Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

383results about How to "Uniform welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

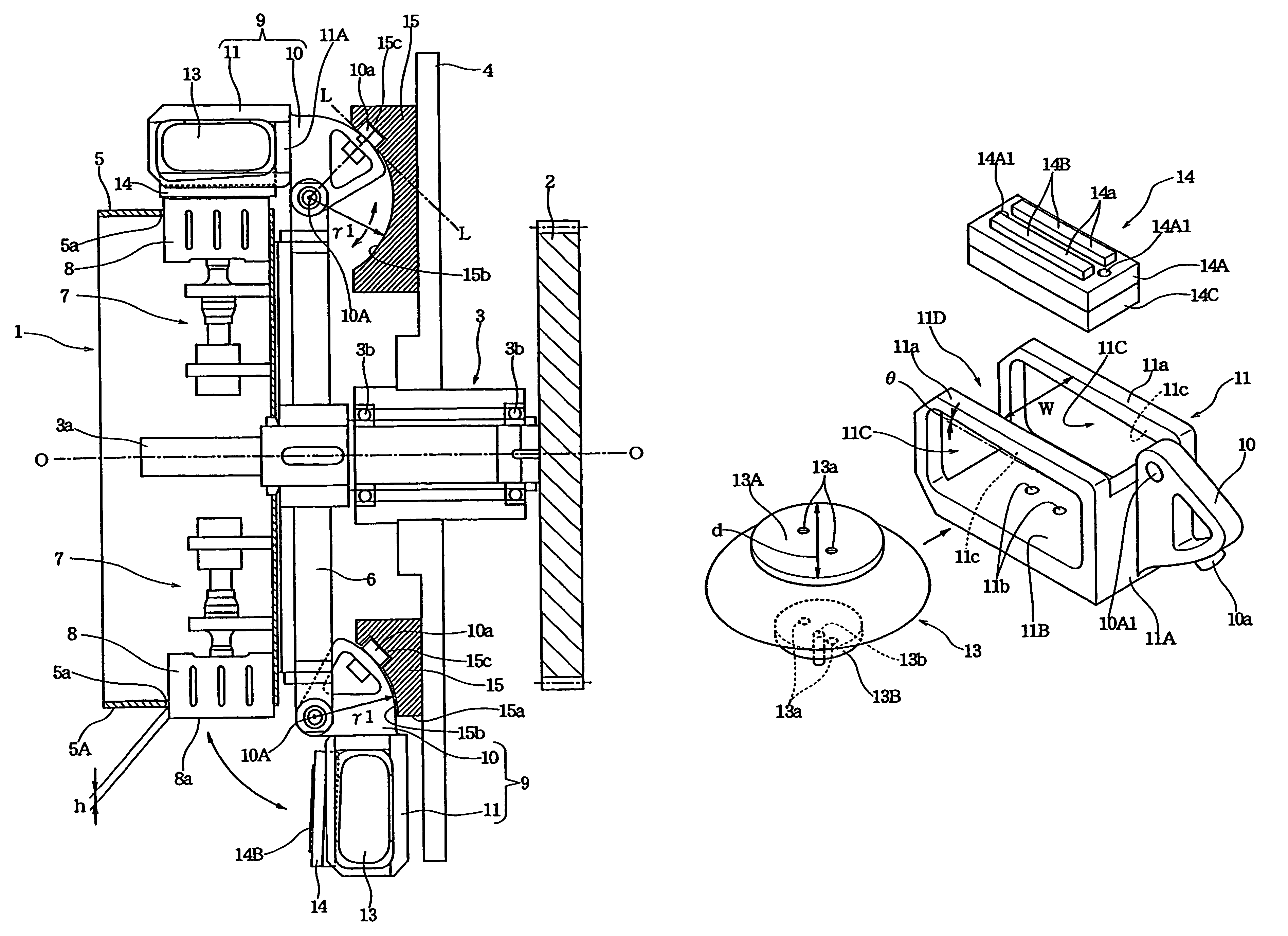

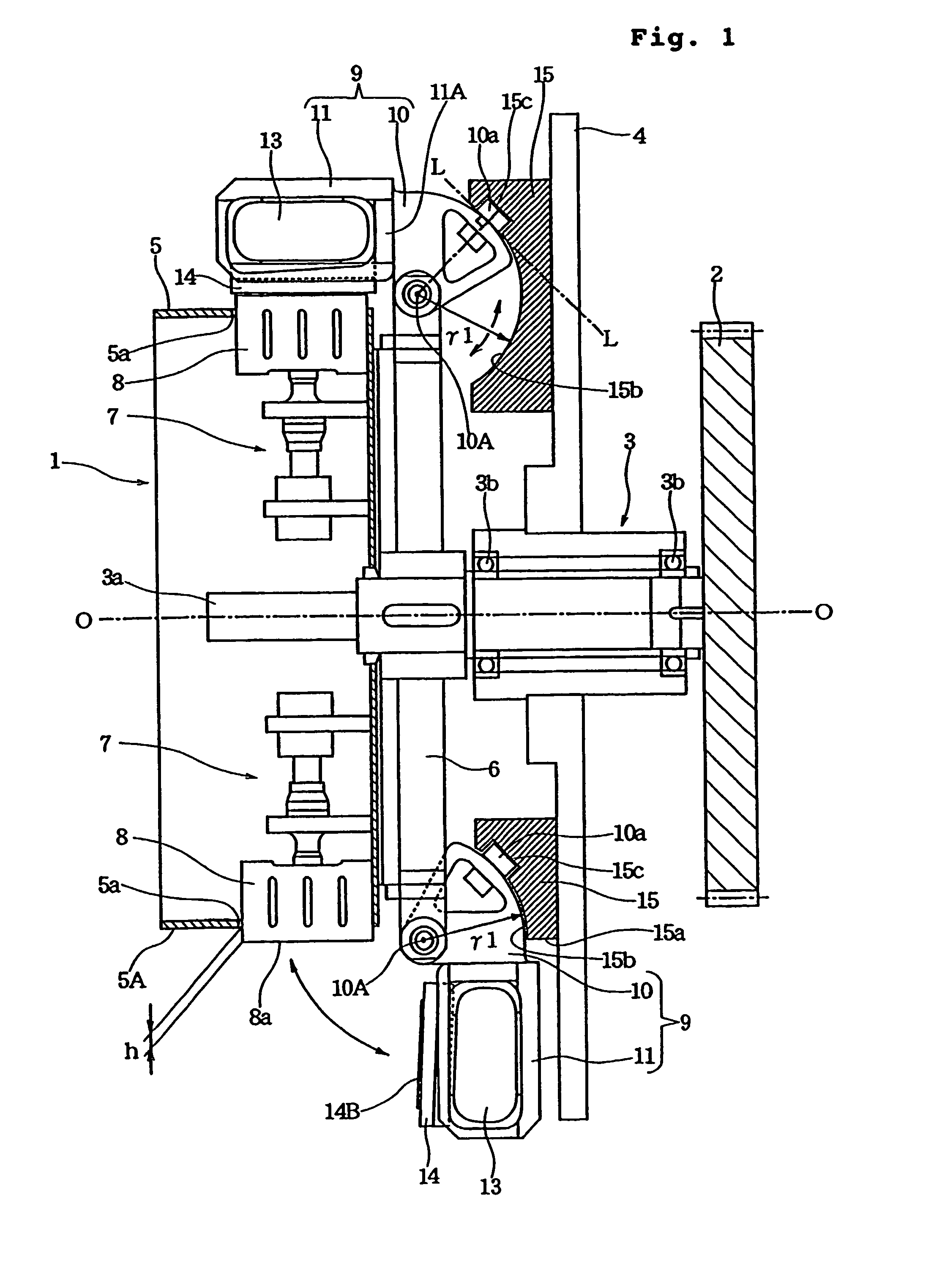

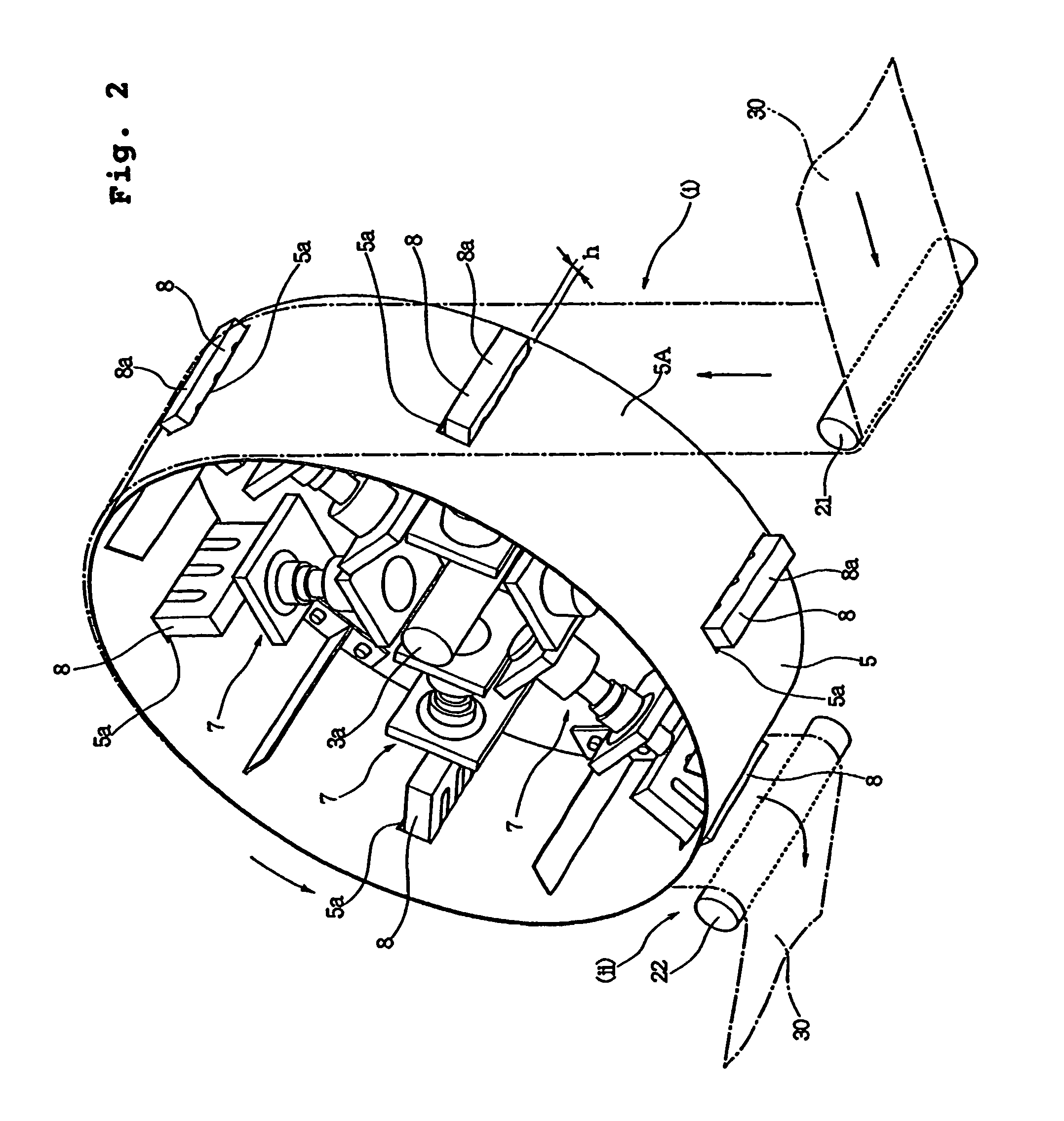

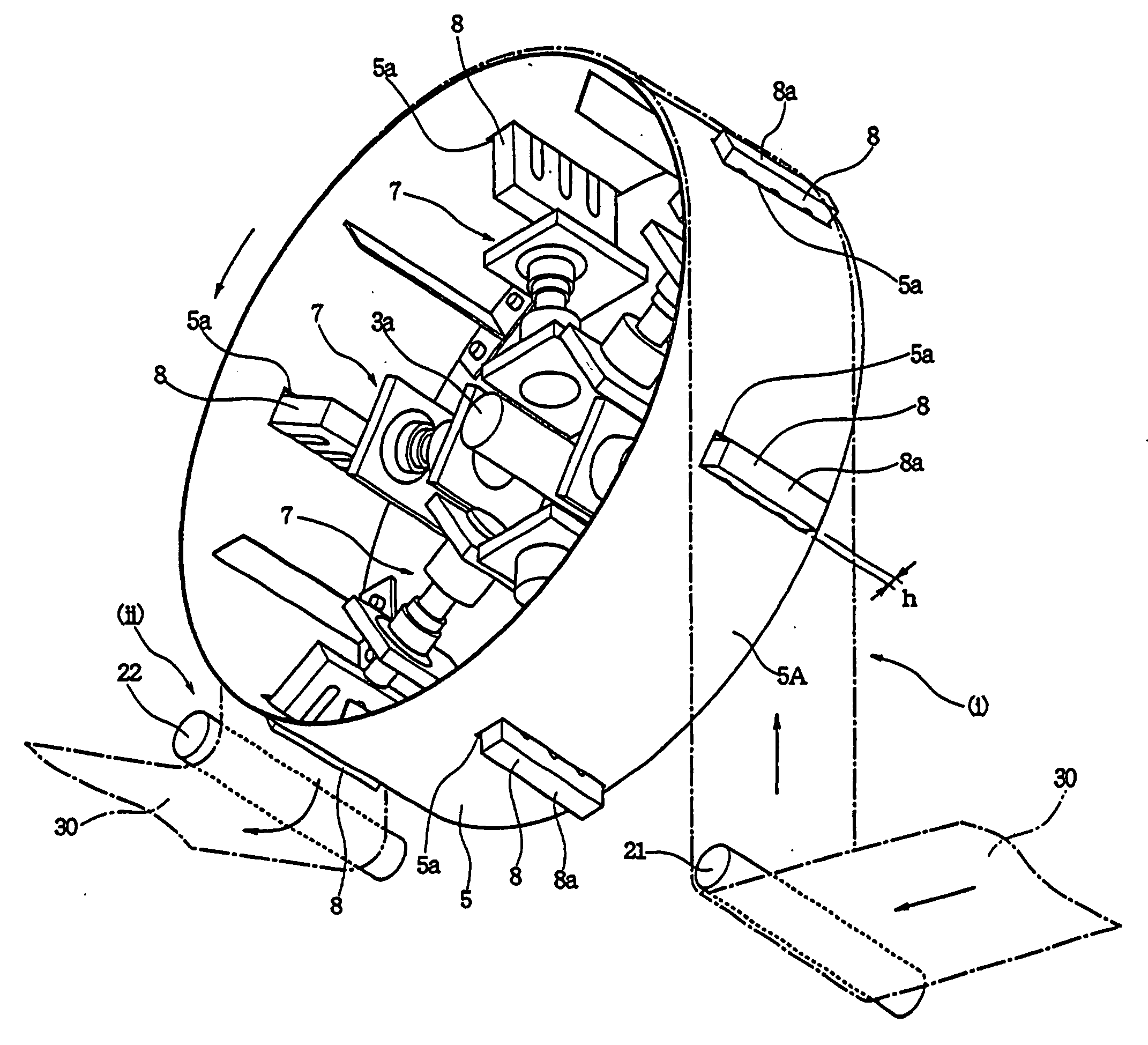

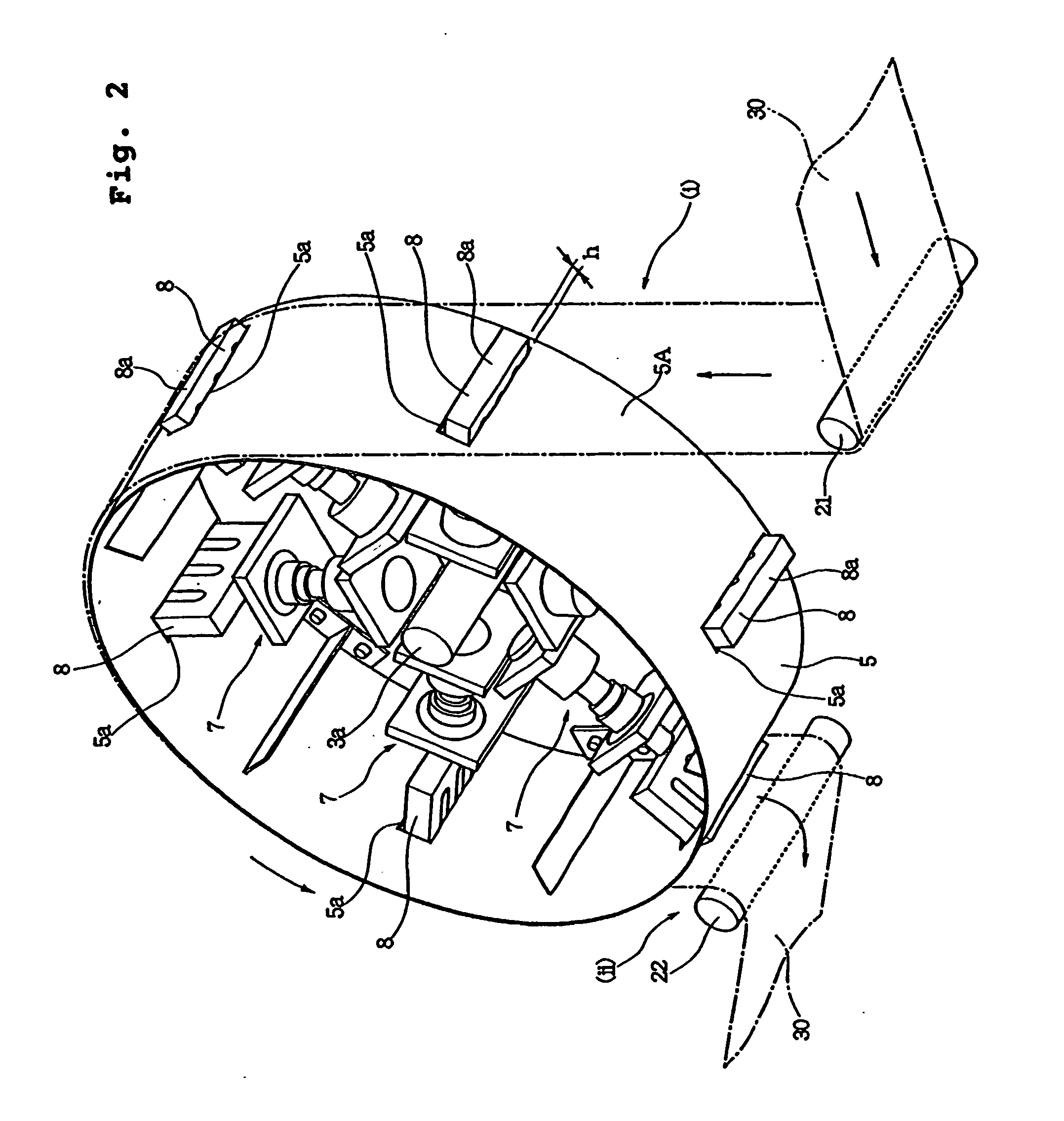

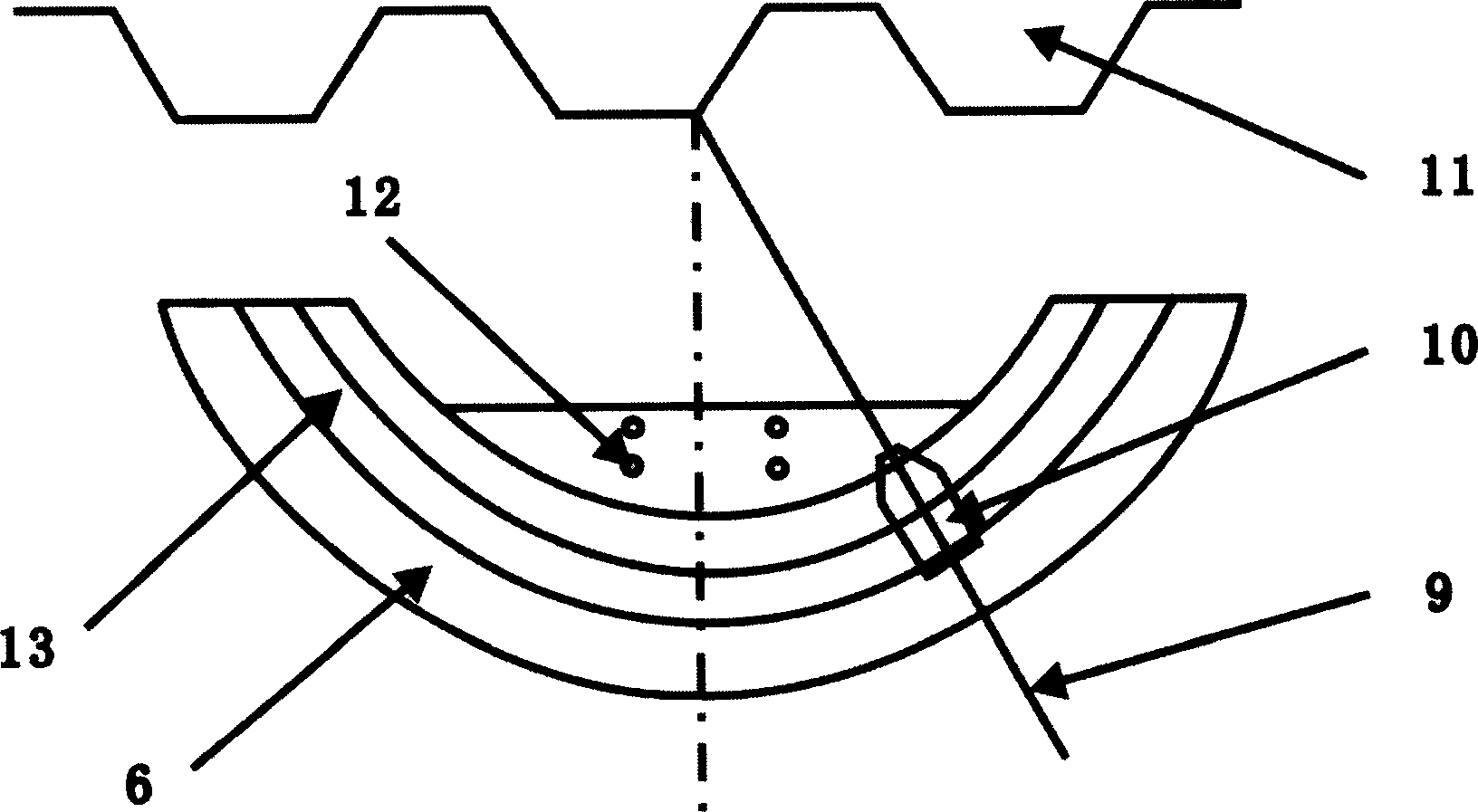

Sealing apparatus and manufacturing process of soft article having sealed portion

