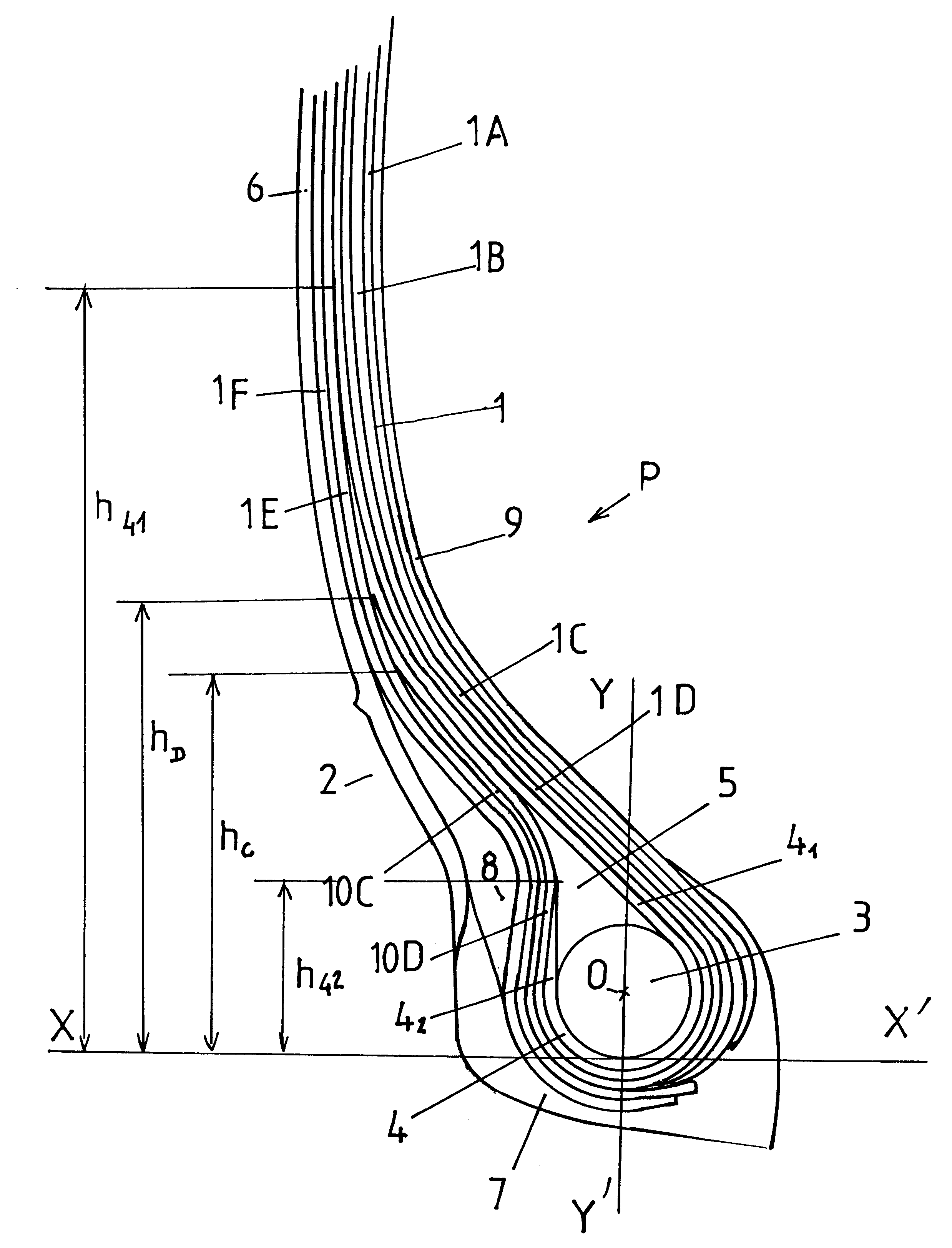

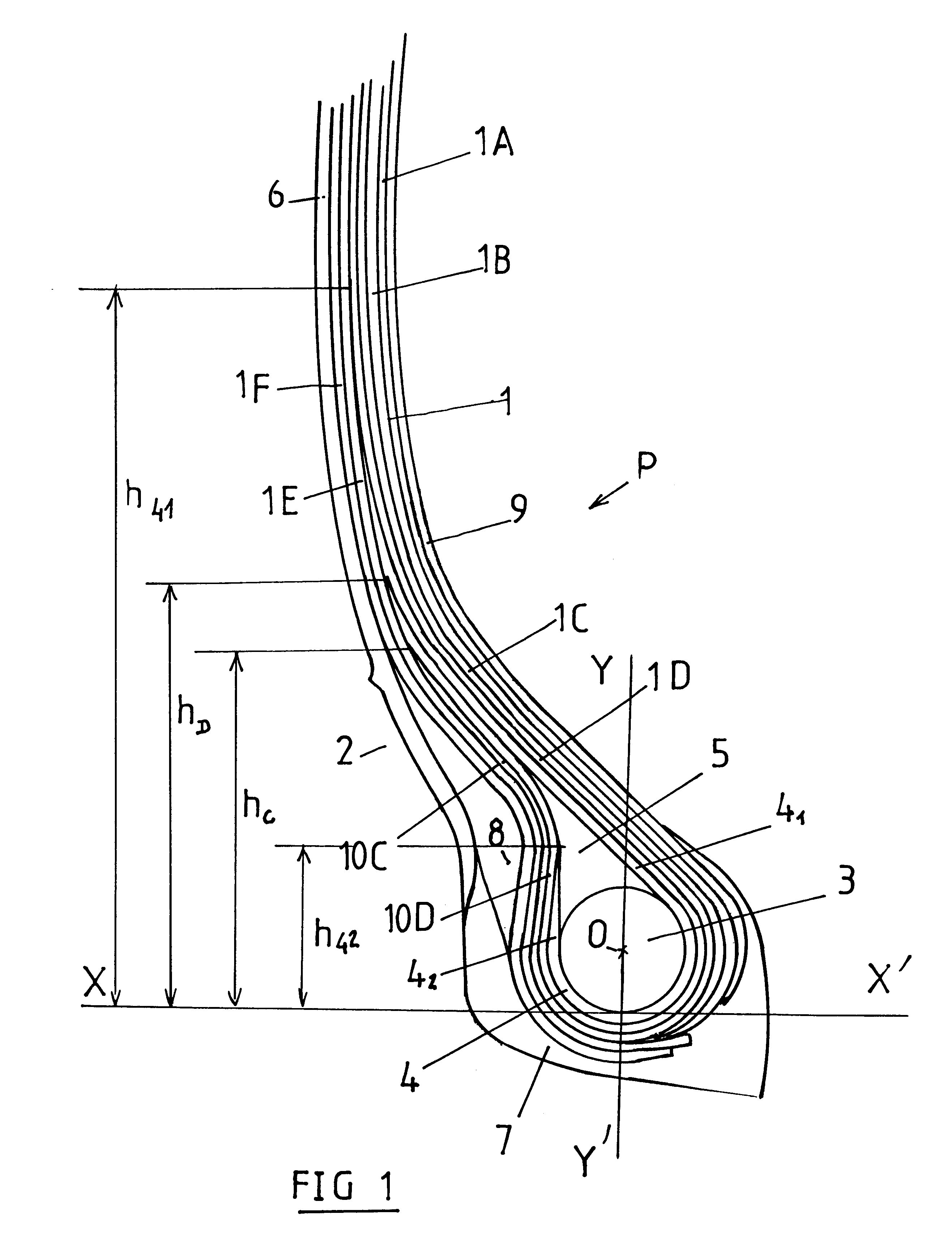

Carcass reinforcement for aircraft tires

InactiveUS6595257B2Reduce the overall diameterPrecise positioningPneumatic tyre reinforcementsTyre beadsEngineeringGravity center

