Inertia ejection device for pressing machine and inertia ejection method for workpiece on pressing machine

A technology of ejection device and press, applied in the field of inertial ejection, which can solve the problems of bouncing out of the cavity and not falling back to the original position, automatic line, interruption, high speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

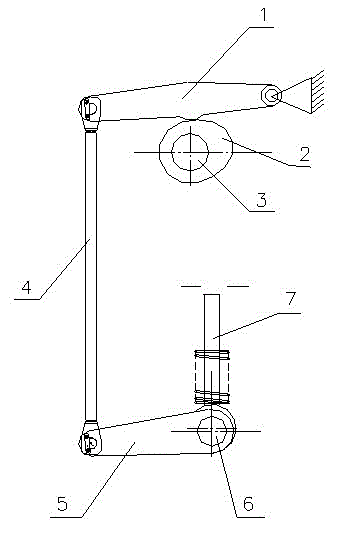

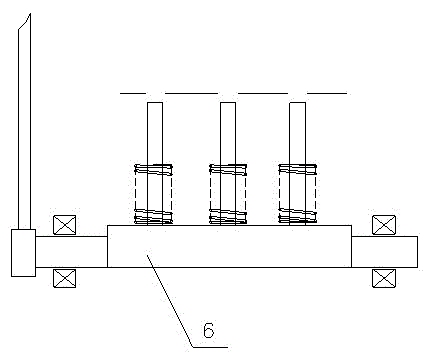

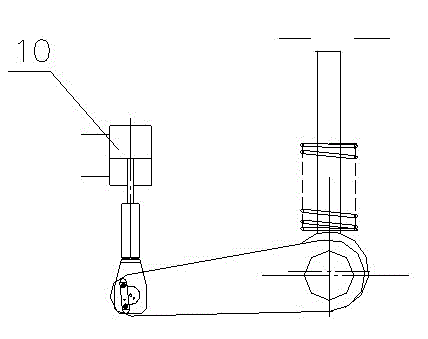

[0027] like Figure 4-5 As shown, a kind of press inertial ejection device of the present embodiment 1 includes a ejector rod 7, and an ejector rod driving mechanism that drives the ejector rod 7 to make up and down linear reciprocating motions, and the ejector rod A counterweight 8 is movable on the 7, and the mass of the counterweight 8 is more than 10 times the mass of the ejector rod 7 and the workpiece. Because the mass of the ejector rod 7 increases greatly under the increase of the counterweight 8, at the moment when the workpiece is loosened, the existence of the counterweight 8 reduces the potential energy stored by the ejector rod driving mechanism due to elastic deformation. Release speed, the smaller speed obtained by the ejector rod 7 and the workpiece is not enough to make the workpiece bounce out of the cavity, and under the condition of obtaining the same large elastic deformation energy, the bounce height of the workpiece will be no greater than before 1 / 10 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com