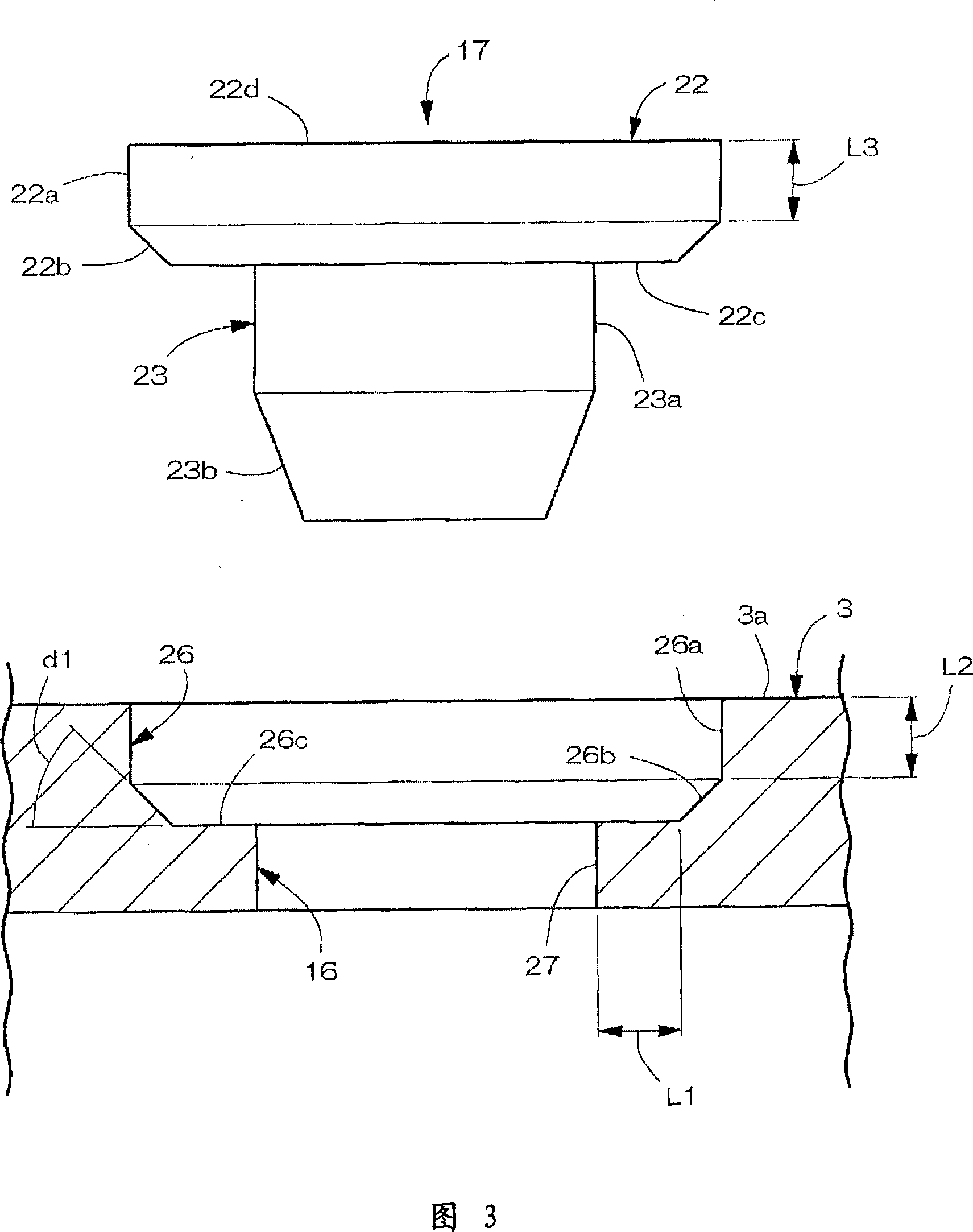

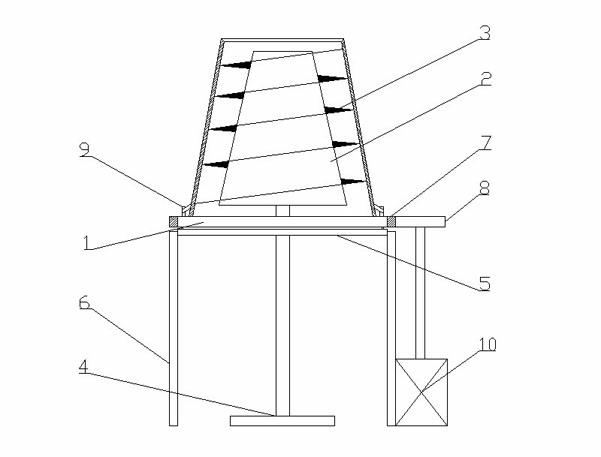

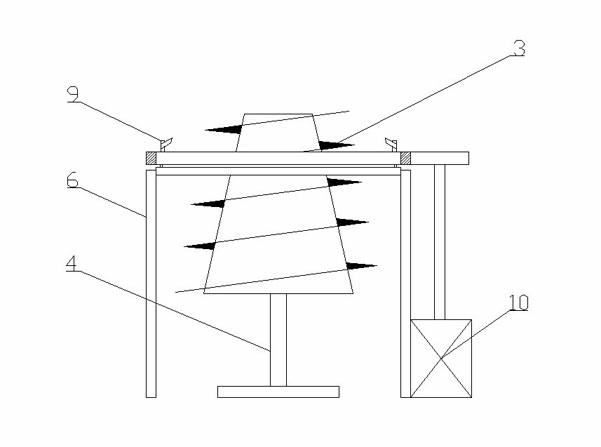

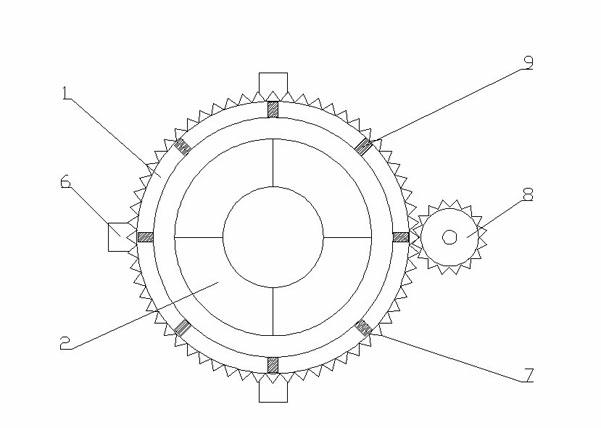

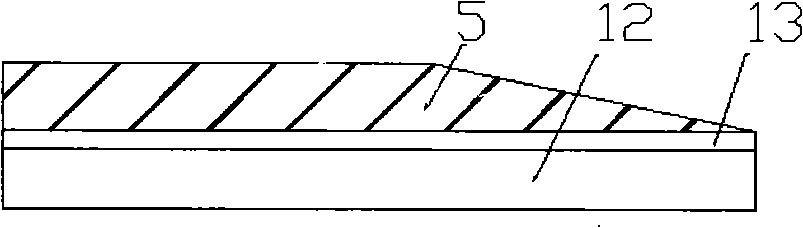

Disclosed is a sealing apparatus wherein, as a drum (5) and a rotary base (6) are rotated together, a follower (10a) of a rocking support member (9) rockably provided on the outer periphery of the rotary base (6) is guided along a cam groove (15c) of a cam member (15) to drive the rocking support member (9) to rock. When the rotary drum (5) reaches a predetermined rotational position, an anvil (14) supported by the rocking support member (9) is urged onto a horn (8), and then, when it reaches another rotational position, the anvil (14) is moved away from the horn (8). Since the anvil (14) is driven by the rocking motion of the rocking support member (9), entire operation becomes quite simple, and a continuous soft work can be certainly clamped between the horn (8) and the anvil (14).

Owner:UNI CHARM CORP

Sealing apparatus and manufacturing process of soft article having sealed portion

InactiveUS20040106506A1Difference in strengthDifference in tastePaper-makingLaminationEngineeringCam

Disclosed is a sealing apparatus wherein, as a drum (5) and a rotary base (6) are rotated together, a follower (10a) of a rocking support member (9) rockably provided on the outer periphery of the rotary base (6) is guided along a cam groove (15c) of a cam member (15) to drive the rocking support member (9) to rock. When the rotary drum (5) reaches a predetermined rotational position, an anvil (14) supported by the rocking support member (9) is urged onto a horn (8), and then, when it reaches another rotational position, the anvil (14) is moved away from the horn (8). Since the anvil (14) is driven by the rocking motion of the rocking support member (9), entire operation becomes quite simple, and a continuous soft work can be certainly clamped between the horn (8) and the anvil (14).

Owner:UNI CHARM CORP

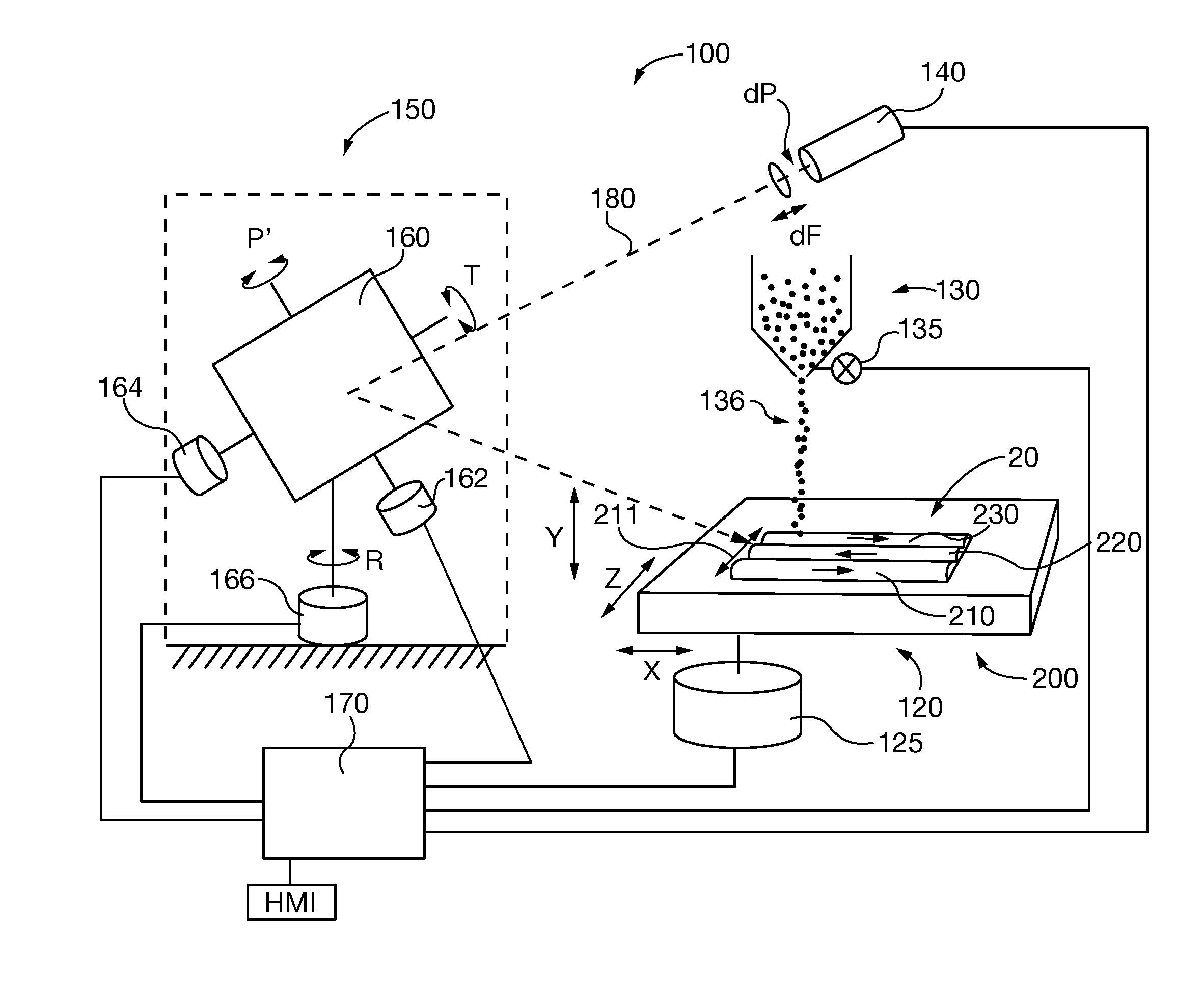

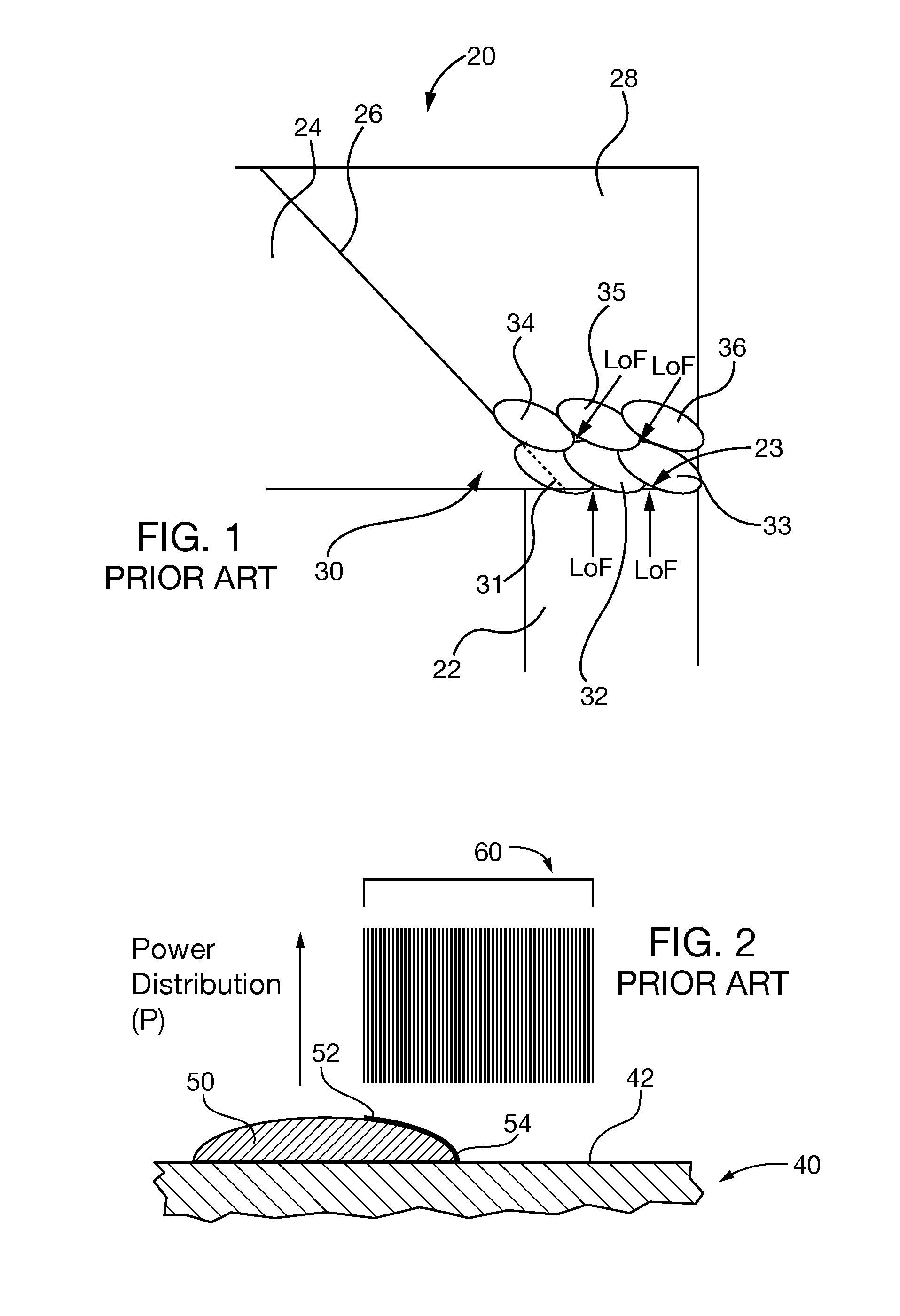

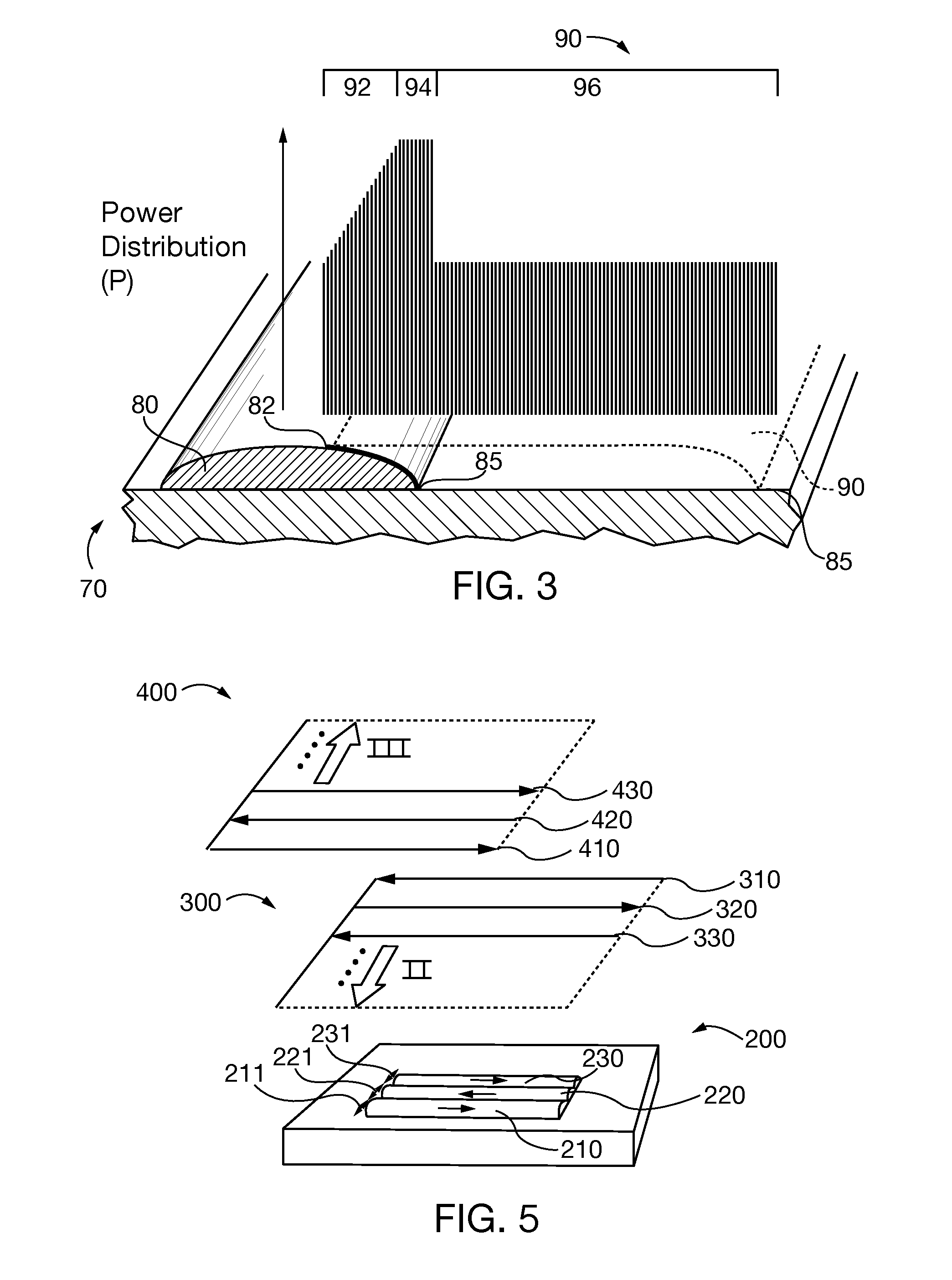

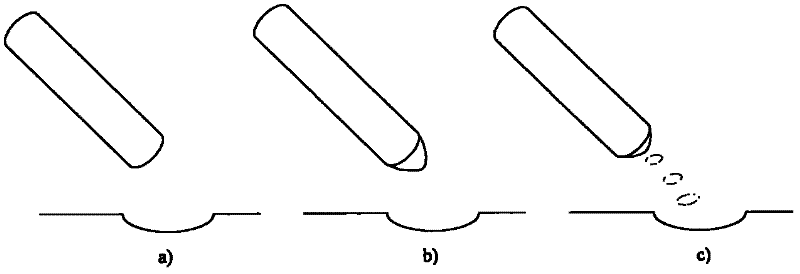

Superalloy laser cladding with surface topology energy transfer compensation

ActiveUS20140072438A1Without degrading structural propertyUniform weldingTurbinesMechanical working/deformationTurbine bladeEnergy transfer rate

A superalloy substrate, such as a turbine blade or vane, is fabricated or repaired by laser beam welding to clad one or more layers on the substrate. Laser optical energy is transferred to the welding filler material and underlying substrate to assure filler melting and adequate substrate surface wetting for good fusion. Energy transfer is maintained below a level that jeopardizes substrate thermal degradation. Optical energy transfer to the filler and substrate is maintained uniformly as the laser beam and substrate are moved relative to each other along a translation path by varying the energy transfer rate to compensate for localized substrate topology variations.