An aircraft tire, inflated to a high pressure, comprising a tread connected to two beads 2 by way of two sidewalls 6, each bead having at least one annular reinforcing element 3, a crown reinforcement and a radial carcass reinforcement 1 comprising a number of axially inner plies 1A to 1D greater than or equal to two, which radial carcass reinforcement plies have textile reinforcing elements. Among the axially inner plies 1A to 1D, at least half the total number of axially inner plies 1C, 1D are turned up in each bead about at least one annular reinforcing element 3, at least one and at most three of the remaining axially inner plies 1A, 1B being not turned up in any of the beads and having ends situated radially below a straight line XX' parallel to the axis of rotation of the tire and passing through the radially innermost point of the cross-section of the annular reinforcing element 3 and axially inside a straight line YY', perpendicular to the axis of rotation and passing through the center of gravity O of the cross section of the annular reinforcing element 3.

Owner:MICHELIN RECH & TECH SA

Sorgo rod skin and core separating device

ActiveCN110126040AClamp evenlyUniform depthTree debarkingPlant material mechanical workingEngineeringMechanical engineering

The invention provides a sorgo rod skin and core separating device. The device comprises a feeding groove, a frame plate, a discharging groove, a rotating ring, a fixed ring, a first clamping plate, atension spring, a second clamping plate, a placing groove, screws, a screw motor, a pushing plate, a support, an electric telescopic rod, a first sliding block, a second sliding block, a connecting shaft, a positioning shaft, a limiting groove, a clamping face, a first ejecting block, cutting knives and a second ejecting block. The frame plate is located between the feeding groove and the discharging groove, the placing groove is integrally arranged over the feeding groove, the screws are fixedly connected to the left side and the right side above the feeding groove, the cutting knives and the clamping face are in inwards-concave arc shapes, at the normal state, the cutting knives are longer than the clamping face by 0.3 cm, when the second sliding block makes complete contact with the second ejecting block, a ring is formed between the cutting knives, when the ring-shaped cutting knives carry out peeling on the sorgo rod, the angle is more complete, and the peeling quality is higher.

Owner:泰安市乐农园艺科技工程有限公司

Clamping device for thin-wall parts

InactiveCN102886752AImprove the positioning accuracy of the center of the circleClamp evenlyWork holdersFLANGE CAPClip device

The invention relates to a clamping device for solving the clamping of thin-wall parts, and provides a clamping device for thin-wall parts. The clamping device for thin-wall-parts structurally comprises a blind flange, sealing rings, a pressing ring, a space ring and chuck sleeve, wherein the blind flange is fixedly connected with the chuck sleeve; the pressing ring, one sealing ring, the space ring and the other sealing ring are arranged in a hole of the chuck sleeve in sequence from the inside out; and the pressing ring is located at one end of the blind flange. By utilizing the flexible deformation of the sealing rings, the outer circles of the thin-wall parts are clamped. Compared with the prior art, the clamping device for thin-wall parts has the advantages and beneficial effects of improving the circle center positioning precision of the thin-wall parts, evenly clamping the thin-wall parts and ensuring that the outer circles of the thin-wall parts are free of clamping mark and deformation. The clamping device is capable of solving the clamping of the outer circles of the thin-wall parts with the wall thickness of 1mm.

Owner:SHANGHAI XINYUE METER FACTORY

Work fixture for cylindrical optical element

The invention discloses a work fixture for a cylindrical optical element. A clamping and fixing structure is formed by utilizing a fixed bottom plate structure and a clamping device; a through hole isformed in the middle of the fixed bottom plate structure; multiple clamping claws are uniformly and fixedly arranged on the inner wall of the through hole of the fixed bottom plate structure and canmove along the direction perpendicular to the inner wall of the through hole, so that a workpiece is clamped; the multiple clamping claws move inwards or outwards along one center so as to fix the optical element, so that the optical element is uniformly stressed, the stability on clamping the optical element is improved, and the clamping claws are prevented from getting loose; and through a locking mechanism, during the detection process of the optical element, the occurrence of the phenomenon that the optical element is inaccurate in centering so as to influence processing or detecting due to the poor stability of the clamping claws and the dead weight of the optical element is avoided.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com