Circular seam welder for automobile wheels

A technology of girth seam welding machine and wheel, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low wheel welding efficiency, distortion of workpiece, affecting the quality and yield of wheel finished products, etc. The effect of improving welding efficiency, improving welding efficiency and yield, and being less prone to distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

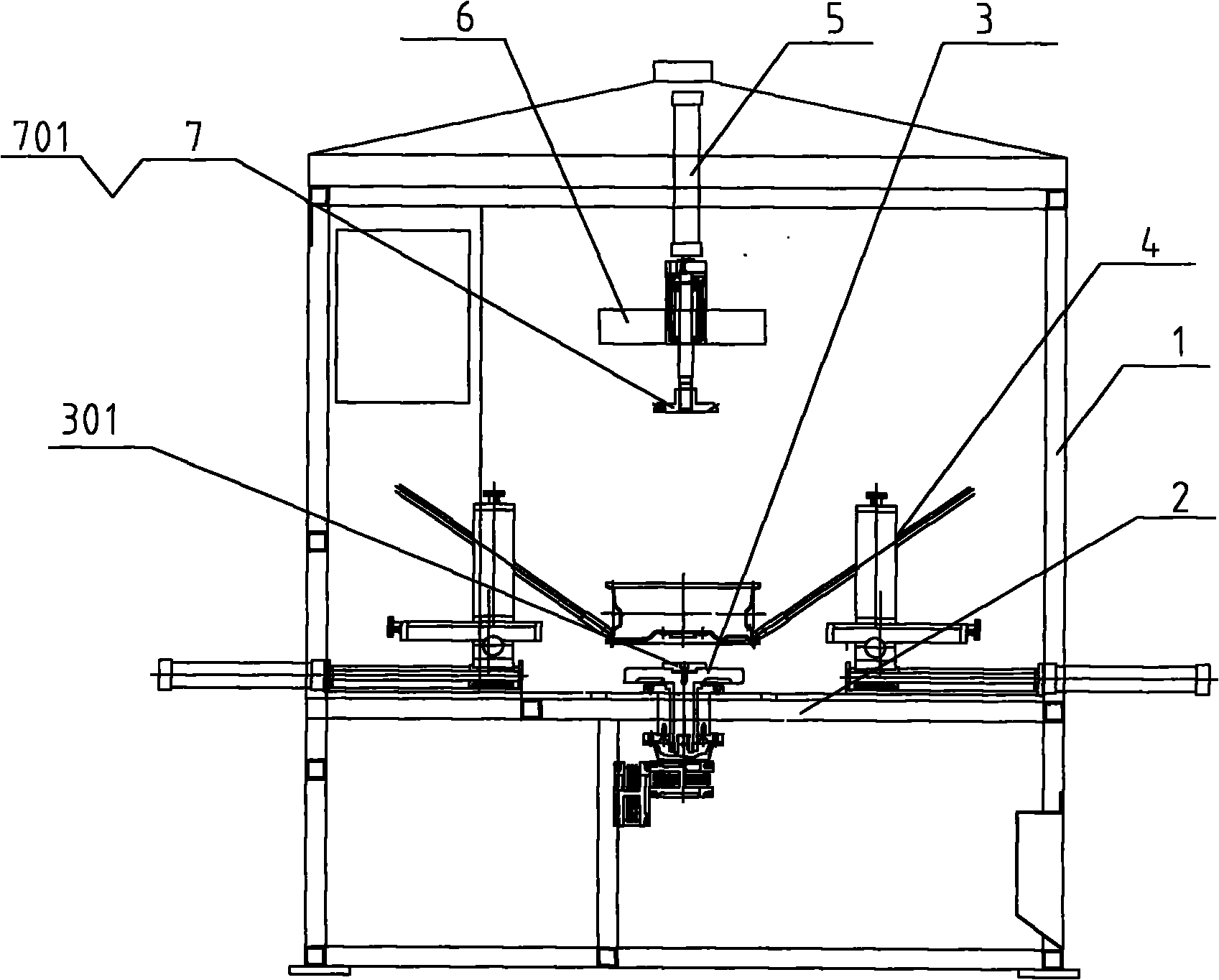

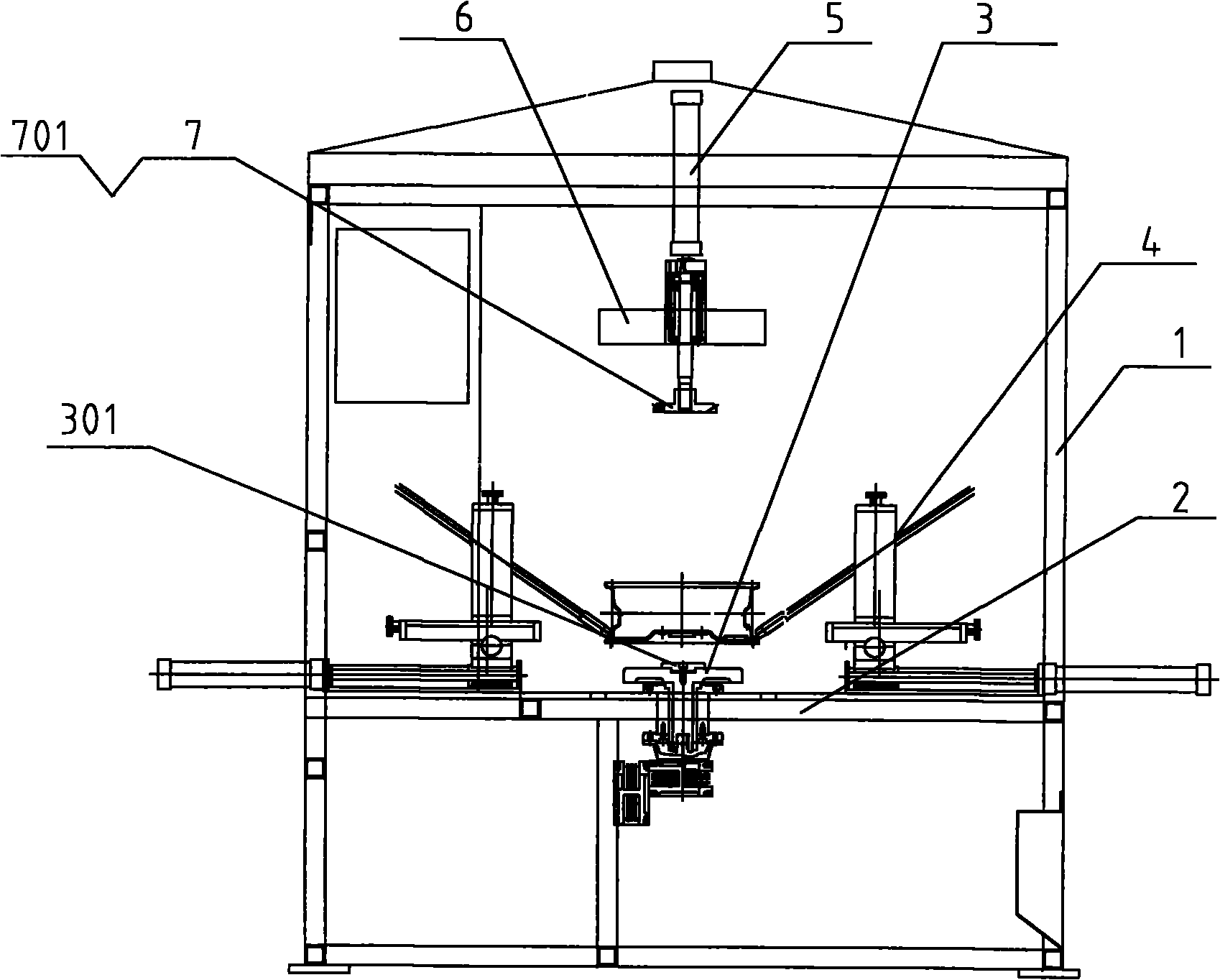

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

[0011] Such as figure 1 As shown, the automobile wheel girth welder in this embodiment includes a machine body 1, a workbench 2 inside the machine body, a rotatable workpiece clamping device 3 arranged on the workbench 2, and a welding torch 4, wherein the welding torch 4 has three (only two of which can be seen in the figure) are arranged on the workbench 2 around the workpiece at intervals of 120 degrees. In this embodiment, the rotatable workpiece clamping device 3 is a positioning plate, and positioning pins (not shown in the figure) are provided near the edge of the positioning plate, and a tire expansion 301 is provided at the center of the positioning plate. In this embodiment, a cylinder 5 is provided on the top of the machine body 1, and a pressure plate 6 and a chuck 7 are pivotally connected to the cylinder, wherein the chuck 7 is provided with an expansion cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com