Owner:SIEMENS ENERGY INC

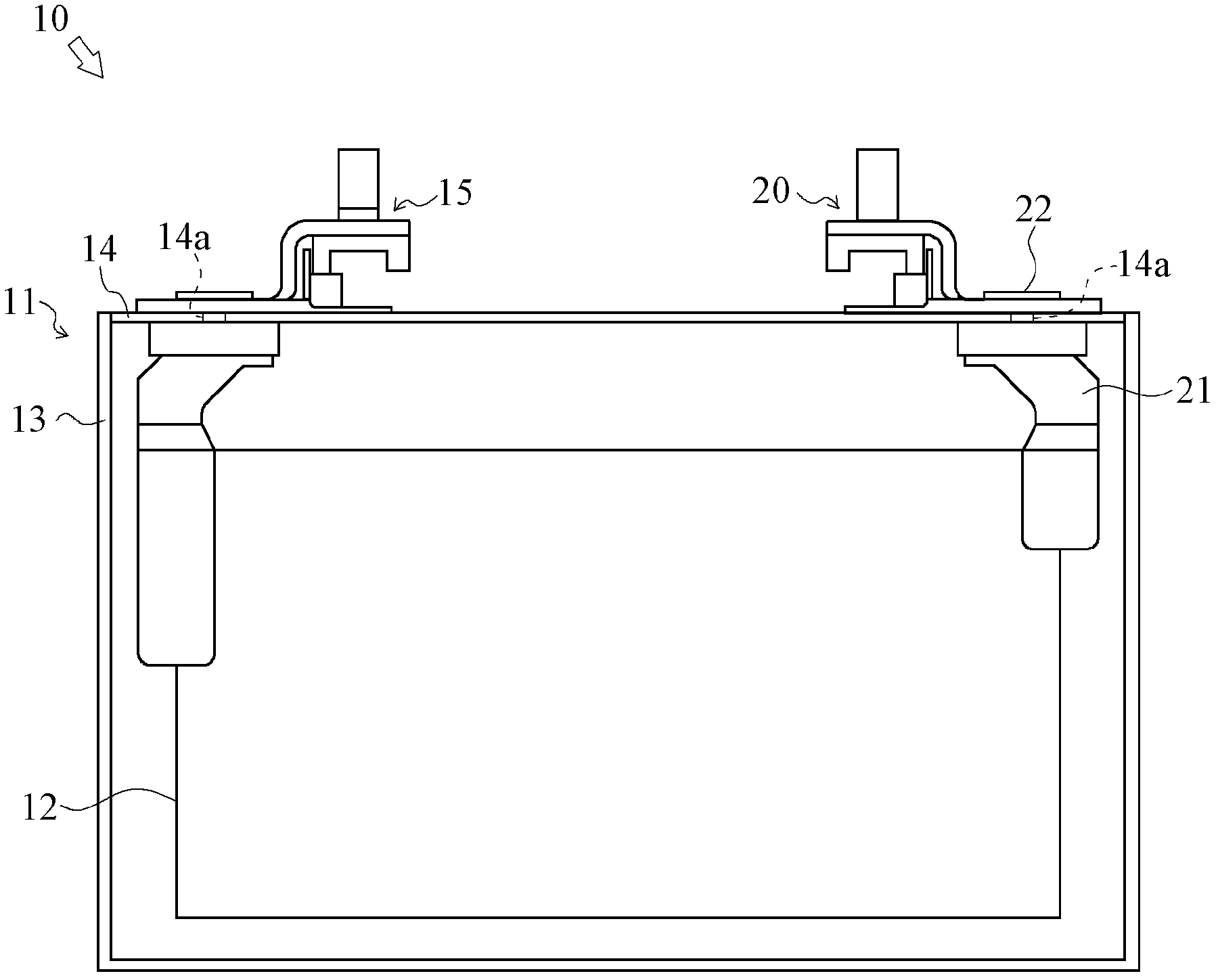

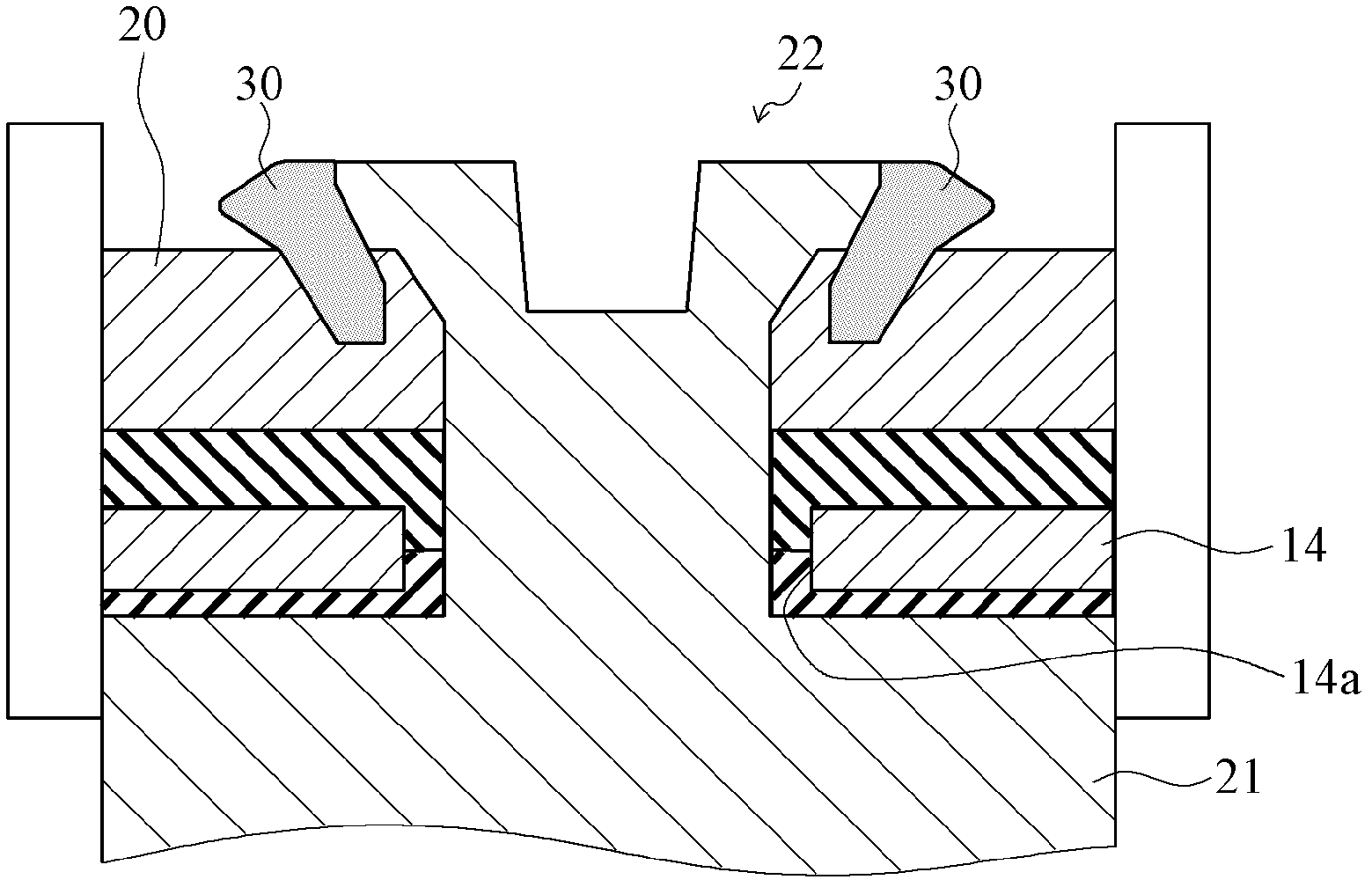

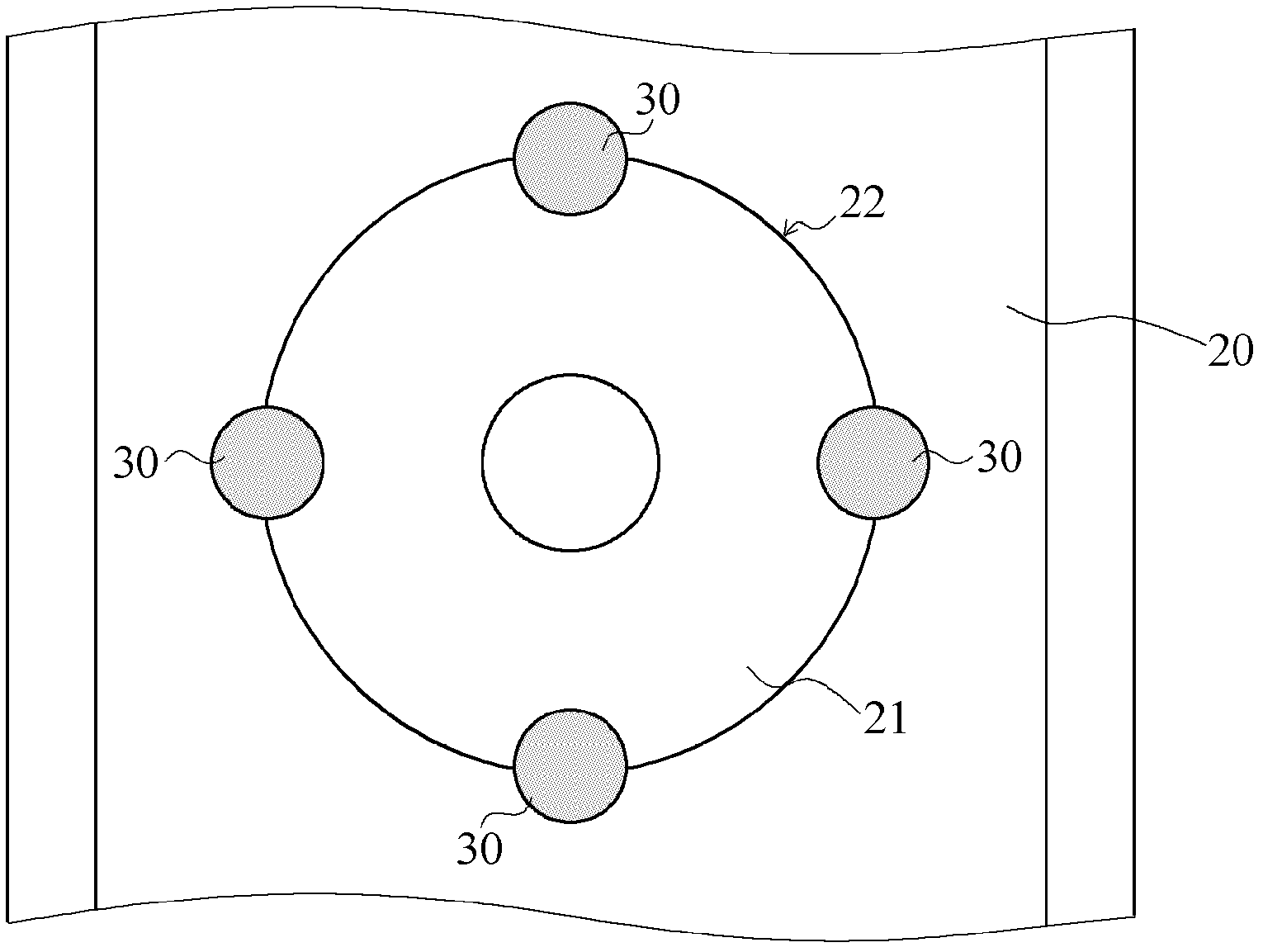

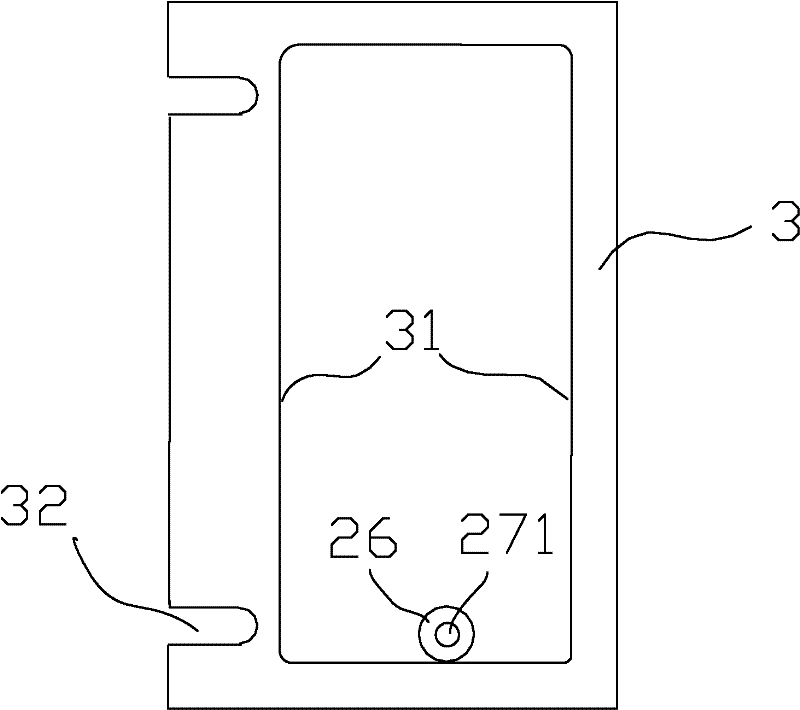

Method of laser-welding and method of manufacturig battery including the same

ActiveCN102427909AUniform weldingFinal product manufactureSmall-sized cells cases/jacketsLaser processingLaser light

Provided is a method of laser-welding that can achieve uniform welding of a member with large laser reflectance on a surface thereof. A laser welding step (S1) includes a surface roughening step (S11) in which a first laser processing device irradiates laser light to a surface (each welding portion (31)) of a welding section (30, 30, 30, 30) between a negative electrode terminal (20) (a first member) and a negative electrode lead (21) (a second member) and carries out roughening, thereby forming a laser marker (32) on the surface; and a welding step (S12) in which a second laser processing device irradiates laser light to each welding portion (31) roughened in the surface roughening step (S11) and melts each welding portion (31), thereby carrying out the laser-welding of the negative electrode terminal (20) to the negative electrode lead (21).

Owner:TOYOTA JIDOSHA KK

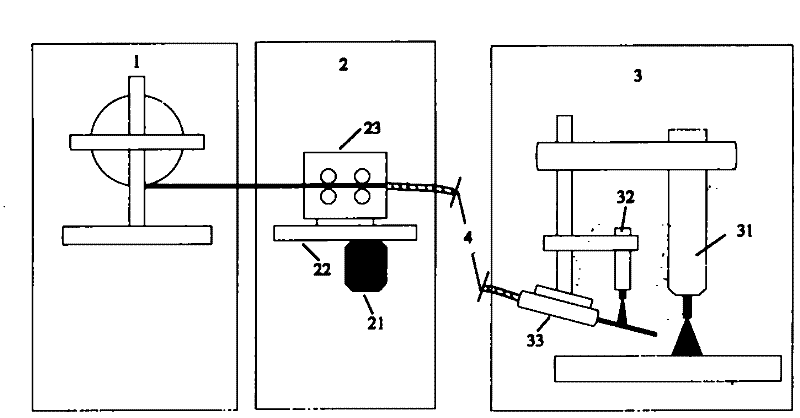

Cold metal transition welding method and device thereof

The invention aims at providing a cold metal transition welding method and a device thereof. The device consists of an MAG (Metal Active Gas) welding wire automatic feeding unit, a vibration wire feeding unit and an argon arc hot wire welding gun unit; the MAG welding wire automatic feeding unit is connected with the vibration wire feeding unit; the vibration wire feeding unit is connected with the argon arc hot wire welding gun unit through a hose; the argon arc hot wire welding gun unit comprises a straightener, an auxiliary arc welding gun and a main TIG (Tungsten Inert Gas) arc welding gun; and the auxiliary arc welding gun and the main TIG arc welding gun compose a heating source of the argon arc hot wire welding gun unit. The welding method comprises the following steps of: switching on a welding main circuit, and initiating a main TIG arc to heat a welding workpiece; and starting the MAG welding wire automatic feeding unit and a vibrating motor after the arcing of an auxiliary arc is stable. According to the cold metal transition welding method and the device thereof, the welding process is stable, the welding quality is even, the wire-feeding speed and the welding current are independently adjusted, the device is simple, and the cost is low. Based on the ordinary MAG welding wire feeding and arc wire-heating equipment, the vibration wire feeding unit is introduced, thewire heating manner is changed, thus, the cold metal transition welding is realized.

Owner:LIAONING SUPOR SHOWER EQUIP

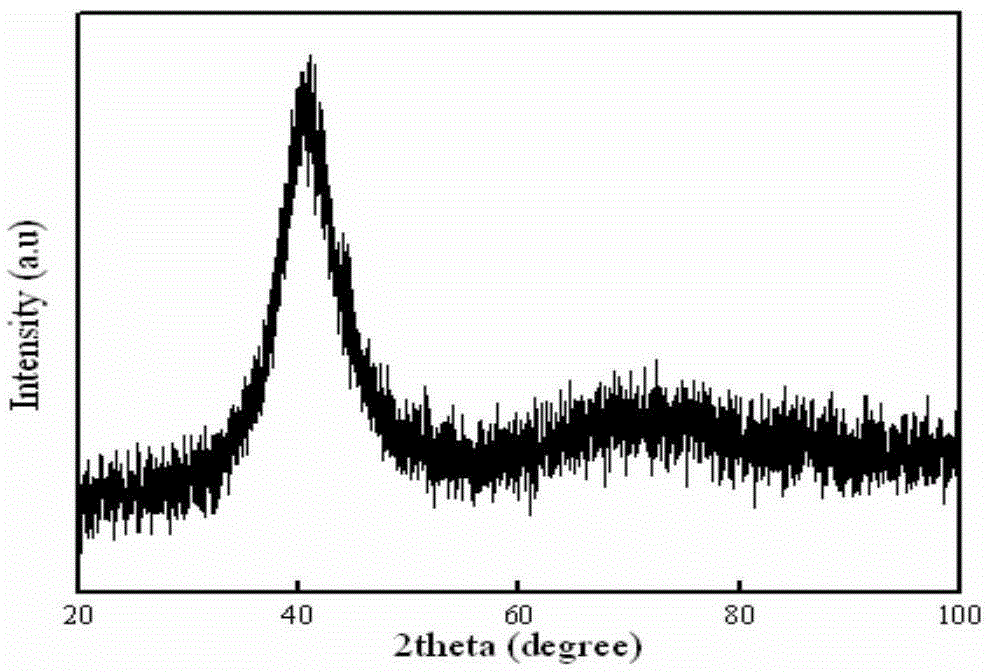

Active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, preparation method for active amorphous brazing filler metal and brazing process

InactiveCN105252169AImprove wettabilityImprove toughnessWelding/cutting media/materialsSoldering mediaUltra-high-temperature ceramicsRoom temperature

The invention discloses active amorphous brazing filler metal for brazing ZrB2-SiC ceramic materials, a preparation method for the active amorphous brazing filler metal and a brazing process, particularly relates to Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal for brazing ZrB2-SiC ultra-high-temperature ceramic materials, a preparation method for the Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal and a brazing process, and belongs to brazing filler metal in the amorphous and metallurgy fields. The components of the brazing filler metal comprise, by atomic percentage, 36.0-42.0% of Cu, 30.0-35.0% of Ti, 16.0-23.0% of Zr and the balance Ni. The melting temperature of the active amorphous brazing filler metal is 1110-1150 K, and the brazing temperature is 1183-1273 K. The Cu-Ti-Ni-Zr high-temperature active amorphous brazing filler metal obtained through the rapid condensation technology has good wettability. The room temperature shearing strength of the ZrB2-SiC ultra-high-temperature ceramic materials brazed through the amorphous brazing filler metal in a vacuum brazing mode can be as high as 160 MPa and much higher than that of Cu-based and Ag-based brazing filler metal.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Turbine cylinder block sealing surface repairing process

The invention relates to the field of steam turbines, in particular to a turbine cylinder block sealing surface repairing process. According to the turbine cylinder block sealing surface repairing process, adopted cold metal transition (CMT) welding is an MIG / MAG additive manufacturing technique, and the process is used for repairing the turbine cylinder block sealing surface. According to turbinecylinder block materials including P265GH and medium high temperature and high pressure steam, Ni-based alloy welding wire Ni-Cr-Mo is selected as an additive manufacturing material. According to theturbine cylinder block sealing surface repairing process, cold metal transition (CMT) additive manufacturing is used for repairing the sealing surface, operation is easy, the efficiency is high, andthe bonding force is better.

Owner:浙江翰德圣智能再制造技术有限公司

Laser Weld Process For Seam Welded Electrochemical Devices

ActiveUS20100326967A1Reduce temperature peaksConstant lengthCell component detailsLaser beam welding apparatusHermetic sealEngineering

A method for making an electrochemical device enclosure is described. The methods comprises the steps of forming first and second casing members; inserting electrochemically active materials within the first casing member; mating the first casing member to the second casing member, thereby forming an interface therebetween; providing a laser welding apparatus comprising a laser; intermittently turning a laser beam on and off while traversing the laser in a first welding pass 360 degrees along the perimeters of the first and second casing members, thereby forming a first intermittent set of welded and unwelded sections at the interface between the casing members; and intermittently turning the laser beam on and off while traversing the laser in a second welding pass 360 degrees along the perimeters of the first and second casing members, thereby forming a second intermittent set of welded sections at the interface between the first and second casing members. The first and second intermitted welded sections combine to provide a complete hermetic seal around and along the circumference of the casing members interface.

Owner:WILSON GREATBATCH LTD

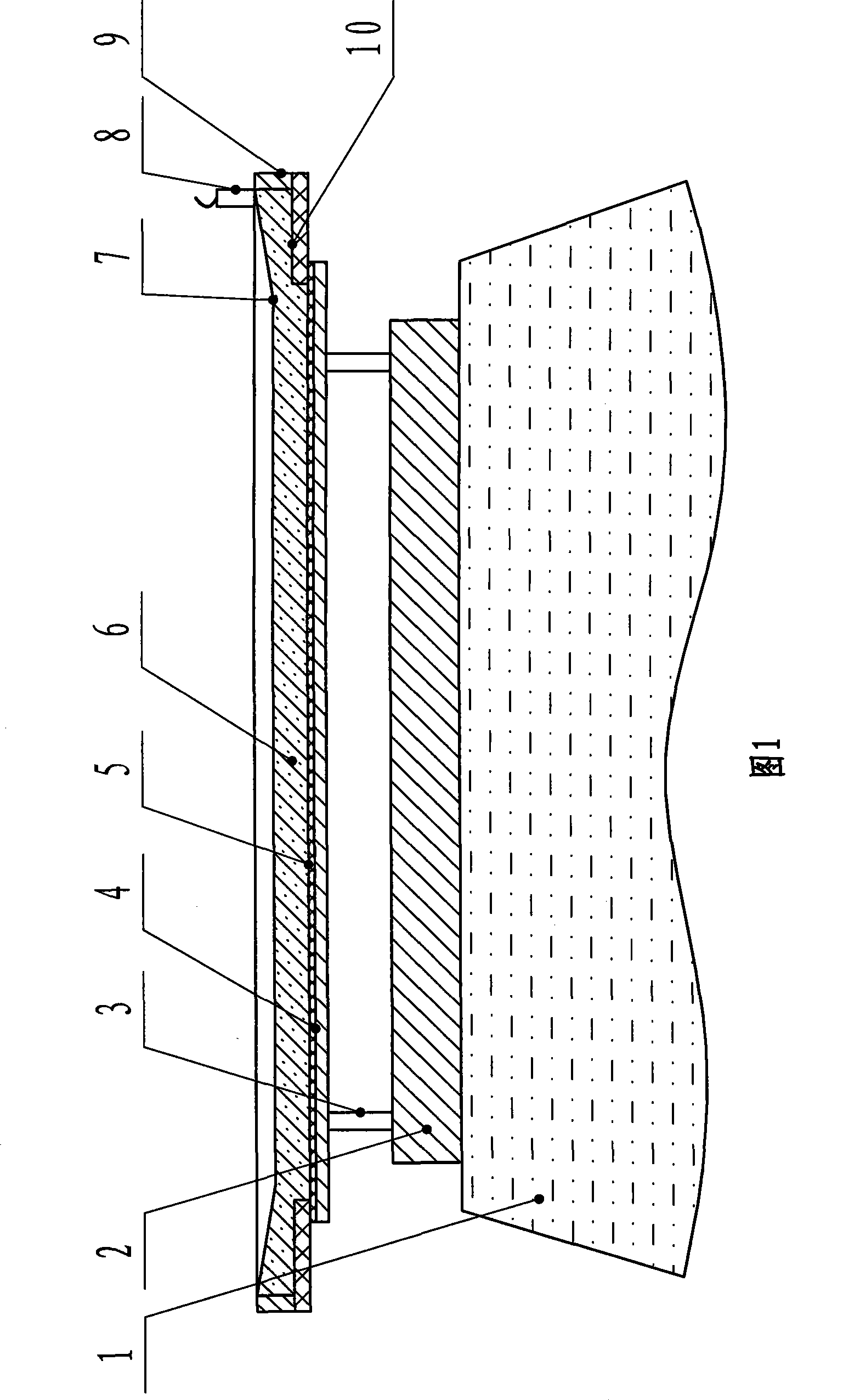

Method for producing copper alloy plate composite steel plate

InactiveCN101372065AGuaranteed stiffnessReliable weldingWelding/soldering/cutting articlesNon-electric welding apparatusSheet steelHardness

The invention provides a method used for manufacturing a copper alloy composite steel plate; the substrate material is carbon steel plate and the composite plate is copper alloy plate; the manufacture method comprises the manufacture steps as follows: I matching: copper alloy composite plate and normal carbon steel plate which comply with the national standard and usage technical requirement according to the detection are combined in pairs according to the requirement of final products; II: stress troughs of 8-10mm deep and 10-12mm wide are arranged at the circumference of the copper alloy composite plate; III: grinding the surface: oxides and sundries on the explosive combination surface of the substrate and the composite plate are removed; subsequently, a protection layer is uniformly coated on the contact surface of composite plate and dynamite; IV explosive welding: the composite plate and the substrate are supported by copper fulcrum or aluminium fulcrum and welded together by virtue of explosive welding. The combination rate of the manufacture method of the copper alloy plate and the composite steel is more than 99%, with the hardness of HB130-150, thus completely meeting the requirement of copper motor plate on the hardness.

Owner:太原钢铁(集团)有限公司

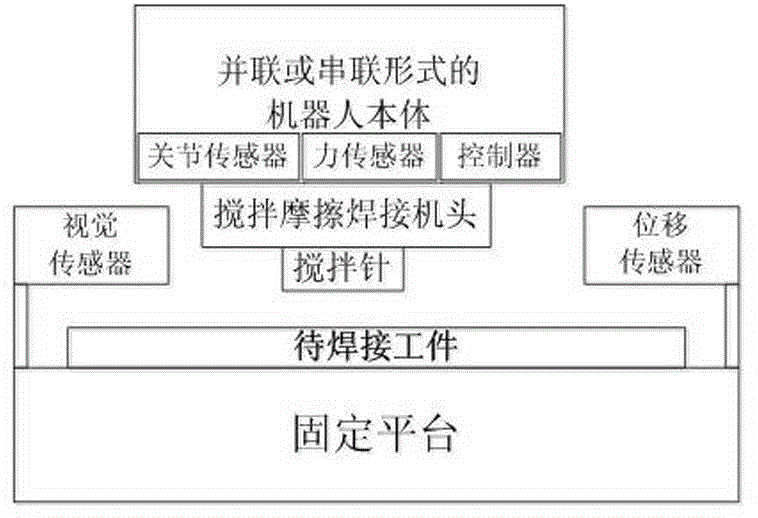

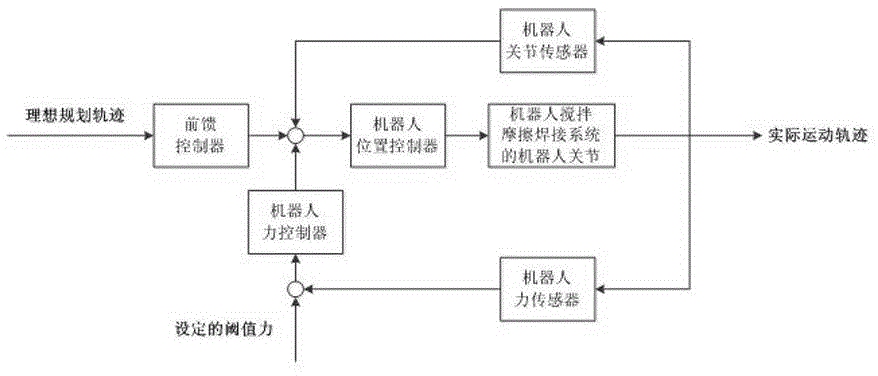

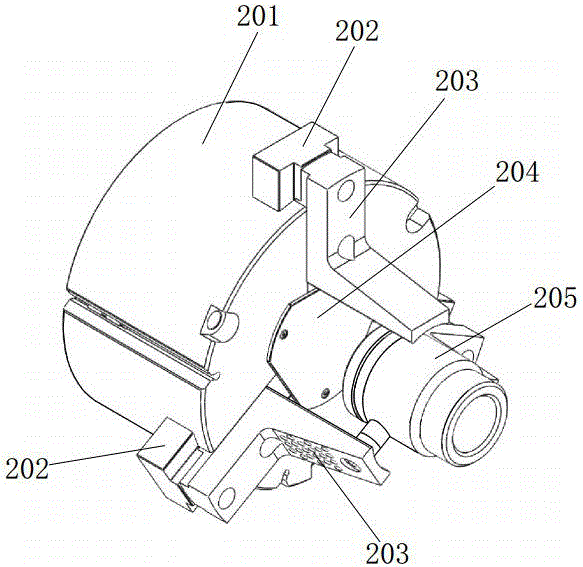

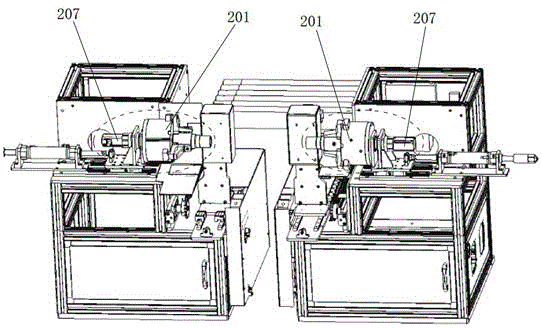

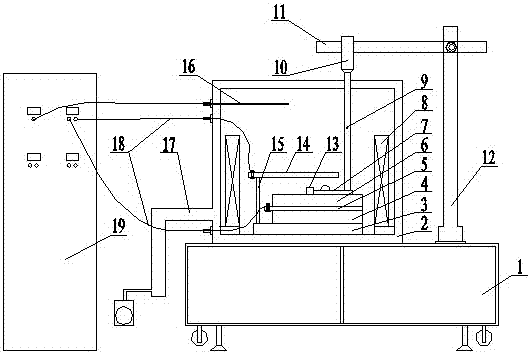

Robot stirring friction welding system and force position parallel loop hybrid control method thereof

ActiveCN104607795AConstant contact forceReal-time control of high-precision motionNon-electric welding apparatusFriction weldingContact force

The invention discloses a robot stirring friction welding system which comprises a robot body, a stirring friction welding machine head, a stirring needle, a fixing platform, a displacement sensor and a visual sensor. The stirring friction welding machine head is arranged below the robot body and fixedly connected with a mechanical arm of the robot body, the robot body controls the stirring friction welding machine head to move, and the stirring needle is arranged below the stirring friction welding machine head and moves along with the stirring friction welding machine head. The displacement sensor and the visual sensor are arranged on the fixing platform, and the fixing platform is used for carrying a workpiece to be welded. The contact force of the stirring needle of the stirring friction welding machine head and the workpiece to be welded is constant, the stirring needle moves along an ideal welding track, welding is uniform, the welding depth is consistent, the welding track is obtained through a control algorithm of an inverse kinematics or kinetic model, the welding track is accurate, convenience and practicability are achieved, and a robot can be controlled in real time to complete the high-precision movement for stirring friction welding.

Owner:宁波中创焊接技术有限公司

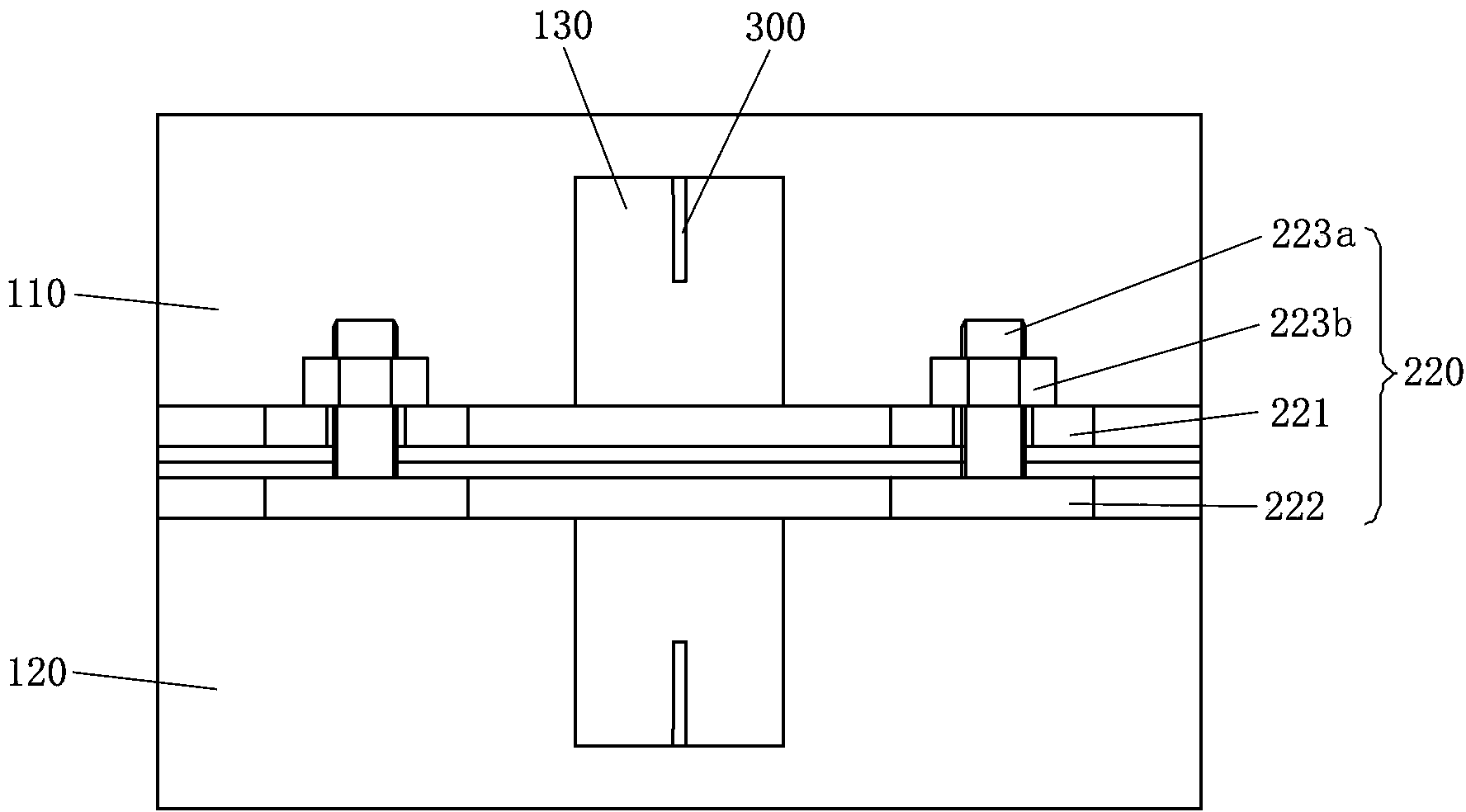

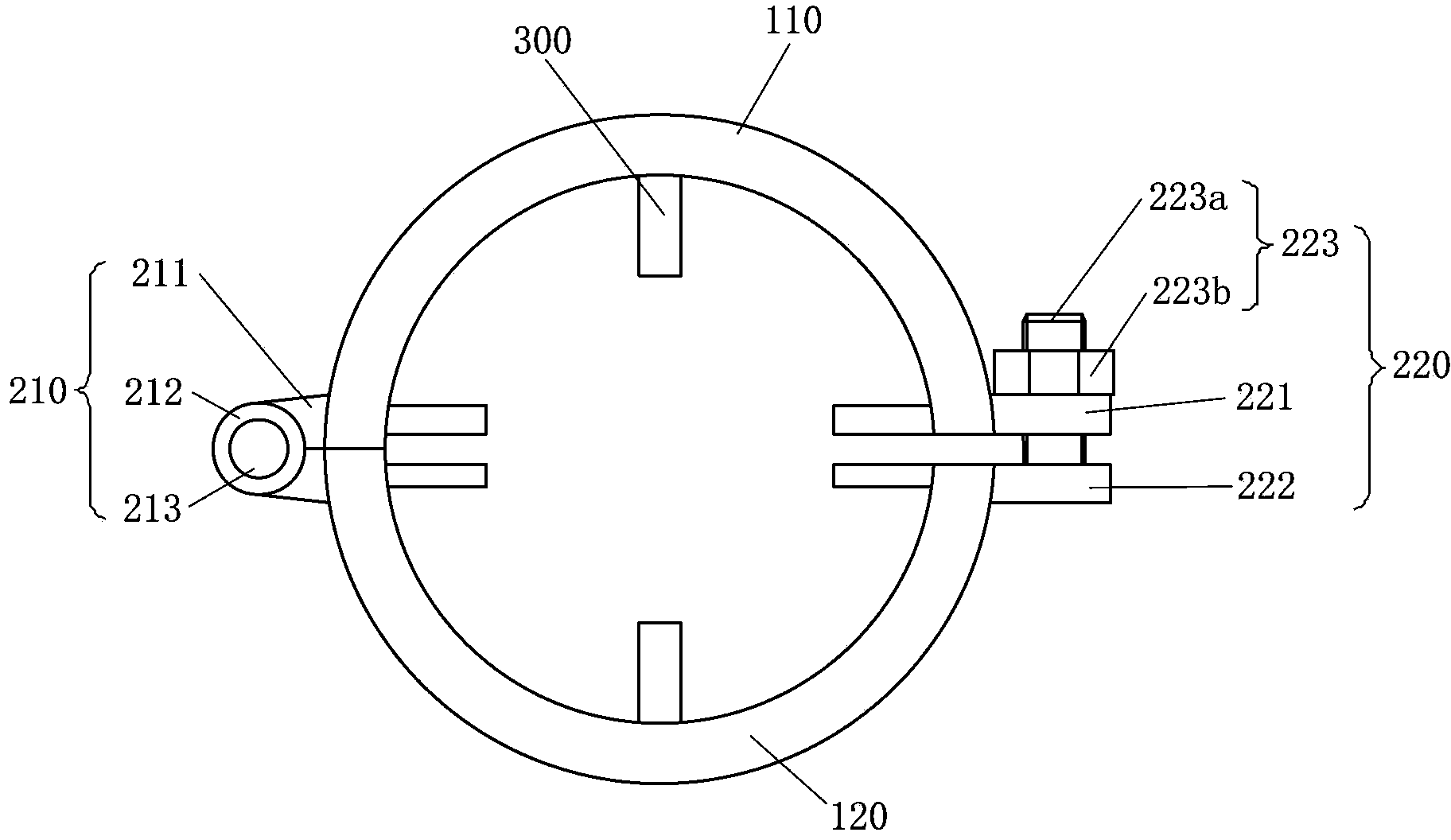

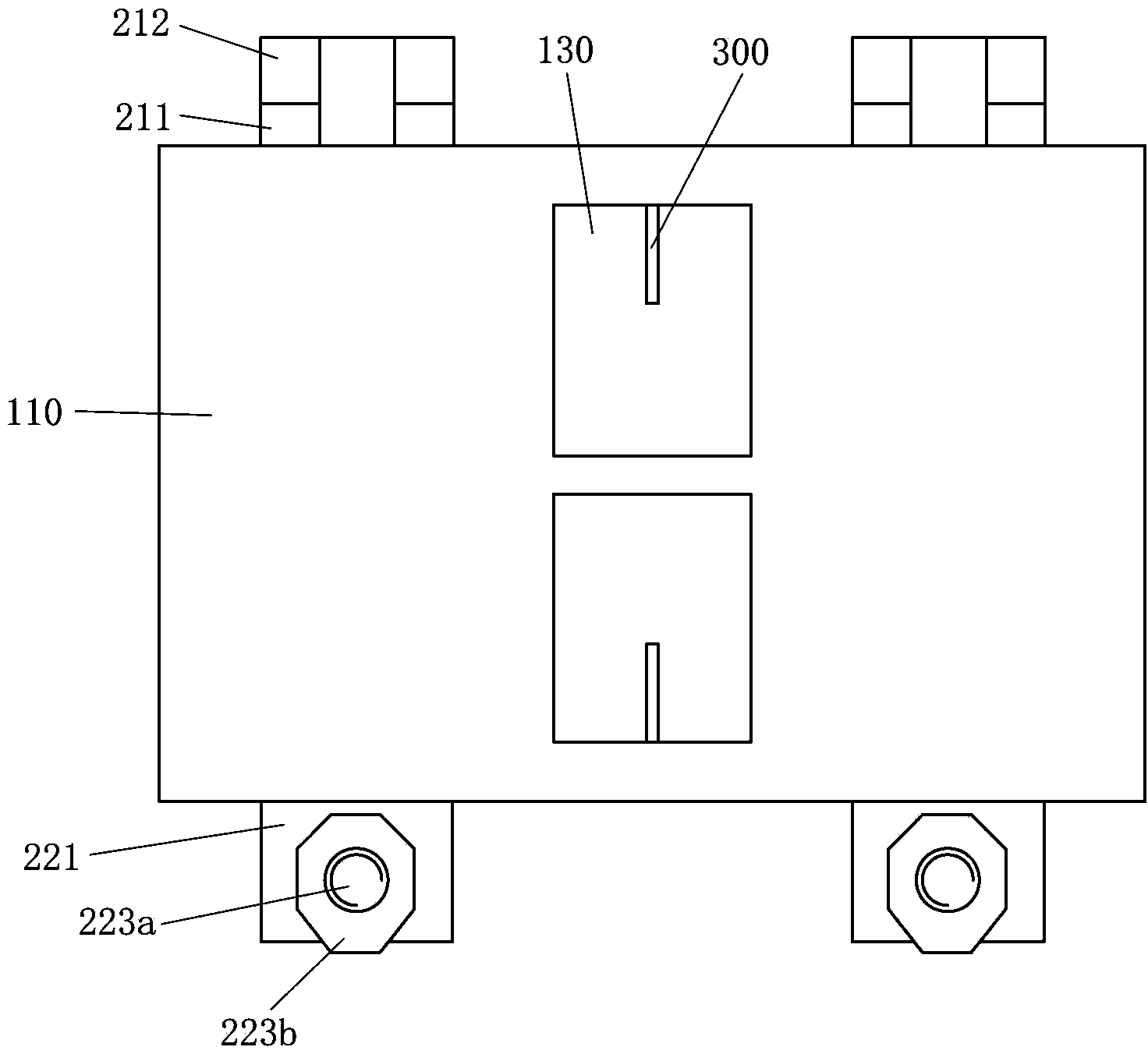

Pipeline outer opening aligning device and pipeline grouping welding method

ActiveCN103639642ASmall pairing costSimple and efficient operationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAxial length

The invention provides a pipeline outer opening aligning device and a pipeline grouping welding method. The pipeline outer opening aligning device comprises a body, a first connecting piece, a second connecting piece and at least two blocking pieces, wherein the body is cylindrical and composed of two semi-cylindrical parts, the first connecting piece is used for hinging the first ends of the two semi-cylindrical parts, the second connecting piece is arranged at the second ends of the two semi-cylindrical parts and used for fixedly connecting the second ends of the two semi-cylindrical parts, the blocking pieces have a preset certain thickness and protrude inwards from the inner surface of the body at preset intervals in the peripheral direction of the body at the roughly middle position in the axial length direction of the body, and the body is provided with openings which are formed between the blocking pieces in the peripheral direction of the body so that the side portions of the blocking pieces can be exposed. According to the pipeline outer opening aligning device, grouping cost is low, operation is easy and convenient to carry out, construction efficiency is high, weld joints formed after grouping are uniform, weld stress is small, and pipeline welding quality can be guaranteed.

Owner:PANGANG GRP ENG TECH

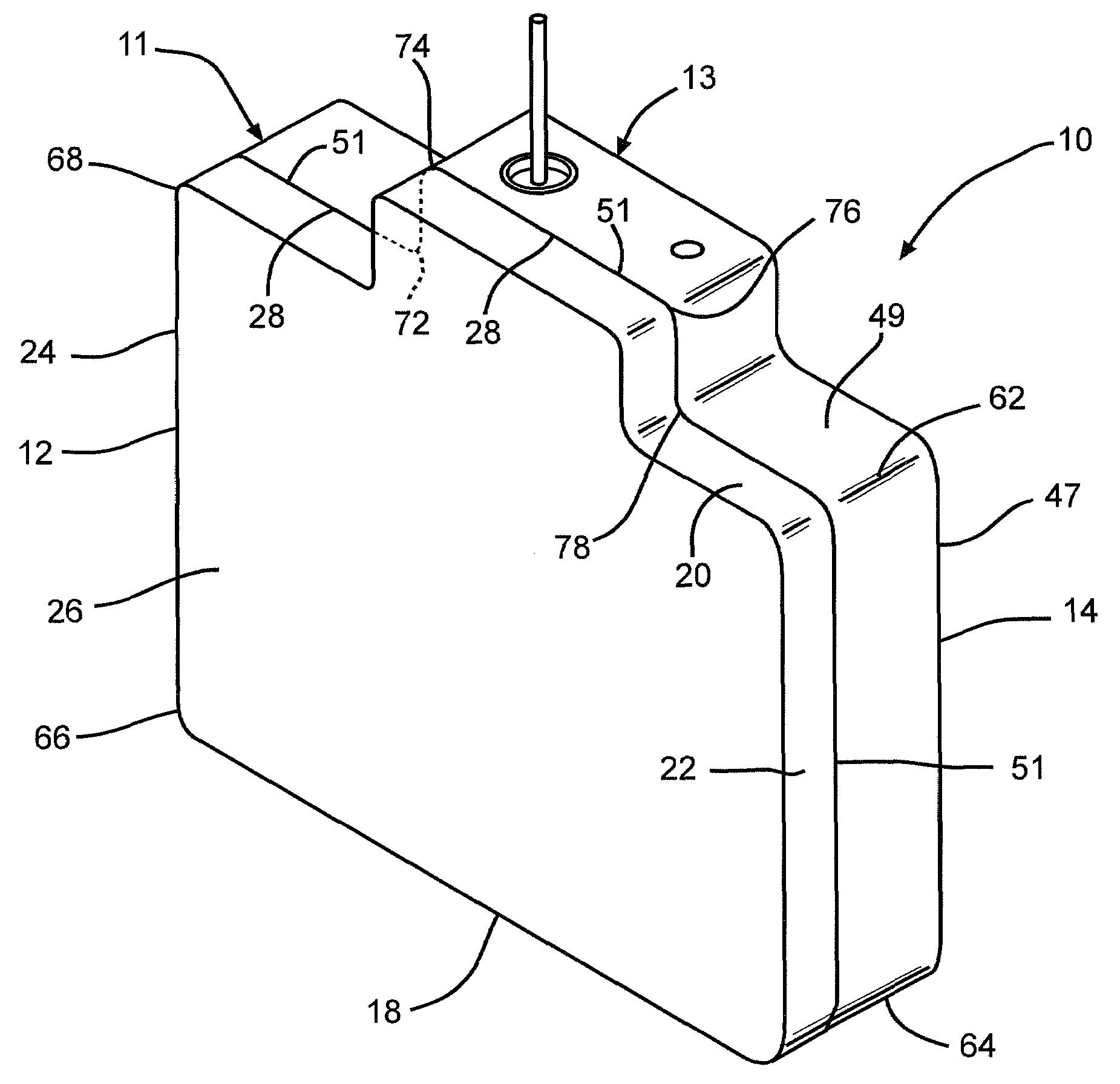

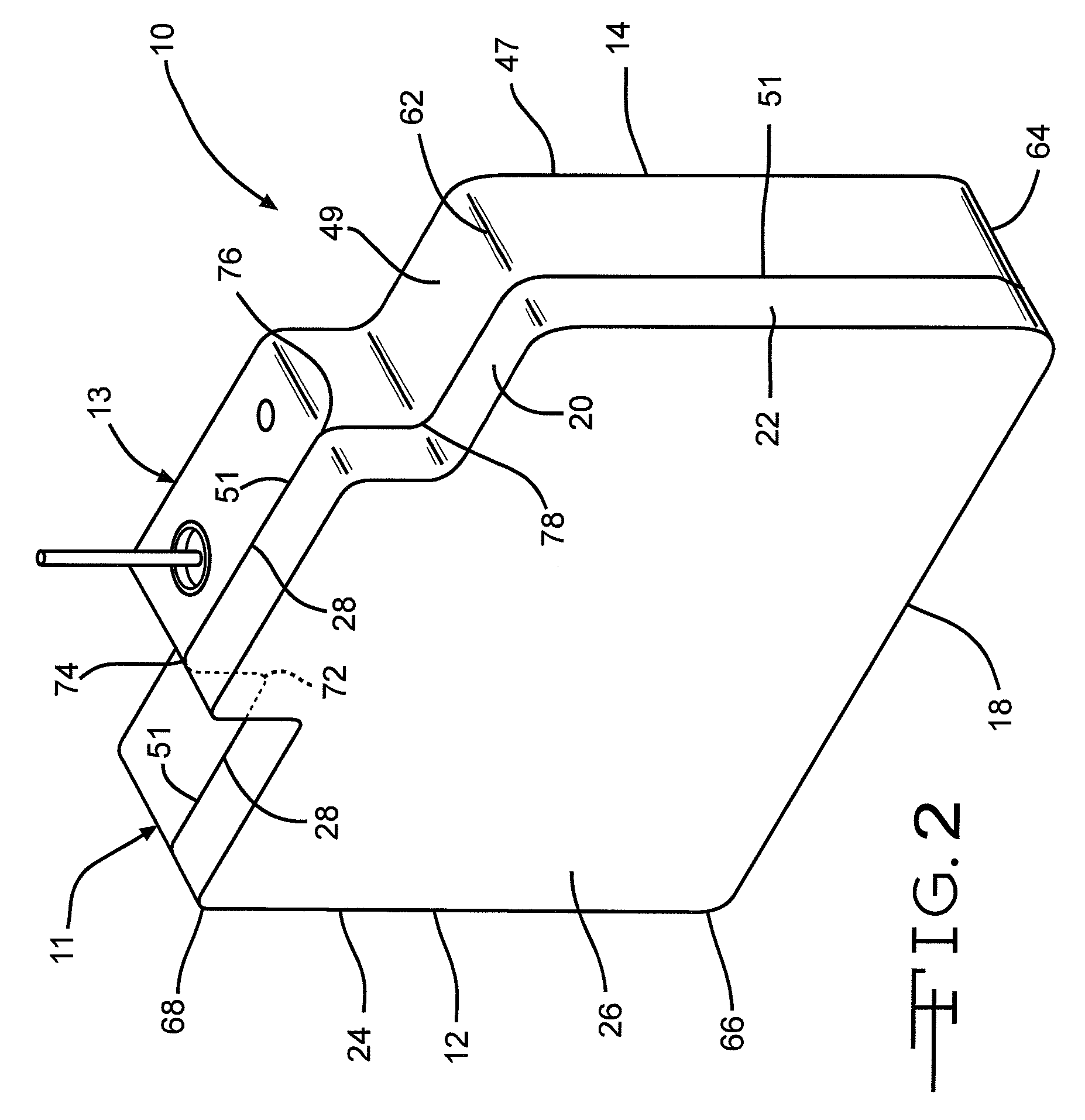

Sealed battery

ActiveCN101083310AReduce areaReliable leak tightnessNon-aqueous electrolyte accumulatorsCell component detailsEngineeringBearing surface

The present invention provides a sealing battery, which prevents electrolyte from remaining in the injecting hole and joints a sealing bolt and injecting hole. After injecting electrolyte into the battery box through the injecting hole, to joint the sealing bolt on the injecting hole to seal the injecting hole. The sealing bolt is arranged with a head and a axis extending from the lower surface of the head. The injecting hole is arranged with a chimeric concave part to table the head of the sealing bolt and a chimeric part of the axis part which is pressed into the sealing bolt. The chimeric part of the injecting hole includes: vertical inner surface part; taper inner surface part with taper surface shaped which turns narrow downwards; and bearing surface part to support the lower surfaceof the head of the sealing bolt. The head of the sealing bolt includes: lower surface; vertical outer surface part which is opposite to the vertical inner surface part of the injecting hole; and taper outer surface part with taper surface shaped which is opposite to the taper inner surface part of the injecting hole and turns narrow downwards.

Owner:MAXELL HLDG LTD

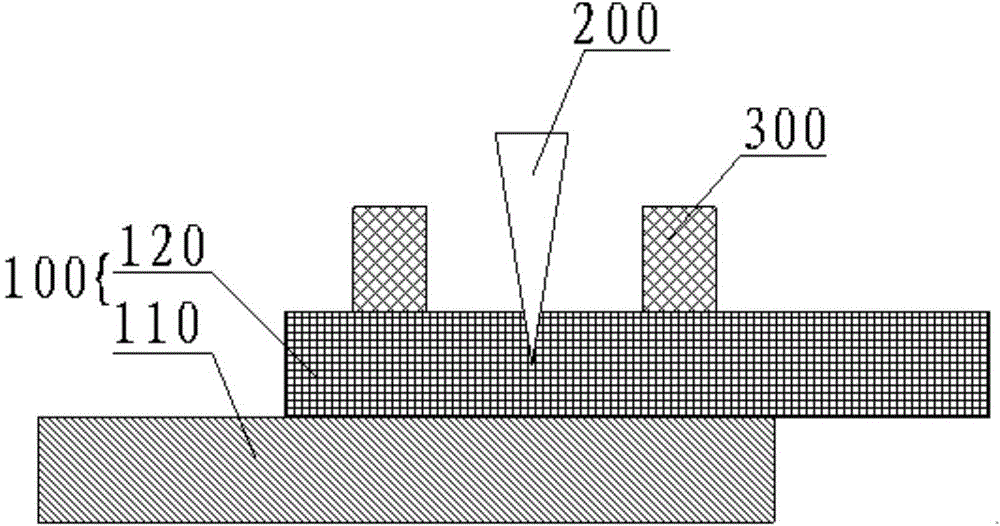

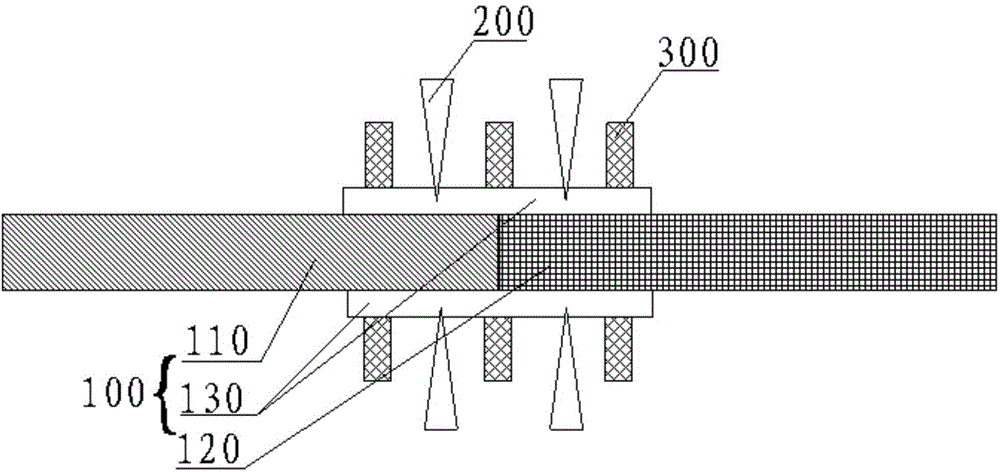

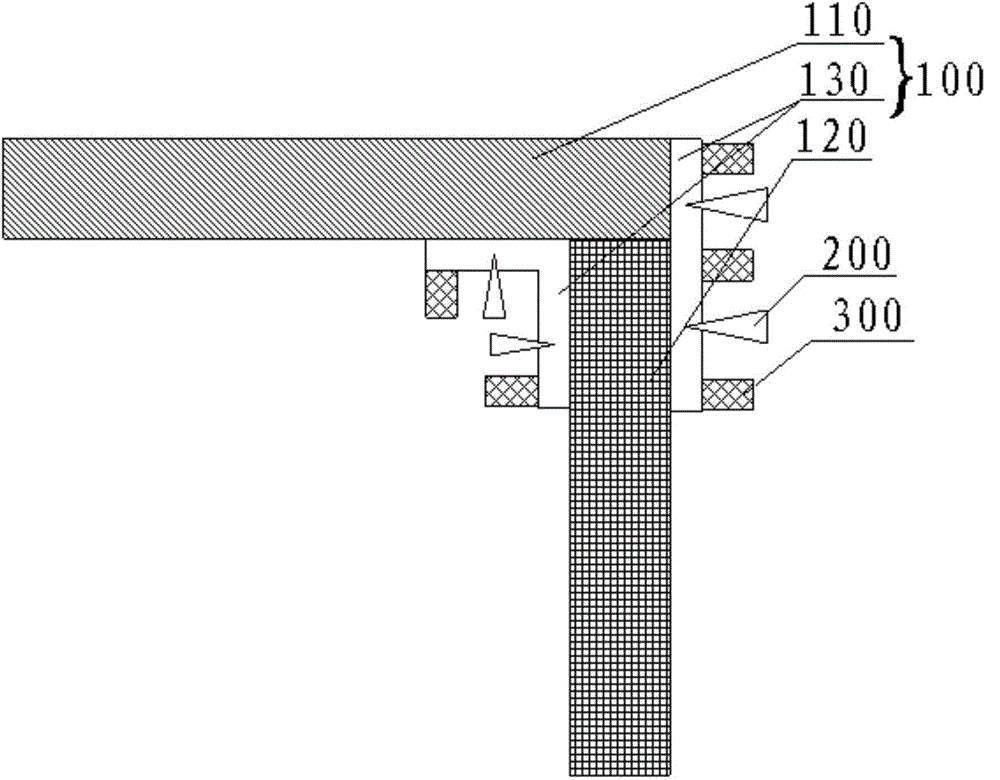

Welding method for thermoplastic composite material

The invention discloses a welding method for a thermoplastic composite material. The welding method comprises the following steps: S1: pre-treating a surface to be welded of a first workpiece and a surface to be welded of a second workpiece, wherein the first workpiece is the thermoplastic composite material and the second workpiece is the thermoplastic composite material or a metal material; and S2: welding and fixing the surface to be welded of the first workpiece and the surface to be welded of the second workpiece to obtain a combined body to be welded, wherein the metal material is arranged in the combined body to be welded, focusing laser and scanning the surface of the metal material in the combined body to be welded according to a pre-set path to finish a welding process. According to the welding method, the thermoplastic composite material and the thermoplastic composite material, and the thermoplastic composite material and the metal material are smoothly welded by the laser; welding lines are uniform and the welding quality is high; and the welding method has a wide application prospect in the fields of new energy source automobiles, unmanned aerial vehicles, and aviation fields.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

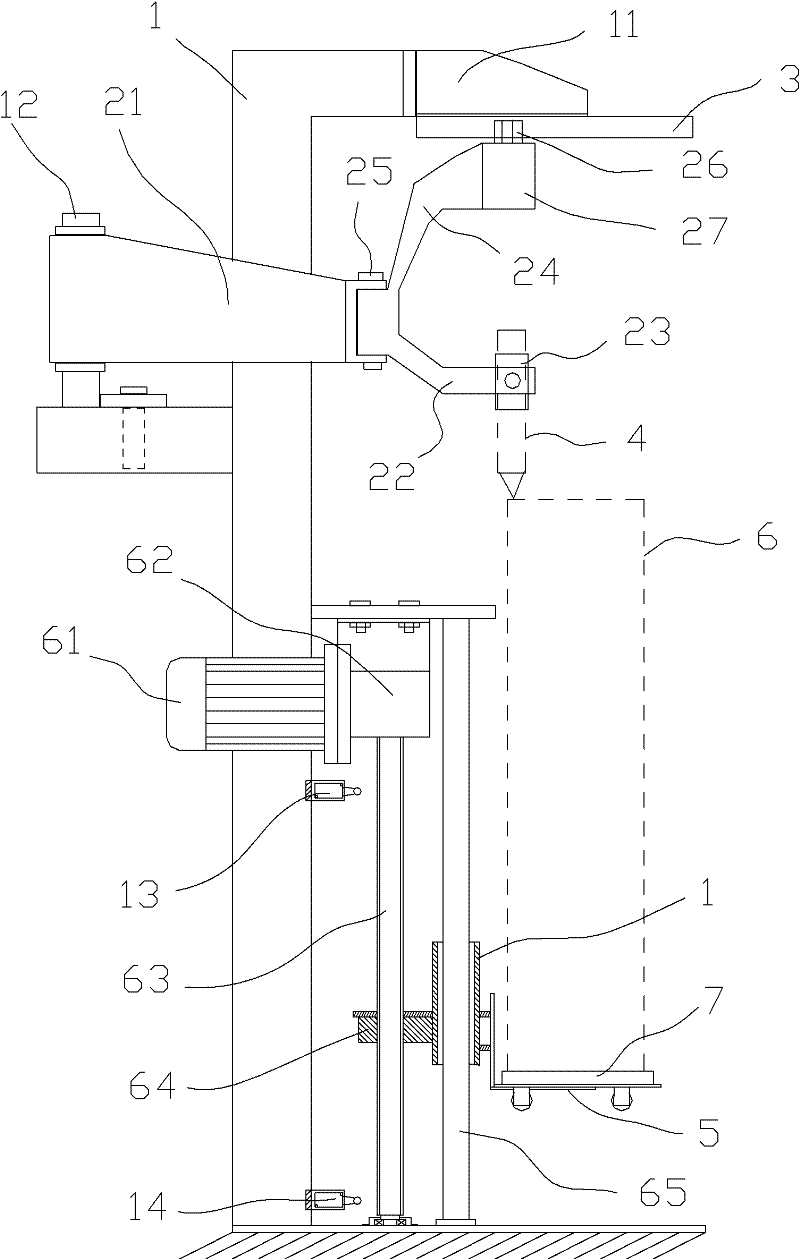

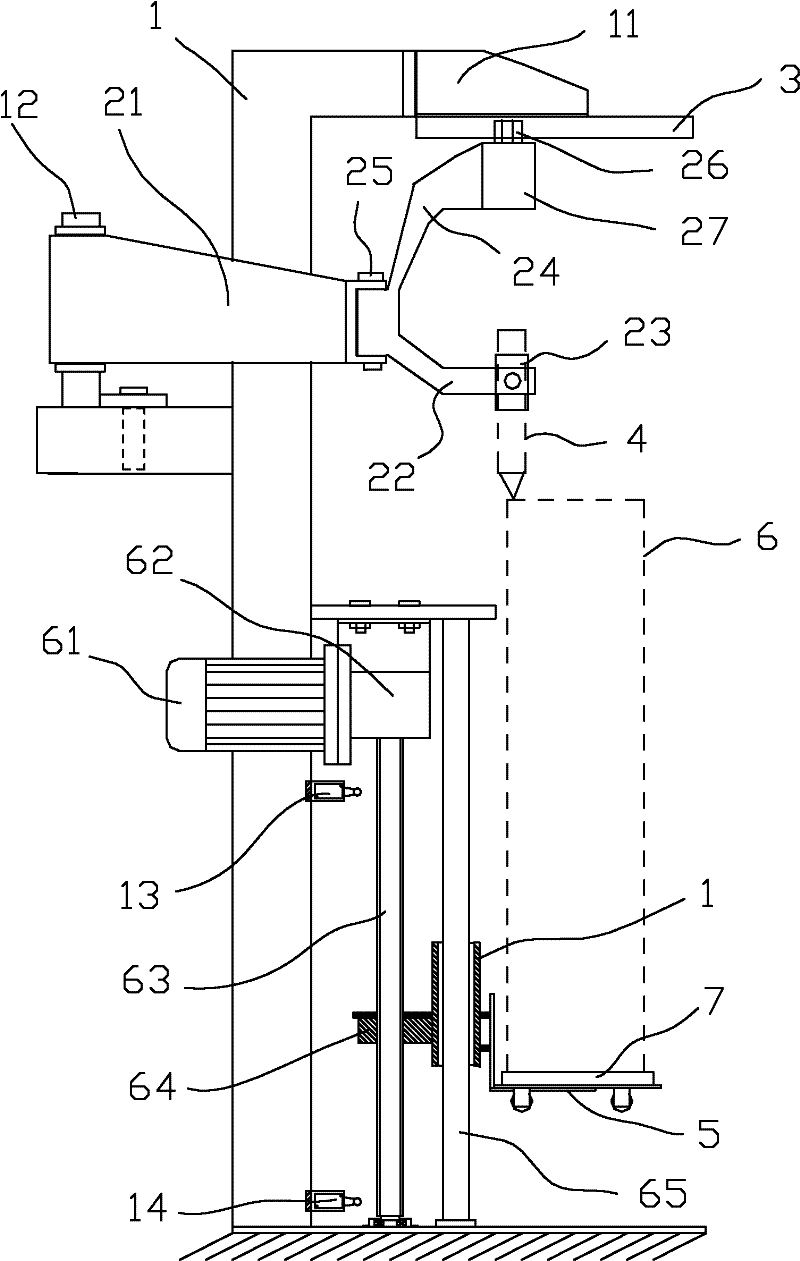

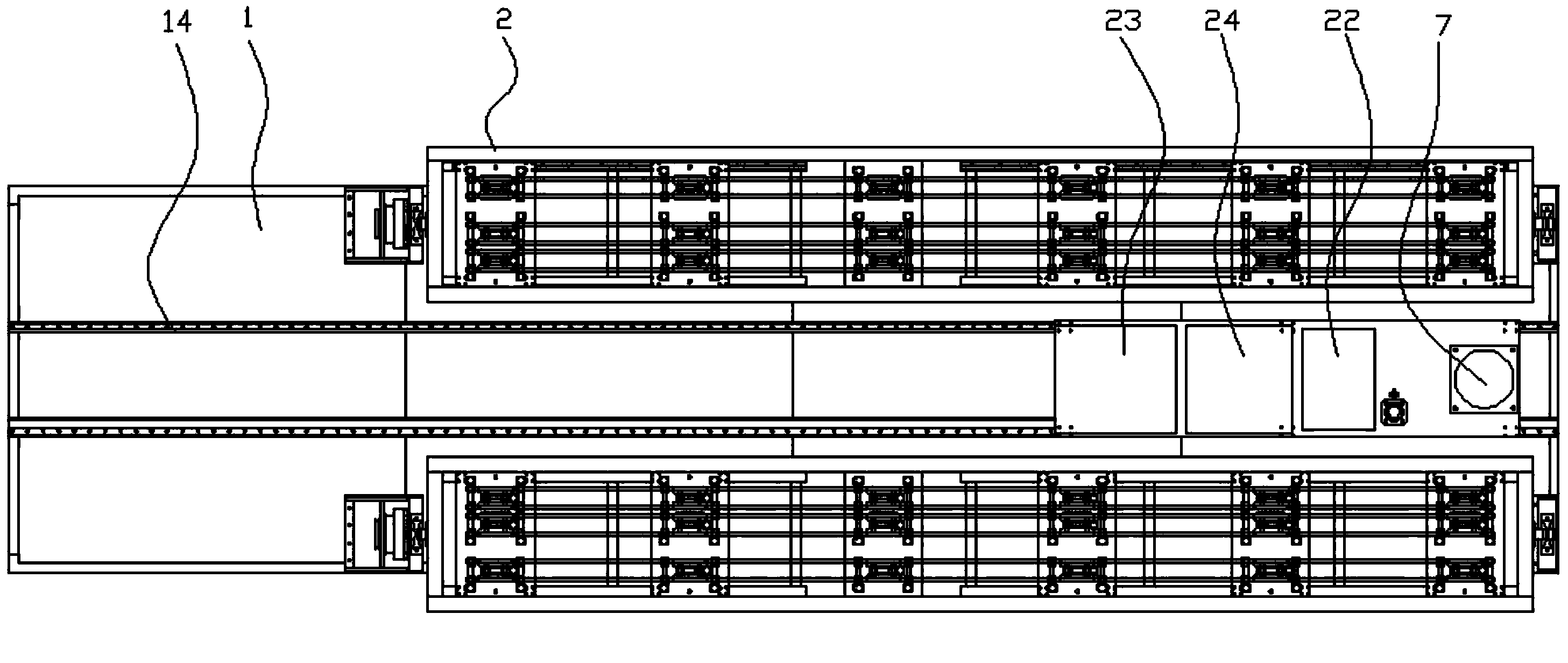

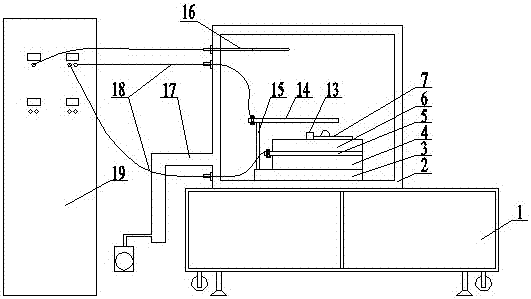

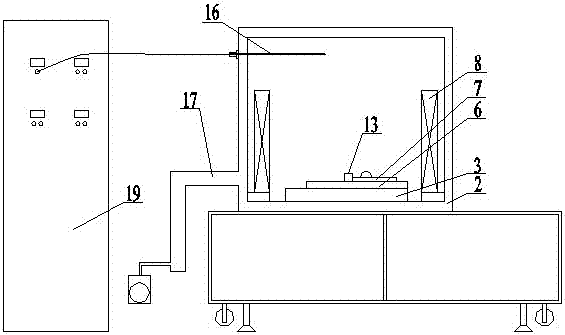

Corrugated-type board automatic welding machine

InactiveCN1907624ASolve the relative position relationshipAvoid influenceElectrode supporting devicesControl systemElectric machinery

The invention relates to a corrugated sheet automatic welding machine, wherein it comprises a frame and a movable cart at the bottom of frame; the frame has a walking system with long axle and short axle while the long axle drives motor and the short axle executes motor; the long axle and the long axle drive motor are connected by gear and tooth bar; the rotation axle of short axle drive motor is connected to the short axle via gear; the welding seam track system comprises a horizontal track executor, a vertical track executor; the welding gun swinger comprises a base, an arc rotation disc, a welding gun clamper, a welding gun clamper fixer and a motor driver; the control system comprises a main control tank, a control panel, an input module, a micro processing module, a storage module, a power module, a welding swinger executing module, a walking system executing module, and a welding seam track module. Said welding machine can weld when the welding gun is always at best position, to realize automatic welding, with uniform welding seam.

Owner:成都鑫兴众力科技发展有限公司

Welding seam tracking device

The invention discloses a welding seam tracking device. The welding seam tracking device comprises a welding gun, an electric lifting device, a quick lifting device and two tracking rollers, wherein the lower part of the quick lifting device is provided with a sliding seat, the electric lifting device is connected with the sliding seat, the two tracking rollers are optional and are respectively arranged on a rolling shaft in a sleeving way, the two tracking rollers are connected with the electric lifting device through a left connecting frame and a right connecting frame, and the welding gun is arranged on a manual three-dimensional fine adjustment device and is connected with the electric lifting device through an oscillation welding device; the electric lifting device is also provided with a linear rectangular guide rail. The welding seam tracking device disclosed by the invention has the advantages that the structure is simple, the operation is convenient, tracking welding on a workpiece of which the shape is irregular can be carried out, left-side tracking or right-side tracking can be selected according to the shape of the workpiece, a welding seam is uniform, the welding quality is stable, and the automation degree is high.

Owner:JINAN HUAXIN AUTOMATION ENG

Assembly welding fixture and welding process for tank body and stirring blades of concrete mixer

ActiveCN102672374AAvoid transitional ledgesImprove the mixing effectWelding/cutting auxillary devicesArc welding apparatusButt weldingSpiral blade

The invention relates to an assembly welding fixture for a tank body and stirring blades of a concrete mixer and a process for welding by utilizing the welding fixture. According to the welding process, the moulded large partitioned stirring blades are attached to a blade parent plate on an inner cone male die correspondingly one by one and are subjected to butt welding to form an integral spiral blade in the partitioned tank body; the inner cone male die is pushed into the partitioned tank body by a lifting device, so that the spiral blade is in bonded with the tank body to weld quickly and fill gaps, and after bonding, the bonding part of the spiral blade and the partitioned tank body is subjected to spot welding; and a tank body rotating substrate which is put into the partitioned tank body is rotated and contracted by matching with the lifting device, so that the blade parent plate on the inner cone male die is separated from the large partitioned spiral blades, and the inner cone male die withdraws from the partitioned tank body. By the welding fixture and the welding process, the influence of harmful gas and dust on the health condition of operators due to small operation space during the welding in the tank body is avoided.

Owner:LUOYANG CIMC LINYU AUTOMOBILE

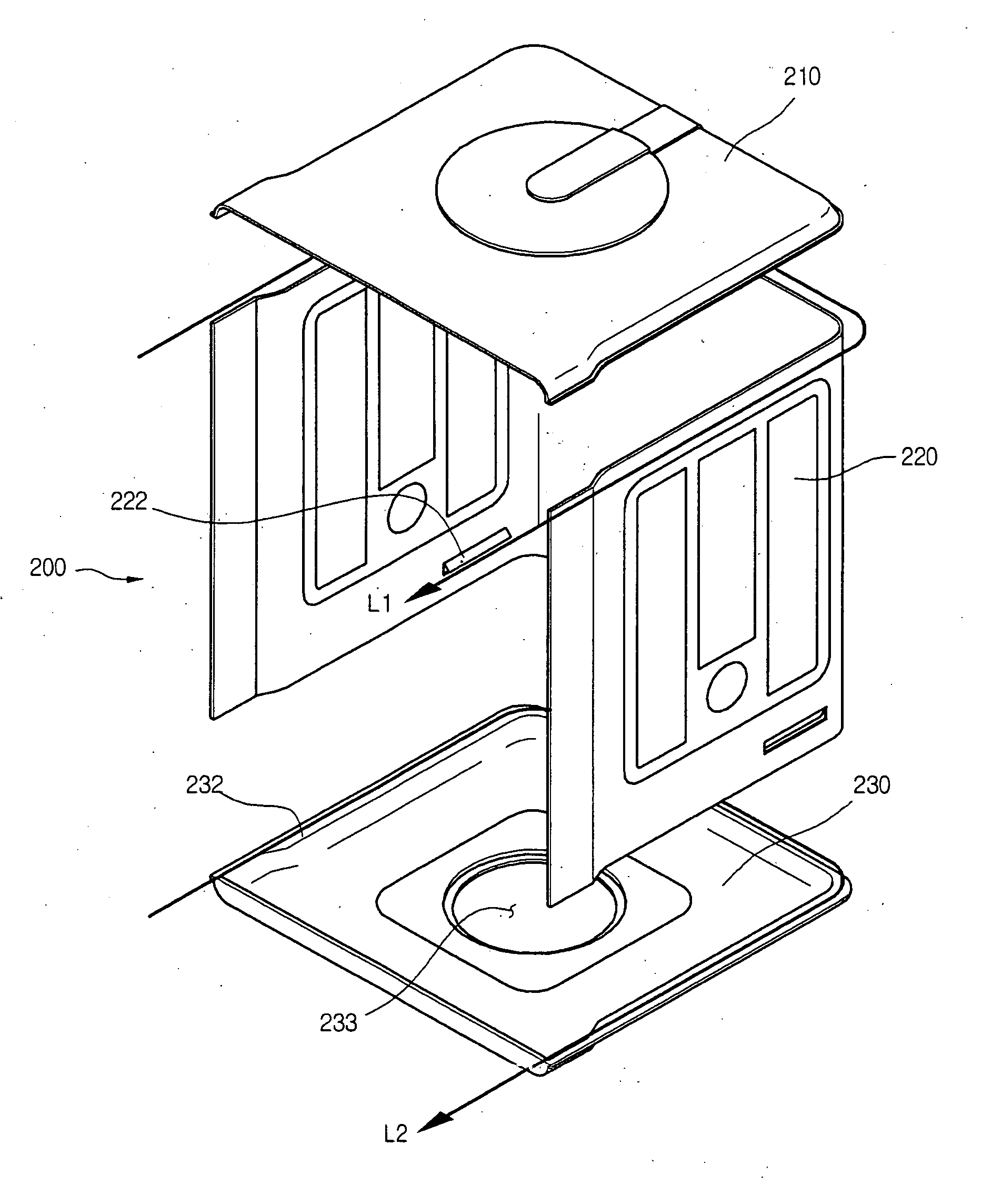

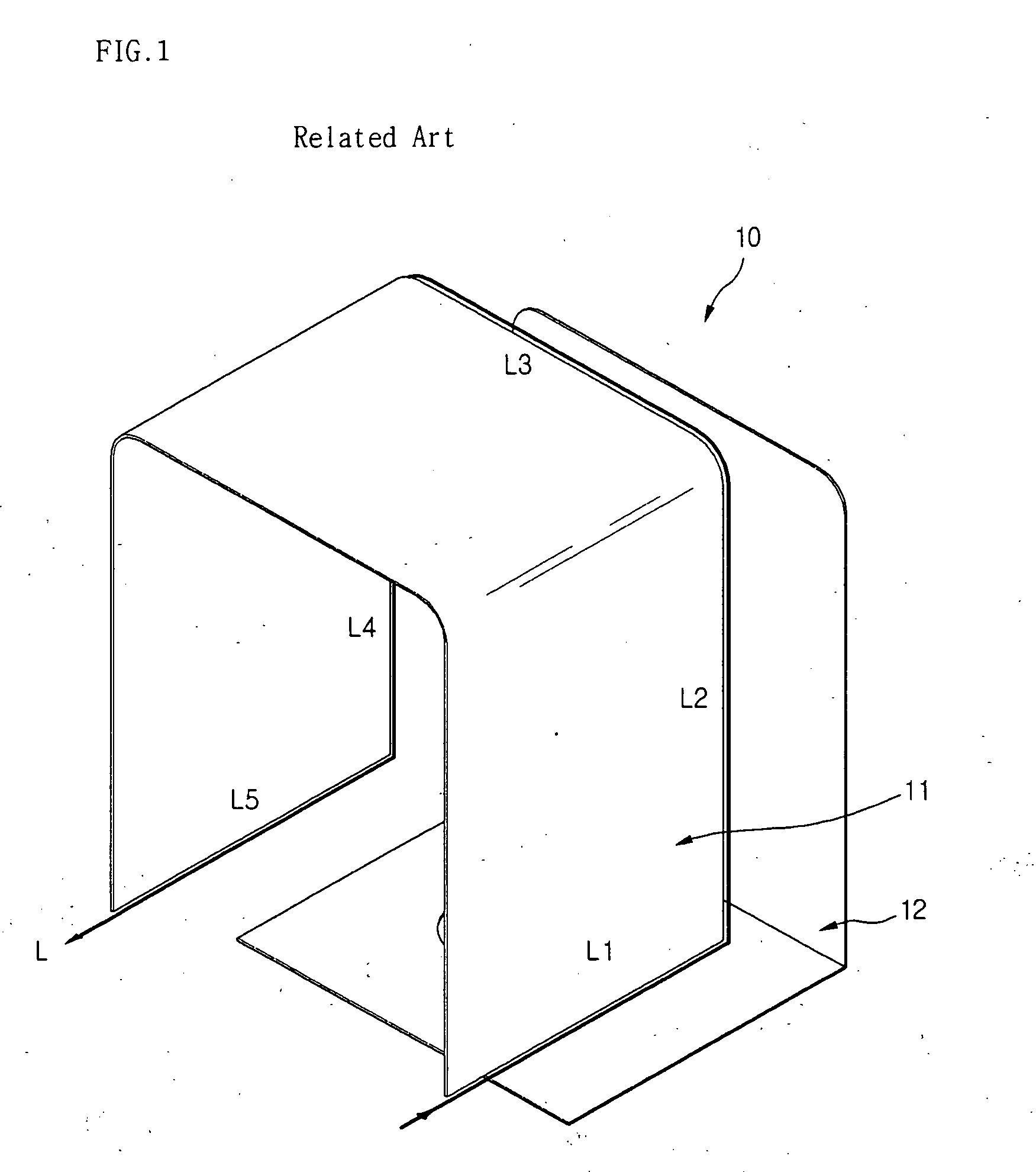

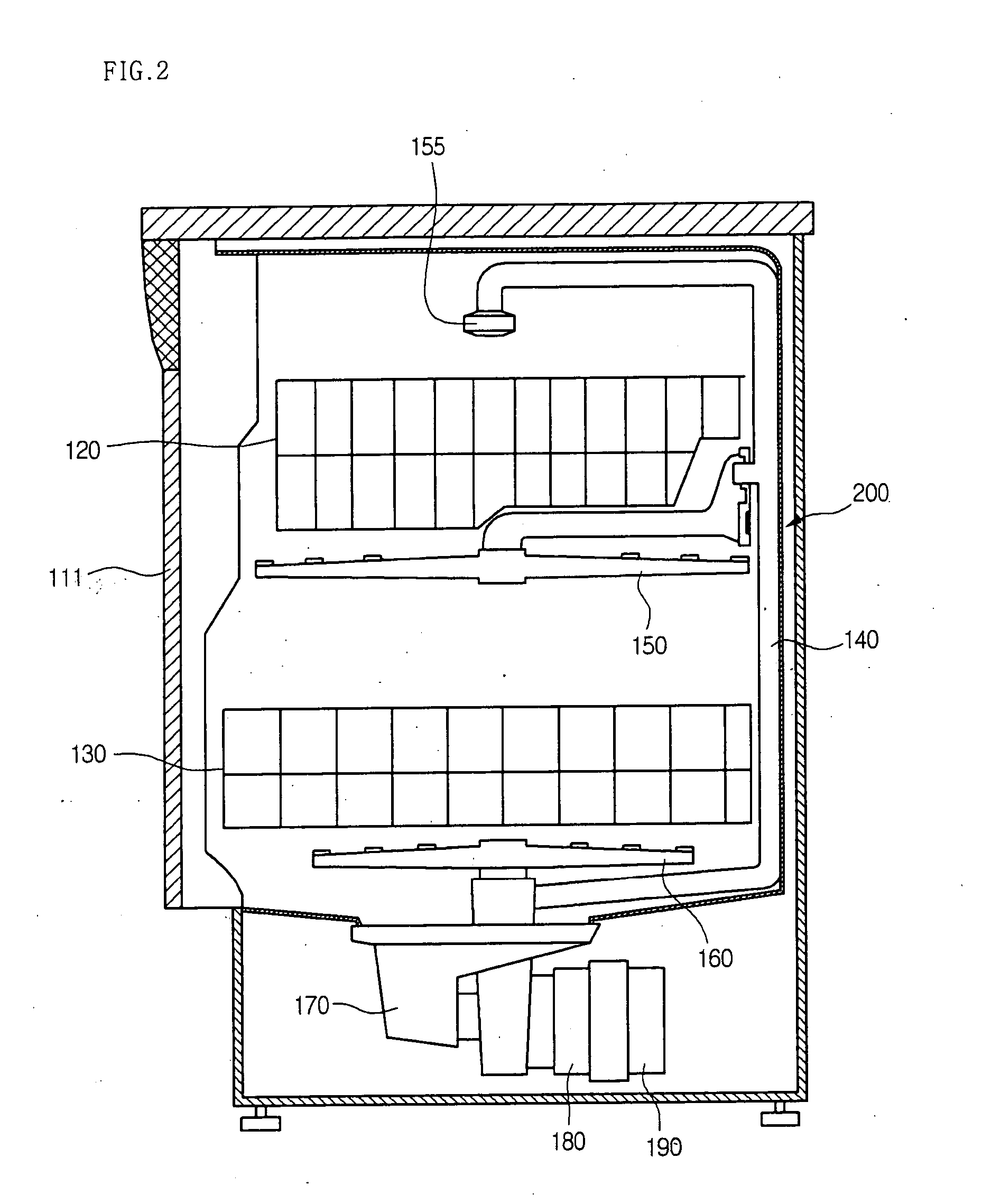

Tub construction for dishwasher

InactiveUS20050285487A1Fast timeMinimize timeTableware washing/rinsing machine detailsKitchenware cleanersArchitectural engineeringSeam welding

A tub construction for a dishwasher is provided. The tub construction includes an upper panel, a lower panel disposed below the upper panel, and an intermediate panel perpendicularly connecting the upper and lower panels. The tub construction of the present invention not only allows for a quicker assembly of the tub, but also an easier changing of the tub's outer dimensions. Furthermore, when seam welding, by changing the dimensions of the flanges at the corners, wrinkles at the corners are prevented, creating an even, leak-proof welding line.

Owner:LG ELECTRONICS INC

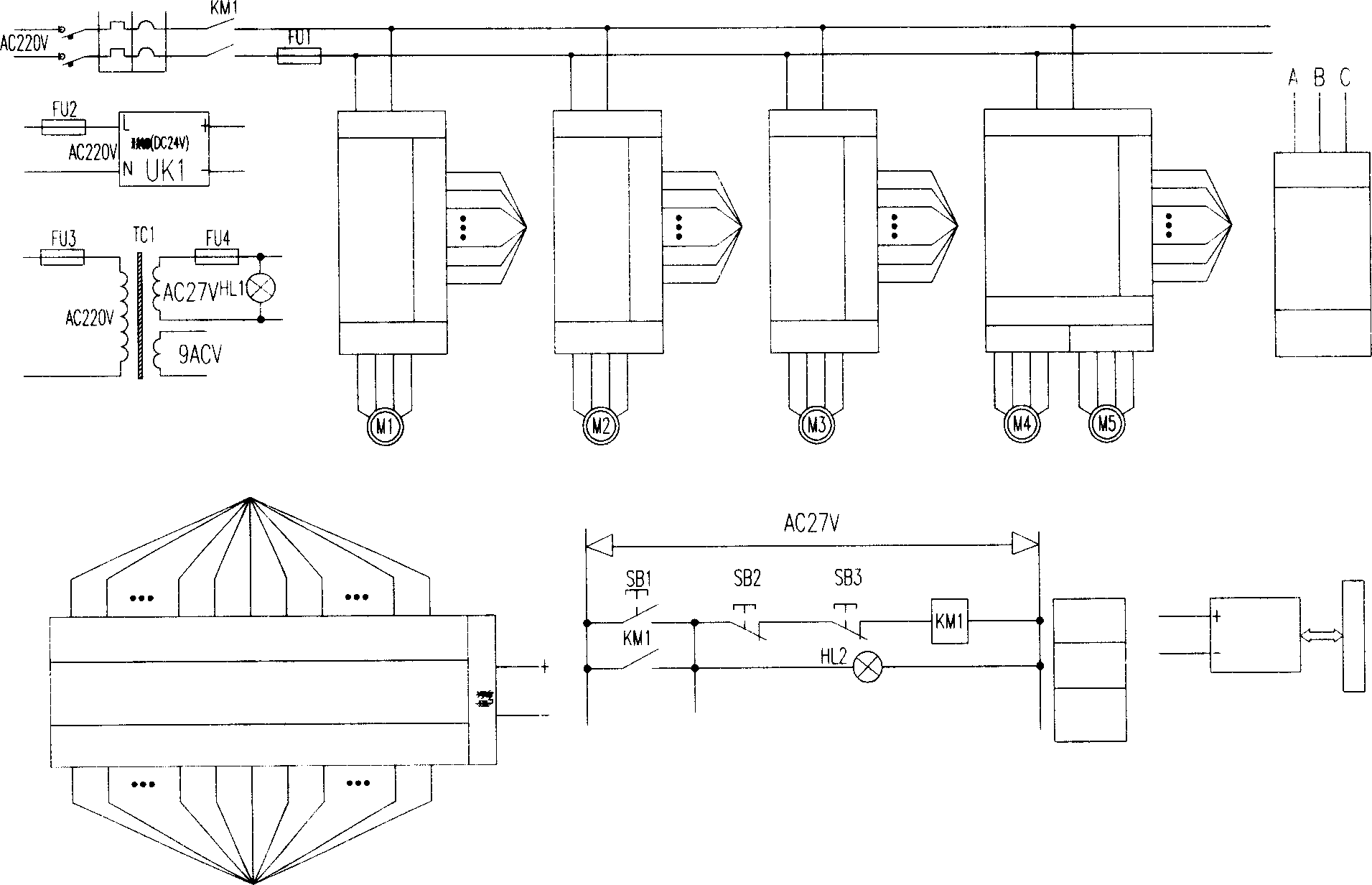

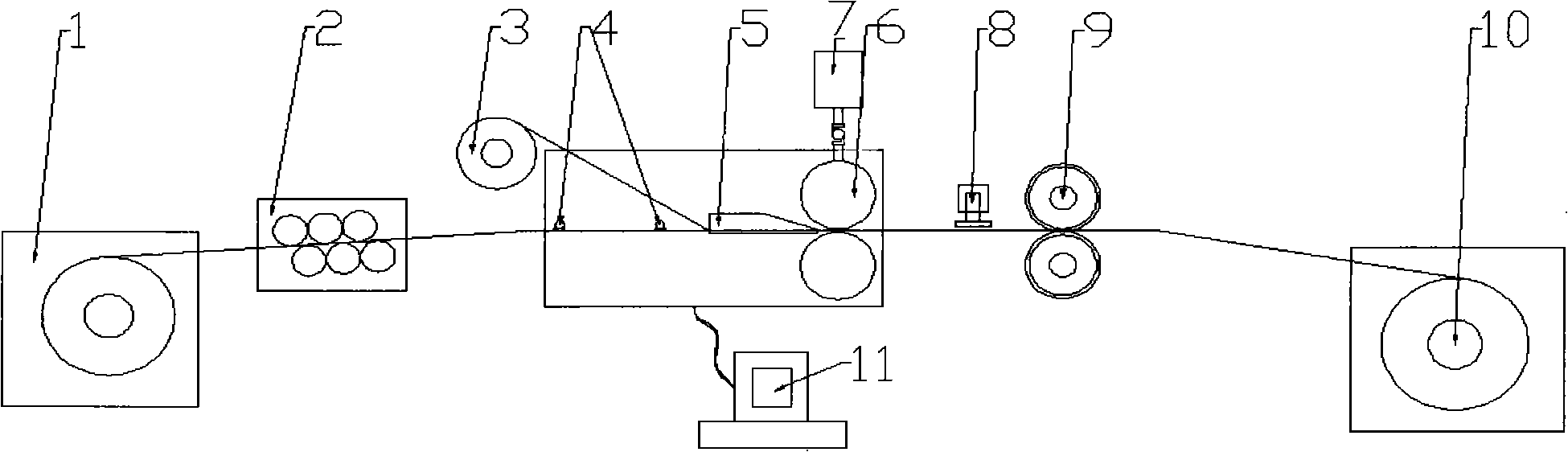

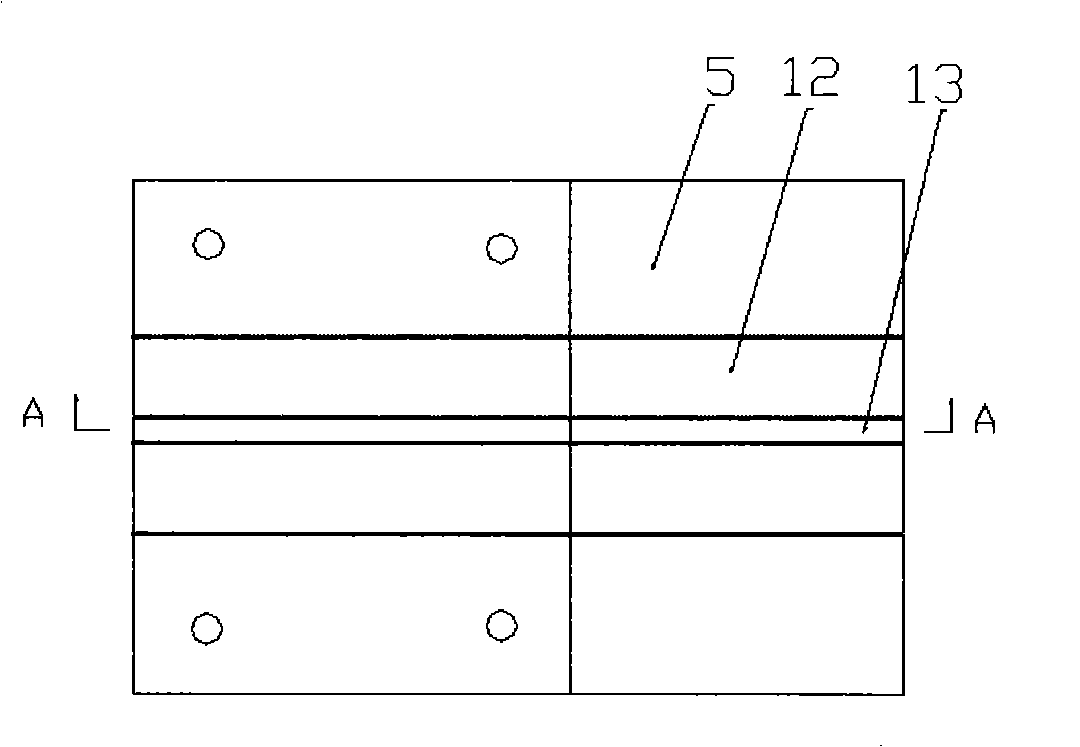

Roll welding device for producing noble metal composite band

InactiveCN101870034AImprove work efficiencyReduce labor intensityWelding with roller electrodesWelding power supplyEngineering

The invention discloses a roll welding device for producing a noble metal composite band. The roll welding device comprises a coiled material feeding mechanism, a leveling mechanism, a composite band feeding disk, a positioning mould, a roll welding wheel, a welding cylinder, a traction mechanism, a coiled material discharging mechanism, a welding power supply and an IPC controller, wherein the coiled material feeding mechanism, the leveling mechanism, the composite band feeding disk, the positioning mould, the roll welding wheel, the traction mechanism and the coiled material discharging mechanism are arranged in order; the welding power supply is connected with the IPC controller; and the IPC controller is connected with the welding cylinder. The roll welding device for producing the noble metal composite band has the advantages of high continuous welding speed, high welding quality and high production efficiency.

Owner:东莞市中一合金科技有限公司 +1

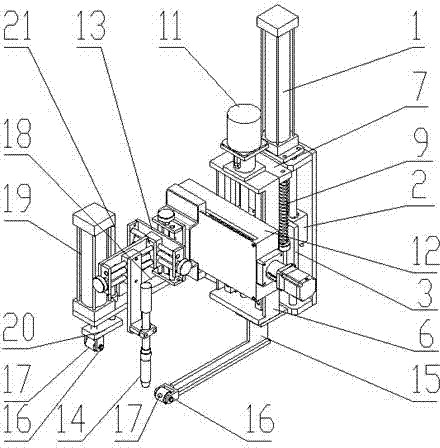

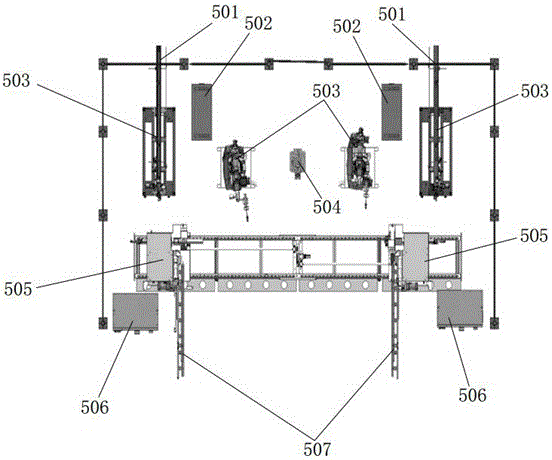

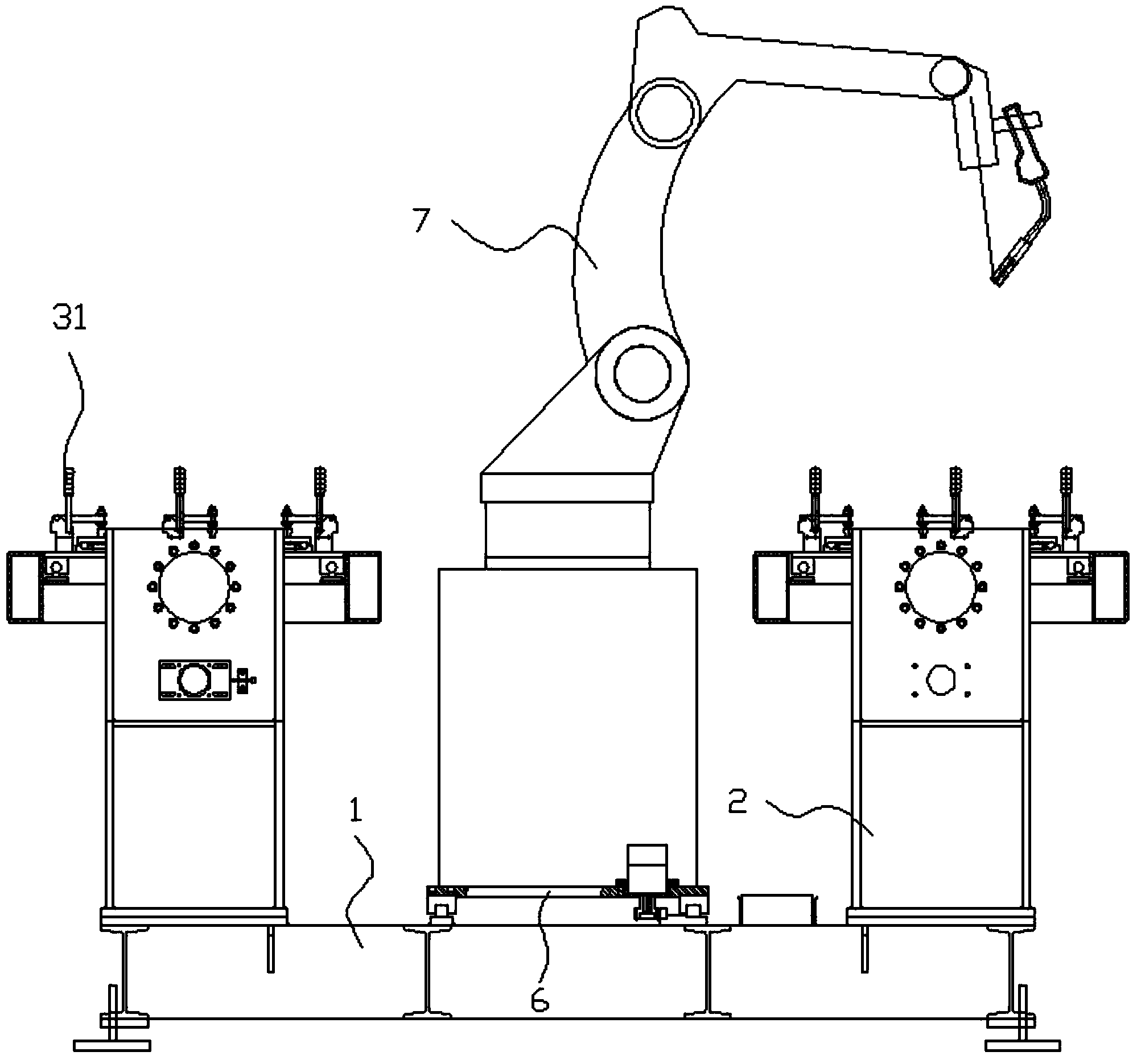

Full-automatic welding equipment

ActiveCN106695235ASteady designImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentAssembly line

The invention discloses full-automatic welding equipment. Left and right connectors of a pipe and a trunk of the pipe are manually placed on a connector feeding mechanism and a feeding and discharging guide rail correspondingly, the left and right connectors of the pipe are grabbed by an industrial robot to a rotation welding mechanism, the trunk of the pipe is conveyed to the welding position through a chain, the rotation welding mechanism is provided with a clamping part and a servo motor, the left and right connectors of the pipe are clamped by the clamping part, and the two sides of the clamping part achieves packing and will achieve automatic positioning, the servo motor rotates to drive the left and right connectors of the pipe and the trunk of the pipe to rotate simultaneously; and a welding mechanism on the six-shaft industrial robot welds the connecting positions of the left and right connectors of the pipe and the trunk of the pipe, after welding is carried out, the welded pipe is conveyed out through discharging mechanisms on the other side of a left sliding table and the other side of a right sliding table to be conveyed to the lower layer of the feeding and discharging guide rail to be guided out, and the pipe automatically flows to an assembly line through an inclined rail. The full-automatic welding equipment is high in welding efficiency, free of limitation, stable in welding effect, good in coincidence and capable of welding truss pipes with multiple specifications, different lengths and multiple models in a full-automatic manner.

Owner:SHENZHEN YINUO JIYE TECH CO LTD

Lithium-ion battery laser welding sealing technology

InactiveCN101229607AImprove reflectivityIncrease profitCell component detailsLaser beam welding apparatusElectrical batteryLithium-ion battery

The invention relates to a laser beam welding and sealing technology for Li-ion battery, which realizes consecutive sealing weld to the battery shell and the battery cover of a Li-ion battery using a laser welder with 600 Hz to 20 KHz of output frequency. The laser beam welding and sealing technology for Li-ion battery of the invention carries out a consecutive sealing weld on the Li-ion battery by means of continuous output of laser energy or high frequency of the laser welder. The welding way can maintain the melting state of a welding seem all the time and push forward. The welding has the advantages of good welding effect as well as smooth and beautiful appearance; furthermore, the nugget zone in the welding centre is completely melted during welding; therefore, after cooling, the residual inter-stress of the welding joint is weak and bad phenomena such as cracking is avoided.

Owner:湖北盐光能源科技有限公司

Laser welding method for ultrasonic vibration along with welding

ActiveCN109759700AReduce residual stressReduce stress concentrationLaser beam welding apparatusMetalWelding joint

The invention relates to a laser welding method for ultrasonic vibration along with welding, and belongs to the field of welding. According to the method, preheating is applied in the welding process,and ultrasonic vibration is applied to the front side of a weld joint at a certain distance behind a molten pool; a corresponding relation exists between the preheating temperature T and the distanced from the top end of an ultrasonic head to the welding position, wherein the relation expression is as follows: T is equal to 30d-40, the unit T is DEG C, and the unit d is mm; and the position, thepower and the force of ultrasonic application are adjusted according to the mechanical property of materials under the preheating temperature. According to the laser welding method, the welding residual stress can be effectively reduced, pores and cracks are reduced, and thus the fatigue performance of the weld joint is improved, and the welding deformation is reduced. By adopting the method, thetemperature gradient in the cooling process can be effectively reduced, and the residual stress is reduced; and the plasticity of the ultrasonic application area can be improved, and the ultrasonic effect is better. The ultrasonic impact can effectively reduce residual stress, refine crystal grains and reduce pores and cracks, and thus the fatigue performance of the weld joint is improved; and the metal plastic extension of the weld joint can effectively reduce the welding deformation.

Owner:DALIAN UNIV OF TECH

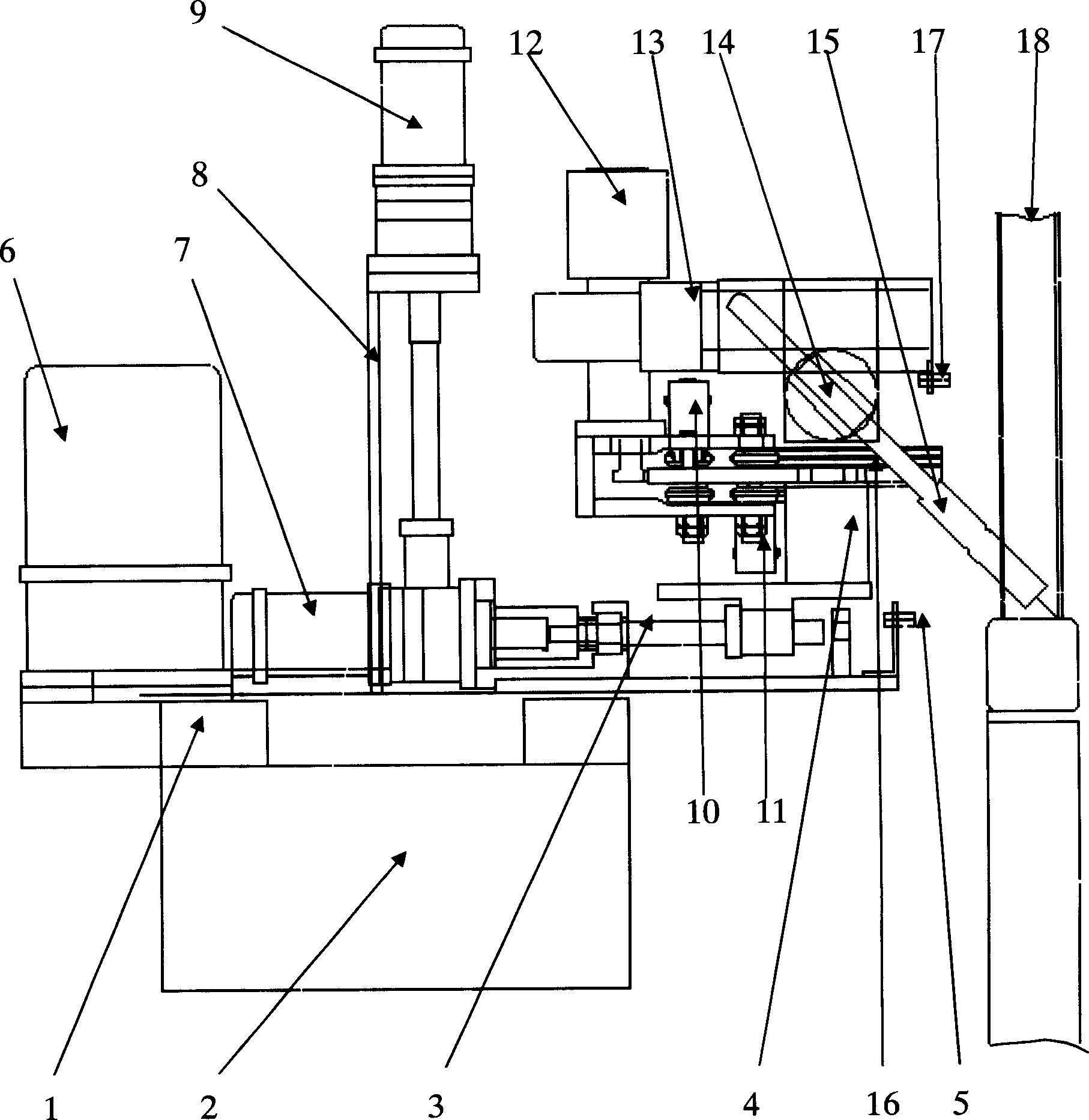

Locomotive capacitor shell seam welding machine

InactiveCN102407407AUniform weldGood weldment qualityWelding/cutting auxillary devicesAuxillary welding devicesSeam weldingWeld seam

The invention relates to a locomotive capacitor shell seam welding machine, which comprises a welding gun, a rack, a working platform, a mechanical arm composed of front and back swing arms hinged with each other, a profile modeling frame horizontally fixed to the rack, and a travelling mechanism moved along a track and a drive device of the travelling mechanism; the other end of the back swing arm is hinged with the rack, so that the front and back swing arms can rotate on horizontal plane; a welding gun fixture is fixed to the front swing arm; the profile modeling frame is provided with the track matched in shape with section of capacitor shell to be welded; and the front swing arm is provided with a connecting arm fixedly connected with the travelling mechanism. The locomotive capacitor shell seam welding machine adopts a mechanical automatic welding process, has uniform welding seam and good weldment quality and can not only improve the quality of the product but reduce the labor intensity, improve the working efficiency and decrease the production cost.

Owner:ANHUI TONGFENG ELECTRONICS

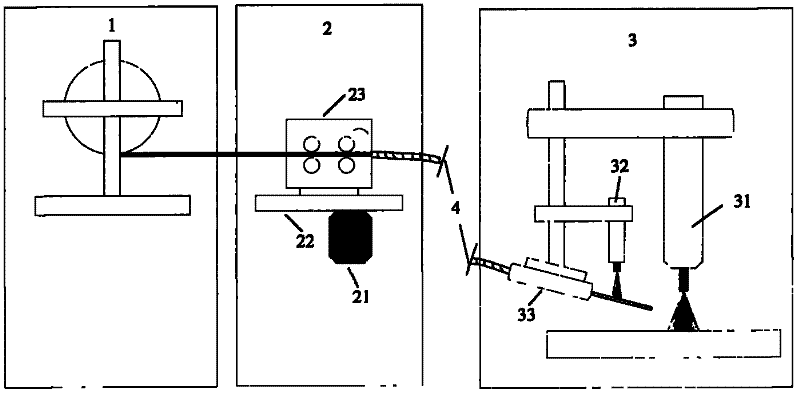

Heterogeneous metal laser-ultrasonic compound welding method and device

ActiveCN107984085ANarrow phase change rangeInhibition of mass productionLaser beam welding apparatusUltrasonic weldingLap joint

The invention provides a heterogeneous metal laser-ultrasonic compound welding method and device. The two advanced technologies of laser welding and ultrasonic consolidation are combined, that is, heterogeneous materials to be welded are connected in an overlap mode to form a lap joint, the position to be welded is welded in a laser welding mode, and the connecting purpose is realized. Under the condition that the temperature of the joint to be welded is below 10-30% of the melting point of an upper layer base material, ultrasonic welding is conducted, and efficient connection of the joint isrealized. According to the heterogeneous metal laser-ultrasonic compound welding method and device, the problem that a brittle joint is formed during welding of heterogeneous materials through a traditional welding method is solved, the problem that only a high energy beam welding method is adopted, though massive formation of intermetallic compound can be partially restrained, the strength of thejoint is still not high is also solved, and the problem difficult to solve that ultrasonic consolidation is only adaptive to low-melting-point thin plate welding is solved.

Owner:NANCHANG UNIV

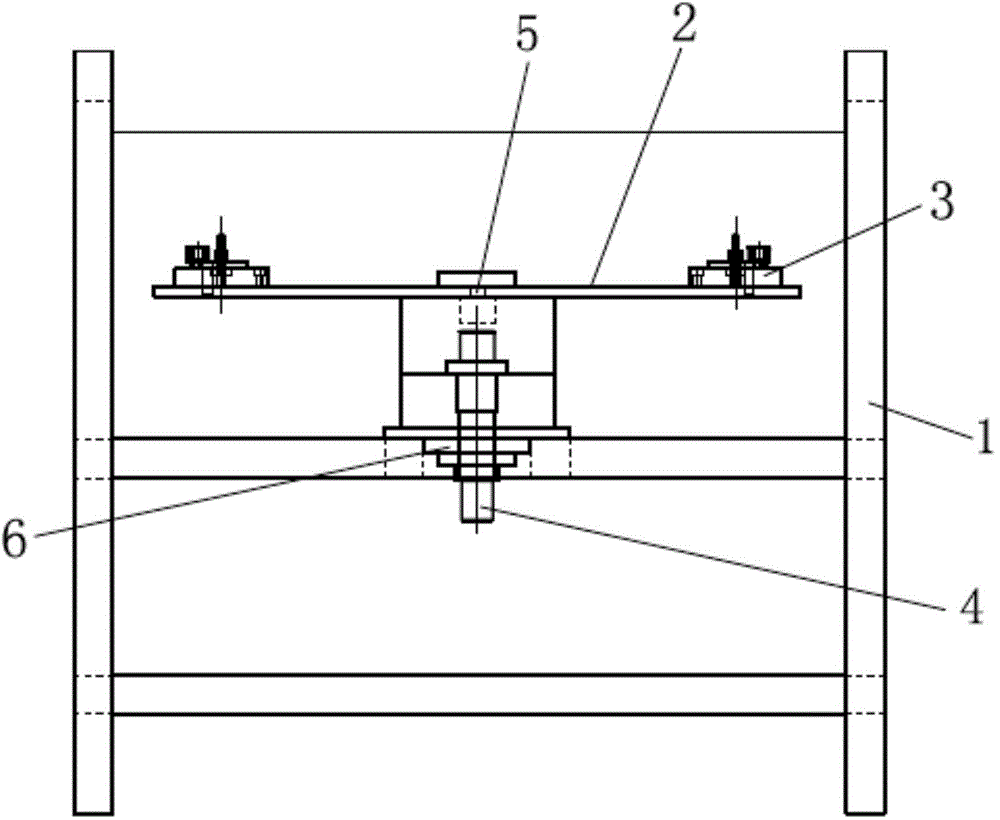

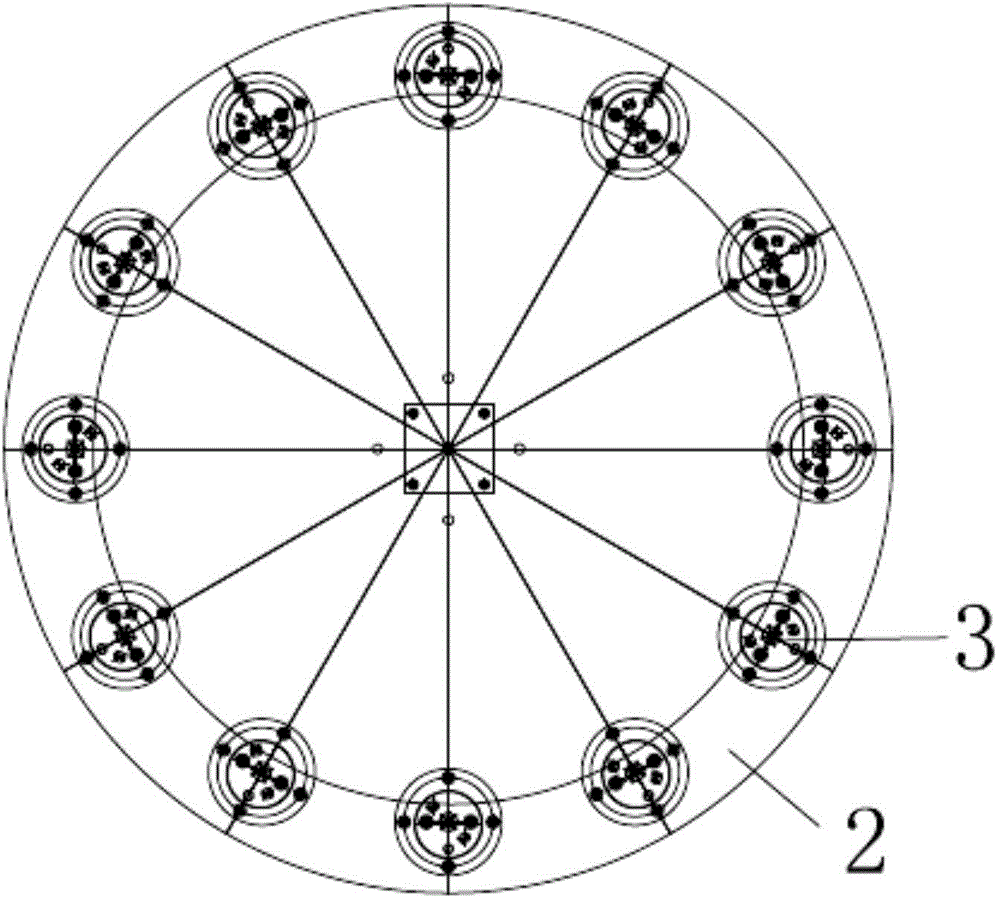

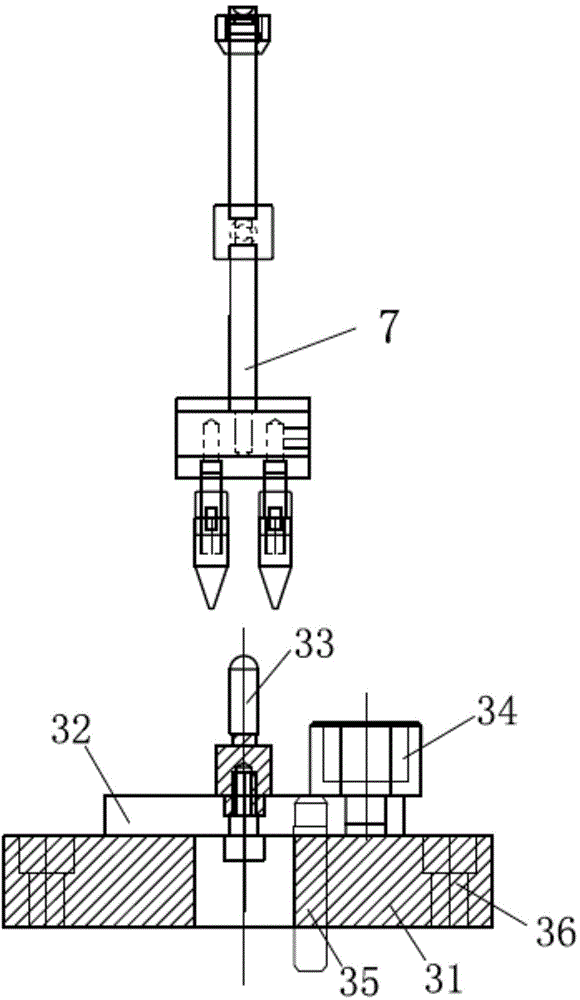

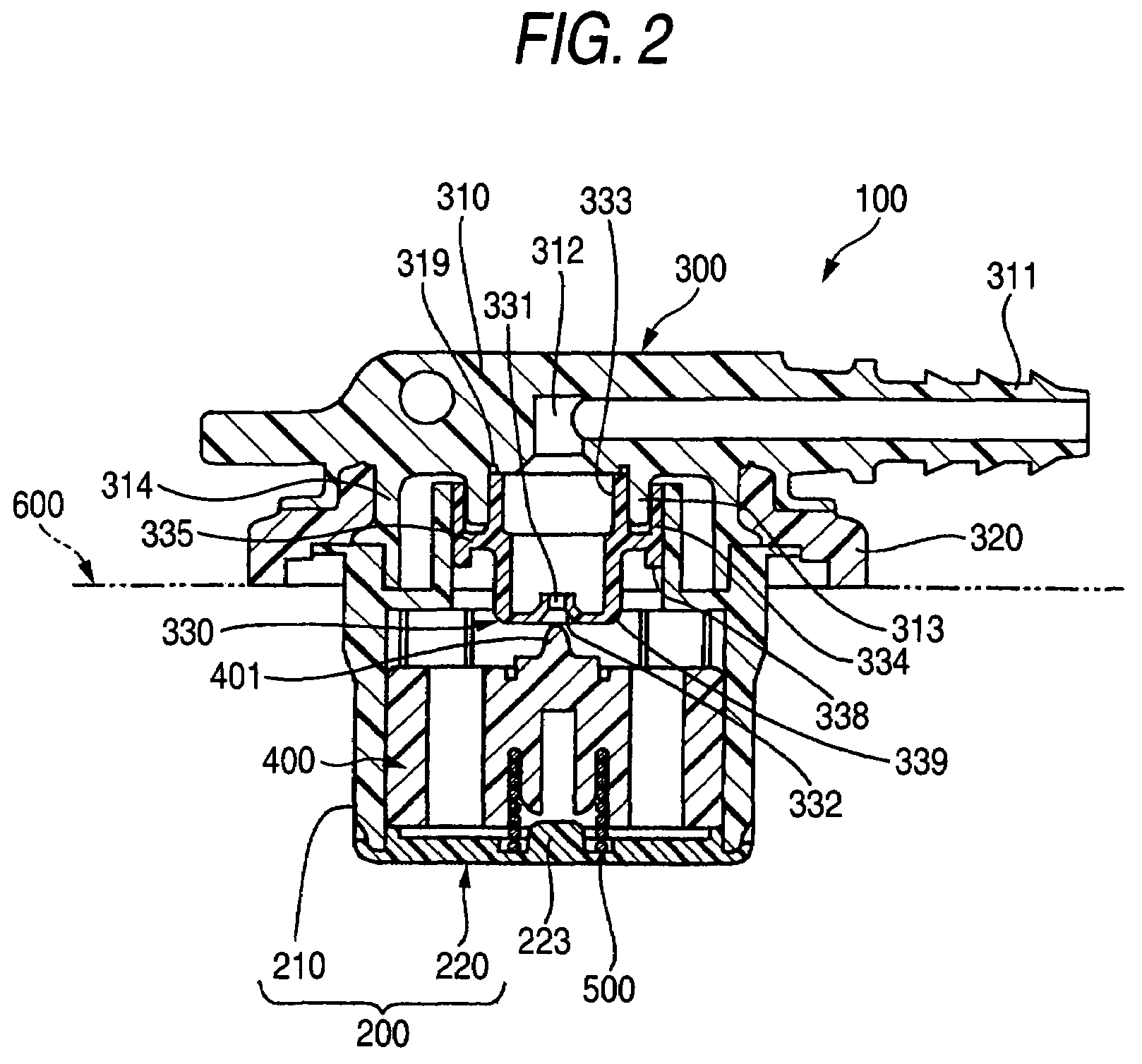

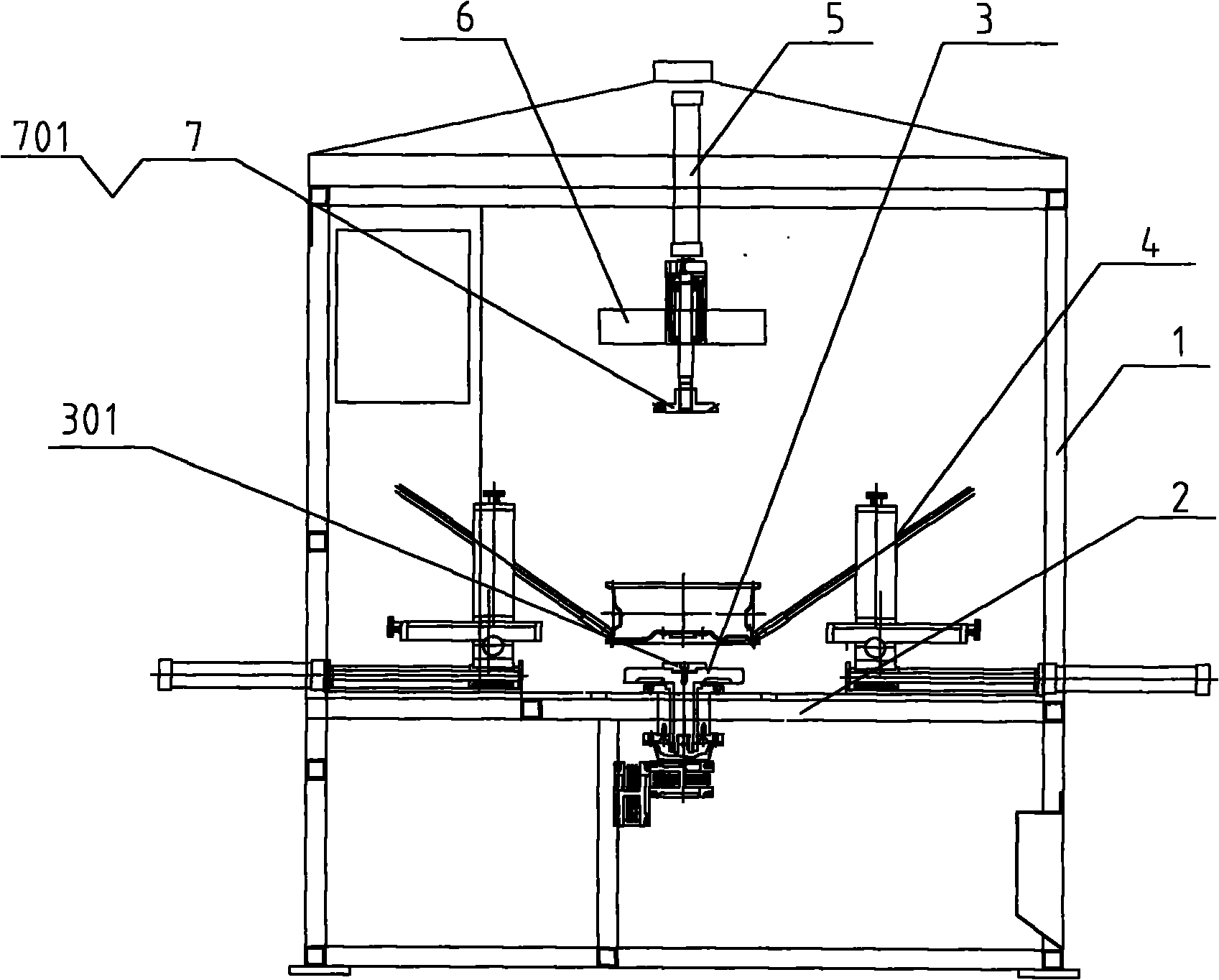

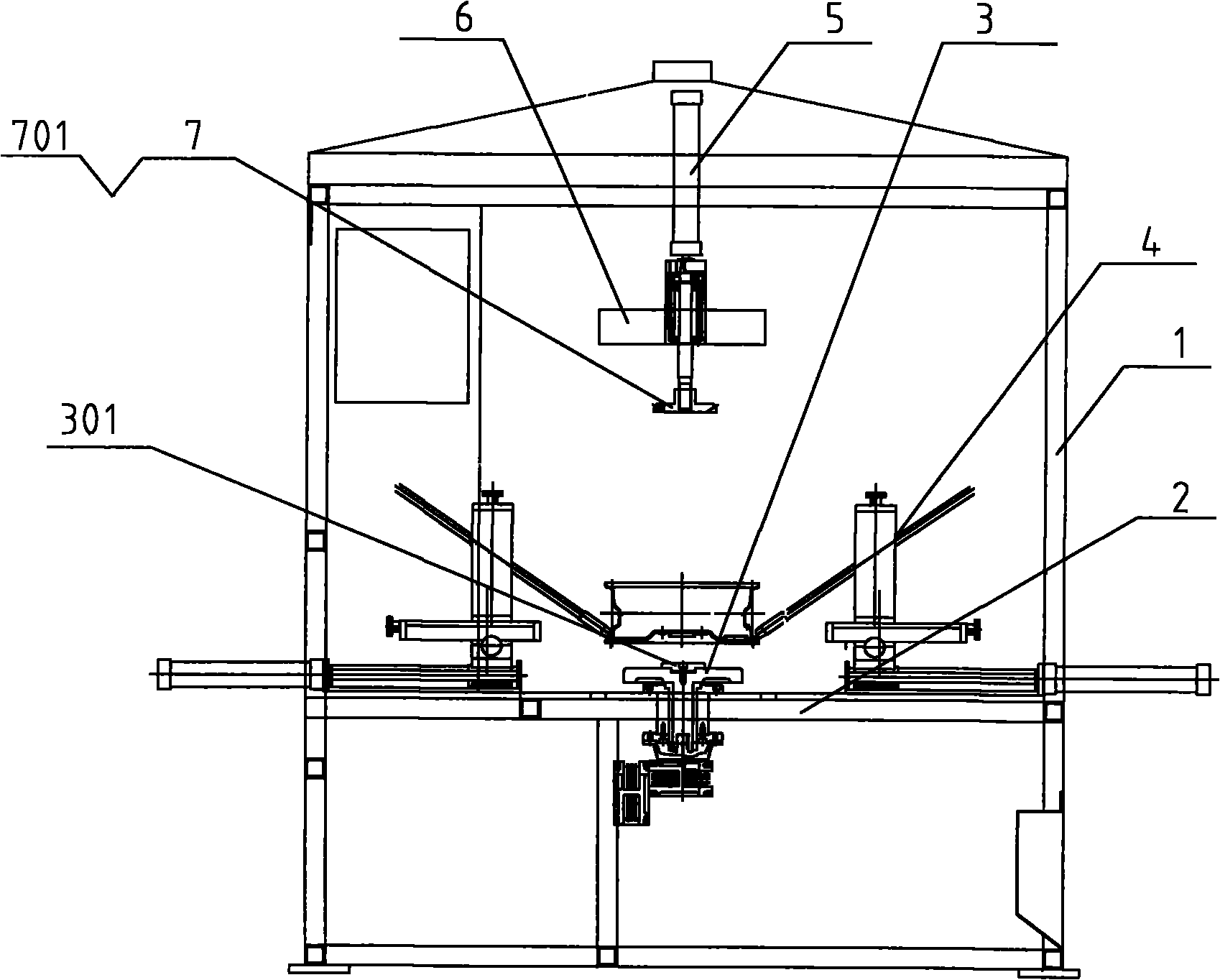

Exhaust pipe welding set of compressor upper shell

InactiveCN104690390ALittle variabilityReduce dependenceHeating appliancesWelding/cutting media/materialsEngineeringExhaust pipe

The invention discloses an exhaust pipe welding set of a compressor upper shell. The exhaust pipe welding set comprises a supporting bracket (1) and a rotating disc which is rotatably connected with the bracket (1), wherein a plurality of welding clamps (3) which are used for fixing the compressor upper shell (8) and an exhaust pipe (9) are uniformly distributed in the circumferential direction of the rotating disc (2); the lower end of the exhaust pipe (9) is sleeved by a welding ring (10); a welding gun (7) which is used for welding is arranged on the side edge of the bracket (1); and the welding device further comprises a controller which is used for controlling the rotating disc (2) and the welding gun (7) to be matched to start and stop intermittently. When the welding device is used for welding, the operation is convenient and orderly, the welding performance is stable the changeability is small, the undesirable phenomenon of weldment leakage is reduced, the welding quality of the weldment is greatly enhanced and relatively strong practicability is achieved.

Owner:WUHU DECHUANG ELECTRIC

Stainless steel welding protecting agent

InactiveCN101168222AUniform weldingRealize single-sided welding and double-sided moldingWelding/cutting media/materialsSoldering mediaAl powderMass ratio

The invention discloses oxidation-resistant preservative materials of the welding back surface of non-corrosive steel, being mainly adaptable for the welding of non-corrosive steel of which the nickelic amount is less than 25% and other steel. The invention is composed of main materials, binding agent and deflocculating agent, wherein the main materials are powder of which the grain diameter is 10 mum to 20 mum. According to mass percent, the powder is composed of the components, including 15%-20% NaF, 30%- 40% Al powder, 35% - 40% CaCO3 and 10%- 15% manganese powder and the sum of the component is 100%. The mass ratio of the main materials and the binding agent is between 5 to 1 and 8 to 1. The preservative materials of the invention are coated on the back surface of the non-corrosive steel. In the time of welding, the invention is capable of preventing oxidation, abscess and oxidizing substances from being mixed, protecting the soldering seam, and resolving the oxidation problem of the back surfaces of the non-corrosive steel of which the nickelic amount is less than 25 % and other steel in the time of welding.

Owner:XIAN UNIV OF TECH

Electric welding core wire of high manganese steel wire made by forging rolling process

InactiveCN1431081AImprove toughnessHigh strengthWelding/cutting media/materialsSoldering mediaWeld seamUltimate tensile strength

Owner:张汉涛

Special robot welding machine for joist

ActiveCN104014900AImprove welding efficiencySimple inputWelding/cutting auxillary devicesAuxillary welding devicesJoistReducer

The invention relates to joist welding, and discloses a special robot welding machine for a joist. The special robot welding machine comprises a main engine base, a rotating frame and a moving trolley, a main support and an auxiliary support are arranged on the main engine base, the two ends of the rotating frame are arranged on the main support and the auxiliary support through bearings respectively, and a welding robot is arranged on the moving trolley; a controller is further arranged on the main engine base, a harmonic speed reducer is arranged on the main support, a first servo motor is arranged below the harmonic speed reducer and synchronously connected with the harmonic speed reducer, and one end of the rotating frame is connected with the harmonic speed reducer. The moving trolley and the servo motor on the main support are controlled through the PLC, and the welding robot is taught to simulate a welding track, so that full automation is achieved, labor is liberated completely, only feeding and discharging procedures need to be finished manually, other procedures are automatic, labor intensity of workers is greatly reduced, welding efficiency is improved, and welding is even.

Owner:江苏沃达电子科技有限公司

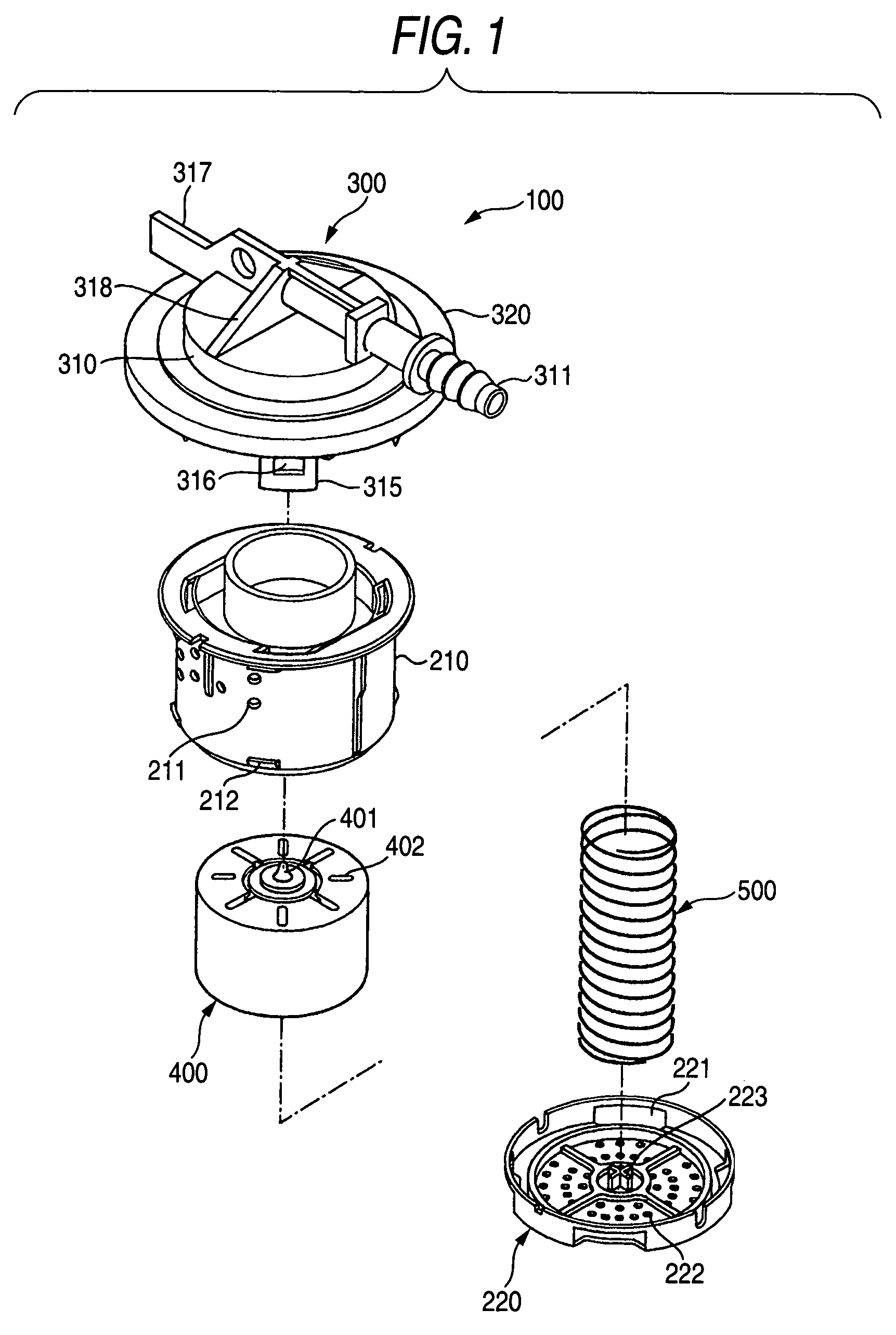

Method for manufacturing float valve apparatus

InactiveUS7661193B2Minimize occurrenceImprove adhesionOperating means/releasing devices for valvesWelding/cutting auxillary devicesSpin weldingEngineering

In a method for manufacturing a float valve apparatus including a valve case, an upper lid incorporated into this valve case to form a valve chamber, and a float valve liftably arranged inside the valve chamber, the upper lid being provided with a lead-out pipe connected to piping of the outside, an exhaust hole which communicates with this lead-out pipe and is opened in an inner surface of the upper lid, and a seal cap which is mounted so as to enclose this exhaust hole and forms a valve seat on which the float valve abuts, the seal cap is welded to an inner surface of the upper lid by spin welding.

Owner:PIOLAX CO LTD

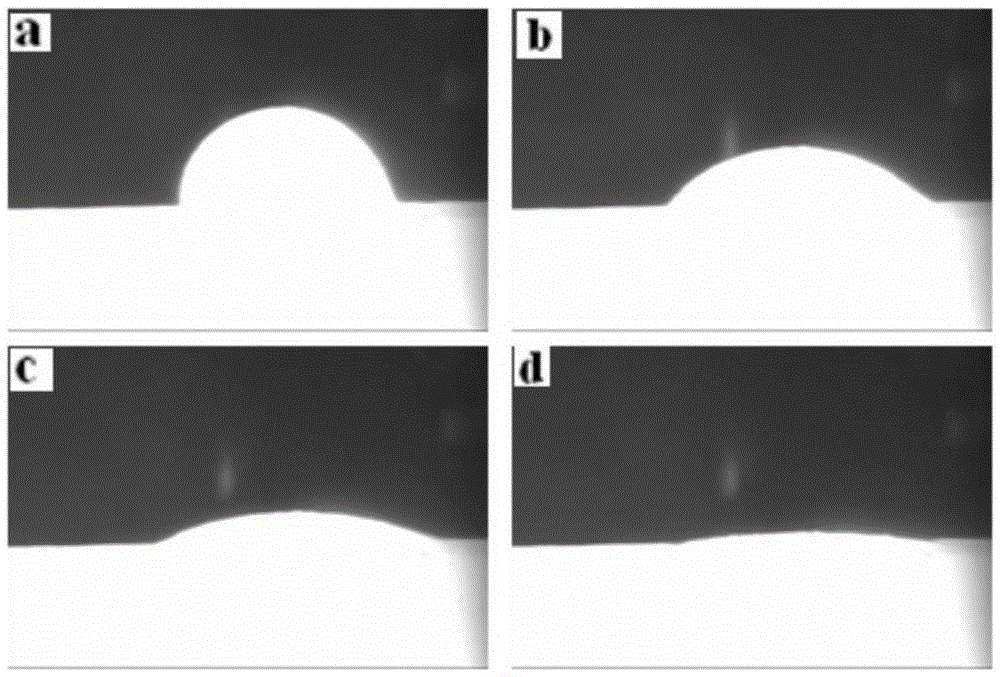

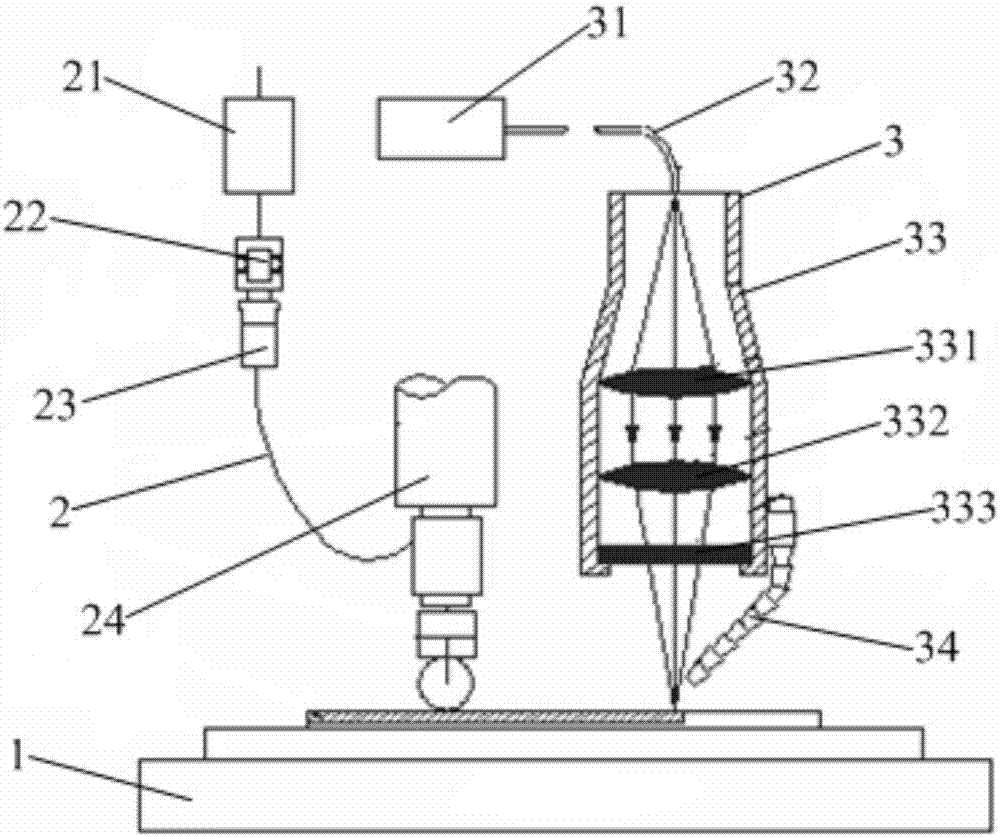

Material wettability improvement device and method based on multi-field coupling

ActiveCN107052494AImprove wettabilityWay to overcomeMuffle furnacesPreparing sample for investigationEngineeringMechanical engineering

The invention provides a material wettability improvement device and method based on multi-field coupling. The material wettability improvement device comprises an operation platform, a vacuum furnace stored on the operation platform, a high-voltage power supply control box, an ultrasonic auxiliary device, an electric field auxiliary device and a magnetic field auxiliary device. A rack on one side of the vacuum furnace is provided with a guide rail stand column. The upper end of the guide rail stand column is provided with a movable cross beam. An ultrasonic transducer is fixed to the cross beam. An ultrasonic variable-pressure rod stretches into the vacuum furnace through a corrugated pipe. The electric field auxiliary device is arranged below the ultrasonic variable-pressure rod. A sample is stored on an insulating ceramic plate and positioned through a stop block. The inner side of the vacuum furnace is further provided with a magnetic field power coil which generates a variable magnetic field after being applied with current. By adoption of the material wettability improvement device and method, the sample can be wetted under mutual assistance of an ultrasonic vibration load, an electric field and the magnetic field, and the problems that existing additionally arranged auxiliary equipment is simplex in applying mode, the ultrasonic applying mode is large in power loss, and simplex assistance is unobvious in sample wettability improvement effect are solved.

Owner:HENAN UNIV OF SCI & TECH

Circular seam welder for automobile wheels

InactiveCN102380723ANot easy to twist and deformImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a circular seam welder for automobile wheels. The circular seam welder comprises a welder body, a workbench arranged in the welder body, a rotatable workpiece clamping device arranged on the workbench and at least two welding guns, wherein the welding guns are uniformly arranged on the workbench around workpieces. Because the at least two welding guns are arranged, the welding efficiency is greatly improved. In addition, due to the introduction of a workpiece compacting and swelling component, the deformation of the wheels in the welding process is also greatly reduced, and the welding effect is also remarkably improved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com